Patents

Literature

96results about How to "Improve styling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

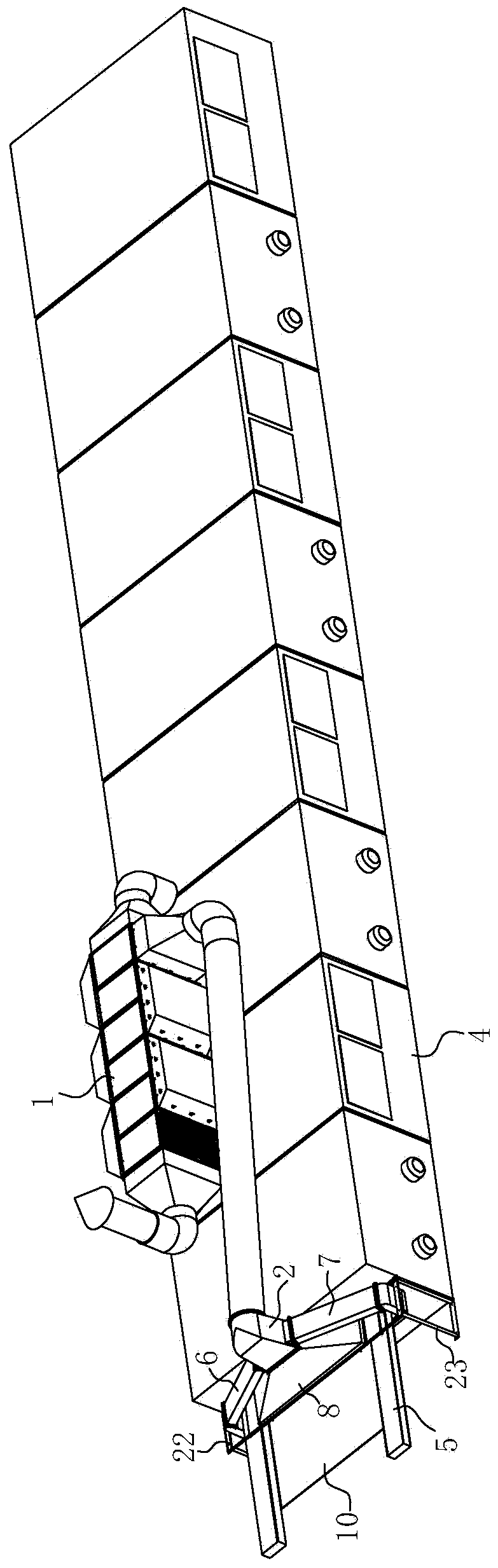

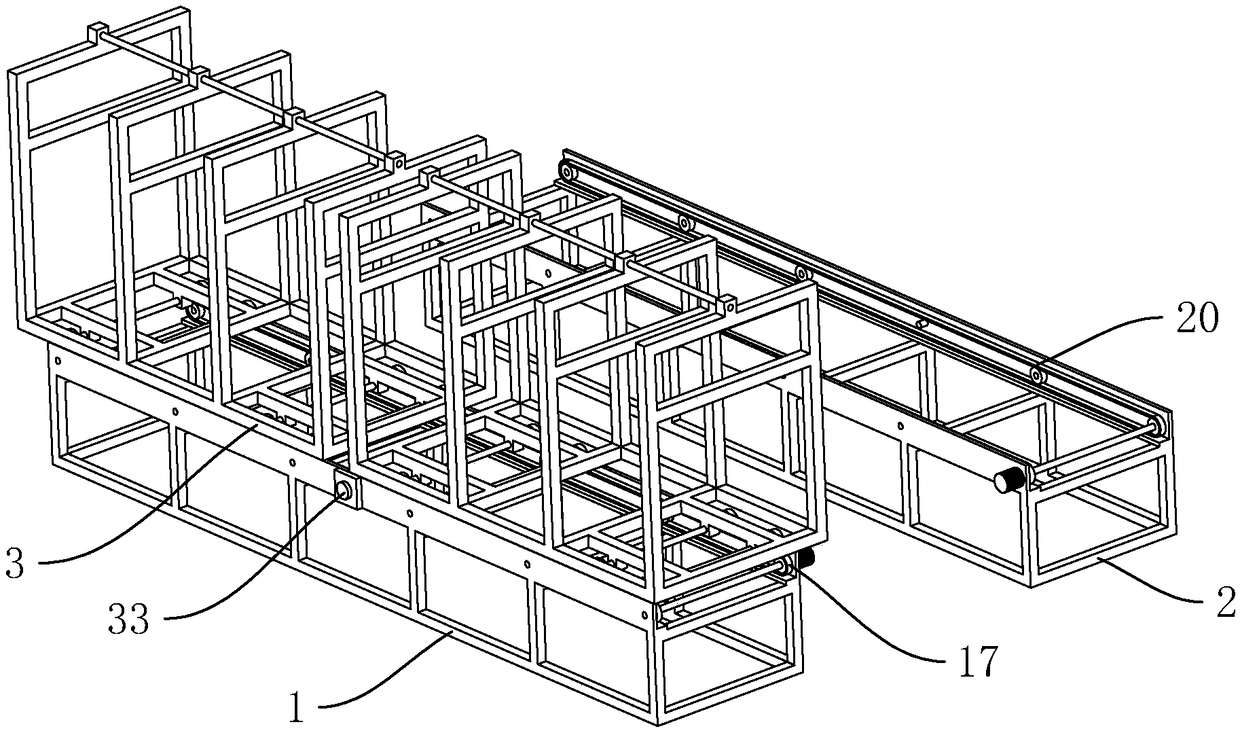

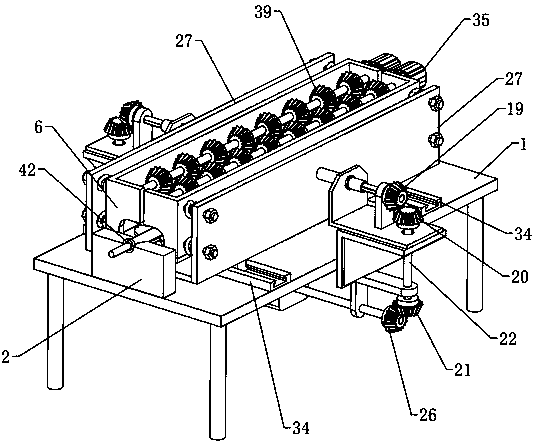

Multi-deflection bending shaping device and bending shaping method for furniture wood processing

InactiveCN110271069AImprove accuracyAvoid deformationPressure wood treatmentWood treatment detailsClamp connectionDrive shaft

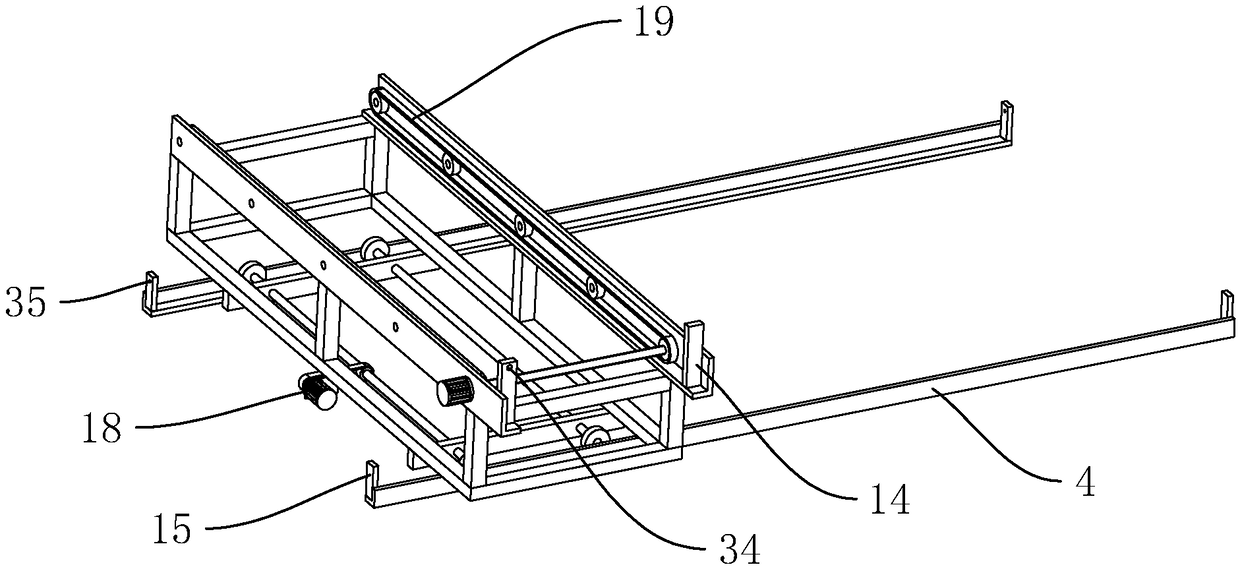

The invention discloses a multi-deflection bending shaping device for furniture wood processing. The device is composed of a material inlet platform, a soaking tank, a fumigation box, a heat-preservation levelling platform, a bending shaping box and a material outlet platform, the material inlet platform is provided with a first conveyer belt, a second conveyer belt is obliquely arranged in the soaking tank, a third conveyor belt and a steam spray pipe are arranged in the fumigation box, and the heat-preservation levelling platform is composed of a base seat, lifting rods and a lifting platform; the interior of the bending shaping box is connected with each first hot pressing roller through one corresponding first hydraulic rod and is connected with each second hot pressing roller through one corresponding second hydraulic rod, driven gears of the second hot pressing rollers are connected with a driving gear chain of a driving shaft, and the bending shaping box communicates with a hot air fan; and a slide groove of a bottom plate in the material outlet platform is in clamp connection with a T-shaped supporting foot of a motor, and the motor is connected with a horizontal push rod. The device provided by the invention realizes a bending shaping method of soaking, steam fumigation, low-pressure levelling, repeated hot roll bending and repeated hot roll shaping, is suitable for wood with different deflection, and has high bending and shaping efficiency, and high accuracy, and the shaped wood is not easy to deform.

Owner:利辛县爱侣家俱加工有限公司

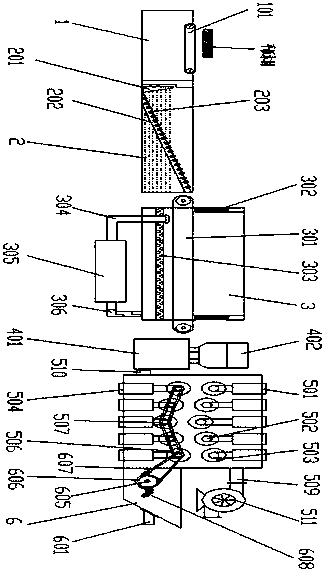

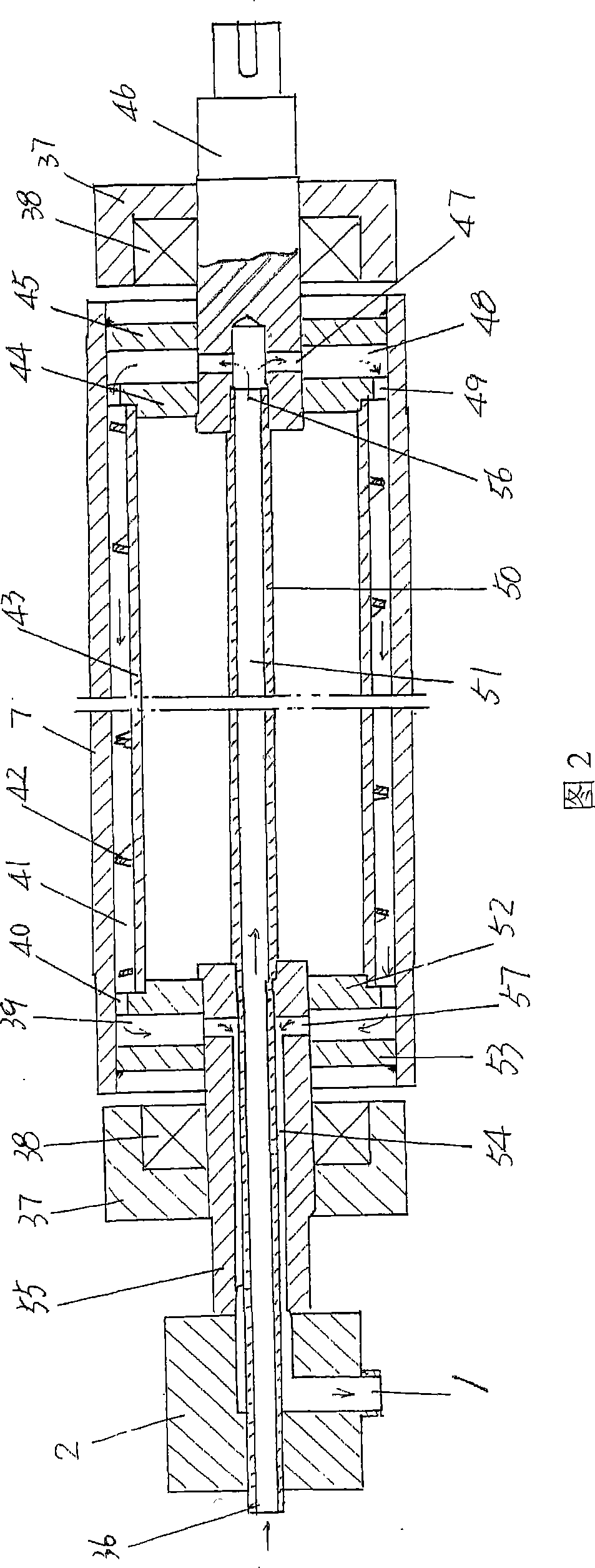

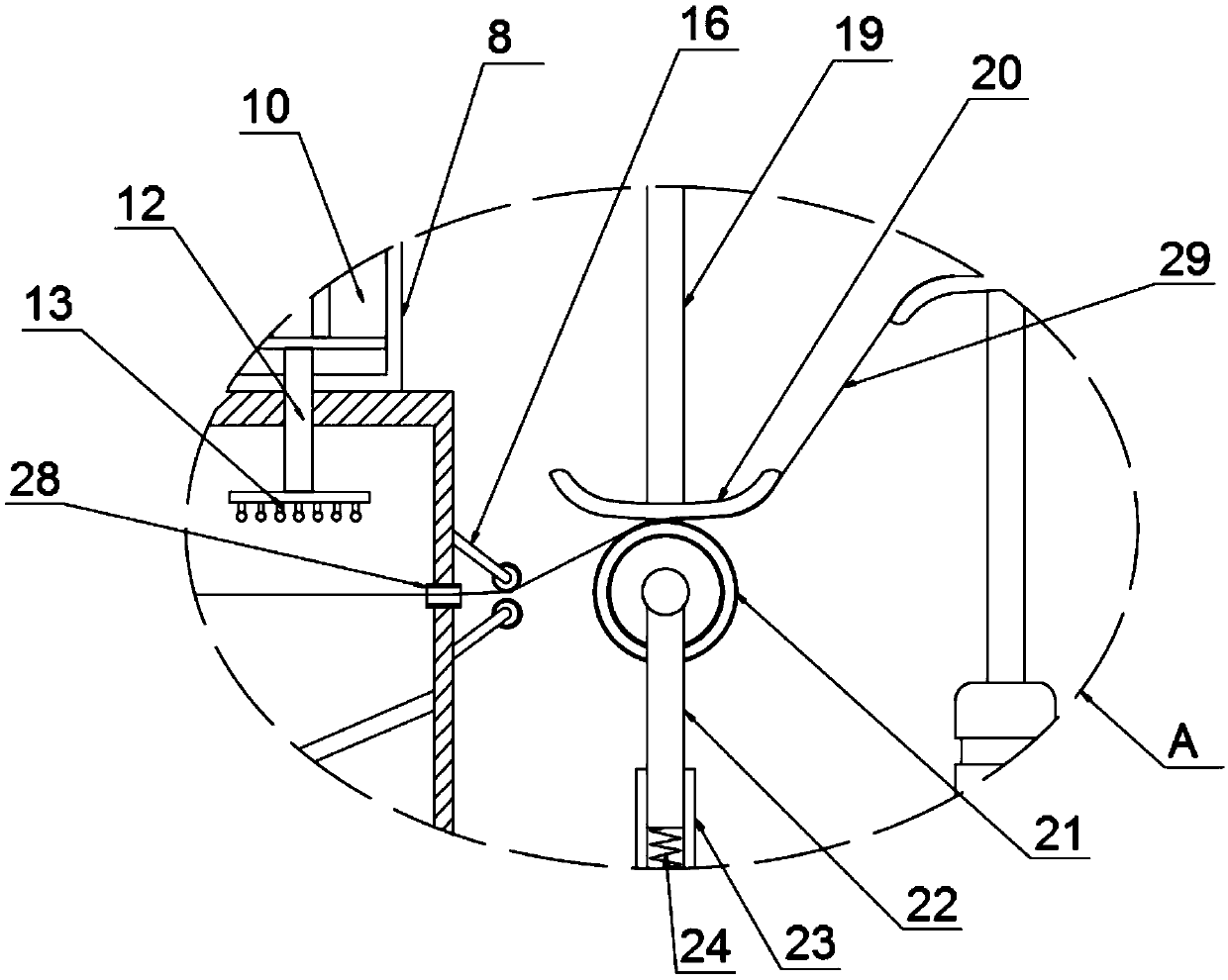

Non-woven feather, hemp felt forming mechanism

ActiveCN101250795ASave electricityImprove styling efficiencyFelting apparatusRotary pressNonwoven fabricElectric power

A nonwoven fabric wool and linen felt modeling mechanism belongs to the nonwoven mechanic technique field, which comprises a couple of left and right frames whose tops are respectively distributed with a first and a second acting cylinders, a couple of hot-press rolls which are pivoted on the left and the right frames in parallel from the top to the bottom and links the hot-press roll on a couple of the hot-press rolls and the first acting cylinder, a couple of cool-press rolls which are pivoted on the left and the right frames in parallel from the top to the bottom and corresponds to a couple of the hot-press rolls and links a cool-press roll on a couple of the cool-press rolls and the second acting cylinder, a dynamic drive device which is arranged on one frame of the left and the right frames and drives and links the hot-press and the cool-press rolls, wherein two heat oil reflux devices are formed on a couple of the hot-press rolls separately, and two coolant reflux devices are formed on a couple of the cool-press rolls separately. The nonwoven fabric wool and linen felt modeling mechanism has the advantages of realizing continuously modeling of the wool and linen felt, not only improves the modeling efficiency but also saves energy, which saves electric power for heating conductive oil simultaneously.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

