Patents

Literature

63 results about "Relative resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relative resistance. The ratio of the resistance of a piece of a material to the resistance of a piece of specified material, such as annealed copper, having the same dimensions and temperature.

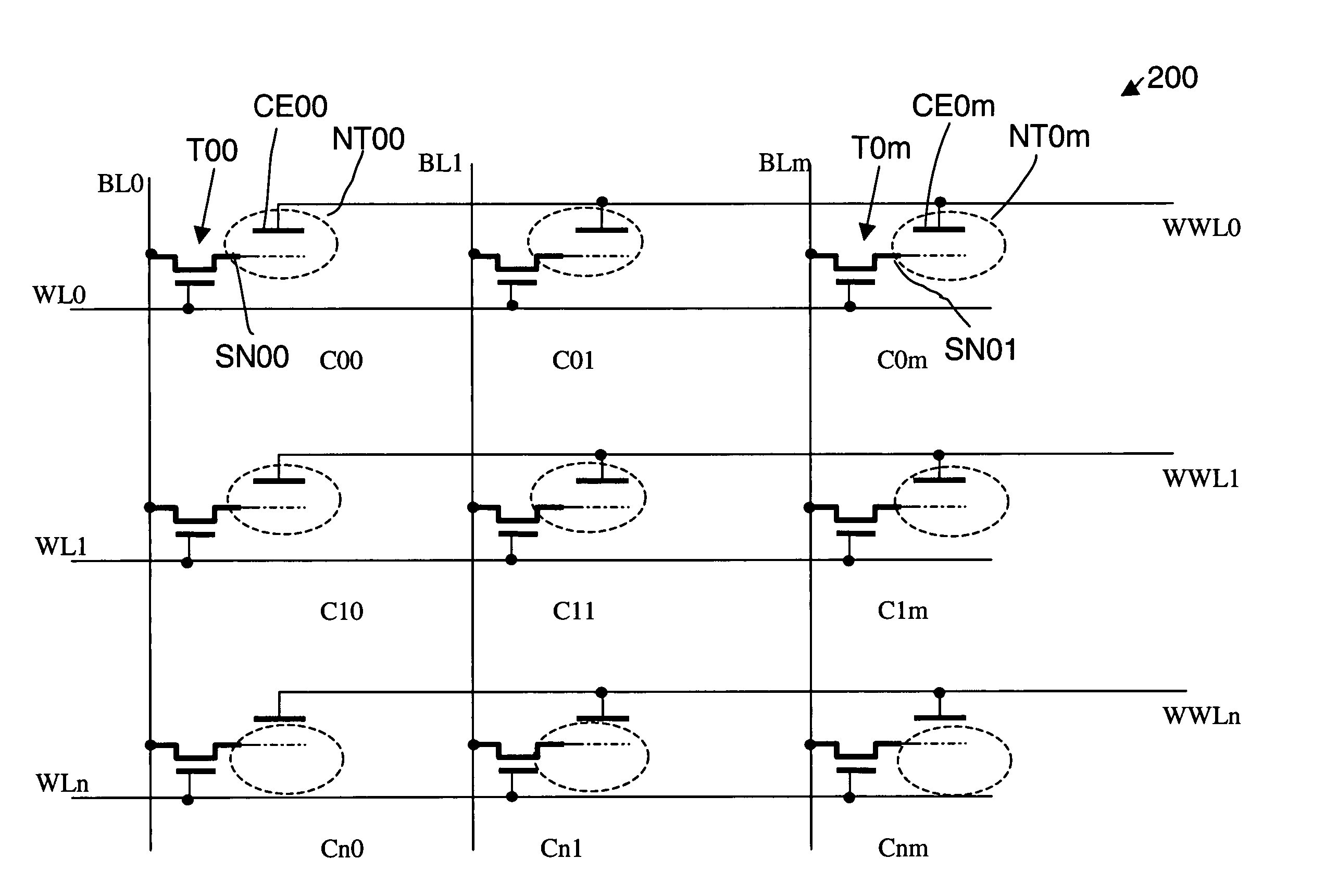

Memory arrays using nanotube articles with reprogrammable resistance

A memory array includes a plurality of memory cells, each of which receives a bit line, a first word line, and a second word line. Each memory cell includes a cell selection circuit, which allows the memory cell to be selected. Each memory cell also includes a two-terminal switching device, which includes first and second conductive terminals in electrical communication with a nanotube article. The memory array also includes a memory operation circuit, which is operably coupled to the bit line, the first word line, and the second word line of each cell. The circuit can select the cell by activating an appropriate line, and can apply appropriate electrical stimuli to an appropriate line to reprogrammably change the relative resistance of the nanotube article between the first and second terminals. The relative resistance corresponds to an informational state of the memory cell.

Owner:NANTERO

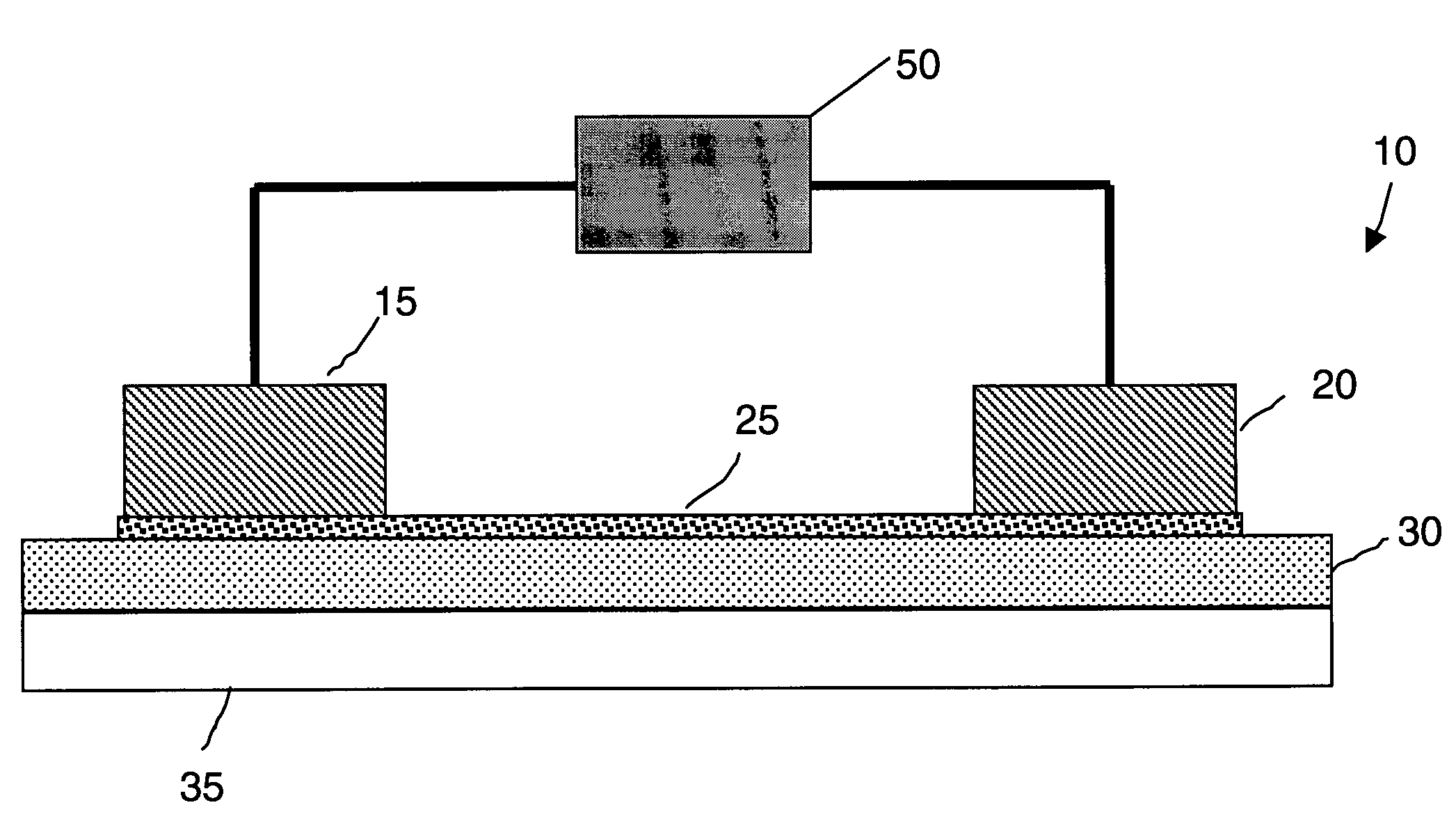

Two-terminal nanotube devices and systems and methods of making same

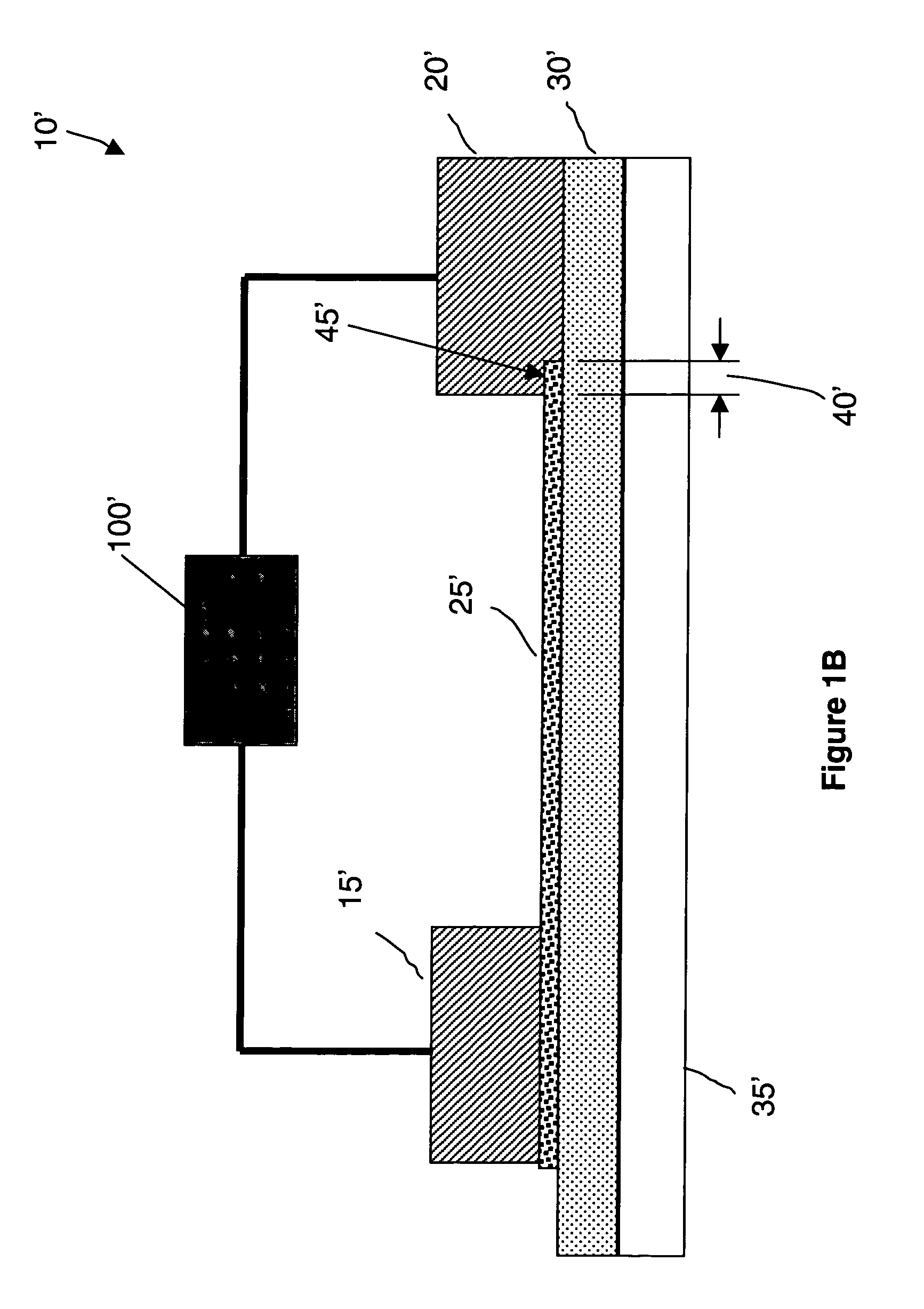

ActiveUS20080012047A1Minimize flow of heatImprove conductivityNanoinformaticsSolid-state devicesHigh resistanceNanotube

