Patents

Literature

52results about How to "Improve orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

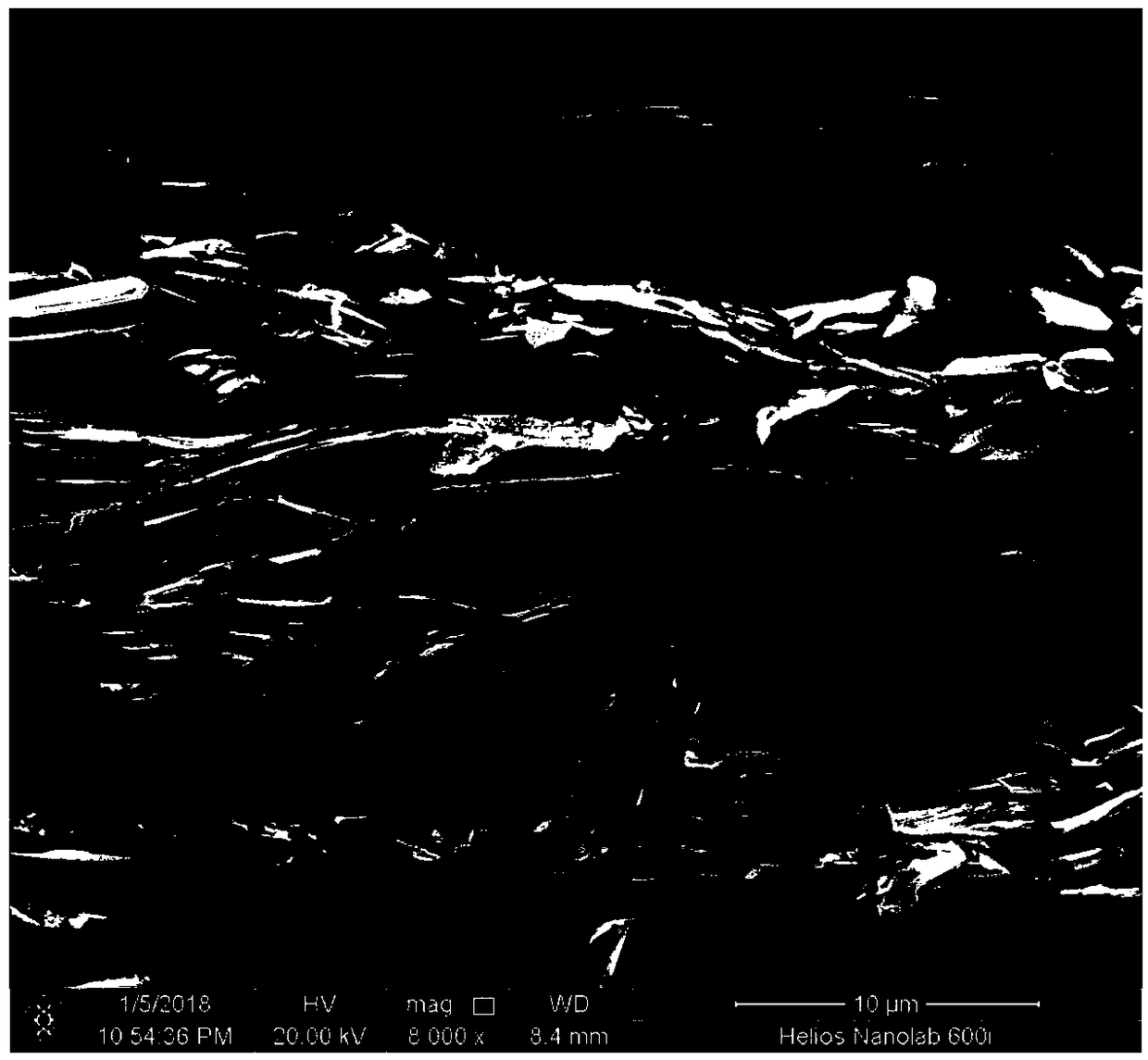

Method for preparing high-strength polyacrylonitrile-based precursor for carbon fiber

ActiveCN101724922ARegularity and compactnessImprove orientationArtificial filament washing/dryingArtificial filament heat treatmentSolventSolution polymerization

The invention discloses a method for preparing a high-strength polyacrylonitrile-based carbon fiber precursor. The method comprises the steps of: using azodiisobutyronitrile to trigger acrylonitrile and a comonomer to perform homogeneous solution polymerization in dimethyl sulfoxide to obtain spinning solution, and controlling the temperature of the spinning solution to be between 40 and 70 DEG C and the solid content to be between 18 and 24 percent; performing monomer removal on the spinning solution under the pressure of between -60 and -78kPa, and performing deaeration treatment under the pressure of between -78 and -97kPa; then extruding the spinning solution into a spin duct in a coagulation bath with a temperature of between 35 and 65 DEG C and a dimethyl sulfoxide concentration of between 50 and 70 percent for molding through a spinneret, and obtaining PAN-based as-spun fiber through 45 to 75 percent of minus stretch in the coagulation bath; then molding and stretching through a secondary coagulation bath, a third coagulation bath, a fourth coagulation bath and a fifth coagulation bath; and obtaining the high-strength polyacrylonitrile-based carbon fiber precursor through solvent removal by water scrubbing, hot water stretch, oiling, drying and densification, steam stretch, and hot air setting. The tensile strength of the high-strength polyacrylonitrile-based carbon fiber precursor reaches 10.2cN / dtex.

Owner:ZHONGFU SHENYING CARBON FIBER

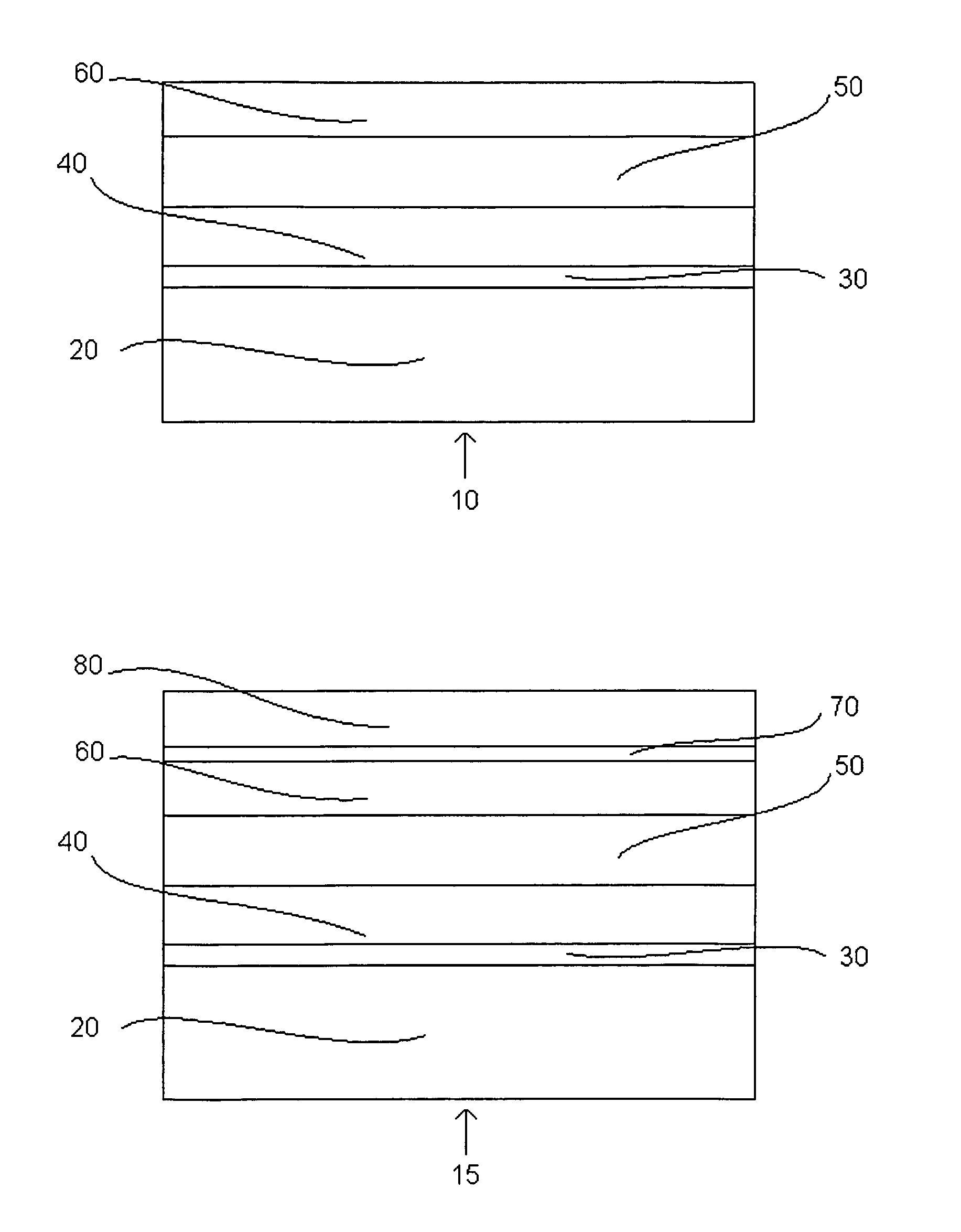

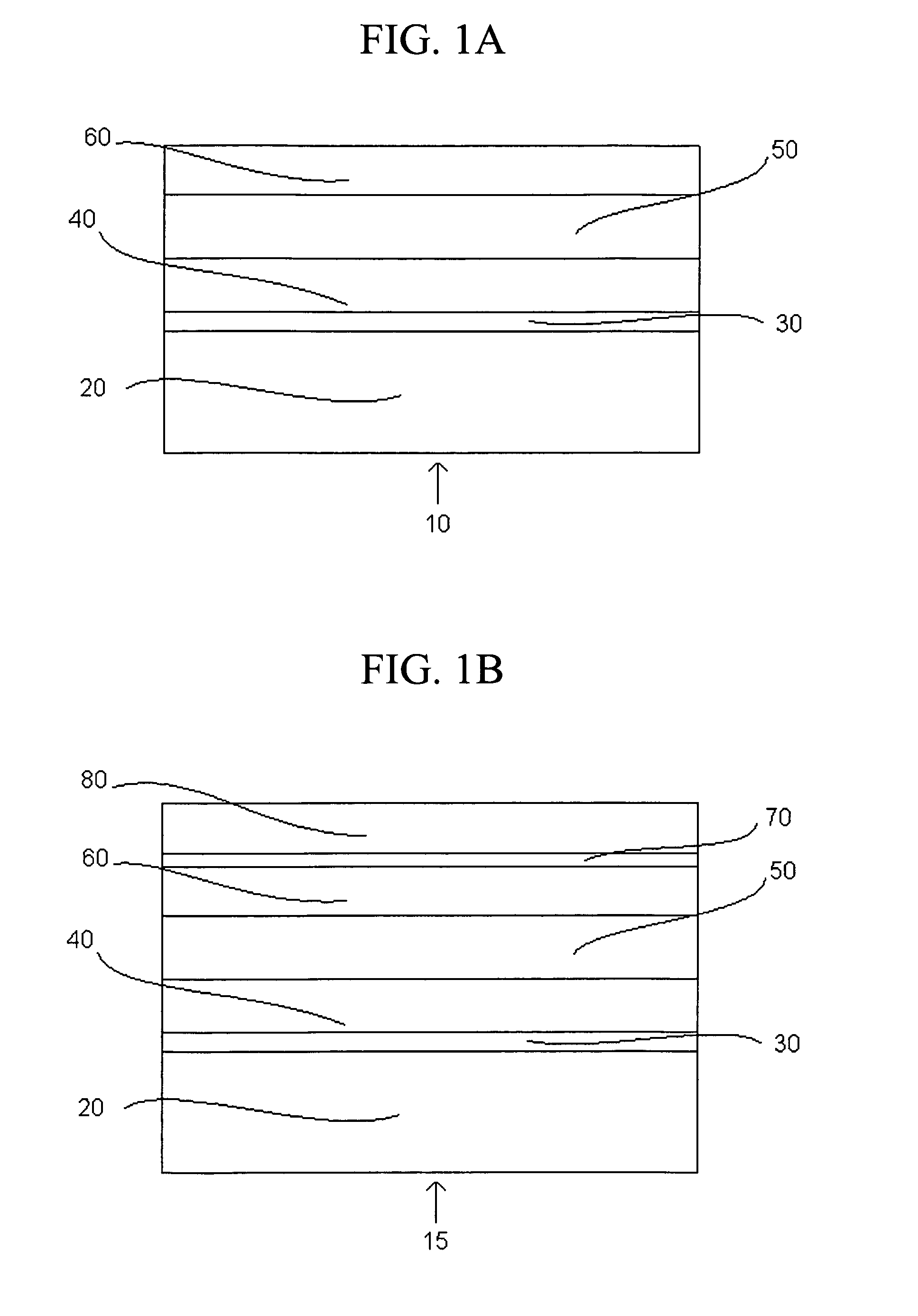

Detecting compounds with liquid crystals

ActiveUS7135143B2Improve orientationReduce orientationBioreactor/fermenter combinationsMaterial nanotechnologyLiquid crystalMetal

A device for detecting a compound in a sample includes a substrate and a self-assembled monolayer. The substrate includes a support with a metallized top surface, and the self-assembled monolayer includes an alkanethiol attached to the metallized top surface of the substrate and having a functional group that reversibly or irreversibly interacts with the compound. A liquid crystal is disposed on the self-assembled monolayer opposite the side of the self-assembled monolayer attached to the metallized top surface of the substrate. The liquid crystal includes a moiety that interacts with the functional group of the alkanethiol. When the compound is present in a sample that that contacts the self-assembled monolayer, the orientation of the liquid crystal is altered.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

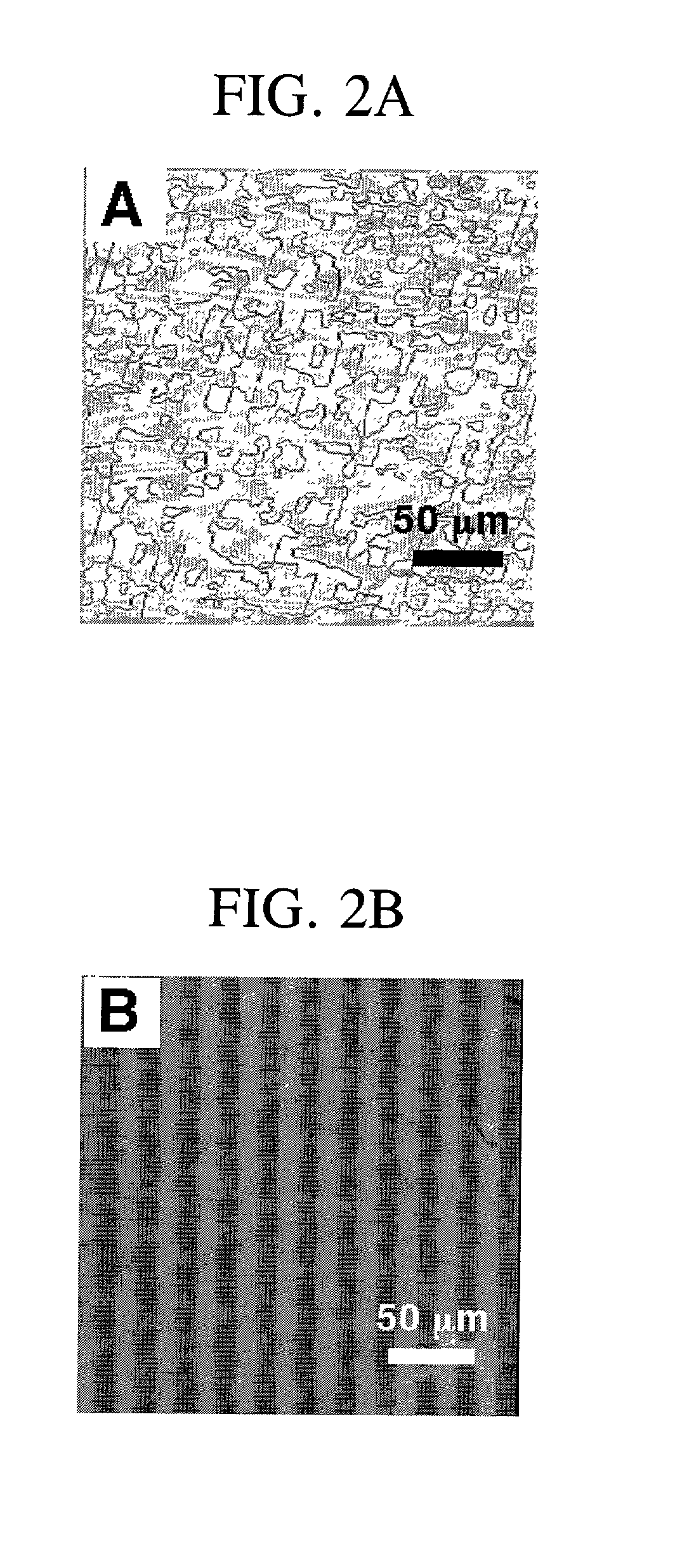

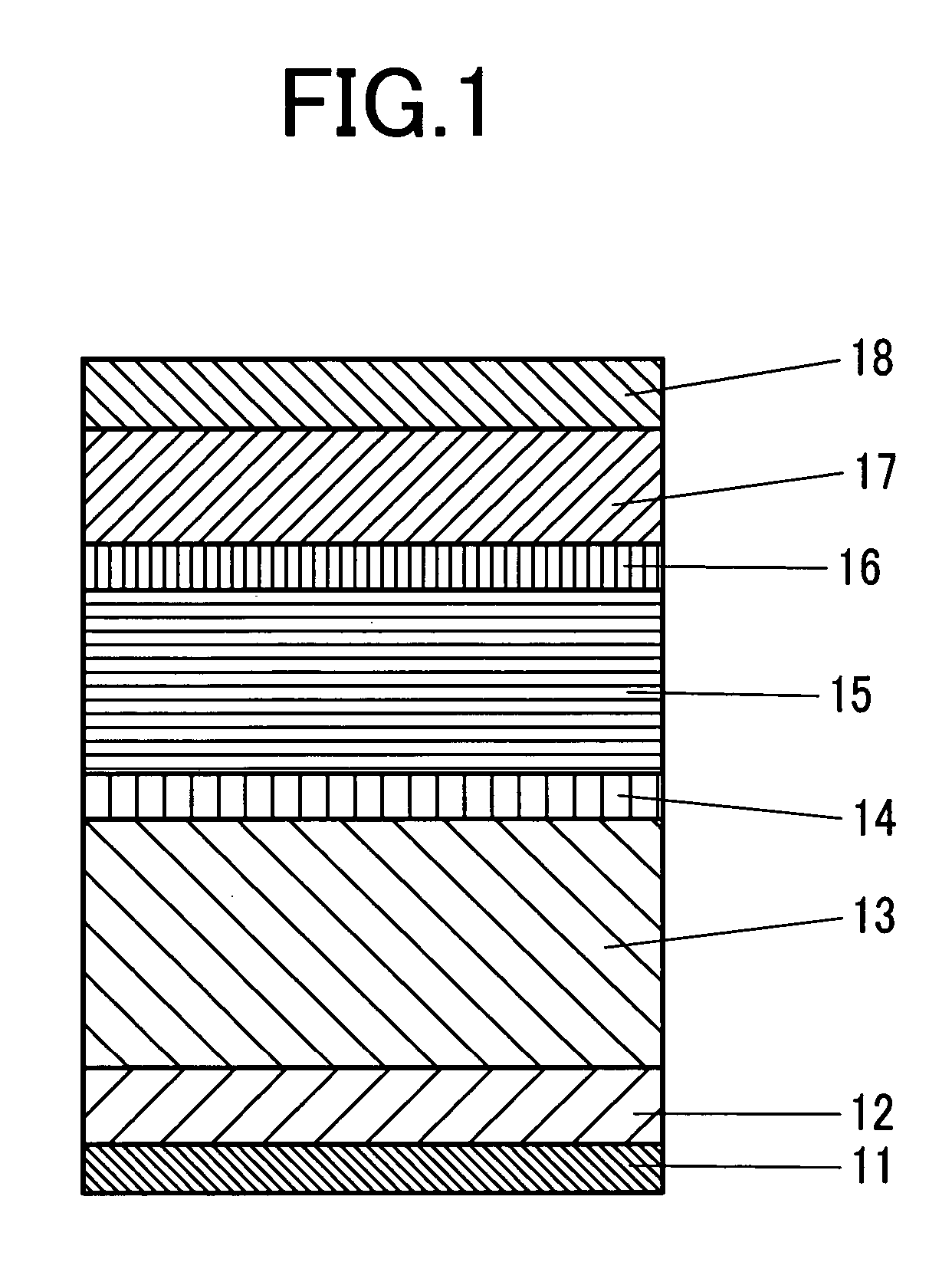

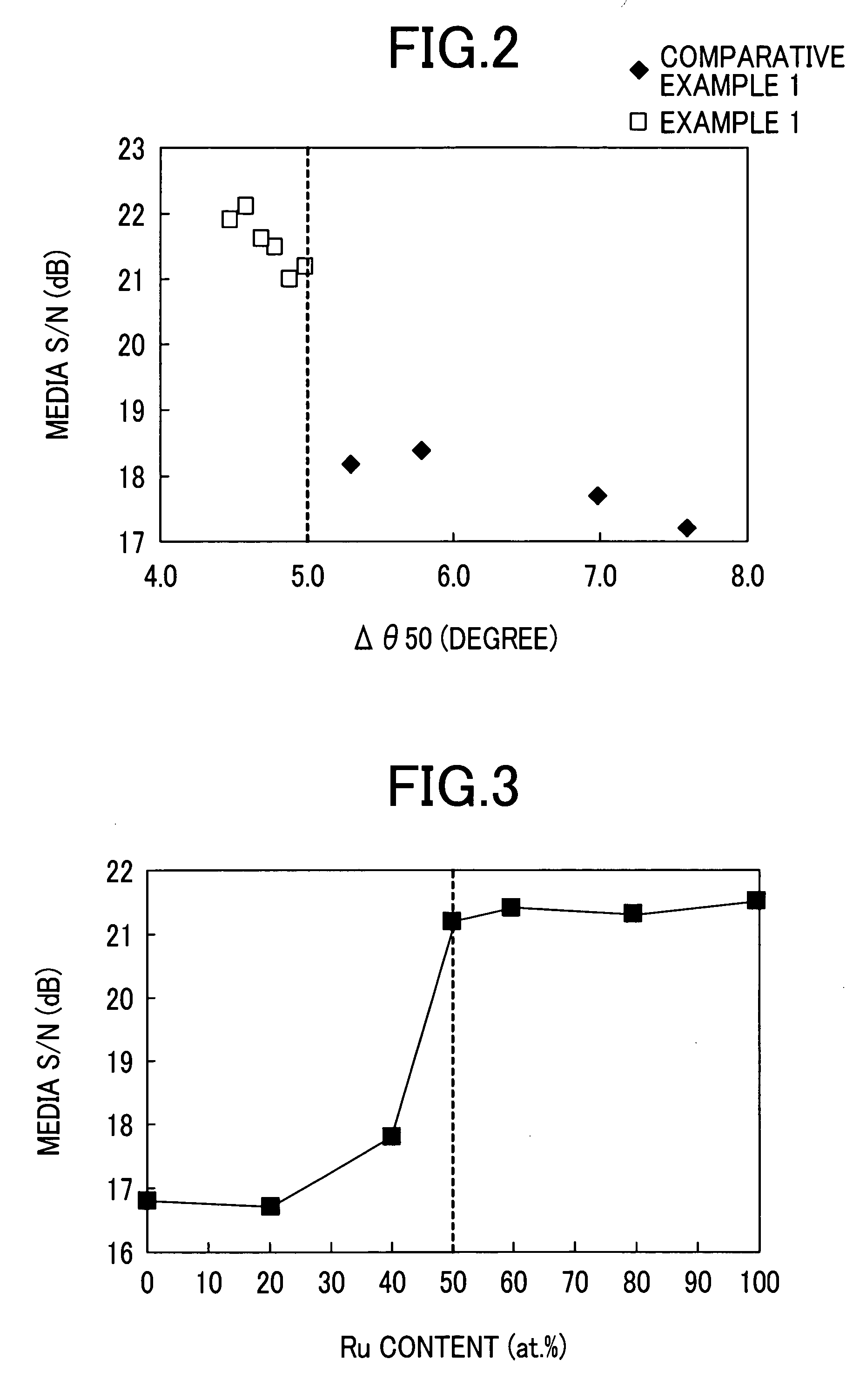

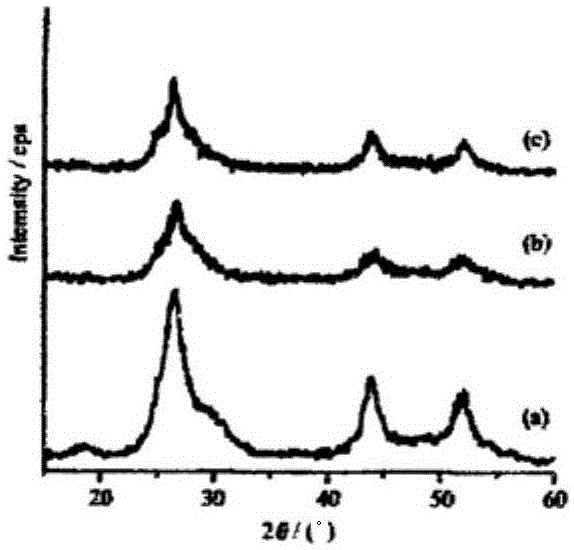

Perpendicular magnetic recording medium and manufacturing of the same

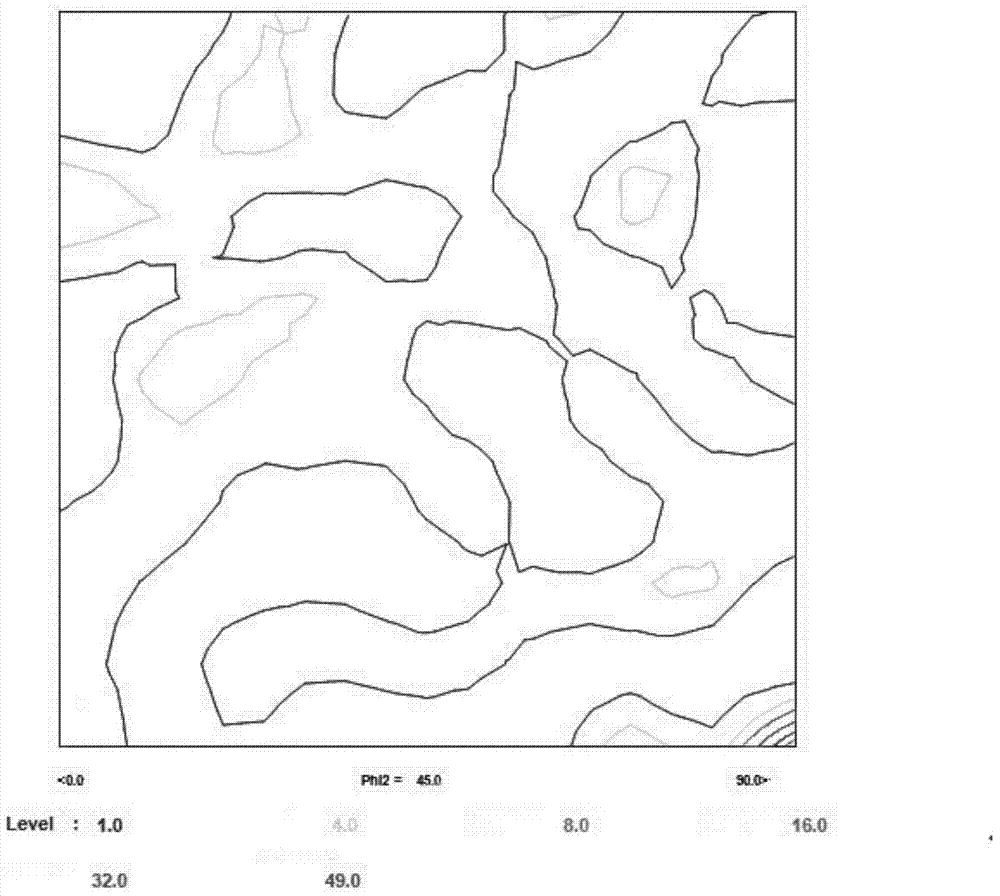

InactiveUS20050058854A1Improve orientationHigh s/n valueCombination recordingBase layers for recording layersX-ray scattering techniquesRocking curve

