Patents

Literature

57results about How to "Improve styling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane spandex and its manufacturing method, cottons and silks and swimwear

InactiveCN1396320AFit closelyImprove styling qualityMonocomponent polyurethanes artificial filamentConjugated synthetic polymer artificial filamentsUreaChemistry

The present invention is related to polyurethane elastic fiber which is characterized by consisting from polyurethane urea and polyurethane and preparation thereof. The polyurethane elastic fiber of present invention can be used for the usage of swimming suit by way of such excellent anti-chlorine brittle function and thermoset property.

Owner:OPELONTEX CO LTD 50

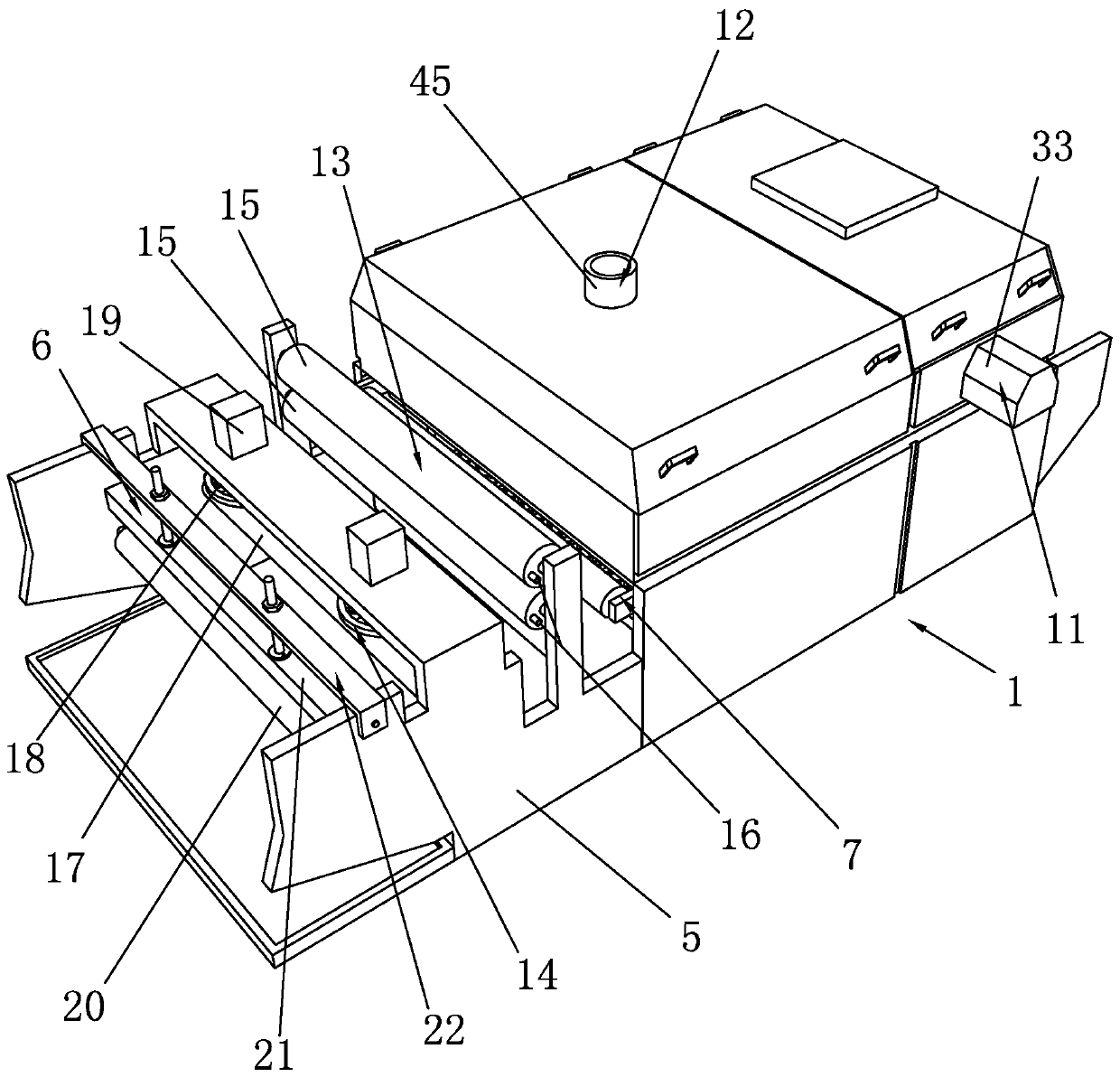

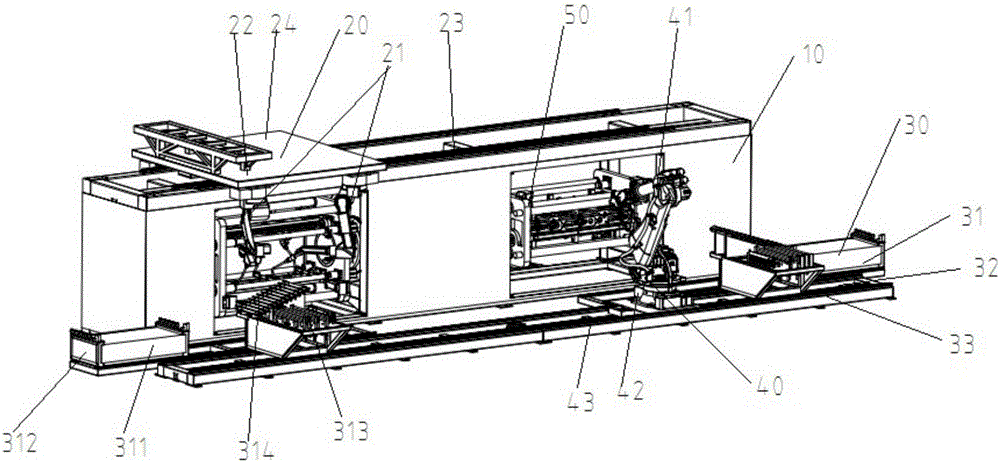

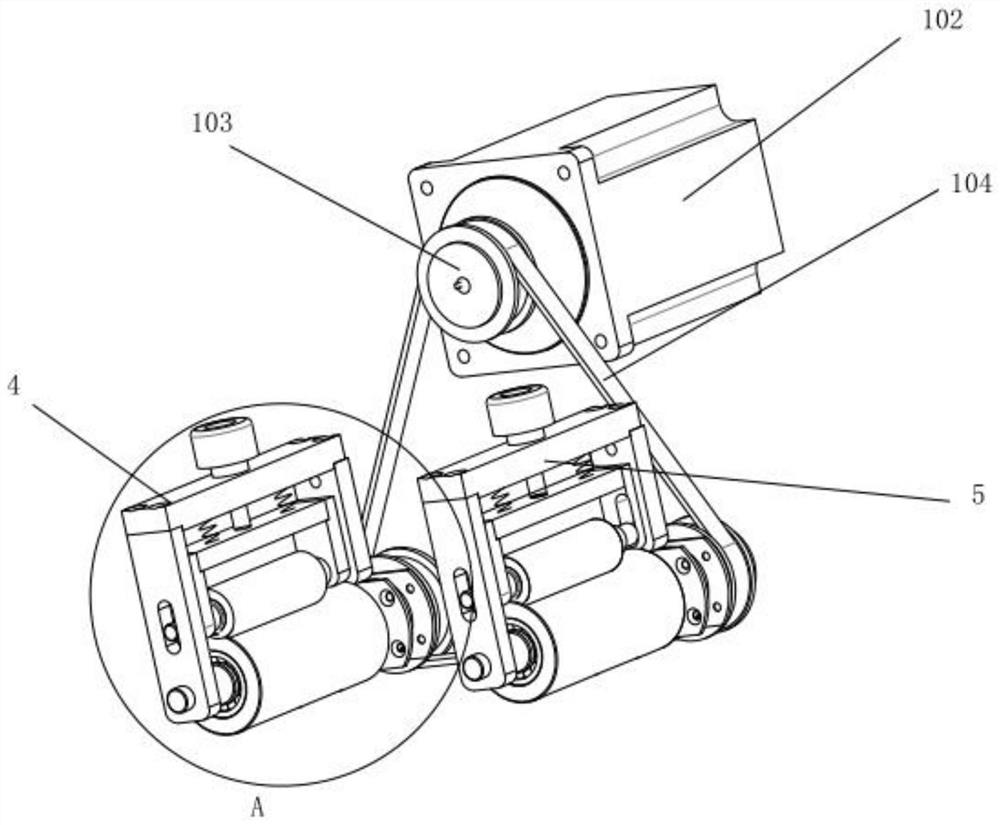

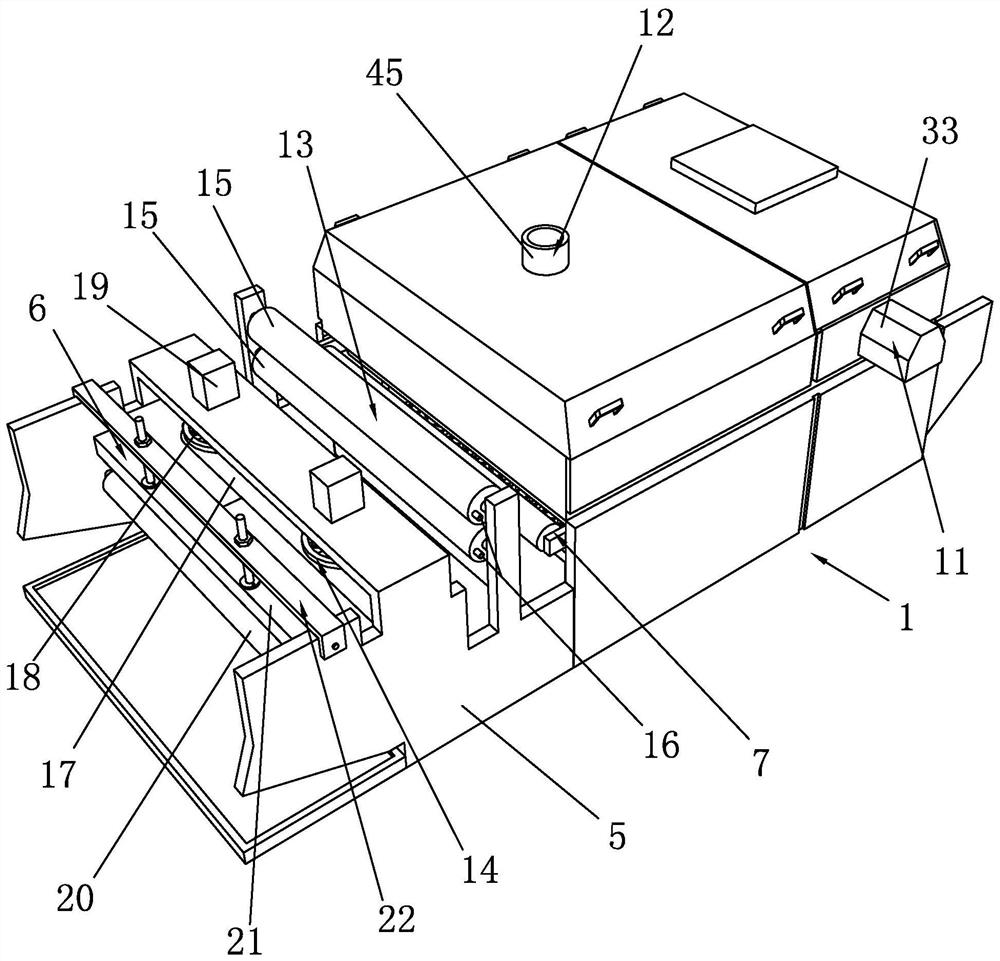

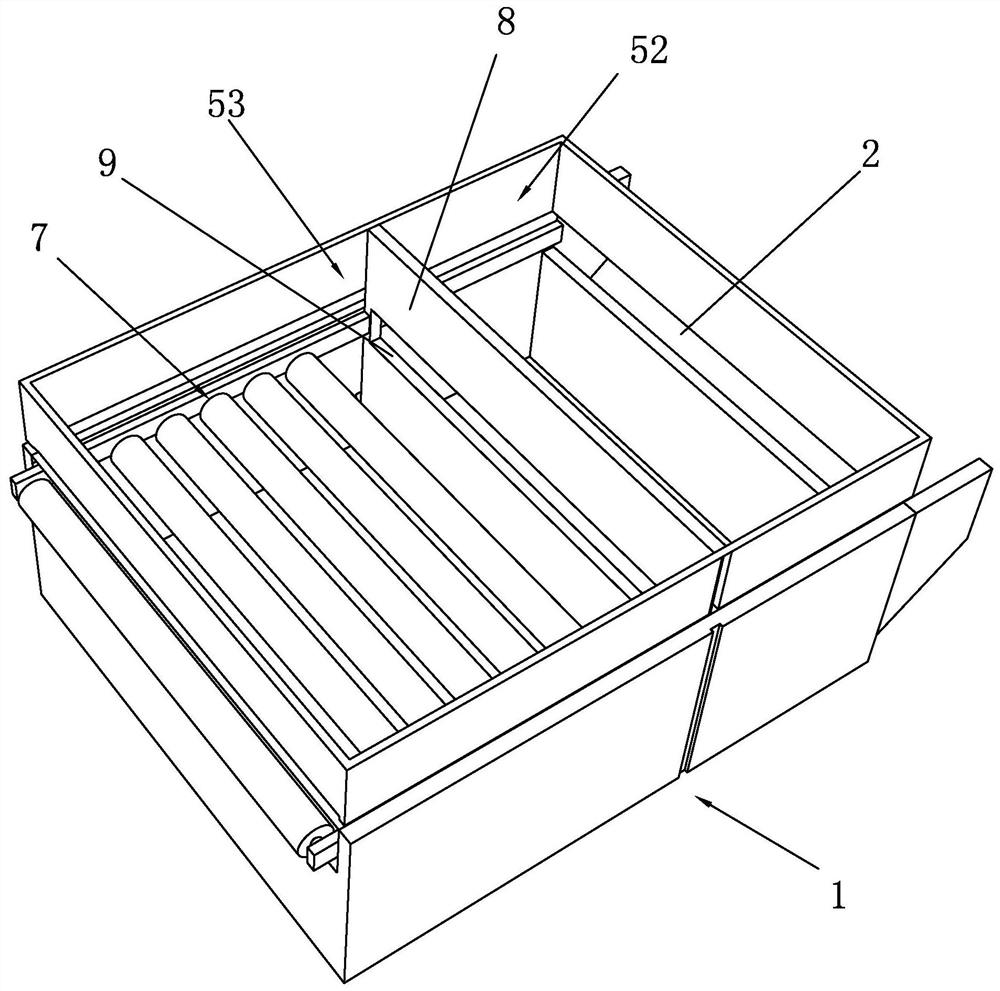

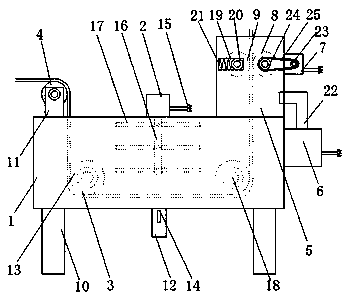

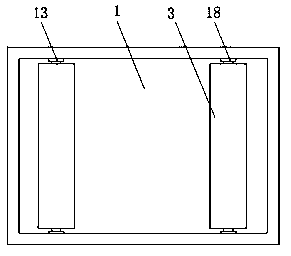

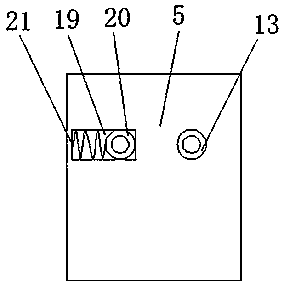

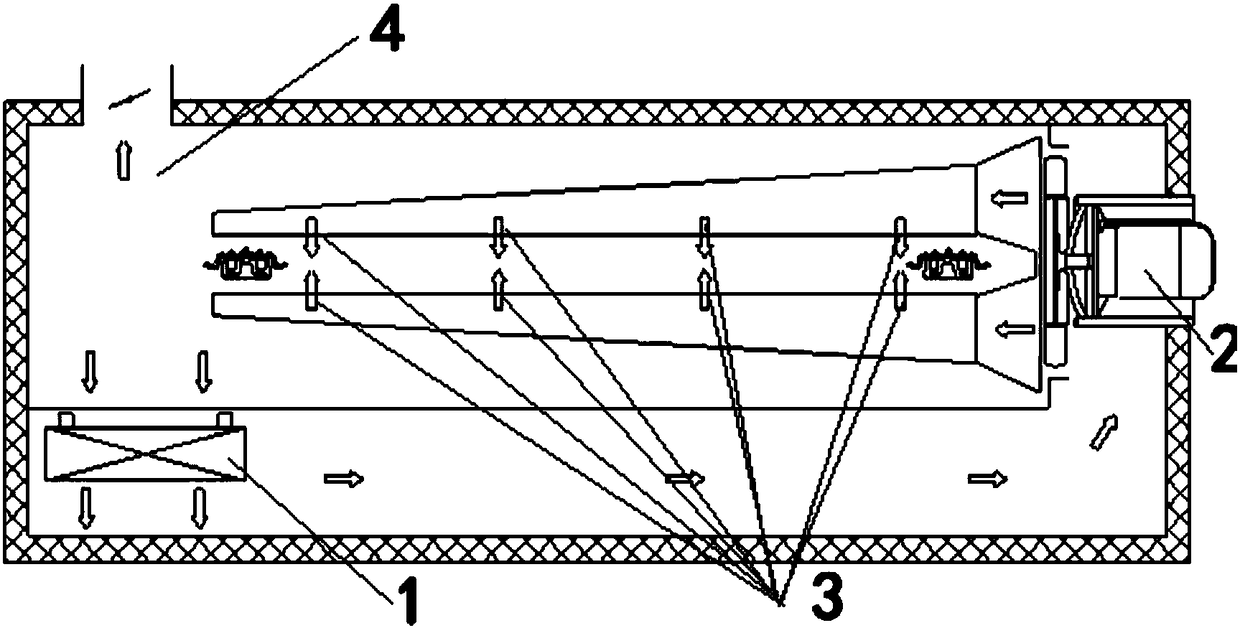

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

