A device and method for preparing oriented electrospun fibers

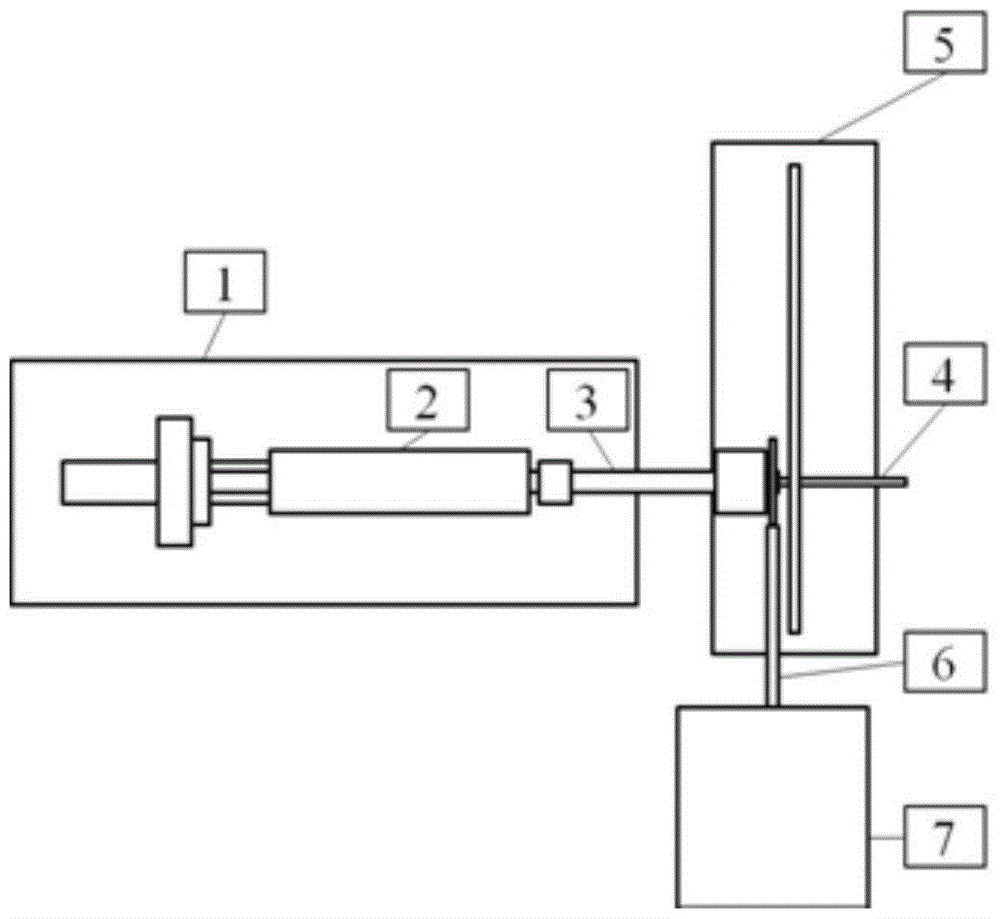

An electrospinning and orientation technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problem of poor fiber orientation, low fiber orientation, affecting material uniformity, etc. problem, to achieve the effect of improving the degree of orientation, good orientation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

