Patents

Literature

54results about How to "Uniform and stable heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

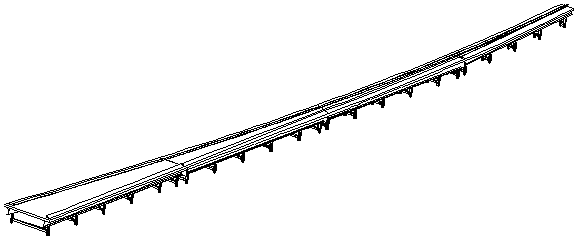

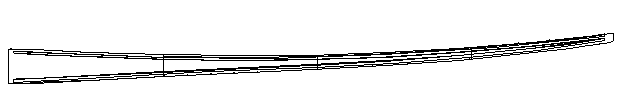

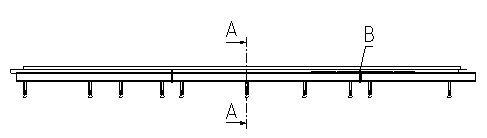

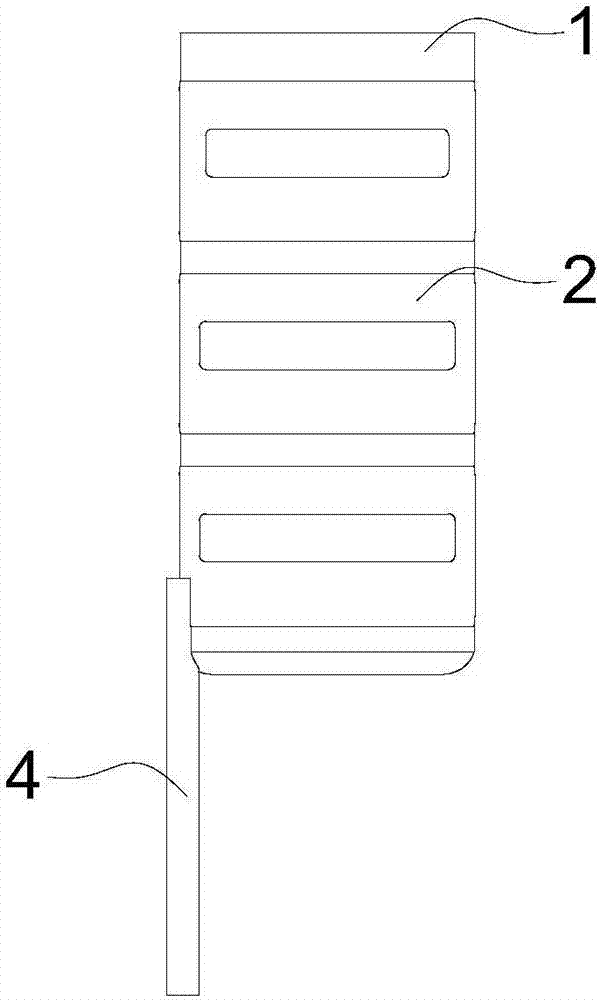

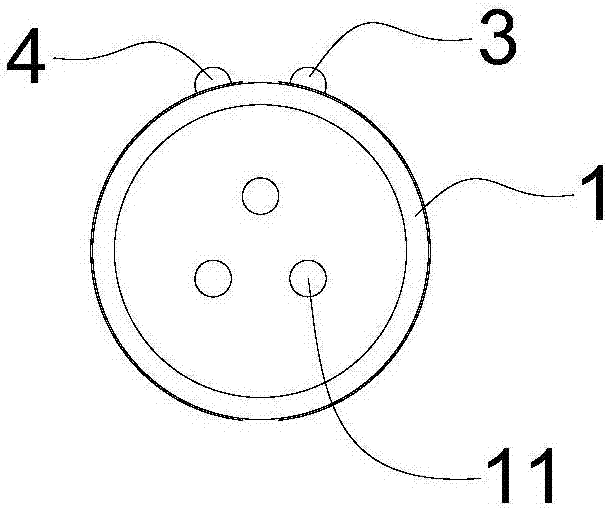

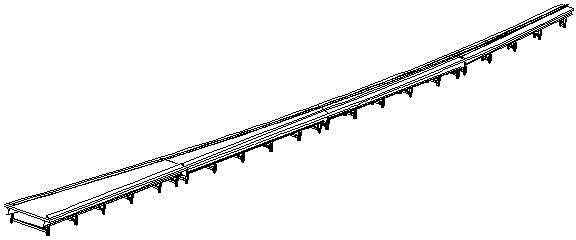

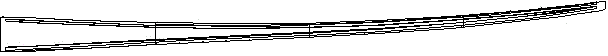

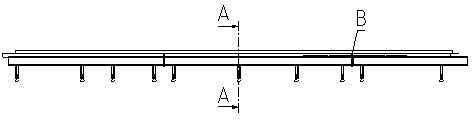

Fabrication method of wind power vane web mold

The invention relates to a fabrication method of a wind power vane web mold. Metal is adopted as a material. The method comprises the steps that 1) a foundation support is prefabricated and arranged in the length direction of a preformed wind power vane web, 2) a mold heating layer with the same surface area as the foundation support is arranged on the fabricated foundation support, 3) a surface steel plate is horizontally laid on the upper surface of the formed mold heating layer, 4) a flanging mechanism of the wind power vane web mold is arranged on the upper surface of the surface steel plate, 5) a plurality of vacuum holes for mounting vacuum nozzles are formed on the outer side of the flanging mechanism in the length direction of the wind power vane web mold, the vacuum nozzles are connected with a peripheral vacuum pump by vacuum pipes connected with the vacuum nozzles, and 6) all sections of wind power vane web mold are sequentially connected from the wide section to the narrow section by end part connection components to form the complete wind power vane web mold. The method is simple and direct in process, low in cost and reusable, and facilitates popularization and application, and the processing mold does not deform easily.

Owner:中材科技(萍乡)风电叶片有限公司

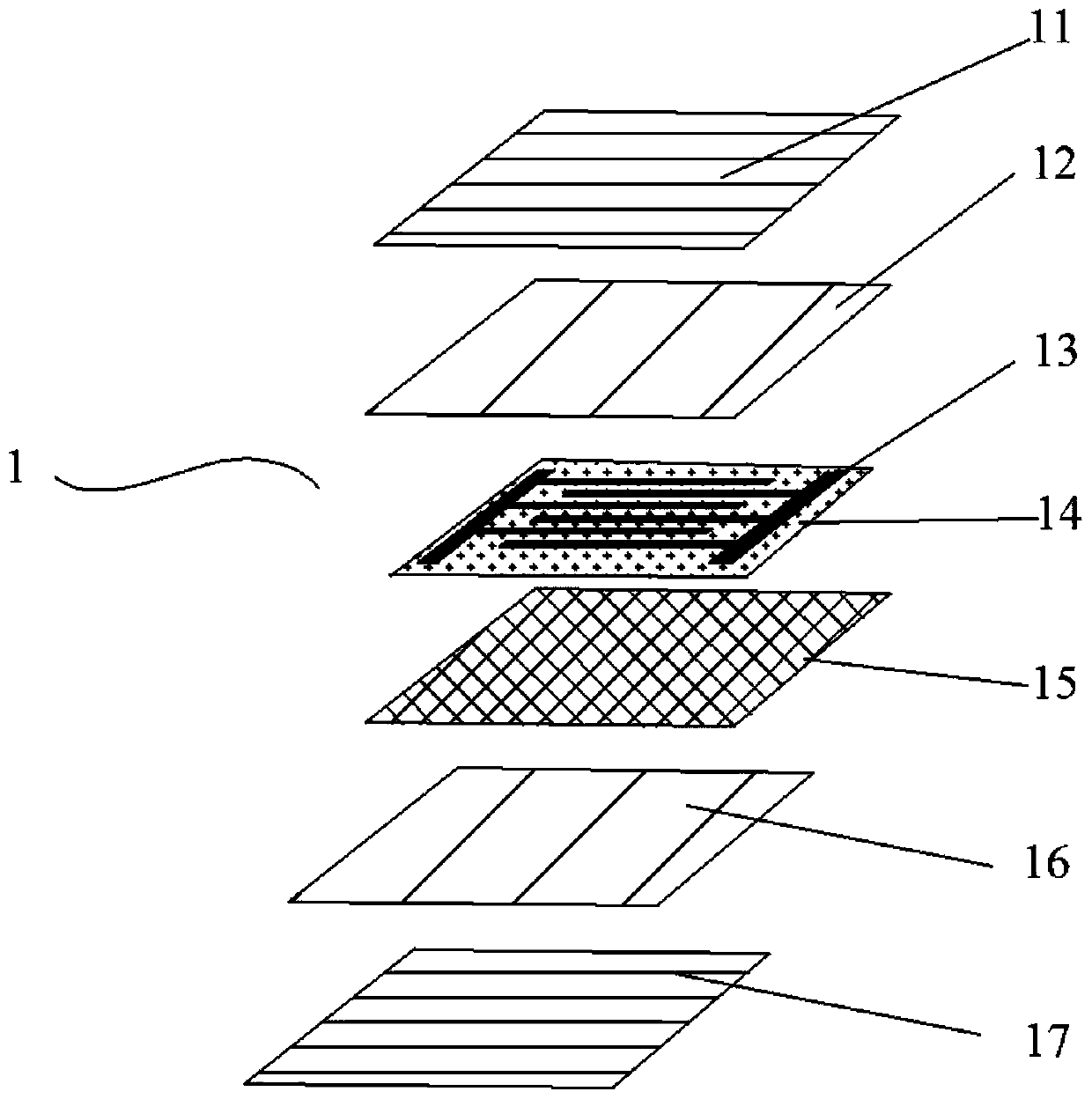

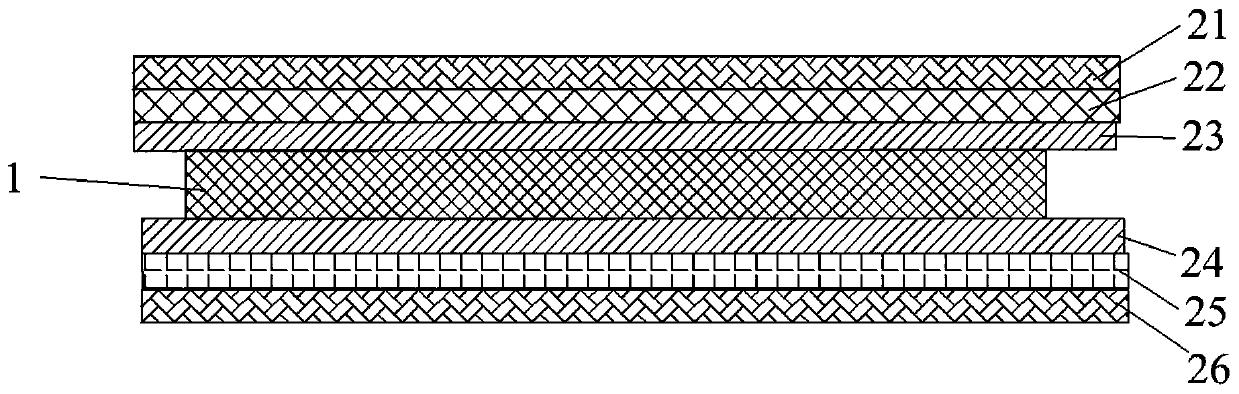

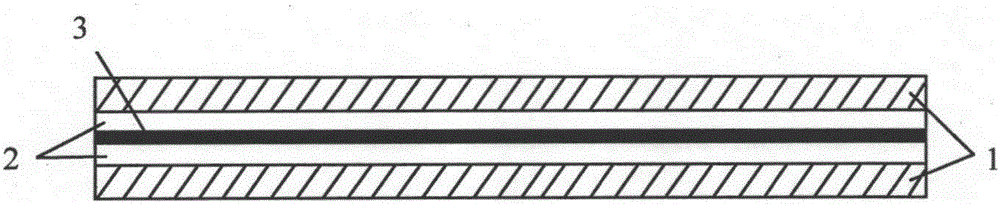

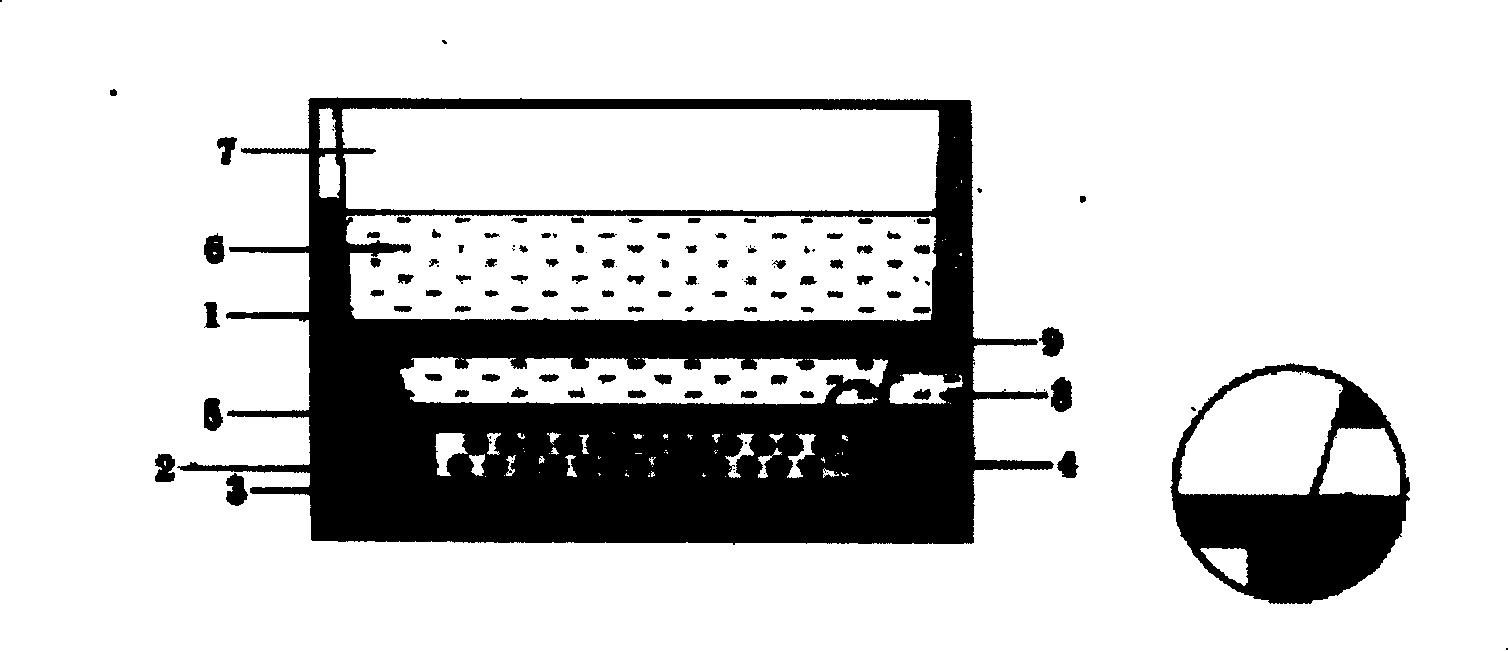

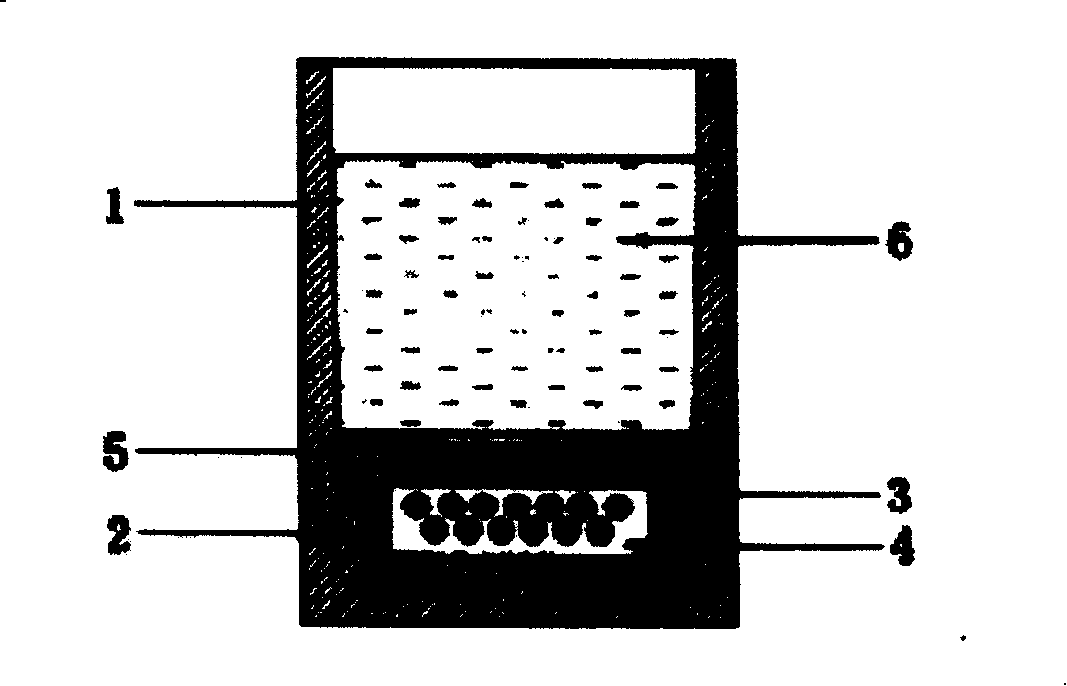

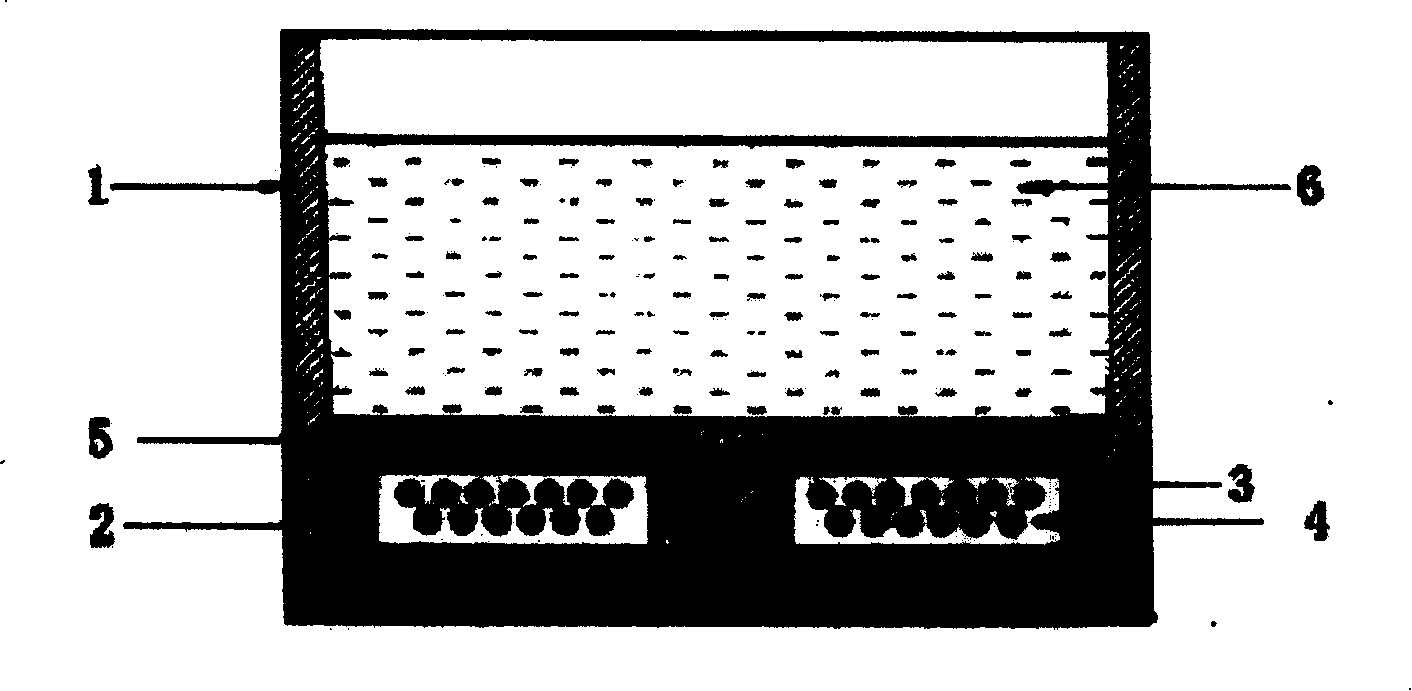

Graphene heat-emitting film assembly with single-side far infrared radiation function and bed warmer based on graphene heat-emitting membrane assembly

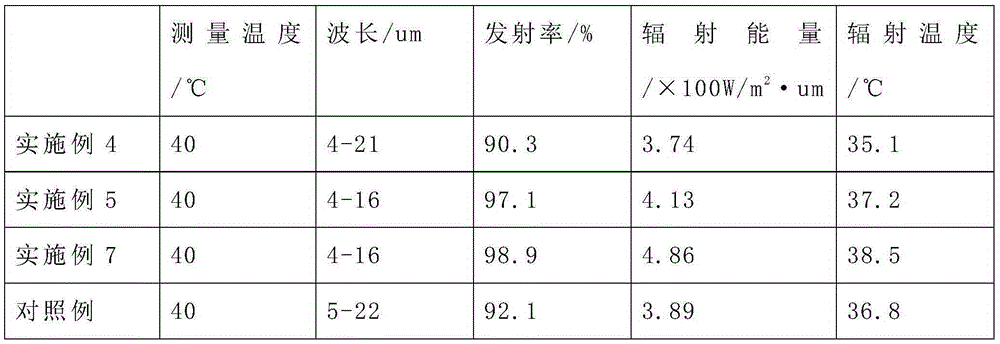

PendingCN110475396AUniform and stable heatingImprove the effect of physical therapyOhmic-resistance electrodesChemical industryBlood circulationFar infrared

The invention discloses a graphene heat-emitting film assembly with a single-side far infrared radiation function and a bed warmer based on the graphene heat-emitting film assembly. According to the graphene heat-emitting film assembly of the invention, one surface of a graphene heat-emitting film layer, which is far away an electrode layer, is provided with a far infrared reflecting layer. The graphene heat-emitting film assembly disclosed by the invention has an excellent infrared reflection effect and is more energy-saving; the bed warmer based on the graphene heat-emitting film assembly has the advantages of good heat-emitting stability, high temperature rise speed, uniform heat emission and soft material, and can realize the physical therapy functions of promoting blood circulation, repairing cells, preventing diseases and the like..