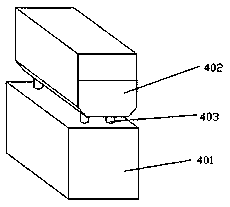

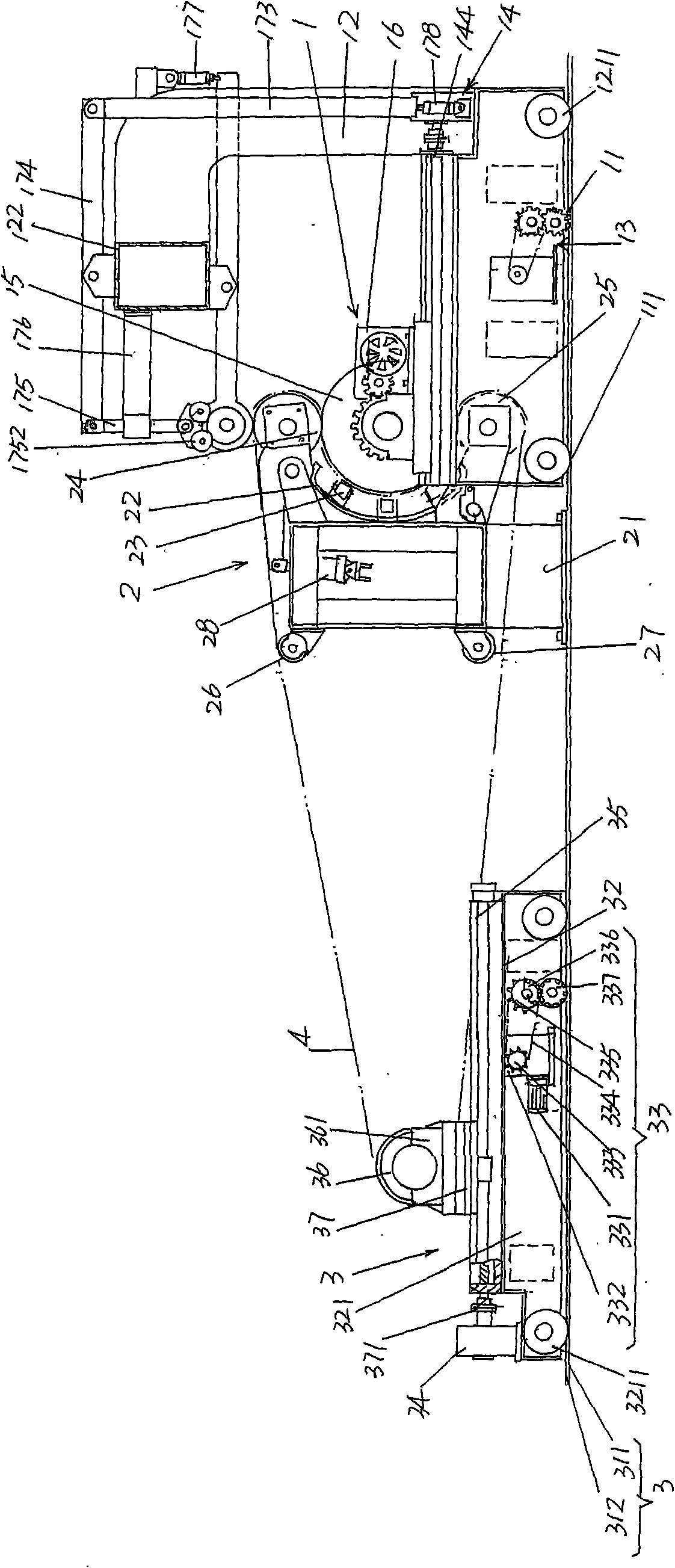

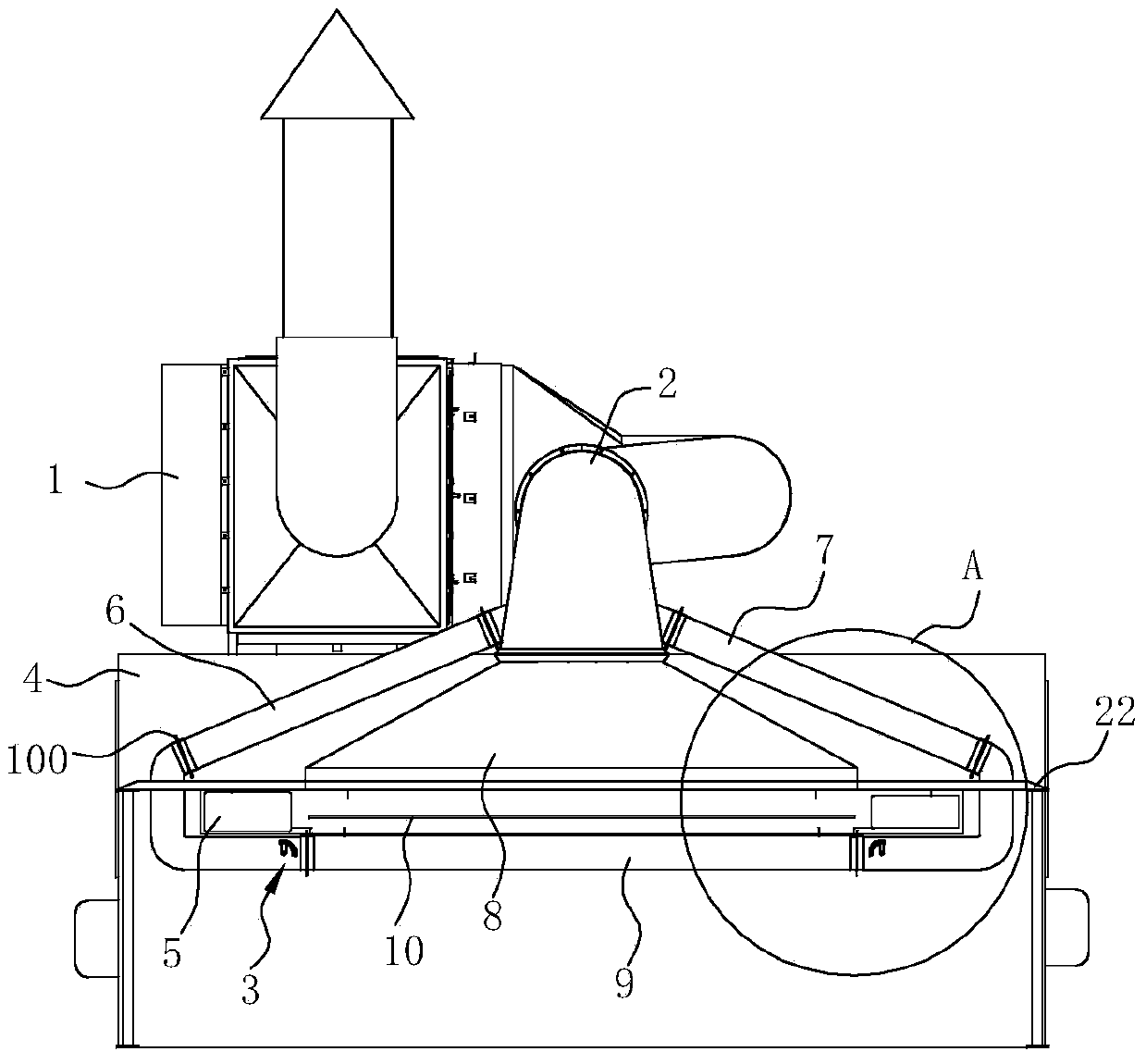

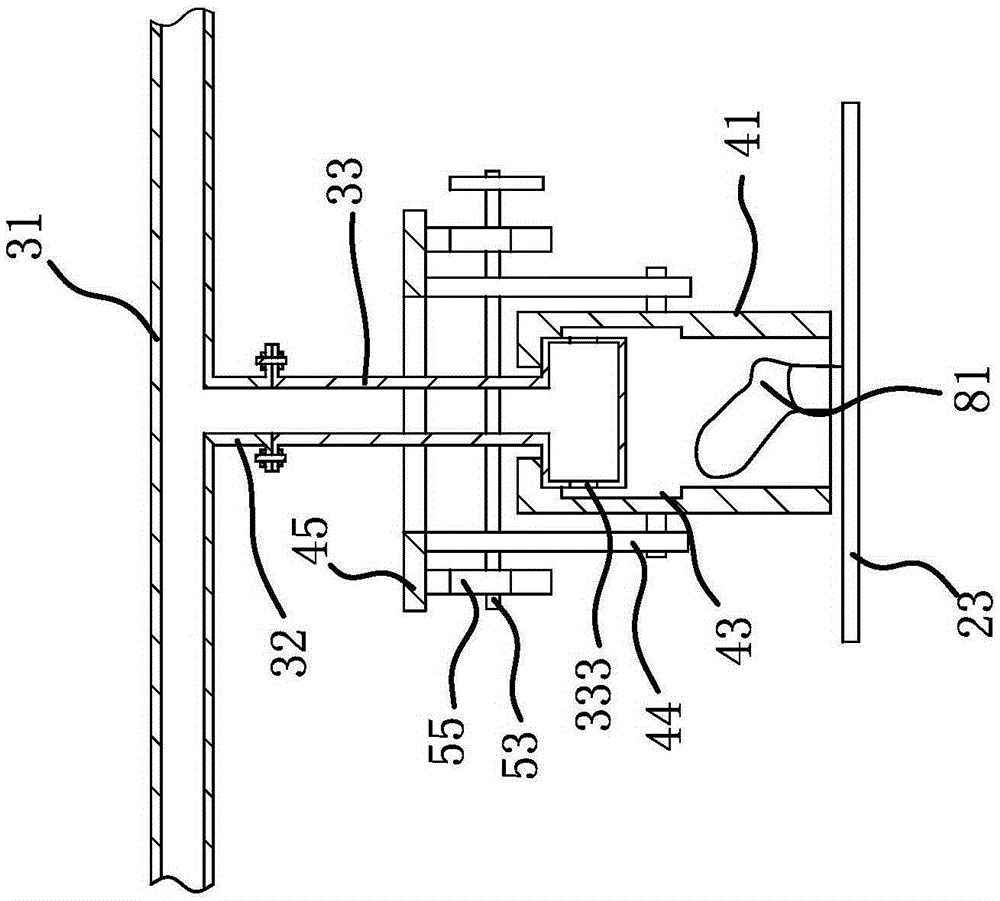

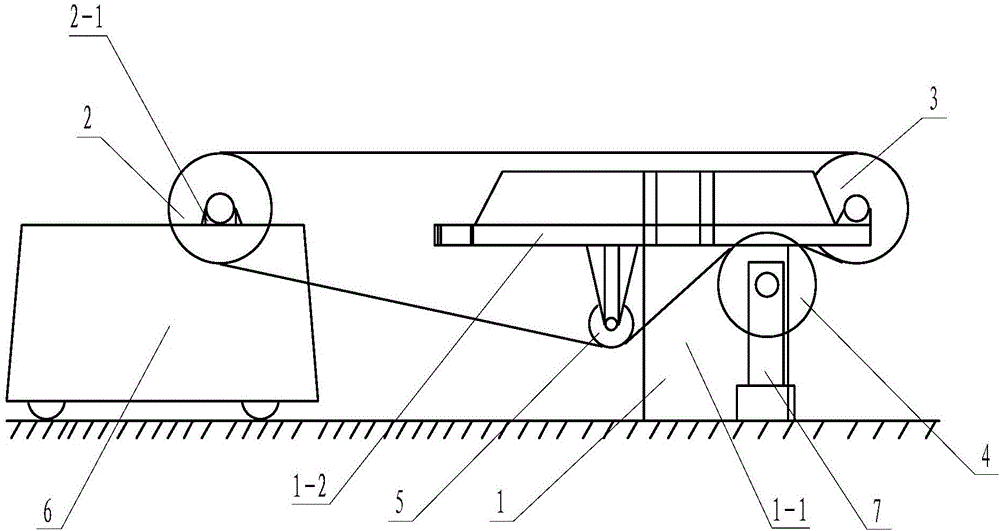

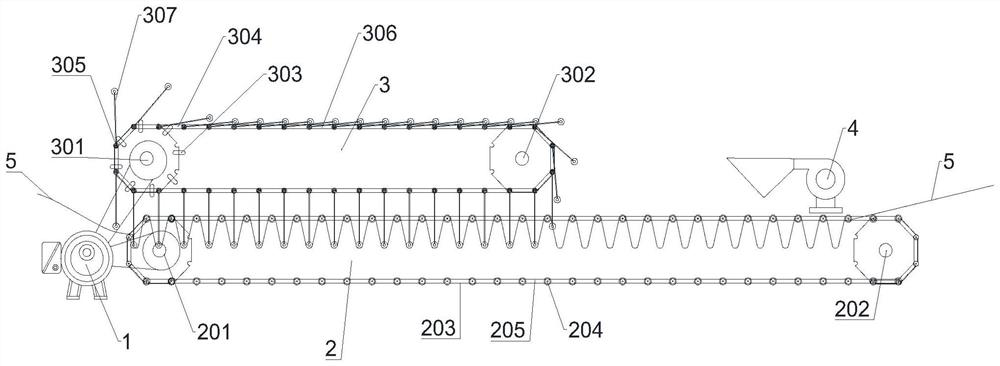

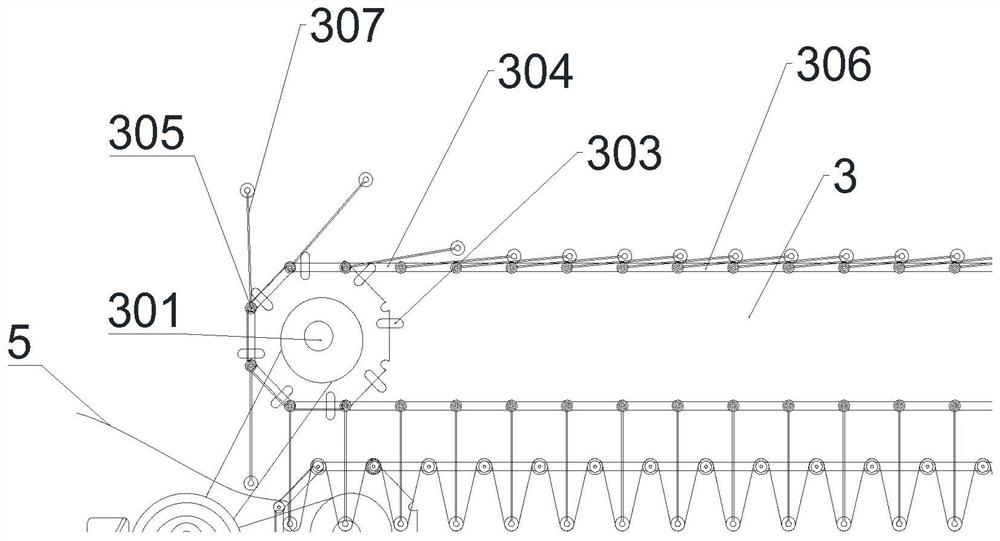

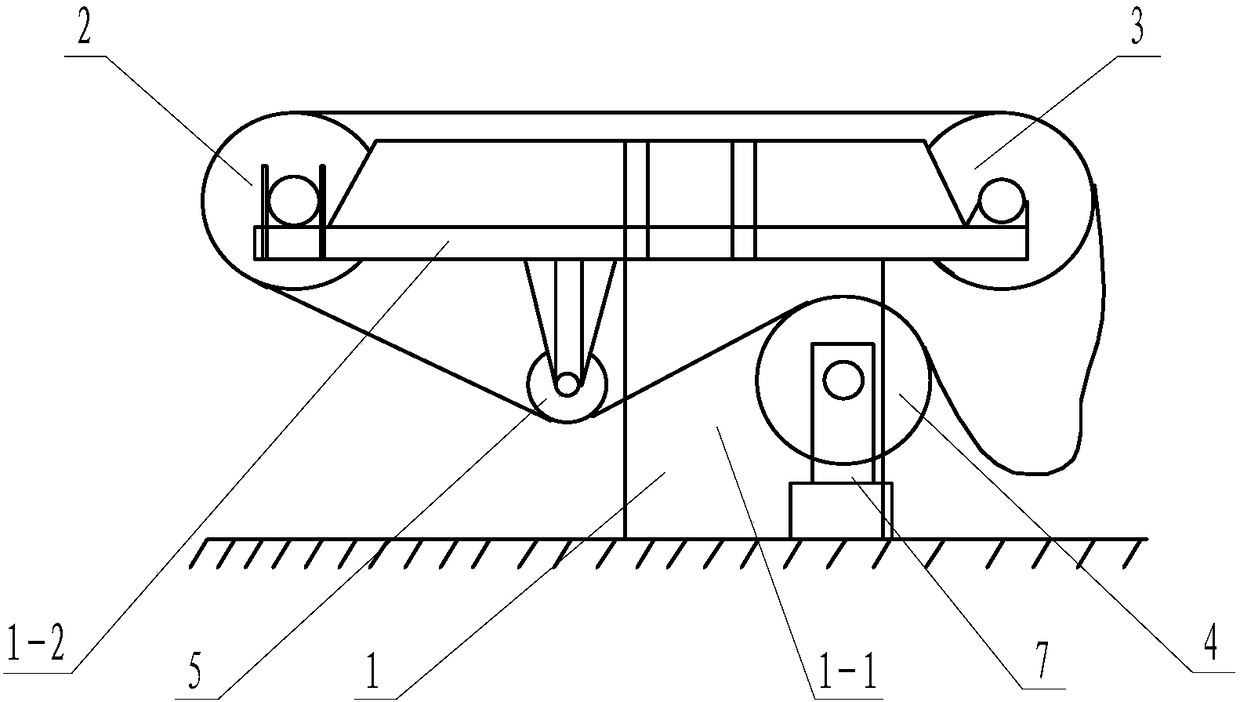

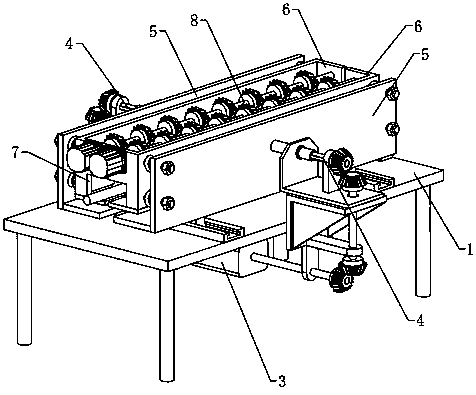

Papermaking felt setting machine

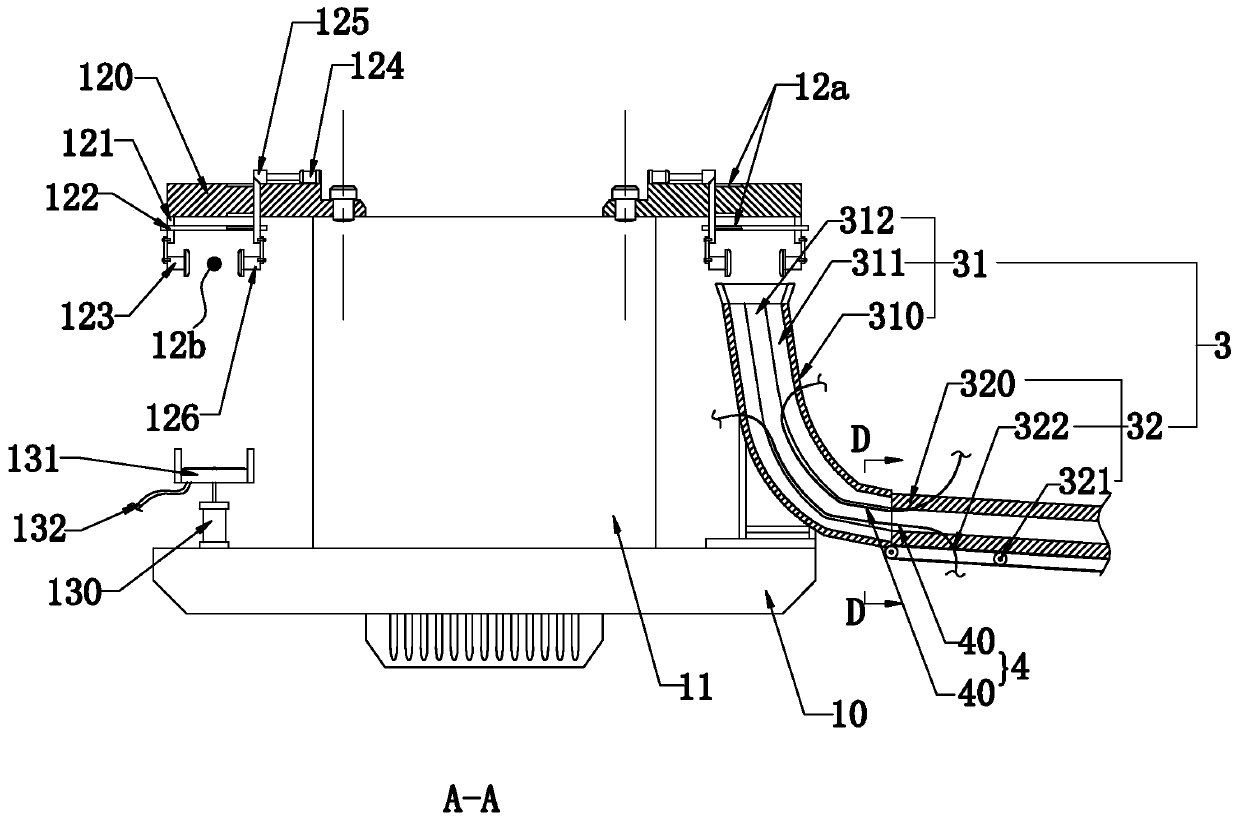

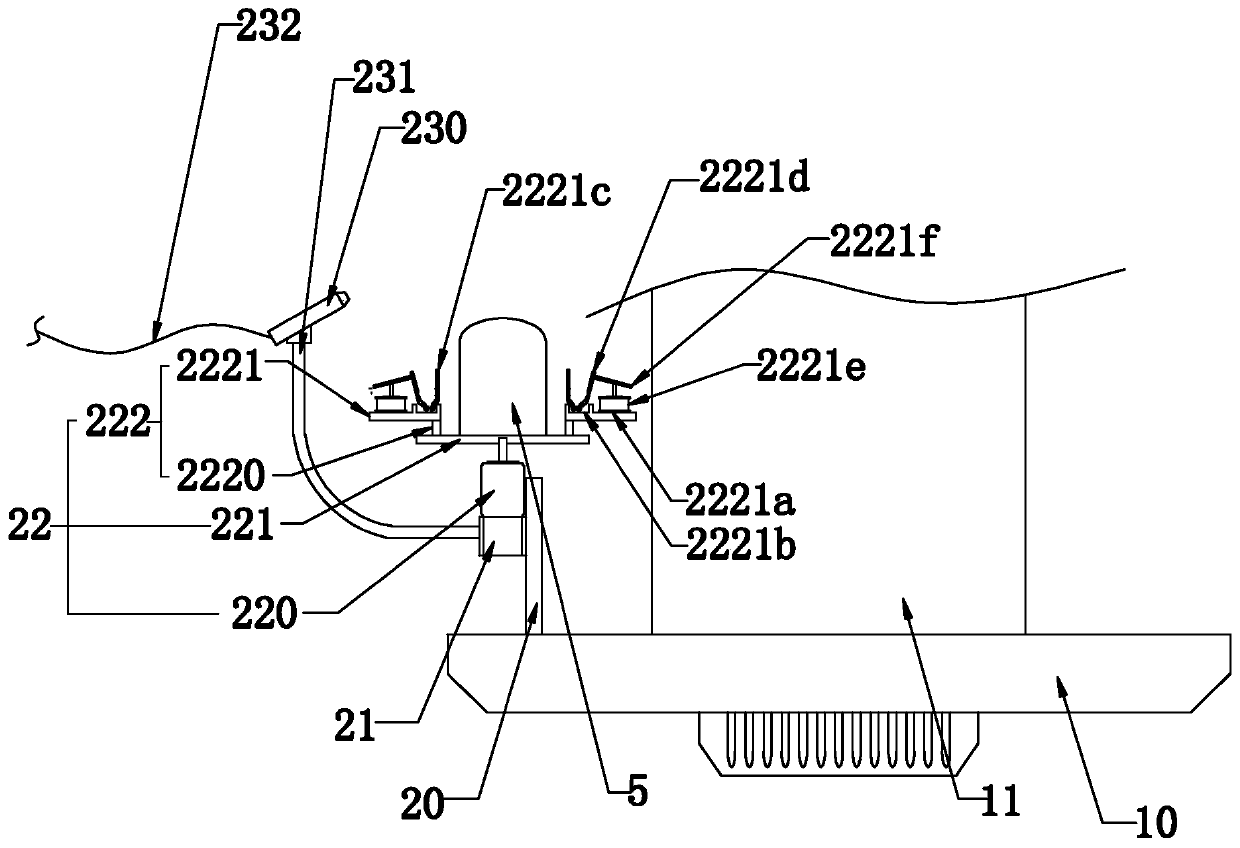

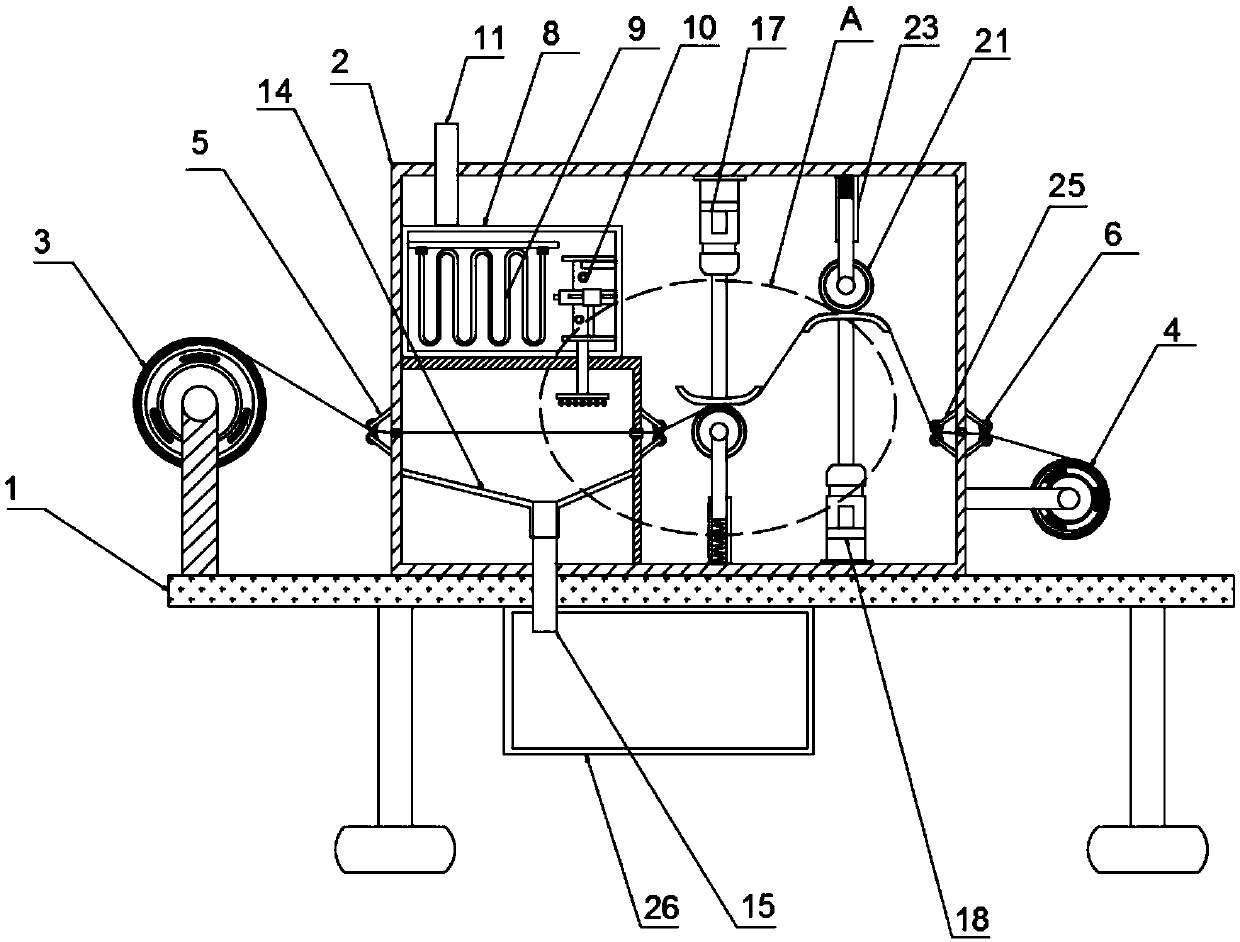

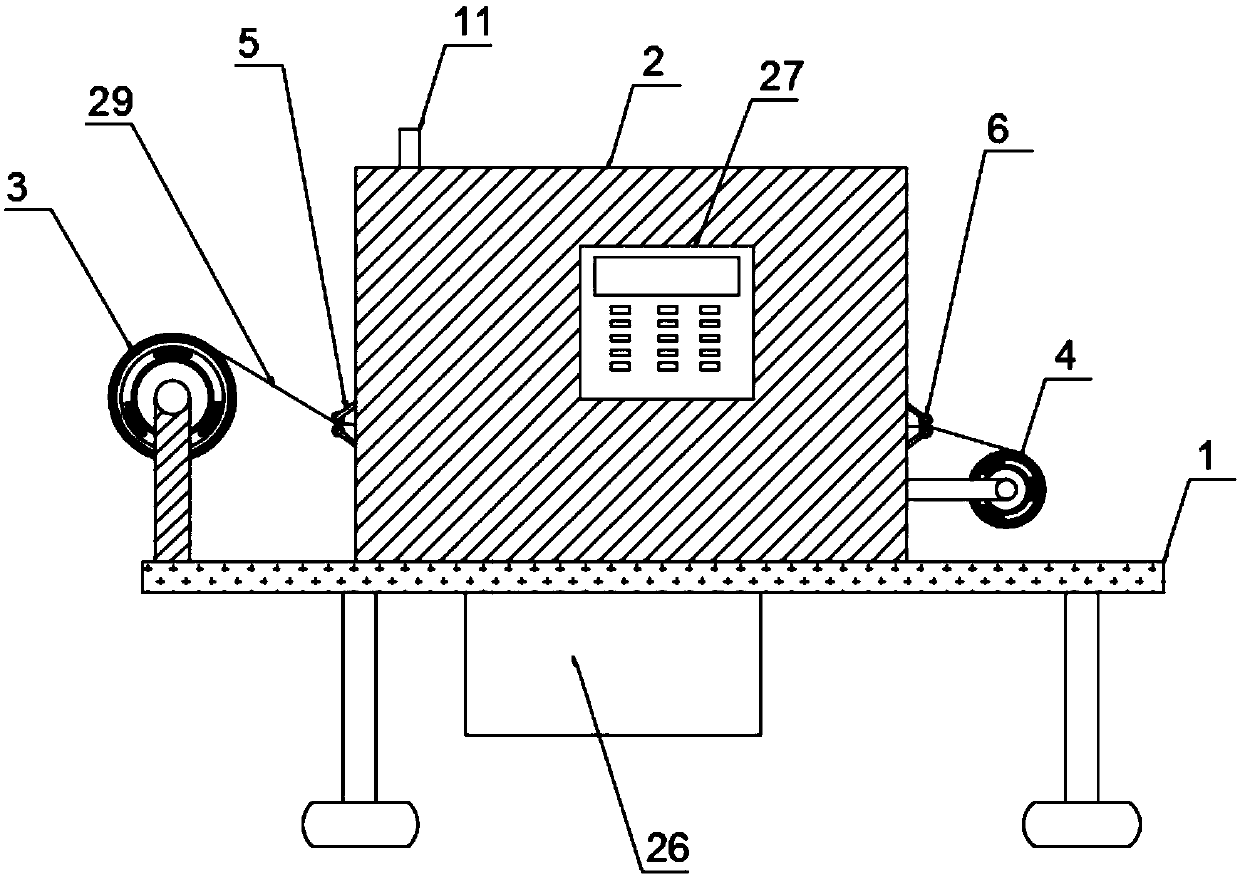

InactiveCN101581021AWon't burnImprove styling efficiencyHeating/cooling textile fabricsVehicle framePapermaking

The invention relates to a papermaking felt setting machine and belongs to the technical field of nonwoven machinery. The papermaking felt setting machine comprises a roller setting mechanism, a cambered cover radiation setting mechanism and a walking trolley tension mechanism; the roller setting mechanism comprises a pair of racks, a walking frame, a heating roller, a heating roller drive device and a felt forced holding device, wherein the racks are laid on a terrace or a stand; one side of each rack in the length direction is provided with a trolley groove; the walking frame is provided with an upper crossbeam a lower crossbeam and a pair of bearing seats; the bottom of each bearing seat is provided with a trolley; the trolley and the trolley groove form a rolling pair; a containing cavity of each bearing seat is provided with a walking device of the walking frame; the upper part of each bearing seat is also provided with a heating roller moving device; the heating roller is arranged on the heating roller moving device; the heating roller drive device is arranged on the heating roller moving device; and the felt forced holding device is arranged on the walking frame and also corresponds to the upper part of the heating roller. The papermaking felt setting machine has the advantages that the papermaking felt setting machine can improve the setting efficiency of a papermaking felt and save energy.

Owner:常熟市天顺无纺设备有限公司

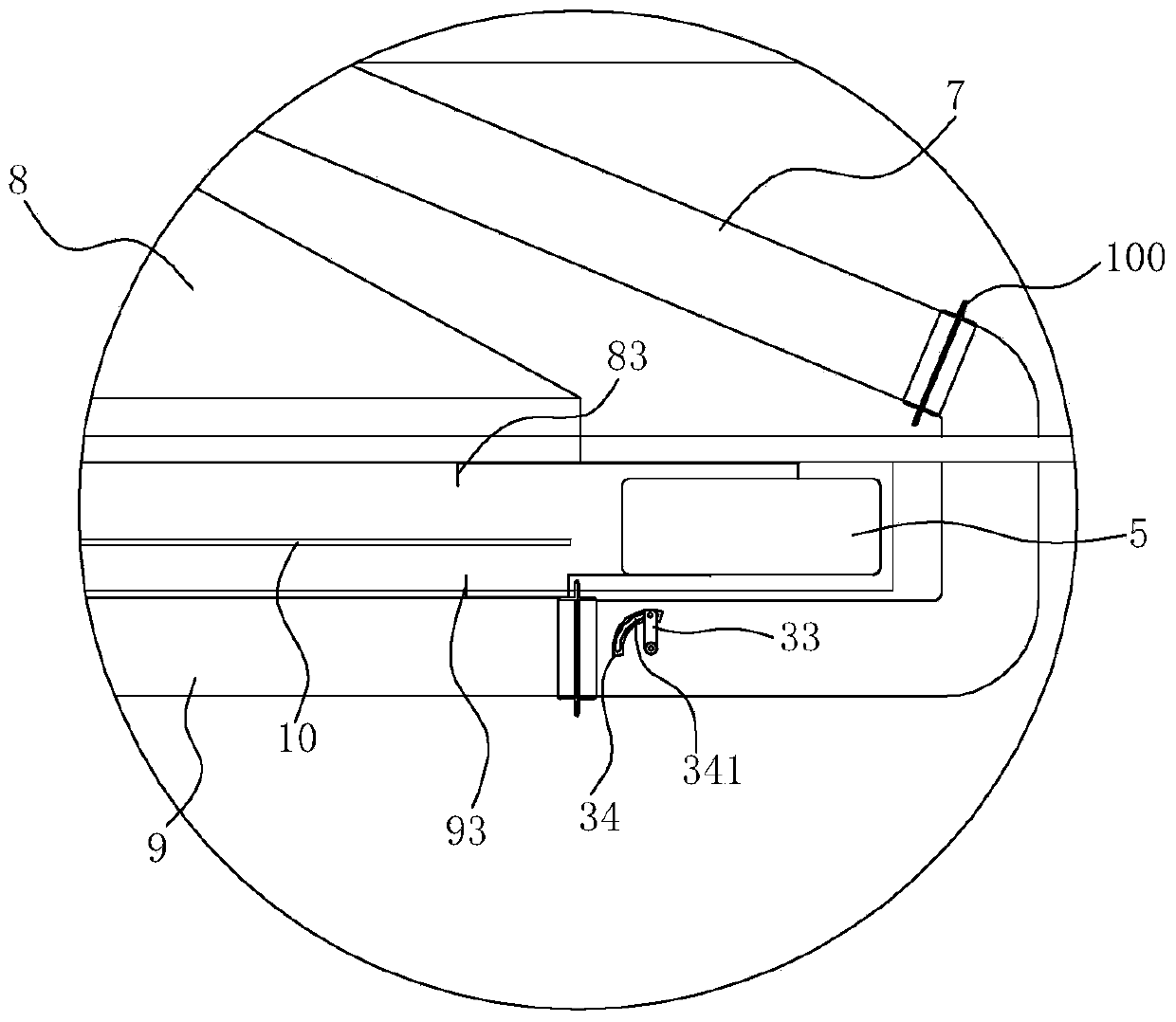

Exhaust gas heat reclaiming device for setting machine and setting machine using exhaust gas heat reclaiming device

InactiveCN104213355AReduce churnShorten heating timeDrying gas arrangementsHeating/cooling textile fabricsAir volumeEngineering

The invention discloses an exhaust gas heat reclaiming device for a setting machine. The exhaust gas heat reclaiming device comprises a reclaiming head, a first air guiding passage, a second air guiding passage, an upper air outtake component and a lower air outtake component, wherein the reclaiming head is used for distributing hot air volume; the upper ends of the first air guiding passage and the second air guiding passage are respectively connected with the lateral air outlet of the reclaiming head; the upper air outtake component is arranged on a middle air outlet of the reclaiming head and is shaped like a bell mouth with a narrow upper end and a wide lower end; the upper air outtake component is provided with a first air outlet of which the port is downward; a plurality of air guide plates which can uniformly distribute air volume are arranged in the upper air outtake component at intervals; the lower air outtake component is horizontally arranged; the two ends of the lower air outtake component are respectively connected and communicated with the lower ends of the first air guiding passage and the second air guiding passage; the lower air outtake component is provided with a second air outlet of which the port is upward; the second air outlet is over against the first air outlet, so that the air blown by the first air outlet and the air blown by the second air outlet respectively form an air curtain. The tridimensional air curtains can pre-dry fabrics clamped between the tridimensional air curtains, so that energy source is saved; by the setting machine using the heat reclaiming device, the fabric feeding speed is increased, and the setting efficiency is improved.