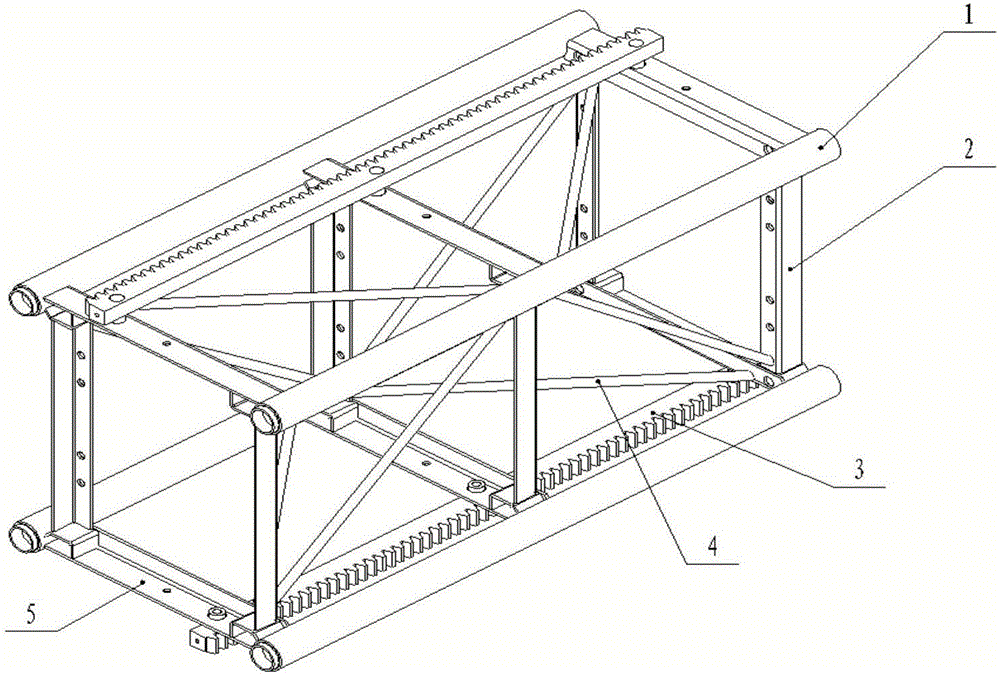

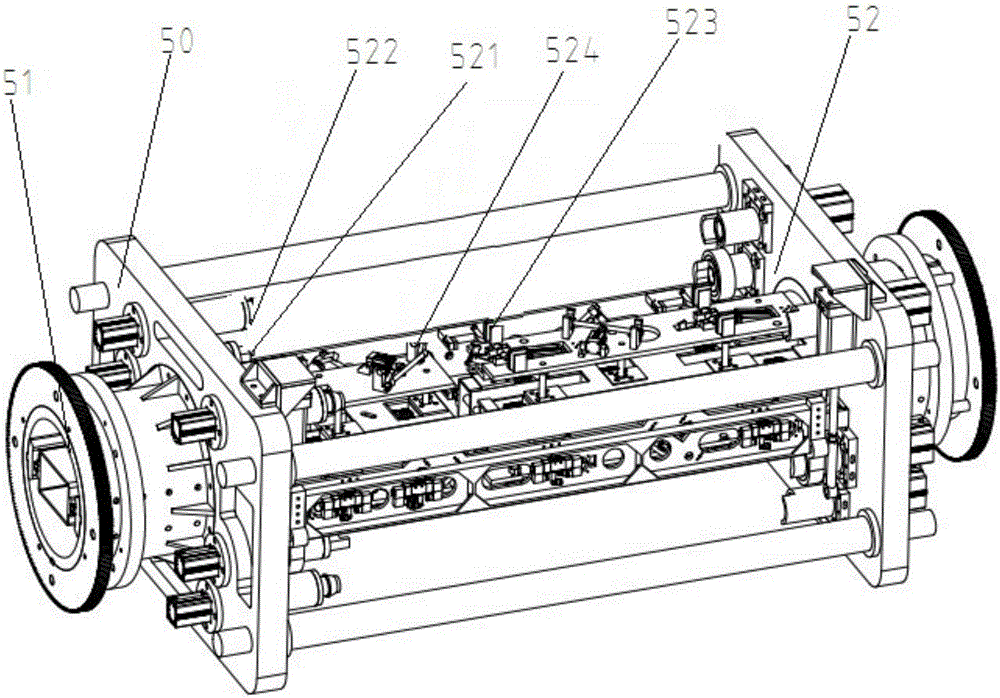

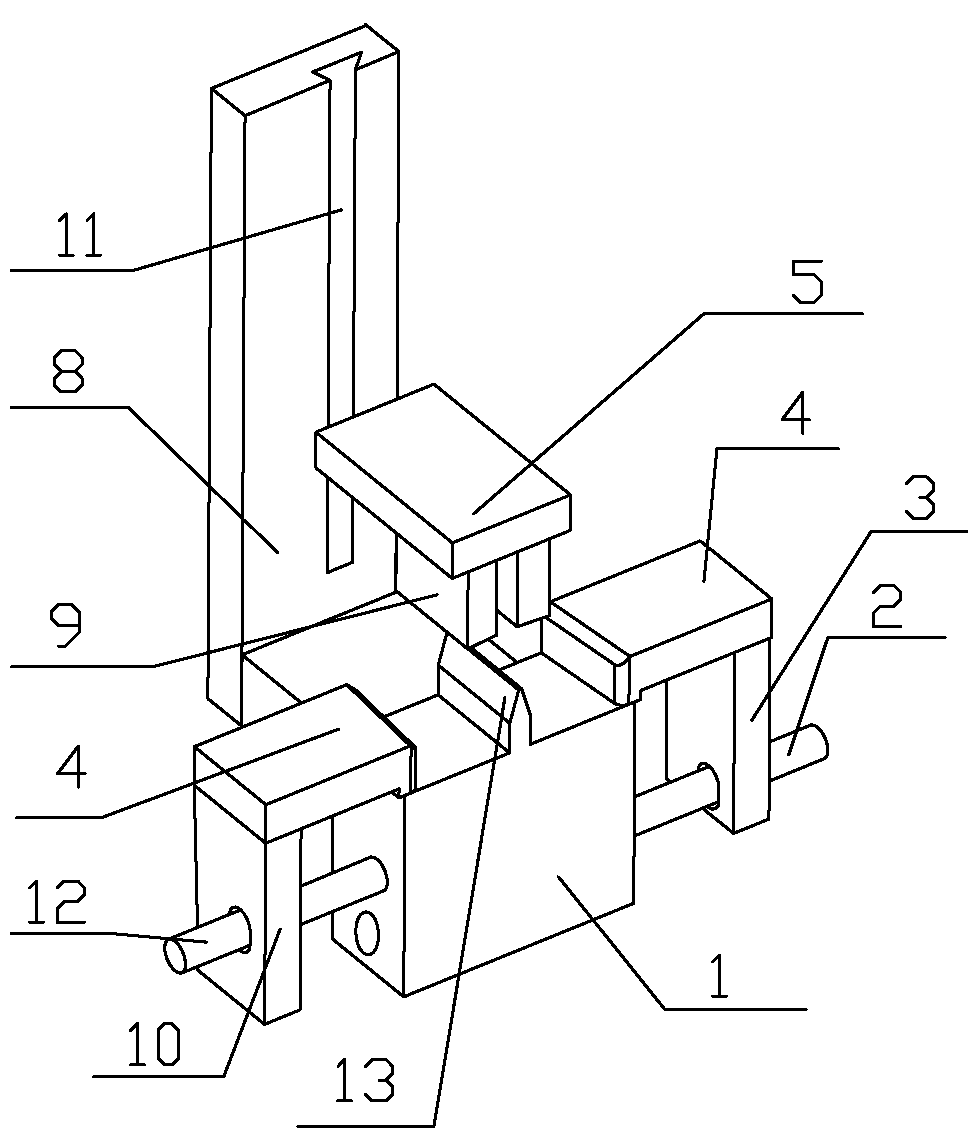

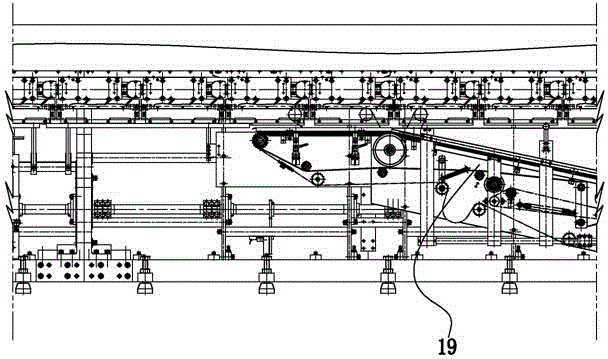

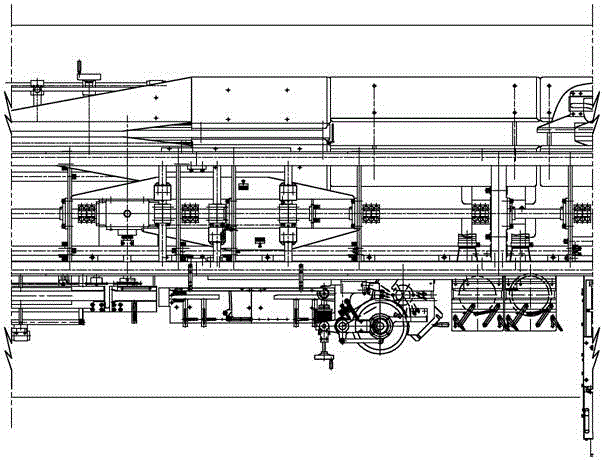

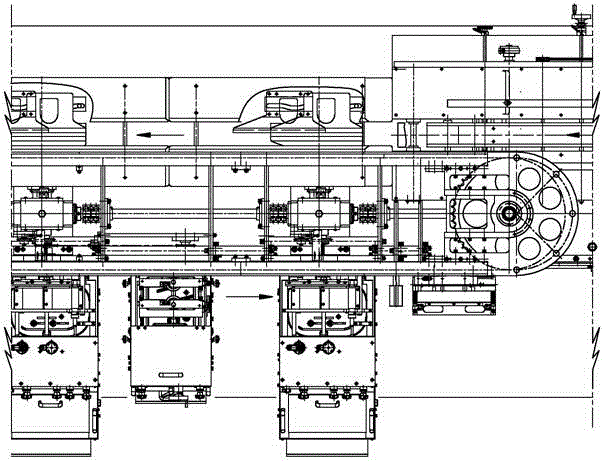

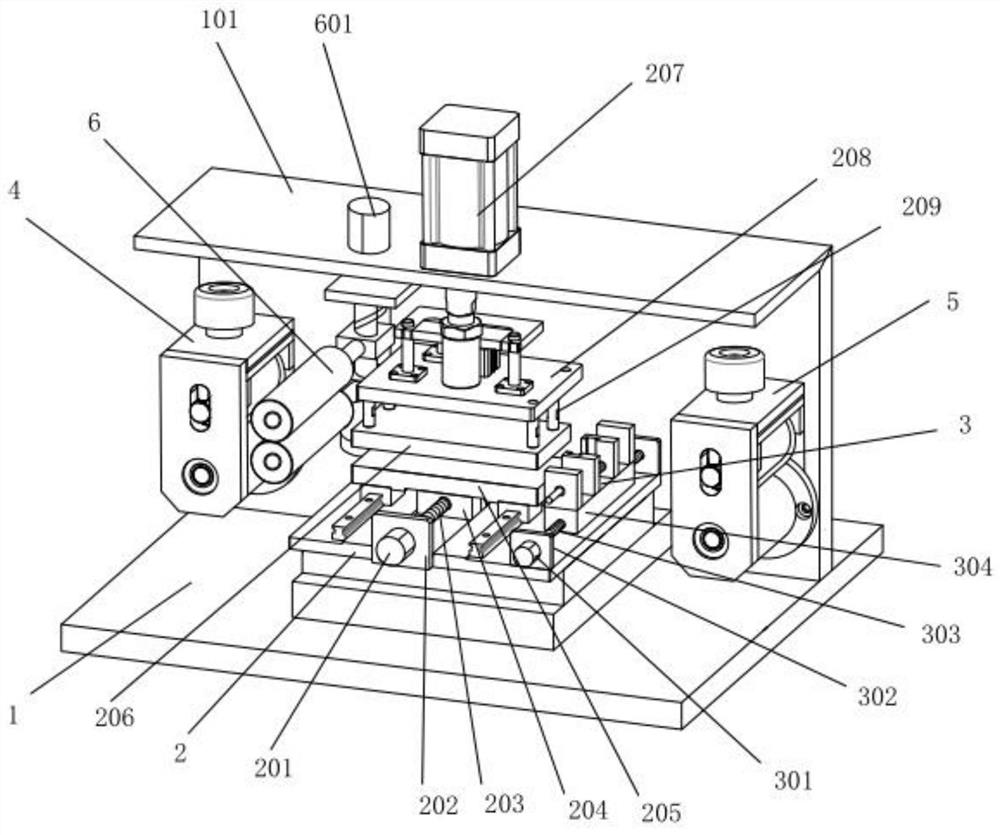

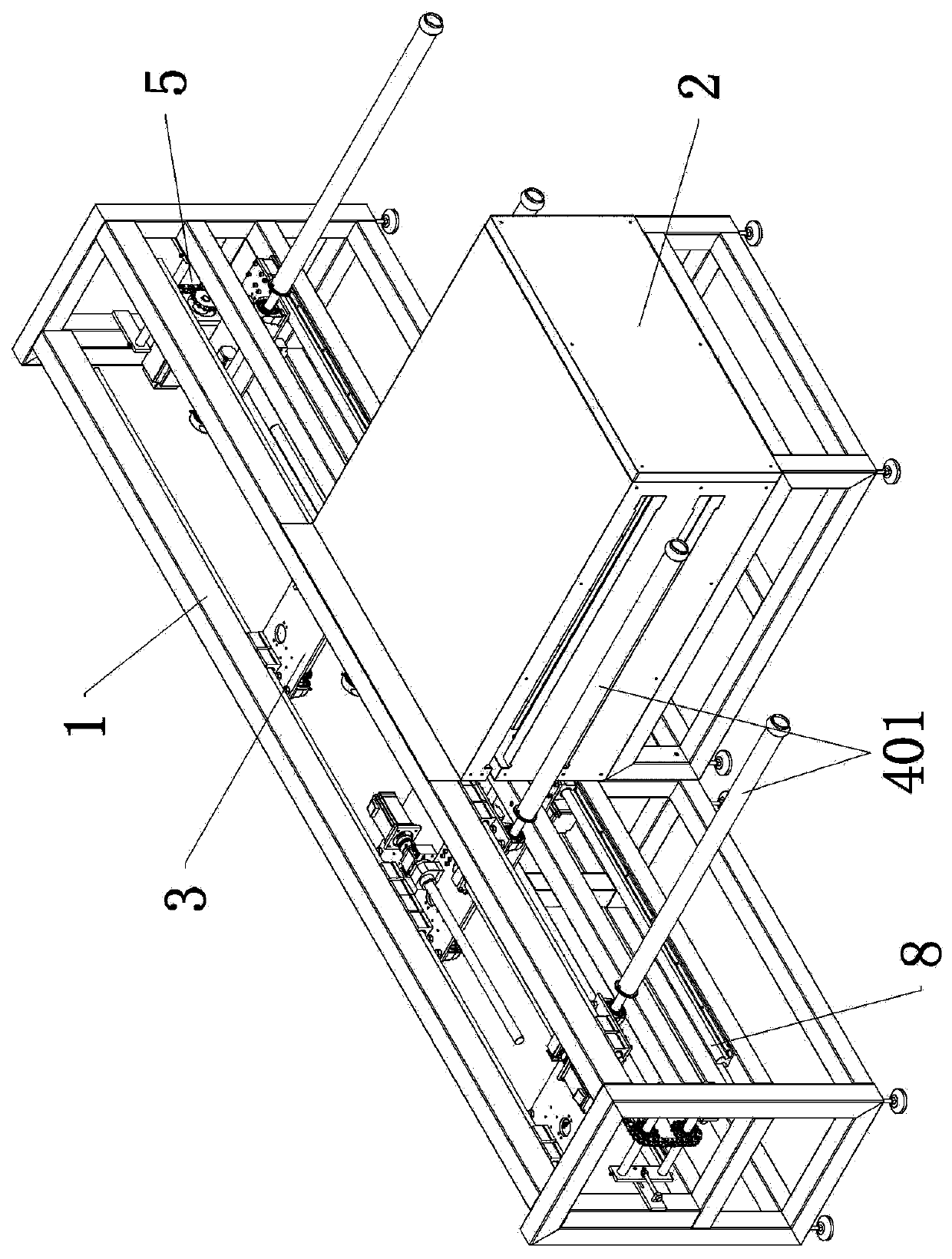

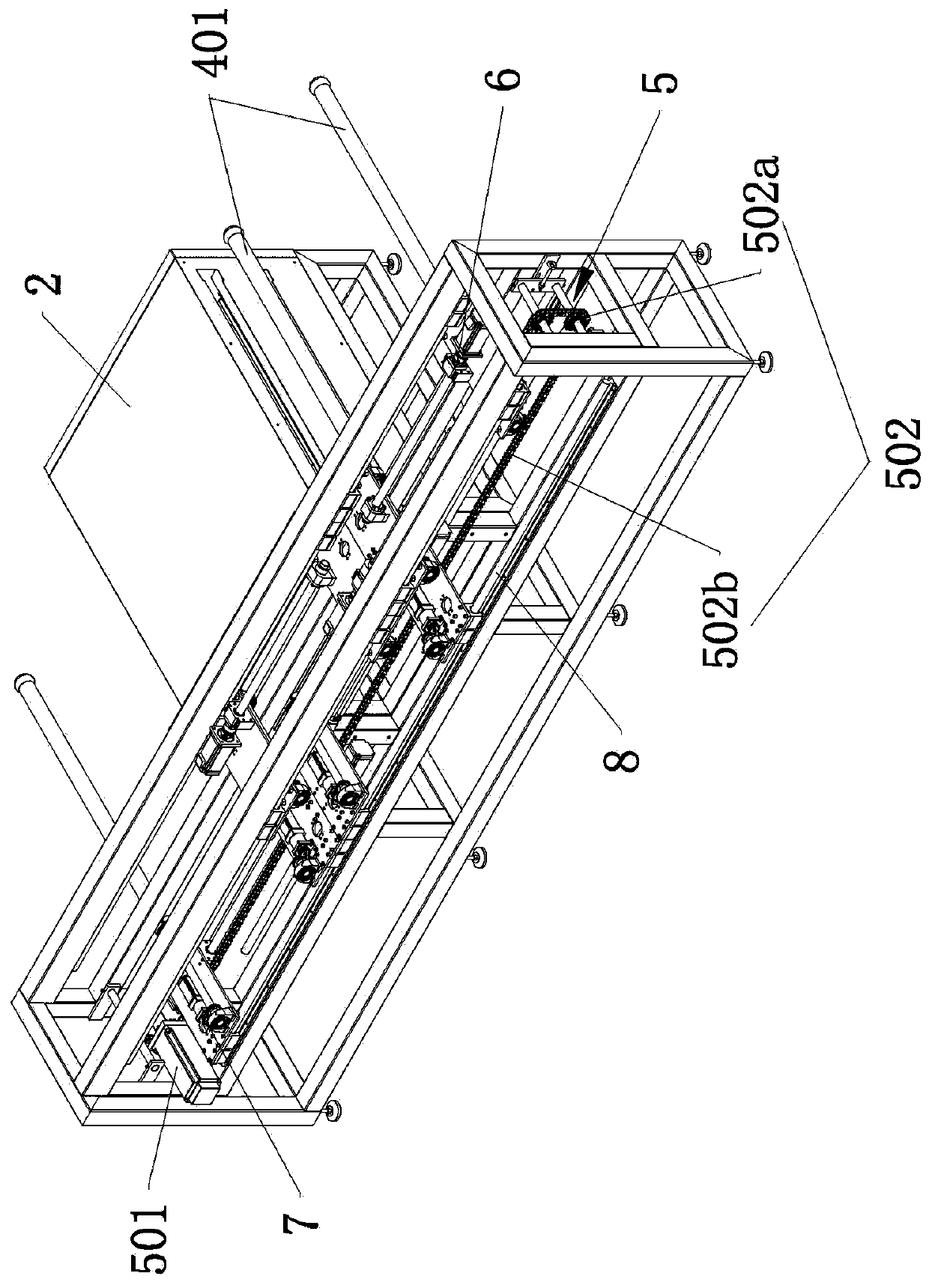

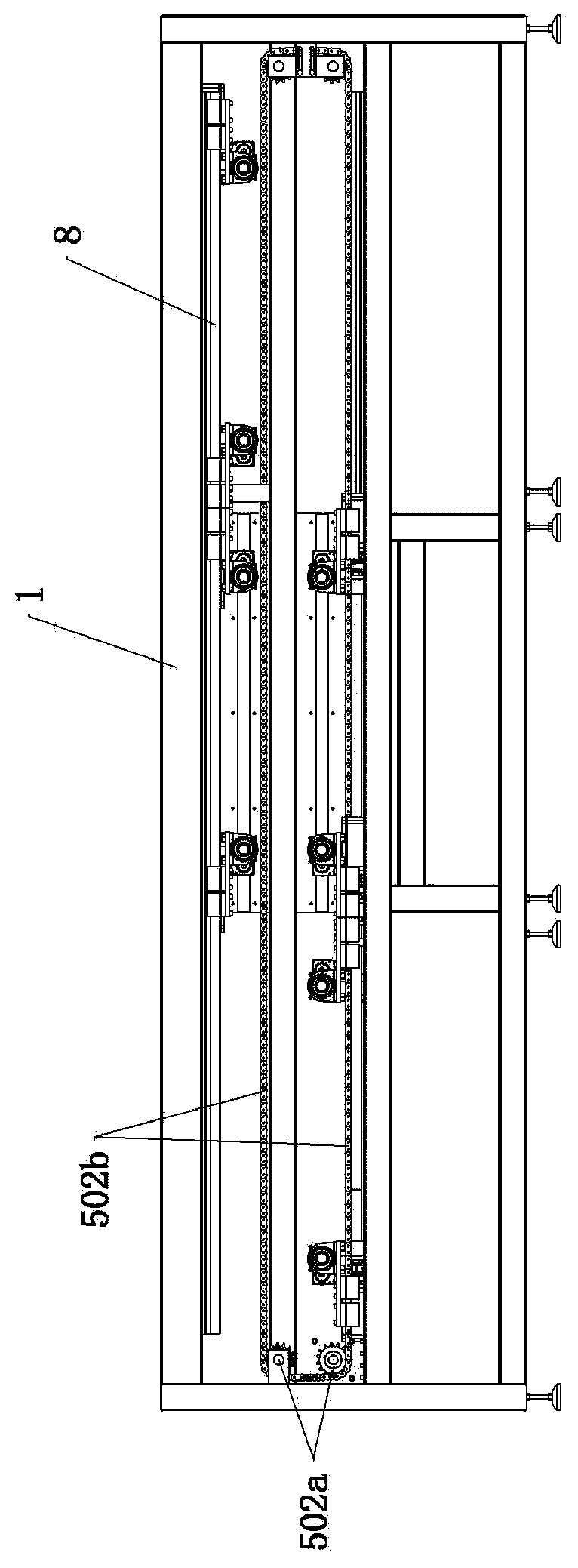

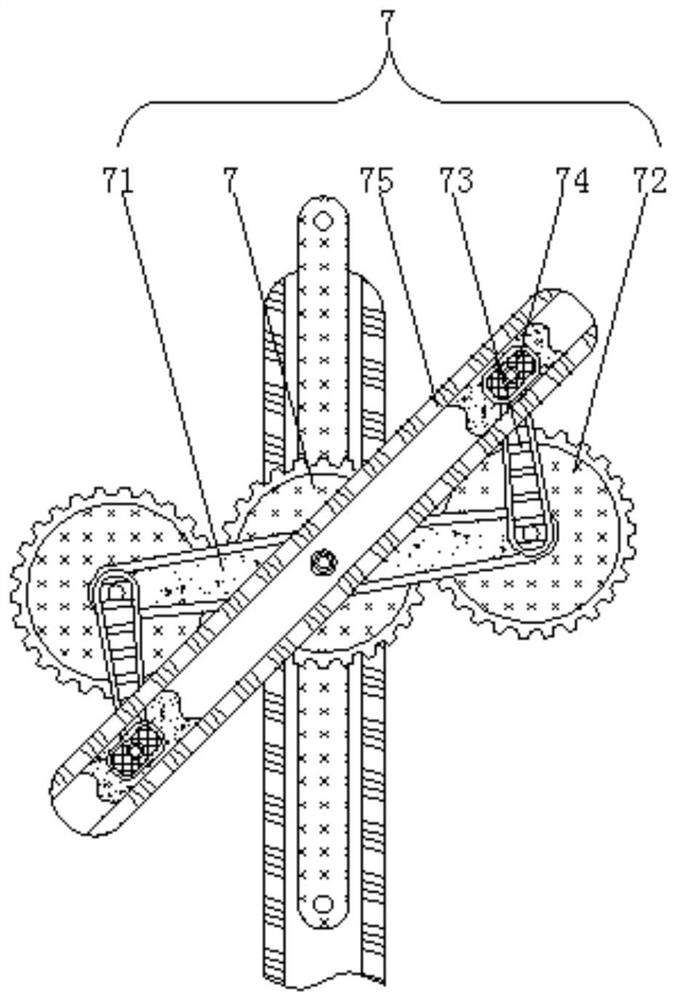

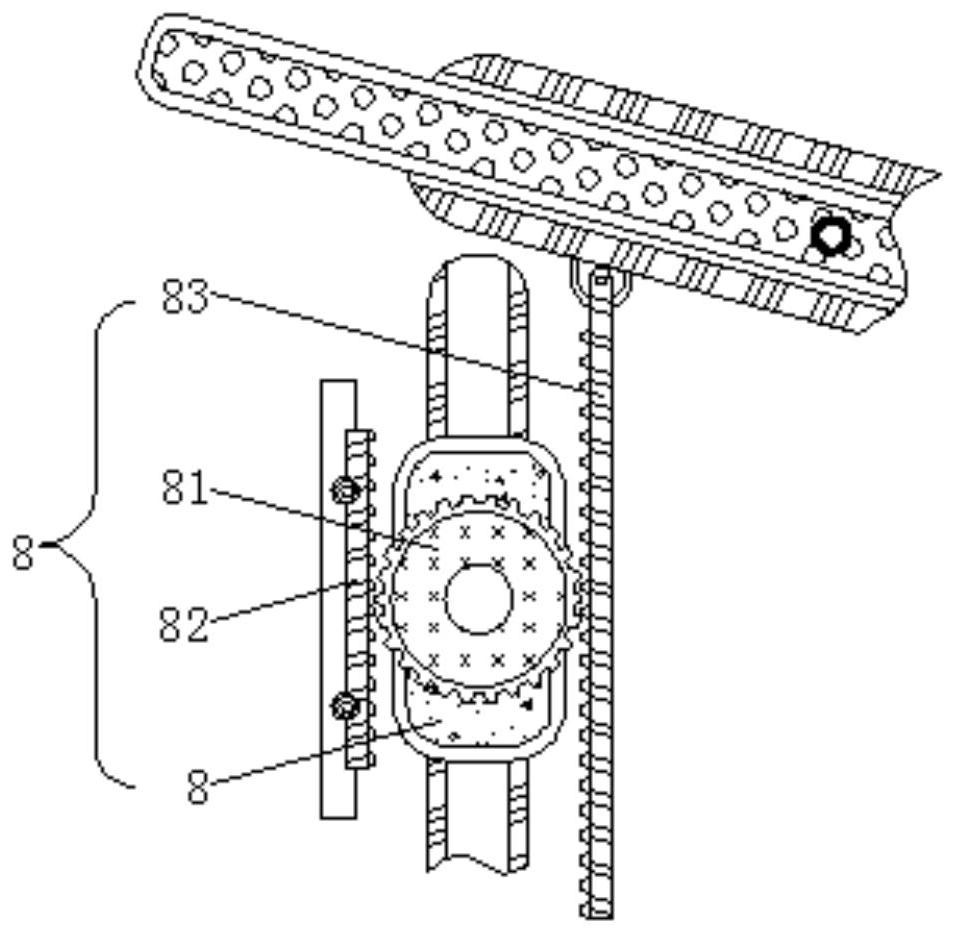

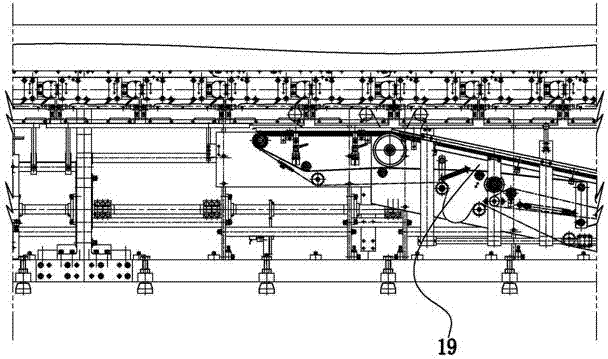

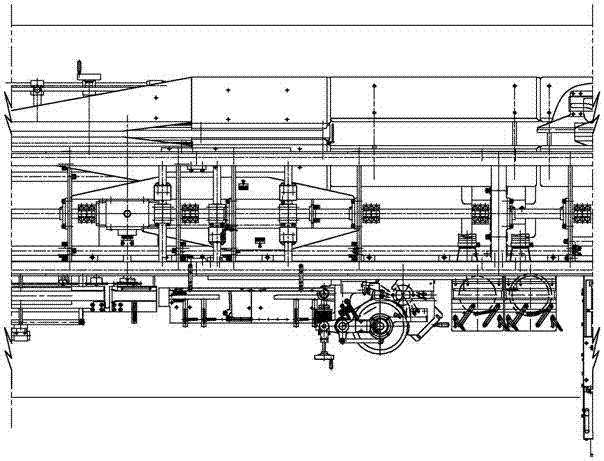

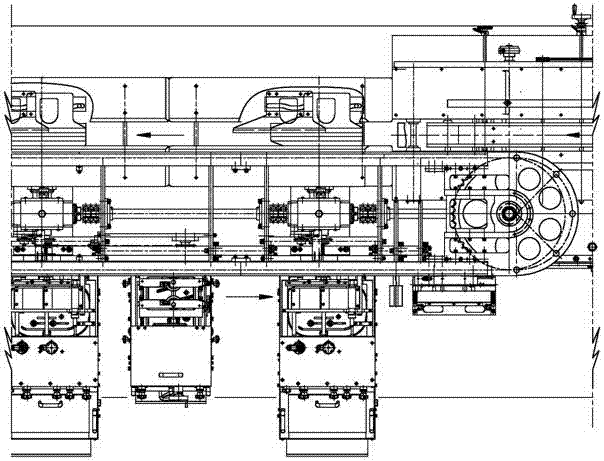

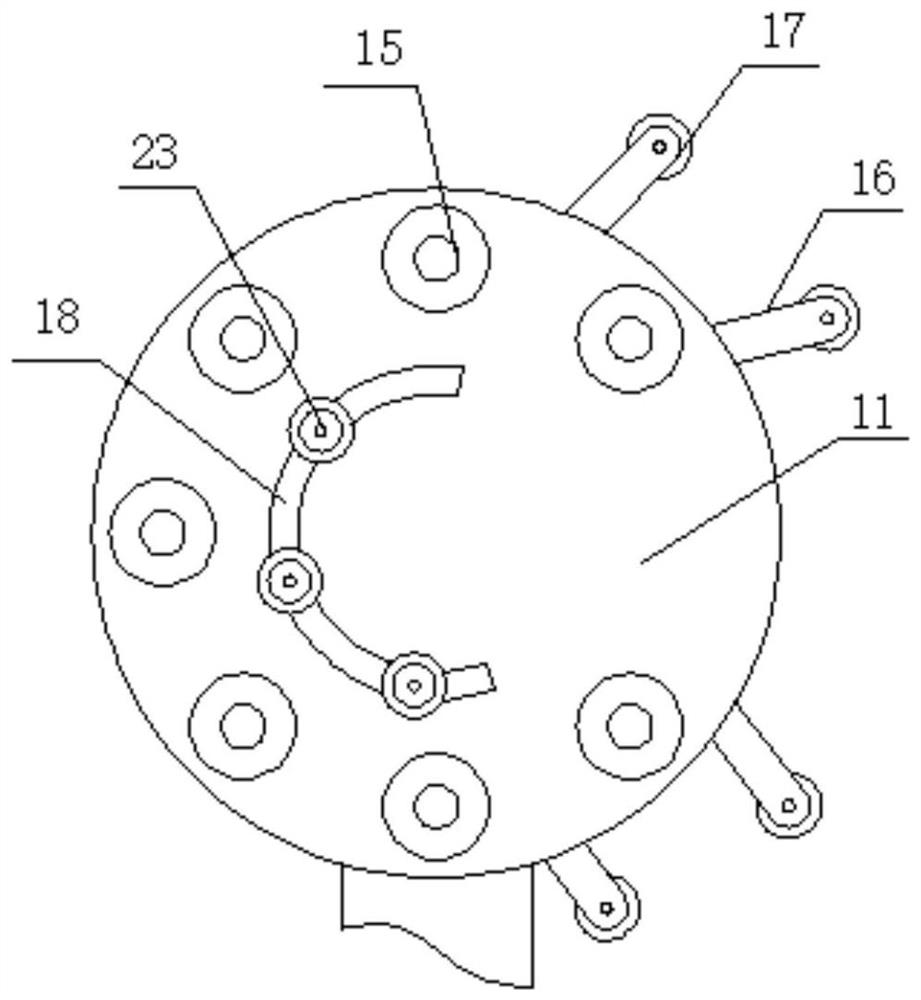

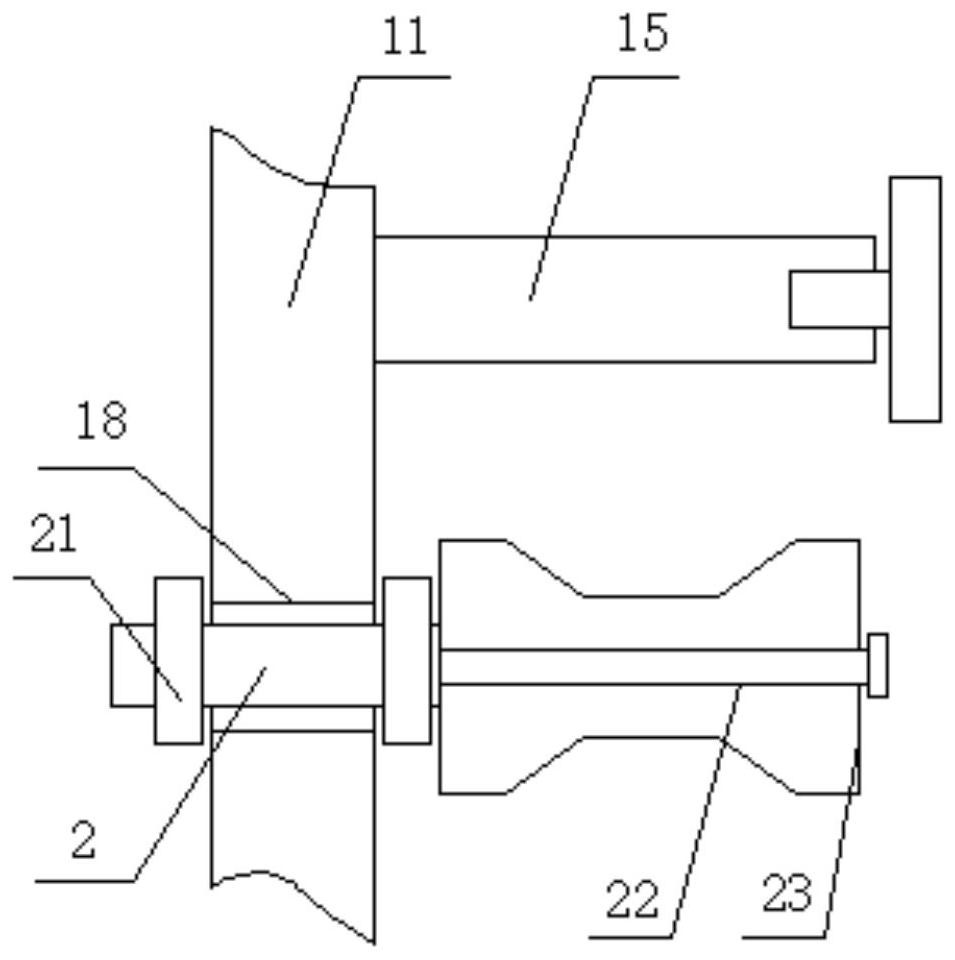

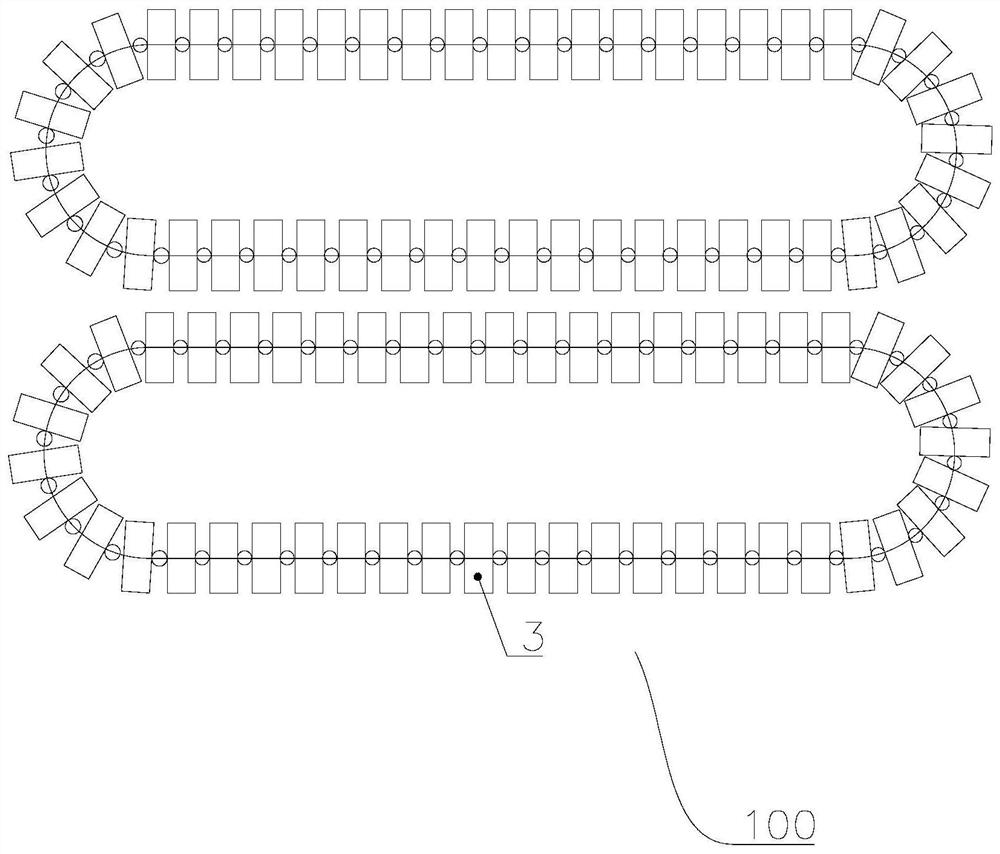

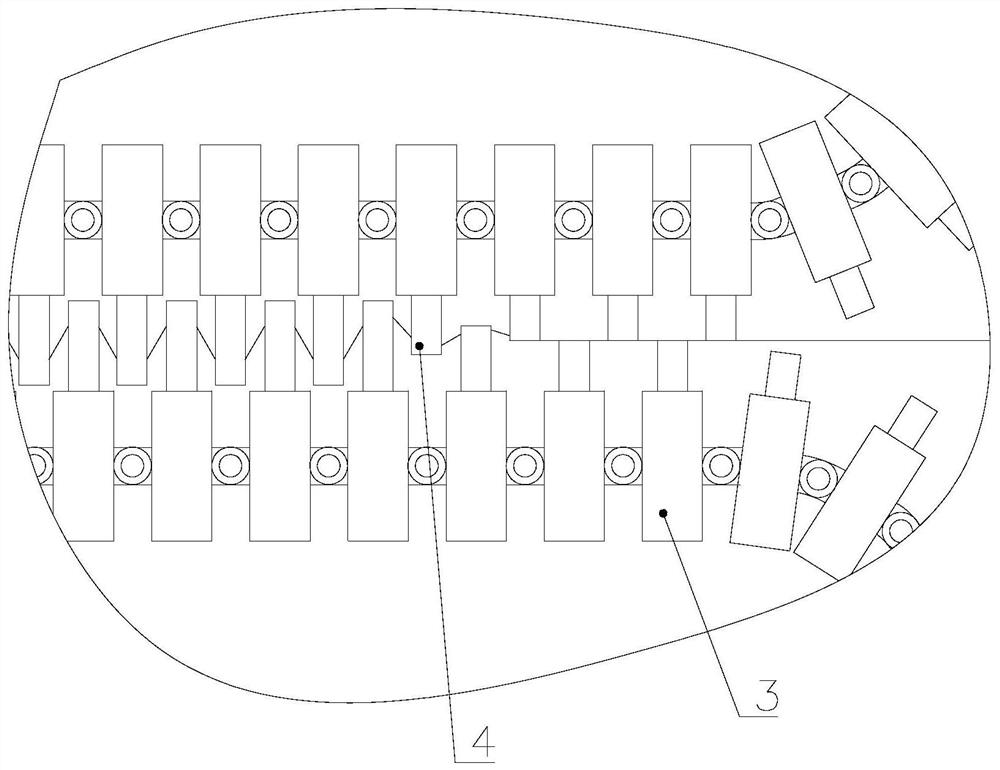

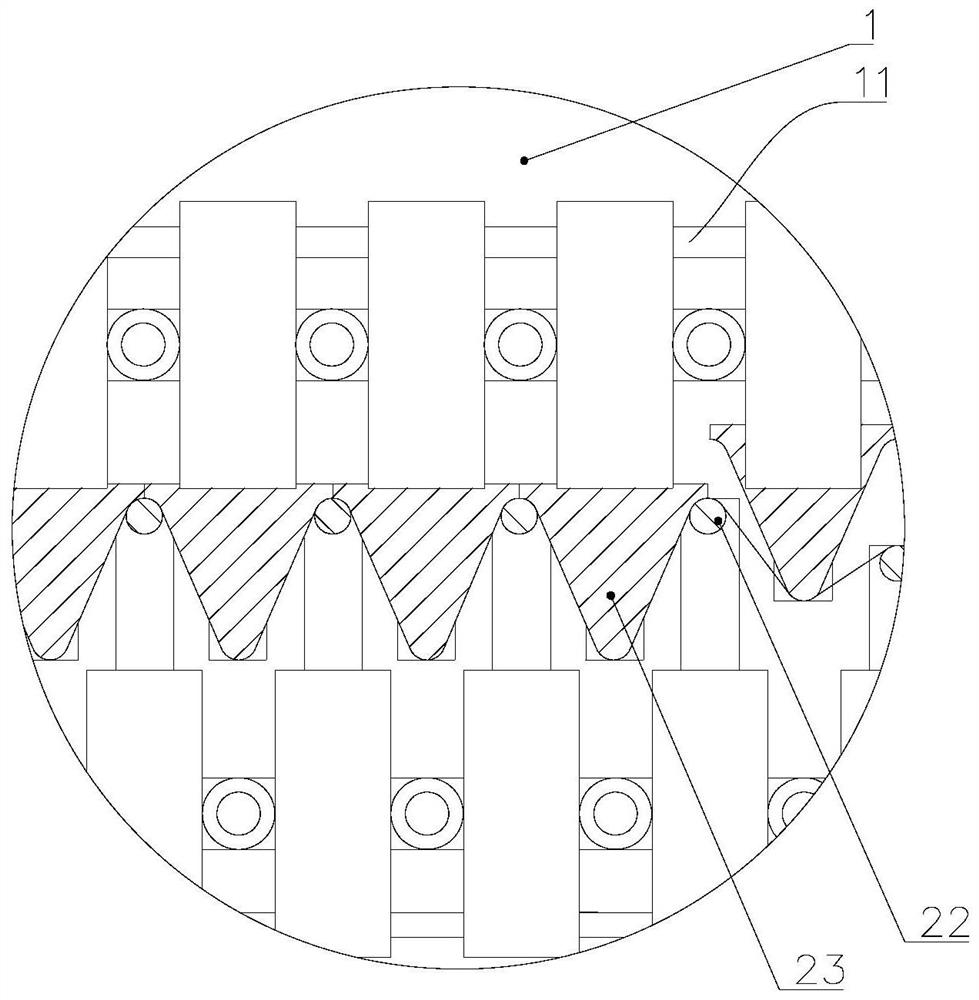

System and method for full-automatic welding of standard joint of building hoist

InactiveCN106112298AIncrease labor intensityImprove working environmentWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsWorking environment

The invention relates to engineering machinery equipment and methods, in particular to a system and method for full-automatic welding of a standard joint of a building hoist. The system comprises a body, a welding system, feeding systems, a handling system, tool systems and discharging systems. Each feeding system comprises a material table, a material table transfer platform and a material table walking rail. The handling system comprises a handling robot, a handling robot transfer platform and a handling robot walking rail. Each tool system comprises a rotary standard joint tool and a component clamping mechanism. The welding system comprises welding robots, a welding robot transfer platform and a welding robot walking rail. Each discharging system comprises a discharging robot, a discharging robot transfer platform and a discharging robot walking rail. The system and method have the beneficial effects that by means of the overall automatic feed, welding and discharging tool robot system, the stability and welding quality of products are improved, the labor production efficiency is improved, the labor intensity of workers is reduced, and the work environment of the workers is improved.

