Down-leakage-proof down product and production method of down product

A production method and anti-leakage technology, which is applied in the field of clothing, can solve the problems of needle eating, stuffy feeling, static electricity, and affecting product quality, and achieve the effect of increasing colors and varieties, increasing warmth, and a neat and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

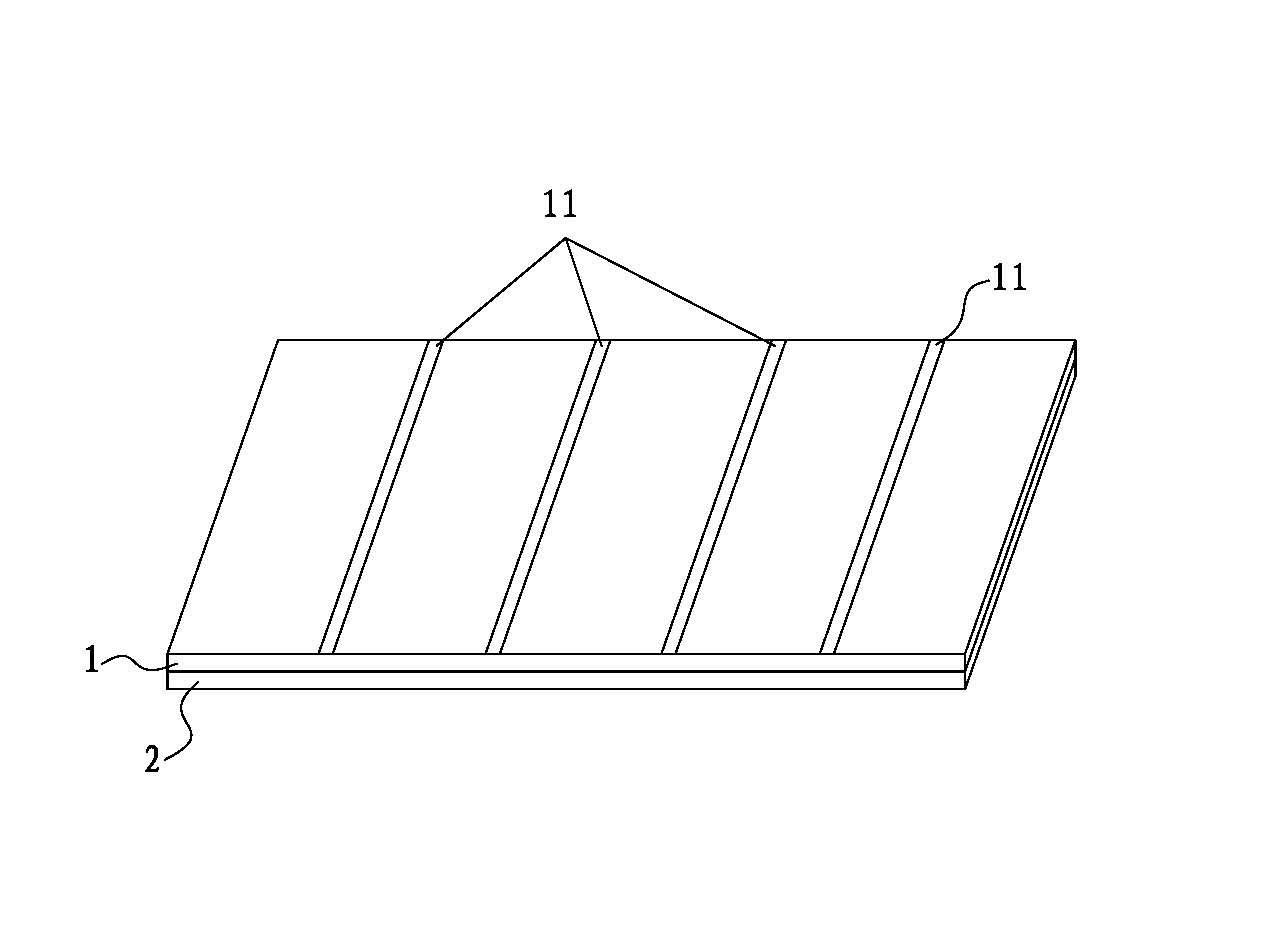

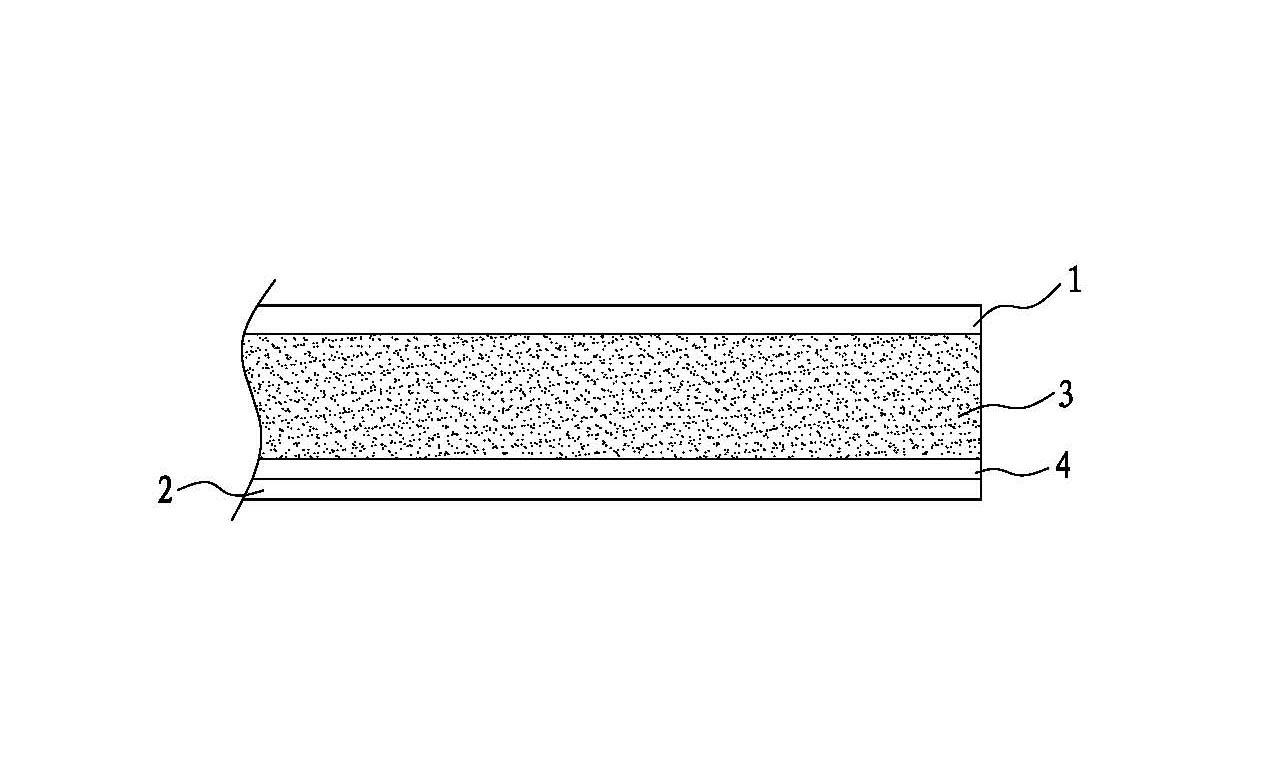

[0029] Such as figure 1 , figure 2 Shown is the first embodiment of a leak-proof down and down product of the present invention, which includes a face cloth 1, a lining 2, a down 3, and a down-proof medium 4.

[0030] Down 3 is filled between the face cloth 1 and the inner cloth 2.

