Patents

Literature

55results about How to "Speed up printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

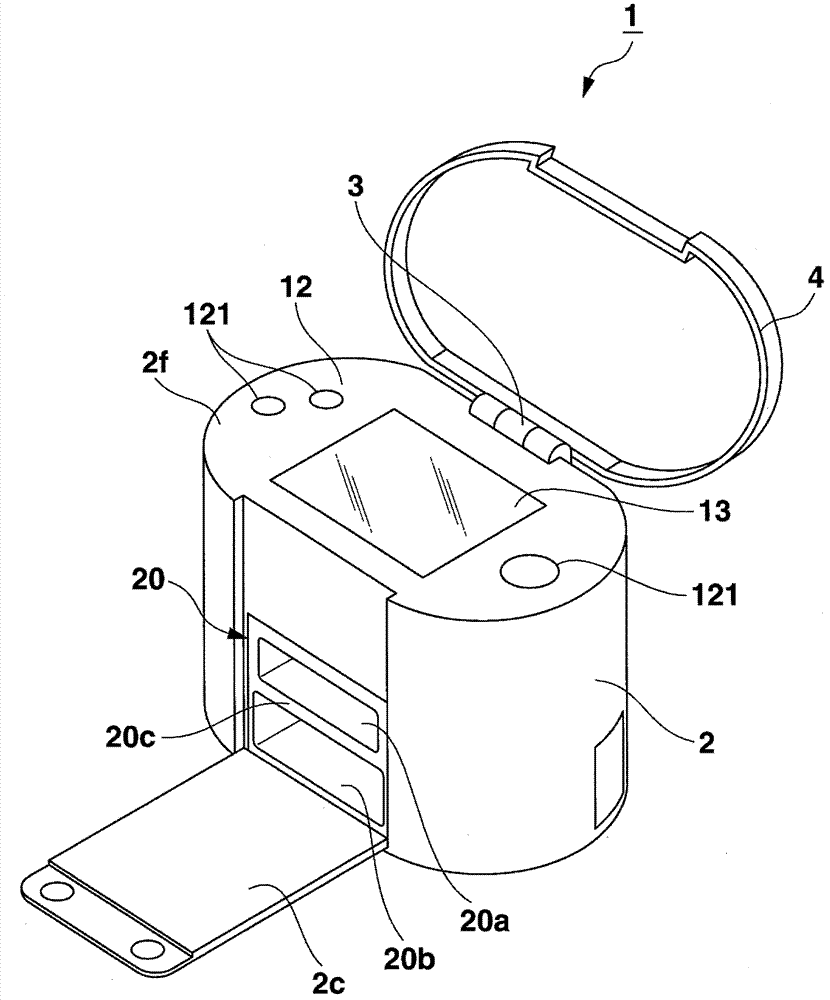

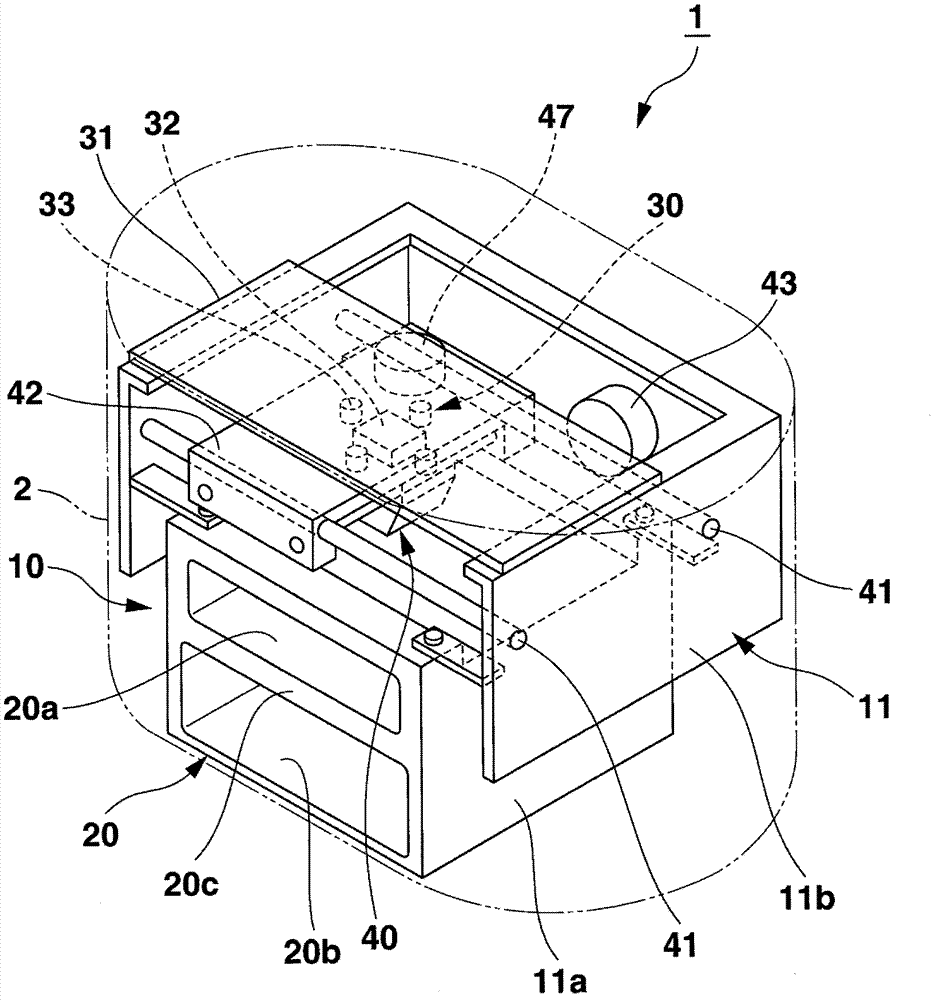

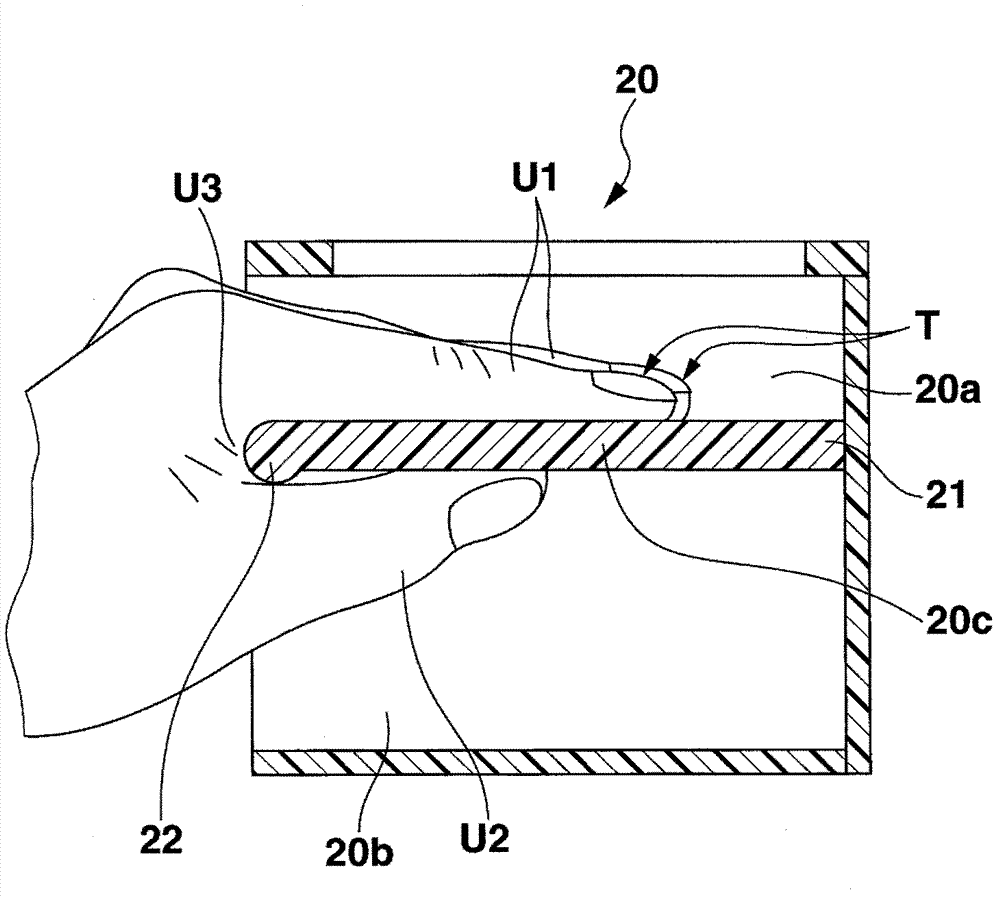

Print apparatus and print control method

ActiveCN102756557AShorten the timeSpeed up printingTypewritersOther printing apparatusTarget surfaceCurve shape

A print apparatus includes a selection unit, a print unit and control unit. The selection unit categorizes a curve-shape of a print target surface into one specific shape pattern among a plurality of shape patterns having shapes whose degrees of curving are different from each other. The print unit has a recording head that applies ink on the print target surface. The control unit controls the print unit to set an ink amount to be applied at the edge parts of the print target surface to predetermined amount which is set corresponding to the specific shape pattern.

Owner:CASIO COMPUTER CO LTD

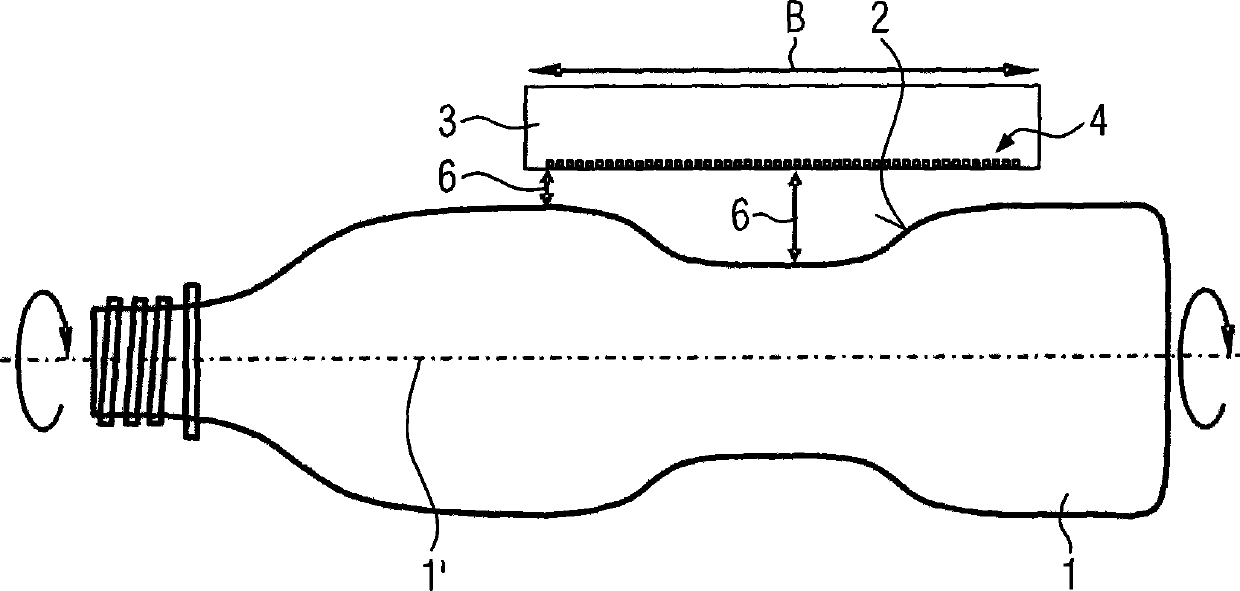

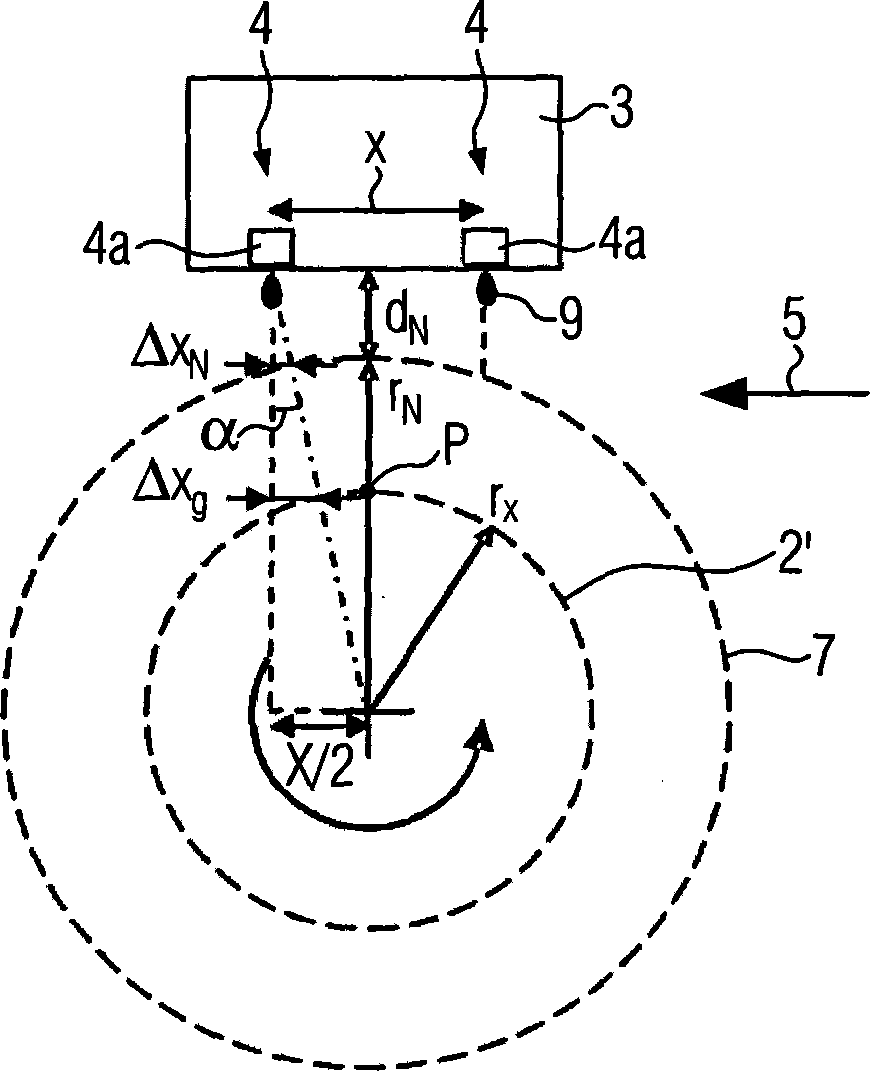

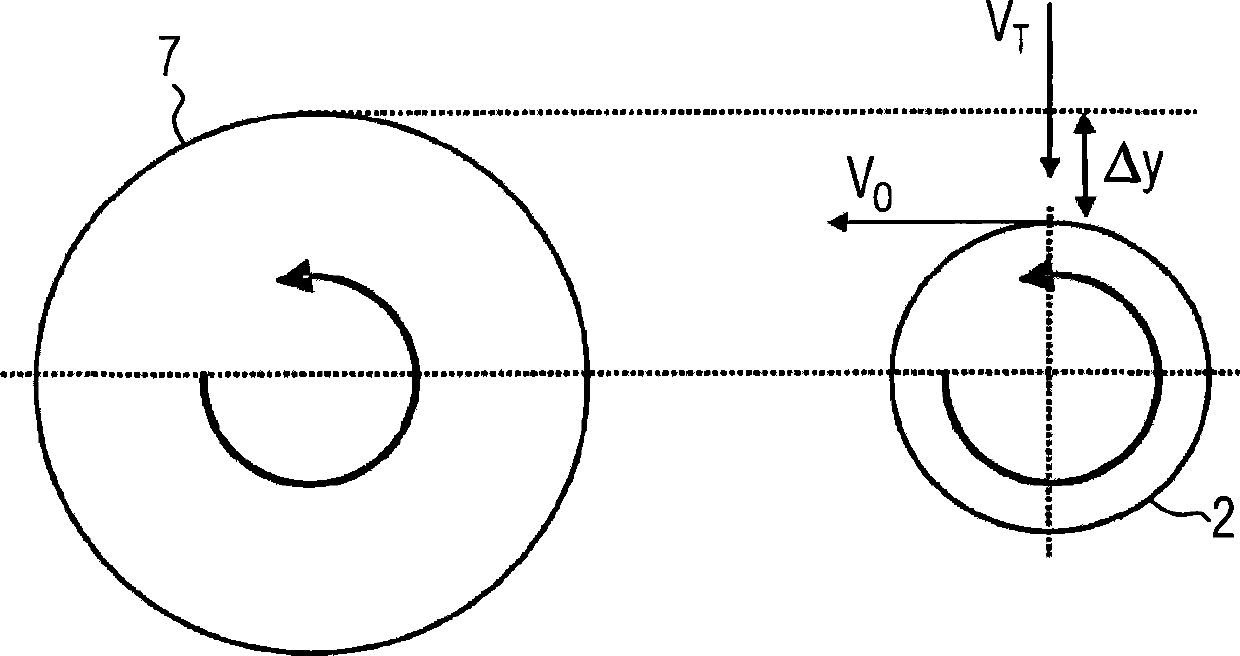

Method and device for ink-jet printing on curved container surfaces

ActiveCN103144442AImprove matchImprove printing qualityTypewritersPower drive mechanismsEngineeringMotion direction

Owner:KRONES AG

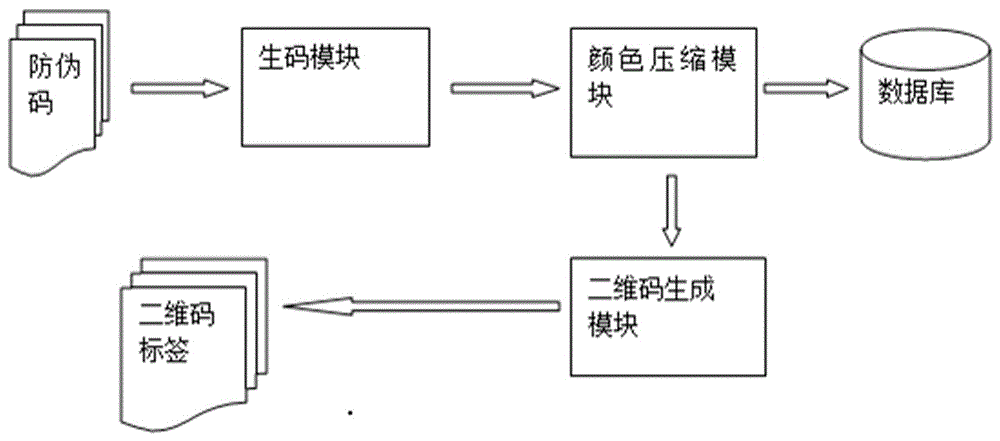

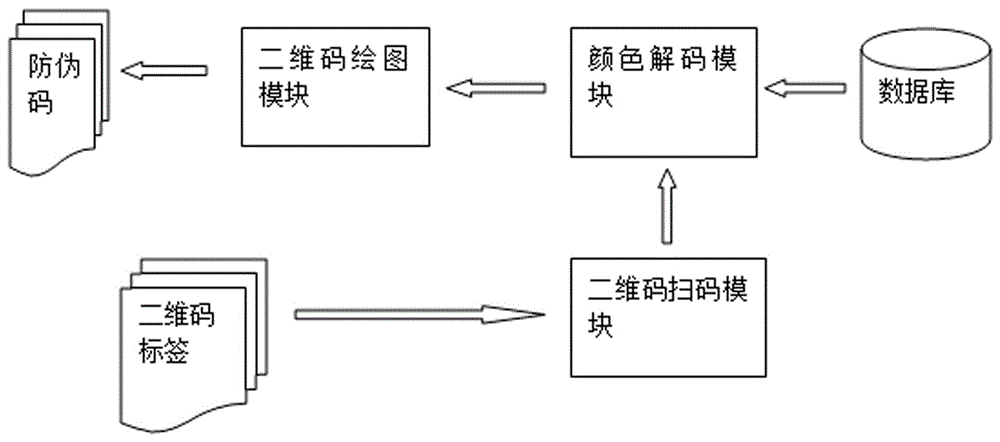

Random color two-dimensional code based anti-counterfeiting method and device

The invention discloses a random color two-dimensional code based anti-counterfeiting method, which comprises the steps of S1, adopting random color two-dimensional codes to be associated with anti-counterfeiting information, coding anti-counterfeiting information, association information and two-dimensional code color information through a database table, storing the coded information into a database, wherein the color of each two-dimensional code is allocated randomly; S2, processing the two-dimensional codes in the step S1 into tags which are attached to commodities or directly printing the two-dimensional codes on packages of commodities; S3, recognizing the anti-counterfeiting information, the association information and the two-dimensional code color information carried in the two-dimensional codes through a two-dimensional code recognition device; S4, performing color decoding on the two-dimensional code color information recognized in the step S3 through codes of the database table, and finally outputting the decoded colors according to a preset shape; and S5, distinguishing the authenticity according to the recognized anti-counterfeiting information. By adopting random color two-dimensional codes generated according to the method and a random background, a generated PDF with two-dimensional codes being vectors can be printed with high quality directly.

