Patents

Literature

1328results about "Inspecting textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

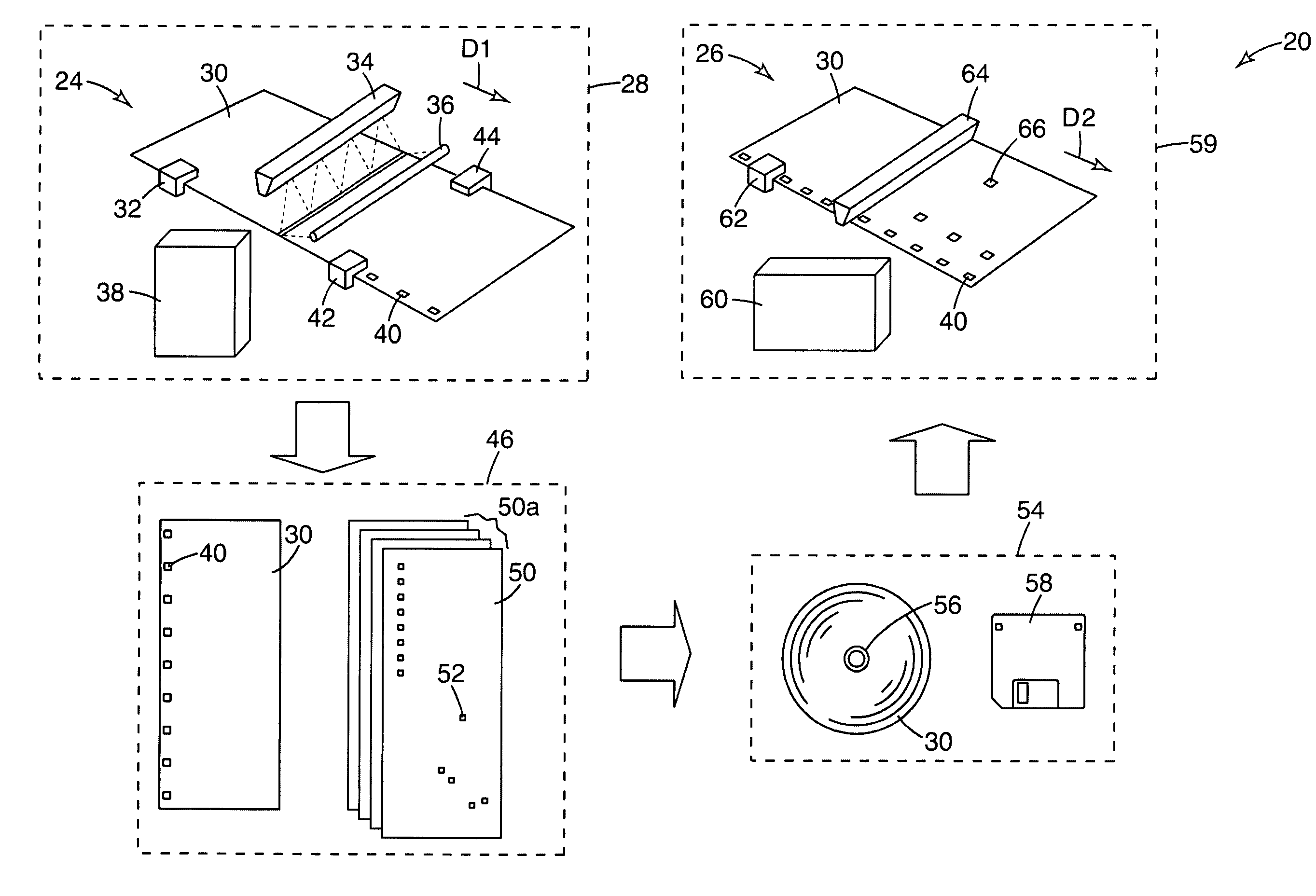