Owner:广州市特威工程机械有限公司

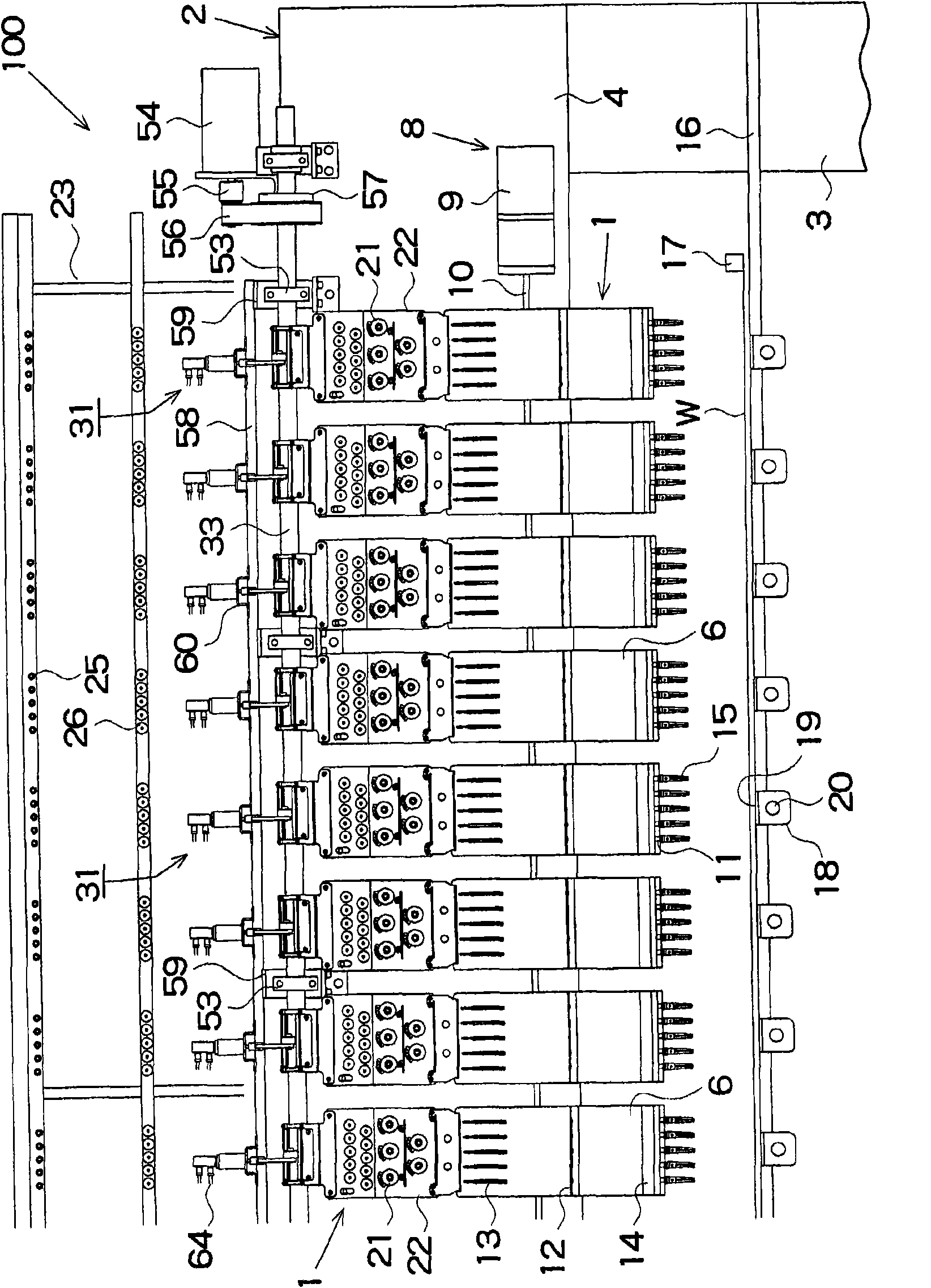

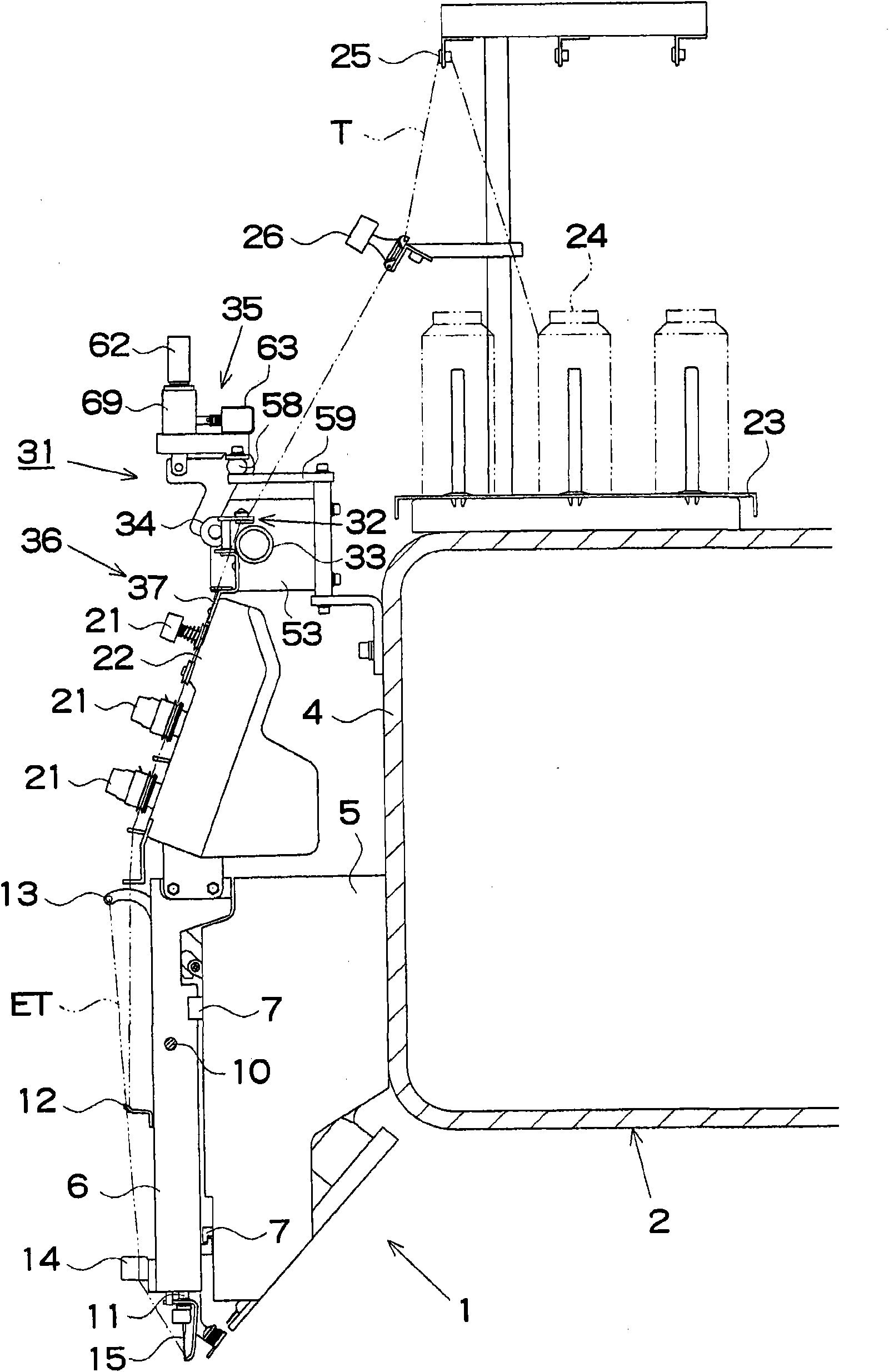

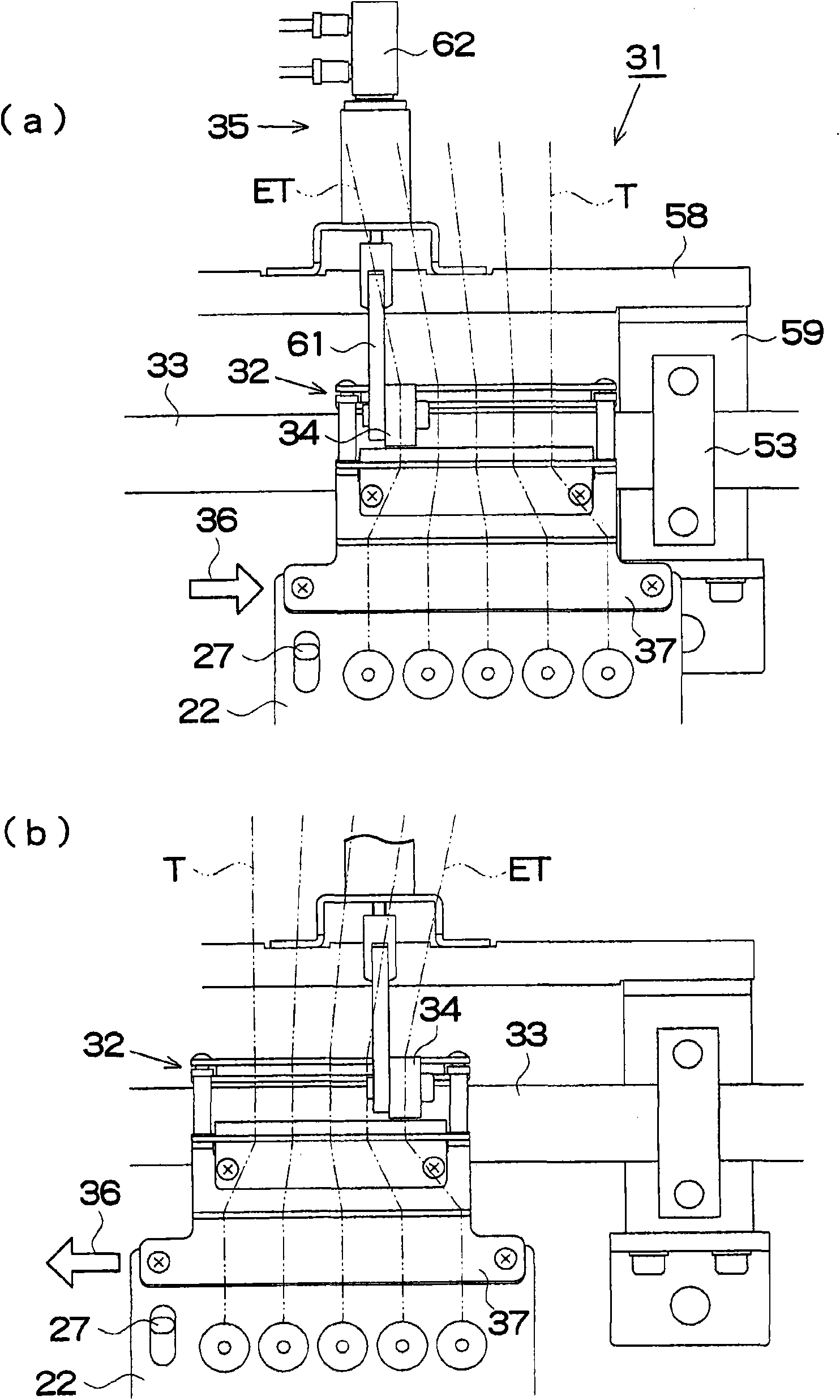

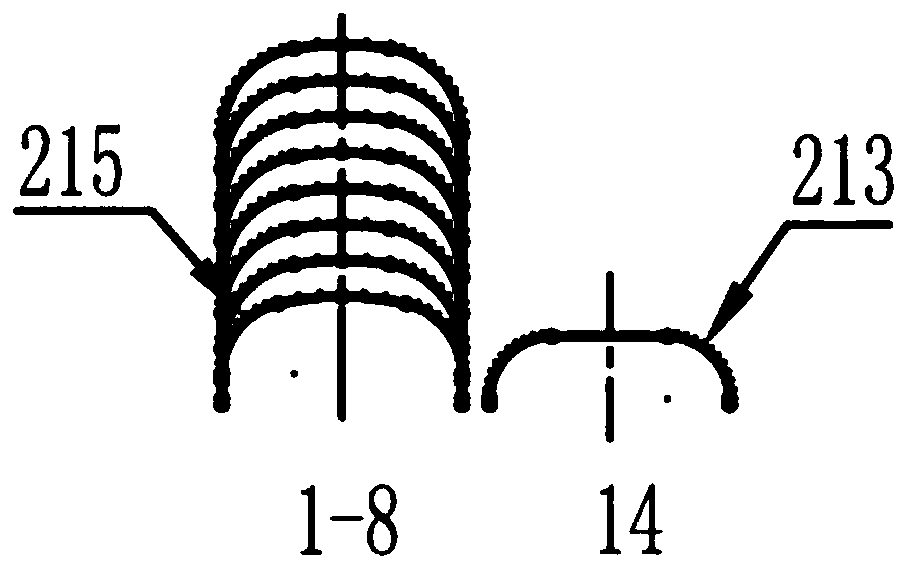

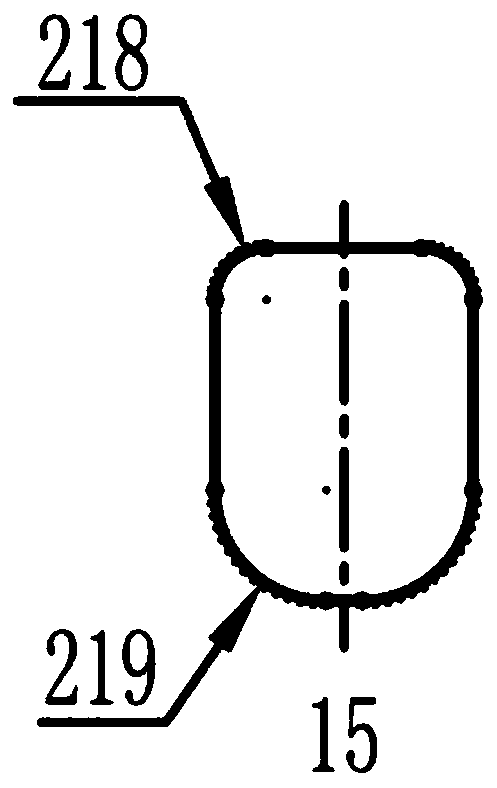

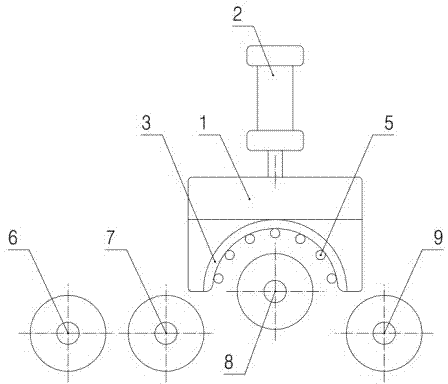

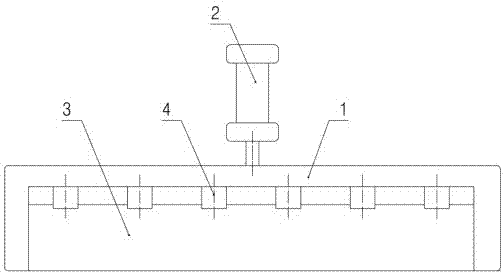

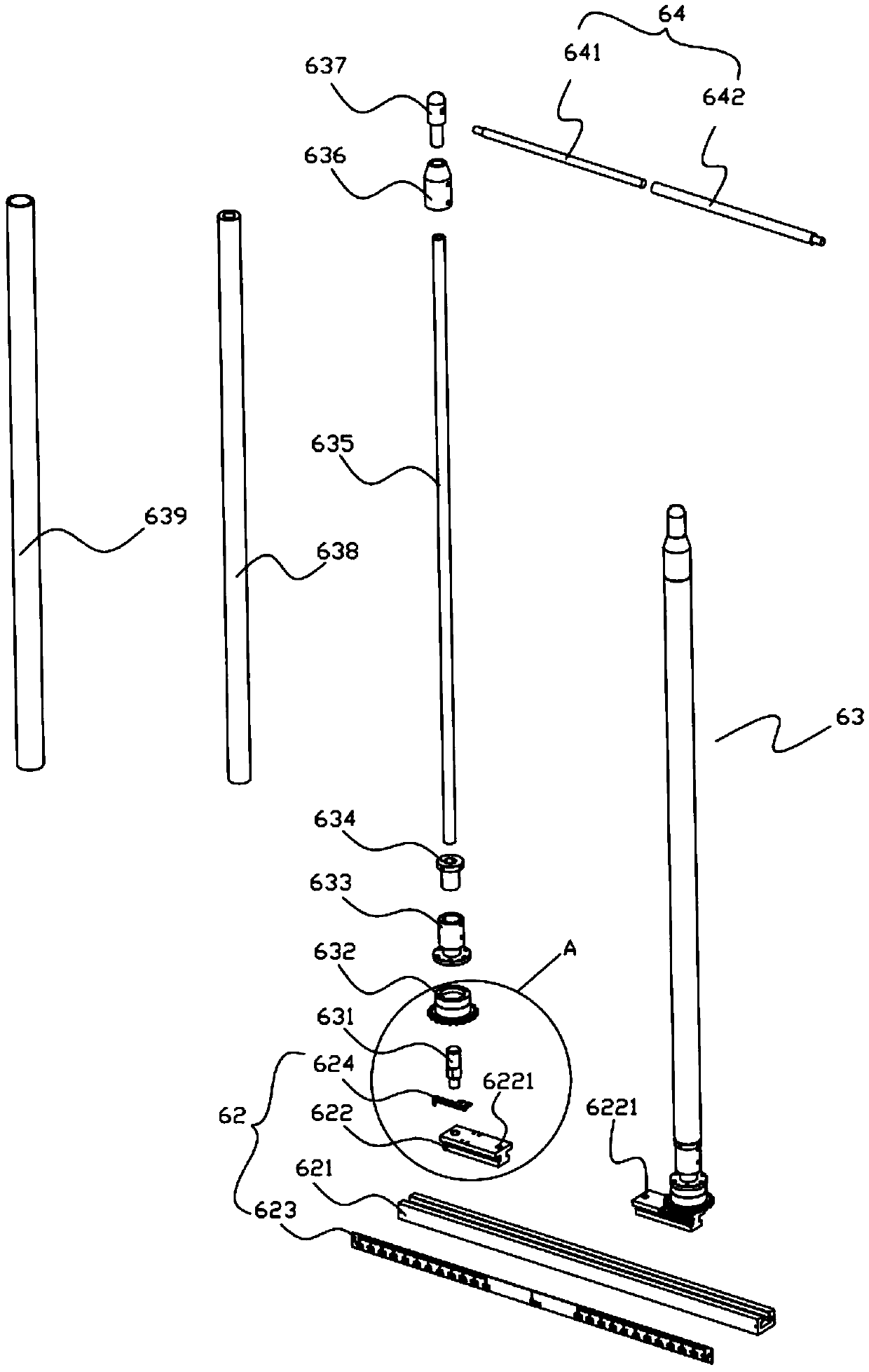

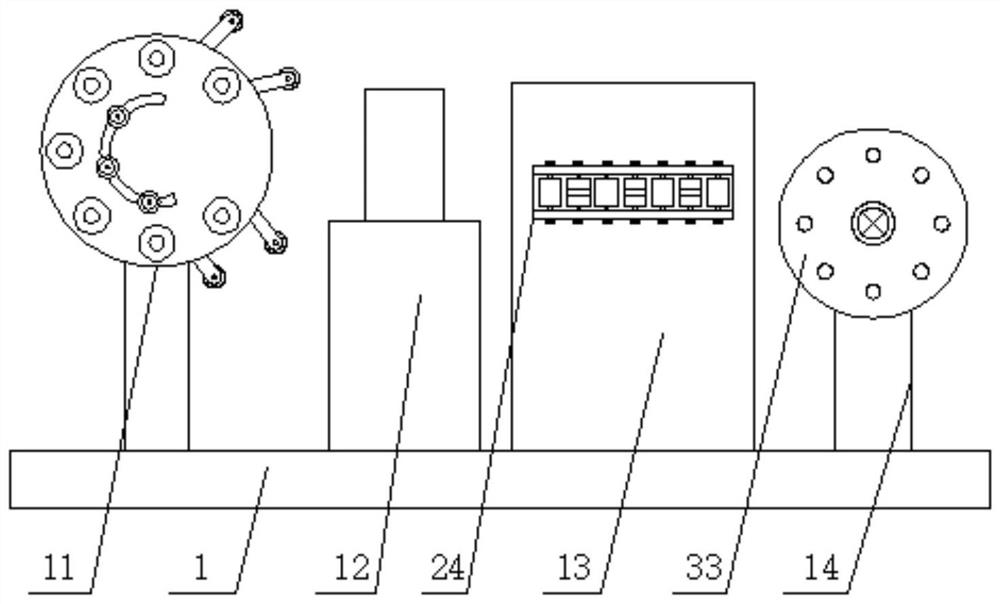

Needle thread feeding device for multi-needle embroidery sewing machine

ActiveCN101597841AReduce in quantityImprove styling qualitySewing measuring devicesThread-break detectorsEngineeringSewing machine

The present invention provides a needle thread feeding device for a multi-needle embroidery sewing machine that moves a sewing machine head to selectively locate one of a plurality of needles in a sewing position, and feeds out, out of a plurality of needle threads, a selected needle thread passing through the needle in the sewing position from a needle thread supply source to the needle, the needle thread feeding device includes a drive roller having a length that extends across the plurality of needle threads, a needle thread guide mechanism that arranges the needle threads side by side in an axial direction of the drive roller and guides the needle threads, a pressure roller that presses the selected needle thread onto the drive roller, and a thread distributing mechanism that relatively moves the needle thread guide mechanism and the pressure roller in the axial direction of the drive roller in synchronization with movement of the sewing machine head. The thread distributing mechanism interposes the selected needle thread between the drive roller and the pressure roller.

Owner:BARUDAN KK

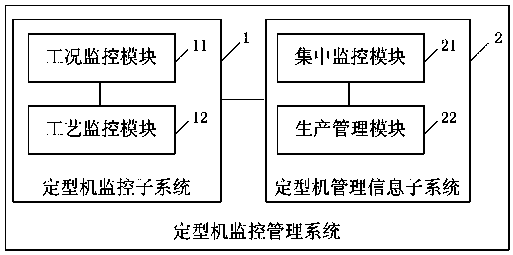

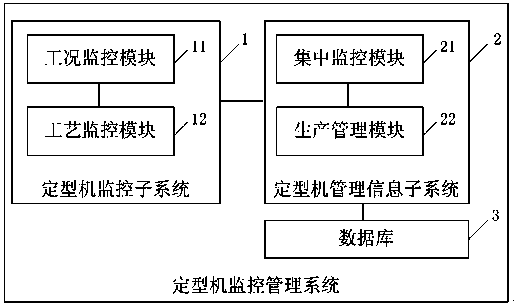

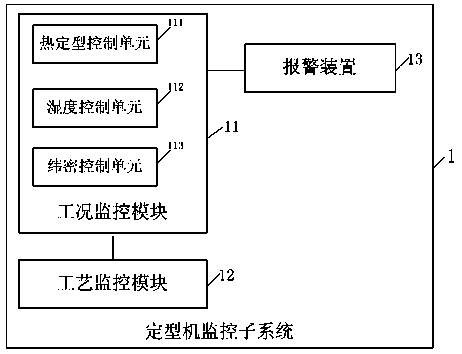

Setting machine monitoring and management system

ActiveCN103376782AAvoid lossReduce qualityHeating/cooling textile fabricsTotal factory controlIndustrial EthernetAutomatic control

The invention discloses a setting machine monitoring and management system which comprises setting machine monitoring subsystems and a setting machine management information subsystem. Each setting machine monitoring subsystem is used for monitoring one setting machine and comprises a working condition monitoring module and a process monitoring module. Communication between the setting machine management information subsystem and the multiple setting machine monitoring subsystems can be achieved through the industrial Ethernet, and the setting machine management information subsystem comprises a concentrating monitoring module and a production management module. By means of the setting machine monitoring and management system, automatic control over setting process links can be strengthened, the energy utilization rate is improved, the production management and the process monitoring of a dying plant can be effectively combined, the setting quality is improved, the reworking rate is reduced, analysis and finding of the reworking reasons are facilitated, and the production efficiency is improved.

Owner:佛山市南海天富科技有限公司

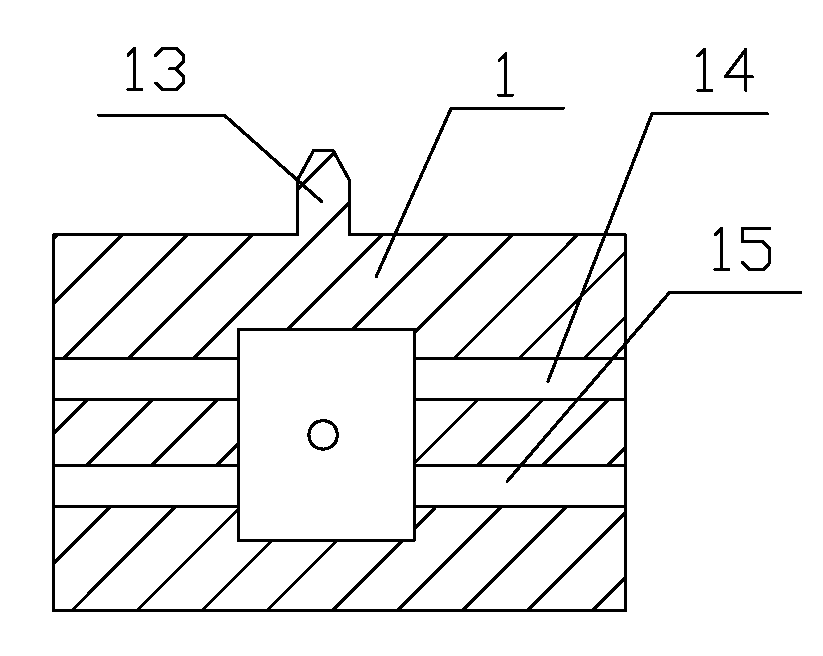

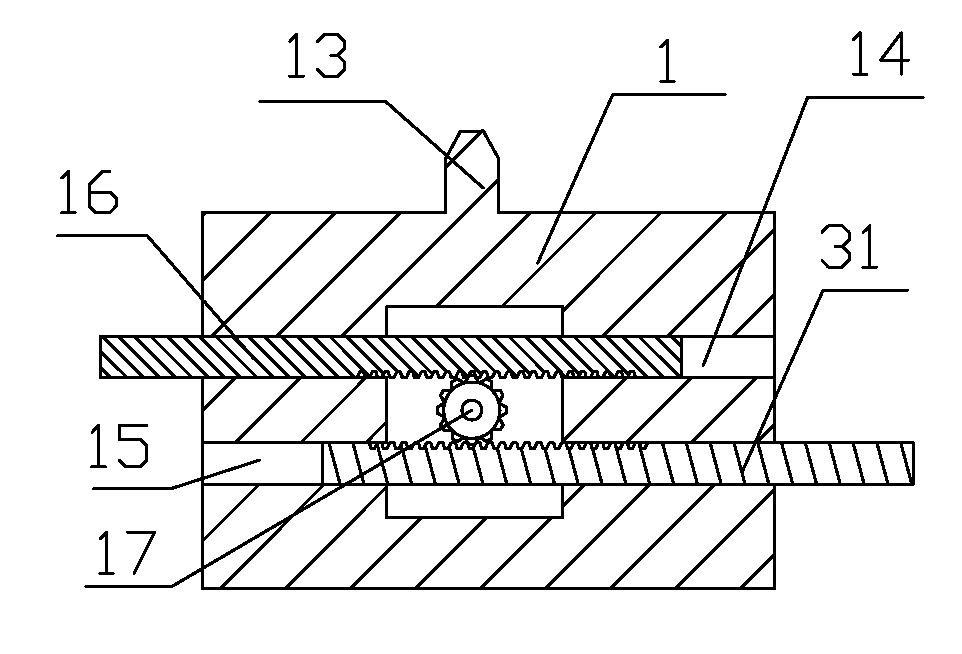

Foil shaping device

InactiveCN102290258ASave human effortIncrease productivityCapacitor manufactureEngineeringMechanical engineering

The invention relates to a conductive chaff shaping device which comprises a bottom correction die, an upper correction die, two horizontal correction flat dies and a fixing plate; the middle part of the upper end surface of the bottom correction die is provided with a lug, and the bottom correction die is fixed at the lower end part of the fixing plate; the upper correction die comprises a fixing block and two correction blocks; the correction blocks are fixed at the lower end surface of the fixing block; a groove channel is arranged between the two correction blocks; the fixing block is provided with a boss, and the fixing plate is provided with a guide groove; each horizontal correction flat die comprises a horizontal correction block; the two horizontal correction flat dies are respectively positioned above the left side and the right side of the bottom correction die; the horizontal correction flat dies at two sides are respectively provided with a left connecting block and a right connecting block; the left connecting block and the right connecting block are respectively connected with a left guide post and a right guide post; the bottom correction die is provided with a left groove channel and a right groove channel; one end of the left guide post is fixed on the left connecting block, and the other end of the left guide post is positioned in the left groove channel; and one end of the right guide post is fixed on the right connecting block, and the other end of the right guide post is positioned in the right groove channel. The shaping device provided by the invention has a simple structure, and is labor saving and cost saving.

Owner:陈坤

A smooth modeling method for a centrifugal pump volute

ActiveCN109711045AReduce molding costsImprove styling qualitySpecial data processing applicationsNumerical controlVisual inspection

The invention belongs to the technical field of three-dimensional modeling of centrifugal pumps, and particularly relates to a smooth modeling method for a volute of a centrifugal pump. According to the method, modeling is carried out based on UG NX, tools such as an equal-parameter curve and a bridging curve are adopted to be used in cooperation, and the problems that according to a common volutemodeling method, manual visual inspection is adopted, modeling distortion is likely to happen, and curved surface connection is not smooth when the volute partition tongue part is processed can be effectively solved. According to the method, the complete smooth transition between the curved surfaces of the separation tongue part of the centrifugal pump volute can be realized, so that no further processing is needed in the actual manufacturing process of the centrifugal pump, and the modeling quality is improved while the modeling cost is reduced. According to the volute modeling completed through the method, the modeling structure is clear, curved surface transition is natural and attractive, and the method can improve the precision and accuracy of centrifugal pump CFD simulation, finiteelement analysis and mold numerical control machining.

Owner:CHINA AGRI UNIV

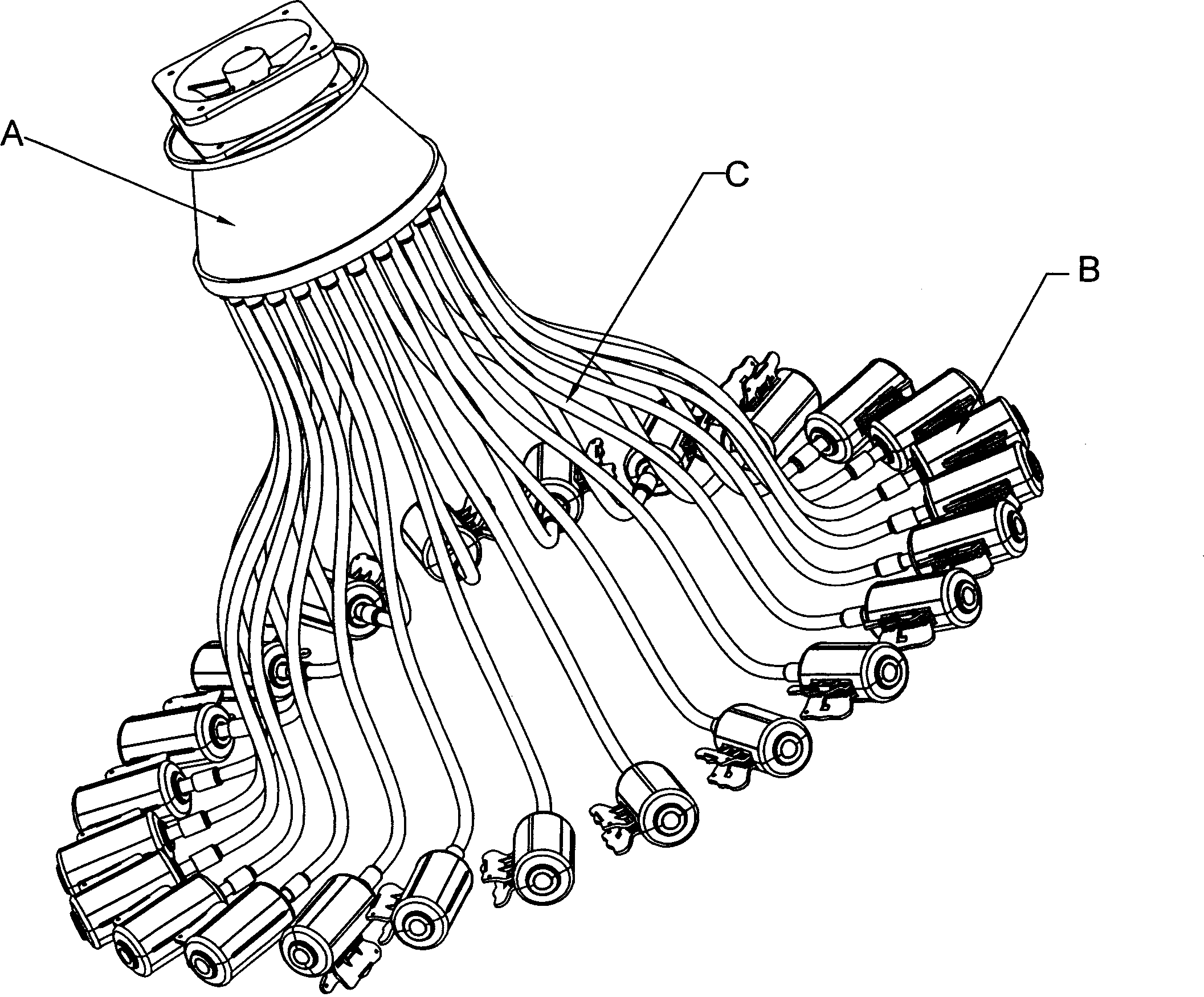

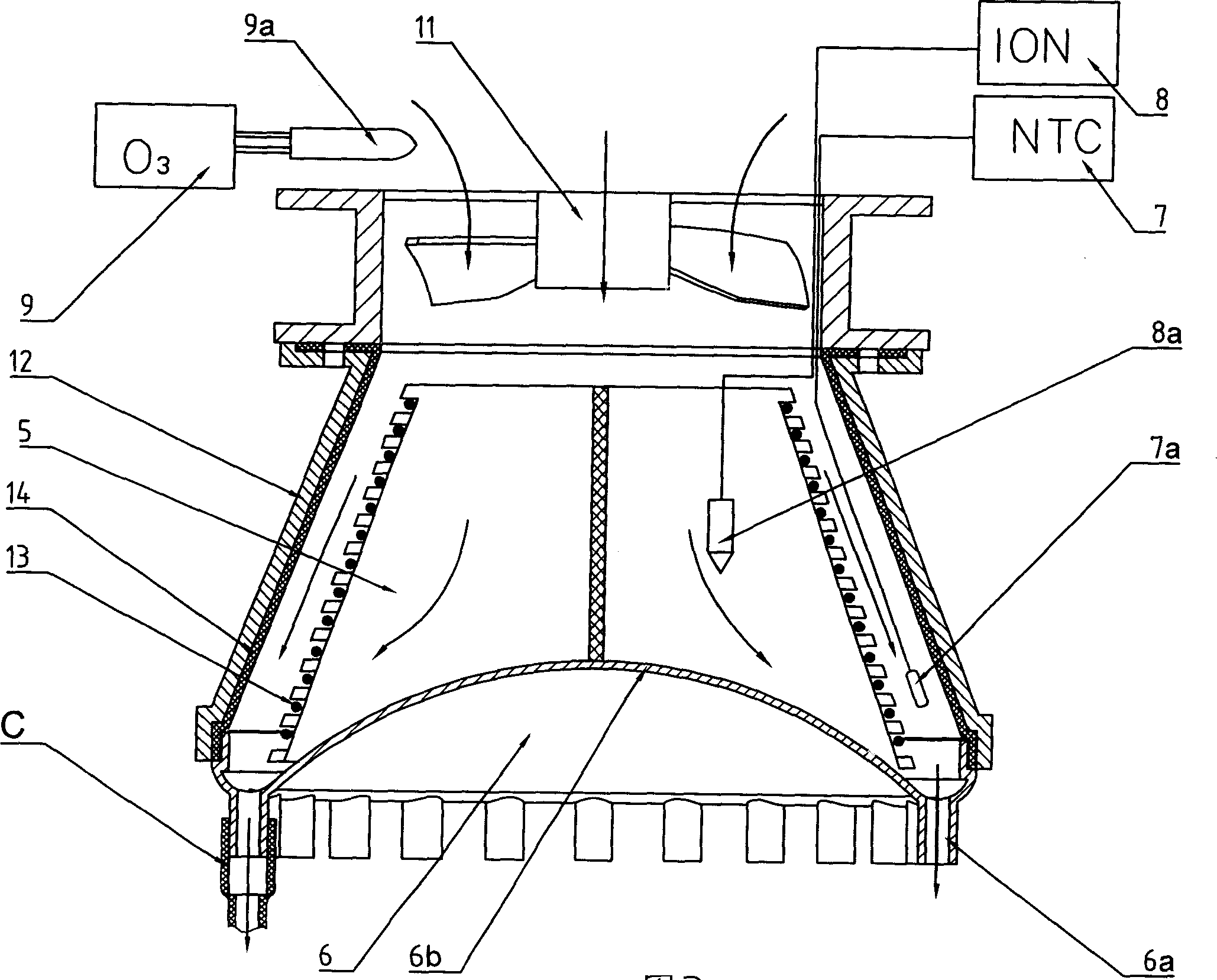

Hot-aie perming-hair method and apparatus

InactiveCN1849961AHigh perm efficiencyImprovement of consumption environmentCurling devicesEngineeringGuide tube

The present invention discloses a hot air perming method. Said method is characterized by that it utilizes a hot air source to simultaneously provide hot air for several hair rollers, and makes the temperature in every hair roller be retained at 40-150 deg.C so as to make the rolled hair be formed. Said invention also discloses a hot air perming equipment, it includes hot air machine, hat air conduit and several hair rollers.