Owner:SHANGHAI HUIMOU NETWORK TECH

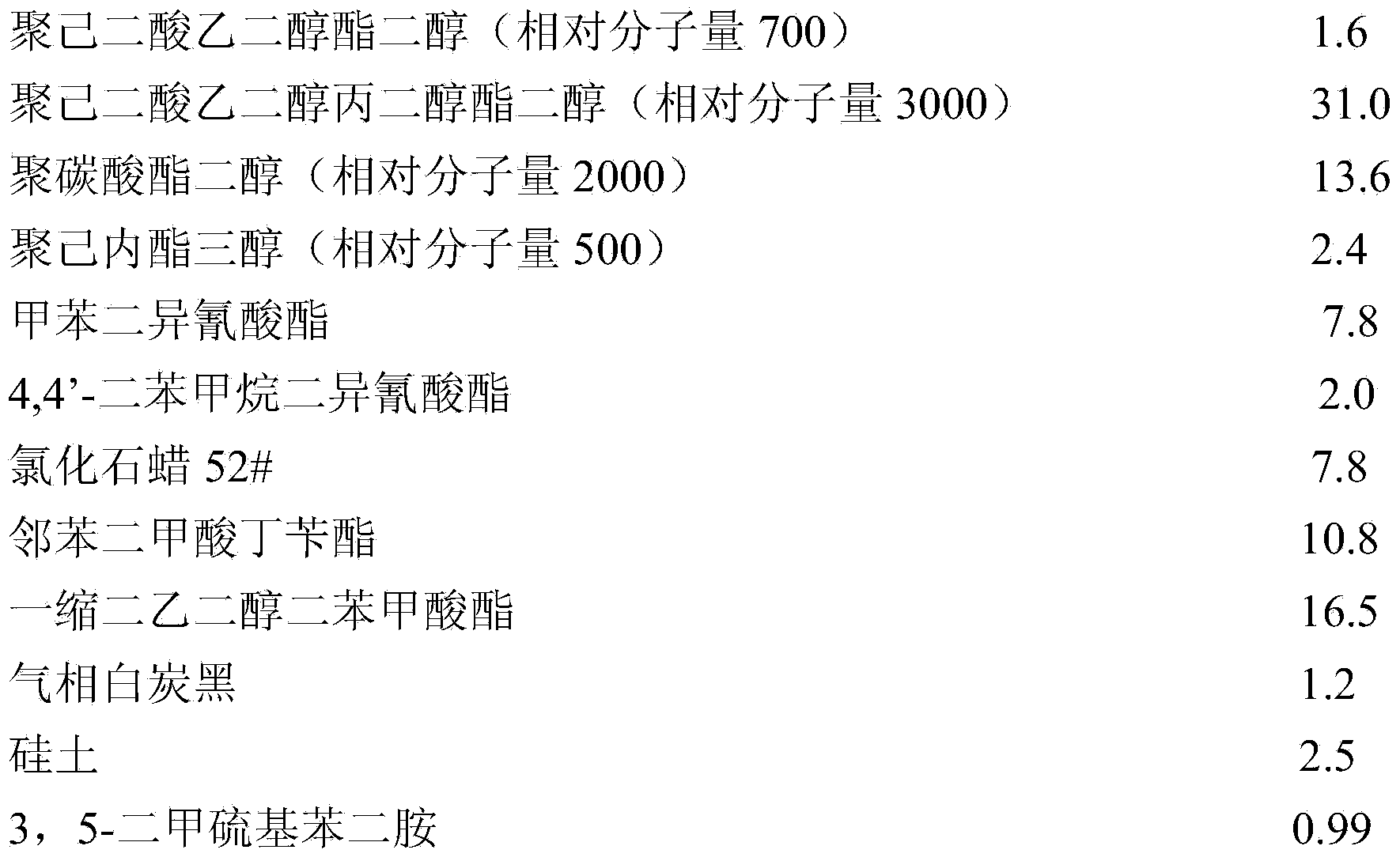

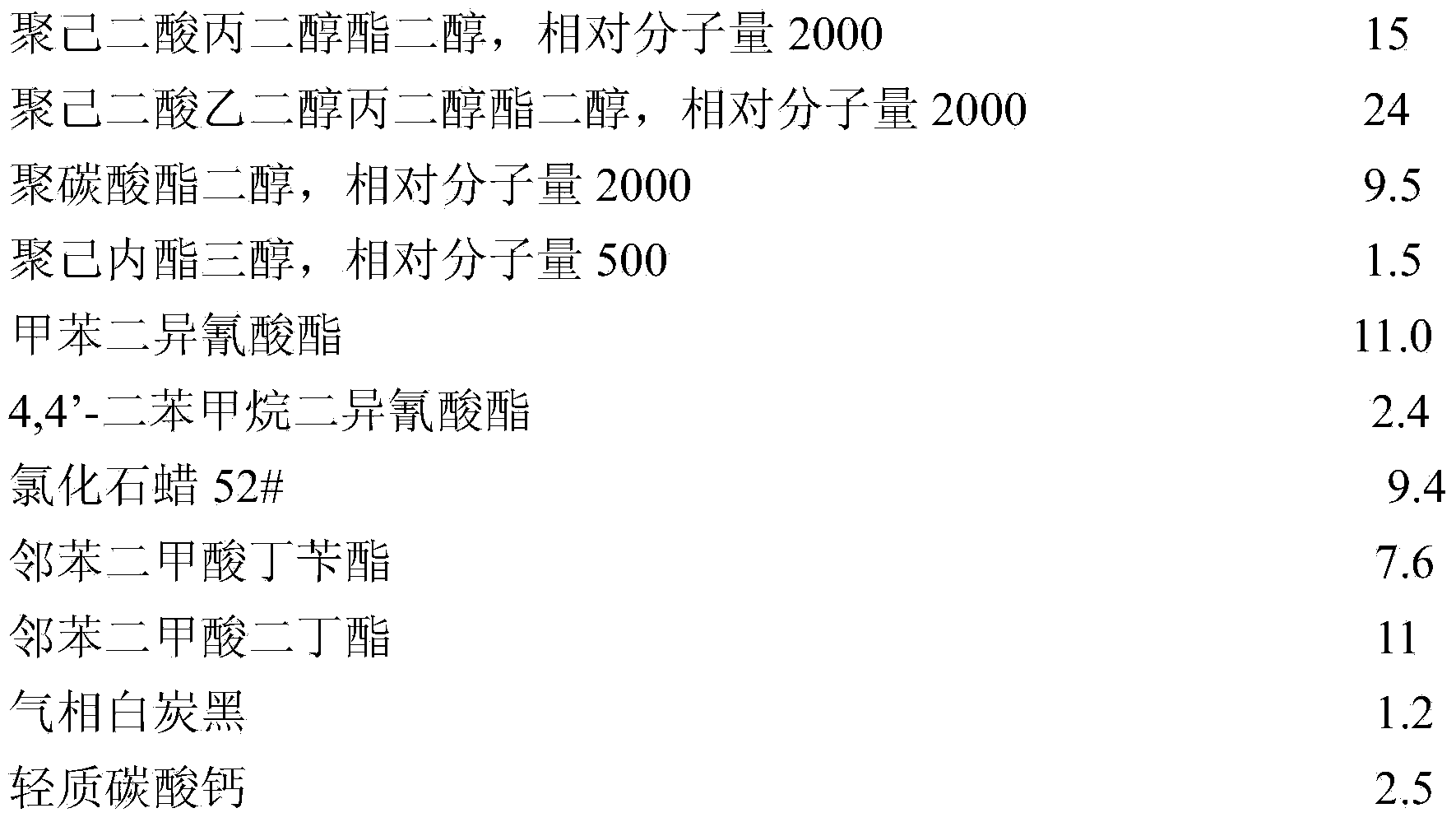

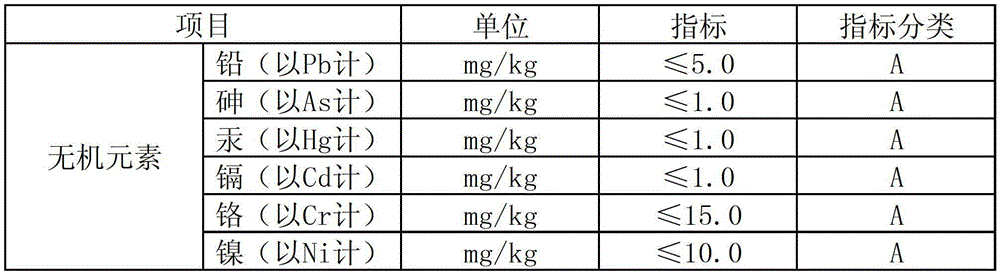

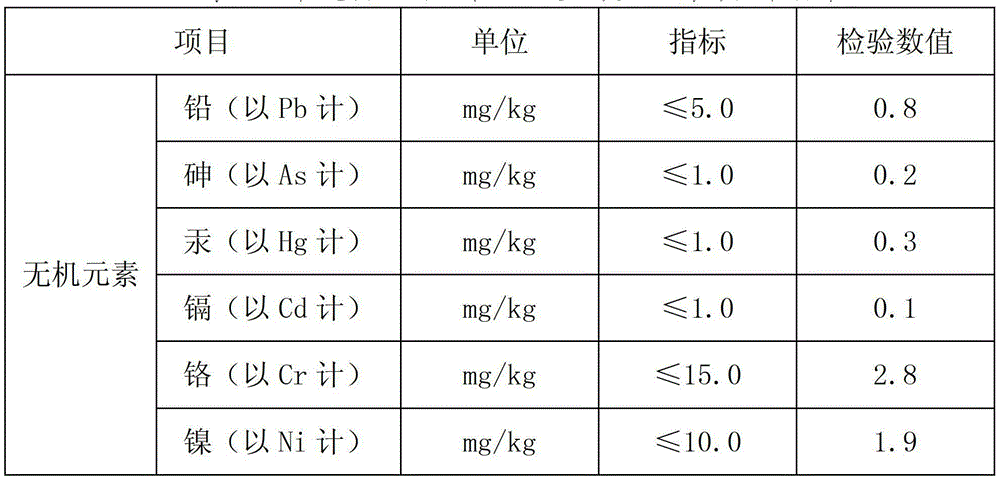

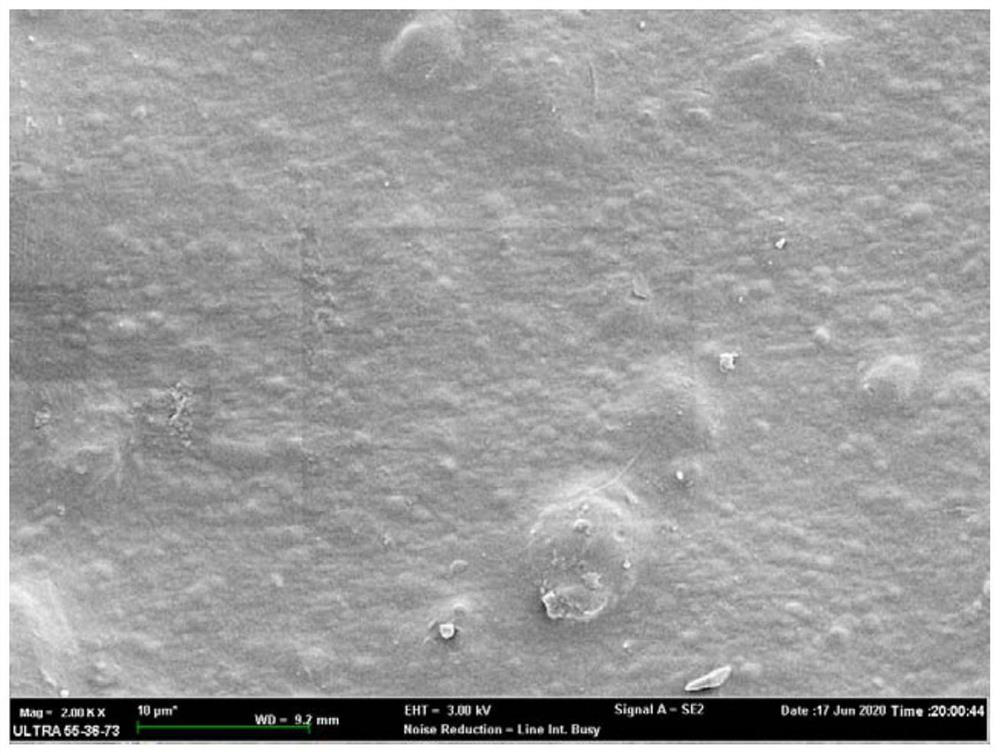

Solvent-resistance polyurethane rubber roller and manufacturing method and application thereof

The invention discloses a solvent-resistance polyurethane rubber roller and a manufacturing method and application thereof, and belongs to the field of rubber roller preparing. The solvent-resistance polyurethane rubber roller is achieved through combination of multicomponent systems and is formed by mixing and pouring a material component A, a material component B and a material component C, wherein the material component A comprises, by mass, 40%-60% of polyester polyol and 7%-20% of toluene disocynate, the material component B comprises, by mass, 2%-10% of 4-4'-diphenylmethane diisocyanate, 5%-40% of plasticizer and 1%-4% of filler, and the material component C comprises, by mass, 2.5%-8% of chain extender and 0.02%-0.05% of catalysts. The wear-resistance, solvent-resistance and mechanical properties of the solvent-resistance polyurethane rubber roller are obviously improved, and the solvent-resistance polyurethane rubber roller can be widely used in the fields of printing, coating and painting.

Owner:东莞华工佛塑新材料有限公司

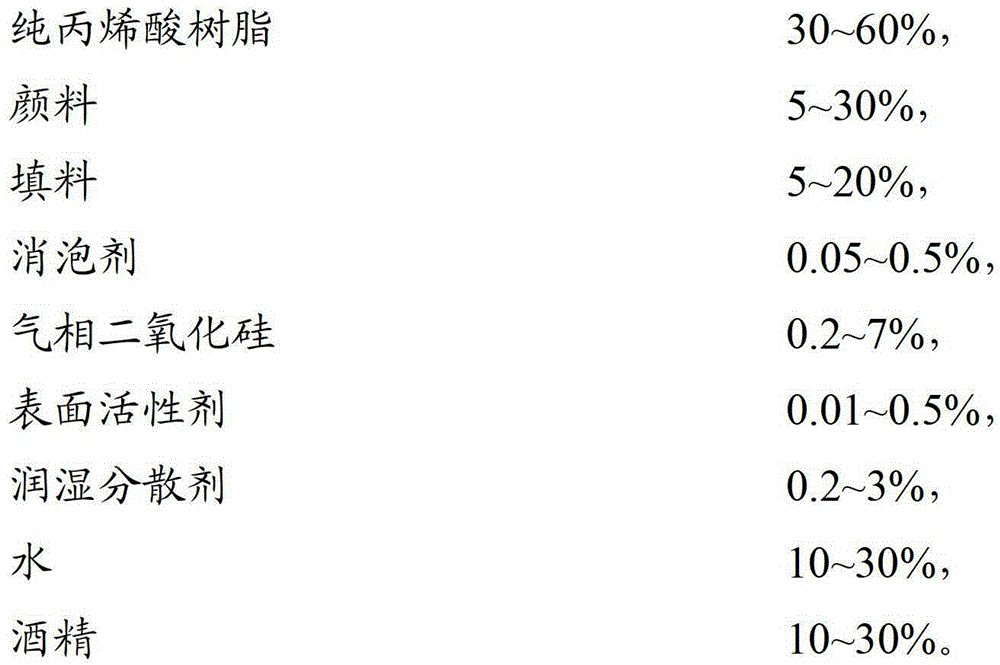

Special water-based ink for printing tipping paper for cigarette and preparation method thereof

The invention provides special water-based ink for printing tipping paper for a cigarette. The special water-based ink comprises pure acrylic resin, pigment, packing, a defoamer, fumed silica, surfactant, wetting dispersant, water and alcohol. A preparation method of the water-based ink is also provided by the invention. Compared with other ink for printing the tipping paper for the cigarette, the special water-based ink for printing the tipping paper for the cigarette disclosed by the invention has the advantages that the ink can be diluted by pure water; the consumption is reduced; and the ink does not burn or blast, does not belong to dangerous chemicals, and increases the printing, transporting and storing safety. The water tolerance, the curling resistance and the printing adaptability of the ink are greatly improved; and the printing effect can be equivalent to those of alcohol-soluble ink and solvent-based ink. In a word, the water-based ink disclosed by the invention is simple in cost, low in price, good in printed adhesive force, strong in water resistance, and fast to dry. Thus, the water-based ink is especially suitable for package printed matters such as foods, beverage and medicaments.

Owner:哈尔滨绿科科技有限公司

Method and composition for removing residual ink image from offset printing blanket

InactiveCN101484540ASpeed up printingImprove clarityChemical paints/ink removersPrinting pressSURFACTANT BLEND

A thickened aqueous cleaning solution for removing residual ink images from the surface of a blanket used in offset lithographic printing which has been subjected to printing using radiation-curable ink. The cleaning solution comprises an alkaline builder, a thickener, a co-solvent, a surfactant and water. A method for removing the residual ink images from the blanket comprises removing the blanket from the offset lithographic printing press, applying a layer of the thickened aqueous cleaning solution to the blanket, rubbing the surface of the blanket, for example with rags or a scouring pad, and removing the soiled cleaning solution.

Owner:ENVIRO IMAGE SOLUTIONS

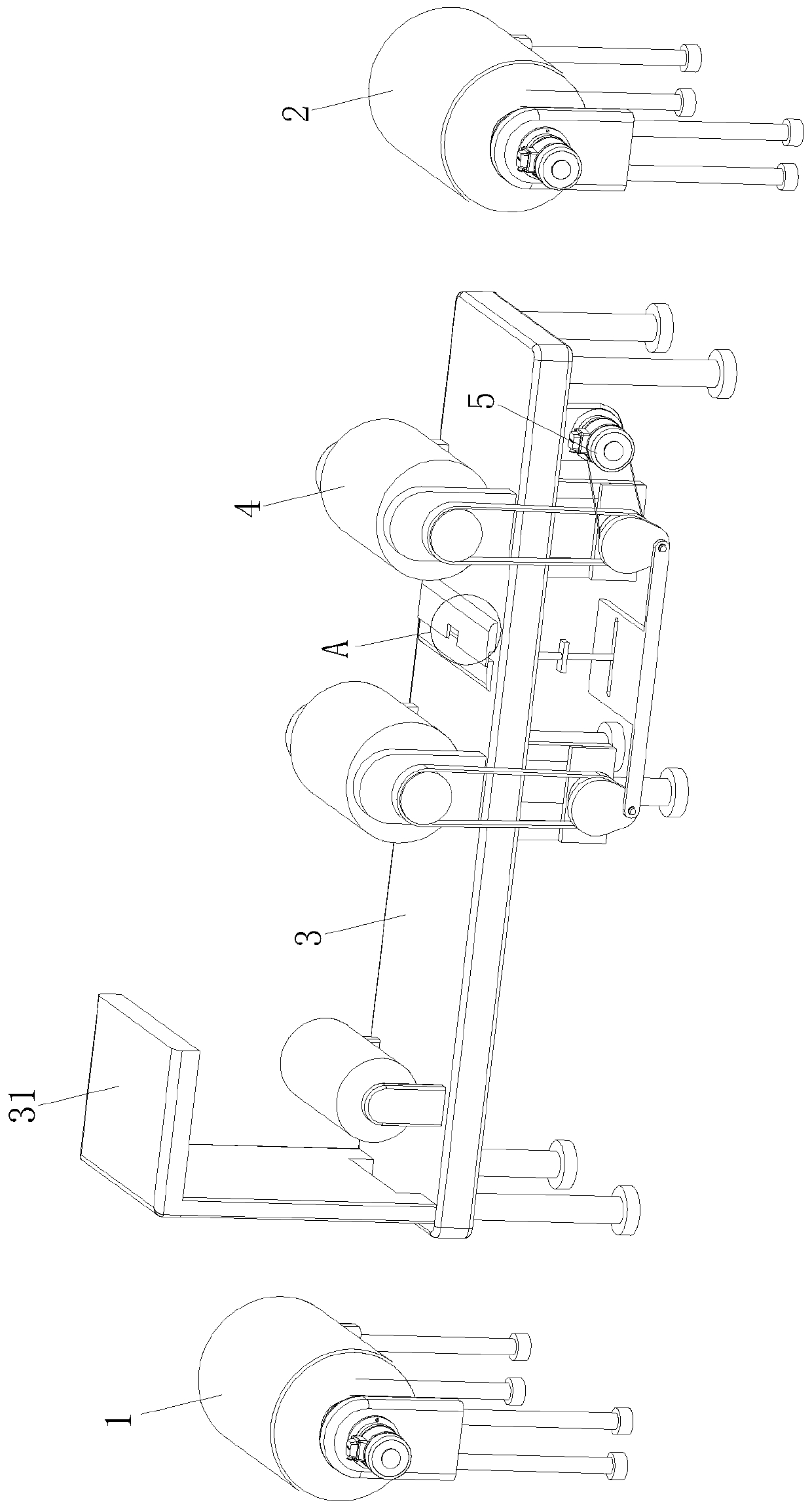

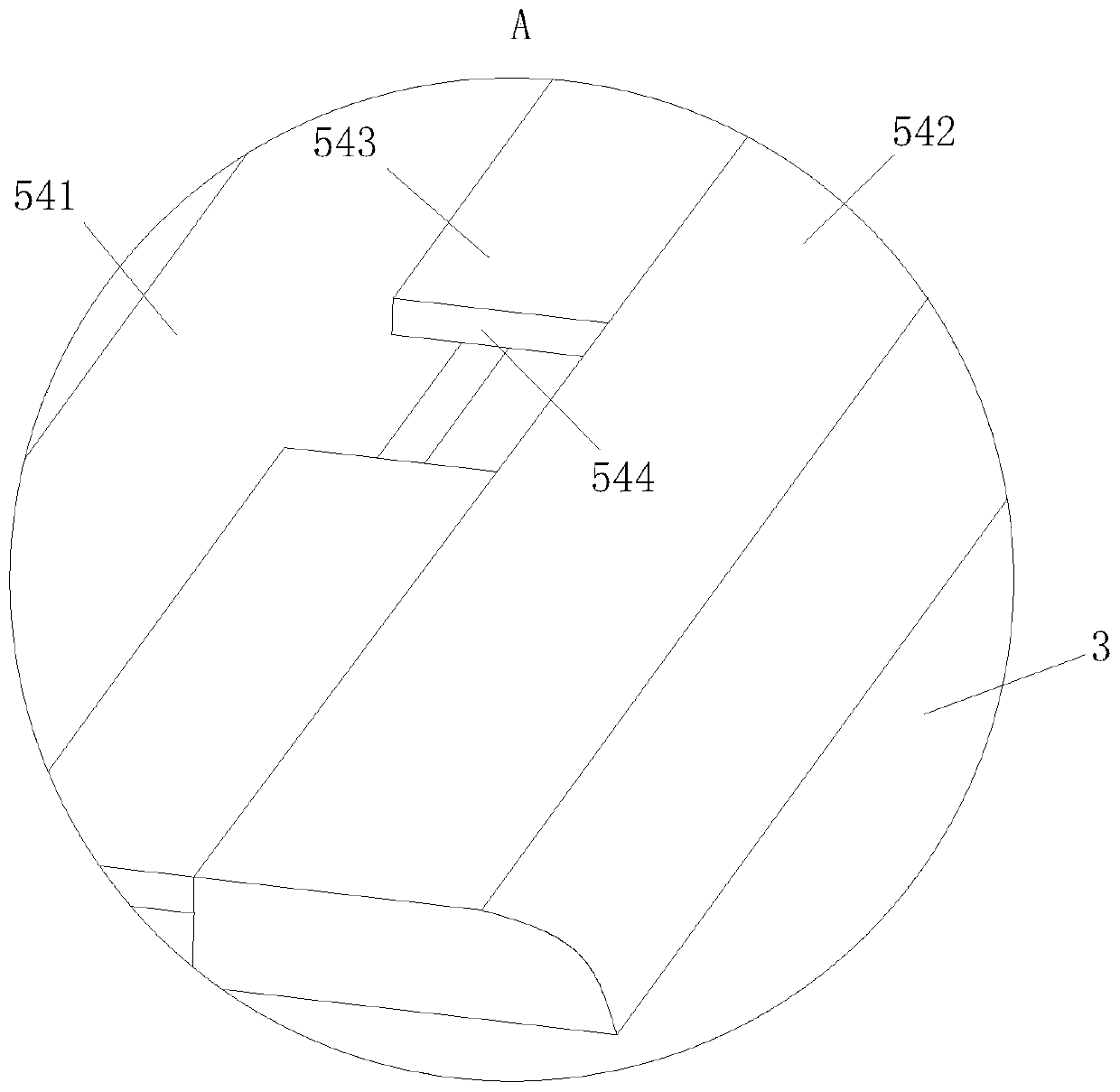

Multicolour screen printing machine

The present invention discloses a multicolour silk-screen printing machine, including machine frame, several printer heads mounted on the machine frame, drying equipment placed among the several printed heads, drive device, transfer device and final drying device. Said transfer device includes driving roller, driven roller, metal conveyer belt and stock fixing device, the driving roller or / and drive roller is equipped with driving pin which can be combined with pin hole on the metal conveyer belt, two sides of machine frame are equipped with spacing guideway respectively for preventing metal conveyer belt from producing jump and leftward and rightward displacement and ensusing striaght movement of the conveyer belt. Said invention is suitable for screen printing various materials.

