Low-power-consumption series LED lamp strip

A technology of LED light strips and LED lamp beads, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problem of not being able to have too many modules for a single LED light strip, and achieve prolongation of life. Effect of avoiding brightness difference and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

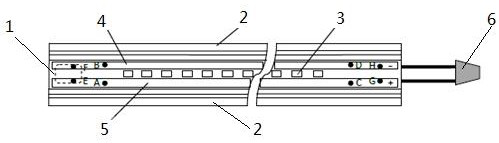

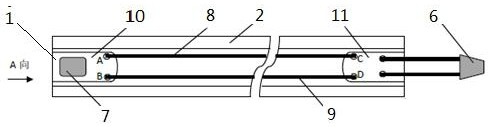

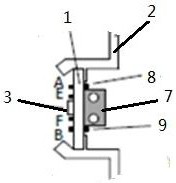

[0012] Please refer to the attached figure 1 , 2 As shown in , 3, the light strip module is in the middle of the front of a rectangular PCB board, and a number of LED lamp beads 3 are installed in an orderly series. Two copper foil strips 5 and 4 are arranged in parallel on both sides of the lamp beads 3. The electrodes supply power to the LED lamp bead 3 to form a light strip module. On the back of the PCB board, corresponding to the two copper foil strips 4 and 5 parallel to the front of the PCB board, two wires 9 and 8 are respectively used to connect to the two wires parallel to the front of the PCB board. The starting ends B, A of the copper foil strips 4, 5 are connected to the terminals D, C electrodes, which is equivalent to connecting two wires 9, 8 in parallel on the two copper foil strips 4, 5 parallel to the front of the PCB board, so as to shunt the PCB. The current flowing through the two parallel copper foil strips 4 and 5 on the front of the board reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com