Lateral shaping tapered wedge mechanism

A technology of side shaping and wedge, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve different problems, achieve the effect of improving orientation and compact mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is described in detail below through specific examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as limitations to the technical solution of the present invention.

[0034] The technical solution of the present invention does not improve the shaping module on the opposite side, and belongs to the prior art, so this part will not be described in detail.

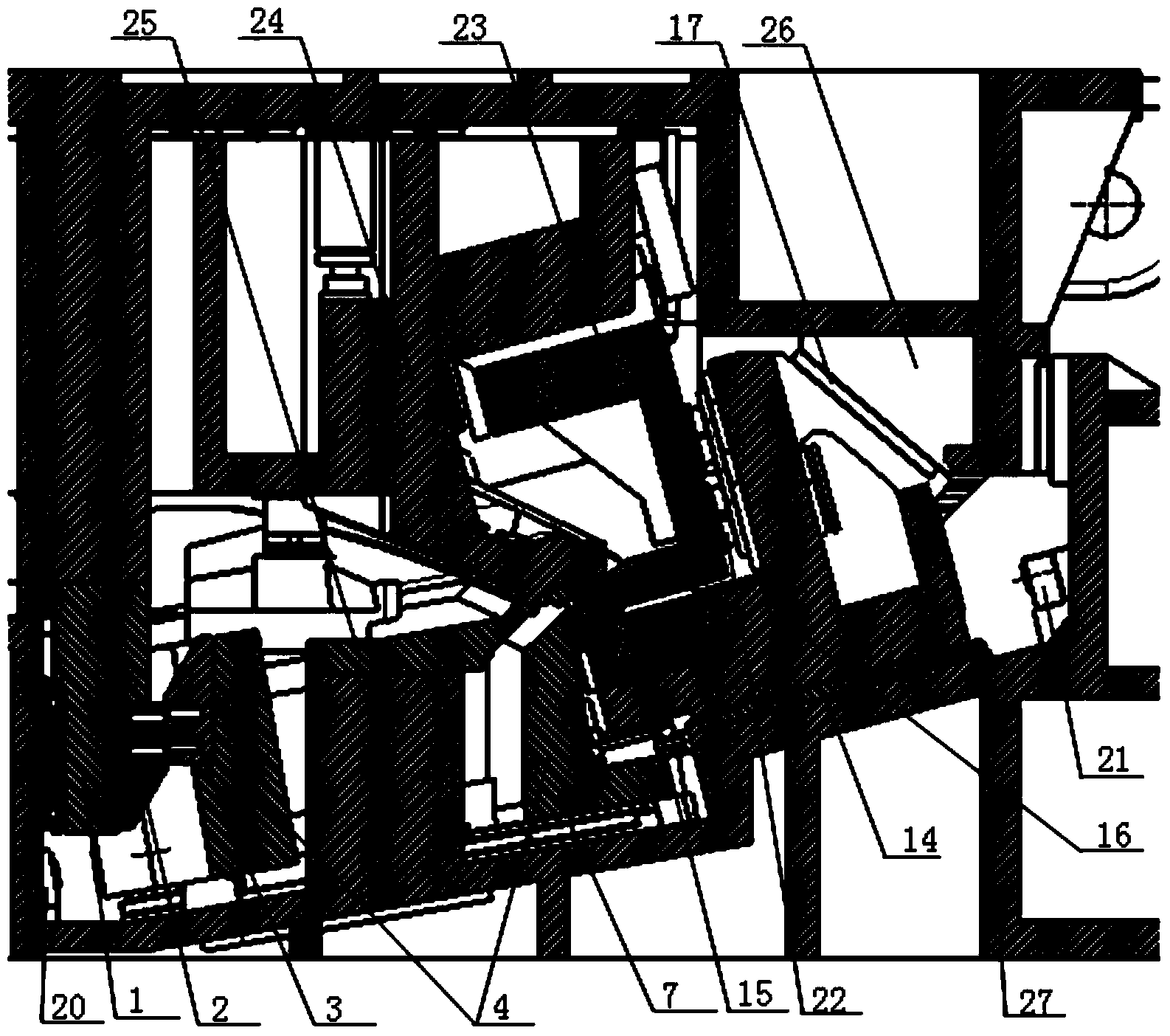

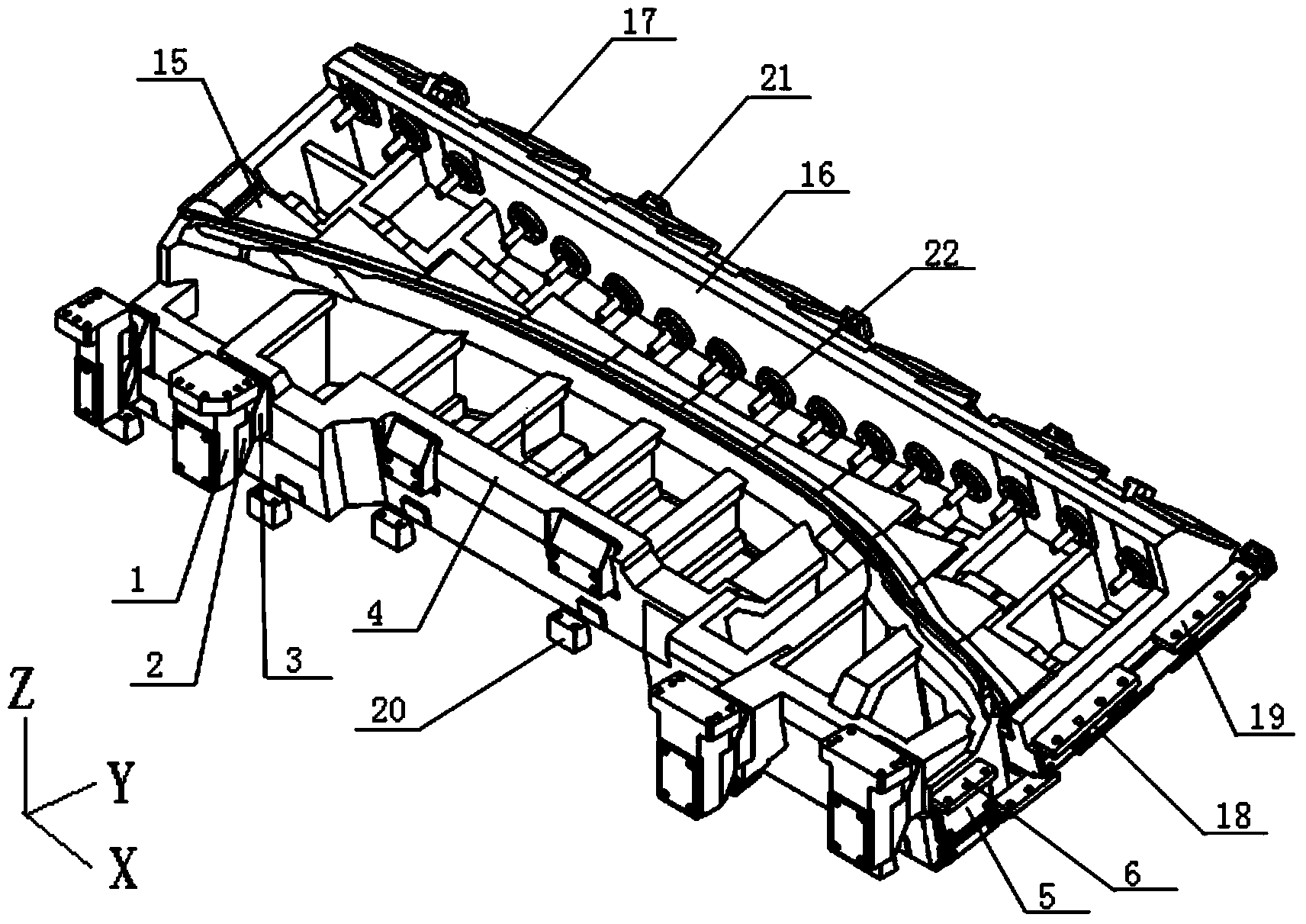

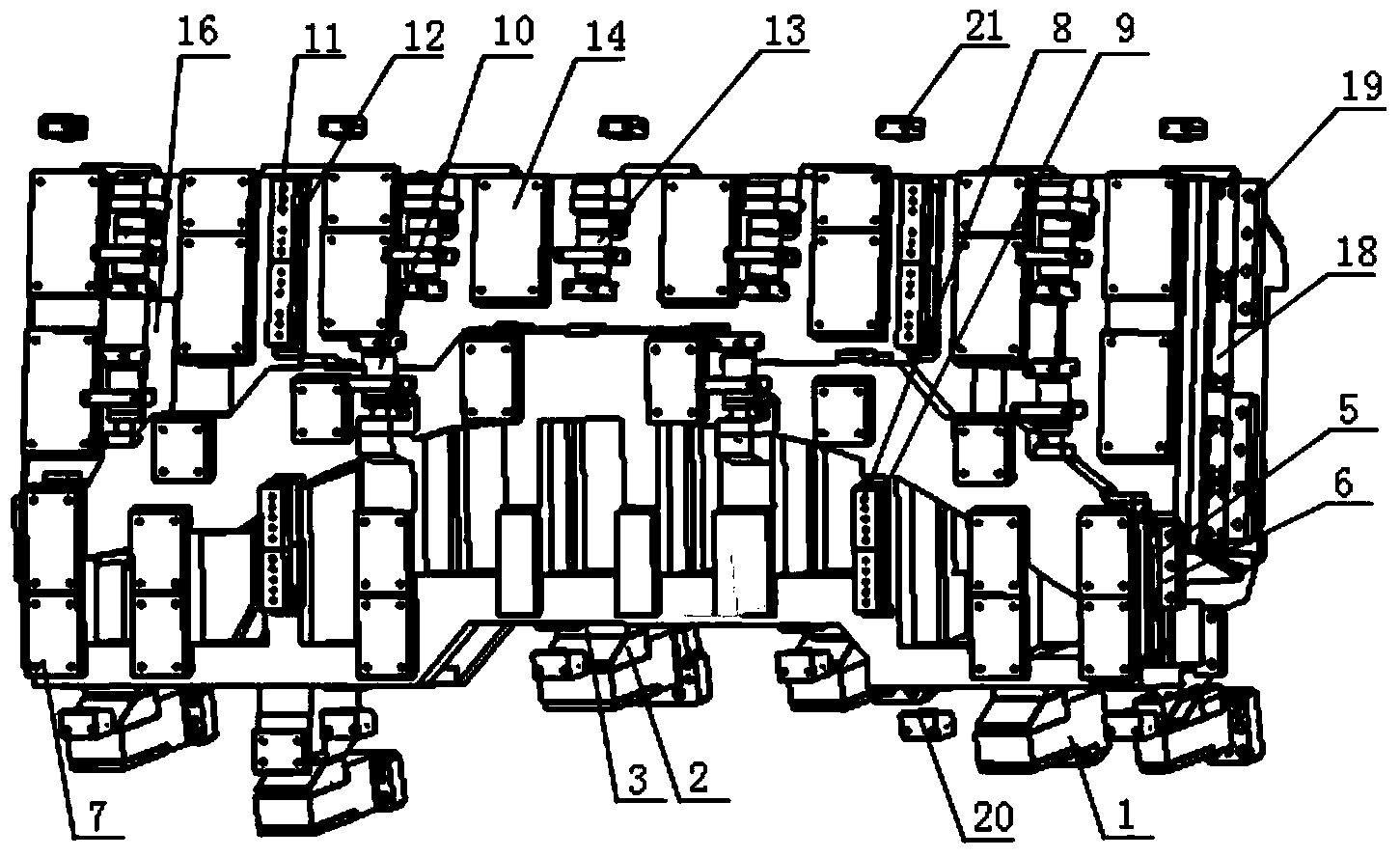

[0035] Such as Figure 4 to Figure 6 As shown, a side shaping wedge mechanism includes a wedge module, a lower mold module and a shaping module;

[0036] The wedge module includes an upper mold driving block 101, a wedge guide plate A102, a wedge guide plate B103, a side extraction wedge 104, a pressure plate A105, a guide plate A106, a guide plate B107, a clamping plate 108, a connecting block 109, and a drive cylinder 110 And wedge guide plate C111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com