Piezoelectric power generator

A piezoelectric power generation and piezoelectric body technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, generators/motors, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve large loads, Problems such as deformation of piezoelectric elements and difficulty in power generation efficiency, etc., to achieve the effect of high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

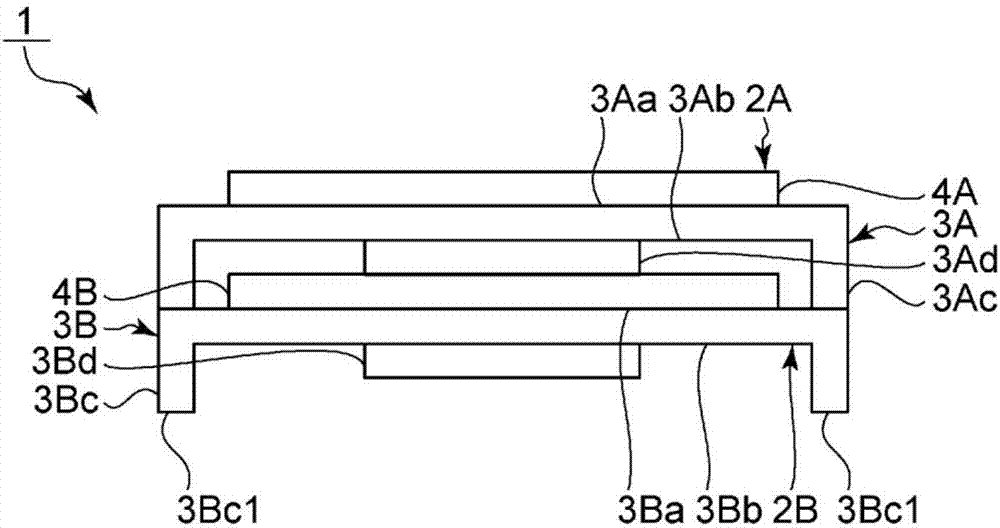

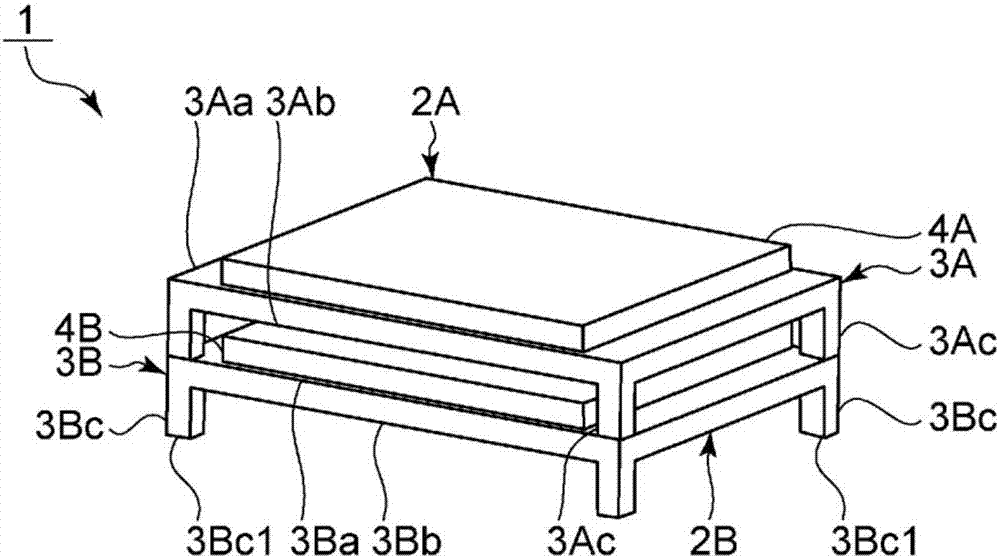

[0051] figure 1 It is a front view of the piezoelectric generator according to the first embodiment of the present invention. figure 2 It is a perspective view of the piezoelectric generator of the first embodiment.

