Patents

Literature

795results about How to "Large amount of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

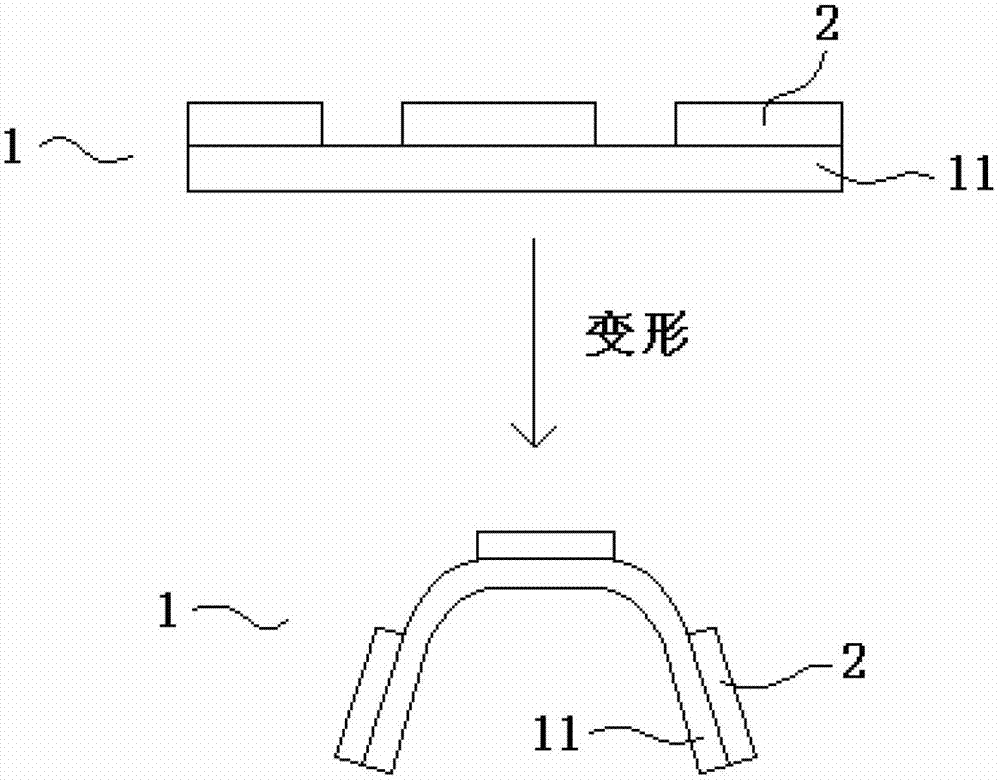

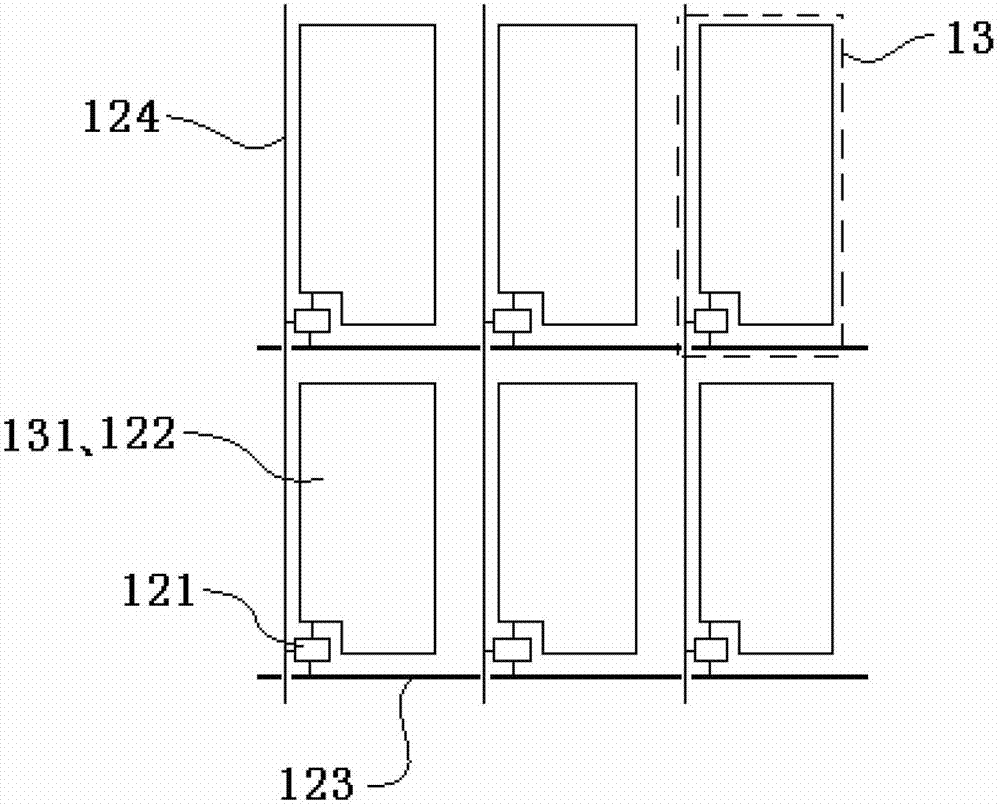

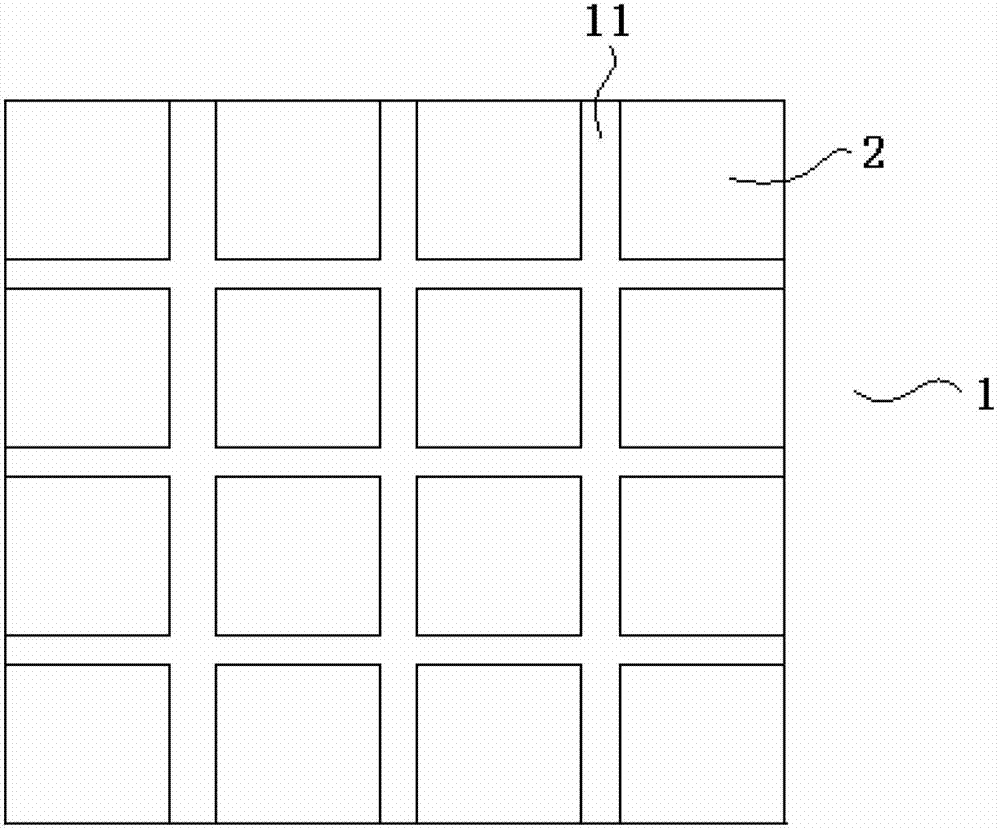

Flexible display substrate and preparation method thereof as well as flexible display device

ActiveCN102969320ANot easy to damageSmall amount of deformationFinal product manufactureSolid-state devicesLiquid-crystal displayOrganic electroluminescence

The invention provides a flexible display substrate and a preparation method thereof as well as a flexible display device, belongs to the technical field of flexible display, and can solve the problem that the conventional flexible display substrate is easily damaged during deformation, small in deformation quantity, low in display performance, high in cost, or difficult in preparation. The flexible display substrate comprises a hard material layer which is arranged at a vulnerable position of the flexible display substrate. The preparation method of the flexible display substrate comprises a step of forming a graph of the hard material layer. The flexible display device comprises the flexible display substrate. The flexible display substrate can be used in the flexible display devices such as an organic electroluminescent display device, a flexible electrophoretic display device and a flexible liquid crystal display device.

Owner:BOE TECH GRP CO LTD

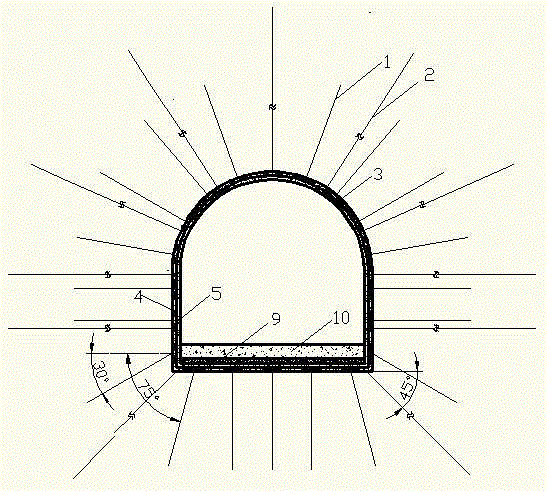

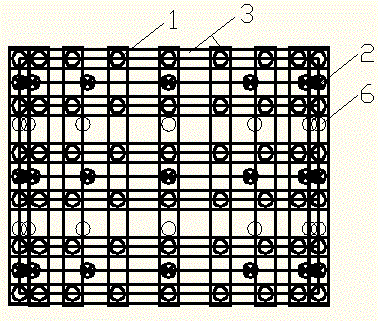

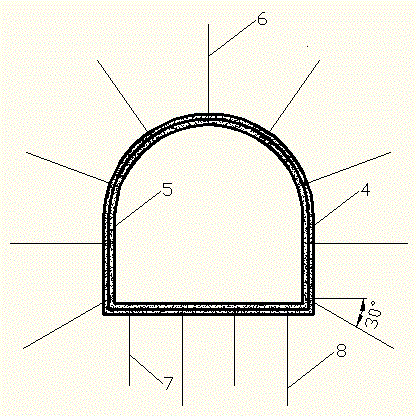

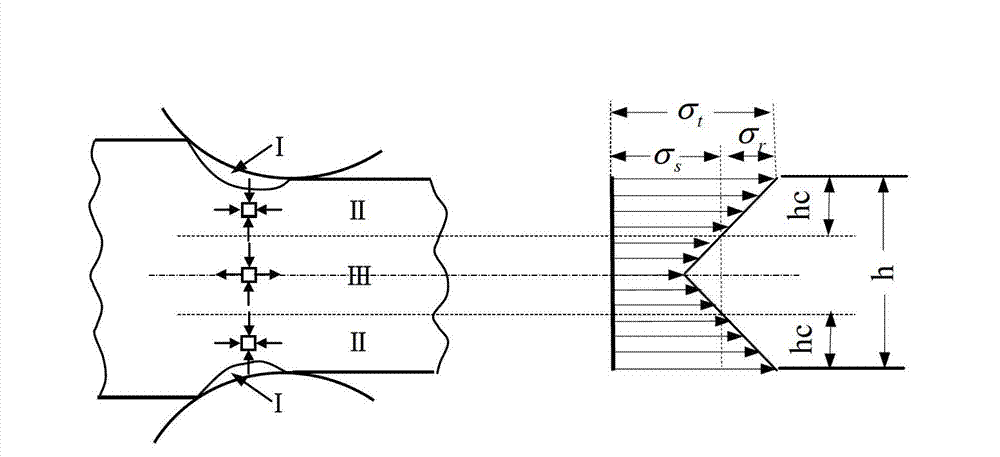

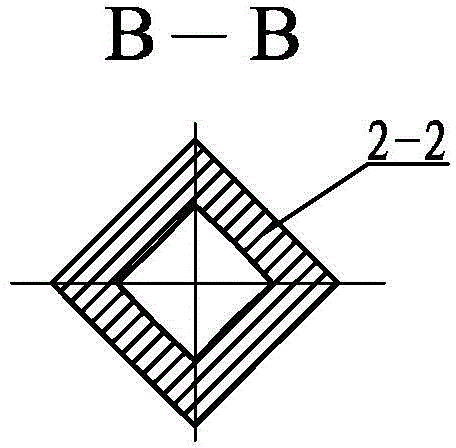

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

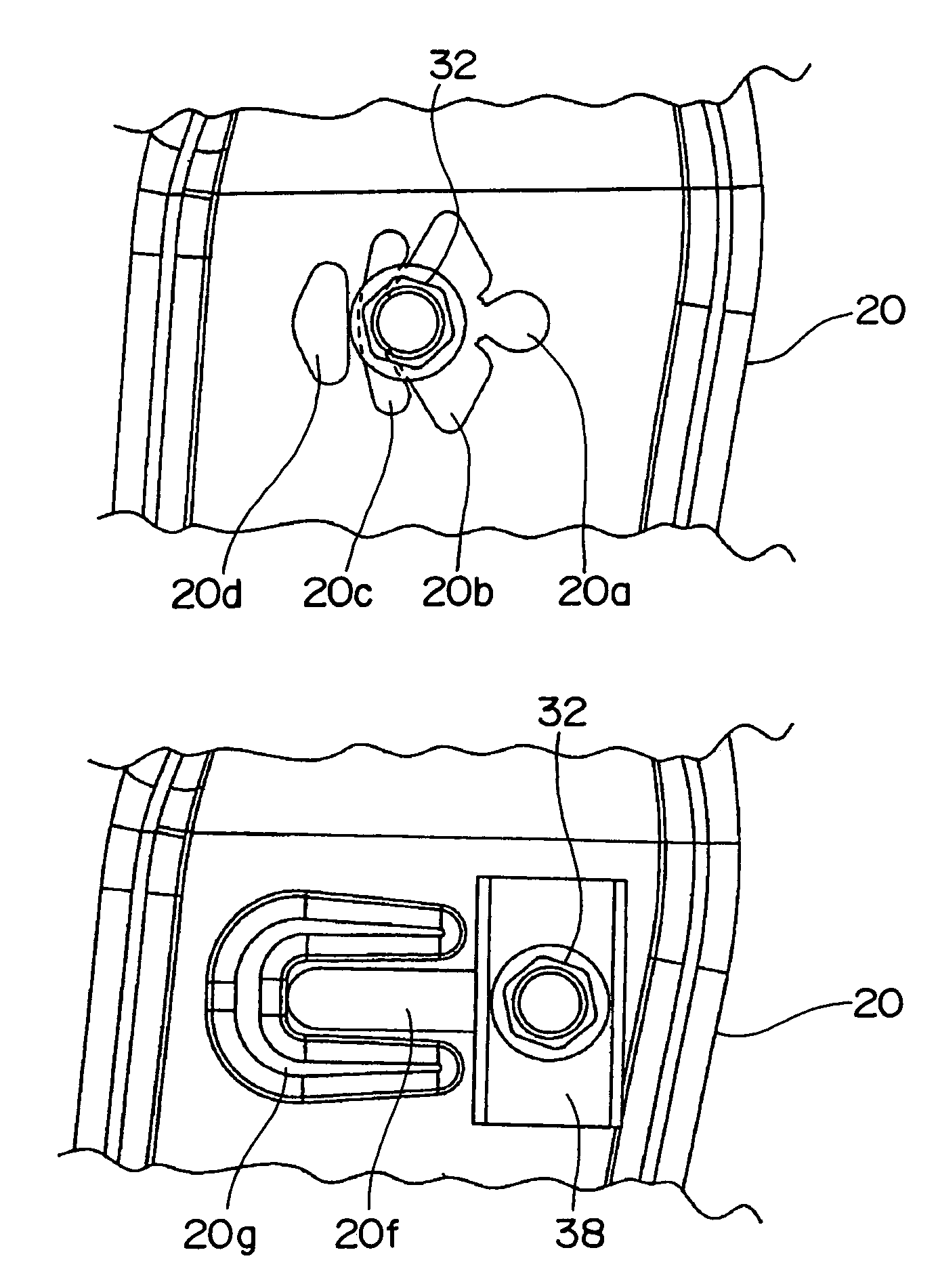

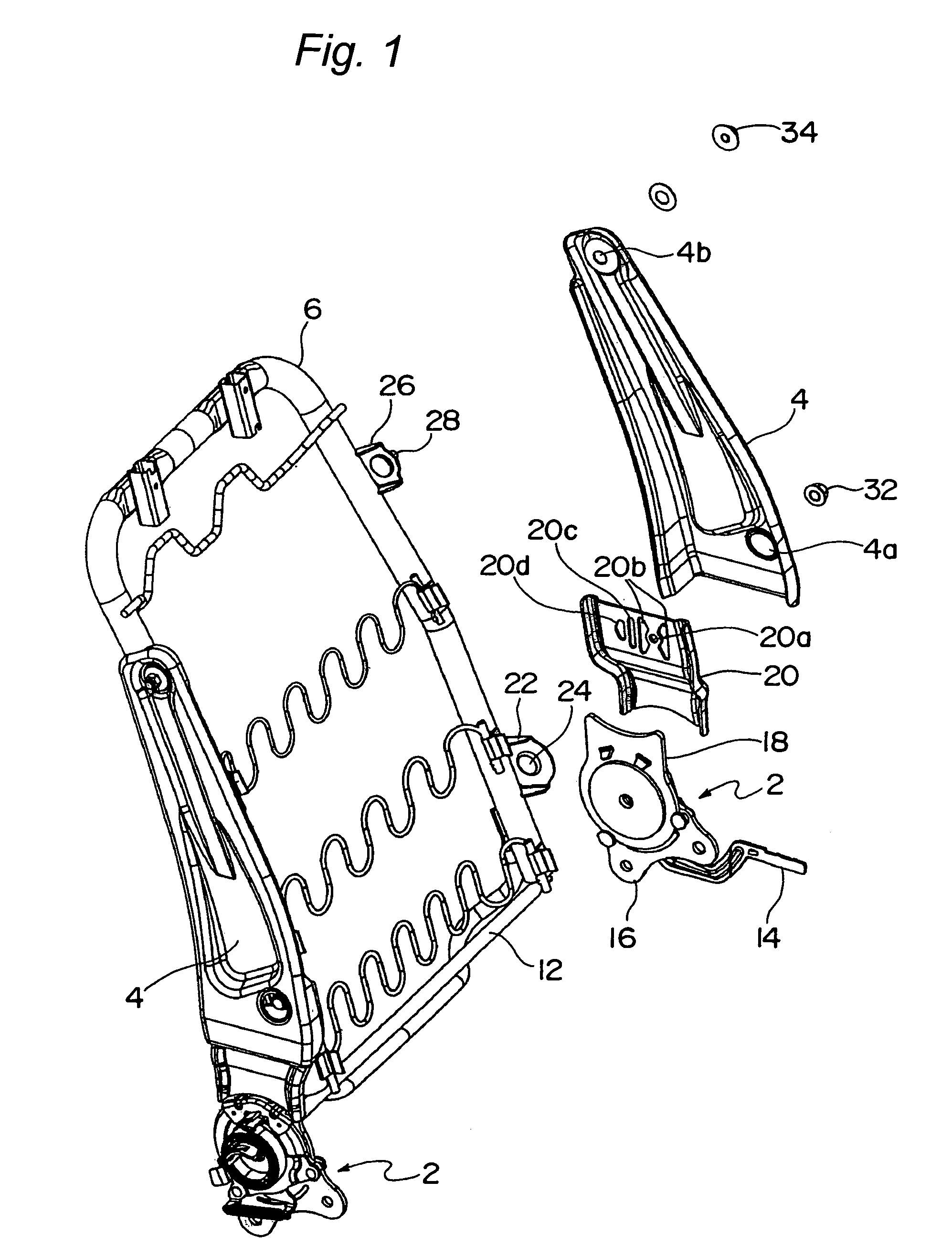

Automobile seat

InactiveUS7070236B2Easy constructionImprove securityVehicle seatsPedestrian/occupant safety arrangementEngineeringBack rests

An automobile seat includes a seat cushion and a seat back tiltably mounted on the seat cushion. The automobile seat also includes a seat cushion frame, a side frame mounted on the seat cushion frame, a seat back frame mounted on the side frame so as to be rotatable within a limited angle, and a fastening member mounted on the seat back frame. The side frame has an insertion hole defined therein in which the fastening member is inserted and also has an impact absorbing structure. When a load greater than a predetermined value is inputted to the seat from behind, a lower portion of the seat back frame is pushed upon a rearward movement of a seat occupant to thereby cause the fastening member to move rearward while deforming the impact absorbing structure. As a result, the seat back frame rotates with respect to the side frame, and an impact is absorbed by deformation of the impact absorbing structure.

