Patents

Literature

3364results about How to "Smooth entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

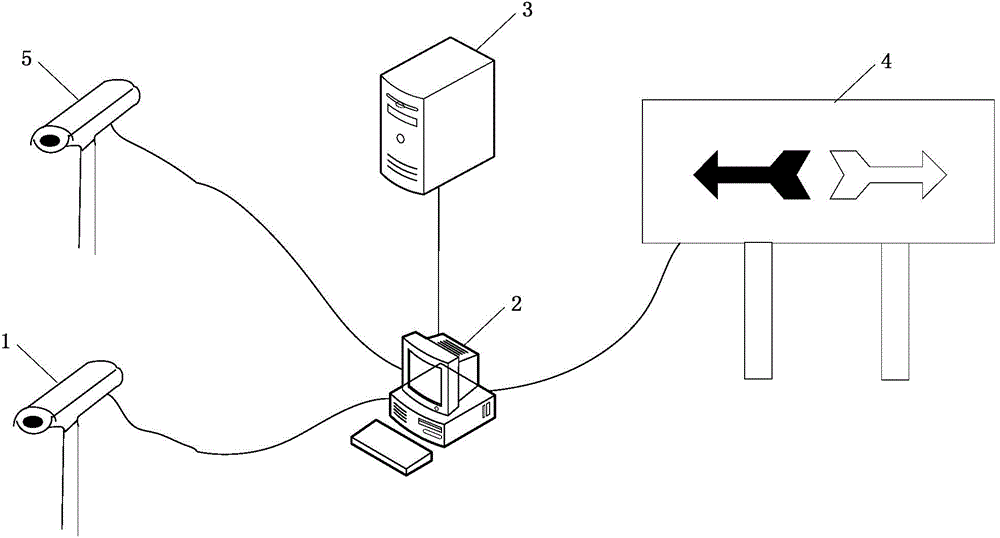

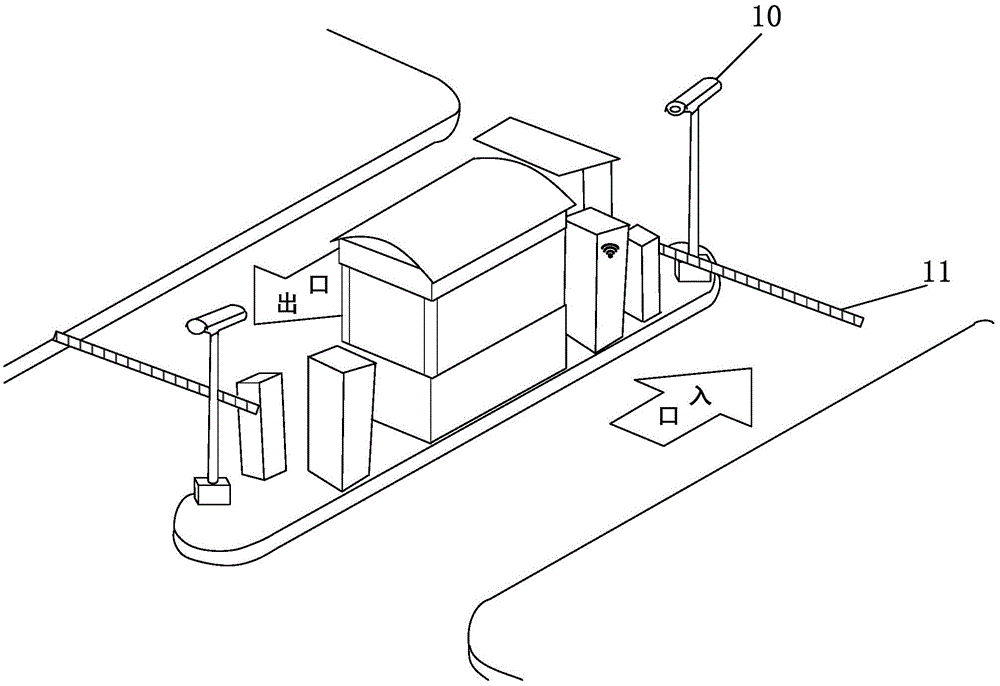

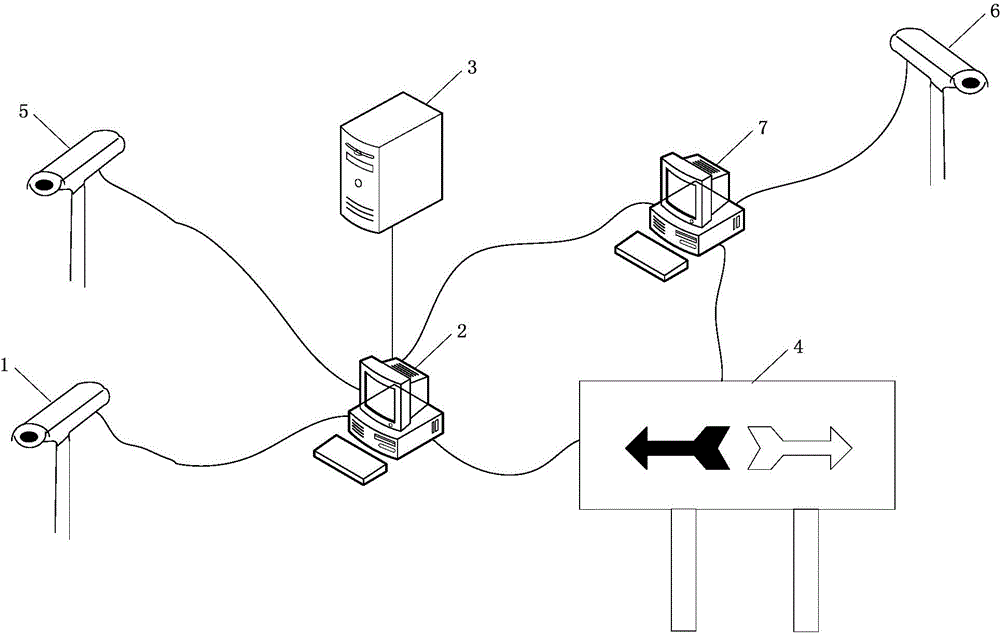

Parking lot control system

InactiveCN103985270ASmooth entryReduce parking timeIndication of parksing free spacesParking areaControl system

The invention discloses a parking lot control system. The parking lot control system comprises an entrance detection terminal, a vehicle guide device, an information storage device, a guide prompt device, a vehicle positioning device, a guide route correcting device and a plurality of parking space detection terminals. The entrance detection terminal is used for obtaining vehicle information of vehicles entering a parking lot in the position of the entrance of the parking lot. The information storage device is used for storing preset vehicle information and the vehicle information obtained through the entrance detection terminal, wherein each piece of preset vehicle information corresponds to a parking space. The vehicle positioning device is used for positioning vehicles running on passageways inside the parking lot. The vehicle guide device is used for generating guide routes between the current positions of vehicles and the target parking spaces according to the preset vehicle information. The guide route correcting device is used for correcting the guide routes. The guide prompt device is used for guiding vehicles to run to the parking spaces according to the guide routes. According to the parking lot control system, vehicles can be guided to smoothly run into the parking spaces in the parking lot, parking time is shortened, and the utilization efficiency of the parking spaces in the parking lot is improved.

Owner:北京数字智通科技有限公司

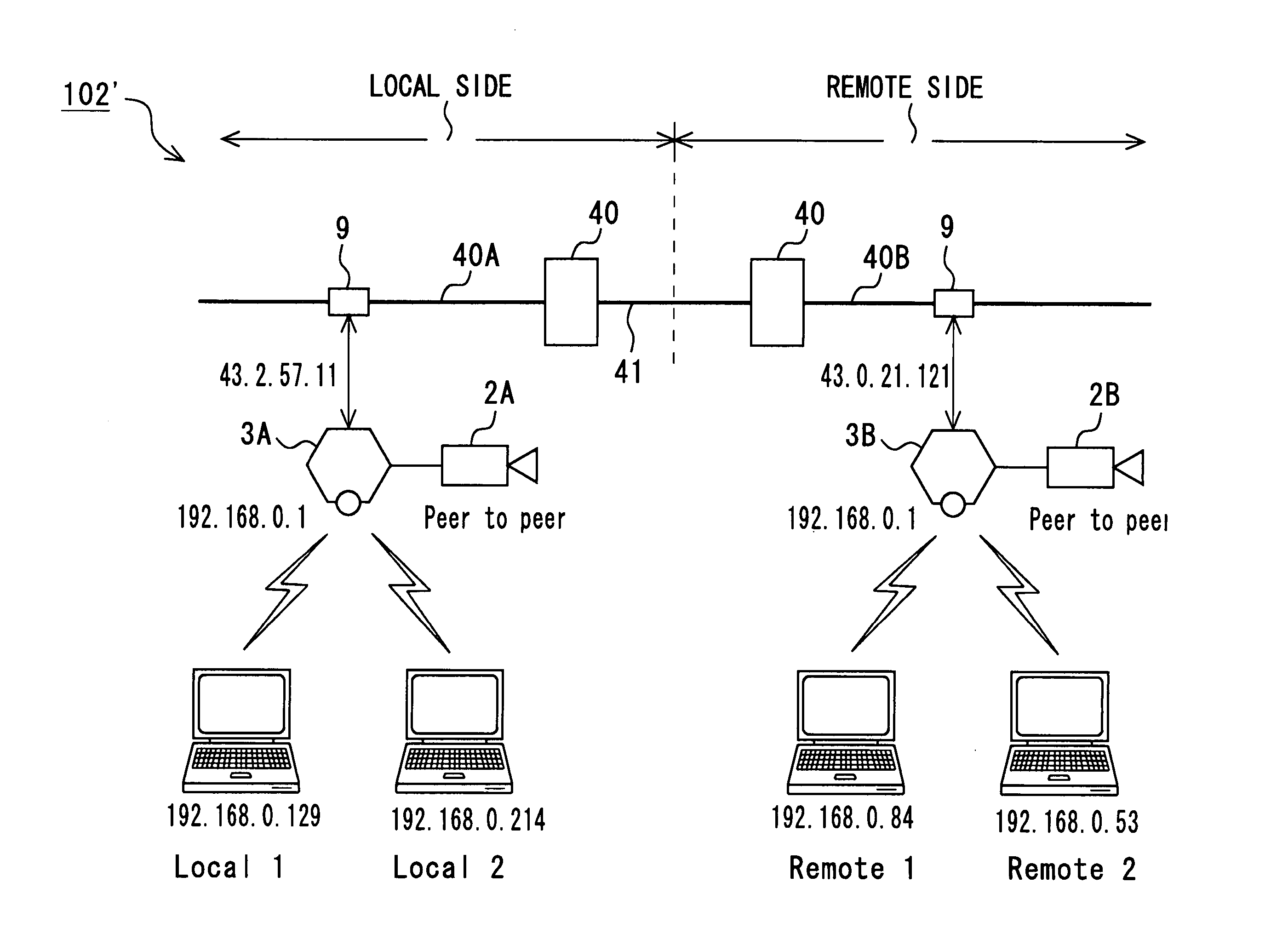

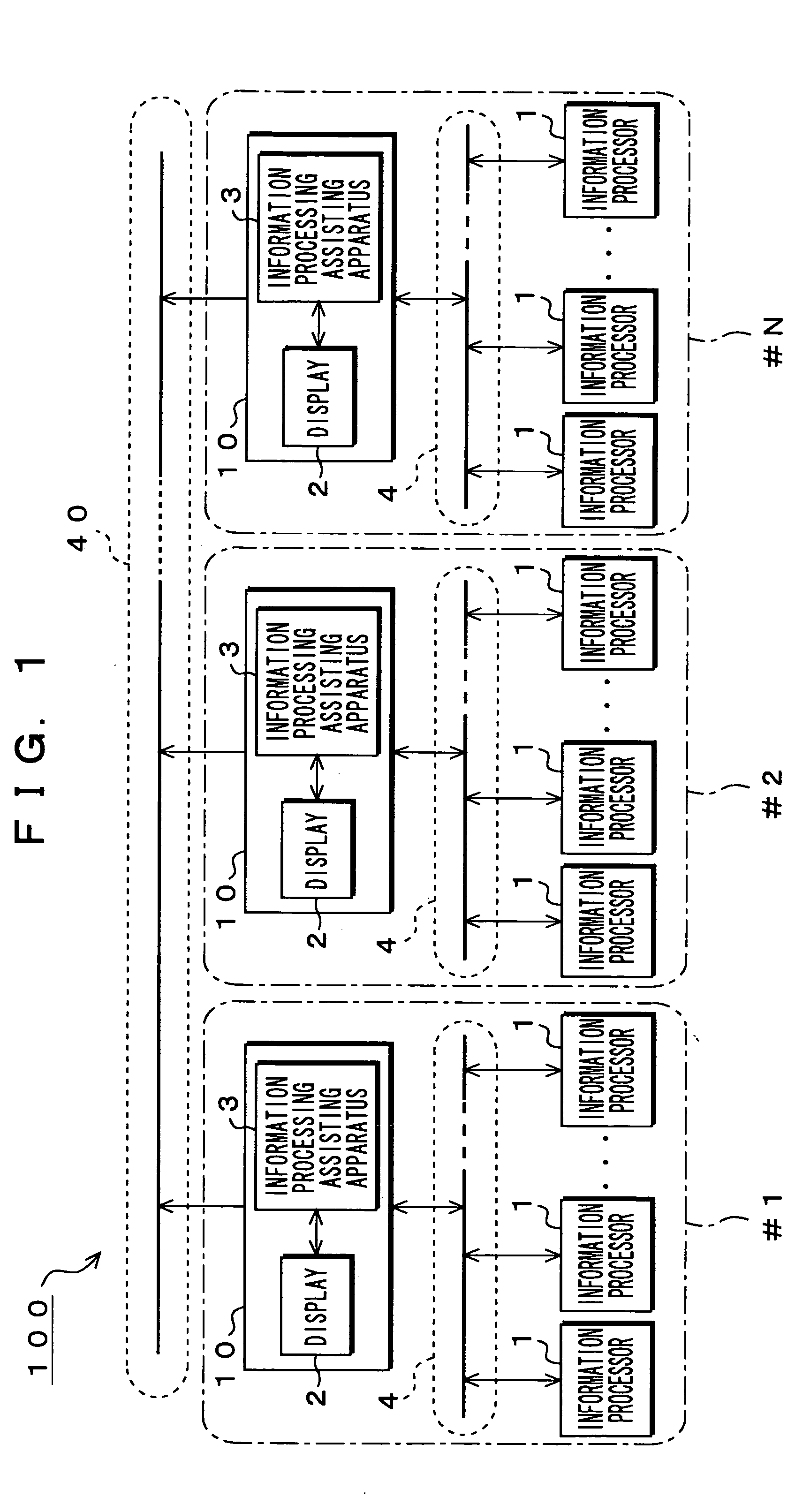

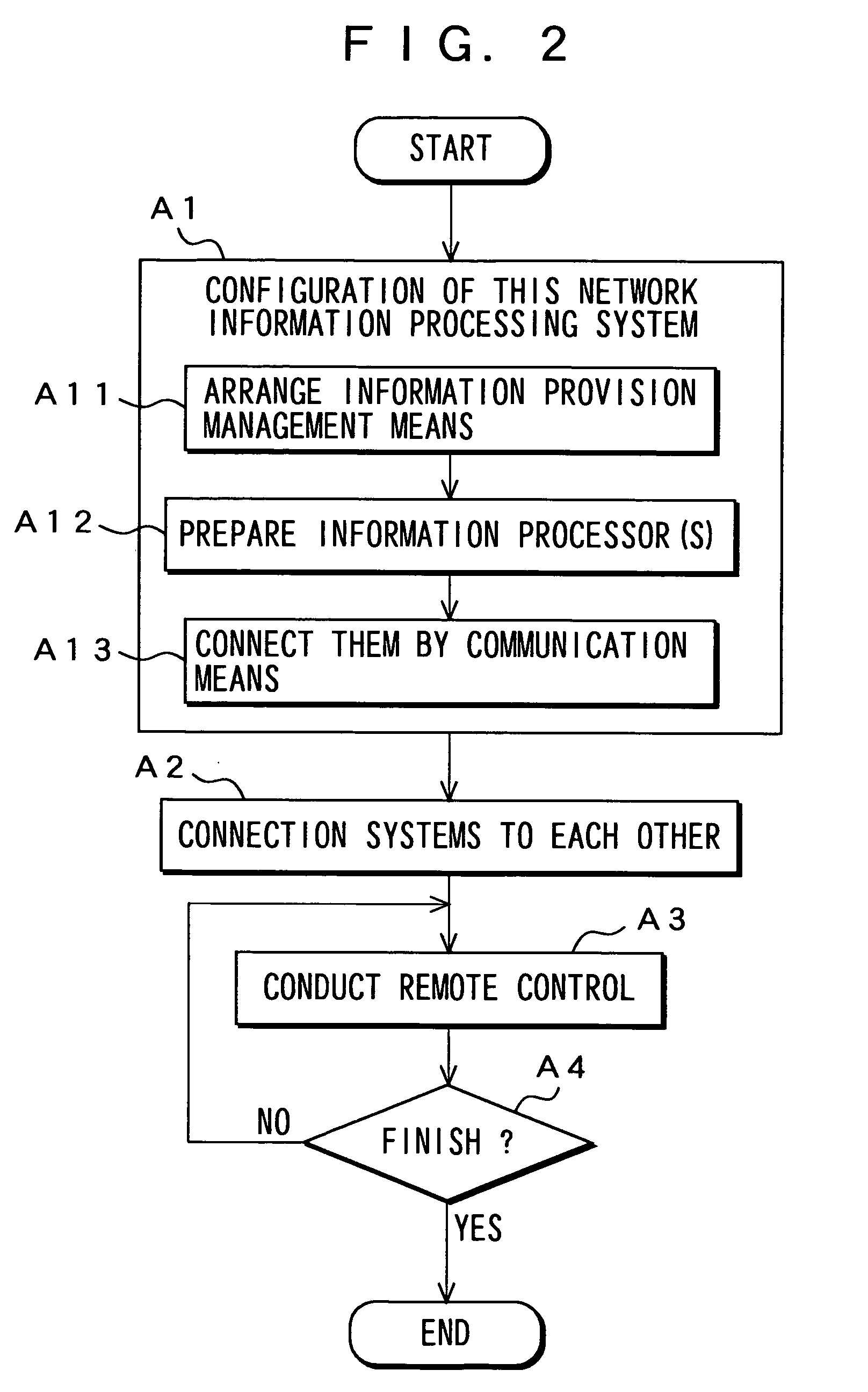

Network information processing system and information processing method

InactiveUS20050071430A1BuildSmooth entrySpecial service provision for substationTelevision conference systemsInformation processingPersonal computer

The present network electronic conferencing system 101 comprises, as shown in FIG. 4, at least one notebook personal computer PCi (i=1-3), a communicator (3A) or a projector (2A) for processing at least information transferred from this notebook personal computer PCi and providing electric information contents including display information, and an access point (6) for connecting this communicator (3A) to each of the notebook personal computers PCi. The communicator (3A) delivers all at once identification information packets for identifying the projector (2A), the notebook personal computers PCi, the access point (6), etc., while the notebook personal computer PCi displays identification information and selects electronic devices including the communicator (3A) and the other notebook personal computers PCi. It is possible for a user to easily attend his or her intended conference etc.

Owner:SONY CORP

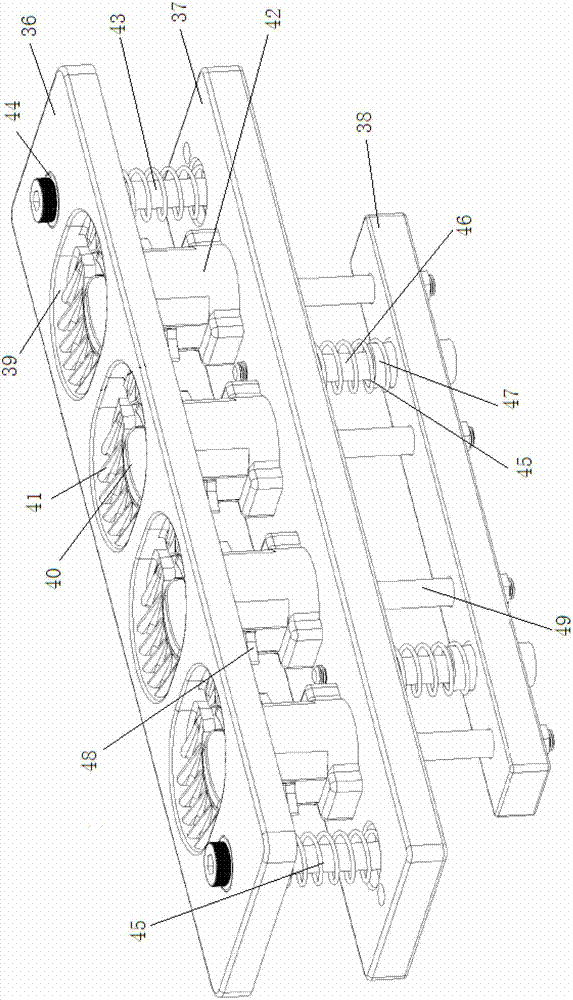

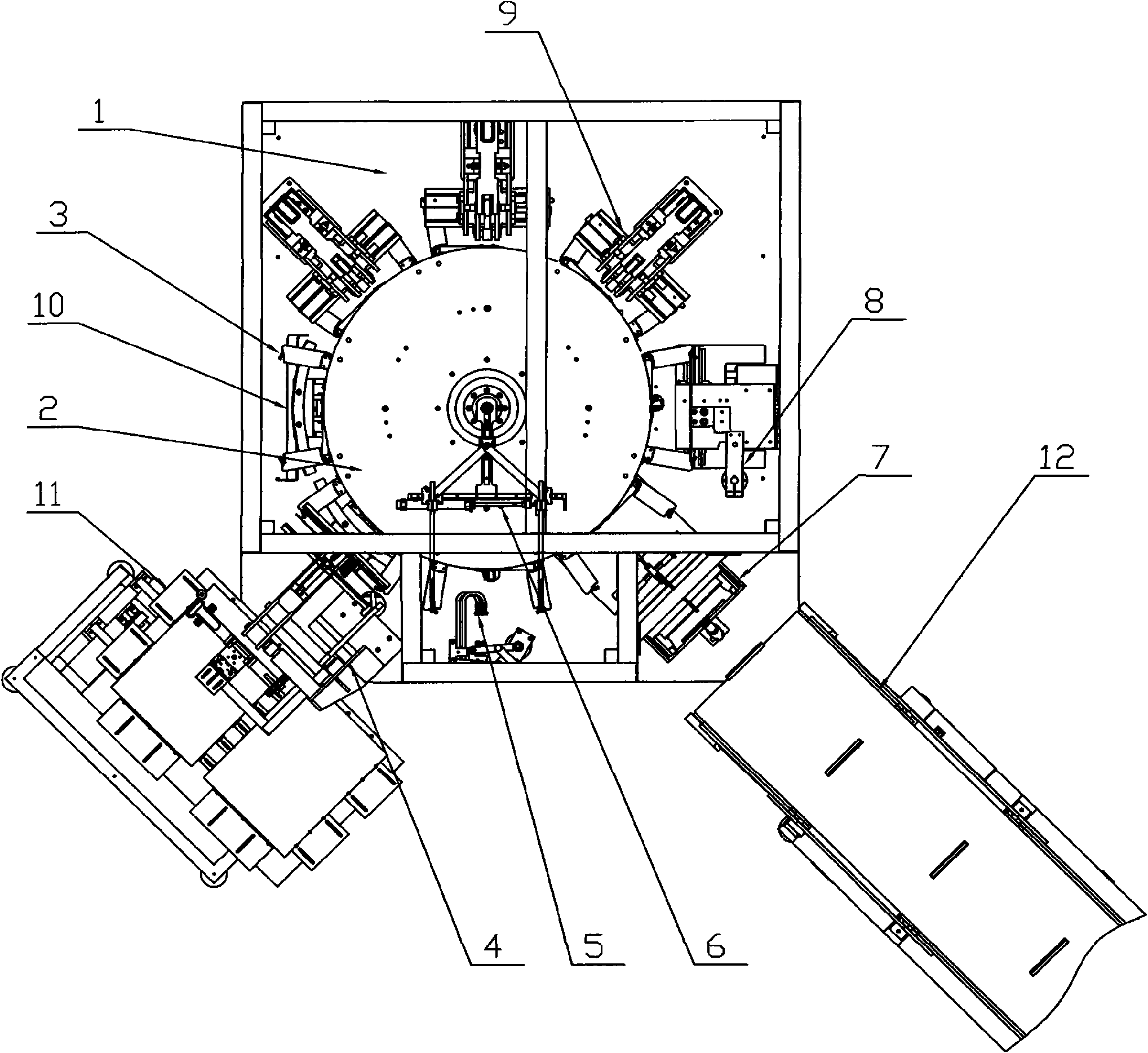

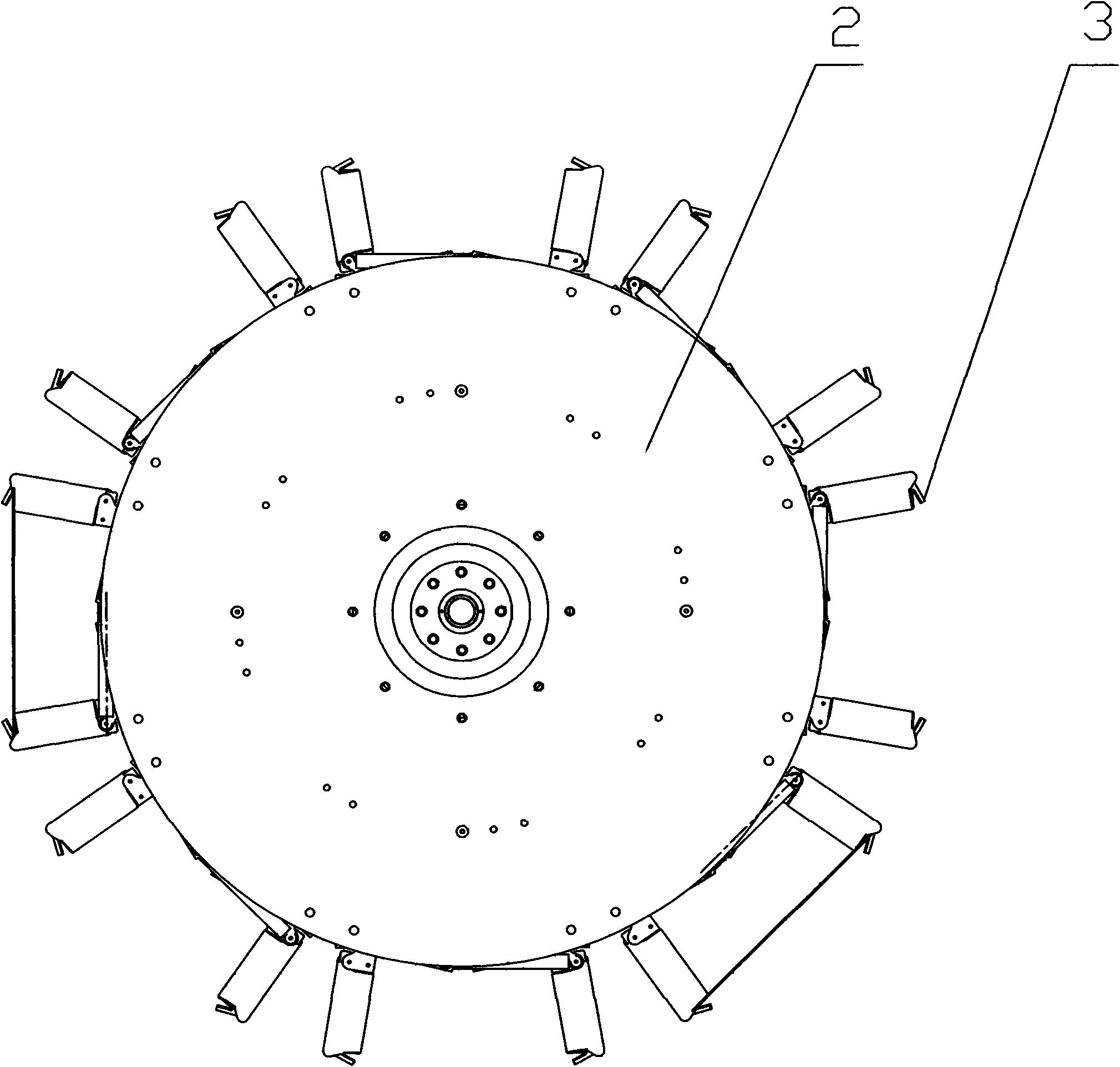

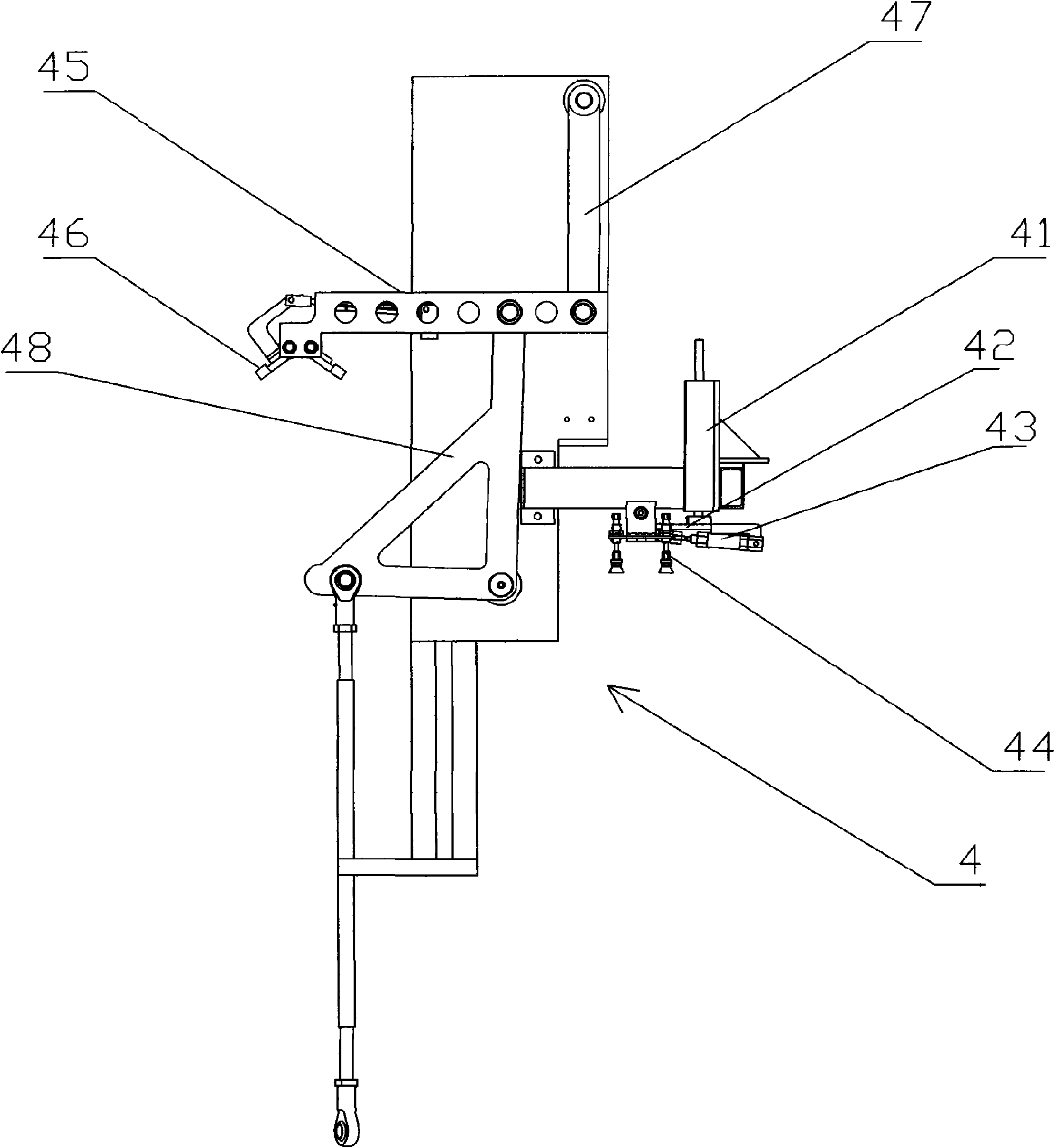

Multifunctional automatic dumpling machine

InactiveCN102726671AGood synchronizationSimple designFood shapingFood preparationSkin rollingBiomedical engineering

The invention discloses a multifunctional automatic dumpling machine, comprising a rack, a skin rolling mechanism, a skin conveyer belt, a punching skin conveying mechanism, a stuffing filling unit, a die closing unit, an encircling intermittent movement dumpling forming template, a disk conveying mechanism, a placement mechanism, an intermittent driving unit and a stepping motor, wherein the punching skin conveying mechanism structurally has a structure that blanking holes on upper and lower side synchronous belts are vertically alignment, the stuffing filling unit realizes multi-hole quantification and synchronization stuffing filling; the contact surface between the skin and the template is reduced by 90% by using the structure of a movable template on the encircling intermittent movement dumpling forming template; protrusion ribs have certain gradients, thus the skins do not adhere to the template and can smoothly enter the forming die; and die assembly can be complete by the projection and concave cavity, thus the produced dumpling has beautiful appearance, and the advantages of firm bonding and low cost are achieved.