[0052] Such as figure 1 As shown, the piezoelectric power generating device 1 has a first power generating element 2A and a second power generating element 2B. exist figure 1 Among them, the first power generating element 2A is provided on the second power generating element 2B.

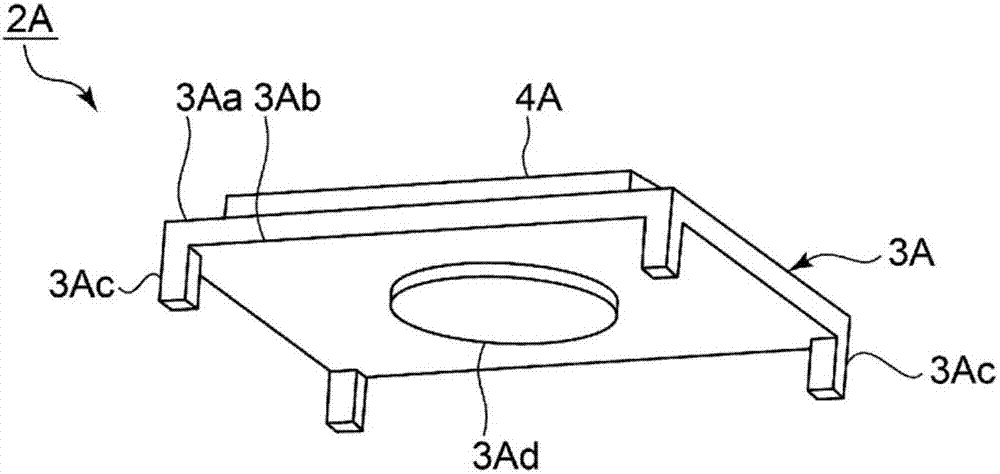

[0053] The first power generating element 2A has a support body 3A and a piezoelectric body 4A.

[0054] The support body 3A is made of, for example, a conductive material such as a metal or an alloy, or an insulating material such as a ceramic material. The support body 3A has a flat part, a convex part 3Ad, and a support part 3Ac which is a leg part. The flat portion of the support body 3A, the convex portion 3Ad, and the support portion 3Ac are integrally formed. The planar p...

no. 2 approach

[0083] Figure 10 It is a front view of the piezoelectric generator of the second embodiment.

[0084] In the piezoelectric power generating device 11 , the shape of the protrusions 13Ad, 13Bd of the supports 13A, 13B of the first and second power generating elements 12A, 12B is different from that of the first embodiment. Except for the above points, the piezoelectric power generator 11 has the same configuration as the piezoelectric power generator 1 of the first embodiment.

[0085] The convex portion 13Ad of the support body 13A of the first power generating element 12A has a base portion 13Ad0 and a step portion 13Ad1 of one stage.

[0086] The base portion 13Ad0 is provided on the lower surface of the planar portion of the support body 13A. The base portion 13Ad0 protrudes from the central portion of the planar portion of the support body 13A. Base portion 13Ad0 has a circular shape when viewing support body 13A in a direction perpendicular to the lower surface of sup...

no. 3 approach

[0094] Figure 14 It is a front view of the piezoelectric generator of the third embodiment.

[0095] The piezoelectric power generating device 21 differs from the first embodiment in that it has three or more power generating elements 22 . Each power generating element 22 has the same configuration as that of the first power generating element 2A in the first embodiment.

[0096] In the piezoelectric power generating device 21, a plurality of power generating elements 22 are stacked vertically. Each power generating element 22 is overlapped similarly to the first and second power generating elements 2A, 2B of the first embodiment. When the piezoelectric body 4A of the uppermost power generating element 22 in the piezoelectric power generating device 21 is pressed downward, the piezoelectric body 4A of each power generating element 22 other than the uppermost power generating element 22 is also pressed by the support body 3A. The convex part 3Ad presses.

[0097] Here, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com