Patents

Literature

35results about How to "Stamping realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

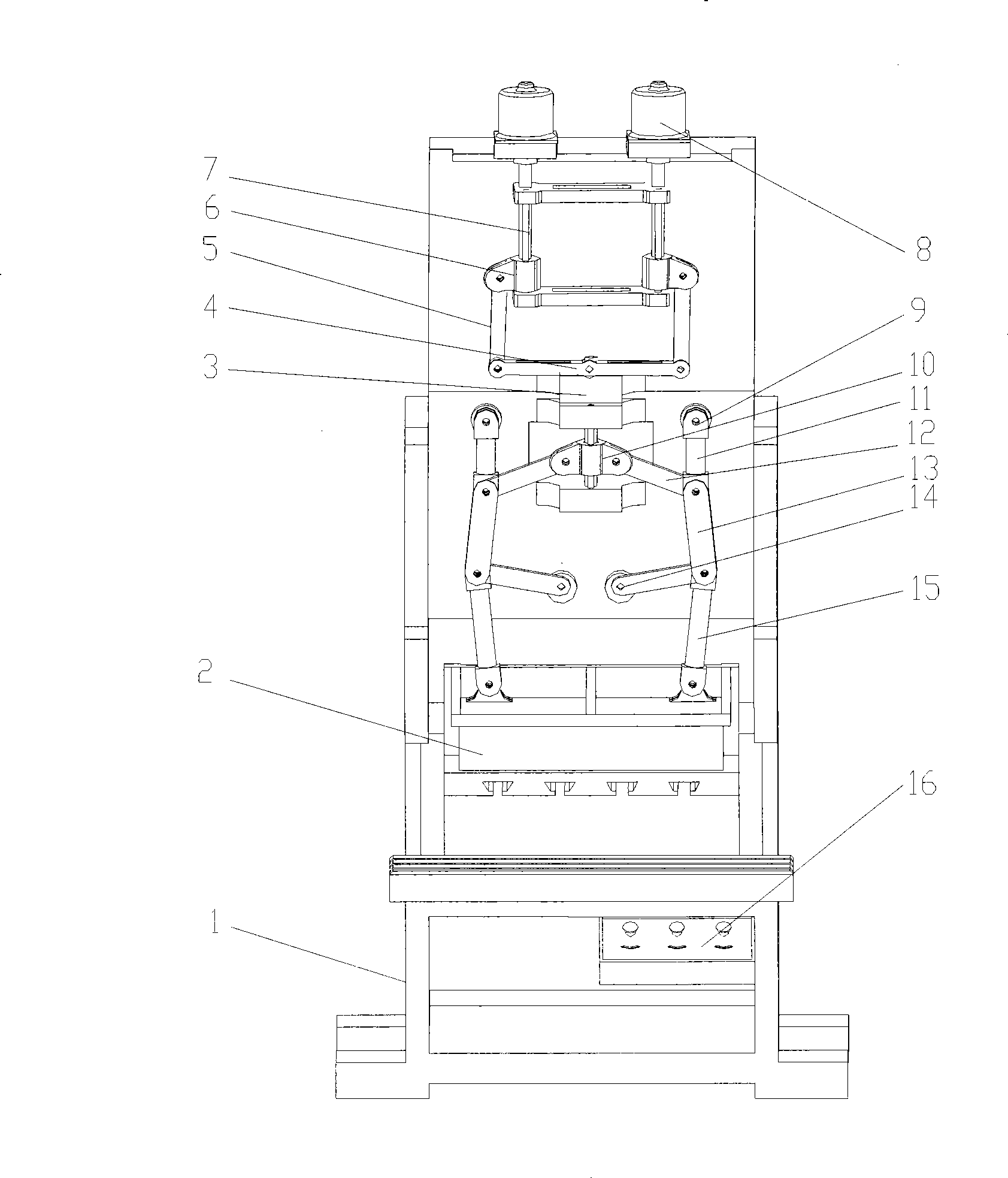

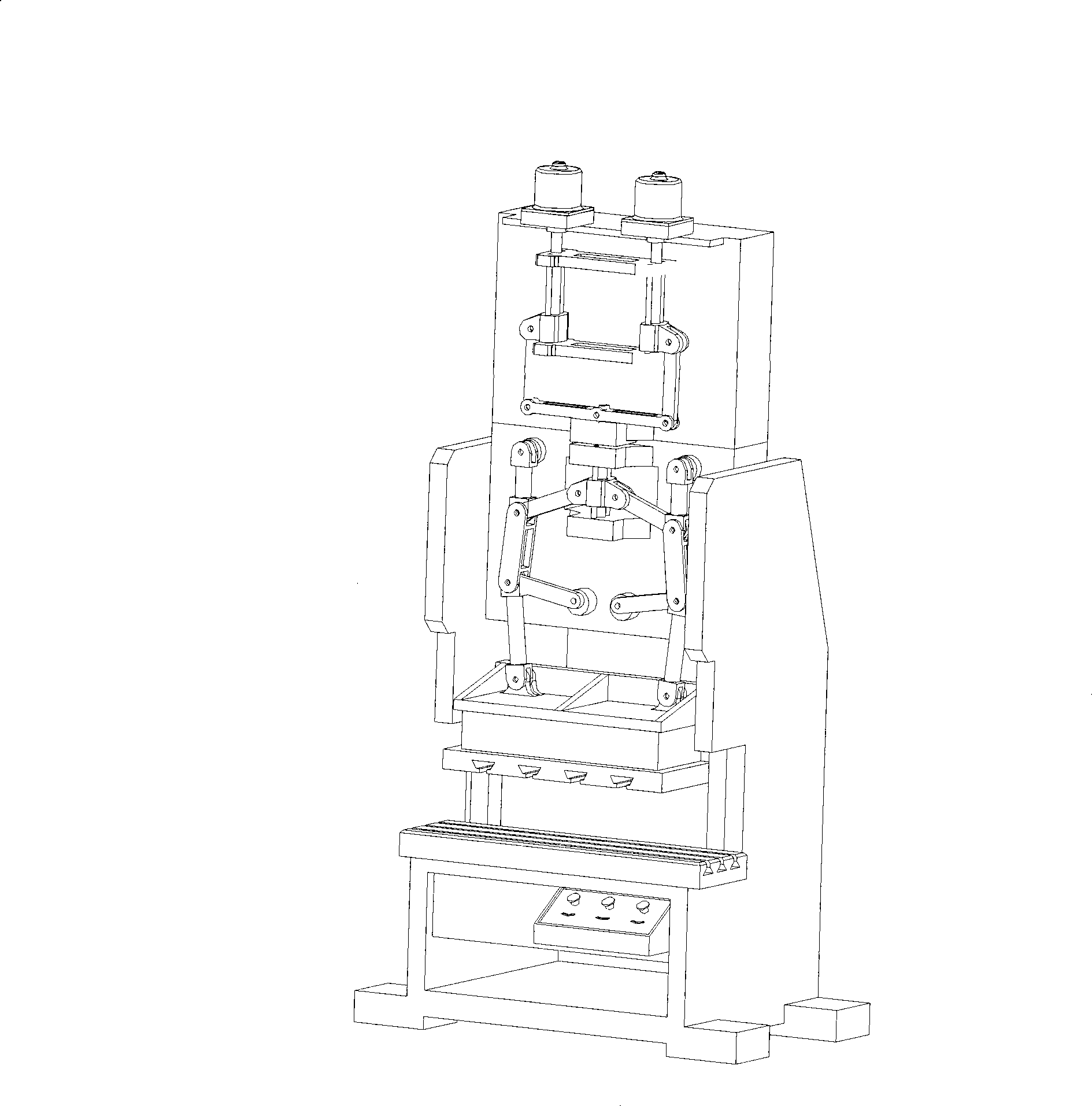

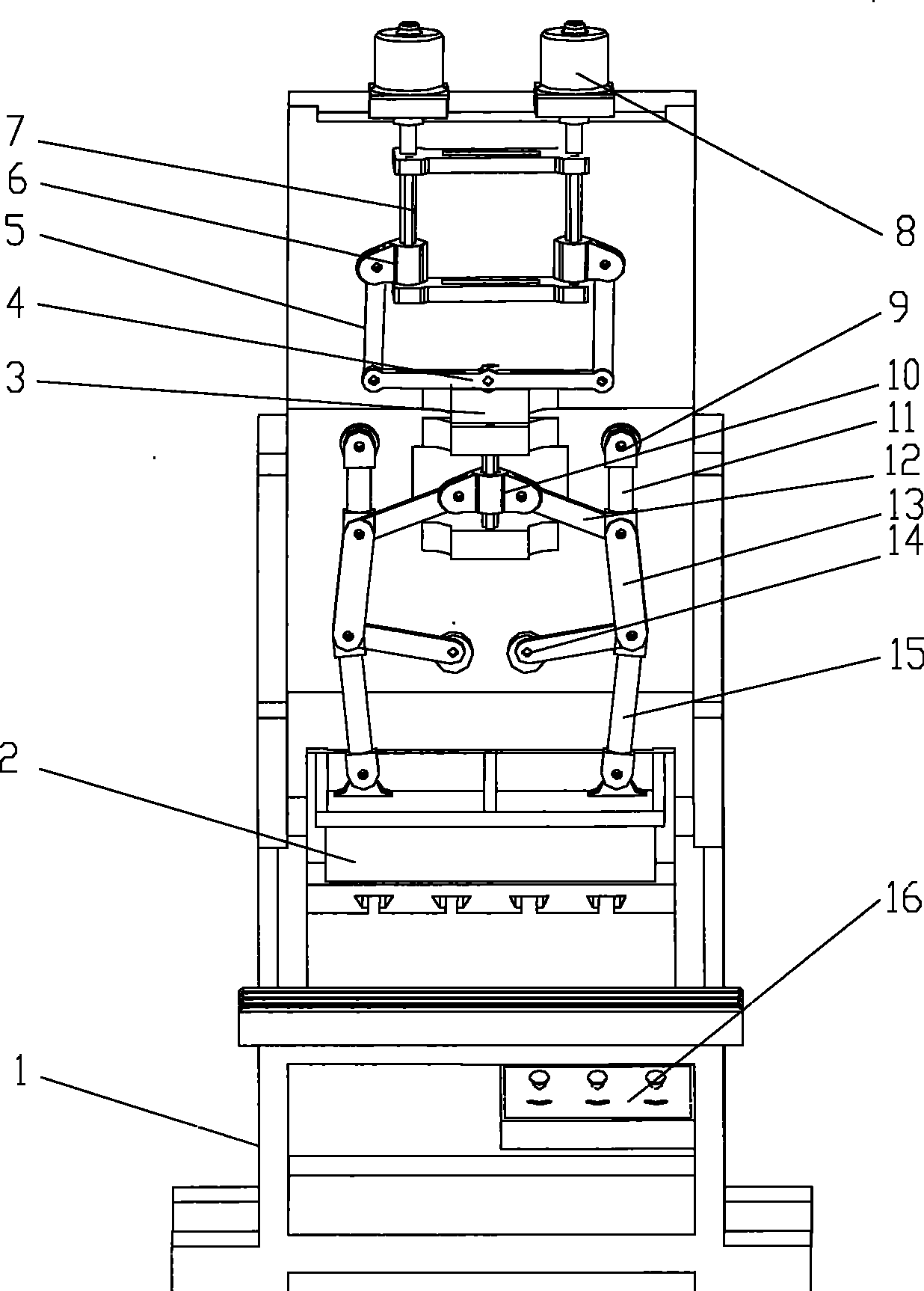

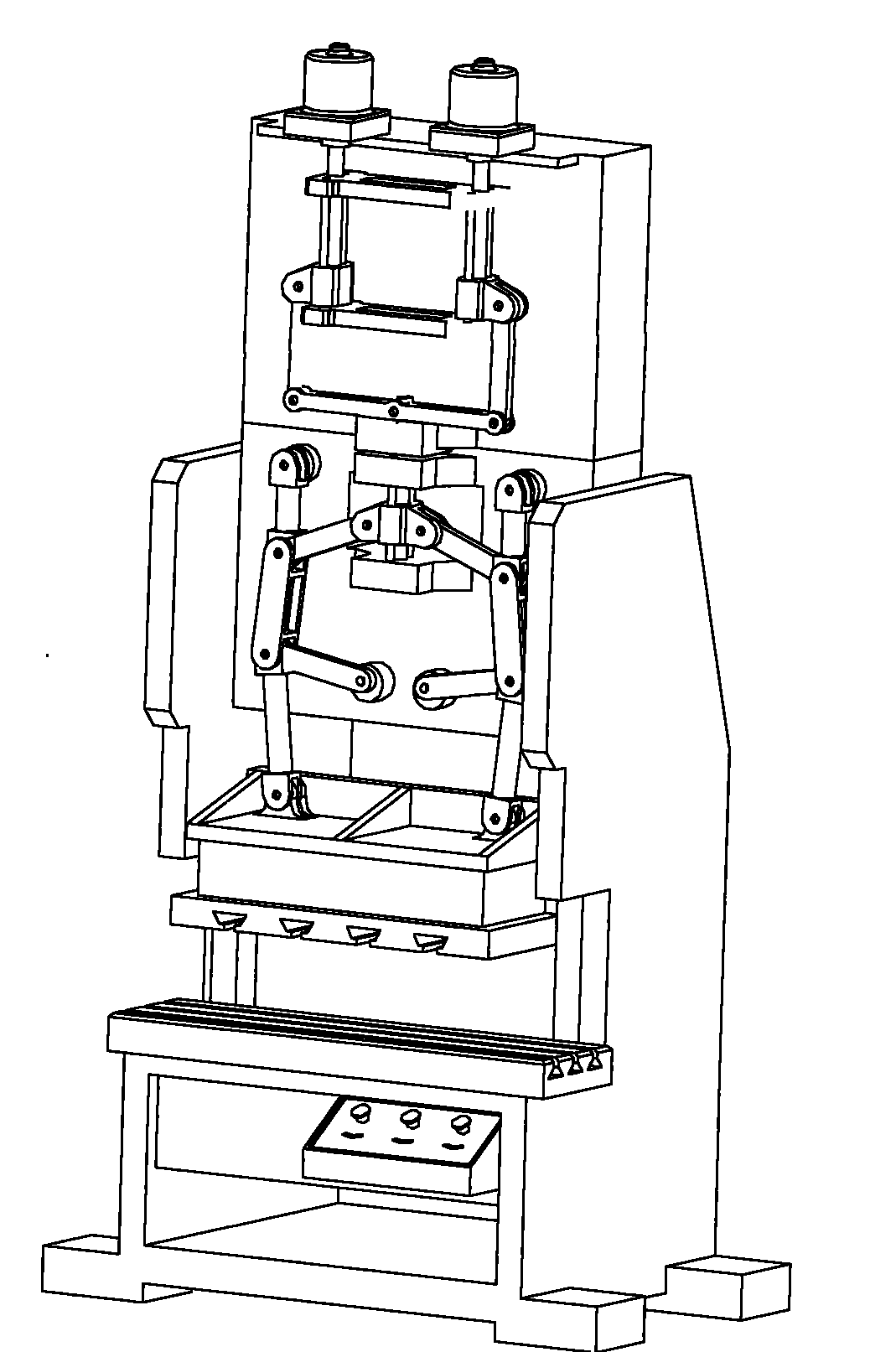

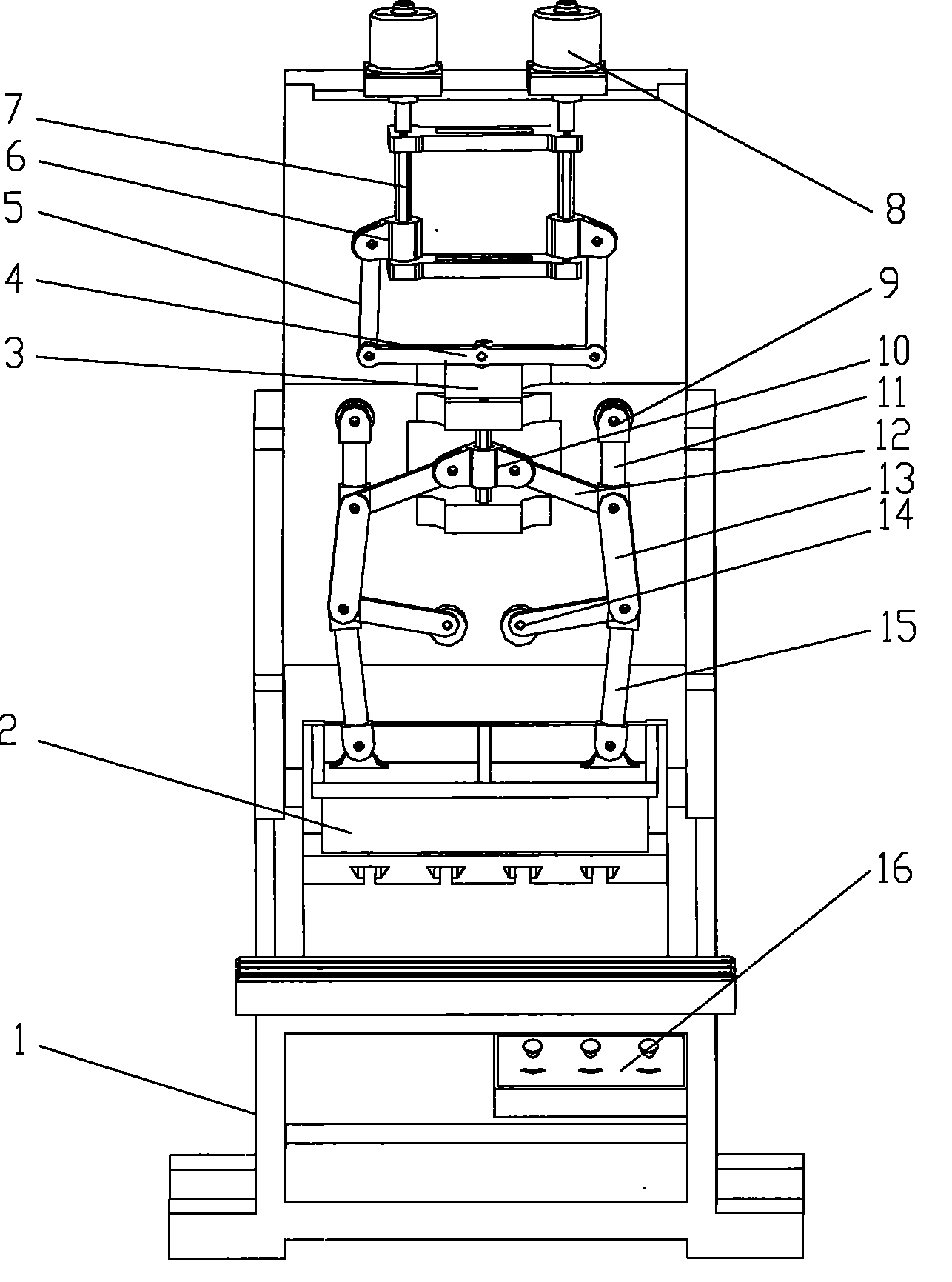

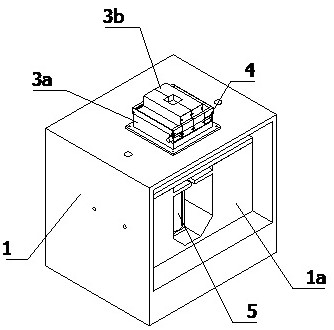

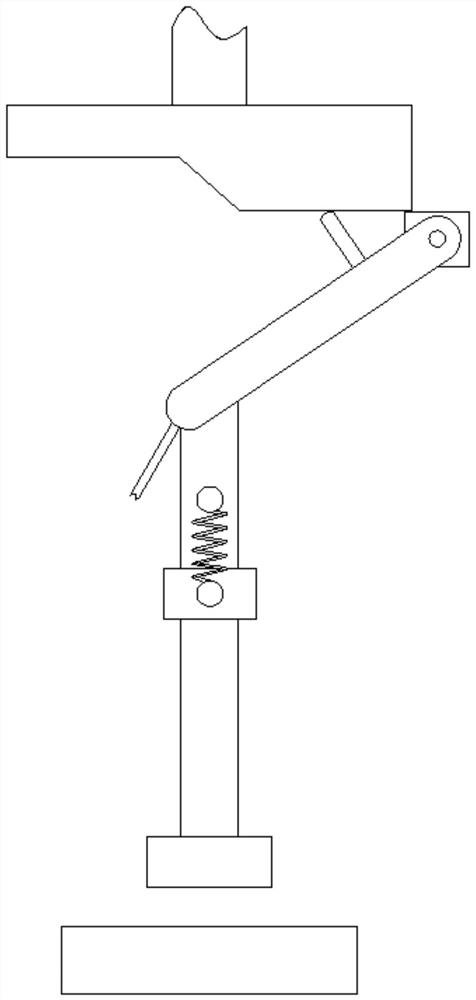

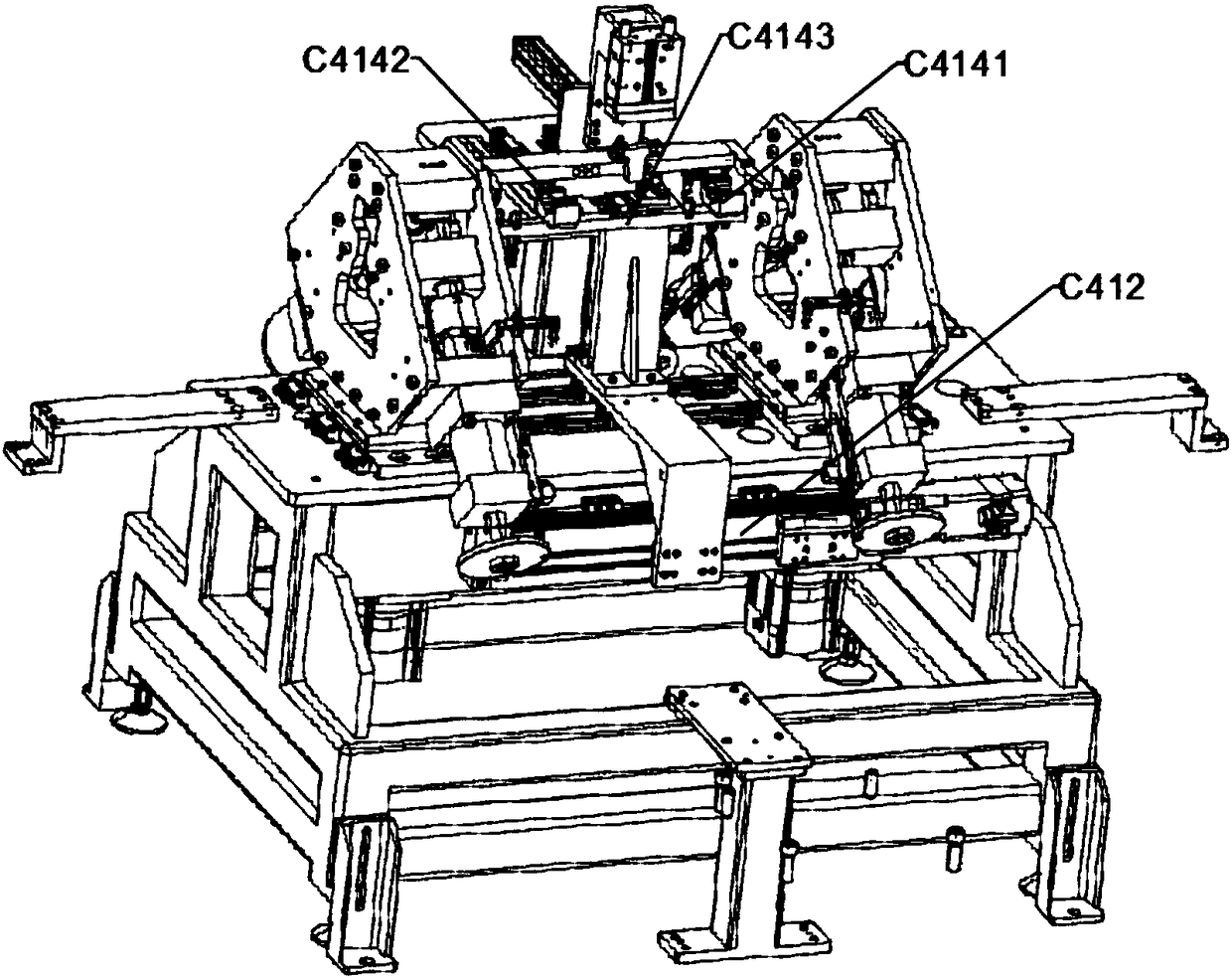

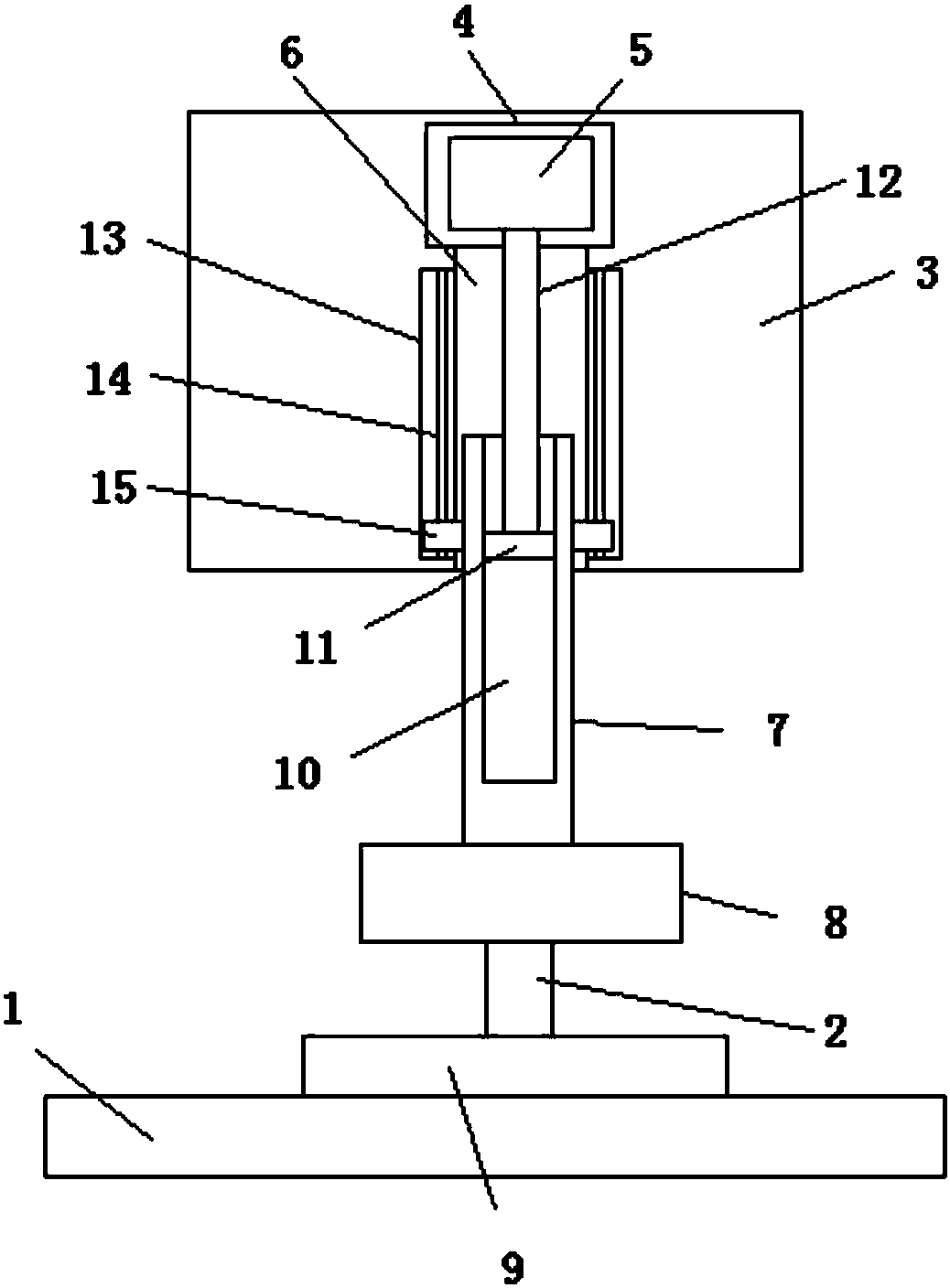

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876AGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, a horizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAO TONG UNIV