Disclosed here is a perpendicular magnetic recording medium for realizing a high media S / N value without degrading the magnetic isolation of crystal grains from each another. The perpendicular magnetic recording medium comprises a substrate, a soft magnetic underlayer formed on the substrate, an intermediate layer formed on the soft magnetic underlayer, and a magnetic recording layer formed on the intermediate layer. The intermediate layer consists of at least two or more layers and contains Ru or an Ru alloy and the magnetic recording layer is made of a material containing a CoCrPt alloy and oxygen. The crystallo graphic orientation of the recording layer can be improved enough without increasing the crystal grain size if a full width at half-maximum Δθ50 of the Rocking curves of the Ru (0002) diffraction peak measured by an X-ray diffraction method is 5° and under.

Owner:HITACHI LTD

Preparation method of oriented shell-core structural superfine composite fiber

InactiveCN103526336AImprove electrospinning performanceImprove mechanical propertiesFilament/thread formingConjugated cellulose/protein artificial filamentsFiberSynthetic materials

The invention relates to a preparation method of oriented shell-core structural superfine composite fiber. The preparation method comprises the steps of dissolving biological activity natural macromolecule in a solvent, and stirring to obtain a shell spinning solution; dissolving polylactic acid (PLLA) and polyoxyethylene (PEO) in the solvent, and stirring to obtain a core spinning solution; and respectively extracting the shell spinning solution and the core spinning solution, jetting and stably and coaxially electrospining to obtain the shell-core structural superfine composite fiber. The shell-core structural superfine composite fiber, which effectively combines synthetic materials and natural materials, integrates mechanical performance and biocompatibility of fiber and can prepare the shell-core structural superfine composite fiber which is relatively high in orientation degree in large scale as conventional mechanical spinning; and the oriented superfine composite fiber prepared by the preparation method has application prospect in repairing tendon, ligament and other tissues.

Owner:DONGHUA UNIV

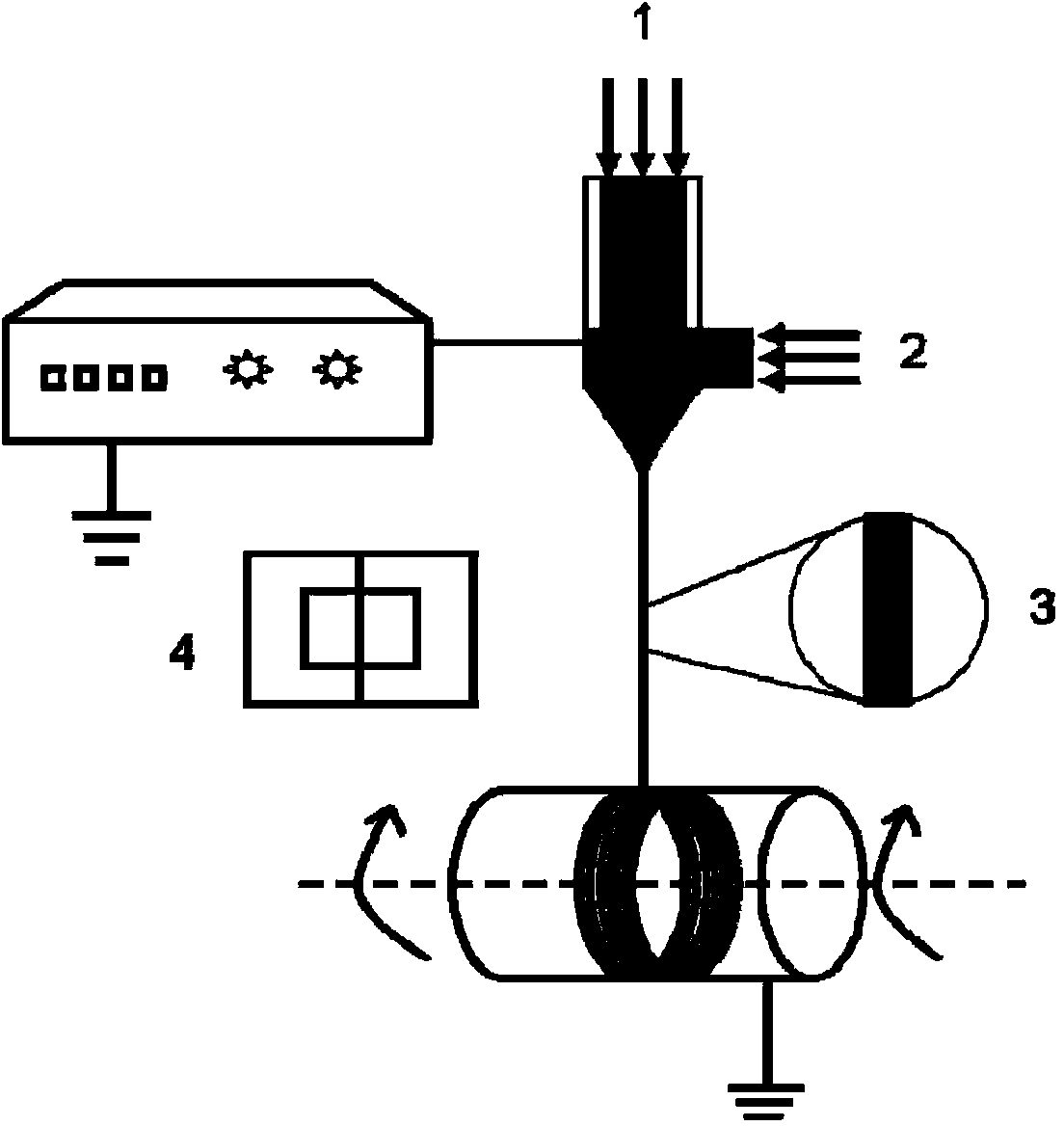

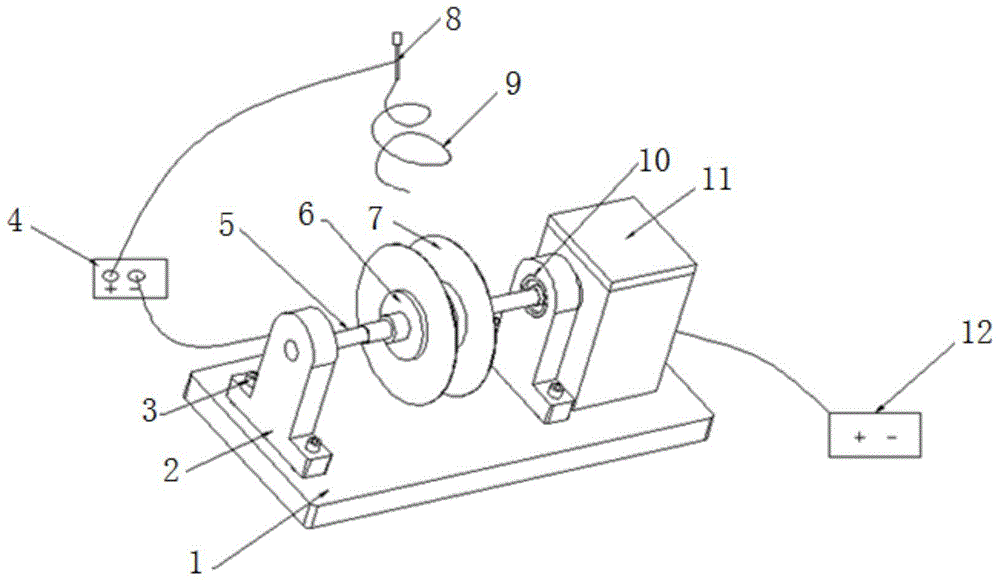

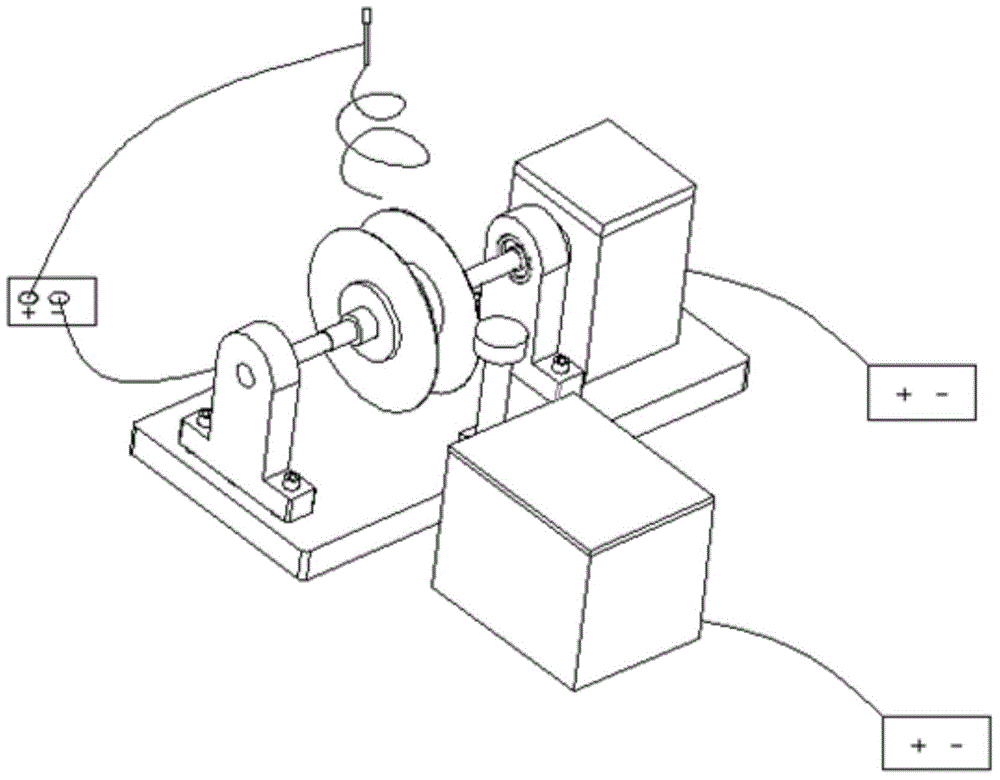

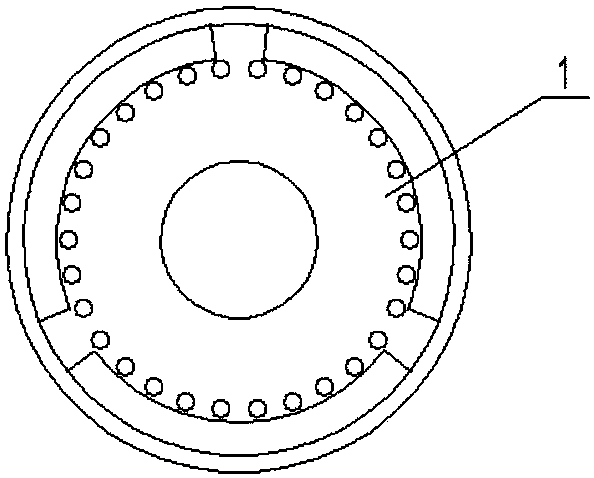

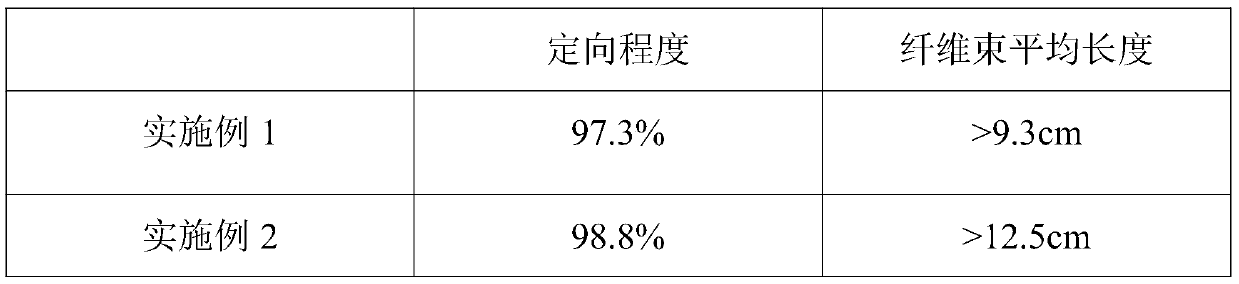

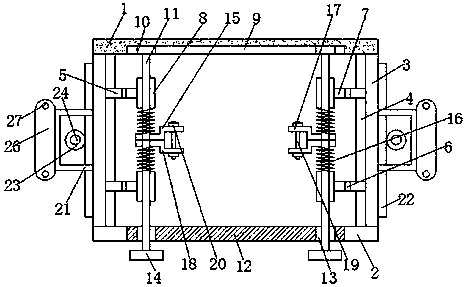

Electrostatic spinning collection device and method, and electrostatic spinning equipment

The invention discloses an electrostatic spinning collection device and electrostatic spinning equipment with the device. The device comprises a directional fiber collector and a rotatable planar fiber receiver, wherein the directional fiber collector comprises a rotating shaft, two parallel disks mounted on the rotating shaft and a driving unit coupled with the rotating shaft; negative voltage is applied to the disks; fibers formed by splitting charged jet flow released from a positive voltage end are suspended between the two parallel disks in a directional manner; the rotatable planar fiber receiver comprises a receiving disk, and a rotation driving mechanism and a reciprocating driving mechanism which are coupled to the receiving disk; the reciprocating driving mechanism is used for supporting the receiving disk to get into or get out of a space between the two parallel disks; the rotary driving mechanism is used for rotating the receiving disk so as to adjust an angle of the fibers collected to the disk surface of the receiving disk. The invention also discloses an electrostatic spinning collection method using the electrostatic spinning collection device. The fibers electrically spun by the electrostatic spinning collection device are high in directing degree and are suitable for constructing highly ordered fiber tissue structures.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

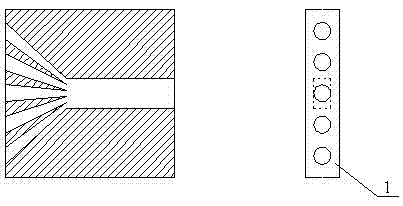

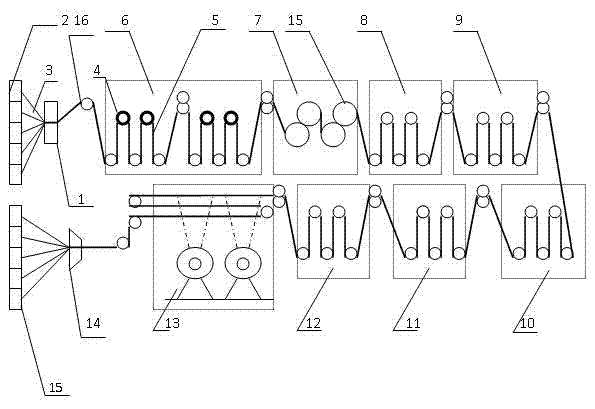

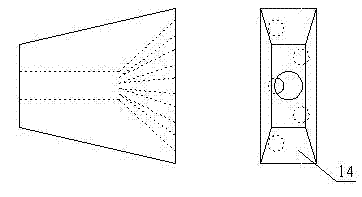

Braid continuous mercerizing machine and processing method thereof

ActiveCN102926149AImprove orientationChange the crystalline structureMercerising of yarns/threads/filamentsSucessive textile treatmentsSewageFiber

The invention relates to field of fiber mercerizing processing, and particularly to a mercerizing machine used for mercerizing processing braids woven by fibers. The mercerizing machine comprises an alkali-soaking reacting area, an alkali squeezing area, a backflow alkali removing area and a drying area, and the alkali-soaking reacting area, the alkali squeezing area, the backflow alkali removing area and the drying area are arranged in sequence. A telescopic roller is used to control tensile stress of fiber braids inside the alkali-soaking reacting area, a ladder-shaped reversing flush alkali removing groove is adopted inside the backflow alkali removing area, strong alkali liquid, weak alkali liquid and hot water are sequentially used to remove alkali liquid carried by the fiber braids, and a hot air dryer is used to dry the fibers in a drying system. The braid continuous mercerizing machine achieves continuous mercerizing production of the fiber braids, provides industrial application of fiber mercerizing with equipment foundations, and at the same time has the advantages of being large in output, simple to operate, and saving water resources, reducing discharge of polluted water and being high in mercerizing quality.

Owner:无锡市鳌尊生态科技有限公司

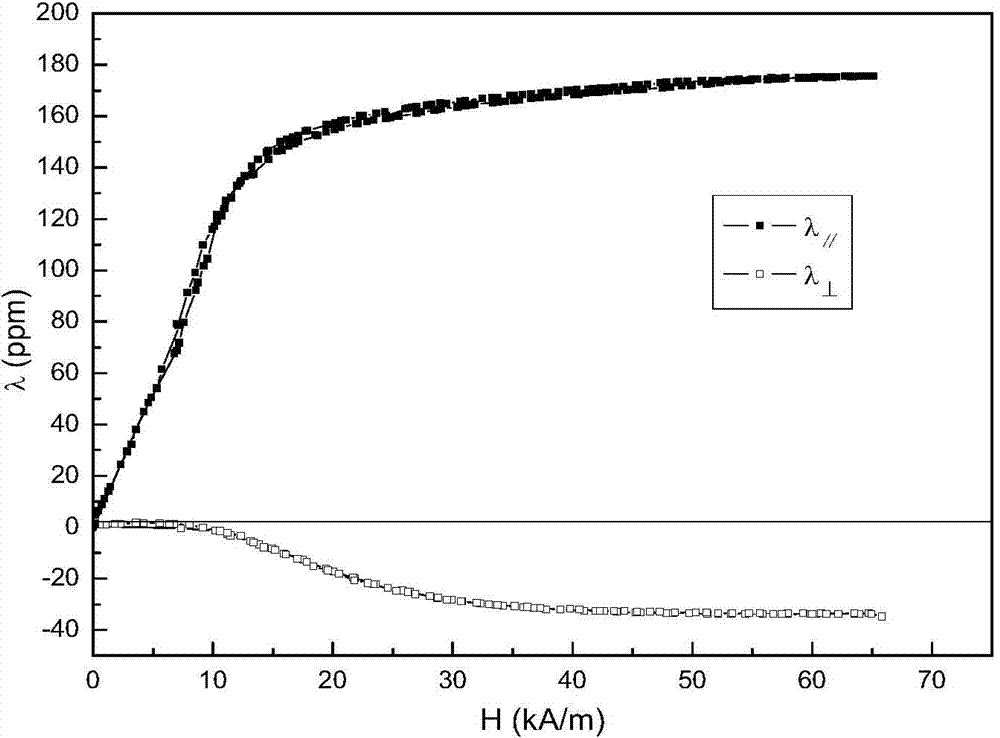

Fe-Ga-Al alloy strip with high magnetostrictive properties and preparation method thereof

ActiveCN104711475AImprove orientationStrong Gaussian textureSolid state diffusion coatingMagnetostrictive material selectionCrystalliteAtomic ratio

The invention belongs to the field of magnetic materials, and relates to a Fe-Ga-Al alloy strip with high magnetostrictive properties and a preparation method thereof. The Fe-Ga-Al alloy strip is characterized in that a matrix of the alloy strip is a Fe-Ga-Al three-component alloy with a composition of Fe100-x-y-zGaxAlyMz, wherein M is one or more of B, Cr, V, Ti, Mn, MnS and NbC; and by calculating according to atomic ratios, x is equal to 7.5-25, y is equal to 5-15, x+y is equal to 15-30, z is equal to 0.1-1.0, and the balance is iron. The preparation method comprises the following steps: performing nitriding heat treatment for a short time respectively after hot rolling and cold rolling; introducing [N] into the process of heat treatment to ensure that [N] together with Al and other nitrides in the matrix form element combination so as to form tiny nitrides which are precipitated out; taking these precipitated phases as an inhibitor to inhibit the grain growth in the process of first-time recrystallization; and then performing second-time recrystallization and high-temperature heat treatment to finally obtain the Fe-Ga-Al alloy strip with a strong gauss texture. The magnetostrictive coefficient (3 / 2) lambdas of the alloy strip can reach more than 200ppm.

