Far-infrared carbon fiber composite heating film

A far-infrared carbon fiber, composite heating film technology, applied in electric heating devices, ohmic resistance heating, electrical components and other directions, can solve the problems of short service life, difficult to fold, small application range, etc., to achieve good internal conductivity and heating performance, The effect of improved safety and stability and high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

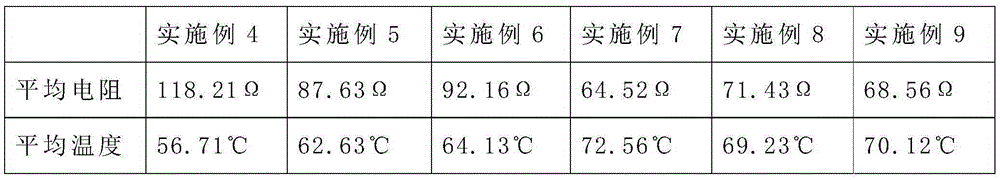

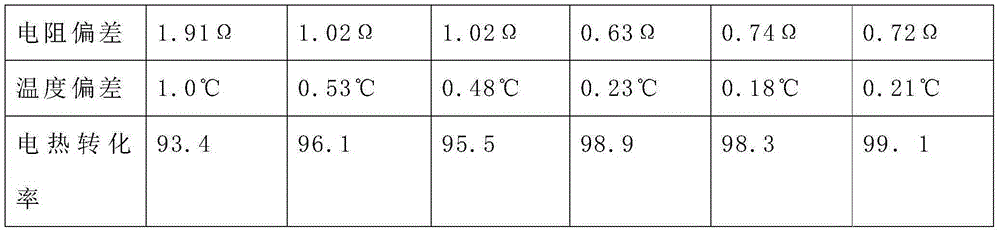

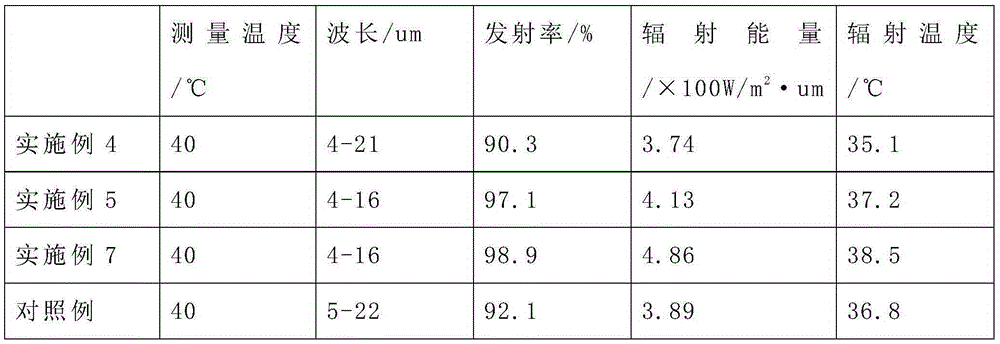

Examples

Embodiment 1

[0030] A far-infrared carbon fiber composite heating film, comprising an upper base layer, a lower base layer, a carbon fiber composite heating layer, an upper insulating flame-retardant, temperature-resistant and waterproof layer, and a lower insulating, flame-retardant, temperature-resistant and waterproof layer, the carbon fiber composite heating layer is located on the upper base Between the bottom layer and the lower base layer, the outer sides of the upper base layer and the lower base layer are respectively wrapped with an upper insulating flame-retardant, temperature-resistant and waterproof layer and a lower insulating, flame-retardant, temperature-resistant and waterproof layer.

Embodiment 2

[0032] Based on the far-infrared composite heating film described in Example 1, the far-infrared carbon fiber composite heating film described in this embodiment is further provided with an adhesive layer between the carbon fiber composite heating layer and the upper base layer and the lower base layer, It is helpful for the adhesive connection between the carbon fiber composite heating layer and the upper and lower base layers.

Embodiment 3

[0034] Based on the far-infrared composite heating film described in 1, the far-infrared carbon fiber composite heating film described in this embodiment further defines that the insulating, flame-retardant, temperature-resistant and waterproof layer is prepared by high-temperature compounding of the following raw materials in parts by weight: 10 parts of vinyl fluoride, 7 parts of novolac epoxy resin, 1 part of antimony trioxide, 3 parts of acrylic acid, 4 parts of polyether sulfone, and 6 parts of rubber; the upper base layer and the lower base layer are selected from heat-shrinkable polyurethane and / or or non-woven fabric;

[0035] Preparation:

[0036] 1) Preparation of insulating, flame-retardant, temperature-resistant and waterproof layer:

[0037] Grind polytetrafluoroethylene, phenolic epoxy resin, antimony trioxide, acrylic acid, polyether sulfone and rubber into fine powder respectively, then mix them evenly, heat them at high temperature and stir them evenly to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com