Pressure assembly mechanism

An assembly mechanism and pressure technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as separation and damage to parts or products, and difficulty in separating tools from parts or products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

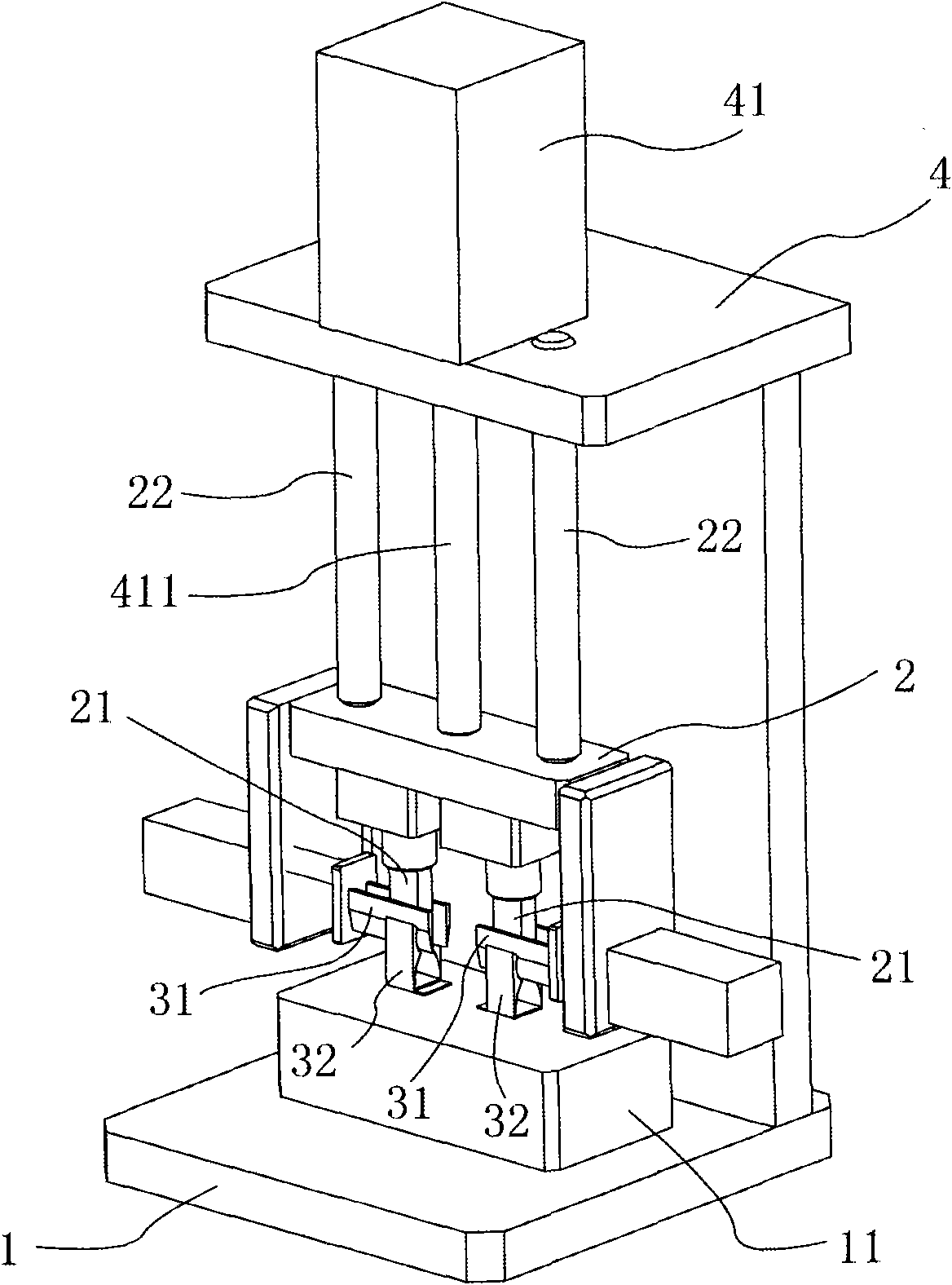

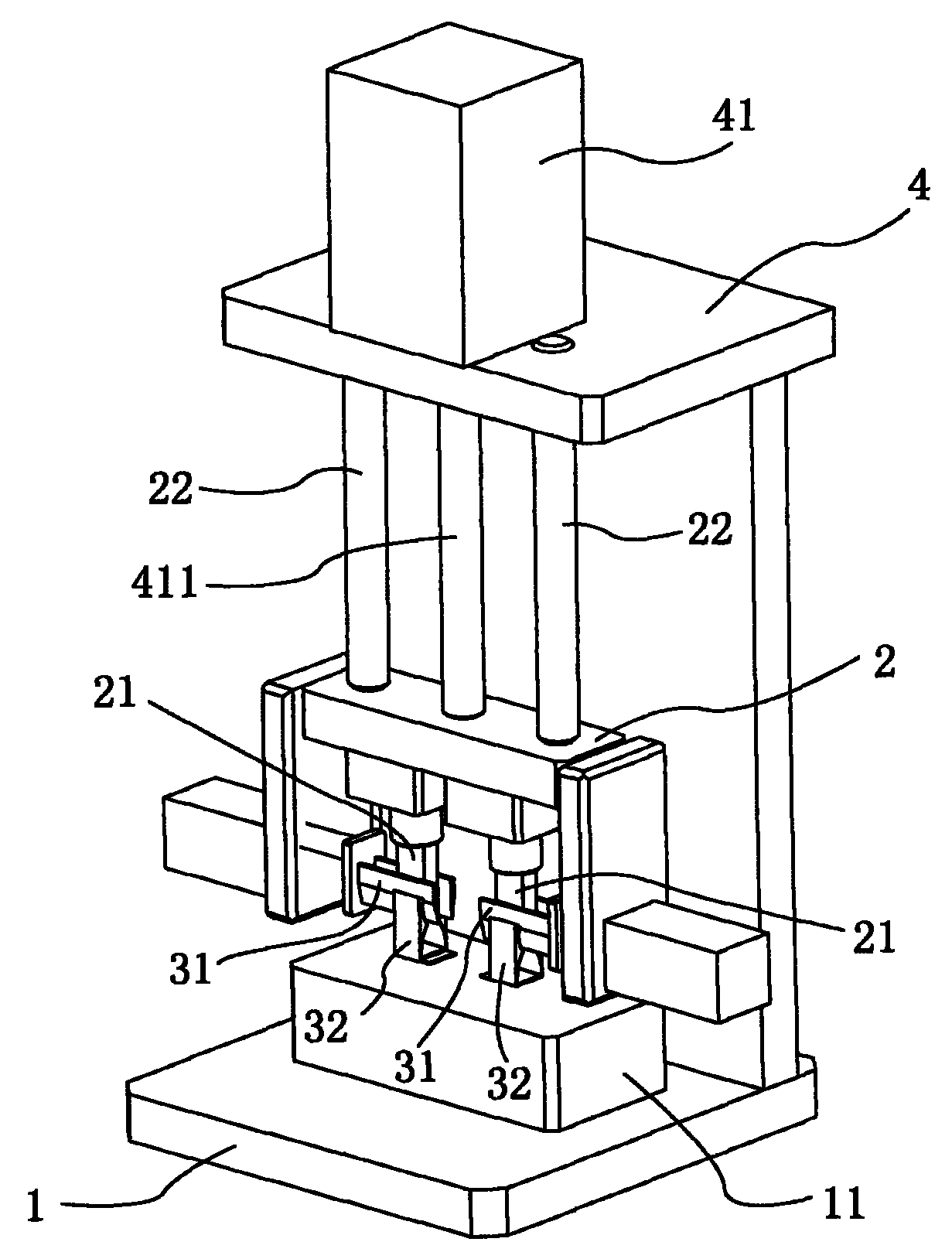

[0014] Such as figure 1 The pressure assembly mechanism shown is mainly used to push a small product into another product. A lower template 11 is arranged on the base 1, and a larger product 32 is placed on the lower template 11 by tools such as clamps. Fixing, the smaller product 31 is placed in the position where the product 32 is combined and assembled and assembled by the pressure of the upper punch 21; the upper punch 21 is installed on the upper die fixing plate 2, and the upper die fixing plate 2 passes through the guide sleeve The guide rods 22 along the left and right sides can slide up and down, and the positions of the upper and lower ends of the guide rods 22 are fixed, wherein the upper end is connected on the cylinder fixed plate 4, and the cylinder 41 is placed on the cylinder fixed plate 41. The head of the piston rod 411 The part is connected with the upper mold fixed plate 2.

[0015] Wherein the rod-shaped head of the upper punch 21 is in contact with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com