Owner:安旭 +3

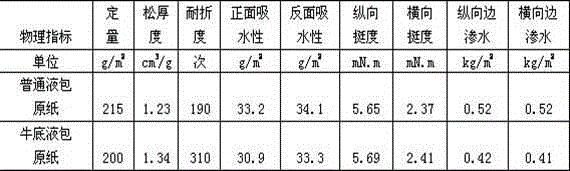

Bovine base solution packaging raw paper

The invention relates to a bovine base solution packaging raw paper used in production of liquid packaging boxes. The base solution packaging raw paper comprises a surface layer, a core layer, a base layer and a coating layer and is characterized in that the surface layer comprises chemical hardwood pulp and softwood pulp; the core layer comprises mechanical pulp, chemical hardwood pulp and unbleached pulp; the base layer comprises unbleached pulp; and the coating layer comprises calcium carbonate, porcelain clay, adhesive, a water-retaining agent and a water repellent agent. The base solution packaging raw paper disclosed by the invention has the advantages of environment protection, low cost, high physical strength as well as good decoration property and printing performance of products, accordance with the food requirement and no harm to human bodies, wherein the using amount of chemicals is reduced so that the environment pollution is reduced, and the using amount of chemicals is reduced so that the cost is reduced.

Owner:万国纸业太阳白卡纸有限公司

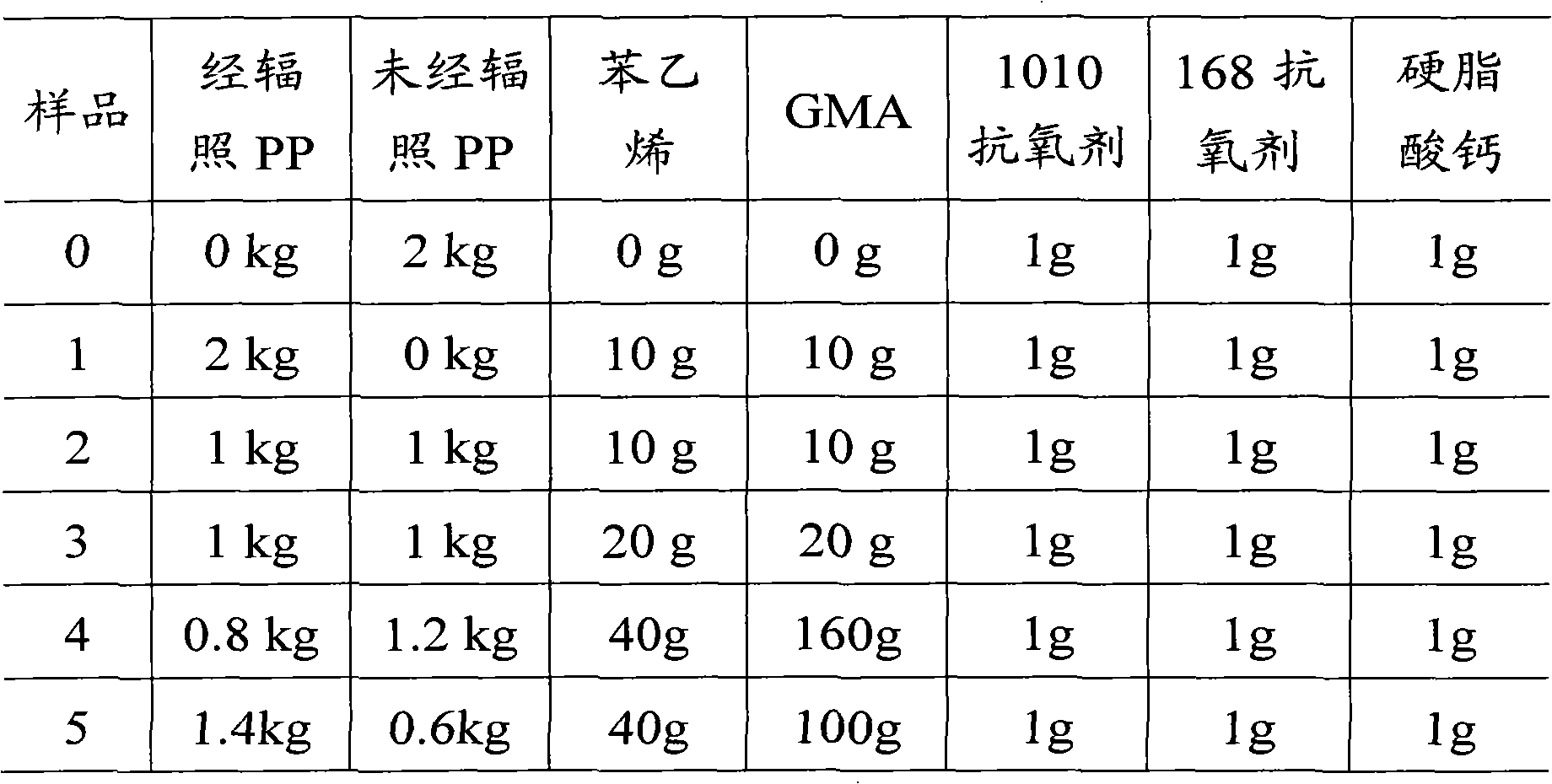

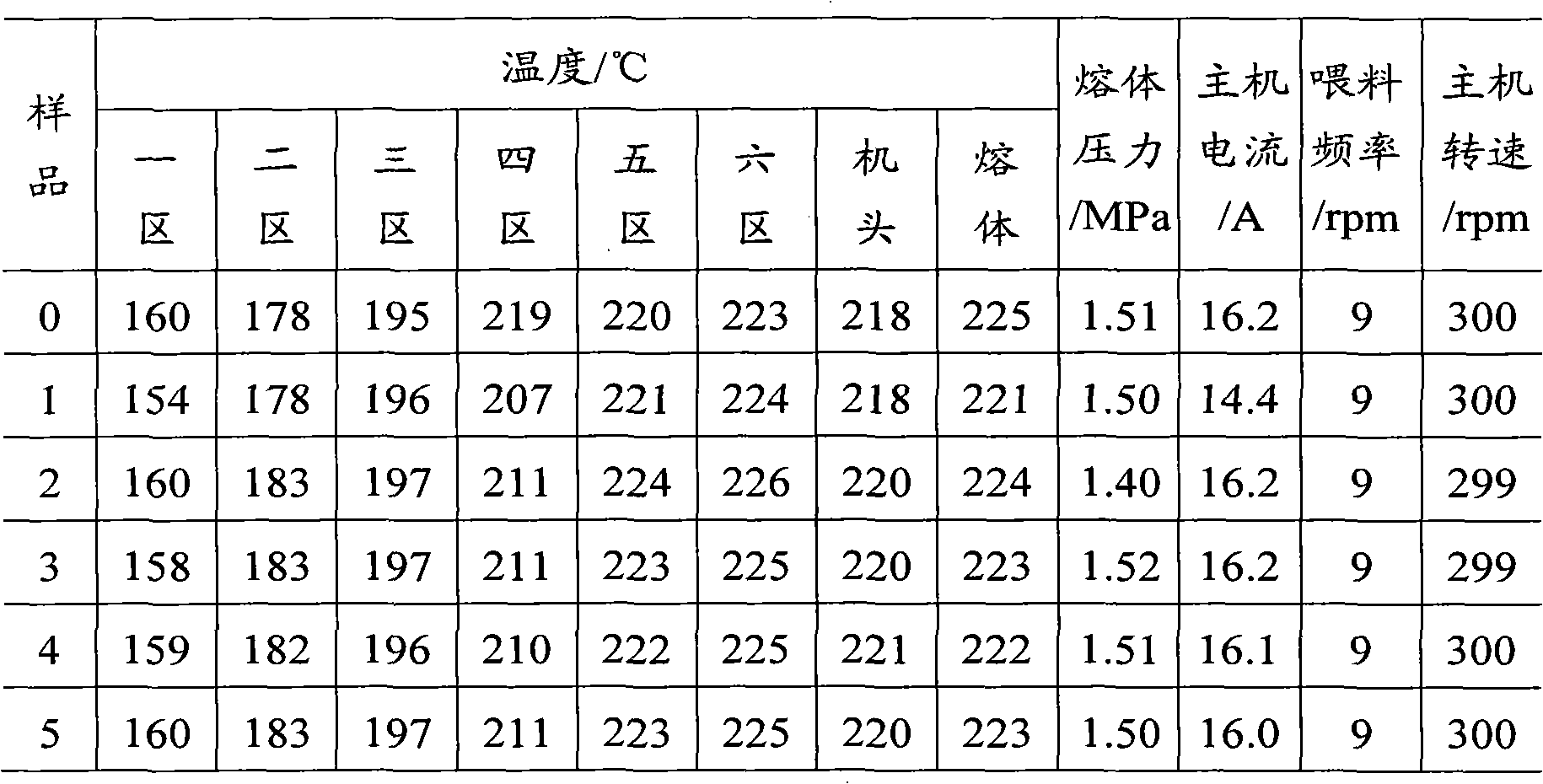

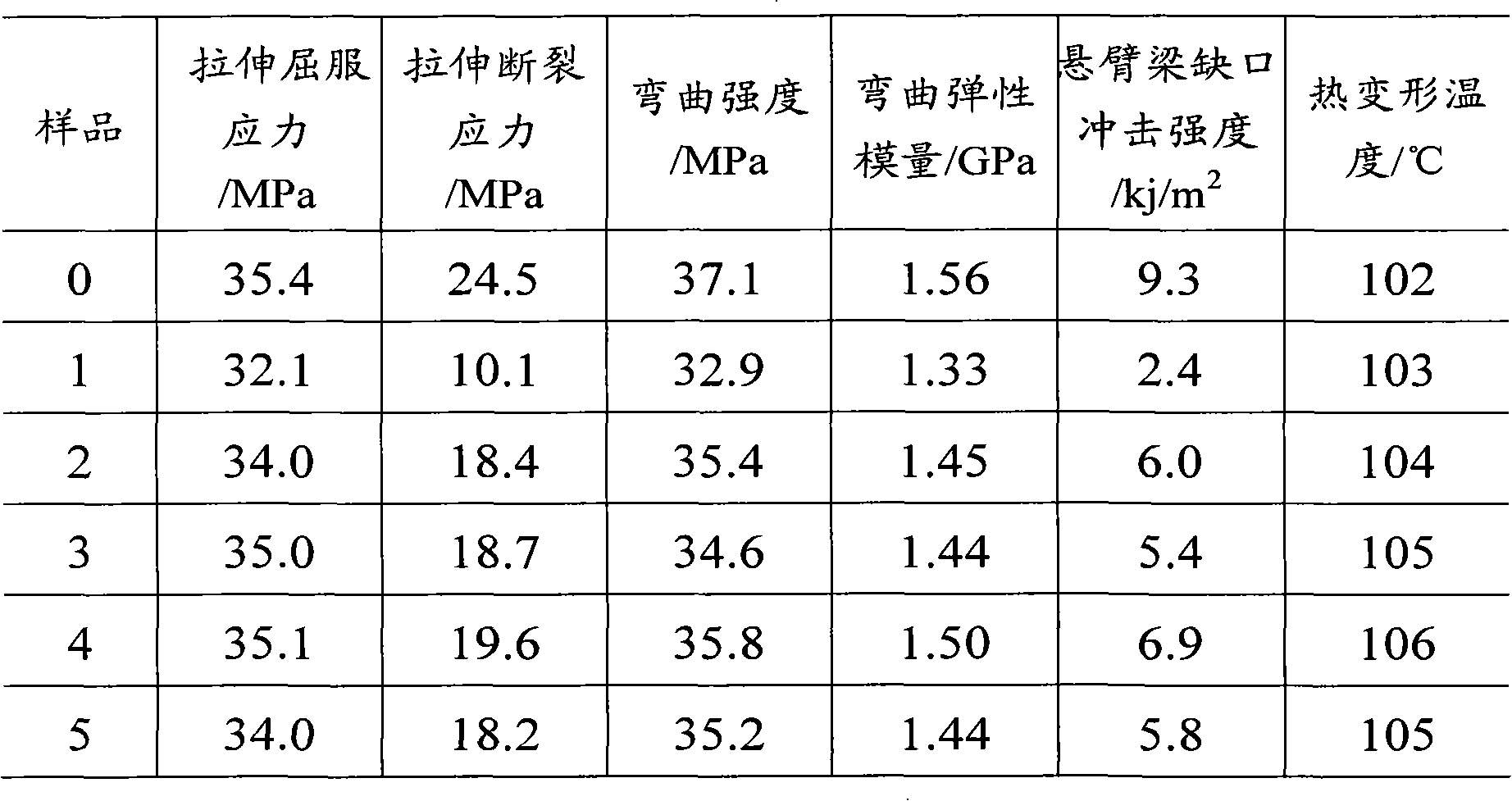

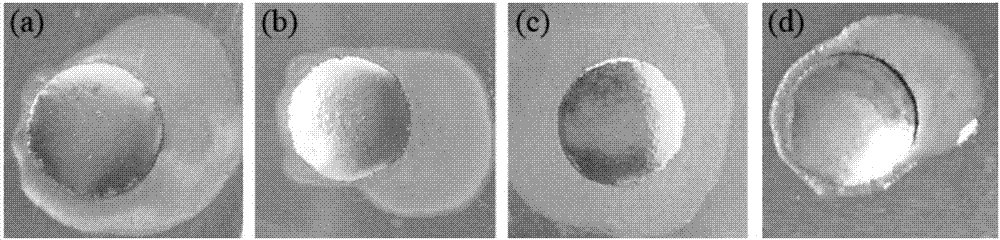

Functionalized polypropylene for flexible packages, preparation method thereof and functionalized polypropylene used for preparing flexible packages by the method

InactiveCN101676309AHigh grafting rateGuaranteed uniformityFlexible coversWrappersPre irradiationGlycidyl methacrylate

The invention provides functionalized polypropylene (PP) for flexible packages and a preparation method thereof. The functionalized PP for flexible packages comprises the following components: (a) 30to 70 weight parts of irradiated PP powder; (b) 30 to 70 weight parts of non-irradiated PP powder; and (c) 0.4 to 15 weight parts of polar co-monomer formed by subjecting the irradiated PP powder in component (a) and the non-irradiated PP powder in component (b) to graft copolymerization, and optionally comprising (d) antioxidant and / or lubricant, wherein, the PP powder in component (a) is irradiated in the protective presence of nitrogen with the irradiation source thereof being a cobalt source, the irradiation dose thereof being 20kGy to 60kGy, and the dose rate thereof being 2 to 0.5 kGf / h.The invention intends to prepare PP with higher polarity and improve the print and compound properties of PP films by grafting the polar monomer of glycidyl methacrylate (GMA) and styrene on PP powder on the basis of the pre-irradiation method.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

High-performance low-temperature soldering lead-free solder paste and preparation method thereof

ActiveCN107160052AAvoid residueHigh speedWelding/cutting media/materialsSoldering mediaBoiling pointSolder ball

The invention discloses a high-performance low-temperature soldering lead-free solder paste and a preparation method thereof. The soldering lead-free solder paste comprises, by weight, 0.2-2.5% of a combined surfactant, 0.1-1.0% of an antifoaming agent, 0.01-0.1% of an active strengthening agent, 0.1-1.0% of a normal-temperature activity inhibitor, 0.5-1.5% of a thixotropic agent, 2.5-6.0% of a cosolvent, 2.7-5.9% of a resin film-forming agent, and the balance Sn-based solder alloyed powder; and the combined surfactant is formed by mixing liquid saturated monocarboxylic acid and solid unsaturated low-boiling-point acid according to the weight ratio of 1:2-1:9. The high-performance low-temperature soldering lead-free solder paste and the preparation method thereof can solve the common problems of a large quantity of black residues and solder balls and the like of current low-temperature soldering lead-free solder pastes after welding, meanwhile, the paste has the characteristics of being good in storage stability and not dried in the long-time printing process, and the high-performance low-temperature soldering lead-free solder paste is particularly suitable for the field of assembly of low temperature electronic surfaces.

Owner:SOUTH CHINA UNIV OF TECH

Scrape-removable water-based ink for flexographic printing and preparation method thereof

The invention provides scrape-removable water-based ink for flexographic printing, which comprises raw materials of color paste, base ink and an admixture, wherein the base ink comprises water-based silver ink, shading black, peeling oil and protective water-based oil. The invention further provides a preparation method of the scrape-removable water-based ink for flexographic printing. The preparation method comprises the steps as follows: step 1, the water-based silver ink is prepared for reserve; step 2, the shading block is prepared for reserve; step 3, the peeling oil is prepared for reserve; step 4, the protective water-based oil is prepared for reserve; step 5, the base ink is prepared for reserve; step 6, the color paste is prepared in an agitator for reserve; step 7, the color paste prepared in the step 6 is added to water and dispersed and ground in a dispersion machine for reserve; and step 8, the color paste, the base ink and the admixture are taken by weight percentage andevenly agitated and mixed, and then the product is prepared. The invention provides the one-step water-based ink and the manufacturing method thereof, which have the advantages that the production process flow of special water-based ink is changed, the manufacturing time is shortened, production procedures are reduced and complete grinding is not needed.

Owner:HENAN UNIV OF SCI & TECH

Braille printing technology

InactiveCN101323219AEasy to printSimple printing processPattern printingOther printing apparatusChinese charactersSheet film

The invention relates to a braille printing technology, comprising the following steps: professional braille typesetting, that is, the automation of letter input, compilation, typesetting, inspection, collation and even output of the braille in the publishing process is realized through the professional braille and the Chinese characters comparison compilation and typesetting system provided by the Chinese braille computer system; film outputting - the laser typesetting machine is used for putting out the braille symbol in the graphic form; silk screen forme curing - the tension is controlled within 0.8-1.1 (N / cm), the adopted mesh number is 40-60 meshes / centimeters, extrusion coating is 12-16 layers with a 0.2 - 0.5mm thickness; preparing printing ink with uv varnish material and thickener; page making up and adjusting; oil layer extrusion coating; infrared heating and leveling; ultraviolet uv solidifying. The braille printing technology is rapid in print speed, good in printed letters and adhesion of patterns, colorless and transparent, press resistant, wear resistant, low in cost, etc. The braille can be directly printed on reading matters with letters. The double-side printing can be performed and the printing quality is not affected. The ideal braille printing effect can be acquired. The printing can be performed on the ordinary printing materials. The printing carrier of the braille is widened.

Owner:张小文

Preparation method of inorganic micro-powder/PBAT full-degradable composite film

PendingCN111647183ASustainable developmentIn line with the concept of \"green packaging\"Composite filmThin membrane

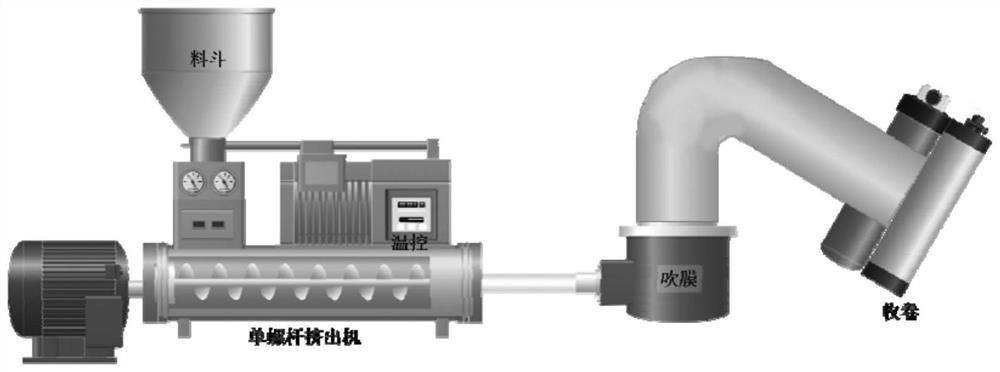

The invention provides a preparation method of an inorganic micro-powder / PBAT full-degradable composite film. A certain proportion of inorganic micro-powder is added before the process of producing the PBAT film through hot melting film blowing, so that the fully-degradable composite film with excellent performance is produced; the inorganic micro-powder is derived from various kinds of stone powder in the nature and is rich in reserves and low in price; by adding a certain amount of inorganic micro-powder, the easy adhesion characteristic of the PBAT film is reduced, the stiffness of the filmis improved, and therefore the PBAT film blowing bag making process is facilitated; meanwhile, the production cost is reduced by adding the inorganic micro-powder, and a shortcut is provided for rapid popularization and application of full-degradable materials.

Owner:ZHEJIANG SCI-TECH UNIV

Production process of crystalline silicon double-sided solar battery

InactiveCN102664217AEliminates thermal diffusion stepLeave out the edgeFinal product manufactureSemiconductor devicesTrappingOptoelectronics

The invention relates to a production process of a crystalline silicon double-sided solar battery, comprising the following steps of: etching to enable a silicon substrate to have an etched face; manufacturing a window which accords with an electrode pattern on a backlight face of the silicon substrate; carrying out heat treatment on the silicon substrate to form a PN junction in the window; washing the silicon substrate; plating at least two layers of antireflection films on a light reflective face of the silicon substrate; plating the antireflection film on a backlight face of the silicon substrate; printing electrode slurry on a silk screen; and sintering to obtain a metal electrode so as to finish the manufacturing of a battery cell. The production process disclosed by the invention is ingenious in concept, is compatible with a conventional industrial battery production line and is easy for industrial manufacture; compared with the conventional solar battery, an electrode grid line is not arranged on the light reflective face of the double-sided solar battery so as to prevent the electrode grid line of the light reflective face from shielding sunlight; the backlight face is provided with a light trapping structure and an antireflection film layer so that the backlight face of the battery also can absorb and utilize the sunlight; and the antireflection films of the light reflective face and the backlight face can passivate the solar battery, so as to be good for improving the efficiency of the battery.

