Patents

Literature

1098results about How to "Realize the clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

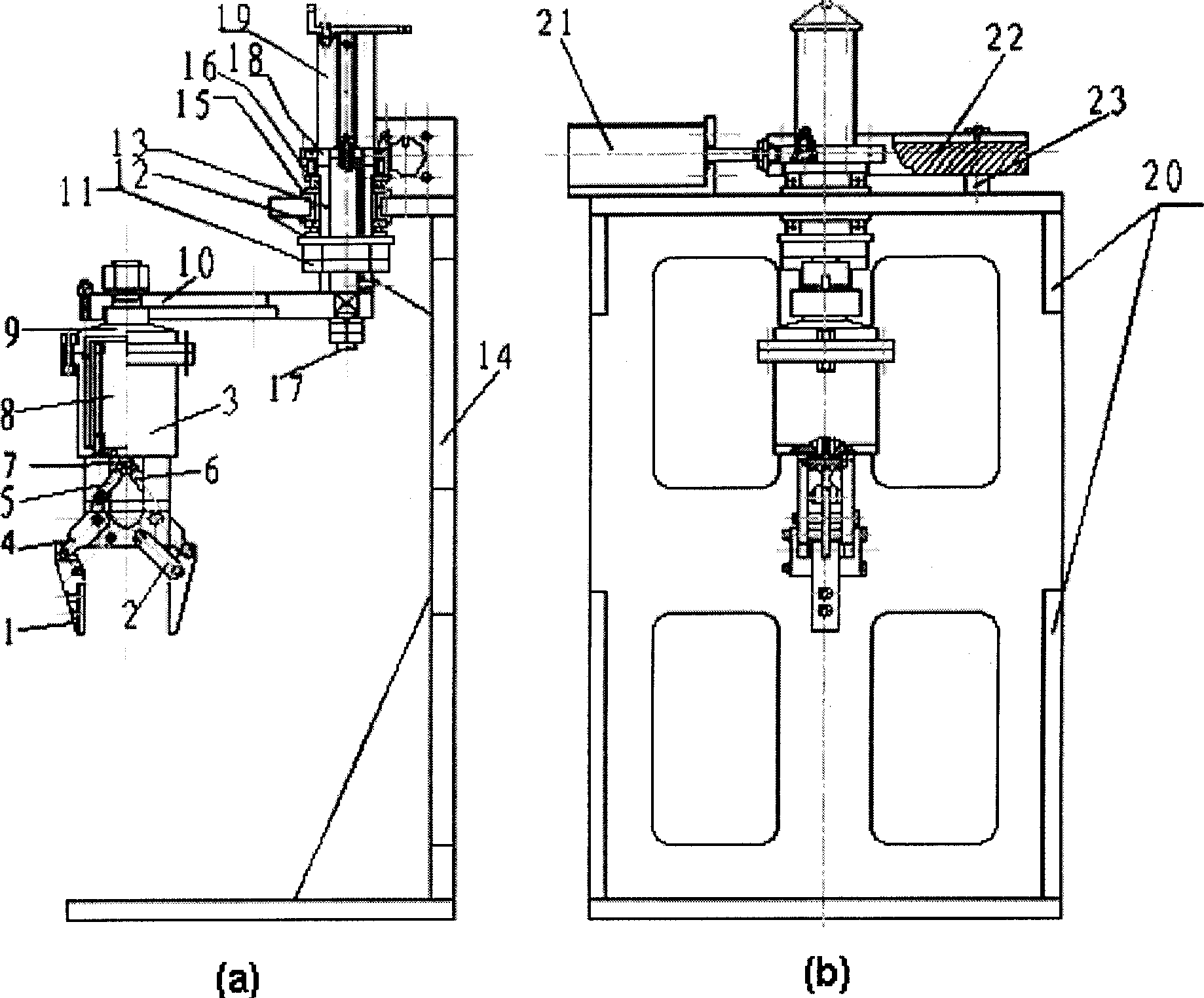

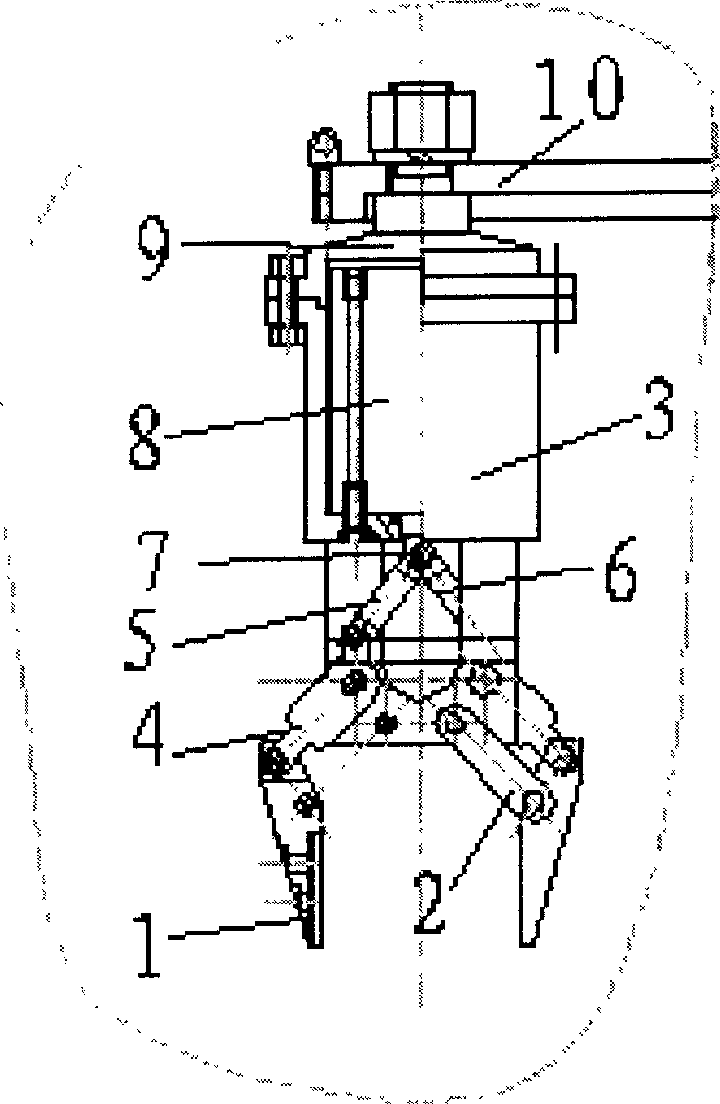

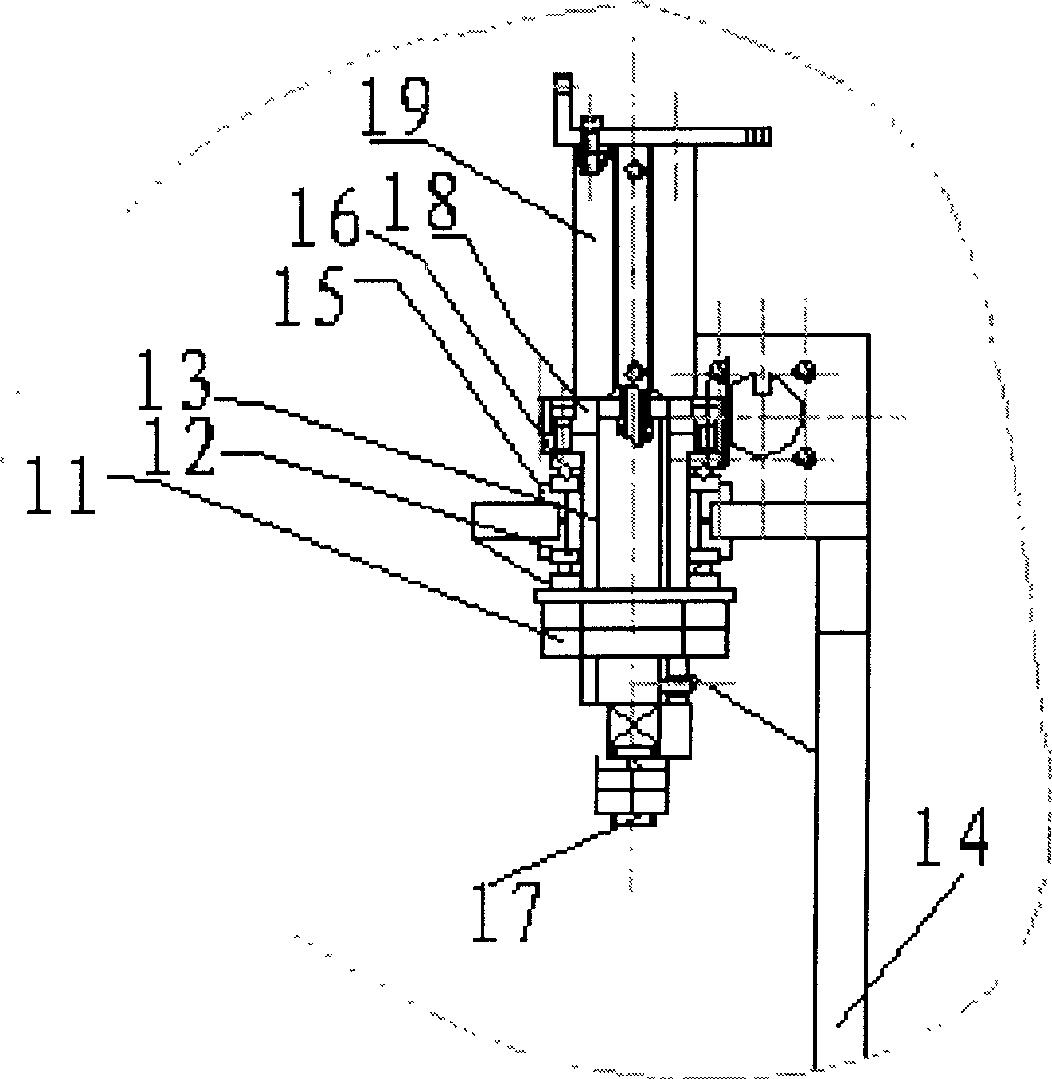

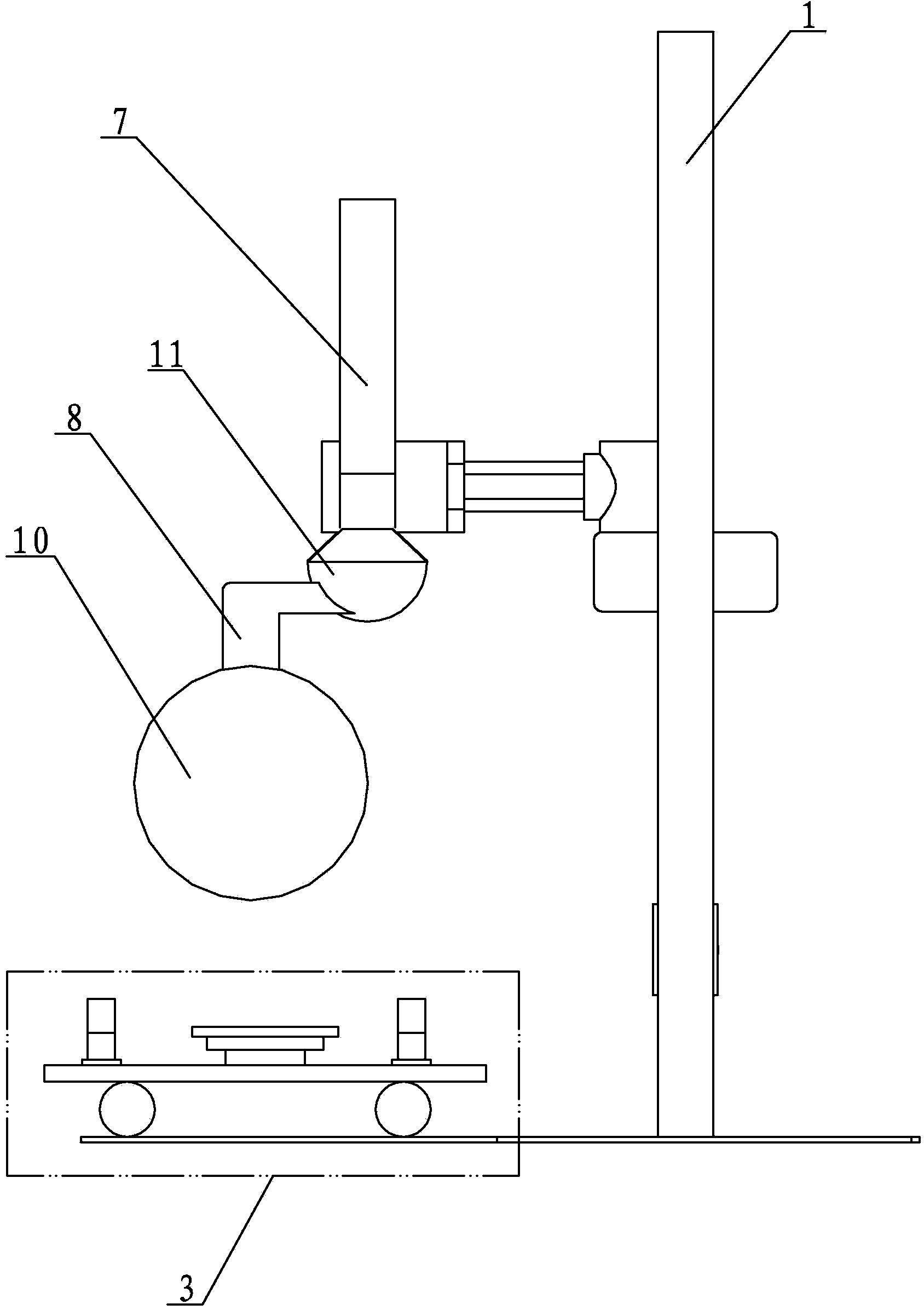

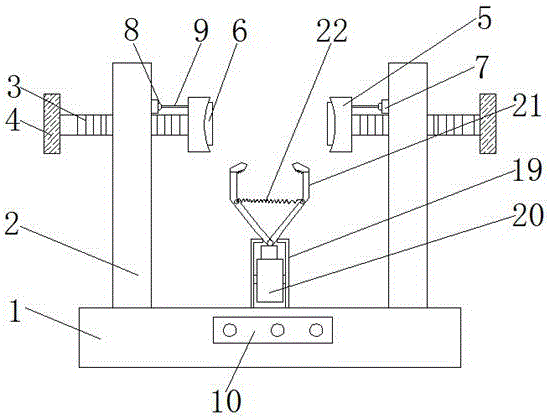

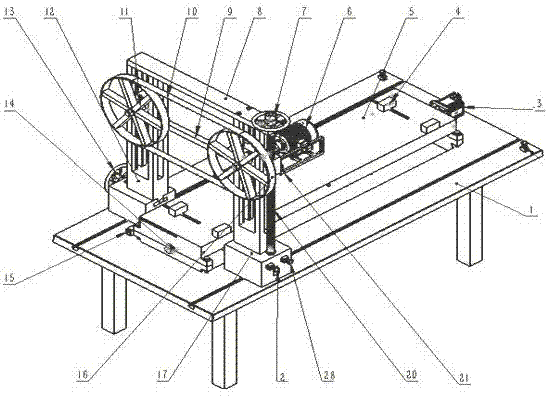

Full pneumatic combined multifunctional industrial manipulator

InactiveCN1701928ARealize the clamping effectAchieve shiftProgramme-controlled manipulatorGripping headsEngineeringActuator

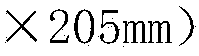

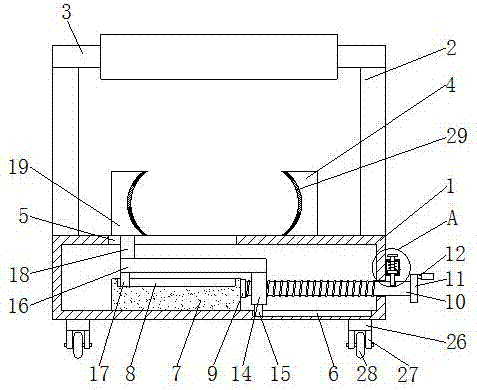

The invention discloses total aerodynamic composite type multifunctional industrial manipulator comprised interchangeable end effector set on suspension arm to clamp workpiece, and aerodynamic system comprised air supply, processor for air supply, two two-position three-way electromagnetic valves, one two-position five-way electromagnetic directional selecting valve, two precompression cylinders, a reciprocating cylinder, and PLC predetermined control program for cylinders to control displacement, mechanical clamp and up-down motion of interchangeable end effector. This invention uses totally gas to drive, selects corresponding mechanical clamper, vacuum absorb hand and gas pocket expand hand for different works to complete work quickly, and increases its application area and utilization rate.

Owner:西安思源职业学院

Clamping device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

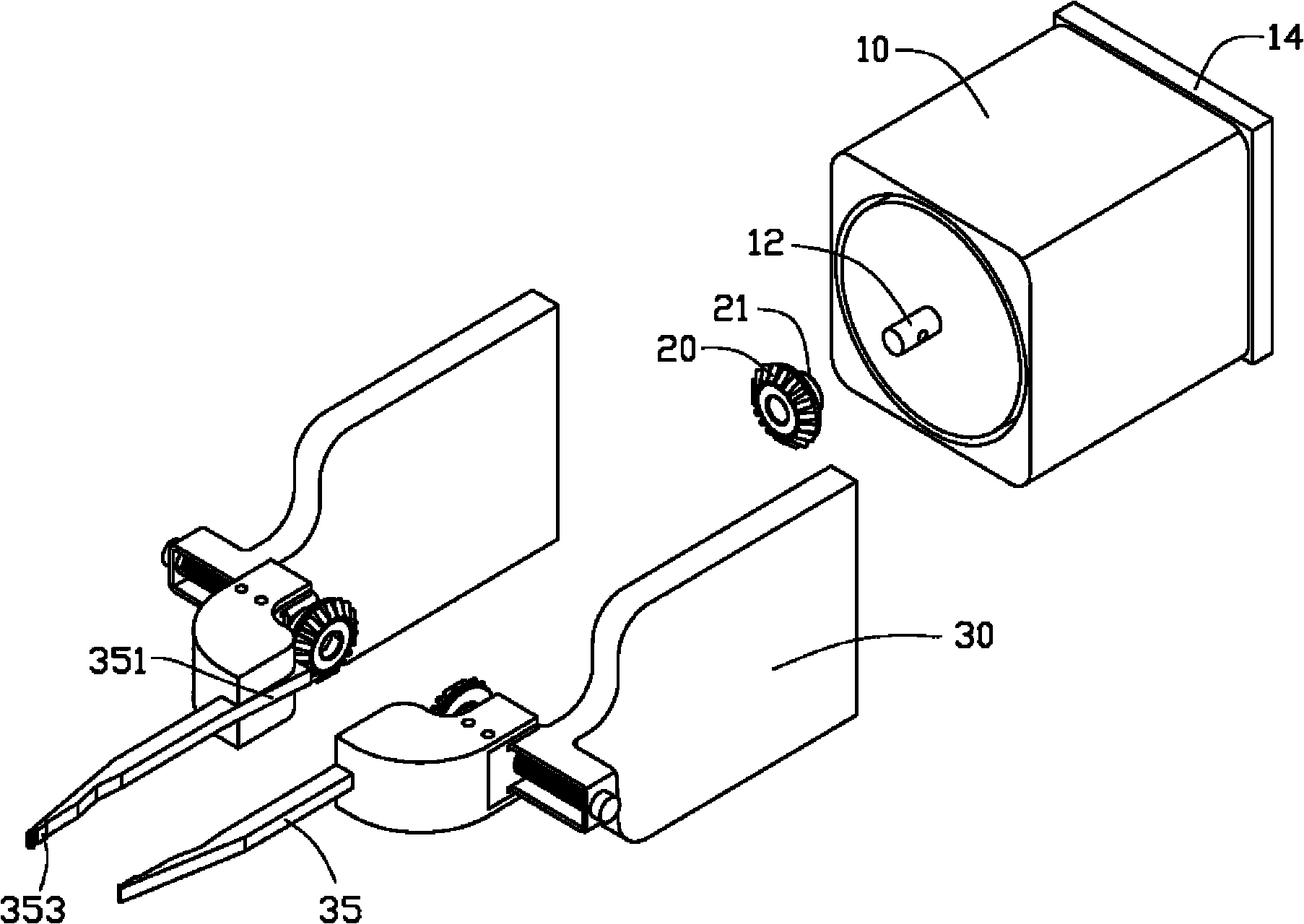

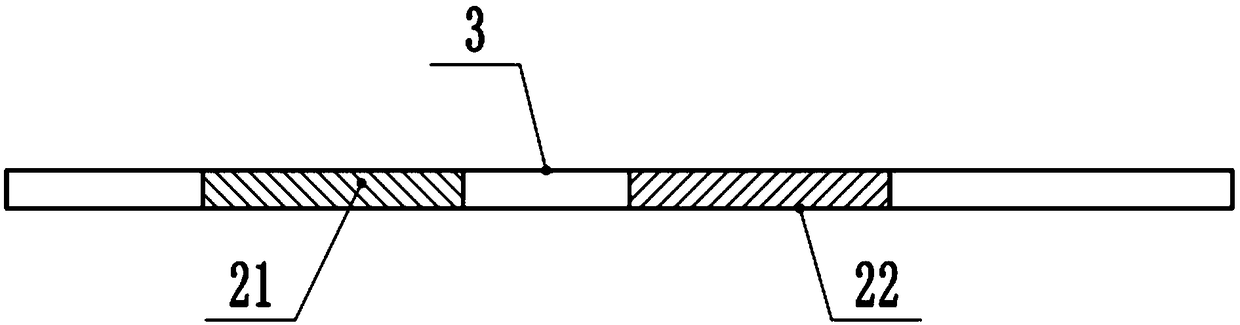

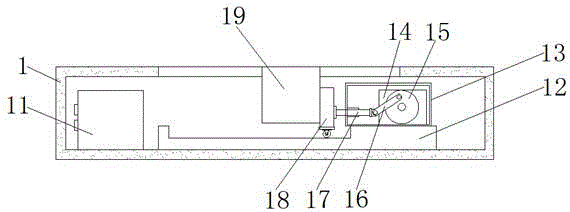

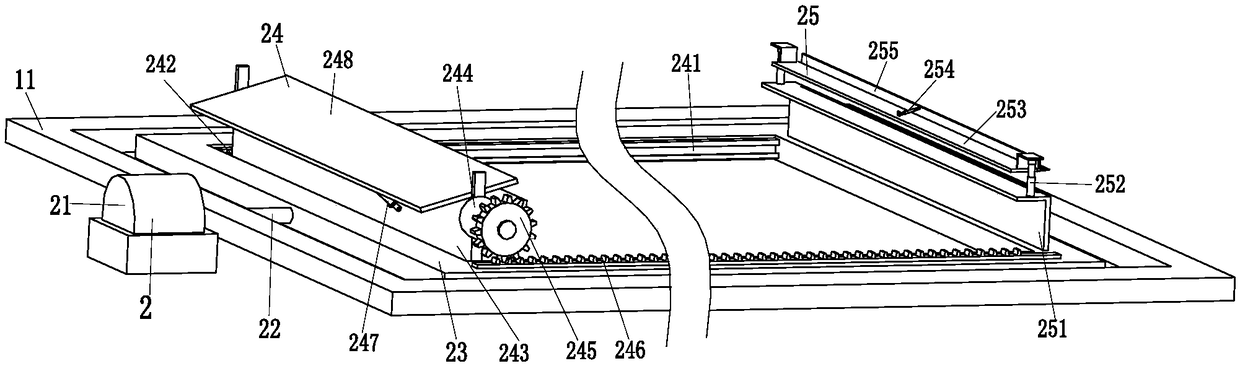

Conveyer device for single-chip microcomputer chip processing process

InactiveCN104401648AImprove efficiencyEasy positioning and transportConveyorsConveyor partsEngineeringMicrocomputer

The invention provides a conveyer device for the single-chip microcomputer chip processing process, belongs to the technical field of machinery and solves the problems of unstable transportation, low transport efficiency and the like existing at each processing station when a single-chip microcomputer chip is processed. The conveyer device for the single-chip microcomputer chip processing process comprises a base; the base is provided with a rotating roller I and a rotating roller II; the rotating roller I is connected with a conveying motor; a conveyer belt is arranged between the rotating roller I and the rotating roller II and is fixedly provided with a plurality of positioning boxes; one side of the conveyer belt is provided with a rotating column; the upper end of the rotating column is fixedly provided with a lifting air cylinder; the end part of the lifting air cylinder is fixedly provided with a rotating arm; the end part of the rotating arm is fixedly provided with a vacuum chuck. The single-chip microcomputer chip is clamped and placed through the rotating arm, and is stably transported through the conveyer belt and the positioning boxes, and the efficiency is high.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

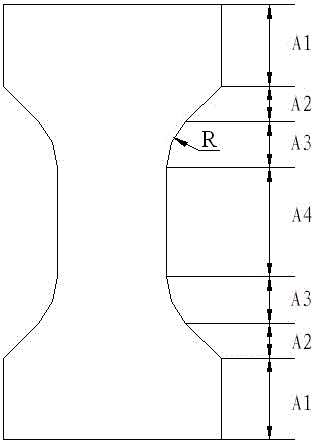

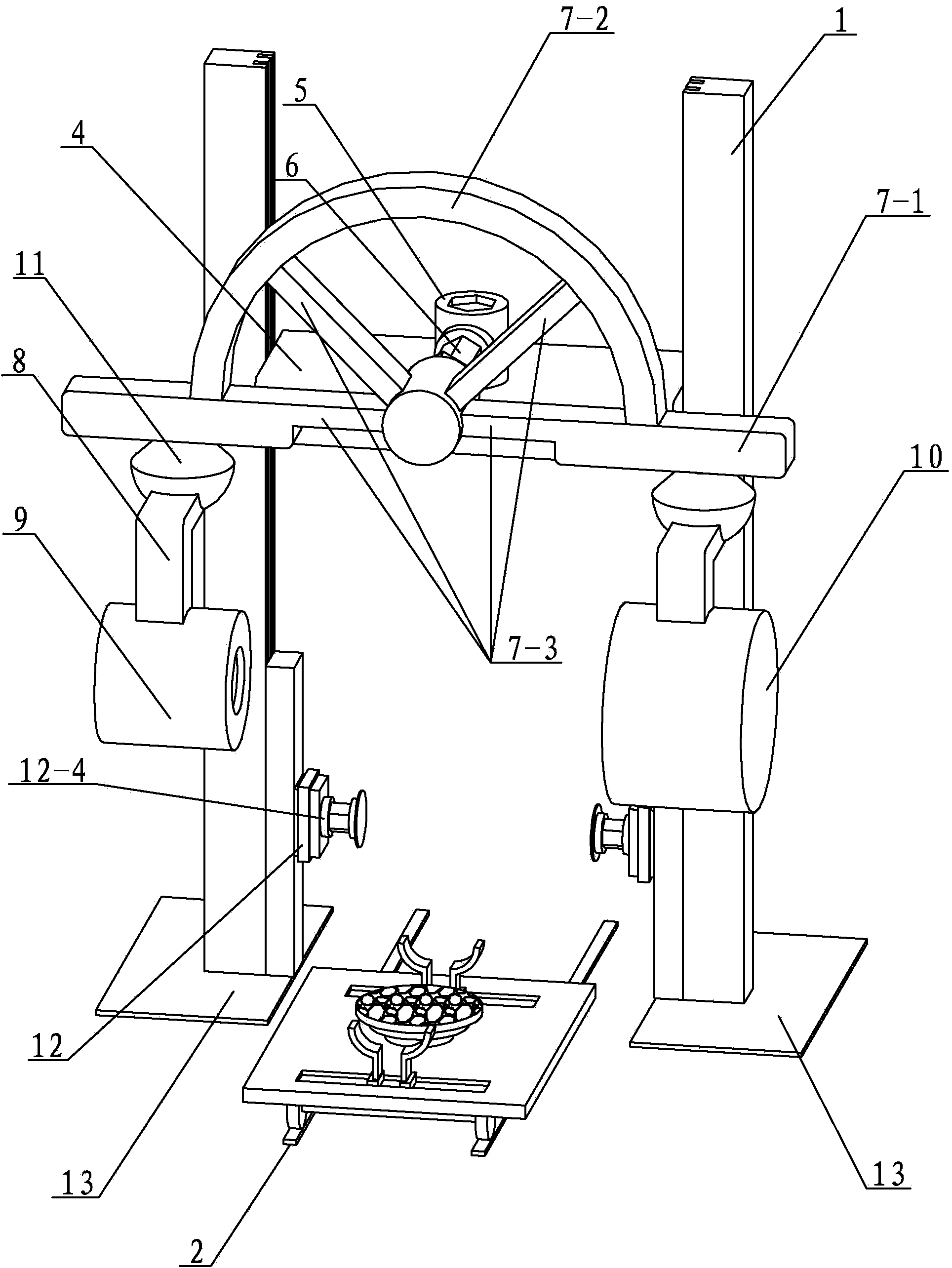

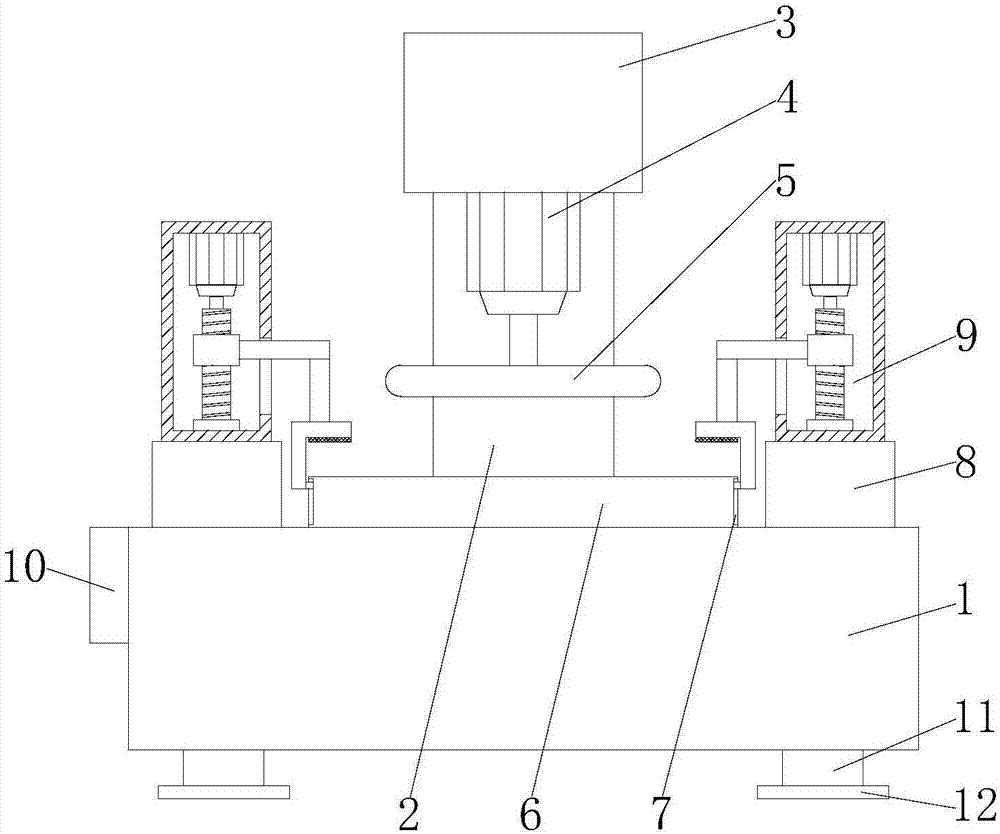

Test piece of concrete direct tensile test, test piece forming die and integrated equipment

ActiveCN106018044AReduce difficultySave manpower and material resourcesPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringButt joint

The invention discloses a test piece of a concrete direct tensile test, a test piece forming die and integrated equipment. According to the invention, the test piece of the concrete direct tensile test, the test piece forming die of the concrete direct tensile test and the integrated equipment of the concrete direct tensile test are provided; the test piece of the concrete direct tensile test is a square-cross section equal thickness dumbbell-type tension test piece; the test piece forming die of the concrete direct tensile test comprises a side mold framework and a base plate, the side mold framework is formed by performing butt joint on two linked side plates; and the integrated equipment of the concrete direct tensile test comprises a loading framework, a loading mechanism, a test piece tensioning clamper, a test piece deformation test clamp and a data acquisition system. The Test piece of concrete direct tensile test, the test piece forming die and the integrated equipment have the advantages of reasonable design, simple structure, environmental protection, high efficiency and accurate testing.