Owner:合肥微晶材料科技有限公司

Far-infrared carbon fiber composite heating film

The invention relates to a far-infrared carbon fiber composite heating film, which comprises an upper base layer, a lower base layer, a carbon fiber composite heating layer, an upper insulated flame-retardant and heat-resistant waterproof layer and a lower insulated flame-retardant and heat-resistant waterproof layer, wherein the carbon fiber composite heating layer is located between the upper base layer and the lower base layer; and the upper insulated flame-retardant and heat-resistant waterproof layer and the lower insulated flame-retardant and heat-resistant waterproof layer coat the outer sides of the upper base layer and the lower base layer, wherein the far-infrared carbon fiber composite heating film is preferably carbon fiber cloth or carbon fiber composite paper. The far-infrared carbon fiber composite heating film is simple in structure, has good flexibility and can be freely cut and folded; the flexibility is not affected in a low-temperature condition; the load resistance deviation does not exceed 8% after a single side is folded for 1,000 times at a speed of 30times / min; the security and the stability are significantly improved; the service life is long; and furthermore, the far-infrared carbon fiber composite heating film has high external insulativity, high-temperature resistance, open fire resistance and waterproofness, the internal conductivity and the heating property are good and the security is high.

Owner:石家庄邦迪高分子材料有限公司

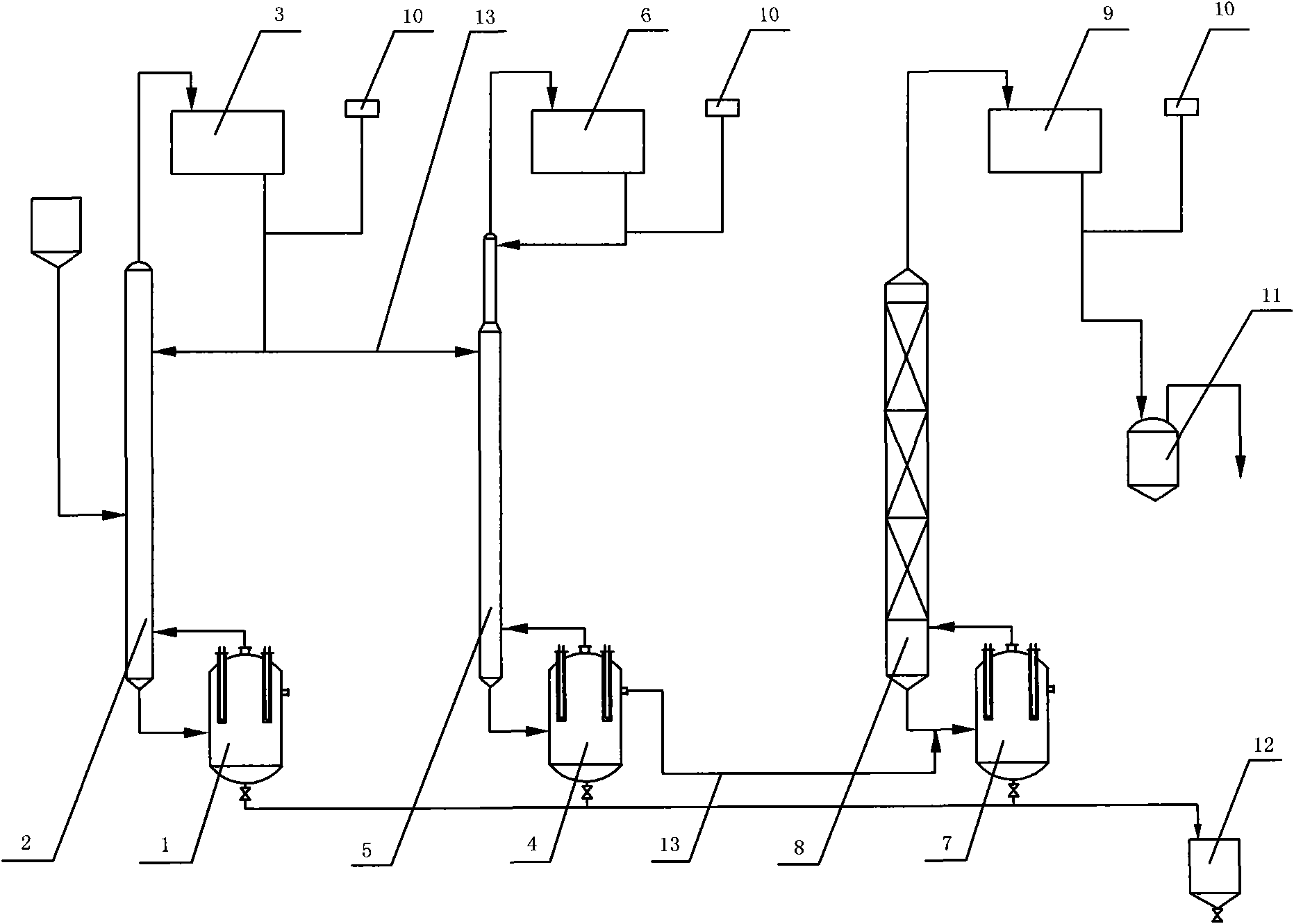

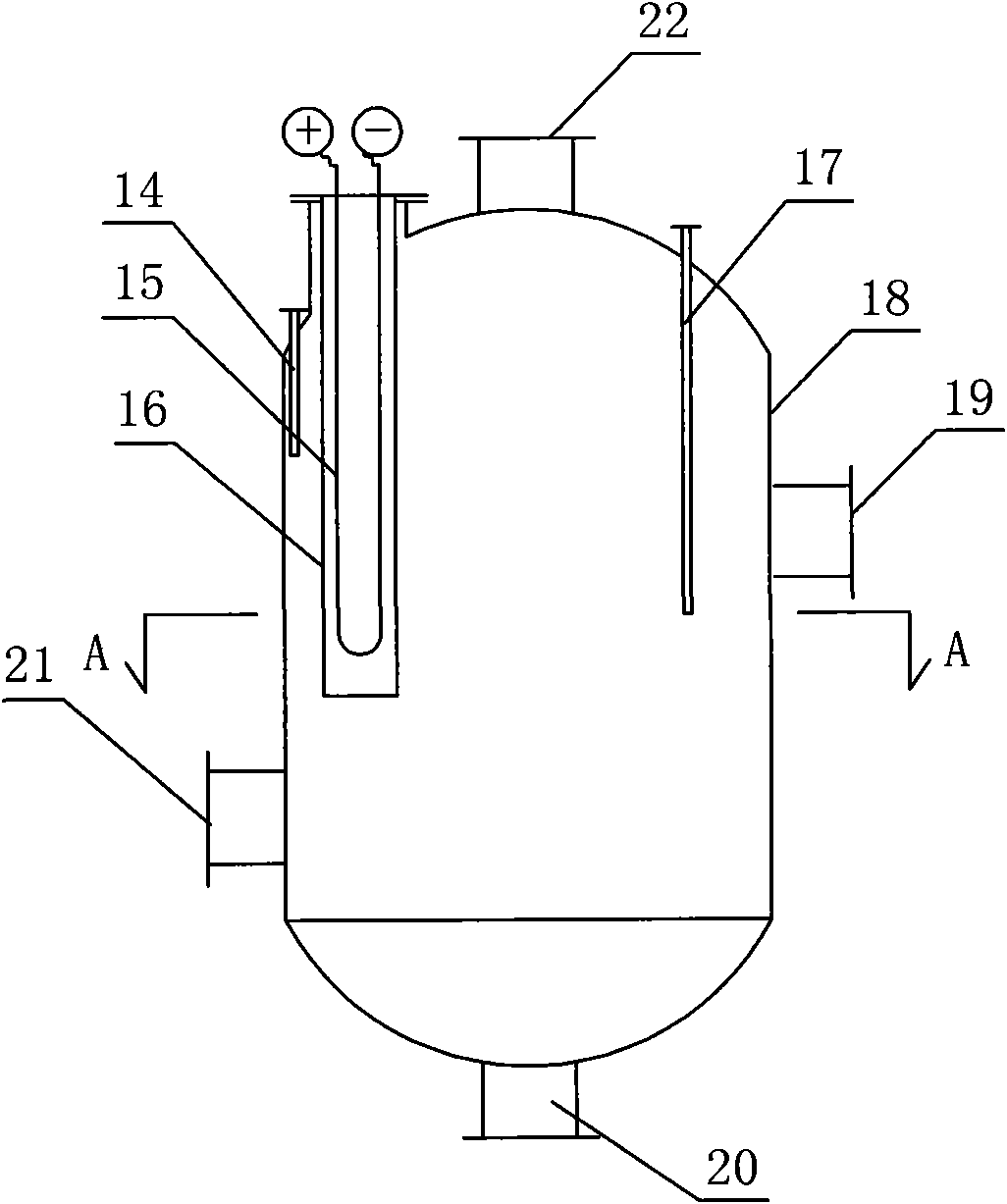

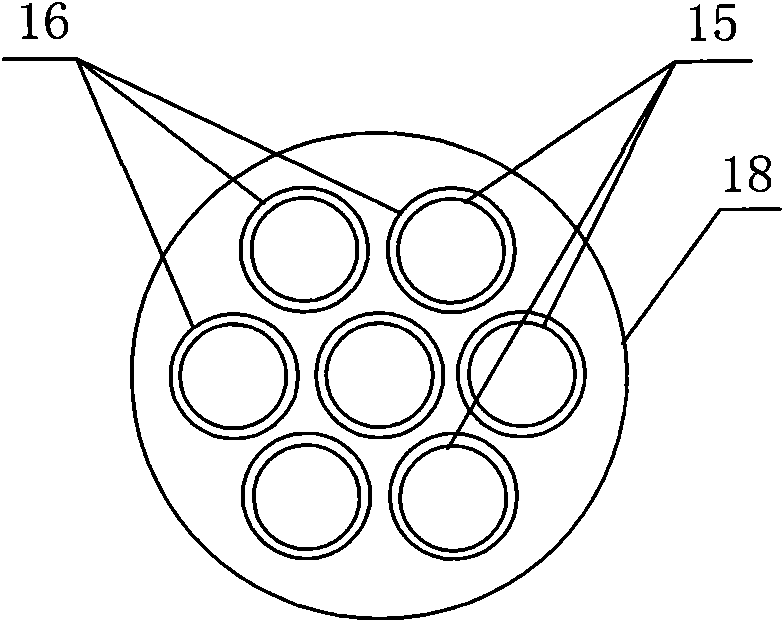

Rapidly heating distillation device in titanium tetrachloride refining process

InactiveCN101844802AUniform and stable heatingUniform and stable productionTitanium halidesDistillationTower

The invention belongs to the technical field of titanium sponge production by a magnesium method and in particular relates to a rapidly heating distillation device in a titanium tetrachloride refining process. The invention adopts a technical scheme that: the rapidly heating distillation device in the titanium tetrachloride refining process comprises a distillation still, a distillation tower, a cooler, a respiration tank, a ground tank and a finished product storage tank which are connected with one another sequentially through pipelines. The rapidly heating distillation device has the advantages of raising the temperature uniformly and stably, realizing automation easily, increasing production yield by 30 percent, reducing energy consumption by 15 percent, greatly improving the purity of the products, saving energy and reducing consumption, greatly improving the quality of the products and protecting the surrounding environment, along with simple and rapid operation, stable production, good separation effect and low production cost.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