Owner:杨正刚

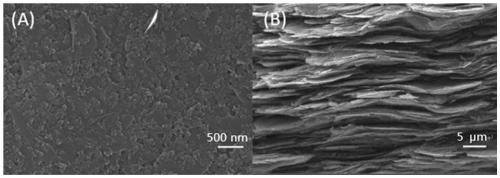

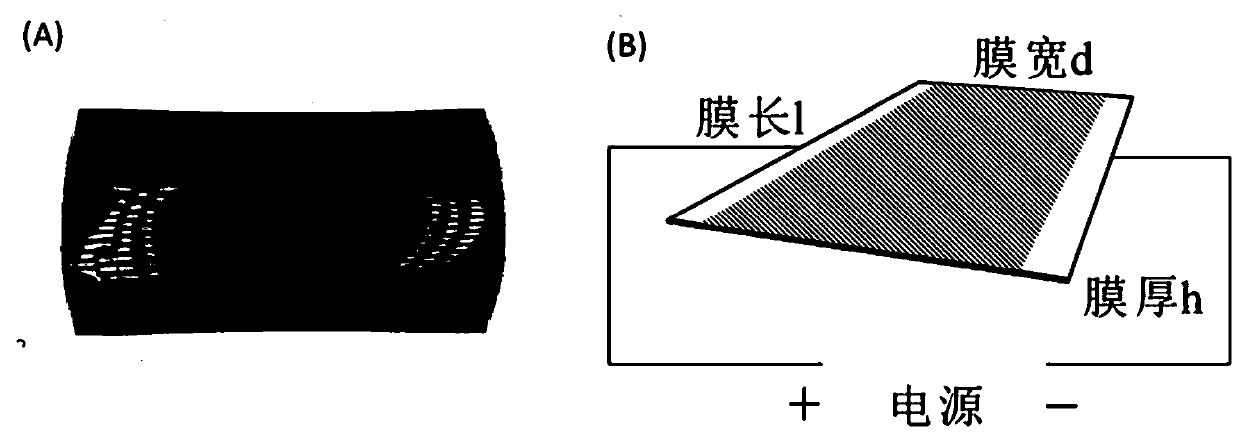

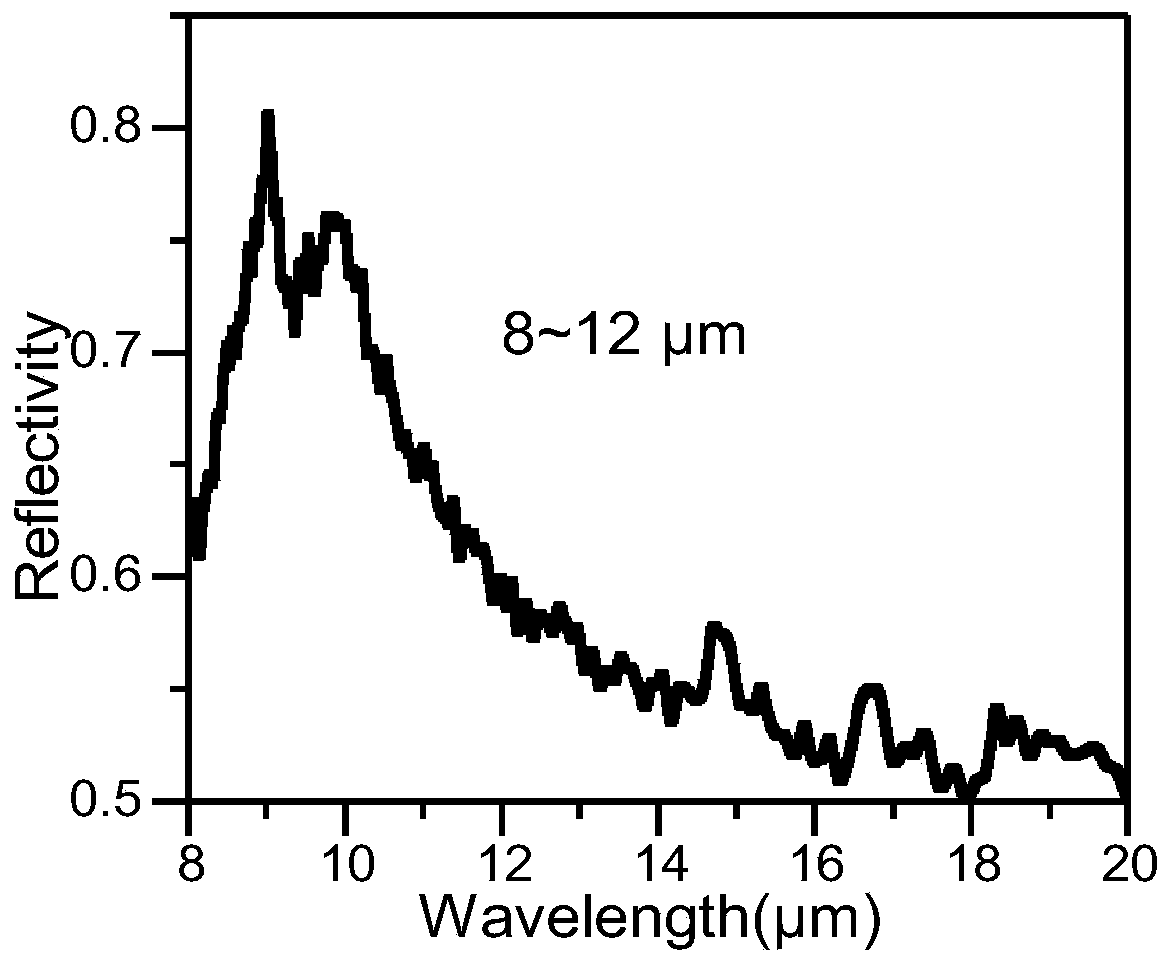

Method for preparing oily electrothermal conversion ink, and ink prepared by preparation method

The invention provides a method for preparing an oily electrothermal conversion ink. The method comprises: crushing expanded graphite to obtain crushed expanded graphite; pre-mixing the crushed expanded graphite, an electric conduction filler, a resin, an auxiliary agent and a solvent to obtain a premix; adding a solvent to the premix, and stirring to obtain a uniform and foam-free ink precursor dispersion liquid; and peeling the ink precursor dispersion liquid to obtain the oily electrothermal conversion ink, wherein the mass percentages of the resin, the solvent and the auxiliary agent respectively are 10-40%, 35-80% and 0.3-4%. According to the present invention, the prepared oily electrothermal conversion ink has good adaptability to printing processes, and further has high electrothermal film uniformity.

Owner:XIAMEN UNIV +1

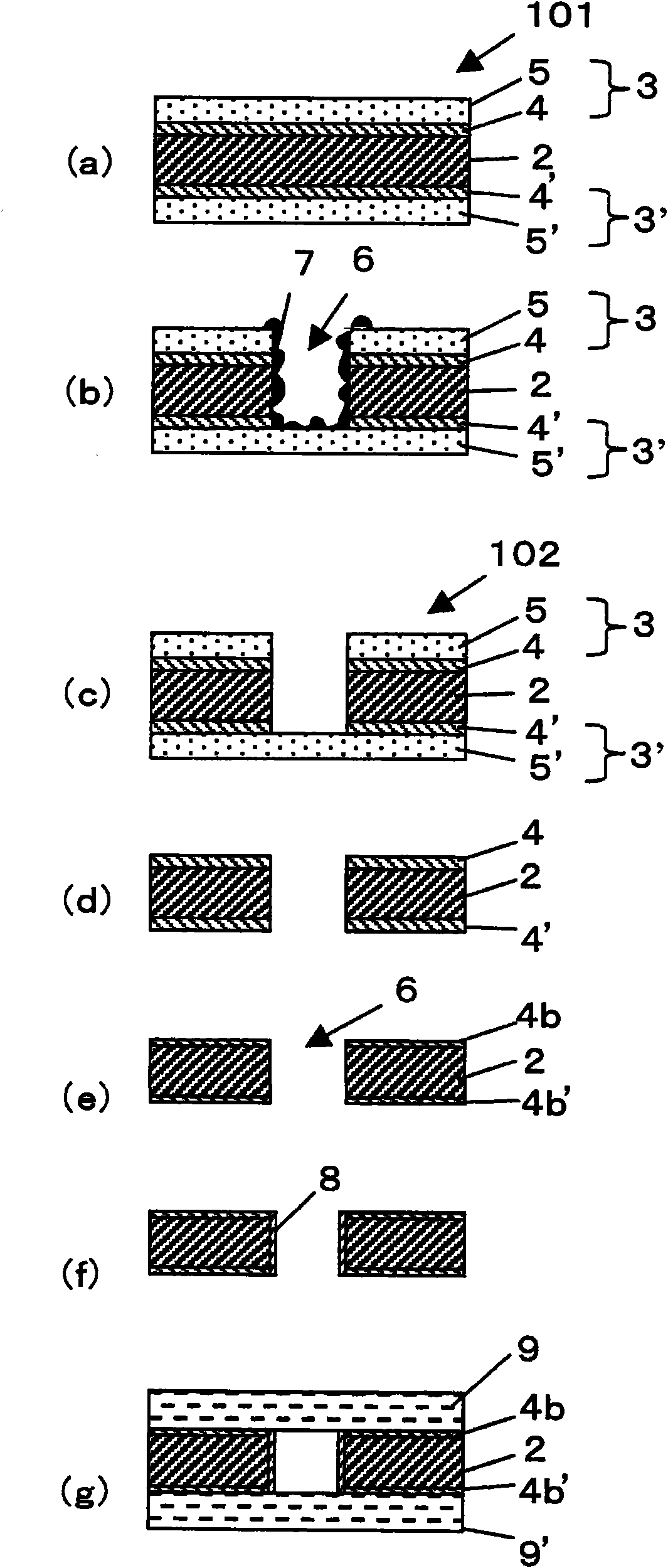

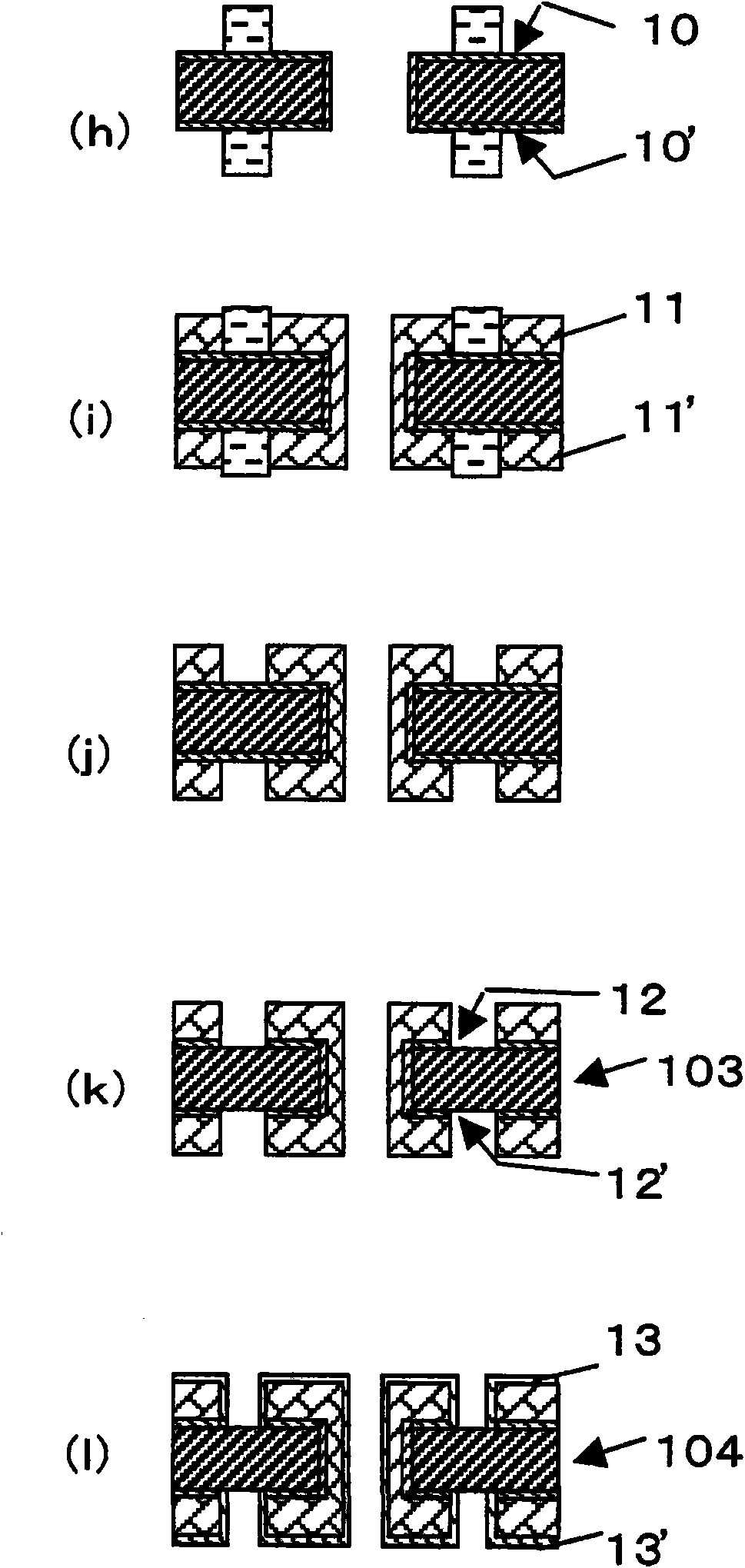

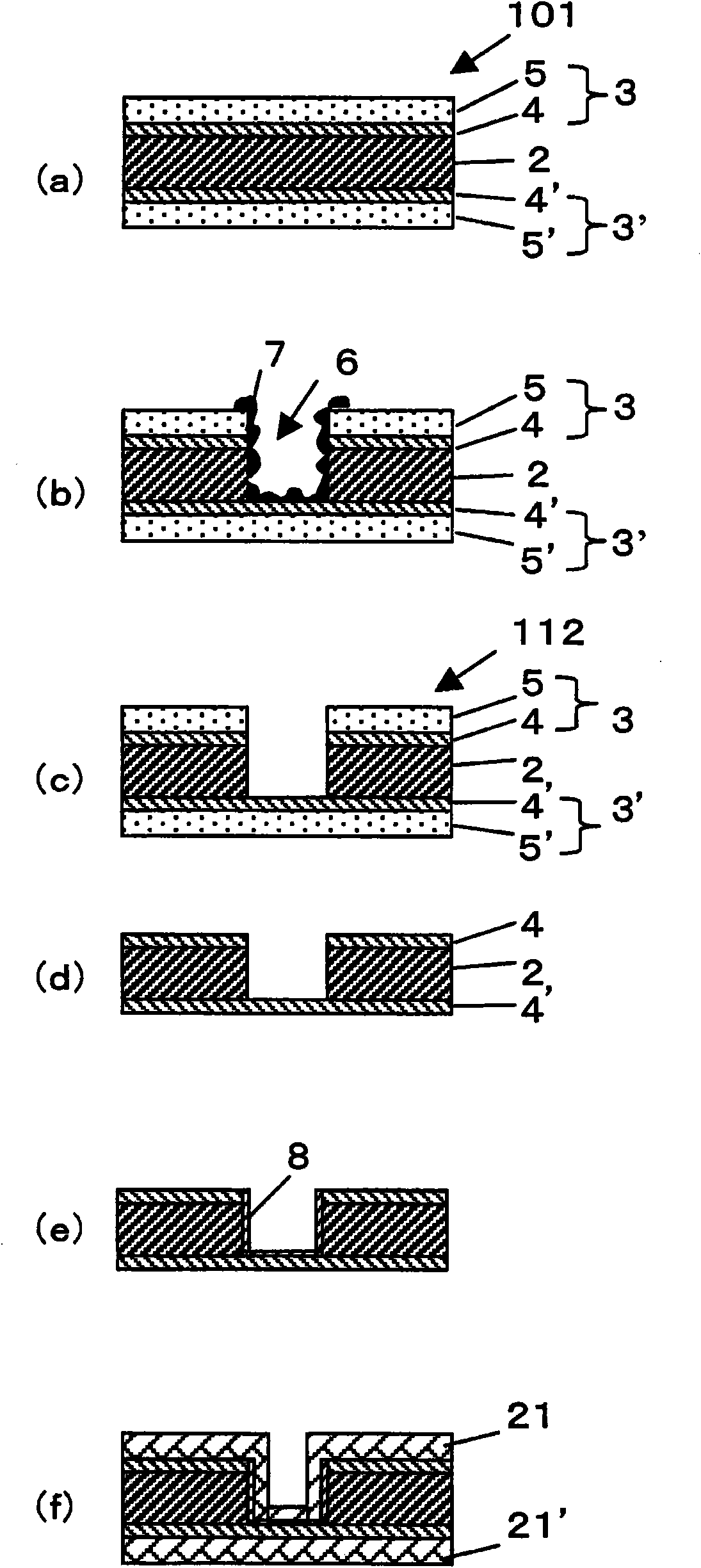

Method for manufacturing printed wiring board

InactiveCN101897246AGood dimensional stabilityAvoid stretchingInsulating layers/substrates workingCircuit precursor manufactureProduction rateEngineering

Provided is a method for manufacturing with high productivity a printed wiring board having high dimensional stability. The manufacturing method is provided with a step of preparing a metallic laminated body wherein a metal layer having an inner metal layer section and a protection layer section is laminated on at least one side of an insulating resin layer, with the inner metal layer section on the side of the insulating resin layer; a step of forming a via hole on the metal layer and the insulating resin layer; a step of performing blast processing after forming the via hole; and a step of removing the protection layer section after performing blast processing.

Owner:UBE IND LTD

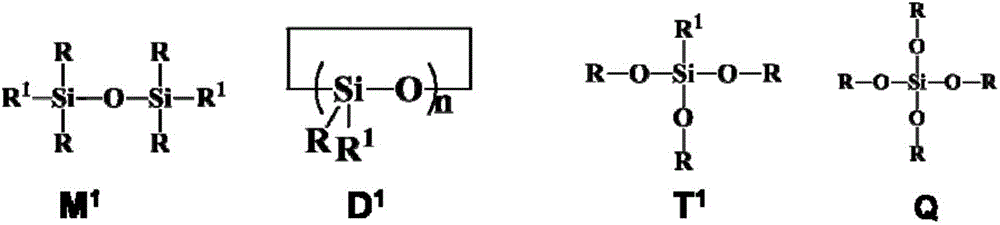

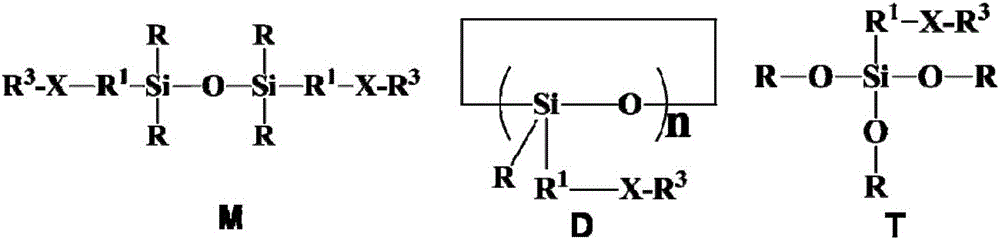

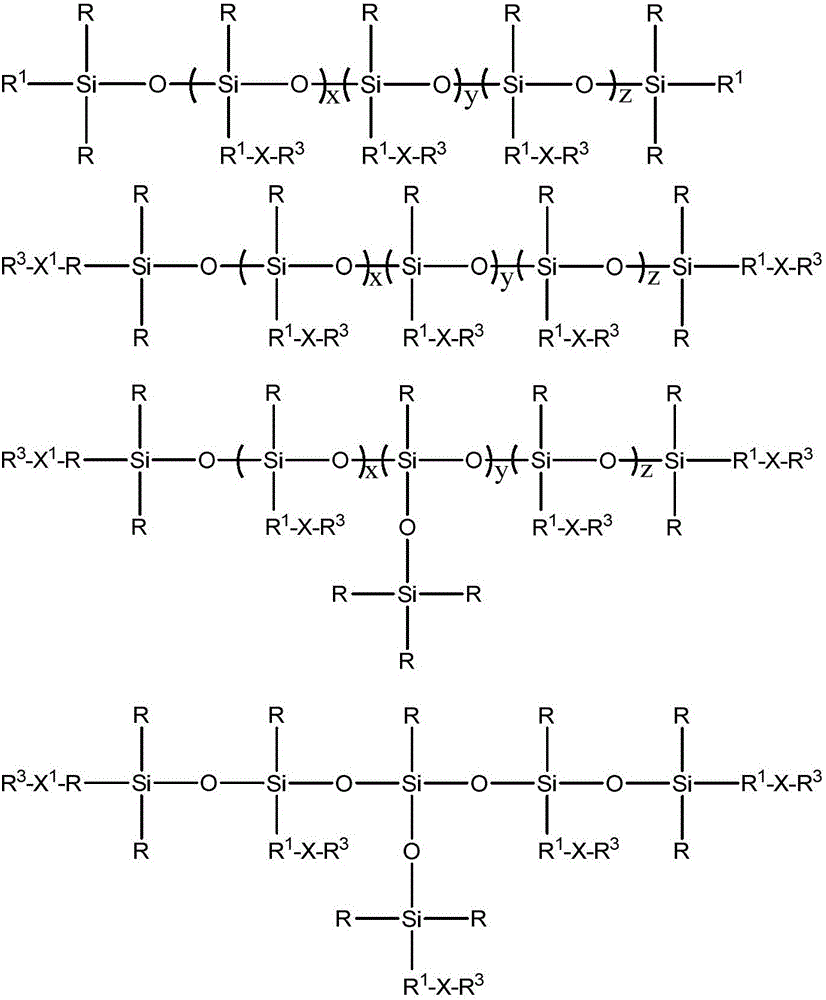

Fluorine-containing alkenyl polysiloxane, preparation method thereof and application

The invention belongs to the field of material chemical synthesis, and discloses fluorine-containing alkenyl polysiloxane, a preparation method thereof and an application. The preparation method for the fluorine-containing alkenyl polysiloxane mainly comprises the following steps: (1) under the action of a solvent and a catalyst, enabling alkenyl siloxane units M1, D1 and T1 to react with a nucleophilic reagent of a fluorine-containing chain segment R3X, and purifying the obtained reaction liquor after the reaction is ended, thereby obtaining fluorine-containing alkenyl polysiloxane M, D and T; and (2) enabling at least one of D and T and at least one of D1, T1 and Q to generate hydrolytic condensation reaction under the action of the catalyst, adding M or M1 to generate end capping reaction after the reaction is ended, and purifying the reaction product to obtain the fluorine-containing alkenyl polysiloxane with a line-type or a body-type structure. The fluorine-containing alkenyl polysiloxane is added, so that a solvent-free organic polysiloxane composite forms a surface with lower surface energy, and therefore, a fluoride-containing siloxane anti-adhesion coating with lower release force is obtained.