Owner:UNIV OF SCI & TECH BEIJING

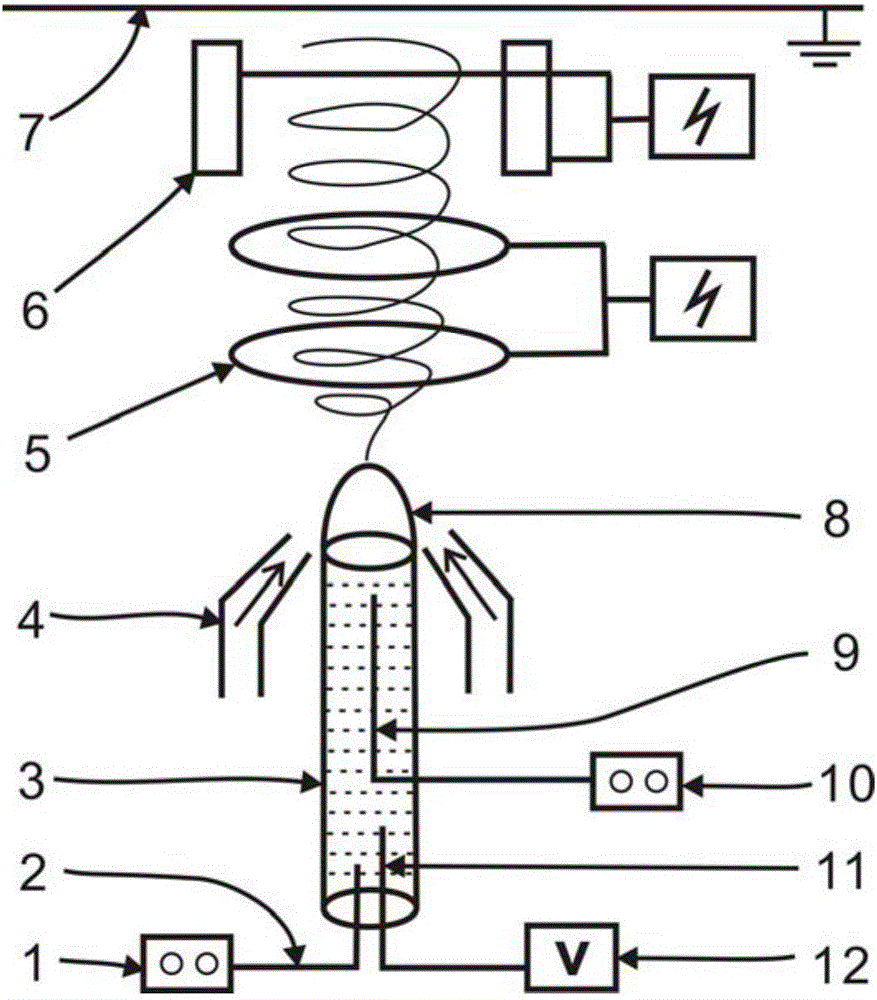

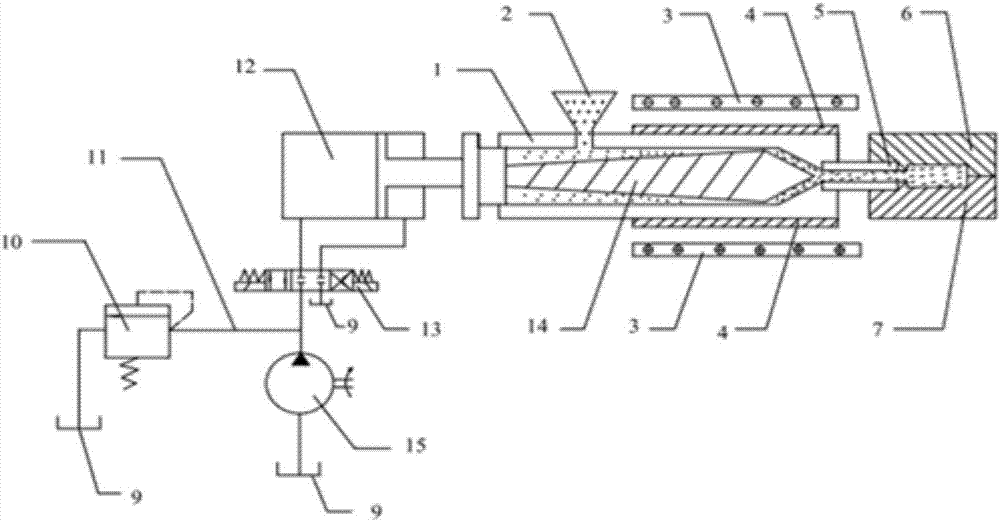

Airflow and air bubble spinning device for preparing ordered fiber material based on assistance of magnetic field

InactiveCN105734699AChange the microstructureImprove orientationFilament/thread formingMicrostructureAirflow

The invention discloses an air bubble spinning device for preparing ordered fiber materials based on the assistance of a magnetic field. By setting a magnetic control device between a bubble injection tube and a receiving device, the longitudinal magnetic control device can realize jet flow when forming fiber materials. Convergence in the longitudinal direction, the transverse magnetic control device can realize the stretching of the jet in the transverse direction, and the controllability of the jet trajectory can be realized through the action of the magnetic field, so as to solve the problem of excessive jet angle and jet flow in the existing air bubble spinning process. The unsteady swing leads to the technical problem of chaotic and disordered fiber collection, changes the fiber microstructure, and improves the orientation degree of the fiber.

Owner:SUZHOU UNIV

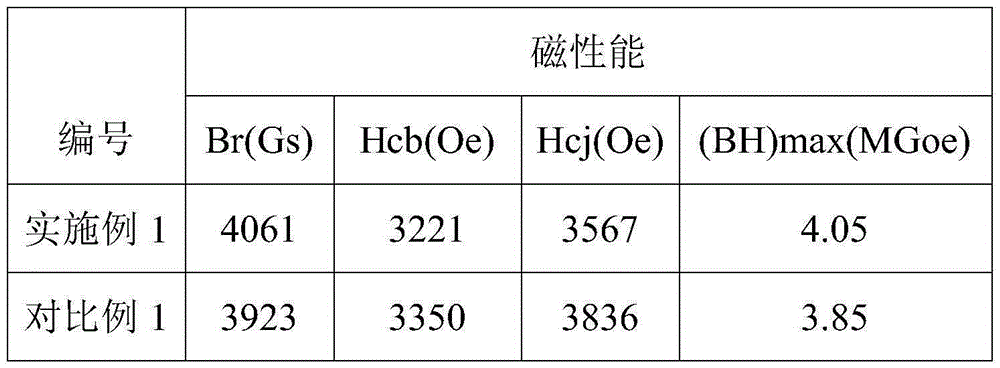

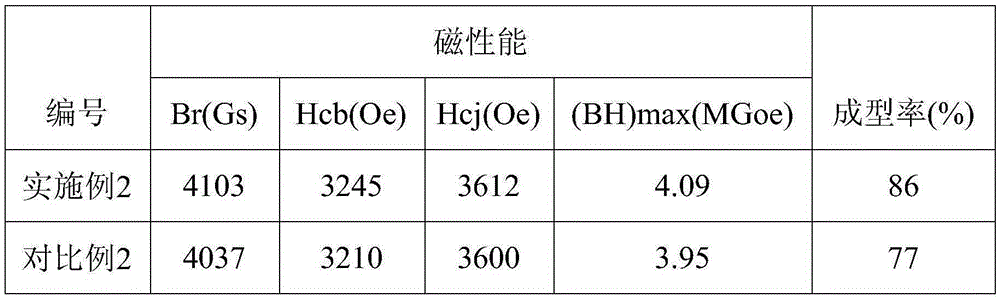

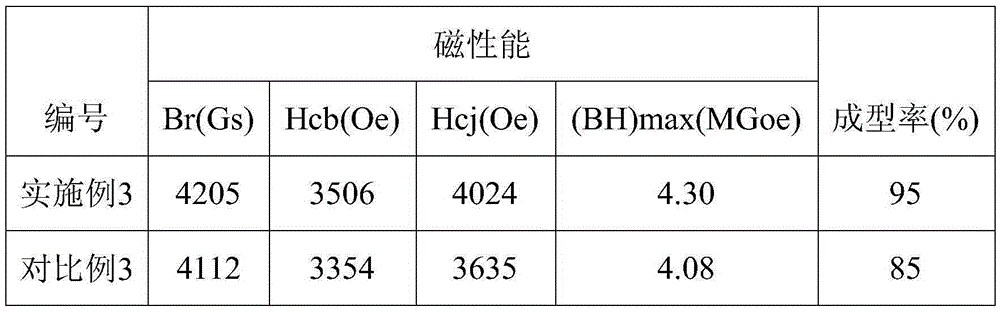

Method for manufacturing dry press permanent magnetic ferrite

ActiveCN105384434AOptimization of particle size and morphology of magnetic powderImprove orientationMagnetic powderMass ratio

The invention discloses a method for manufacturing dry press permanent magnetic ferrite. The method comprises the following specific operating steps: selecting a pre-sintering material, adding multiple needed additives according to a mass ratio, and performing ball milling; storing the slurry subjected to ball milling until the slurry is dried; drying the magnetic powder, adding 0-0.6 percent of calcium stearate, 0.8-1.2 percent of an alcohol camphor solution and 0-0.4 percent of talcum powder, and dispersing the material by using a high-speed dispersion machine after the materials are uniformly mixed and stirred; tempering the magnetic powder at the temperature of 60-90 DEG C; molding in a magnetic field of 8000Oe or more, thereby obtaining a formed body with the height of 1.2-2cm; maintaining the temperature of the green body at the temperature of 350-400 DEG C for 1-3 hours, and maintaining the temperature at the temperature of 1150-1350 DEG C for 0.1-3 hours; and grinding, cleaning and detecting. The method disclosed by the invention has the beneficial effects that on one hand, technology improvement is performed, and a low-temperature tempering process is increased, so that the particle size and shape of the magnetic powder can be optimized, the degree of orientation is improved, and the magnetic performance is further improved; on the other hand, due to improvement of additives in the granulation process, compression molding is promoted, and the yield is further improved.

Owner:武穴东磁磁材有限公司

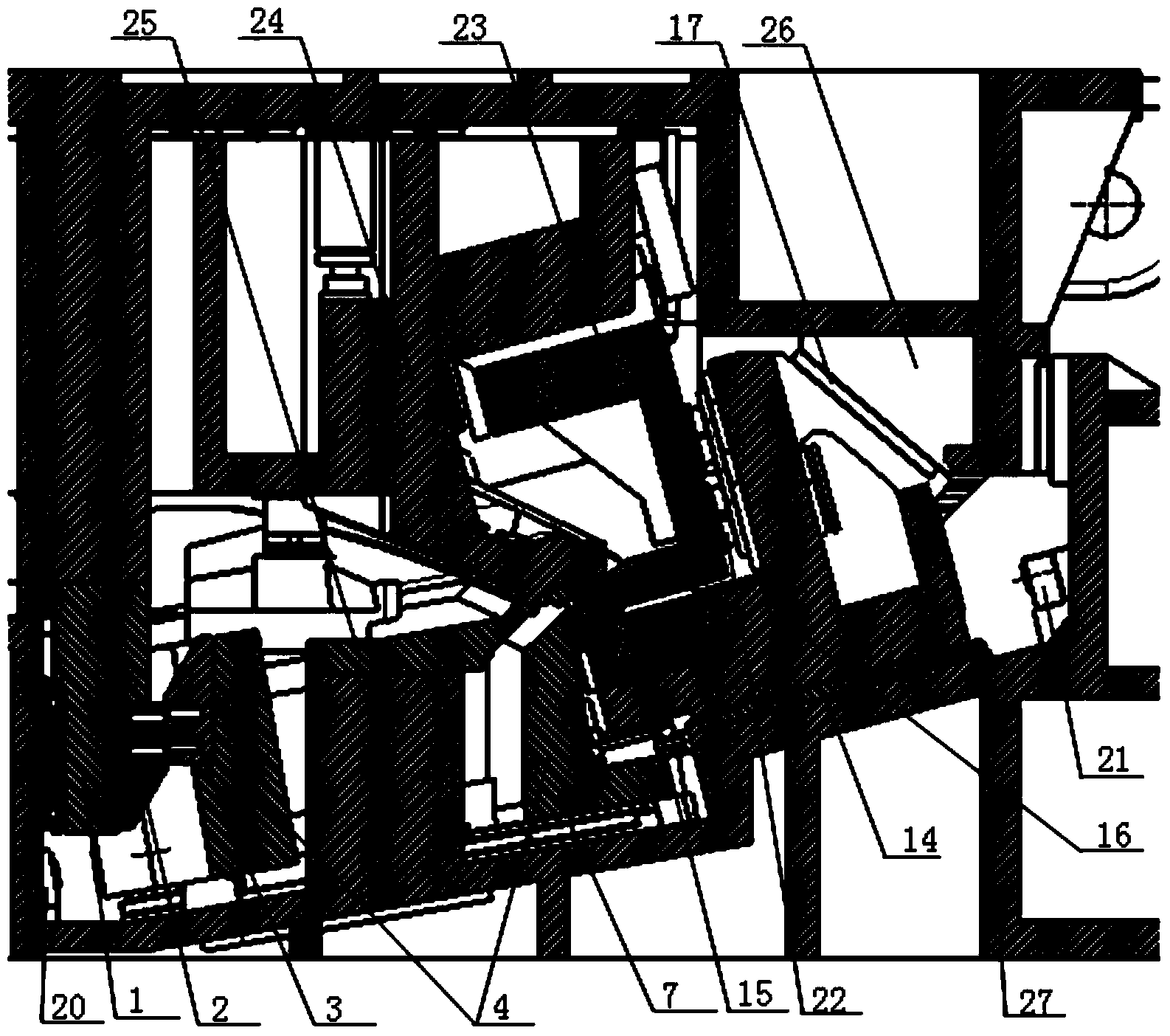

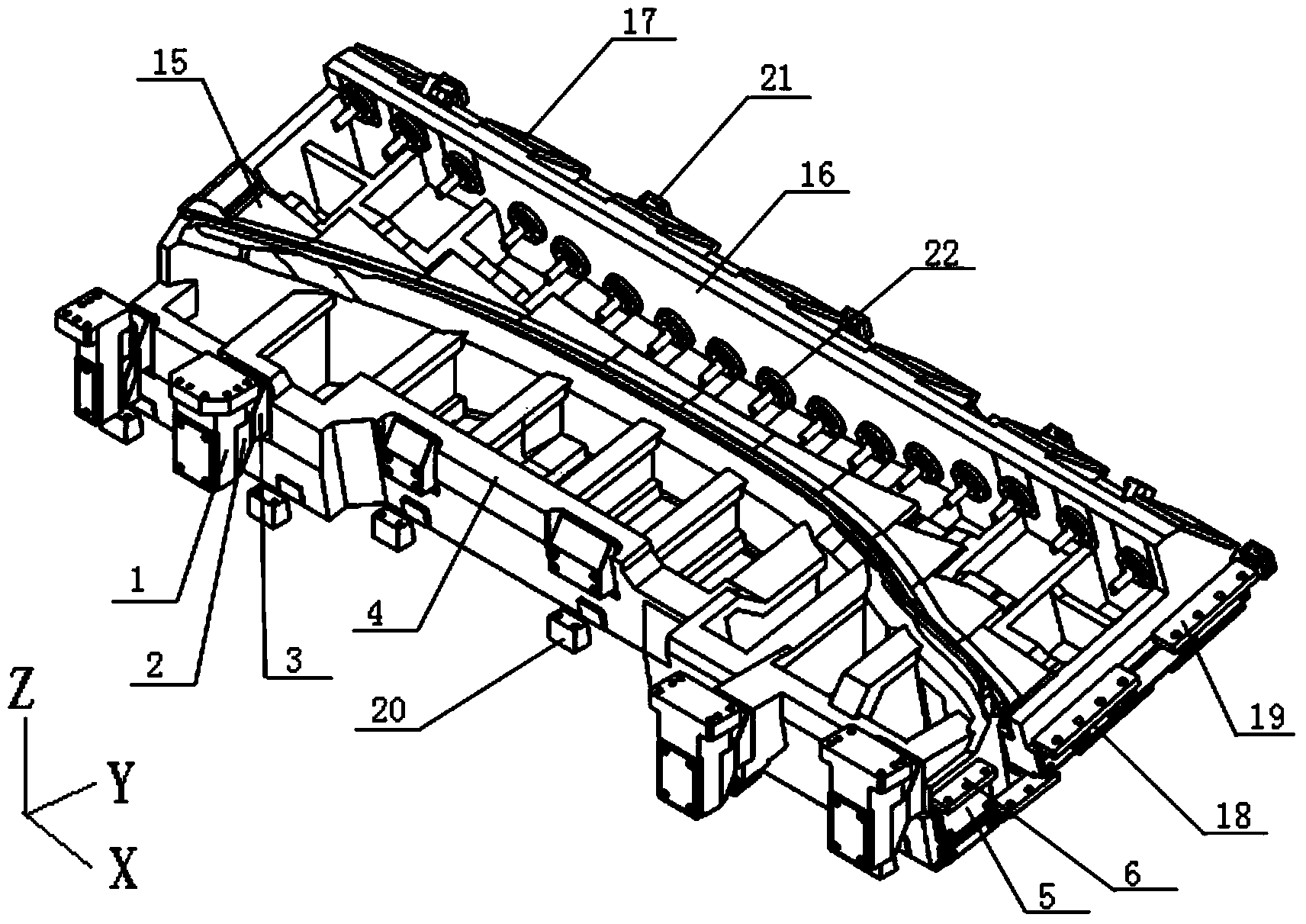

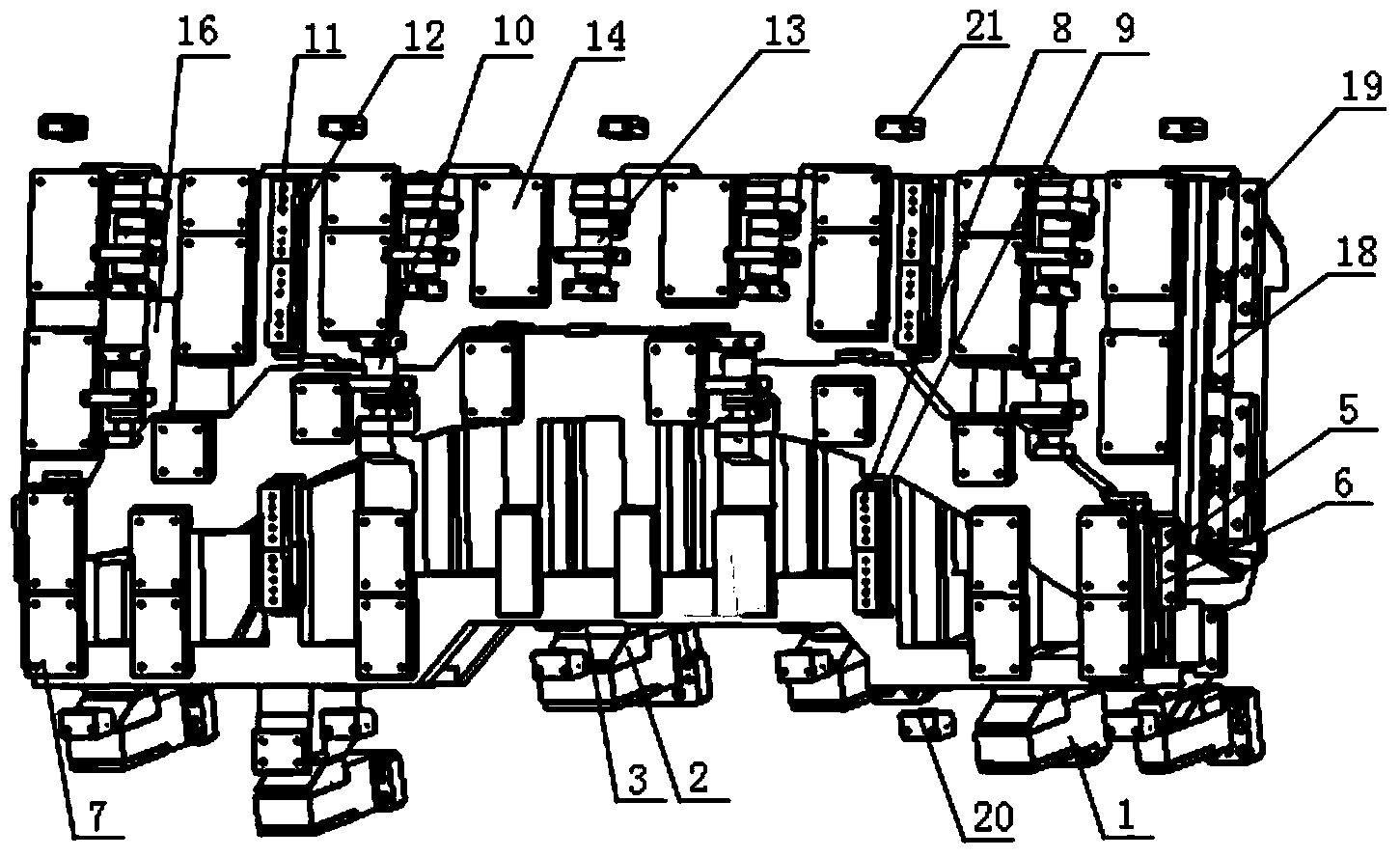

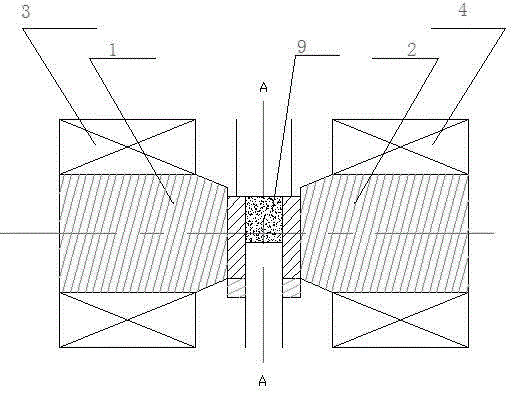

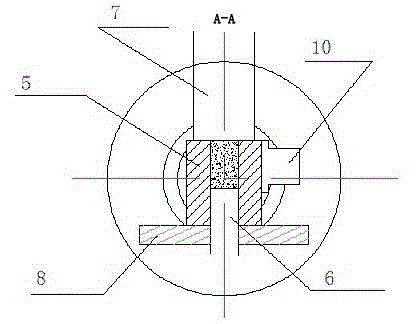

Lateral shaping tapered wedge mechanism

InactiveCN103861957AThe mold structure is compactImprove orientationShaping toolsEngineeringMechanical engineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Pneumatic rotating guide propulsion drilling machine

PendingCN108049812AEnhance orientation positioning effectImprove drilling efficiencyDrill bitsDirectional drillingDrill bitEngineering

The invention discloses a pneumatic rotating guide propulsion drilling machine, which is provided with a guide positioning sleeve in a round barrel body shape. A pneumatic motor is fixedly arranged inthe guide positioning sleeve; a tail part air inlet guide pipe of the pneumatic motor convexly extends from the tail end of the guide positioning sleeve; an air inlet drilling pipe is externally connected; a front end exhaust hole plate of the pneumatic motor is fixedly arranged on the front end surface of the guide positioning sleeve through a convex lug; a rotating shaft of the pneumatic motorconvexly extends from the front end of the guide positioning sleeve and is provided with a drill bit. The horizontal directional propulsion can be effectively performed in real time, and is particularly applicable to the construction of underground perforation horizontal directional hole drilling and reaming.

Owner:ANHUI CHUANGQI MONITORING EQUIP

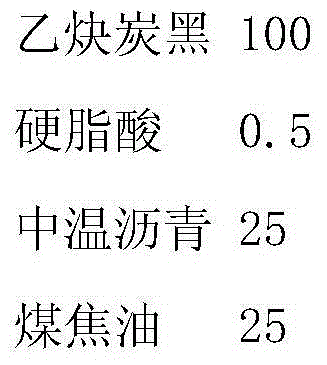

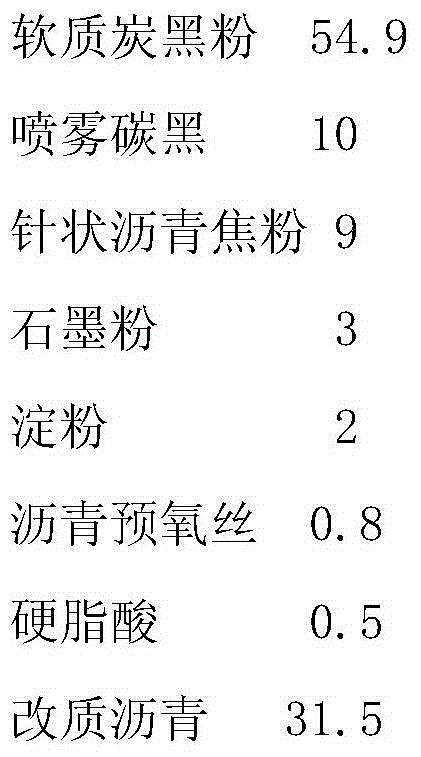

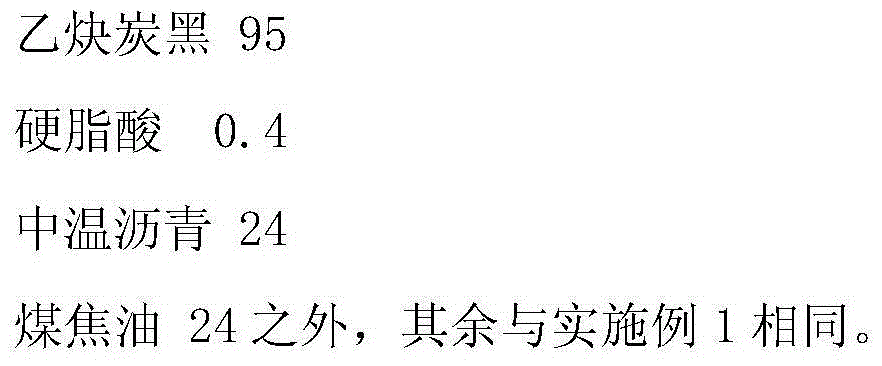

Material for preparing locomotive traction motor carbon brush

ActiveCN106032328AImprove wear resistanceImprove orientationCeramicwareDiesel locomotiveCarbon black

The invention discloses a material for preparing a locomotive traction motor carbon brush. The material comprises soft carbon black powder, sprayed carbon black, pitch coke powder, graphite powder, a pore forming agent, a directional auxiliary agent, modified asphalt and a lubricant. According to the present invention, the carbon brush prepared from the material has characteristics of high rupture strength, good direction change performance and high passing current density, and is used for the diesel locomotive traction motor and the electric locomotive traction motor.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Piezoelectric texture ceramic injection forming machine

InactiveCN107344386AIncreased and improved piezoelectricityImprove reliabilityCeramic shaping apparatusElectricitySpray nozzle

The invention discloses a piezoelectric texture ceramic injection forming machine. The piezoelectric texture ceramic injection forming machine comprises a material barrel and a screw arranged in an inner cavity of the material barrel. The tail end of the screw stretches out of one end of the material barrel and is connected with a hydraulic drive device providing power, the other end of the material barrel is provided with a nozzle communicating with the inner cavity of the material barrel, and an outlet of the nozzle is connected with a die. The material barrel is further provided with a hopper communicating with the inner cavity and electric field generation devices symmetrically arranged on the two sides of the material barrel and used for generating electric fields to orient piezoelectric ceramic grains, the grains flow into the material barrel through the hopper and are pushed by the screw to flow through an external electric field to be injected into the die through the nozzle, operation is convenient, the technology is simple, feasibility is high, and the requirement for multiple products complex in shape is met.

