Patents

Literature

44results about How to "Affect the assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

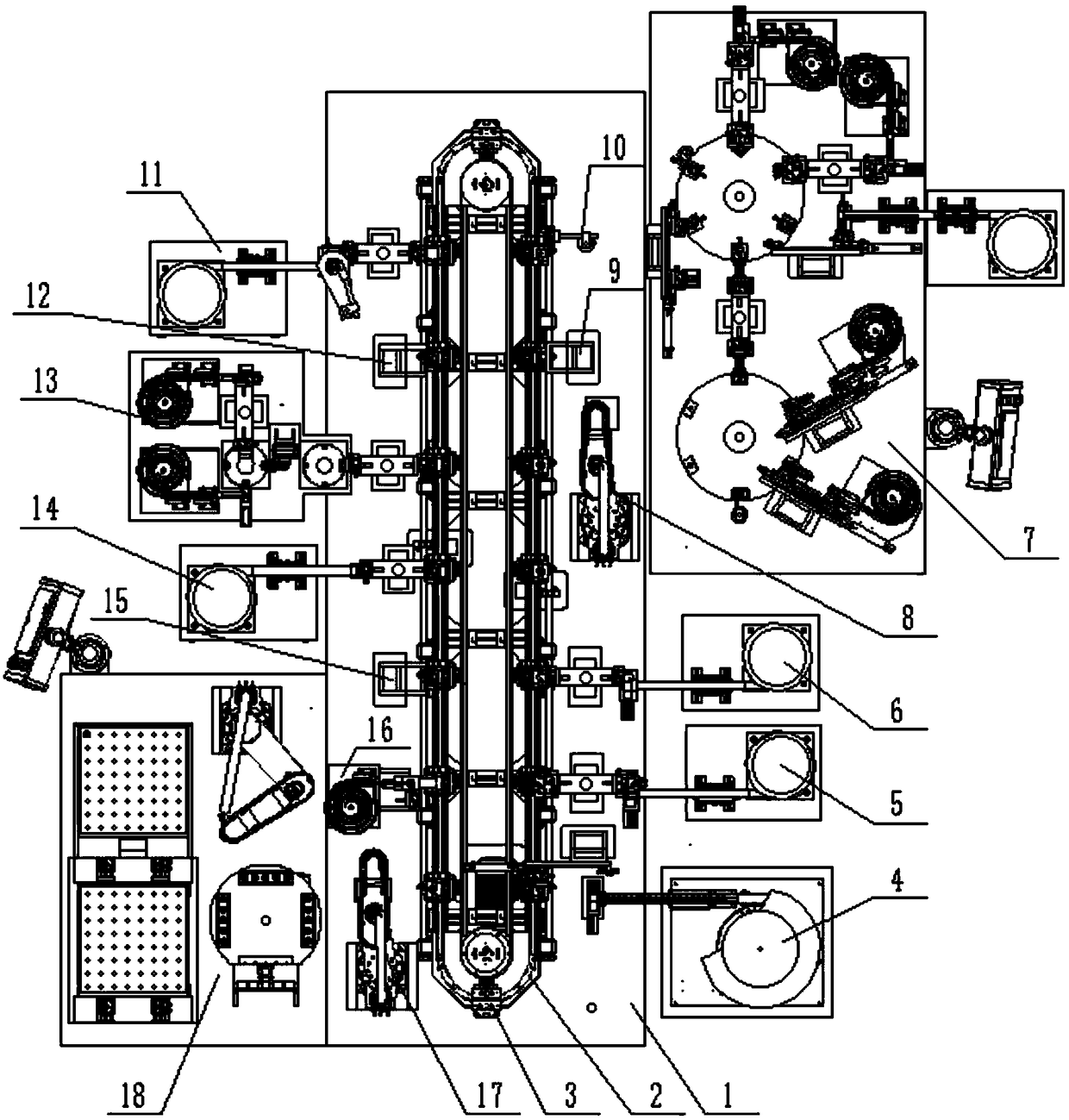

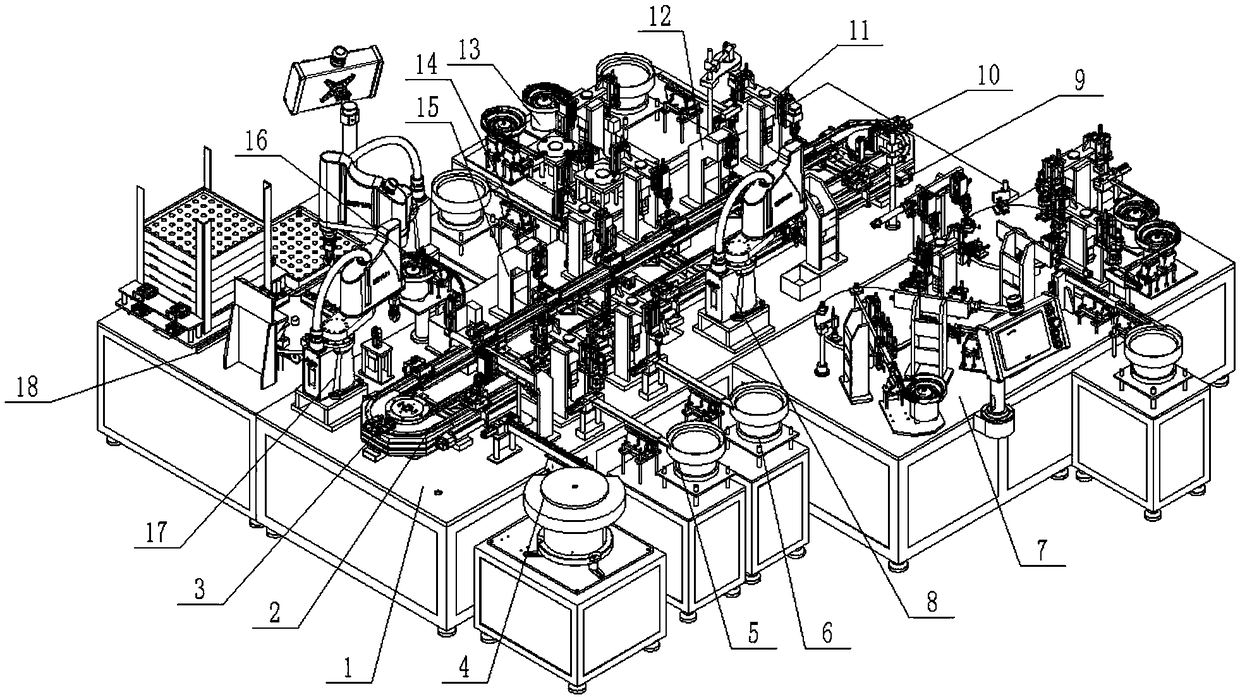

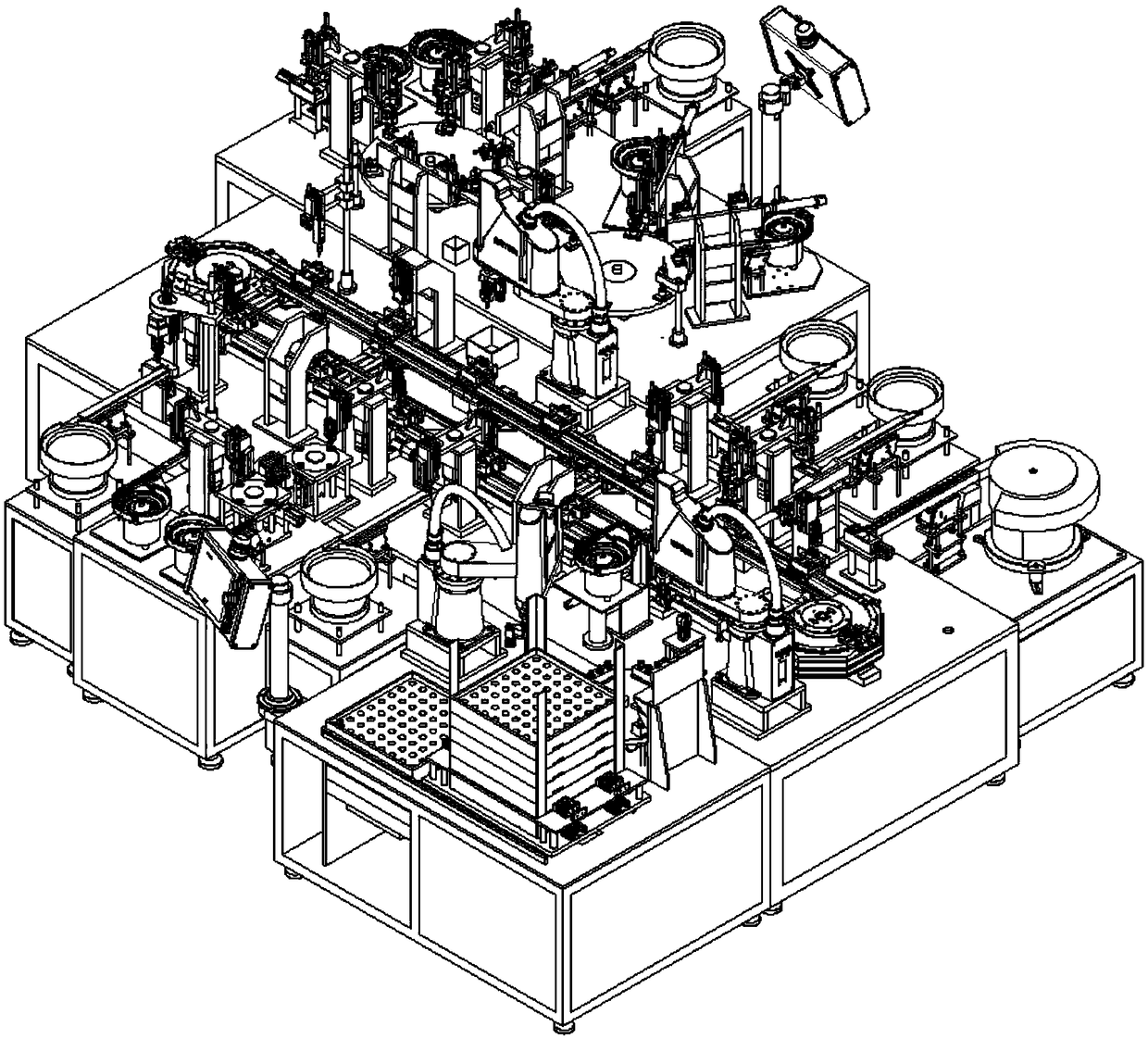

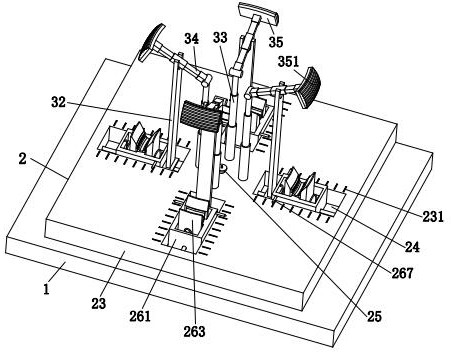

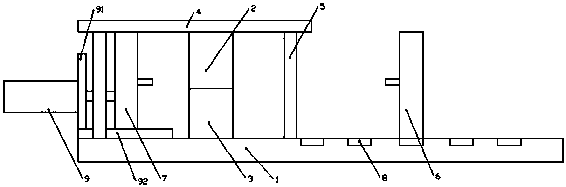

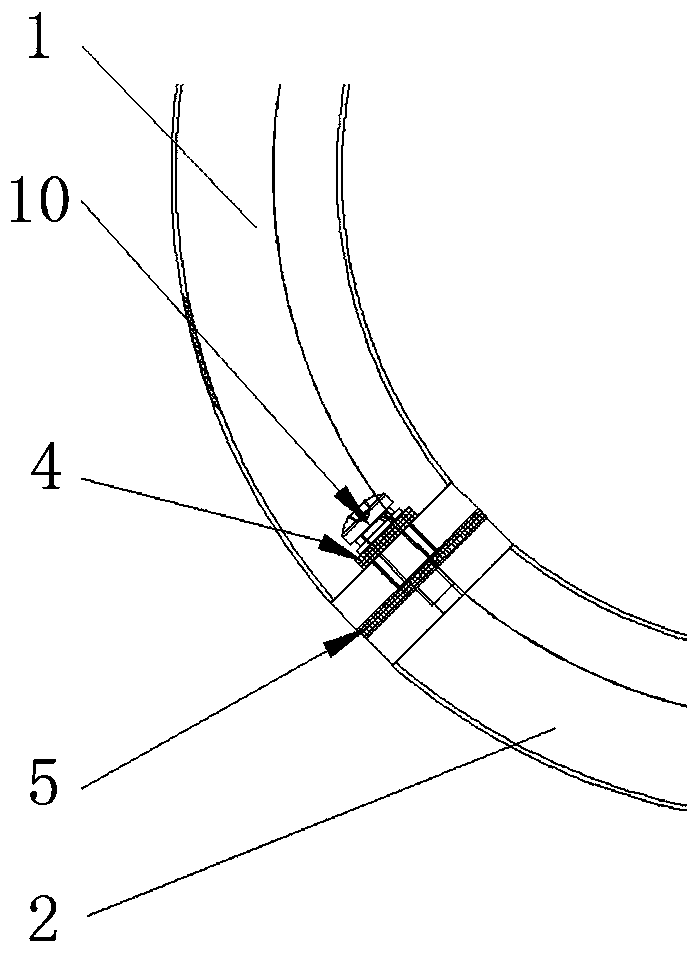

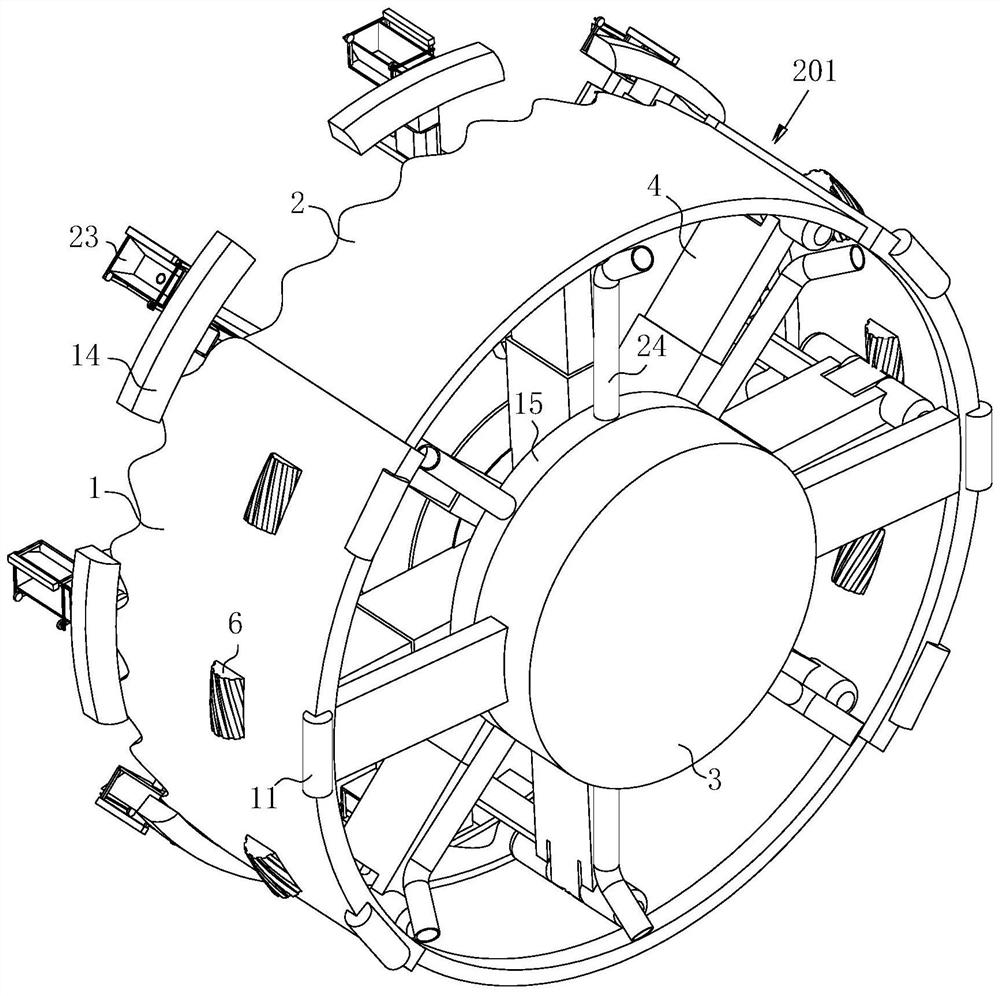

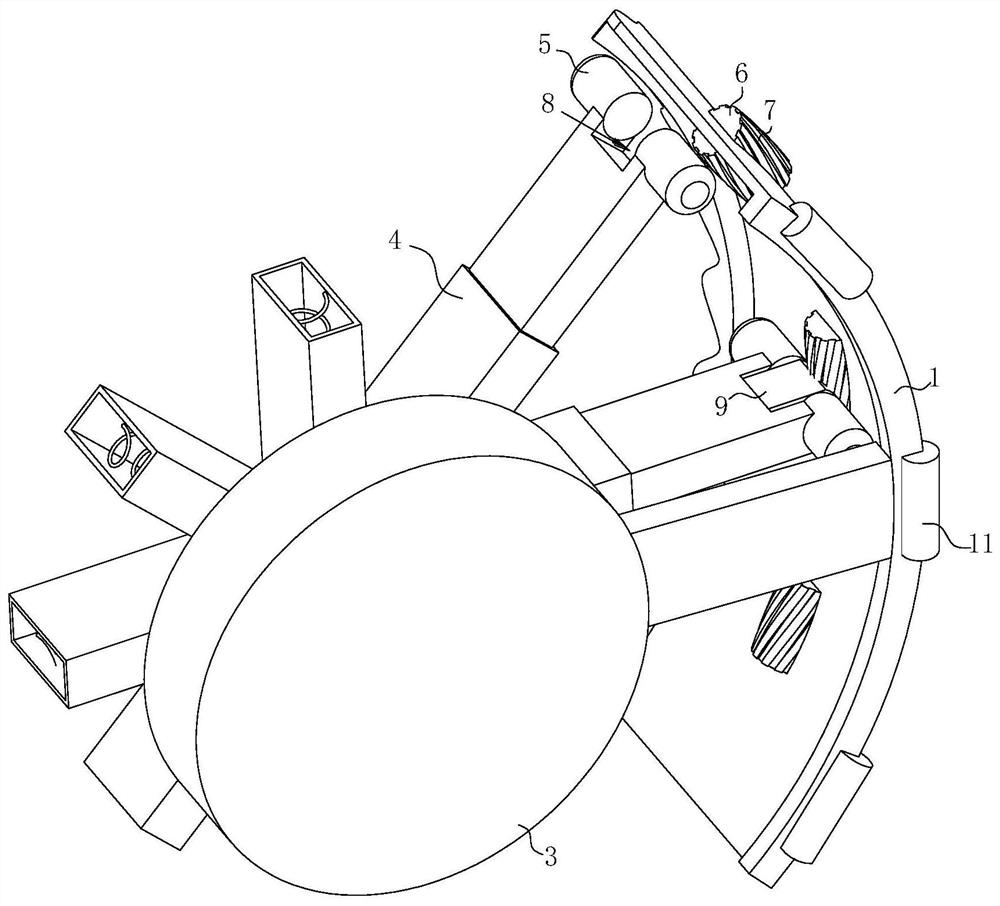

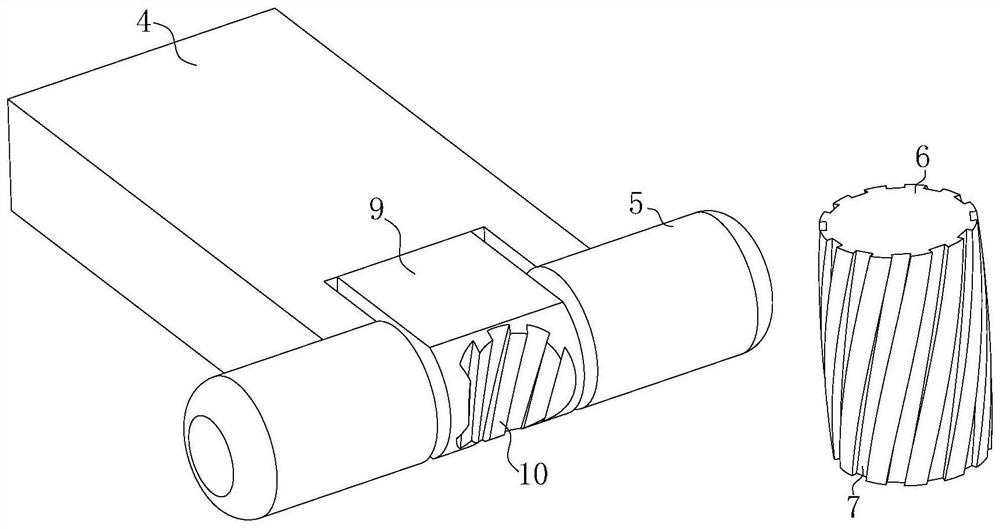

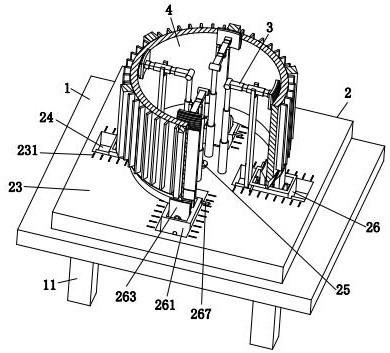

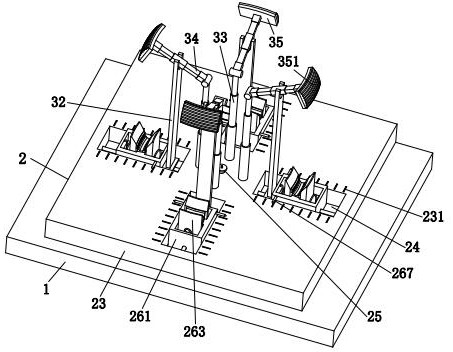

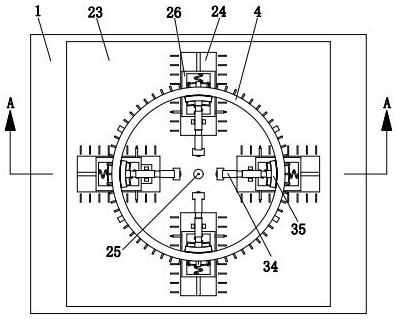

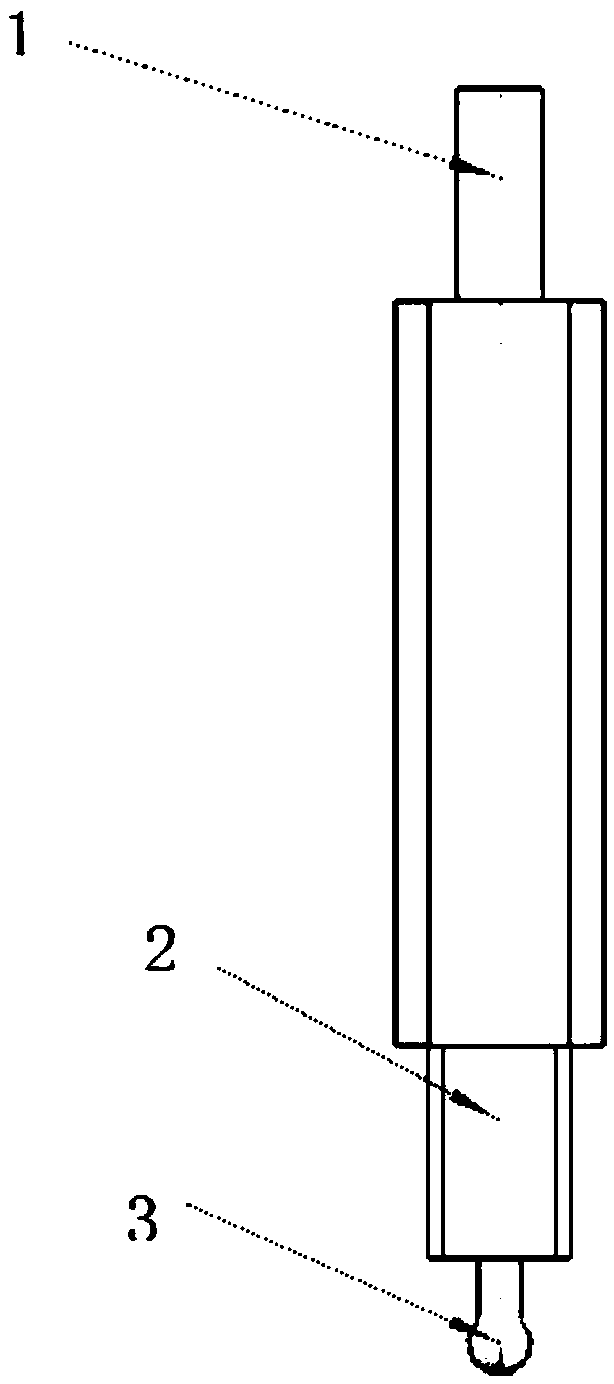

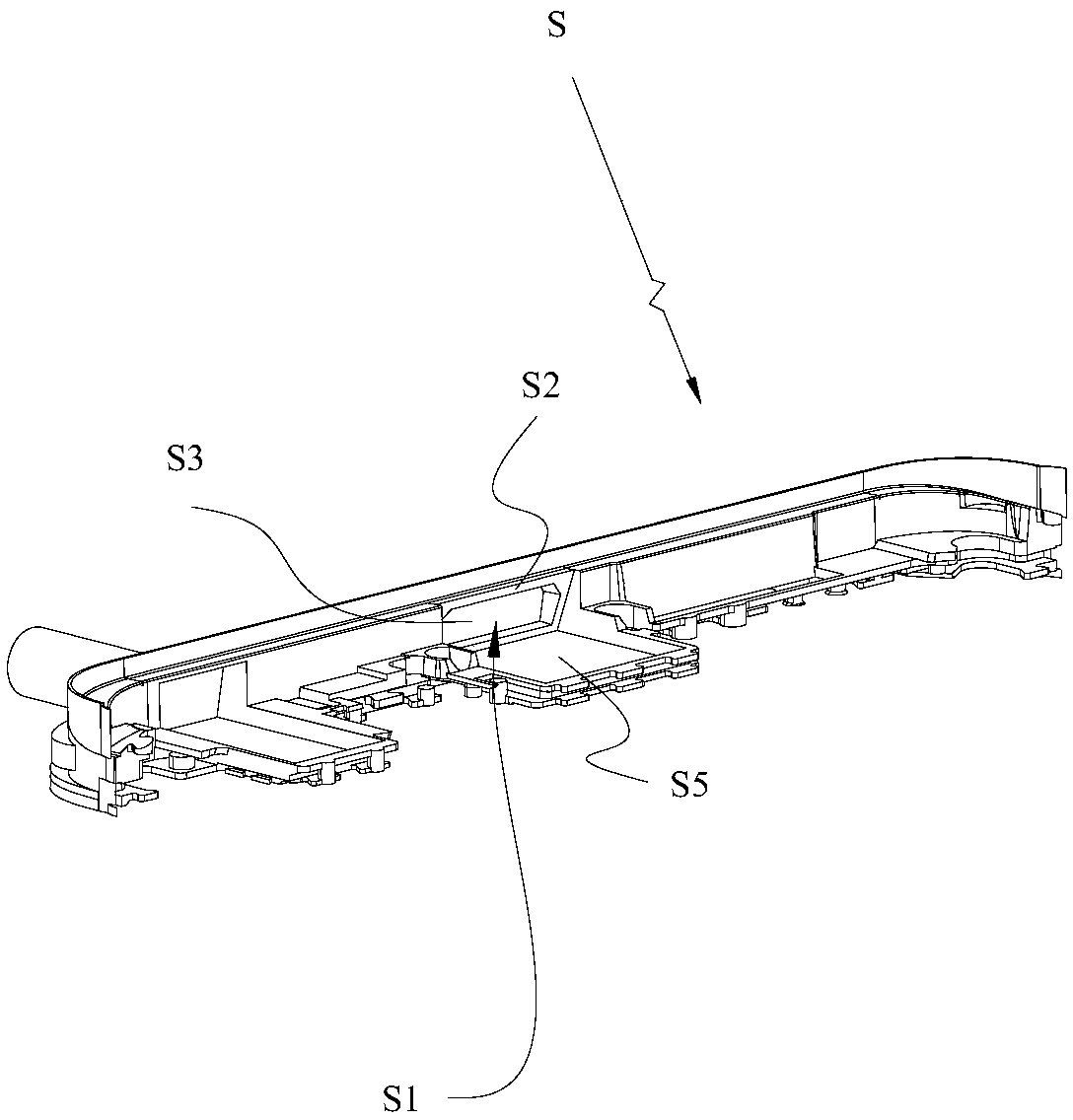

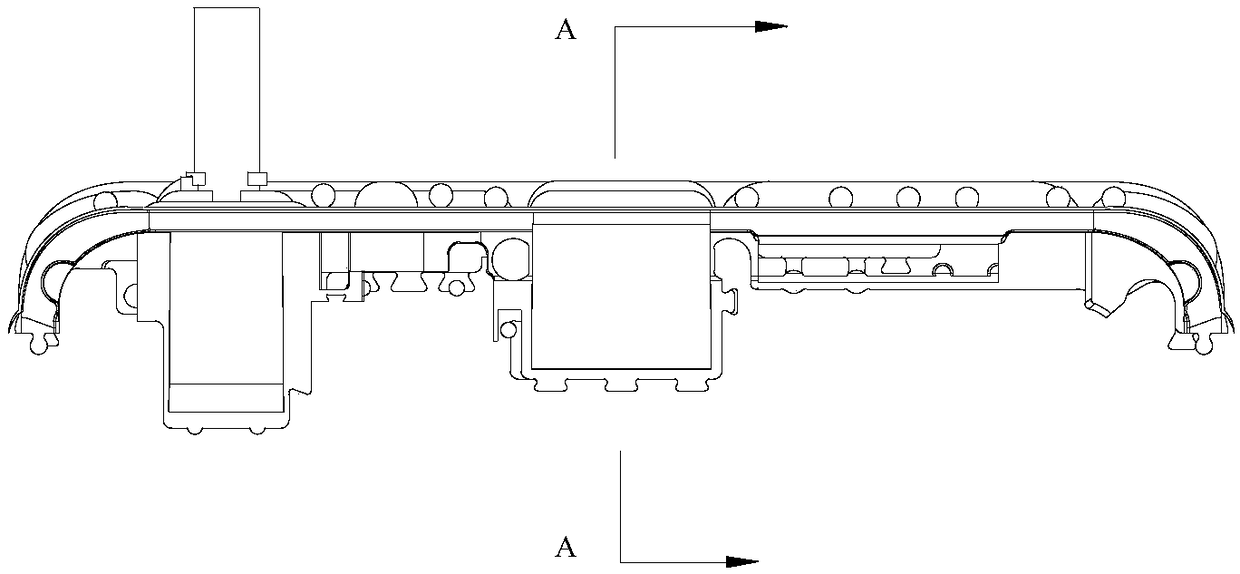

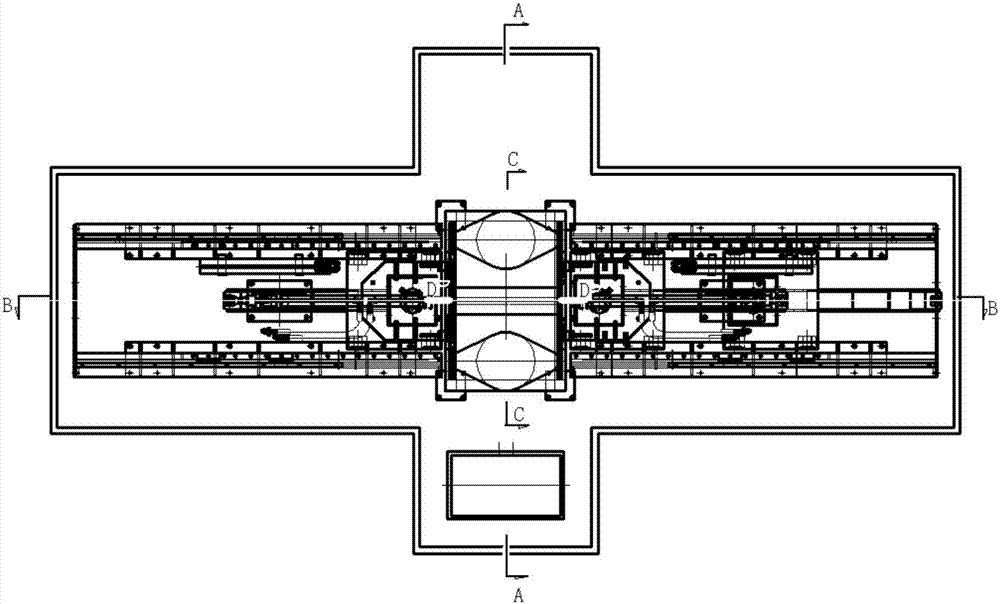

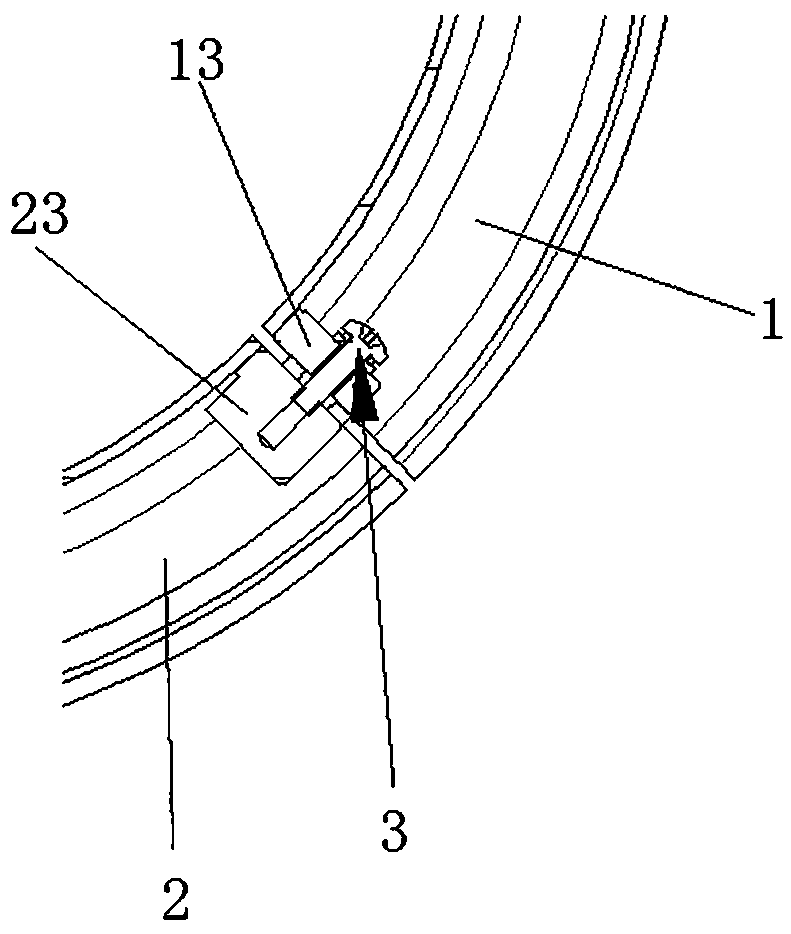

Automatic assembly line of valve element of water valve

PendingCN109290792AAssembly line compactHigh positioning accuracyAssembly machinesMetal working apparatusAssembly lineEngineering

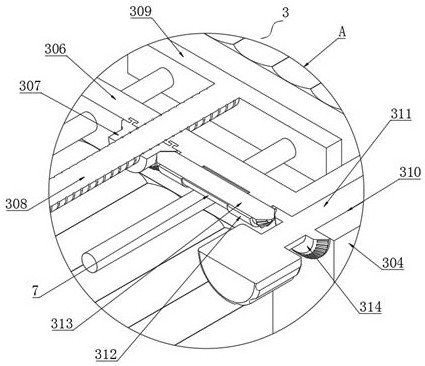

The invention discloses an automatic assembly line of a valve element of a water valve, and belongs to the field of automatic assembly. The automatic assembly line comprises a worktable which is provided with an annular assembly line. The annular assembly line is provided with a plurality of workpiece tools, and the periphery of the annular assembly line is sequentially provided with a valve element shell feeding device, a first sealing ring assembly device, a wear-resisting pad assembly device, a valve stem assembly device, a valve stem assembly feeding device, a valve stem assembly press fitting device, a ceramic piece oil filling device, a fixed ceramic piece assembly device, a gasket assembly device, a sealing pad assembly device, a sealing pad press fitting device, a jump ring assembly device, a valve element discharging mechanical arm and a valve element detecting device.