Owner:朱景超

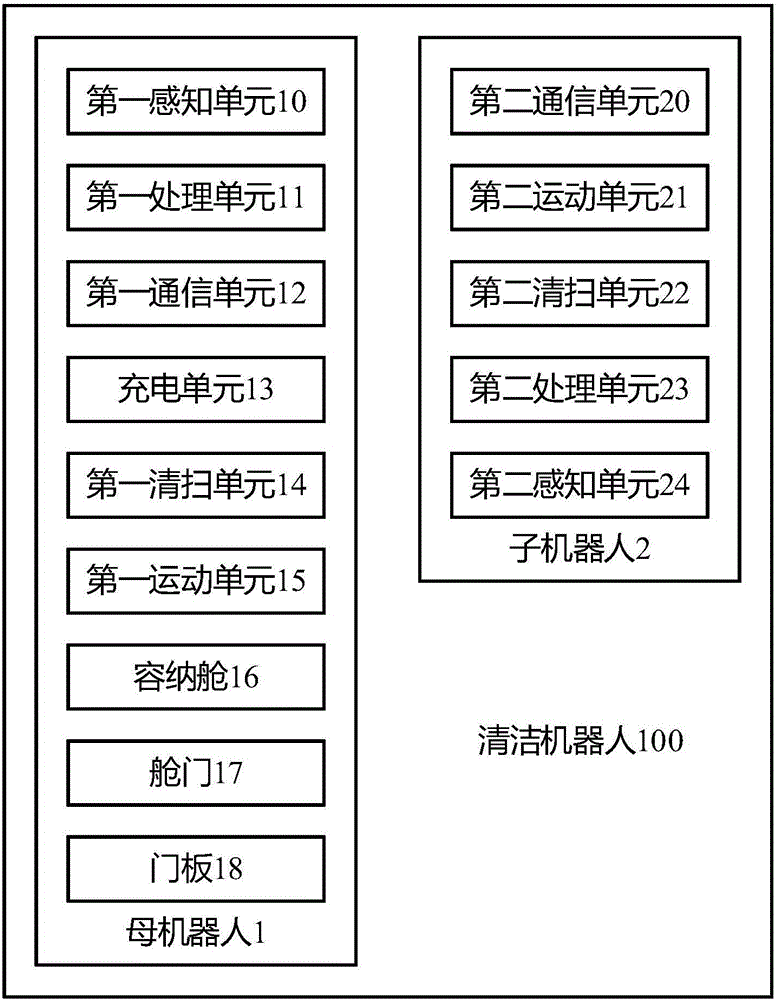

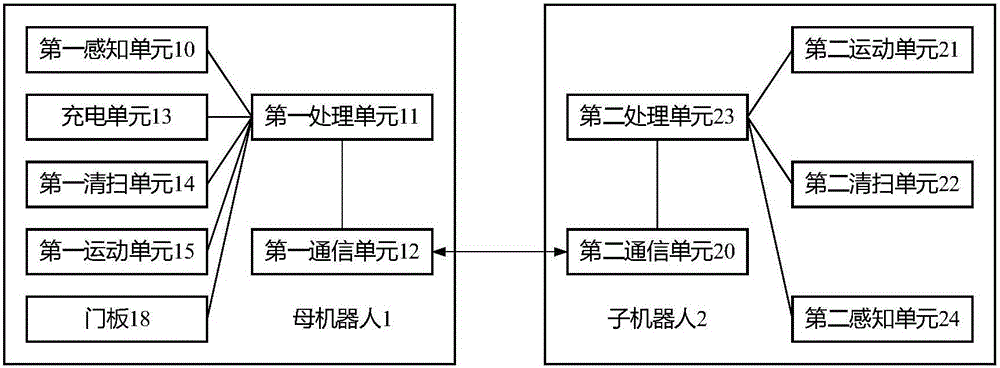

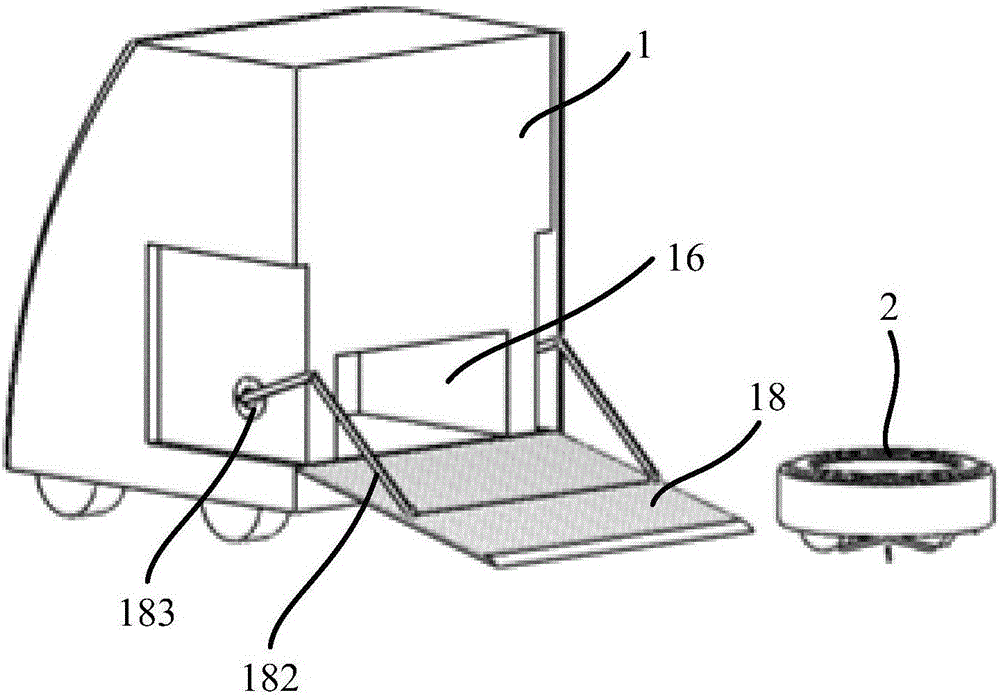

Cleaning robot and working method for cleaning robot

InactiveCN105686766AStrong cleaning ability and battery lifeIncrease storage spaceAutomatic obstacle detectionProgramme-controlled manipulatorRobot perceptionControl theory

The invention relates to a cleaning robot.The cleaning robot comprises a primary robot body and at least one secondary robot body.The primary robot body carries the at least one secondary robot body, and is larger than the secondary robot body in size, and the primary robot body perceives the environment parameters of a target area; whether the primary robot body enters the target area or not is judged according to the environment parameters; if the primary robot body can not enter the target area, a first command is transmitted to the secondary robot body; the secondary robot body receives the first command; when the secondary robot body receives the first command, the secondary robot body is separated from the primary robot body and enters the target area to clean the target area.According to the embodiment in the technical scheme, the target area where the primary can not enter can be cleaned through the secondary robot body carried by the primary robot body; as the secondary robot body is small in size, the secondary robot body can smoothly enter the target area to conveniently complete cleaning work for the target area.

Owner:BOE TECH GRP CO LTD

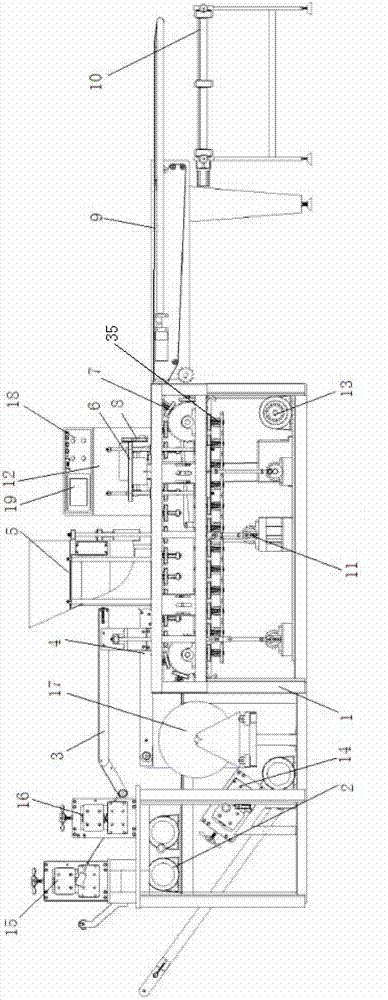

Method for packaging large flatbreads and fully-automatic flatbread packaging machine for achieving same

InactiveCN101590920ASimple methodImprove processing efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringPlastic bagEngineering

The invention relates to a method for packaging large flatbreads and a fully-automatic flatbread packaging machine for achieving the same. The method comprises the following steps: taking bags: picking up packaging bags; opening the packaging bags: opening bag openings of the packaging bags; keeping the packaging bags open: using a mechanism to keep the bag openings of the packaging bags in an open state; filling the large flatbreads: filling the large flatbreads into plastic bags smoothly by using a conveying belt and a charge mechanism; vacuumizing the plastic bags: discharging the air in the plastic bags to the outside by using a vacuumizing pipe; and sealing the plastic bags: sealing the bag openings of the plastic bags to finish the packaging. The fully-automatic flatbread packaging machine comprises a stander, a turntable arranged on the stander, and a plurality of pairs of clips arranged on the periphery of the turntable. The periphery of the turntable is provided with a bag-delivering mechanism, a bag-opening mechanism, an oscillating bag-opening mechanism and the charge mechanism in turn, and then the periphery of the turntable is provided with a vacuumizing sealing mechanism for vacuumizing the air in the plastic bags and sealing the bag openings preliminarily, a sealing mechanism for completely sealing the bag openings of the plastic bags, and a shedding mechanism for taking down the plastic bags from the clips in turn.

Owner:ZHONGSHAN NCA

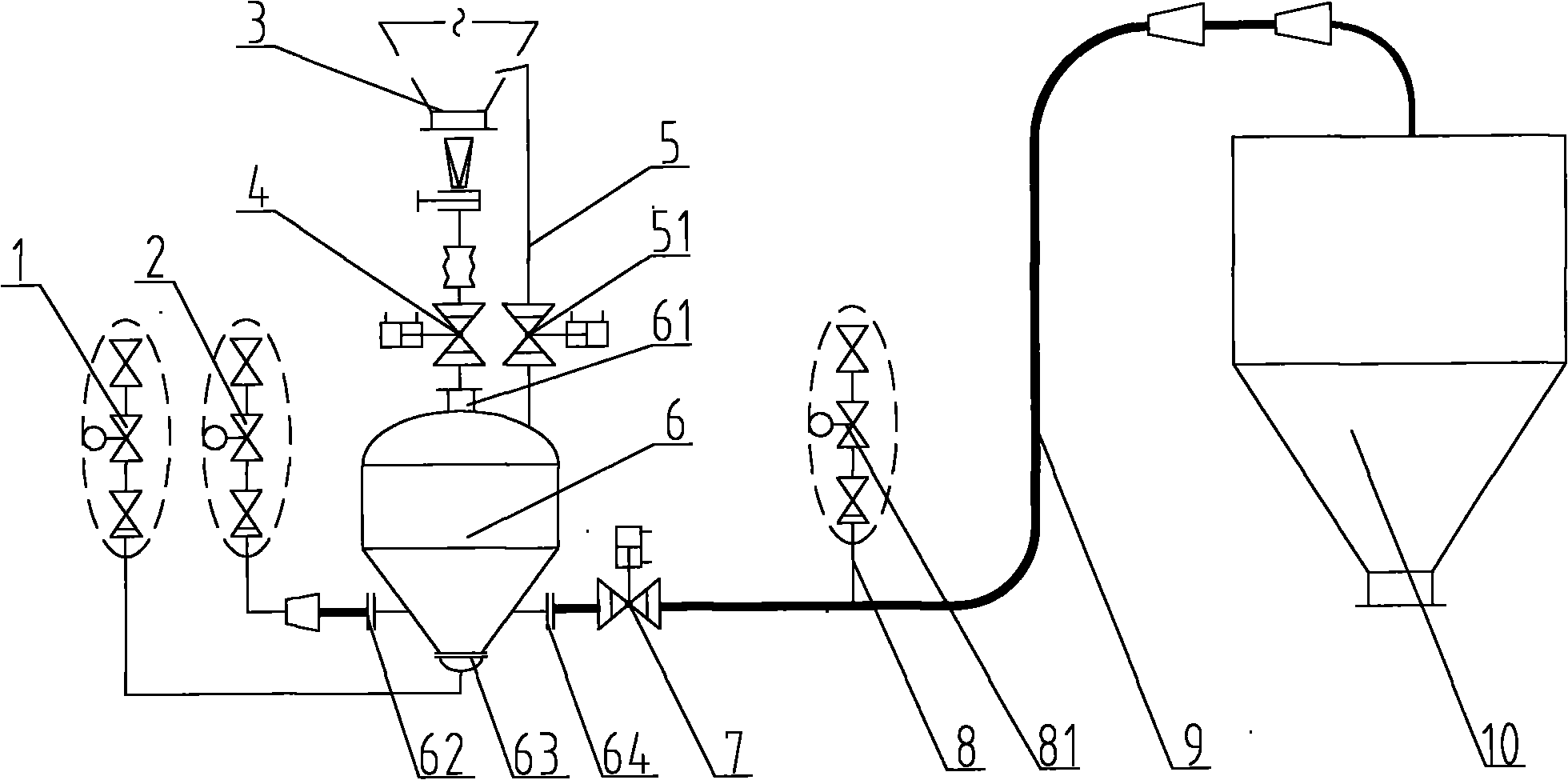

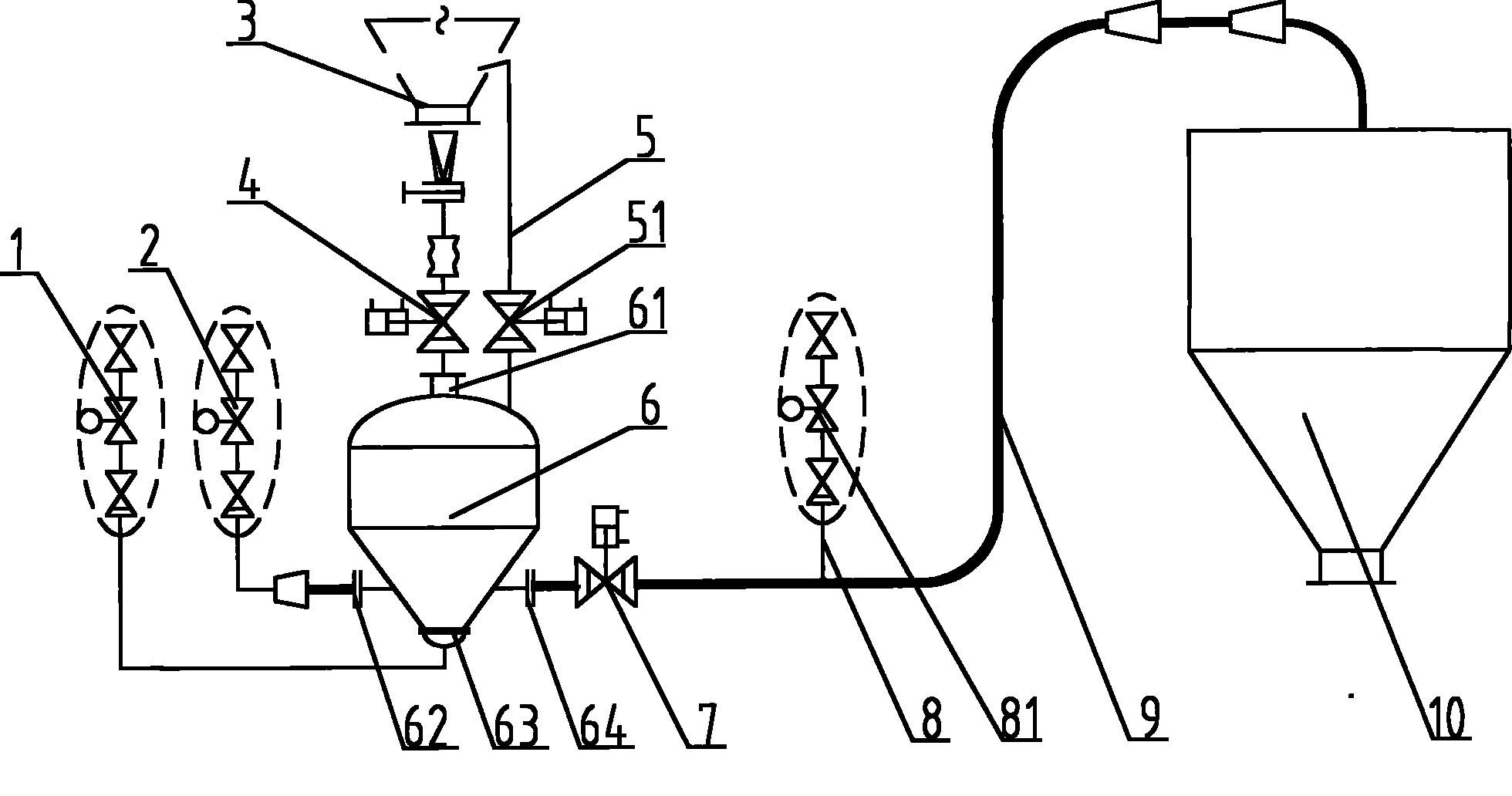

Pneumatic conveyer

The invention discloses a pneumatic conveying device, which comprises a bin pump and a delivery duct. The driving air inlet of the bin pump is connected with a bin pump cone and is in the same central line with the discharging hole of the bin pump. The diameter of the delivery duct is increased gradually. The device also comprises at least one air make-up duct. The air make-up duct is provided with a plurality of openings circumferentially distributed along the inner wall of the delivery duct. The opening direction is consistent with the flowing direction of a solid-gas mixture. The working process comprises three steps, namely feeding, fluidifying and adjusting the flow rate of the solid-gas mixture. Air is introduced into the delivery duct by the air make-up duct to adjust pressure in the delivery duct and adjust the flow velocity of solid-gas mixture so as to ensure that the solid-gas mixture has proper flow velocity, thus lowering the wear rate of the delivery duct, reducing the possibility of delivery duct blockage, and ensuring the working reliability of the pneumatic conveyer.

Owner:FUJIAN LONGKING

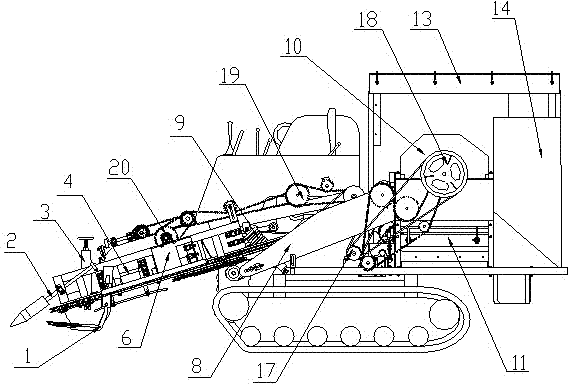

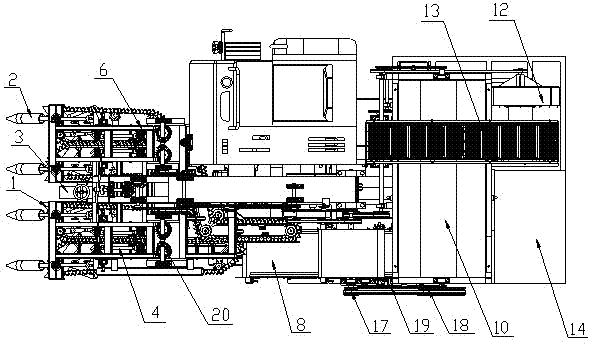

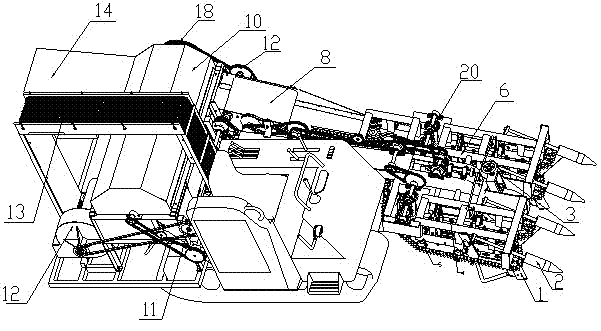

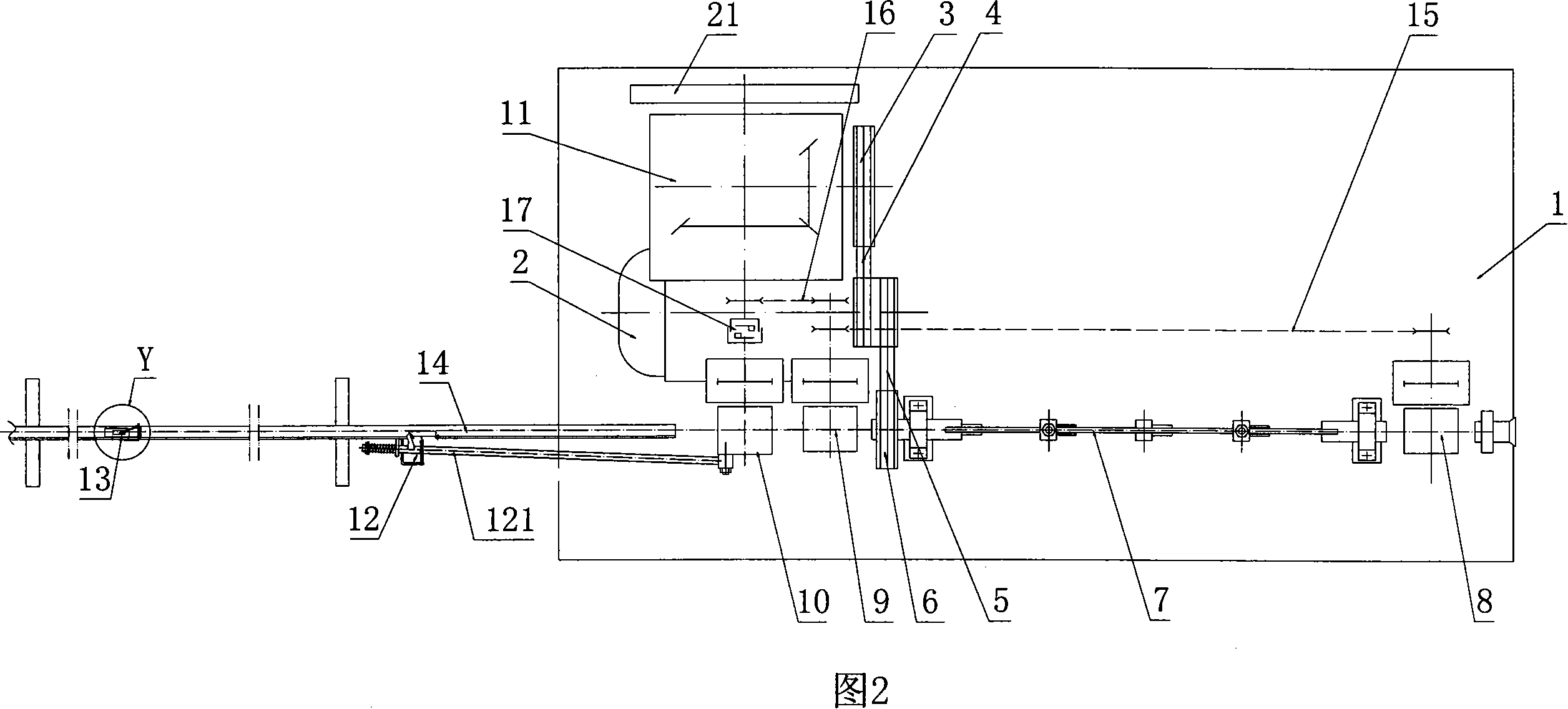

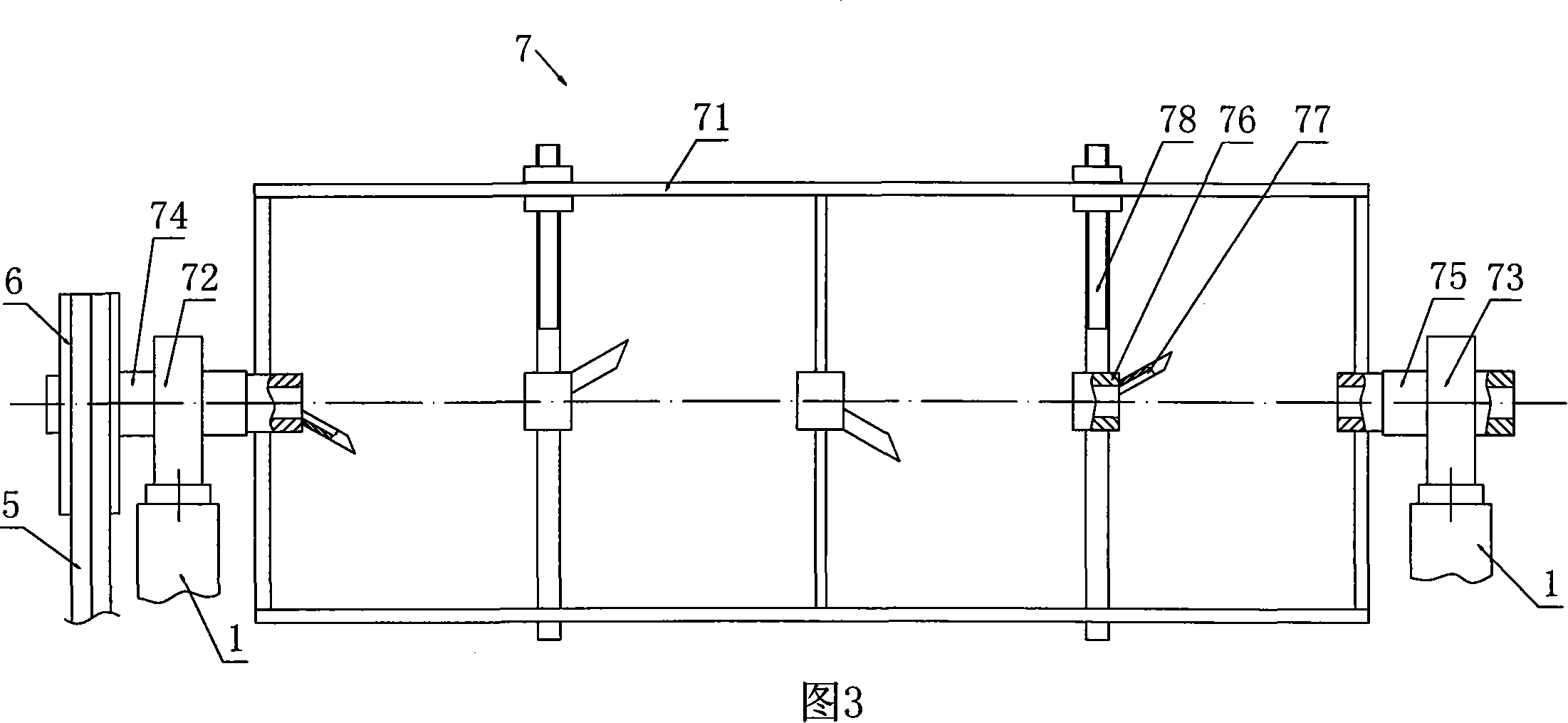

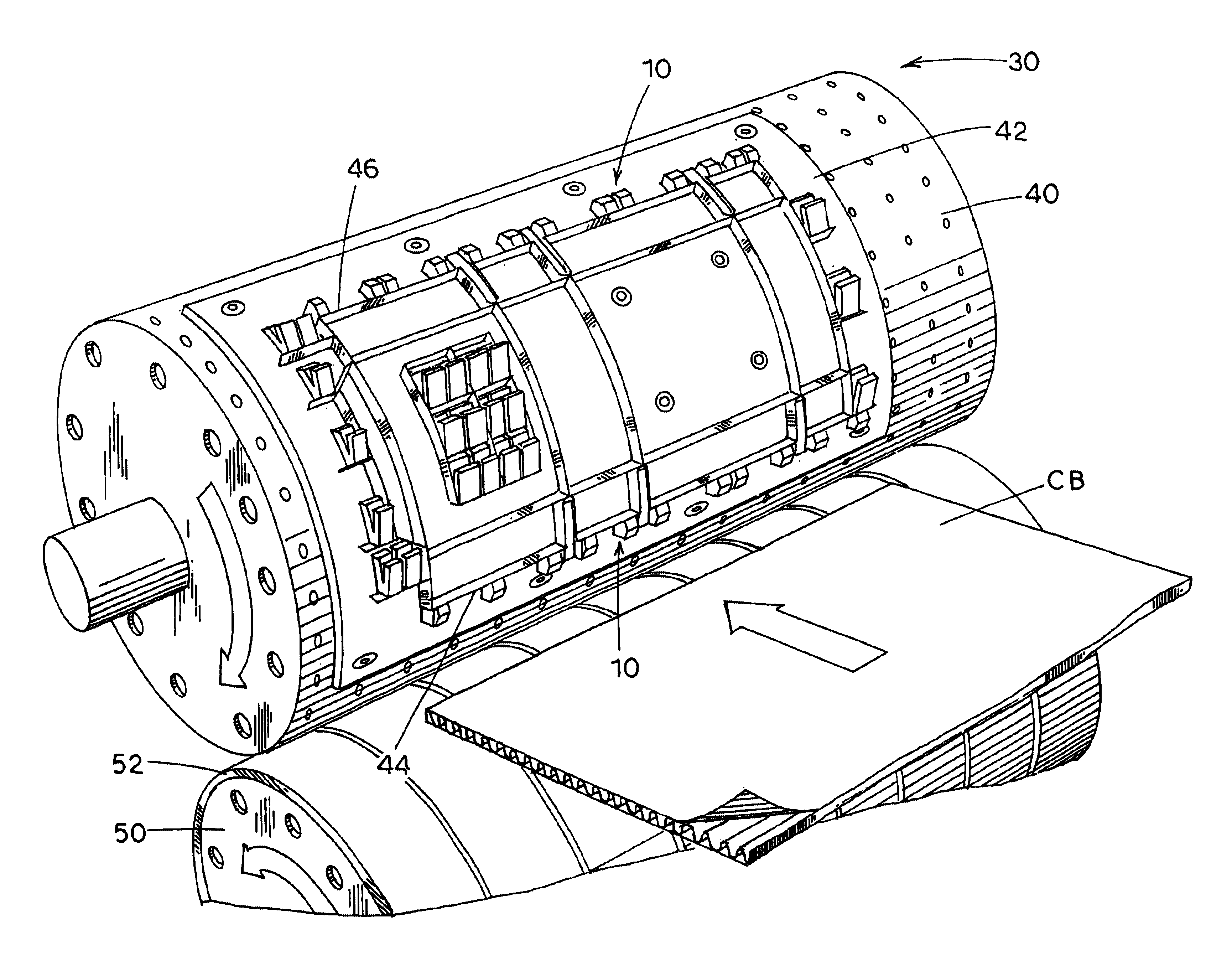

Two-ridge four-row whole-feeding peanut combine harvester

InactiveCN103039175AAchieve harvestRealize the clamping effectDigger harvestersThreshersEngineeringCombine harvester