Owner:崔政 +1

Multifunctional adhesive bookbinding machine

InactiveCN105799357ALong setting timeExtend curing timeBook making processesEngineeringMechanical engineering

The invention relates to a multifunctional adhesive bookbinding machine. The multifunctional adhesive bookbinding machine comprises a book feeding acceleration mechanism, a manual book placing table, a rack, a book processing and arranging device, a cover feeding mechanism and a book processing and conveying device which are connected sequentially. The book processing and arranging device is arranged on the upper right side of the rack. The book processing and conveying device is arranged on the upper left side of the rack. A housing is arranged on the book processing and arranging device and the book processing and conveying device. The multifunctional adhesive bookbinding machine is reasonable in structure design and used automatically and conveniently. Meanwhile, the setting time of books and solidification time of hot melt adhesive are increased, so that the setting quality of the books is improved, and the books are made to be distinct in corner angle, clear in outline, and attractive inn appearance. The cost is low, and the multifunctional adhesive bookbinding machine is suitable for wide production and application for enterprises.

Owner:PINGHU BIND EX MACHINERY

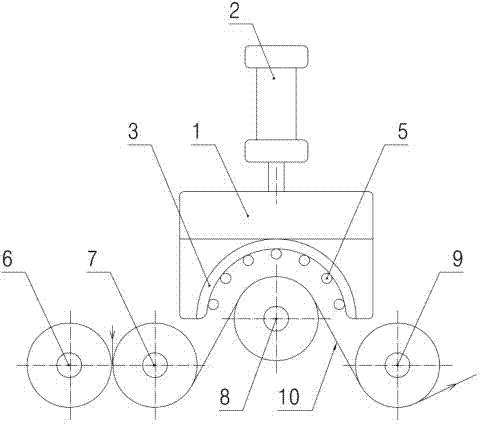

Rattan shaping device for rattan furniture processing

InactiveCN111844315AAchieving continuity stereotypesImprove straightening and setting efficiencyCane mechanical workingReed/straw treatmentStructural engineeringIndustrial engineering

The invention discloses a rattan shaping device for rattan furniture processing. An L-shaped plate frame is fixedly arranged on a base table; a shaping table is arranged right below the horizontal plate of the L-shaped plate frame on the base table; a left guide frame and a right guide frame are arranged on the vertical plate face of the L-shaped plate frame and located on the two sides of the shaping table correspondingly. An edge grinding table is arranged between the left guide frame and the shaping table; a trimming table is arranged between the right guide frame and the shaping table; a shaped rattan passes through the trimming table; a motor II drives a screw II to rotate; the screw rod II drives a nut seat II to move on a supporting table to enable the position of the supportingtable to be adjusted; and pushing rods at the two ends of the nut seat II are rotated to push a first cutting block and a second cutting block to move upwards, the distance between the first cutting block and the second cutting block is matched with the width of the rattan, trimming operation is conducted on the shaped rattan through the first cutting block and the second cutting block, and rattanshaping and trimming are synchronously completed.

Owner:安徽振华柳木工艺品有限公司

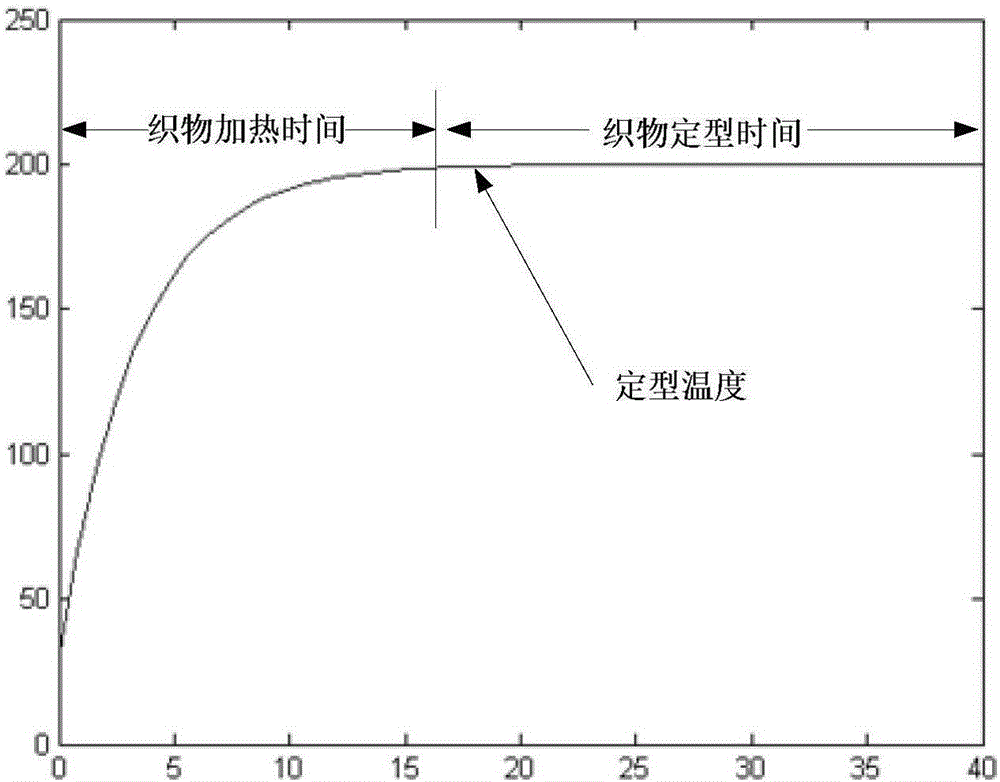

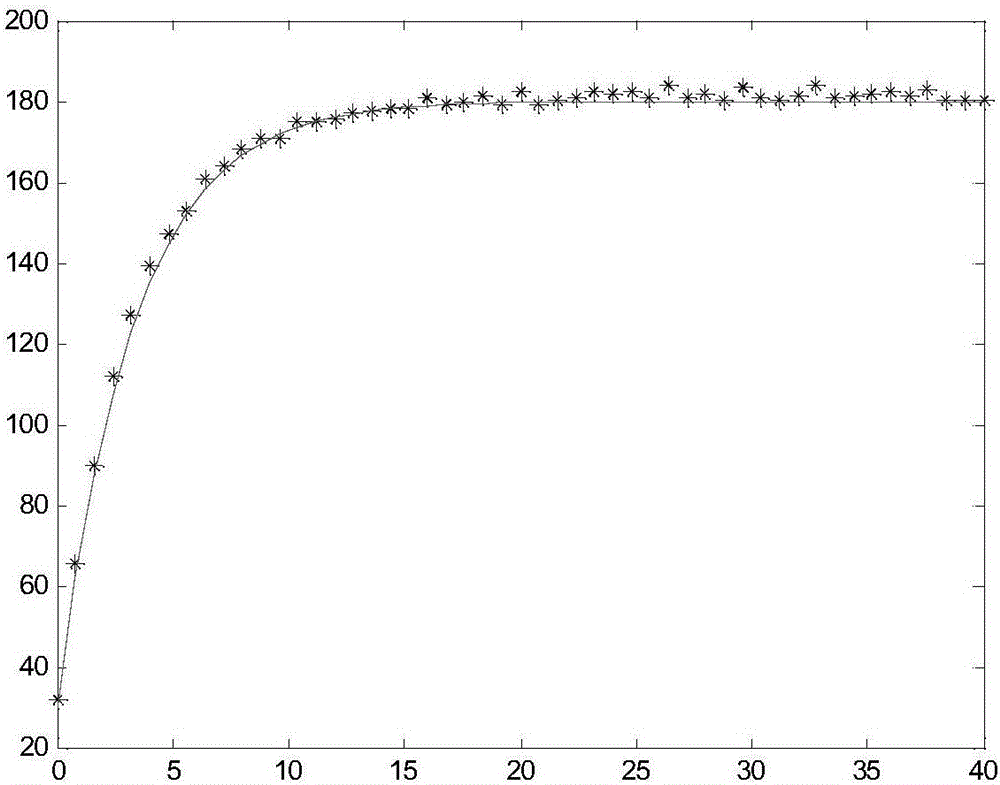

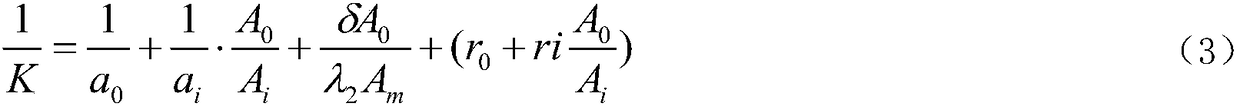

Method for setting speed of setting machine in dry cloth heat setting

InactiveCN106400365AReduce energy wasteReduce wasteHeating/cooling textile fabricsHeating timeProcess engineering

The invention discloses a method for setting a speed of a dry cloth setting machine in heat setting. The method can accurately determine the total time of fabric setting by calculating the heating time of the fabric so that a reasonable setting machine speed can be set and energy waste in the setting process is reduced. The method provides a strong technical support for improving setting quality of the setting machine.

Owner:ZHEJIANG SCI-TECH UNIV

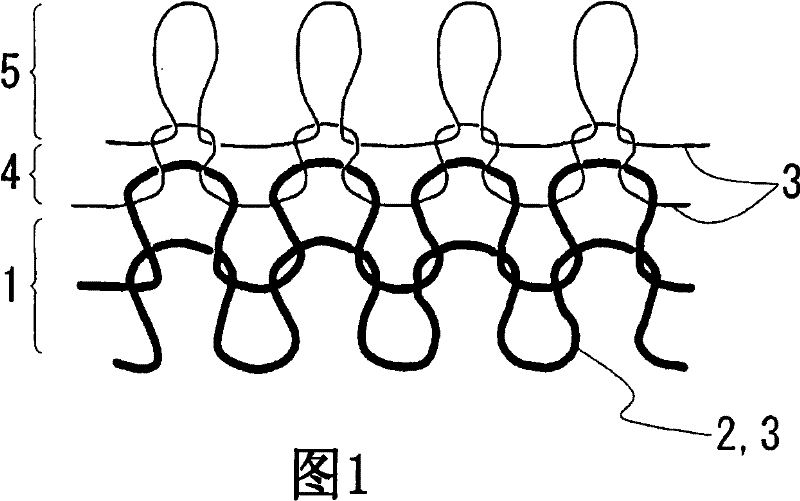

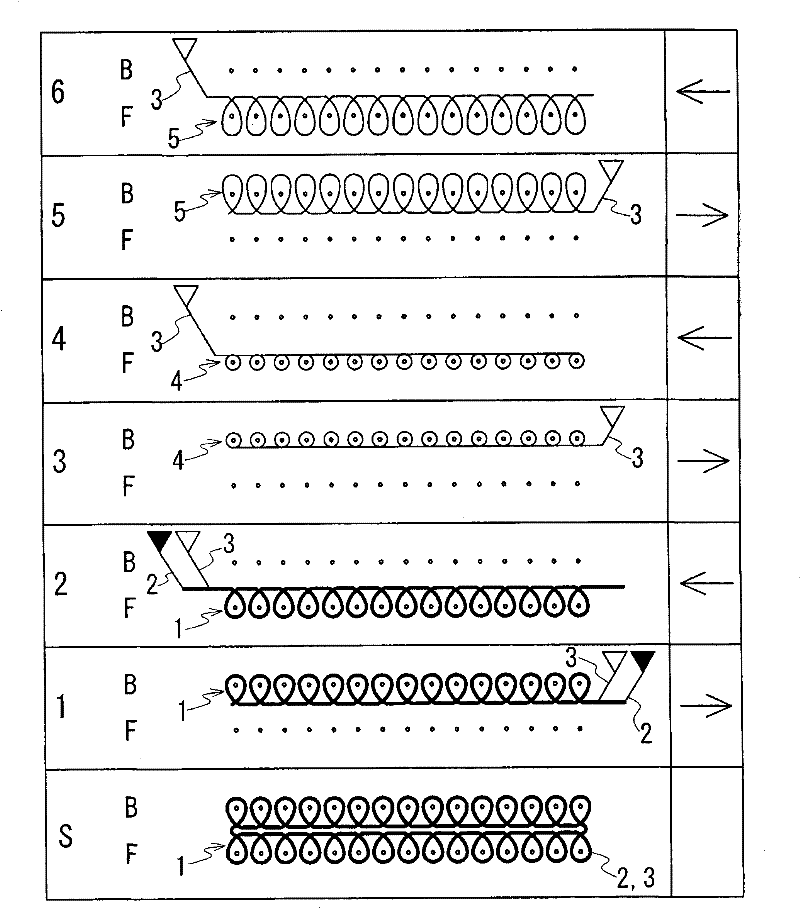

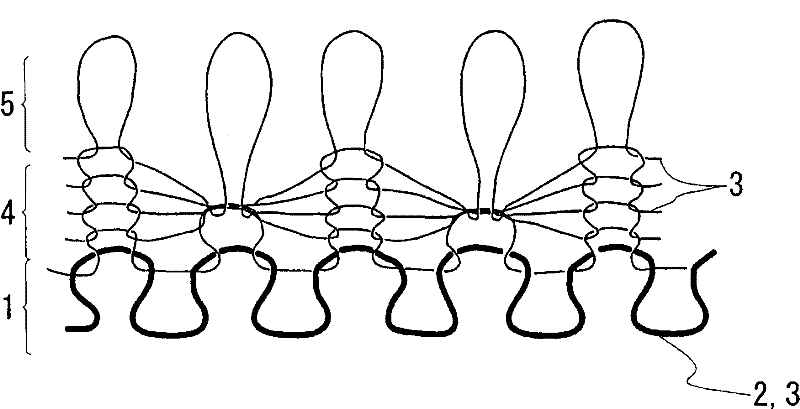

Tubular knitted fabric having opening portion in knitting terminal side and knitting method

The present invention provides a tubular knitted fabric with a peristome at the knitting terminal side and the knitting method, the quality and the style of which are excellent, it uses the cheap elastic yarn used in the yarn plating and knitting and it can reliably prevent the wire off of the open end part while the yarn feeding hole is not increased. The tubular knitted fabric of the invention is a tubular knitted fabric which is knitted by the flat-bed machine and is provided with a peristome at the knitting terminal side. The woven fabric main body (1) of the tubular knitted fabric simultaneously feeds the main yarn (2) and the plated yarn (3) provided with elasticity to the knitting needle and the knitted plating yarn is formed to be tubular. The peristome formed at the knitting terminal side of the knitted fabric body (1) is composed of a terry knitted fabric part (4) and a final coil horizontal arranging part (5), wherein, the terry knitted fabric part (4) is horizontally arranged contacting to the knitting coil knitted by the main yarn (2) and the plating yarn (3), is formed by horizontally arranging the plating yarn (3) and is at least knitted for one coil with the stitchdensity value which is smaller than the stitch density when do plating yarn knitting and it is formed by the terry and the coil of which is small; the final coil horizontal arranging part (5) next tothe terry knitted fabric part (4) is knitted using the plating yarn (3) with the stitch density value which is larger than the stitch density value when knits the terry knitted fabric part (4).

Owner:SHIMA SEIKI MFG LTD

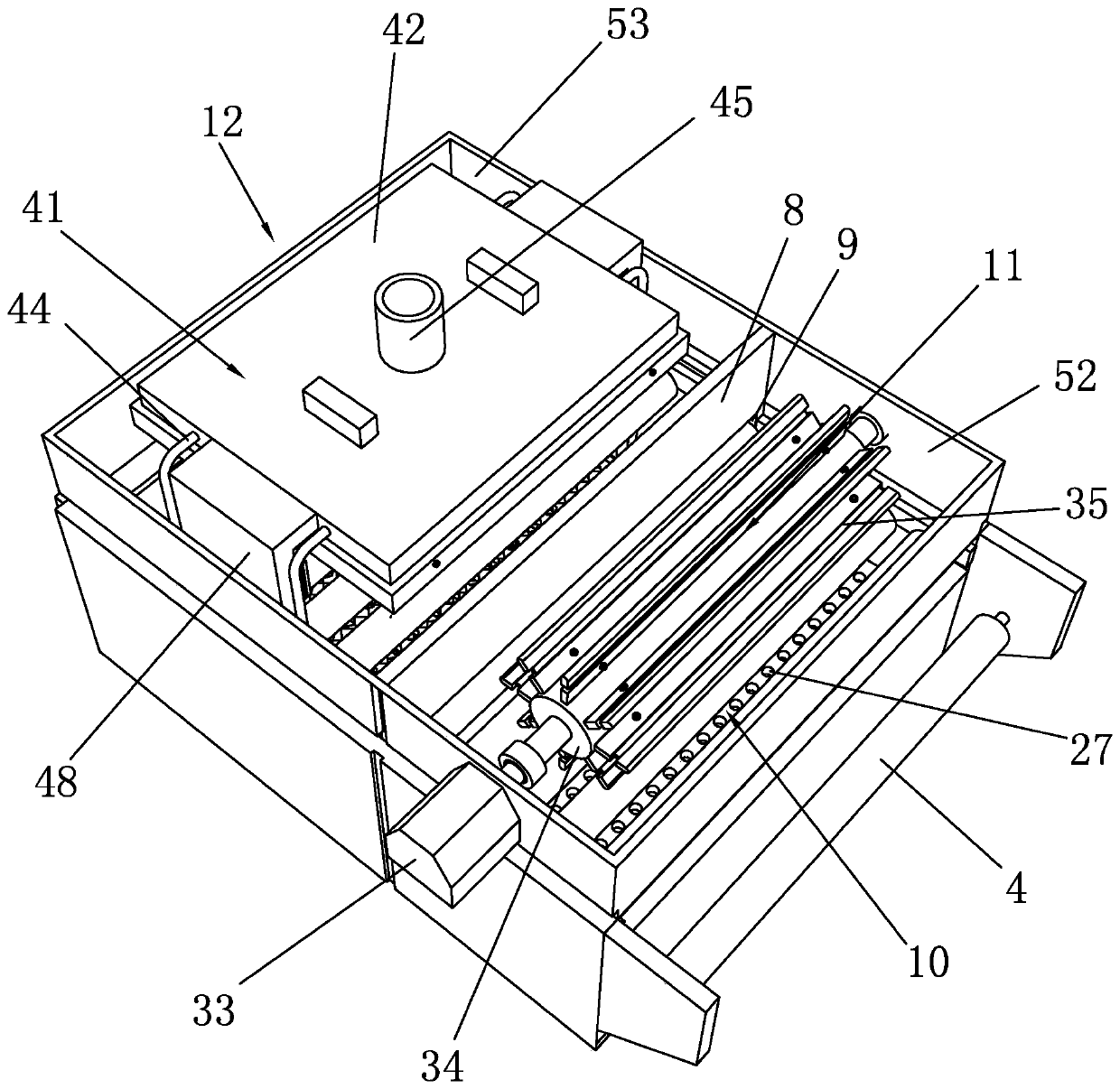

Numerical control setting machine

PendingCN111206359AIncrease the number ofIncrease productivityShaping/stretching tubular fabricsNumerical controlControl engineering

The present invention relates to a numerical control setting machine. The numerical control setting machine comprises a setting frame, an oven and setting mechanisms, and also comprises moving seats and a driving assembly, wherein the moving seats are mounted on the setting frame through a slideway; the setting mechanisms are mounted on the corresponding moving seats, and the setting mechanisms and the oven are located on a same side of the setting frame; the driving assembly drives the moving seats to move back and forth along the setting frame; and the oven is at least provided with an inletfor the setting mechanisms to enter or leave the oven. The driving assembly controls multiple groups of setting assemblies to enter or leave the oven, so that the number of fabrics subjected to setting by drying in machine operation is increased and the production efficiency is improved; and the front and rear groups of setting assemblies enter or leave the oven alternately to finish setting by drying and replacement of the fabrics alternately, so that the utilization rate of the oven is improved, the width and the volume of the oven are reduced, and the energy consumption of the oven is reduced. The numerical control setting machine is simple in structure, convenient to operate, small in overall volume, low in energy consumption and small in setting temperature difference, and meets thesetting requirement of high quality.