Owner:山东红宝自动化有限公司

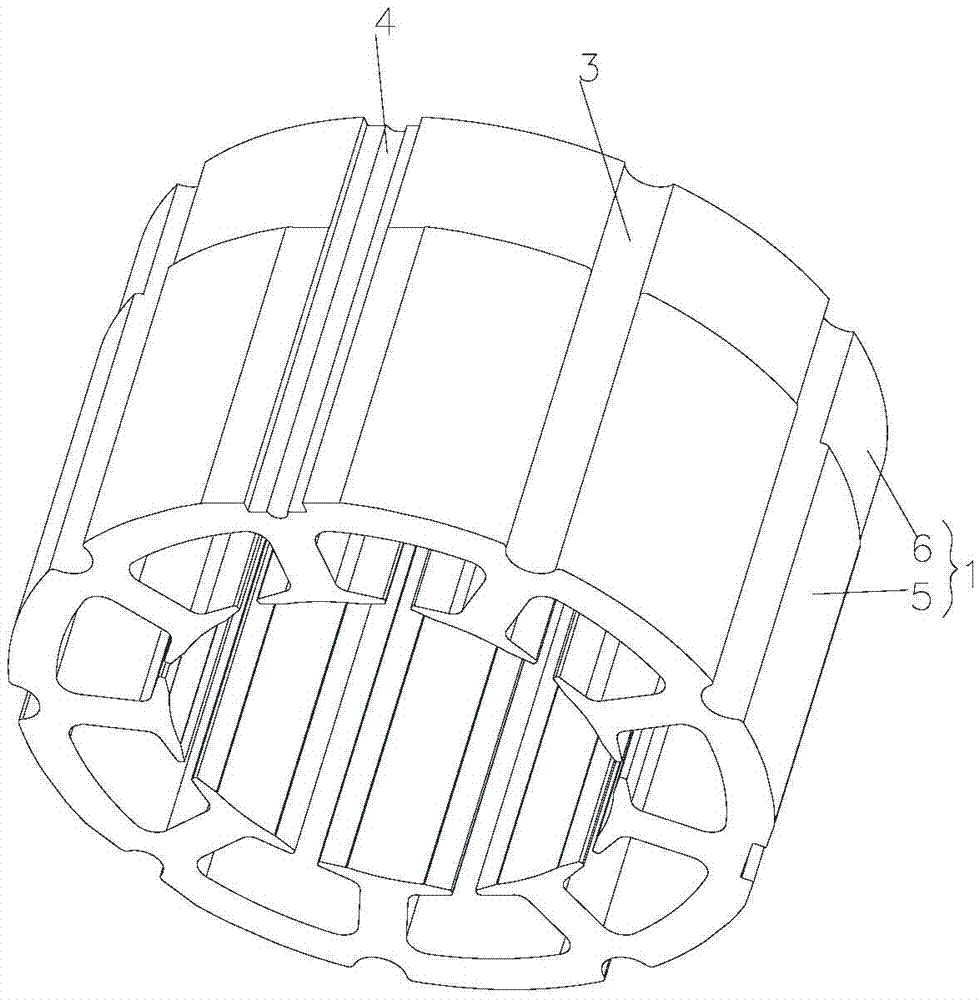

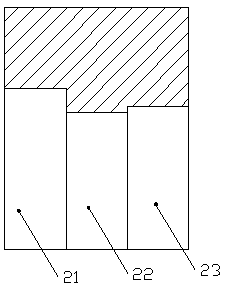

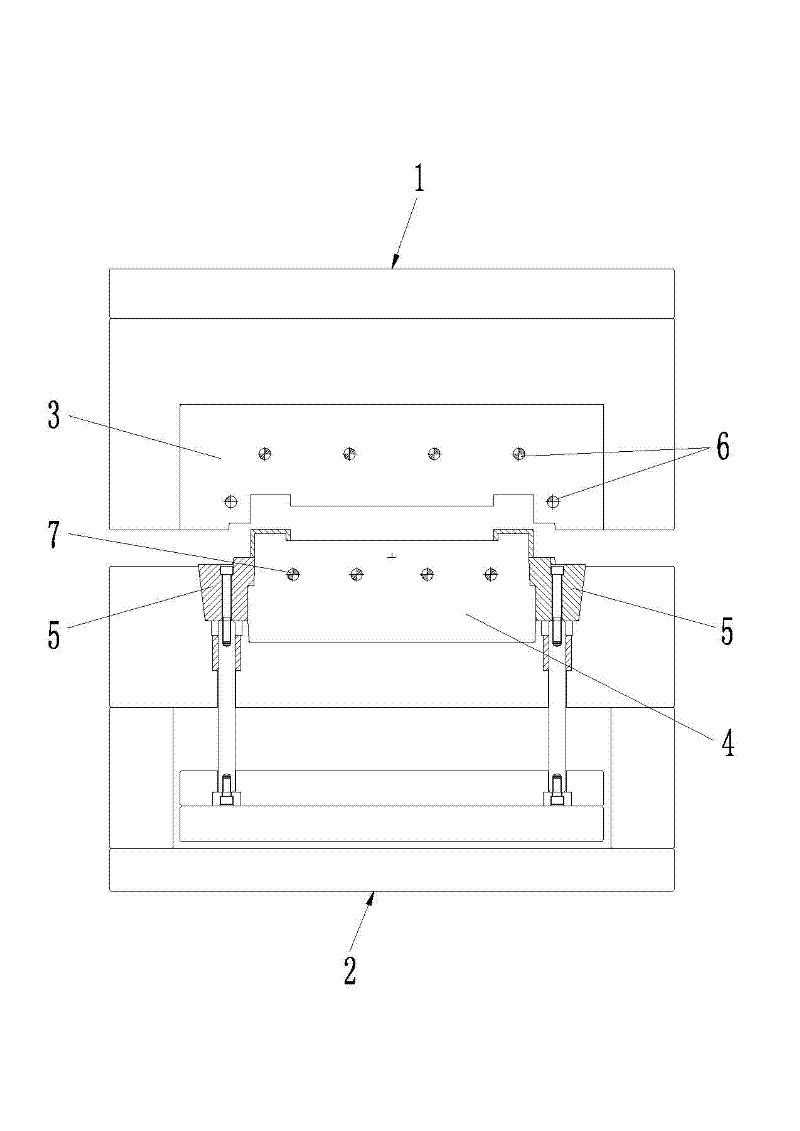

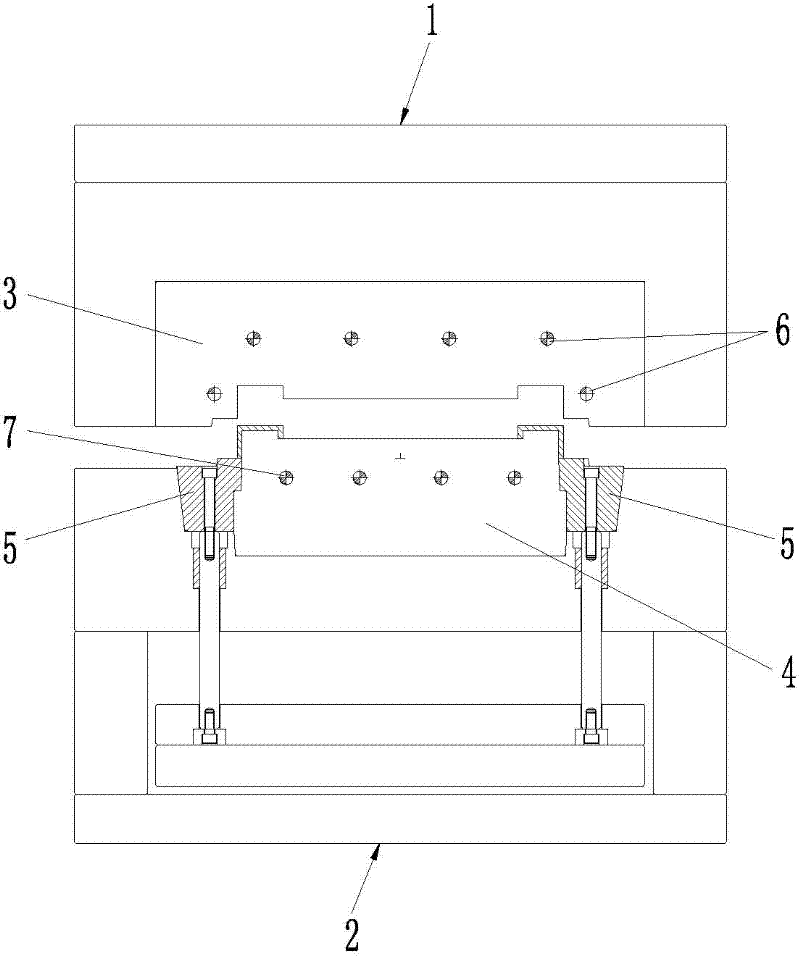

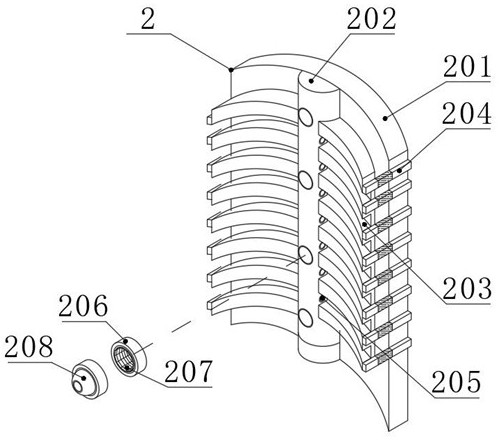

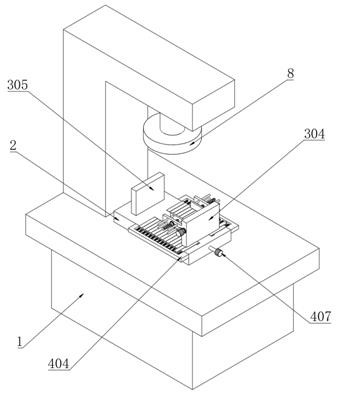

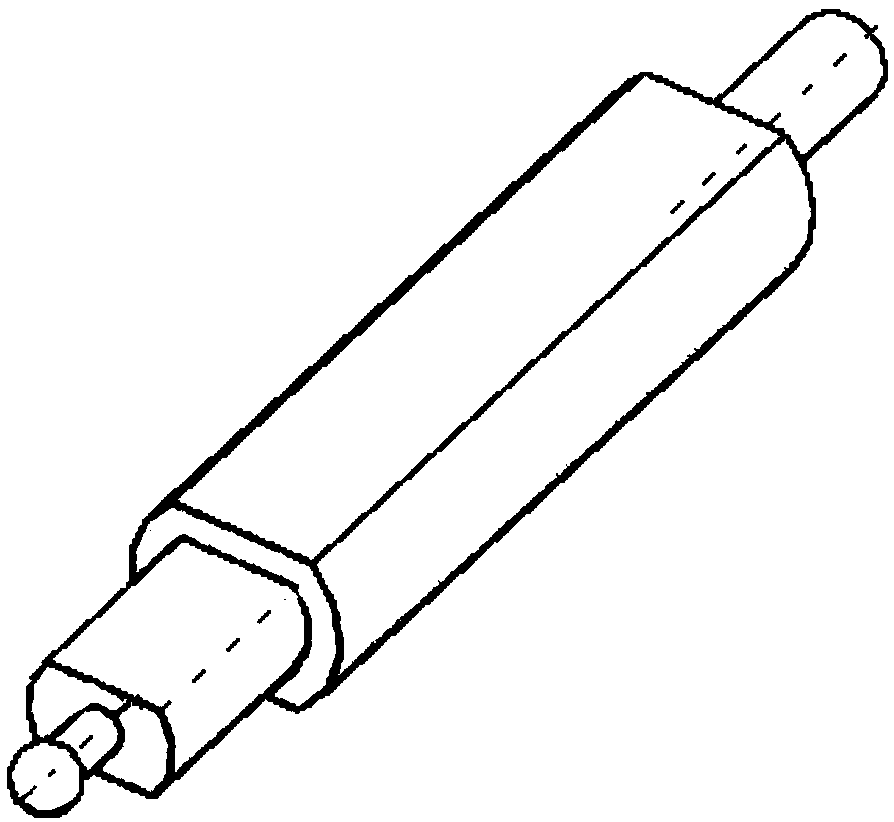

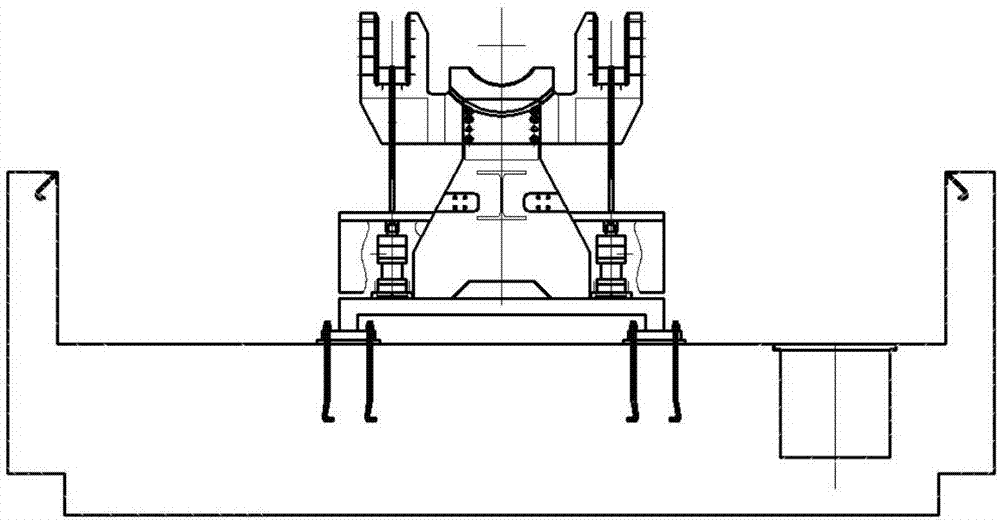

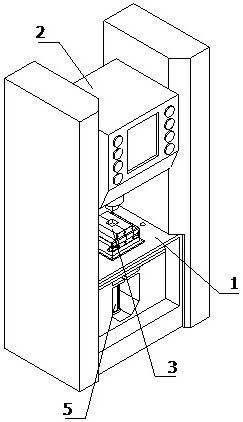

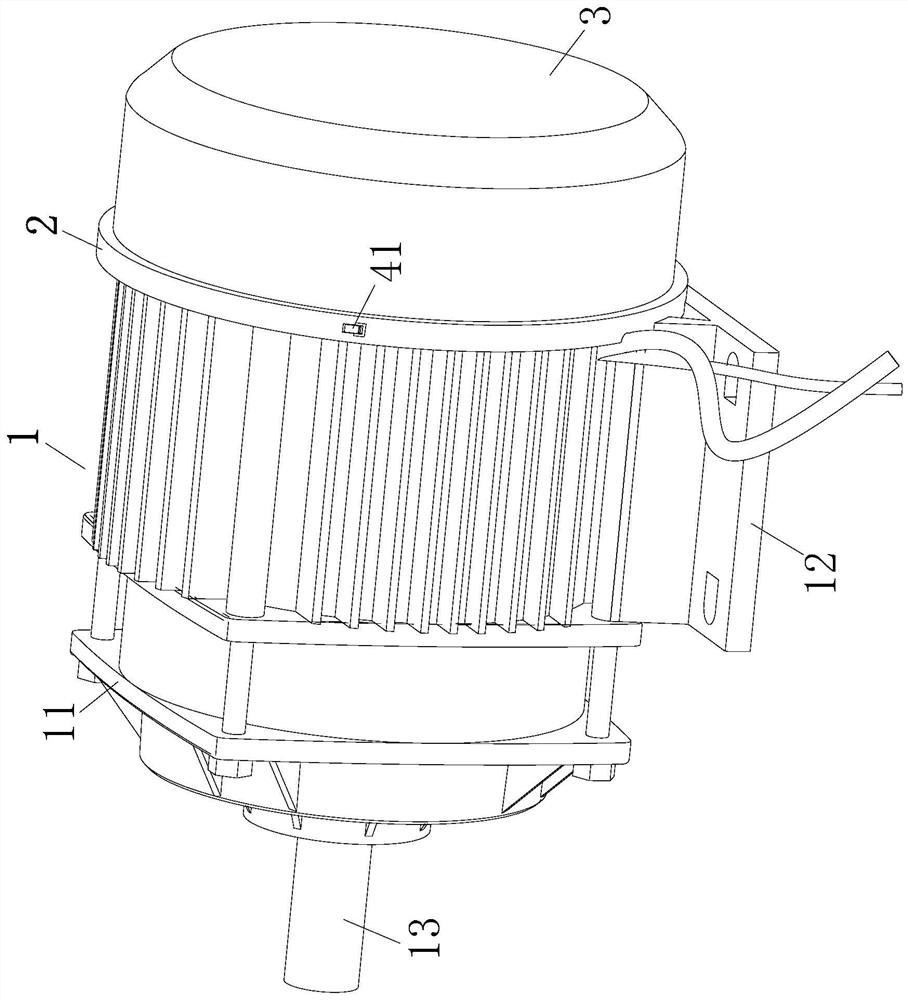

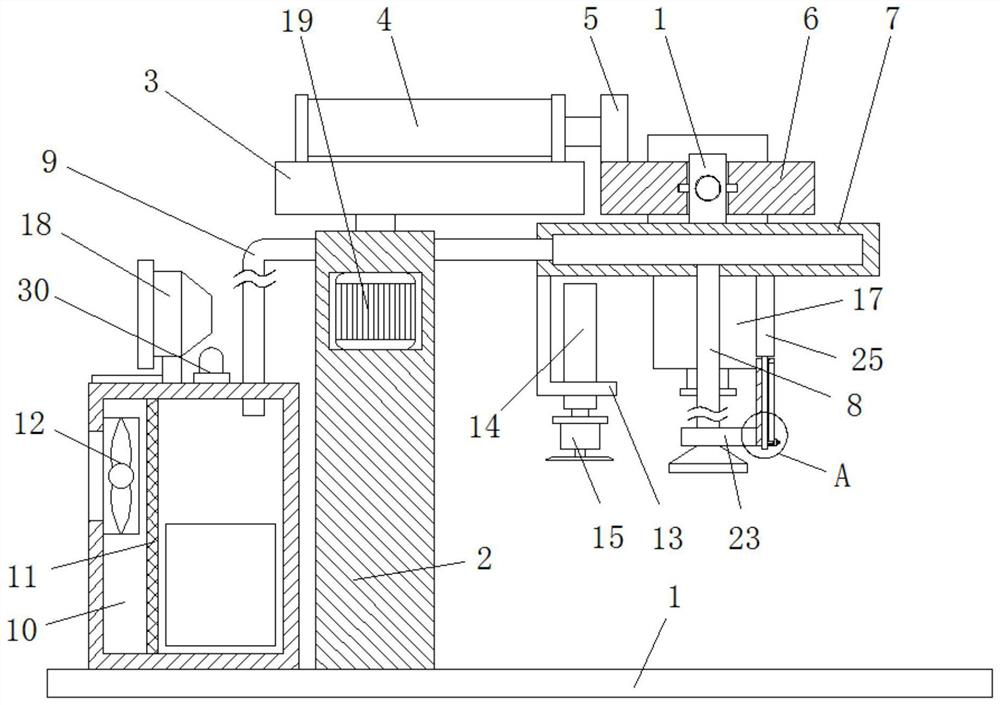

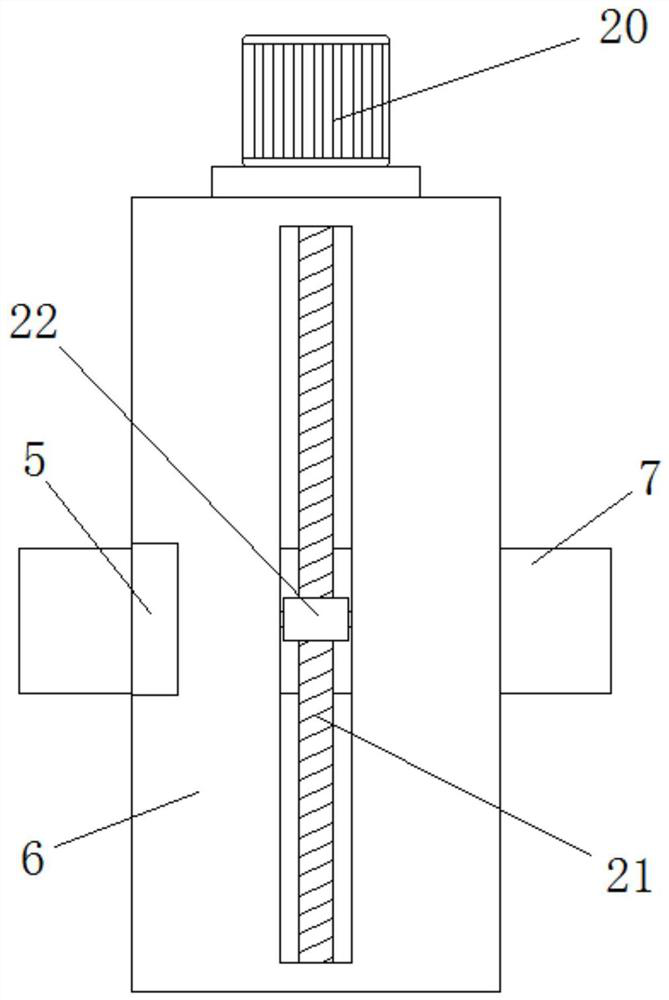

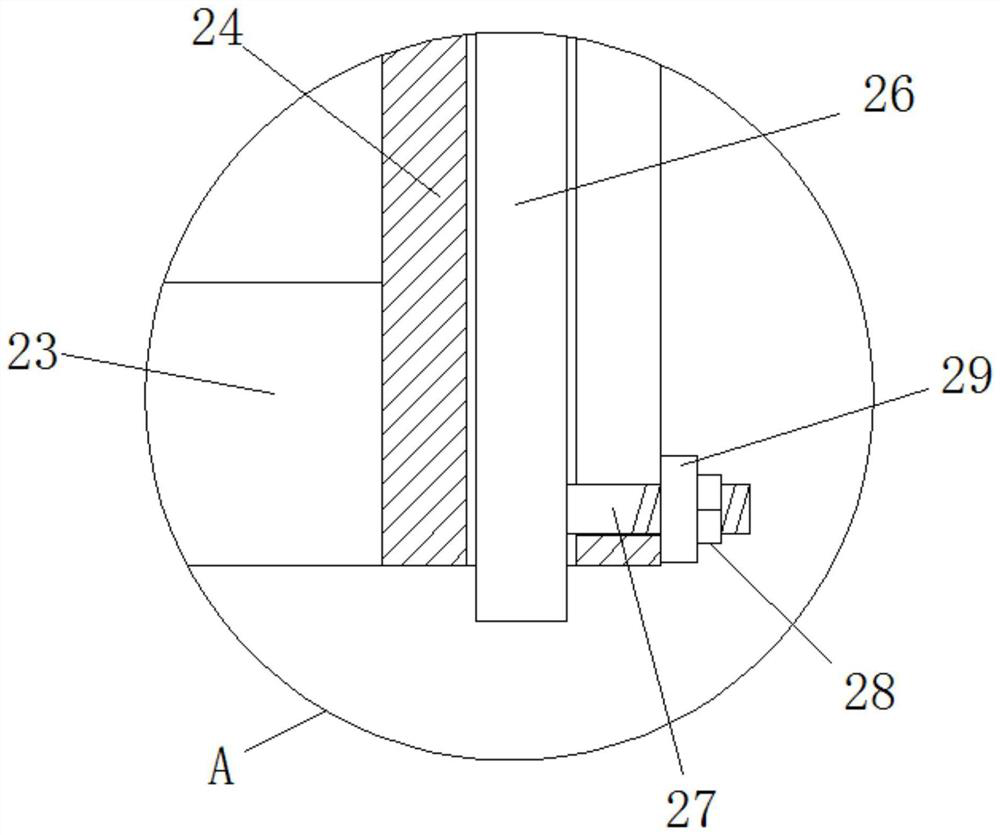

Pressing device for motor machining

ActiveCN113824283AImprove the pressing effectAvoid shakingWork holdersManufacturing dynamo-electric machinesElectric machineStructural engineering

The invention relates to the technical field of motor machining, and particularly relates to a pressing device for motor machining. The device comprises a base, a bearing unit and a pressing unit, the bearing unit is mounted at the upper end of the base, and the pressing unit is arranged on the bearing unit; a traditional pressing device cannot effectively fix a motor shell through an extrusion mode so that the motor shell lacks stability during machining; and due to the fact that the motor shell is prone to small-amplitude deviation in the machining process, mutual friction is prone to occurring between the pressing table and the motor shell, the pressing table causes pressing marks to the two ends of the motor shell, and later assembling of the motor shell is affected. According to the invention, motor shells with different diameters can be supported, and meanwhile, the stability of the motor shells can be ensured so that the fixing effect of the motor shells can be ensured; and the motor shell can be fixed in multiple directions, and a condition that indentation is caused to the upper end of the motor shell, and later assembling of the motor shell is affected is avoided.