Disclosed is a two-ridge four-row whole-feeding peanut combine harvester. The two-ridge four-row whole-feeding peanut combine harvester comprises a driving device, a clamping conveying device, a peanut picking sorting device and a peanut lifting device, the clamping conveying device comprises a two-ridge four-row clamping conveying collecting device and a conveying device, the two-ridge four-row clamping conveying collecting device comprises a clamping chain rack and clamping chains I, II, III, IV and V, a peanut vine clamping conveying path A is achieved by meshing of the clamping chain I and the clamping chain II, a peanut vine clamping conveying path B is achieved by meshing of the clamping chain III and the clamping chain IV, the clamping conveying collecting device further comprises a clamping collecting device, and the clamping conveying path A, the clamping conveying path B and conveyed peanut vines are gathered at a position of the clamping collecting device. By means of the two-ridge four-row whole-feeding peanut combine harvester, two-ridge four-row peanut vines can be harvested, clamped and conveyed, peanuts can be picked, sorted and collected, the work efficiency of the peanut combine harvester is improved, and time costs are lowered.

Owner:QINGDAO AGRI UNIV +1

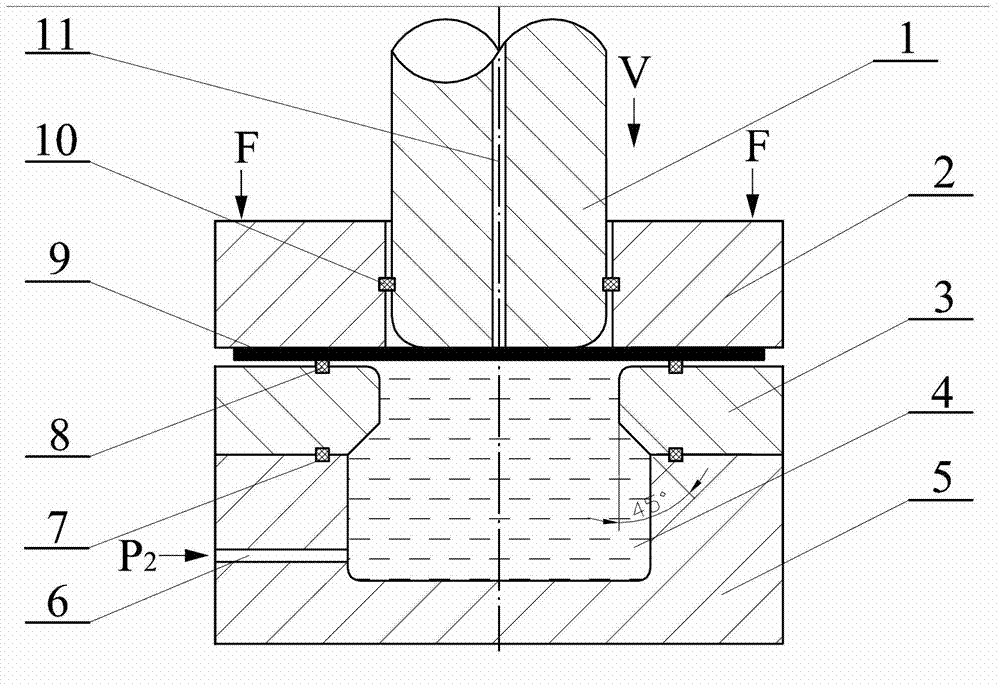

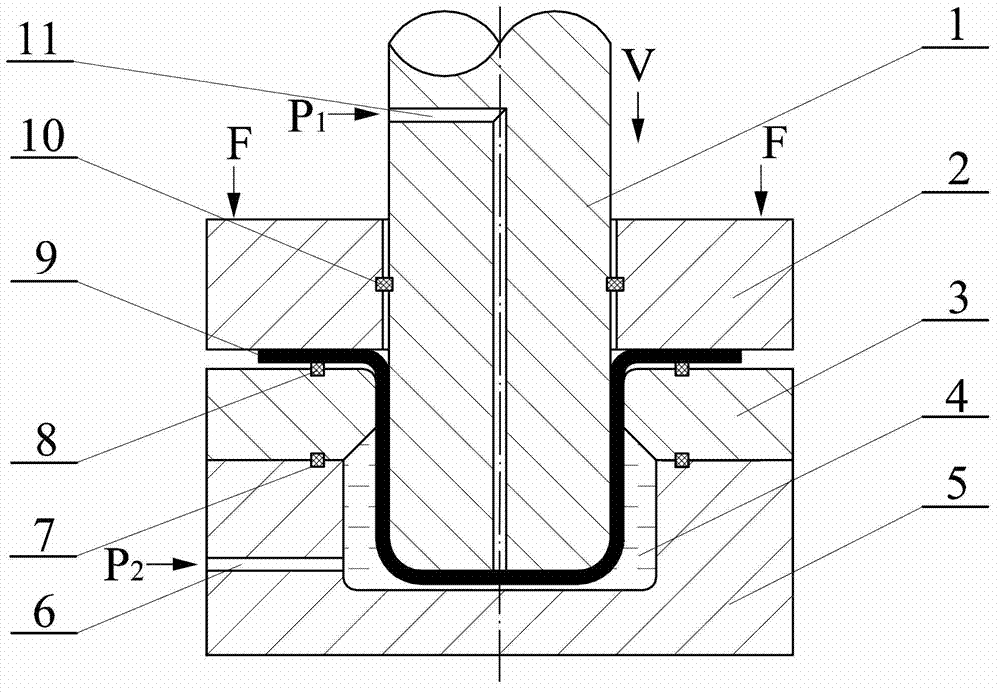

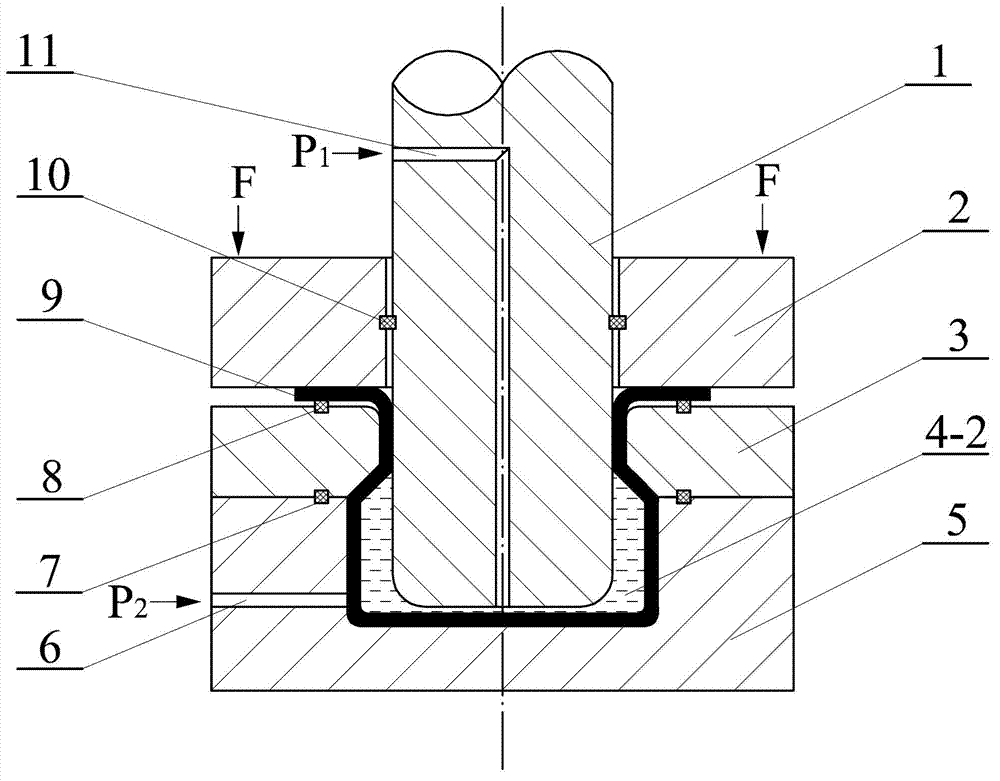

Hydraulic forming device and method of reducing cylindrical part

A hydraulic forming device and method of a reducing cylindrical part relate to a hydraulic forming device and method of a metal plate. Aiming at the bottleneck problems of high cost, long cycle and poor forming property in a roll welding process used due to the fact that the reducing cylindrical part, the section of an axis part of which is of a bottle shape with a small upper part and a big lower part, is difficult to machine by using the traditional plate hydraulic forming method, the device comprises a lower concave die and an upper concave die; a blank holder and a convex die are arranged above the upper concave die; the shape of a cavity in the concave die is in accordance with the shape of the outer outline of a finally-formed cylindrical part, namely the cavity is configured into a reducing cylinder with the aperture gradually reduced from the bottom to the top or reducing in a stepped form; and the lower concave die and the convex die are respectively provided with an injection hole. The forming method sequentially comprises the following steps of: injecting medium in the cavity, arranging blanks, pressing the blanks, applying backpressure, downwards moving the convex die, and pressing in the inner cavity of a pre-formed part in order to close to the die. The blanks are under the action of a pressure difference of inner and outer dynamic fluids in the forming process due to the injection holes arranged in the convex die, the die-close forming of the blanks is finished at one step, and the formed part can be smoothly taken out due to the design of the combined concave die.

Owner:HARBIN INST OF TECH

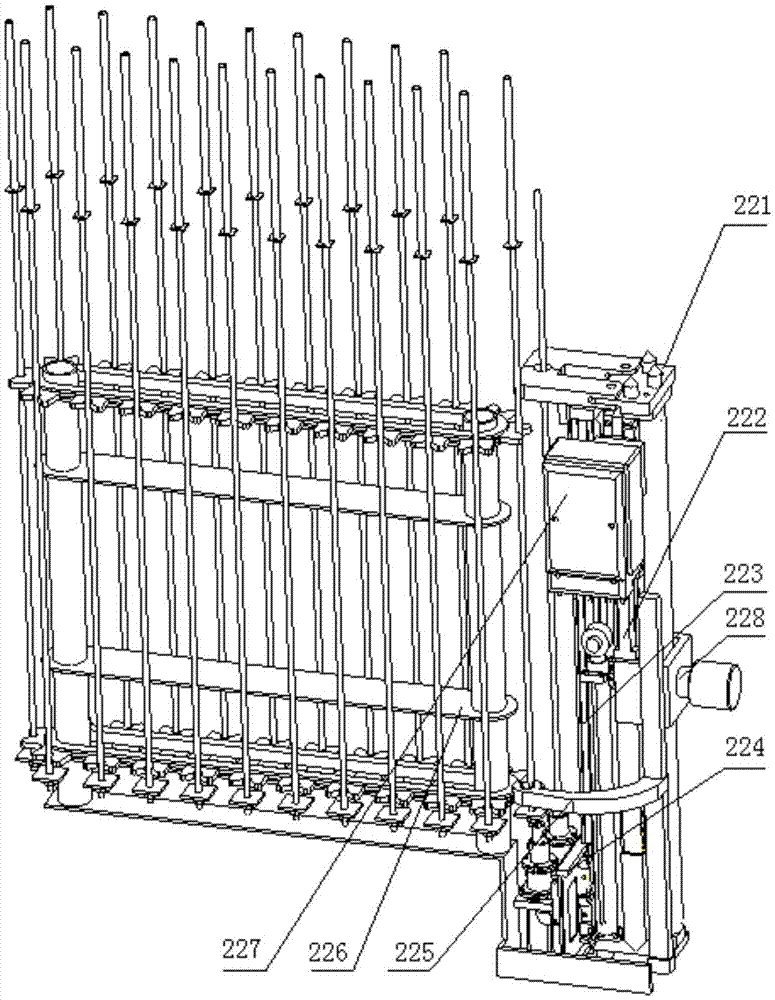

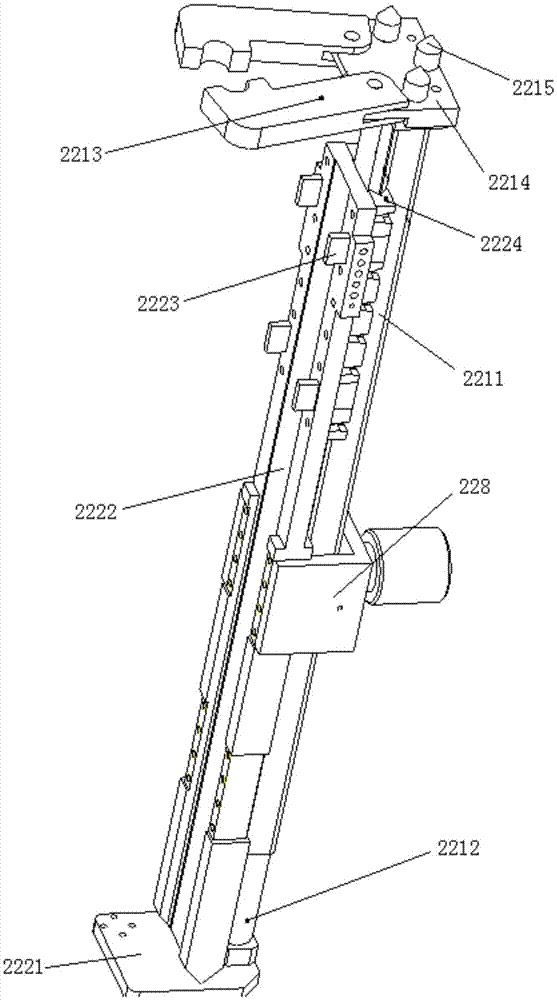

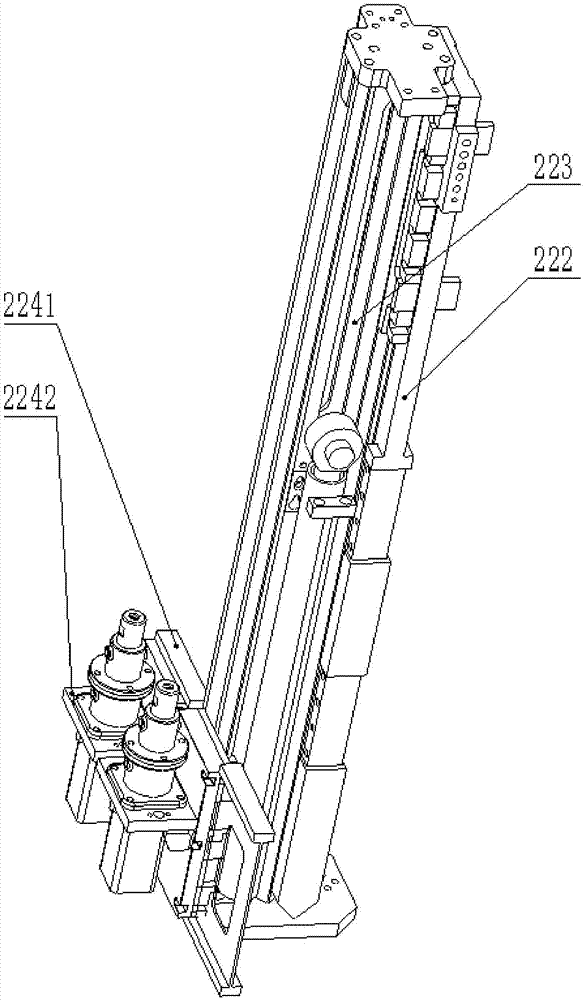

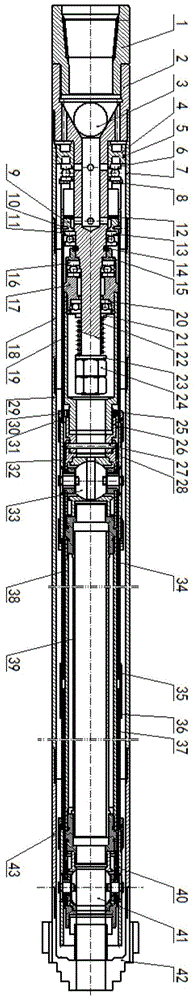

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

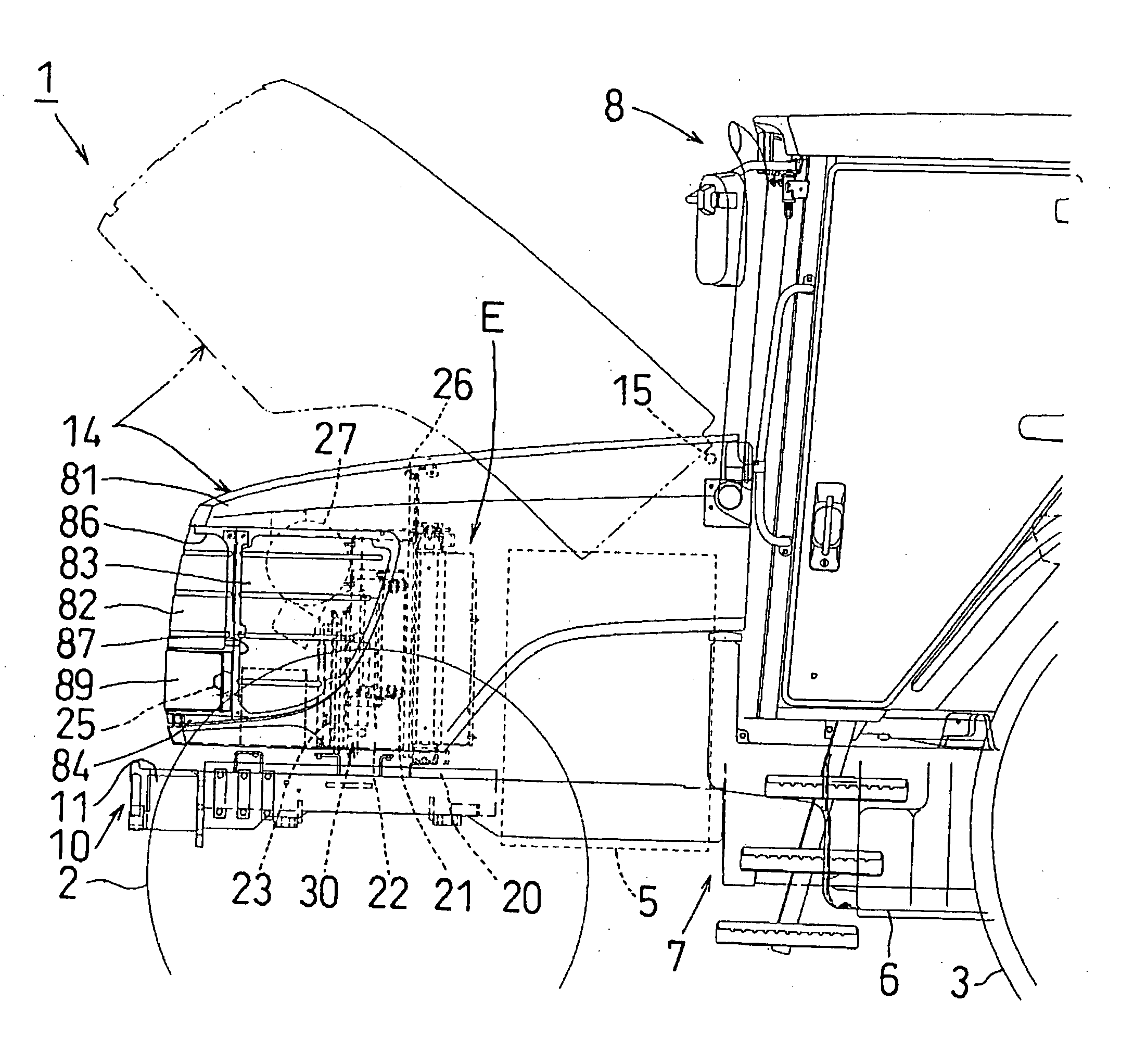

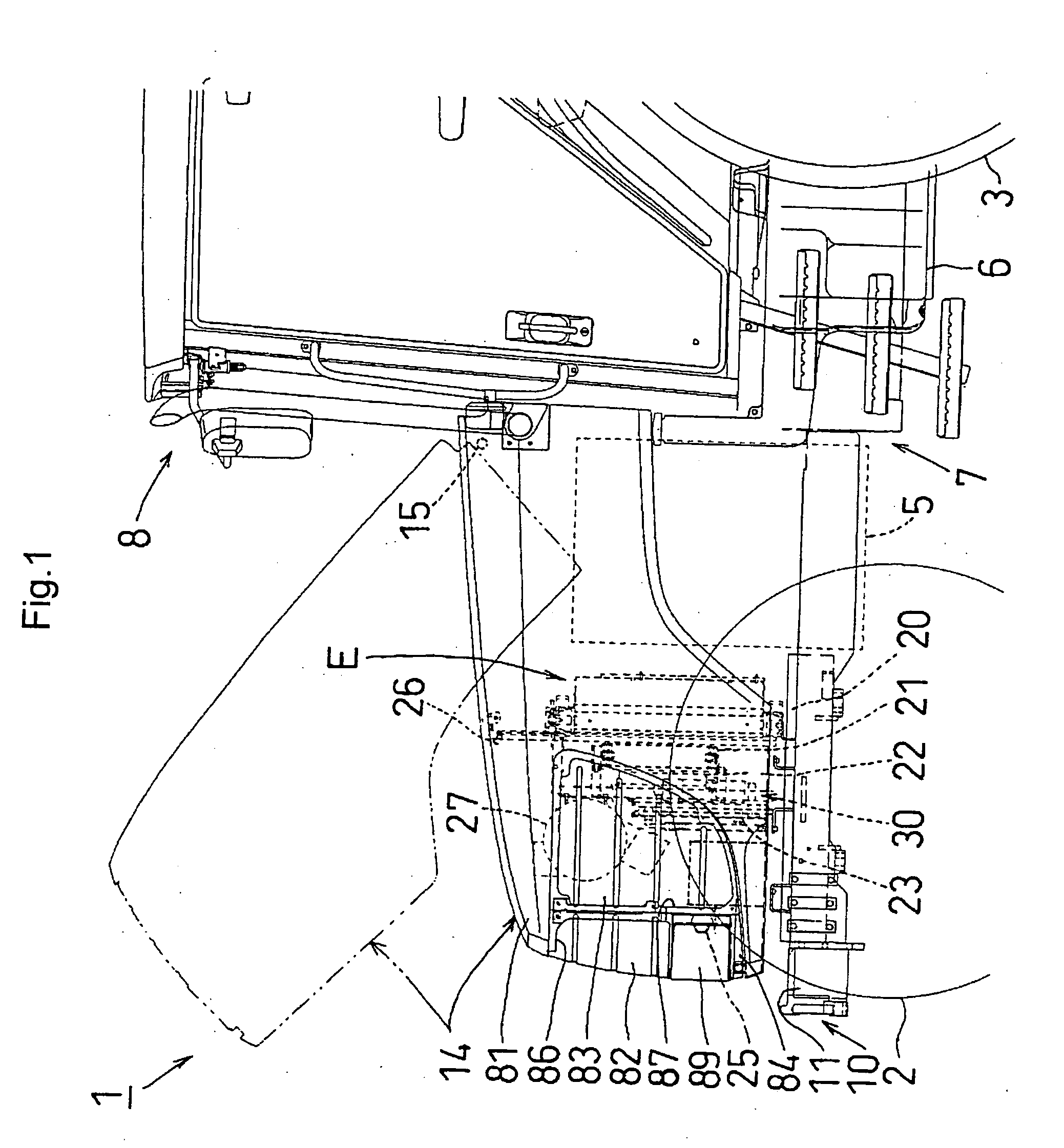

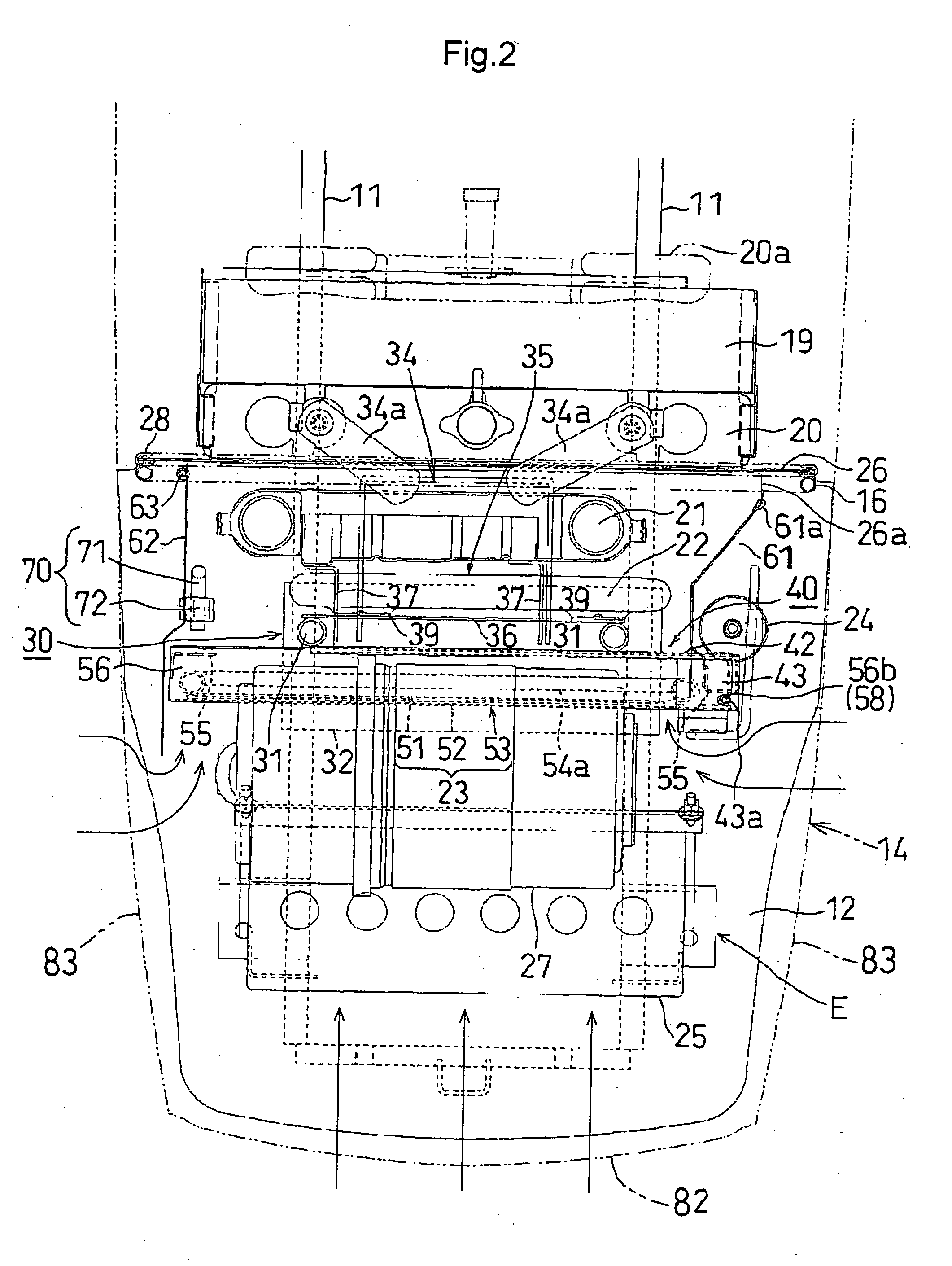

Work vehicle

ActiveUS20050211487A1InhibitionAvoid cloggingMachines/enginesSuperstructure subunitsEngineeringEngine room

A work vehicle includes a traveling vehicle body and a hood provided at a front portion of the vehicle body for covering an engine room. The hood includes a front face having a plurality of first air vent holes and right and left side faces each having a plurality of second air vent holes. A radiator is mounted inside the hood, ambient air being drawn in through the first and second air vent holes toward the radiator. A vent hole area ratio of each side face of the hood determined by the second air vent holes is set smaller than a vent hole area ratio of the front face of the hood determined by the first air vent holes.