Owner:ZHEJIANG NEU MACHINERY EQUIP CO LTD

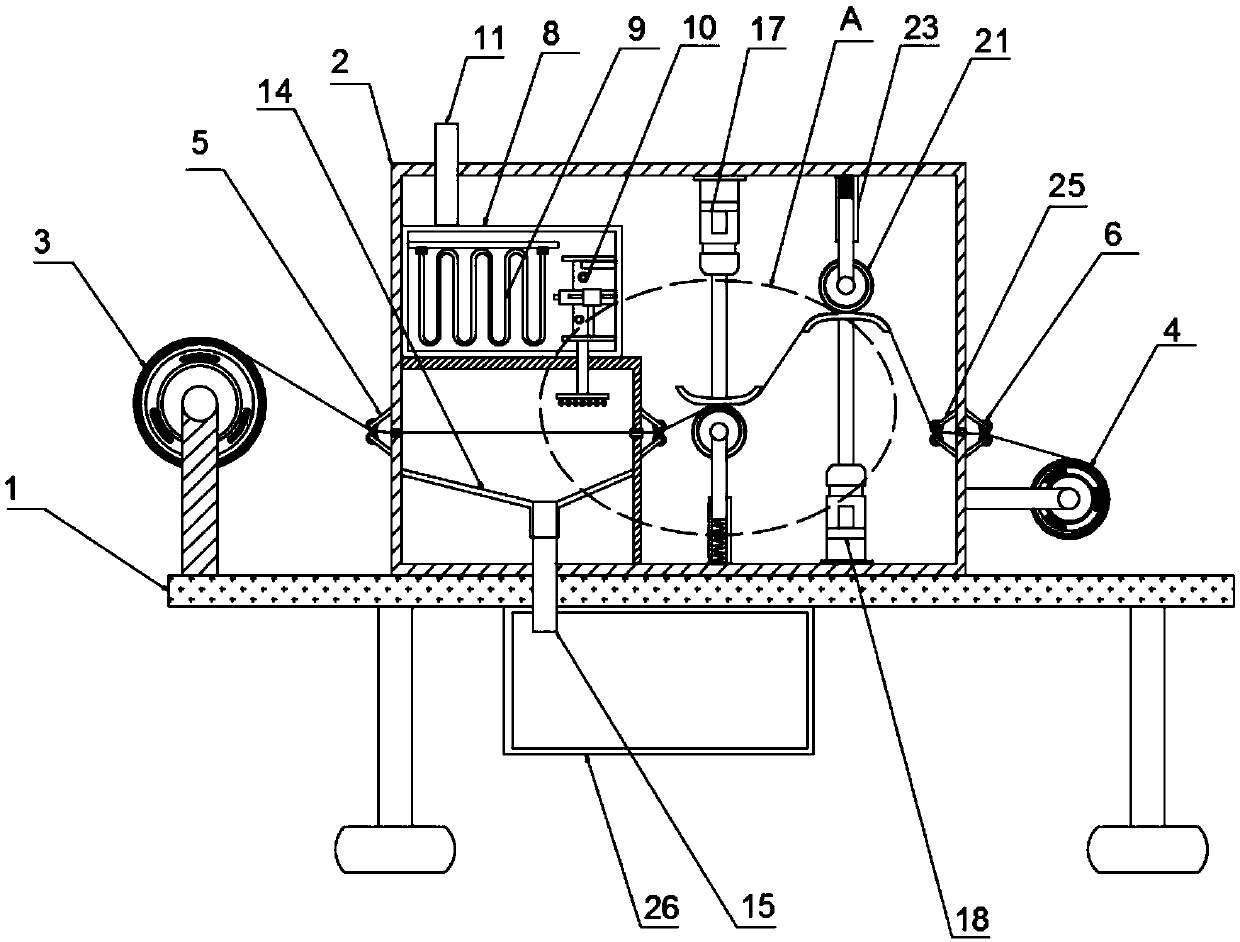

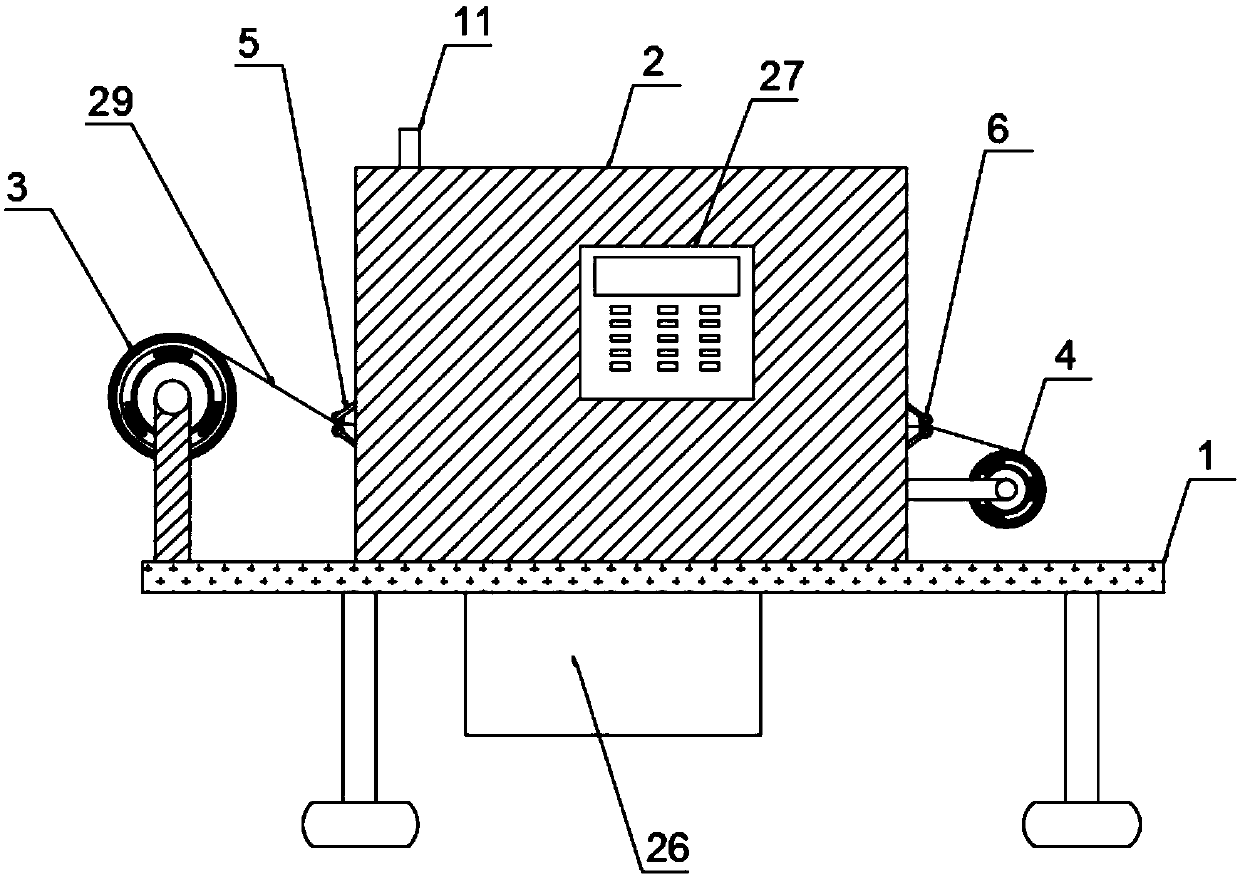

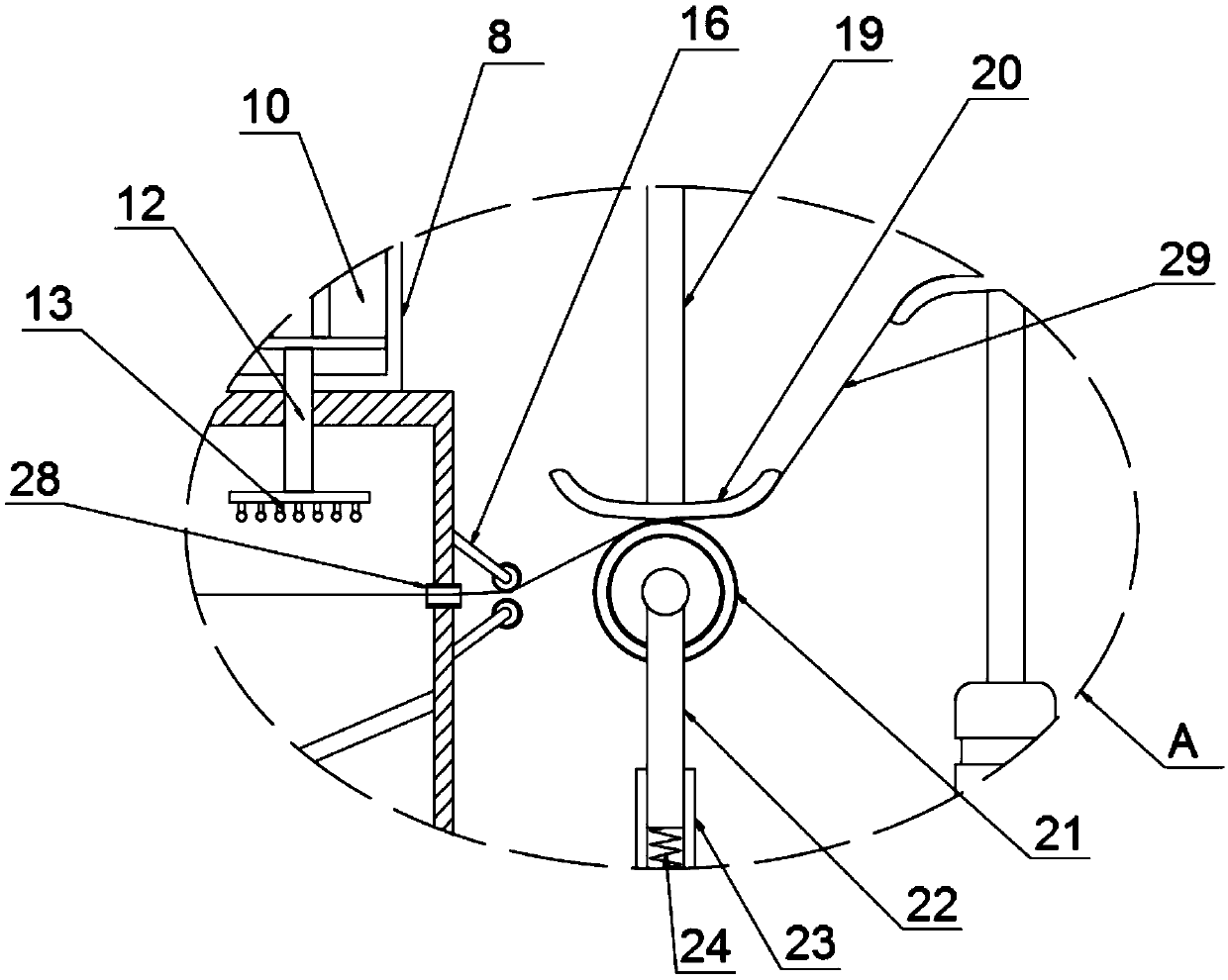

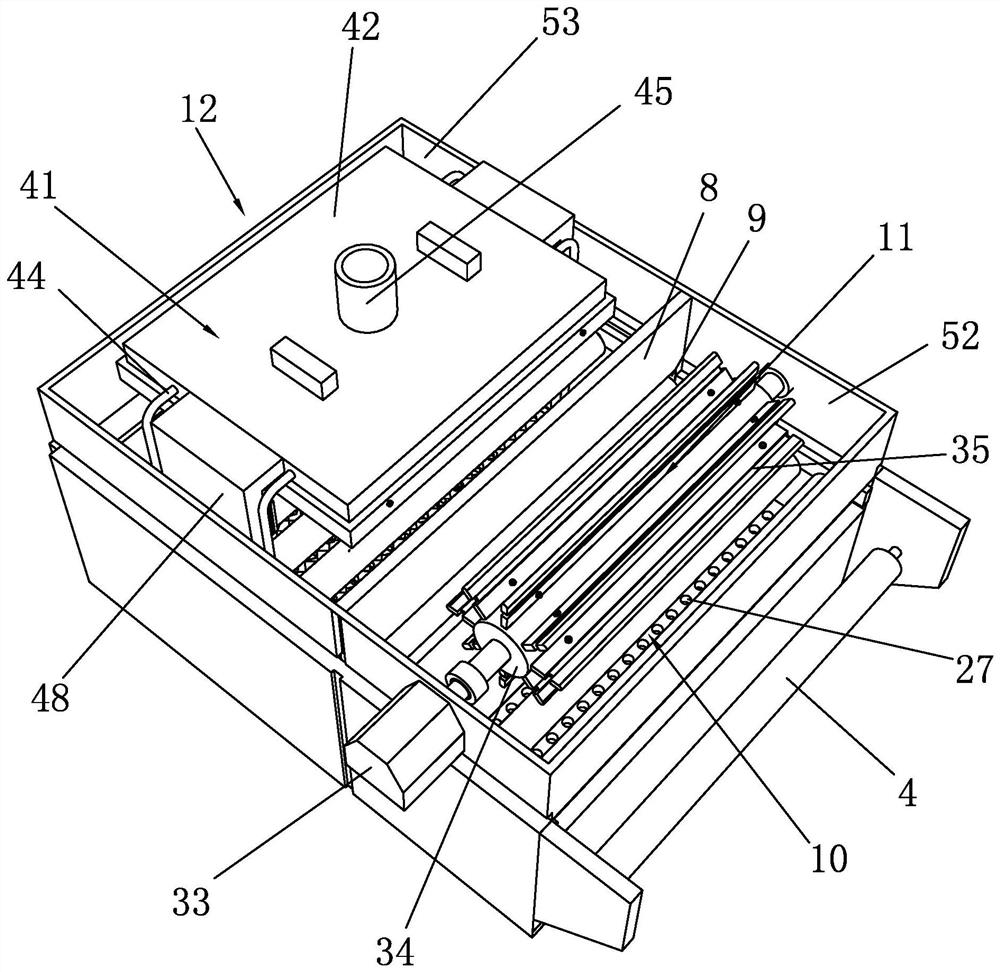

Embroidery thread splicing and shaping equipment and method

InactiveCN109610112AImprove styling efficiencyImprove styling qualityTextile treatment by spraying/projectingWater sourceEngineering

The invention discloses embroidery thread splicing and shaping equipment and an embroidery thread splicing and shaping method. The embroidery thread splicing and shaping equipment comprises a workbench, wherein a shaping box is arranged at the top of the workbench; a thread winding roll is arranged on one side of the shaping box, and a recycling roll is arranged on the other side of the shaping box; a first adjusting roll is arranged on one side wall of the shaping box, and a second adjusting roll is arranged on the other side wall of the shaping box; a humidifying box is arranged inside the shaping box; a hot water box is arranged at the top of the humidifying box; a heating tube is arranged in an inner cavity of the hot water box; a pressure pump is arranged on one side of the heating tube. A water source in the hot water box is heated by the heating tube, the pressure pump sprays the heated water source onto an embroidery thread in the humidifying box from a spray head on the end part of a water outlet pipe, and hot pressing plates are matched with pressing rolls to perform extrusion shaping on the wet embroidery thread; the spliced embroidery thread is shaped by utilizing a hotshaping principle, so that the shaping efficiency and the shaping quality of the embroidery thread are improved, the embroidery thread is not prone to deform and fall off during storage, and the quality of a product is improved.

Owner:NANTONG GOD OF HORSES THREAD

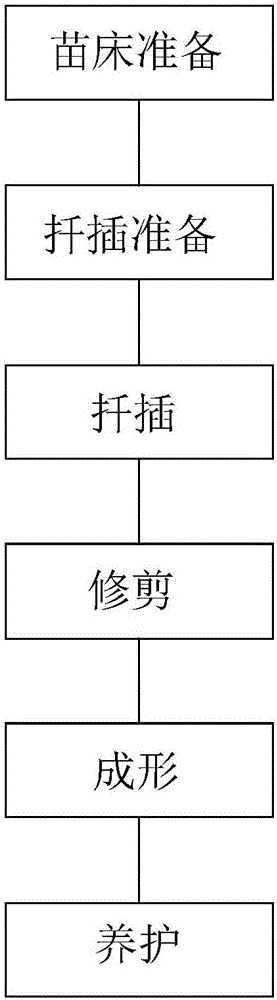

Photinia fraseri shape directive culture method for landscape engineering

ActiveCN105993759AAvoid infringementImprove survival rateCultivating equipmentsHorticulture methodsLandscape engineeringBiology

The invention discloses a photinia fraseri shape directive culture method for landscape engineering, belonging to the field of arbor directive shaping culture methods. The invention aims to provide a photinia fraseri shape directive culture method for landscape engineering, which can enhance the shaping quality of the photinia fraseri which is pruned into a cylinder. The technical scheme is as follows: the method comprises the following steps: seedbed preparation, cuttage preparation, cuttage, pruning, forming and maintenance. The method is suitable for shape pruning of arbors.

Owner:NANJING HONGSEN SEEDLINGS CO LTD

High-strength anti-static coated abrasive tool cloth base and treatment process thereof

ActiveCN112677063AHigh strengthImprove antistatic performanceAbrasion apparatusAgricultural engineeringMechanical engineering

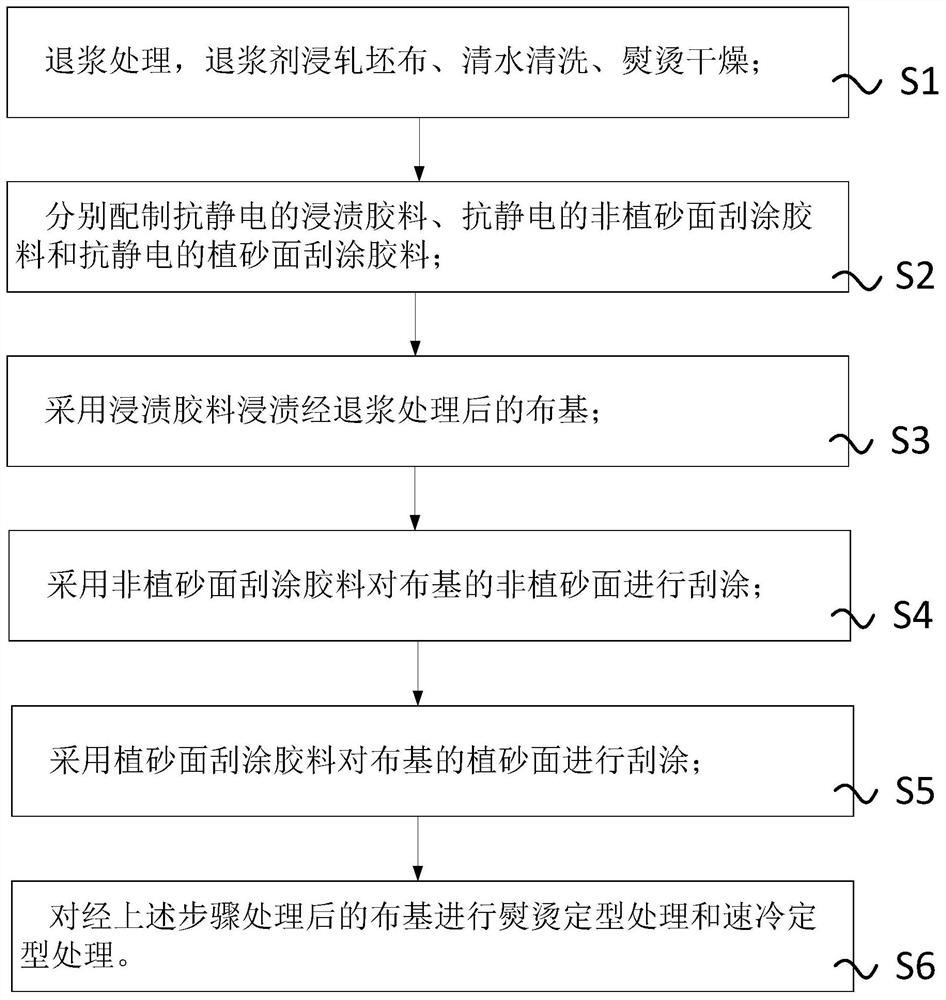

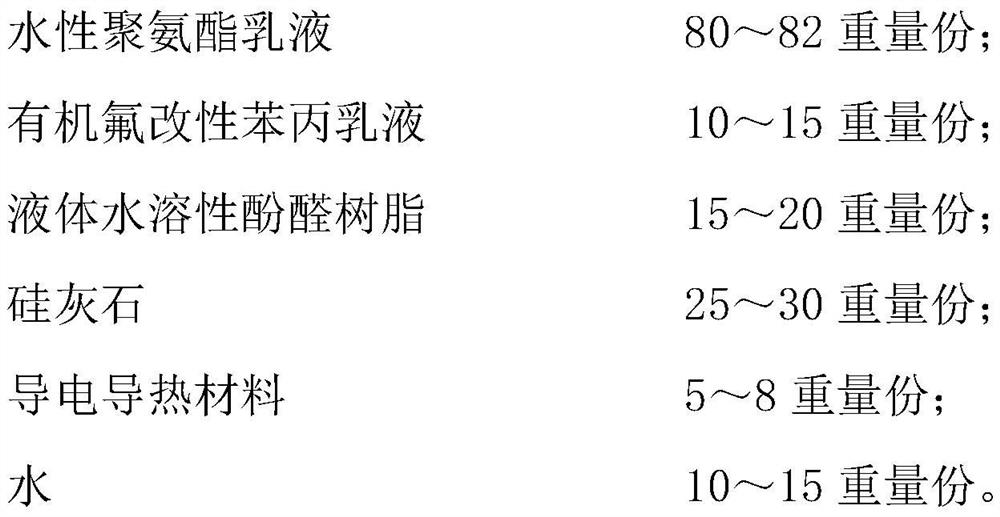

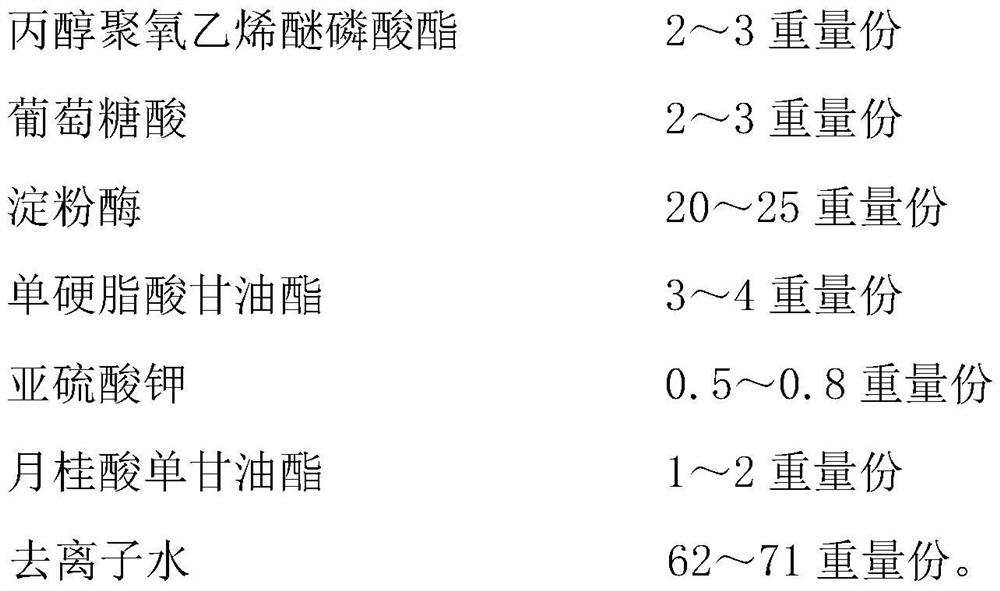

The invention provides a treatment process of a high-strength anti-static coated abrasive tool cloth base. The treatment process comprises the following steps of S1, conducting desizing treatment; S2, respectively preparing an anti-static impregnated sizing material, an anti-static non-sand-planting surface blade coating sizing material and an anti-static sand-planting surface blade coating sizing material; S3, impregnating by adopting the impregnated sizing material; S4, conducting blade coating on the non-sand-planting surface of the cloth base by adopting the non-sand-planting surface blade coating sizing material; S5, conducting blade coating on the sand planting surface of the cloth base by adopting the sand planting surface blade coating sizing material; and S6, conducting ironing setting treatment and quick-cooling setting treatment on the cloth base treated in the above-mentioned steps. The invention further provides a coated abrasive tool cloth base. Through impregnation, non-sand-planting surface blade coating and sand-planting surface blade coating, the treated cloth base forms a conductive channel from the non-sand-planting surface to the sand-planting surface, so that the anti-static property of the cloth base is improved; the mechanical strength of the cloth base is improved through the sizing material in the cloth base; and through ironing setting treatment and quick-cooling setting treatment, internal molecules of the cloth base are directionally arranged in the setting process, and the strength of the cloth base is improved.

Owner:SUZHOU FAR EAST ABRASIVES

A setting machine for fabric finishing

ActiveCN109944006BIncrease moisture contentPlay the role of preheatingSucessive textile treatmentsHeating/cooling textile fabricsThermodynamicsMechanical engineering

Owner:绍兴柯桥如川纺织科技有限公司

Calendering shaping device for polyethylene glycol terephthalate (PET) nano reinforced plate production line

ActiveCN102555143AEvenly heatedSmall temperature differenceProduction linePolyethylene terephthalate

The invention discloses a calendering shaping device for a polyethylene glycol terephthalate (PET) nano reinforced plate production line, which can reduce the temperature difference between upper and lower surfaces of a strip blank during shaping. The device comprises a frame, wherein the frame is sequentially provided with a pair of cooling calendering rollers parallel to each other, a front shaping heating roller and a back shaping heating roller; and the frame is provided with a shaping heating device which is matched with the front shaping heating roller above the front shaping heating roller. The shaping heating device matched with the front shaping heating roller is arranged above the front shaping heating roller, so that the upper and lower surfaces of a PET plate strip blank are heated when passing through the front shaping heating roller, the temperature difference between the upper and lower surfaces of the PET plate strip blank is reduced and the calendering shaping device can shape PET plates with the thickness of more than or equal to 2mm, namely PET thick plates.