Owner:方泰(广东)科技有限公司

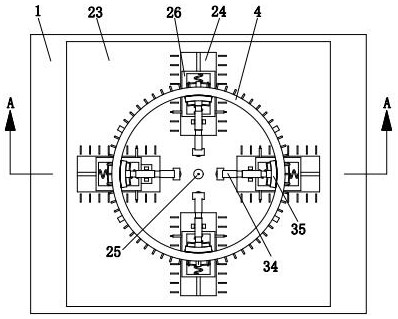

Waterproof treatment method for mobile terminal and mobile terminal

ActiveCN103701963AAvoid failureAffect shapeTelephone set constructionsTectorial membraneLiquid-crystal display

The invention discloses a waterproof treatment method for a mobile terminal and the mobile terminal. The method comprises the following steps: fully jointing an LCD (Liquid Crystal Display) module and a touch screen; sticking protective films to the outer surface of a shell and the outer surface of the LCD module to prevent coating by waterproof coatings; vacuumizing all components of the mobile terminal, and coating waterproof coatings onto the surfaces of all components; jointing a backlight module to the LCD module by adopting a double faced adhesive tape, and removing the protective films; assembling all components into the mobile terminal. The LCD module and the touch screen are jointed fully, and a layer of waterproof coating is coated on the outer layer of each component of the mobile terminal to allow the components to be isolated from water or current-conducting liquid, so that failures of circuits caused by short circuit are prevented, and waterproofness is realized.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

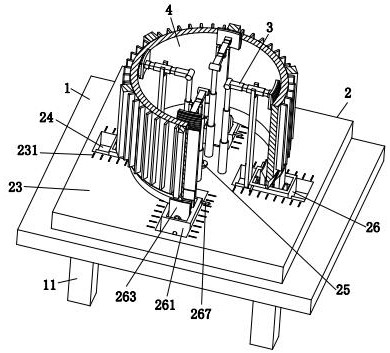

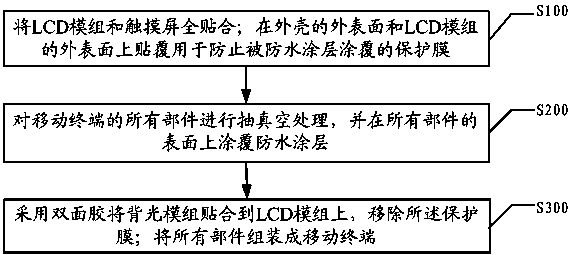

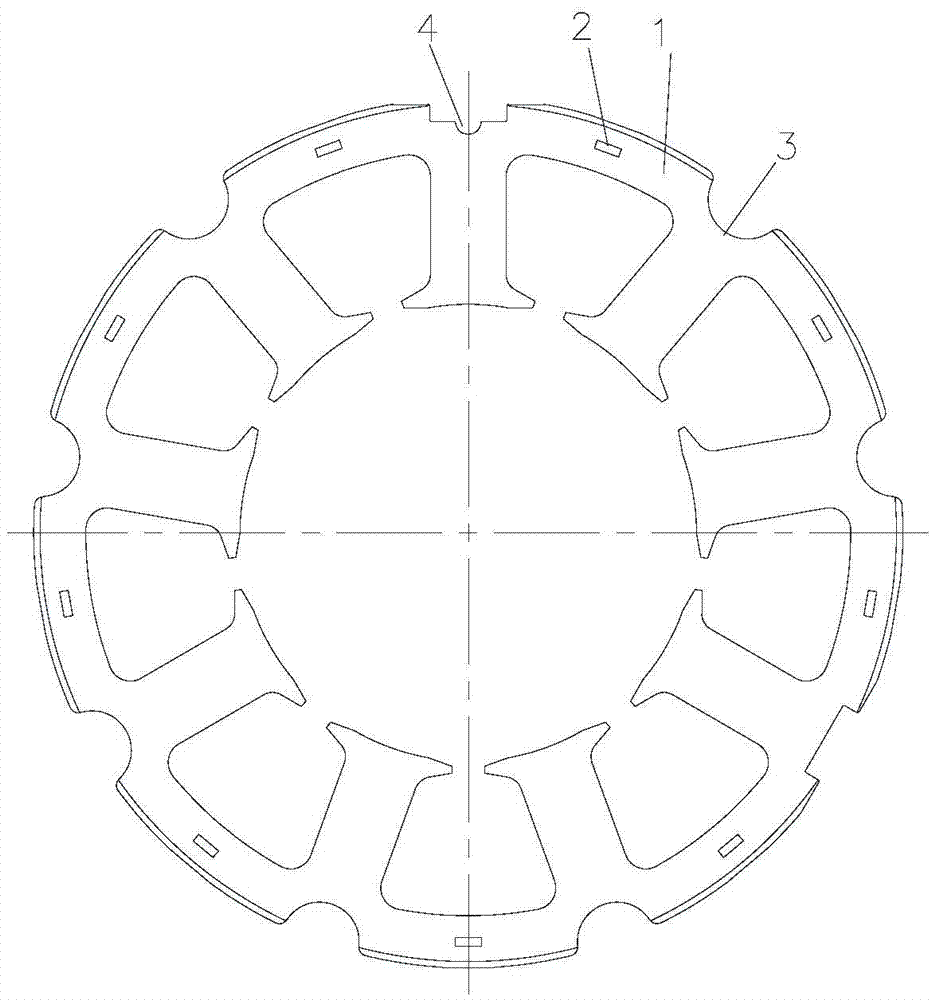

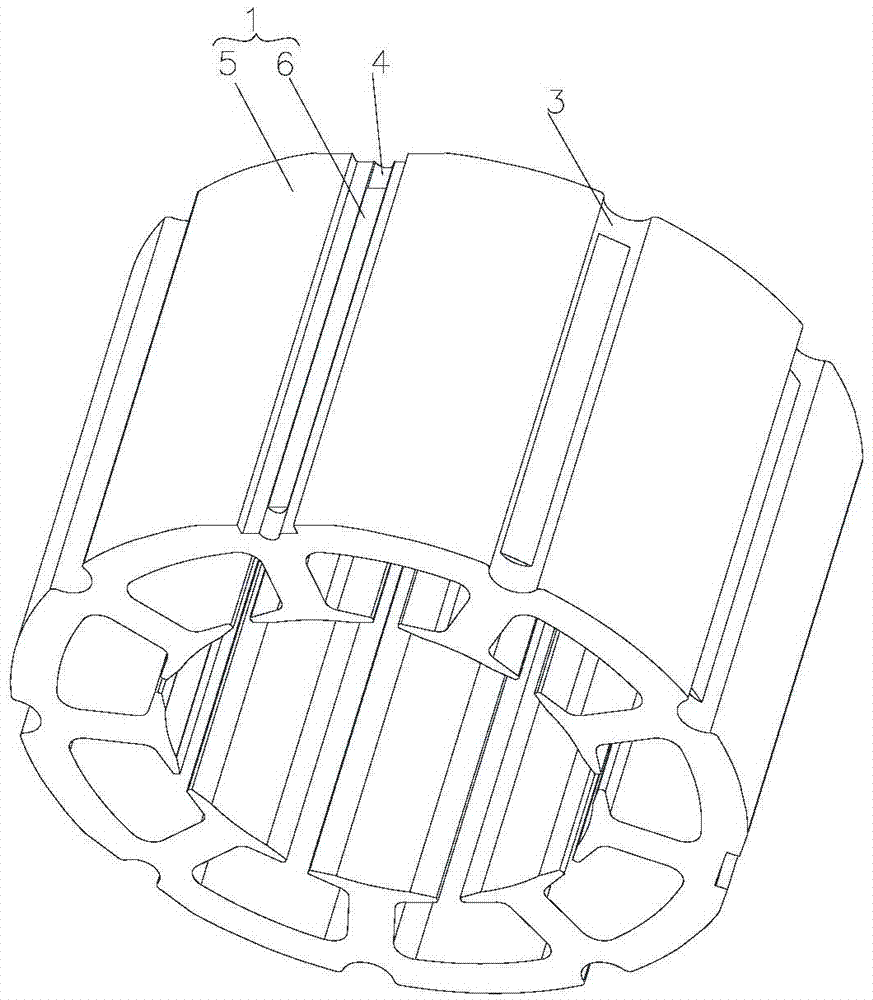

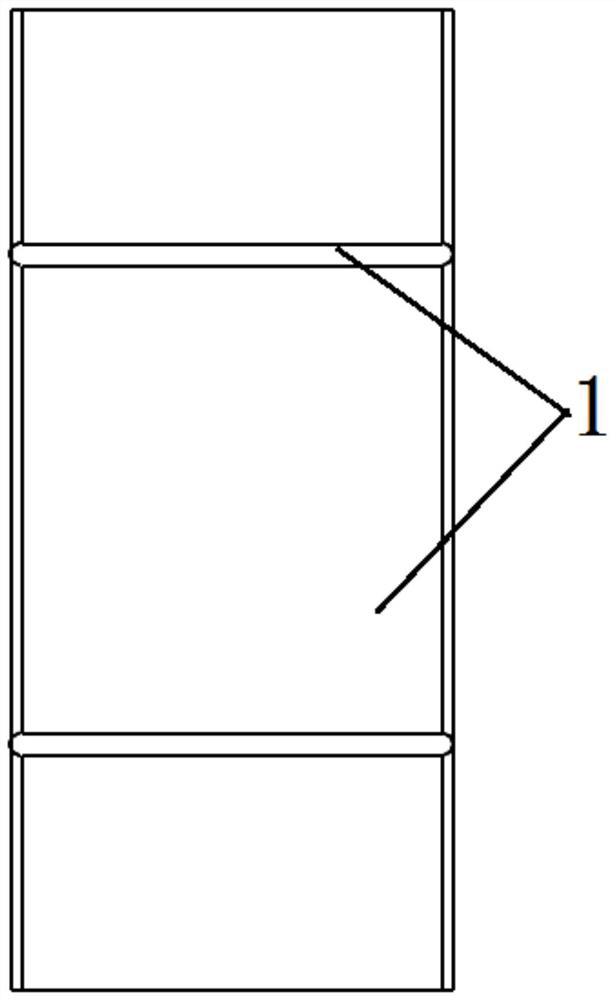

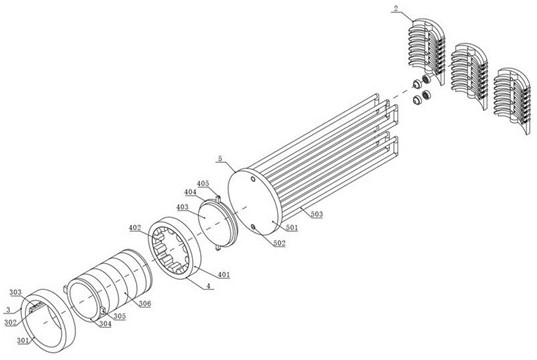

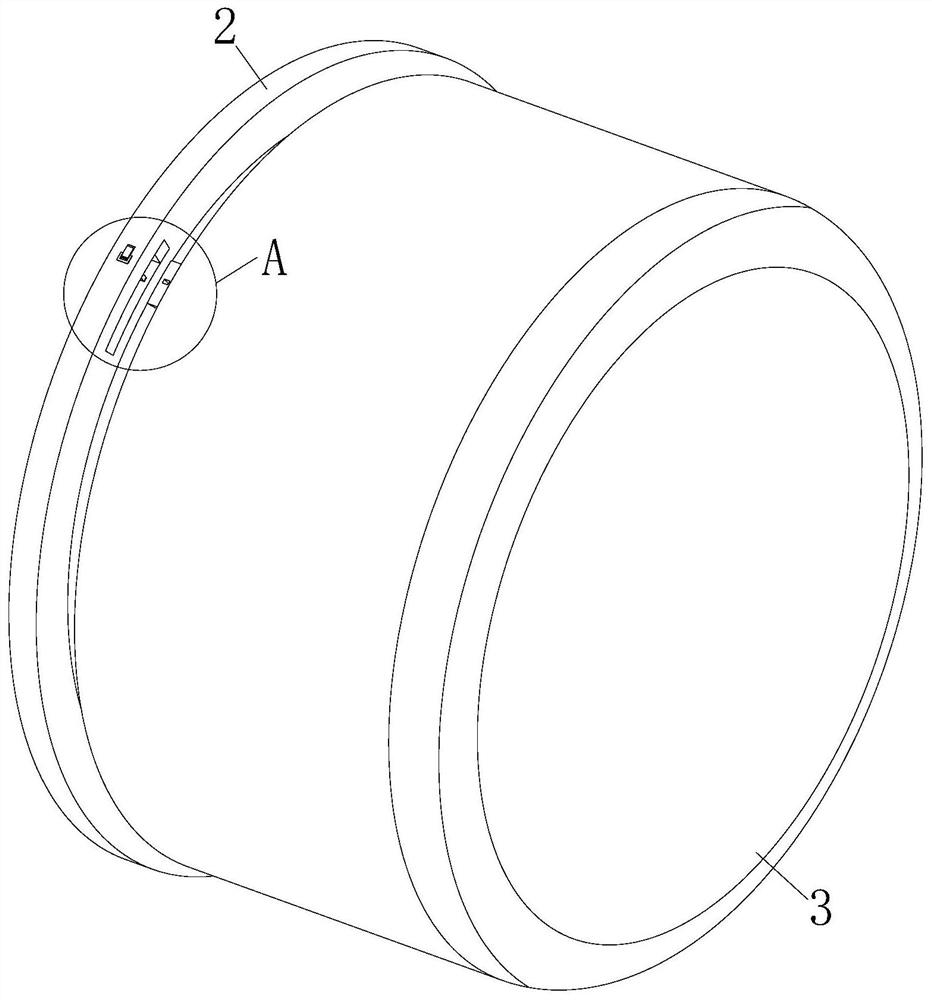

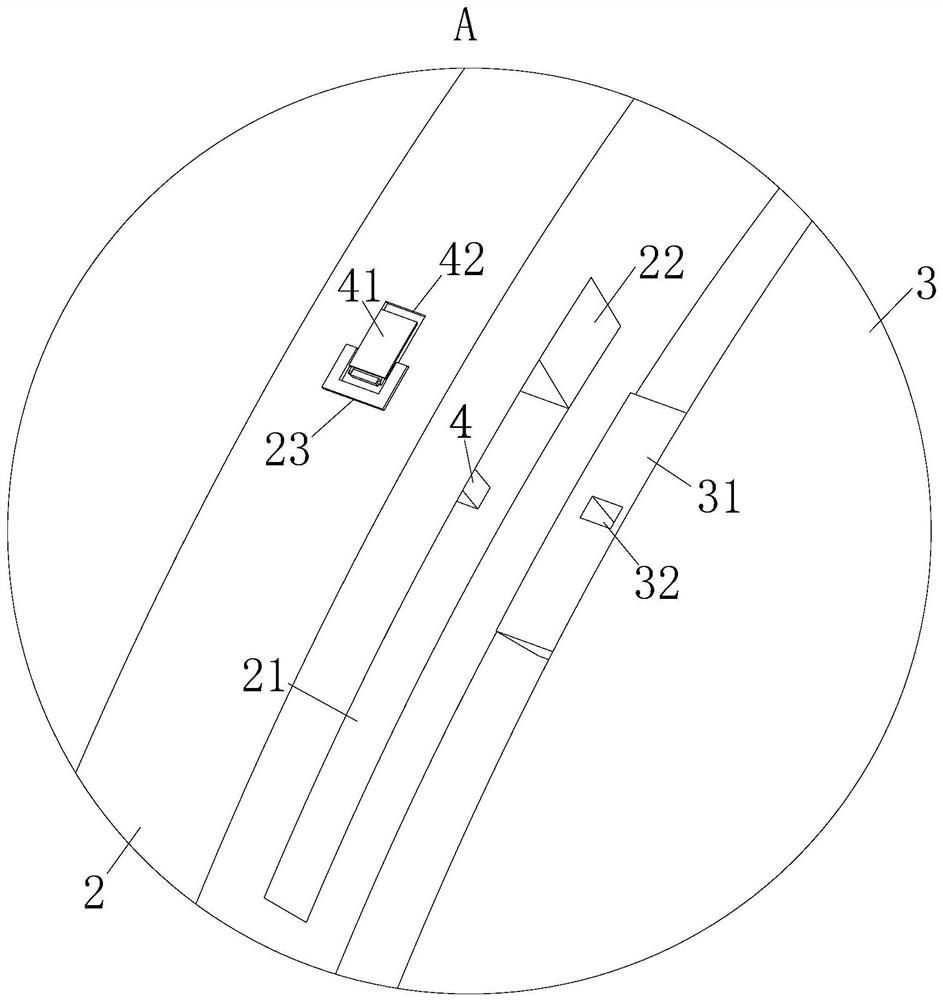

Motor stator structure and motor

ActiveCN105449878ASmall amount of deformationLarge amount of deformationMagnetic circuit stationary partsStress concentrationPhysics

