Secondary lens, solar cell mounting body, light gathering solar energy unit, light gathering solar energy device, and light gathering solar energy module

A solar cell and secondary lens technology, applied in photovoltaic modules, photovoltaic power generation, lenses, etc., can solve the problems of solar cell unit 403 output current reduction, excessive manpower and material resources, etc., to suppress the reduction of fill factor) and alleviate excessive concentration , to prevent the effect of excessive concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〉

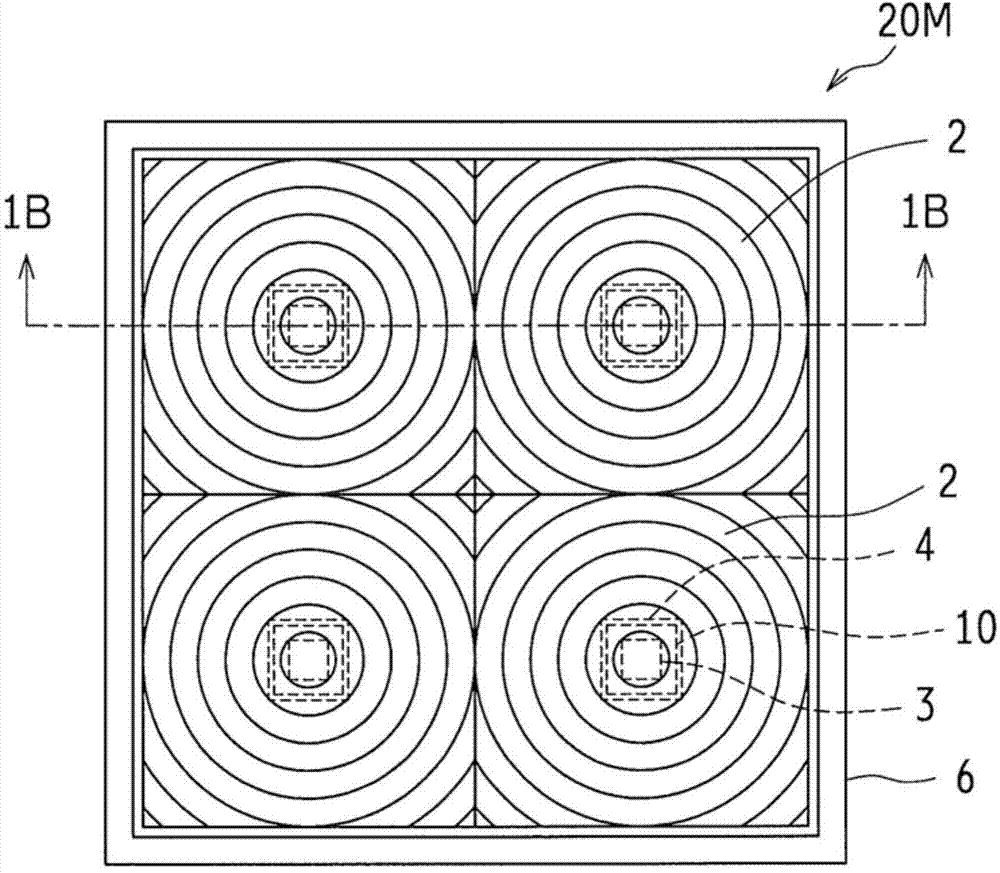

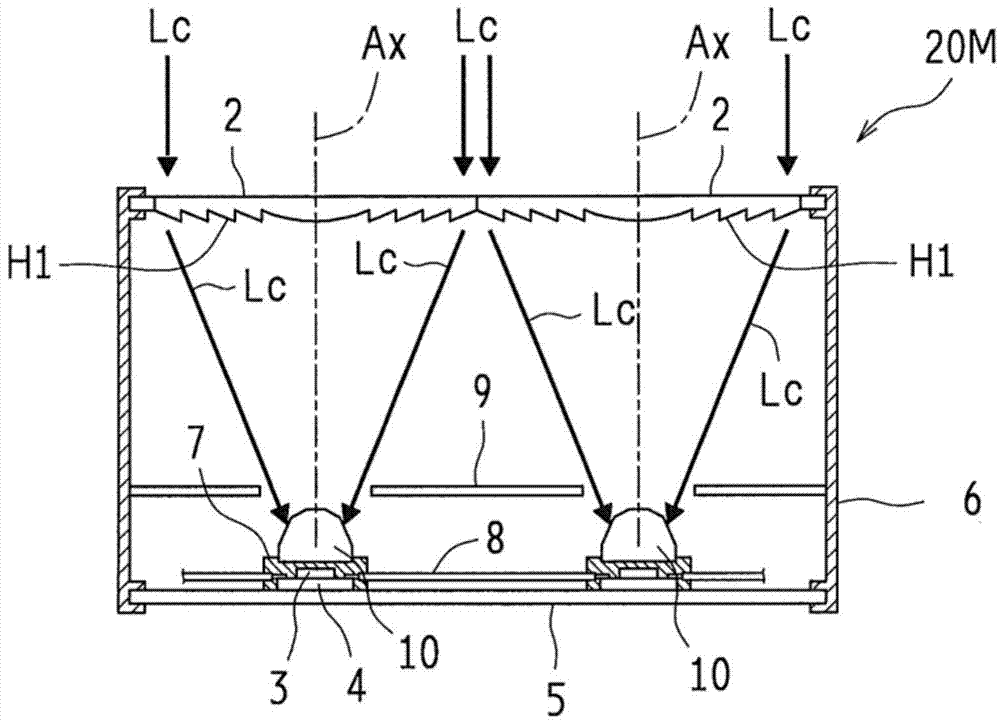

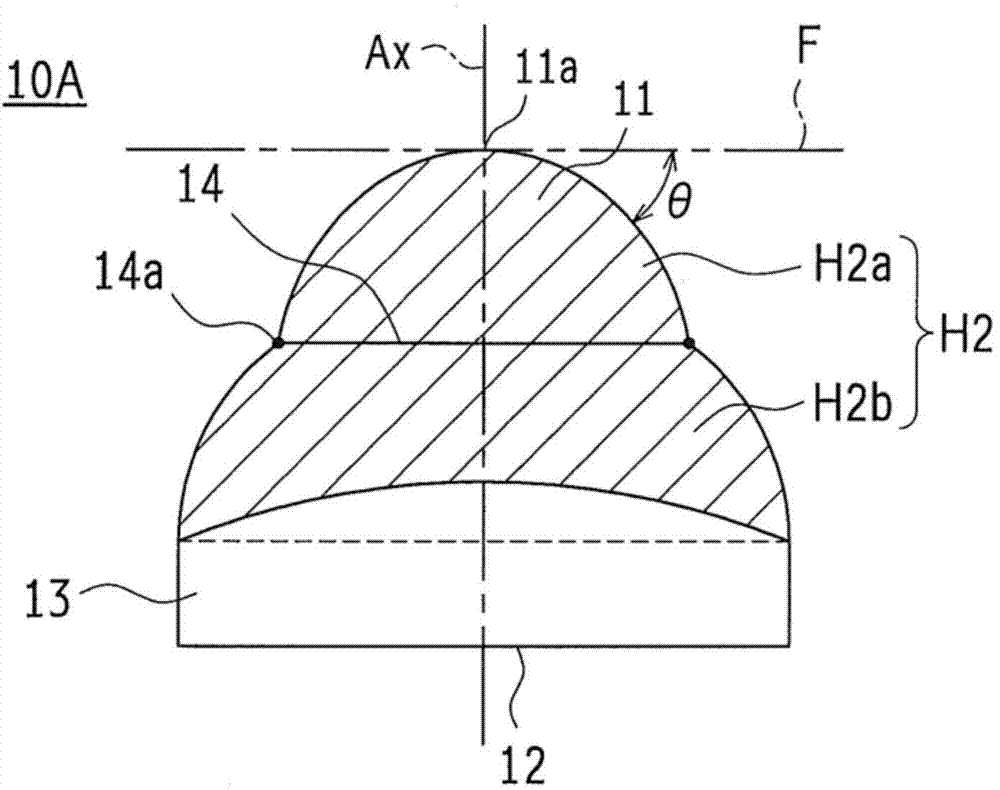

[0156] Figure 1A and Figure 1B It is a schematic diagram illustrating the structure of the concentrating solar power generation module of the present invention, Figure 1A is a plan view viewed from the incident surface of sunlight Lc, Figure 1B yes Figure 1A Sectional drawing of line 1B-1B. and, Figure 2A and Figure 2B Showing the shape of the secondary lens of the first embodiment, Figure 2A for the side view, Figure 2B is a stereogram. in, Figure 2A The oblique lines in indicate the area of the optical refraction surface of the incident part described later.

[0157] The concentrating solar power generation module 20M is a concentrating solar power generation unit in which a concentrating lens 2 which is a primary optical system, a secondary lens 10A which is a secondary optical system according to the first embodiment, and a solar cell 3 are arranged as a set. (hereinafter also simply referred to as cells) are arranged in multiple groups, and in order ...

no. 2 approach 〉

[0199]Next, a second embodiment of the secondary lens will be described.