Owner:苏州源林纺织机械科技有限公司

Novel badminton feather inserting machine with heating device

The invention relates to the field of badminton production and particularly discloses a novel badminton feather inserting machine with a heating device, which comprises a device main body. A perforating device is movably mounted at the upper end in the device main body; a driving gear is fixedly mounted at the left end in the device main body; a feather inserting device is movably mounted at the lower end in the device main body; the inclination of a conveying belt is larger than that of a lower inclined block, when the feather inserting device moves rightwards, the distance between the lowerend and the conveying belt can be gradually shortened, therefore, the protruding block which is arranged at the bottom end of a heating compression block and has the same appearance as the extrusion groove extrudes the inner feather, the feather exceeding the edge of the extrusion groove can be cut off while the feather is flattened, and therefore the feather is ensured to be consistent in size and appearance. When the heating compression block continues to move upwards to overcome the acting force of a spring to enable the upper end of a sealing block to enter a liquid cavity, water in the liquid cavity can move outwards through a gap of the sealing block to enter the water passing groove and finally make contact with feather on the conveying belt to wet the feather while extruding the feather, and therefore the feather extruding and flattening efficiency is improved.

Owner:江山市三鑫体育用品有限公司

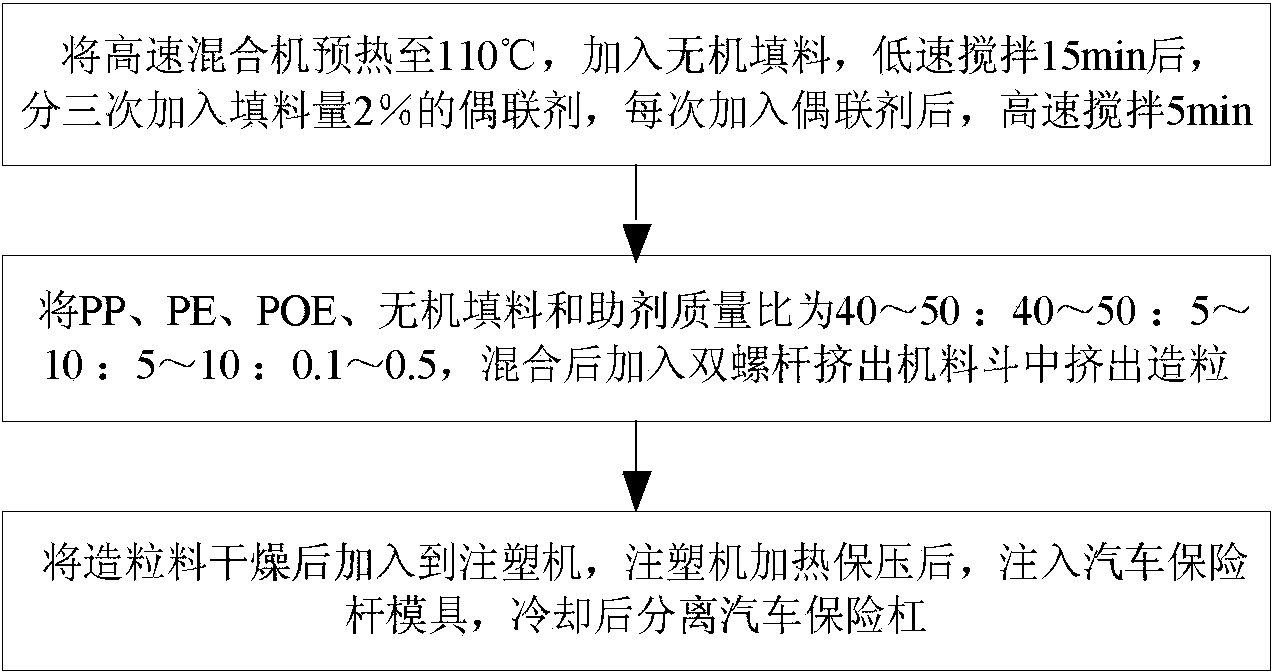

Preparation method of polypropylene car bumper

The invention relates to a preparation method for car parts, and particularly relates to a preparation method of a polypropylene car bumper. The preparation method is as follows: preheating a high speed mixer to 110 DEG C, adding an inorganic filler for low-speed stirring for 15min, adding a coupling agent of 2% of the filler amount in three times, after each time adding of the coupling agent, performing high-speed stirring for 5min, then releasing the inorganic filler; mixing PP (polypropylene), PE (polyethylene), POE (polyolefin elastomer), the inorganic filler and an additive in a mass ratio of 40 ~ 50:, 40 ~ 50:5 ~ 10:5 ~ 10:0.1 ~ 0.5, then adding into a twin-screw extruder hopper for granulation; drying a granulation material, then adding into an injection molding machine for heating and pressure holding, injecting into a car bumper mold, and cooling to separate to obtain the car bumper. The preparation method solves the technical problems by providing a good comprehensive performance, low cost and middle and low level car and light truck special-purpose bumper material prepared by using a small amount of the POE for toughening, the inorganic filler for filling and the like for blending modification.

Owner:GUILIN FUGANG NEW MATERIAL

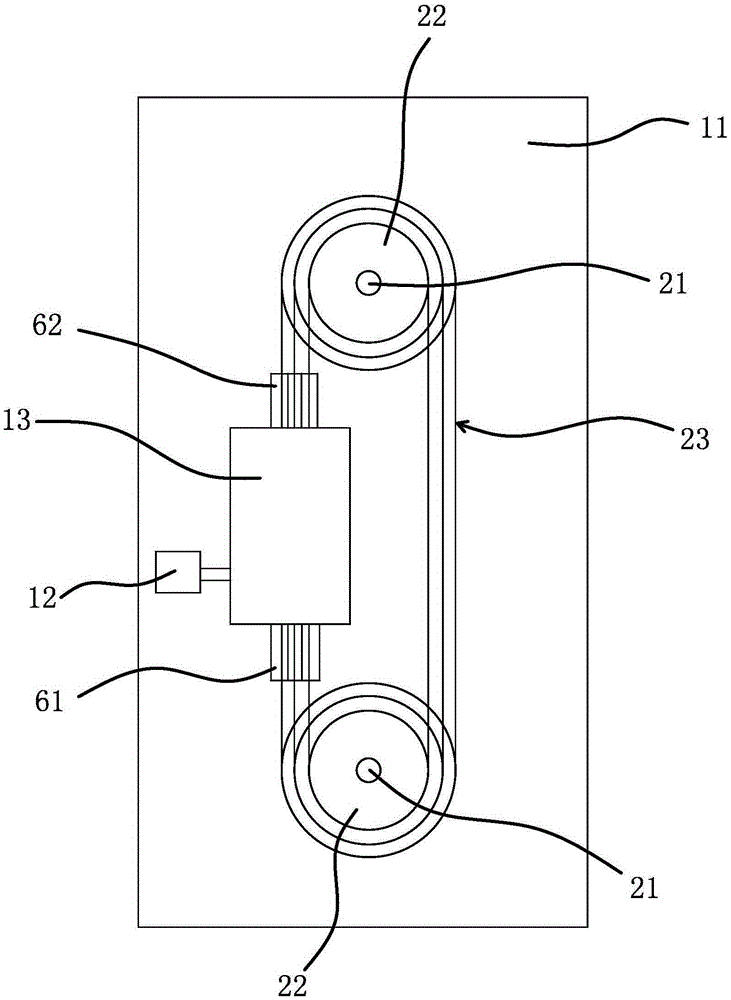

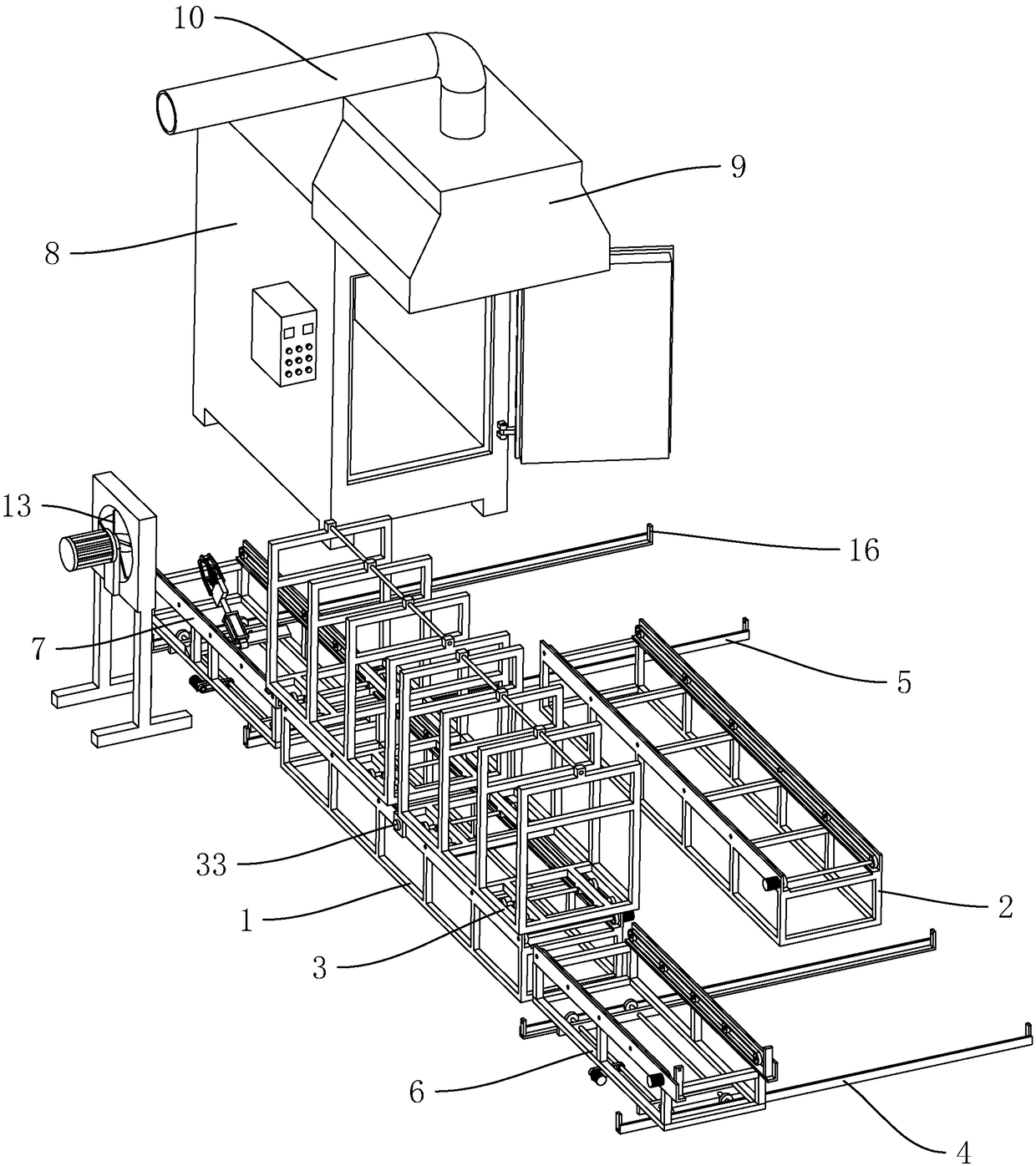

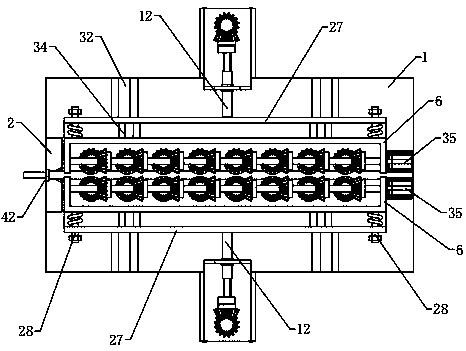

A sock steam setting machine

ActiveCN103726249BImprove styling efficiencyMobile unificationHeating/cooling textile fabricsShaping/stretching tubular fabricsSOCKSGas collecting tube

The invention provides a sock steam setting machine, which belongs to the technical field of machinery. The utility model solves the technical problems such as insufficient shaping of socks in the existing steam setting machine for socks. The sock steam setting machine includes a frame, a steam generator, a steam setting room, a controller and a transmission chain. One side of the transmission chain passes through the steam setting room, and each transmission chain is fixed with a steam setting room for socks. It is fixed on the frame. There are steam pipes corresponding to the transmission sprocket in the steam setting room. There are several steam branch pipes at the lower end of the steam pipe. The steam branch pipes are all connected with a connecting pipe. A control mechanism is provided between the trachea and the steam setting chamber that can drive the air collecting pipe to slide up and down so that the air collecting pipe opens the air outlet and covers the sock cover plate or closes the air outlet so that the air collecting pipe is located above the sock cover plate. The invention has the advantages of making the socks have the same steam-setting effect and ensuring the quality of the socks.

Owner:浙江汉保利罗针织股份有限公司

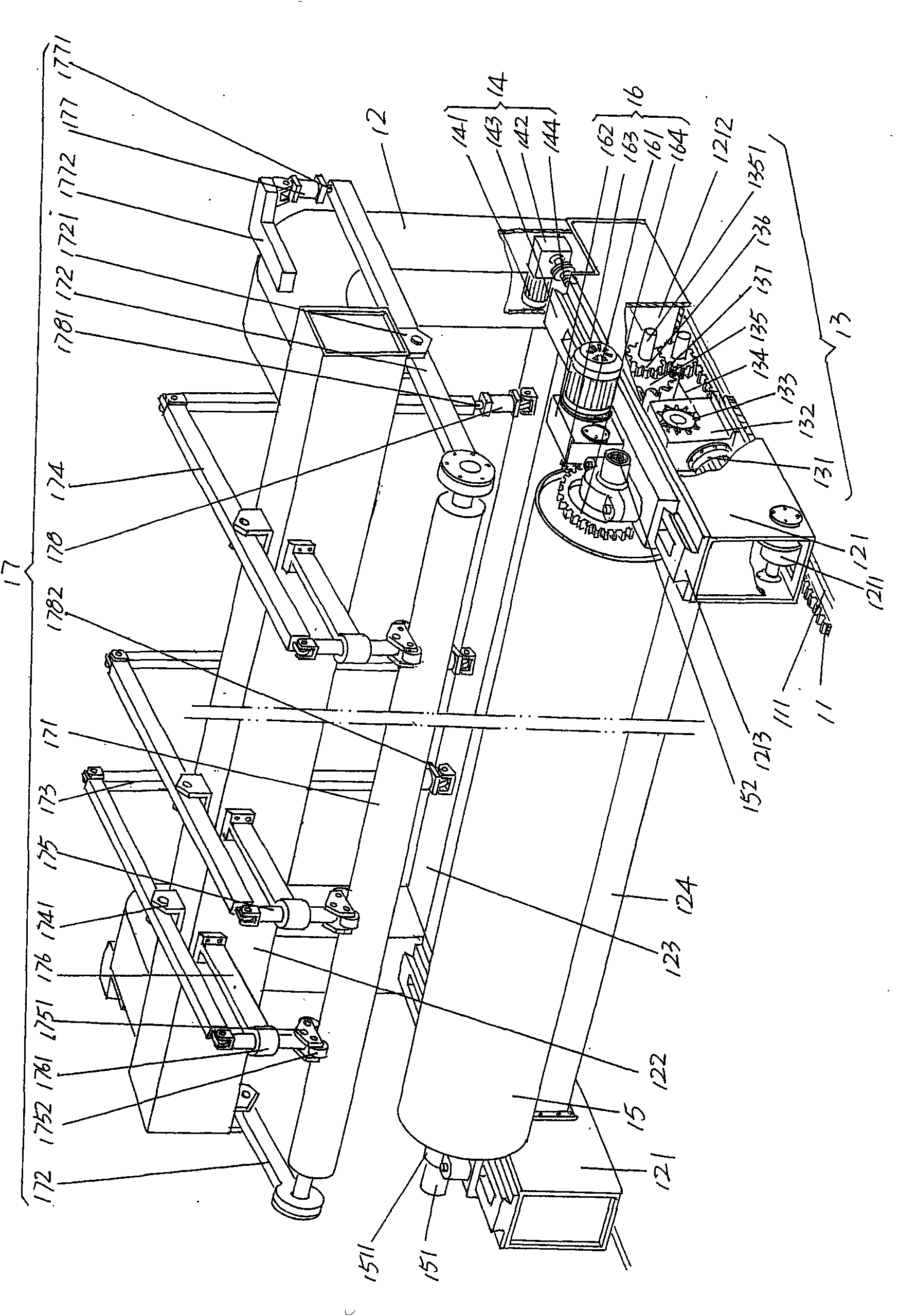

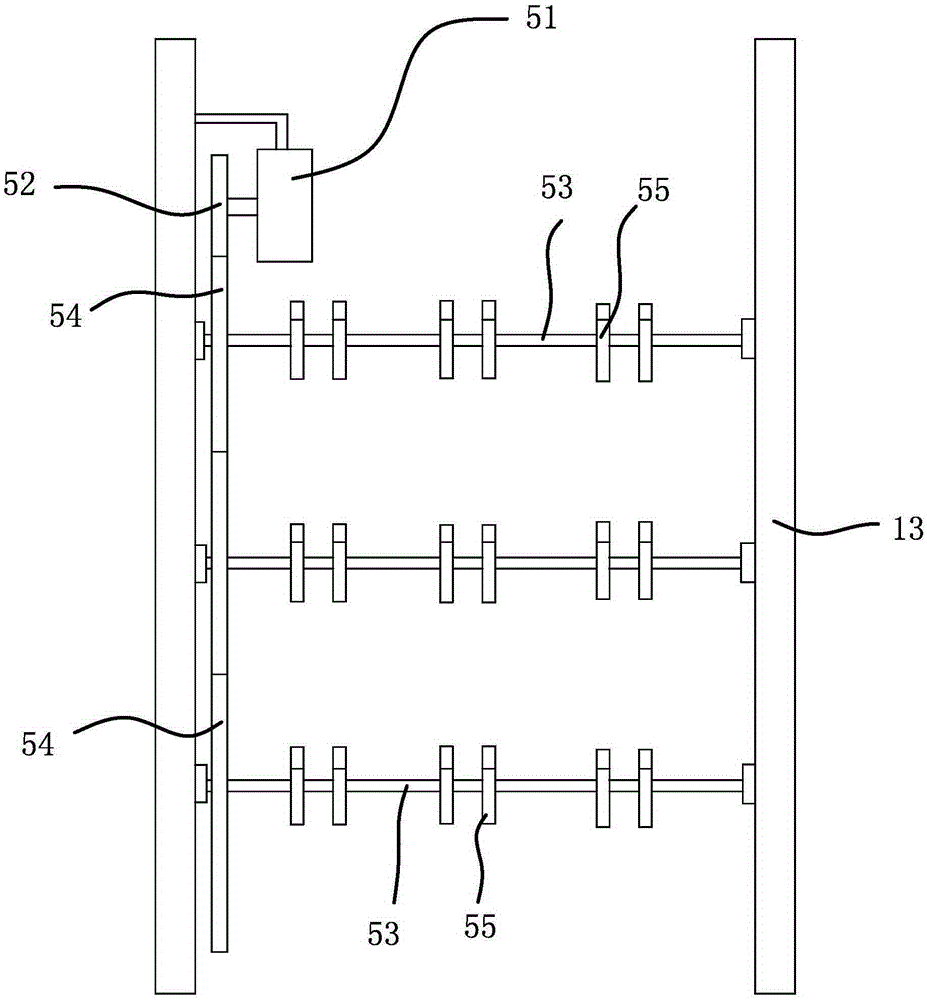

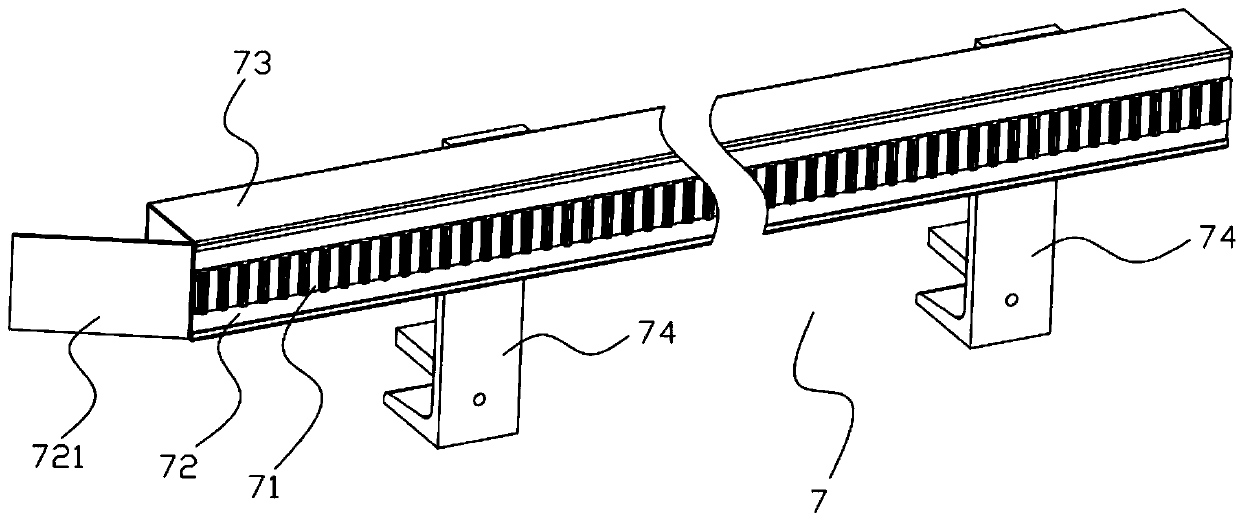

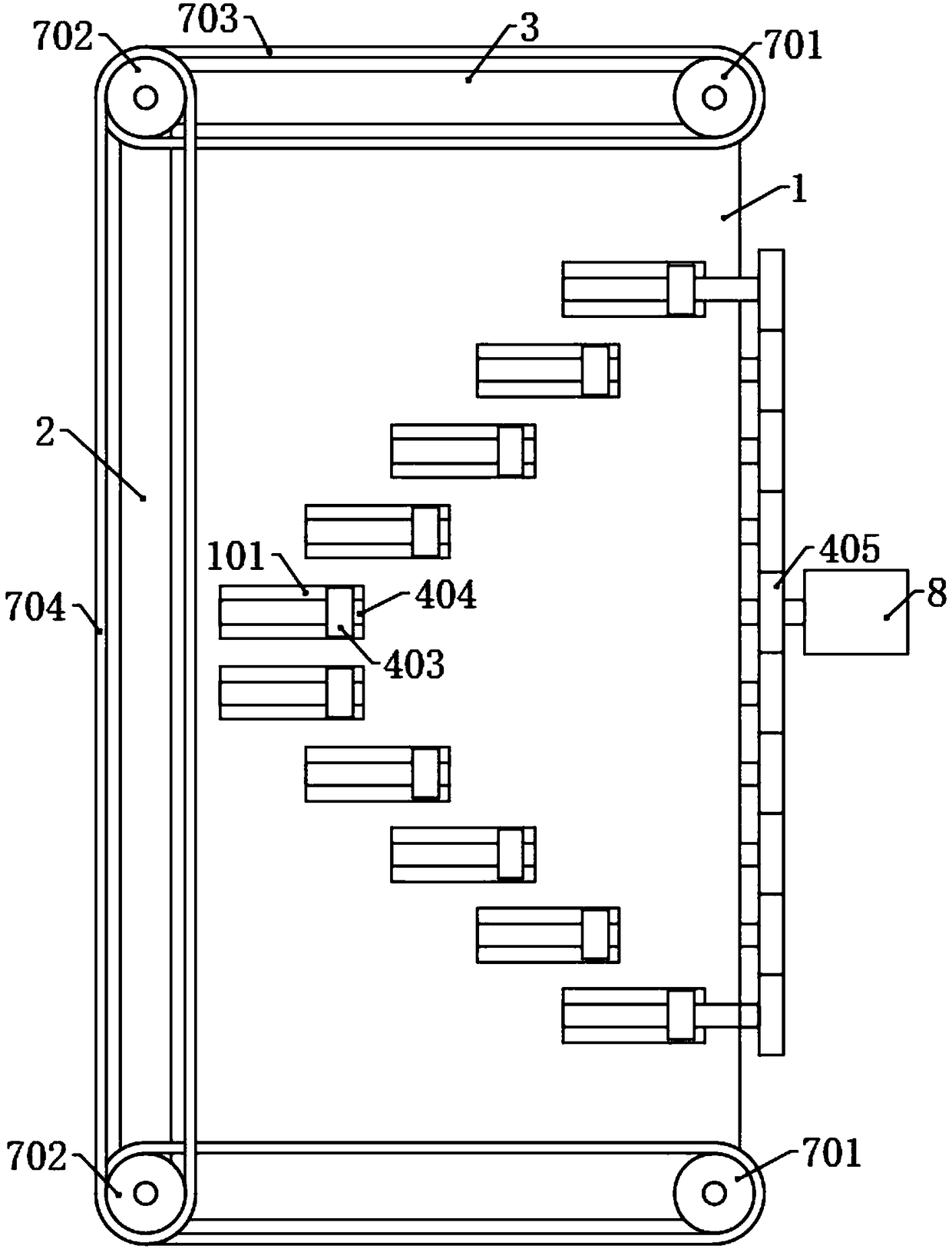

Sock shaping system

ActiveCN109112757AImprove styling efficiencyThe shaping operation is simple and convenientShaping/stretching tubular fabricsEngineeringMechanical engineering

