Patents

Literature

383results about How to "Achieve demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

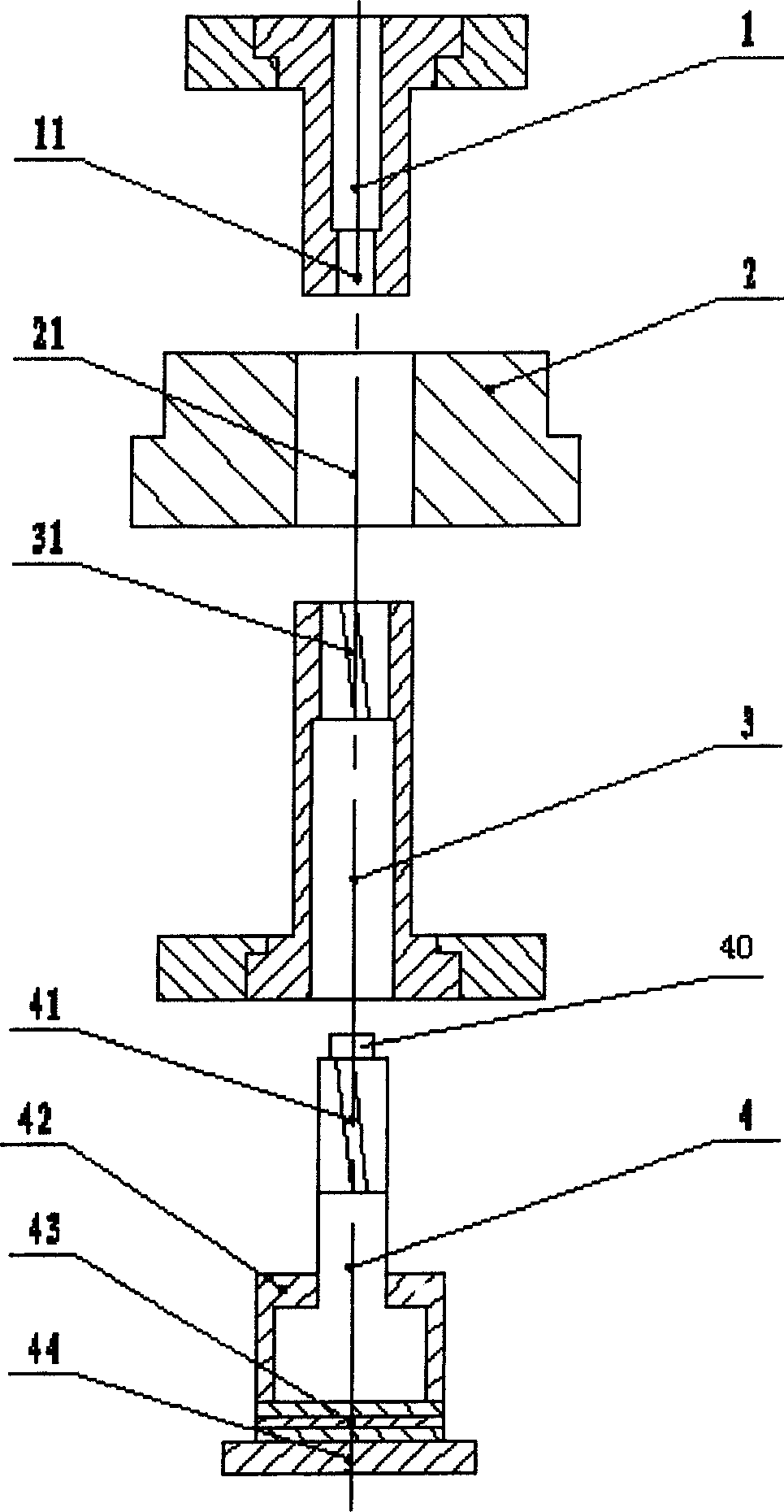

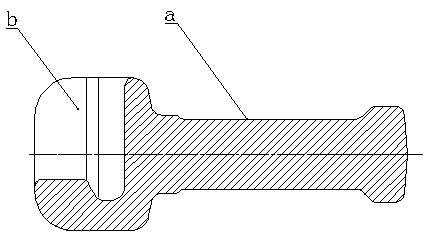

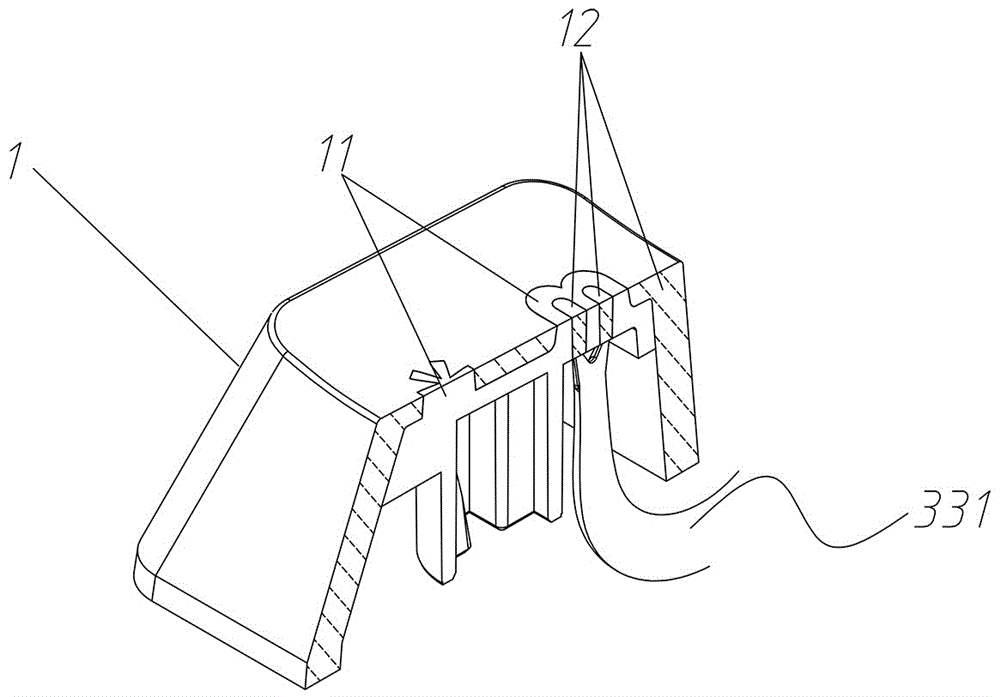

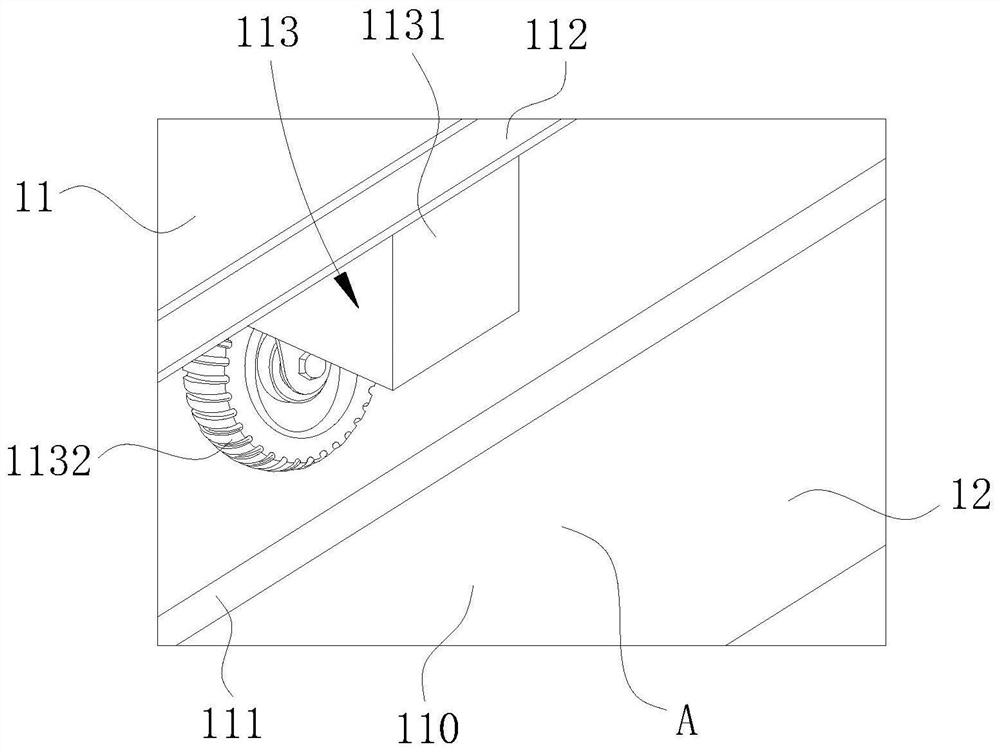

Manufacture method and die for powder metallurgy inside spin ratchet wheel

The invention relates to a method for producing powder smelt screw ratchet, which comprises: mixing the materials, compressing molding, sintering, compressing and shaping, to obtain the ratchet. The invention also discloses a relative mould, which is formed by a compressing upper punch, compressing middle mould, compressing lower punch; the upper part of lower punch has the inner screw tooth matched with the outer screw tooth; the upper punch is sliding matched with the middle mould; the middle mould is sliding matched with the lower mould; the compressing core rod has compressing core rod, friction plate, and rotation element; the upper part of compressing core rod has outer screw tooth; the lower end of core rod and the upper end of rotating element have friction plate between them, while their contact surface has lubricant. The invention, via the rotation of core rod, realizes the one-time molding and demoulding of inner screw ratchet, to improve the yield and reduce the cost.

Owner:南通市海门常乐粉末冶金厂

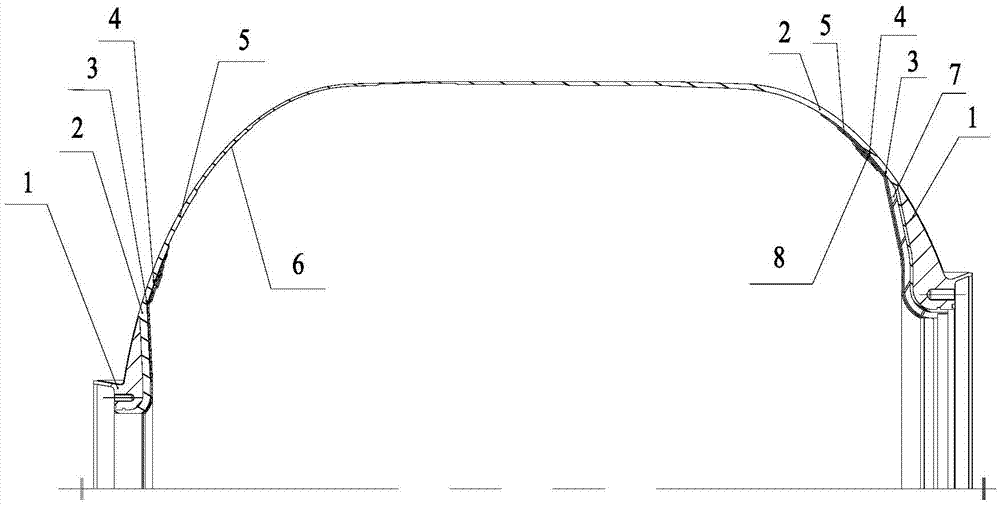

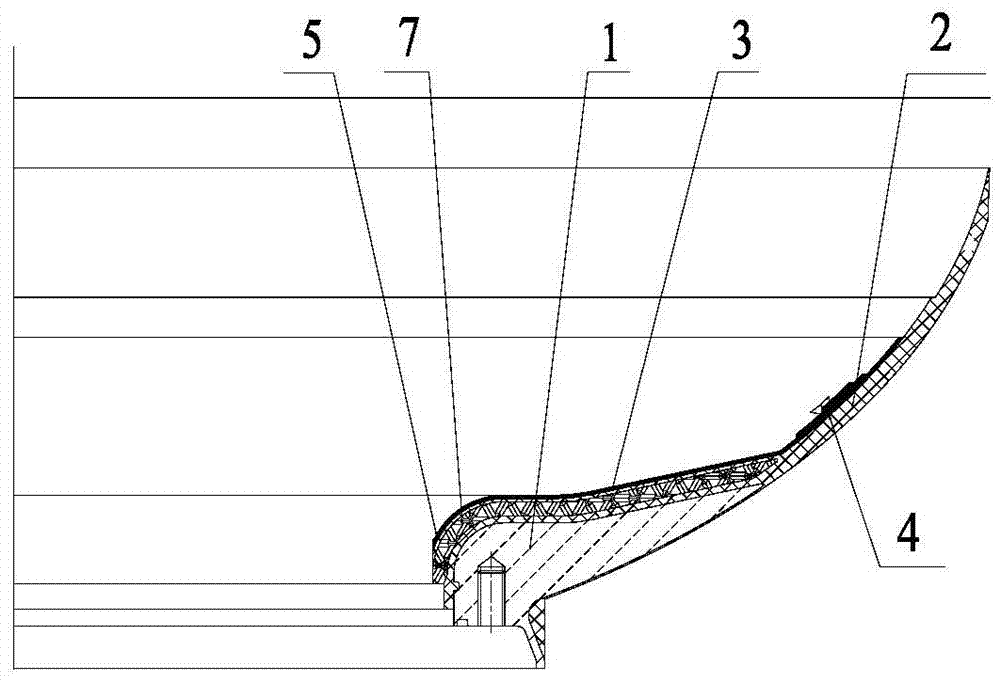

Seal head heat insulating layer forming method and mold of filament winding engine heat insulating structure

ActiveCN105437521AOvercome stabilityOvercome the defect of low bonding strengthDomestic articlesVulcanizationEngineering

The invention discloses a seal head heat insulating layer forming method of a filament winding engine heat insulating structure. A cover layer and a bottom layer of a seal head heat insulating layer are firstly and independently formed in a vulcanization and compression manner and then overall formed in a vulcanization and compression manner, and the defect that the forming quality stability and consistency of manual SMT technology products are low is overcome. A release agent is sprayed or release cloth is pasted in the direction with the decreasing diameter at the crack arrest point, a proper tackiness agent is adopted in other lining layers, and the releasing effect of the cover layer and the bottom layer of the manufactured seal head heat insulating layer is good. In addition, when the seal head heat insulating layer is a rear seal head heat insulating layer, an EPDM heat insulating material wrapping structure is adopted in a T-1 anti-elation layer, and therefore the seal head heat insulating layer is isolated from a high-strength aluminum alloy connector. According to a provided integral forming mold, two sets of tools of the integral forming mold and a bottom layer forming mold can be achieved only by replacing an upper integral mold and an upper bottom layer mold, the structure is simple, and cost is low. Meanwhile, locating and mold releasing can be achieved well, and mold stripping of products is facilitated.

Owner:湖北三江航天江北机械工程有限公司

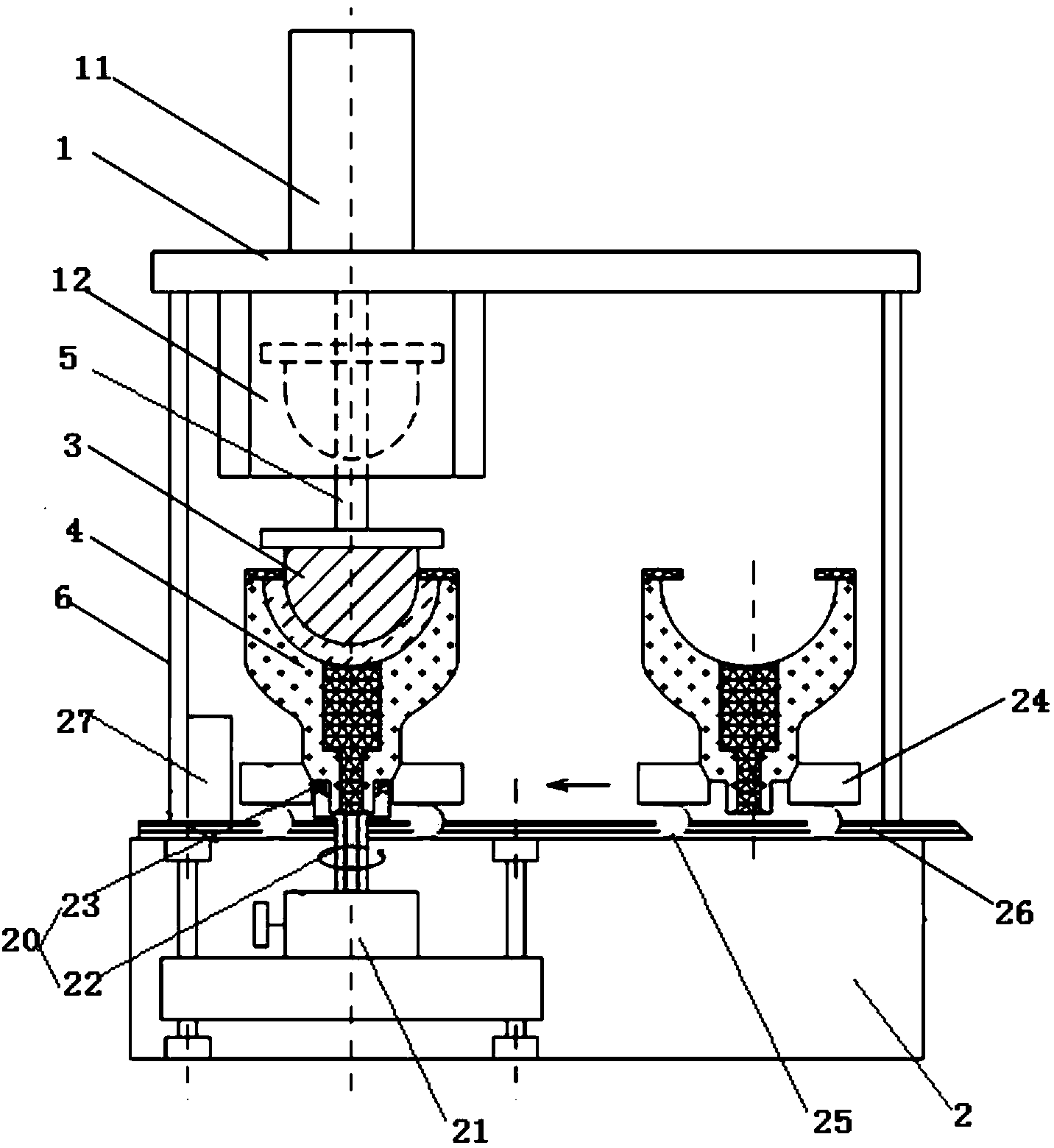

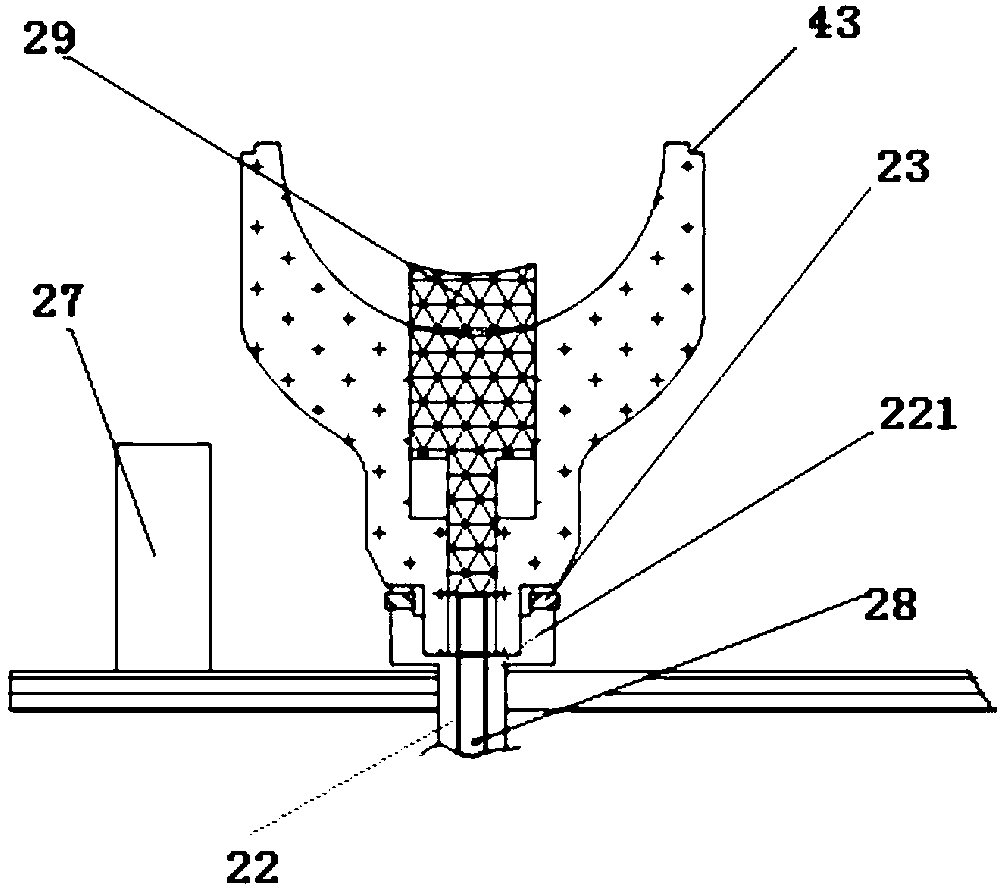

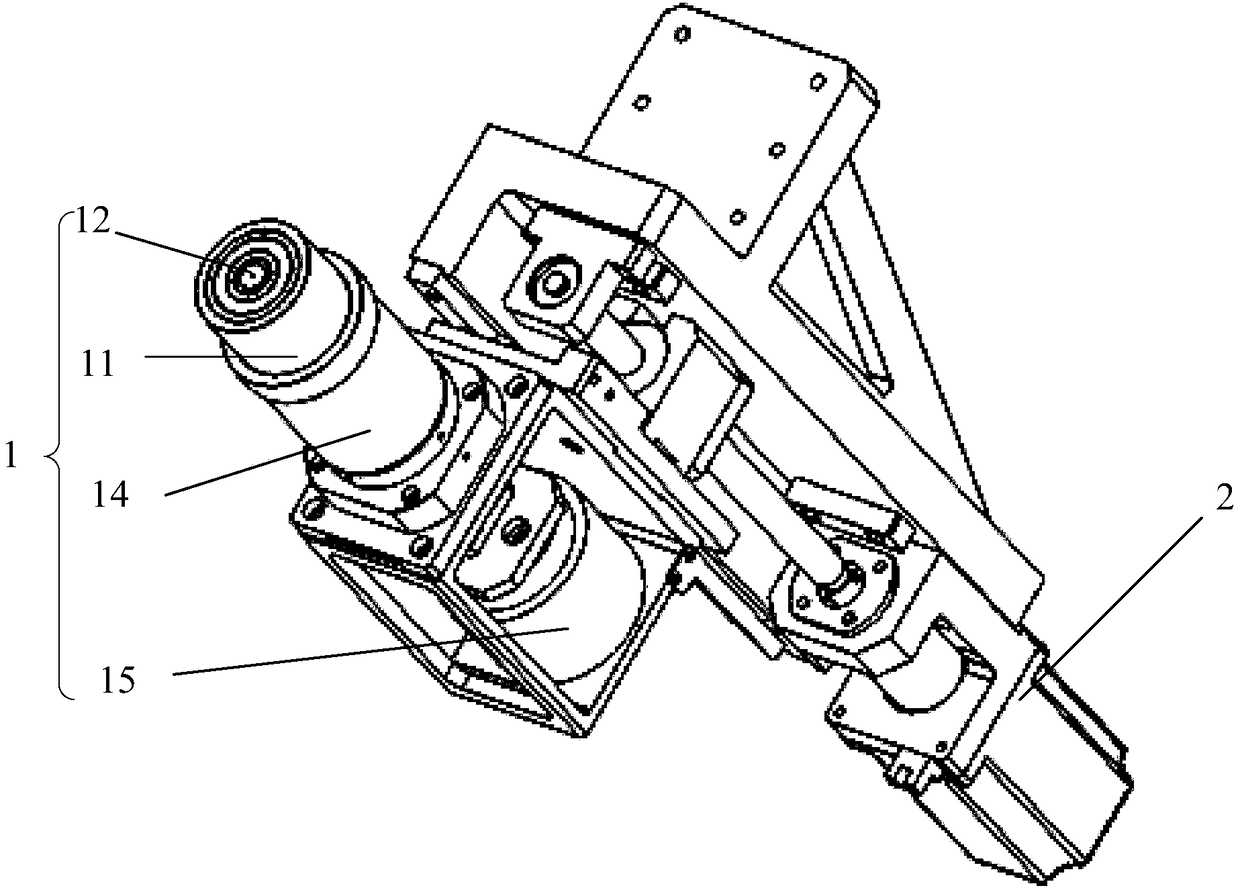

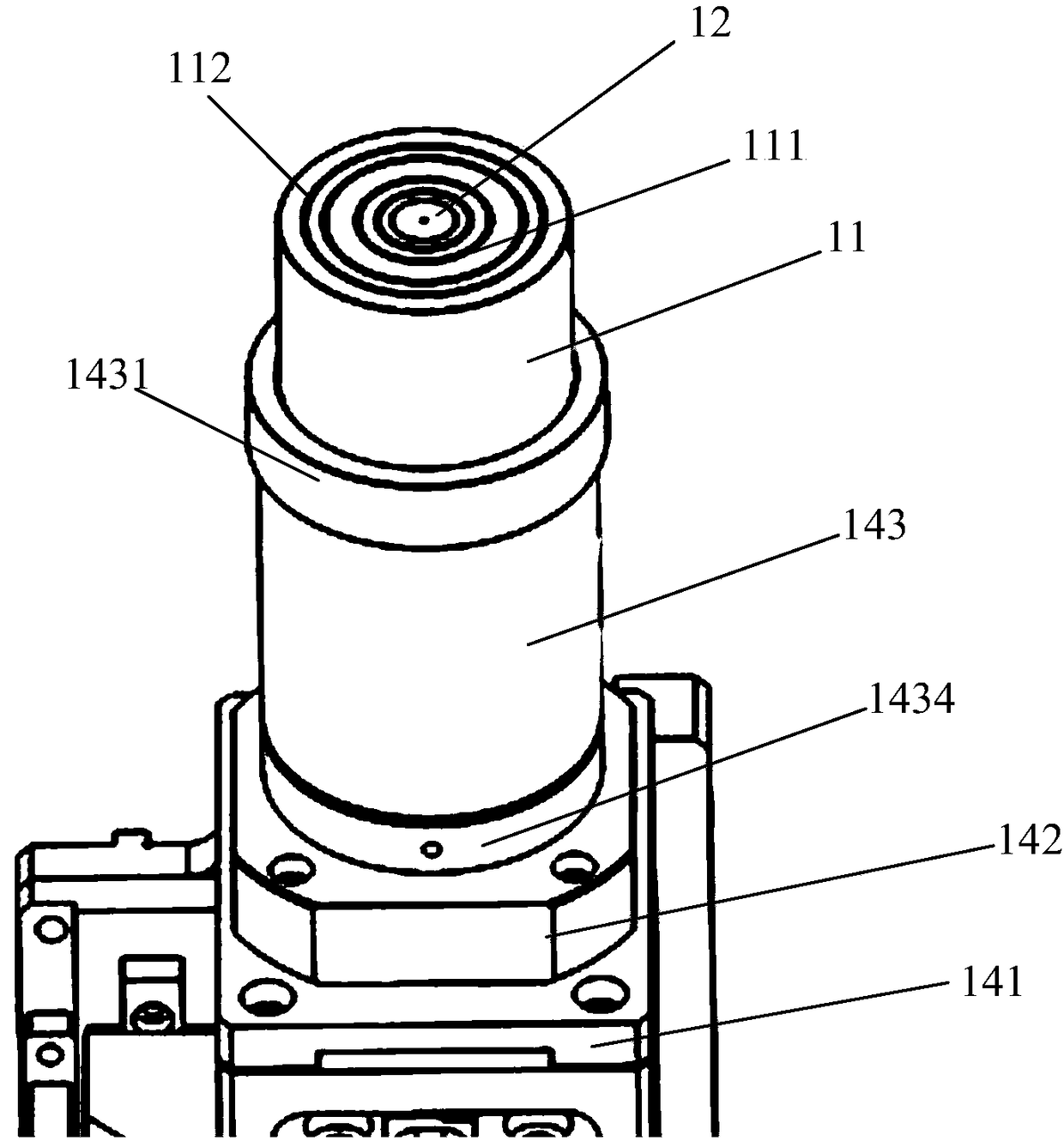

Spinning and molding device for glassware

ActiveCN103819075AAccuratePrecise positioningGlass pressing apparatusElectrical and Electronics engineeringEngineering

The invention discloses a spinning and molding device for glassware, which comprises a molding operation system consisting of an upper operating floor and a lower operating floor. A pair of vertically opposite moulds is arranged between the upper operating floor and the lower operating floor; the upper mould is a male mould and the lower mould is a female mould; a pressing jacking device provided with one end connected with the male mould is arranged on the upper operating floor; a positioning mechanism used for positioning the female mould in an operating position and a driving and rotating device used for driving the female mould to rotate are arranged on the lower operating floor; the positioning mechanism comprises a liftable support platform used for supporting the female mould, and a holder arranged on the supporting platform; the holder can be used for positioning the female mould through clamping the female mould in the circumferential direction. As the positioning of the female mould of the molding device is accurate, the molding precision of the obtained glassware is largely improved, and the male mould is preheated in the molding operation system, so that time and labor are saved.

