Injection molding anisotropic bonded neodymium-iron-boron magnetic shoe radiation orientation forming method and device

An anisotropic, radiation-oriented technology, applied in inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of low performance of bonded magnets, low oriented magnetic field strength, incomplete orientation, etc., to achieve simple structure, The effect of improving magnet performance and high degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

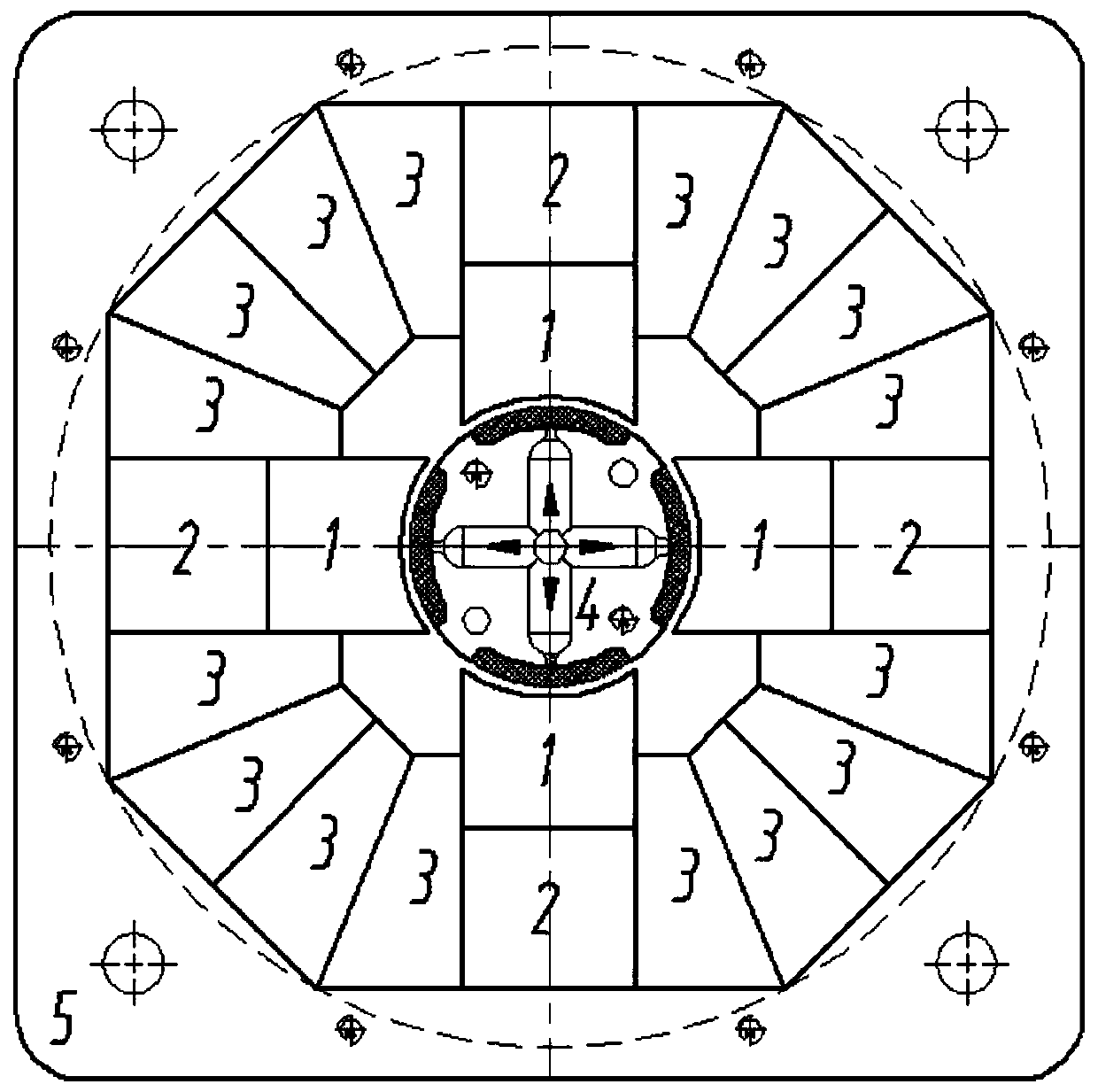

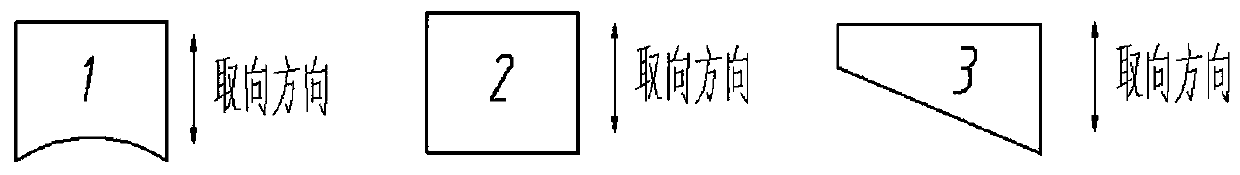

[0025] Such as Figure 1-4 As shown, this embodiment provides an injection molding anisotropic bonded NdFeB magnetic tile radiation orientation molding device, including A-type oriented permanent magnet 1, B-type oriented permanent magnet 2, C-type oriented permanent magnet 3, magnetic flux The channel and the inner mold core 4, the non-magnetic outer mold core 5, the A-type oriented permanent magnet 1, the B-type oriented permanent magnet 2, the C-type oriented permanent magnet 3, the magnetically conductive flow channel and the inner mold core 4 are arranged in different places. Inside the magnetically permeable outer mold core 5, the magnetically permeable flow channel and the inner mold core 4 are arranged in the center of the non-magnetically permeable outer mold core 5, the A-type oriented permanent magnet 1, the B-type o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com