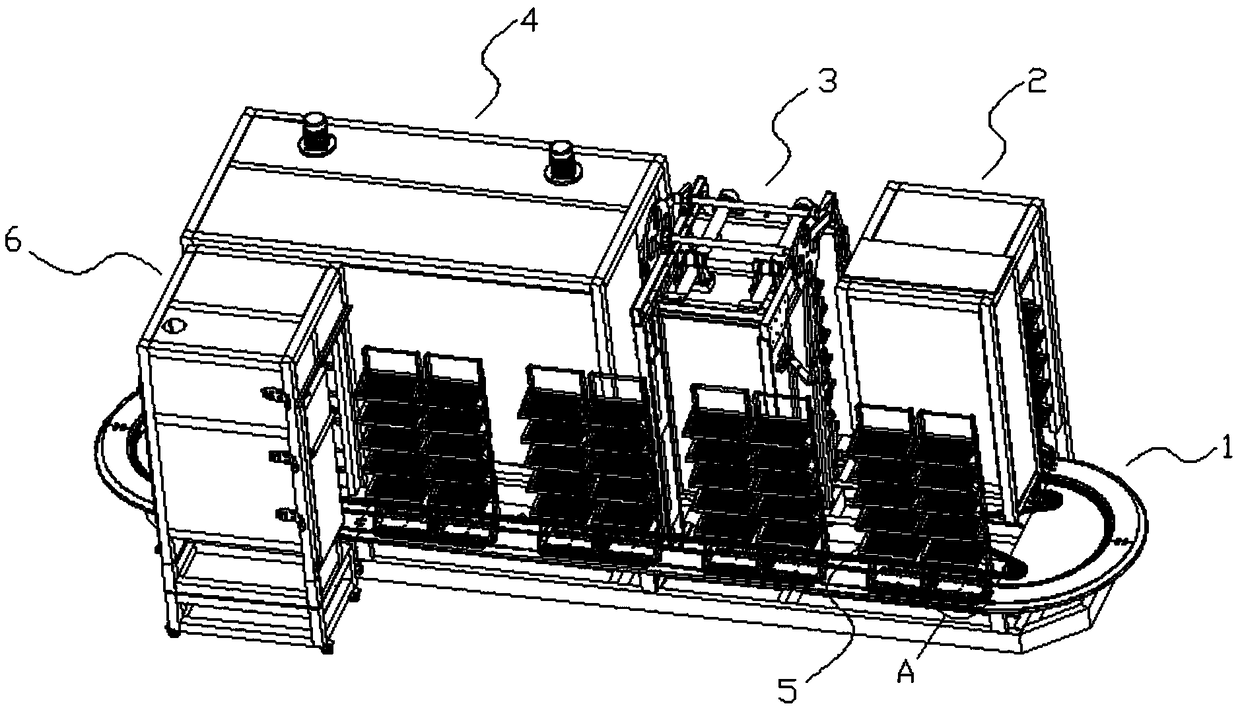

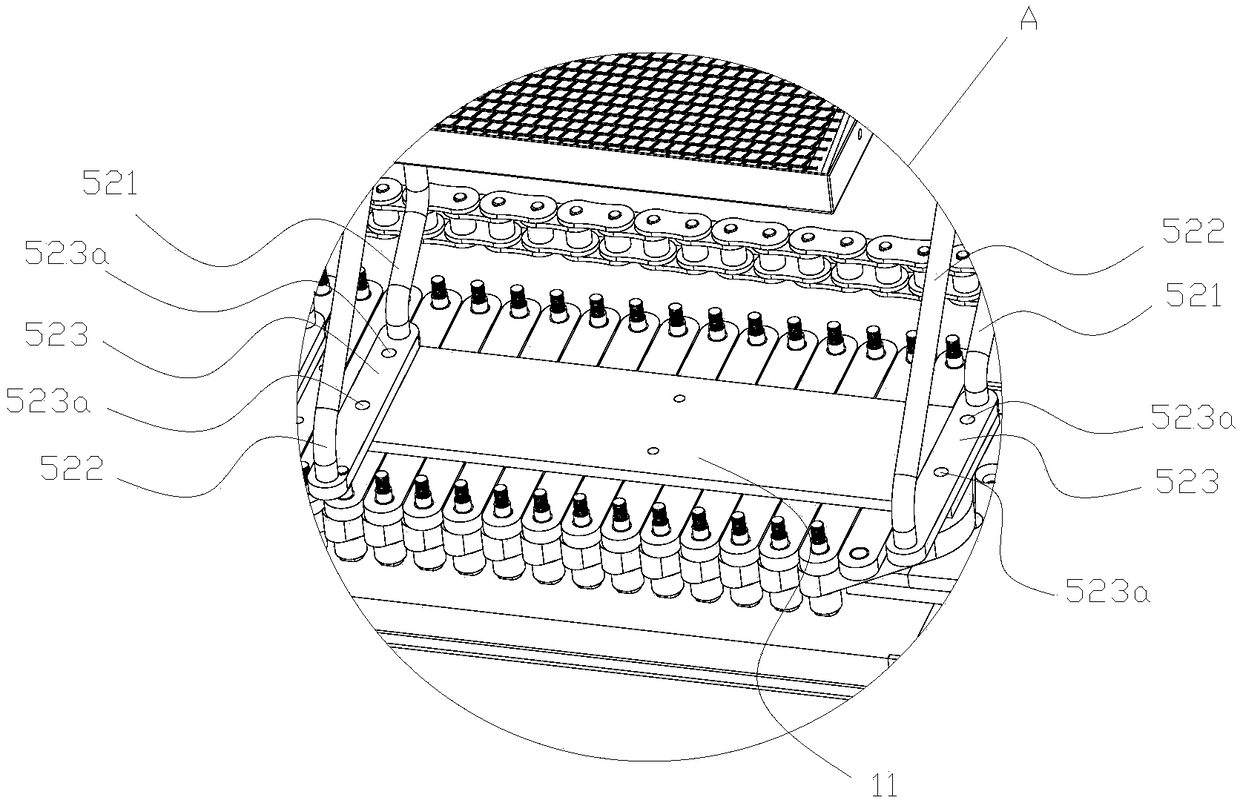

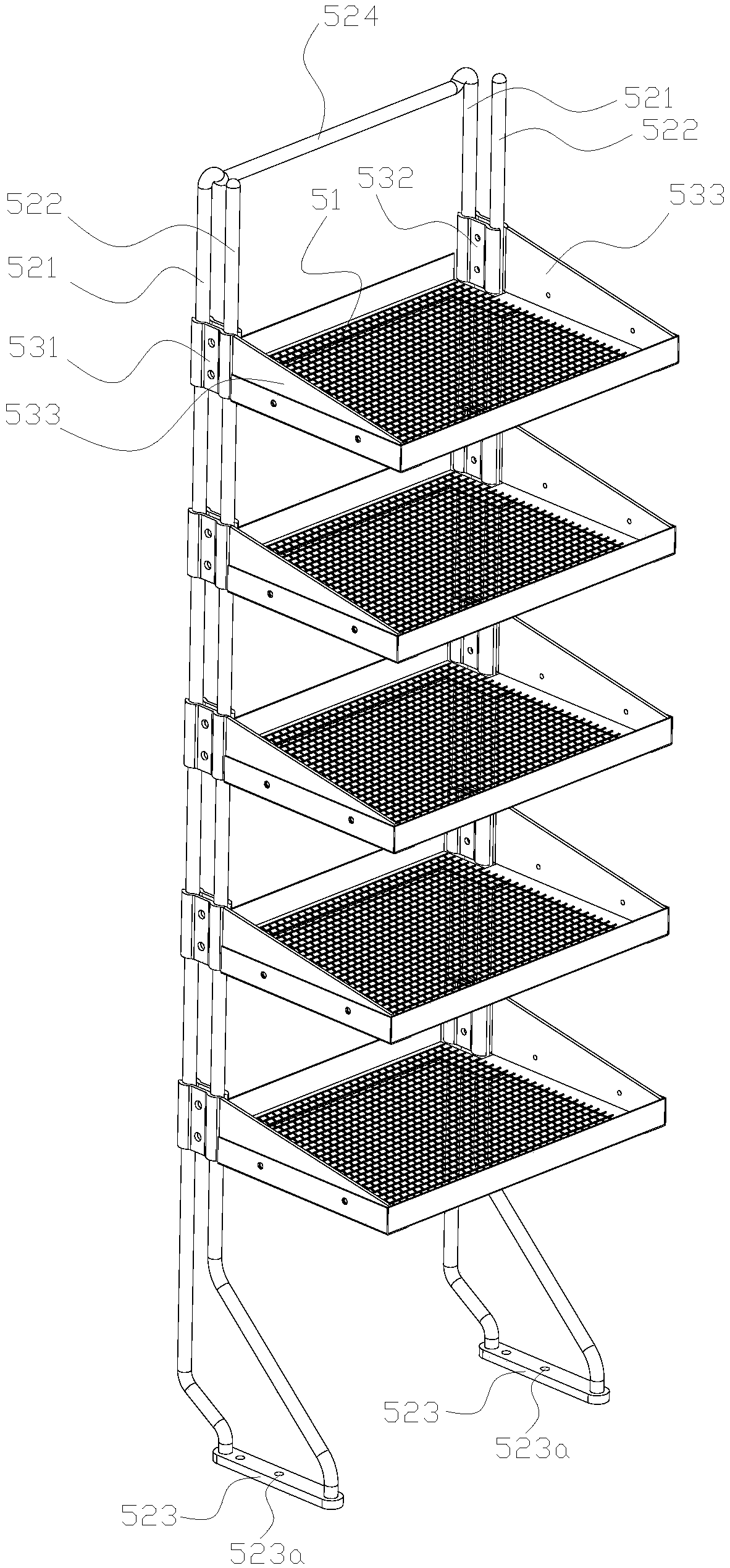

The invention discloses a sock shaping system and relates to the technical field of sock production systems, aiming at solving the problems that brackets are easily stacked together in a sock shapingprocess so that the shaping efficiency is slowed down. The sock shaping system is characterized by comprising a first longitudinal rail and a second longitudinal rail, which are arranged in parallel and have the same length, wherein the first longitudinal rail is provided with a plurality of movable frames; a plurality of rolling wheels are arranged on the movable frames; a first transverse rail and a second transverse rail, which are used for bearing the first longitudinal rail and the second longitudinal rail, are arranged at two end positions of the first longitudinal rail and the second longitudinal rail respectively; the first transverse rail is provided with a first short rail which is longitudinally arranged; the second transverse rail is provided with a second short rail which is longitudinally arranged; a plurality of rolling wheels are arranged on the first short rail and the second short rail; the upper surfaces of the first short rail and the second short rail are leveled with the upper surfaces of the first longitudinal rail and the second longitudinal rail; a shaping machine with an opening formed toward the second transverse rail is further arranged at one side, faraway from the second longitudinal rail, of the second transverse rail. The sock shaping system is reasonable in structure, and the movable frames can move according to a specific rack to avoid stacking.

Owner:嘉兴美克斯袜业有限公司

Shoe setting machine

PendingCN108813819AIncreased shaping outputAdaptableShoemaking devicesInsolesFixed frameIndustrial engineering

A shoe setting machine comprises a conveying track, a preheating box, a setting box and a drying box, wherein the preheating box, the setting box and the drying box are sequentially arranged on the conveying track along a conveying trajectory. The shoe setting machine also comprises a shoe frame and a cooling box, wherein the shoe frame is installed on the conveying tack, the cooling box is arranged on the conveying track, the shoe frame comprises multiple shoe plates, a fixing frame and multiple supporting frames, the multiple shoe plates are fixedly connected with the supporting frames, andthe multiple supporting frames are detachably connected with the fixing frame. The shoe setting machine integrates multiple functions, is high in setting efficiency and large in setting yield and saves the labor costs of enterprises.

Owner:DONGGUAN KEMEI MACHINERY

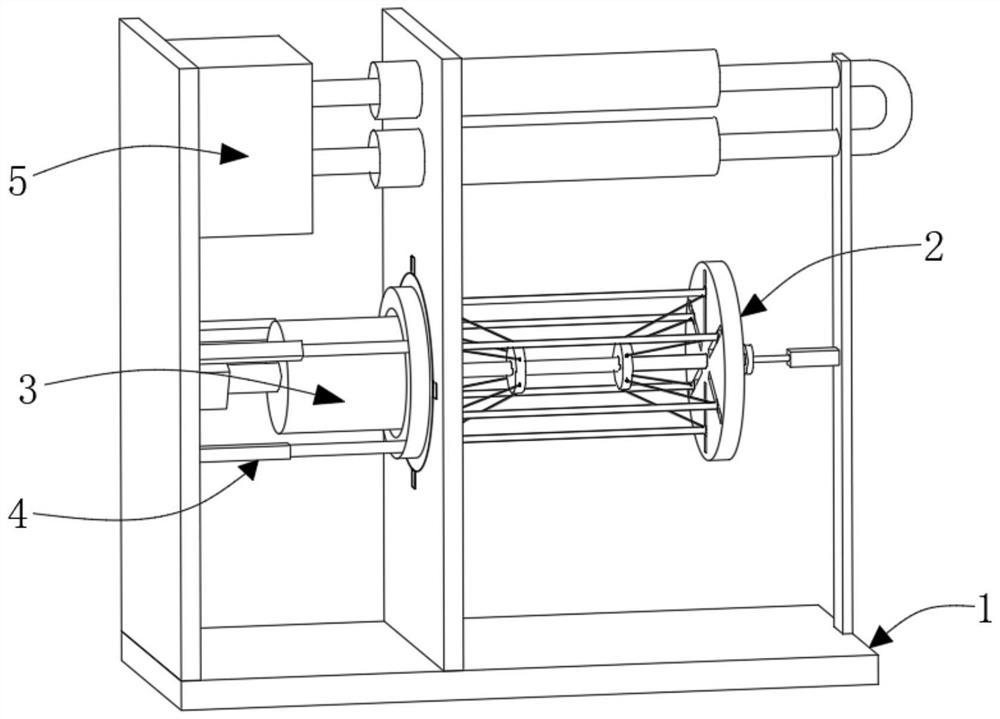

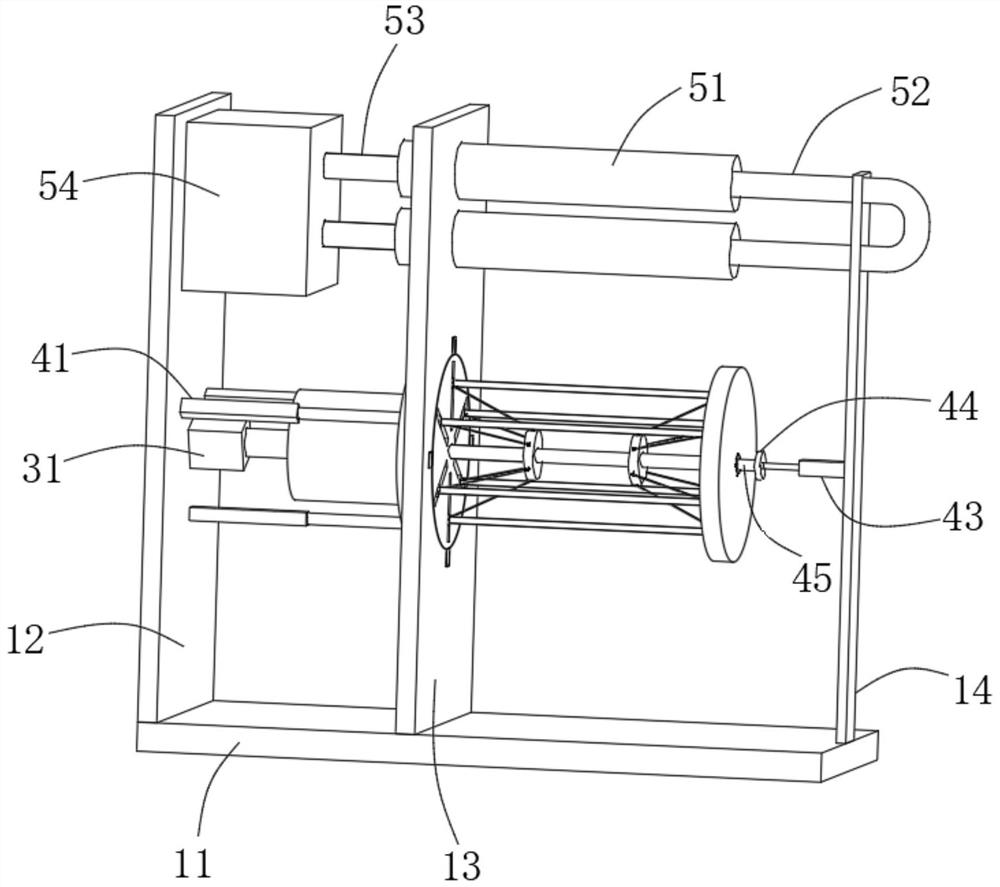

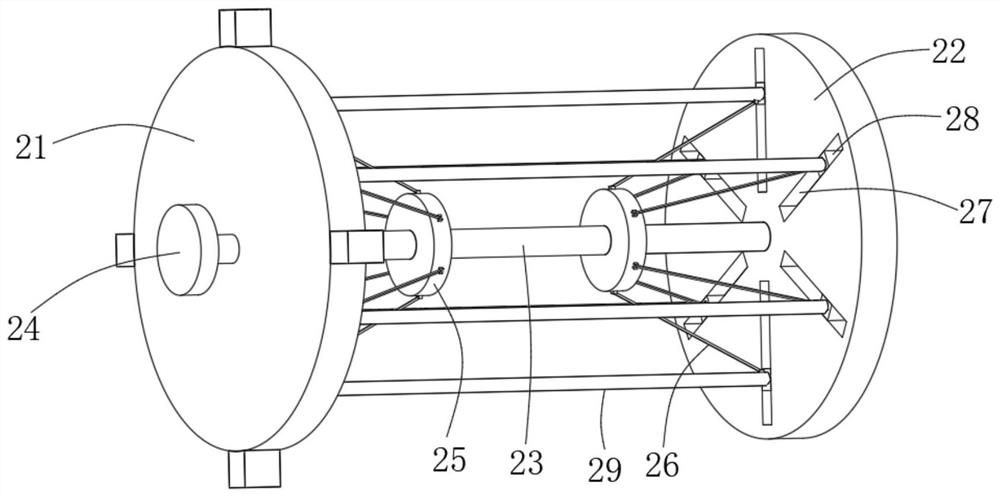

Device for shaping freely-cut fabric of cylindrical fabric

ActiveCN113136669ADoes not affect windingEasy to assemble and disassembleShaping/stretching tubular fabricsCircular discEngineering

The invention discloses a device for shaping a freely-cut fabric of a cylindrical fabric. The device comprises a rack, a supporting mechanism, a driving mechanism, a clamping mechanism and a heating mechanism; the rack comprises a flat plate, a first vertical plate, a second vertical plate and a third vertical plate; the first vertical plate, the second vertical plate and the third vertical plate are sequentially and fixedly connected to the upper end face of the flat plate from left to right; a round opening is formed in the second vertical plate; a large bearing is embedded in the round opening; a first spline groove is formed in an inner ring of the large bearing; the supporting mechanism comprises a first disc and a second disc which are distributed in a left-right manner; the first disc is in spline fit with the first spline groove; a second spline groove is formed in the center of the side, away from the first disc, of the second disc; a two-way threaded rod is coaxially and rotationally connected between the first disc and the second disc; and the left end of the two-way threaded rod extends to the left side of the first disc and is fixedly connected with a friction plate. The device is wide in application range, uniform in heating, good in fabric shaping effect and high in efficiency.

Owner:上海丝诚纺织有限公司

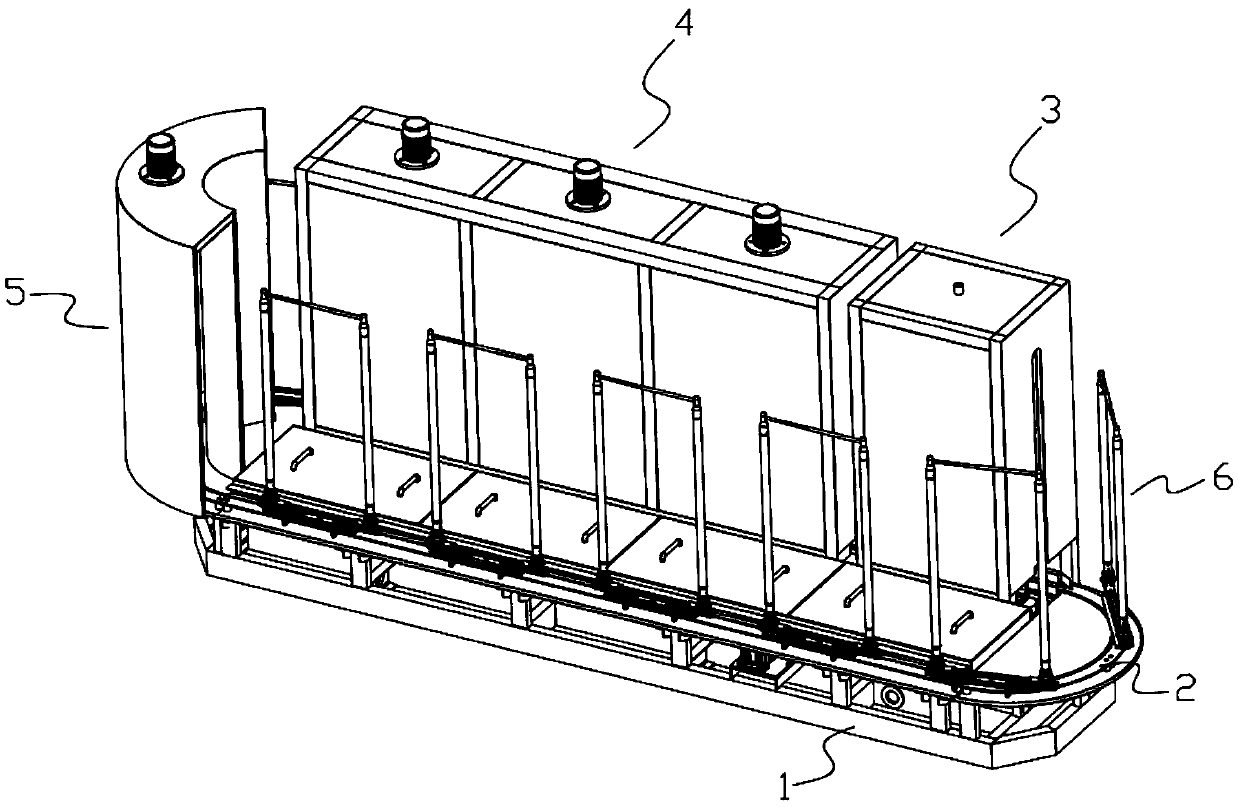

Setting machine

PendingCN109097940AImprove styling qualitySave manpower and timeSucessive textile treatmentsTextile treatment containersSynchronous frameChassis

The invention discloses a setting machine which comprises a bottom frame, a conveying track, a steam setting tank, a drying device and a cooling device. The conveying track is arranged on the bottom frame, and the steam setting tank, the drying device and the cooling device are sequentially arranged on the conveying track. The setting machine is characterized by further comprises a plurality of rotary setting frames and a synchronous frame; the multiple rotary setting frames are arranged on the conveying track, and the synchronous frame is mounted on the bottom frame, is arranged in the steamsetting tank and the drying device; the synchronous frame meshes with the rotary setting frames and drives the rotary setting frames to carry out rotational movement when the rotary setting frames aredriven by the conveying track to move into the steam setting tank and the drying device along paths of the conveying track. Compared with the traditional setting modes, the setting machine has the advantages that manual operation can be replaced with machines, accordingly, large amounts of labor and time can be effectively saved, and the cloth cover setting efficiency and setting quality can be improved.

Owner:DONGGUAN KEMEI MACHINERY

Preparation process of high-temperature bubble-reducing double-rib double-color reinforced spiral corrugated pipe

The invention discloses a preparation process of a high-temperature bubble-reducing double-rib double-color reinforced spiral corrugated pipe, and belongs to the field of corrugated pipes. According to the scheme, a push plate stably extrudes raw materials to the position between an upper extrusion plate and a lower extrusion plate through limiting between a limiting block and a sliding rod, so that the raw materials are formed into the corrugated pipe between the upper extrusion plate and the lower extrusion plate, when raw materials are extruded to the position between the upper extrusion plate and the lower extrusion plate, a heat conduction pipe is inserted into a groove, liquid carbon dioxide is released into a main annular groove, heat is transmitted into the main annular groove through an arc-shaped plate, the corrugated pipe between the upper extrusion plate and the lower extrusion plate is cooled through the liquid carbon dioxide, the shaping efficiency is improved, the liquid carbon dioxide permeates into the inner walls of the upper extrusion plate and the lower extrusion plate through the arc-shaped plate, so that a solid-liquid semi-permeable film is separated from the inner walls of the upper extrusion plate and the lower extrusion plate, and damage to the corrugated pipe due to the fact that the corrugated pipe adheres to the inner walls of the upper extrusion plate and the lower extrusion plate is effectively reduced.

Owner:JIANGXI TIANFENG CONSTR GRP PLASTIC STEELTECH

Shaping device for wood door machining

The invention discloses a shaping device for wood door machining in the technical field of wood door machining equipment. The shaping device comprises a base, a first fixing plate, a second fixing plate and movable plates. A plurality of wood doors are placed between the two movable plates, all movable lead screws rotate at the same time through a motor and a gear, the positions of the movable plates are adjusted according to the thickness of the wood doors, accordingly, the wood doors are extruded and shaped through side pressing plates, operation is simple, and shaping is convenient. The screw pitches of the movable lead screws are sequentially increased, and when the movable plates move to any position, the distances between the adjacent movable plates are the same, accordingly, the same-batch multiple wood doors the same in thickness are conveniently shaped at the same time, time and labor are saved, and the shaping efficiency is high. Upper pressing plates move along with the movable plates through movable grooves, sliding blocks and limiting plates, then, a guide rod drives connecting rods and the upper pressing plates to move downwards through lifting lead screws, accordingly, the side edges of the wood doors are shaped, and shaping is comprehensive. The shaping device is simple in operation and convenient to use, wood frames and nails are not needed, materials are saved, and the shaping effect is good.