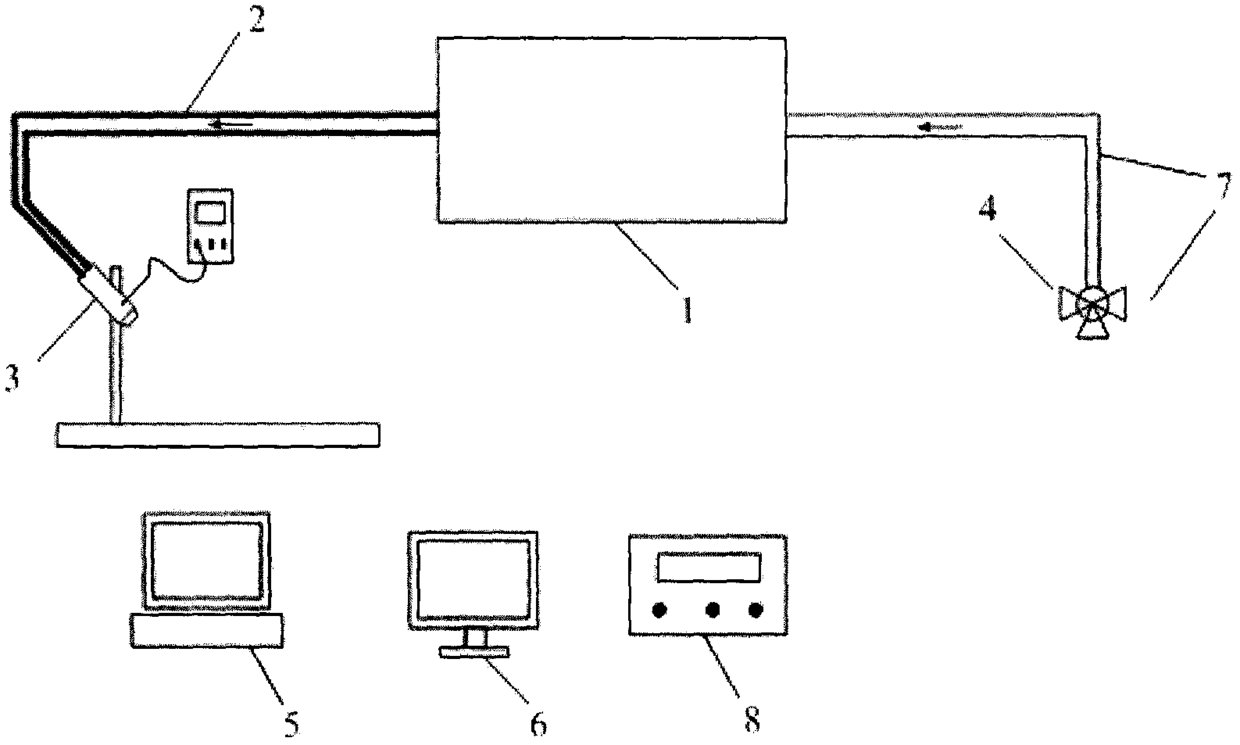

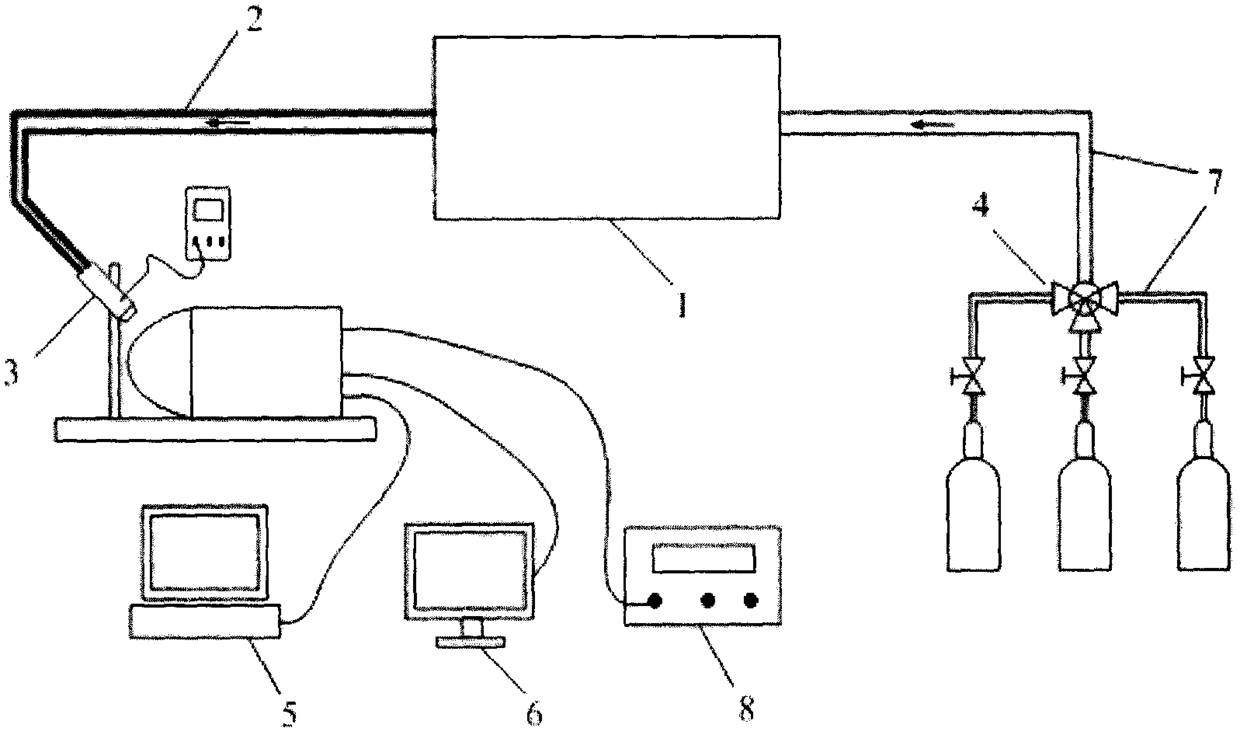

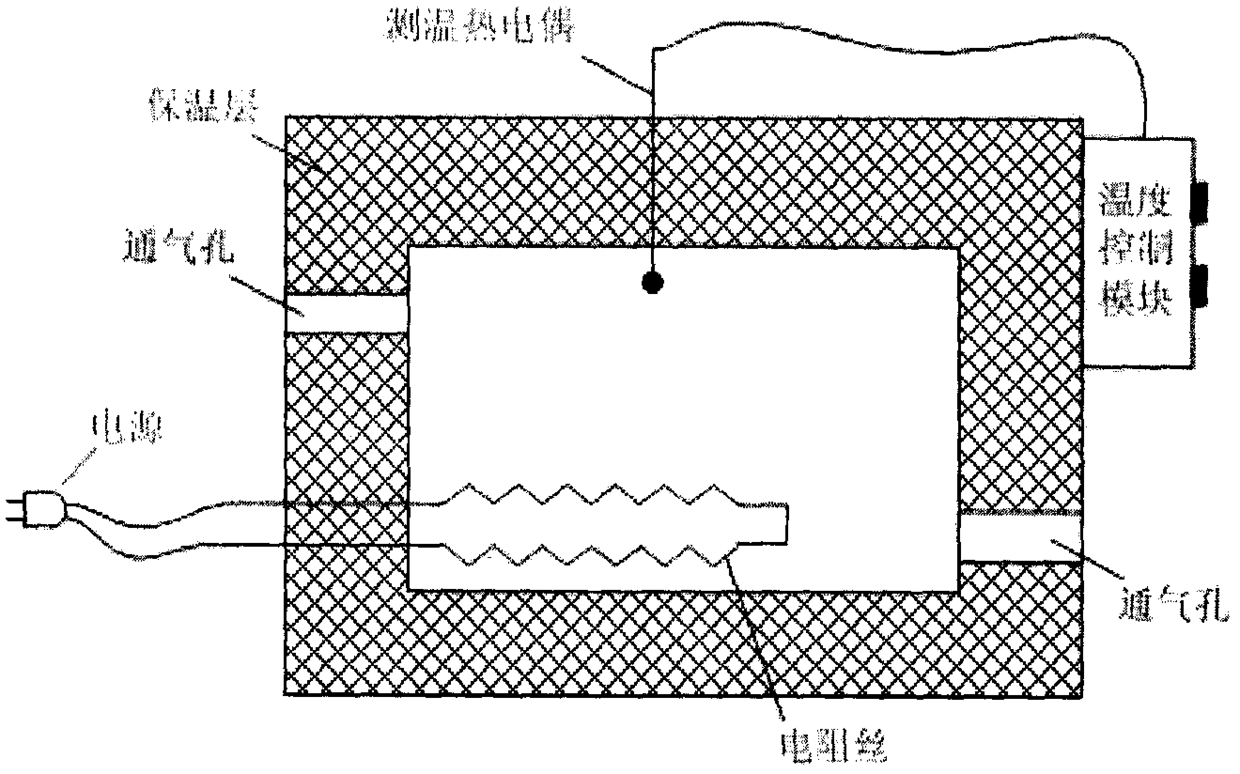

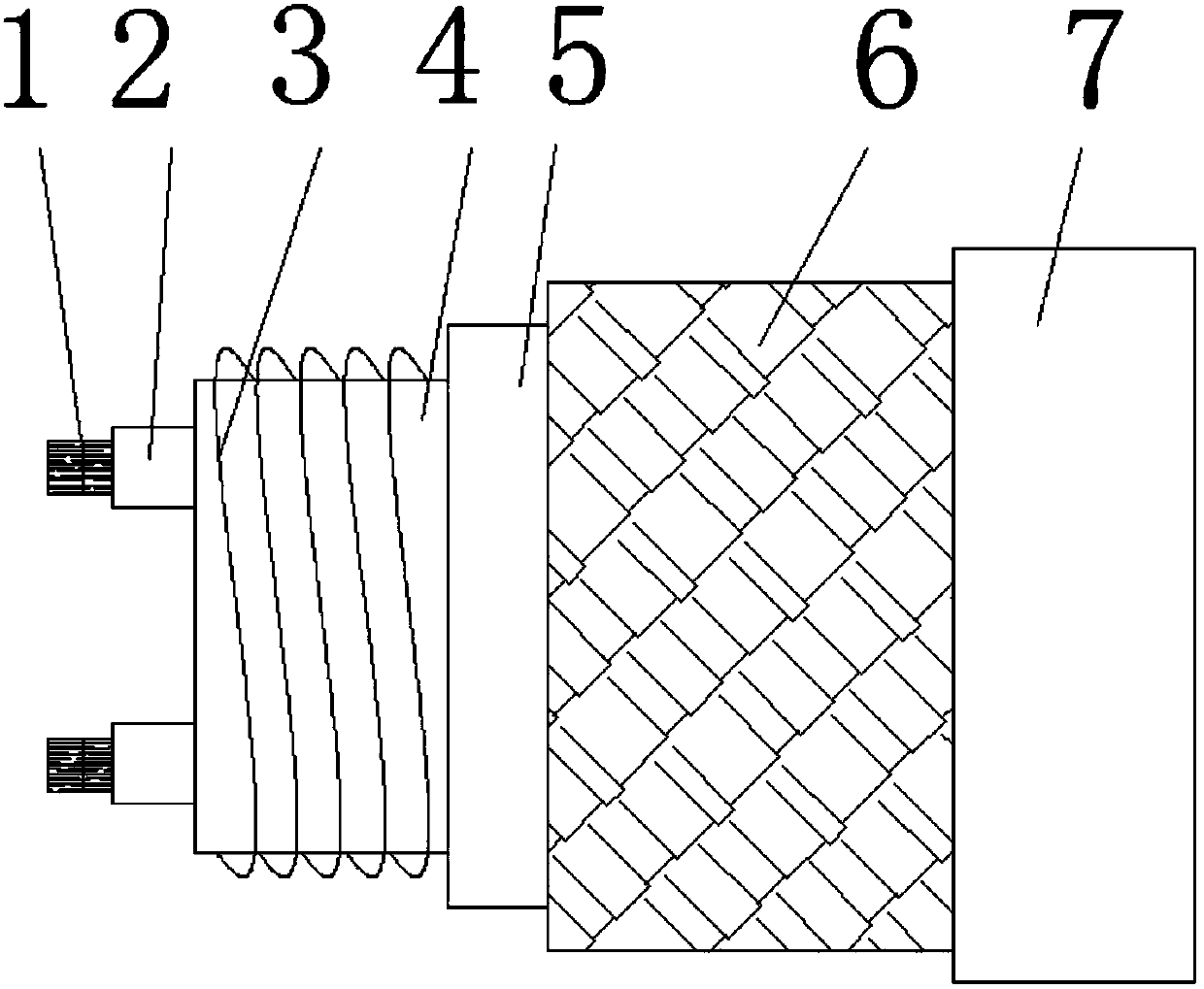

An infrared imaging seeker thermal flow imaging test device

ActiveCN108811528BUniform and stable heatingVerify the imaging effectInstrumentsHeat flowEngineering

The invention discloses an infrared imaging seeker heat flow imaging test device, which comprises a constant temperature heating chamber, a heat insulation conduit, a nozzle, a multi-channel gas valve, an image acquisition module, and a monitoring module. The multi-channel gas valve is used for mixing different gases. It is output to the constant temperature heating chamber through the conduit; the constant temperature heating chamber is used for constant temperature heating of the gas in the chamber; one end of the heat insulation conduit is connected to the constant temperature heating chamber, and the other end is connected to the nozzle, which is used to insulate and transport the heated gas; the nozzle is used to The gas delivered through the heat-insulated conduit is sprayed to the infrared imaging seeker head cover; the image acquisition module is connected with the infrared imaging seeker to collect and store the image data output by the infrared imaging seeker; the monitoring module is connected to the infrared imaging seeker It is used to observe the infrared image of the infrared imaging seeker in real time. The implementation of the invention can qualitatively simulate the aero-optical effect of the infrared imaging seeker during high-speed flight, and verify the imaging effect of the infrared imaging seeker under the thermal effect condition.

Owner:AEROSPACE SCI & IND MICROELECTRONICS SYST INST CO LTD

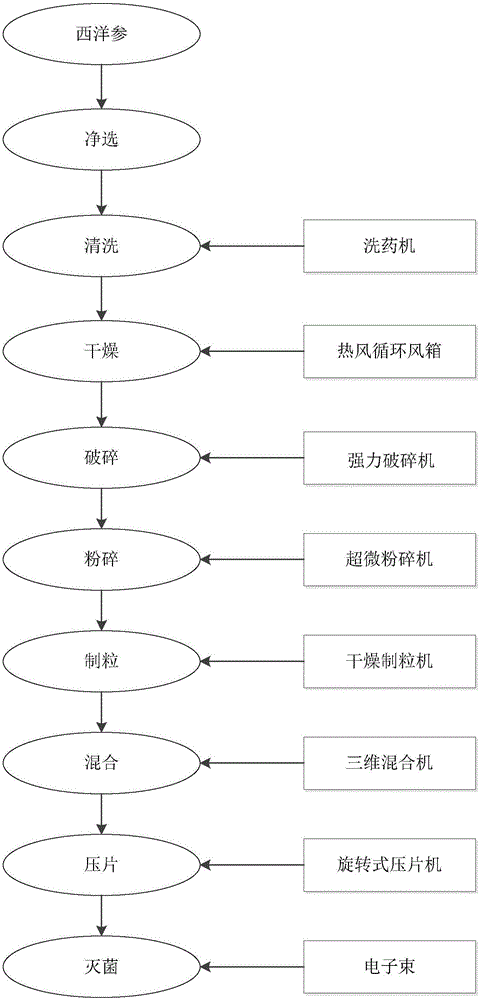

Preparation method of panax quinquefolius raw powder tablets

InactiveCN105902587ADisintegrates quicklySpeed up entryNervous disorderPill deliveryBioavailabilityProcessing cost

The invention discloses a preparation method of panax quinquefolius raw powder tablets, and belongs to the technical field of health care products. The method comprises nine steps: sorting, cleaning, drying, crushing, grinding, granulating, mixing, tabletting and sterilizing. The panax quinquefolius raw powder tablets do not contain any auxiliary materials; the bioavailability of product is increased; the product is more convenient to use, with longer guarantee period, lower processing cost, good dispersibility, miscibility and absorbability, thus the effective constituents of panax quinquefolius enter human body quickly; the original taste is reserved, and the health care function is increased; moreover, the dosage can be exponentially reduced, thereby effectively increasing utilization ratio of rare resources.

Owner:HEBEI LIN YITANG MEDICAL CO LTD

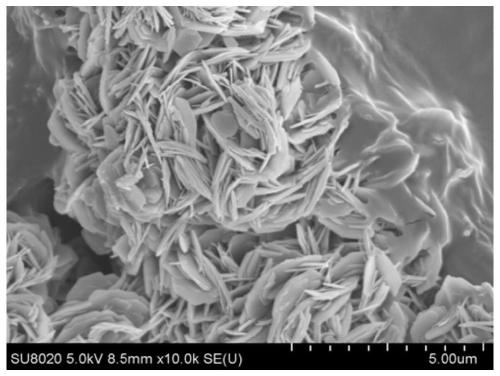

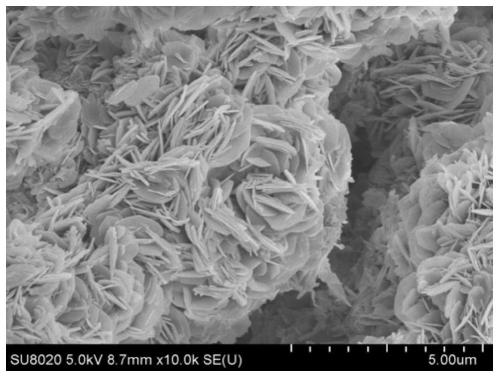

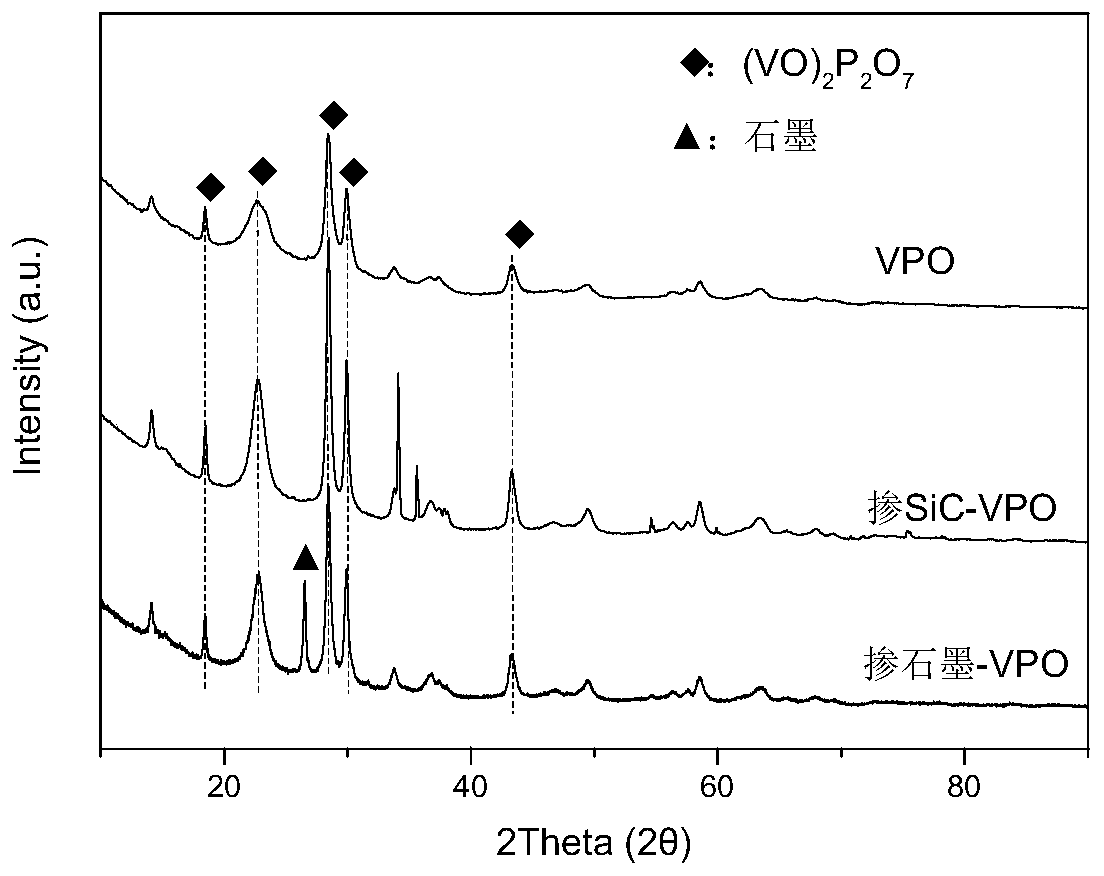

Oxyvanadium phosphate catalyst and preparation method and application thereof

InactiveCN109731594AEvenly heatedUniform and stable heatingOrganic chemistryPhysical/chemical process catalystsAlcoholPhosphate

The invention belongs to the technical field of catalysis and mainly relates to a preparation method of an oxyvanadium phosphate catalyst and application of the oxyvanadium phosphate catalyst in maleic anhydride preparation using selective n-butane oxidation. The preparation method includes the steps of firstly, mixing a vanadium source, benzyl alcohol, C1-C8 monohydric alcohol and a heat-conduction material to obtain a mixture, and performing reaction, wherein the heat-conduction material is at least one of SiC, graphite, graphene and carbon nanotubes; secondly, mixing the reaction product obtained in the first step with a phosphorus source, heating to 100-200 DEG C, and performing reaction to obtain a oxyvanadium phosphate precursor; thirdly, calcining to obtain the oxyvanadium phosphatecatalyst. The preparation method has the advantages that the heat-conduction material is added during the preparation and can effectively achieve heat conduction to solve the problem of local overheat; the uniform and stable formation of active phase is promoted effectively, the catalyst is promoted to be heated evenly during reaction, and catalyst performance is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-elastic electric-induced-heating compound film and preparation method thereof

InactiveCN106003889AIncrease elasticityImprove tensile propertiesLamination ancillary operationsSynthetic resin layered productsCarbon nanotubeRoom temperature

The invention provides a high-elastic electric-induced-heating compound film and a preparation method thereof. The preparation method for the high-elastic electric-induced-heating compound film is characterized by comprising the following steps: 1) soaking a carbon nano tube film into a graphene suspension liquid for a period of time, and then taking out and naturally airing under room temperature, thereby obtaining a flexible nanometer conductive film; 2) taking an elastic film as an elastic adhering substrate, applying a certain tensile force to the two ends thereof, stretching for a certain elongation and then fixing, and coating the upper surface of the elastic adhering substrate with a layer of liquid elastic adhesive; 3) pressing and soaking the flexible nanometer conductive film on the liquid elastic adhesive and curing the adhesive under a certain condition; 4) releasing the tensile force applied to the elastic adhering substrate and driving the flexible nanometer conductive film to retract, thereby obtaining the electric-induced-heating compound film. The electric-induced-heating compound film acquired according to the preparation method has the advantages of light weight, high flexibility and high elasticity as well as excellent anti-ageing property, safety and long service life.

Owner:DONGHUA UNIV

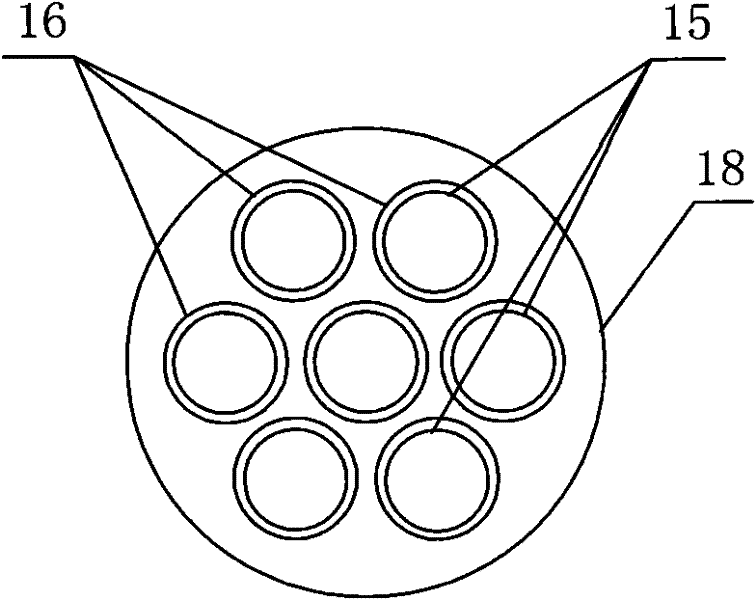

Parallel constant-power heat tracing band and manufacturing method thereof

InactiveCN108024400AImprove interface contact resistanceExtend your lifeHeating element shapesElectrical resistance and conductanceConstant power

The invention discloses a parallel constant-power heat tracing band and a manufacturing method thereof, and relates to the field of a heat tracing band. The manufacturing method comprises the following steps of 1) preparing a metal wire electrode; 2) preparing a bus insulating layer; 3) performing extrusion of the bus insulating layer; 4) performing irradiation cross linking; 5) performing heatingbody extrusion and heating element winding; 6) preparing an insulating inner sheath and a reinforced outer sheath; 7) performing extrusion of the insulating inner sheath; 8) performing secondary irradiation cross linking; 9) weaving a metal woven shielded layer; and 10) performing extrusion of the reinforced outer sheath. By virtue of structural innovation of adding the bus insulating layer on the outer layer of the metal conductive electrode, the interface contact resistance is improved and product service life is prolonged; by virtue of process innovation of adopting a co-extrusion processmethod, expansion difference is lowered; by adopting a manufacturing method of an equal-tension regular structure stranded wire, the requirements of ultra thin appearance and high length extrusion ofthe bus insulating layer can be ensured; by adding the step of one time of irradiation cross linking, product durability is improved; and the parallel constant-power heat tracing band is uniform and stable in heating, suitable for the majority of environments, and resistant to water and oil.