Owner:CHINA BUILDING MATERIALS ACAD

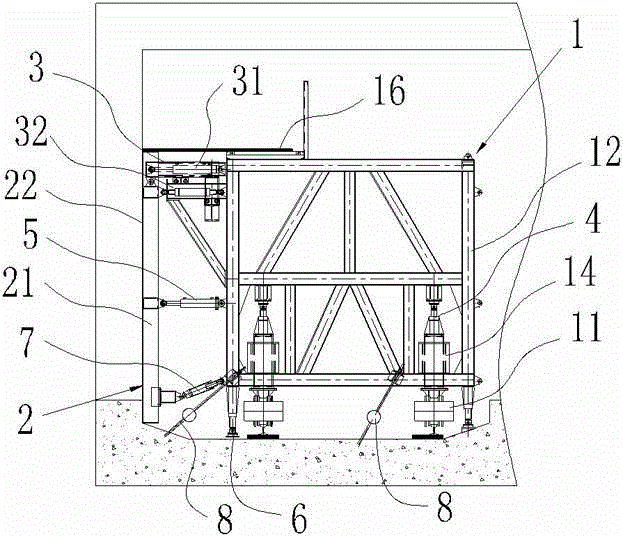

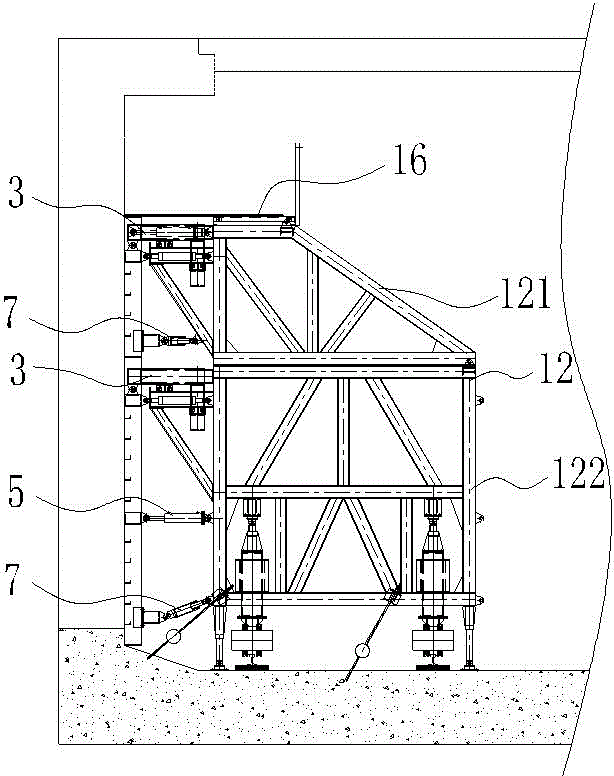

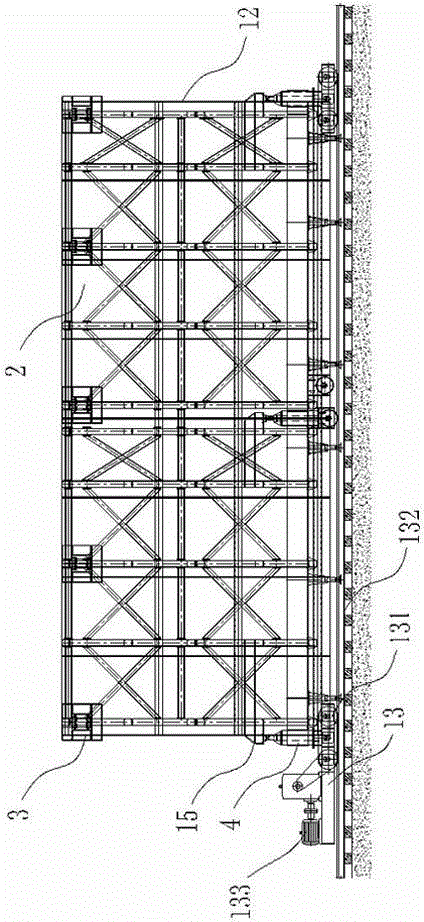

Hydraulic self-moving steel mould trolley and construction method thereof

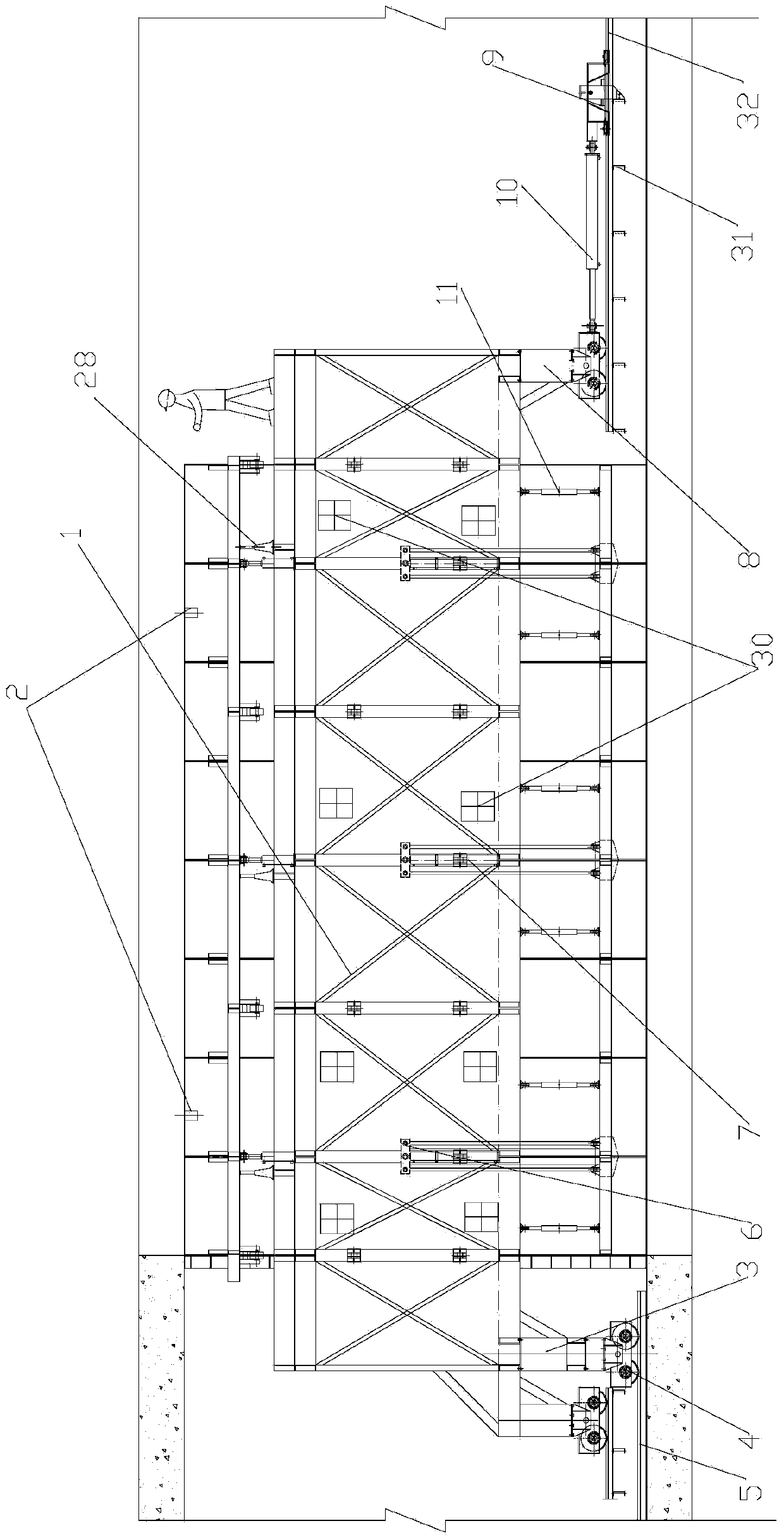

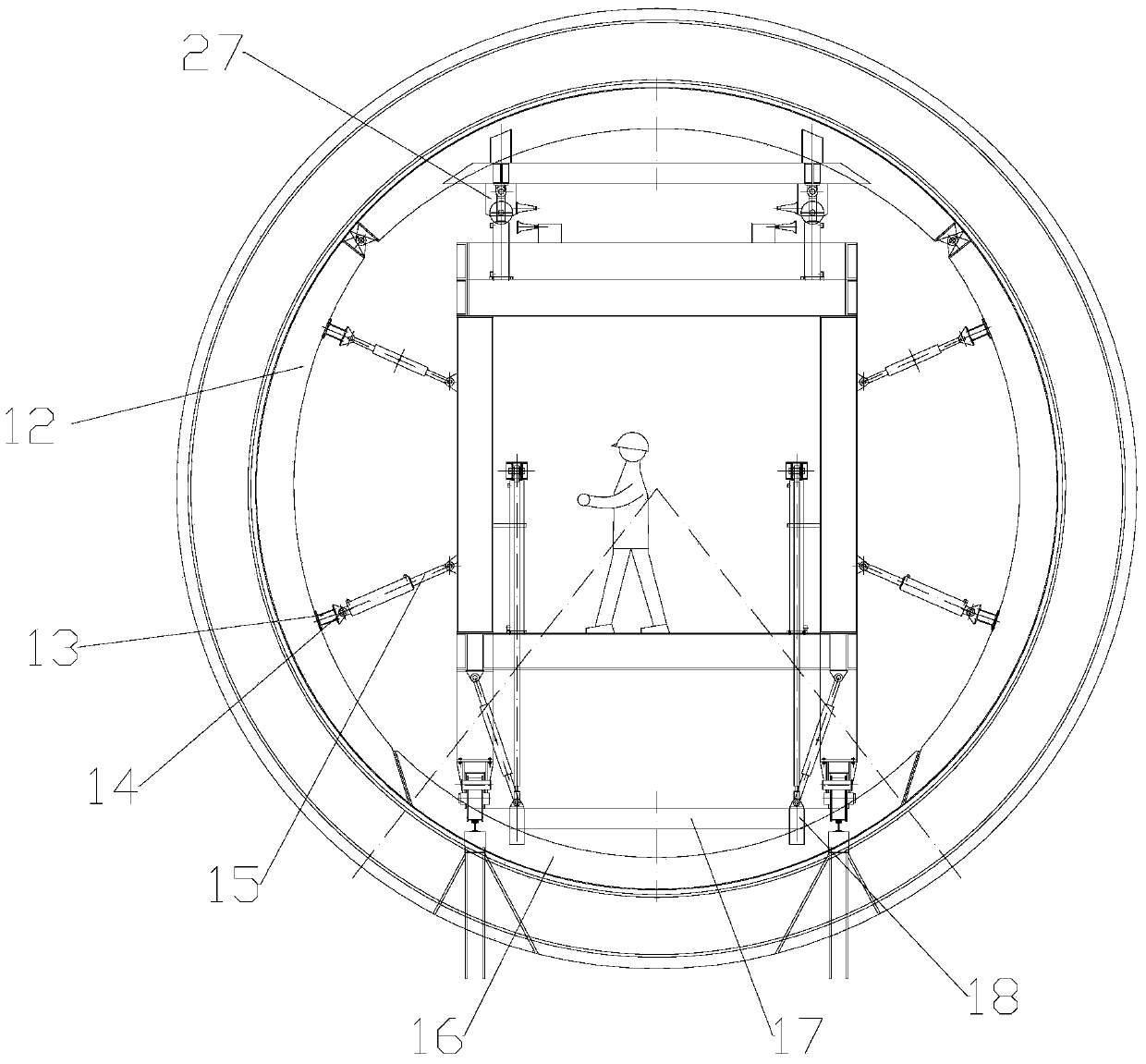

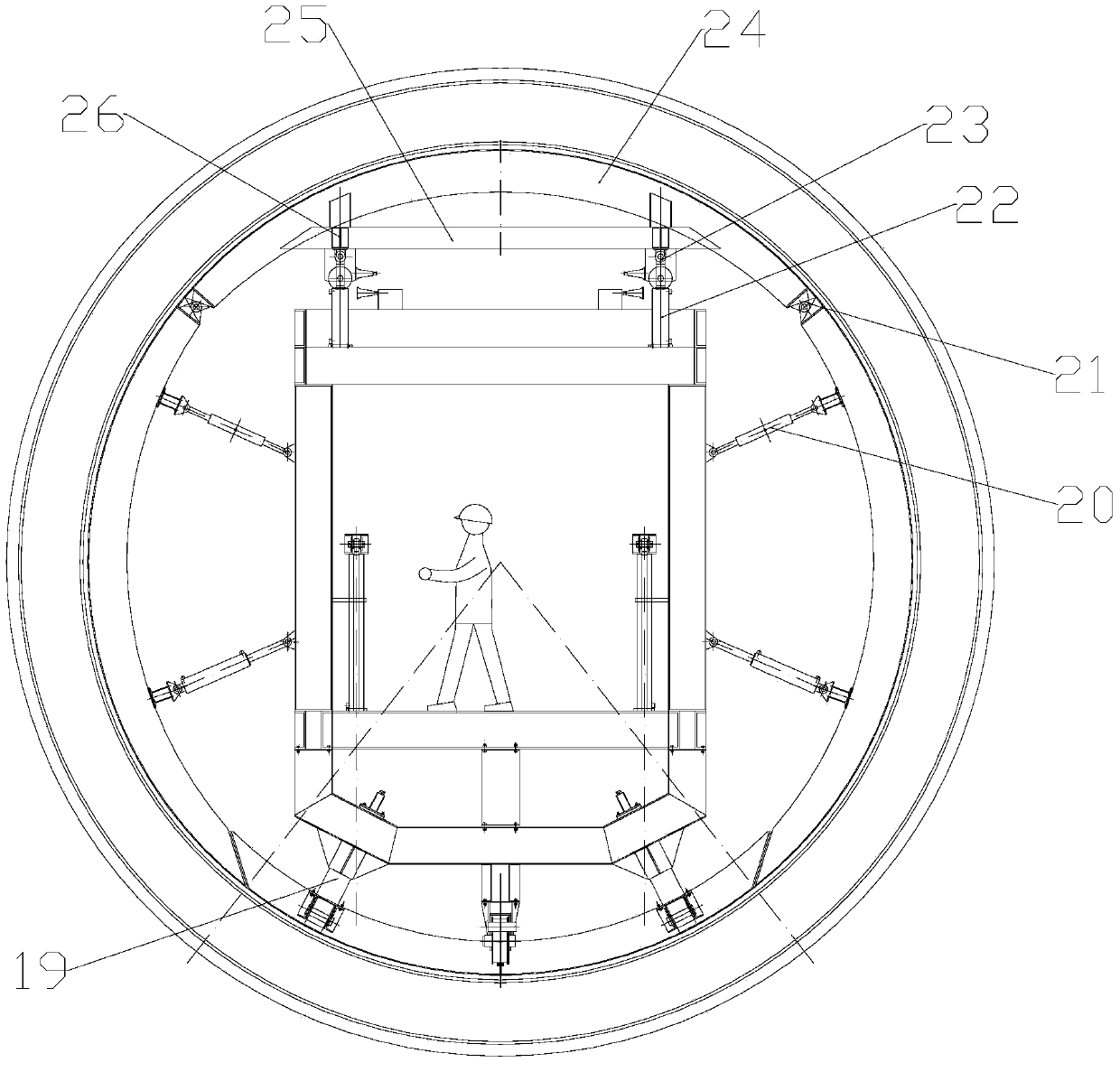

ActiveCN103437782AFlexible removal locationEasy to moveUnderground chambersTunnel liningHydraulic controlMaterials science

The invention relates to a hydraulic self-moving steel mould trolley and a construction method of the hydraulic self-moving steel mould trolley. The hydraulic self-moving steel mould trolley is used for full-section circular tunnel concrete lining construction. The hydraulic self-moving steel mould trolley comprises a trolley moving device, a trolley structural frame, a steel structure combination formwork and a hydraulic control device, the trolley structural frame is arranged on the trolley moving device, the trolley structural frame is movably connected with the trolley moving device, the steel structure combination formwork is arranged in the trolley structural frame, the steel structure combination formwork is hinged to the trolley structural frame, and the hydraulic control device is used for controlling the hydraulic self-moving type steel mould trolley. The hydraulic self-moving steel mould trolley is simple in structure, convenient to install, strong in adaptability and capable of carrying out demoulding on concrete at the bottom of the tunnel at first and repairing concrete construction defects in time.