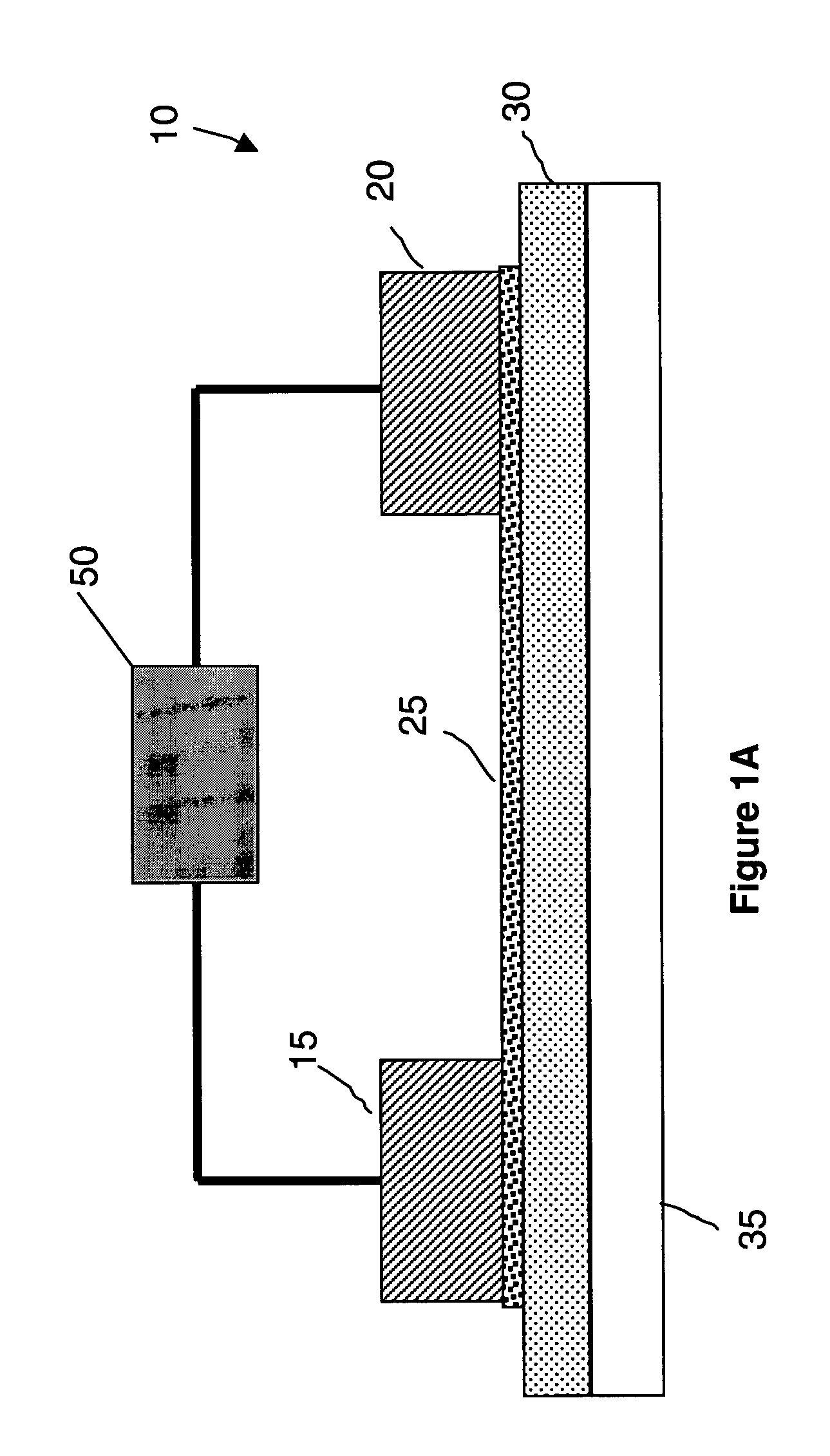

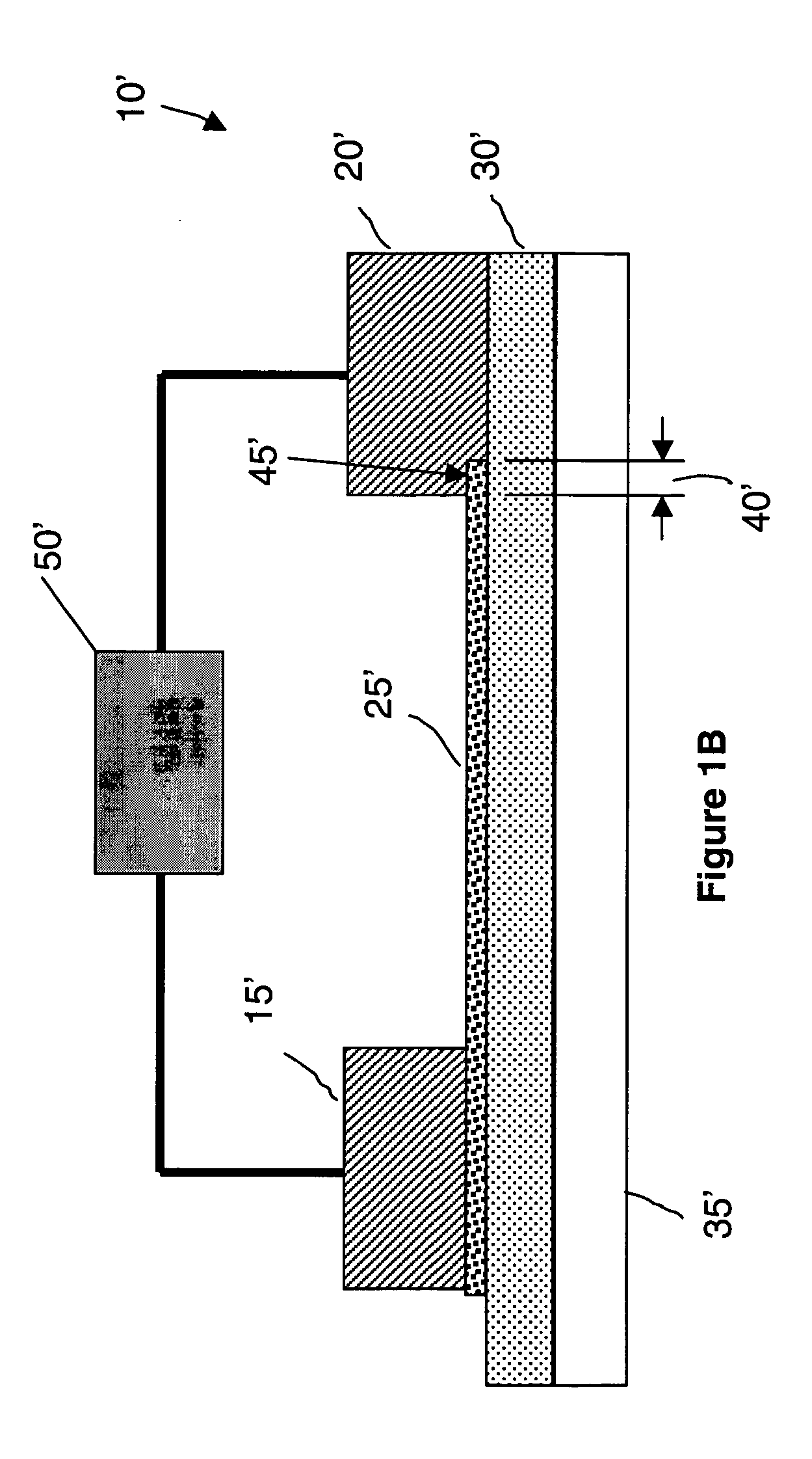

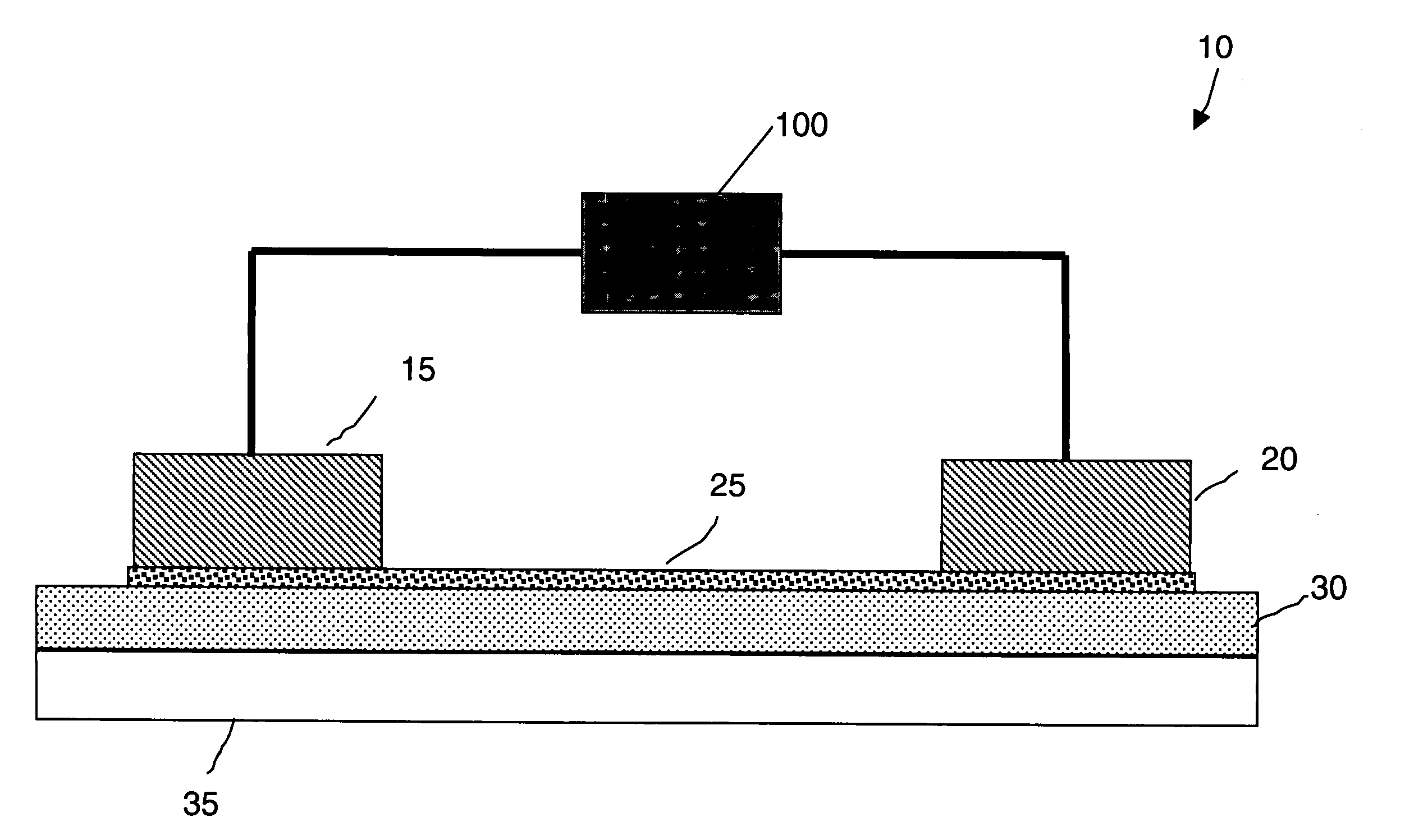

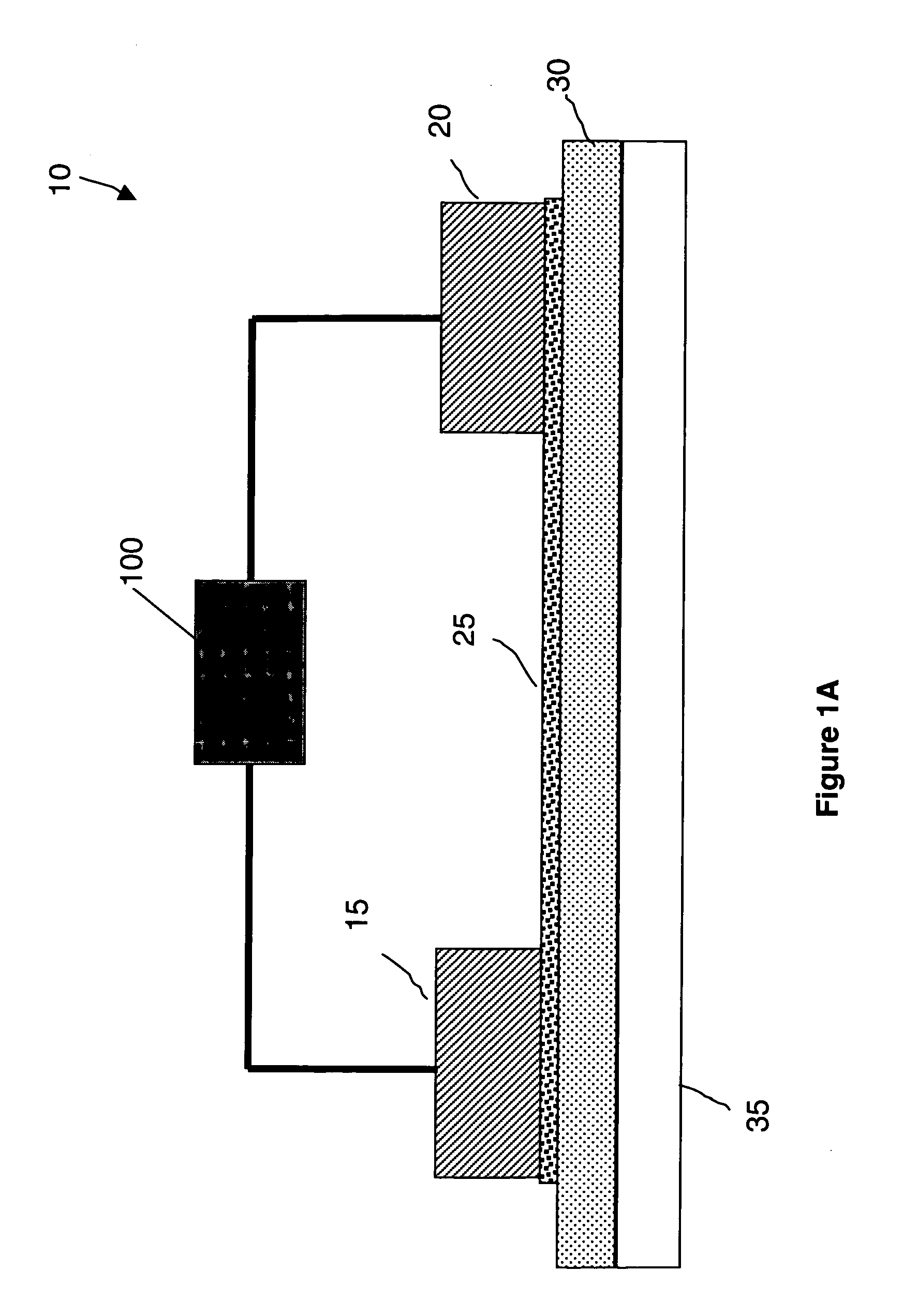

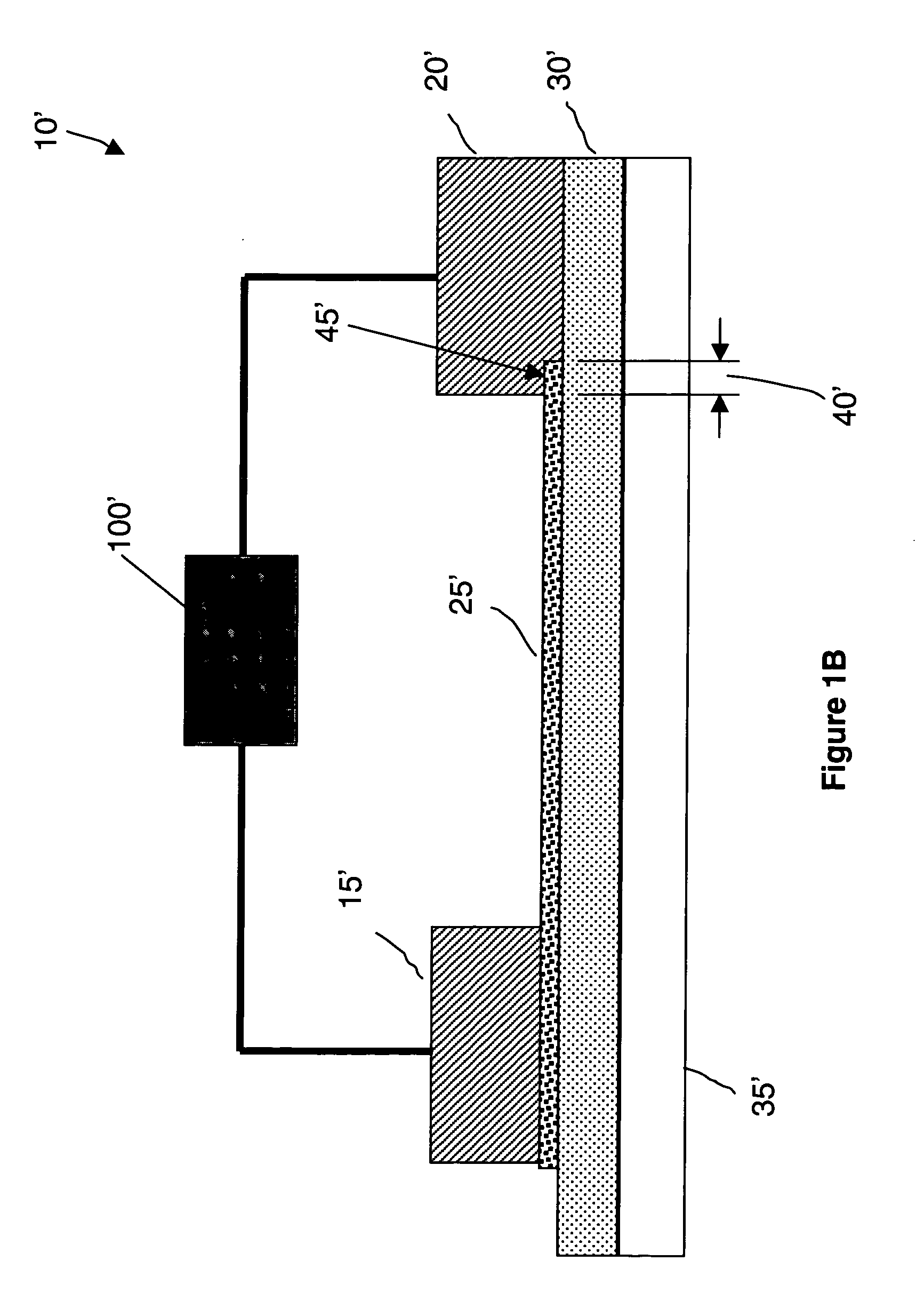

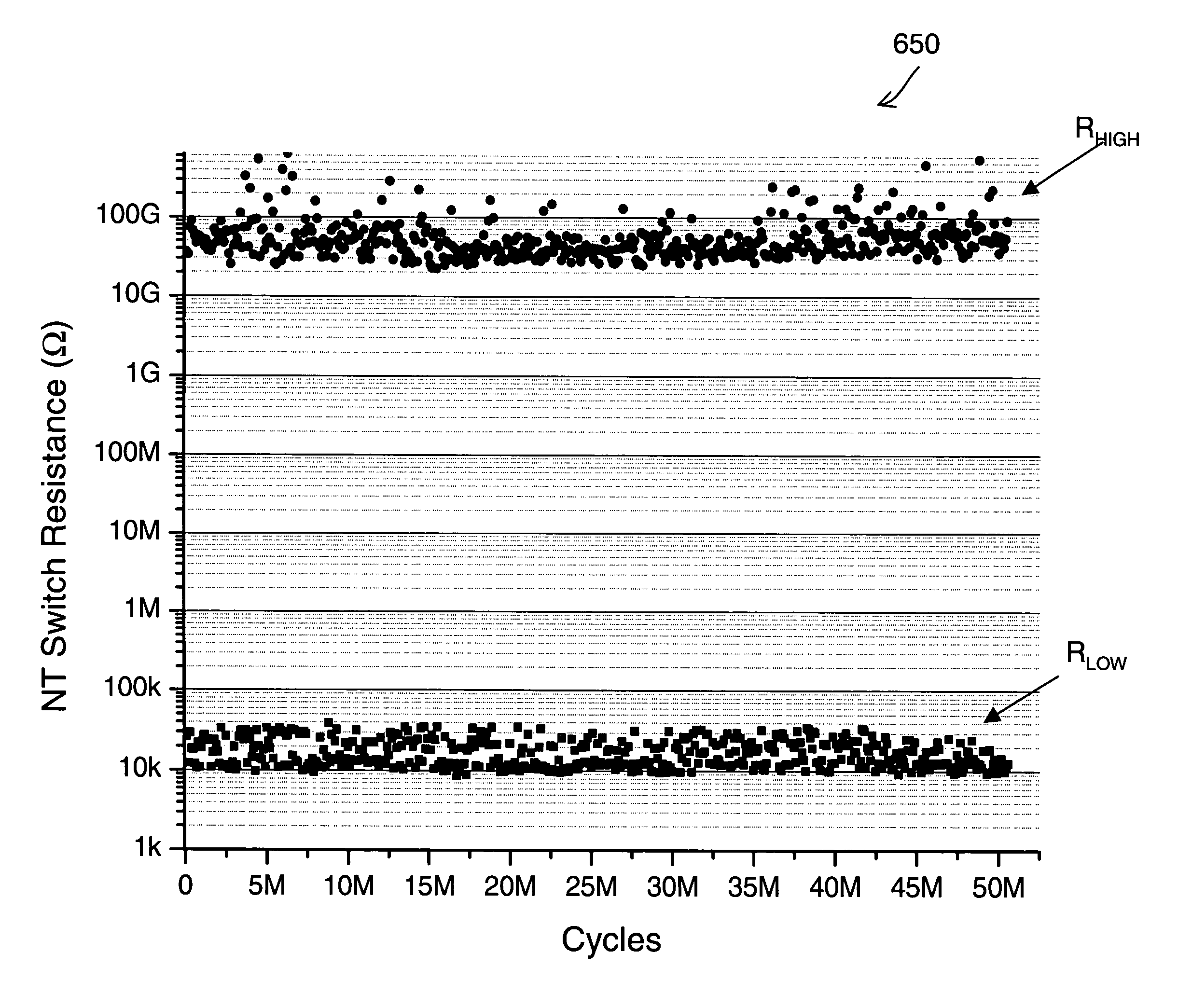

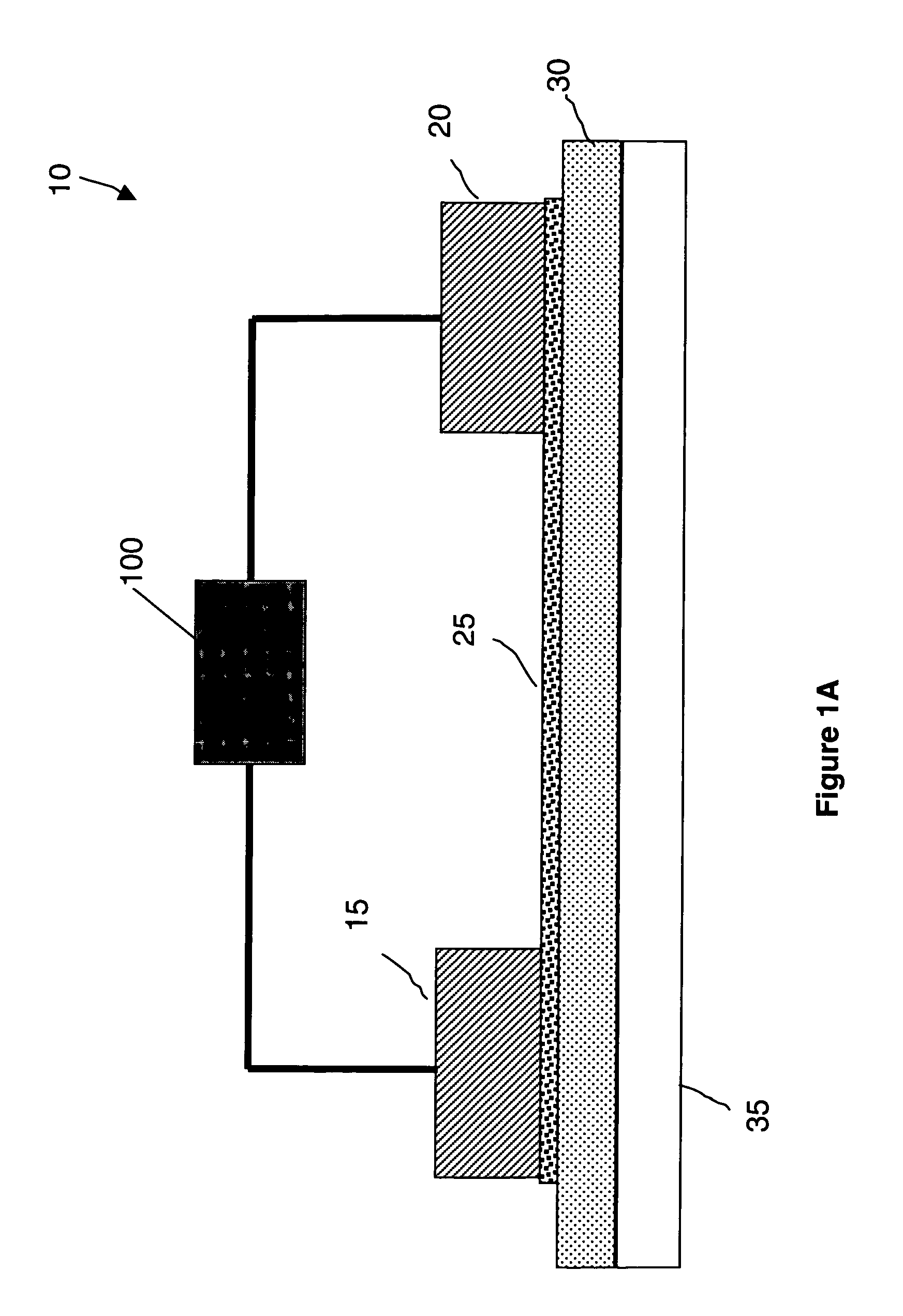

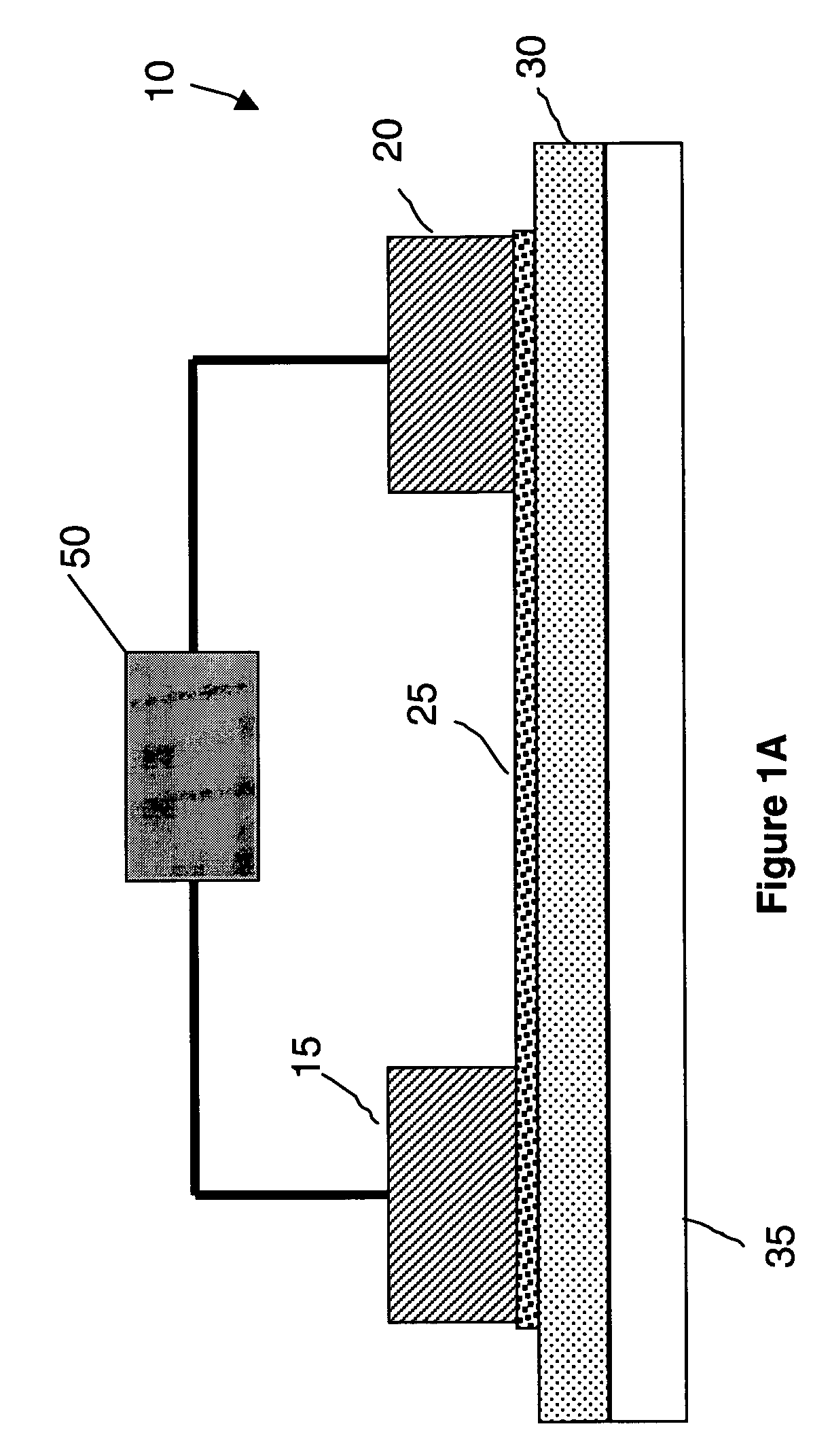

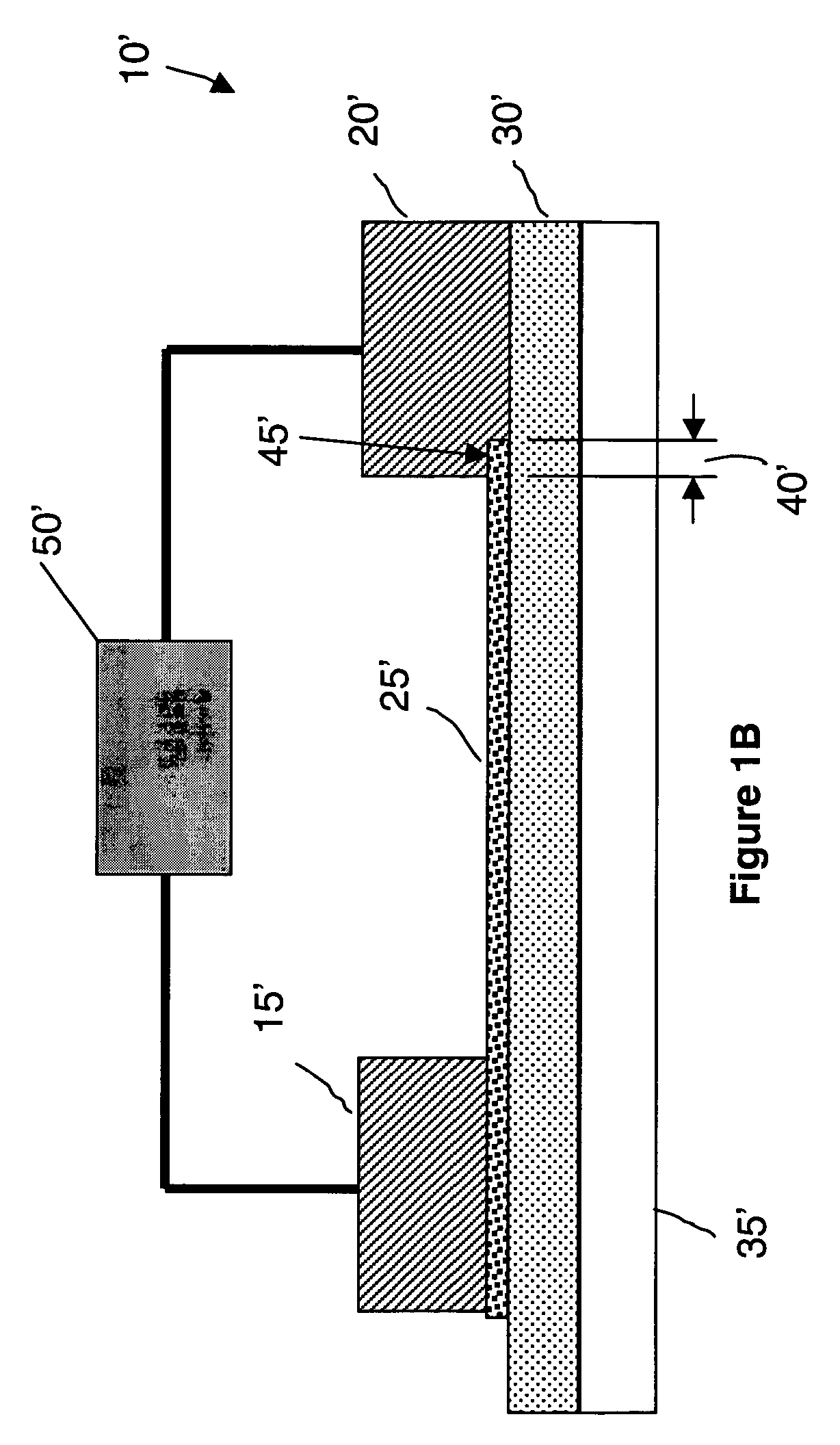

A two terminal switching device includes first and second conductive terminals and a nanotube article. The article has at least one nanotube, and overlaps at least a portion of each of the first and second terminals. The device also includes a stimulus circuit in electrical communication with at least one of the first and second terminals. The circuit is capable of applying first and second electrical stimuli to at least one of the first and second terminal(s) to change the relative resistance of the device between the first and second terminals between a relatively high resistance and a relatively low resistance. The relatively high resistance between the first and second terminals corresponds to a first state of the device, and the relatively low resistance between the first and second terminals corresponds to a second state of the device.

Owner:NANTERO

Two-terminal nanotube devices and systems and methods of making same

ActiveUS7781862B2Minimize flow of heatImprove conductivitySemiconductor/solid-state device detailsNanoinformaticsHigh resistanceElectricity

A two terminal switching device includes first and second conductive terminals and a nanotube article. The article has at least one nanotube, and overlaps at least a portion of each of the first and second terminals. The device also includes a stimulus circuit in electrical communication with at least one of the first and second terminals. The circuit is capable of applying first and second electrical stimuli to at least one of the first and second terminal(s) to change the relative resistance of the device between the first and second terminals between a relatively high resistance and a relatively low resistance. The relatively high resistance between the first and second terminals corresponds to a first state of the device, and the relatively low resistance between the first and second terminals corresponds to a second state of the device.

Owner:NANTERO

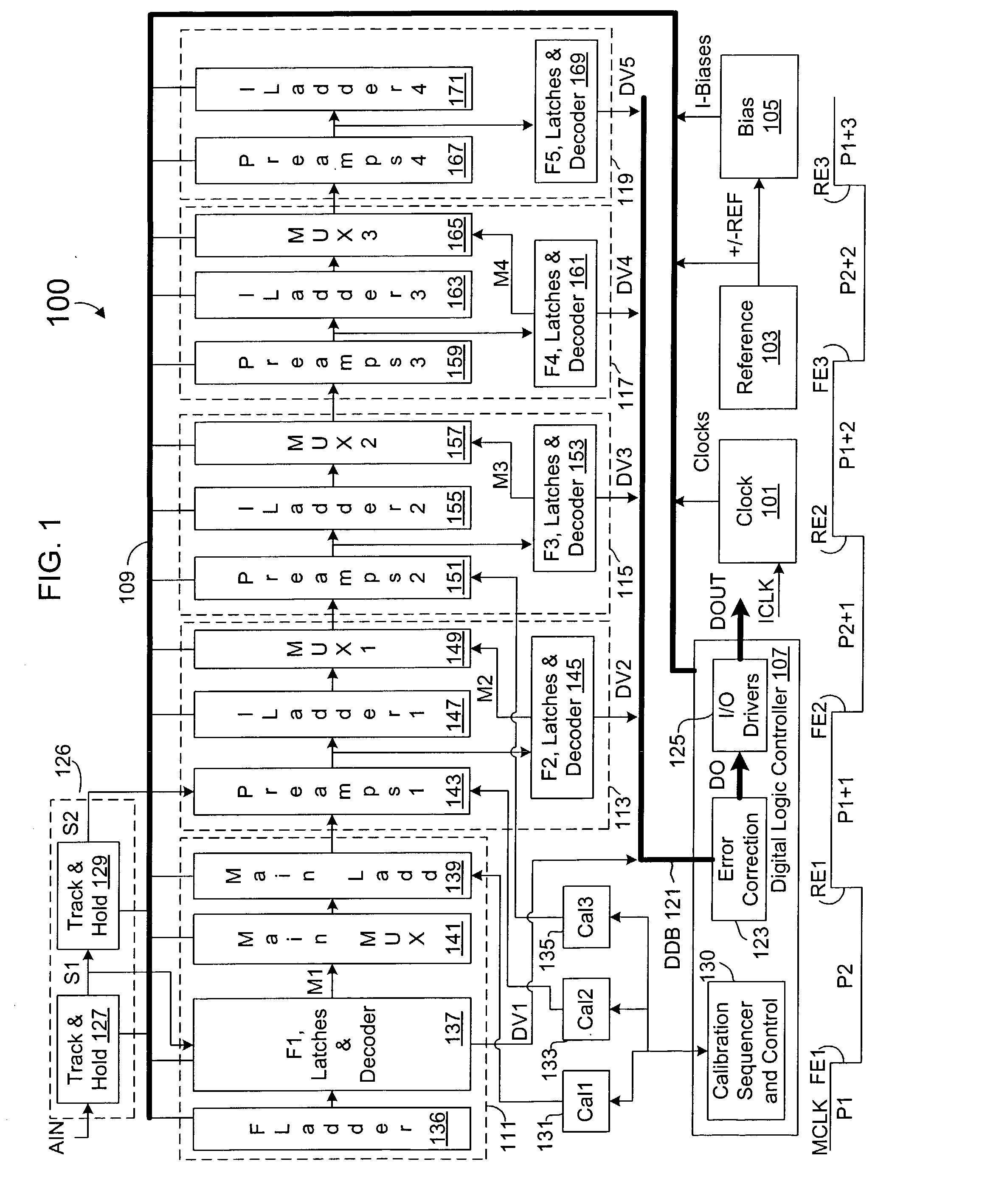

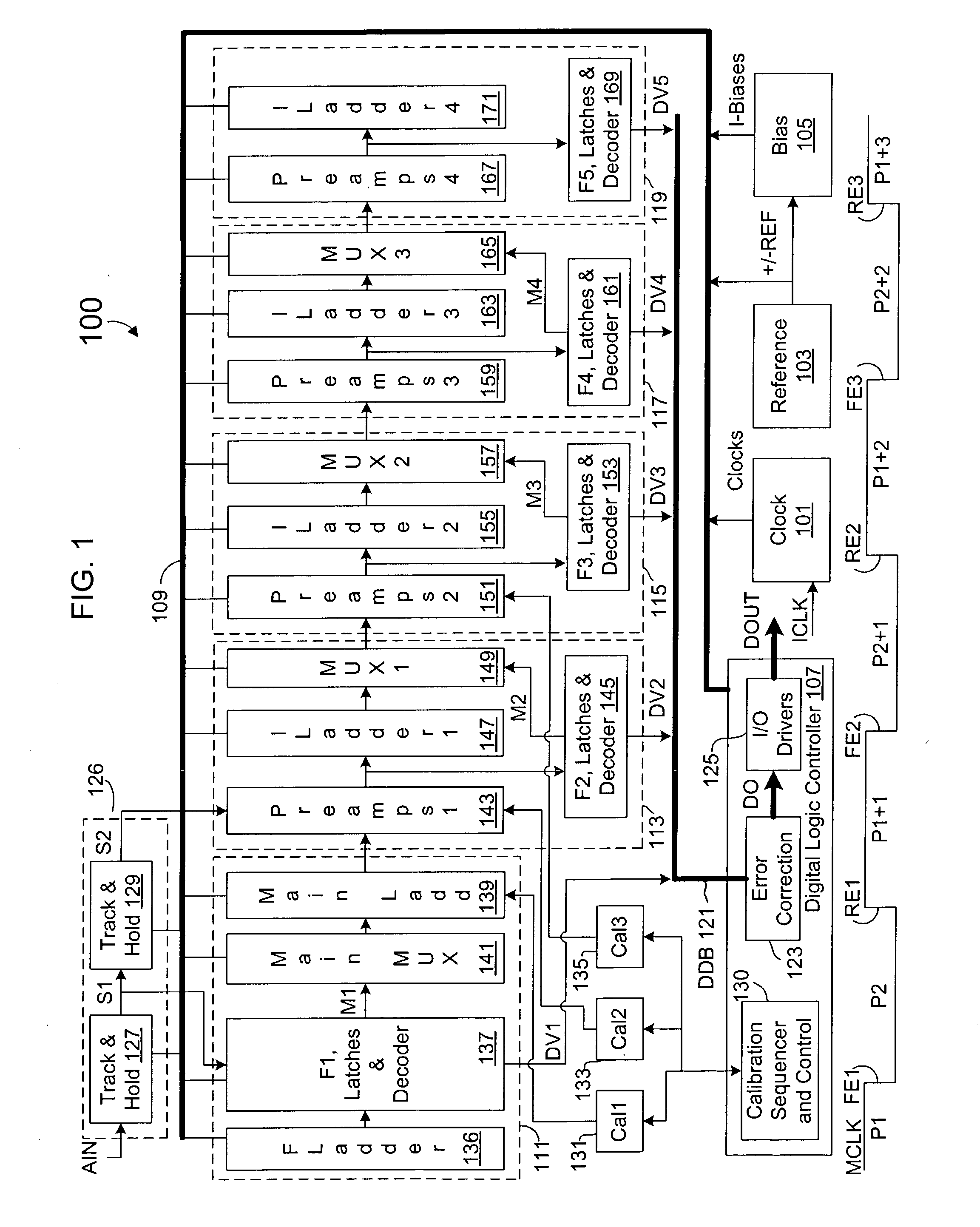

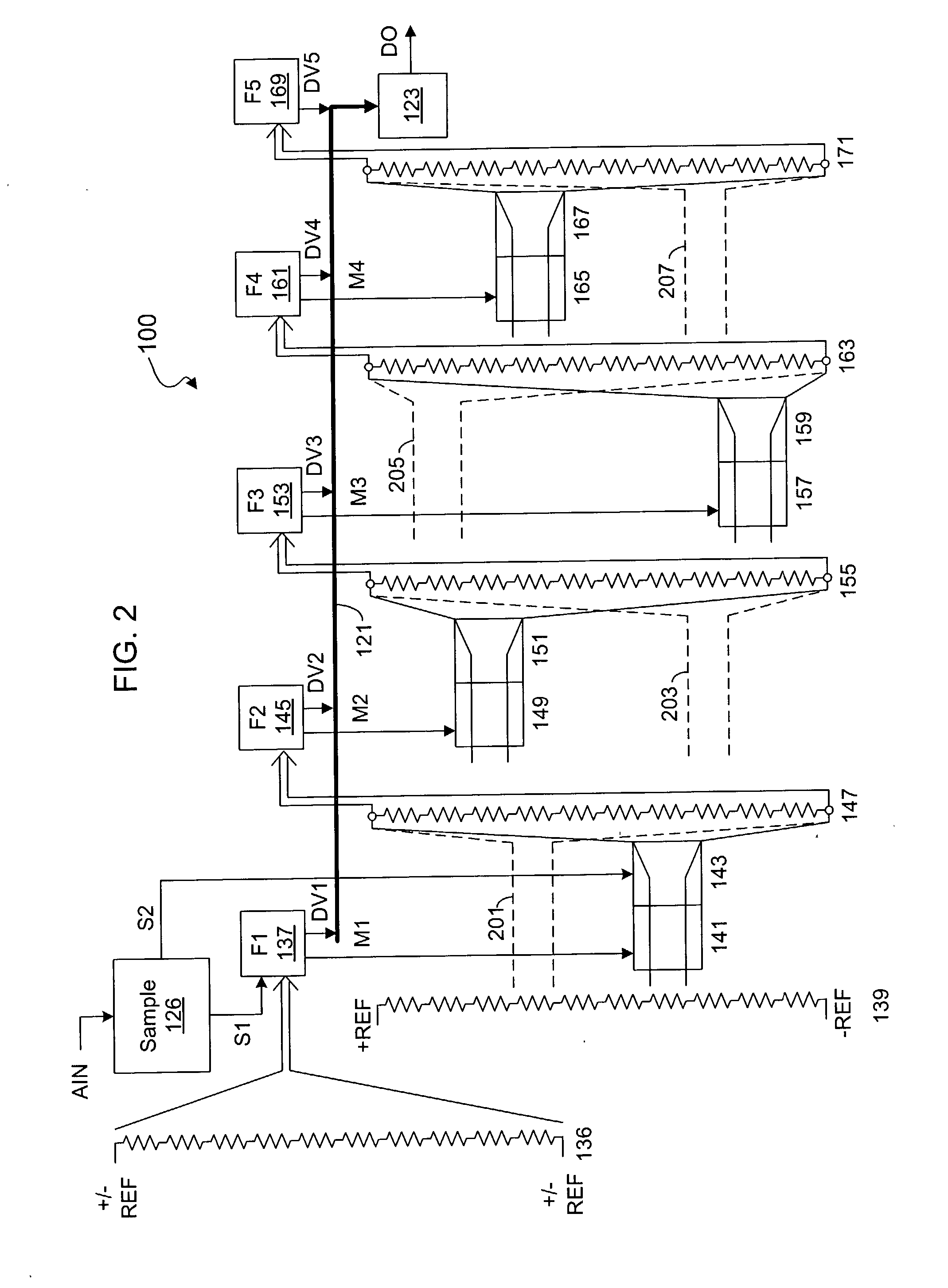

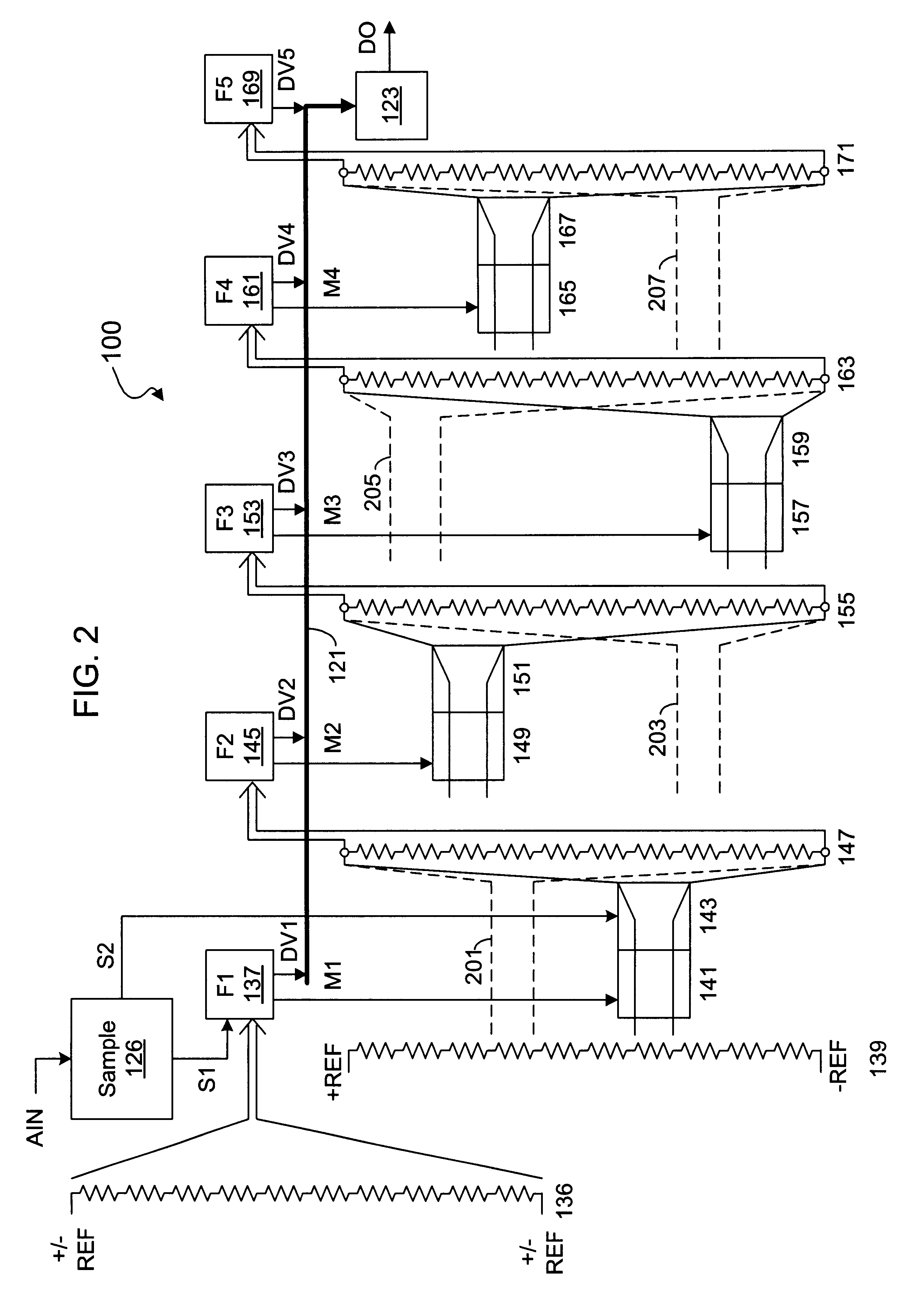

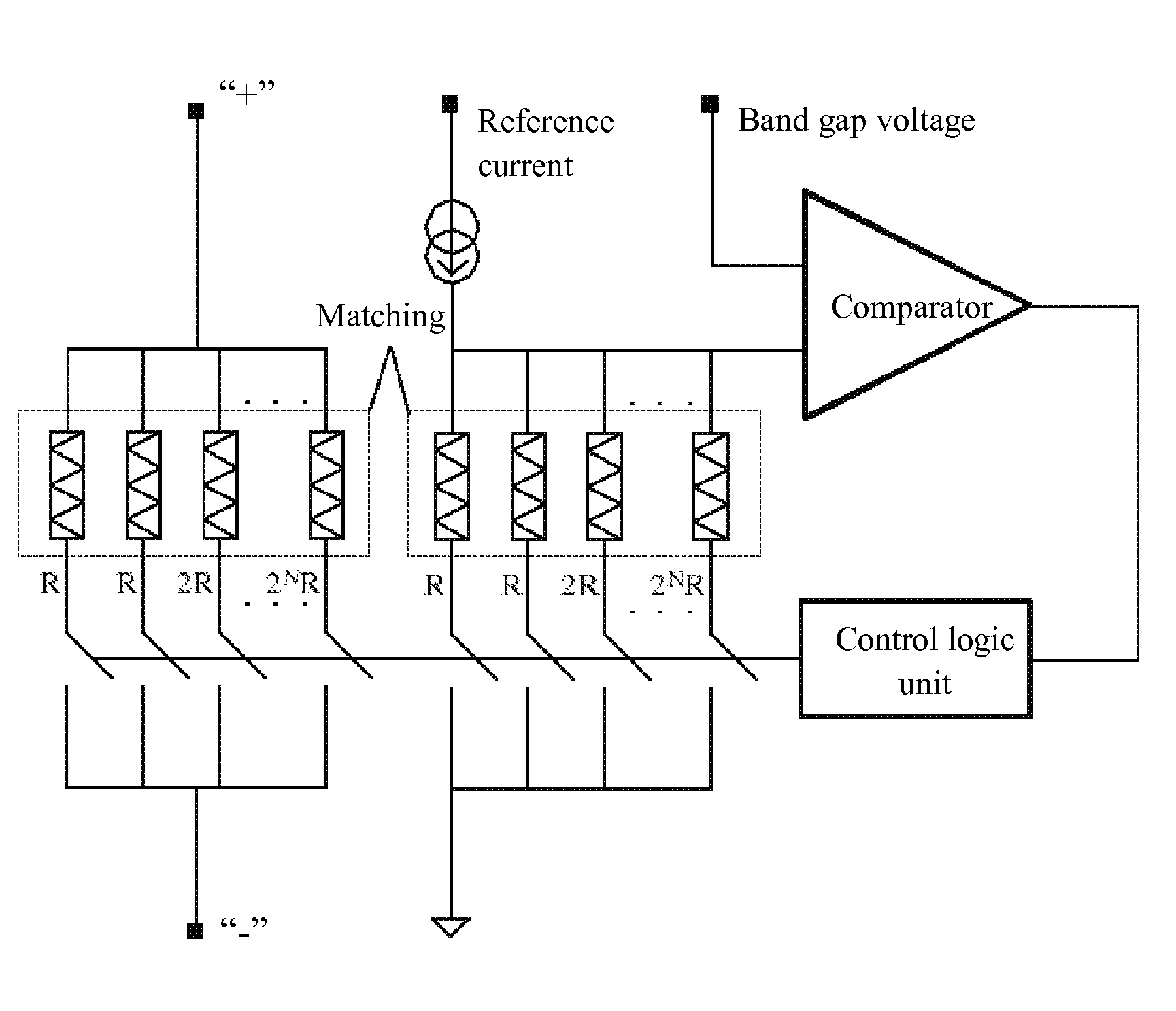

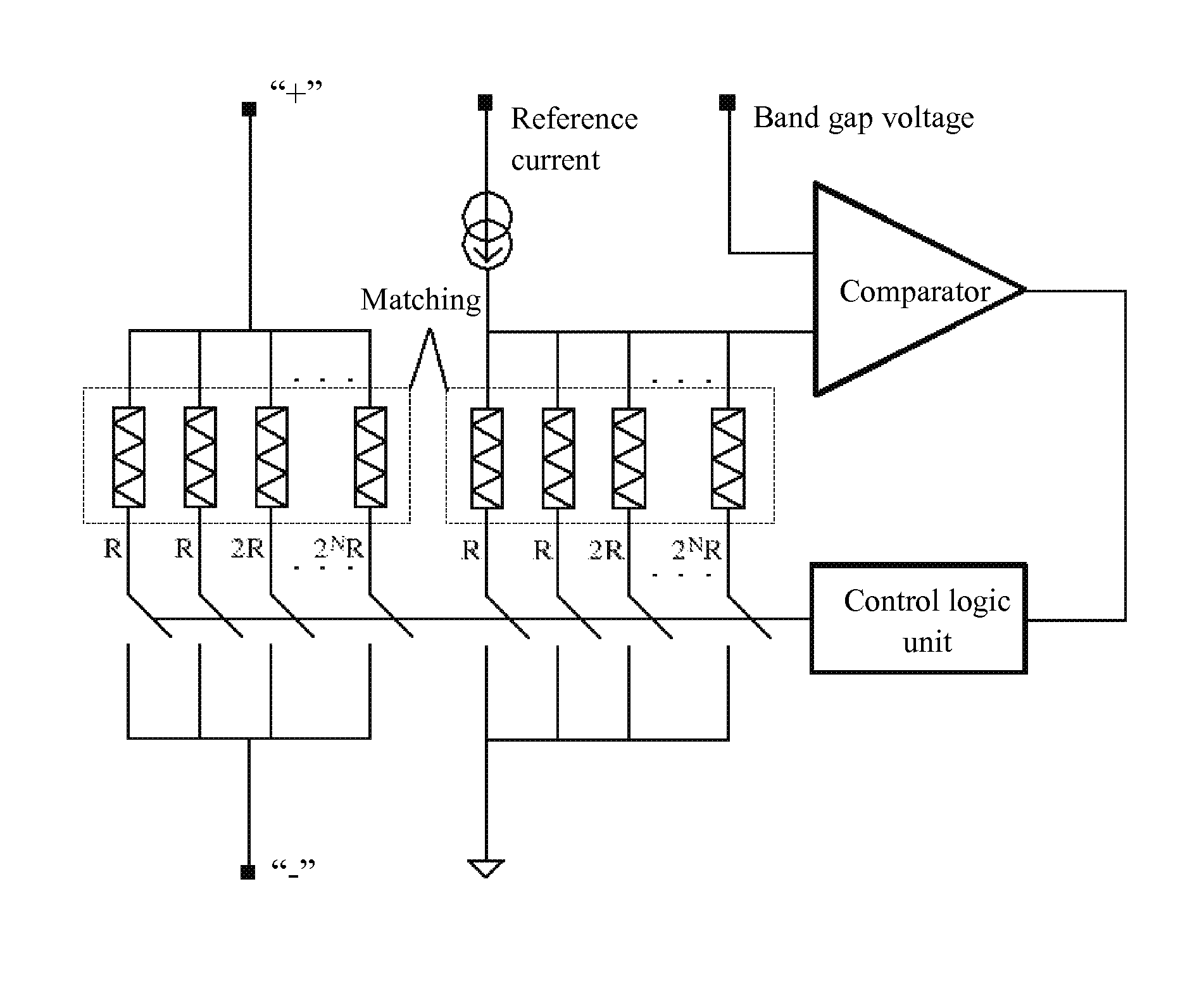

Calibration of resistor ladder using difference measurement and parallel resistive correction