Owner:ANHUI HERTE ELECTRIC CO LTD

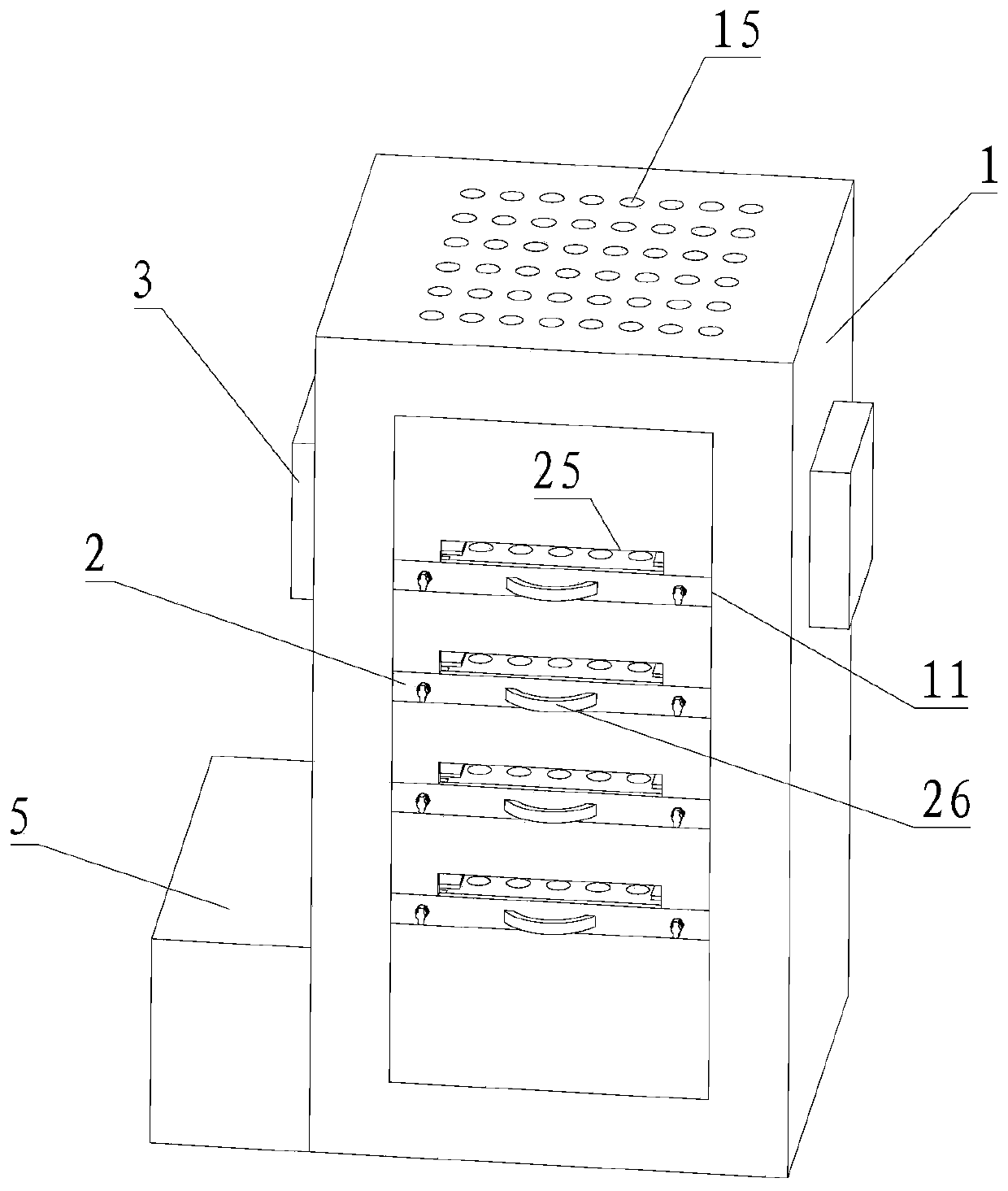

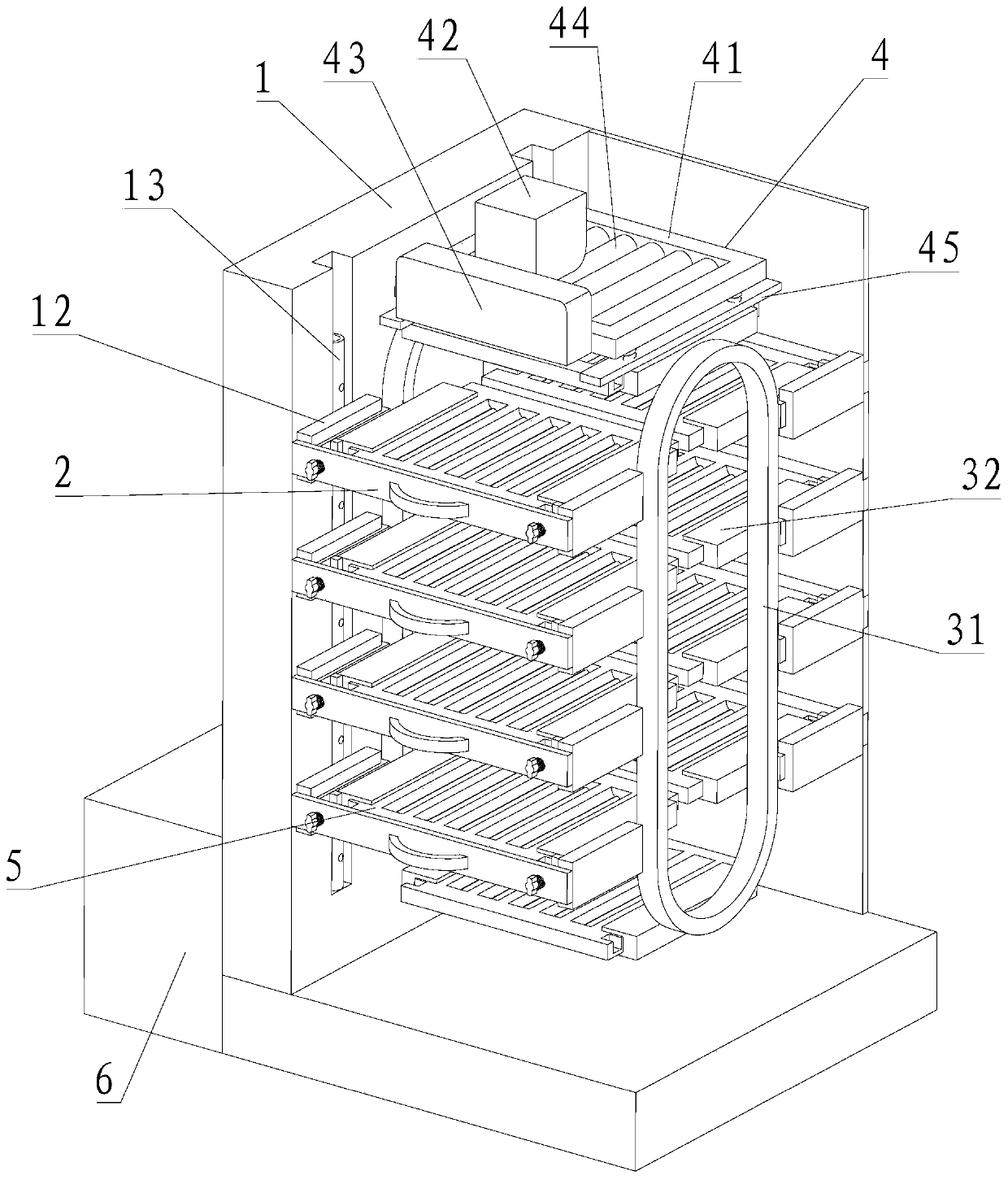

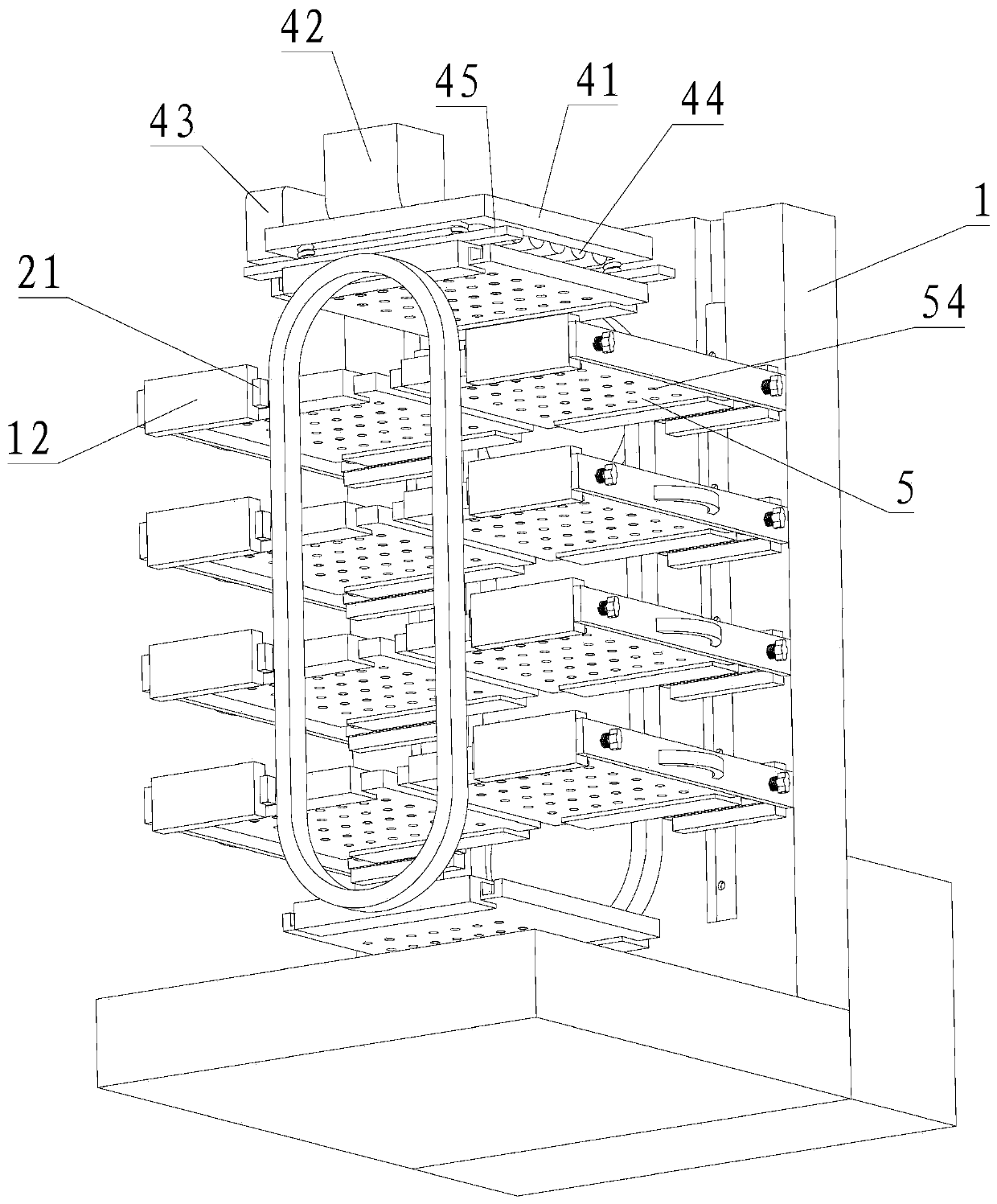

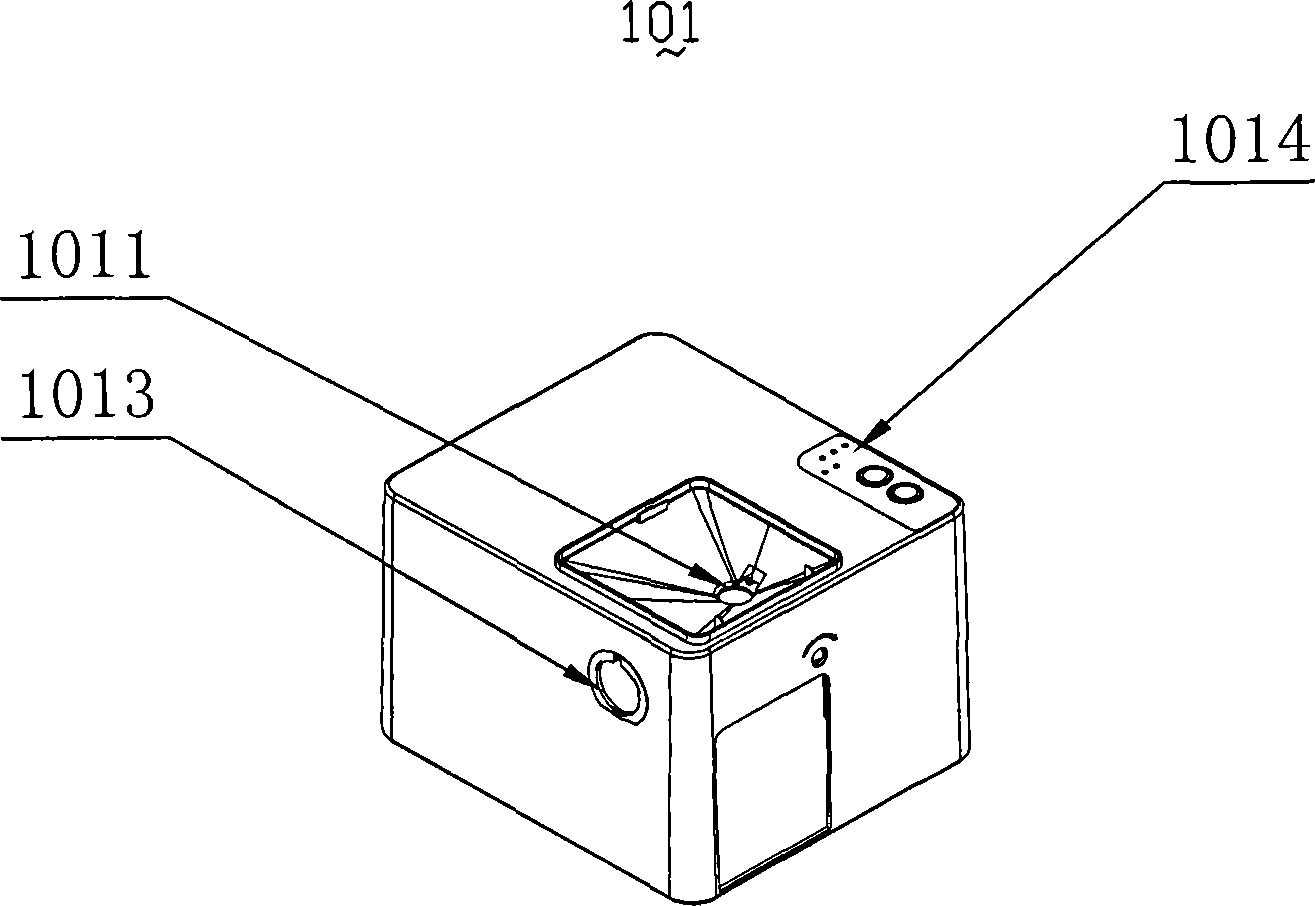

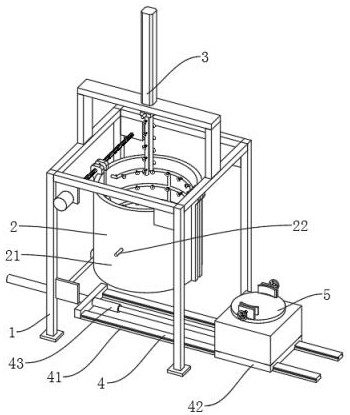

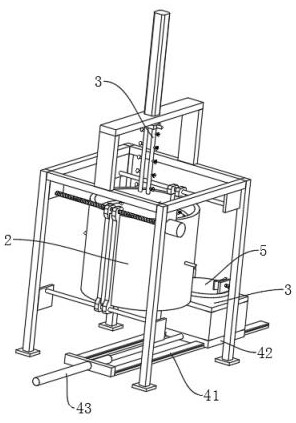

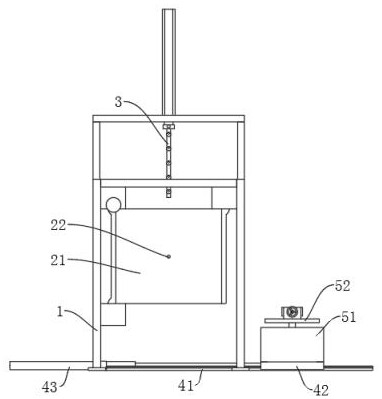

Hatching device with egg turning function

InactiveCN110800643ASimple structureSmall change in transmission ratioPoultry incubationEngineeringMechanical engineering

The invention relates to the field of breeding facilities, in particular to a hatching device with an egg turning function. The hatching device comprises an incubator, drawer boards, rotating devices,an egg turning device and hatching trays. The surface of the incubator is provided with an opening, the drawer boards are arranged in the opening, inner side walls of the incubator are provided withslide grooves, and the slide rods are fixedly connected to two ends of the drawer boards and slidably connected in the slide grooves. Rotating shafts penetrating the drawer boards are rotationally connected to the drawer boards, and one end, on the inner side of the incubator, of each rotating shaft is fixedly connected with a clamping block. The hatching device has advantages that by separation of the egg turning device and the hatching trays, the multiple hatching trays share one egg turning device, and the hatching amount of the hatching device is unlimited by the egg turning device; the independent egg turning device is simple in structure and low in transmission ratio variation, and stability and uniformity in an egg turning process are realized.