Owner:CHINA THREE GORGES CORPORATION +1

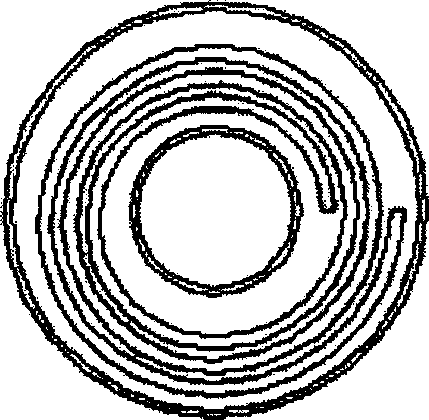

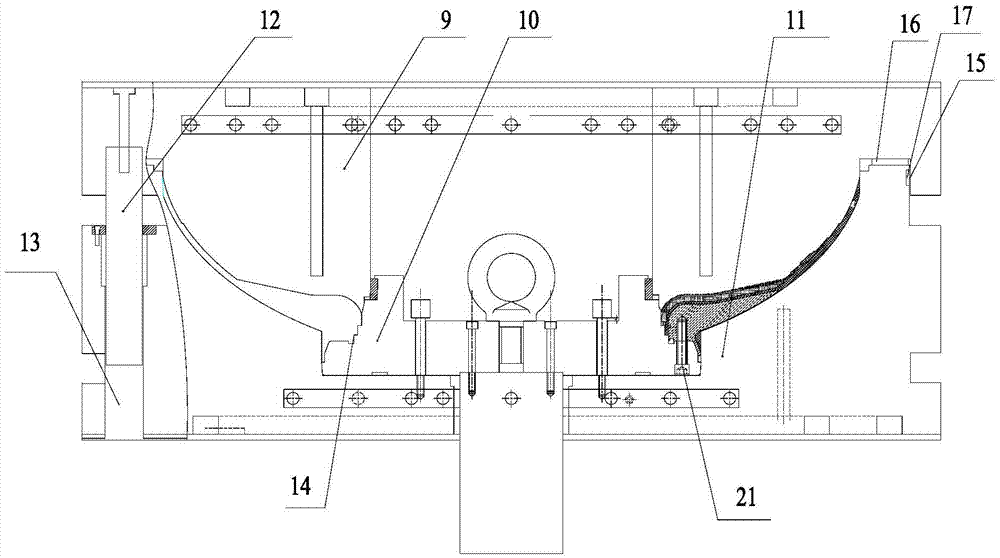

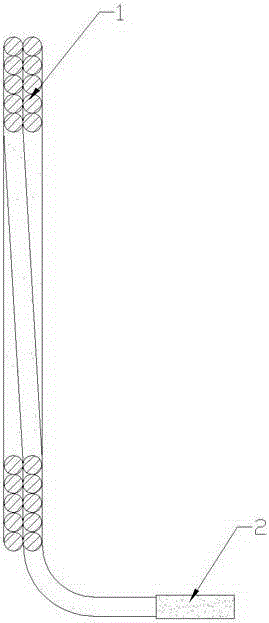

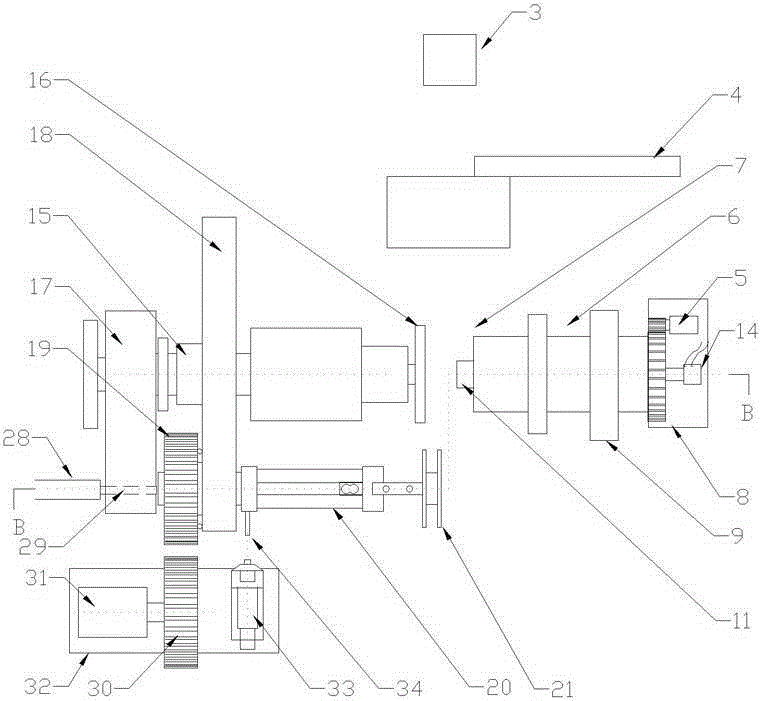

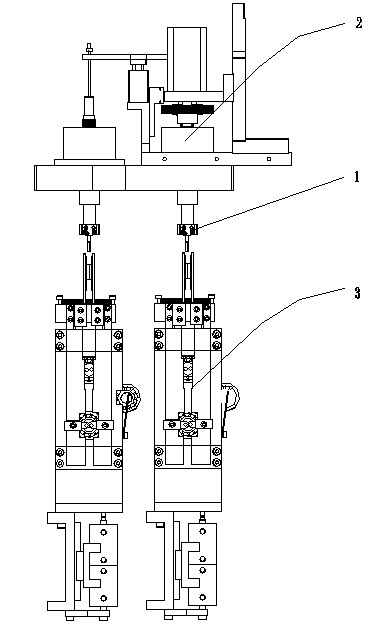

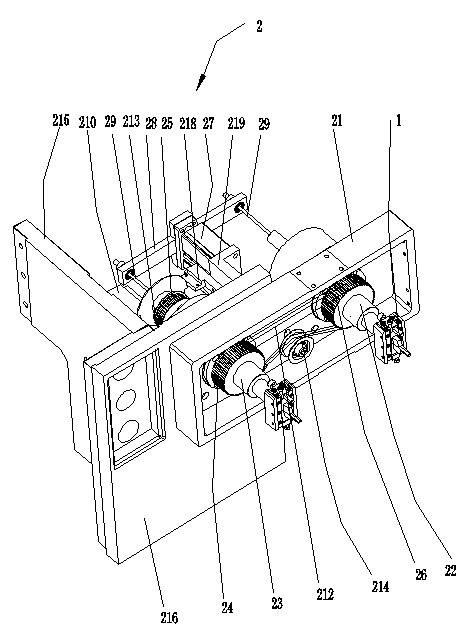

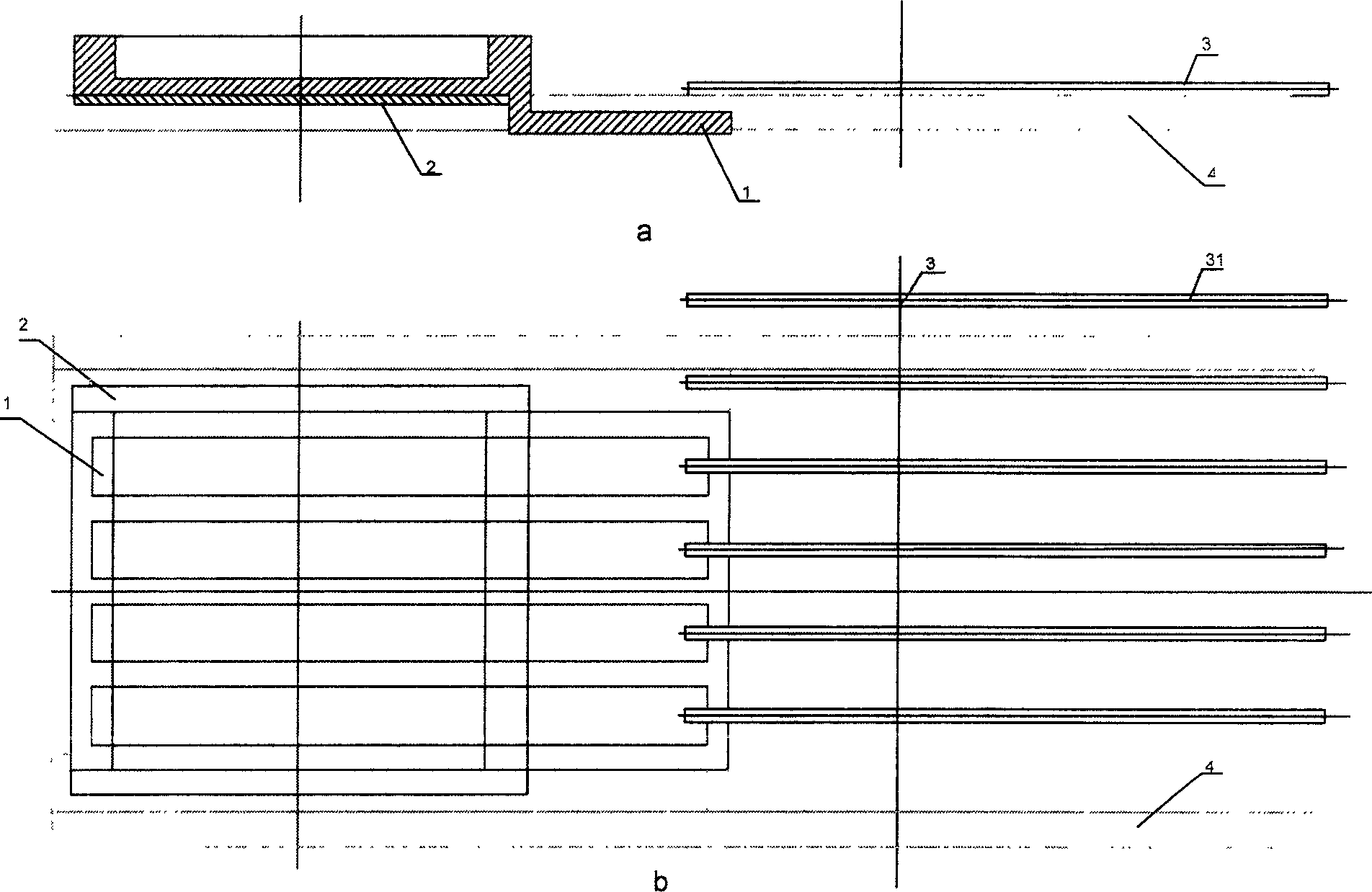

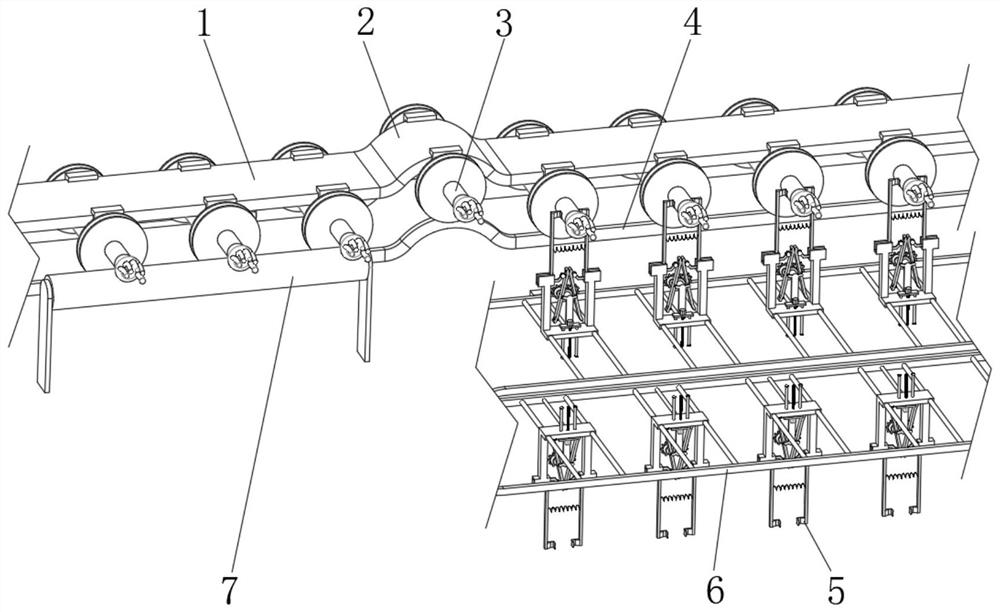

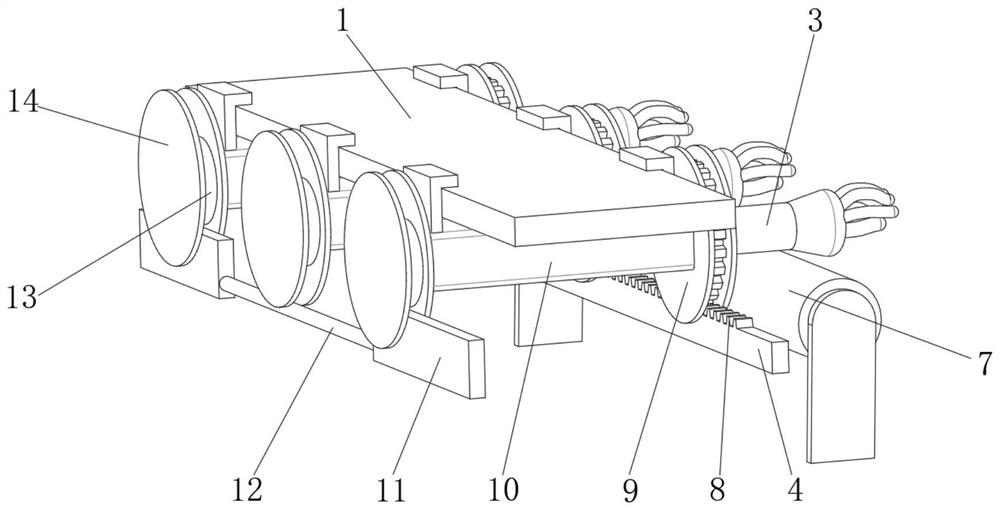

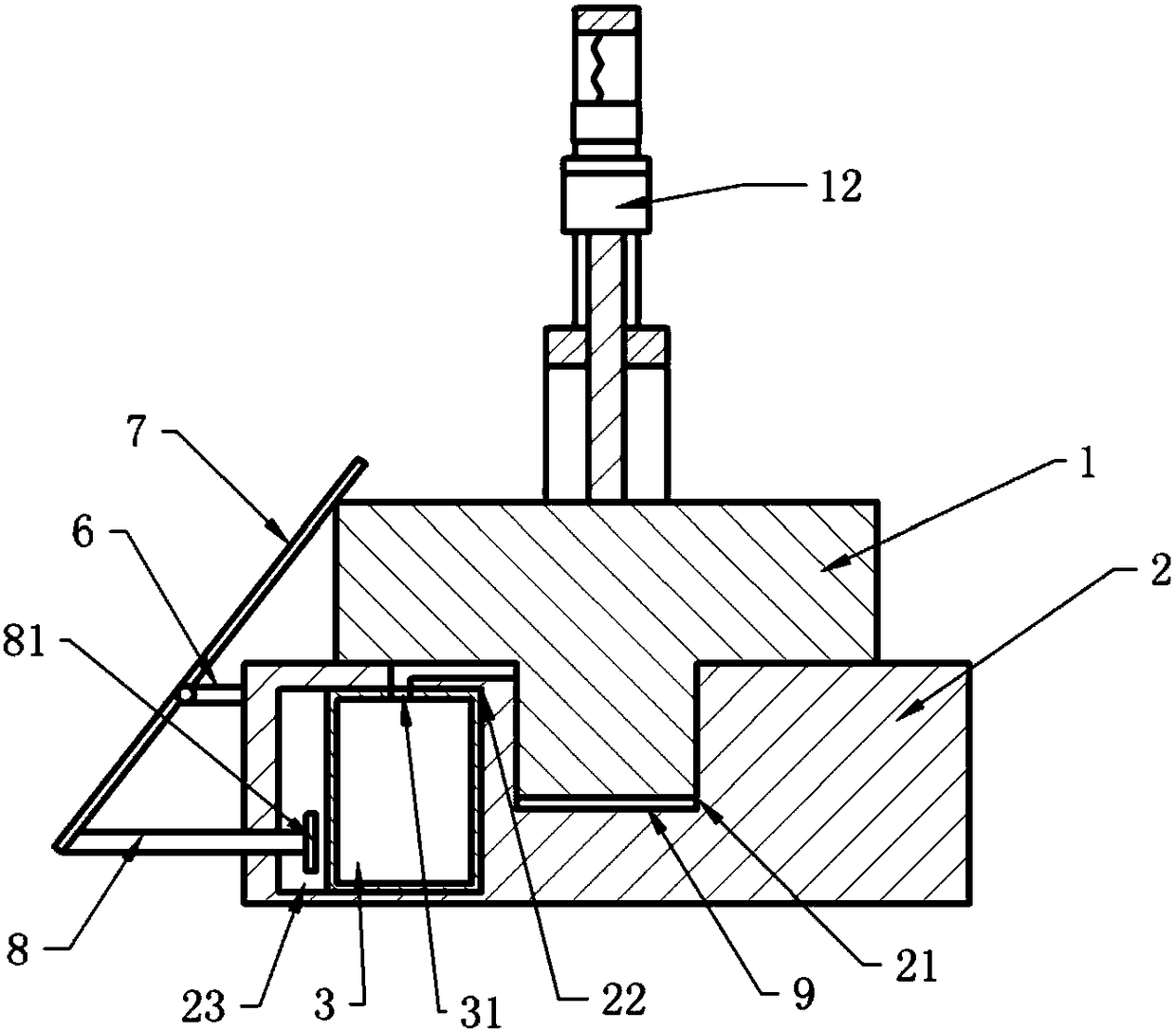

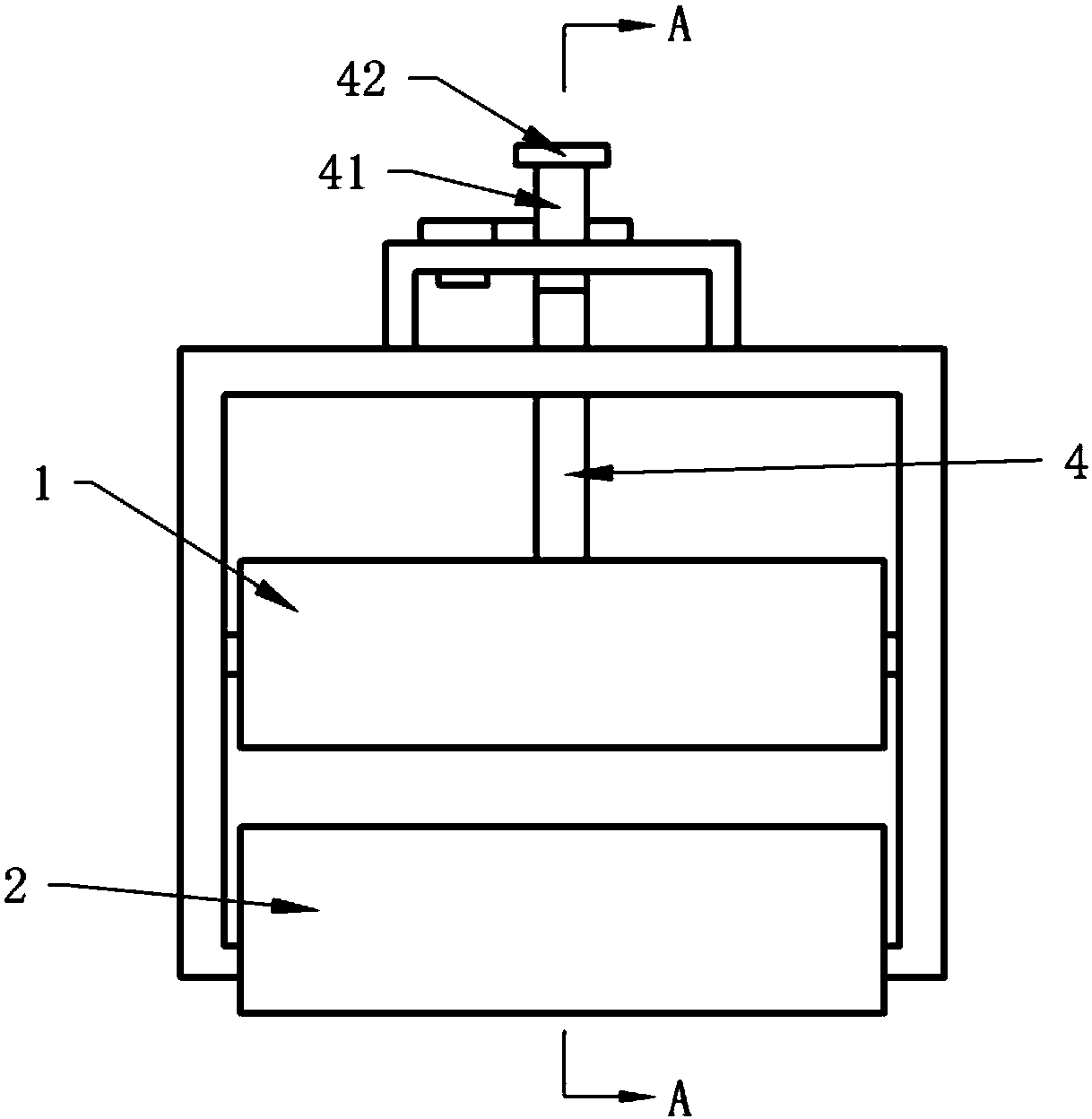

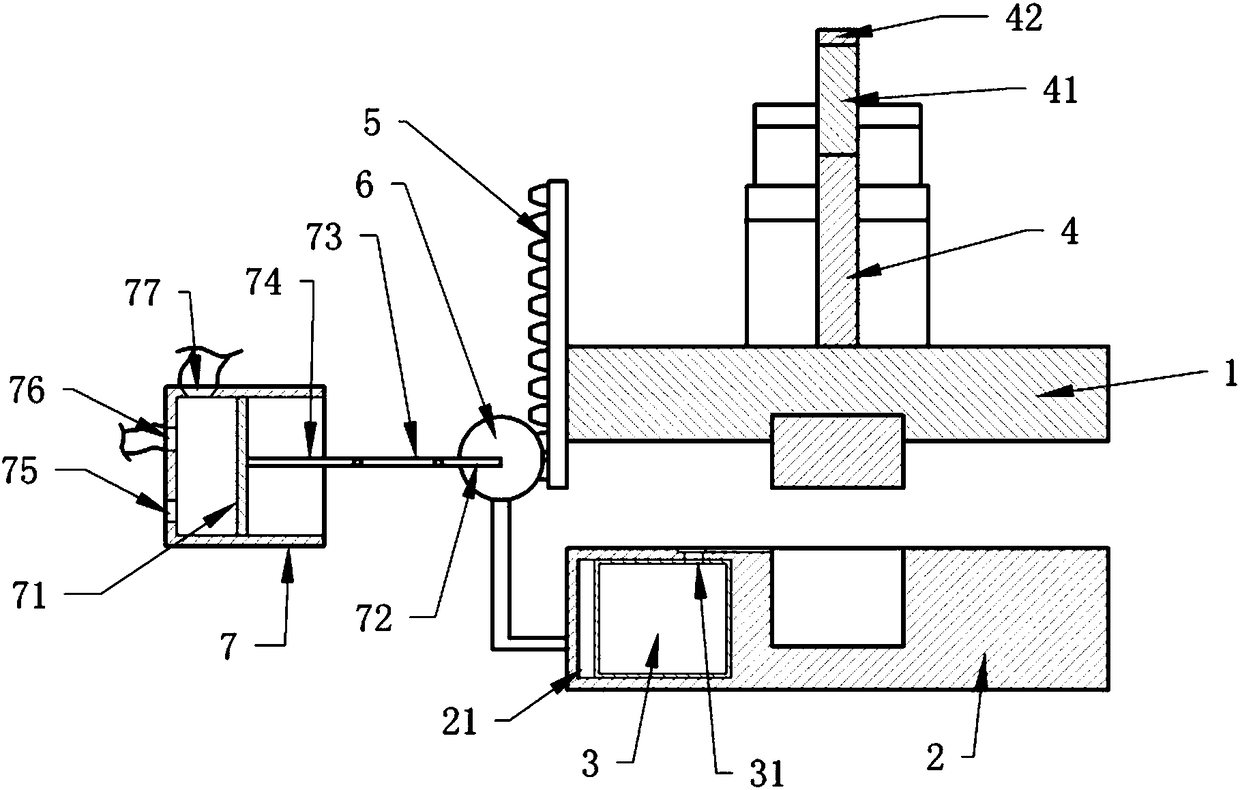

Double-outer-lead-terminal coil winding machine and winding process

ActiveCN105225829ARealize the winding processAchieve demouldingCoils manufactureWinding machineRotational axis

The invention relates to a double-outer-lead-terminal coil winding machine and a winding process. The winding machine structurally comprises a coil sorting component, a mechanical arm component, a left rotating and winding component, a right rotating and winding component, a clutch drive component, a machine base and a program controller. The left rotating and winding component and the right rotating and winding component are arranged on a base, and rotating shaft components in the left rotating and winding component and the right rotating and winding component are coaxially and oppositely arranged; the left rotating shaft of the left rotating and winding assembly is further fixedly provided with a rectangular rotation block provided with a pre-wind-up component. The winding process of the double-outer-lead-terminal coil winding machine includes the steps of system resetting, coil feeding, pre-winding-up, winding and demoulding. By means of the double-outer-lead-terminal coil winding machine and the winding process, double-outer-lead-terminal coils can be machined and produced conveniently and rapidly, and production efficiency is high.

Owner:资兴市弘电电子科技有限公司

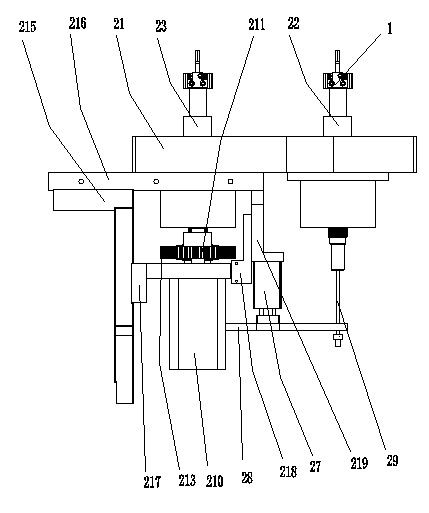

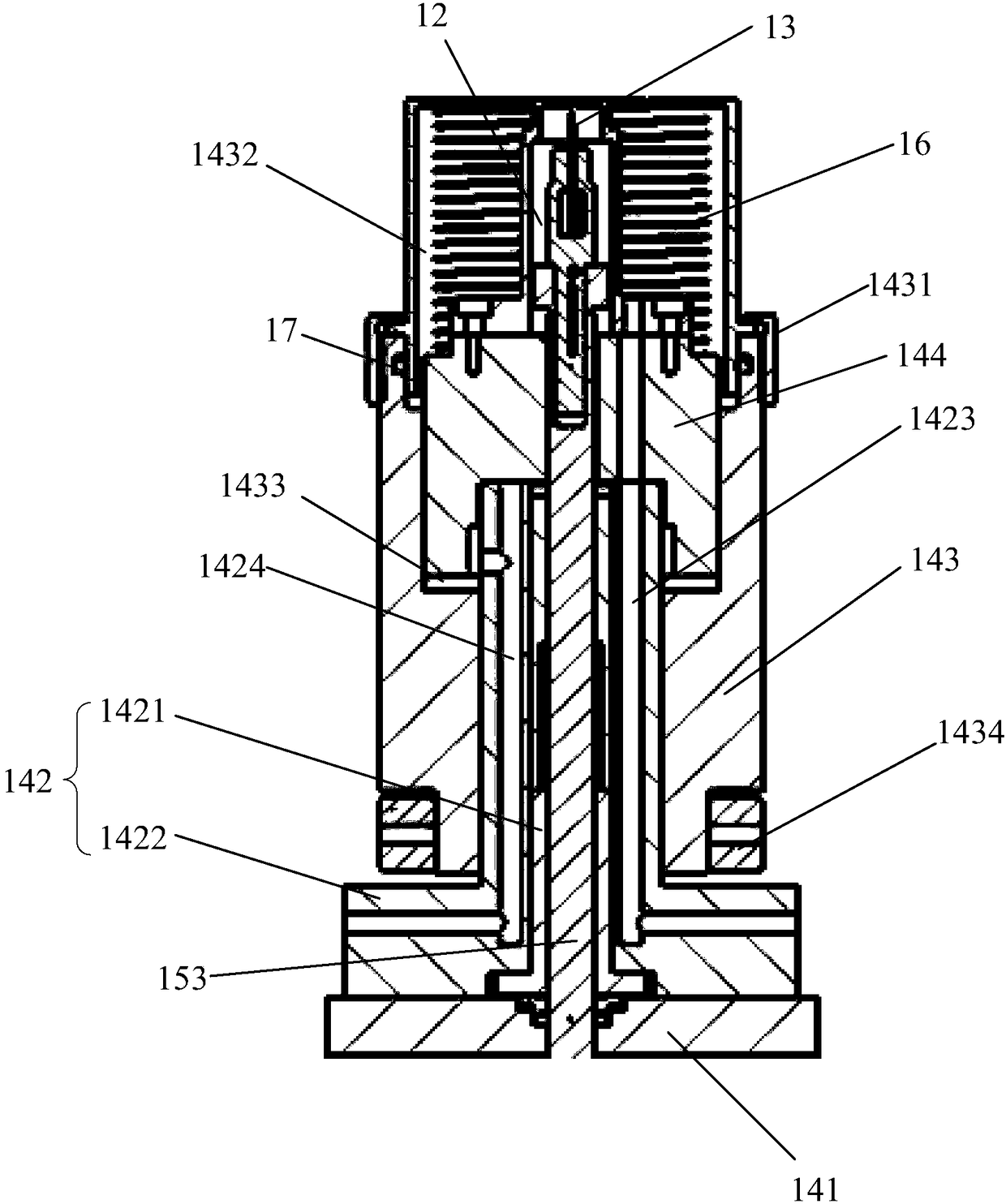

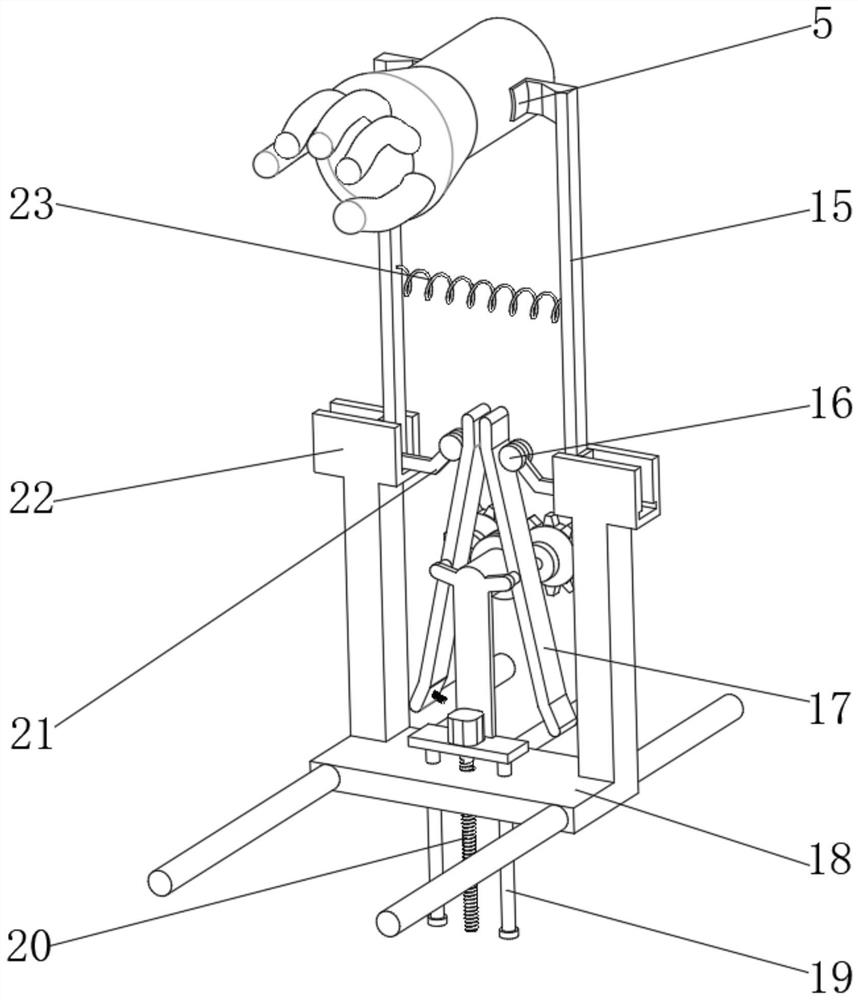

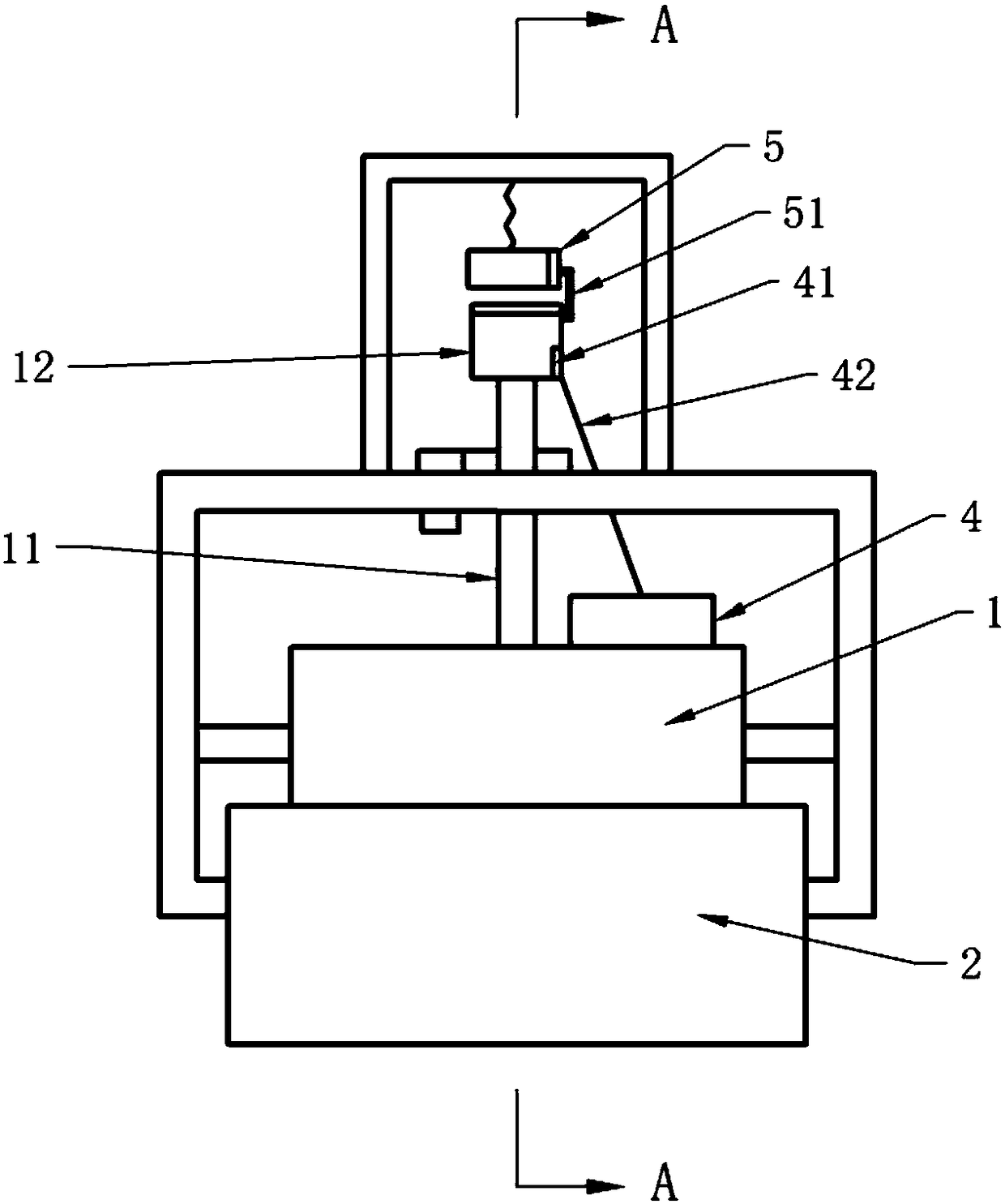

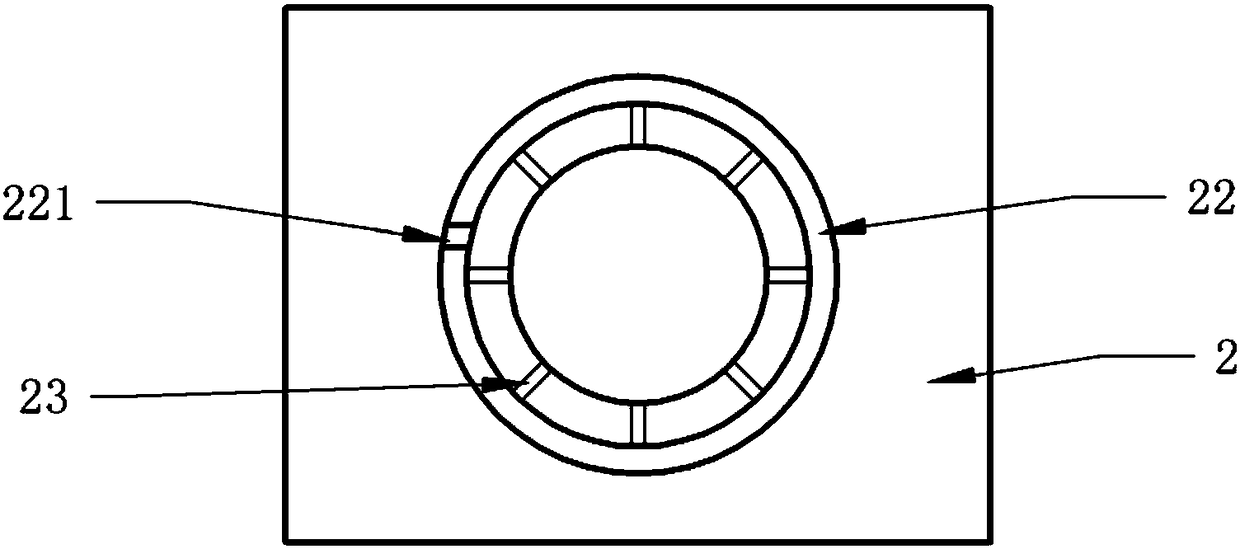

Winding system of winding machine

InactiveCN101917097ASolution to short lifeReliable and smooth windingManufacturing dynamo-electric machinesWinding machineWind system

The invention discloses a winding system of a winding machine, which comprises a stand, demolding mechanisms, a demolding power mechanism and coil twisting mechanisms, wherein the demolding mechanisms and the coil twisting mechanism are both fixed on the stand; the front parts of a first winding mold fixture main shaft and a second winding mold fixture main shaft are respectively and fixedly provided with the demolding mechanisms with uniform structure; and the coil twisting mechanisms with uniform structure are respectively arranged in front of winding molds adjacent to the demolding mechanisms. The reliable and smooth winding, demolding and twisting of coils of a micromotor can be realized by reasonably installing and designing the demolding mechanisms, the demolding power mechanism and the coil twisting mechanisms, so that the automation of winding, demolding and twisting is realized. Thus, the production efficiency is greatly improved, the uniformity of products can be improved, and stale and reliable coil sheets can be provided for the subsequent rounding process. The coil demolding mechanisms, the demolding power mechanism and the coil twisting mechanisms are stable and reliable and have the advantages of long service life and high precision.