Owner:KUBOTA LTD

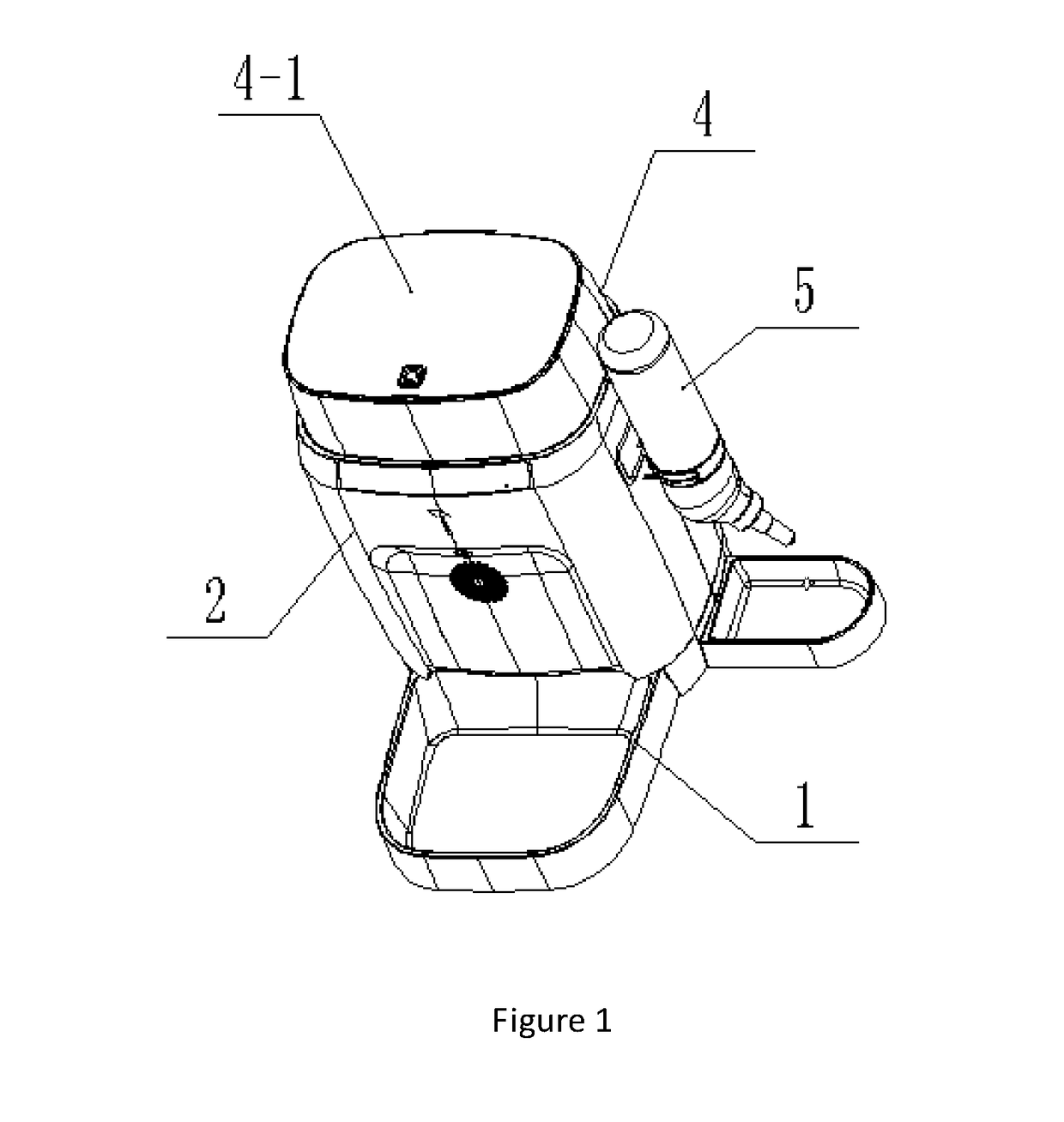

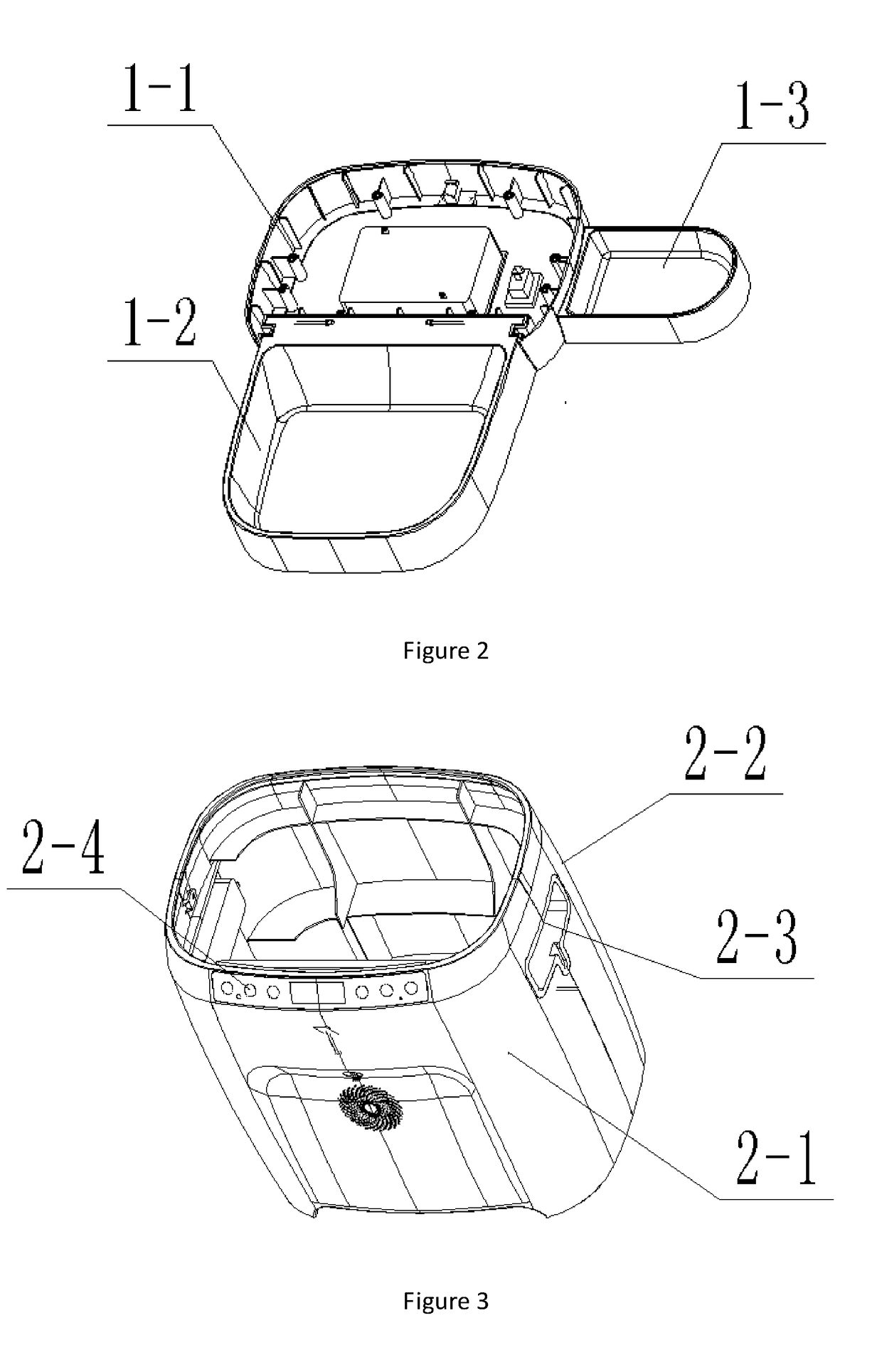

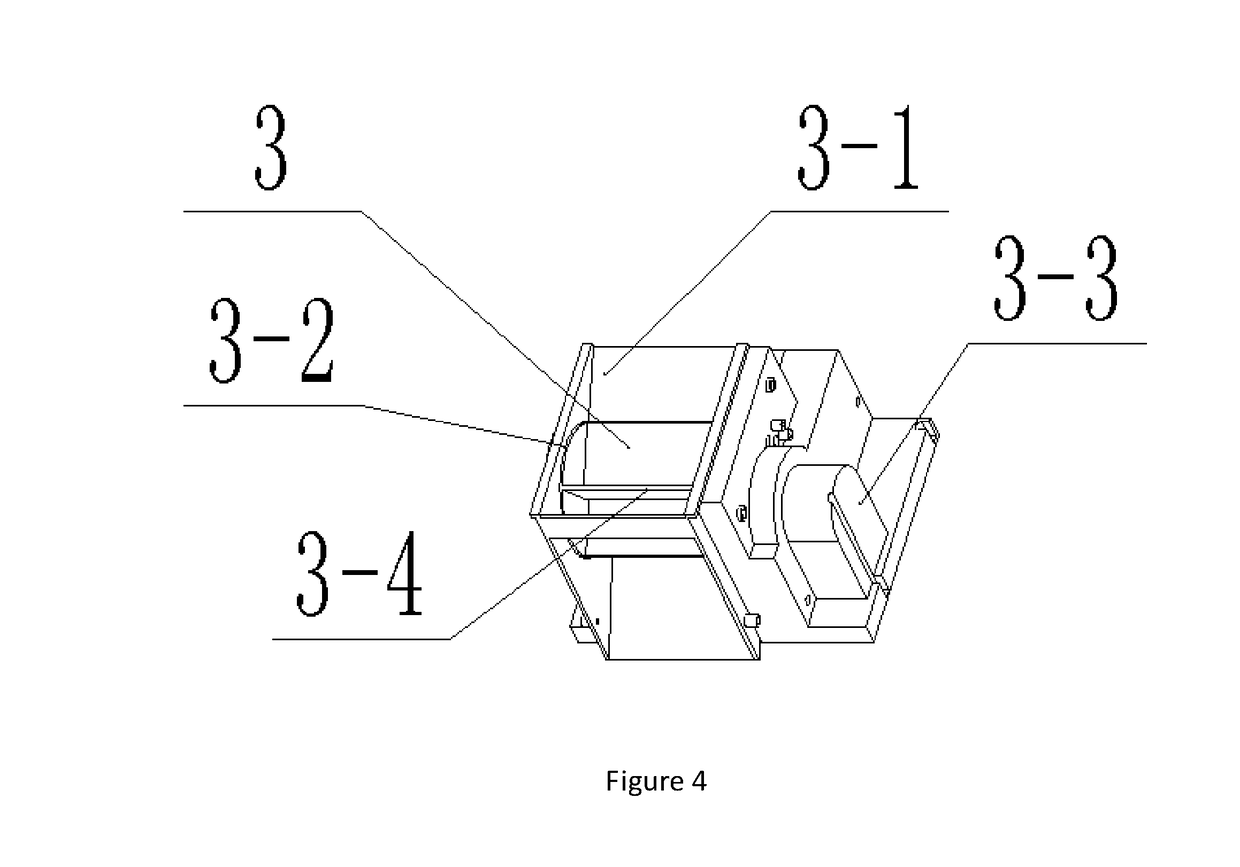

Novel pet feeder

InactiveUS20190059322A1Smooth entryFood lay off smoothlyAnimal watering devicesAnimal feeding devicesTerminal equipmentEngineering

The utility model discloses a novel pet feeder, comprising a base, a shell body, a discharging system, a material bucket, and a water bottle; the base consists of a base shell, a food disk and a water disk; the front side of base shell is provided with a buckle hook plugged in a chute arranged on the food disk; the shell body is fixed on the base; the shell body is composed of a front shell, a back shell, a handle and a control panel. The novel pet feeder can realize remote and accurate feeding control and instant video signaling of good vision by means of a terminal device; the grain discharging condition also can be monitored in real time and effectively controlled, The improved material stirring system makes food discharge more accurately. The effective anti-blocking mechanism can guarantee the normal discharge of food.

Owner:SHENZHEN BENKEI TECH CO LTD

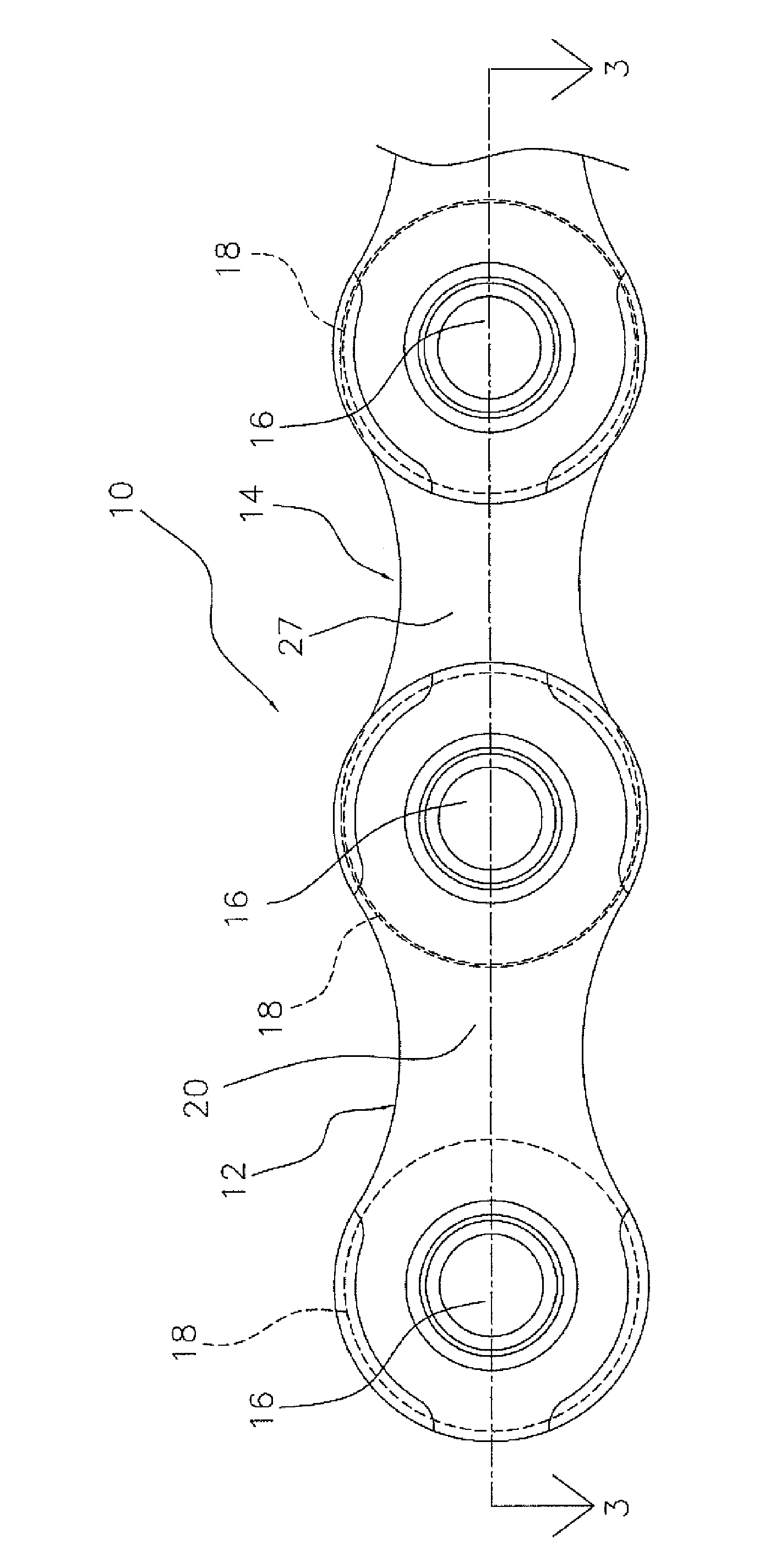

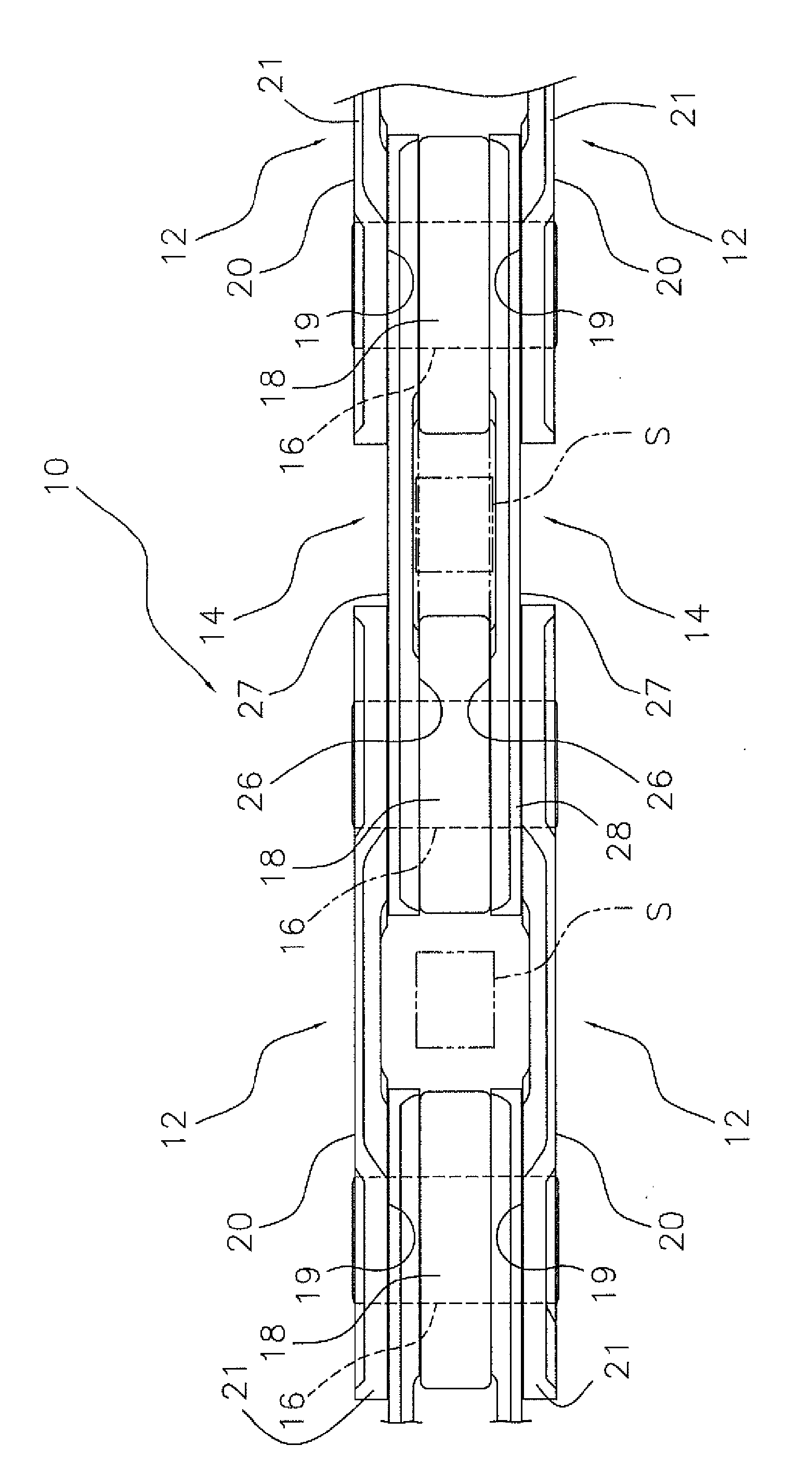

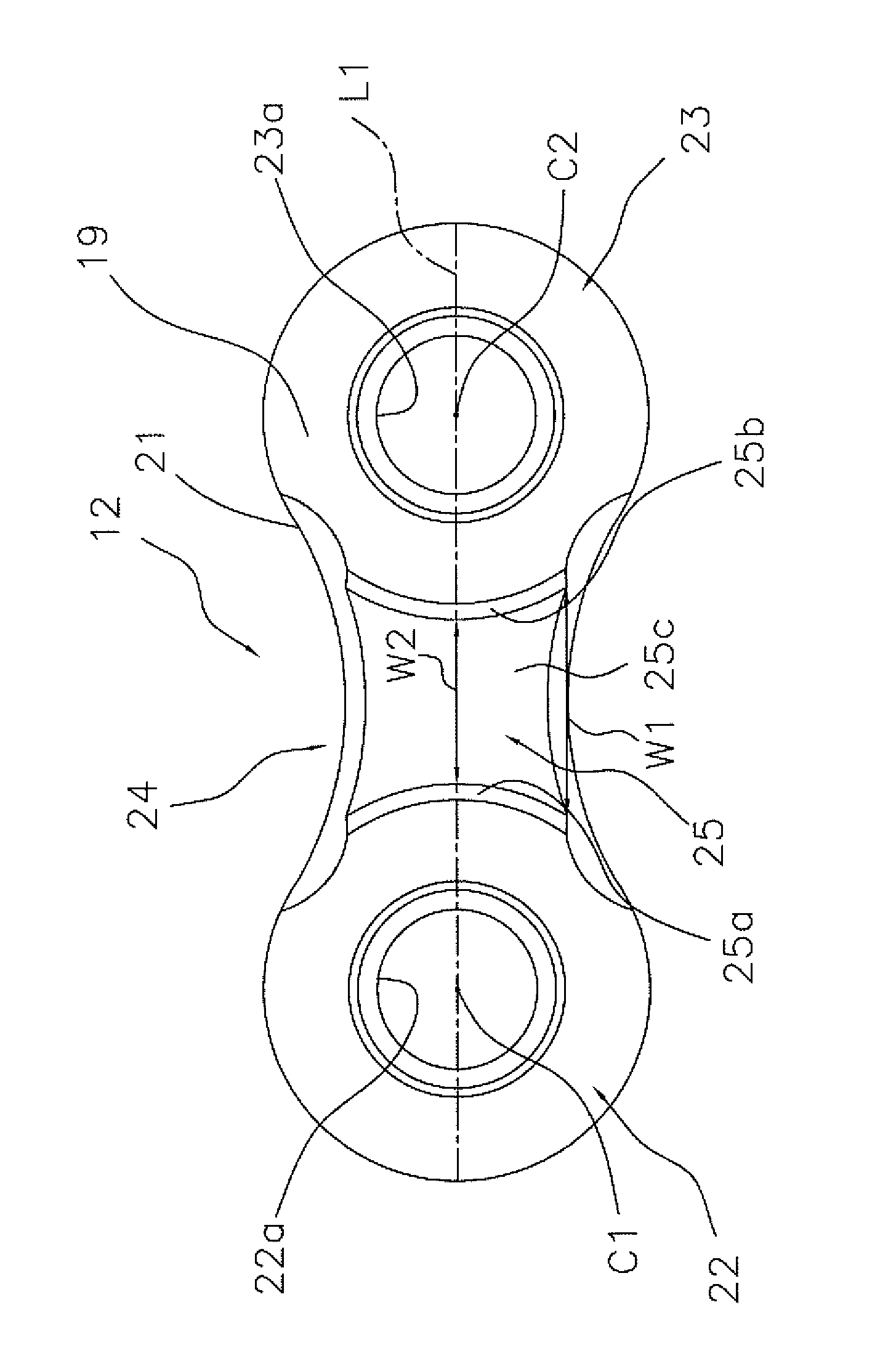

Inner link plate for bicycle chain

An inner link plate is provided for a bicycle chain. The inner link plate has a longitudinal centerline, an inside surface arranged to face another inner link plate when the chain is assembled, an outside surface opposite to the inside surface, and an outer peripheral edge disposed between the inside and outside surfaces. The bicycle inner link plate basically has a first end portion, a second end portion and a connecting portion. The first and second end portions are each provided with a connecting opening. The connecting portion includes a recess disposed on the inside surface of the connecting portion. The recess has a maximum longitudinal width on the outer peripheral edge, and a minimum longitudinal width in a region adjacent the longitudinal centerline. The recess at least extends from the outer peripheral edge to the longitudinal centerline.

Owner:SHIMANO INC

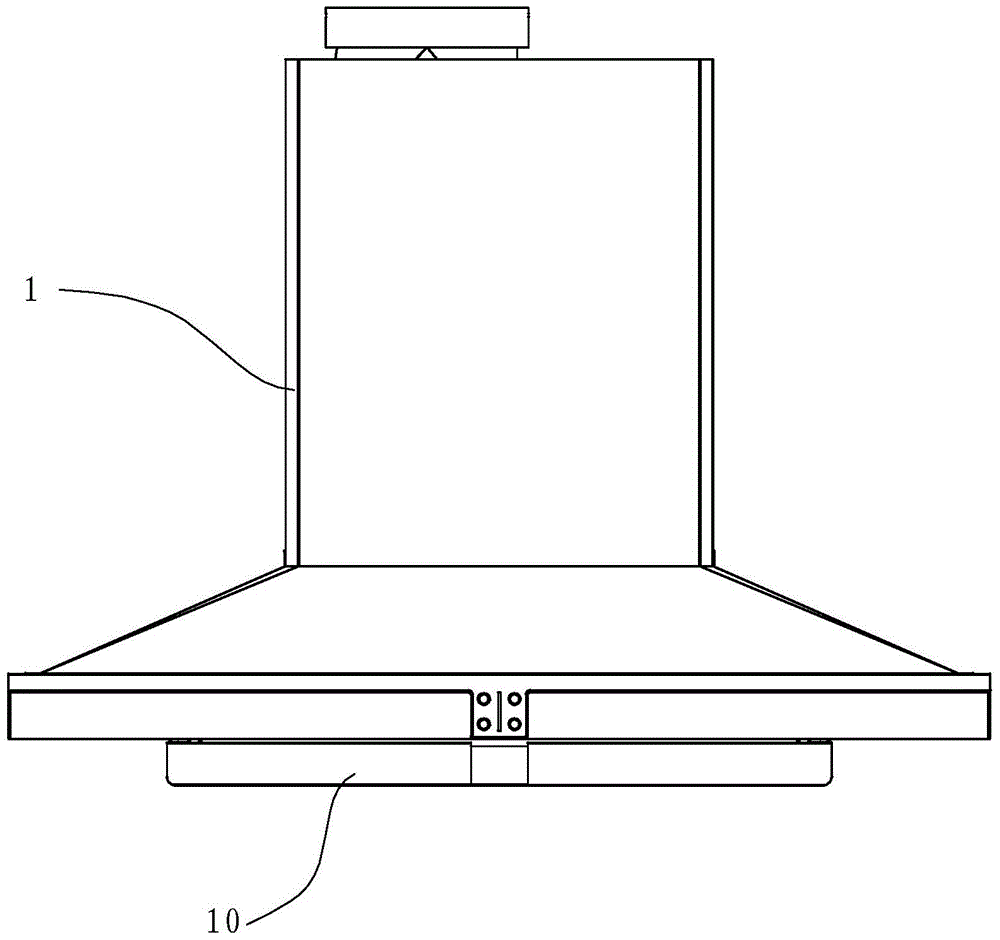

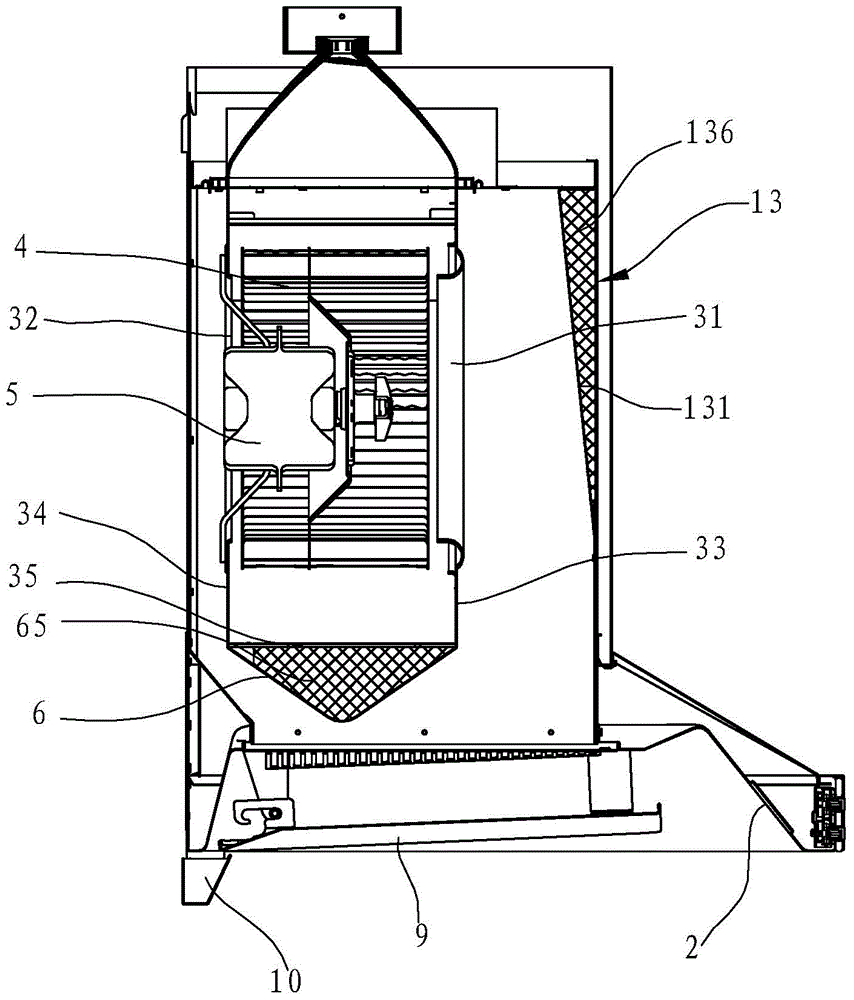

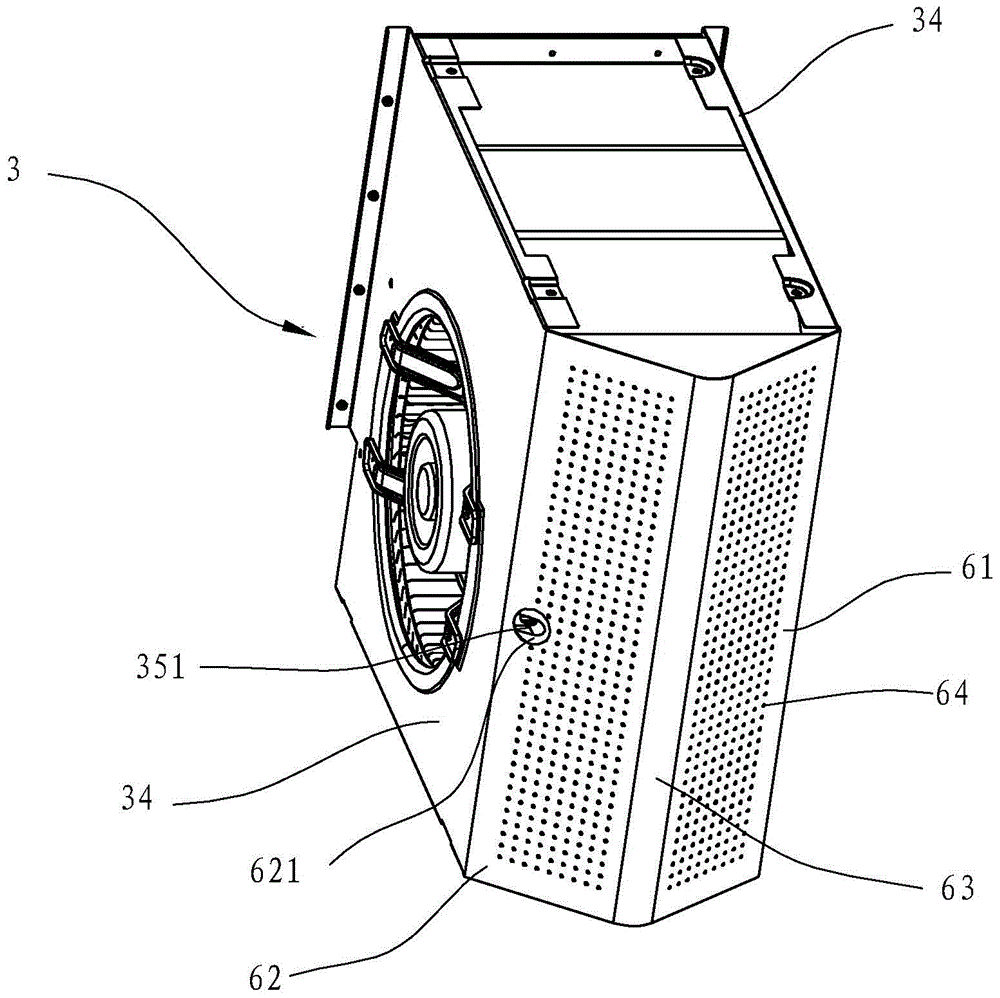

A silent range hood

InactiveCN103697512BSmooth entryPlay the role of diversionDomestic stoves or rangesLighting and heating apparatusMedium frequencyExhaust fumes