Owner:SHAANXI UNIV OF SCI & TECH

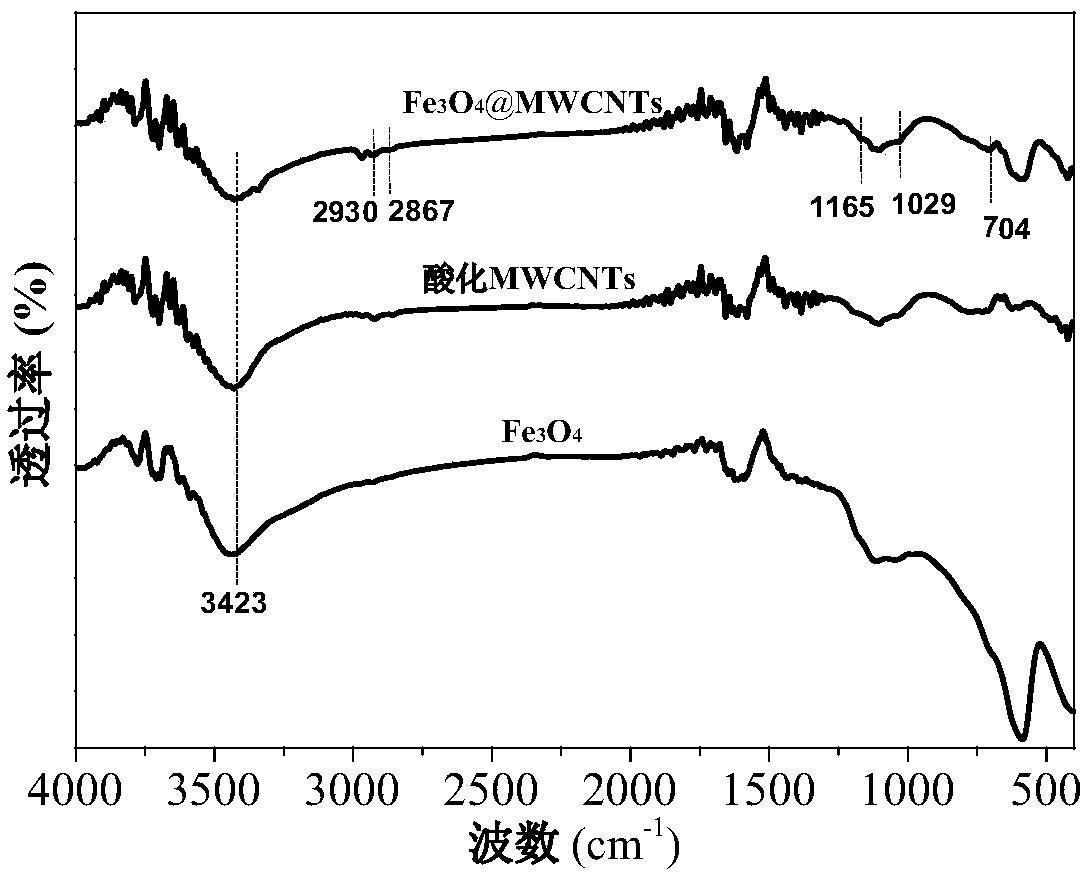

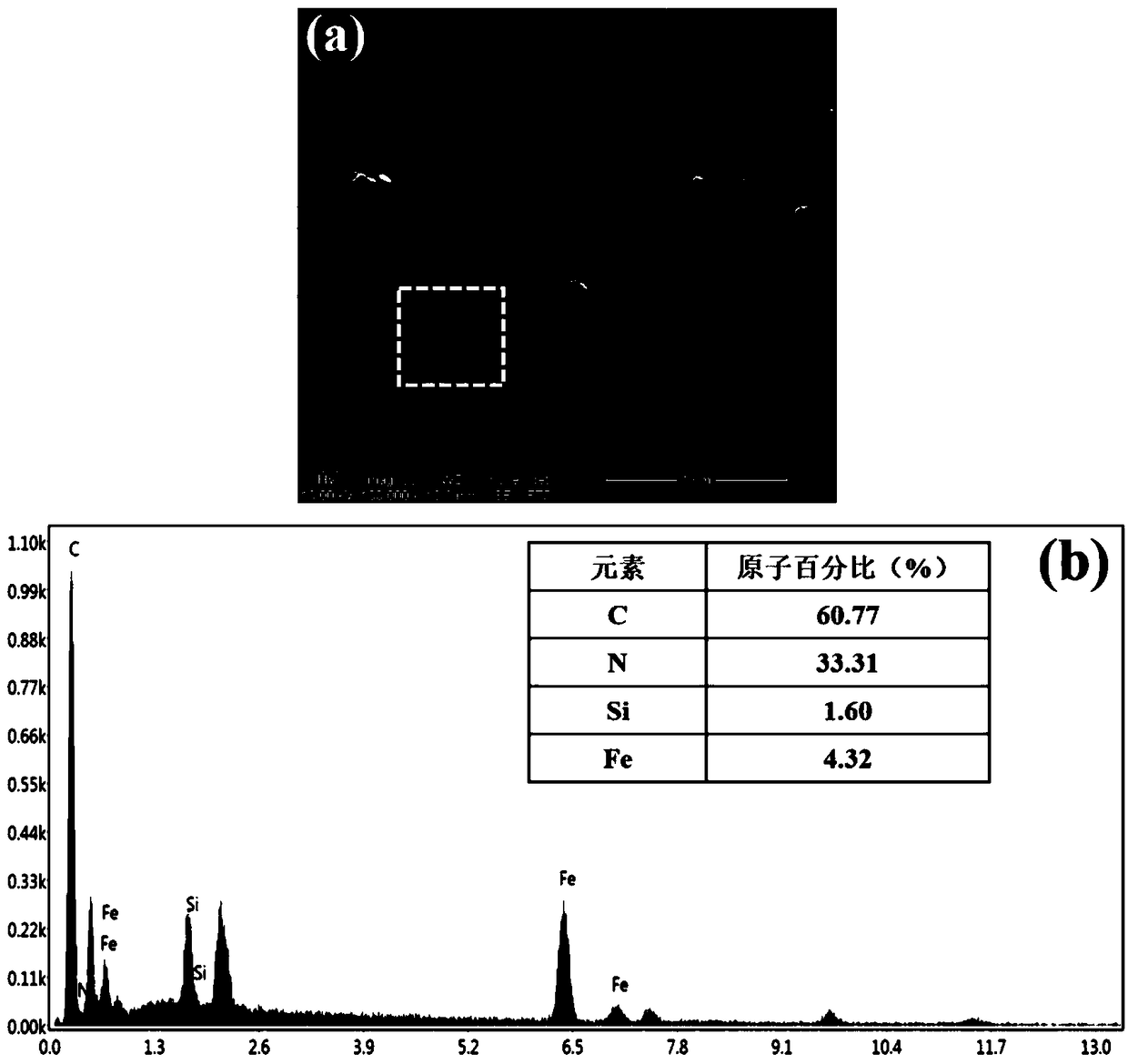

Preparation method of magnetic orientation carbon nano tube reinforced glass fiber epoxy composite material

ActiveCN109385906ASolve the problem of being easily filtered by fiber fabricsImprove orientationTextiles and paperDispersityFiltration

The invention discloses a preparation method of a magnetic orientation carbon nano tube reinforced glass fiber epoxy composite material, and the method comprises: dispersing carbon nano tubes into anorganic solvent, and modifying the carbon nano tubes by adopting a silane coupling agent to prepare silanized carbon nano tubes; then adding ferroferric oxide nano magnetic balls, and carrying out hydrolytic condensation, filtration, water washing, and spraying drying to obtain ferroferric oxide grafted carbon nano tube nano-powder; then mixing the nano-powder, a dispersing agent and epoxy resin,carrying out stirring and three-roller grinding, adding a curing agent, uniformly mixing to obtain a mixture, and coating the surface of a glass fiber fabric with the mixture; finally, vacuumizing andkeeping the vacuum state, and applying an external magnetic field until the resin is completely solidified. According to the invention, by the resin flow shear force and magnetic field synergistic effect, the carbon nano tubes can be effectively oriented in the glass fiber reinforced composite material, the dispersity of the carbon nano tubes is improved, and the mechanical property of the composite material is stably improved. In addition, the orientation of the carbon nanotubes is controllable in direction and efficient, and industrial production is convenient.

Owner:HOHAI UNIV

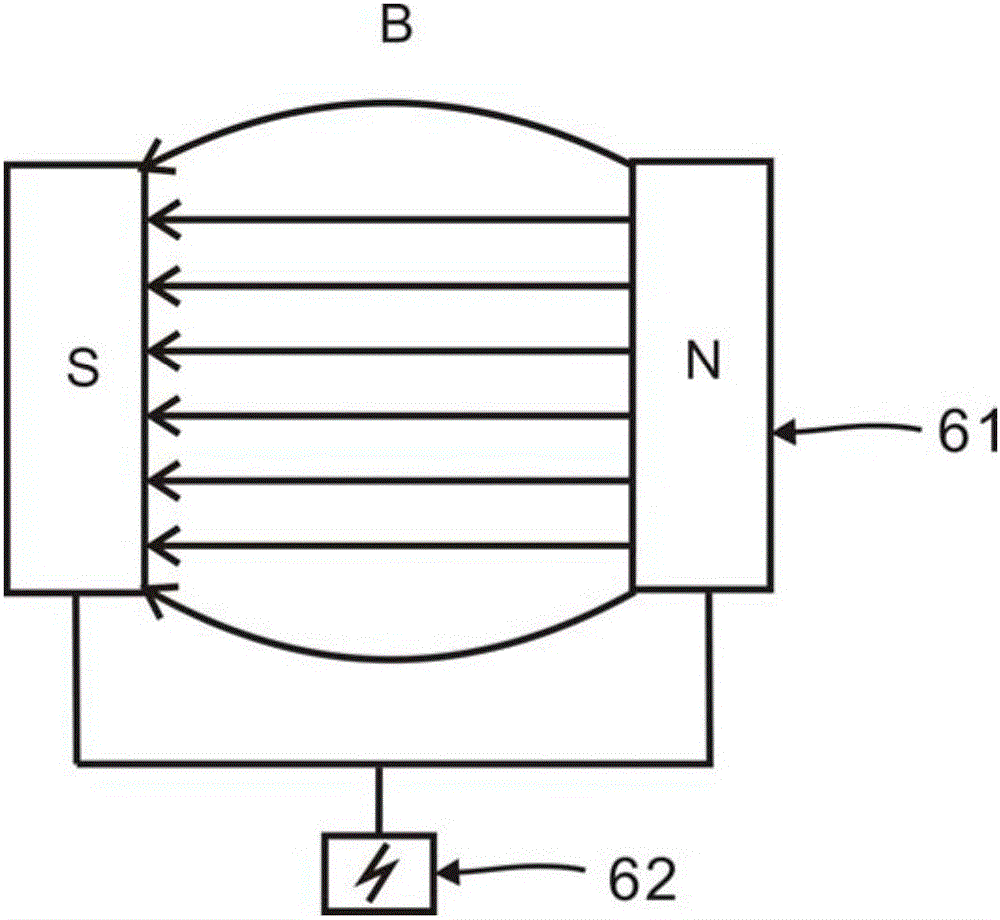

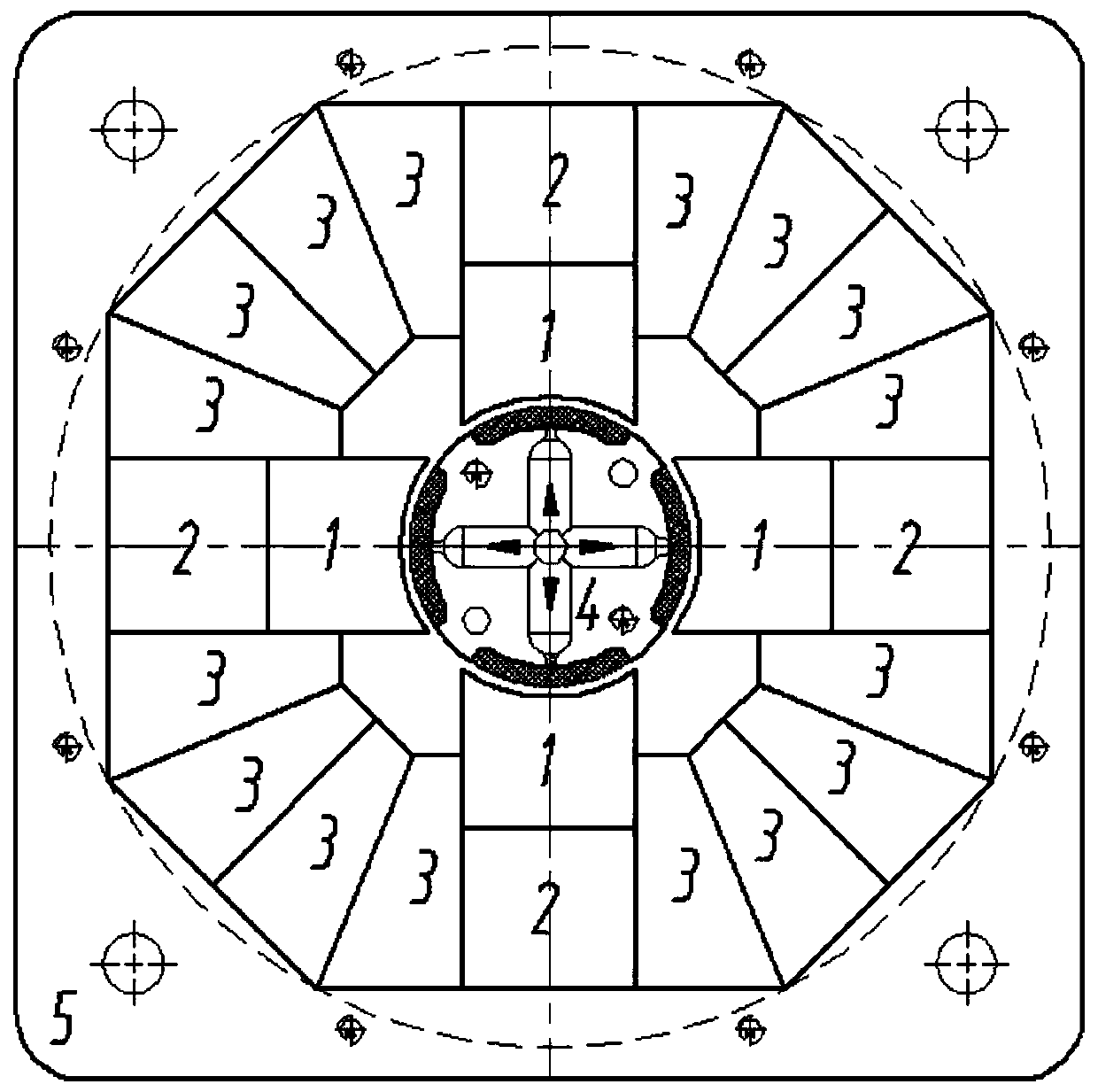

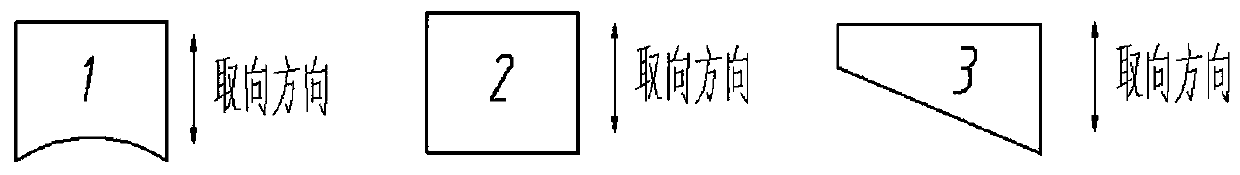

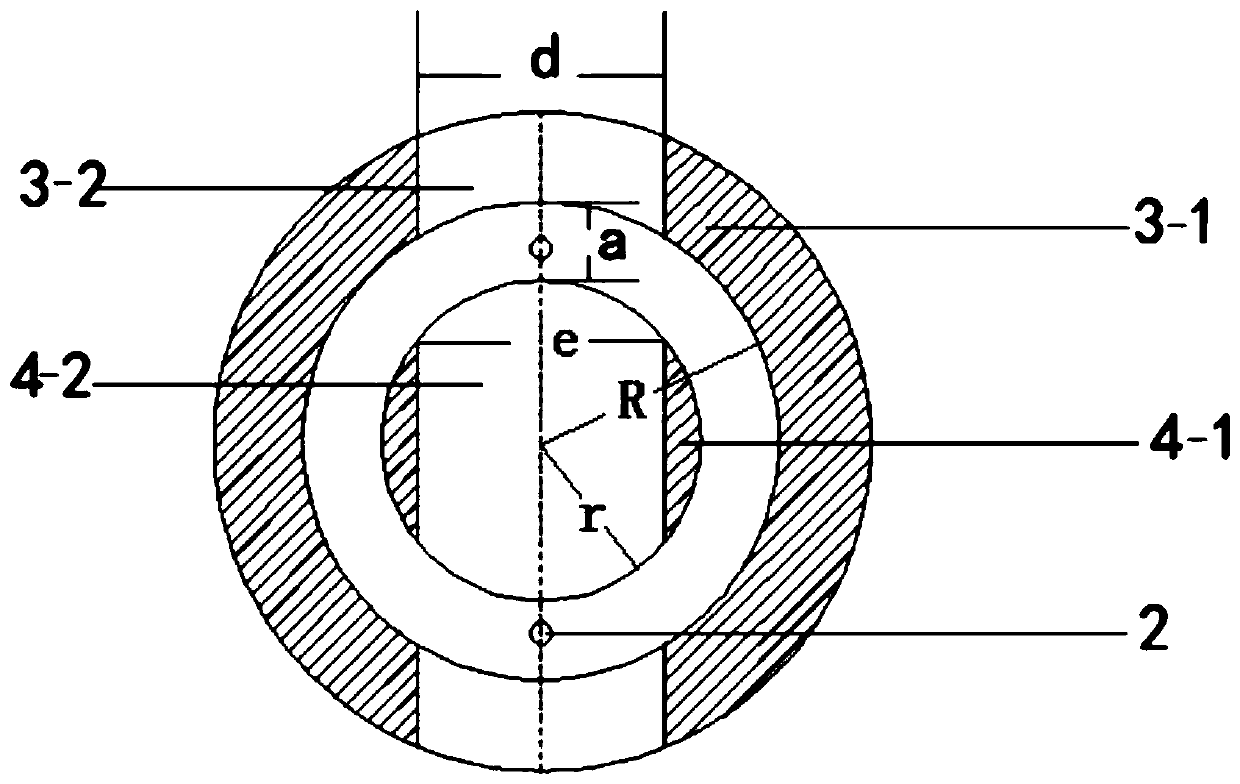

Injection molding anisotropic bonded neodymium-iron-boron magnetic shoe radiation orientation forming method and device

ActiveCN110931236ASimple structureImprove orientationInductances/transformers/magnets manufactureNeodymium iron boronMaterials science

The invention provides an injection molding anisotropic bonded neodymium-iron-boron magnetic shoe radiation orientation forming method and an injection molding anisotropic bonded neodymium-iron-boronmagnetic shoe radiation orientation forming device. The device comprises an A-type oriented permanent magnet, a B-type oriented permanent magnet, a C-type oriented permanent magnet, a magnetic flow channel, an inner mold core and a non-magnetic outer mold core, the problems that a conventional built-in permanent magnet orientation field adopted by an anisotropic injection molding neodymium-iron-boron bonded magnet is low, and the orientation degree of a product is not high are solved, the orientation magnetic field in the mold is larger than 1T based on the HALBACH array and combination of permanent magnets of different specifications, and then the injection molding neodymium-iron-boron orientation process is met. On the basis of permanent magnet orientation magnetic circuit combination design, anisotropic injection molding neodymium iron boron tile-shaped magnet radiation orientation is achieved, the material performance (BH)max is larger than 11 MGOe, and the product surface magneticinduction intensity is larger than 2000 Gs.