Owner:CHONGQING KNVAN ELECTRONICS

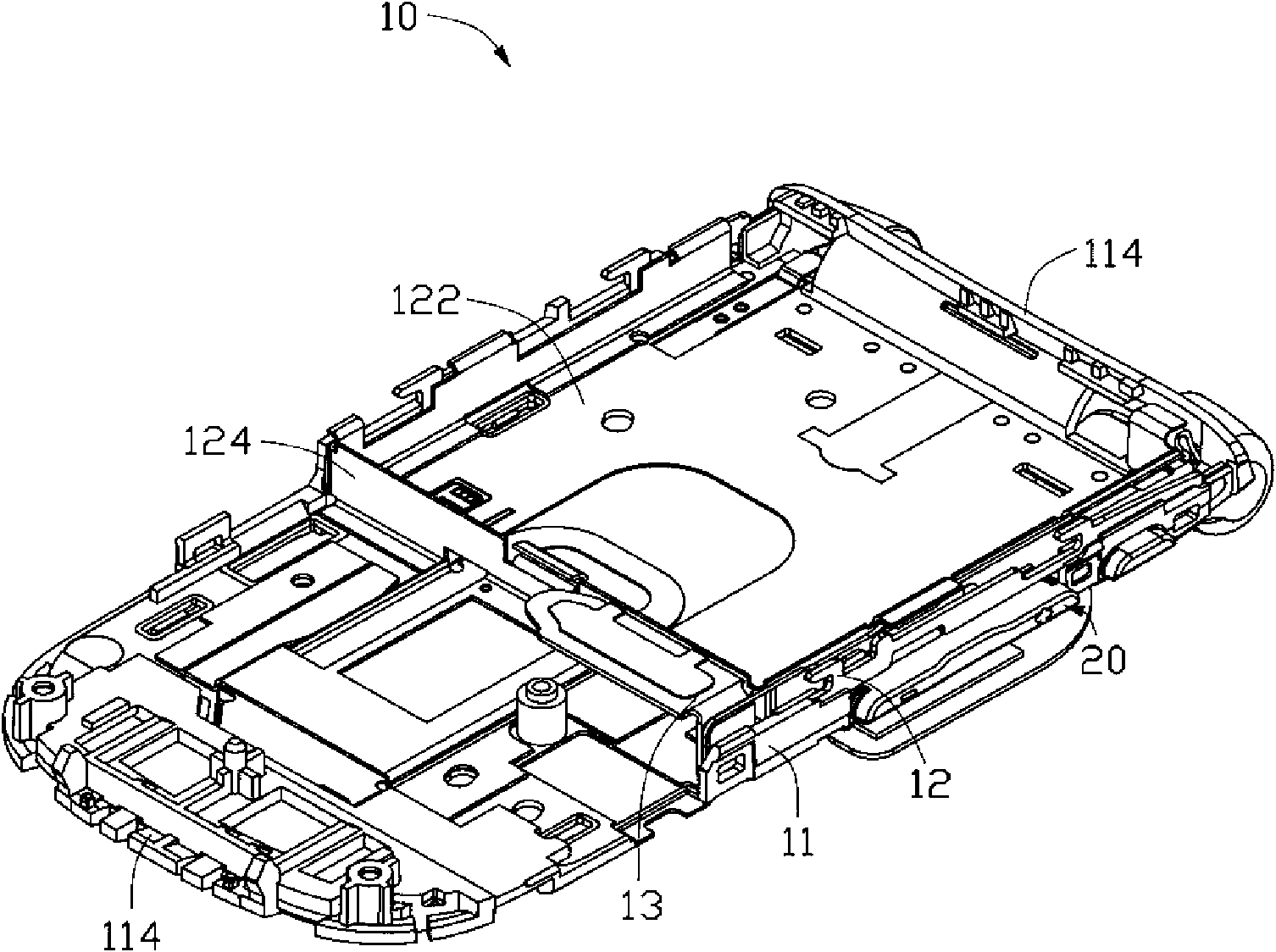

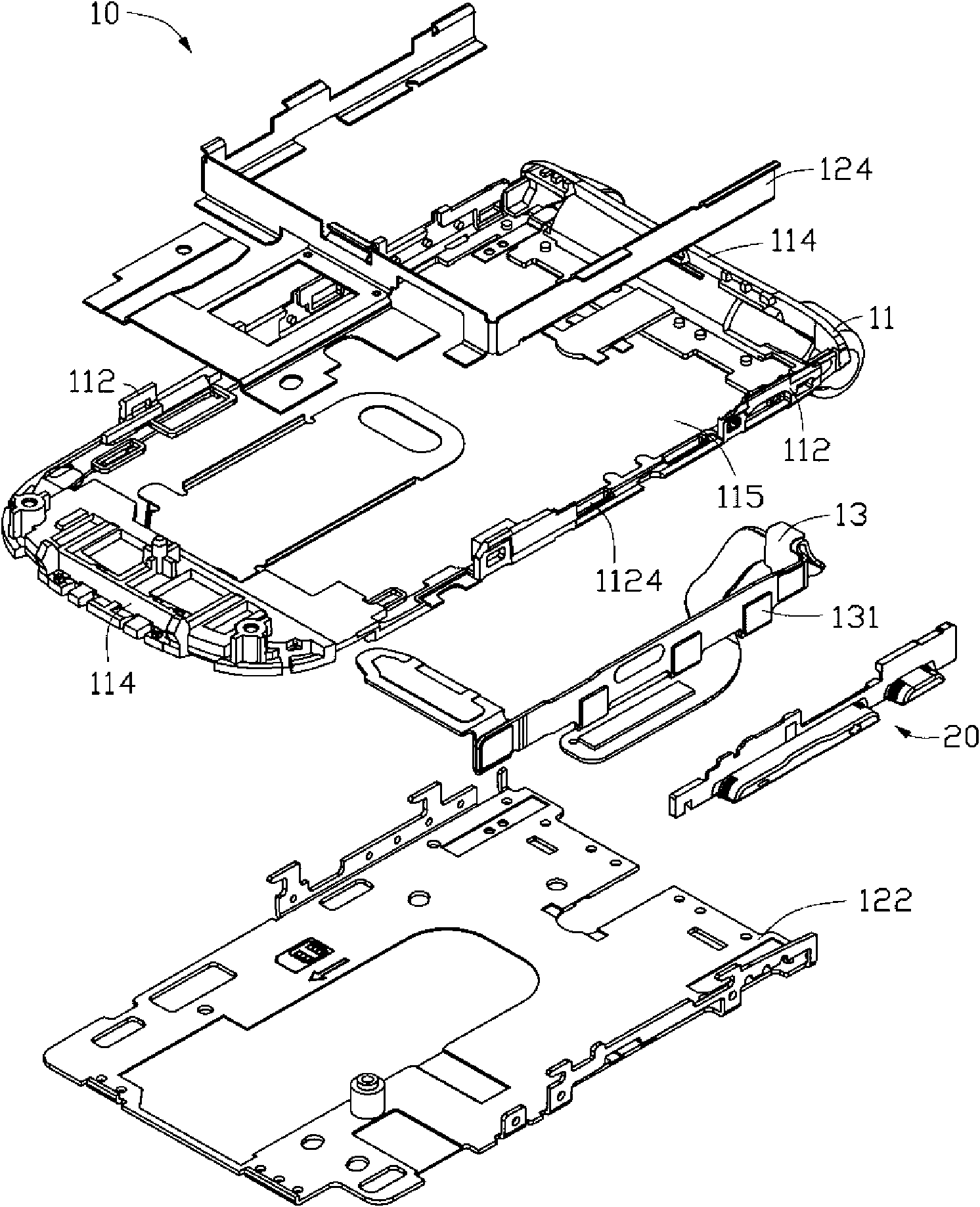

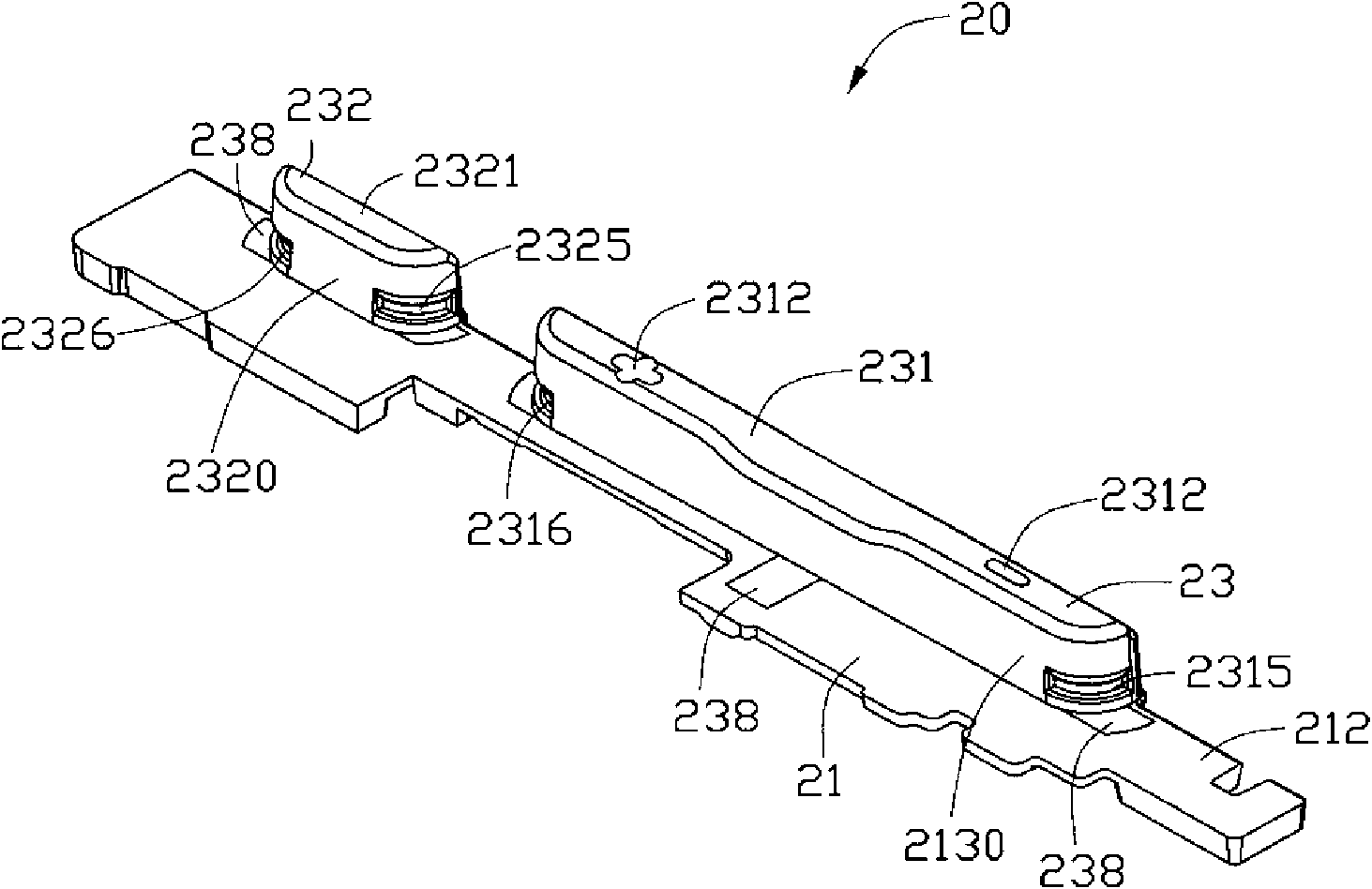

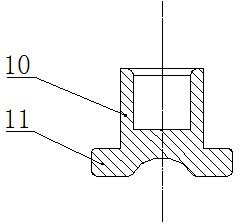

Side key and electronic device applying same

InactiveCN101859659AEase of ejectionAvoid damageEmergency actuatorsEmergency casingsPrinted circuit boardEngineering

The invention discloses a side key, which is used for an electronic device of a printed circuit board with a shell or arranged inside a shell. The side key comprises a support and a key body which are molded by double-material injection. The support is connected with the shell of the electronic device, a contact used for triggering the printed circuit board of the electronic device is formed on the support, and the contact and the support are respectively formed on two opposite sides of the support. A groove used for the ejection of the side key during double material injection molding is formed on the surface of the side key, which is connected with the support. The groove enables the molded side key to be ejected out of an injection mold conveniently, thereby improving molding yield, avoiding the damage to the mold if that the side key is kept in the injection mold, and prolonging the service life of the mold. The invention also provides an electronic device applying the side key.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Hollow brick manufacturing device

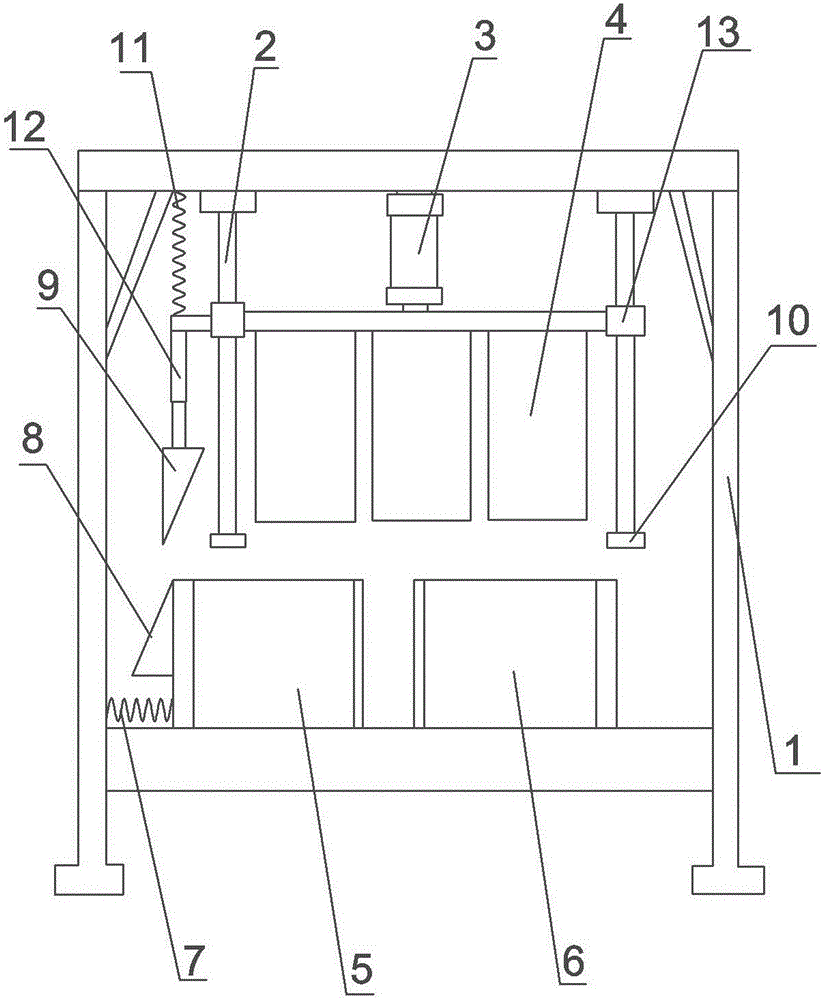

InactiveCN105666644AAvoid weakening or even crackingEasy to operateMouldsMould auxillary partsEngineeringMechanical engineering

This patent application discloses a hollow brick manufacturing device, which includes a frame, a lifting mechanism and a mold structure. The lifting mechanism includes a cylinder, a forming block, two sliding rods and two sliding sleeves; The rods are respectively located on both sides of the cylinder and one end of each sliding rod is statically connected to the upper end of the frame; the two sliding sleeves are respectively slidingly connected to the two sliding rods; the forming block is statically connected to the output end of the cylinder; the two ends of the forming block of the cylinder are connected to the sliding The sleeve is statically connected; a sliding sleeve is connected with a first wedge; the mold mechanism includes a slide seat, a first spring, a first mold cavity and a second mold cavity; the slide seat is located at the lower part of the frame, and the first mold cavity and the second mold cavity The second mold cavities are all located on the sliding seat, and the second mold cavity is slidably connected with the sliding seat. The second mold cavity is provided with a second wedge matched with the first wedge; one end of the first spring is connected to the second spring. The mold cavity is connected, and the other end is connected with the frame. This patent application can avoid causing the brick body to break when the hollow brick is manufactured.

Owner:重庆市合川区狮滩矸砖厂

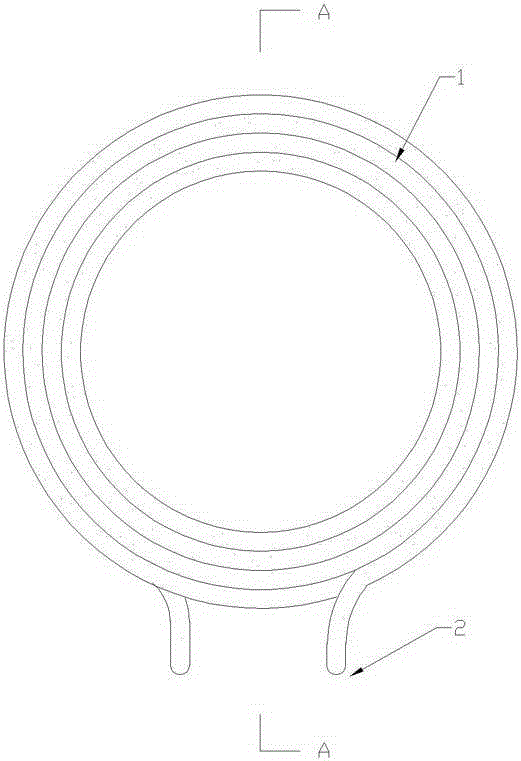

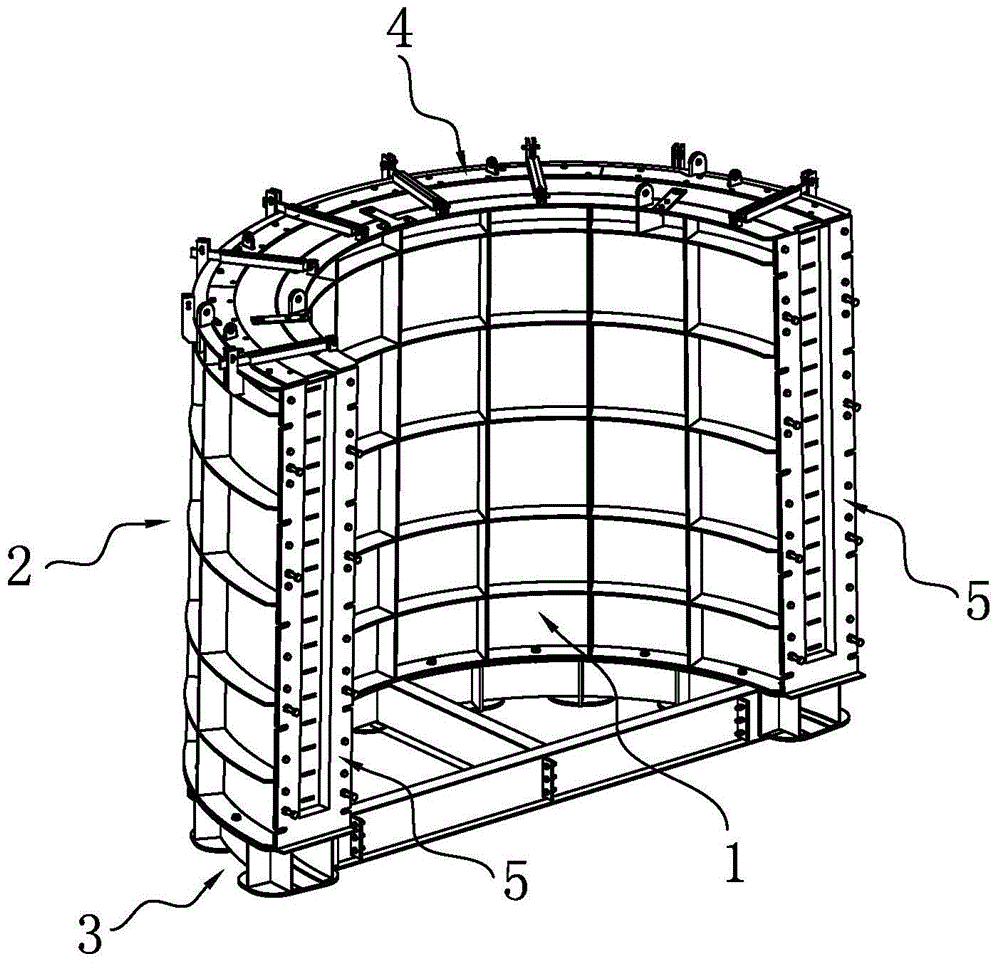

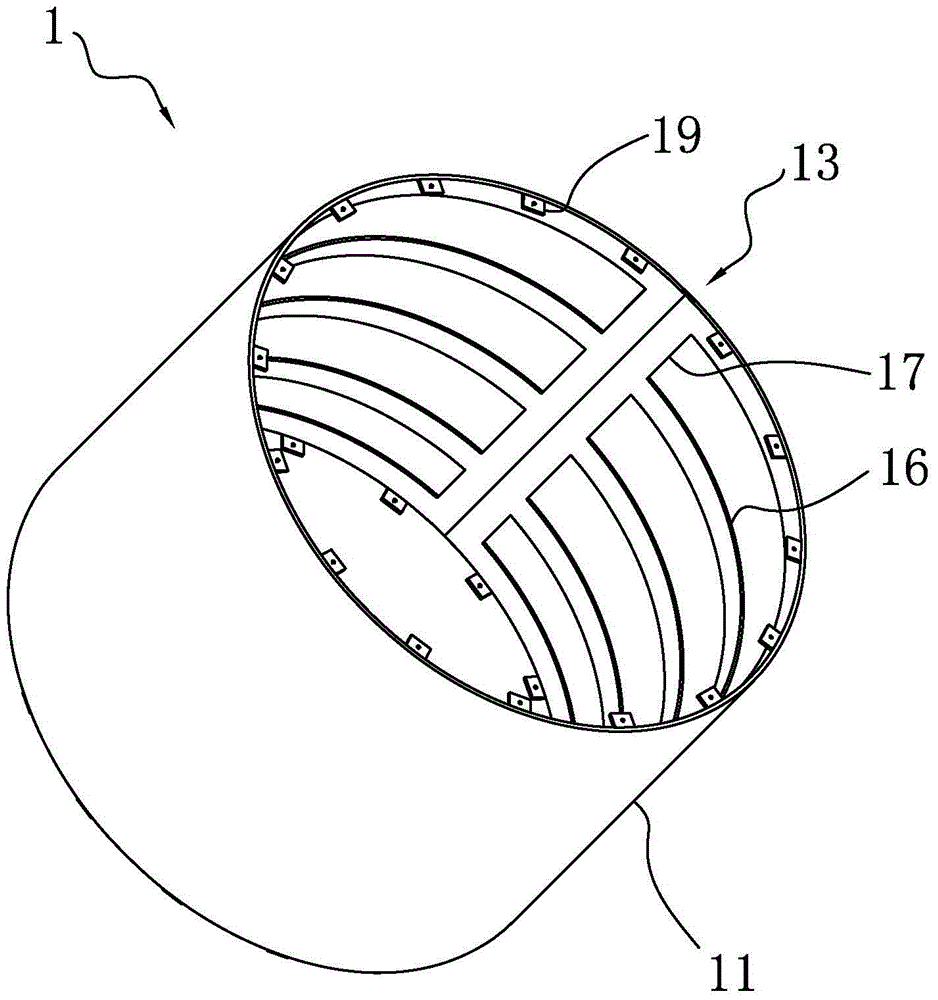

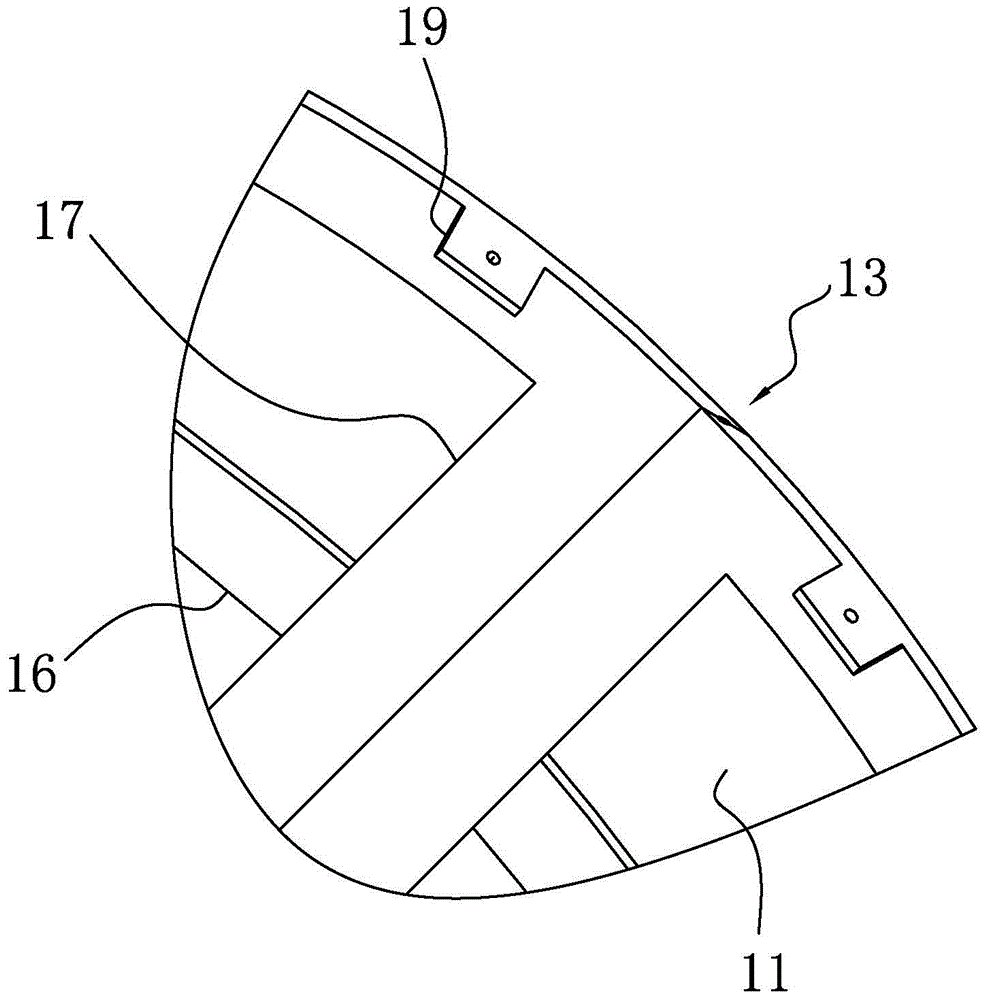

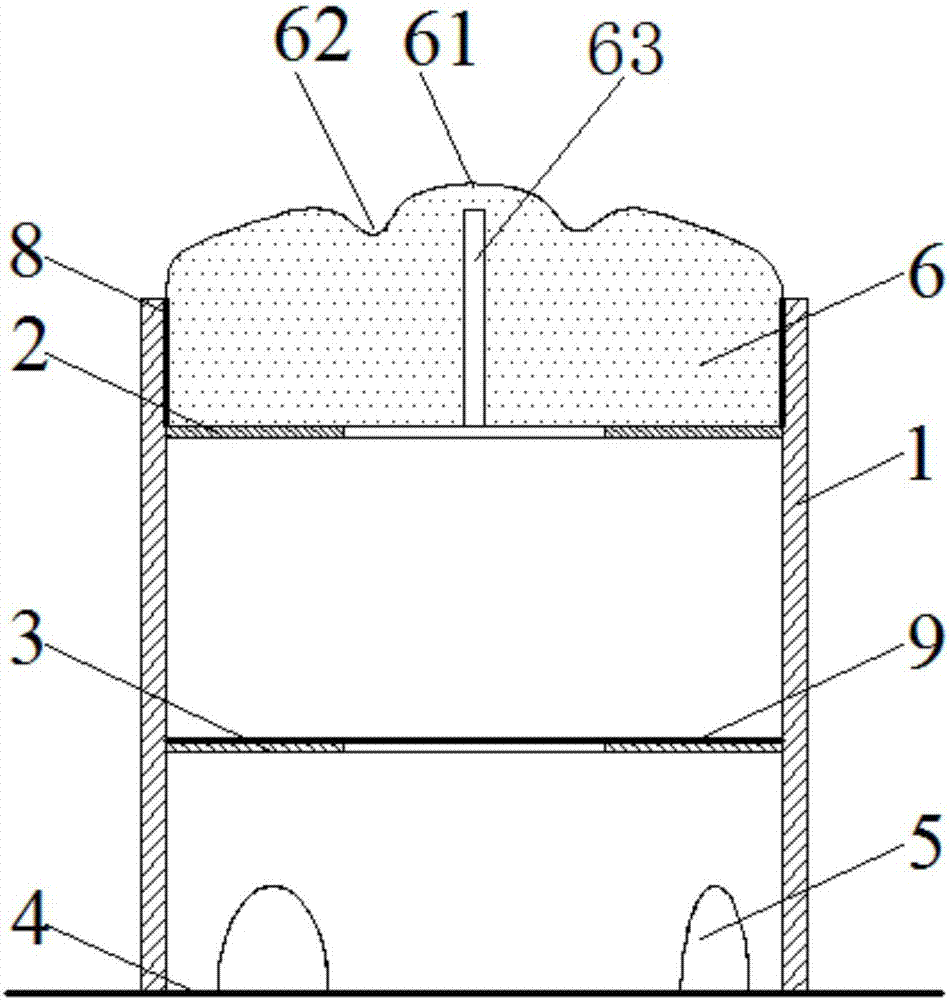

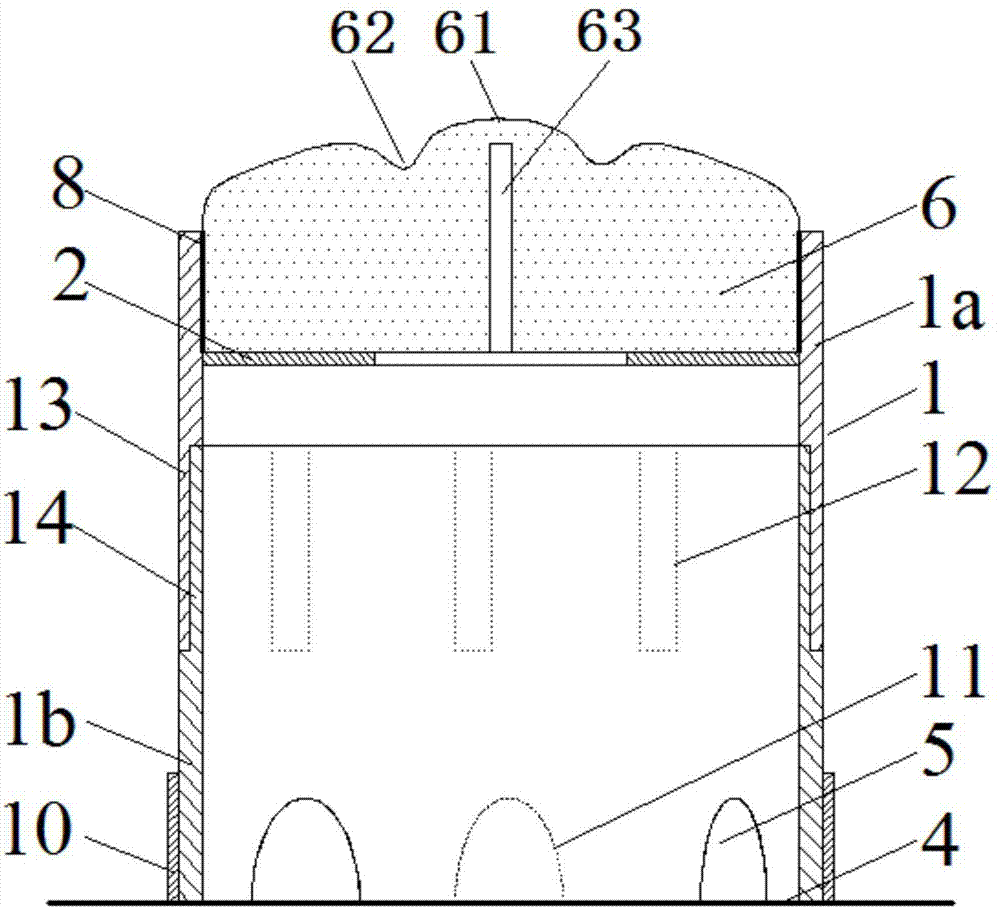

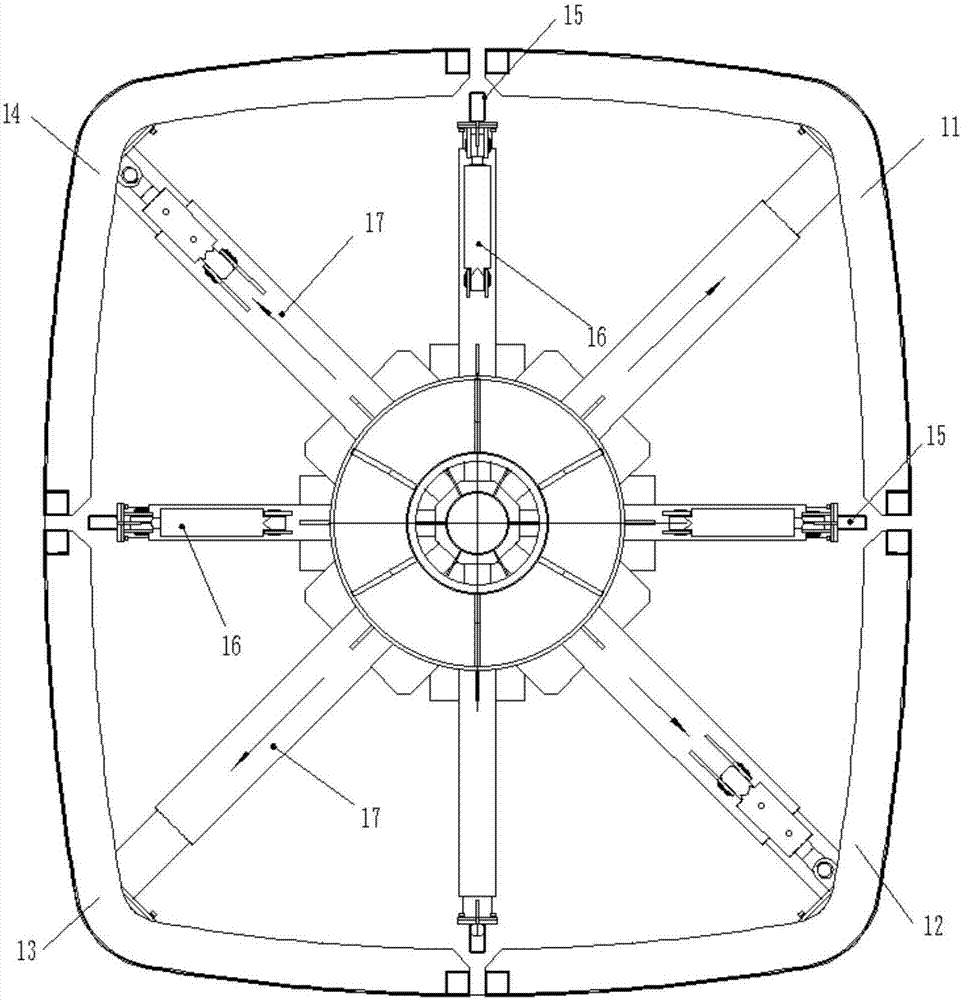

Internal mould, demoulding method thereof, mould for prefabricated concrete tower sections and production method

