Patents

Literature

258results about "Thread-break detectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

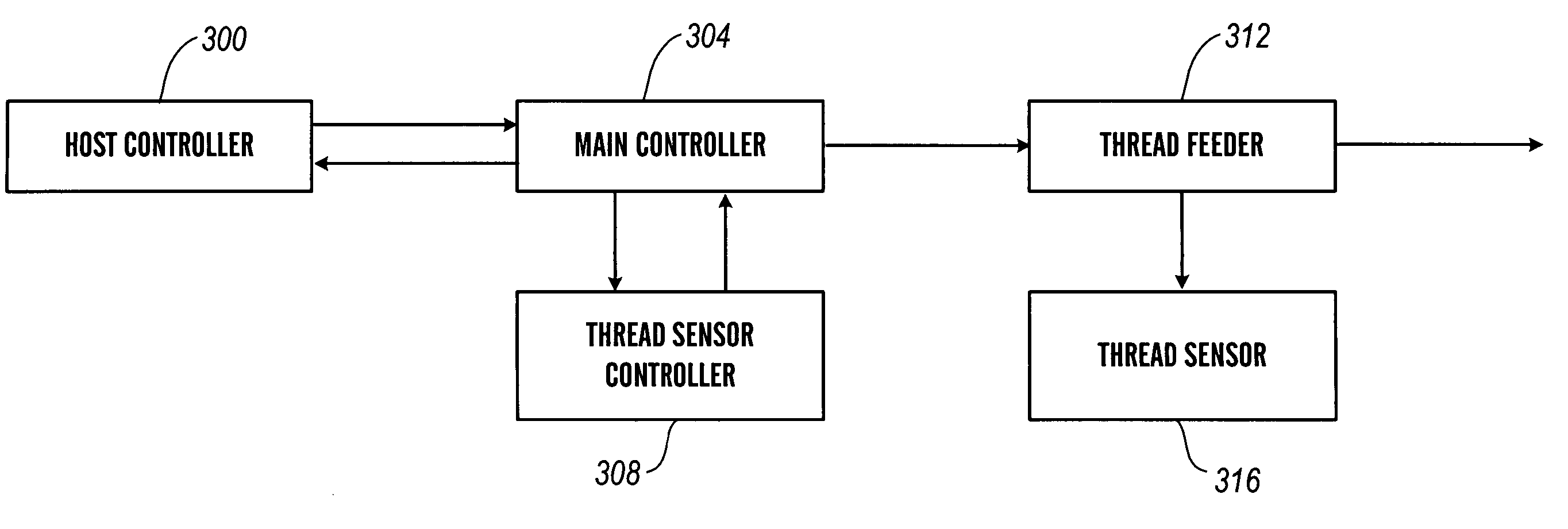

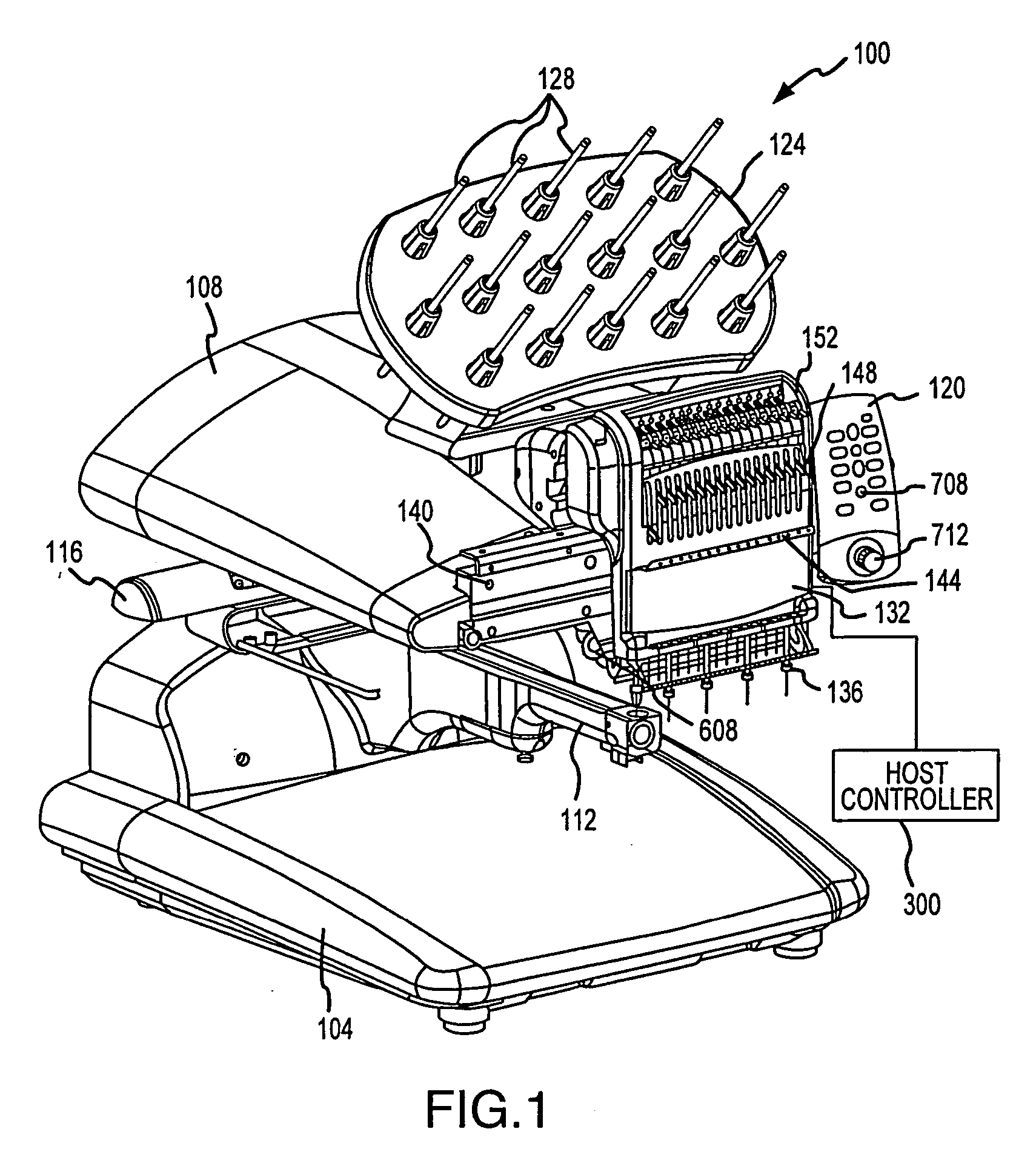

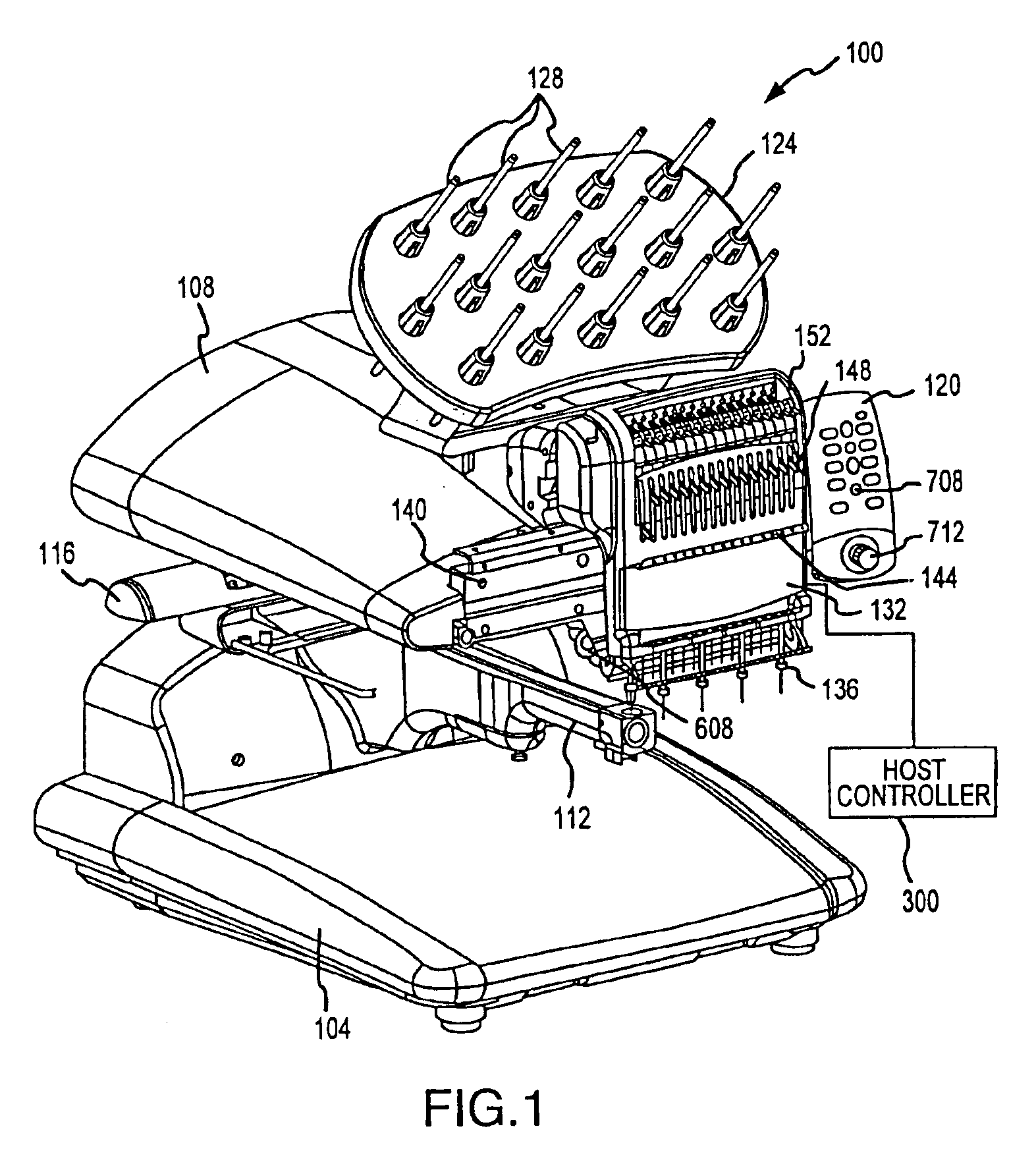

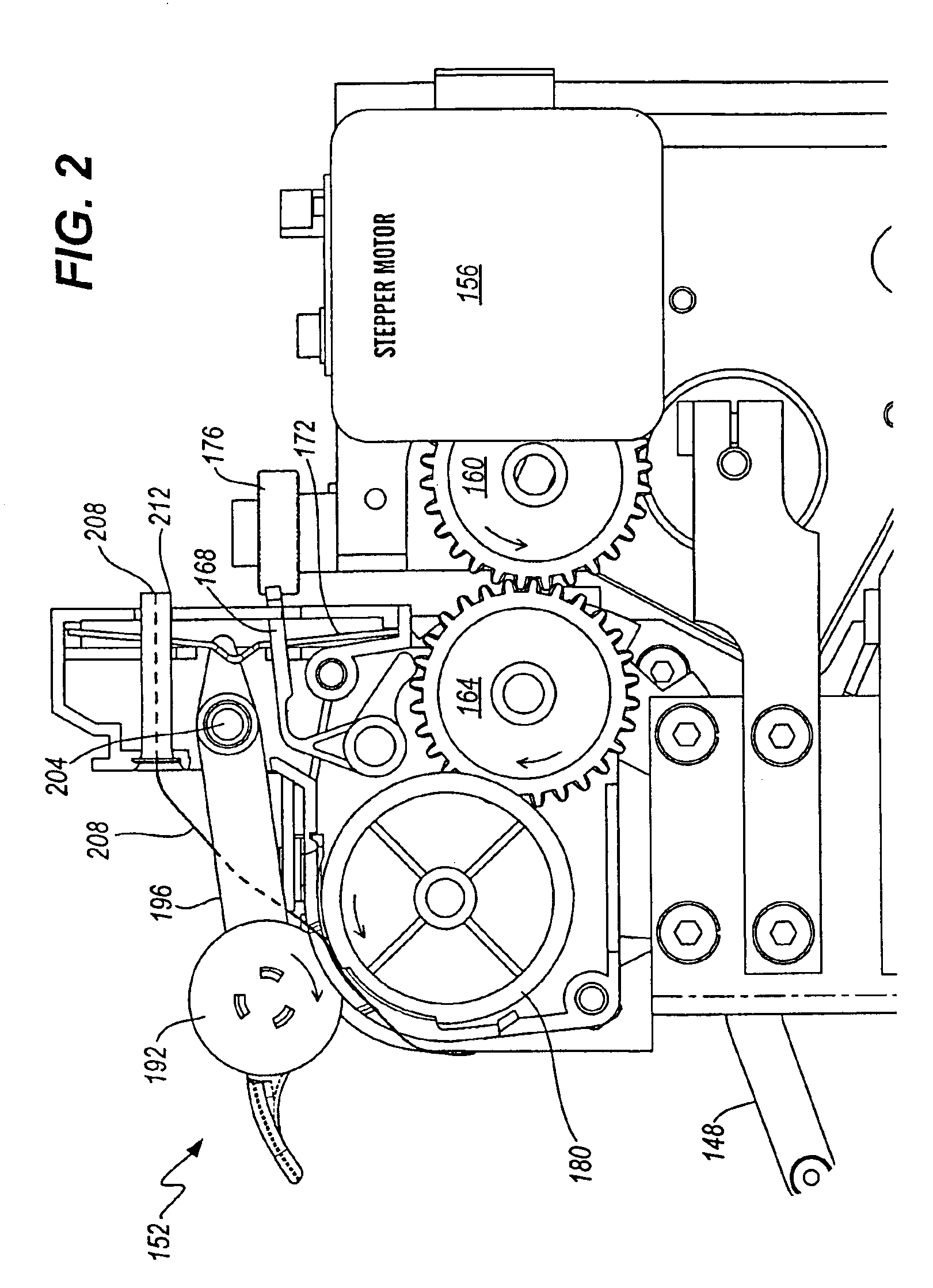

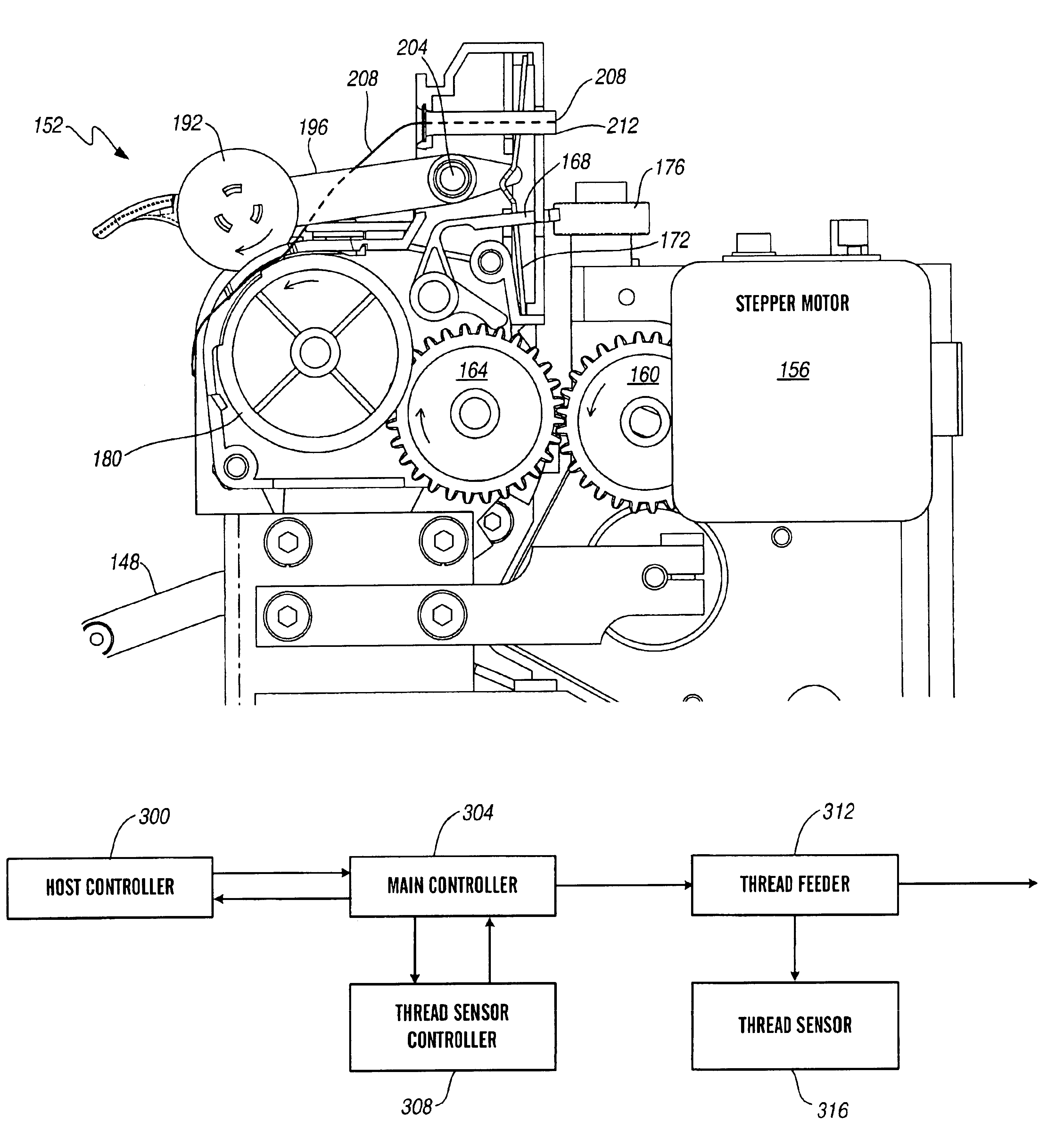

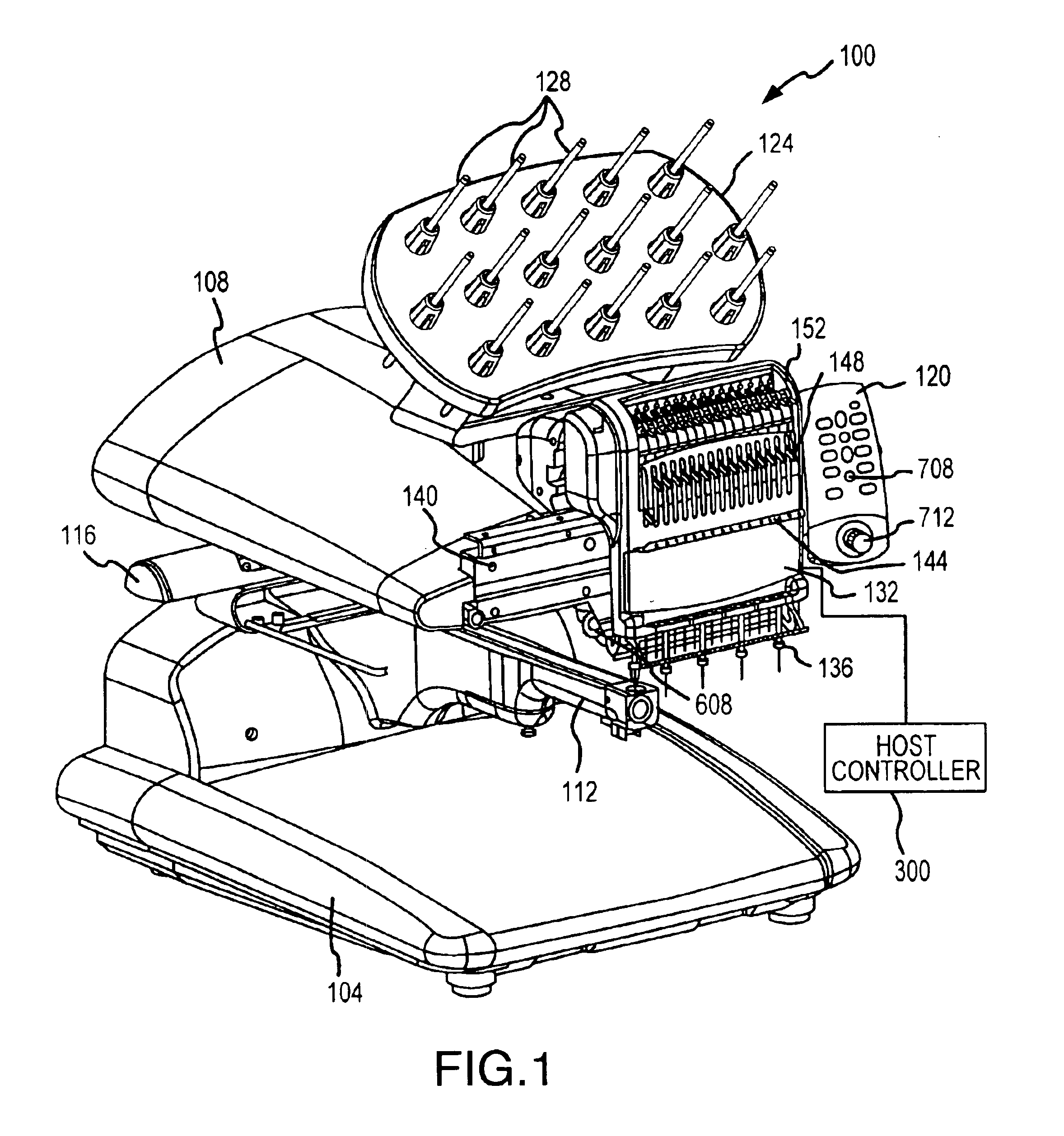

Computerized stitching including embroidering

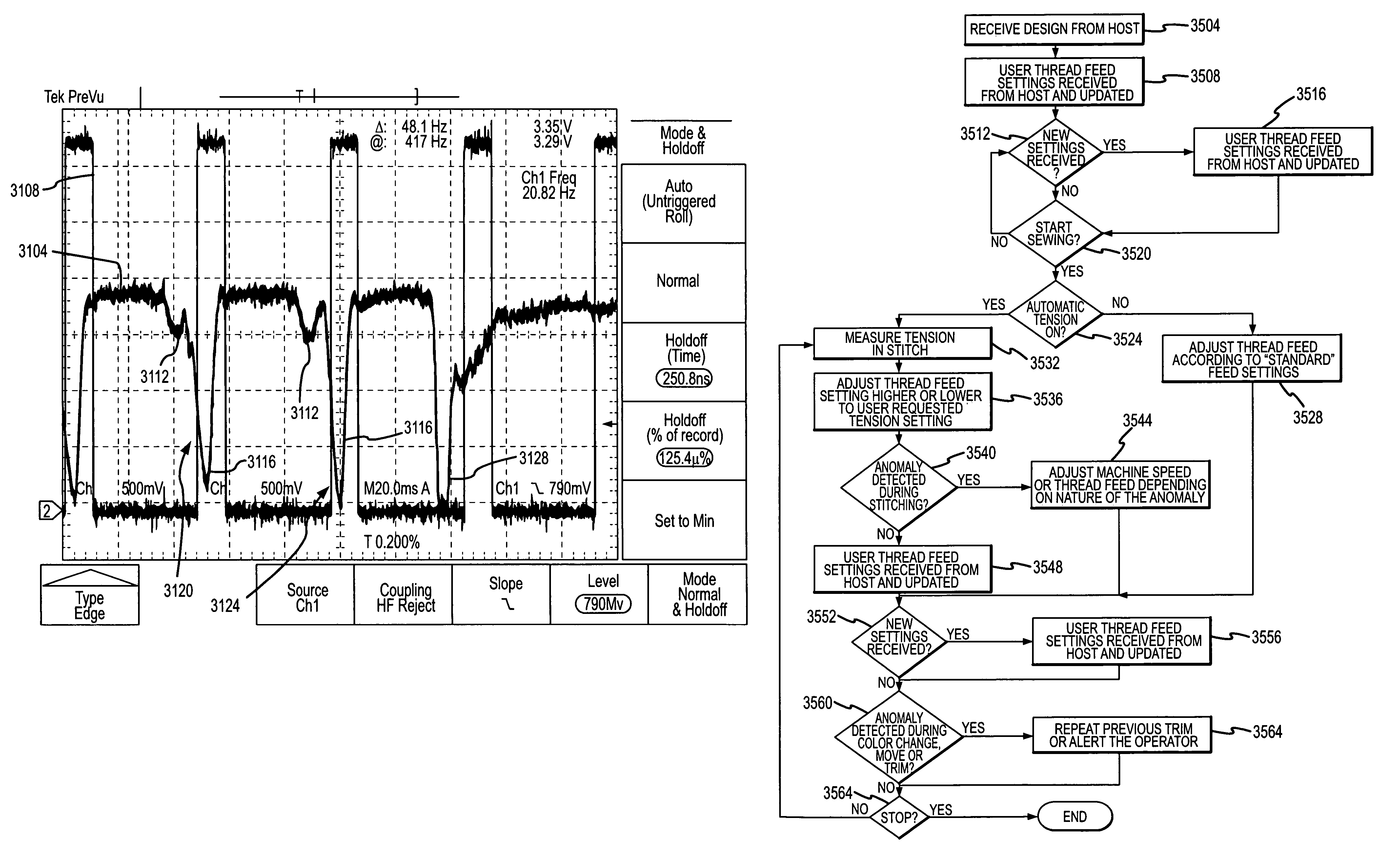

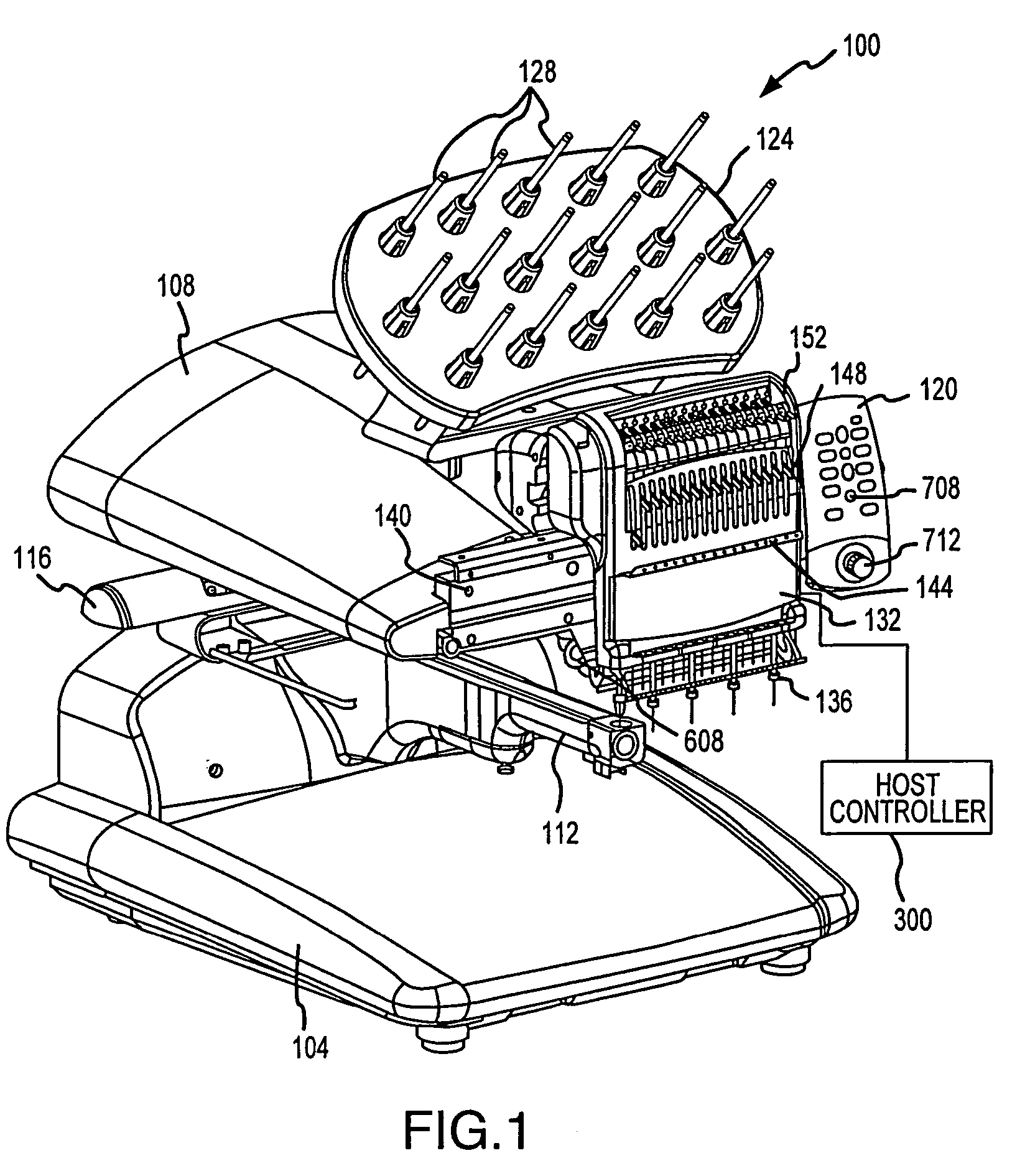

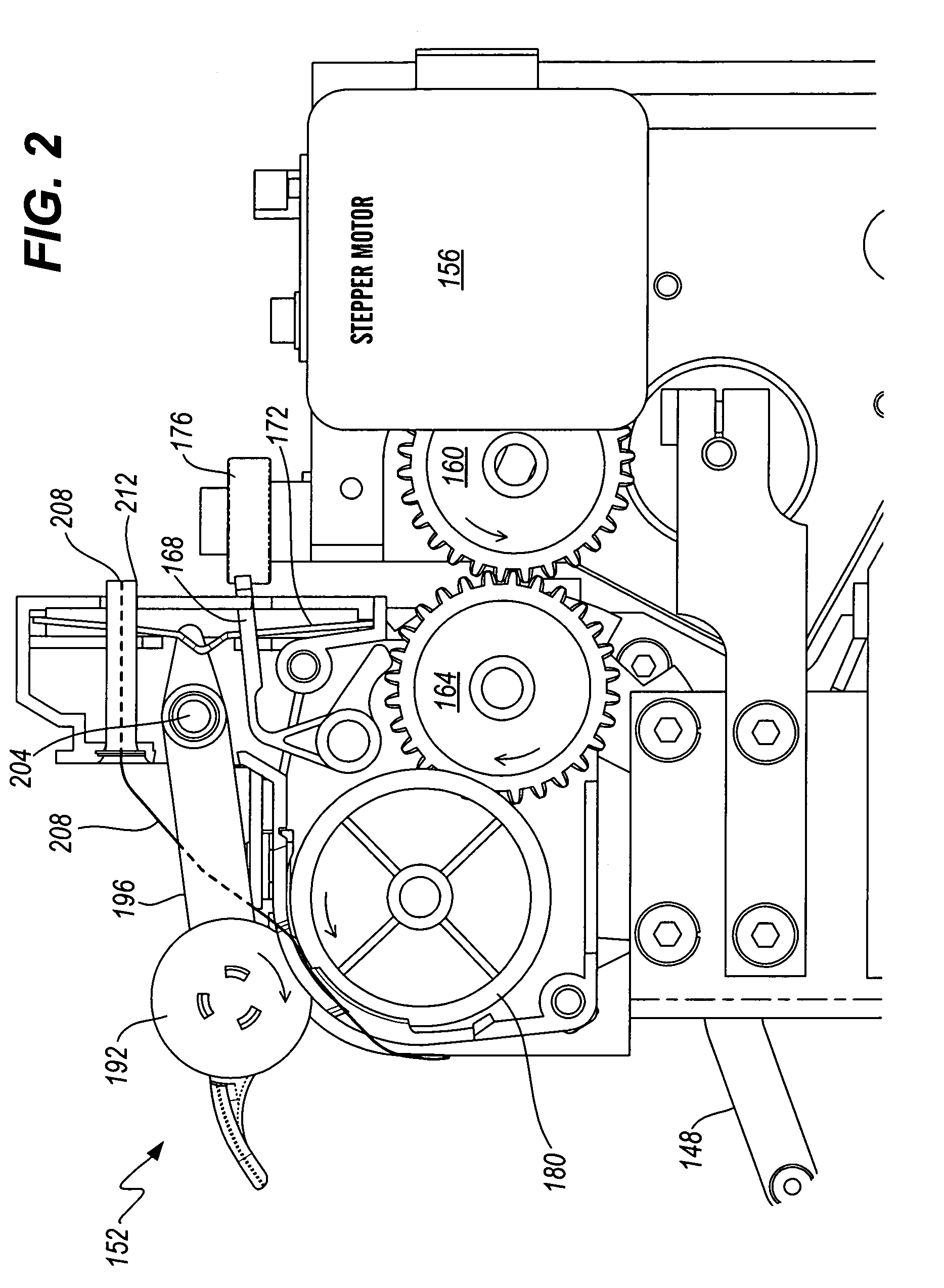

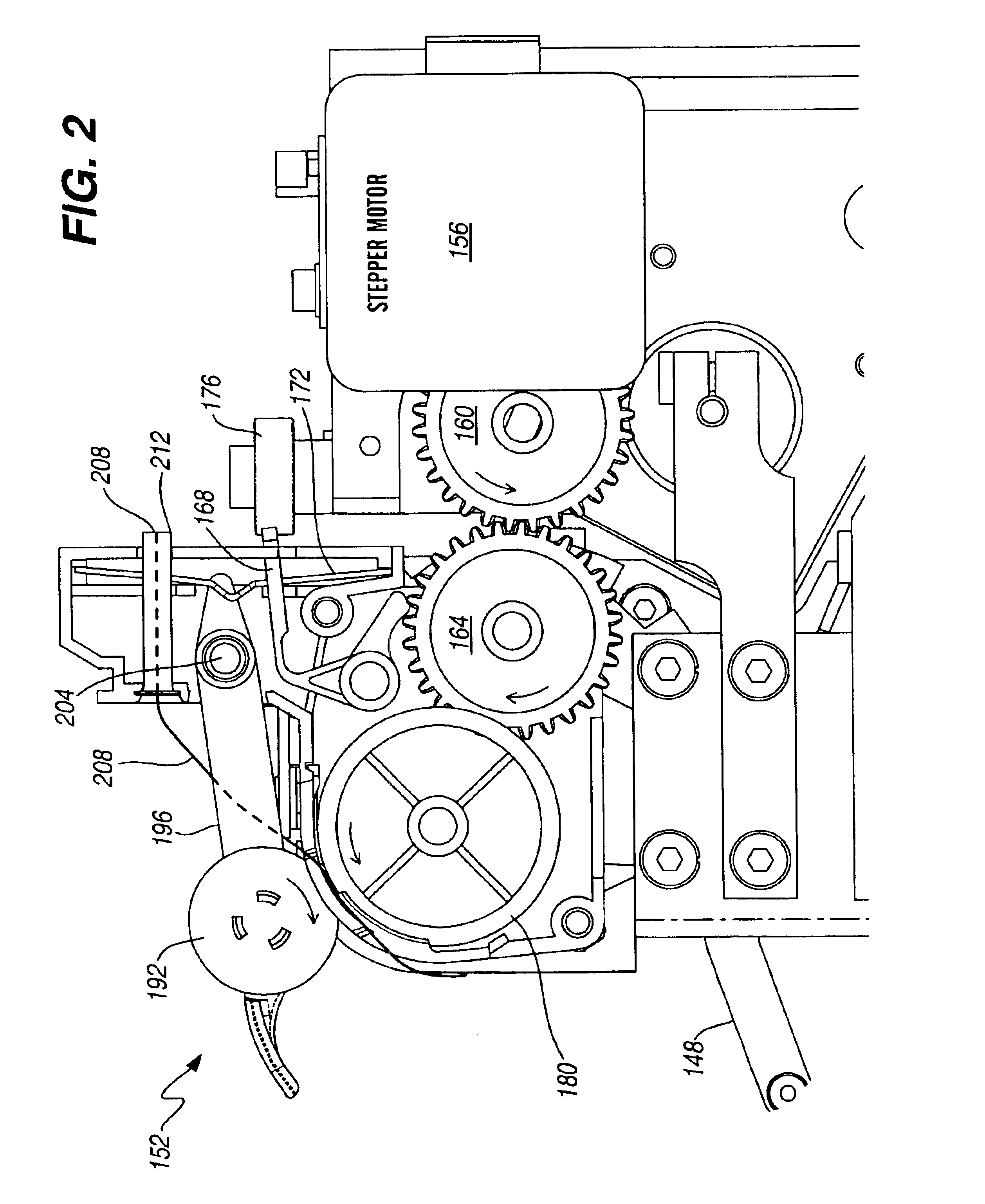

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

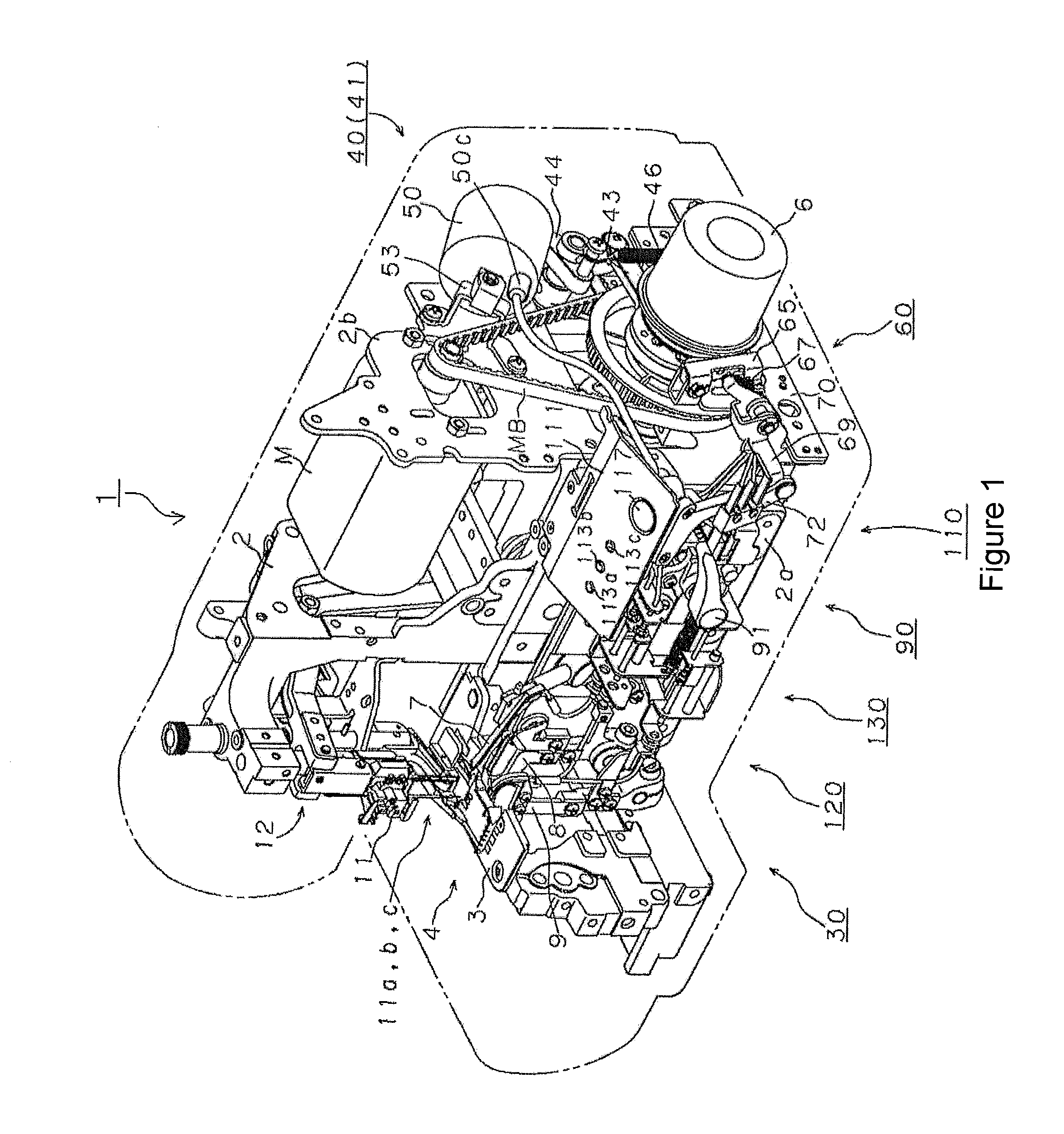

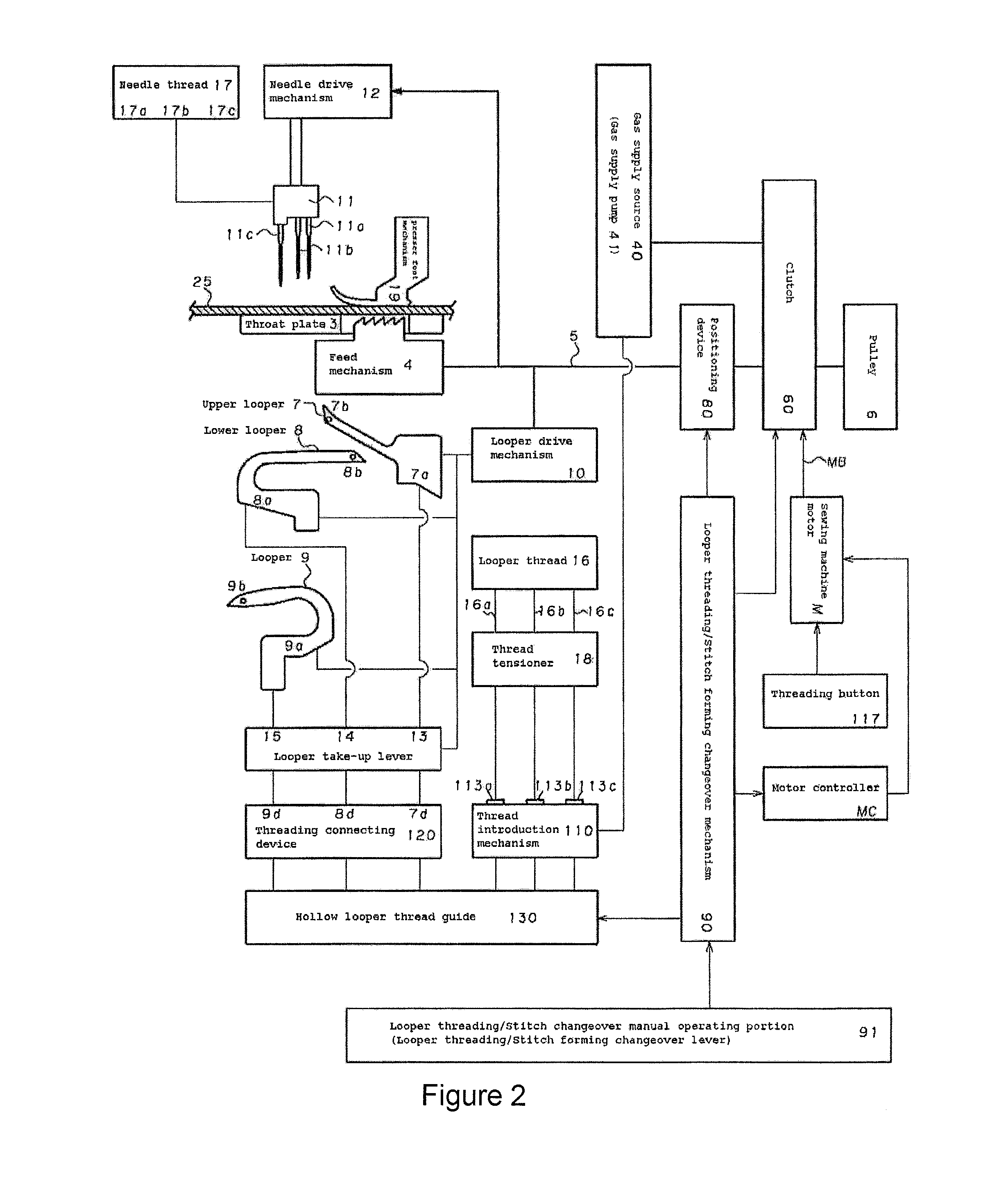

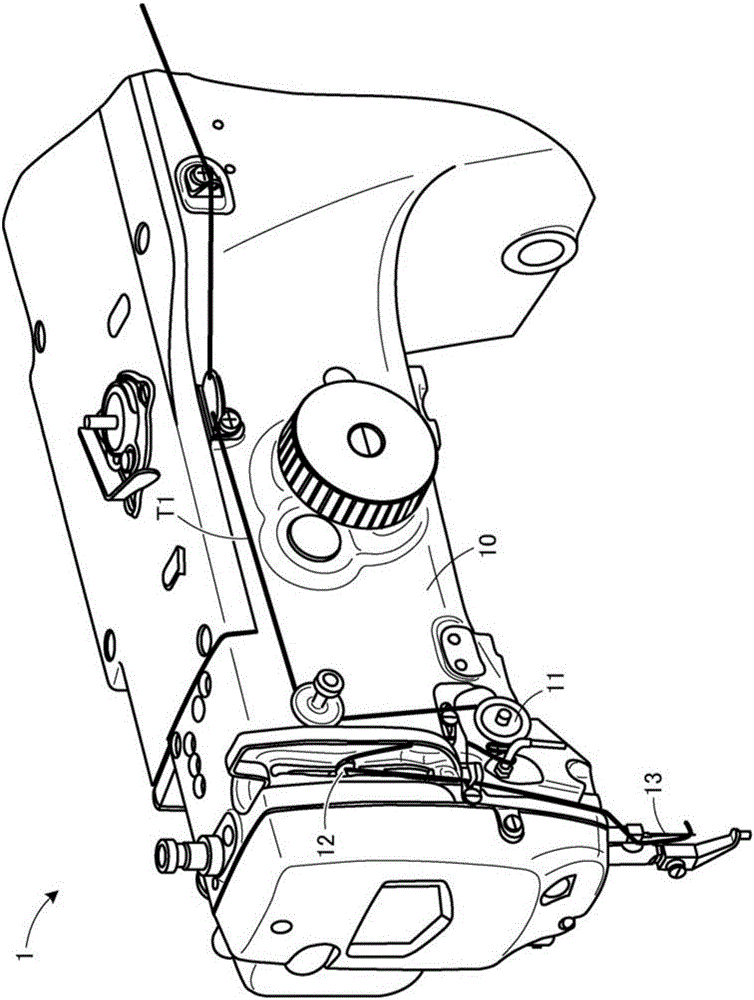

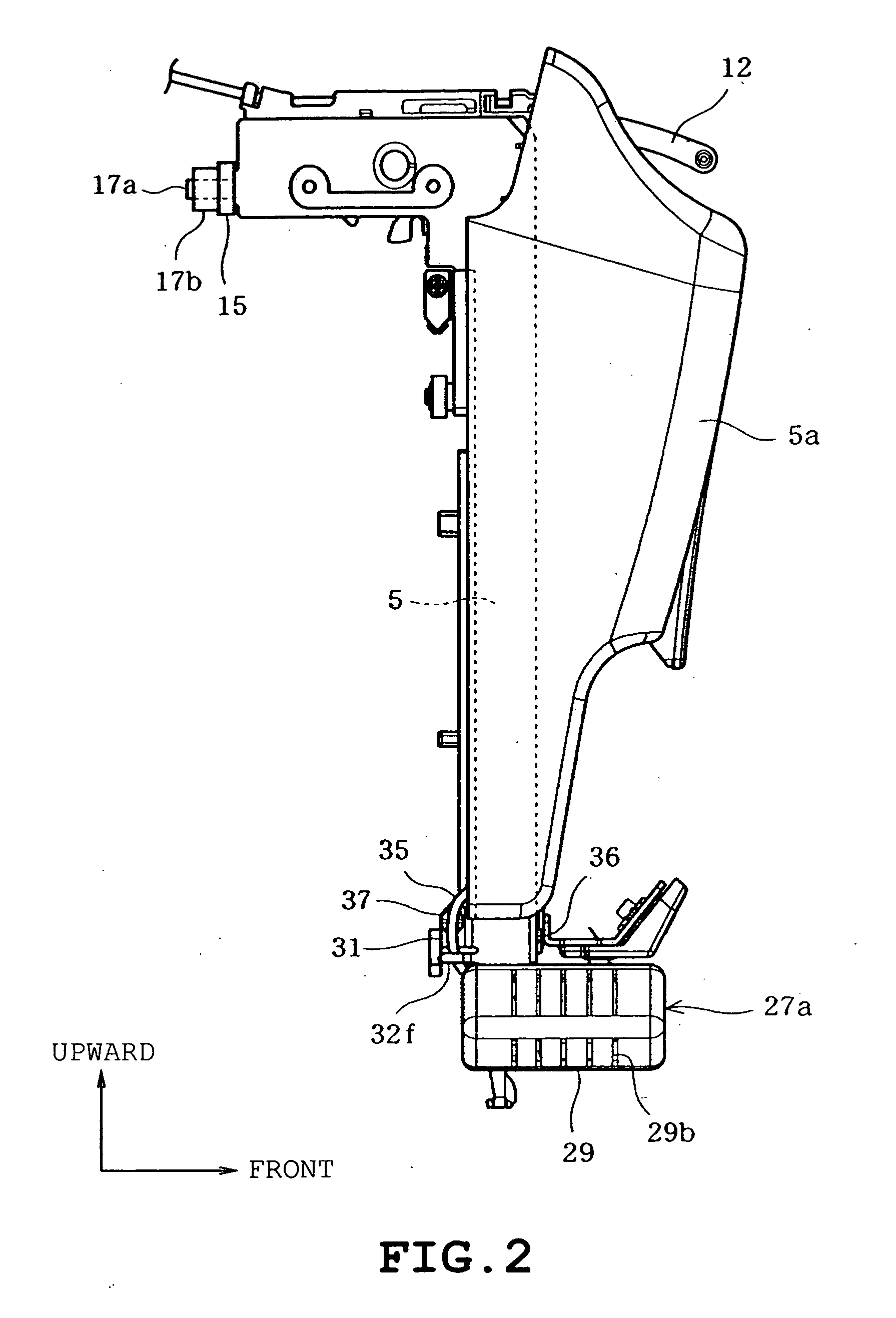

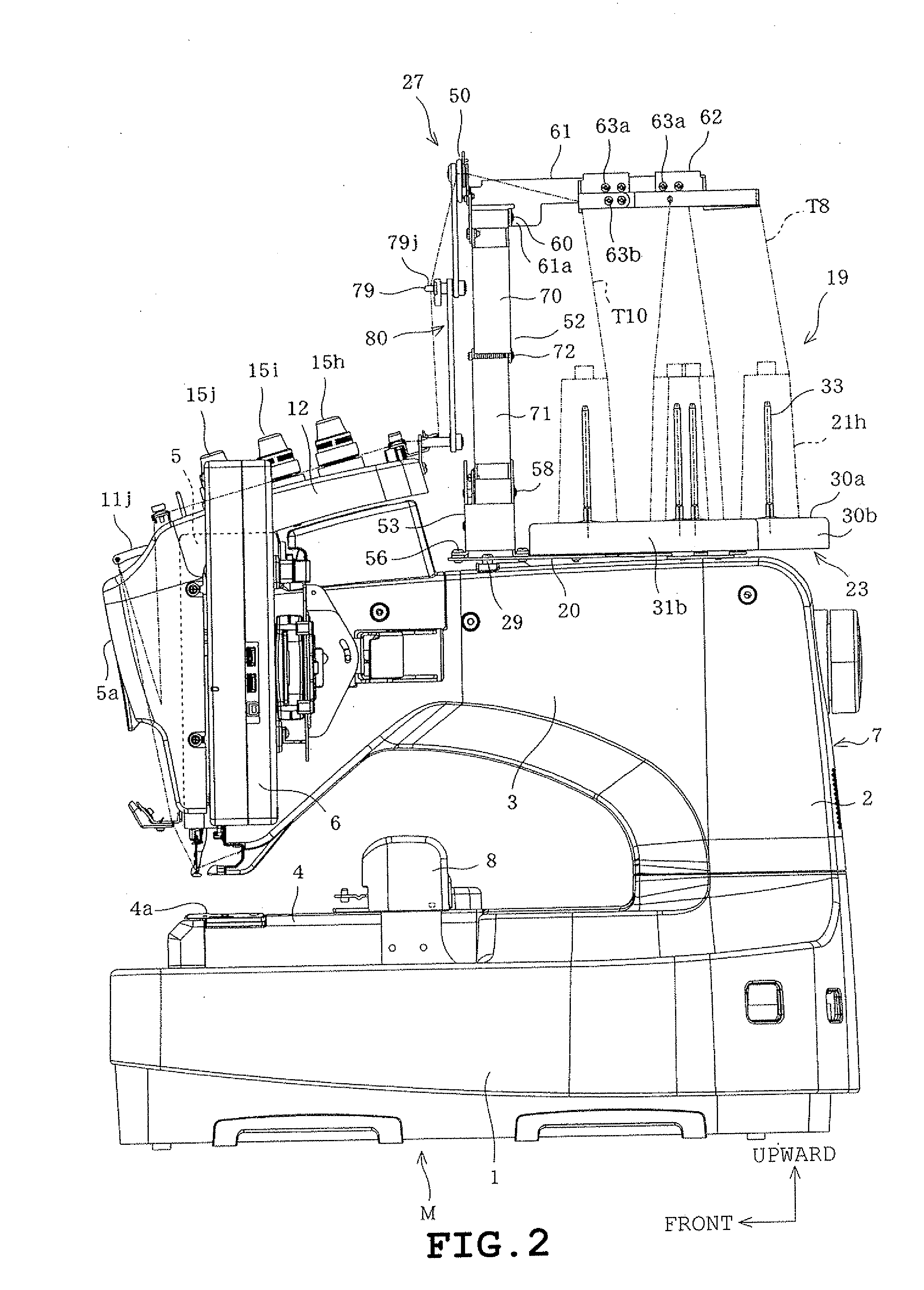

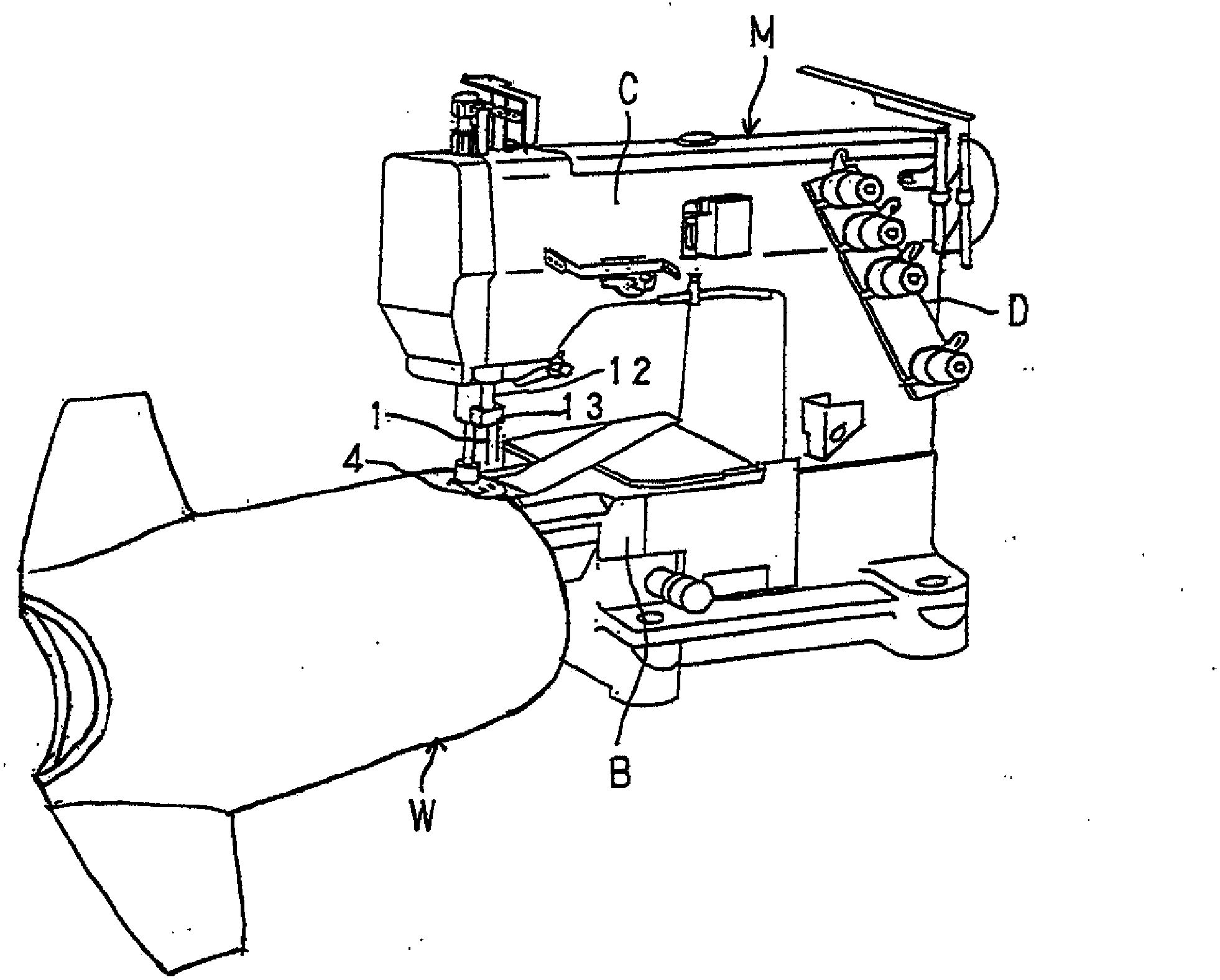

Gas Carrying Threading Device of Sewing Machine

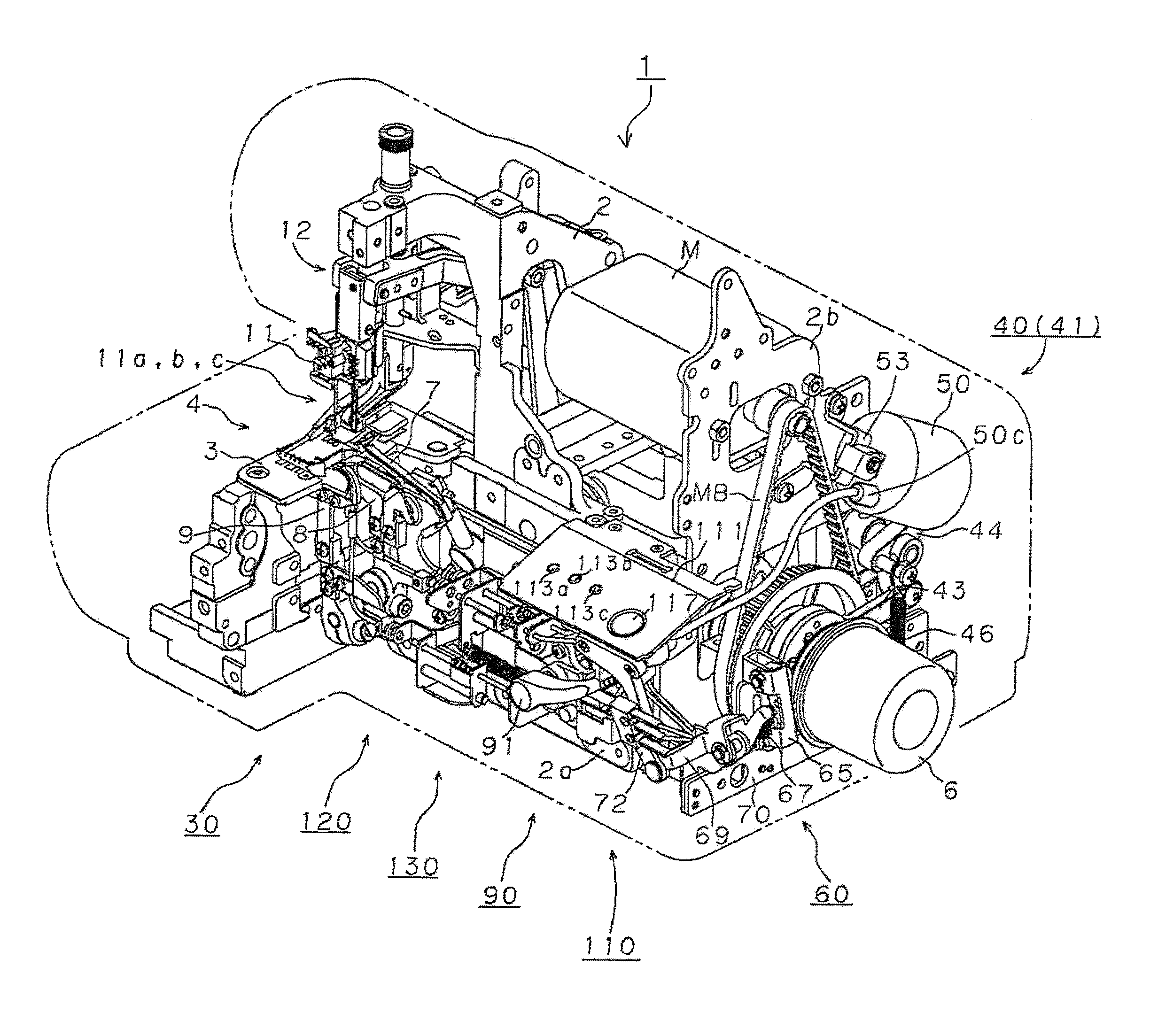

ActiveUS20120210922A1Easy to handleEasy to operateThread-break detectorsNeedle-threading devicesTransmitted powerDrive shaft

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

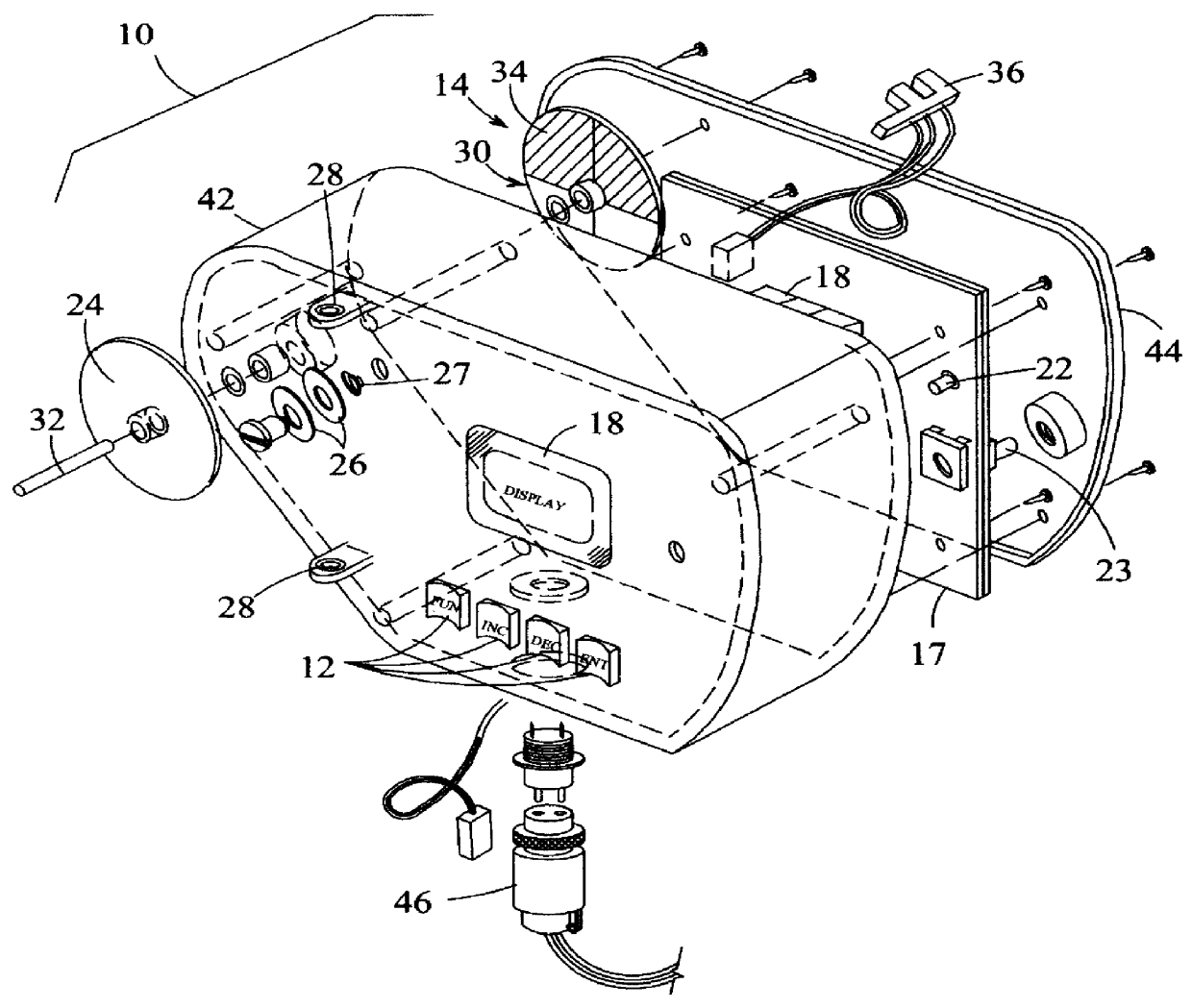

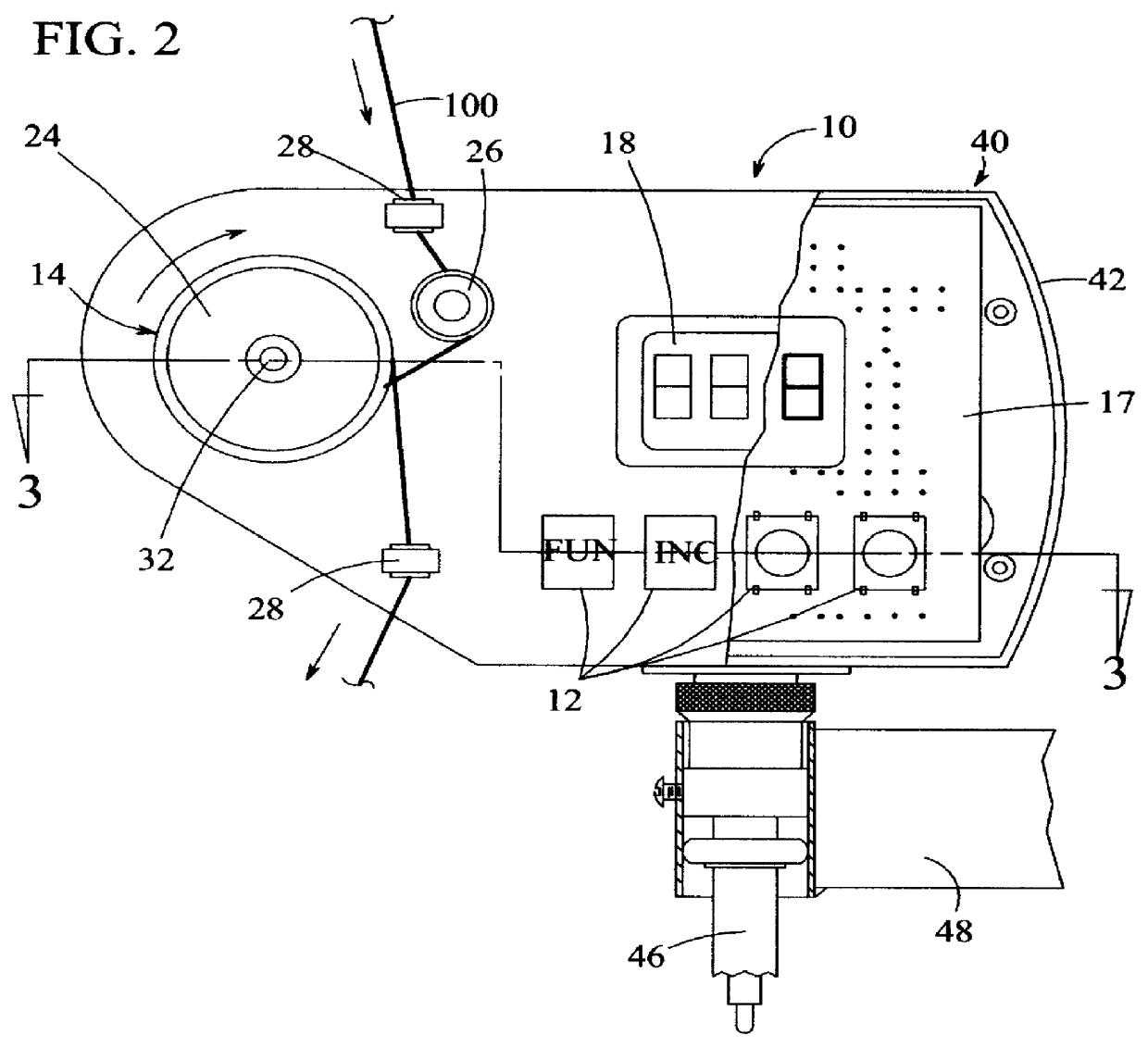

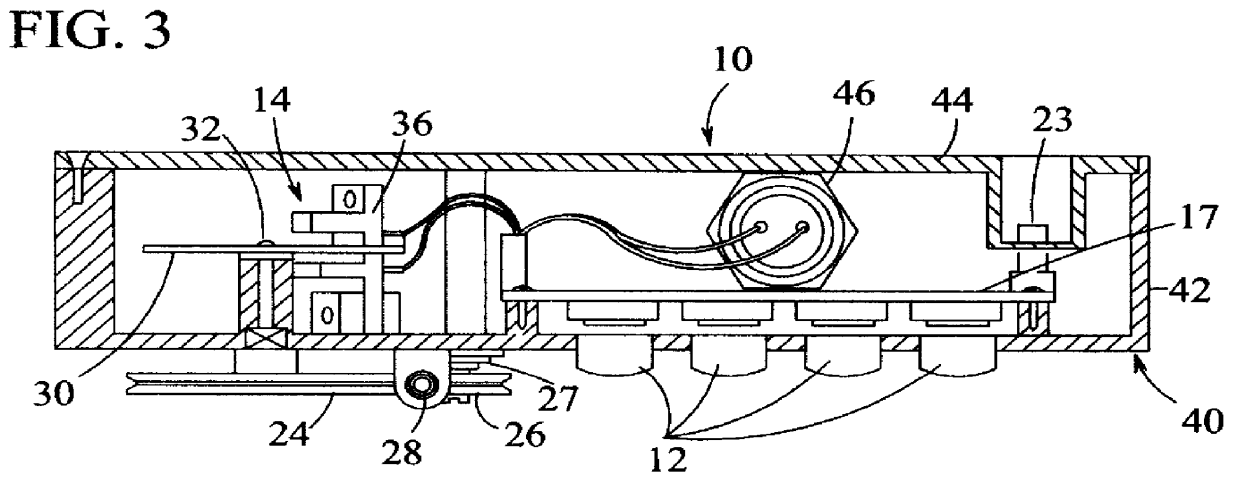

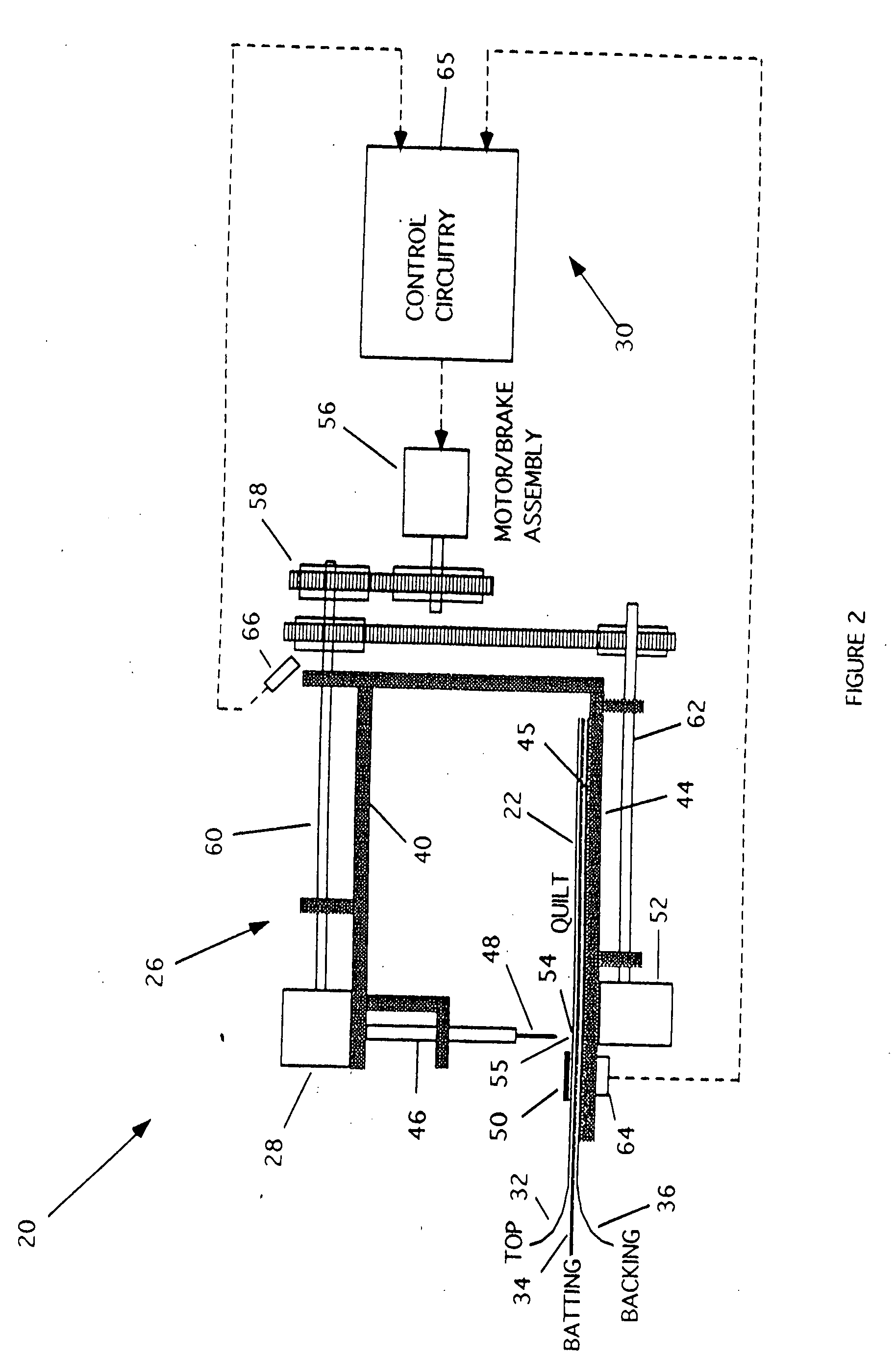

Apparatus and method for monitoring consumption of sewing thread supply

InactiveUS6092478AIncrease the number ofProgramme-controlled sewing machinesHand sewingEngineeringControl circuit

An apparatus for monitoring consumption of a supply of thread includes entry keys for allowing a user to input an initial supply of thread, and a minimum allowable supply of thread, and a detector for providing signals indicative of the rate of thread consumption. The apparatus also includes a control circuit for receiving the initial supply, the minimum allowable supply, and the signal indicative of the rate of thread consumption. The control circuit then calculates a consumed amount of thread and an actual supply of thread remaining, and produces a display signal indicative of the actual supply and / or the consumed amount, and an alarm when the actual supply of thread is equal to or less than the minimum allowable supply. The apparatus further includes a display panel for displaying the actual supply and the consumed amount upon receipt of the display signal from the control circuit.