The invention discloses a silent range hood comprising a machine enclosure and an exhaust fume collecting hood with an air inlet, wherein a spiral casing is arranged in the machine enclosure and is provided with a front air inlet and a back air inlet. The silent range hood is characterized in that a sound absorption flow guide hood is arranged on a front cover plate of the machine enclosure and is just opposite to the front air inlet of the spiral casing, a closed cavity is formed between the sound absorption flow guide hood and the front cover plate of the machine enclosure, a plurality of first micro-pores communicated with the closed cavity are formed in a back panel, opposite to the front air inlet, of the sound absorption flow guide hood, and the closed cavity is filled with first sound absorbing cotton. According to the invention, the sound absorption flow guide hood is just opposite to the front air inlet of the spiral casing and is provided with the micro-pores and the closed cavity is filled with the sound absorbing cotton, so that most of low-frequency, medium-frequency and high-frequency noise radiated outwards from the front air inlet can be absorbed; by reasonable selections of the aperture and the center distance of the micro-pores and the filling area of the sound absorbing cotton, the sound absorbing effect can be further strengthened.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

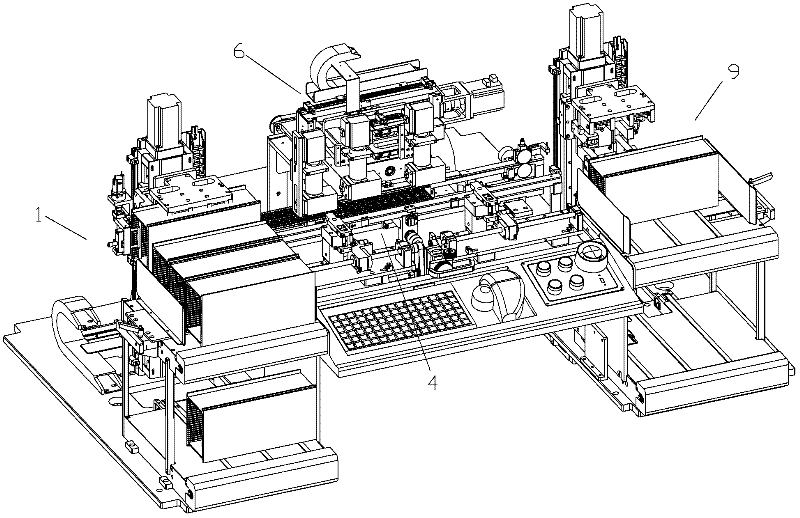

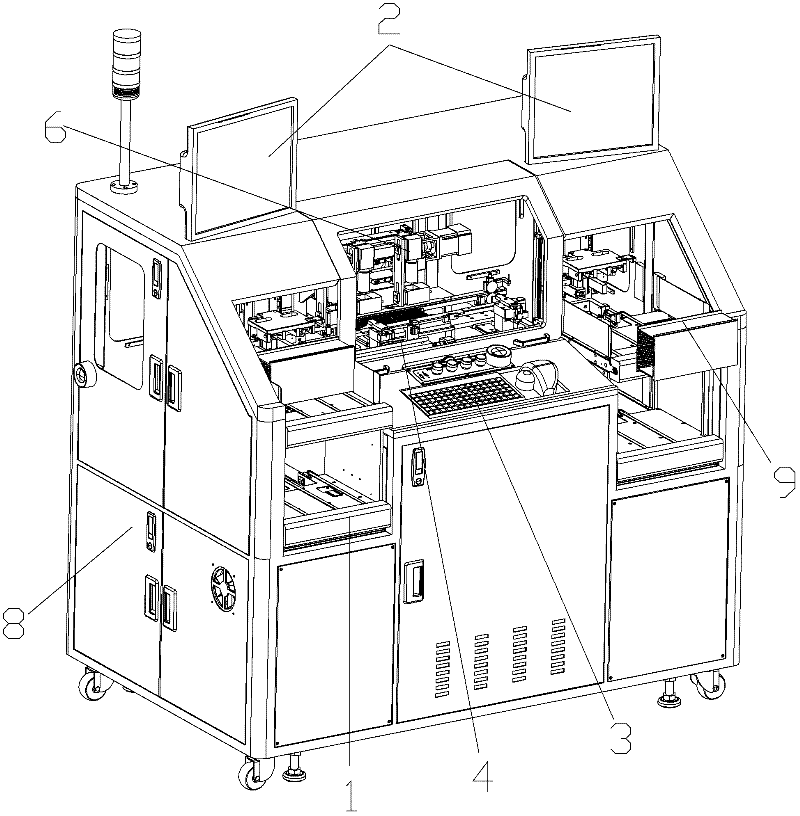

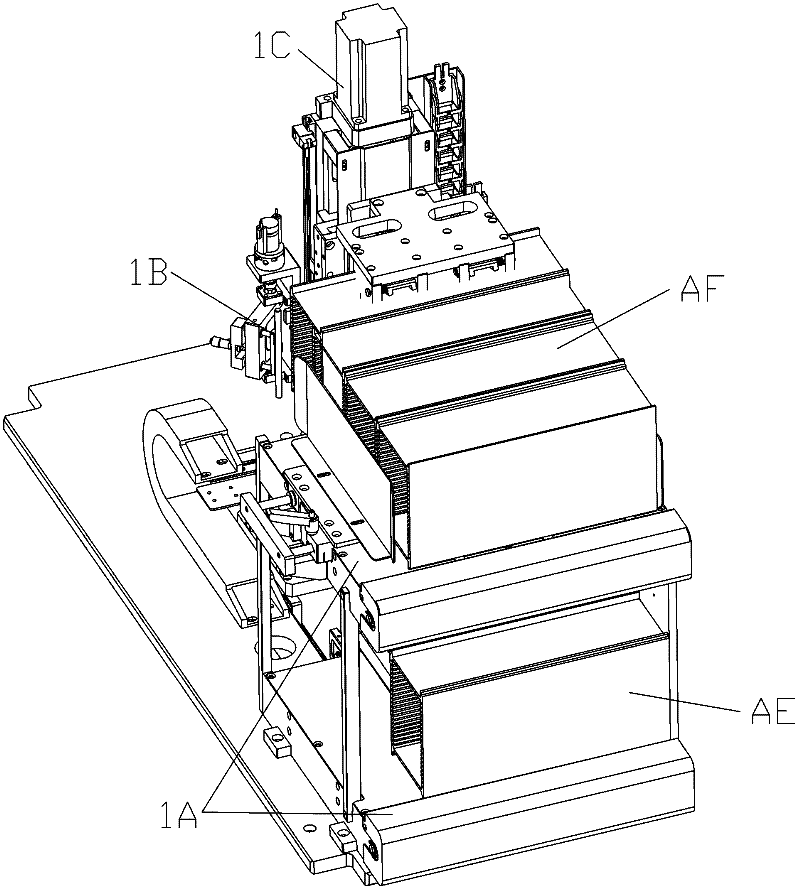

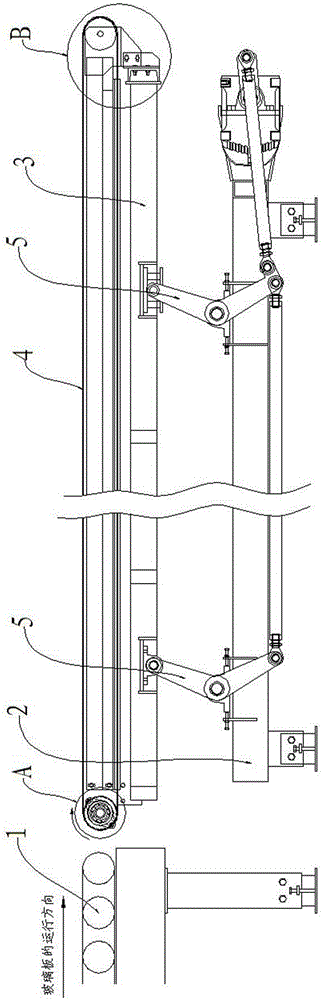

Tertiary optical detection machine for IC (integrated circuit) strips and operating method thereof

ActiveCN102359968ASmooth entryOptically investigating flaws/contaminationConveyor partsEngineeringIntegrated circuit layout

The invention discloses a tertiary optical detection machine for IC (integrated circuit) strips and an operating method thereof. The tertiary optical detection machine comprises a strip conveying system and an optical detection system. The strip conveying system comprises a strip conveying guide rail, guide rail grooves which are opposite to each other are respectively arranged on a front sectionand a rear section of the strip conveying guide rail, and strips can be inserted into the guide rail grooves from two sides in the length direction. The optical detection system comprises an illumination device and a track moving device, wherein the track moving device is used for driving the illumination device to move in both length and width directions of the strips, and the illumination device comprises a camera and a coaxial light generator below the camera. Besides, the position relation of the coaxial light generator and the camera includes that light emitted from the coaxial light generator and coaxial with a lens of the camera is reflected by the strips and then is emitted to the lens directly through the coaxial light generator. Information of chip wires can be shot through the camera by the aid of the coaxial light generator mounted below the camera, and high-definition pictures can be shot when the track moving device drives the illumination device to move in a high speed.

Owner:SHENZHEN GRAND INNOSYS CORP

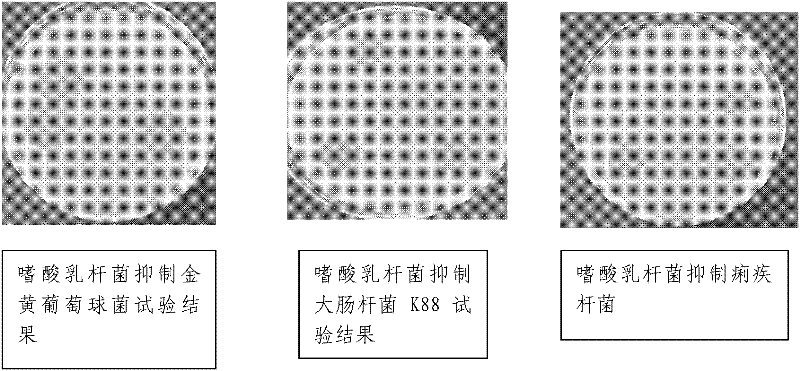

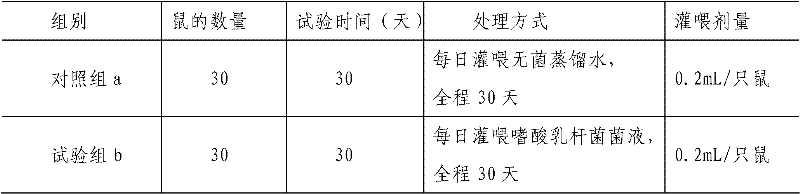

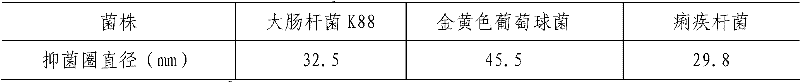

Lactobacillus acidophilus and application thereof and feed additive thereof and premix compound thereof

ActiveCN102559539AStrong stress resistanceImprove immunityBacteriaMicroorganism based processesBiotechnologyHigh density

The invention belongs to the field of biotechnology, and relates to Lactobacillus acidophilus and application thereof and a feed additive thereof and a premix compound thereof. The Lactobacillus acidophilus of the invention has strong stress tolerance, and can tolerate simulated gastric fluid and simulated bile salt so as to guarantee that a great quantity of viable bacteria can smoothly enter the intestinal tract of an animal, and the viable bacteria play a probiotic role, so that the immunity of the animal is improved, and the breeding cost is reduced. The product obtained from the Lactobacillus acidophilus of the invention through culture, high-density fermentation and addition of protectant has a high content of viable Lactobacillus acidophilus, can be added as a biological feed additive in the drinking water or feed for breeding animals, and can be prepared into feed such as premix compound and so on, so as to reduce the addition of antibiotics, indeed improve the intestinal tract health and the immunity of animals, and increase the production performance of animals.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

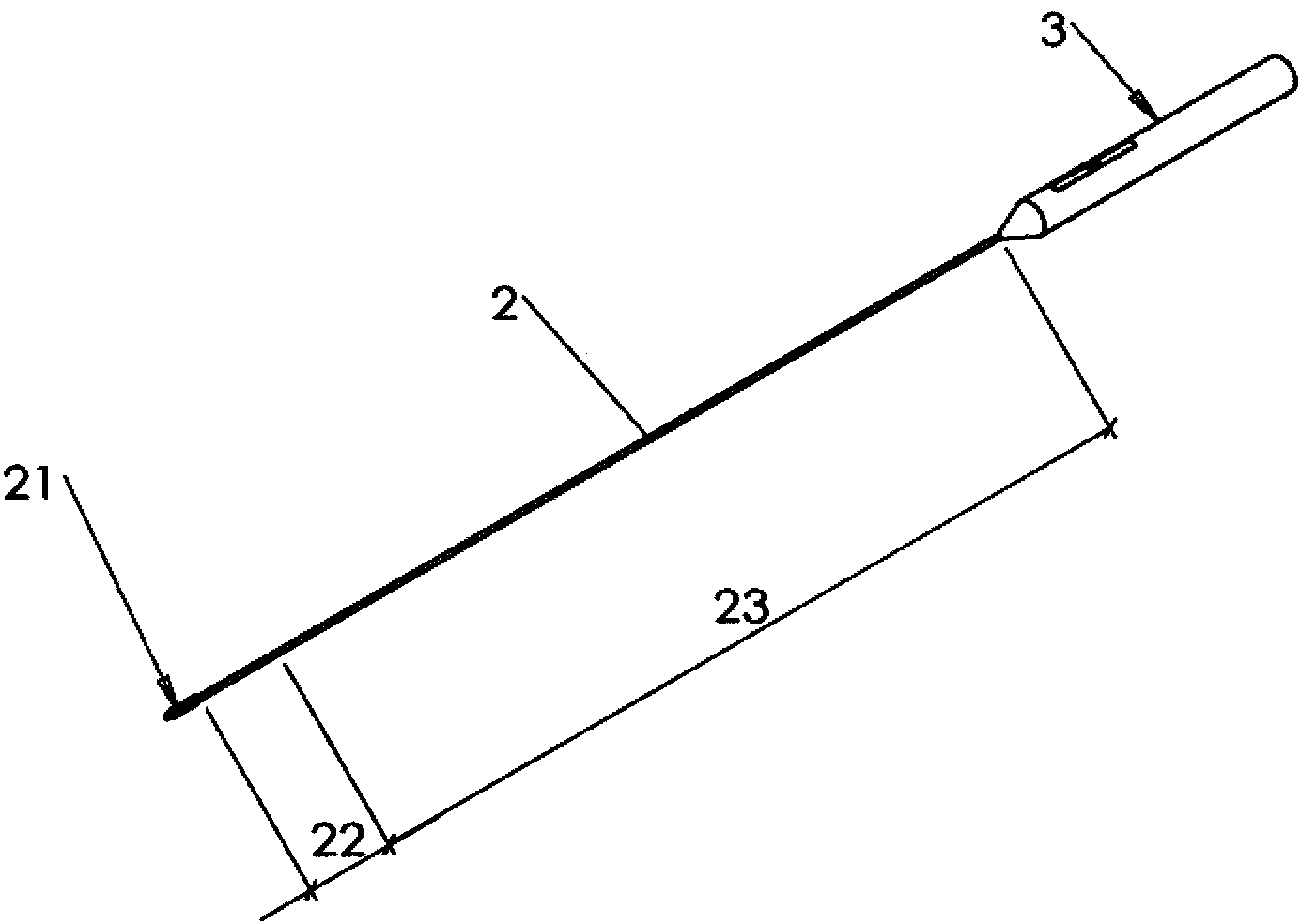

Sealed sampling device for gas sample

The invention discloses a sealed sampling device for a gas sample. The sealed sampling device comprises an outer pipe, an inner pipe and a double-layer pipe, wherein the outer pipe comprises a connecting mandrel for controlling slurry to enter and exit from a channel, a drill bit and a connecting pipe assembly positioned between the connecting mandrel and the drill bit; the inner pipe at least comprises a connecting sleeve, an upper ball valve, a sealing pipe and a lower ball valve; one end of the connecting sleeve is rotatably connected to the connecting mandrel in a sleeving manner; a core barrel is arranged between the upper ball valve and the lower ball valve, and serves as a storage carrier of a core; the core barrel can be sealed by closing the upper ball valve and the lower ball valve; the tail end of the double-layer pipe is against the connecting mandrel and can move back and forth under the control of the connecting mandrel; and a control element for controlling the opening and closing of the upper ball valve and the lower ball valve is arranged at the front end of the double-layer pipe, so that the upper and lower ball valves are opened or closed by moving the control element forwards or backwards. Therefore, the device is compact in structure, good in seal effect and wide in application range; and during drilling, only the outer pipe rotates and the rest of components do not rotate, thereby ensuring that the core can smoothly enter the core barrel.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

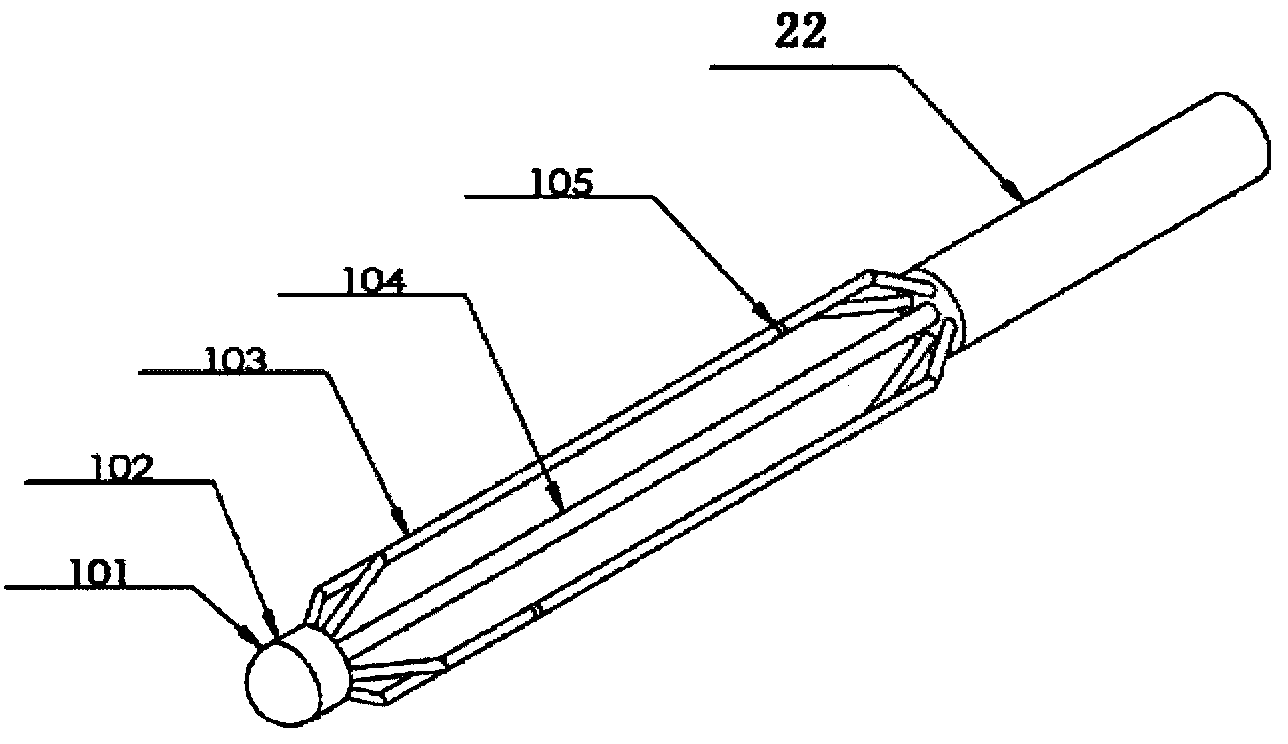

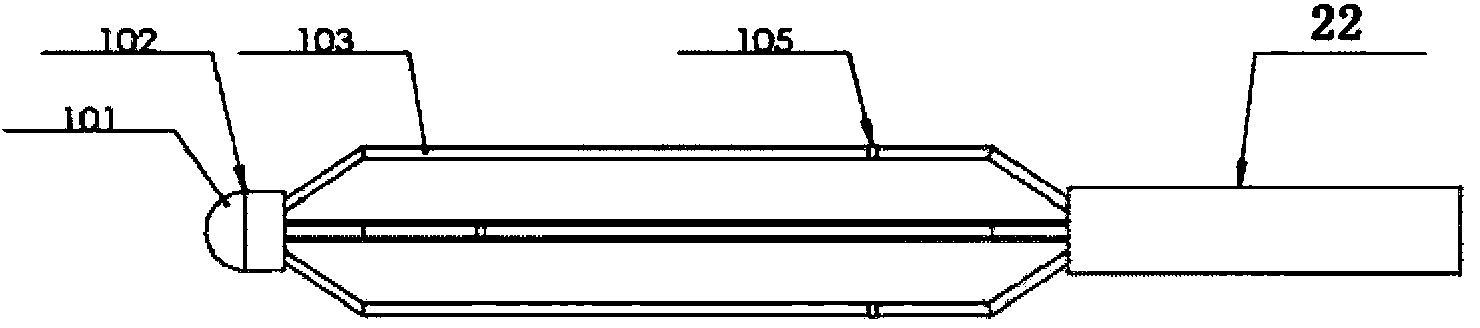

Multi-electrode ablation catheter

InactiveCN103908334AReduce placementShorten the timeSurgical instruments for heatingCatheterBlood vessel

The invention relates to a multi-electrode ablation catheter which comprises a catheter, electrodes distributed on the catheter, a wire connected onto the electrodes to transmit signals and radio frequency energy and a handle used for adjusting the shape of the catheter. The electrodes comprise basket-shaped electrodes and head electrodes arranged at the farthest end of the catheter. The catheter comprises a basket-shaped section with the basket-shaped electrodes, a flexible transition section and a main body section coupled to the handle, wherein the basket-shaped section is formed by a center catheter and a plurality of branch catheters evenly distributed around the center catheter and connected with the center catheter at two ends. The basket-shaped electrodes are formed by electrodes distributed on the branch catheters, and contracting, base state and stretching of the branch catheters relative to the center catheter are achieved by controlling the handle. The catheter can be contracted to conveniently enter the renal artery vessel to be transferred to the position nearby a target spot of a complex structure, the catheter can extend after the catheter reaches the place to cling to the vessel wall completely, protrusions are not formed in the middle, the problem that the vessel is irritated to be narrow due to the fact that a certain position is ablated too much is solved, and blood flow of the renal artery is not affected.