Owner:安徽忠盛新型装饰材料有限公司

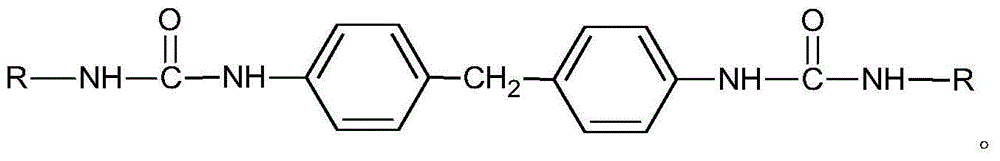

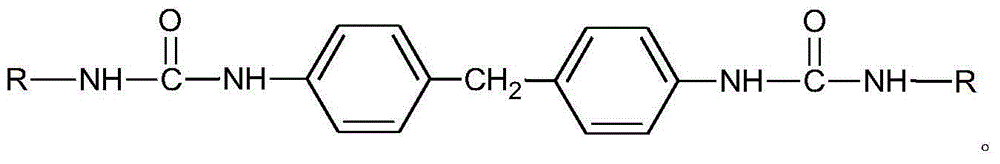

A kind of production method of polyurethane urea elastic fiber with high heat setting efficiency

ActiveCN103469341BImprove heat setting efficiencyReduce consumptionMonocomponent polyureas artificial filamentDiphenylmethaneFiber

Owner:ZHEJIANG HUAFENG SPANDEX

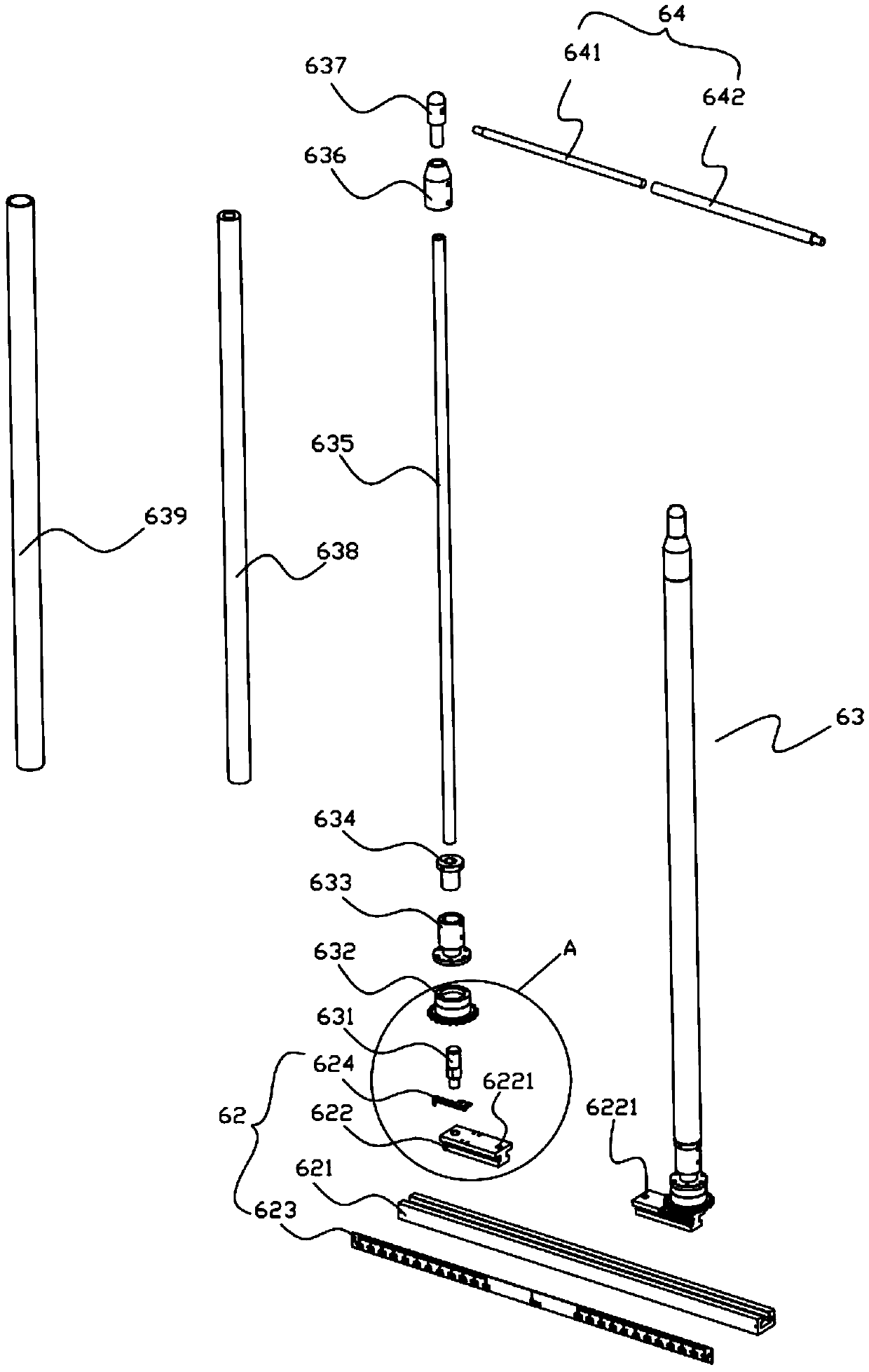

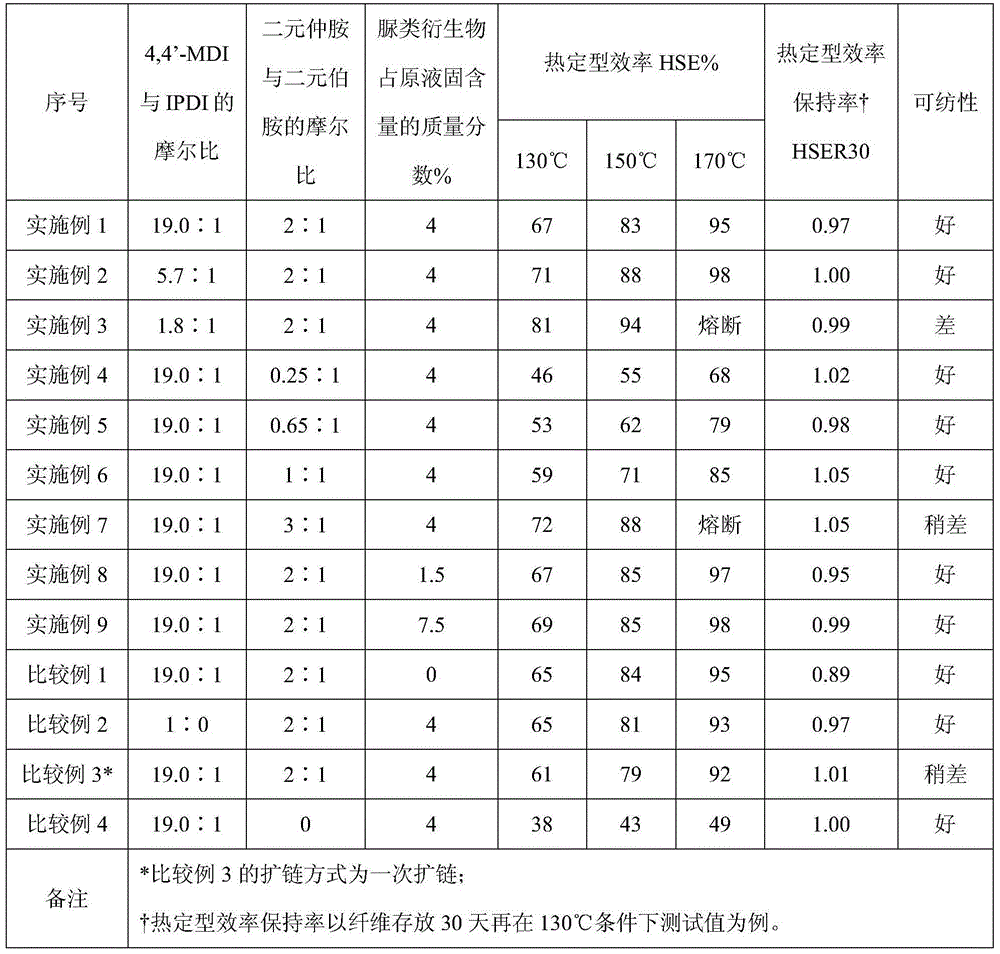

Multi-station elbow correction system and method for producing spiral lamp tube

PendingCN109824251AImprove heating and setting efficiencyImprove styling efficiencyGlass reforming apparatusEngineering

The invention relates to a multi-station elbow correction system for producing a spiral lamp tube. The system comprises a melting device used for softening a straight lamp tube and a spiral mold making the straight lamp tube shaped as the spiral lamp tube, and is characterized by comprising a rotary type conveying assembly used for receiving the spiral lamp tube from the spiral mold, a rectification assembly arranged on the rotary type conveying assembly, used for shaping the spiral lamp tube and achieving bending of a free end of the spiral lamp tube and a correction assembly arranged at an output end of the rotary type conveying assembly. A multi-station elbow correction method for producing the spiral lamp tube comprises the steps of S1, melting of a straight hose, S2, rectification andshaping of the spiral lamp tube and S3, correction and shaping of the spiral lamp tube. The multi-station elbow correction system and method for producing the spiral lamp tube have the advantages that the production efficiency is quick, and the preparation quality is high.

Owner:浙江江山三友电子有限公司

Embroidery thread splicing and shaping equipment and method

InactiveCN109610112AImprove styling efficiencyImprove styling qualityTextile treatment by spraying/projectingWater sourceEngineering

The invention discloses embroidery thread splicing and shaping equipment and an embroidery thread splicing and shaping method. The embroidery thread splicing and shaping equipment comprises a workbench, wherein a shaping box is arranged at the top of the workbench; a thread winding roll is arranged on one side of the shaping box, and a recycling roll is arranged on the other side of the shaping box; a first adjusting roll is arranged on one side wall of the shaping box, and a second adjusting roll is arranged on the other side wall of the shaping box; a humidifying box is arranged inside the shaping box; a hot water box is arranged at the top of the humidifying box; a heating tube is arranged in an inner cavity of the hot water box; a pressure pump is arranged on one side of the heating tube. A water source in the hot water box is heated by the heating tube, the pressure pump sprays the heated water source onto an embroidery thread in the humidifying box from a spray head on the end part of a water outlet pipe, and hot pressing plates are matched with pressing rolls to perform extrusion shaping on the wet embroidery thread; the spliced embroidery thread is shaped by utilizing a hotshaping principle, so that the shaping efficiency and the shaping quality of the embroidery thread are improved, the embroidery thread is not prone to deform and fall off during storage, and the quality of a product is improved.

Owner:NANTONG GOD OF HORSES THREAD

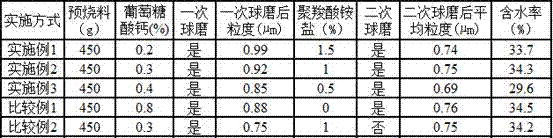

A kind of manufacturing method of permanent magnet ferrite

ActiveCN105384433BNarrow particle size distributionImprove liquidityInorganic material magnetismMetallurgySteel ball

The invention relates to the technical field of permanent magnetic ferrites, in particular to a manufacturing method of a permanent magnetic ferrite. The manufacturing method comprises the following steps of taking a certain mass of permanent magnetic ferrite preburning materials, and adding 0.3-0.5% of SiO2 and 0.5-0.7% of CaCO3 in percentage by mass; adding 0.2-0.4% of calcium gluconate to a mixed material, and using a steel ball of which the diameter is D1 for performing wet-method ball milling so as to obtain a primary grinding sizing material; taking out the primary grinding sizing material, adding 0.5-1.5% of polyocarboxy acid ammonium salt in percentage by weight, and using a steel ball of which the diameter is D2 for performing wet-method ball milling so as to obtain a secondary grinding sizing material, wherein D1 is greater than D2; performing dehydration treatment on the secondary grinding sizing material, loading the dehydrated sizing material into a mold, performing orientation shaping under a magnetic field of 10000-14000GS, and then performing sinter molding. The manufacturing method disclosed by the invention has the beneficial effects that the permanent magnetic ferrite is prevented from being cracked when being sintered, the product quality is improved, and the overall performance is improved.

Owner:霍山东磁电子科技有限公司

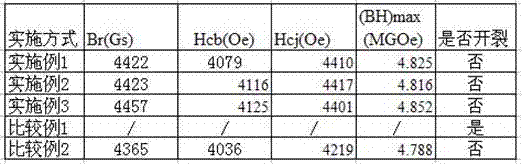

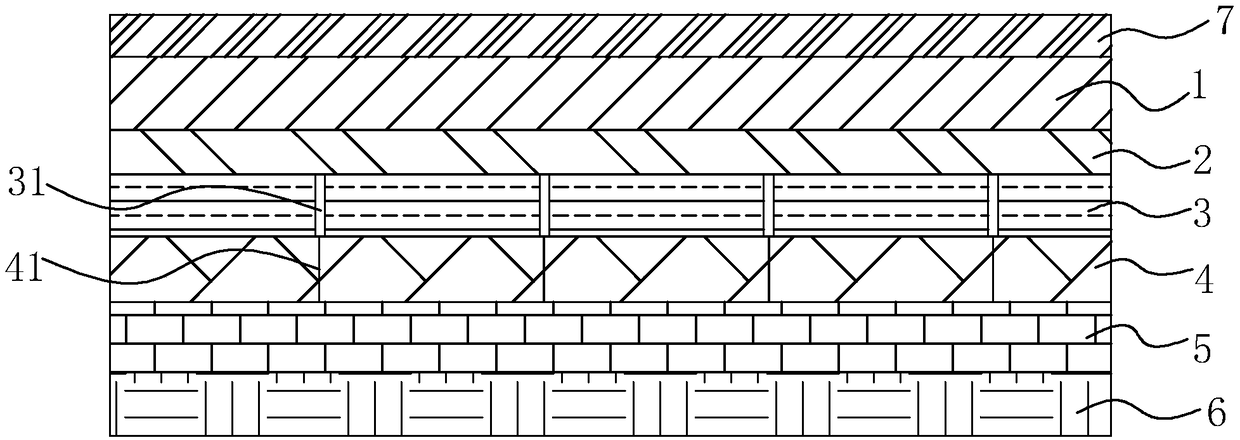

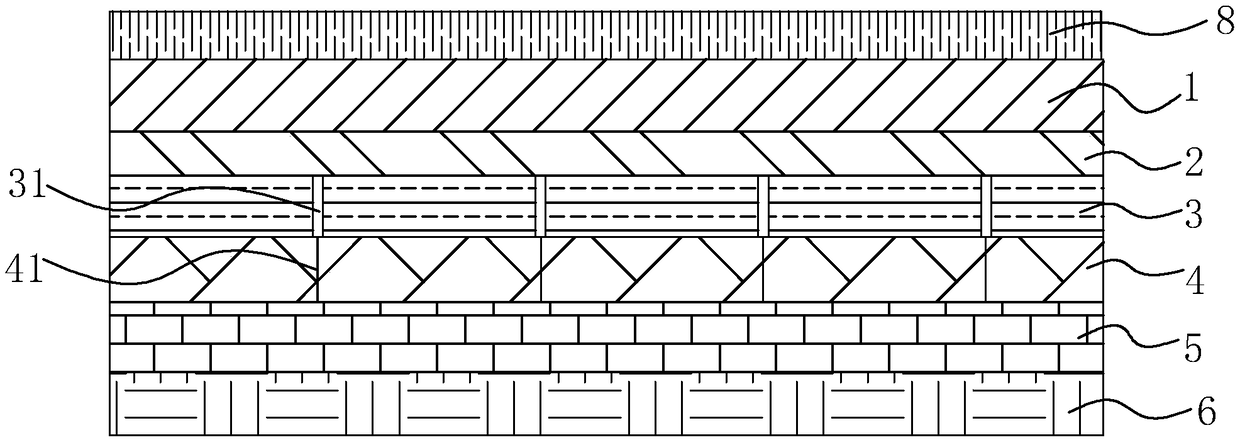

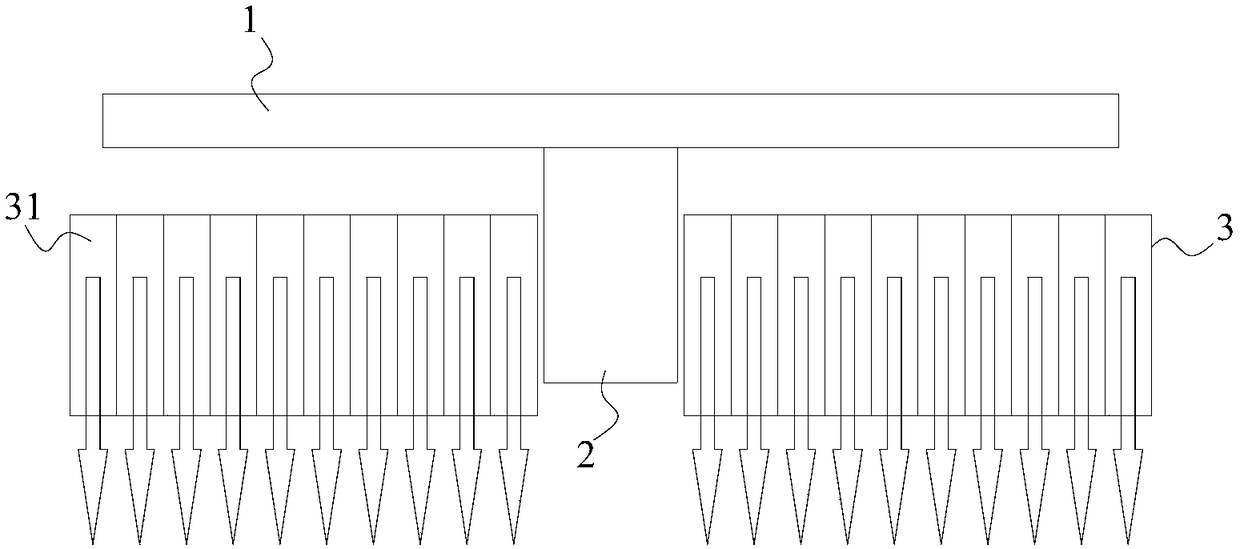

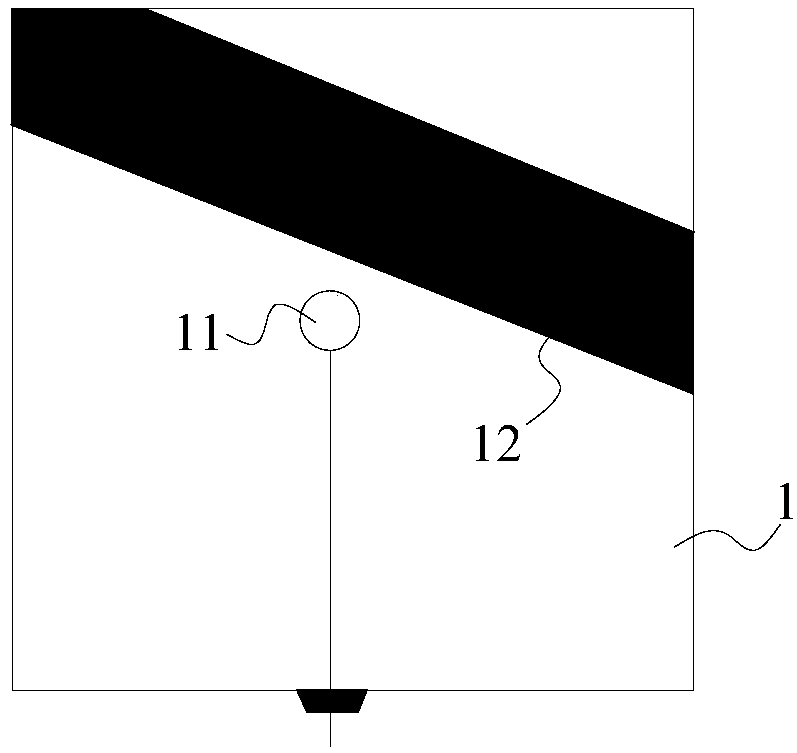

Multi-layer tamper-proof disposable digital anti-counterfeiting label and production method thereof

ActiveCN108520693AImprove insect repellent performanceImprove styling efficiencyStampsIdentification meansTamper resistanceSurface layer

The invention relates to the field of anti-counterfeiting labels, and discloses a multi-layer tamper-proof disposable digital anti-counterfeiting label, which sequentially comprises an anti-counterfeiting label surface layer, an isolation layer, a solid glue layer, a vacuum aluminum plating layer, an adhesive layer and a silicone oil bottom paper from inside to outside, the viscosity of between the isolation layer and the solid glue layer is less than that between the solid glue layer and the vacuum aluminum plating layer. When the anti-counterfeiting label is lifted, the anti-counterfeiting label surface layer and the isolation layer are completely removed and separated from the solid glue layer, so that the purpose of non-repeated use of the anti-counterfeiting label is realized. Meanwhile, the production method is simple, so that the method is suitable for large-scale popularization.

Owner:南京中印防伪科技有限公司

Machine vision light source

InactiveCN108563085AImprove styling efficiencyGood effectTelevision system detailsColor television detailsMachine visionLight reflection

The invention is suitable for the technical field of vision, and provides a machine vision light source comprising a displayer, a camera which is arranged in the central area of the displayer and a cellular board which is arranged on the front side of the displayer and surrounds the camera. Compared with the light sources in the prior art, the displayer is arranged and the camera is arranged in the central area of the displayer, and the cellular board is arranged on the front side of the displayer and surrounds the camera so that the machine vision light source is enabled to become a type of general light source equipment and cope with multiple occasions requiring using the light source, the light source formation efficiency is high and the effect is ideal, and the parallel light source can be realized without meticulously designing the light reflection lid or calculating the focus and other tedious schemes.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

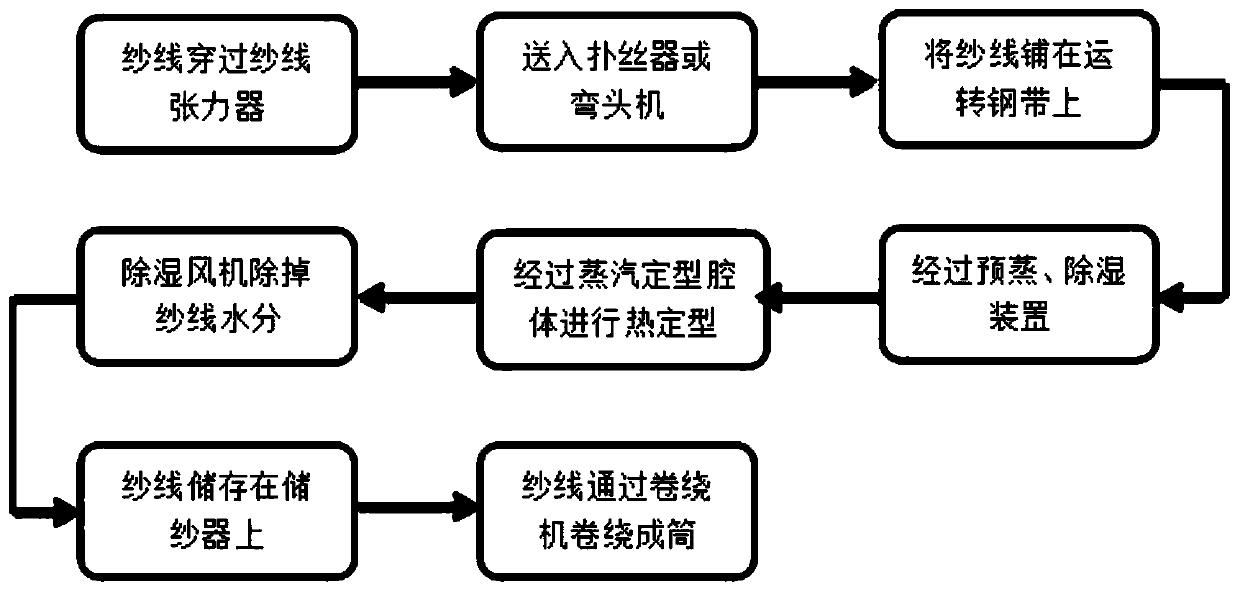

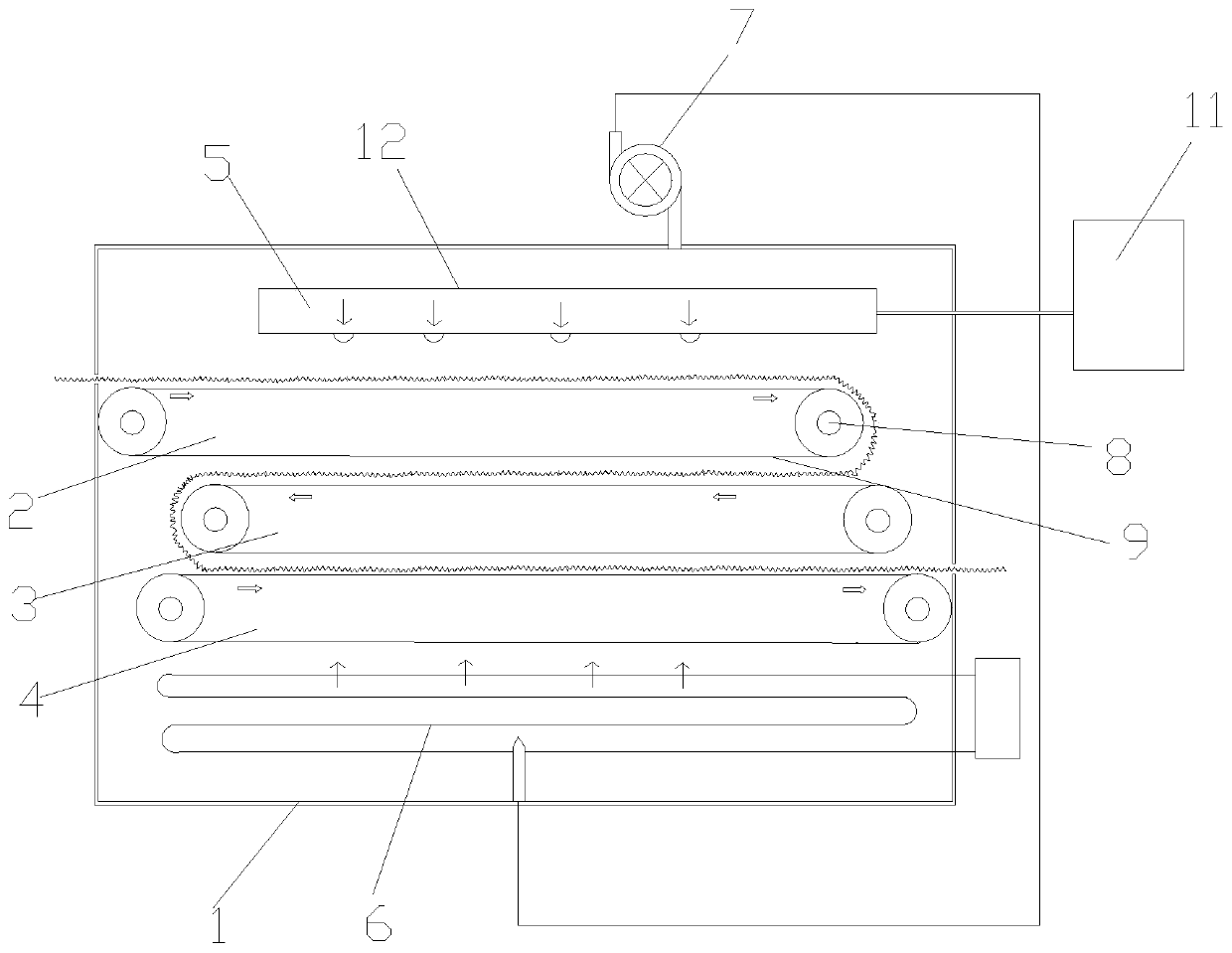

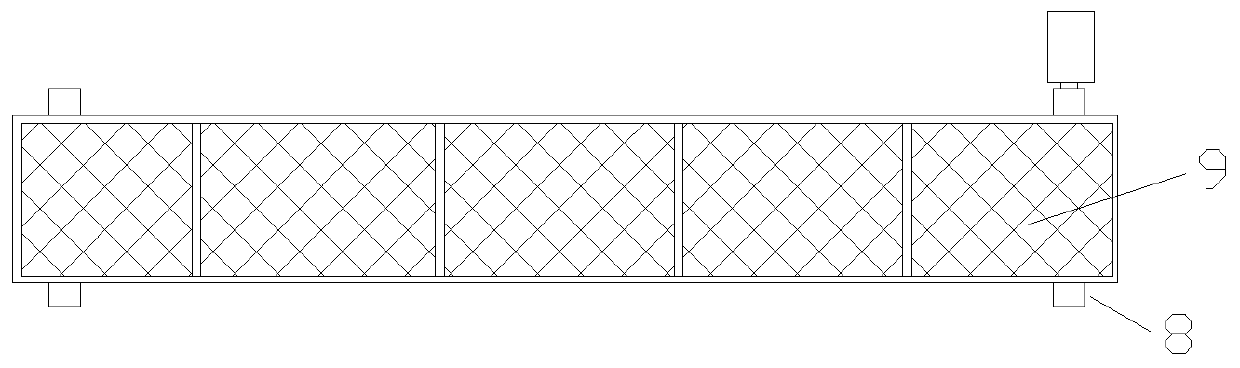

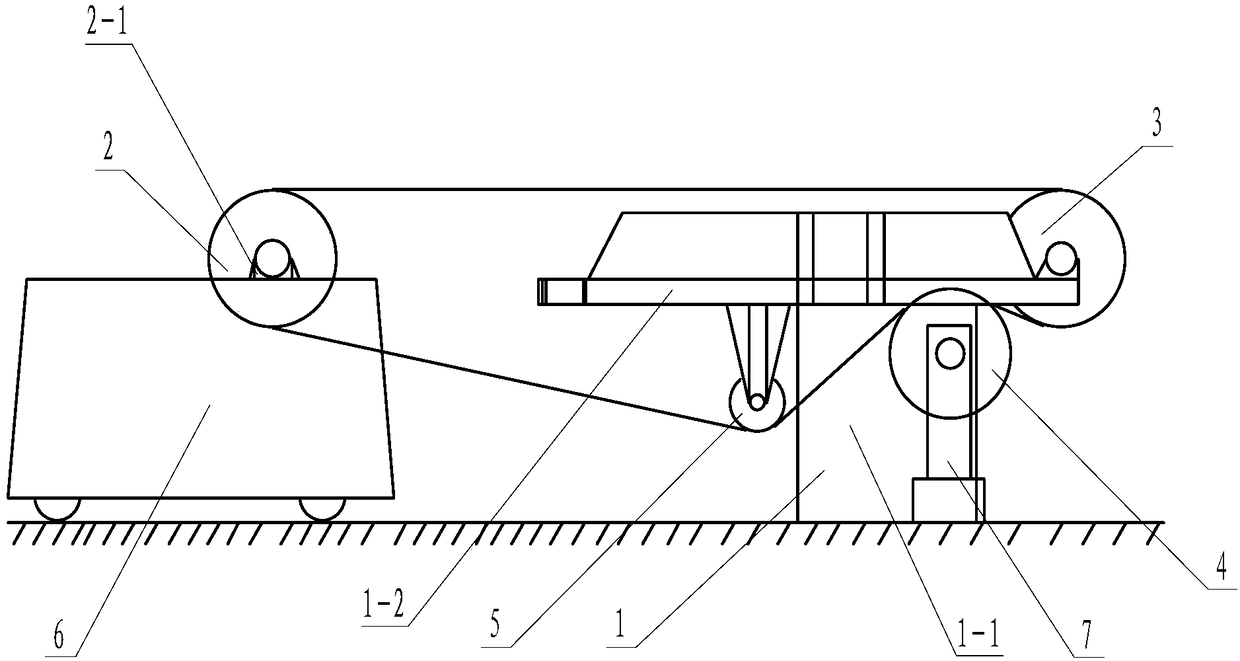

Novel carpet yarn production process method and setting machine for superheated steam