Owner:DELTA KOGYO CO LTD

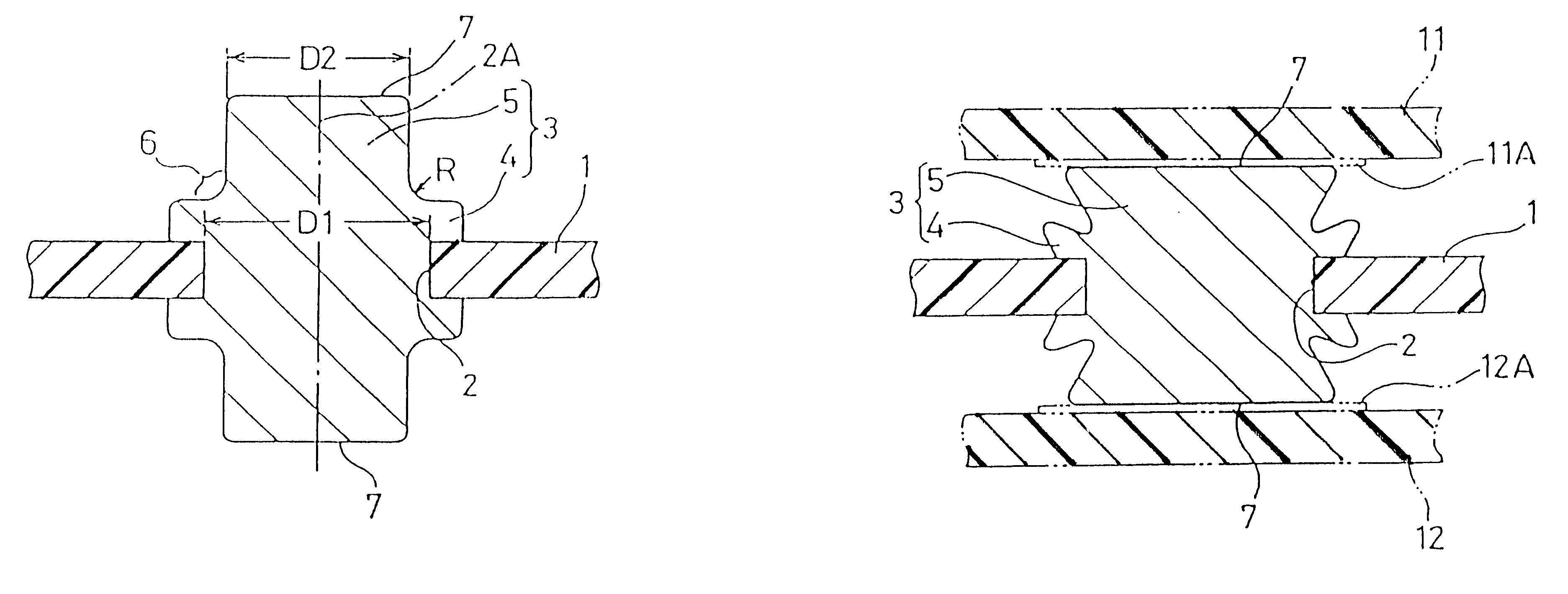

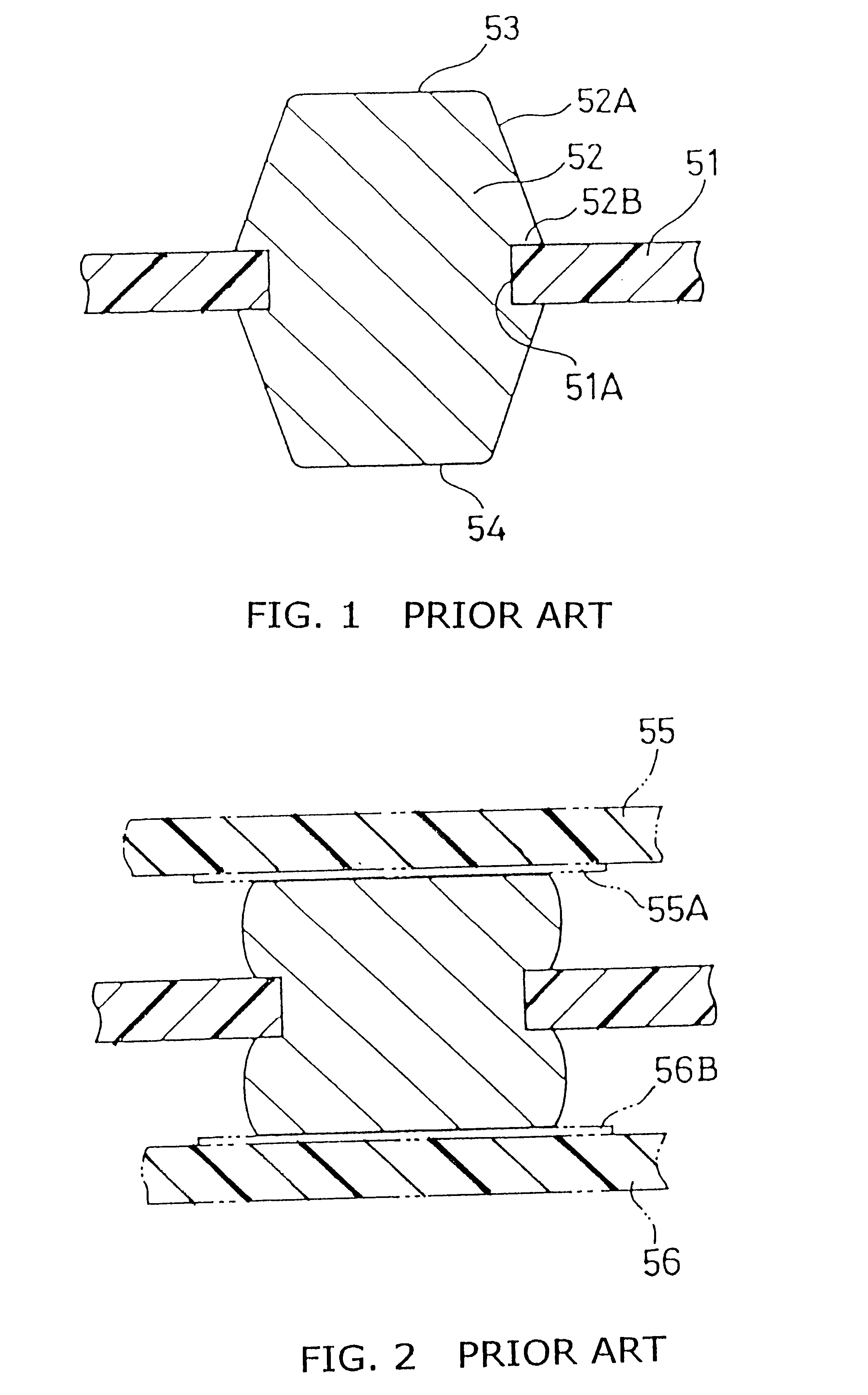

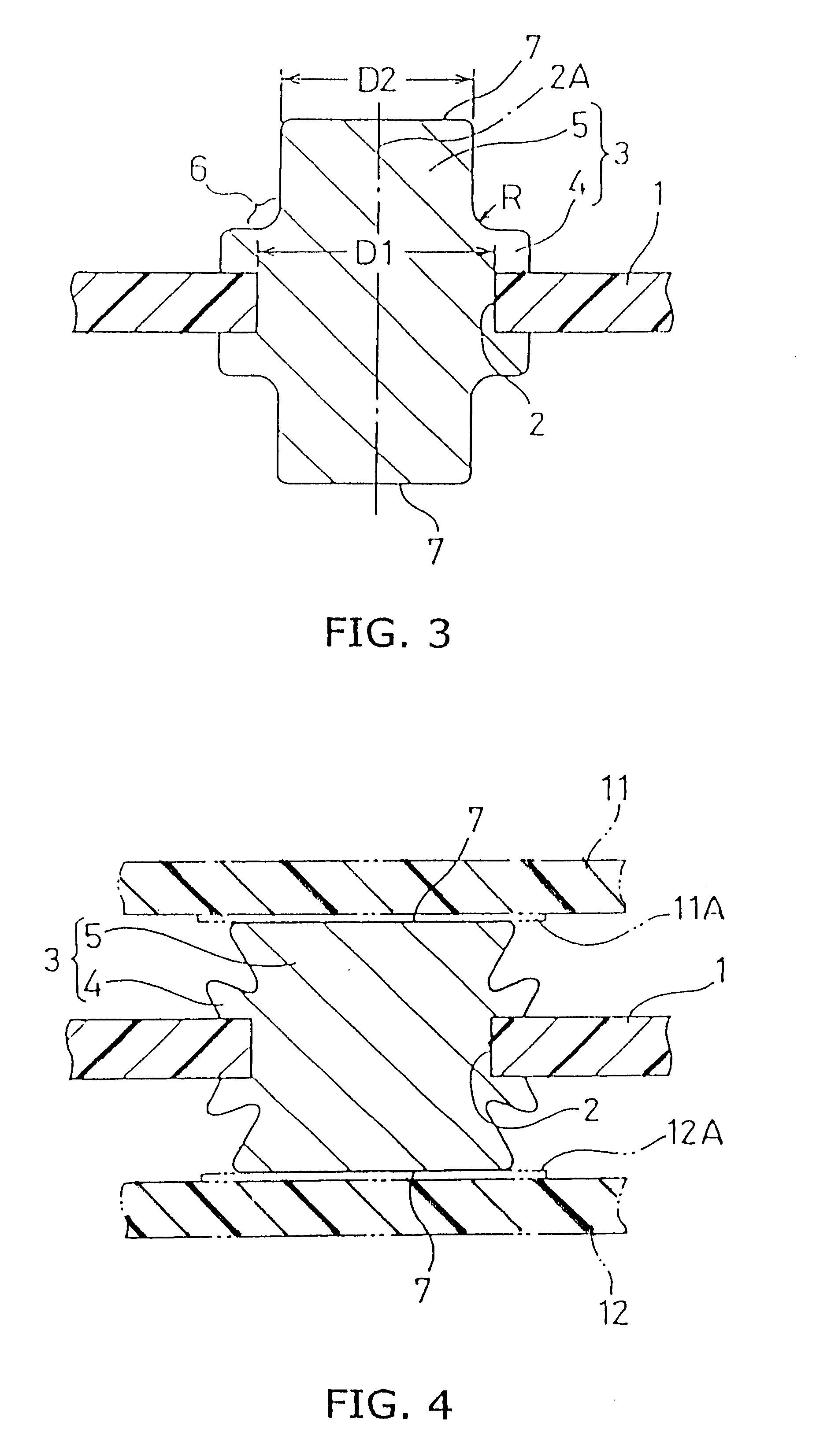

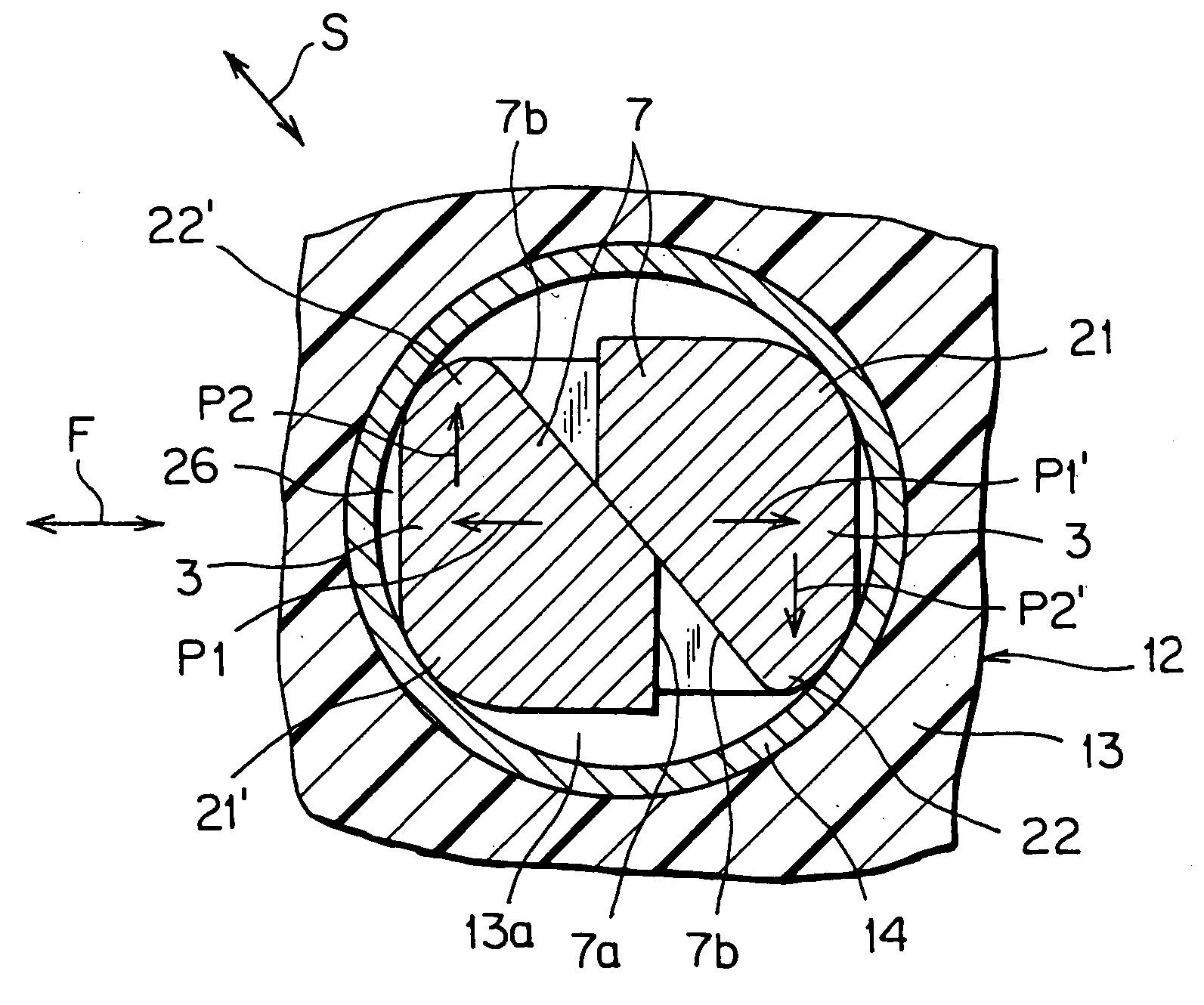

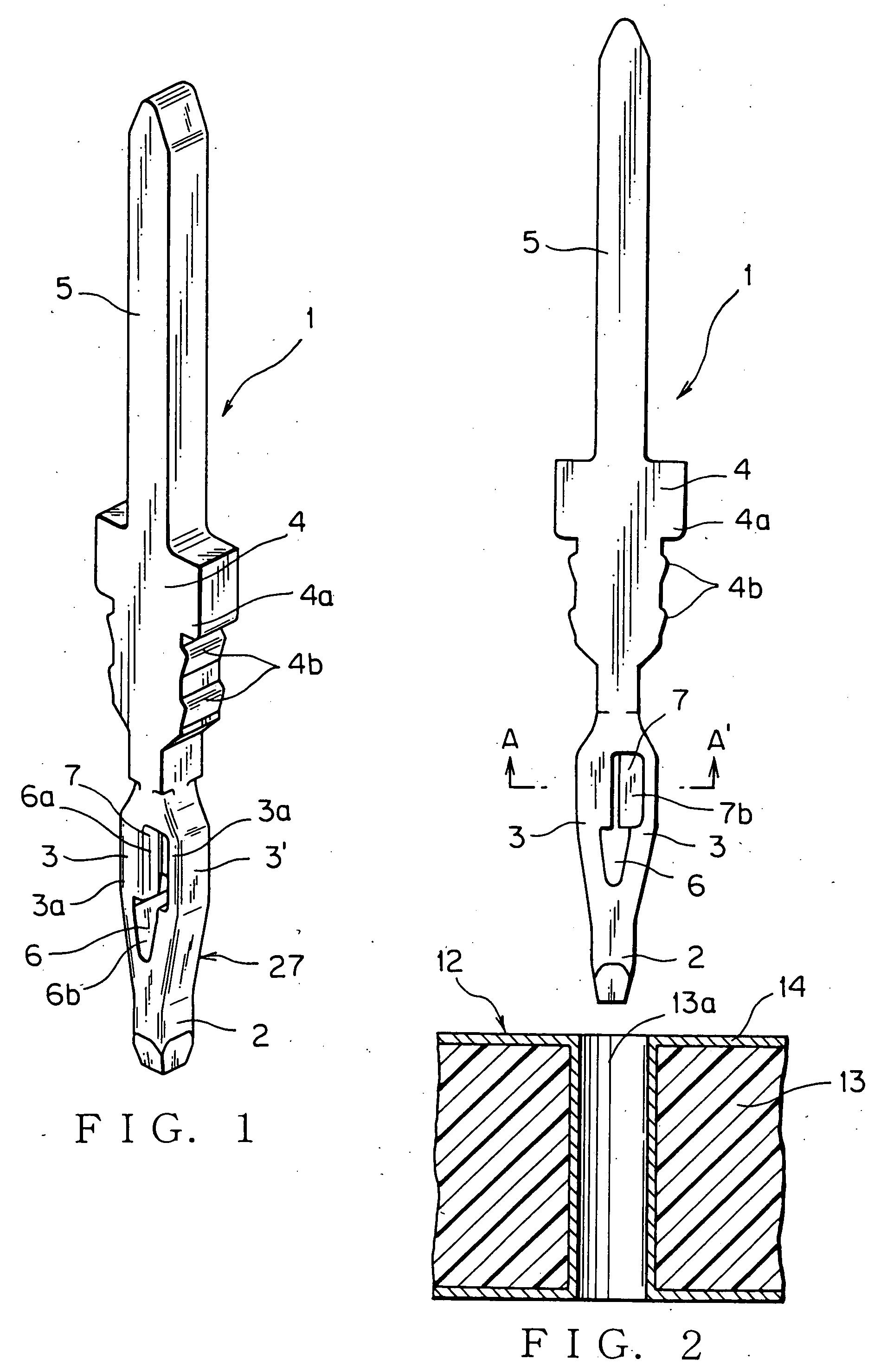

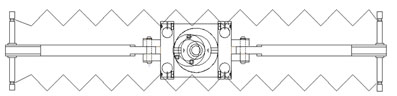

Intermediate electrical connector

InactiveUS6280207B1Large amount of deformationContact stabilityPrinted circuit assemblingSecuring/insulating coupling contact membersElastomerEngineering

An intermediate electrical connector comprises a support plate (1) which is made of a dielectric material and has at least one support aperture (2) having an inside diameter; and at least one conductive member (3) provided through the support aperture to short-circuit circuit portions of connection objects. The conductive member is made of a conductive elastomer and comprises a retention section (4) with flange portions for engage with the support aperture to attach the conductive member to the support plate; and an elastic protruded section (5). The elastic protruded section extends from the retention section in a direction of thickness of the support plate to form at opposite ends contact faces (7) for elastic contact with the circuit portions (11A, 12A) of the connection objects (11, 12) and has, adjacent to the retention section, shoulder (6) portions having an outside diameter which is smaller than the inside diameter of the support aperture.

