Relay base automatic assembly line

An automatic assembly and production line technology, applied in assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problems of small size of the conductive sheet parts of the shell, small size of the small relay base, and displacement of the assembly position of the shell terminals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings, wherein the moving parts of the power part not mentioned in this embodiment, such as the sliding base 2421, the clamping seat 321, etc., all use cylinders as The power component, so the principle of its action will not be repeated in this embodiment.

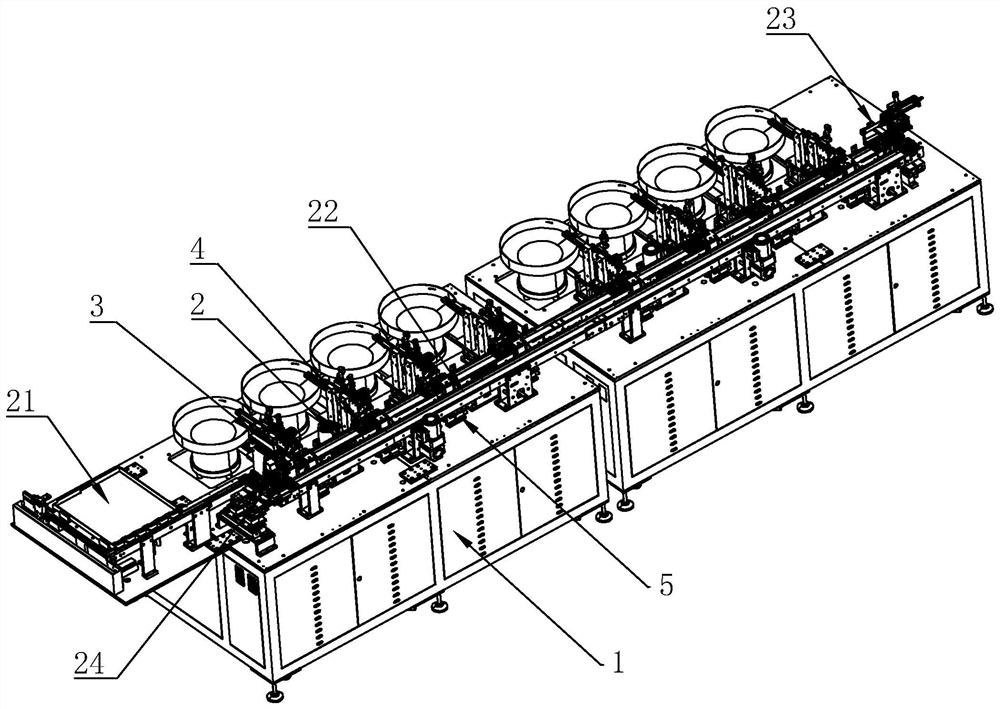

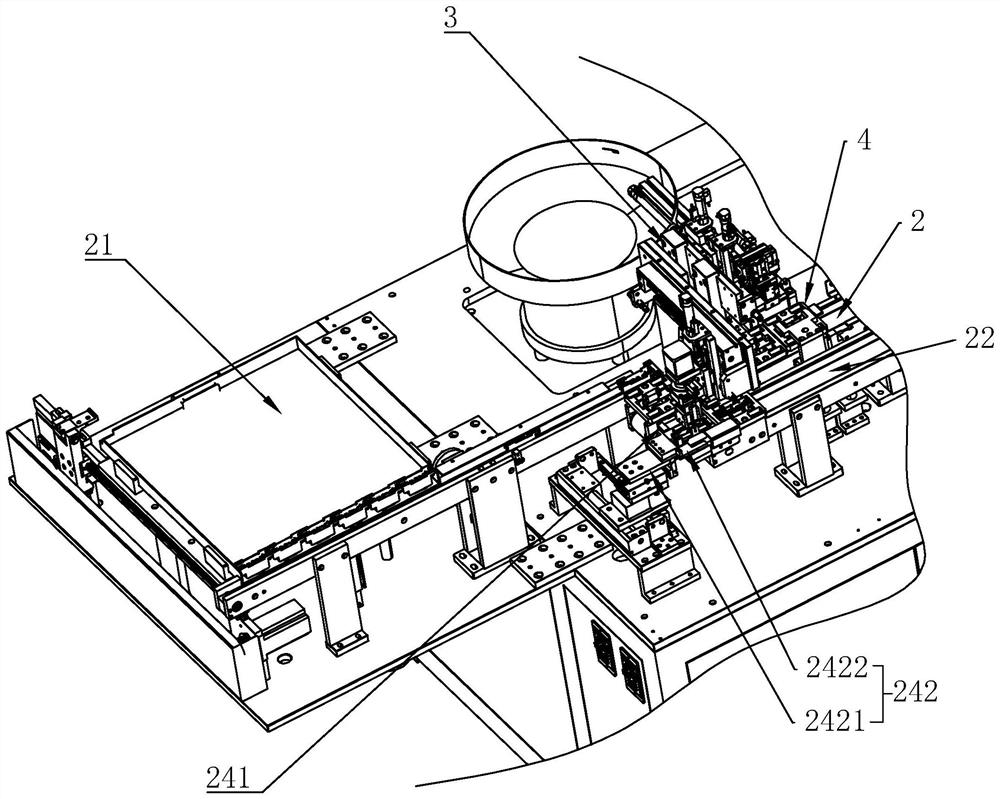

