Patents

Literature

914 results about "Sewing needle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sewing needle, used for hand-sewing, is a long slender tool with a pointed tip at one end and a hole (or eye) at the other. The earliest needles were made of bone or wood; modern needles are manufactured from high carbon steel wire and are nickel- or 18K gold-plated for corrosion resistance. High quality embroidery needles are plated with two-thirds platinum and one-third titanium alloy. Traditionally, needles have been kept in needle books or needlecases which have become objects of adornment. Sewing needles may also be kept in an étui, a small box that held needles and other items such as scissors, pencils and tweezers.

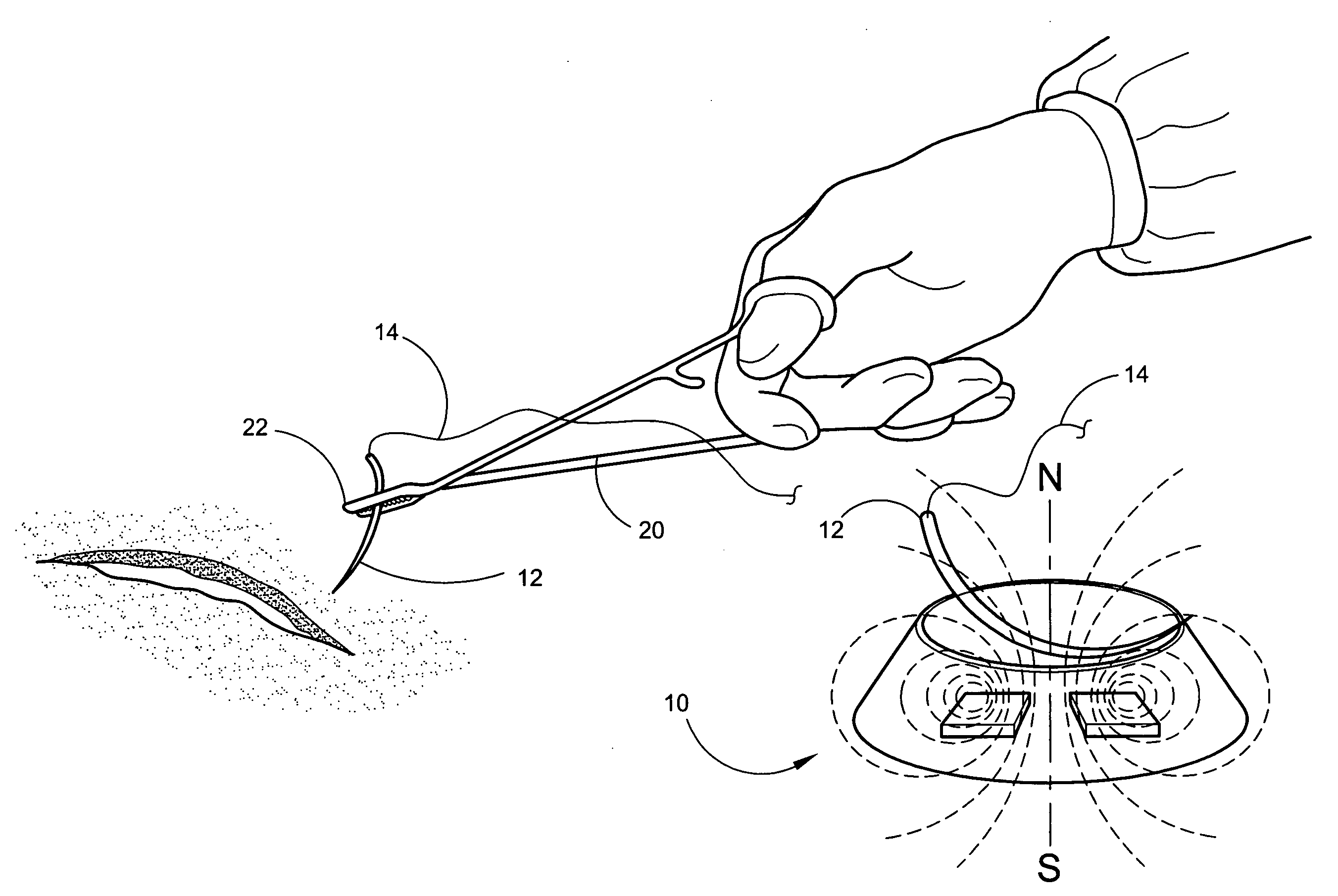

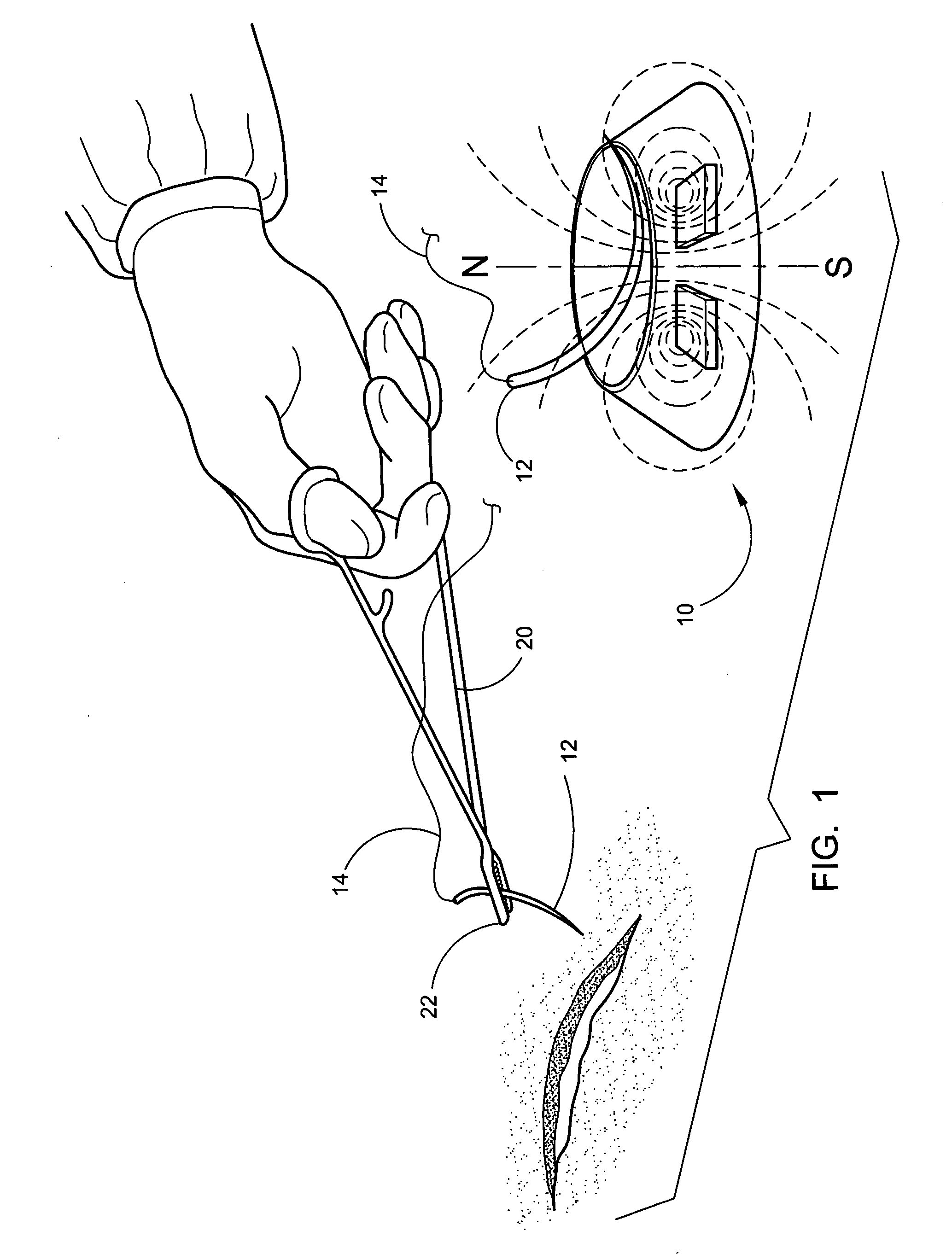

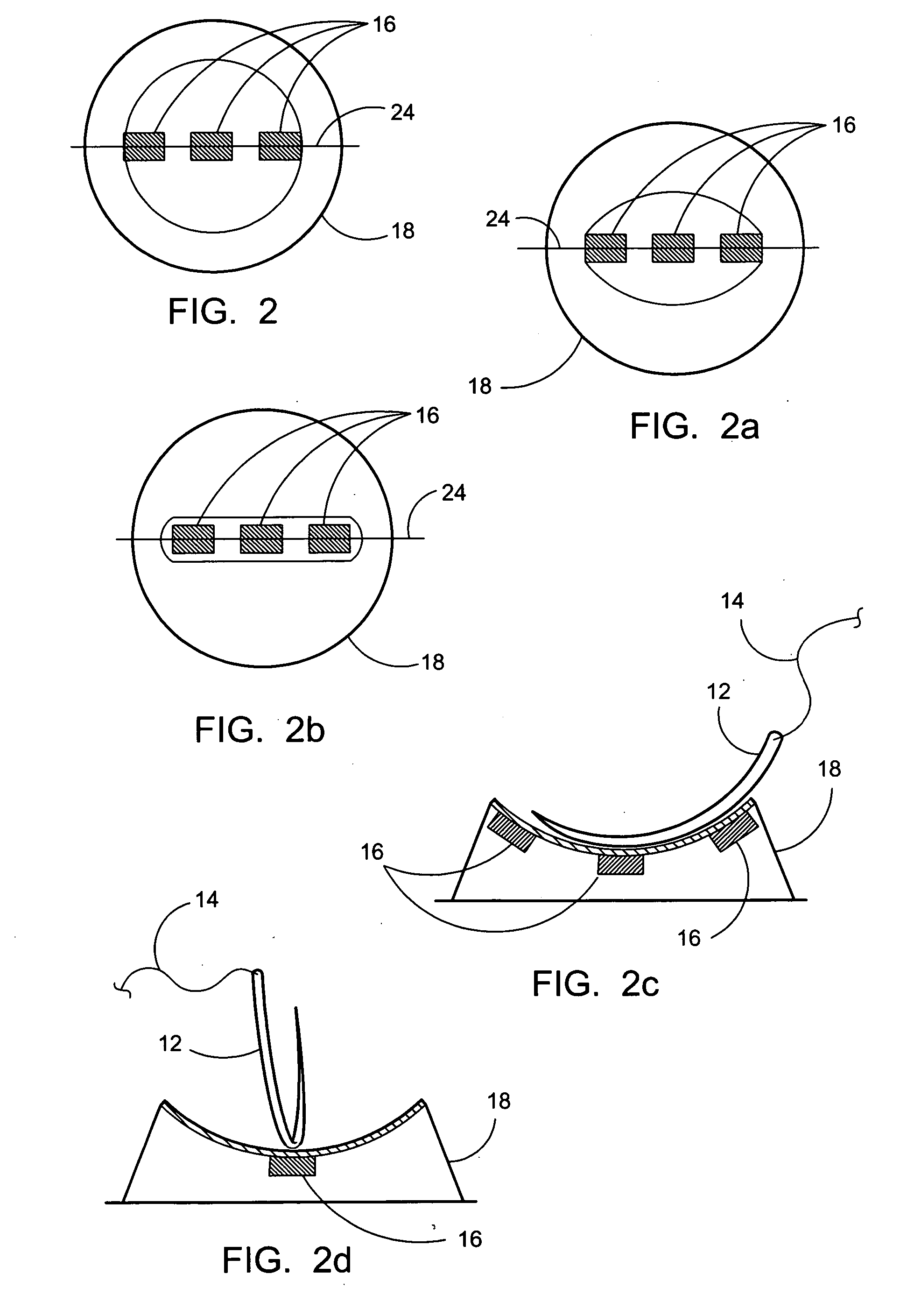

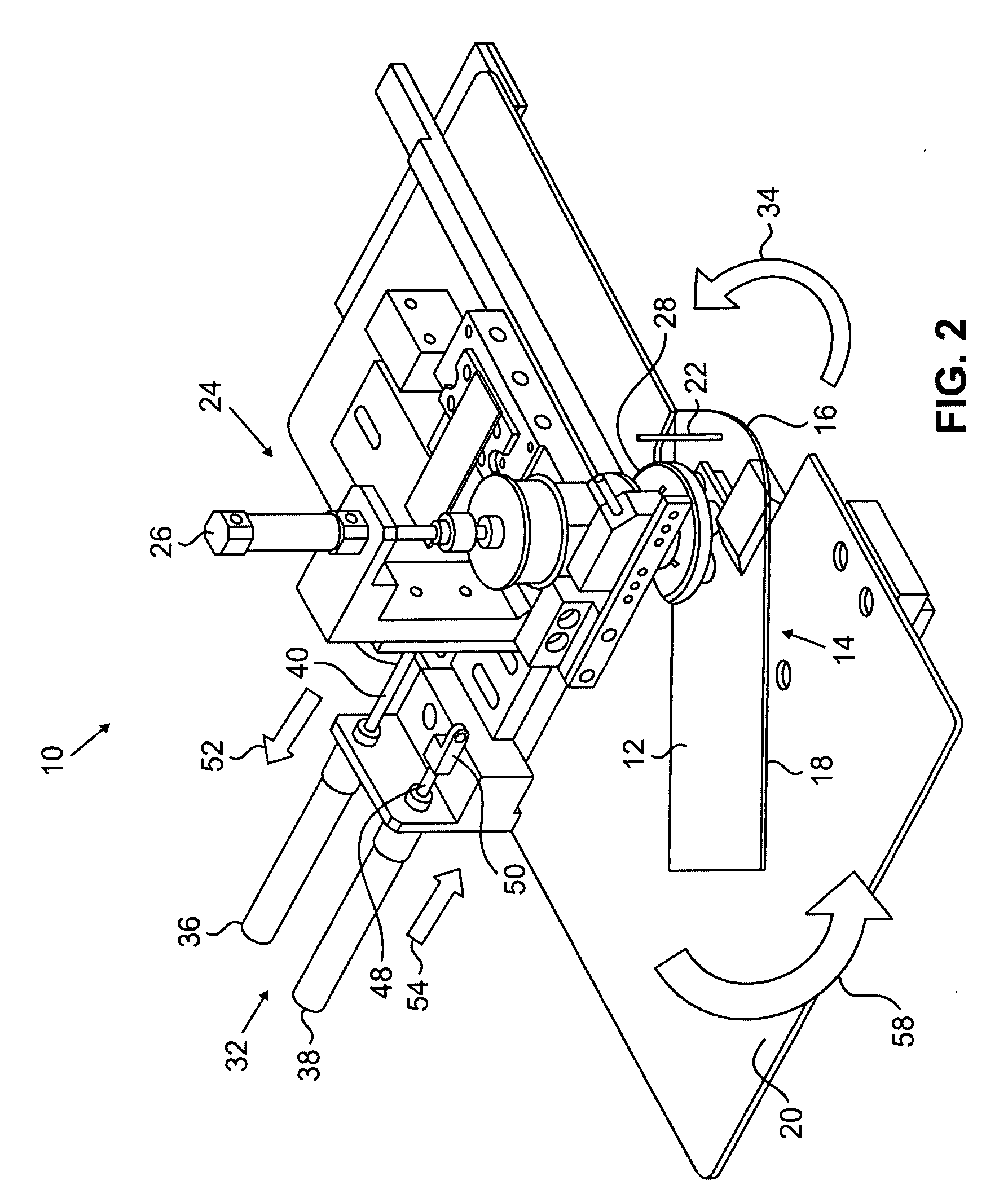

Magnetic needle positioner

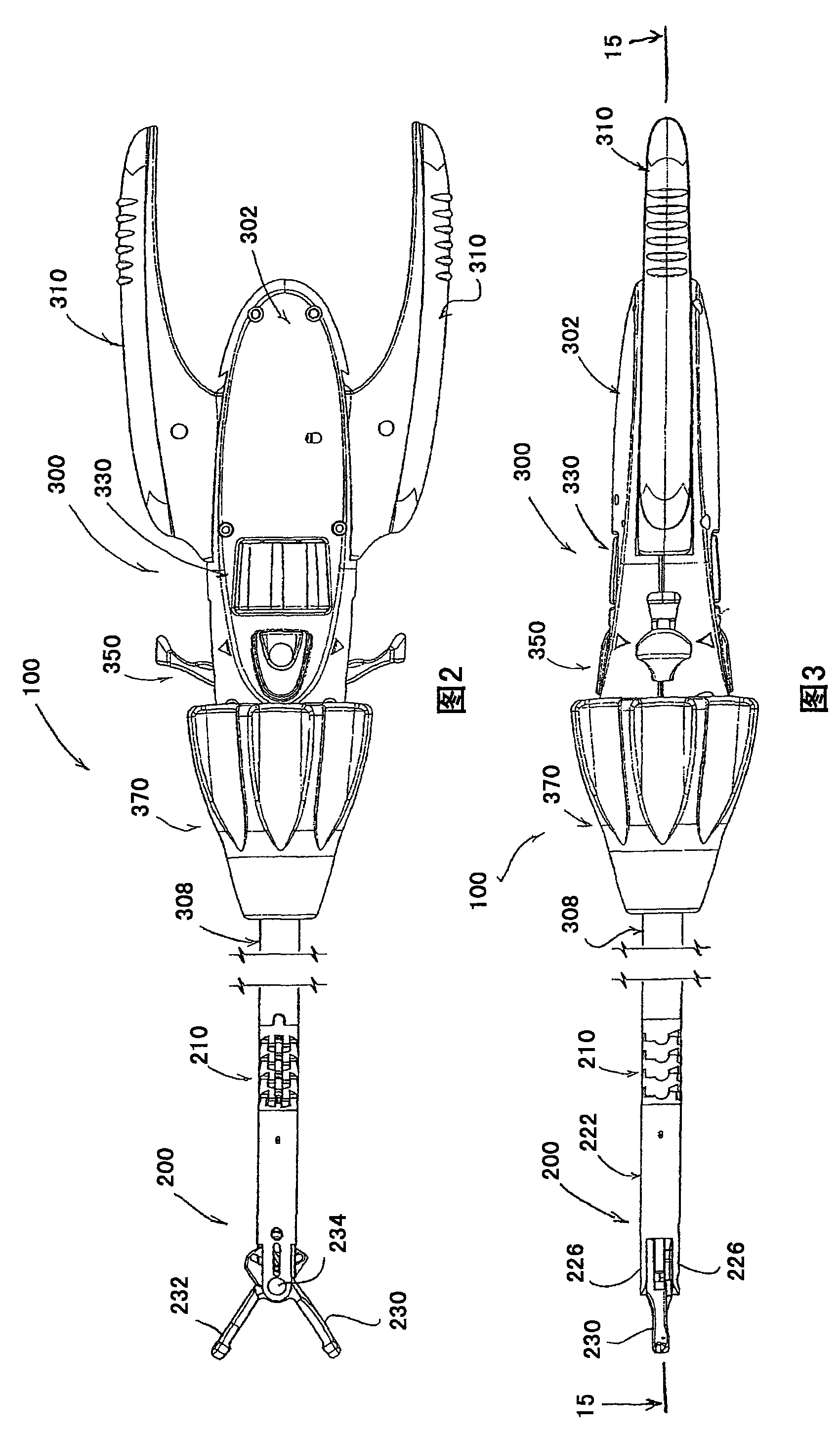

InactiveUS20070055294A1Easy to controlSimple methodSuture equipmentsSurgical needlesSewing needleField strength

A device and method for maintaining a curved sewing needle in an upright position when the needle is deposited thereon during suturing or sewing. The device features a base with a top surface on which a curved needle may be removably deposited. Once deposited upon the top surface of the base, a magnetic field of sufficient force and vector holds the needle to a substantially vertical position wherein it is easier to grasp by a tool or fingers for the next suture. Coaxing the needle to the upright position from a sideways deposit on the top surface can be provided by a sufficient field strength and assisted by dimensioning the top surface of the base to mechanically assist the magnetic force on the deposited needle and also by employing a magnetized needle.

Owner:GIAP BRANDON

Thread-guiding-type pepper selfing fruit marking method

InactiveCN104115742ALess laborLess time consumingPlant genotype modificationCapsicum annuumPollination

The invention discloses a thread-guiding-type pepper selfing fruit marking method and belongs to the technical field of plant breeding. The thread-guiding-type pepper selfing fruit marking method comprises the following steps: firstly selecting selfing single plants, and marking by hanging a tag; secondly, selecting flowers about to bloom in the selected selfing single plants; threading a filament into a hand sewing needle with a certain specification (0.2-0.4mm), and tieing a knot at one end close to a needle hole; threading a guiding thread of the hand sewing needle through a pedicel part of each flower to be bloomed; leaving the tail end, about 2-3cm long, of the filament into the pedicel part as a marker of a selfing pollination flower; manually pollinating the marked flowers; and harvesting fruits with filament markers in the pedicel parts in a physiological mature period.

Owner:王红侠

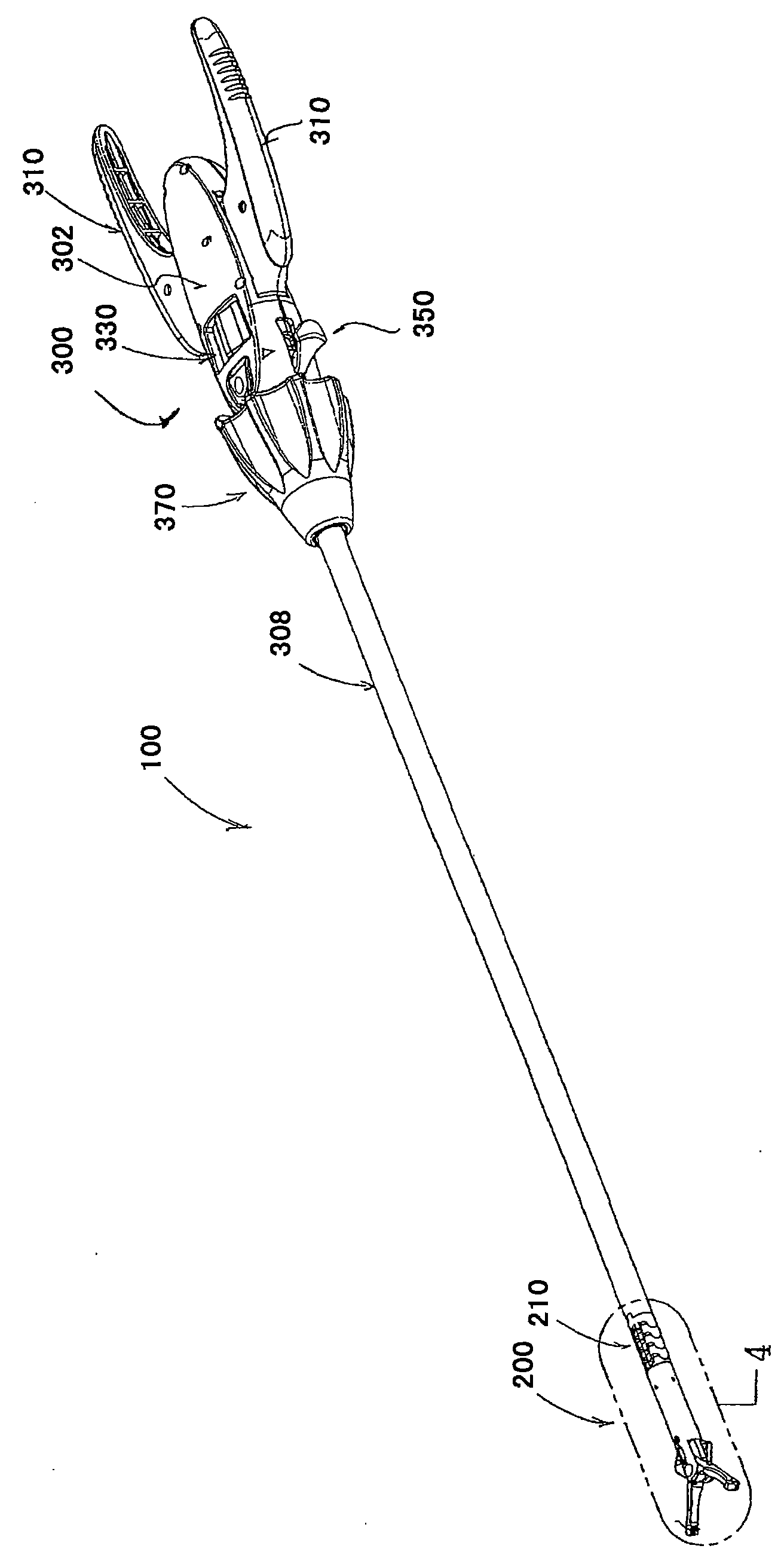

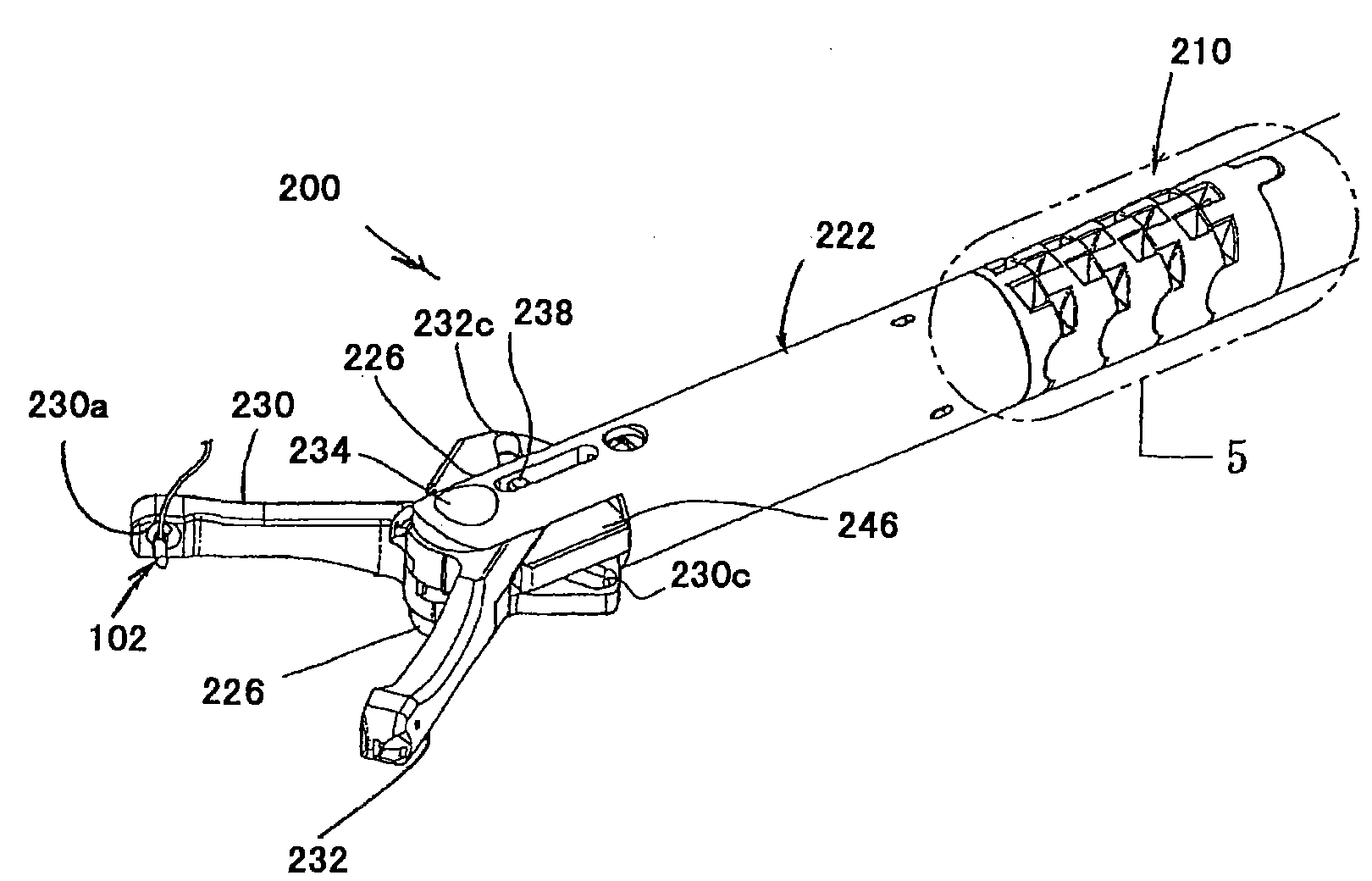

Endoscope sewing device

The invention discloses a device, system and method for sewing or stitching an endoscope through an admitting pipe and the like and provides an endoscope sewing device, comprising a handle component, a slender shaft supported by the handle component and extending out from the handle component, and an end effector supported on the remote end of the slender shaft. The end effector comprises a journal component and a pair of apposed jaws, wherein the journal component is applied to be hinged in one direction between a basic linear structure or an off-axis structure; and the pair of apposed jaws are related with each other pivotally and each limits a groove for containing sewing needles on tissue exposure surface thereof.

Owner:TYCO HEALTHCARE GRP LP

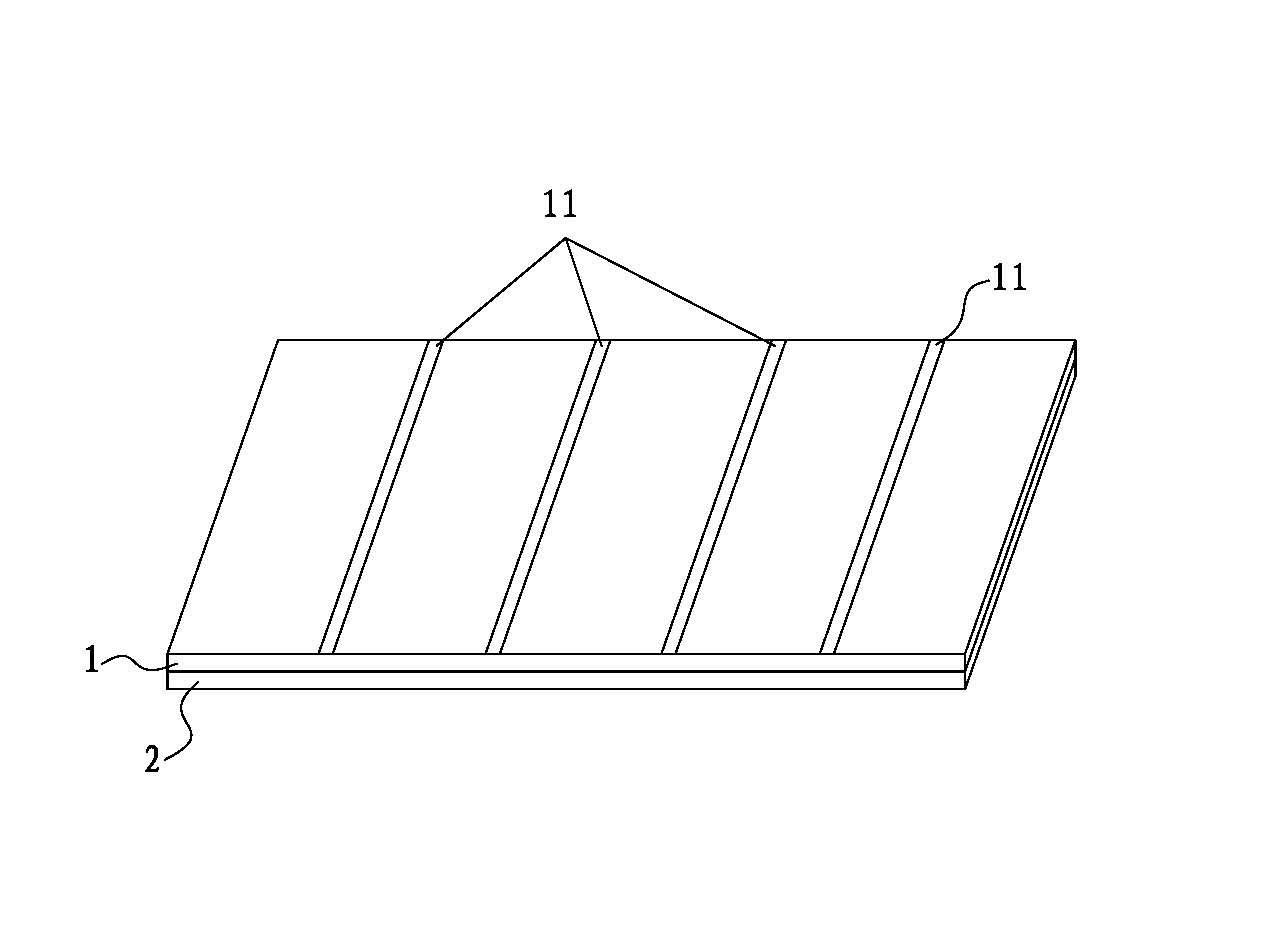

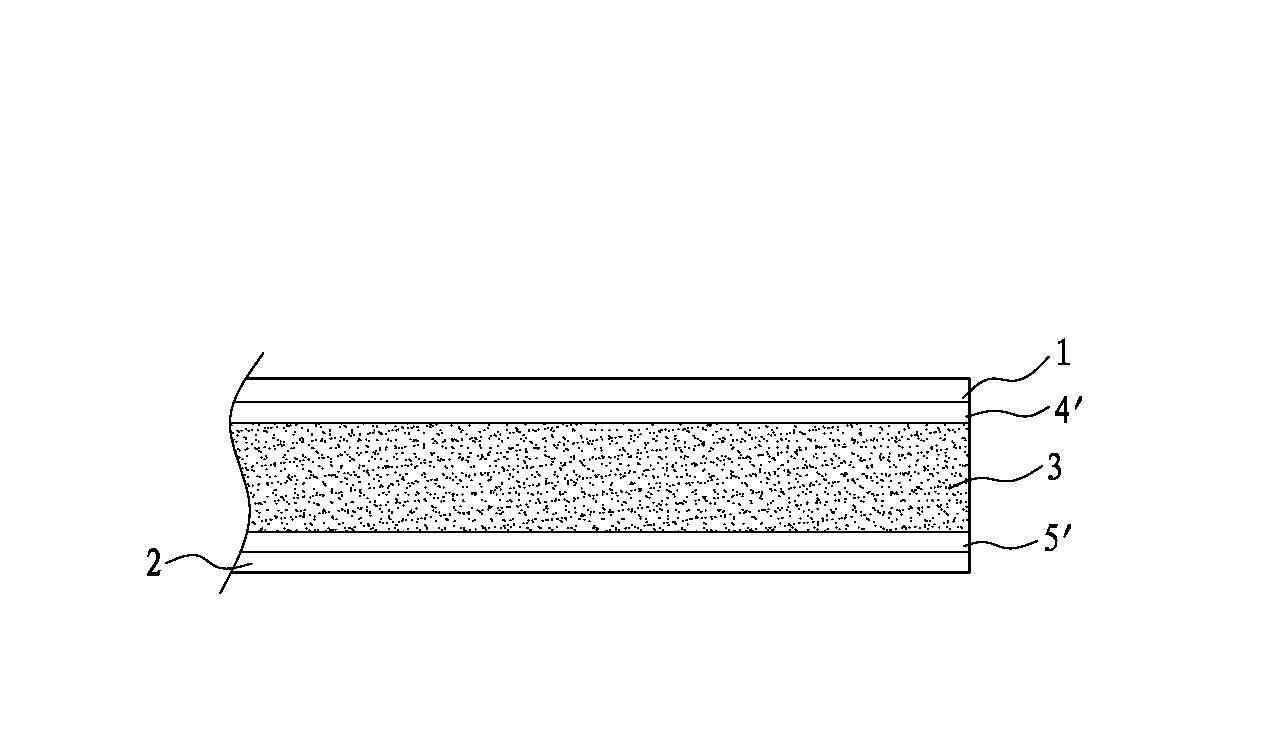

Down-leakage-proof down product and production method of down product

InactiveCN102599663AHigh densityPrevent the problem of velvet leakageOvergarmentsBed-coversEngineeringMoisture

The invention discloses a down-leakage-proof down product and a production method of the down product. The down product comprises a shell fabric, a lining fabric, down and a layer of down-proof medium. The down is filled between the shell fabric and the lining fabric, the down-proof medium clings to the inner surface of the shell fabric or the inner surface of the lining fabric, and ultrasonic-wave quilted seams or glued hot-press quilted seams are performed between the shell fabric and the lining fabric. As the air-moisture permeable down-proof medium is combined with the lining fabric or the shell fabric in a press fit way and the down-proof medium is high in density, the down-leakage problem caused by a low fabric density and sewing needle holes can be effectively solved.