Owner:SINGER COMPANY NV THE

Stitch Outlet Detection Device, Sewing Machine And Stitch Outlet Detection Method

The invention provides a stitch outlet detecting device of a sewing machine which can detect a stitching with high accuracy and is unaffected by elongation of a thread or sewing unevenness. The stitch outlet detecting device (21) of a sewing machine forms a stitch by detecting a top thread loop formed by a sewing needle by using a rotary kettle and by causing a top thread and a bottom thread to cross each other. The device comprises: a rotary member (33), which rolls the top thread to the center of a thread path extending from a thread reel of the top thread; a motor (29) which causes the rotary member to rotate so as to apply a tension to the top thread upon feeding the top thread from the thread reel; and a detection unit (22) which monitors a predetermined portion immediately before the upper top loop is released from the rotary kettle, and detects the stitch outlet of the behavior of the motor in the predetermined portion.

Owner:JUKI CORP

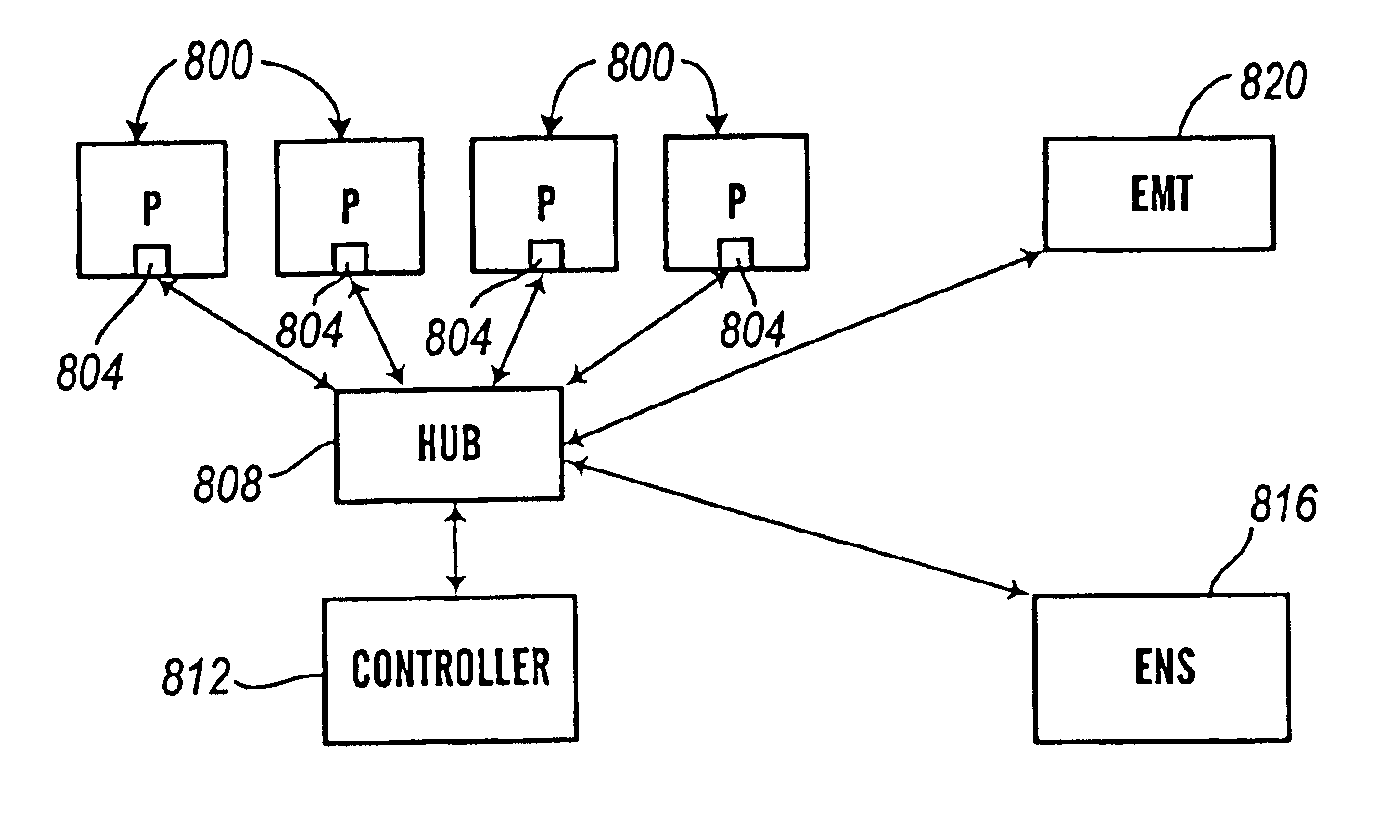

Computerized stitching including embroidering

InactiveUS6983192B2Reduce in quantityIncrease flexibilityProgramme-controlled sewing machinesCombination sewing machinesControl systemEngineering

A plurality of stitching machines and a control system used in stitching patterns into a plurality of items is capable of flexible control. The plurality of stitching machines may include one or more clusters of stitching machines, with each cluster able to stitch patterns into items independently of other clusters. Stitching machines within the plurality of stitching machines, or within the clusters of stitching machines, may be set to stitch patterns into items using one of a synchronized mode and an unsynchronized mode. When in the synchronized mode, the stitching machines perform stitching substantially synchronously with other stitching machines, and when in the unsynchronized mode the stitching machines perform stitching independently of the status of other stitching machines.