The invention discloses a motor stator structure and a motor. The motor stator structure comprises a stator iron core (1) and a framework, wherein through holes (3) and locating slots (4) matching the framework are formed in the stator iron core (1), the locating slots (4) are formed in the bottoms of the through holes (3), and the stator iron core (1) is further provided with a stress adjustment structure. According to the motor stator structure provided by the invention, a problem that installation is affected by stator deformation due to concentration of stress on the stator in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

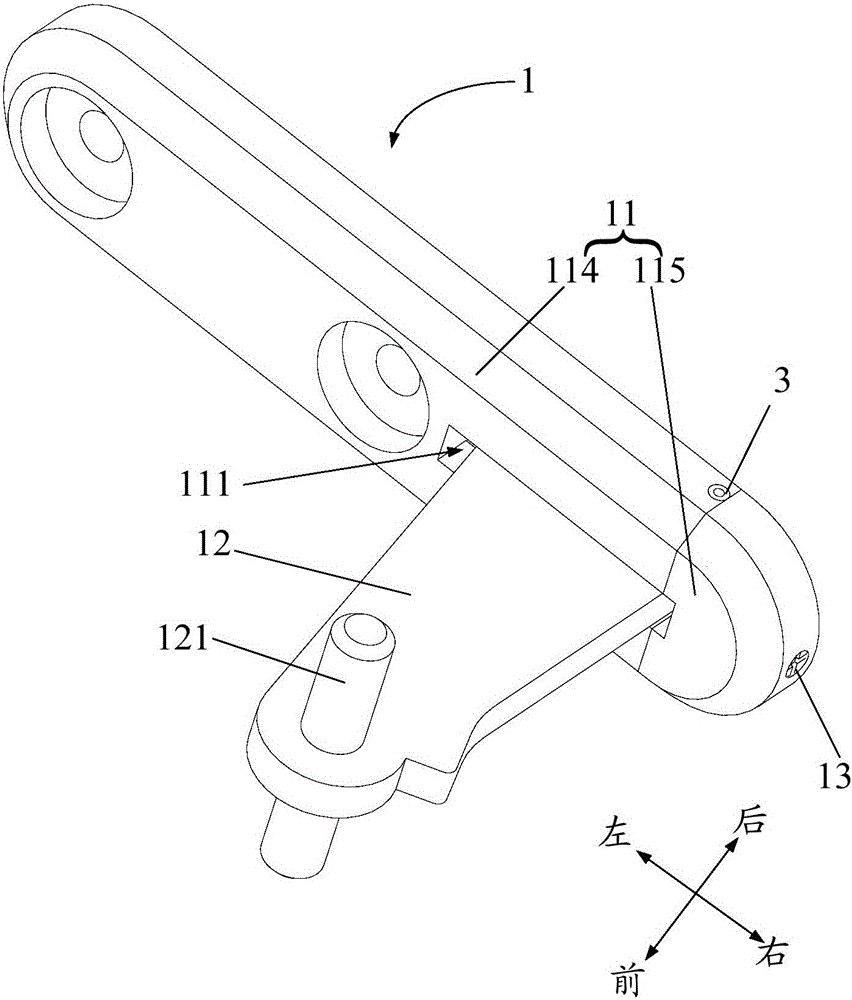

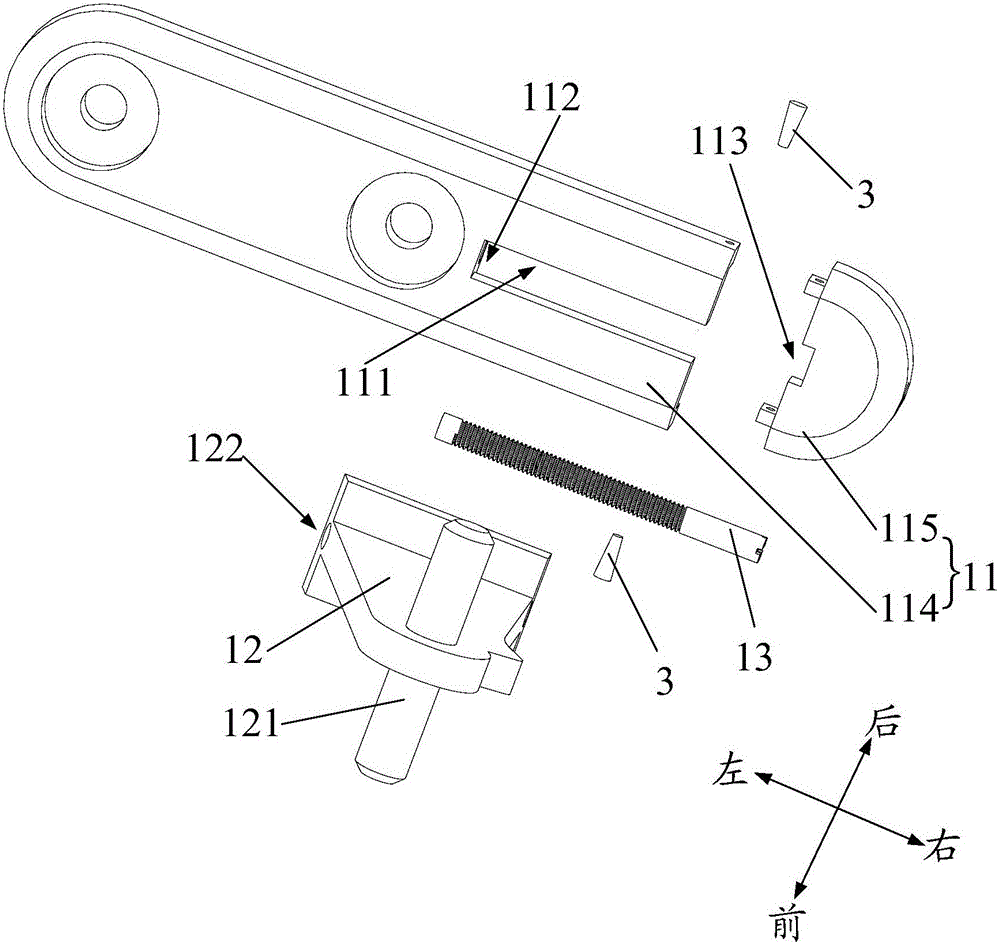

Hinge and refrigerator

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

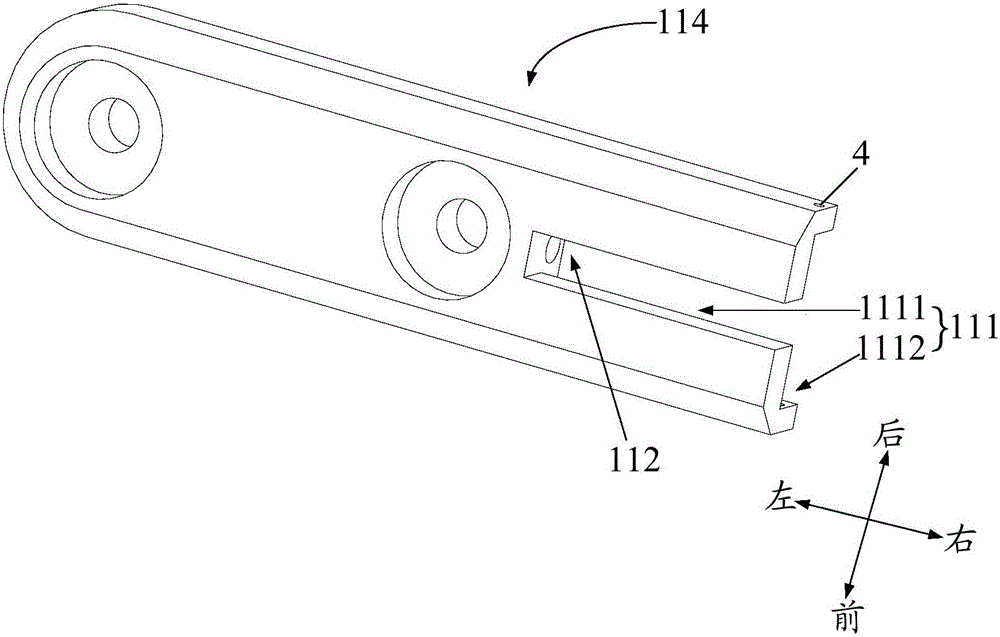

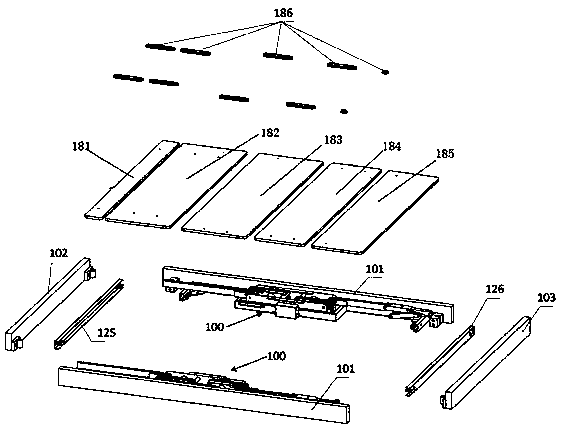

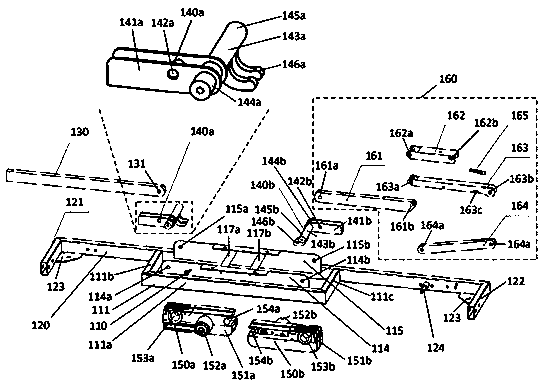

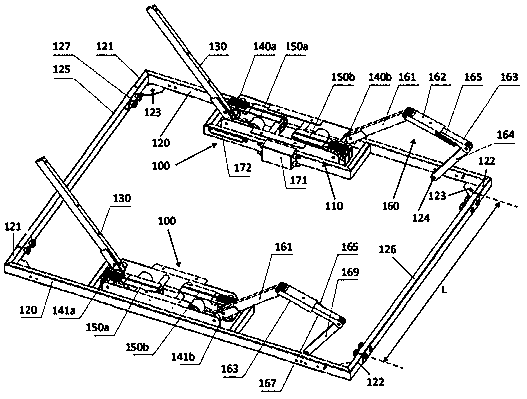

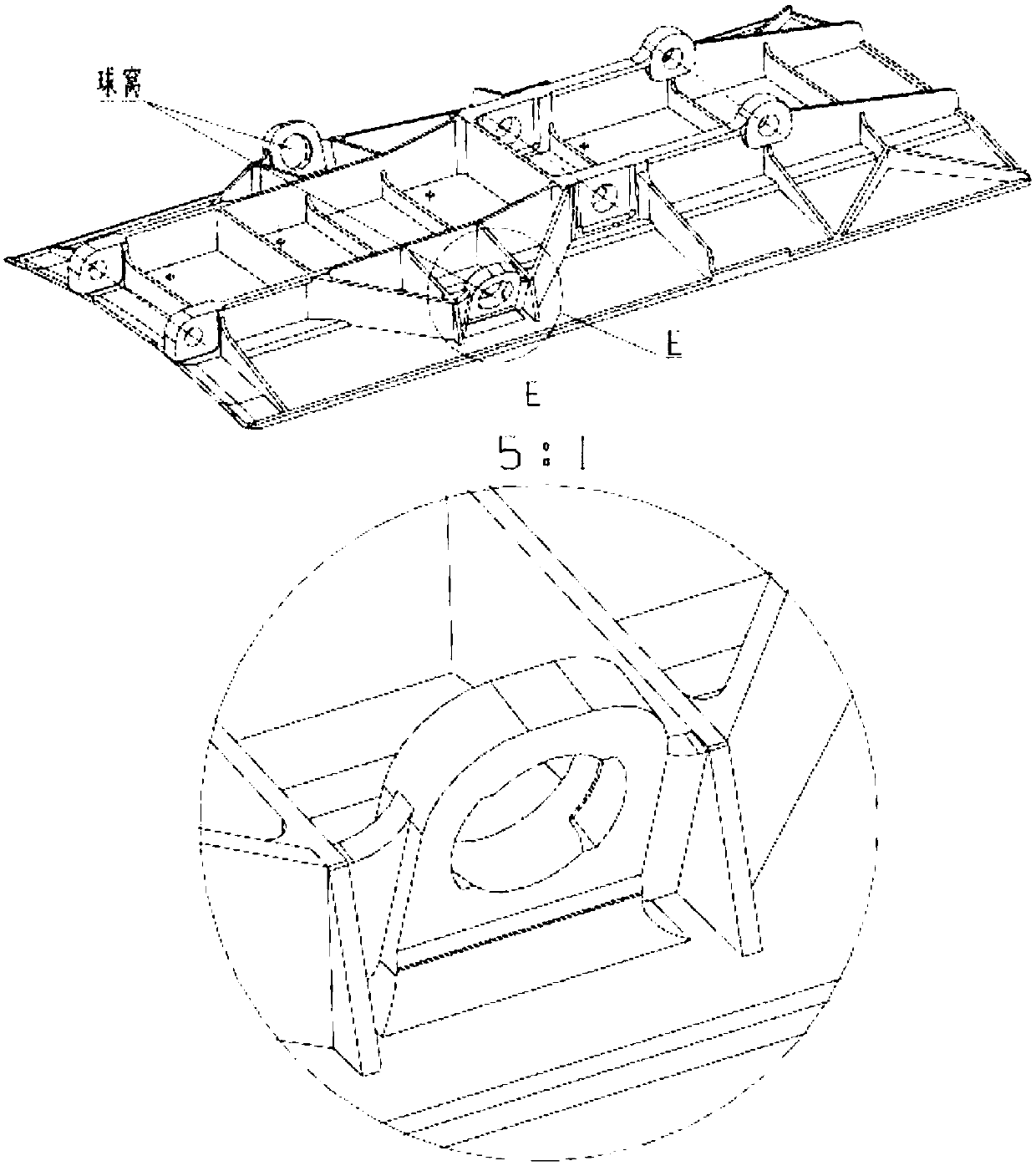

Adjustable electric bed

The invention relates to an adjustable electric bed which comprises a bed plate assembly. The bed plate assembly comprises a head plate, a backboard, a hip plate, a thigh plate and a shank plate whichare distributed in sequence; a bed plate support for the bed plate assembly comprises a pair of transverse rods, longitudinal rods and longitudinal rods, wherein the transverse rods are transverselyspaced, longitudinally aligned and arranged in parallel, and the longitudinal rods are longitudinally spaced, transversely aligned and arranged in parallel. The driving assembly is installed on the bed plate support and comprises driving supports installed on the opposite sides of the two transverse rods respectively, the driving supports are in a U shape, and an installation space is jointly formed between the driving supports and the transverse rods. The present invention is advantageous in that the body position can be adjusted based on the sleep preference of the user, thereby enabling theuser to obtain the maximum comfort during sleep, and can be easily assembled to improve the assembly efficiency and increase the assembly experience of the user.

Owner:江苏里高智能家居有限公司

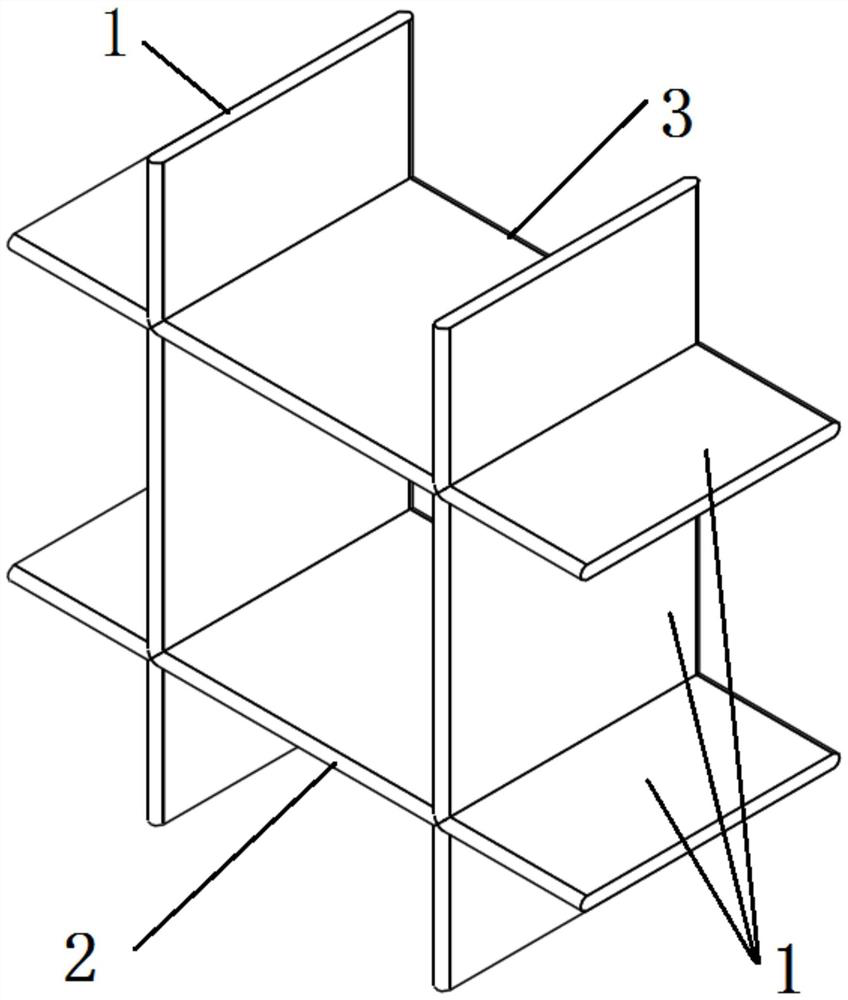

Grid rudder and aircraft

PendingCN111731467AThe absolute value of the slope of the tangent line decreases continuouslyReduce structural strengthAircraft controlFlight vehicleRudder

The invention provides a grid rudder and an aircraft. The grid rudder comprises a plurality of partition plates which are connected with each other and form a grid structure; wherein each partition plate is oppositely provided with a windward side and a leeward side along the two ends of the intersection line of the partition plates, at least one part of the windward side is provided with a notch,and the absolute value of the tangent slope of the outer surface where the notch is located is continuously reduced along the direction from the windward side to the leeward side, a flow guide curvedsurface is formed at the windward side, square arrangement at the windward side is avoided, and under hypersonic speed environment, on one hand, differential pressure resistance and friction resistance are reduced, power efficiency is improved, the total heat generated by heating of the windward side is reduced, and the structural strength of materials of the grid structure is guaranteed; on theother hand, the condition of local high heat generated by protruding parts such as edges and corners under the condition of airflow friction is improved, the aerodynamic heat of the grid structure isreduced, the thermal environment distribution of the grid structure is improved, and the temperature distribution uniformity is improved, so that the structural thermal stress is reduced, and the strength performance is optimized.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

Flange assembling device for hollow composite insulator

The invention relates to a flange assembling device for a hollow composite insulator. The flange assembling device comprises an assembling base; an insulator positioning assembly arranged on the assembling base, wherein the insulator positioning assembly comprises an insulator positioning upper die and an insulator positioning lower die, a first positioning cavity is formed in the lower end of theinsulator positioning upper die, a second positioning cavity is formed in the upper end of the insulator positioning lower die, and the first cavity and the second cavity are jointly matched to forma positioning cavity for installing an insulator; and a flange positioning assembly which comprises a pair of flange positioning plates which are respectively positioned at two sides of the insulatorpositioning assembly. The device has the advantages that the assembling base, the insulator positioning assembly and the flange positioning assembly are matched, so the flanges at the two ends of an insulator can be assembled only through one assembling oil cylinder; the structure is simple, the whole assembling process is very convenient, and the device is suitable for assembling flanges of insulators of different sizes.

Owner:JIANGSU XIANGYUAN ELECTRIC EQUIP

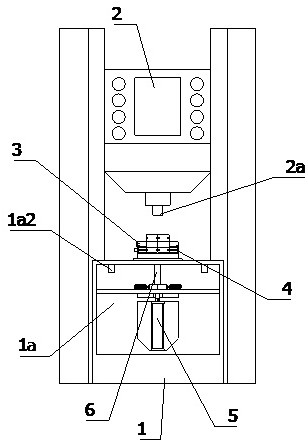

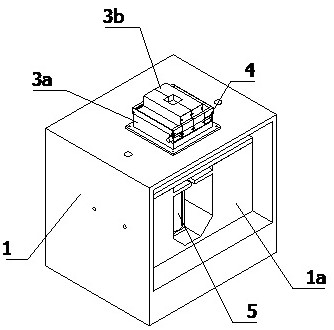

New energy battery integral press-down assembling device

ActiveCN113725456AEasy to movePrecise positioningPrimary cell manufactureAssembling battery machinesNew energyStructural engineering

The invention discloses a new energy battery integral press-down assembling device, and the device comprises an assembling device body used for fixing a battery box so as to realize integral press-down assembling of a battery body into the battery box, and the assembling device body comprises a sliding seat and a camera visual judgment system arranged above the sliding seat. The camera visual judgment system can judge whether the battery box is fixed at a preset position or not and whether the posture is right or not; a positioning assembly is arranged on the sliding seat, and comprises a fixed plate fixed to the position, close to one end, of the sliding seat, a sliding plate arranged to the position, close to the other end, of the sliding seat and oppositely spaced from the fixed plate, and clamping plates symmetrically arranged to the positions, close to the two sides, of the sliding seat. The sliding plate can horizontally move against or away from the fixed plate; the two clamping plates can synchronously and horizontally move in a manner of abutting against or leaving away from each other; the fixed plate, the sliding plate and the two clamping plates jointly clamp and fix the battery box. Therefore, the speed and accuracy of fixing the battery box can be effectively improved, the positioning is firm, and the fixing posture of the battery box is correct.