Owner:HIROSE ELECTRIC GROUP

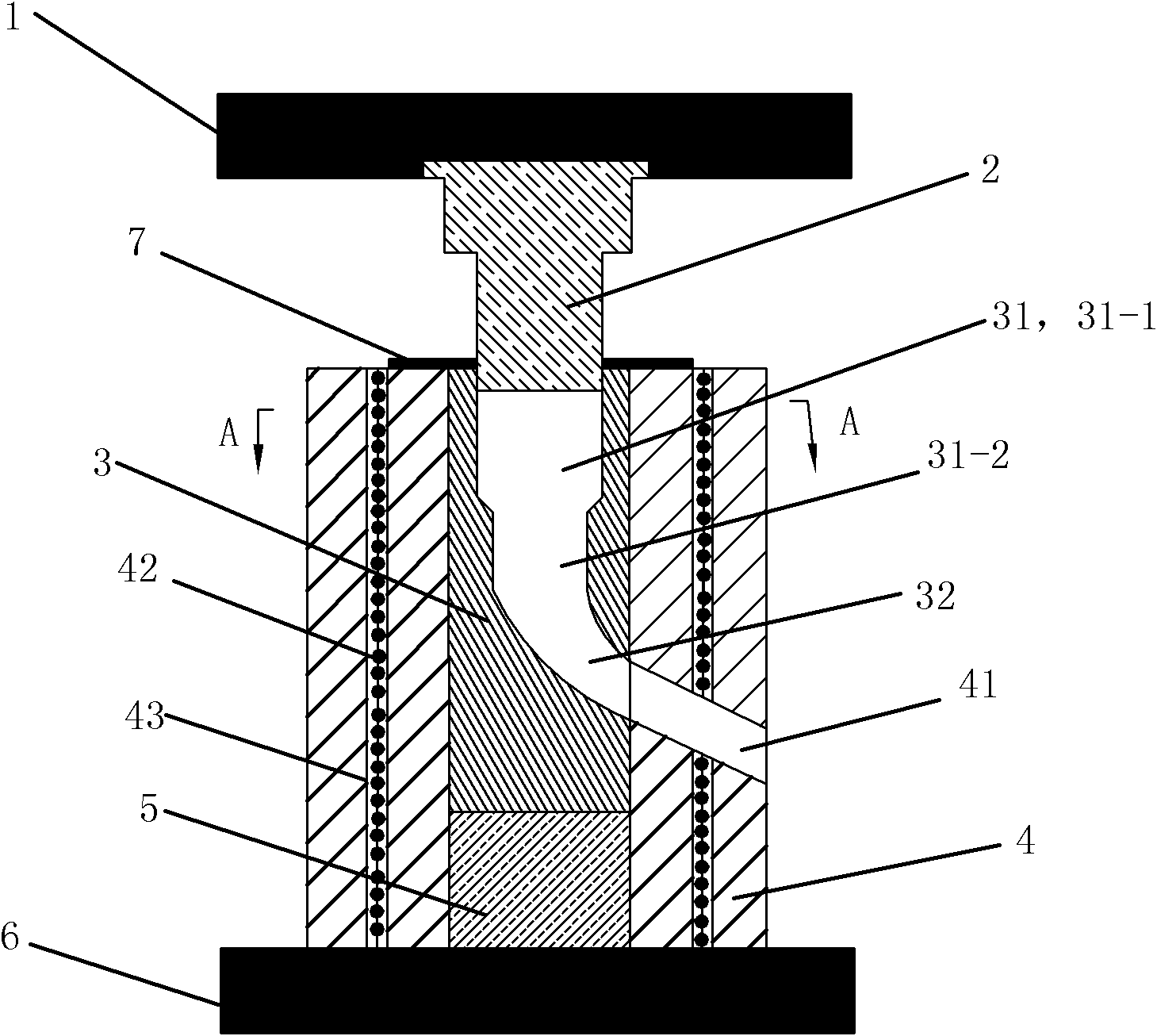

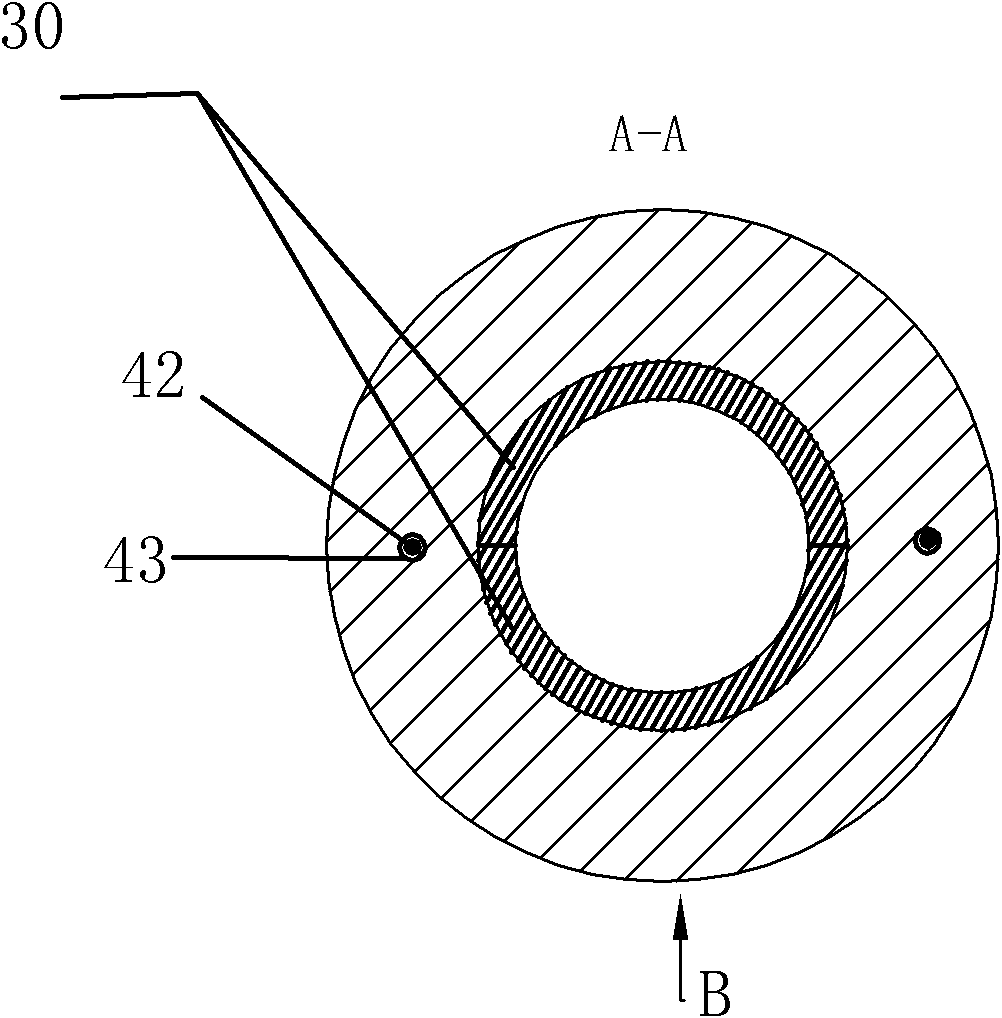

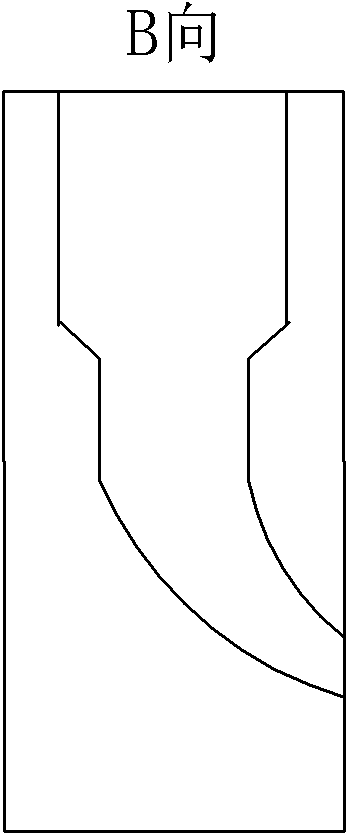

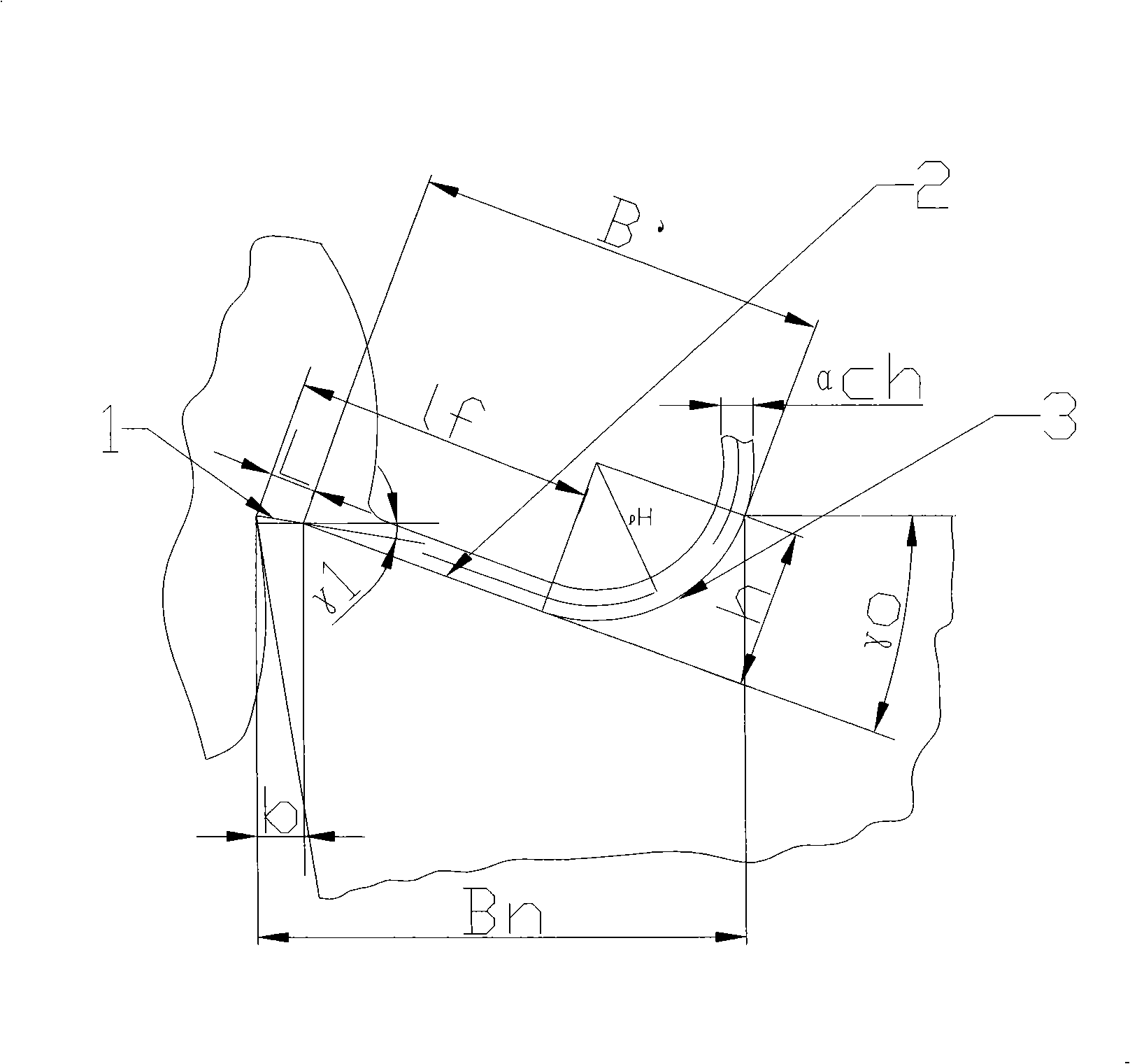

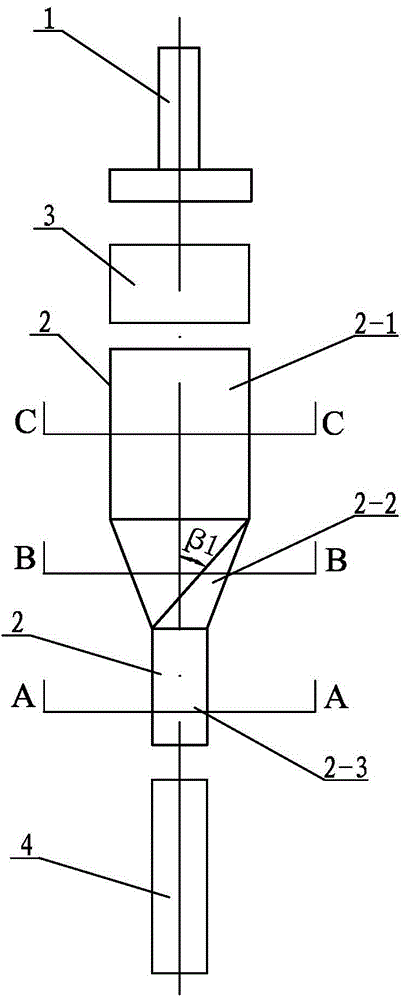

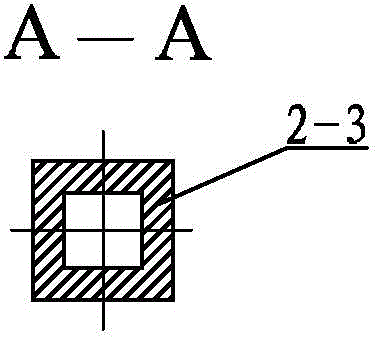

Method and die for forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets

InactiveCN101850376ASmall grain sizeSolve the problem of not being able to continuously prepare large-size semi-solid billetsExtrusion diesSemi solidLarge deformation

The invention discloses a method and a die for the forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets. The preparation method comprises a predeformation process and an isothermal spheroidizing heat treatment process, wherein in the predeformation process, uniform deformation of large deformation amount is realized by the die for the forward extrusion and variable diameter bending extrusion; cutting a magnesium alloy bar stock which is subjected to large deformation by a fixed size; heating the magnesium alloy bar stock cut by the fixed size at the temperature of between 520 and 580 DEG C under the protection of argon, and keeping the temperature of the obtained magnesium alloy bar stock for 10 to 30 minutes; and processing a bending extrusion angle of the die to be over 90 degrees. The method has the advantages of small predeformation resistance, large and uniform deformation, safety, reliability and no three-waste pollution. The grains of the prepared magnesium alloy semi-solid billets have fine size, are uniform and have a shape close to that of a sphere. The method solves the problem that the conventional SIMA method cannot continuously prepare the large-size semi-solid billets and meets the requirements of the semi-solid thixoforming workpieces for large-scale continuous production.

Owner:CHANGZHOU INST OF TECH

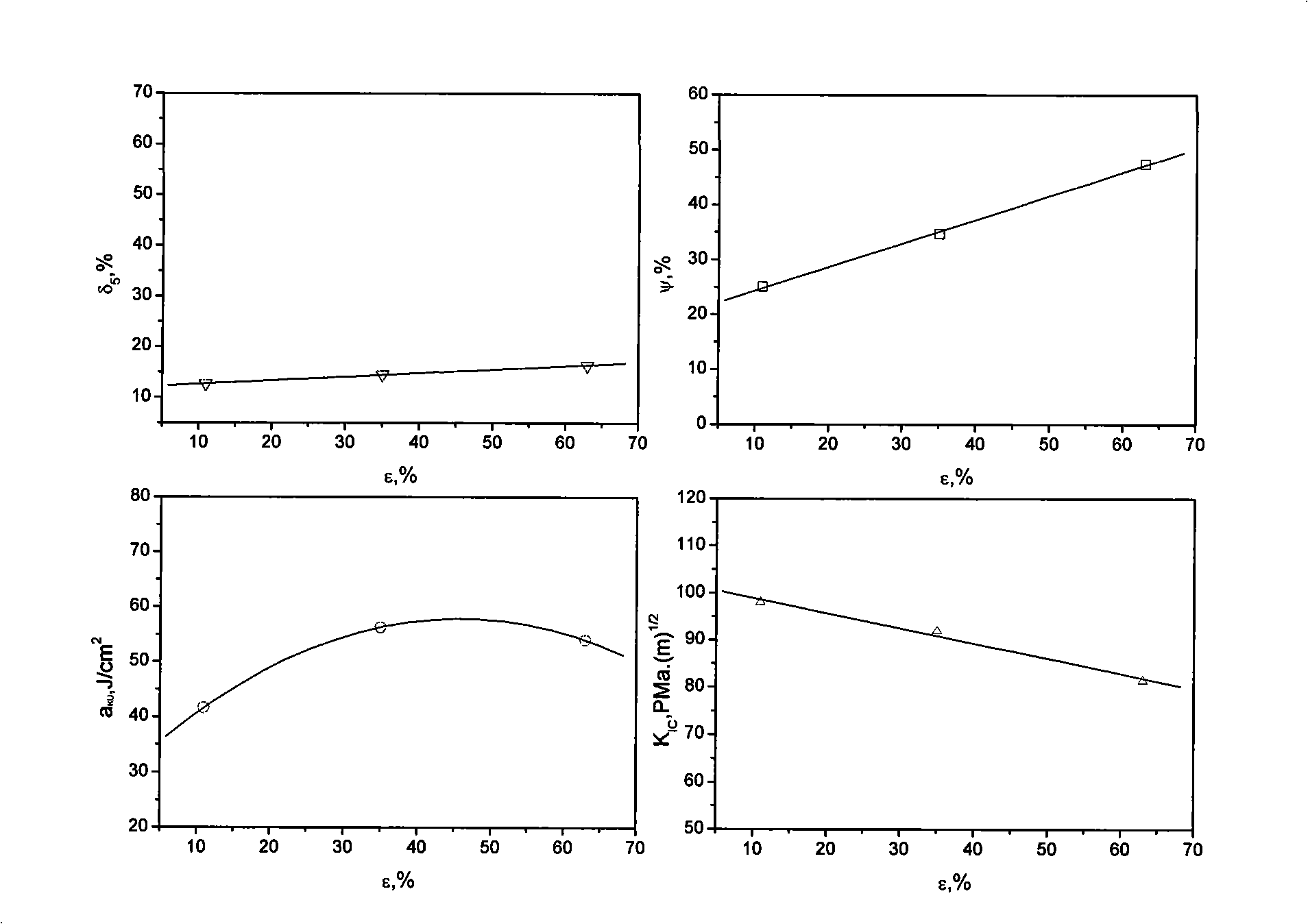

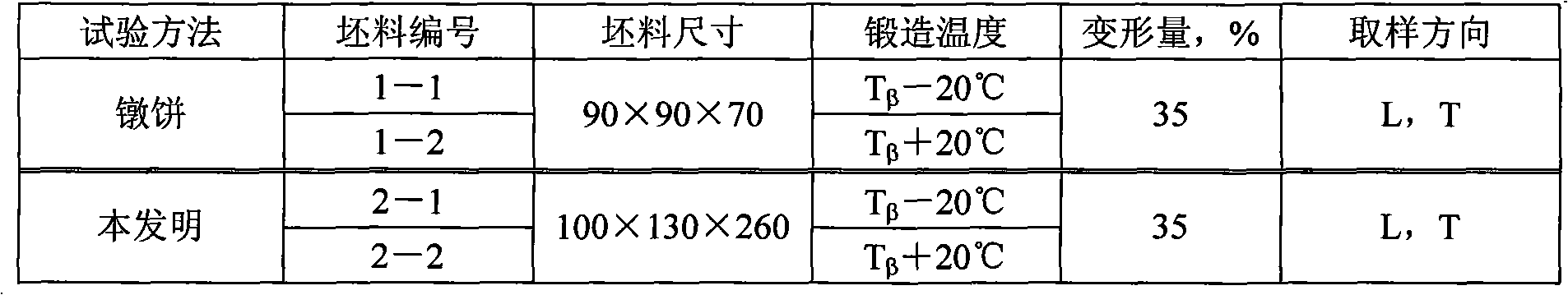

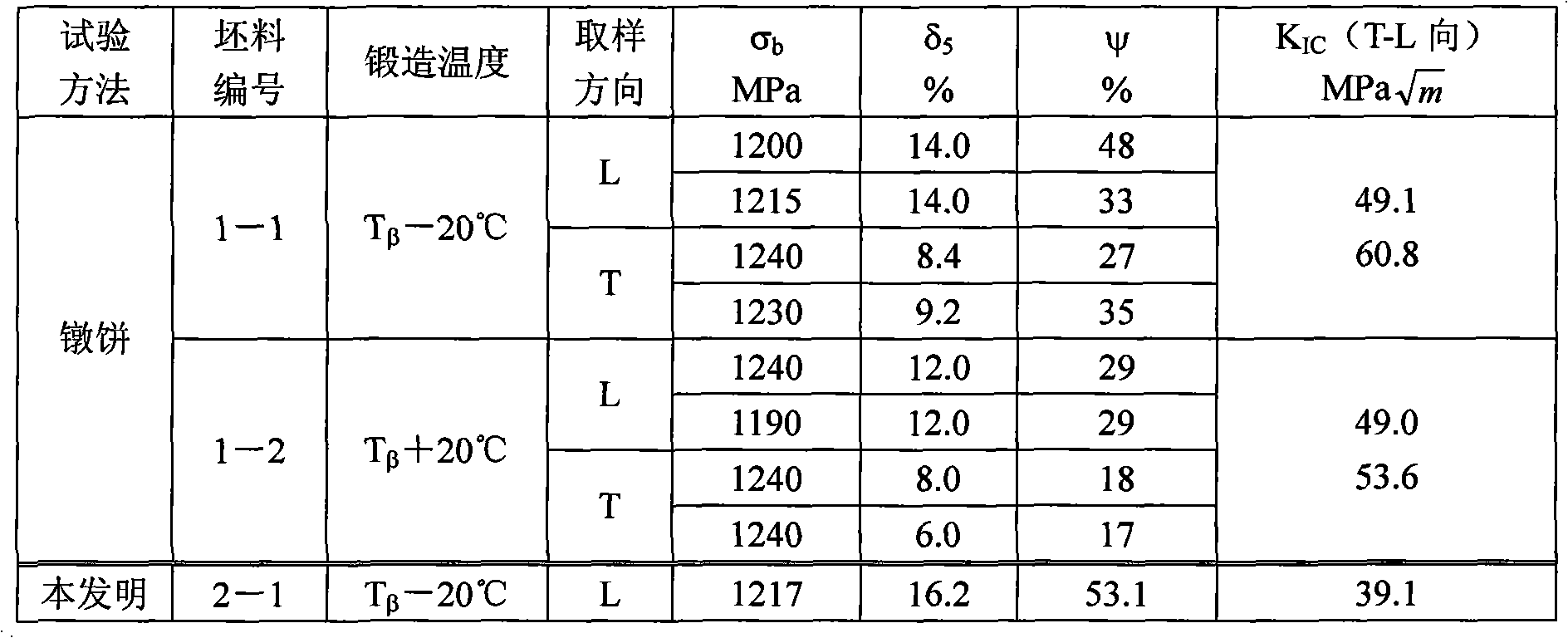

Titanium alloy smithing technological parameter testing method

The invention relates to a test mode of a titanium alloy smithing technological parameter. The test mode has the steps that: (1) multi-forging various-direction smithing is performed on a titanium alloy steel bar to obtain an original structure which is as uniform as possible; (2) the steel bar after substituting forging is made into stocks under the temperature ranging from 30 to 50 DEG C below a Beta transformation point (TBeta); (3) the stocks are preheated for 1 to 2 hours under the temperature which is about 200 DEG C, and then are coated with special lubricant Ti-6 of a titanium alloy die forming; (4) the surface of a die is preheated until the temperature is more than 350 DEG C, the die forming is finished with 1 to 2 fire levels, and three different deformation amounts of 10 percent, 35 percent and 60 percent are obtained on a forgeable piece; (5) after the forgeable piece is processed through heat treatment, various types of mechanical property samples are get from the parts with different deformation amounts, and the quantitative relation between the parameters such as the smithing temperature, the heat preservation time, the deformation amounts, etc. and the mechanical property as well as microscopic constitutions is determined. A technician can adjust the sizes of the stocks according to the quantitative relation, and ensure reasonable deformation amounts on a stamp work, thereby obtaining the optimum matching between the plasticity and the fracture toughness.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

Material of polyethylene in super high molecular weight for obstruction guard of highway, and fabricating method

InactiveCN1958274AReduce harmGood value for moneyDomestic articlesUltrahigh molecular weightCarbon steel

An anticollision protecting fence material for highway is prepared from ultrahigh molecular weight polyethene (UHMWPE) through pre-swelling, dissolving and pugging in dual-screw extruder, extruding out for shaping, and stretching for strengthening. It has high longitudinal tension strength (100-180 MPa) and large longitudinal elongation rate at break (50-350%).

Owner:肖久梅 +1

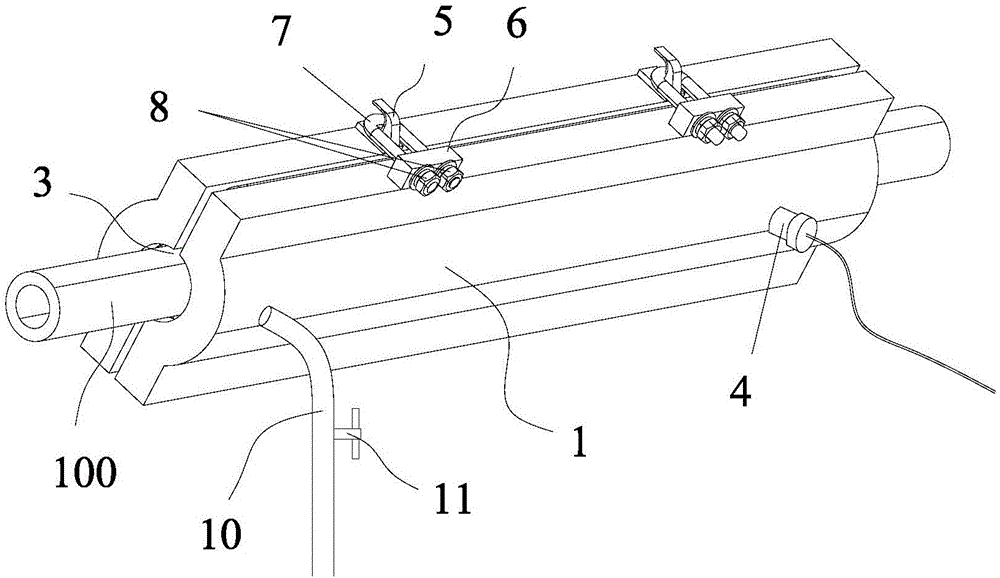

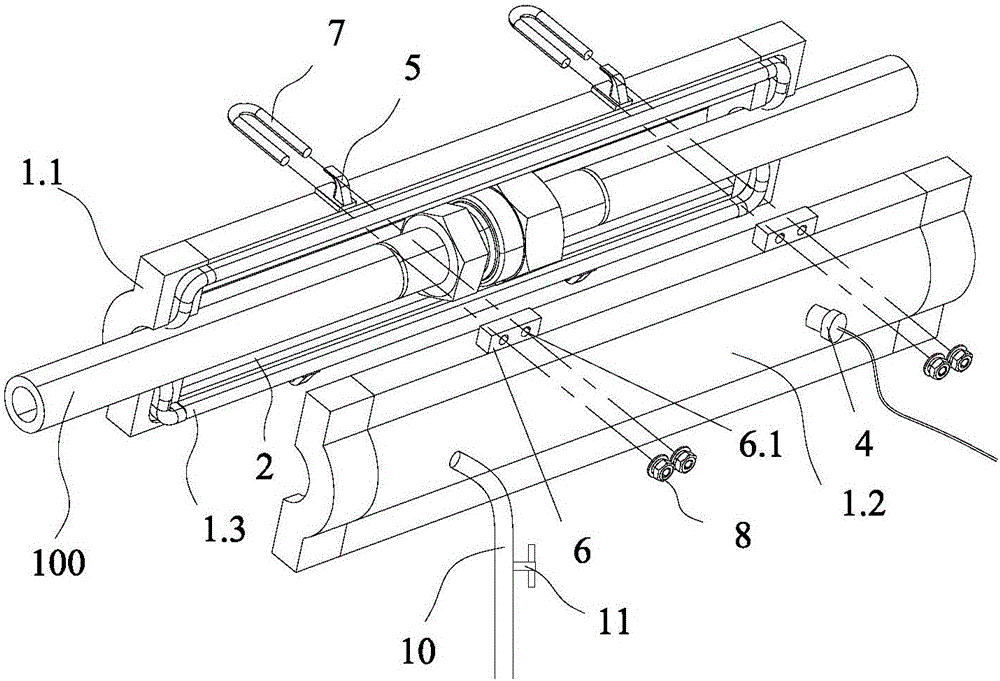

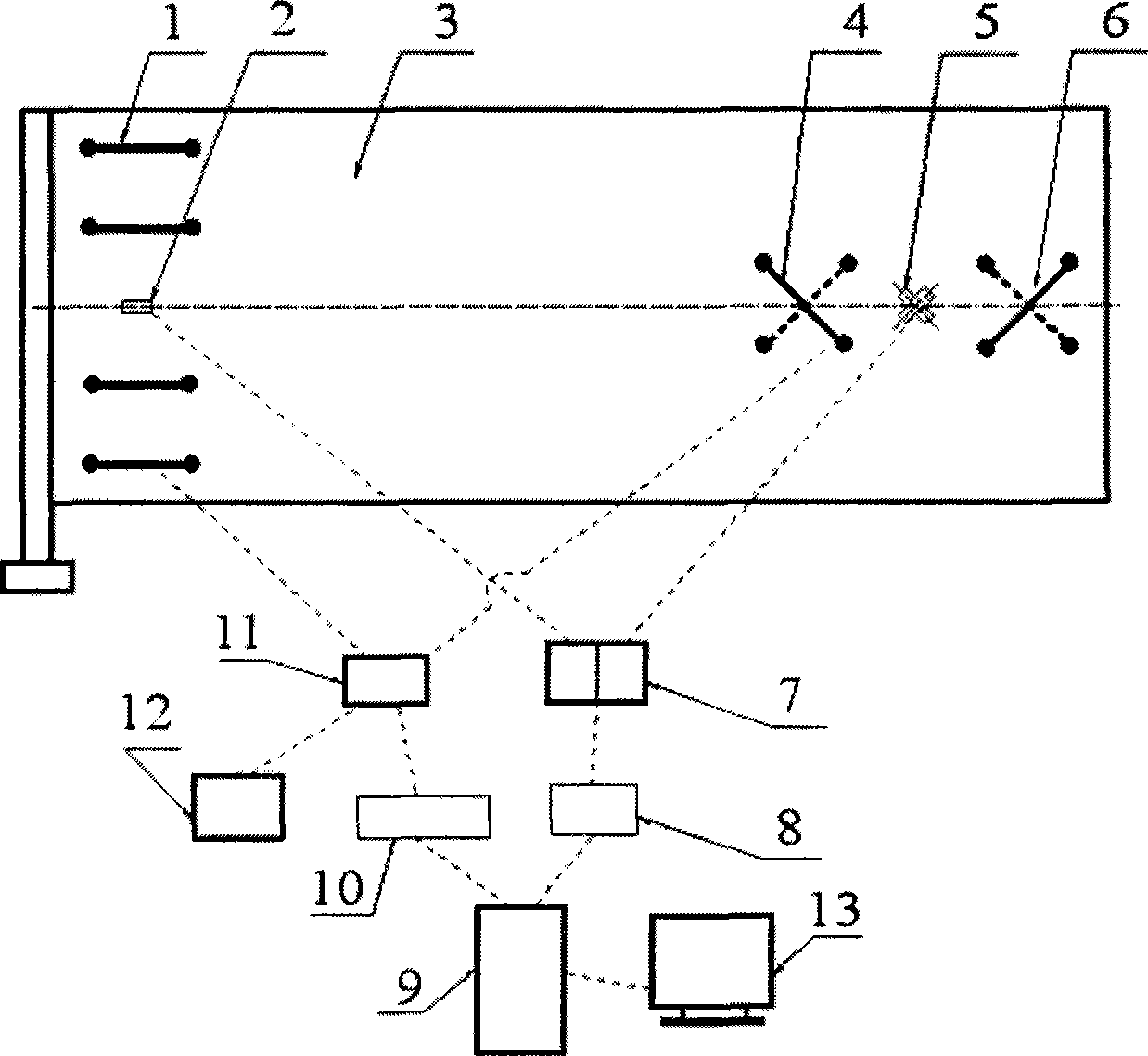

Pipeline leakage detection device and detection method

The invention discloses a pipeline leakage detection device and detection method. The device comprises a wrapping body (1) which coats a detected pipeline segment (100) and forms annular sealing; the wrapping body (1) extends along the axis of the detected pipeline segment (100), and a space (2) for containing gas is reserved between the inner wall face of the wrapping body (1) and the outer wall of the detected pipeline segment (100); the two ends of the wrapping body (1) are provided with through holes (3) for containing the detected pipeline segment (100); a gas leakage induction device (4) for monitoring whether leakage is generated to the detected pipeline segment (100) or not is arranged on the wrapping body (1); and the gas leakage induction device (4) is electrically connected with an external controller. After the structure is adopted, the pipeline leakage detection device which can carry out gas leakage detection and alarming and discharge leaked gas to a designated place and meanwhile achieves whole-process monitoring of a pipeline connector, a weld joint and a whole pipeline is provided.

