Chromium-based alloy and manufacturing method thereof

A technology of chromium-based alloys and manufacturing methods, which is applied in the field of chromium-based alloys for fuel cell connection plates and its manufacturing, can solve the problems of impact toughness not meeting the requirements, limiting the application of chromium-based alloys, and high ductile-brittle transition temperature of chromium, so as to achieve the goal of using Long life, improved organizational structure, high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

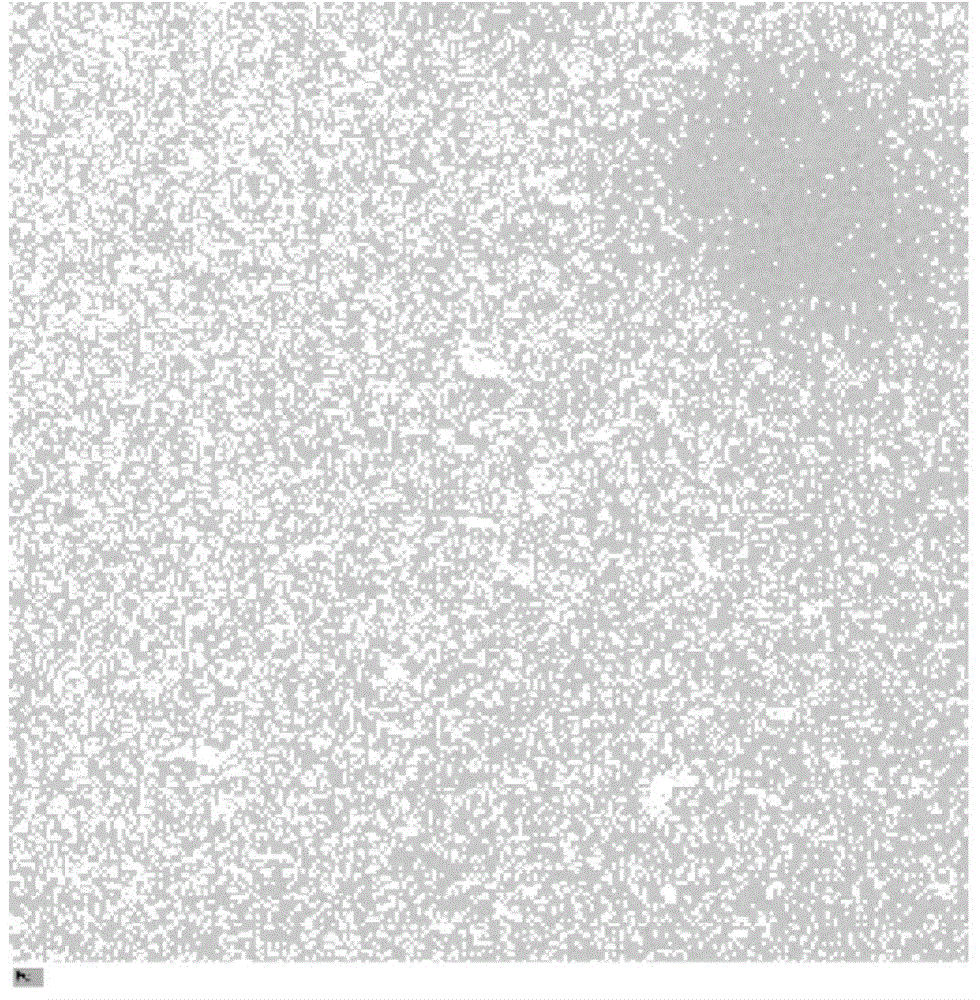

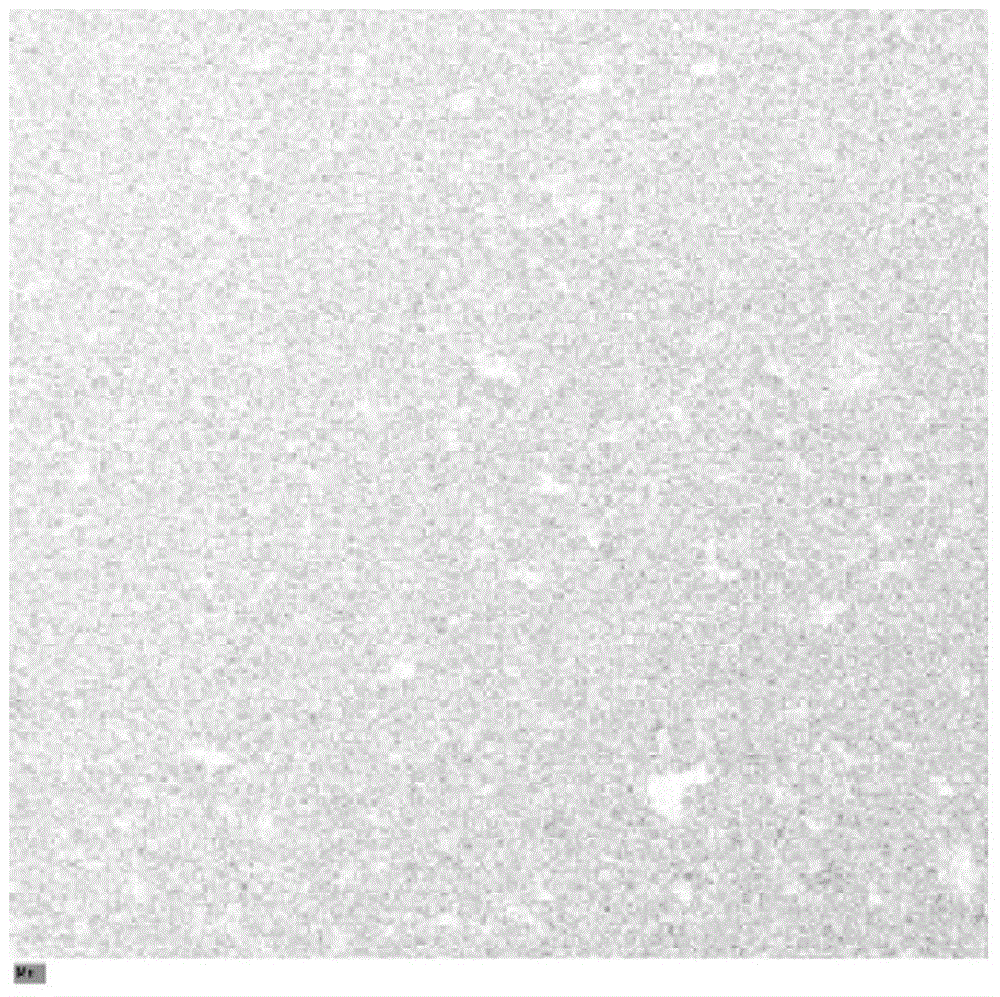

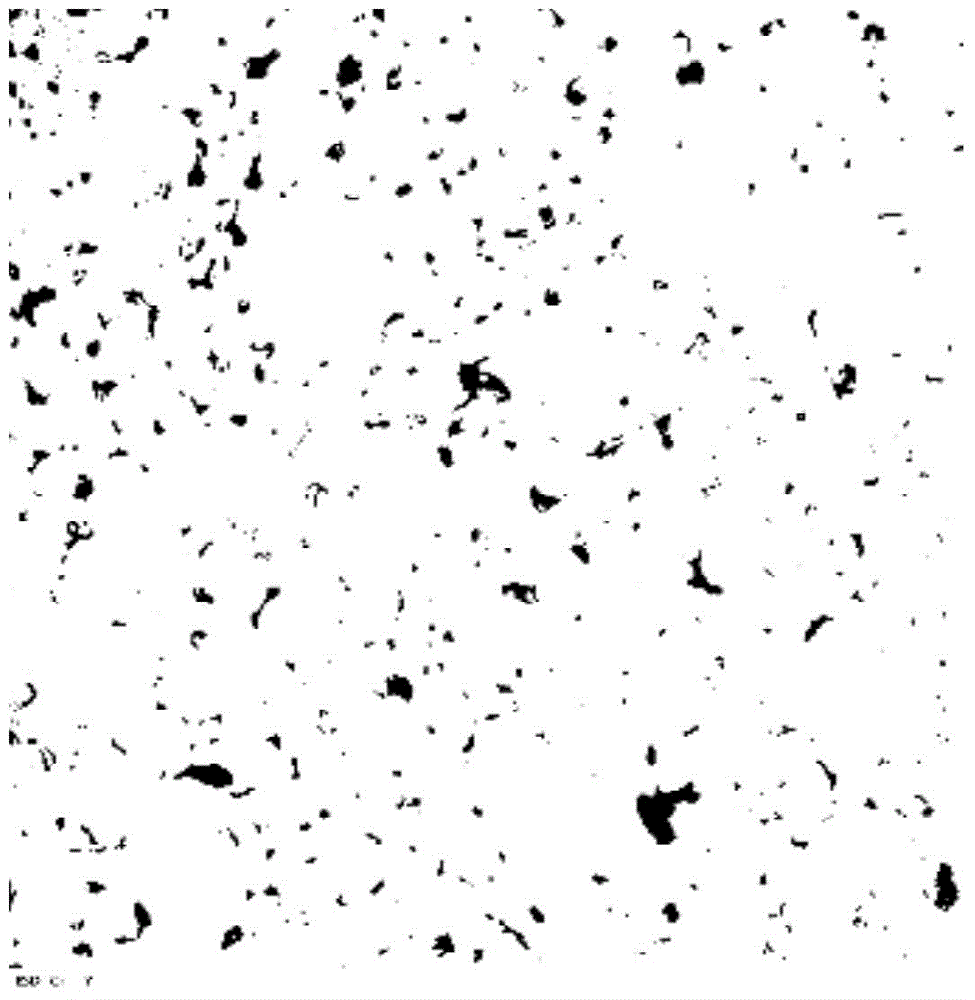

Image

Examples

Embodiment 1

[0030] 1) Design material composition and mixing: the composition of the chromium-based alloy material is 5% iron, 1.0% yttrium oxide, 13% manganese, and the rest is chromium; iron is added in the form of pure iron powder, and manganese is added in the form of manganese powder. Chromium is added in the form of reduced chromium powder or electrolytic chromium powder; the specific ratio is as follows: pure iron powder: 5%; manganese powder: 13%; yttrium oxide powder: 1%; reduced chromium powder or electrolytic chromium powder: 80.7%, Powder lubricant: 0.3%; according to the ratio, mix in a double-cone or V-shaped mixer or other mixers.