Owner:国科广化(南雄)新材料研究院有限公司 +2

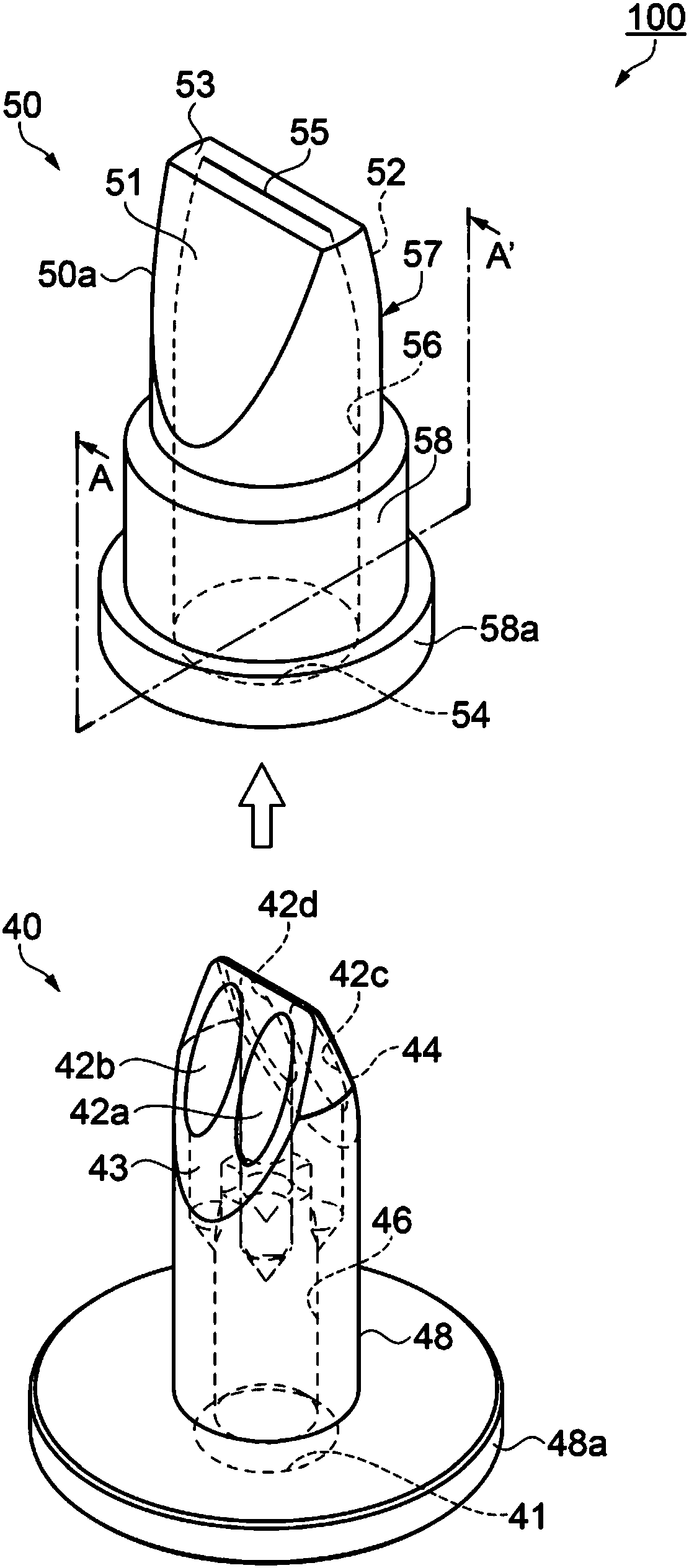

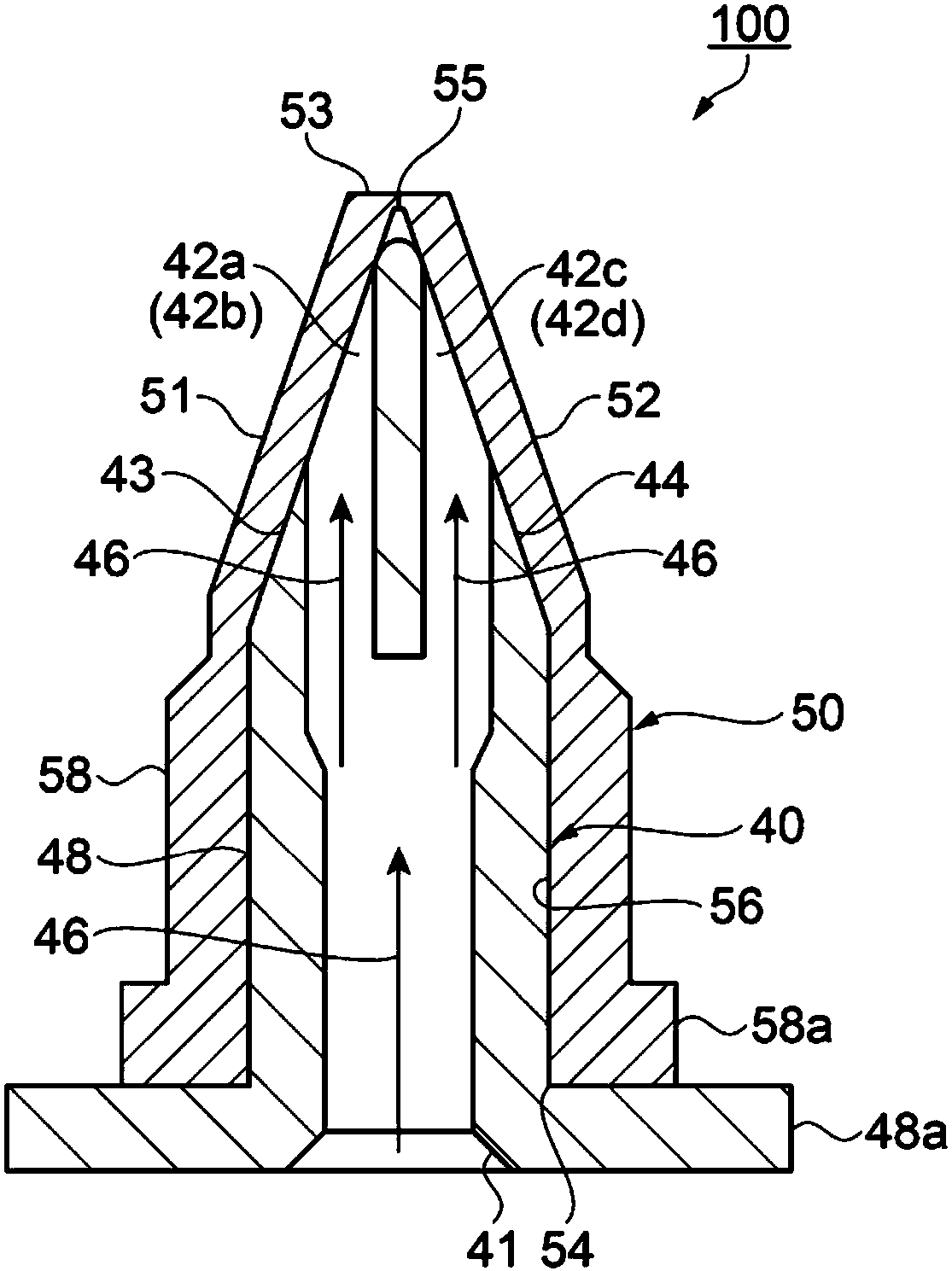

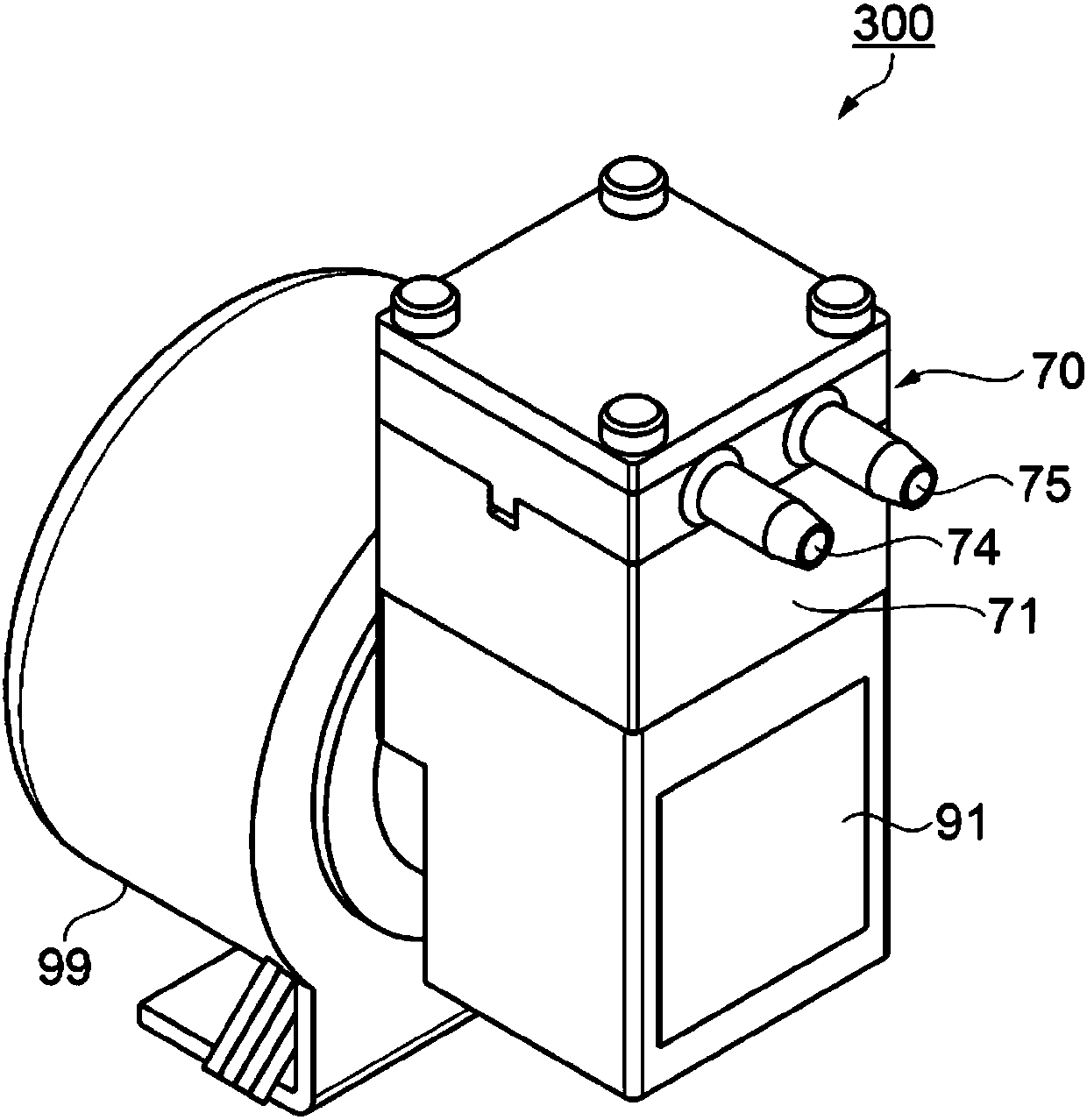

Check valve, diaphragm pump, and printing apparatus

InactiveCN107762831AStable pressure deliveryImprove qualityPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

Owner:SEIKO EPSON CORP

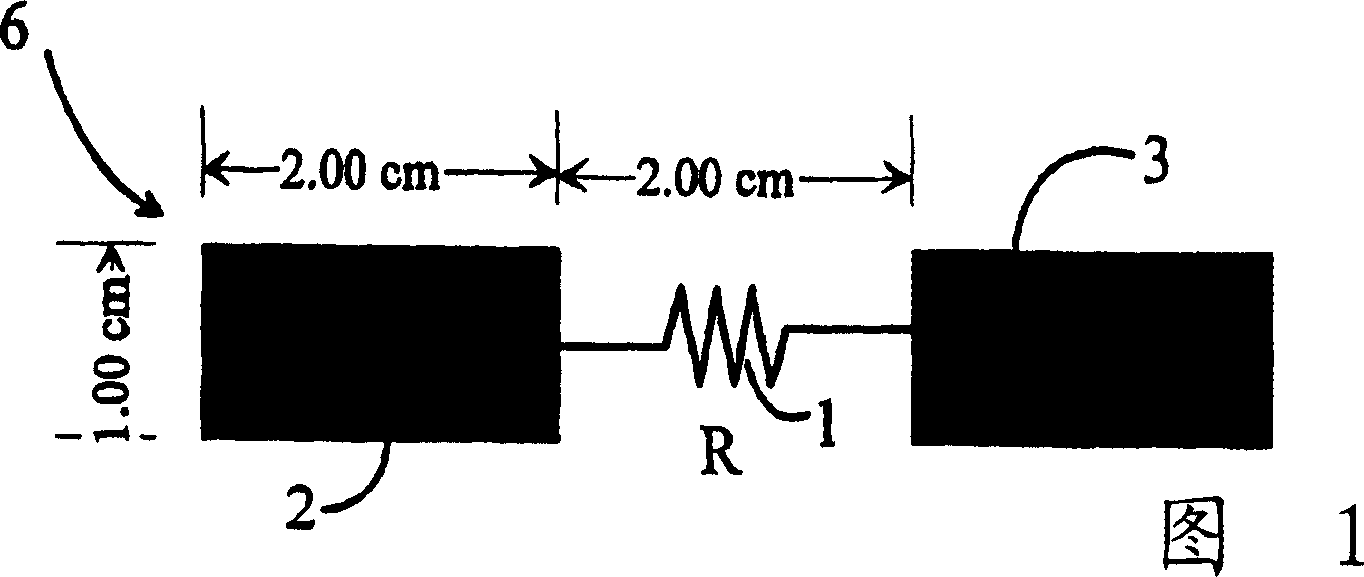

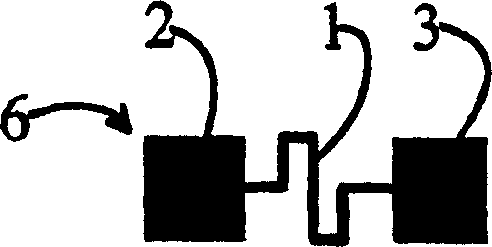

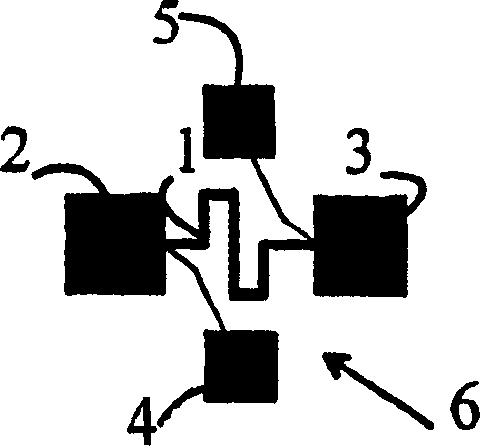

Method for detecting objects and a system for solving content of a symbol

InactiveCN1823340ALow costSimple measurement electronicsSensing record carriersRecord carriers used with machinesElectrical resistance and conductanceConductive materials

This publication discloses a method for identifying items, such as sheets of paper, or packages, a resistance mark arrangement, and reading apparatus. According to the method a mark made of electrically conductive material on the item is read contactlessly, in order to identify the item (7), or determine its properties. According to the invention, the precise absolute or relative resistance value of at least one electrically conductive mark (6) is determined and the measured resistance value is converted, for example, with the aid of a coding table or calculation formula, into information depicting the identity or properties of the item.

Owner:AVANTONE OY

Method for density compensation by drop size adaptation

ActiveCN107009770AAvoid Brightness DifferencesEquilibrium volatilityVisual presentationOther printing apparatusMechanical engineeringDrop size

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Production method of high-gloss one-sided dual-color heat transfer anodized aluminum

InactiveCN102303440ARealize integrated productionExcellent adhesionSynthetic resin layered productsMetal layered productsFractionationEthyl acetate

The invention discloses a production method of high-gloss one-sided dual-color heat transfer anodized aluminum, which comprises the processes of release coating, color layer coating, heating and drying, accurate aluminizing and adhesive layer curing. In the processes, anatase metal powder enabling the gloss of the anodized aluminum to be increased is added in a color layer for spraying, and ethyl acetate is added in the anatase metal powder to be used as a developing agent of color chromatographic fractionation. By adopting an anodized aluminum production technology, printing and gold blocking effects are greatly improved, and especially, gloss of thermoprinted characters, patterns and lines is greatly increased.

Owner:江苏卫星新材料股份有限公司

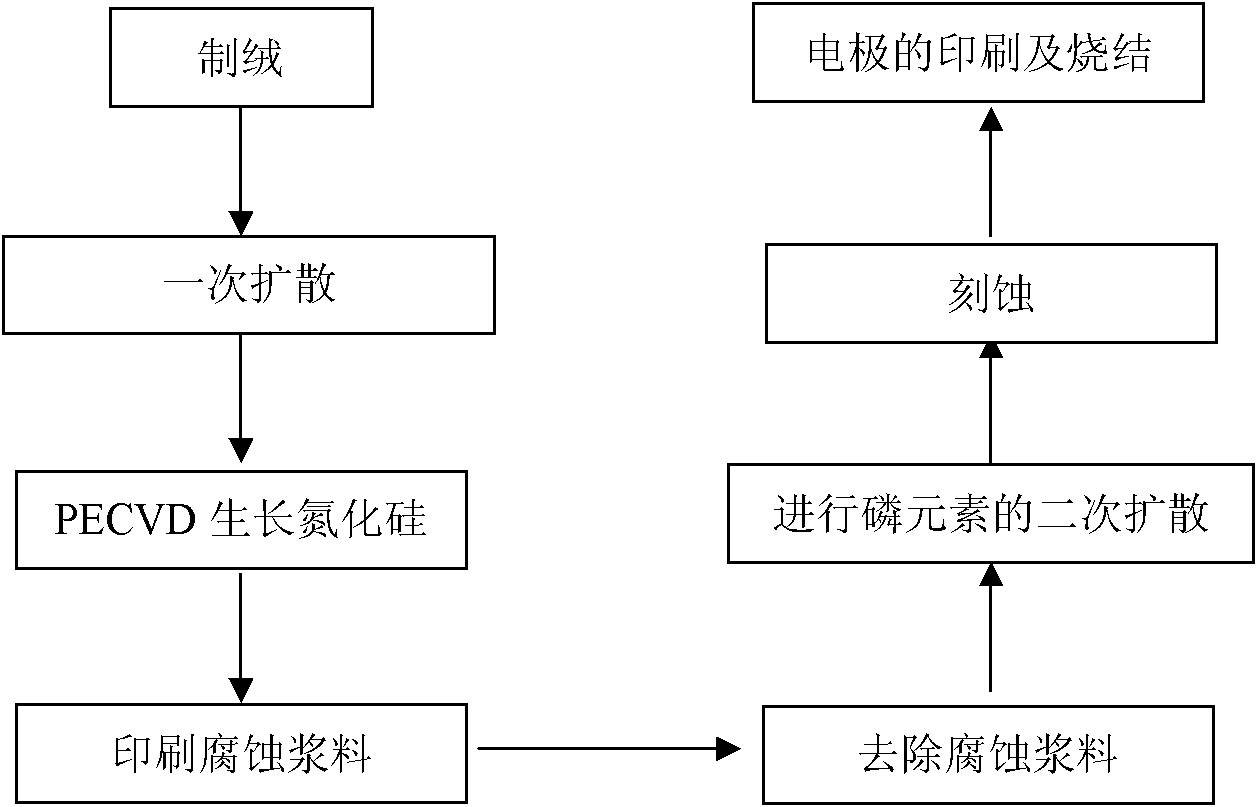

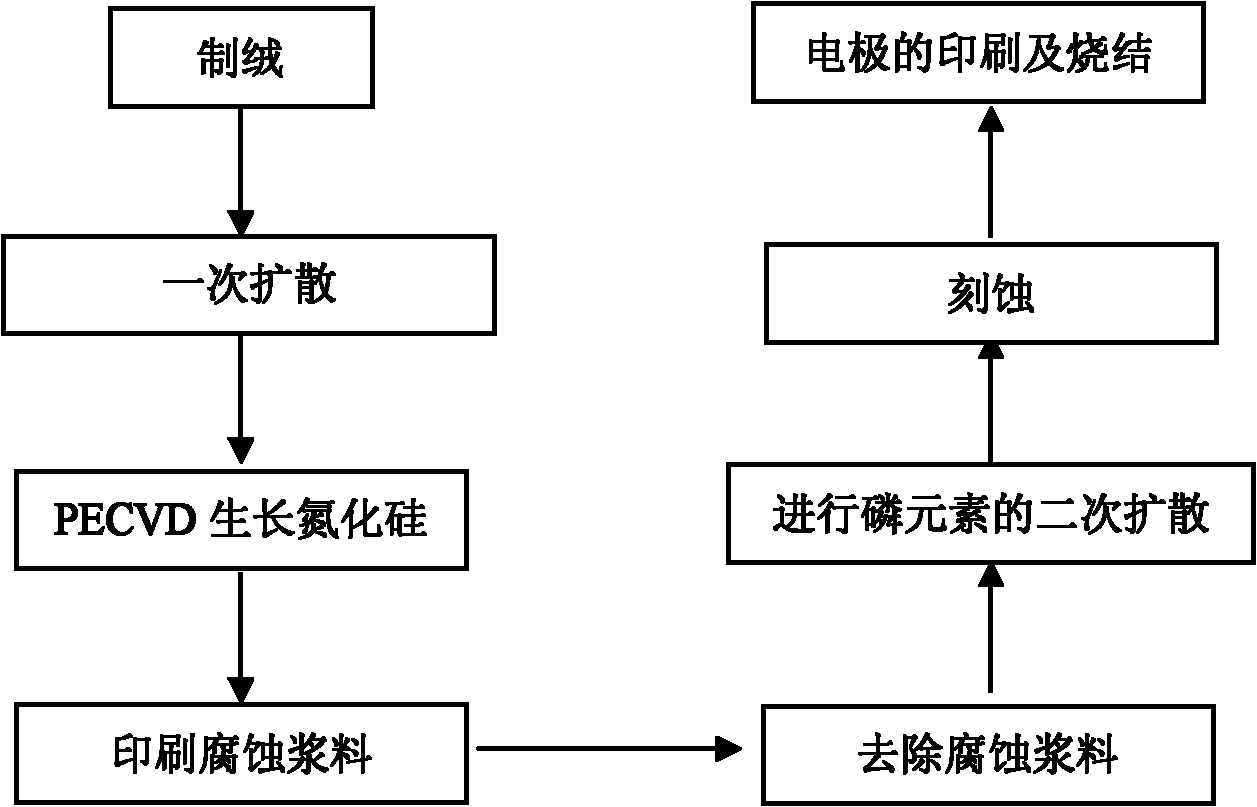

Process for preparing selective emitter of monocrystalline silicon solar cell with corrosion slurry method

InactiveCN102122683ASimple processSpeed up printingFinal product manufactureSemiconductor devicesSilicon nitrideCorrosion

The invention relates to a process for preparing a selective emitter of a monocrystalline silicon solar cell with a corrosion slurry method. A utilized technology is designed based on a common cell plate production line, the original step of growing an antireflecting film by adopting PECVD (Plasma Enhanced Chemical Vapor Deposition) is advanced to the completion of primary diffusion, meanwhile, the printing step and the removing step of corrosion slurry and secondary diffusion of a phosphorus element are added. Silicon nitride is simultaneously utilized as a barrier layer of the secondary diffusion and the antireflecting film of a cell plate. In the invention, the silicon nitride is utilized as the barrier layer of the diffusion, and the step of growing the antireflecting film by adopting the PECVD is an indispensable procedure for producing the monocrystalline silicon cell plate, therefore no addition step is added. The silicon nitride barrier layer of a selective emitter region is broken by the corrosion slurry; compared with a general physical method, the process does not need a special device and high temperature; and compared with a general chemical method, the process is simple. After the process is utilized, the average conversion efficiency of the cell plates produced in batches by a company reaches 18.5%, which is far higher than the industrial average level and achieves world-leading levels.