Owner:厦门微亚智能科技股份有限公司

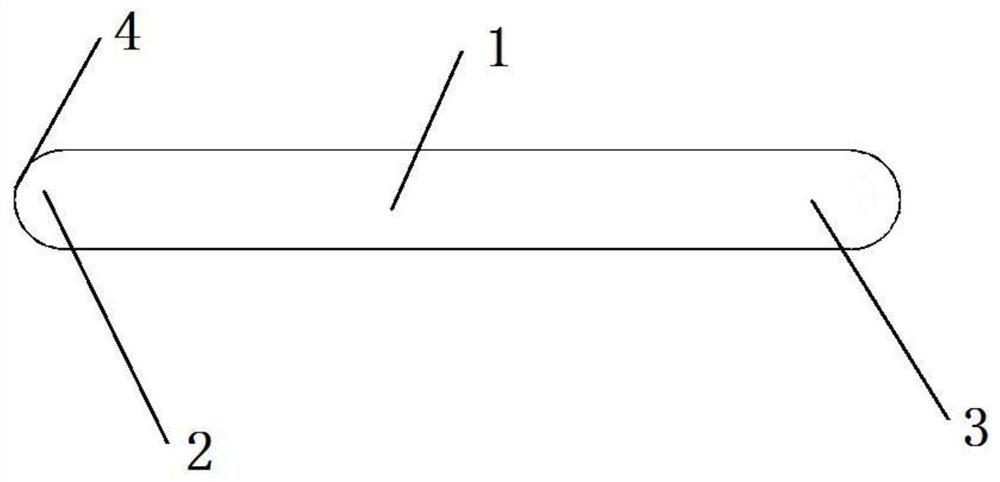

Stepped drill reamer for machining aircraft skin rivet holes

PendingCN107900421AReduce occupancyImprove processing timeTransportation and packagingStepped drillsReamerDrill

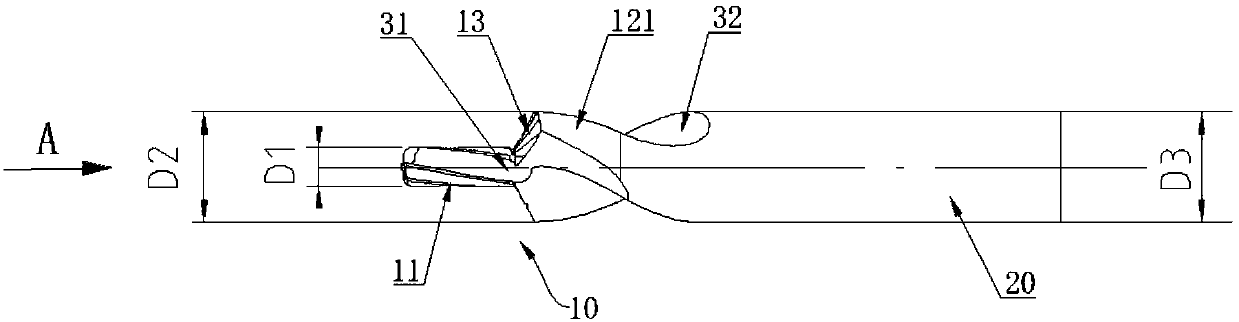

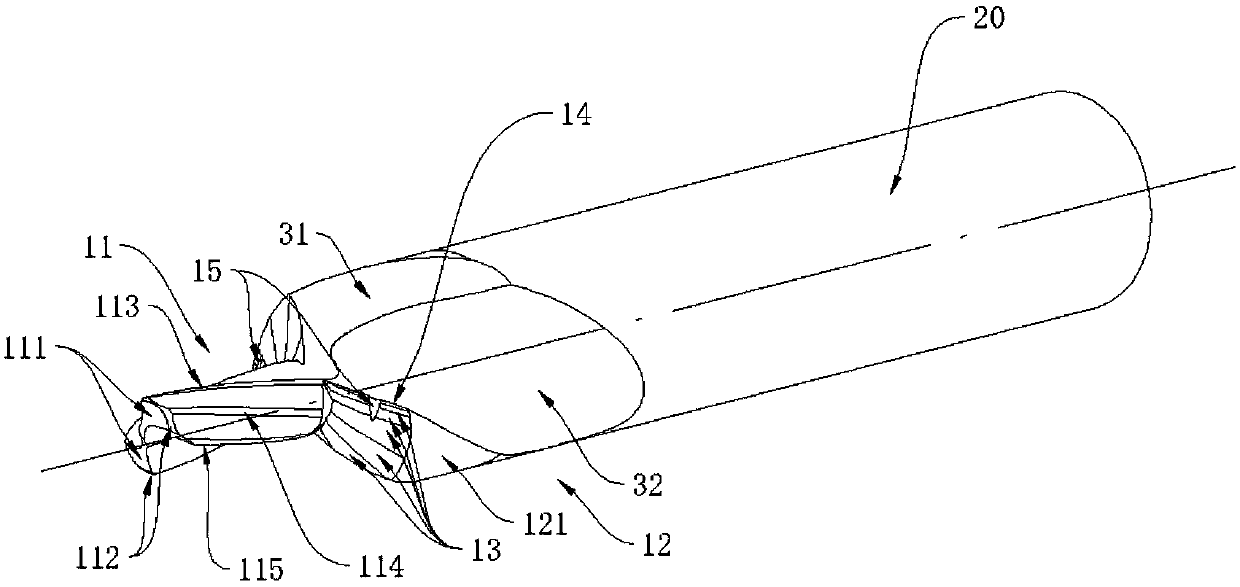

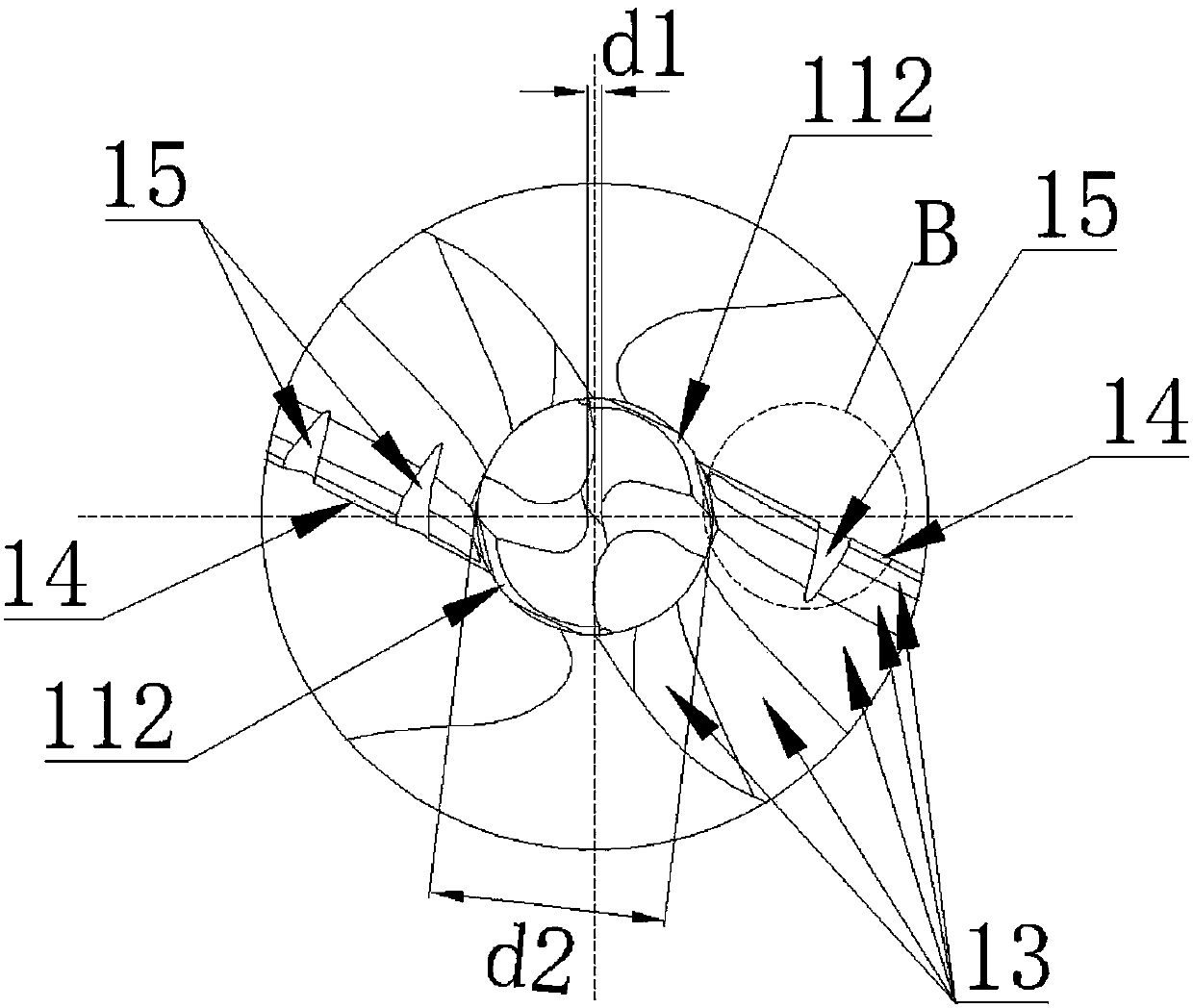

The invention provides a stepped drill reamer for machining aircraft skin rivet holes. The problems of a traditional method that machining efficiency is low; production cost is high; and machining quality cannot meet requirement can be solved. A reamer body comprises a first cylinder and a second cylinder which are concentrically connected into a whole from front to back; the diameter D1 of the first cylinder is smaller than the diameter D2 of the second cylinder; two first slag discharging grooves which are centrally symmetrical are formed in the periphery of the first cylinder, and two landsare formed on the periphery of the first cylinder; two second slag discharging grooves which are centrally symmetrical are formed in the periphery of the second cylinder; the two first slag discharging grooves in the periphery of the first cylinder both extend to the periphery of the second cylinder; the first slag discharging grooves and the second slag discharging grooves in the second cylinderare connected; the periphery of the second cylinder is divided to form two circumferential edges by the two first slag discharging grooves and the two second slag discharging grooves in the second cylinder; each land on the first cylinder is connected with the corresponding circumferential edge of the second cylinder in a transition mode through a stepped angle; the core thickness d1 of the firstslag discharging groove ranges from 0.25D1 to 0.35D1; the core thickness d2 of the second slag discharging groove ranges from 0.25D2 to 0.35D2; and d1 is smaller than d2.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

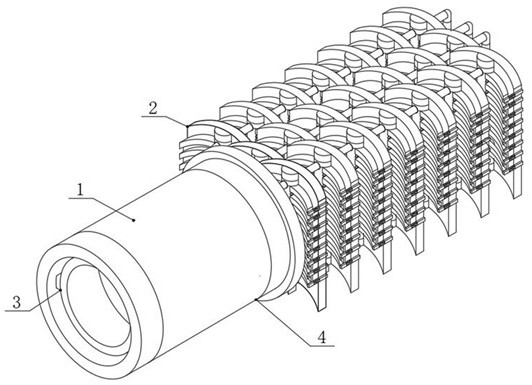

Efficient heat dissipation device for automobile vent pipe

InactiveCN107701283AEasy to useImprove cooling effectSilencing apparatusMachines/enginesEngineeringHeat sink

The invention provides an efficient heat dissipation device for an automobile vent pipe. The device comprises two insulation covers with the semi-annular cross sections; the two insulation covers arerotationally connected through a rotating shaft, a heat dissipation cover with the semi-annular cross section is arranged inside each insulation cover, the axis of the heat dissipation covers coincides with the axis of the insulation covers, heat dissipation pieces are arranged between the heat dissipation covers and the insulation covers, the insulation covers and the heat dissipation covers areconnected through the heat dissipation covers, a limiting groove is formed in the outer surface of a pipe body of the automobile vent pipe, a limiting edge matched with the limiting groove is arrangedon the inner surface of each heat dissipation cover, the two heat dissipation covers are matched to form a cavity for fixing the automobile vent pipe, when an automobile runs, air rapidly passes a cavity formed between the heat dissipation covers and the insulation covers, hot air on the automobile vent pipe can be dissipated more rapidly, and heat dissipation of the automobile vent pipe is moreefficient.

Owner:浙江邝记汽车零部件有限公司

Chromium-based alloy and manufacturing method thereof

InactiveCN104419855AImprove corrosion resistanceImprove high temperature performanceFuel cellsManganese

A chromium-based alloy and a manufacturing method thereof. The chromium-based alloy comprises following components, by mass, 4-6% of Fe, 0.8-1.2% of Y2O3, 0.1-15% of Mn, not more than 2% of unavoidable impurities and the balanced chromium. The manufacturing method comprises following steps: designing the composition of the components, mixing the components, pressing the components, dewaxing the components and sintering the components to obtain the alloy, cooling the alloy, and analyzing and detecting the alloy. The chromium-based alloy is manufactured with manganese so that an organization structure of a part can be effectively improved since the manganese and manganese-iron alloy are low in melting point and can form liquid-phase sintering when the temperature is higher than 1246 DEG C, thereby finally improving the performances of the part and enabling a corrosion-resistant performance and a high-temperature performance of the chromium-based alloy to be better with influence on thermal-expansion coefficient of the material being less. The chromium-based alloy is excellent in the corrosion-resistant performance and the high-temperature-resistant performance, can be used as a joint plate in a fuel cell, is higher in operation temperature, is longer in service life and is free from greatly influencing assembly and usage since the thermal-expansion coefficient of the alloy matches with other assemblies in the fuel cell.