Owner:MELCO INT

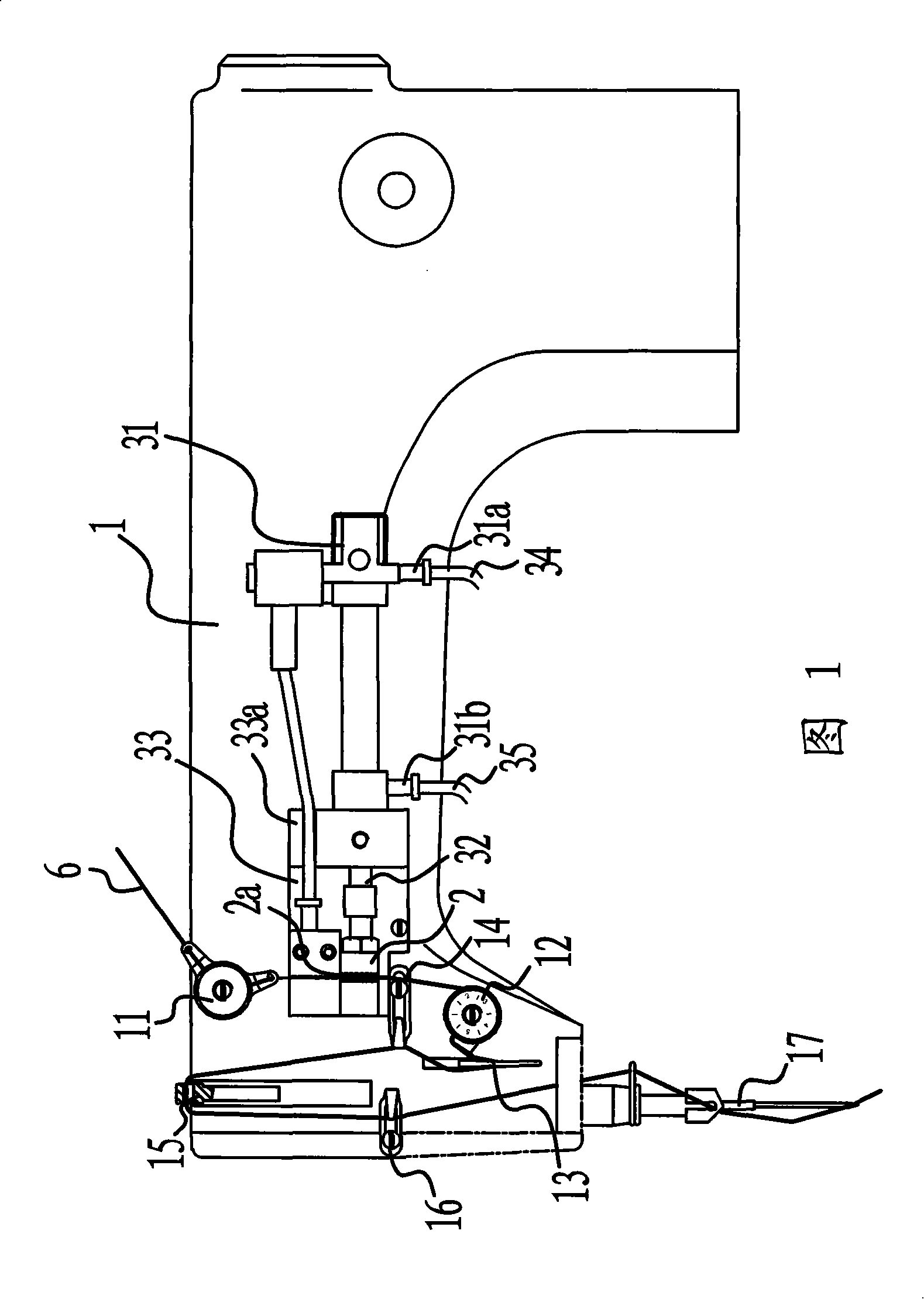

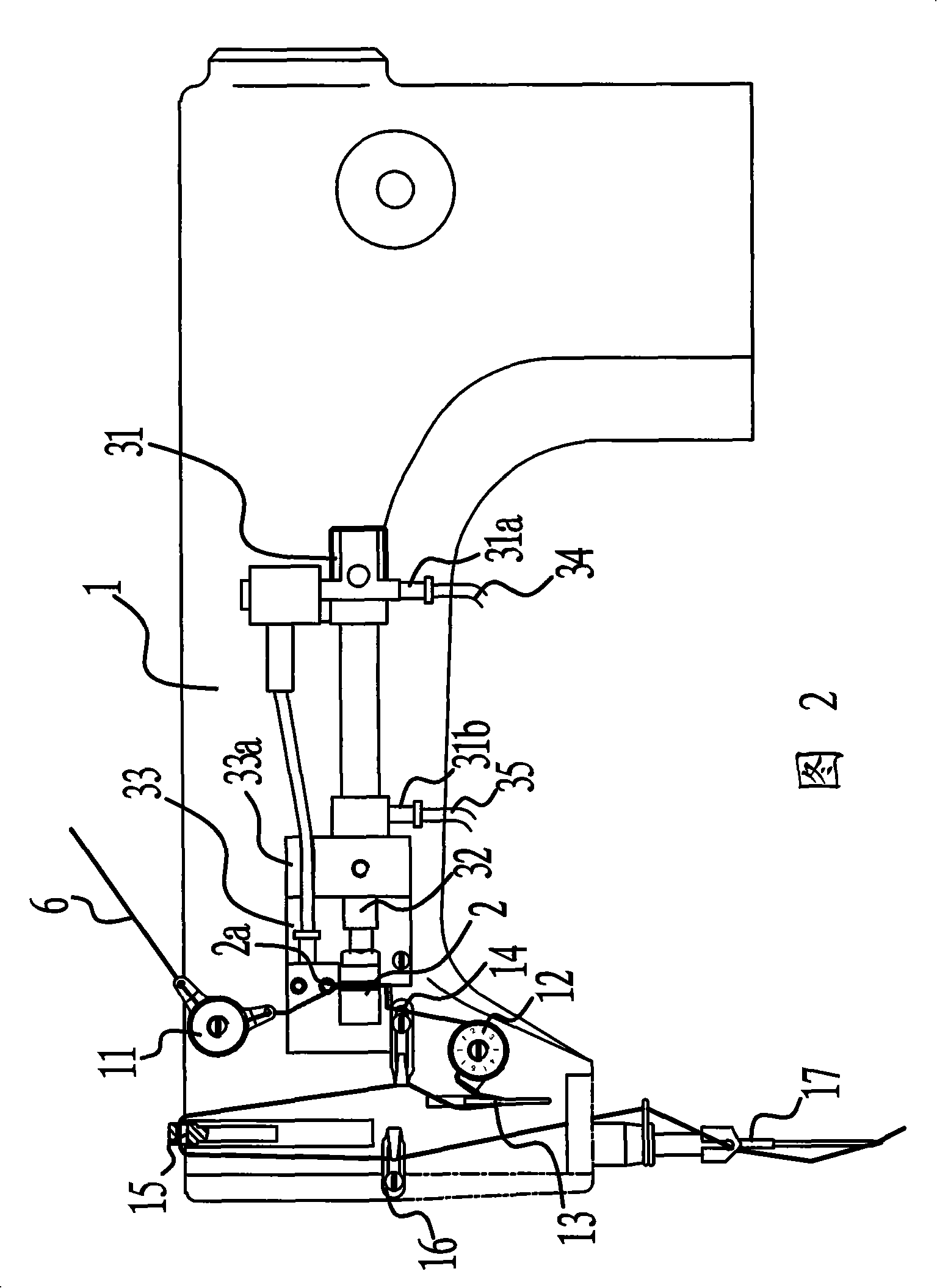

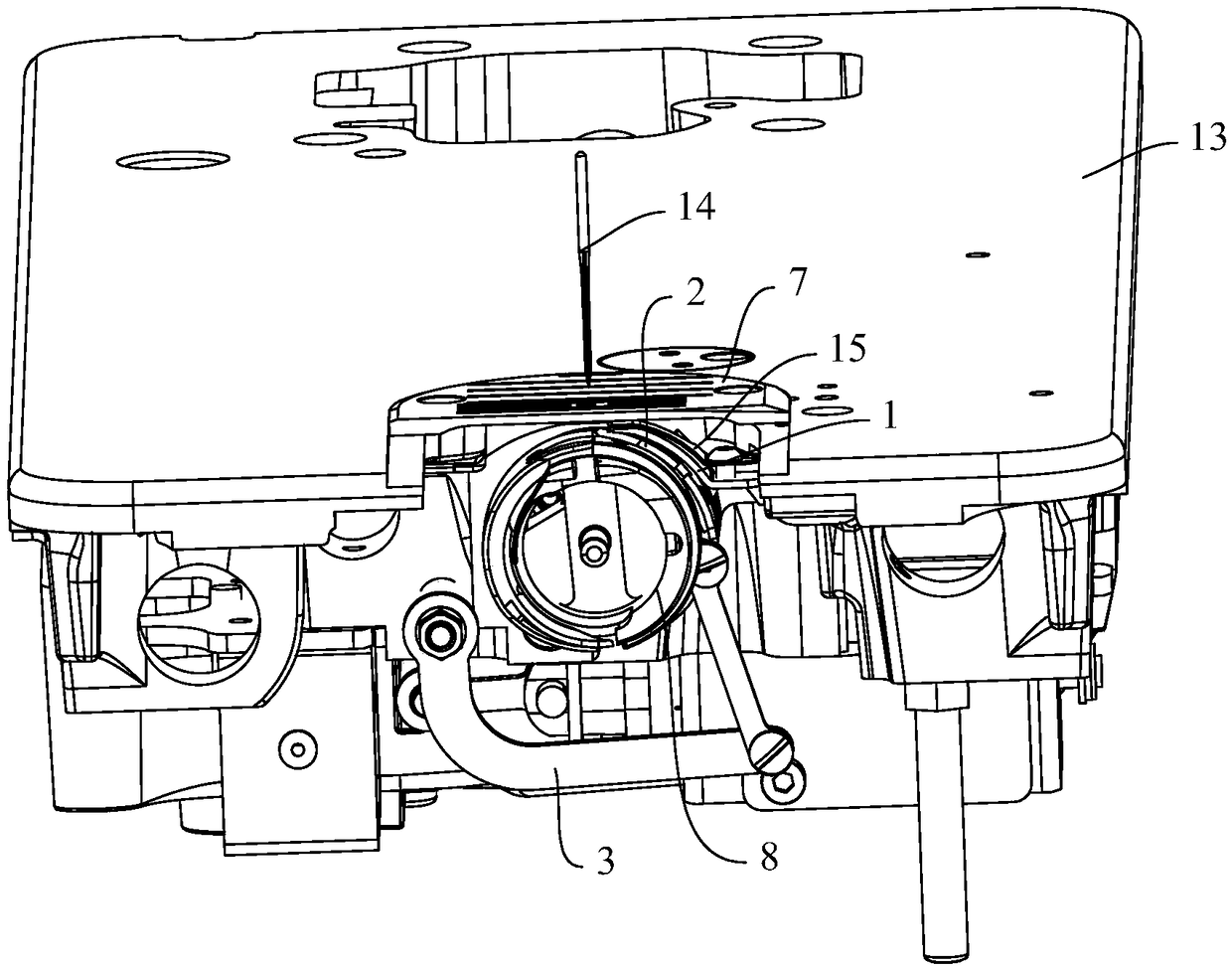

Thread drawing device of sewing machine

InactiveCN101158089AImprove sewing qualityImprove work efficiencyNeedle severing devicesThread-break detectorsEngineeringComputer control

The invention provides a wire grip of a sewing machine, pertaining to the sewing machine field, which solves the problem that: an ordinary computer controlled flat bed sewing machine tends to cause a nest-shaped stitch. The wire grip of the sewing machine is positioned on a machine head of the sewing machine and between a small wire clamping nut and a wire clamping device; the wire grip consists of a wire drawing head arranged on the machine head and a drive device that can ensure the wire drawing head to slide to and fro along the level direction, and the wire drawing head is provided with a through hole for passing a sewing wire. The wire grip of the sewing machine has the advantages that the nest shaped stitch does not be produced during the sewing process, so the stitch is beautiful; moreover, the wire grip has the advantages of simple whole structure, convenient operation and using, low manufacturing cost, and good working stability.

Owner:JACK SEWING MASCH CO LTD

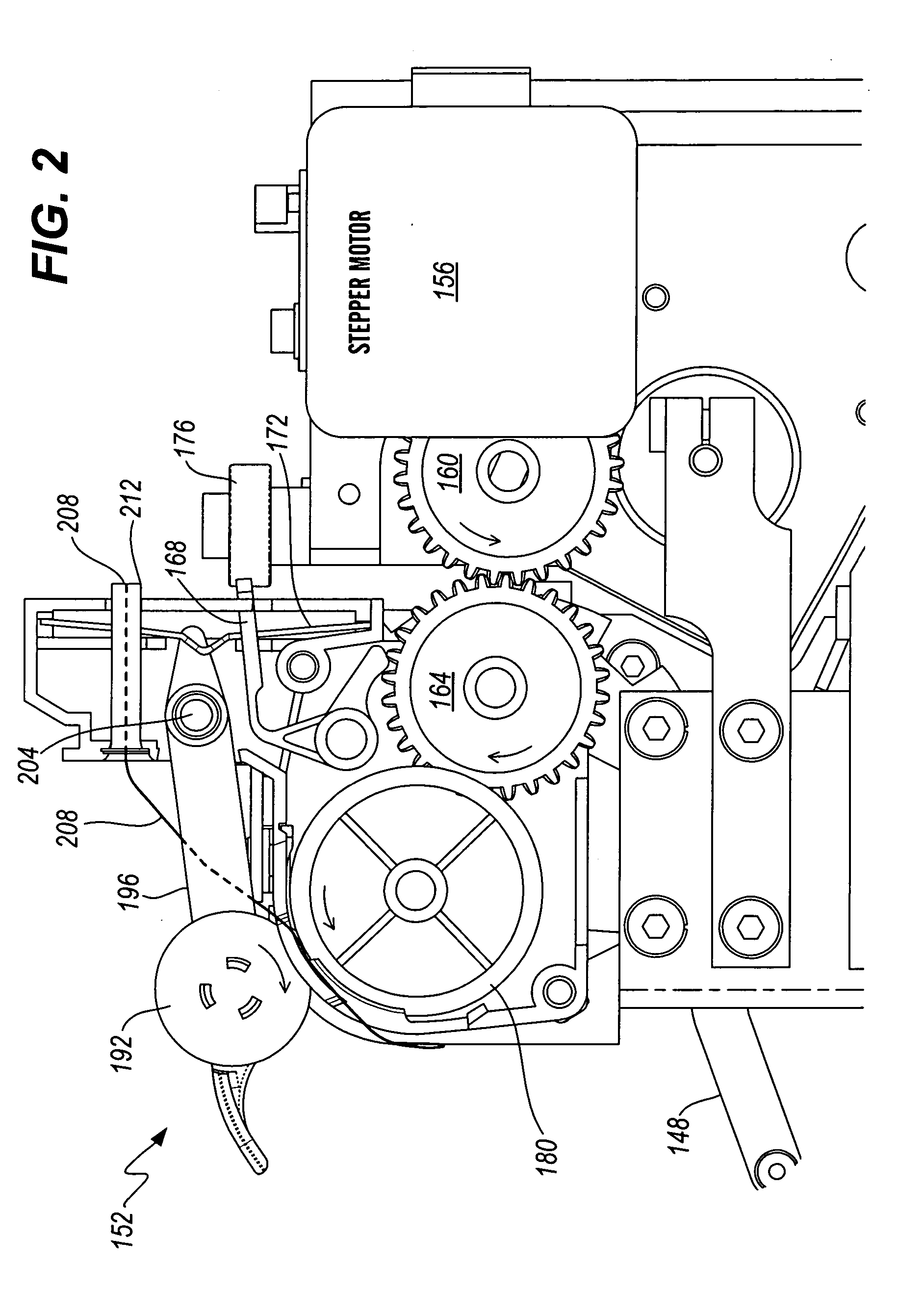

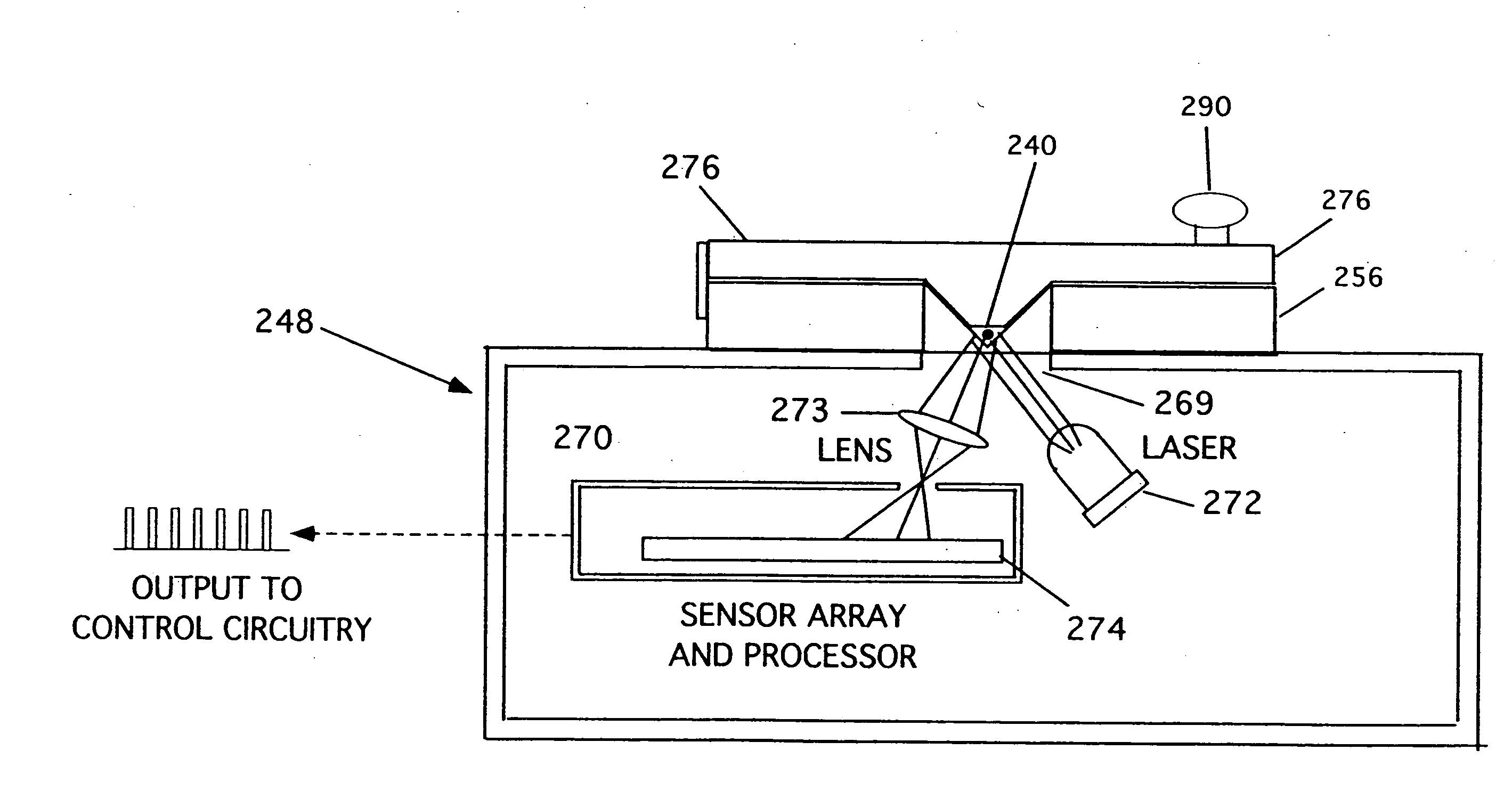

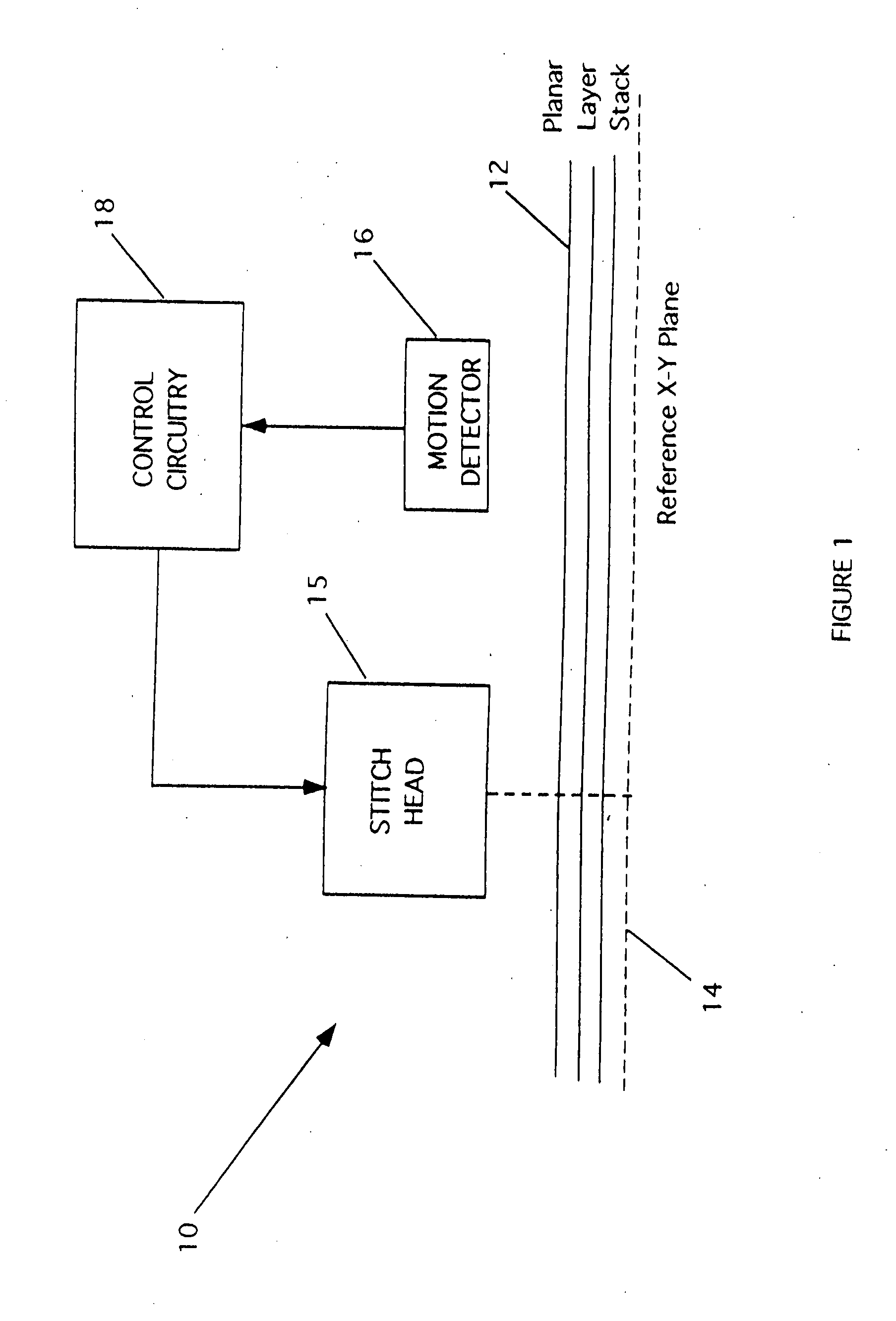

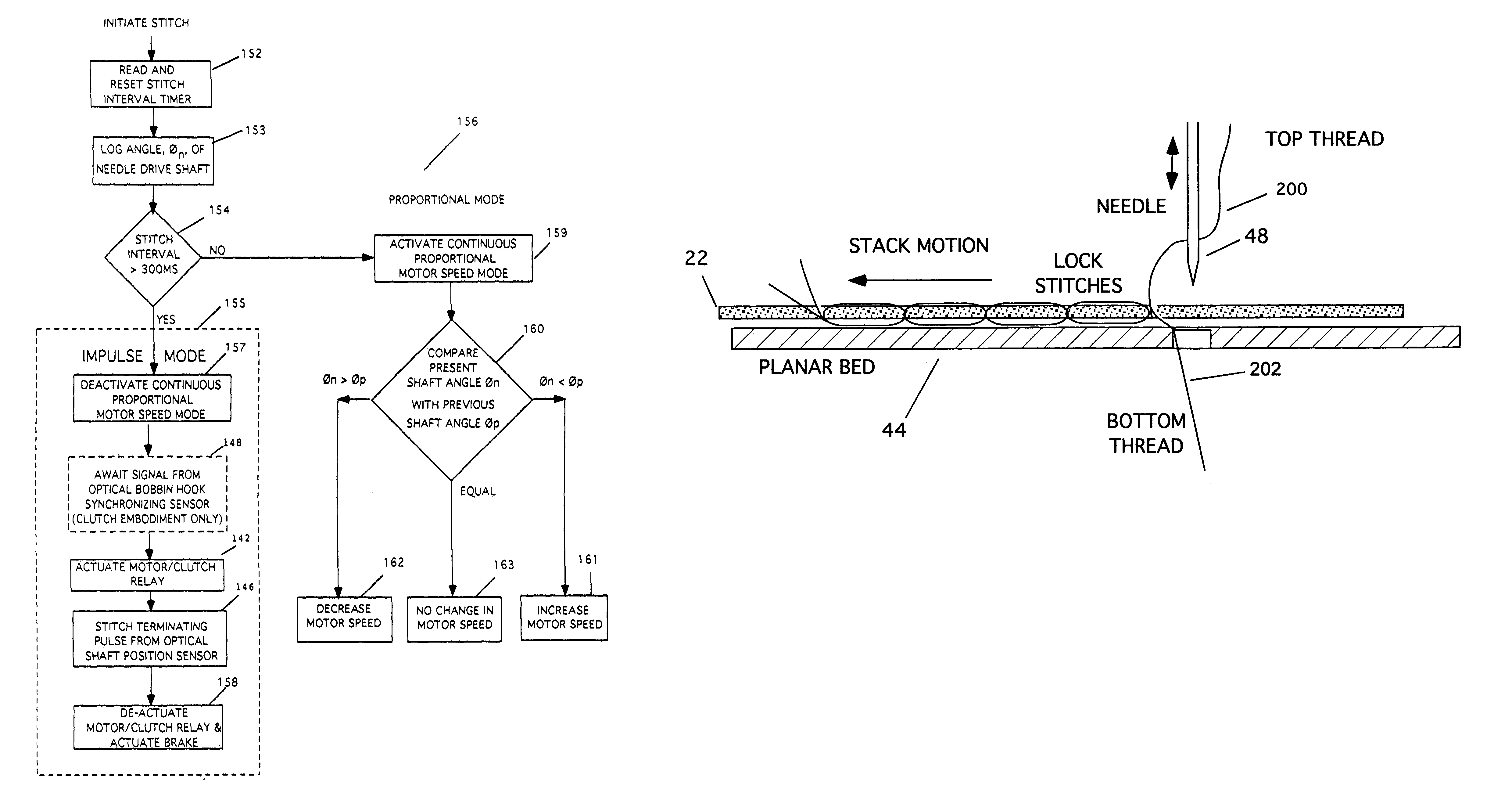

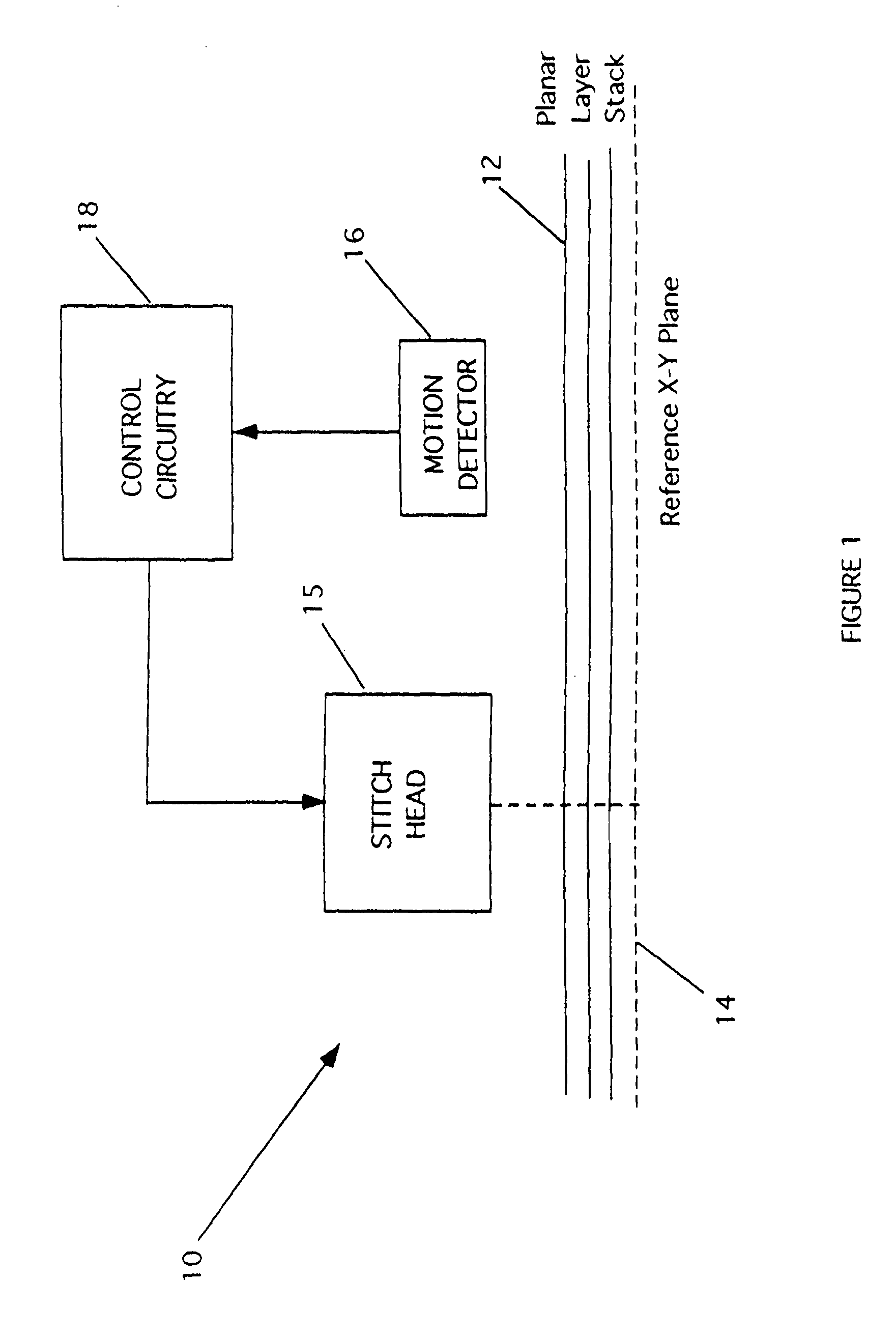

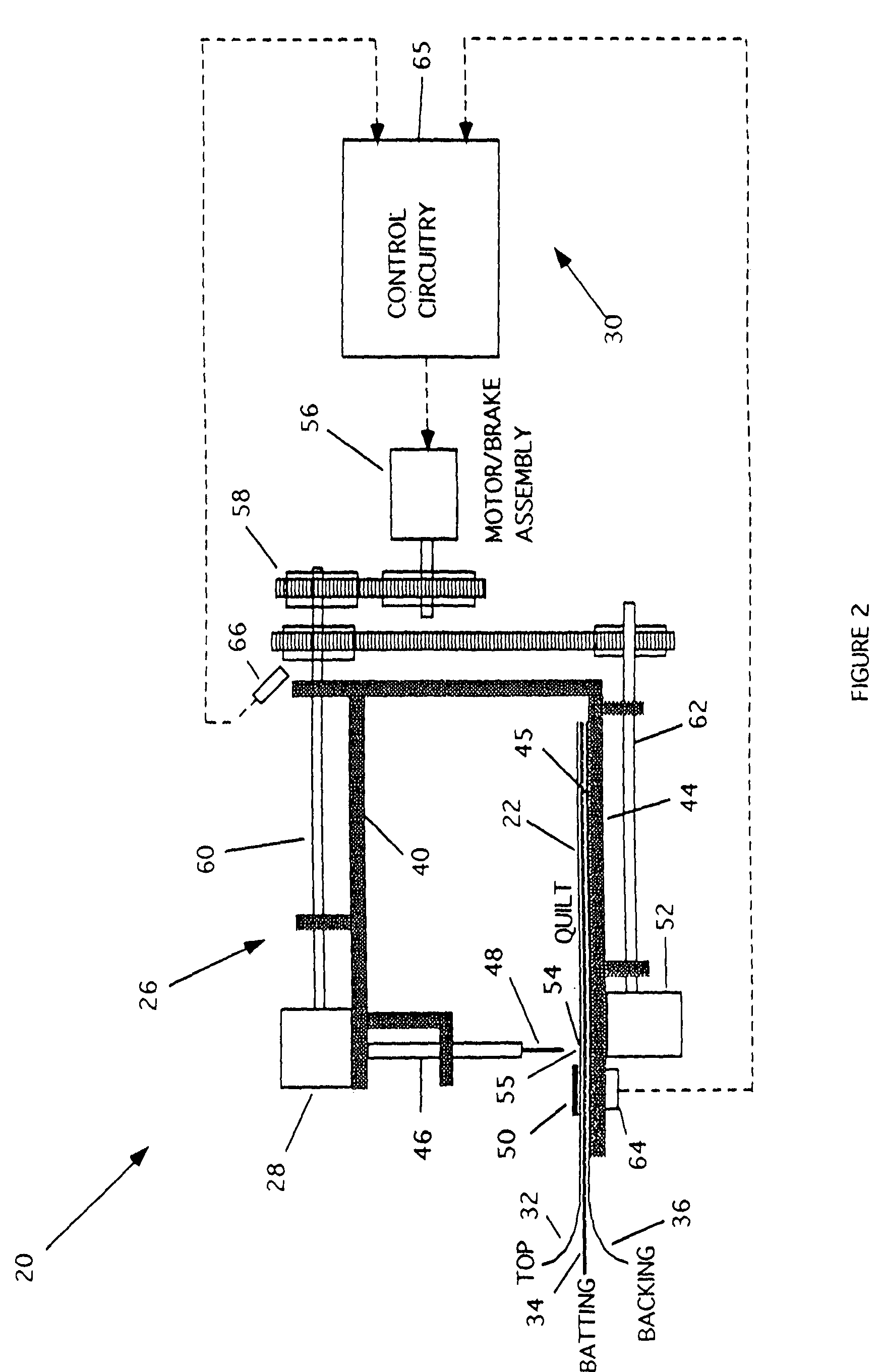

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS20070256619A1Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