Owner:福建省新魁强禽业发展有限公司

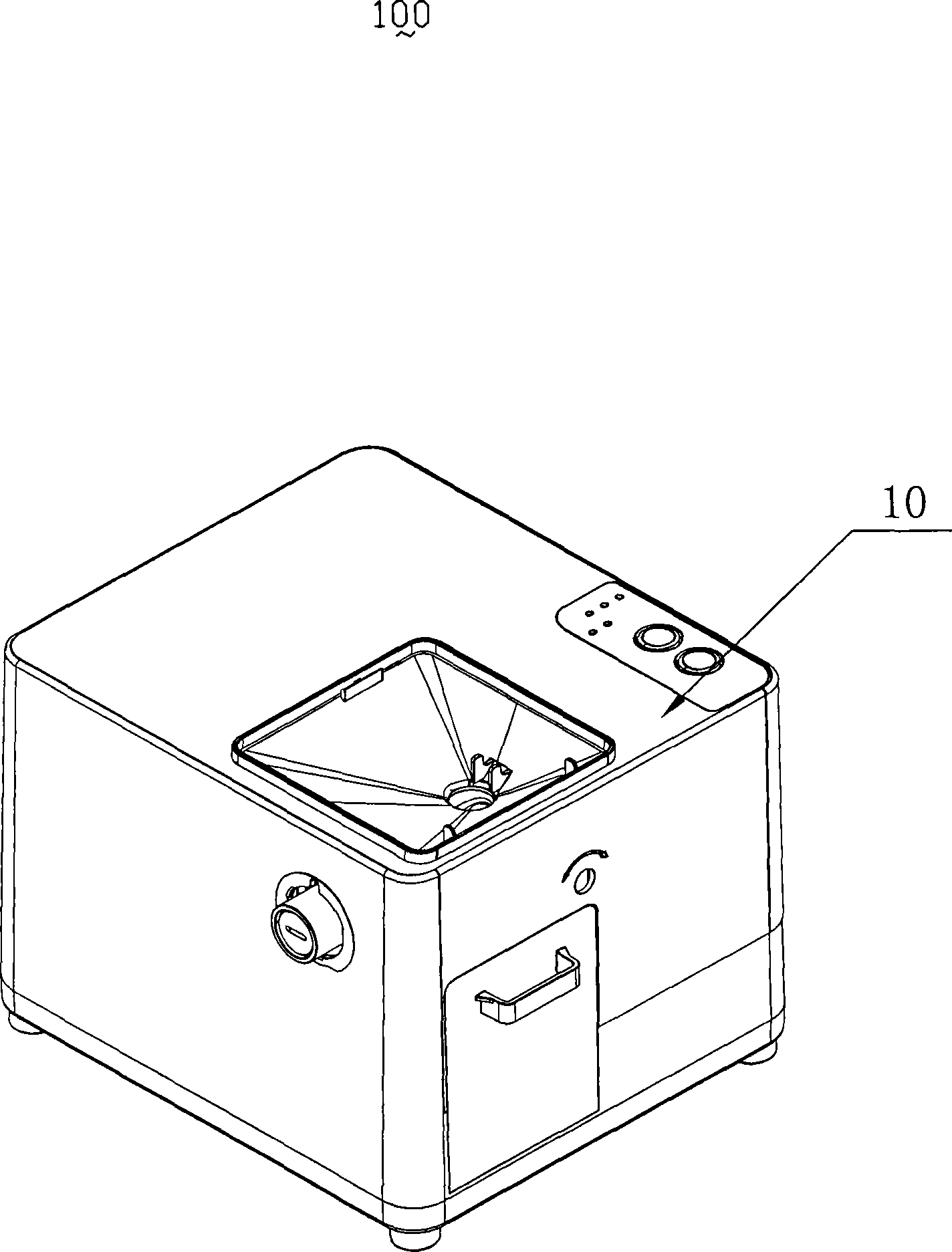

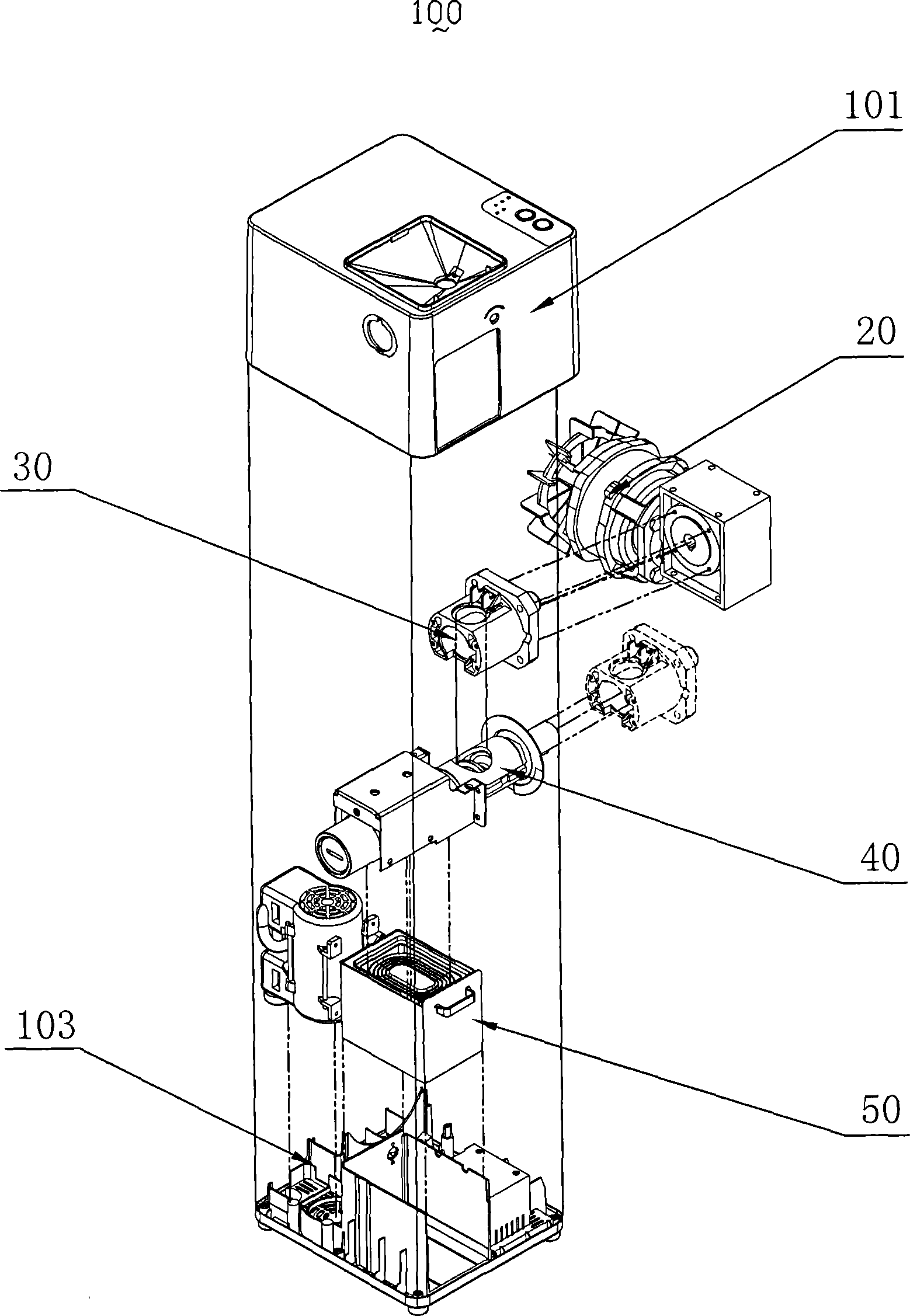

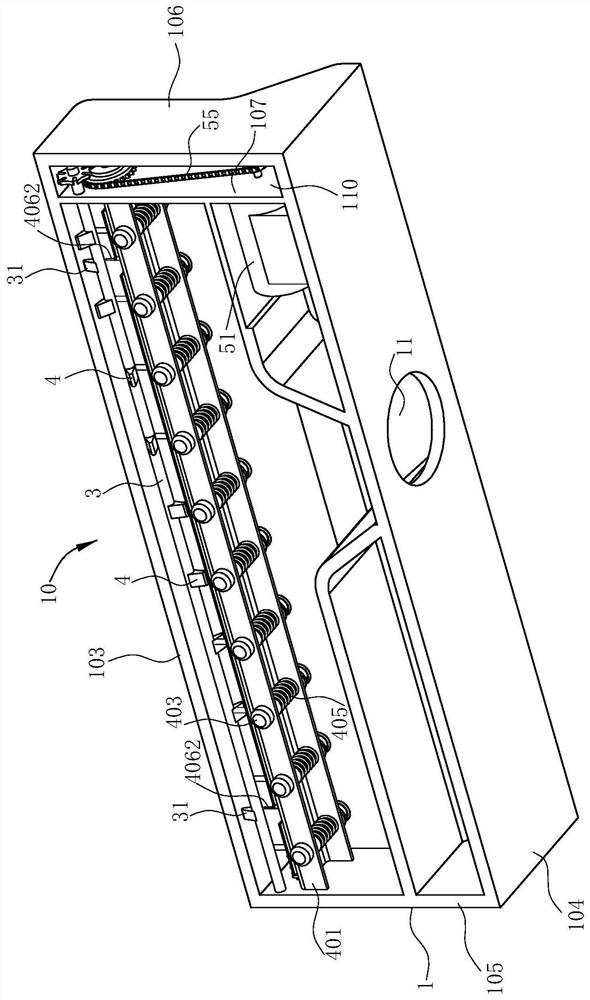

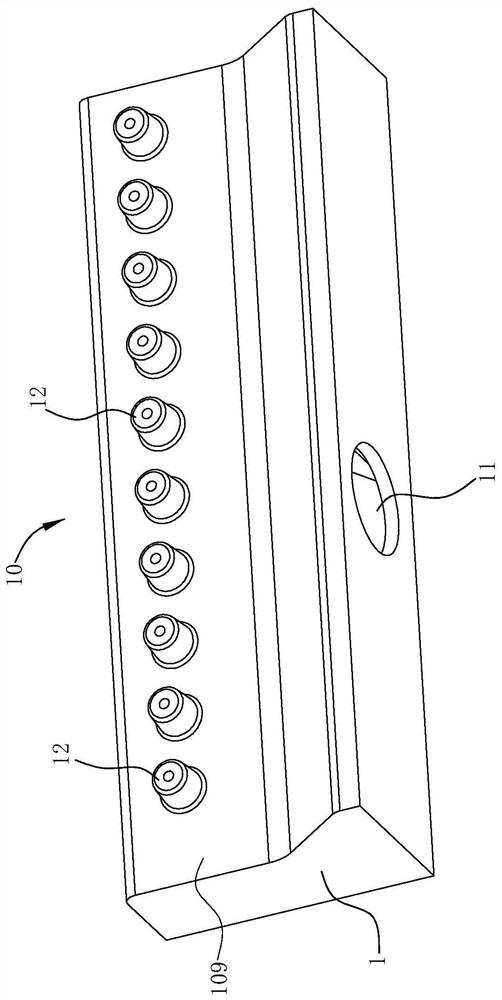

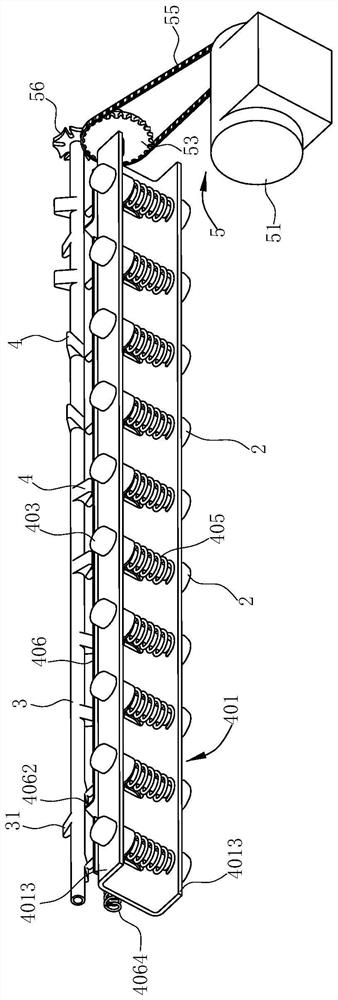

Domestic miniature oil press and oil pressing method

The invention relates to a domestic miniature oil press which is good in cooling effect and safe to use, and an oil pressing method. The domestic miniature oil press comprises a driving mechanism and a pressing mechanism, wherein the driving mechanism provides power for the pressing mechanism; a material to be pressed enters the pressing mechanism and is pressed; the pressing mechanism comprises a heating device and a pressing cylinder; the heating device is in contact with the outer wall of the pressing cylinder, so that the material to be pressed in the pressing cylinder is pressed and heated simultaneously. The invention also provides an oil pressing method. The oil pressing method comprises the following steps of heating the pressing cylinder to the temperature between 100 and 150 DEG C by using the heating device; putting the material to be pressed into the pressing mechanism and pressing, so that the material to be pressed is quickly heated as soon as the material enters the pressing cylinder, and all materials to be pressed can be heated and pressed synchronously. The oil press has the advantages of high oil pressing speed, safety in use, convenience in daily maintenance, and long service life of equipment.

Owner:东莞市格非电器有限公司

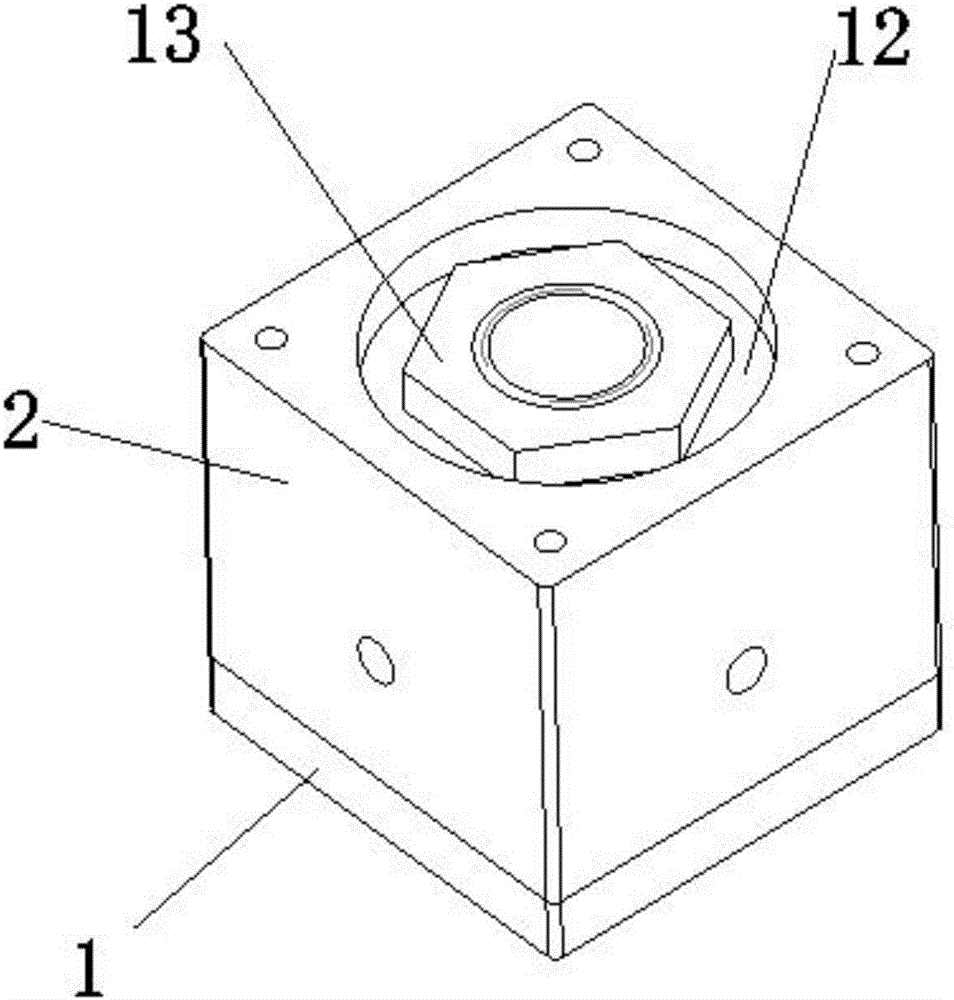

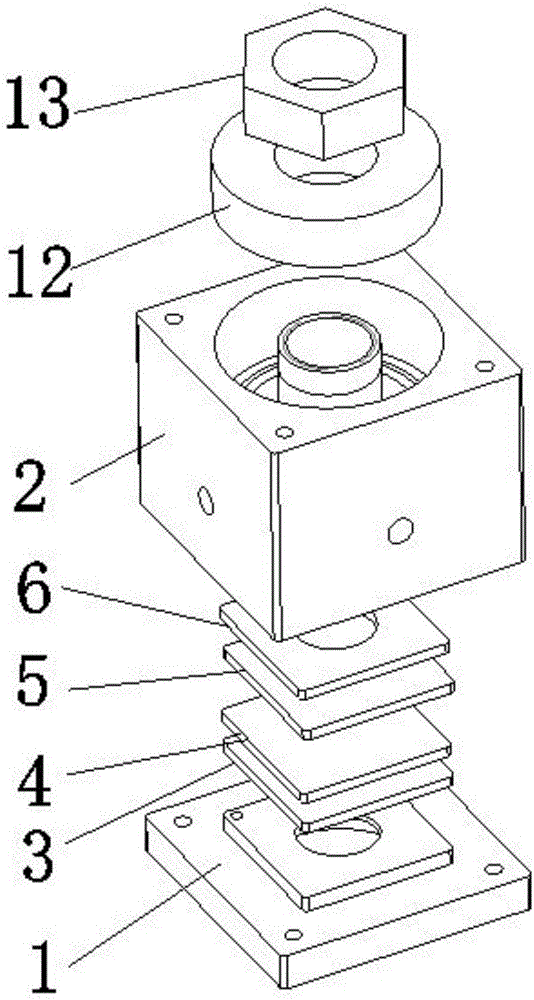

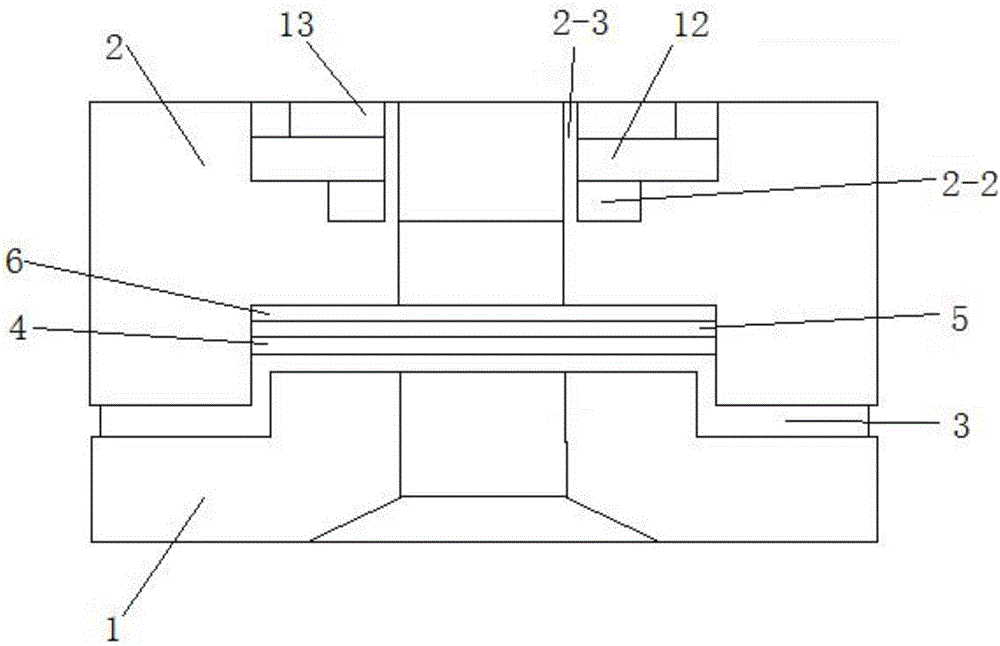

Circulating water bath high-temperature micro etching visualization clamping model and use method thereof

The invention discloses a circulating water bath high-temperature micro etching visualization clamping model and a use method thereof. The model comprises a light condensing cover, a water bath base, a water bath base seal film, an etching glass sheet, an observation glass sheet, a light condensing cover seal film, a bolt, a gland and a nut; the water bath base and the light condensing cover are aligned and are connected through the bolt; the water bath base seal film, the etching glass sheet, the observation glass sheet and the light condensing cover seal film are sequentially placed in a cavity formed between the light condensing cover and the water bath base from bottom to top in an overlaid manner; the gland is mounted below the water bath base through the nut. Through integrated observation and heating functions, the etching glass sheet truly simulates the true seepage dynamic state of the underground oil deposit, and a water bath cavity of a base also can truly simulate various micro experiments at the temperature below 100 DEG C; the water bath cavity can carry out real-time circulation, through the water bath, the whole metal is heated, the metal can make face contact with the etching glass sheet for heating, heating is more uniform and stable, and the simulated site environment temperature is more true.

Owner:SOUTHWEST PETROLEUM UNIV

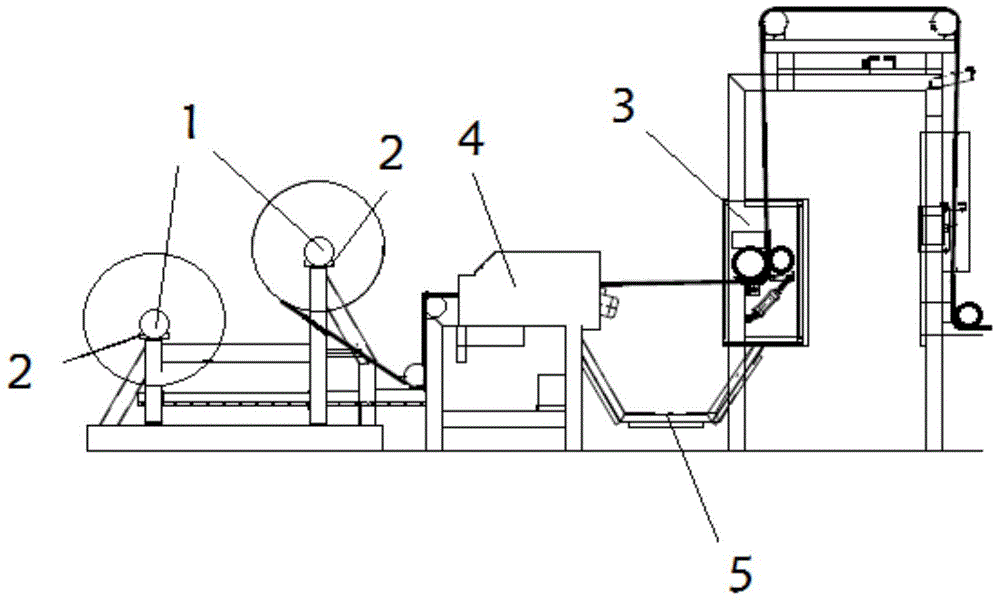

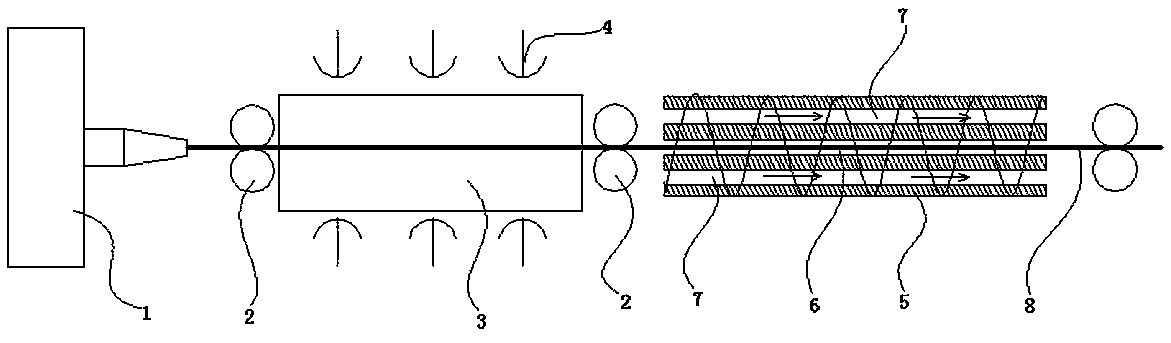

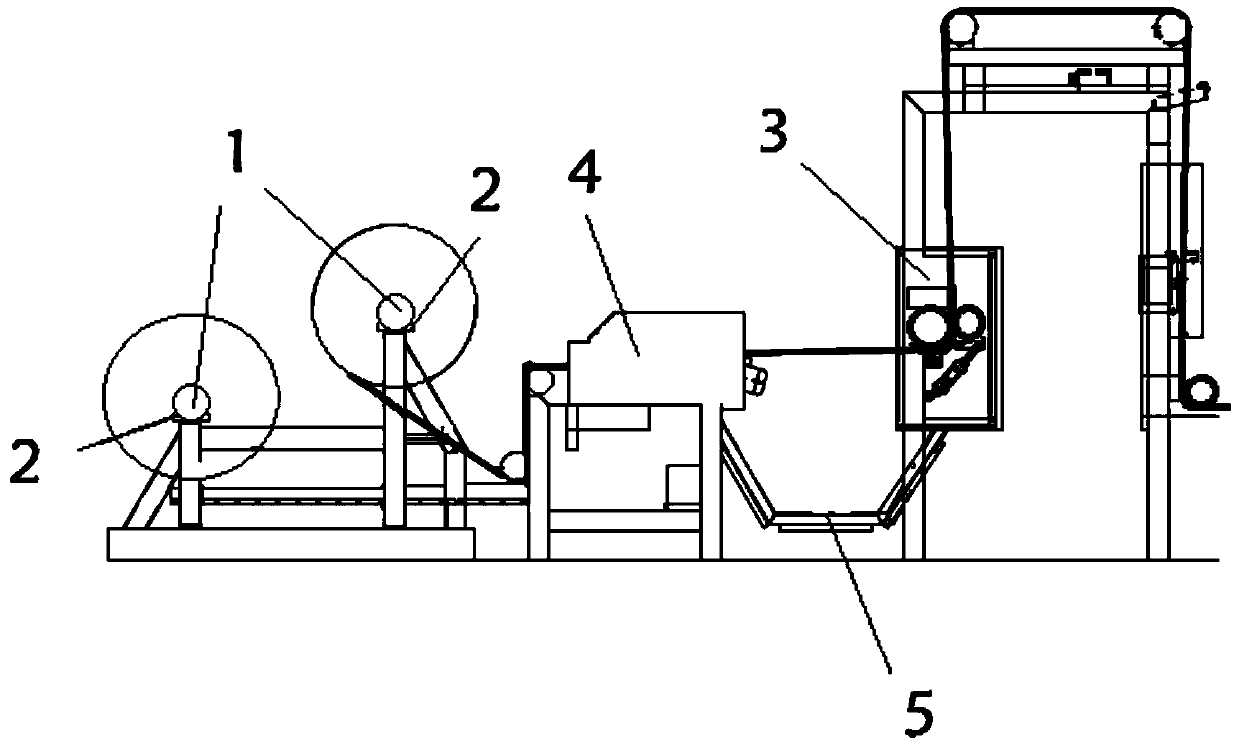

Film-drawing loading equipment for sandwiched film of automobile front windshield