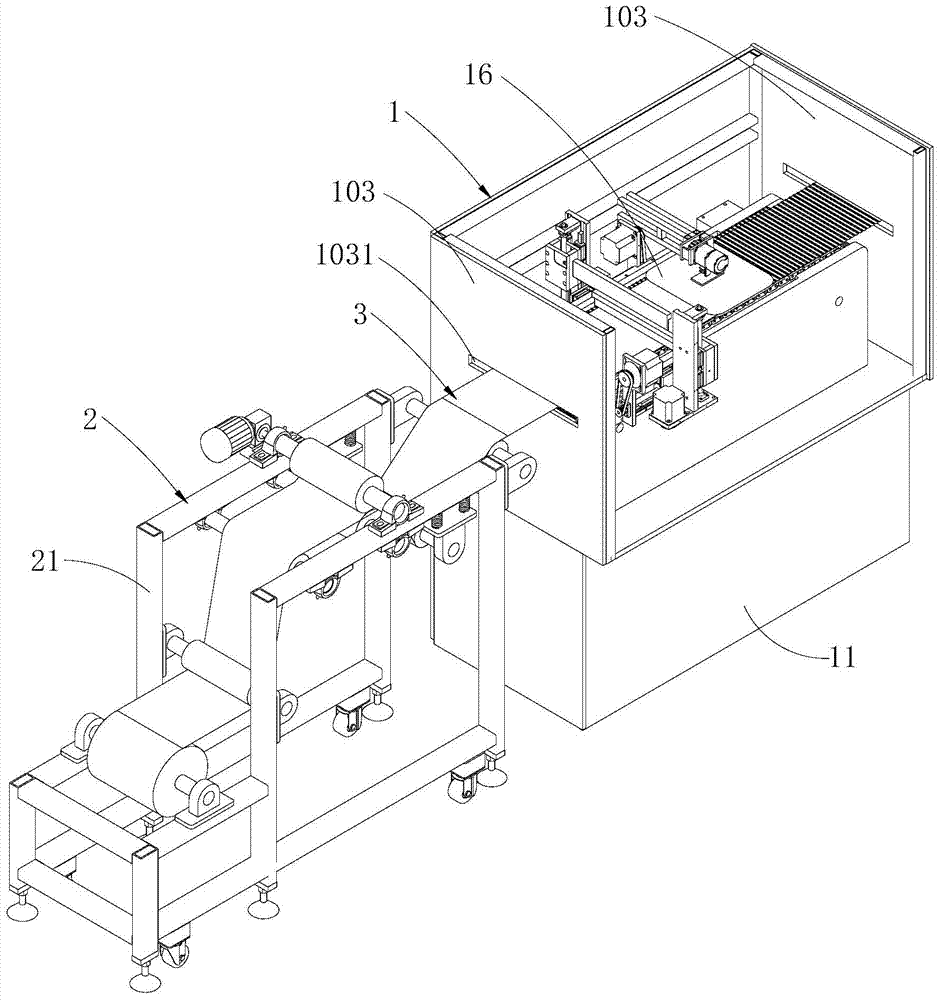

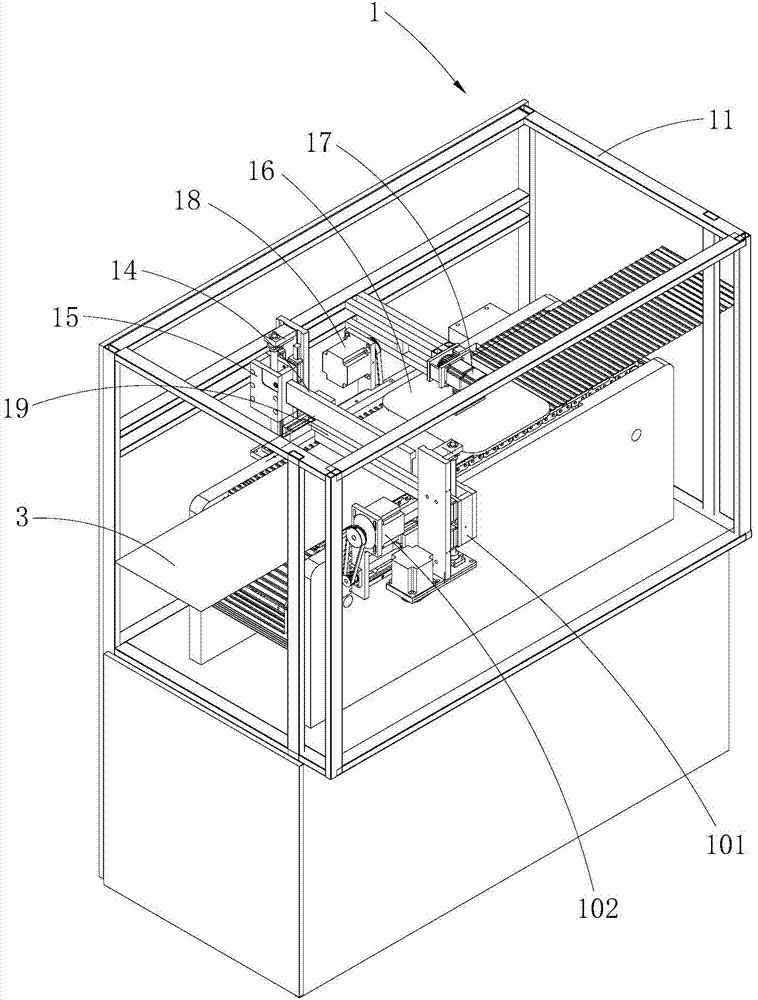

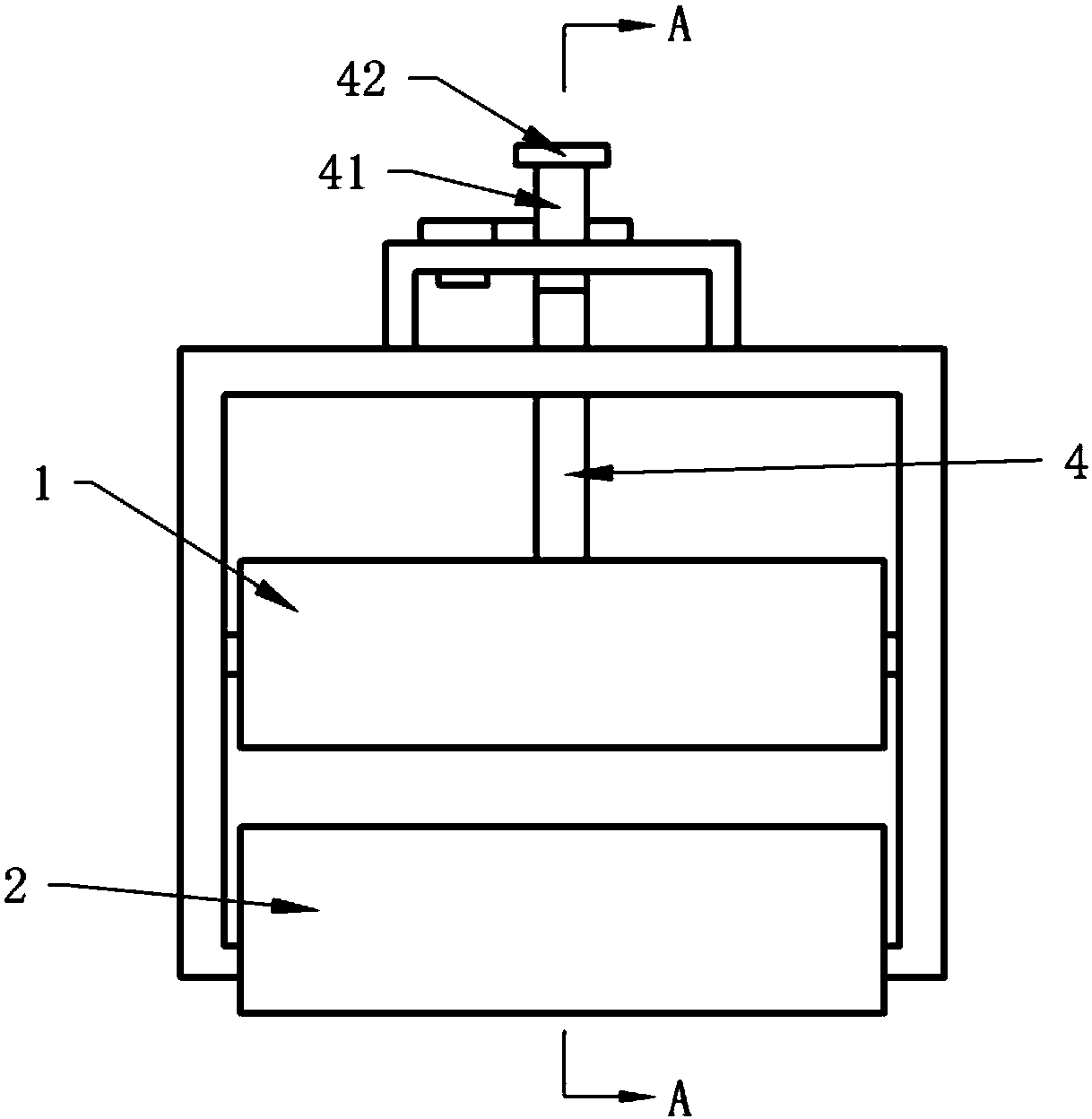

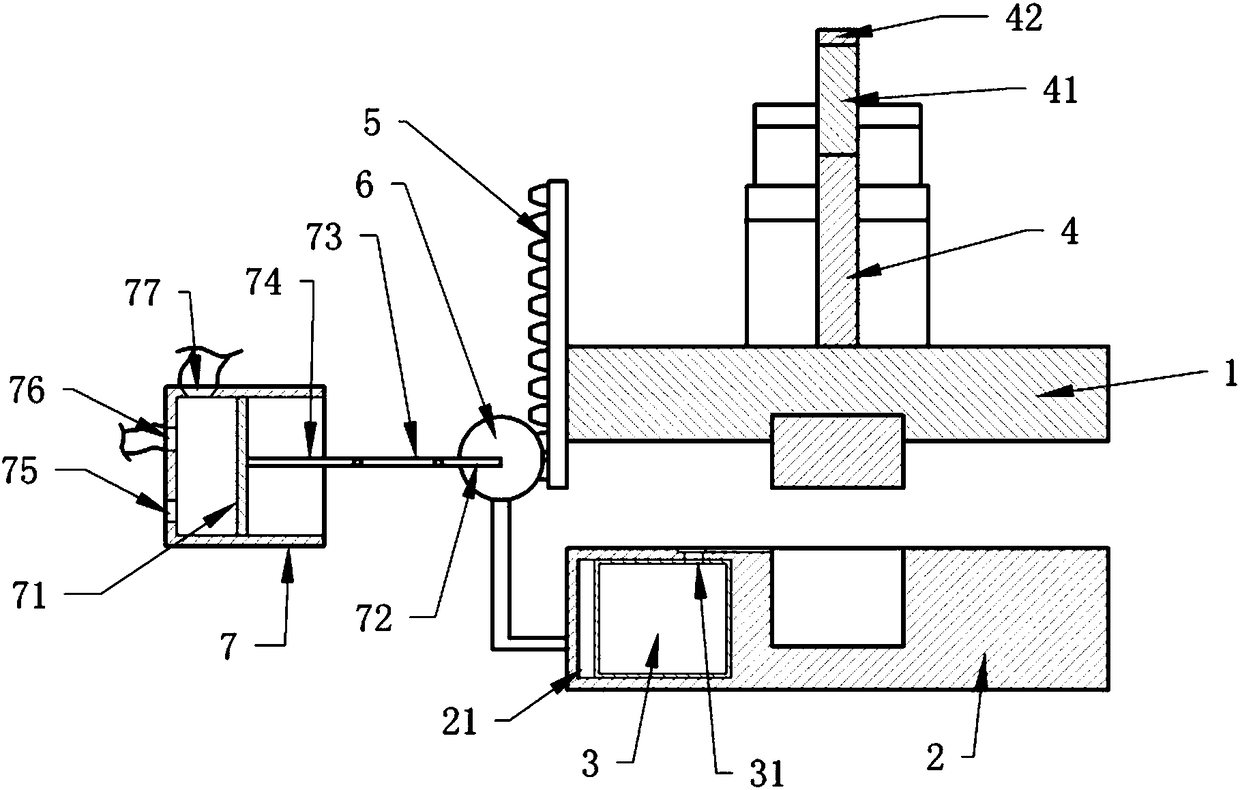

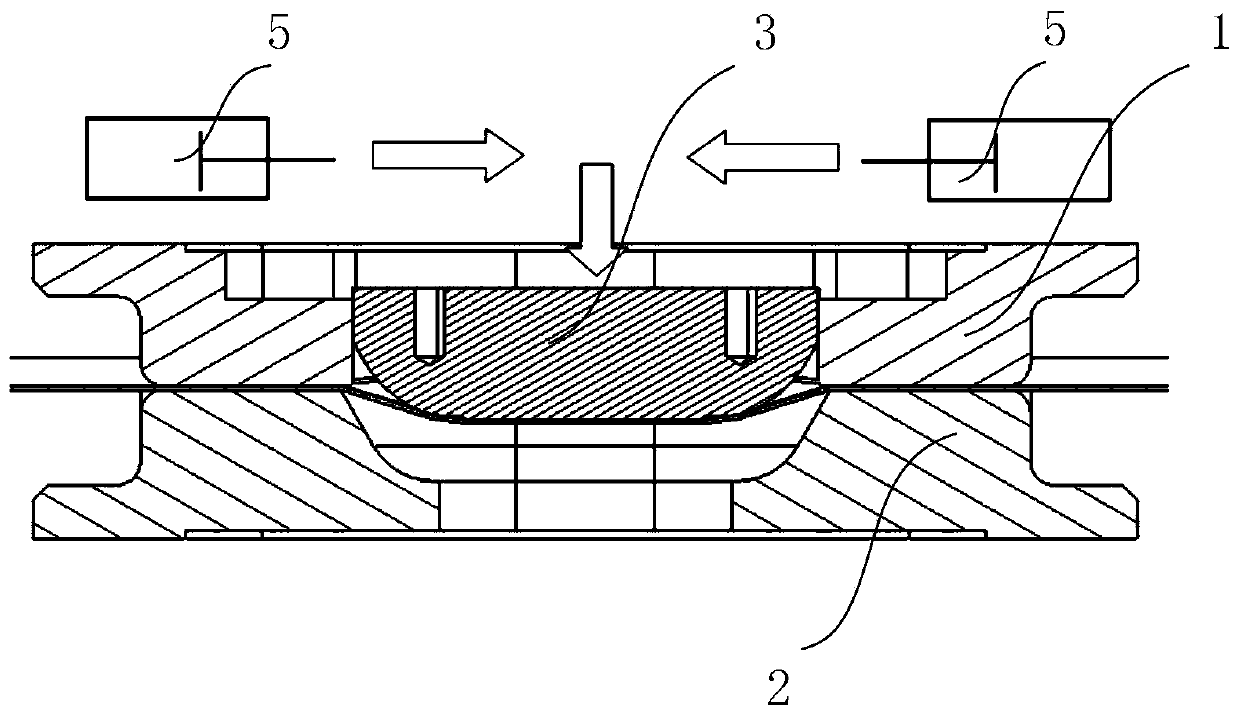

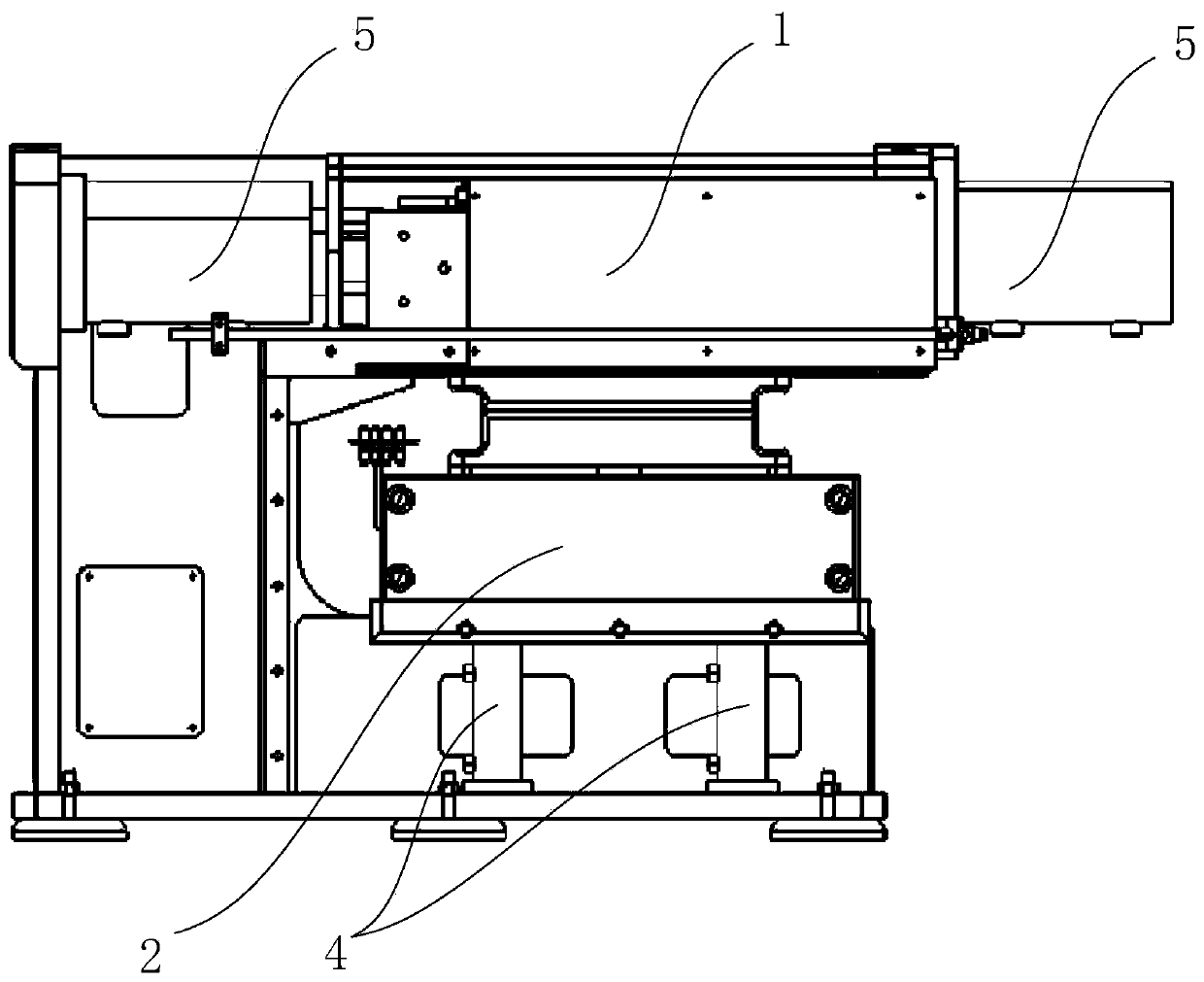

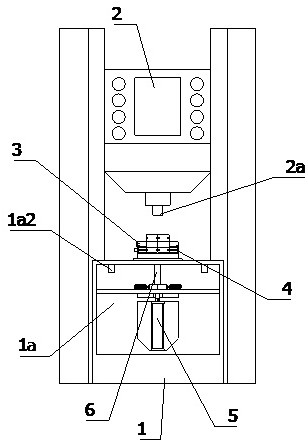

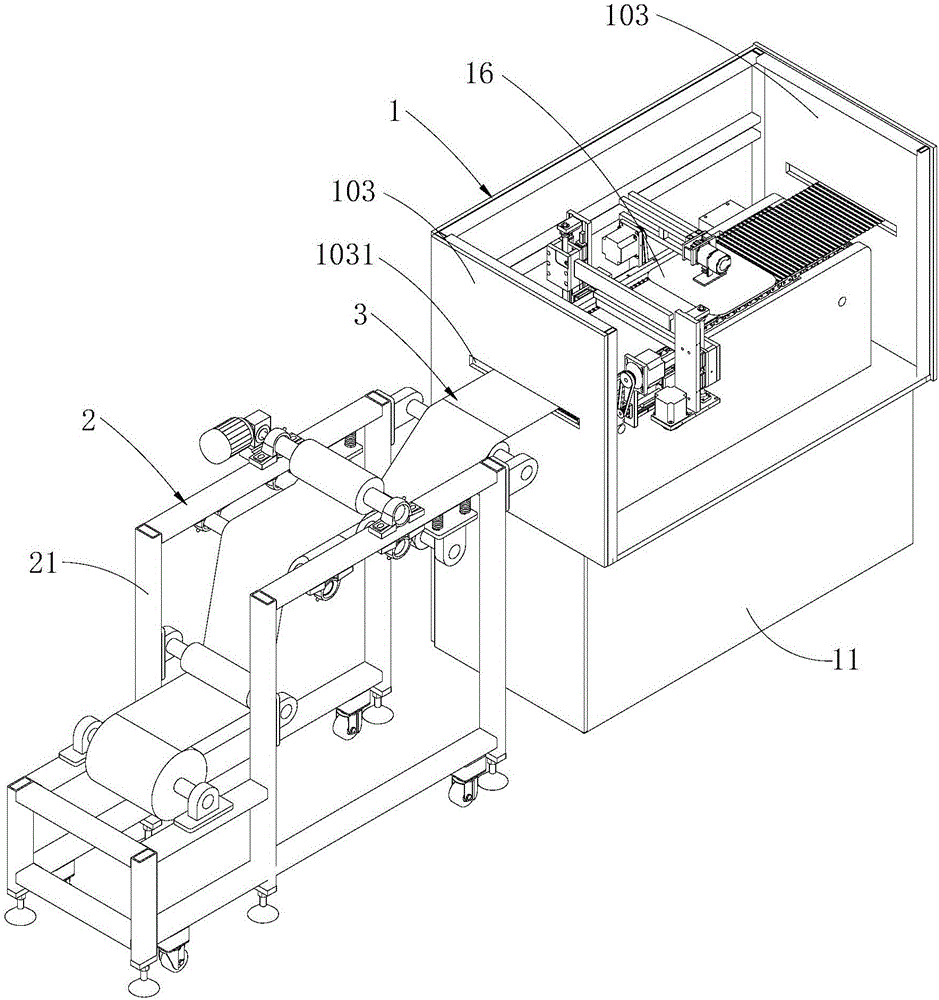

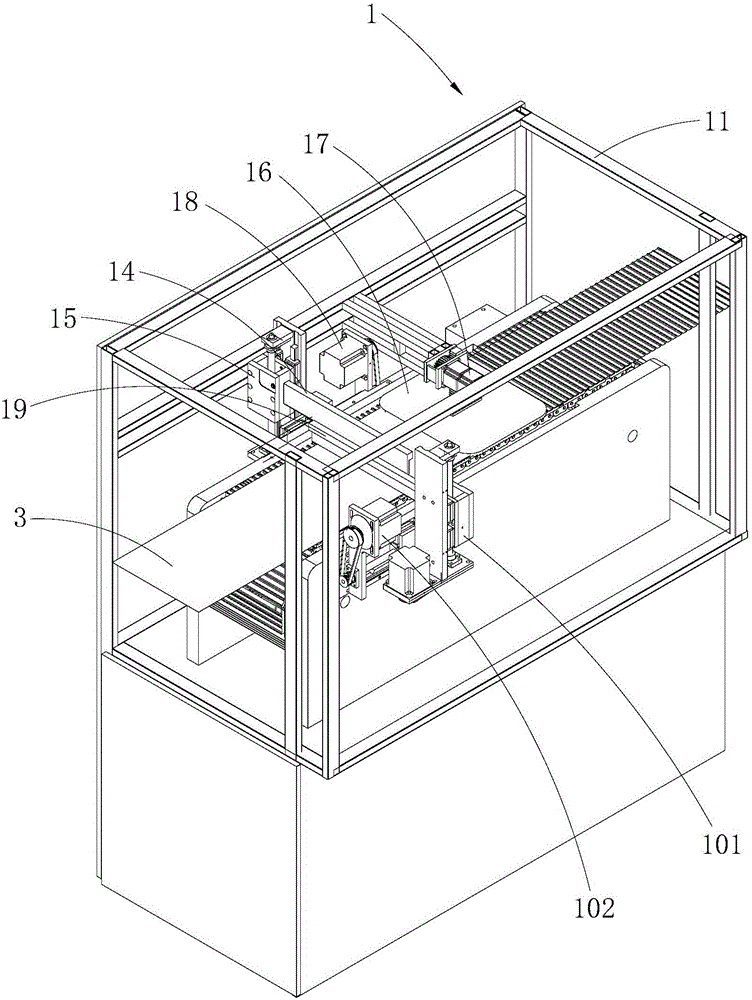

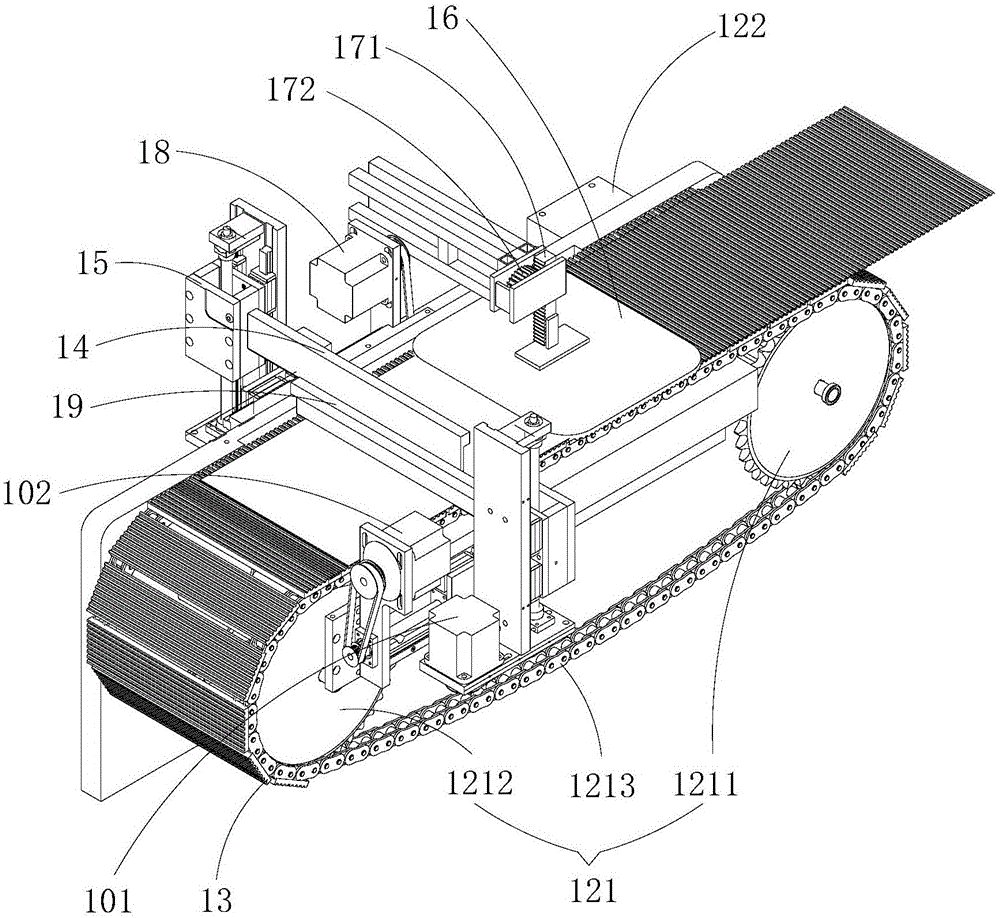

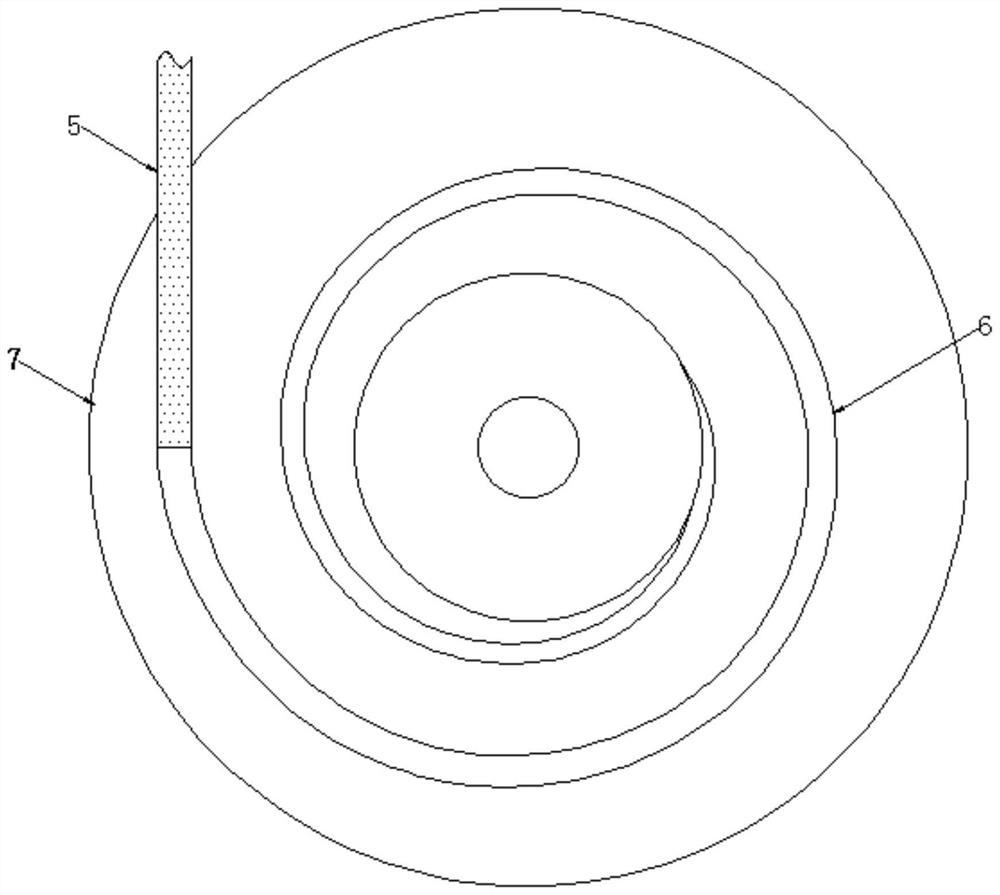

Stamping device of corrugated foils and production device of corrugated foils

ActiveCN103537539AStamping is effectiveEffective realization of stamping formingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention is applied to the field of production equipment of corrugated foils and discloses a stamping device of corrugated foils. The stamping device comprises a first frame, a conveying mechanism, a forming die, a stamping head, a first lifting component, a pressure-holding shaping plate, and a second lifting component, wherein the conveying mechanism having a conveying component is mounted on the first frame, the forming die having a forming recess is mounted on the conveying component and capable of conveying and moving foils, the stamping head disposed above the forming die is used for pressing one foil into the forming recess to shape the foil, the first lifting component is used for driving the stamping head to ascend and descend, the pressure-holding shaping plate disposed above the forming die is used for pressure-held shaping of the shaped foil, and the second lifting component is used for driving the pressure-holding shaping plate to ascend and descend. A conveying direction of the pressure-holding shaping plate is behind the stamping head. The invention further discloses a production device of the corrugated foils. The production device comprises a shaping device of the corrugated foils and a conveying device used for conveying the foils to the stamping die. The stamping device and the production device have the advantages that production efficiency is high and shaping quality of the corrugated foils is good.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Die for automobile part

The invention belongs to the technical field of automobile part machining and discloses a die for an automobile part. The die comprises an upper convex die and a lower concave die. The lower concave die is internally provided with a feeding bin, the feeding bin is internally provided with a material storage air bag, and the material storage air bag is provided with a material outlet and a feedingopening. The lower concave die is provided with a feeding slot and material guide slots. The die further comprises an inverted-U-shaped bracket, the bracket comprises a transverse rod and a vertical plate, and the upper surface of the upper concave die is rotatably connected with a screw rod penetrating through the transverse rod. The die further comprises a drive piece, and the drive piece comprises a first gear and a rack. One side of the lower concave die is provided with a supporting frame, the supporting frame is provided with a rotating shaft, the first gear is fixed to one end of the rotating shaft, and the other end of the rotating shaft is provided with a rotary table. One side of the lower concave die is provided with a gas storage barrel, and the gas storage barrel is internallyand slidably connected with a piston. The die further comprises a first connection rod, a second connection rod and a third connection rod, wherein the first connection rod, the second connection rodand the third connection rod are hinged in sequence. By means of the die for the automobile part, the problem that in the prior art, a stamped and formed automobile part is in close fit with the lower die so that the formed automobile part is not prone to be taken out is solved.