Owner:林鹭峰

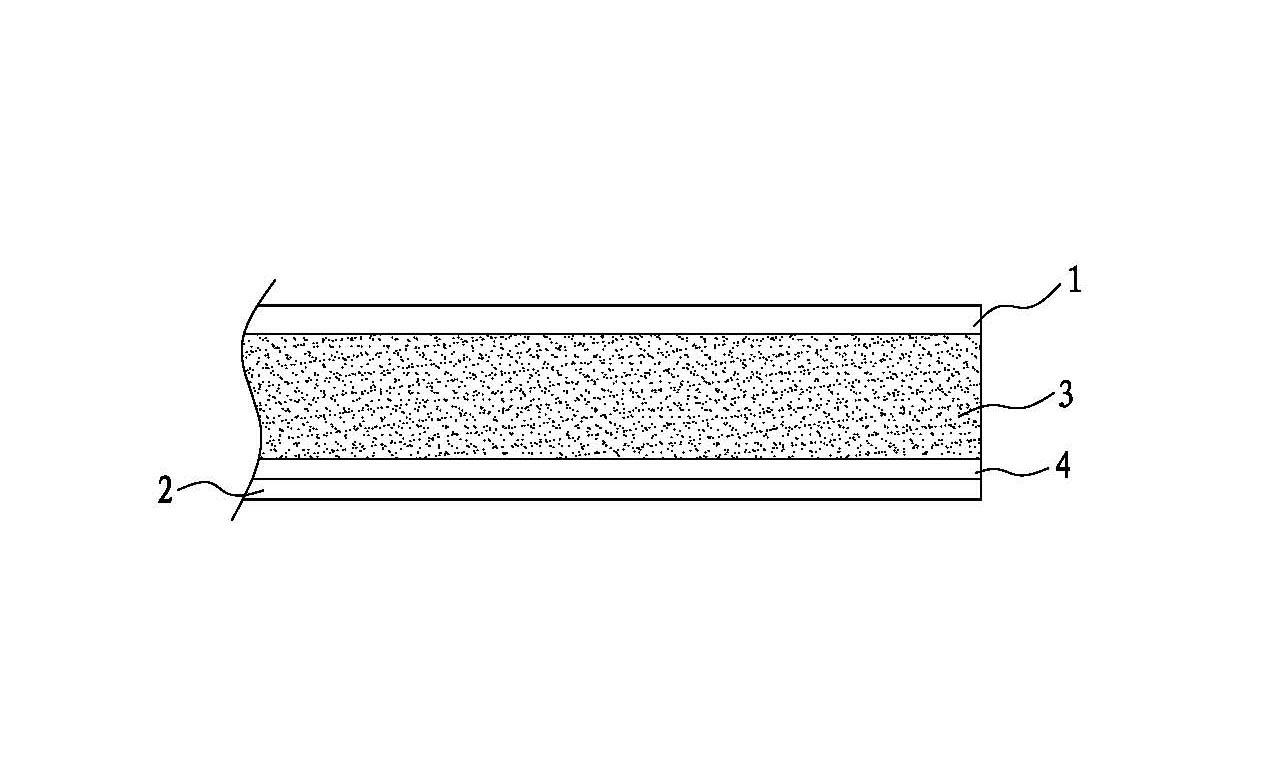

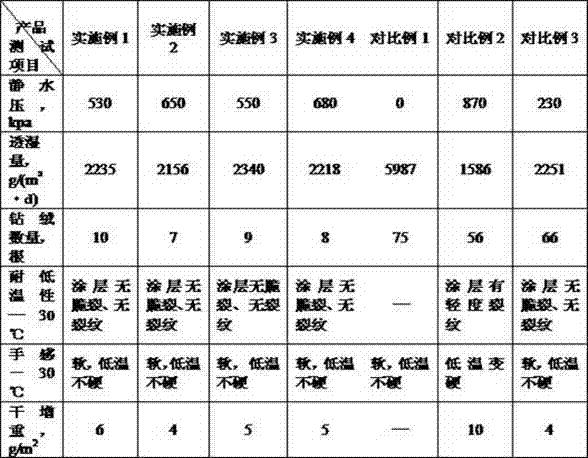

Down coat fabric treatment method for preventing down feather from escaping from needle holes

ActiveCN103614922ASolve the problem of drilling woolSolve the problem of drilling down, especially the problem of sewing needle hole drillingFibre typesPolymer scienceAdhesive

The invention discloses a down coat fabric treatment method for preventing down feather from escaping from needle holes. The down coat fabric treatment method is mainly technically characterized in that 100 parts by weight of a polyether polyurethane coating adhesive, 20-30 parts of a hydroxy terminated polydimethylsiloxane emulsion, 1-1.5 parts of an isocyanate cross-linking agent, 1.2-1.8 parts by weight of a cross-linking promoter, 3-5 parts of silicon dioxide extinction powder and 15 parts of butanone or toluene are mixed to prepare a coating adhesive, which is applied to a fabric by a floating knife coating machine, and the dry weight increase reaches 4-6 g / m<2>. The effect of preventing down feather from escaping from sewing needle holes is good, and the cold resistance, moisture permeability, washing fastness and flexibility of a fabric are ensured.

Owner:DANDONG UNIK TEXTILE

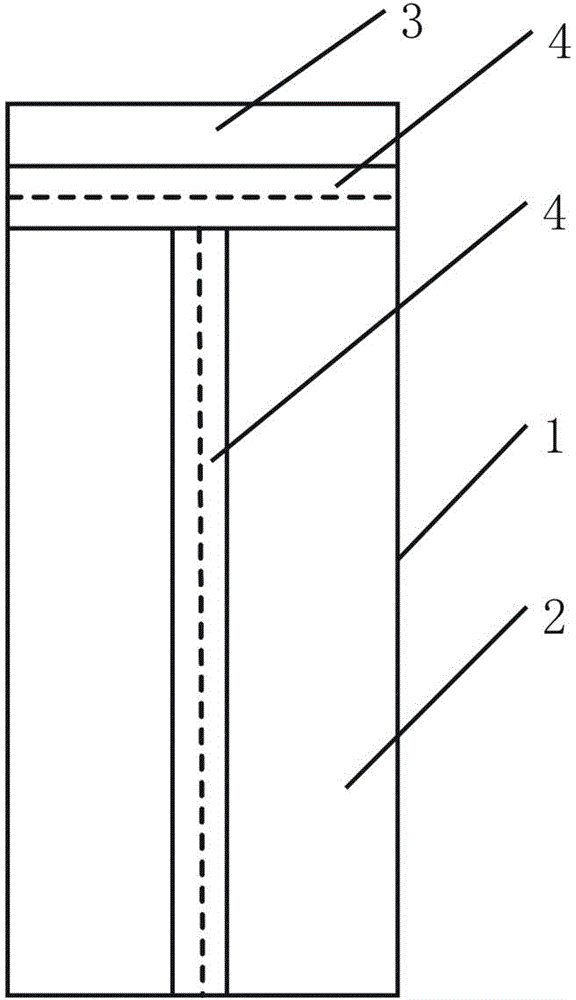

Preparation method of pinhole-free dedusting filter bag

ActiveCN104436866AHigh filtration precisionImprove dust removal efficiencyDispersed particle filtrationFiltration separationEngineeringNonwoven fabric

The invention discloses a preparation method of a pinhole-free dedusting filter bag. A filter bag is adopted, wherein the filter bag is sewn by a punched felt or nonwoven cloth the dustward surface of which is compounded with a polytetrafluoroethylene micro-pore film; a bag body is sewn by three stitches, and the bag opening is sewn by four stitches. The preparation method of the pinhole-free dedusting filter bag is characterized in that the sewing needle and thread of the filter bag is compounded with a micro-pore band which is sintered and shaped in a single surface in a hot pressing mode, and the micro-pore band covers stitch clearances of the bag body and the bag opening, so that the filtering precision at the stitch clearances of the sewn filter bag is improved; the hot pressing temperature is 400-1000 DEG C, and the compounding pressure is 0.2-1MPa. Compared with the prior art, the pinhole-free dedusting filter bag is high in filtering precision, good in dedusting efficiency, and the technical scheme is especially suitable for filter bags used for filtering PM2.5 dust; the effective filtering rate of PM2.5 dust can reach 99.99%; the pinhole-free dedusting filter bag is convenient to manufacture, is low in production cost, has a good use effect, and the preparation method is a PM2.5 filter bag manufacturing method with good application prospect and practical value.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

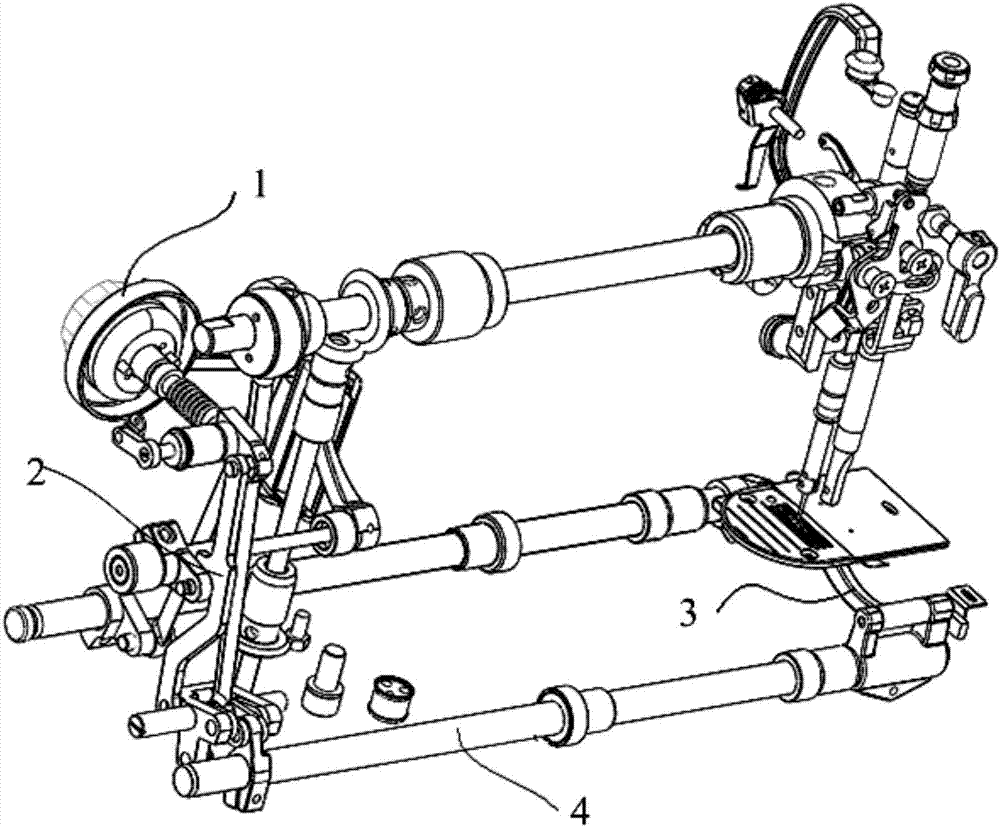

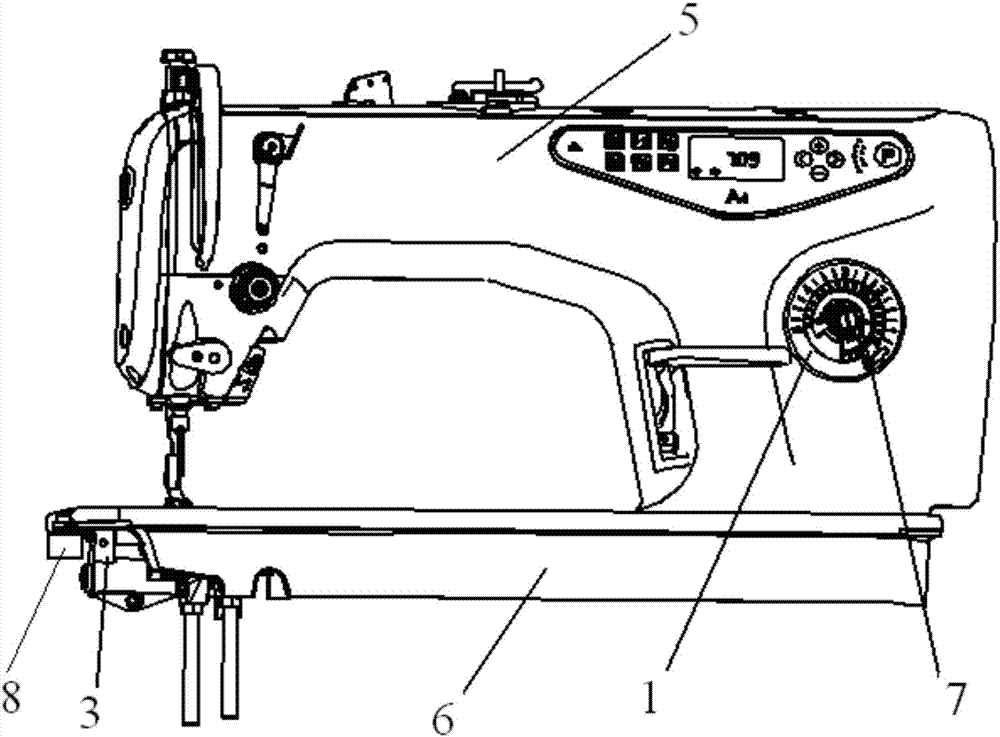

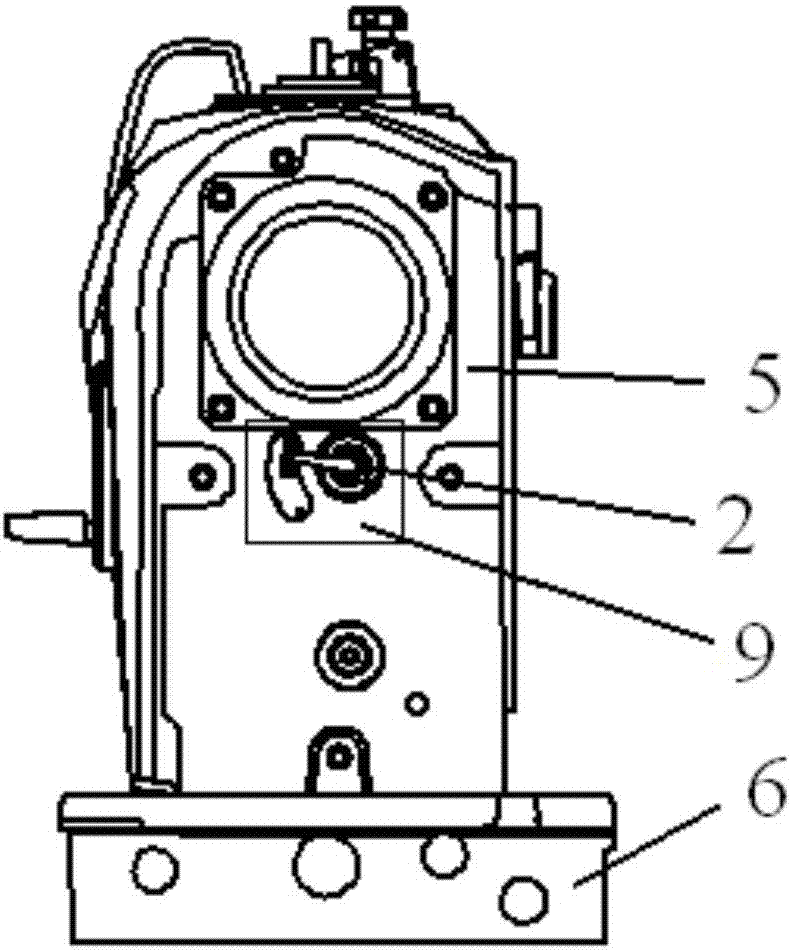

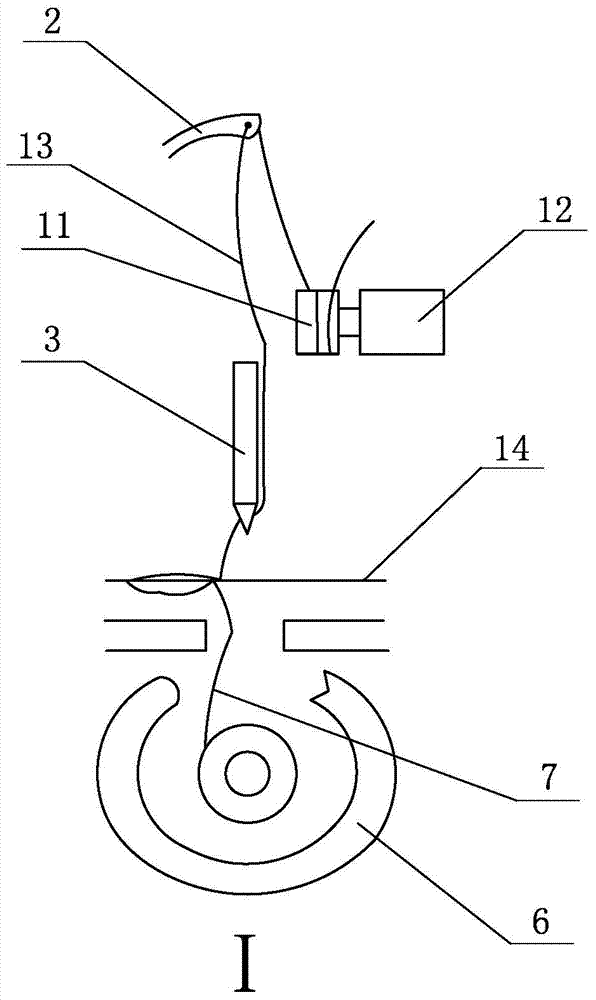

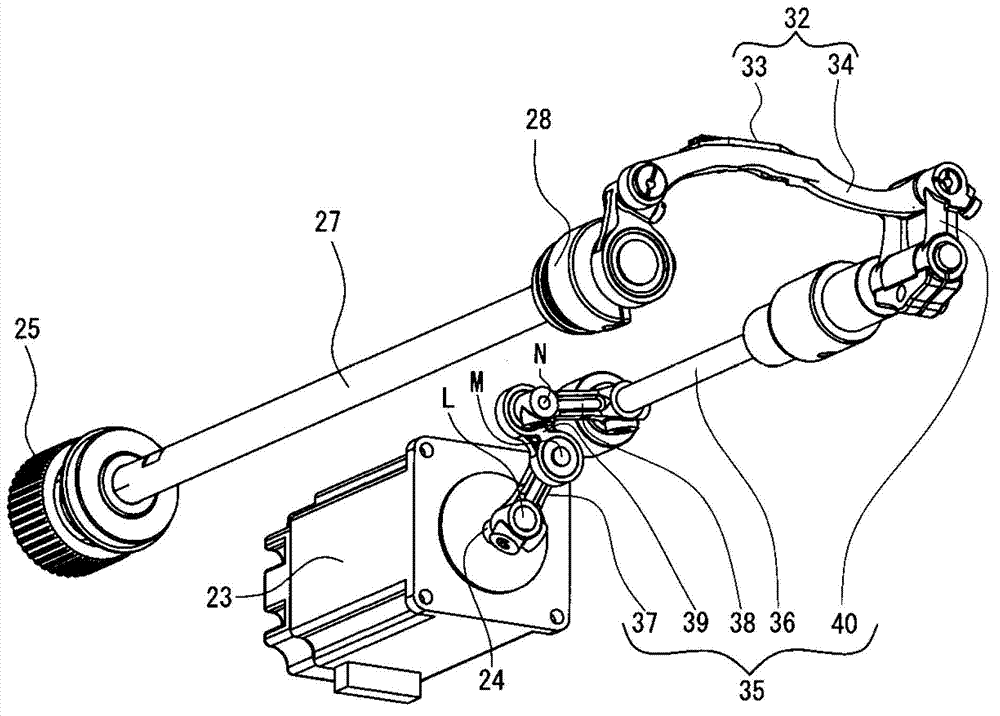

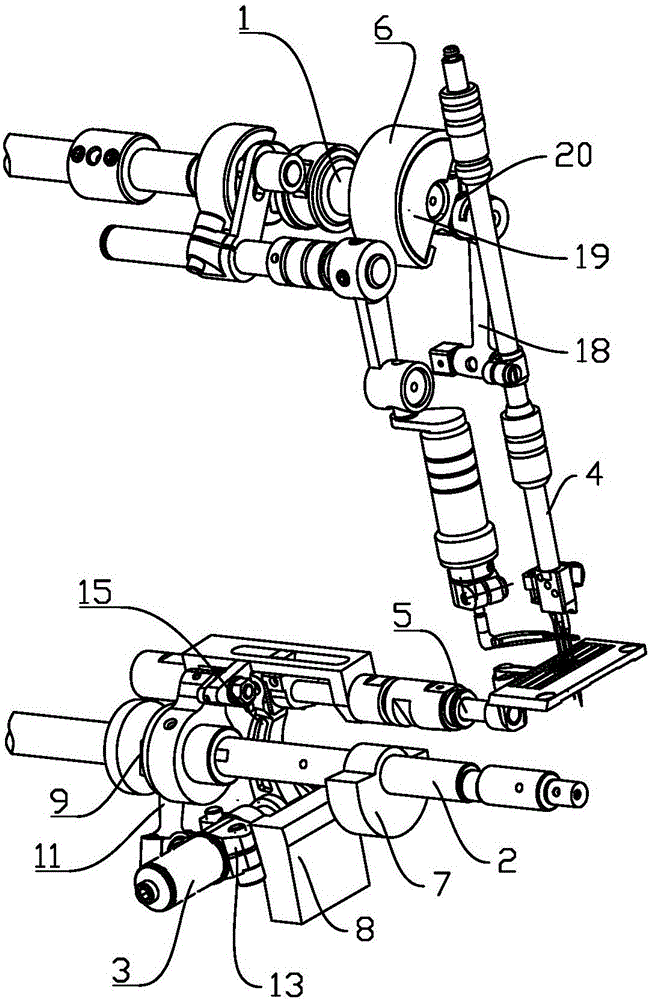

Sewing boundary automatic sewing system and sewing method

ActiveCN106988027AImprove sewing efficiencyHigh precisionProgramme-controlled sewing machinesControl systemEngineering

The invention provides a sewing boundary automatic sewing system and a sewing method. The system comprises a needle pitch detection mechanism, a boundary detection mechanism disposed at the preset distance from a needle hole sewed by a sewing machine needle, and a control system. The needle pitch detection mechanism and the boundary detector are connected with the control system. The control system acquires the current sewing needle pitch in real time according to the needle pitch detection mechanism, and judges whether or not the current sewing state is the terminal sewing according to signals of the boundary detector; if yes, the control system calculates the number of sewing stitches sewn to the fabric boundary with the current sewing needle pitch and performs the sewing according to the number of the sewing stitches; if not, the sewing machine sews normally. The needle pitch detection mechanism is a parameter sensor for collecting swing parameters of feeding tooth holders. According to the sewing boundary automatic sewing system and the sewing method, the automatic sewing process from the last stage to the terminal of the fabric is realized; the sewing efficiency and the sewing precision are improved; the labor cost is lowered.