Owner:杭州科德磁业有限公司

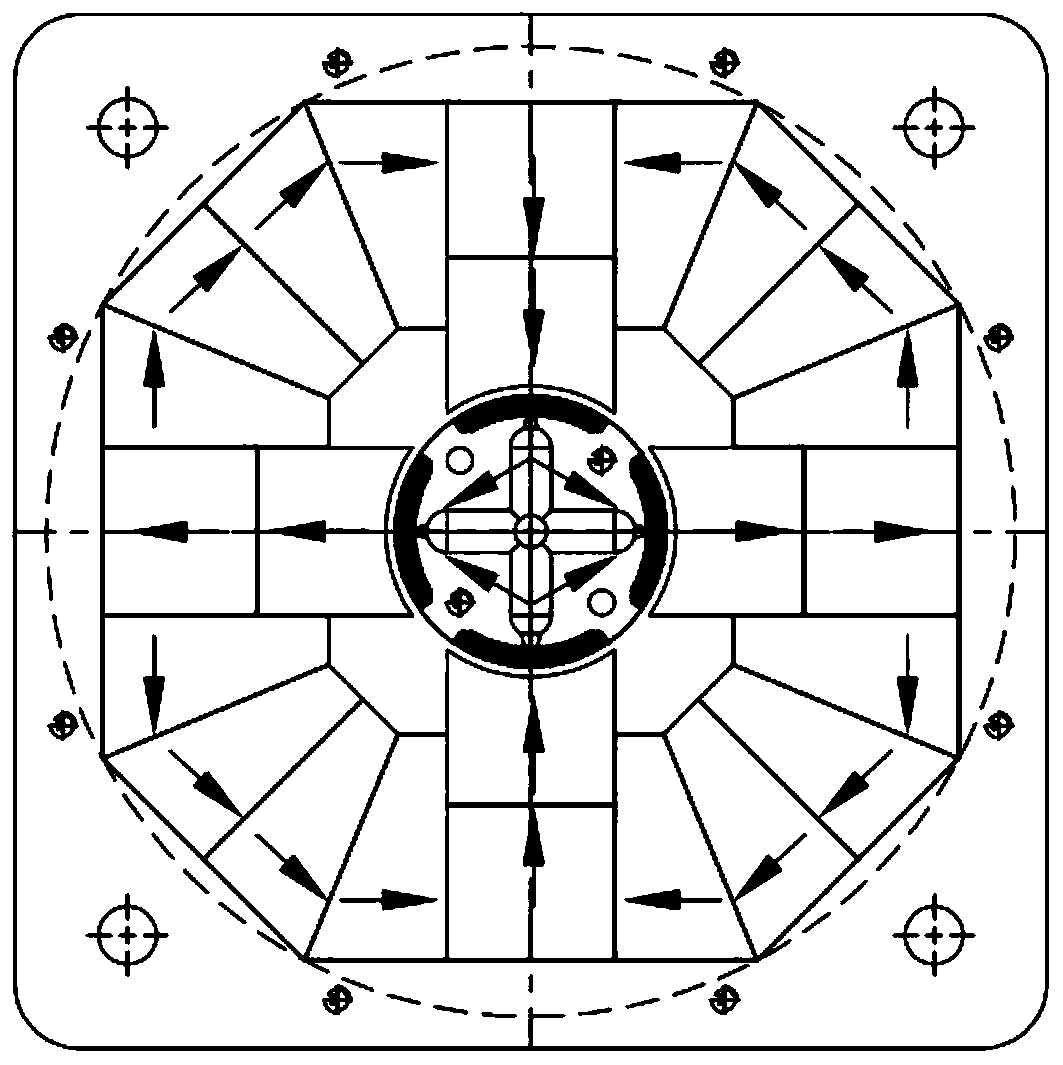

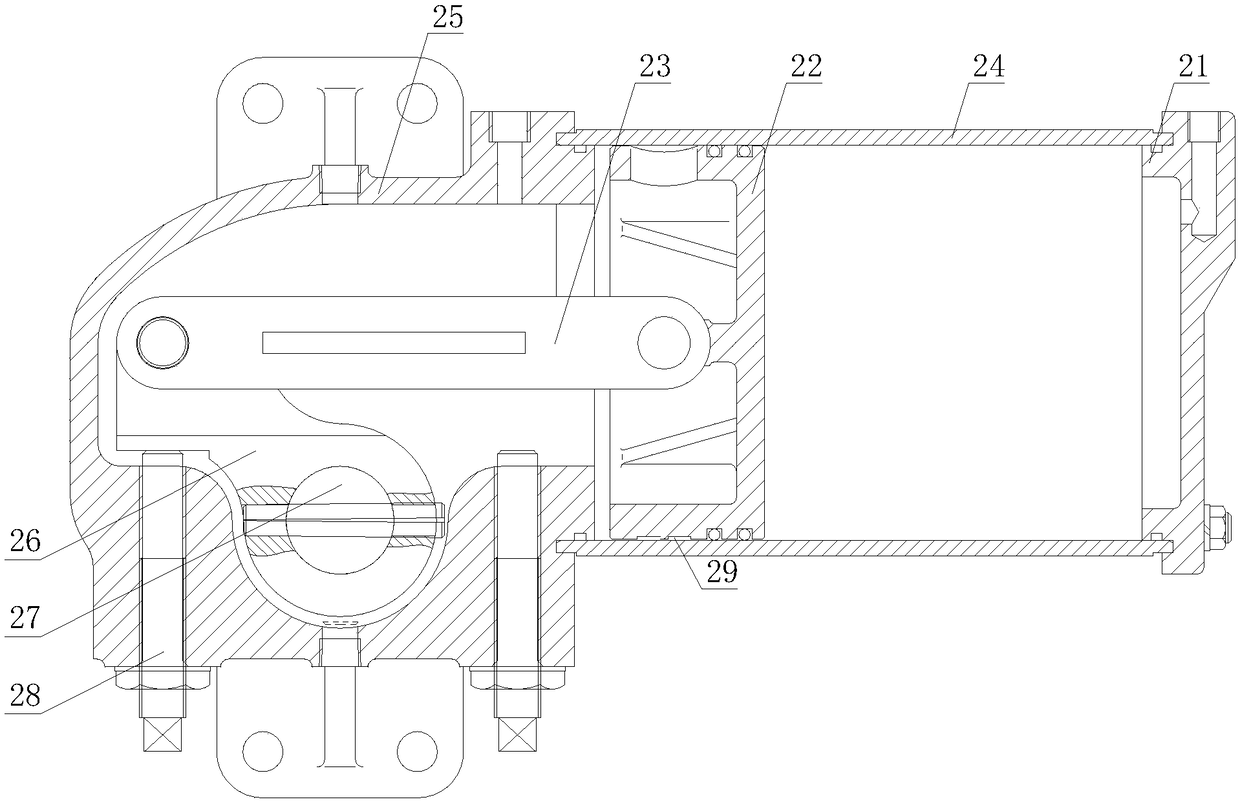

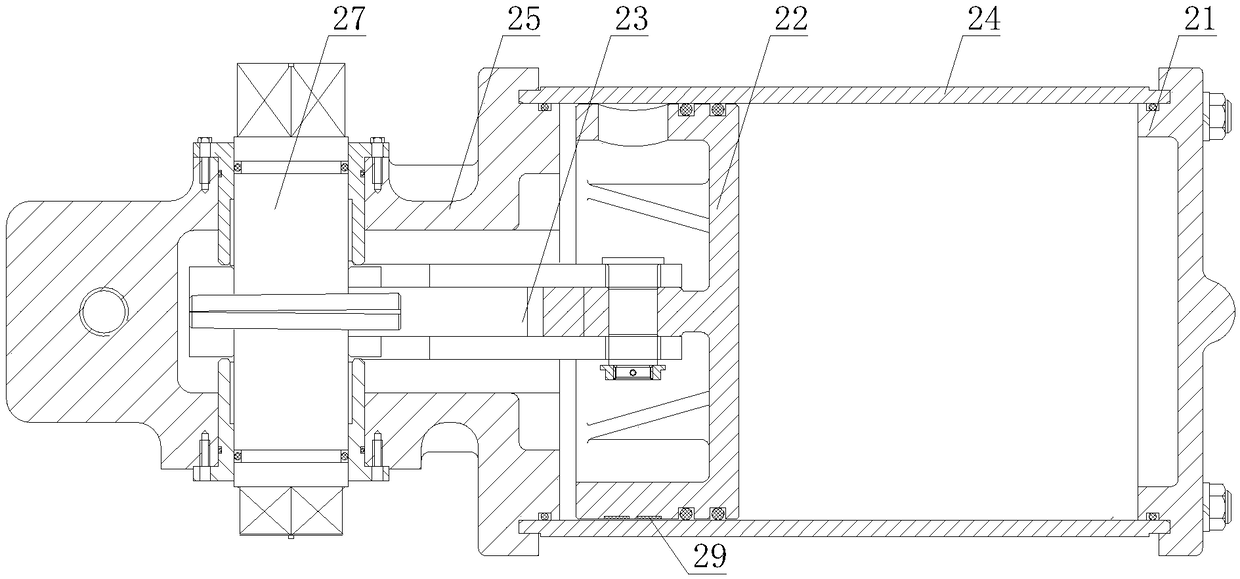

Pneumatic cinder ball valve

InactiveCN109210233AImprove orientationReduce frictional resistance and wearPlug valvesOperating means/releasing devices for valvesPistonCinder

The invention discloses a pneumatic cinder ball valve, comprising a ball valve body and a pneumatic device. The pneumatic device comprises a cylinder back cover, a piston, a connecting plate, a cylinder, an actuator housing, a crank, a rotating rod and an adjusting positioning screw. The ball valve body comprises a valve body, a ball body, a support column, a valve stem, a bracket, a valve cover and an automatic compensation device. A single-cylinder double action means is connected with a unique actuator. The piston adopts a wear-resistant guide ring, which not only improves the guiding of the cylinder, but also reduces the frictional resistance and wearing of the piston, thereby improving the sealing performance. Multiple self-lubricating wear-resistant bushings are used throughout a rotation process to reduce the friction coefficient. The valve opens and closes quickly, accurately and flexibly. The ball body inside the valve body adopts a shaft-supporting structure, which reduces the operating torque of the ball valve and enhances the sealing reliability. Displacement of the ball body after being pressed can be prevented, and influence of pressure of the medium can be avoided. The automatic compensating device adopts a combination of soft and hard laminated sealing, and has the dual advantages of metal hard sealing and elastic sealing.

Owner:高昂

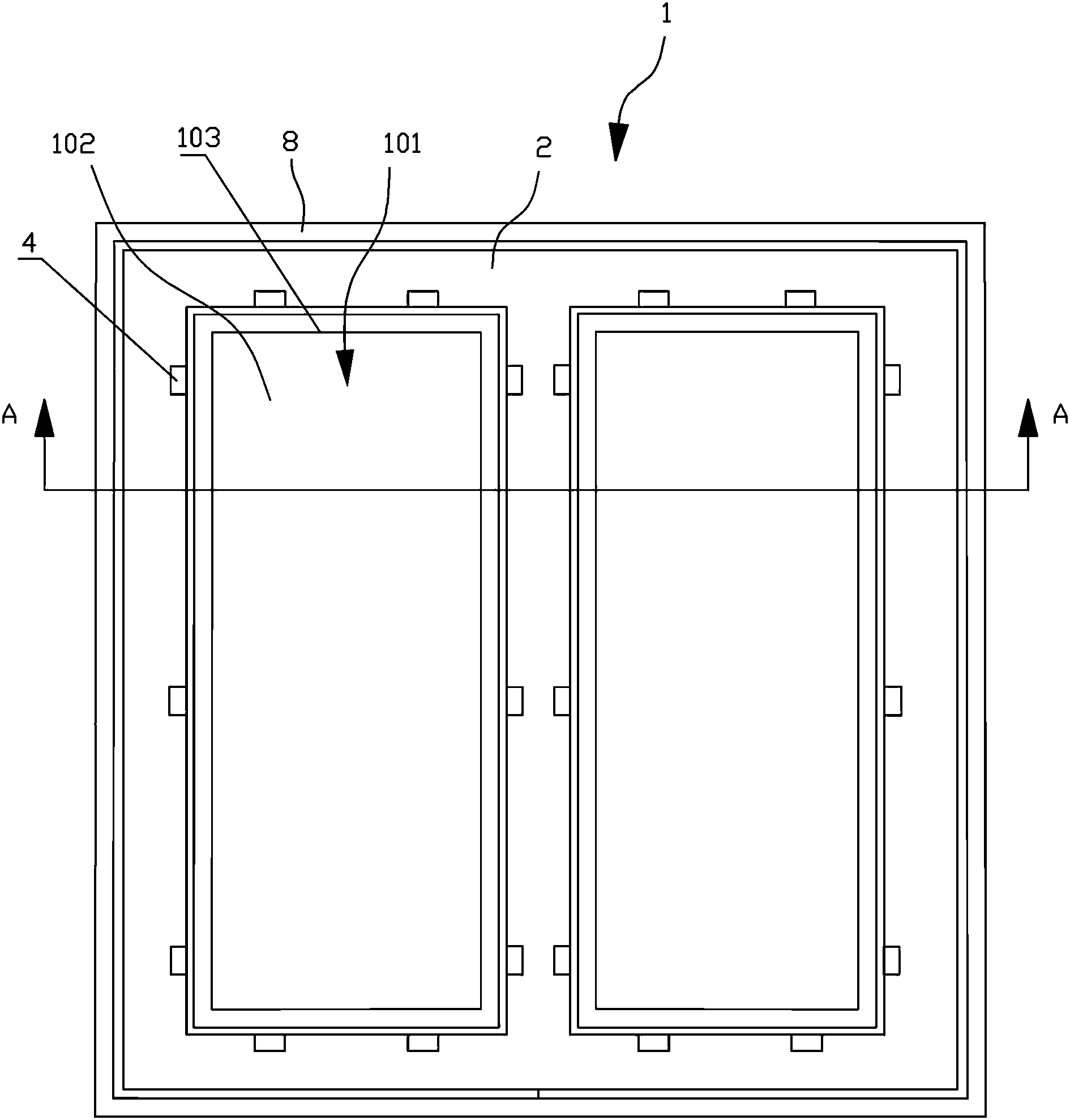

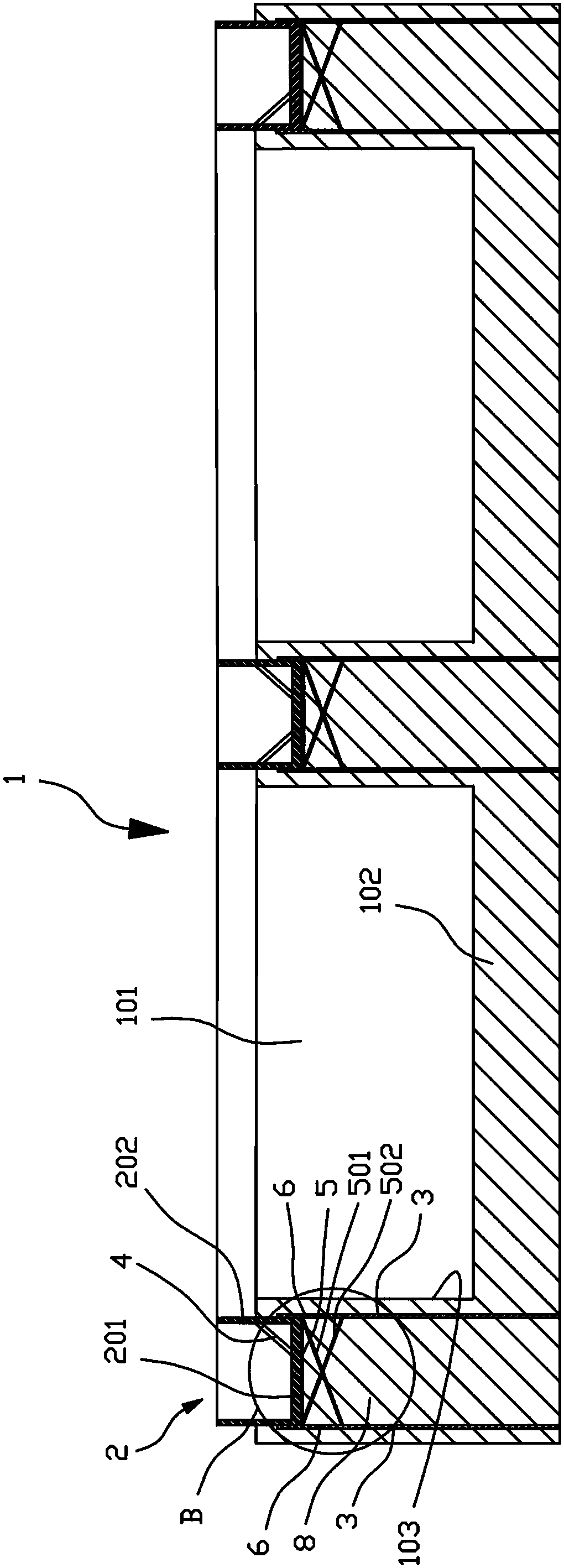

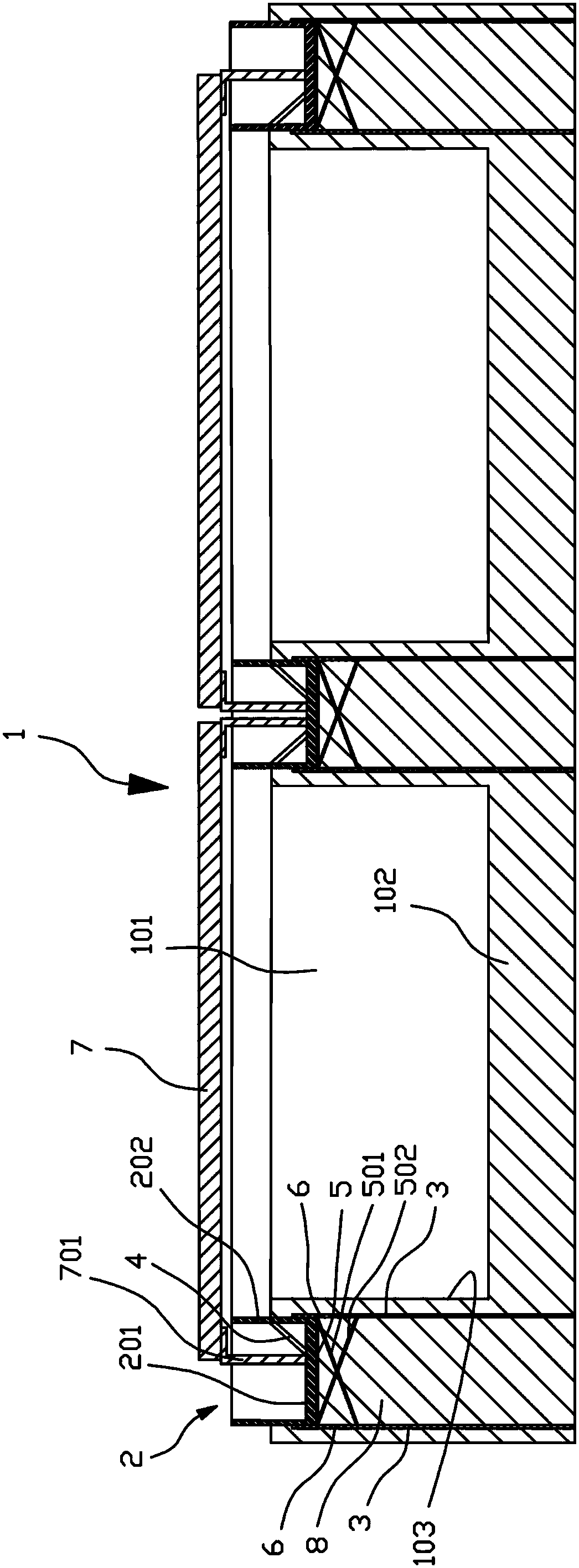

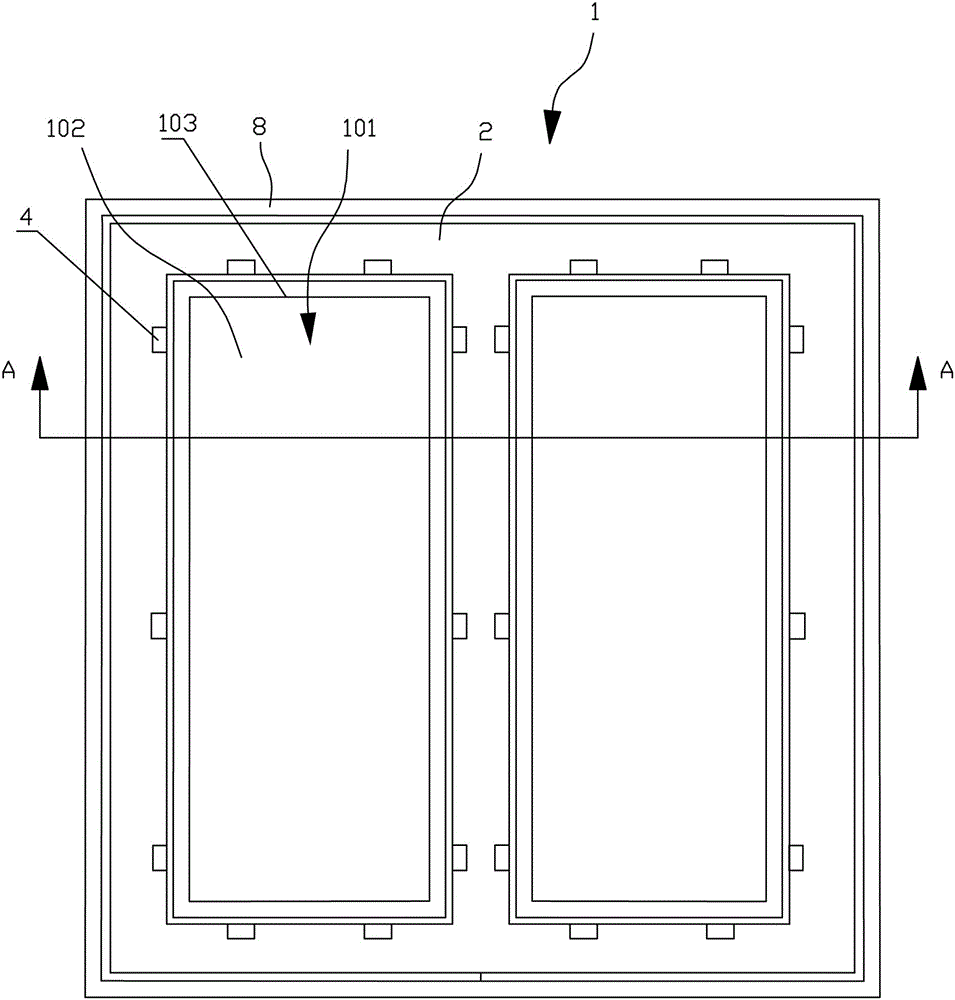

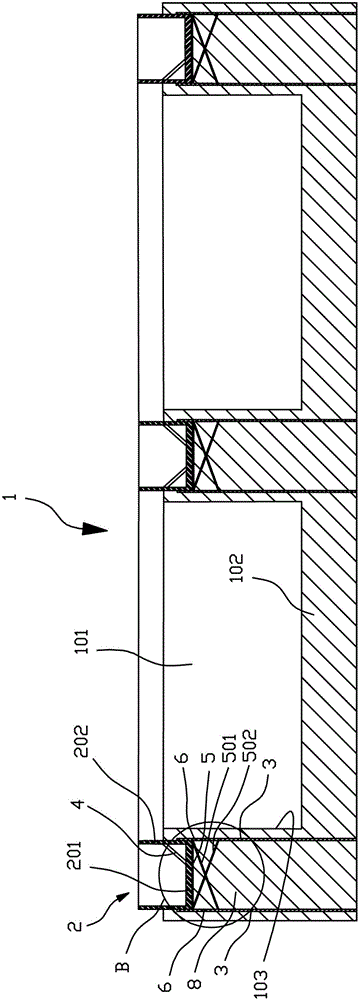

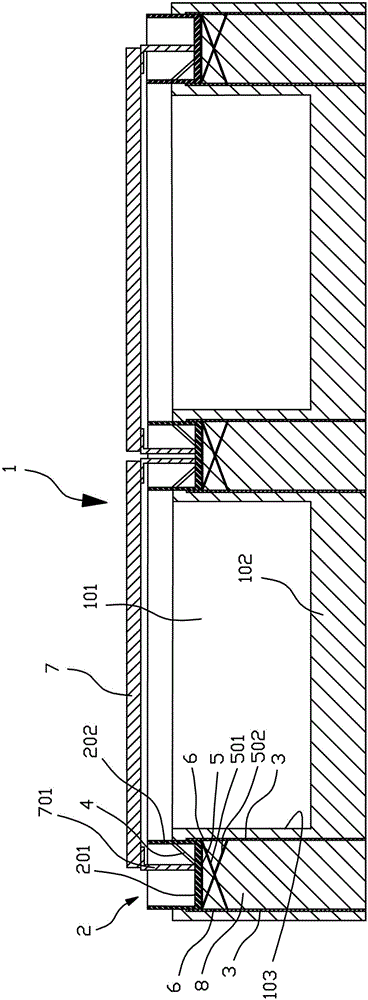

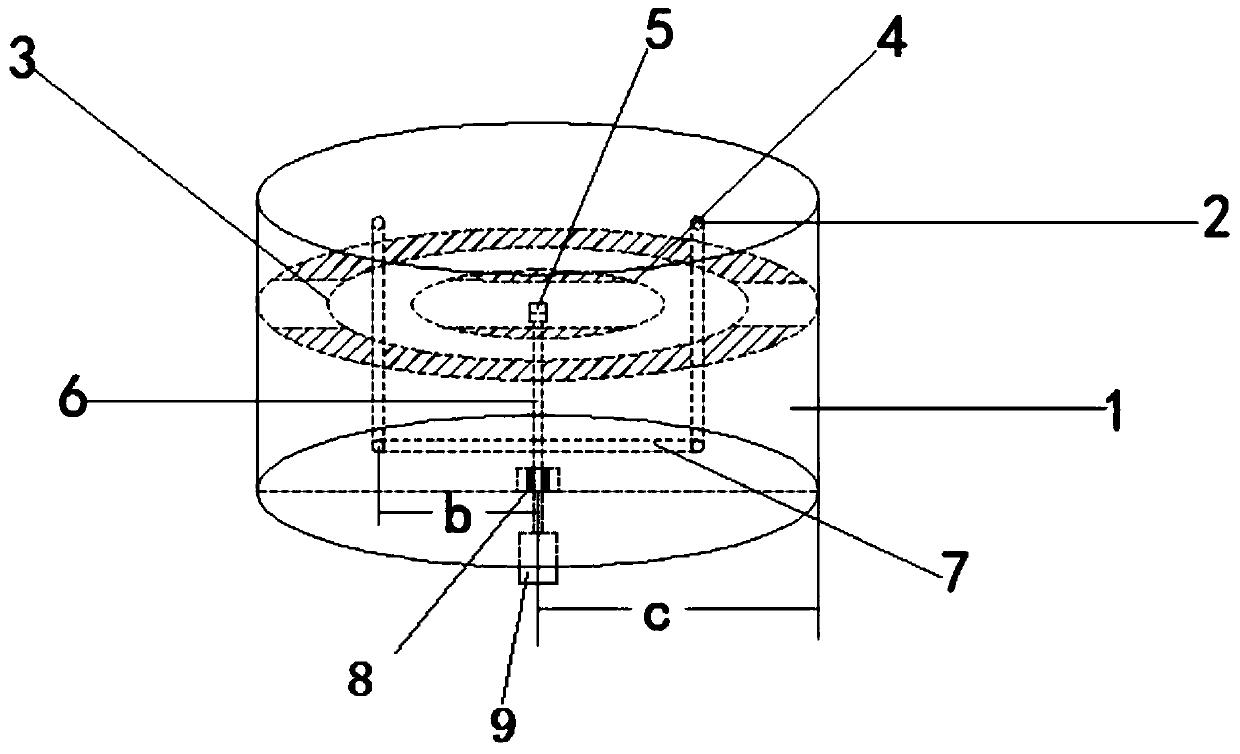

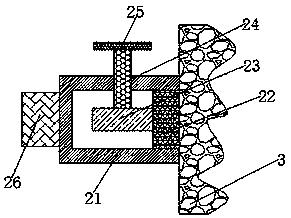

Concrete precast pile stream curing pool

ActiveCN103381620APrecise positioningDoes not affect placementCeramic shaping apparatusMarine engineering

The invention discloses a concrete precast pile stream curing pool comprising a plurality of pool bodies (101), wherein water seal tanks (2) are arranged on the outer sides of the top ends of the four side walls of each pool body (101), surround the pool body (101) and are communicated with one another; the two adjacent side walls of every two adjacent pool bodies (101) share the same water seal tank (2); each pool body is provided by a pool cover (7); a cover rim (701) is arranged on the edge of each pool cover (7) and extends downwards into the corresponding water seal tank (2); guiding and positioning devices, which are used for guiding and positioning the pool covers (7) in the process that the pool covers (7) are lifted to cover the pool bodies (101), are arranged in the water seal tanks (2) on the outer sides of the top ends of the side walls of the pool bodies (101) or on the pool covers (7). According to the concrete precast pile stream curing pool, the pool covers (7) can be positioned accurately and the water seal tanks can be prevented from being deformed due to collision.