InactiveUS20030151532A1Electric signal transmission systemsAnalogue-digital convertersDifferential measurementComplementary pair

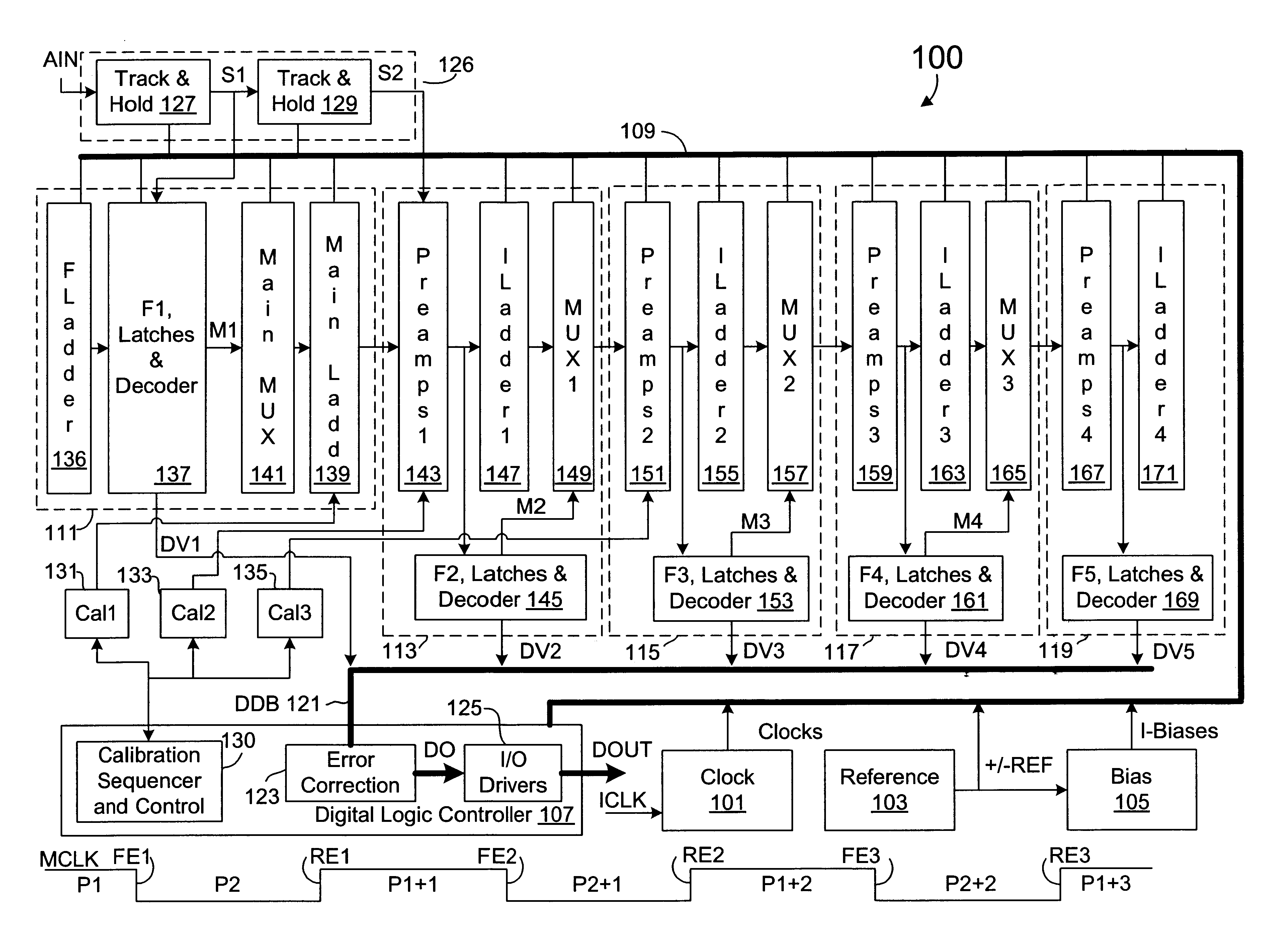

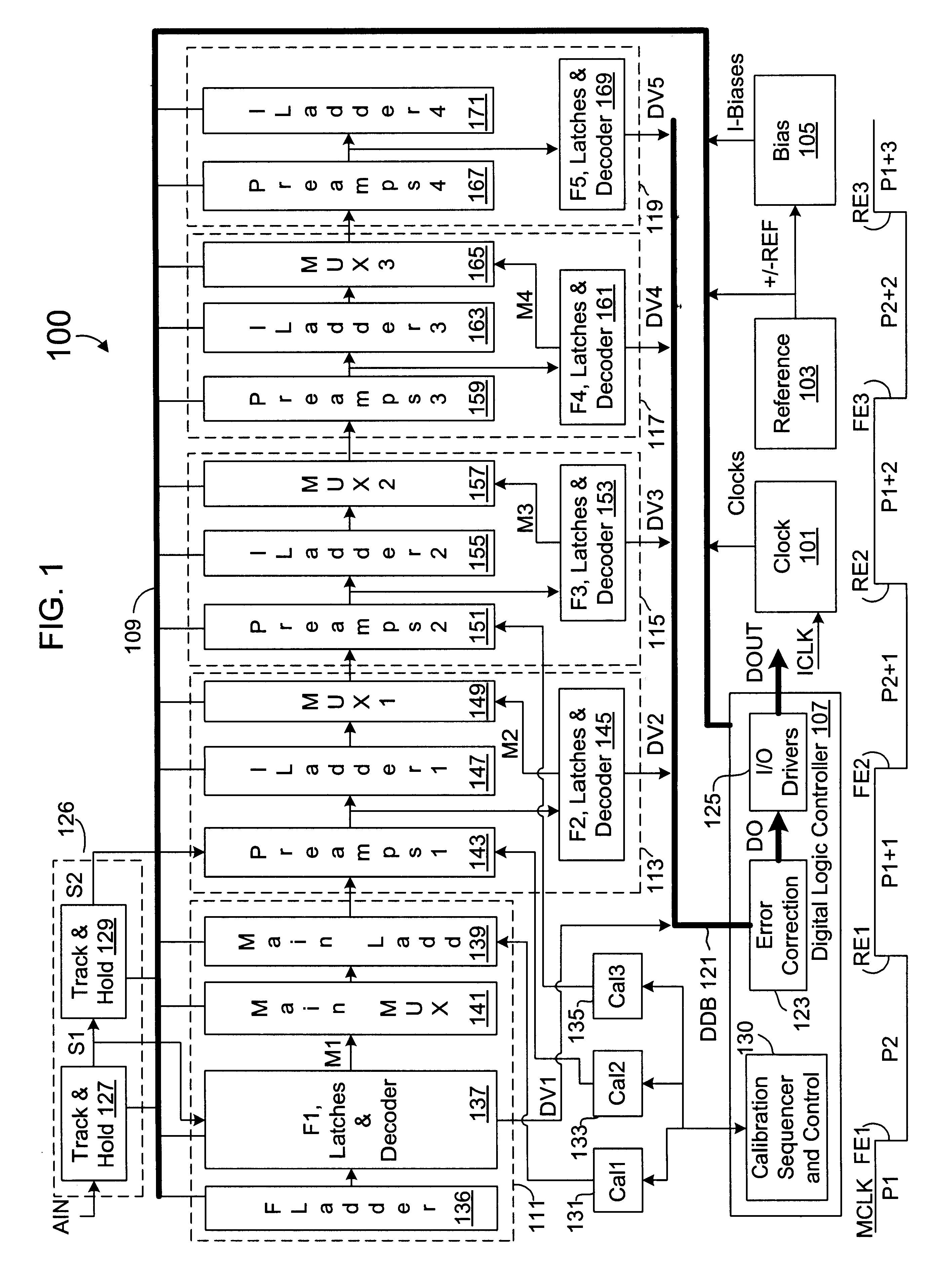

A calibration system and method for a resistor ladder that employs relative measurement and adjustment between pairs of resistors. The system includes a resistor tree of complementary pairs of programmable resistors coupled to the resistor ladder, a measurement circuit that measures voltage differences between complementary pairs of programmable resistors, and control logic. The control logic controls the measurement circuit to measure a voltage difference between each complementary pair of programmable resistors and adjusts the relative resistance of each complementary pair of programmable resistors to equalize voltage. The measurement is facilitated by a sigma-delta ADC that converts a measured voltage difference into a bit stream. The programmable resistors are implemented with binary weighted resistors that are digitally adjusted one LSB at a time. Lower and upper adjustment thresholds may be employed to avoid unnecessary over-adjustments while maintaining a requisite level of accuracy.

Owner:INTERSIL INC

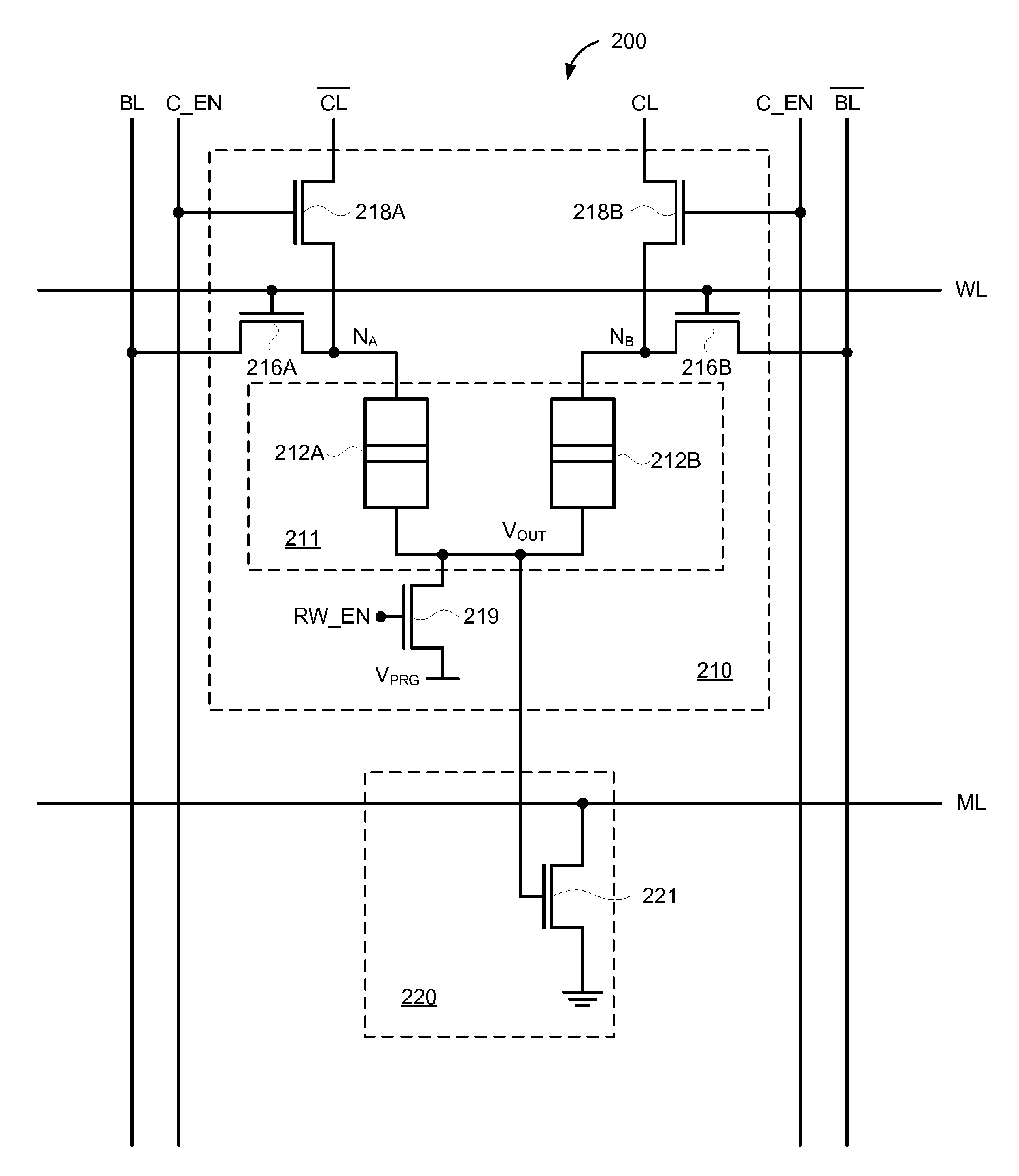

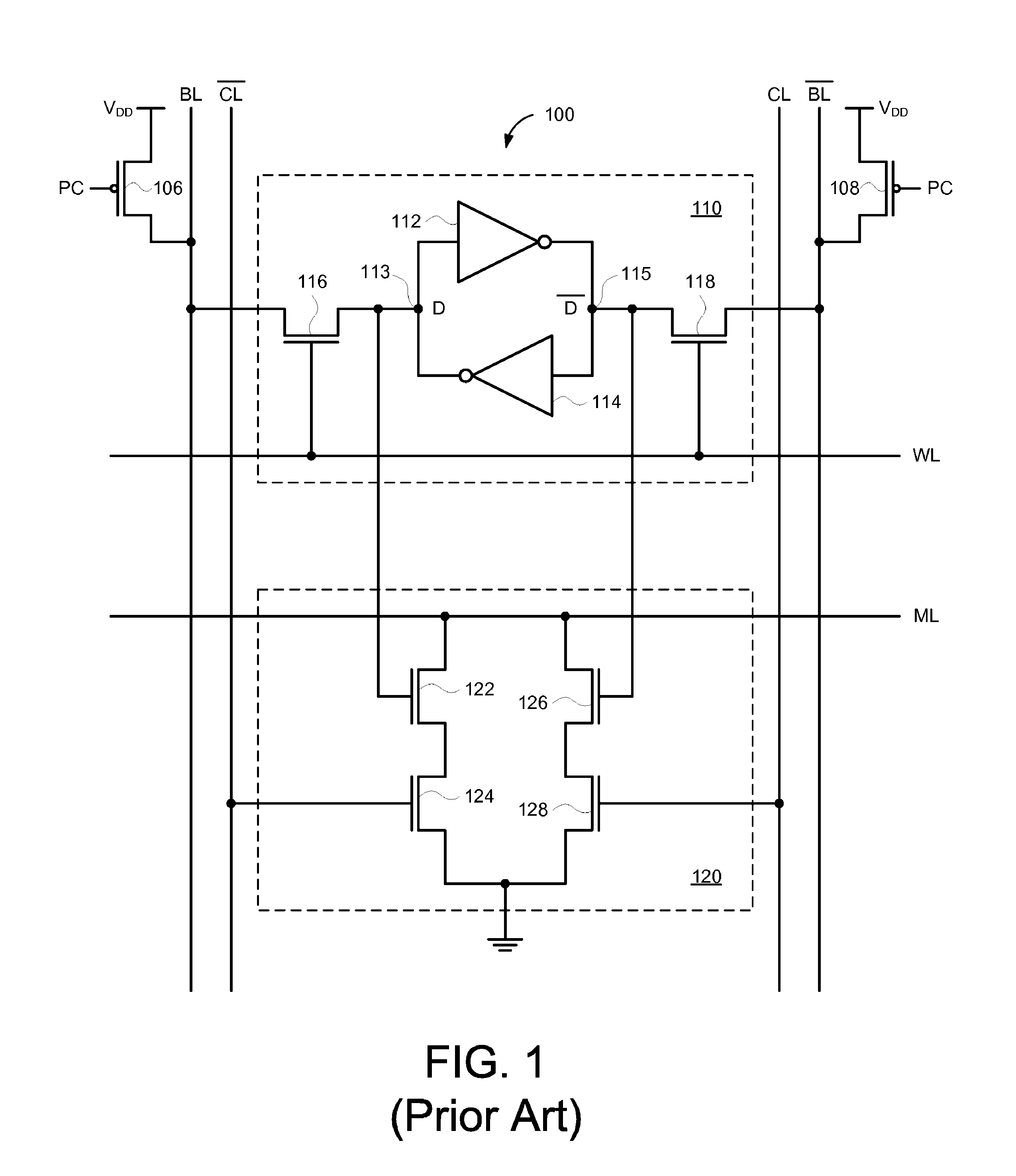

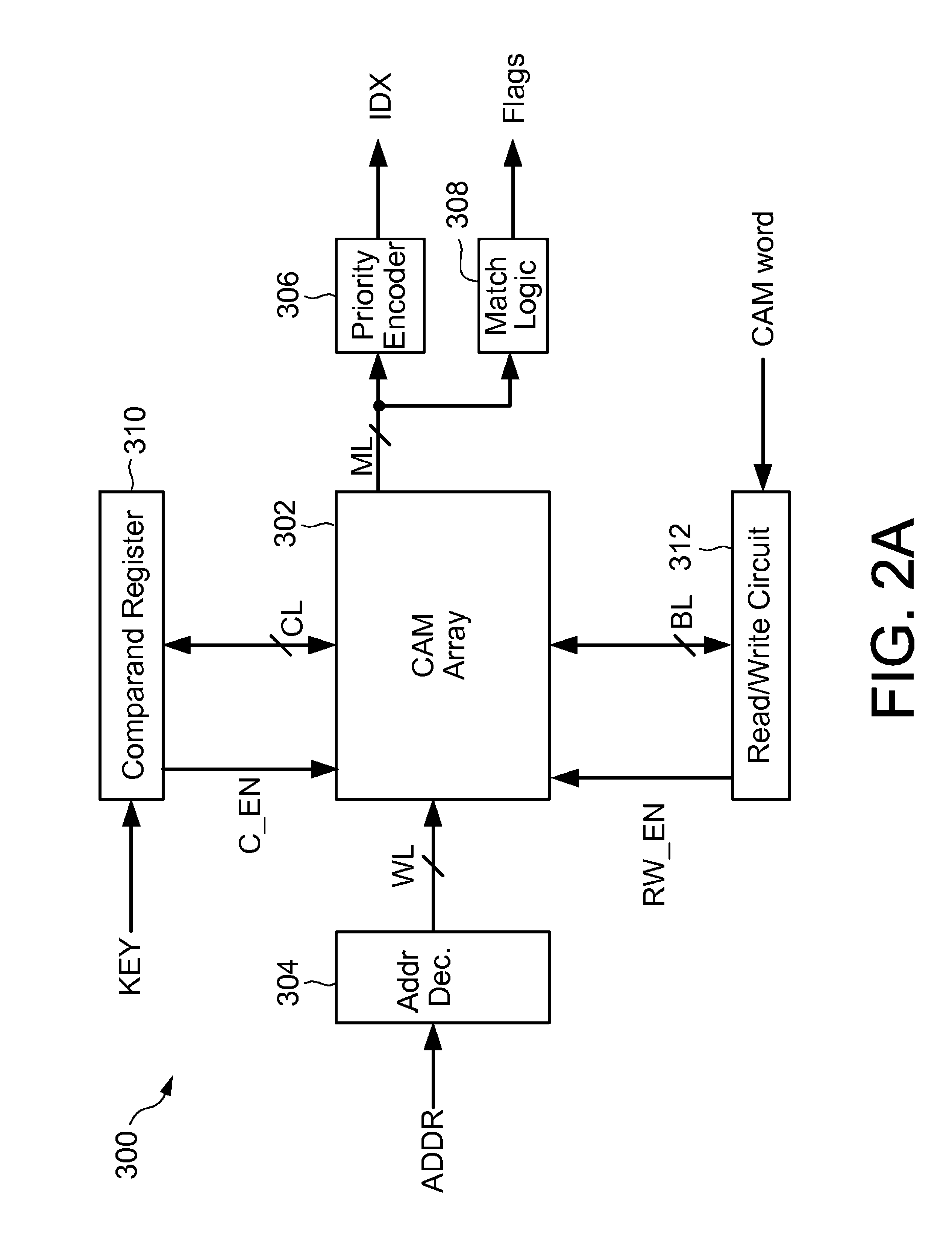

Content addressable memory device having spin torque transfer memory cells

A CAM device includes an array of CAM cells each having a spin torque transfer (STT) storage cell to store a data bit. Each STT storage cell includes a first magnetic tunnel junction (MTJ) element coupled between a first input node and an output node of the CAM cell, a second MTJ element coupled between a second input node and the output node of the CAM cell, and a first match transistor coupled between the match line and ground potential and having a gate coupled to the output node. The logic state of the data bit is represented by the relative resistances of the first and second MTJ elements.

Owner:AVAGO TECH INT SALES PTE LTD

Memory arrays using nanotube articles with reprogrammable resistance

A memory array includes a plurality of memory cells, each of which receives a bit line, a first word line, and a second word line. Each memory cell includes a cell selection circuit, which allows the memory cell to be selected. Each memory cell also includes a two-terminal switching device, which includes first and second conductive terminals in electrical communication with a nanotube article. The memory array also includes a memory operation circuit, which is operably coupled to the bit line, the first word line, and the second word line of each cell. The circuit can select the cell by activating an appropriate line, and can apply appropriate electrical stimuli to an appropriate line to reprogrammably change the relative resistance of the nanotube article between the first and second terminals. The relative resistance corresponds to an informational state of the memory cell.

Owner:NANTERO

Calibration of resistor ladder using difference measurement and parallel resistive correction

InactiveUS6628216B2Electric signal transmission systemsAnalogue-digital convertersDifferential measurementComplementary pair

Owner:INTERSIL INC

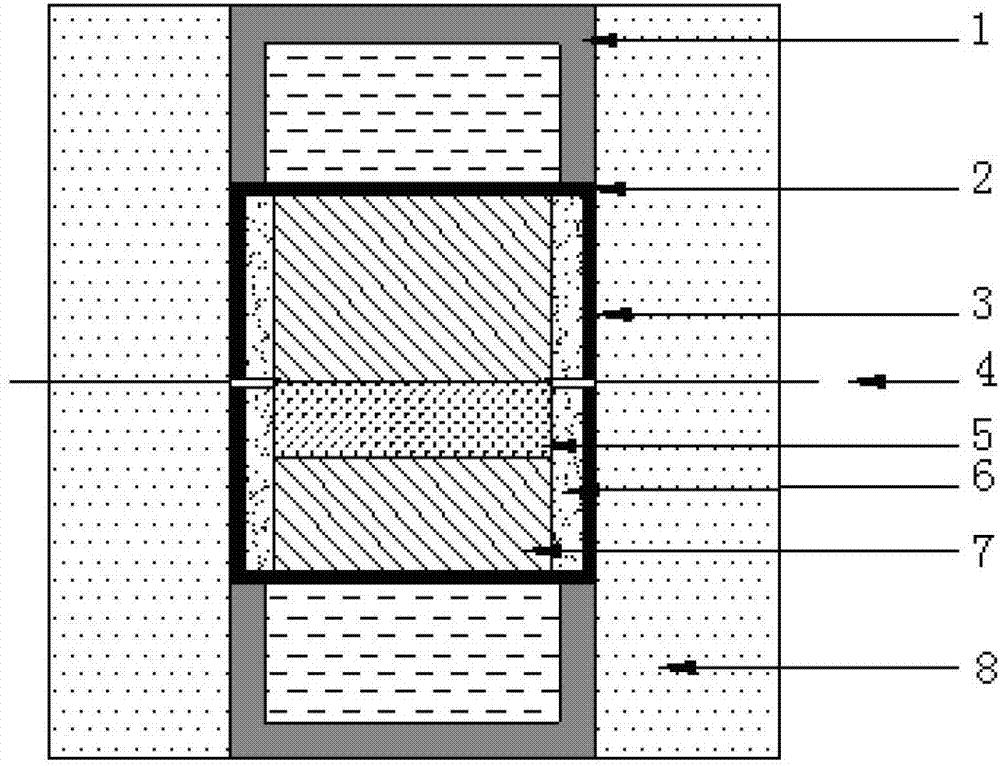

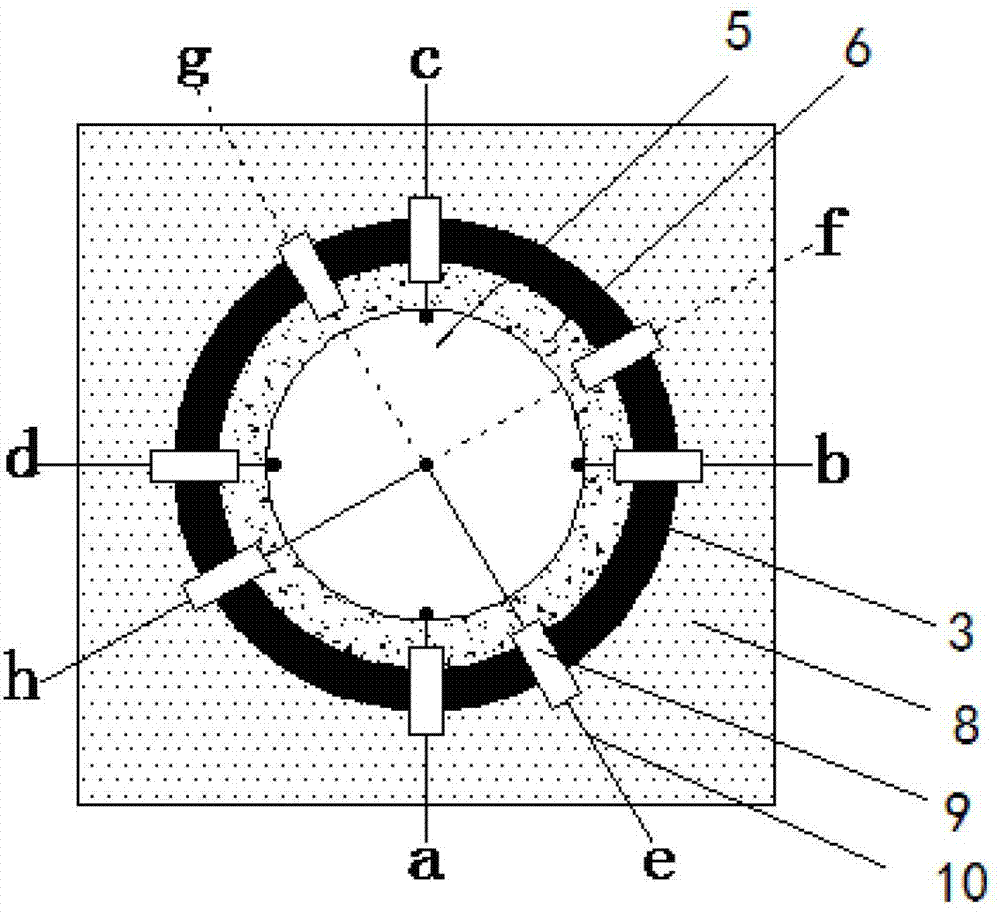

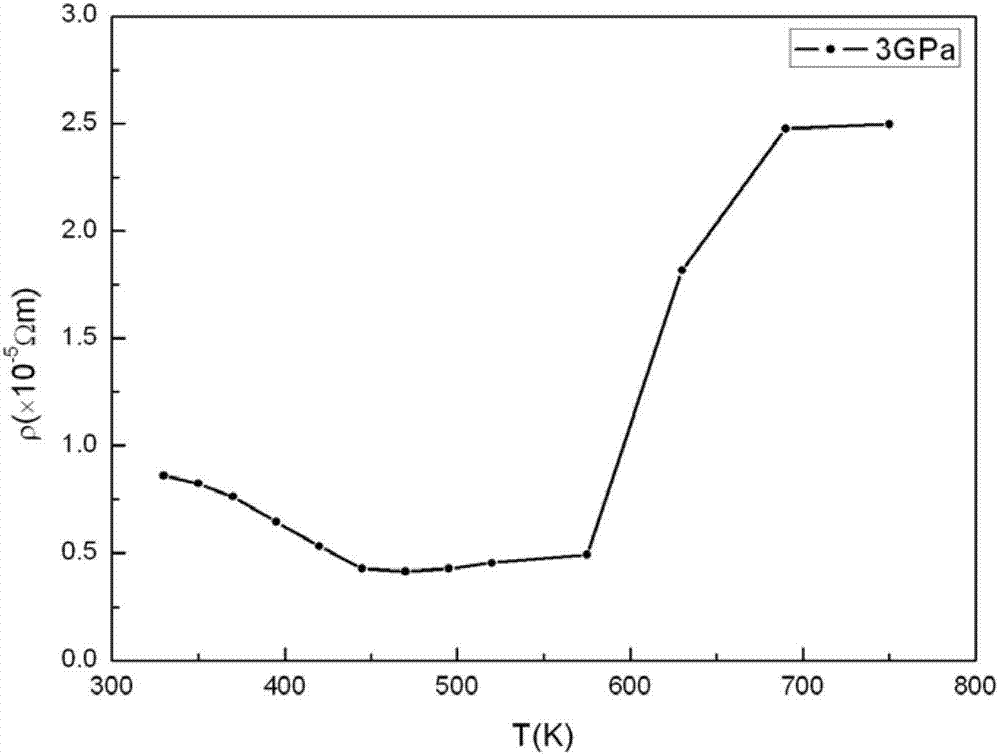

Device and method for carrying out in-situ testing on transport properties of conductor materials at high temperature and high pressure

InactiveCN103399044AEasily brokenGuaranteed insulation performanceMaterial resistanceElectrical conductorCopper wire

The invention discloses a device and a method for carrying out in-situ testing on the transport properties of conductor materials at high temperature and high pressure, and belongs to the field of high-pressure science and technologies and material science technologies. In the device, four copper wires (4) are introduced to a side face of a high-temperature and high-pressure synthetic assembling block and used as electrodes for measuring the resistivity, two pairs of thermocouples (10) are introduced for measuring seebeck coefficients, and welding points of a sample (5) and the electrodes as well as the sample (5) and the thermocouples (10) are fixed by using a pressure generated by a high-temperature and high-pressure device. The resistivity of the sample is calculated through measuring relative resistance values RA and RB and the thickness d of the sample subjected to pressurization; the seebeck coefficient of the sample is calculated through measuring a potential difference Vef between positive poles of the two pairs of thermocouples and a potential difference Vhg between negative poles of the two pairs of thermocouples. The method disclosed by the invention is simple, easy to implement, high in success rate, and good in experimental repetition rate; a problem that wires and the thermocouples are easy to fracture at the high pressure is solved; a situation that measured electrical signals are interfered by heating current is prevented, thereby ensuring the accuracy of results.