Owner:JACK SEWING MASCH CO LTD

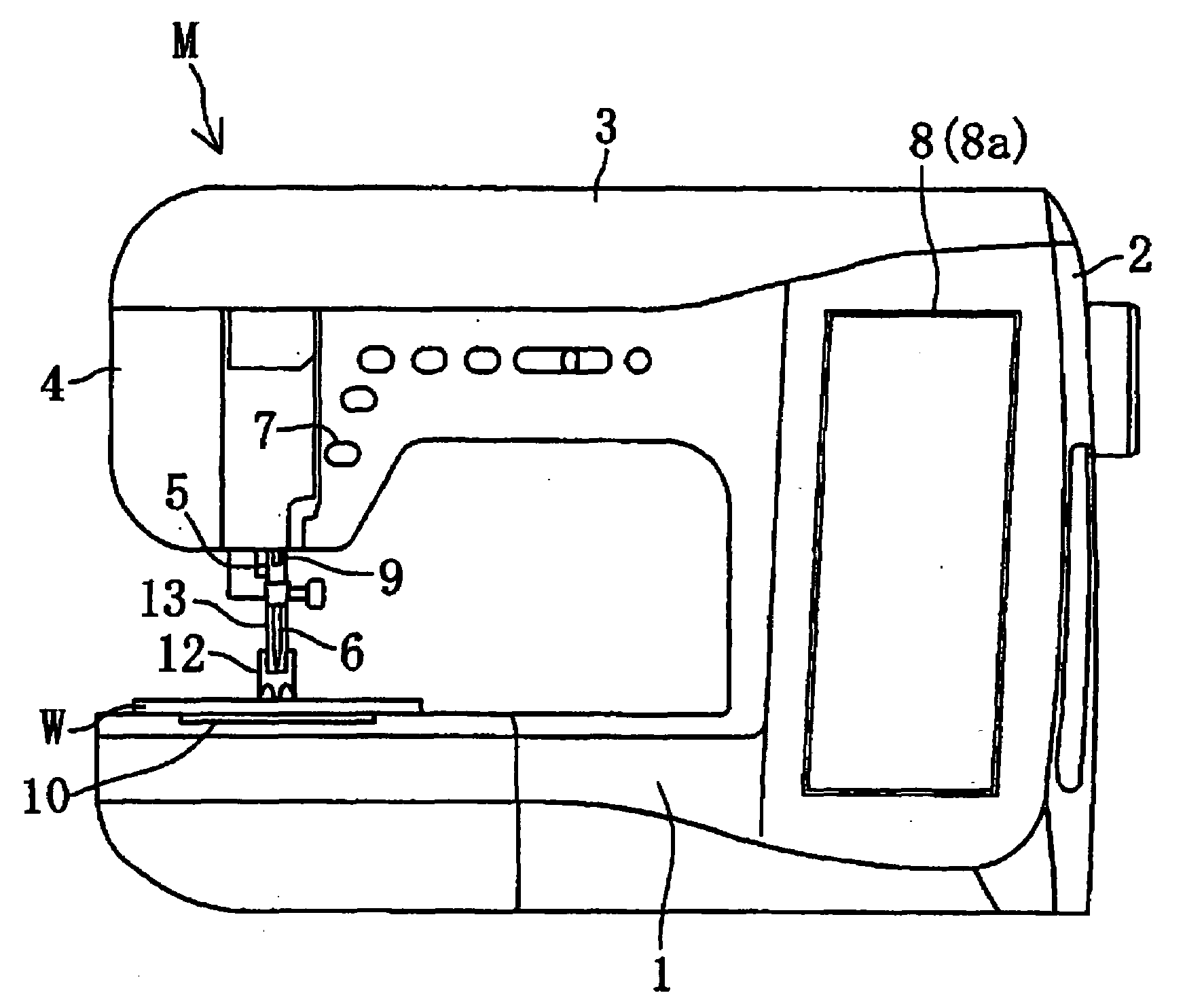

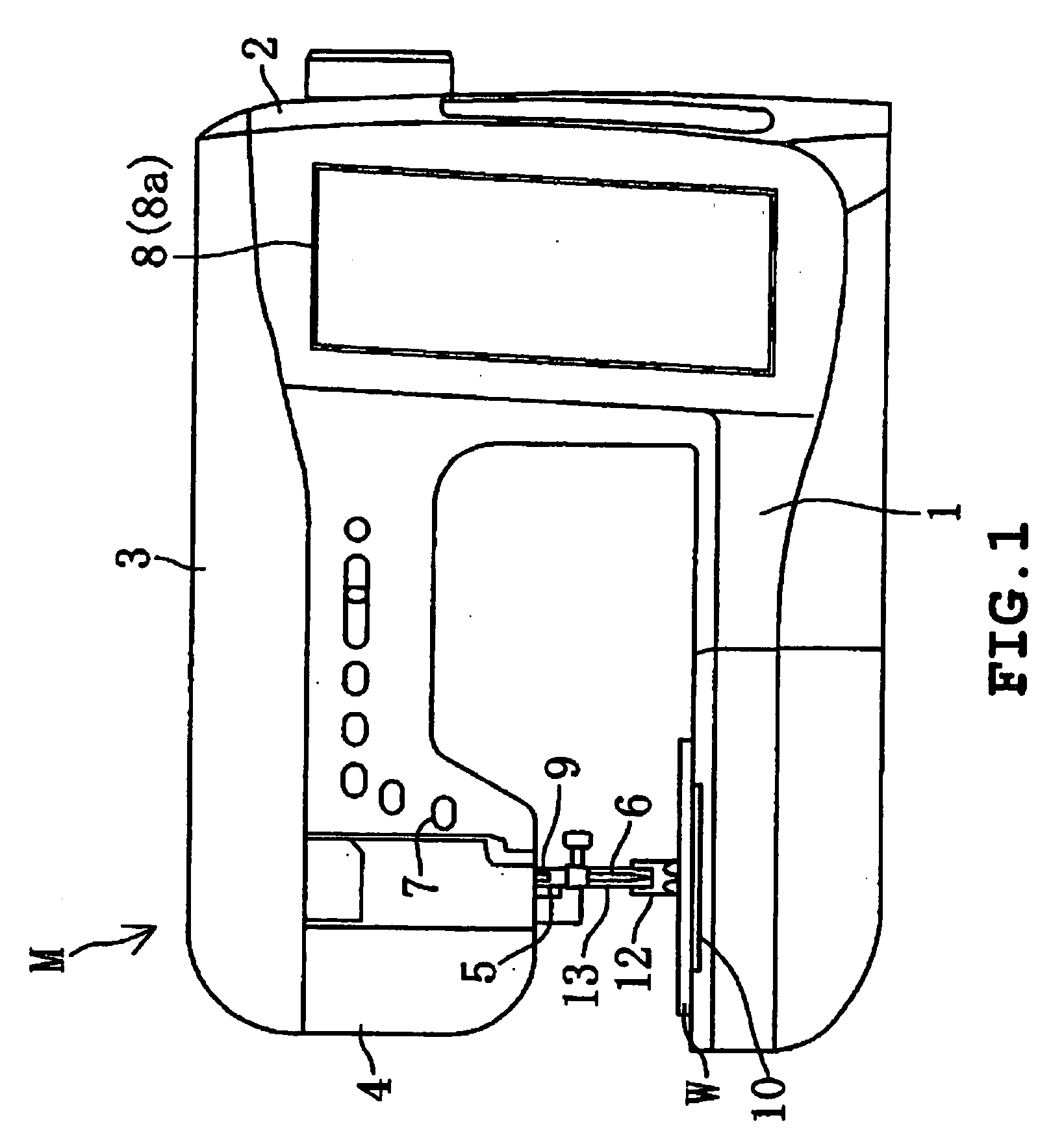

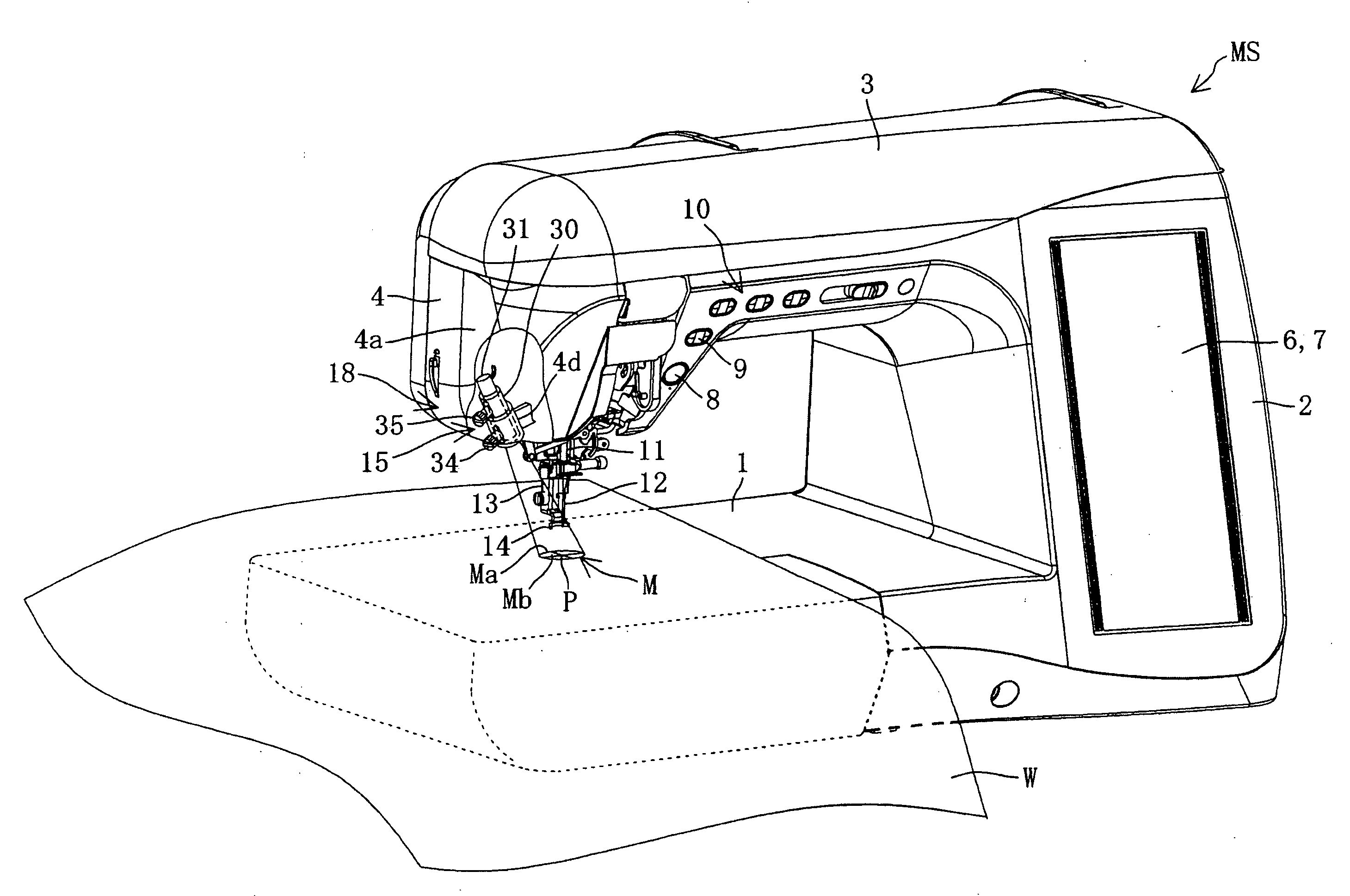

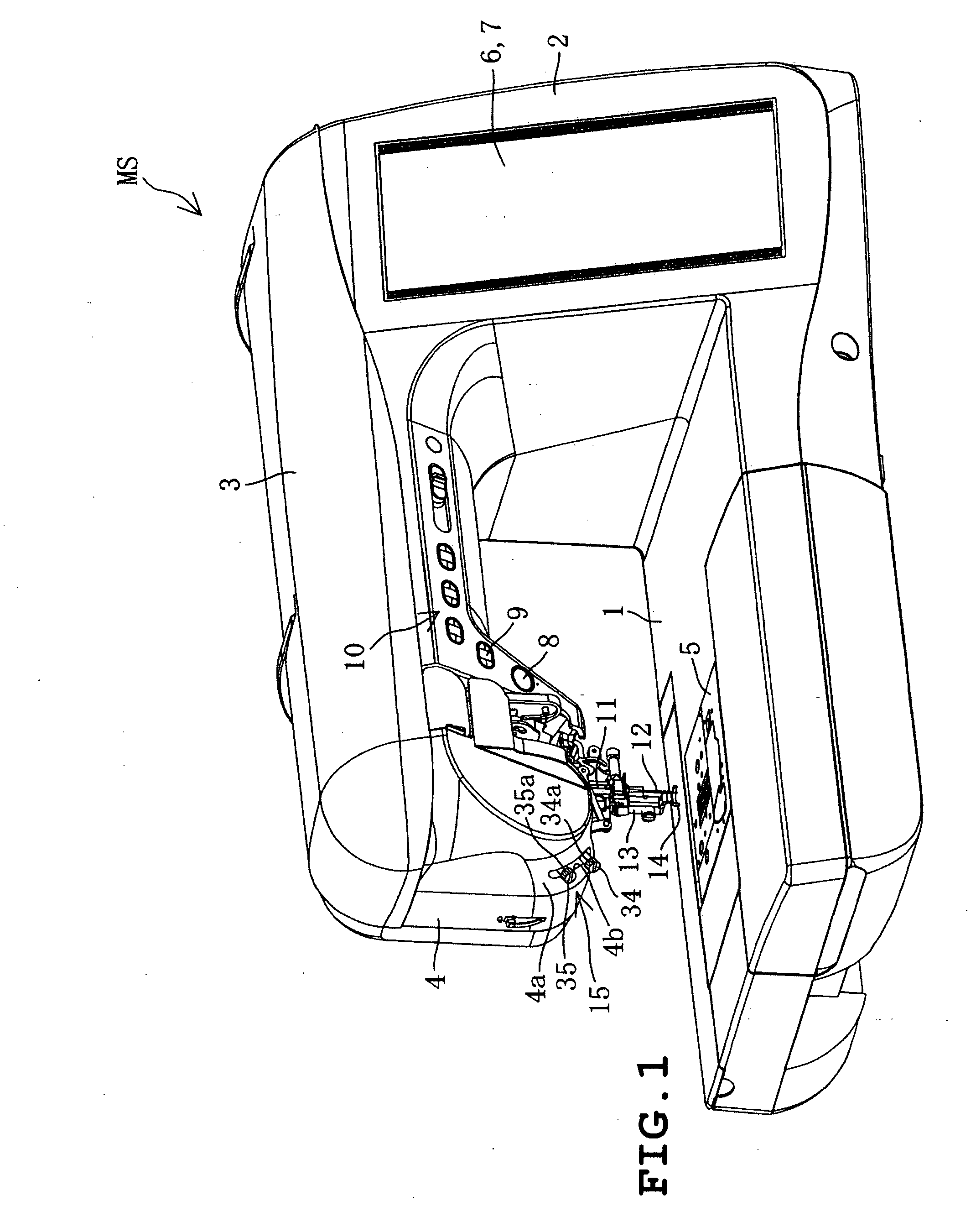

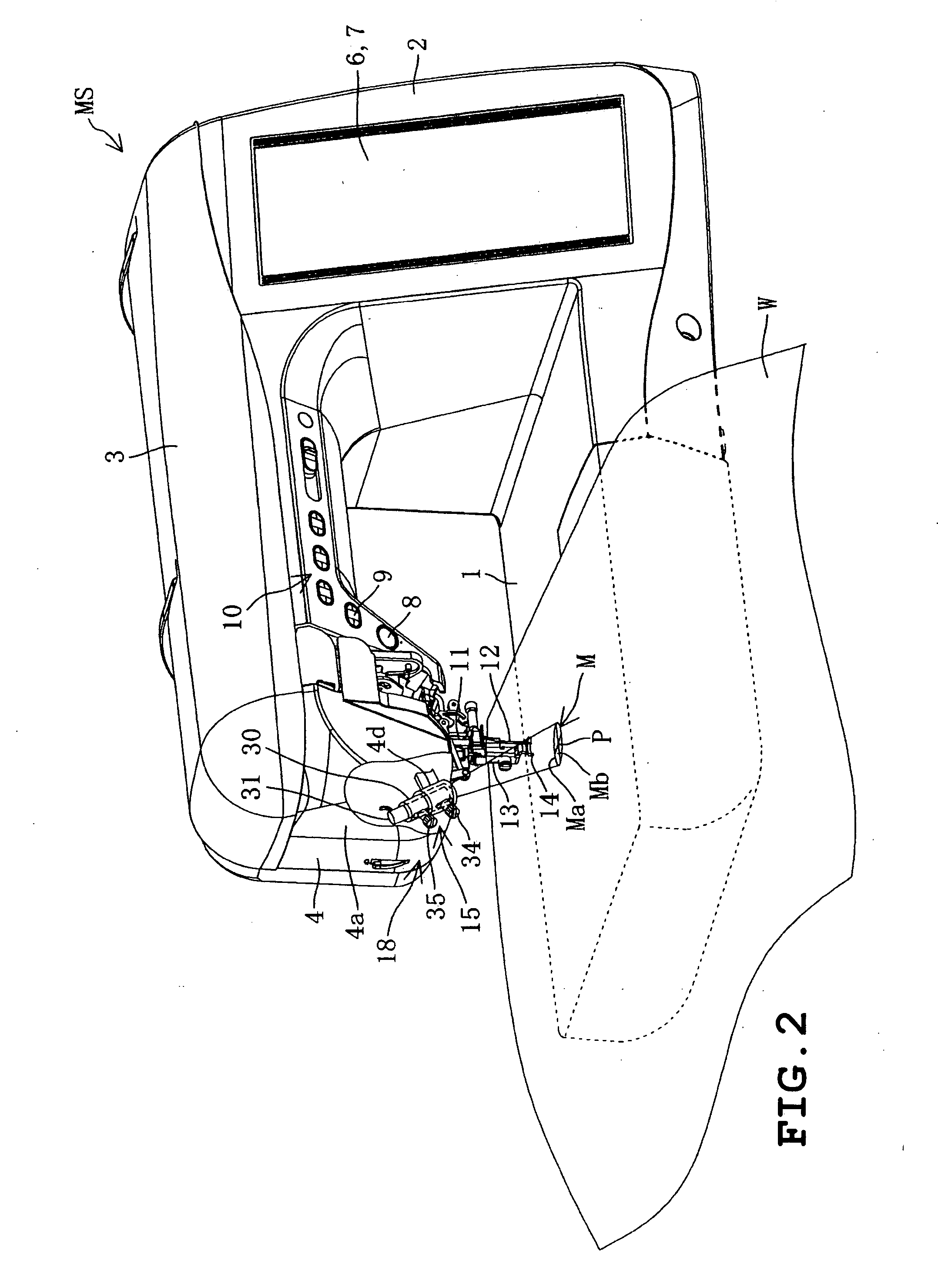

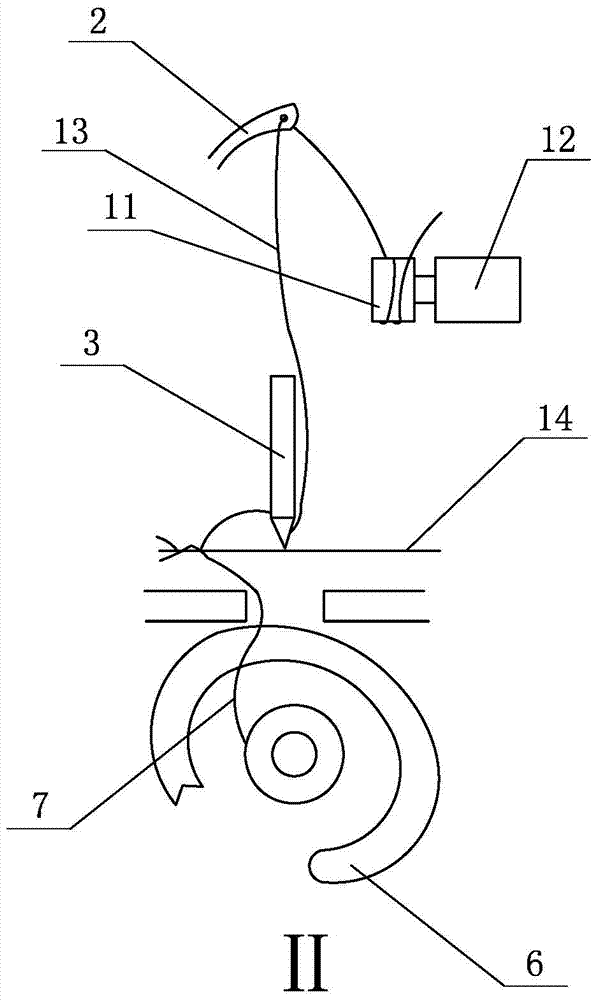

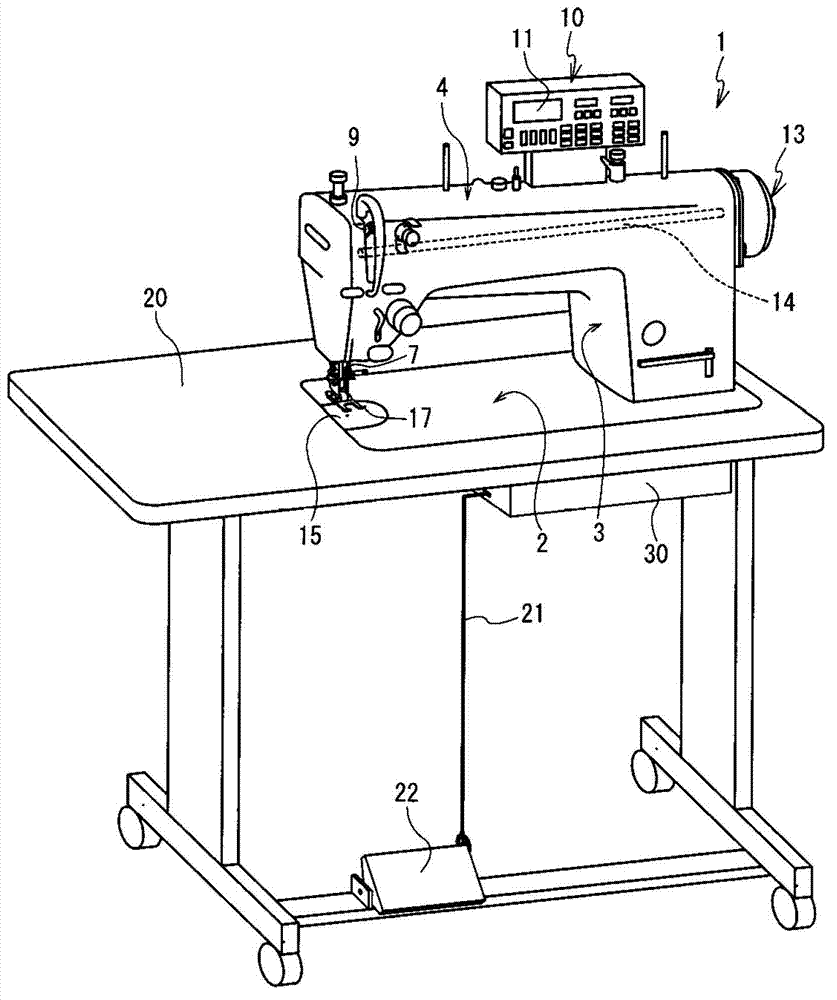

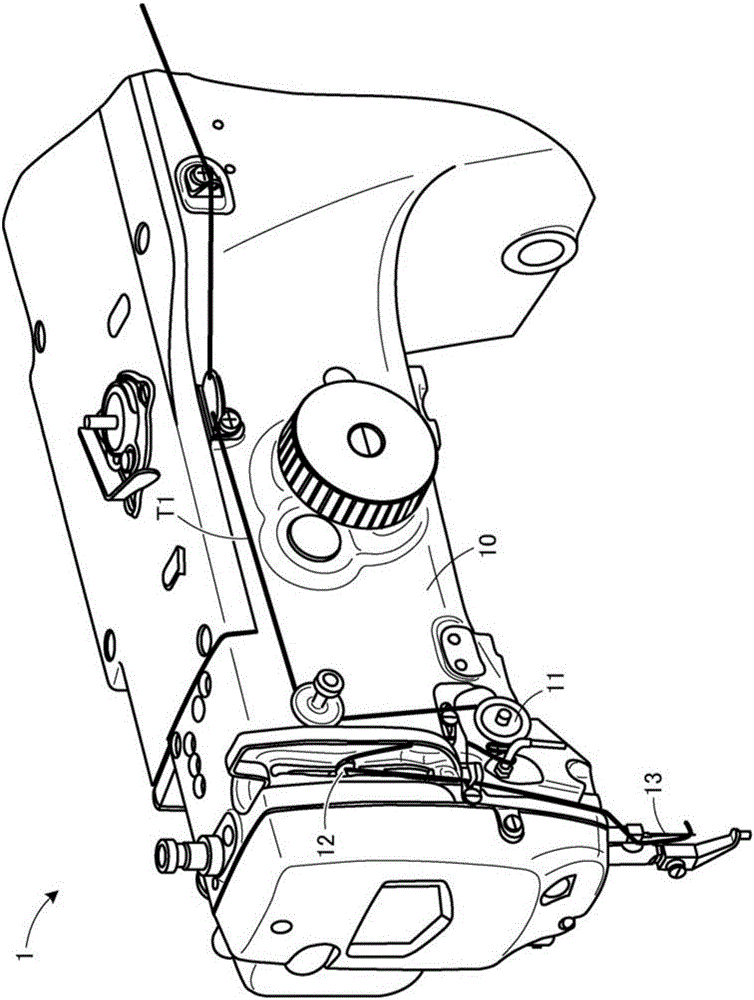

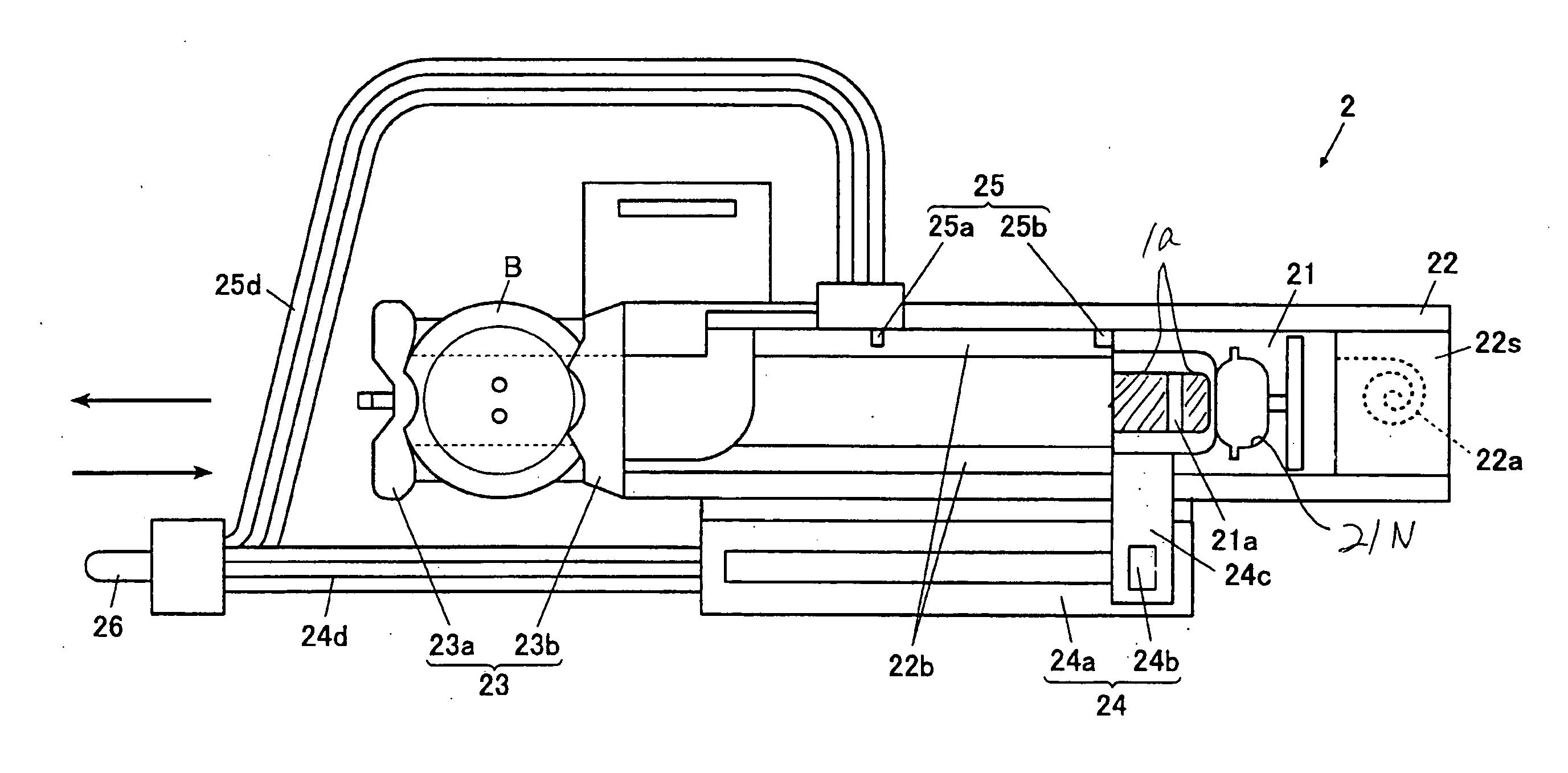

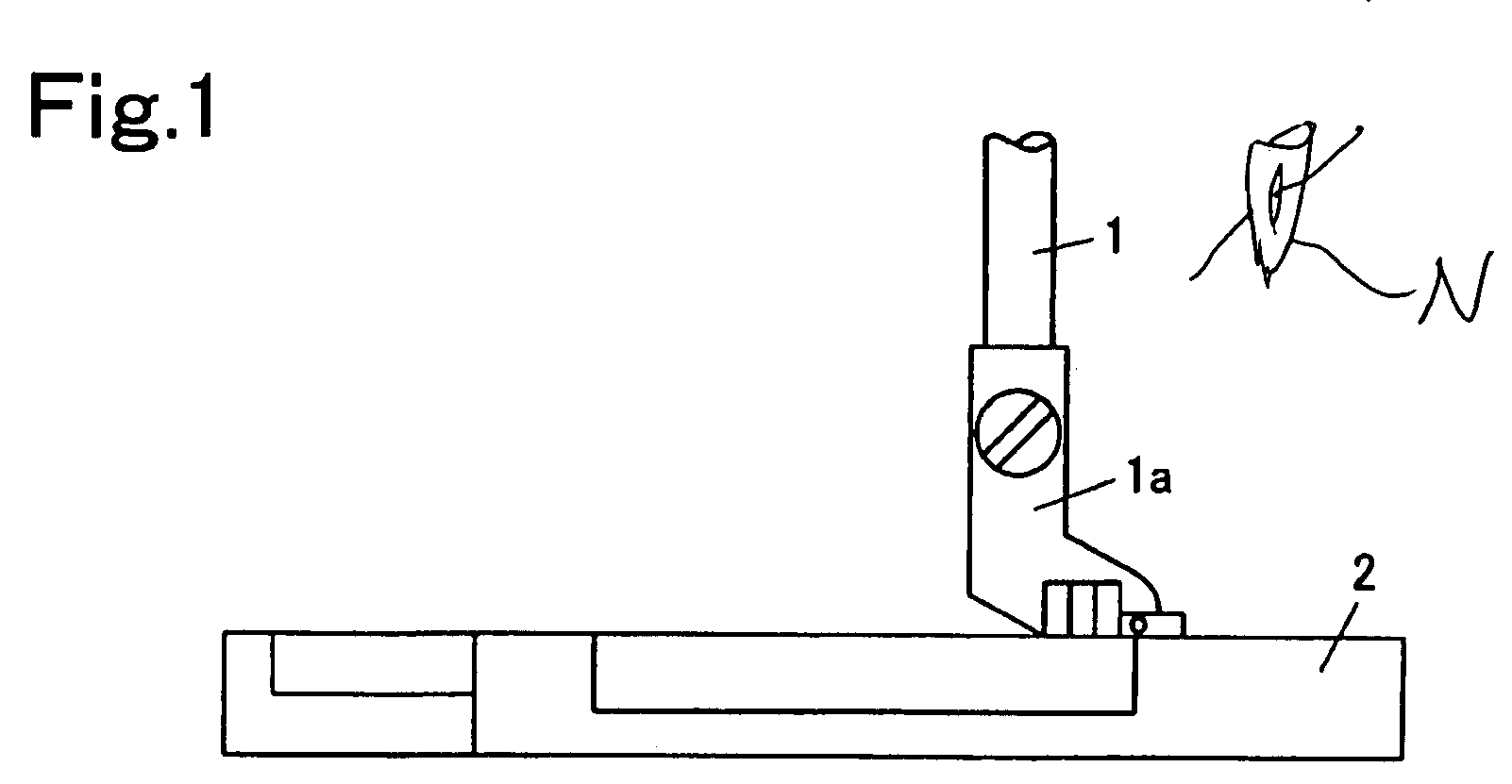

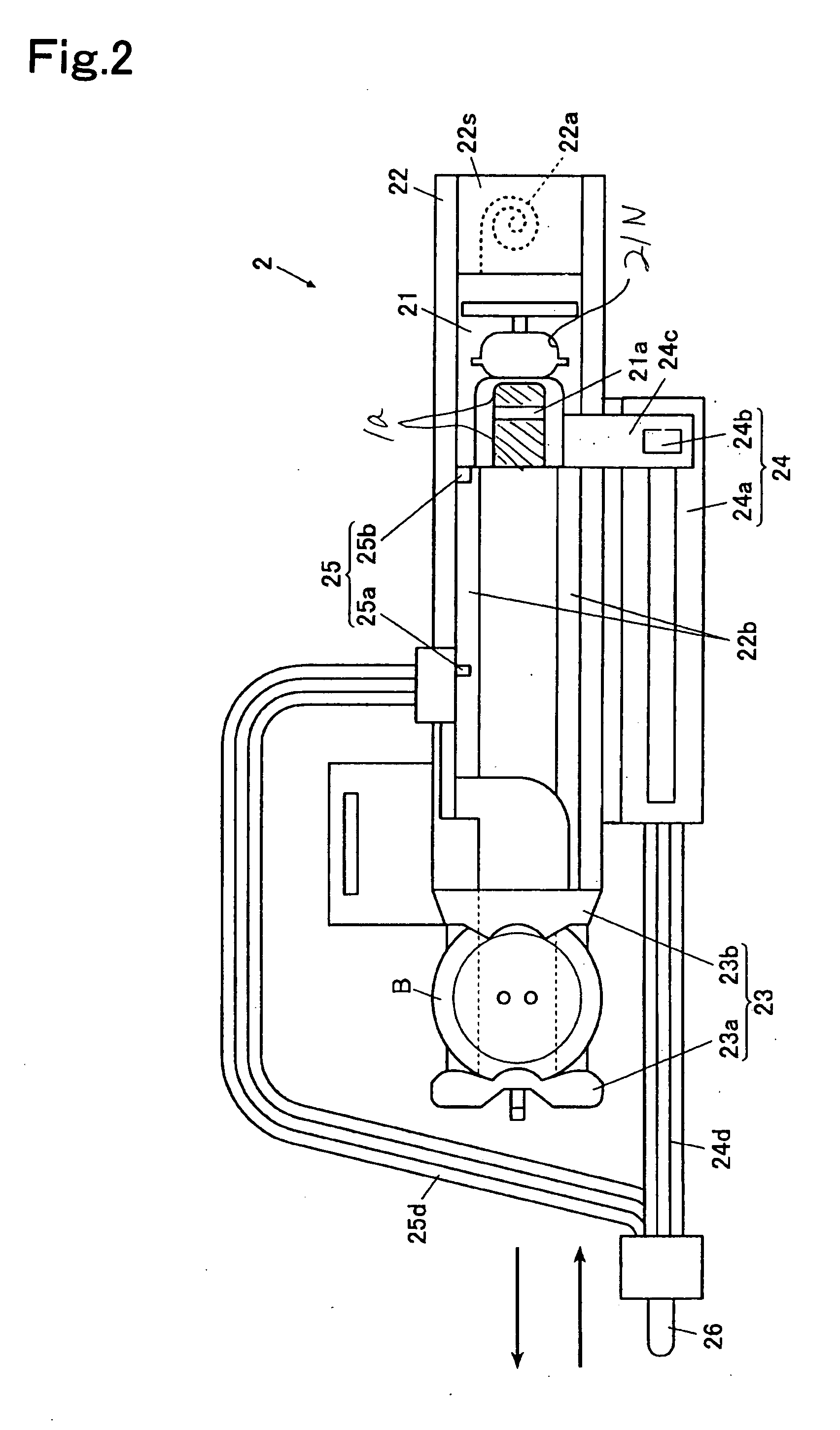

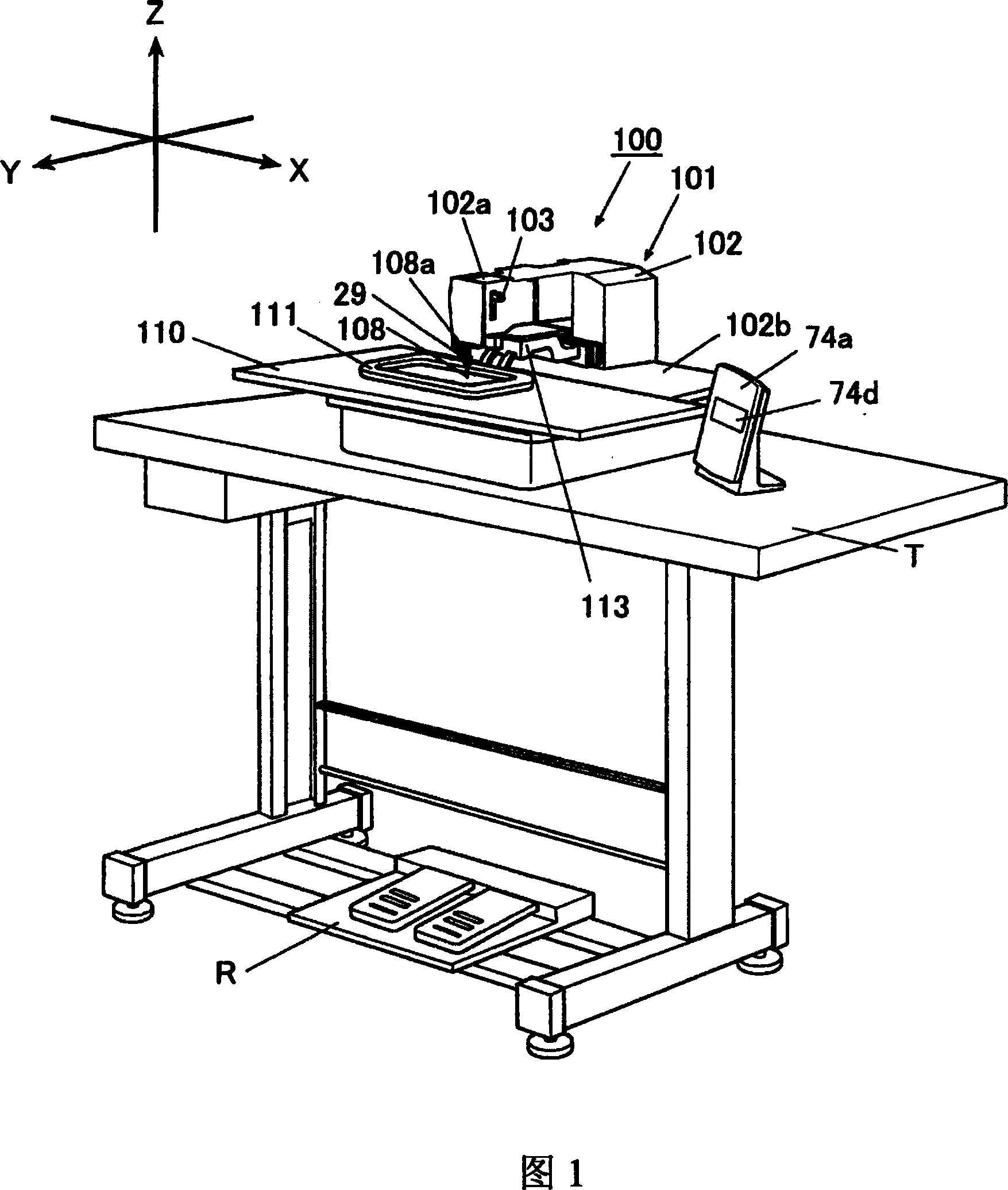

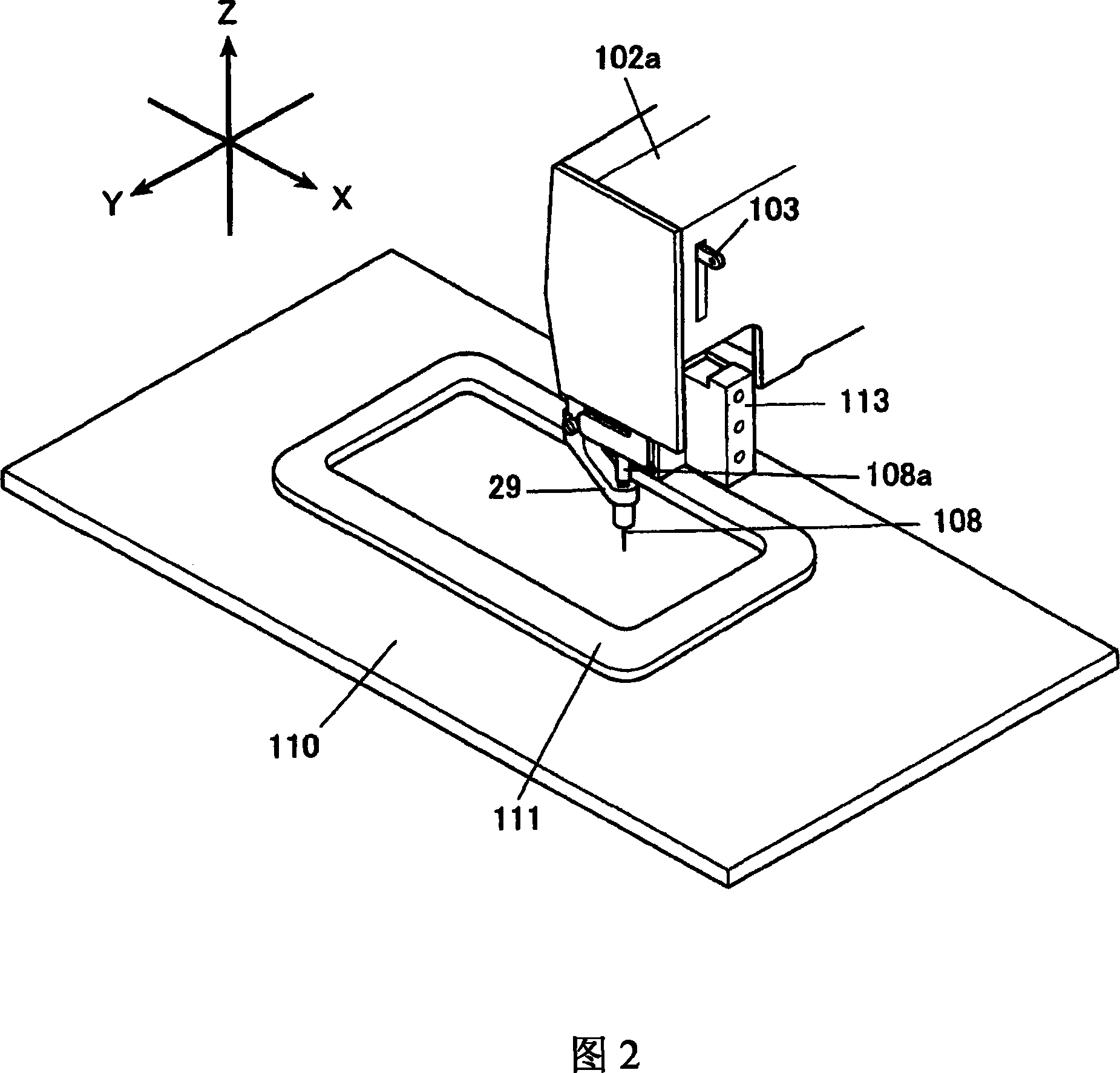

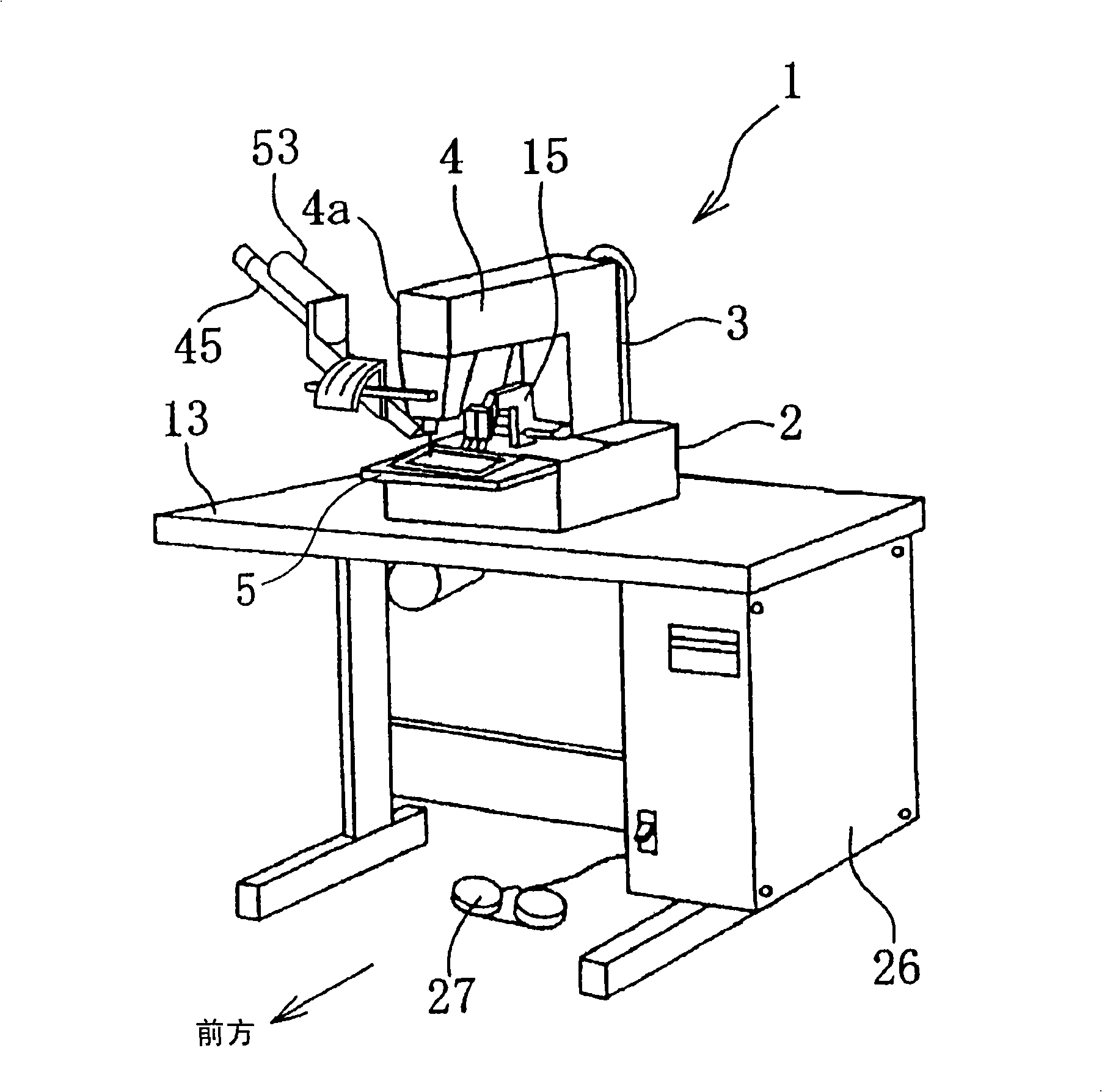

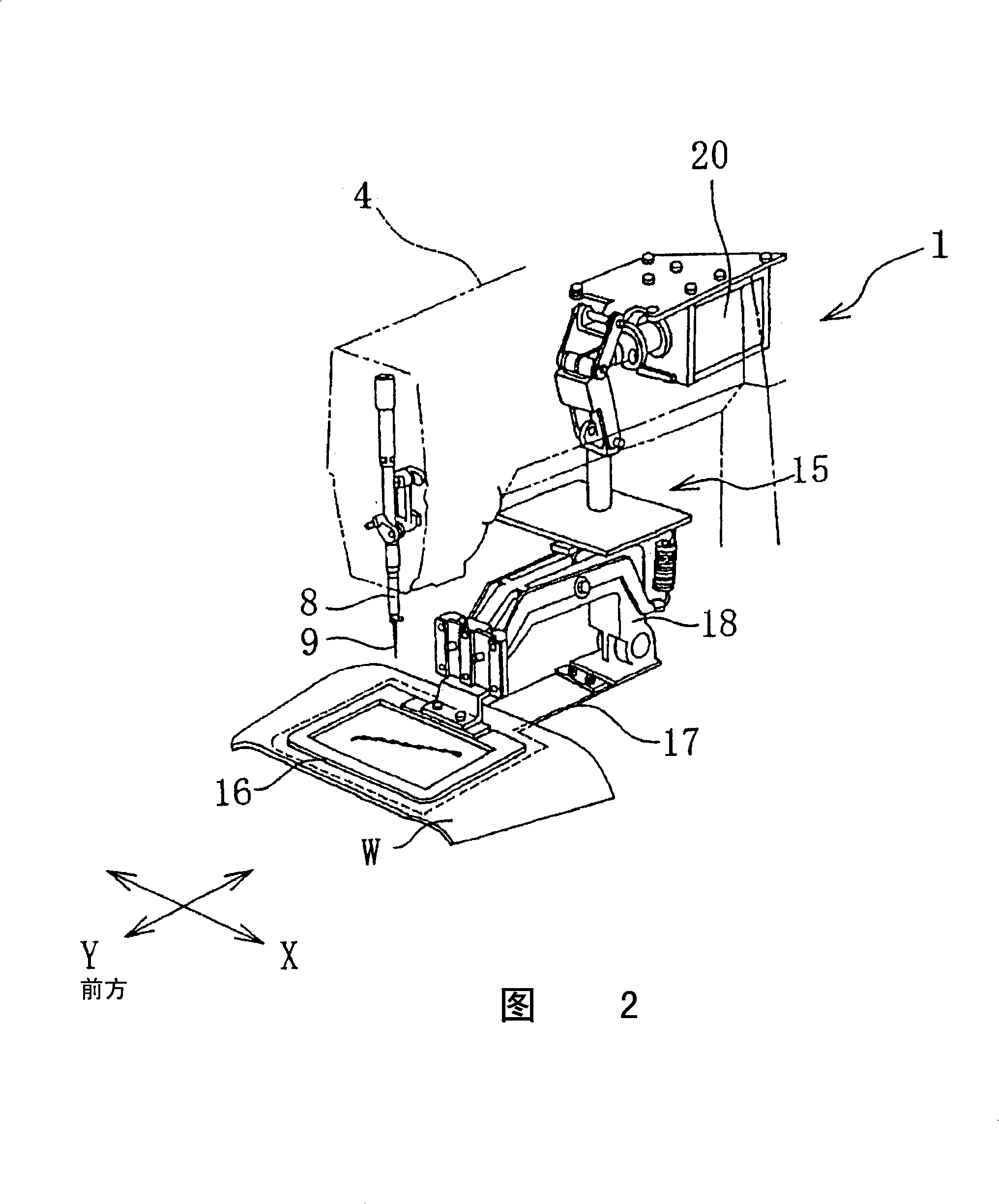

Sewing machine

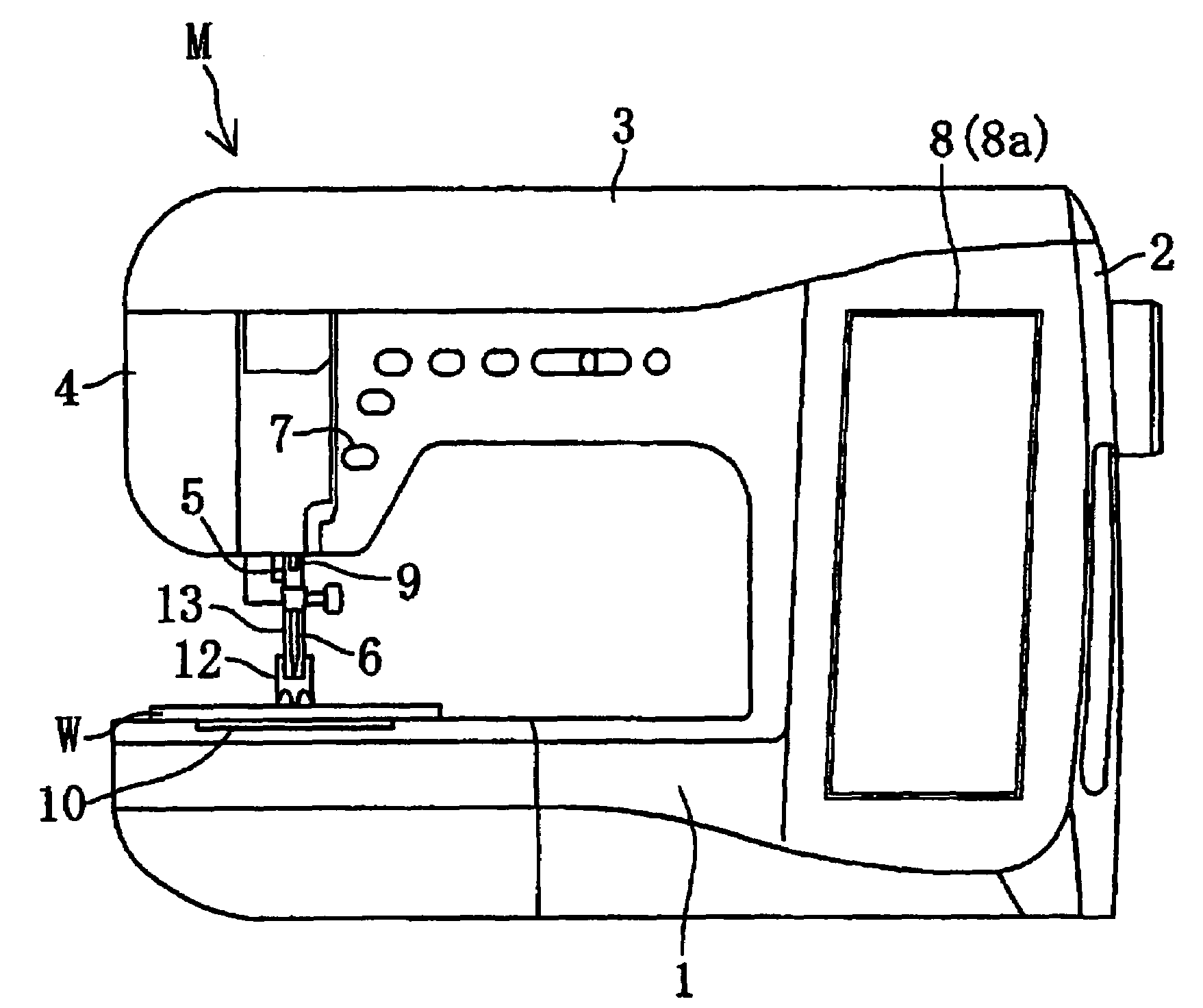

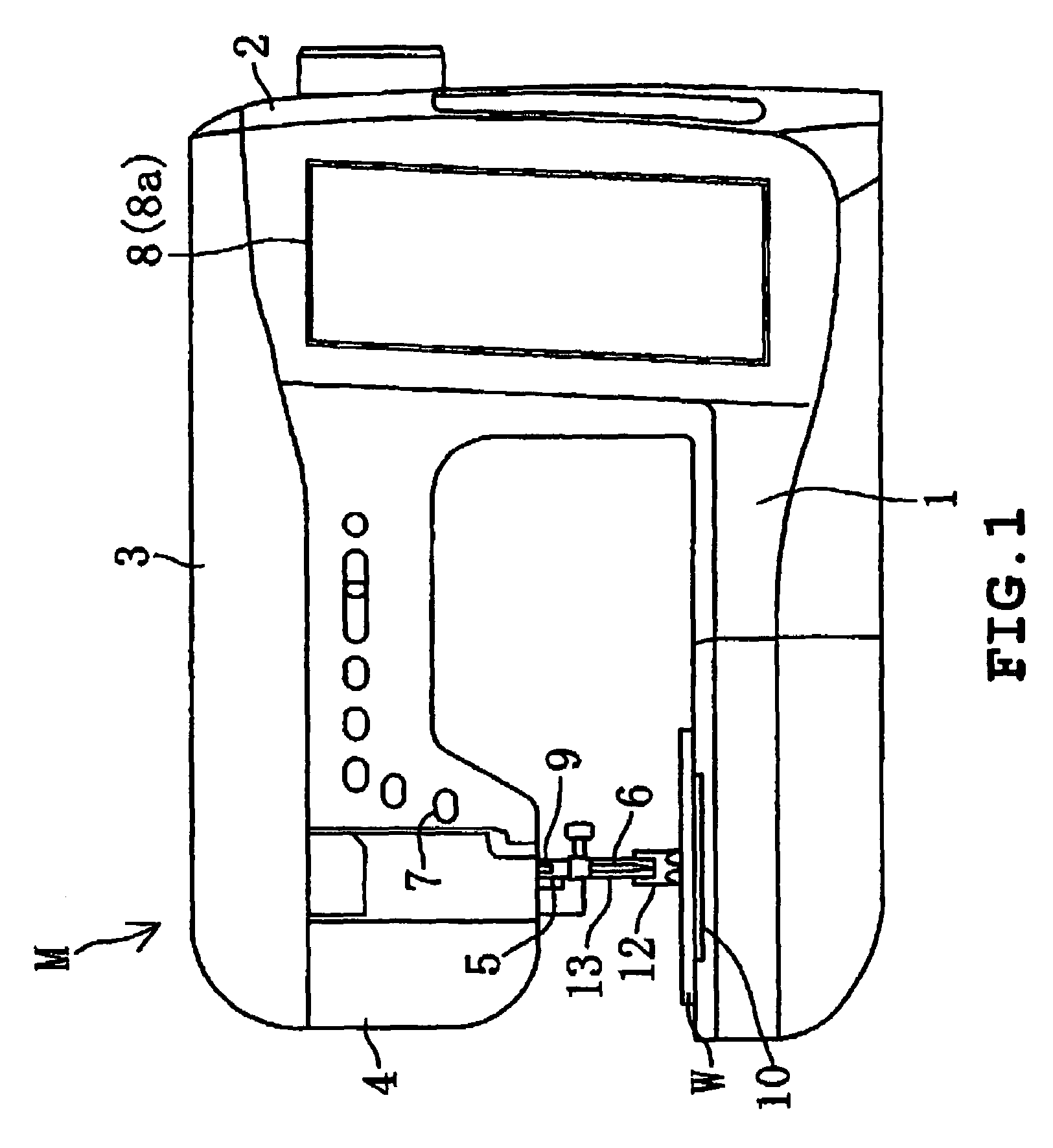

ActiveUS20080078313A1Amount of movement is limitedProgramme-controlled sewing machinesPressersEngineeringSewing needle

A sewing machine capable of sewing while a workpiece cloth is moved by a manual operation includes a needlebar having a lower end to which a sewing needle is attached, a needlebar driving mechanism vertically driving the needlebar via a main shaft, a presser foot pressing the workpiece cloth, an imaging device imaging at least an area of the workpiece cloth near to the sewing needle, a movement amount operating device obtaining by operation a movement amount of the workpiece cloth based on image data supplied from the imaging device, a setting device setting a stitch pitch on the workpiece cloth, a comparing device comparing the obtained movement amount of the workpiece cloth and the set stitch pitch, a cloth movement limiter limiting movement of the workpiece cloth by the manual operation, and a control device controlling the cloth movement limiter according to a result of comparison.