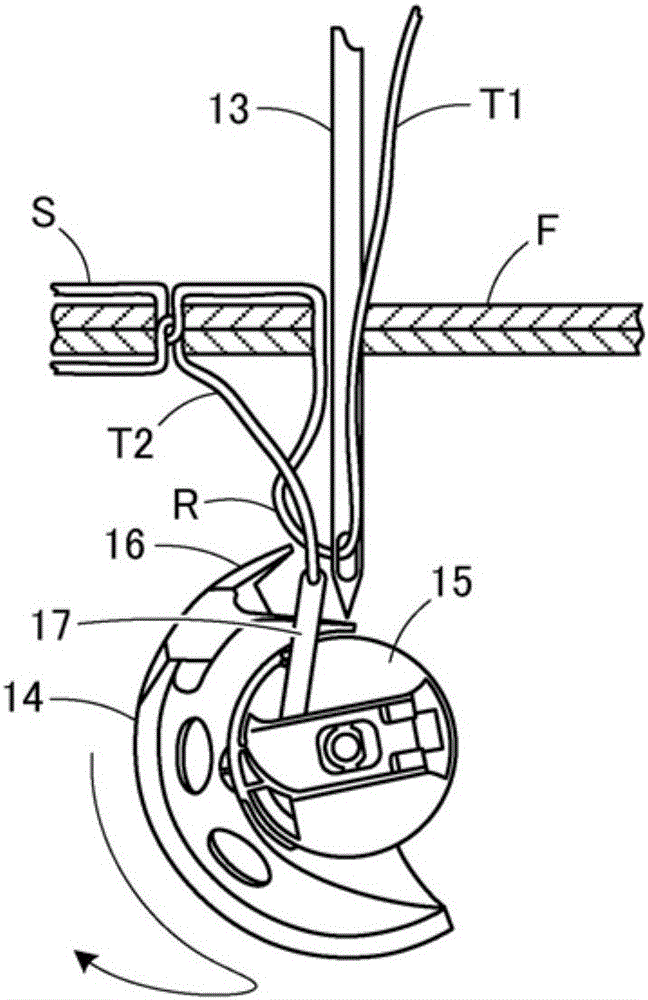

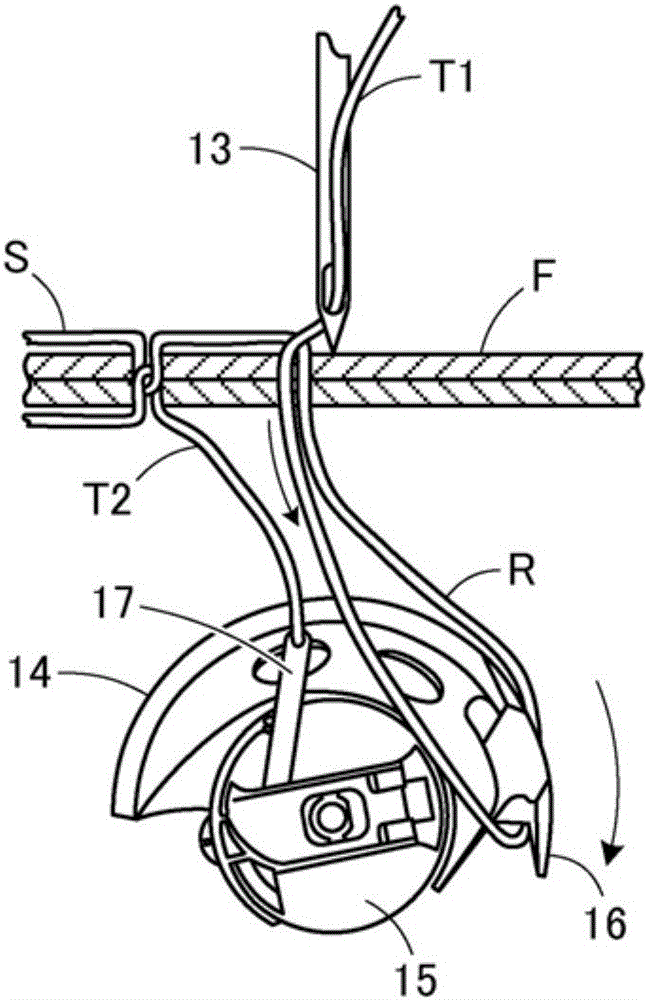

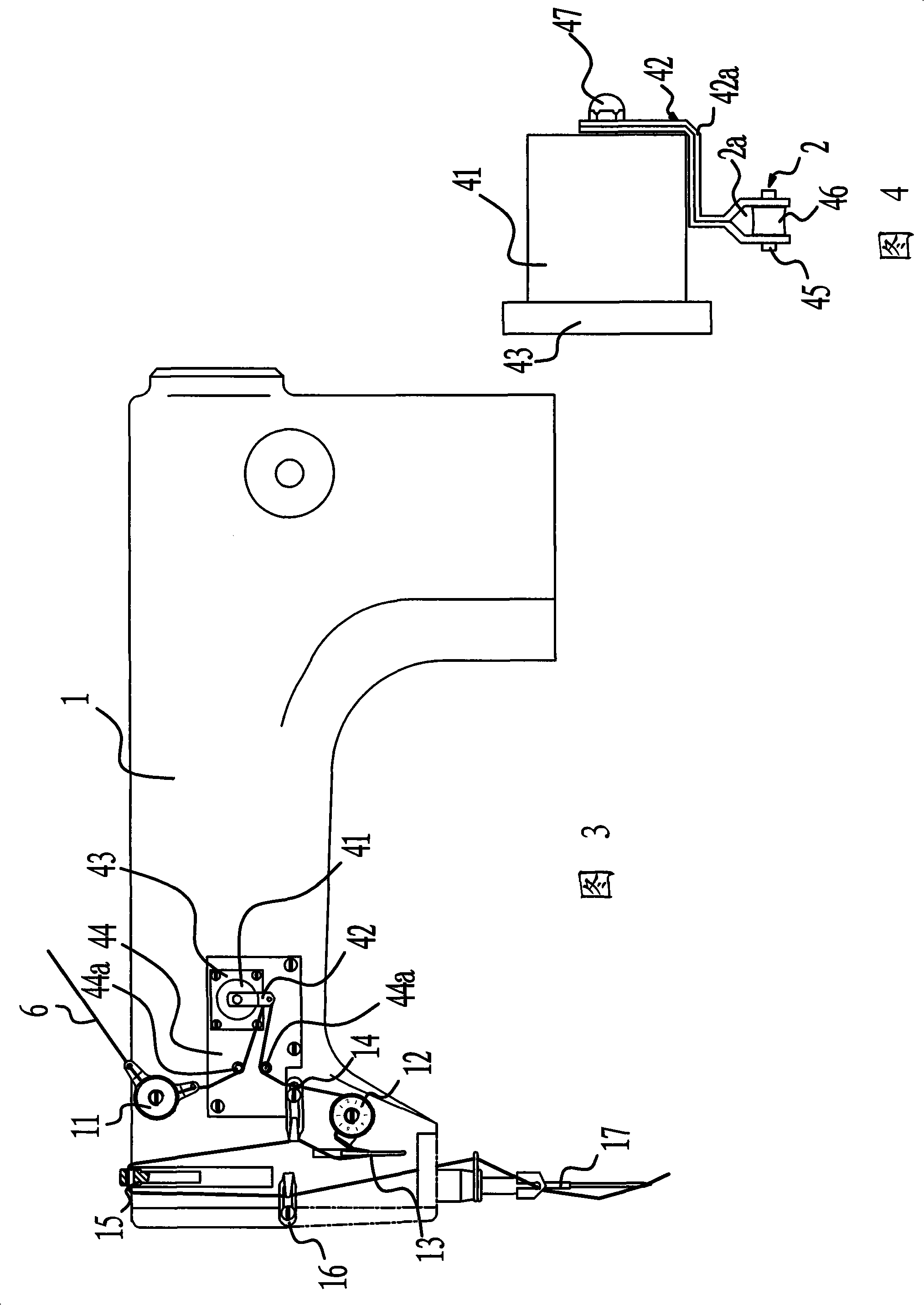

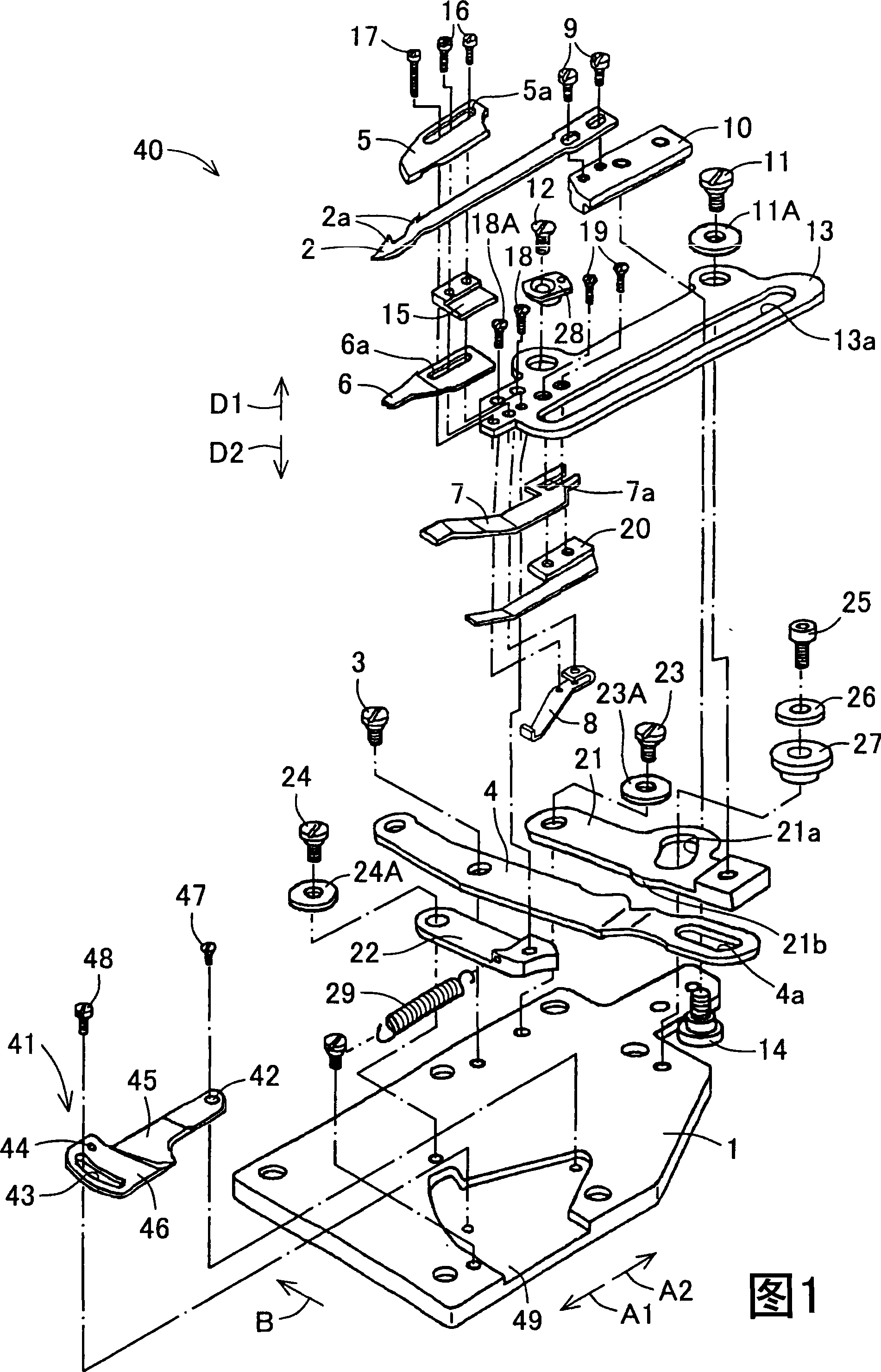

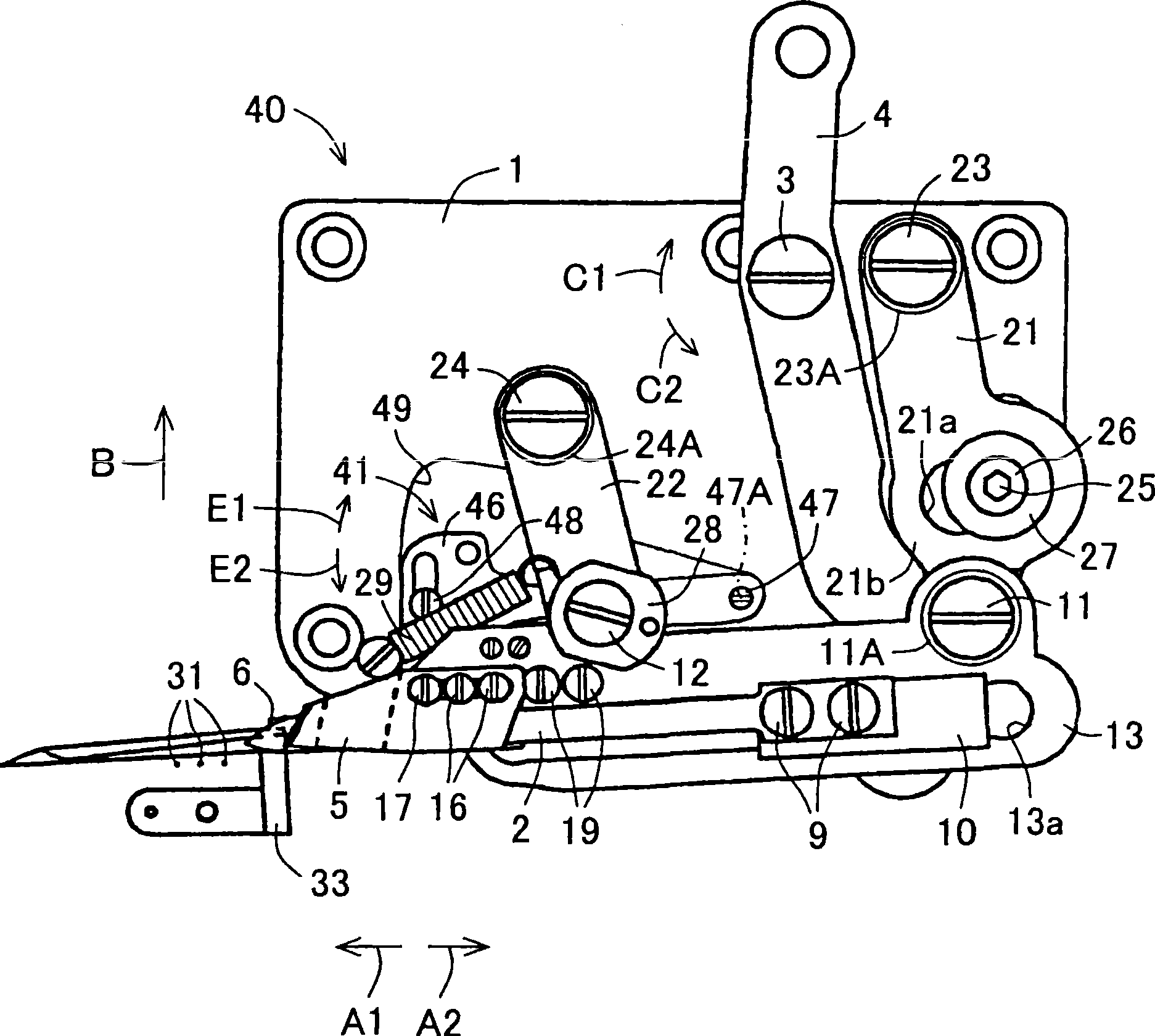

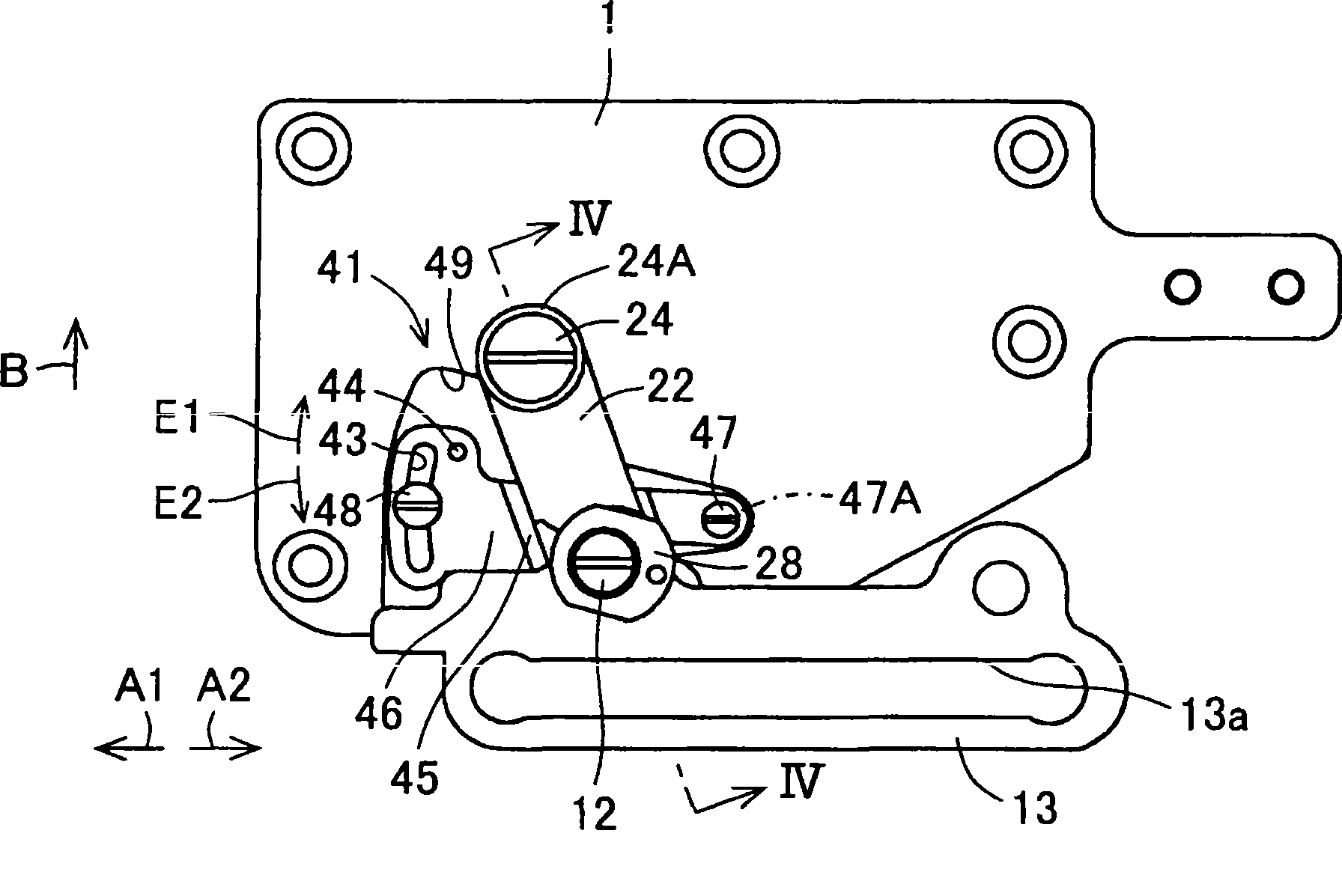

Wire-cutting device for sewing machine

InactiveCN101424015ADoes catchEasy to adjust and accurateNeedle severing devicesThread-break detectorsYarnWire cutting

The present invention provides a yarn cutting device of sewing machine, which can authentically capture an upper thread coil with a movable blade for cutting off. The height position of a blade holding base (13) which holds a movable blade (2), a fixed blade (5) and a yarn clamping plate (7) in the up-and-down direction can be adjusted with a height adjusting part (41). The height of the blade holding base (13) is adjusted with the height adjusting part (41) so that the movable blade which is adjacent with the entering positions of needle supporting plate and curved needle and enters from a narrow space between the lower surface of needle supporting plate and upper surface of curved needle is configured to a position that does not contact a random surface selected from the lower surface of needle supporting plate and upper surface of curved needle. The upper thread coil is caught authentically by a yarn hooking part of movable blade (2) for being cut off.