Owner:ZHENGZHOU UNIV

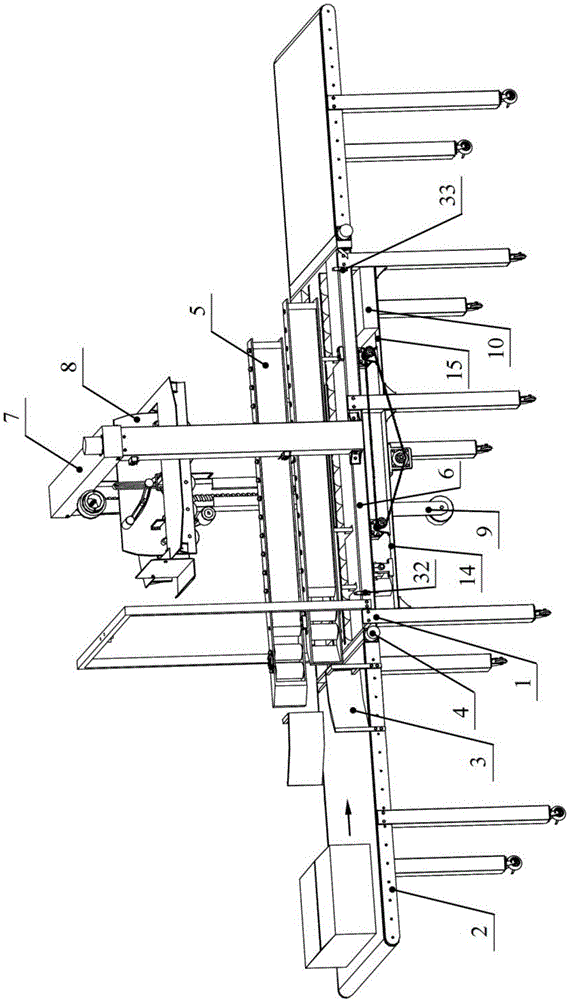

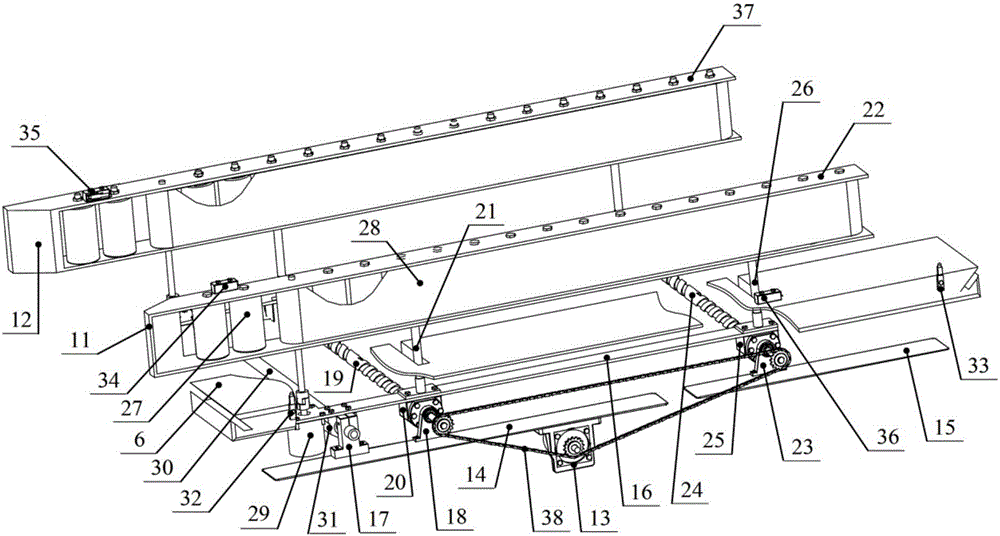

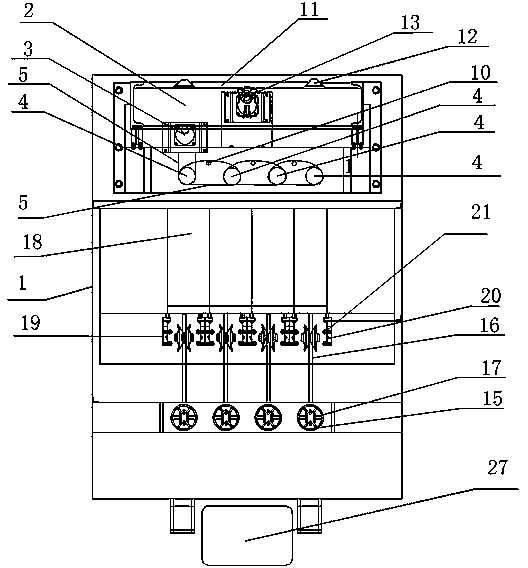

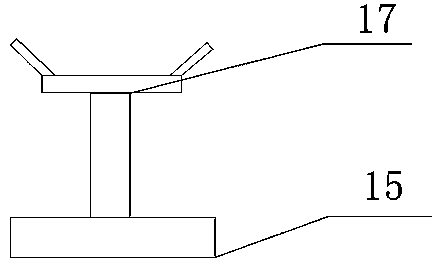

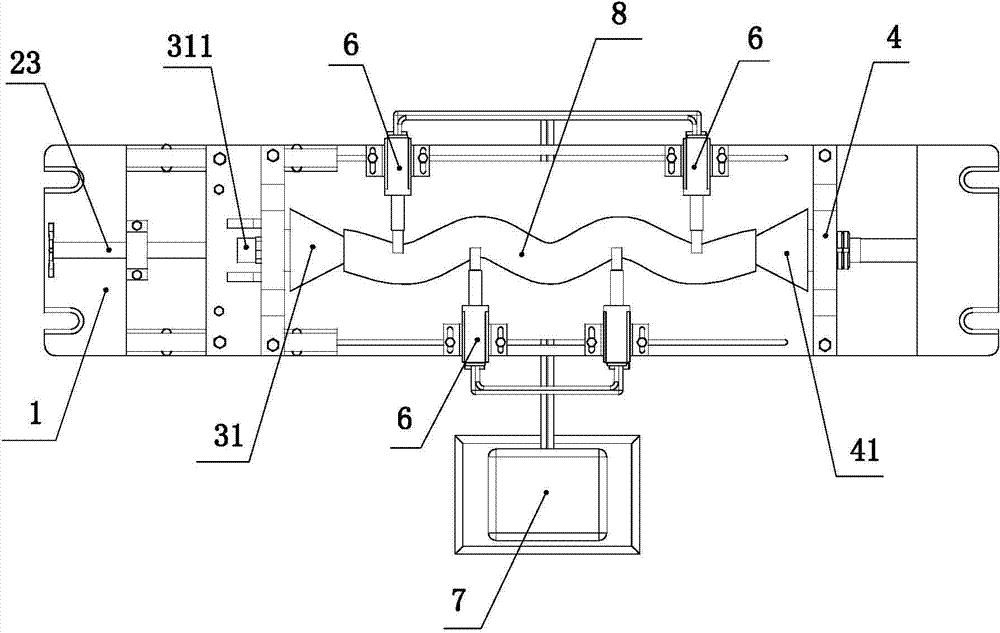

Full-automatic adhesive tape carton sealing machine for multi-specification express cartons and working method

ActiveCN106144054AImprove packaging efficiencyAchieve straightWrapper twisting/gatheringAdhesive beltWide beam

The invention discloses a full-automatic adhesive tape carton sealing machine for multi-specification express cartons. The machine comprises a frame consisting of left, middle and right three sections of beams, wherein a left cross beam of the left section is provided with a guide plate and a first alternating-current speed reducing motor; a middle wide beam at the middle section is provided with an automatic centering and clamping device; door frame type automatic lifting devices are vertically arranged on two sides of the automatic centering and clamping device; a carton sealing machine upper machine core device is mounted between the automatic lifting devices and the automatic centering and clamping device; and a carton sealing machine lower machine core device and a controller for controlling the first alternating-current speed reducing motor, the automatic centering and clamping device, the automatic lifting devices and the carton sealing driving mechanism are arranged below the middle wide beam. The machine realizes continuous full-automatic adhesive tape sealing of the express cartons with different specifications, improves the adhesive tape sealing efficiency, reduces the labor cost, and improves the economic benefit of Taobao sellers. The invention further discloses a working method suitable for the full-automatic adhesive tape carton sealing machine for the multi-specification express cartons.

Owner:江苏新美星物流科技有限公司

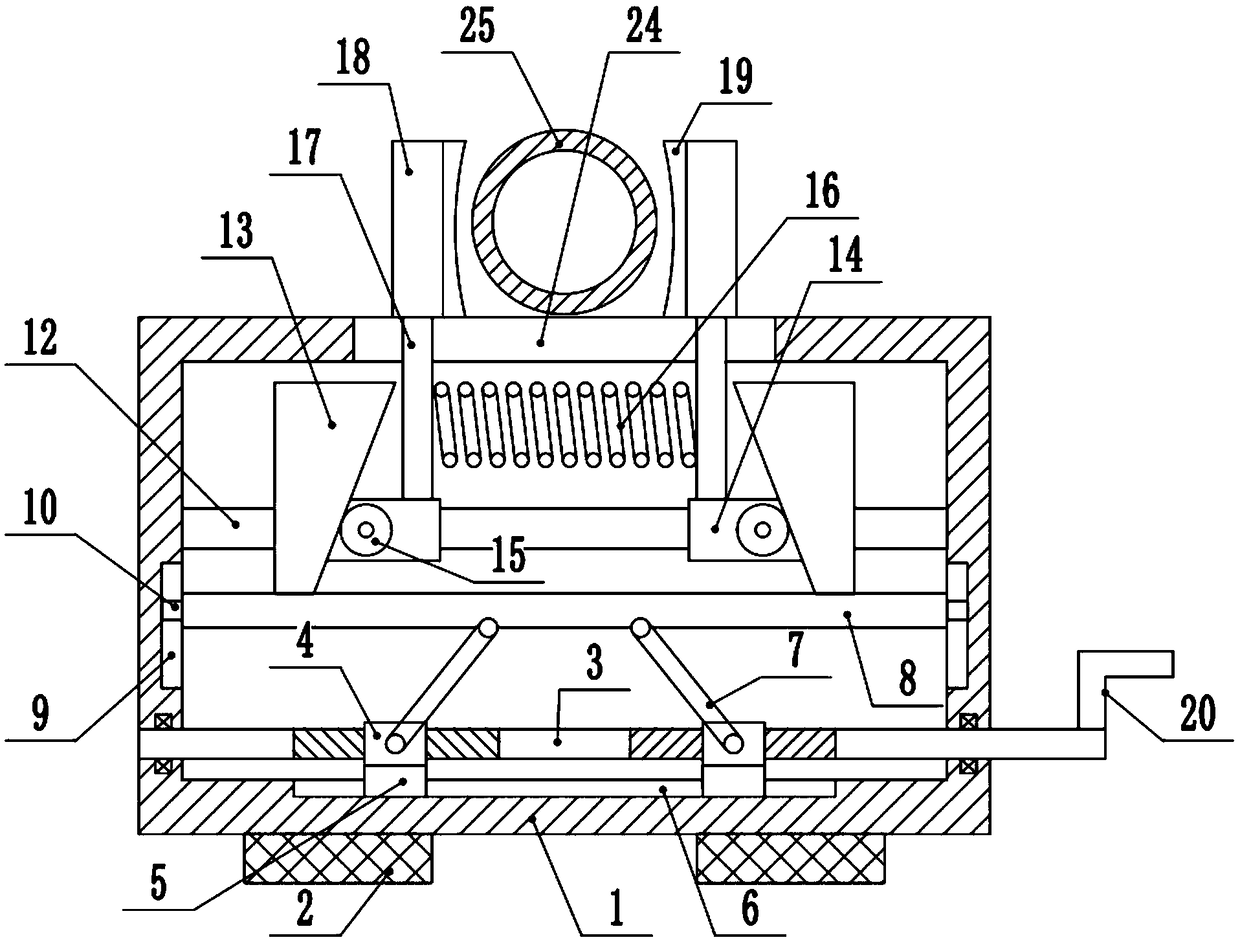

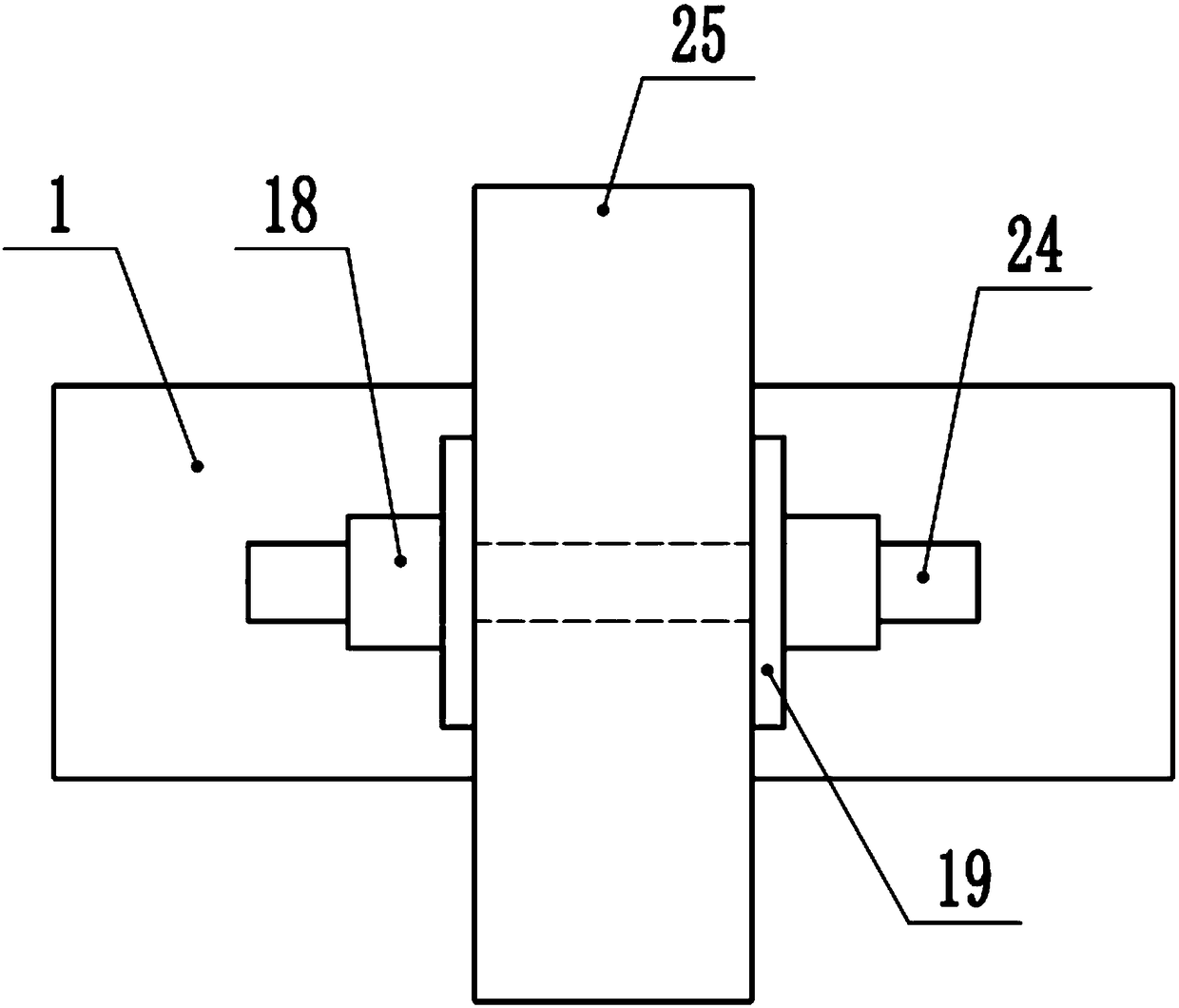

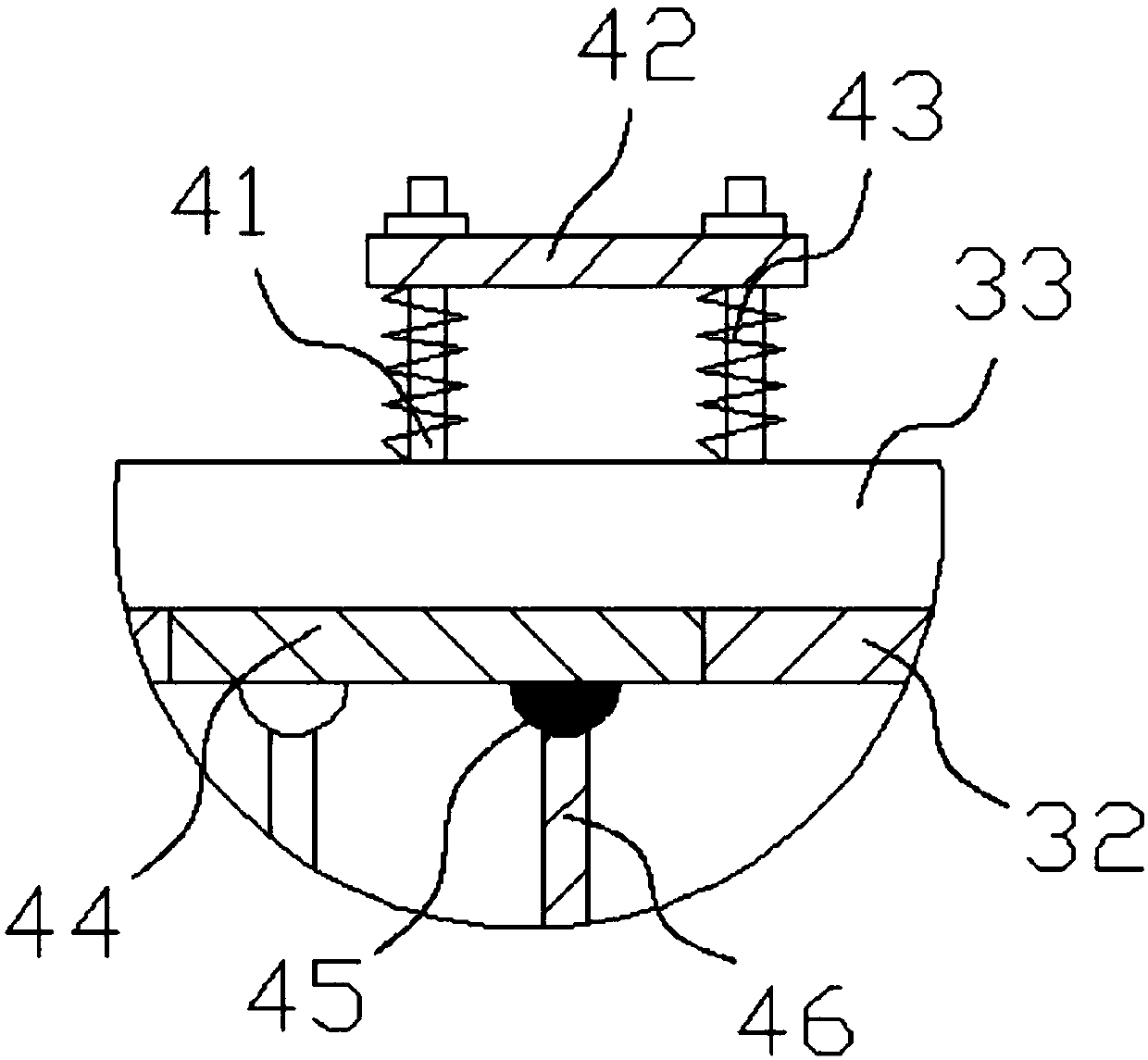

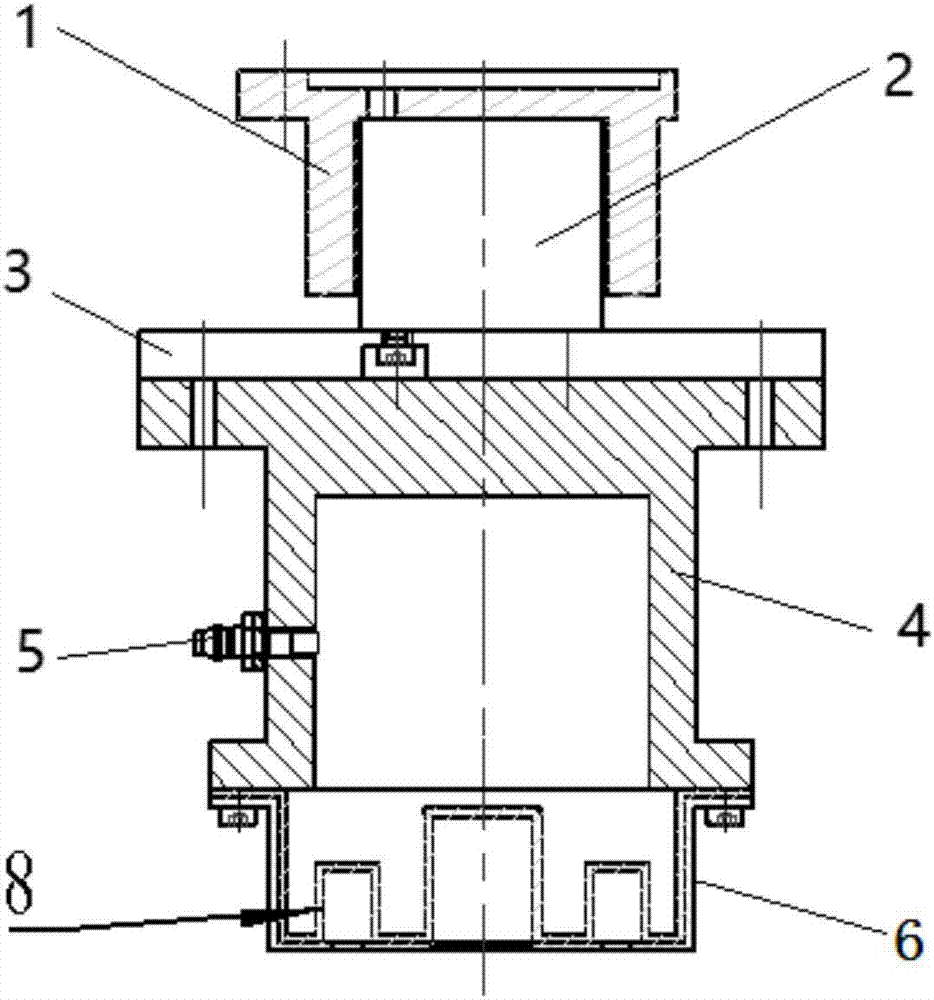

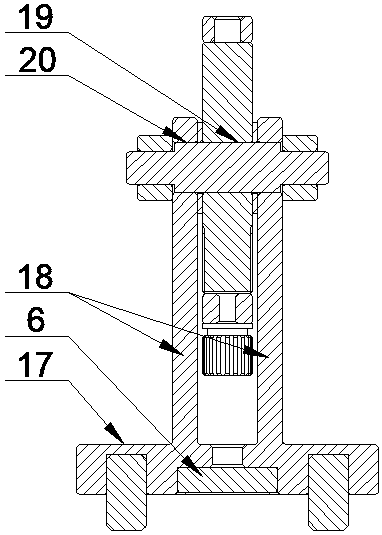

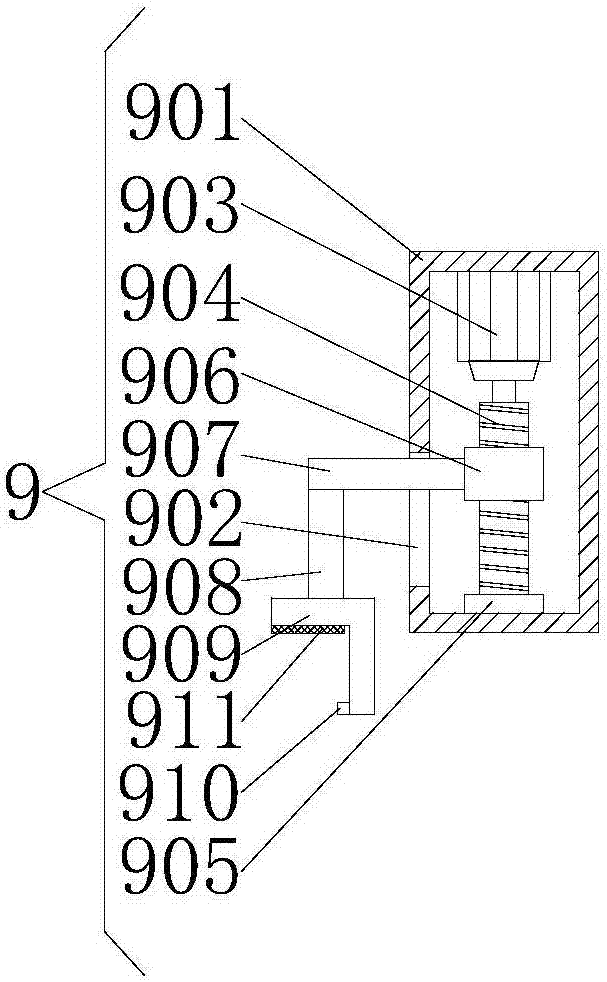

Multifunctional rock core holder for rock core scale nuclear magnetic resonance test

ActiveCN104048982AResearch Mechanical ParametersRealize the clamping effectAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceRock core

The invention discloses a multifunctional rock core holder for a rock core scale nuclear magnetic resonance test. According to the multifunctional rock core holder, an end cover of the holder is connected with a fixing plug by a bolt; a circulating hydraulic oil outlet is an opening in the fixing plug; the fixing plug is connected with a barrel body; the barrel body is connected with an oil cylinder; a downstream oil injection hole of the oil cylinder, an upstream oil injection hole of the oil cylinder and a circulating hydraulic oil inlet are openings in the oil cylinder; the oil cylinder is connected with an end cover of the oil cylinder and is sealed by a sealing ring; a test sample upstream water injection hole is an opening in a test sample upstream cushion block; the test sample upstream cushion block is directly inserted into a piston; a test sample downstream water injection hole is an opening in a test sample downstream cushion block; the test sample downstream cushion block is directly inserted into the end cover of the holder; a rock core test sample is placed between the test sample upstream cushion block and the test sample downstream cushion block; a displacement sensor support is connected with the piston; the displacement sensor support is connected with a pressure rod type displacement sensor. The multifunctional rock core holder is simple in structure and convenient to use, and can be used for carrying out porous medium percolation-mechanics researches of different temperatures, different stress conditions, different pore pressure and different rock core sizes.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