Owner:BROTHER KOGYO KK

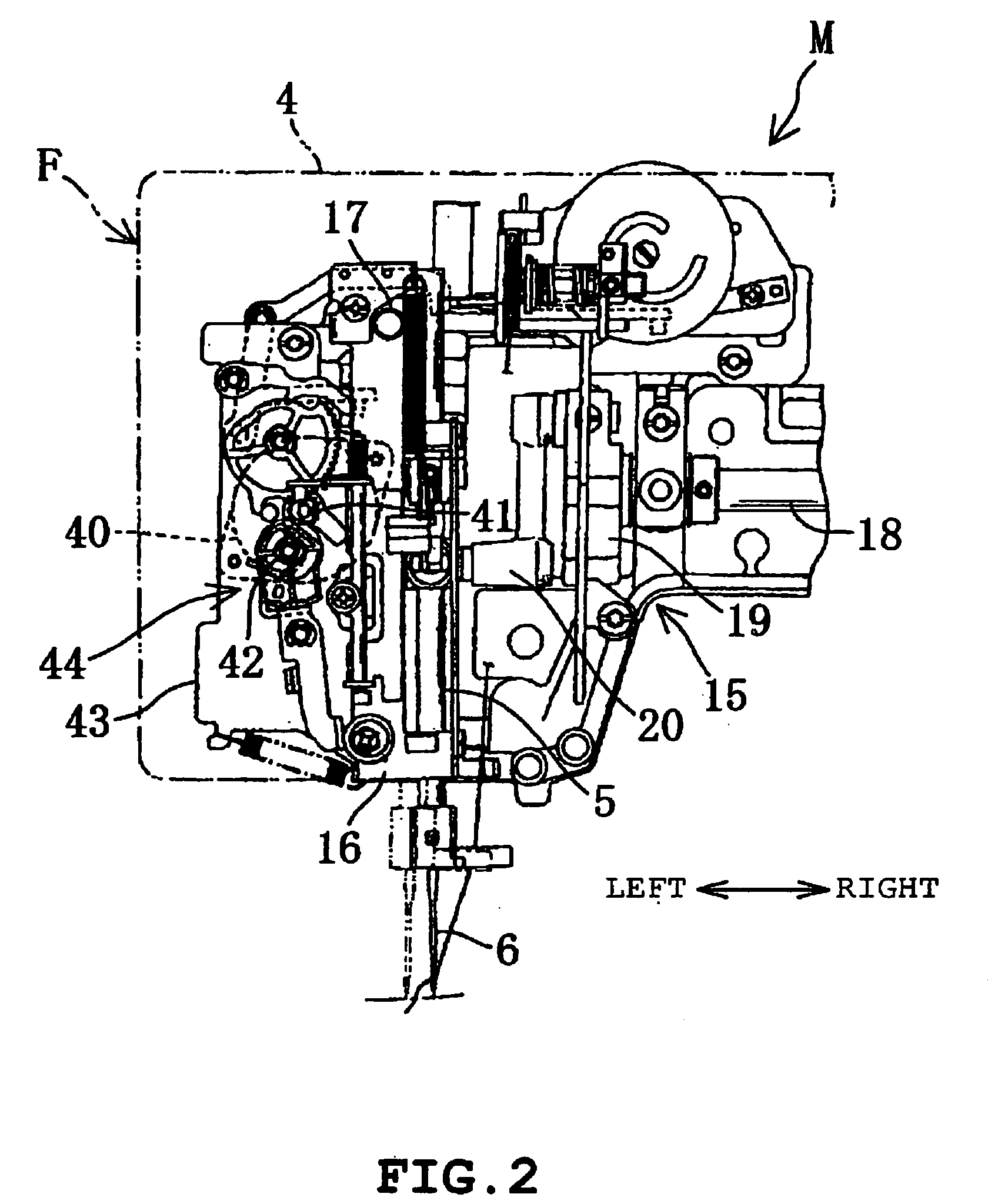

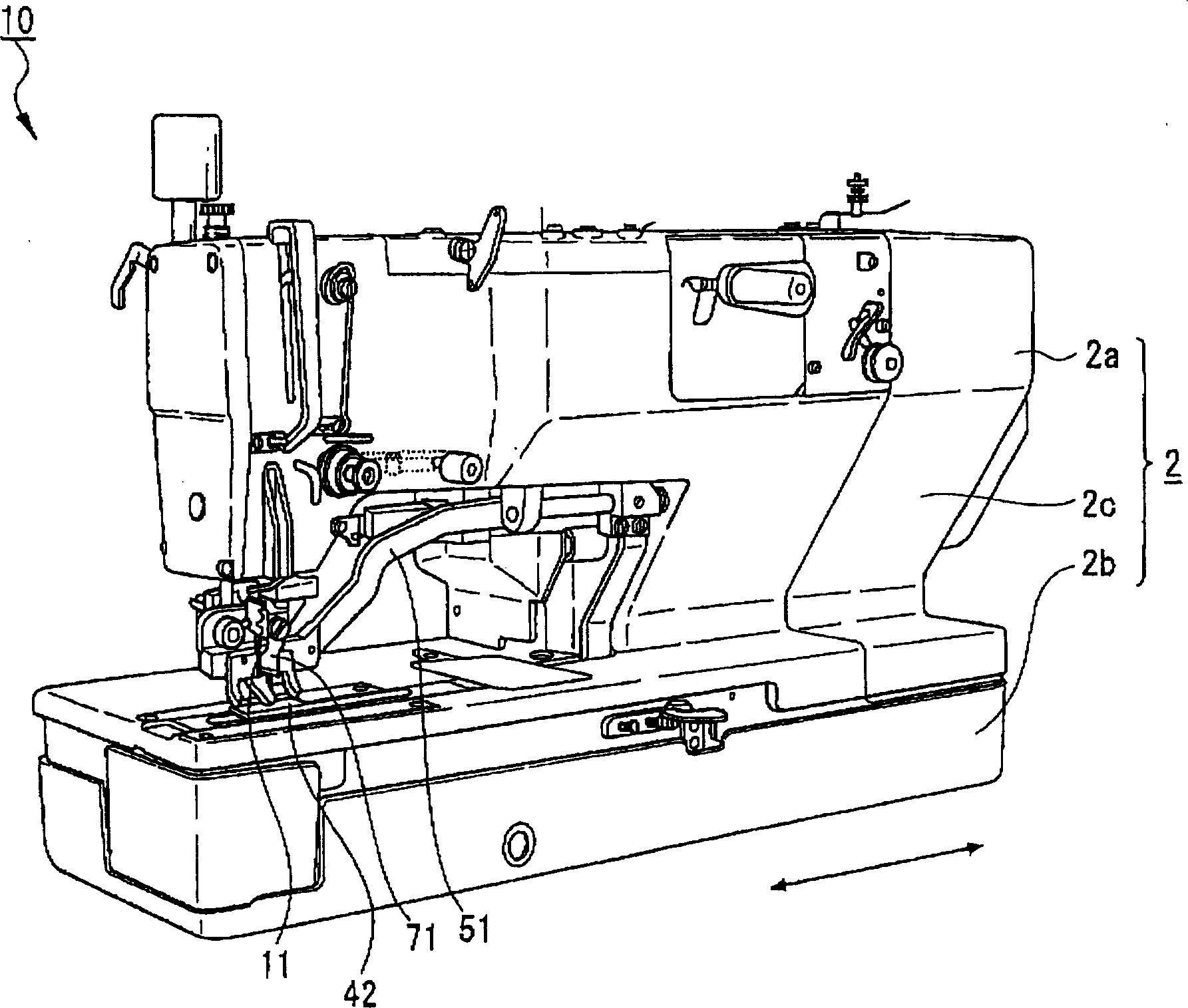

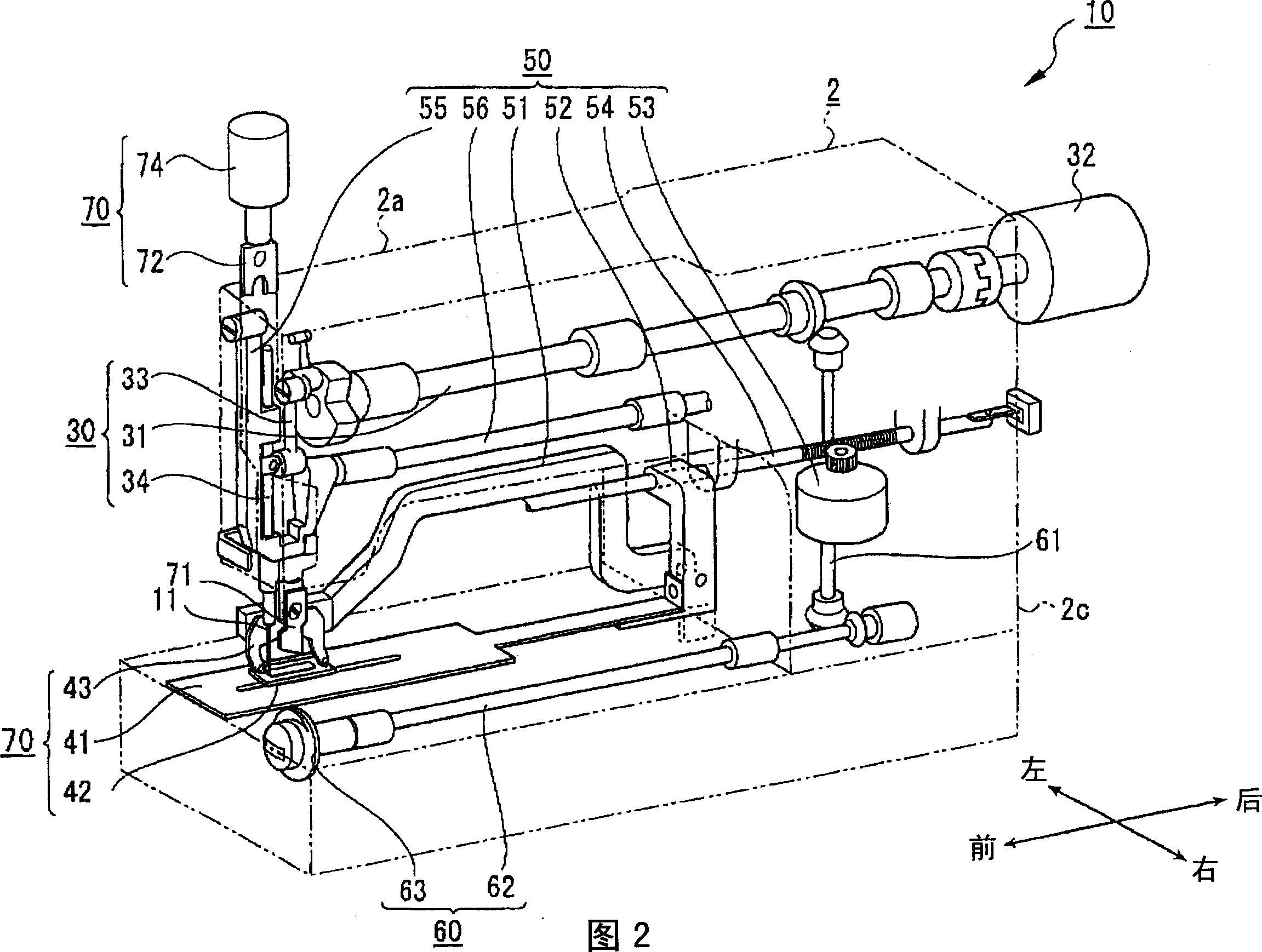

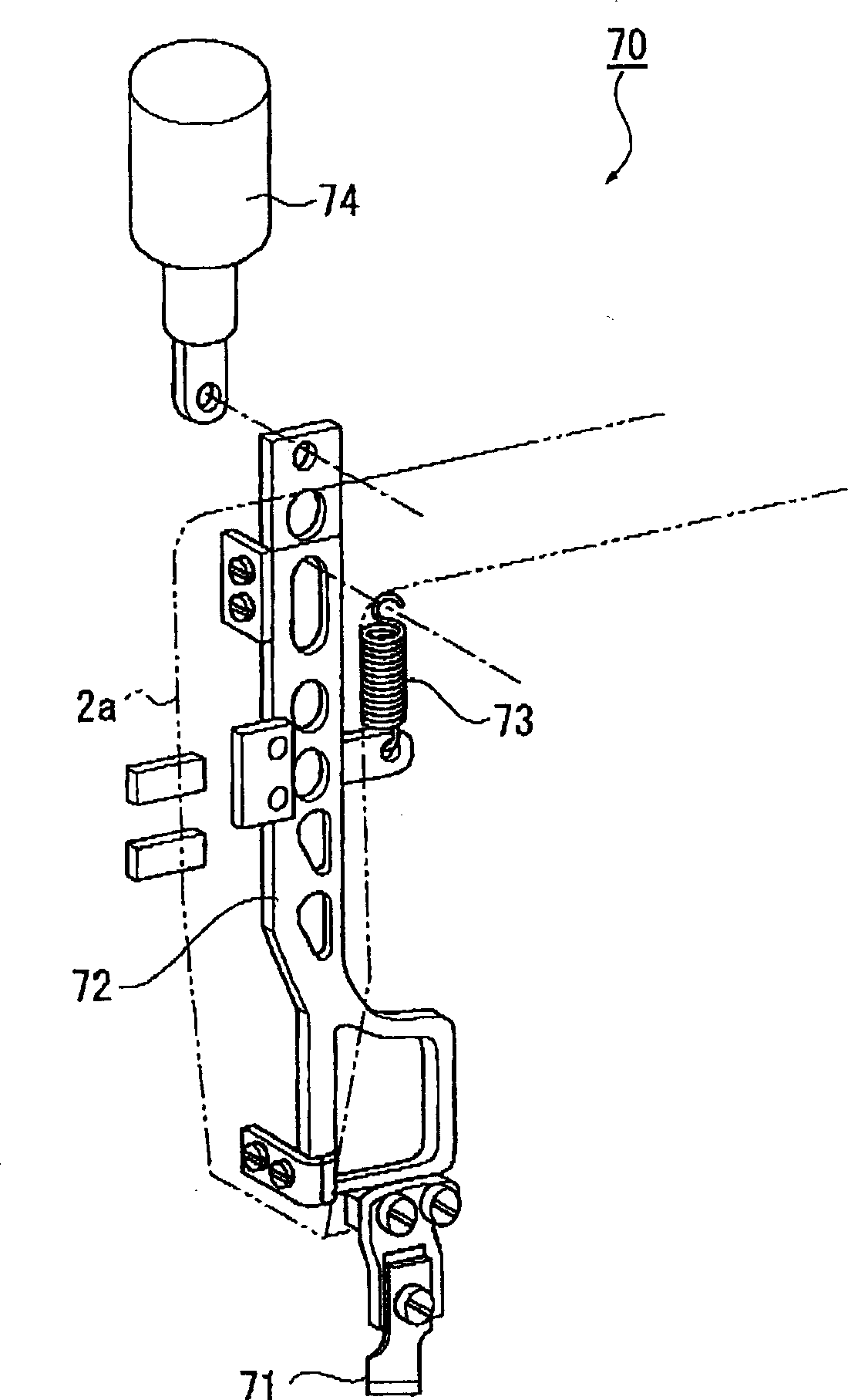

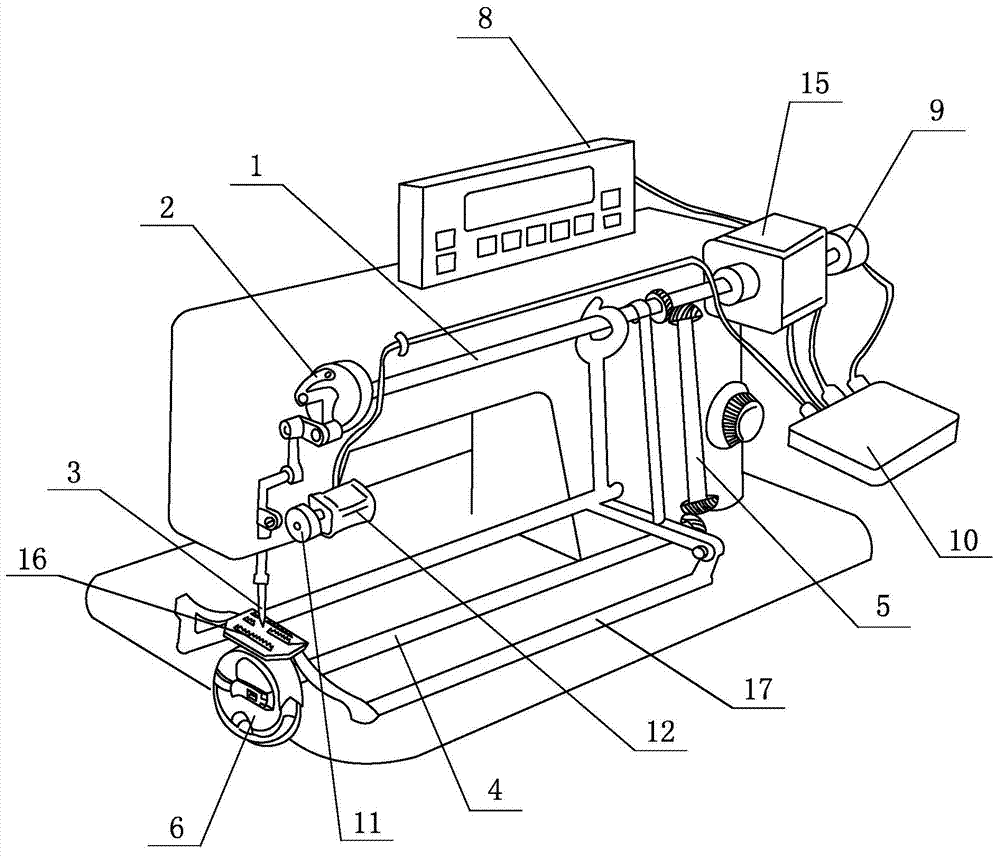

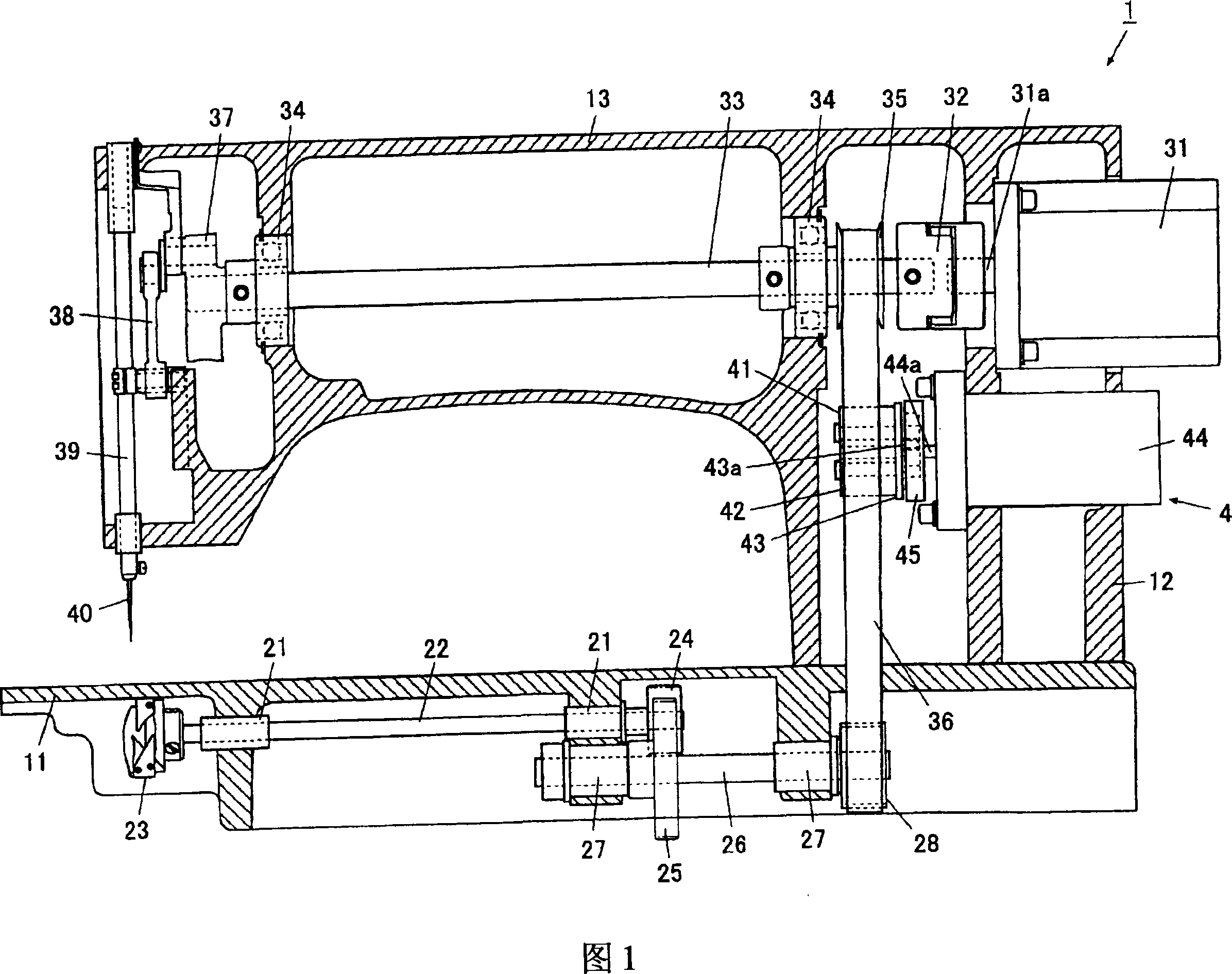

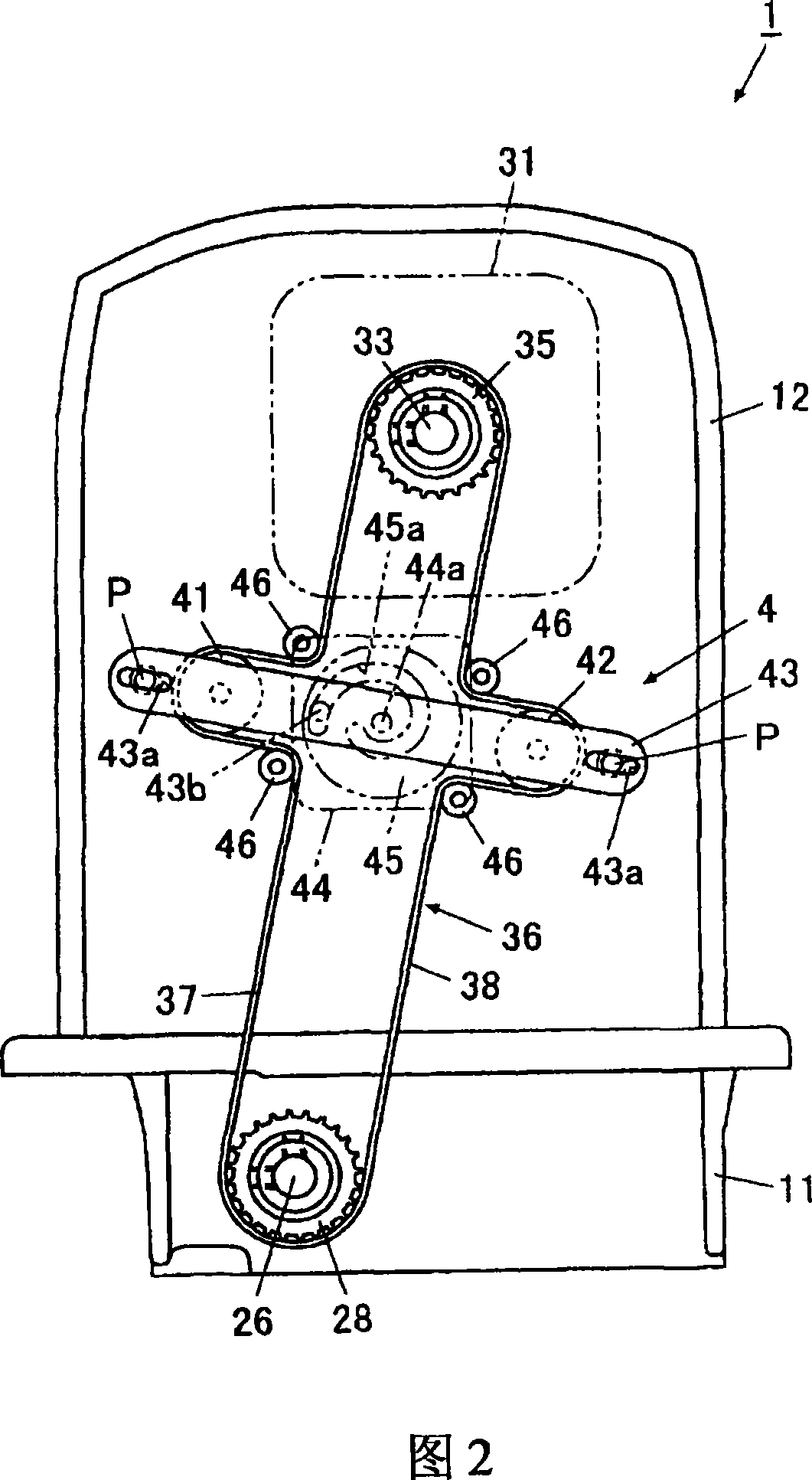

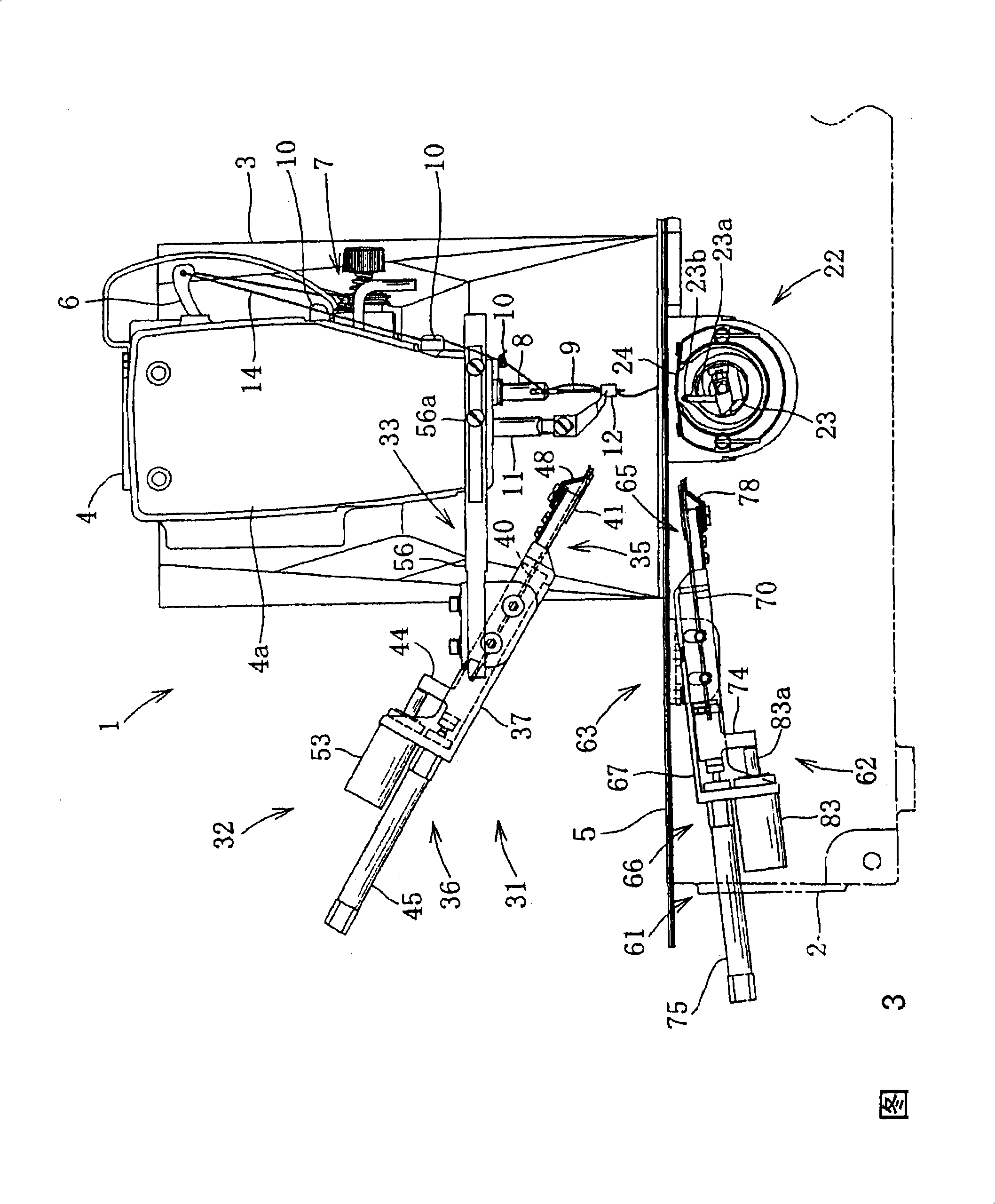

Sewing machine

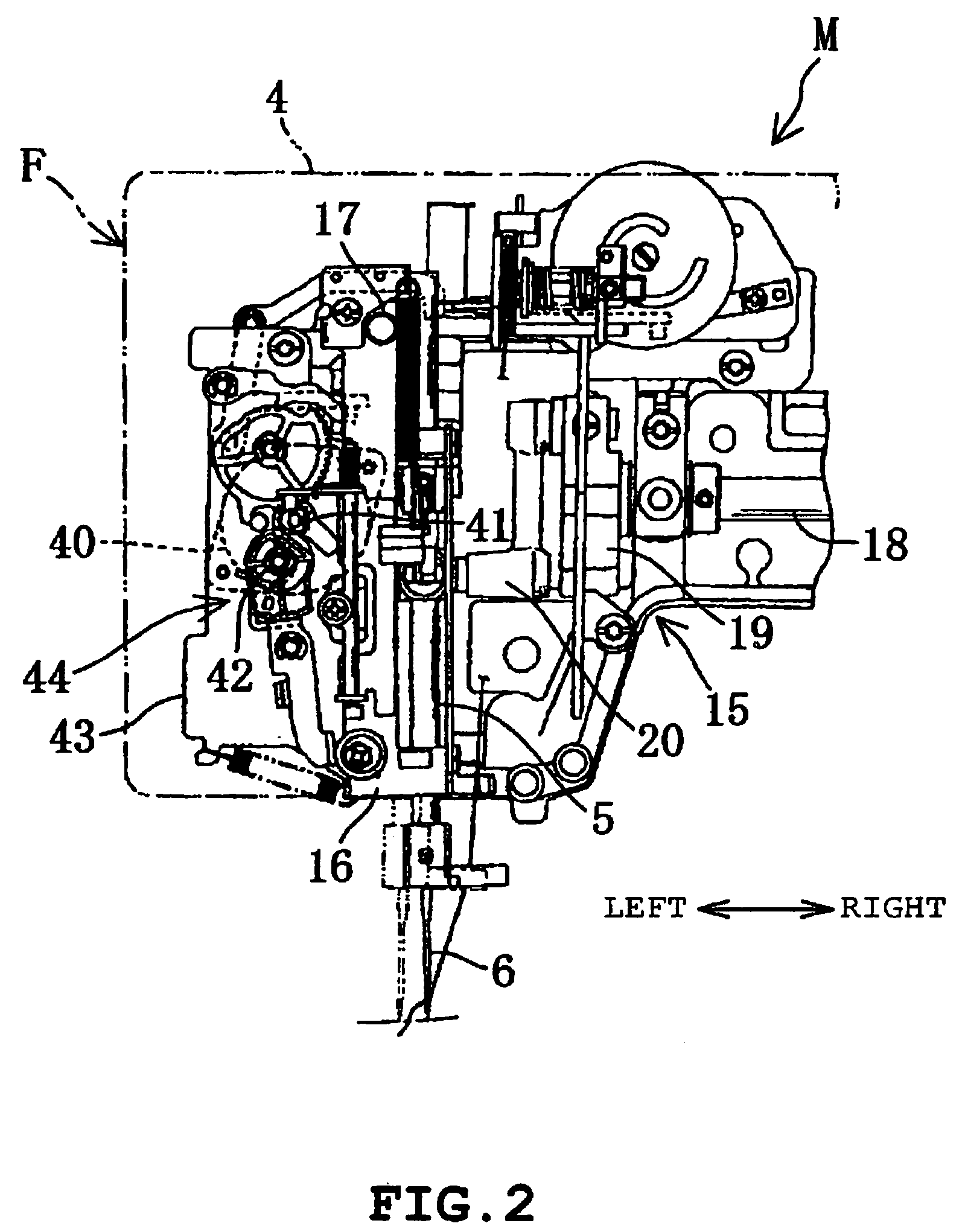

ActiveCN1611650AFast and efficient sewingImprove efficiencyProgramme-controlled sewing machinesNeedle severing devicesSewing needleIndustrial engineering

The invention provided a sewing machine for improving the efficiency of sewing work and quickening it. The sewing machine is provided with a needle driving means 30, a cloth pressing means 40, a moving means 50 for positioning a sewing needle 11 to cloth, an input means 20 for inputting the setting relating to sewing, a storage means 103 for respectively storing sewing data and successive sewing data composed of two or more pieces of the sewing data, and an operation control means 100 for controlling respective parts on the basis of the respective stored sewing data. The order of sewing is specified for two or more pieces of sewing data and is inputted by the input means 20 and the storage means 103 stores it. The operation control means 100 makes the sewing of the sewing data or the successive sewing data be successively performed according to the stored order and waits for the detection of re-pressing by the cloth pressing means every time sewing is performed for the respective successive sewing data or sewing data for which the order is specified.

Owner:JUKI CORP

Workpiece cloth positioning guide device for sewing machine

A workpiece cloth positioning guide device for a sewing machine includes a projector which projects a sewing reference mark onto an upper side of workpiece cloth placed on a sewing bed of the sewing machine. The projector projects light emitted from the light source onto a needle drop reference point of the sewing needle of the sewing machine from obliquely above so that a sewing reference mark including a circle having a center at the needle drop reference point on the upper side of the workpiece cloth and the sewing reference mark guides the workpiece cloth when the workpiece cloth is positioned in sewing.

Owner:BROTHER KOGYO KK

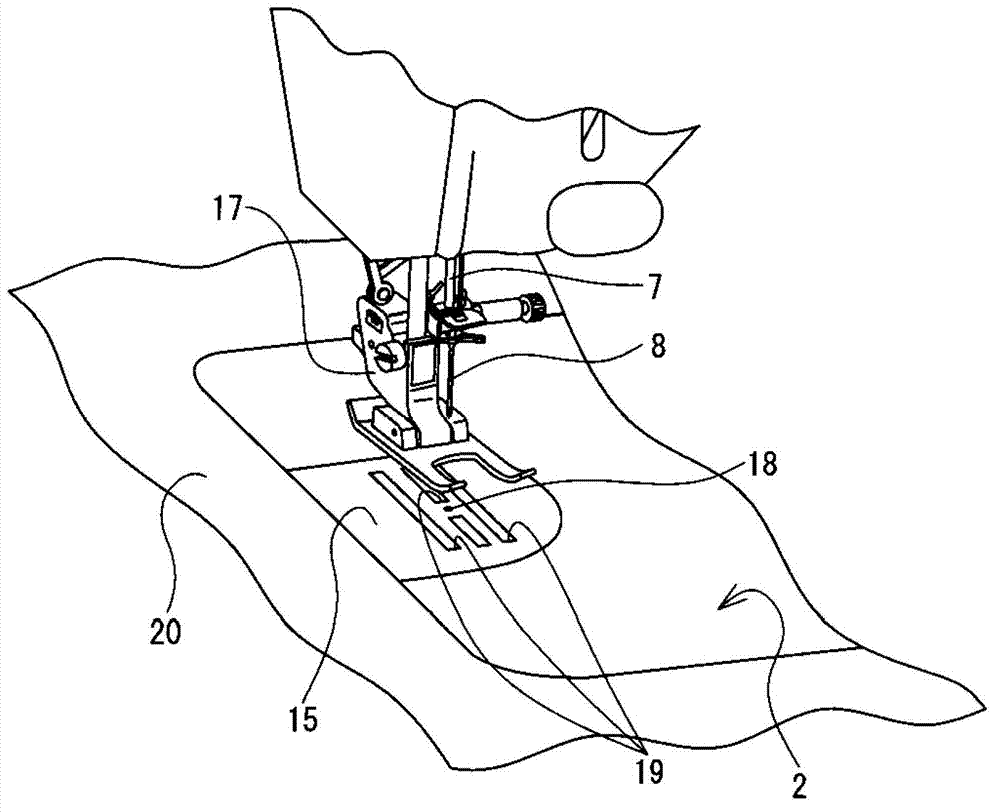

Automatic thread feeding system of sewing machine and control method thereof

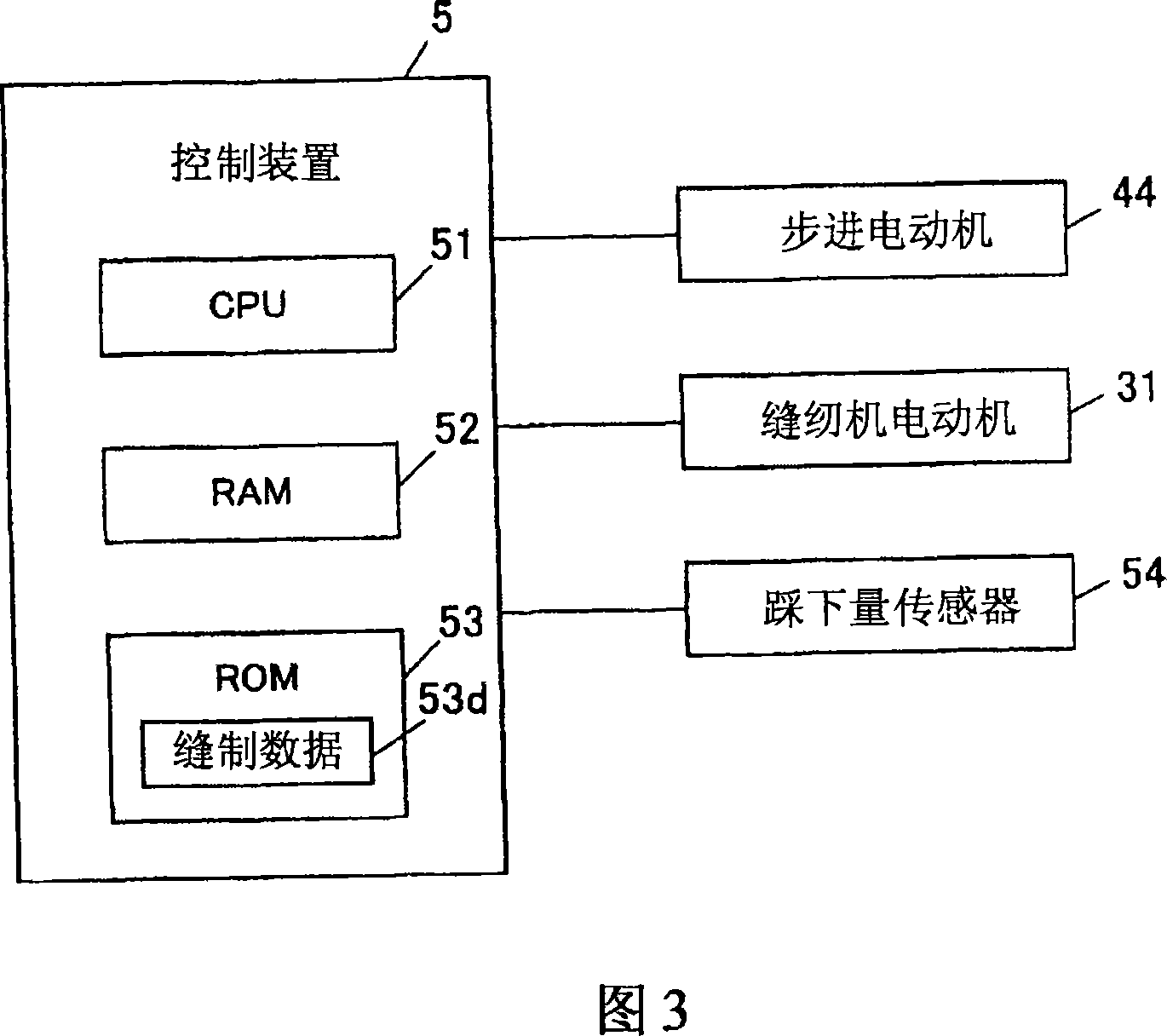

InactiveCN104120547AConsistent outputConsistent pitchProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftElectric machinery

The invention discloses an automatic thread feeding system of a sewing machine. The automatic thread feeding system comprises an upper shaft, a lower shaft, a control device, a cloth feeding system and a sewing thread tension adjusting device. One end of the upper shaft is connected with a sewing machine driving mechanism, and the other end of the upper shaft is connected with a thread take-up lever and a sewing needle; one end of the lower shaft is connected with the upper shaft through a transmission shaft, and a rotating shuttle is arranged at the other end of the lower shaft and wound with a sewing bottom thread. The automatic thread feeding system is characterized in that the sewing thread tension adjusting device comprises a rotating body and a stepping motor, the rotating body is connected with an output end of the stepping motor, the sewing machine driving mechanism and a control end of the stepping motor are connected with the control device, the rotating body is wound with a sewing upper thread, and the sewing upper thread penetrates through the thread take-up lever and is connected with the sewing needle. The control method includes the steps of parameter setting, sewing needle sewing, rotating body taking up, cloth moving and rotating body paying off. The sewn stitches are in order, and sewing quality is high.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

Sewing machine and control method of sewing machine

ActiveCN102899813ASimple compositionReduce switching frequencyProgramme-controlled sewing machinesWork-feeding meansControl engineeringSewing needle

The invention relates to a sewing machine utilizes individual electric motors to drive a main shaft and a cloth delivery mechanism, and a control method of the sewing machine. The sewing machine has a main electric motor and a cloth delivery electric motor. The sewing machine drives the main shaft. The main shaft enables a sewing needle to move up and down. The cloth delivery electric motor drives the cloth delivery mechanism. A power transmission mechanism of the sewing machine converts each rotation movement toward a direct or opposite directions of an output shaft of the cloth delivery electric motor into swinging motion in which the cloth delivery mechanism goes back and forth horizontally and swing once, so that the power of the cloth delivery electric motor is transmitted to the cloth delivery mechanism. A CPU of the sewing machine detects a main rotation angle (S11). The main rotation angle is the rotation angle of the output shaft of the main electric motor. The CPU detects cloth delivery rotation angles (S13, S19). Each cloth delivery rotation angle is the rotation angle of the output shaft of the cloth delivery electric motor. The CPU calculates rotation speeds (S16, S22) indicated to the cloth delivery electric motor through the main rotation angle and the cloth delivery rotation angles.