Owner:NINGBO XINGJIAN SPACE MACHINERY +1

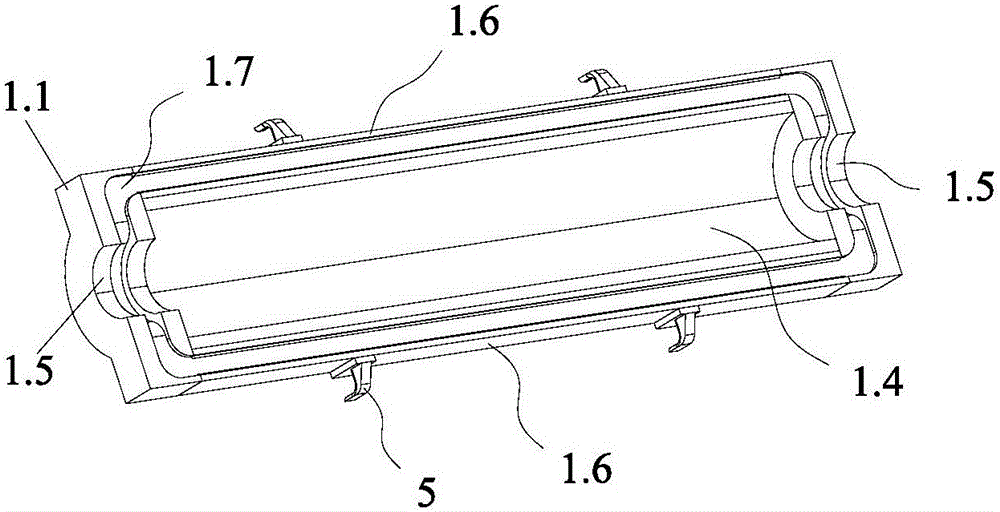

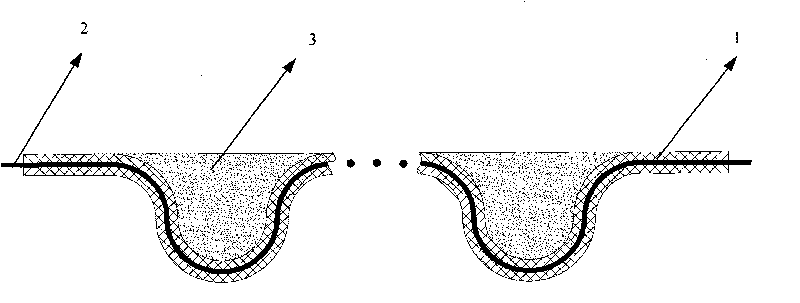

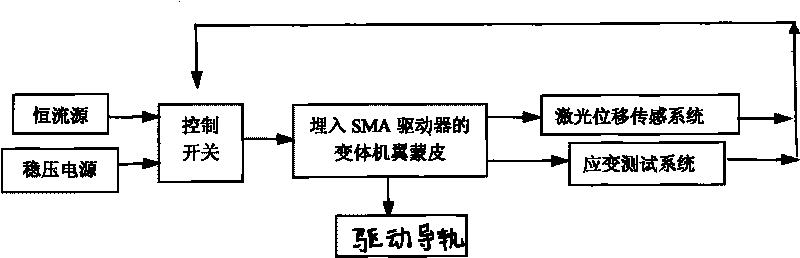

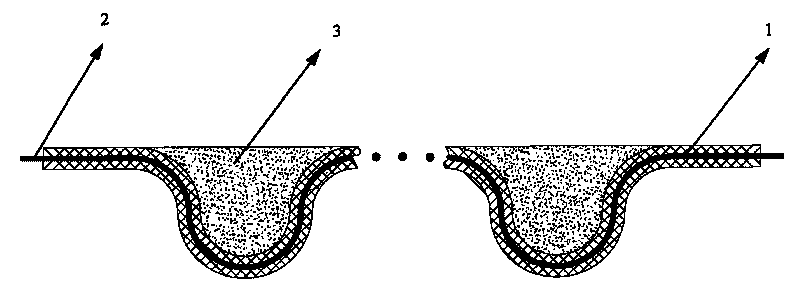

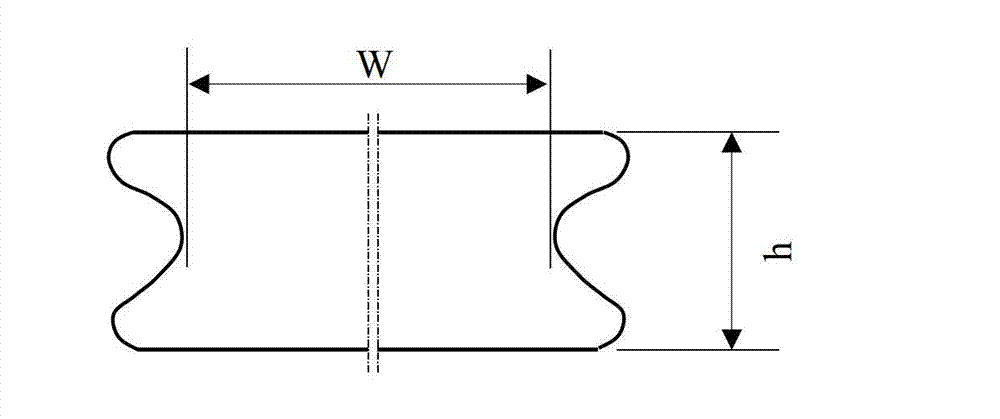

Skin of morphing wing and drive method thereof

InactiveCN101708772AImprove flexibilityLarge amount of deformationWingsMorphing wingRoom temperature

The invention provides a skin of a morphing wing, which is made from fiber-reinforced composite material (1). The skin is characterized in that: a shape memory alloy driver (2) is arranged between the two layers of the fiber-reinforced composite material (1); the wave trough of the upper layer fiber-reinforced composite material is internally filled with silica-based rubber (3) for meeting the requirements of smoothness, continuity and whole gas tightness on the surface of the wing; the fiber-reinforced composite material (1) and the shape memory alloy driver (2) are jointly pressed into to a corrugated structure under room temperature; the shape memory alloy driver (2) is in the shape of a high-temperature memory straight line; and the silica-based rubber (3) can be solidified under normal temperature. The invention also provides a drive method of the skin of the morphing wing. The skin of the morphing wing has the corrugated structure, thereby having high flexibility, large morphing amount and fast morphing response speed on the morphing direction, having high carrying capability on the perpendicular morphing direction, and having simple structure, light weight and reliable performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

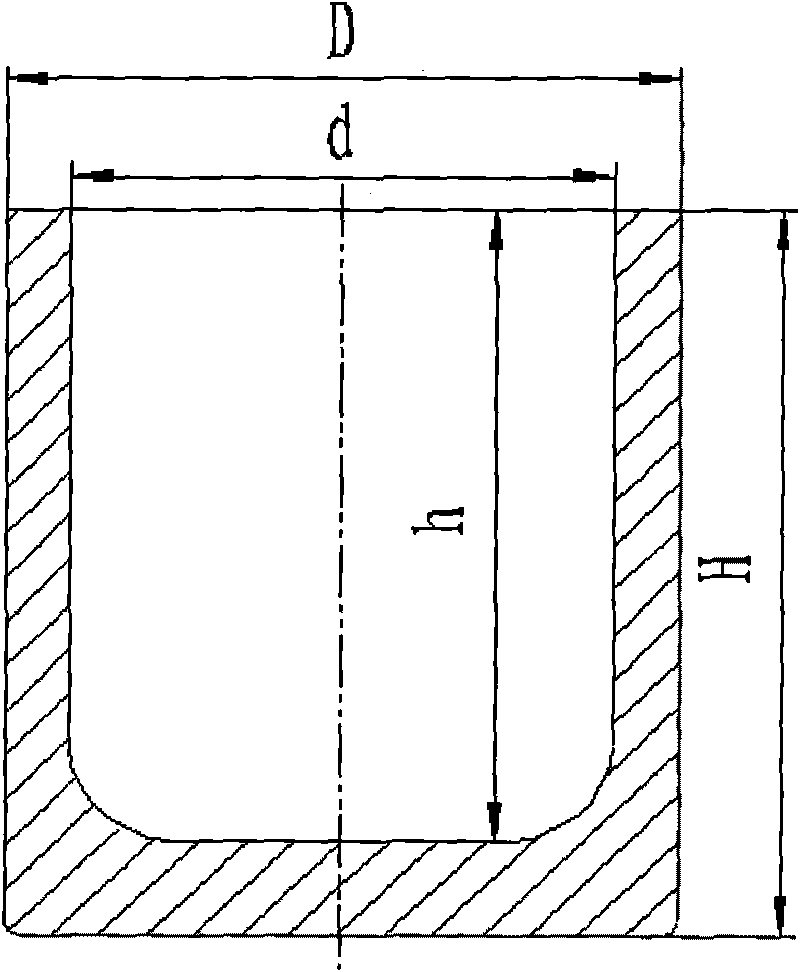

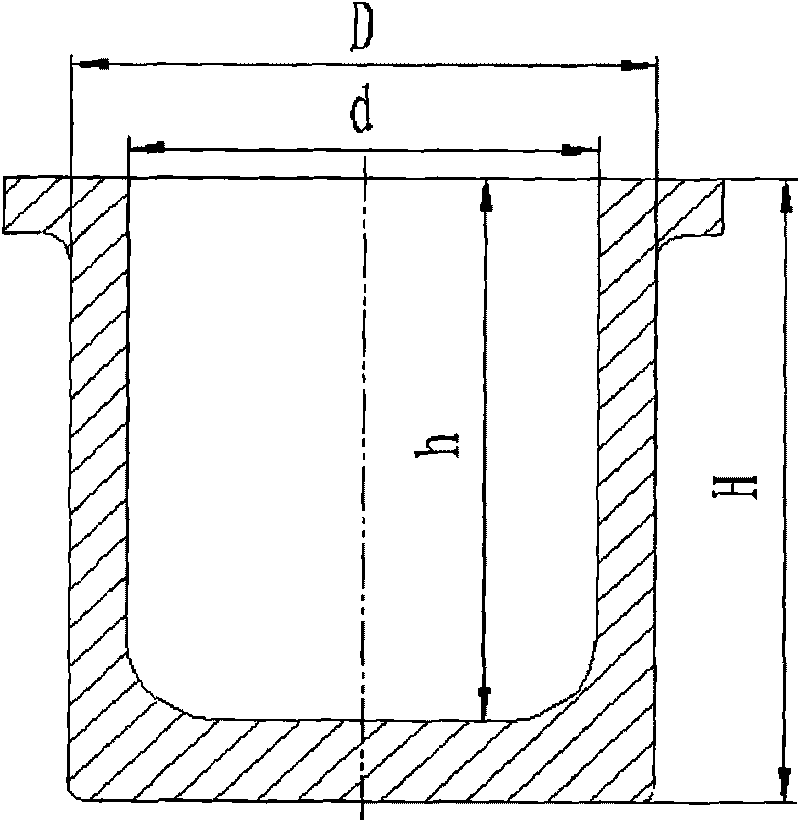

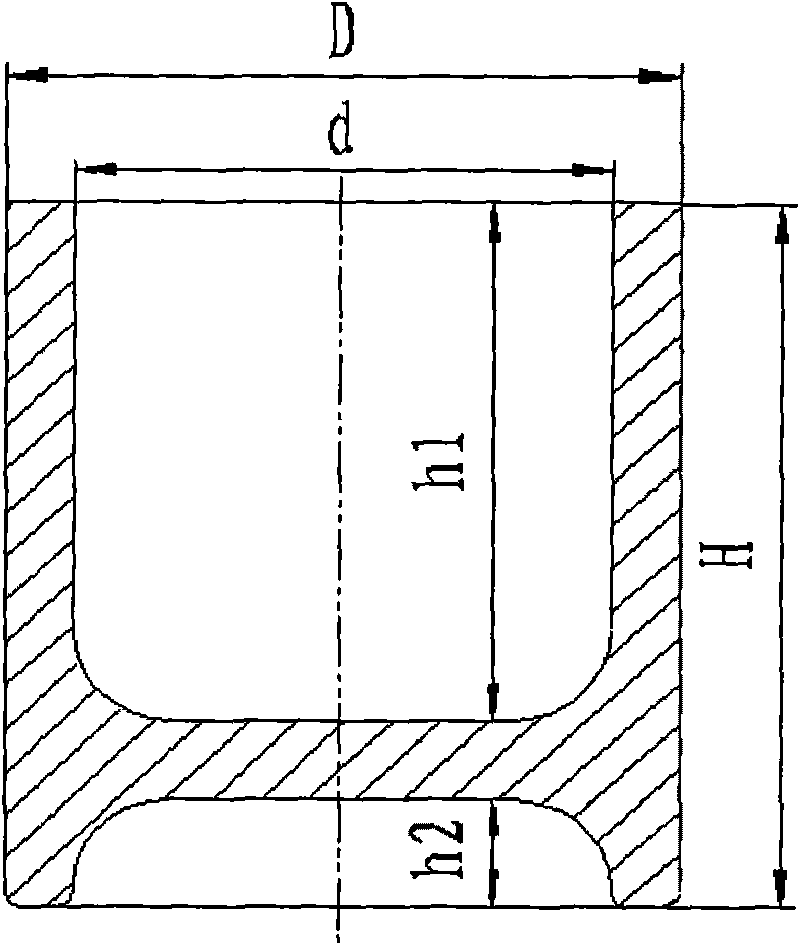

Upsetting and extruding precision die-forging forming method for large titanium alloy deep tube parts

ActiveCN101693279ALower supply standardsLower purchase priceMetal-working apparatusMetallurgyTitanium alloy

The invention discloses an upsetting and extruding precision die-forging forming method for large titanium alloy deep tube parts. The method includes that: firstly, enabling draft of a tube body die to range from 1 degree to 3 degrees, enabling the outer diameter of a blank to be 50% to 98% of that of a die tube body, enabling the height of the blank to be 60% to 150% of that of the tube body; spraying a protective lubricating layer with thickness ranging from 0.2mm to 3mm on the blank; heating the blank in an electric furnace under 5 DEG C to 50 DEG C of the temperature phase-transition point (alpha +beta / beta), enabling the heating coefficient to be larger than or equal to 0.6 min / mm, simultaneously preheating the die for 6h to 24h at a temperature ranging from 200 DEG C to 450 DEG C; finally, installing the die on a pressure machine, a die forging hammer or a counter-blow hammer, and forging the diathermal blank inside a die cavity. The upsetting and extruding precision die-forging forming method for producing the large titanium alloy deep tube parts is simple in procedure operation, stable and reliable in performance, and is easy to control quantity and to realize large-batch industrialized production of products.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

A method of processing cobalt-base alloy superfine thin-walled tubes for stents

ActiveCN102363256AHigh dimensional accuracySmooth inner and outer surfacesRoll mill control devicesMetal rolling arrangementsLoad carryingControllability

The invention relates to a forming technology of superfine thin walled tubular products for vessel stents in the field of treatment, specifically to a method of processing cobalt-base alloy superfine thin walled tubes for novel coronary artery stents. The method solves the problems of great difficulty in tubular product processing and low yield of tubular products in a conventional technology. The method for forming finished products comprises the successive technological processes of smelting, forging, hot rolling, hot rolling punching, honing and cleaning of inner surfaces and outer surfaces, annealing, cold rolling / drawing, annealing, and repeated cold rolling / drawing. During overall process of the repeated cold rolling, diameter reducing deformation of the tubular products should be controlled in each pass, and match relationship between the diameter reducing deformation and wall reducing deformation should be well adjusted for guaranteeing that load carrying capability of inner walls does not exceed sigma b (breaking strength) and thus for preventing horizontal microscopic breakage. With rough blanks of the tubular products being acquired in high temperature conditions and the cobalt-base alloy tubular products being acquired through rolling at a room temperature, the processing method guarantees high dimensional precision, bright and clean inner and outer surfaces and excellent mechanical property of the tubular products; and is easy to realize and has high controllability and high economic benefit.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

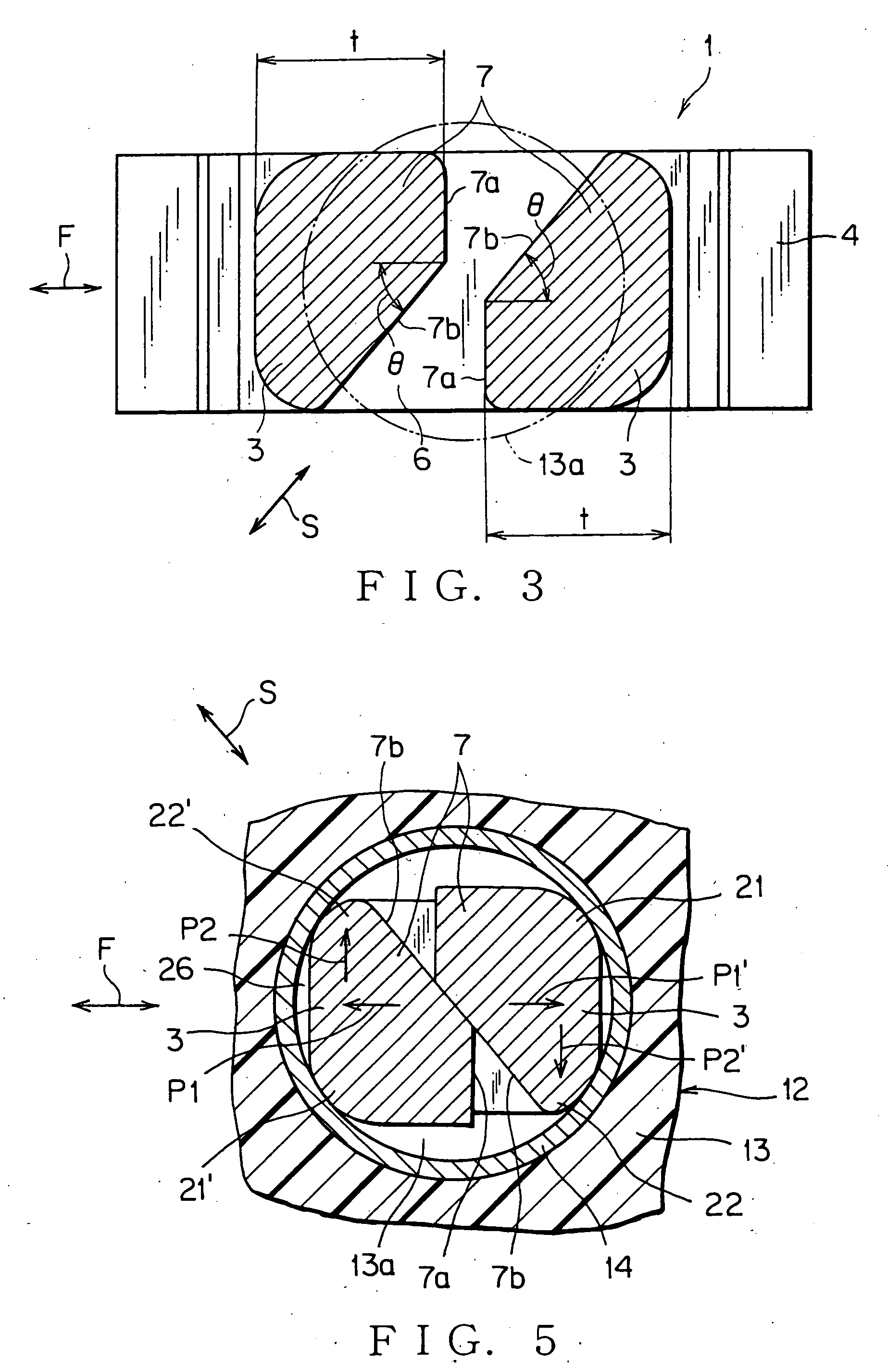

Press-fit terminal and circuit board module using the same

InactiveUS20050250356A1Improve connection workabilityIncrease forceElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

