Gravity self-centering self-locking clamp

A self-centering and self-locking clip technology, applied in the field of machining, can solve the problems of increasing the scrap rate, strong dependence, easy to crush the workpiece, etc., and achieve the effect of strengthening the connection firmness, strong versatility, and easy clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

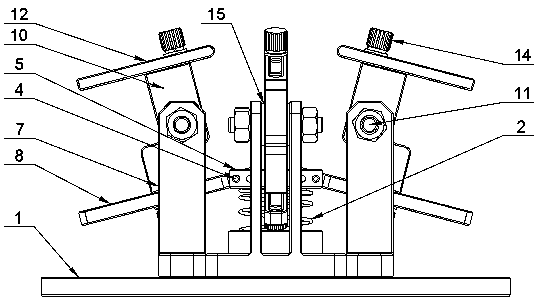

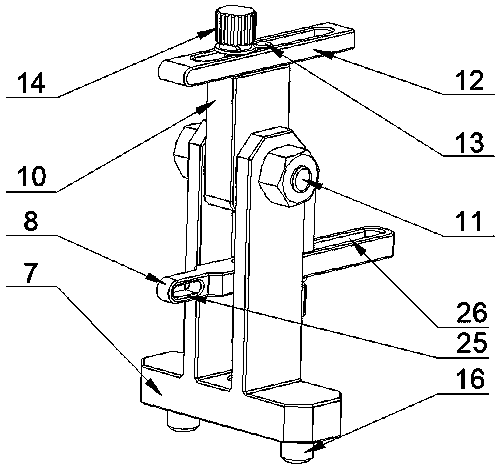

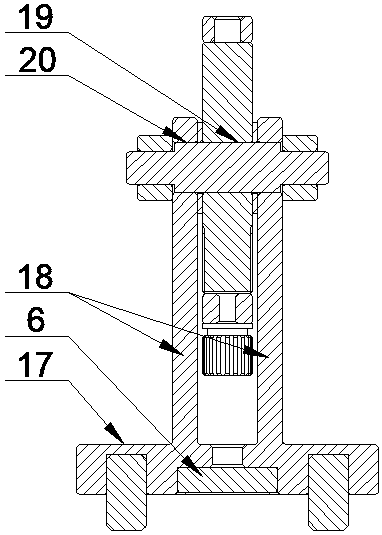

[0032] Such as Figure 1~Figure 5 As shown, the present invention discloses a gravity self-centering self-locking fixture, which is composed of a chassis 1, a load-bearing structure and four clamping units, the chassis 1 is cylindrical, and the clamping unit is movably fixed on the chassis around the load-bearing structure 1, the distance between the clamping units is equal and the distance to the bearing structure is also equal. The clamping unit is composed of clamping rod 12, lifting rod 8, clamping arm 10 and column 7, and the column 7 is supported by support rod I17 and two supports Two support rods II18 are fixed on the support rod I17 in parallel and vertically. A circular through hole I19 is provided in the middle of the clamp arm 10, and a circular through hole II20 is provided on each of the two support rods II18. The through hole I19 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com