Owner:JILIN UNIV

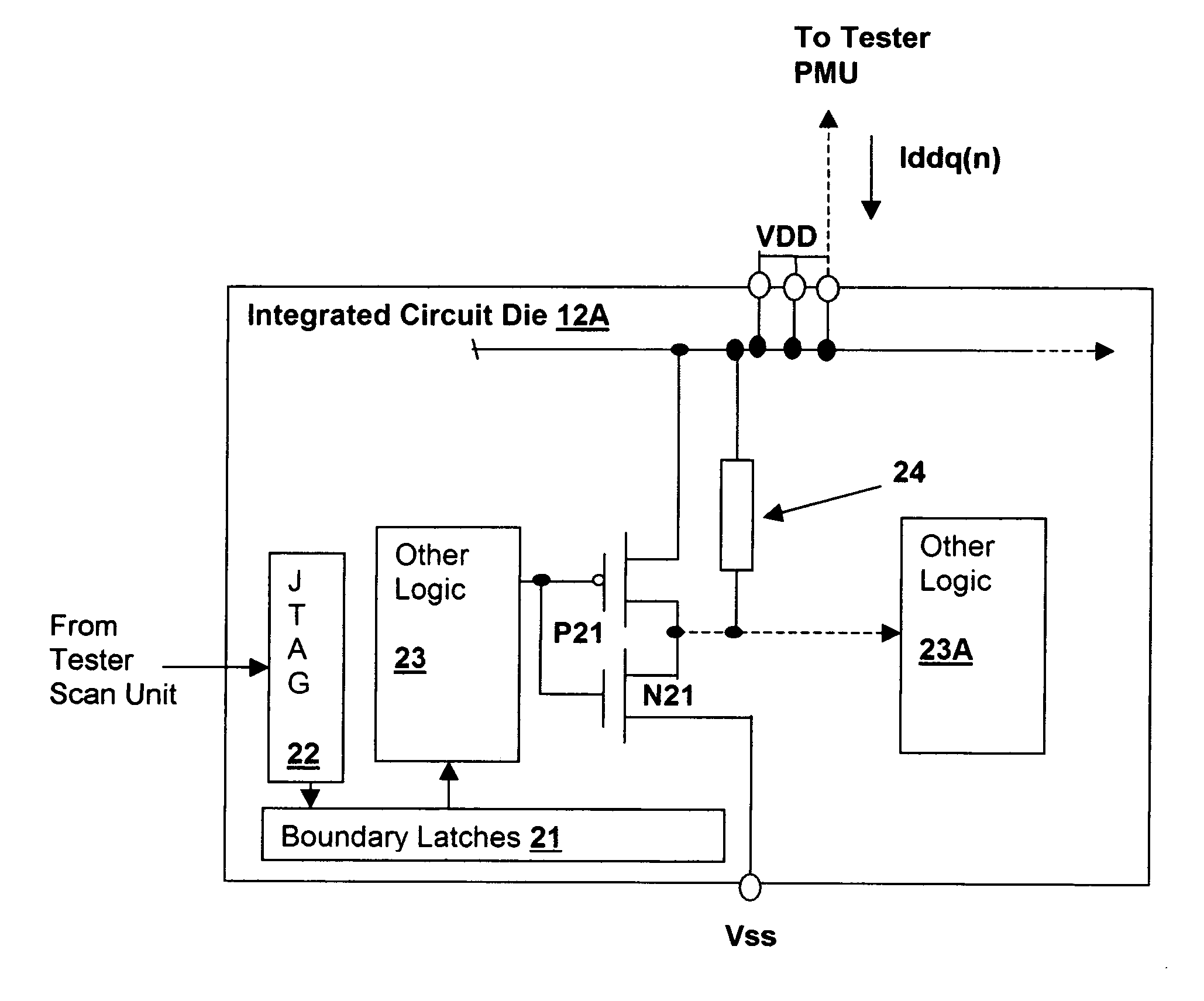

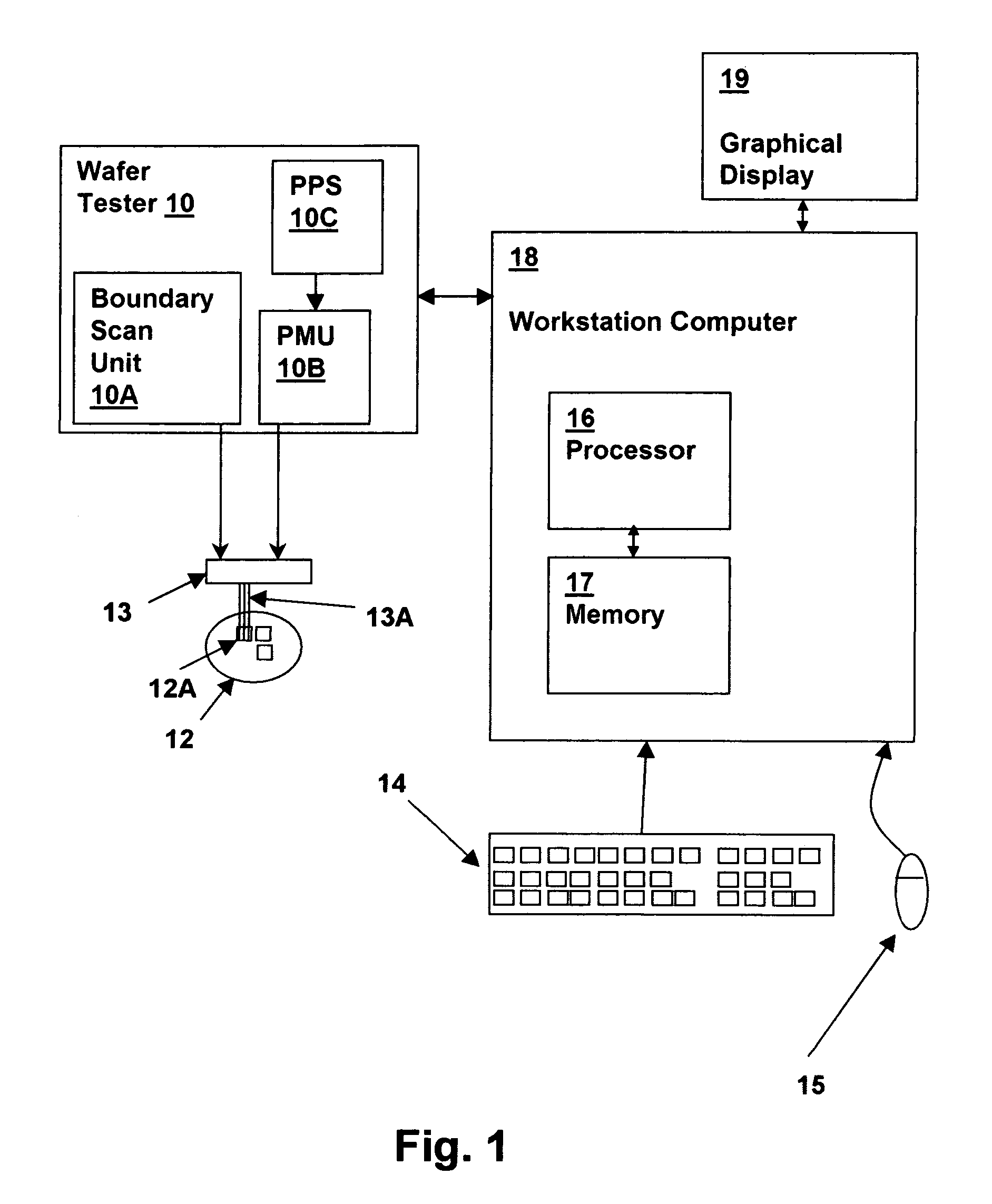

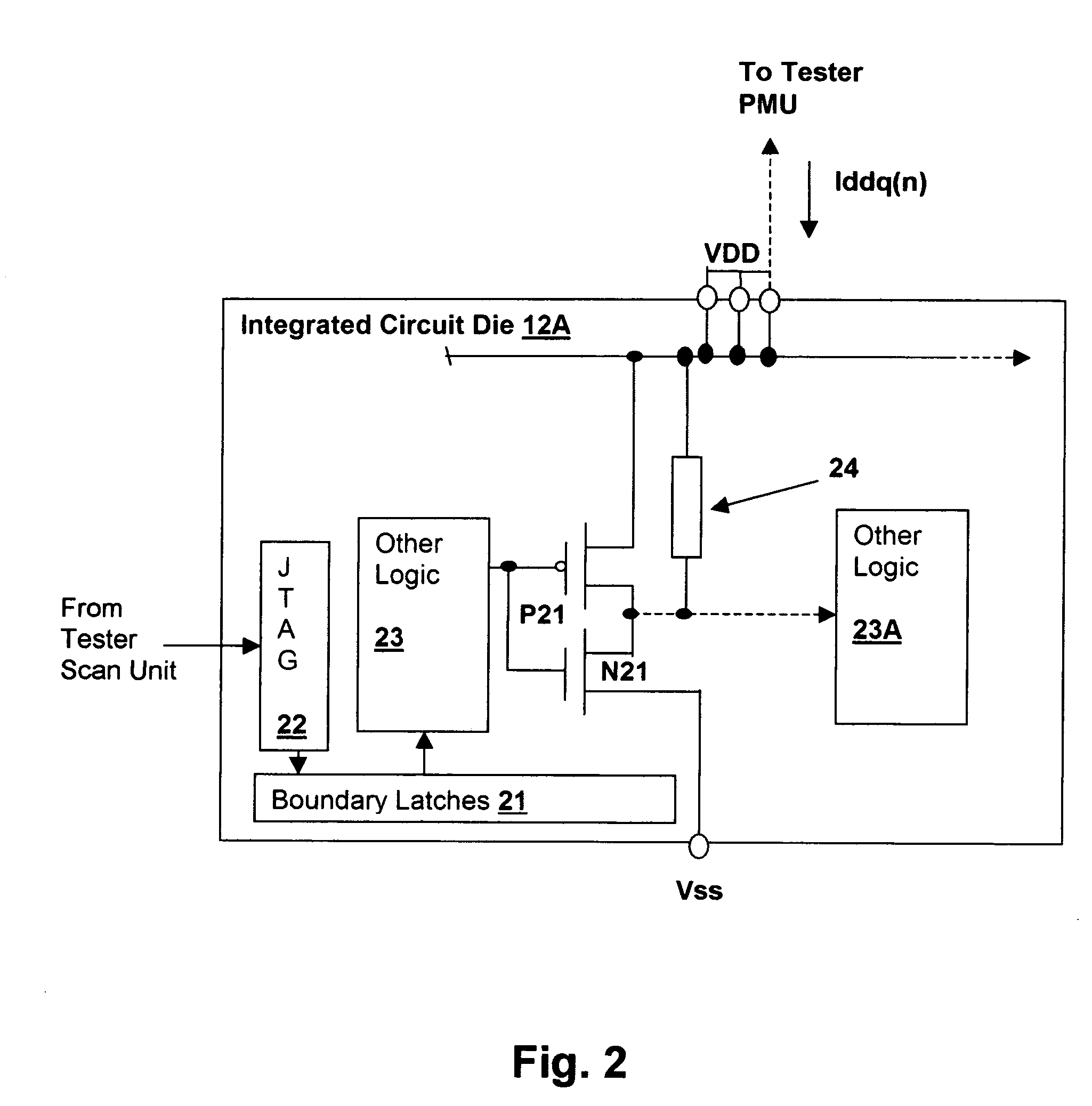

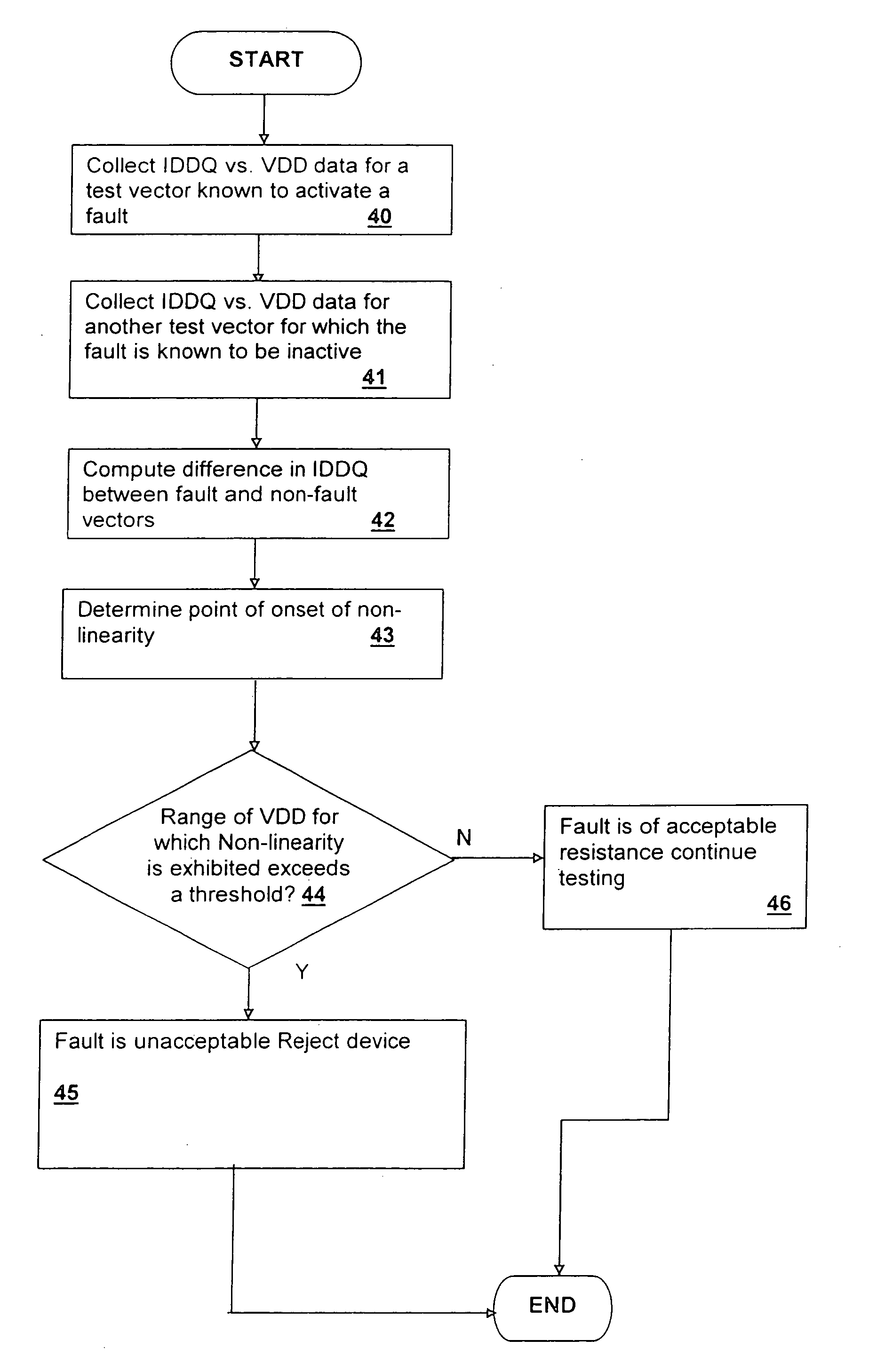

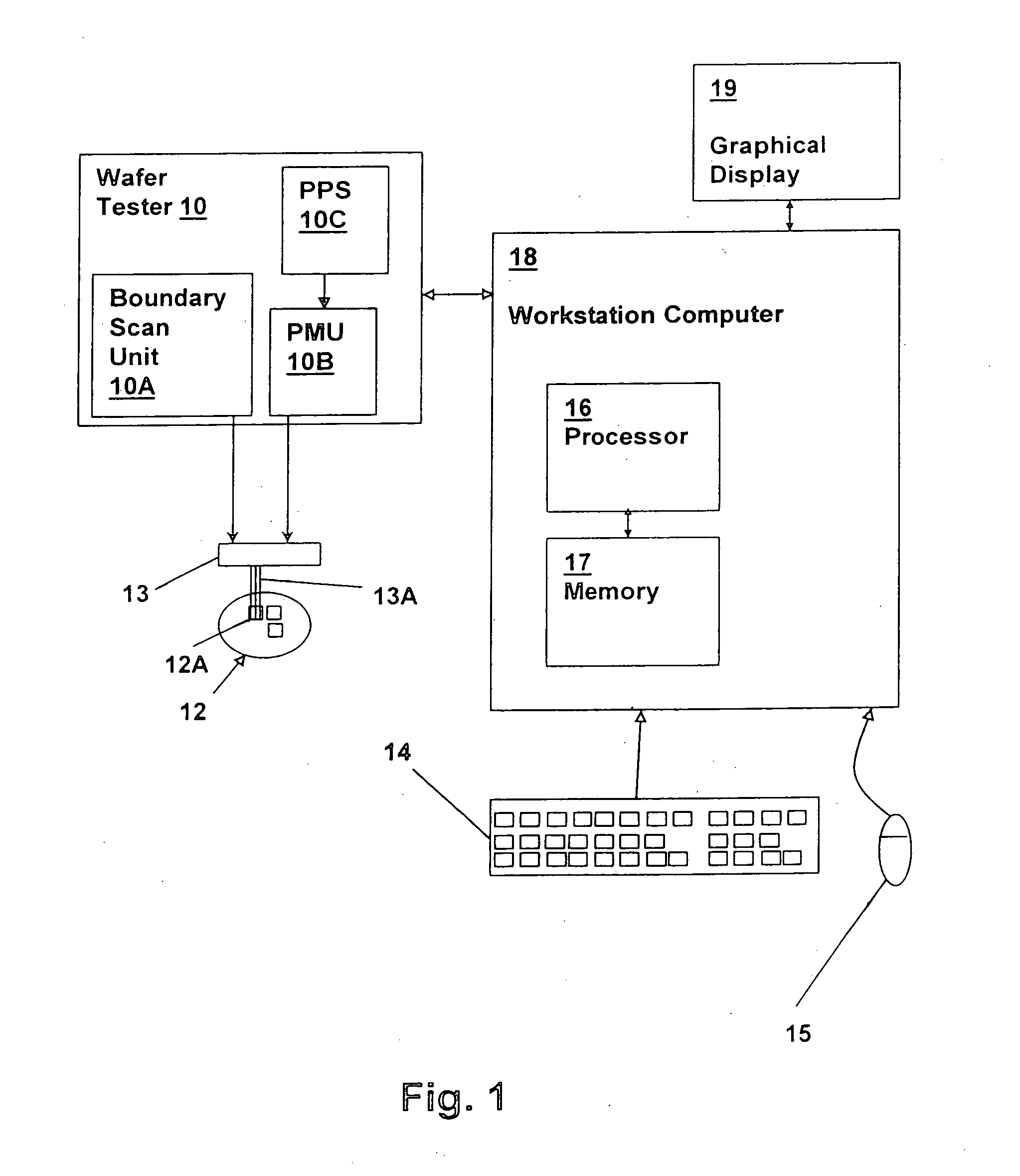

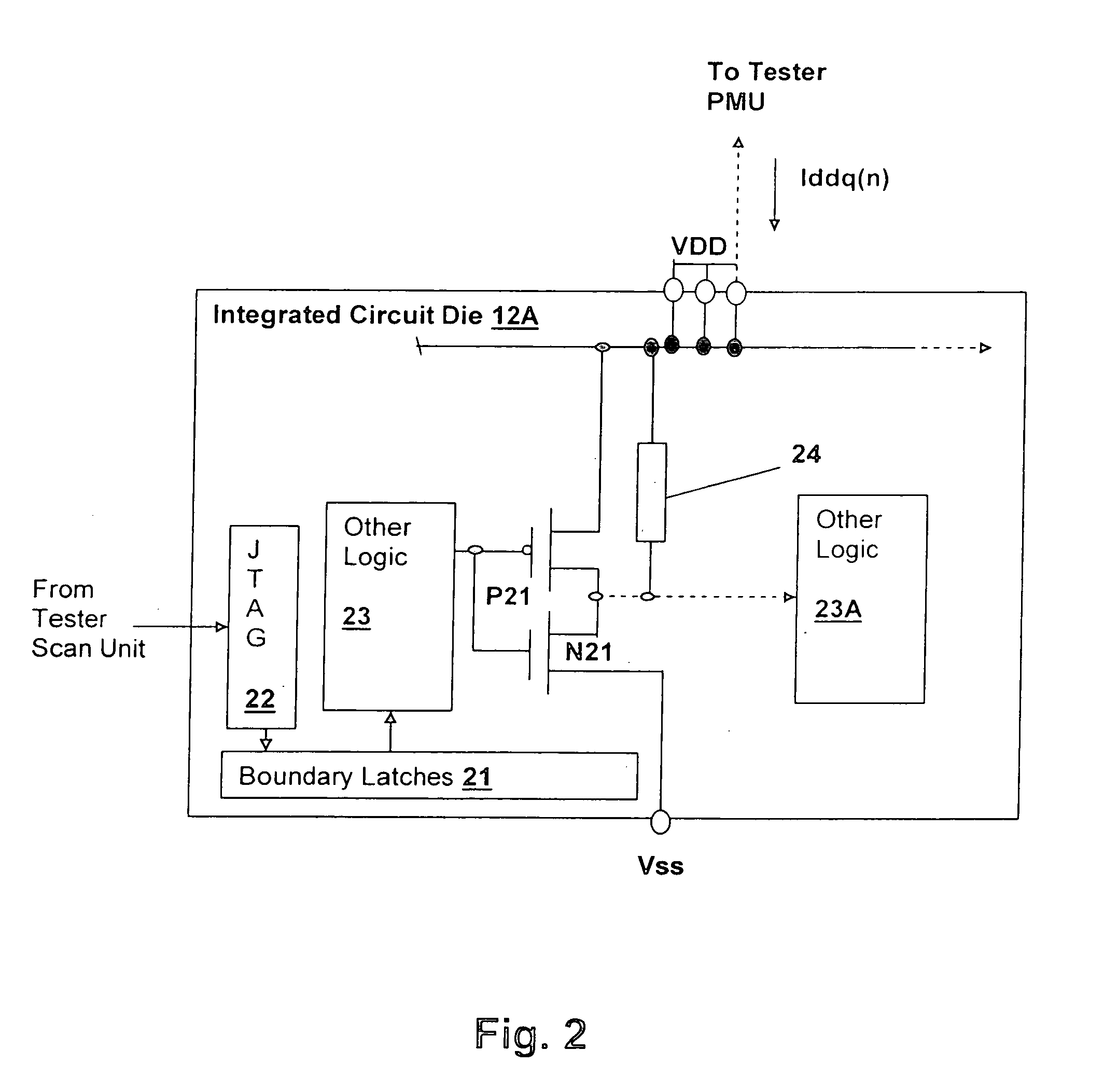

Method and system for defect evaluation using quiescent power plane current (IDDQ) voltage linearity

InactiveUS20050125711A1Easy to testCurrent/voltage measurementError detection/correctionCircuit delayPeak value

A method and system for defect evaluation using IDDQ voltage linearity provides improved IDDQ testing for determining whether manufacturing defects in a VLSI device are likely to cause functional faults. IDDQ data is collected at multiple power plane voltages (VDDs) for a test vector at which a fault is activated. The IDDQ vs. VDD is then examined and a range of VDDs over which the characteristic IDDQs are non-linear with respect to VDD is determined. Peaks in the first derivative of the IDDQ vs. VDD curve indicate a particular VDD at which the onset of non-linearity in the IDDQ occurs. The VDD point below which the curve is non-linear indicates the relative resistance of a fault with respect to the driving point resistance of the node at which the fault is located. The relative resistance is directly determinative of additional circuit delay cause by the fault and / or whether the fault will cause a logic level transmission failure. Therefore, the range of VDDs for which the IDDQ curve is linear provides a pass / fail indication that can be used to reject devices in manufacturing test.

Owner:IBM CORP

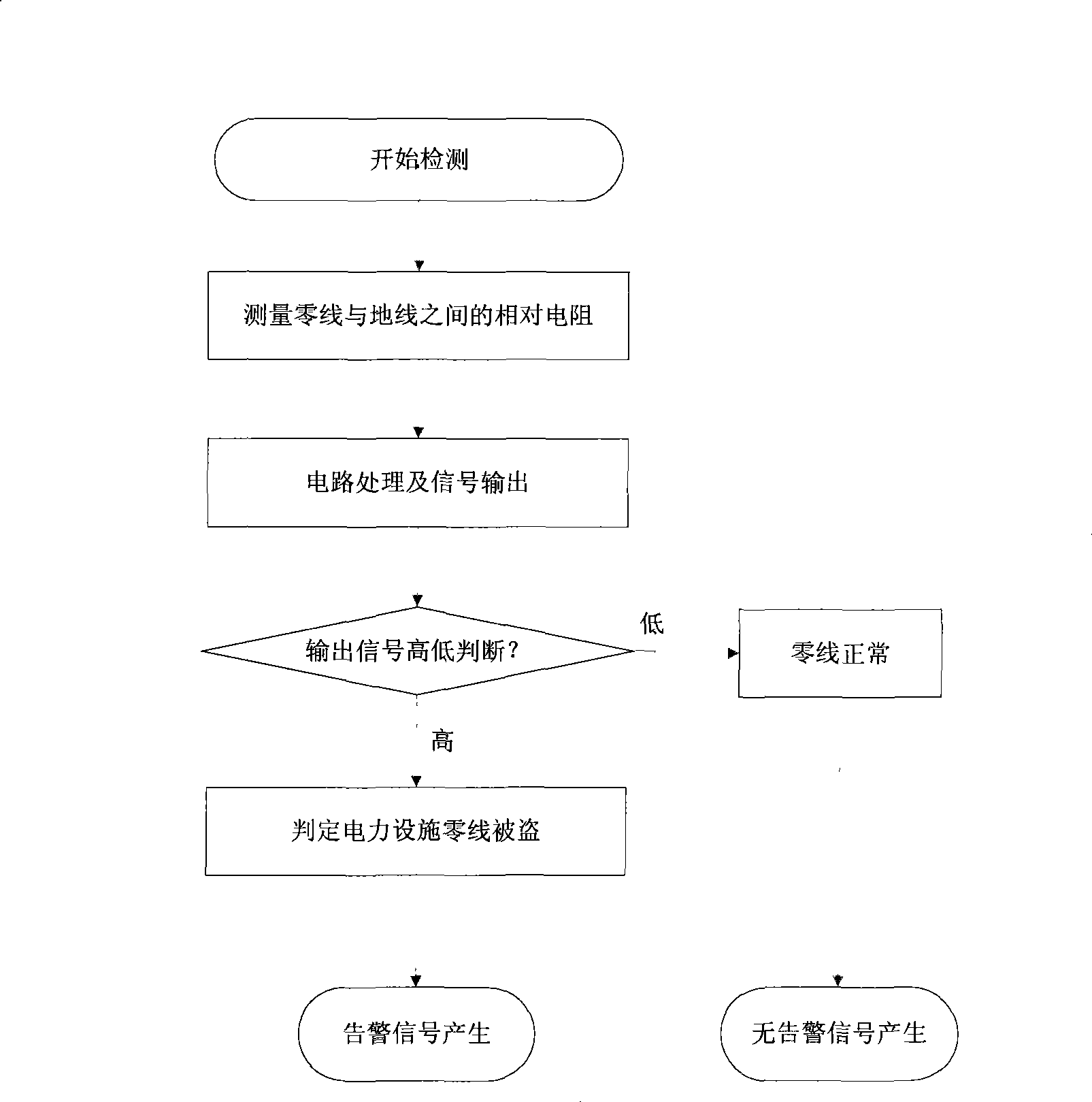

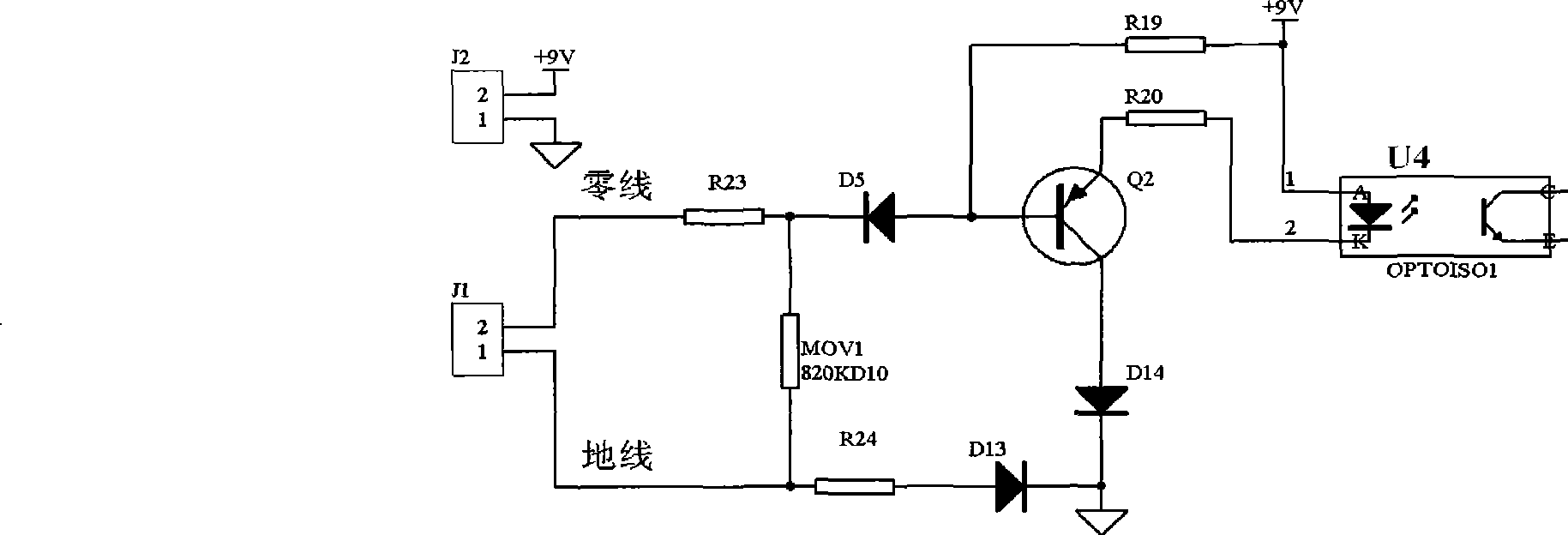

Electric power facilities theft monitoring method and monitor thereof

InactiveCN101504430ASimple methodEasy to operateResistance/reactance/impedenceBurglar alarm by disturbance/breaking stretched cords/wiresLine resistanceElectrical resistance and conductance

The invention discloses a theft monitoring method and a monitor by the method for low-voltage electrical installations such as cables, transformers and the like, and belongs to the technical field of antitheft. The electrical installation theft monitoring method comprises the following steps: measuring relative resistance between a zero line and an earth wire; and judging the size of the resistance, generating theft alarm information if the resistance is in the resistance range under the condition of open circuit of the zero line, otherwise not alarming. The electrical installation theft monitor comprises a signal acquisition module which is provided with a zero line interface and an earth wire interface and is used for measuring zero line resistance to the earth to generate on / off state signals of the zero line. The method is simple, has high operability and high accuracy of 100 percent, and can realize low cost.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