[0031] 2) Pressing, the above mixed powder is pressed on a forming press, which can be pressed by ordinary molding, the forming pressure is 700Mpa, and the forming density is 6.2g / cm 3 .

[0032] 4) Dewaxing and sintering: Carry out in the vacuum sintering integrated with dewaxing and sintering; the dewaxing temperature is 400°C, the time is 20...

Embodiment 2

[0036] 1) Design material composition and mixing: the composition of the chromium-based alloy material is 5% iron, 1.0% yttrium oxide, 7% manganese, and the rest is chromium; iron is added in the form of 434L stainless steel and ferromanganese master alloy powder, and manganese is added in the form of Ferromanganese master alloy powder (manganese content is 85-90%, carbon content is less than 0.2%, the rest is less than 2%, and the rest is iron). The chromium part is added in the form of reduced chromium powder or electrolytic chromium powder, and part is added in the form of 434L stainless steel mother alloy. Add in the form of alloy powder; the specific ratio is as follows: 434L stainless steel powder: 4.8%; ferromanganese alloy powder: 8%; yttrium oxide powder: 1%; reduced chromium powder or electrolytic chromium powder: 85.7%; powder lubricant: 0.5%; Mix in double cone or V-shape mixer or other mixers according to the ratio.

[0037] 2) Pressing, pressing the above mixed p...

Embodiment 3

[0042]1) Design material composition and mixing: the composition of chromium-based alloy materials is 5% iron, 1.0% yttrium oxide, 2% manganese, and the rest is chromium; iron is added in the form of 434L stainless steel, and manganese is added in the form of pure manganese powder. Most of the chromium is added in the form of reduced chromium powder or electrolytic chromium powder, and a small part is added in the form of 434L stainless steel; the specific ratio is as follows: 434L stainless steel: 6%; manganese powder: 2%; yttrium oxide powder: 1%; Chromium powder or electrolytic chromium powder: 90.7%, powder lubricant: 0.3%; mix in double-cone or V-shaped mixer or other mixers according to the proportion.

[0043] 2) Compression, the above mixed powder is pressed on a forming press, which can be pressed by warm compression molding, the forming pressure is 700Mpa, and the forming density is 6.3g / cm 3 .

[0044] 4) Dewaxing and sintering: Carry out in the vacuum sintering in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com