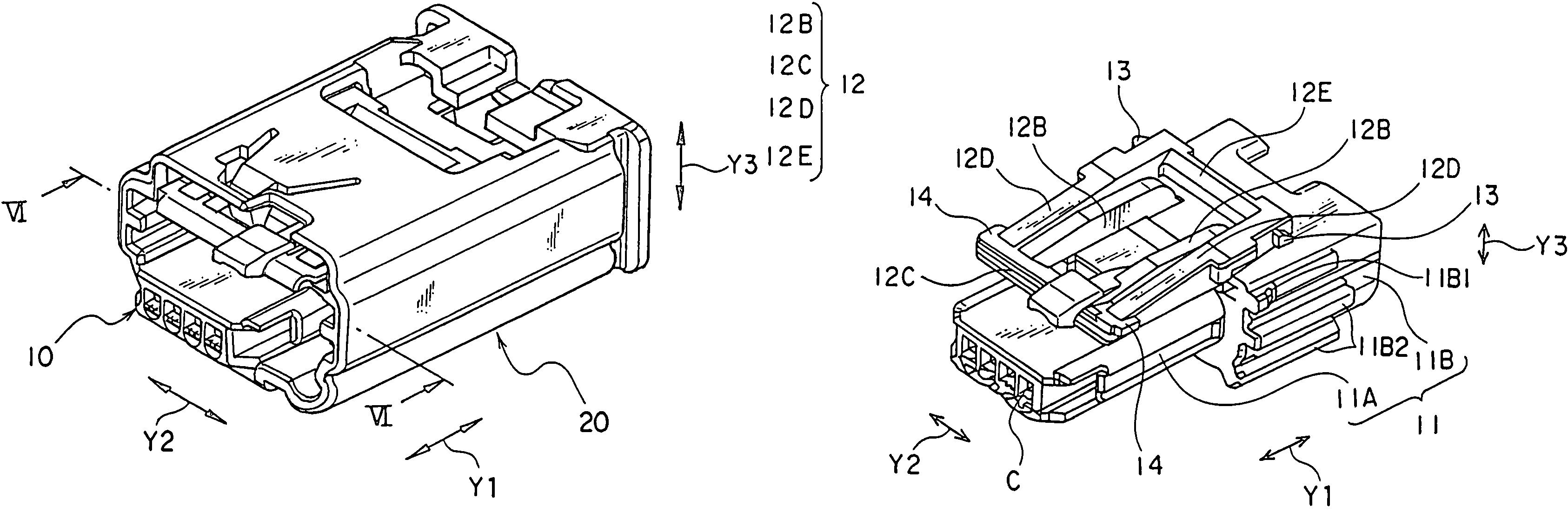

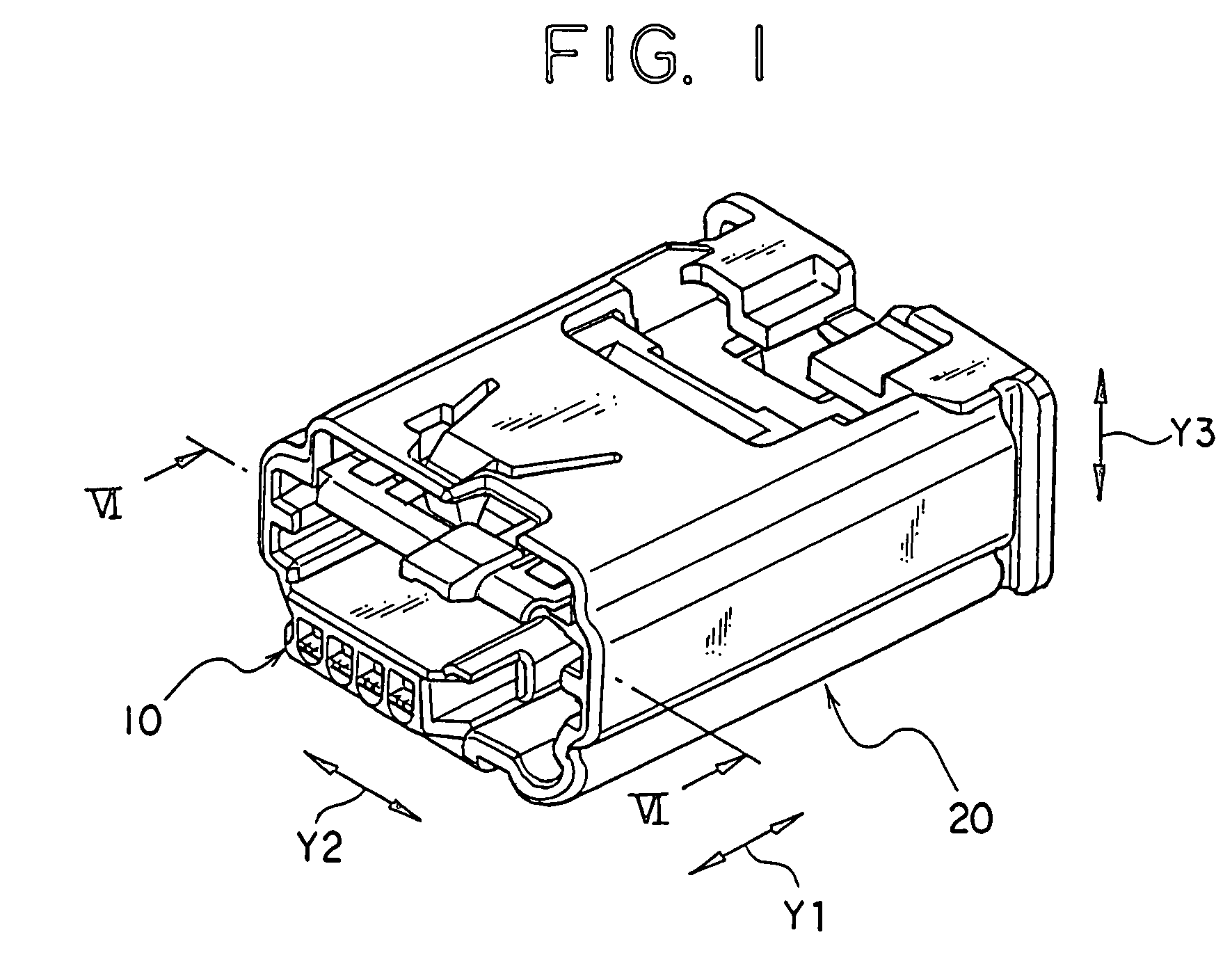

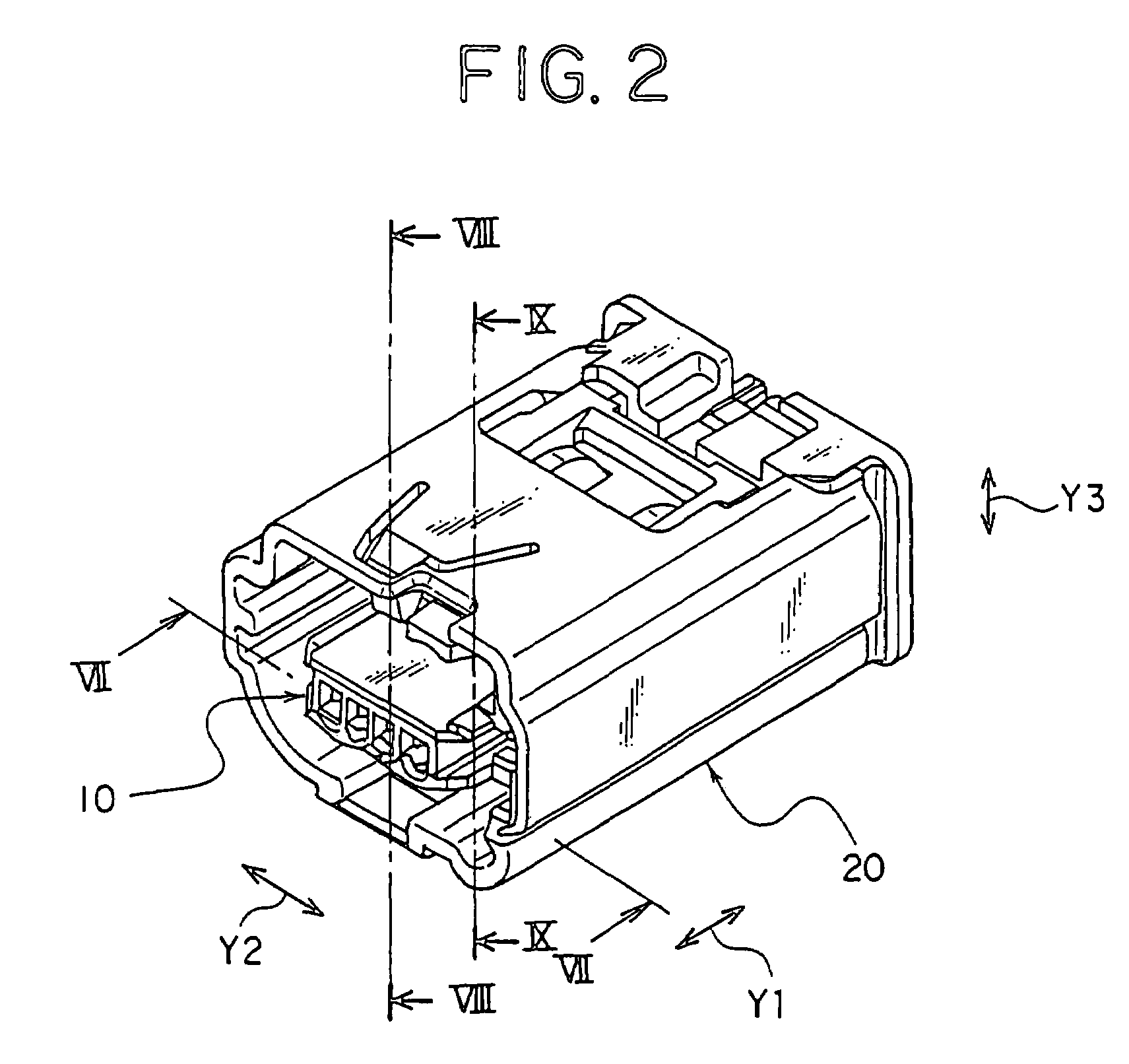

Connector having a female connector housing and a housing cover

ActiveUS7559787B2Effective and reliable engagementLarge amount of deformationCoupling device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

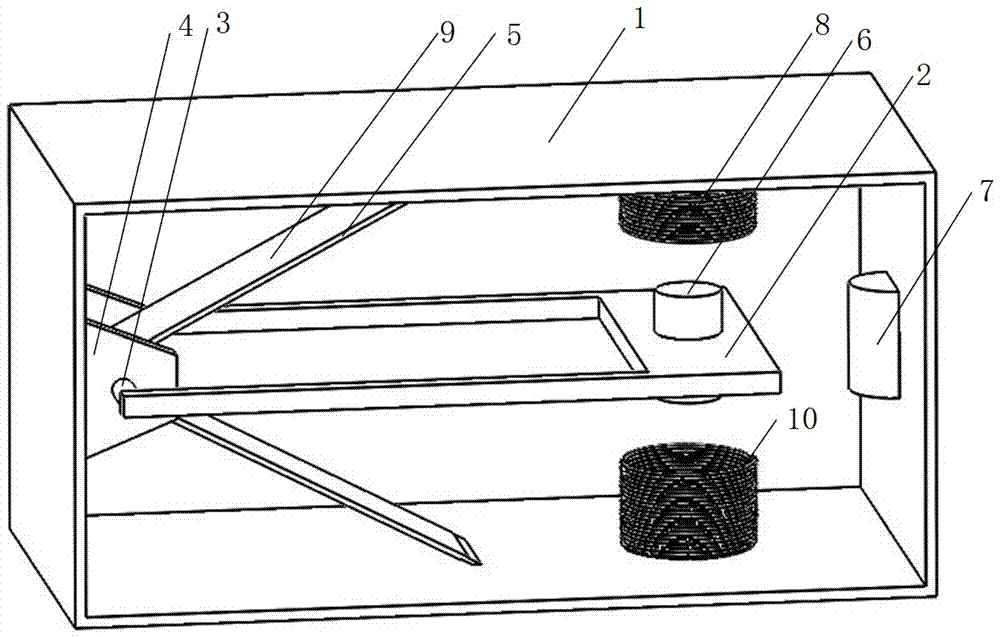

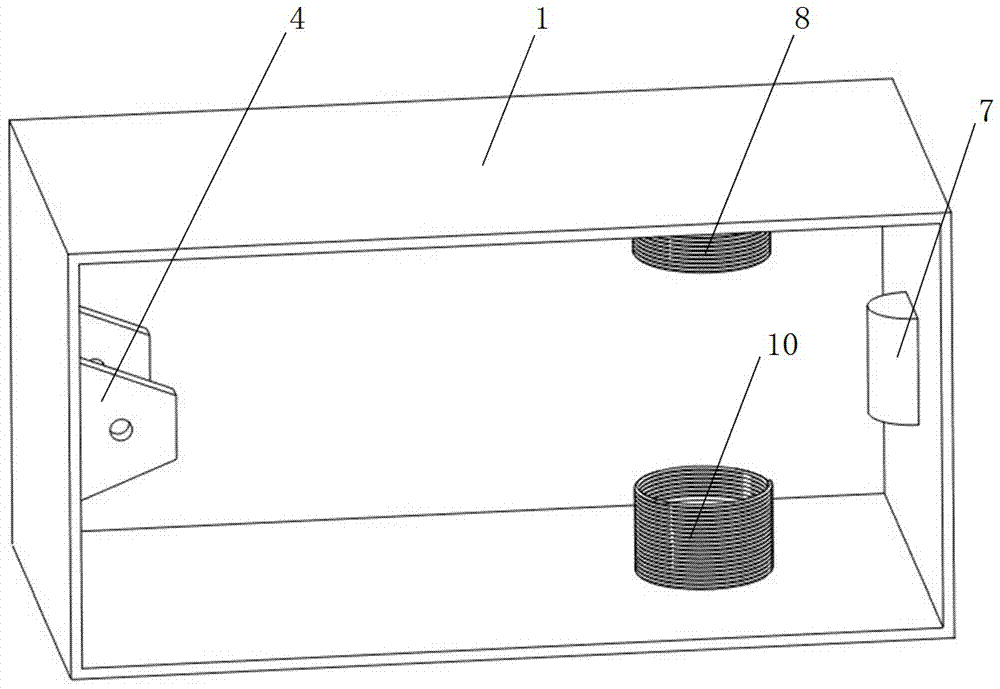

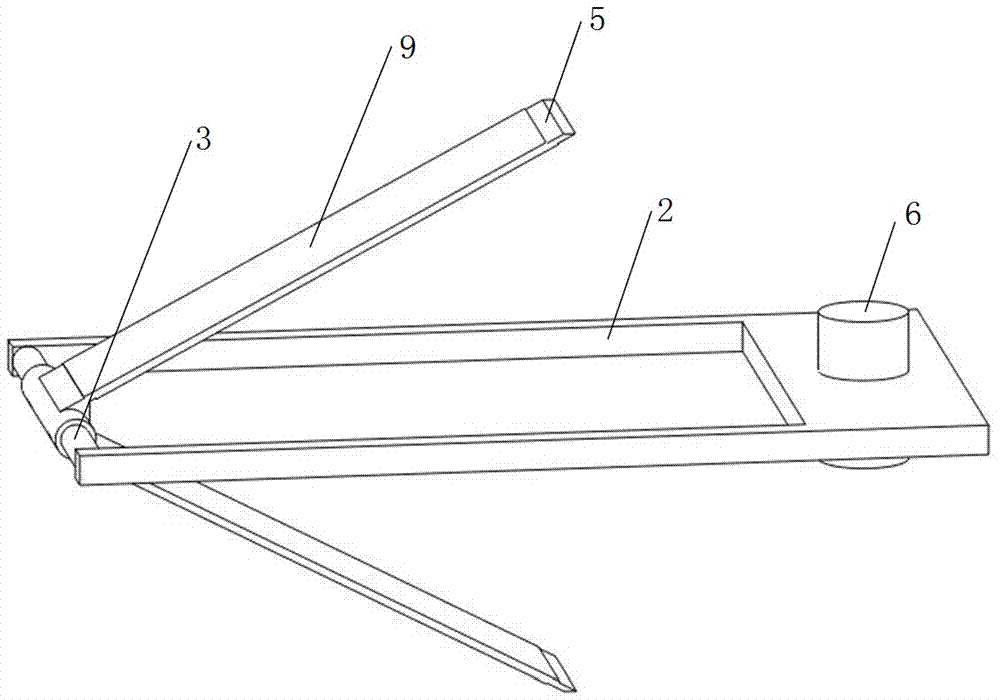

Spring leaf-type bistable electromagnetic piezoelectric composite energy collecting device

ActiveCN106899233AHigh utilization rate of space structureImprove energy harvesting efficiencyPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesElectricityNatural state

The present invention relates to a spring leaf-type bistable electromagnetic piezoelectric composite energy collecting device, including a static mechanism and a movable mechanism. The static mechanism comprises a housing, and the housing is internally provided with a bearing bearer, a fixed magnet, an upper coil and a lower coil. The movable mechanism comprises a pendulum frame, a spring piece and a vibration magnet and a spring piece is a V-shaped or U-shaped sheet. In the natural state, the upper and lower ends of the spring piece are in contact with the inner top wall and the inner bottom wall of the housing respectively. The vibration magnet and the fixed magnet are magnetized in the axial direction and repel each other. Under the action of external vibration excitation, the swinging of the pendulum frame drives the rotation of a rotating shaft, and then the spring piece and a piezoelectric element are deformed and the electric charge is generated. The electric energy is outputted through an electrode terminal lead. When the vibration magnet on the pendulum frame swings up and down, the magnetic field around the magnet also moves, the coil in the magnetic field cuts the magnetic induction lines and generates induced current, and the current is output through the lead.

Owner:HEFEI UNIV OF TECH

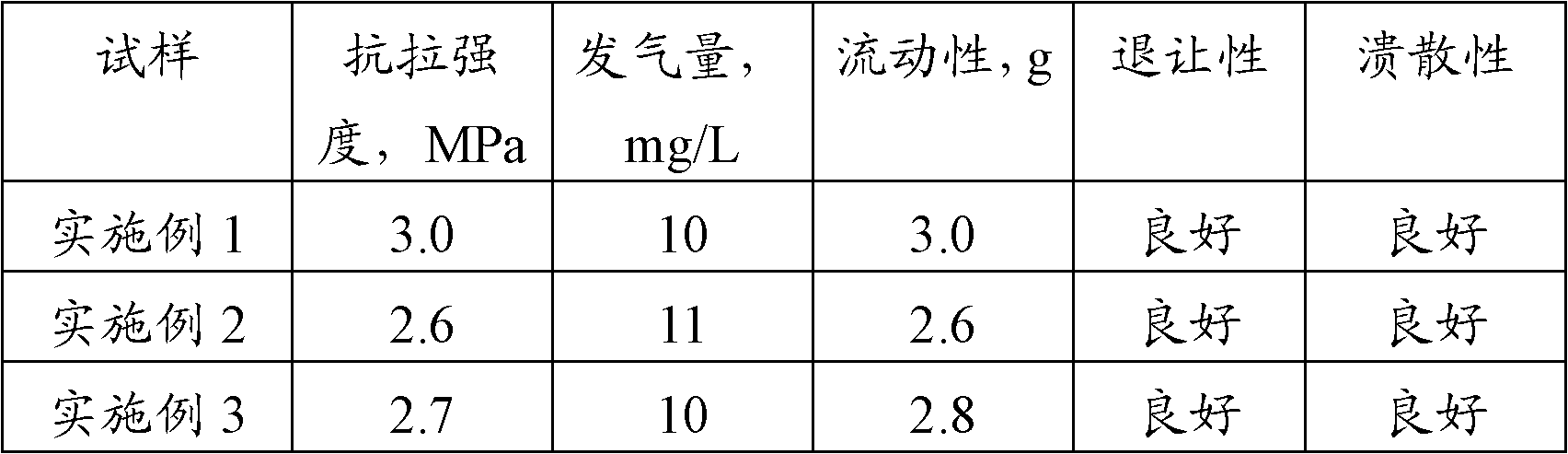

Core sand mixing process, heated core box core-making process and sand core prepared therefrom

InactiveCN102000777ASmall capacityReduce wearFoundry mouldsMoulding machinesPolyresinMaterials science

The invention provides a core sand mixing process, comprising the following steps of: (a) mixing ceramic sand and calcined sand according to the weight proportion of 4:6-6:4; and (b) primarily mixing the ceramic sand and the calcined sand for 20-30s, adding a curing agent into a mixture of the ceramic sand and the calcined sand, mixing for 50-60s, then adding heated core box resin, and mixing for 120-150s, wherein the addition amount of the heated core box resin accounts for 1.8-2.5% of the total weight of the ceramic sand and the calcined sand, and the weight of the curing agent accounts for 20-30% of that of the heated core box resin. The invention further provides a heated core box core-making process comprising the core sand mixing process. In the core sand mixing process, the ceramic sand and the calcined sand are adopted as raw sand, less abrasion is generated in a core making process, and the demoulding performance of sand cores is good; the consumption amount of the resin is lower so that more resin are saved and the cost is low; the sand cores of the ceramic sand and the calcined sand have good collapsibility and the cavity quality of a produced casting is better; and the ceramic sand resources are more sufficient.

