Highlight die and temperature control system thereof

A temperature control system and mold technology, applied in the field of temperature control system, can solve the problems of low production efficiency, high investment cost, long molding cycle, etc., and achieve the effects of high production efficiency, energy saving, and compact mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

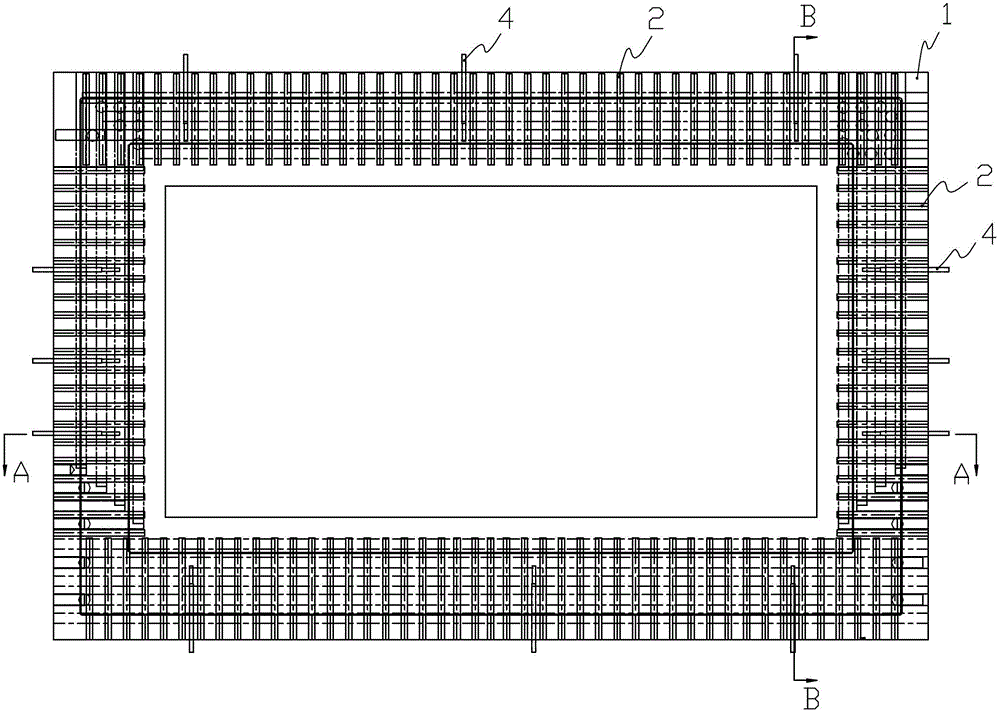

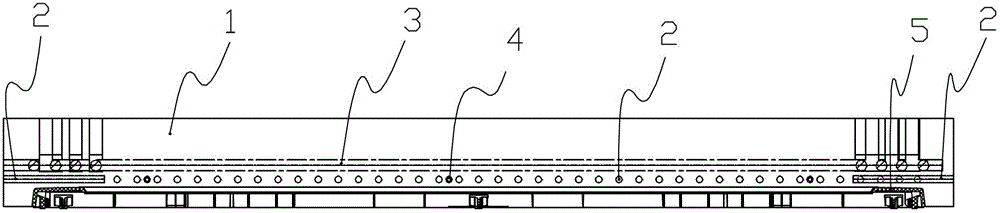

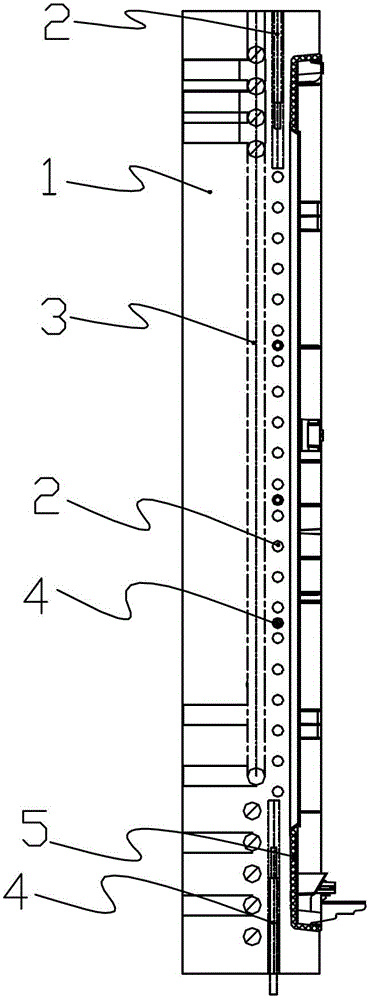

[0022] see figure 1 , figure 2 and image 3 , a high-gloss mold, including a movable mold and a fixed mold 1. An electric heating rod 2, a thermocouple 4 and a cooling channel 3 are arranged on the fixed mold. Preferably, the electric heating rod is located on the side of the fixed mold close to the parting surface, and the cooling channel is located outside the electric heating rod. There are several electric heating rods above, which are evenly arranged in the circumferential direction of the fixed mold, and a thermocouple is arranged between two or more adjacent electric heating rods. Preferably, there are twenty-four electric heating rods and twelve thermocouples.

[0023] In the above method, the fixed mold can also be replaced by a cavity plate or other suitable molding parts. If it is replaced by a cavity plate, electric heating rods, thermocouples and cooling channels are arranged on the cavity plate. Preferably, the electric heating rod is located on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com