Fiber-optic cable alignment system

A technology of optical fiber cable and optical fiber, applied in the field of electro-optical converter and optical transmission device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] terminal

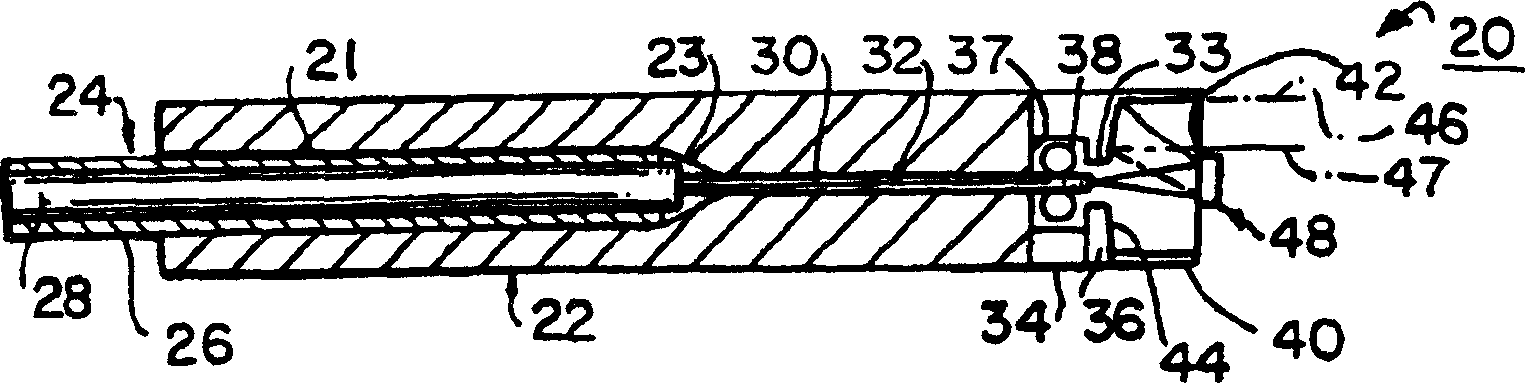

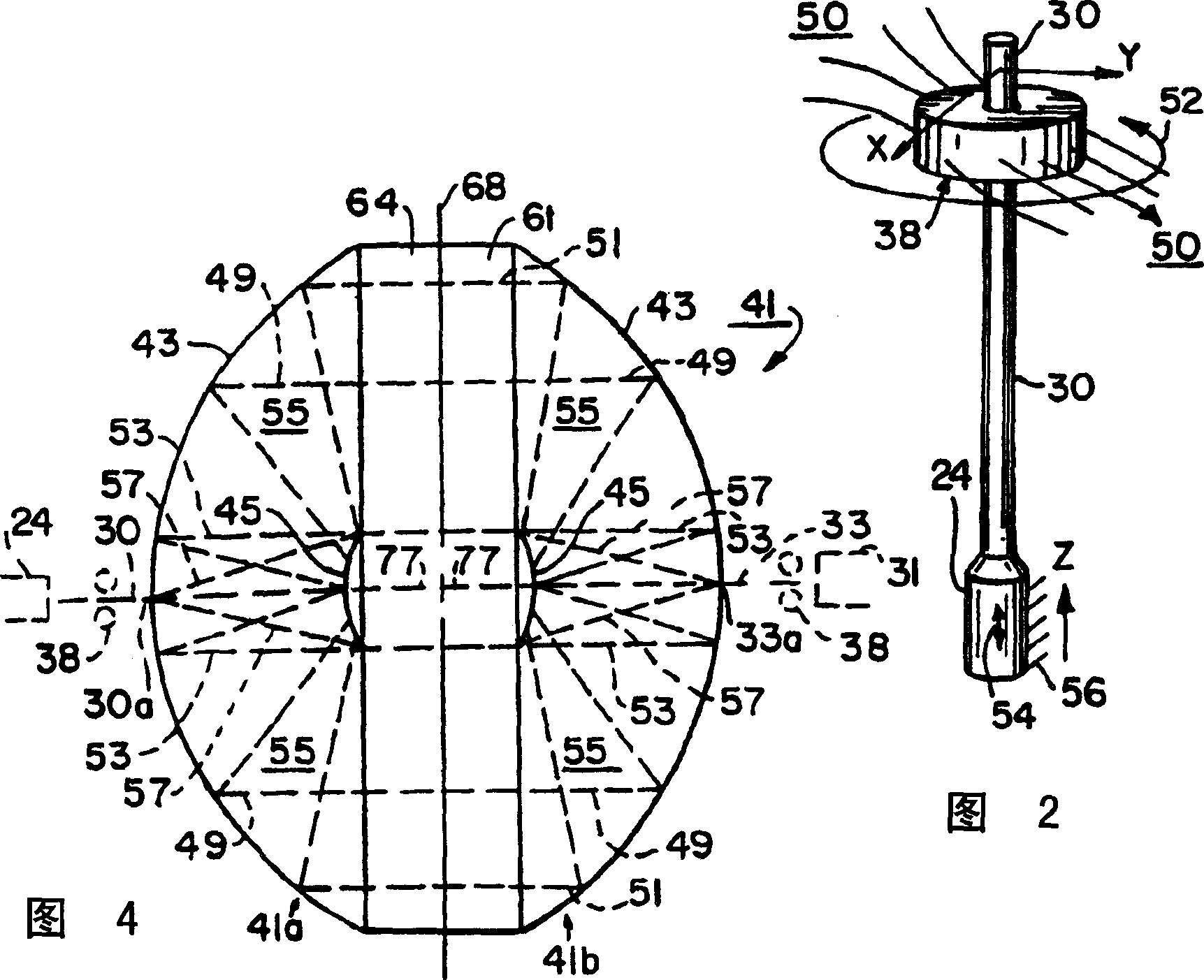

[0055] figure 1 is a cross-sectional view of a fiber optic cable termination 20 constructed in accordance with the present invention.

[0056] Terminal 20 includes a standard ceramic ferrule 22 with a larger hole 21 that tapers at 23 to form a significantly smaller fiber conductor passage 32 .

[0057] Conforming to the ferrule 22 is the end of the fiber optic cable 24 comprising a single mode optical fiber 30 extending through the passageway 32 and the cladding 28 having a different refractive index than the optical cable core 30 and finally the outer protective coating 26 . Typical dimensions of the cable are: the outer diameter of the cable with the coating 26 is 250 microns; the diameter of the cable without the coating 26 is 125 microns; and the diameter of the optical fiber or core 30 is 8 microns.

[0058] The diameter of the cable is relatively small; in particular, the diameter of the core is only 0.008 millimeters (about 0.0003 inches). Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com