Owner:WEICHAI POWER CO LTD

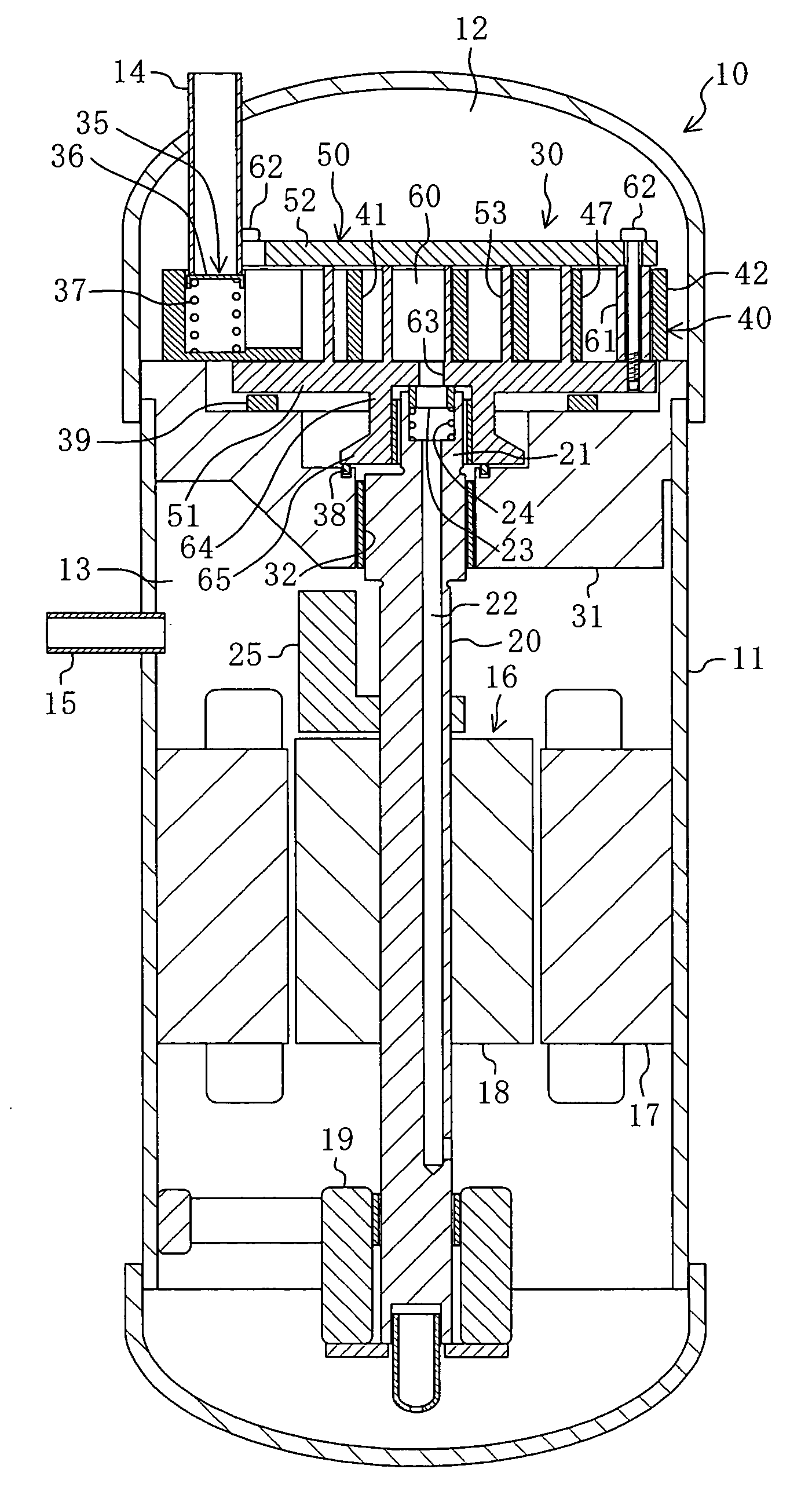

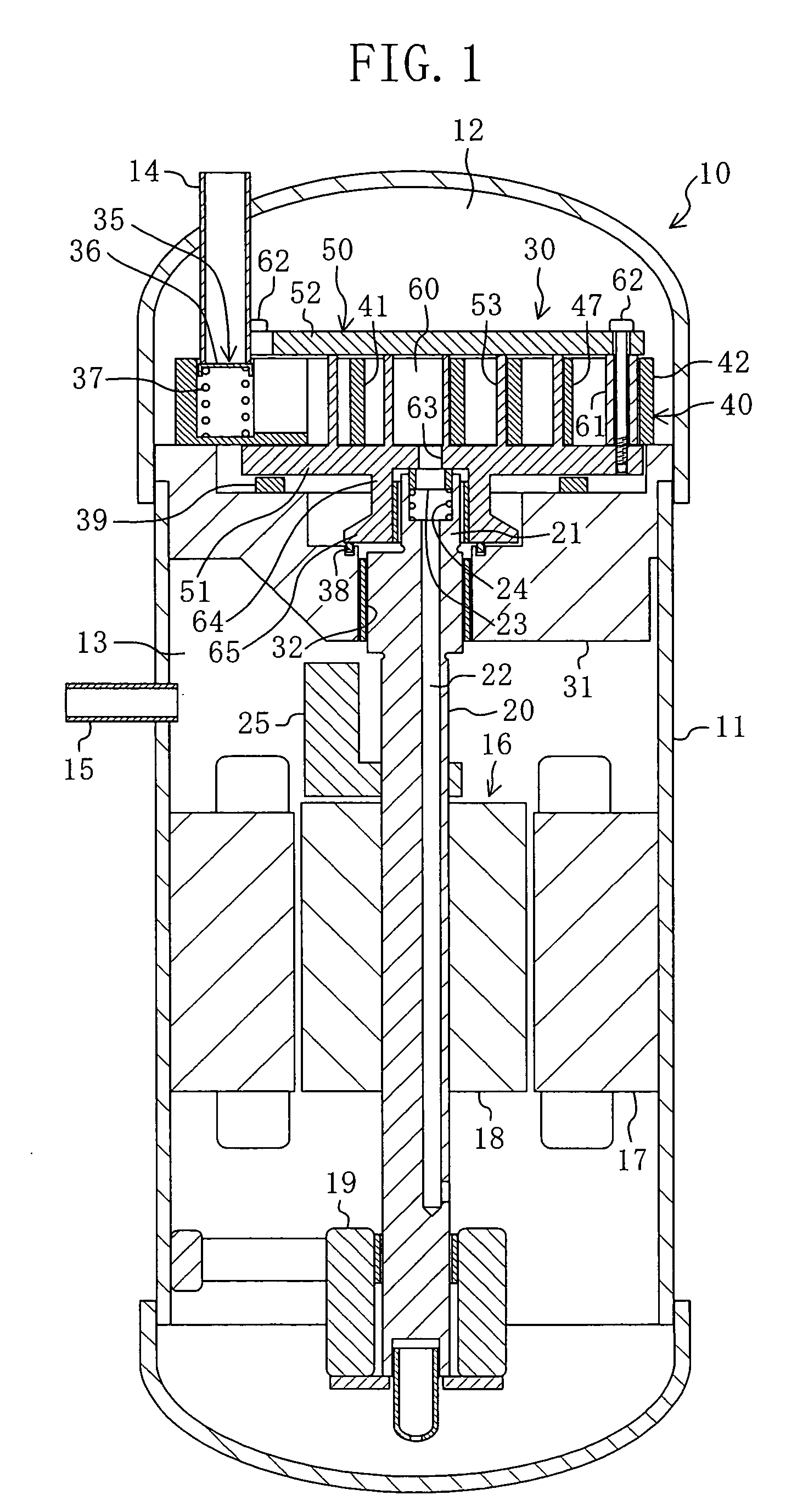

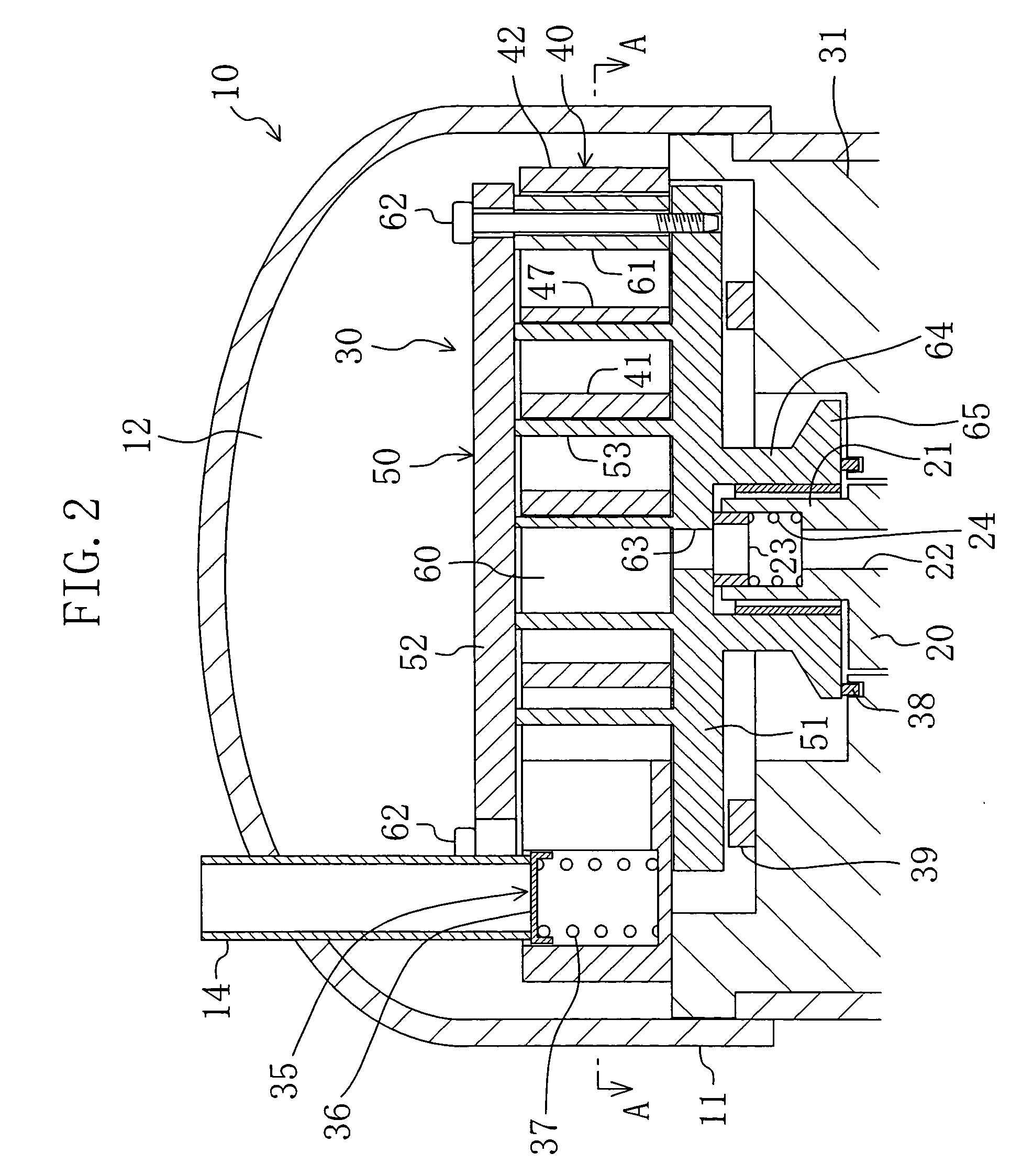

Scroll type fluid machine

InactiveUS20040101428A1Improve reliabilityIncrease frictional resistanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

A stationary scroll (40) is provided with a stationary side wrap (41) and an outer peripheral portion (42). The stationary side wrap (41) is formed into a spiral wall shape. The outer peripheral portion (42) is formed into a ring-like shape enclosing the periphery of the stationary side wrap (41). The movable scroll (50) is provided with a first flat plate (51), a movable side wrap (53), and a second flat plate (52). The movable side wrap (53) is formed into a spiral wall shape. Additionally, the movable side wrap (53) is caught between the first flat plate (51) and the second flat plate (52), with the movable side wrap (53) in mating engagement with the stationary side wrap (41). In the movable side wrap (53), the first flat plate (51) is formed integrally with the movable side wrap (53). Additionally, the second flat plate portion (52) is formed as a separate body from the first flat plate (51) and the movable side wrap (53) and is coupled to the first flat plate (51) with a bolt (62).

Owner:DAIKIN IND LTD

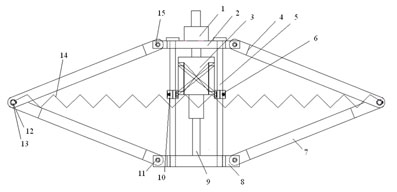

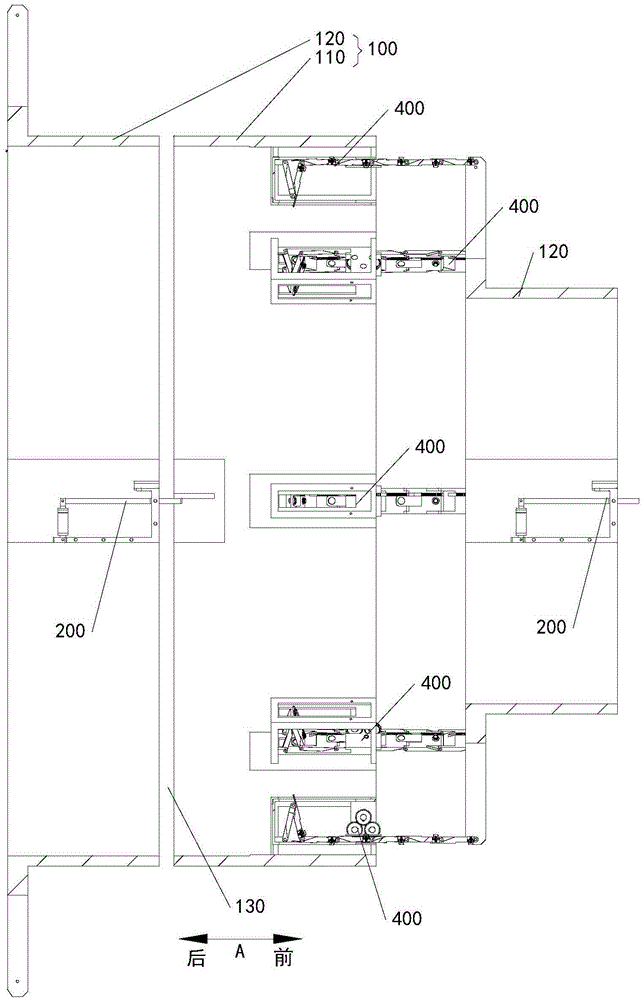

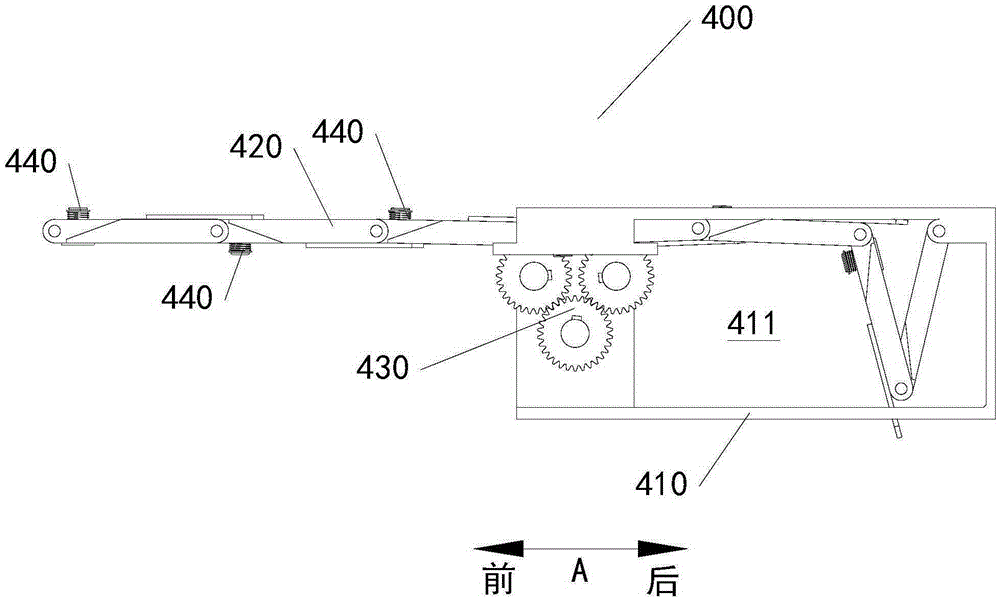

Motor drive-based robot vertical bounce mechanism

InactiveCN102050165AImprove obstacle performanceSimple structural designVehiclesMotor driveEngineering

The invention relates to a motor drive-based robot vertical bounce mechanism and belongs to the technical field of bounce robots. The mechanism is characterized by comprising a base (8), an upper cover plate (2), a central motor (1), a central guide pillar (9), a central cylindrical cam (3), two ridge rods and two folding mechanisms, wherein the central cylindrical cam (3) is fixedly connected to an output shaft at the lower end of the central motor (1) and is matched with the central guide pillar (9) through a central blind hole; the two ridge rods are symmetrically fixed on corresponding side guide pillars (5) and are matched with a groove of the central cylindrical cam (3); and the folding mechanisms are hinged between the upper cover plate (2) and the base (8). A spiral groove on the outer surface of the central cylindrical cam is moved downwards under the exogenic action when the central cylindrical cam is rotated, a six-bar mechanism is driven to deform, the gravity of the mechanism is moved downwards, and an extension spring generates internal stress, so that the motor drive-based robot vertical bounce mechanism makes a robot bounced, and has a compact structure design and high movement reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

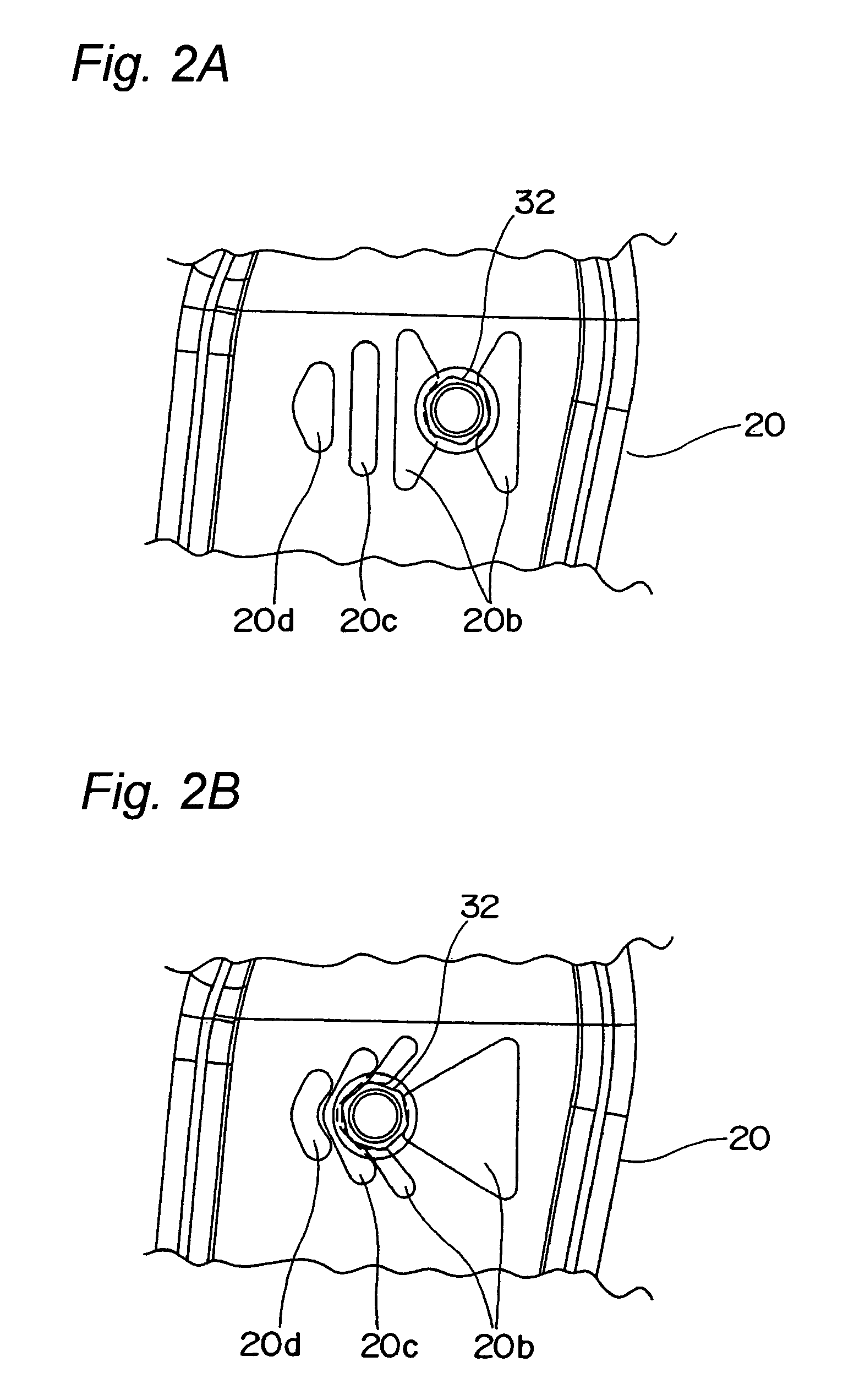

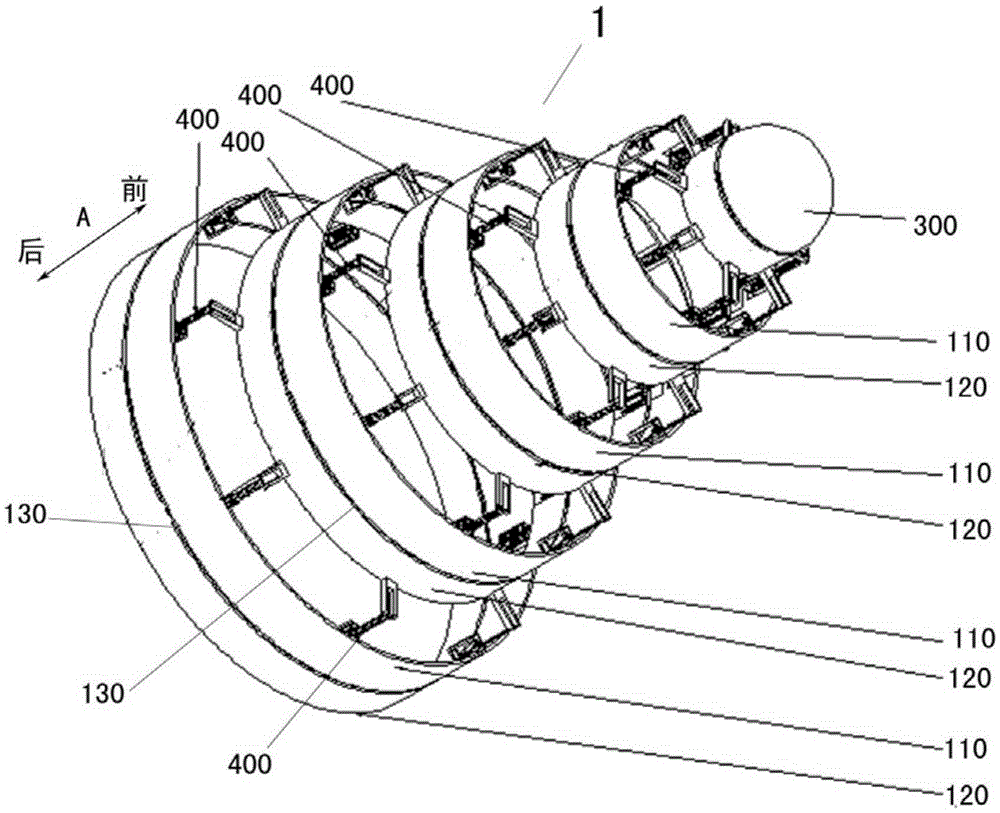

Deformation nose cone of aircraft

The invention discloses a deformation nose cone of an aircraft. The deformation nose cone comprises a plurality of annular body segments, a plurality of bending mechanisms, a front cone and a plurality of telescopic mechanisms. Each annular body segment comprises a first sub body segment and a second sub body segment, and a bending gap exists between each first sub body segment and the corresponding second sub body segment. The bending mechanisms are arranged between the first sub body segments and the second sub body segments and used for driving the first sub body segments to move between a straight position and a bent position. The front cone is arranged on the forefront of the annular body segments. Each telescopic mechanism is telescopically connected between the corresponding two adjacent annular body segments, located between the annular body segment at the forefront end and the front cone and used for changing the distance between the corresponding two adjacent annular body segments and the distance between the annular body segment at the forefront end and the front cone. The deformation nose cone of the aircraft in the embodiment has the beneficial effects of being capable of achieving complex deformation, large in deformation and the like.

Owner:TSINGHUA UNIV

Manufacturing method of super-thick steel plate

ActiveCN103111464AReduced compression ratio requirementsLarge amount of deformationTemperature control deviceMetal rolling arrangementsThick plateIndustrial engineering

The invention discloses a manufacturing method of a super-thick steel plate (thickness is 60 millimeters) and belongs to the steel plate production field of metallurgical industry. The manufacturing method of the super-thick steel plate comprises the following steps: firstly, sending a plate blank which is heated to a certain temperature and removed an oxide scale to cooling space to conduct forced cooling, surface temperature cooling a phase transition temperature of the super-thick plate material above Ar 1, then by short time temperature returning, the surface temperature rising to the range between 780 DEG C and 880 DEG C, and sending the plate bland to a rolling mill to roll as soon as possible; when the surface temperature of the plate blank being higher than 880 DEG C, needing to conduct the forced cooling again, and then conducting the subsequent rolling. A cooling-temperature returning-rolling process can be repeated for many times if needed till rolling to the needed thickness of the super-thick steel plate. The manufacturing method of a super-thick steel plate can increase dependent variable of the central area by increasing temperature difference between a surface layer and the central area and has the advantages of being beneficial to refining central organization and improving impact toughness, beneficial to removing center porosity of the super-thick plate, and capable of reducing double strand shape on lateral sides of the super-thick plates. The manufacturing method of a super-thick steel plate further has the advantages of being saving in investment, and flexible to operate.