InactiveCN104986969AReduce labor intensityNo need for artificial pine filmEngineeringUltimate tensile strength

The invention relates to film-drawing loading equipment for a sandwiched film of an automobile front windshield. The film-drawing loading equipment comprises a film loading rack used for placing a film roll, a film transmission driving device, and a film releasing driving device, wherein the film transmission driving device is connected with the film loading rack and used for diving a film to move to a heating formation device; the film releasing driving device is arranged between the film loading rack and the film transmission driving device and is used for automatically releasing the film roll after the film roll is used up, so as to connect the film roll with a latter film roll. Compared with the prior art, as the film releasing driving device can release the former film roll after the former film roll is used up automatically instead of manual film releasing, the labor intensity of an operator is reduced.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

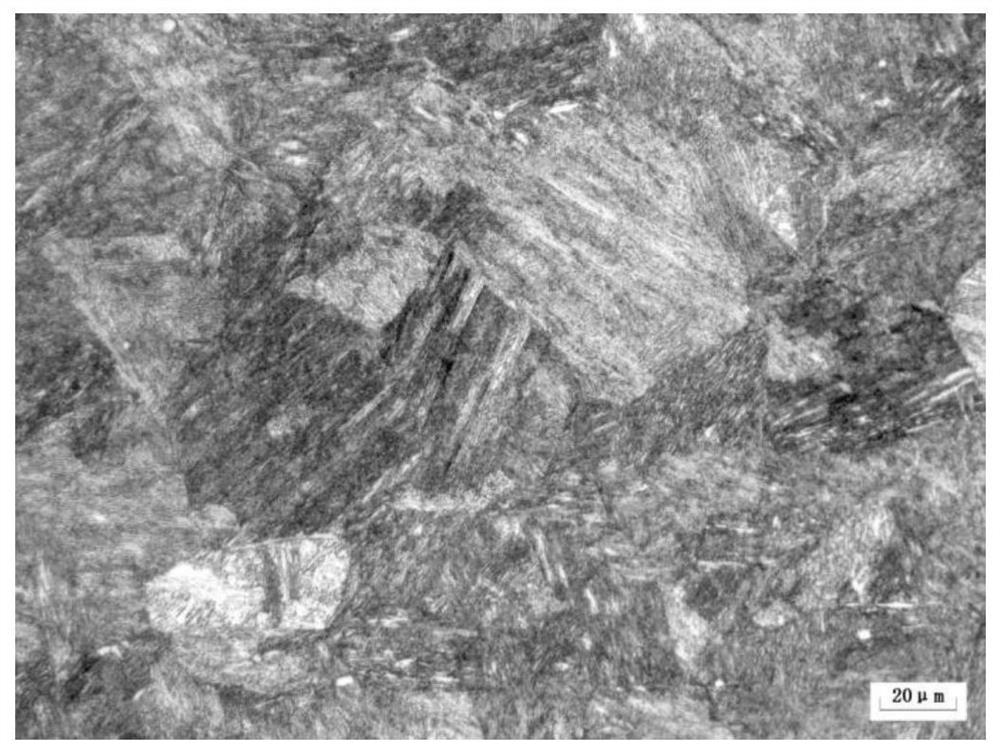

Annealing process of 04Cr13Ni5Mo super martensitic stainless steel medium plate for water and electricity

PendingCN112430714AReduce pickling timesImprove product surface qualityFurnace typesHeat treatment furnacesMartensitic stainless steelSteel plates

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

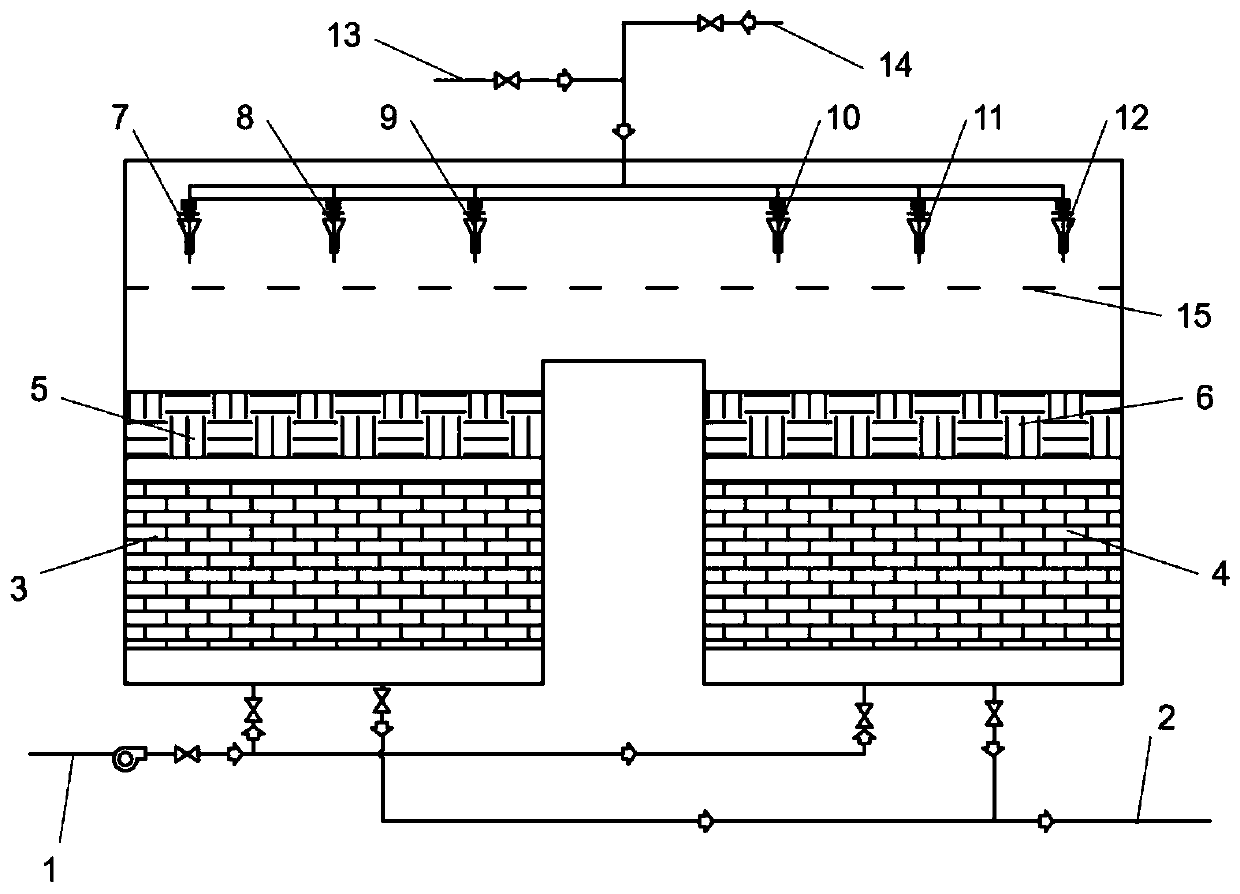

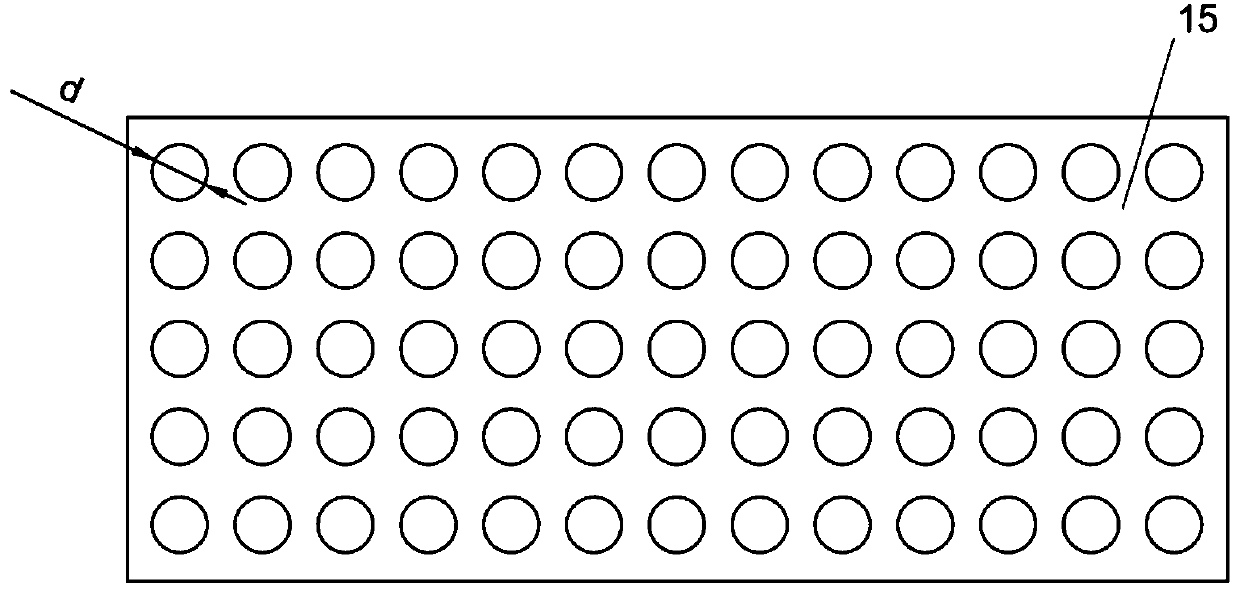

RCO waste gas treatment multipoint distributed combustion system and application method thereof

PendingCN111457401AEvenly heatedExtended service lifeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemPtru catalyst

The invention discloses an RCO waste gas treatment multipoint distributed combustion system and an application method thereof, and belongs to the technical field of waste gas treatment equipment. Thesystem comprises a combustion furnace and a gas input pipeline distributed on the outer portion of the combustion furnace. Multiple combustors are distributed in the combustion furnace, meanwhile, distribution plates with through holes evenly formed in the surfaces are arranged between the combustors and catalyst layers, multipoint distributed combustion can be achieved, it is ensured that catalysts are overall heated evenly, and excessive heating and damage are avoided; the service life of catalysts is prolonged; and the system adopts flow direction conversion operation, organic gas in wastegas is converted into CO2 and H2O through catalytic combustion, toxic and harmful waste gas is changed into non-toxic and harmless gas, and therefore pollution is treated.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

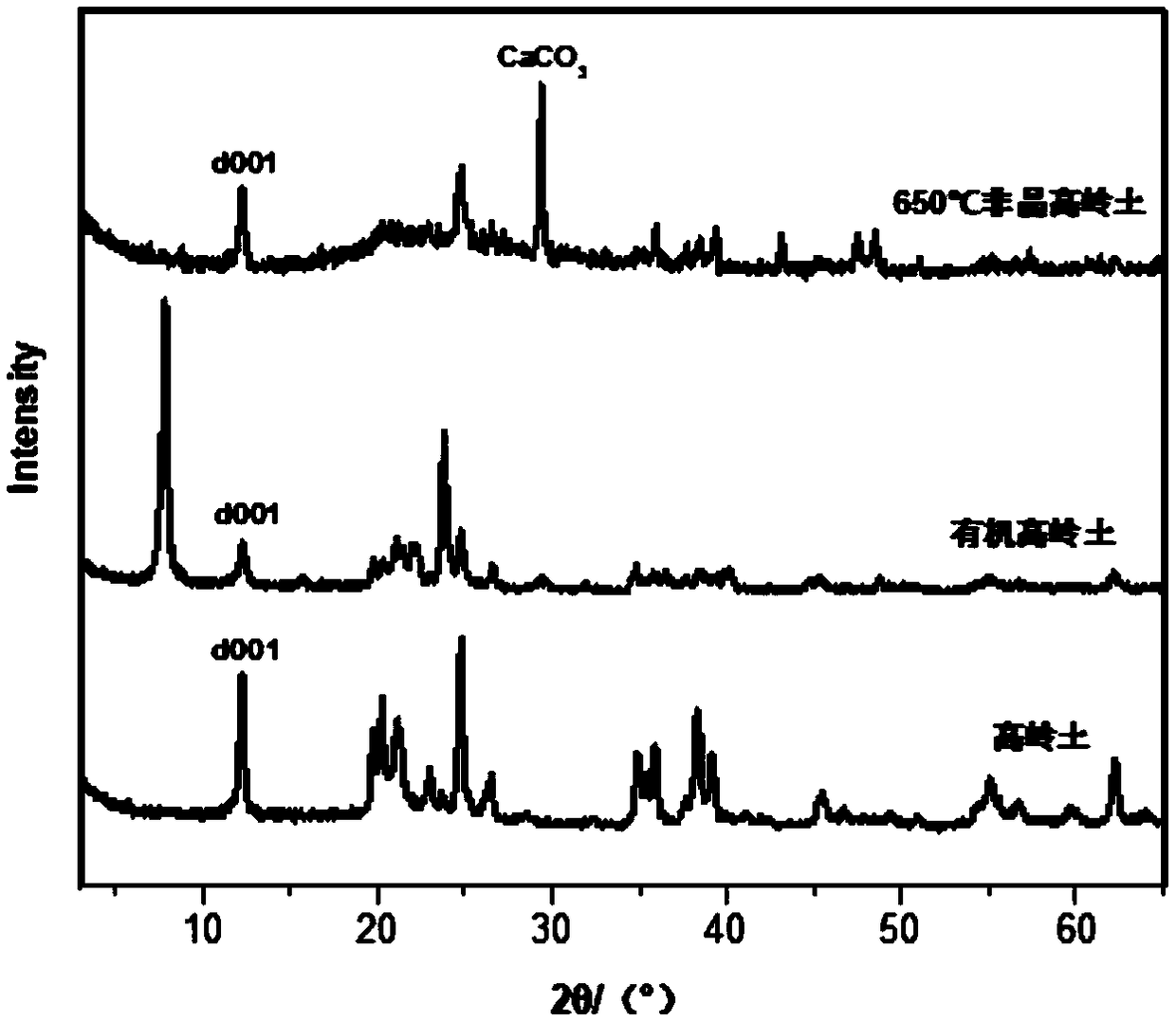

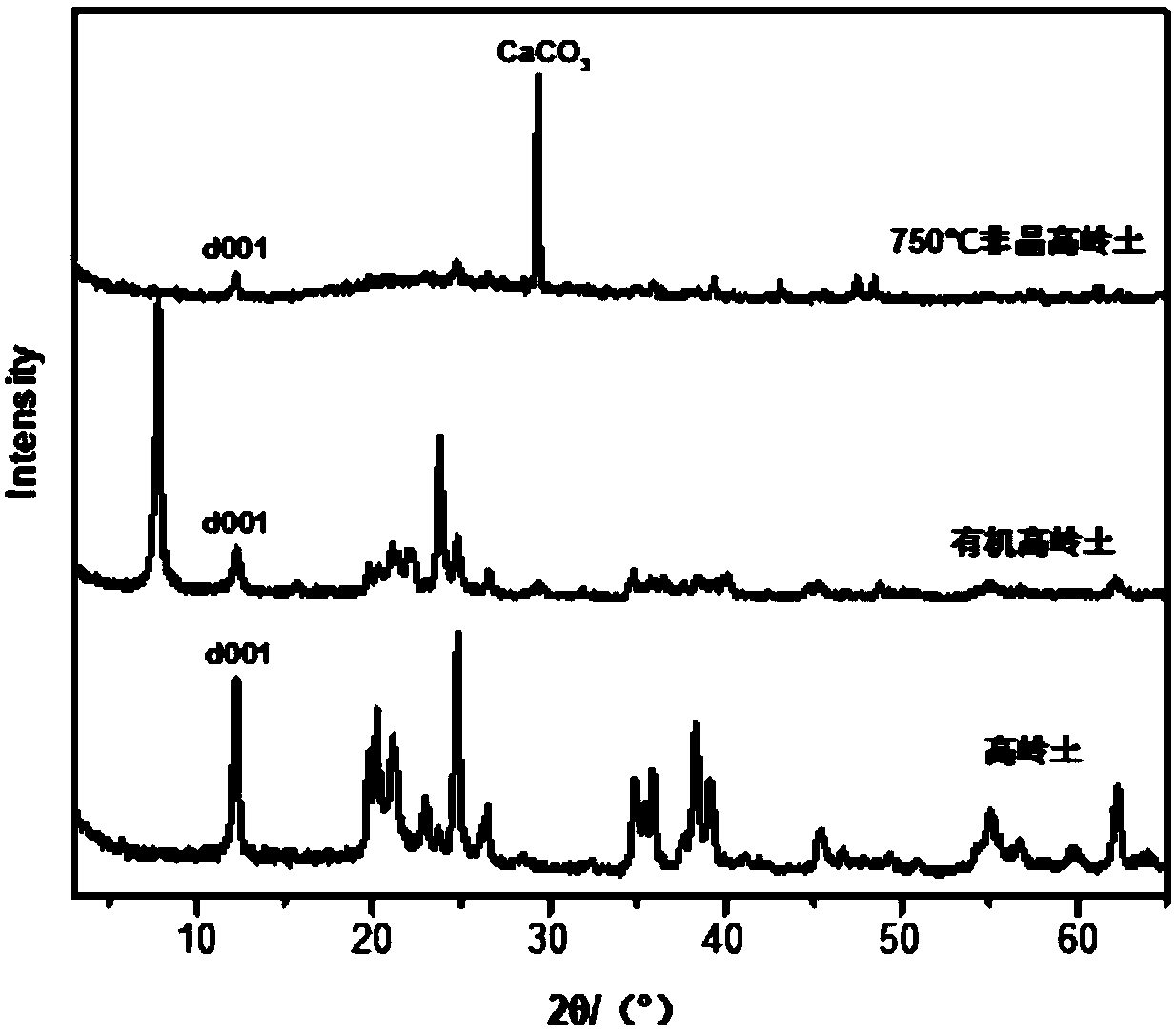

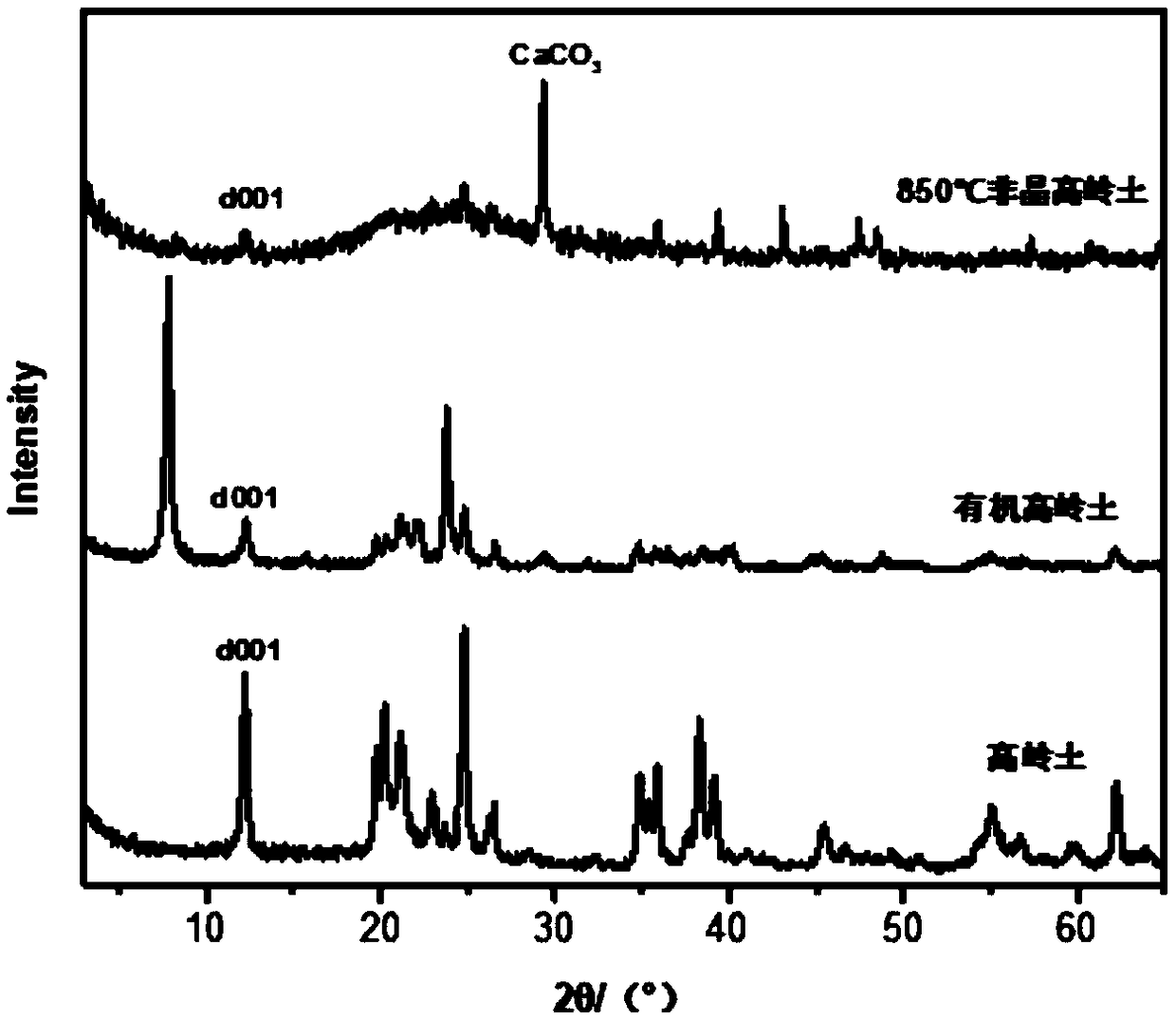

Method for rapidly non-crystallizing flash hot organic kaolin

ActiveCN109485056ASmall temperature fluctuation rangeUniform and stable heatingChemical industrySilicon compoundsRetention timeHeating furnace

The invention discloses a method for rapidly non-crystallizing flash hot organic kaolin. The method comprises the following steps: grading raw kaolin powder, performing intercalation compounding withdimethyl sulfoxide to prepare organic kaolin, grinding and drying, spraying the organic kaolin into a vertical heating furnace, and performing rapid non-crystallizing by a flash heating method at a flash heating temperature of 650-1050 DEG C. The non-crystallizing transformation rate is controlled by regulating the flash heating temperature and the material retention time. According to the methoddisclosed by the invention, the non-crystallizing transformation temperature of the kaolin is effectively reduced, and the transformation rate of the non-crystallized kaolin is stable and controllable. The method is simple in process, energy-saving, high-efficiency and high in treatment quantity, and the product quality is stable and uniform.