[0031] The anti-fleece medium 4 and the inner surface of the lining 2 are bonded together; the bonding methods are glued hot pressing quilting (staggered linear bonding) or ultrasonic quilting (full surface bonding).

[0032] The face cloth 1 and the inner cloth 2 are provided with ultrasonic quilting or hot pressing quilting 11 connected by glue. The quilting 11 is a regular straight line; the width of the quilting is greater than or equal to 1 mm, and the spacing is greater than or equal to 35 mm. In the present invention, the quilting can also be regular horizontal, vertical, oblique lines, or irregular lines or patterns.

[0033]

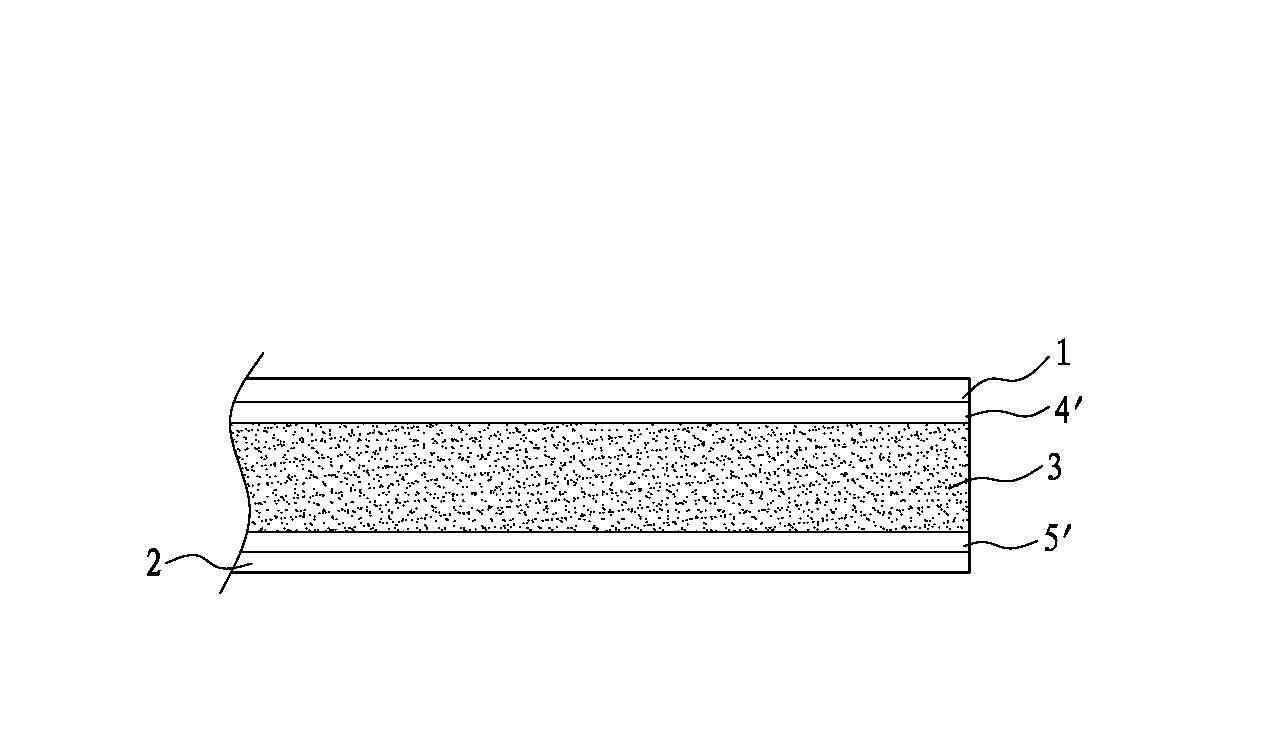

[0034] Such as figure 1 , image 3 Shown is the second embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com