Owner:NBTM NEW MATERIALS GRP

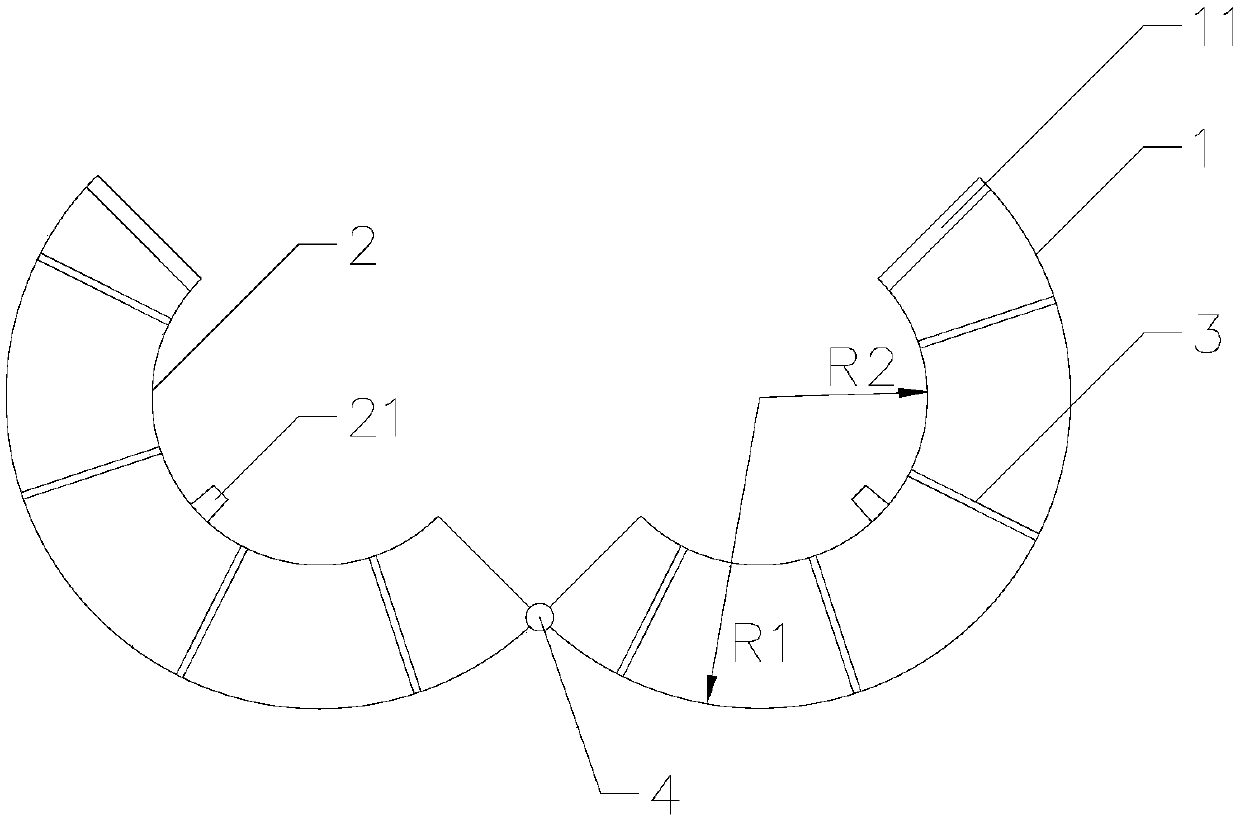

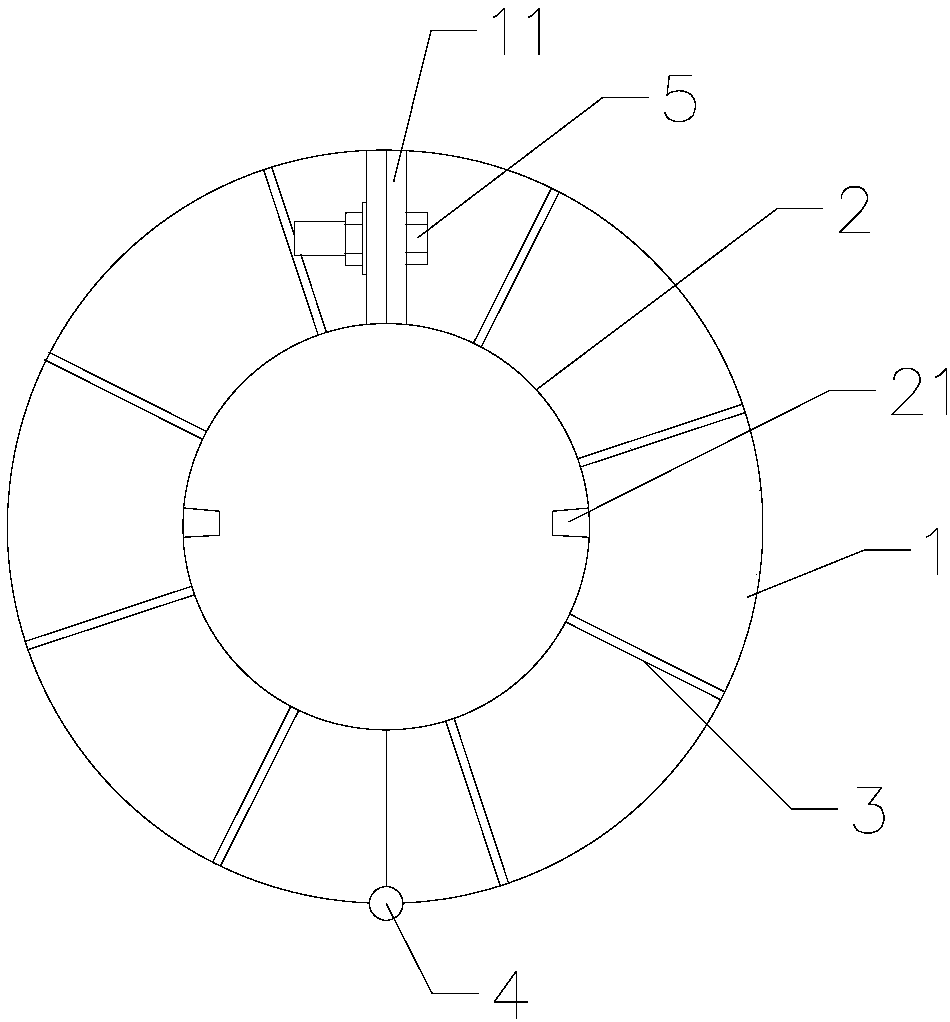

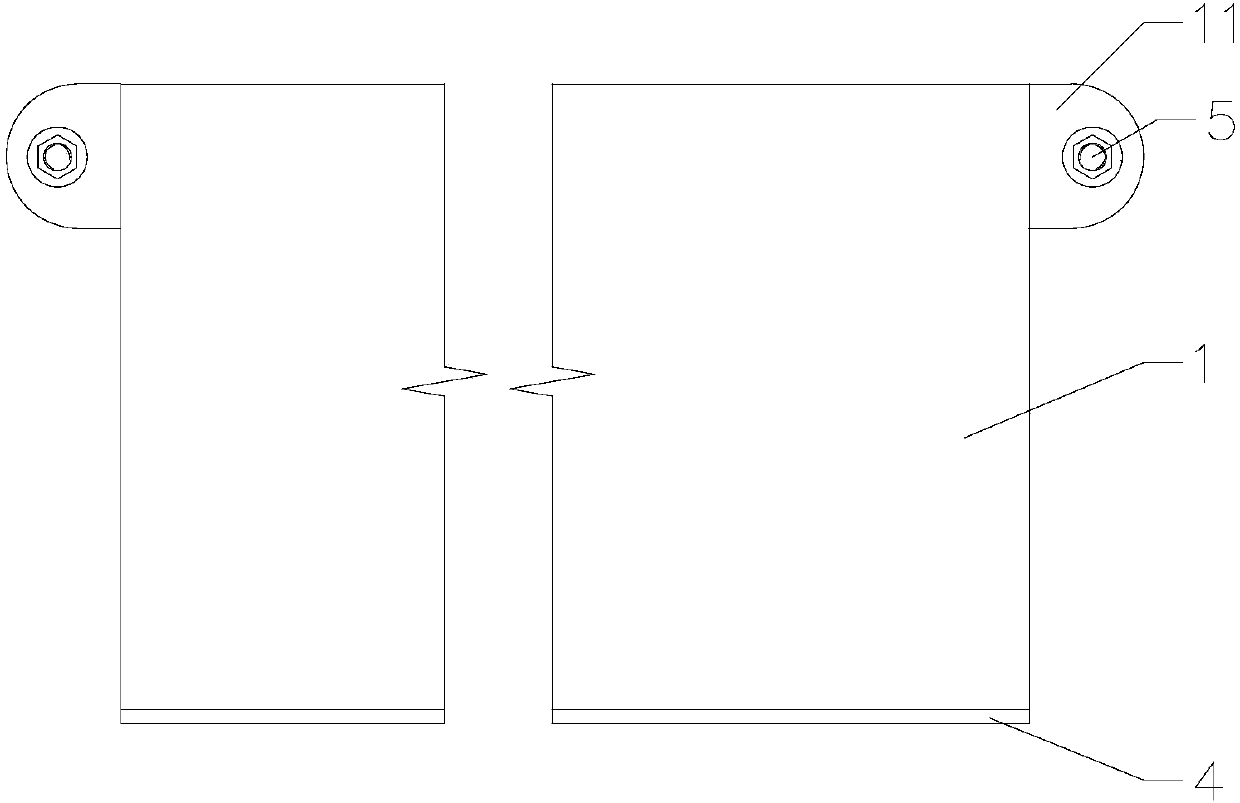

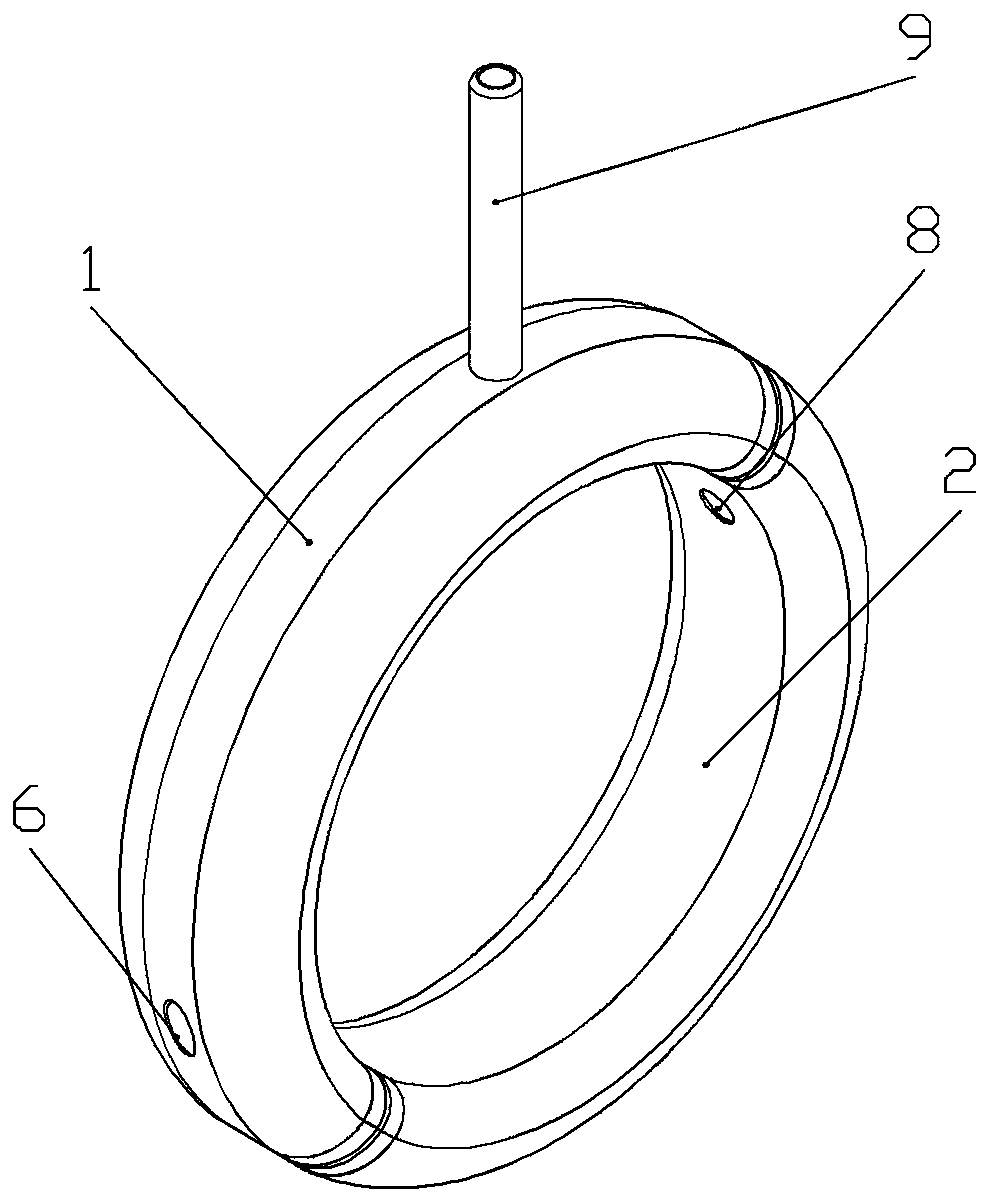

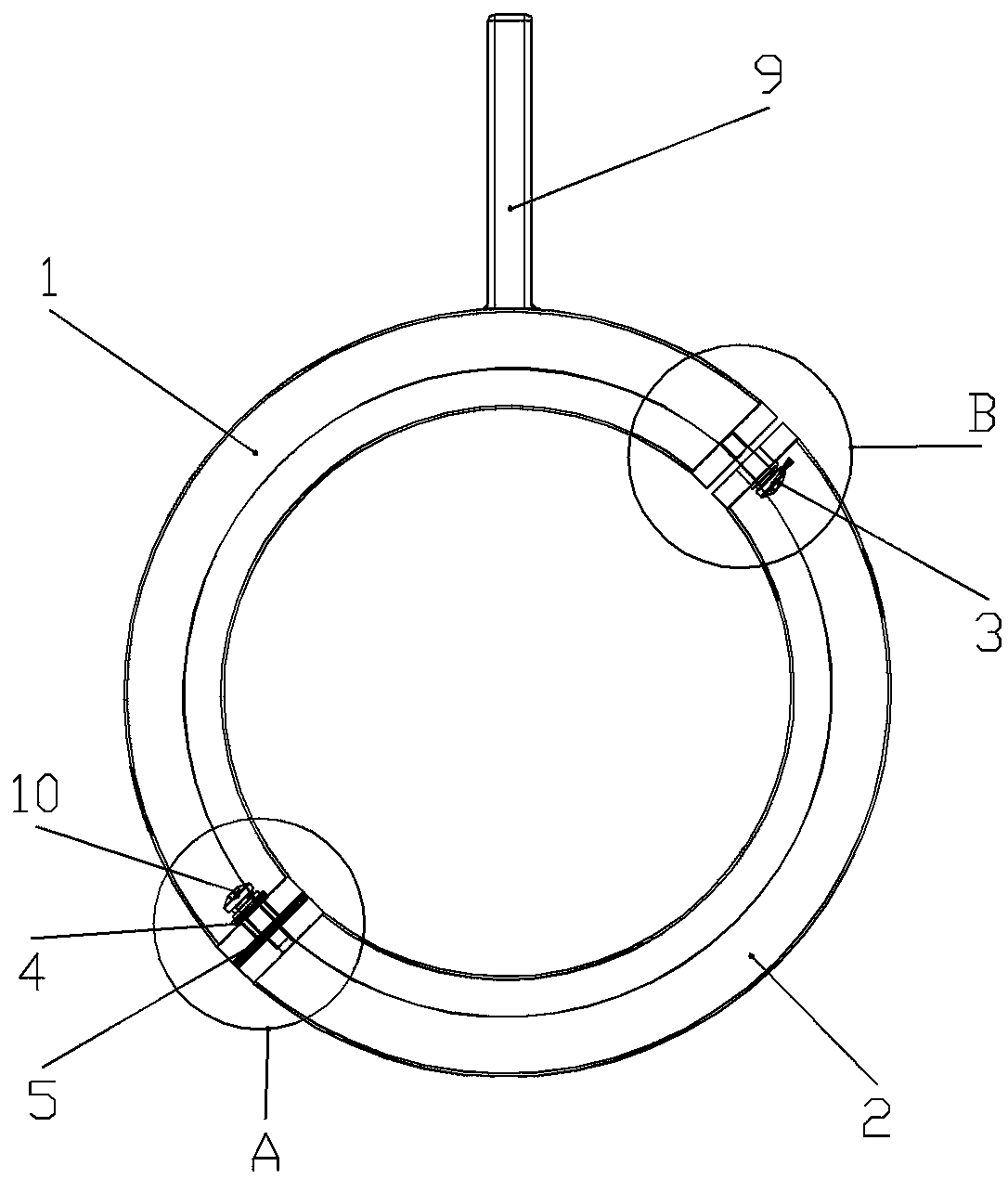

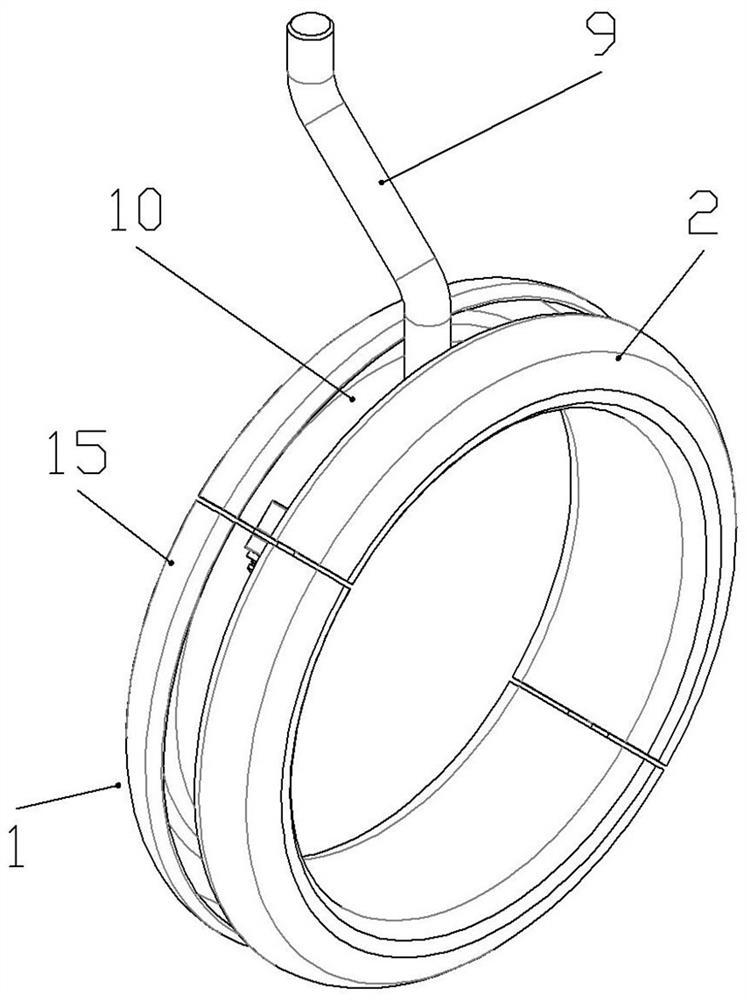

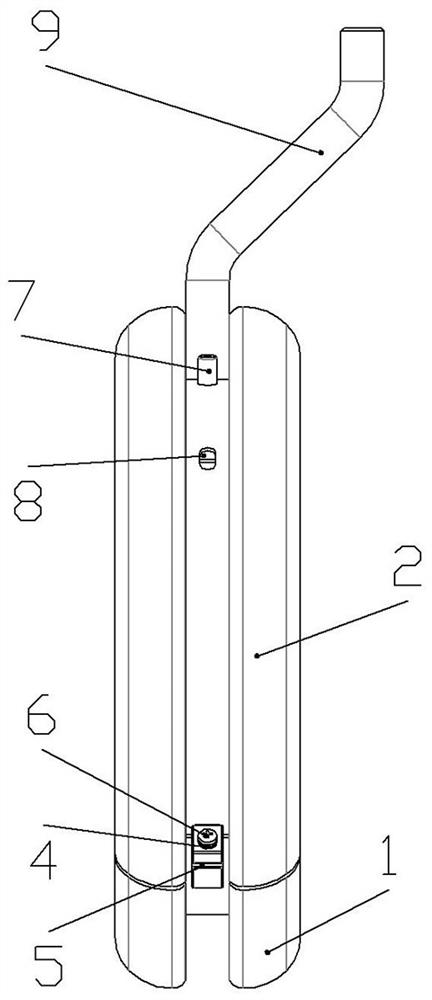

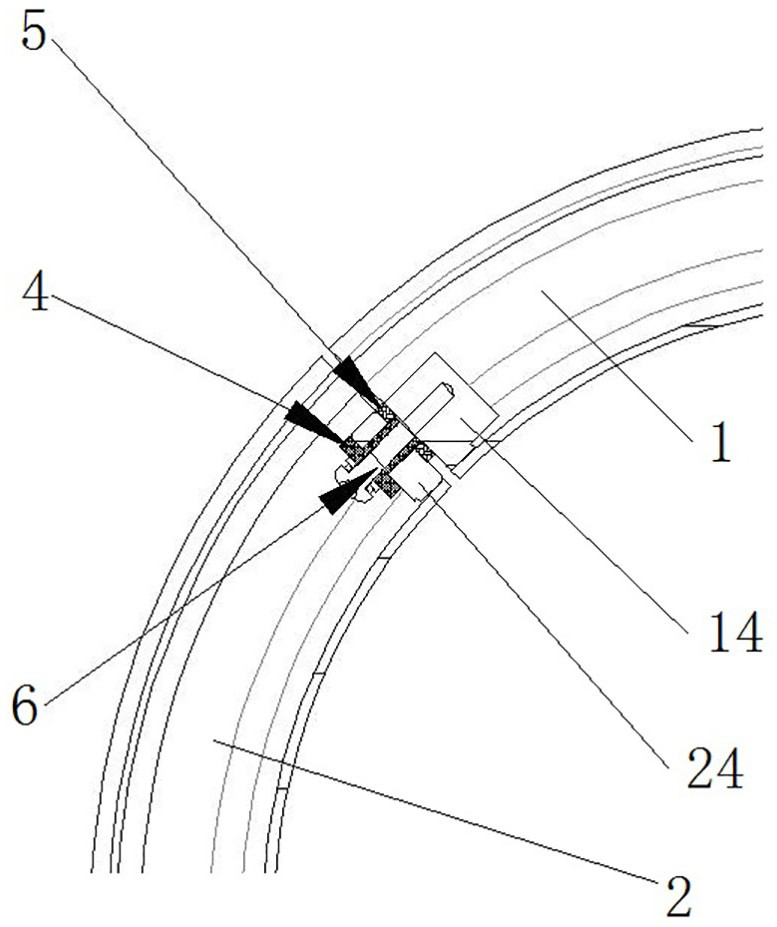

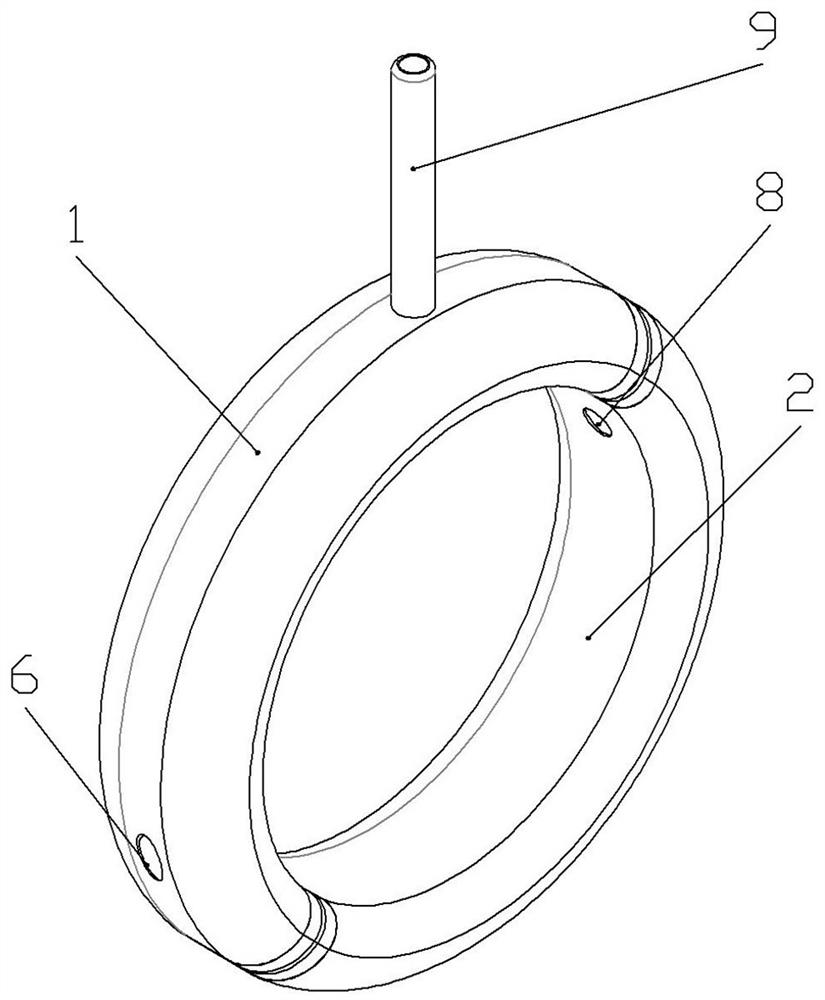

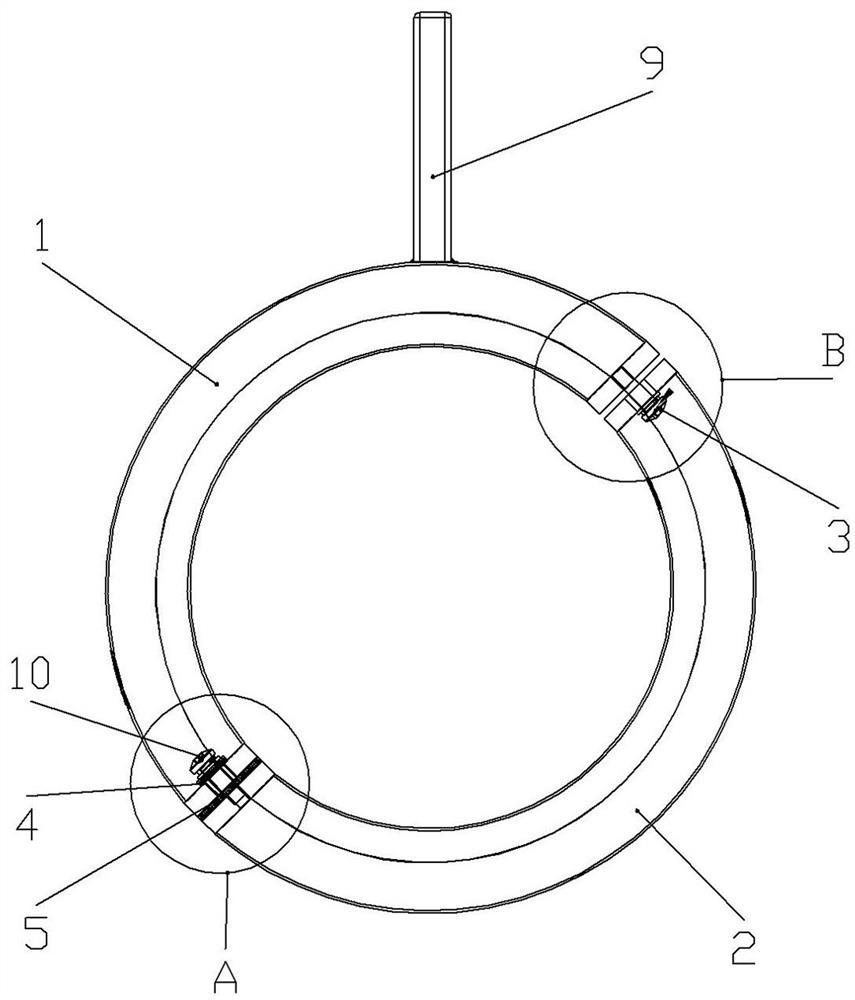

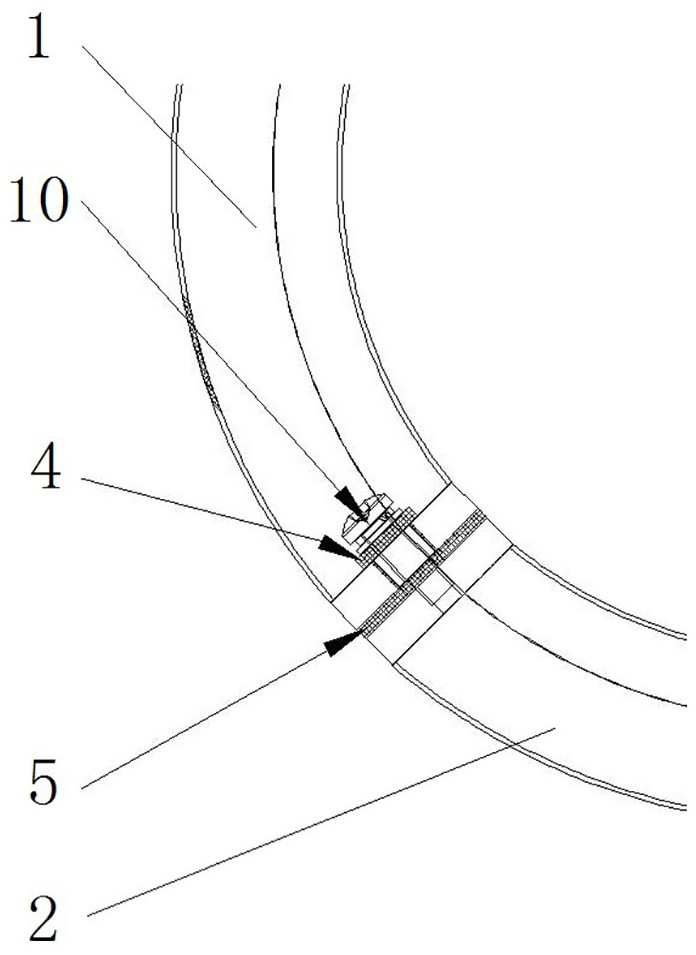

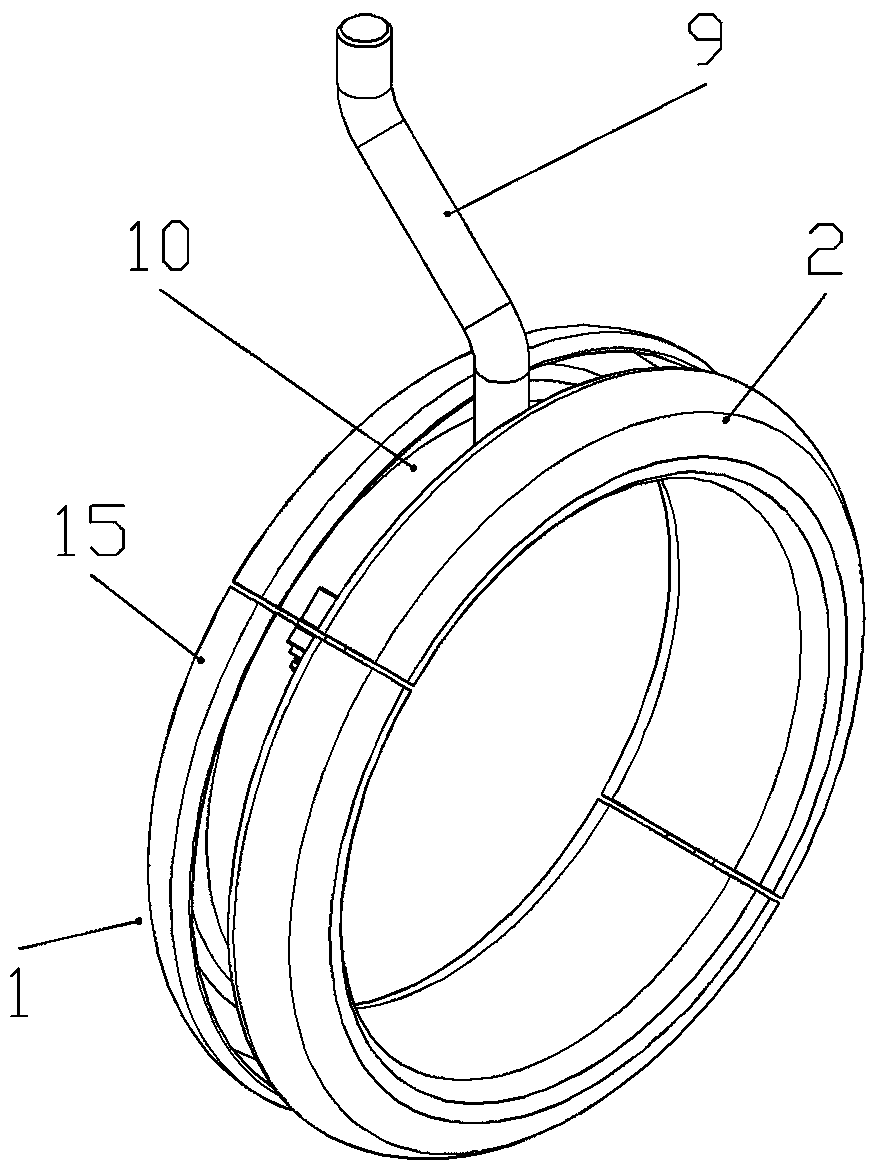

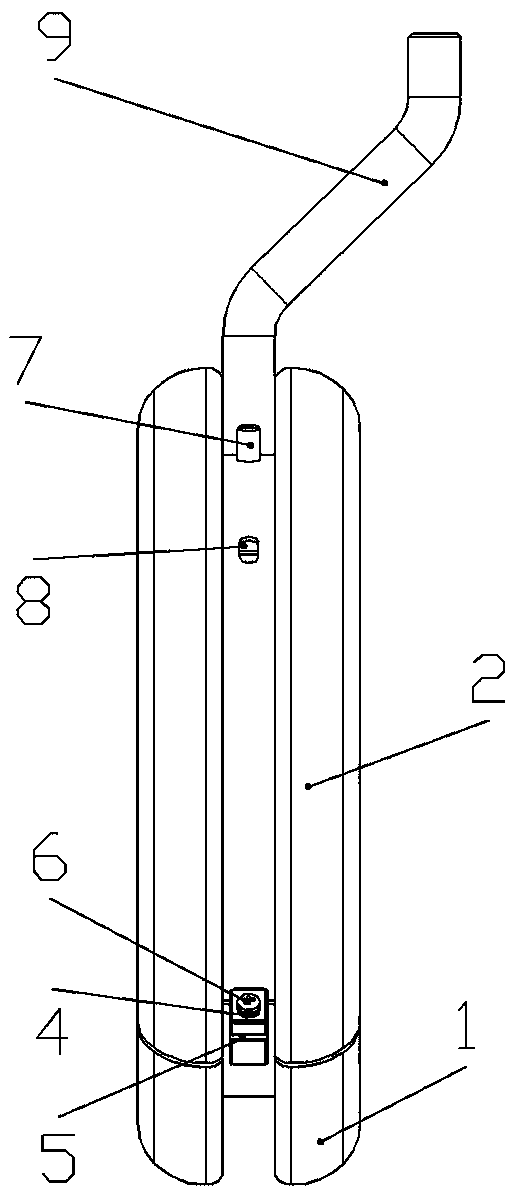

Shielding case and voltage transformer using same

ActiveCN110619998AUniform electric field distributionEasy connectionTransformersTransformers/inductances coils/windings/connectionsVoltageEngineering

The invention relates to a shielding case and a voltage transformer using the same. The shielding case comprises two arc-shaped pipes which are oppositely combined into a ring shape and used for beingfixed to an outer side of a primary winding of the voltage transformer in an embracing mode, wherein plugs are respectively fixed at two ends of the two arc-shaped pipes, an insulating plate is arranged at one folding position between the two arc-shaped pipes and is fixedly connected with the two arc-shaped pipes through metal bolts; at the folding position, a through hole matched with the metalbolt is formed in the plug of one of the two arc-shaped pipes, a threaded hole matched with the metal bolt is formed in the plug of the other arc-shaped pipe, and an insulating part is arranged between the plug provided with the through hole and the metal bolt, an operation hole used for tightening the metal bolt is formed on an outer circumferential wall of an end, close to the insulating plate,of the arc-shaped pipe where the plug provided with the through hole is located, and the metal bolt serves as a main stress component, so connecting stability of insulating connecting ends of the twoarc-shaped pipes is guaranteed.

Owner:HENAN PINGGAO ELECTRIC +2

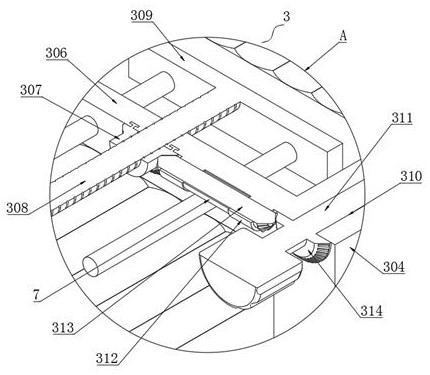

Novel derusting device for design and processing of fabricated steel structure

ActiveCN113618585AAffect the assemblyEasy to cleanGrinding carriagesGrinding machinesUltimate tensile strengthMechanical engineering

The invention discloses a novel derusting device for design and processing of a fabricated steel structure, and belongs to the technical field of derusting of steel structures. The novel derusting device comprises two arc-shaped supporting plates and two elastic arc-shaped connecting plates. Supporting rods rotate to drive cleaning brushes to brush and clean rust on the inner wall of steel, so that the inner wall of the steel can be kept clean, and the situations that the rust on the inner wall of the steel cannot be cleaned in time, consequently, the steel is continuously rusted, and therefore the service life of the steel is shortened, and the use stress strength is reduced are avoided. A moving frame is driven to move once when every two supporting rods rotate and pass through rolling wheels, so that the cleaning area of the cleaning brushes is larger than the moving distance of the moving frame, and the situation that the inner wall of the steel cannot be completely cleaned due to the fact that the moving frame moves too fast is avoided. In the rotating process of the supporting rods, the supporting rod acts on air bags to collect the cleaned rust slag on the inner wall of the steel, and the situation that the residual rust slag affects assembly of workpieces is avoided.