Owner:YAMATO SEWING MASCH MFG CO LTD

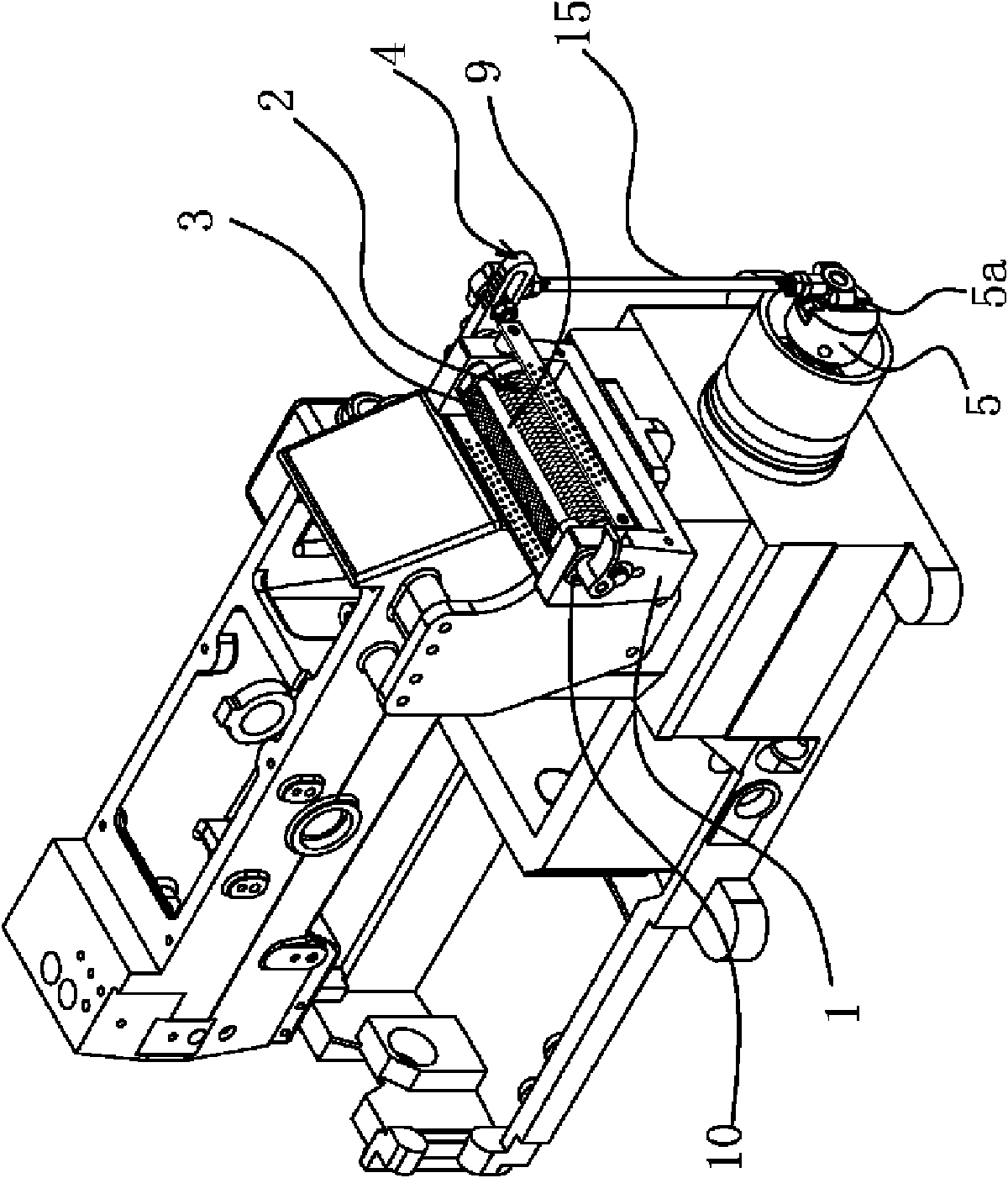

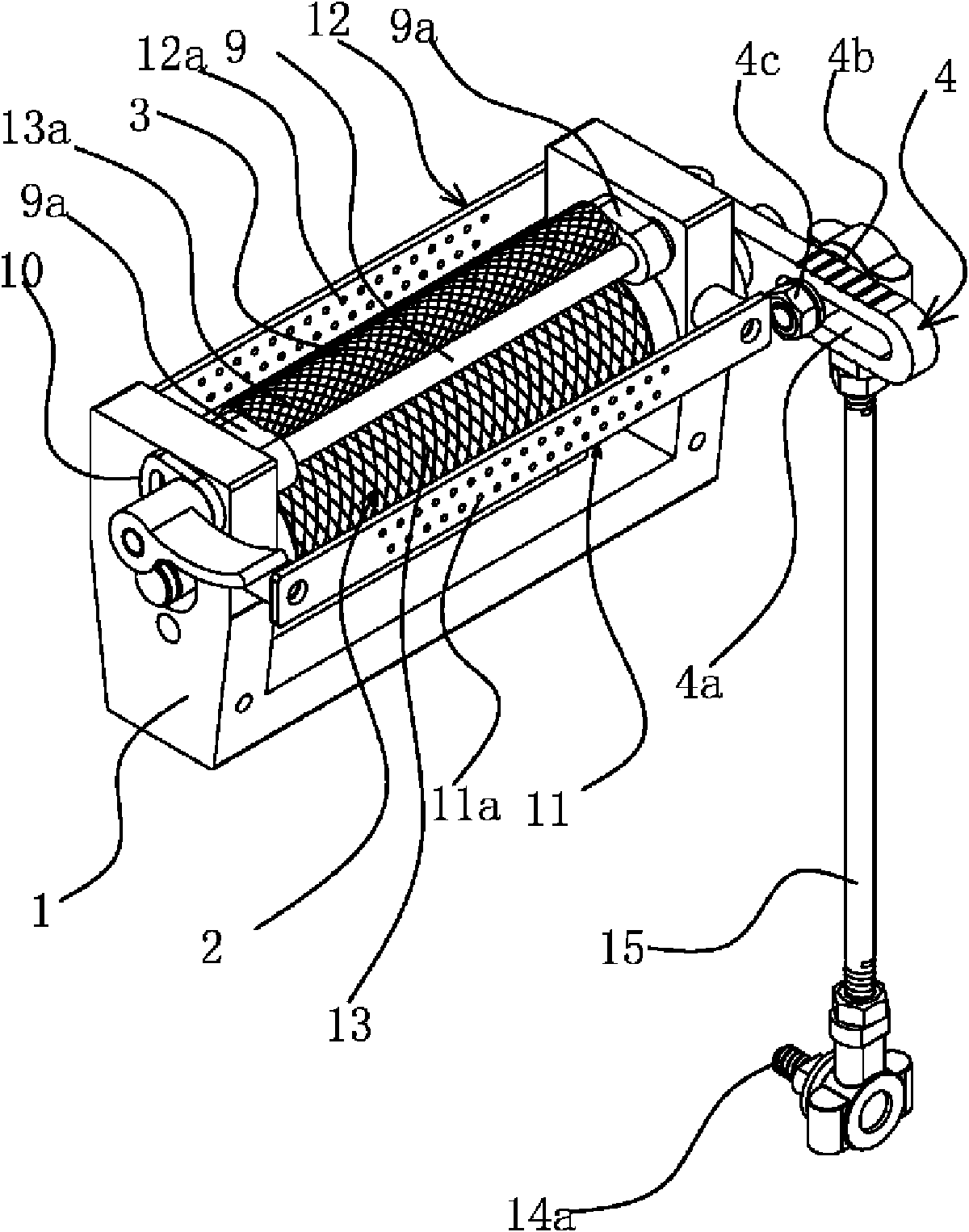

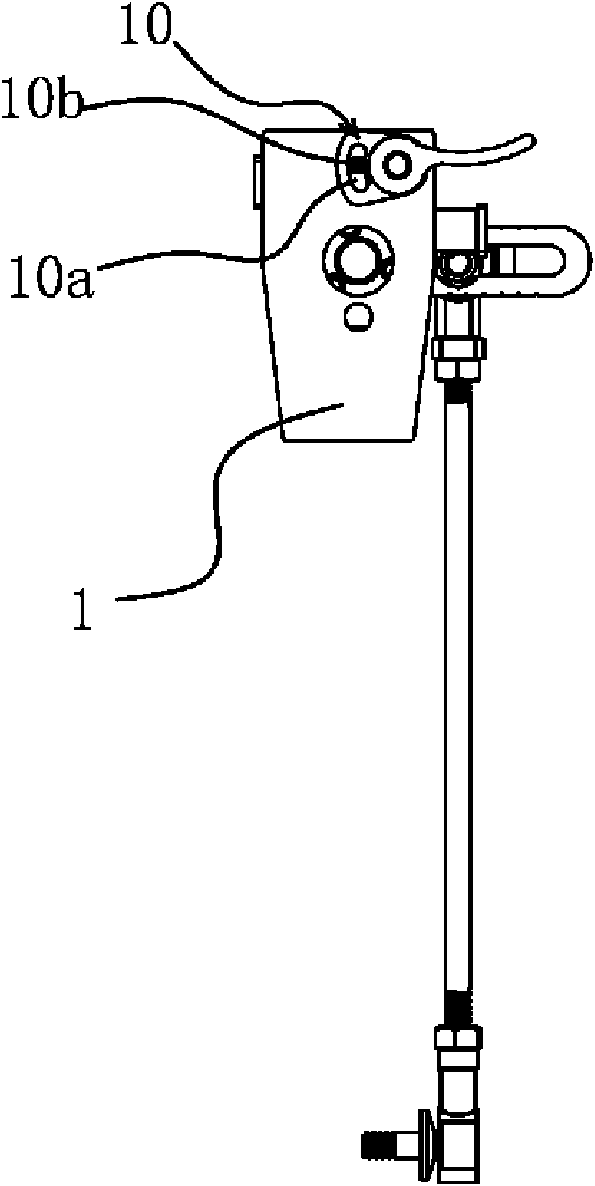

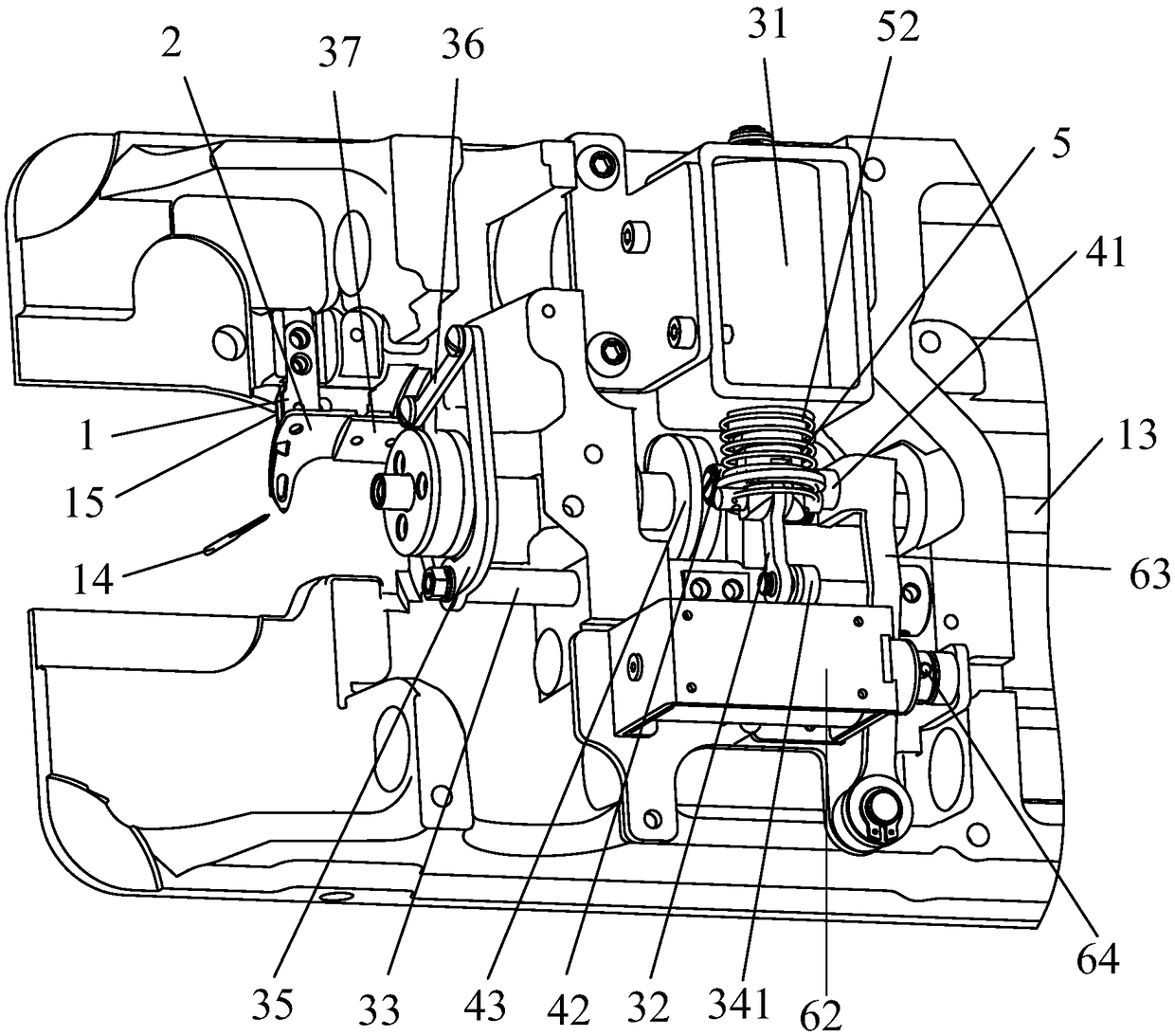

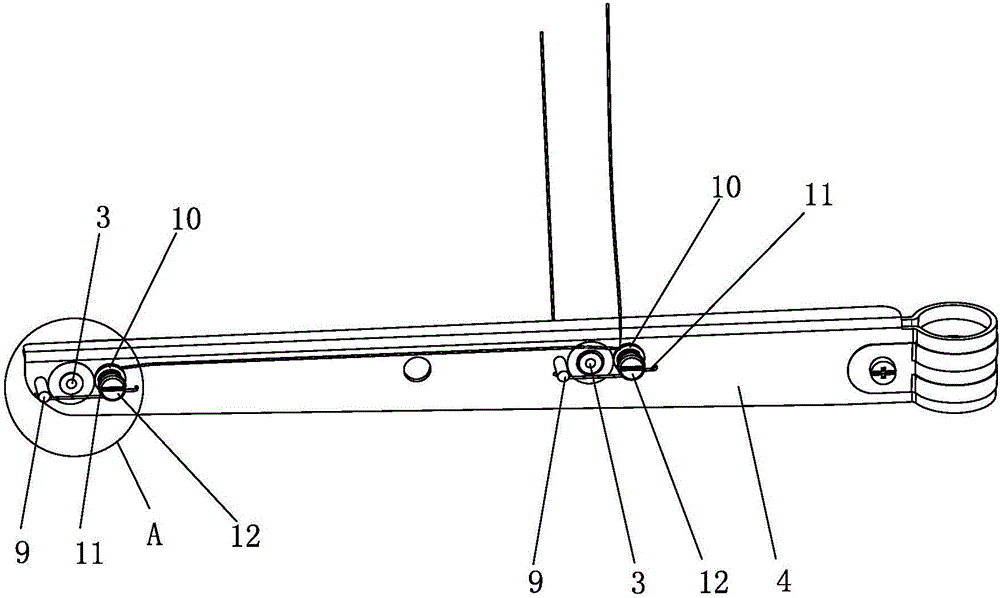

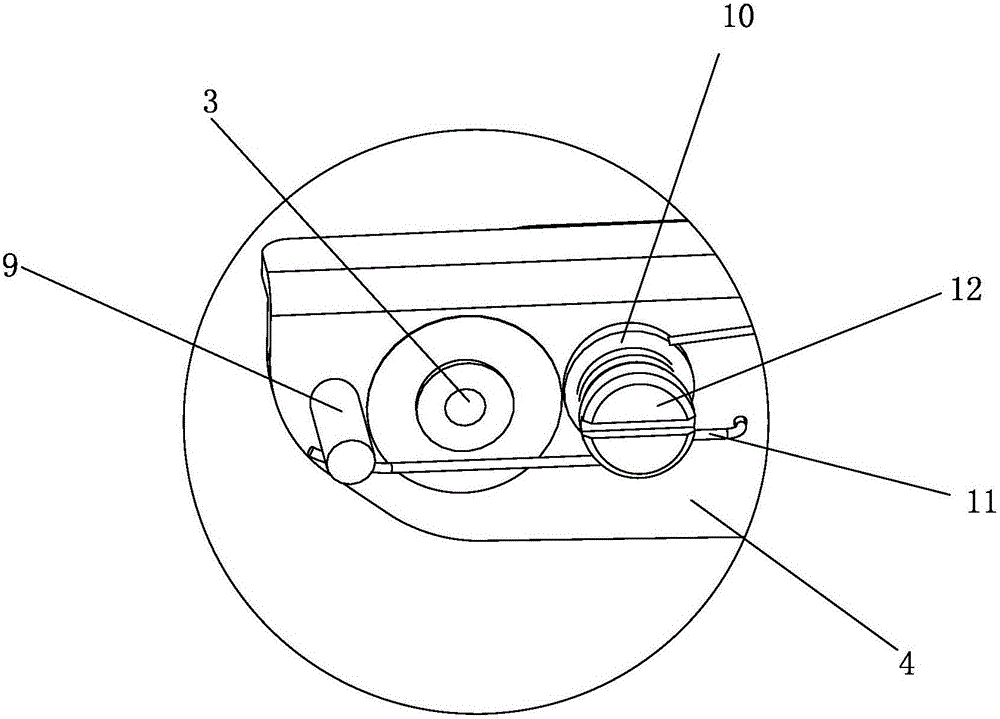

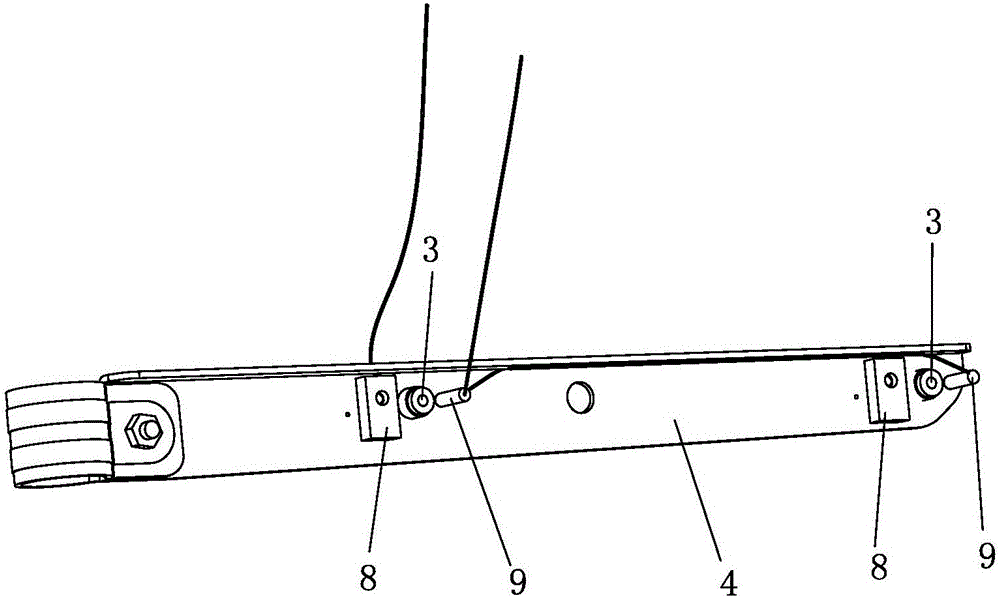

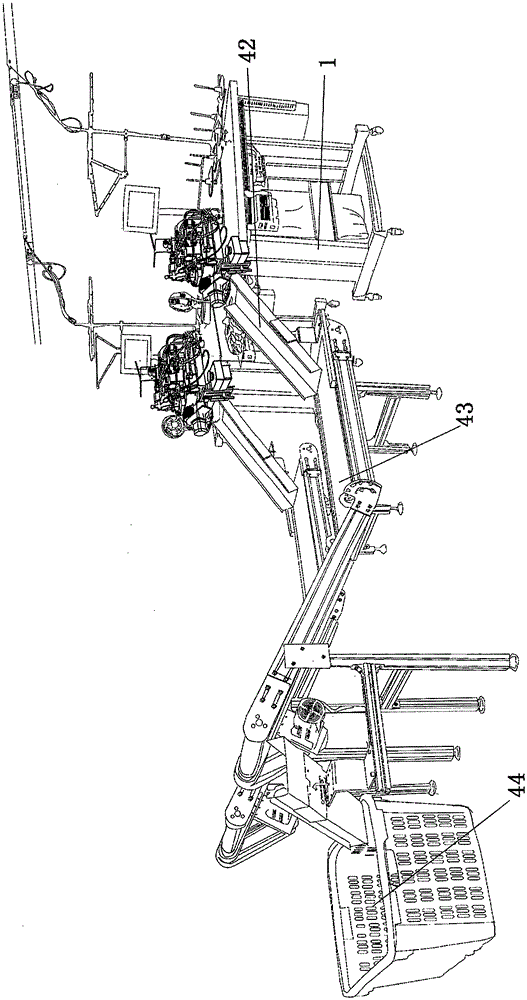

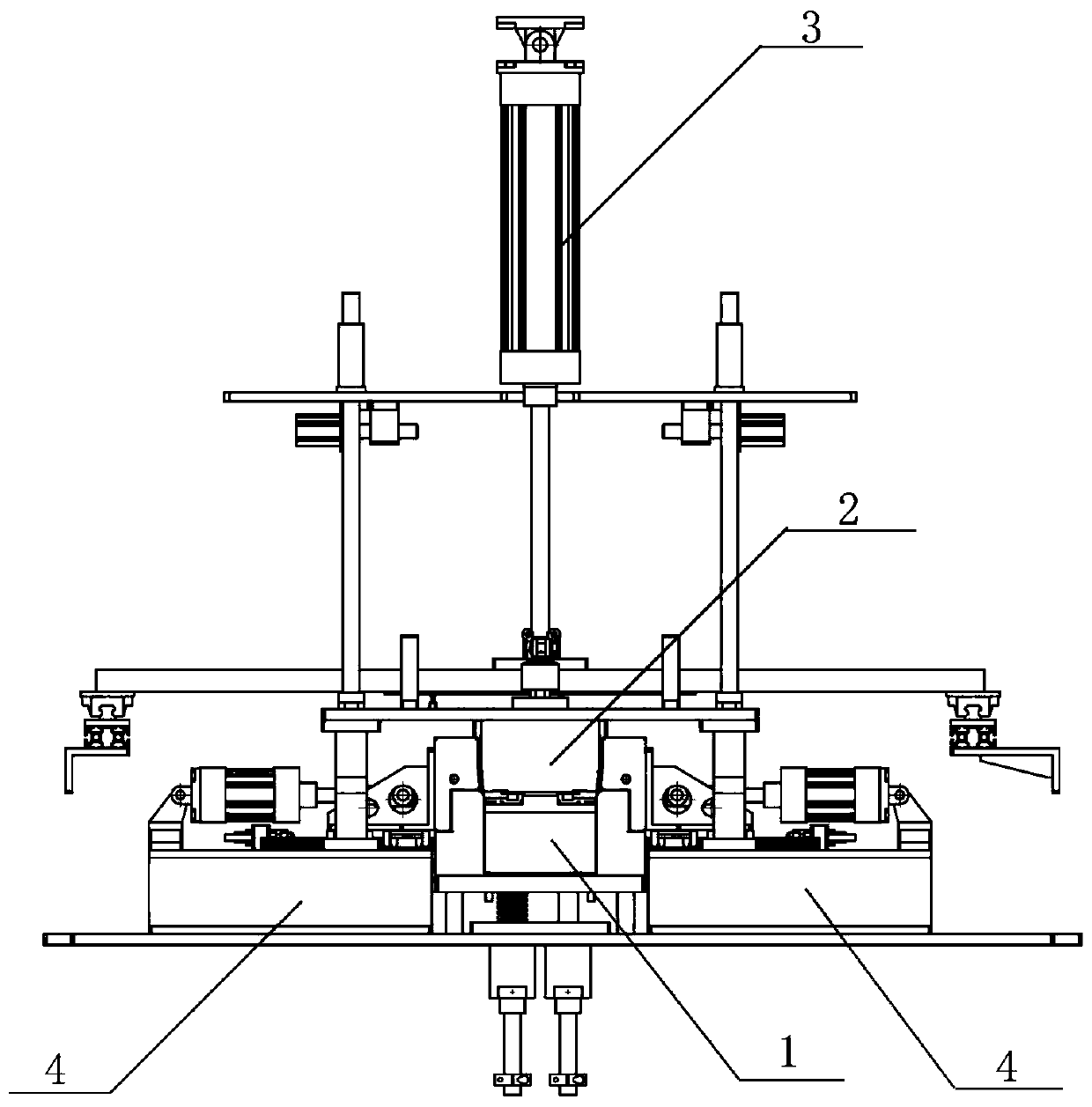

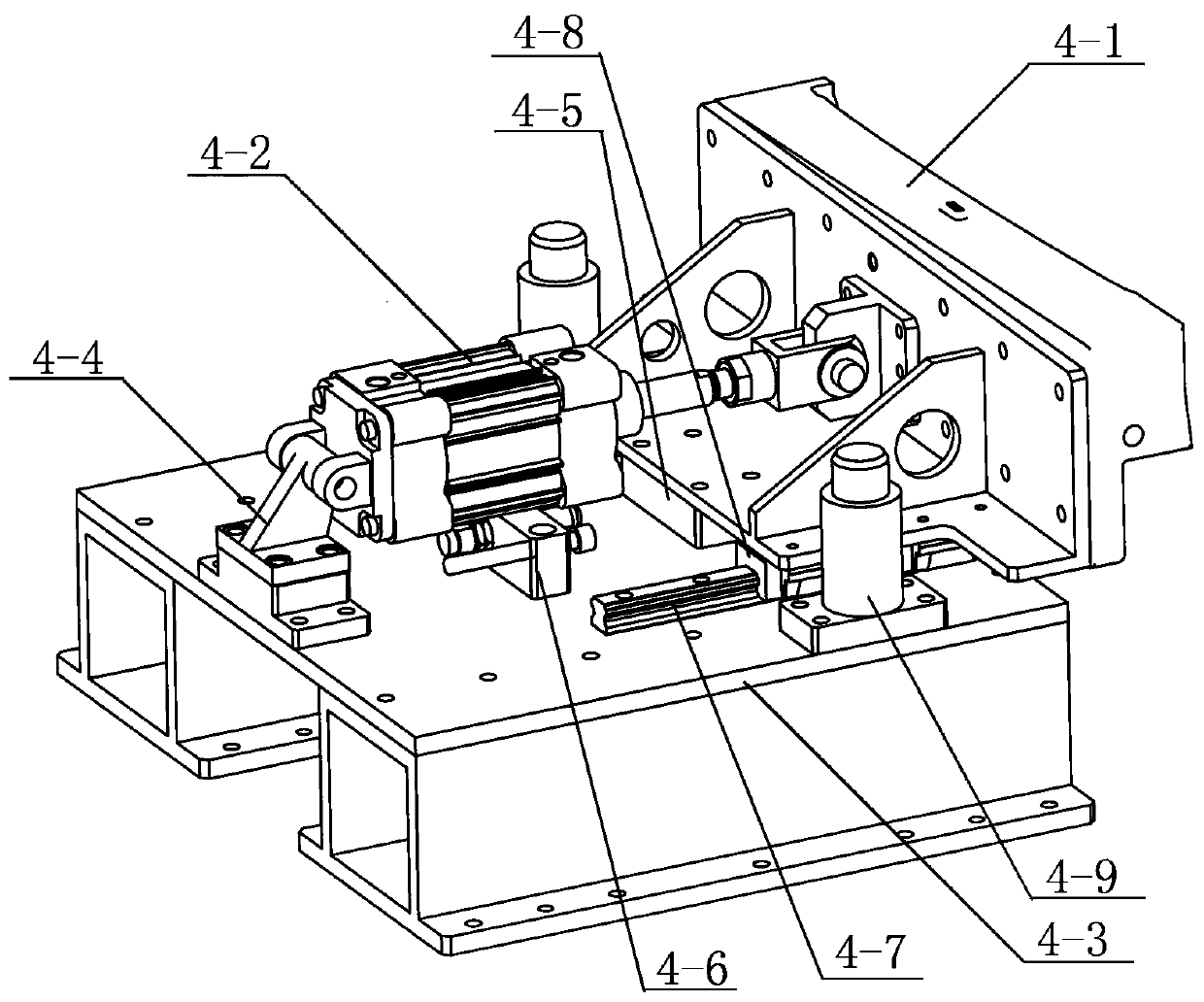

Elastic yarn conveying device in multi-needle machine

ActiveCN101624761AImprove work efficiencyCompact structureSewing-machine control devicesThread-break detectorsYarnDrive wheel

The invention provides an elastic yarn conveying device in a multi-needle machine, which belongs to the technical field of machinery and solves inconsistent tightness and other the technical problems during the conveying of a plurality of yarns existing in the prior multi-needle machine yarn clamper. The elastic yarn conveying device of the multi-needle machine comprises an installation base arranged on a stand, wherein a cylindrical drive wheel and a cylindrical pinch roller are fixed on the installation device axially, the axe of the drive wheel is parallel to the axe of the pinch roller, and the drive wheel can freely rotate around the axe of the drive wheel and the pinch roller can freely rotate around the axe of the pinch roller, the pinch roller is pressed on the drive wheel, the shaft of the drive wheel is radically connected with a crank, the crank is connected to a main shaft of the multi-needle machine through a drive mechanism, the rotation of the main shaft enables the crank to swing through the drive mechanism, and a unidirectional clutch mechanism enabling the drive wheel to unidirectionally rotate is arranged between the crank and the drive wheel. The elastic yarn conveying device has synchronization of yarn feeding amount and rotation speed of the machine, ensures consistent tightness of different speeds, and improves the working efficiency of the multi-needle machine because the yarn feeding amount can be adjusted according to different requirements.

Owner:浙江振盛缝制机械有限公司

Computerized stitching including embroidering

InactiveUS6871605B1Reduced thread tensionReduce needProgramme-controlled sewing machinesHand sewingEngineeringScrew thread

Owner:MELCO INT

Method and device for detecting bobbin threads of sewing machine

InactiveCN105734848AReduce wasteImprove quality and efficiencyThread-break detectorsBobbinMachine maintenance

The invention relates to the technical field of sewing, in particular to a method and a device for detecting bobbin threads of a sewing machine. The technical scheme includes that the device comprises a bobbin, a push plate, a cushion block, a photoelectric sensor, a clamping plate and a spindle controller, the photoelectric sensor is arranged between the cushion block and the clamping plate, the cushion block is arranged on the push plate, and the bobbin is arranged on a bobbin case, on one side of the photoelectric sensor, of the sewing machine. One lateral surface of the bobbin is alternately provided with a plurality of high light areas and low light areas, the other lateral surface of the bobbin is provided with magnetic steel, a transmitting end and a receiving end of the photoelectric sensor face the bobbin on the bobbin case and are connected to the spindle controller, and whether the bobbin threads are used up or not is detected according to a certain detection method. The method and the device for detecting the bobbin threads of the sewing machine have the advantages that using up and breaking of the bobbin threads and withdrawal of a needle without threads can be detected out timely and accurately, an operator can be timely reminded of bobbin replacement or machine maintenance for clearing abnormity, and formation of idle stitches only with needle threads but without the bobbin threads is avoided.

Owner:XIAN TYPICAL IND

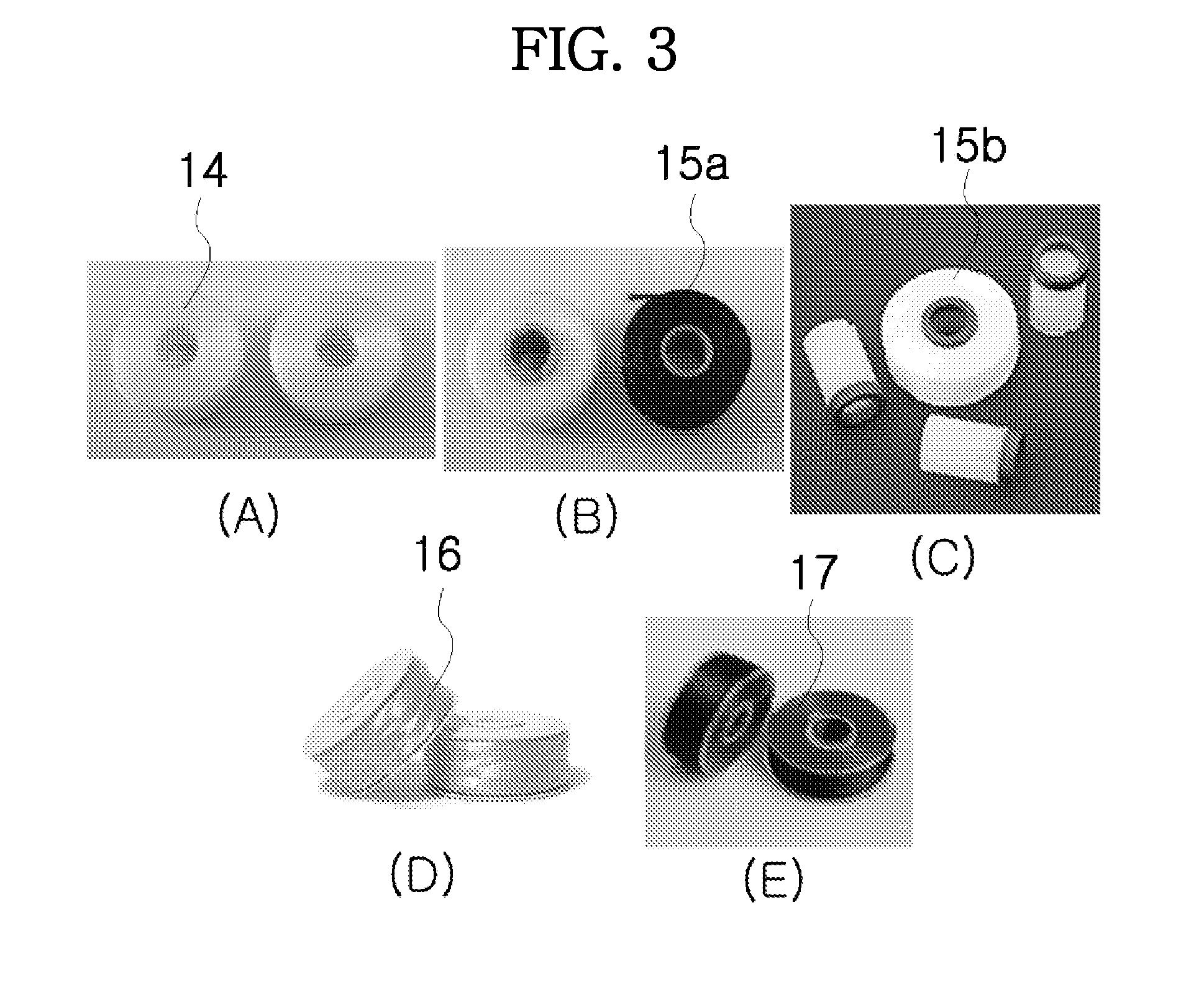

Spool holder and sewing machine provided therewith

ActiveUS20110011319A1Light weightImprove refining effectSewing-machine control devicesFilament handlingEngineeringSewing machine

Owner:BROTHER KOGYO KK

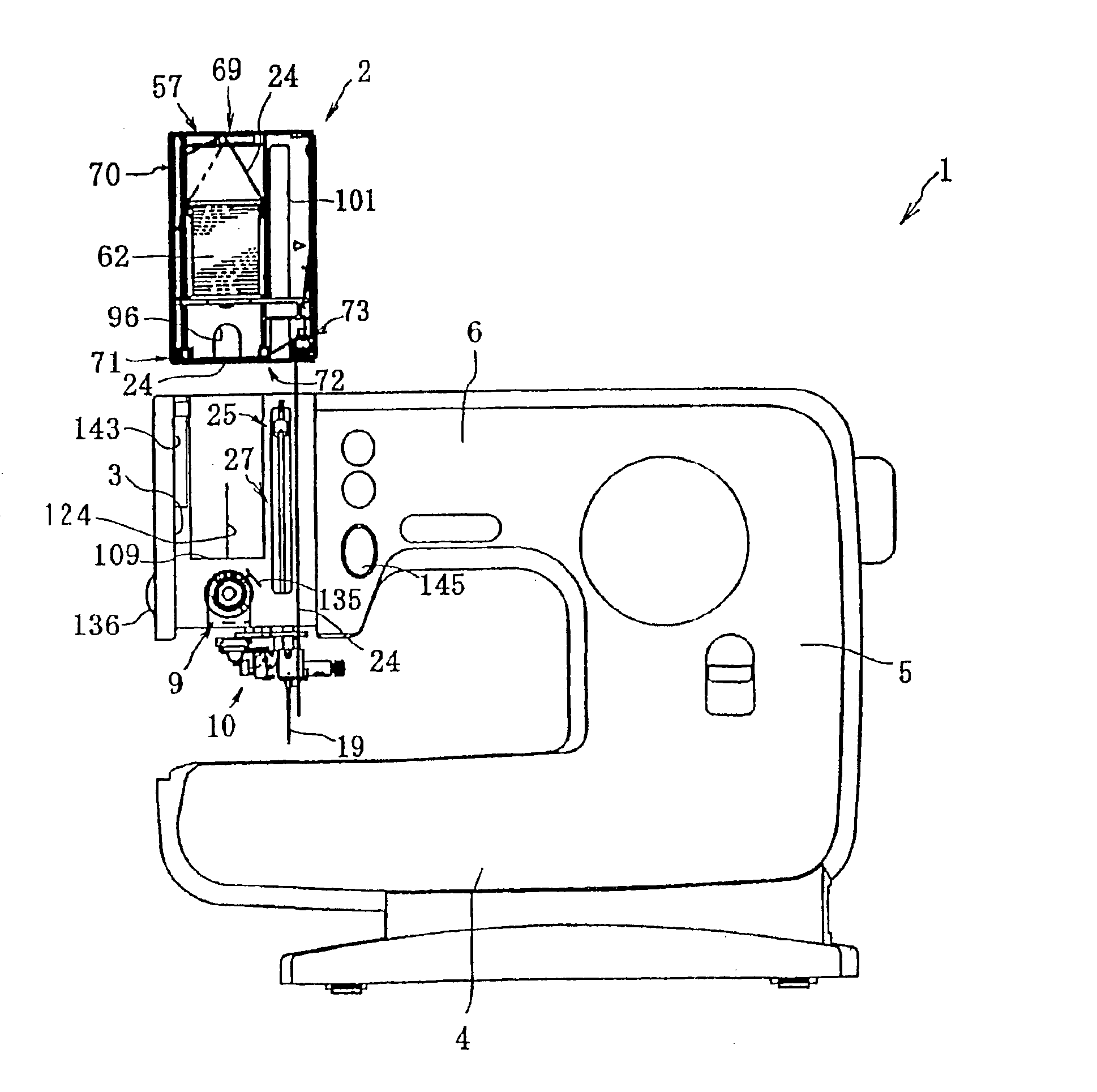

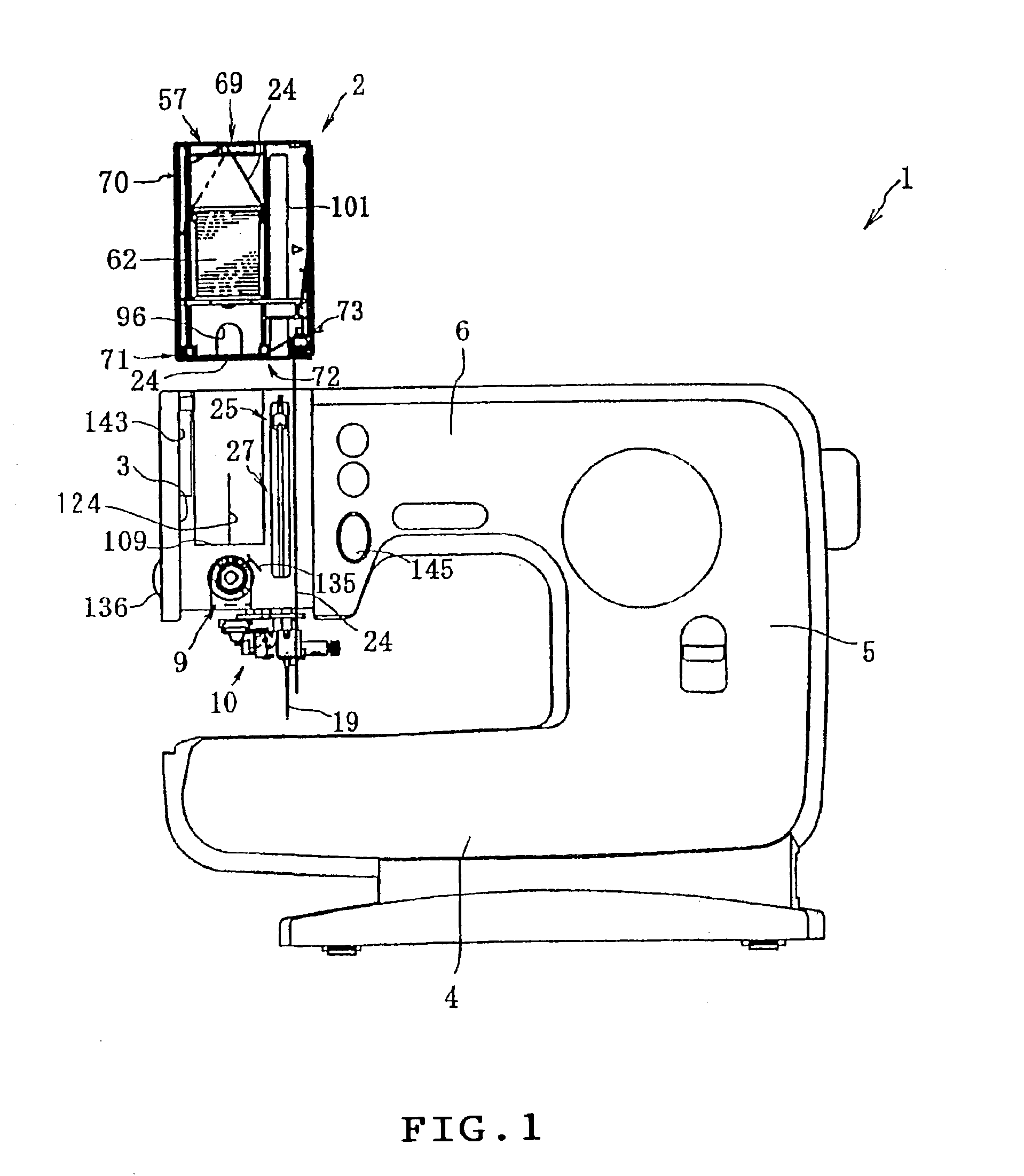

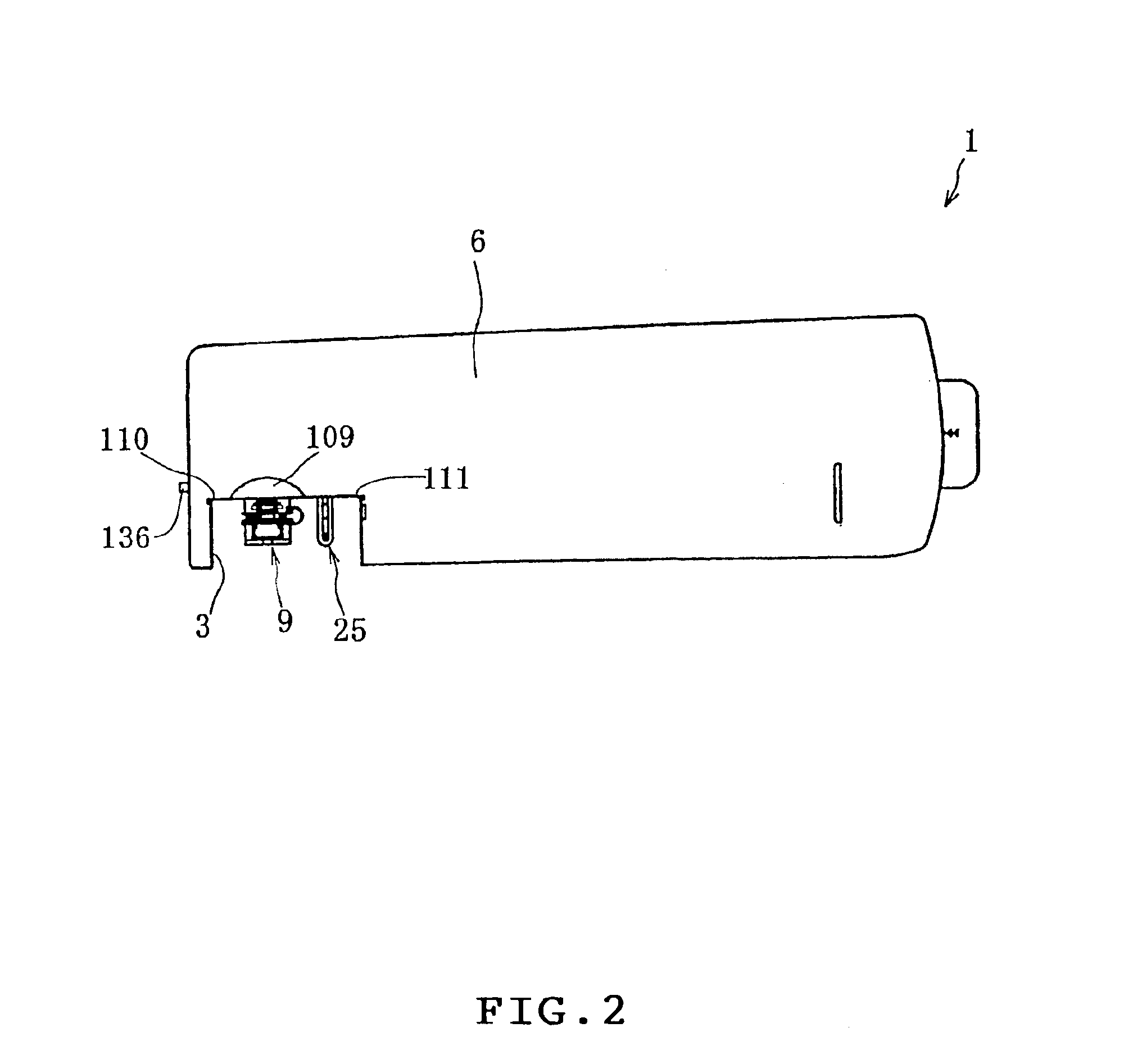

Sewing machine with needle thread cassette and needle thread cassette

InactiveUS6883447B1Improve handlingEasy to operateSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine with a needle thread cassette, wherein a cassette mount (3) is reduced in size. The cassette mount (3) including a thread take-up lever travel region is formed in the form of a vertical groove in the arm head of the sewing machine. A needle thread cassette (2) having a thread bobbin (62) vertically received therein is removably mounted on the cassette mount (3) vertically from above. With a thread take-up lever (25) stopped in a position corresponding to a needle top stop position, the needle thread cassette (2) is mounted on the cassette mount (3), whereby the thread is engaged with the thread guard of the thread take-up lever (25) and a thread tension regulator (9).

Owner:BROTHER KOGYO KK

Illumination device for multineedle sewing machine and the multineedle sewing machine

An illumination device for a multineedle sewing machine includes an illuminating member which has a light source and located at a lateral side of a needle bar case and is disposed so as to open portions of needle bars and portions of needles, a light amount adjusting unit which adjusts an amount of light of the light source, and a control unit which controls the light amount adjusting unit with movement of the needle bar case by the needle bar case moving mechanism together with the illuminating member so that a predetermined illuminance is maintained at least in part of an illuminated area which is illuminated by the light source. The part of the illuminated area is located near the needle drop position.

Owner:BROTHER KOGYO KK

Spool holder and sewing machine provided therewith

InactiveUS20110011318A1Easy to replaceCompact storageSewing-machine control devicesFilament handlingSewing machine

Owner:BROTHER KOGYO KK

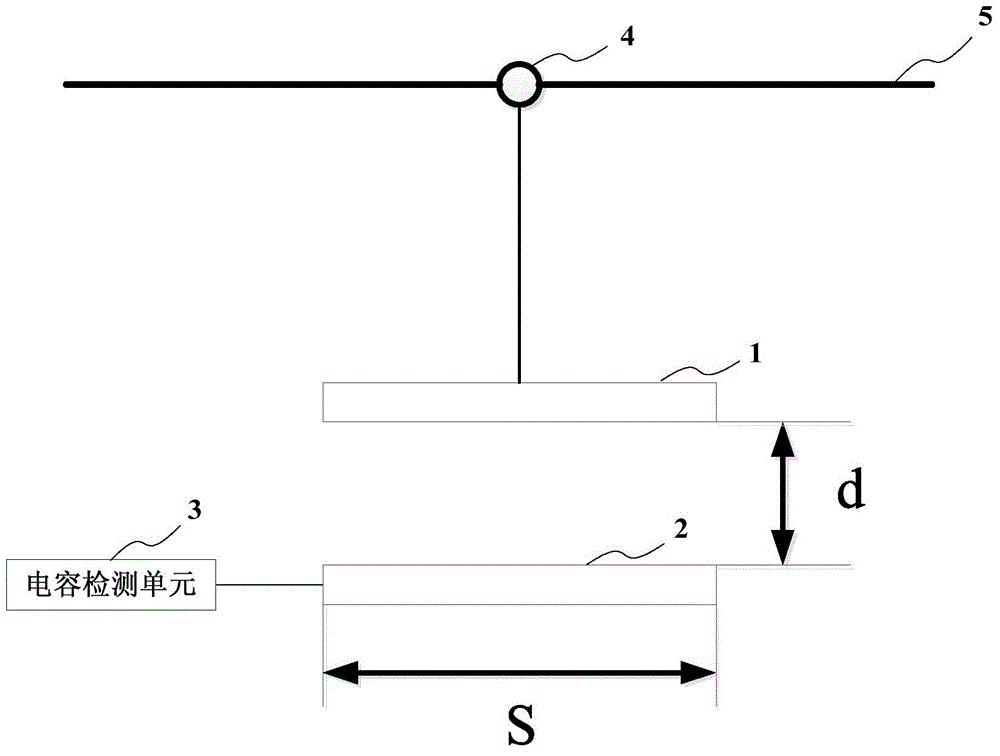

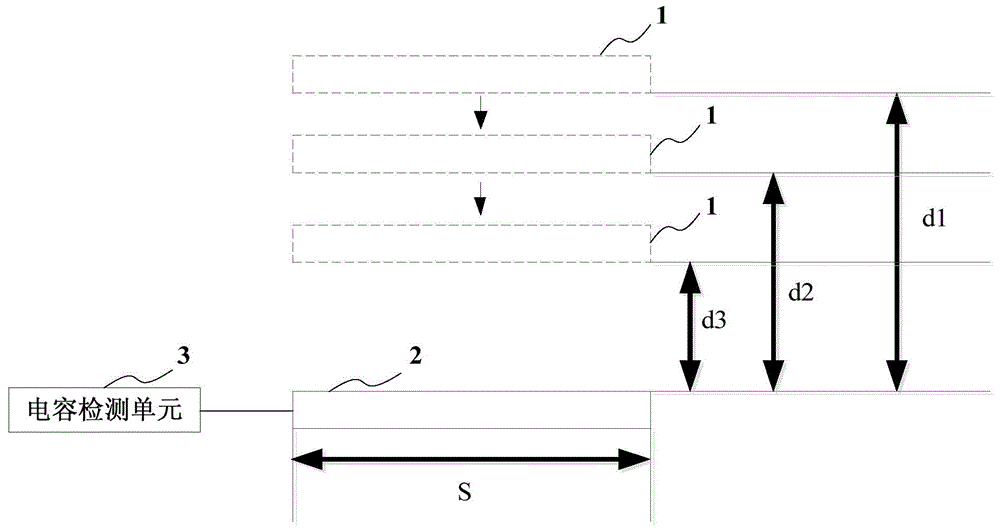

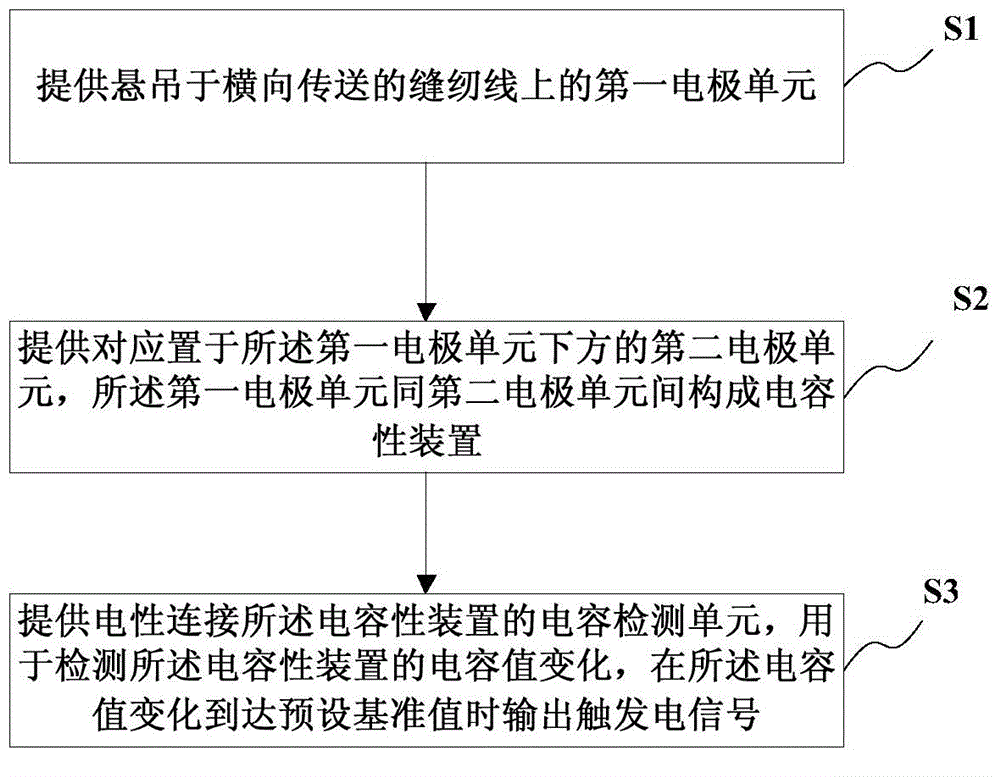

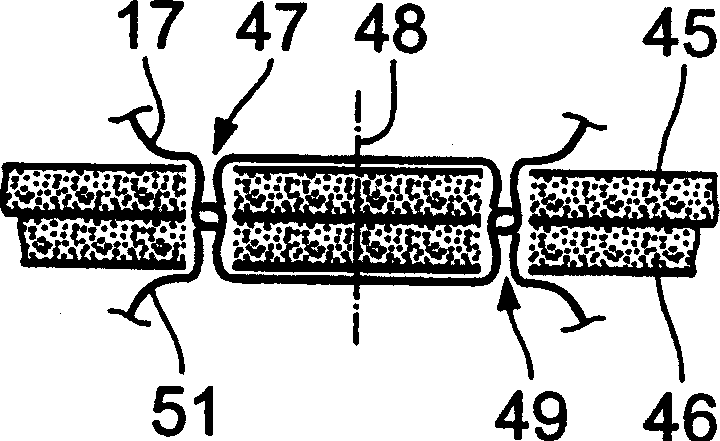

Sewing thread position detection device and sewing thread position detection method

ActiveCN104562467AEffective detection of disconnectionEffective detection of slackThread-break detectorsCapacitanceRemote touch

The invention provides a sewing thread position detection device and a sewing thread position detection method. The sewing thread position detection device comprises a first electrode unit, a second electrode unit and a capacitance detection unit, wherein the first electrode unit is overhung on a transversely-conveyed sewing thread, the second electrode unit is arranged below the first electrode unit correspondingly, a capacitive device is formed between the first electrode unit and the second electrode unit, and the capacitance detection unit electrically connected to the capacitive device is used for detecting capacitance changes of the capacitive device, and outputting electric trigger signals when the capacitance is changed to reach a preset reference value. The sewing thread position detection device and the sewing thread position detection method have the advantages that capacitive remote touch induction is adopted, breakage of an upper thread can be judged effectively, looseness degree of the upper thread can be detected effectively, and high flexibility and simple structure are achieved. .

Owner:JACK SEWING MASCH CO LTD

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS7793602B2Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

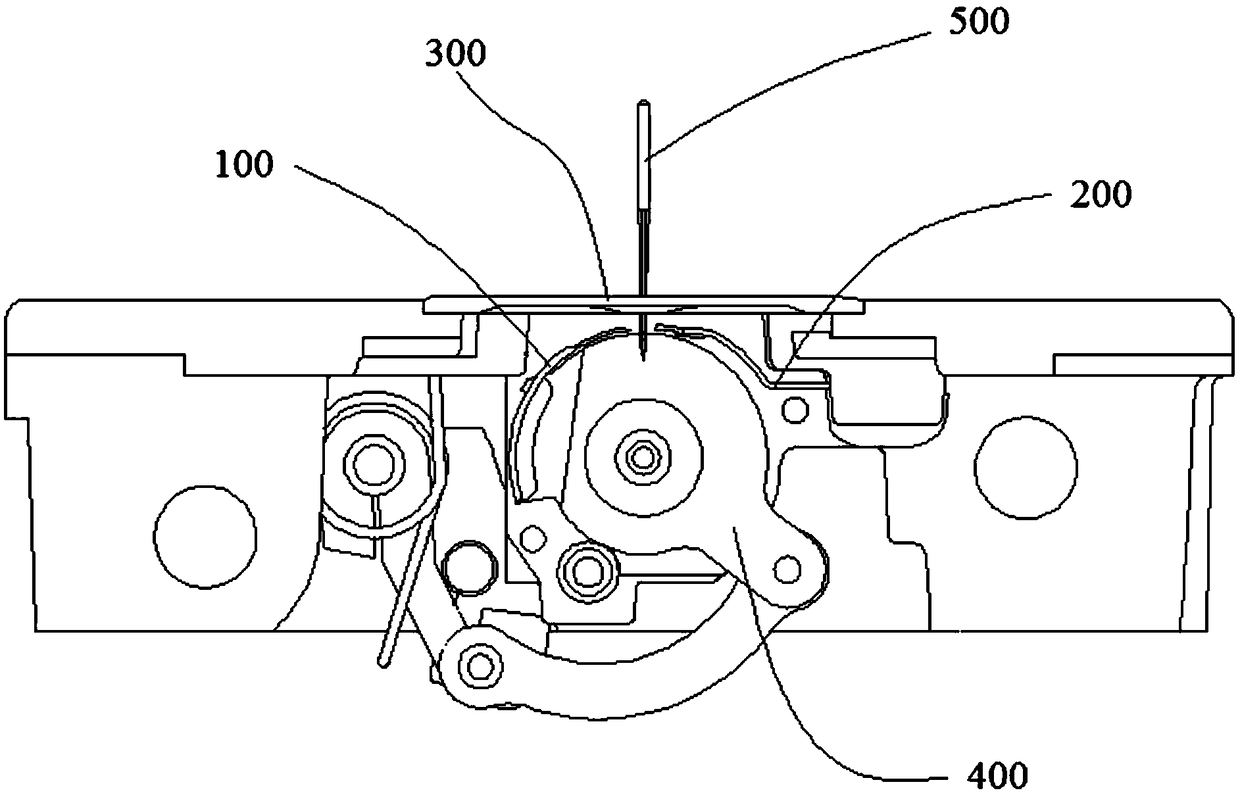

Thread cutting mechanism and sewing machine

ActiveCN109234925AStable sewingImprove qualityNeedle severing devicesThread-break detectorsEngineeringSewing machine

The invention provides a thread cutting mechanism. The mechanism includes a fixed cutter having a fixed cutting edge and a movable cutter having a movable cutting edge. The movable cutter can move inthe direction close to or away from the fixed cutter, a thread distribution groove is formed in the movable cutter, and the movable cutting edge and the thread distribution groove are opposite to eachother in the movement direction of the movable cutter. After sewing is over, at the time of thread cutting, bottom threads and surface threads are allowed to enter the thread distribution groove of the movable cutter, and the movable cutter drives the bottom threads and the surfaces threads to move in the direction near the fixed cutter until the movable cutting edge and the fixed cutting edge bite and cut the bottom threads and the surface threads; at the time of stitching, surface thread residues are allowed to enter the thread distribution groove of the movable cutter, and the movable cutter drive the surface thread residues to move in the direction close to the fixed cutter until the movable cutting edge and the fixed cutting edge bite and cut the surface thread residues. After sewingis over, at the time of thread cutting, the surface threads and the bottom threads are cut off, the surface thread residues are cut off at the time of stitching, the thread cutting problem and the 'bird's nest' problem during stitching are solved at the same time, and high-quality and stable sewing of a sewing machine is achieved.

