Spring leaf-type bistable electromagnetic piezoelectric composite energy collecting device

A technology of piezoelectric compounding and energy harvesting, applied in electromechanical devices, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of narrow operating frequency band of energy harvesters and limited power generation efficiency, etc. problem, to achieve the effect of improving energy harvesting efficiency, enhancing piezoelectric effect, and increasing electromagnetic induction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

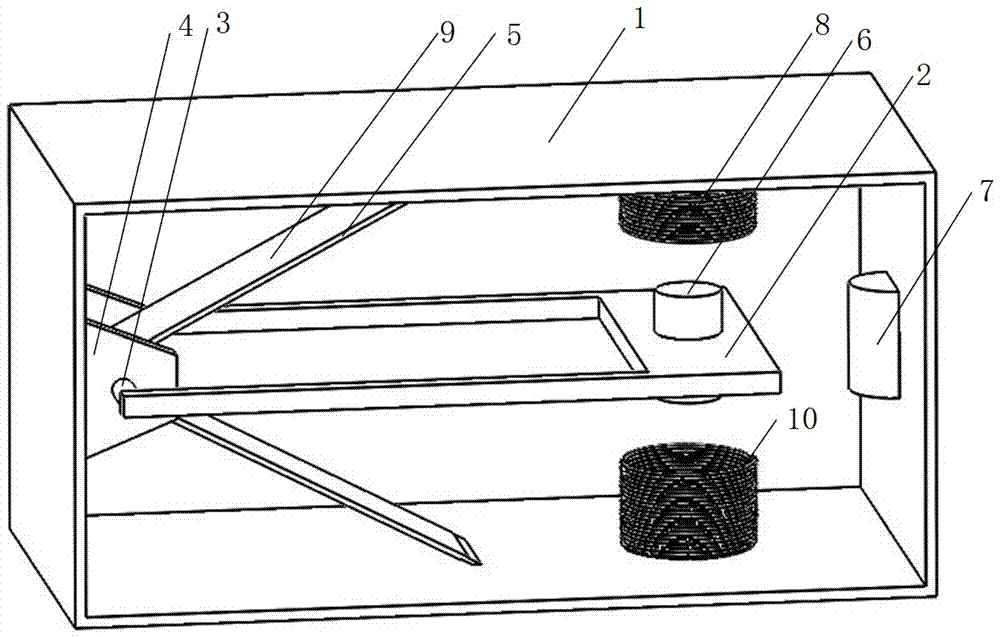

[0034] see figure 1 , a spring leaf type bistable electromagnetic piezoelectric composite energy harvesting device includes a static mechanism and a dynamic mechanism.