Owner:SHANGHAI MICROPORT EP MEDTECH CO LTD

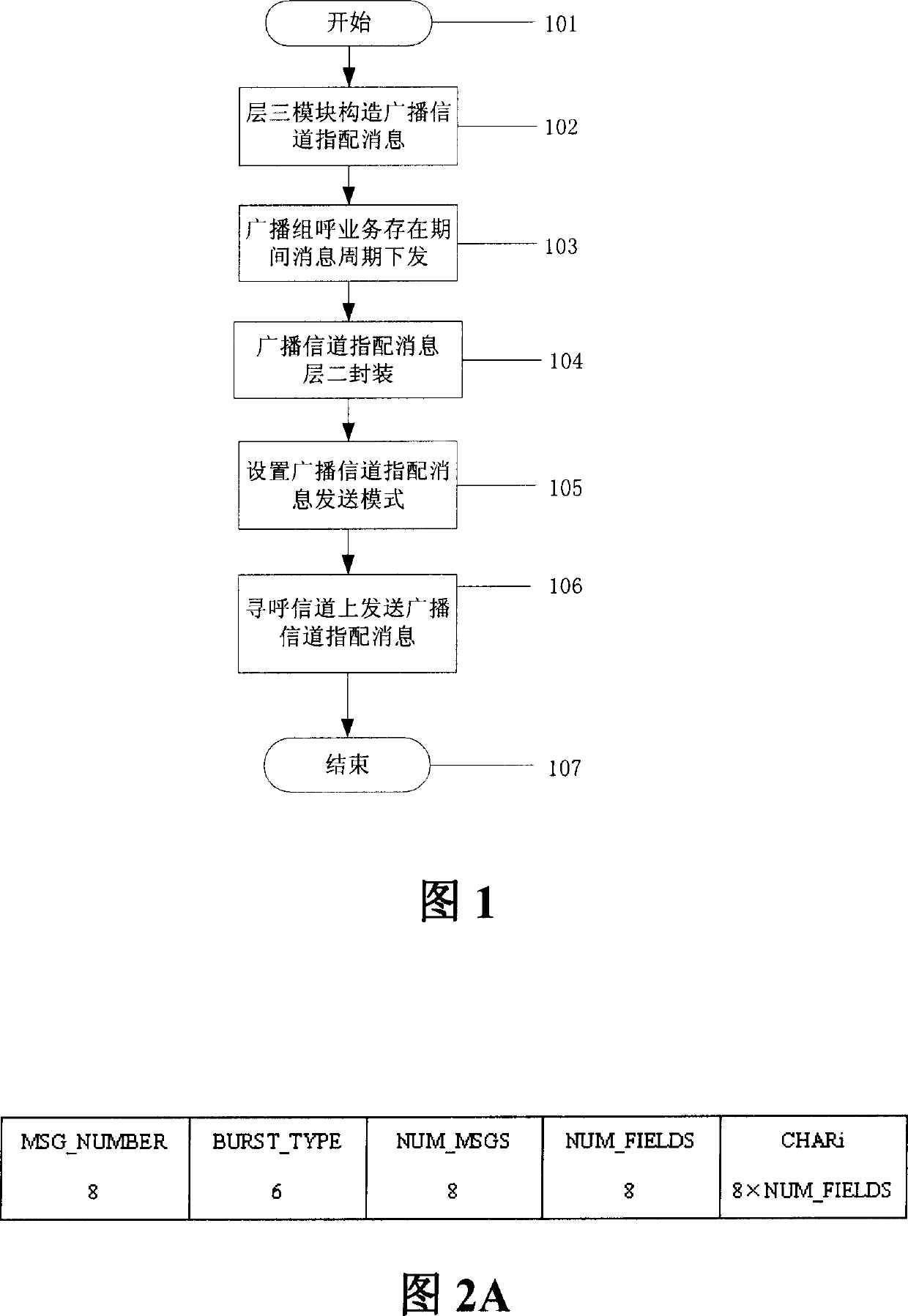

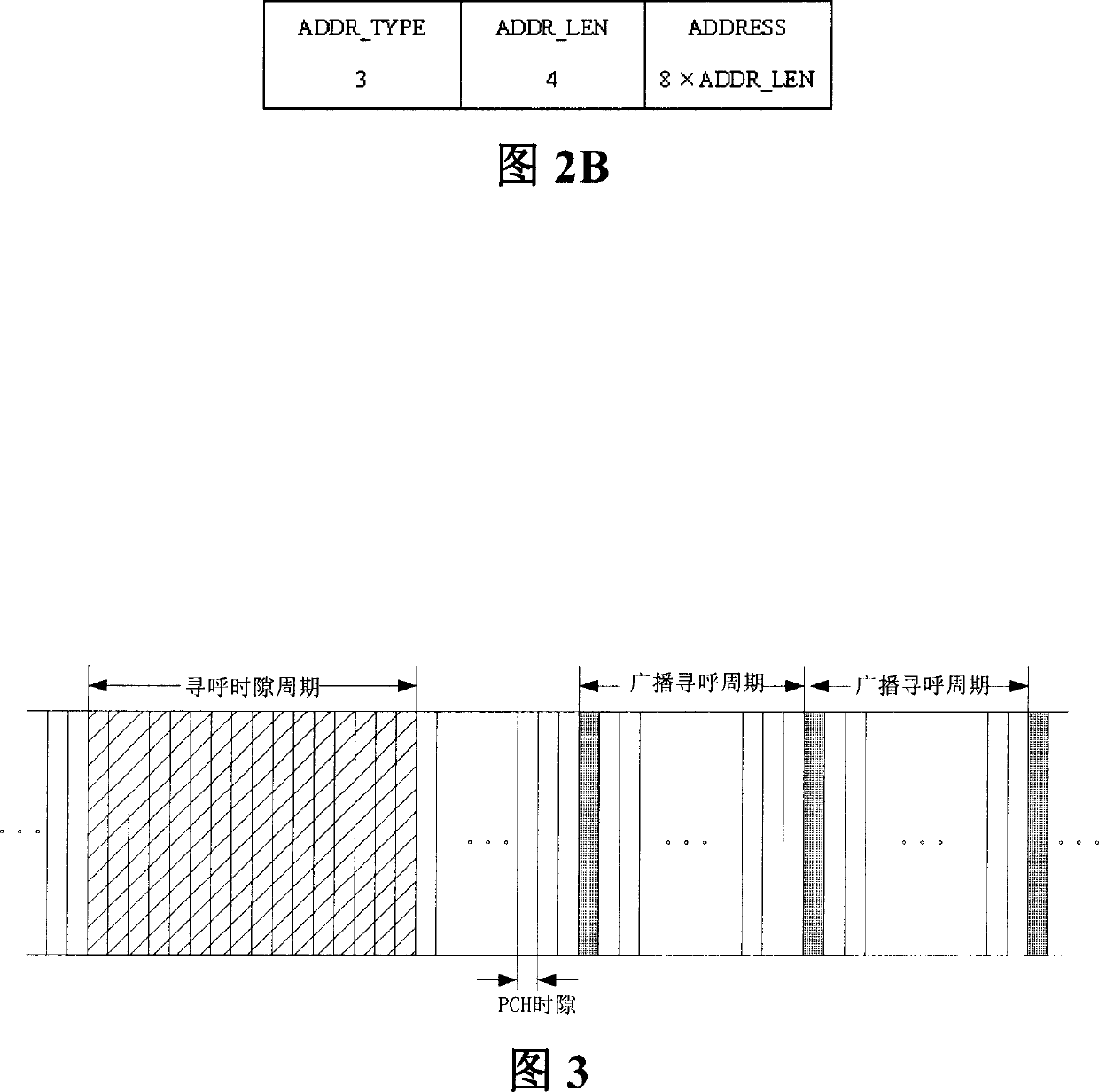

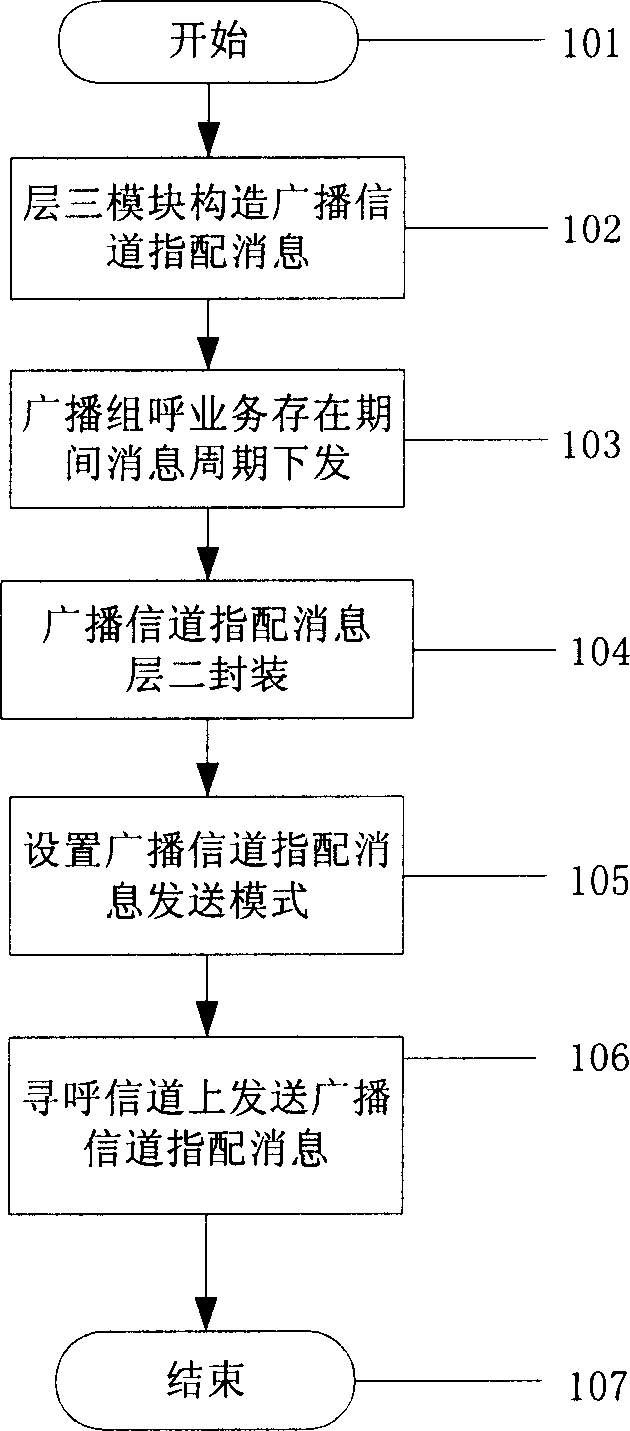

Method for transmitting broadcast channel assignment message in CDMA standard group communication system

ActiveCN1829340AReduce durationQuick responseRadio/inductive link selection arrangementsGroup communication systemsBroadcast channels

The present invention relates to a broadcast channel assignment message transmitting method in CDMA assembly communication system, used for transmitting broadcast channel assignment message to broadcast group calling service each called terminal. It features adopting continue transmitting and cycle transmitting combined transmit mode transmitting said broadcast channel assignment message in paging channel, wherein said continue transmitting mode being continue transmitting said broadcast channel assignment message in multiple time slot of one paging time slot cycle, said cycle transmitting mode being using one defined cycle to proceed cycle transmitting said broadcast channel assignment message. The present invention raises systematical reliability.

Owner:SHENZHEN ZTE TRUNKING TECH CORP

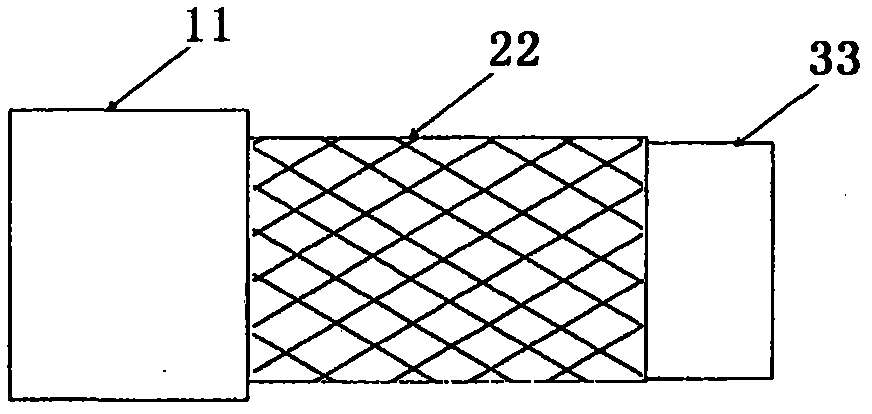

Novel liquid injection and activation process for lithium ion batteries

InactiveCN102315417ASpeed up entrySmooth entrySecondary cells charging/dischargingCell component detailsElectrical batteryPre-charge

The invention relates to a novel liquid injection, infiltration and pre-charging process for lithium ion batteries. The process comprises the following steps: (S1) carrying out vacuum operation on a lithium ion battery before liquid injection, injecting a predetermined amount of electrolyte, and filling a proper amount of film forming additive gas into the battery after injection of electrolyte is finished; (S2) employing the manner of cyclical fluctuation negative pressure infiltration, wherein, fluctuation of negative pressure is expressed with a waveform function instead of a simple first grade linear function; (S3) carrying out formation under the conditions of changing negative pressure and changing temperature, wherein, the negative pressure and temperature both increase gradiently with time, a charging current is not constant and varies in a manner of small gradient increase. The invention enables a predetermined amount of electrolyte to be rapidly absorbed by anode and cathode materials and diaphragms of the battery, and absorption time is short while full absorption is realized, thereby improving the utilization rate of the electrolyte and shortening time for liquid injection; addition of a proper amount of film forming additive gas is beneficial for the formation of SEI membranes and enables inreversible capacity loss of the battery in initial charge to be reduced; the method of pre-charging brought forward in the invention enables uniform and stable SEI membranes to form on the surface of electrodes, thereby improving safety performance and electrochemical performance of lithium ion batteries; the process is simple and is easy to control, investment cost for equipment used in the process is low, and the process is easy to realize.

Owner:HUNAN UNIV

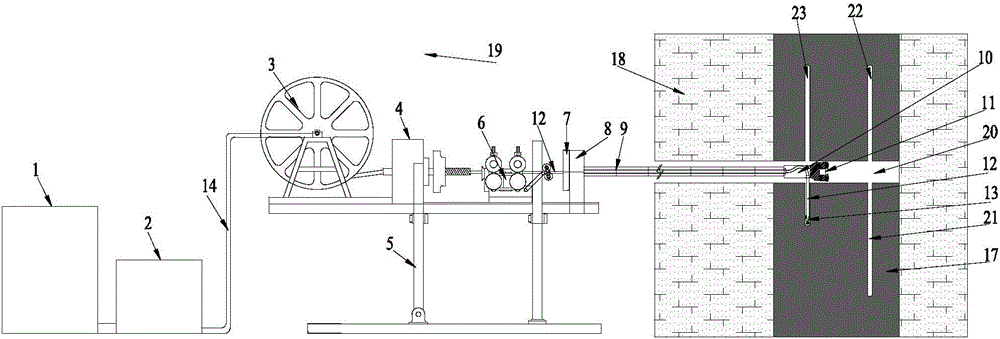

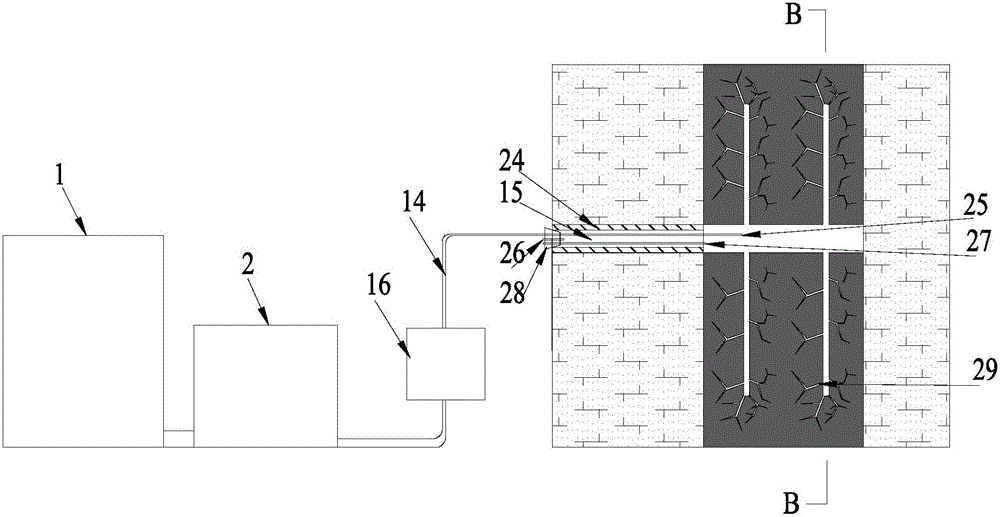

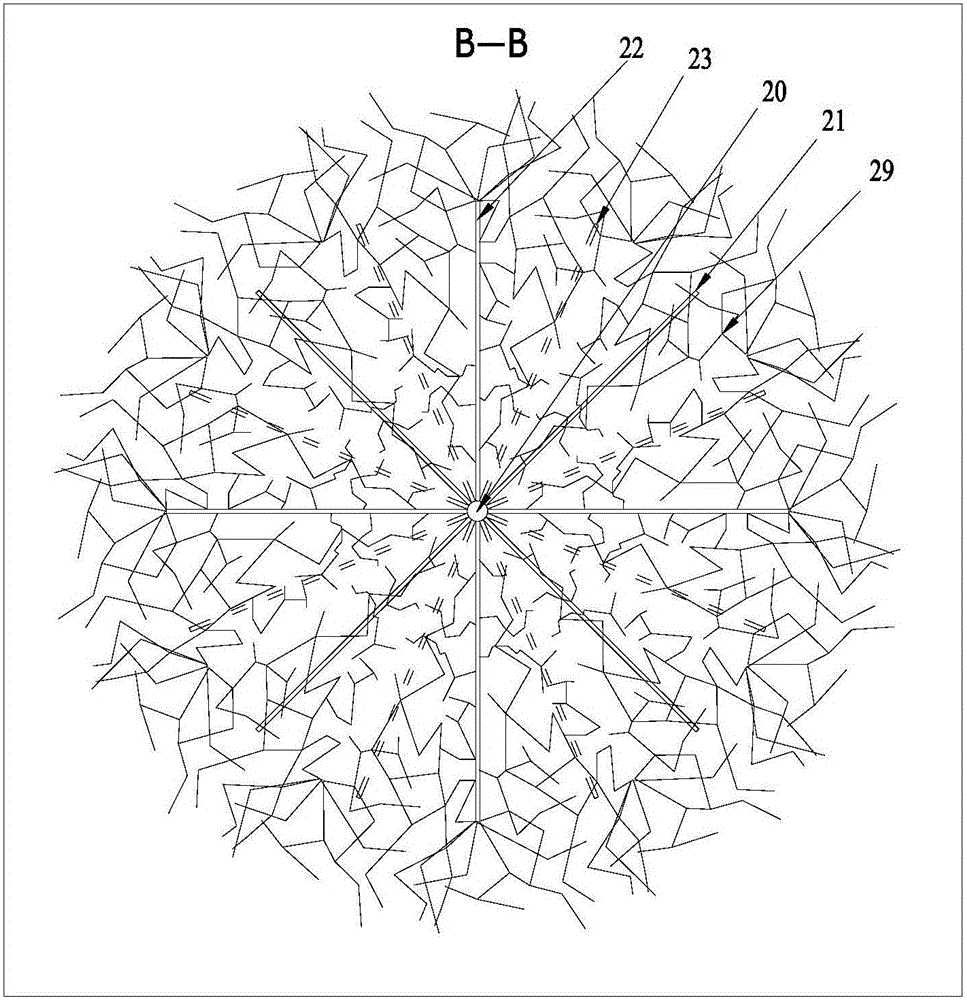

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

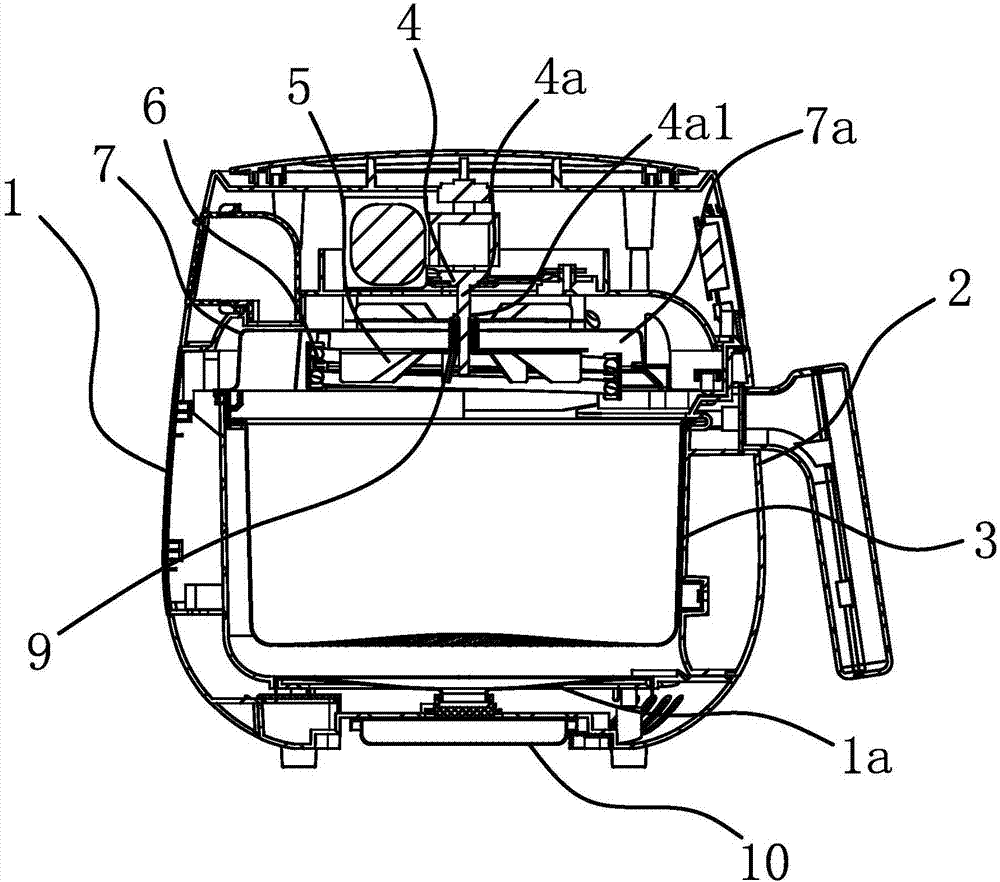

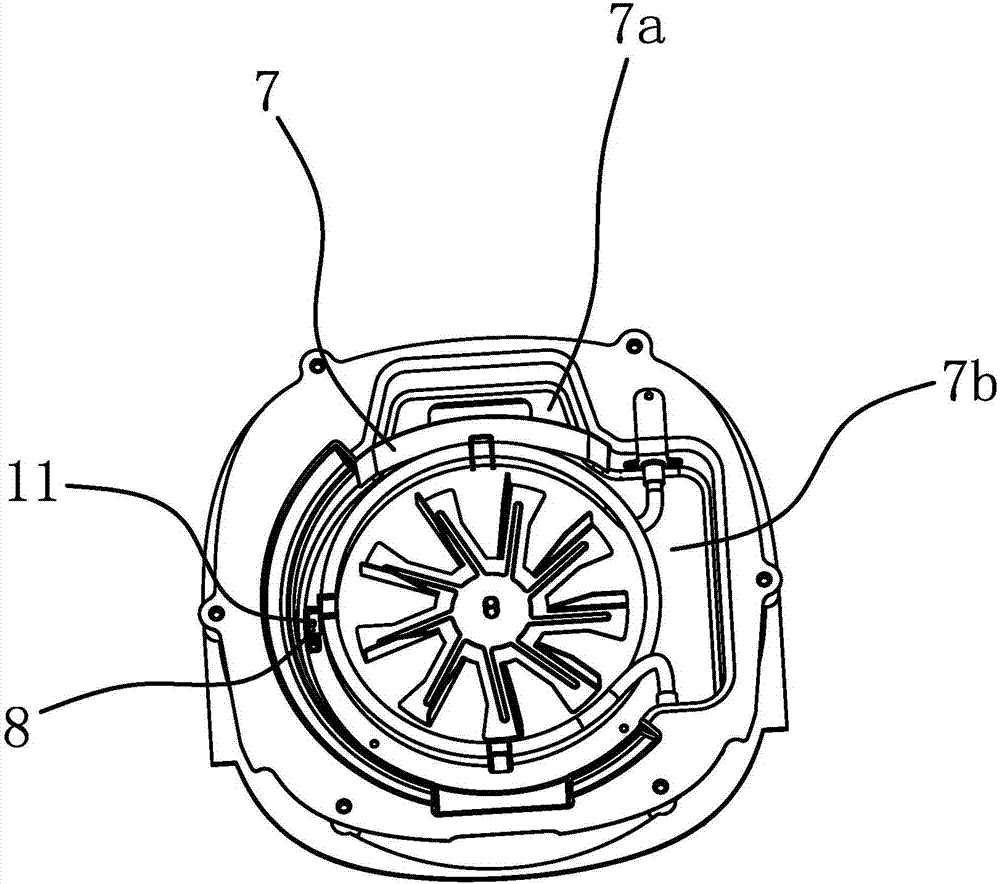

Compact air fryer

The invention provides a compact air fryer, which belongs to the field of mechanical technology. The air fryer solves the problem in the prior art of inconvenient cleaning. The compact air fryer includes a housing with a cavity in the interior. The side part of the housing is provided with an opening communicating with the inner cavity. The opening is provided with a door plate which can be opened and closed. The door plate is fixedly connected with a frying basket. When the door plate is buckled, the frying basket is located in the housing. The air fryer comprises a motor, a fan blade and a heating pipe. The upper part of the fan blade and the housing is provided with a recessed connecting cavity. The motor is fixedly connected into the connecting cavity. The fan blade and the heating pipe are located at the connecting cavity. The fan blade is detachably connected to a rotary shaft of the motor. The heating pipe is arranged in a conical and helical manner and forms an annular heating part. The compact air fryer is convenient to clean.

Owner:浙江手拉手电器科技有限公司

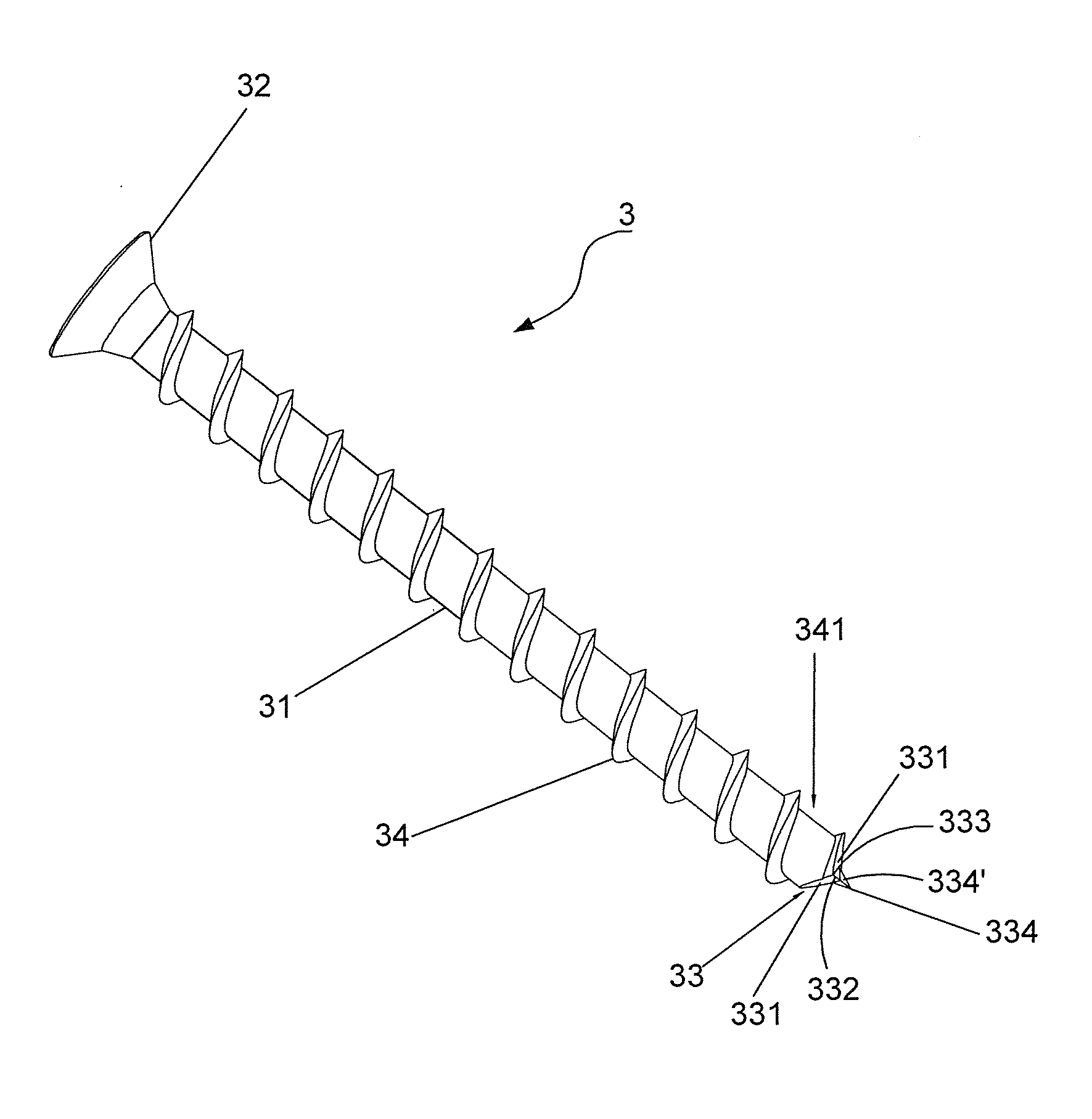

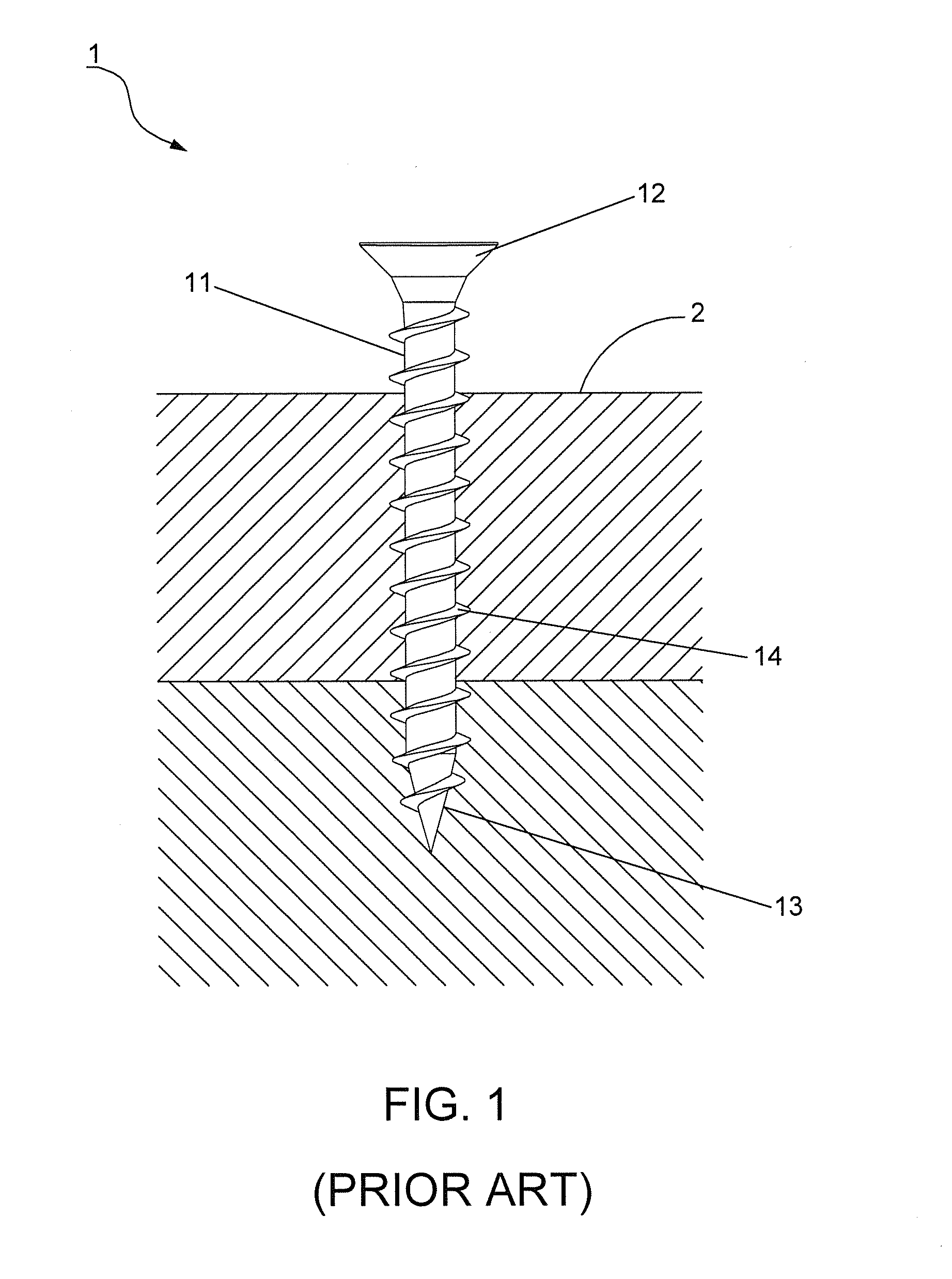

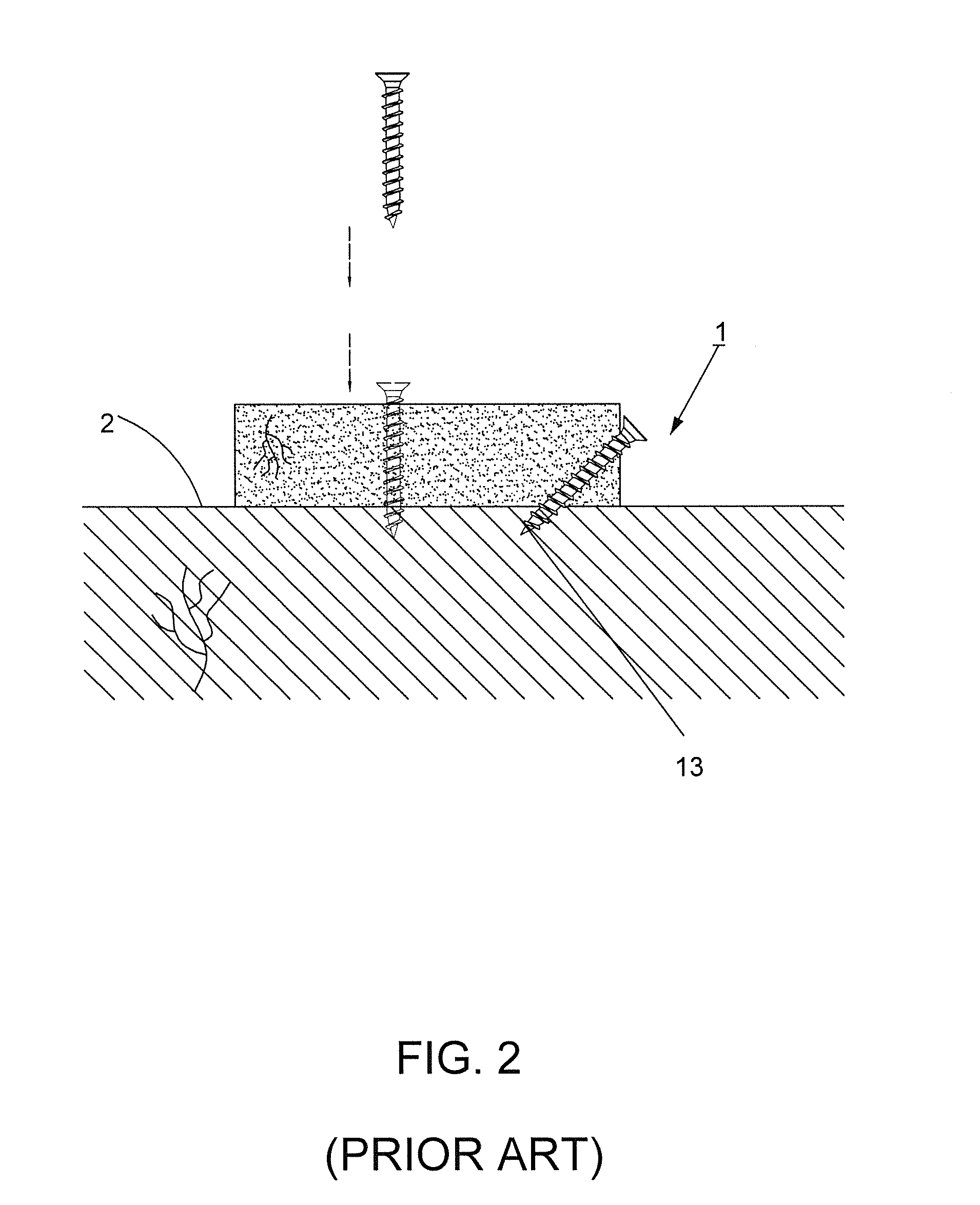

Screw

A screw includes a positioning member defined on inclined cutting planes of a drilling portion of the screw for stably allowing a cutting edge constructed at a convergence of the cutting planes to cut efficiently. A threaded section formed on a shank of the screw is extended toward the cutting edge and connected with one end of the cutting edge. The positioning member helps the screw fixedly stand on an object. The cutting edge and the cutting planes allow cutting debris to be swiftly and smoothly extruded therefrom into the threaded section for avoiding the piling of the considerable cutting debris. Thereby, the screwing torque is reduced and the drilling speed is promoted. Preferably, the fastened screw is sunken in the object, and the fastening operation is completed successfully.