Owner:BROTHER KOGYO KK

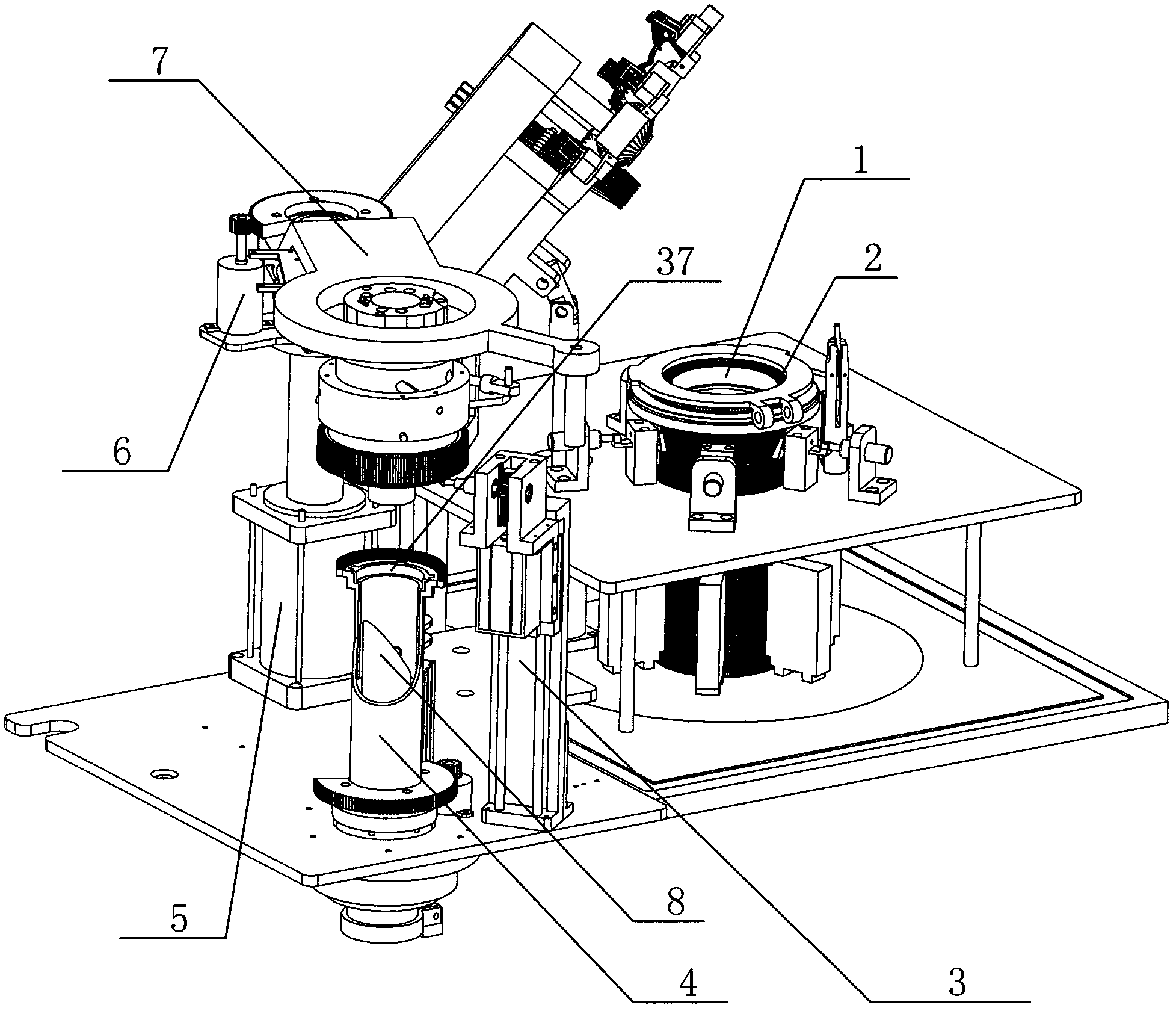

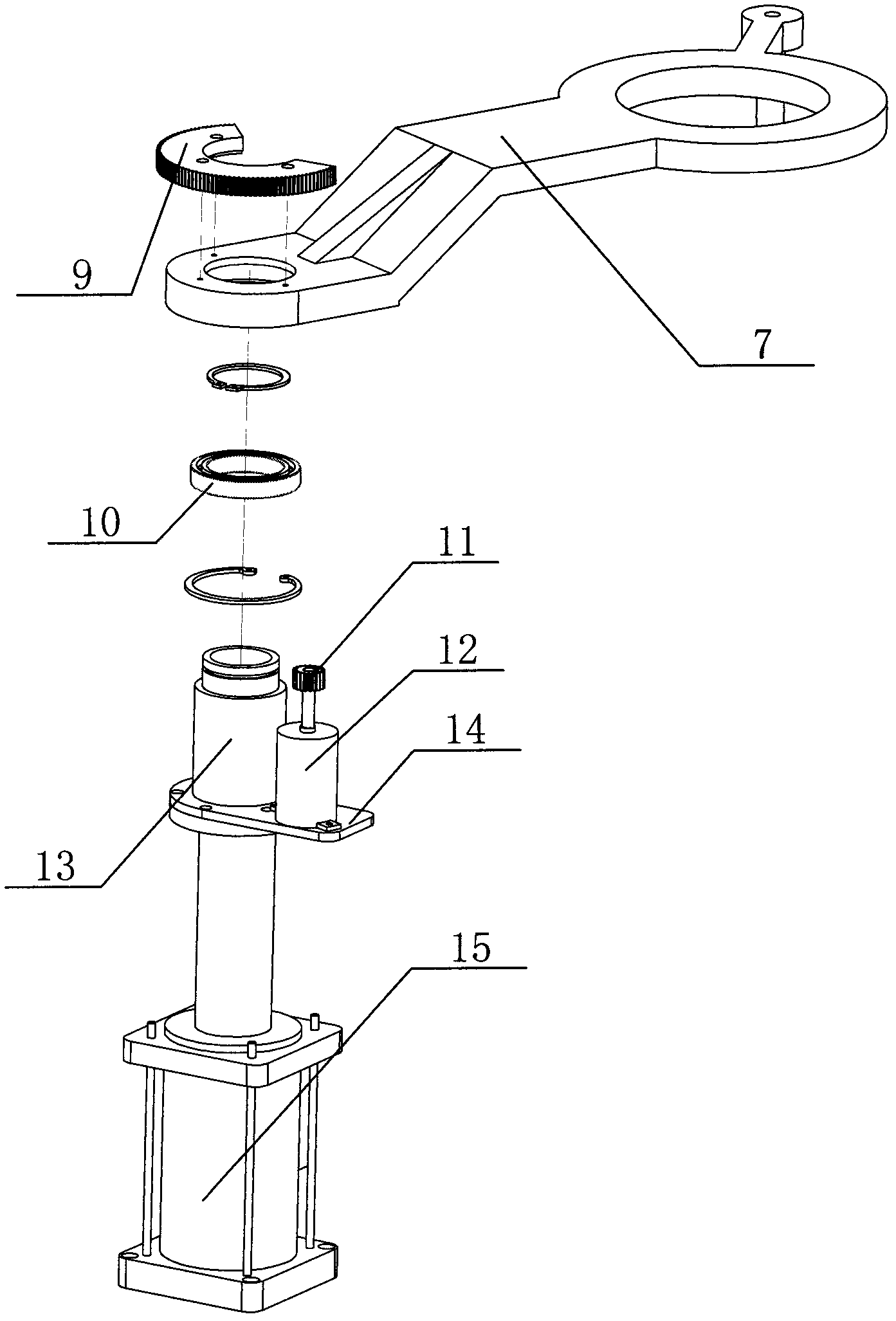

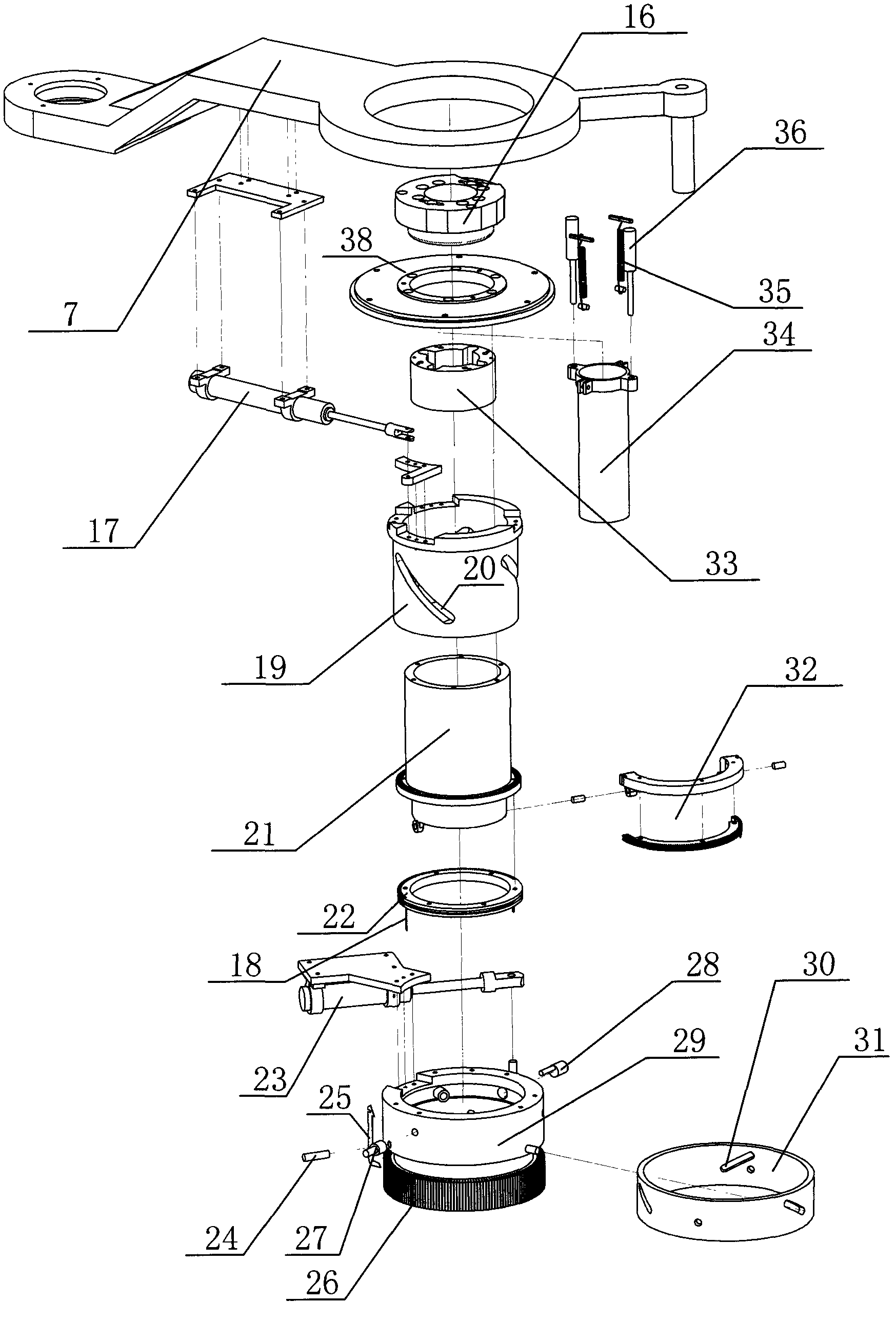

Sock knitting method and device for changing sock head from open state into closed state during knitting

ActiveCN103015028ARealize the process of automatic sewing endMechanical cleaningPressure cleaningSewing needleBiomedical engineering

The invention discloses a sock knitting method and device for changing a sock head from an open state into a closed state during knitting. The sock knitting method comprises a sock knitting process, a sock head picking process, a process of changing the sock head from the open state to the closed state and a process of enabling the sock head to enter a sewing needle frame, which are carried out in sequence. The sock knitting device comprises a sock picking device, a sock turnover device and the sewing needle frame, which are respectively arranged on the side edge of a needle drum. According to the invention, through the picking device, the sock turnover device and the sewing needle frame which are automatically combined during knitting, the sock head is changed from the open state to the closed state, so that a technical purpose of automatically sewing the sock heads on a sock knitting machine is achieved.

Owner:ZHEJIANG ROSSO EQUIP MFG

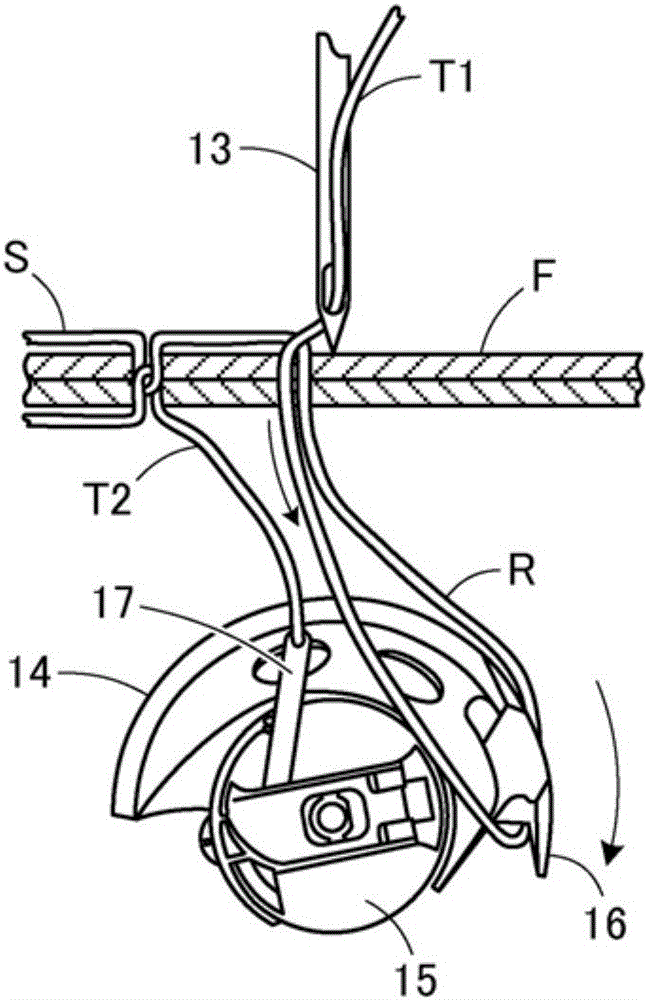

Stitch Outlet Detection Device, Sewing Machine And Stitch Outlet Detection Method

The invention provides a stitch outlet detecting device of a sewing machine which can detect a stitching with high accuracy and is unaffected by elongation of a thread or sewing unevenness. The stitch outlet detecting device (21) of a sewing machine forms a stitch by detecting a top thread loop formed by a sewing needle by using a rotary kettle and by causing a top thread and a bottom thread to cross each other. The device comprises: a rotary member (33), which rolls the top thread to the center of a thread path extending from a thread reel of the top thread; a motor (29) which causes the rotary member to rotate so as to apply a tension to the top thread upon feeding the top thread from the thread reel; and a detection unit (22) which monitors a predetermined portion immediately before the upper top loop is released from the rotary kettle, and detects the stitch outlet of the behavior of the motor in the predetermined portion.

Owner:JUKI CORP

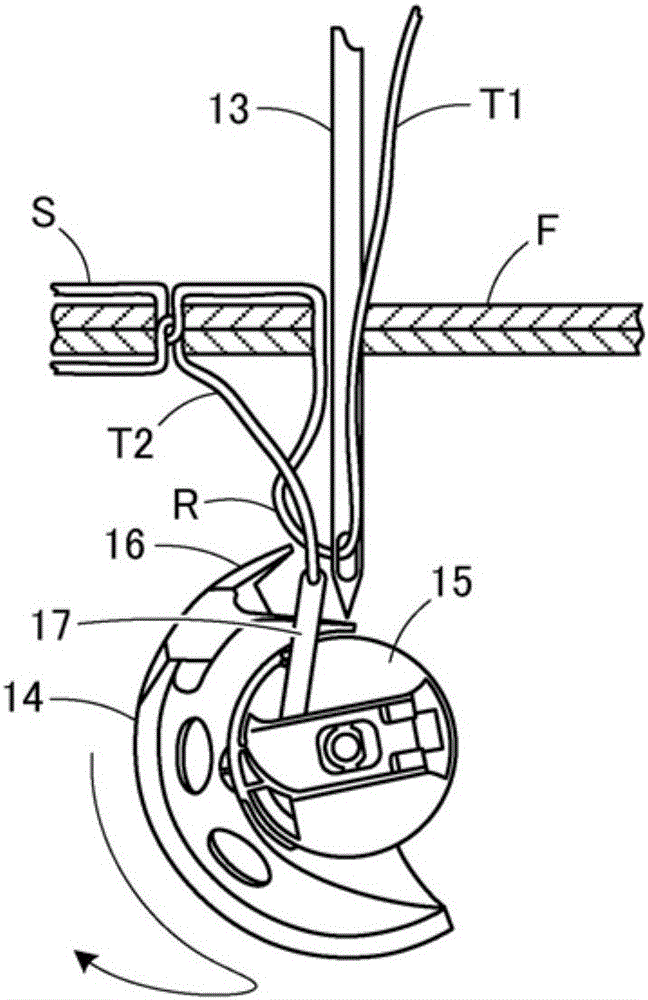

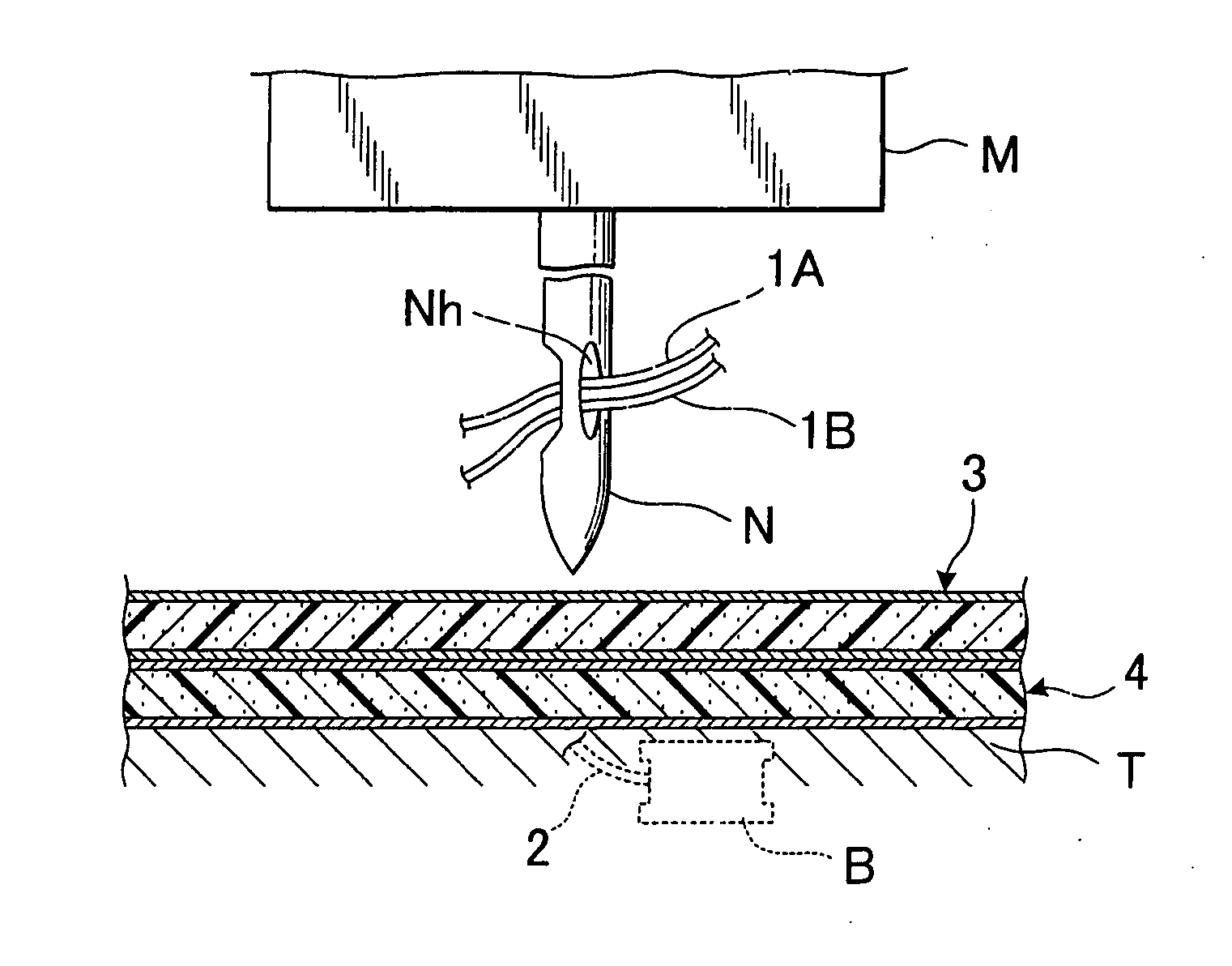

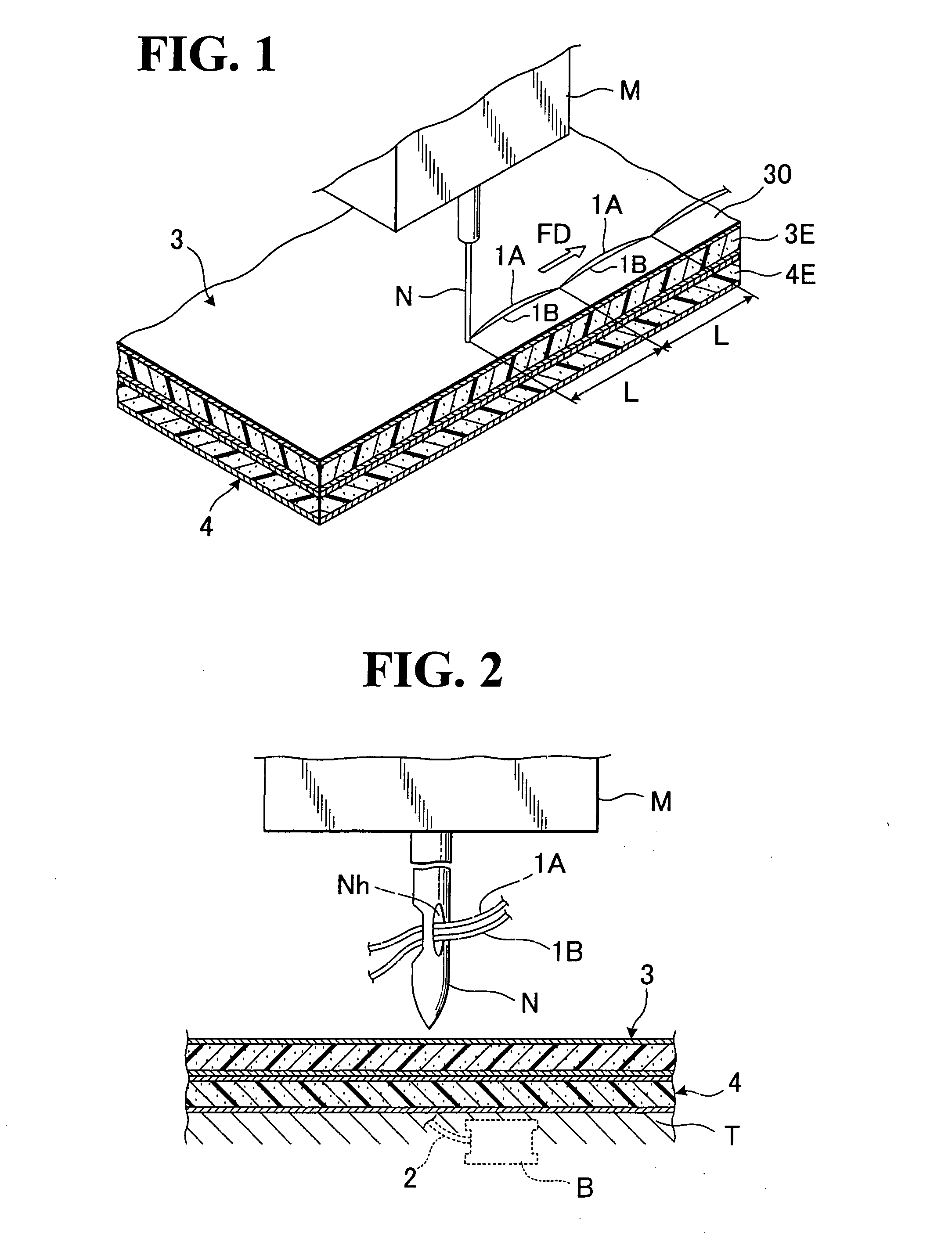

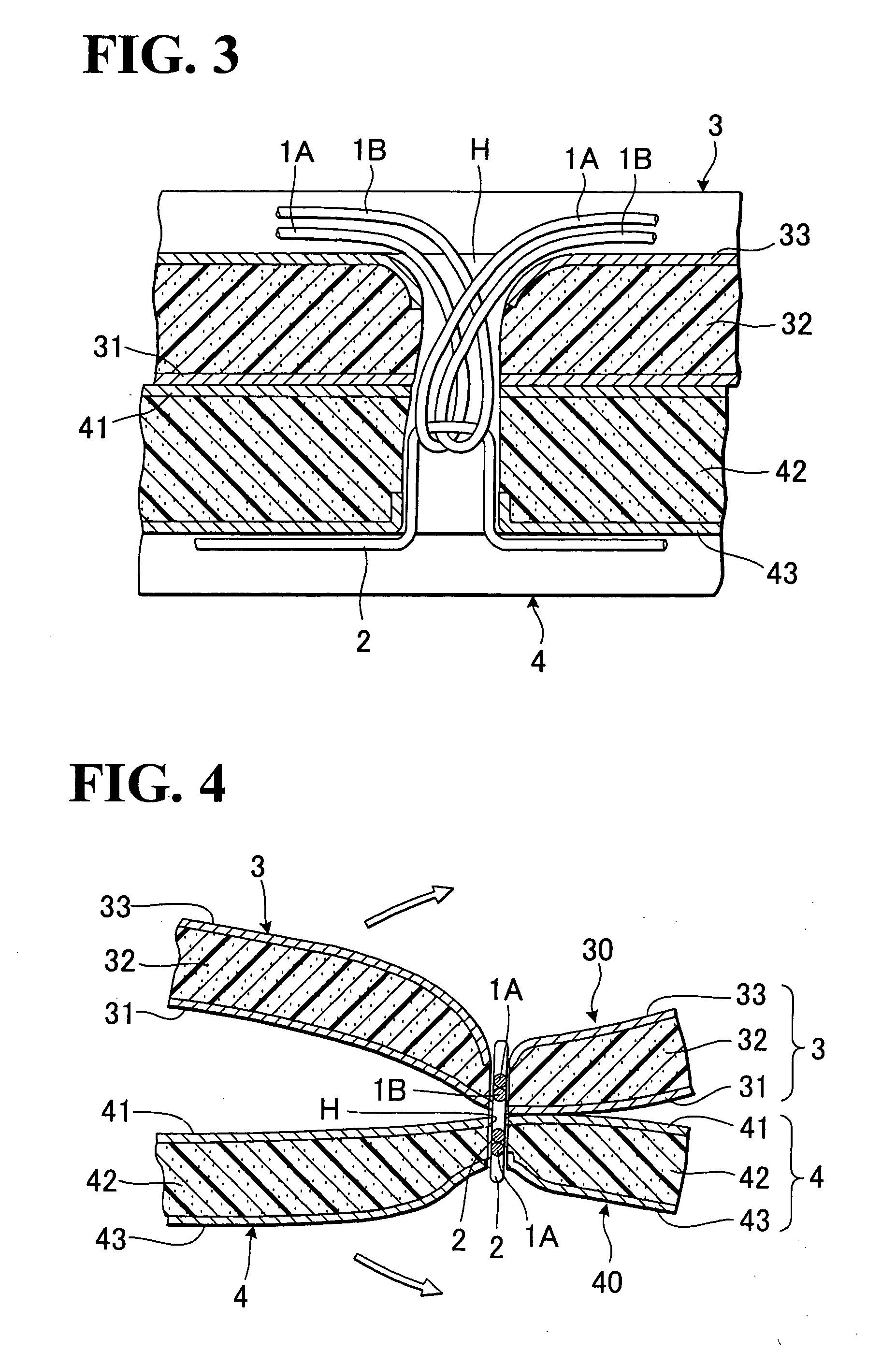

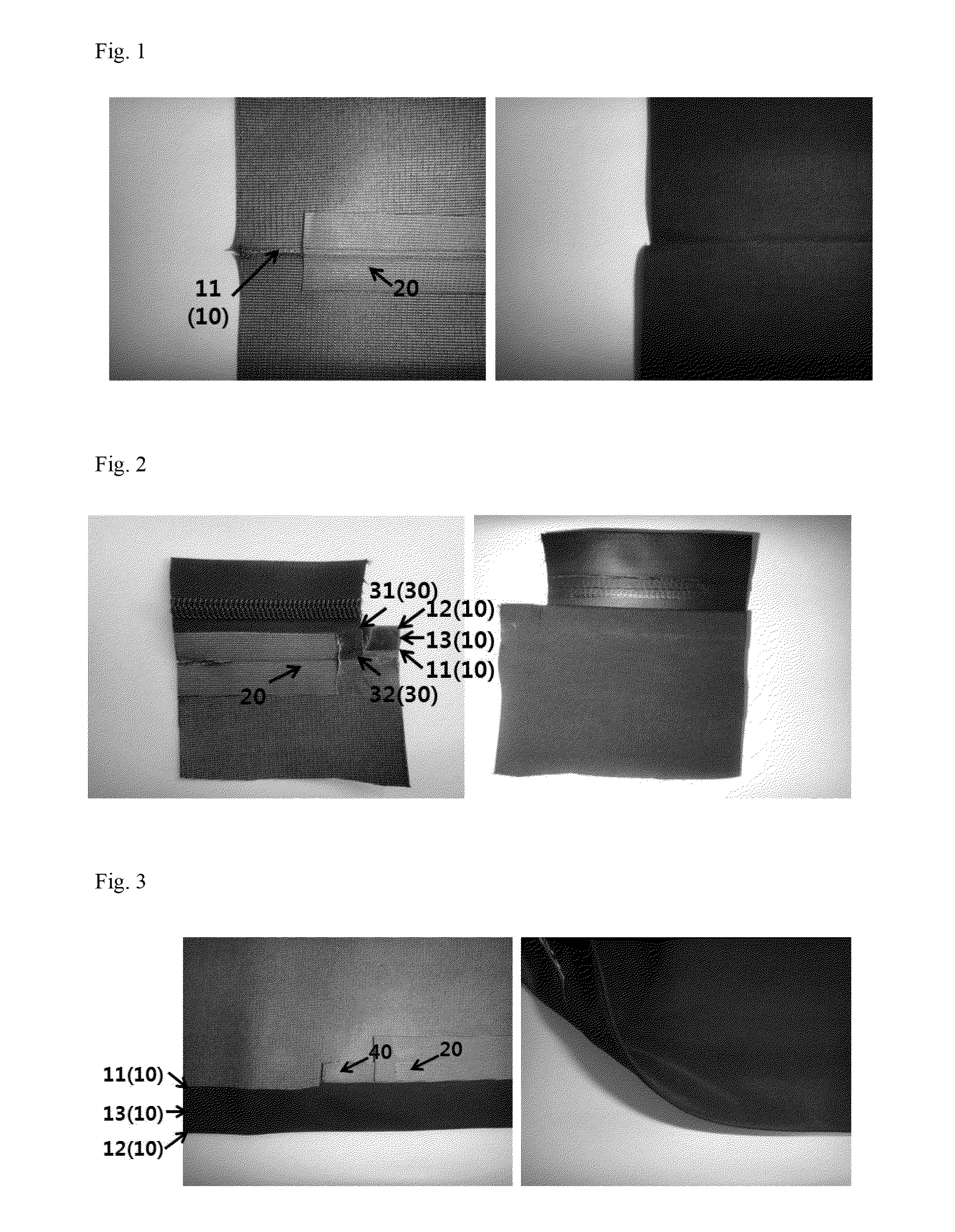

Method for sewing together covering elements adapted to undergo foaming process

A method for sewing together covering elements is provided, in which two first threads and a second thread are used in a sewing machine having sewing needle means. In operating the sewing machine, the covering elements are fed at a given feeding pitch, such that the two first threads are entwined about the second thread in each of needle holes formed by the sewing needle means in the covering elements. Those entwined three threads fill and close the needle hole, thereby preventing leakage of a liquid foaming agent at a foaming process for forming a foamed product integral with the covering elements. The sewing needle means may comprise one sewing needle, in which case, both two first threads are used in that one sewing needle, or alternatively may comprises two sewing needles, in which case, the two first sewing threads are respectively used in the two sewing needles.

Owner:TACHI S CO LTD

Sewing machine

ActiveCN101100793AImprove sewing qualityImprove sewing efficiencySewing-machine control devicesNeedle barsRing deviceTime transfer

The present invention is to improve sewing efficiency through omitting the regulating work of the installation position of a kettle (or a beating ring device) generated through the thickness of the matter to sewing or the rotation delay of sewing speed as well as a kettle (or a beating ring device). A sartorius comprises an upper axis, which keeps a needle of a sewing needle move up and down; a lower axis, driving a sewing catching unit which catches the upper thread of the sewing needle to swing with the lower thread; a drive source, applying rotary drive on the upper axis and the lower axis; an upper axis rotary part, rotating along with the upper axis; a lower axis rotary part, rotating along with the lower axis; a drive transferring part, which loop shaped frames set on the upper axis rotary part and the lower axis rotary part, at the same time transfers the rotary drive of a rotary part rotated by means of the drive source to another rotary part, the drive transferring part ensures the length rate of two frame parts connecting with the position between the upper axis and the lower axis rotary part to be alter automatically through outside force.

Owner:JUKI CORP

Sewing machine

ActiveUS7620472B2Amount of movement is limitedProgramme-controlled sewing machinesSewing-machine control devicesSewing needleImaging data

A sewing machine executing a free-motion capable of sewing while a workpiece cloth is manually moved by an operator includes a needlebar having a lower end to which a sewing needle is attached, a needlebar driving mechanism vertically driving the needlebar via a main shaft, a presser foot pressing the workpiece cloth manually moved by the operator, an imaging device imaging at least an area of the workpiece cloth near to the sewing needle, a movement amount operating device obtaining by operation a movement amount of the workpiece cloth based on image data from the imaging device, a setting device setting a stitch pitch on the workpiece cloth, a comparing device comparing the obtained movement amount of the workpiece cloth and the set stitch pitch, a cloth movement limiter limiting movement of the workpiece cloth by the manual operation, and a control device controlling the cloth movement limiter according to a result of comparison.

Owner:BROTHER KOGYO KK

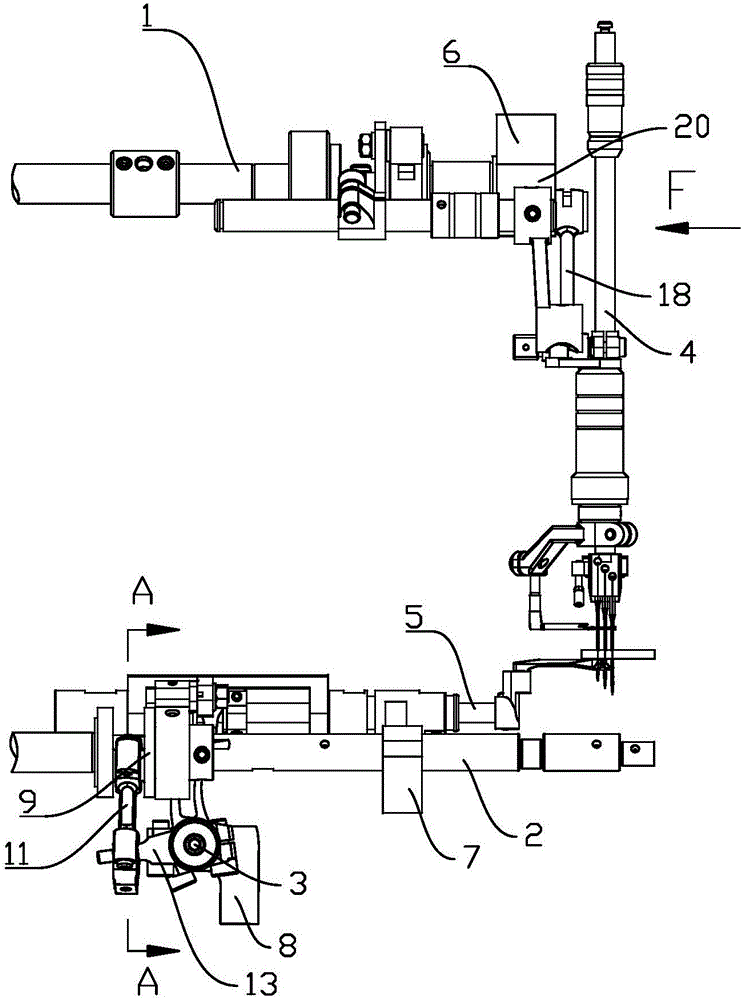

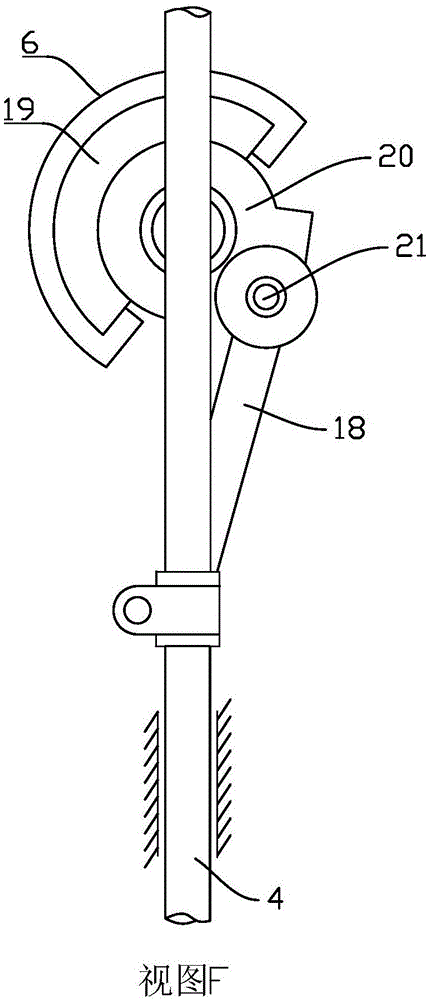

Full-automatic covered edge sewing machine

InactiveCN106757805AWon't wasteFast productionWorkpiece carriersWork-feeding meansEngineeringSewing needle

The invention relates to a full-automatic covered edge sewing machine which comprises a rack, a worktable and a machine head. The worktable is installed above the rack, the machine head is provided with a sewing needle for sewing a material with the edge to be covered, an X-axis mechanism, a Y-axis mechanism, a W-axis mechanism, a compression plate mounting seat, a compression plate, a binding tape feeding mechanism, a binding tape cutting mechanism and a unloading mechanism are installed above the worktable, the worktable is provided with a feeding station, a material sewing station and a material unloading station according to the working procedures, the X-axis mechanism, the Y-axis mechanism and the W-axis mechanism drives the compression plate to compress the material and move the material from the feeding station to the material sewing station, the binding tape feeding mechanism synchronously delivers binding tapes to the material sewing station, the binding tapes are sewn on the side of the material by using the sewing needle to achieve edge covering, the binding tape cutting mechanism cuts off too long binding tapes, the material with the edge covered is fed into the unloading station and is pushed and moved out of the worktable by the unloading mechanism.