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

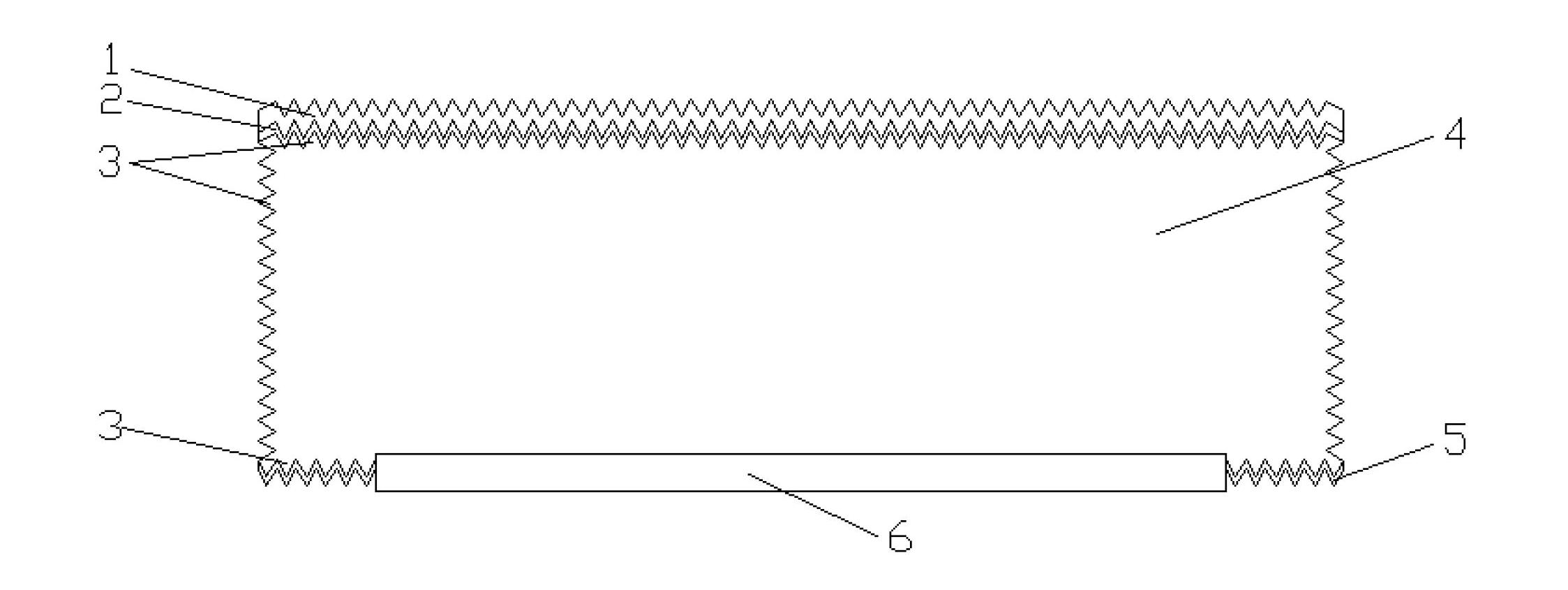

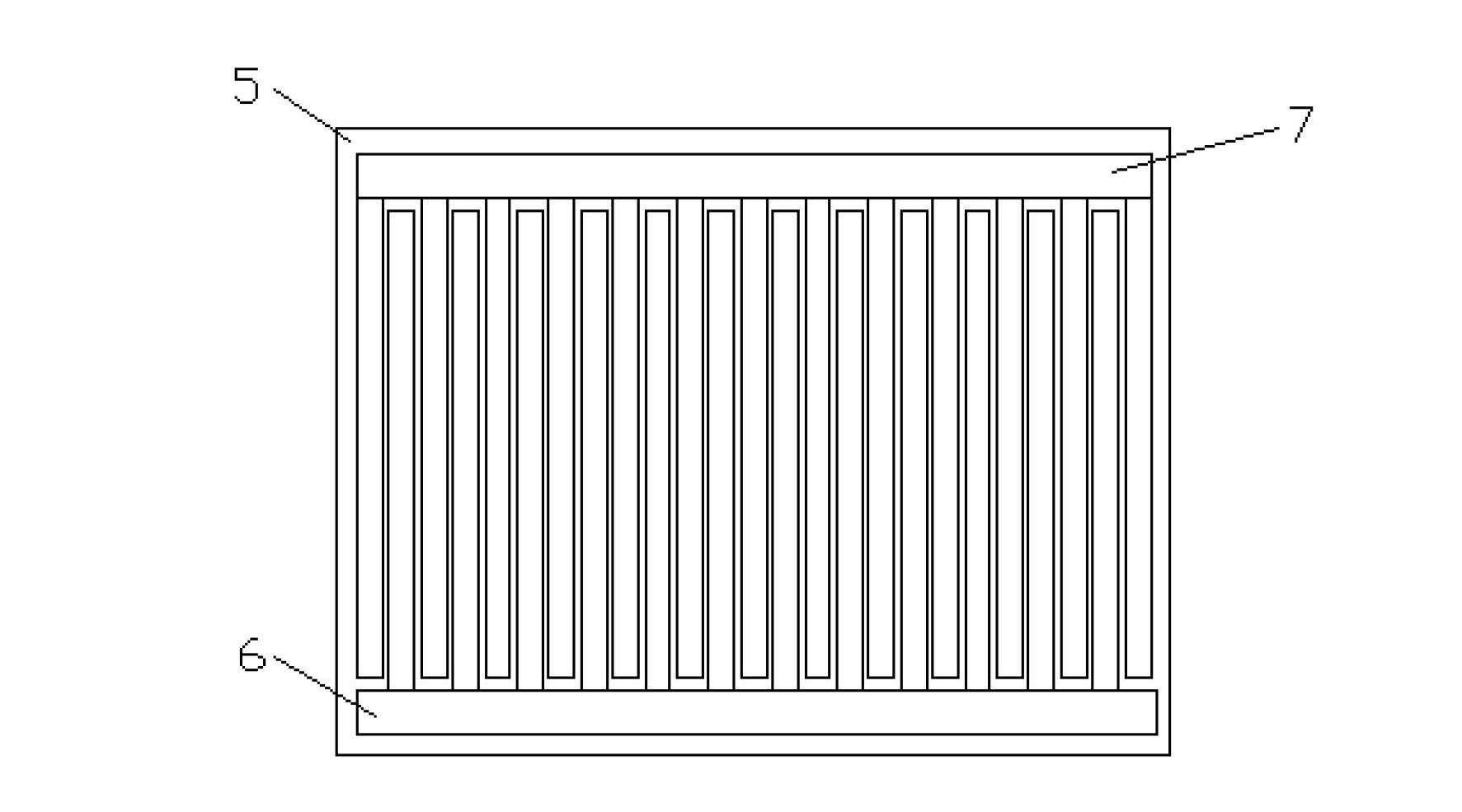

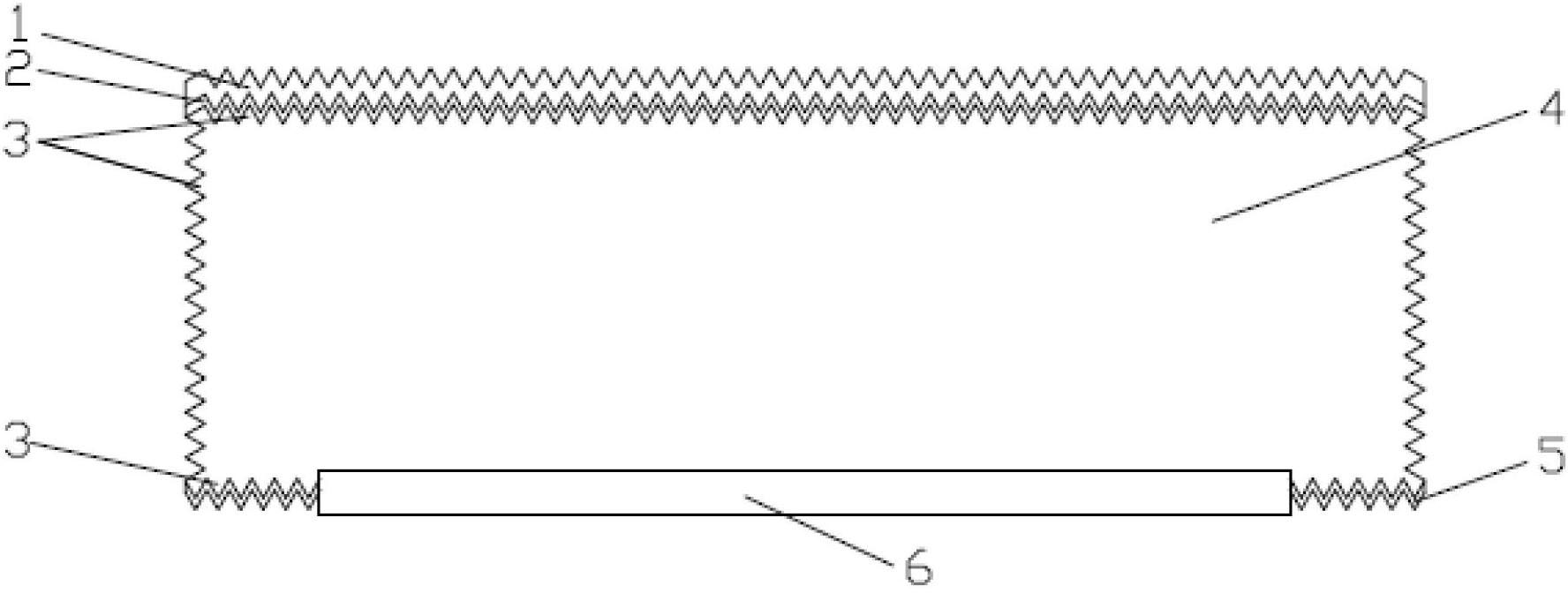

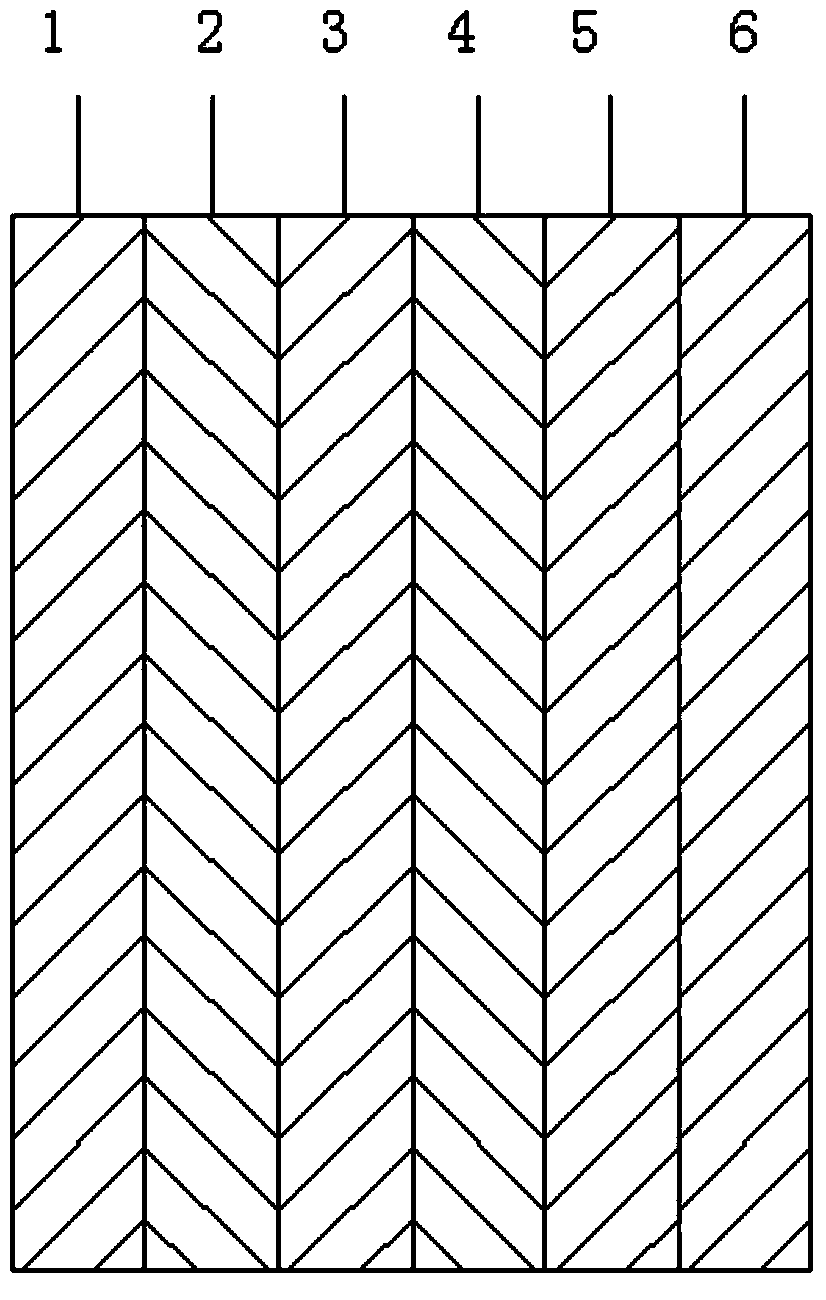

Inner liner paper of cigarettes for women

InactiveCN103924484ASpeed up printingIncreasing the thicknessSpecial paperSynthetic resin layered productsPolyethylene terephthalatePulp and paper industry

The invention discloses inner liner paper of cigarettes for women. The inner liner paper sequentially comprises a PET (polyethylene terephthalate) film (1), a release layer (2), a volatile oil layer (3), a pattern printing layer (4), a transfer adhesive layer (5) and an inner liner paper layer (6) from inside to outside. According to the inner liner paper of cigarettes for women, no aluminum foil is used; the volatile oil layer is arranged between the release layer and the pattern printing layer, and therefore, the inner liner paper has fresh scents of various flowers.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