Owner:TAIWAN SHAN YIN INT CO LTD +1

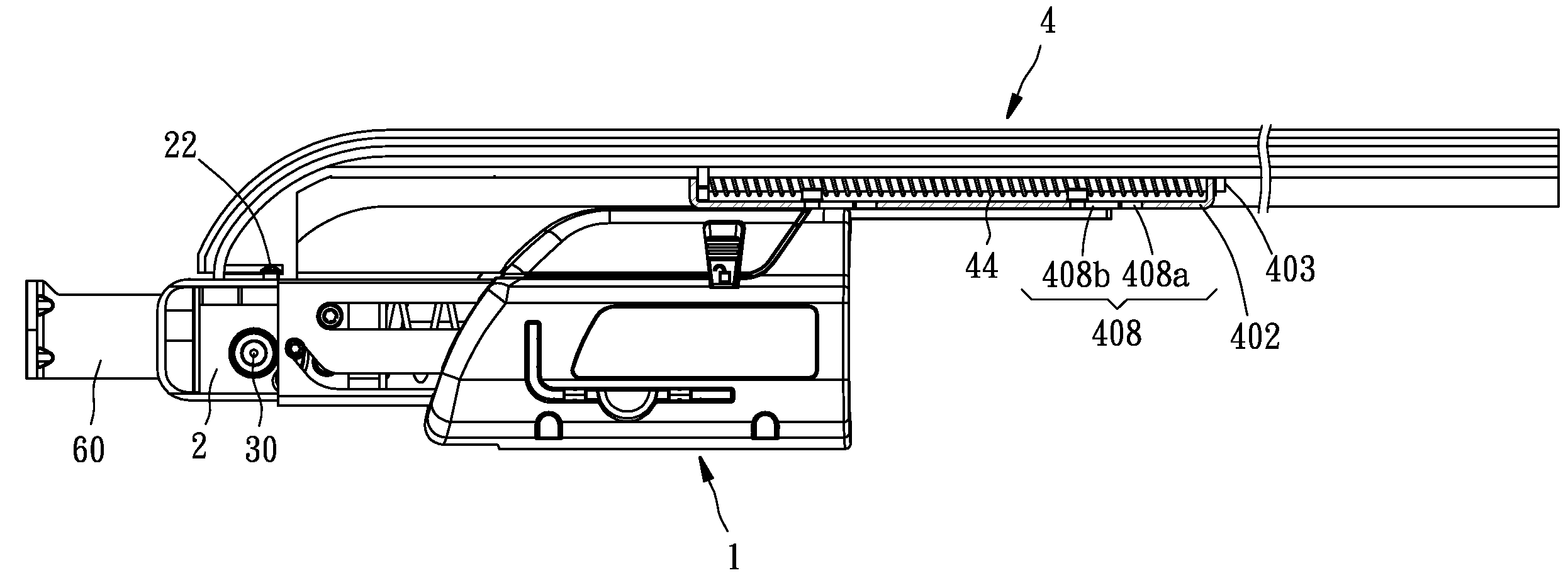

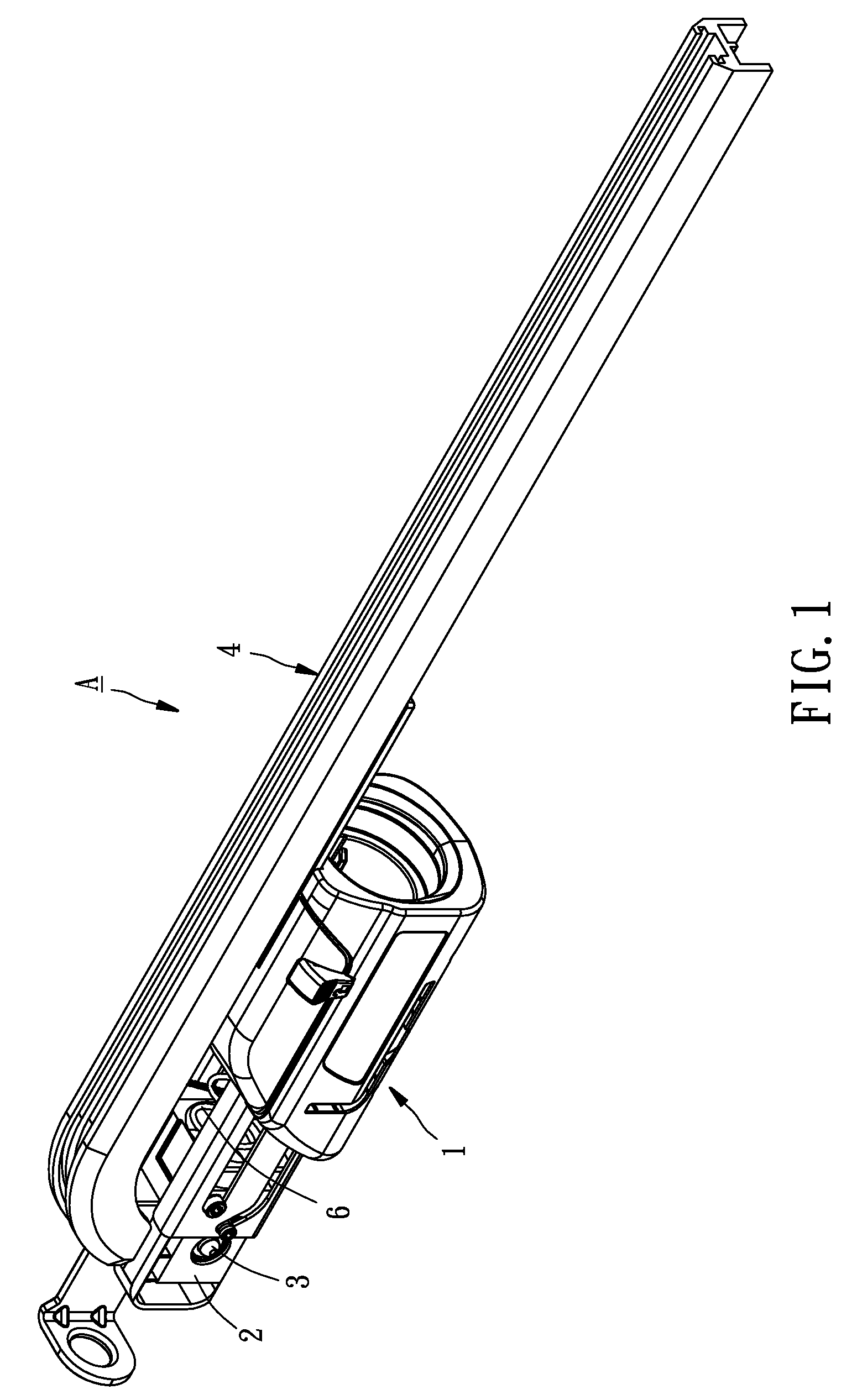

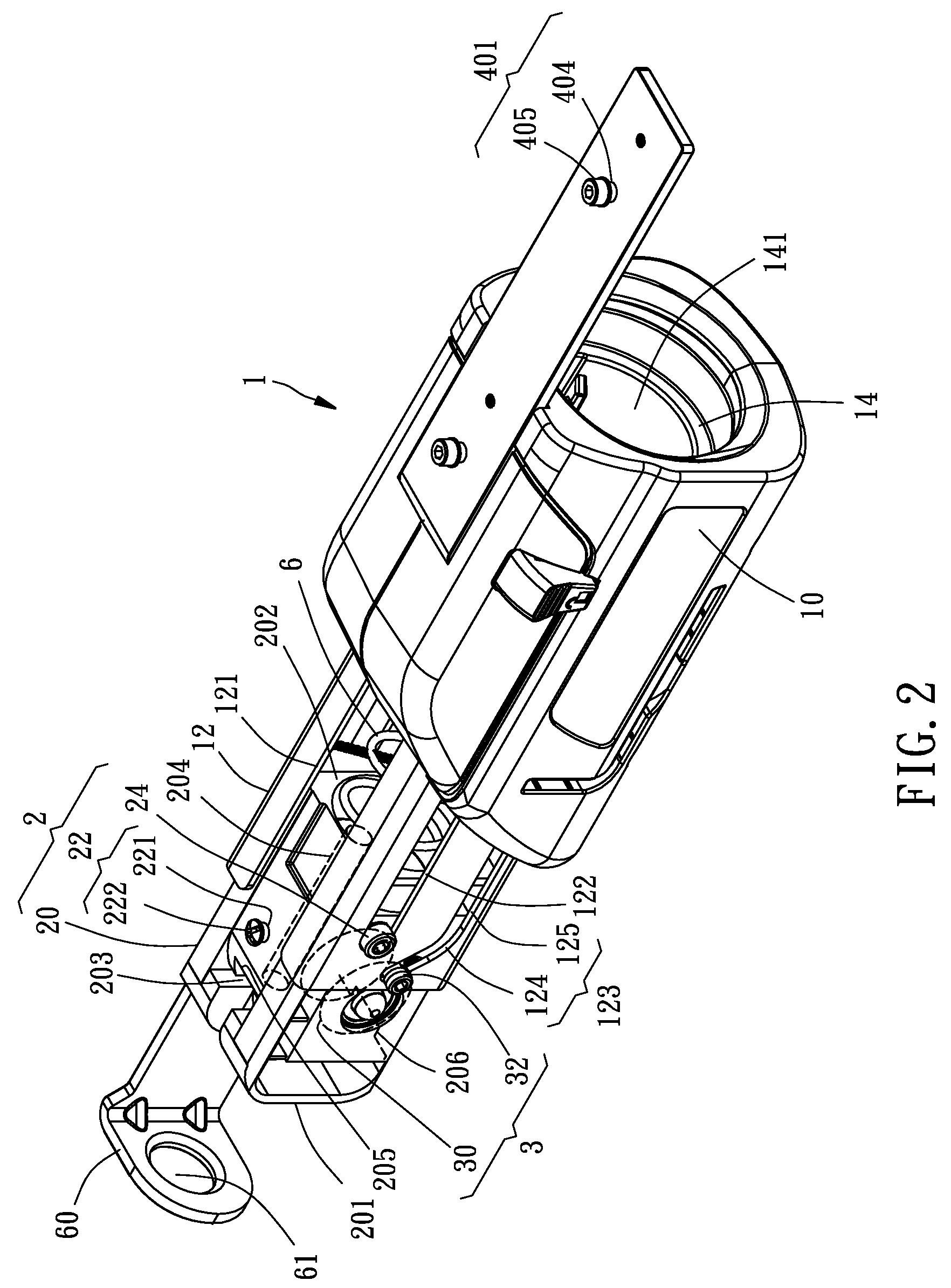

Automatic screw feeding apparatus for power screwdriver

InactiveUS7866236B2Smooth entryReduce loadCoin-freed apparatus detailsSpannersEngineeringStraight path

Owner:MOBILETRON ELECTRONICS

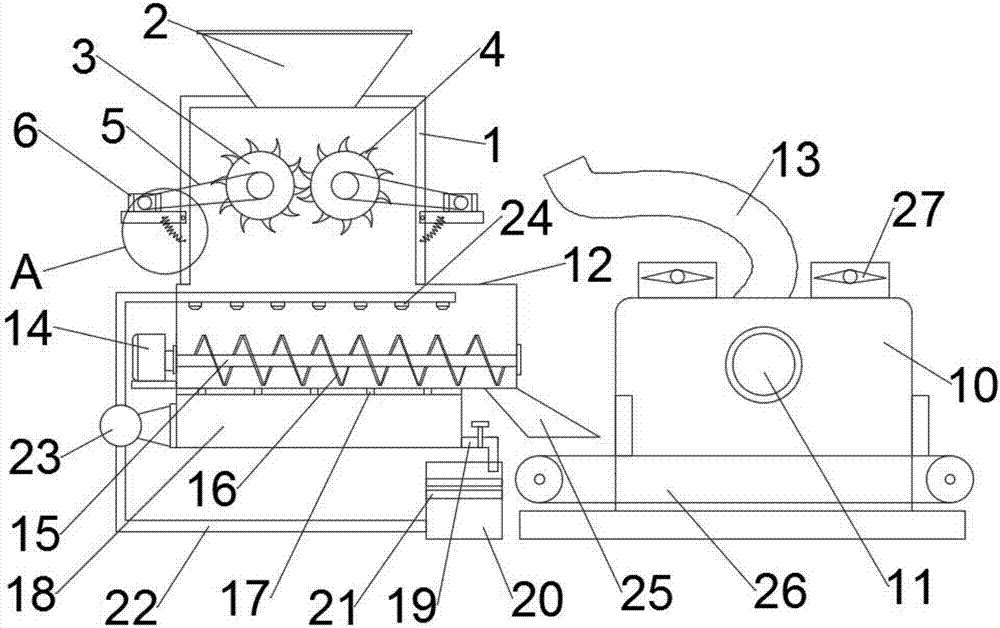

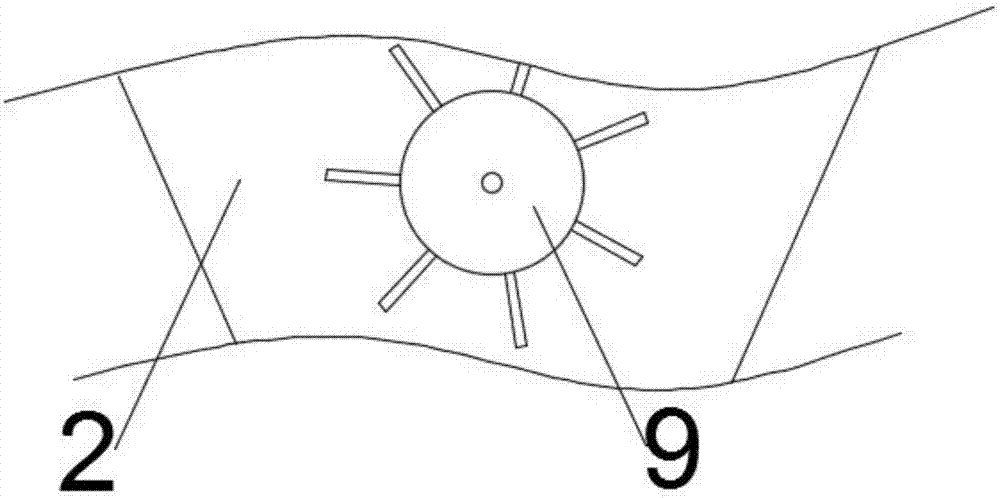

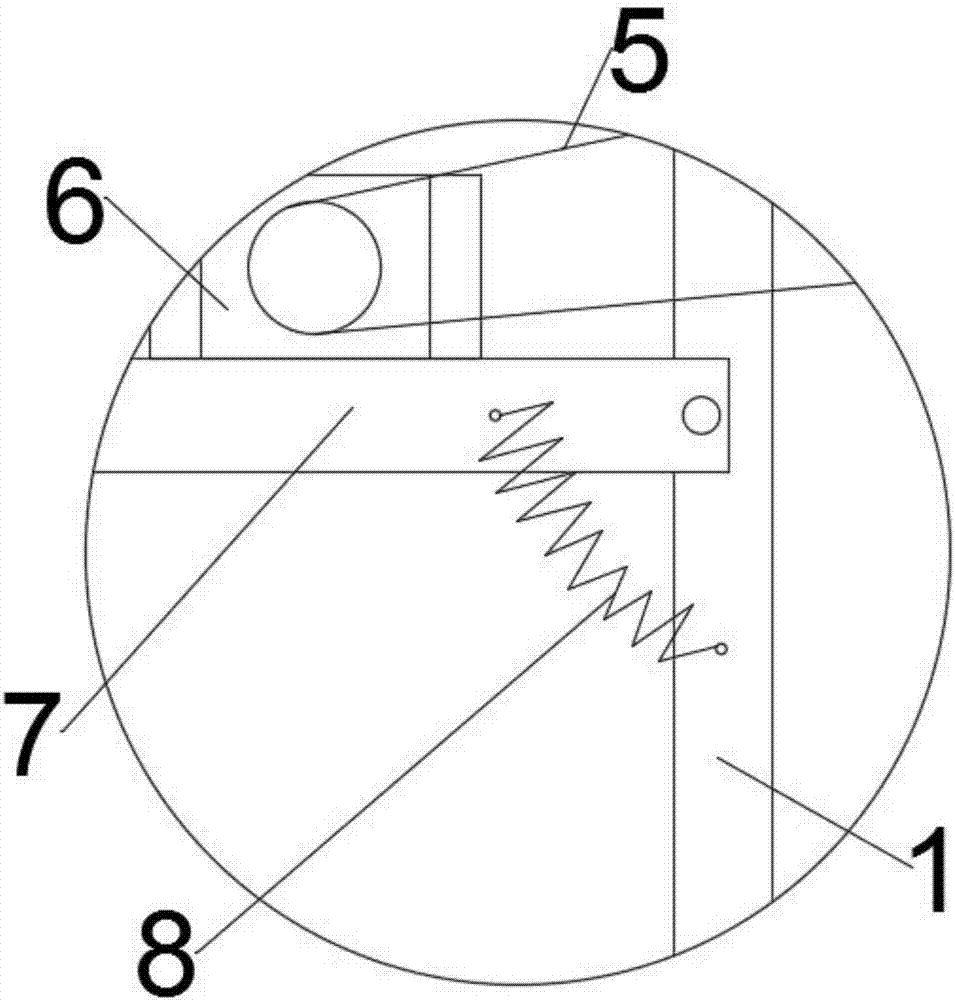

Continuous integrated waste plastic garbage crushing and cleaning treatment device

InactiveCN107116725ASmooth entryImprove cleanlinessPlastic recyclingMechanical material recoveryPull forceWater vapor

The invention discloses a continuous integrated waste plastic garbage crushing and cleaning treatment device. The device comprises a crushing machine body; a feed hopper is arranged at the top of the crushing machine body; a poking turntable is arranged in the feed hopper; a pair of rotating circular rollers is arranged in the middle position of an inner cavity of the crushing machine body in parallel; a movable support plate is hinged to the outer side wall, opposite to the rotating circular rollers, of the crushing machine body; a transmission motor is mounted above the movable support plate; an output shaft of the transmission motor is connected to center rotating shafts of the rotating circular rollers through transmission conveying belts; and the top position of a box body of a quick drying box communicates with a water vapor discharge pipe. The transmission motor enables the transmission conveying belts to always keep in a tensioned state through self weight and tension of a powerful tension spring; and dissipated water vapor is discharged through the water vapor discharge pipe, so that subsequent finished products are directly used in a dried state.

Owner:苏天平

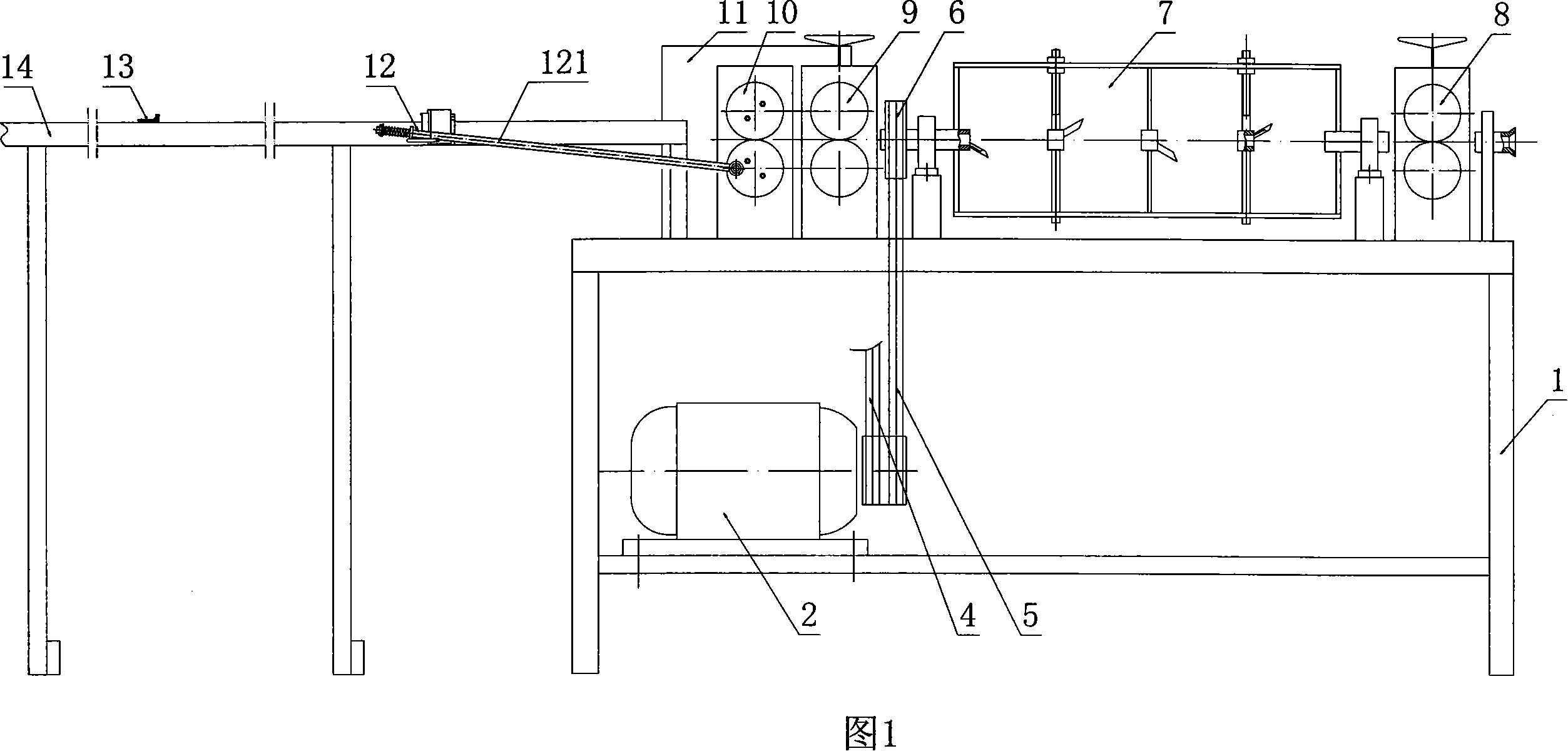

Machine for straightening and cutting steel bar

The invention relates to the mechanical technology field of reinforcing bar processing, which is a reinforcing bar straightening cutter, comprising a frame, a drive mechanism, a drawing mechanism, a straightening mechanism, a shearing and cutting mechanism and a material-holding frame. One front end of a straightening die casing of the straightening cutter is provided with a guide fin with a front flaring, which is convenient for the reinforcing bar to penetrate. The shearing and cutting mechanism consists of a driving cutter, a driven cutter, a shearing double roller, a signal generator, a clutch mechanism, a basic reset mechanism of cutter and an accurate reset mechanism of cutter. When then signal generator gives a shearing signal, the clutch mechanism of the clutch receives the signal to conduct dynamic clutch. After the reinforcing bar is cut, the driving cutter and the driven cutter return to a starting position via the basic reset mechanism of the cutter. The interaction of a positioning pin and a spiral groove of the accurate reset mechanism of the cutter make the driving cutter and the driven cutter return back to the starting position, thereby realizing precision cutting of the reinforcing bar and improving automatization.