Owner:东莞市雅满豪机械科技有限公司

Novel textile downproof technology

InactiveCN105821670AIncrease productivityGood fleeceLight resistant fibresLiquid repellent fibresAdhesiveEngineering

Disclosed is a novel textile downproof technology .The novel textile downproof technology comprises the following steps of 1, selecting a fabric, wherein the fabric is a plain weave fabric woven by nylon full-stretching silk, the yarn count is 20 D-40 D, and the density is 290 Tex-400 Tex; 2, performing water-repellency arrangement on the fabric, wherein the grade of getting wet is not smaller then 3; 3, performing calendering on the fabric obtained after water-repellency arrangement through a calender, wherein the pressure is 9-11 MPa, the temperature is 100-110 DEG C, and the speed is 30-40 m / min; 4, preparing a coating adhesive .The downproof effect is achieved through the good combination of a base fabric and the coating adhesive, particularly, the downproof effect at a sewing needle hole is achieved, meanwhile, the selected and prepared coating adhesive can ensure comprehensive indicators of downproofness, cold resistance, moisture penetrability, washing fastness, flexibility and the like of the fabric with the low weight increment, and the wearing comfort of the fabric is better on the premise of achieving functionality .

Owner:JIANGSU DONGBANG TECH

Method for quickly positioning selfing fruit of pepper

The invention discloses a method for quickly positioning a selfing fruit of pepper, and belongs to the technical field of plant breeding. The method comprises the following steps: firstly, selecting a selfing single plant, and marking the single plant; secondly, selecting a flower to bloom in the marked single plant within 12h; thirdly, cutting off the front end of a needle hole of a hand sewing needle with a certain specification of 0.2-0.4mm to form a semi-concave structure, and cutting off a needle tip of the other end; fourthly, threading a thin thread into a semi-concave hole, and threading the thin thread and the semi-concave structure into a receptacle part of the flower to bloom within 12h; fifthly, cutting off a section of the thin thread which is about 2-3cm long, wherein the section of thin thread serves as a mark of a selfing pollination flower in the receptacle; sixthly, manually pollinating the marked flower; seventhly, harvesting a fruit marked by the thin thread in the receptacle in a physiological maturity period.

Owner:李兰华

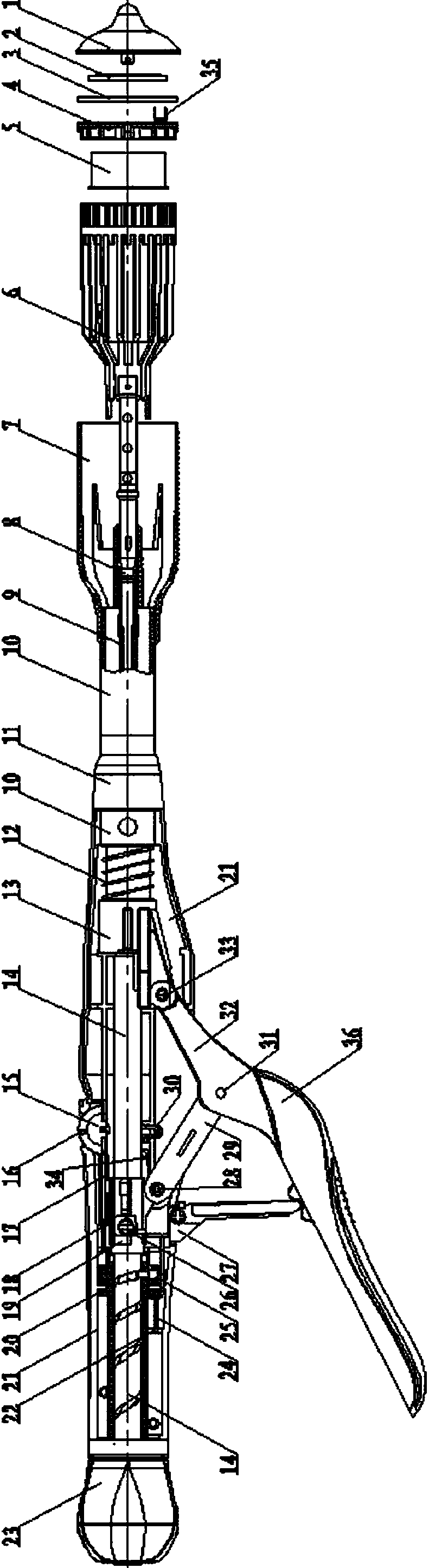

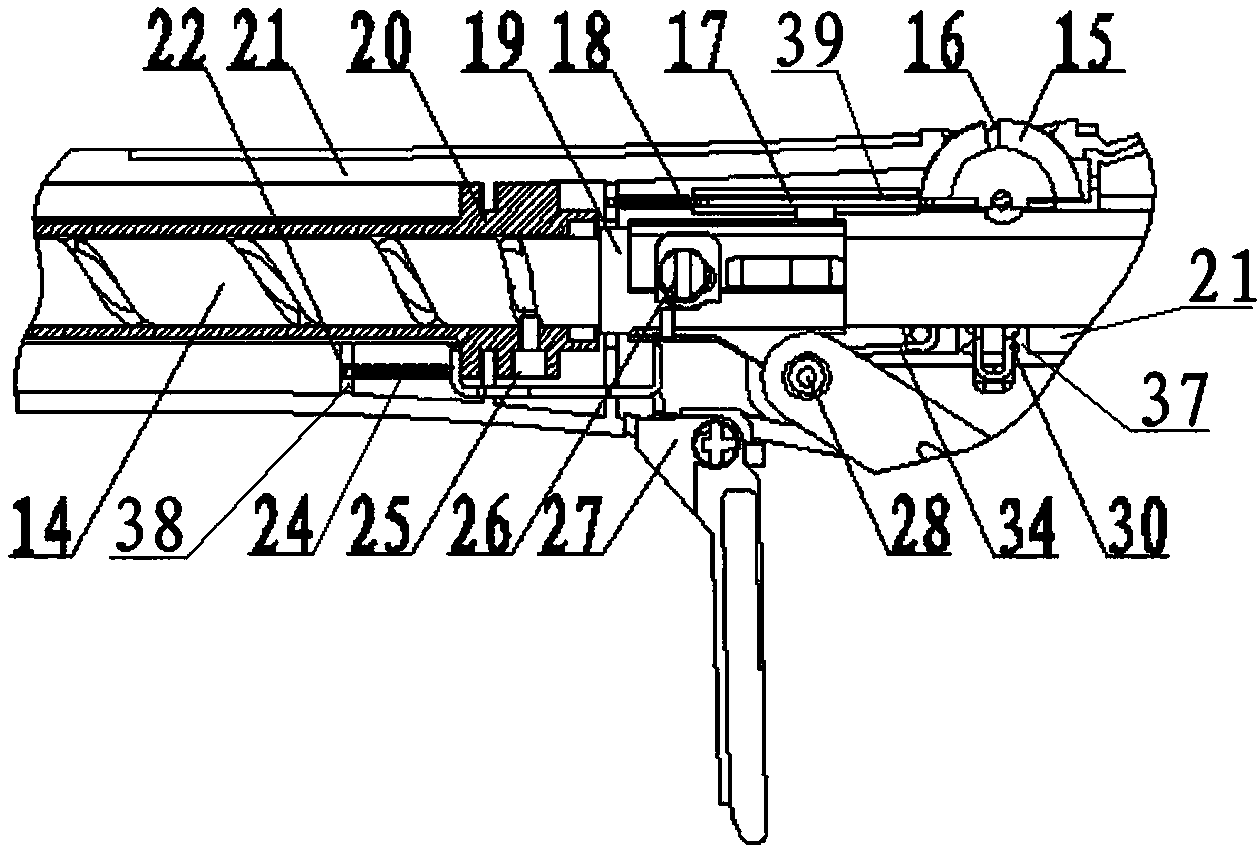

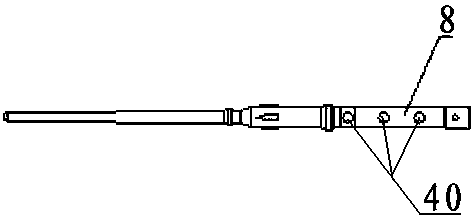

Disposable guide type anorectal hemorrhoid anastomat

The invention relates to a disposable guide type anorectal hemorrhoid anastomat, which is suitable for being used as an anorectal hemorrhoid incising and sewing surgical instrument. The disposable guide type anorectal hemorrhoid anastomat comprises an abutting nail seat, a pad cutter ring, an abutting nail piece, a nail bin, an annular cutter, a needle pushing piece, a needle bin cover, a positioning shaft, a connecting pipe, an aluminum pipe, a locking ring, a reset spring, a push pipe, a screw, an indication shield, an indication block, an indication pull piece, a spring I, a bolt, an adjusting pipe, a fixing handle, an adjusting knob, an safety card, a spring II, a top post, a moving block, a safety block, a positioning pin I, a support rod, a sounding block, a positioning pin III, a movable handle, a positioning pin II, a torsion spring, a sewing needle and a movable handle shield; the left end of the movable handle is movably connected with the right end of the support rod of which the left end is movably connected with the fixing handle; the moving block is fixed on the screw; the adjusting pipe is matched with a threaded section at the left end of the screw by the top post; the adjusting knob is fixed at the left end of the adjusting pipe.; the sounding block is fixed in a sounding block mounting groove of the fixing handle, and the safety block is movably connected with the fixing handle.

Owner:WUXI SHENKANG MEDICAL INSTR EQUIP

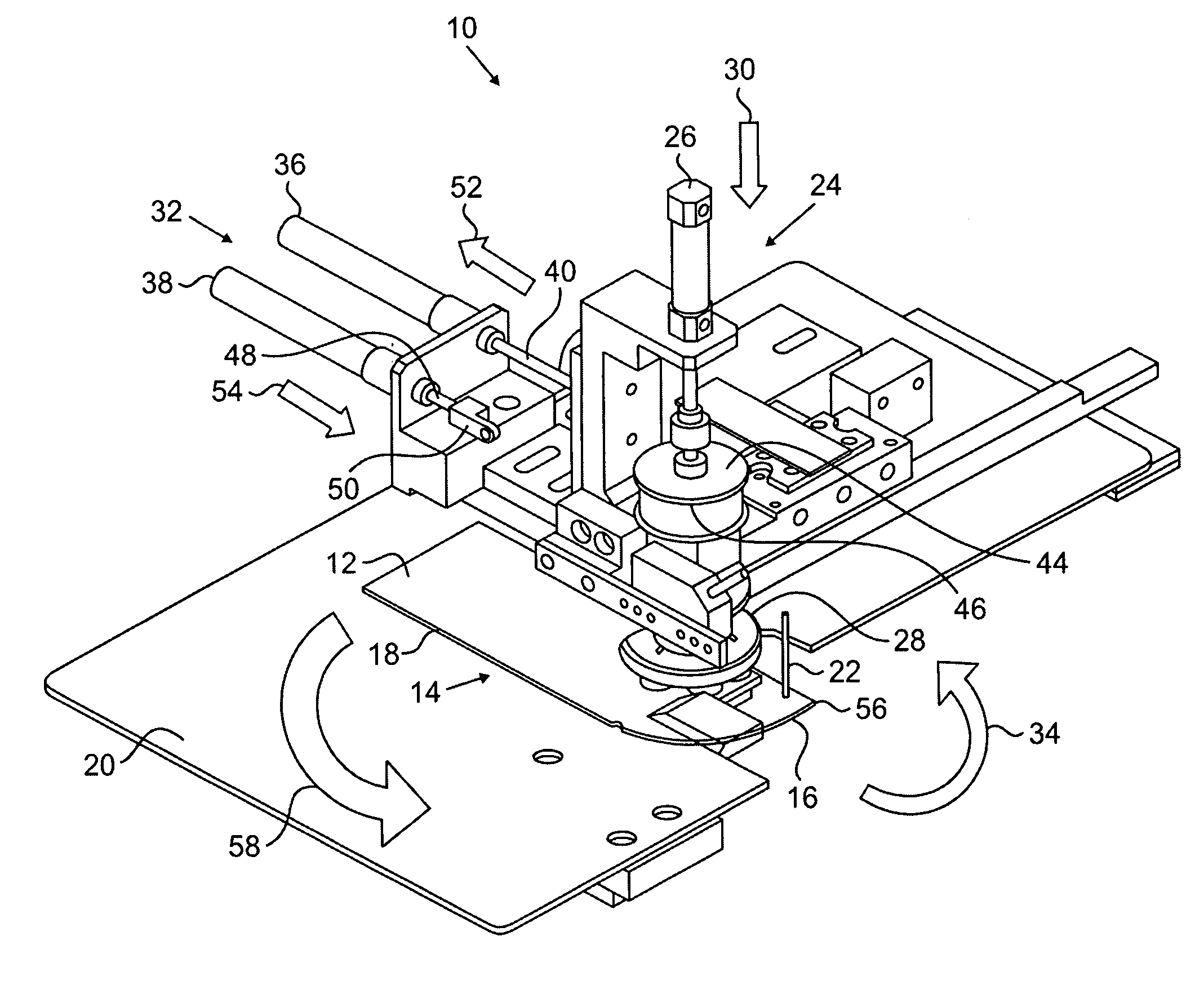

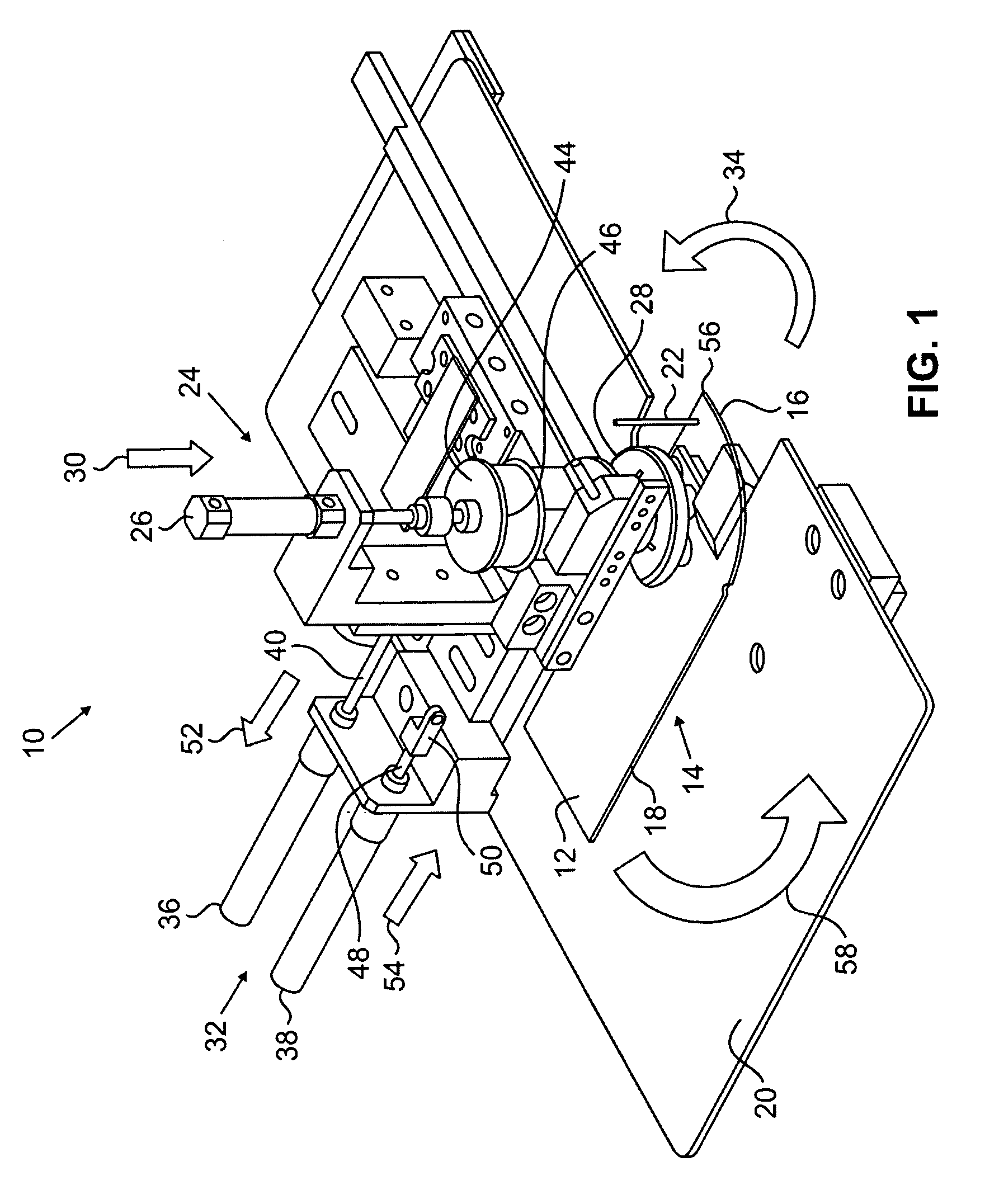

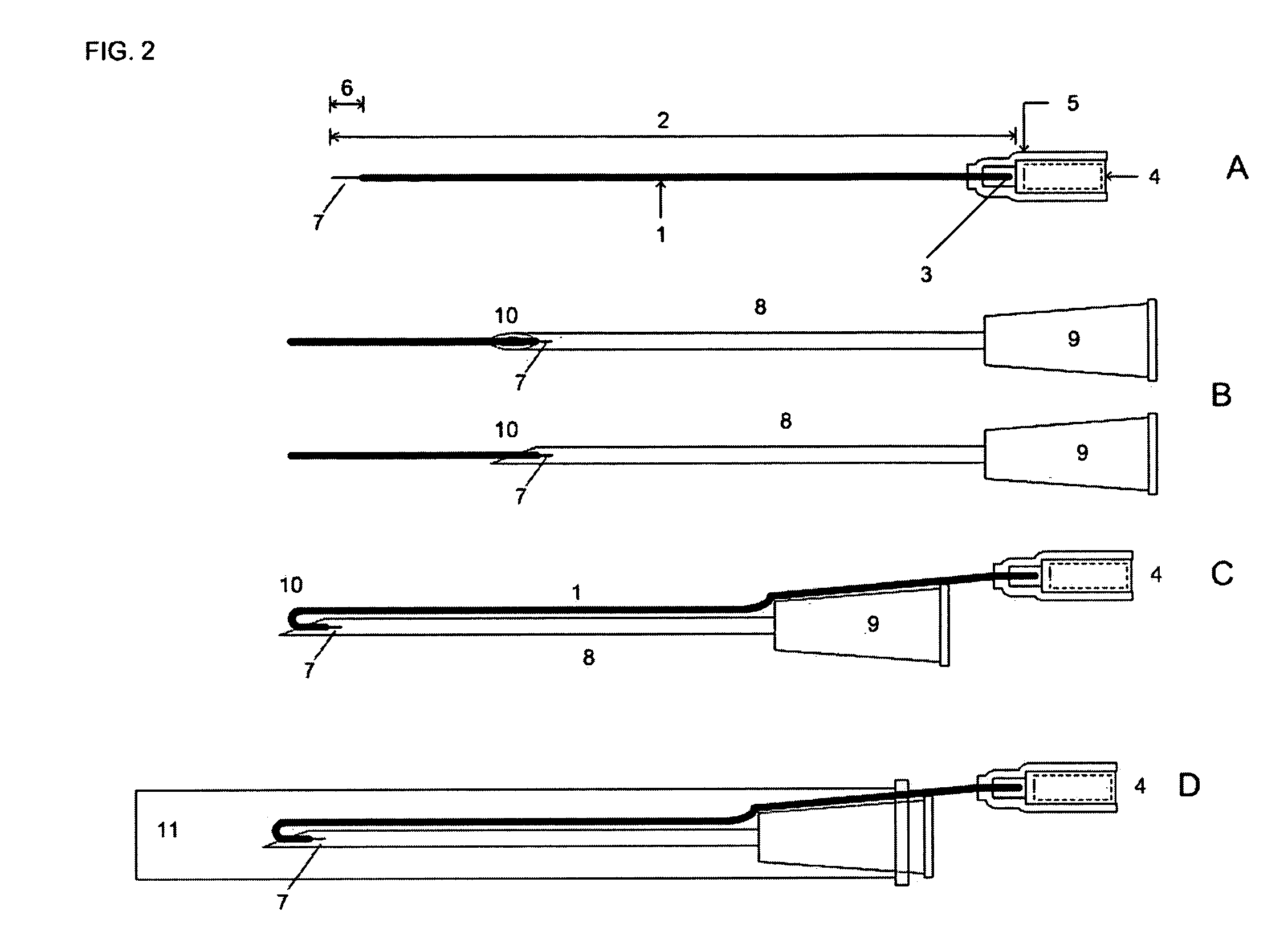

Curved edge sewing systems

ActiveUS20080115710A1Quality improvementImprove consistencyWork-feeding meansEngineeringSewing needle

A curved edge sewing system sews a curved edge of a cloth, such as a curved edge of a fly. The curved edge sewing system has a cloth support table, and a sewing needle located at a sewing position relative to the cloth support table. A cloth presser device moves towards and away from the cloth support table and rotates relative to the sewing needle. A first driver is operatively connected to the cloth presser device and moves the cloth presser device towards and away from the cloth support table. A second driver is operatively connected to the cloth presser device and rotates the cloth presser device relative to the sewing needle. A controller has a first signal supplied to the first driver and actuates the first driver, and a second signal supplied to the second driver and actuates the second driver.

Owner:YKK CORP

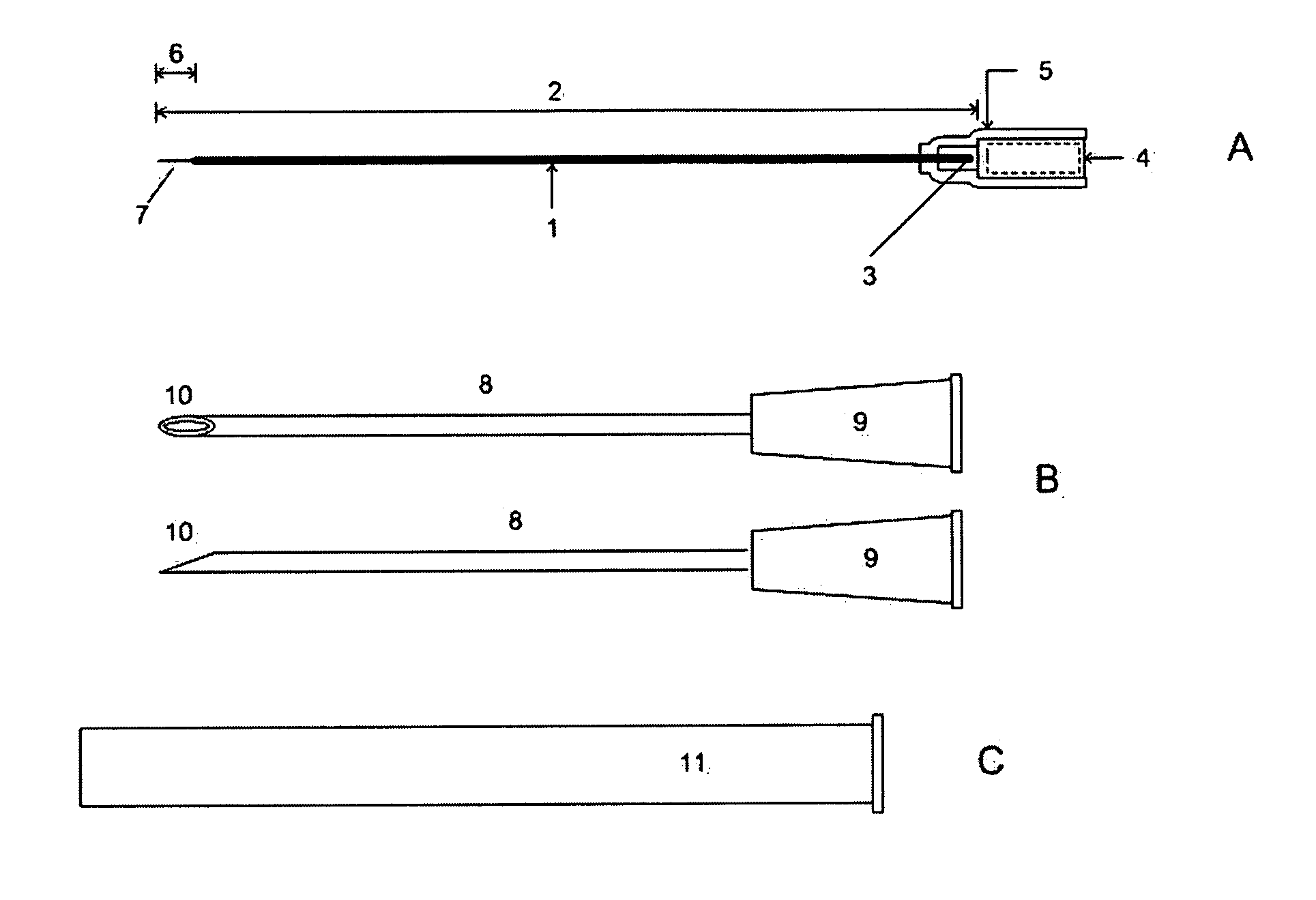

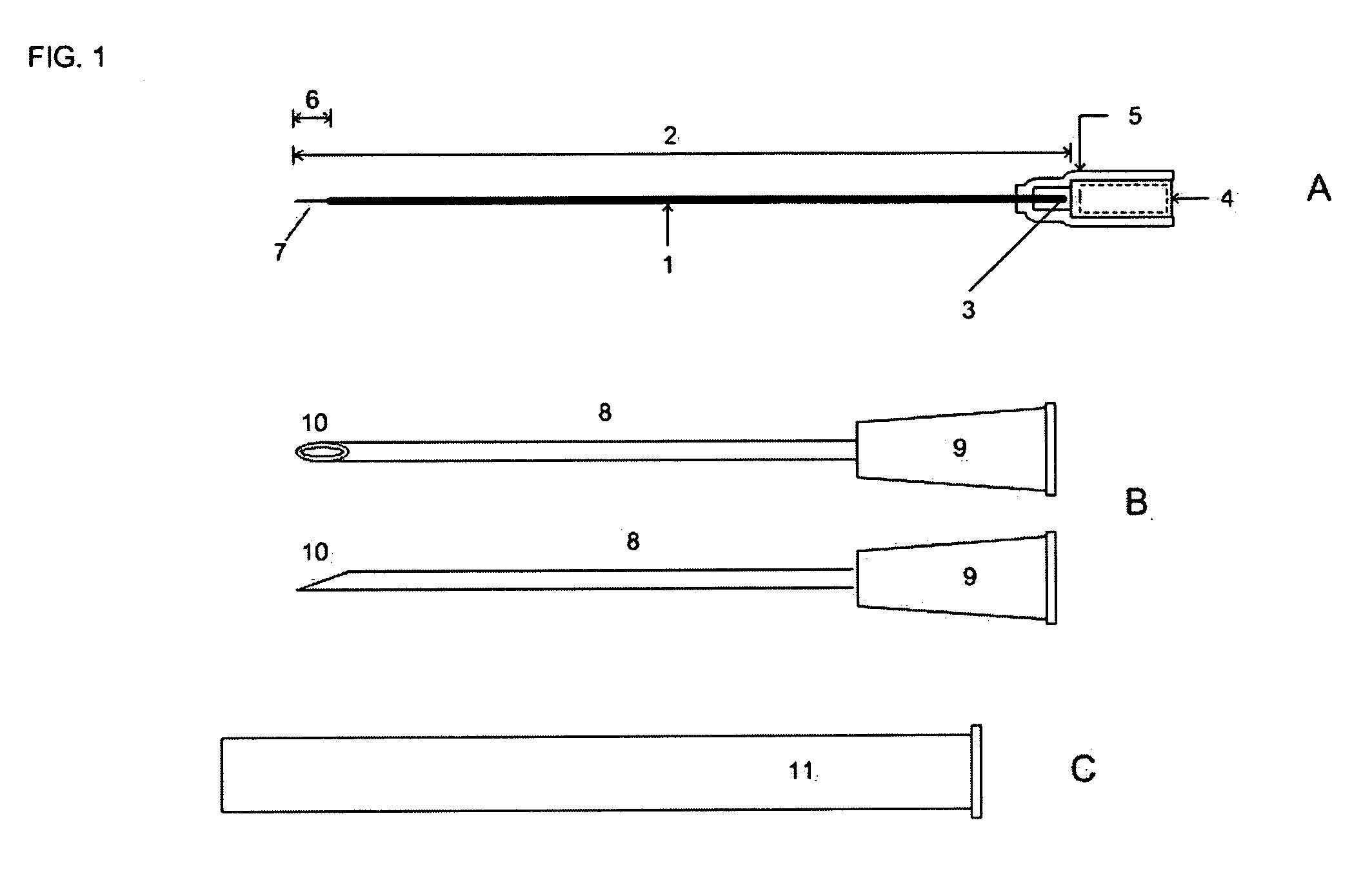

Technique for design, and placement, of a subdermal Ag-Ag/Cl biopotential electrode

A chronic subdermal silver-silver / chloride (Ag—Ag / Cl) electrode for the recording of biopotentials is disclosed. The electrode is comprised of an Ag—Ag / Cl distal end that is placed subdermally by various methods. The recording electrode is made of solid, multi-stranded or a ball of pure silver and the whole length of the electrode is insulated except for the distal end which is used for voltage recordation. The electrode can be placed subdermally by an introducer apparatus such as hypodermic or sewing needle, a split-cannula, a staple, or a suture. Once placed, the introducer apparatus can be removed leaving the recording wire / element in place. The recording electrode can be placed at any location on the body to record the local biopotential (EEG, EOG, EMG, EKG, etc). It can be left in place for hours, days, or weeks, as it will record without any further adjustment.

Owner:IVES JOHN RICHARD +1

Sewing machine

ActiveUS20080006191A1Quality improvementDetection errorProgramme-controlled sewing machinesEngineeringSewing needle

The sewing machine includes a presser body, a presser frame, a button holding device including a fixed portion and a sliding portion, a position detecting device including a sliding base attached to the presser frame and a sliding member coupled to the presser body and slidable with respect to the sliding base, a button diameter detecting switch, and a control device. The control device obtains, from the position detecting device, a shift amount of the presser body from a sewing start position when the button diameter detecting switch detects that a sewing operation is carried by a length that corresponds to a diameter of a button, and controls a drive of a sewing needle and the feeding of the workpiece such that a buttonhole stitch corresponding to the diameter of the button is formed.