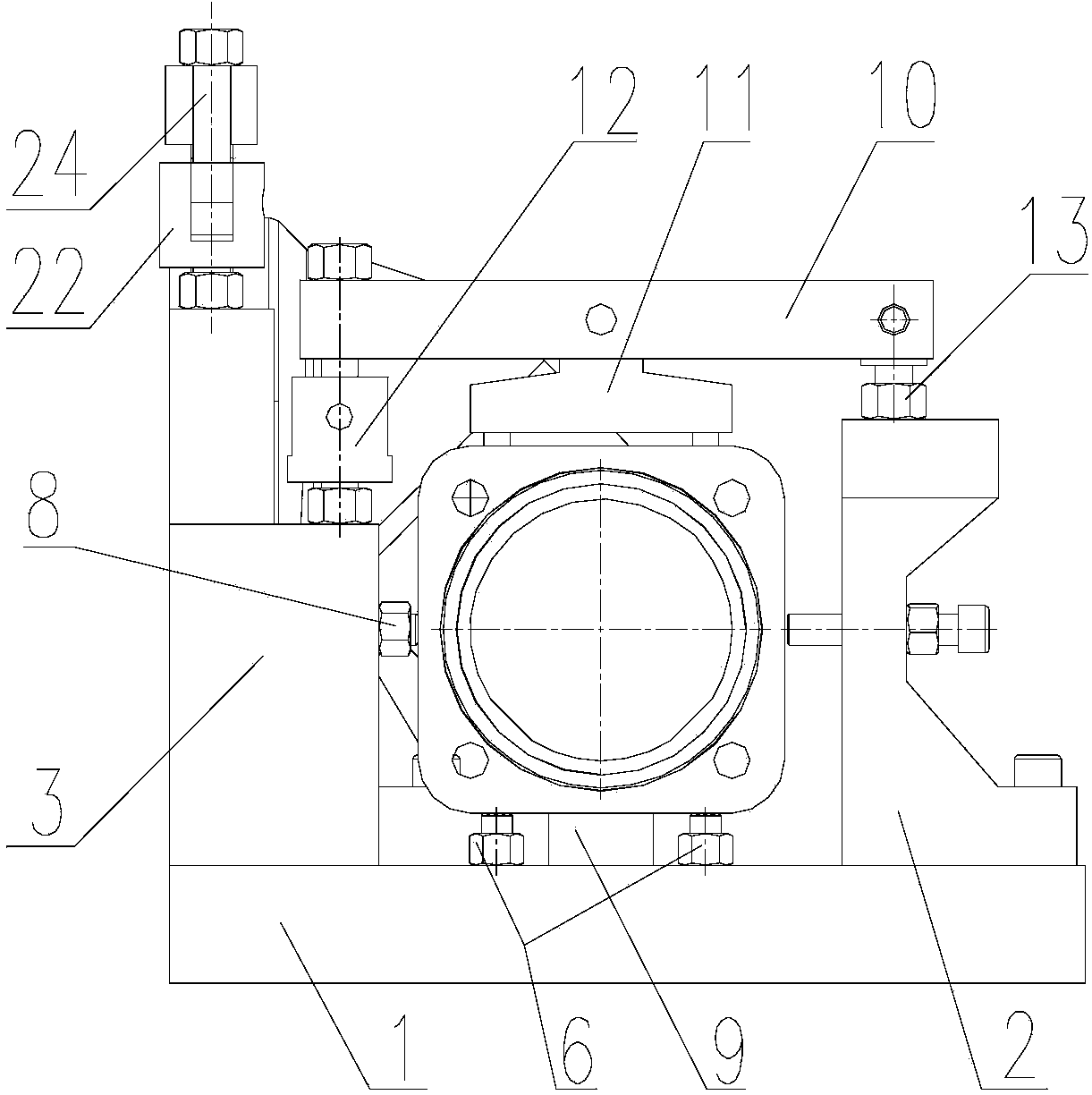

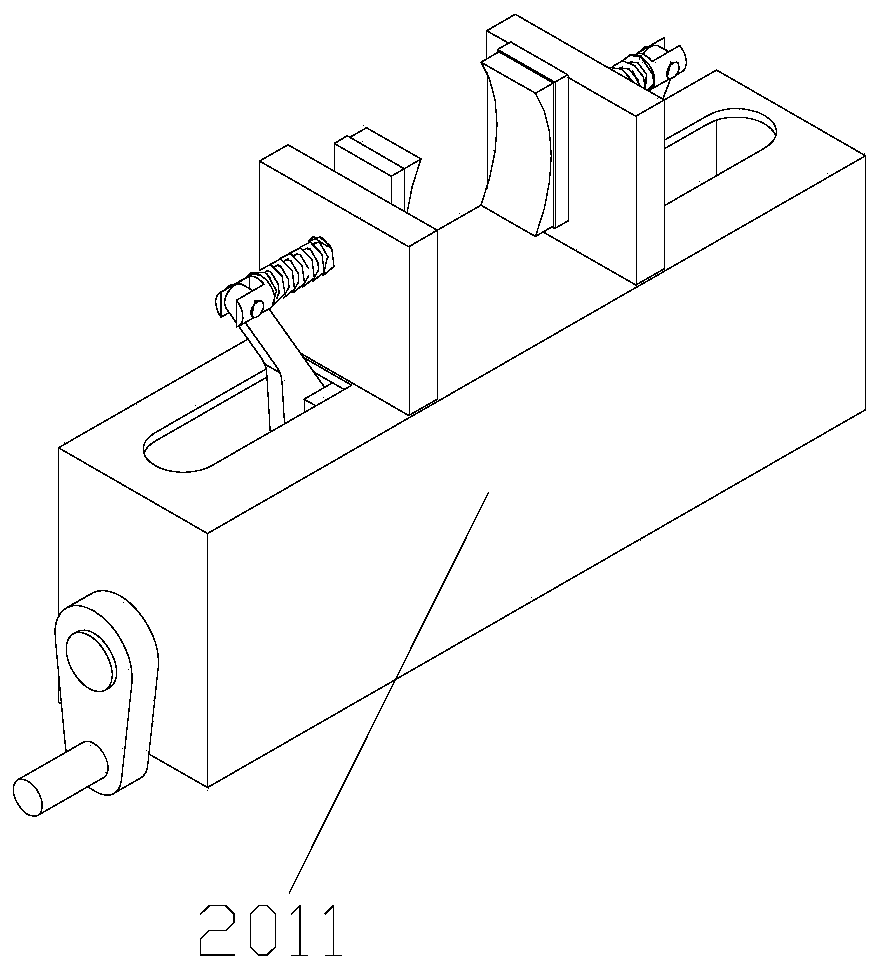

Fixture special for machining of end face of special bend

ActiveCN104289940ARealize the clamping effectSimple structureWork clamping meansPositioning apparatusEngineeringBiomedical engineering

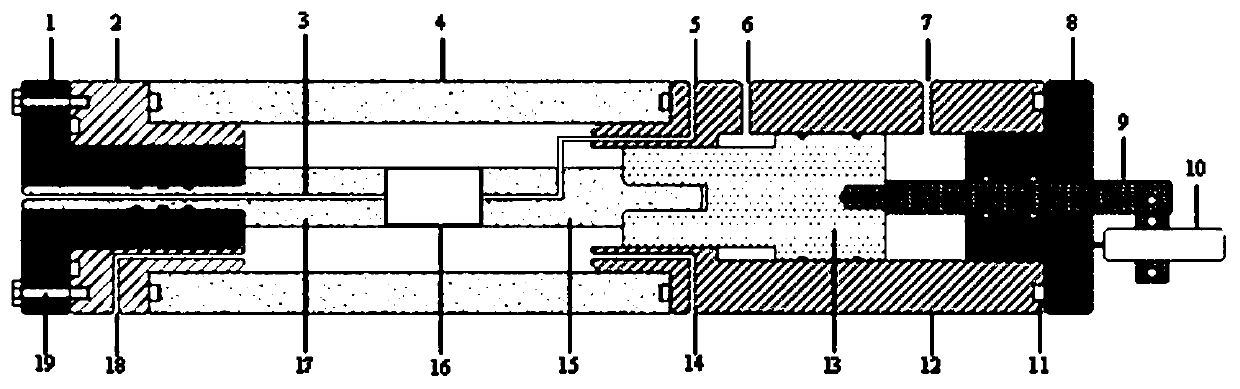

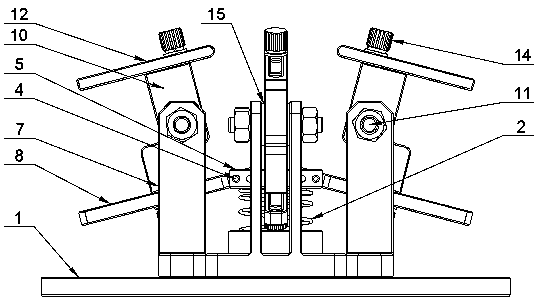

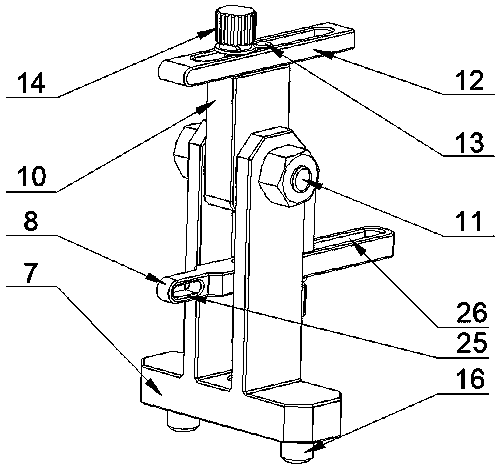

The invention relates to a fixture special for machining of an end face of a special bend. The fixture is mainly used for clamping the bend during machining of the end face of the special bend. The fixture comprises a bottom plate, a first support, a second support, a third support, a first compressing device, a second compressing device and a positioning device. The first support, the second support and the third support are all fixed on the bottom plate. The first compressing device is fixed over the first support and the second support. The second compressing device is fixed over the second support and the third support. The compressing devices are perpendicular to each other. When the fixture is in service, an orifice end of a square bend is fixed in a cavity formed by the first support, the second support and the first compressing device, and an orifice end of a round bend is fixed in a cavity formed by the second support, the third support and the second compressing device; bend clamping in the process of end face machining for special bends is achieved. The fixture is simple in structure and convenient to operate; clamping of the special bends is achieved; end face machining efficiency is improved.

Owner:JIANGSU WANSHENG FOUNDRY

Clamping workbench for building steel pipe machining

InactiveCN108818062AMeet processing needsReasonable structurePositioning apparatusMetal-working holdersArchitectural engineeringSelf locking

The invention discloses a clamping workbench for building steel pipe machining. The clamping workbench comprises a fixing box. A rotation rod is arranged at the bottom end in the fixing box. Movable blocks are arranged at the middle portions of the two ends of the rotation rod. Limiting blocks are arranged at the lower ends of the movable blocks. A guiding rod is arranged at the upper end in the fixing box. A left-hand thread is arranged at the middle portion of the left end of the rotation rod. A right-hand thread is arranged at the middle portion of the right end of the rotation rod. A lifting plate is hinged to the upper ends of the movable blocks through hinge rods. Wedge blocks are fixed to the two sides of the upper end of the lifting plate. Guide sleeves are arranged at the middle portions of the two ends of the guiding rod. Guiding balls are arranged at the middle portions of the front ends of the guiding sleeves. Clamping rods are arranged at the middle portions of the upper ends of the guiding sleeves, and the upper ends of the clamping rods penetrate guiding grooves and are connected with clamping blocks. According to the clamping workbench for building steel pipe machining, the clamping rods move in the opposite directions, the clamping function of a to-be-machined steel pipe is achieved through the self-locking function of the wedge blocks, and various machining needs of the building steel pipe are met; and the whole process is simple in operation, and reliability is high.

Owner:周国京

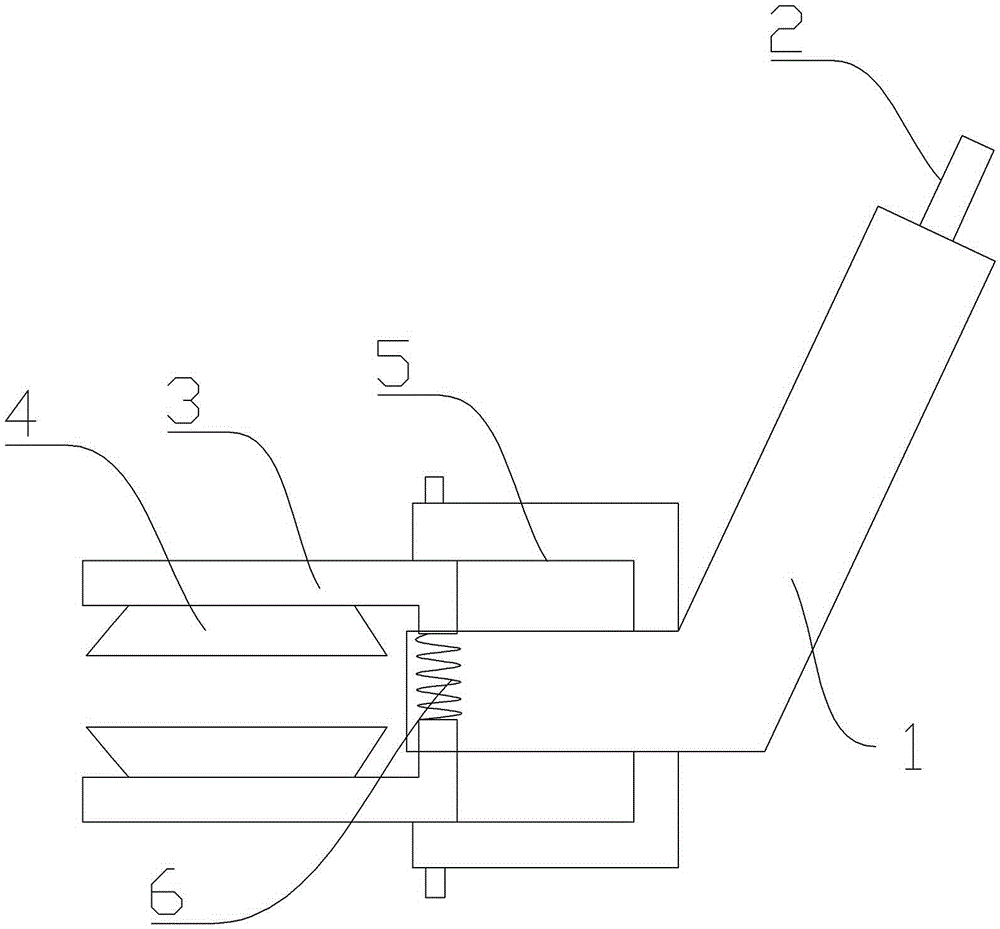

Glass transfer clamping equipment

ActiveCN105417947AImprove fixed timeImprove transmission efficiencyGlass transportation apparatusFixation timeBiochemical engineering

The invention relates to the field of glass processing equipment and in particular relates to glass transfer clamping equipment. The glass transfer clamping equipment comprises a support rod, wherein a connecting rod connected with a transfer mechanism is arranged at one end of the support rod and a clamping mechanism is arranged at the other end of the support rod; the clamping mechanism comprises two parallel clamping plates; suckers are arranged on opposite surfaces of the two clamping plates; the clamping plates are connected with the end of the support rod in a sliding manner; a spring is arranged between the two clamping plates; a compressing plate is also arranged on the support rod; threaded holes are formed in the compressing plate; screws are arranged on the clamping plates and are in threaded connection with the compressing plate by passing through the threaded holes. The glass transfer clamping equipment has the beneficial effects that through relative movement of the screws and the compressing plate, the screws can drive the clamping plates to move to achieve clamping and loosening of glass; the glass transfer clamping equipment is convenient to operate, is fast and firm in clamping and has the effect of greatly increasing the glass fixation time, thus improving the glass transfer efficiency.

Owner:滁州众石玻璃科技有限公司

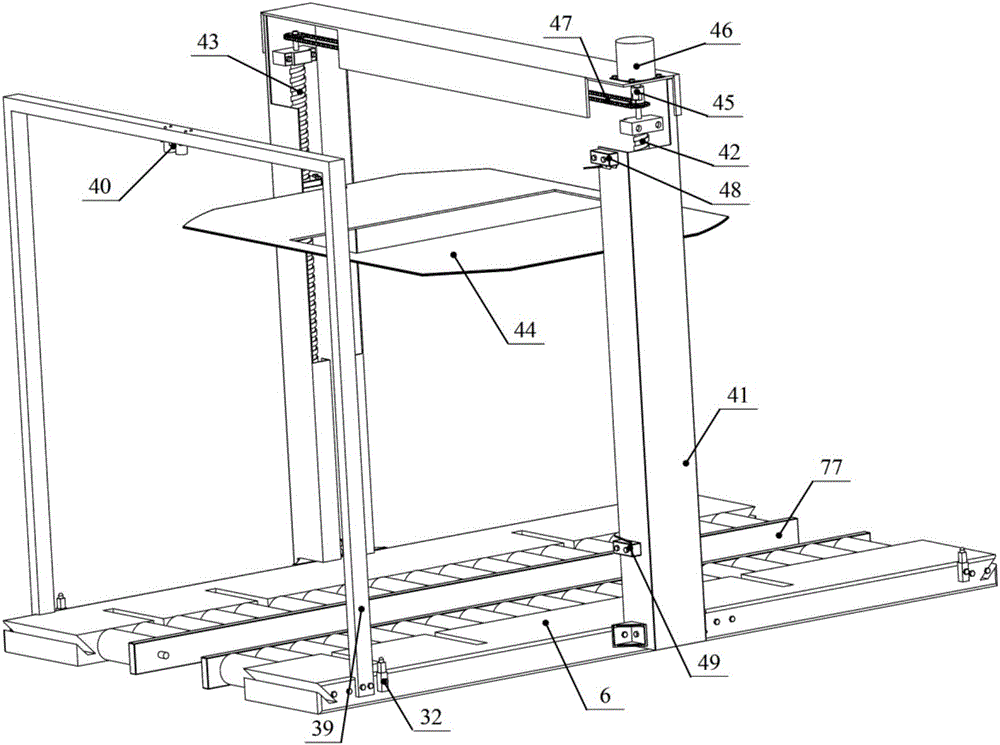

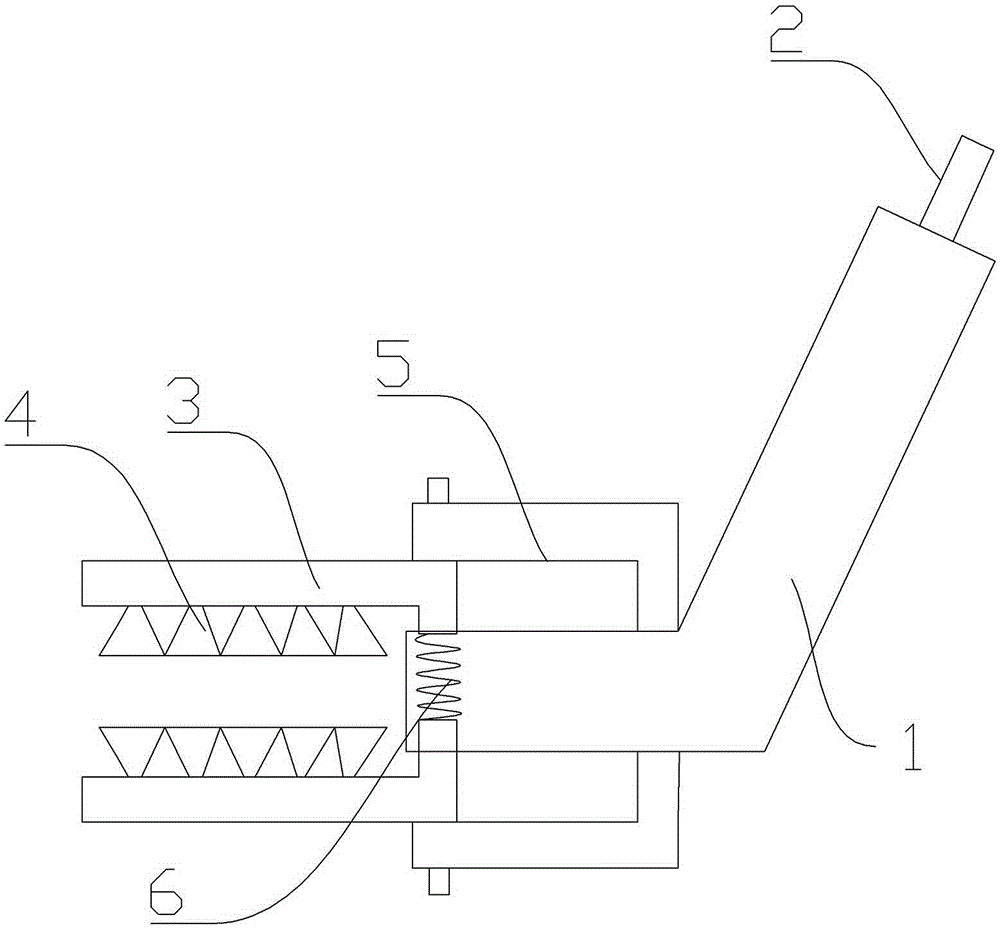

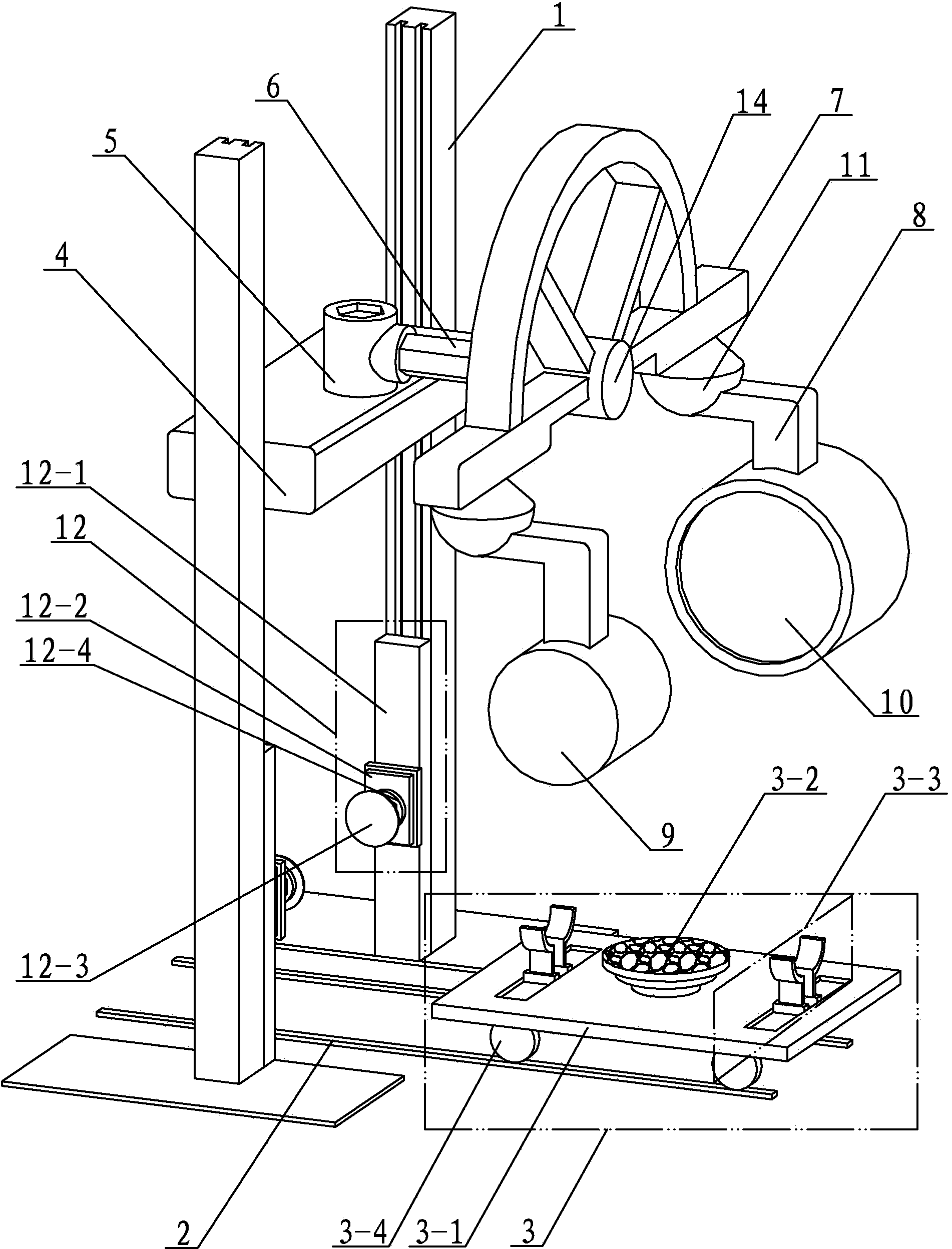

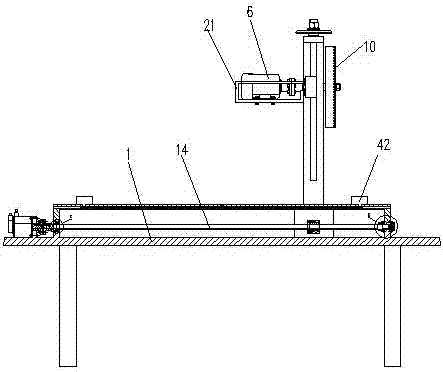

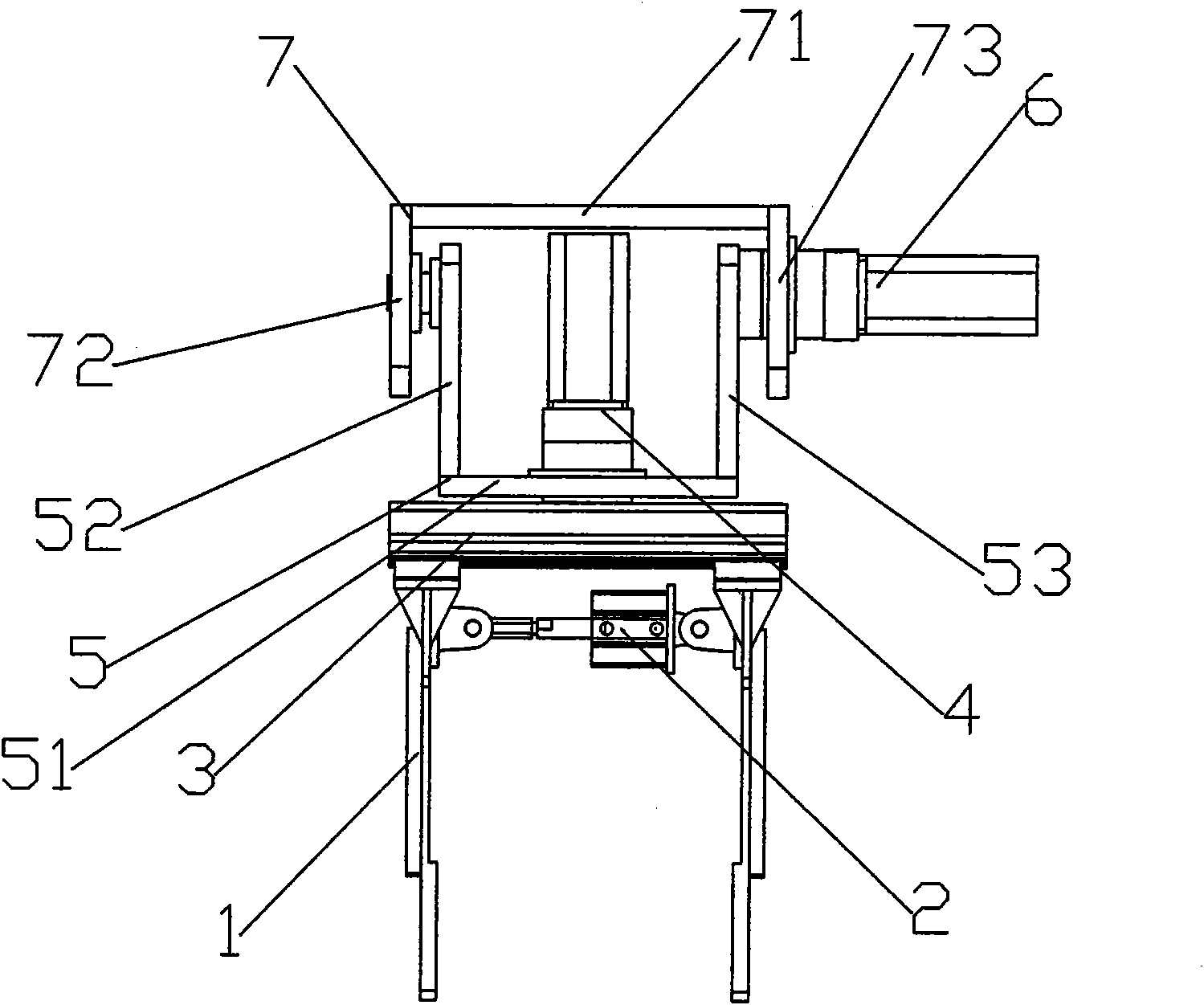

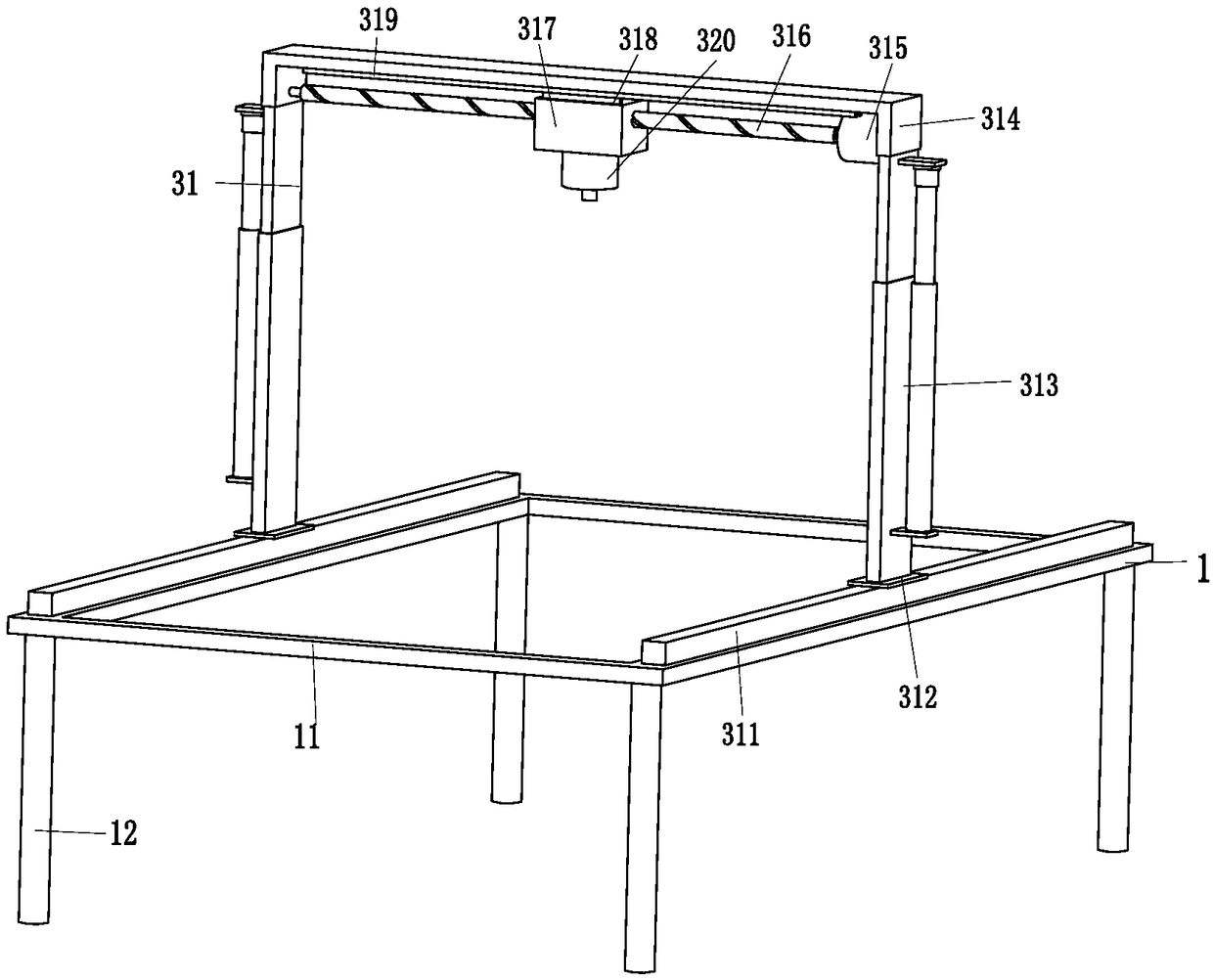

Wood nondestructive testing device capable of conducting imaging in real time at any angle

