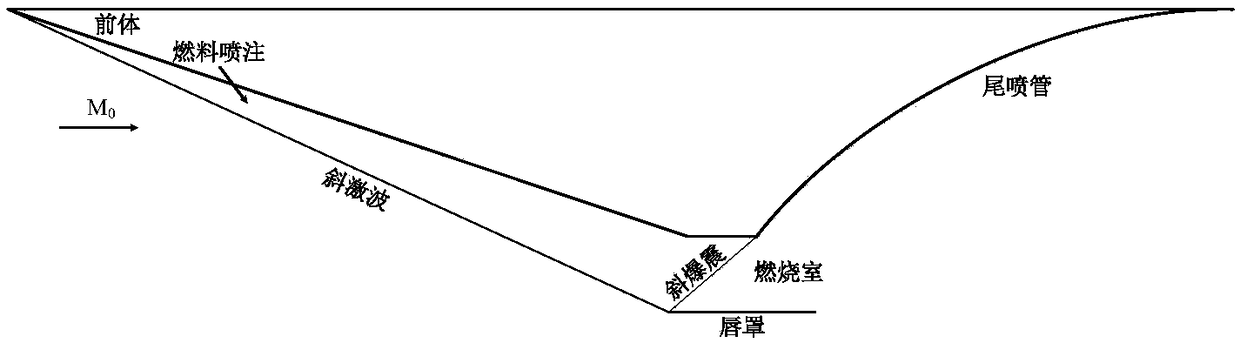

Engine annular combustion chamber in high-mach-number flight and spiral inclined knocking combustion method

An annular combustion chamber, high Mach number technology, used in ramjet engines, mechanical equipment, etc., can solve the problems of insufficient fuel and air mixing, weakened engine performance, oblique detonation, stationary instability, etc., and achieves Mach reflection. The effect of suppressing, reducing relative resistance, and preventing flow congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes the implementation of the present invention through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the present invention.

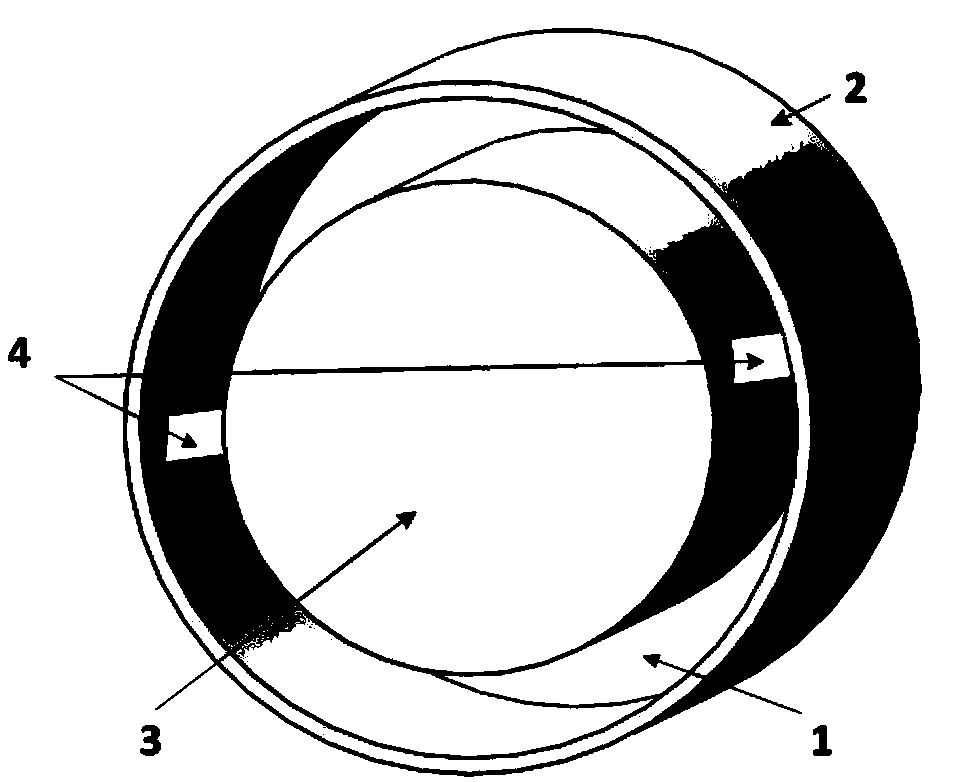

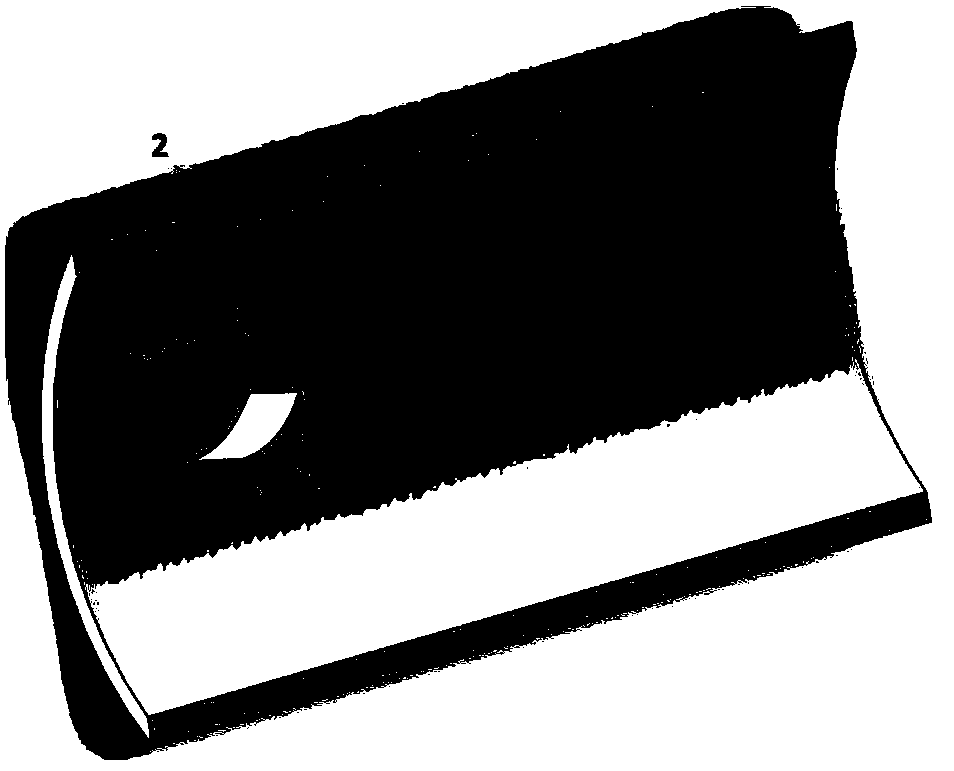

[0027] A high Mach number in-flight engine annular combustion chamber, comprising: an inner column 3, a shell 2 and a shock wave generator 4. The shell 2 surrounds the outer side of the inner column 3 at a certain interval, and the inner wall of the shell 2 and the outer wall of the inner column 3 An annular combustion chamber 1 is formed in between. The annular gap between the inner wall of the outer shell and the outer wall of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com