Owner:UNIV OF SCI & TECH BEIJING

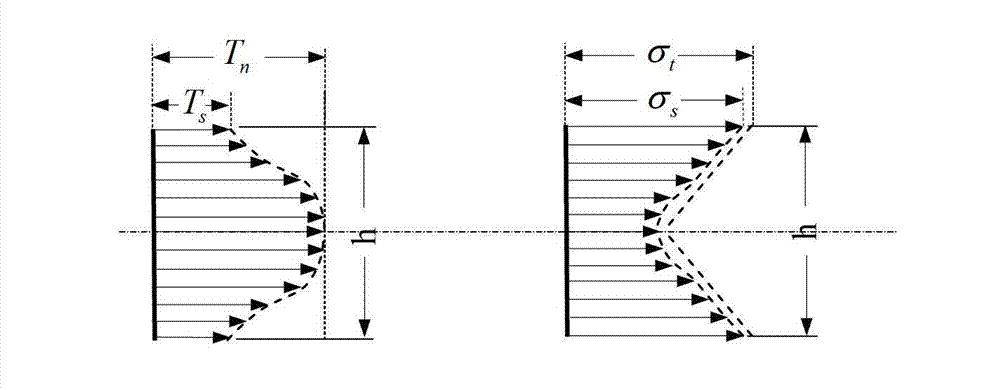

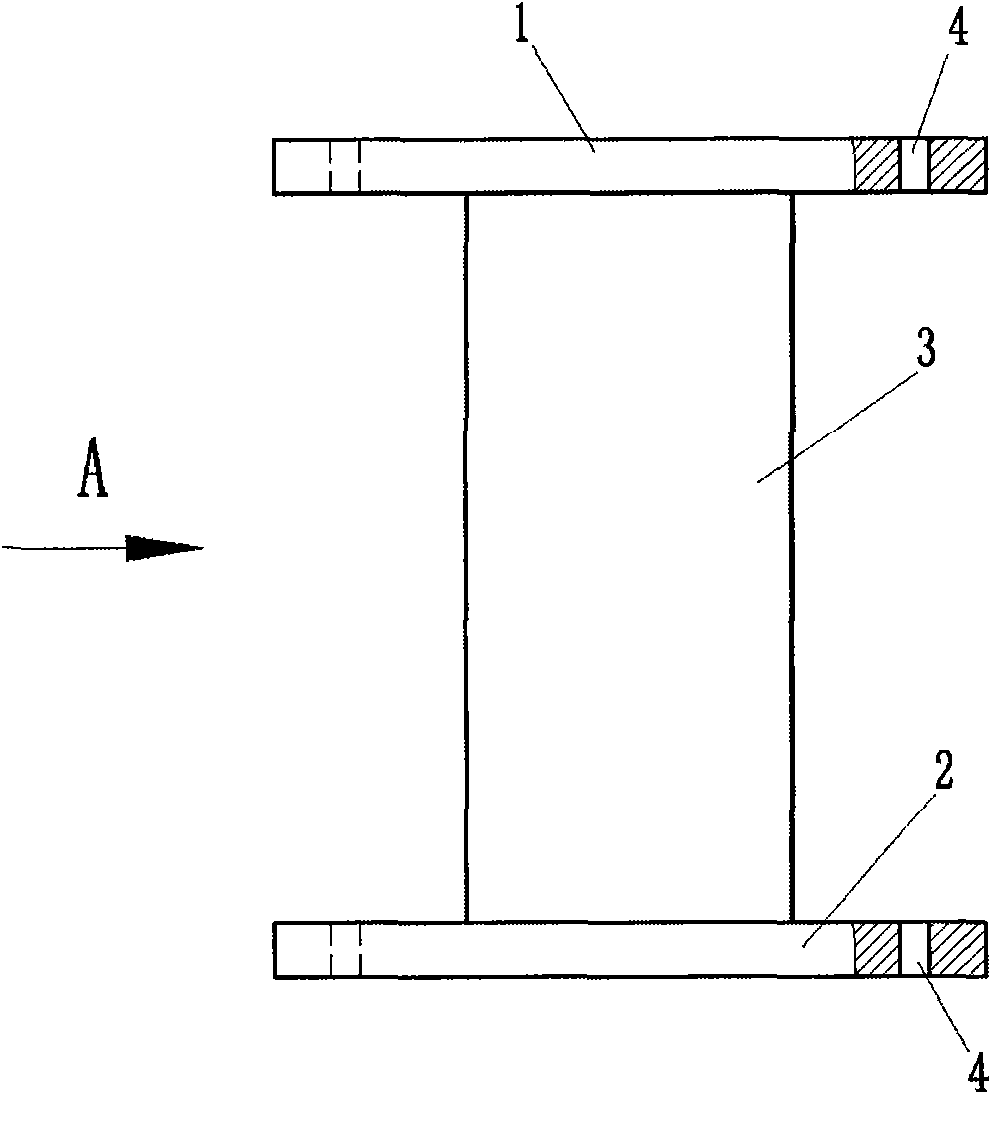

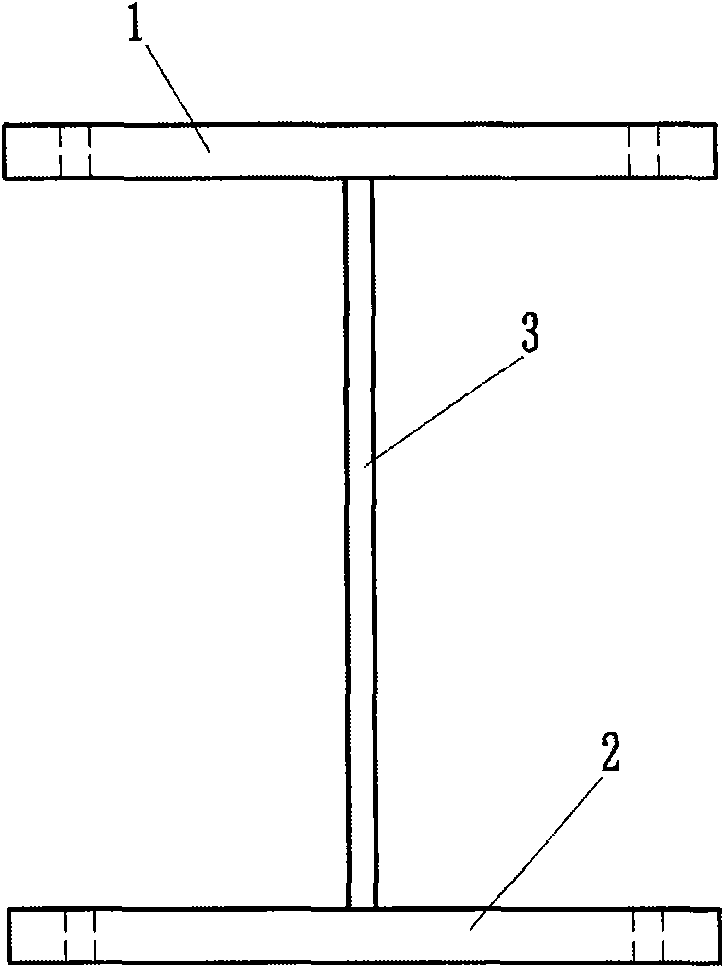

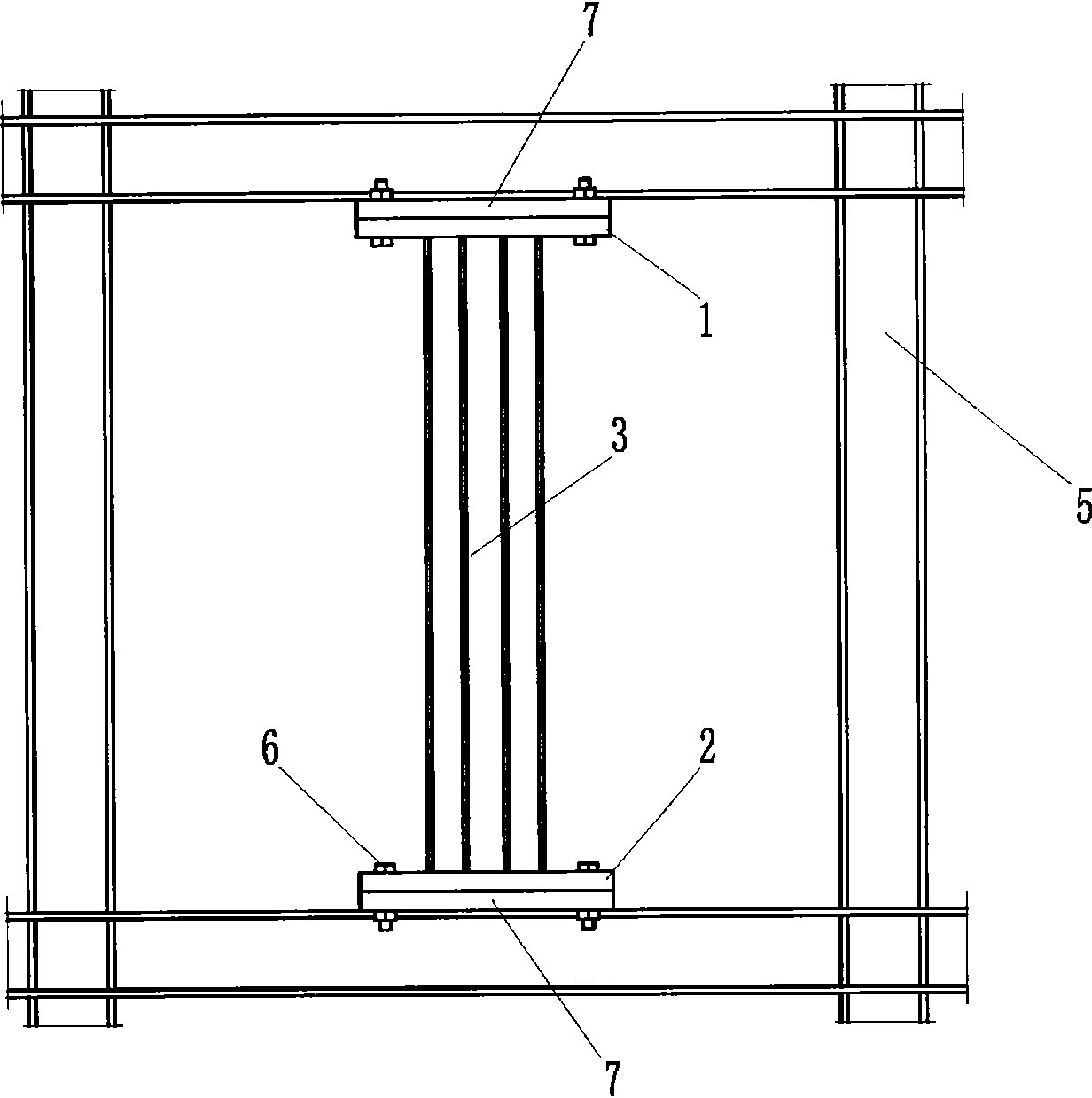

Shearing-type metal bending energy-wasting damper

InactiveCN101629432AIncrease the number ofCompact structureBridge structural detailsShock proofingMetallic materialsSnubber

The invention relates to a shearing-type metal bending energy-wasting damper which belongs to the field of civil engineering structural damping technology, in particular to a metal damper used for damping and wasting energy. The shearing-type metal bending energy-wasting damper is characterized in that an adopted core metal energy-wasting element is at least one metal plate that realizes the energy-wasting capacity by bending, wherein two ends of the metal plate are respectively and fixedly connected with an upper connecting plate and a lower connecting plate and vertical to the upper connecting plate and the lower connecting plate; and the thickness direction of the metal plate is accordant with the direction of the shearing force borne by a building structure. The shearing-type metal bending energy-wasting damper realizes the energy wasting by utilizing favorable plastic deformation capacity of steel products, and the like as well as larger deformation quantity by utilizing the bending deformation, is easy to be processed and convenient and flexible for use, can effectively improve the anti-seismic performance of the building structure and a bridge structure, and has novel and reasonable structure, strong applicability and wide market popularization and application prospects.

Owner:TSINGHUA UNIV

Electrified railway chromium-zirconium-copper contact line and machining process thereof

ActiveCN104342575AMaximum total rolling deformationLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopperSolid solution

The invention discloses a preparation method of an electrified railway chromium-zirconium-copper contact line. Copper is taken as a substrate, 0.30-0.70% of Cr and 0.10-0.35% of Zr in percentage by weight are added into the substrate, and the total sum of impurities is no greater than 0.05%. The preparation method comprises the following steps: performing vacuum melting and vacuum horizontal continuous casting, thereby obtaining a long-length large cross section chromium-zirconium-copper continuous cast blank; performing full hot continuous rolling and on-line solid solution, thereby obtaining a long-length chromium-zirconium-copper line rod disc; drawing and peeling the disc, and performing cold continuous rolling, thereby reducing the diameter; further performing aging treatment to reinforce the disc; further performing cold continuous rolling by using a Y-type rolling machine, thereby pre-forming the line; and finally performing fine drawing formation once. The chromium-zirconium-copper contact line produced by using the preparation process is fine and uniform in grain, free of defect, high in strength, high in conductivity and high in softening temperature, and applicable to industrialized production.

Owner:YANTAI WANLONG VACUUM METALLURGY

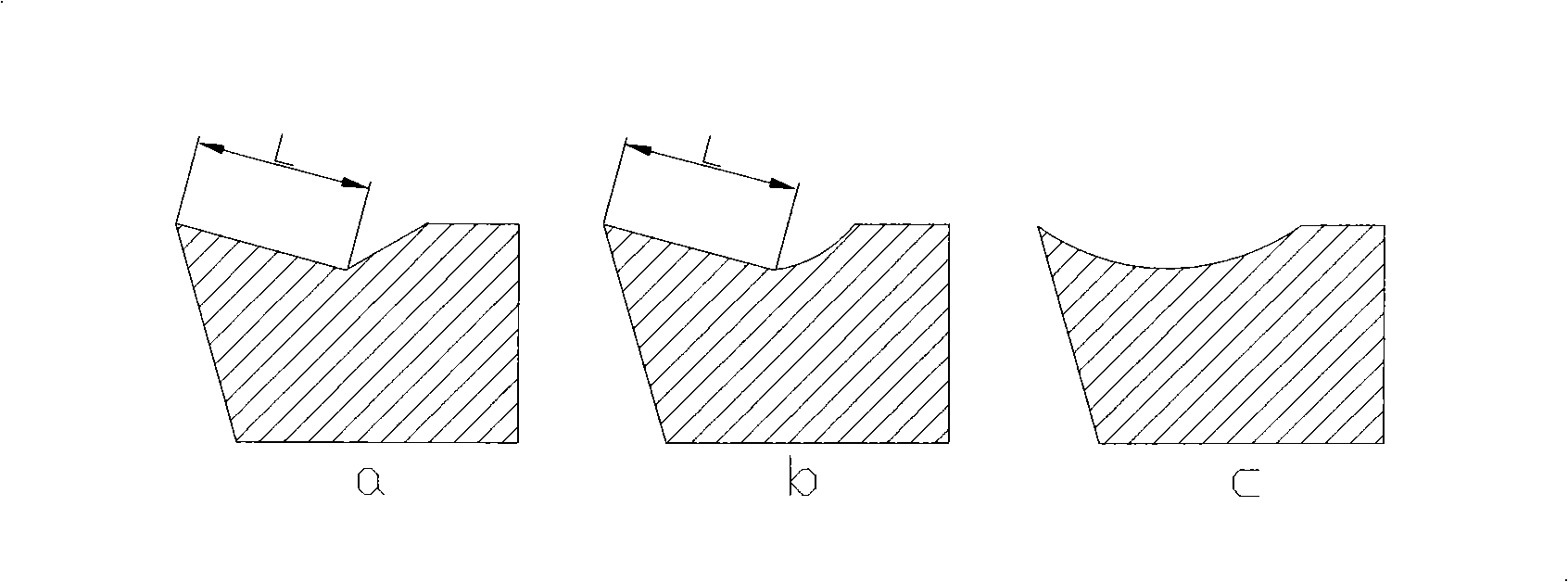

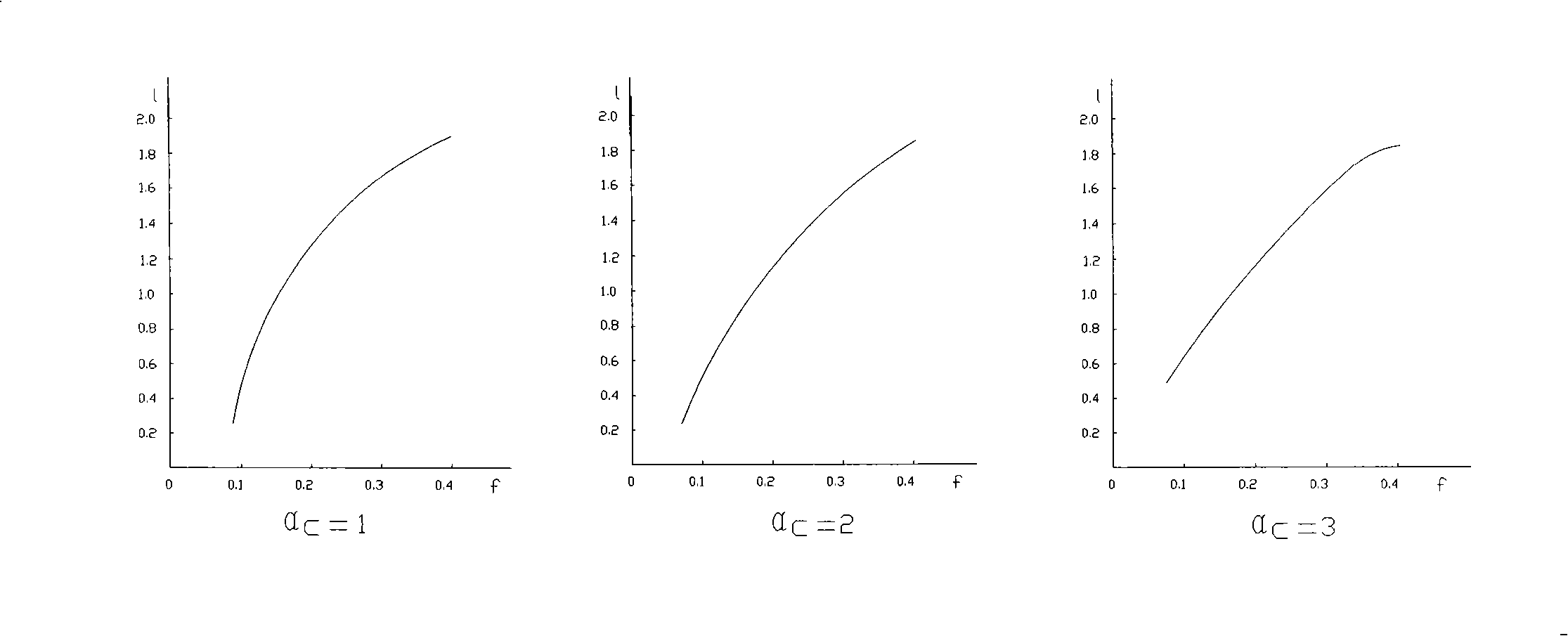

Knife tool chip breaker

InactiveCN101323027ASmooth entryLarge amount of deformationTurning toolsRake angleAutomatic processing

The invention discloses a tool chip breaker, solving the problems of difficult chip breaking caused by great material plasticity and elasticity in the process of automatic processing and thin-cutting. The key of the invention is that a section of major first face and a first front angle are added in the cutting edge of a linear arc-shaped chip breaker, and the back of the major first face is a major second face; according to the parameters of cutting thickness, the major first face and the major second face, the corresponding curvature radius of an arc chip reeling slot is calculated. The tool chip breaker has the advantages that: as a section of the linear major first face is added in the cutting edge, the curvature radius of the arc chip reeling slot is reasonable, the chip deformation is increased, the effect of chip reeling and breaking is improved; the angle of the cutting edge is increased, the strength of the cutting edge is strengthened and the cutting depth is deepened; the new structure ensures that the chip goes into the chip reeling slot more smoothly.