InactiveCN103792244AOvercome limitationsImprove clarityMaterial analysis by transmitting radiationSlide plateTest object

The invention discloses a wood nondestructive testing device capable of conducting imaging in real time at any angle to solve the problems that due to the fact that an existing testing device can not test a tested object at any angle and can usually test the object only in the two-dimensional plane, time for collecting images is long, definition is low, and the images can not be timely and coherently obtained, and relates to a wood testing device. According to the wood nondestructive testing device, two supports are vertically arranged in parallel, a slide rail is located between the two supports, a loading trolley is arranged on the slide rail in a slidable mode, radial moving sliding plates are arranged on the inner side walls of the two supports in a slidable mode, a swing adjusting motor is fixedly installed on the radial moving sliding plates, one end of an extension arm is connected with the swing adjusting motor, the other end of the extension arm is connected with a supporting arm through a rotating adjusting motor, the two ends of the supporting arm are respectively connected with a movable hinged joint, and a supporting rod is arranged on each hinged joint, and a ray transmitter and a receiver are fixedly arranged at the lower ends of the supporting rods respectively. The wood nondestructive testing device is used for testing wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

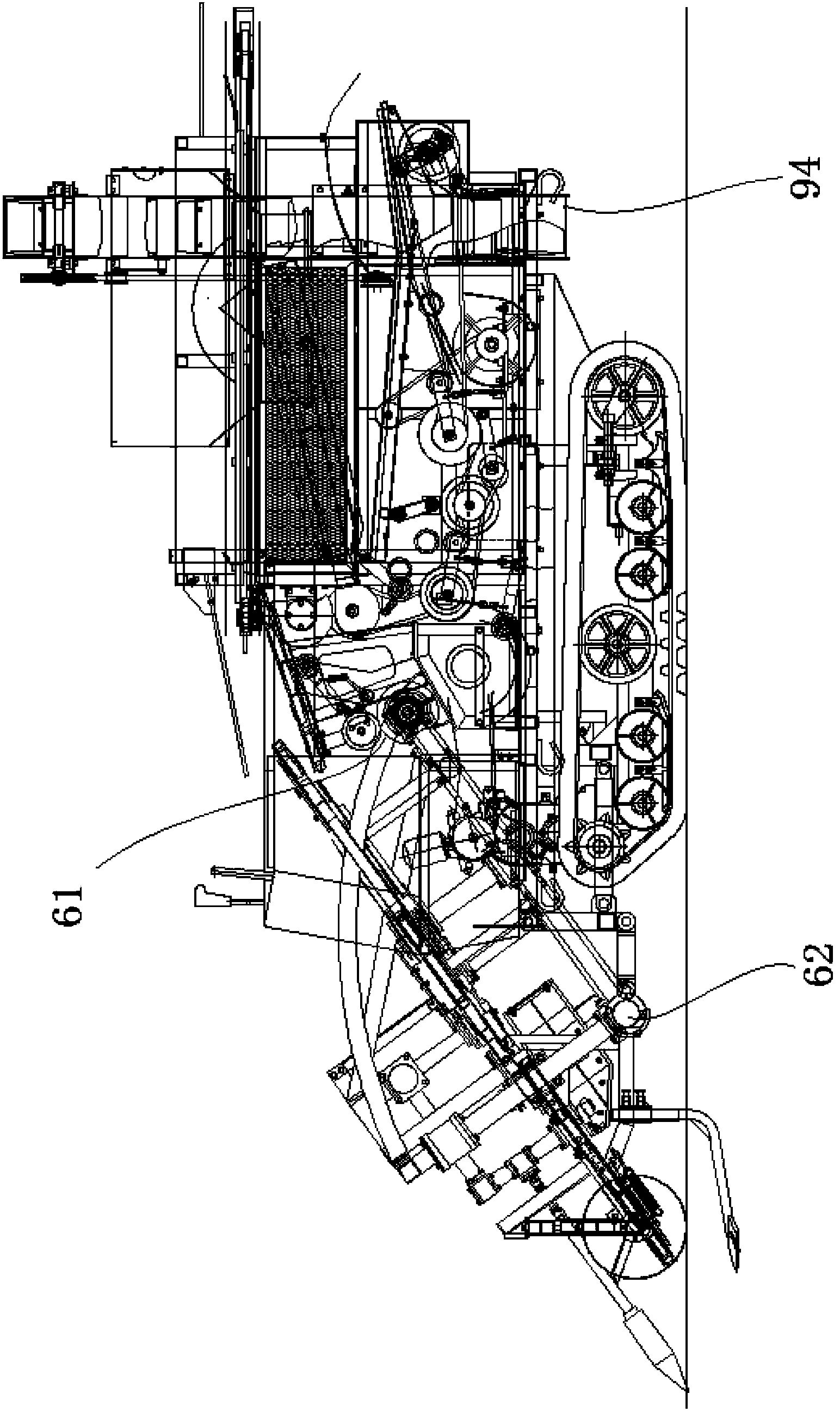

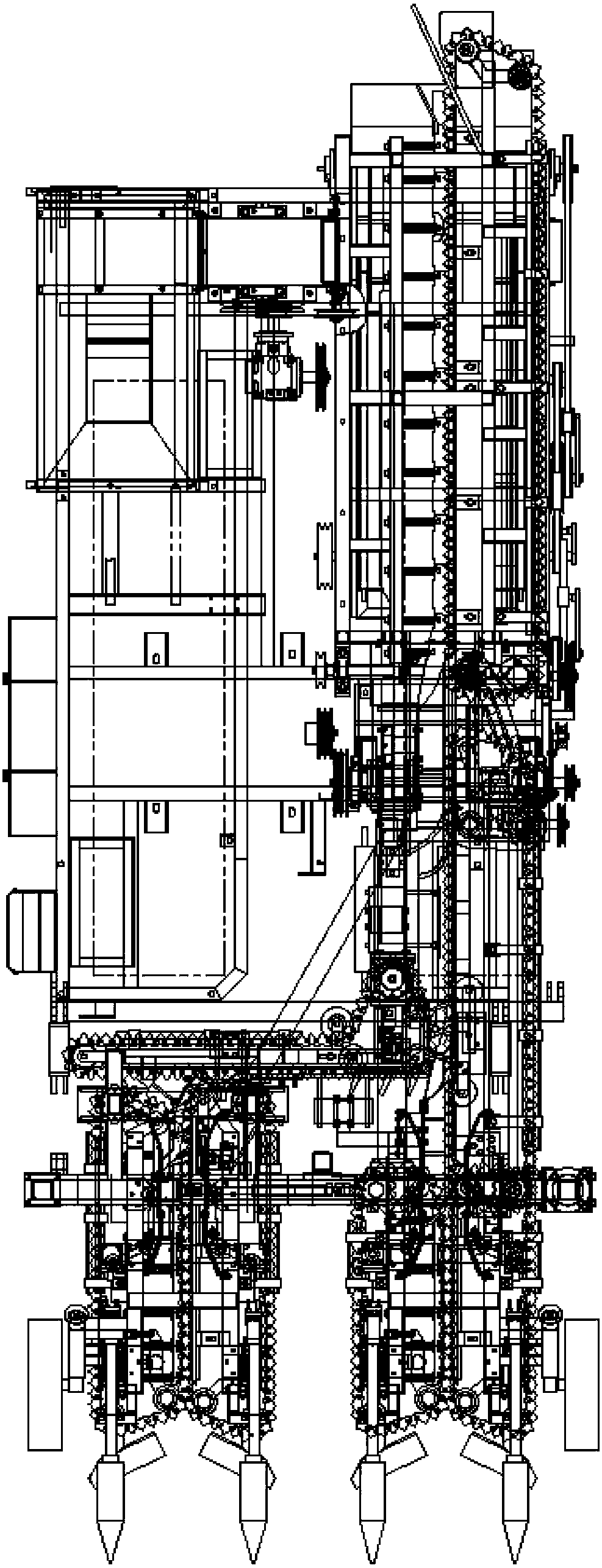

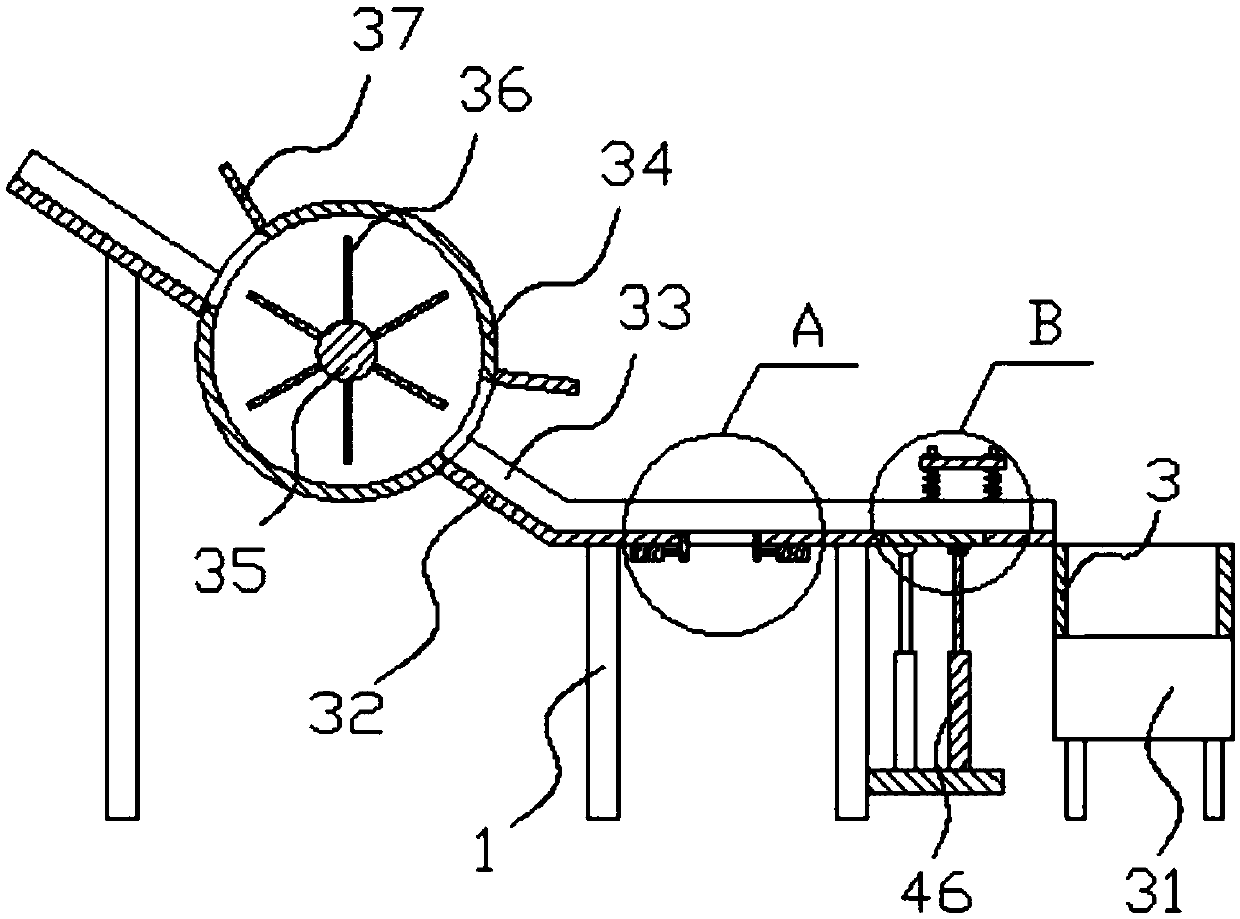

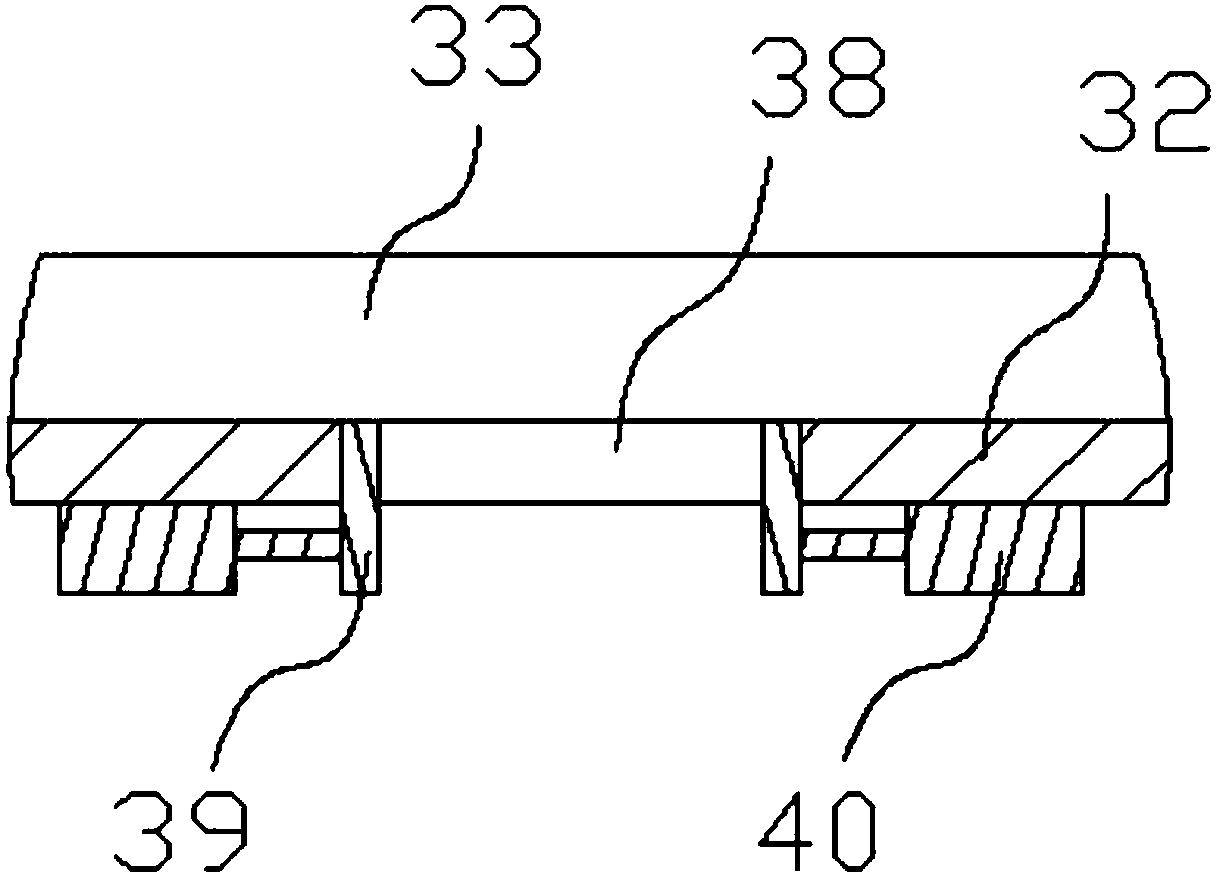

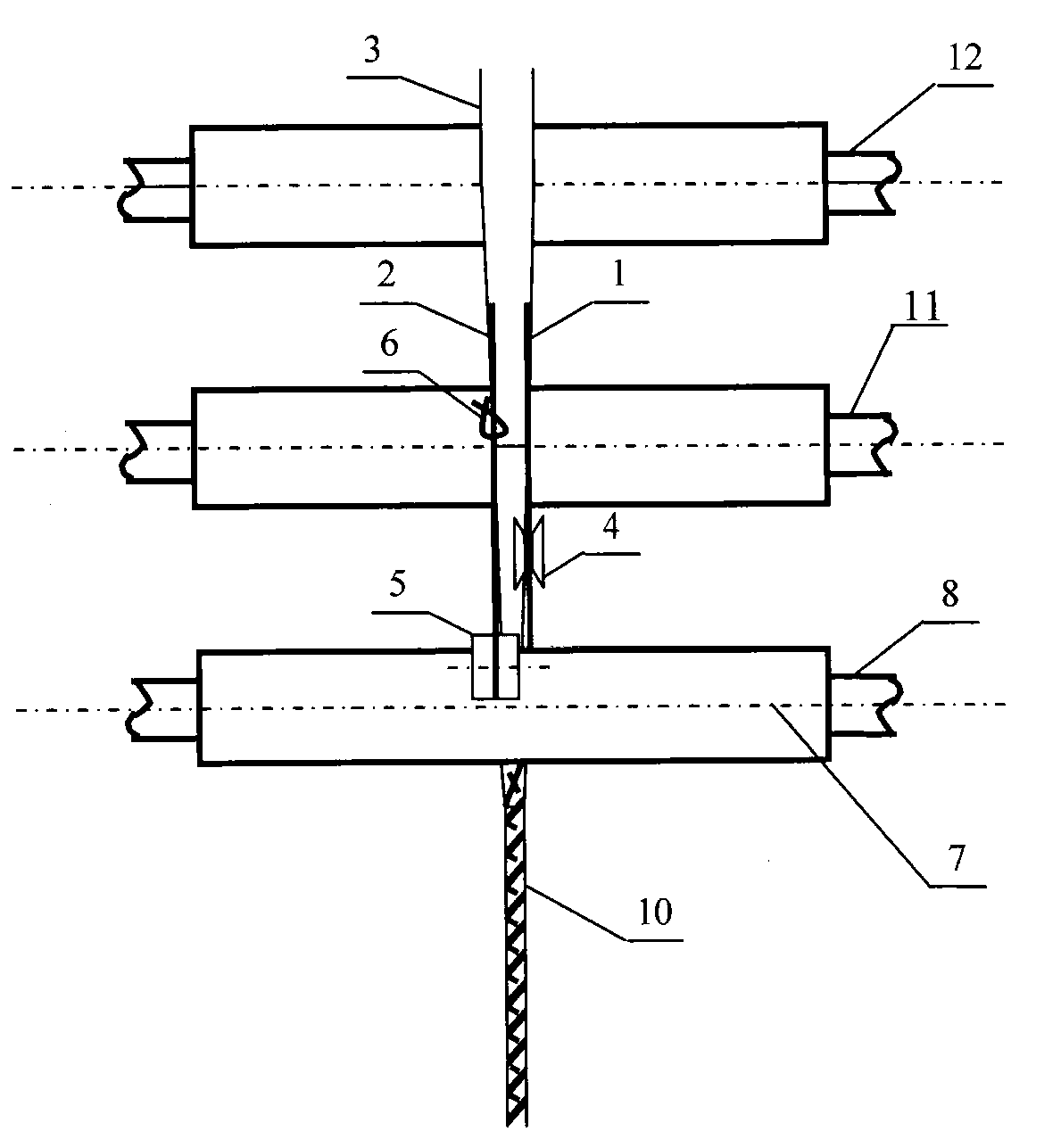

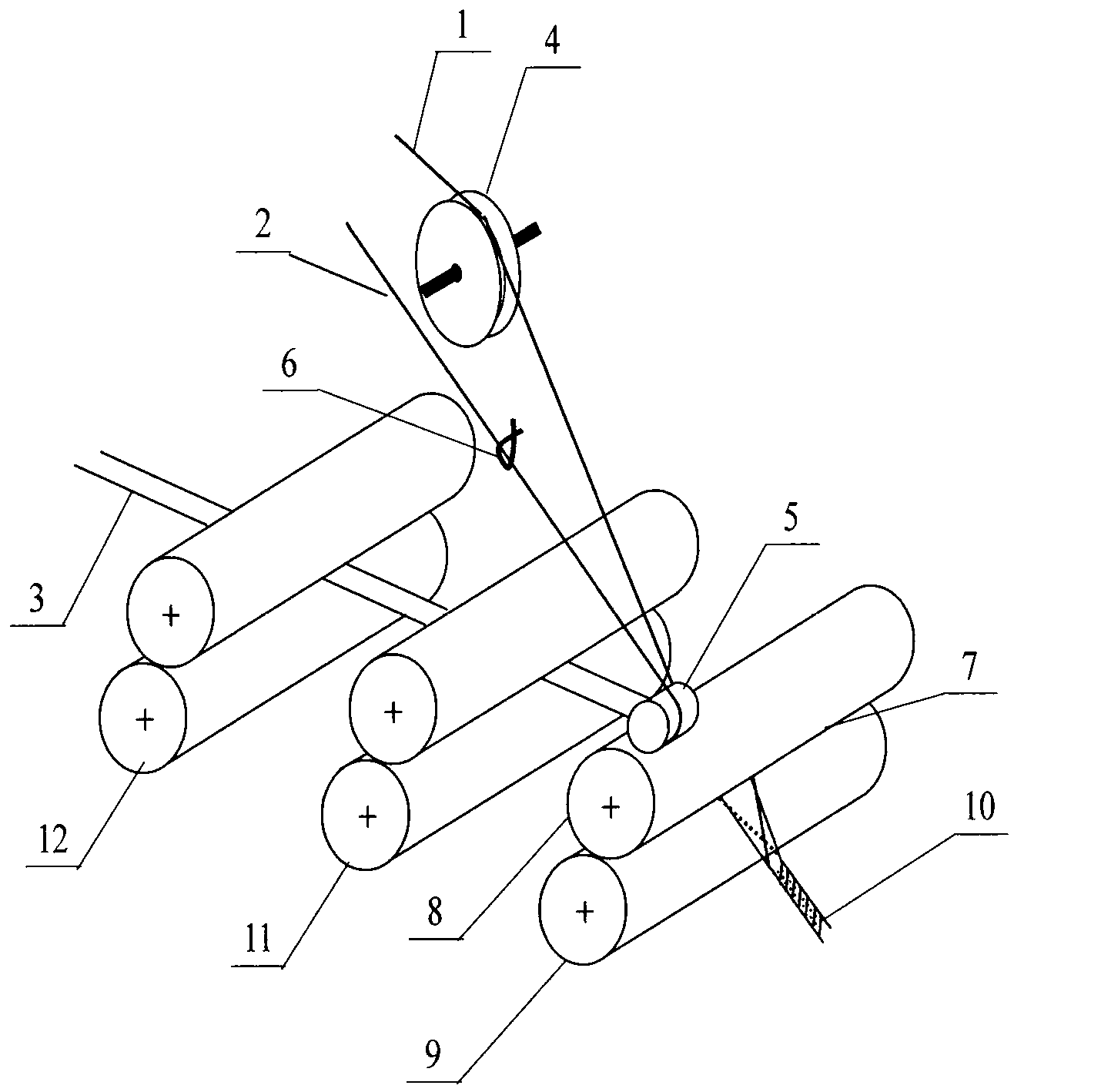

Double-ridge peanut combined harvester

The invention relates to a double-ridge peanut combined harvester which can simultaneously harvest four rows of peanuts in two ridges. The double-ridge peanut combined harvester is characterized in that a clamping conveying mode implemented by the aid of elastic pressure rod assemblies and clamping chains on a harvest table is matched with devices such as shifting finger belts and elastic pressure plates to realize conveying turning, so that a double-ridge combined conveying form is implemented; a weld holder is movably fixed onto a lower main beam along the axial direction of the lower main beam, the weld holder, a first pulling clamping chain fixedly connected onto the weld holder and assemblies such as the first elastic pressure rod assembly and the fifth elastic pressure rod assembly horizontally move left and right together, and the extension length of a second pressure rod on the second elastic pressure rod assembly is adjusted, so that the second pressure rod and a fifth pressure rod keep connected with each other, and the extension length of the second pressure rod can be manually adjusted according to the distance between the two ridges of peanuts; an oblique conveying mode of peanut seedling vines can be transited into a horizontal conveying mode by the aid of a transitional clamping conveying device, so that the height of the integral harvester is reduced, and the gravity center of the integral harvester is lowered. The double-ridge peanut combined harvester has the advantages that the structure of the peanut combined harvester is greatly optimized, and the universality and the safety of the double-ridge peanut combined harvester are improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Workpiece finishing clamping device

ActiveCN105856070ASimple organizationEasy to useGrinding work supportsMechanical engineeringEngineering

The invention discloses a workpiece finishing clamping device which comprises a base. Support plates are symmetrically mounted on two top sides of the base, each support plate is provided with a lead screw on the upper portion in a penetrating manner, one end of the lead screw is fixedly provided with a handle, the other end of the lead screw is fixedly provided with a clamping plate, a groove is formed in the clamping plate, a cushion is fixedly arranged in the groove, and a sensor is arranged on one side of the support plate, close to the clamping plate. The workpiece finishing clamping device is simple in mechanism and convenient to use, and the clamping effect on workpieces is achieved; for the internal arrangement of the base, fixing and adjusting effect on the workpieces is achieved under the action of a longitudinal block, a motor, a rotary plate, a connecting arm, a connecting rod and a positioning block which are all matched with the lead screws, the handles and the clamping plates, and machining efficiency of the workpieces is improved; fixing effect on the workpieces is further achieved through the application of a cylinder and under the action of tongs and a reset spring.

Owner:盐城森诺建材科技有限公司

Bamboo splitting machine capable of automatically screening bamboo barrel specification

InactiveCN107803344AGuaranteed accuracyImprove efficiencyWood splittingIrregularity removal devicesHinge angleEngineering

The invention relates to a bamboo breaking machine capable of automatically screening bamboo tube specifications, comprising a frame, a screening device, a bamboo tube blanking device and a bamboo breaking mechanism. The screening device includes a screening conveying plate and a conveying guard plate. The horizontal part of the screening conveying plate is provided with a screening slot and a feeding slot for defective products. The feeding slot for defective products is equipped with a lifting block for feeding defective products. The lower part of the unloading lifting block is provided with a triangular distribution of defective product blanking hinge seats, and the defective product blanking hinge seat is hingedly matched with the cylinder push rod of the defective product blanking lifting cylinder; the present invention adopts a screening groove to match a screening intercepting block Realize a bamboo tube screening with a diameter specification, which can intercept oval and bent bamboo tubes, and set a lowering block for defective products under the screening block to remove the intercepted defective products, ensure the accuracy of screening, and improve the screening and conveying. s efficiency.