Owner:江苏江海杭萧绿色建筑科技有限公司

A pressing device for motor processing

ActiveCN113824283BImprove the pressing effectAvoid shakingWork holdersManufacturing dynamo-electric machinesElectric machineryCompression device

Owner:方泰(广东)科技有限公司

An injection mold without draft and an injection molding method using the same

InactiveCN102294789AShorten the manufacturing cycleSmall sizeCoatingsProcess engineeringMechanical engineering

The invention relates to the technical field of injection mold equipment, in particular to an injection mold without a draft and an injection molding method using the mold, an injection mold without a draft, the ejection system includes a push block, and the fixed There are steam flow passages around the mold cavity and the movable mold core. Through the steam flow passage, the movable mold core and the fixed mold cavity can be rapidly heated and cooled during mold closing and injection molding. The overall balanced and non-inclined ejection reduces the size of the original mold; an injection molding method for an injection mold without a draft, through the clamping and injection of the movable mold core and the fixed mold cavity with steam channels all around glue, heating, cooling, and mold opening, the product is heated rapidly first, and when the product is formed, it is in the process of holding pressure, and the fixed mold cavity and the movable mold core are rapidly cooled at the same time, which can reduce the production cost of the mold and avoid the product from being out of the mold If the slope is too small, the product will be whitened or stick to the mold, or if the angle is too large, the appearance and assembly will be affected.

Owner:毅昌金型(东莞)五金制品有限公司

Self-cleaning heat exchanger with high ventilation effect

PendingCN114543352AImprove heat transfer residence timeReduce generationHeat recovery systemsSpace heating and ventilation detailsEngineeringMechanical engineering

The invention discloses a self-cleaning heat exchanger with a high ventilation effect, and belongs to the technical field of ventilation and heat exchange, the self-cleaning heat exchanger comprises an outer sleeve, a pipe sleeve mechanism is fixedly mounted in an inner cavity of the outer sleeve, a direction adjusting mechanism is arranged on one side of the outer sleeve, and a heat exchange mechanism is fixedly mounted on one side of the direction adjusting mechanism. According to the heat exchange device, heat exchange air is in contact with the surfaces of the fin components to achieve heat exchange of media in the heat exchange tubes, the air is blown on the surfaces of the fin components and then extends to the two sides of the surfaces of the fin components through the interaction of the spoilers, and after air flow penetrates through the surfaces of the fin components, vortexes are generated due to pressure changes of the rear sides of the fin components; on one hand, the air pressure vortex can prolong the air heat exchange staying time and effectively improve the heat exchange efficiency, and on the other hand, the staying vortex can perform particle capture through circulation on the surfaces of the dust collection plates, so that generation of dust on the outer walls of the fin components can be effectively reduced through the fin mechanisms and the dust collection plates which can be stacked, and the maintenance resistance is effectively improved.

Owner:山东华业阳光新能源有限公司

A shielding case and a voltage transformer using the shielding case

ActiveCN110619999BPrecise positioningFirmly connectedTransformersInductancesTransformerStructural engineering

The invention relates to a shielding case and a voltage transformer using the same. The shielding cover comprises two arc-shaped pieces which are oppositely combined into a ring shape and used for being fixed to an outer side of a primary winding of the voltage transformer in an embracing mode, an opening is formed in the radial outer side of each arc-shaped piece, connecting blocks are fixed to the positions, at the bottoms of the openings, of two ends of the arc-shaped pieces respectively, an insulating plate is arranged at one folding position between the two arc-shaped pieces and is fixedly connected with the two arc-shaped pieces through a metal bolt, the size of the opening meets the requirement for operating the metal bolt, and the metal bolt is immersed into the opening. At the folding position, a through hole matched with the metal bolt is formed on one connecting block of the two arc-shaped pieces, a threaded hole matched with the metal bolt is formed on the other connectingblock, an insulating part is arranged between the connecting block provided with the through hole and the metal bolt, the metal bolt serves as a main stress component, so connecting stability of insulating connecting ends of the two arc-shaped pieces is guaranteed.

Owner:HENAN PINGGAO ELECTRIC +2

Overall pressing assembly device for new energy battery

InactiveCN114420989AEasy to movePrecise positioningAssembling battery machinesFinal product manufactureNew energyControl theory

The invention discloses a new energy battery integral press-down assembling device which comprises an assembling device body used for fixing a battery box so as to realize integral press-down assembling of a battery body into the battery box, and the assembling device body comprises a sliding seat and a camera visual judgment system arranged above the sliding seat. The camera visual judgment system can judge whether the battery box is fixed at a preset position or not and whether the posture is right or not; a positioning assembly is arranged on the sliding seat and comprises a fixed plate fixed to the position, close to one end, of the sliding seat, a sliding plate arranged to the position, close to the other end, of the sliding seat and oppositely spaced from the fixed plate, and clamping plates symmetrically arranged to the positions, close to the two sides, of the sliding seat. The sliding plate can horizontally move against or away from the fixed plate; the two clamping plates can synchronously and horizontally move in a manner of abutting against or leaving away from each other; the fixed plate, the sliding plate and the two clamping plates jointly clamp and fix the battery box; the speed and accuracy of fixing the battery box can be effectively improved, the positioning is firm, and the fixing posture of the battery box is correct.

Owner:厦门竣铭科技有限公司

A processing method for a ball socket groove

ActiveCN108080752BSolve the problem of not being able to find the center of the ball socketAffect the assemblyAxis of symmetryEngineering

The invention discloses an electrode ball socket groove machining method with a self-aligning function. An electrode includes an electrode clamping section at the tail end of the electrode and connected with an electric spark machine tool, and an electrode working section for ball socket machining. The front end of the electrode working section is provided with a ball head used for aligning the center of a ball socket; the electrode working section is of an axial-symmetry structure including a pair of arc-shaped surfaces symmetrical about the axis of symmetry; and the center of the ball head is located in the extension line of the axis of symmetry of the arc-shaped surfaces of the electrode working section. By modifying a conventional electrode, an electric spark machining device has a correcting function and ensures that a groove machining by the electrode is concentric with a sphere, so that the assembly requirements can be met.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

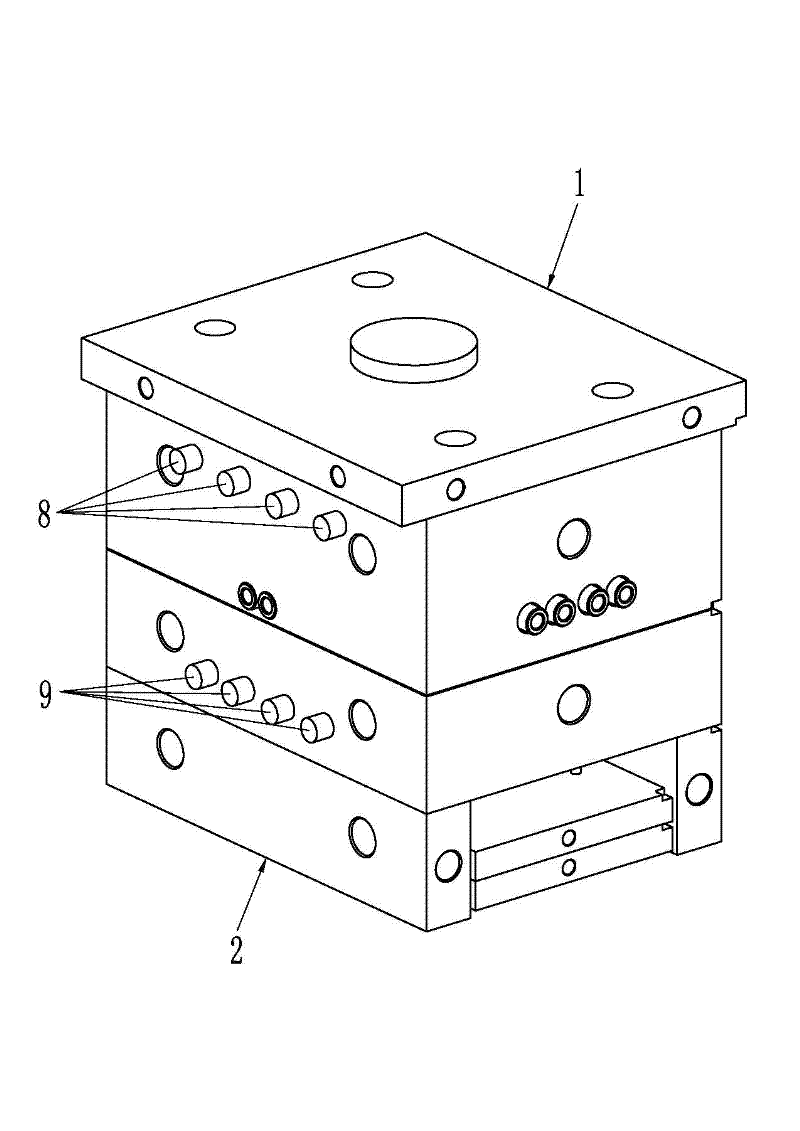

Mold assembly

PendingCN108790050AAffect usabilityAffect the assemblyDomestic articlesInjection mouldingMaterials science

The invention provides a mold assembly and belongs to the technical field of injection molding. The mold assembly comprises a mold main body provided with a mold cavity and an aluminum insert which accommodated in the mold cavity and is provided with a step lug. The mold assembly also comprises an inner slide block which comprises a barb part stretching right below the step lug and an embedding groove which retracts reversely relative to the extending direction of the barb part, wherein the upper surface where the embedding groove is formed and the horizontal plane form a first angle, the lower surface where the embedding groove is formed and the horizontal plane form a second angle, and the first angle is smaller than the second angle; the mold assembly also comprises a pushing assembly for pushing the inner slide block to be far away from or close to the step lug along the direction, forming a third angle, with the horizontal plane; the third angle is greater than the first angle butsmaller than the second angle. Only by changing the bottom surface of a projecting tongue to a plane, forming the second angle, with the horizontal plane, other all structural demands of a plastic accessory can be met. The bottom surface of the projecting tongue is a non-functional surface of the whole plastic accessory, so that use and assembly of the plastic accessory are not affected.

Owner:OPD TECH SHENZHEN

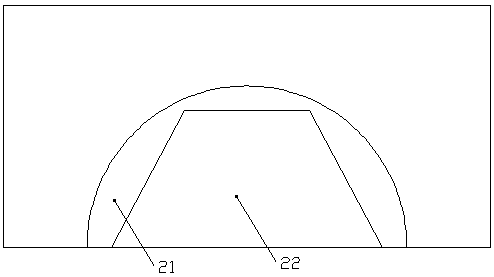

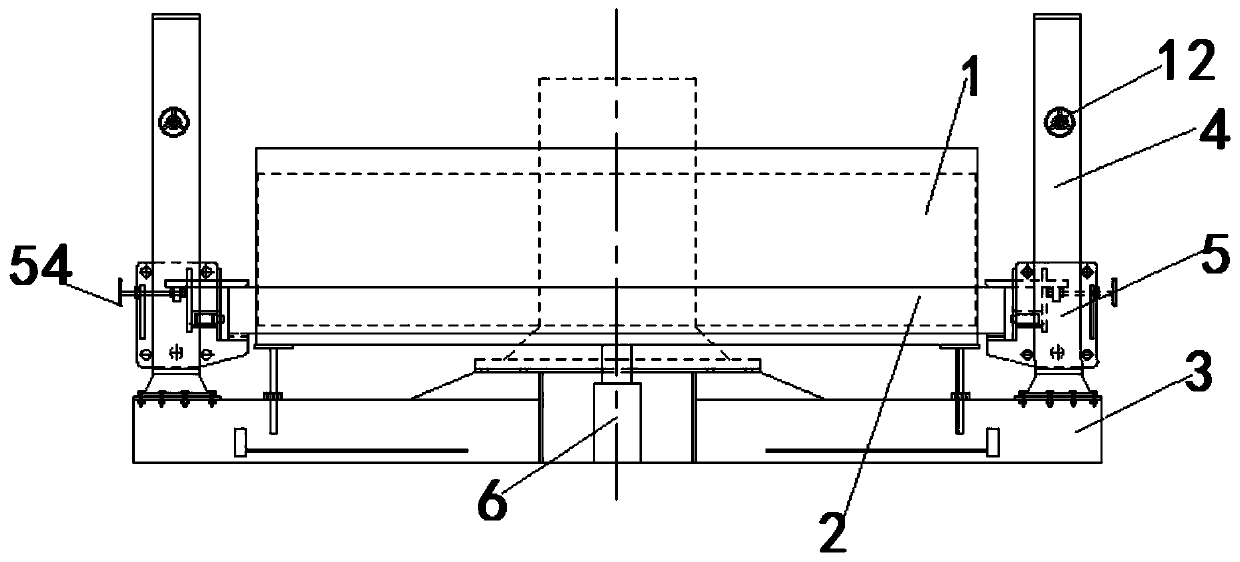

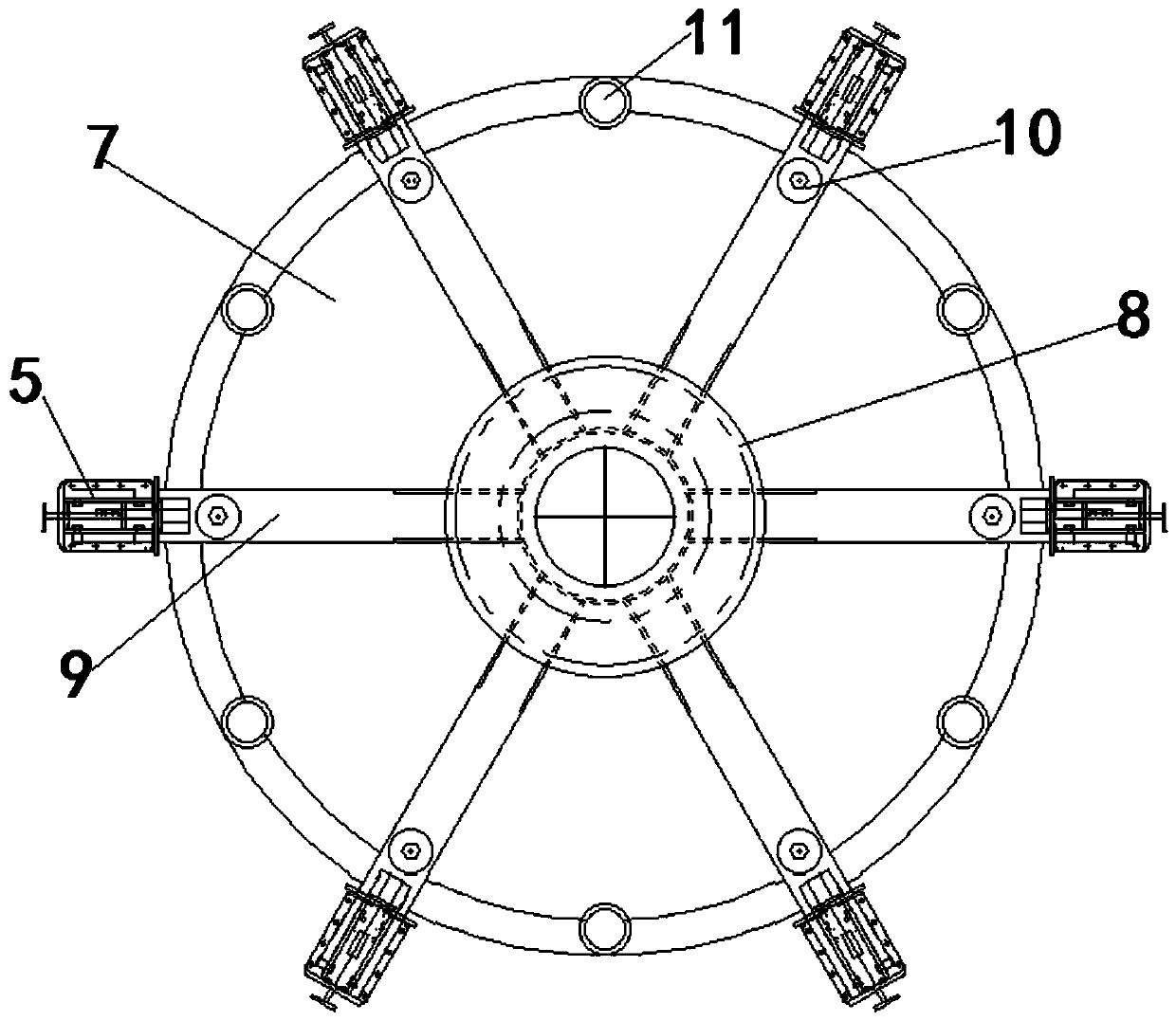

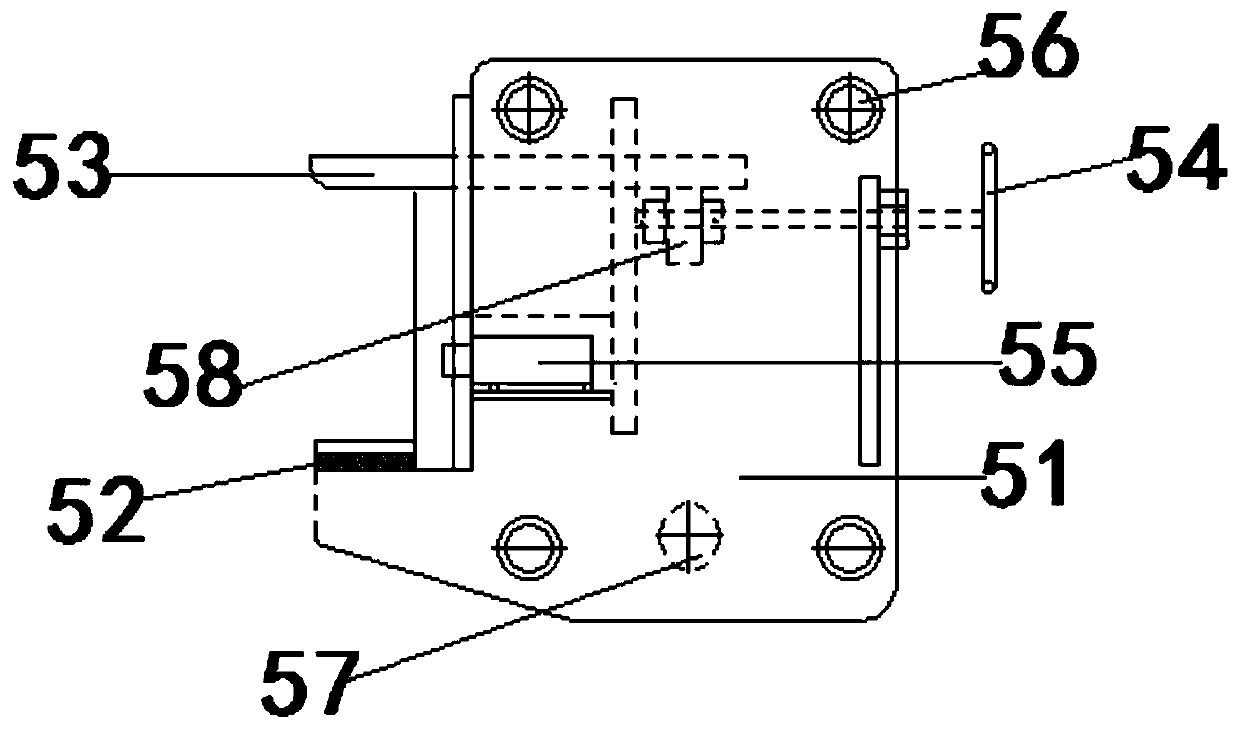

Motor stator and rotor assembling and separating device

ActiveCN110971089AGuaranteed levelnessAvoid tilting,Centering/balancing rotorsElectric machineClassical mechanics

The invention discloses a motor stator and rotor assembling and separating device, and is applied to a motor. The motor comprises a stator and a rotor. A reinforcing ring is nested outside the rotor.The motor stator and rotor assembly and separation device comprises a base for supporting a motor, a stand column which is vertically arranged on the base, a clamping jaw device which is used for clamping and fixing a reinforcing ring, and a synchronous lifting device which is arranged on the base, can ascend and descend and is used for providing power for assembling or separating a rotor; the clamping jaw device is movably arranged on the stand column so that the clamping jaw device can ascend and descend synchronously when the synchronous lifting device ascends and descends. By using the motor stator and rotor assembling and separating device provided by the invention, the assembling or separating operation efficiency of large and medium-sized motor stators and rotors can be improved, and the separating and assembling quality of the motor stators and rotors can be effectively ensured.

Owner:BAOTOU CRRC MOTOR CO LTD

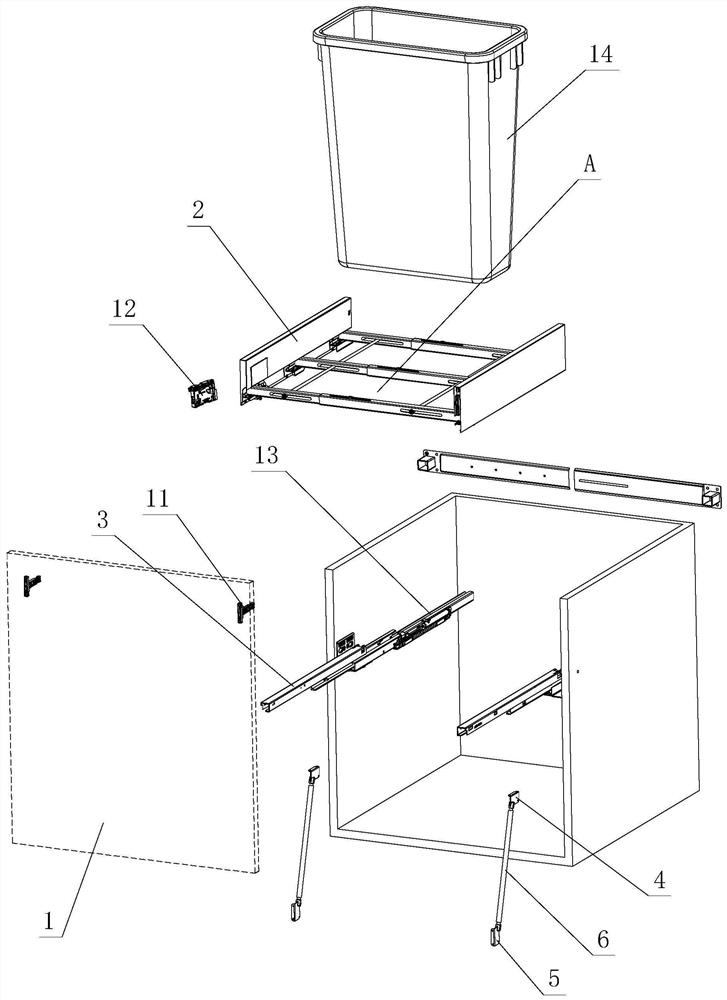

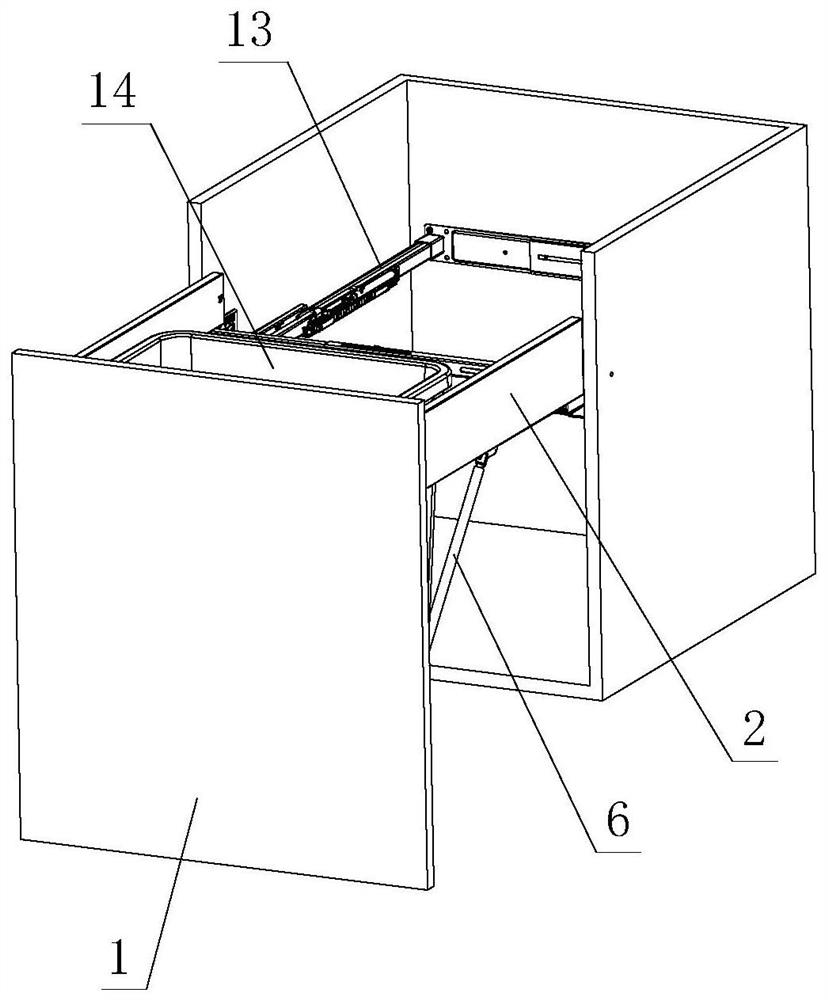

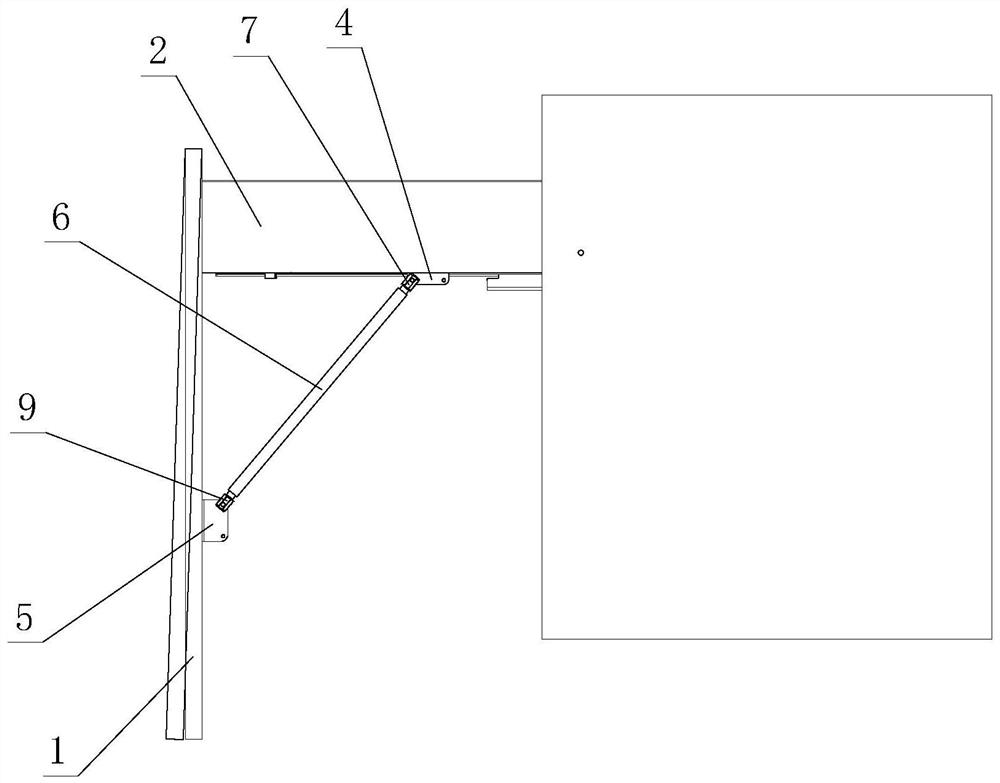

Angle adjusting structure of drawer panel

PendingCN111806925AStable angle adjustmentProblems that affect the neatness of the appearanceRefuse receptaclesEngineeringStructural engineering