Owner:JACK SEWING MASCH CO LTD

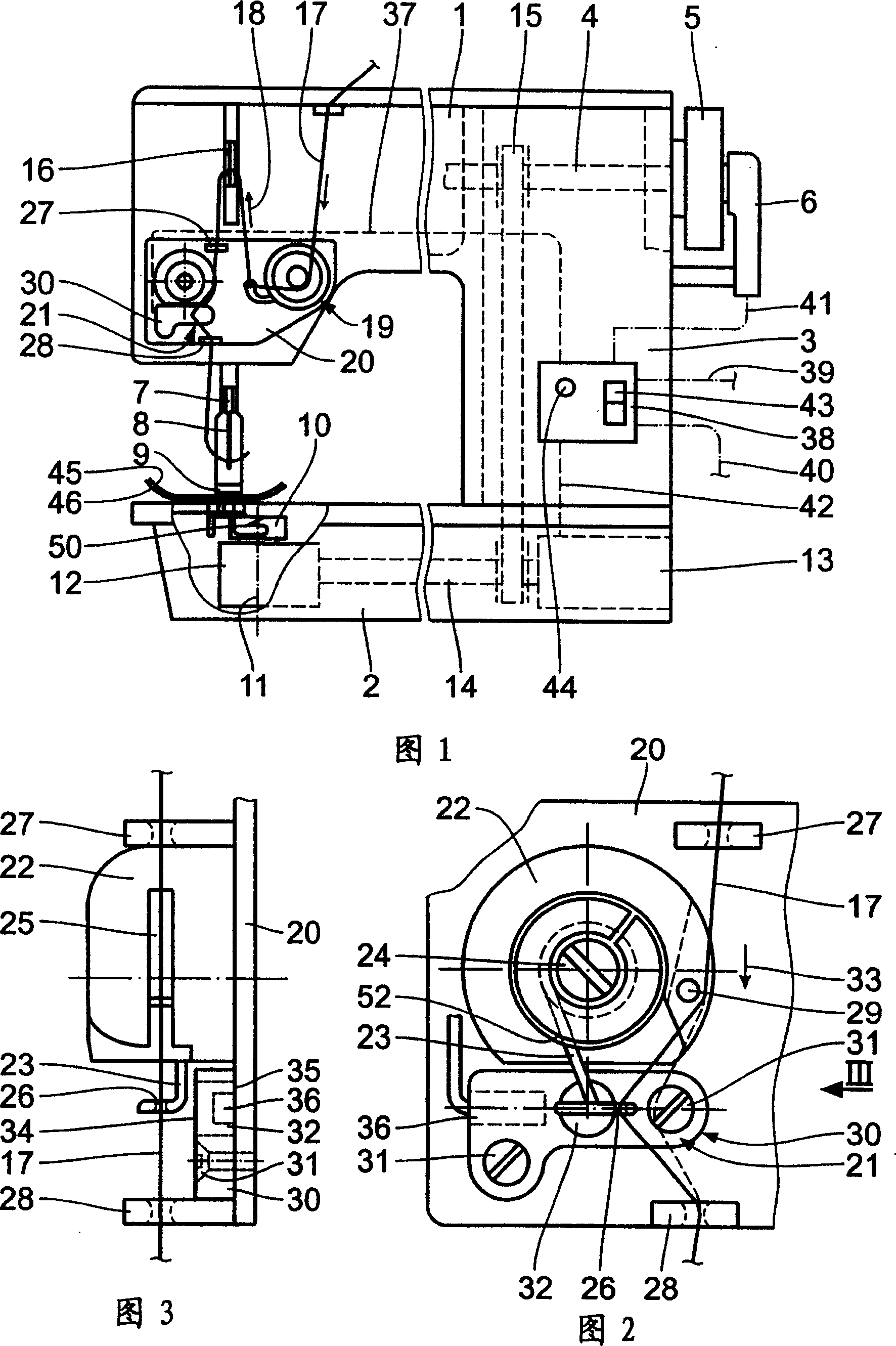

Thread breakage detection device for sewing machine

A stitch balancing thread tension 11 of a sewing machine 1 includes a rotary disk 17 having a surface extending perpendicular to an axial direction of a shaft 16 on which the rotary disk 17 is mounted. The thread breakage detection device includes a permanent magnet member 21 attached to the surface of the rotary disk 17, a hole element 22 that detects a magnetic field generated at the permanent magnet member 21 and outputs detection signals, and a detection unit that detects the thread breakage based on the detection signals from the hole element 22. Because the thread breakage detection device is integrally formed to the stitch balancing thread tension 11, the thread breakage detection device can be provided to the sewing machine 1 without increasing a number of components and the size of the sewing machine 1.

Owner:BROTHER KOGYO KK

Thread-free alarming device and sewing machine

InactiveCN105926199AMeet wireless disconnection detectionReduces the chance of rethreadingSewing-machine control devicesThread-break detectorsEngineeringClosed state

The invention belongs to the technical field of sewing devices and particularly relates to a thread-free alarming device and a sewing machine. The thread-free alarming device comprises a main body and more than one thread through hole and is characterized in that a switch device controlled to be opened or closed by a sewing thread is arranged at each thread through hole; the switch devices are in parallel connection or in series connection with each other; when a thread is supplied, the sewing thread applies force action to the switch devices, then the switch devices are in an open state, and a circuit is in an off state; when the thread is not supplied or the thread is broken, the switch devices are not stressed, the switch devices are in a closed state, the circuit is in an on state, and an alarm generates alarm. The thread-free alarming device is capable of detecting a plurality of threads, and is simple in structure and low in production cost and use cost; the position of a thread rack is far away from the sewing part, so that the probability of rethreading by staff caused by the threads in the thread through holes are used up when the threads are broken or no threads are supplied can be reduced to a great extent.