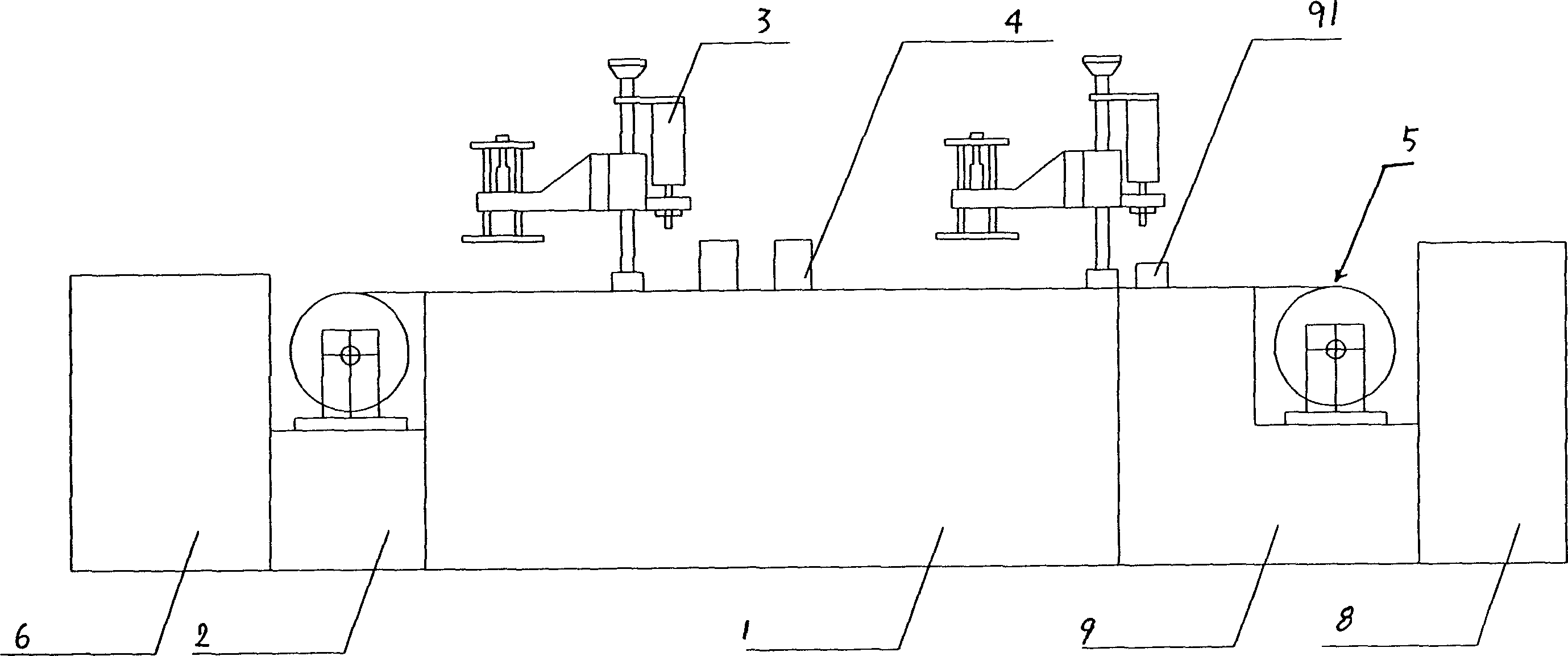

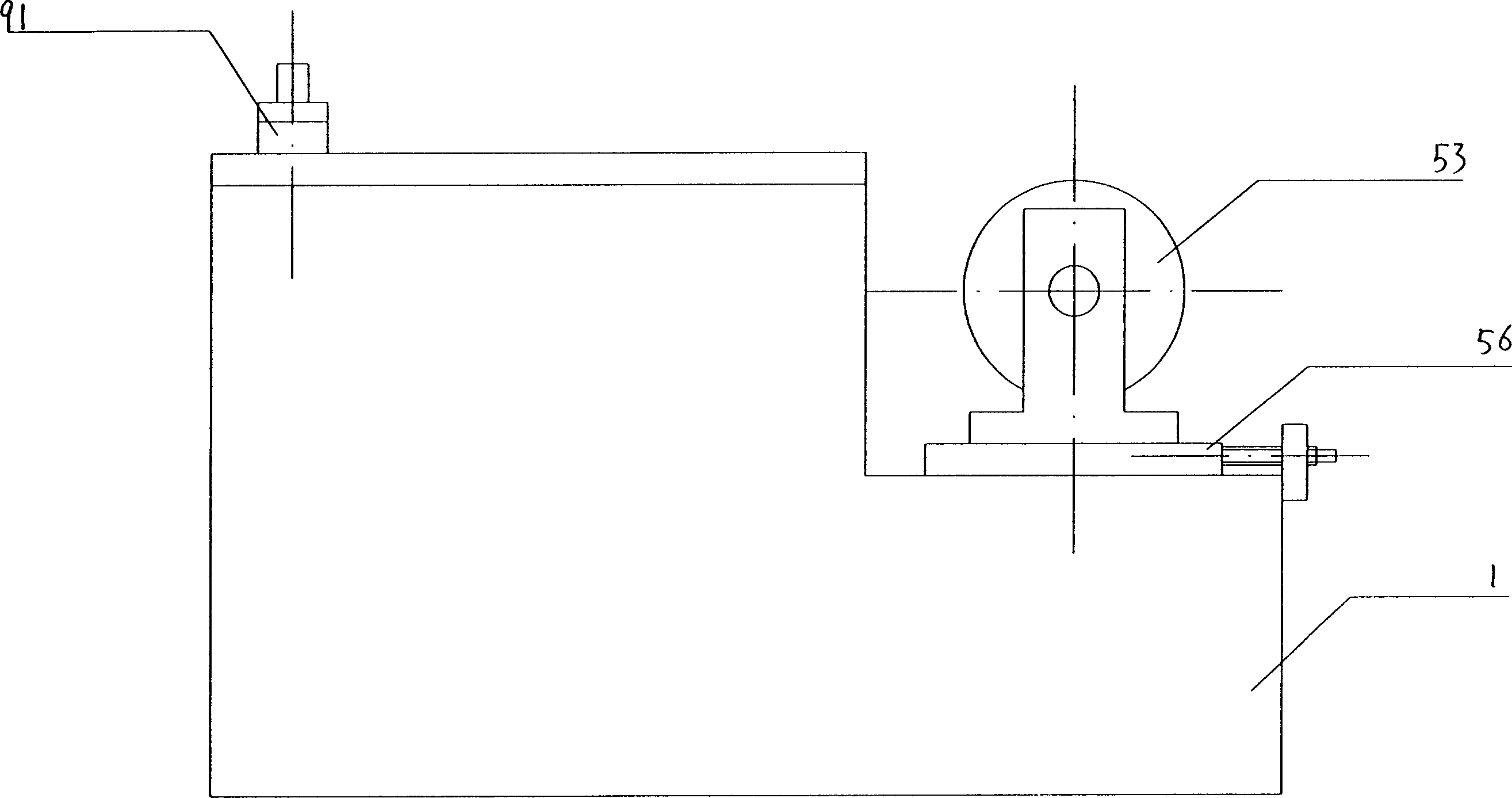

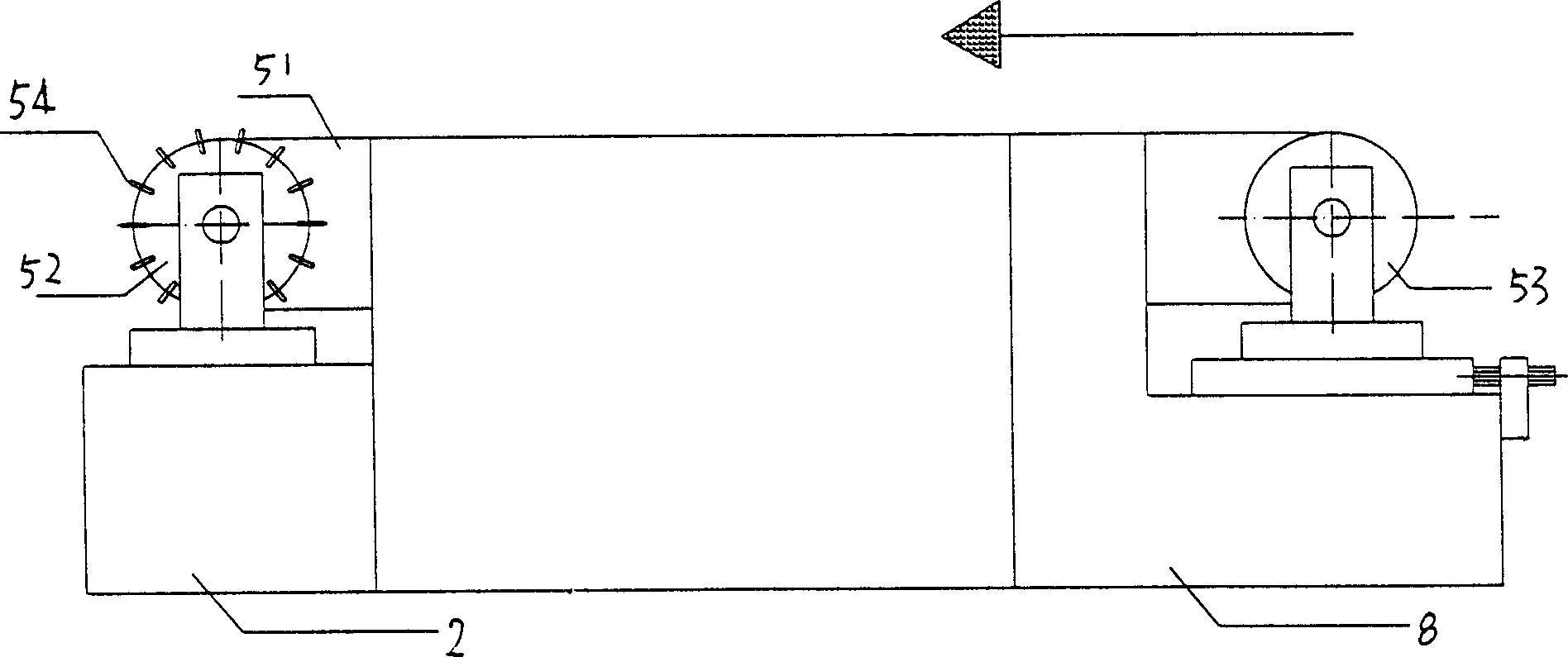

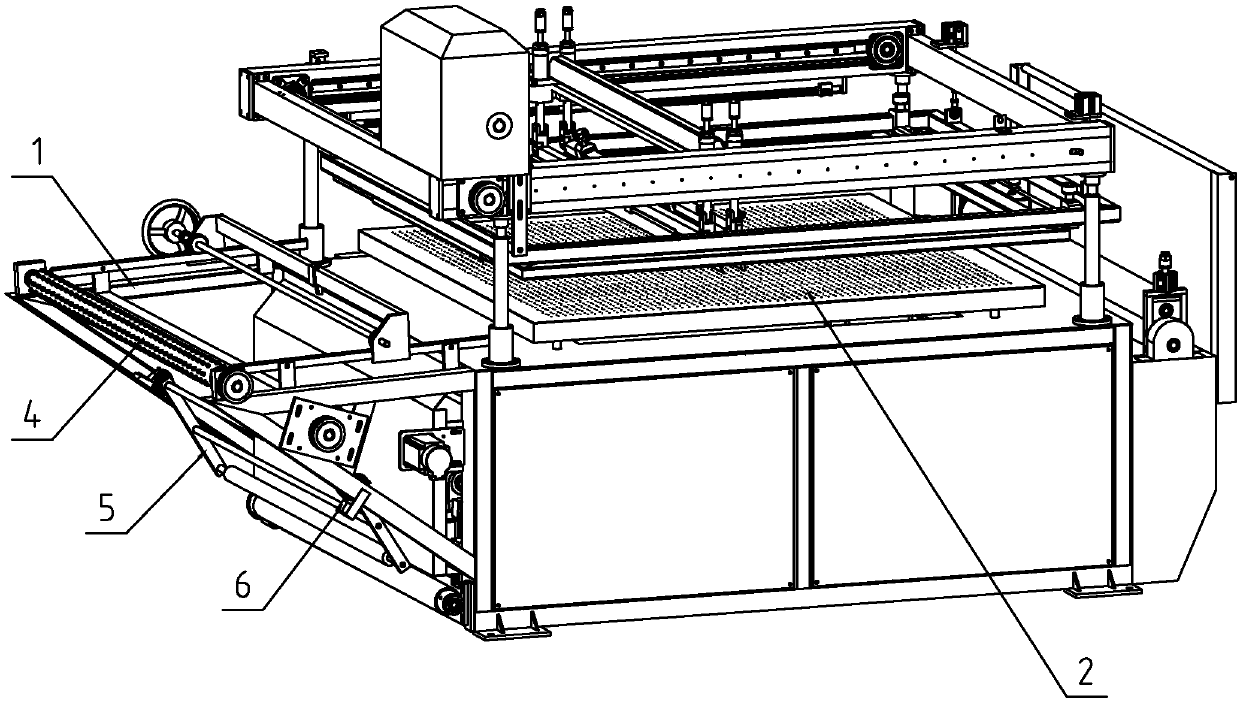

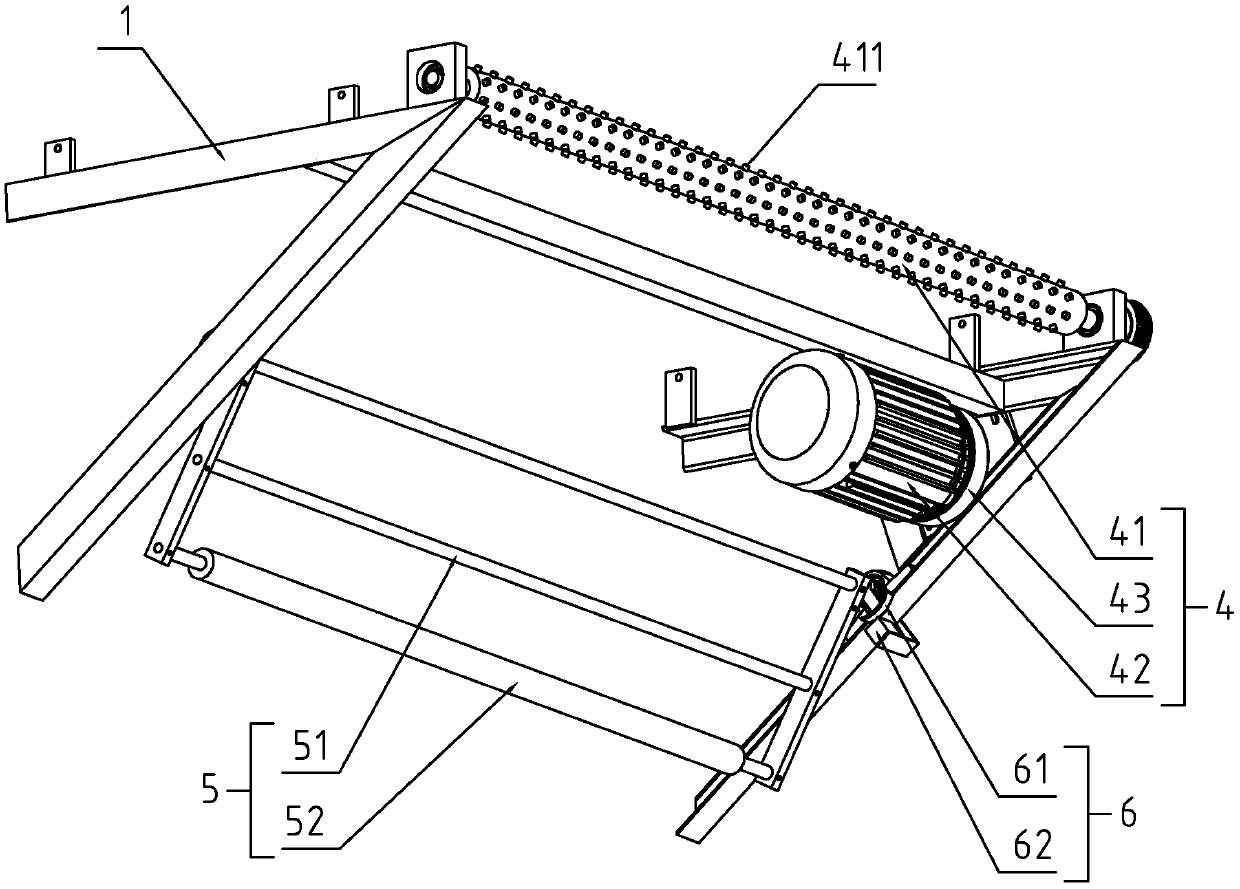

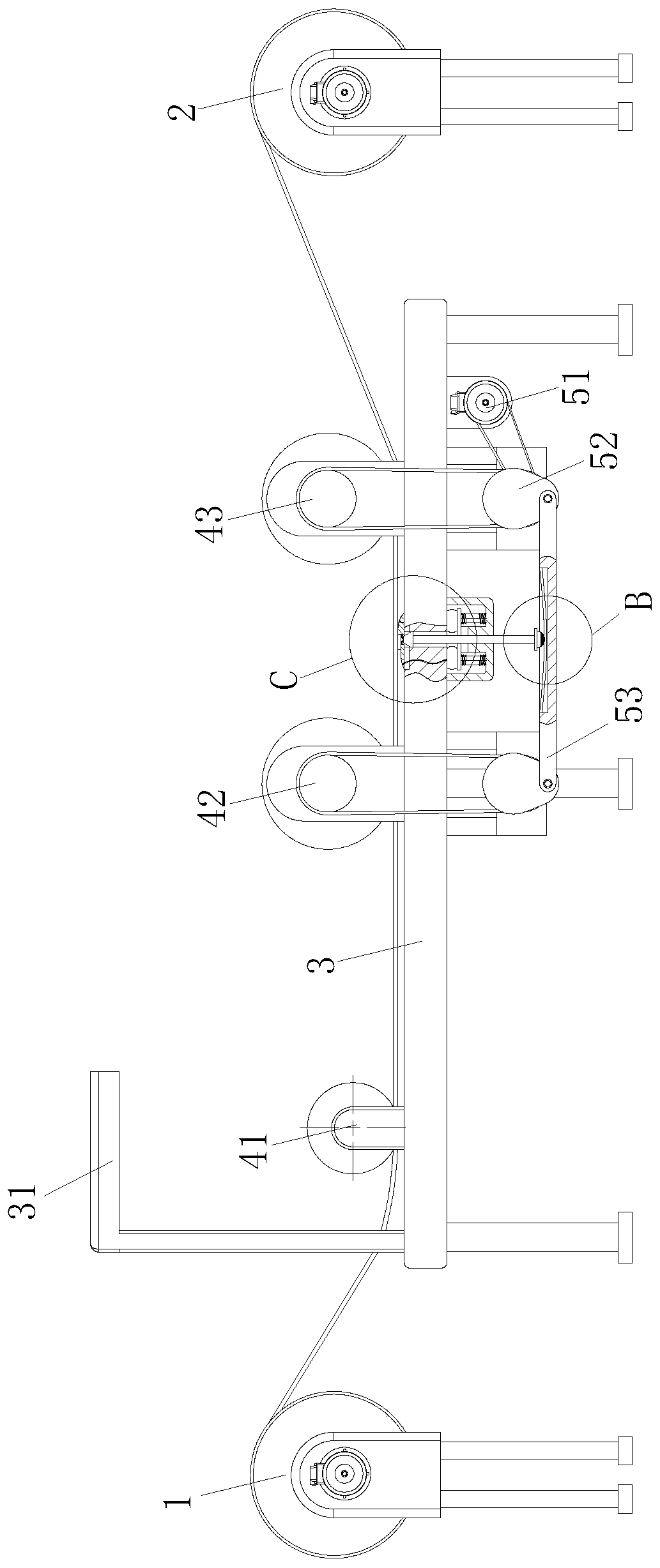

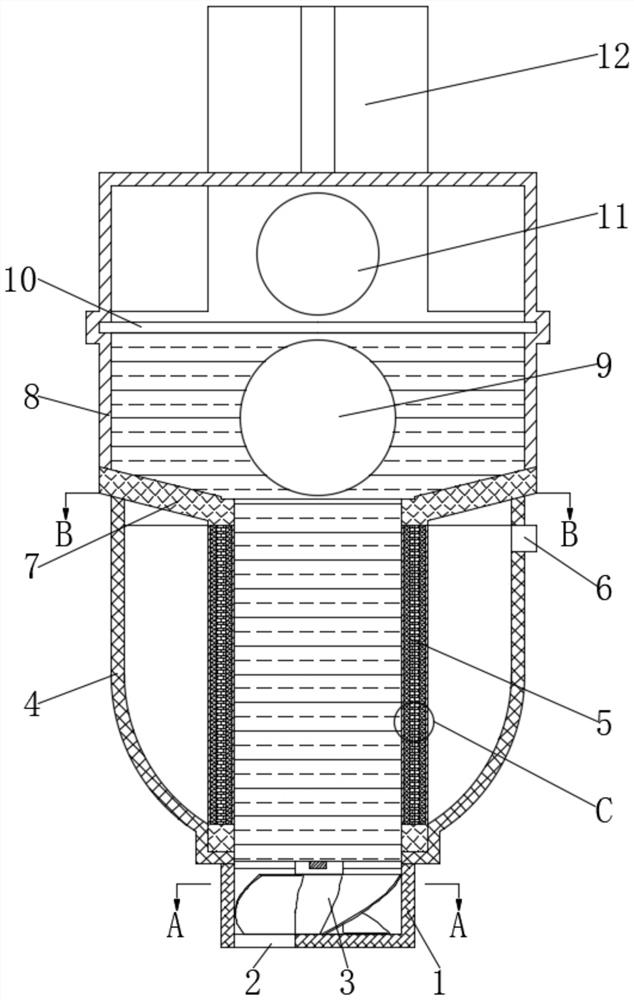

Tensioning device for screen printing machine

PendingCN109605916AReduce pulling forceImprove printing and drying effectScreen printersMagnetic powderMagnetic particle clutch

The invention discloses a tensioning device for a screen printing machine. The technical scheme of the device is characterized by comprising a machine frame, a printing device and a drying device; themachine frame is further provided with a printing tensioning mechanism and a drying tensioning mechanism; the printing tensioning mechanism comprises a tensioning roller and a tensioning motor, wherein the tensioning roller is used for allowing a strip-shaped material to be wound therearound, and an output end of the tensioning motor is provided with a magnetic powder clutch used for driving thetensioning roller to maintain the constant tension of the strip-shaped material; and the drying tensioning mechanism comprises a gravity tensioning frame capable of tensioning the strip-shaped material wound around the tensioning roller under the action of gravity, wherein the gravity tensioning frame is located at a feeding end of the drying device, one end of the gravity tensioning frame is rotationally connected to the machine frame, the other end of the gravity tensioning frame is provided with a gravity roller, and the gravity tensioning frame can maintain the strip-shaped material woundaround the tensioning roller in a tensioned state through the gravity roller under the action of gravity in the process of axially rotating around the machine frame. The tensioning device can keep thestrip-shaped material automatically tensioned, so that the printing effect and the drying effect of the strip-shaped material are improved.

Owner:温州欧宏机械有限公司

Scrape-removable water-based ink for flexographic printing and preparation method thereof

The invention provides scrape-removable water-based ink for flexographic printing, which comprises raw materials of color paste, base ink and an admixture, wherein the base ink comprises water-based silver ink, shading black, peeling oil and protective water-based oil. The invention further provides a preparation method of the scrape-removable water-based ink for flexographic printing. The preparation method comprises the steps as follows: step 1, the water-based silver ink is prepared for reserve; step 2, the shading block is prepared for reserve; step 3, the peeling oil is prepared for reserve; step 4, the protective water-based oil is prepared for reserve; step 5, the base ink is prepared for reserve; step 6, the color paste is prepared in an agitator for reserve; step 7, the color paste prepared in the step 6 is added to water and dispersed and ground in a dispersion machine for reserve; and step 8, the color paste, the base ink and the admixture are taken by weight percentage and evenly agitated and mixed, and then the product is prepared. The invention provides the one-step water-based ink and the manufacturing method thereof, which have the advantages that the production process flow of special water-based ink is changed, the manufacturing time is shortened, production procedures are reduced and complete grinding is not needed.

Owner:HENAN UNIV OF SCI & TECH

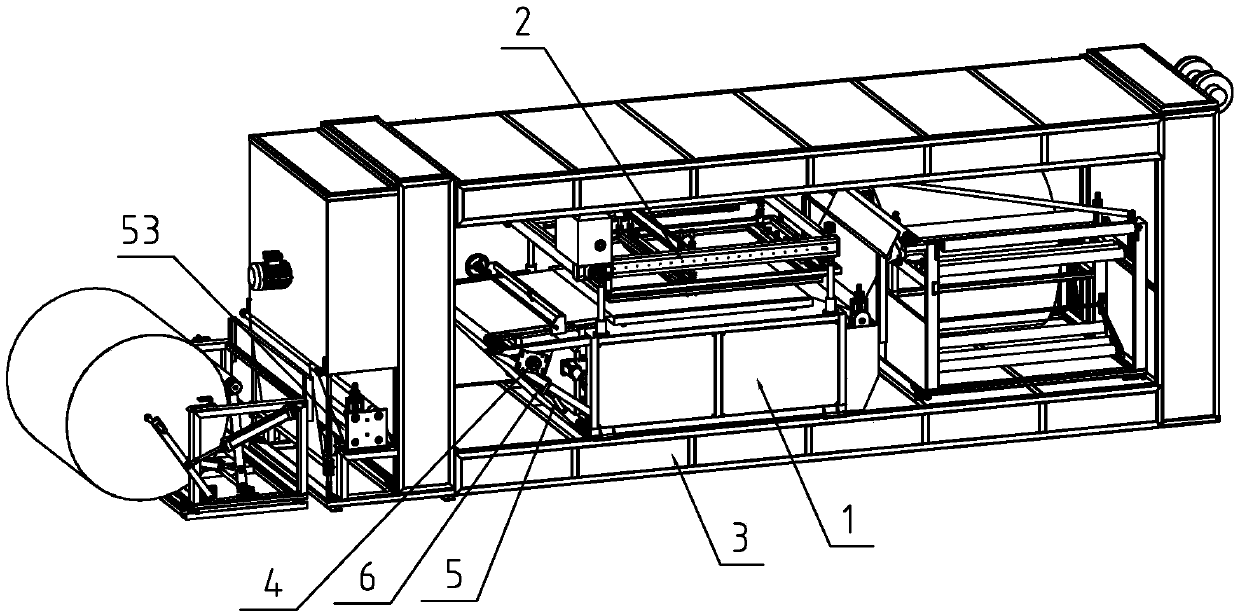

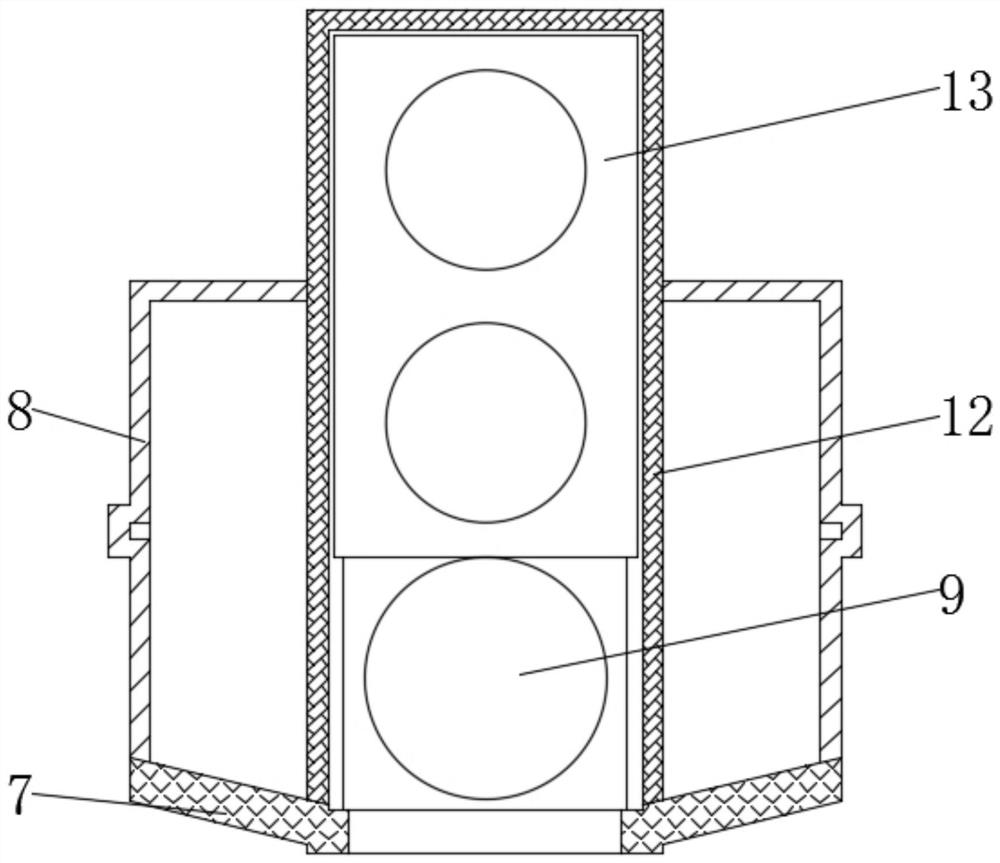

Anti-counterfeiting printing press

InactiveCN111532022AEasy to useAchieve preheatingRotary pressesPrinting press partsProcess engineeringPrinting press

The invention belongs to the technical field of printing press equipment, and particularly relates to an anti-counterfeiting printing press which includes a feed roller, a discharge roller, a work table, a printing unit and a heating unit. The printing unit includes a rolling wheel, a printing wheel and a drying wheel; the heating unit includes a motor, a cam, a hinge plate, a heating block and anejector rod; the ejector rod is slidably connected in a through hole, the bottom end of the ejector rod is slidably connected in a second slide groove, and the top end of the ejector rod is in contact with the heating block; the anti-counterfeiting printing of packaging paper is realized by the cooperation of the feed roller, the discharge roller, the work table, the printing unit and the heatingunit; and the situation of shrinking and curling of the packaging paper due to a large temperature difference of the packaging paper in the process of direct contact with the drying wheel is avoided,the printing processing quality of the packaging paper is ensured, and therefore the packaging paper can still ensure a relatively flat surface after printing processing.