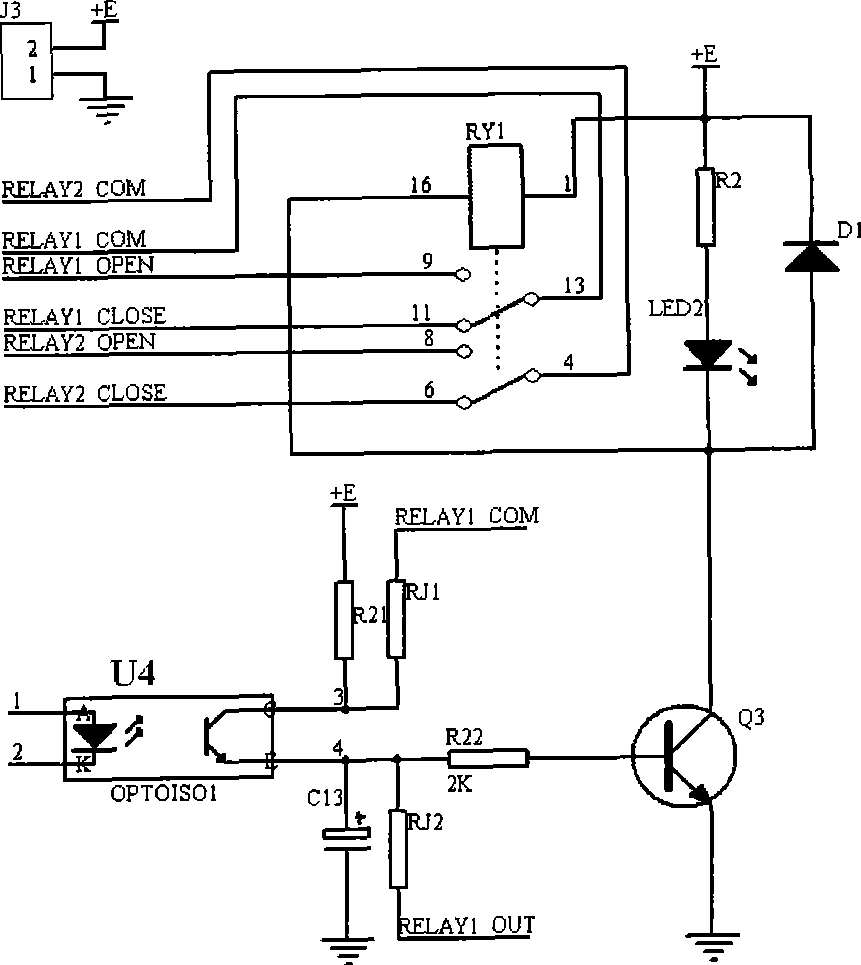

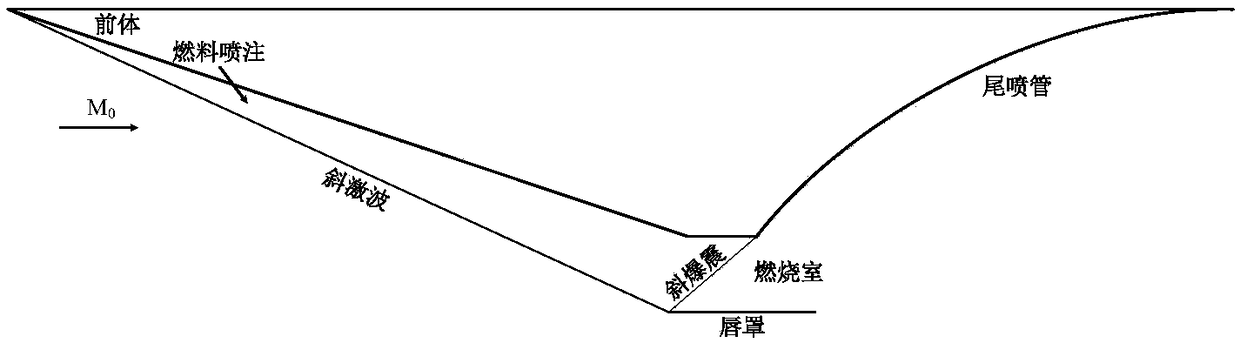

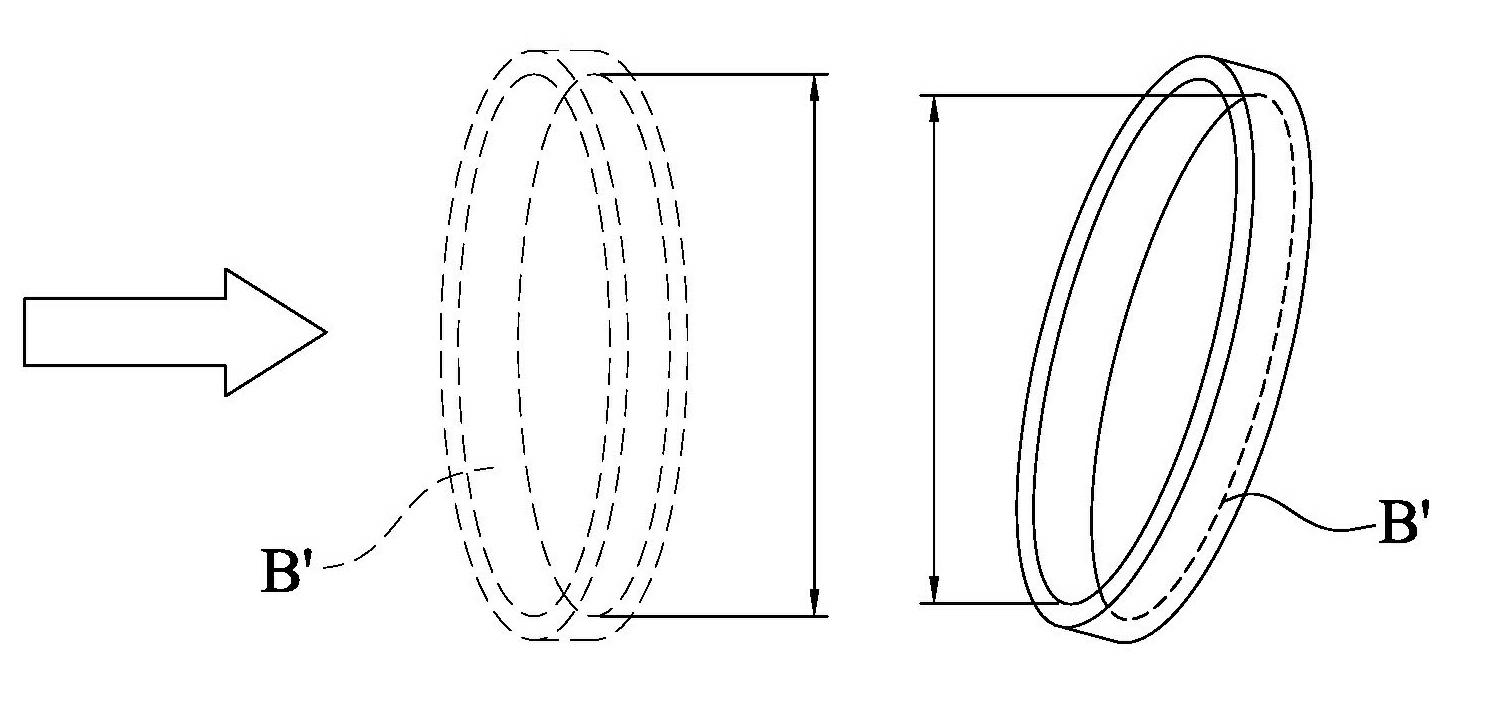

Engine annular combustion chamber in high-mach-number flight and spiral inclined knocking combustion method

ActiveCN109322761AInhibition reflexImprove controllabilityRam jet enginesShock waveCombustion chamber

The invention provides an engine annular combustion chamber in high-mach-number flight and a spiral inclined knocking combustion method. The engine annular combustion chamber comprises an inner cylinder, an outer shell and a shock wave generation device; the outer shell is encircled on the outer side of the inner cylinder; an annular combustion chamber is formed between the inner wall of the outershell and the outer wall of the inner cylinder; supersonic combustible gas flows in the axial direction of the annular combustion chamber; the shock wave generation device is positioned in the annular combustion chamber, and the placing direction thereof is towards the gas current flowing direction; the supersonic combustible gas currents pass through the shock wave generation device as an obstacle to generate shock waves; the shock waves ignite the combustible gas and induce to generate inclined knocking waves; and the inclined knocking waves are spirally developed in the annular combustionchamber to finally ignite the combustible gas in the whole annular combustion chamber. The engine annular combustion chamber can prominently improve the fuel mixing under the condition of high mach number, inhibits the mach reflection of the inclined knocking, reduces the total pressure loss caused by the inclined knocking combustion, improves the inclined knocking controllability, and reduces relative resistance of the shock wave generation device.

Owner:中国空气动力研究与发展中心吸气式高超声速技术研究中心

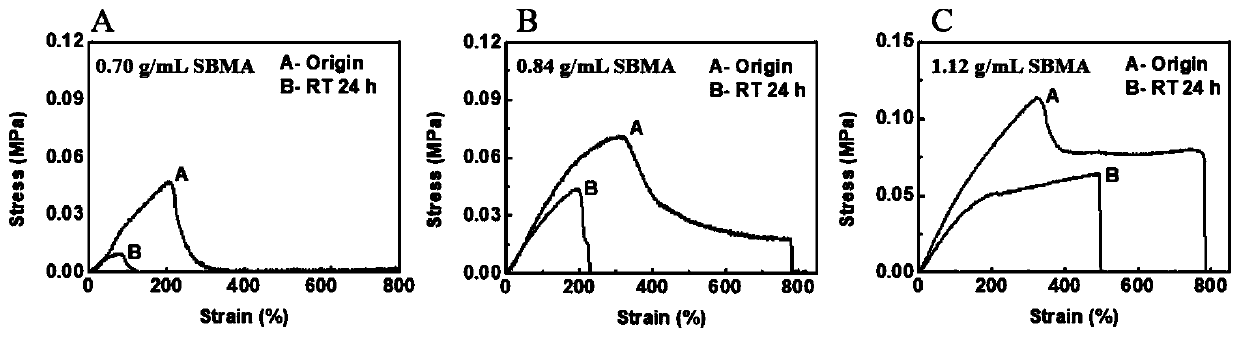

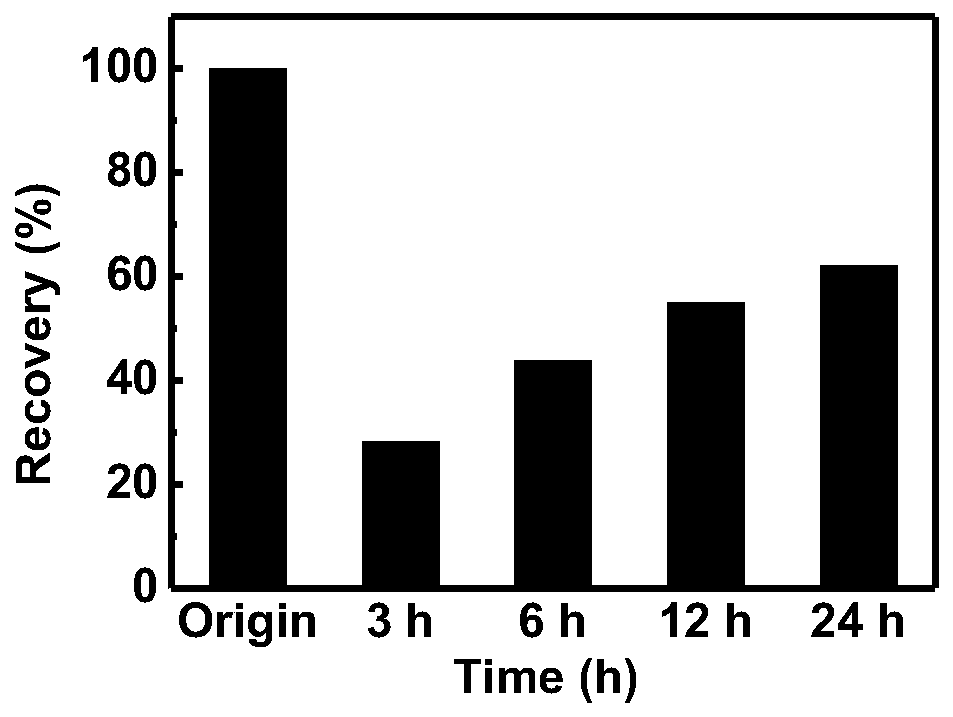

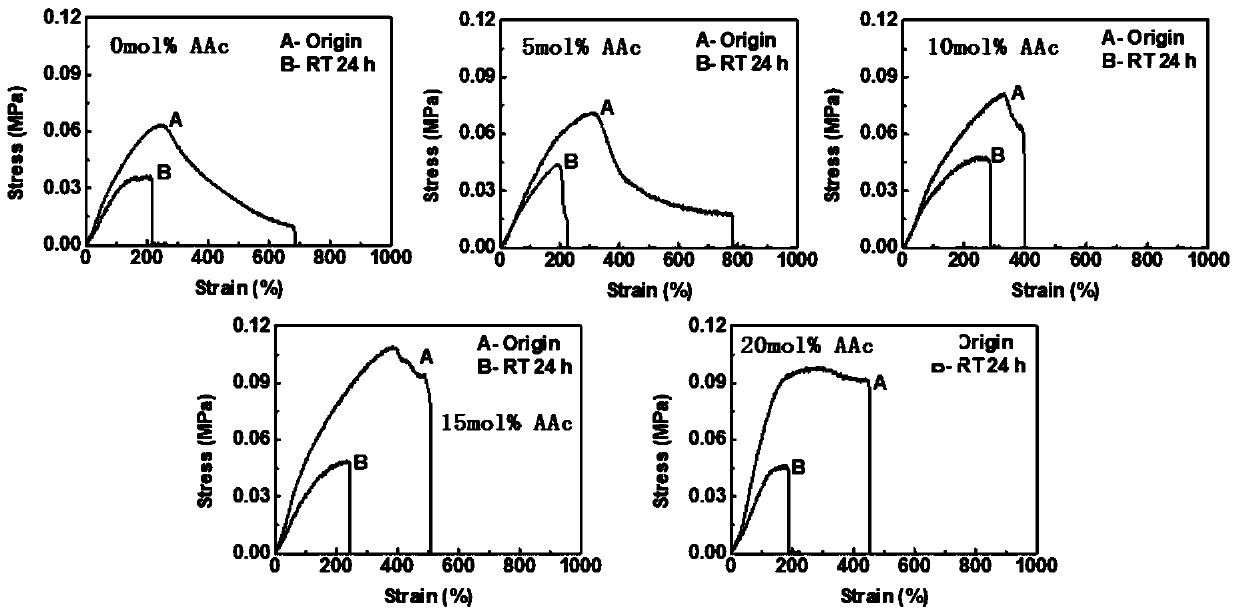

Chitosan/zwitter-ion and acrylic acid copolymer double network self-healing hydrogel and preparation method thereof

The invention discloses chitosan / zwitter-ion and acrylic acid copolymer double network self-healing hydrogel and a preparation method thereof, and relates to the technical field of hydrogel. The hydrogel is of a double network structure, and formed by a first network and a second network in a mutually penetrating mode, the first network is a physical cross-linking network formed by chitosan and polyvalent negative ions, the second network is a copolymer network formed by a zwitter-ion monomer and an acrylic acid monomer, the first network intersperses in the second network, the chitosan and the polyvalent negative ions are selected to form the first network, the zwitter-ion monomer and the acrylic acid monomer are selected to form the second network, the double network self-healing hydrogel, obtained by the cross-linking purely physical effect, with the mutually interspersed first network and the second network makes the hydrogel have excellent mechanical performance and self-healing ability, the high relative resistance change rate is provided when deformation occurs, and the chitosan / zwitter-ion and acrylic acid copolymer double network self-healing hydrogel has broad applicationprospects in the field of soft electronics, especially as biomedical sensors.

Owner:ZHEJIANG UNIV OF TECH

Method and system for defect evaluation using quiescent power plane current (IDDQ) voltage linearity

A method and system for defect evaluation using IDDQ voltage linearity provides improved IDDQ testing for determining whether manufacturing defects in a VLSI device are likely to cause functional faults. IDDQ data is collected at multiple power plane voltages (VDDs) for a test vector at which a fault is activated. The IDDQ vs. VDD is then examined and a range of VDDs over which the characteristic IDDQs are non-linear with respect to VDD is determined. Peaks in the first derivative of the IDDQ vs. VDD curve indicate a particular VDD at which the onset of non-linearity in the IDDQ occurs. The VDD point below which the curve is non-linear indicates the relative resistance of a fault with respect to the driving point resistance of the node at which the fault is located. The relative resistance is directly determinative of additional circuit delay cause by the fault and / or whether the fault will cause a logic level transmission failure. Therefore, the range of VDDs for which the IDDQ curve is linear provides a pass / fail indication that can be used to reject devices in manufacturing test.

Owner:IBM CORP

Method for cultivating honeysuckle flower number 2

InactiveCN103782758AFull of nutritionImprove adaptabilityHorticultureResource utilizationCold resistance

The invention relates to the technical field of pasture resource utilization, in particular to a method for cultivating honeysuckle flower number 2. The method includes: (1) cultivating parent strong roots; (2) hybridizing and combining parents; (3) domesticating resistance of the honeysuckle flower number 2 progressively; (4) domesticating cold resistance of the honeysuckle flower number 2 progressively. The cultivated honeysuckle flower number 2 cultivated by the method has the advantages of (1) wide growing area, (2) tolerance to barren soil, (3) tolerance to draught, wet and high temperature, (4) rich roots, strong tillering capability, (5) relative resistance to low temperature, (6) high plants, growing speed and output, and (7) rich nutrients including amino acid and micronutrient, crude protein content of fresh honeysuckle flower number 2 reaches to 8.21%, equivalently the crude protein content of the dry honeysuckle flower number 2 reaches to 10.6%, the crude protein content is one percent point more than that of rice, both beasts and birds love to eat, and the honeysuckle flower number 2 is a great grass variety with multiple functions.

Owner:贵州华农高科牧草业发展有限公司

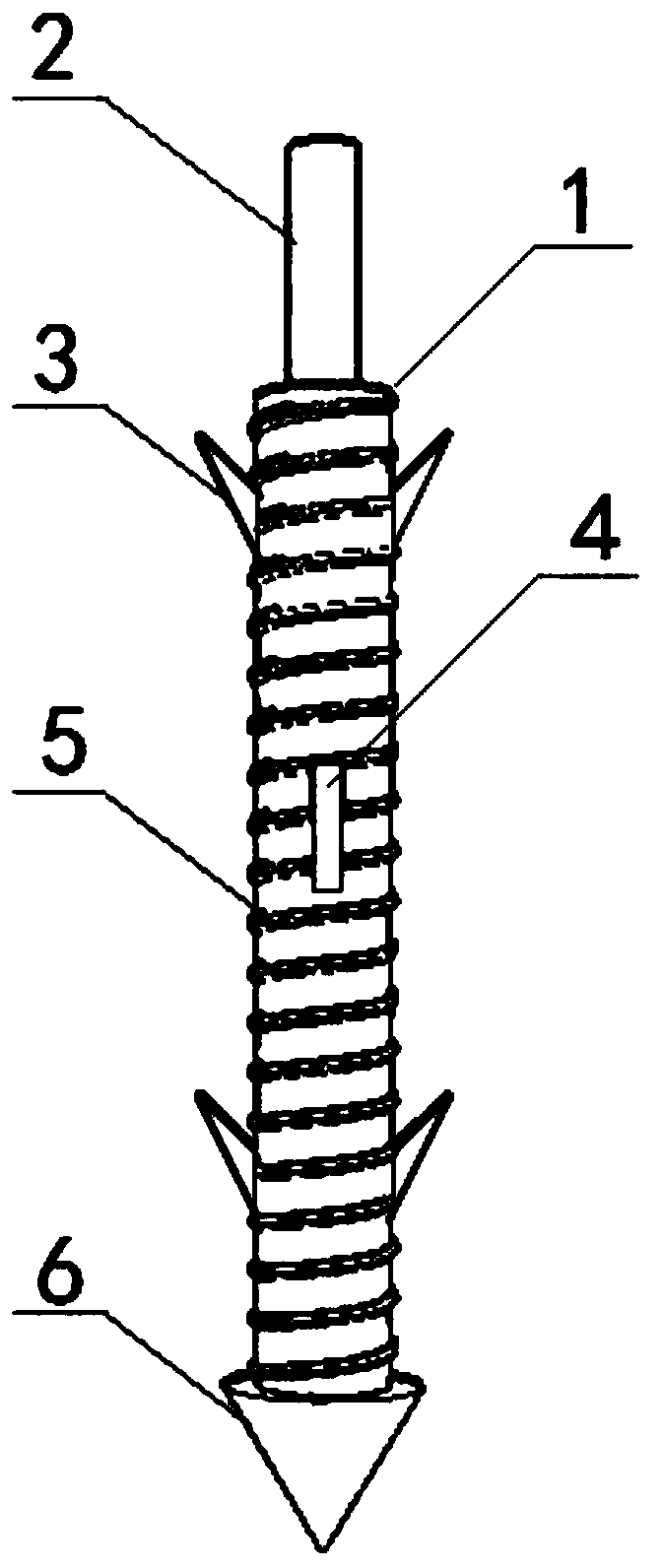

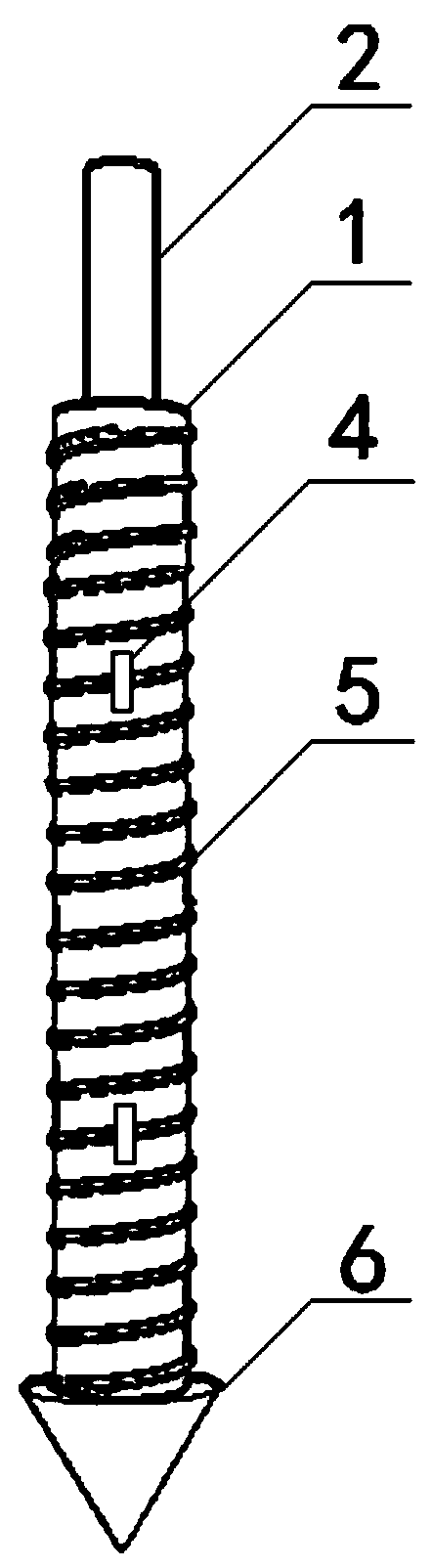

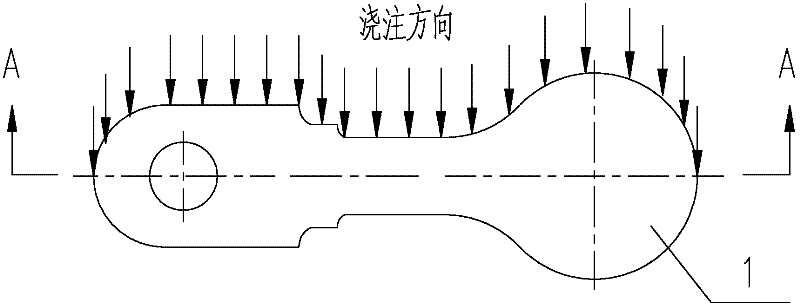

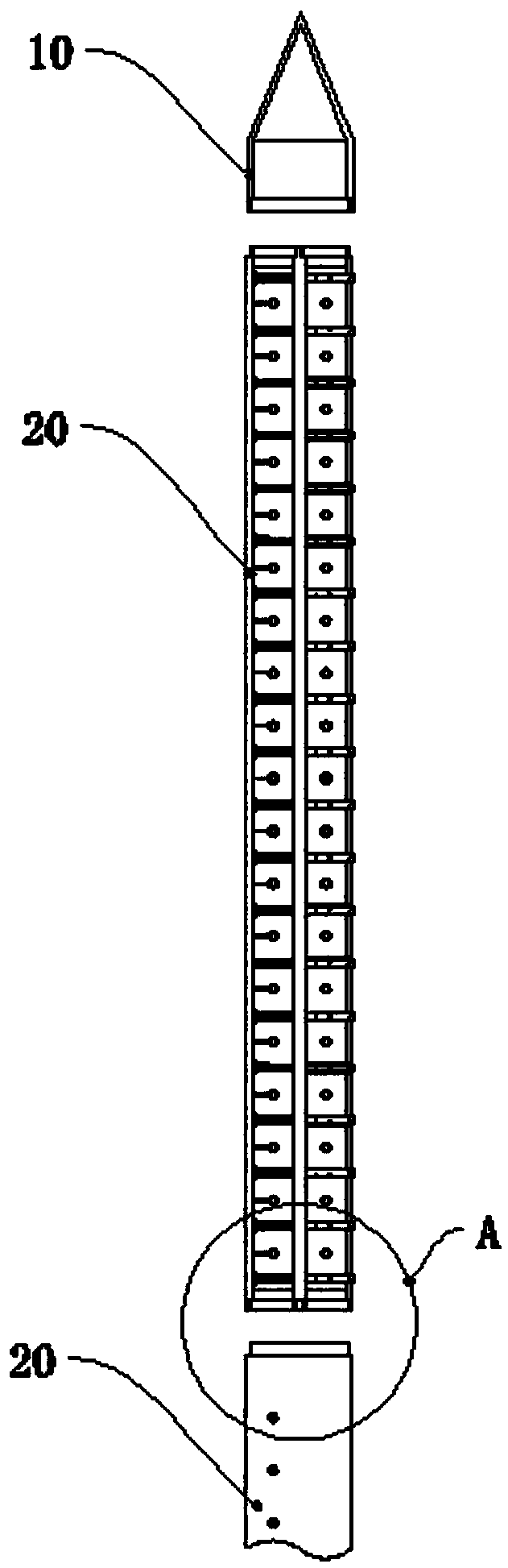

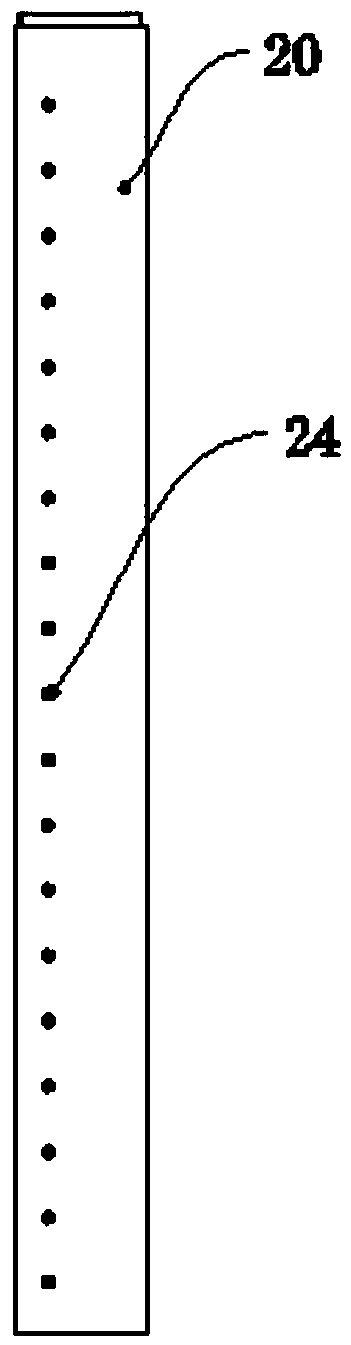

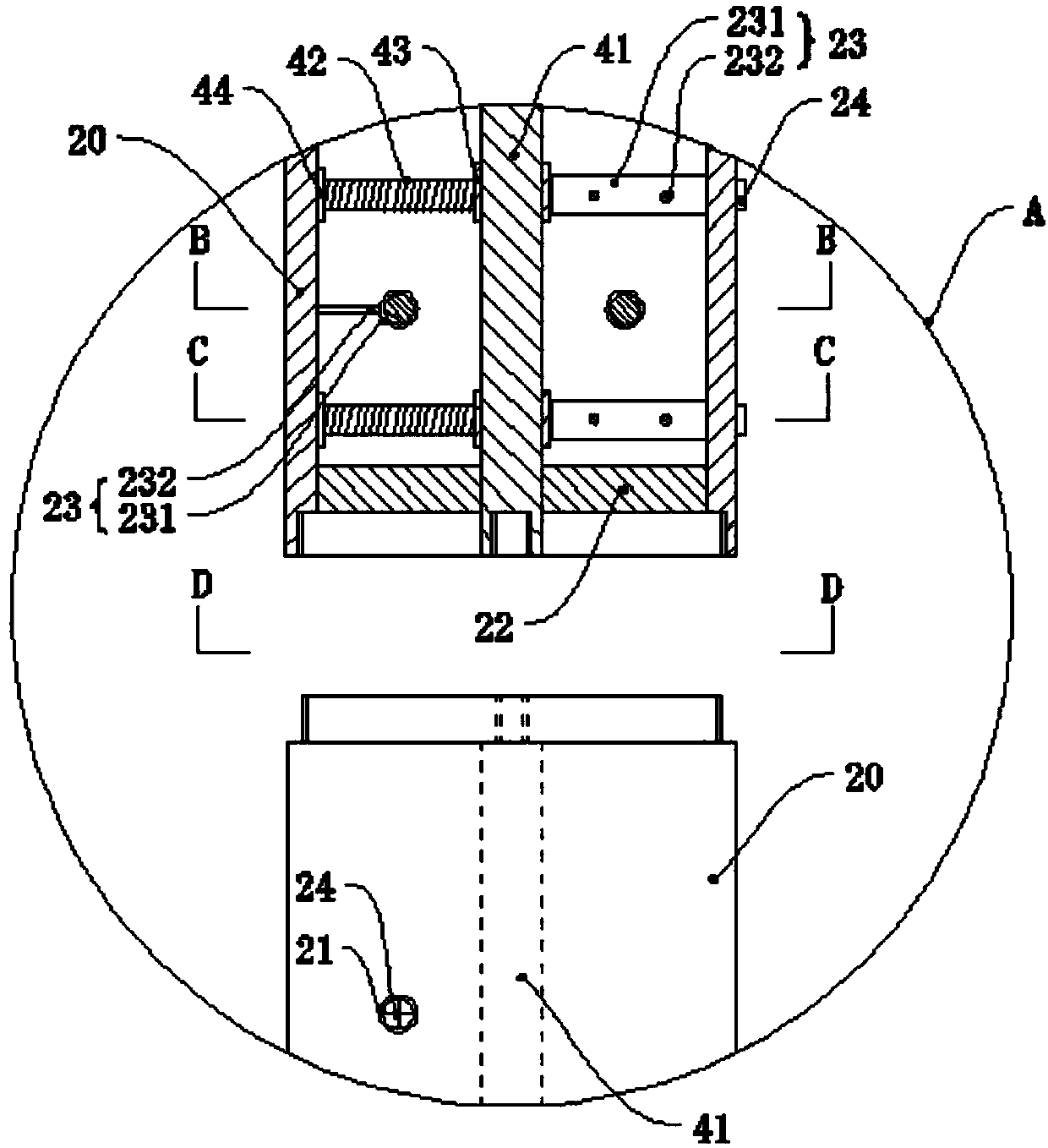

Combined barb type anchor rod

InactiveCN110387882AImprove the support effectIncrease resistanceBulkheads/pilesAnchoring boltsEngineeringRelative resistance

The invention discloses a combined barb type anchor rod. The combined barb type anchor rod comprises an outer sleeve, wherein one end of the outer sleeve is used for being driven into the ground, theother end of the outer sleeve is inserted with an inner pull rod; a barb which can rotate relative to the inner pull rod is arranged on the side wall of the inner pull rod; a long hole which can enable the barb to extend out is formed in the side wall of the outer sleeve; and when the inner pull rod is pulled to enable the inner pull rod to axially move relative to the outer sleeve, the barb can extend out of the long hole. Therefore, the combined barb type anchor rod has the advantages that the barb which can rotate relative to the inner pull rod is arranged on the inner pull rod, the long hole which can enable the barb on the inner pull rod to extend out is arranged on the outer sleeve, and after the outer sleeve is driven into soil or placed into a pouring pool, the inner pull rod is pulled outwards relative to the outer sleeve, so that the barb on the inner pull rod extends out of the long hole in the outer sleeve, and the barb on the inner pull rod can be inserted into the soil orpoured concrete, and as a result, the relative resistance between the outer sleeve and the soil or concrete is increased, and the supporting effect of the anchor rod is improved.