Owner:DONGGUAN UNIV OF TECH

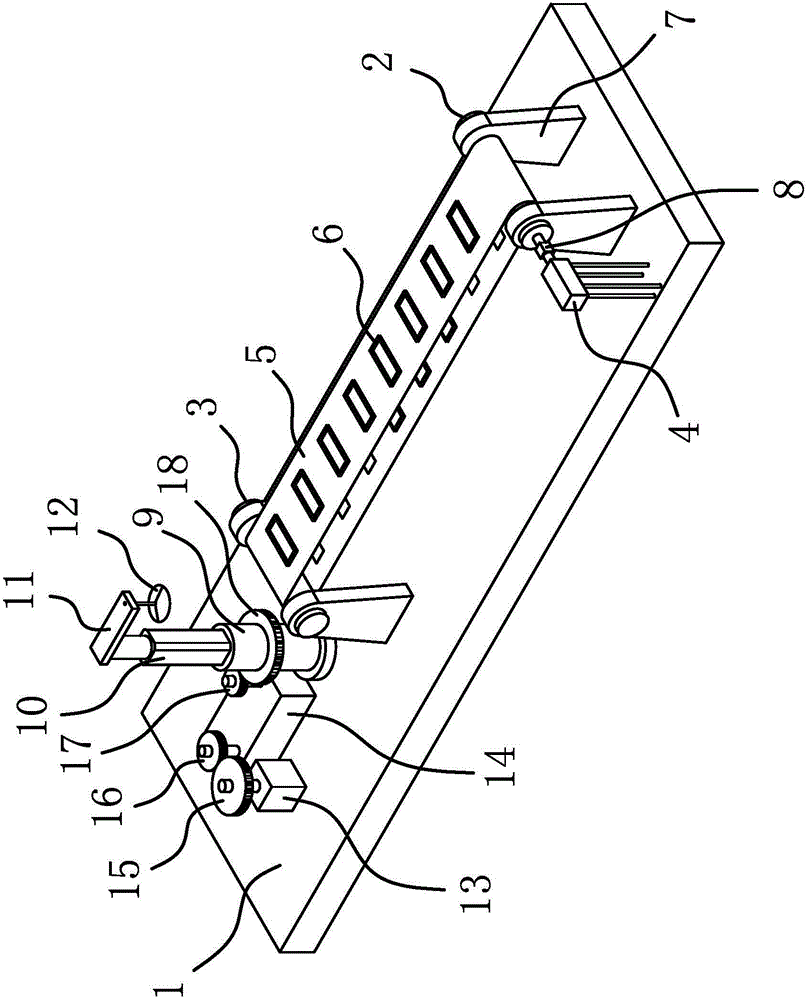

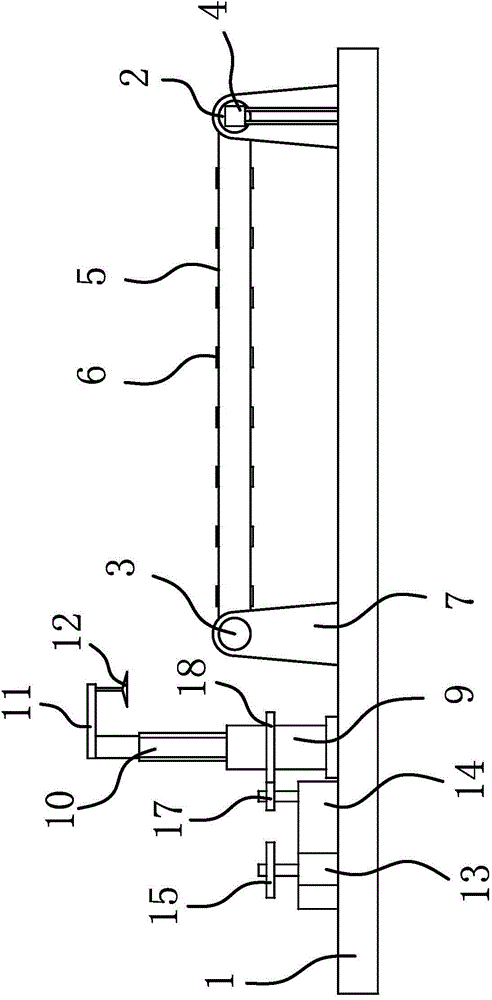

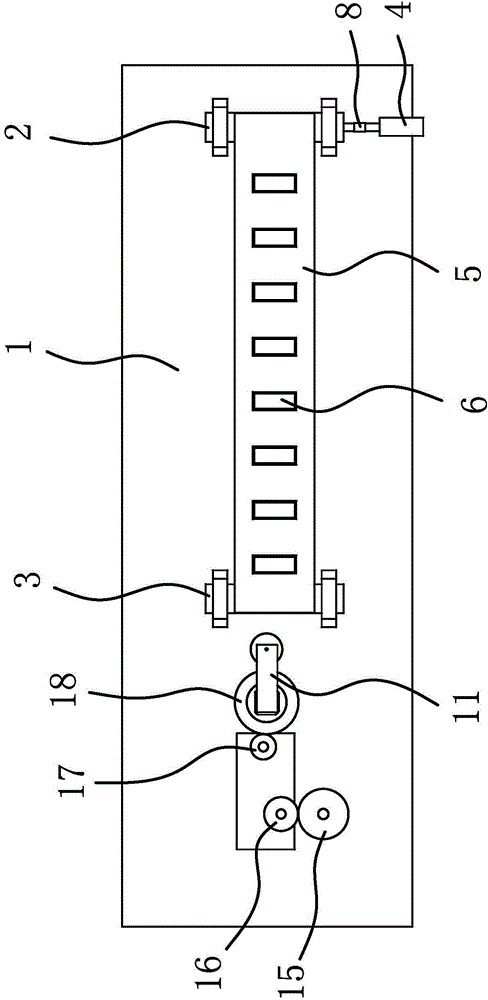

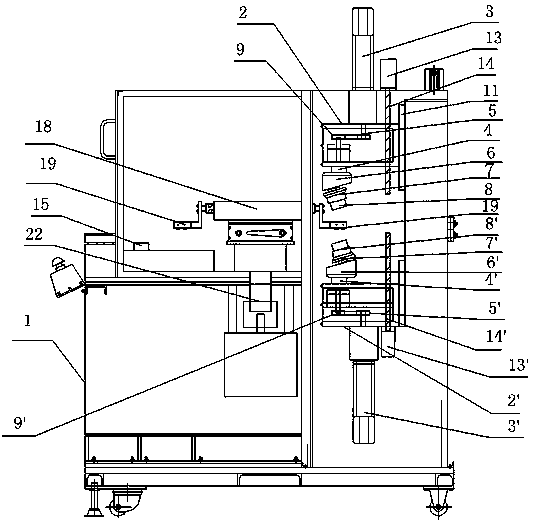

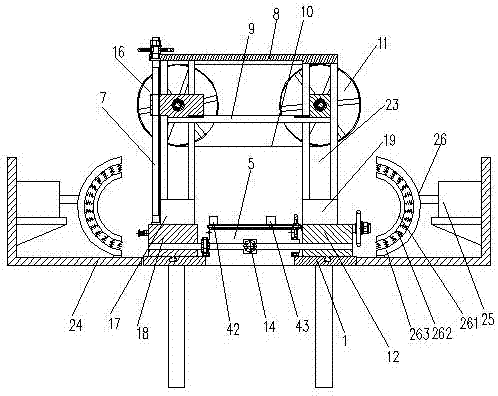

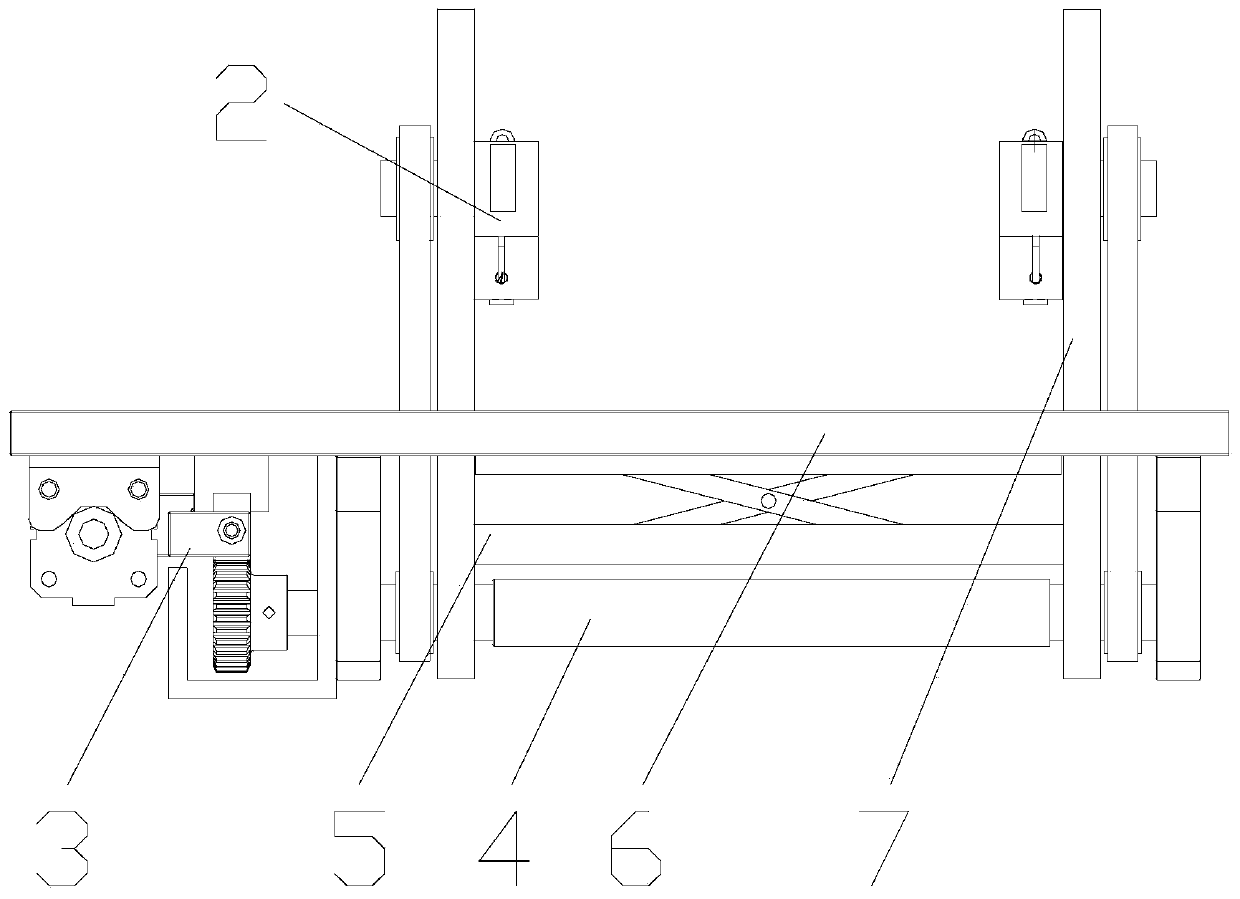

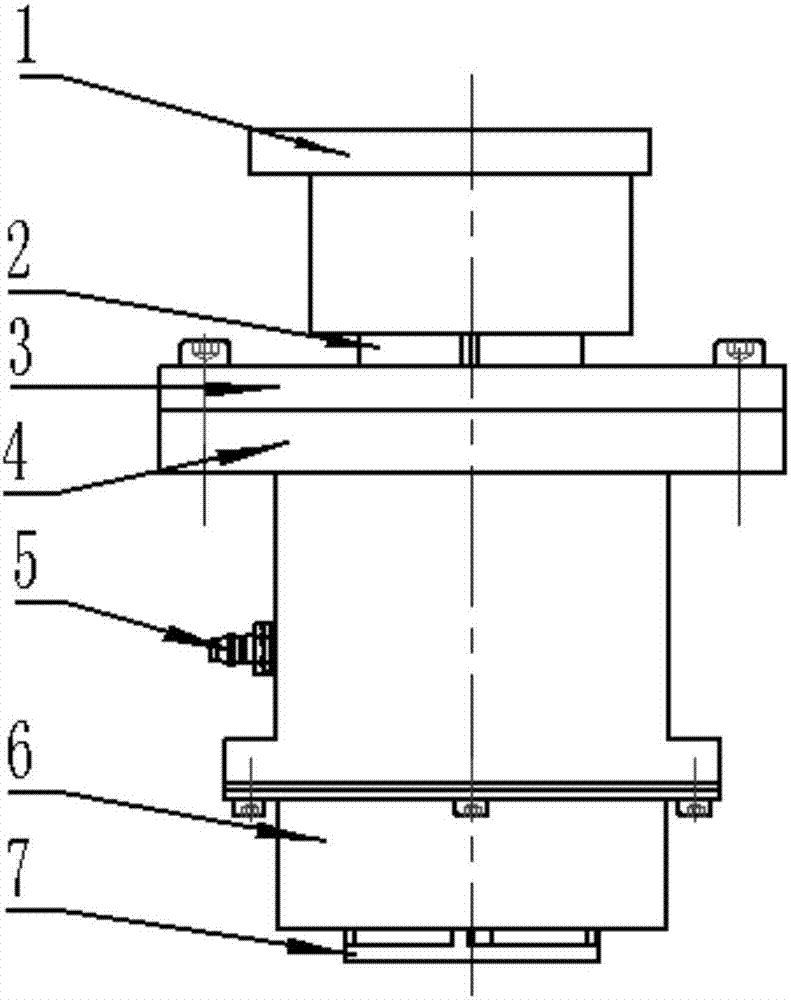

Multi-shaft double-sided automatic cleaning machine for lenses

ActiveCN103611715AHigh degree of automationImprove work efficiency and cleaning qualityFlexible article cleaningCleaning using toolsEngineeringAutomation

The invention discloses a multi-shaft double-sided automatic cleaning machine for lenses, and belongs to the technical field of machinery manufacturing. The multi-shaft double-sided automatic cleaning machine for the lenses comprises a rack (1), a lens conveying device, a lens clamping device, a rotating device and a lens cleaning device are arranged on the rack (1), the lens cleaning device comprises sliding supports (2 and 2') which are arranged vertically and symmetrically and slidably connected on the rack (1), a lifting device is arranged on the rack (1), motors (3 and 3') and rotating shafts (4 and 4') are arranged on the sliding supports (2 and 2'), the motors (3 and 3') drive the rotating shafts (4 and 4') to rotate via driving belts (5 and 5'), and rotating wheels (6 and 6'), rotary grinding discs (7 and 7') and cleaning heads (8 and 8') are arranged on the rotating shafts (4 and 4') in sequence. The multi-shaft double-sided automatic cleaning machine for the lenses can feed, clamp and clean the lenses automatically and is high in automation level, manual cleaning is replaced completely, lens cleaning quality and working efficiency can be improved, and production cost is lowered.

Owner:LINHAI JINZHENG MACHINERY

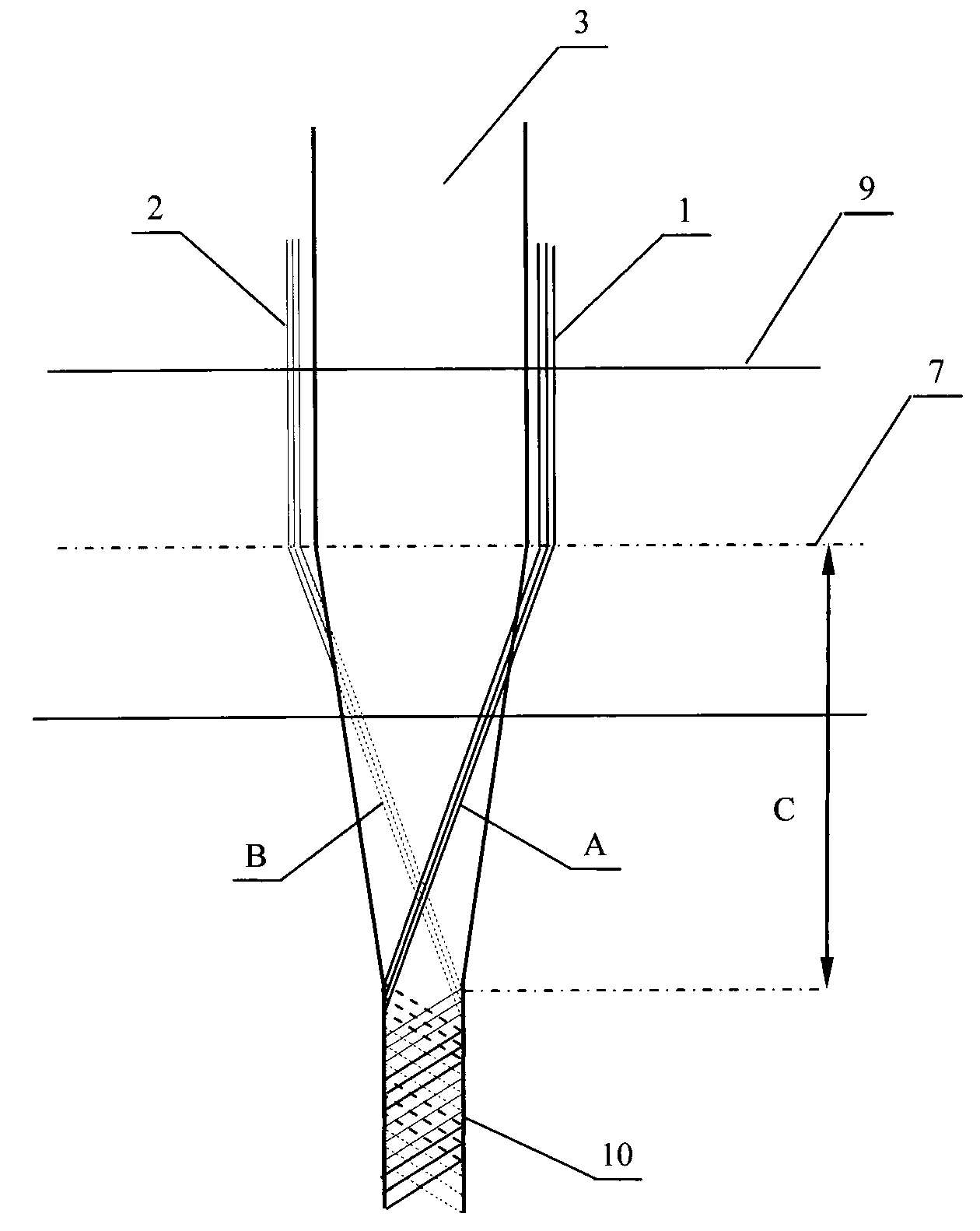

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

Improved log sawing machine

PendingCN107336286AOptimize the installation structureHigh precisionGripping devicesClamping devicesReciprocating motionSmall footprint

The invention discloses an improved log sawing machine, which comprises an operating desk, a saw bench and a saw blade device. The saw bench is arranged on the operating desk. The saw blade device is connected with the operating desk in a sliding mode. The saw blade device is arranged on the saw bench. The saw bench is provided with at least one clamping device of magnetic type. The operating desk is provided with at least two adjustable clamping devices. The log sawing machine has the advantages of being compact in structure, small in occupied area, achievable in adopting an ordinary feed screw nut pair for driving the reciprocating motion of the saw blade device, achievable in adopting a travel switch for simple control, high in cutting efficiency, low in labor intensity and convenient to operate. Furthermore, the improved log sawing machine is a practical woodworking machinery product of mechanical and electrical integration, and has a certain promotion value; the clamping device has a good improved effect, thereby being suitable for clamping logs of different sizes.

Owner:TAIZHOU POLYTECHNIC COLLEGE

Steel structure welding and clamping device for building

ActiveCN111390470AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses a steel structure welding and clamping device for a building. The device comprises a protection cover and two supporting vertical plates, a driving mechanism and a lifting mechanism are mounted in the protection cover, a supporting plate is mounted on the top of the protection cover, a strip hole is formed in the supporting plate, the two supporting vertical plates penetrate through the strip hole, extend into the protection cover, and are matched with the driving mechanism, the lifting mechanism is mounted above the driving mechanism and is mounted between the two supporting vertical plates, the two ends of the lifting mechanism are mounted on the two supporting vertical plates, a clamping mechanism is mounted on the inner side of each supporting vertical plate, asteel structure can be clamped, welding precision is ensured, under the effect of the driving mechanism, the steel structure can be driven to rotate, a worker can conveniently weld the steel structure, the lifting mechanism can lift the steel structure required to be clamped to the same horizontal plane of the clamping mechanism, the clamping mechanism can conveniently clamp the steel structure, and the work efficiency can be improved.