The invention relates to an angle adjusting structure of a drawer panel. The angle adjusting structure comprises a panel, a side plate and a sliding rail assembly, and is characterized in that the sliding rail assembly at least comprises a movable sliding rail, the side plate is detachably arranged on the movable sliding rail, and the panel is detachably arranged on the side plate; a first connecting piece is arranged on the side plate or the movable sliding rail, a second connecting piece is arranged on the panel, a connecting rod is arranged between the first connecting piece and the secondconnecting piece, and an adjusting piece is arranged between the connecting rod and the first connecting piece and / or the second connecting piece; the connecting rod moves on the first connecting piece and / or the second connecting piece through adjustment of the adjusting piece and drives the panel to obliquely move relative to the side plate or the movable sliding rail in the moving process, thereby realizing the angle adjustment of the panel. The upper position and the lower position of the panel can be attached to a cabinet body better when the panel is closed, and the problems that in theprior art, the height size of the panel is quite large, or the manufacturing specification is inconsistent, or dislocation occurs during installation, so that a gap is formed between the panel and thecabinet body when the panel is closed, and appearance regularity is affected are solved.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

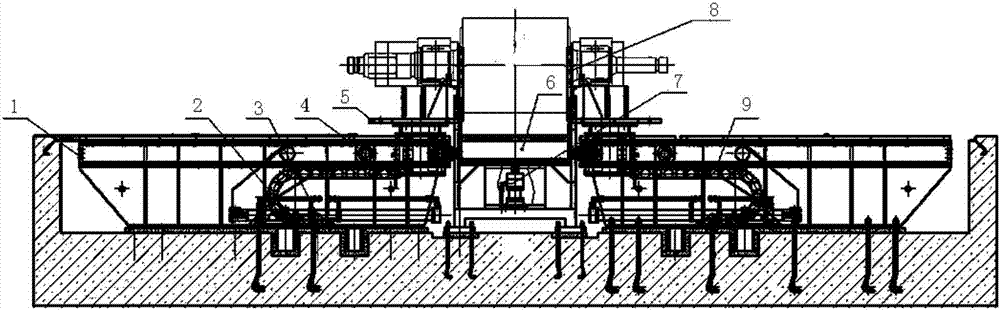

High-precision steel rail universal mill roll disassembly and assembly device

PendingCN107570535AAchieve precision assemblyAffect the assemblyMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a high-precision steel rail universal mill roll disassembly and assembly device, and belongs to the technical field of section steel universal mill roll disassembly and assembly equipment. According to the technical scheme, the high-precision steel rail universal mill roll disassembly and assembly device comprises a roll supporting and adjusting mechanism, an operation side roll box supporting and adjusting mechanism and a transmission side roll box supporting and adjusting mechanism; a roll bracket in the roll supporting and adjusting mechanism is fixed to a roll bracket base (6); the roll bracket is provided with a guide and guard adjusting rod (7) and roll clamping grooves (8) correspondingly; a working platform (5) in the operation side roll box supporting andadjusting mechanism is fixed to a moving trolley base (4); the moving trolley base (4) is arranged on a moving trolley foundation (1); and the transmission side roll box supporting and adjusting mechanism and the operation side roll box supporting and adjusting mechanism have the same structure. The high-precision steel rail universal mill roll disassembly and assembly device has the beneficial effects that high-precision disassembly and assembly of steel rail universal mill rolls can be realized, the assembly quality of the steel rail universal mill rolls is improved, steel rail production isstabilized, the yield and the production efficiency of steel rail production are raised and improved.

Owner:HANDAN IRON & STEEL GROUP +1

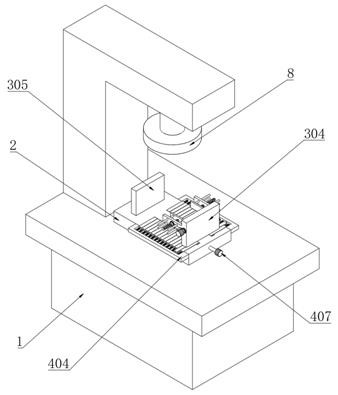

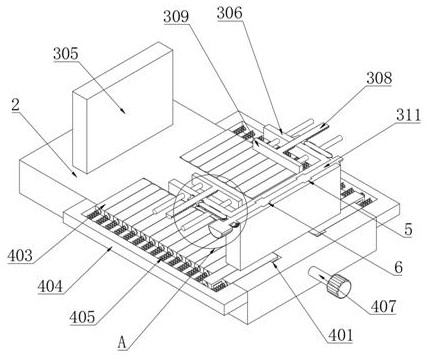

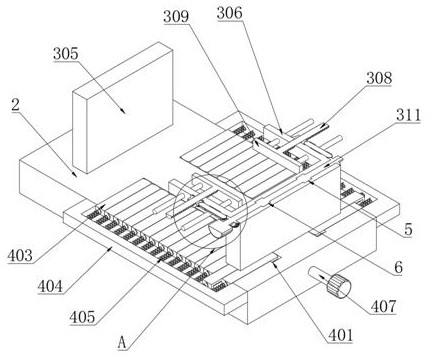

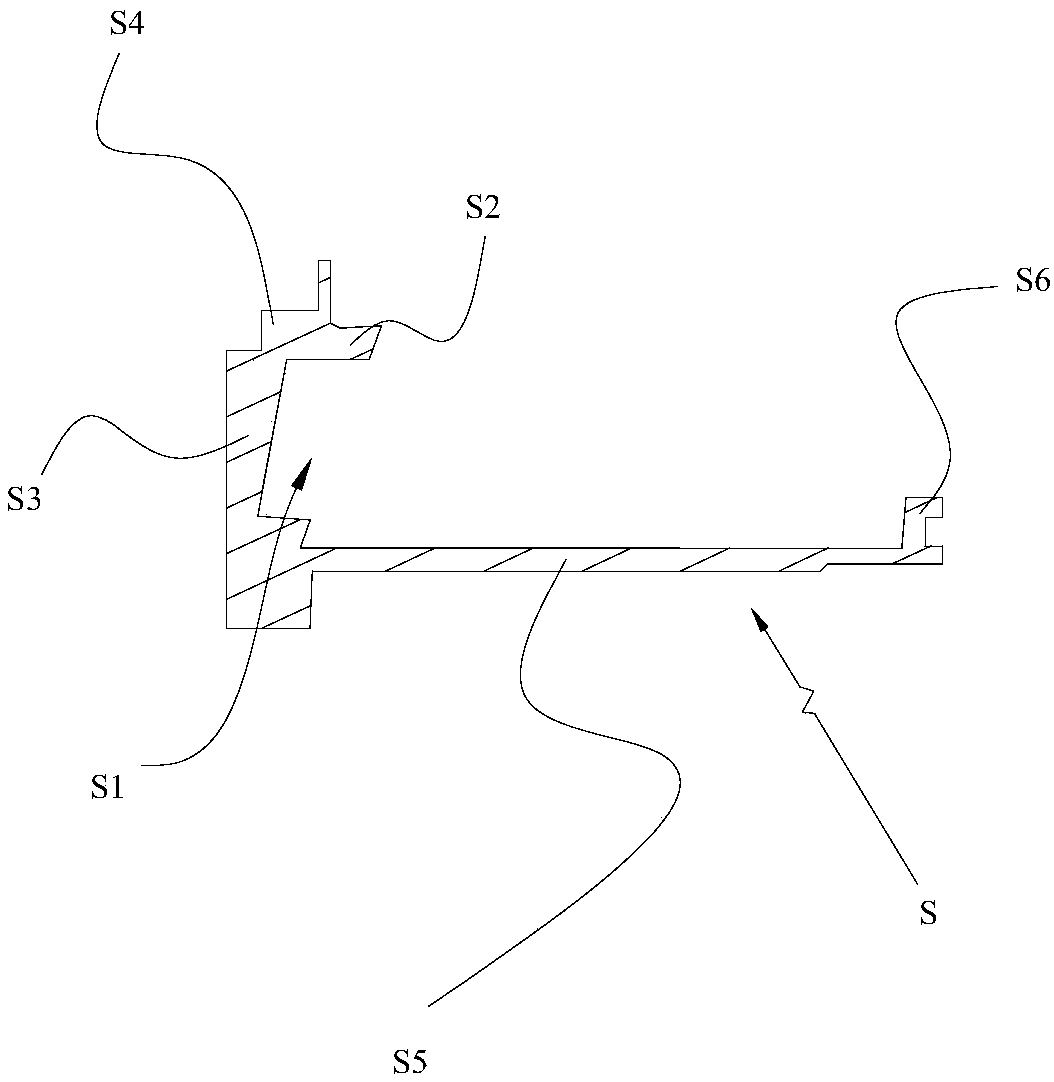

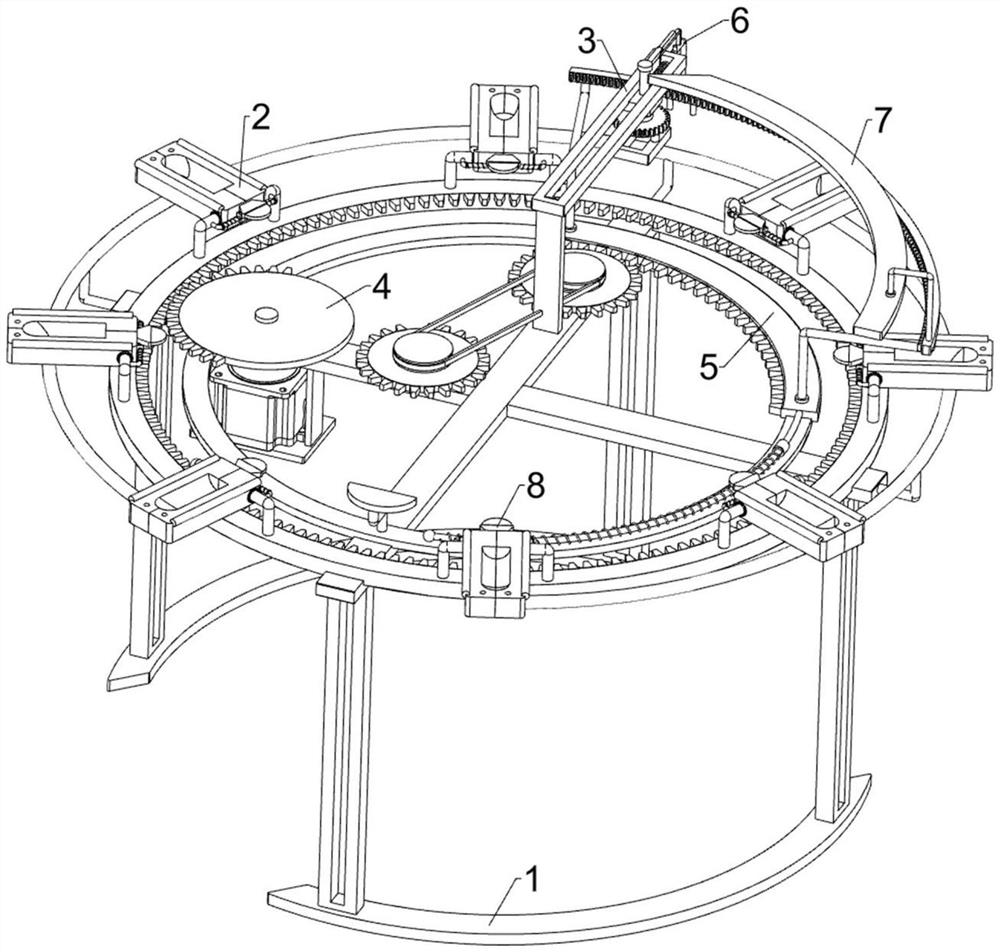

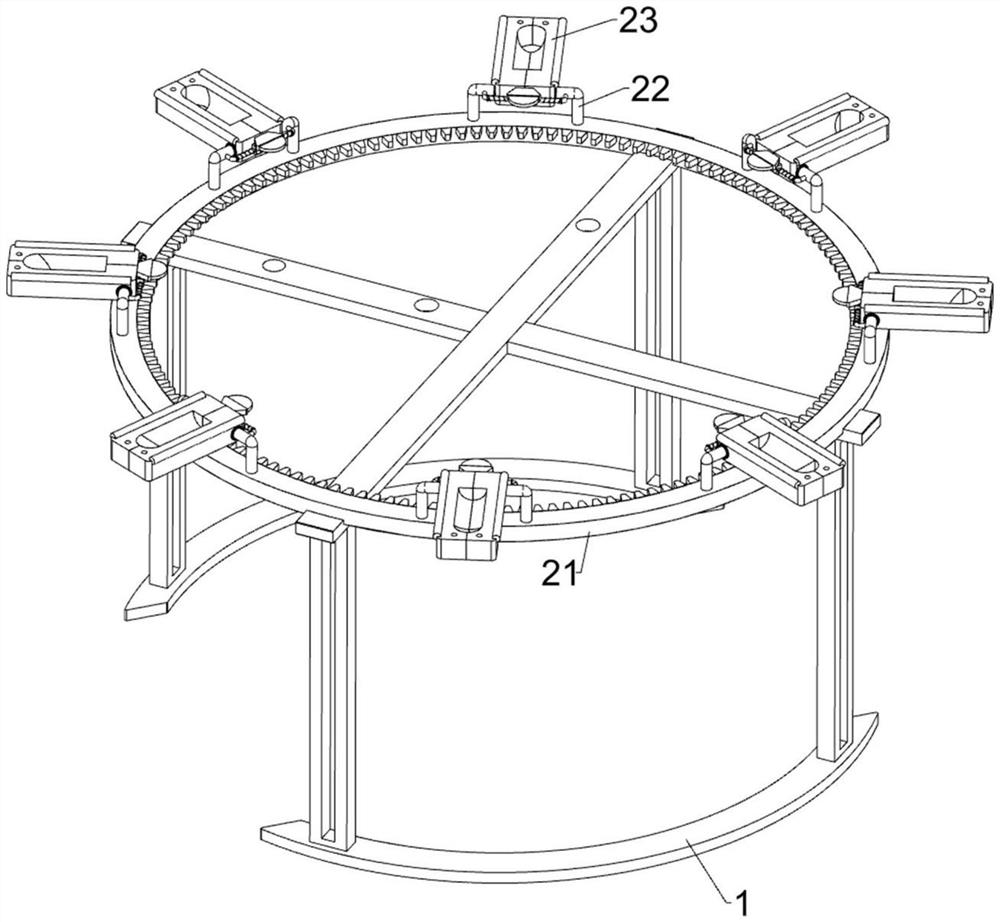

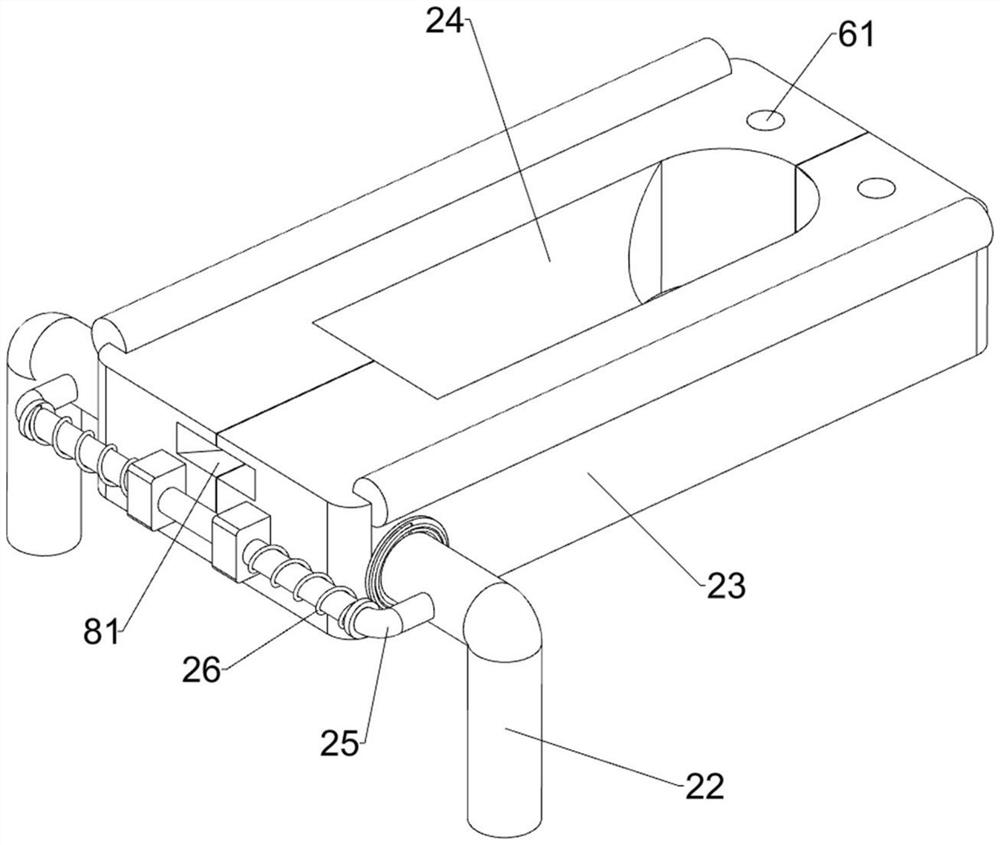

A plastic faucet spool assembly device

ActiveCN112606413BReduce the burden onAffect the assemblyDomestic articlesMechanical engineeringPhysics

The invention relates to an assembly device, in particular to an assembly device for a plastic faucet valve core. The purpose of the present invention is to provide a plastic faucet spool assembly device capable of automatic assembly. A plastic faucet spool assembly device includes: a bracket; a rotating and placing component installed on the bracket; a tightening component installed on the bracket. The invention has a tightening and fixing component and an automatic fixing component, which can fix the position of the placement plate through the cooperation of the slot and the insertion rod when the faucet is tightened, preventing the placement plate from being separated when the faucet is tightened, thereby affecting the function of the faucet. Assembling; the present invention has a blanking assembly, and through the cooperation of the first convex plate and the second convex plate, the device can separate the plates placed on both sides, thereby facilitating the replacement of the faucet by the staff, reducing the time for replacing the faucet, and improving the Productivity.

Owner:FUZHOU YINSHENGWANG SANITARY WARE

Coach bolt hot extrusion forming equipment

ActiveCN113976793AImprove molding qualityAffect the assemblyBoltsForging/hammering/pressing machinesStructural engineeringMachine

The invention relates to the field of coach bolt stamping forming, in particular to coach bolt hot extrusion forming equipment. The equipment comprises a stamping table, a stamping machine and a stamping die, the stamping die comprises a fixed die block and two movable die blocks, the two movable die blocks are symmetrically arranged at the top of the fixed die block, the symmetrical face of the two movable modules is the middle section of the fixed module, the two movable modules can relatively slide on the fixed module, the fixed module is further provided with a driving device used for driving the two movable modules to relatively slide, the stamping table is further provided with a supporting table used for supporting a coach bolt, and the supporting table is also provided with a lifting device for lifting the coach bolt. According to the equipment, through cooperation between the fixed die and the movable die, the coach bolt can be attached to the edge of the movable die after being punched and formed, the forming quality of the coachbolt is improved, and the situation that assembly is affected when the coach bolt is used is avoided.

Owner:浙江科腾精工机械股份有限公司

Shielding case and voltage transformer using the shielding case

ActiveCN110619998BPrecise positioningFirmly connectedTransformersTransformers/inductances coils/windings/connectionsTransformerStructural engineering

The invention relates to a shielding case and a voltage transformer using the same. The shielding case comprises two arc-shaped pipes which are oppositely combined into a ring shape and used for beingfixed to an outer side of a primary winding of the voltage transformer in an embracing mode, wherein plugs are respectively fixed at two ends of the two arc-shaped pipes, an insulating plate is arranged at one folding position between the two arc-shaped pipes and is fixedly connected with the two arc-shaped pipes through metal bolts; at the folding position, a through hole matched with the metalbolt is formed in the plug of one of the two arc-shaped pipes, a threaded hole matched with the metal bolt is formed in the plug of the other arc-shaped pipe, and an insulating part is arranged between the plug provided with the through hole and the metal bolt, an operation hole used for tightening the metal bolt is formed on an outer circumferential wall of an end, close to the insulating plate,of the arc-shaped pipe where the plug provided with the through hole is located, and the metal bolt serves as a main stress component, so connecting stability of insulating connecting ends of the twoarc-shaped pipes is guaranteed.

Owner:HENAN PINGGAO ELECTRIC +2

DC drive permanent magnet variable-frequency motor

The invention belongs to the technical field of motors, and particularly relates to a DC drive permanent magnet variable frequency motor. The motor comprises a motor body. The motor body comprises a frame and a base, one end of the motor body is connected with a rotating shaft, the frame is connected with a fixing ring, the outer end of the fixing ring is provided with an end cover, the end part of the end cover is symmetrically provided with locking blocks, the side surface of each locking block is provided with a first locking groove, and the end surface of the fixing ring is provided with an arc-shaped groove. An elastic block is arranged in the arc-shaped groove, a second locking groove is formed in the side wall of the arc-shaped groove, and a locking plate is slidably connected to the interior of the second locking groove. By arranging the fixing ring and the end cover which are matched with each other, the end cover can be conveniently and quickly opened, a fan and the end coverin the motor are cleaned, the structure of the motor is greatly simplified, the size of the motor is reduced, interference between the motor and the outside during installation is reduced, and the convenience and practicability of the motor during use are improved.

Owner:台州市路桥聚鑫电子有限公司

Voltage transformer and shielding case thereof

ActiveCN110619997ADistribution does not affectEvenly distributedTransformersInductancesTransformerConductor Coil

The invention relates to a voltage transformer and a shielding case thereof. The shielding cover comprises two arc-shaped pieces which are oppositely combined into a ring shape and used for being fixed to an outer side of a primary winding of the voltage transformer in an embracing mode, wherein an opening is formed in a radial outer side of each arc-shaped piece, connecting blocks are fixed to the positions, at bottoms of the openings, of two ends of each arc-shaped piece respectively, opposite ends of the two arc-shaped pieces are fixedly connected through a bolt and are mutually conductive,the size of the opening meets the requirement of operating the bolt, the bolt is immersed in the opening, a through hole is formed in one of the two connecting blocks at the end corresponding to a nut of the bolt, a threaded hole matched with the bolt is formed in the other connecting block, and the bolt can be installed in the opening of the arc-shaped piece provided with the through hole, penetrates through the through hole and is in threaded connection with the threaded hole. After the two arc-shaped pieces are fixedly connected through the bolt, an electric field on the shielding cover can be uniformly distributed without additionally arranging a shielding pipe, so assembly efficiency of the voltage transformer is improved, and the cost of the voltage transformer is reduced.

Owner:HENAN PINGGAO ELECTRIC +2

Die iron slag removal device for casting

The invention relates to the technical field of casting, and discloses a die iron slag removal device for casting. The die iron slag removal device for casting comprises a base, a supporting column is fixedly connected to the left side of the upper end of the base, the supporting column is connected with a rotating mechanism and connected with a supporting plate through the rotating mechanism, a pushing air cylinder is fixedly connected to the upper end of the supporting plate, the output end of the pushing air cylinder is fixedly connected with a movable block, the lower end of the movable block is fixedly connected with a movable seat, the movable seat is connected with a driving mechanism and connected with an adsorption plate through the driving mechanism, a cavity is formed in the adsorption plate, and the front end of the lower side wall of the cavity is fixedly connected with an adsorption pipe. According to the die iron slag removal device for casting, through the mode that grinding is matched with adsorption, residual slag in a die can be rapidly removed, the removal efficiency is high, the workload of workers is reduced, visual inspection can replace human eye observation, and therefore the phenomenon of incomplete removal can be prevented, and the subsequent casting quality is ensured.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com