Owner:向天立

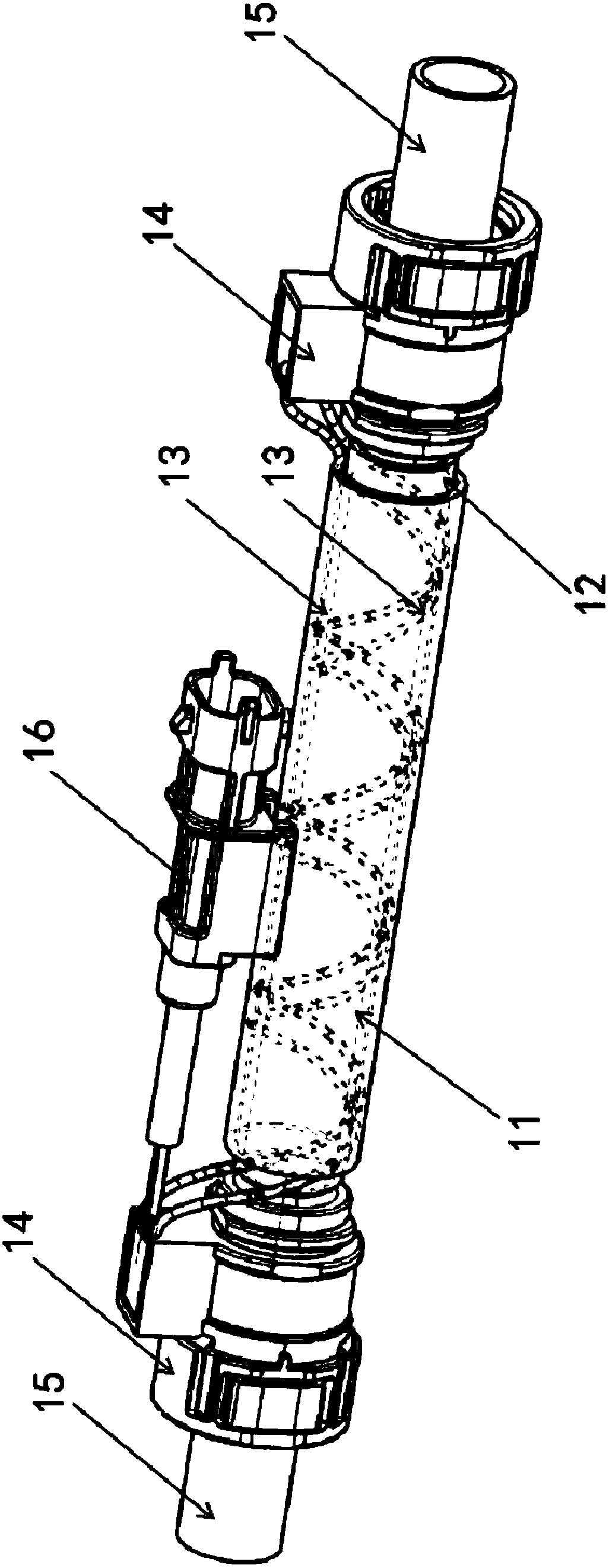

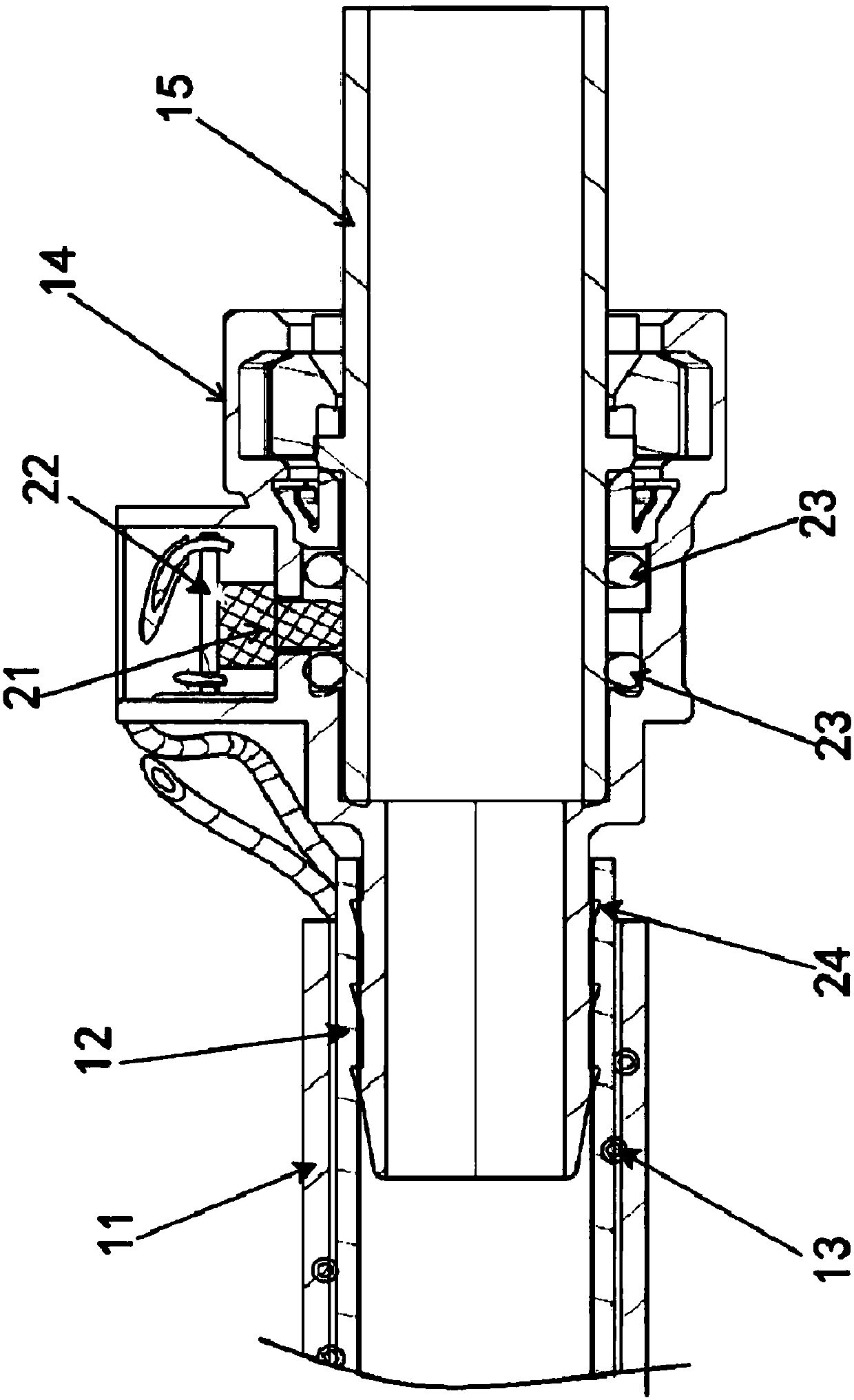

Electric conduction type crankcase ventilation pipe

PendingCN107740893AAvoid cloggingGuaranteed to workPipe couplingsPipe heating/coolingElectrical and Electronics engineeringConduction type

The invention discloses an electric conduction type crankcase ventilation pipe. The ventilation pipe comprises a sealing pipe and quick-fitting joints arranged at the two ends of the sealing pipe; twoguide wires are arranged on the outer side of the sealing pipe; the quick-mounting joints at the two ends are provided with microswitches which are positioned on the inner walls of insertion holes respectively and circuit boards connected with the microswitches, and the two ends of the two guide wires are connected to the circuit boards at the corresponding ends to form a conduction loop; and thecircuit board at one end is further connected with an external electrical plug, and the electric plug is used for being connected with an automobile master control ECU so as to output on-off signals.According to the electric conduction type crankcase ventilation pipe, the wires, the microswitches, the circuit boards and the electric plug are arranged and connected to the automobile main controlECU, after an automobile is started, whether the crankcase ventilation pipe is in a conduction state can be monitored online, so as to ensure that combustible gas separated by an oil-gas separation system in a crankcase can smoothly enter an air inlet system of an air cylinder for re-burning, so that emission of harmful gas is further reduced, and pollution to the atmosphere is reduced.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

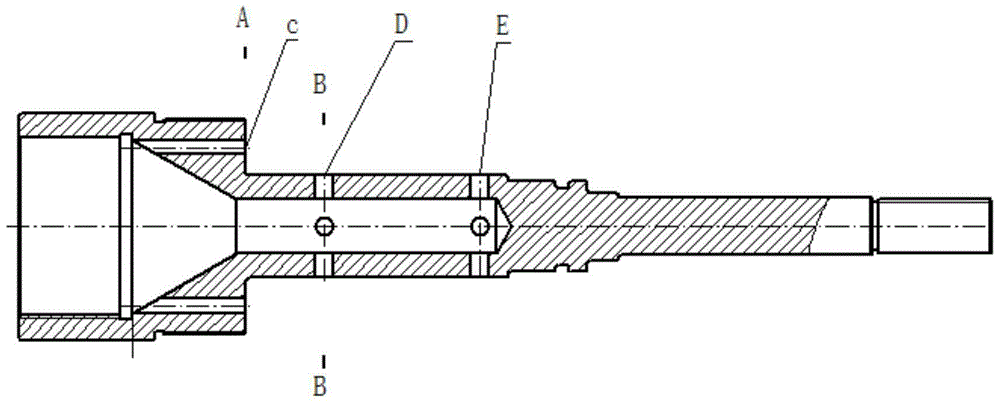

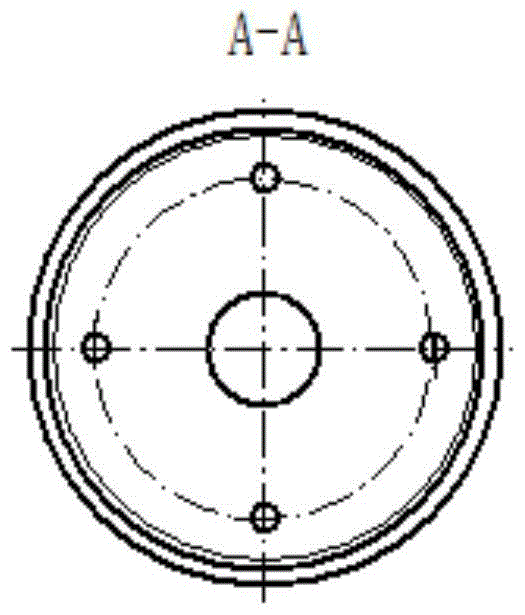

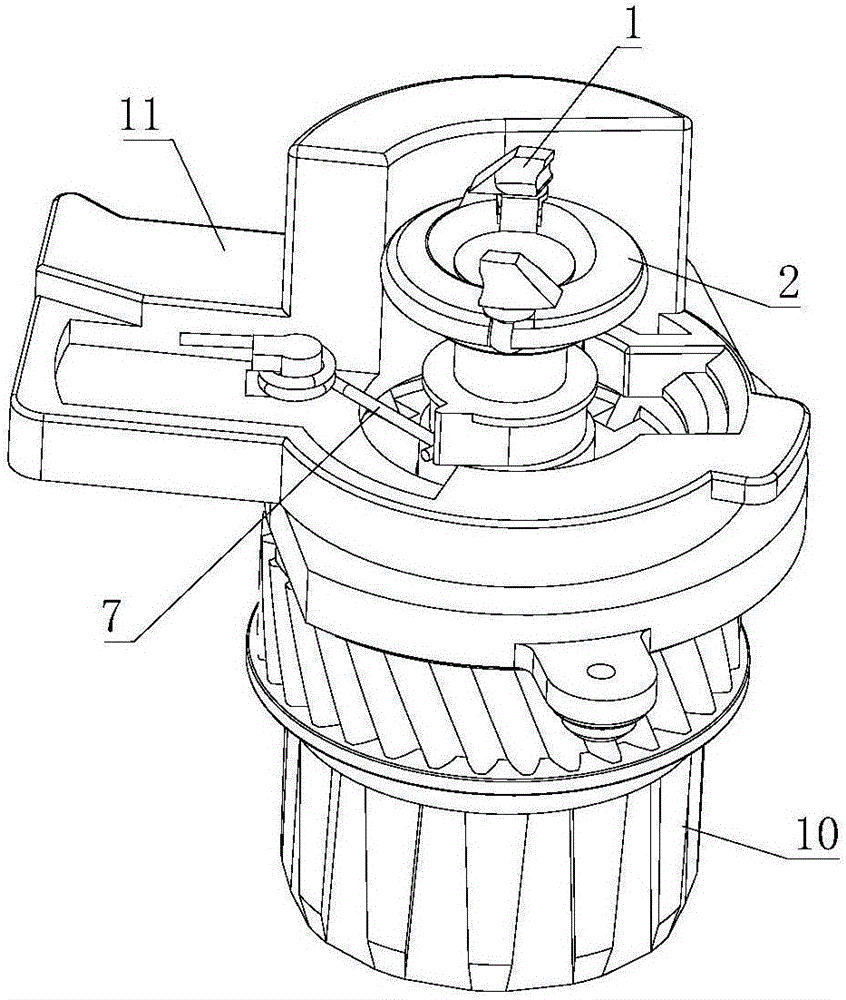

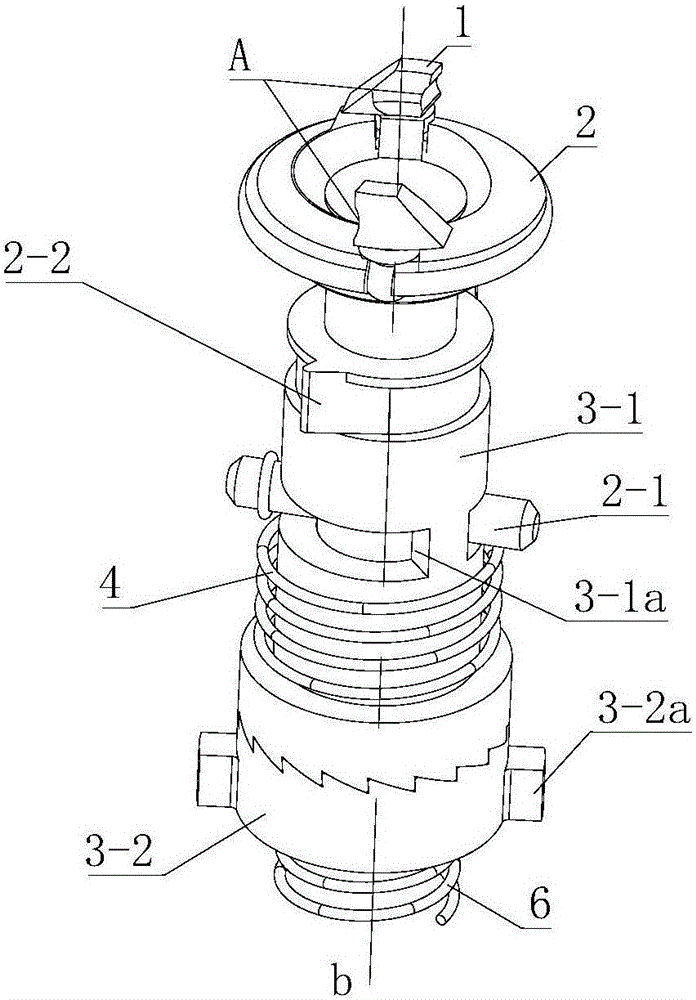

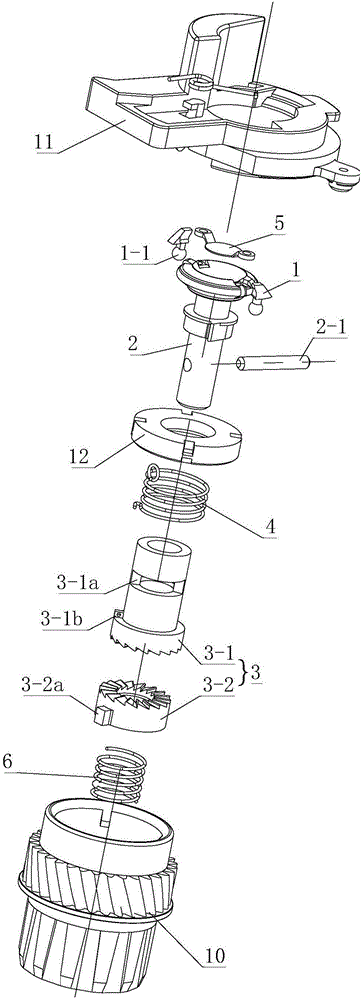

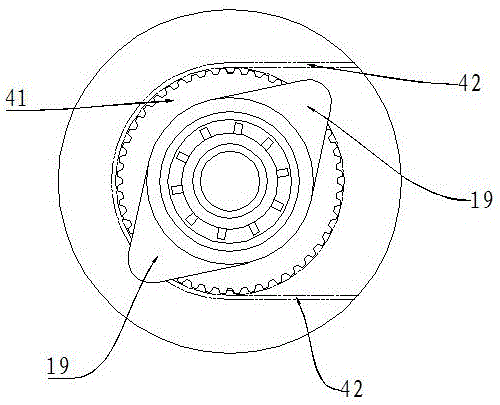

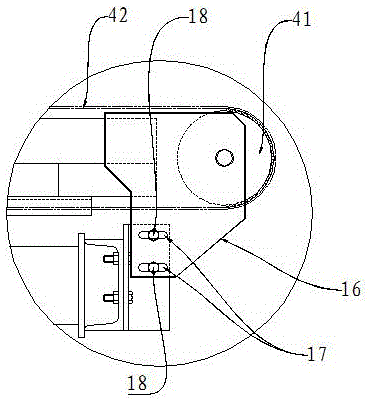

Driving force receiving assembly of photosensitive drum

ActiveCN105843008ASmooth entryNo getting stuckElectrographic process apparatusStress pointEngineering

The invention discloses a driving force receiving assembly of a photosensitive drum. The driving force receiving assembly of the photosensitive drum is used for receiving rotating force of a driving head of an image forming device and transmitting the rotating force to the photosensitive drum through a photosensitive drum gear arranged at the end part of the photosensitive drum to drive the photosensitive drum to rotate. The driving force receiving assembly comprises a driving force receiving part, a driving force transmission part and a gear matching part, wherein the driving force receiving part is engaged with an engaging part of the driving head of the image forming device; the driving force transmission part is connected with the driving force receiving part and the gear matching part; the gear matching part is matched with the photosensitive drum gear; and the driving force receiving assembly is engaged with the driving head in a manner of forming a fixed angle by a vertical intersection line of the center point of the engaging part and the rotating center line of the driving head and the vertical intersection line of a stress point of the driving force receiving part and the rotating center line of the driving force transmission part. By the driving force receiving assembly, driving force transmission can be stably and reliably achieved; and the condition that a process cartridge is smoothly put in / taken out can be ensured.

Owner:ZHUHAI UN TERN IMAGING PROD

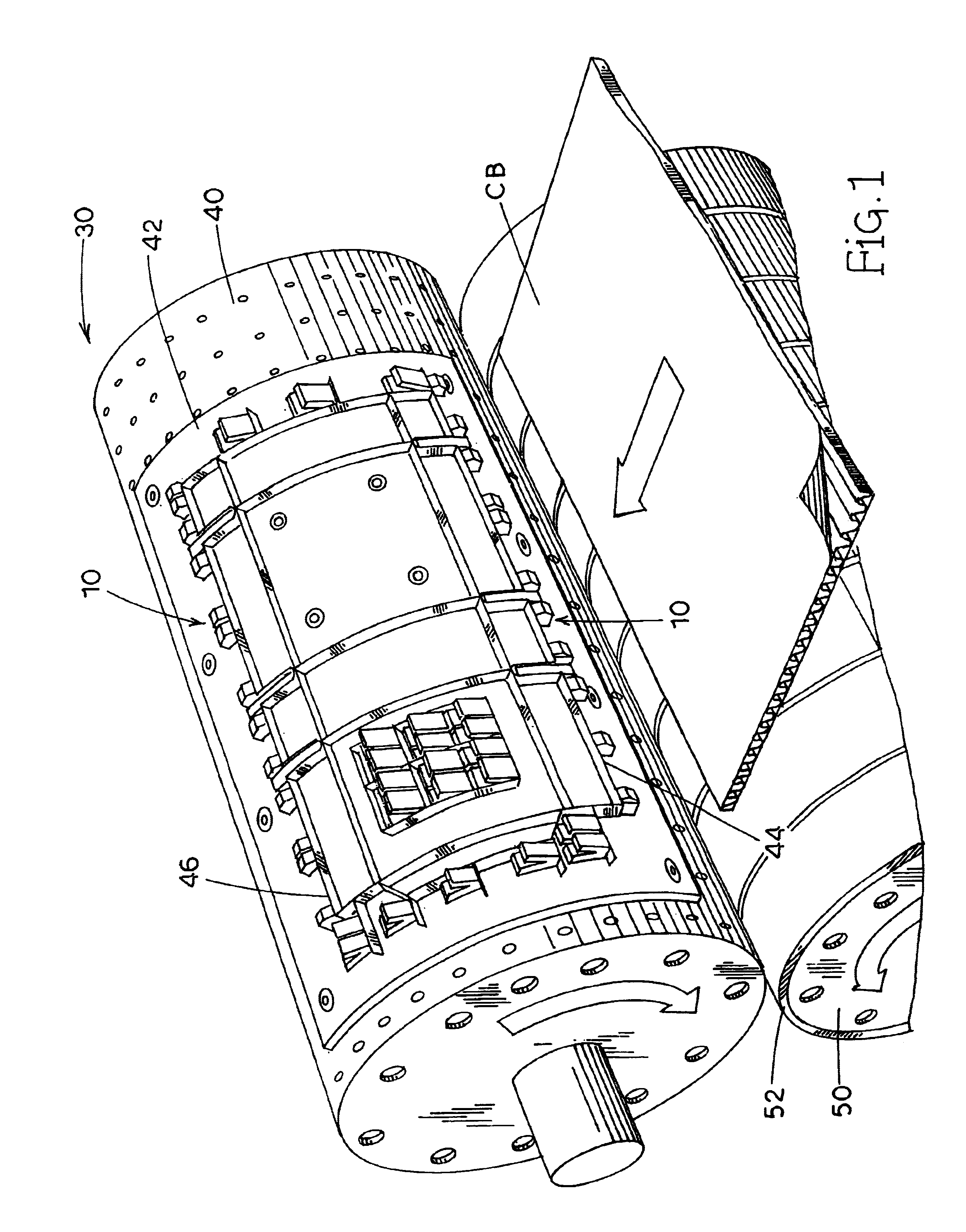

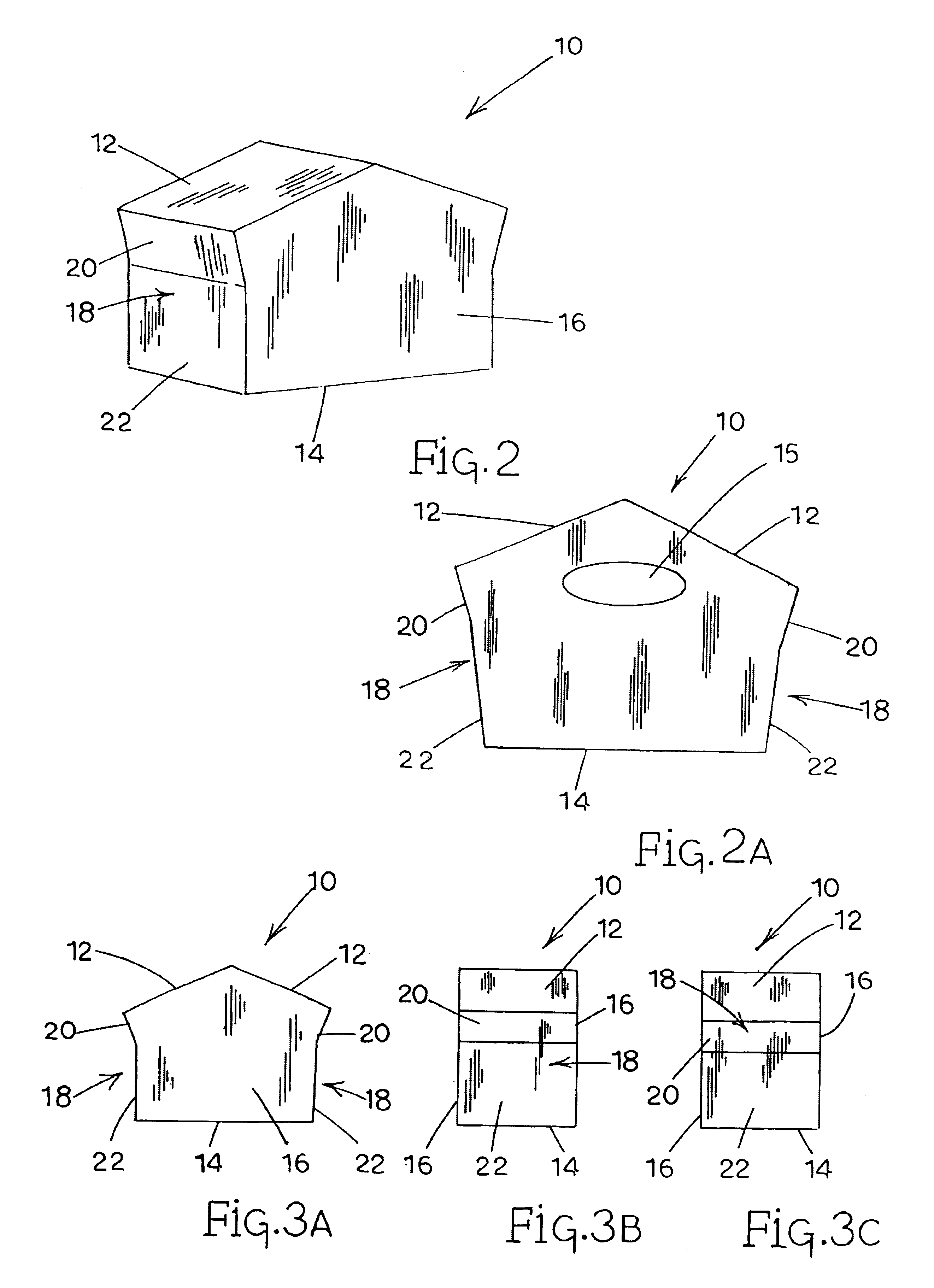

Trim edge stripper for a corrugated board rotary cutting die

InactiveUS6966245B1Smooth entryEfficient separationStock shearing machinesMetal working apparatusScrapEngineering

A rotary cutting die includes a trim stripper having a generally pentagonal shape which forcibly separates severed trim scrap from cut corrugated board, directing the scrap material generally downwardly and away from the trimmed corrugated board product. The pentagonal shaped stripping member mounts on the surface of a die board adjacent a trim cutting blade and is formed of a resilient material, such as closed cell rubber, which deforms elastically when forced into contact with the incoming blank of material. The angled nature of the stripper surface allows the stripper to smoothly contact and capture the leading edge of the blank, greatly reducing the potential for an initial destructive misalignment at the stripper-blank interface. More particularly, the angled upper surface of the pentagonal shaped member is oriented such that as the stripper is brought into contact with the blank and deformation of the resilient stripper occurs, the engaged angled surface tends to hold the blank material against an adjacent anvil cylinder. Simultaneous with this holding action of the stripper, the cutting blade engages and penetrates the blank material, effectively severing or trimming the edge of the blank and producing a segment of scrap. As the elastically deformed stripper begins to recoil, and return to it's original pentagonal shape, the angled surface of the stripper remains in general contact with the severed scrap and continues to hold the scrap material firmly against the anvil surface. By doing such, the stripper effectively forces the severed scrap material to be expelled from the rotary die assembly along a tangent to the anvil cylinder that is angled or directed significantly lower than the path taken by the trimmed corrugated board product.

Owner:CONTAINER GRAPHICS

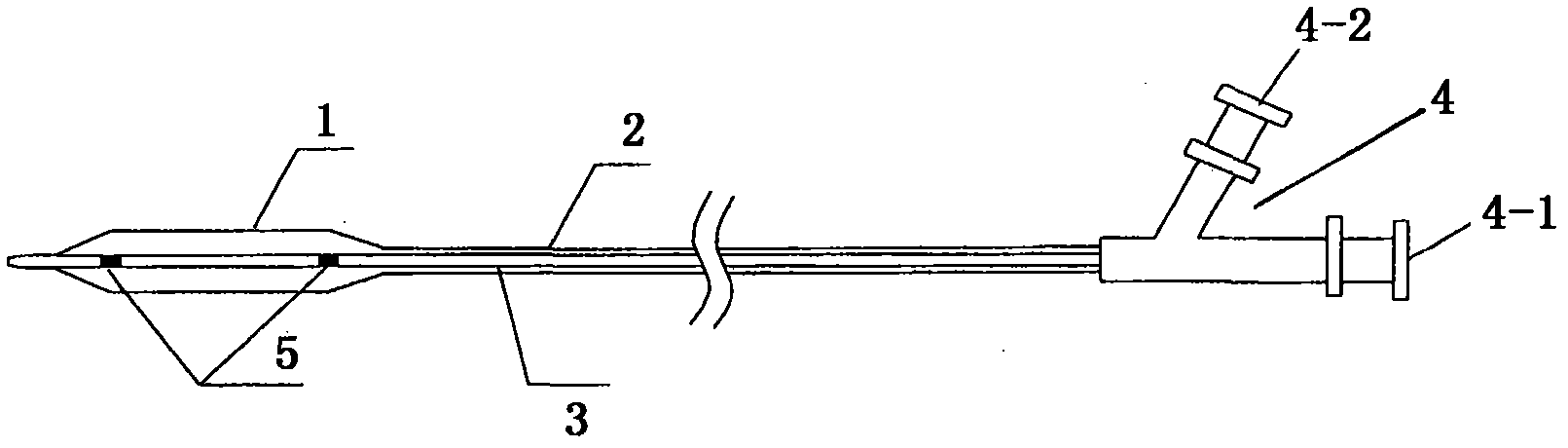

Sacculus dilatation catheter

ActiveCN102139136ASmooth entryEnough thrustStentsBalloon catheterBalloon dilatation catheterVascular disease

The invention provides a sacculus dilatation catheter for blood vessel dilatation surgery. The sacculus dilatation catheter comprises a sacculus, a push rod, an inner tube and a connecting device, wherein the push rod is positioned between the sacculus and the connecting device and connects the sacculus and the connecting device, and the inner tube extends and passes through the internal spaces of the sacculus and the push rod. The sacculus dilatation catheter is characterized in that: at least one of the push rod and the inner tube is made of weaving silk reinforcing tube. The sacculus dilatation catheter can smoothly pass through circuitous, diffuse calcification and even long-segment occlusive blood vessels in vascular disease interventional therapy surgery.

Owner:SHANGHAI VASOLUTIONS MEDTECH CO LTD

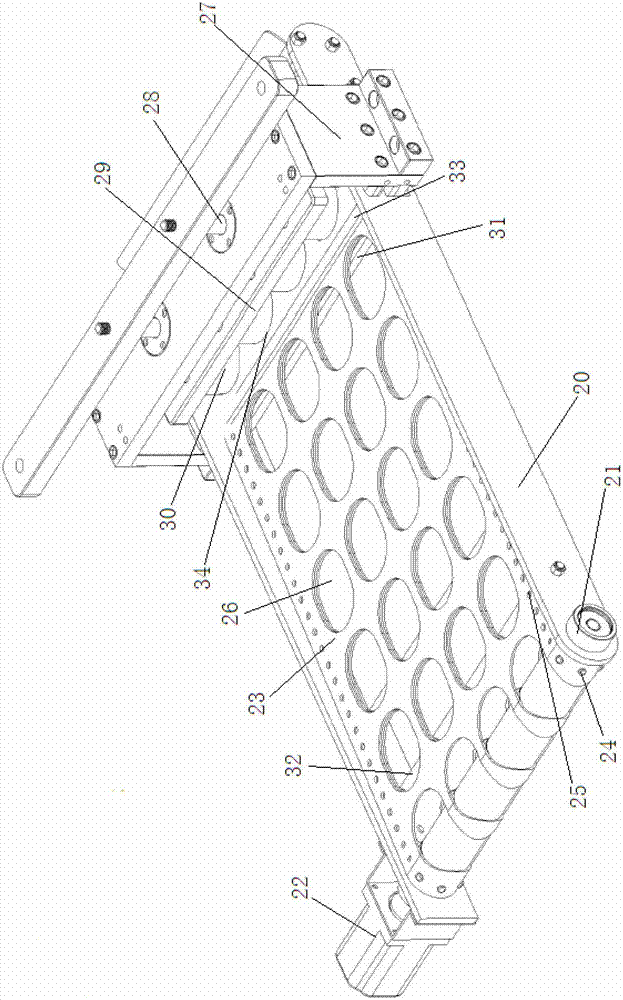

Lifting type belt plate fetching machine

ActiveCN105059896ASmooth entryEntry does not produceConveyorsConveyor partsRelative motionManufacturing line

The invention discloses a lifting type belt plate fetching machine. The lifting type belt plate fetching machine is correspondingly arranged at the tail end of a roller way used for conveying glass plates in a glass production line. The lifting type belt plate fetching machine comprises a base, a belt conveying rack, a lifting mechanism and a belt conveying mechanism horizontally mounted on the belt conveying rack. A belt conveying motor used for driving the belt conveying mechanism to operate is arranged at one end of the belt conveying rack. The belt conveying rack is horizontally mounted on the lifting mechanism. The lifting mechanism is fixed to a base. A lifting mechanism transmission station in transmission connection with the lifting mechanism is arranged on one side of the base. The lifting mechanism transmission station drives the belt conveying rack to act through the lifting mechanism so that the belt conveying mechanism can have certain displacement in the horizontal direction while the vertical height of the belt conveying mechanism is changed, and accordingly the glass plate at the tail end of the roller way is transferred onto the belt conveying mechanism. According to the lifting type belt plate fetching machine, the conveying speed of the belt conveying mechanism is the same as that of the roller way, in this way, it is guaranteed that the glass plate enters a belt of the belt conveying mechanism smoothly, relative movement is avoided, the quality of glass is improved, and the rate of finished products is increased.

Owner:HENAN HAICHUAN ELECTRONICS GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com