PendingCN110424121AShorten the lengthEfficient heating and settingTextile treatment containersHeating/cooling textile fabricsElectricityTemperature control

The invention discloses a novel carpet yarn production process method and a setting machine for superheated steam. The technical scheme includes that the method includes the steps: S1 enabling yarns to penetrate a yarn tension device; S2 feeding the yarns into a yarn flapping device or a bender, and laying the yarns on a running steel belt; S3 performing pre-evaporation and dehumidifying the yarnsby a dehumidification device; S4 performing heat setting by a steam setting cavity; S5 removing yarn moisture by a dehumidification fan; S6 storing the yarns on a yarn storage device, and winding theyarns to form a yarn cylinder by a winding machine. Temperature control electric heating rods are additionally arranged in the setting cavity, steam led in by a steam mechanism is heated to generatethe superheated steam, efficient and comprehensive heat setting of the yarns can be implemented by a setting mode under the combined action of steam and electric heating, an S-shaped conveying mechanism is arranged in the setting cavity, so that the yarns are set along an 'S'-shaped direction, the length of the setting cavity is shortened, the superheated steam penetrates the front surfaces and the back surfaces of the yarns, the yarns are sufficiently set, and setting efficiency is obviously improved.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

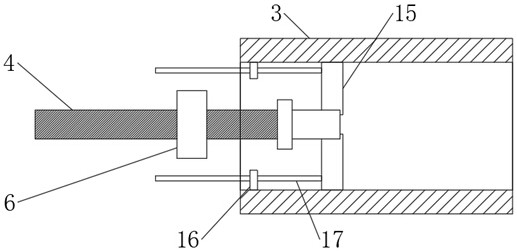

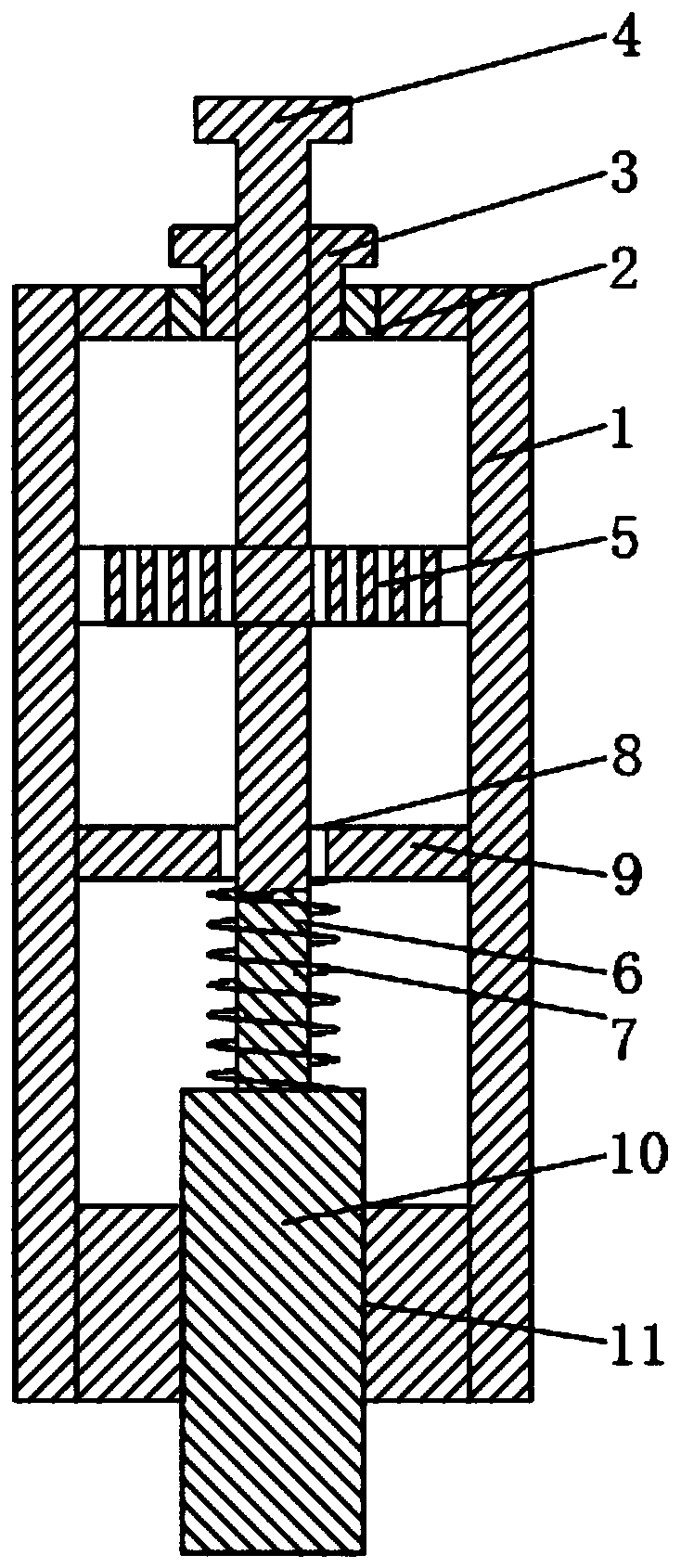

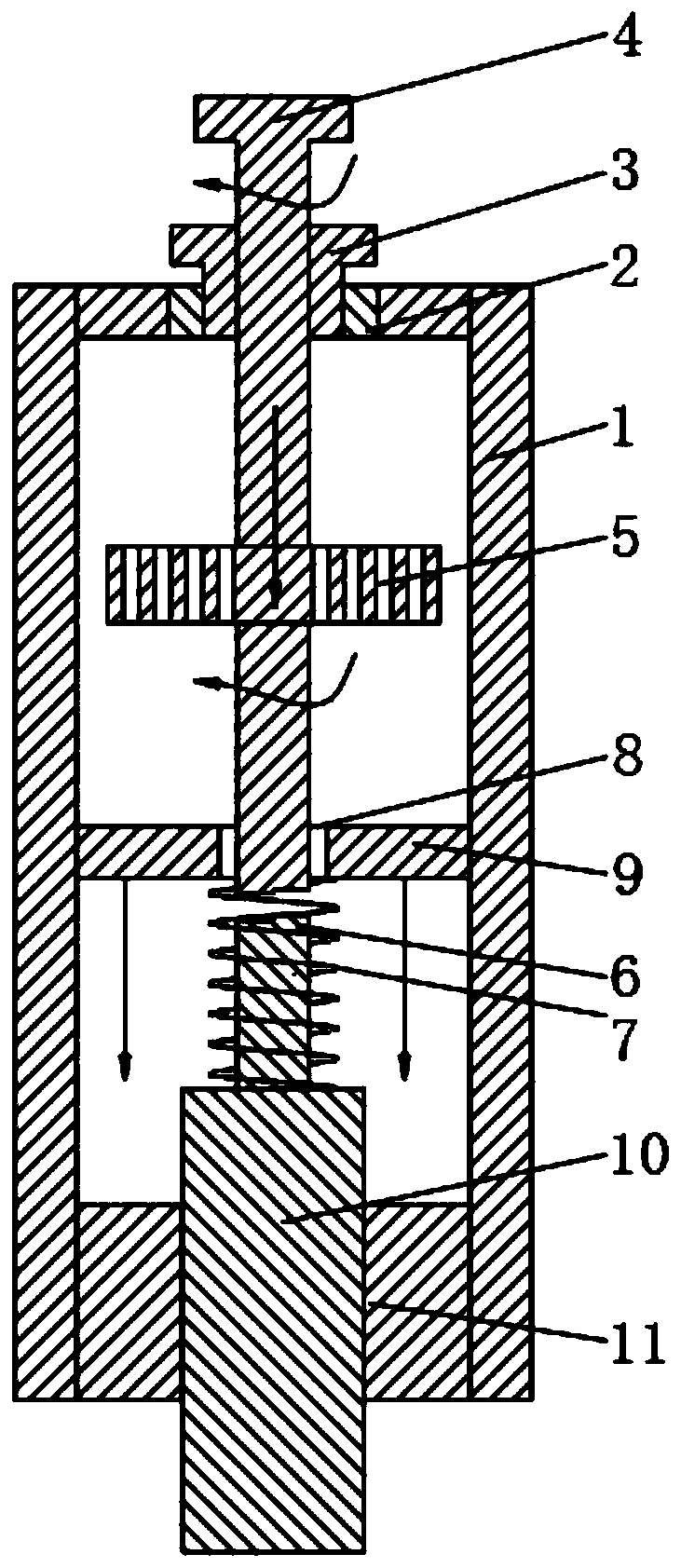

Electric brush pressure self-adjusting conductive slip ring structure

The invention relates to the technical field of electrical equipment, and discloses an electric brush pressure self-adjusting conductive slip ring structure. The structure comprises a fixing sleeve, an outer ring and an inner ring, the fixing sleeve is installed on the inner ring, and the inner ring is electrically connected with the outer ring through an electric brush. After the electric brush pressure self-adjusting conductive slip ring structure is mounted and fixed, the pressure between the outer ring and the electric brush can be adjusted by rotating the threaded sleeve, the limitation of the cantilever length and a mounting reference surface is broken through, so the same slip rings are suitable for the design of various electrical products, universality is high, the change of product design is facilitated, and the product research and development efficiency and product shaping efficiency are improved; and meanwhile, after the slip ring is installed, the pressure of the electricbrush can still be measured and adjusted, the requirement for the installation precision is lowered; and, secondly, the pressure change between the outer ring and the electric brush is kept within asmall range all the time under the action of the spring, the contact pressure is guaranteed to be kept within the most appropriate interval, and the higher precision requirement is met.

