Collection device and preparation method of directional continuous nanofiber bundles

A nanofiber, collecting device technology, used in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of inability to maintain continuity, low fiber orientation, and low spinning orientation, and achieve easy operation. , the effect of high degree of orientation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing oriented continuous nanofiber bundles is specifically implemented according to the following steps:

[0040] Step 1. Add the ceramic precursor and the spinnable polymer to the solvent to prepare the spinning solution;

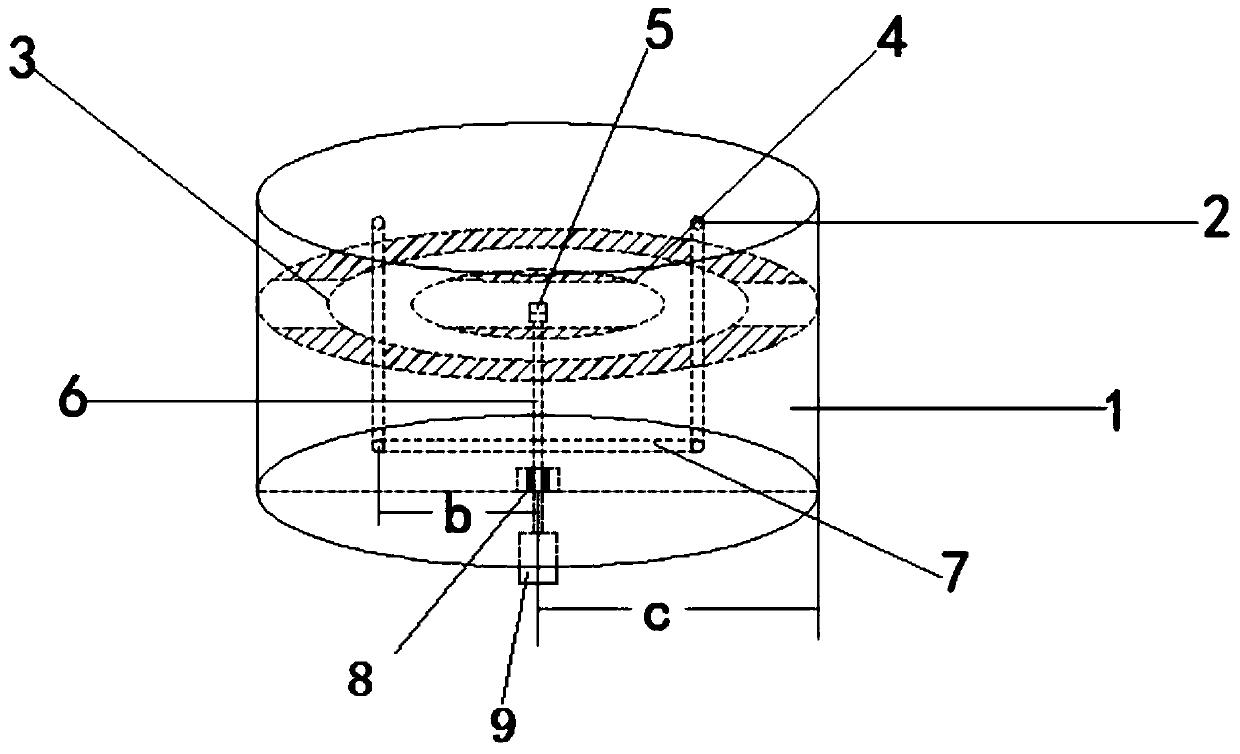

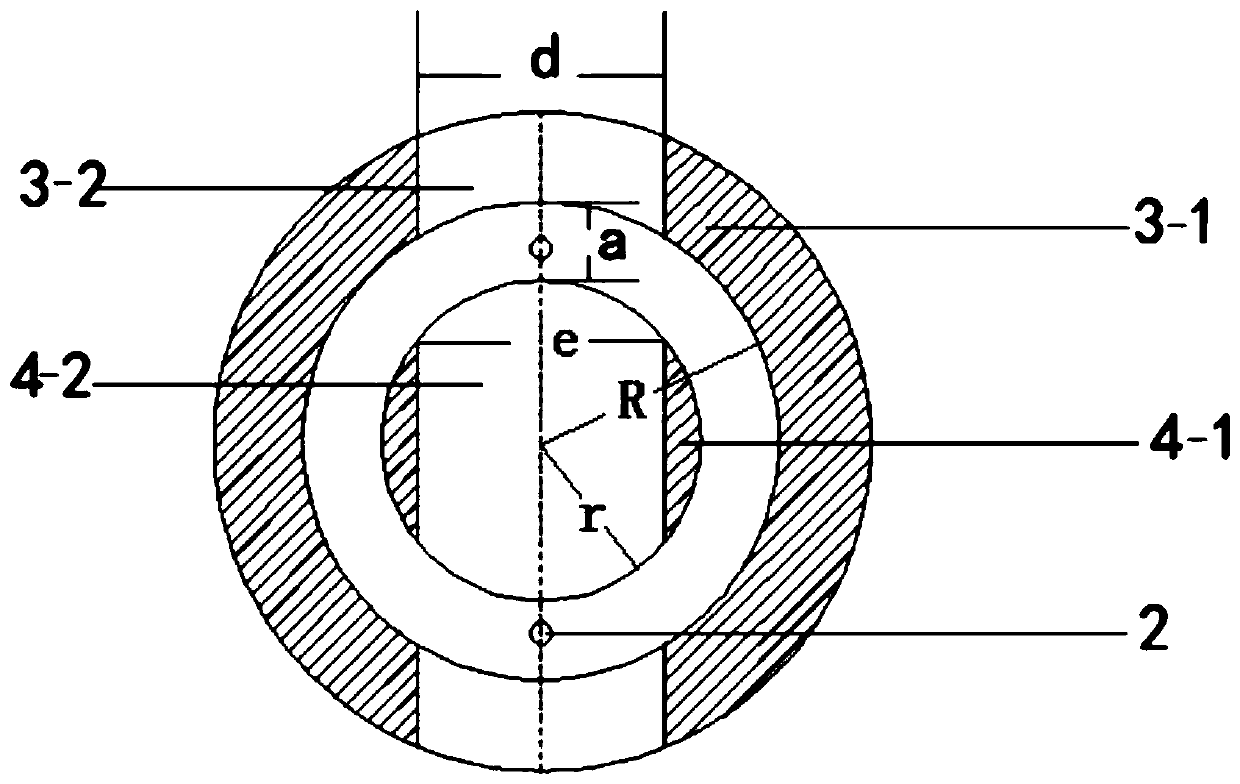

[0041] Step 2. Build a directional continuous fiber bundle collection device;

[0042] Step 3. Apply the electrospinning equipment, and set the operating parameters of the electrospinning equipment for fiber preparation, and collect the fibers with the oriented continuous fiber bundle collecting device built in step 2 to obtain the oriented continuous fiber bundle.

[0043] Electrospinning equipment is YFSP-T spinning machine.

[0044] All reagents used are chemically pure.

[0045] In step 1, the specific concentration of the spinning solution is composed of the following substances in terms of mass percentage: ceramic precursor 0%-30%, spinnable polymer 10%-30%, solvent 40%-90%, the sum of the above components is 100% .

[0046] The ceramic...

Embodiment 1

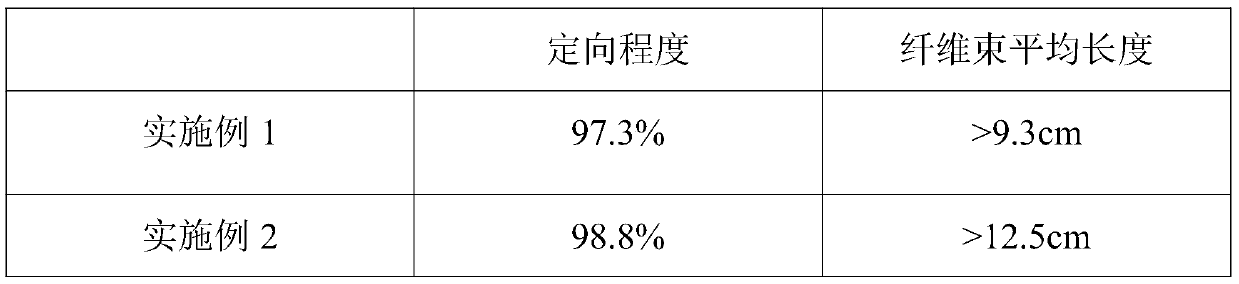

[0050] Example 1 Preparation of oriented PMMA nanofiber bundle

[0051] Step 1. Add 1 g of polymethyl methacrylate (PMMA) to 9 g of N,N-dimethylformamide solvent to completely dissolve the spinning solution;