Owner:江苏民扬塑胶科技有限公司

Piled sheet and process for producing the same

InactiveCN101198743AGood form stabilityImprove surface wear resistanceLayered productsFibre treatmentEngineeringNonwoven fabric

A piled sheet composed of three layers entangled / united with each other. The three layers have a layer structure which is an entangled nonwoven fabric (A) made of ultrafine fibers / polyurethane sheet (B) / woven or knit fabric (C) or an entangled nonwoven fabric (A) made of ultrafine fibers / woven or knit fabric (C) / polyurethane sheet (B), wherein the entangled nonwoven fabric (A) has piles of the ultrafine fibers formed on the surface. Part of the ultrafine fibers constituting the entangled nonwoven fabric (A) pass through the polyurethane sheet (B) and the woven or knit fabric (C) in this order or through the woven or knit fabric (C) and the polyurethane sheet (B) in this order, at least part of the ultrafine fibers passing through these being bonded to the polyurethane constituting the polyurethane sheet (B). The piled sheet having such features has excellent shape retentivity, e.g., the property of not deforming even through long-term use. The sheet has satisfactory surface wearing resistance and a soft satisfactory texture giving a high-grade feeling.

Owner:KURARAY CO LTD

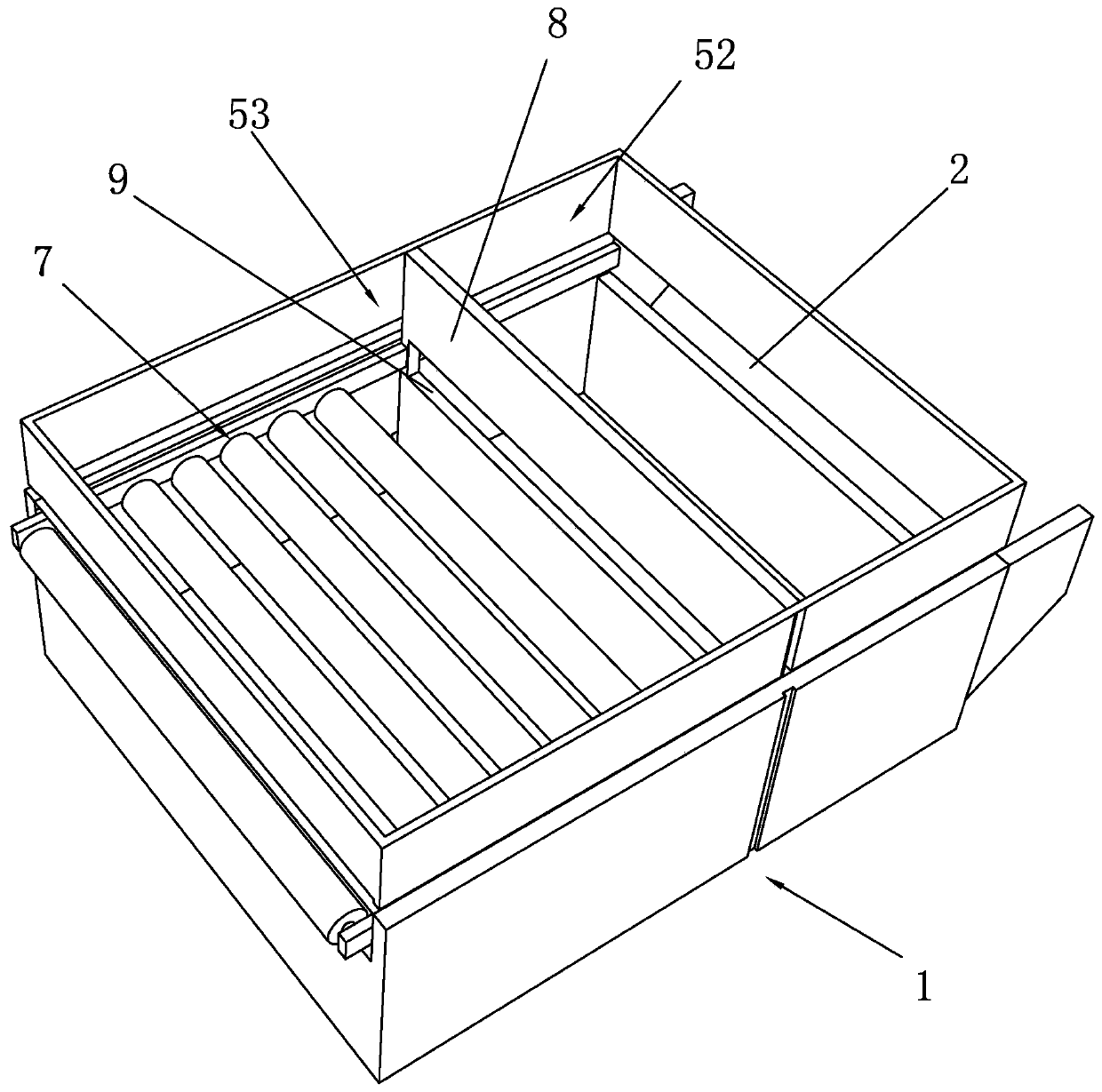

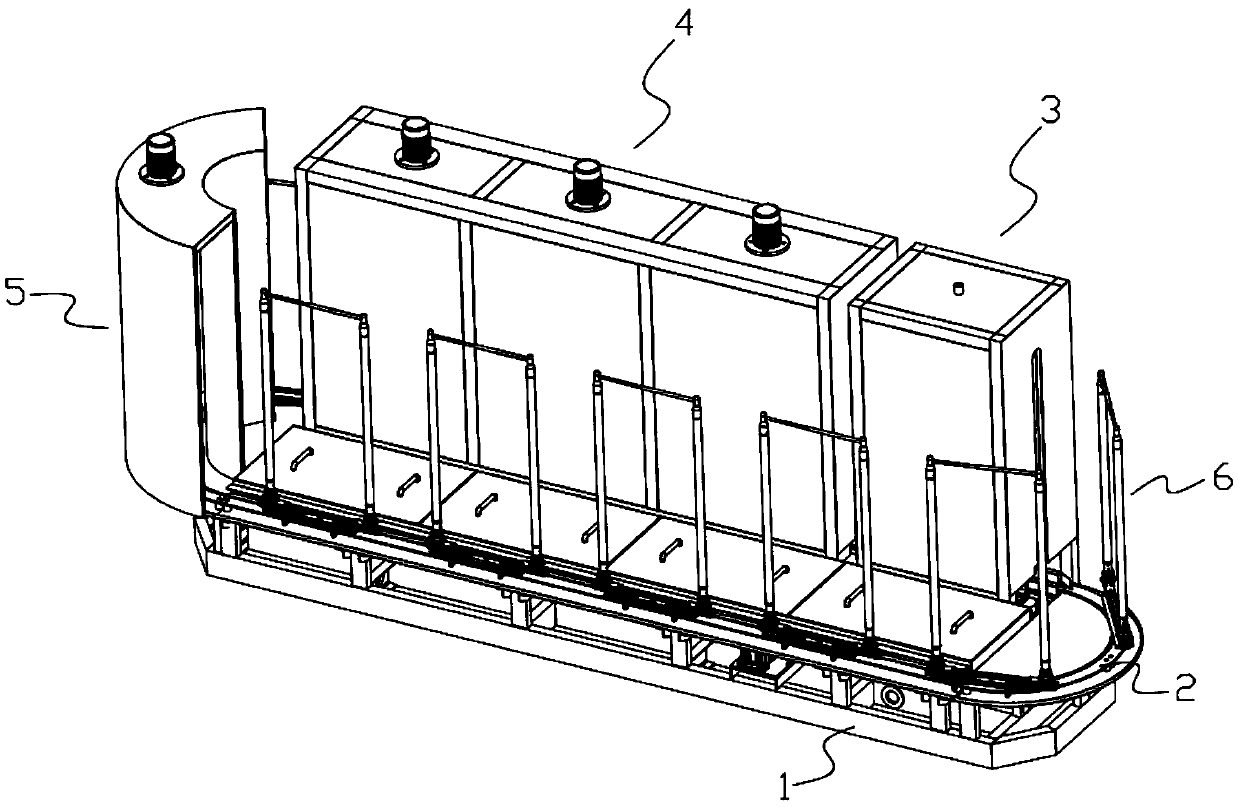

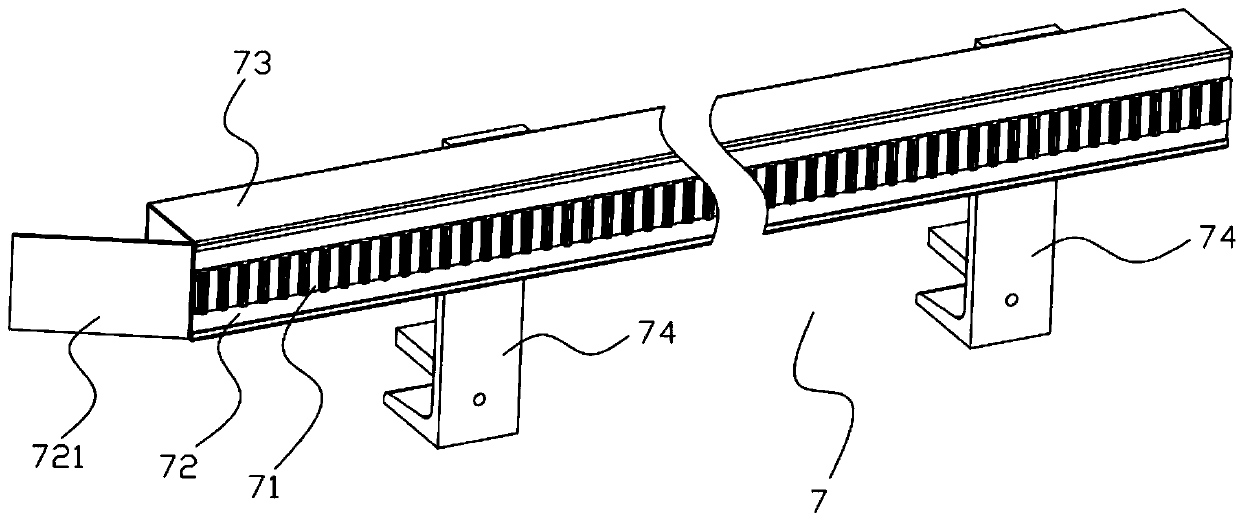

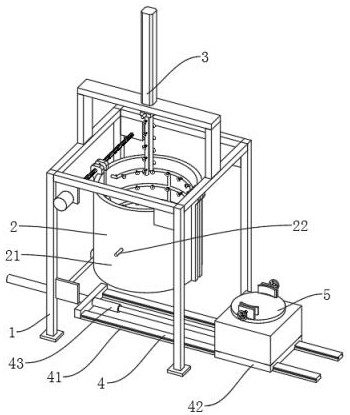

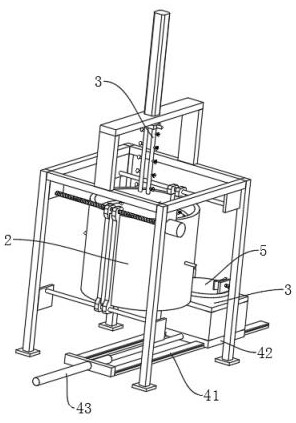

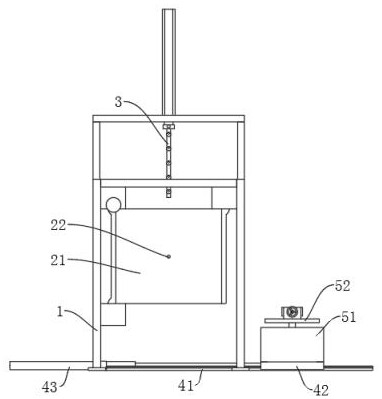

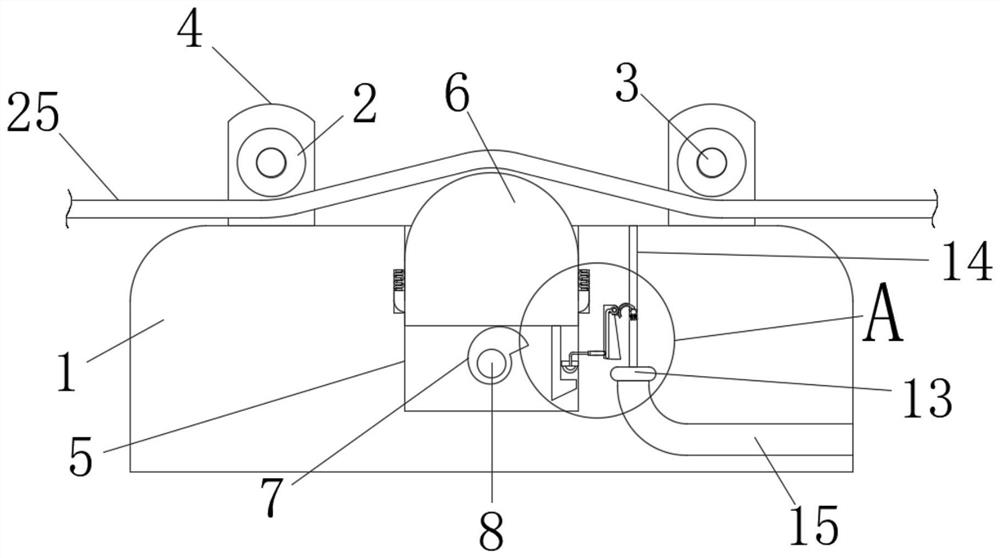

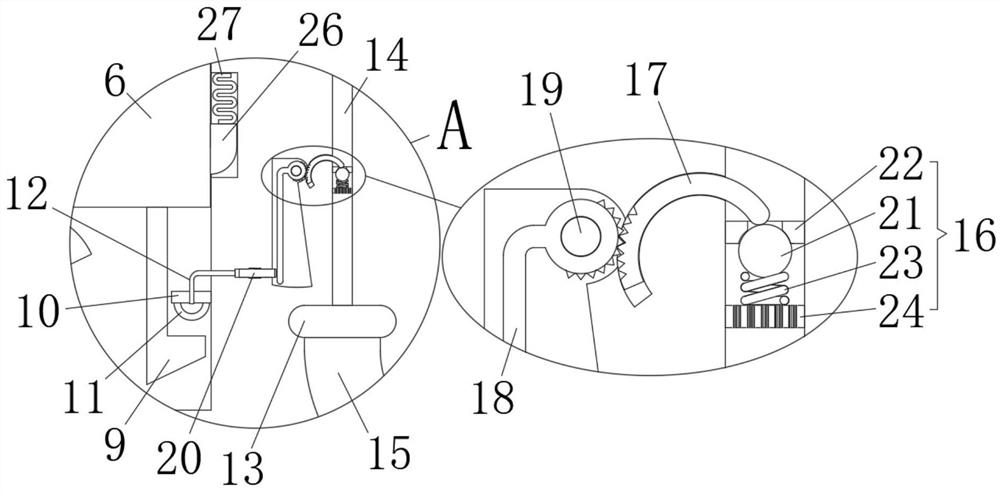

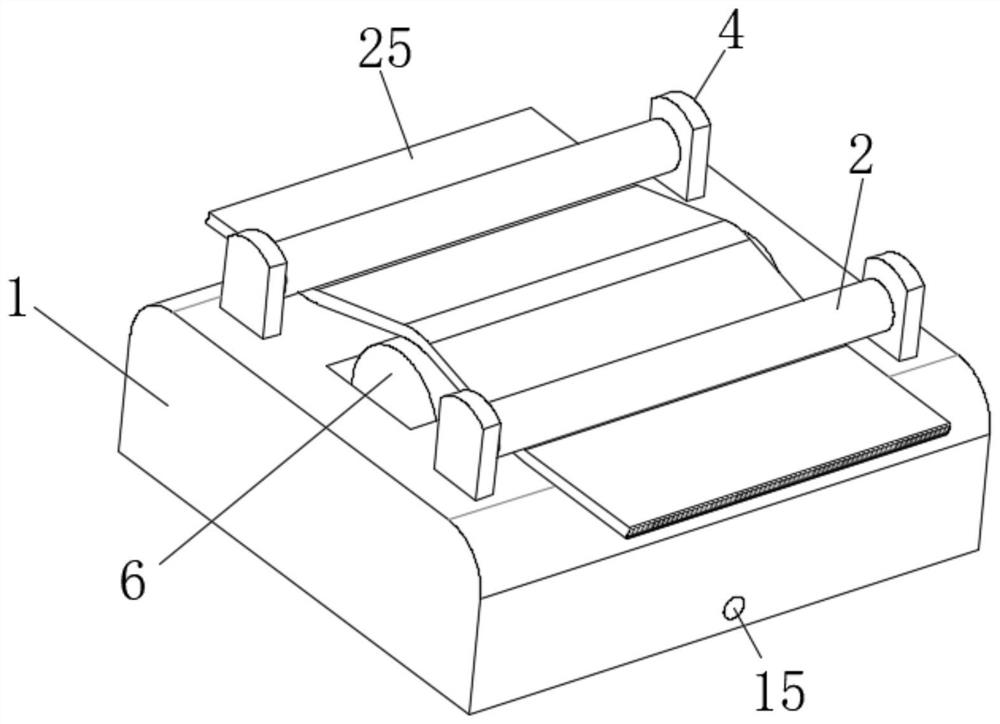

Setting machine

PendingCN109097940AImprove styling qualitySave manpower and timeSucessive textile treatmentsTextile treatment containersSynchronous frameChassis

The invention discloses a setting machine which comprises a bottom frame, a conveying track, a steam setting tank, a drying device and a cooling device. The conveying track is arranged on the bottom frame, and the steam setting tank, the drying device and the cooling device are sequentially arranged on the conveying track. The setting machine is characterized by further comprises a plurality of rotary setting frames and a synchronous frame; the multiple rotary setting frames are arranged on the conveying track, and the synchronous frame is mounted on the bottom frame, is arranged in the steamsetting tank and the drying device; the synchronous frame meshes with the rotary setting frames and drives the rotary setting frames to carry out rotational movement when the rotary setting frames aredriven by the conveying track to move into the steam setting tank and the drying device along paths of the conveying track. Compared with the traditional setting modes, the setting machine has the advantages that manual operation can be replaced with machines, accordingly, large amounts of labor and time can be effectively saved, and the cloth cover setting efficiency and setting quality can be improved.

Owner:DONGGUAN KEMEI MACHINERY

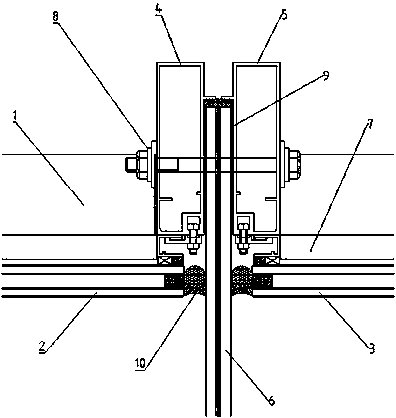

Ornamental glass rib external cantilevering technology of frame-hidden-type glass curtain wall

InactiveCN107700724AImprove styling qualityIncreased beauty of linesWallsBuilding material handlingArchitectural engineeringFirst glasses

The invention relates to an ornamental glass rib external cantilevering technology of a frame-hidden-type glass curtain wall and belongs to the technical field of building curtain wall application. Vertical first glass and second glass are connected to a cross beam, and a first vertical column is connected to the vertical side wall of the first glass; and a second vertical column is connected to the vertical side wall of the second glass, and a glass rib is connected between the first vertical column and the second vertical column. The ornamental glass rib external cantilevering technology ofthe frame-hidden-type glass curtain wall is a novel modeling form, the simplex line aesthetic feeling of a traditional curtain wall is enriched, the spatial stereoscopic feeling of plane curtain wallexternal-cantilevering ornaments is improved, mounting is firm, the potential safety hazard that a traditional glue fixing mode loses efficacy is avoided, a mounting technology is convenient and fast,and construction operation is facilitated accordingly.