Owner:BEIJING TIANHENG CONSTR

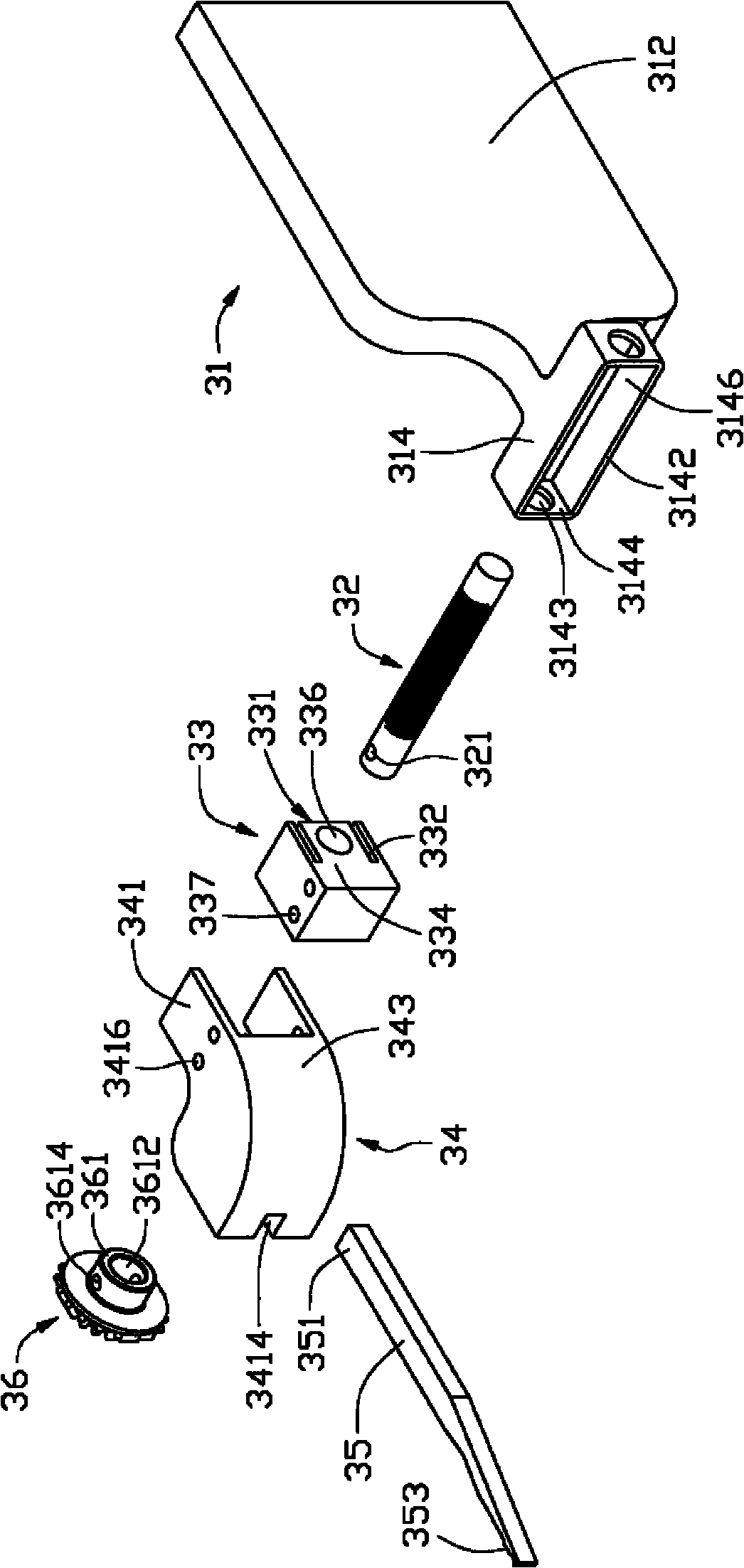

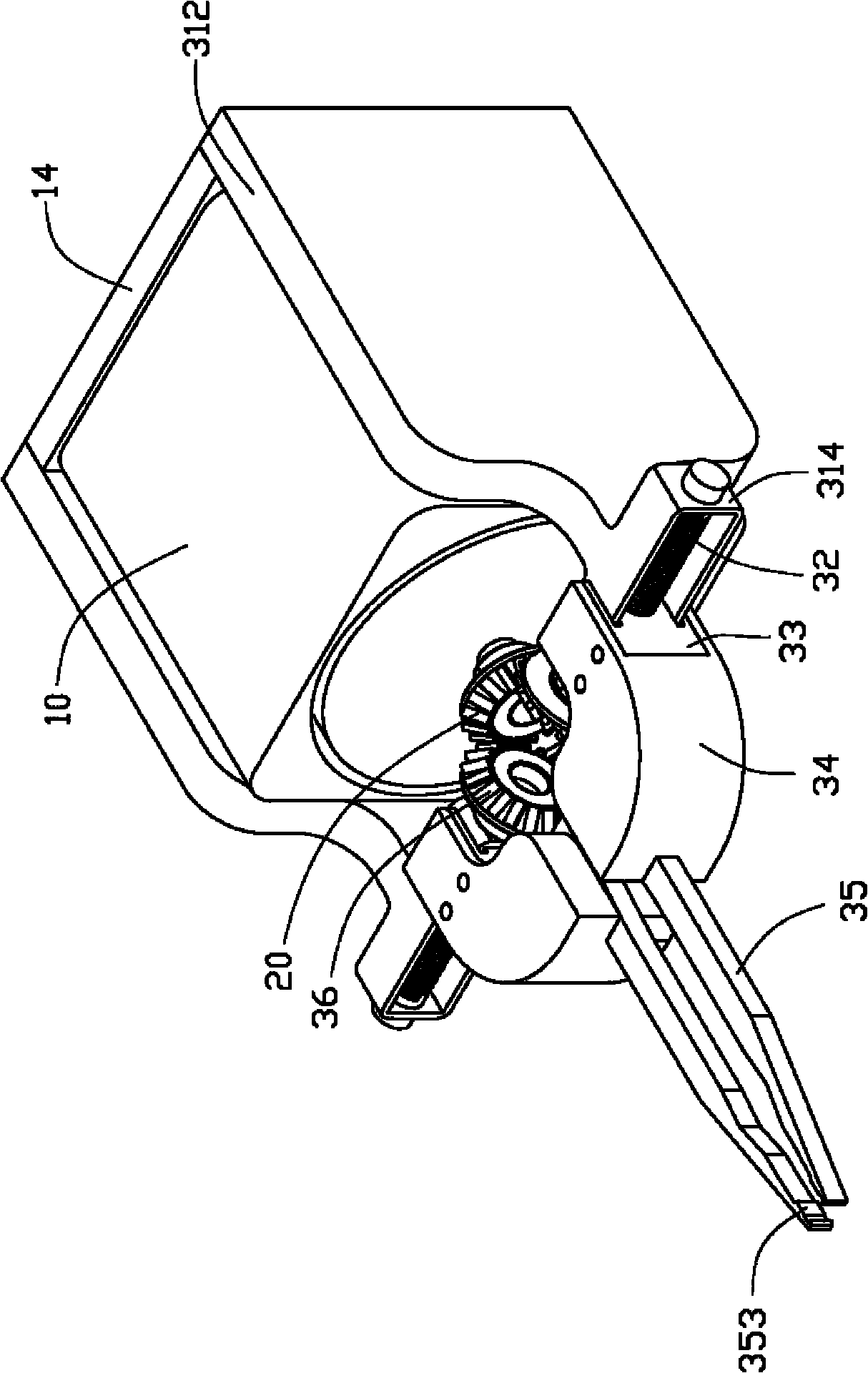

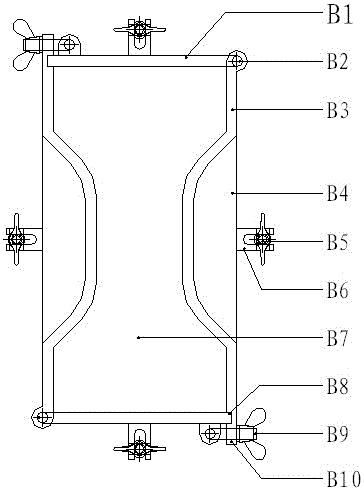

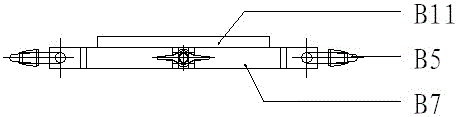

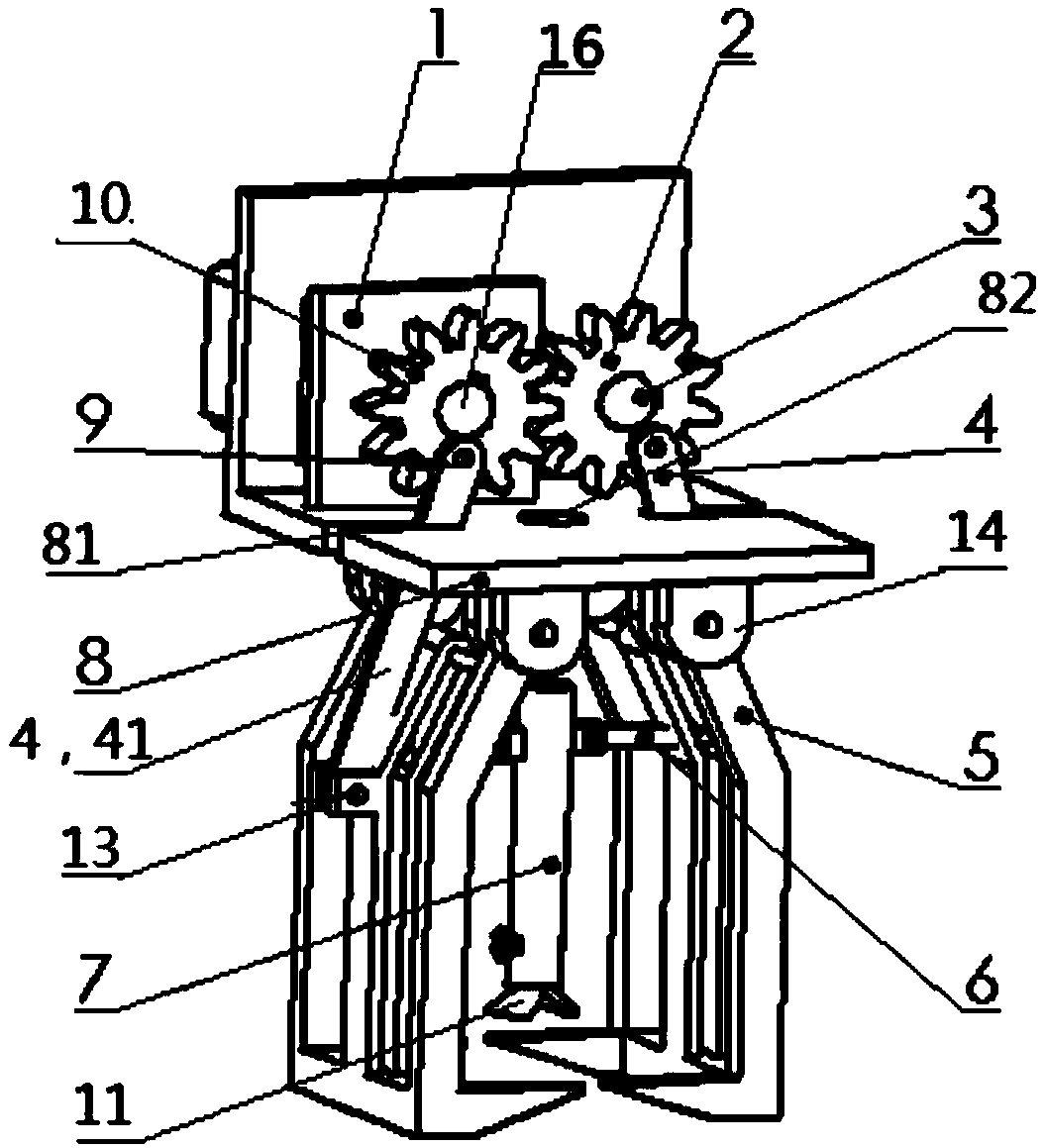

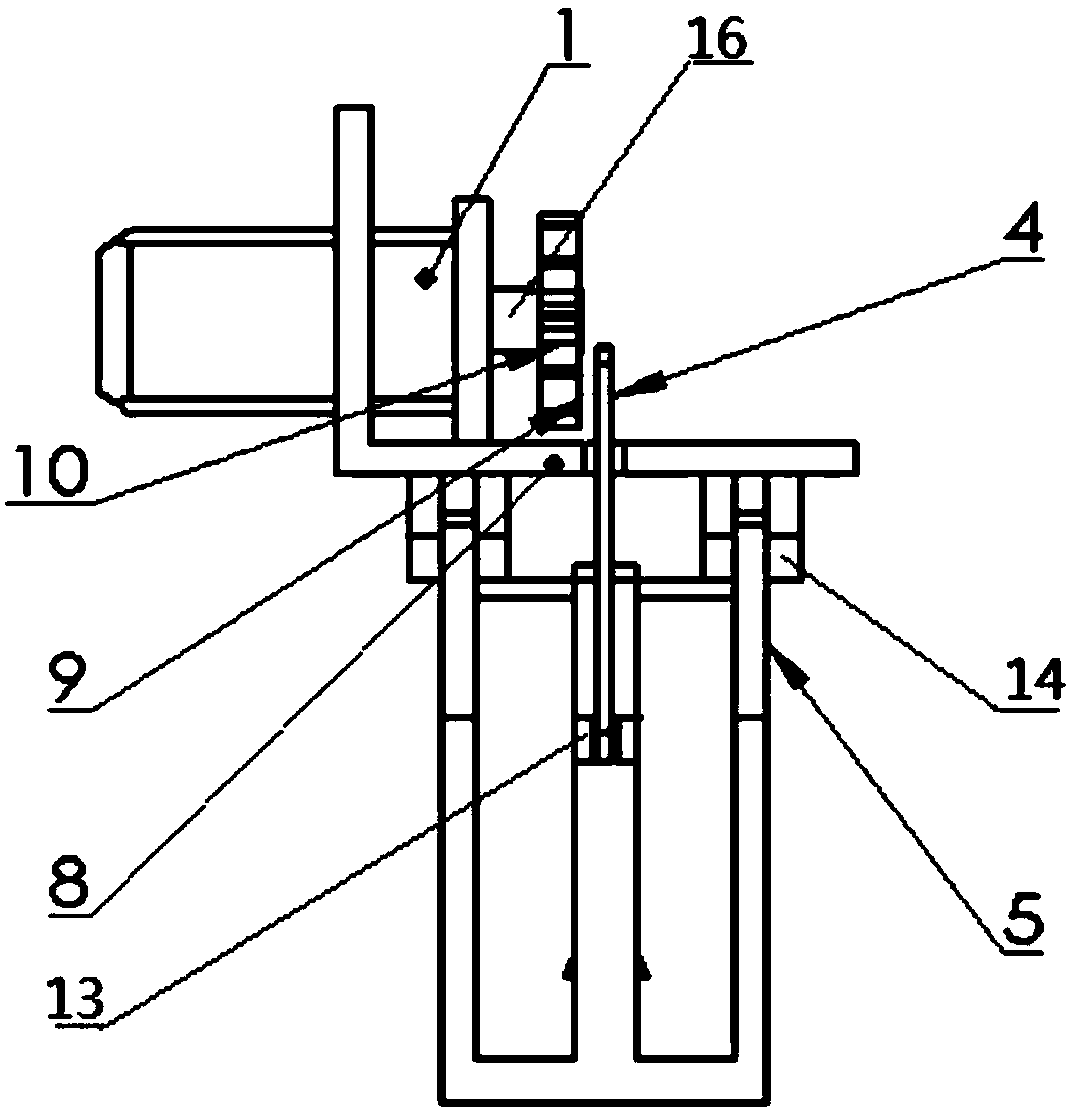

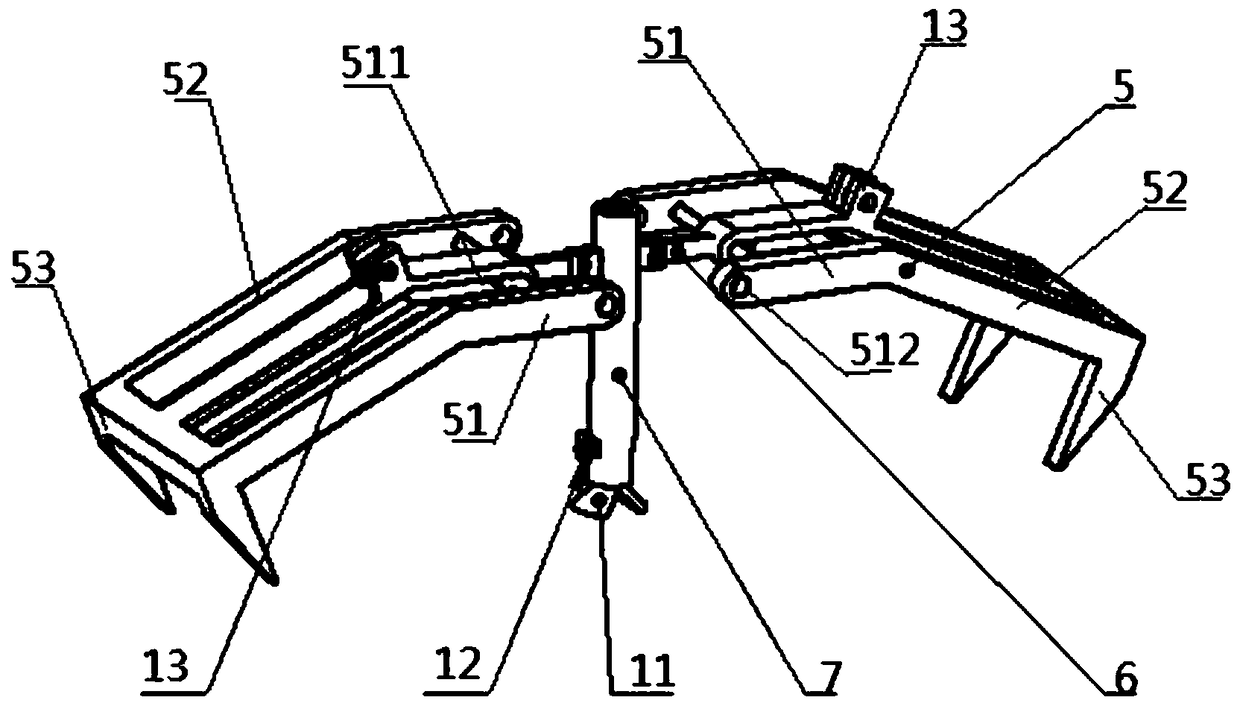

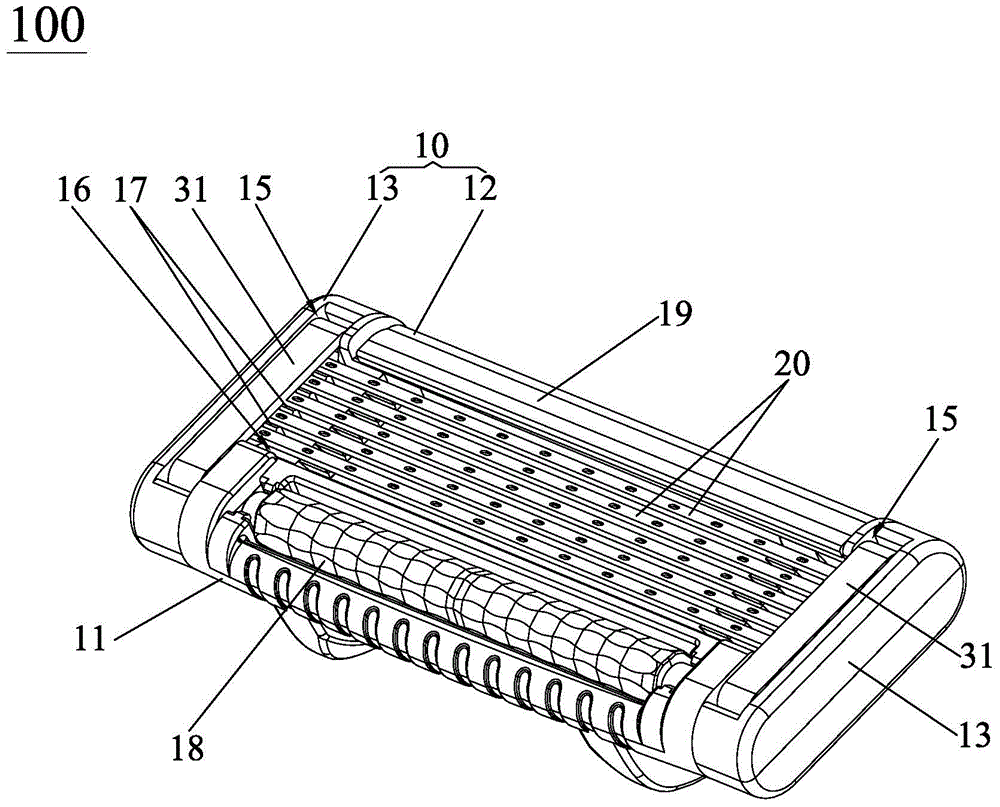

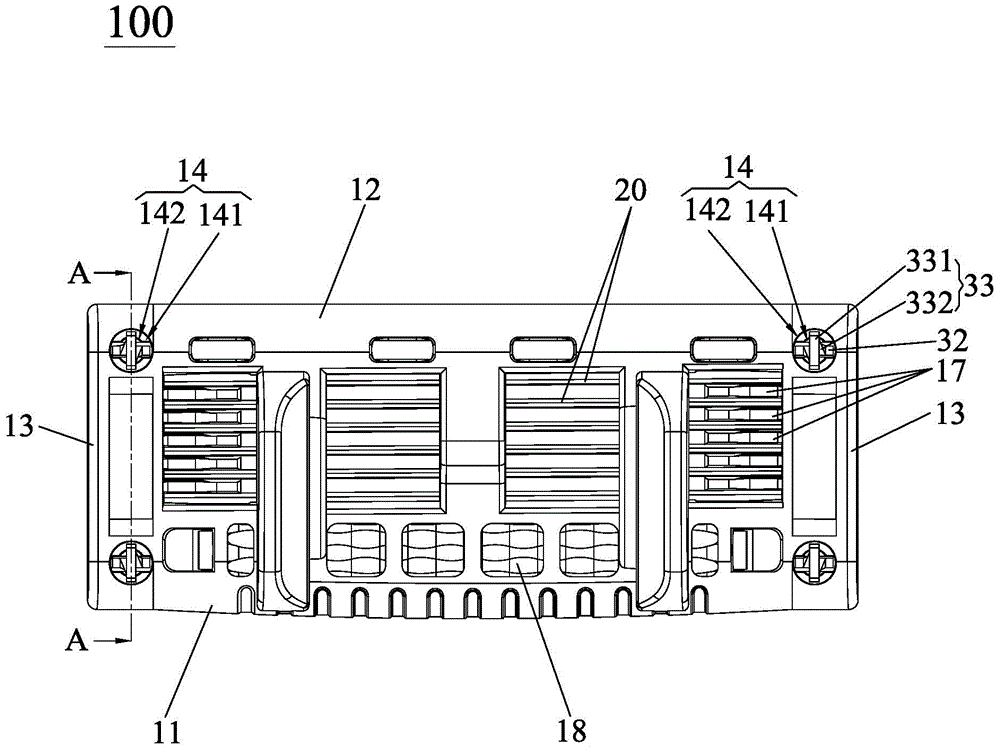

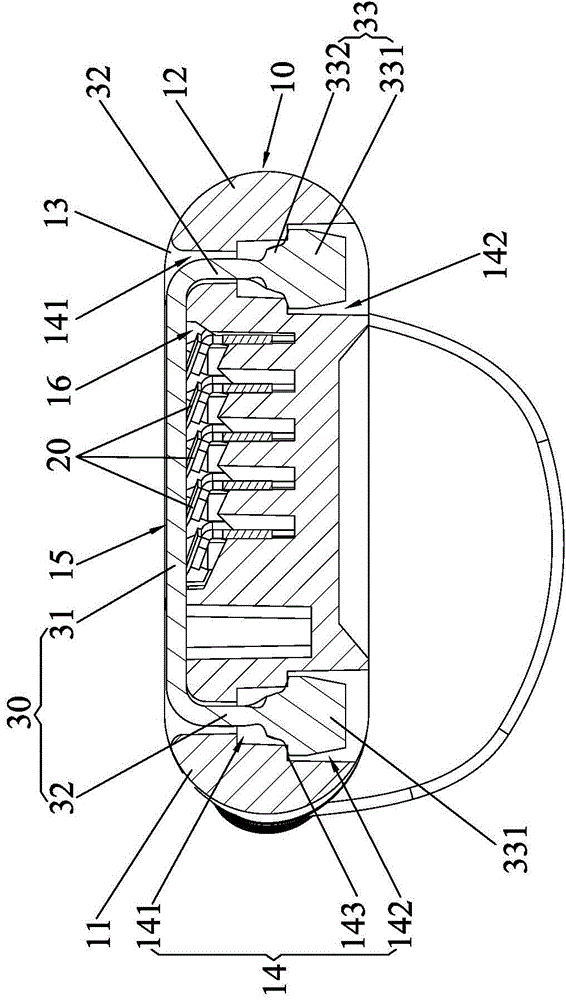

Transmission tower climbing robot clamping device and robot thereof

The invention relates to a transmission tower climbing robot clamping device for clamping angle steel. The invention aims at providing a clamping device for a transmission tower climbing robot which can effectively clamp angle steel and can overcome obstacles. A climbing robot clamping device for power transmission tower comprises a box body, a transmission mechanism arranged on the box body, a clamping mechanism for clamping angle steel and a tight-pressing mechanism linked with the clamping mechanism arranged on the outside of the box body, the transmission mechanism comprises an electric motor, a gear transmission mechanism driven by an electric motor and a transmission lever one end of which is mounted on the gear transmission mechanism, the other end of the drive lever is fixed on theclamping mechanism, driven by the gear transmission mechanism, the transmission lever can make an S-shaped motion, the clamping mechanism can make a closing and opening action under the driving of the transmission lever to achieve clamping or loosening of the angle steel, and the ejecting mechanism can achieve the clamping and retracting of the angle steel with the closing and opening action of the clamping mechanism.

Owner:SHANDONG JIANZHU UNIV

Shaver head and assembling method thereof

ActiveCN104669318AImprove firmnessReduce length requirementsMetal working apparatusRazor stropFront edge

The invention discloses a shaver head and an assembling method thereof. The shaver head comprises a shell, a clamping piece and a shaving blade, wherein the shell is provided with a front edge, a rear edge, a side edge and a through hole positioned between the front edge and the rear edge; the shaving blade is assembled on the side edge along the first direction and is stopped by the side edge; the through hole sequentially comprises a connecting hole and a counter bore along the first direction; the counter bore is connected with the connecting hole; a step structure is arranged between the connecting hole and the counter bore in a surrounded manner; the clamping piece comprises an abutting pressing section, an inserting section and a twisting section; the abutting pressing section stretches across the shaving blade; the inserting section is bent relative to the abutting pressing section; the twisting section is connected with the inserting section and is positioned in the counter bore and in front of the inserting section; the twisting section and the inserting section in the connecting hole are staggered from each other; the twisting section is also abutted to the step structure; the inserting section can be downwards tightened by the twisting section; the abutting pressing section is abutted to and pressed against the shaving blade along the first direction when the inserting section is tightened by the twisting section; and the shaving blade is clamped between the abutting pressing section and the side edge, so that the shaving blade is clamped reliably, and the utilizing efficiency of the clamping piece is high.

Owner:温州美葆剃须系统有限公司

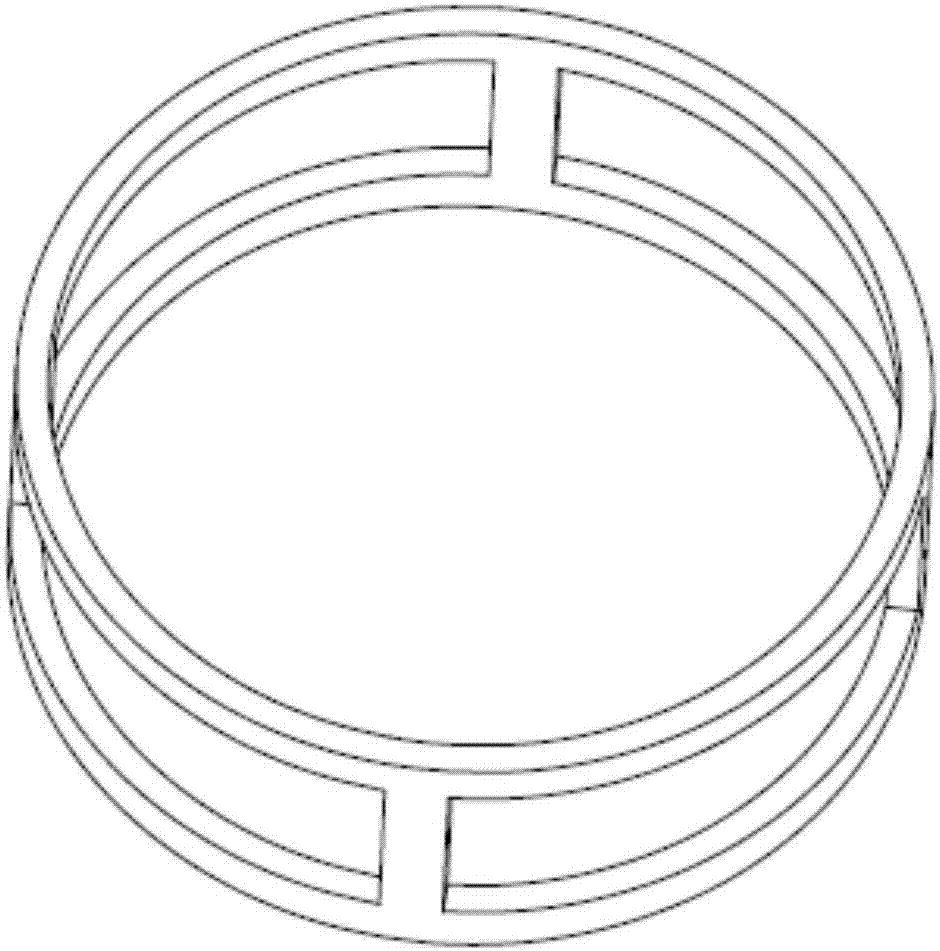

Air bag clamping device used for lossless clamping of low-rigidity framework type part

ActiveCN107414448APrecise and non-destructive clampingAvoid clampingProgramme-controlled manipulatorGripping headsButt jointEngineering

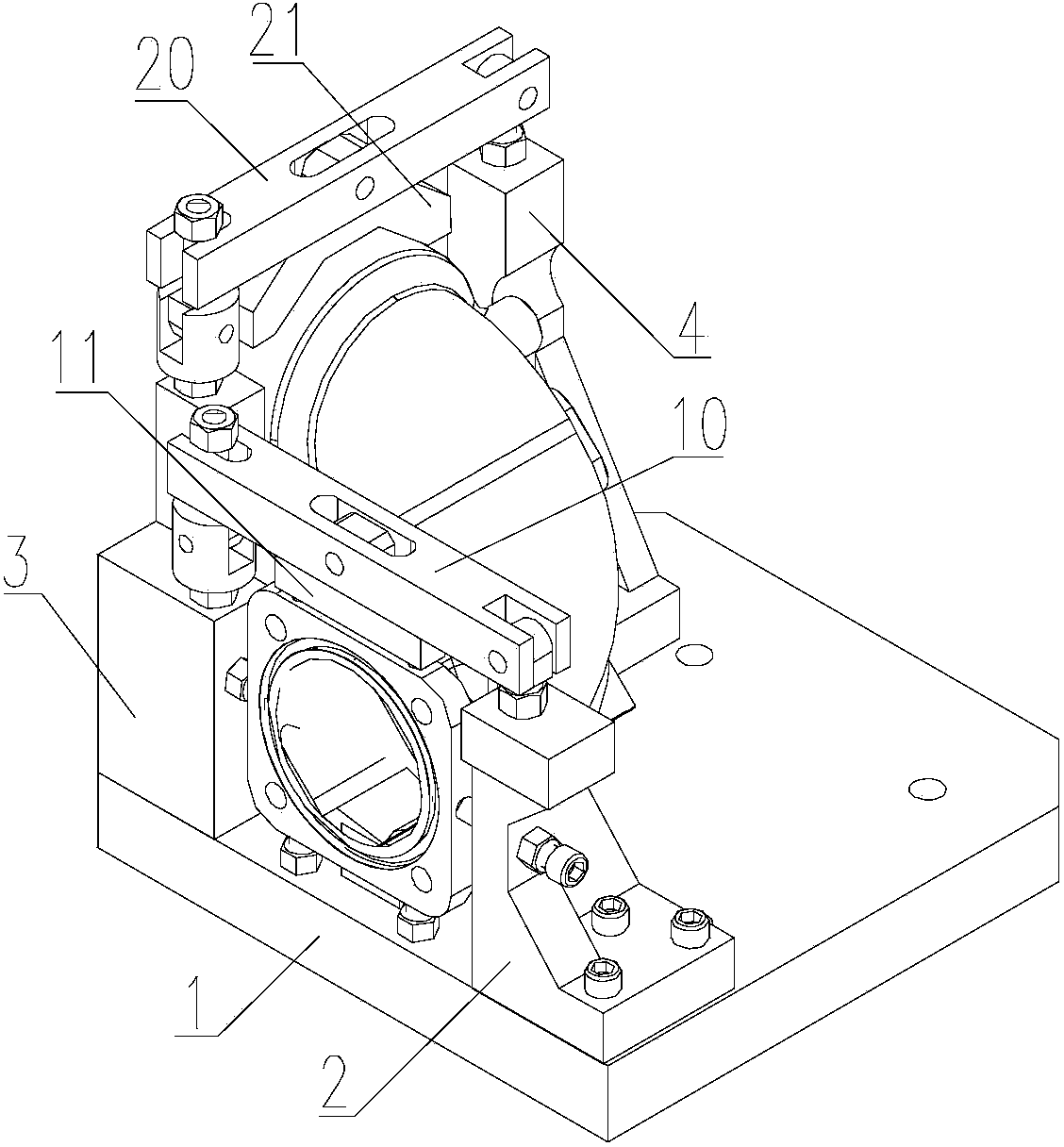

The invention discloses an air bag clamping device used for lossless clamping of a low-rigidity framework type part and belongs to the technical field of microoperation and micro electro mechanical systems. The air bag clamping device comprises an air cavity seat, a holding frame, an air bag and an air way assembly. The air bag is of a structure with one end opened and one end closed, wherein the closed end of the air bag is provided with a cylindrical cavity concave inwards and a circular-ring-shaped cavity coaxial with the cylindrical cavity, the circular-ring-shaped cavity is used for being matched with a ring-shaped face of a framework type part, and the cylindrical cavity is used for being in shaft fit with the assembling position. The shape of the holding frame and the shape of the air bag are consistent, and one or more openings are machined in each of the two opposite circumferential faces of a circular-ring-shaped cavity of the holding frame. The opening end of the air cavity seat is in butt joint with the opening end of the air bag. The holding frame is arranged on the outer surface of the air bag in a sleeving manner and is fixed to the end face of the opening end of the air cavity seat. The air way assembly communicates with a cavity of the air cavity seat through an air pipe connector and is used for inflating and deflating of the air bag. By means of the air bag clamping device, the low-rigidity framework type to-be-assembled part can be extruded in double directions accurately in a lossless manner.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

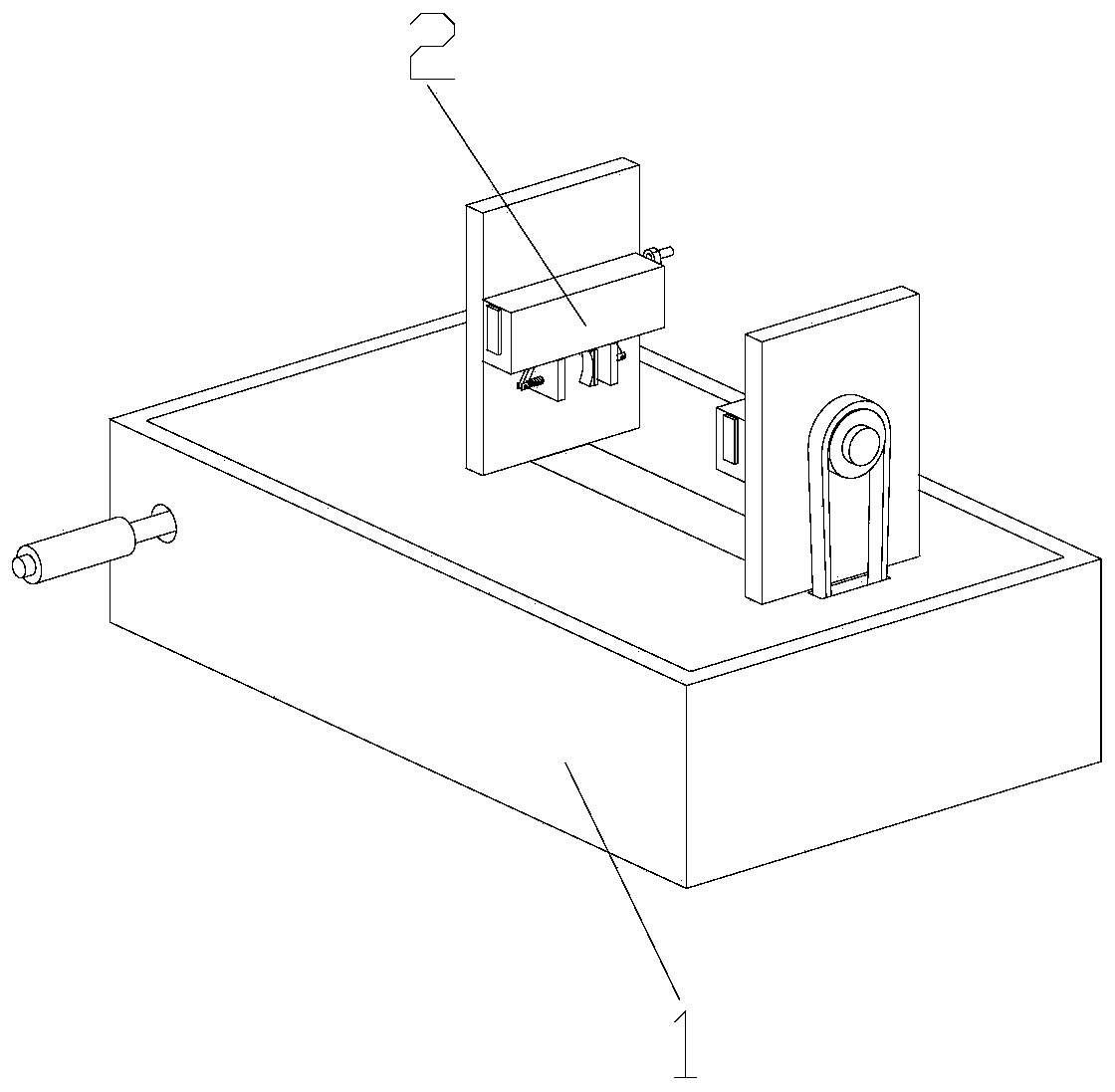

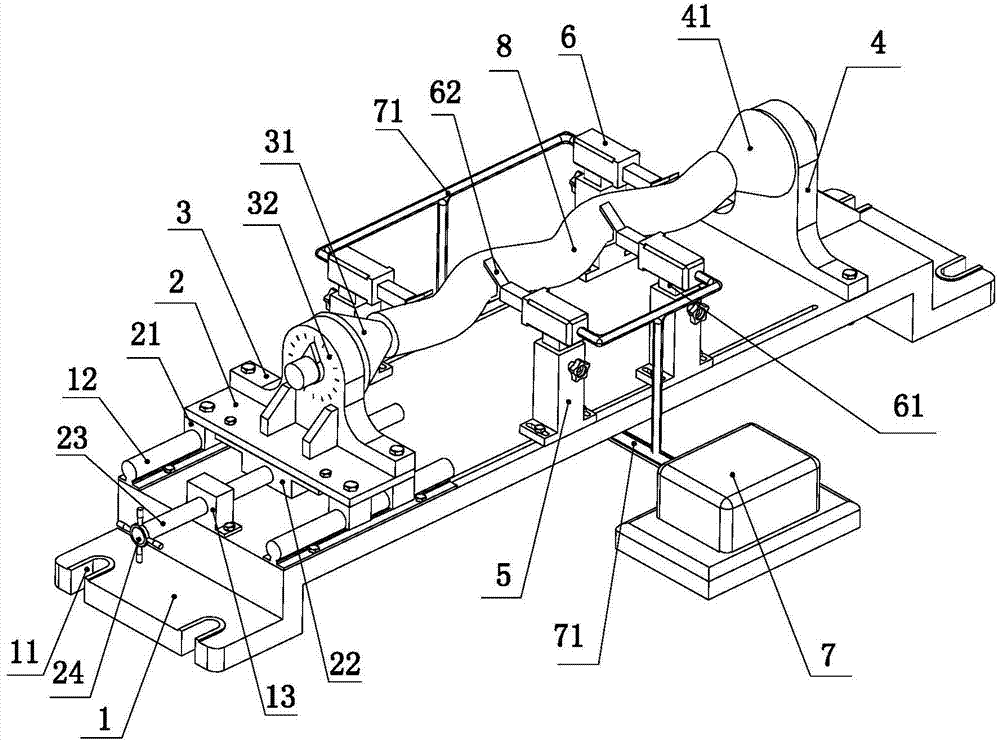

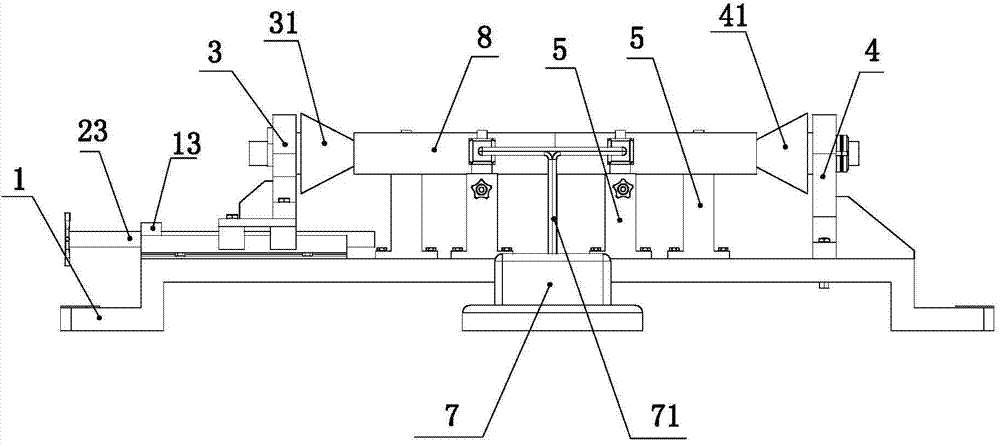

Flexible clamping device of bent pipe

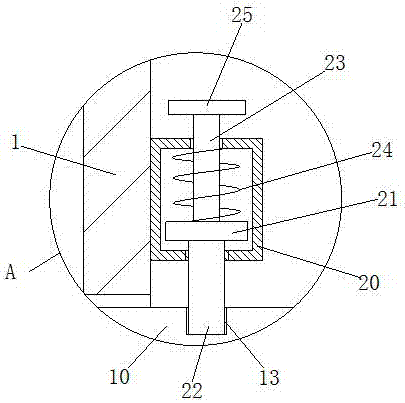

ActiveCN104722619AStable clampingRealize the clamping effectMetal-working feeding devicesPositioning devicesEngineeringMachining