Owner:邢台国泰发电有限责任公司

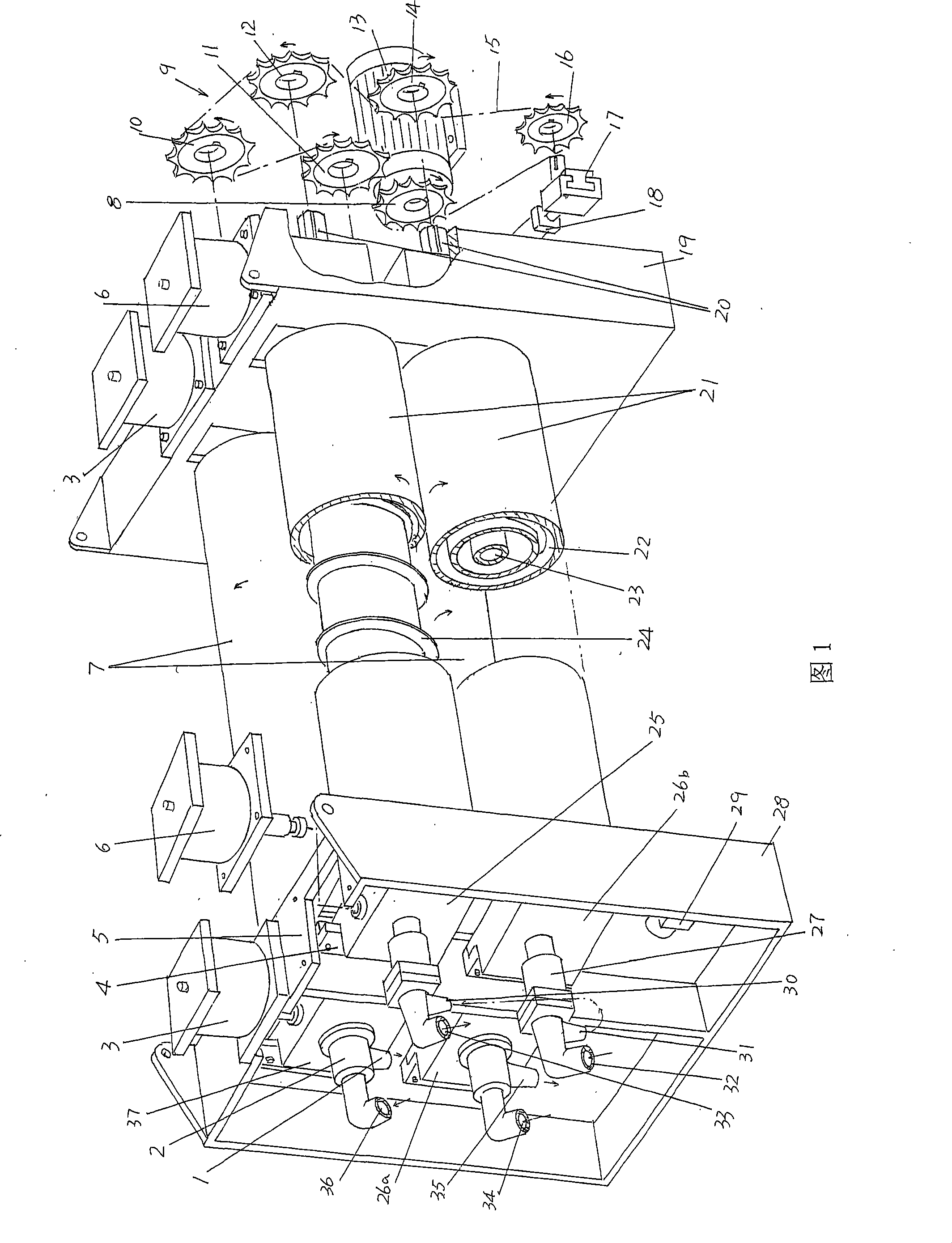

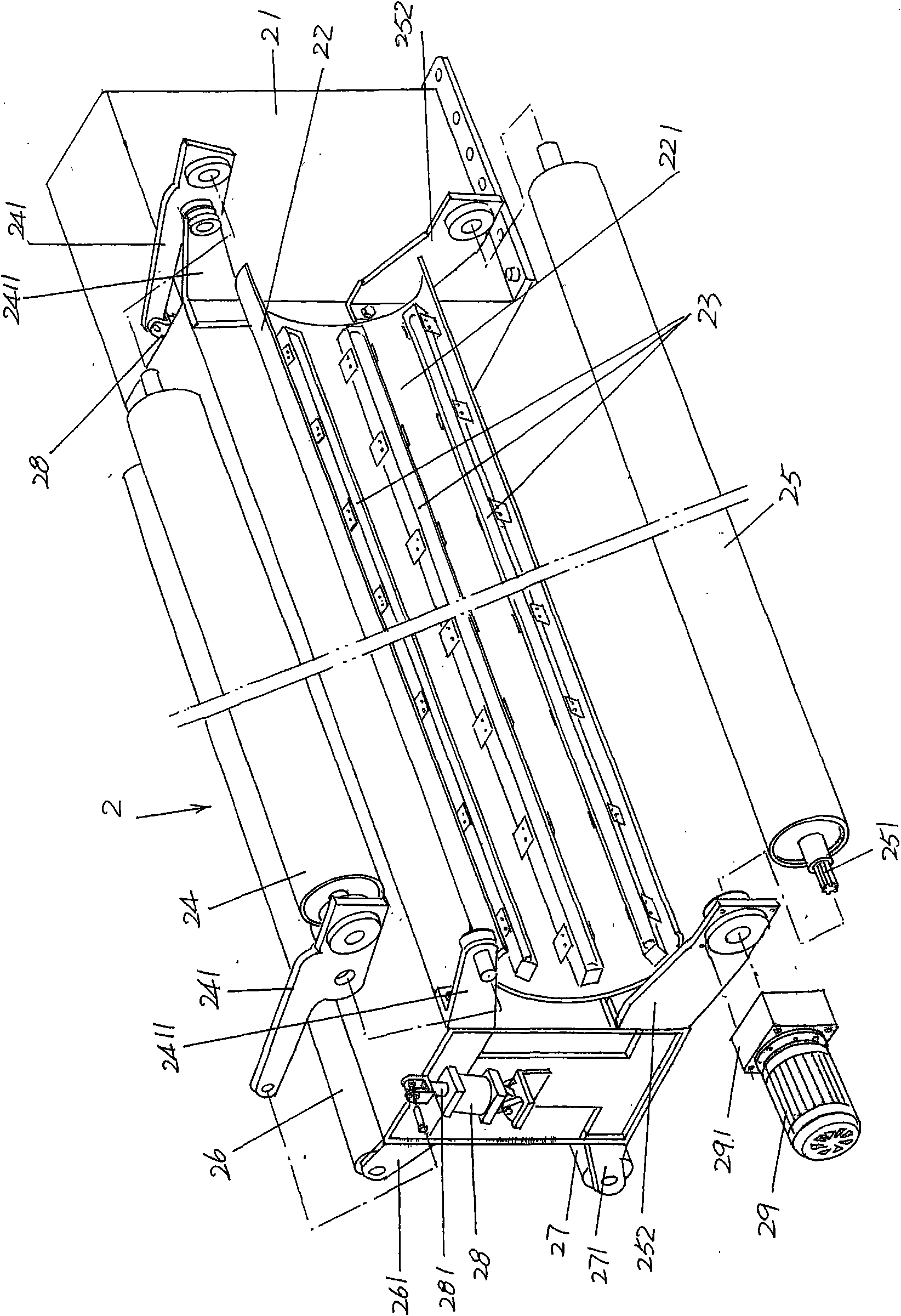

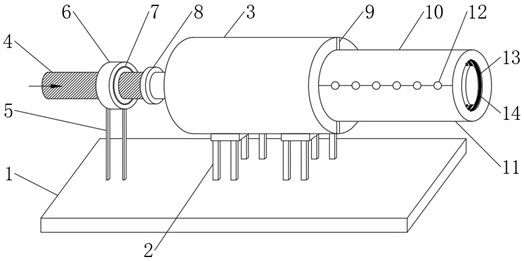

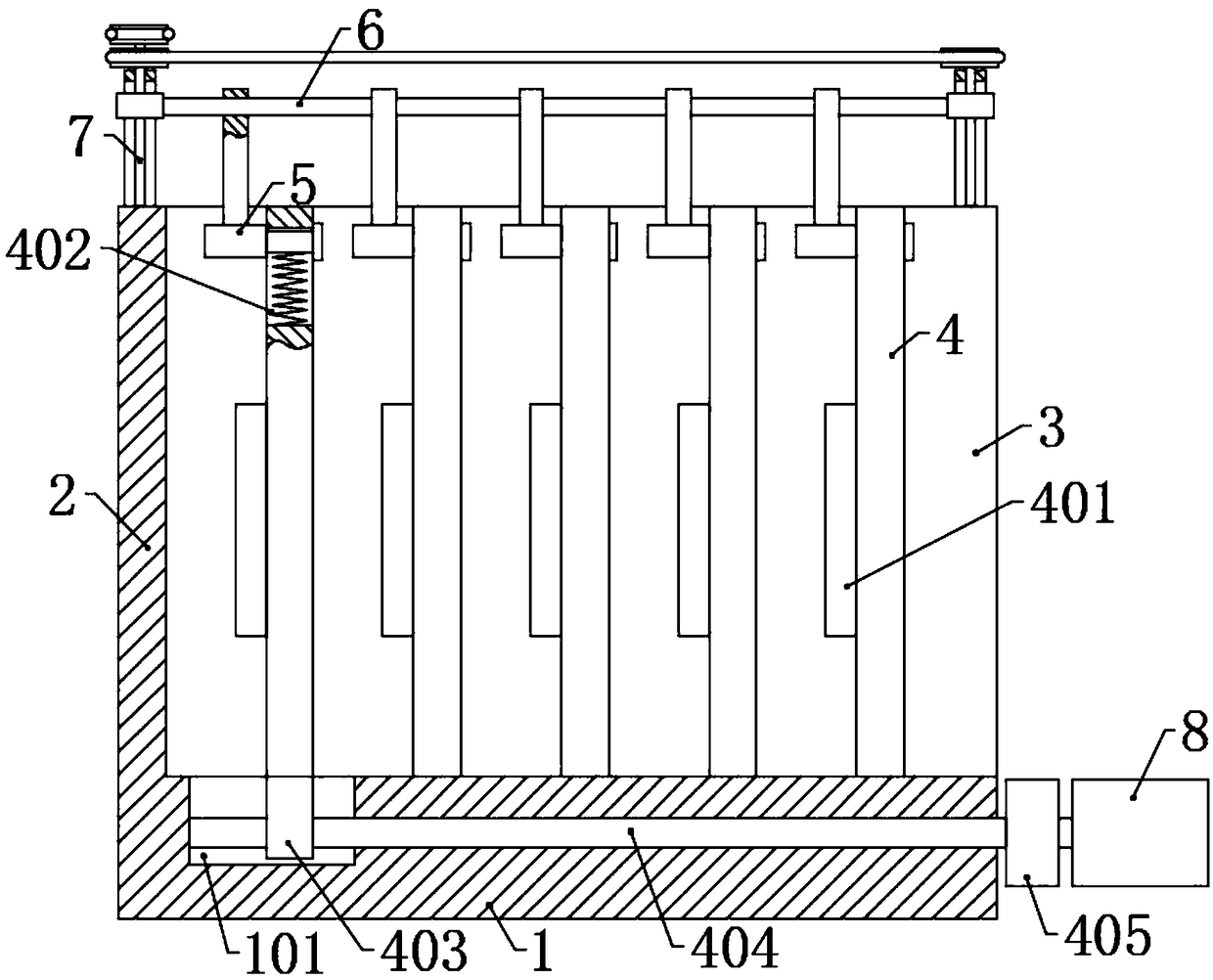

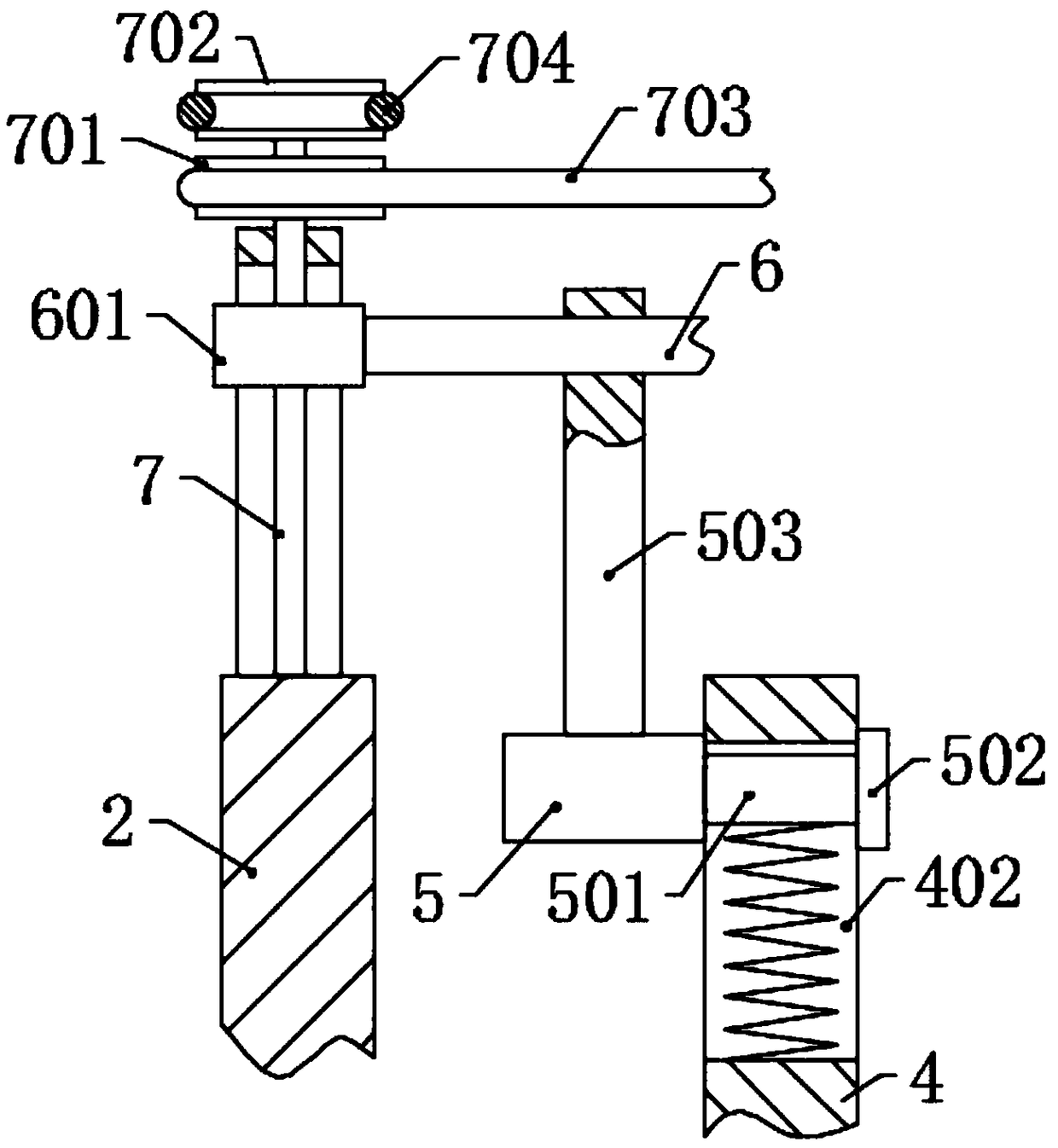

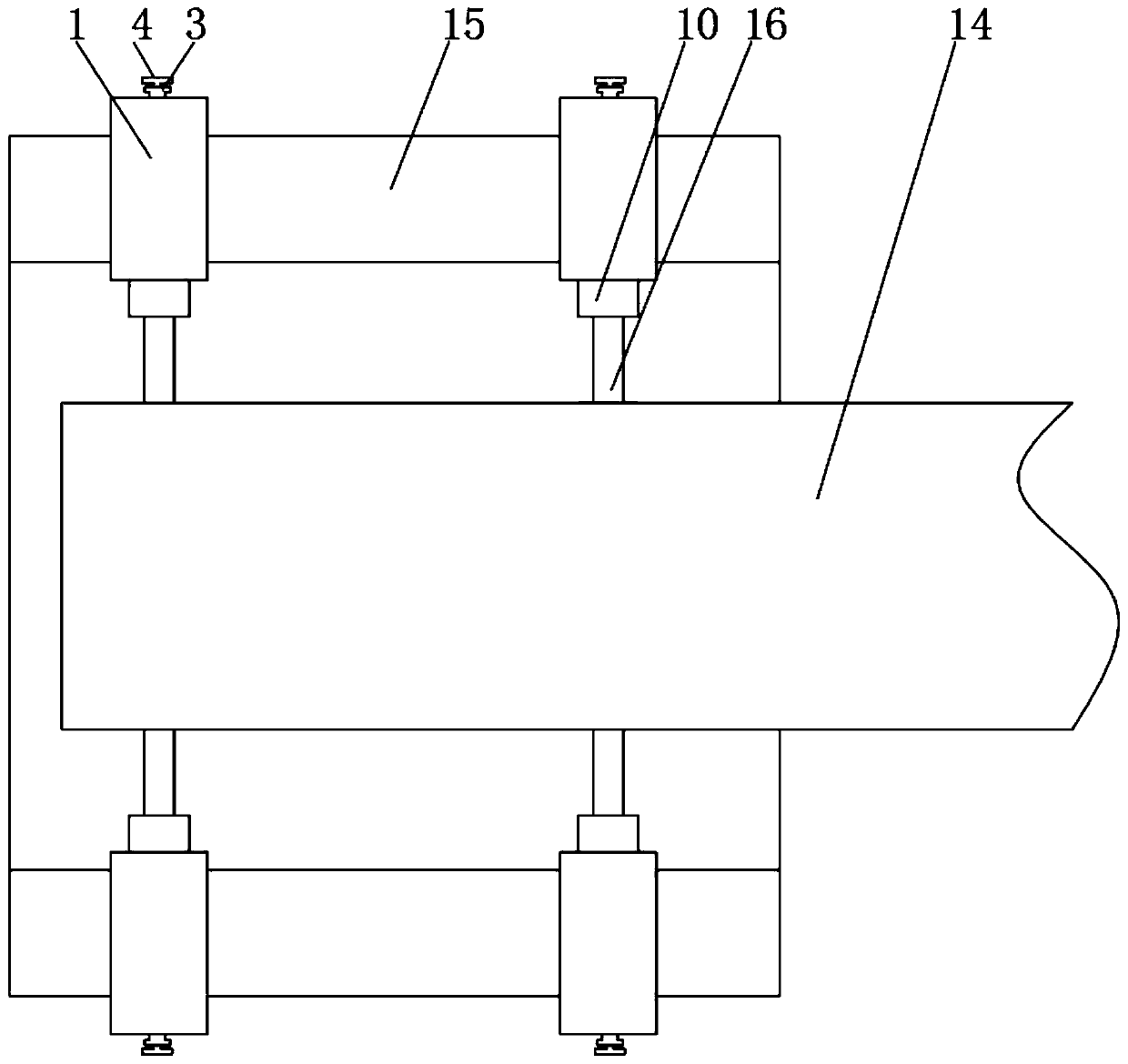

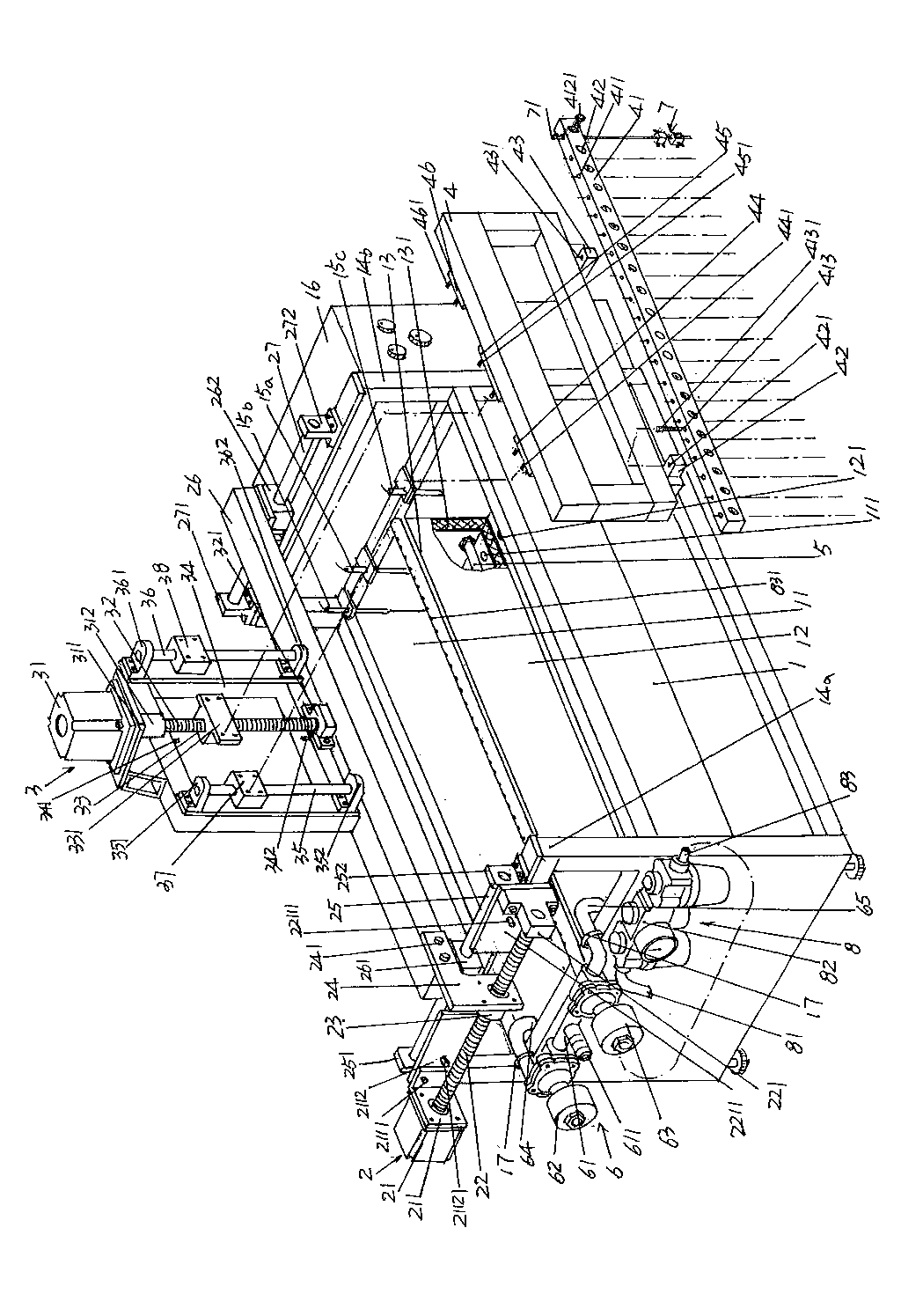

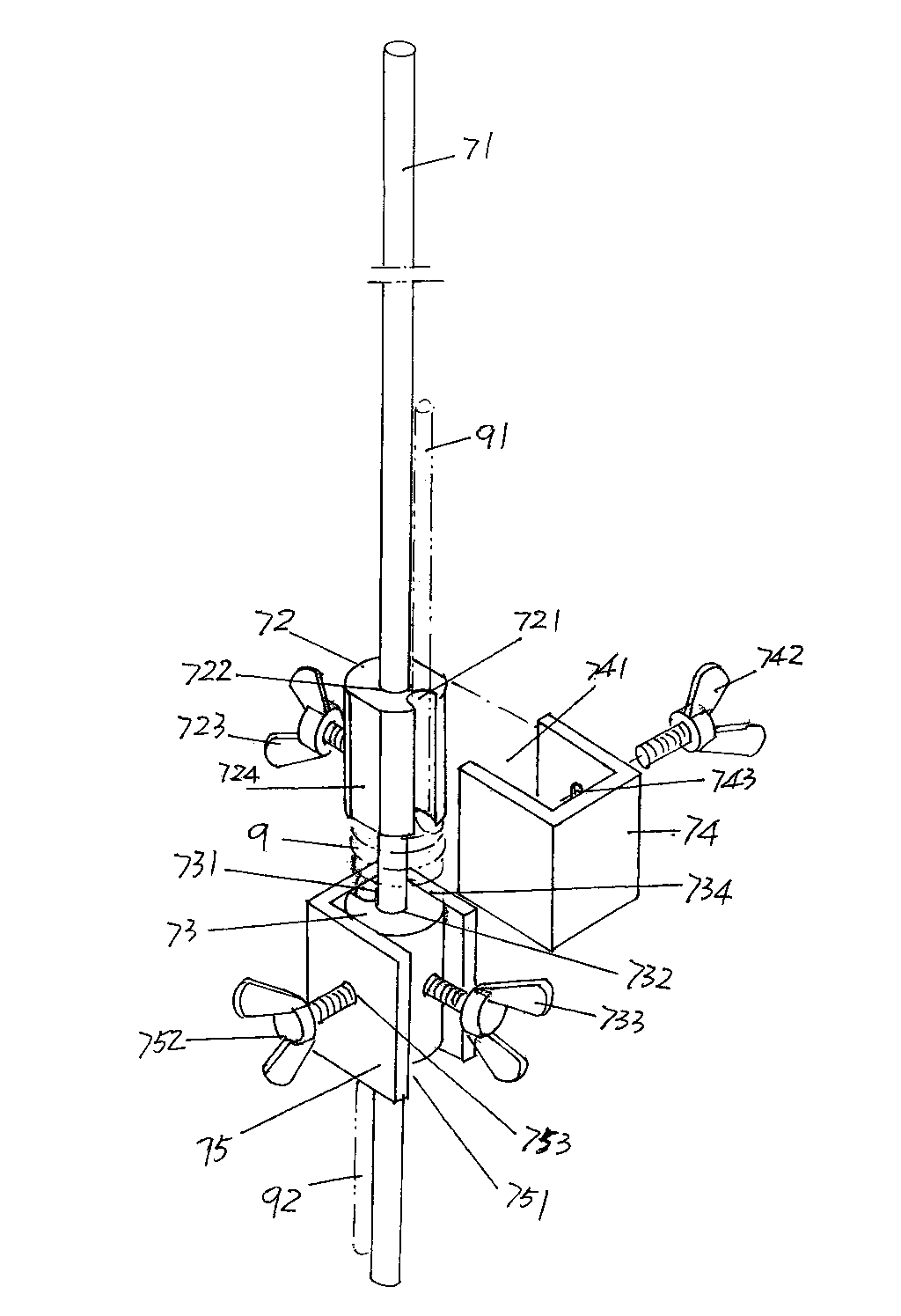

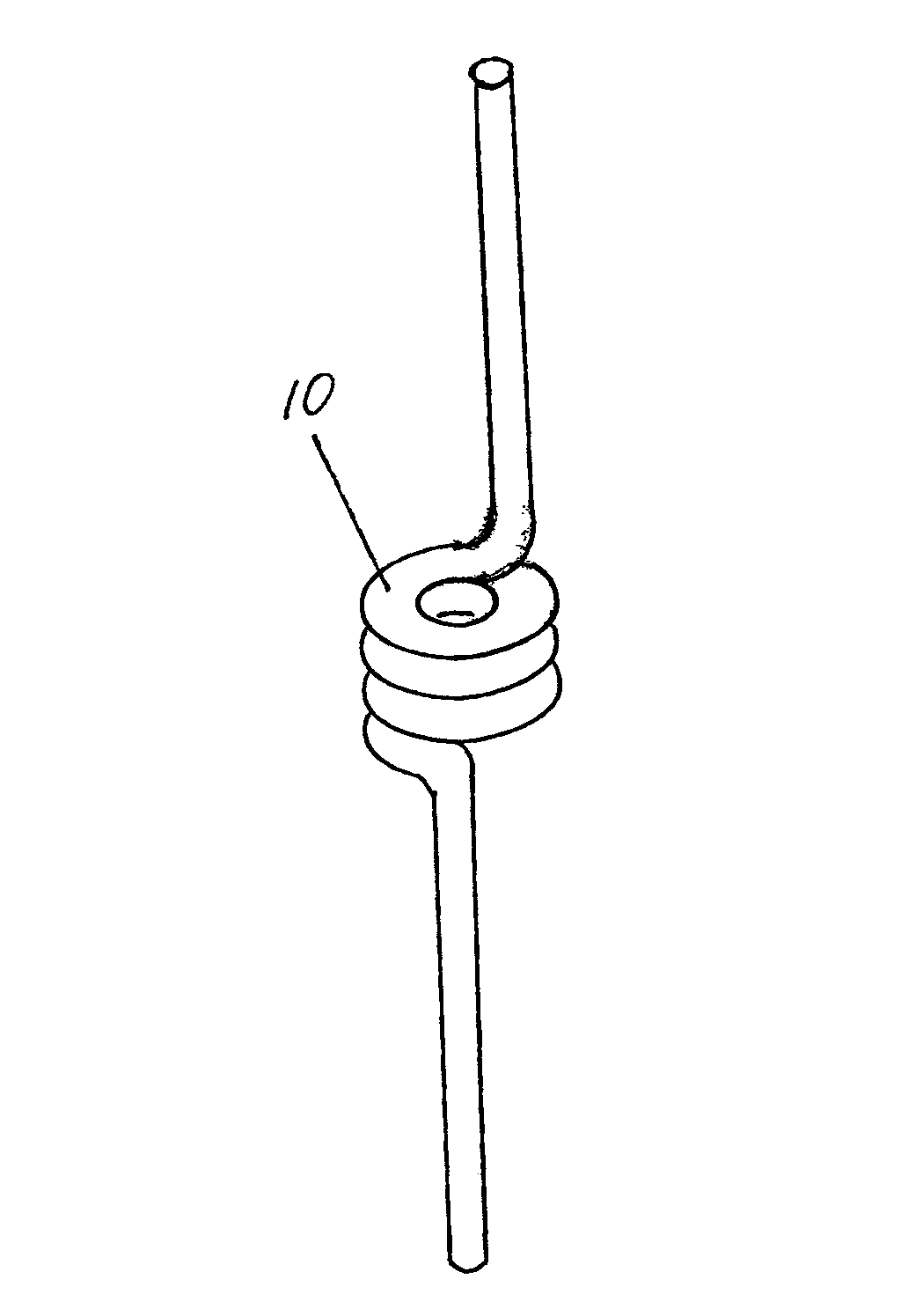

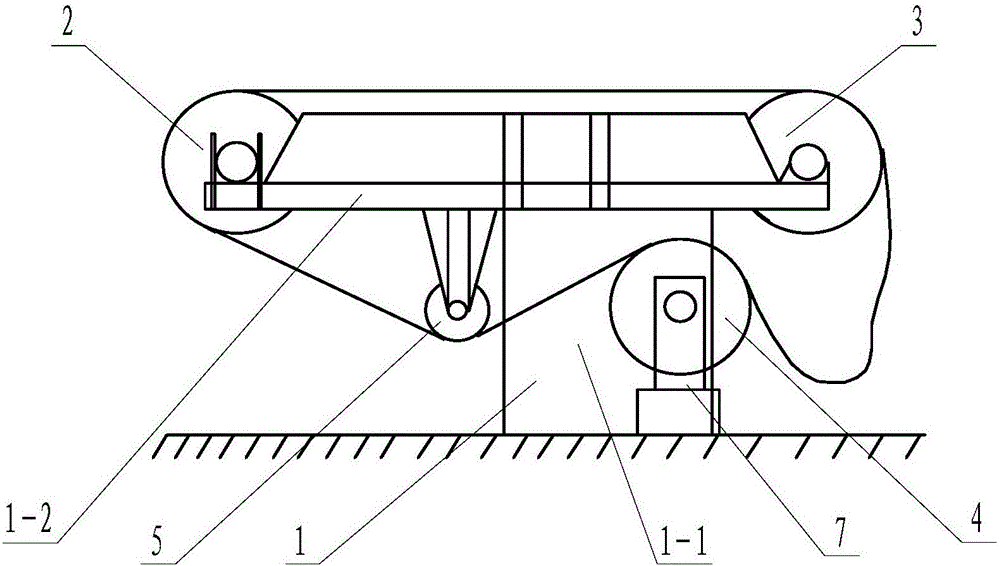

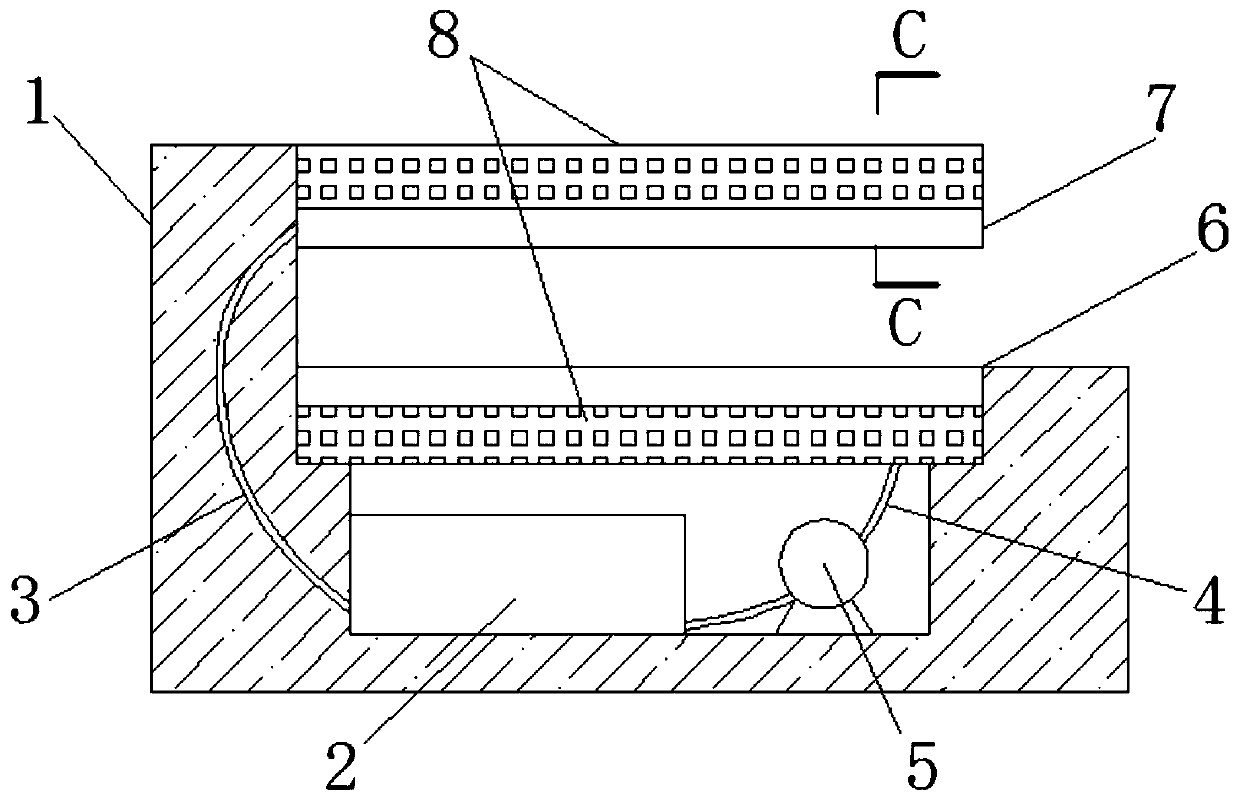

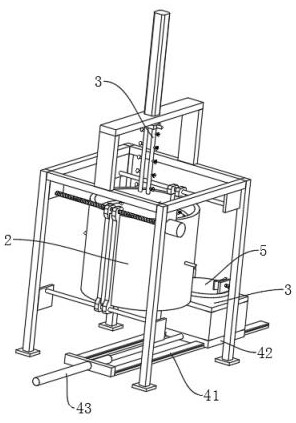

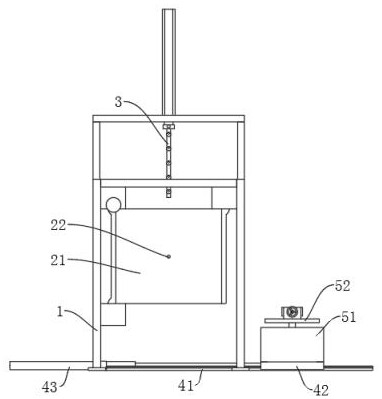

Semiautomatic forming device for spring wire

ActiveCN102708996AQuality assuranceImprove styling efficiencyManufacturing extensible conductors/cablesCantileverWater tanks

The invention discloses a semiautomatic forming device for a spring wire, and belongs to the field of devices special for electric wire and cable machining. The semiautomatic forming device comprises a water tank, a horizontal movement mechanism, a hanging bar frame lifting mechanism, a hanging bar frame, a heater, a water supply mechanism and a group of spring wire clamping mechanisms, wherein the water tank is divided into a hot water chamber and a cold water chamber; the horizontal movement mechanism is arranged above the water tank; the hanging bar frame lifting mechanism is arranged on the horizontal movement mechanism; the hanging bar frame is provided with a spring wire clamping mechanism seat, and is arranged on the hanging bar frame lifting mechanism; the heater is arranged in the hot water chamber; the water supply mechanism is arranged on the water tank; each spring wire clamping mechanism comprises a hanging bar, a first wire clamping seat, a second wire clamping seat, a first wire pressing seat and a second wire pressing seat; the upper end of each hanging bar is connected with the spring wire clamping mechanism seat, and the lower end of the hanging bar forms a cantilever end; a first sliding hole is reserved in the center of each first wire clamping seat, and a first wire end embedding slot is reserved on one side of each first wire clamping seat; and a second sliding hole is reserved in the center of each second wire clamping seat, and a second wire end embedding slot is reserved on one side of each second wire clamping seat. The semiautomatic forming device has the advantages that the water tank is used for shaping the spring wire, so that quality can be ensured; shaping efficiency can be improved; power consumption can be reduced; the semiautomatic forming device is simple in structure; and a forming effect can be ensured.

Owner:JIANGSU ZHONGLI GRP CO LTD

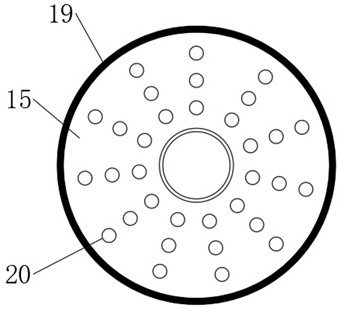

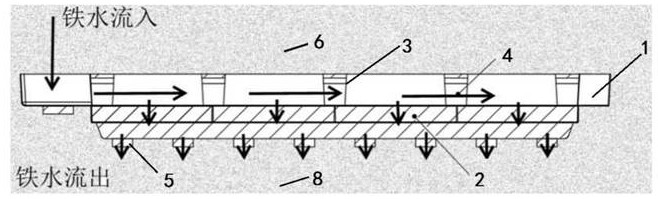

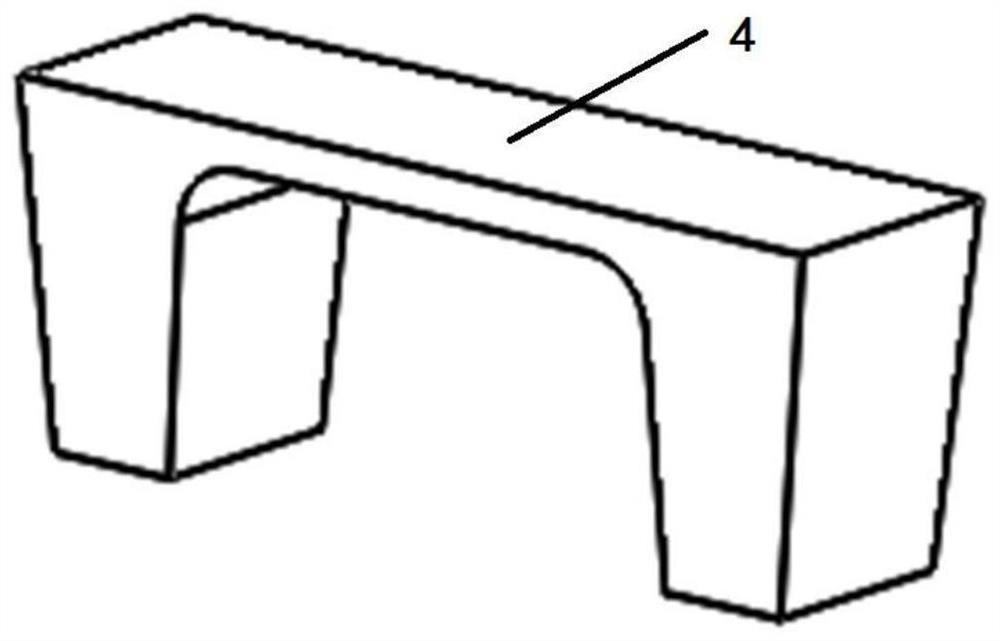

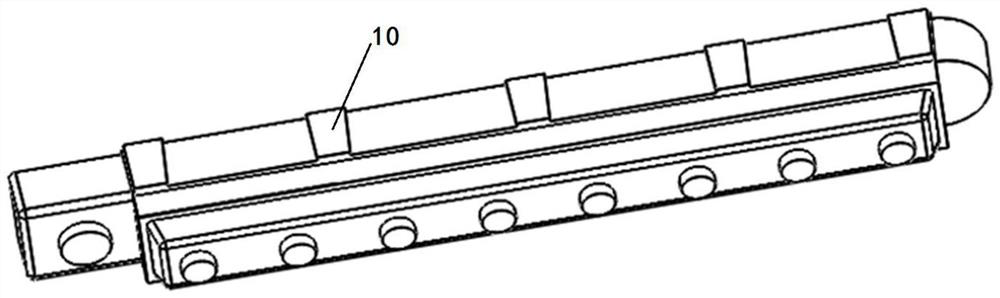

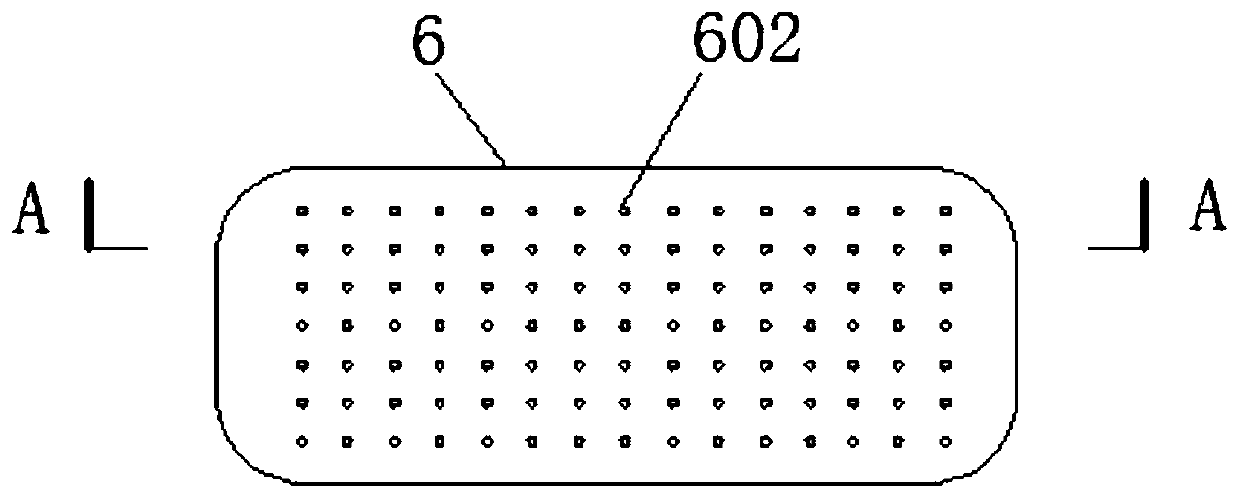

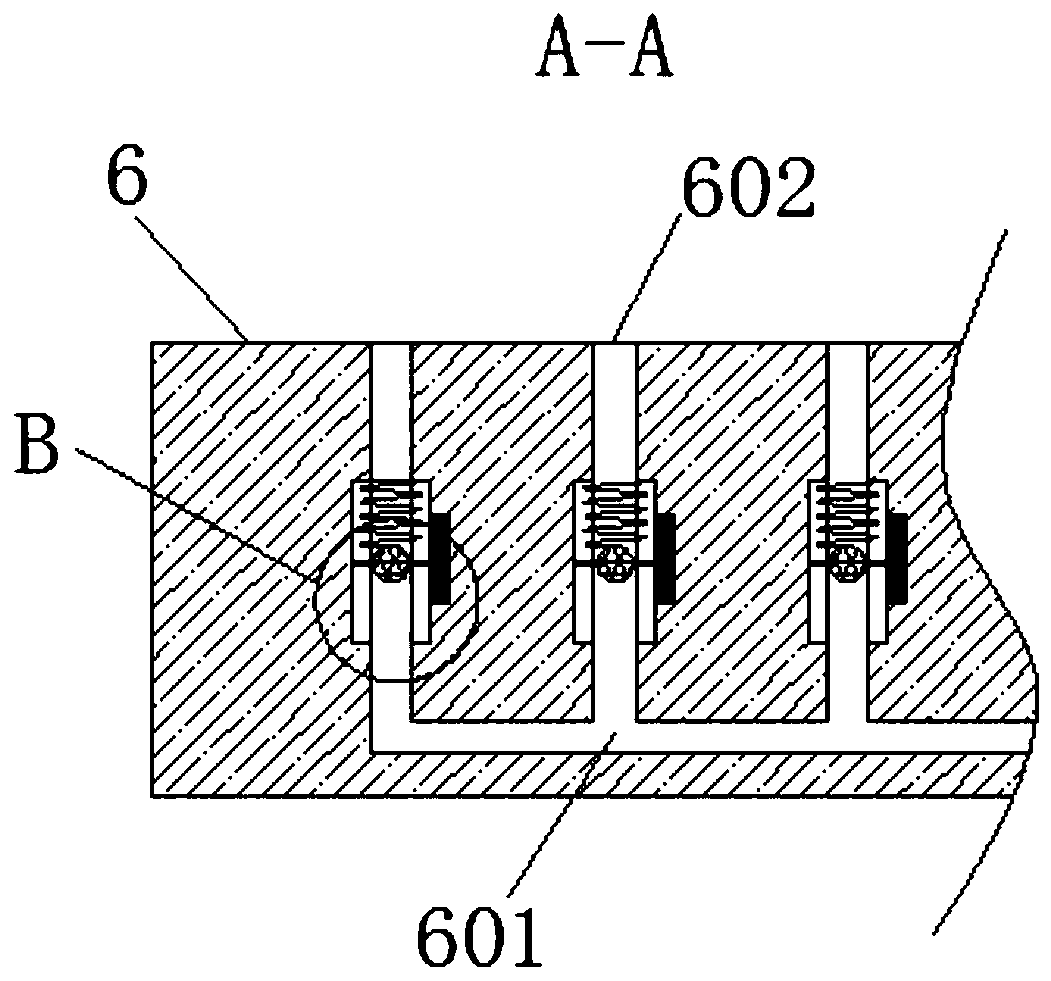

Ductile iron pouring system with filtering and positioning device and use method of ductile iron pouring system