Owner:CHONGQING YINSHENG MOLD

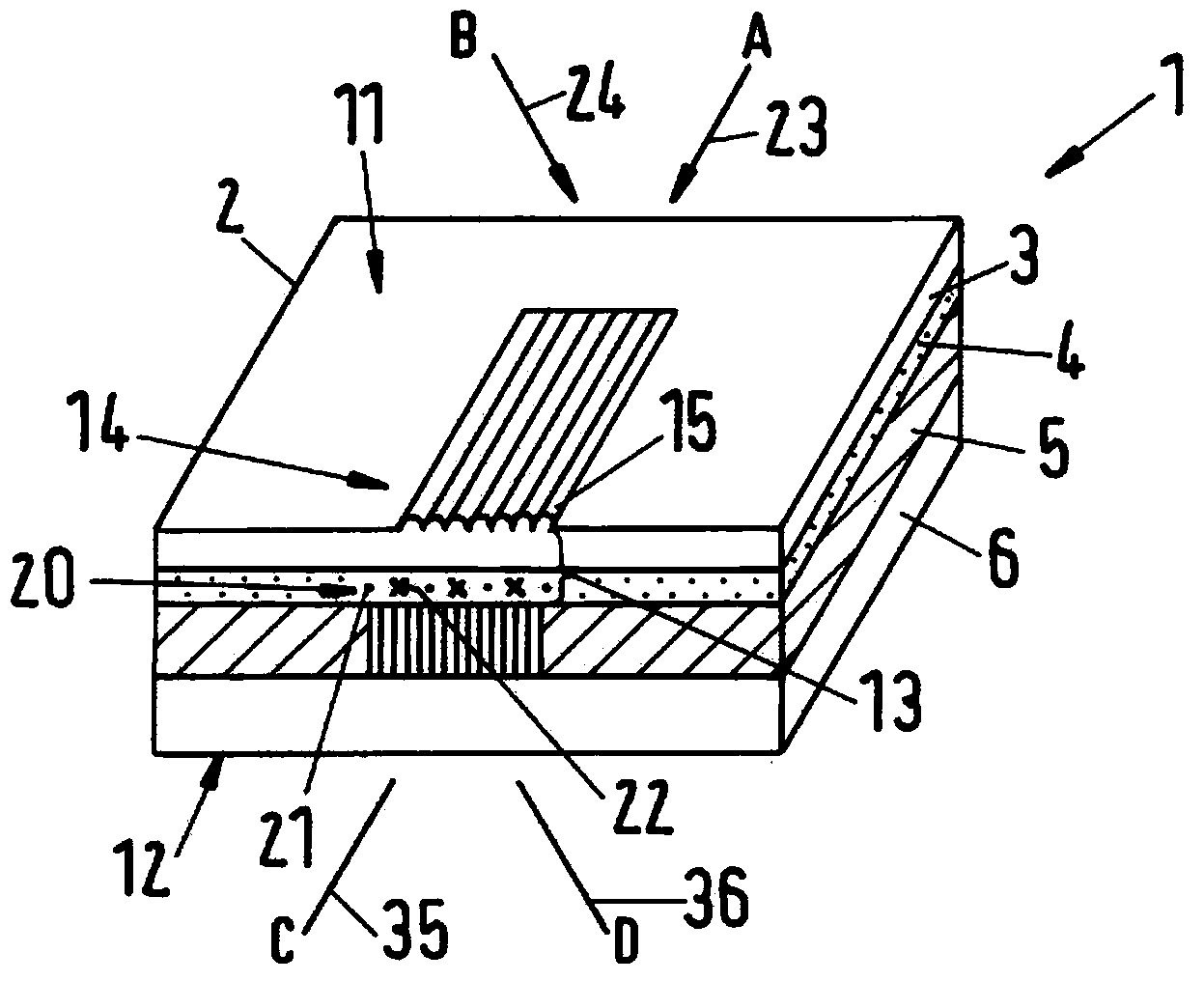

Security document having a perforation window, and method for the production thereof

ActiveCN104203589AStamping realizationOther printing matterInformation cardsDirect observationPaper document

The invention relates to a method for producing a security document, a method for verifying a security document, and a security document, which comprises: a document body (2) having a front side (11) and an opposite back side (12), wherein the document body (2) is produced using at least one planar, self-supporting opaque layer (5), which is integrated into the document body (2) between the front side (11) and the back side (12), and wherein at least one optically verifiable security feature (13, 14, 15) is formed in the document body (2), which security feature has different optical effects with regard to an observation through the front side (11) and an observation through the back side (12), wherein a plurality of through-holes (30) are formed in the opaque layer (5) and arranged in such a way that the at least one optically verifiable security feature (13, 14, 15) can be optically detected both in an observation through the front side (11) and in an observation through the back side (12), wherein one of the two observations is a through-view observation (35, 36) that occurs through the through-holes in the opaque layer, and the other is a direct observation (25, 26) that does not occur through the through-holes, and the at least one optically verifiable security feature (13, 14, 15) is designed in such a way that different optical effects can be detected in the direct observation (25, 26) and in the through-view observation (35, 36), the difference of said optical effects not being caused by the presence of the opaque layer (5) and / or the through-holes (30).

