Motor stator structure and motor

A technology for motor stator and stator punching, which is applied to the shape/pattern/structure of the magnetic circuit, static components of the magnetic circuit, etc., can solve the problems affecting assembly, stator deformation, etc., and achieve the effect of reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

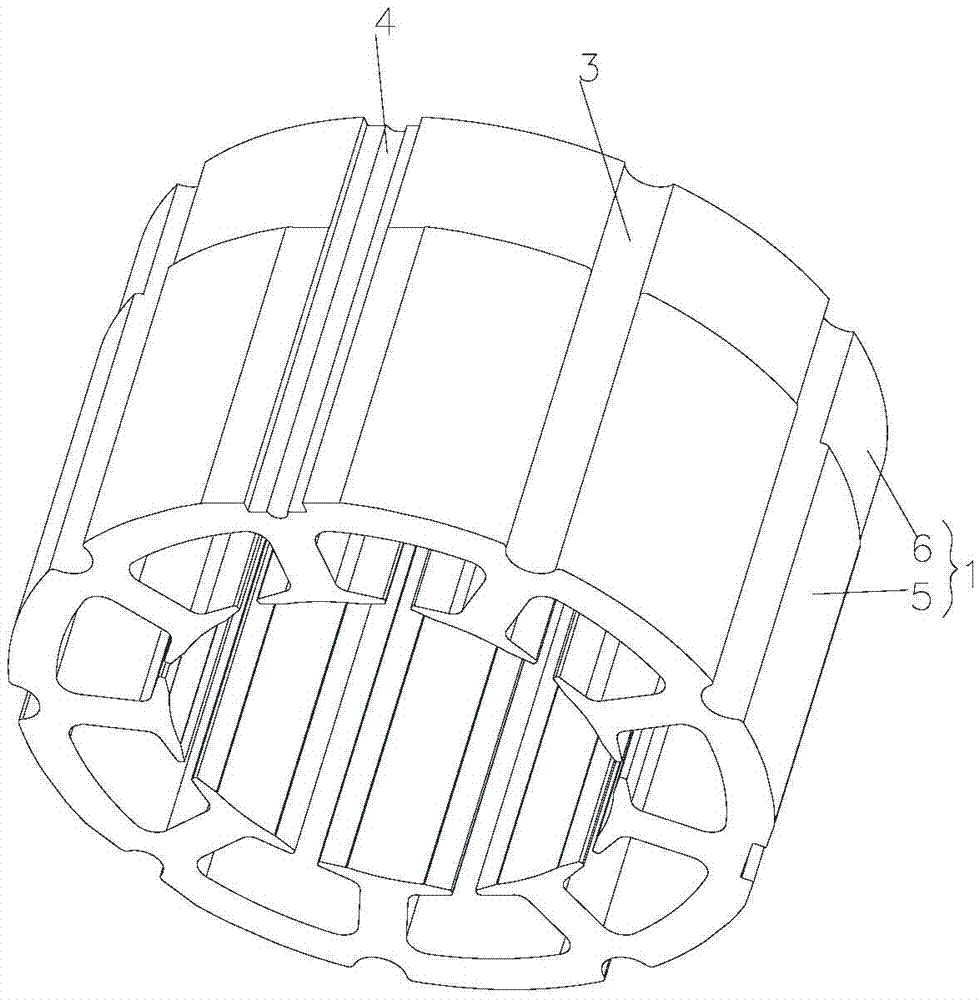

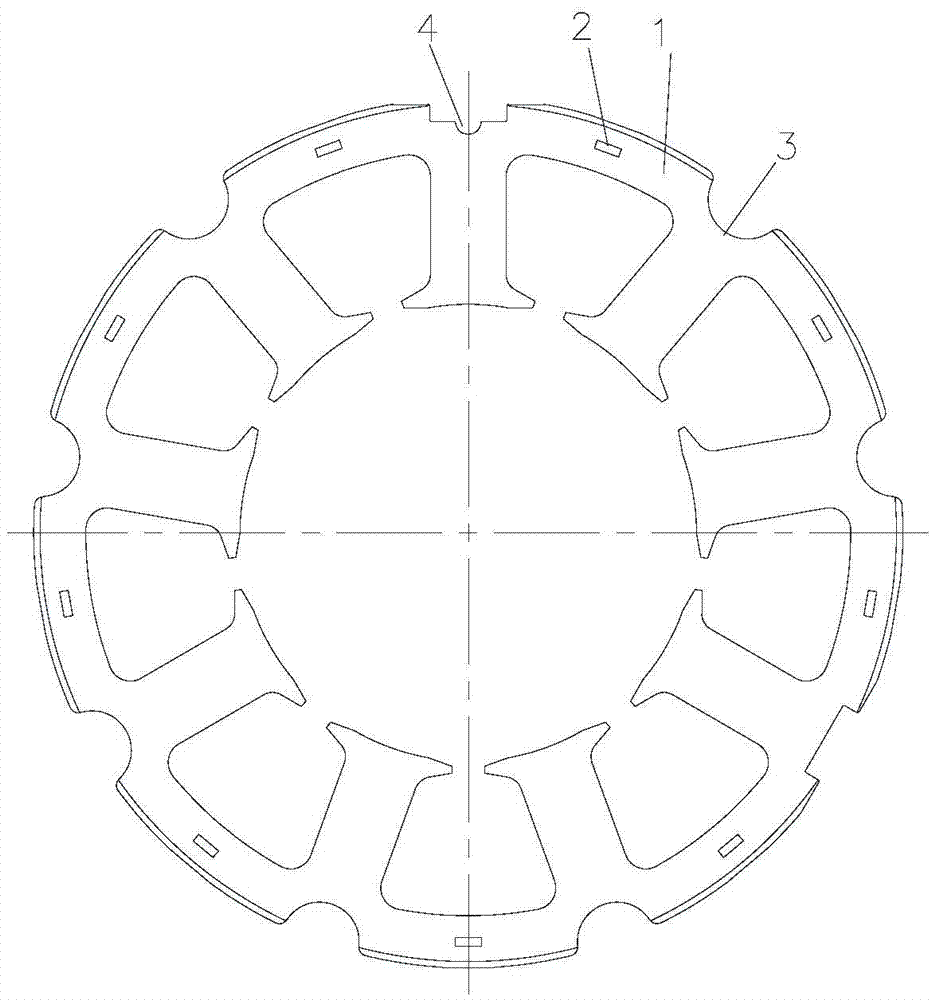

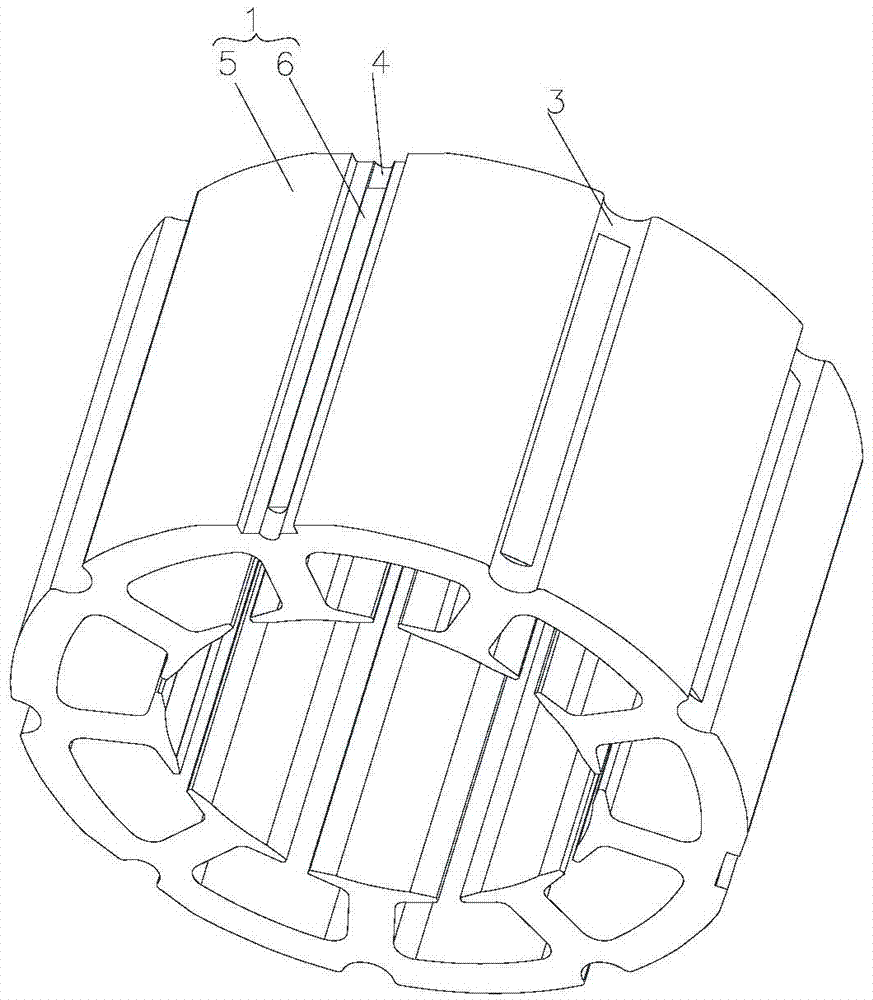

[0025] Please refer to Figure 1 to Figure 7 As shown, according to the embodiment of the present invention, the stator structure of the motor includes a stator core 1 and a skeleton. The stator core 1 is provided with a flow hole 3 and a positioning groove 4 matched with the skeleton. The positioning groove 4 is arranged at the bottom of the flow hole 3. The stator core 1 also has a stress adjustment structure.

[0026] Among them, the stator core is formed by stacking conventional stator punches, and is buckled together by buckle points. After the stator is laminated, it is assembled with the skeleton, and then the subsequent processing is carried out; among them, the commonly used skeleton and stator assembly methods mostly use the buckle point design of the skeleton, and the buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com