[0200] Figure 7A to Figure 7D Showing the shape of the secondary lens 10B of the second embodiment, Figure 7A is a stereogram, Figure 7B is a top view, Figure 7C From Figure 7A The side view viewed in the direction of the arrow X1, Figure 7D From Figure 7A A side view viewed in the direction of the arrow X2.

[0201] The difference between the secondary lens 10B of the second embodiment and the secondary lens 10A of the first embodiment is that in the secondary lens 10B of the second embodiment, four positions around the second optical refraction surface H2b are further formed. Corner 16. Therefore, in the secondary lens 10B of the second embodiment, the cross-sectional shape of the second optical refraction surface H2b of the secondary lens 10B in the direction perpendicular to the optical axis is the same as that of the optical refraction surface H1 of the condenser lens 2 in the directi...

no. 3 approach 〉

[0207] refer to Figure 9A to Figure 14B Next, the secondary lens 100 , the concentrating solar power generation device 30 , the concentrating solar power generation module 30M, and the solar cell mounting body 1 of the present embodiment will be described.

[0208] Figure 9A It is a top view showing the concentrating solar power generation device 30 and the concentrating solar power generation module 30M according to the third embodiment of the present invention as viewed from the concentrating lens 2 side.

[0209] Figure 9B so in Figure 9A The cross-sectional state of the arrow 9B-9B indicates Figure 9A A cross-sectional view of the concentrated solar power generation device 30 and the concentrated solar power generation module 30M shown. In addition, in consideration of the convenience of viewing the drawings, shading representing cross-sections is partially added.

[0210] The concentrating solar power generation device 30 has a concentrating lens 2 , which is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com