Owner:BUNDESDRUCKEREI GMBH

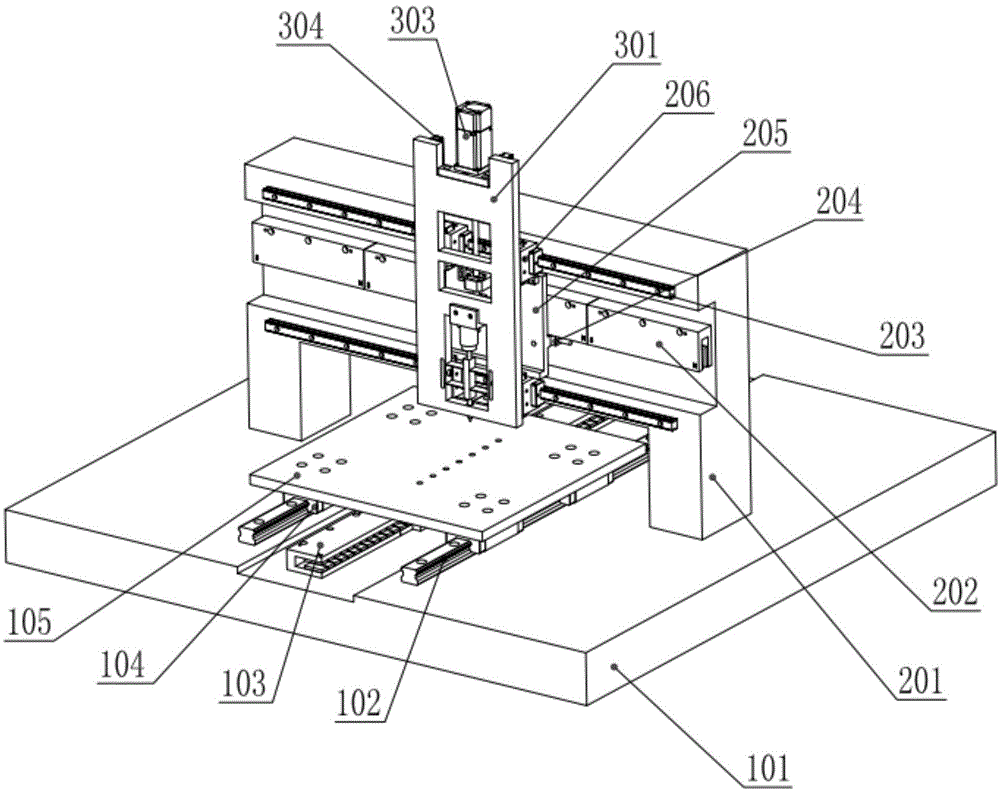

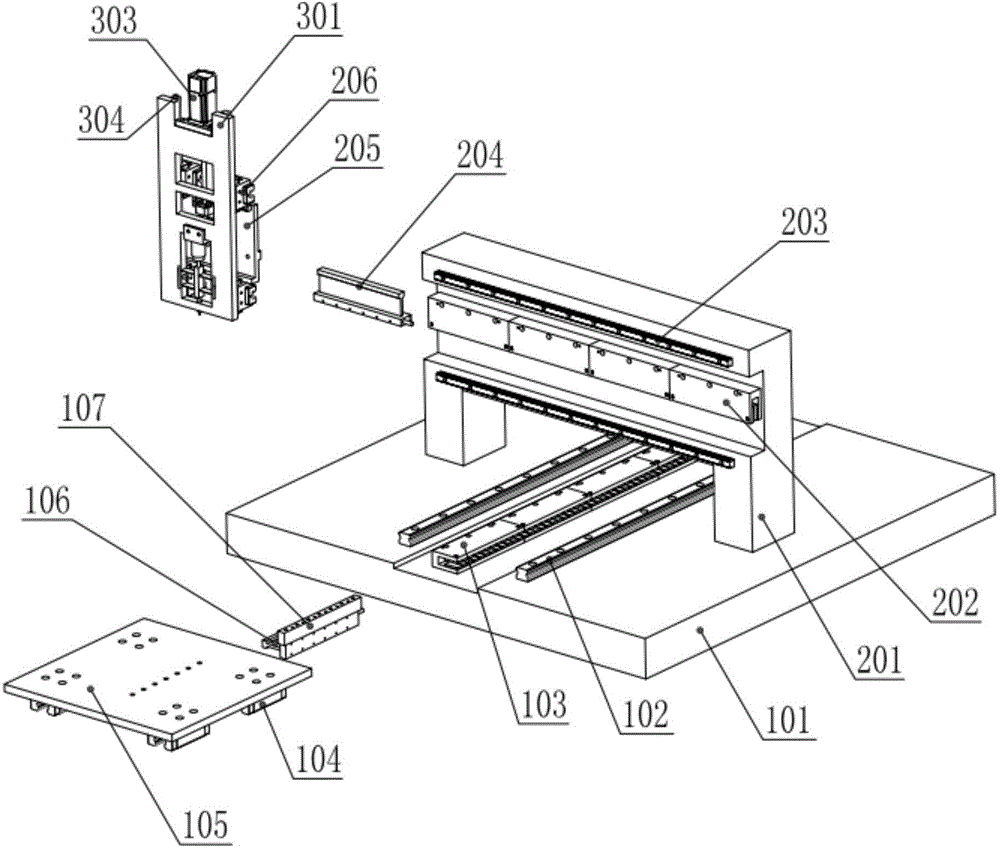

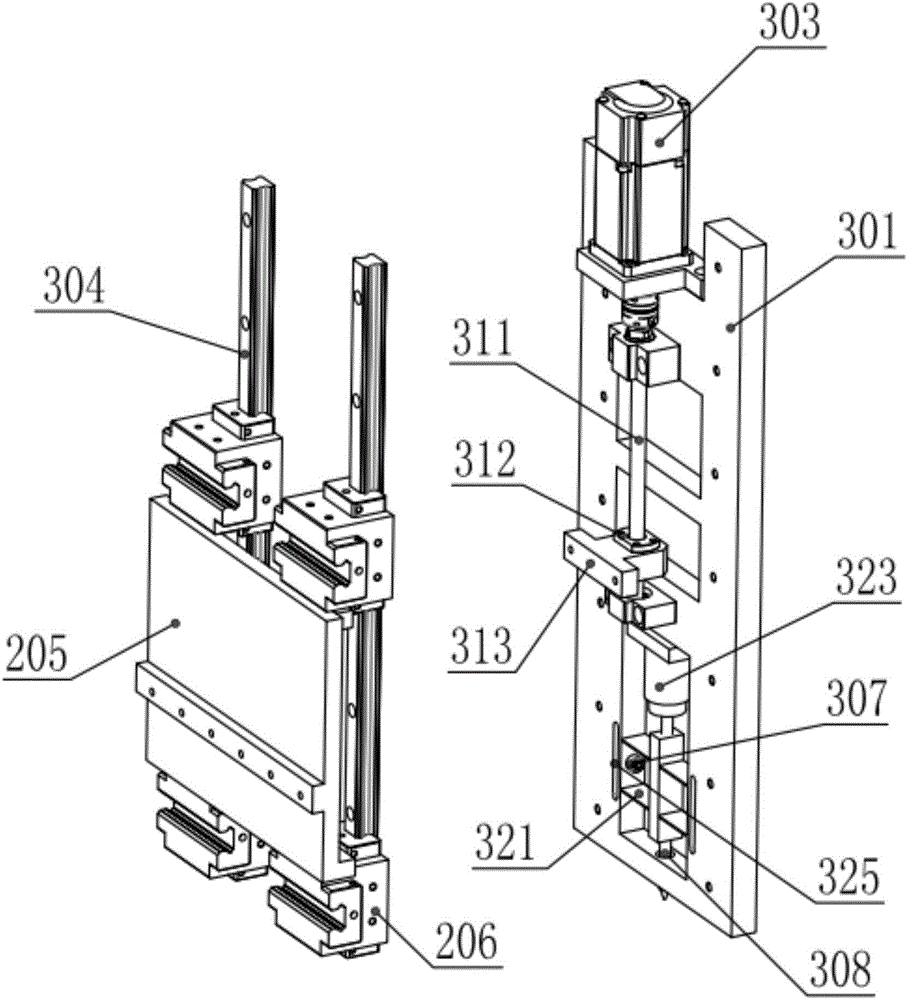

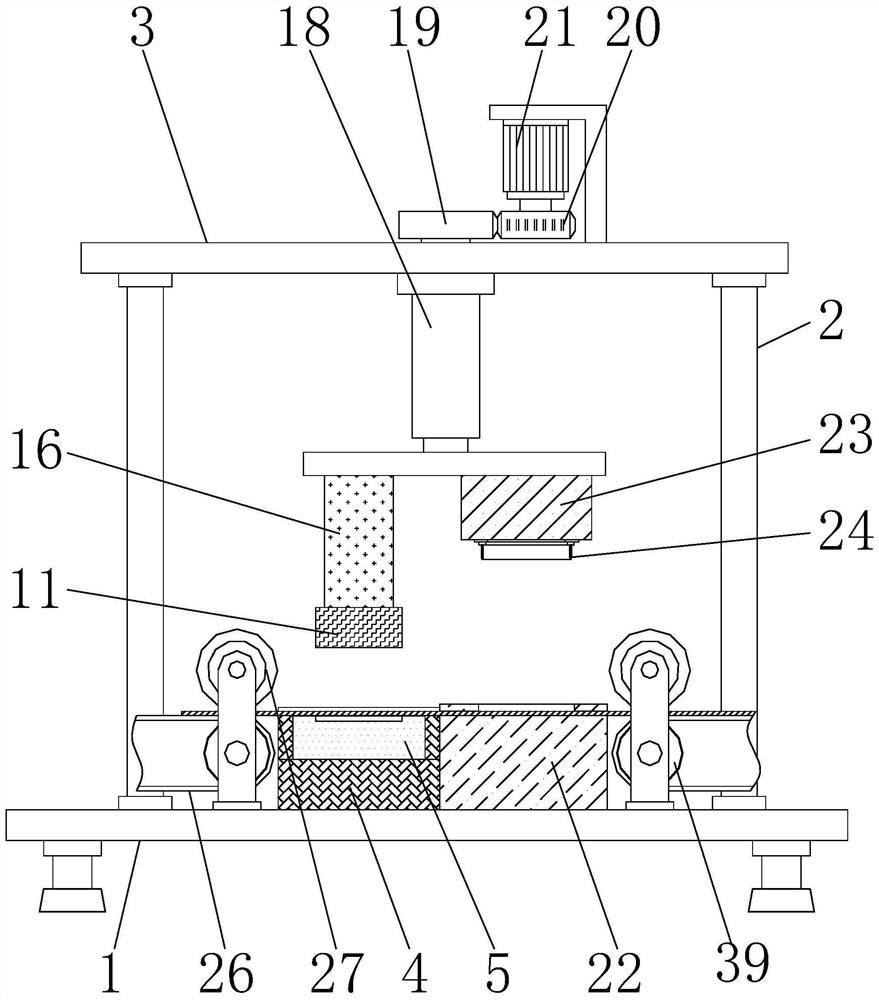

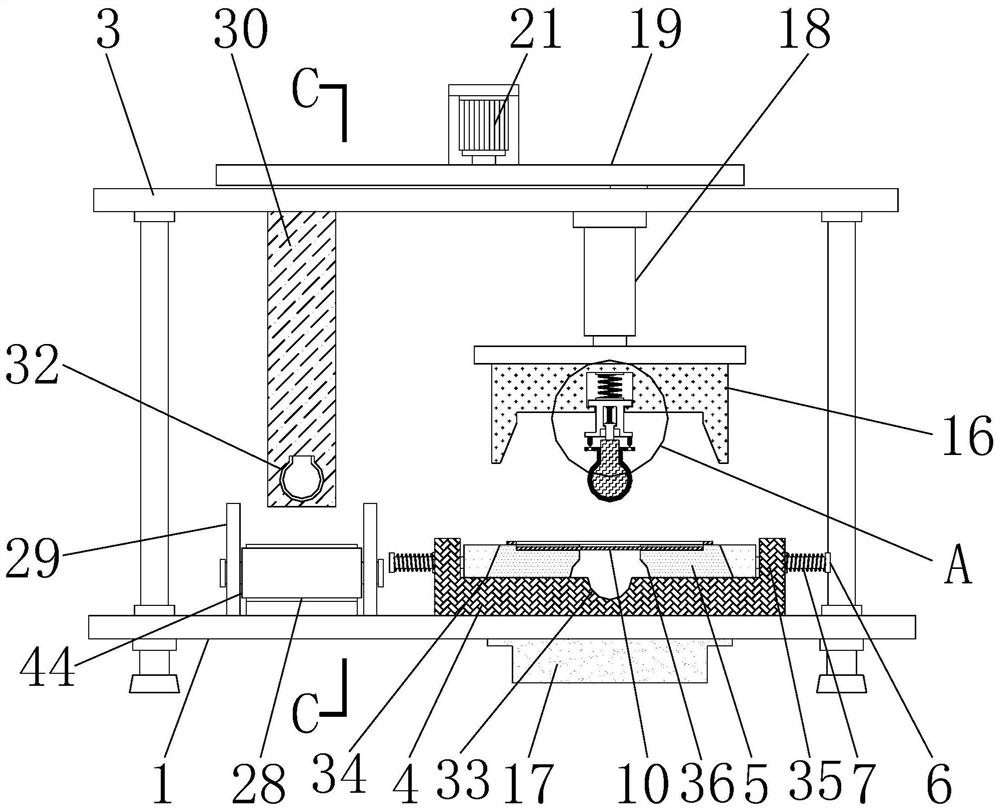

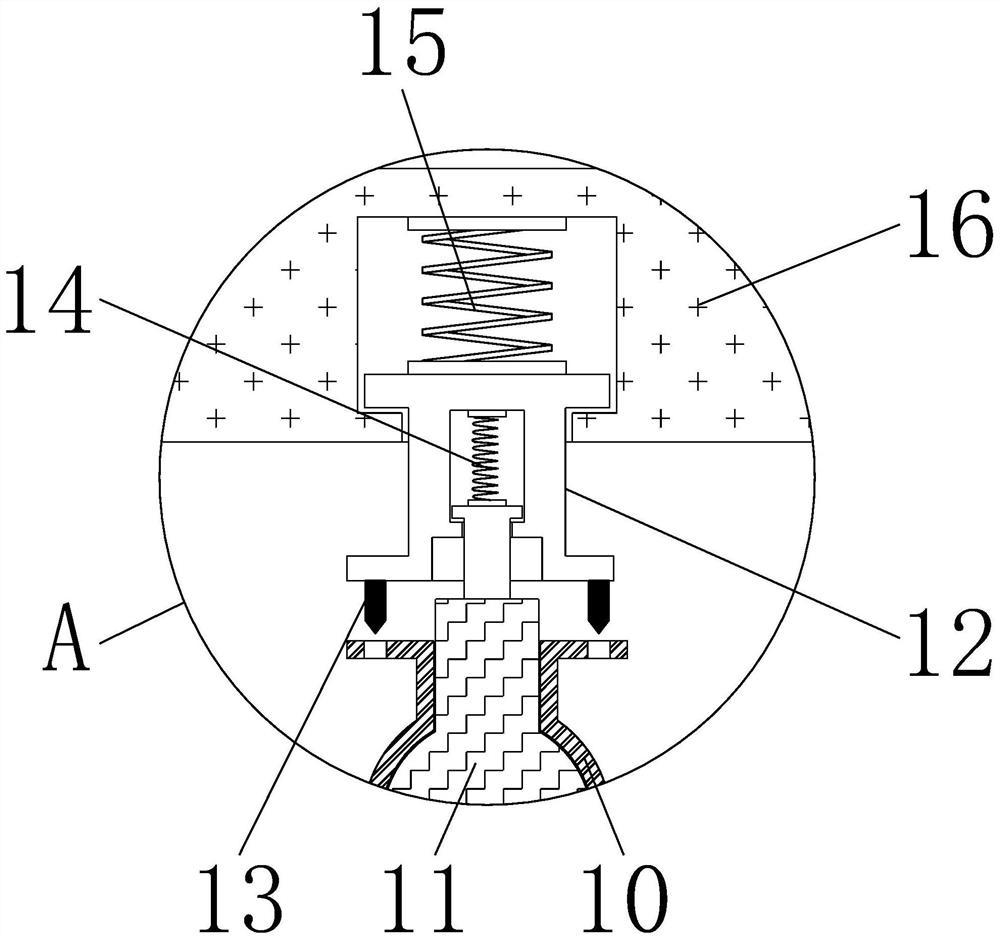

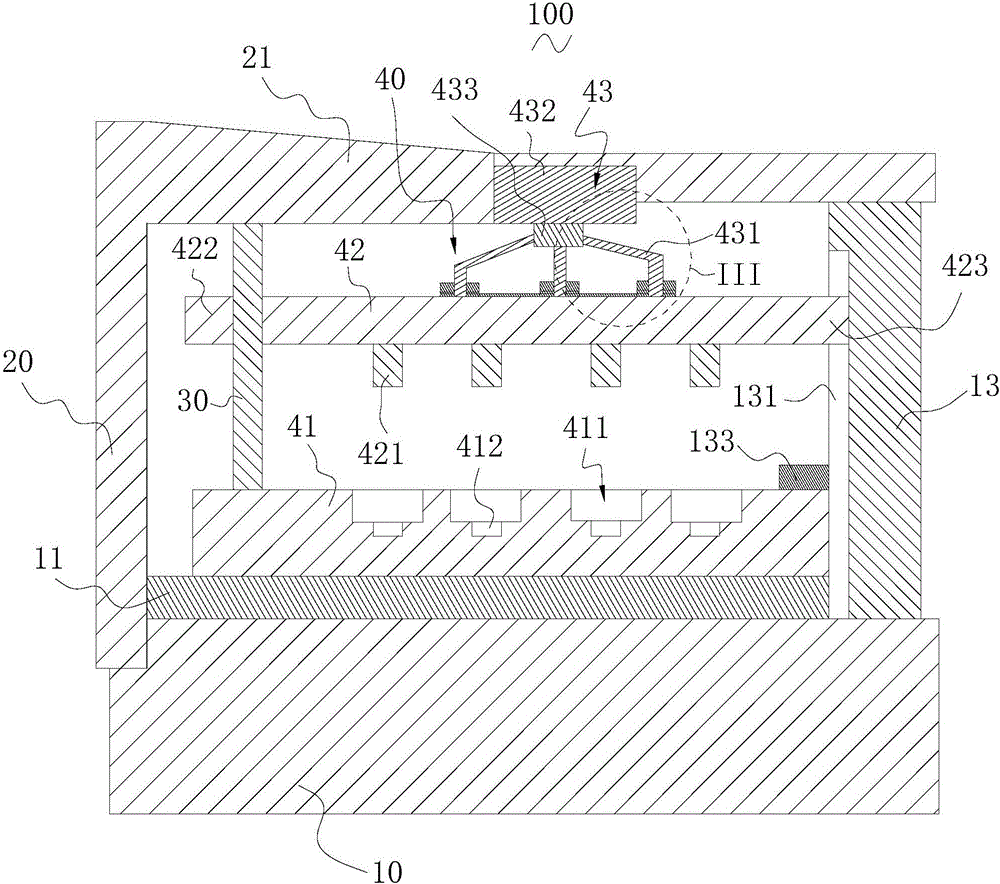

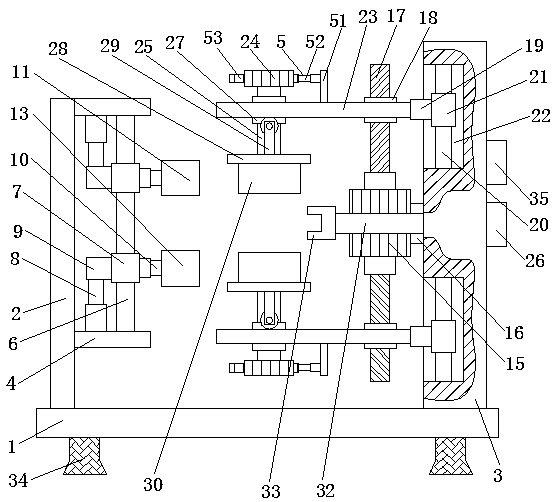

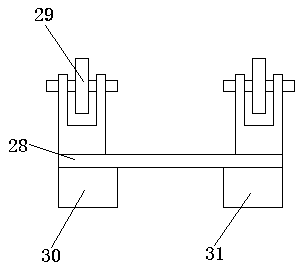

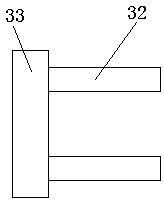

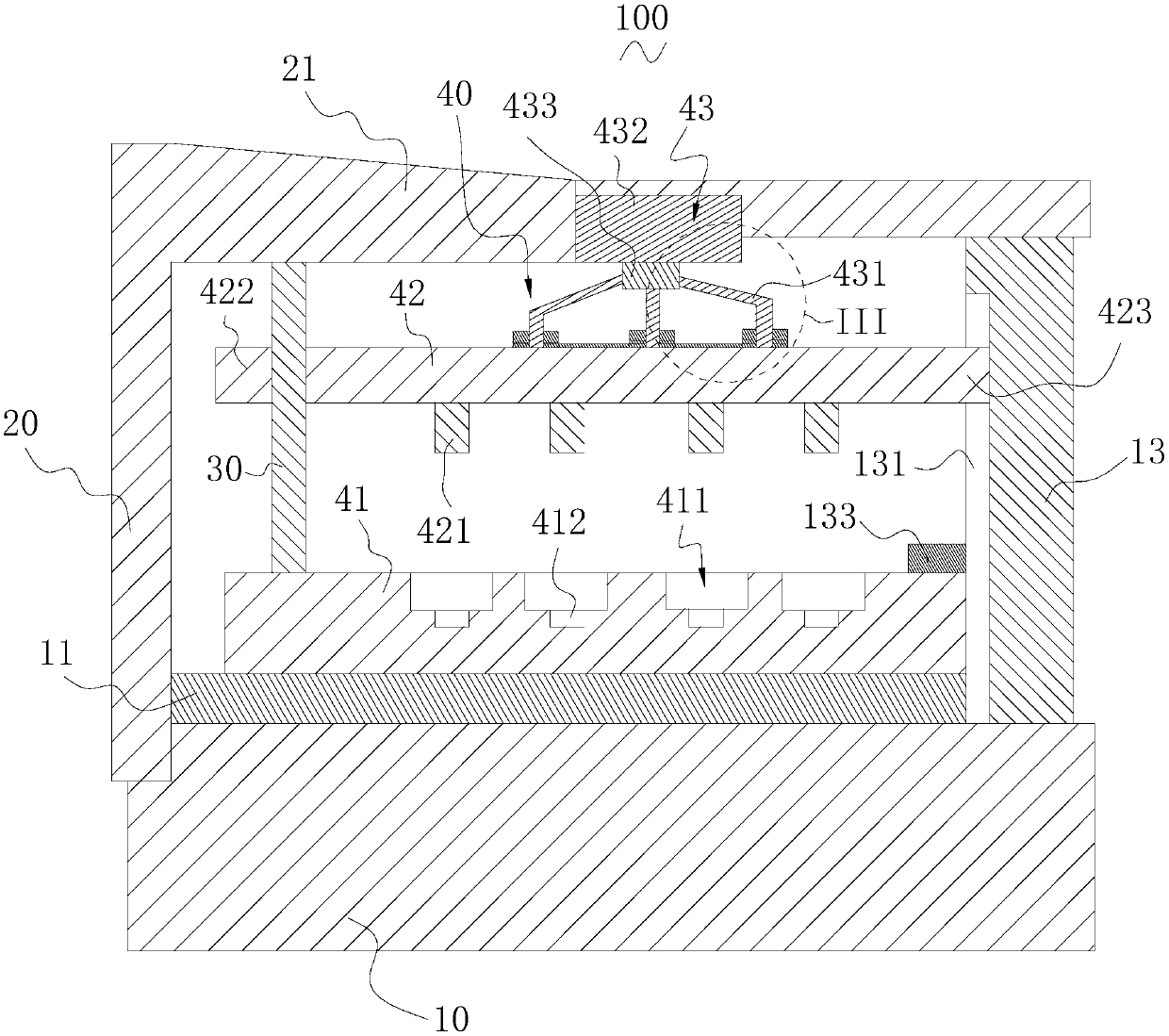

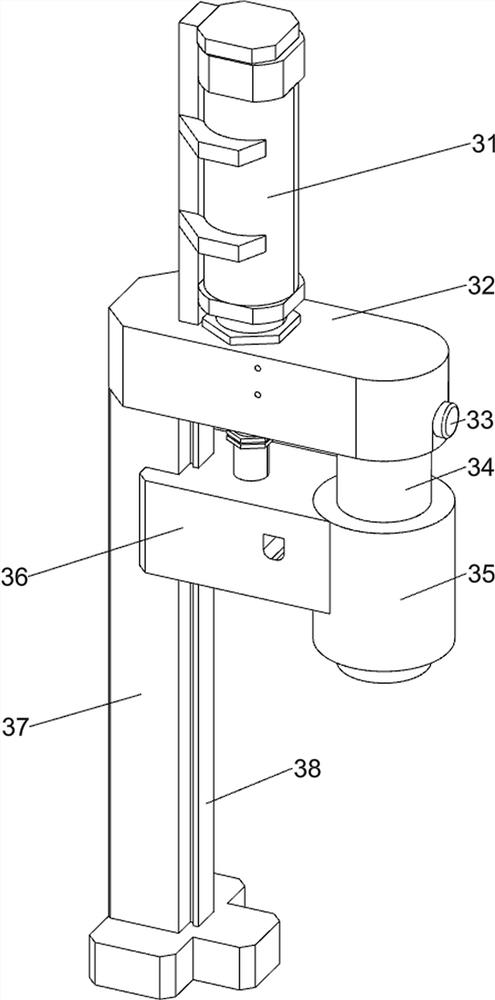

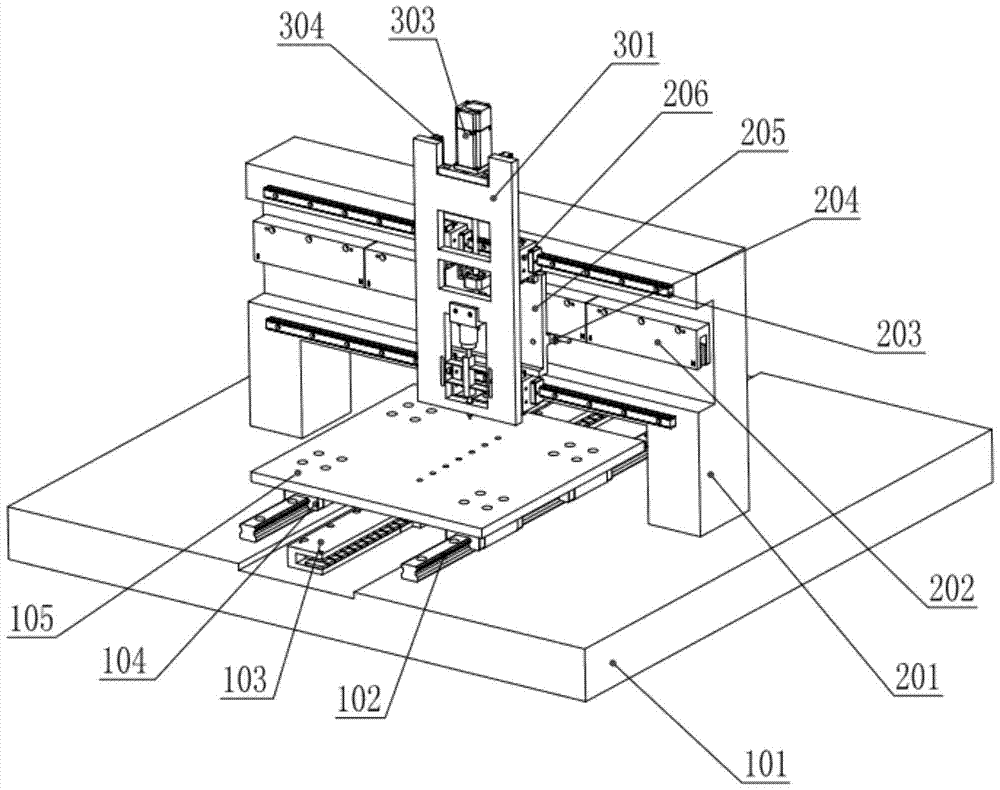

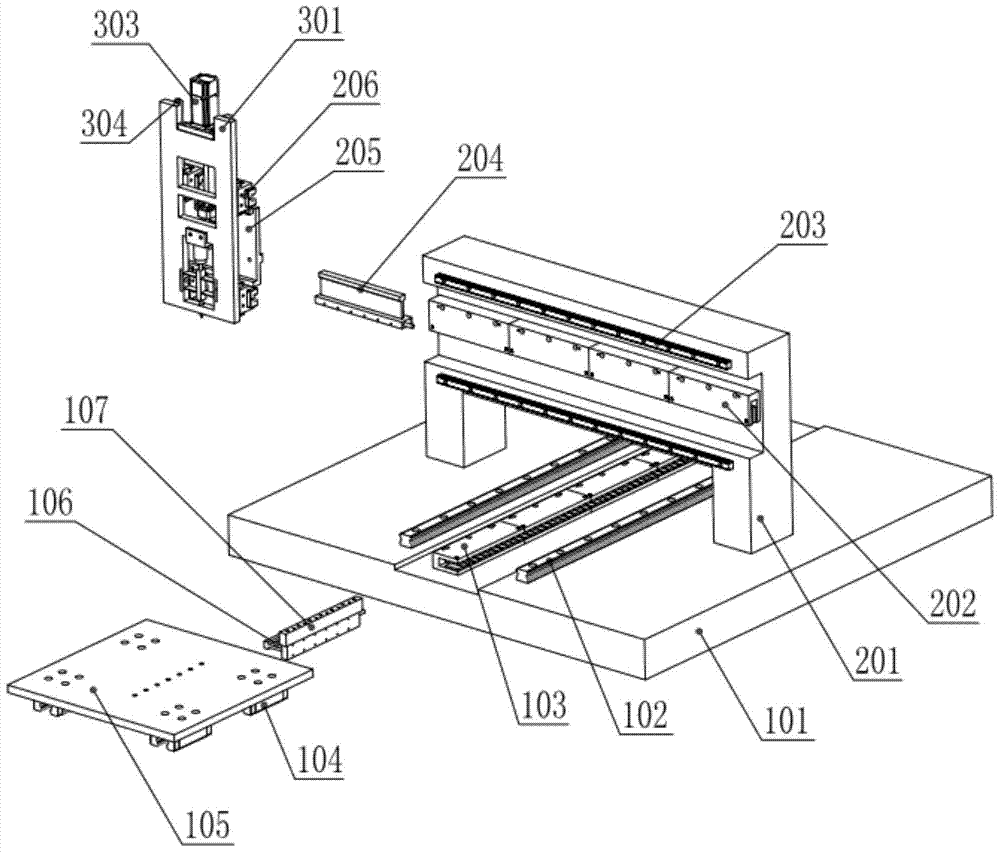

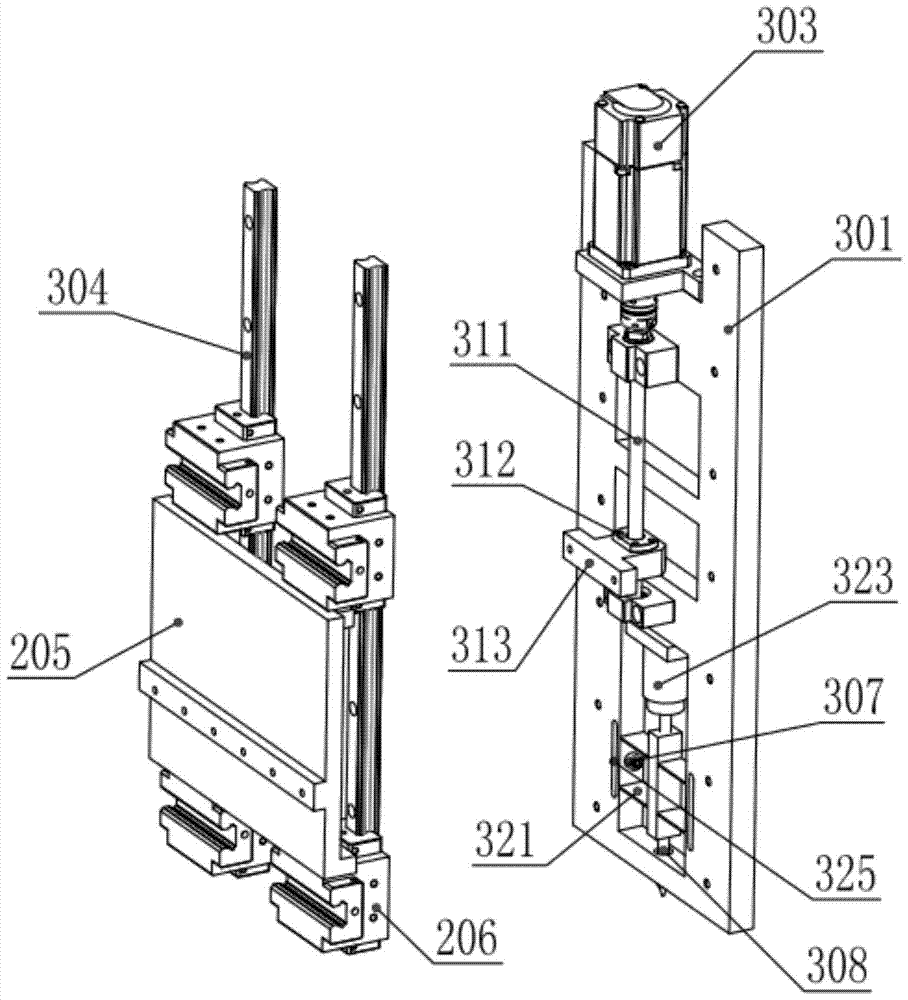

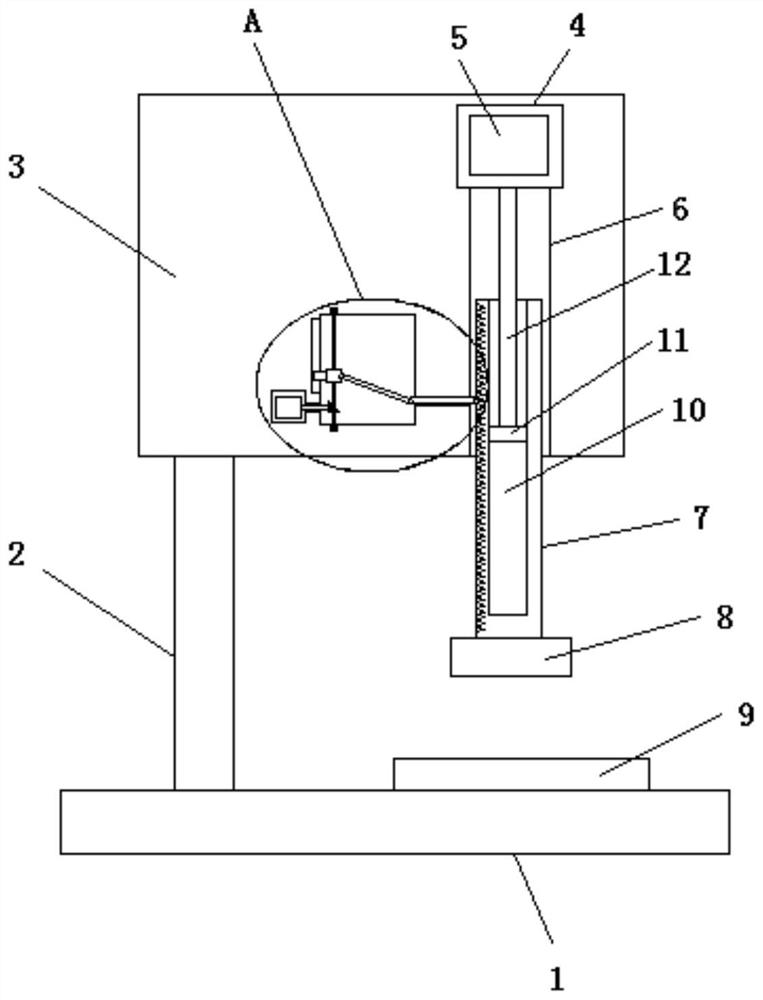

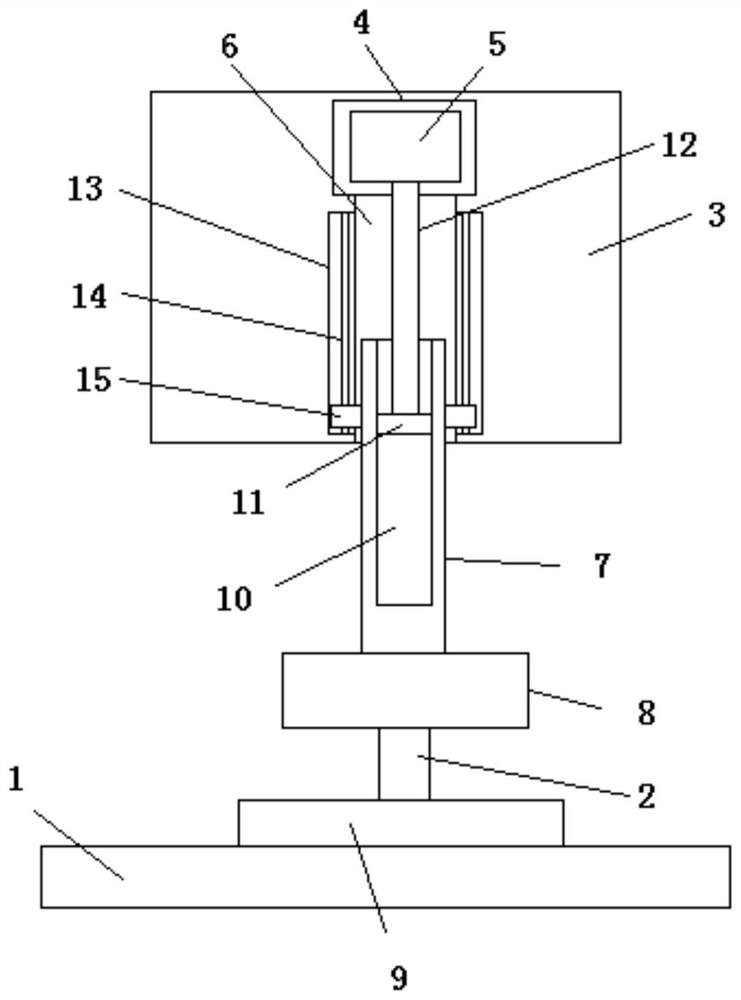

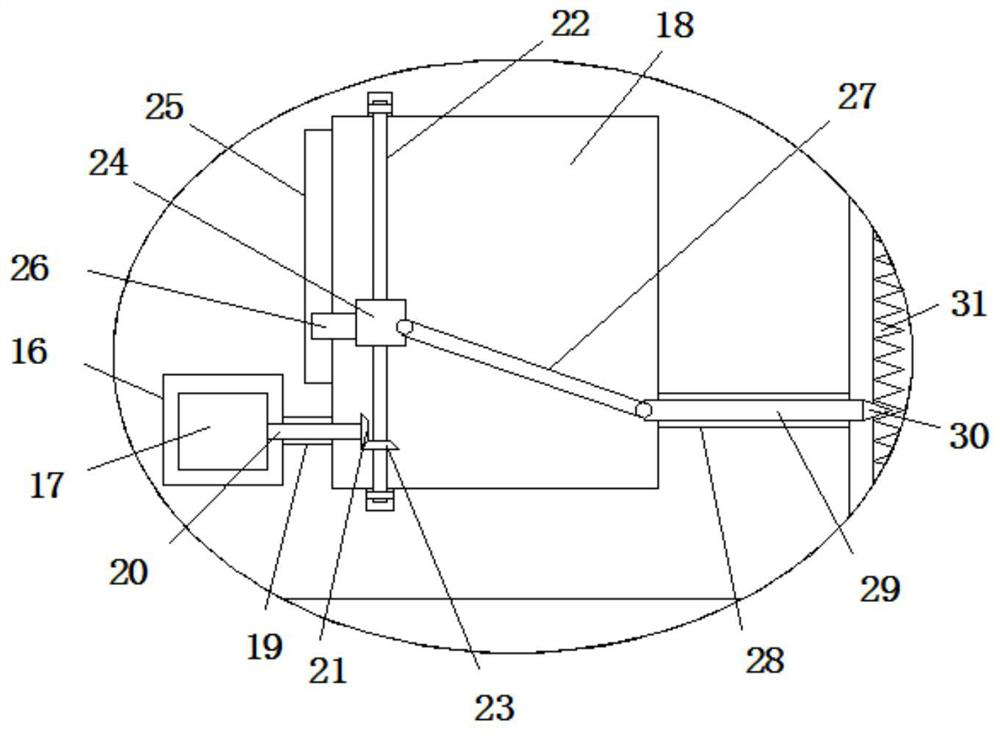

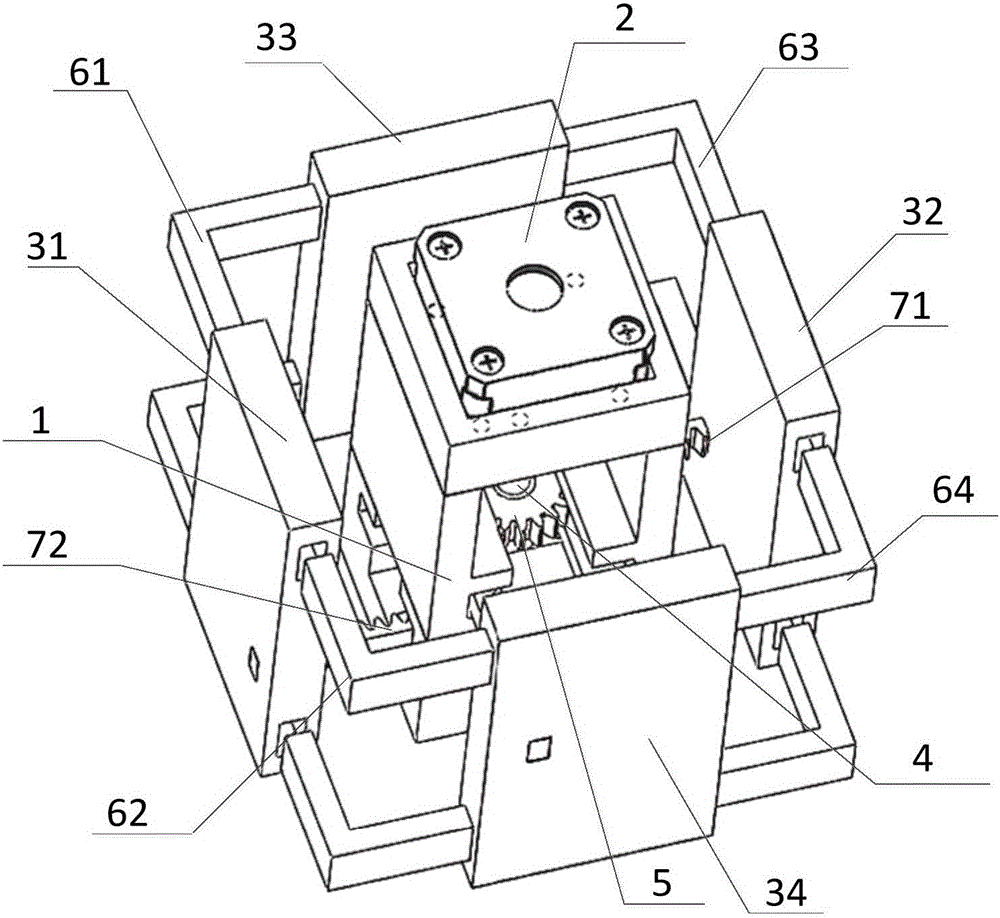

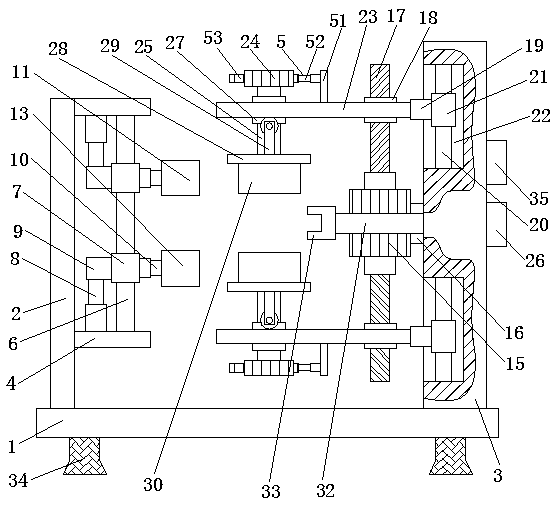

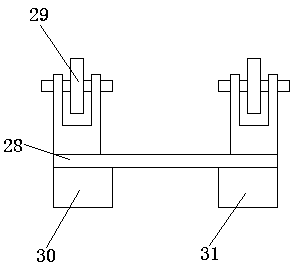

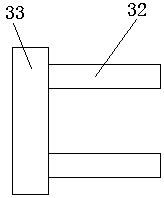

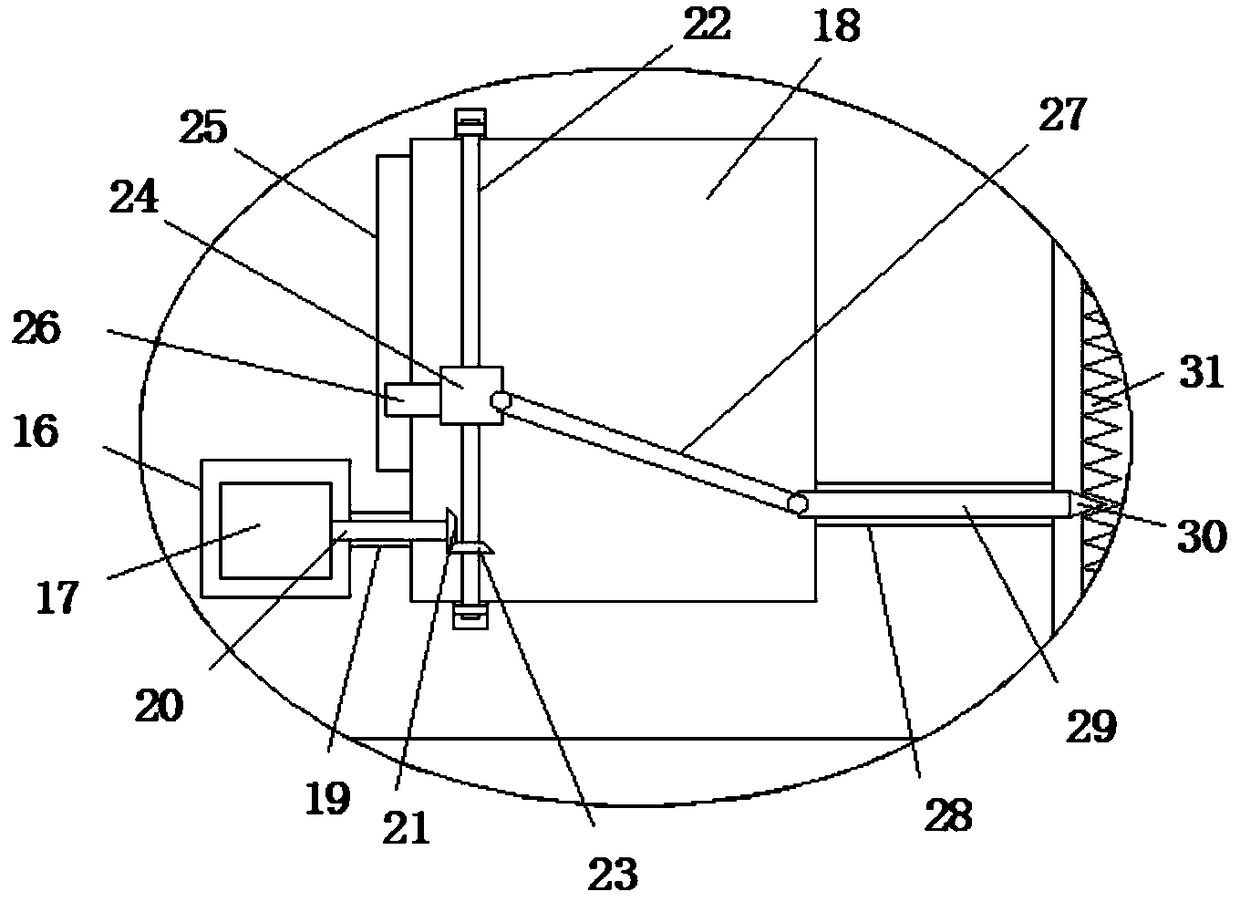

Dynamic characteristic self-adapting matching micro structure array precise processing machine tool

ActiveCN104485290AReduce alignment timeReduce movement deviationDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structurePunching

The invention provides a dynamic characteristic self-adapting matching micro structure array precise processing machine tool, which comprises a Y-direction moving mechanism, an X-direction moving mechanism and a Z-direction precise punching mechanism, wherein the X-direction moving mechanism is fixedly arranged on a base through an X-direction support frame, the Z-direction precise punching mechanism is arranged X-direction guide rails of the X-direction moving mechanism through an X-Z linkage platform and an X-Z composite guide rail slide block, and realizes the X-direction movement under the X-direction driving by the X-direction moving mechanism, and a workpiece is placed on a Y-direction moving platform of the Y-direction moving mechanism and realizes the Y-direction movement through the Y-direction moving mechanism. The Z-direction precise punching mechanism can realize the fine regulation on dynamic characteristics according to different punching frequencies, the consistent dynamic response performance is obtained, in addition, the position force switching composite control can be realized, and the consistency processing of the micro structure array is realized. The invention provides a precise micro punching machine tool with the advantages that the aligning time is shortened, the moving deviation is reduced, and the processing efficiency and the processing precision are improved.