Owner:CHINA UNIV OF MINING & TECH

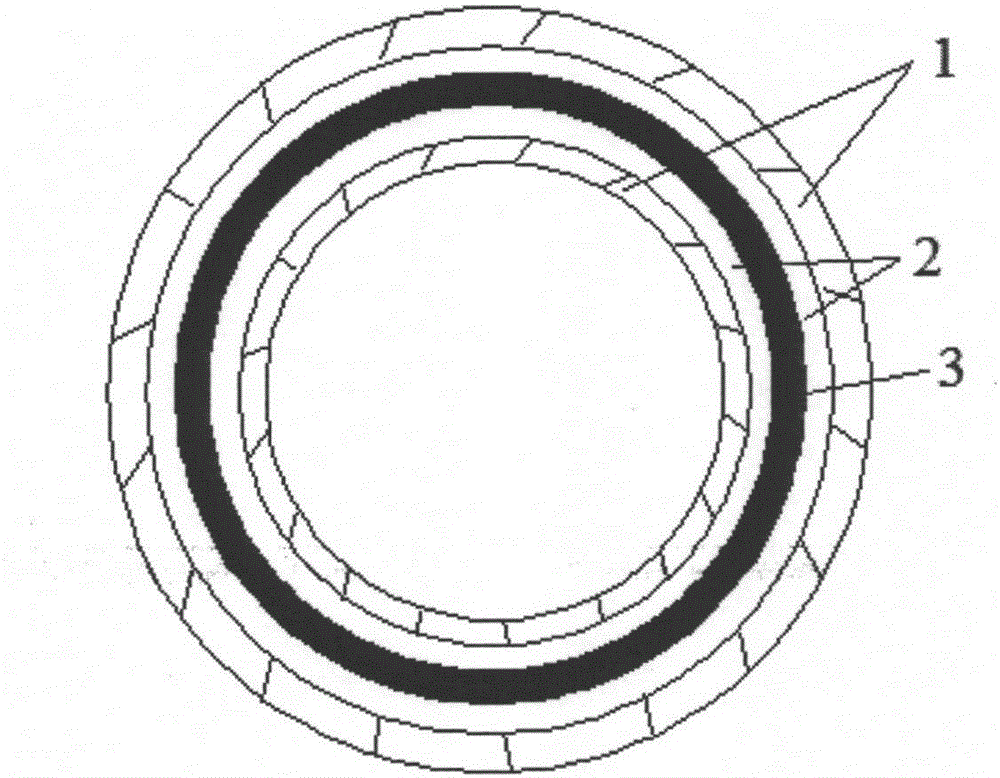

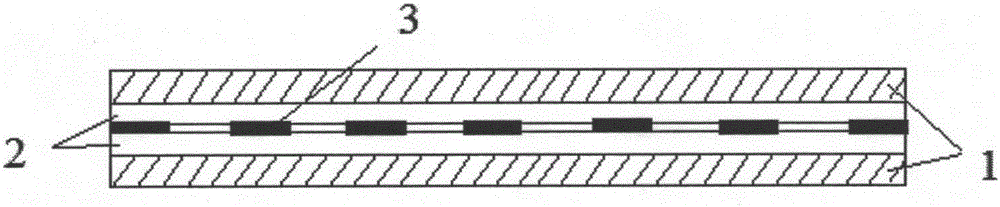

Periphery-wrapped heating baking cup based on glass base and preparation method thereof

PendingCN107028221ATo achieve the purpose of circumferential heatingFast heatingTobacco devicesScreen printingResistor

The invention discloses a periphery-wrapped heating baking cup based on a glass base and a preparation method thereof. The bottom of the glass base is provided with air inlets, and the side wall of the glass base is provided with a silver-palladium resistor which is in a strip shape and arranged in a zigzag mode; the outer wall of the glass base is provided with a positive leading wire and a negative leading wire, and the silver-palladium resistor is electrically connected with the positive leading wire and the negative leading wire separately and is turned on. The preparation method includes the steps that silver-palladium pulp is printed on the side wall of the glass base in a transfer mode through screen printing to form the silver-palladium resistor; the glass base with the silver-palladium resistor on the side wall is subjected to high-temperature twice sintering so that the silver-palladium resistor and the glass base can be fused into a whole. According to the periphery-wrapped heating baking cup based on the glass base and the preparation method thereof, the glass base is in combined with silver-palladium, so that the purpose of circumferential heating is achieved, when the periphery-wrapped heating baking cup is in use, a cigarette is inserted from a cup opening of the glass heating base, and through the situation that the glass base is directly in contact with the cigarette, the periphery-wrapped heating baking cup has the advantages of being environmentally friendly, healthy, sanitary, reliable, rapid in temperature rising speed, and light and compact in structure.

Owner:CHINA TOBACCO YUNNAN IND

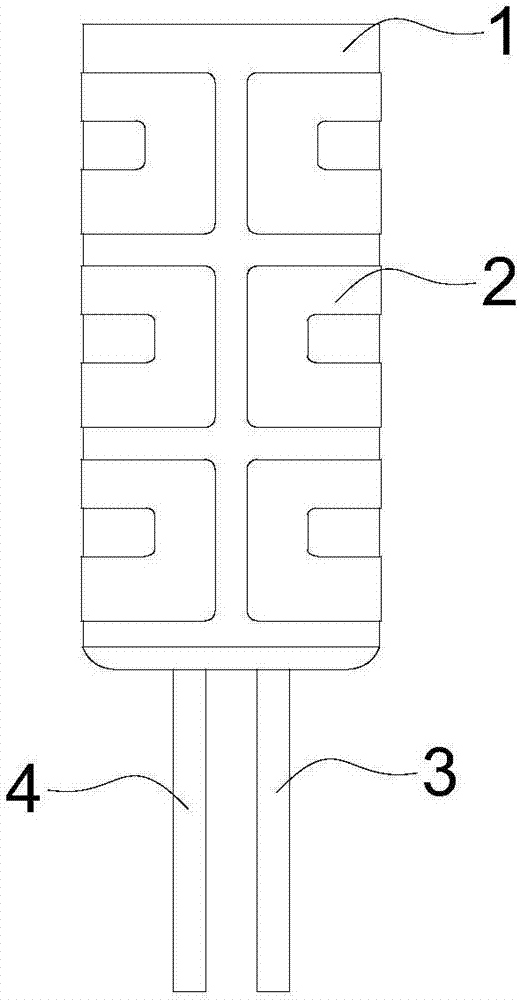

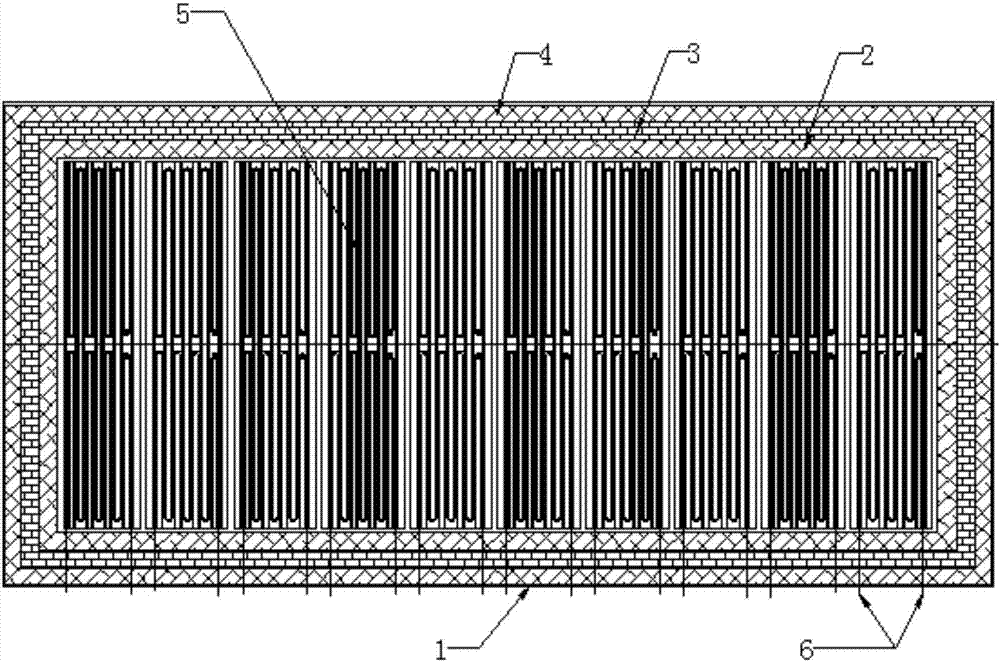

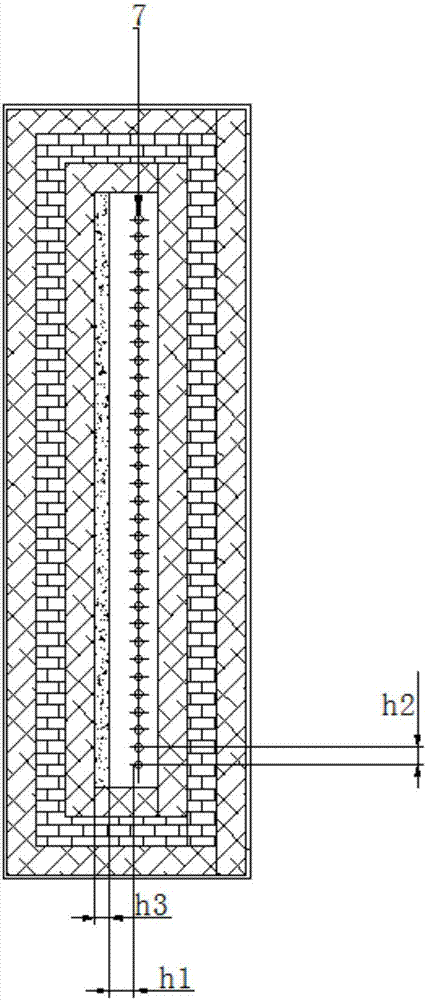

Heating structure of annealing furnace

InactiveCN107130091AImprove thermal insulation performanceUniform and stable heatingFurnace typesHeat treatment furnacesInsulation layerStress relief

The invention discloses a heating structure of an annealing furnace. The heating structure is arranged in a furnace, the furnace comprises a shell and three heat-insulation layers, the heat-insulation layers are positioned on the inner wall of the shell, and every two adjacent heat-insulation layers seamlessly tightly cling to each other. The heating structure comprises a plurality of electric furnace heating wire discs and heating wires, the heating wires are in one-to-one correspondence with the electric furnace heating wire discs and are connected with the electric furnace heating wire discs, the group number of heating wires is equal to the number of the electric furnace heating wire discs, and the multiple electric furnace heating wire discs are parallelly arranged along the length direction of the furnace at intervals; each group of heating wires comprises two single wires, the two single wires of each group of heating wires are connected with two ends of the corresponding electric furnace heating wire disc, and the heating wires are mounted in furnace disc holes of the shell and are nickel-chromium wires; a plurality of annealing furnace tubes are further arranged in the furnace, and to-be-annealed wires can pass the annealing furnace tubes. The heating structure has the advantages the inside of the furnace can be uniformly and stably heated, accordingly, the wires can be uniformly and stably annealed, and good stress relief effects can be realized; the inside of the furnace is heated by the nickel-chromium wires, and accordingly the heating structure is low in energy consumption, long in service life and low in cost; the furnace is excellent in heat-insulation performance, and accordingly energy consumption further can be reduced.

Owner:昆山金源光电科技有限公司

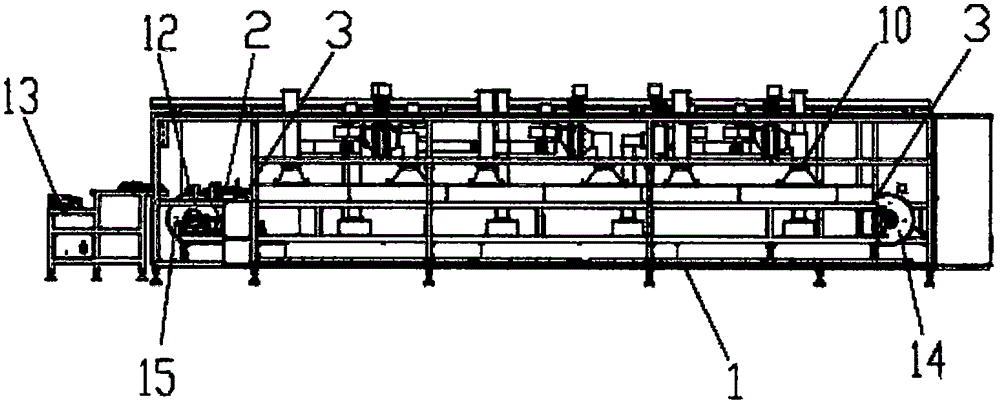

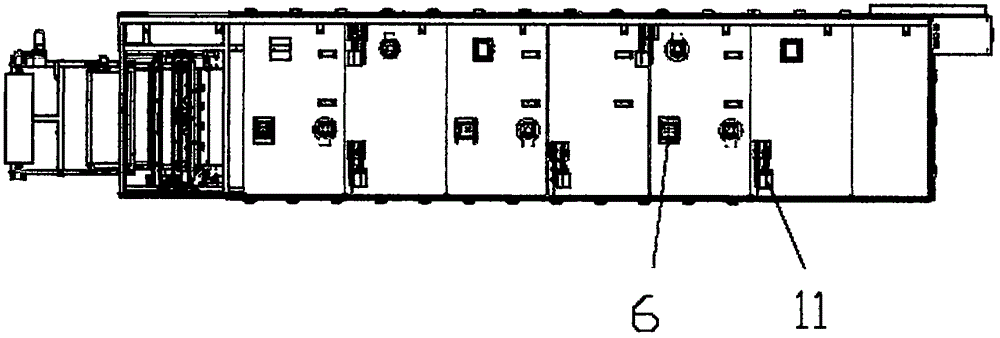

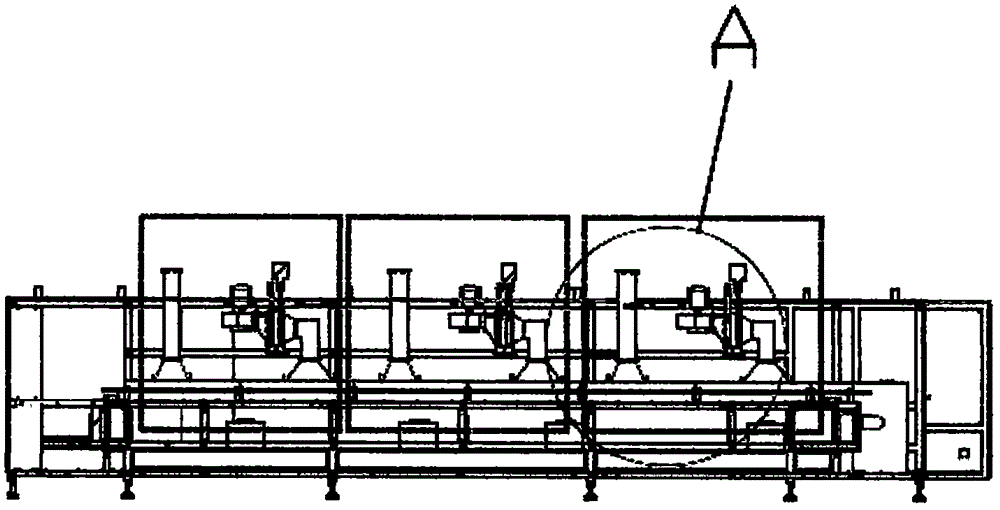

Carbon fiber manufacturing assembly line

InactiveCN107699984AImprove orientationGood material strengthFibre chemical featuresElectric energyHOLDING CHAMBER

The invention relates to a carbon fiber manufacturing assembly line, which comprises a precursor production device, a pre-oxidizing device, a carbonizing device and a graphite device, which are orderly arranged along the assembly line. The pre-oxidizing device comprises a graphite heating holding chamber and traction mechanisms arranged at both ends of the graphite heating holding chamber; the periphery side of the graphite heating holding chamber is provided with a flame source; the carbonizing device comprises a high-frequency sensing heater of which periphery is coiled with a coil; the high-frequency sensing heater is provided with a penetrated dual-layered channel, wherein an inner channel is a fiber channel, and an outer channel is an air curtain channel around the inner channel; thegraphite heating holding chamber is matched with the flame source; the graphite has good heat conductivity, and can play the effect of holding heat, thus the fiber heating is uniform and stable; the high-frequency sensing heater applies the property of conductivity performance of the fiber after pre-oxidizing, thus the fiber in the fiber channel can be heated itself, the main heating object of thepower energy is fiber; the heating object is more targeted, and the energy consumption is greatly reduced.

Owner:王春龙

Heating molding device for cement culvert pipe production and using method thereof

ActiveCN112123541AUniform and stable heatingImprove styling efficiencyCeramic shaping apparatusHeat settingMaterials science

The invention discloses a heating molding device for cement culvert pipe production and a using method thereof. The heating molding device comprises a support frame and an outer ring heating molding mechanism, wherein the outer ring heating molding mechanism is arranged on the support frame, and an inner ring heating molding mechanism is arranged in the center of the outer ring heating molding mechanism; and the inner ring heating molding mechanism is arranged above the support frame, a moving mechanism is arranged on the lower side of the support frame, and a rotating supporting mechanism isarranged at the upper end of the moving mechanism. According to the heating molding device for cement culvert pipe production and the using method thereof, a cement culvert pipe is driven to rotate during heat setting through rotation of a rotating disc; meanwhile, hot air sources and water mist sprayed out of first spray heads and second spray heads on the inner side and the outer side of the cement culvert pipe are sprayed to the inner surface and the outer surface of the culvert pipe, so that the cement culvert pipe is subjected to water mist curing firstly and then subjected to hot air drying, heating is more stable and uniform, and the shaping efficiency and quality of the cement culvert pipe are improved; and in addition, a supporting box is driven to move through a sliding base, sothat the cement culvert pipe conveniently enters and exits the outer ring heating molding mechanism, and operation convenience is improved.

Owner:衡阳市畅通管业有限公司

Fabrication method of wind power vane web mold

The invention relates to a fabrication method of a wind power vane web mold. Metal is adopted as a material. The method comprises the steps that 1) a foundation support is prefabricated and arranged in the length direction of a preformed wind power vane web, 2) a mold heating layer with the same surface area as the foundation support is arranged on the fabricated foundation support, 3) a surface steel plate is horizontally laid on the upper surface of the formed mold heating layer, 4) a flanging mechanism of the wind power vane web mold is arranged on the upper surface of the surface steel plate, 5) a plurality of vacuum holes for mounting vacuum nozzles are formed on the outer side of the flanging mechanism in the length direction of the wind power vane web mold, the vacuum nozzles are connected with a peripheral vacuum pump by vacuum pipes connected with the vacuum nozzles, and 6) all sections of wind power vane web mold are sequentially connected from the wide section to the narrow section by end part connection components to form the complete wind power vane web mold. The method is simple and direct in process, low in cost and reusable, and facilitates popularization and application, and the processing mold does not deform easily.