The invention provides an internal mould, a demoulding method thereof, a mould for prefabricated concrete tower sections and a production method. The internal mould provided by the invention comprises an internal formwork, both ends of the internal formwork are connected, so that the internal formwork is curved into the shape of a barrel, both ends of the internal formwork are provided with slopes, and the slopes of both ends of the internal formwork are matched with each other and form a demoulding opening. The demoulding method of the internal mould provided by the invention includes the following step: one end, which is located inside the demoulding opening, of the internal formwork is moved simultaneously along the radial direction and tangent direction of the internal mould to get close to the center of the internal mould and extend into the space in the internal formwork. The internal mould provided by the invention can be used for casting a whole ring, the overall elastic deformation of the internal formwork can be conveniently utilized to implement the demoulding and restoration of the internal mould, and a great deal of welding work can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

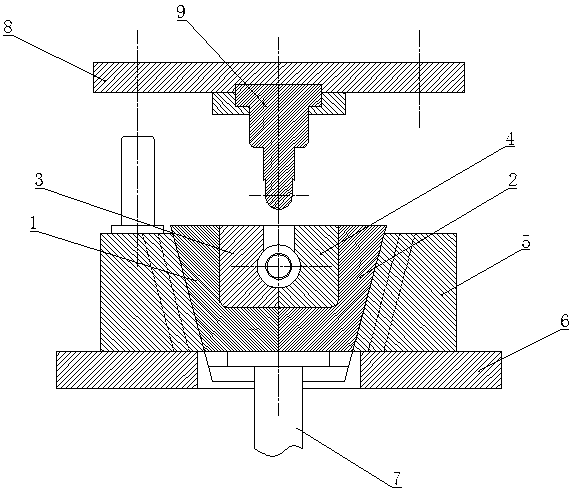

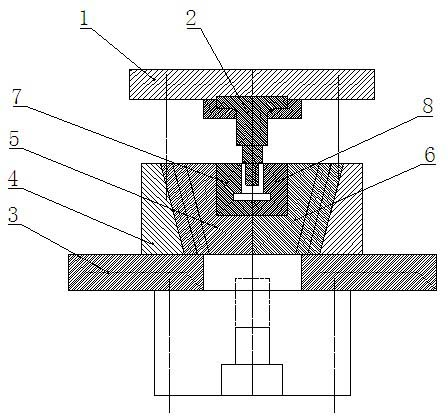

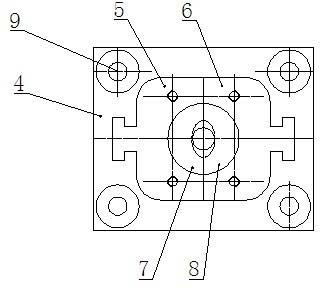

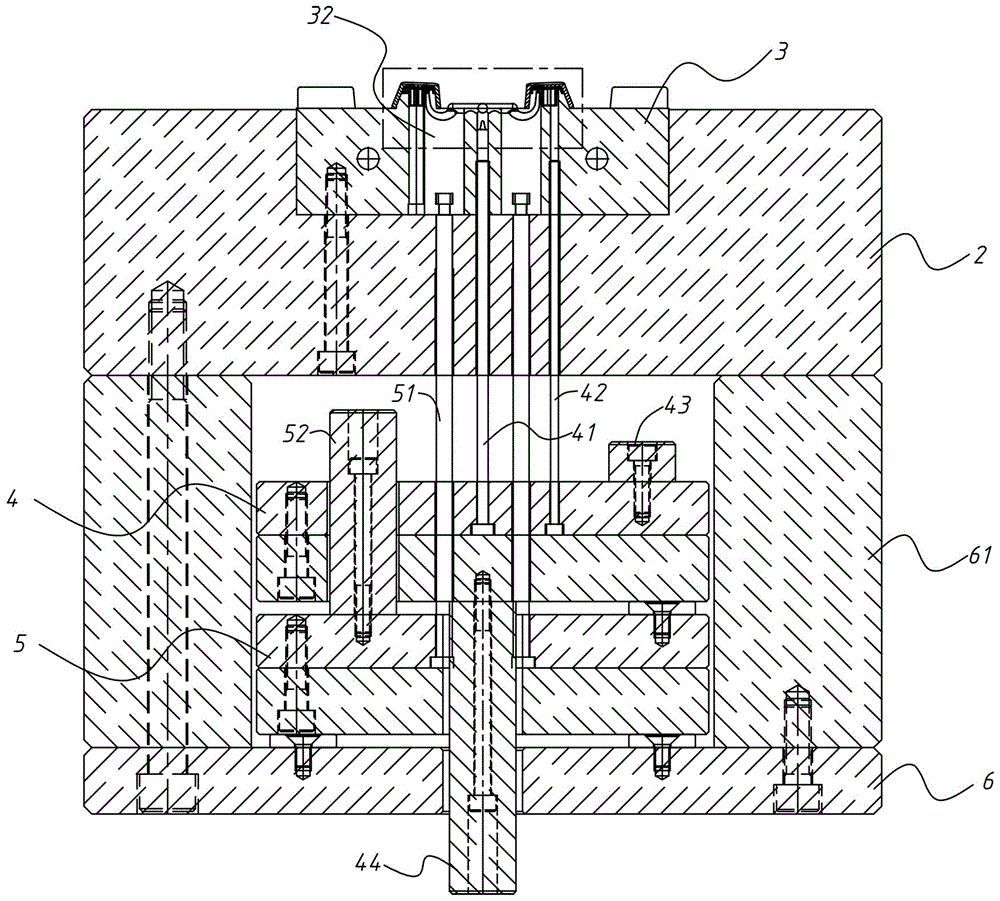

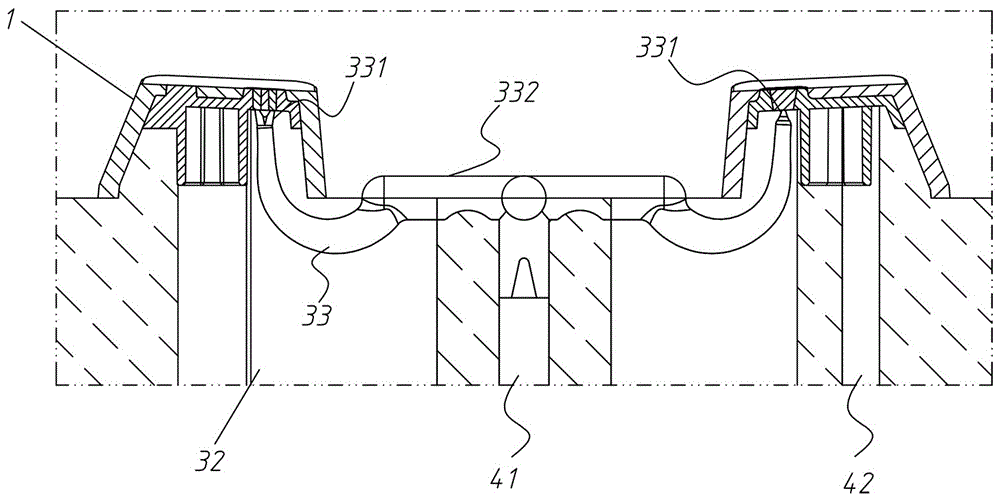

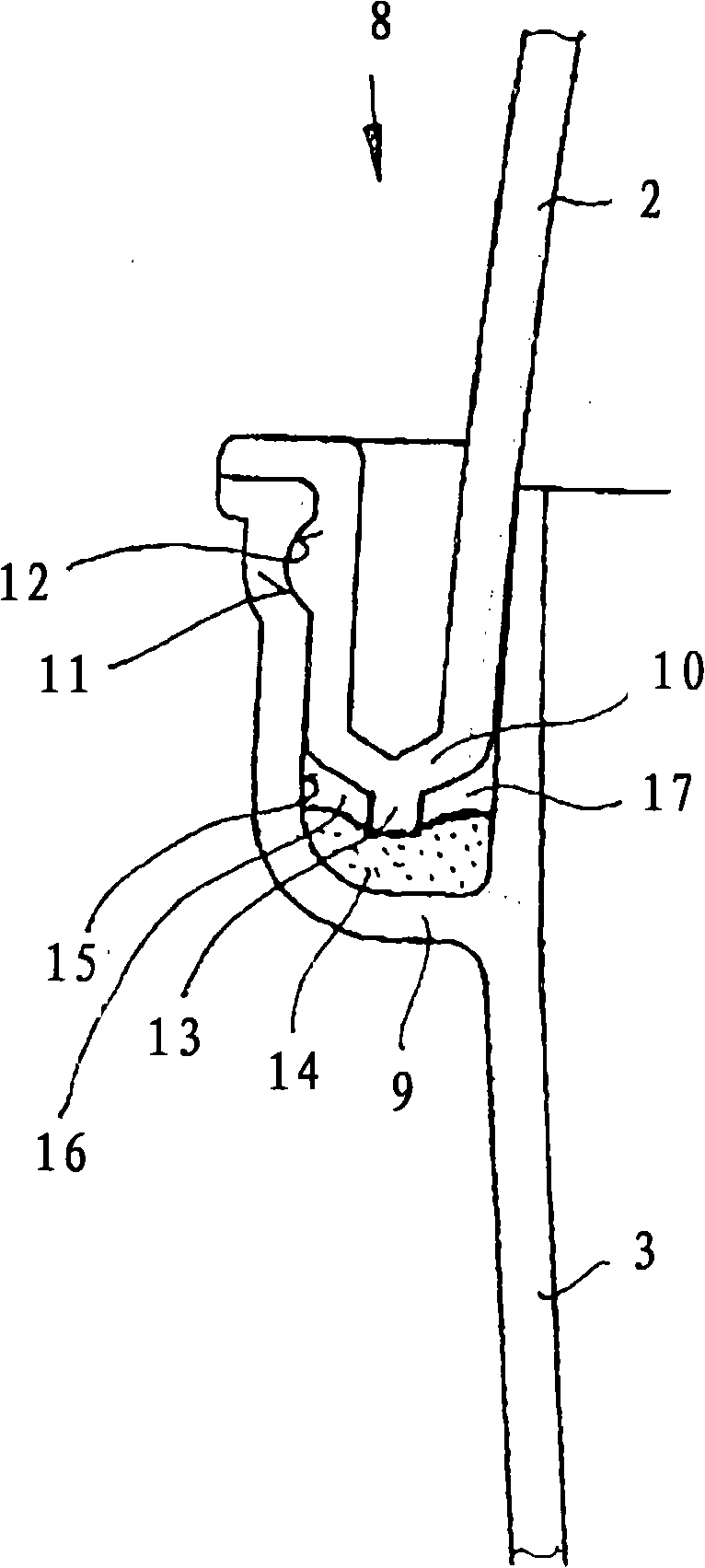

Forging and moulding die for composite insulator ball socket fitting

ActiveCN102989968AReduce scrap rateAchieve demouldingForging/hammering/pressing machinesEngineeringComposite insulators

The invention relates to a forging and moulding die for a composite insulator ball socket fitting. The forging and moulding die is characterized by comprising an upper die plate, a convex die, movable die holders, a fixed die holder, a lower die holder and a demoulding mandril, wherein the convex die is arranged on the upper die plate; a left die core and a right die core are respectively arranged on the left movable die holder and the right movable die holder, and the left die core and the right die core are assembled to form a cavity for accommodating the ball socket fitting; the fixed die holder is fixed on the lower die plate, an inner cavity is formed in the center of the fixed die holder, the left movable die holder and the right movable die holder are arranged in the inner cavity of the fixed die holder, and the left movable die holder and the right movable die holder are matched with the side wall of the inner cavity of the fixed die holder through a guide structure, wherein the upper end of the guide structure inclines outwards. In the compression process, a ball socket fitting blank is subjected to pre-forging and trimming and then put in the die cores, the convex die moves downwards, and a ball socket is subjected to once compression moulding in the die cores; in the demoulding process, a demoulding cylinder jacks upwards, the die cores move upwards along with the left movable die holder and the right movable die holder, so that the demoulding is realized; and the forging and moulding die is high in compression efficiency, and the manufactured ball socket fitting is low in rejection rate.

Owner:RUGAO DASHENG LINE EQUIP

Side wall concrete construction method employing side wall trolley

ActiveCN103556817AImprove problems with heavy burdensImprove stabilityForms/shuttering/falseworksCantilevered beamPipe fitting

The invention discloses a side wall concrete construction method employing a side wall trolley. The employed side wall trolley is formed by a side wall trolley unit or longitudinal splicing of a plurality of side wall trolley units, the side wall trolley unit comprises a trolley moving and fixing system and a steel moulding plate connecting and positioning system; the construction steps are the followings in sequence: paving a walking track, precoating a release agent, enabling the trolley to move and take place, adjusting a screw jack, repeatedly adjusting an extension-type cantilever beam and a hydraulic jack, adjusting a bearing jack, mounting a lateral screw rod jack, mounting a foot margin inhaul cable, mounting an anti-floating screw rod jack, mounting an opposite-support pipe fitting, mounting a closing-up net and a water stop steel plate, casting concrete, stripping and the like, that building a steel pipe support and a spliced template is not required can be achieved, after the adoption of the invention, the mounting and the demounting speeds are fast, three-direction accurate adjustment can be achieved, the construction is stable and reliable, the concrete surface flatness is good, and joint deviation is small.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

Chip stripping device

InactiveCN108133907AAchieve demouldingEven by forceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention provides a chip stripping device. The chip stripping device includes an absorption platform used for absorbing a blue film, wherein an absorption face of the absorption platform is provided with a plurality of absorption holes; a boss used for pre-demolding a chip and arranged in the absorption platform capable of moving upward and downward in a direction perpendicular to the absorption face so as to enable the boss to protrude from the absorption face or to be accommodated in the absorption platform; a jacking needle used for jacking the chip so as to stripping the blue film andarranged in the boss and capable of moving upward and downward in a direction perpendicular to the absorption face relative to the boss so as to enable the jacking needle to protrude from the boss orto be accommodated in the boss; a first lifting mechanism used for driving the absorption platform to move upward and downward and connected with the absorption platform; and a second lifting mechanism used for driving the jacking needle to move upward and downward and connected with the jacking needle. In this way, the chip can be stripped gradually and chip failure can be avoided effectively.

Owner:CETC BEIJING ELECTRONICS EQUIP

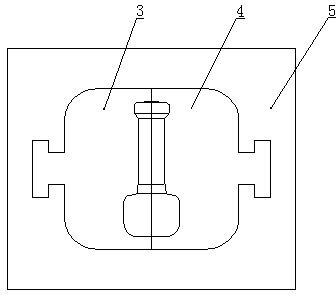

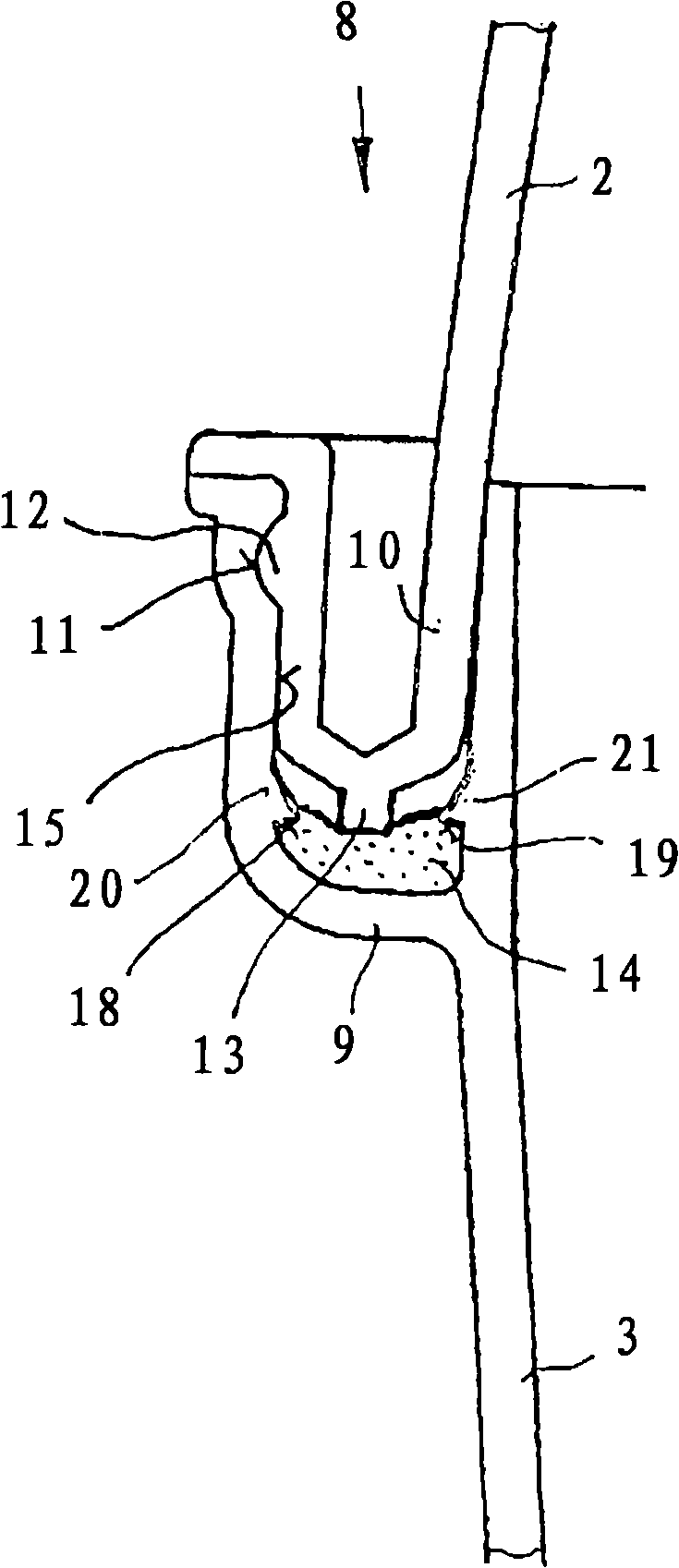

One-time forming mold for steel cap of pin type insulator

InactiveCN102284619AAchieve demouldingGood punching effectShaping toolsEjection devicesEngineeringPin insulator

The invention relates to a one-time forming mold for a pin-type insulator steel cap, which includes an upper template and a lower template. The left mold and the right mold, the outside of the left mold and the right mold are provided with a T-shaped slider structure, the mold base is provided with a T-shaped guide groove that can fit the T-shaped slider, and the T-shaped guide groove is formed from the bottom of the mold base The outside extends obliquely upwards; the inner surfaces of the left mold and the right mold are respectively connected with a left mold core and a right mold core by bolts, and the combination of the left mold core and the right mold core forms a cavity of a pin-type insulator steel cap. Through the cooperation of the punch and the left and right mold cores, the pin-type insulator steel cap is punched and formed at one time, and the punching effect is good and the yield is high. When demoulding, the left and right molds are lifted by the demoulding cylinder below, so that the left and right molds are opened to both sides under the action of the T-shaped slider and the T-shaped guide groove, and the demoulding of the steel cap is realized.