Owner:GUANGDONG UNIV OF TECH

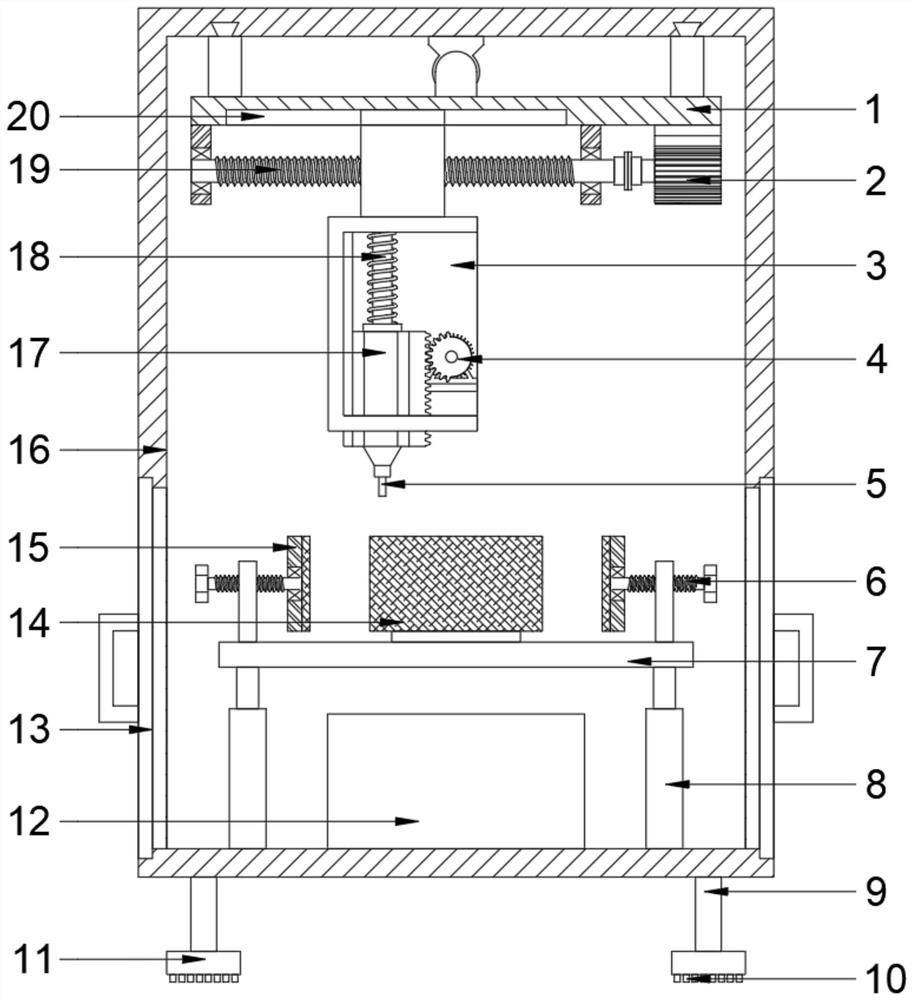

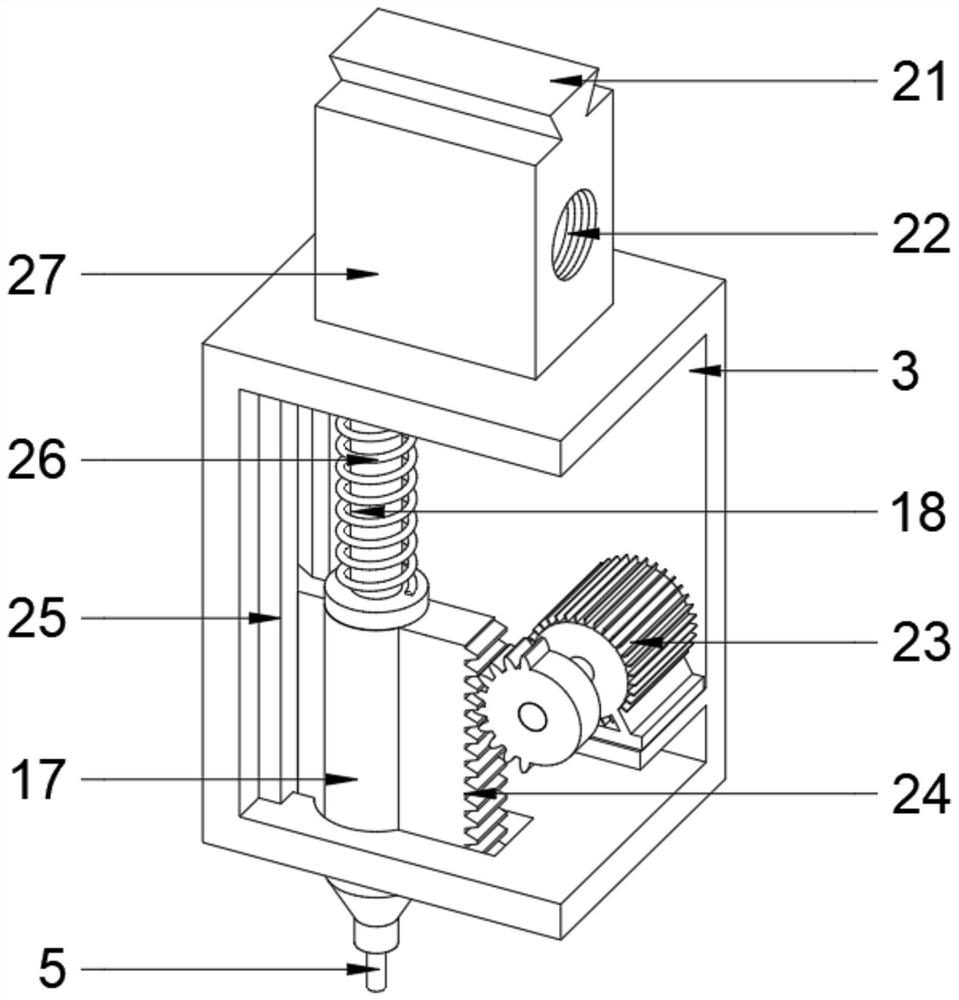

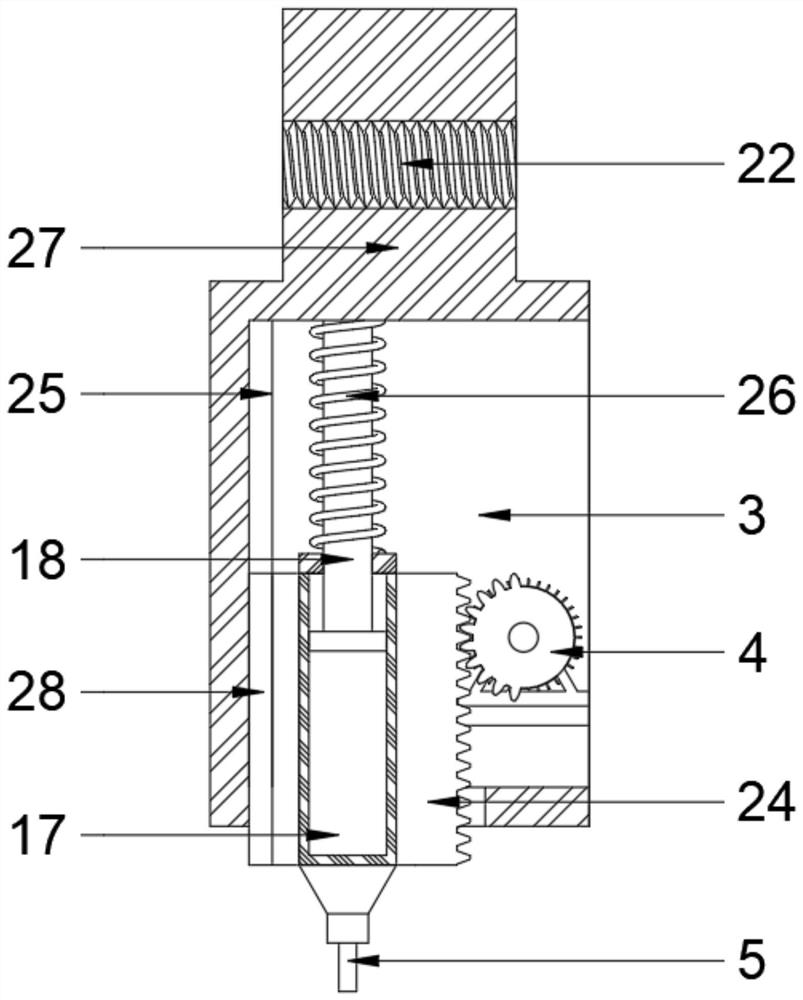

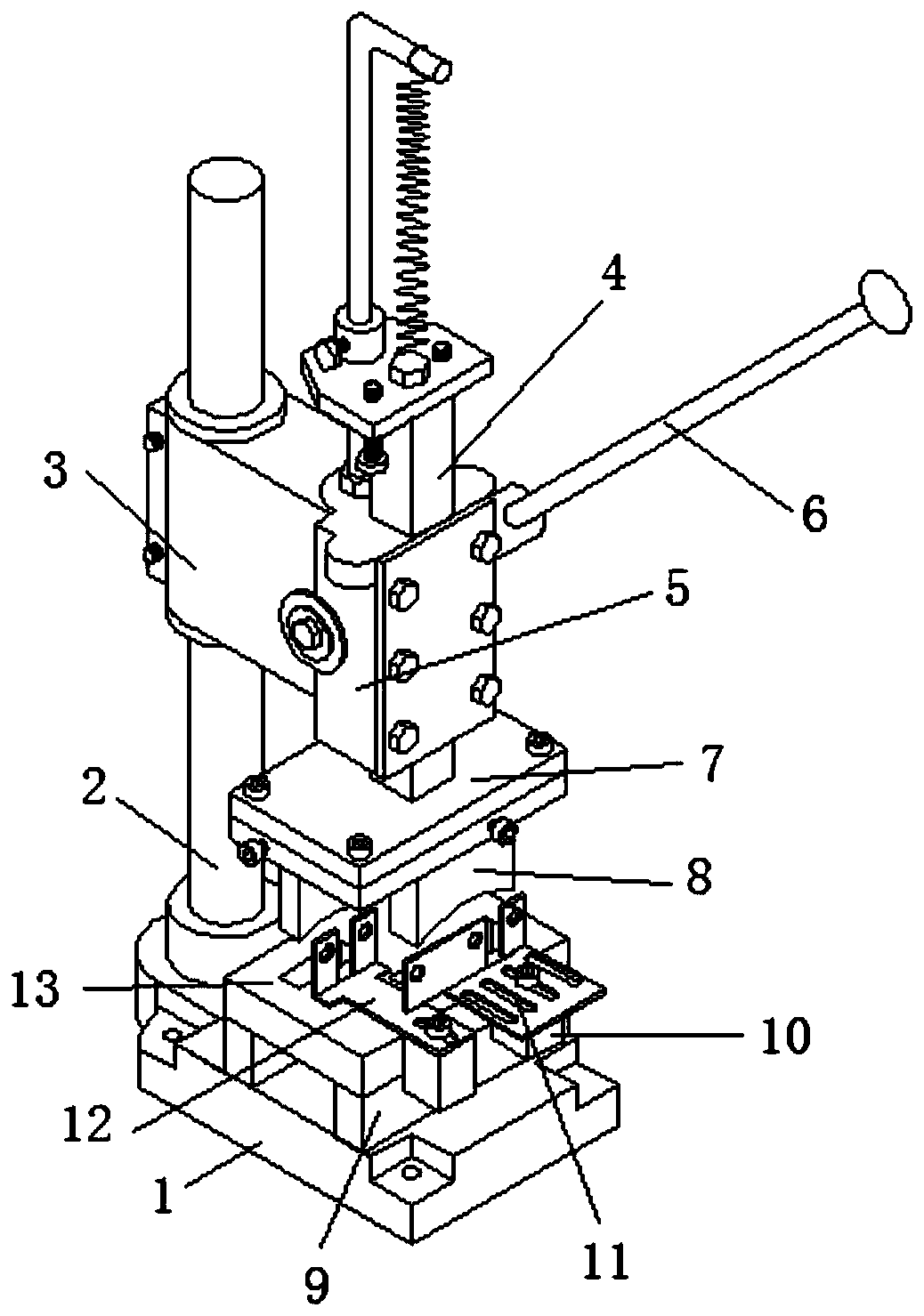

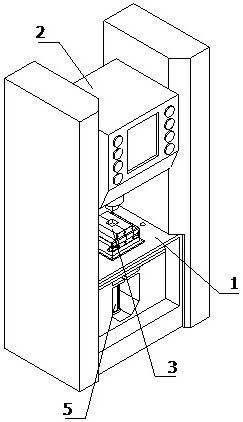

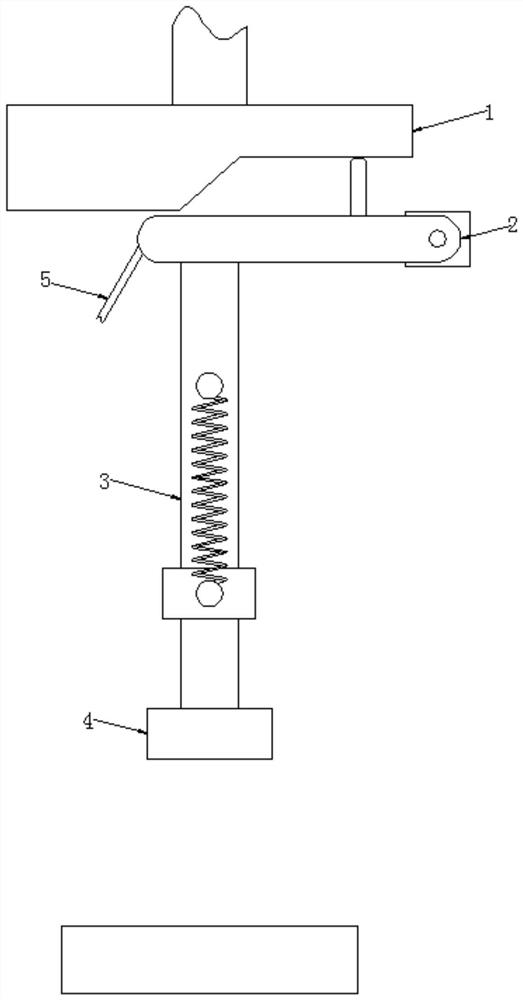

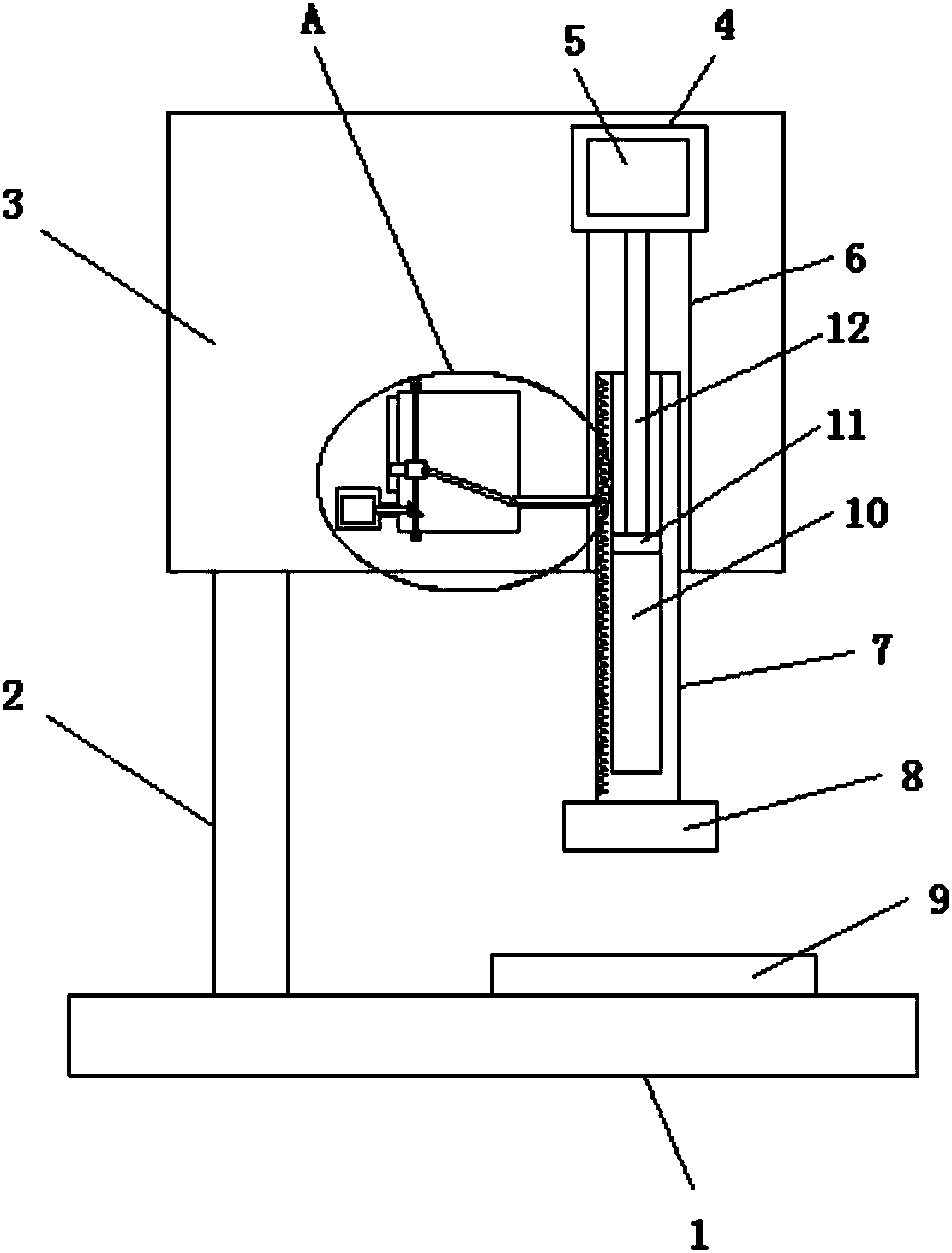

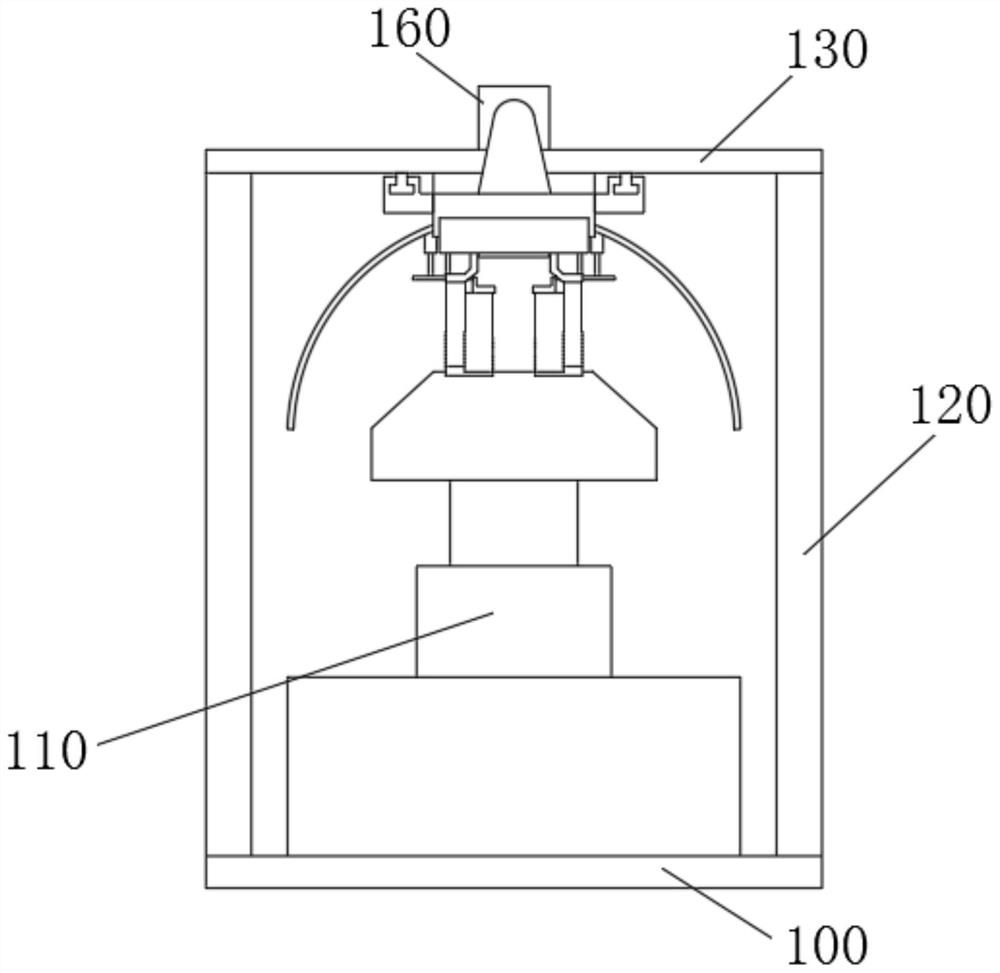

Workpiece stamping device with clamping function

InactiveCN112453158AAvoid damageStamping realizationMetal-working feeding devicesPositioning devicesGear wheelElectric machinery

The invention discloses a workpiece stamping device with a clamping function. The workpiece stamping device with the clamping function comprises a box body, a stamping assembly and a clamping assembly, the stamping assembly and the clamping assembly are arranged inside the box body, the stamping assembly comprises a stamping mechanism, a first adjusting device and a second adjusting device, the clamping assembly comprises a workbench, lifting rods and a clamping device, the clamping device comprises clamping bolts and clamping plates, the four clamping bolts are in threaded connection with mounting plates correspondingly, and the four clamping plates are rotationally connected with the four clamping bolts correspondingly. According to the workpiece stamping device with the clamping function, the clamping bolts and the clamping plates are matched with the workbench and the lifting rods to clamp workpieces of different sizes, and protection pads are matched to prevent the clamping platesfrom excessively clamping the workpieces to damage the edges of the workpieces; and a stamping sliding sleeve and a stamping sliding rod are adopted, an incomplete gear is matched with a rack, a stamping motor is used for driving to drive a stamping tool to ascend, the elastic force effect of a stamping spring is used for driving the stamping tool to quickly descend, and stamping of the workpieces is achieved.

Owner:钟德养

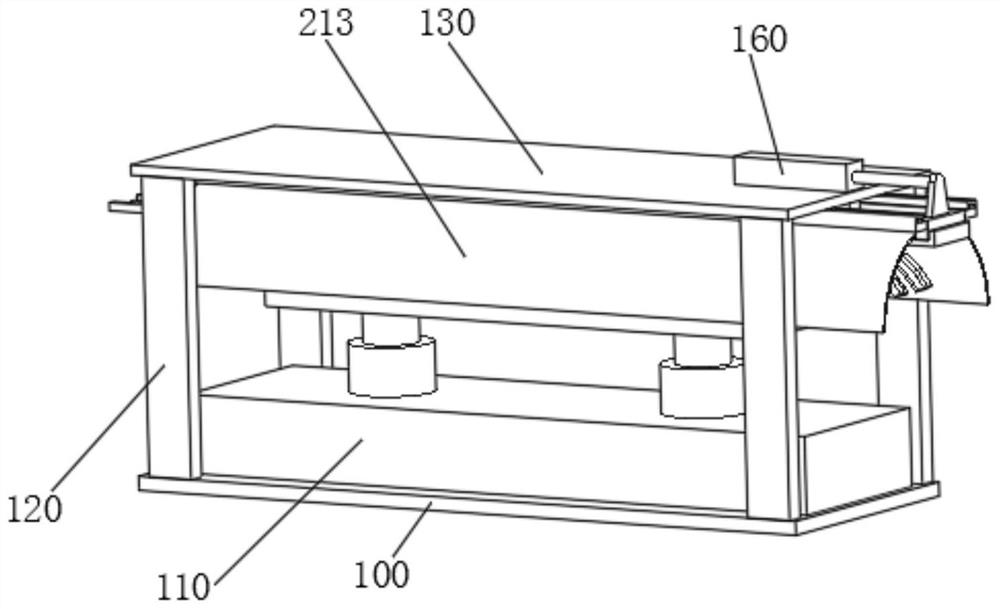

Machining stamping device facilitating automatic ejection of waste

InactiveCN111760961AEasy stampingEasy to collectMetal-working feeding devicesStripping-off devicesStructural engineeringMachining

The invention relates to a machining stamping device facilitating automatic ejection of waste. The device comprises a bottom plate, the top of the bottom plate is connected with a top plate through avertical rod, a stamping female die unit is arranged in the middle of one side of the bottom plate, machined workpiece conveying units are installed at the positions, at the two ends of the stamping female die unit, on the bottom plate, and a machined workpiece conveying unit is installed at the position, on one side of the stamping female die unit, of the bottom plate; and an automatic demoldingunit is fixedly arranged at the position, corresponding to the top of the machined workpiece conveying unit, of the lower portion of the top plate, a movable male die stamping unit and a to-be-machined workpiece cutting unit are arranged on the lower portion of the top plate, and the male die stamping unit and the to-be-machined workpiece cutting unit are of an integrated structure. The machiningstamping device has the advantages that the purposes of conveying, cutting, stamping and demolding workpieces and conveying the machined workpieces can be achieved, and stamping and demolding efficiency is improved while the safety risk of manual work is prevented; and meanwhile, the characteristic of effectively collecting the waste can be achieved.