Owner:中材科技(萍乡)风电叶片有限公司

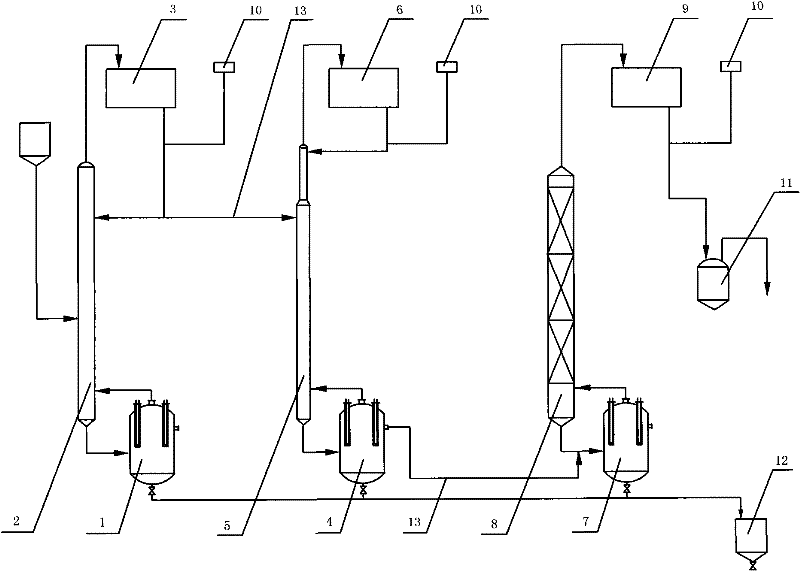

Liquid metal container bottom heating device and application thereof

InactiveCN100402193CStable temperatureImprove thermal efficiencyMelt-holding vesselsHeat conductingNonferrous metal

This invention relates to a device used for preheating, warming and insulating fining vessel in processing non-ferro metals, which comprises a vessel used for filling liquid metal, a heating room inserted in the bottom of the vessel, a heater set in the heating room and a heat conducting board. The heat conducting board separates the heating room and said vessel, and the top connects metallic flux, the lower supplies heat, by which to heat liquid metal. The device has high calorific efficiency, and can control temperature; in addition, the heater can be changed freely without interrupting operation.

Owner:SHENZHEN PYROTEK

Infrared radiation temperature control method for spraying production line

ActiveCN112859969AMeet individual differencesMeet needsAuxillary controllers with auxillary heating devicesTemperature controlPhysical chemistry

The invention discloses an infrared radiation temperature control method for a spraying production line, a plurality of catalytic heating plates are arranged in an infrared radiation furnace, any catalytic heating plate is provided with a temperature sensor, and the infrared radiation temperature control method comprises the following steps of: simulation temperature detection, contrast temperature recording, fine adjustment, synchronous temperature rise adjustment, calculation of the temperature regulation coefficient of each catalytic heating plate, catalytic heating plate fine-tuning reference selection, and temperature control. According to the method, temperature control correlation and real-time temperature monitoring of the catalytic heating plates can be achieved, overall temperature control adjustment is carried out through the correlation coefficient, the individual difference of the catalytic heating plates and the furnace chamber temperature difference adjustment requirements are met, the product is heated uniformly and stably, the curing stability of the product is improved, and the qualified rate of the product is greatly improved. And a reflectivity attenuation self-adaptive adjusting function is realized, so that the temperature of the furnace chamber is stable and uniform, the curing temperature is stable, and the phenomena of non-uniform curing and incomplete curing are prevented.

Owner:GENERAL LUMINAIRE KUNSHAN CO LTD

Anti-corrosion method of electrostatic chuck

ActiveCN111081517AGood thermal conductivityUniform and stable heatingElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsPlasma processing

The invention provides an anti-corrosion method of an electrostatic chuck and aims prevent active free radicals from corroding the electrostatic chuck. According to the method, inert gas is introducedinto a channel on the electrostatic chuck. The invention further provides a chamber cleaning method for a plasma processing device. With the method provided by the invention adopted, the problem thatthe adhesion layer of the electrostatic chuck is easily corroded by high-activity free radicals can be effectively solved; the electrostatic chuck can keep a good heat conduction function; and the yield of a manufactured wafer can be obviously improved. A blocking control piece is not needed, and therefore, the process of the method is simple and convenient, and the cost of the method is low; noextra pollution is generated; a protection effect is good; and the service life of a plasma cavity and the service life of the electrostatic chuck can be greatly prolonged.

Owner:CHANGXIN MEMORY TECH INC

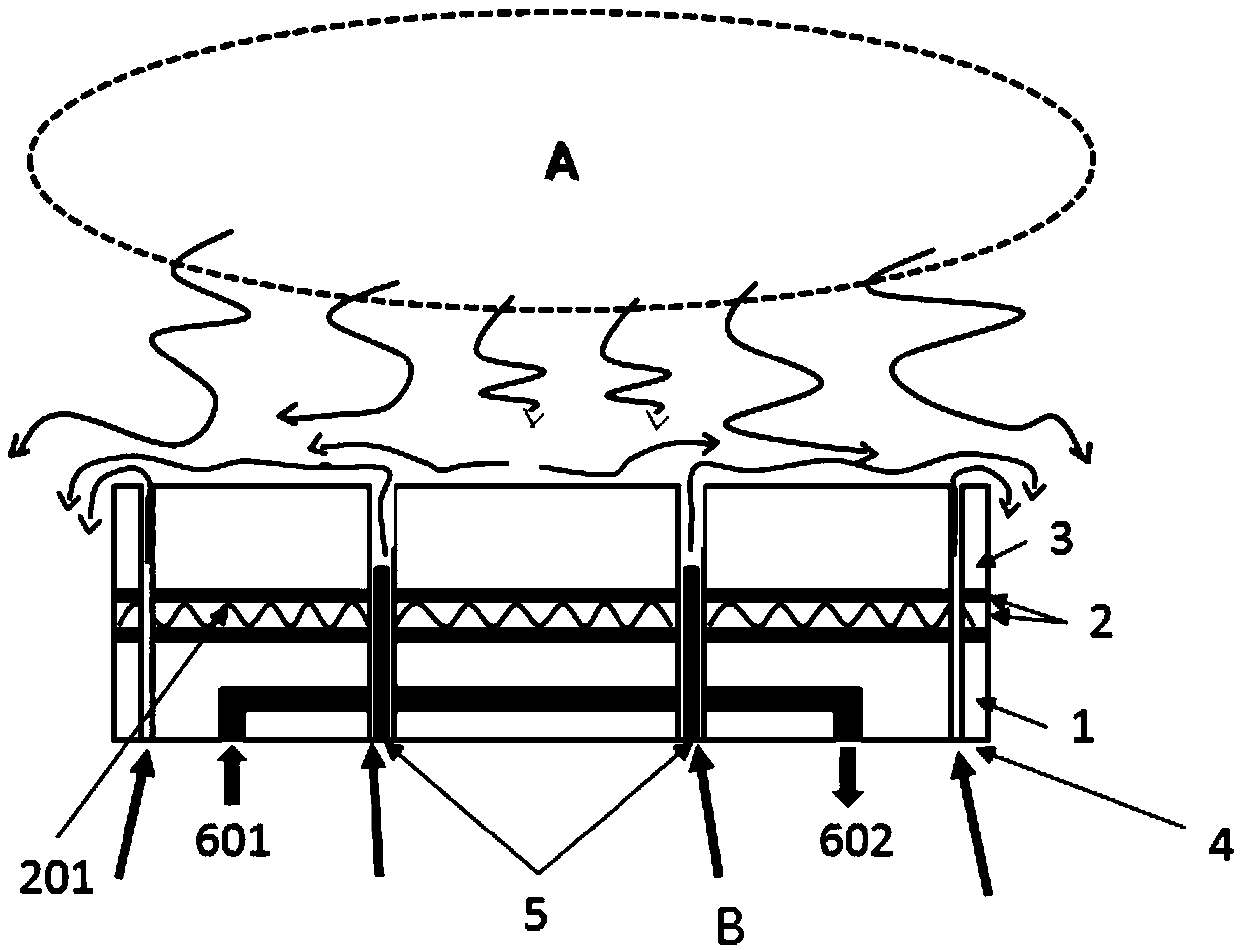

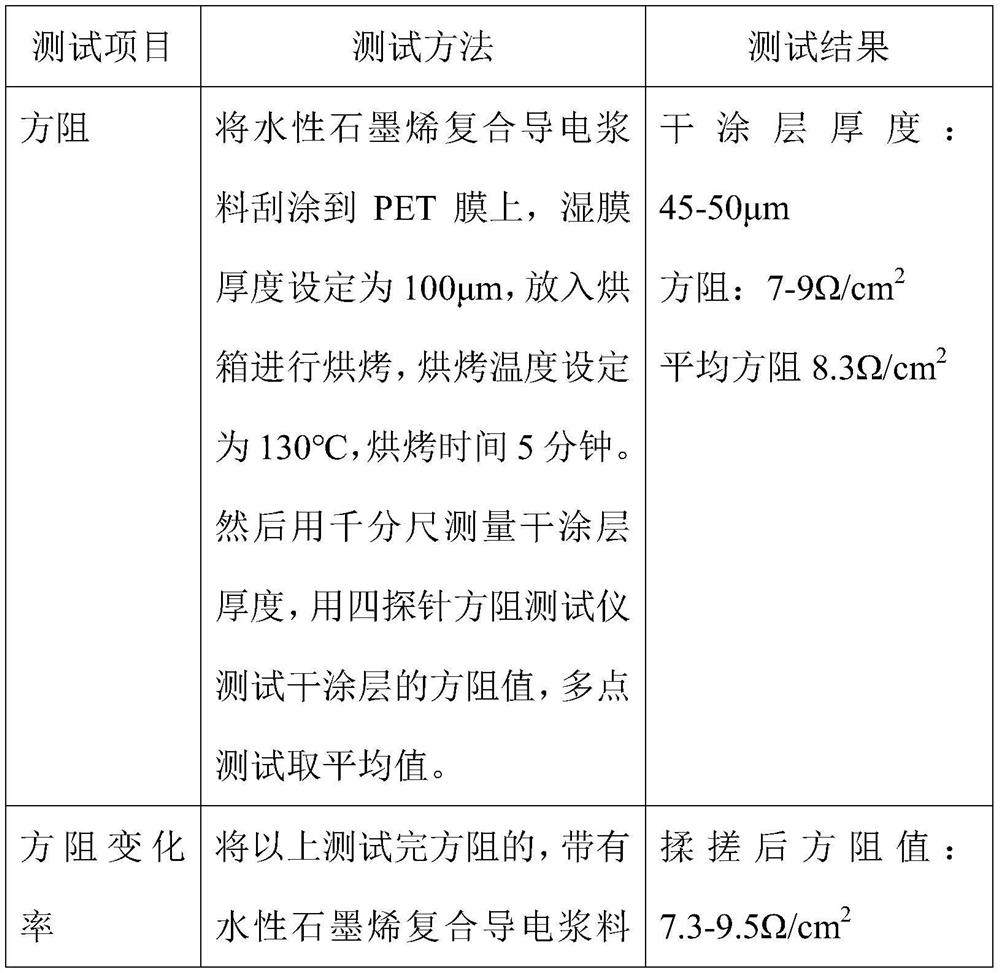

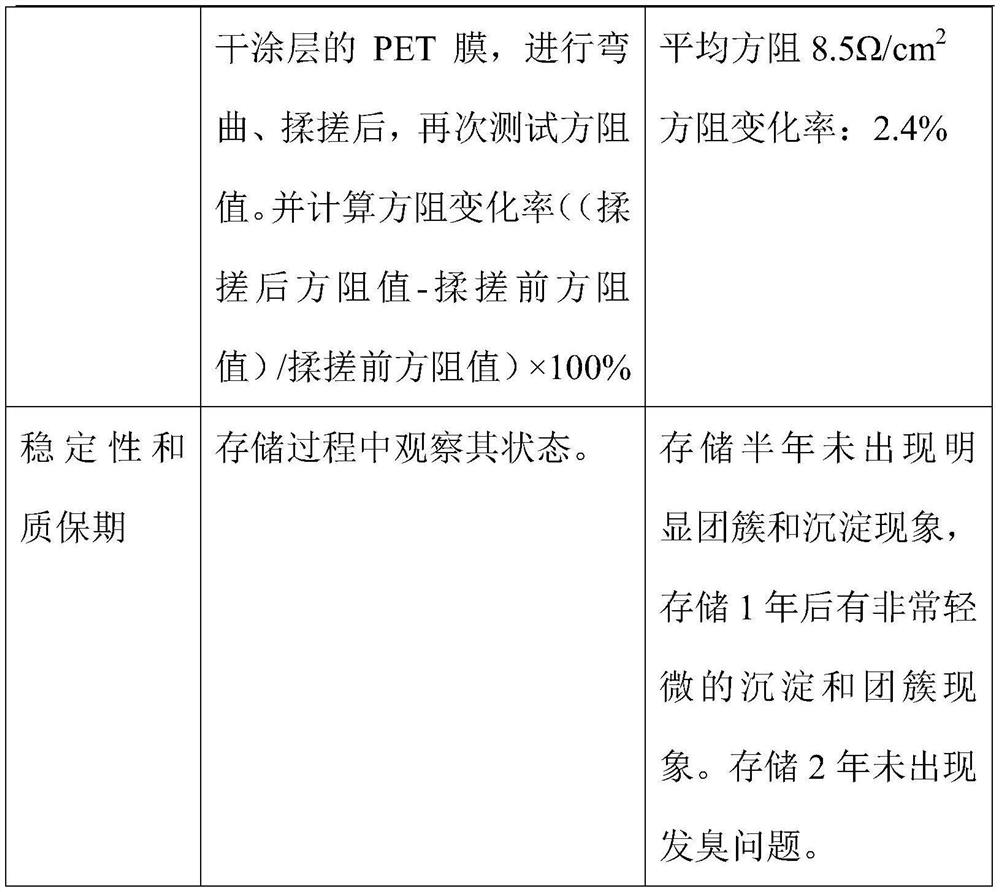

Water-based graphene composite conductive paste, manufacturing method of paste and graphene heating film

PendingCN114783653ADispersion fully fine and uniformSolve precipitationNon-conductive material with dispersed conductive materialHeating element materialsActive agentSlurry

The invention belongs to the technical field of electric heating materials, and particularly relates to water-based graphene composite conductive paste, a manufacturing method of the paste and a graphene heating film. The conductive slurry contains deionized water, graphene powder, graphite powder, carbon black powder, an emulsifier, a thickener, a dispersant, a pH regulator, talcum powder, a nonionic surfactant, a defoaming agent, a preservative and a binder. The graphene powder, the graphite powder and the carbon black powder in the conductive paste are fully refined and uniformly dispersed, are not clustered or precipitated, are not easy to deteriorate and stink, and are longer in shelf life. The prepared graphene heating film can obtain lower sheet resistance and better resistance stability, and the sheet resistance can be modulated according to requirements.

Owner:江苏思峻机械设备有限公司

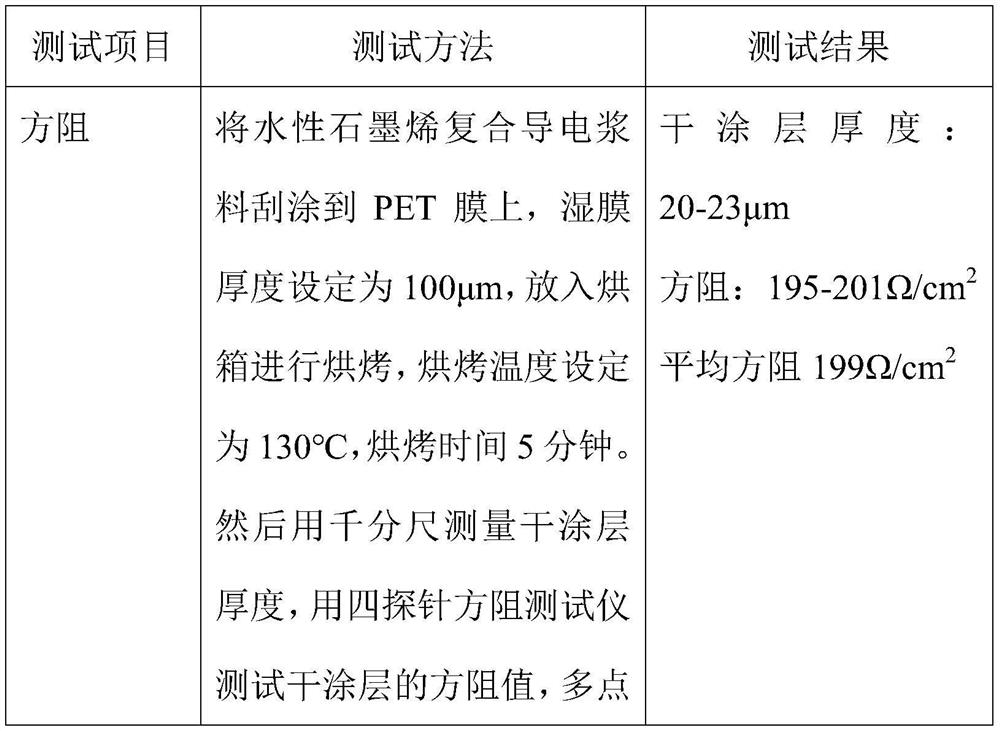

Rapidly heating distillation device in titanium tetrachloride refining process

InactiveCN101844802BUniform and stable heatingUniform and stable productionTitanium halidesTetrachlorideDistillation

The invention belongs to the technical field of titanium sponge production by a magnesium method and in particular relates to a rapidly heating distillation device in a titanium tetrachloride refining process. The invention adopts a technical scheme that: the rapidly heating distillation device in the titanium tetrachloride refining process comprises a distillation still, a distillation tower, a cooler, a respiration tank, a ground tank and a finished product storage tank which are connected with one another sequentially through pipelines. The rapidly heating distillation device has the advantages of raising the temperature uniformly and stably, realizing automation easily, increasing production yield by 30 percent, reducing energy consumption by 15 percent, greatly improving the purity of the products, saving energy and reducing consumption, greatly improving the quality of the products and protecting the surrounding environment, along with simple and rapid operation, stable production, good separation effect and low production cost.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Rare earth halosilicate red long-afterglow phosphor, and preparation method thereof

InactiveCN102226086BIncrease surface areaUniform and stable heatingLuminescent compositionsRare earth ionsPhosphor

Owner:LONGNANXIAN SHUNDE MINGHUI FLUORESCENT MATERIAL

A gas distribution device and a gas water heater using the device

ActiveCN111750537BReduce wearReduce the number of movesFluid heatersFuel supply regulationMechanicsFuel gas

The invention relates to a gas distribution device and a gas water heater using the device, wherein the gas distribution device includes a casing, a nozzle, a rotating shaft, a power mechanism and a blocking member, and at least one first valve for supplying gas into the casing is provided on the casing. There are at least two air inlets and nozzles arranged at intervals on the side wall of the housing. The rotating shaft extends axially along the direction in which the nozzles are arranged at intervals. The power mechanism is used to drive the rotating shaft to rotate around its own axis, and the blocking member is used to block the nozzles. There are at least two blocking members and each blocking member corresponds to a nozzle, and the blocking members at different positions and in different numbers move toward the nozzle with the rotation of the rotating shaft to block the gas flow entering the corresponding nozzle or move away from the nozzle to Open the corresponding nozzle. There are multiple blocking parts in this way, even if one of the blocking parts is worn out, the other blocking parts can still work normally, and the adjustment of the gas flow can still be carried out, and the fault tolerance rate is high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Cast film drying equipment

InactiveCN105835272AReduce manufacturing costReduce energy consumptionEnvironmental resistanceSmoke Emission

The invention discloses a casting film drying equipment, which comprises a frame, a main engine transmission mechanism and a casting mechanism for feeding materials. The main engine transmission mechanism includes a steel belt and a transmission device for driving the steel belt to run. The transmission device includes a motor, a driving drum and a driven drum, the casting mechanism is arranged at one end of the steel belt, and the outer coating of the steel belt is provided with a hot air circulation drying mechanism, and the hot air circulation The upper end of the drying mechanism is connected with at least one set of thermal energy conversion mechanism, and the thermal energy conversion mechanism includes a thermal energy collector, a fan, a heat exchanger and an exhaust pipe. The hot air circulation drying mechanism is connected, and the other end of the hot air circulation drying mechanism is connected to the exhaust pipe; realize the heat source generated by steam, electric heating box, electric heating rod or infrared rays, and the waste heat source of flue gas discharged from industrial boilers into hot air drying Dry features, low energy consumption, uniform and stable temperature, can bring greater profit margins to demand enterprises, accelerate the development of enterprises, and belong to environmental protection and energy-saving engineering projects.

Owner:肇庆市宏华电子科技有限公司

A film-drawing and film-loading device for an interlayer diaphragm of an automobile front windshield

The invention relates to a film-drawing and film-loading device for an interlayer diaphragm of an automobile front windshield, comprising: a film-loading frame for placing a film roll; a diaphragm transmission drive device connected with the film-loading frame for driving the Film to heating forming device; film loosening drive device, located between the upper film frame and the film transmission drive device, used to automatically release the roll of film when the roll of film is used up, so as to carry out the forward and backward film roll Contact film. Compared with the prior art, the membrane loosening drive device of the present invention can automatically loosen a roll of membrane when the roll of membrane is about to be used up, without manual loosening of the membrane, reducing the labor intensity of operators.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com