Owner:湖南建工集团装饰工程有限公司

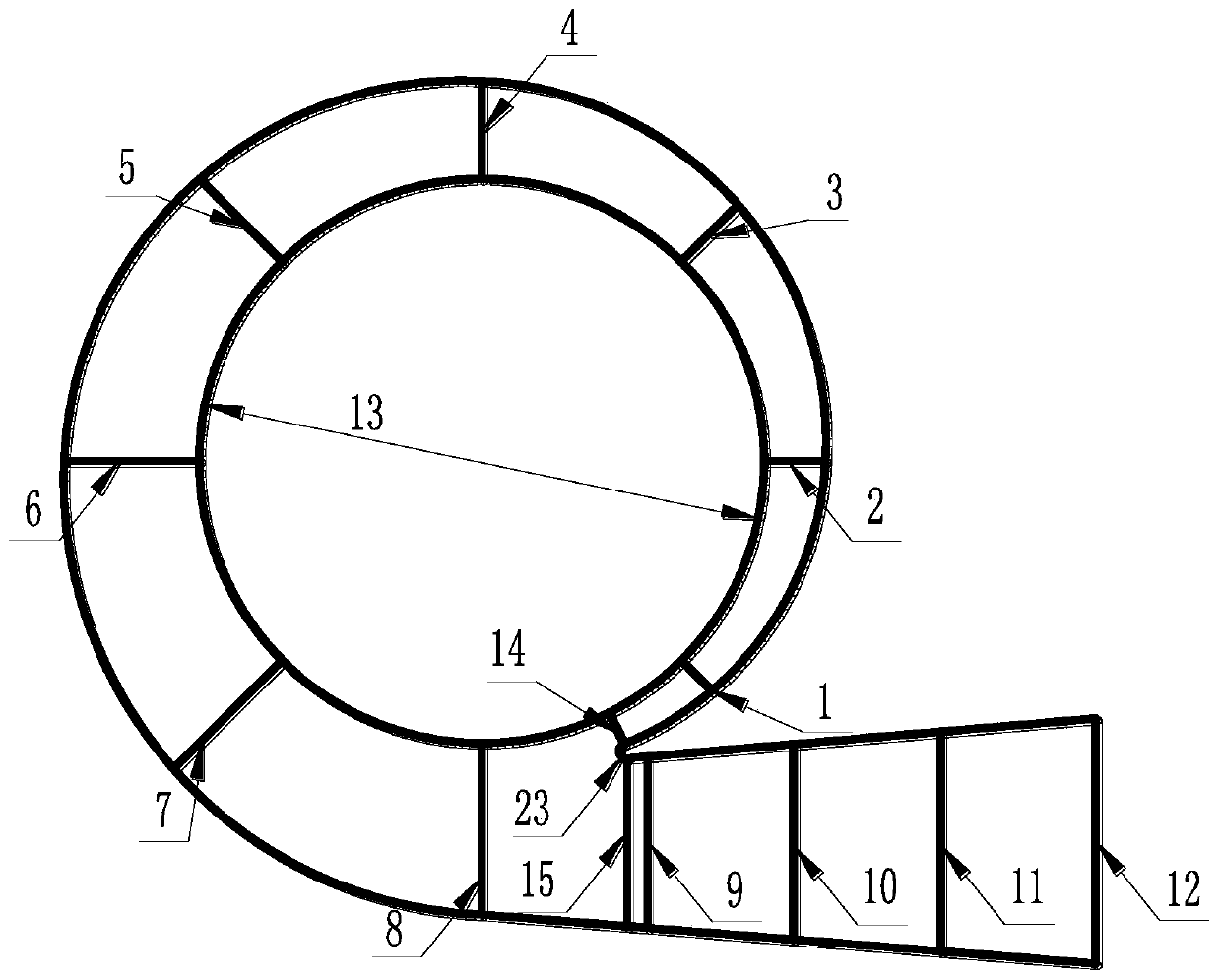

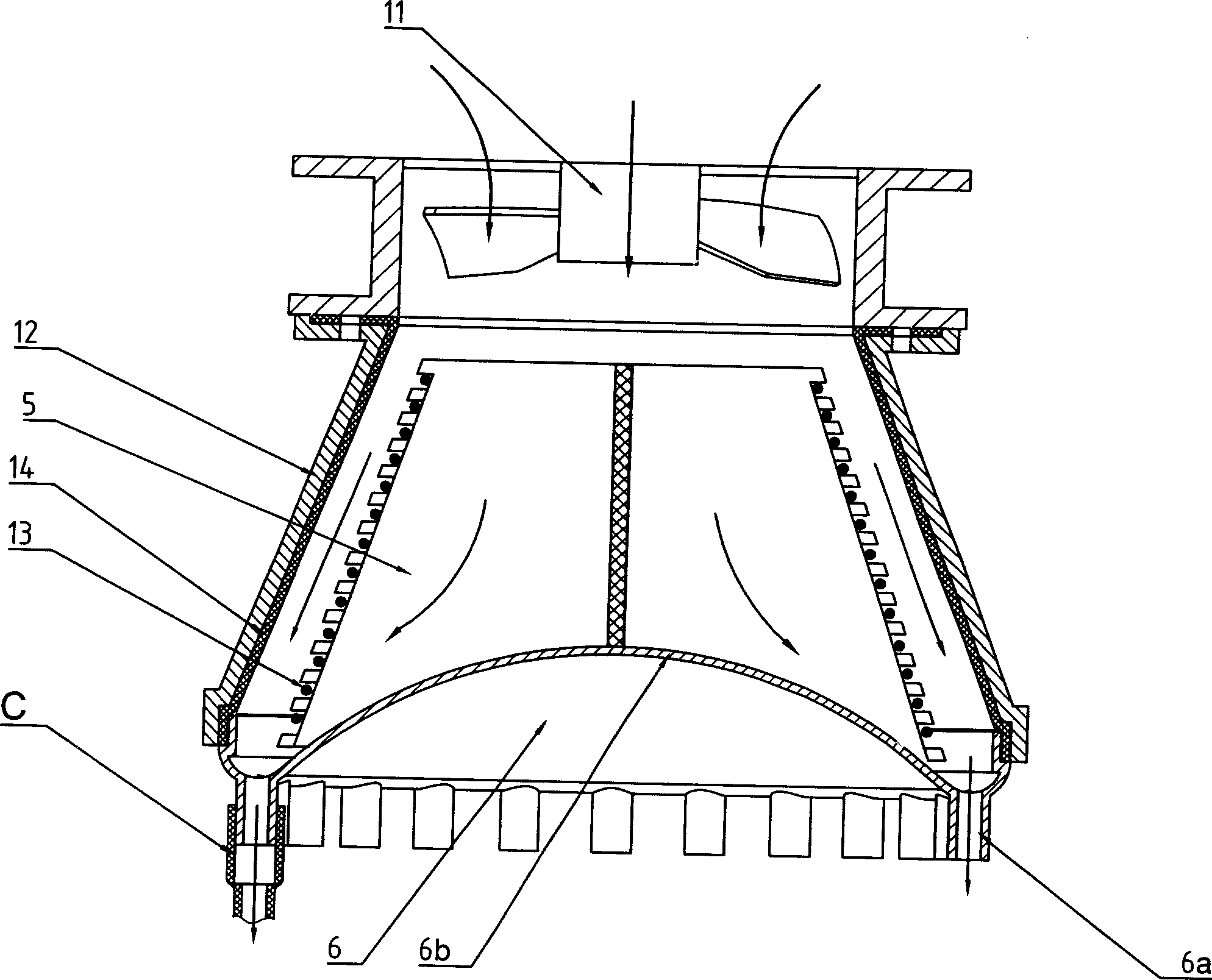

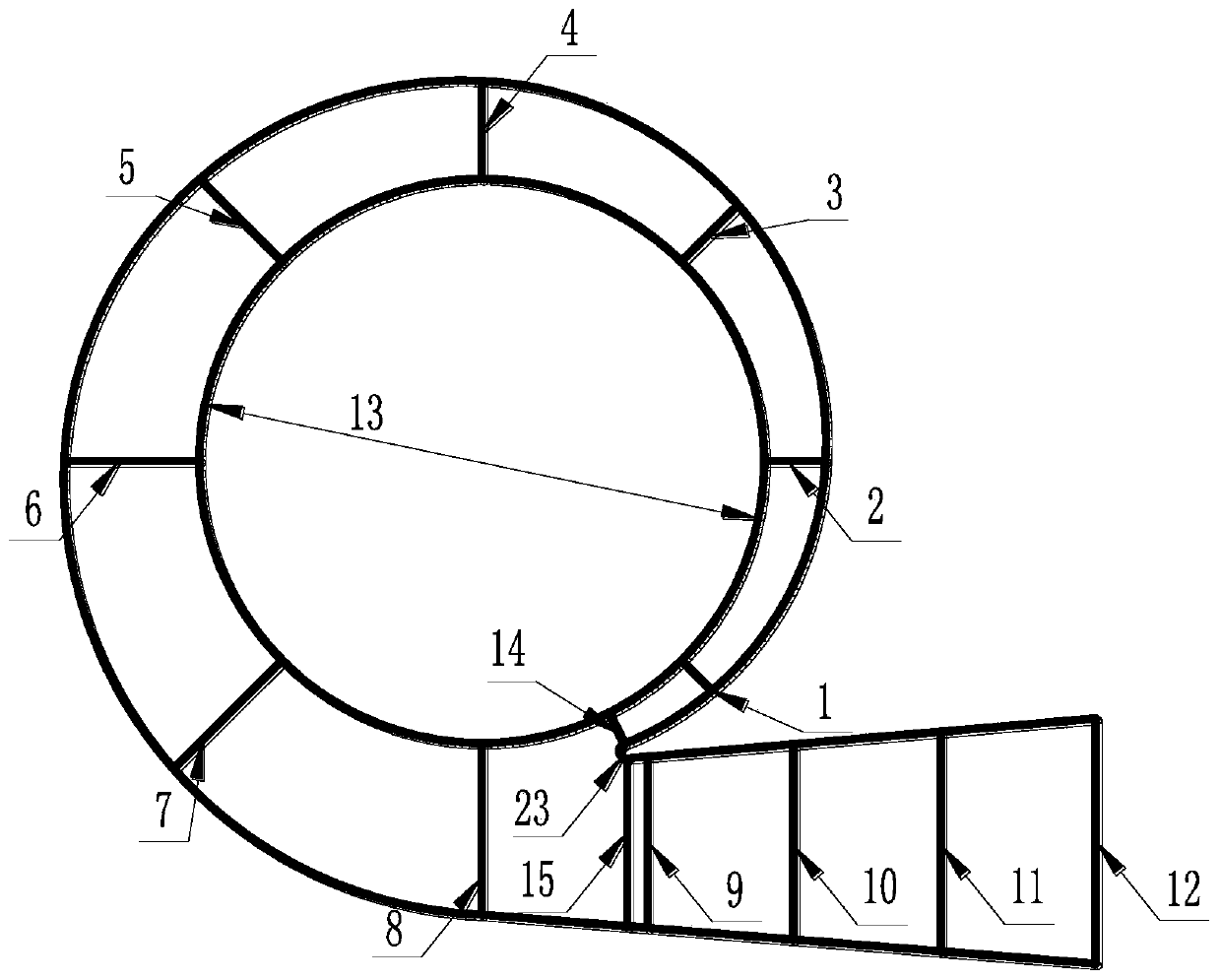

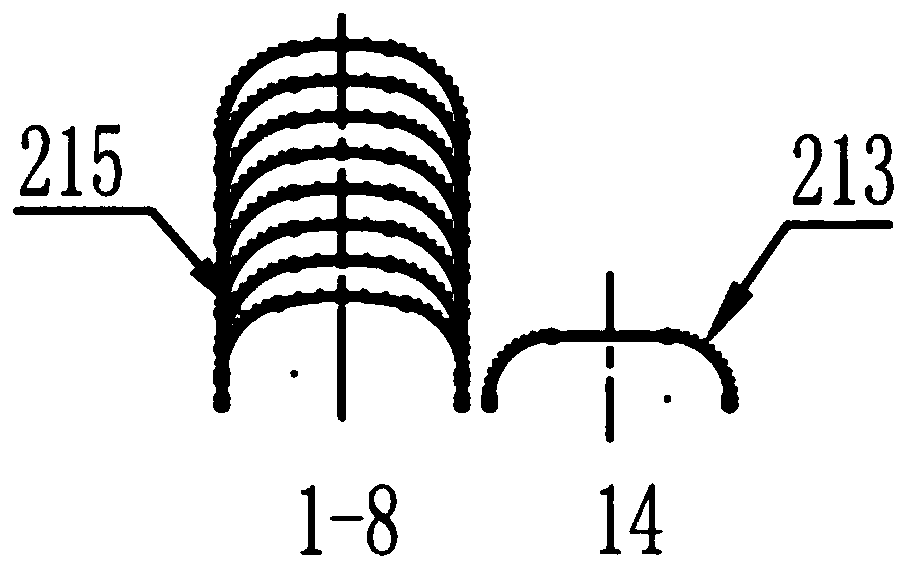

Heating molding device for cement culvert pipe production and using method thereof

ActiveCN112123541AUniform and stable heatingImprove styling efficiencyCeramic shaping apparatusHeat settingMaterials science

The invention discloses a heating molding device for cement culvert pipe production and a using method thereof. The heating molding device comprises a support frame and an outer ring heating molding mechanism, wherein the outer ring heating molding mechanism is arranged on the support frame, and an inner ring heating molding mechanism is arranged in the center of the outer ring heating molding mechanism; and the inner ring heating molding mechanism is arranged above the support frame, a moving mechanism is arranged on the lower side of the support frame, and a rotating supporting mechanism isarranged at the upper end of the moving mechanism. According to the heating molding device for cement culvert pipe production and the using method thereof, a cement culvert pipe is driven to rotate during heat setting through rotation of a rotating disc; meanwhile, hot air sources and water mist sprayed out of first spray heads and second spray heads on the inner side and the outer side of the cement culvert pipe are sprayed to the inner surface and the outer surface of the culvert pipe, so that the cement culvert pipe is subjected to water mist curing firstly and then subjected to hot air drying, heating is more stable and uniform, and the shaping efficiency and quality of the cement culvert pipe are improved; and in addition, a supporting box is driven to move through a sliding base, sothat the cement culvert pipe conveniently enters and exits the outer ring heating molding mechanism, and operation convenience is improved.

Owner:衡阳市畅通管业有限公司

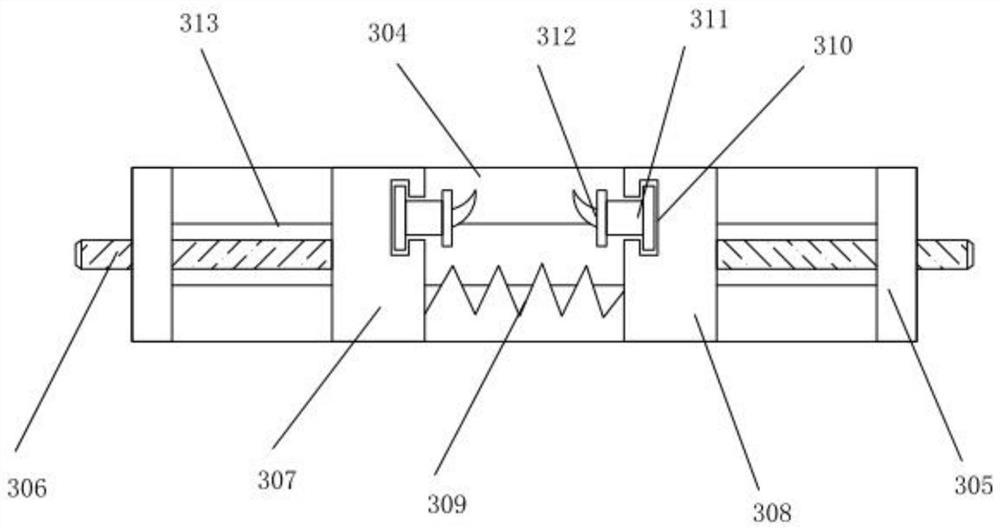

Cooling equipment for processing packaging belt

The invention discloses cooling equipment for processing a packaging belt. The cooling equipment comprises a cooling liquid tank, a motor I, a steering roller, a guide roller, a delivering barrel, anair blower, a motor II, a transmission roller and a squeezing roller; the cooling equipment is characterized in that the cooling liquid tank is arranged on a bracket; the motor I is arranged at the top of the cooling liquid tank; connection shafts are arranged at two ends of the steering roller; connection shafts are arranged at two ends of the guide roller; the delivering barrel is arranged at the top of the cooling liquid tank; the air blower is arranged on an outer wall of the cooling liquid tank; connection shafts are arranged at two ends of the transmission roller; connection shafts are arranged at two ends of the squeezing roller. According to the cooling equipment disclosed by the invention, a spring is arranged between one end in a fixed groove and a fixed ring; the fixed ring is convenient to move in the fixed groove through the spring, so that the squeezing roller can move in the delivering barrel and the packaging belt which moves along the transmission roller is convenientto squeeze; the packaging belt cooled by cooling liquid can be squeezed and shaped and the shaping efficiency of the packaging belt is improved.

Owner:芜湖三华包装科技有限公司

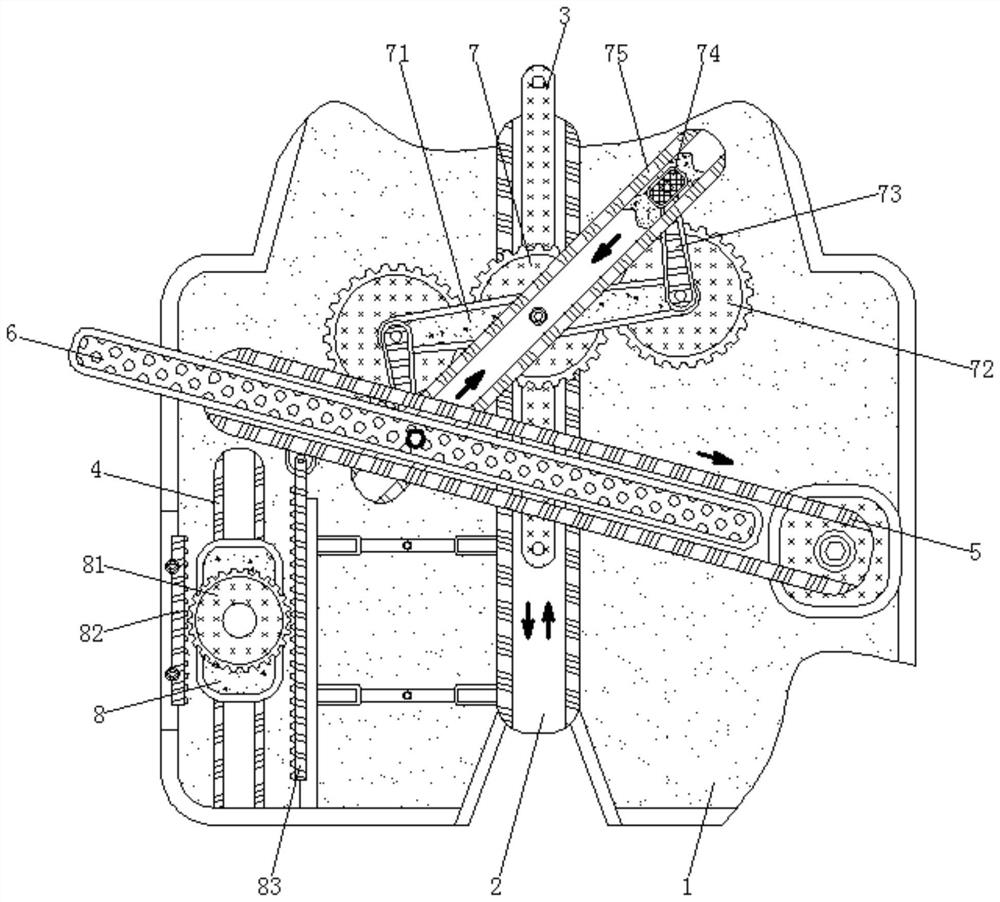

Anti-deformation device for warp knitted fabric after forming

The invention relates to the technical field of knitted fabrics, and discloses an anti-deformation device for a warp knitted fabric after forming. The device comprises a driving gear mechanism; a connecting rod is rotatably connected to the axis of the driving gear mechanism; an auxiliary gear mechanism is rotatably connected to the end, away from the driving gear mechanism, of the connecting rod; a rotating rod is fixedly connected to the axis of the auxiliary gear mechanism; the surface of the rotating rod is rotationally connected with a sliding block; and the axis of the connecting rod is rotationally connected with a double-face guide rail. According to the anti-deformation device for the warp knitted fabric after forming, a driving guide rod slides along the surface of a first guide rail to drive the driving gear mechanism and the connecting rod to move along with a driving guide rod, and the front face of the double-face guide rail pushes a pulley mechanism arranged on the surface of a supporting rod to drive the supporting rod to slide along the surface of a guide groove, so that the positions of pin fixing holes in the surface of the supporting rod are changed, the linear position of warp knitted fabric shaping can be rapidly adjusted, and shaping of the warp knitted fabric is facilitated.

Owner:广西贺州锐佳塑胶五金制品有限公司

A multifunctional glue binding machine

InactiveCN105799357BLong setting timeExtend curing timeBook making processesEngineeringMechanical engineering

The invention relates to a multifunctional adhesive bookbinding machine. The multifunctional adhesive bookbinding machine comprises a book feeding acceleration mechanism, a manual book placing table, a rack, a book processing and arranging device, a cover feeding mechanism and a book processing and conveying device which are connected sequentially. The book processing and arranging device is arranged on the upper right side of the rack. The book processing and conveying device is arranged on the upper left side of the rack. A housing is arranged on the book processing and arranging device and the book processing and conveying device. The multifunctional adhesive bookbinding machine is reasonable in structure design and used automatically and conveniently. Meanwhile, the setting time of books and solidification time of hot melt adhesive are increased, so that the setting quality of the books is improved, and the books are made to be distinct in corner angle, clear in outline, and attractive inn appearance. The cost is low, and the multifunctional adhesive bookbinding machine is suitable for wide production and application for enterprises.

Owner:PINGHU BIND EX MACHINERY

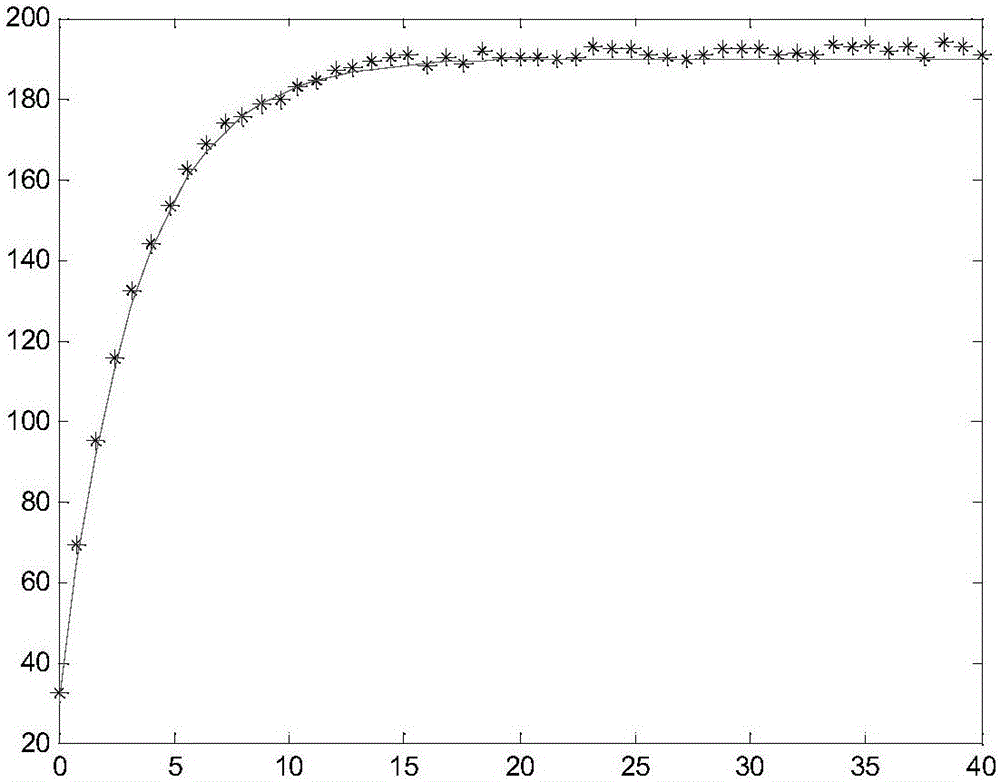

A method for estimating the hot air temperature of a setting machine using the heat of heat conduction oil as the heat source

InactiveCN106066937BReduce measurement linksAccurate acquisitionSpecial data processing applicationsInformaticsEstimation methodsEngineering

The invention discloses a hot air temperature estimating method of a setting machine using heat conductive oil heat as heat source; mechanism analysis and practical testing are combined so as to save certain temperature measuring nodes, thus relatively accurately obtaining hot air t2 value, reducing hardware cost of the setting machine, and providing strong technical supports for improving the setting machine quality.

Owner:ZHEJIANG SCI-TECH UNIV

An intermittent elastic round rope braiding machine

A kind of intermittent elastic round rope knitting machine proposed by the present invention comprises a frame, a fixed disk is fixedly installed on one end surface of the frame of the frame, a braiding device is fixedly connected to the surface of the frame, and a braiding device is fixedly connected to the surface of the frame. A heating box is fixedly installed on the surface, and the other end surface of the frame is fixedly connected with a winding bracket, and one side surface of the fixed plate is fixedly connected with a coil positioning rod, and the coil positioning rods are evenly distributed on the fixed plate at equal angles One side of the surface of the fixed plate is fixedly connected with a connecting frame at one end of the side of the fixed plate, and the other end of the connecting frame is rotatably installed with a side guide wheel, and the other side of the surface of the fixed plate is provided with an arc-shaped installation groove. The side of the arc-shaped mounting groove is slidingly installed with a fixing screw, and one end of the surface of the fixing screw is threaded with a fixing nut, and the other end of the fixing screw is provided with a round rod, which can greatly improve the convenience and stability of use and ensure Weaving quality and efficiency.

Owner:泰安科鼎特工贸有限公司

A Smooth Modeling Method for Centrifugal Pump Volute

ActiveCN109711045BReduce mold costImprove styling qualityGeometric CADDesign optimisation/simulationNumerical controlVisual inspection

The invention belongs to the technical field of three-dimensional modeling of centrifugal pumps, and particularly relates to a smooth modeling method for a volute of a centrifugal pump. According to the method, modeling is carried out based on UG NX, tools such as an equal-parameter curve and a bridging curve are adopted to be used in cooperation, and the problems that according to a common volutemodeling method, manual visual inspection is adopted, modeling distortion is likely to happen, and curved surface connection is not smooth when the volute partition tongue part is processed can be effectively solved. According to the method, the complete smooth transition between the curved surfaces of the separation tongue part of the centrifugal pump volute can be realized, so that no further processing is needed in the actual manufacturing process of the centrifugal pump, and the modeling quality is improved while the modeling cost is reduced. According to the volute modeling completed through the method, the modeling structure is clear, curved surface transition is natural and attractive, and the method can improve the precision and accuracy of centrifugal pump CFD simulation, finiteelement analysis and mold numerical control machining.

Owner:CHINA AGRI UNIV

A vibrating cooling device for a cloth setting machine

ActiveCN111893690BStable Vibration WorkEfficient cooling and setting workHeating/cooling textile fabricsCold airEngineering

The invention relates to the technical field of cloth shaping, in particular to a vibrating cooling device for a cloth shaping machine, comprising a bottom plate, a rotating cylinder is arranged on the upper end of the bottom plate, a positioning shaft is movably sleeved in the middle of the rotating drum, and a positioning shaft is fixedly connected to the end of the positioning shaft. Side ear plate, the lower end of the side ear plate is fixedly connected with the bottom plate, a control groove is opened on the upper surface of the bottom plate, a lifting seat and a pressure column are arranged in the inner cavity of the control groove, the lower end of the lifting seat contacts the pressure column, and the upper end of the lifting seat extends Outside the bottom plate, the invention realizes the stable vibration work of the lifting seat, and at the same time blows out the cold air flow intermittently through the branch pipe cavity to realize the efficient cooling and shaping of the cloth. The function is stable and powerful, and the shaping efficiency and quality of the cloth are improved. Invented as an independent working unit, it can be flexibly set on the fabric processing line.

Owner:湖州五兴达丝绸整理有限公司

Processing equipment for wave-shaped filter cloth with framework and using method

InactiveCN113181712ALittle impact on operationImprove styling efficiencyAir-treating devicesDispersed particle filtrationAdhesive glueMechanical engineering

The invention discloses processing equipment for wave-shaped filter cloth with a framework and a using method. The processing equipment for the wave-shaped filter cloth with the framework comprises a rack, shaping rods and move grooves, wherein the shaping rods are arranged on the rack in the direction perpendicular to the length direction of the rack, each shaping rod comprise a lower shaping rod and an upper shaping rod, the lower shaping rods and the upper shaping rods are alternately arranged at equal intervals in the length direction of the rack, and the shaping rods can do translational motion in the direction perpendicular to the axis of the shaping rods and the length direction of the rack; the shaping rods can also do translational motion in the direction parallel to the length direction of the rack; the mold grooves are at least formed in the lower shaping rods or the upper shaping rods and are formed in the sides, which make contact with the wave-shaped filter cloth, of the shaping rods at equal intervals in the length direction of the shaping rods, and glue can be injected into the mold grooves. According to the device, the wave-shaped filter cloth can be shaped into a wavy shape, the shaping efficiency is high, the shaping precision is high, glue can be applied to the surface of the wave-shaped filter cloth and solidified into a framework, the forming effect is improved, the attractiveness is enhanced, and the automation degree is high.

Owner:昆山卓景电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com