Owner:河南工学院

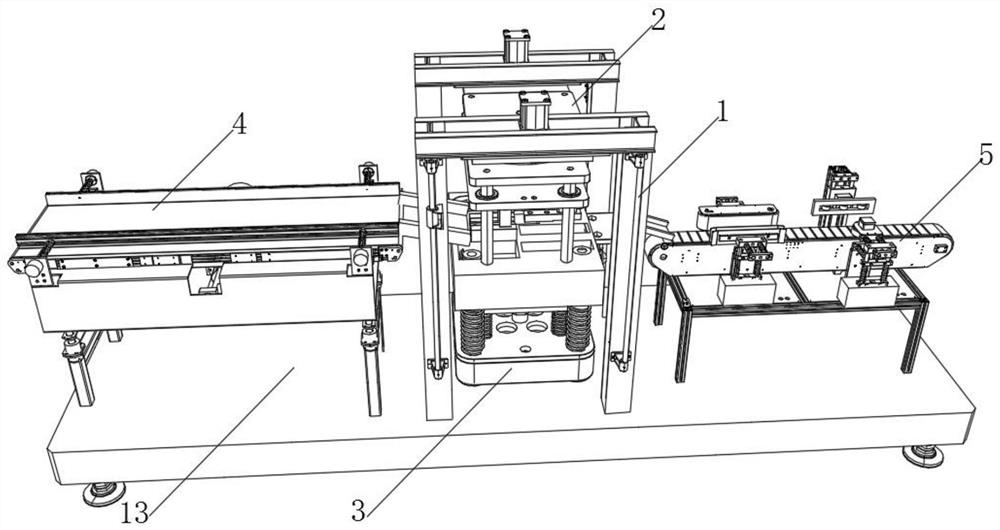

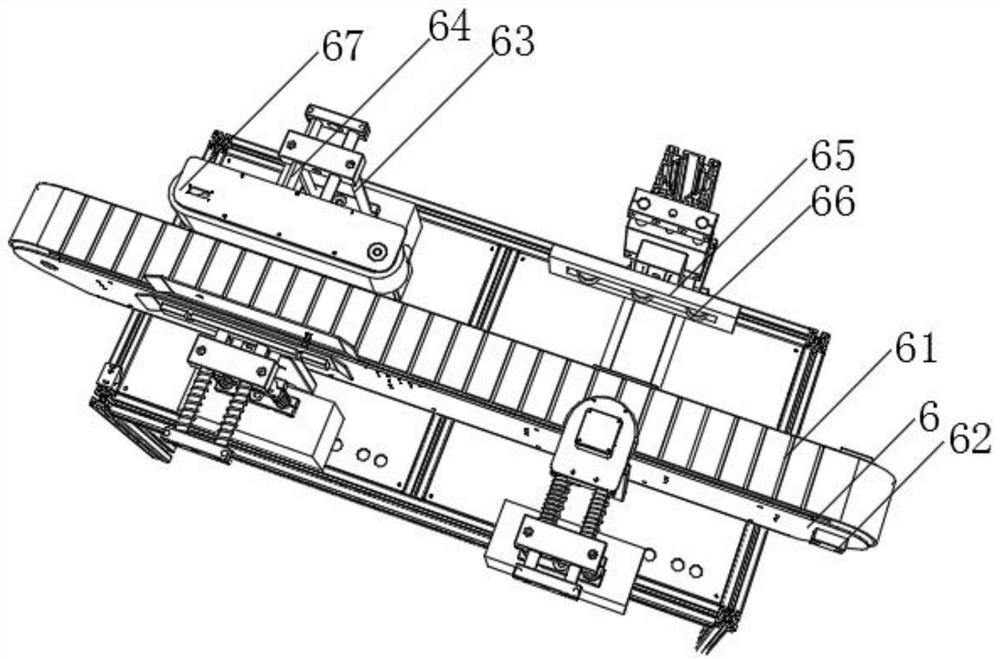

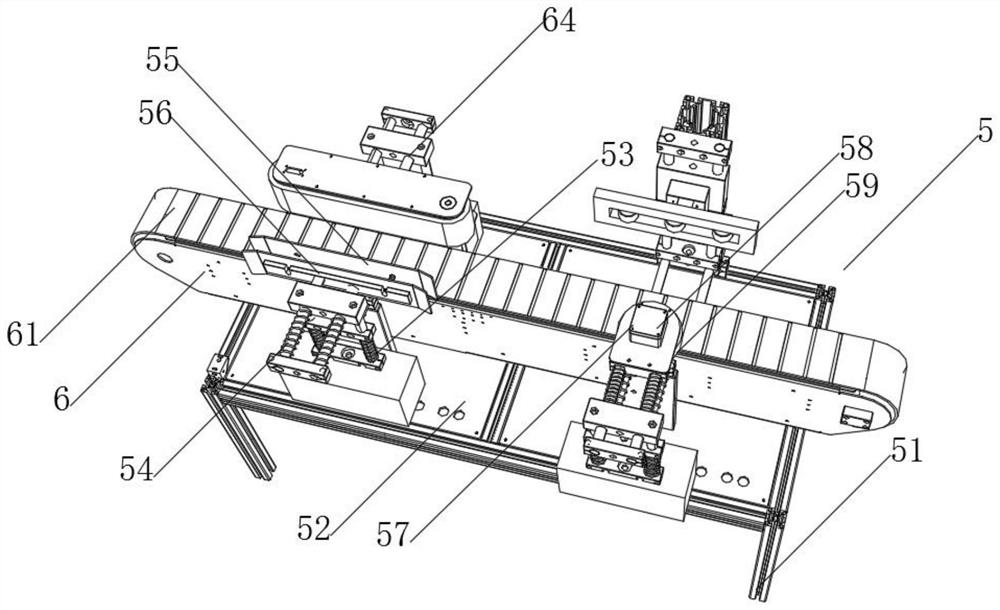

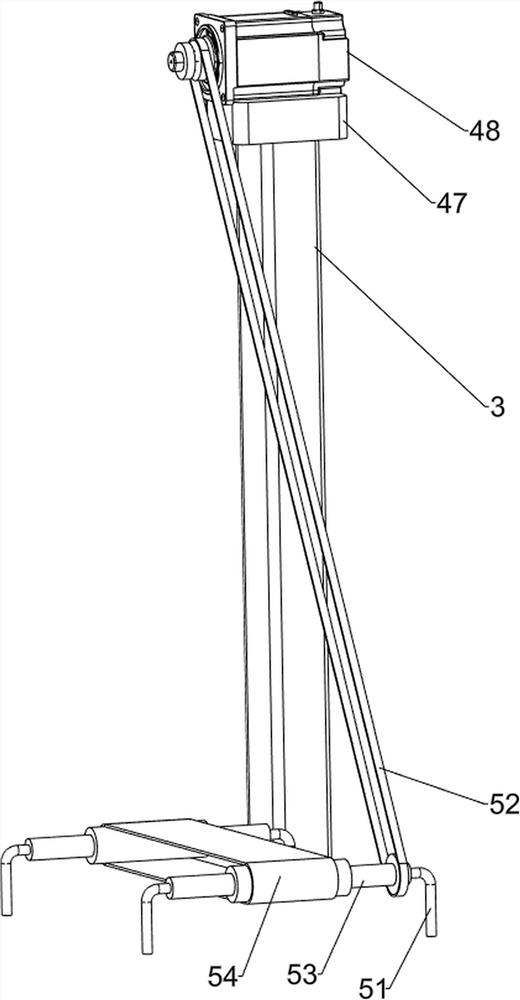

Full-automatic refrigerator handle tube punching device

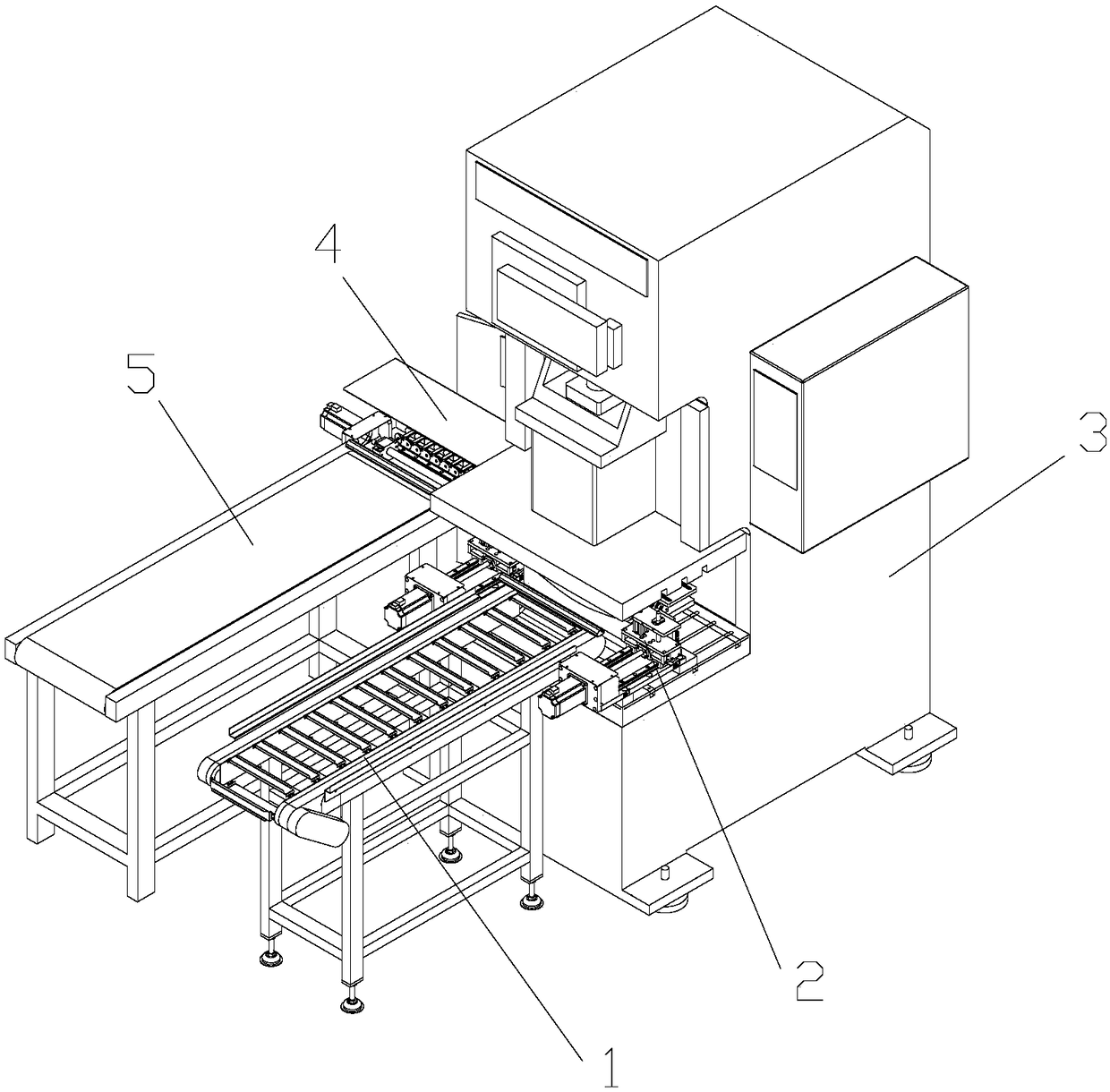

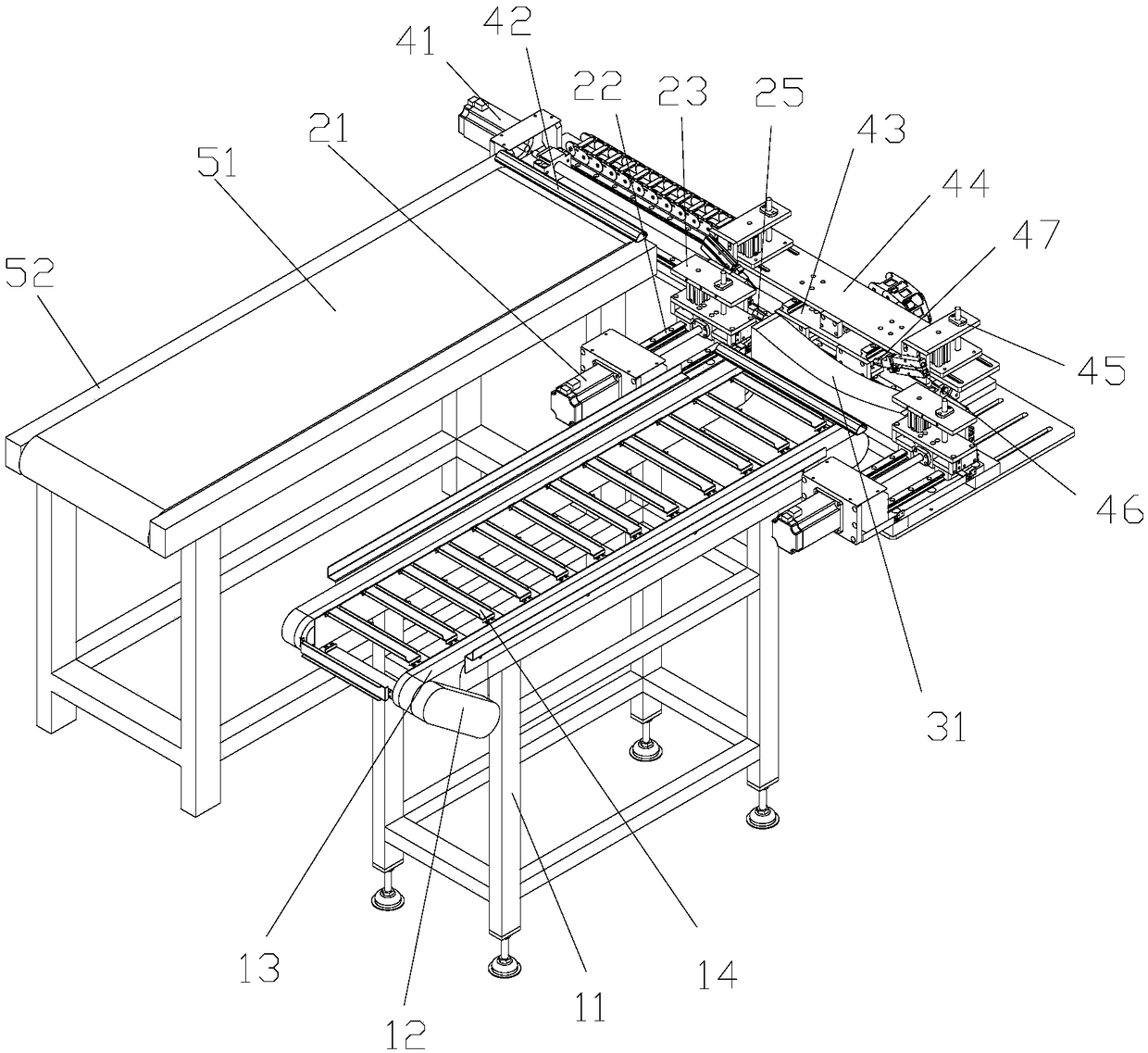

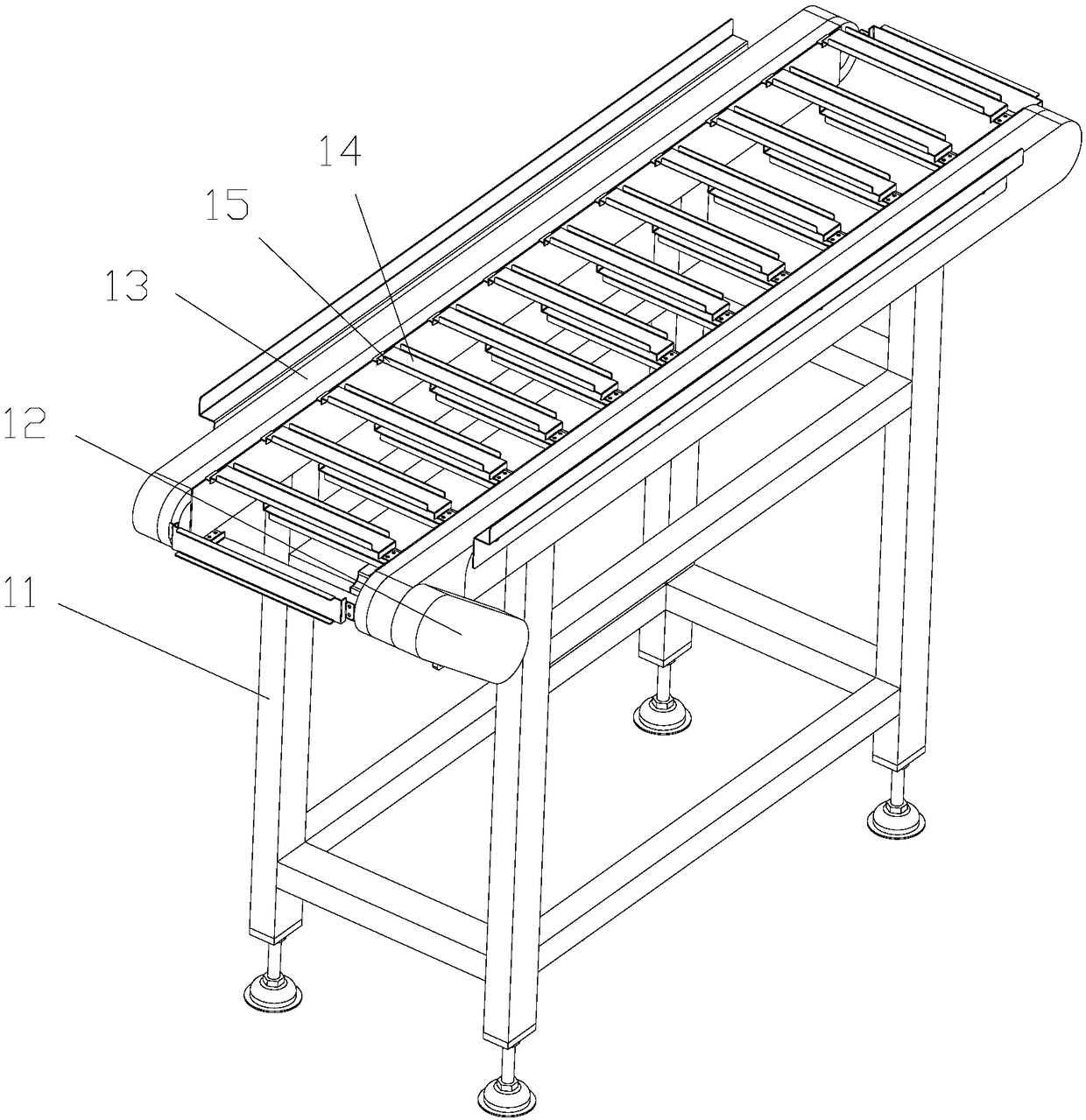

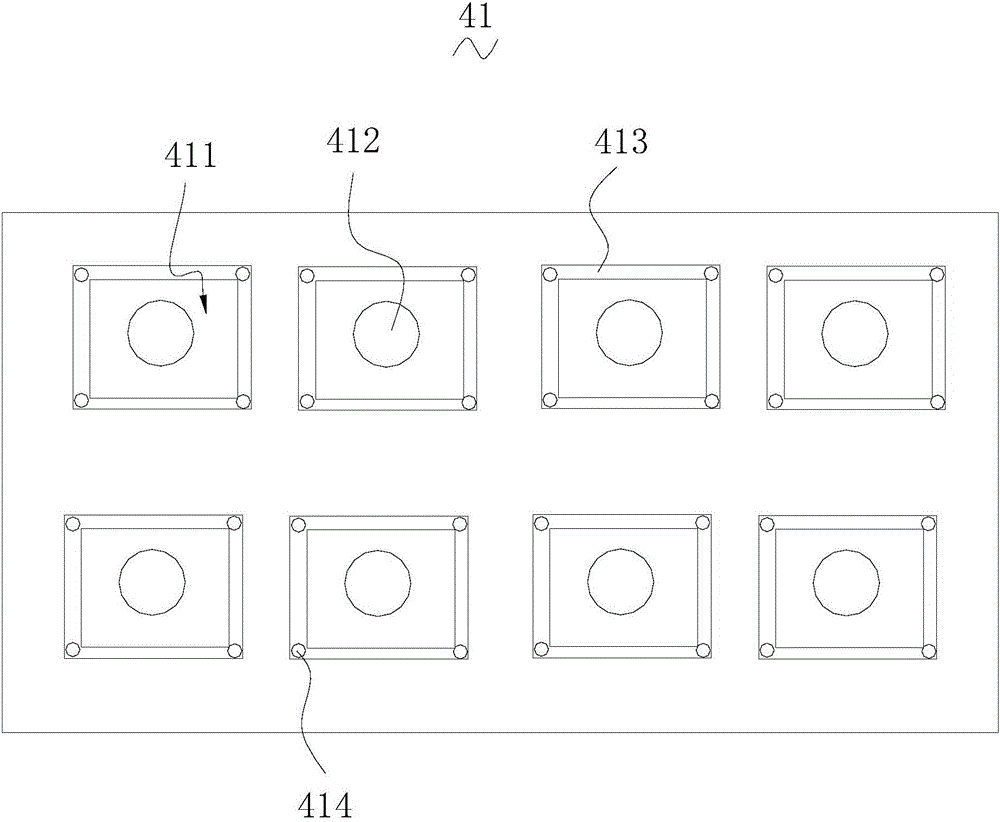

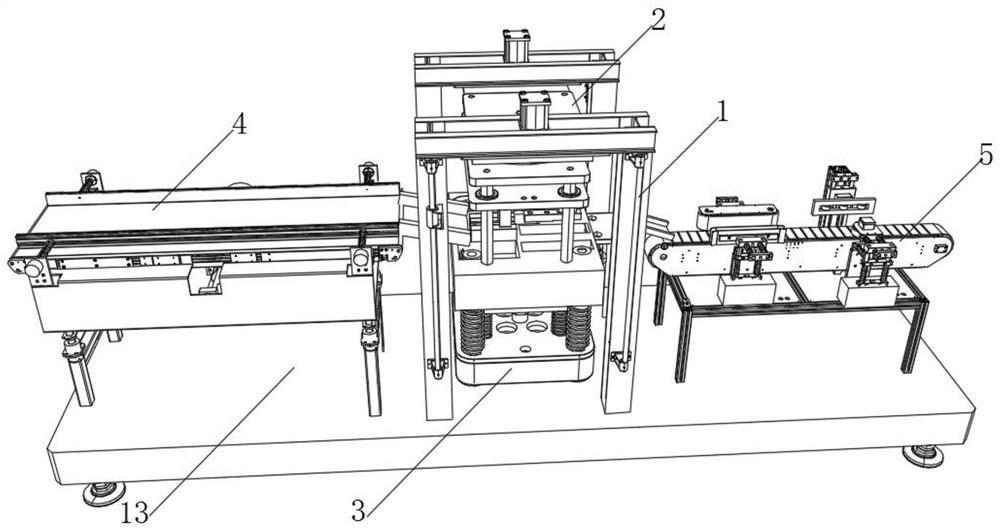

PendingCN108380775AStamping realizationRealize automatic feeding processMetal-working feeding devicesPositioning devicesPunchingOutput device

The invention relates to a full-automatic refrigerator handle tube punching device. The full-automatic refrigerator handle tube punching device comprises an automatic feeding device, a first transferdevice, a punching device, a second transfer device and an output device. Through cooperation of the automatic feeding device, the transfer device and the punching device specially designed, the full-automatic refrigerator handle tube punching device can realize automatic loading, punching and unloading without needing manual operation, can realize line production, greatly improves the machining efficiency, and reduces the production cost; and punched products are excellent in consistency, low in defective rate and broad in market prospect.