Owner:GUANGDONG UNIV OF TECH

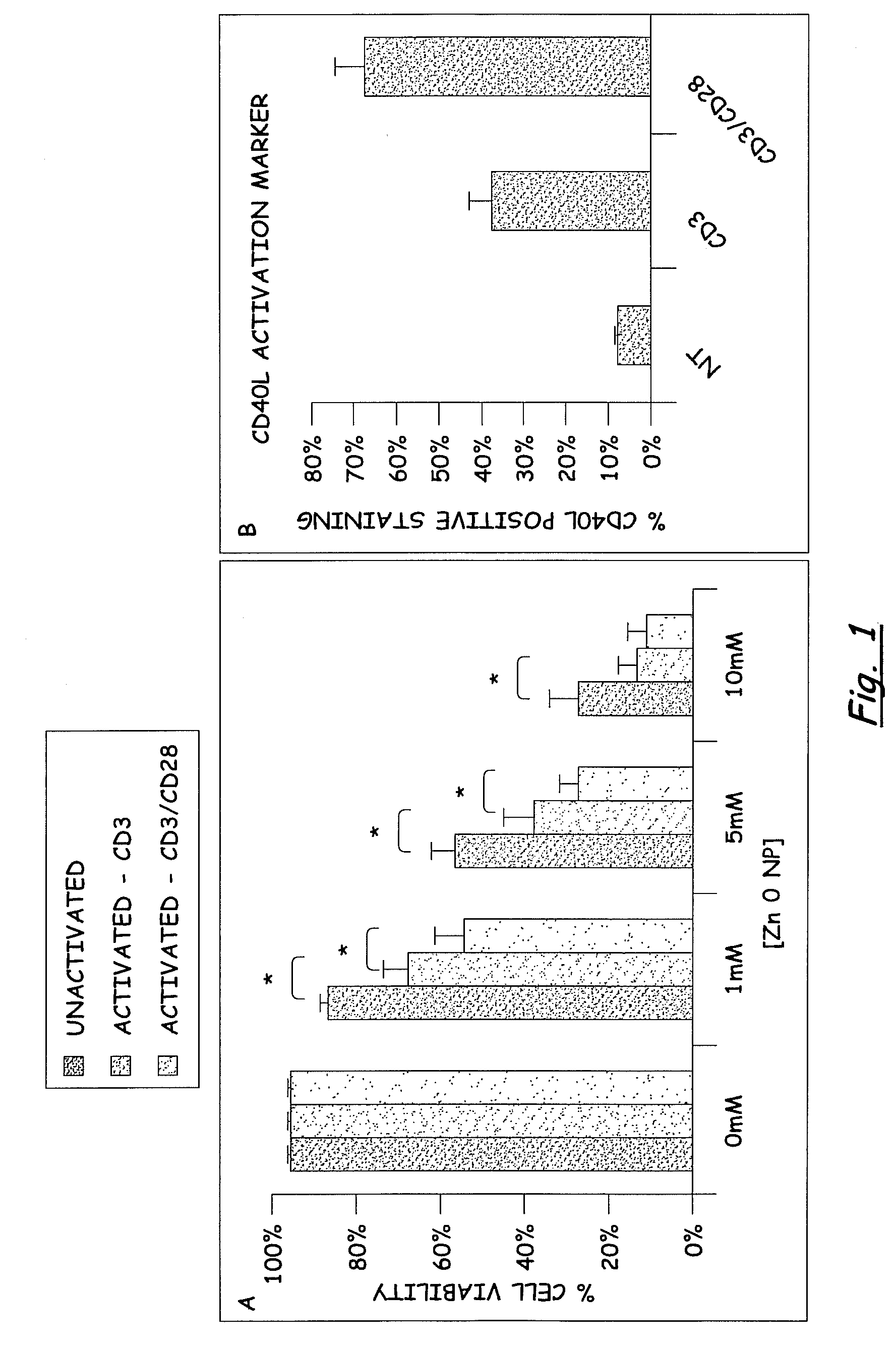

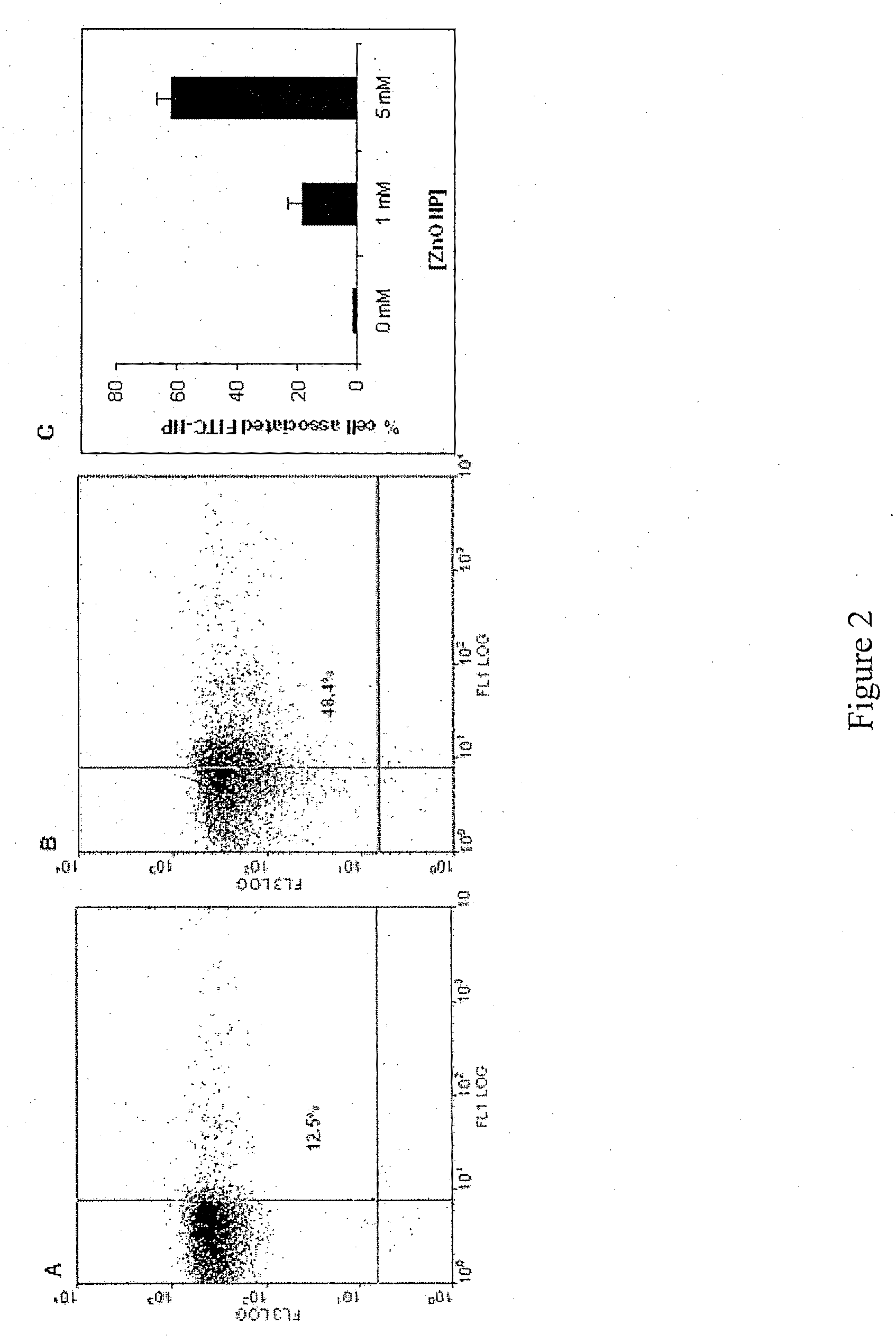

PREFERENTIAL KILLING OF CANCER CELLS AND ACTIVATED HUMAN T CELLS USING ZnO NANOPARTICLES

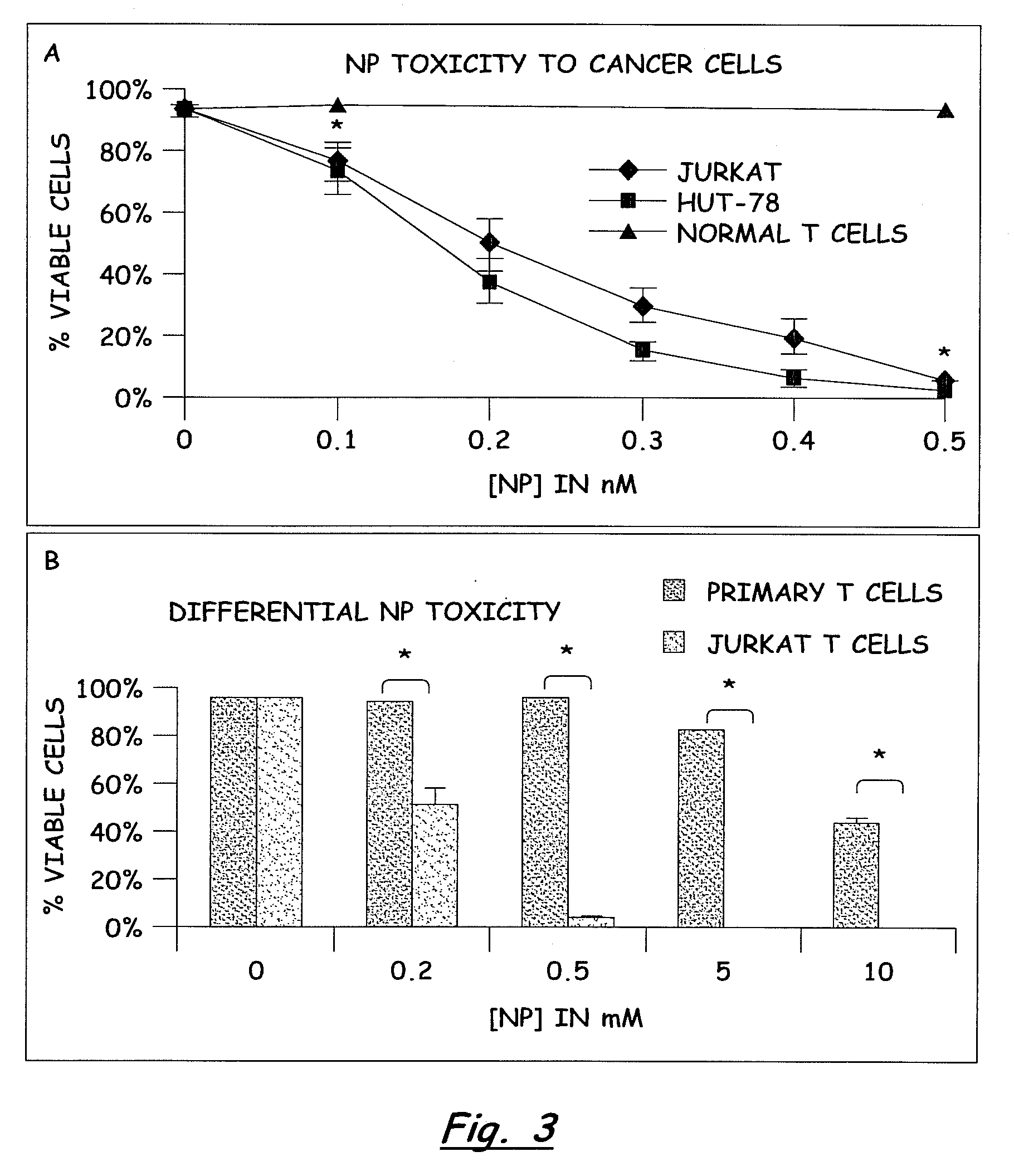

ActiveUS20090136580A1Potential utilityImprove abilitiesBiocideOrganic active ingredientsDiseaseCancer cell

Here we disclose the response of normal human cells to ZnO nanoparticles under different signaling environments and compare it to the response of cancerous cells. ZnO nanoparticles exhibit a strong preferential ability to kill cancerous T cells (˜28-35X) compared to normal cells. Interestingly, the activation state of the cell contributes toward nanoparticle toxicity as resting T cells display a relative resistance while cells stimulated through the T cell receptor and CD28 costimulatory pathway show greater toxicity in direct relation to the level of activation. The novel findings of cell selective toxicity towards potential disease causing cells indicate a potential utility of ZnO nanoparticle in the treatment of cancer and / or autoimmunity.

Owner:BOISE STATE UNIVERSITY

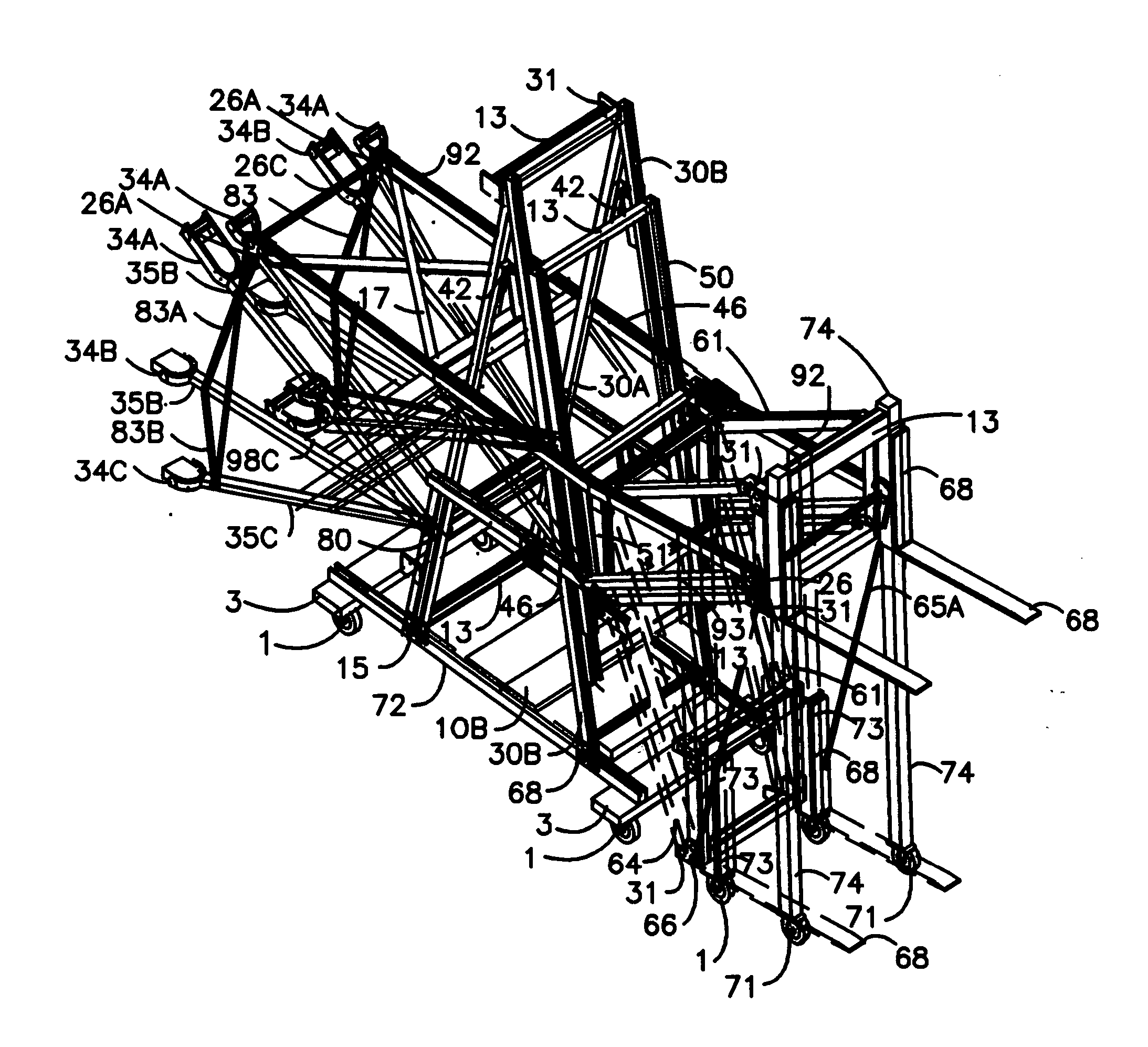

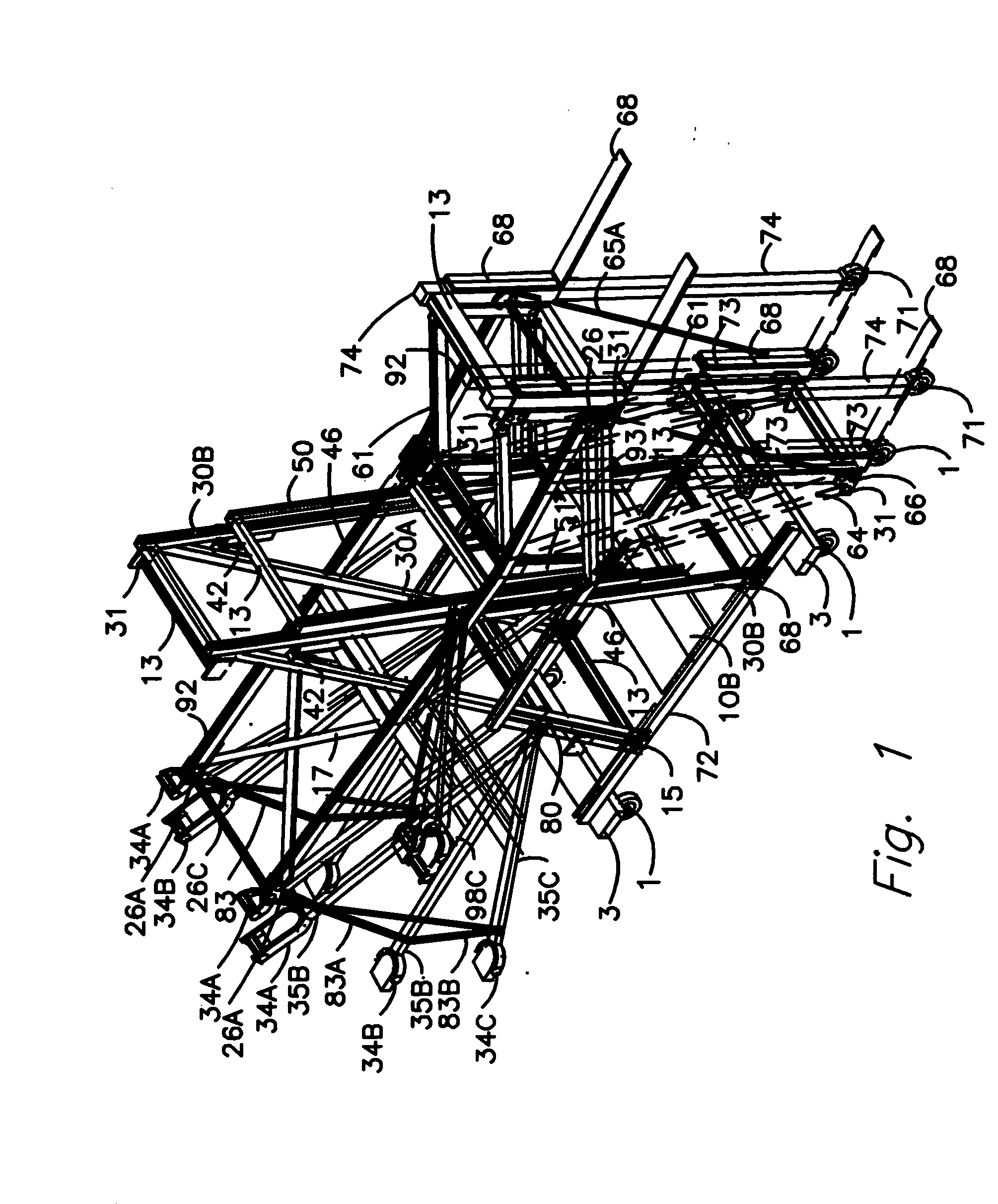

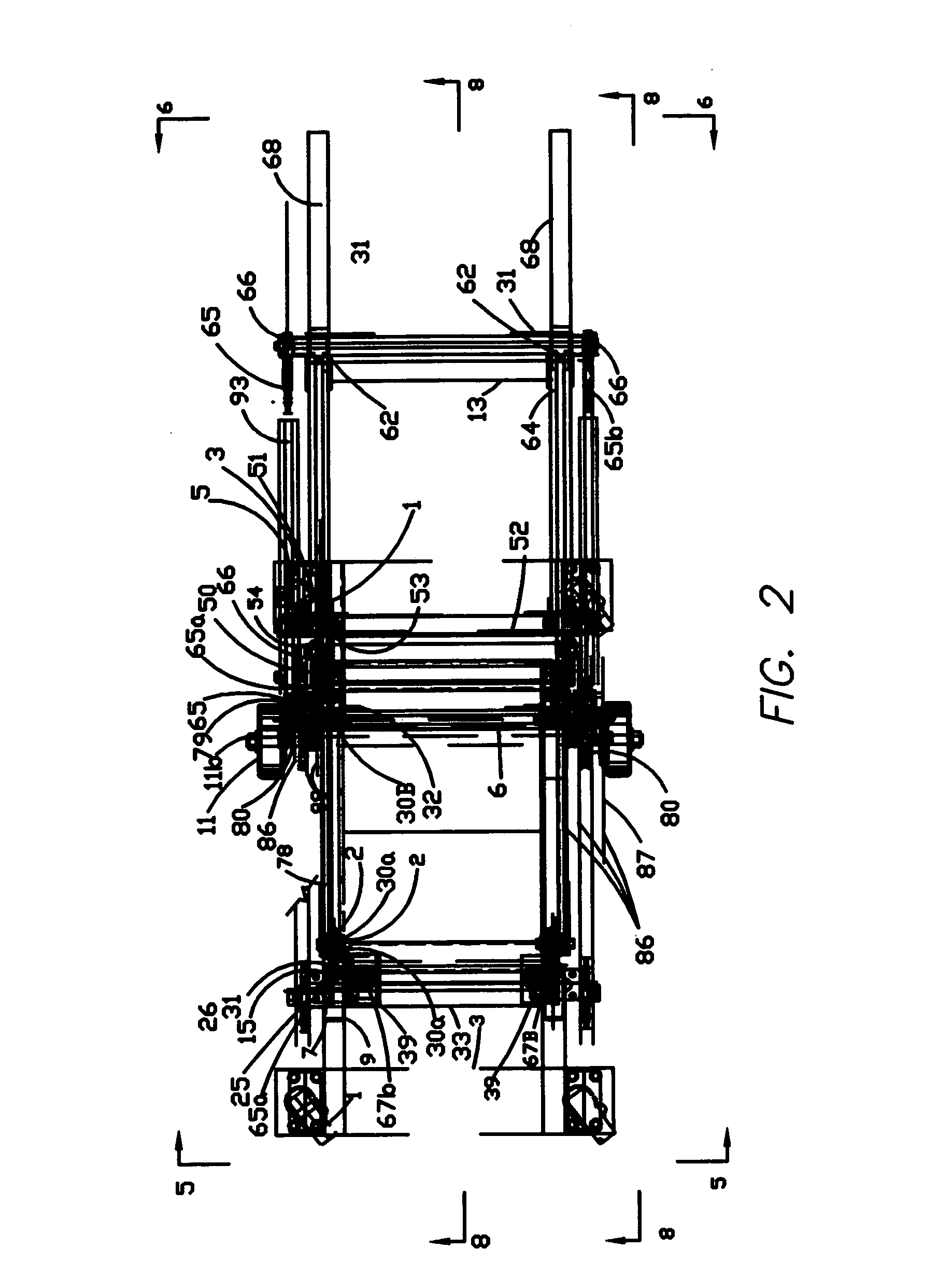

Hand truck/forklift aparatus

InactiveUS20060182582A1Efficient and effectiveMore user friendlySupporting partsLifting devicesContinuous useJackscrew

The hand truck / forklift as disclosed in this application is new and useful as an improvement in manually operated lifting trolleys in that it is versatile, fast, safe, practical and user friendly for transporting and lifting loads commonly carried on a hand truck, and with the preferred optional use of an electric hoist and cable actuating assembly lift apparatus overcomes some limitations of use in enclosed environments and (or) raised structurally spanned floors without special provisions for excessive air changes or special structural reinforcements in floor construction as would be required for most power operated lifting trolleys currently available for lifting weights comparable to the lifters body weight or heavier. This lift assembly is versatile in that it may be used is a basic lifting trolley with various optional features which include a mountable base carriage trolley, an extensible mast and cable or chain assemblies, the parallel actuating arm (rotary frame) or the lift actuating electric hoist to lift loads less than or comparable to the lifters body weight. When this lift apparatus is used in this most basic form it lifts loads faster and in some cases safer and efficiently when compared to other manually operated lifting trolleys. The rotary frame of the manually operated lift assembly is preferably adapted with a sleeved punched post assembly at the outer end with a spring loaded caliper and pin assembly operated by a hand controlled lever on the rear frame extension and a sleeved cable to secure the load at selected heights, and to serve as a safeguard for holding the raised load on the lift fork. The optional addition of the parallel lifting arm to the extensible mast even further increases the vertical lifting height and frontal range of the lift apparatus including lifting from depths beyond the level of the loading dock. This invention in either form can also be used as a practical, versatile, convenient, fast and economical supplement to conventional hand trucks and forklifts by transporting and lifting loads onto and from delivery trucks to work counters, shelves, standard hand trucks etc. and stacking loaded pallet units for handling by heavier conventional lifts for improved efficiency in either indoor or outside material handling operations, and yet capable without the optional extensible mast and its actuating rear mounted jack assembly of being manually loaded onto a delivery truck to perform these lifting functions at stops along the truck route. The present lift apparatus is also equipped with an electric hoist significantly reduce the resultant impact of stopping on structurally suspended floors, avoid tilt-over, to maximize the frontal, height and depth range of the lift trolley apparatus and actuate mounting and subsequent dismounting with the use of an electric winch and cable all in succession based on the relative resistance to movement of the lift assembly components in this continuous hoist cable pulling motion with all lift trolley features mounted and by means of the optional use of cables or chains and reverse movement of the lift trolley A-frame and the indirectly attached load fork to dismount the carriage trolley.