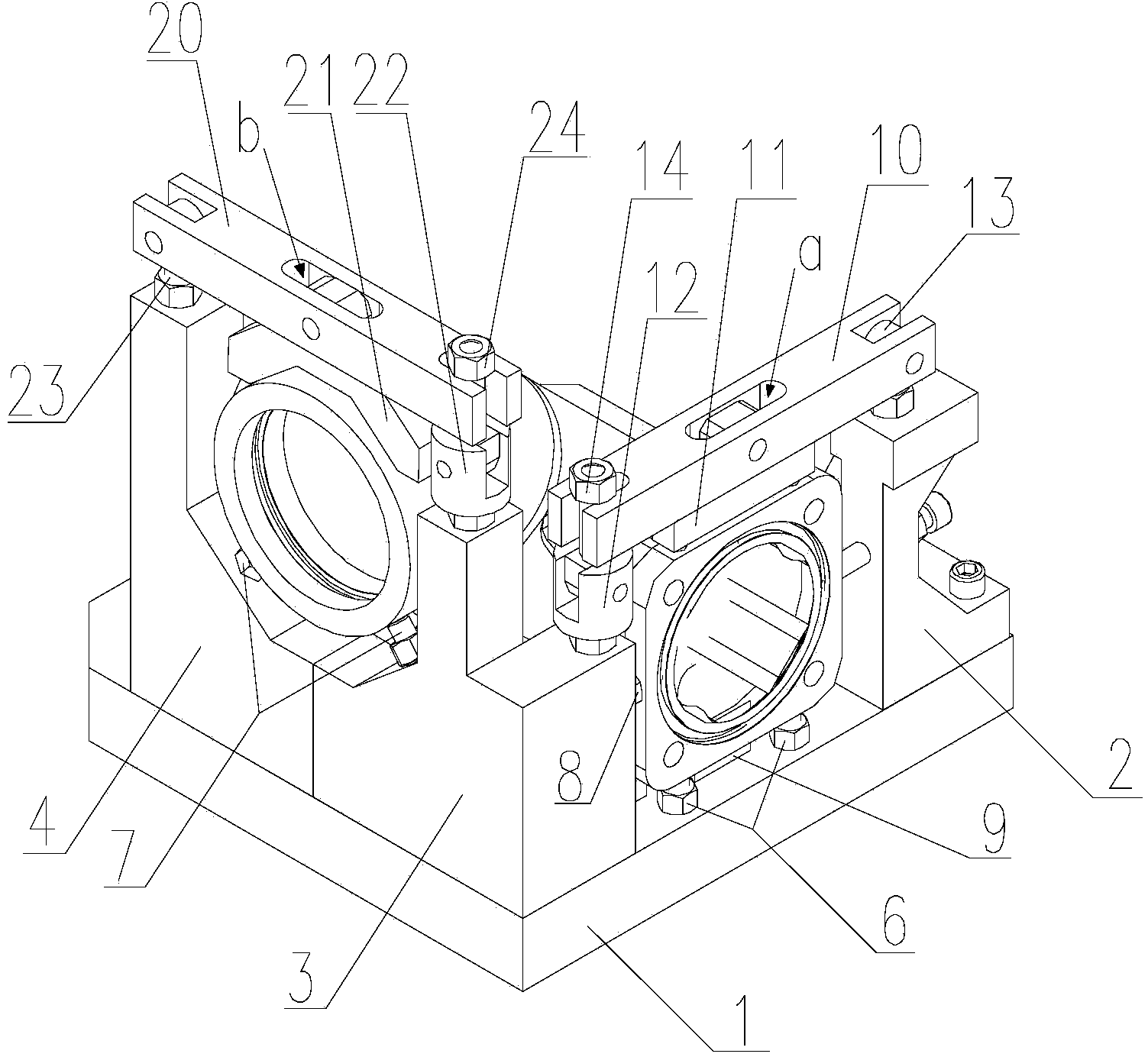

A flexible clamping device of a bent pipe is applied to indexing hole machining of the bent pipe and used for solving the problem that the bent pipe is not convenient to clamp or fix. A movable platform is arranged on the top of a rack in a sliding mode, a movable support is arranged on the movable platform, and a movable thrusting piece is movably installed at the upper portion of the movable support through a rotating shaft. A fixed support corresponding to the movable support is arranged at the other end of the top of the rack, a fixed thrusting piece is rotationally installed at the upper portion of the fixed support through a rotating shaft, and the pipe is clamped through the cooperation of the fixed thrusting piece and the movable thrusting piece. Oil cylinders are arranged on the front side and the rear side of the part, between the fixed support and the movable support, of the rack respectively, piston rods of the oil cylinders are provided with chucks, and the bent pipe is clamped in a horizontal plane through the cooperation of the chucks on the front side and the rear side. According to the clamping device, the bent pipe can be firmly clamped, the bent pipe can be rotated without dismounting the pipe, an indexing hole can be conveniently machined, and the machining precision is guaranteed.

Owner:山东深图智能科技有限公司

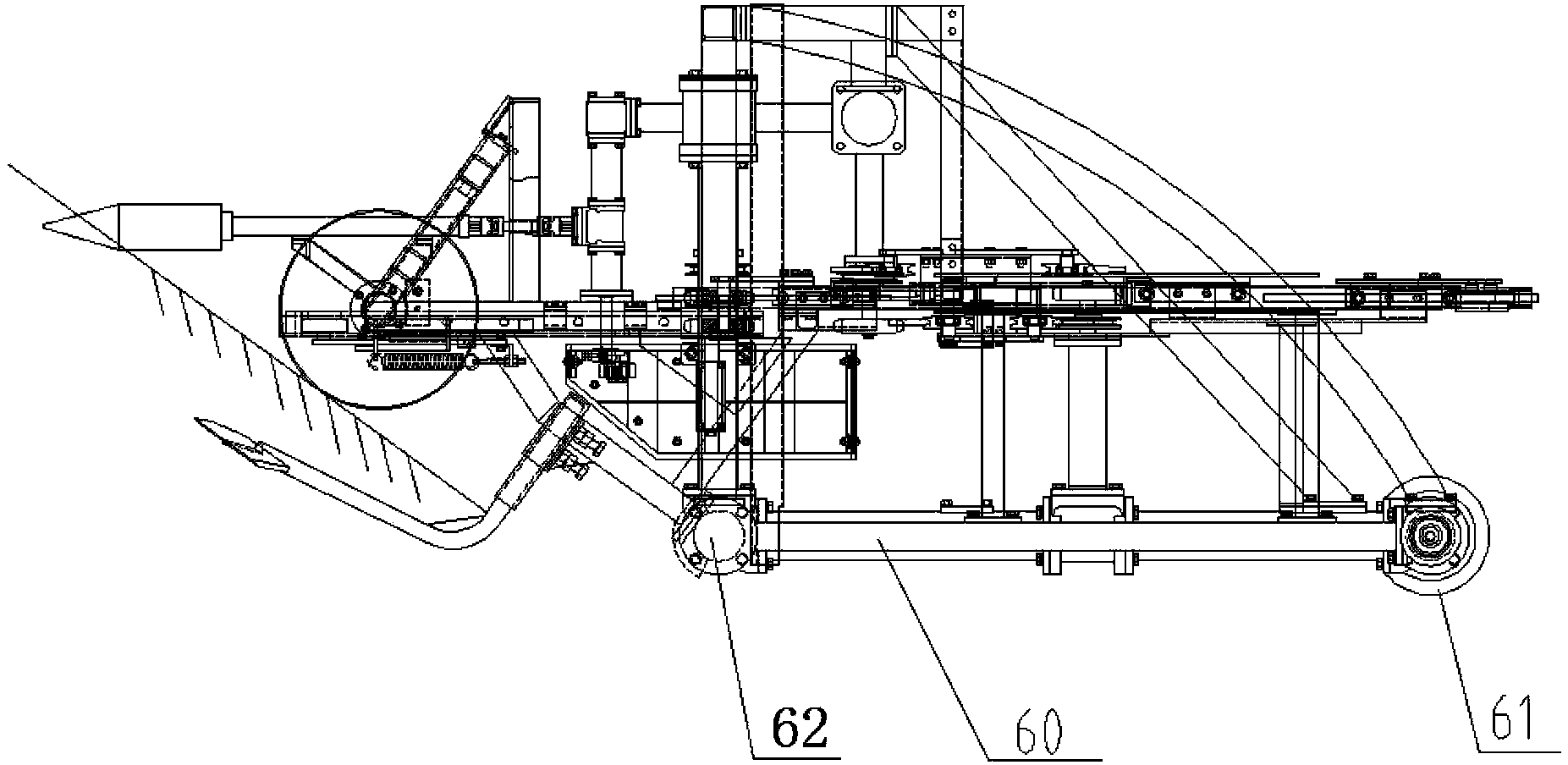

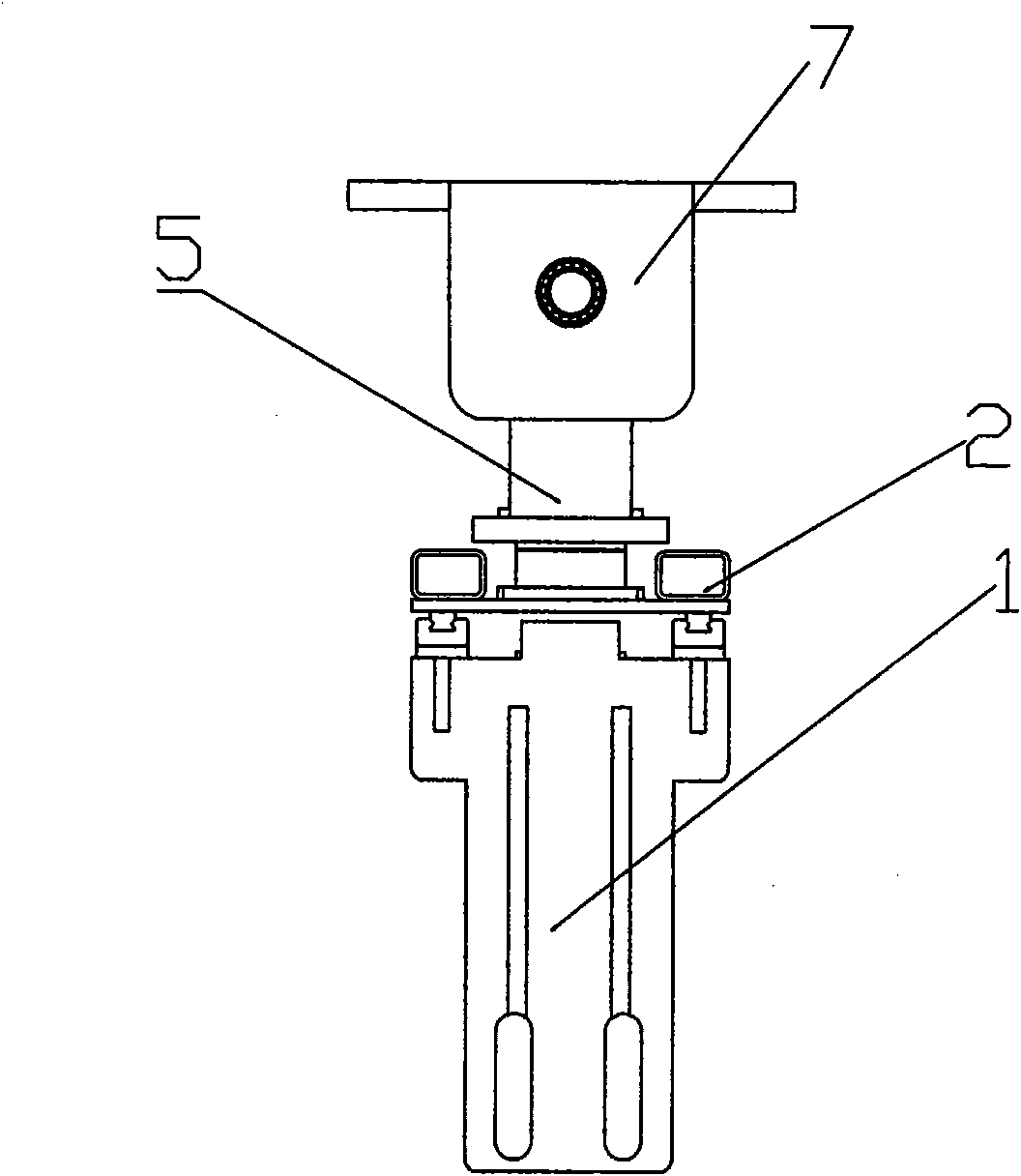

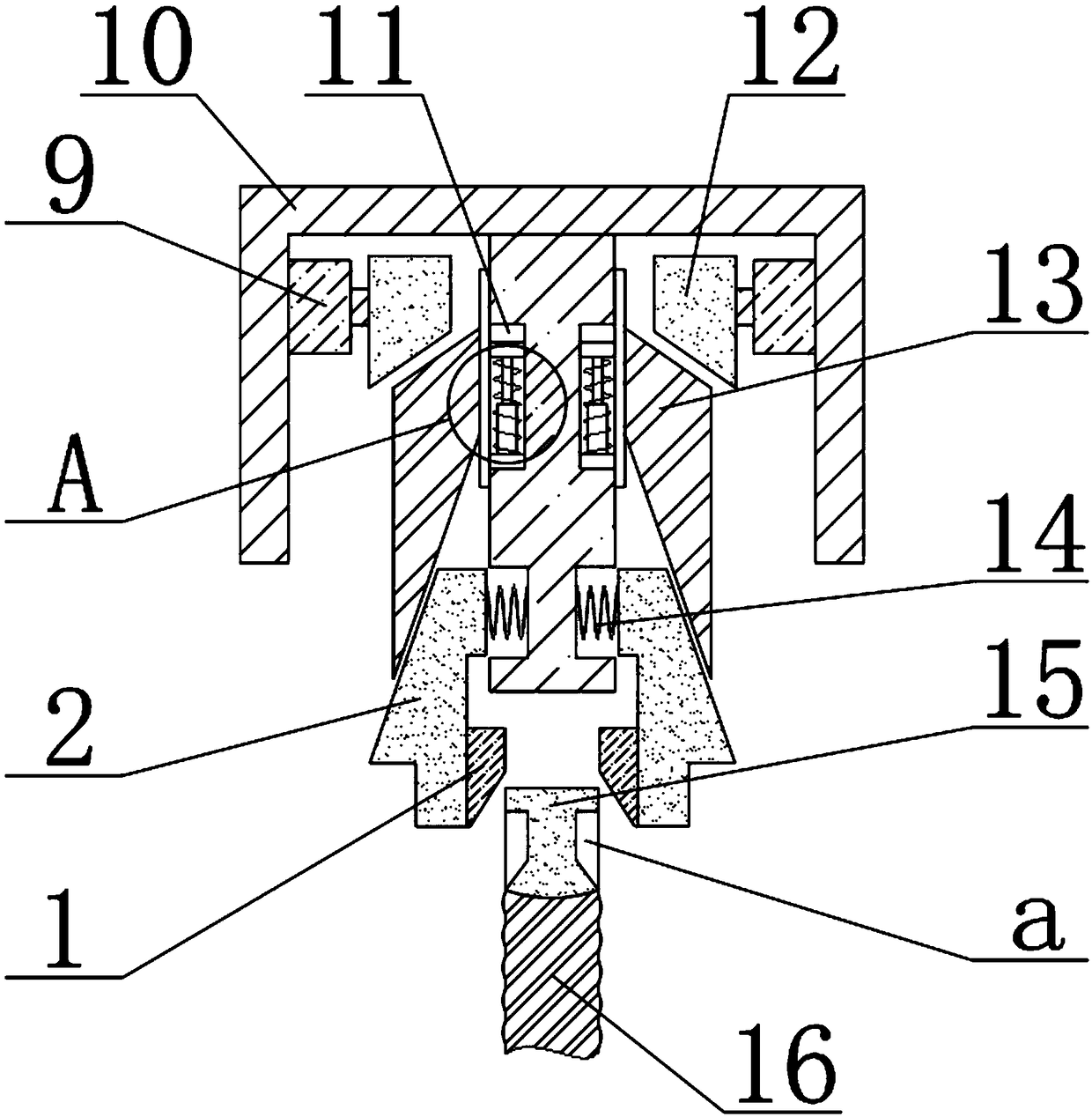

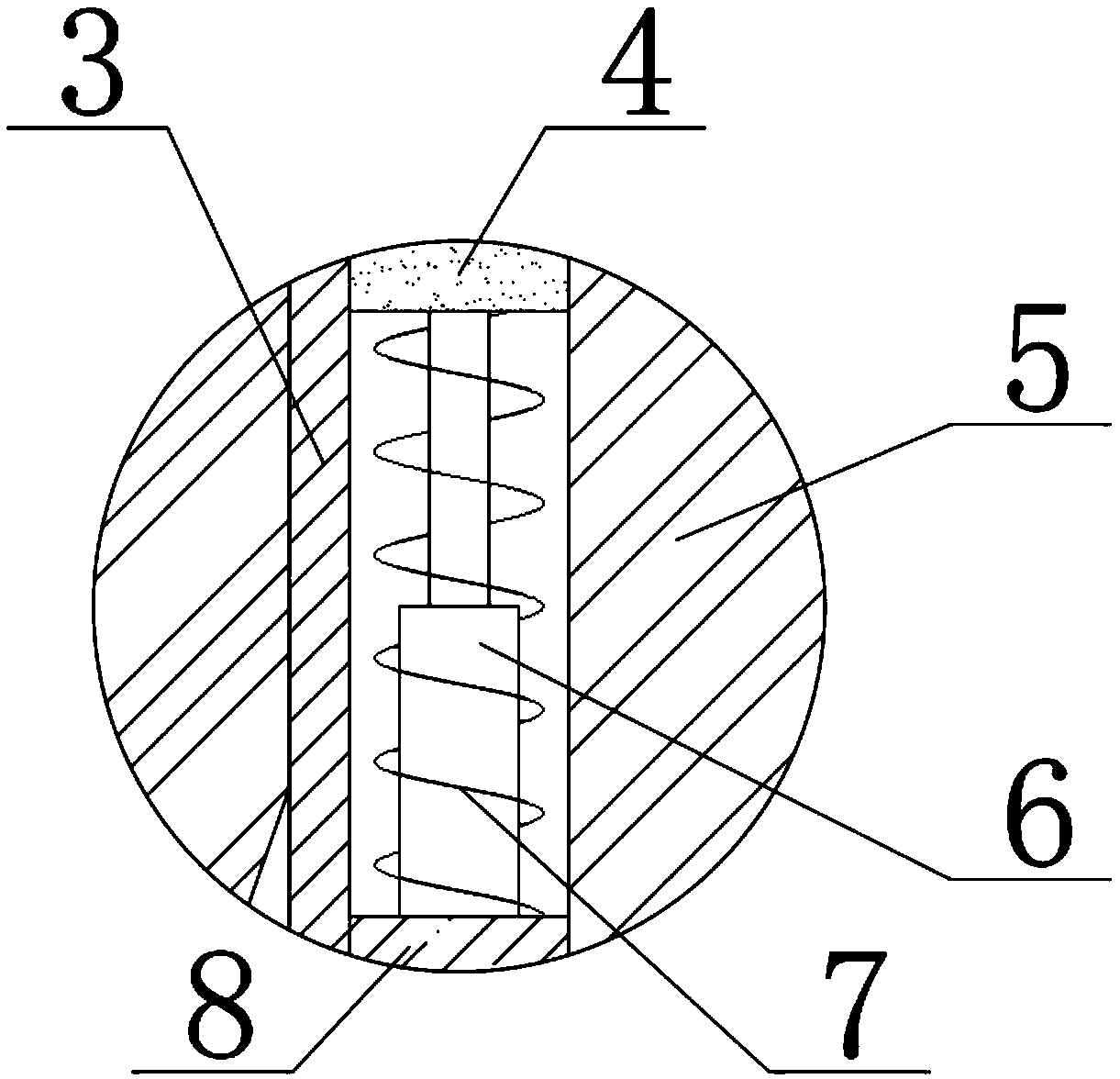

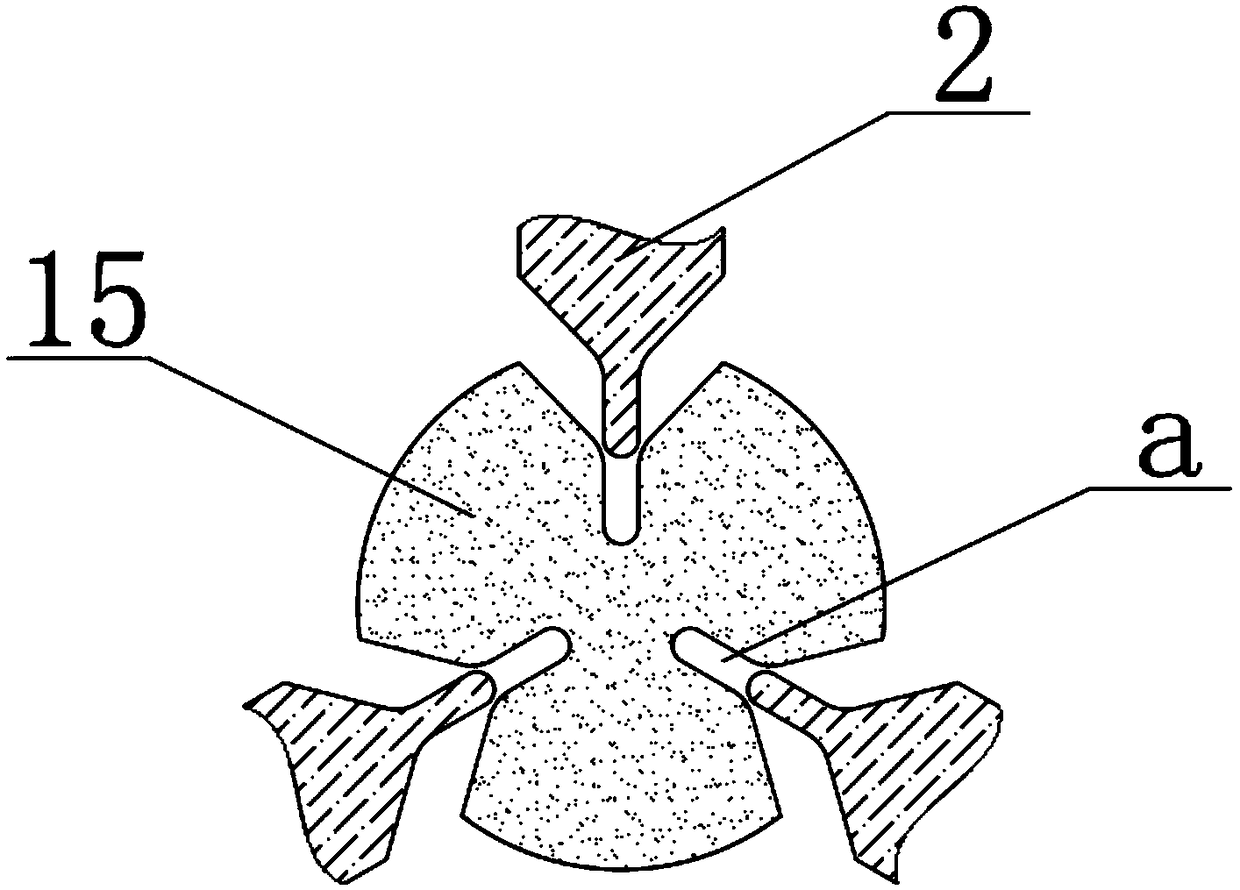

Clamping manipulator for tobacco dedicated charging basket

ActiveCN101670577AAchieve releaseRealize the clamping effectTobacco preparationManipulatorRectangular coordinatesEngineering

The invention discloses a clamping manipulator for a tobacco dedicated charging basket, comprising a paw guide rail, two paw clamping sheets, a rotary servo motor, a swinging servo motor and a three-dimensional rectangular coordinate robot, wherein two paw clamping sheets can slide along with the paw guide rail and are mutually connected via a cylinder; the rotary servo motor is fixed on the supporting seat of a first motor and can drive the paw guide rail to rotate; the swinging servo motor is fixed on the supporting seat of a second motor and can drive the supporting seat of the first motorto rotate; and the three-dimensional rectangular coordinate robot is connected with the supporting seat of the second motor. The scheme controls clamping, dumping, shaking, transporting and releasingof the charging basket by the clamping paw by controlling the components of the cylinder, the servo motor, the rectangular coordinate robot and the like, thus realizing automation control, improving feed liquor preparing efficiency, avoiding quality accident of artificially missending material, lowering raw material consumption and worker labor intensity to the utmost, and improving workshop sanitary environment.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Transport cart for textile winding wheel

InactiveCN107284501ASolve dropNot easy to dropHand carts with multiple axesHand cart accessoriesConductor CoilCart

The invention discloses a transport cart for textile winding wheels. The transport cart comprises a box, supports are fixedly connected to the two sides of the back of the top of the box respectively, a handrail is fixedly connected to the top of each support, a first clamping block is fixedly connected to the right side of the top of the box, a through groove is formed in the top of the inner wall of the box, and a first sliding groove is formed in the right side of the bottom of the inner wall of the box. By arranging the box, the first clamping block, the through groove, the first sliding groove, a bearing platform, a second sliding groove, a movable base, a screw, a rotating plate, a handle, a clamping groove, a screw block, a first sliding block, a movable column, a second sliding block, a movable block, a second clamping block, a protection box, a connecting block, a third clamping block, a movable column, a spring and a pulling block which cooperate with one another, the clamping effect is achieved, when workers transport the winding wheels, the winding wheels are not likely to fall off, it is guaranteed that cloth cannot be polluted, the working efficiency of the workers is improved, and the transport cart is suitable for application and popularization.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

Gravity self-centering self-locking clamp

PendingCN110014315AImplementation intoEasy to grabPositioning apparatusMetal-working holdersModular designSelf locking

The invention discloses a gravity self-centering self-locking clamp. The gravity self-centering self-locking clamp is composed of a chassis, a bearing structure and two or more clamping units. Each clamping unit is composed of a clamping rod, a lifting rod, a clamping arm and a stand column. The stand columns and chassis are fixed. The clamping arms are fixed on the stand columns and can rotate along the stand columns. The clamping rods are fixed at the top ends of the clamping arms. The lifting rods are fixed at the bottom ends of the clamping arms. The bearing structure is composed of a spring and a carrier plate. The spring makes contact with the chassis. The carrier plate is fixedly connected with the lifting rod. The modular design is adopted, gravity and elastic force are combined through the lever principle, products are automatically clamped when being placed in the clamp and automatically loosened when being taken out from the clamp, and the clamp has the automatic centering effect and the self-locking effect.

Owner:徐旭东

Milling cutter clamping equipment for mechanical manufacturing

The invention relates to the technical field of mechanical equipment, in particular to milling cutter clamping equipment for mechanical manufacturing. The milling cutter clamping equipment comprises aclamping block, an air cylinder, a clamping shaft, a supporting frame and a milling cutter. The clamping shaft is fixedly connected to the center inside the top end of the supporting frame, a telescopic rod is fixedly connected to the top end of a first sliding rail, the outer side of the telescopic rod is sleeved with a first spring, a pressing block is fixedly connected to the top end of the telescopic rod, a clamping barrel is fixedly connected to the outer side of the sliding block, air cylinders are fixedly connected to the tops of the inner walls of the two sides of the supporting frame, driving blocks are fixedly connected to the tail ends of main shafts of the air cylinders, the clamping block is fixedly connected to the tail end of a second spring, a clamp block is fixedly connected to the inner side of the bottom end of the clamping block, a clamping groove is formed in the outer side of a fixing block, and the milling cutter is fixedly connected to the bottom end of the fixing block. The milling cutter clamping equipment is scientific and reasonable in structure, convenient to replace and maintain, capable of ensuring axial stability and fastening of a milling cutter shaft and worthy of being popularized, and has huge economic benefits and wide market demands.