Owner:JACK SEWING MASCH CO LTD

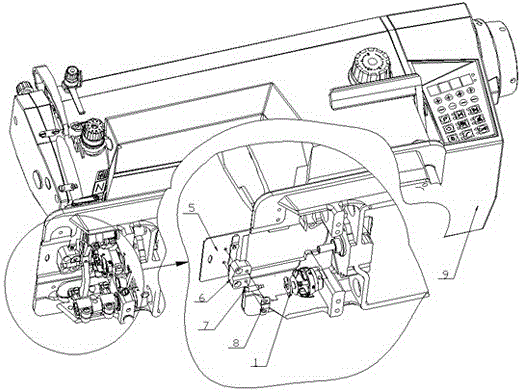

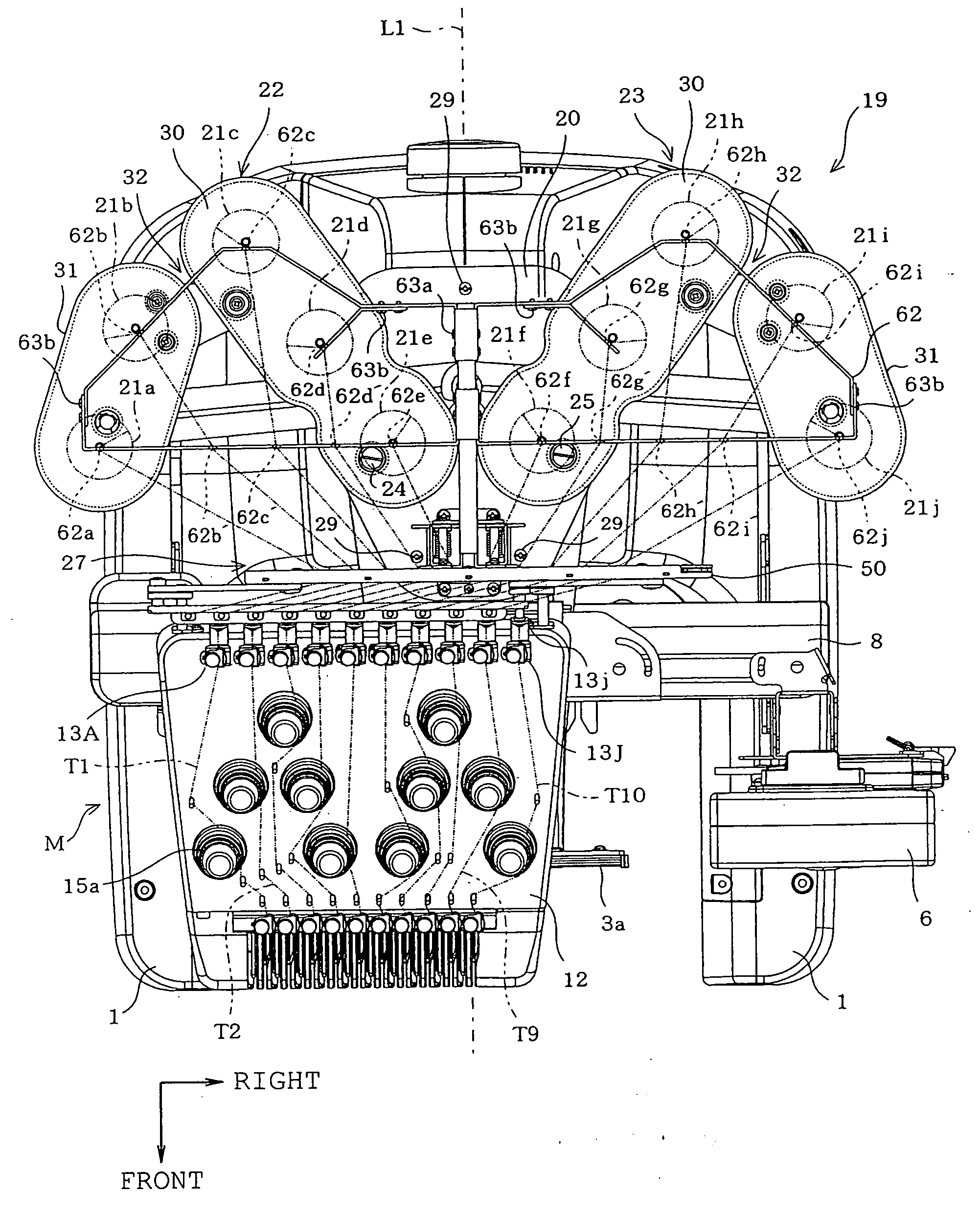

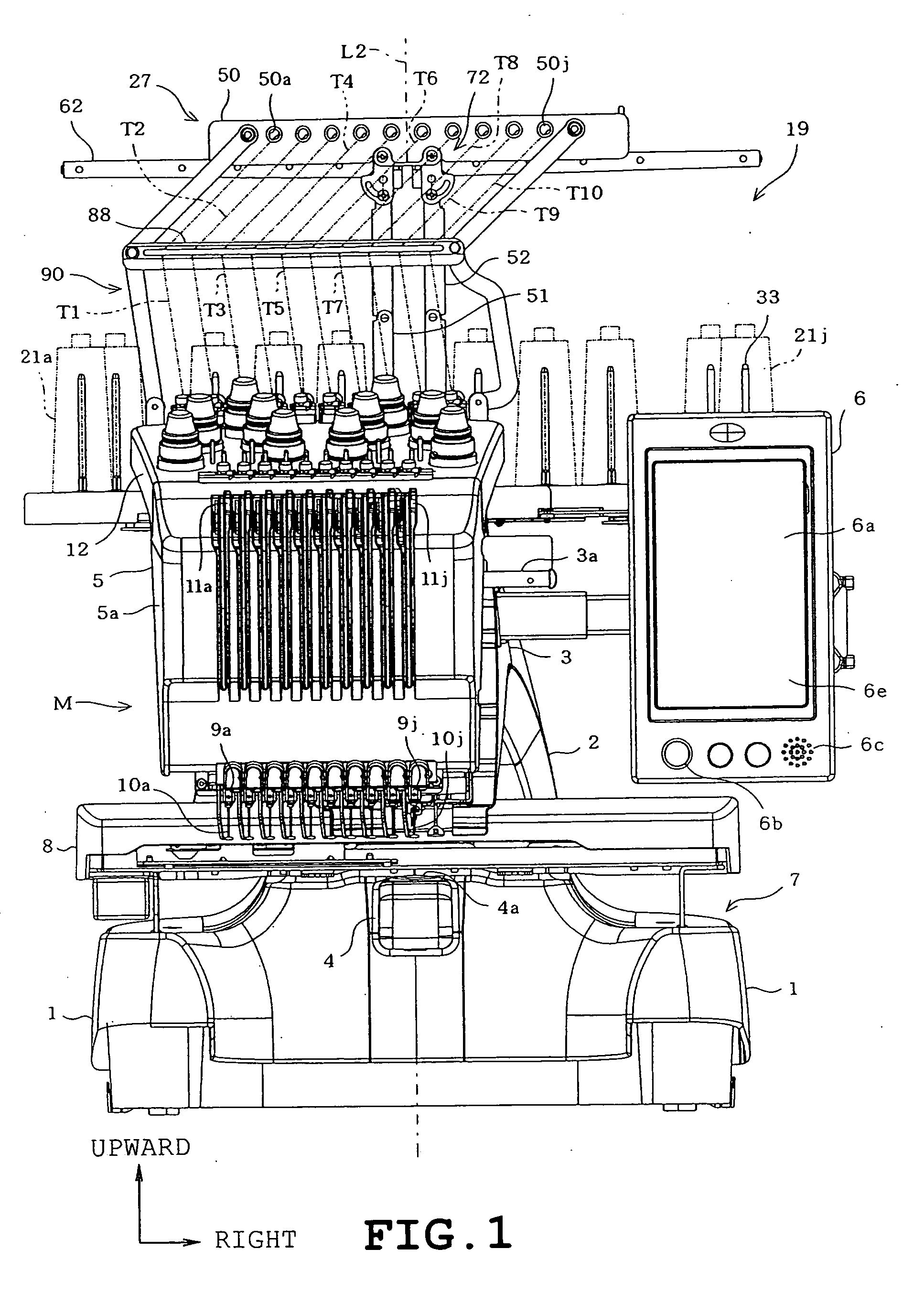

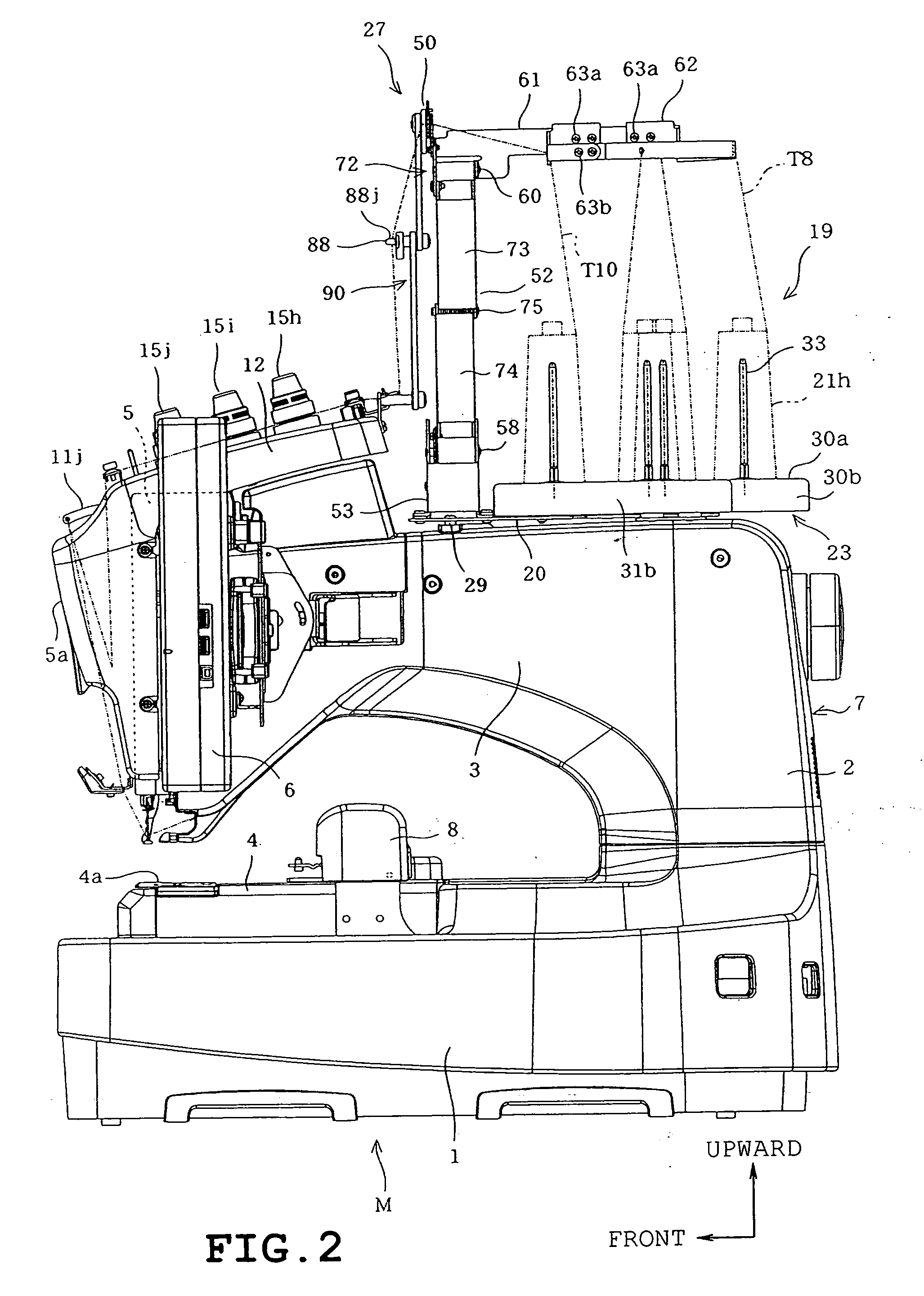

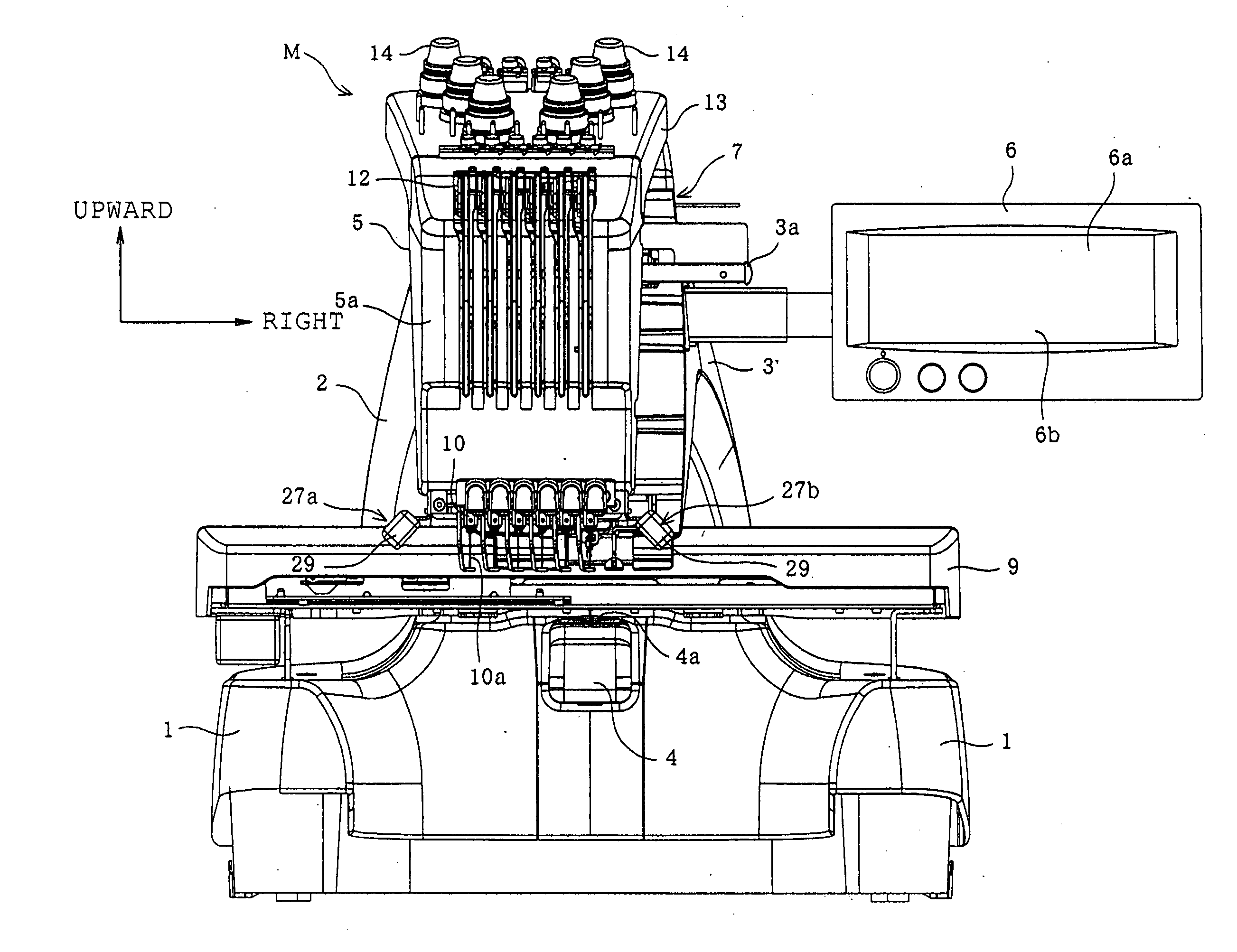

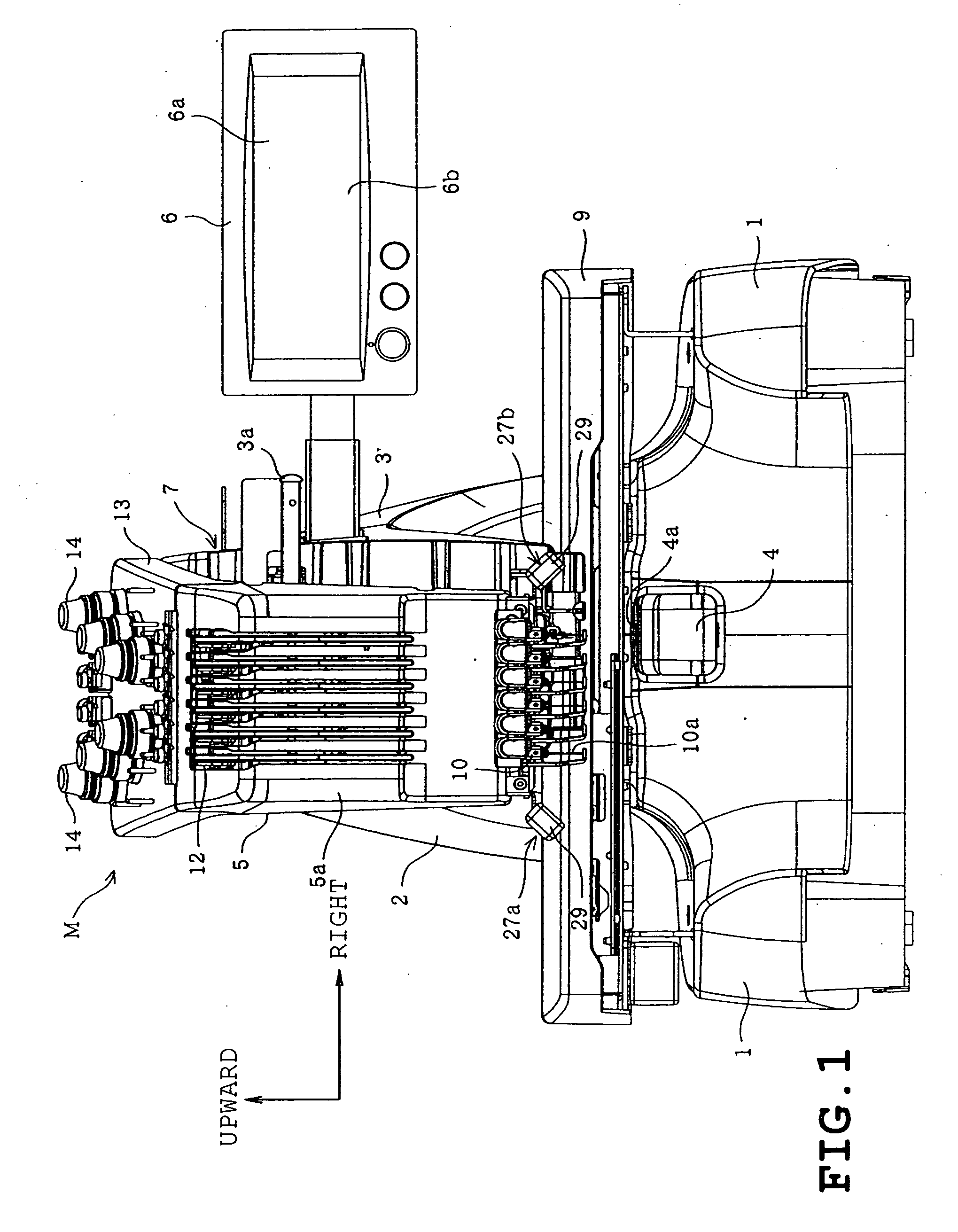

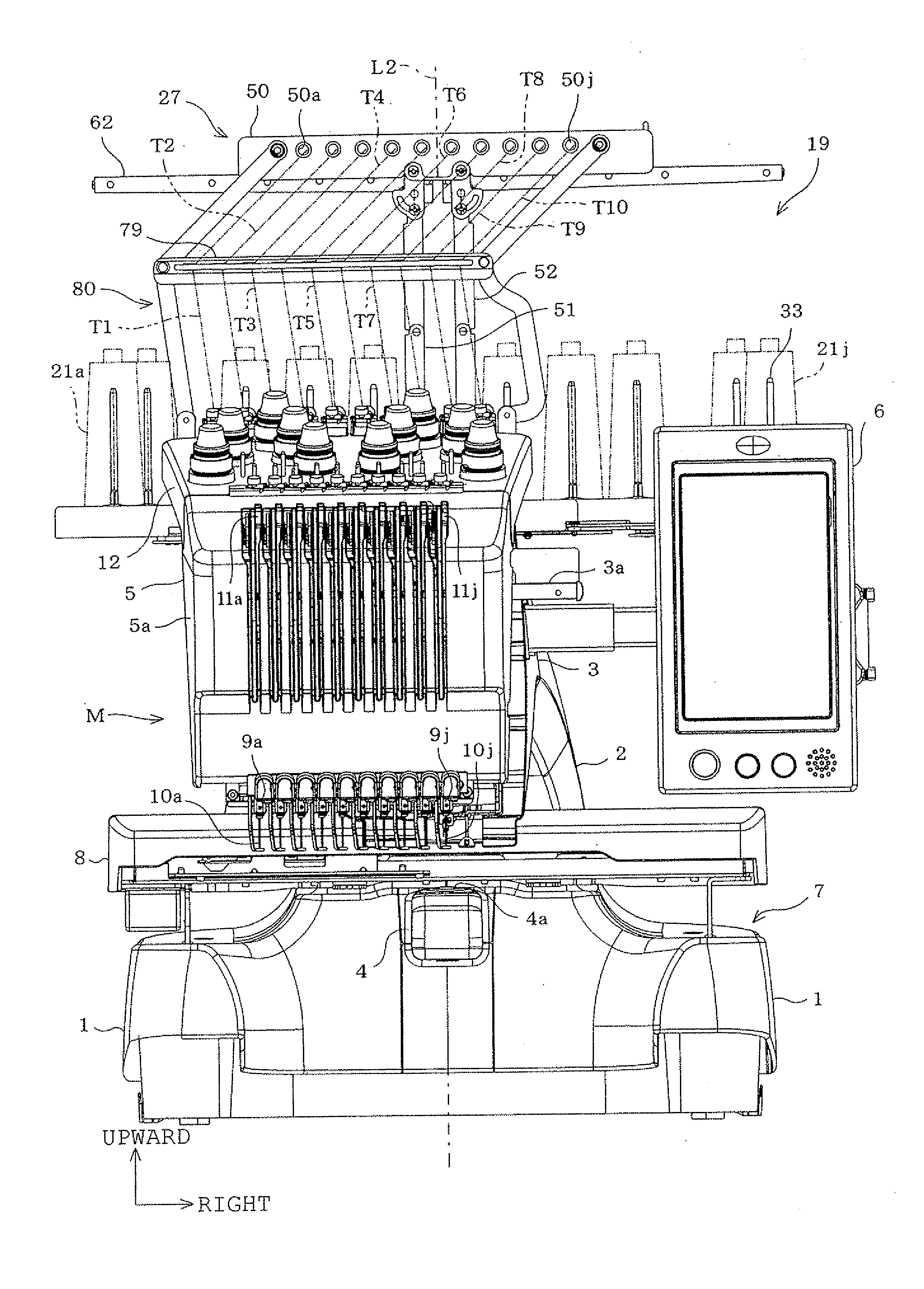

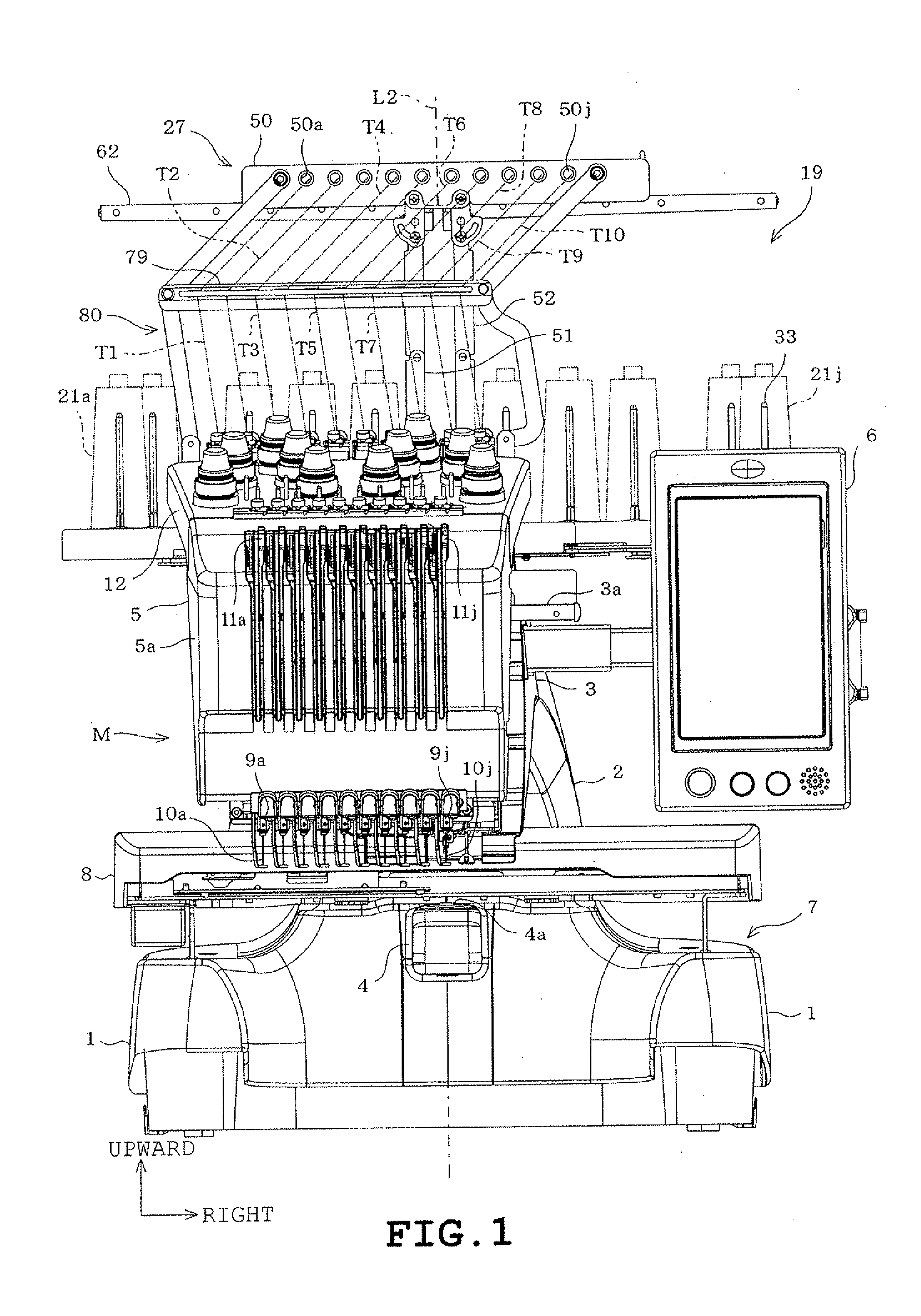

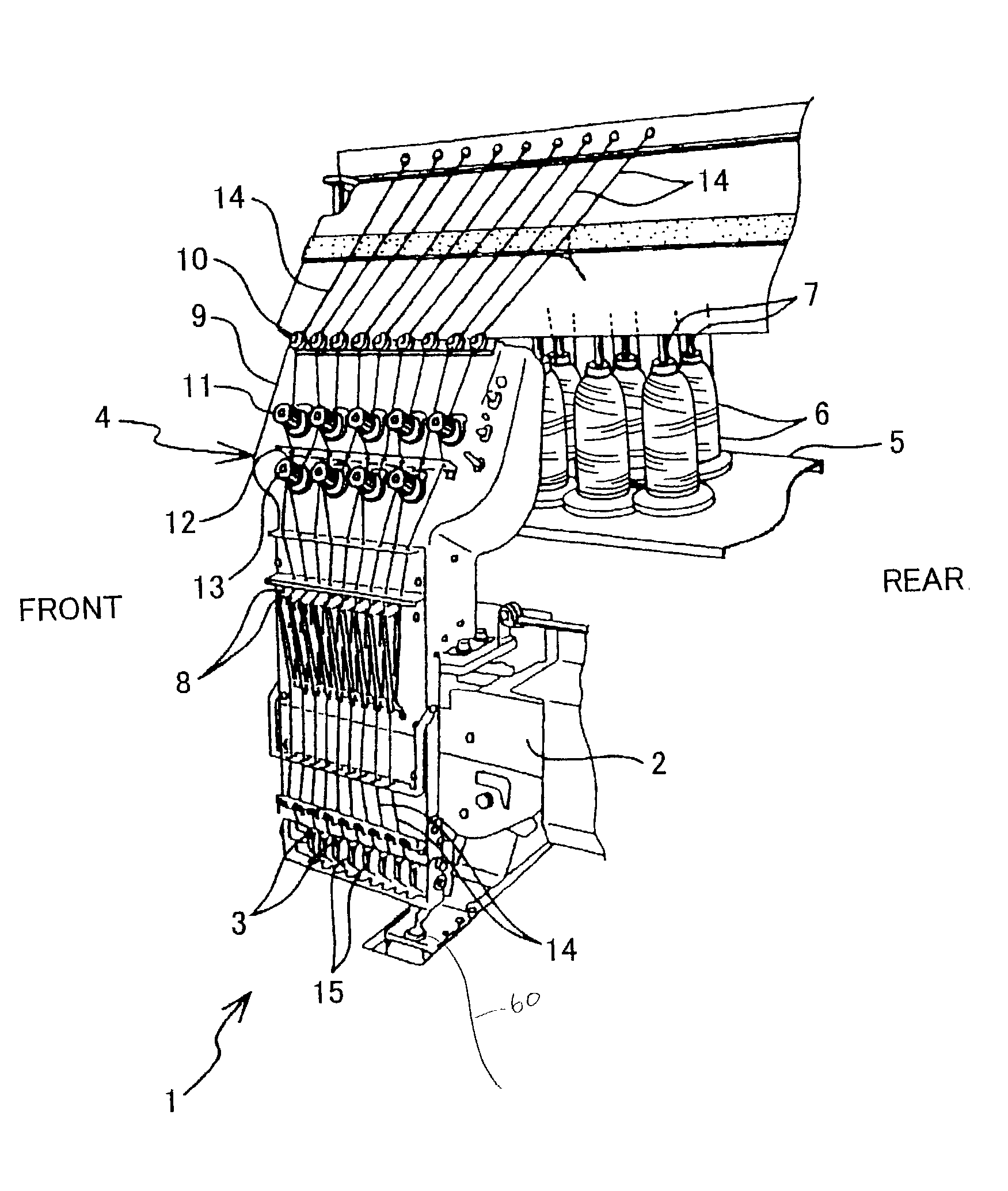

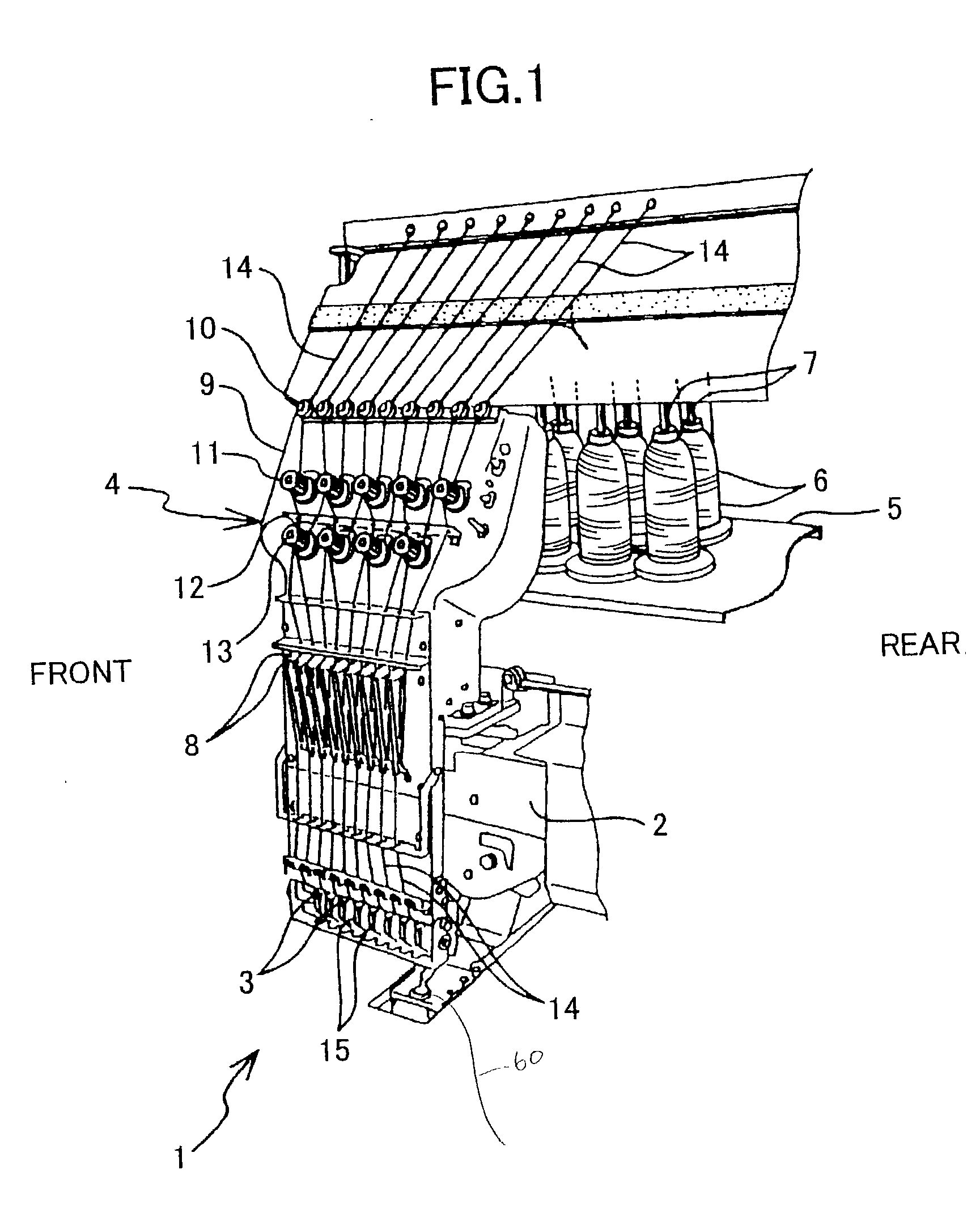

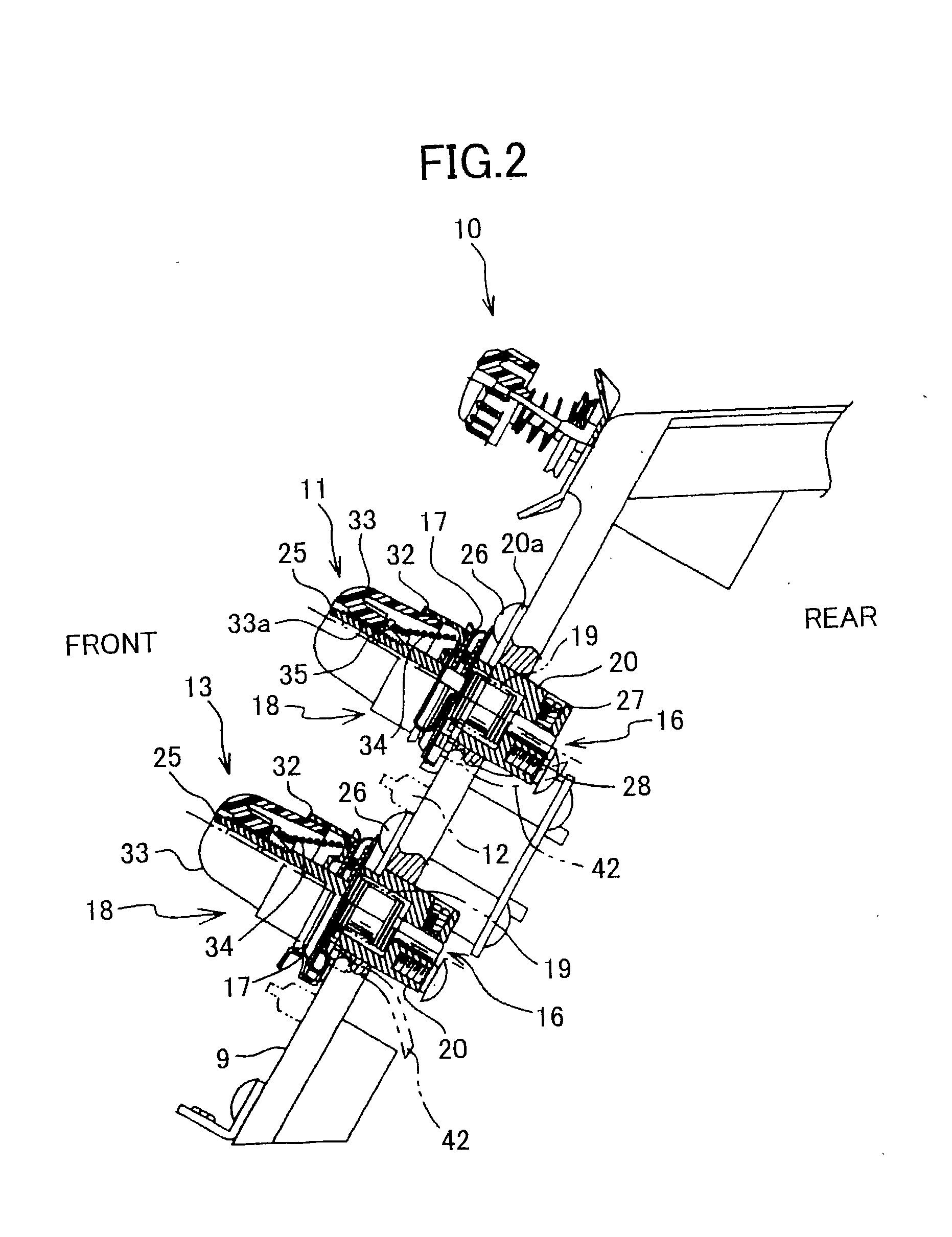

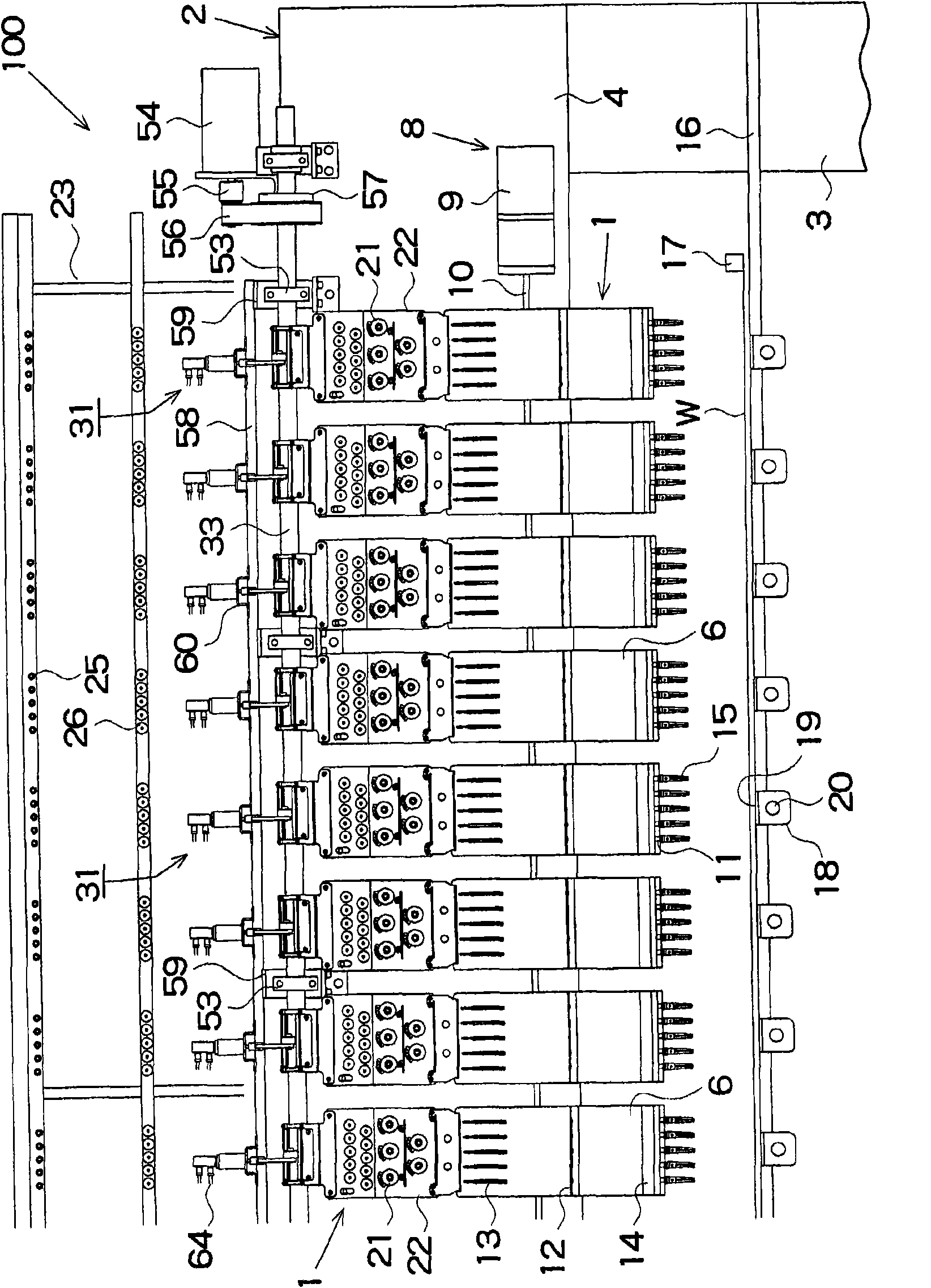

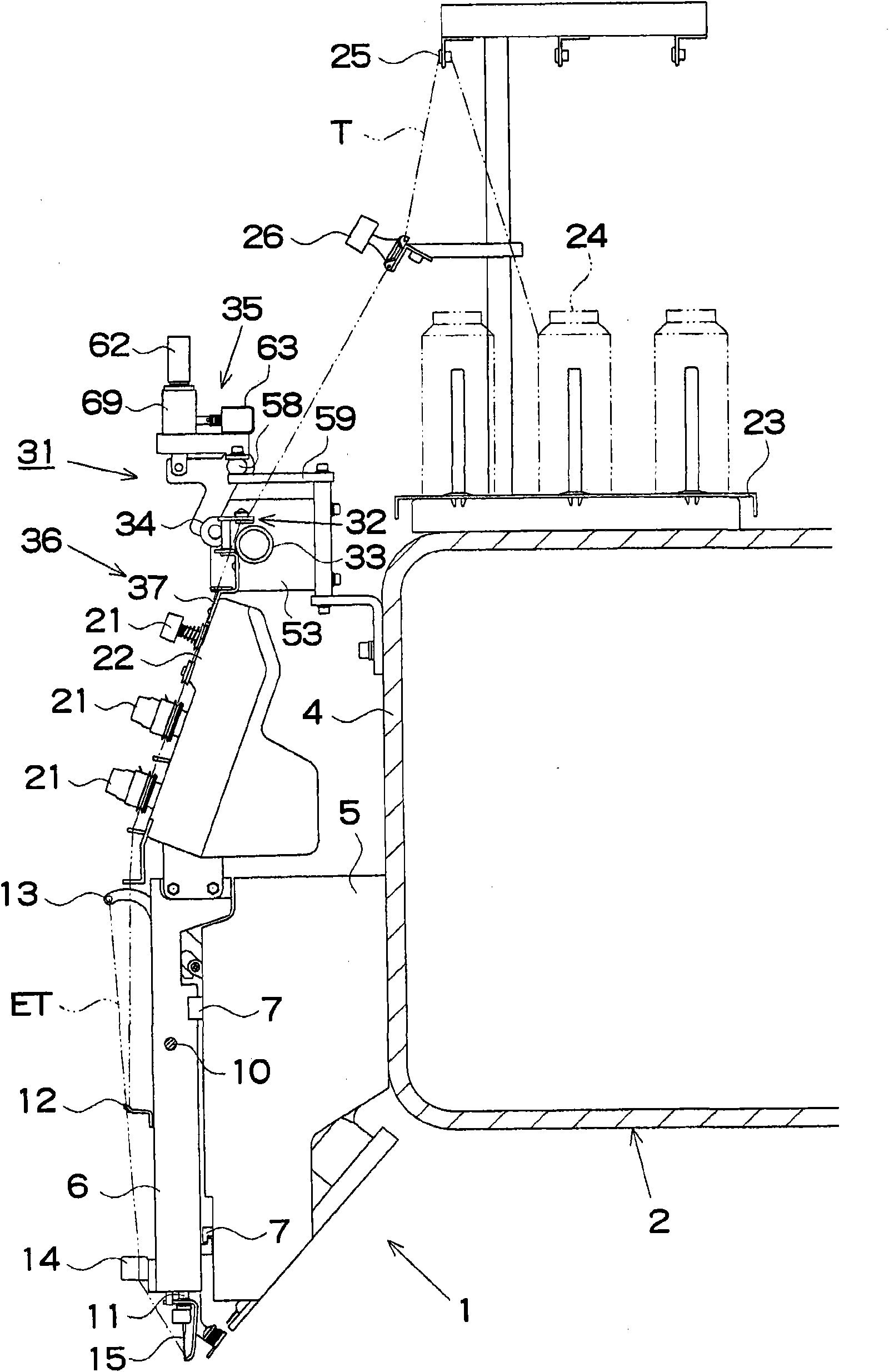

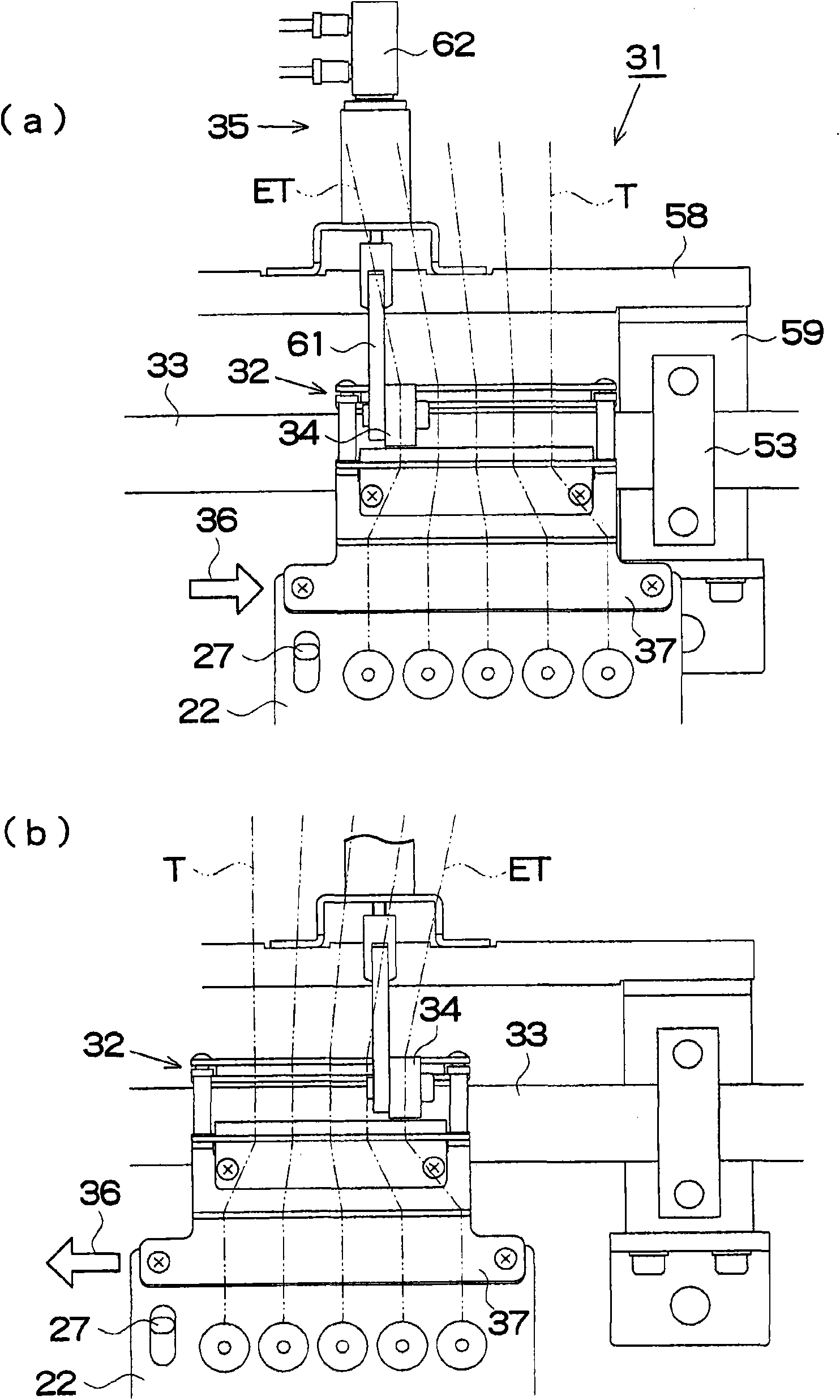

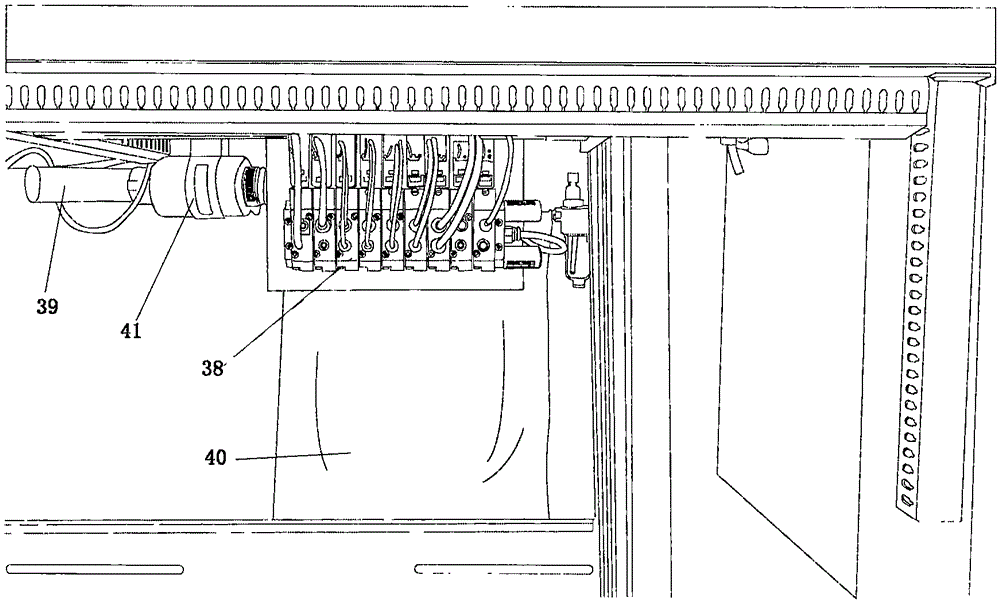

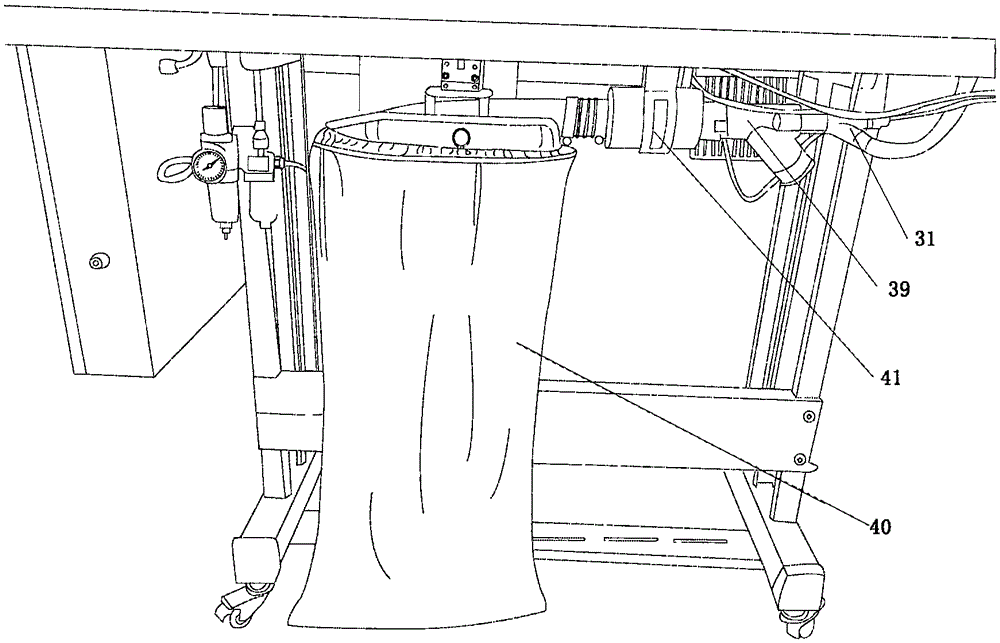

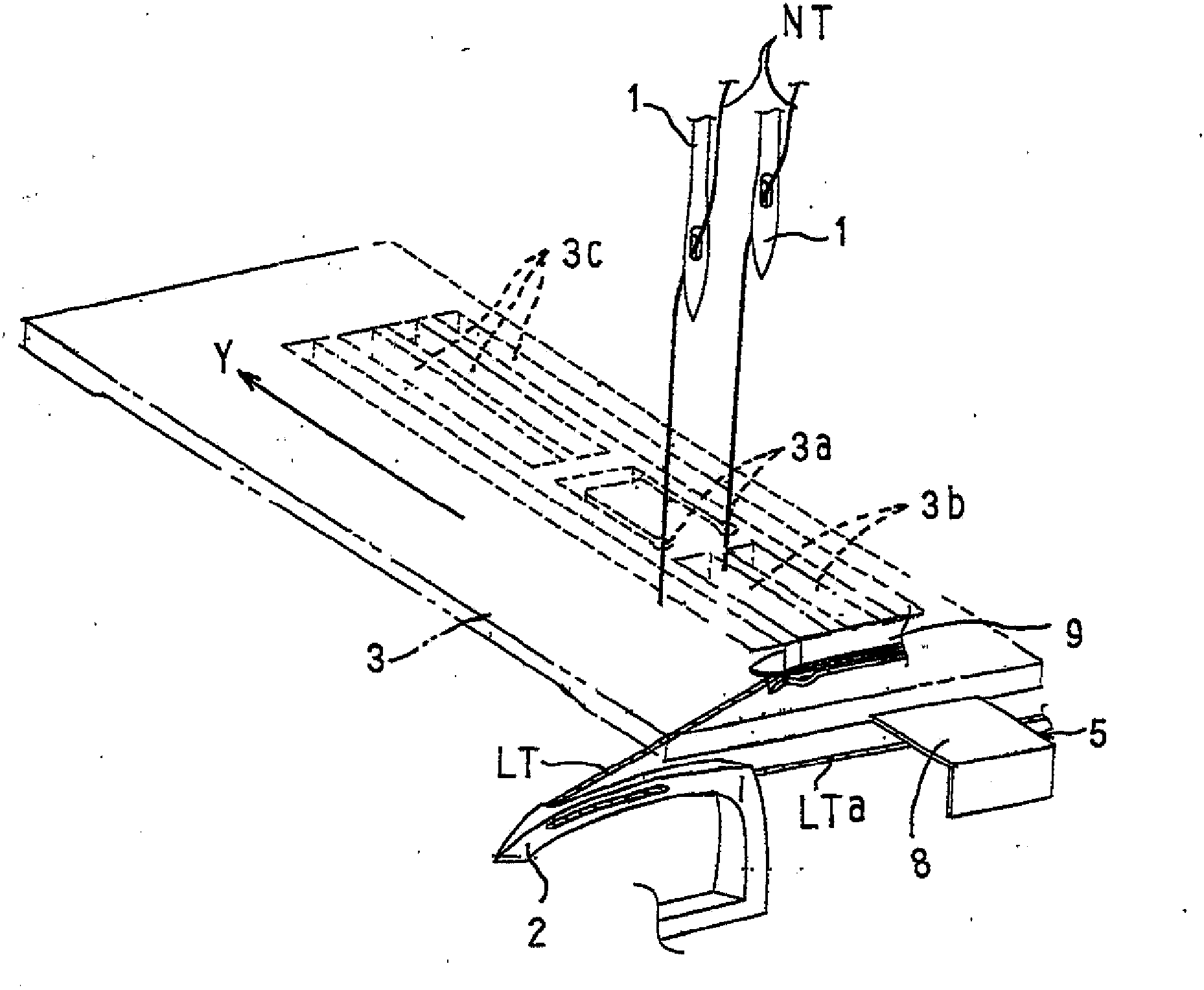

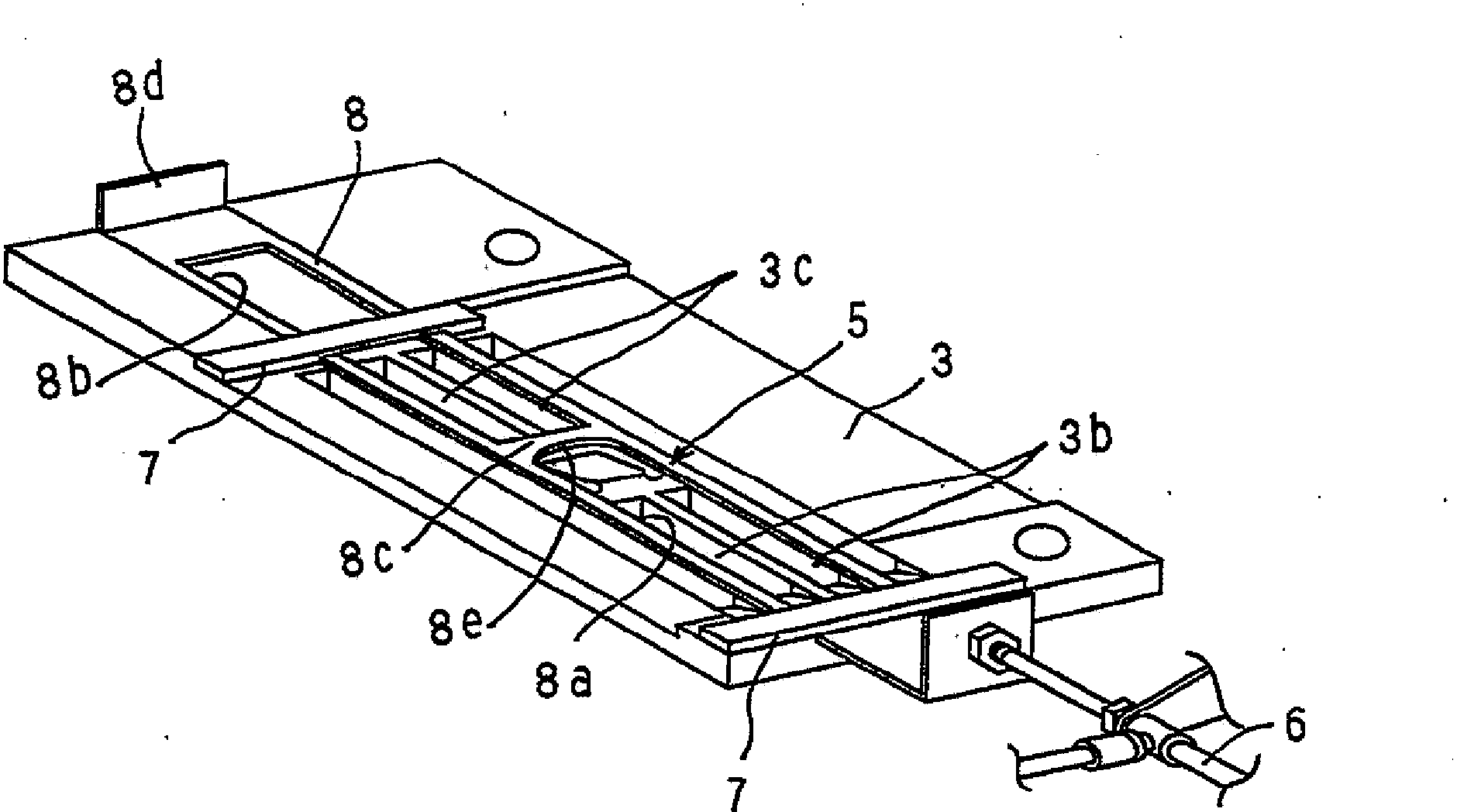

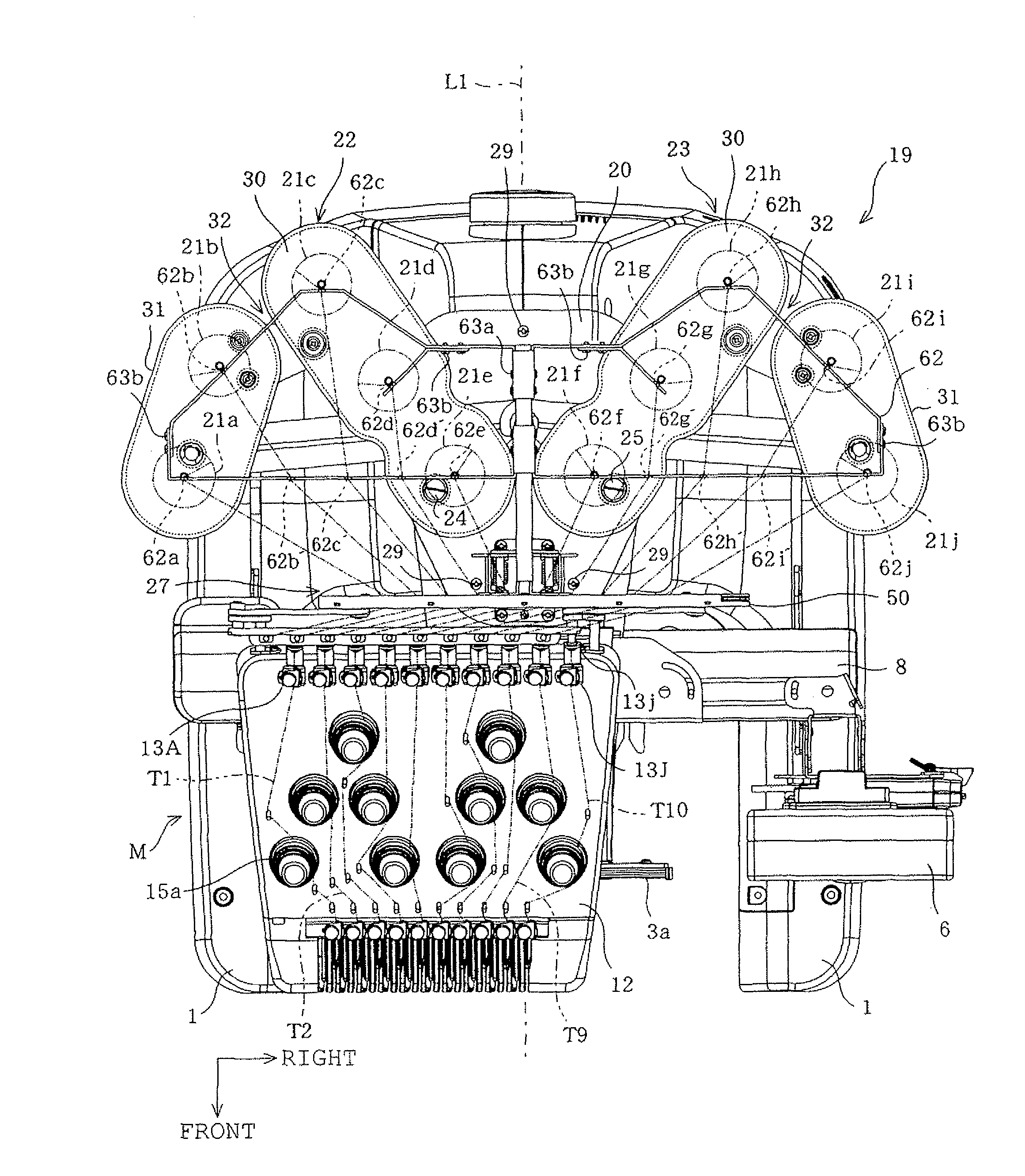

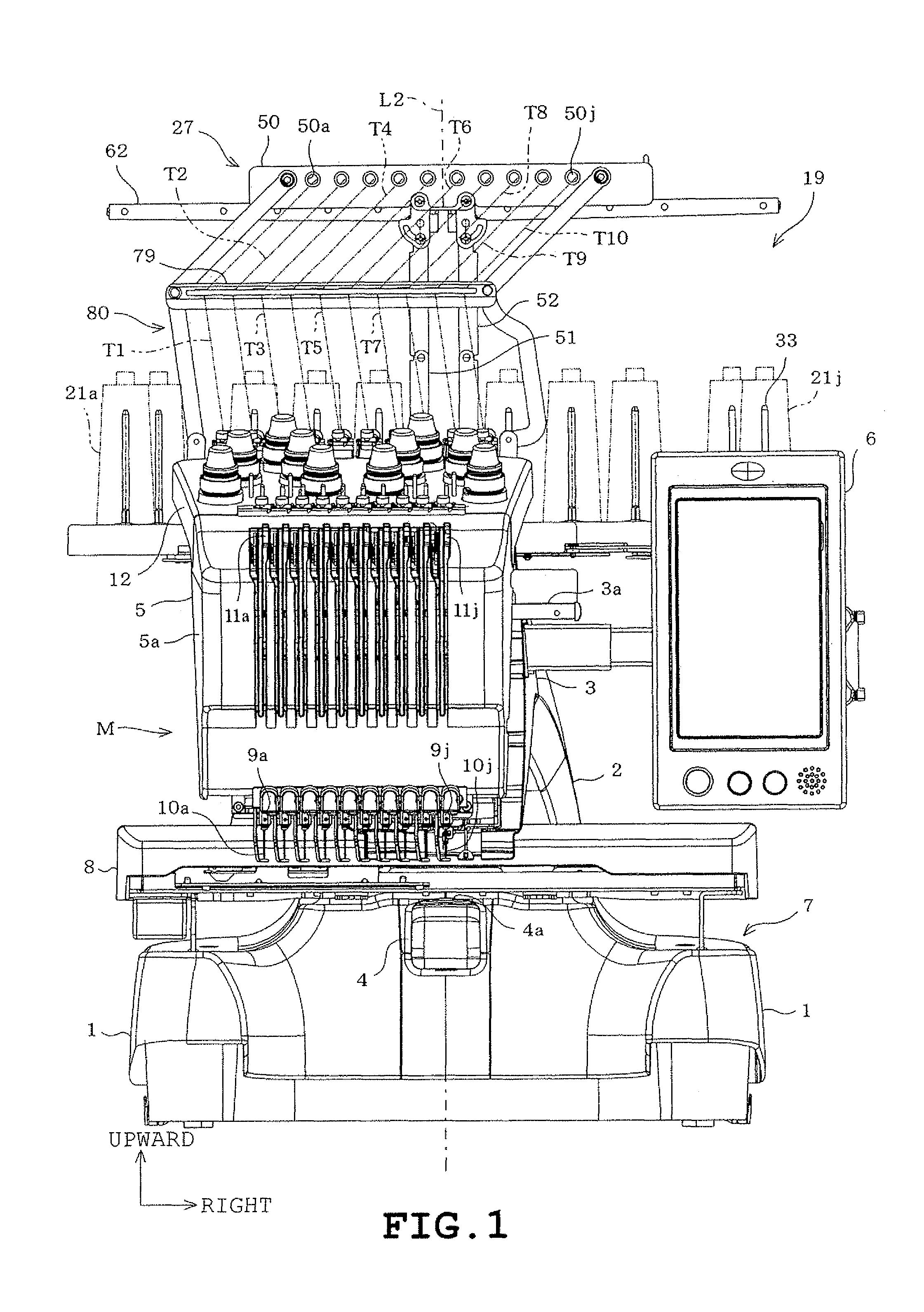

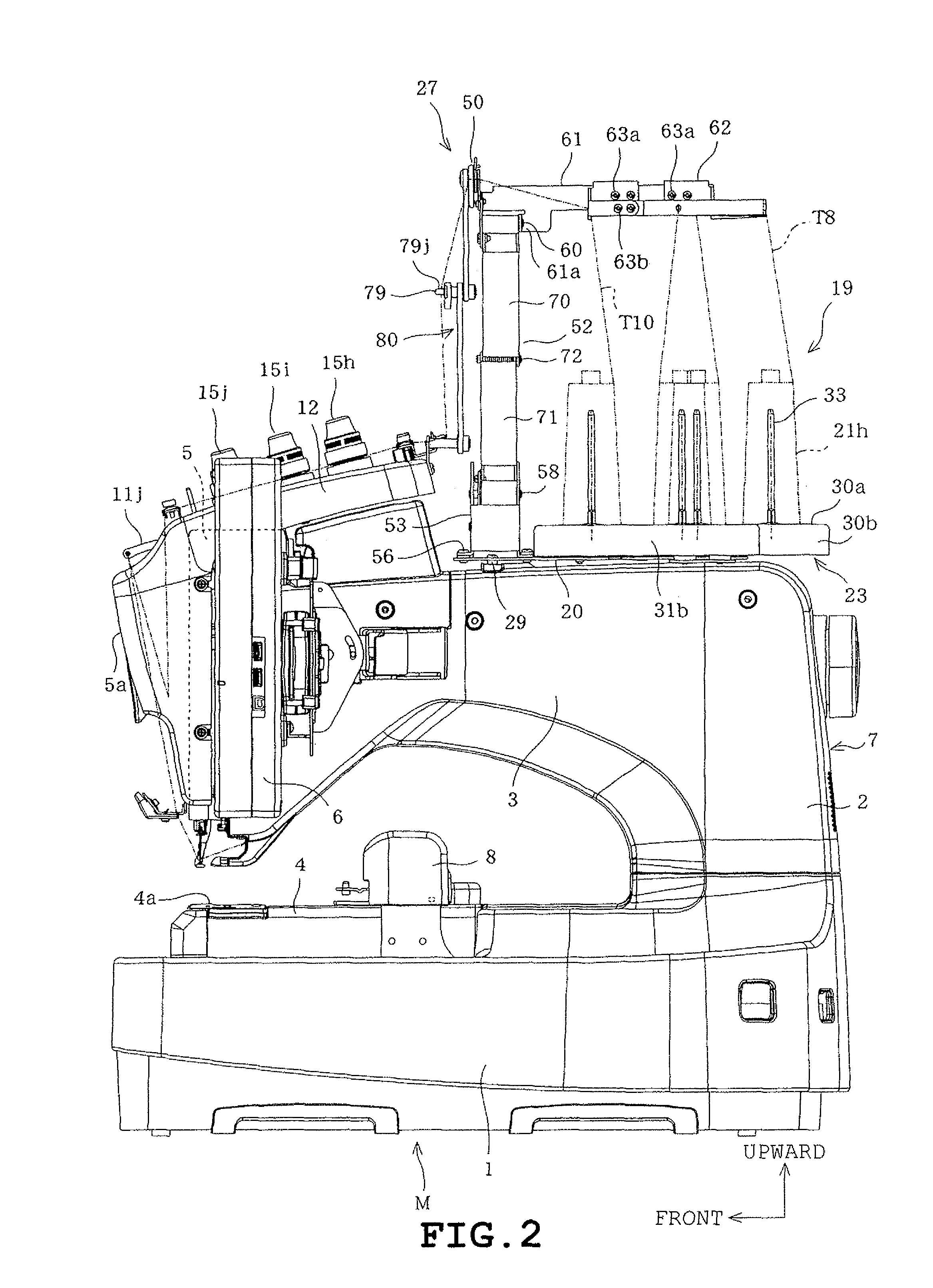

Needle thread feeding device for multi-needle embroidery sewing machine

ActiveCN101597841AReduce in quantityImprove styling qualitySewing measuring devicesThread-break detectorsEngineeringSewing machine

The present invention provides a needle thread feeding device for a multi-needle embroidery sewing machine that moves a sewing machine head to selectively locate one of a plurality of needles in a sewing position, and feeds out, out of a plurality of needle threads, a selected needle thread passing through the needle in the sewing position from a needle thread supply source to the needle, the needle thread feeding device includes a drive roller having a length that extends across the plurality of needle threads, a needle thread guide mechanism that arranges the needle threads side by side in an axial direction of the drive roller and guides the needle threads, a pressure roller that presses the selected needle thread onto the drive roller, and a thread distributing mechanism that relatively moves the needle thread guide mechanism and the pressure roller in the axial direction of the drive roller in synchronization with movement of the sewing machine head. The thread distributing mechanism interposes the selected needle thread between the drive roller and the pressure roller.

Owner:BARUDAN KK

Intelligent glove hemming machine having display screen

ActiveCN105297298AAutomate operationAvoid quality problems such as empty edges, double sides, uneven edges, etc.Needle severing devicesPressersWire cuttingContinuous operation

The invention discloses an intelligent glove hemming machine having a display screen. The intelligent glove hemming machine comprises a frame, a table plate and a unit assembly and is characterized in that the table plate is fixed onto the frame; and the unit assembly is arranged on the table plate and comprises a wire-leading device, a machine head device, a rubber string feeding-in device, a wire-cutting device, a stripping device and a control device. The intelligent glove hemming machine having the display screen has following advantages: automated operation is achieved; quality problems such as margins, double sides and uneven sides are solved during manual operation are effectively avoided; automated continuous operation is achieved and production efficiency is enhanced; an operation process is simple and easily mastered; a user can operate two or multiple machines at the same time; and usage cost is decreased.