Owner:宁波中淳高科股份有限公司

Hot air circulation structure and oven

The invention discloses a hot air circulation structure and an oven, and belongs to the field of baking equipment. An upper heating pipe and a lower heating pipe of the hot air circulation structure are arranged at the top and the bottom of an inner container respectively, a cover plate covers the back of the inner container, an air duct is formed between the cover plate and the back of the innercontainer, an upper air inlet and a lower air inlet are formed in the positions, corresponding to the upper heating pipe and the lower heating pipe, of the cover plate respectively, and a plurality ofstrip-shaped air outlets are distributed between the upper air inlet and the lower air inlet in parallel in the vertical direction. An upper air heater and a lower air heater are arranged on the upper portion and the lower portion of the air duct respectively corresponding to the upper air inlet and the lower air inlet so as to respectively pump hot air at the upper portion and the lower portionof the inner container into the air duct for hot air circulation. The strip-shaped air outlets have a good guiding effect on the hot air, and the guiding performance of the cover plate on the hot airflow direction is improved. The multiple air outlets are distributed in the cover plate in parallel in the vertical direction, the air outlet uniformity is improved, the temperature field uniformity in the inner container is improved, and the baking efficiency and the coloring uniformity of baked food are improved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

Method of preparing CdS nano particles through room-temperature solid-phase reaction

InactiveCN105036179AHigh purityImprove orientationMaterial nanotechnologyCadmium sulfidesThioureaBovine serum albumin

The invention discloses a method of preparing CdS nano particles through a room-temperature solid-phase reaction. The method includes the following steps: weighing CdSO4.8H2O, thiourea and NaOH according to the mass ratio of 1:1.6:6; finely grinding the CdSO4.8H2O and the thiourea respectively and grinding the CdSO4.8H2O and the thiourea with NaOH; adding bovine serum albumin and continuously grinding the mixture for 30 min to obtain a fine bright light-yellow thick substance; washing and filtering the thick substance with distilled water and anhydrous ethanol alternately; and naturally drying the mixture to obtain a bright light-yellow powder which is the CdS nano particles. The method is mild in reaction condition, is simple in operation and is green and energy-saving in production. The CdS nano particles are high in purity, are small in size, are uniform in granularity and are good in dispersion property, are high in oriented degree and are excellent in crystal from and crystal lattice.

Owner:JINHUA VOCATIONAL TECH COLLEGE +1

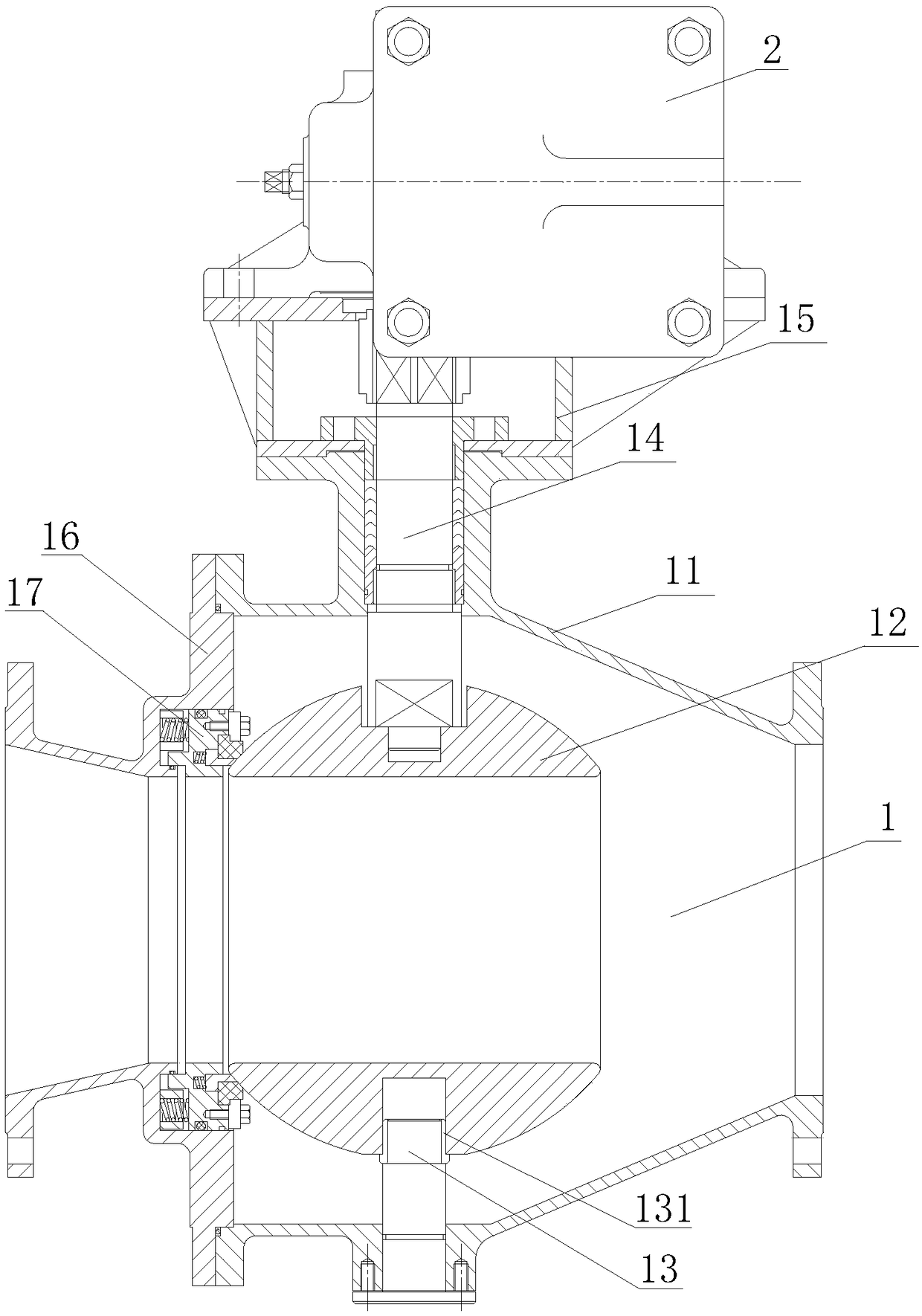

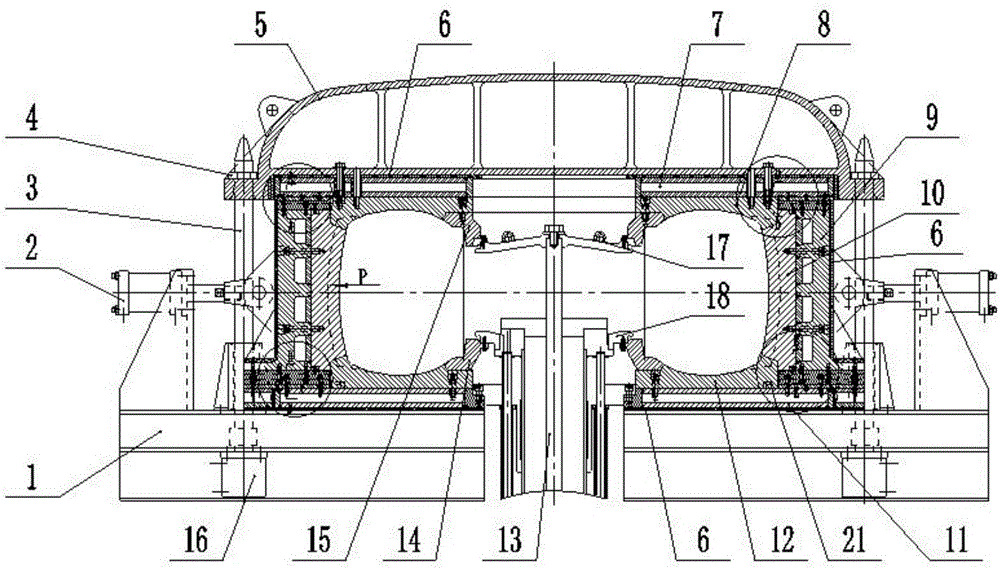

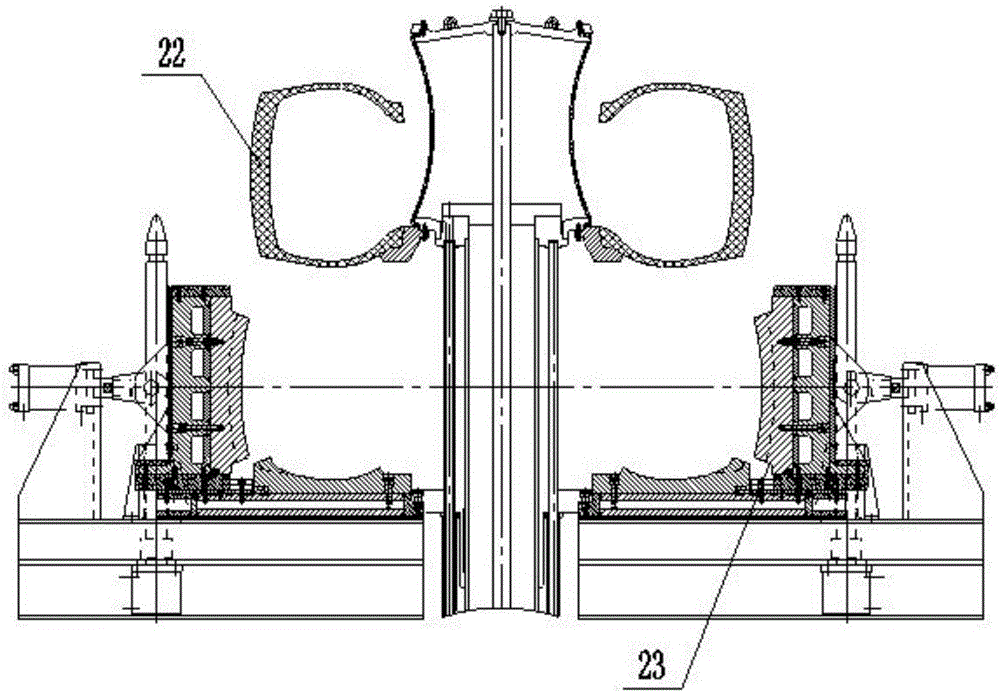

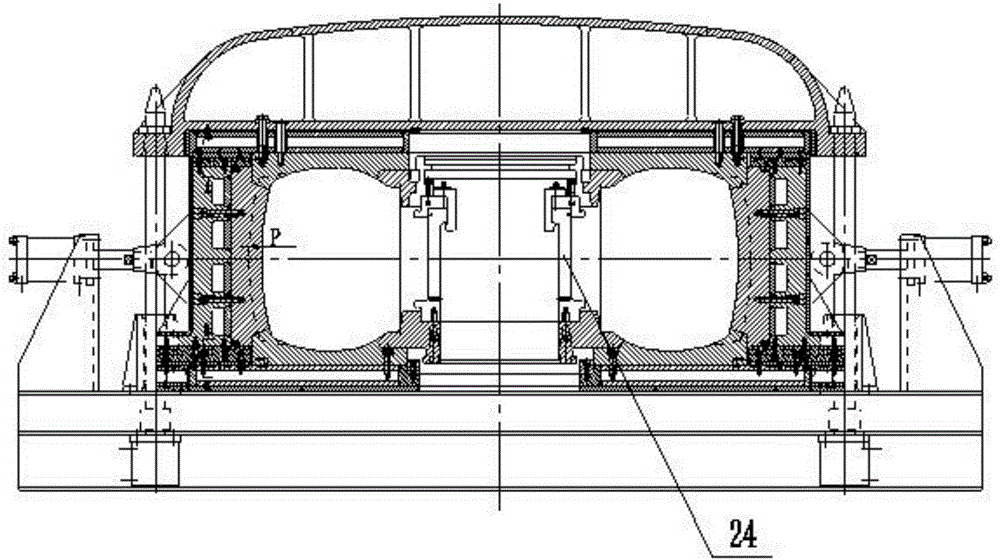

Hot plate type giant tire vulcanizing equipment

The invention discloses hot plate type giant tire vulcanizing equipment and belongs to the technical field of rubber equipment. The hot plate type giant tire vulcanizing equipment comprises a main machine and a giant tire mold. The main machine comprises a vulcanizing cavity and a base. The giant tire mold is installed in the vulcanizing cavity and comprises a plurality of pattern blocks. A sliding block is arranged on the back face of each pattern block. A pattern block mold opening-closing driving device is arranged in the position, corresponding to each sliding block, of the outer side of the base. The problems that mold opening-closing equipment of giant tire vulcanizing equipment is huge in size and complex in structure are solved, the vulcanizing heating mode is further improved, installation matching of the mold is improved, and a clamping mechanism is adopted for improving the vulcanizing efficiency.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Concrete precast pile stream curing pool

ActiveCN103381620BPrecise positioningDoes not affect placementCeramic shaping apparatusMarine engineering

The invention discloses a concrete precast pile stream curing pool comprising a plurality of pool bodies (101), wherein water seal tanks (2) are arranged on the outer sides of the top ends of the four side walls of each pool body (101), surround the pool body (101) and are communicated with one another; the two adjacent side walls of every two adjacent pool bodies (101) share the same water seal tank (2); each pool body is provided by a pool cover (7); a cover rim (701) is arranged on the edge of each pool cover (7) and extends downwards into the corresponding water seal tank (2); guiding and positioning devices, which are used for guiding and positioning the pool covers (7) in the process that the pool covers (7) are lifted to cover the pool bodies (101), are arranged in the water seal tanks (2) on the outer sides of the top ends of the side walls of the pool bodies (101) or on the pool covers (7). According to the concrete precast pile stream curing pool, the pool covers (7) can be positioned accurately and the water seal tanks can be prevented from being deformed due to collision.

Owner:宁波中淳高科股份有限公司

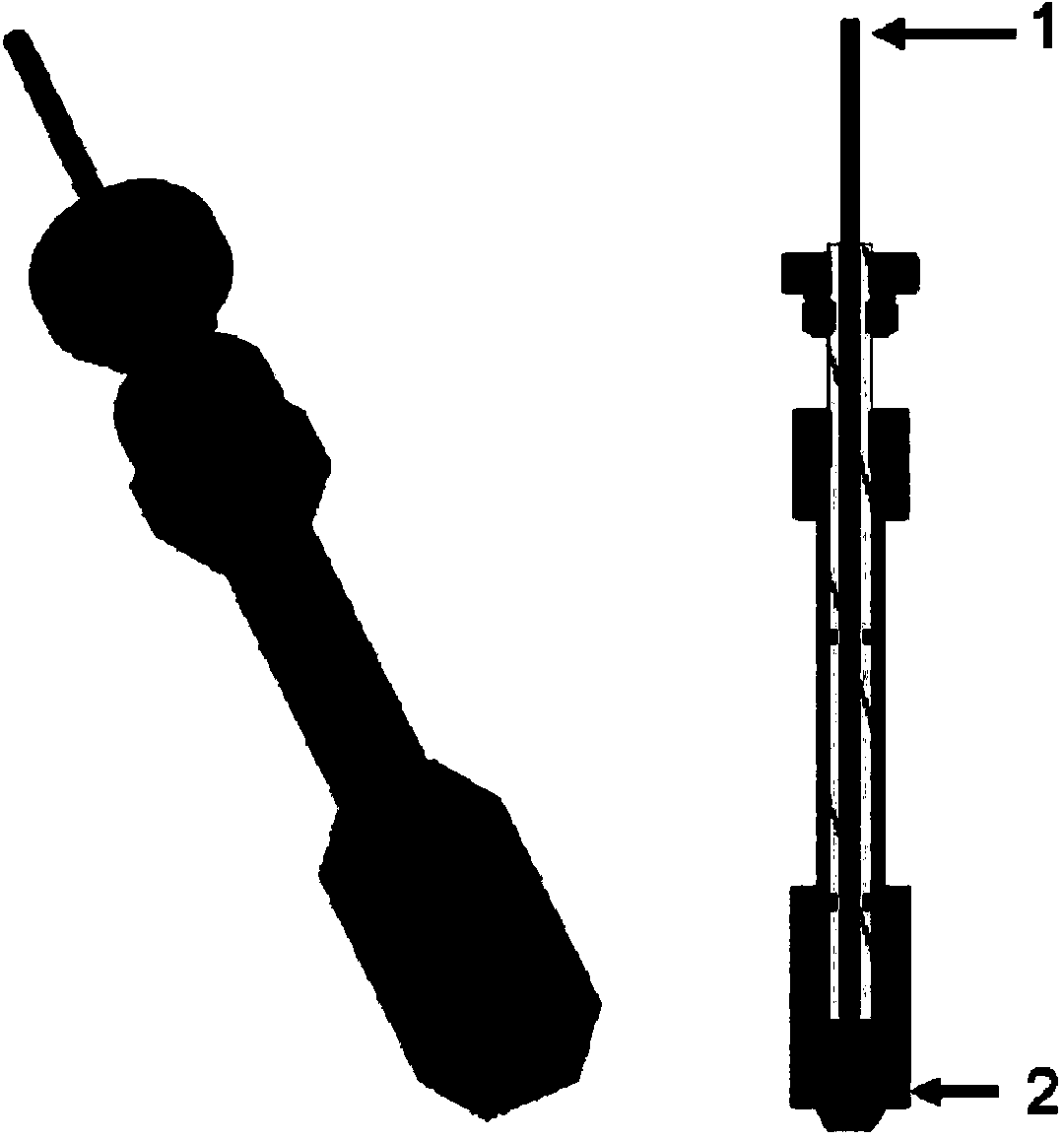

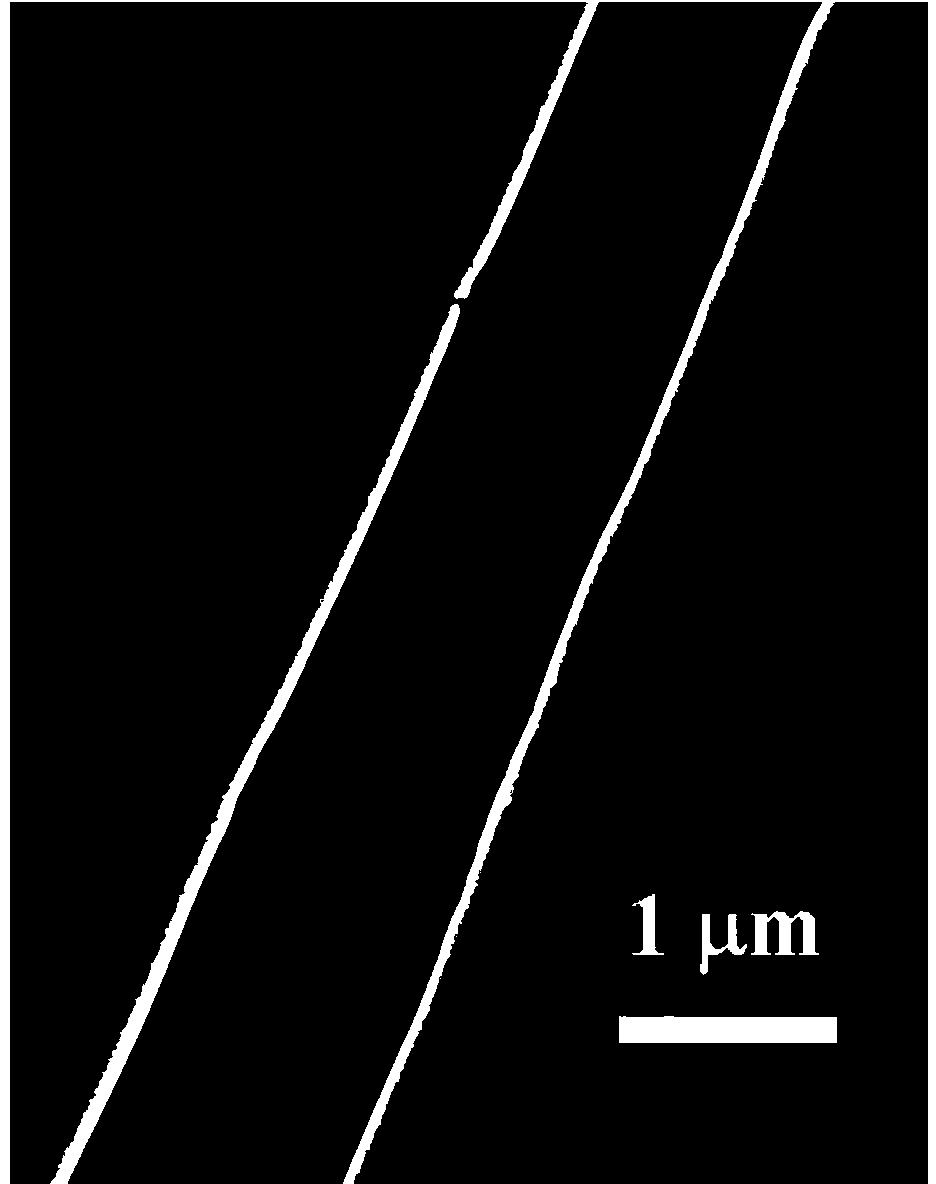

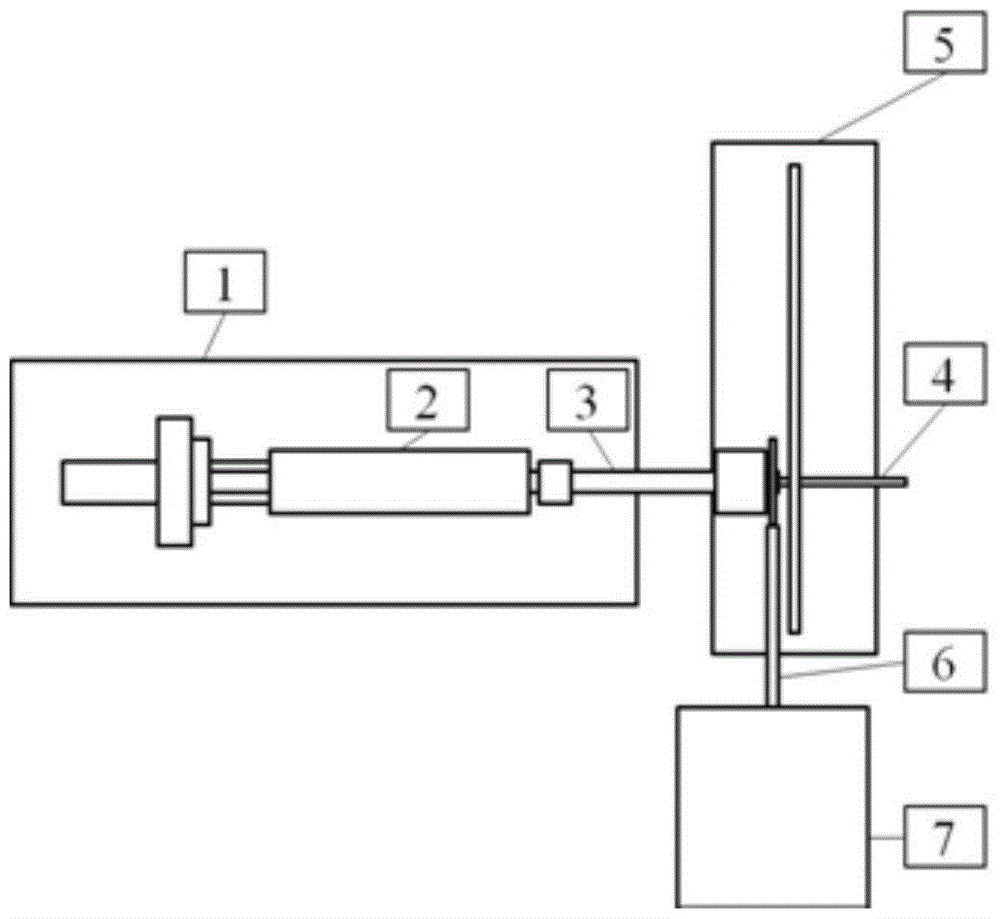

A device and method for preparing oriented electrospun fibers

ActiveCN104818536BReduce the cross-sectional areaImprove orientationFilament/thread formingFiberSpinning

The invention discloses a directional arranged electrostatic spinning fiber preparation apparatus which comprises a solution control system and a spinning reception system, wherein the solution control system comprises a metallic needle head, a propulsion device for controlling the flow velocity of spinning solution in the metallic needle head and an electrostatic generating device for controlling the electrostatic voltage on the metallic needle head, and the spinning reception system comprises a rotating disc receiver and a drive unit for driving the rotating disc receiver to rotate. The rotating disc receiver is cylindrical, the side surface is wrapped by a reception layer for receiving electrostatic spinning material, and the axial direction of the metallic needle head is parallel to the axial direction of the rotating disc receiver. The metallic needle head is arranged in a curved surface, where the side surface of the rotating disc receiver is located, and a gap is arranged between the metallic needle head and the bottom close to the rotating disc receiver. The method disclosed in the invention controls and regulates the orientation degree of electrostatic spinning fibers by controlling DC voltage, the flow velocity of polymer solution, the distances between the metallic needle head and the rotating disc receiver, the rotating speed of the rotating disc receiver and the diameter of the rotating disc receiver. The operation performance is good.