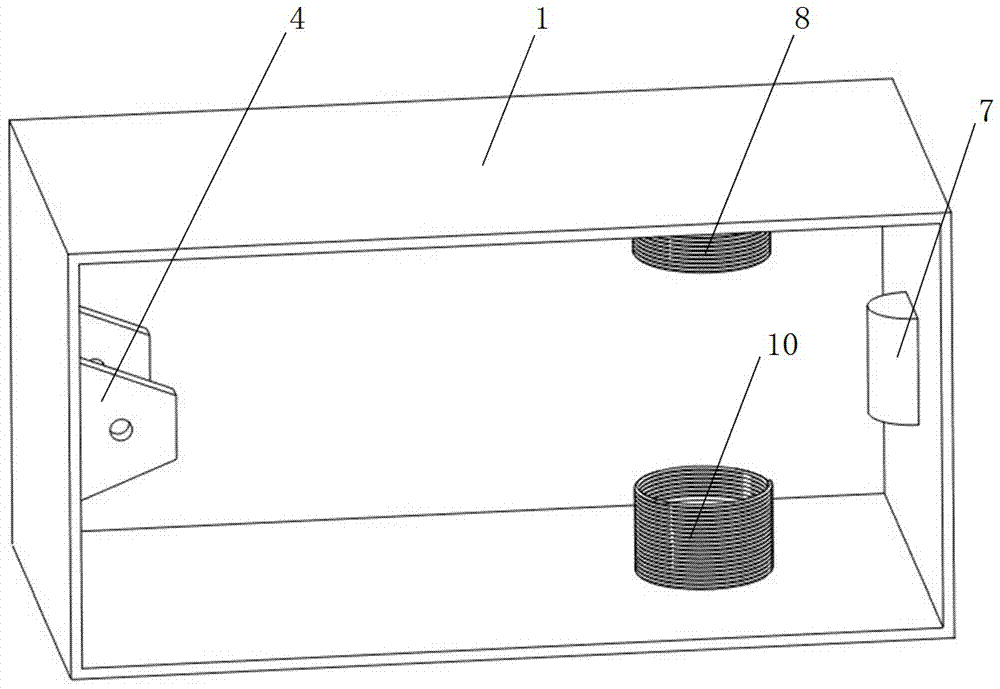

[0035] see figure 2 , the static mechanism includes a box-type casing 1, a bearing support 4 is installed in the middle of one side of the casing 1, and a columnar fixed magnet 7 is installed in the middle of the opposite side; the casing 1 adjacent to the fixed magnet 7 An upper coil 8 is installed on the inner top, and a lower coil 10 is installed on the inner bottom, and the upper coil 8 and the lower coil 10 correspond up and down. The material of the casing 1 is aluminum, and the inner top wall and the inner bottom wall of the casing 1 are respectively provided with insulating layers, so as to avoid conduction with the upper coil 8 and the lower coil 10 .

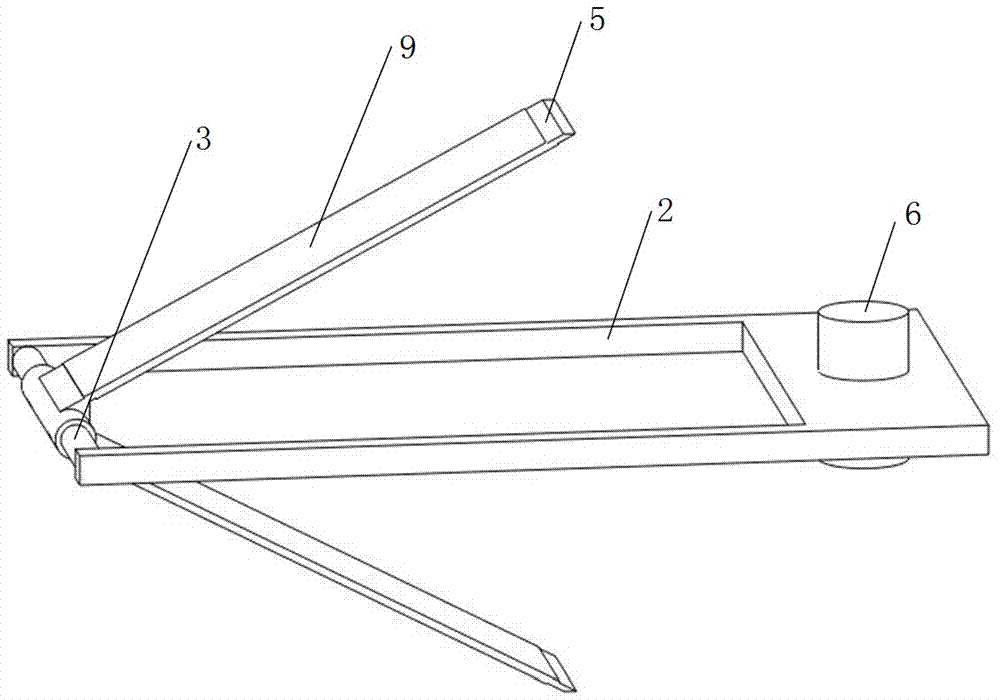

[0036] see image 3 , the dynamic mechanism includes a rectangular frame-type pendulum frame 2, and the material of the pendulum frame 2 is copper...

Embodiment 2

[0040] see Figure 5 , Figure 6 and Figure 7 , in this embodiment, three upper coils 8 are installed on the inner top of the casing 1 adjacent to the fixed magnet 7, and three lower coils 10 are installed on the inner bottom; three columnar vibrator magnets 6 are installed on the other end of the pendulum frame 2; Two ends of each vibrator magnet 6 correspond to three upper coils 8 and three lower coils 10 respectively. Other structures are the same as embodiment 1, and the working principle is the same as embodiment 1.

[0041] This embodiment uses three vibrator magnets 6, three upper coils 8 and three lower coils 10, which can greatly increase the electromagnetic power generation of the coils; on the other hand, since the number of vibrator magnets 6 has increased to three, the frame The sum of the repulsive force of the magnets on the 2 ends will also be doubled. Compared with Example 1, the upper stable position of the pendulum frame 2 during the vibration process w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com