Owner:SHARPTON GEORGE

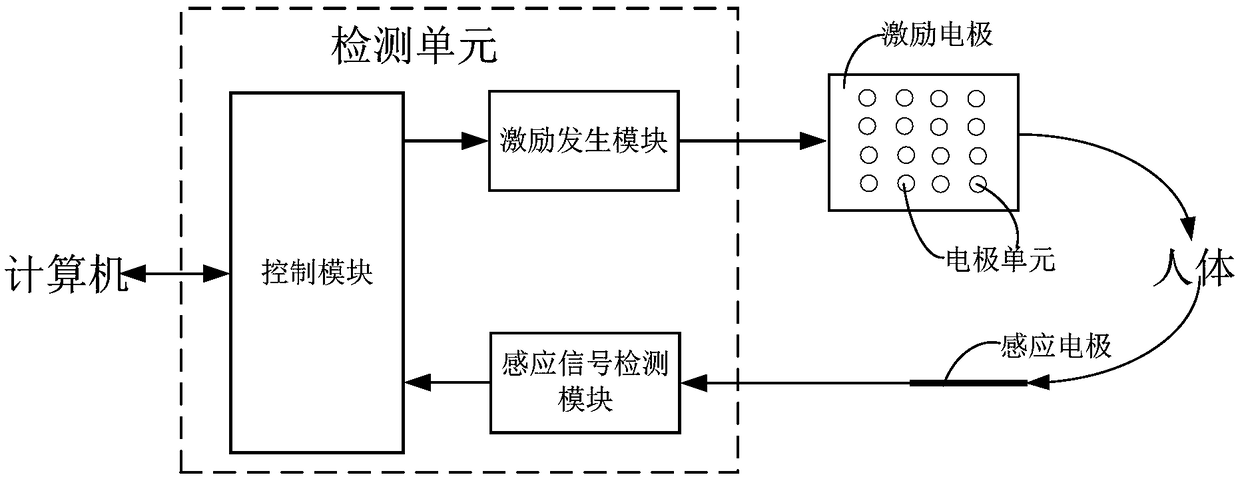

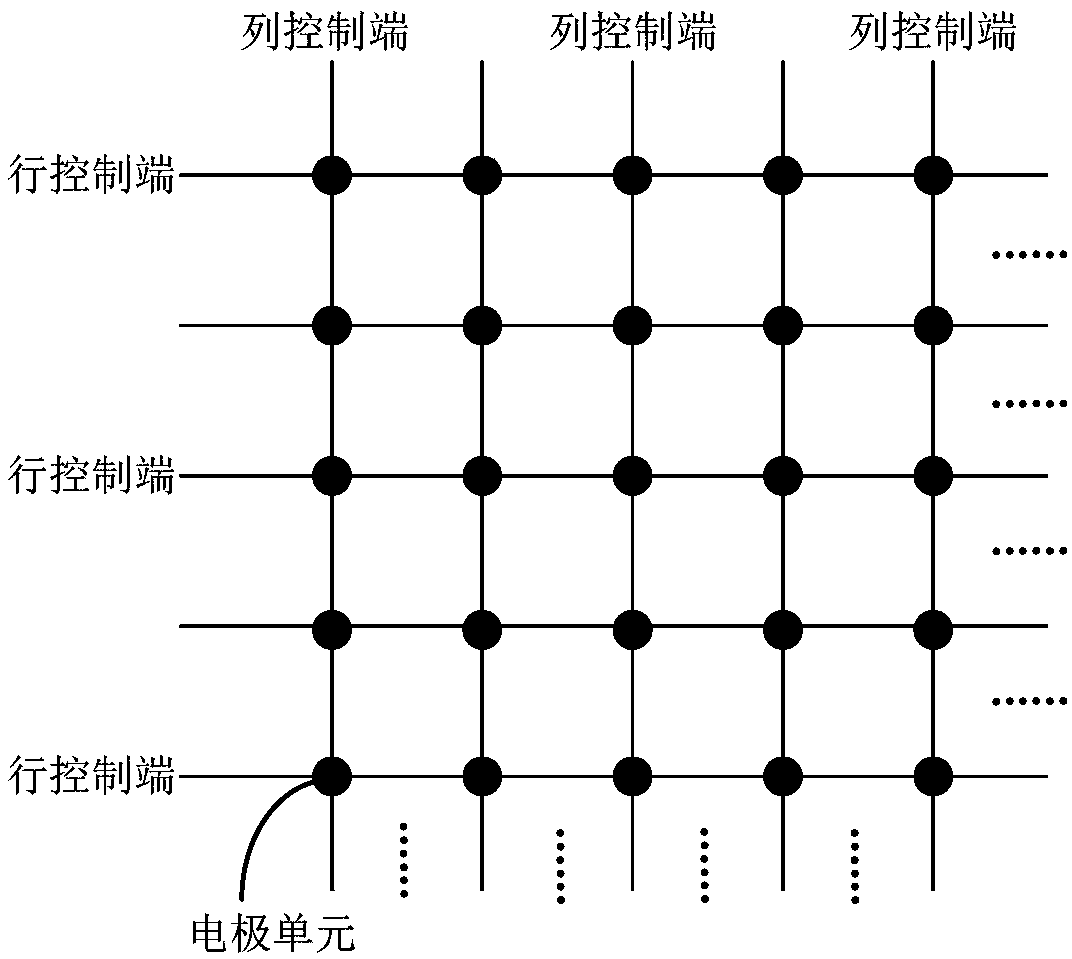

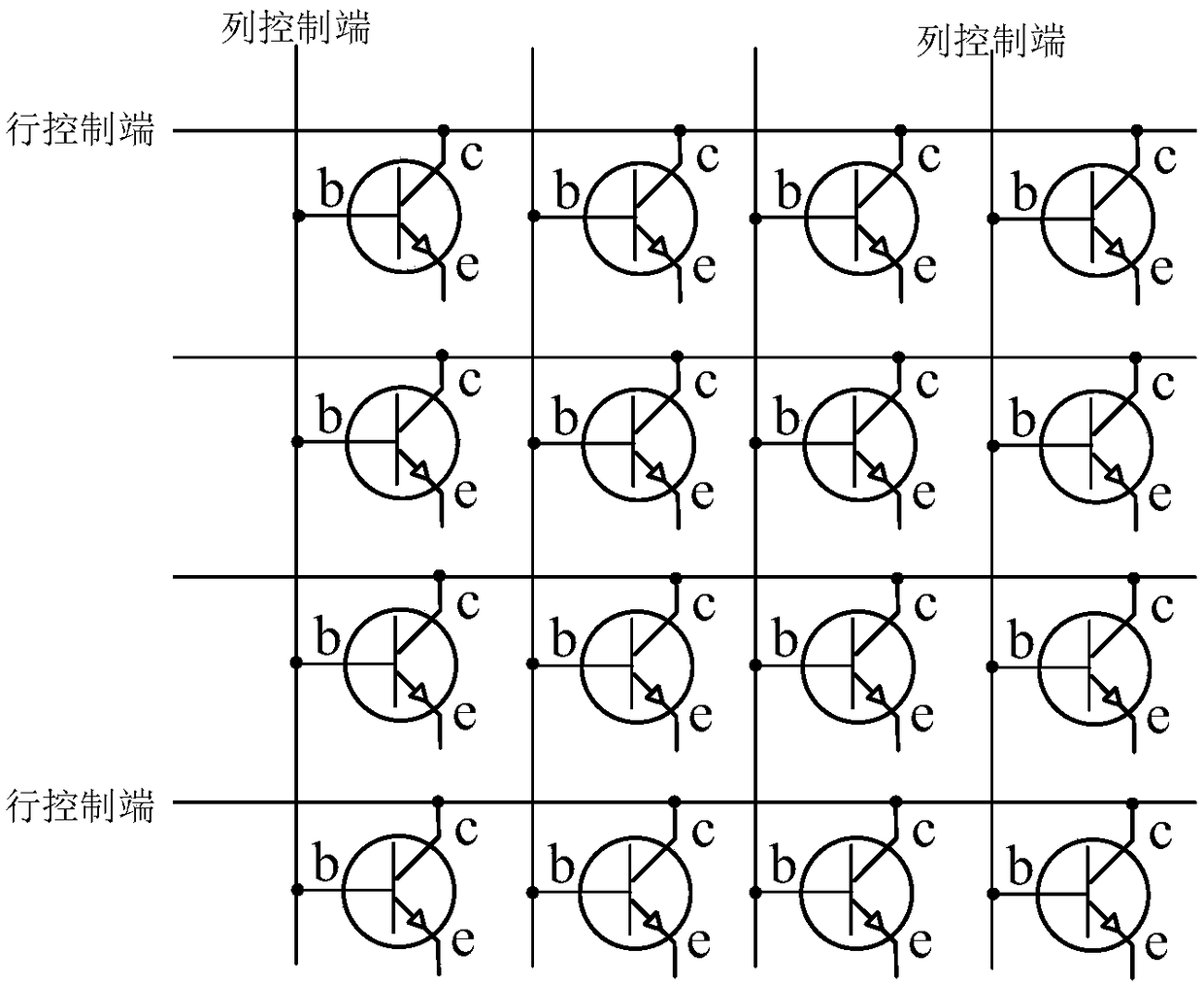

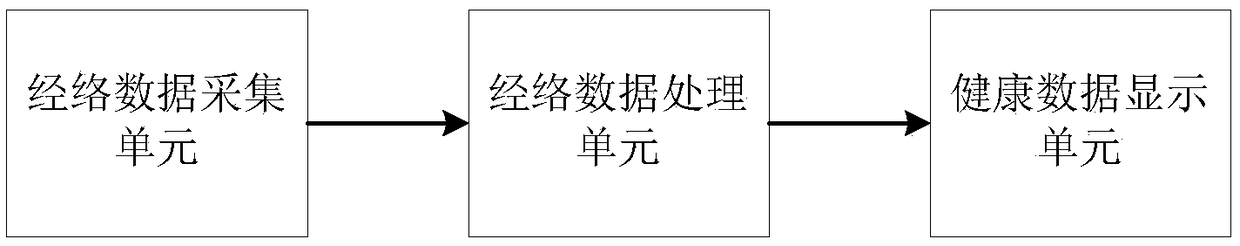

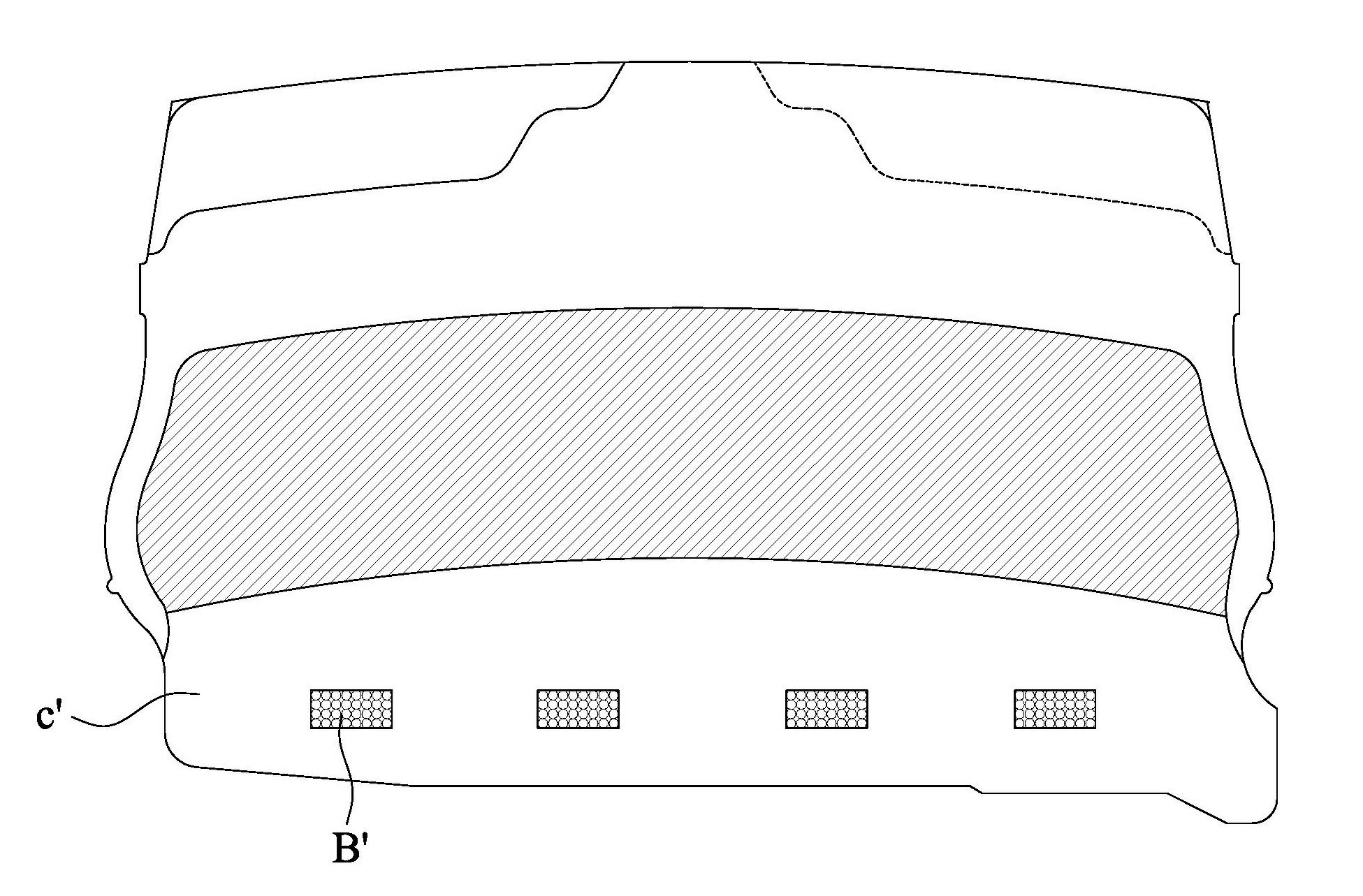

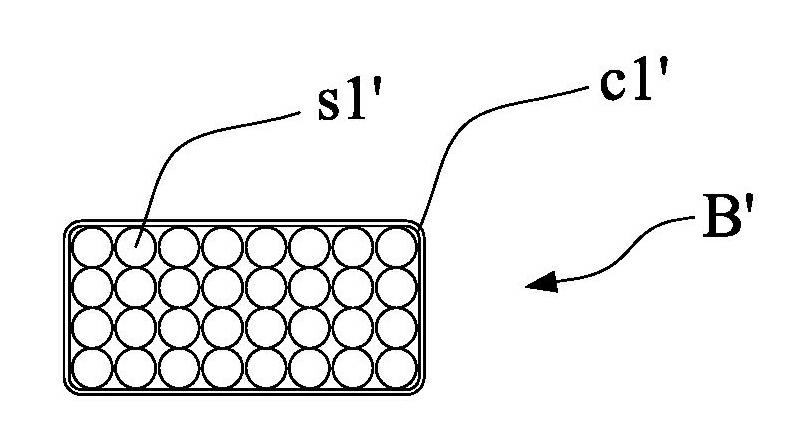

Meridian point positioning device and method

ActiveCN109481286ALow costReduce complexityDevices for locating reflex pointsDiagnostic recording/measuringElectrical resistance and conductanceElectrical bonding

The invention discloses a meridian point positioning device and method. The device comprises a detecting unit and an excitation electrode and an induction electrode electrically connected to the detecting unit, wherein the excitation electrode and the induction electrode are both in contact with the human body to form a loop; the detecting unit is used for driving the excitation electrode to output an excitation signal and acquire an induction signal through the induction electrode; the excitation electrode adopts a plurality of electrode units to form an array structure, and the control module is used for controlling an excitation generating module to drive each electrode unit to output an excitation signal and obtain a corresponding induction signal to calculate the point where the bodyresistance is the smallest as the point position. Compared with the prior art, the point position is determined by calculating the relative resistance value in the loop, no sensor is required, and thehardware implementation cost is greatly reduced. At the same time, the electrode unit is achieved by a triode, and the gating of the electrodes in the array is achieved by row and column double-end control. The line connection and the control complexity are greatly reduced.

Owner:全息(山东)智能医疗科技有限公司

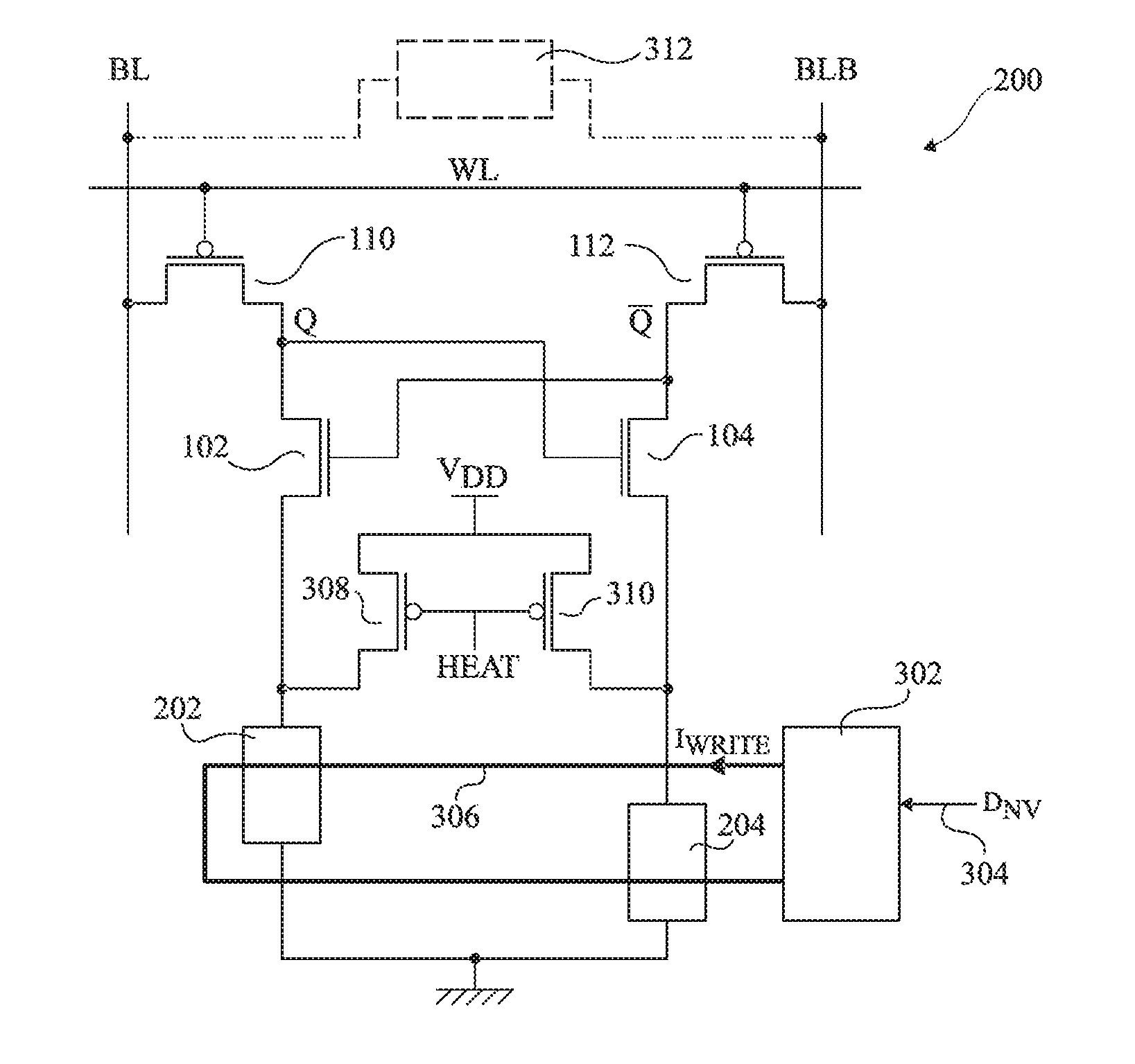

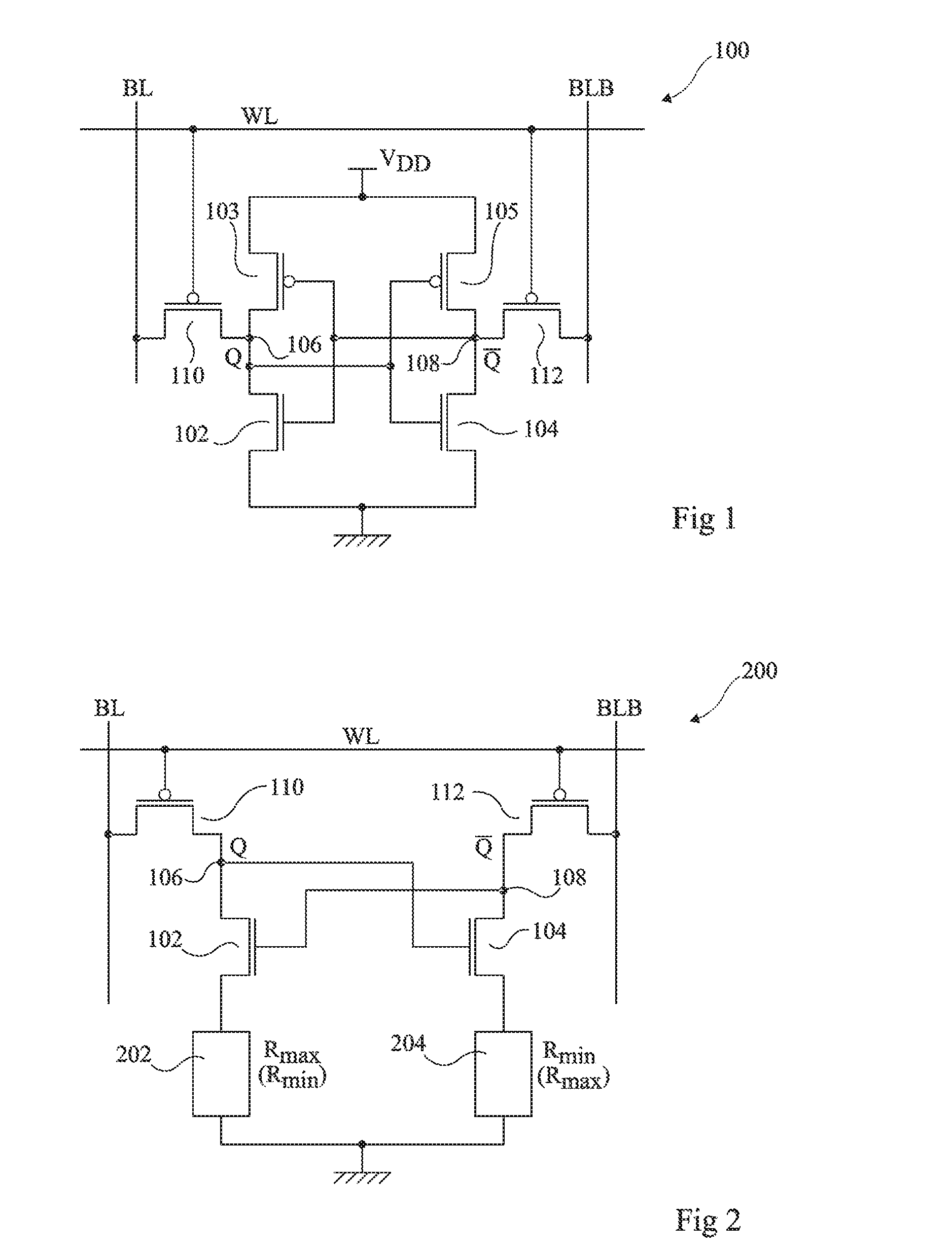

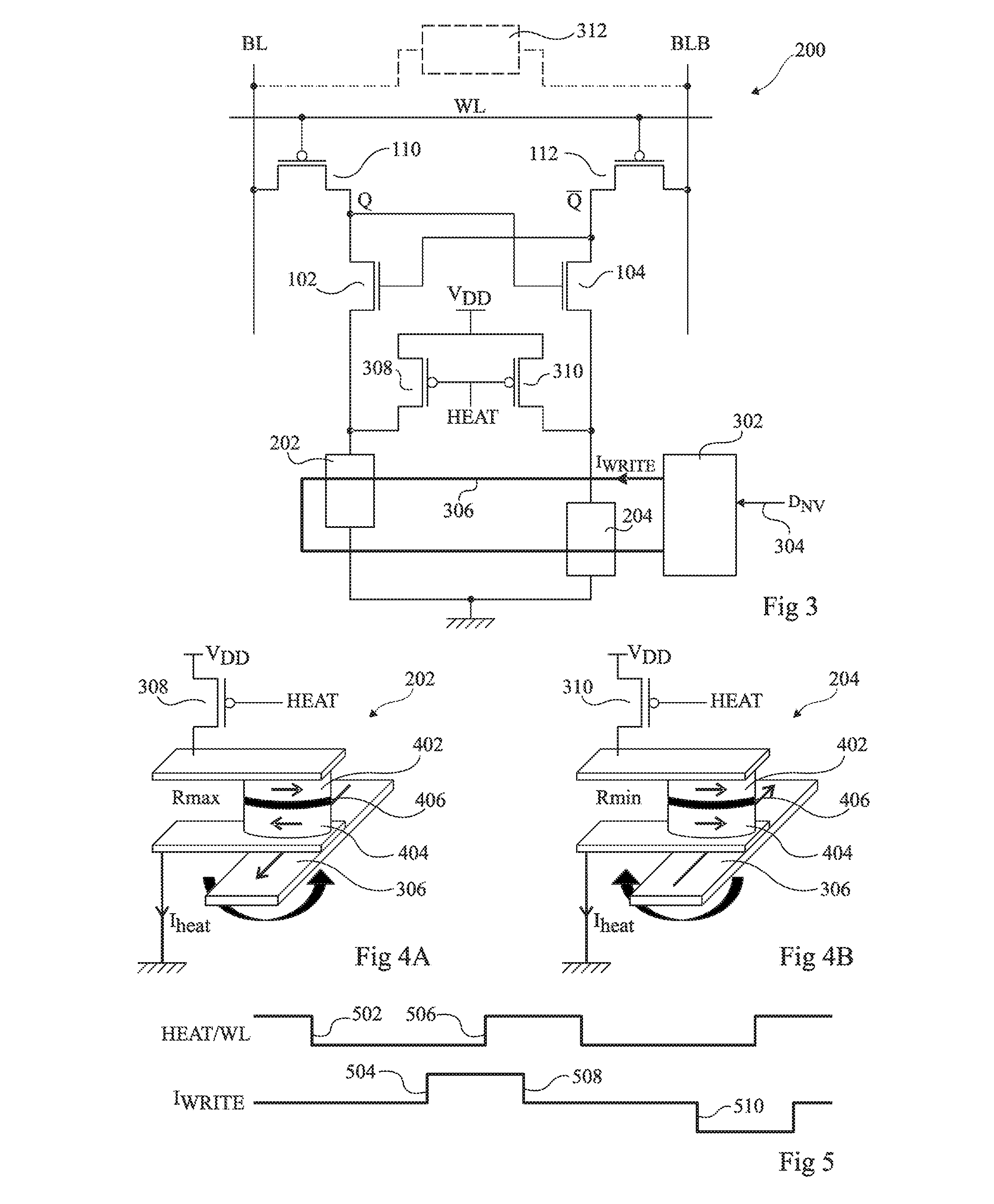

Volatile/non-volatile memory cell

ActiveUS20140070844A1Need be addressProgrammable logic circuit arrangementsSolid-state devicesData valueNon-volatile memory

The invention concerns a memory device comprising at least one memory cell comprising: a first transistor (102) coupled between a first storage node (106) and a first resistance switching element (202) programmed to have a first resistance; and a second transistor (104) coupled between a second storage node (108) and a second resistance switching element (204) programmed to have a second resistance, a control terminal of said first transistor being coupled to said second storage node, and a control terminal of said second transistor being coupled to said first storage node; and control circuitry (602) adapted to store a data value (DNV) at said first and second storage nodes by coupling said first and second storage nodes to a first supply voltage (VDD, GND), the data value being determined by the relative resistances of the first and second resistance switching elements.

Owner:CENT NAT DE LA RECHERCHE SCI +1

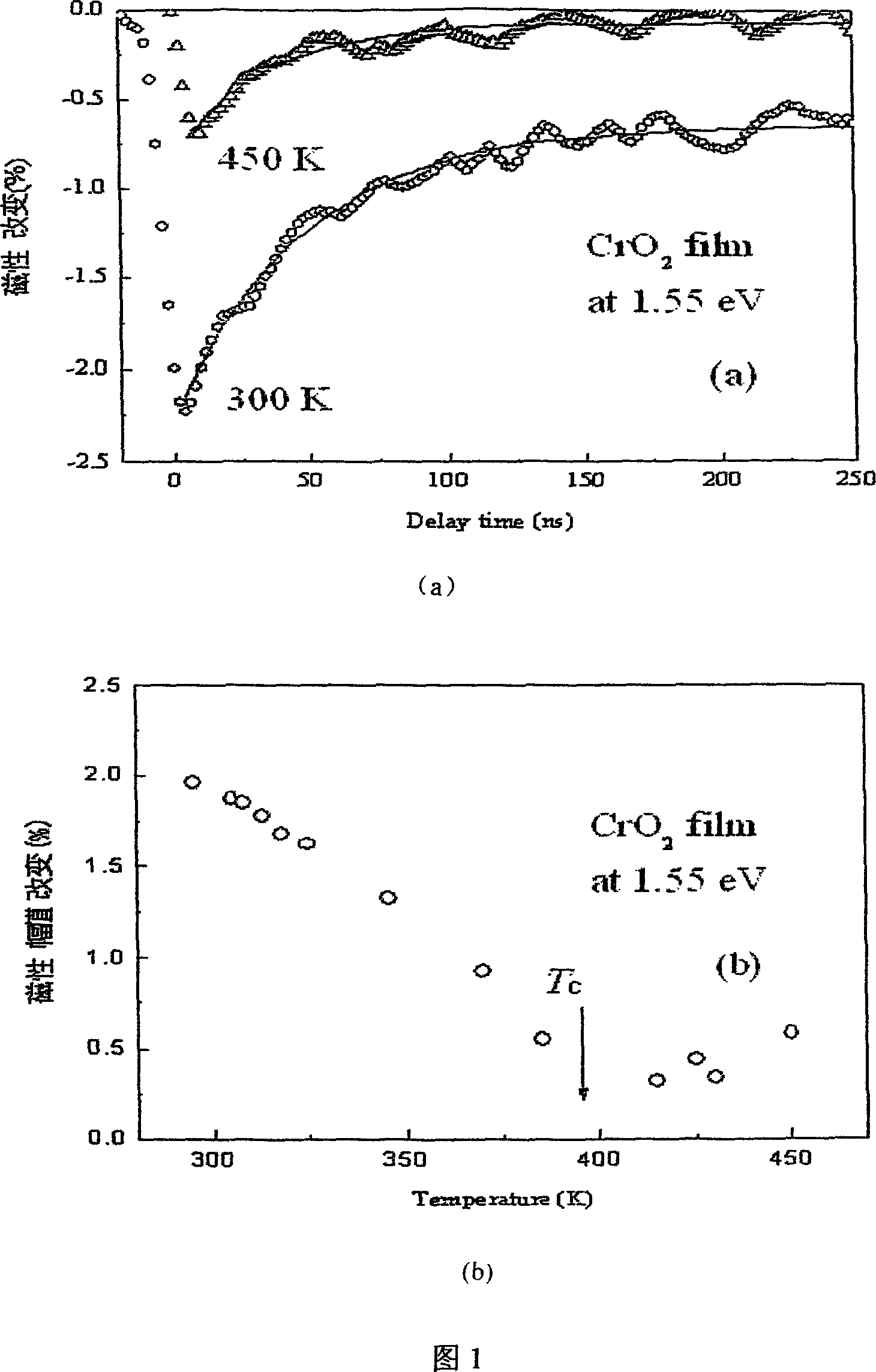

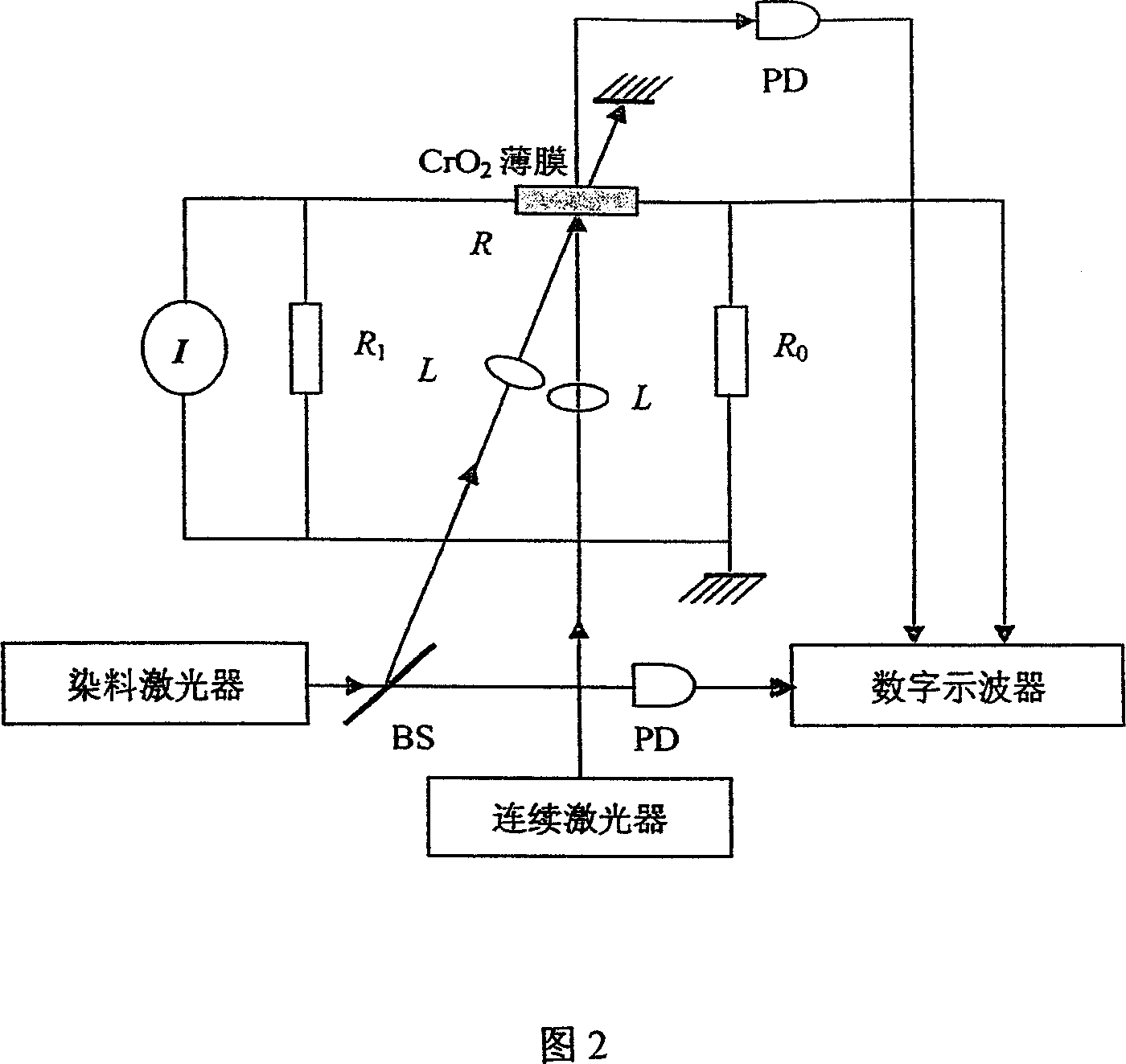

Method for changing magnetism of ferromagnet CrO2 film using laser induction effect

InactiveCN1929049AAchieving a magnetic changeElucidate the physical mechanismDigital storageMagnetic layersRoom temperatureOptoelectronics

This invention discloses one method to change iron magnetic CrO2 film by use of laser inductance effect, which comprises the following steps: in room temperature, using photon energy as 2.0eV-3.5eV impulse laser to light iron magnetic film; exerting electrical filed onto CrO2 film to ajust changeable volume of film under laser induction and relative resistance change.

Owner:NANJING UNIV

Composite material air release valve plate for compressor and preparation method thereof

ActiveCN102344643ALight in massLower natural frequencyPositive displacement pump componentsPositive-displacement liquid enginesFiberPoly ether ether ketone

The invention provides a composite material air release valve plate for a compressor and a preparation method thereof. The material of the air release valve plate is a polyetheretherketone-carbon fiber mixture, and the mixture comprises 1-30 wt% of carbon fiber and 70-99 wt% of polyetheretherketone. Compared with the prior art, the invention has the following advantages that: (1) the air release valve plate is formed by one step through injection molding, thereby saving other processing procedures and being flexible for production; (2) since the composite material is substituted for the metalmaterial, the change of the material changes the natural frequency, so that the noise performance of the compressor can be obviously improved; (3) compared with the metal air release valve plate, thecomposite material air release valve plate has greatly longer flexible life; and (4) since the composite material has much lower specific gravity than stainless steel, the relative resistance force is smaller in the air release process, so that the consumed power of the compressor can be easily lowered.

Owner:XIAN QINGAN REFRIGERATION EQUIP CO LTD

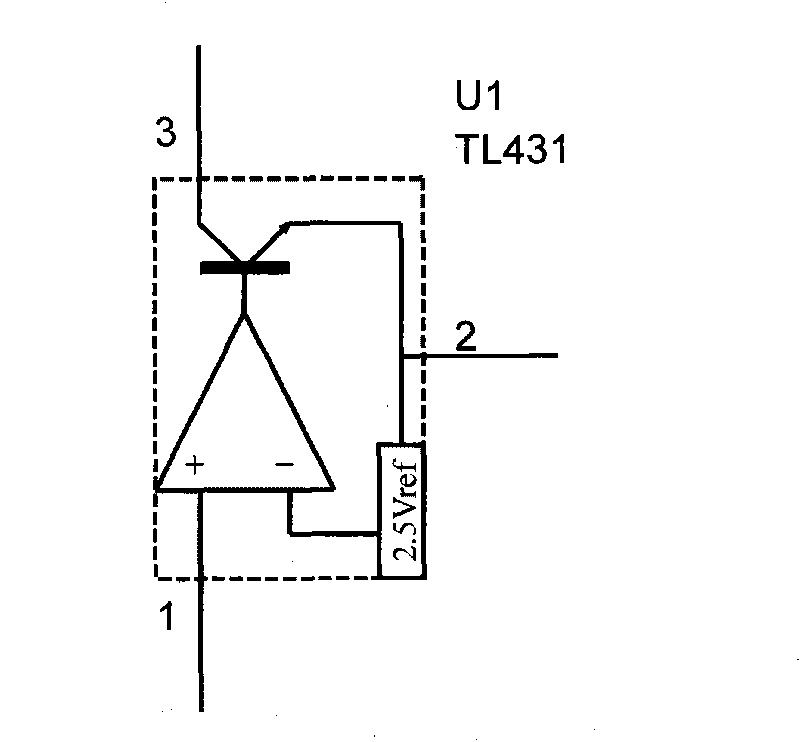

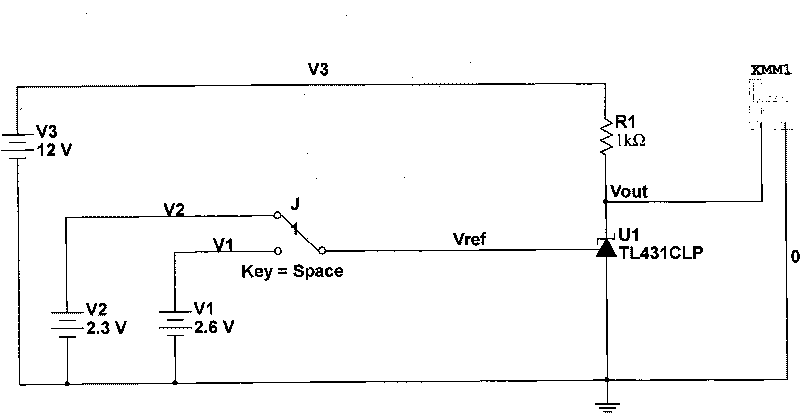

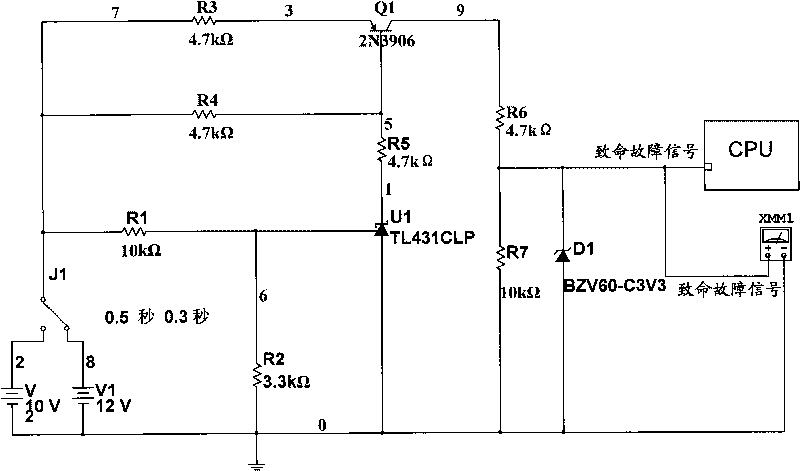

Circuit structure capable of realizing critical failure signal generation function on network communication terminal equipment

ActiveCN101697564ASimple structureLow costSupervisory/monitoring/testing arrangementsData resettingWork performanceTerra firma

The invention relates to a circuit structure capable of realizing a critical failure signal generation function based on a TL431 chip on network communication terminal equipment, wherein the TL431 chip comprises a reference terminal, a positive terminal and a negative terminal, and the circuit structure comprises a power supply module, a first resistance, a second resistance, a third resistance, a fourth resistance, a switch triode and a seventh resistance. Because a differential amplifier in the TL431 chip, an NPN triode and the circuit structure of a reference voltage source are skillfully used and the switch triode and the relative resistances in the periphery circuit are utilized, the circuit structure capable of realizing the critical failure signal generation function based on the TL431 chip on the network communication terminal equipment not only has simple and practical structure, but also has the advantages of low cost, stable and reliable work performance and wider application range, and establishes a solid foundation for the further development of network communication terminal products.