Owner:滁州三界外工业设计有限公司

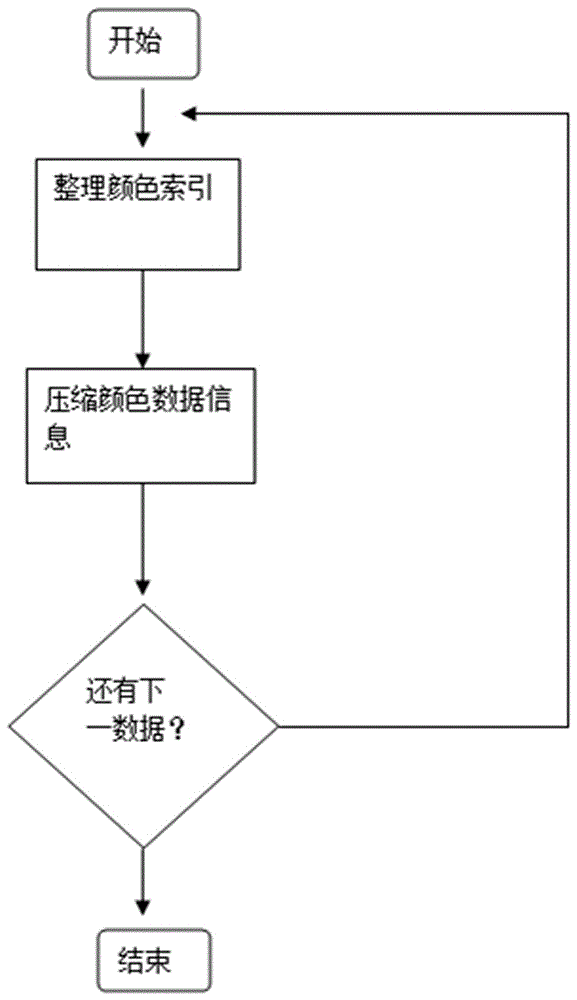

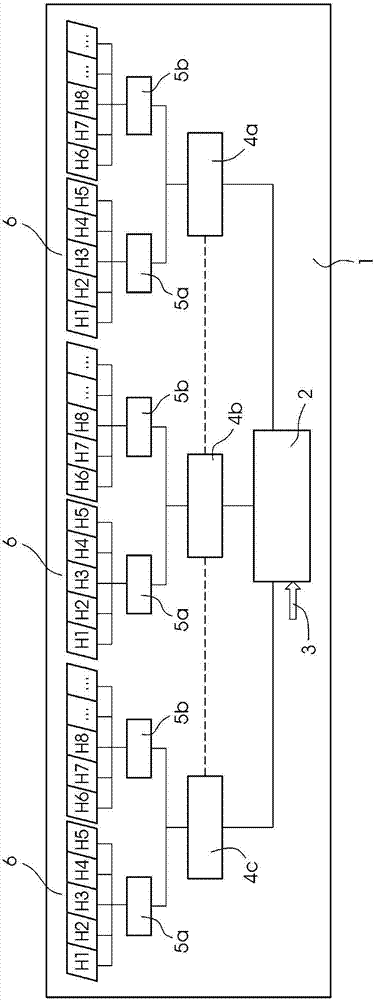

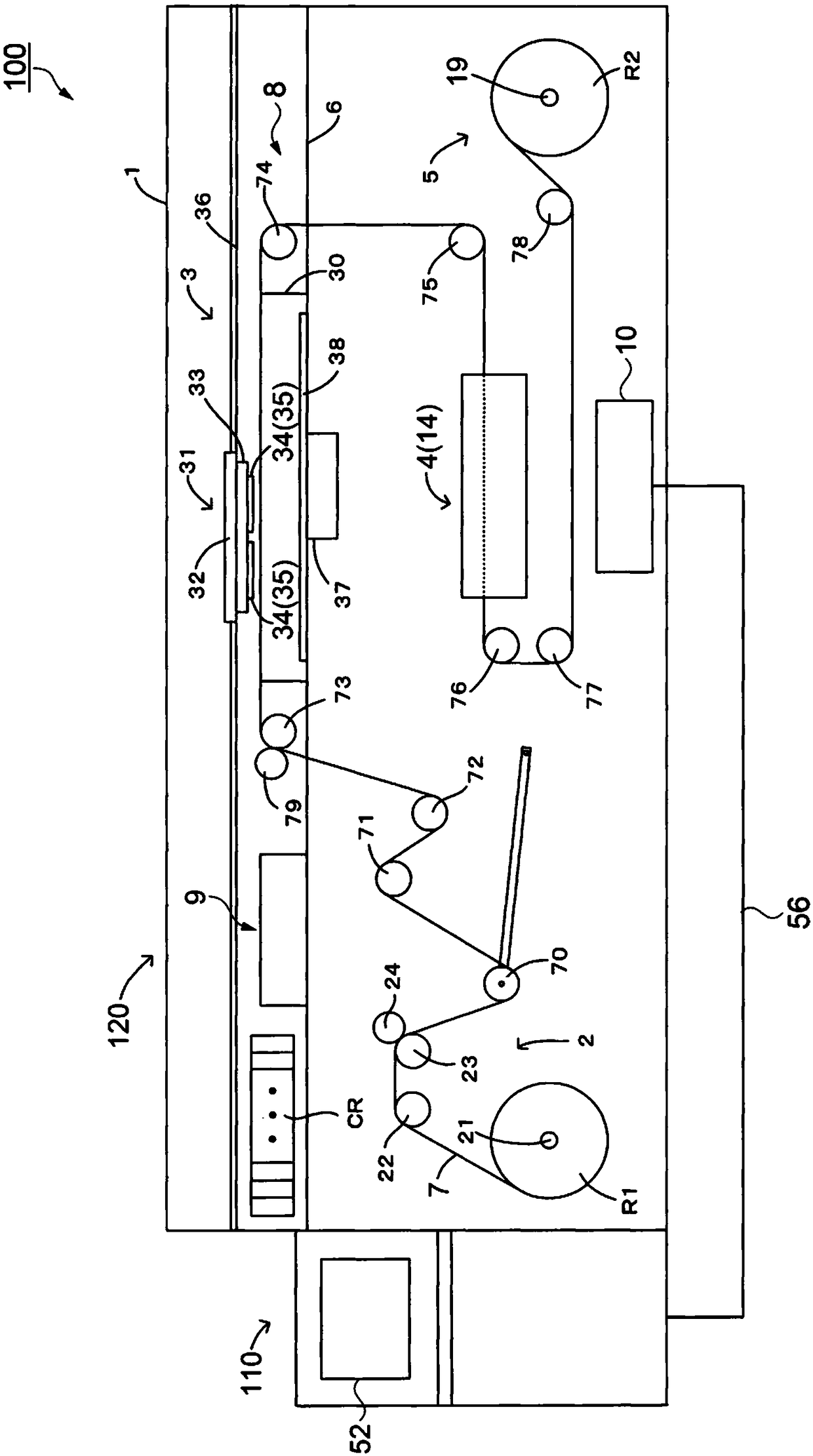

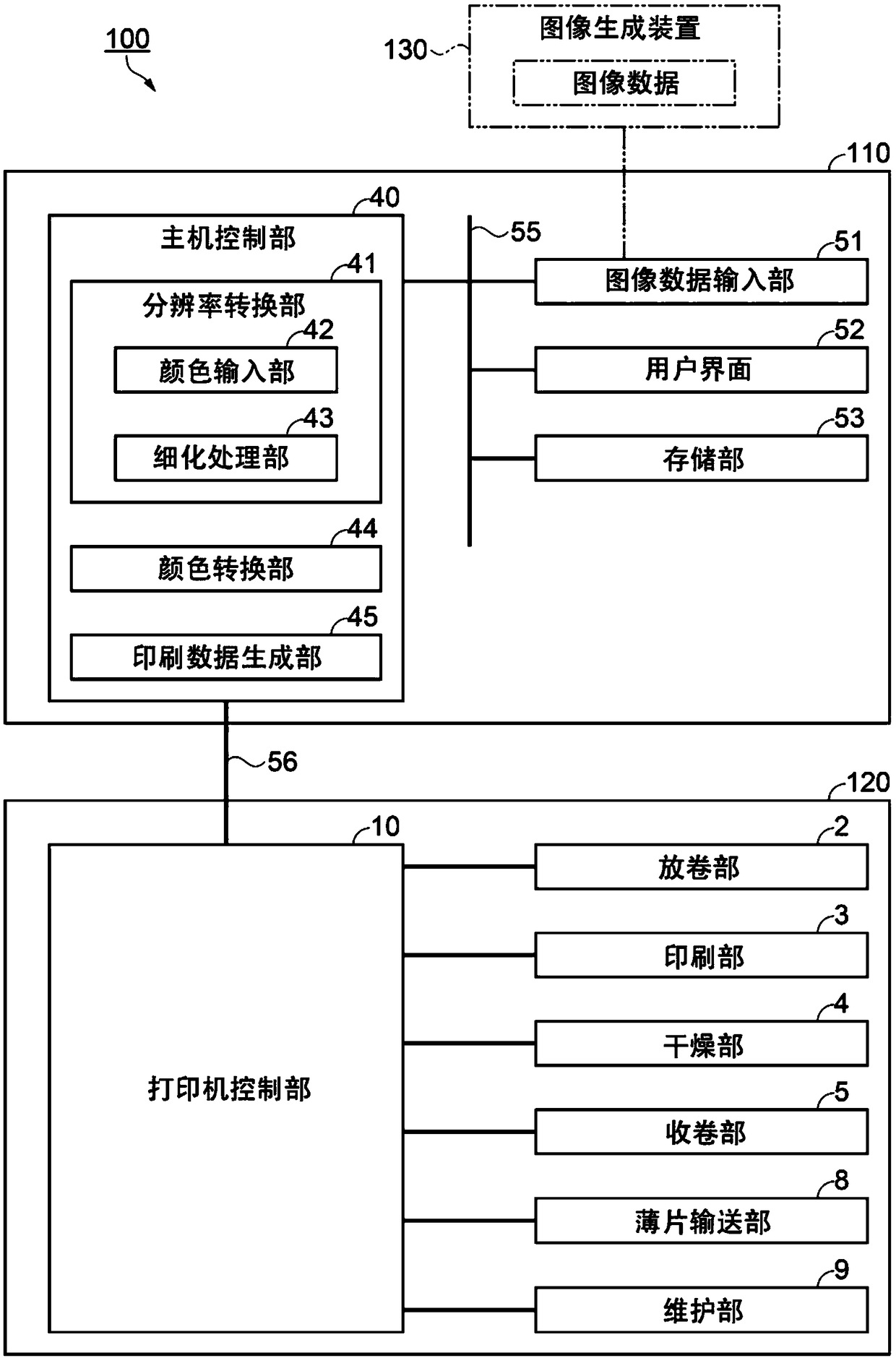

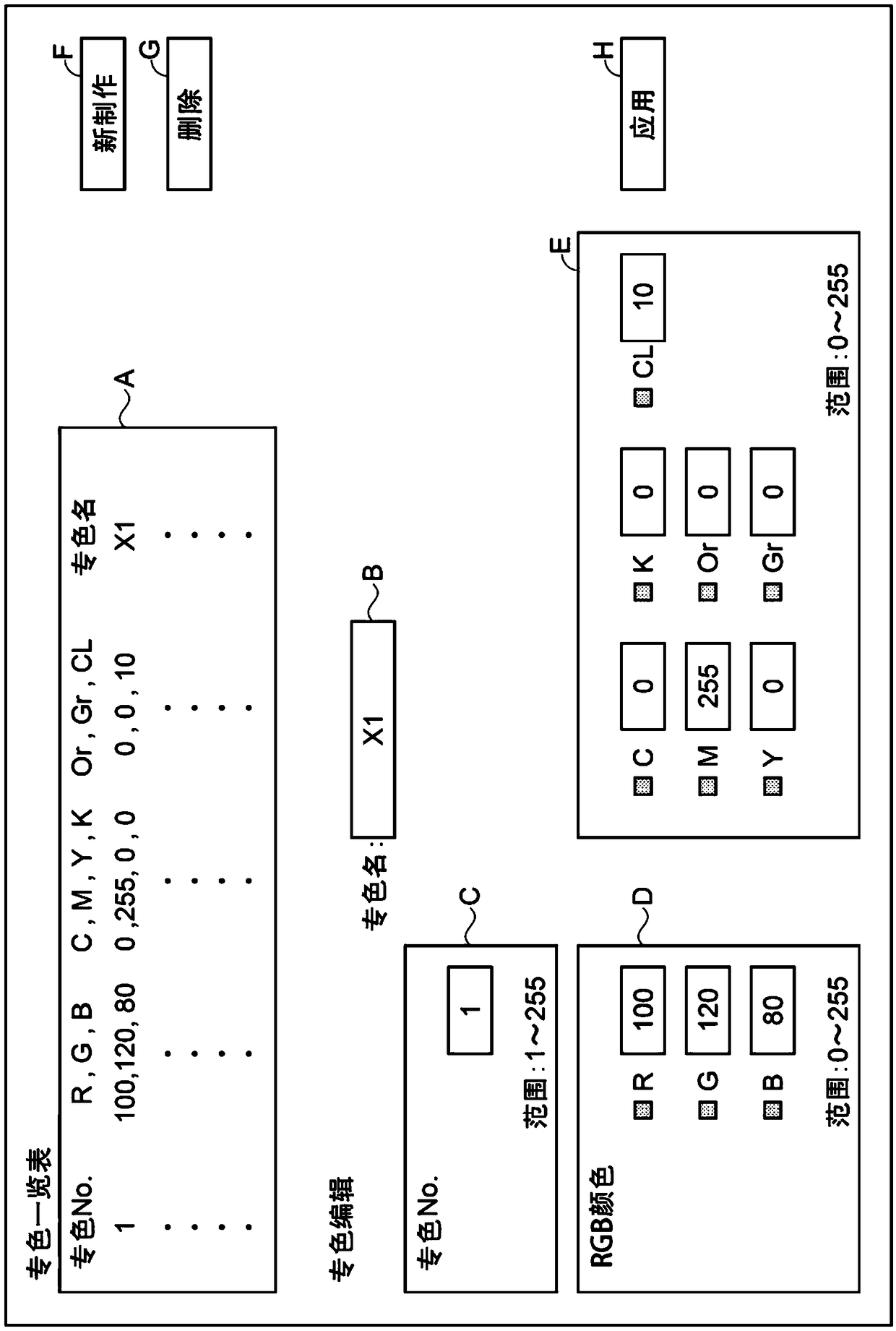

Image processing device and printing system

ActiveCN109016866AImprove qualitySpeed up printingPrintingPictoral communicationImaging processingColor transformation

The invention provides an image processing device and a printing system. The image processing device is characterized by comprising a user interface (52), an image data inputting section (51) that inputs image data, a resolution converting section (41) that converts the image data to resolution corresponding to a printing device (120), a color converting section (44) that generates ink amount data, and a print data generating section (45) that generates print data based on the ink amount data, in which the resolution converting section includes a color inputting section (42) that inputs the spot color and the specific condition for performing a spot color replacement of replacing the spot color in the specific condition by the color converting section through the user interface, and a thinning processing section (43) that performs a simple thinning process on a spot color region (91) including the spot color in a case in which a thinning process of converting the resolution of the image data to a second resolution lower than the first resolution is performed.

Owner:SEIKO EPSON CORP

Bovine base solution packaging raw paper

Owner:万国纸业太阳白卡纸有限公司

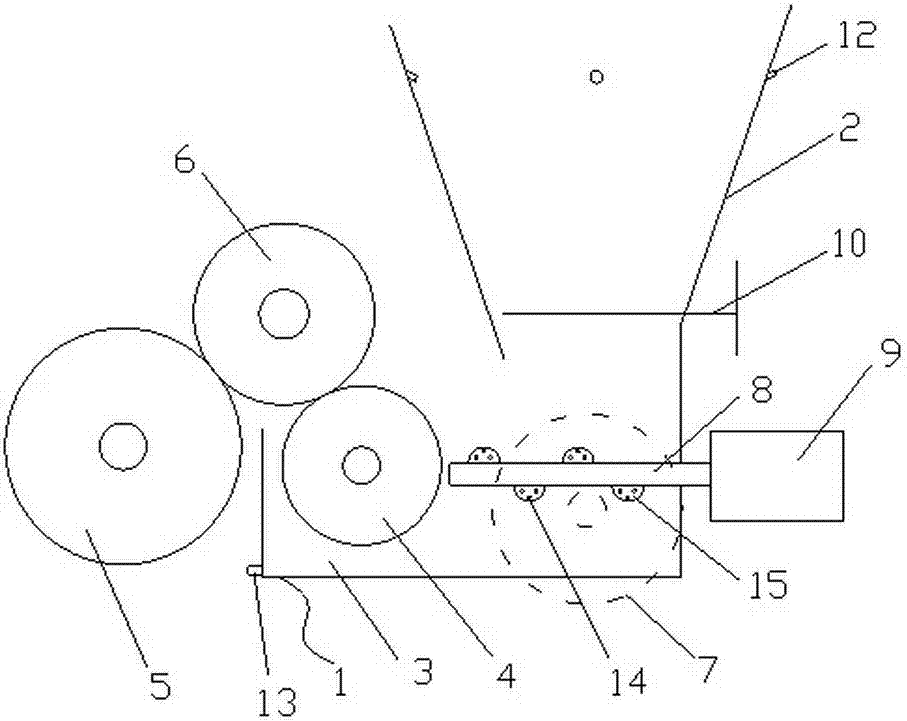

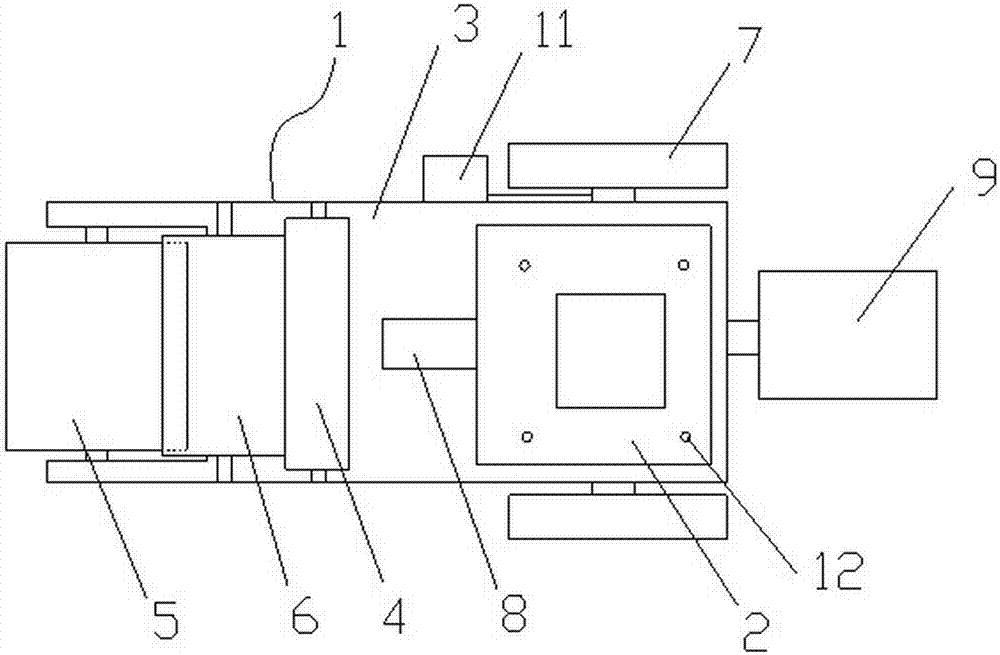

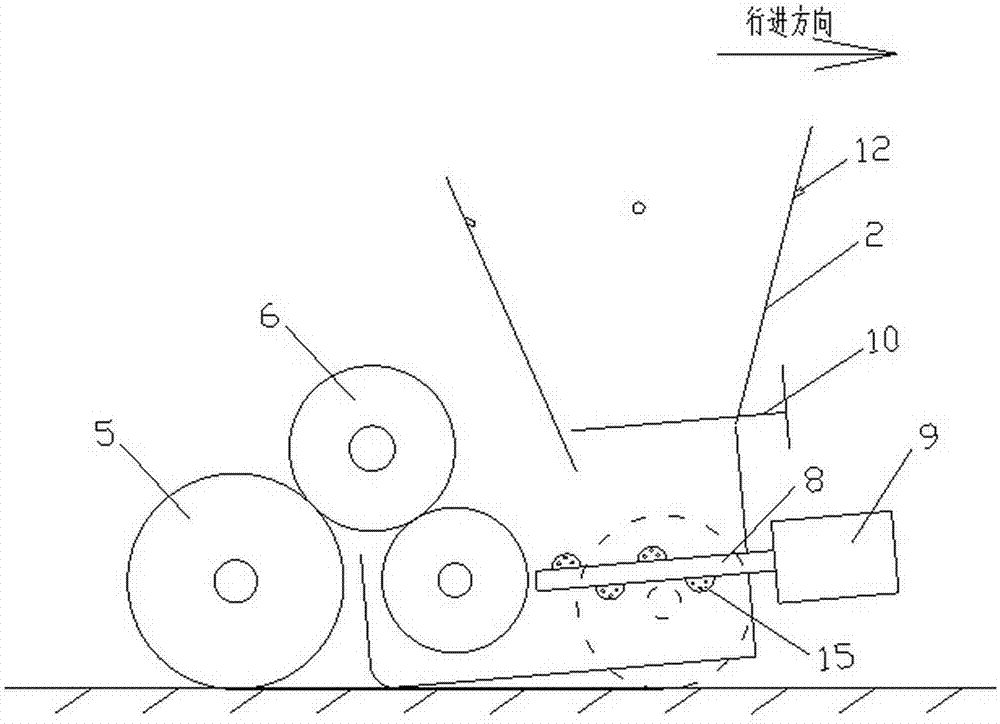

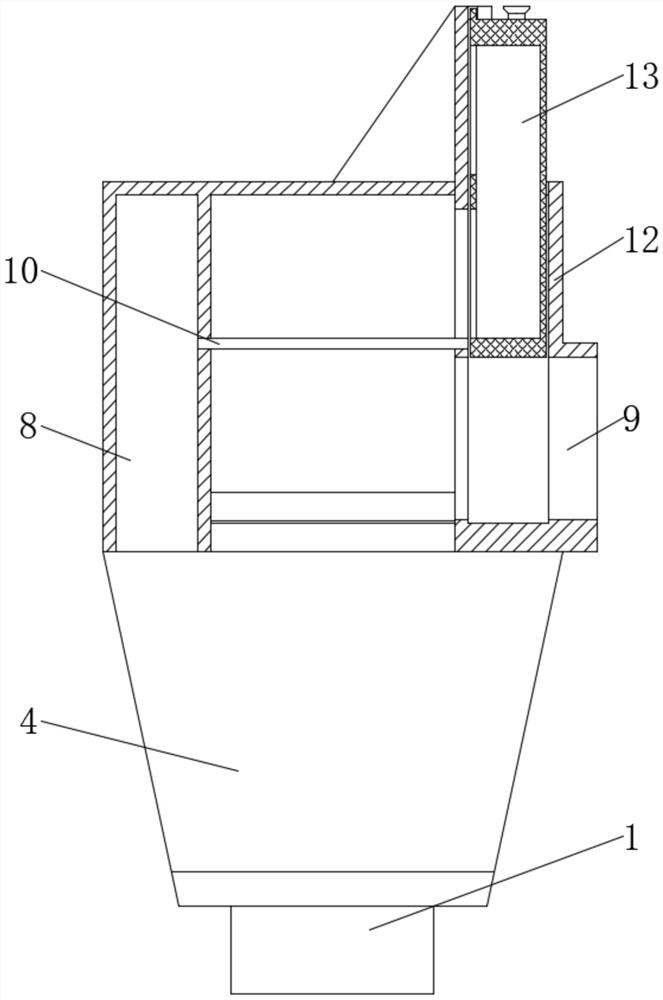

Single-color spraying and printing dual-purpose machine for terrace printing and work method thereof

The invention relates to a single-color spraying and printing dual-purpose machine for terrace printing and a work method thereof. The machine is characterized in that the single-color spraying and printing dual-purpose machine for terrace printing comprises a walking frame and a containing hopper arranged on the walking frame; a storage pond is arranged on the lower portion of the containing hopper, a material transferring roller is arranged in the storage pond, a transfer printing roller is arranged at the first end of the walking frame, a middle roller is arranged between the transfer printing roller and the material transferring roller, a walking wheel is arranged at the second end of the walking frame, and the walking wheel and the transfer printing roller serve as supporting wheels for advancing of the walking frame. The single-color spraying and printing dual-purpose machine for terrace printing is simple in structure and reasonable in design, and printing of the terrace surfacepattern can be improved.

Owner:FUZHOU ROYAL FLOOR

Printing machine for textile fabric

InactiveCN113212000AIncrease the effective frequencyHigh frequencyTypewritersTextile printerPrinting ink

The invention relates to the technical field of textile fabric processing, and discloses a printing machine for textile fabric. The printing machine comprises a spray head, spray holes are formed in the right side of the bottom of the spray head, a segmentation impeller is movably installed in the spray head, and an extrusion cavity is fixedly connected to the top of the spray head. Through the arrangement of silicon film piezoelectric ceramic elements and silica gel films, when the silicon film piezoelectric ceramic elements perform a piezoelectric effect, a piezoelectric ceramic plate is bent; when the two silicon film piezoelectric ceramic elements are both bent inwards, the ink in the middle is extruded and discharged from the spray holes, and first-time acting is performed; when the two silicon film piezoelectric ceramic elements are bent outwards, water is extruded, certain pressure is applied to the water, the water presses the silica gel films downwards, the ink is pressed again, the ink is sprayed out of the spray holes, and second-time acting on the ink is completed, so that the effective frequency of the silicon film piezoelectric ceramic elements is increased; and in addition, the printing ink spraying frequency is improved, and the printing efficiency is improved.

Owner:柯珊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com