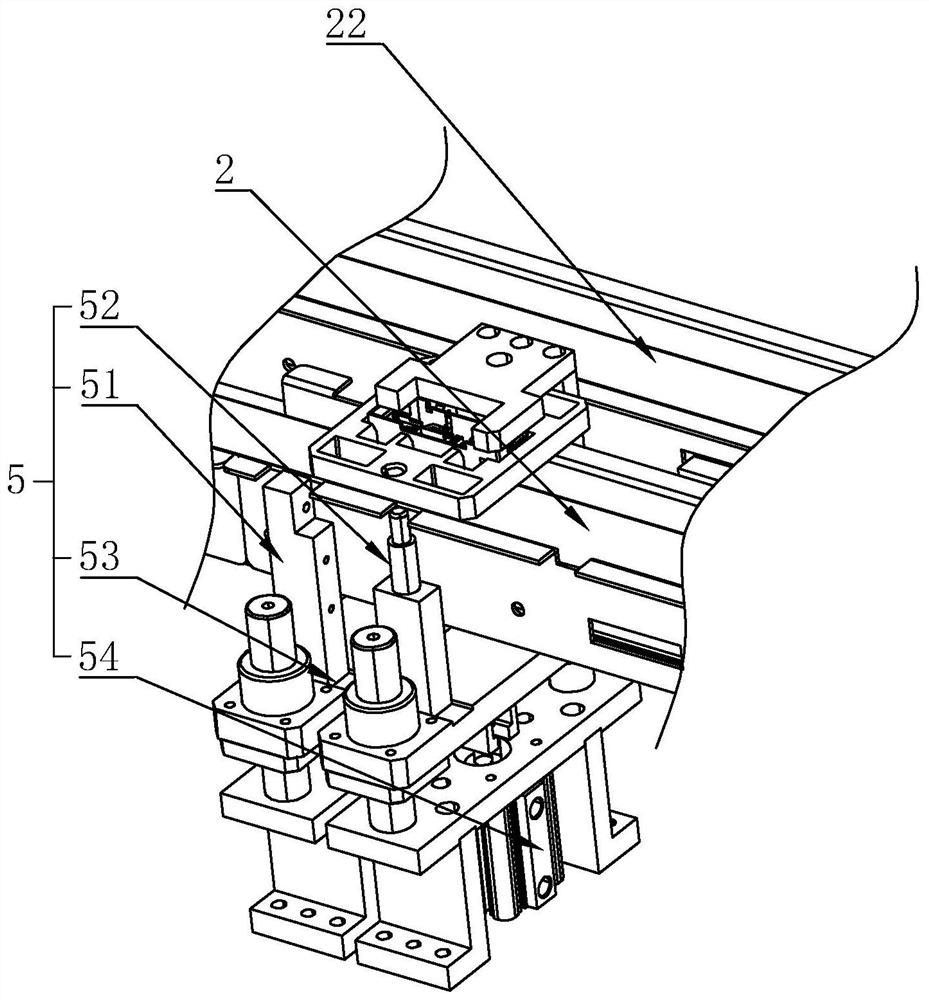

[0019] refer to Figures 1 to 4 As shown, a relay base automatic assembly production line in this embodiment includes a frame 1, a conveyor belt 2 and several component assembly devices 3 all arranged on the frame 1, and several component assembly devices 3 are arranged along the conveyor belt. 2 The longitudinal direction is evenly spaced from each other, and the clamp base 4 is placed on the conveyor belt 2, and the positioning device 5 for positioning the clamp base 4 is provided below the conveyor belt 2 relative to the assembly device 3 of each component. When assembling , the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com