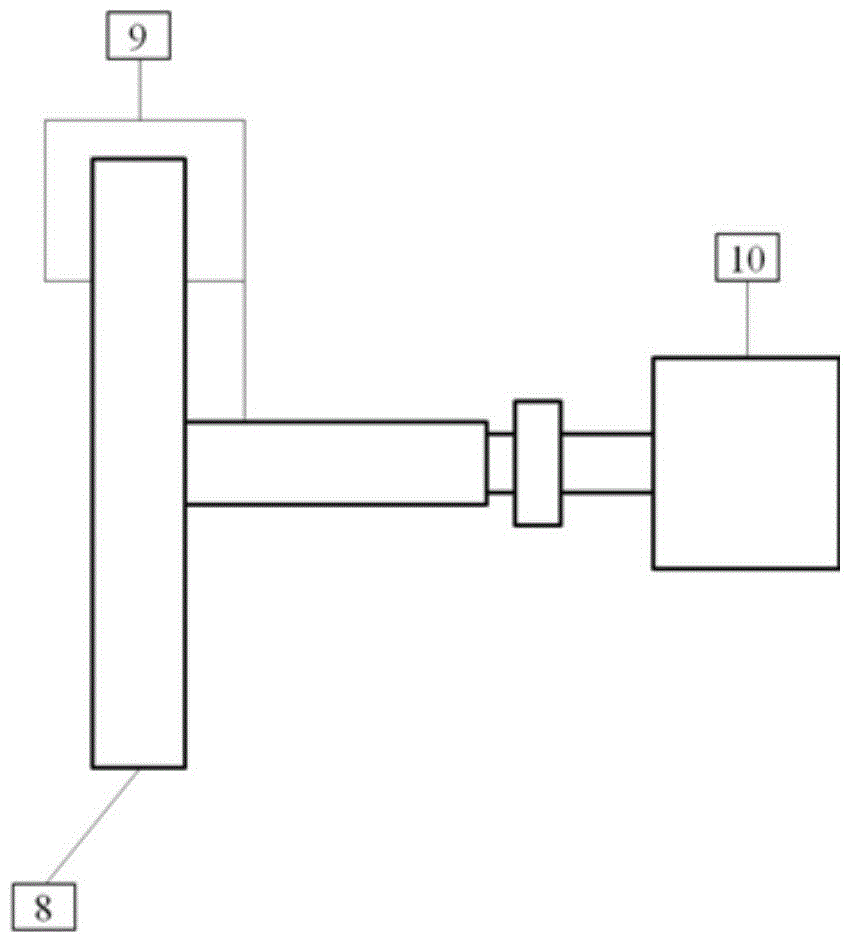

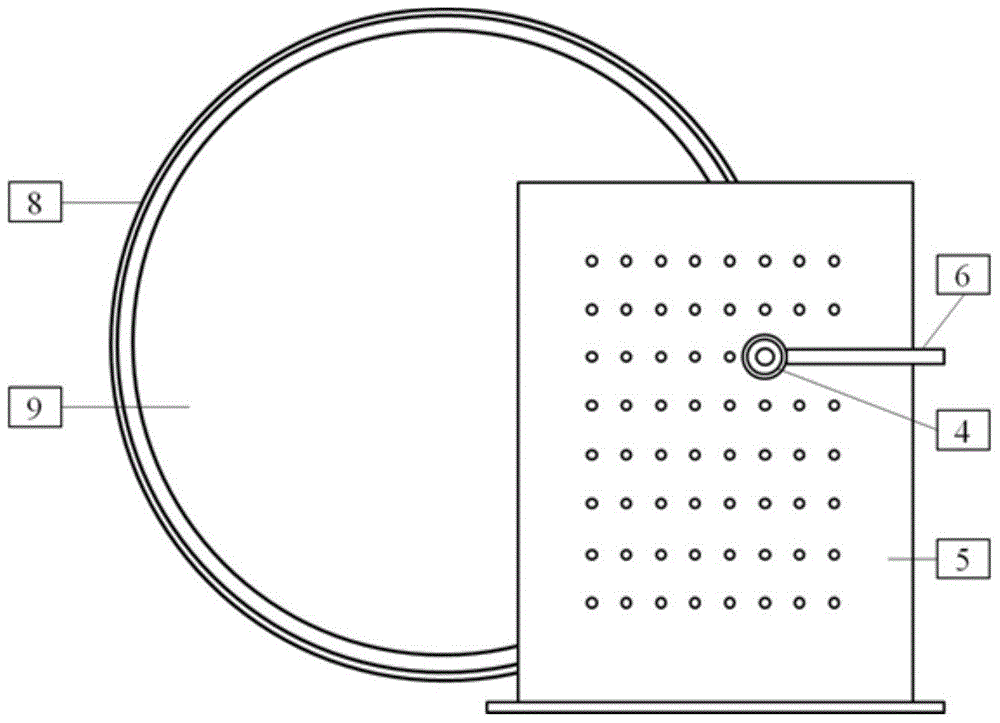

Method used

Image

Examples

Embodiment 1

[0041] Mix the silk fibroin aqueous solution with a concentration of 8wt% and the PEO (9000g / mol) solution with a concentration of 5wt% at a volume ratio of 4:1, and mix well to obtain a spinning solution. Add the spinning solution into the syringe, the needle is a 16G needle, the needle is connected to a high-voltage electrostatic generator, the flow rate of the solution is 0.5ml / h, the receiving distance is 15cm from the needle to the receiver of the turntable, the temperature is kept at room temperature, and the humidity is controlled at 30%, adjust the rotational speed of the turntable receiver to 800rpm, turn on the electrostatic generator and adjust the voltage to 10kV. Spinning under these conditions, the oriented electrospun material is received on the side of the turntable receiver with a diameter of 40 cm, the direction of fiber orientation is parallel to the side circumference direction of the turntable receiver, and the thickness of the material increases with time....

Embodiment 2

[0043]Mix the silk fibroin aqueous solution with a concentration of 8wt% and the PEO (9000g / mol) solution with a concentration of 5wt% at a volume ratio of 4:1, and mix well to obtain a spinning solution. Add the spinning solution into the syringe, the needle is a 16G needle, the needle is connected to a high-voltage electrostatic generator, the flow rate of the solution is 0.3ml / h, the receiving distance (the vertical distance between the needle and the receiver of the turntable) is 20cm, the temperature is kept at room temperature, and the humidity is controlled At 30%, adjust the rotational speed of the turntable receiver to 900 rpm, turn on the electrostatic generator and adjust the voltage to 10 kV. Spinning under these conditions, the oriented electrospun material was received on the side of the turntable receiver with a diameter of 30 cm, the direction of fiber orientation was parallel to the circumferential direction of the side of the turntable receiver, and the thickn...

Embodiment 3

[0045] Mix the silk fibroin aqueous solution with a concentration of 8wt% and the PEO (9000g / mol) solution with a concentration of 5wt% at a volume ratio of 4:1, and mix well to obtain a spinning solution. Add the spinning solution into the syringe, the needle is a 16G needle, the needle is connected to a high-voltage electrostatic generator, the flow rate of the solution is 0.2ml / h, the receiving distance (the vertical distance between the needle and the receiver of the turntable) is 15cm, the temperature is kept at room temperature, and the humidity is controlled At 25%, adjust the rotational speed of the turntable receiver to 1000 rpm, turn on the electrostatic generator and adjust the voltage to 6 kV. Spinning under these conditions, the oriented electrospun material was received on the side of the turntable receiver with a diameter of 20 cm, the direction of fiber orientation was parallel to the circumferential direction of the side of the turntable receiver, and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com