Chip stripping device

A technology for stripping devices and chips, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve problems such as damage, chip failure, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

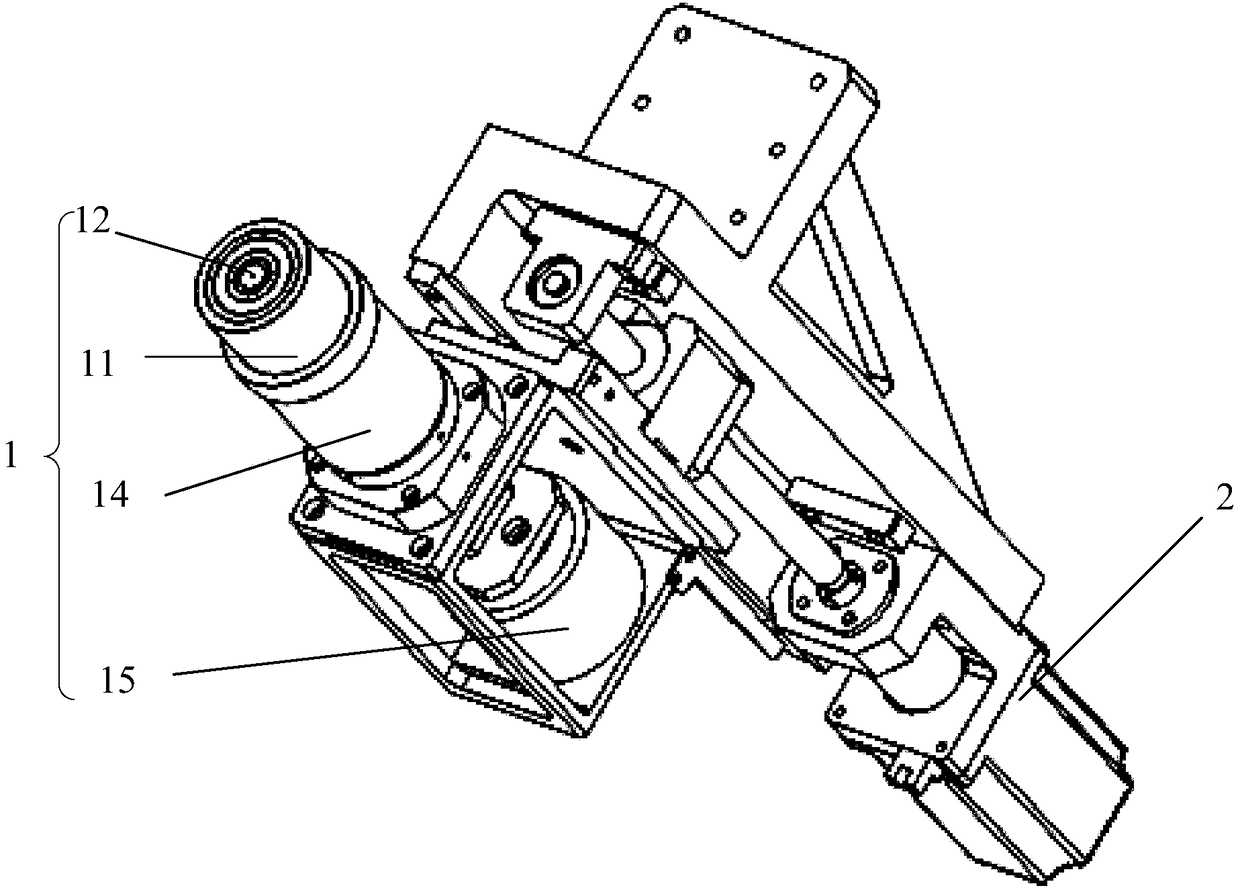

[0053] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a chip peeling device for peeling the blue film on the chip; including:

[0054] A device body 1, said device body 1 comprising:

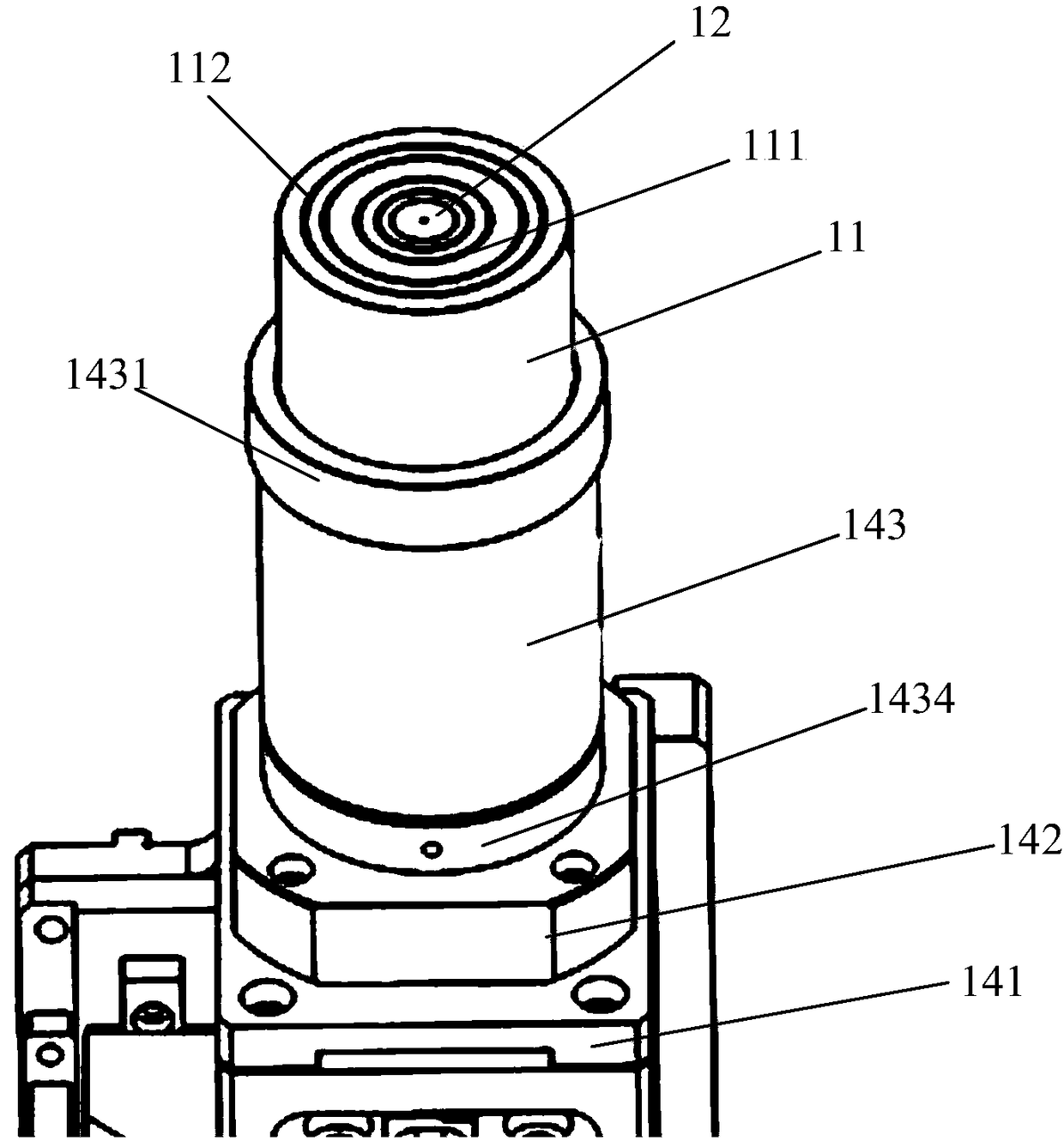

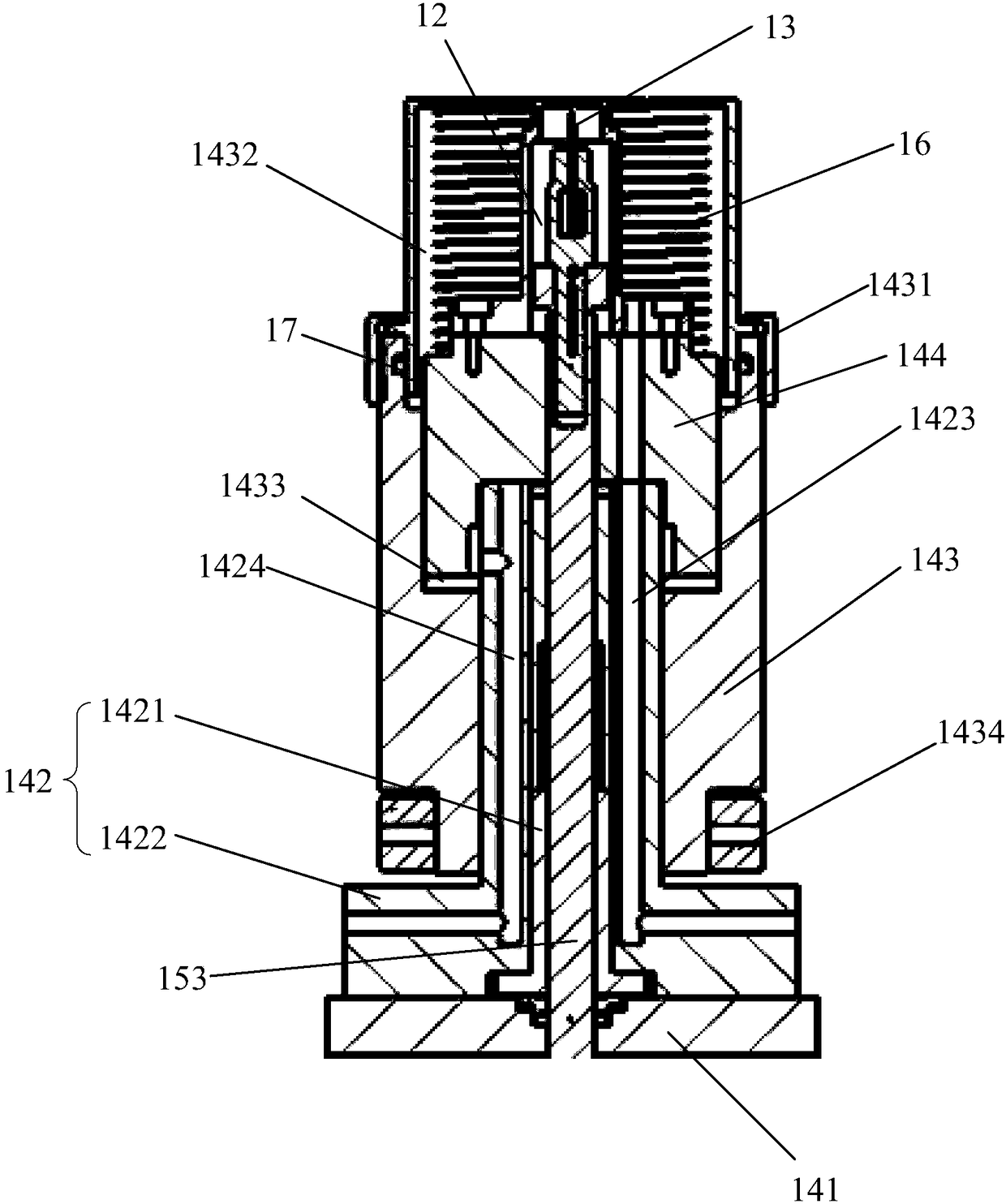

[0055] An adsorption platform 11 for adsorbing the blue film, the adsorption surface 111 of the adsorption platform is provided with a plurality of adsorption holes 112;

[0056] The boss 12 for pre-demolding the chip, the boss is arranged in the adsorption platform 11, and the adsorption platform 11 can move up and down in the direction perpendicular to the adsorption surface 111, so as to Make the boss 12 protrude from the adsorption surface 111 or be accommodated in the adsorption platform 11;

[0057] The thimble 13 for lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com