Owner:NANTONG HANSHUN MACHINERY TECH CO LTD

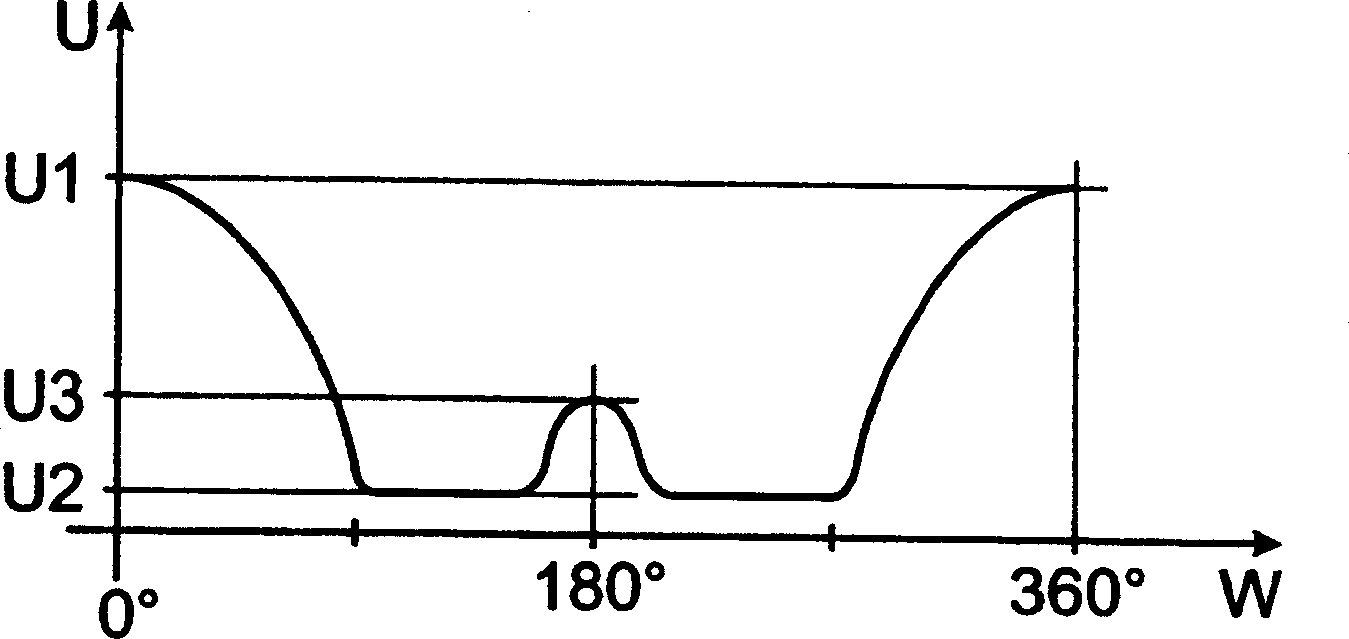

Sewing machine with faulty thread mark detection device

InactiveCN1664214AImplement error detectionNo false detectionDomestic stoves or rangesLighting and heating apparatusControl signalEngineering

The sewing machine is provided with a device (21) to detect an incomplete stitch disposed between a thread winding lever (16) and a needle. The incomplete stitch detection device guides the upper thread (17) and substantially crosses the main direction (33) of the upper thread (17) to have a deflective eye (26). The deflection of the eye (26) produces a change of a magnetic field created by a magnet (32). The change of the magnetic field is detected by a sensor (36) and changed to a control signal of the sewing machine.

Owner:DURKOPP ADLER AG

Sewing method of cloth and double-chain-ring sewing machine

ActiveCN103361889AEasy to operateWon't hurtSewing-machine casingsWork-feeding meansOperabilityEngineering

A sewing method of cloth and a double-chain-ring sewing machine transfer the cloth towards a specified sewing advancing direction along an upper surface of a needle plate, and form a stitch ring at a lower side of the needle plate by utilizing two needles which keep stitching and move up and down, and catch the stitch ring through advancing of a curved needle which can advance and retreat in a direction approximately orthogonal to an up-down moving path of the needle, and utilize a looper thread maintained by the curved needle to wind the caught stitch ring, so that double-chain-ring stitch is formed on the cloth, at the moment, a movement guiding stitch diagonal member is utilized to perform movement guide to a stitch end part which is protruded onto a surface of the cloth when the stitch of the first needle begins, so as to form a state of falling and tilting towards a downstream side of the sewing advancing direction, thereby sewing and processing the stitch end part into the double-chain-ring stitch. Therefore, cut processing for the stitch end part does not cost time, thereby realizing labor saving, raising the efficiency of sewing operation and operability of the cloth, and preventing damages to the cloth.

Owner:YAMATO SEWING MASCH MFG CO LTD

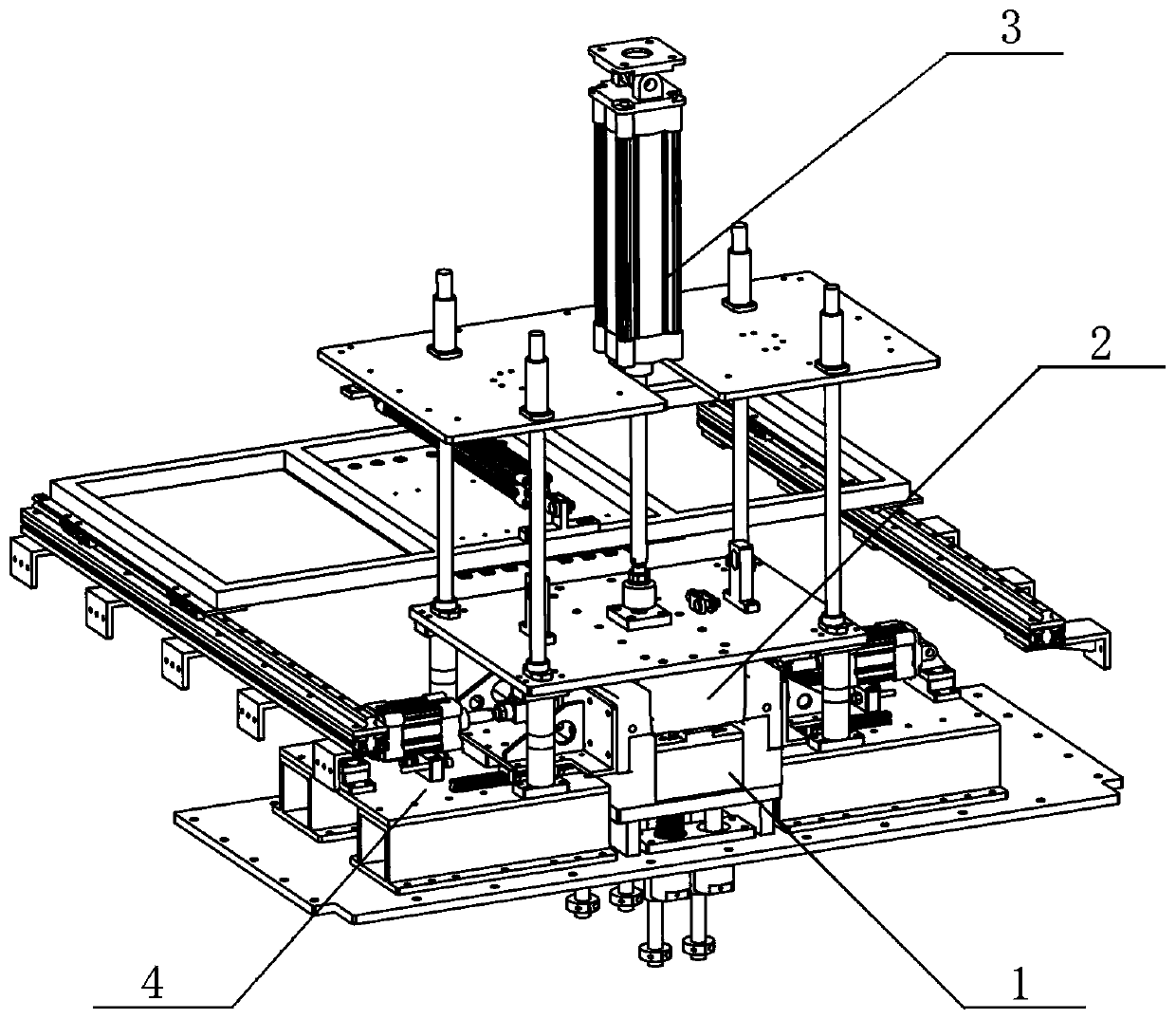

Automatic automobile trim coating device with sewing thread

PendingCN110219105AGuaranteed positionWarranty requirementsThread-break detectorsMechanical engineeringQuality standard

The invention provides an automatic automobile trim coating device with a sewing thread. The coating device comprises a lower mold and an upper mold. The upper mold is provided with a lifting mechanism, and side pushing mechanisms for clamping workpieces on the lower mold are arranged on both sides of the lower mold. The lower mold comprises a lower mold body, lateral lower molds, a lower mold mounting plate, sewing thread middle jacking molds, a main spring component and an auxiliary spring component. Two symmetrical sewing thread middle jacking mold mounting grooves are formed in edge positions, close to both sides, of the lower mold body. The sewing thread middle jacking molds are mounted in the sewing thread middle jacking mold mounting grooves. The automatic automobile trim coating device has the advantages that the sewing thread middle jacking molds with positioning and suction functions and the side pushing mechanisms are added to the lower mold, automatic coating of trim products can be realized; front and back edges of a cover are sucked by vacuum suckers to guarantee the shape stability of the sewing thread during coating, the position degree and flatness of the sewing thread after coating are also ensured, and accordingly, the products meet quality standards.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

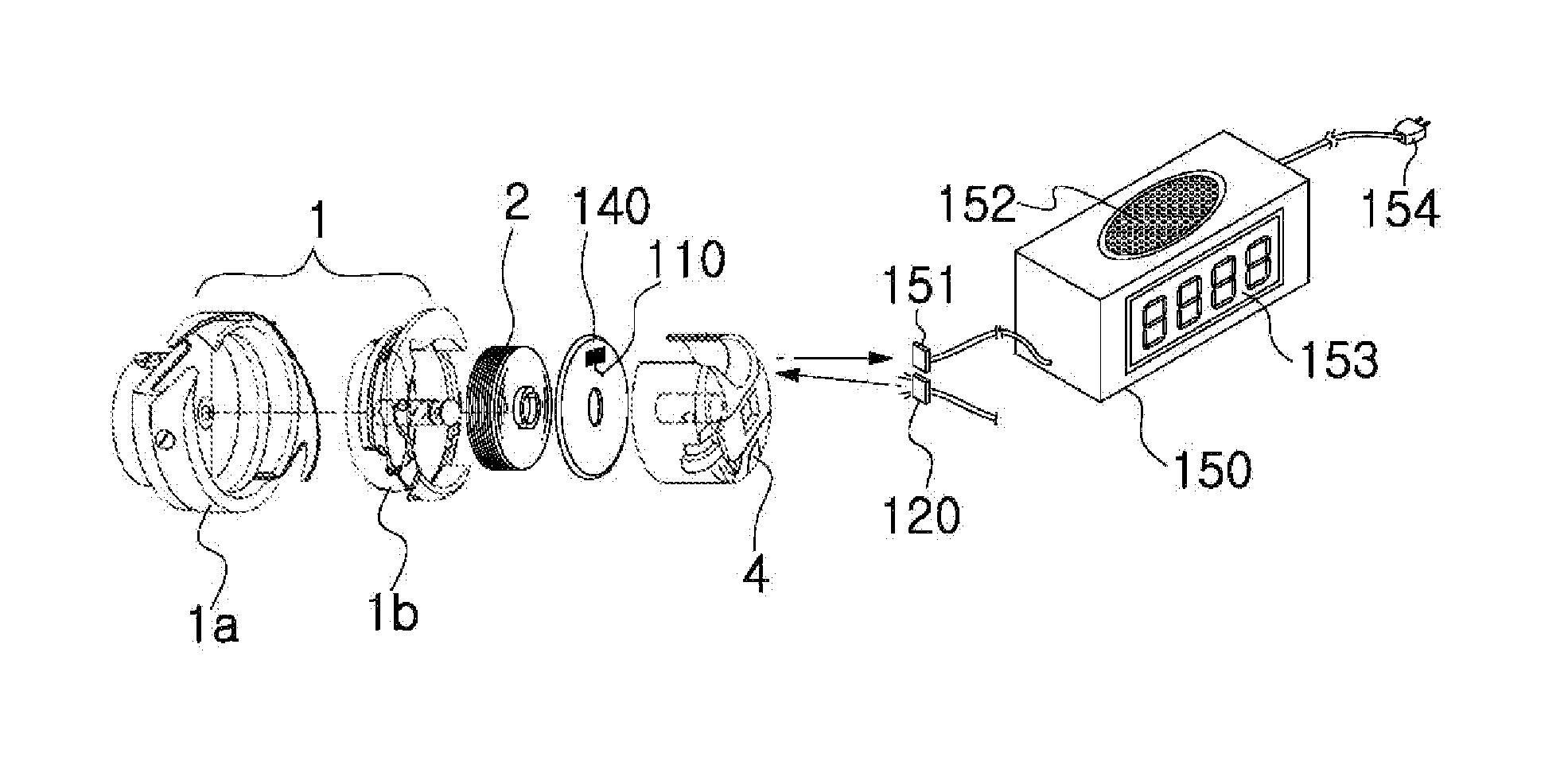

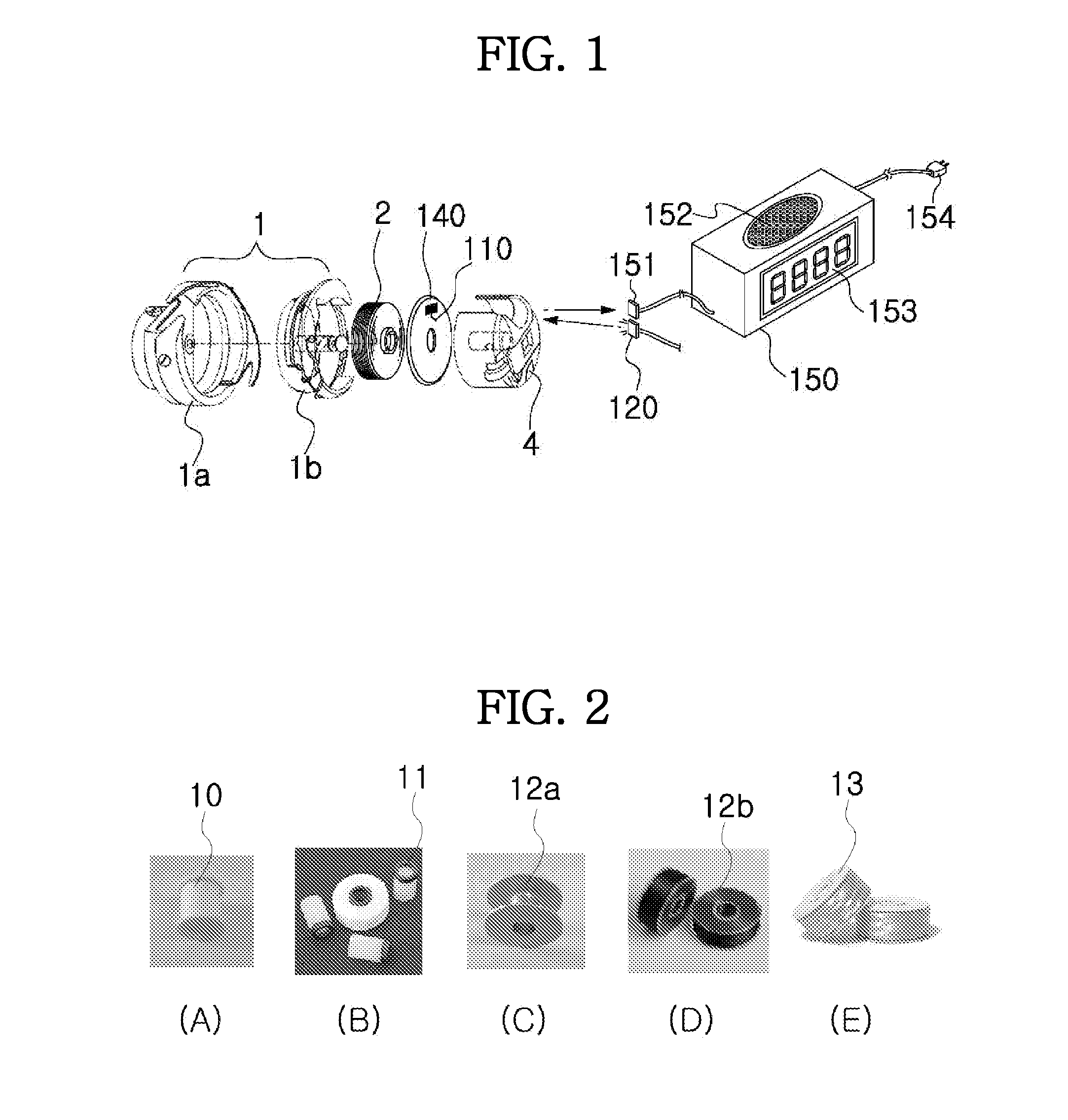

Apparatus and lower thread winding-spool for detecting the ending region of lower thread of sewing machine

InactiveUS20130167763A1Preventing increase of thread bobbin production costAccurate detectionSewing-machine control devicesFilament handlingBobbinEngineering

The present invention relates to a lower thread ending region detection apparatus (LTERDA) that prevents problems associated with poor quality and re-work resulting from false stitchings due to being unable to detect the exhaustion of the lower thread during the sewing operation. The lower thread ending region detection apparatus (LTERDA) comprises the following: a light control unit (LCU), which contacts a part of lower thread wound on a thread bobbin and activates or inactivates at least one of the functions of emitting light, reflecting light, passing or penetrating light and blocking light, due to the effect of the physical movement force (PMF) generated depending on whether the lower thread of the ending region is unwound; a light receiving unit (LRU), which receives the light transferred out by the light control unit (LCU) and outputs a detection signal; and a control and notification unit (CNU), which analyzes the detection signal output from the light receiving unit (LRU) to determine whether the lower thread has reached the ending region and outputs the result to the user.

Owner:BOBBINTEL

Spool holder and sewing machine provided therewith

InactiveUS8251000B2Easy to replaceCompact storageSewing-machine control devicesFilament handlingEngineeringSewing machine

Owner:BROTHER KOGYO KK

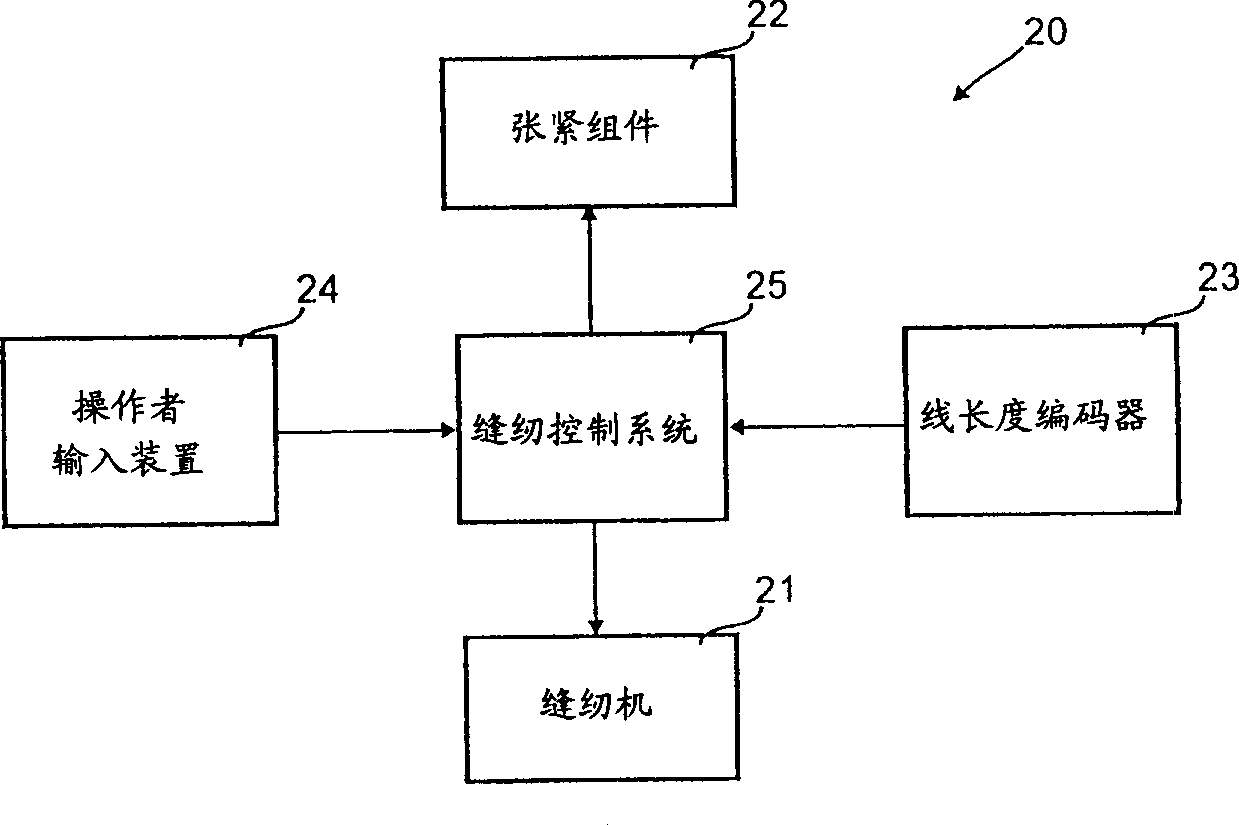

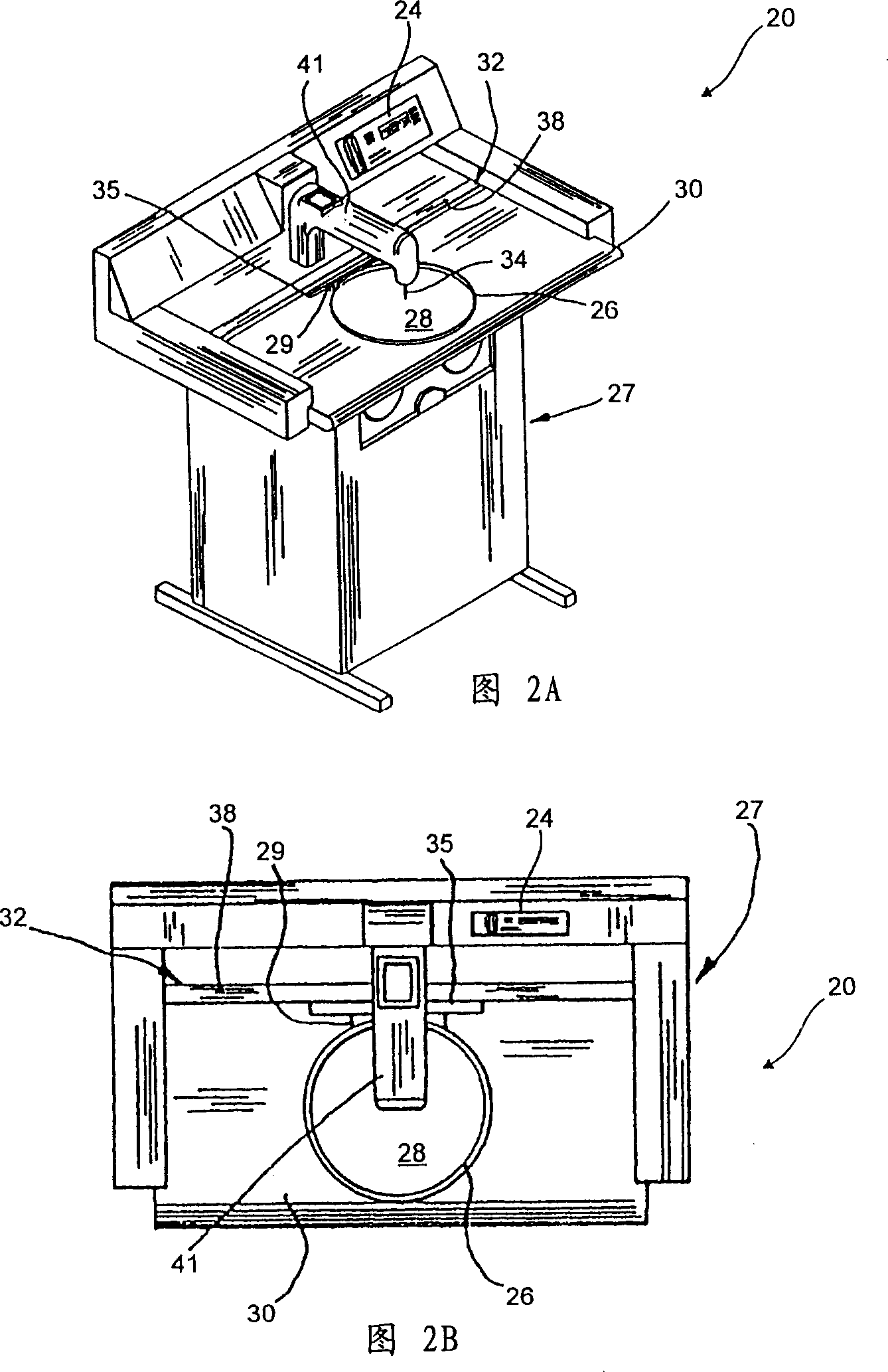

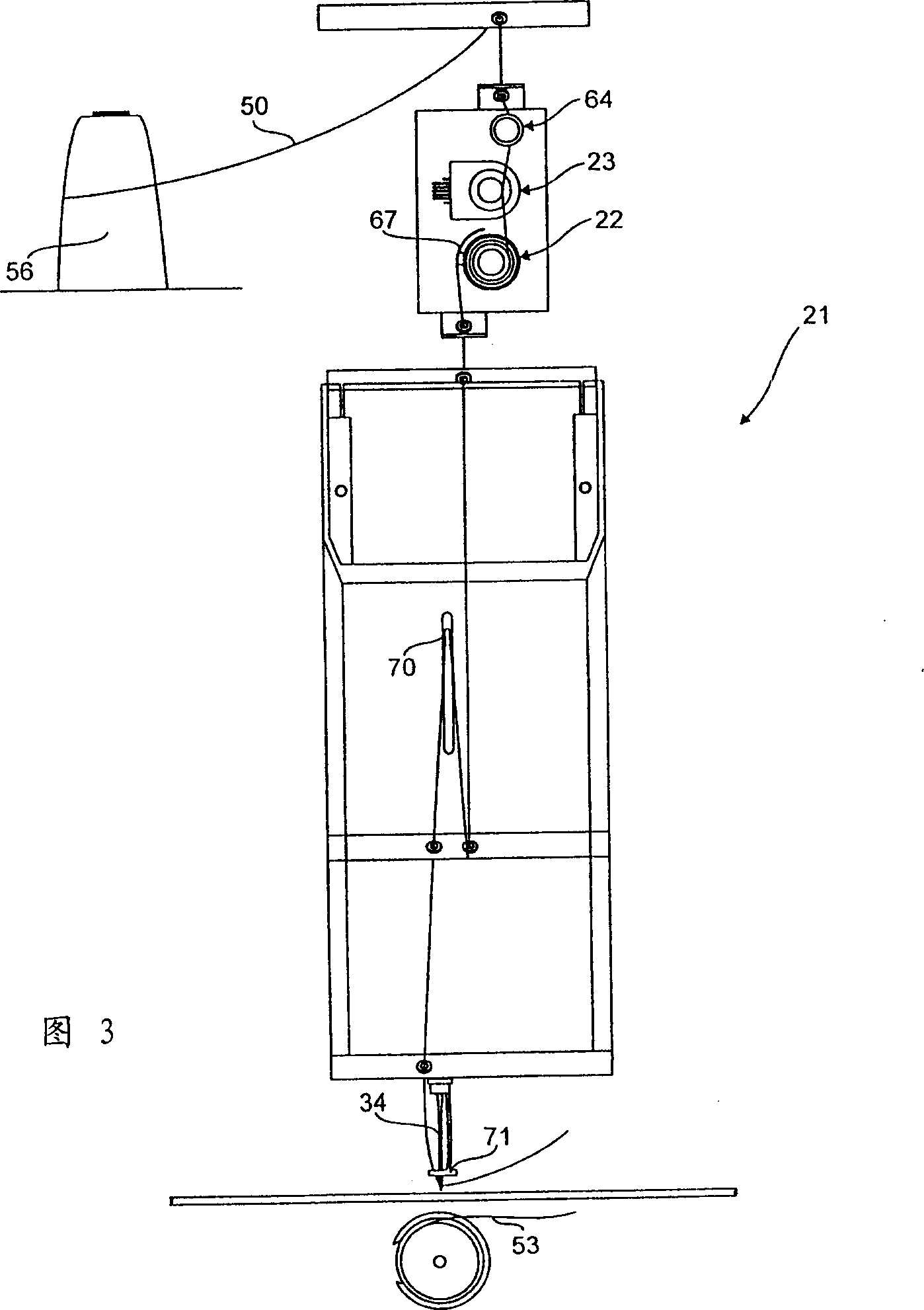

Method and apparatus for automatic adjustment of thread tension

InactiveCN1305547AAccurate adjustmentImprove uniformityProgramme-controlled sewing machinesSewing measuring devicesAutomatic controlControl system

A computerized stitching apparatus that automatically controls thread tension is disclosed. In one embodiment, at least two factors are used to determine the desired thread consumption for the next stitch. A thread length encoder (23) is used to determine the amount of thread actually consumed for a particular stitch. The operator must enter a desired thread length ratio or an equivalent factor related to desired thread length used for a particular stitch into the operator input device (24). Another factor such as speed, stitch length, fabric thickness, or stitch angle change is used with at least the operator's input to determine the desired thread consumption. The tension of the thread is adjusted by a stitch control system (25) which will affect the actual thread consumed for the particular stitch.

Owner:MCET

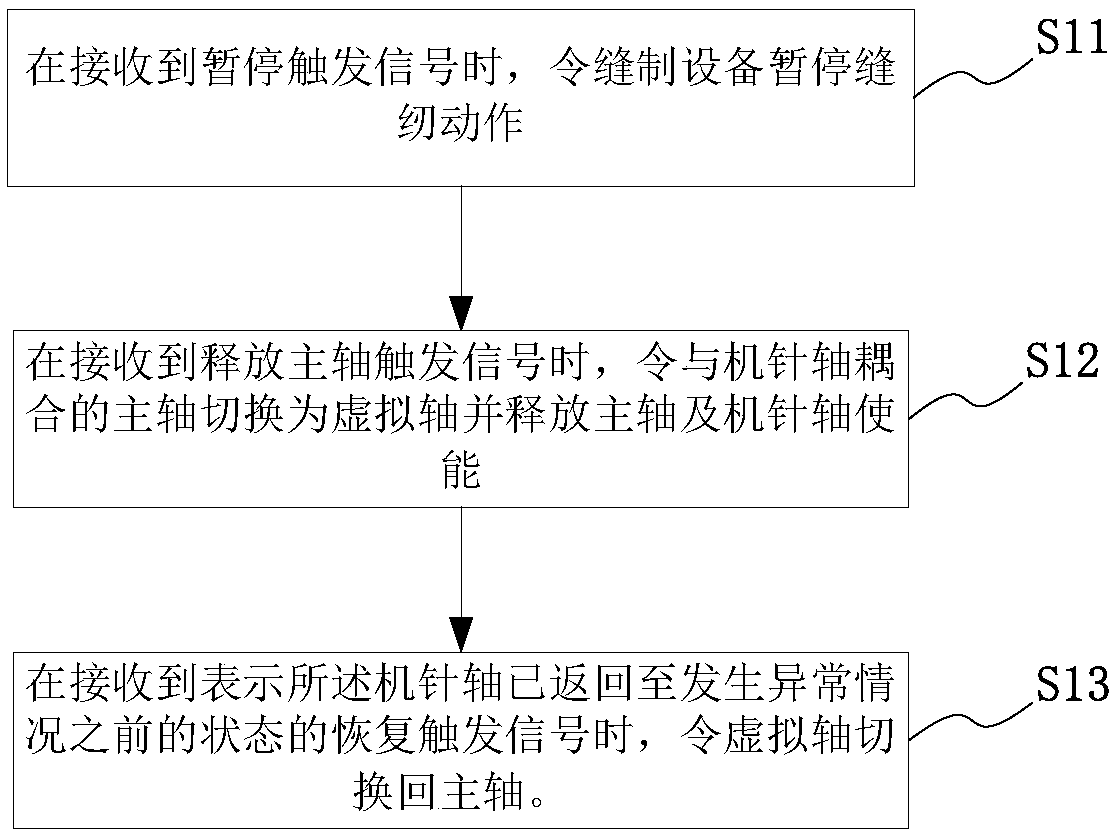

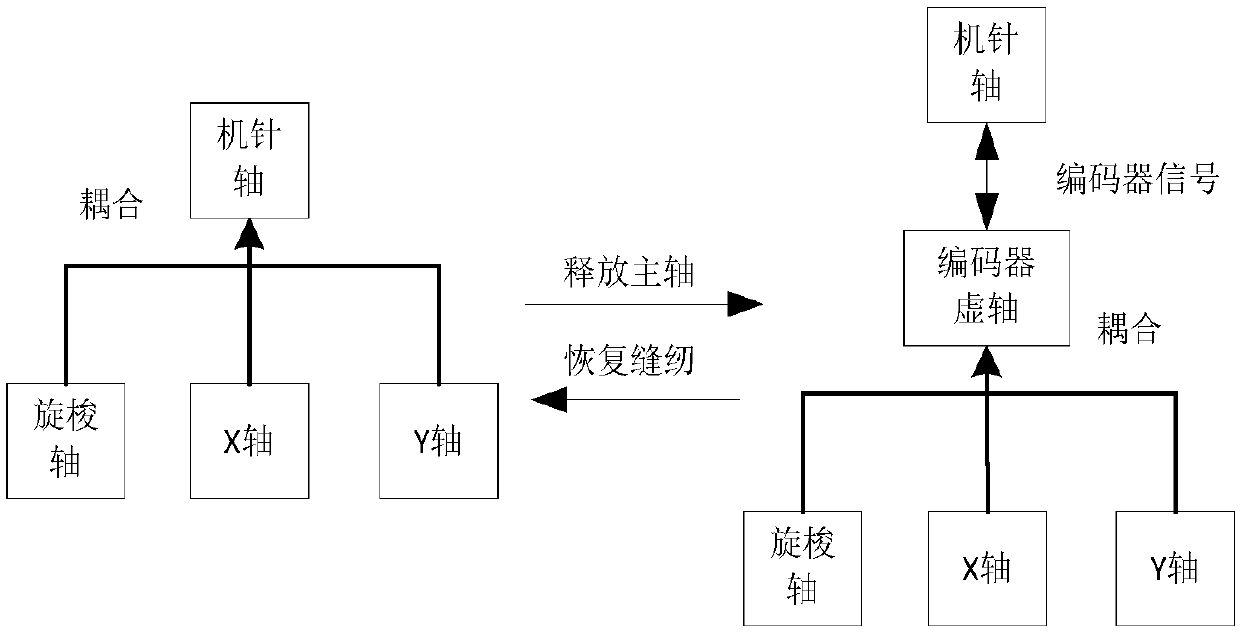

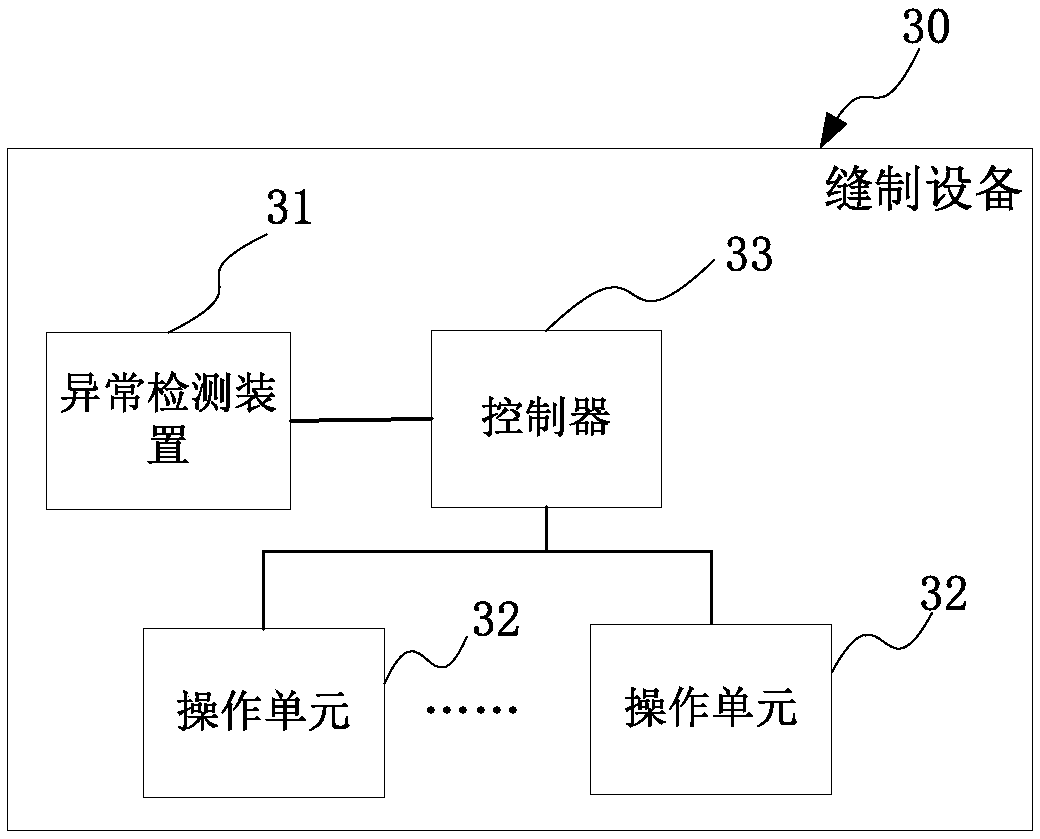

Sewing equipment control method, sewing equipment, controller and storage medium

ActiveCN109629121AResolve detectionSolve the problem of manual debuggingProgramme-controlled sewing machinesThread-break detectorsException handlingElectrical and Electronics engineering

The invention provides a sewing equipment control method, sewing equipment, a controller and a storage medium. When a pause triggering signal is received, the sewing equipment is made to pause the sewing action. When a main shaft releasing triggering signal is received, a main shaft coupled with a machine needle shaft is switched into a virtual shaft, the main shaft and the machine needle shaft are released to be enabled. When a recovery triggering signal indicating that the machine needle shaft has returned to the state before the occurrence of an abnormal condition is received, the virtual shaft is switched back to the main shaft. After it is monitored online that the equipment is stopped, other shafts at a yarn broken position can be manually restored to be in place, and sewing at the current position continues after exception handling, so that the problem that existing sewing equipment cannot detect abnormal recovery in the sewing process or manually debugged is solved, and the product quality is greatly improved.

Owner:JACK SEWING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com