ActiveCN114210931ALow production costImprove styling efficiencyFoundry mouldsCasting cleaning apparatusEngineeringStructural engineering

The invention provides a ductile iron pouring system with a filtering and positioning device and a using method thereof.The ductile iron pouring system comprises a pouring system body, and the pouring system body is in a stepped groove shape and is divided into an upper groove and a lower groove; a plurality of filter screens which are tightly arranged in the length direction of the pouring system are arranged in the lower groove; the groove wall of the upper groove is provided with a convex positioning spigot between two adjacent filter screens, and a filter screen positioning device mounted in the upper groove is arranged between two opposite positioning spigots; the filter screen positioning device is of a gantry type structure, the arrangement direction of two supporting legs at the bottom of the filter screen positioning device is parallel to the width direction of the pouring system, the outer side of each supporting leg is in contact connection with the groove bottom of the upper groove, the inner side of each supporting leg is located above the filter screen, and a gap of 1-2 mm is formed between the inner side of each supporting leg and the filter screen. Cover plate sand core modeling is omitted, the model manufacturing cost is reduced, the modeling work efficiency is improved, the cover plate sand core does not need to be researched during box closing, and the operation difficulty is reduced.

Owner:大连华锐重工铸业有限公司 +1

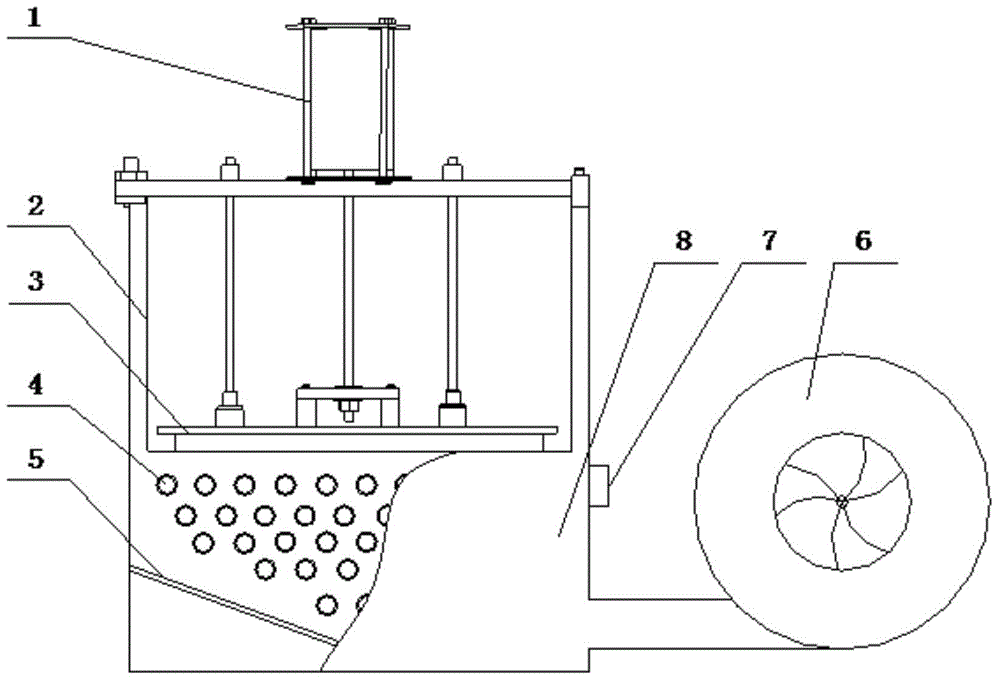

Heat-setting machine for plant fibersleeper mattresses

InactiveCN104480664AHeating evenlyEven heat dissipationHeating/cooling textile fabricsHeat conductingGas cylinder

The invention relates to a heat-setting machine for plant fibersleeper mattresses. The heat-setting machine mainly comprises a rack, a gas cylinder and a heating mechanism, wherein the rack consists of an operation platform, a rack body and a box, the rack body is arranged at the upper part of the operation platform, the box is arranged at the lower part of the operation platform, the gas cylinder is mounted at the top end of the rack body, a hot press plate is mounted on a cylinder rod of the gas cylinder, and the heating mechanism is mounted in the box. The heat-setting machine is characterized in that the heating mechanism consists of finned tubes, a heat-conducting oil heater and a fan, heat is provided for the finned tube by the heat-conducting oil heater, the finned tubes are evenly mounted in the box, and the fan communicated with the inside of the box is mounted at one side end of the box. The heat-setting machine for the plant fiber sleeper mattresses is scientific and reasonable in structural design, has the advantages of high setting efficiency, low energy consumption and capability of realizing uniform heating and guaranteeing the setting quality, and has the higher innovativeness.

Owner:TIANJIN SHENGLONG RUBBERISED MATTRESS

Blanket setting device

ActiveCN106592145AIncrease the lengthImprove styling efficiencyHeating/cooling textile fabricsStretchingMechanical engineeringBlanket

The invention relates to the technical field of blanket processing, and concretely relates to a blanket setting device. The blanket setting device mainly comprises a support, a first hot roller, a drawing roller, a second hot roller, a guiding roller, a bridge crane and a jack; the first hot roller is arranged at one end of the support in a rotatable manner; the first hot roller is driven to rotate; the bridge crane is used for supporting and drawing the drawing roller; bearers are arranged at two ends of the drawing roller, and the bearers are in rotating connection with the drawing roller; the bearers are hinged to the bridge crane; the second hot roller is arranged on the jack in a rotatable manner; the second hot roller is in transmission connection with the first hot roller; the second hot roller is driven to rotate; the linear velocity of the second hot roller is same to that of the first hot roller; the guiding roller is arranged on the support in a rotatable manner; and the guiding roller is positioned between the second hot roller and the drawing roller and is used for increasing the wrap angle of the contact surface of a blanket and the second hot roller. The main purpose of the device is to reduce blanket setting temperature, increase the blanket setting efficiency and improve the blanket setting quality.

Owner:新疆阿勒泰工业用呢有限责任公司

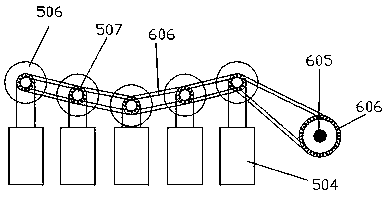

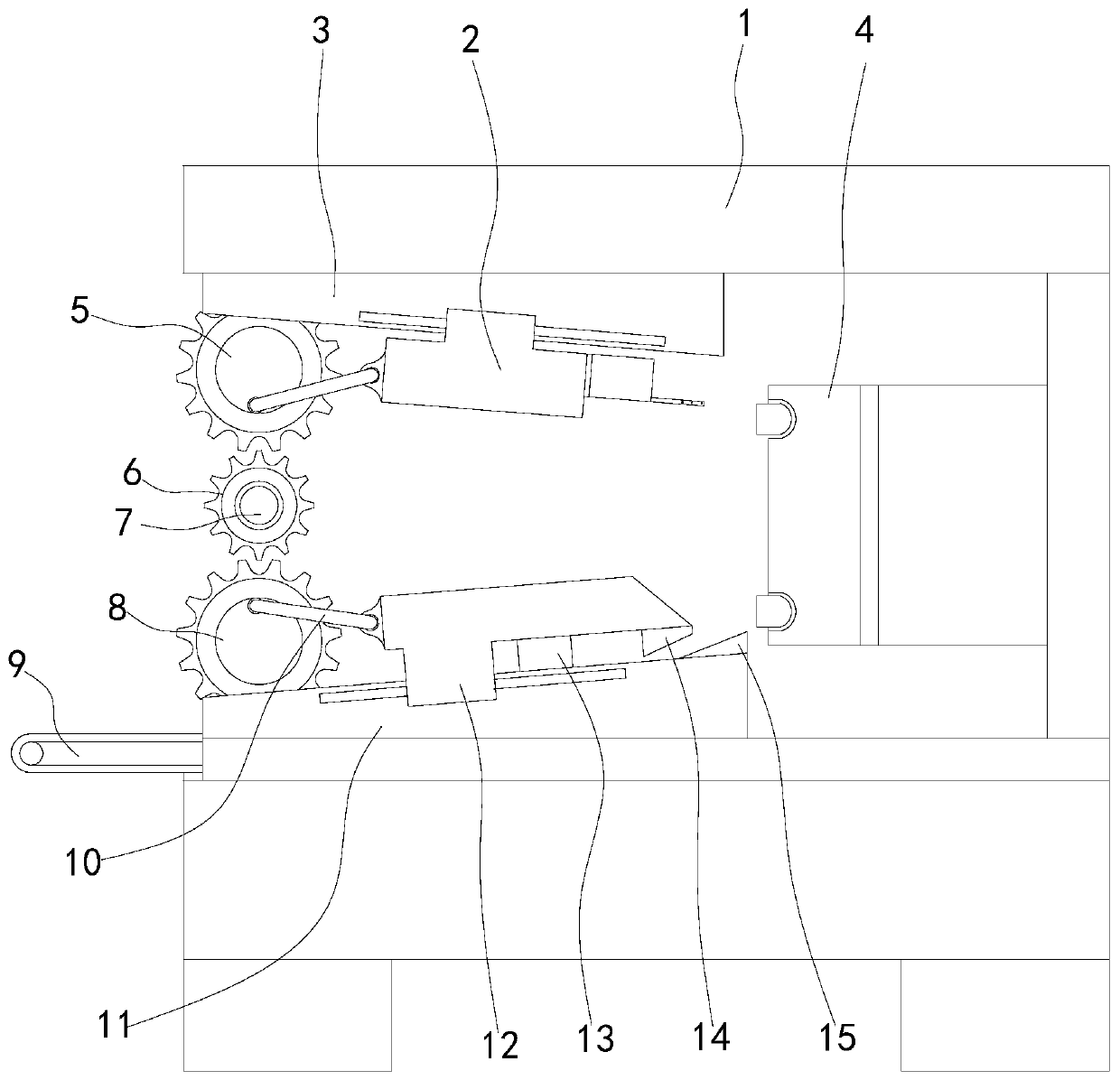

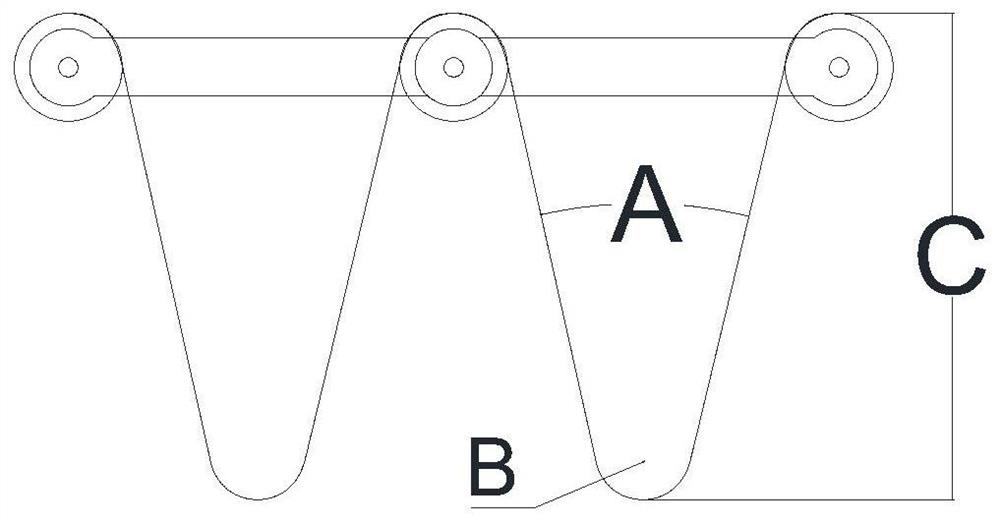

Arm type wavy cloth shaping device and shaping method thereof

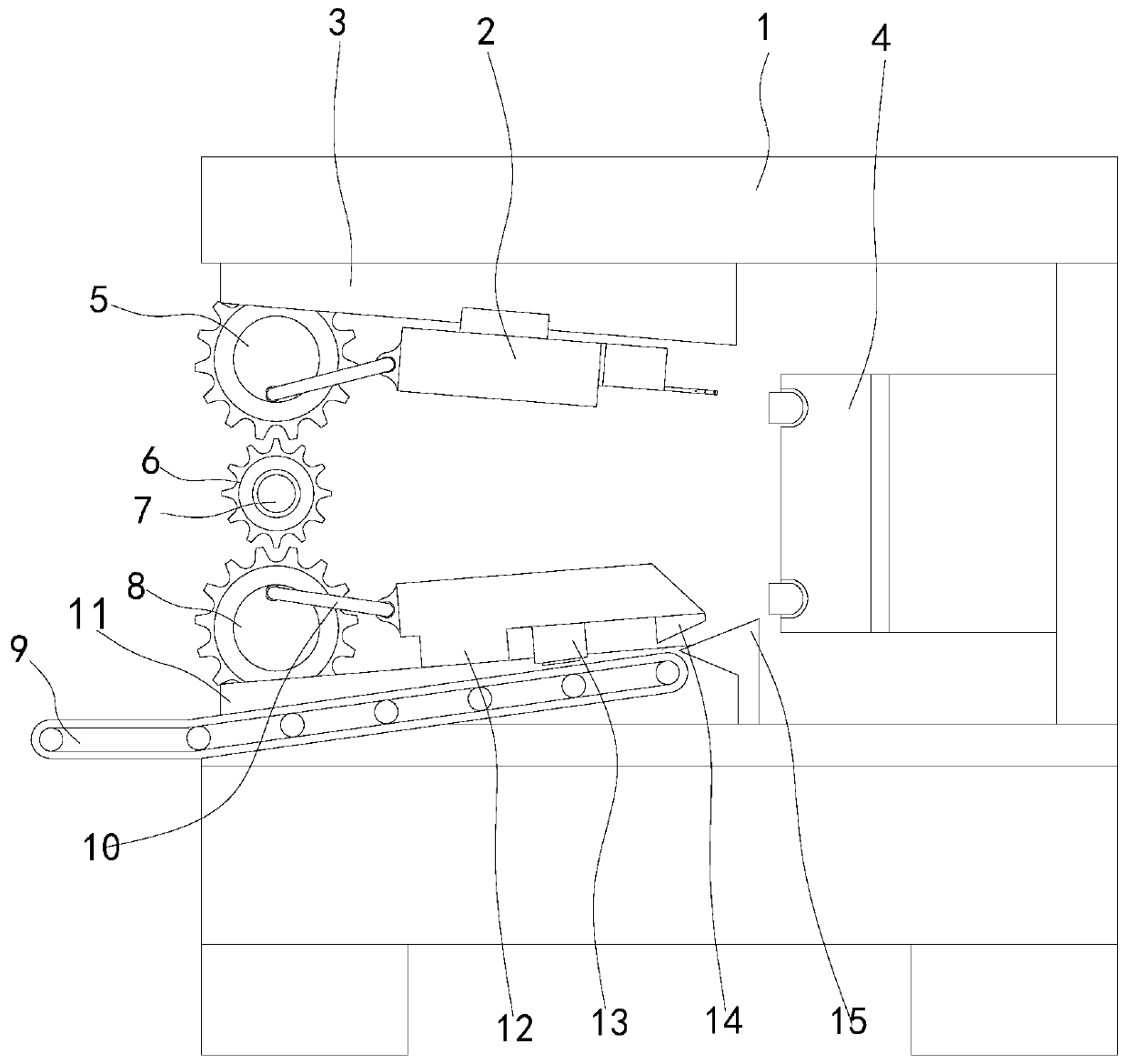

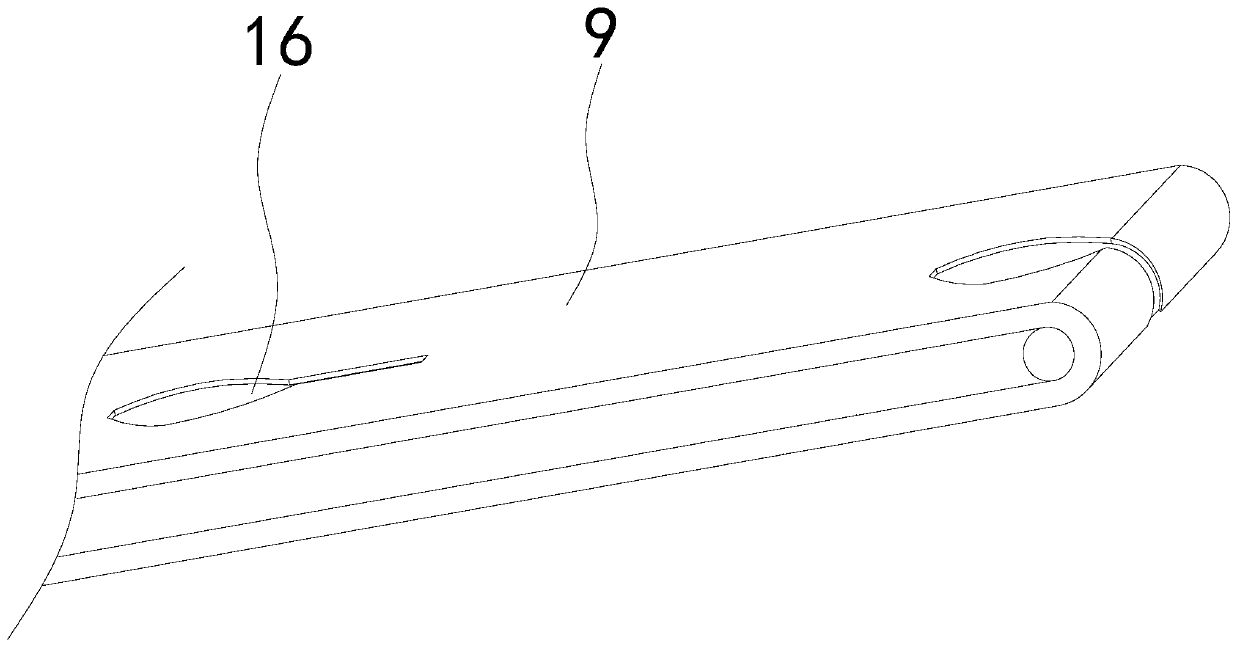

ActiveCN113403787AImprove styling efficiencyEasy to shapeHeating/cooling textile fabricsControl engineeringSprocket

The invention discloses an arm type wavy cloth shaping device and a shaping method thereof, and relates to the technical field of curtain or curtain paper film treatment. The arm type wavy cloth shaping device comprises a first shaping module and a second shaping module which are oppositely arranged in parallel, the first shaping module is provided with a closed first chain, and first rolling shafts are evenly distributed on the first chain; and a first gap is formed between the first rolling shafts, the second shaping module is provided with a closed second chain, movable arm sets are evenly distributed on the second chain, and the movable arm sets are matched with the first gap. The arm type wavy cloth shaping device has the following beneficial effects that the chain wheel structure is adopted to control the movable arm sets and the rolling shafts to move synchronously, a meshing structure of the movable arm sets and the rolling shafts moves continuously and circularly, products can be shaped continuously, and the shaping efficiency is greatly improved; the products are gradually cooled in a wave-shaped state, so that the shaping effect is more ideal; and loss parts similar to paper films do not exist in the shaping process, the cost is saved, and environmental protection is achieved.

Owner:浙江邂美科技有限公司

A blanket shaping device

ActiveCN106592145BIncrease the lengthImprove styling efficiencyHeating/cooling textile fabricsStretchingEngineeringMechanical engineering

Owner:新疆阿勒泰工业用呢有限责任公司

Clothing ironing device based on high-frequency electromagnetic wave principle

InactiveCN111335006ASolve the problem of excessive waste of water resourcesSolve the problem of different levels of moisture in ironingIroning apparatusTextiles and paperWater flowEngineering

The invention relates to the technical field of clothing, and discloses a clothing ironing device based on a high-frequency electromagnetic wave principle. The clothing ironing device comprises an ironing frame, wherein a ball is connected to the interior of an ironing plate; sliding rods are arranged at the left end and the right end of the ball respectively; a metal block is arranged at the right end of the sliding rod on the right side; a variable resistor is connected to the right end of the metal block; a coil is arranged in a water spraying device; and the right end of a magnetic block is connected with an adjusting plate. The airflow in a ventilation tank covered with a clothing piece in a branch gas tank is too low, the metal block in the covered branch gas tank is connected with the variable resistor, the flow speed in the branch gas tank is not large, the airflow pushes an electric metal block of the ball to be separated from the variable resistor, the spiral coil is electrified to generate a magnetic field to push the magnetic block to move rightwards, and the magnetic block drives the adjusting plate to adjust the water flow in a branch water tank, so that the structuresolves the problem of excessive water resource waste of an existing clothing ironing device.

Owner:杭州汉辰服饰有限公司

Transfer device for automobile flexible shaft machining

InactiveCN111422550APlay a buffer roleStable deliveryRollersRoller-waysStructural engineeringManufacturing engineering

The invention relates to the technical field of automobile flexible shaft machining, in particular to a transfer device for automobile flexible shaft machining. The transfer device comprises a machining table, a positioning table arranged at one end of a table surface of the machining table, a bidirectional translation mechanism, a bidirectional buffering mechanism and a bidirectional abutting rotating mechanism. The bidirectional translation mechanism comprises a synchronous driving assembly and two thread moving assemblies, and the bidirectional buffering mechanism comprises two buffering moving assemblies. The bidirectional abutting rotating mechanism comprises two rectangular boxes, the two adjacent ends of the two rectangular boxes are provided with avoiding accesses for avoiding penetrating of a workpiece, each rectangular box is internally provided with one abutting rotating assembly, each abutting rotating assembly comprises a plurality of sliding wheels which are evenly distributed in the horizontal direction of the corresponding rectangular box and can abut against the workpiece, and the positioning table is provided with a positioning groove used for containing one end of the workpiece. By means of the technical scheme, the flexible shaft can be prevented from being clamped in a conveying process, can be stably conveyed, and stability and machining efficiency are improved.

Owner:陈壮

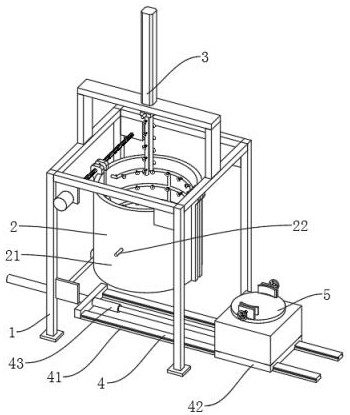

Heating molding device for cement culvert pipe production and using method thereof

ActiveCN112123541AUniform and stable heatingImprove styling efficiencyCeramic shaping apparatusHeat settingMaterials science

The invention discloses a heating molding device for cement culvert pipe production and a using method thereof. The heating molding device comprises a support frame and an outer ring heating molding mechanism, wherein the outer ring heating molding mechanism is arranged on the support frame, and an inner ring heating molding mechanism is arranged in the center of the outer ring heating molding mechanism; and the inner ring heating molding mechanism is arranged above the support frame, a moving mechanism is arranged on the lower side of the support frame, and a rotating supporting mechanism isarranged at the upper end of the moving mechanism. According to the heating molding device for cement culvert pipe production and the using method thereof, a cement culvert pipe is driven to rotate during heat setting through rotation of a rotating disc; meanwhile, hot air sources and water mist sprayed out of first spray heads and second spray heads on the inner side and the outer side of the cement culvert pipe are sprayed to the inner surface and the outer surface of the culvert pipe, so that the cement culvert pipe is subjected to water mist curing firstly and then subjected to hot air drying, heating is more stable and uniform, and the shaping efficiency and quality of the cement culvert pipe are improved; and in addition, a supporting box is driven to move through a sliding base, sothat the cement culvert pipe conveniently enters and exits the outer ring heating molding mechanism, and operation convenience is improved.

Owner:衡阳市畅通管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com