Owner:SUNSEA MACHINERY & HARDWARE CO LTD

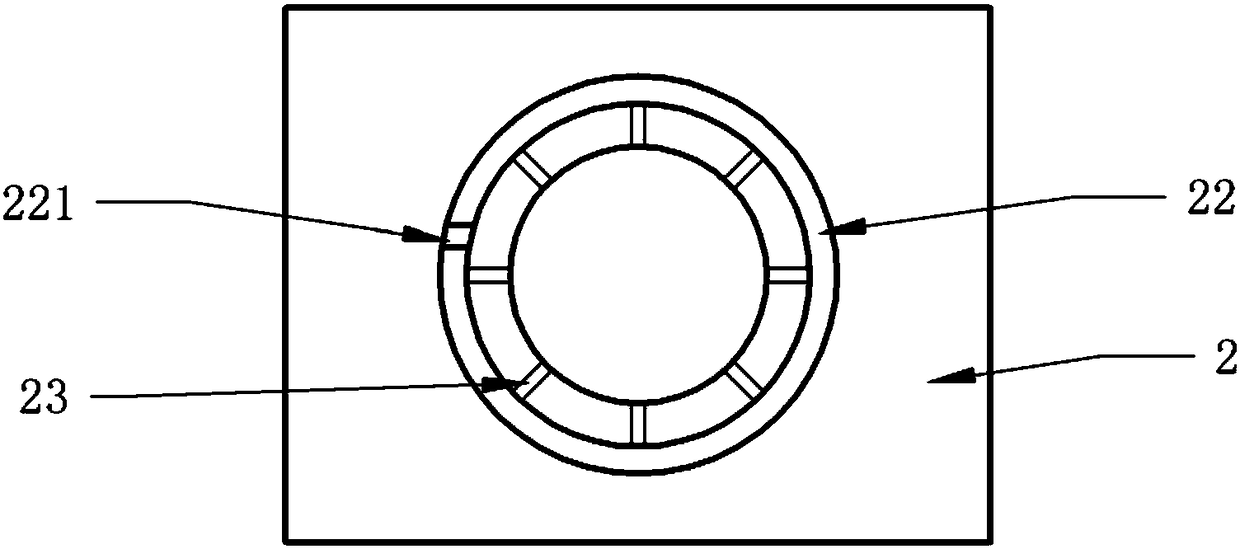

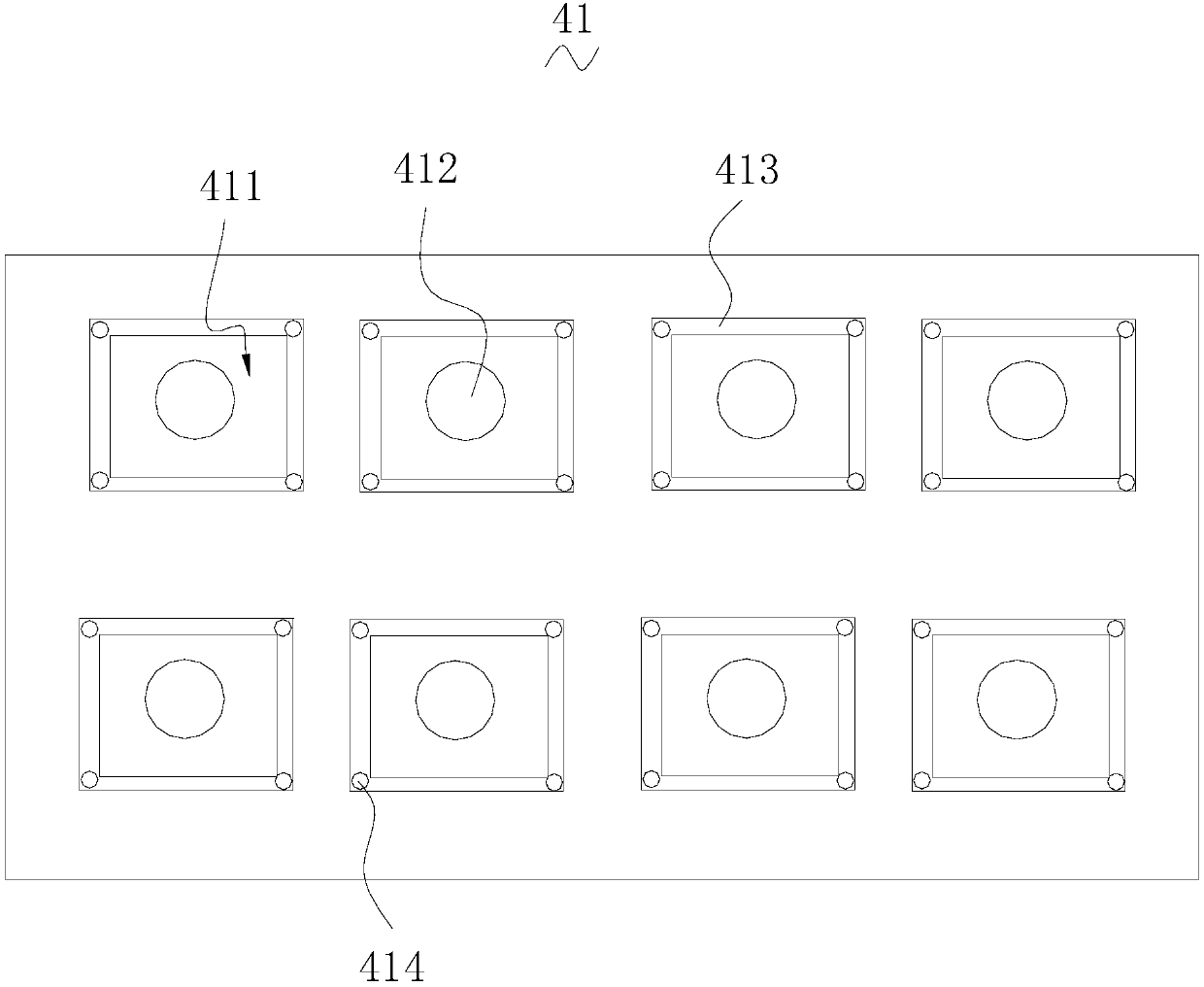

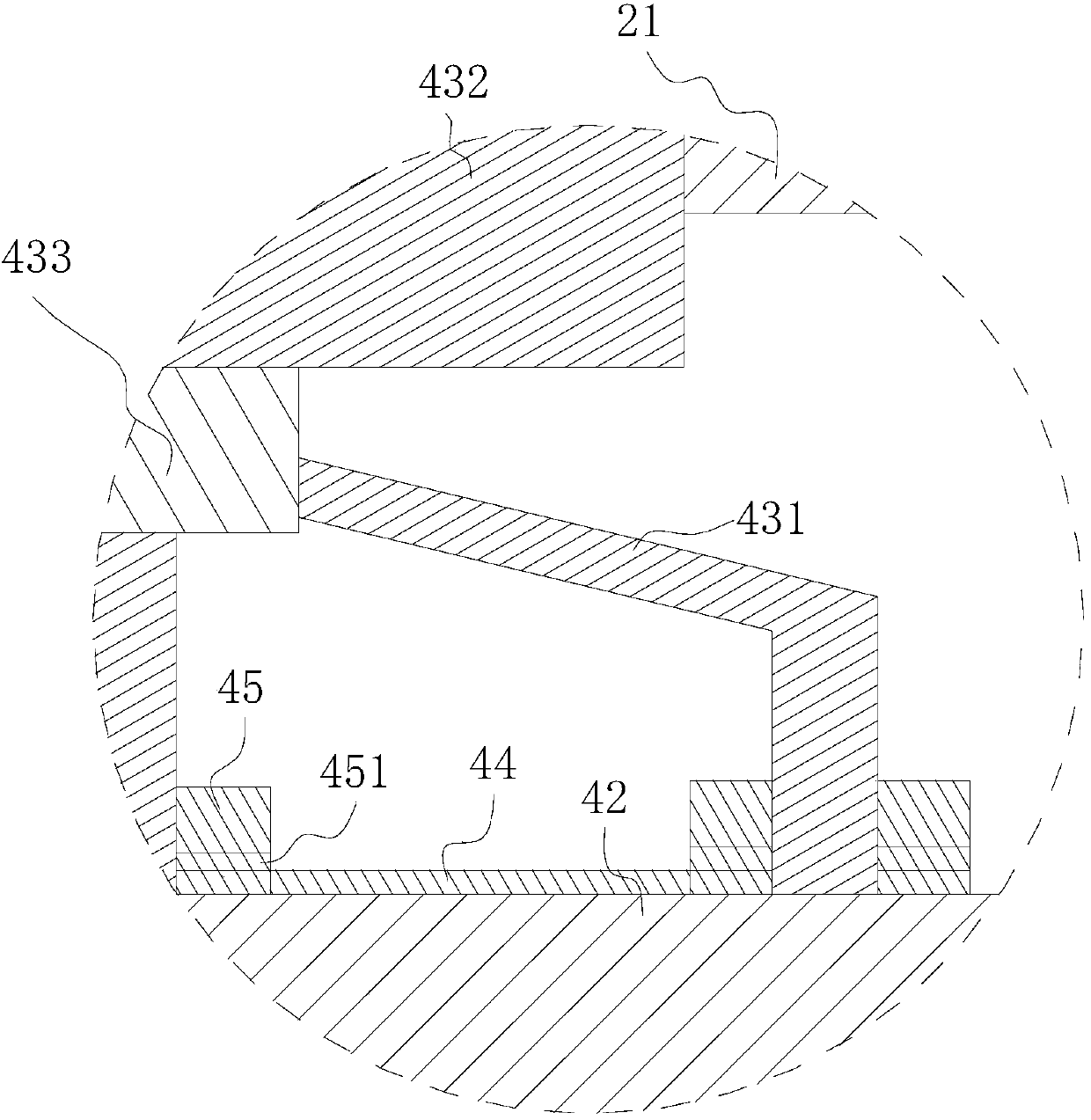

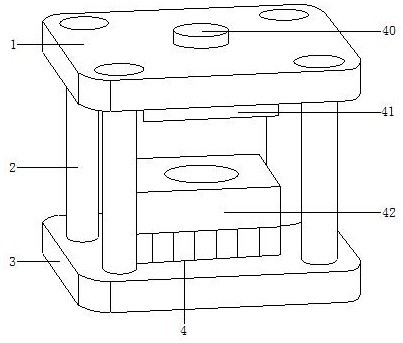

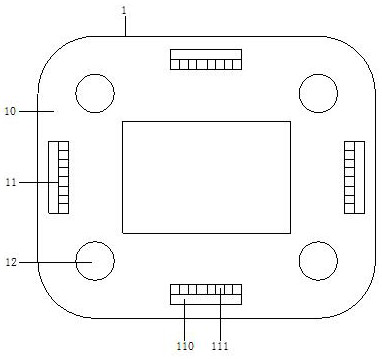

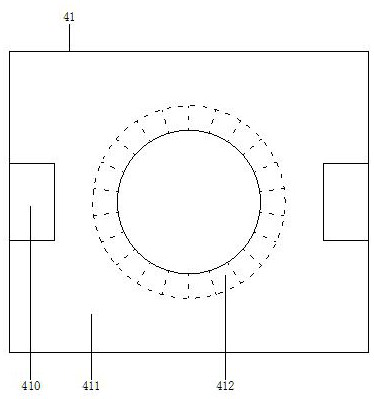

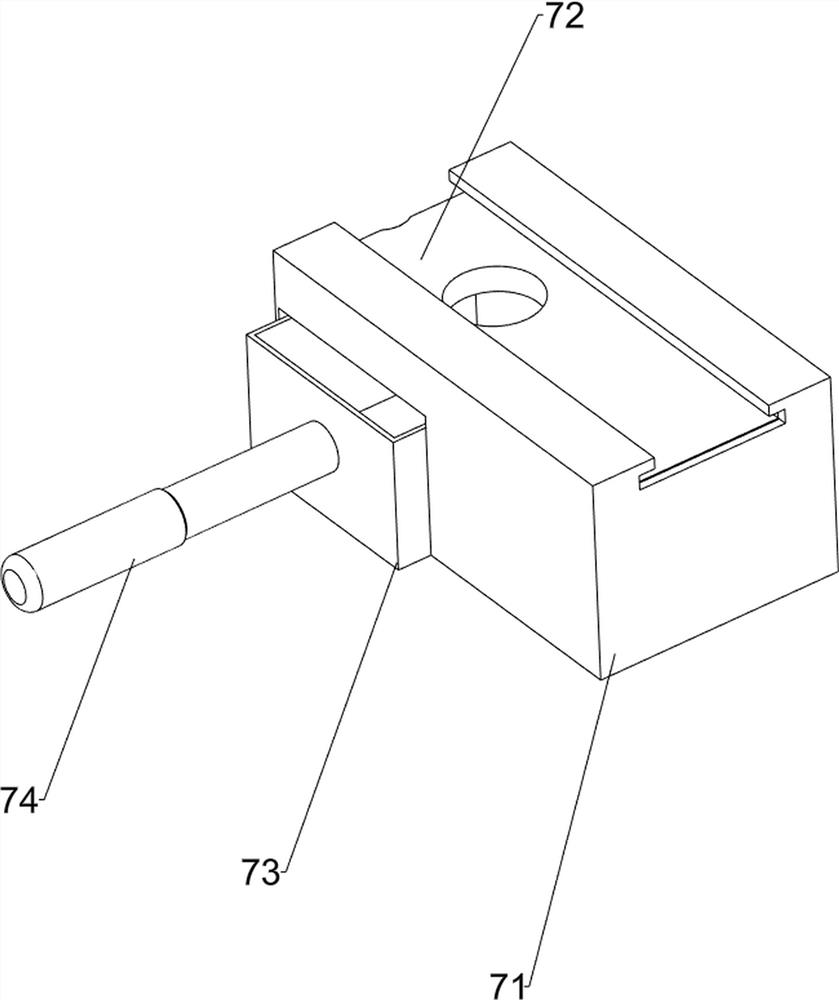

Punching device

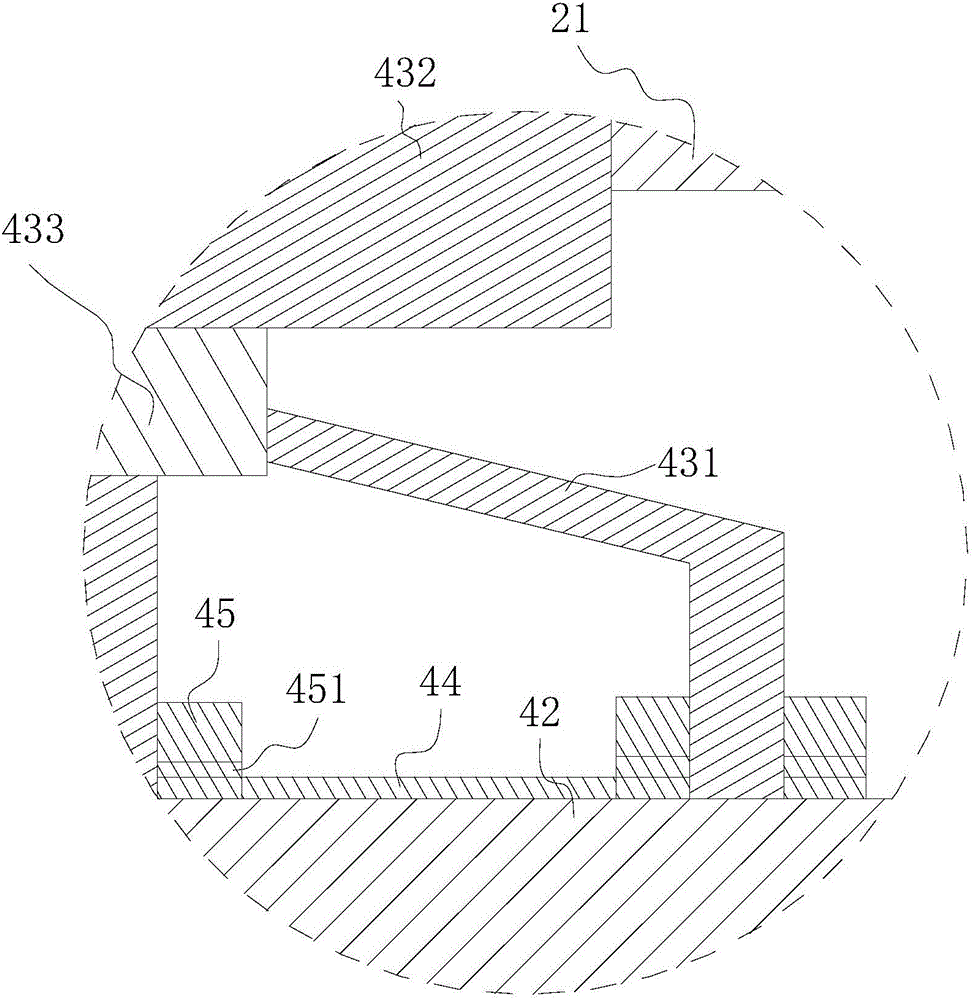

ActiveCN106734551AStamping realizationHigh positioning accuracyShaping toolsPerforating toolsPunchingEngineering

The invention relates to a punching device which comprises a base, a supporting seat, a guide rod and a punching component. A workbench is arranged on the base, a supporting portion is formed at the top of the supporting seat, the punching component comprises a first die holder, a second die holder and a driving member, the first die holder is arranged on the workbench, and the driving member comprises multiple driving portions which are arranged at intervals and connected onto the second die holder. Multiple positioning grooves are formed in the first die holder, a punching hole is formed in the middle of the undersurface of each positioning groove, a positioning ring groove is formed around each positioning groove, multiple positioning columns are arranged in each positioning ring groove, and multiple punches are arranged on the second die holder and respectively align the punching holes in the positioning grooves. The punching device is accurate in positioning and high in punching efficiency.

Owner:台山市汇铭五金压铸有限公司

Intelligent automobile part stamping die and stamping method

ActiveCN113414270AImprove processing efficiencyEasy to transportMetal-working feeding devicesBelt grinding machinesMotor vehicle partElectric machine

The invention discloses an intelligent automobile part stamping die and a stamping method. The intelligent automobile part stamping die comprises a fixed frame, first electric hydraulic rods are fixedly installed on the two sides of the top of the fixed frame, transverse plates are fixedly installed at the telescopic ends of the two first electric hydraulic rods, a stamping mechanism is fixedly installed in the middle of the bottom end of each transverse plate, a fixed base is fixedly installed at the bottom end of the fixed frame, and a die forming mechanism is fixedly installed at the top of the fixed base. According to the scheme, through rotation of an arranged second driving motor, a main rotating roller and a driven rotating roller are matched with a transmission belt to intelligently and mechanically convey automobile parts, meanwhile, according to the sizes of the automobile parts, telescopic pushing plates of second electric telescopic rods on one sides of supporting plates are adjusted to get close to each other, the automobile parts can be conveniently and mechanically conveyed, and are prevented from falling in the conveying process, and the automobile processing efficiency is improved.

Owner:广州宏辉模具有限公司

U type/V type part stamping device and technology thereof

ActiveCN108311573AStamping realizationPrevent rotationShaping toolsEngineeringMechanical engineering

The invention discloses a U type / V type part stamping device and a technology thereof. The U type / V type part stamping device comprises a base plate, a first side plate and a second side plate are fixedly connected to the two sides of the upper surface of the base plate, two transverse plates are fixedly connected to the right side face of the first side plate, and the opposite faces of the two transverse plates are fixedly connected with the top end and the bottom end of a first sliding rod. According to the U type / V type part stamping device and the technology thereof, two U type stamping plates or two V type stamping plates get close to U type parts or V type parts needing to be stamped, stamping of the U type parts or V type parts is completed, stamping of the U type parts or V type parts is achieved through the device and the technology, an enterprise does not need to purchase other stamping devices, the enterprise production cost is reduced, and enterprise development is facilitated; and meanwhile, manual replacement of other stamping devices for stamping parts is not needed, the time of a worker is saved, and the working efficiency of the worker is improved.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

Stamping device

ActiveCN106734551BStamping realizationHigh positioning accuracyShaping toolsPerforating toolsPunching

The invention relates to a punching device which comprises a base, a supporting seat, a guide rod and a punching component. A workbench is arranged on the base, a supporting portion is formed at the top of the supporting seat, the punching component comprises a first die holder, a second die holder and a driving member, the first die holder is arranged on the workbench, and the driving member comprises multiple driving portions which are arranged at intervals and connected onto the second die holder. Multiple positioning grooves are formed in the first die holder, a punching hole is formed in the middle of the undersurface of each positioning groove, a positioning ring groove is formed around each positioning groove, multiple positioning columns are arranged in each positioning ring groove, and multiple punches are arranged on the second die holder and respectively align the punching holes in the positioning grooves. The punching device is accurate in positioning and high in punching efficiency.

Owner:台山市汇铭五金压铸有限公司

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876BGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, ahorizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAOTONG UNIV

