Arm type wavy cloth shaping device and shaping method thereof

A sizing device, wave-shaped technology, applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc., can solve problems such as low efficiency, achieve the effect of improving sizing efficiency, ideal sizing effect, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

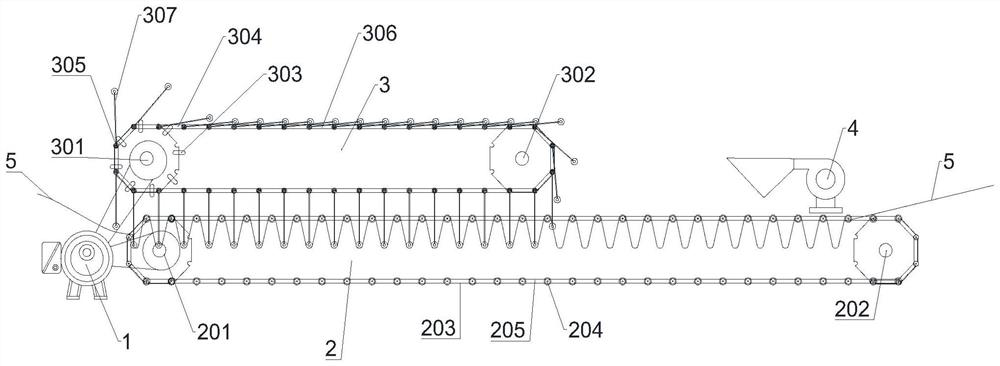

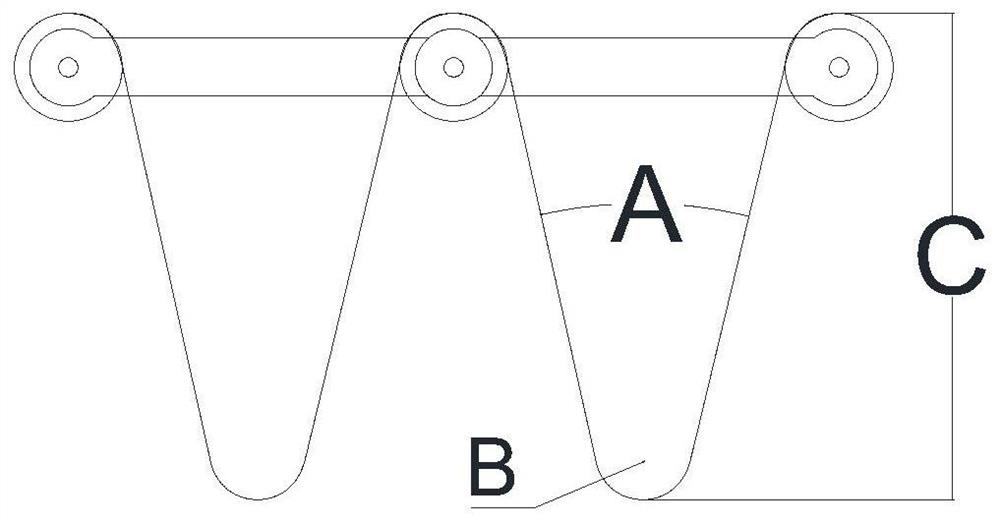

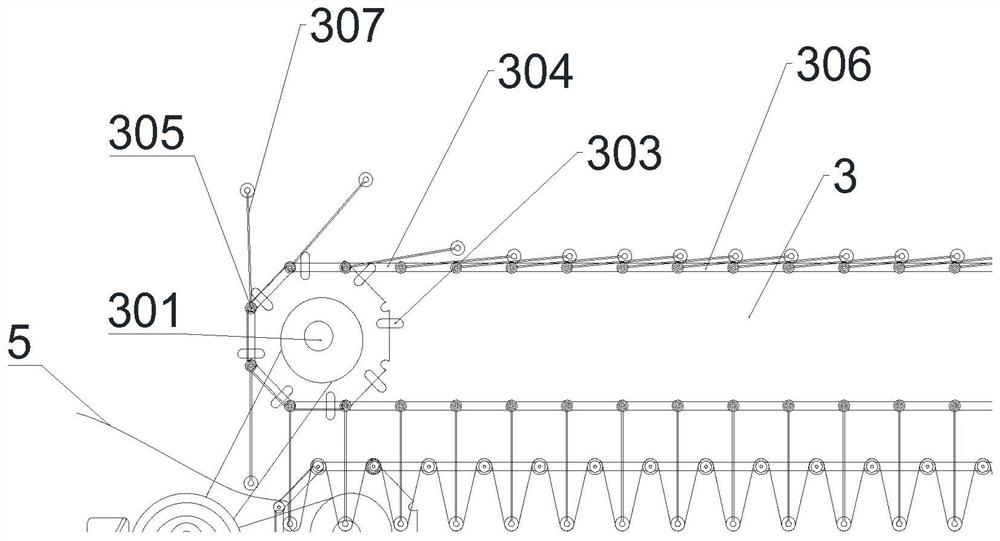

[0033] combined with Figure 1-5 , the arm-type wave-shaped cloth shaping device, including a first shaping module 2 and a second shaping module 3 arranged in parallel, the first shaping module 2 and the second shaping module 3 are conveyor belt-shaped, and the second shaping module The sizing module 3 is connected to the mobile tool. The first sizing module 2 is provided with a closed first chain 203. The first chain 203 is evenly distributed with first rollers 204. Between the first rollers 204 A first gap 205 is provided, and the second sizing module 3 is provided with a closed second chain 304, on which second rollers 305 are evenly distributed, and between the second rollers 305 there are In the second gap 306 , a movable arm group 307 is hinged at the second roller shaft 305 , and the movable arm group 307 cooperates with the first gap 205 . Such as figure 1, the first shaping module 2 is on the bottom, the second shaping module 3 is on the top, and the product 5 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com