Inverted buckle demolding device of complex-shape product

A complex shape and demoulding device technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of increasing mold volume, small part volume, and difficult design, so as to achieve compact mold structure and ingenious demoulding , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

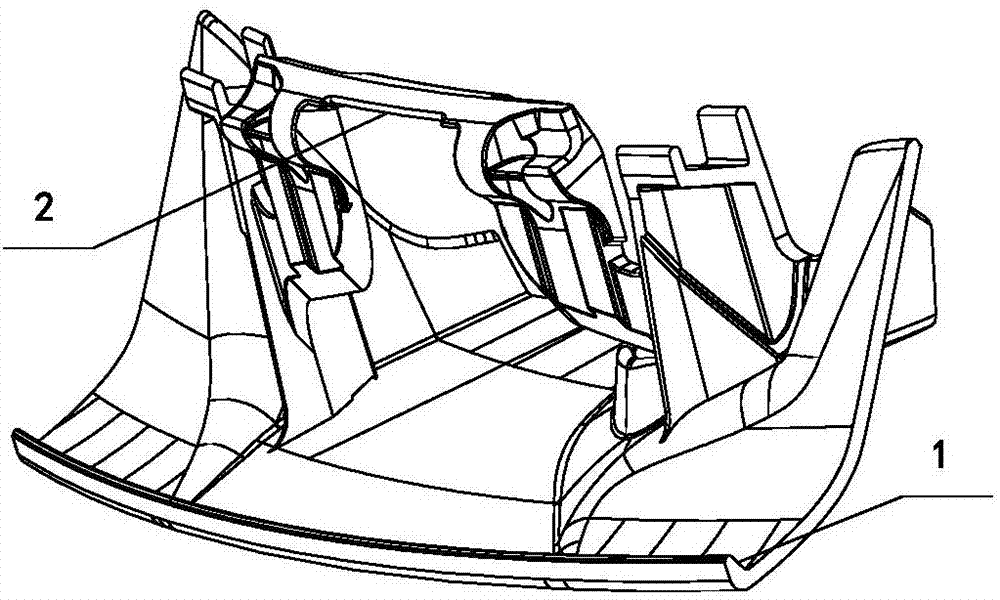

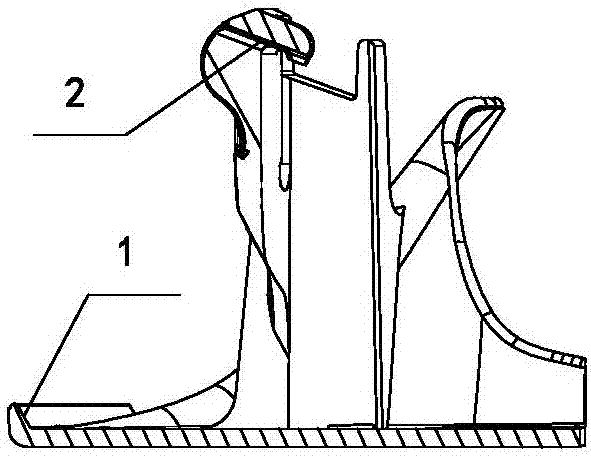

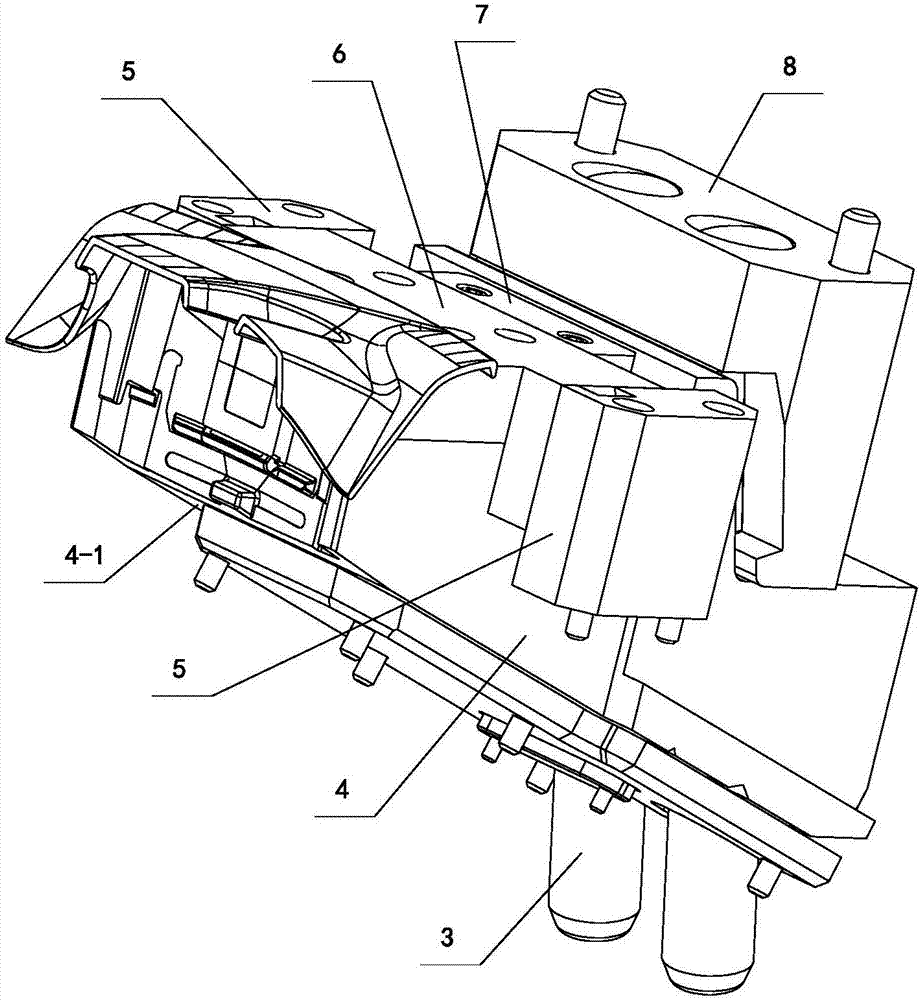

[0028] Depend on Figure 1 to Figure 9 It can be seen from the structural schematic diagram of the undercut stripping device for complex-shaped products of the present invention that the complex-shaped product includes a panel and a gantry bracket protruding from the panel, and a first undercut 1 inclined to the panel is provided at the edge of the panel. A second undercut 2 is provided on the side of the beam of the gantry-type bracket facing the panel. This device includes a first slider mechanism for demoulding the first undercut 1 and a second slider for demoulding the second undercut 2. block mechanism. Wherein the second slider mechanism comprises a second slider 4 and an oblique guide post 3, the big end of the oblique guide post 3 is connected with the upper template of the mould, and the second slider 4 is slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com