Owner:RUGAO DASHENG LINE EQUIP

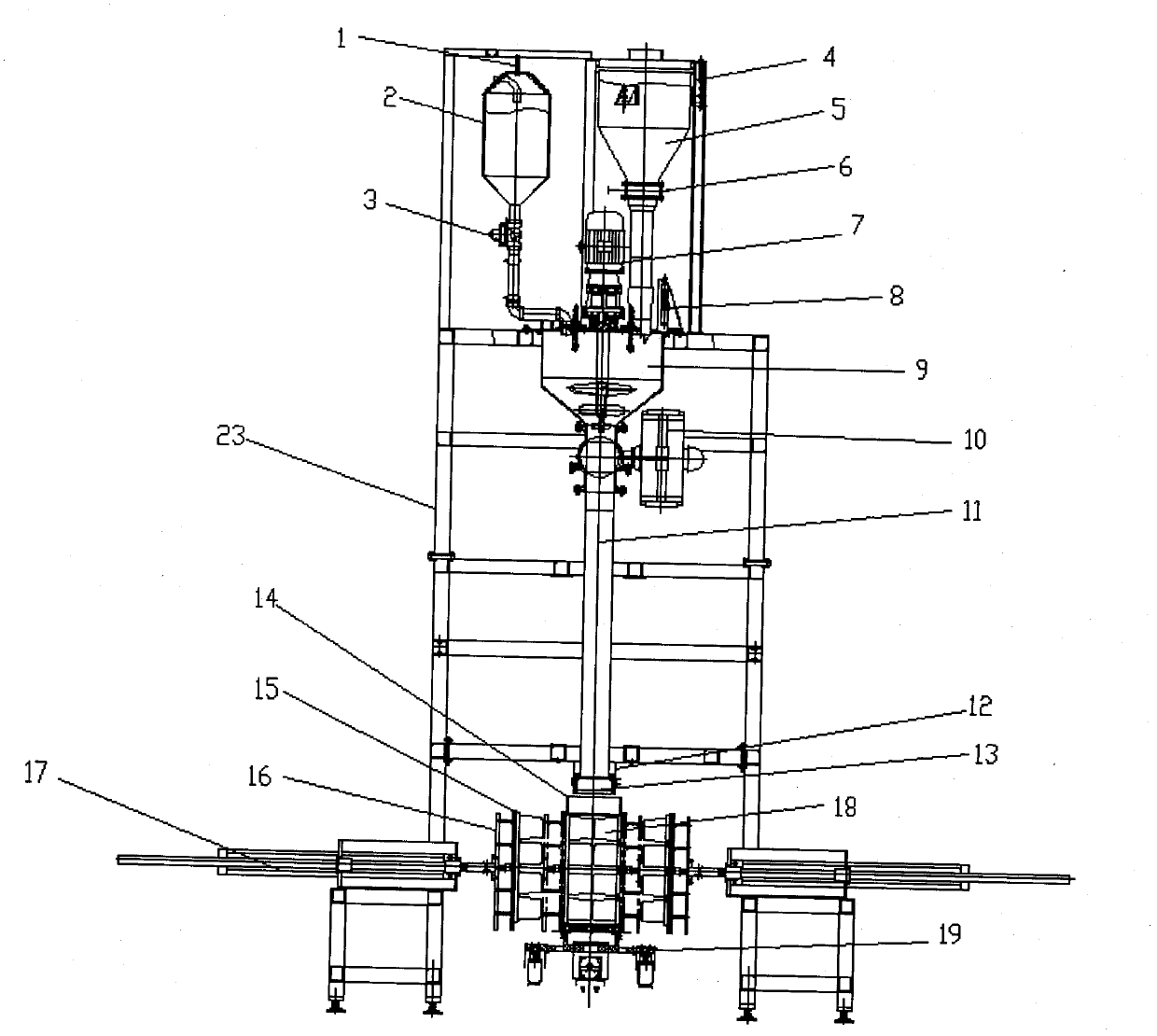

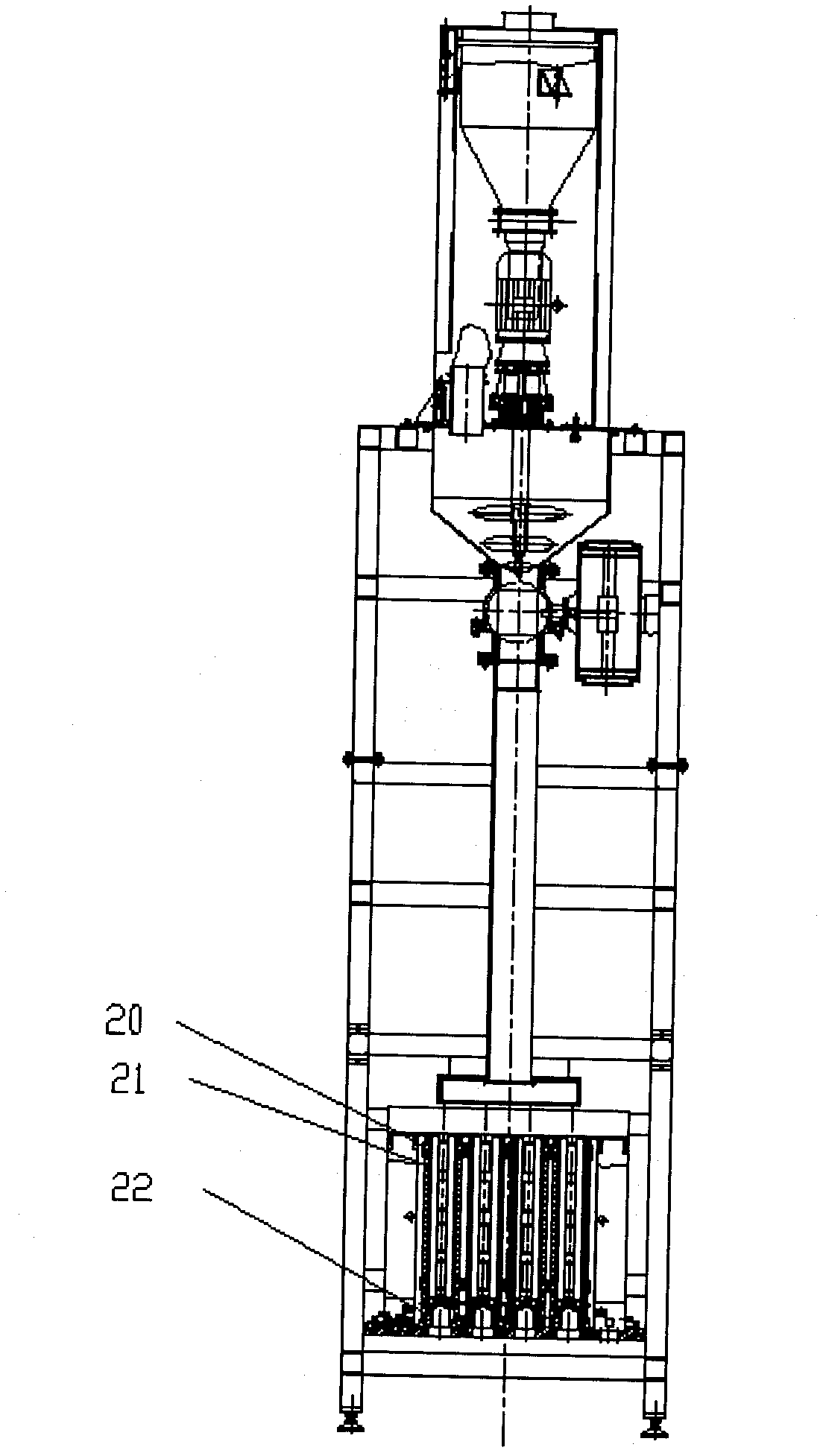

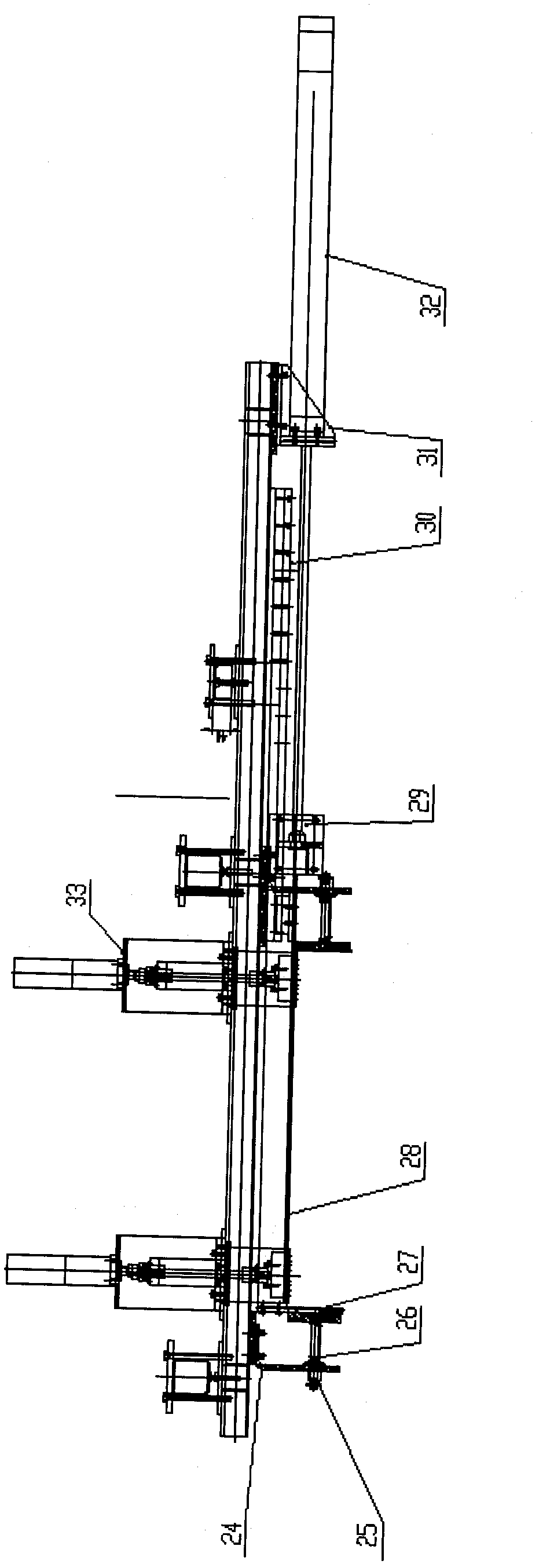

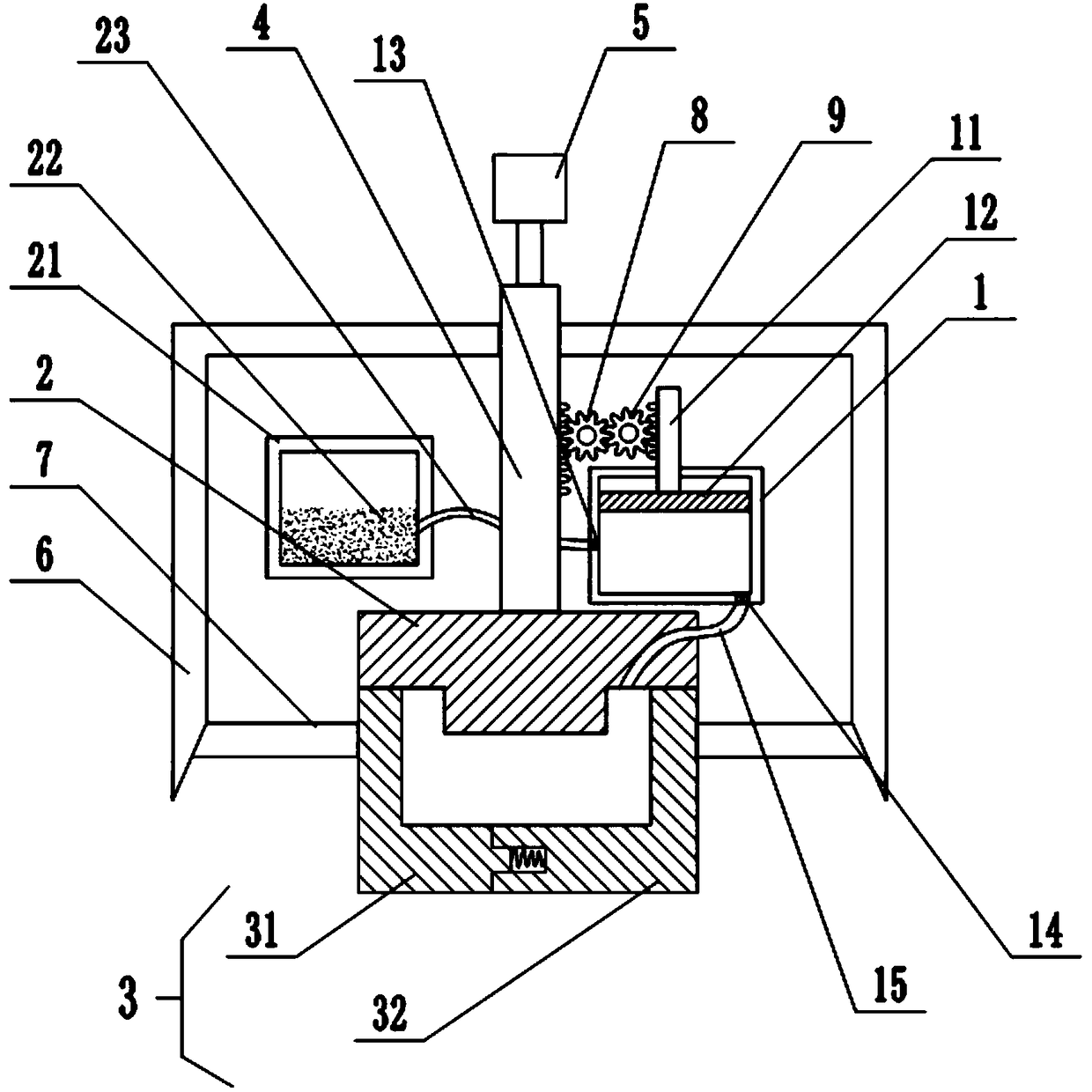

Gypsum building block shaping machine

InactiveCN102672816AAchieve brokenRapid realization of crushing and recyclingCeramic shaping plantsCement mixing apparatusProduction lineMolding machine

The invention provides a gypsum building block shaping machine, comprising a rack and a mould fixedly arranged on a conveyance line. The gypsum building block shaping machine is characterized in that a powder material metering device, a water metering device, a stirring device and a plugging core machine for sealing the mould, scraping, crushing and recovering slurry are respectively installed on the rack; the powder material metering device and the water metering device are respectively installed on the upper part of the rack; powder materials and water can be sent into an internal chamber of a stirring warehouse through a powder material passage and a water passage; and the plugging core machine is installed on the lower part of the rack. In comparison with the current technique, the gypsum building block shaping machine has the advantages of simple structure, low manufacture cost, simple operation, and no redundant slurry discharged, thereby being especially applicable for the shaping of the gypsum building blocks in continuous efficient work of a gypsum building block shaping production line.

Owner:应明

Porous ecological slope protection concrete block precast mold

PendingCN110682415AHighly integratedEasy to operateMouldsMould fastening meansElectric machineryEngineering

The invention discloses a porous ecological slope protection concrete block precast mold which comprises a base, a plurality of outer mold side plates, a push-pull mechanism, an inner mold, a modelingboss, cone pins, telescopic mechanisms and a vibration motor. The outer mold side plates are spliced and enclosed to an outer mold, the bottoms of the outer mold side plates are hinged to the base, one end of the push-pull mechanism is hinged to the base and the other end of the push-pull mechanism is hinged to the outer mold side plates, when the push-pull mechanism moves in extending and retracting modes, the outer mold side plates are horizontally flipped. The inner mold is arranged at the center of the outer mold, the molding boss is arranged on the side surfaces of the outer mold side plates, and when the outer mold side plates are closed, the molding boss is in contact with the side surface of the inner mold. Telescoping mechanisms are arranged at edge corners where every two adjacent outer mold side plates are closed, and the big ends of the cone pins are fixed to the telescoping ends of the telescoping mechanisms. The vibration motor is arranged in the inner mold. The porous ecological slope protection concrete block precast mold can prepare concrete blocks for ecological slope protection, the integration is high, the operation is simple, and use is convenient.

Owner:HUNAN ELECTRICAL COLLEGE OF TECH

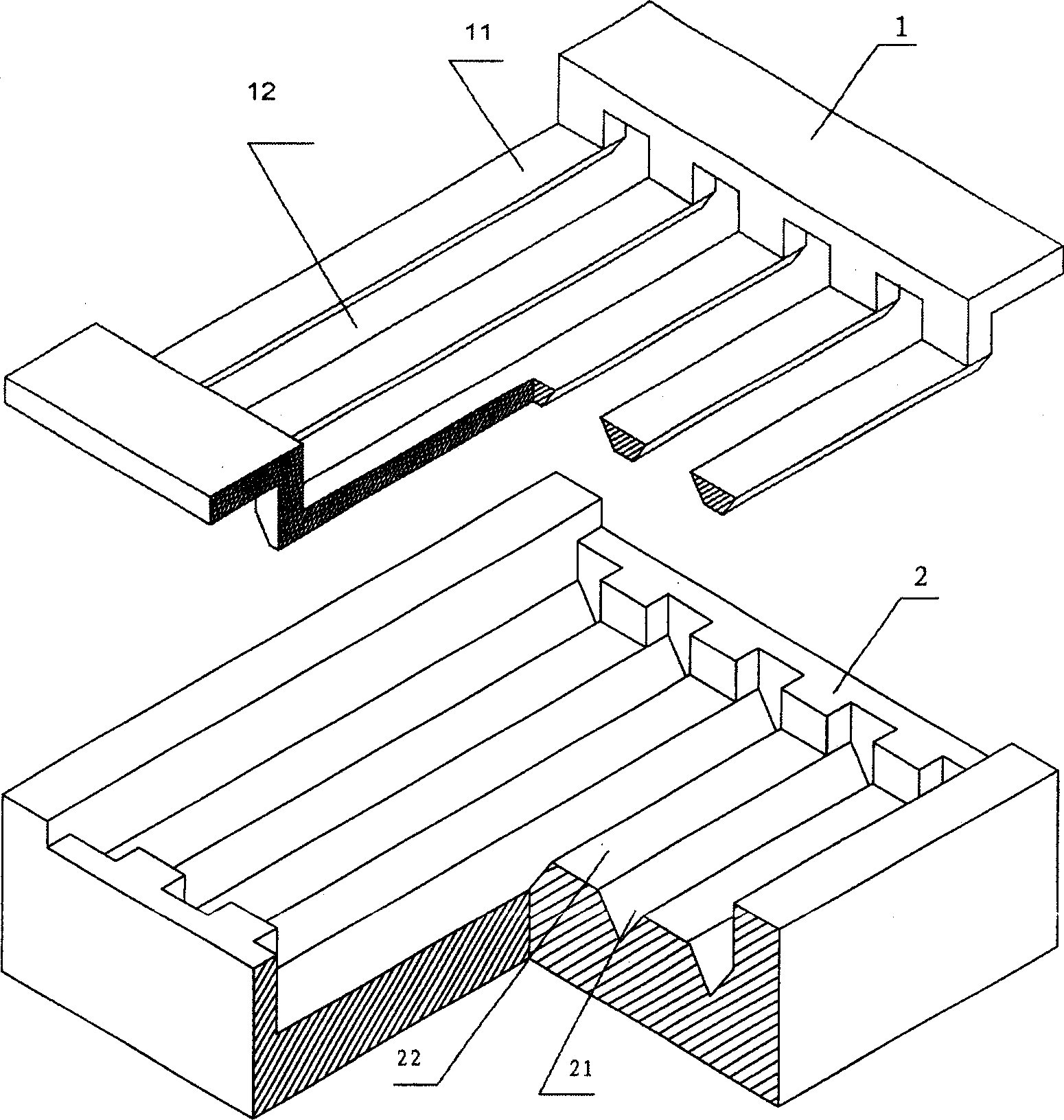

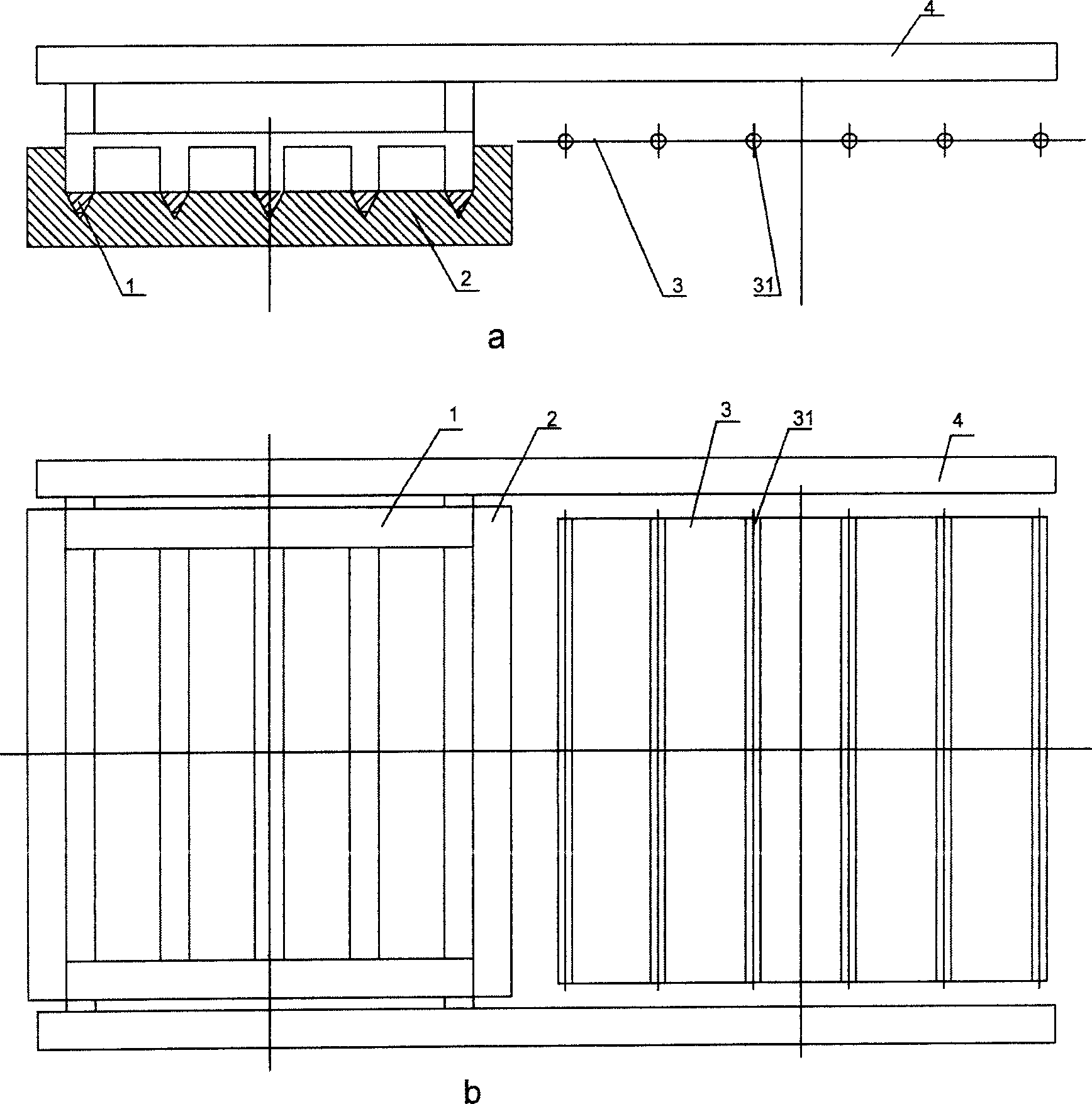

Method and apparatus for half die demolding and transmitting of compacts

InactiveCN1593877AAchieve demouldingRealize transmissionDischarging arrangementMouldsBrickEngineering

The invention relates to a kind of method to demodule and convey the pressed production. The procedure includes: (1)Embed a group of half module that is made of concave strip in the bottom module to form complete bottom module inner; And then put into the material and press to shape. (2) Lift the half module or down the bottom module to take the production and the half module out of the bottom module. (3) The half module supports and carries the pressed above the work table; (4) put down and embed the half module into the carrying unit of the carrier that is in the opposite position to the concave strip; (5) the half module goes back to form complete bottom module inner; (6) take the above steps again. The invention also makes public a kind half demodule of the pressed, conveying device and key unit of it-a kind of under module. The invention and correspondent device can ignore the demand for thickness of the pressed such as ceramic brick. The invention has simple structure so it is easy to manipulate it.

Owner:程晓勤

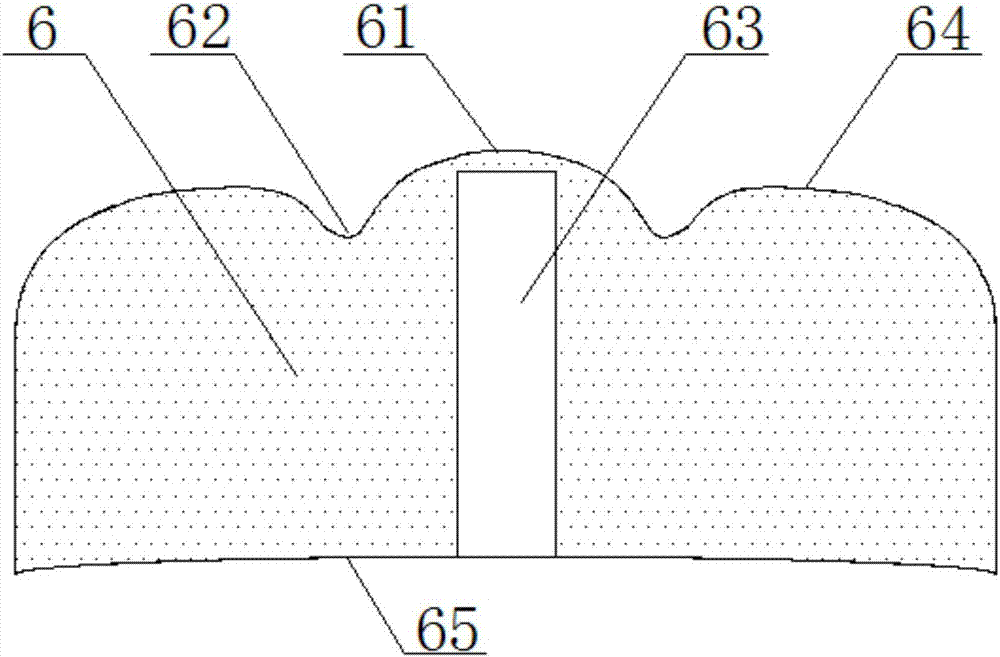

Moxa-moxibustion tool and preparation process thereof

ActiveCN107280965AAdvantages of preparation processWon't fallDevices for heating/cooling reflex pointsPharmaceutical product form changeEngineeringMaximum size

The invention relates to a moxa-moxibustion tool and a preparation process thereof. The moxa-moxibustion tool comprises a moxibustion tool and a moxibustion core, wherein an air hole is formed in the bottom end of the moxibustion tool, the moxibustion tool is of a cylindrical structure, the moxibustion core is fixed to the upper portion of the inner cavity of the moxibustion tool, the upper surface of the moxibustion core protrudes out of the moxibustion tool, and the portion, in contact with a moxa cake, of the inner surface of the moxibustion tool is a flame-retardant face and is of a wedge surface structure. The moxibustion core is the moxa cake, the maximum size of the bottom surface of the moxa cake is 1-5 times of the height of the moxa cake, the bottom surface of the moxa cake is a cambered surface protruding upwards, the center of the upper surface of the cambered surface protrudes and is higher than the upper surface of the cambered surface, the bottom surrounding of the protrusion is downwards sunken and is lower than the upper surface of the moxa cake, a blind hole with a downward opening is formed in the moxa cake, and the hole bottom of the blind hole is located in the protrusion. The invention also correspondingly provides the preparation process of the moxa-moxibustion tool. The moxa-moxibustion tool is aligned during the moxa cake releasing, releasing and installation of the moxa cake can be simultaneously achieved, and working processes are saved. A central hole of the moxa cake is the blind hole, and the blind hole blocks an upper-end outlet of a flue, so that moxibustion smoke only flows downward, and the moxibustion utilization rate is improved.

Owner:湖北蕲艾堂科技有限公司

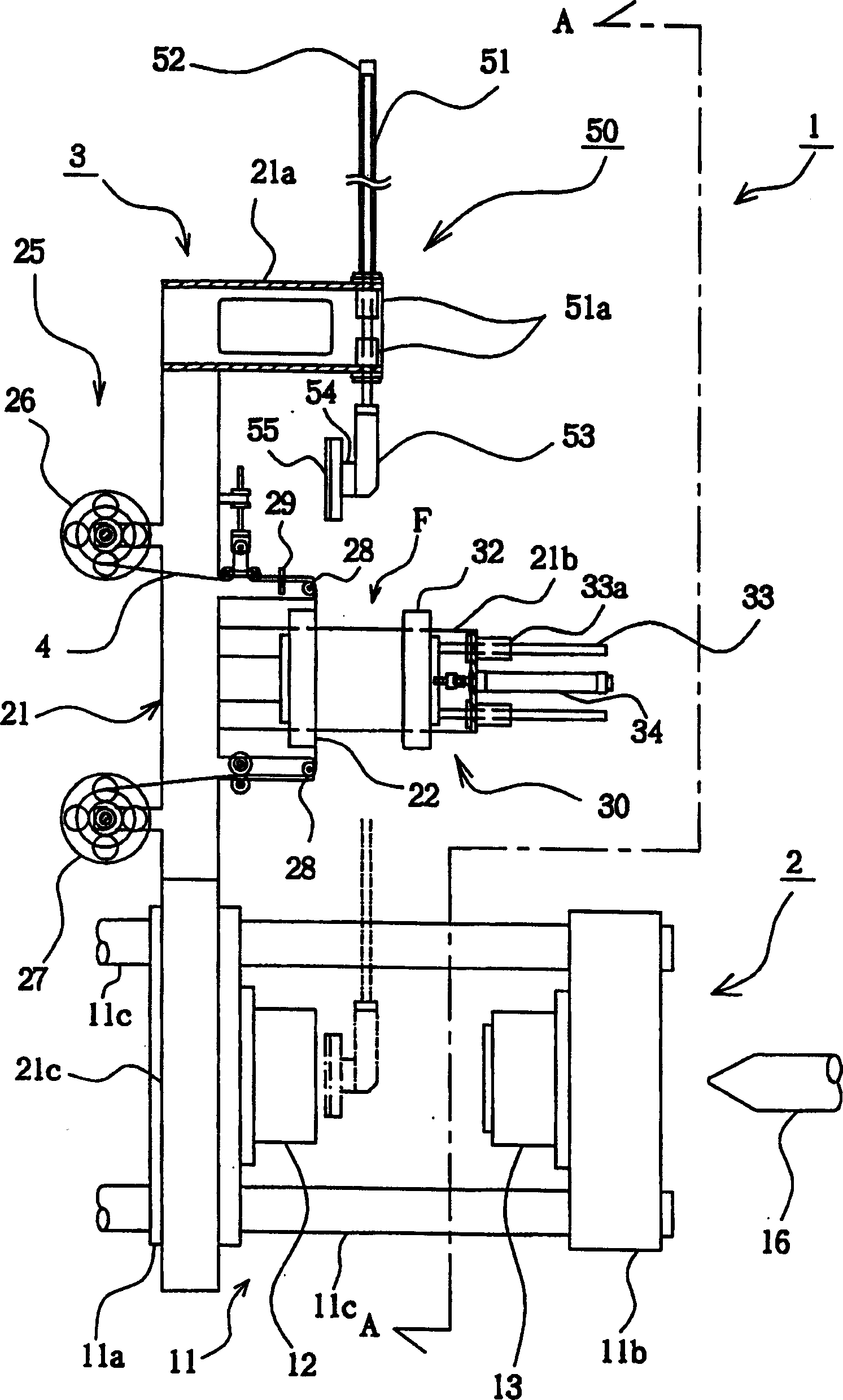

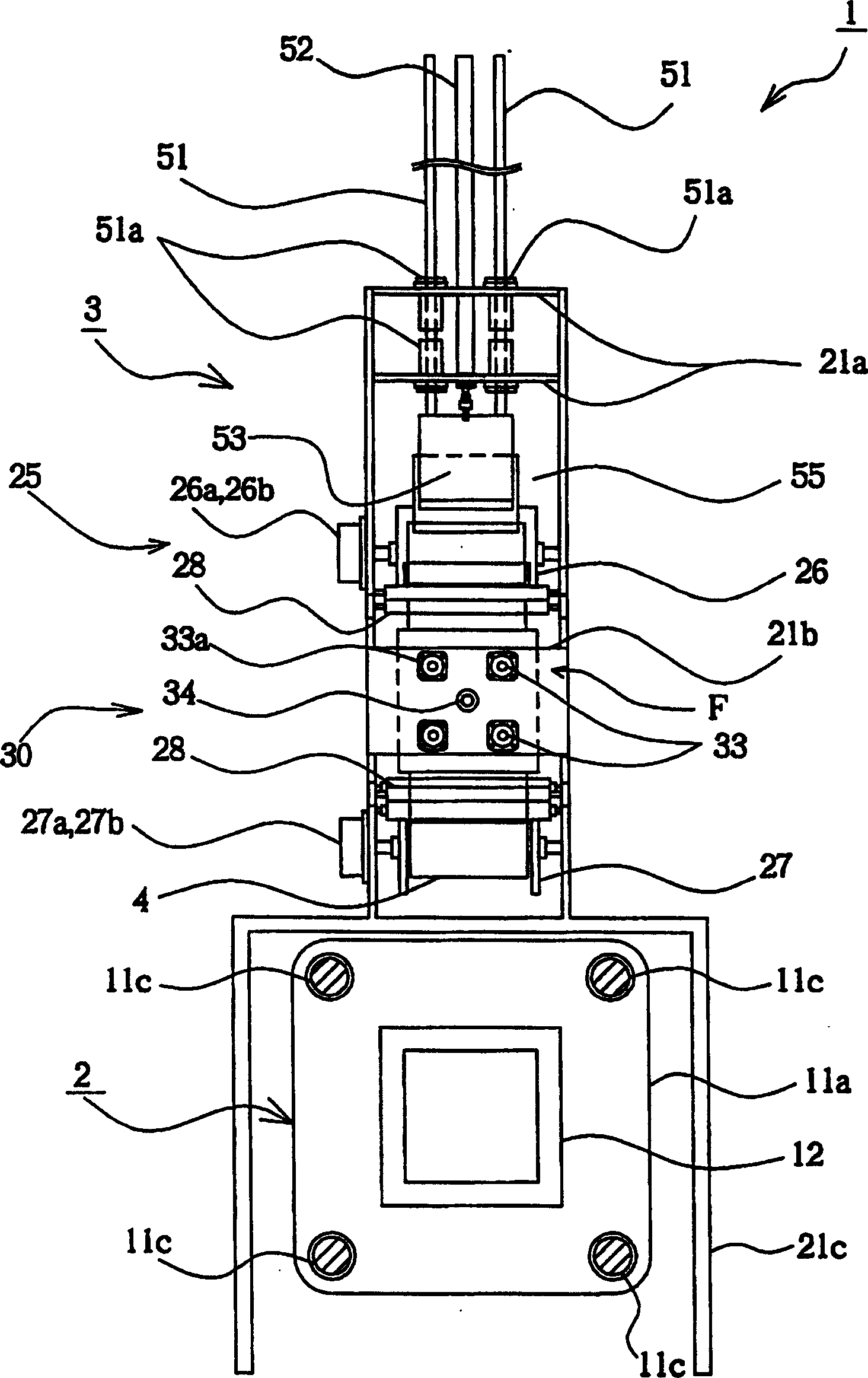

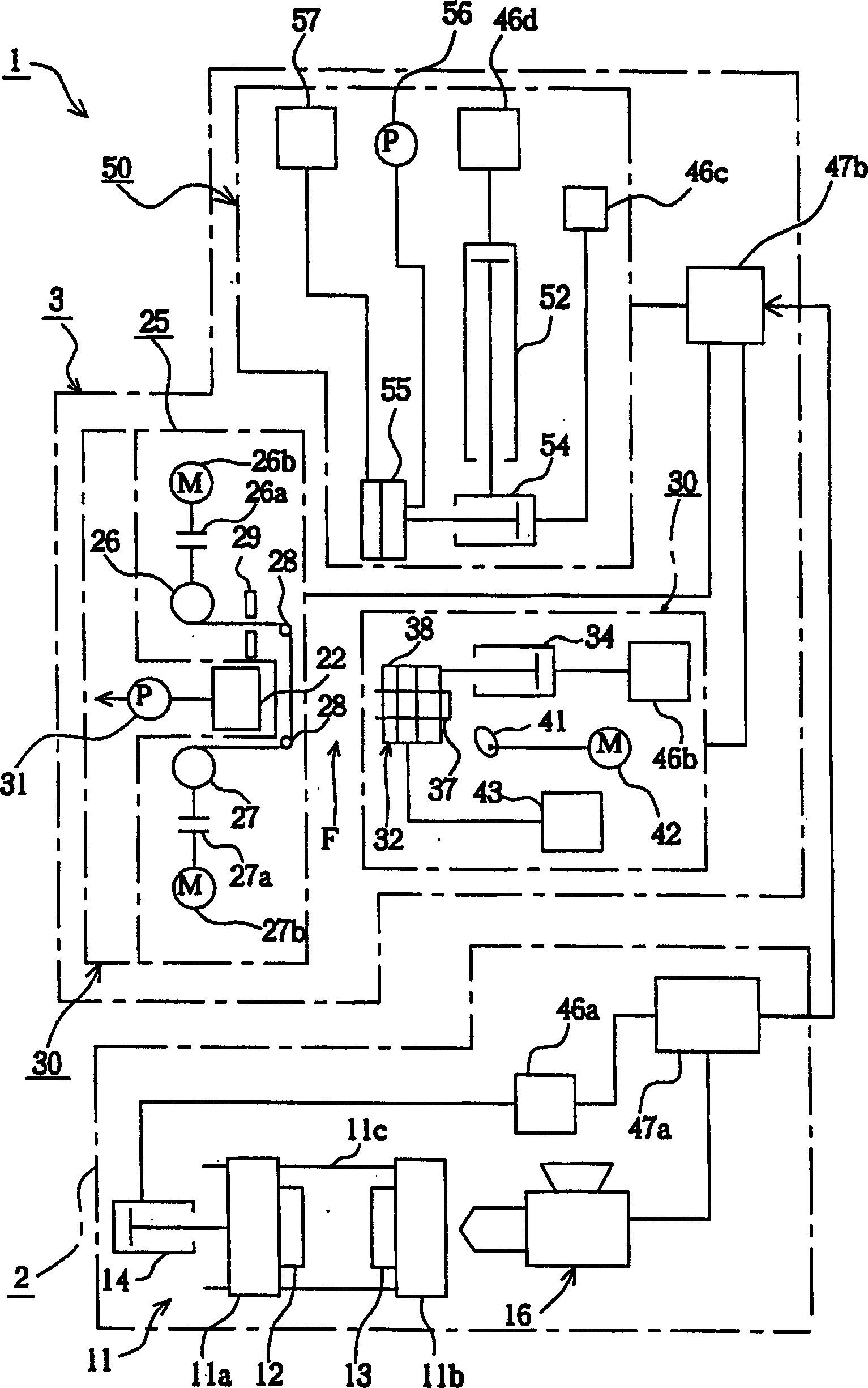

Preliminary forming device, preliminary forming method using the device, and main forming method

A preliminary forming device capable of efficiently applying a pattern even on a deep-drawn or a complicatedly shaped formed product without applying any special working on an existing metal mold of a main forming device, a preliminary forming method using the preliminary forming device, and a main forming method; the preliminary forming device, comprising a film feeder (25) feeding a film with pattern (4) to a preliminary forming part (F) for performing a preliminary forming, a heater (30) movable closely to and away from the preliminary forming part and heating the film with pattern before the preliminary forming so as to be plasticized at the preliminary forming part (F), a preliminary forming mold (22) for preliminarily forming the film with pattern, and a film feeder (50) to feed a forming film for releasing the film from the mold after the preliminary forming of the film with pattern and inserting the film into a main forming mold, wherein, after the forming film is inserted into the main forming mold, resin is fed to provide a formed product with pattern, the preliminary forming being performed by vacuum forming or compressed air forming.