Owner:TAICANG T&W ELECTRONICS CO LTD

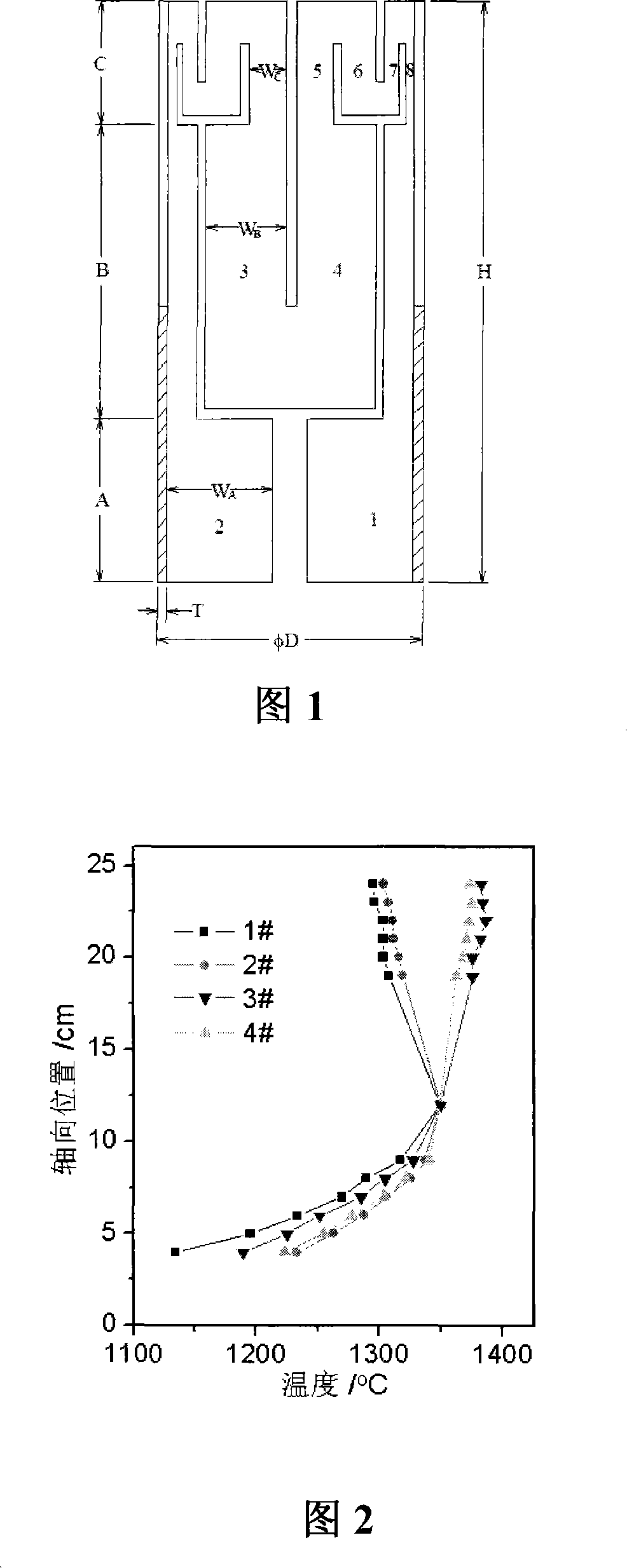

Multiple-temperature area heating body and method for manufacturing same

InactiveCN101086085AAdjust the distributionEnsure stabilityAfter-treatment apparatusElectrical resistance and conductanceGrowth control

The invention relates to a kind of multiple- temperature heater for crystal growth and the preparing method. It is to combine heating units with different resistance together, or slit one heating barrel, to form a series of heating circuit heater with different resistances. The current generates different heat when passes through sections with different resistance and thus forms different temperature- zone; the action range and gradient value of each temperature- zone can be changed by chaning relative resistance or length for each section. The invention can improve the flexibilty for temperature- zone, reduce difficulty for growth control and cost, and is favoable for temeprature- zone stability maintenance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

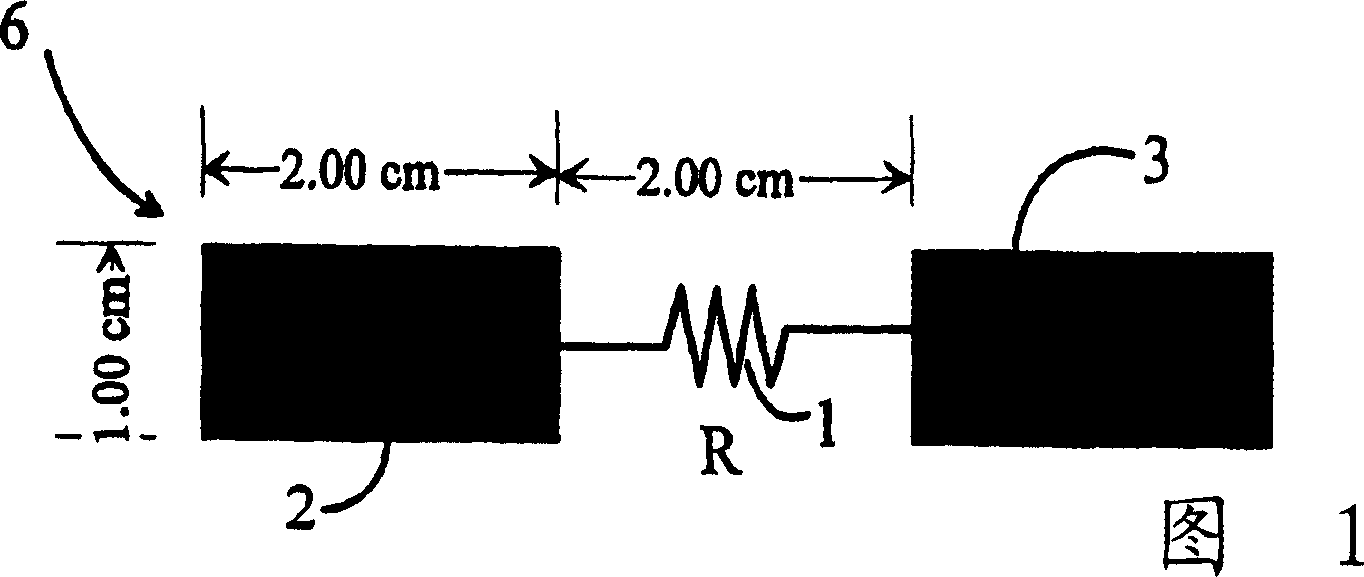

Method for detecting objects and a system for solving content of a symbol

InactiveCN1823340ALow costSimple measurement electronicsSensing record carriersRecord carriers used with machinesElectrical resistance and conductanceConductive materials

This publication discloses a method for identifying items, such as sheets of paper, or packages, a resistance mark arrangement, and reading apparatus. According to the method a mark made of electrically conductive material on the item is read contactlessly, in order to identify the item (7), or determine its properties. According to the invention, the precise absolute or relative resistance value of at least one electrically conductive mark (6) is determined and the measured resistance value is converted, for example, with the aid of a coding table or calculation formula, into information depicting the identity or properties of the item.

Owner:AVANTONE OY

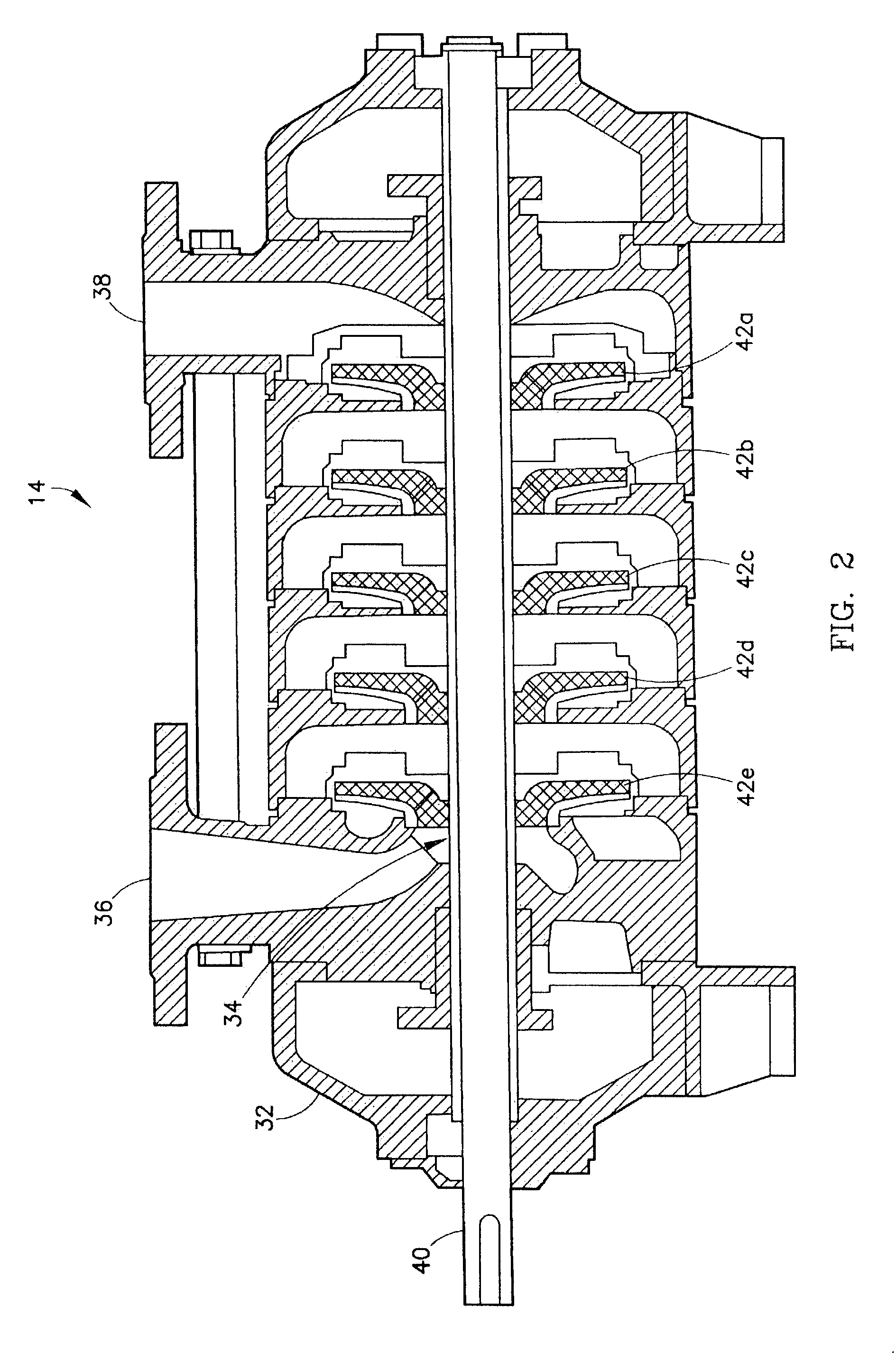

Material testing system for turbines

InactiveUS7096712B2Accurate comparisonPropellersWeather/light/corrosion resistanceImpellerMaterials testing

The wear resistance of impellers used in multi-stage turbine pumps is tested by using a multi-stage turbine pump having impellers with different physical properties to pump a fluid containing small amounts of an abrasive material. After the fluid has been pumped for a time period sufficient to provide measurable wear to the impellers, the impellers are inspected to determine their relative resistance to wear.

Owner:CONOCOPHILLIPS CO

Dynamic adaptive terminal load adjusting method and circuit

InactiveUS20100315120A1Loss of trimming accuracyImprove dynamic performanceReliability increasing modificationsMultiple-port networksLoad circuitHigh resistance

A dynamic adaptive terminal load adjustment method includes comparing a voltage on an on-chip termination impedance driven by an on-chip current source with a voltage of a band gap reference circuit to get an optimal trimming parameter by an adaptive control mechanism, wherein the optimal trimming parameter is applied to a terminal by an output control circuit to have a feedback control. The present invention is on-chip so the cost is saved. The terminal is separated from the adjusting circuit, thus the present invention has a good dynamic performance. Compared with laser trimming, no expensive cost is needed in the present invention. The present invention saves an IO pin without an external device, has the good temperature characteristic and high resistance regulation accuracy. Furthermore, the adjusting circuit is separated from the terminal load circuit by high matching of relative resistance of CMOS process, thus reducing the adverse impact.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

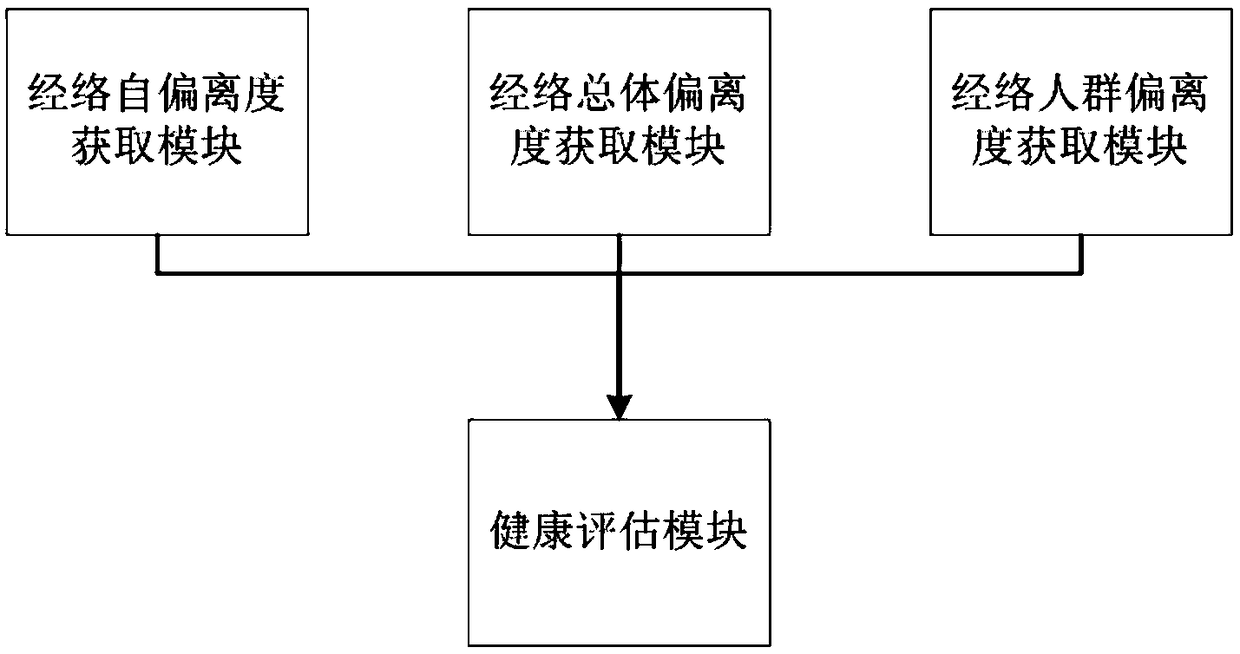

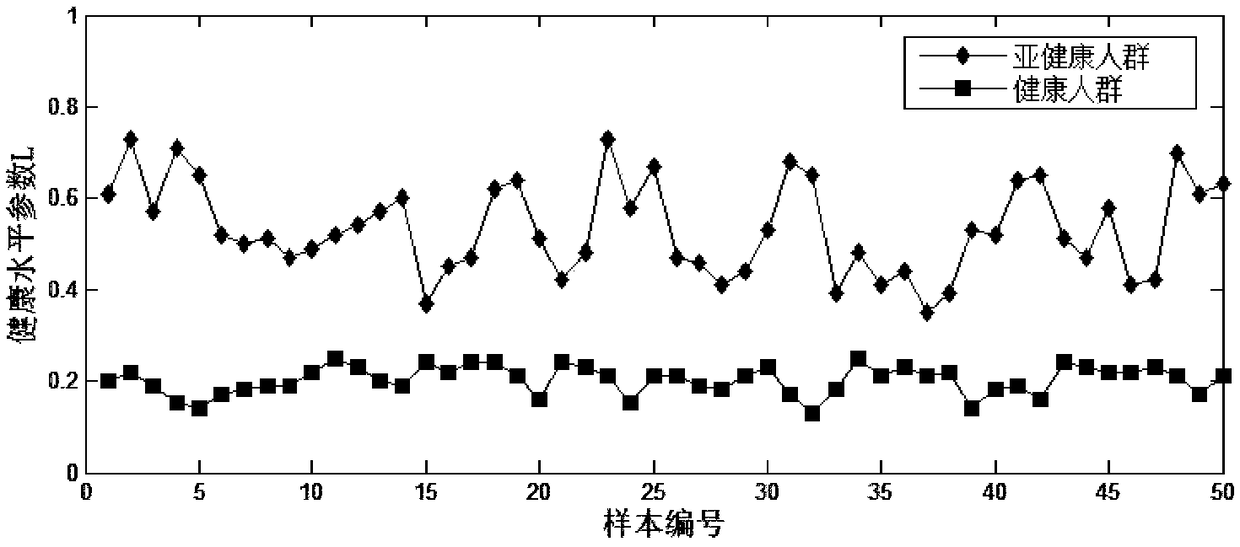

Sub-health quantitative evaluation system based on meridian and collateral balance

ActiveCN109509553AThe operation process is non-invasive and simpleEasy to integrateHealth-index calculationDiagnostic recording/measuringElectrical resistance and conductanceBlood level

The invention discloses a sub-health quantitative evaluation system based on meridian and collateral balance and relates to the technical field of medical equipment. A relative resistance value of skin resistance between Jing-well acupoint of left-right 12 main meridian and Panggong acupoint on the opposite side is measured, deviation degree of a single meridian and deviation degree of the meridian relative to overall level are calculated through a weighted statistics algorithm based on traditional Chinese medicine meridian theory, deviation degree of individual and healthy population is calculated through a big data method, total deviation degree is calculated finally to reflect human body unbalance state, and human body sub-health degree is directly embodied through the data; sub-healthlevel can be evaluated directly and quantitatively through meridian skin resistance characteristics, a certain meridian can be located to prompt the qi-blood level problem that corresponding viscera may have, guiding suggestion can be provided for disease prevention, and the whole operation process is noninvasive, simple and easy to implement, easy for further integration and intelligentization and even capable of realizing real-time monitoring.

Owner:河南源创生命干细胞库科技有限公司 +1

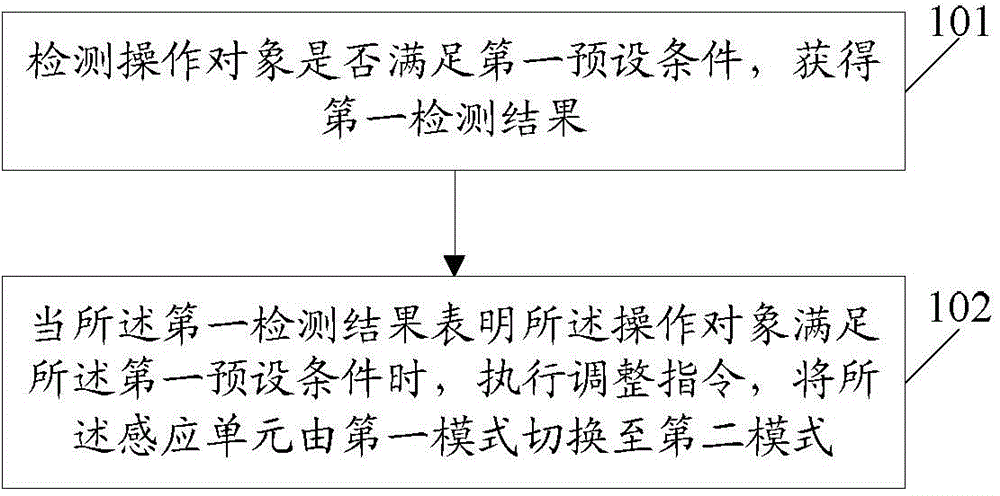

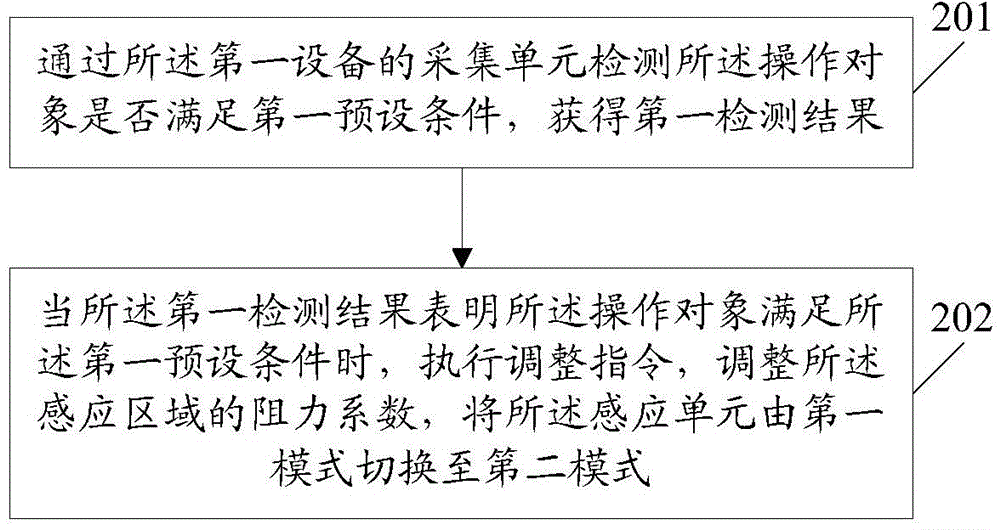

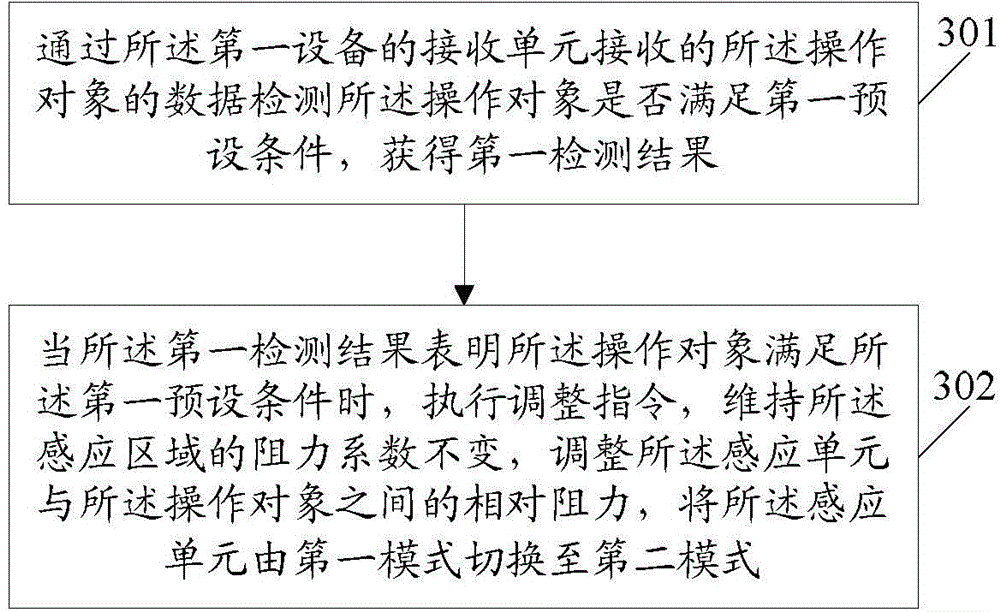

Information processing method and equipment

ActiveCN104635923AImprove operating experienceInput/output for user-computer interactionGraph readingInformation processingComputer science

The embodiment of the invention discloses an information processing method and equipment. The method comprises the steps that it is detected that whether an operation object meets a first preparatory condition or not, and a first detection result is obtained, wherein the operation object is an object of which the relative position changes with an induction area of an induction unit can be detected by the induction unit of first equipment; when the first detection result shows that the operation object meets the first preparatory condition, an adjusting instruction is performed, and a first mode of the induction unit is switched to a second mode, wherein in the first mode, when the induction unit detects the relative position changes of the operation object, the operation object and the induction unit have first relative resistance; in the second mode, when the induction unit detects the relative position changes of the operation object, the operation object and the induction unit have second relative resistance, and the first relative resistance is different from the second relative resistance.

Owner:LENOVO (BEIJING) CO LTD

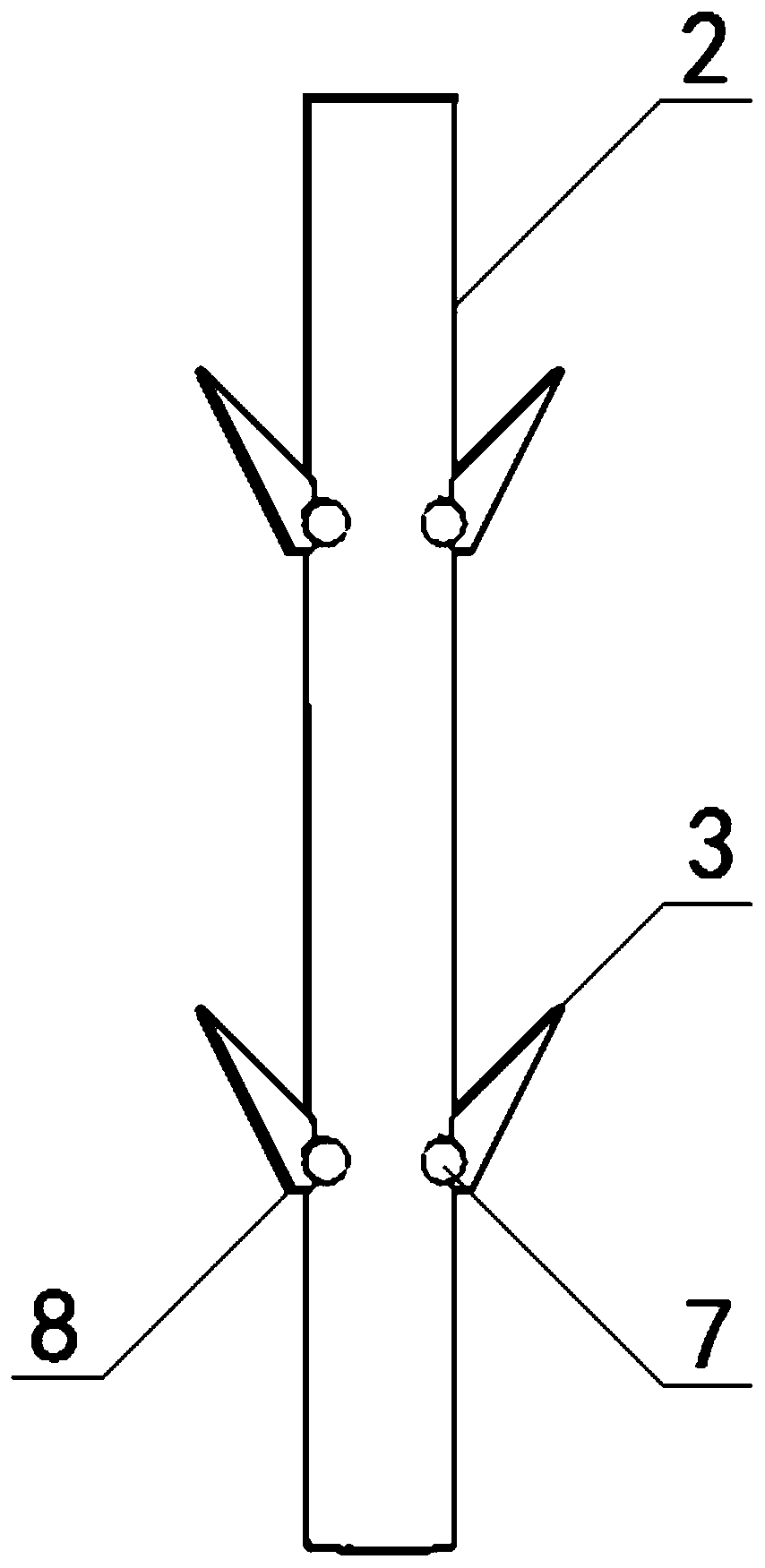

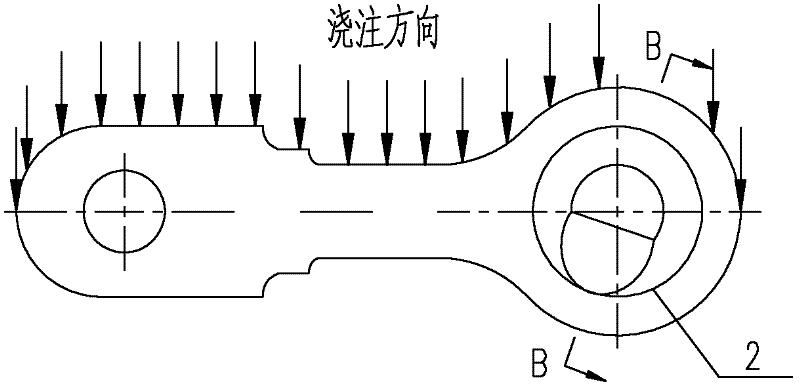

Recyclable anchor rod

ActiveCN107893417ASave maintenance timeIncrease resistanceClimate change adaptationBulkheads/pilesArchitectural engineeringRelative resistance

The invention provides a recyclable anchor rod, and belongs to the technical field of support engineering. The recyclable anchor rod is used for being anchored in a preformed anchor rod hole so as totemporarily support a soil body or rock mass, and comprises a tubular anchor rod body, telescopic clamping jaws used for clamping the tubular anchor rod body into the anchor rod hole, and a clamping jaw telescopic mechanism used for controlling the telescopic clamping jaws to expand and contract; the tubular anchor rod body is internally provided with a cavity; the clamping jaw telescopic mechanism is located in the cavity; and the side wall of the tubular anchor rod body is provided with clamping jaw through holes used for allowing the telescopic clamping jaws to penetrate. According to the recyclable anchor rod, the anchor rod body is provided with the telescopic clamping jaws and the clamping jaw telescopic mechanism, thus, the whole anchor rod can be recycled, the cost is reduced, andmoreover, the relative resistance between the anchor rod and the soil is effectively improved; meanwhile, the complex technology for construction of traditional anchor rods is avoided, grouting consolidation is not needed, the time needed for mortar curing is saved, the situation that the mortar leakage phenomenon during anchor rod grouting occurs, and the construction environment is polluted is prevented, the construction site is kept to be clean, and the environmental friendliness and safety during operation are greatly improved.

Owner:山西广信机械制造有限公司

Solid tire structure

The invention discloses a solid tire structure. The solid tire structure comprises two or more rubber materials, wherein a plurality of rubber fixing steel wires are arranged in an inner layer rubber material, wherein each fixing steel wire is obtained by arranging a single layer steel wire. By using single wire arranged structural mode, the side area of the fixed steel wire is smaller so that the rubber material can be prevented from driving the steel wire to move due to the extruding of a lower die to the rubber material during vulcanizing so as to avoid the inclination of the steel wire; moreover, by using the single wire arranged steel wire structure, the bottom area of the steel wire is increased so that a rim and a bead are more uniformly stressed and relative resistance of the rim and the tire lining is enlarged to a certain degree so as to inhibit poor rolling; moreover, by using a single-row steel wire structure, each interior part of the tire is more uniformly stressed so that the steel wires are uneasy to spread or form displacement in high-load and steering state; therefore, the steel wire wrapping cloth is saved, the swelling damage of the tire due to rapid temperature rising caused by relative peristalsis between the steel wire and the rubber material can be also avoided, and the running performance of the tire is improved.

Owner:CHENG SHIN RUBBER XIAMEN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com