Owner:XI AN JIAOTONG UNIV

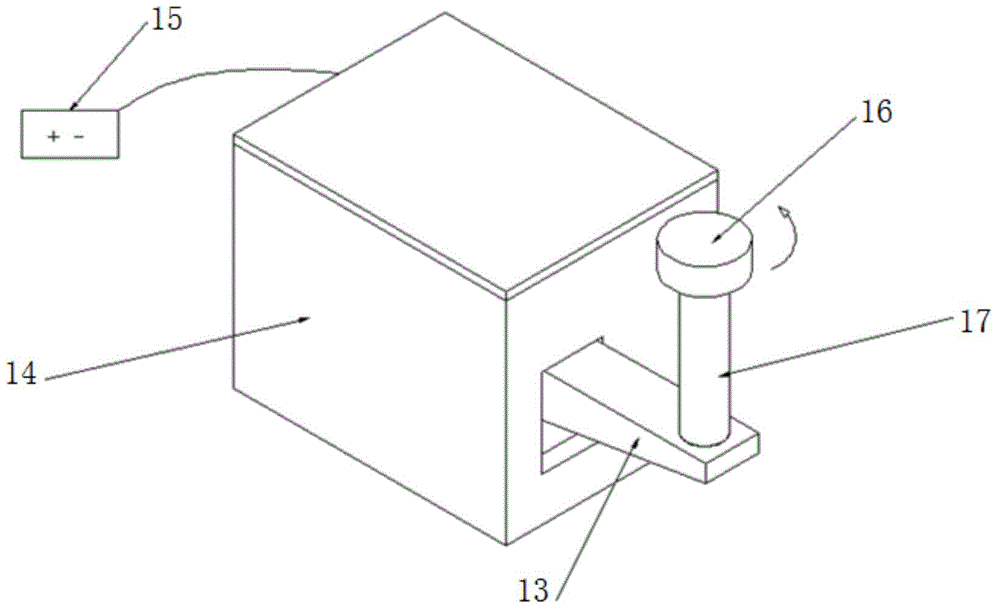

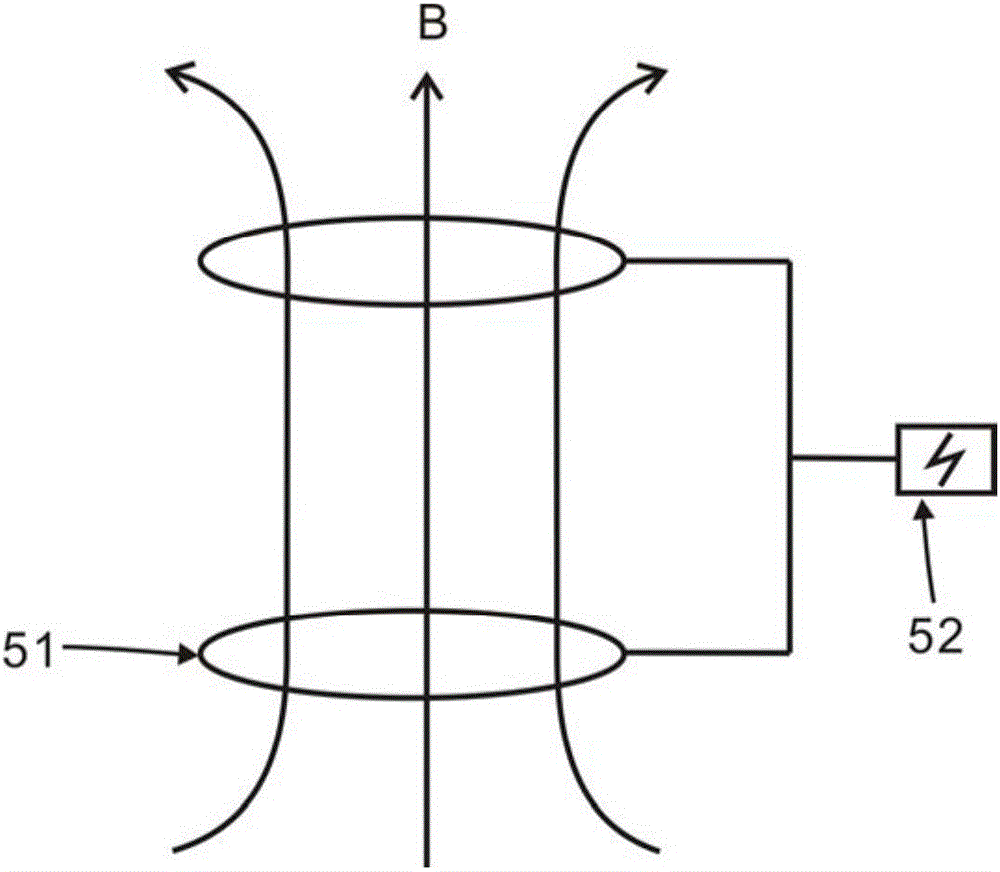

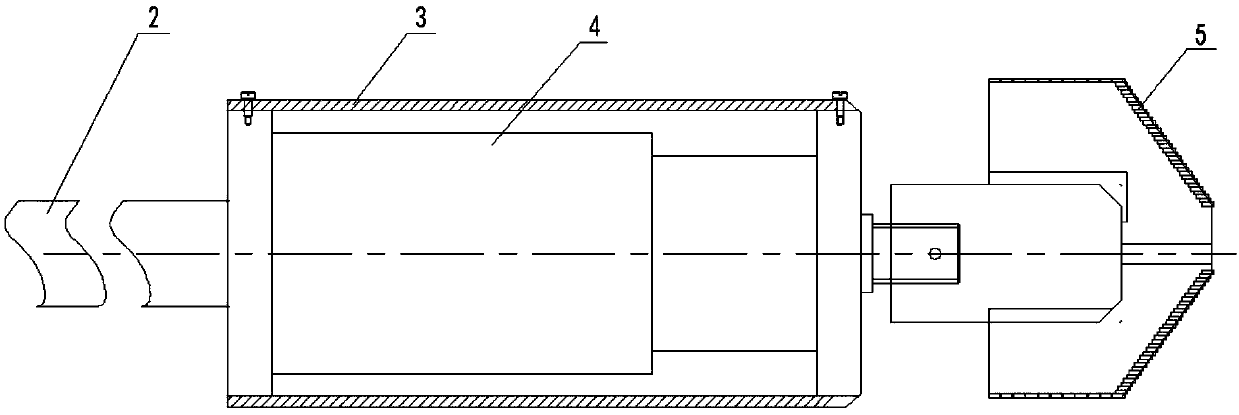

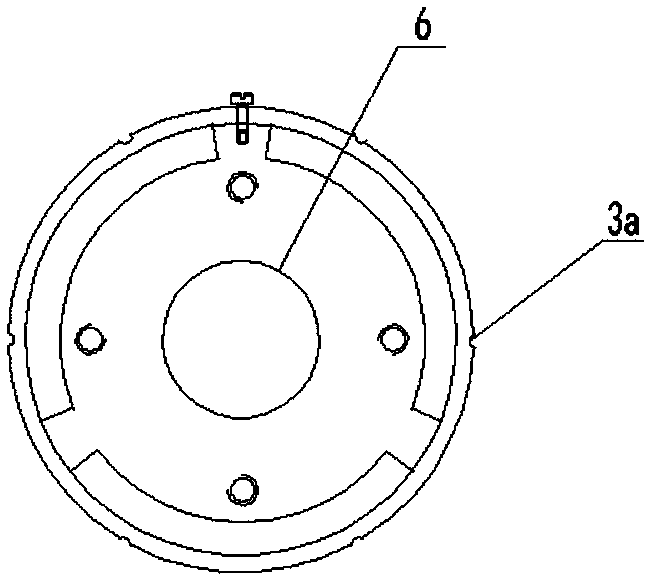

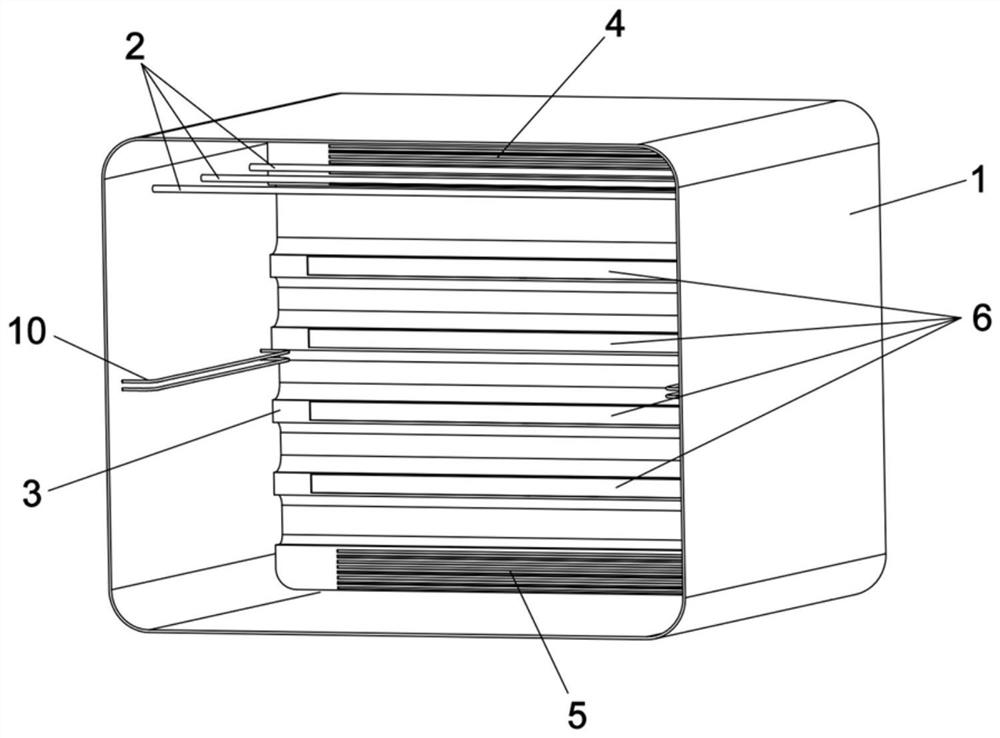

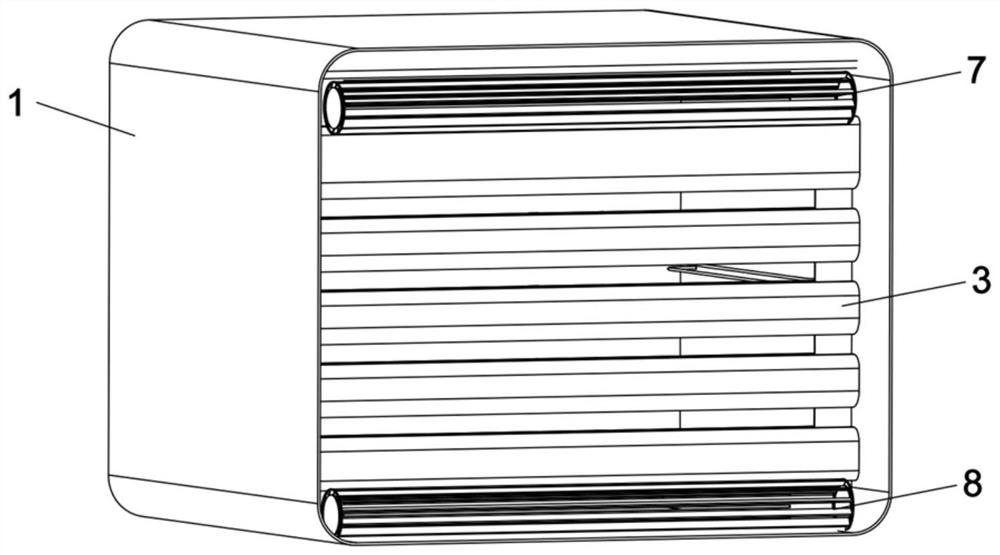

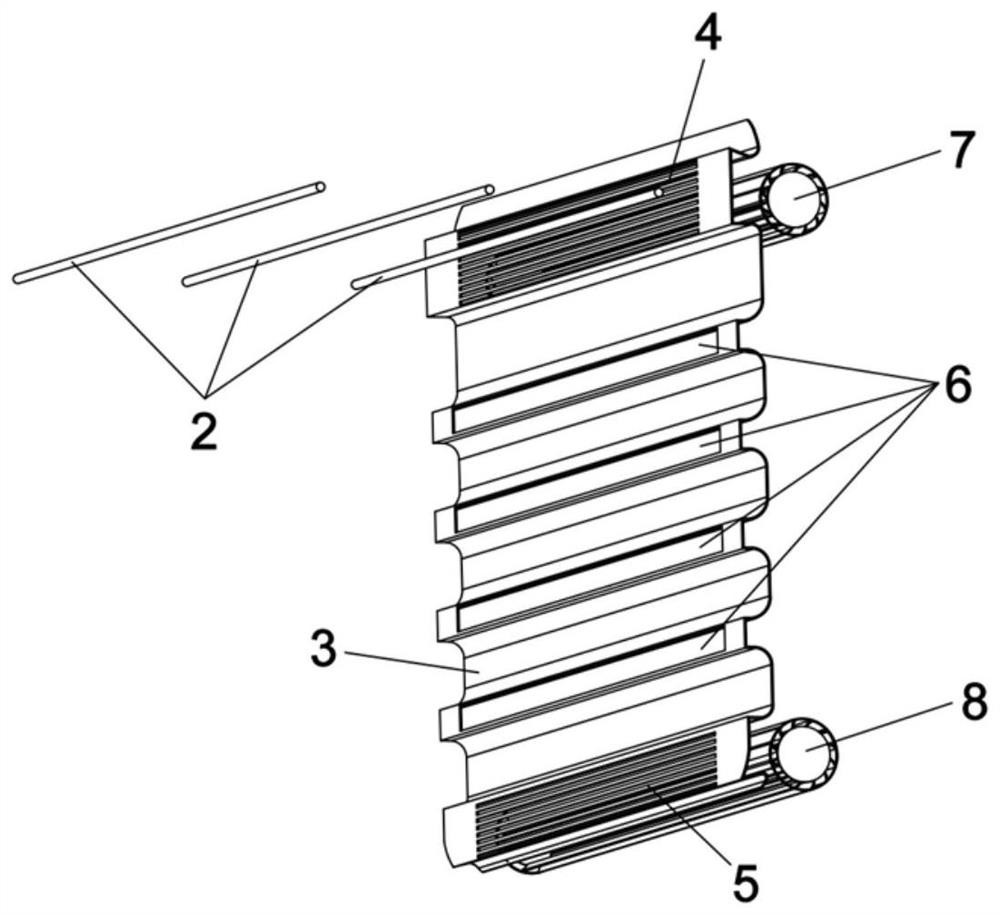

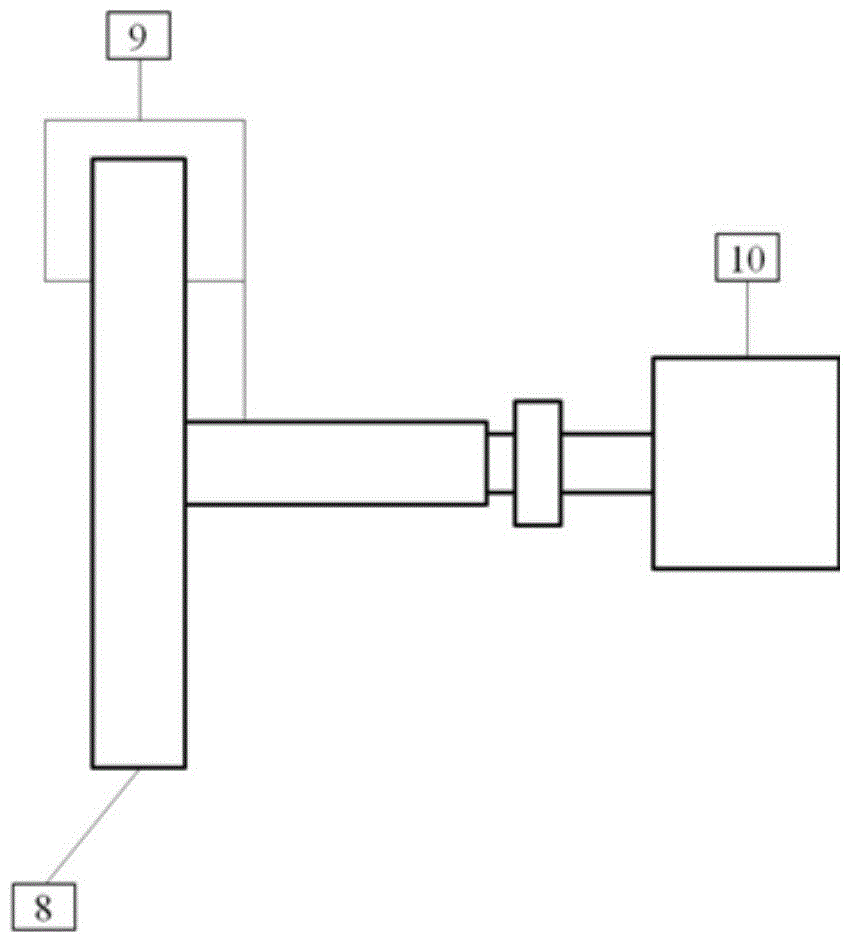

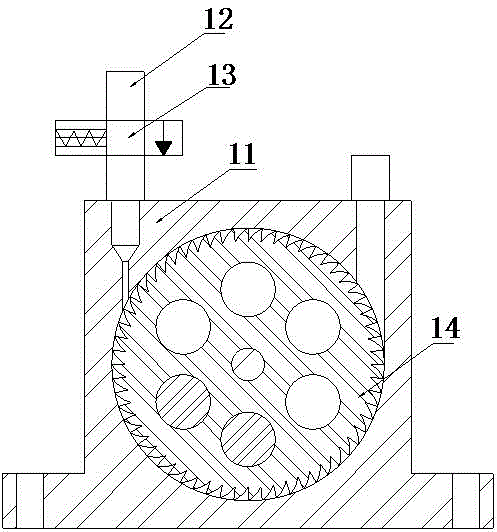

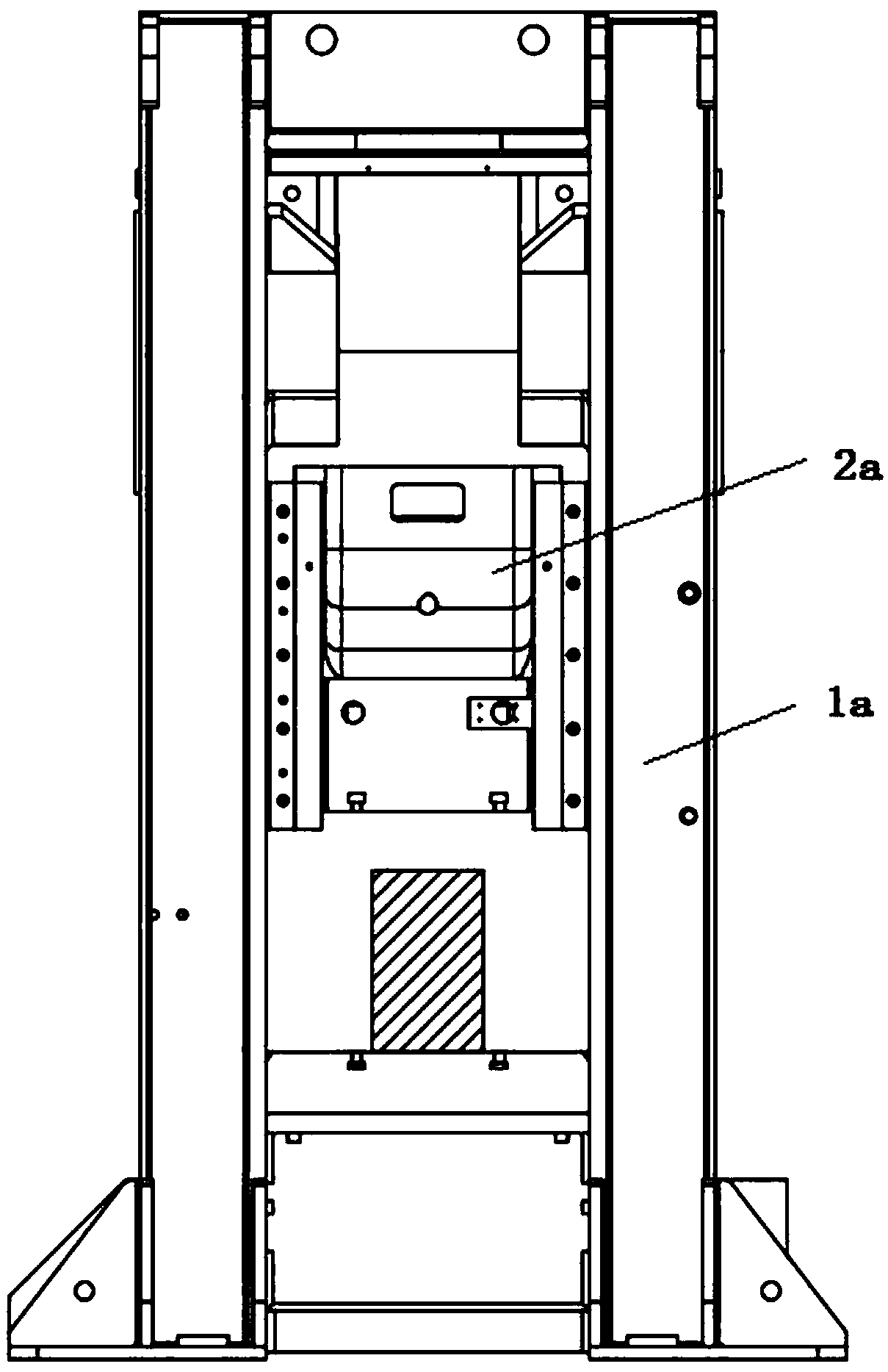

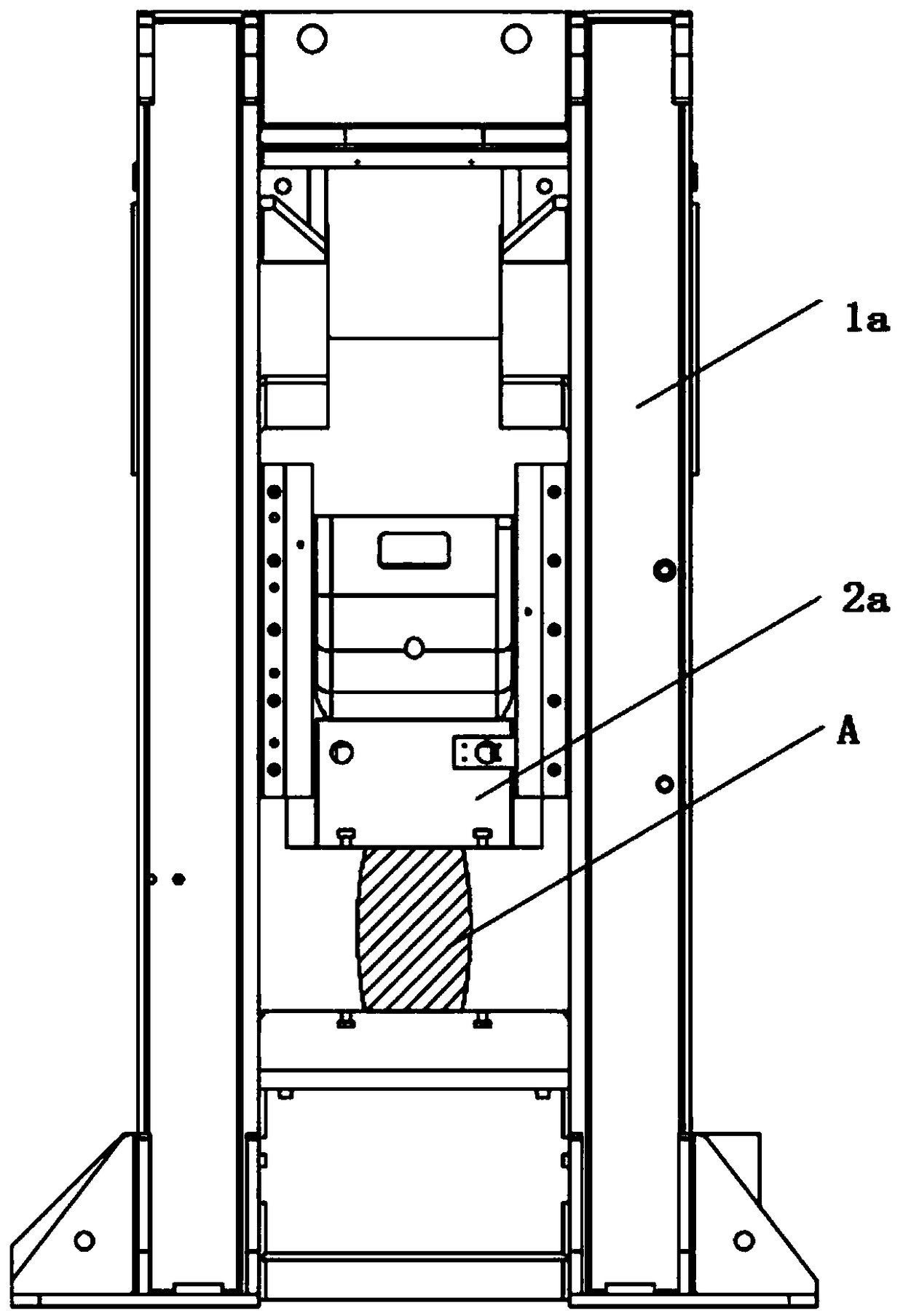

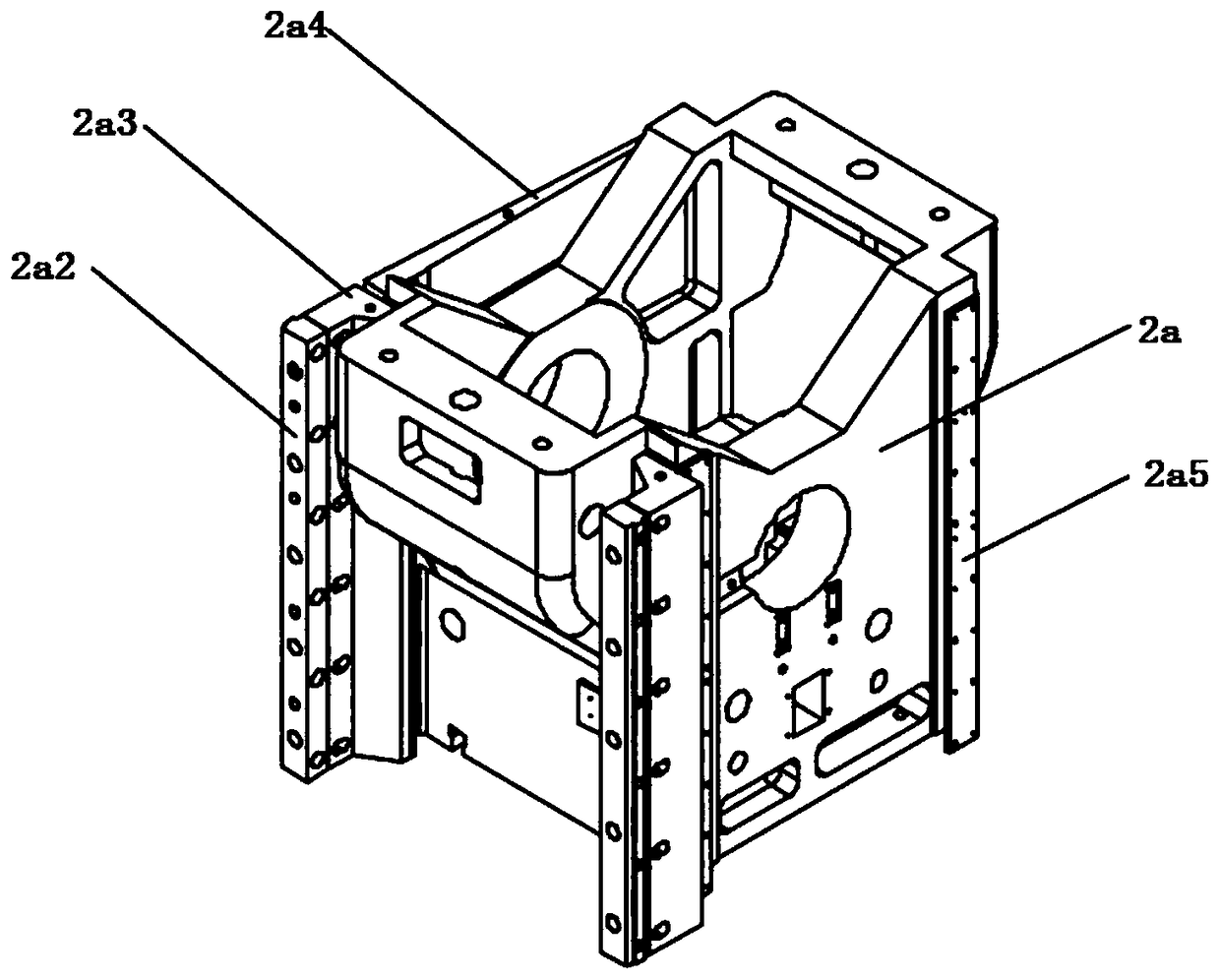

Neodymium iron boron vibration magnetic field molding press device

InactiveCN102909369AReduce magnetic agglomerationImprove orientationMagnetic materialsNeodymium iron boronEngineering

The invention relates to a neodymium iron boron vibration magnetic field molding press device. A vibration system module (10) is arranged at the outer side of a mould (5) positioned between a first electromagnet core (1) and a second electromagnet core (2) of the device. The vibration system module (10) comprises a vibration skeleton (11), an air inlet (12), a solenoid valve (13) and a rotating wheel (14), wherein the vibration skeleton (11) is fixed at the outer side of the mould (5), and the upper end of the vibration skeleton (11) is connected with the air inlet (12); the solenoid valve (13) is arranged on the air inlet (12); and the rotating wheel (14) is arranged in the vibration skeleton (11). The neodymium iron boron vibration magnetic field molding press device has the beneficial effects that the magnetic flocculation in the orientation process is reduced, the degree of orientation is improved, and the magnetic property is finally improved, so that the dispersity of powder is better, and the uniformity is better, and finally, the product density is more uniform, and the magnetic property is higher.

Owner:山西京宇天成科技有限公司

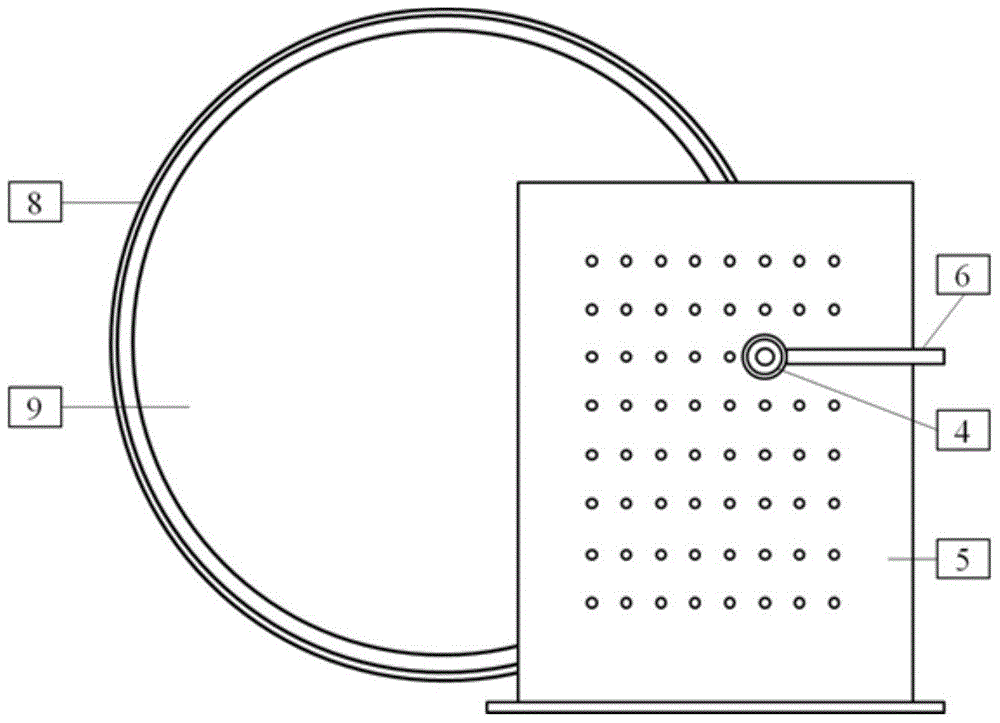

Collection device and preparation method of directional continuous nanofiber bundles

The invention discloses a collection device of directional continuous nanofiber bundles and further discloses a preparation method of the directional continuous nanofiber bundles. The circumferentialbinding force of rotating water flow is fully utilized, directional arrangement of the fiber is realized under the floating force and the rotating tension of an insulating rotating shaft, and therebythe directional continuous nanofiber bundles arranged along the circumferential direction are prepared. In the preparation method, the directional continuous nanofiber bundles can be easily and effectively collected by the collecting device, and problems about difficulty in directional collection of existing electrospinning and in maintenance of continuity are solved.

Owner:XIAN UNIV OF TECH

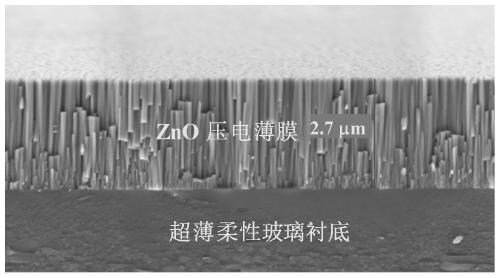

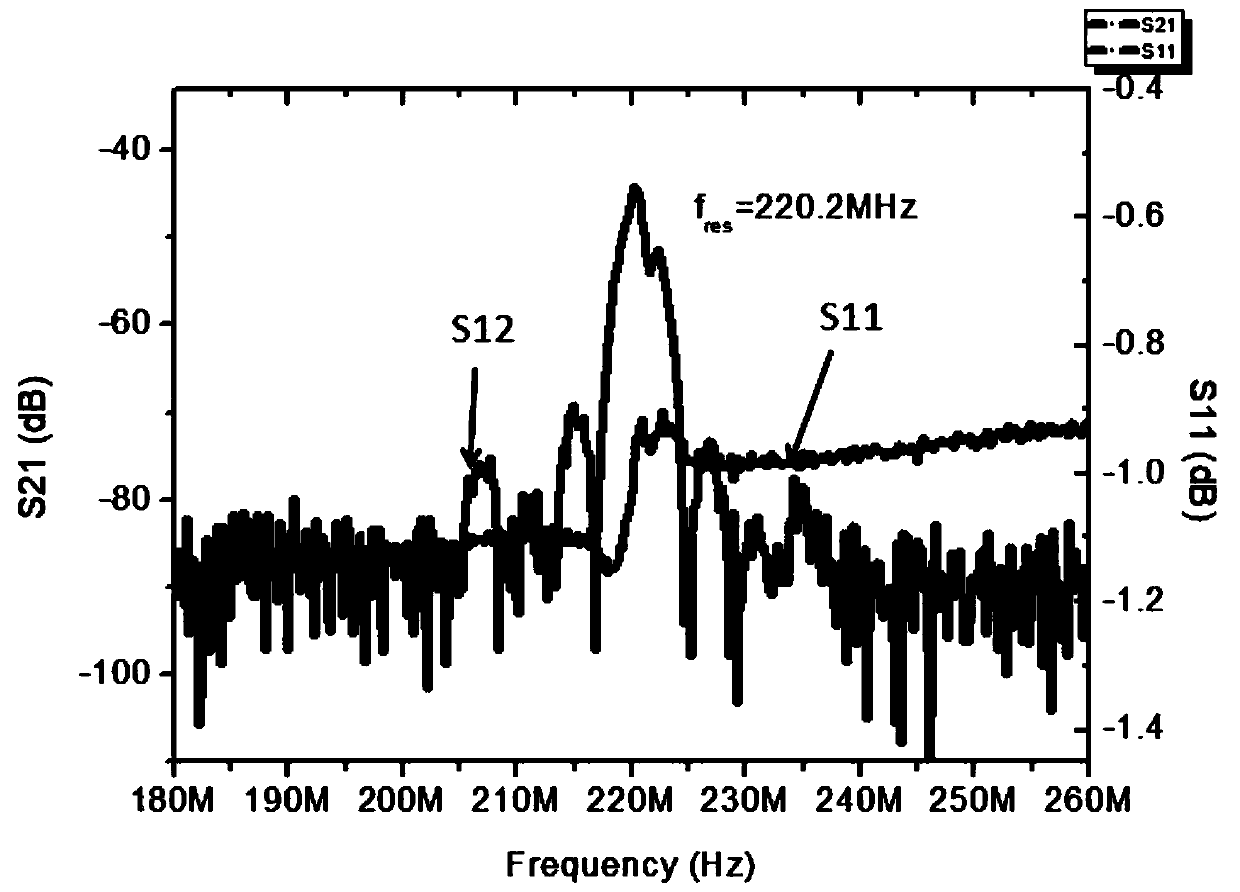

Method for carrying out sputtering deposition to form piezoelectric film on flexible glass

ActiveCN111593332AThe signal amplitude of the device is largeImprove orientationVacuum evaporation coatingSputtering coatingThin membraneSputter deposition

The invention relates to a method for carrying out sputtering deposition to form a piezoelectric film on flexible glass. The method comprises the following steps: S1, enabling the cleaned flexible glass to cling to the surface of a substrate cooling device in a vacuum cavity of a magnetron sputtering film-coating machine; S2, then vacuumizing until a vacuum degree reaches 10<-7> to 10<-3>Pa; S3, depositing a nano-scale ZnO film or AlN film on the surface of the flexible glass through an atomic layer deposition method to obtain film-coated flexible glass; S4, dynamically charging working gas which has a total pressure of 0.2 to 10Pa into the vacuum cavity; and S5, starting a magnetron sputtering source, carrying out reactive sputtering deposition to form the piezoelectric film on the film-coated flexible glass, then charging the atmosphere into the vacuum cavity of the magnetron sputtering film-coating machine, and taking out a sample. The method realizes the operation of carrying out sputtering deposition to form the piezoelectric film on the flexible glass.

Owner:HUNAN ZHONGDA CONSTR ENG TESTING TECH +1

Orientation heat transfer hexagonal boron nitride/cordierite textured ceramic and preparation method thereof

PendingCN108640690ASimple processSignificant directional heat transfer characteristicsCordieriteThermal conductivity

The invention relates to an orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and a preparation method thereof, in particular to textured ceramic and a preparation method thereof. The invention aims to solve the problem of small heat conductivity difference between a direction of the h-BN textured ceramic perpendicular to a slice layer and a direction of the h-BN textured ceramic parallel to the slice layer. The orientation heat transfer hexagonal boron nitride / cordierite textured ceramic is prepared from the components in mass fraction: h-BN powder, MgO powder, nanometer Al2O3 powder and melted quartz powder. The preparation method comprises the steps of weighing the raw materials, mixing the raw materials, evaporating, drying and sieving; then loading into a graphite die, prepressing to obtain a blank body, and finally hot pressing and sintering. According to the orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and the preparation method thereof provided by the invention, the hexagonal boron nitride / cordierite textured ceramic with a texture characteristic is prepared through a hot pressing and sintering technology, and theorientation degree of h-BN crystal particles is improved, so that the orientation heat transfer of the h-BN ceramic is realized, and the heat conductivity difference between the direction perpendicular to the slice layer and the direction parallel to the slice layer is 12.2 times. The orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and the preparation method thereofprovided by the invention are applicable to preparing a textured ceramic heat protection material.