Owner:今井邦雄

Injection die for unshadowed double-colour light-transmitting plastic products

ActiveCN106426780ASimple mold structureLow manufacturing costDomestic articlesMechanical engineeringBuilding construction

The invention relates to an injection die for unshadowed double-colour light-transmitting plastic products. The injection die comprises a male die plate and a male die core arranged on the male die plate. The injection die further comprises a fixed block fixedly inlaid on the male die core, and a top block inserted on the male die core in a manner of being capable of moving up and down along a die opening direction and with one side surface bonded with the fixed block, wherein a half-horn runner is arranged on one side surface bonded with the fixed block, of the top block, the tip of the half-horn runner stretches in a die cavity and is provided with at least one sprue used for carrying out glue injection on a non-light-transmitting layer contained in a light-transmitting layer; the glue injection is directly carried out below the product through the half-horn runner, and construction of a runner below the light-transmitting layer is not required, thus the problem of shadows during light transmitting of the light-transmitting layer is solved, and the quality of the product is improved; and the problem of difficult die release is solved and damage to the product during die release is avoided through adopting a method of secondary die release.

Owner:东莞市竣邦塑胶模具有限公司

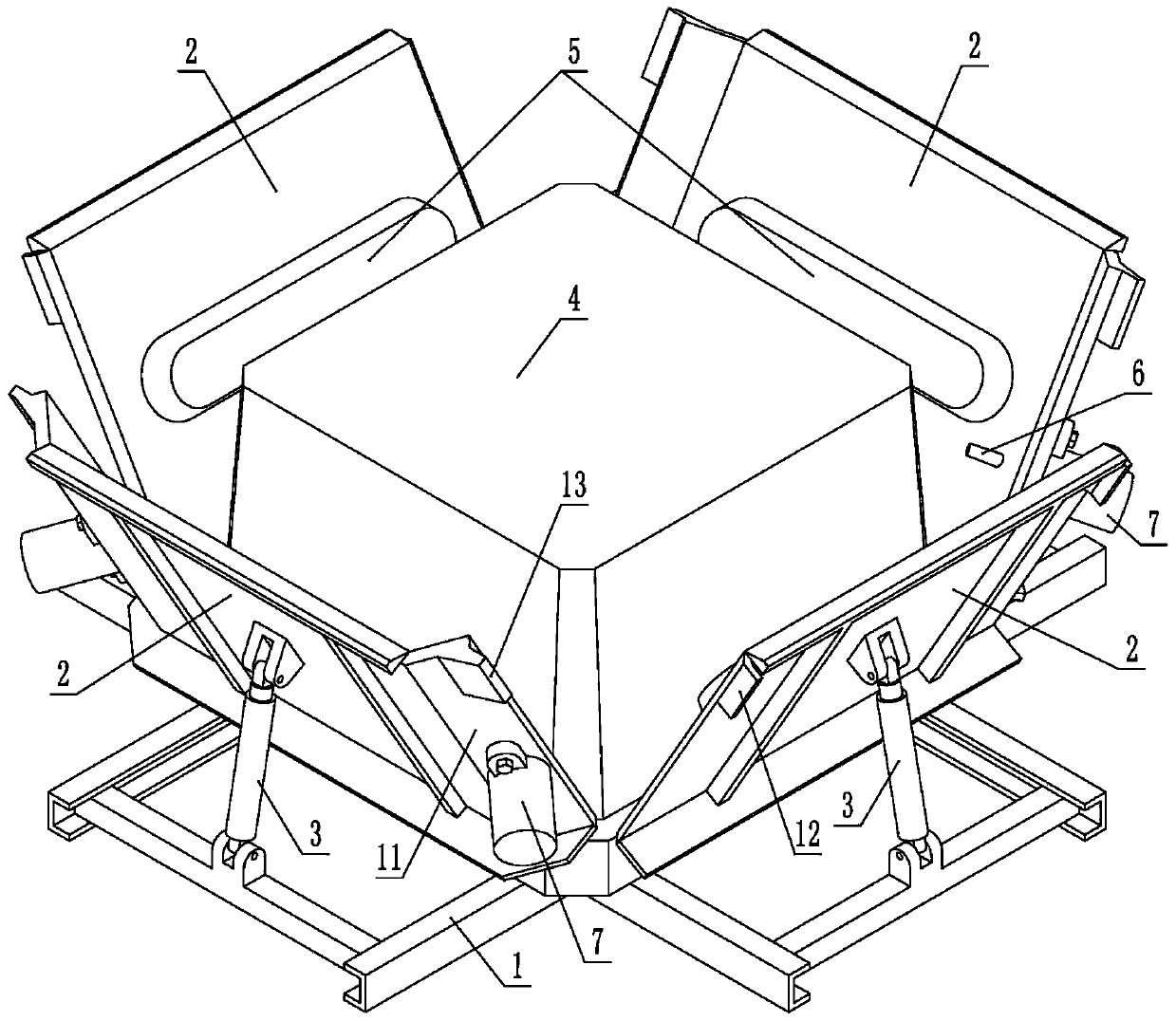

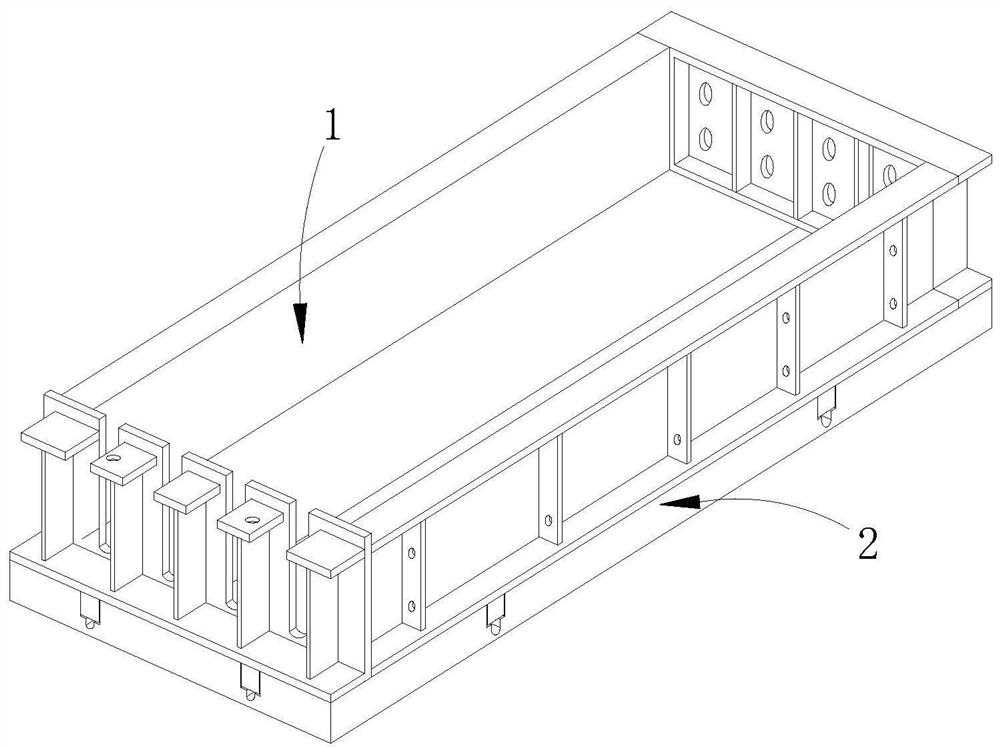

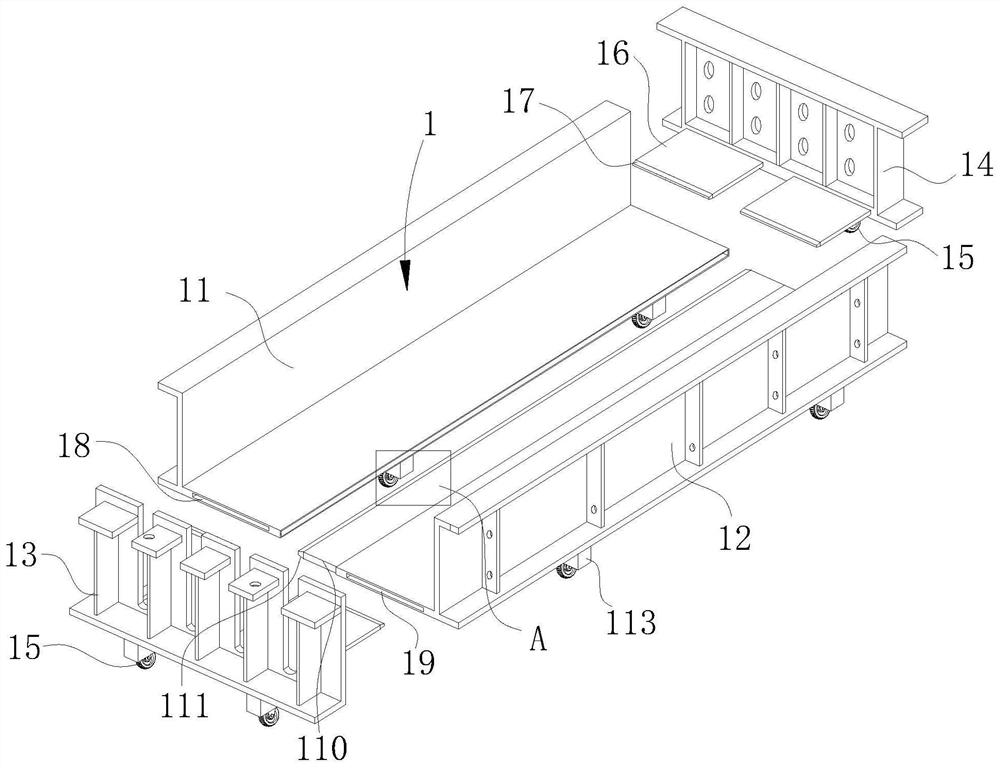

Assembly type precast concrete member die

ActiveCN111605050AEasy to assemble and disassembleAvoid damageMouldsMould fastening meansPrecast concreteArchitectural engineering

The invention relates to an assembly type precast concrete member die. The assembly type precast concrete member die comprises a die mechanism and a bearing mechanism. According to the assembly type precast concrete member die, the die adopts an assembly structure, so that when a prefabricated member is molded and demoulded, the effect of rapidly disassembling and assembling the prefabricated member is achieved through a die split mechanism; meanwhile, in the disassembly and assembly process, the prefabricated member is not required to be carried and overturned, so that the prefabricated member is prevented from being damaged; and specifically, the die is composed of a first master die, a second master die, a first slave die and a second slave die, during form removal, firstly the first slave die and the second slave die are disassembled and assembled, and then one of the first master die or the second master die is removed, so that the demoulding of the prefabricated member is realized.

Owner:界首市宝业瑞祥建筑工业化有限公司

Automatic demolding machine for medical gloves

ActiveCN112476879AImprove device reliabilityImprove stabilityDomestic articlesElectric machineryEngineering

The invention discloses an automatic demolding machine for medical gloves, and relates to the technical field of automatic demolding machines for the gloves. Demolding is realized without participation of a blow-off mechanism. The automatic demolding machine specifically comprises a mold conveying rail used for conveying glove molds and a demolding rail with demolding mechanisms, the glove molds are installed on the mold conveying rail through a conveying fixing seat, the demolding rail is arranged below the mold conveying rail, the demolding mechanisms are evenly distributed on the demoldingrail, and the demolding mechanisms comprise demolding clamps, demolding bases and lifting motors; and a pushing mechanism for pushing the demolding mechanisms to longitudinally move relative to the glove molds is further arranged on one side of the demolding rail. By arranging a lifting stud, the lifting motors, a rotating rod and other structures, a mounting frame can be driven to perform liftingmotion, rolling wheels correspondingly slide on the outer wall of the rotating rod, the motion trails of the rolling wheels are limited through the acting force between the rotating rod and the rolling wheels, and the demolding clamps can achieve demolding without the participation of the blow-off mechanism.

Owner:苏州维凯医用器材科技有限公司

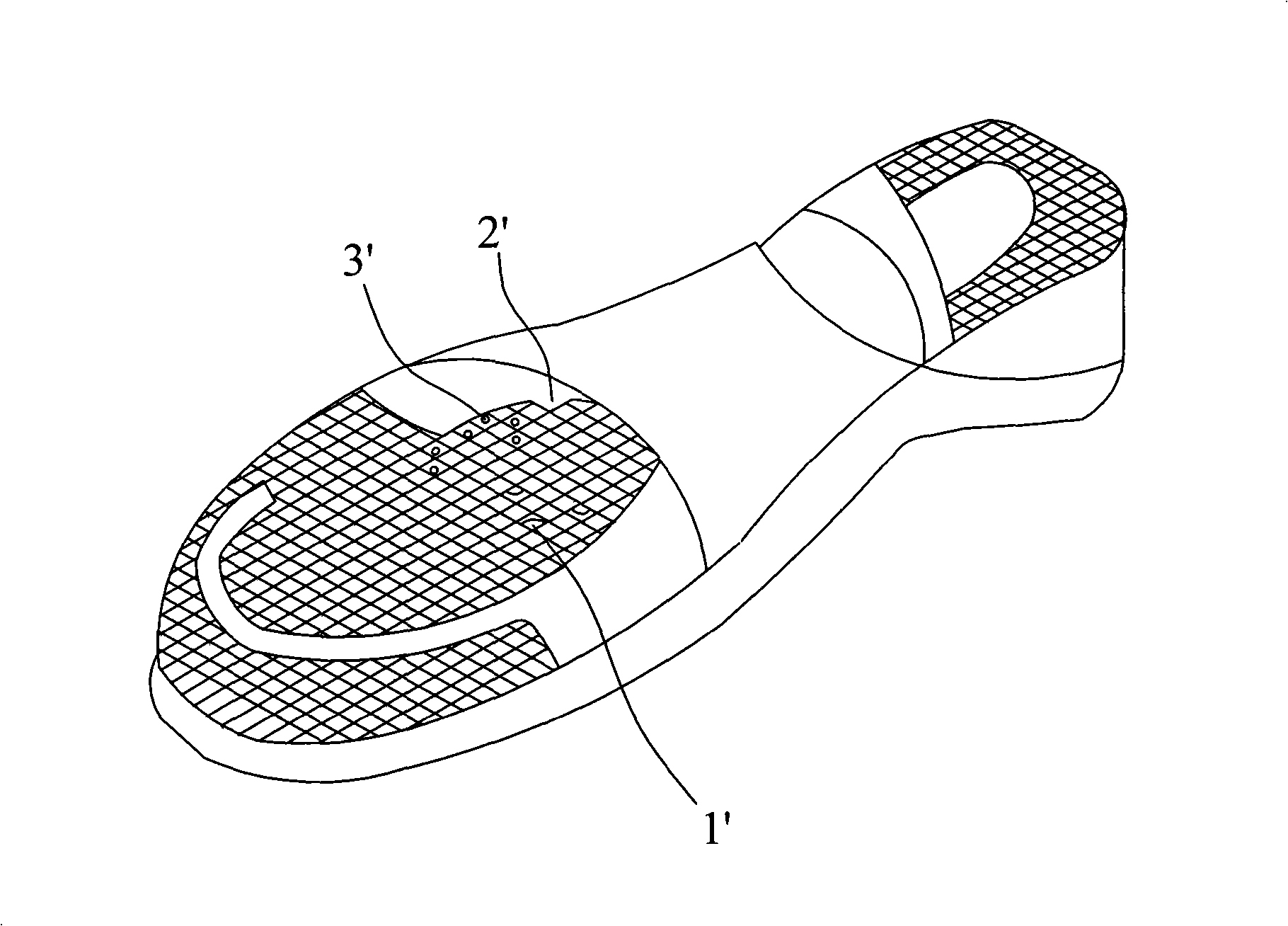

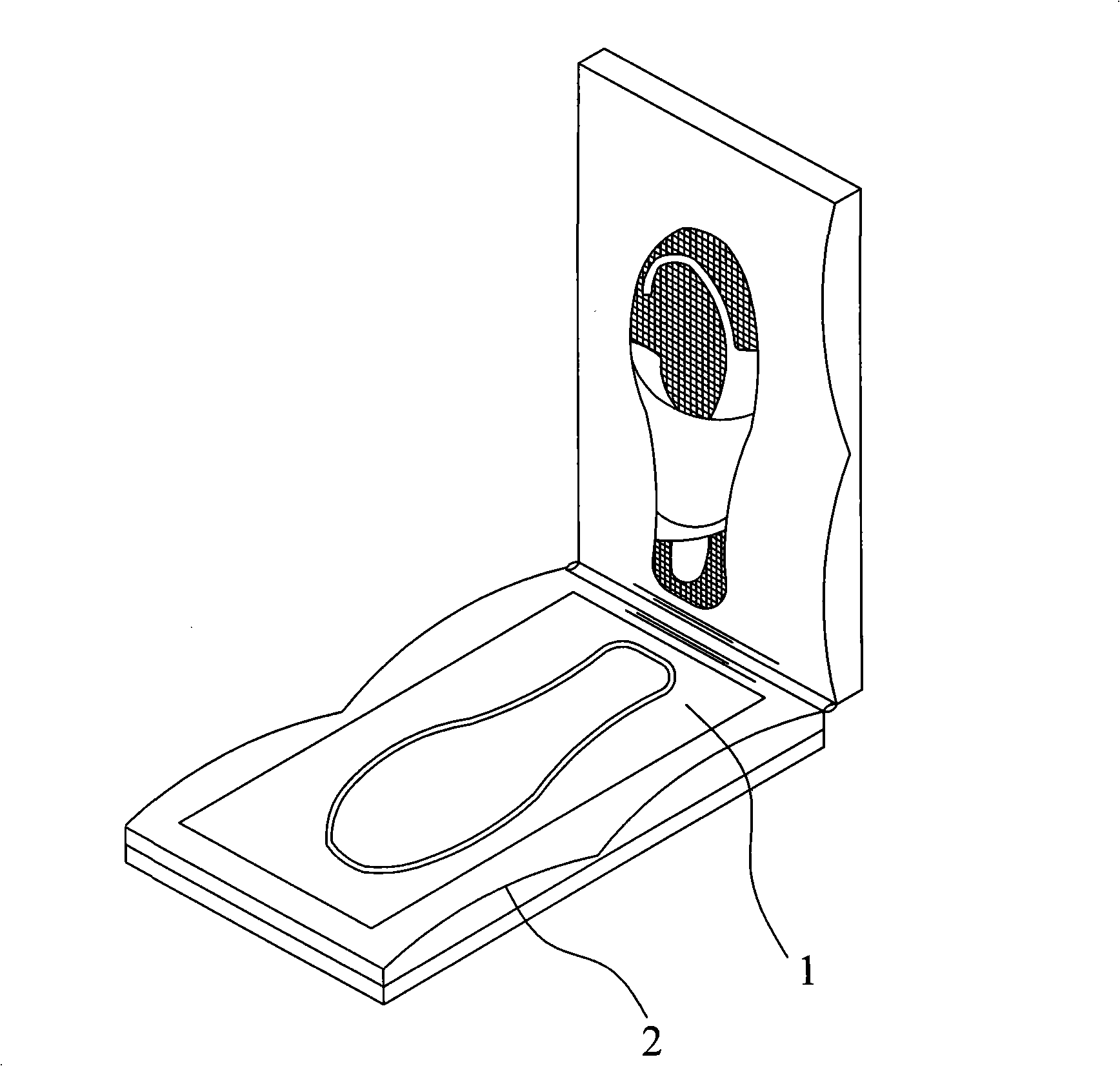

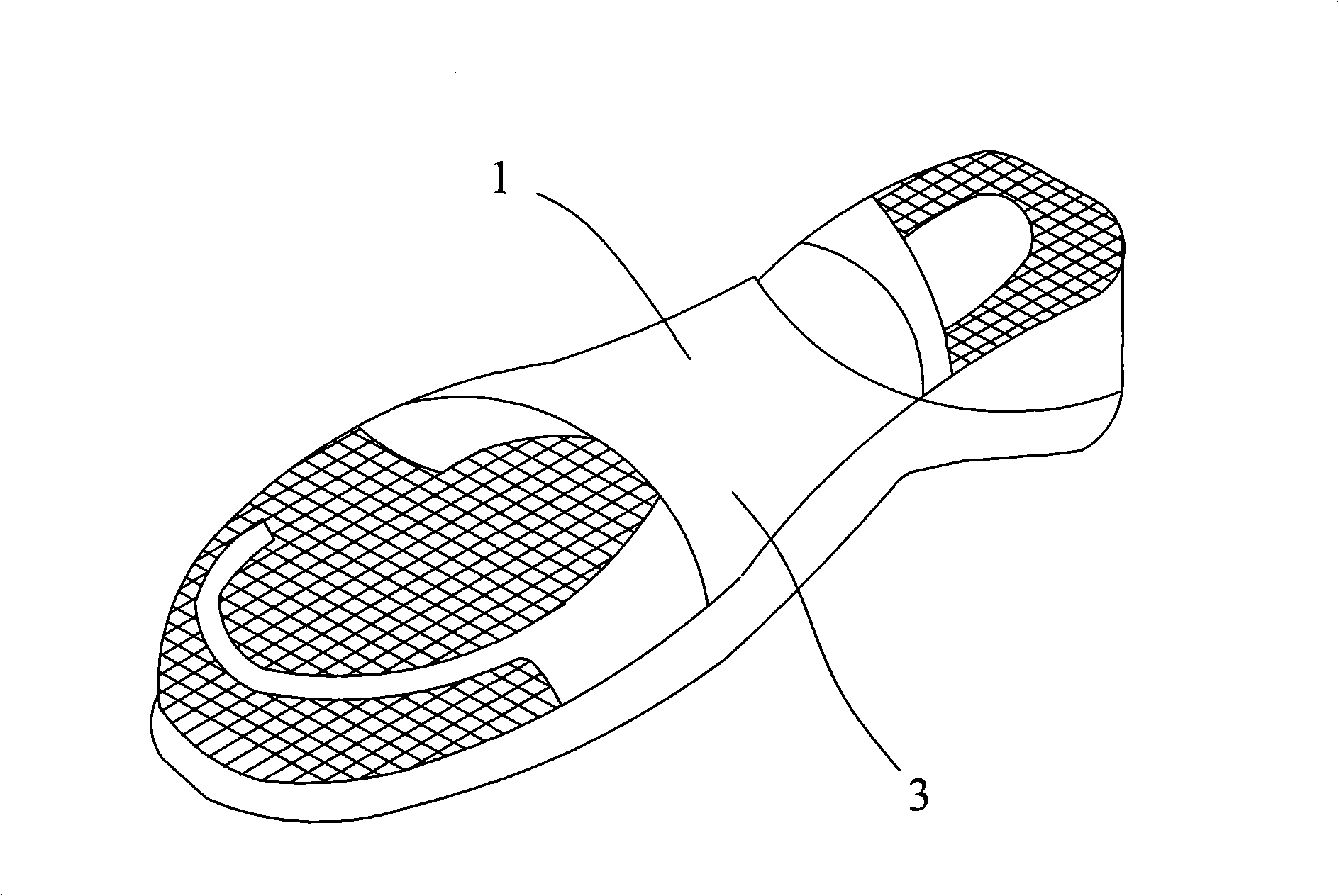

Shoe material processing method

InactiveCN101537688AImprove liquidityImprove finenessDomestic articlesEngineeringMaterials processing

The invention discloses a shoe material processing method which comprises the following steps of: first laying a TPU thin film in the cavity of a lower mould of the shoe material; injecting a liquid PU material into the mould; then leading the shoe material to be formed in the mould; and finally taking out the shoe material and repairing a PU film on the periphery of the shoe material. Compared with the prior art, the method adopts the TPU thin film to substitute a release agent and improves the liquidity of the liquid PU material and the fineness of material in the forming process of the shoe material; the liquid PU material and the TPU thin film are combined into a whole in the cavity of the mould, which can avoid the occurrence of defects including bubbles, nicks, pits and the like, thus reducing the cost of materials and labor cost for repairing the shoe material and enhancing the brightness and smoothness and aesthetic feeling of the formed shoe material; in addition, the TPU thin film is easier to be separated from the mould, thus being capable of realizing the demoulding of the shoe material without spraying the release agent in the mould; besides, the TPU thin film 1 can further enhance the anti-hydrolysis performance of the shoe material.

Owner:DONGGUAN XINGTAI SHOES MATERIAL

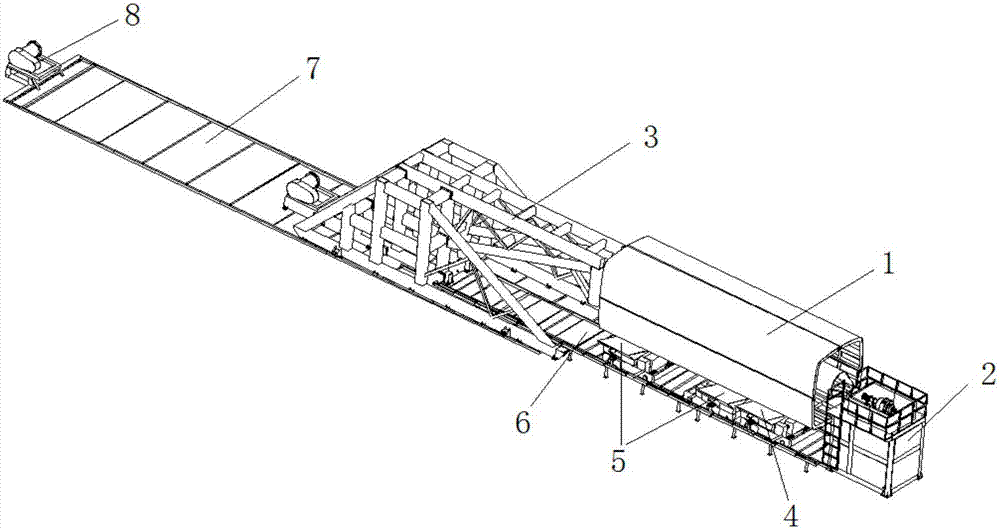

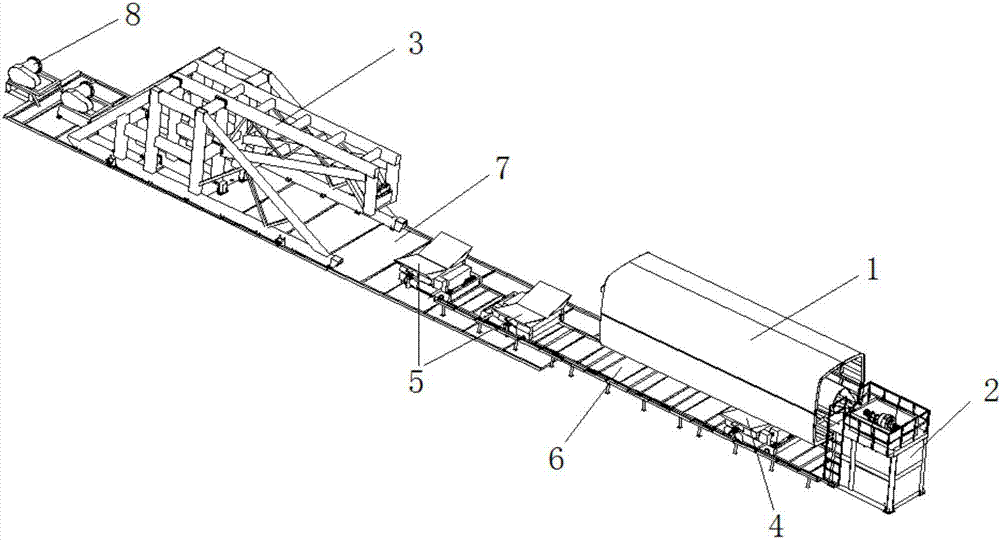

Demolding method and equipment for large-scale winding product

The invention belongs to the technical field of demoulding of winding products, and particularly discloses a demolding method and equipment for a large-scale winding product. The method comprises the steps that a mold and the product can be radially separated through the shrinkage of the opening and closing type mold, and the mold is connected to a machine frame and a cantilever support; the product is supported by second movable trolleys and moves in the direction of the cantilever support so that one end of the mold can be exposed; when the mold is exposed above a half length, the movement of the second movable trolleys is stopped, a first movable trolley is enabled to move to the middle position of the mold and support the mold; the mold is separated from the cantilever support, the cantilever support is enabled to move outwards, then the second movable trolleys are enabled to move so as to drive the product to be continuously demolded until the product is completely separated from the mold, and therefore the whole demolding procesdure is completed; and the equipment is used for implementing the method. The device and the method can effectively solve the de-molding problem in the winding production process of the large-scale oversized and overlong winding products and has the advantages of being convenient and rapid to demold, simple in equipment structure, convenient to operate and the like.