Owner:JUKI CORP

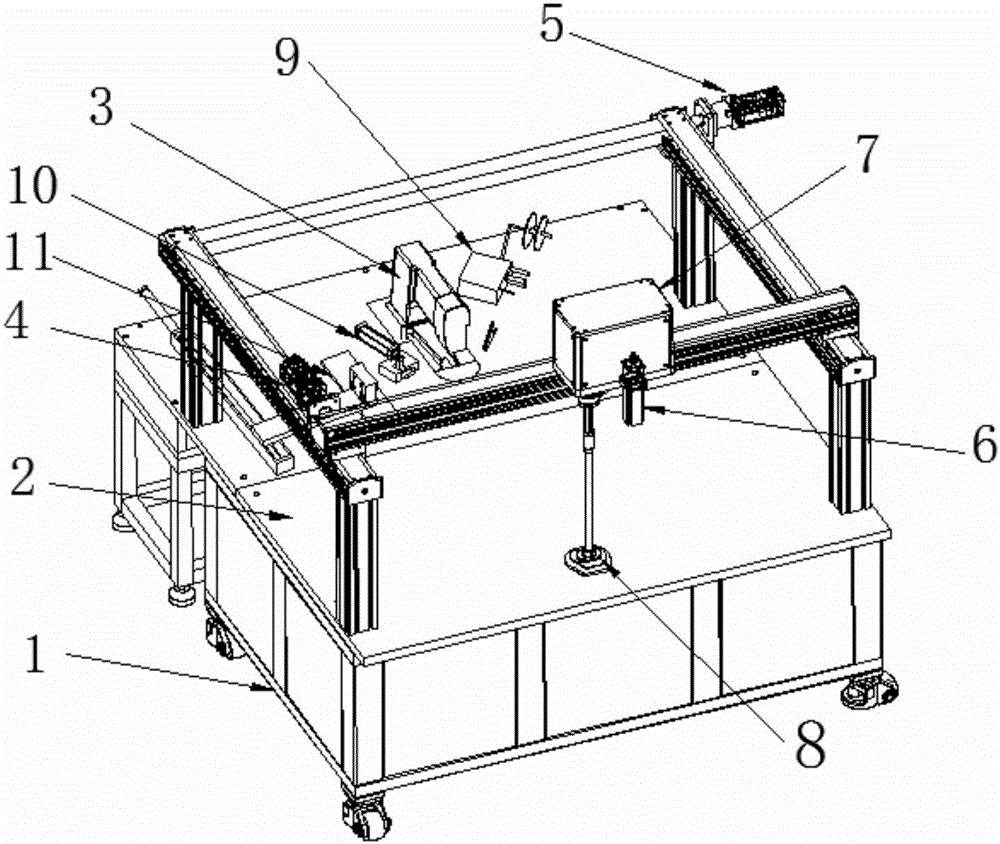

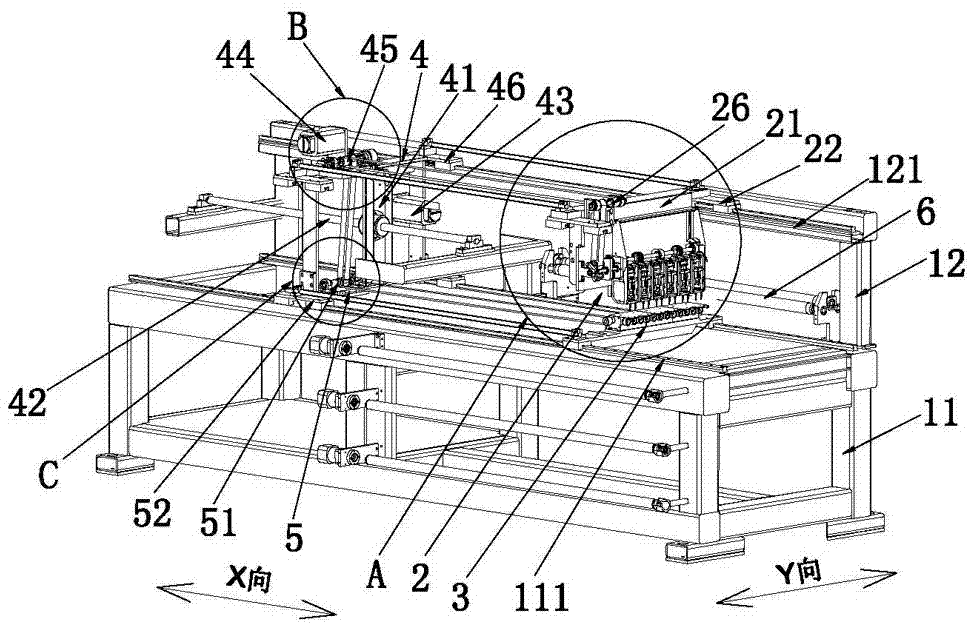

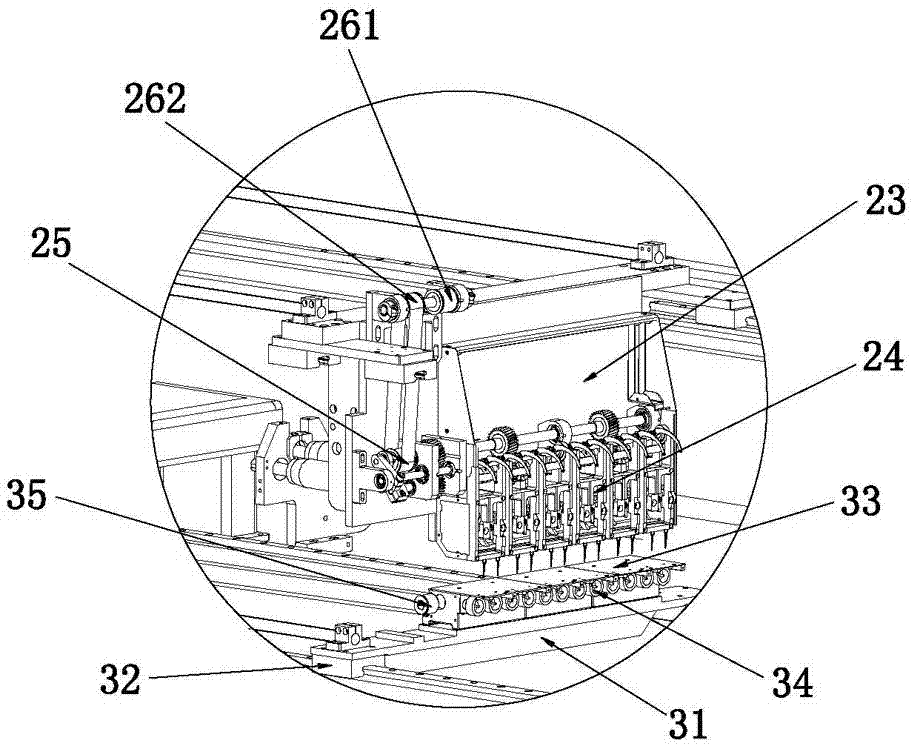

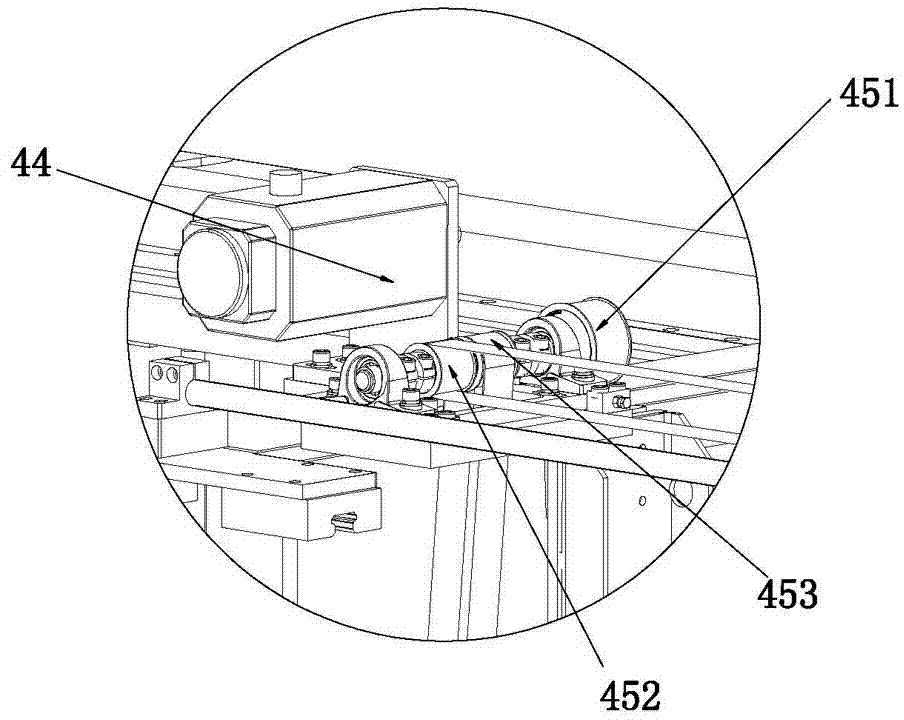

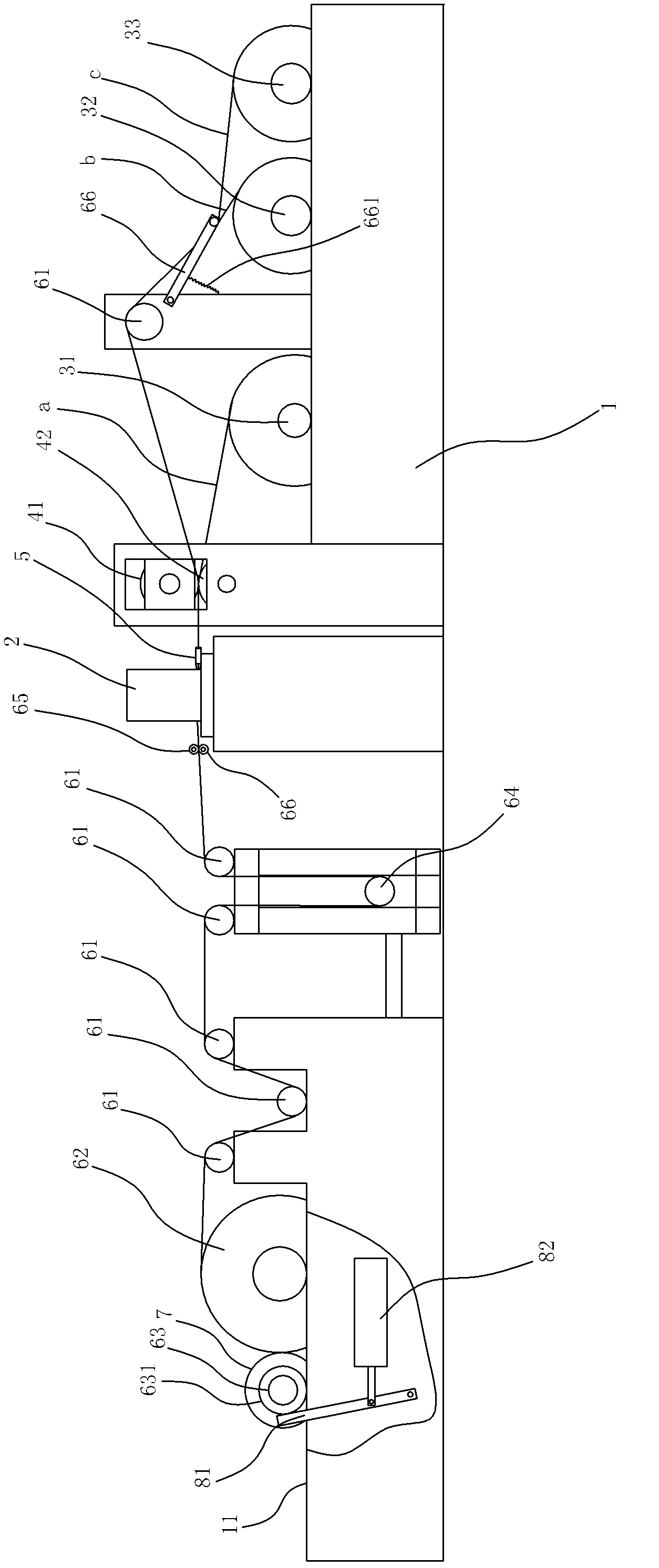

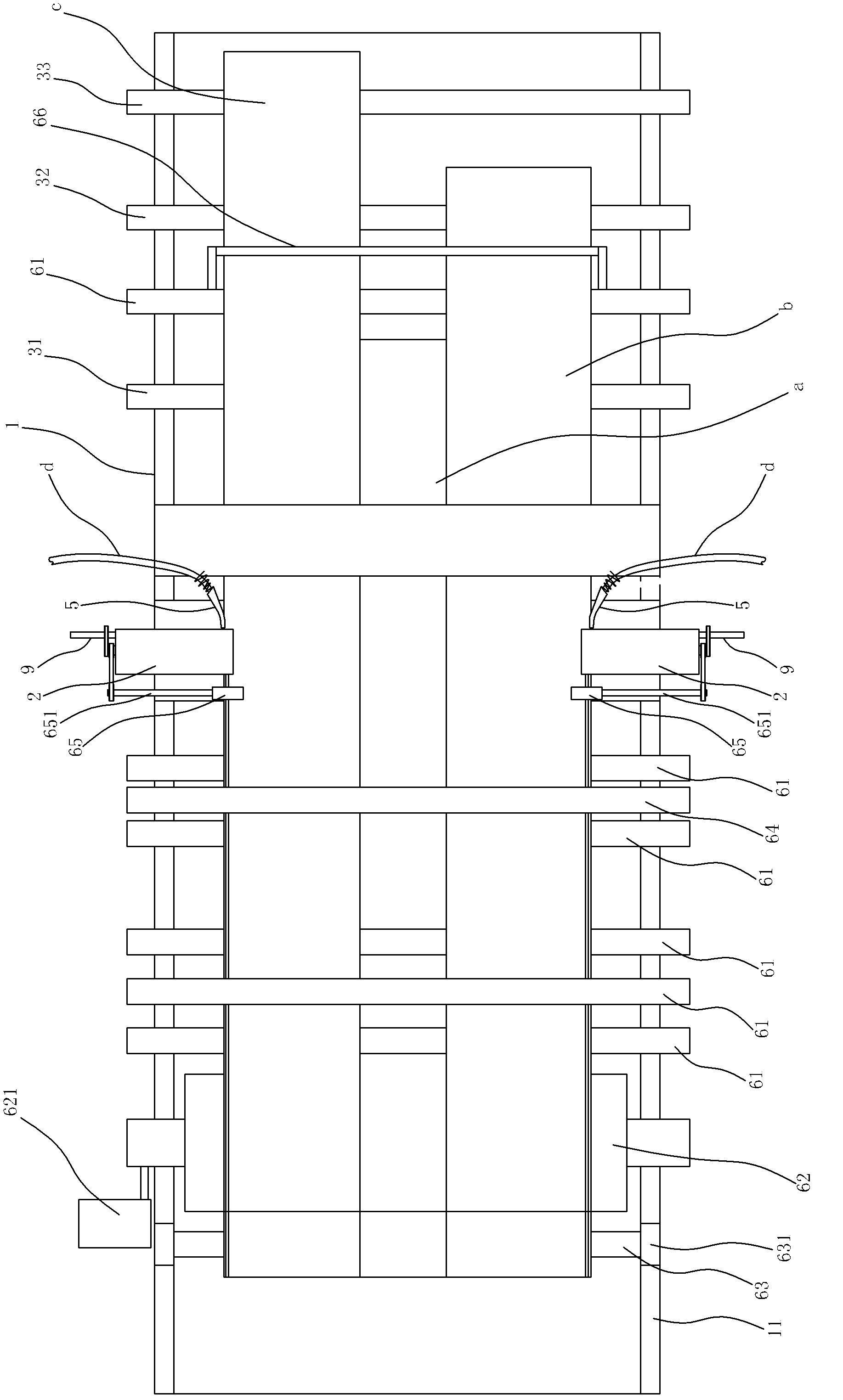

Numerical-control sewing and embroidering quilting machine provided with horizontal multi-needle machine head

InactiveCN104499188ANo mutual interferenceEasy offlineWork-feeding meansMattress sewingNumerical controlMechanical engineering

The invention belongs to the technical field of quilting machines, and particularly relates to a numerical-control sewing and embroidering quilting machine provided with a horizontal multi-needle machine head. The numerical-control sewing and embroidering quilting machine comprises a frame, wherein the frame comprises a rack and an upper frame which is arranged at the upper end of the rack; the frame is provided with the multi-needle machine head capable of moving longitudinally; a rotating shuttle mechanism is arranged under the multi-needle machine head; the frame is provided with a first driving mechanism for driving the multi-needle machine head and the rotating shuttle mechanism to move synchronously; the multi-needle machine head is connected with the upper frame in a sliding manner; the rotating shuttle mechanism is connected with the rack in the sliding manner; the frame is also provided with a second driving mechanism for driving a fabric to be fed horizontally. The multi-needle machine head of the numerical-control sewing and embroidering quilting machine is arranged in a direction vertical to the feeding direction of the fabric, so that two adjacent needles have no interference in sewing trace during sewing, no wired node is formed in a spliced point, and thus the node is unlikely to loosen, and the quality and the attractive appearance of the product are guaranteed; a plurality of sewing needles work simultaneously, so the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH +1

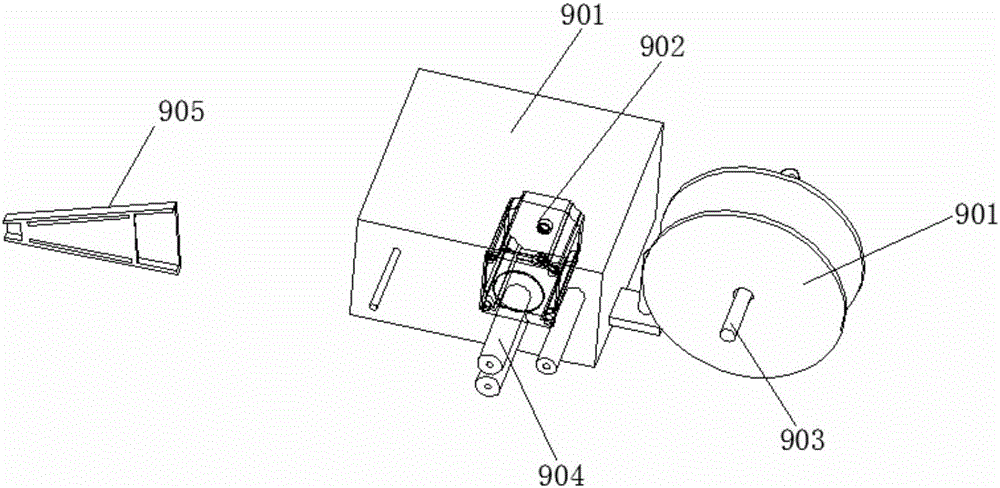

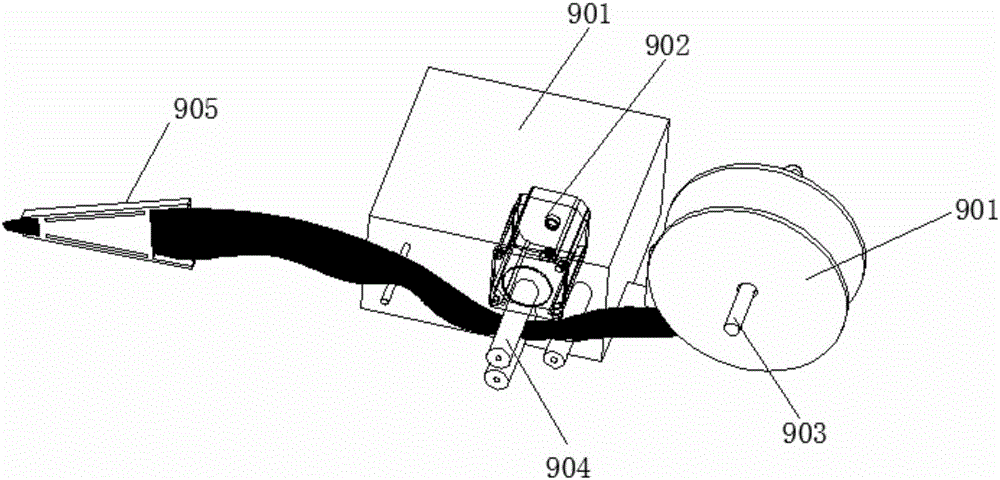

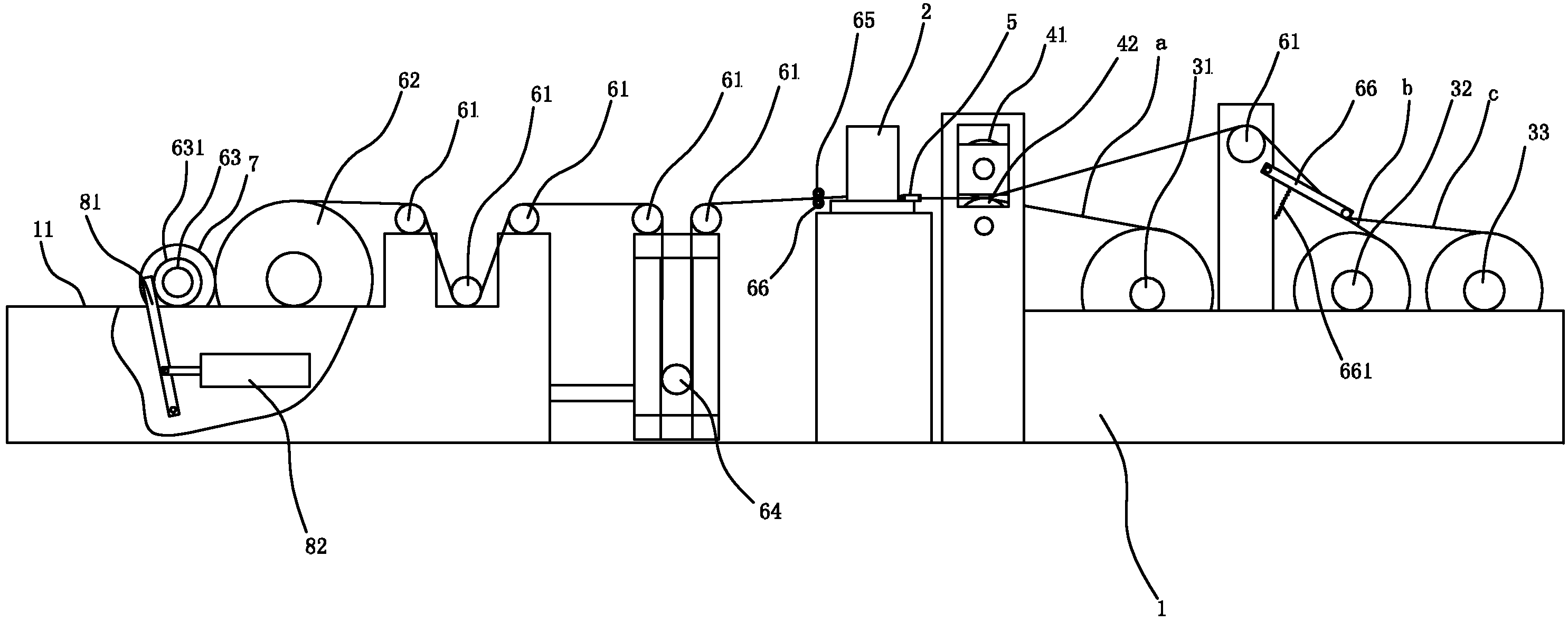

Continuous fabric strap sewing and edge-covering device

InactiveCN102587045AIncrease productivityImprove product qualityWork-feeding meansWork-collecting devicesSewing needle

A continuous fabric strap sewing and edge-covering device is used for sewing two continuous fabric straps in an edge aligning manner and covering edges of the two continuous fabric straps and comprises a framework, a sewing machine, a fabric strap carrying roll, an upper press roll, a lower press roll, a conveying mechanism and an edge covering strap folding guide part. The sewing machine and the knitting strap carrying roll are arranged on the framework, the upper press roll and the lower press roll are arranged on the framework on an input side of the sewing machine, the conveying mechanism is arranged on the framework and used for conveying fabric straps to the sewing machine continuously and comprises a plurality of guide rolls, a conveying roll, a cloth winding roll, a keeping mechanism and a first motor, and the edge covering strap folding guide part is arranged on the front side of a sewing needle of the sewing machine. The guide rolls are arranged on the framework, the conveying roll is arranged on the framework on an output side of the sewing machine, the cloth winding roll capable of moving relative to the conveying roll is arranged on the framework and parallel to the conveying roll, the keeping mechanism arranged on the framework is used for keeping fabrics on the cloth winding roll contacting with the conveying roll, and the first motor is connected with the conveying roll and drives the same to rotate. By the continuous fabric strap sewing and edge-covering device, sewing and edge covering efficiency of continuous fabric straps can be effectively improved, cost is saved and quality is improved.

Owner:冠达星股份有限公司

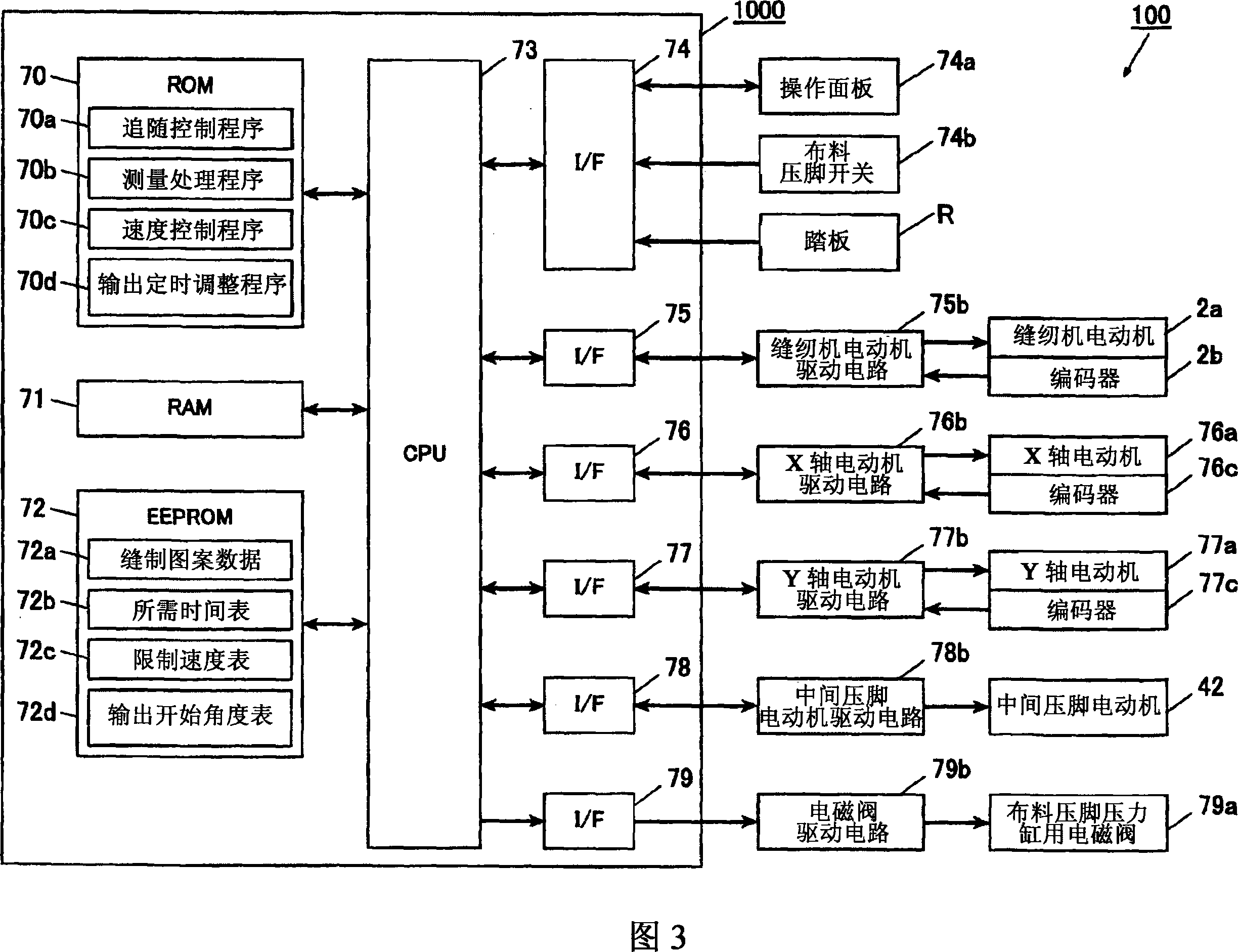

Automatic sewing machine

ActiveCN101100789AAvoid disorderImprove sewing qualityProgramme-controlled sewing machinesSewing-machine control devicesNeedle positionClosed loop

The present invention relates to an automatic sewing sartorius, which implement optimization of sartorius rotary speed and supply time when implementing XY drive to the cloth sewing foot in arbitrary directions through the control of a half closed loop. The sartorius comprises a sewing needle; a orientation unit, which contains a motion quality detecting unit to detect the motion quality of a pulse electromotor which drives a cloth keeping part move to arbitrary positions; a needle position detecting unit, detecting the position of a needle in upper and lower directions; a pattern memory unit, storing sewing pattern data; a motion control unit, to ensure the prescribed difference between the instruction pulse and actual motion, at the same time to output instruction pulses one by one to the pulse electromotor; and a required time memory unit, storing time required for outputting instruction pulse, and time required for motion control unit reference, to begin output the instruction pulse according to the orientation completed by the instruction pulse output when a sewing needle contacts the sewing matter on the needle board.

Owner:JUKI CORP

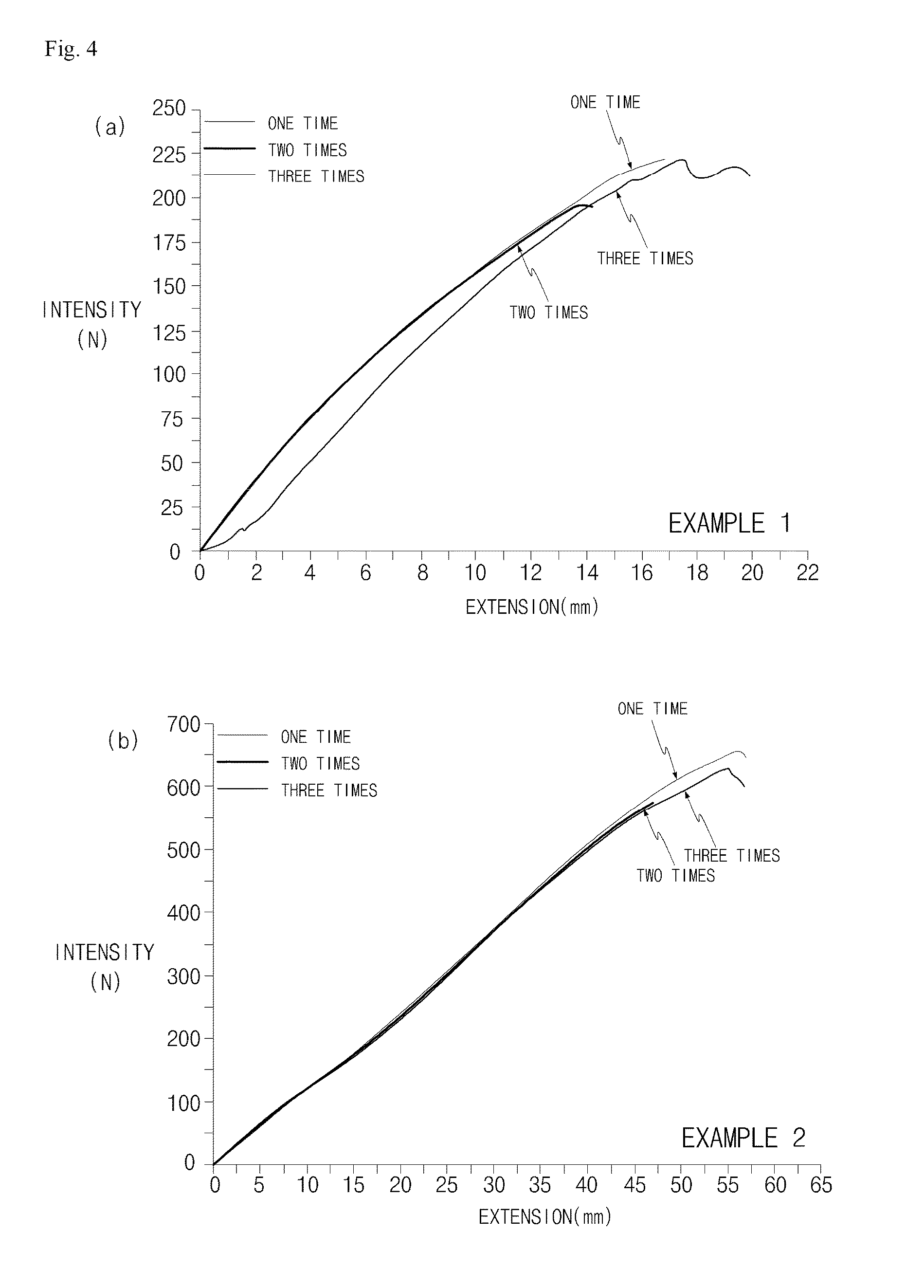

Method for finishing seamless sportswear and outdoor clothing

ActiveUS9023161B2Avoid compressionReduce frictionMechanical working/deformationGarmentsWrinkle skinEngineering

Provided is a finishing treatment method of seamless sportswear and outdoor clothing, including: welding two or more moisture-permeable waterproof fabrics with an ultrasonic welder in a state of overlapping end parts thereof each other; and finishing the end parts of the moisture-permeable waterproof fabrics with a seal sealing tape, whereby in the seamless sportswear and outdoor clothing which are finishing treated according to the embodiments of the present invention, since a sewing part such as over lock and the like is removed, a friction or compression phenomenon can be prevented from being generated from a part to which a pressure is applied, a sewing wrinkle generation phenomenon generated upon sewing and a coating face slip phenomenon of the moisture-permeable waterproof fabric due to a sewing needle can be solved, and excellent tensile strength and waterproof performance can be realized.

Owner:KOREA INST OF IND TECH

Sewing machine and mechanism for reducing vibration of sewing machine

ActiveCN106637729AReduce vibrationReduce noiseSewing-machine control devicesNeedle barsReciprocating motionDrive shaft

The invention relates to a mechanism for reducing vibration of a sewing machine. An upper rotating shaft of the sewing machine is in transmission connection with a sewing needle connection rod capable of realizing up-and-down reciprocating motion; a lower rotating shaft of the sewing machine is in transmission connection with a bending needle connection rod capable of realizing left-and-right reciprocating motion through a transmission shaft; inertia force in a vertical direction is applied to the sewing machine by the up-and-down reciprocating motion of the sewing needle connection rod; inertia force in a left-right direction is applied to the sewing machine by the left-and-right reciprocating motion of the bending needle connection rod. The upper rotating shaft is connected with an upper shaft balancing block, the lower rotating shaft is connected with a lower shaft balancing block, and the transmission shaft is connected with an additional balancing block, so that the upper shaft balancing block, the lower shaft balancing block and the additional balancing block can offset the inertia force generated by rotating parts on the upper rotating shaft, the lower rotating shaft and the transmission shaft when the sewing machine operates; the vibration of the sewing machine can be reduced; the noise generated by the sewing machine can be reduced; the mechanical abrasion of the sewing machine can be reduced; the service life of the sewing machine can be prolonged; the working environment of operators can be improved.

Owner:JACK SEWING MASCH CO LTD

Sewing machine

The present invention relates to a sewing machine which can prevent the sewing of the end of the upper thread cut by an upper thread cutting mechanism that has a first movable blade. The sewing machine comprises the following components: an upper moving mechanism reciprocally moving the upper thread movable blade (40) between a first upper thread take-up position and a second upper thread take-up position by a predetermined distance, an upper thread holding mechanism holding an end of the upper thread (14) cut by the upper thread stretching to the needle hole of the sewing needle, and an upper thread direction adjusting mechanism located on the upper moving mechanism and the upper thread holding mechanism for adjusting a direction in which the upper thread stretching through the needle eye to the upper thread holding mechanism is drawn. The stretching direction of the upper thread is altered by the upper thread direction adjusting mechanism to lead to that the stretching direction of the upper thread in thread end holding state is different from the sewing direction when the sewing starts.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com