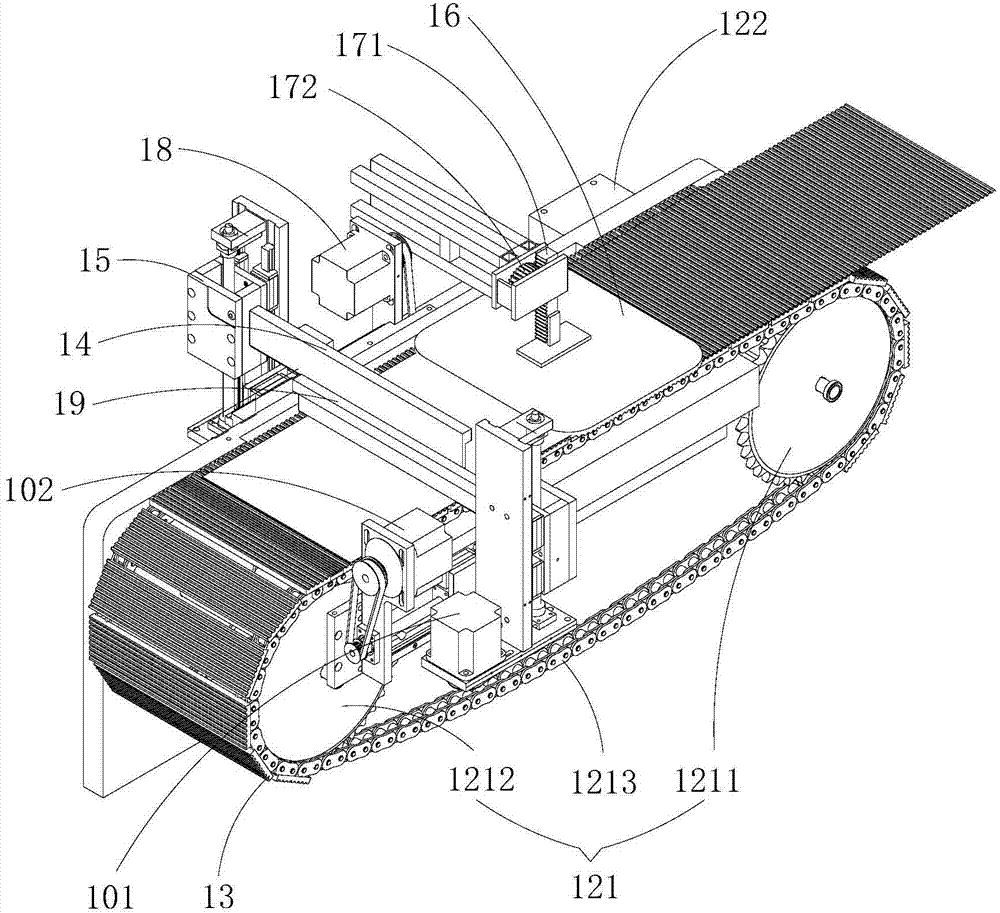

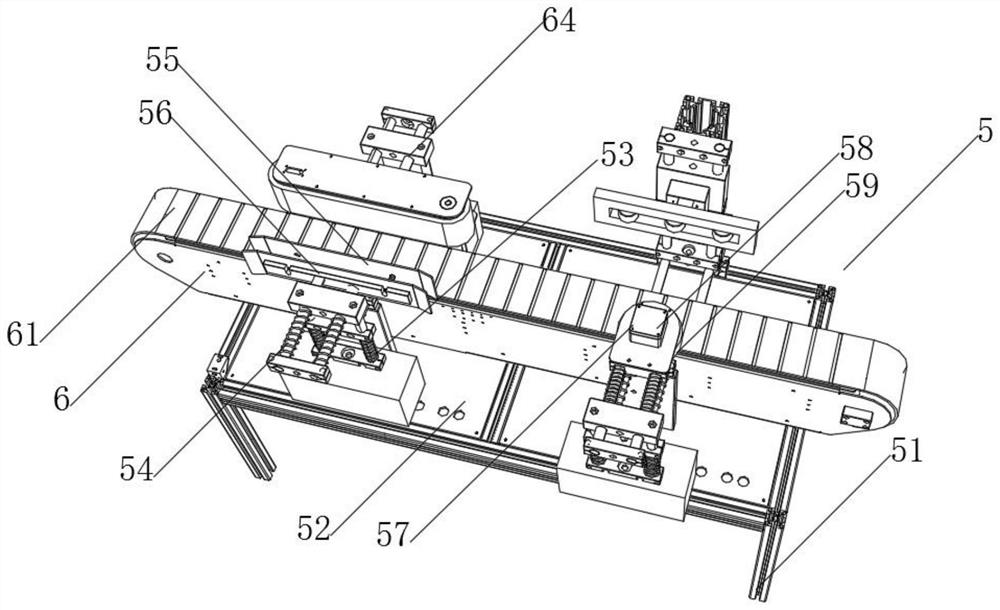

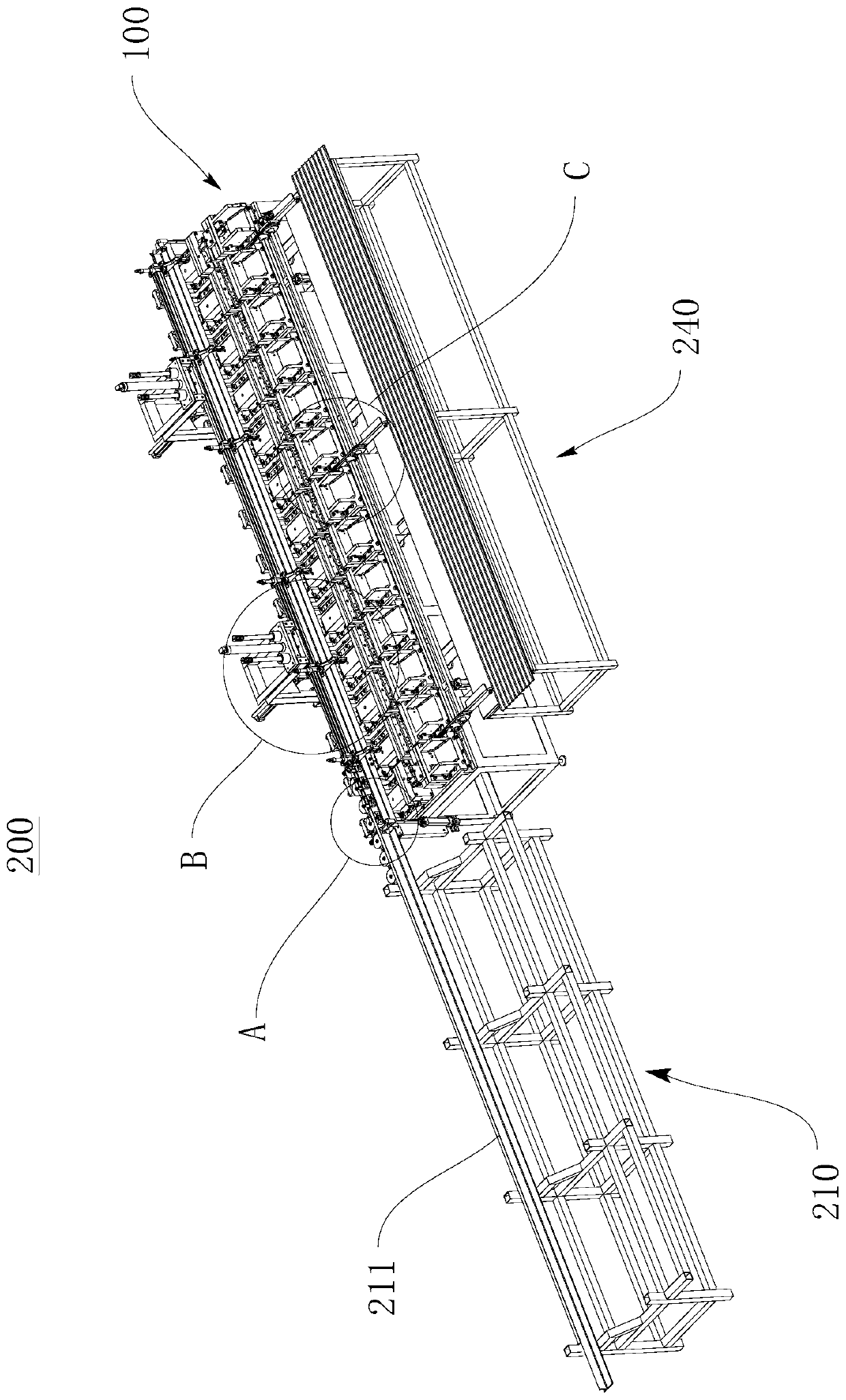

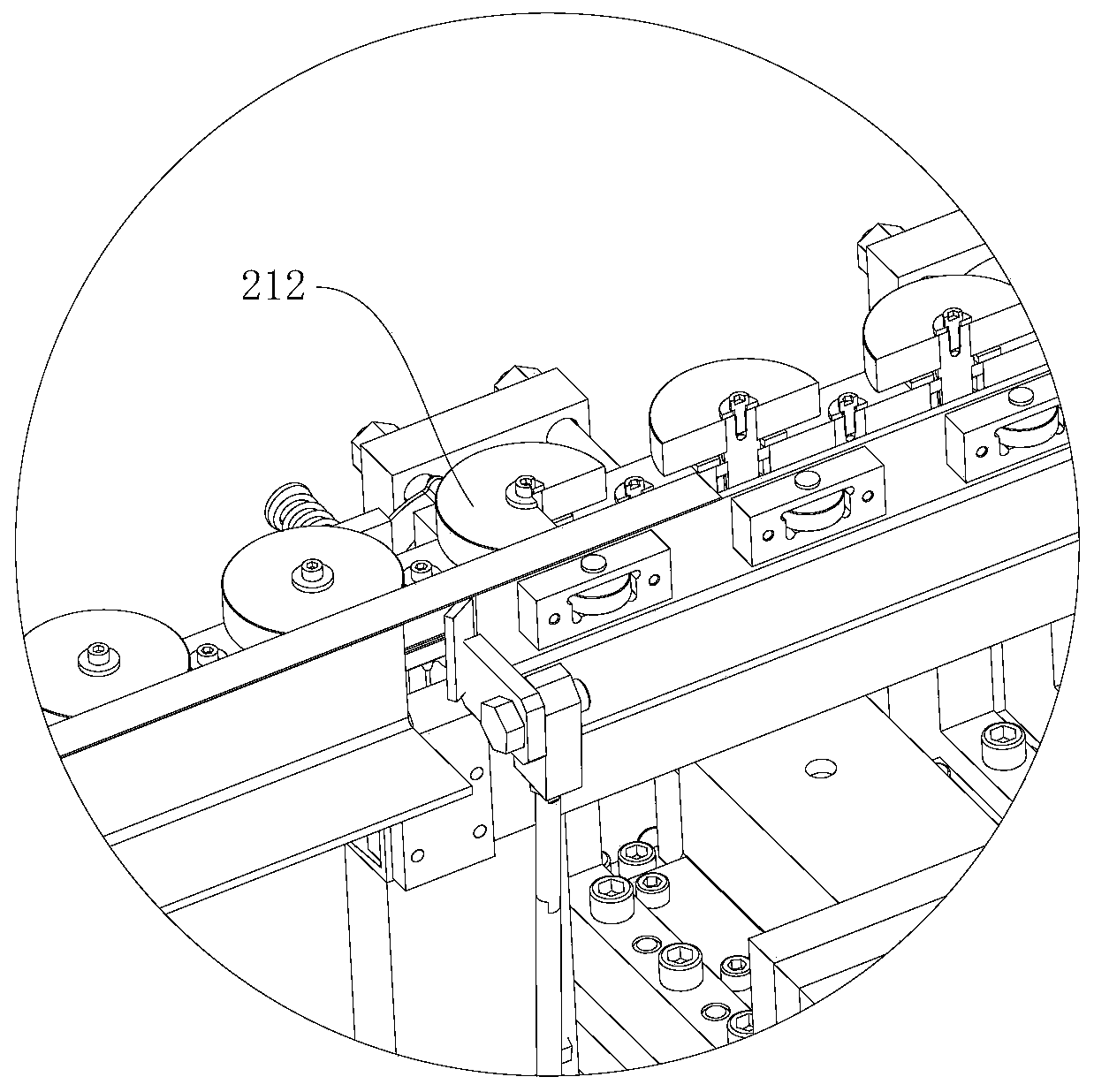

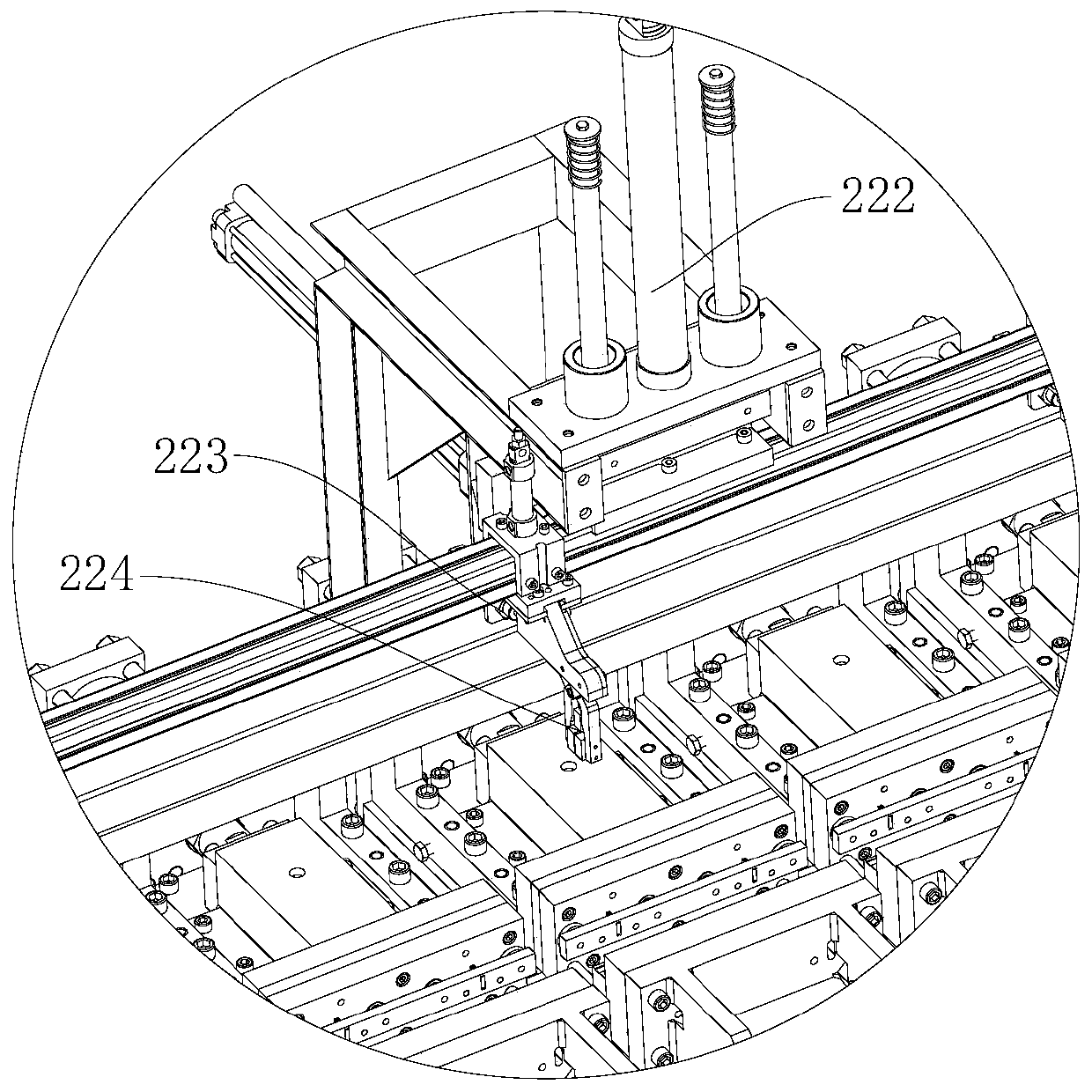

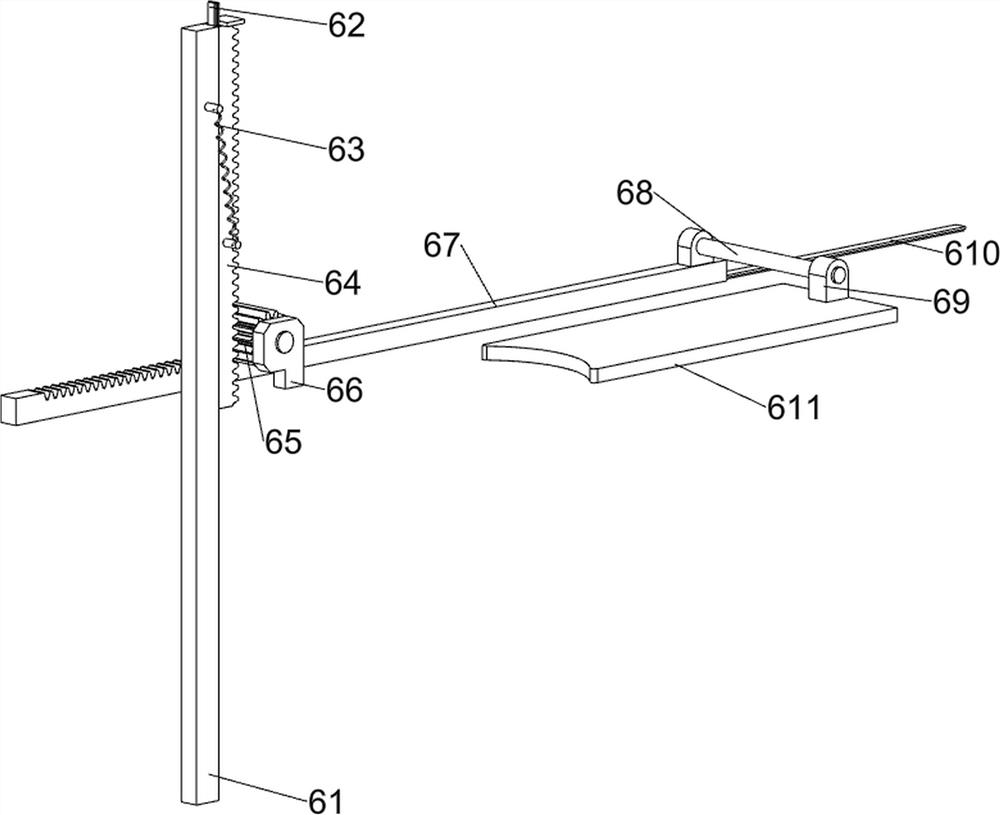

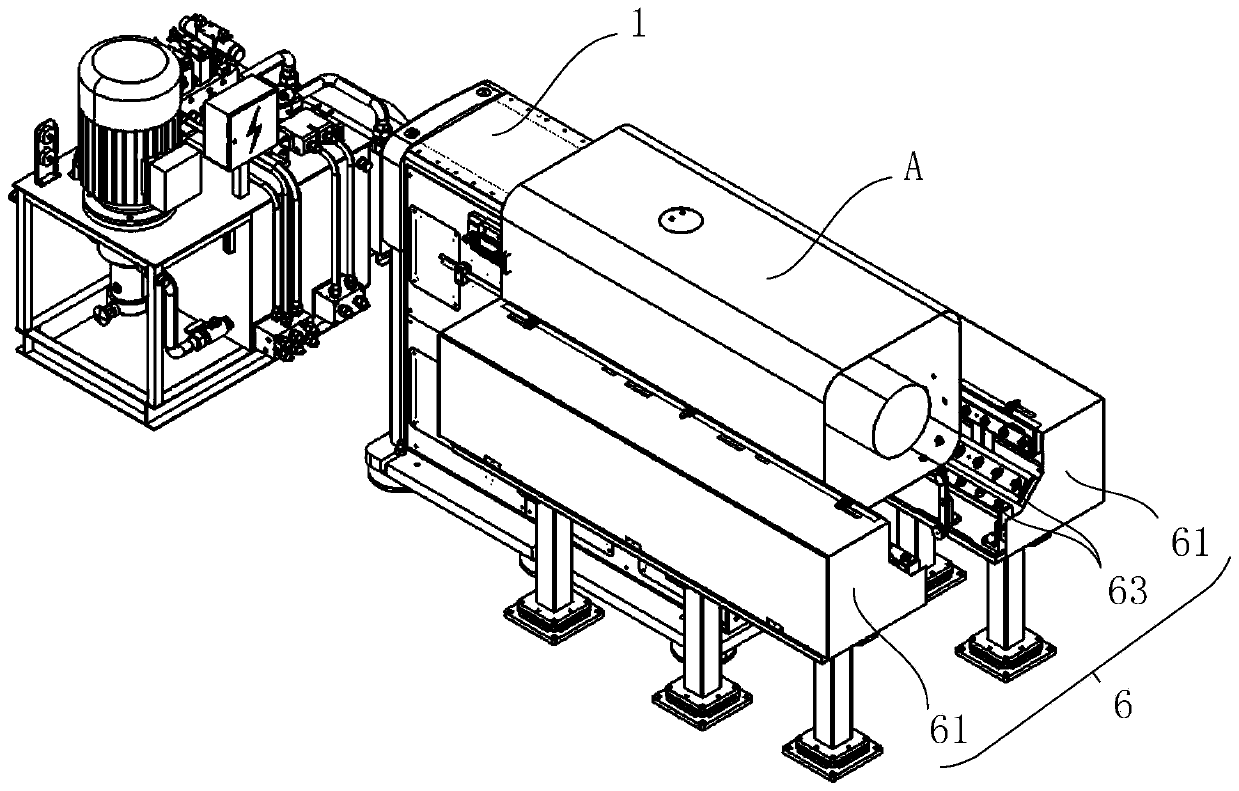

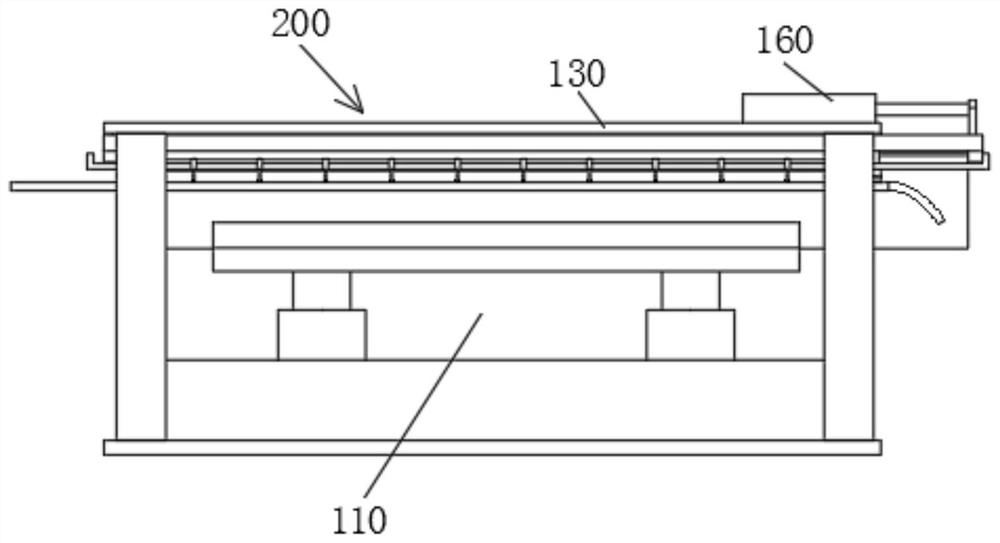

Automatic feeding punch production line

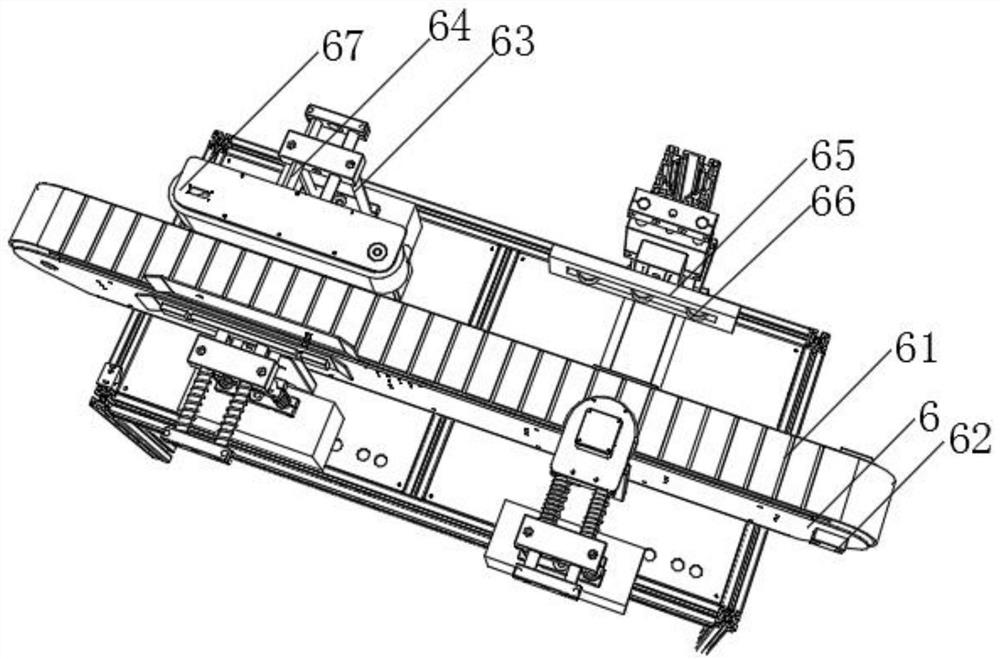

ActiveCN107685099BStamping realizationEfficient processingMetal-working feeding devicesStripping-off devicesProduction linePunch press

The invention provides a punch production line capable of achieving automatic feeding and relates to the technical field of punching production. The punch production line comprises a feeding unit, a clamping unit, a punching unit group, a discharge unit and a storage unit, wherein the feeding unit is used for supplying materials for the punching unit group; the clamping unit is used for clamping the materials from the feeding unit to the punching unit group; the punching unit group comprises a frame and a plurality of punching units which are arranged long the length direction of the frame; identical or different female dies can be mounted on the punching units; gaps exist among the punching units of the punching unit group, and the discharge unit is located at part of the gaps and used for receiving the materials moved out by the clamping unit and conveying the materials to the storage unit. The punch production line has the advantages that thin and long parts with different forming requirements can be punched; in addition, due to the fact that processes such as feeding and discharging can be controlled automatically, the efficient machining of the thin and long parts can be achieved, and machining quality can be guaranteed.

Owner:盐城特诺克科技有限公司

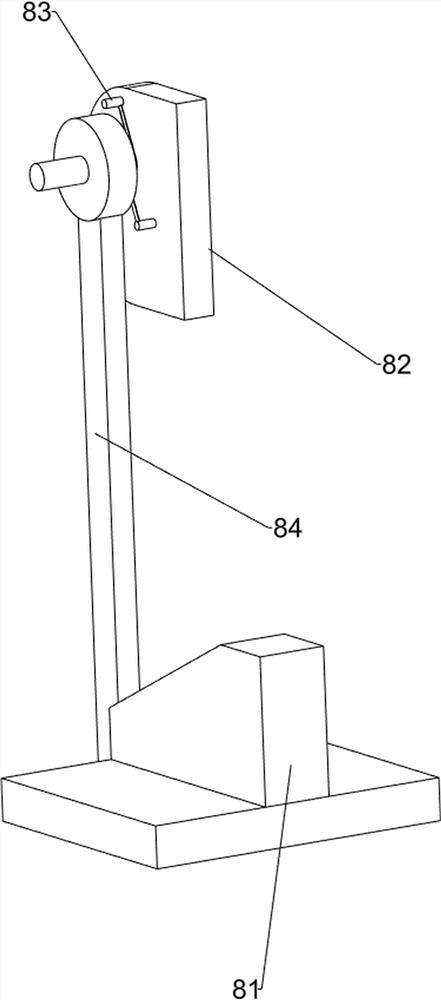

Manual stamping device of sealing rubber and stamping method

The invention discloses a manual stamping device of sealing rubber. The manual stamping device of the sealing rubber is characterized by comprising a base, wherein the base is provided with a supporting cushion block supporting a stamping cushion block, a reference stop block limiting the width of the sealing rubber is connected to the base, and the base is provided with a stamping block which isdriven by an operation device to conduct downward stamping. According to the manual stamping device of the sealing rubber and the stamping method, the manual stamping device is simple in structure, convenient and rapid to use, good in universality and good in forming accuracy and saves time and effort, and good practicability and good application prospect are achieved.

Owner:ANHUI ZHONGDIAN XINGFA & XINLONG TECH CO LTD

Round steel plate stamping equipment for steel processing

ActiveCN112676421AStamping realizationRealize automatic feeding processMetal-working feeding devicesStripping-off devicesMachining processIndustrial engineering

The invention relates to stamping equipment, in particular to round steel plate stamping equipment for steel machining. The technical problem to be solved is to provide round material stamping equipment for steel machining, which is high in steel plate conveying speed, short in machining process time, high in efficiency, more automatic and capable of reducing dependence on manpower. According to the technical implementation scheme of the invention, the round steel plate stamping equipment for steel machining comprises machine legs, a stamping mechanism and a feeding mechanism, wherein the machine legs are arranged on the periphery of a machine base; the stamping mechanism is arranged on one side of the machine base; and the feeding mechanism is arranged on the machine base. Through cooperation of the stamping mechanism and the feeding mechanism, automatic feeding of materials can be achieved, the materials can be stamped easily, and stamping and feeding time is saved.

Owner:温岭市浙江下张钢铁市场有限公司

Barrel punch forming device

PendingCN111451348AStamping realizationAchieve clampingShaping toolsVehicle componentsPunchingClassical mechanics

The invention discloses a barrel punch forming device which comprises an upper die capable of extending into a barrel and a lower die located outside the barrel. The upper die and the lower die are matched with each other to clamp the barrel, a male die is movably arranged on the upper die, a groove for avoiding is formed in the lower die, and the male die can conduct punching on the surface of the barrel; the upper die is a cantilever and is fixedly arranged, and the upper die is kept fixed in the operation process; the lower die is driven by a clamping driver and can move to be close to or away from the upper die so as to clamp or loosen the barrel; the male die is driven by a punching driver to punch, and an avoiding space is provided by the groove in the lower die; the moving directionof the punching driver is perpendicular to the moving direction of the male die, so that the punching driver can be placed in a cavity in the barrel to punch the barrel; and the barrel punch formingdevice can punch a machined and formed barrel structure.

Owner:长春森酉科技有限公司

Packaging sheet rapid stamping die

InactiveCN112453196AImprove stamping precisionImprove pass ratePerforating toolsCleaning using gasesStampingStructural engineering

The invention discloses a packaging sheet rapid stamping die which structurally comprises an upper die plate, stamping supporting rods, a lower die plate and a stamping section die. The stamping supporting rods are connected with the upper die plate and the lower die plate through shafts, the stamping section die is installed on the upper die plate and the lower die plate, the upper die plate andthe lower die plate are same in structure, and the stamping section die comprises a mounting shaft, an upper section die plate and a lower section die plate. The mounting shaft is connected with the upper section die plate and the lower section die plate in a mounted mode, the upper section die plate is installed on the upper die plate, the lower section die plate is installed on the lower die plate, and the upper section die plate and the lower section die plate are same in structure. According to the packaging sheet rapid stamping die, dust collectors are of a concealable structure and are used for collecting metal dust in a large range, a large number of metal chips which are generated between the die and a plate in the plate machining process are collected through rotary dust collectors, the metal chips at the stamping hole position are collected through transverse moving dust collectors, the stamping precision is improved, and the product percent of pass is increased.

Owner:广州迎善信息科技有限公司

A kind of intelligent automobile parts stamping die and stamping method

ActiveCN113414270BImprove processing efficiencyEasy to transportMetal-working feeding devicesBelt grinding machinesMotor vehicle partTransmission belt

The invention discloses an intelligent stamping die for automobile parts and a stamping method, comprising a fixed frame, first electro-hydraulic rods are fixedly installed on both sides of the top of the fixed frame, and the telescopic ends of the two first electro-hydraulic rods are fixedly installed with transverse rods. The middle part of the bottom end of the horizontal plate is fixedly installed with a punching mechanism, the bottom end of the fixed frame is fixedly installed with a fixed seat, and the top of the fixed seat is fixedly installed with a molding mechanism. In this scheme, through the rotation of the second drive motor, the main rotating roller and the slave rotating roller cooperate with the transmission belt to carry out intelligent and mechanized transportation of the auto parts, and at the same time, according to the size of the auto parts, the extension and retraction of the second electric telescopic rod on the side of the support plate is adjusted. Pushing the push plates close to each other is convenient for conveying the auto parts machinery, preventing them from falling during the conveying process, and improving the efficiency of auto processing.

Owner:广州宏辉模具有限公司

A microstructure array precision machining machine tool with adaptive matching of dynamic characteristics

ActiveCN104485290BReduce alignment timeReduce movement deviationDecorative surface effectsSemiconductor/solid-state device manufacturingPunchingThe Internet

Owner:GUANGDONG UNIV OF TECH

Coach bolt hot extrusion forming equipment

ActiveCN113976793AImprove molding qualityAffect the assemblyBoltsForging/hammering/pressing machinesStructural engineeringMachine

The invention relates to the field of coach bolt stamping forming, in particular to coach bolt hot extrusion forming equipment. The equipment comprises a stamping table, a stamping machine and a stamping die, the stamping die comprises a fixed die block and two movable die blocks, the two movable die blocks are symmetrically arranged at the top of the fixed die block, the symmetrical face of the two movable modules is the middle section of the fixed module, the two movable modules can relatively slide on the fixed module, the fixed module is further provided with a driving device used for driving the two movable modules to relatively slide, the stamping table is further provided with a supporting table used for supporting a coach bolt, and the supporting table is also provided with a lifting device for lifting the coach bolt. According to the equipment, through cooperation between the fixed die and the movable die, the coach bolt can be attached to the edge of the movable die after being punched and formed, the forming quality of the coachbolt is improved, and the situation that assembly is affected when the coach bolt is used is avoided.

Owner:浙江科腾精工机械股份有限公司

Stamping device for corrugated foil and production equipment for corrugated foil

ActiveCN103537539BStamping is effectiveEffective realization of stamping formingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

A metal processing auxiliary transfer device for automatic unloading after stamping

ActiveCN110711823BStamping realizationEasy to pushMetal-working feeding devicesPositioning devicesStructural engineeringIndustrial engineering

The invention relates to the technical field of hardware processing, and discloses a metal processing auxiliary transfer device for automatic unloading after stamping, which includes a first turntable, and a first rotating rod is movably connected to the bottom of the first turntable; the first turntable rotates Make the stamping mechanism move to the lowest point and keep it for a short stay; the subsequent spring on the outside of the first connecting rod causes the stamping mechanism to move up, thereby realizing stamping of the material, and the up and down movement of the pull rope causes the circle plate to rotate back and forth, and the circle plate rotates along the pointer to drive the second The three turntables rotate synchronously. When the ring plate rotates counterclockwise, the third turntable remains still, which is beneficial to push the material later. The fourth turntable rotates to make the push rod move left and right to push out the materials on the console. At the same time, the push rod moves up and down to push the material When the rod moves to the right to push the material, adjust the height of the push rod to avoid the position where the push rod exerts force on the material is too low, and the strength of the force on each area of the material varies too much, which is not enough to push the material out of the operation table.

Owner:四会市景顺五金制品有限公司

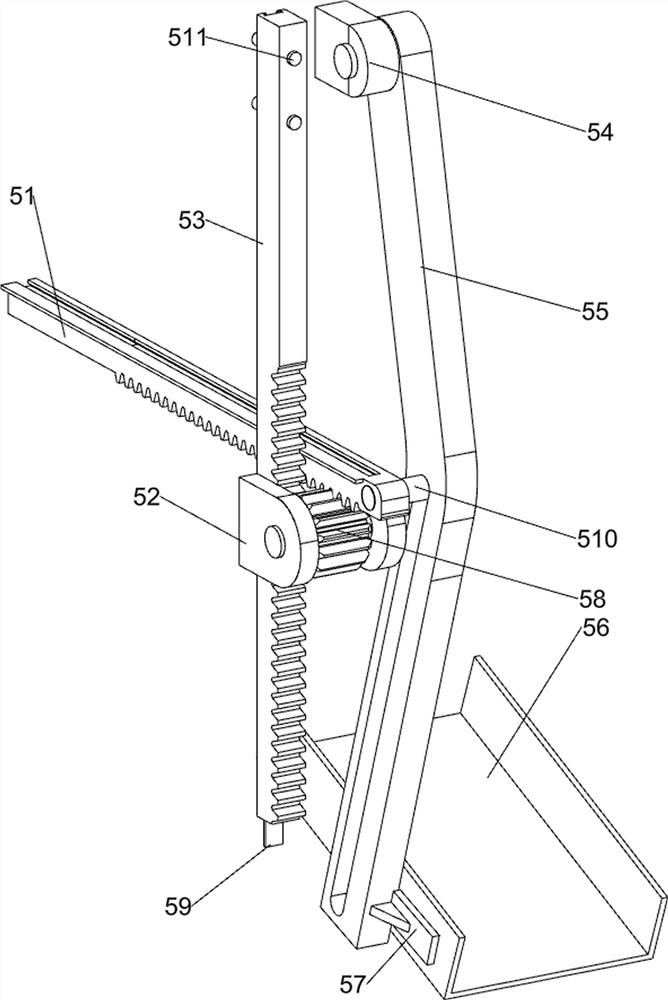

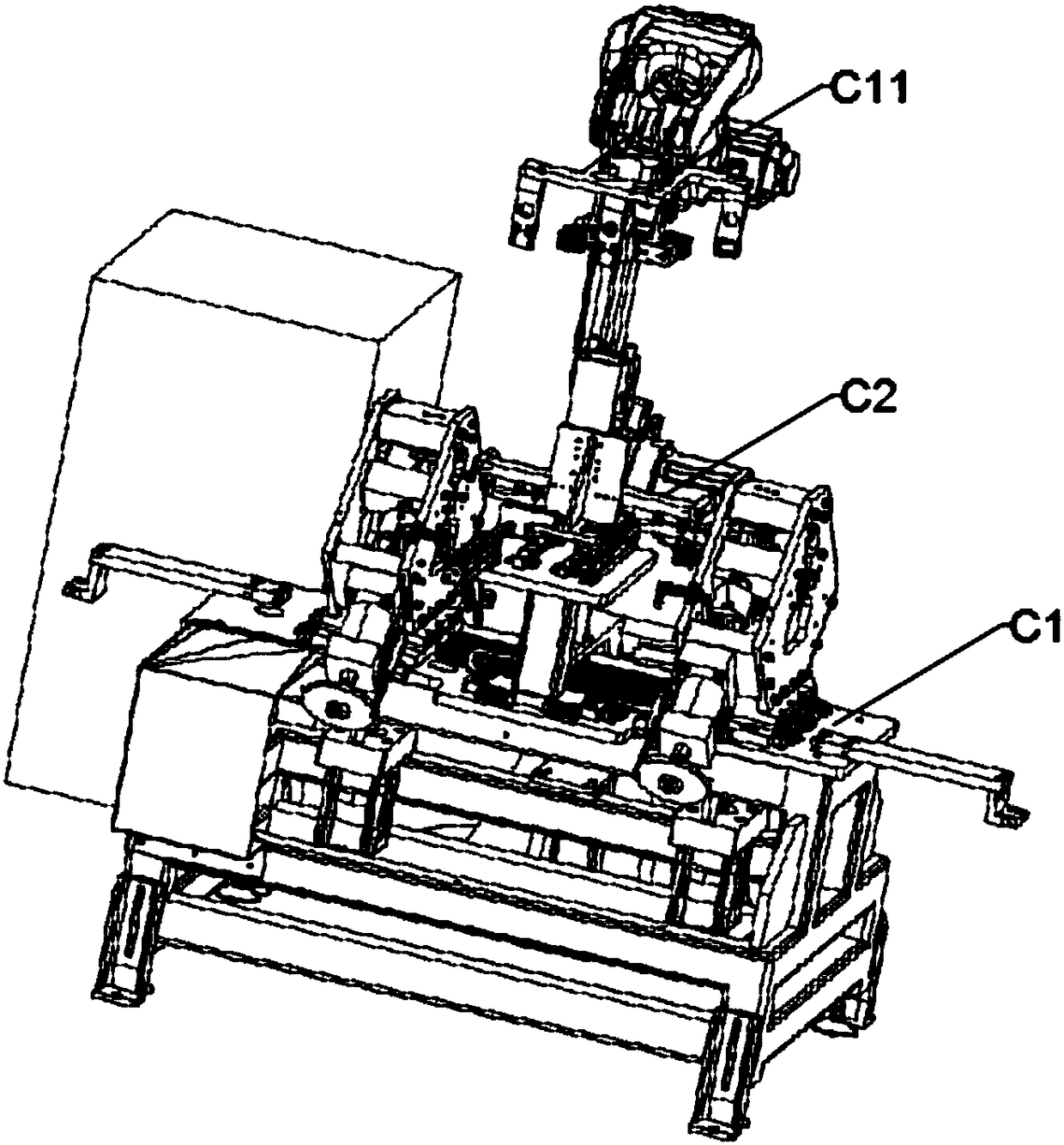

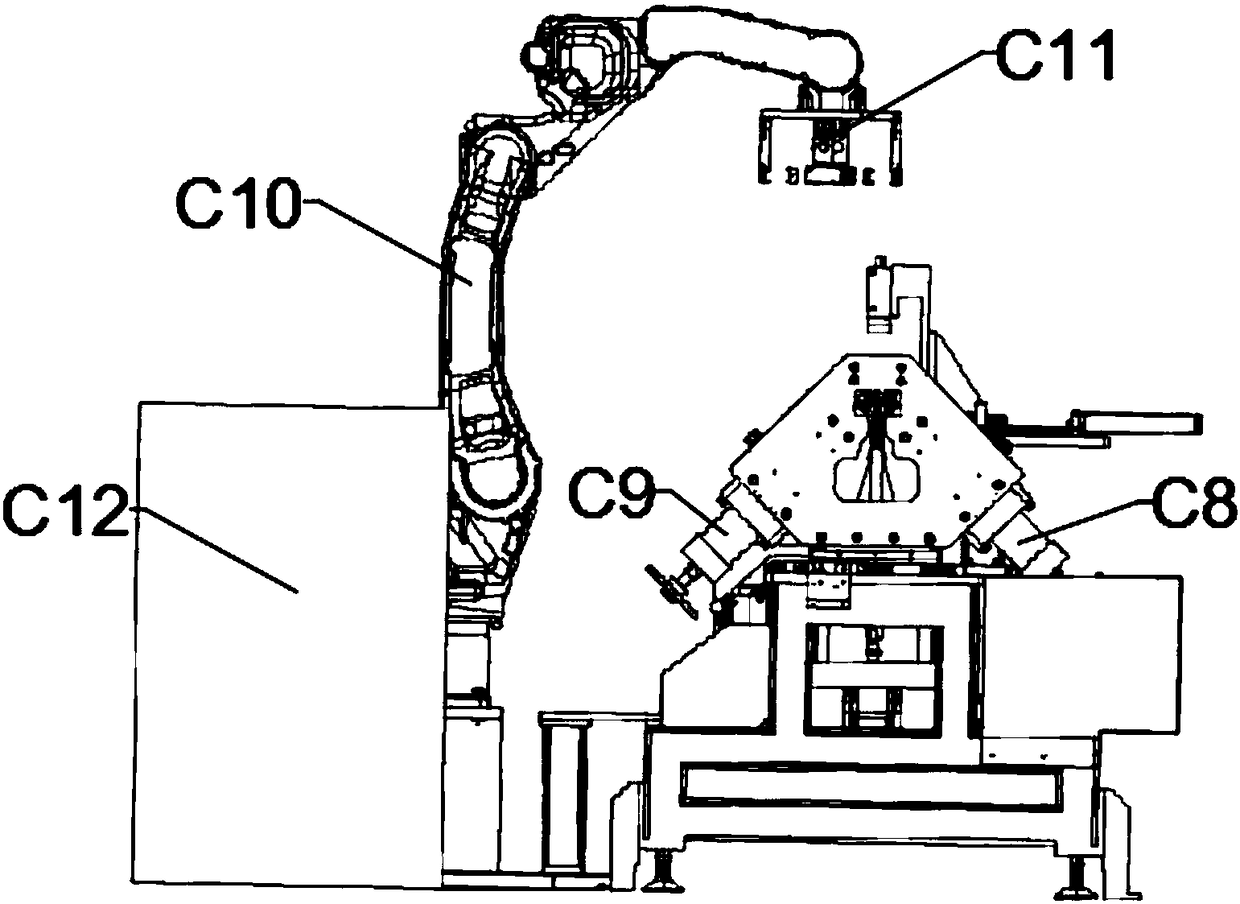

Holder shift point stamping system

InactiveCN108188239ARealize different pick and placeSave time at workMetal-working feeding devicesVehicle componentsRail profileEngineering

The invention discloses a holder shift point stamping system comprising a machine seat. The machine seat is provided with a sliding rail fixing device, and the sliding rail fixing device comprises aninner rail fixing device and an outer rail pusher. The left side and the right side of the sliding rail fixing device are provided with stamping units of the same structure, the stamping units are fixed to a stamping rack, and the stamping rack is fixed to the machine seat. The top of the stamping rack is fixedly provided with an outer rail profile modeling head. The stamping unit comprises a first stamping machine and a second stamping machine of the same structure, and the first stamping machine and the second stamping machine are perpendicular to each other. The machine seat is fixedly provided with a mechanical grabbing arm, and the tail end of the mechanical grabbing arm is provided with a grabbing tool; and the rear of the mechanical grabbing arm is provided with a system control cabinet.

Owner:重庆飞驰汽车系统有限公司

A punch with positioning function

ActiveCN108580629BStamping realizationAchieve positioningShaping toolsClassical mechanicsElectric machinery

The invention discloses a punching machine with a positioning function, which comprises a base, a pillar is fixedly installed on the top side of the base, an upper module is fixedly installed on the top side of the pillar, a first motor chamber is opened on the upper module, and a first motor chamber The first motor is fixedly installed inside, and a through hole is opened on the inner wall of the bottom side of the first motor cavity, and a slide bar is slidably installed in the through hole, and the bottom end of the slide bar extends out of the through hole and is fixedly installed with a stamping block, the slide bar There is a threaded groove on the top of the threaded groove, and a threaded block is installed in the threaded groove. The top side of the threaded block is fixedly installed with a main shaft. The top of the main shaft extends into the cavity of the first motor and is fixedly connected with the output shaft of the first motor. There is a second motor cavity, a second motor is fixedly installed in the second motor cavity, and a cavity is opened on the upper module. The invention positions the stamping block after stamping to prevent the reaction force from damaging the thread block and the thread groove, and has simple structure and convenient operation.

Owner:台州市钟氏电机有限公司

A size-adjustable stamping body

The invention discloses a size-adjustable stamping body. The stamping body comprises a first side plate, a second side plate, a third side plate, a fourth side plate, a first rack, a second rack, a third rack, a fourth rack, a first connector, a second connector, a third connector, a fourth connector, a gear shaft, a duplicate gear and a stamping body frame. The size of the stamping body is adjustable.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Metal sheet drilling equipment for production and machining

PendingCN112808847AStamping realizationImprove drilling efficiencyPerforating toolsMetal-working feeding devicesPhysicsDrill hole

The invention relates to metal sheet drilling equipment, in particular to metal sheet drilling equipment for production and machining. According to the technical problem, the metal sheet drilling equipment for production and machining is simple to operate, can uniformly convey and feed metal sheets, and can timely collect residual metal sheet fragments after drilling. In order to solve the technical problem, the metal sheet drilling equipment for production and machining comprises a first fixing block connected to one side of a bottom plate, a second fixing block connected to the other side of the bottom plate, a discharging frame connected to the side, close to the second fixing block, of the bottom plate, a stamping mechanism connected between the bottom plate and the second fixing block, and a material collecting mechanism connected to the side, close to the first fixing block, of the bottom plate. The metal sheet drilling equipment has the following advantages that through the cooperation between a stamping mechanism and the material collecting mechanism, the metal sheets can be stamped.

Owner:谭润华

A U-shaped/V-shaped part stamping device and its process

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

Punching machine with positioning function

The invention discloses a punching machine with a positioning function. The punching machine with the positioning function comprises a base, wherein a support pillar is fixedly arranged on the top side of the base; an upper die block is fixedly arranged on the top side of the support pillar; a first motor cavity is arranged on the upper die block; a first motor is fixedly arranged in the first motor cavity; a through hole is formed in a bottom side inner wall of the first motor cavity; a slide rod is slidably arranged in the through hole; the bottom end of the slide rod extends to the outsideof the through hole and is fixedly provided with a punching block; a thread groove is formed in the top end of the slide rod; a thread block is arranged in the thread groove; a main shaft is fixedly arranged on the top side of the thread block; the top end of the main shaft extends into the first motor cavity and is fixedly connected with an output shaft of the first motor; a second motor cavity is arranged on the upper die block; a second motor is fixedly arranged in the second motor cavity; and a cavity is arranged on the upper die block. The punching machine with the positioning function provided by the invention is used for positioning a punching block after the punching block is used for punching, prevents a counter-acting force from damaging the thread block and the thread groove, and is simple in structure and convenient to operate.

Owner:台州市钟氏电机有限公司

New energy power battery pole forging processing technology and forging device thereof

InactiveCN114453544AClosely connectedImprove connection strengthForging press detailsCell component detailsPower batteryNew energy

The invention relates to the technical field of battery pole processing, in particular to a new energy power battery pole forging processing technology and a forging device thereof.The new energy power battery pole forging processing technology comprises a bottom plate, a stamping assembly is fixedly installed on the top face of the bottom plate, supporting legs are fixedly connected to the four top corners of the top face of the bottom plate, and a top plate is fixedly connected between the top ends of the four supporting legs; a fixing seat is fixedly connected to the middle of the bottom face of the top plate, a felt table is fixedly connected to the bottom face of the fixing seat, and a linear motor is fixedly connected to one end of the top face of the top plate. According to the invention, through the arrangement of the fixing module and the pushing mechanism, the composite pole blank is placed on the fixing module, and the interface piece and the sealing plate piece are stamped through the forging head, so that the connection between the interface piece and the sealing plate piece is tighter, and gaps and bubbles between the connection positions of the interface piece and the sealing plate piece are removed or reduced; and meanwhile, an impurity layer on the surface of the sealing plate is peeled off through stamping, and follow-up treatment is facilitated.

Owner:广东洋基科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com