[0052] Step 2. Build a collection device for oriented PMMA nanofiber bundles, where a is 2 cm, b is 4 cm, c is 6 cm, and d is 1 cm;

[0053] Step 3. Place the obtained spinning solution in the push pump, place the spinning nozzle above the insulating shaft in the oriented continuous fiber bundle collection device obtained in Step 2, adjust the spinning voltage to 16kv, the advance speed to 0.1mL / h, and the receiving distance It is 15cm, the spinning temperature is at 20℃, the humidity is at 10%, the fiber is ejected, and the insulating shaft 2 is controlled to rotate for oriented collection of the fibers. The speed of the insulating shaft 2 is 20r / min. After 5 minutes, the oriented PMMA nanofiber bundle is finally obtained .

Embodiment 2

[0054] Example 2 Preparation of oriented PVDF-based composite fiber bundle

[0055] Step 1. Add 2g of isopropyl titanate and 2g of polyvinylidene fluoride (PVDF) into a mixed solvent of 4g of N,N-dimethylformamide and 2g of acetylacetone to obtain a spinning solution;

[0056] Step 2. Build a collection device for oriented PVDF-based composite fiber bundles, where a is 3cm, b is 6cm, c is 10cm, and d is 3cm;

[0057] Step 3. Place the obtained spinning solution in the push pump, place the spinning nozzle above the insulating shaft in the oriented continuous fiber bundle collection device obtained in Step 2, adjust the spinning voltage to 20kv, the advance speed to 0.3mL / h, and the receiving distance It is 18cm, the spinning temperature is 25℃, the humidity is 30%, the fiber is ejected, and the insulation shaft 2 is controlled to rotate for directional collection of fibers. The rotation speed of the insulation shaft 2 is 80r / min. After 6 minutes, the oriented PVDF-based composite fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com