Owner:繁昌县通民机械制造有限公司

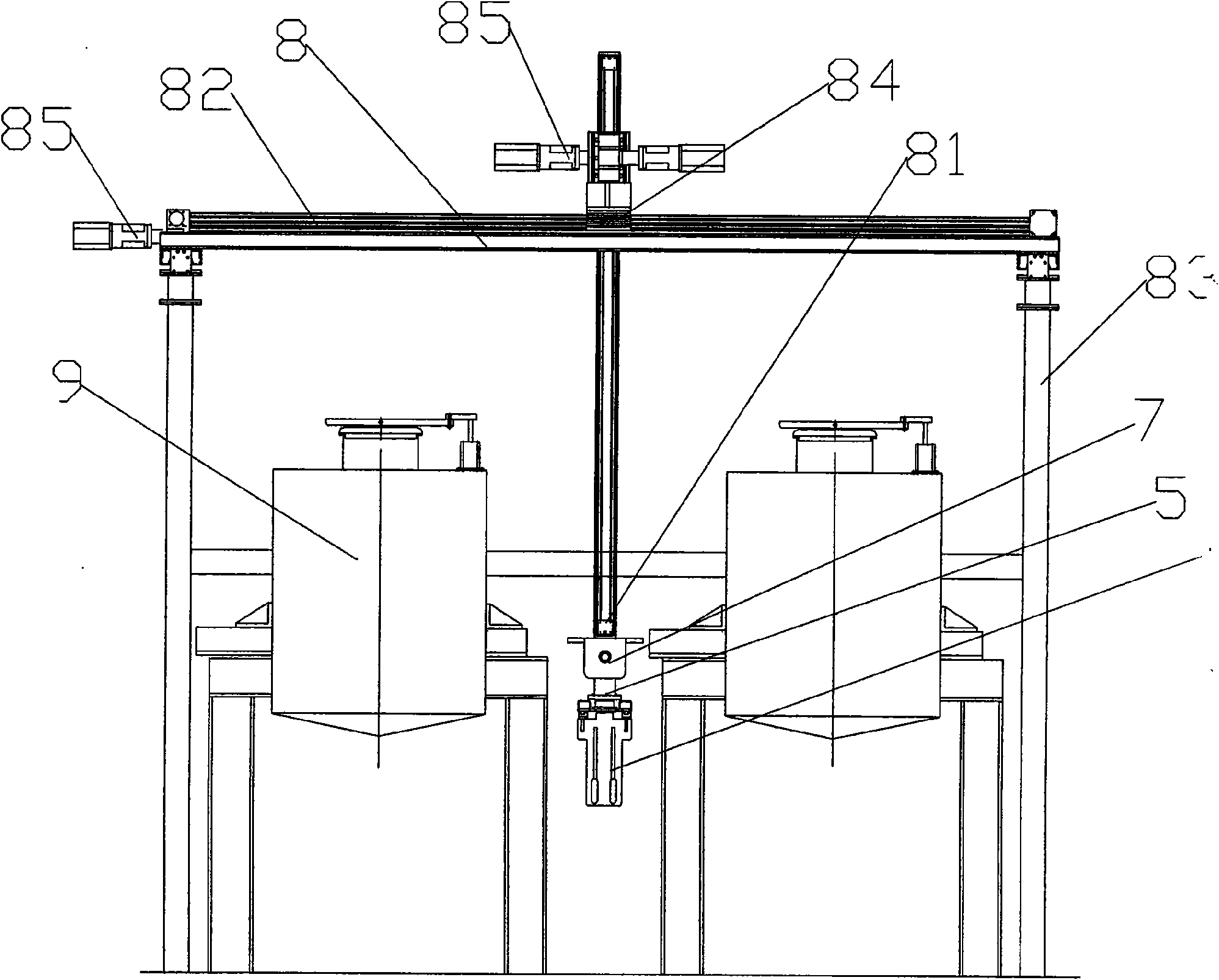

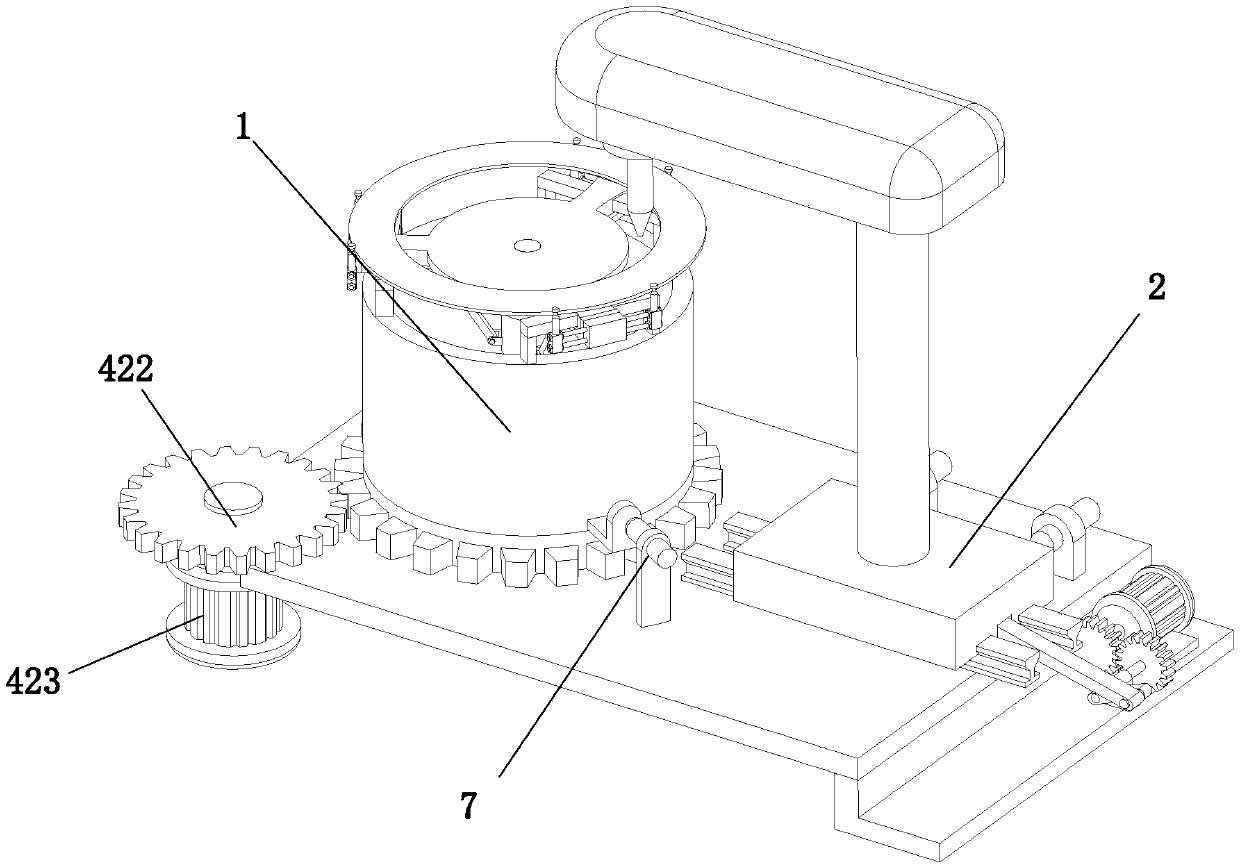

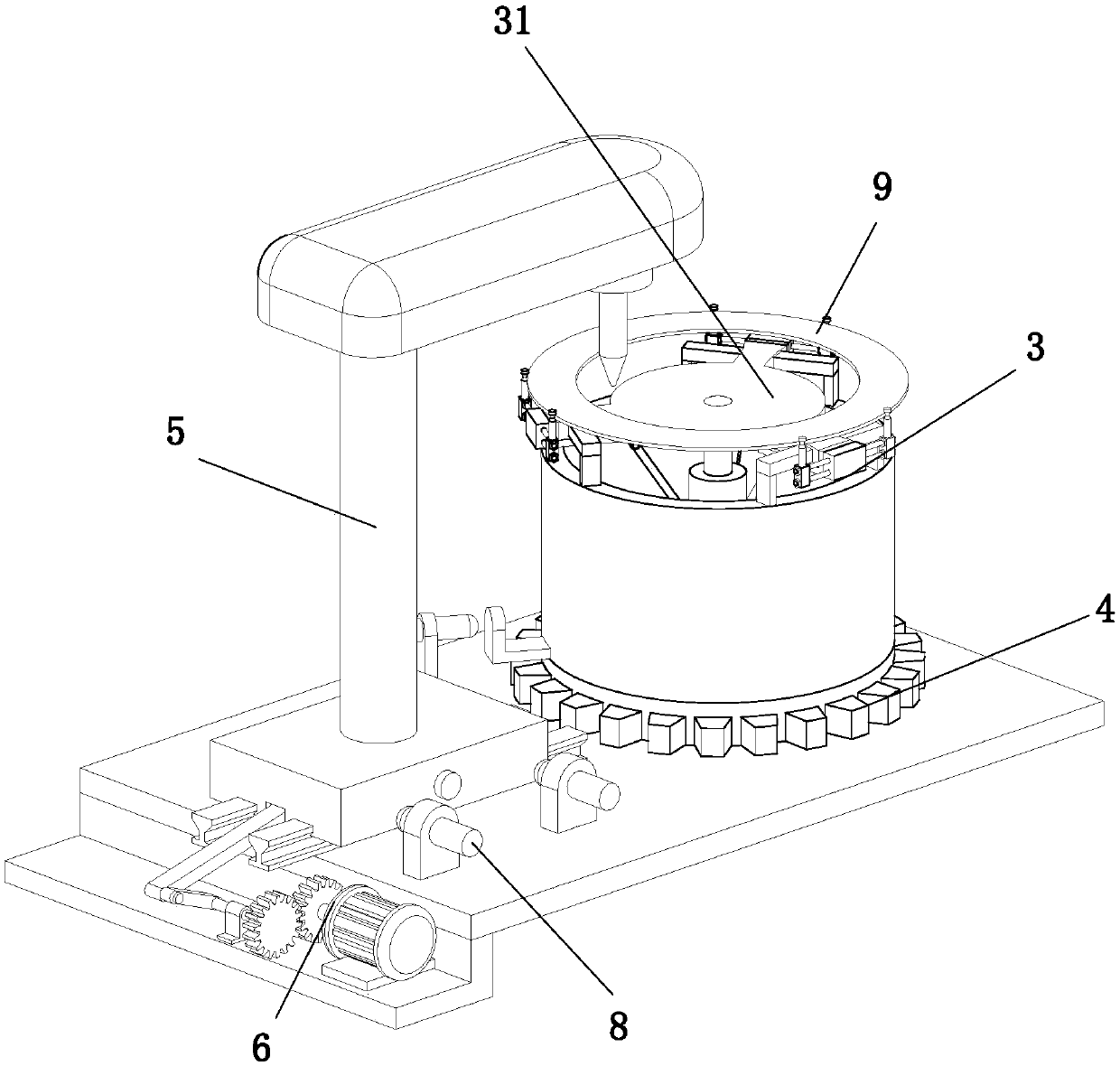

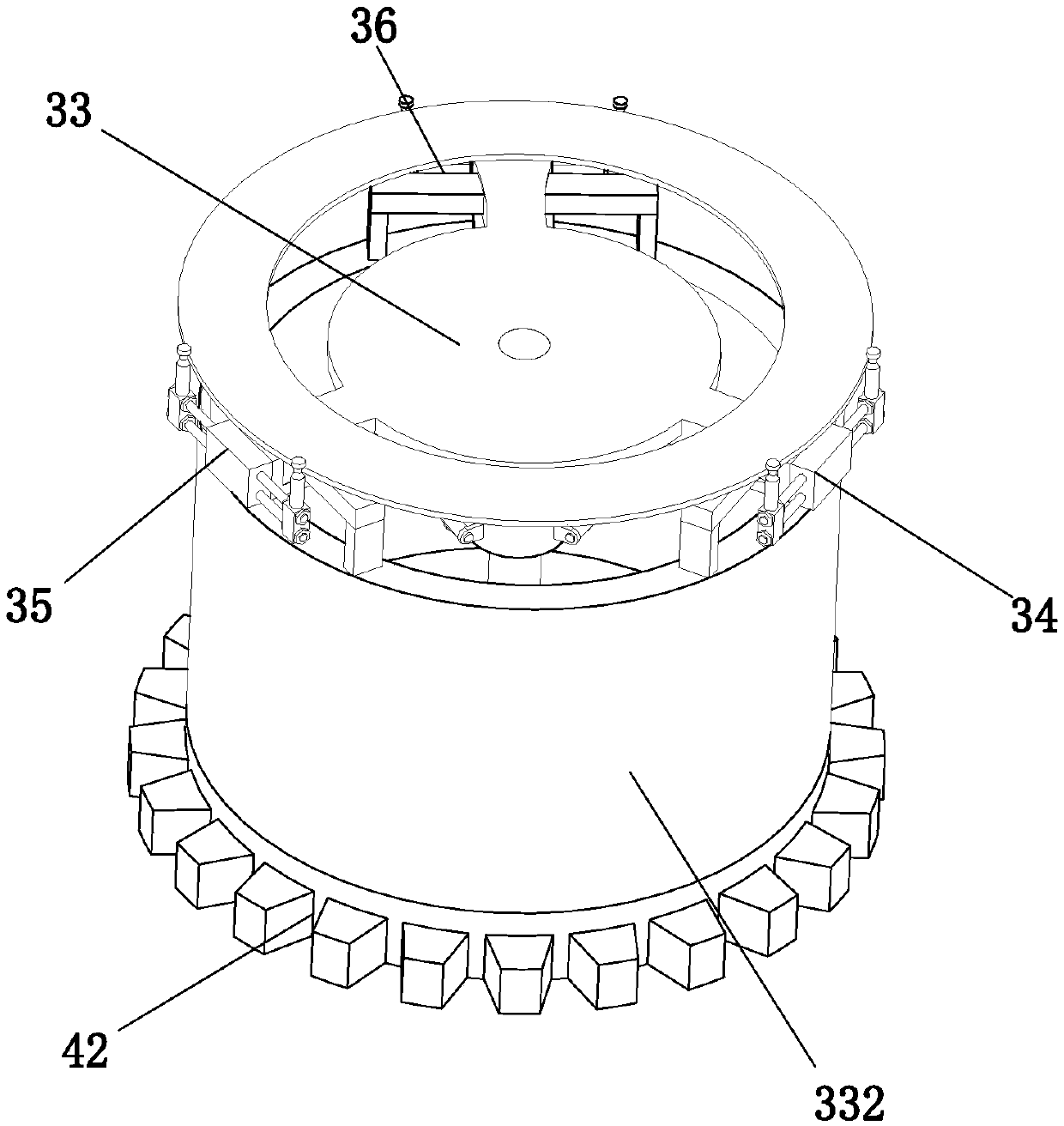

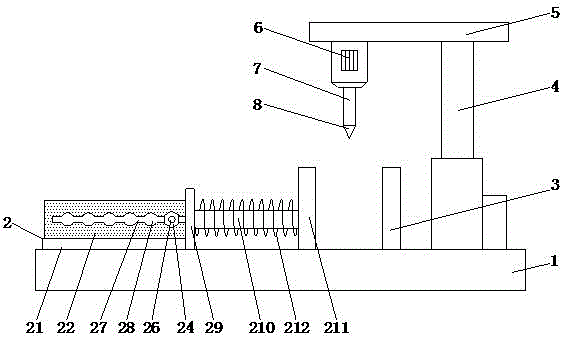

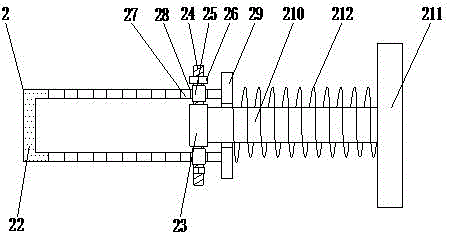

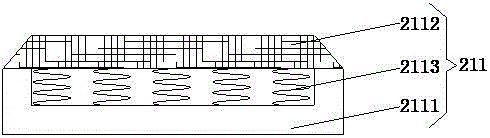

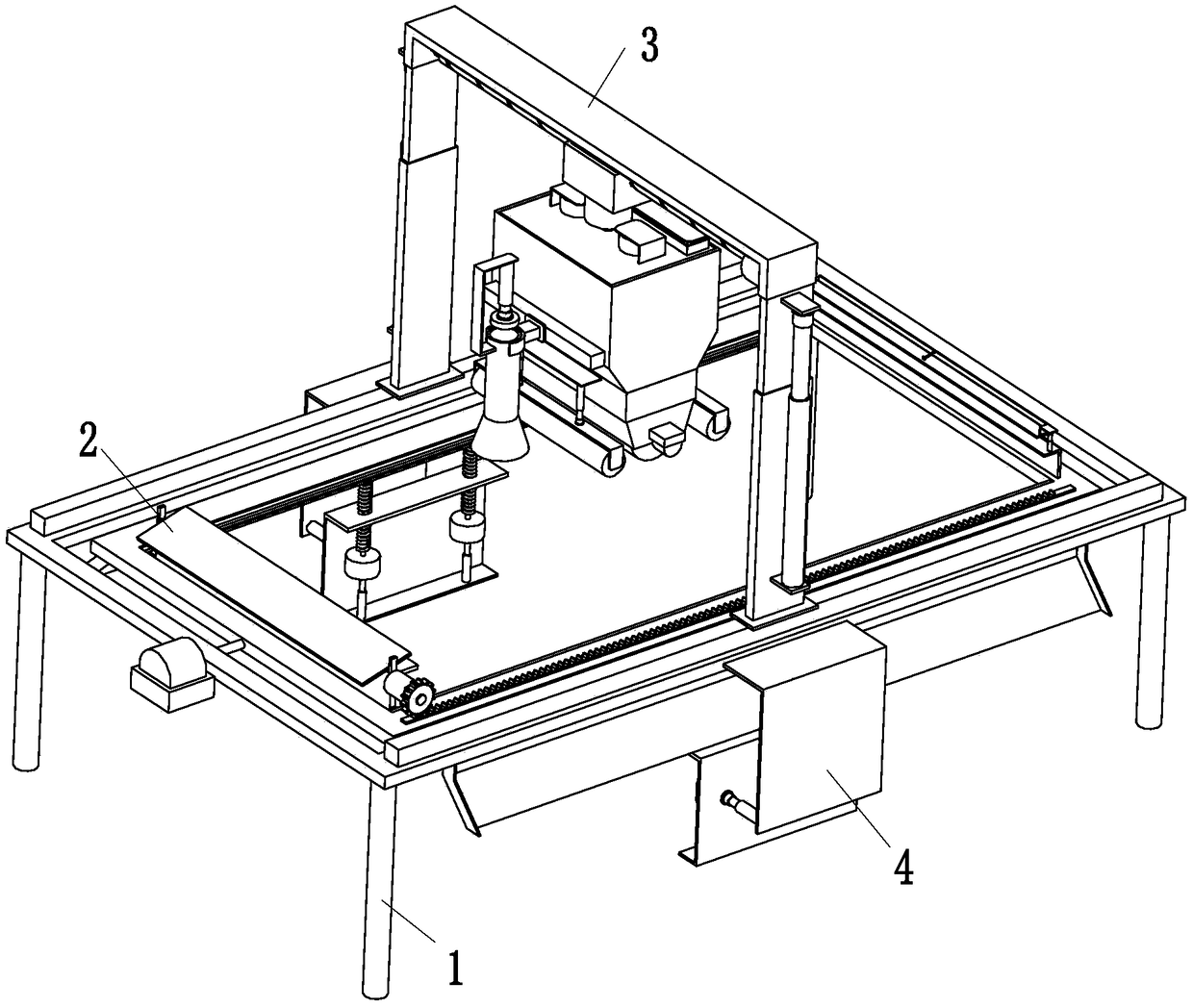

Processing device suitable for drilling disc flanges of plurality of specifications

InactiveCN109093150ARealize the clamping effectRealize automatic drillingFeeding apparatusPositioning apparatusCircular discEngineering

The invention relates to the field of machining, in particular to a processing device suitable for drilling disc flanges of a plurality of specifications, includes a positioning device, a drilling device and a control device, the positioning device comprises a clamping mechanism and a rotating mechanism, the drilling device comprises a vertical drilling machine and an adjusting mechanism, the control device comprises a controller and a sensor assembly. The clamping mechanism comprises a positioning fixture and a driving assembly, and the rotating mechanism comprises a rotating platform and a rotating assembly. The invention can realize automatic clamping and automatic drilling of the disc flange, thereby improving the processing efficiency of the disc flange and reducing the human cost.

Owner:浙江指南针智能科技有限公司

Plate polishing machine for building materials

InactiveCN107309778ASolve the problem of prone to fallingDrop won't appearGrinding carriagesPolishing machinesCantilevered beamArchitectural engineering

The invention discloses a plate polishing machine for building materials, which comprises a workbench. A column is fixedly connected to the center of the rear side of the top of the workbench. The top of the column is fixedly connected to a cantilever beam. The front end of the bottom of the cantilever beam A first motor is fixedly connected, the output end of the first motor is fixedly connected with a polishing wheel, and the center of the top of the workbench is fixedly connected with a storage table. In the present invention, a chute, a bearing platform, a clamping device, a box body, a through groove, a second motor, a screw, a bearing seat, a screw sleeve, a connecting column, a fixing column, a clamping block, a sliding block, a protective pad and a controller are mutually arranged. The cooperation achieves the clamping effect, which solves the problem that the existing plate polishing machine has a poor clamping effect and causes the plate to fall easily, so that when the workers use the plate polishing machine to polish the plate, the plate will not fall off. It improves the practicability of the plate polishing machine and is suitable for popularization and use.

Owner:湖州华科建设工程质量检测有限公司

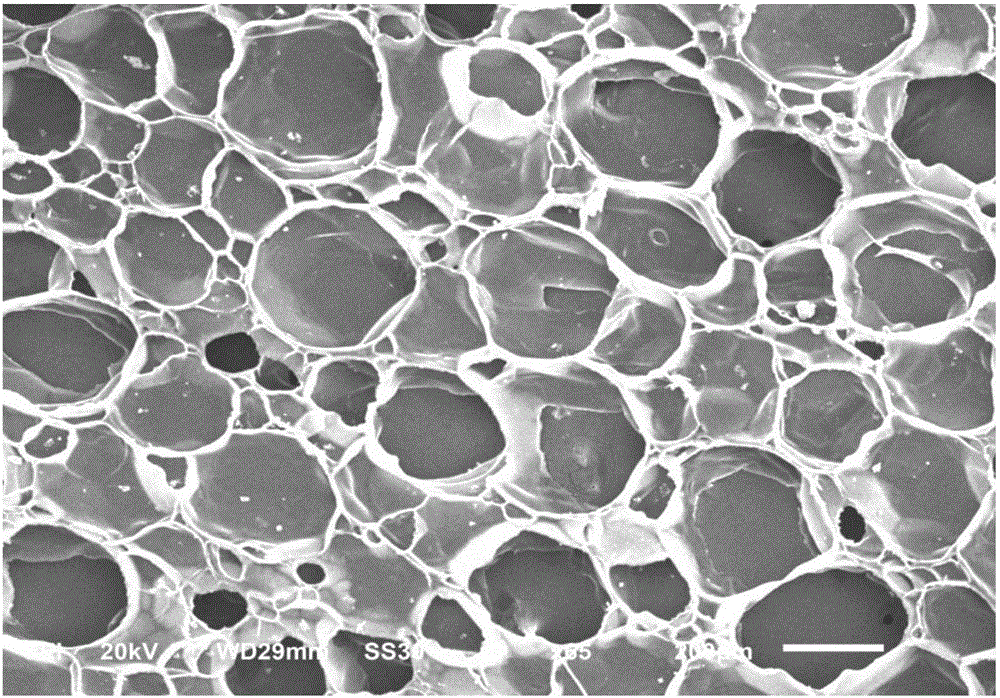

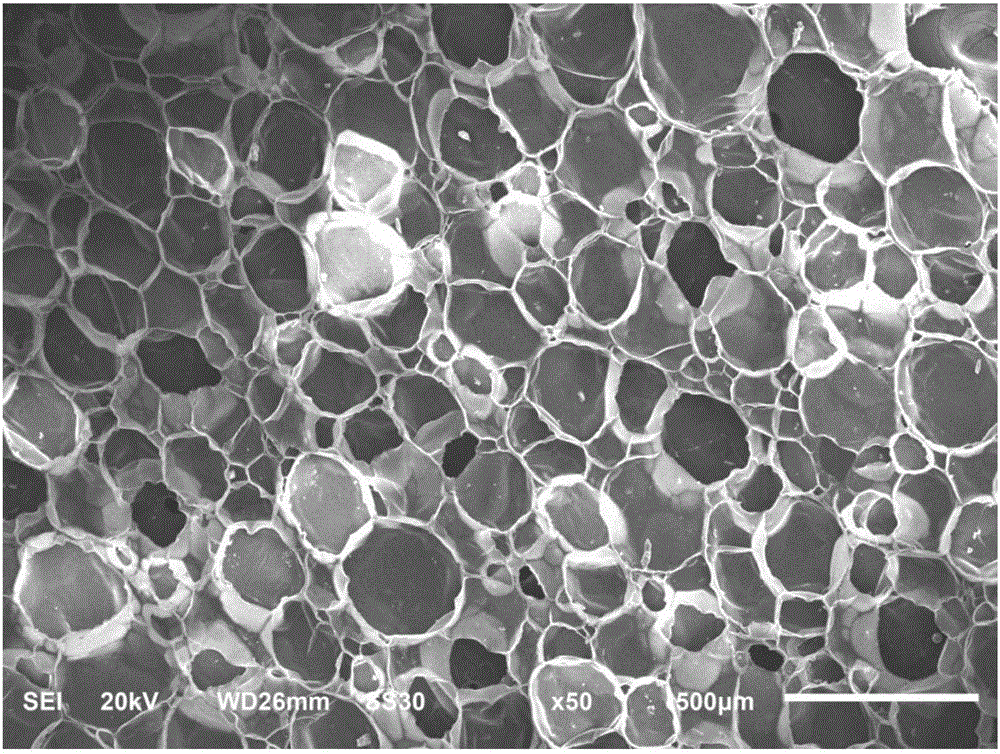

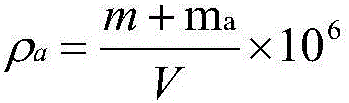

Polymer thin sheet, and manufacturing method and application thereof

ActiveCN106113128ALow densityReduced impact resistanceFunction indicatorsLaminationPolymer scienceCompression set

The invention discloses a polymer thin sheet, and a manufacturing method and application thereof, and belongs to the field of polymer materials and processing. The thickness of the polymer thin sheet is smaller than the average pore size of the thin sheet, the polymer thin sheet is provided with a through hole in the thickness direction so that the polymer thin sheet can be in a cellular board shape, the through hole rate is 20-60%, the thickness is 10-500 [mu]m, and the average pore size is 10-500 [mu]m. The preparation method comprises an unwinding step, a continuous cutting step and a winding step. The precision error of the continuous cutting step is + / -0.02 mm. By the adoption of the method, materials with low density, impact resistance, high compression ratio and low compression permanent deformation performance can be prepared and can be applied to sealing and buffering of electronic equipment. In addition, the method is high in production efficiency, low in production cost and suitable for large-scale industrial application.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Drilling machine for processing of electric appliance accessories

InactiveCN106078270AReduce failure rateAvoid wasting resourcesPositioning apparatusMetal-working holdersElectric machineryDrill bit

The invention discloses a drilling machine for processing of electric appliance accessories. The drilling machine comprises a workbench. A clamping device, a fixed retaining plate and an electric extending rod are sequentially arranged at the top of the workbench from left to right. A connection plate is connected to the top of the electric extending rod fixedly. A drilling motor is fixedly connected to the bottom of the connection plate and on the left side of the electric extending rod. A drill rod is fixedly connected to an output shaft of the drilling motor. A drill bit is fixedly connected to the bottom of the drill rod. The drilling machine for processing of the electric appliance accessories has the advantages that through coordination between the clamping device and the fixed retaining plate, workpieces can be kept stable during drilling of the drilling machine to avoid shaking, so that failure rate of drilling is reduced, resource waste and low economic benefit both caused by damage to the workpieces are avoided, and potential safety hazards caused by unsteadiness and slipping of the workpieces are also avoided; through coordination among fixing columns, fixing blocks, fixing nuts, sliding slots and fixing holes, the clamping device can adapt to the workpieces in different sizes.

Owner:WUXI ZUNBAO ELECTRIC VEHICLE CO LTD

Aluminum-plastic panel coating processing system and aluminum-plastic panel coating technology

ActiveCN108816638AEasy to operateShort costLiquid surface applicatorsSpraying apparatusAluminiumEngineering

The invention relates to an aluminum-plastic panel coating processing system and an aluminum-plastic panel coating technology. The system comprises a support, a hold-down gear, a coating device and two discharging devices. The coating device is installed at the upper end of the support; the hold-down gear is arranged below the coating device; the hold-down gear is installed on the support; and left and right ends of the support are provided with the two discharging devices. In existing coating process, aluminium strips in coils need to be firstly fixed and then manually coated, and the processis tedious and complicated; existing equipment cannot stably fix the aluminium strips in coils and the aluminium strips in coils are not easy to stay in a tighten state for a long time; it is required to coat with various coatings of required thickness during coating; manual coating is not uniform, and residual coatings cannot be recovered timely; concave positions of a coating cannot be filled or leveled up timely; time consumption is high; labor intensity is high; and efficiency is low. By the use of the system and the technology of the invention, the above problems can be solved, and the function of automatically clamping and coating the aluminium strips in coils can be achieved.

Owner:力同铝业(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com