Owner:中林鑫宙竹缠绕发展有限公司

Barrel-shaped composite structural member overall molding method capable of achieving easy demolding

The invention belongs to the technical field of composite material molding, and provides an integral molding method of a cylindrical composite material structural part that is easy to release the mold. The method comprises the following steps: preparing a sealed airbag of a high-temperature and high-pressure resistant material according to the size of the cylindrical composite material structural part to be formed; sealing the sealed airbag after being filled with compressed gas, as a mold for the cylindrical composite material structural part; Molding agent or laying release cloth; the fiber laying of the tubular composite structural part is completed by winding molding method; the tubular composite structural part completed with fiber laying is cured by autoclave-vacuum bag method; the sealed airbag Deflate and decompress to separate the cylindrical composite material structure from the airbag, complete the demoulding process, and obtain the overall cylindrical composite material structure. The method of the invention has simple process, not only can realize the integral molding of various complex cylindrical composite material structural parts, but also is convenient for demoulding, and can obviously reduce the cost.

Owner:DALIAN UNIV OF TECH

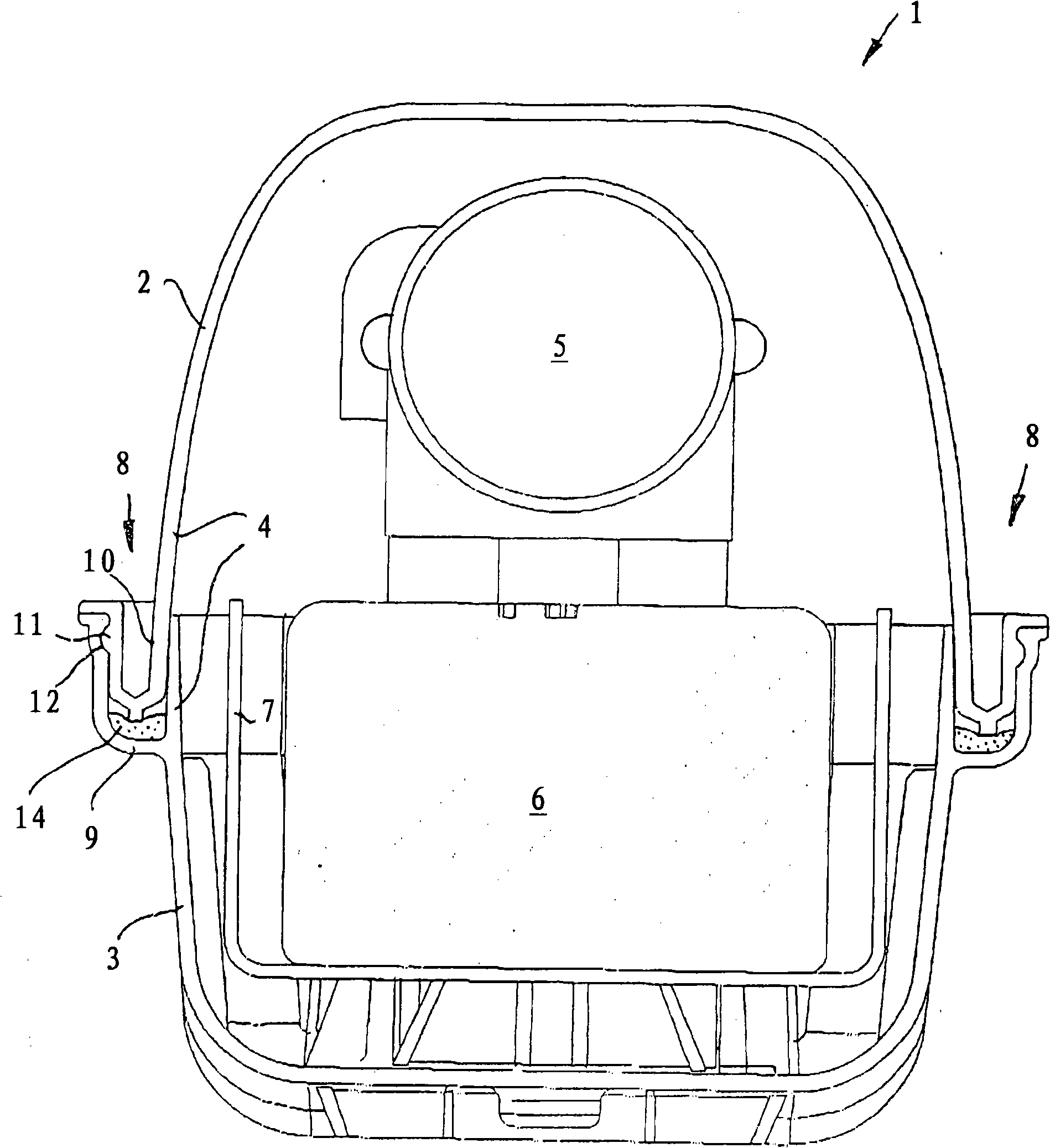

Light

InactiveCN101553691AGood adhesionIncrease the friction surfaceElongate light sourcesProtective devices for lightingGas-discharge lampElastomer

The invention relates to a light (1) especially a wall or ceiling light protected from spray water and used to receive at least one long gas discharge lamp (5), said light comprising a closed housing formed by an at least transparent base part (3) which can be mounted in a fixed location and holds electrical devices, and an at least transparent coupling part (2). The base part (3) and the coupling part (2) are injection-moulded from the same charges of thermoplastic material in a common mould which is essentially symmetrical in terms of the injection process, and overlap along peripheral edges on both sides, one edge being an insertion edge (10) and the other edge being embodied as a U-shaped receiving element (9) for receiving the insertion edge (10). According to the invention, taking into consideration the characteristic features of the transparent or translucent plastic material and the requirements of large-scale production, the light is designed in such a way that the U-shaped receiving element (9) comprises a seal (14) consisting of an elastomer foam forming a smooth outer skin, and the inner wall (15) of the light is provided with a surface structure improving the adhesion, for receiving the seal (14).

Owner:IBV HLDG

Automatic forming mold for automatic parts

The invention relates to the technical field of mold equipment and discloses an automatic forming mold for automatic parts. The automatic forming mold comprises a rack, a guide box, a storage box, anupper mold base and a lower mold base, wherein the lower mold base comprises a first lower mold base and a second lower mold base spliced with each other; the upper mold base is connected with a pushrod; one end of the push rod is connected with a cylinder; two sides of the push rod are connected with an L-shaped rod; the first lower mold base and the second lower mold base are respectively connected with supporting rods; the guide box penetrates through a piston rod; a first rack is arranged on the piston rod and meshed with a first gear; the first gear is meshed with a second gear; a secondrack is arranged on the push rod and meshed with the second gear; the guide box and the upper mold base are communicated with a feed pipe. During injection molding, the upper mold base and the lowermold base are closed, and the molten pattern material is injected into an injection molding cavity from the guide box. During demolding, the upper mold base is separated from the lower mold base, thefirst lower mold base and the second lower mold base are mutually separated, and the injection molding product drops from the interior of the lower mold base so as to realize demolding.

Owner:宁波高盛模具制造有限公司

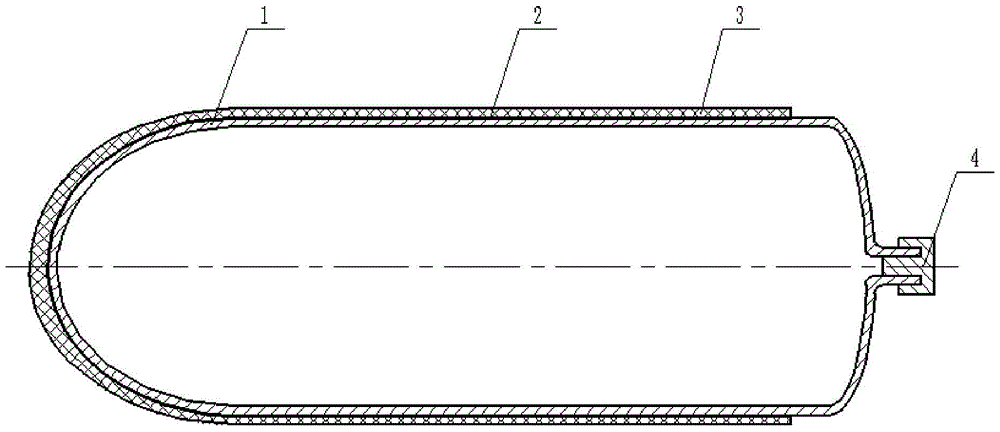

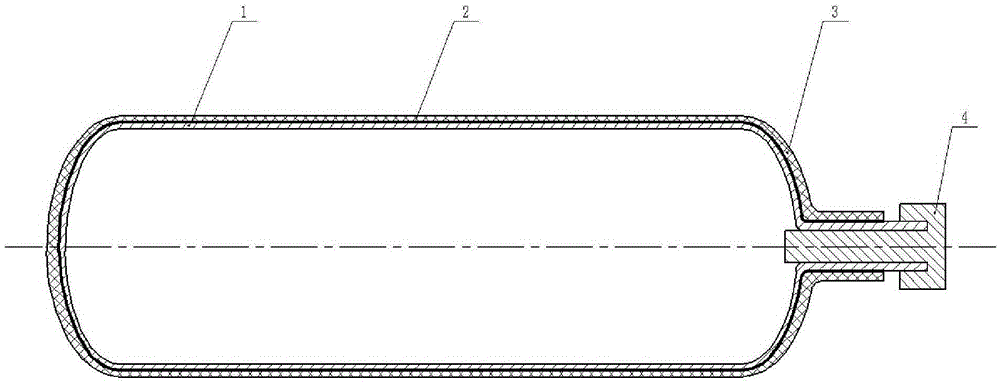

Integral forming method of easy-to-demold composite material storage tank

The invention discloses an integral forming method of an easy-to-demold composite material storage tank, and relates to the technical field of composite material forming. The integral forming method comprises the following steps: preparing a sealed airbag which is made of a high-temperature and high-pressure resistant material according to the size of a to-be-formed composite material storage tank; sealing the sealed airbag after fully filling the sealed airbag with a compressed gas, and using the sealed airbag which is fully filled with the compressed gas as a mold of the composite material storage tank; coating the surface of the sealed airbag with a demolding agent or paving and adhering demolding cloth; completing fiber pavement of the composite material storage tank by adopting a filament winding method; solidifying the composite material storage tank on which filament pavement is completed by adopting an autoclave-vacuum bag method; carrying out gas bleeding and decompression on the sealed airbag, enabling the composite material storage tank to be separated from the sealed airbag, completing a demolding process, and obtaining an integral composite material storage tank. The integral forming method of the easy-to-demold composite material storage tank, disclosed by the invention, has the advantages that the technology is simple, the integral performance of the composite material storage tank can be increased, demolding is convenient, and the cost can be obviously reduced.

Owner:DALIAN UNIV OF TECH

Die for car interior part

ActiveCN108188274ARealize automatic demouldingImprove demoulding efficiencyShaping toolsEngineeringMechanical engineering

The invention belongs to the technical field of die for car parts processing, and discloses a die for a car interior part. The die for the car interior part comprises an upper male die and a lower female die; the lower female die is provided with a support formed by a cross plate and two vertical plates; the upper male die is provided with an electromagnet and a sliding rod penetrating through thecross plate; the cross plate is provided with a drive piece; the top portion of a sliding rod is provided with a support block; the lower portion of the side wall of the support block is provided with a conducting strip; an electric lead is arranged between the conducting strip and the electromagnet; the cross plate is provided with a support frame; a communicating block is arranged between the support frame and the cross plate; an elastic piece is arranged between the top potion of the communicating block and the bottom of the support frame; the communicating block is provided with a power source; the power source is provided with a conductive needle; one end, away from the power source, of the conductive needle is connected with the side wall provided with the conducting strip of the support frame in a sliding mode; the lower female die is internally provided with a cavity; and the cavity is internally connected with an iron block in a sliding mode. The die for the car interior partsolves the problem that the interior parts are tightly attached with the lower die after impact molding to the interior parts in the prior art, leading to the difficulty of removing the car interiorparts.

Owner:CHONGQING YINSHENG MOLD

Die for automobile part

The invention belongs to the technical field of automobile part machining and discloses a die for an automobile part. The die comprises an upper convex die and a lower concave die. The lower concave die is internally provided with a feeding bin, the feeding bin is internally provided with a material storage air bag, and the material storage air bag is provided with a material outlet and a feedingopening. The lower concave die is provided with a feeding slot and material guide slots. The die further comprises an inverted-U-shaped bracket, the bracket comprises a transverse rod and a vertical plate, and the upper surface of the upper concave die is rotatably connected with a screw rod penetrating through the transverse rod. The die further comprises a drive piece, and the drive piece comprises a first gear and a rack. One side of the lower concave die is provided with a supporting frame, the supporting frame is provided with a rotating shaft, the first gear is fixed to one end of the rotating shaft, and the other end of the rotating shaft is provided with a rotary table. One side of the lower concave die is provided with a gas storage barrel, and the gas storage barrel is internallyand slidably connected with a piston. The die further comprises a first connection rod, a second connection rod and a third connection rod, wherein the first connection rod, the second connection rodand the third connection rod are hinged in sequence. By means of the die for the automobile part, the problem that in the prior art, a stamped and formed automobile part is in close fit with the lower die so that the formed automobile part is not prone to be taken out is solved.

Owner:CHONGQING YINSHENG MOLD

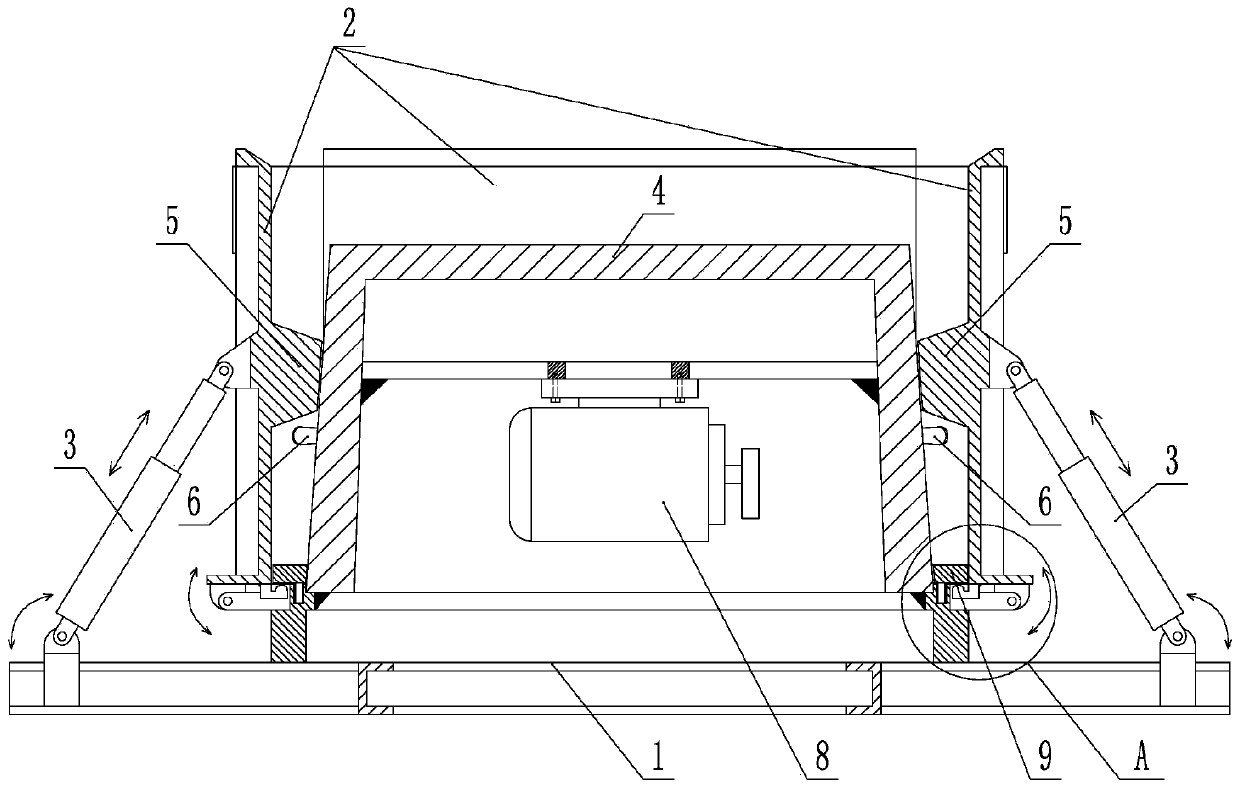

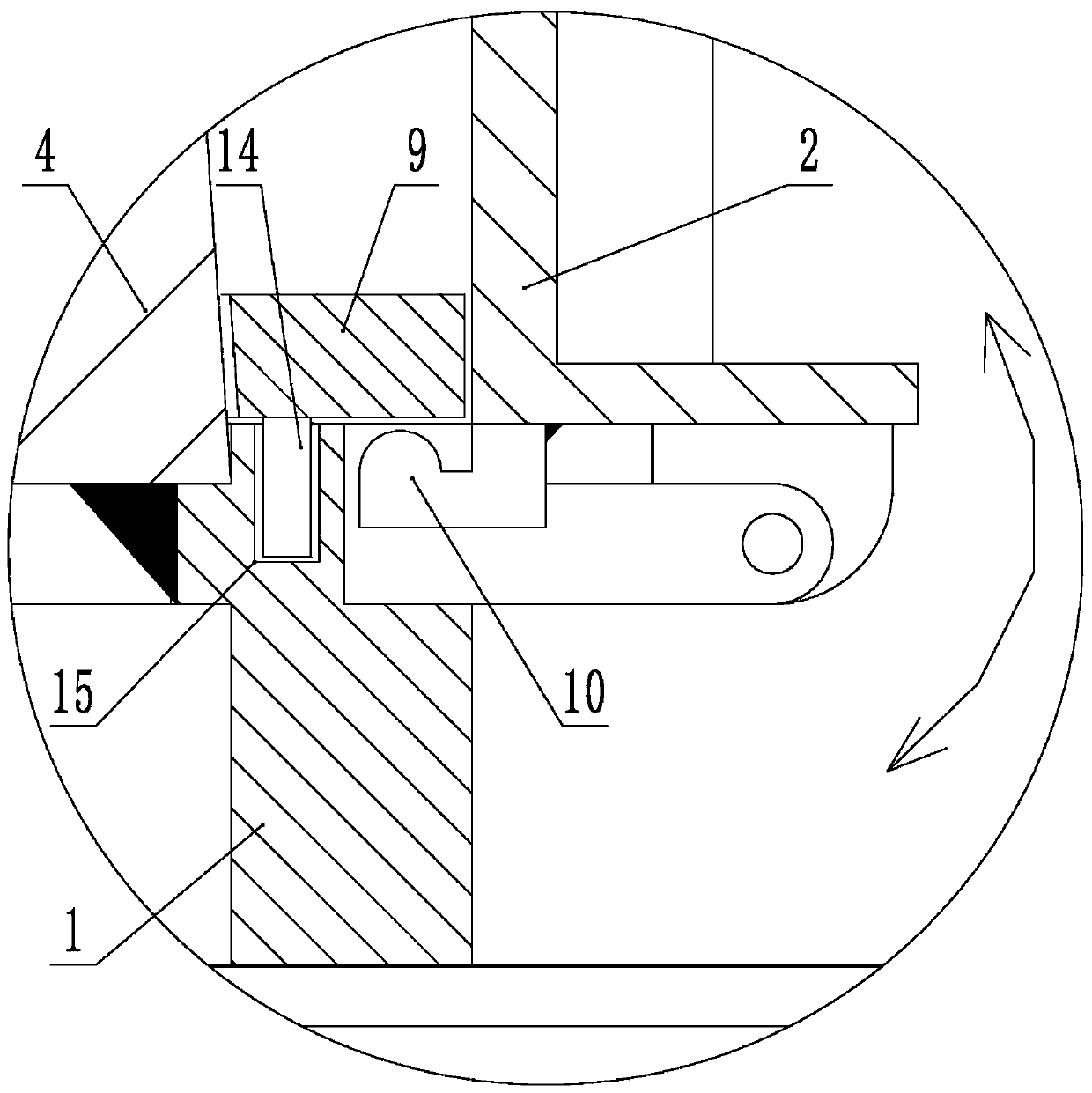

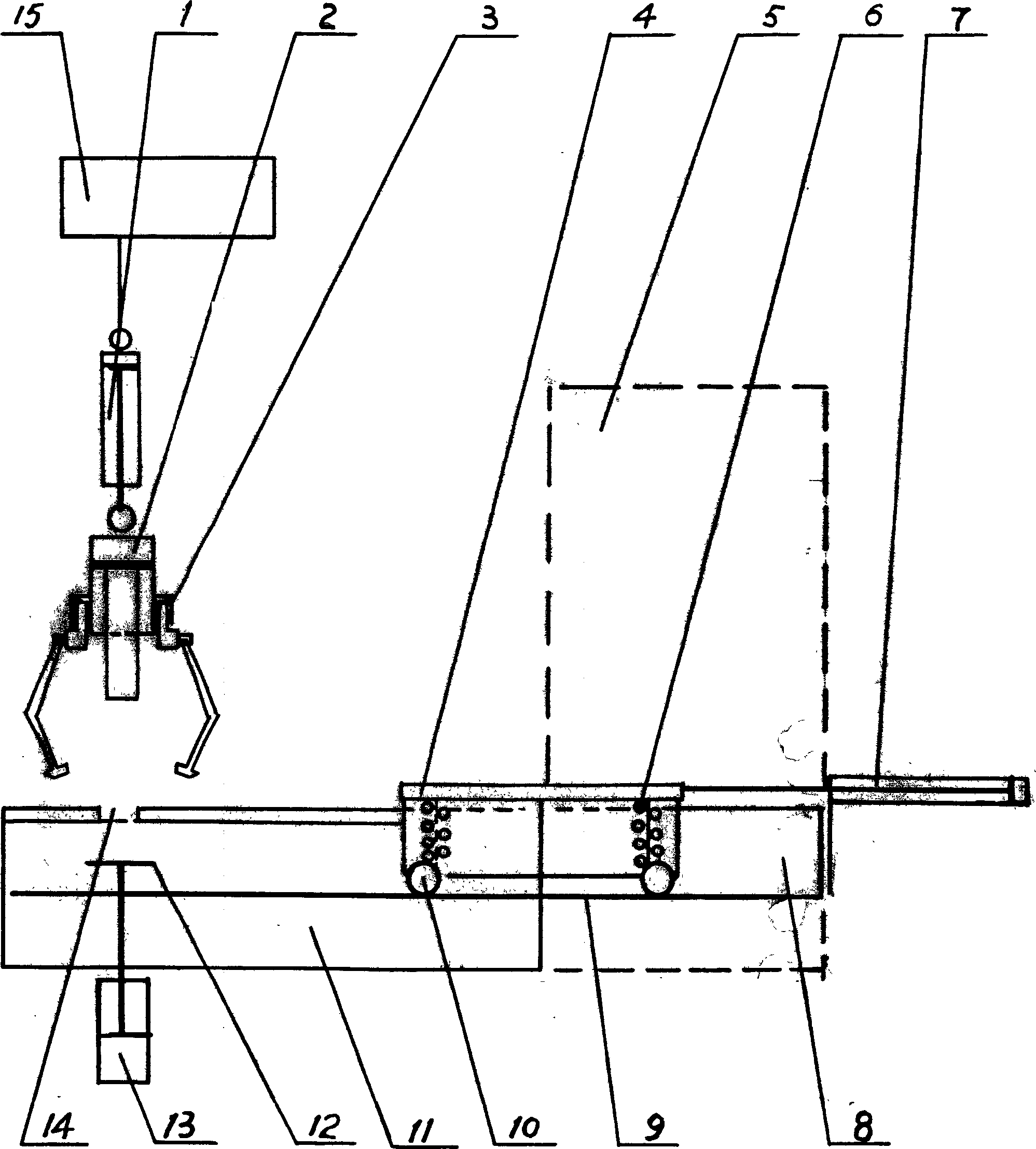

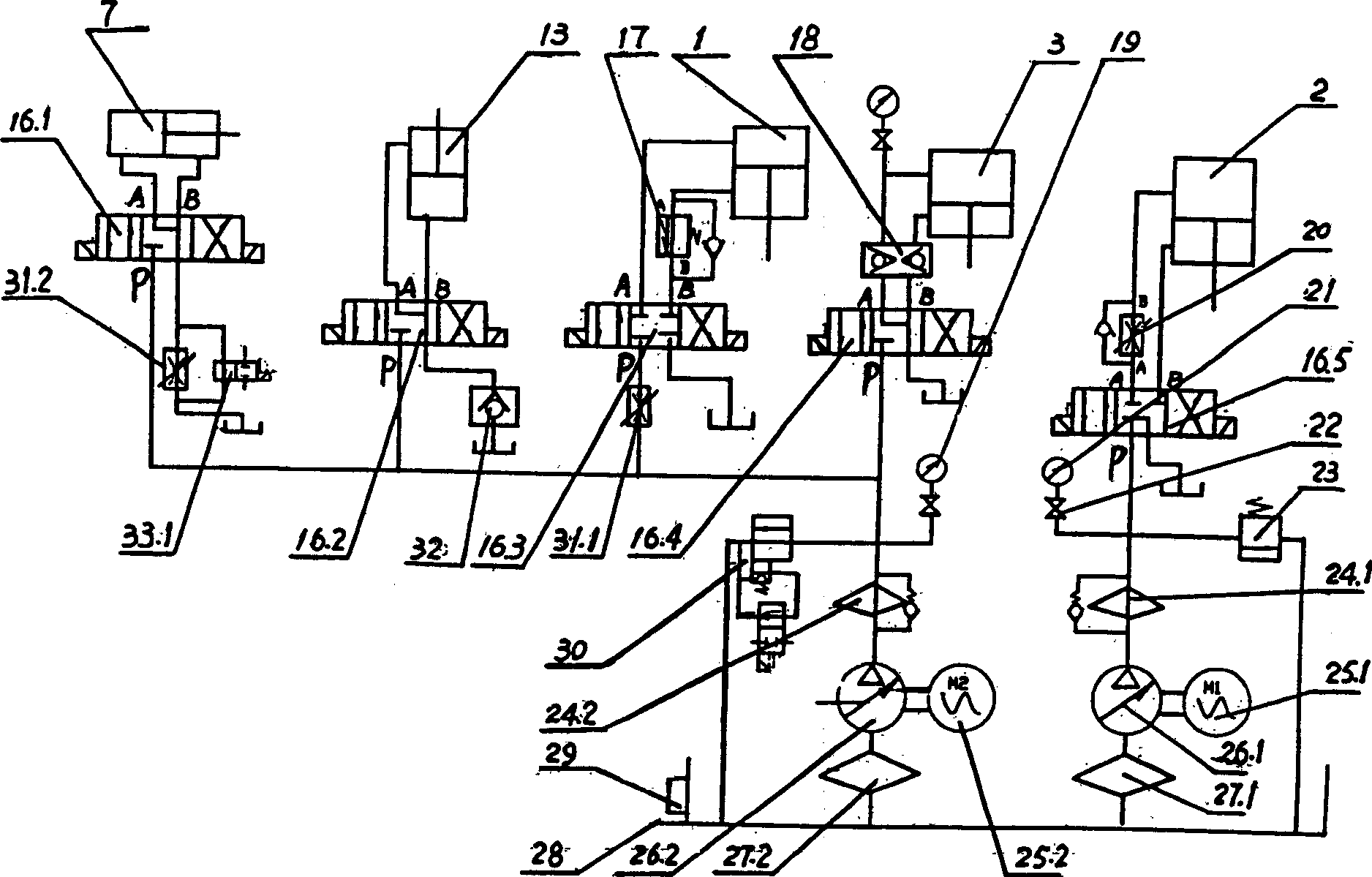

Auxiliary hydraulic set for great tonnage press

InactiveCN1706632AAchieve horizontal displacementReduce labor intensityPressesHydraulic cylinderHydraulic structure

The auxiliary hydraulic set for great tonnage press consists of floating movable platform attached to the press, platform seat and manipulator suspended over the platform seat. The auxiliary hydraulic set features that the floating movable platform is set on the tracks on the platform seat via four rollers and support springs and has one connected translation hydraulic cylinder to constitute displacing mechanism, the platform seat has one demolding stage hole and the manipulator is operated and controlled with the lifting hydraulic cylinder, pushing hydraulic cylinder and clamping hydraulic cylinder over the hole and the supporting hydraulic cylinder below the hole. The completely hydraulic structure can realize the horizontal displacement of the floating platform and the mechanical displacement and demolding of large pressed member.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com