Owner:HARBIN INST OF TECH

X-shaped guide rail of first-level transmission high-speed precise warm die forging machine

PendingCN108687292AOutstanding and Beneficial Technical EffectsUniform gap distributionForging/hammering/pressing machinesThermal expansionSliding contact

The invention discloses an X-shaped guide rail of a high-speed precise warm die forging machine. The X-shaped guide rail comprises a rack, a sliding block and a sliding block guide rail structure. Thesliding block guide rail structure comprises a path guiding plate component. The path guiding plate component comprises four path guiding plates which are fixed to the rack and extend in the slidingdirection of the sliding block. Each path guiding plate is provided with a sliding slope inclining towards the outer side, and the extension line of each sliding slope can penetrate into the sliding block. The path guiding plates are symmetrically arranged on the two sides of the sliding block. The sliding slopes are arranged in a quadrangle manner, and the two diagonal sliding slopes are parallelto each other. The side wall of the sliding block is provided with sliding block guide rail slopes which correspond to the sliding slopes and are in sliding contact with the sliding slopes. The gapsbetween sliding block guide rails are distributed evenly, and the guide rail guiding precision and stability can be effectively improved; and after the sliding block is continuously heated during workand thermal expansion is generated, the precision of the guide rail gaps cannot be influenced, and accordingly the product quality is ensured.

Owner:浙江精勇精锻机械有限公司

Balance adjusting device for laser machine

InactiveCN108581246AImprove orientationEasy to move aroundLaser beam welding apparatusEngineeringSmall range

The invention discloses a balance adjusting device for a laser machine, and relates to the technical field of laser machines. The balance adjusting device comprises an upper top plate and a lower bottom plate. The two sides of the space between the upper top plate and the lower bottom plate are fixedly connected with connection plates correspondingly. Concave rails are fixedly installed on the inner sides of the connection plates. Sliding rods are in sliding connection with the two sides of the interiors of the concave rails, one end of each sliding rod is fixedly provided with a hydraulic cylinder, one end of each hydraulic cylinder is fixedly connected with a hydraulic adjusting rod, one end of each hydraulic adjusting rod is fixedly provided with a sleeve, and the bottom of the upper top plate is provided with a sliding groove. The balance adjusting device for the laser machine can be beneficial to achieving left-right movement of lead screws, meanwhile indirectly can carry out left-right balance displacement on workpieces and is beneficial to improving cutting precision, since the lead screws can slide through stretching and retraction of the hydraulic cylinders, cutting can beconveniently carried out, the cutting efficiency is improved, small-range up-down balance displacement can be carried out on workpieces, and cutting precision can be effectively improved.

Owner:SUQIAN SUHUAN GLASS ARTS & CRAFTS

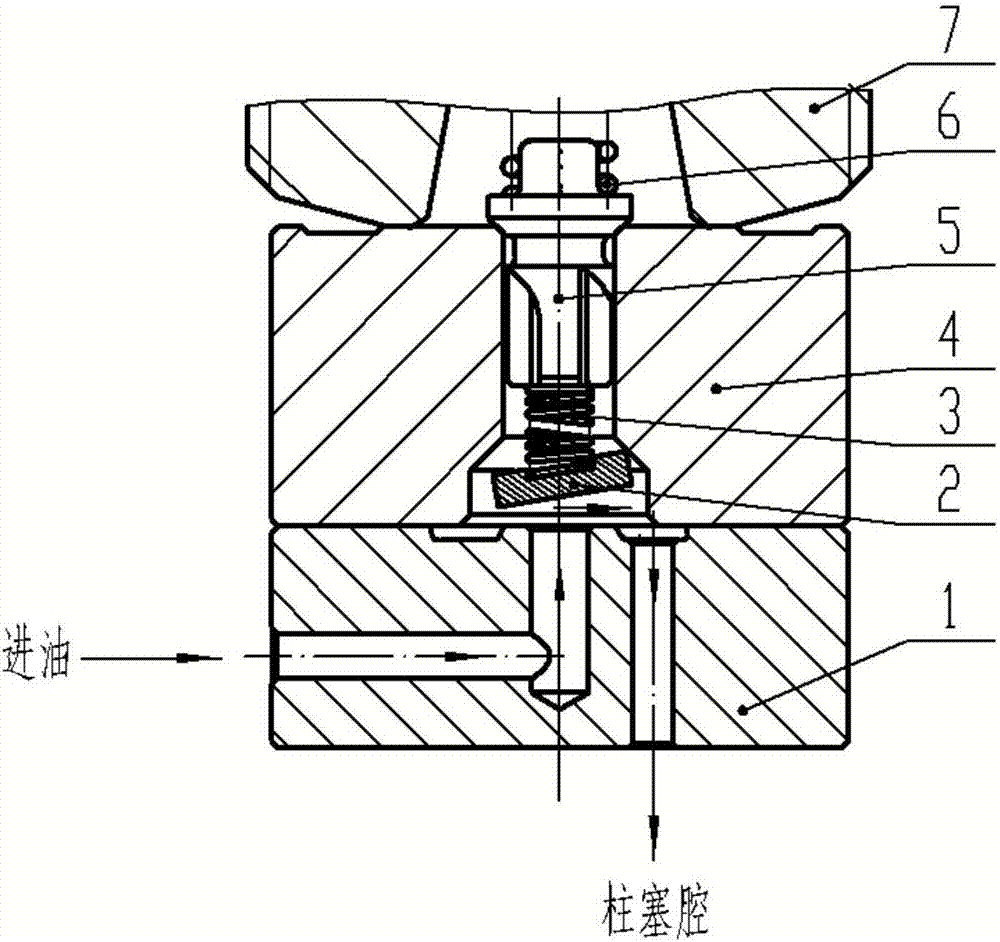

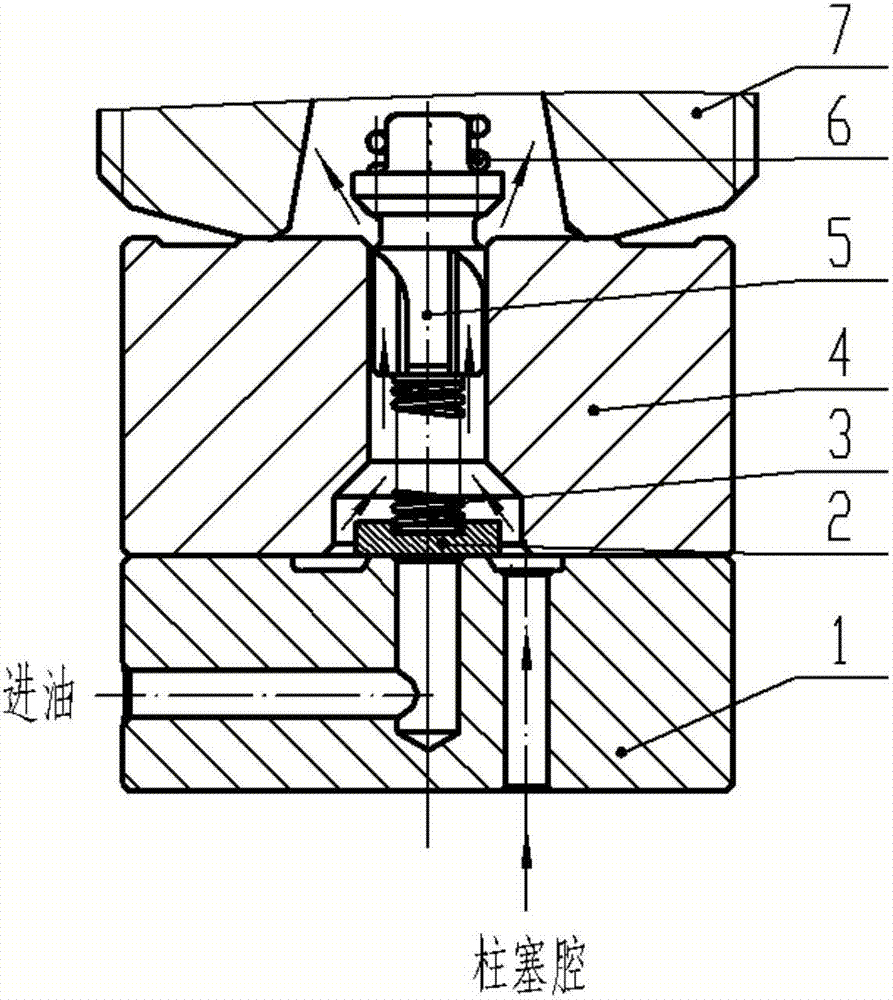

Oil inlet valve and high-pressure common rail fuel pump using same

PendingCN106948987AImprove orientationReduce high pressure fuel returnMachines/enginesFuel injecting pumpsRail pressureFuel oil

The invention discloses an oil inlet valve and a high-pressure common rail fuel pump using the same. The oil inlet valve comprises a circular valve block and a hollow guide cylinder connected onto the circular valve block; the guide cylinder is connected with the circular valve block to form a cylindrical structure with an inner cavity; a plurality of oil holes are formed in the cylinder wall of the guide cylinder. According to the oil inlet valve and the high-pressure common rail fuel pump using the same, the oil inlet valve is stable in motion, capable of timely returning, reliable in sealing and small in failure rate; the high-pressure common rail fuel pump using the oil inlet valve is stable in rail pressure, high in oil supply efficiency and not liable to fuel oil leakage.

Owner:北油电控燃油喷射系统(天津)有限公司

Environment-friendly filter membrane

InactiveCN106345313AImprove orientationGood heat resistanceMembranesSemi-permeable membranesSolventPolyester

The invention relates to an environment-friendly filter membrane, which is composed of the following raw materials in parts by mass: 10-22 parts of polylactic acid fiber, 10-26 parts of polyvinyl alcohol, 10-20 parts of polypropylene, and 24-32 parts of polyhydroxyalkanoate 10-60 parts, 10-60 parts of solvent, 6-16 parts of antibacterial agent and 6-10 parts of additive; wherein, said antibacterial agent is formed by mixing chitin and potassium sorbate, and the mass ratio of chitin and potassium sorbate is 1:1.7~2.1. The advantage of the present invention is that: polylactic acid fiber is used in the formula of the present invention to prepare the filter membrane, which can make the filter membrane have excellent heat resistance, is not easy to deform under high temperature environment, avoids clogging of the pore structure of the filter membrane, and greatly Improve the heating or cooling effect of the air conditioner; and through the synergistic effect of each component, the filter membrane has long-term antibacterial and antibacterial ability, plays a self-cleaning role, and uses environmentally friendly polyhydroxyester fatty materials , improve the environmental performance of the filter membrane.

Owner:JIANGSU HAINA AIR CONDITIONER PURIFICATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com