Owner:DALIAN UNIVERSITY

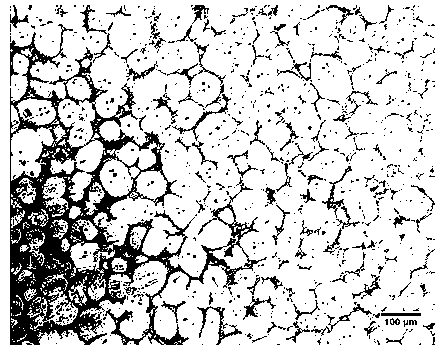

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

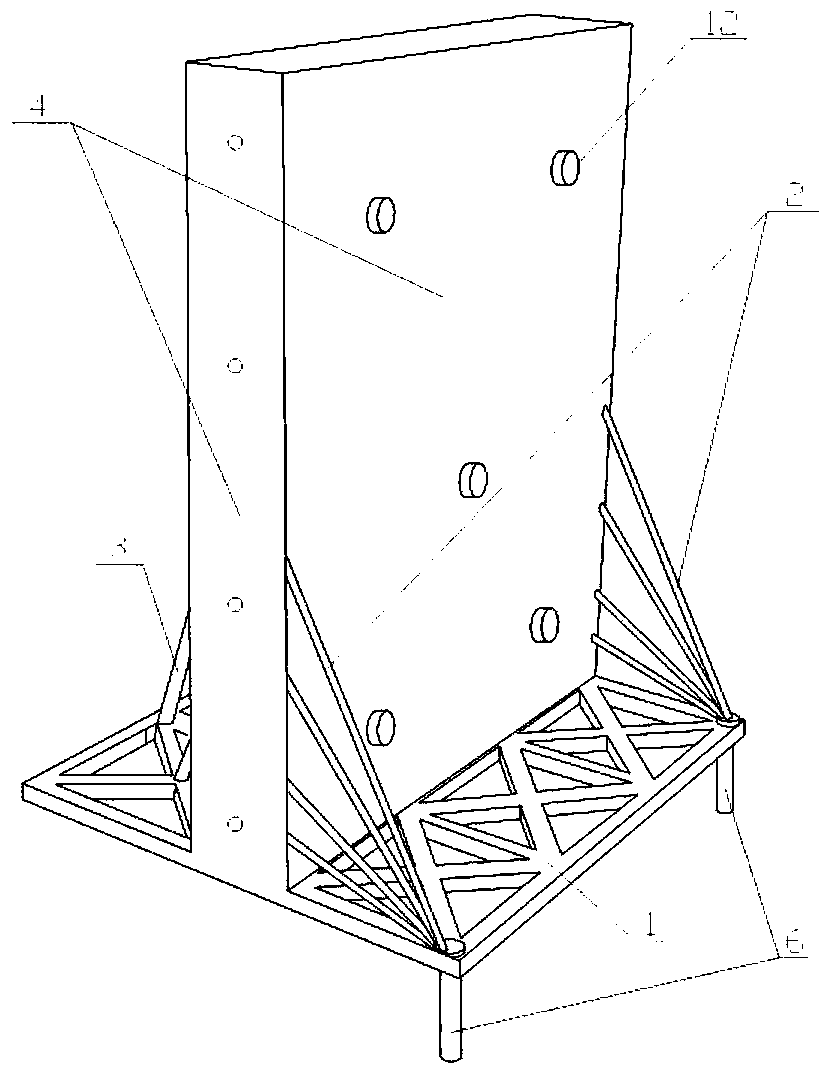

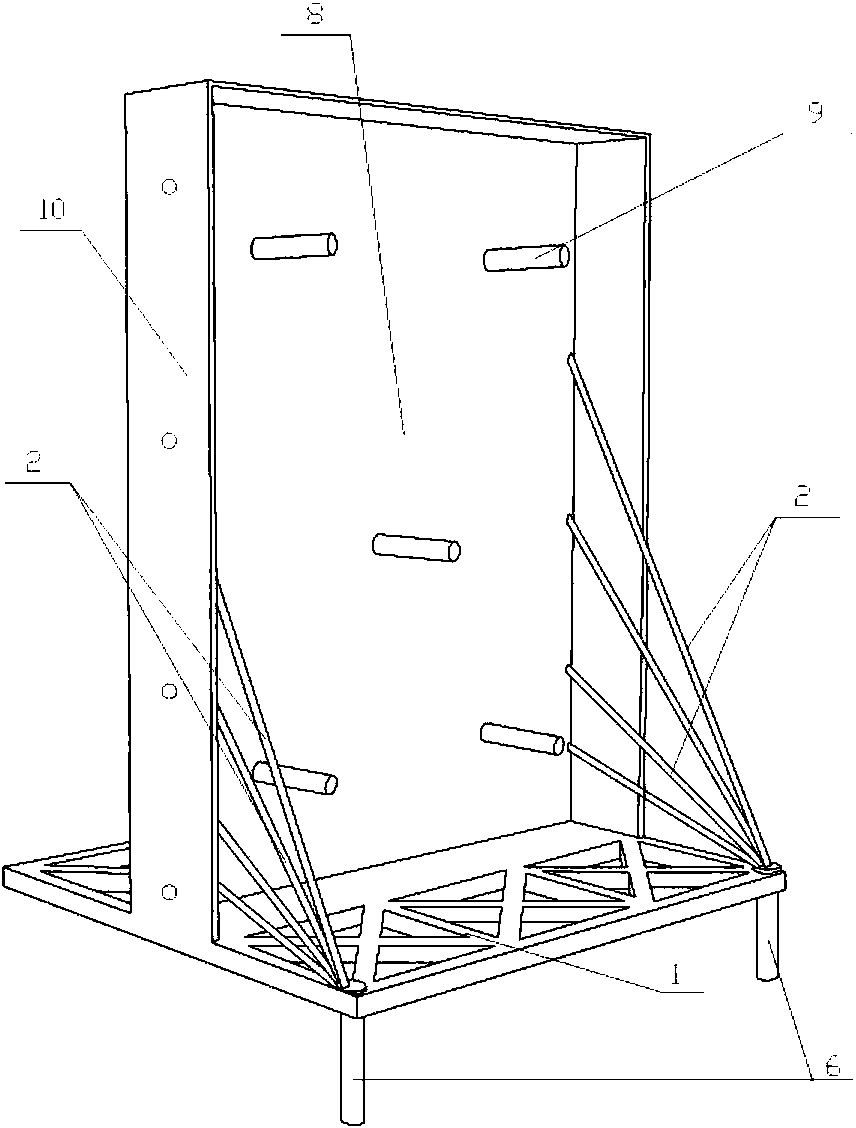

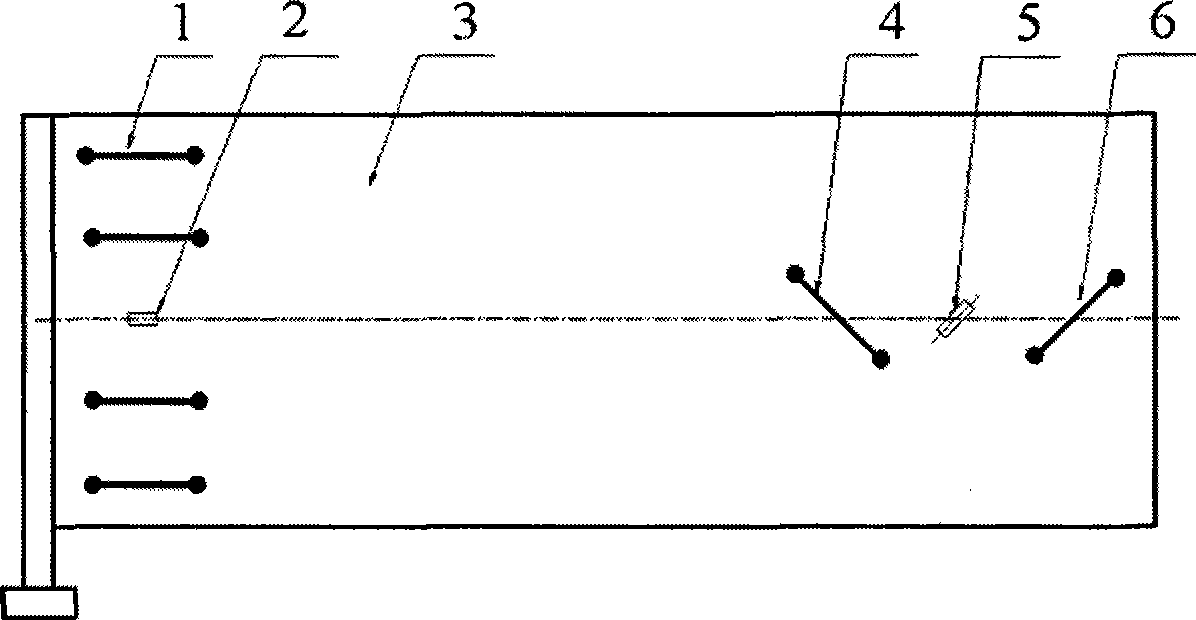

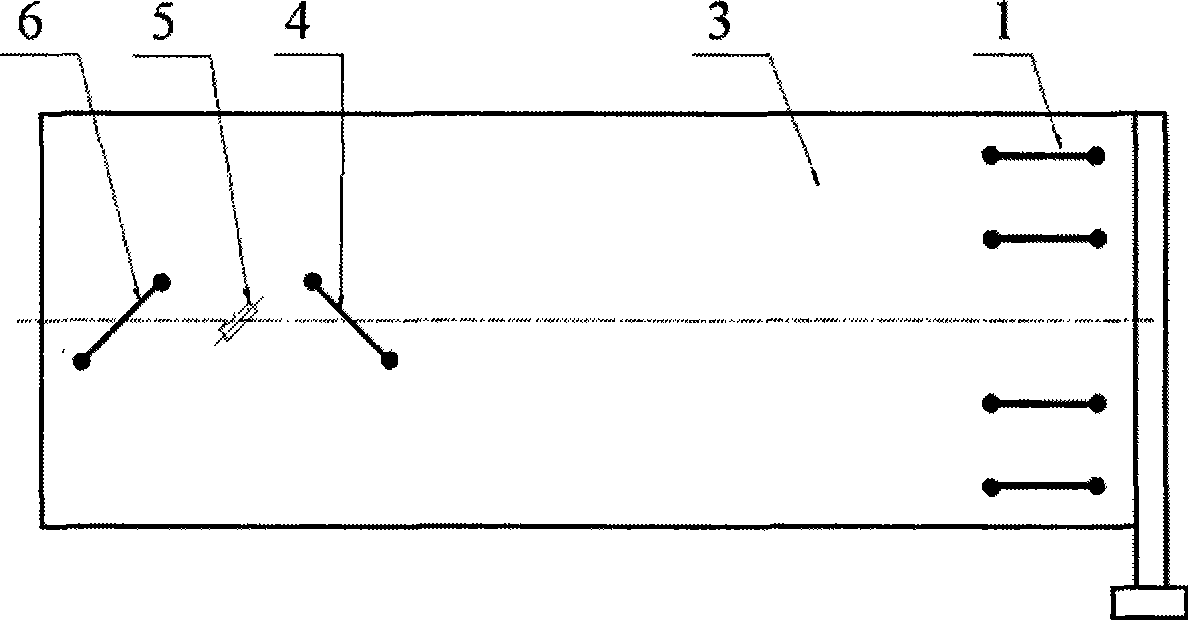

Assembled type movable blast wall

InactiveCN103628583AStrong matchingQuick assemblyBuilding constructionsProtective buildings/sheltersFlow stressEnergy absorption

An assembled type movable blast wall is formed by a plurality of blast wall units in an assembled mode. Each blast wall unit comprises a base, front pull rods, rear compression bars, a supporting frame, energy absorption layers and connecting bolts. Each supporting frame is fixed on the upper surface of the corresponding base, and one or more energy absorption layers are arranged inside each supporting frame in a filling mode. The energy absorption layers are formed by a plurality of prefabricated bodies which are made of EPS flow state concrete in an arrayed mode. A plurality of slide-resistant piles are distributed on the lower surface of each base. When multiple energy absorption layers are arranged, a middle layer is arranged between every two adjacent energy absorption layers. The assembled type movable blast wall can be deformed easily when undergoing impulse loads of the outside, the deformation is large, however, the flow stress level is quite low, in the compression deformation process, a large amount of power is consumed, the power is converted into energy dissipated in all sorts of modes like deformation, collapsing, fracturing and cell wall friction of holes in the structure, and thus the outside impact energy can be effectively absorbed. The assembled type movable blast wall further has the advantages of being rapid in assembling, low in cost and strong in stability.

Owner:AIR FORCE UNIV PLA

Low frequency modal vibration control apparatus and method for simulating bending and torsion for space sailboard

InactiveCN101382806AEasy to implement decouplingReduce vibrationMechanical oscillations controlComputer controlElectricityElectrical resistance and conductance

The invention discloses a device for controlling vibration when simulating the bending and torsional low-frequency modes of a space sailboard, and a method thereof. The device is stuck with a resistance strain gauge on a flexible cantilever plate close to a longitudinal center line of a fixed end with an attitude angle of 0 degree to serve as a bending mode sensor and multi-way shape memory alloy (SMA) springs are symmetrically arranged on the front surface and the rear surface of the flexible plate, with the attitude angle of 0 degree, to serve as a bending mode piezoelectric actuator. Two resistance strain gauges are anti-symmetrically and bilaterally stuck on the flexible plate close to a free end, with the attitude angle of 45 degrees, to form a torsional mode sensor, and four shape memory alloy springs are anti-symmetrically and bilaterally stuck close to the free end to form two paths of torsional mode drivers with opposite phases. The device and the method utilize the optimized allocation of the SMA springs, realize the decoupling of the bending and torsional low-frequency vibrating modes of a large cantilever plate and the purpose of actively controlling the bending mode and the torsional mode of the flexible cantilever plate.

Owner:SOUTH CHINA UNIV OF TECH

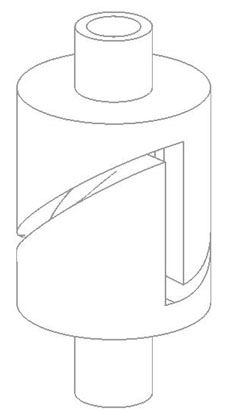

Variable cross-section twisting and molding device and method for metal material

ActiveCN103551415AImprove efficiencyTo achieve the effect of deep refinementExtrusion diesExtrusion mandrelsCrystalliteMetallic materials

The invention provides a variable cross-section twisting and molding device and method for a metal material, relates to a device and a method of a large plastic deformation technology, and aims to solve the problems of an existing twisting process that grain crystal refining can be realized only after a plurality of times of loading are carried out back and forth on the two sides and the production efficiency is low. The device is characterized in that a first twisting mould is composed of a first large cross-section rectangular channel, a first pyramid spiral channel and a first small cross-section rectangular channel in sequence from top to bottom; the cross section of the first pyramid spiral channel is reduced gradually from top to bottom; the cross section of the first pyramid spiral channel is rectangular; a first puncher pin is coaxially arranged above the first twisting mould. The method comprises the following steps: 1. the spiral angle is 10-60 degrees, the length of the spiral channel is 0.5d-3d and the extrusion ratio is 4-100; 2. a blank enters the first large cross-section rectangular channel under the effect of the first puncher pin; 3. the twisting angle of the blank is 90-180 degrees; 4. the variable cross-section twisting of the material is finished to form a part. The variable cross-section twisting and molding device and method for the metal material are used for preparing or machining and molding the high-performance metal material.

Owner:福建祥鑫股份有限公司

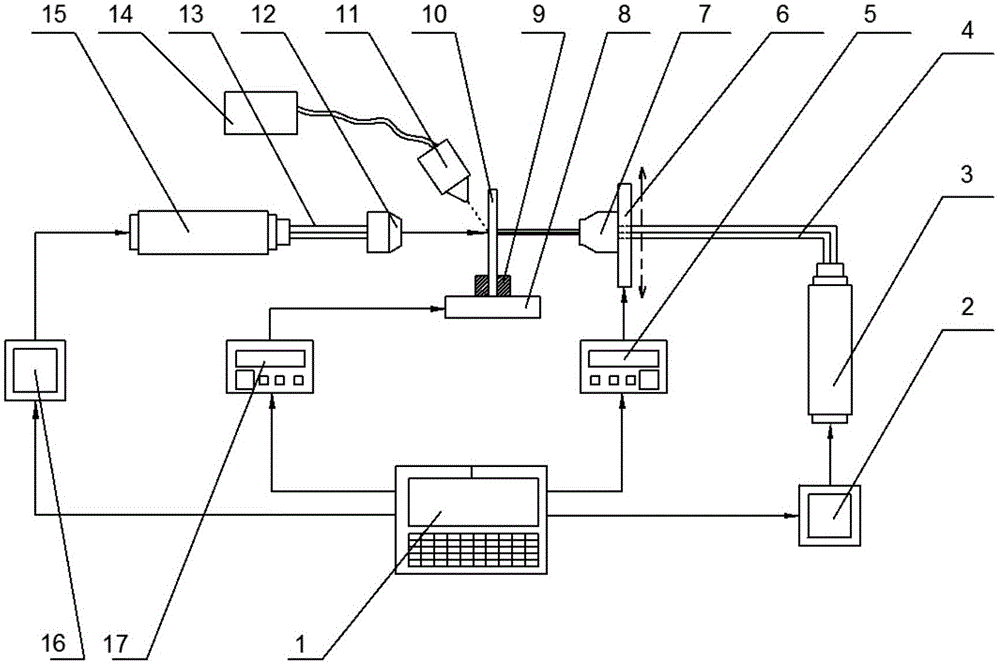

Method and device for thermal-assisted laser peen forming

InactiveCN105033462AImprove surface qualityNo obvious mechanical damageMetal working apparatusLaser beam welding apparatusOptoelectronicsLaser peening

The invention provides a device for thermal-assisted laser peen forming. The device comprises a shot peening laser and a light path part thereof, a heating laser and a light path part thereof, a workpiece clamp control part, a water spraying part and a central control processor part. The central control processor part is connected with the shot peening laser and the light path part thereof, the heating laser and the light path part thereof and the workpiece clamp control part. The shot peening laser and the light path part thereof and the heating laser and the light path part thereof are located on the front face and the back face of a workpiece respectively. The invention further provides a method, adopting the device, for thermal-assisted laser peen forming. According to the device and method, laser-aided heating and laser shot peening are carried out on the two sides of the workpiece respectively at the same time. Due to the fact that part of shot peening area is heated, energy is effectively utilized, and processed materials have good surface property and high-temperature stability; the processing and manufacturing purpose of high-strength high-property plates is effectively achieved, and the requirement of the industry for processing and manufacturing of the materials is met.

Owner:SHANGHAI JIAO TONG UNIV

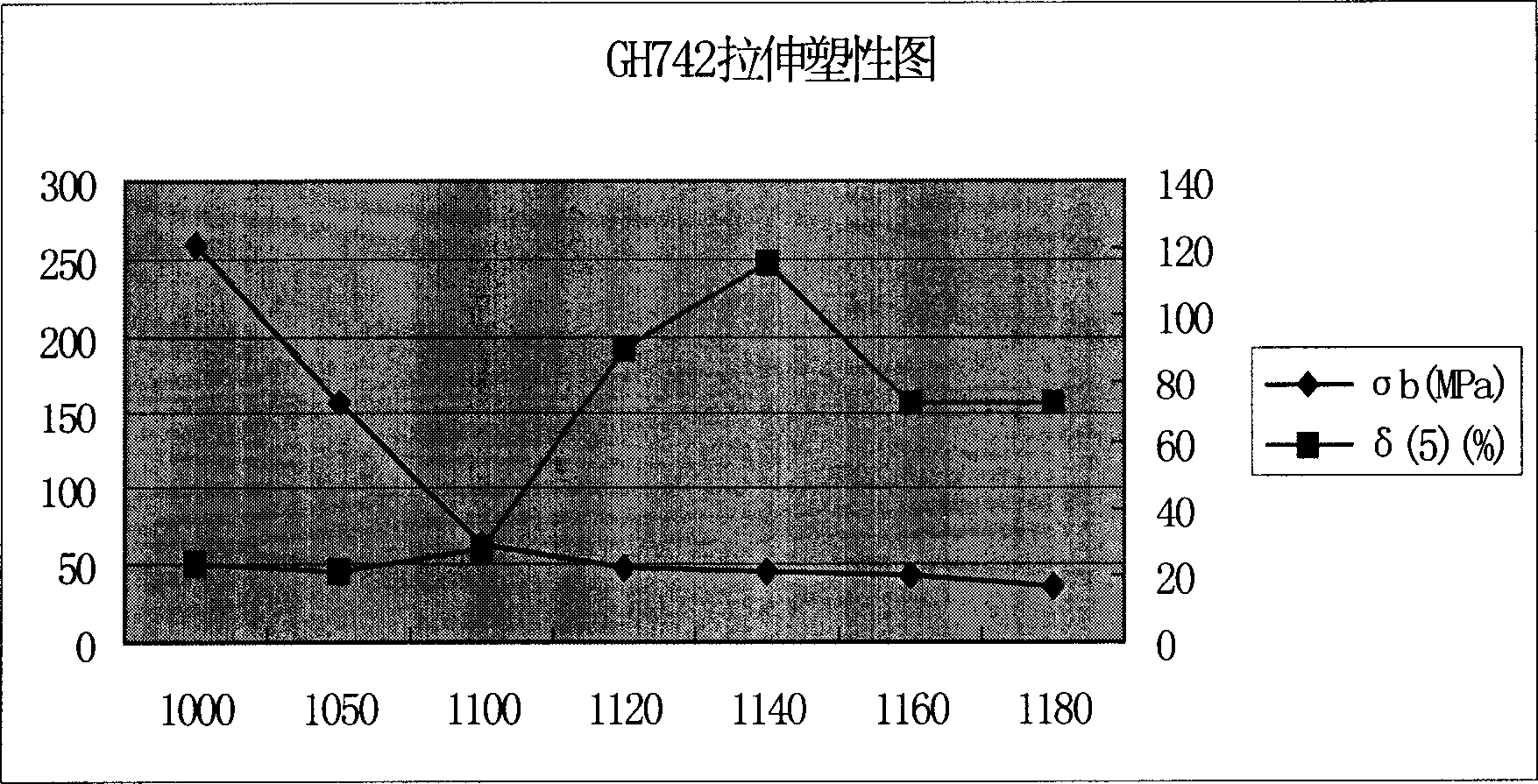

Heat keeping and forging and blank cogging method for GH742 alloy large steel ingot

ActiveCN1683097ATo achieve the purpose of heat preservation forgingReduce lossesMetal-working apparatusFiberAdhesive

The heat insulating, forging and blank cogging method of large GH742 alloy steel ingot features the high temperature adhesive of marketable glass powder with softening temperature over 800 deg.c and the heat insulating material of marketable asbestos blanket with aluminum silicate fiber; the steel ingot heat insulating process including spreading glass powder onto the asbestos blanket and coating the steel ingot after heating at 900 deg.c; the heat insulating period of 5-6 hr; the blank cogging of heating at high temperature with forging time not less than 5 min, reducing amount of 30 mm and deformation amount not less than 50 %; and the performance test of the formed alloy blank. The present invention solves the difficult problem of hot blank cogging and forming large GH742 alloy steel ingot.

Owner:宝武特种冶金有限公司

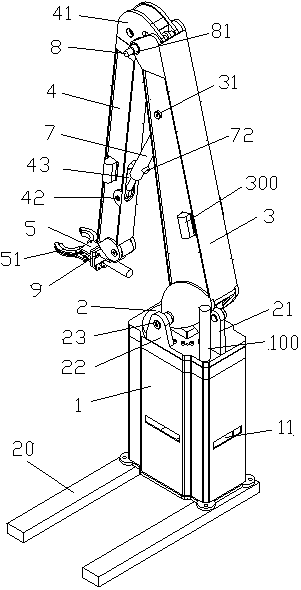

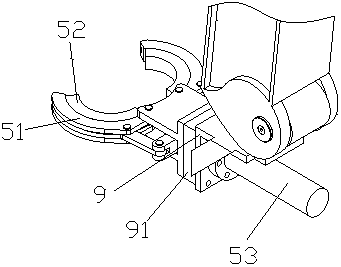

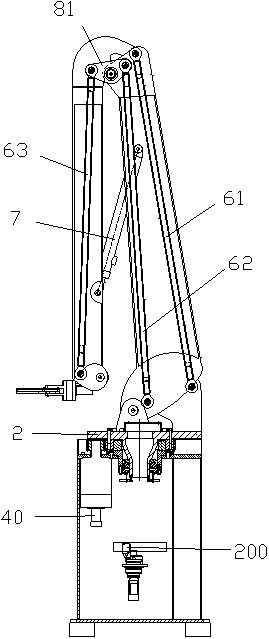

Robot for drilling operation

ActiveCN103696711ALarge amount of deformationPrecise positioningDrilling rodsDrilling casingsImaging processingMaster controller

The invention provides a robot for drilling operation. The robot comprises a base, a rotary table and a mechanical arm, wherein rotary table is arranged on the base, the mechanical arm is hinged with the rotary table and comprises a front arm and a rear arm, and the front arm and the rear arm are of box grinder type structures. The robot for drilling operation, provided by the invention, adopts bionic structure design to realize reasonable structural layout; the front arm and the rear arm simulate an upper arm and a forearm of a human body to be designed to the box grinder type structures, the strength of the front arm and the rear arm is enhanced, and high deformation during robot operation is avoided; meanwhile, a horizontal connecting rod and a bearing connecting rod are arranged in the front arm and the rear arm, the strength is enhanced, and the appearance attractiveness of the robot is also improved; a master controller controls positioning accuracy of the robot via a proportional valve and an absolute encoder so that the robot can be accurately positioned; an image processing and positioning device is additionally arranged and used for accurately distinguishing the position of a drill rod; and a collision prevention sensor is arranged for the sake of safety during operation.

Owner:QINGDAO JIERUI IND CONTROL TECH CO LTD

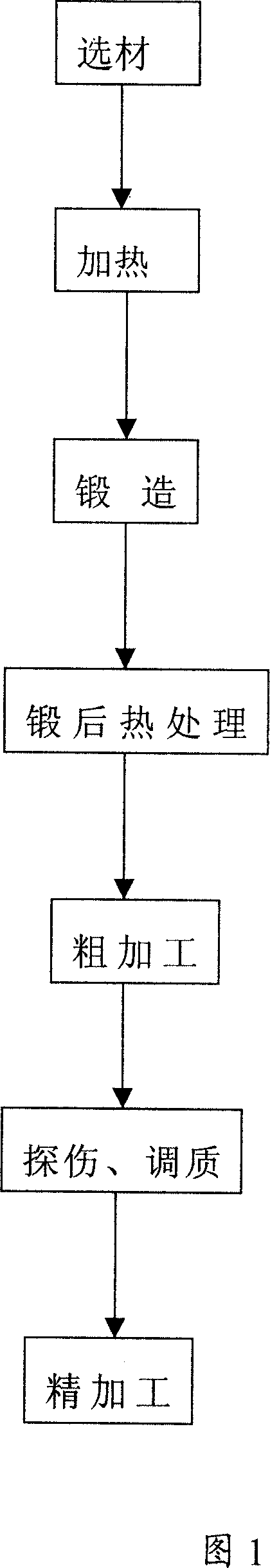

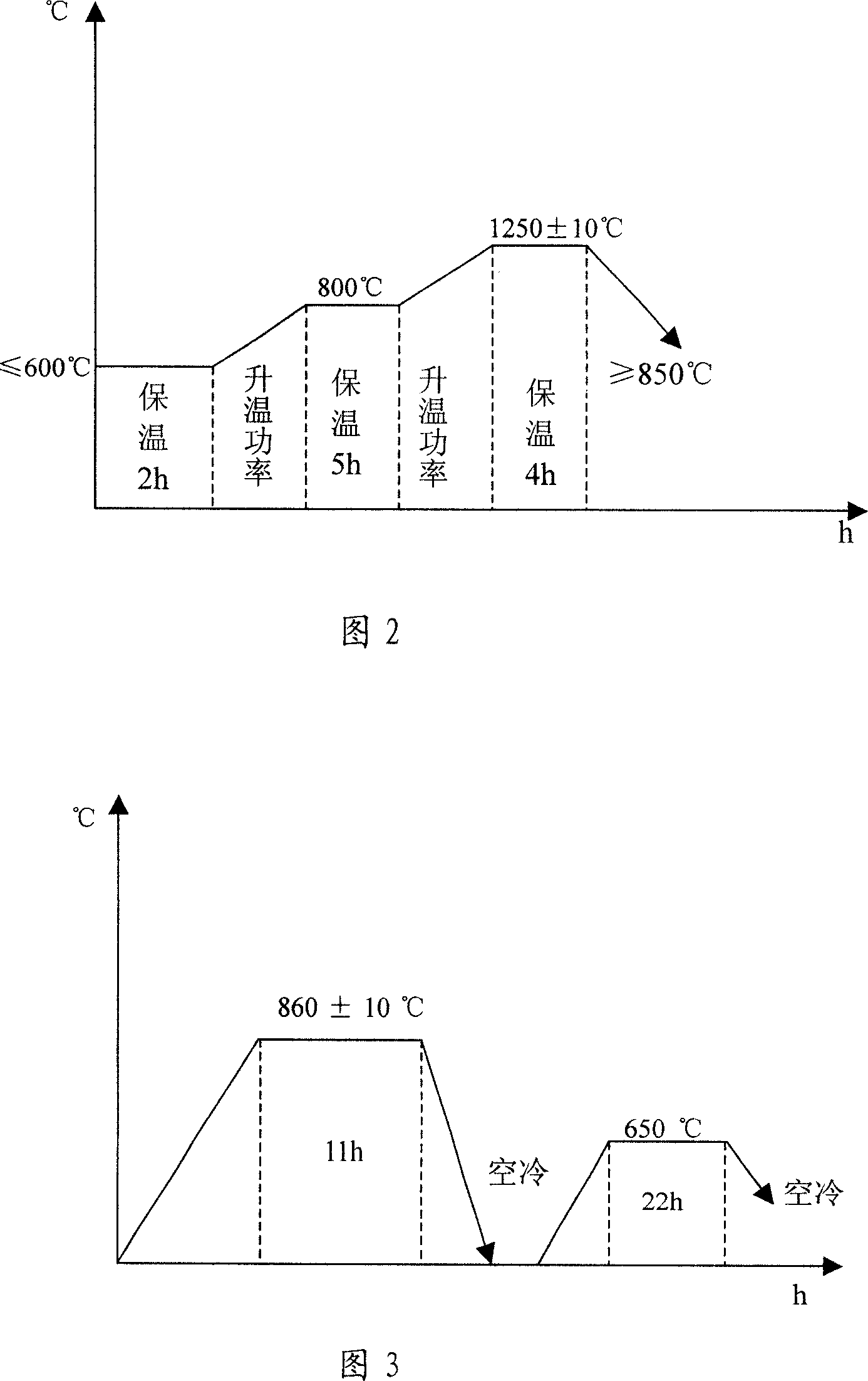

Method for making hammer stem for forging equipment

ActiveCN1962177ALarge amount of deformationImprove mechanical propertiesForging hammersFurnace typesElectricityThermal insulation

The invention relates to a method for producing hammer rod in forge device, wherein it comprises selecting material, forging, thermal treatment, rough treatment, defect detection, adjusting material, and fine treatment. The invention uses steel block, rolling material or forge material refined from steel pack or slag fusion technique. The invention uses gradient heating, multistage thermal insulation to heat, and uses hydraulic machine to forge, and it has defect detection after rough treatment to select different adjustments, therefore, the final metal phase and mechanical property can reach best. The invention can improve the service life of hammer rod, while the average hammer times can reach 300 thousand.

Owner:CHONGQING CHANGZHENG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com