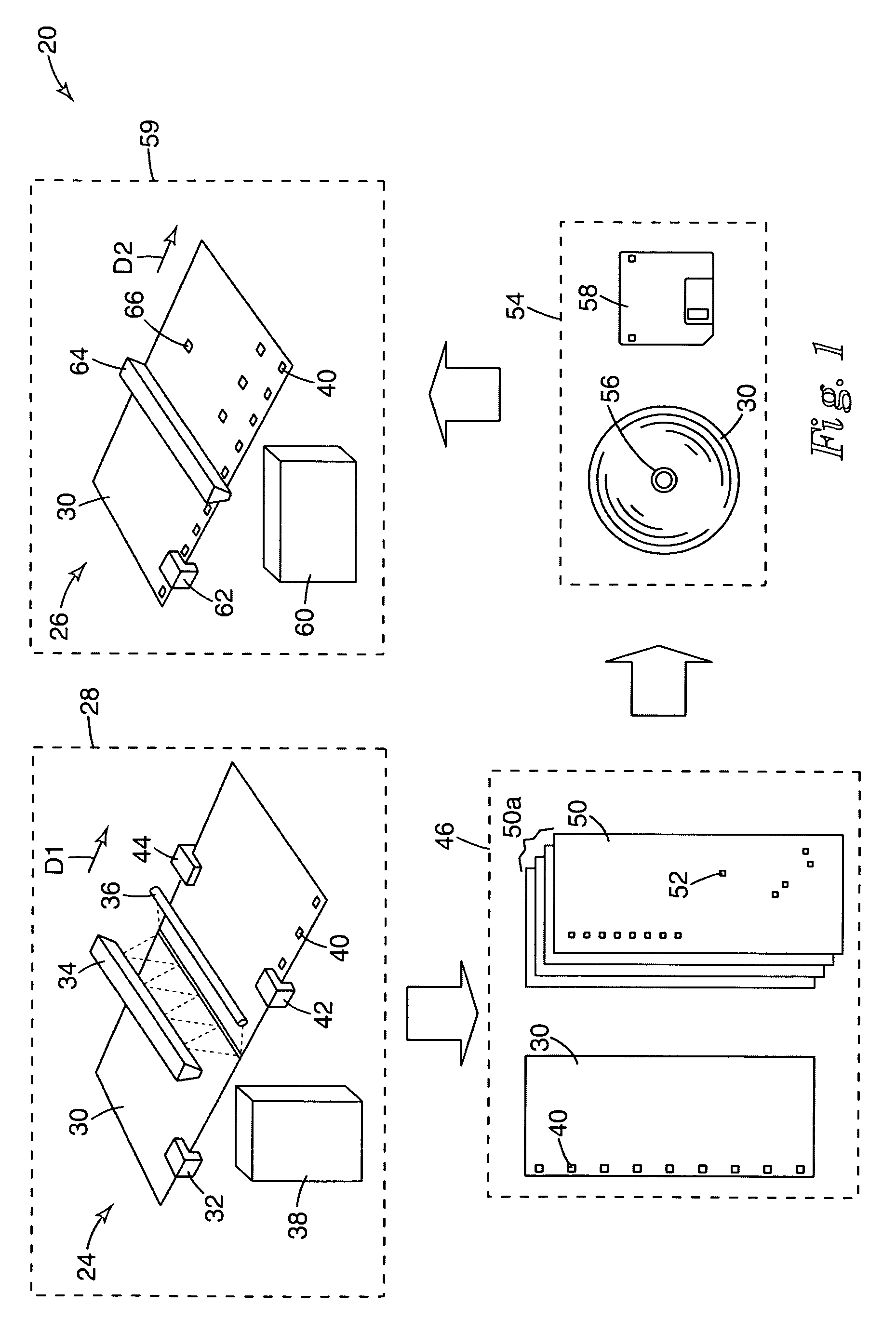

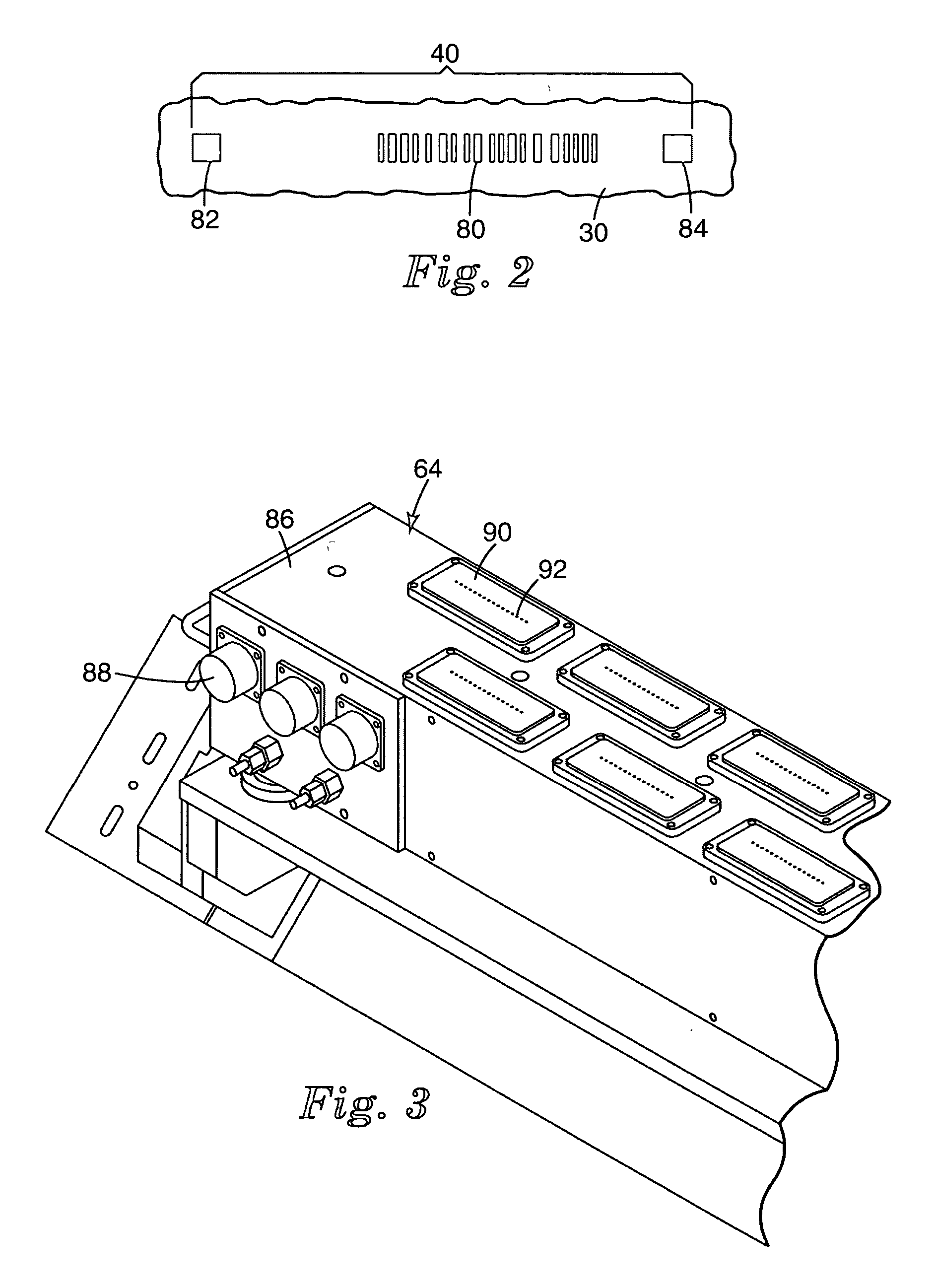

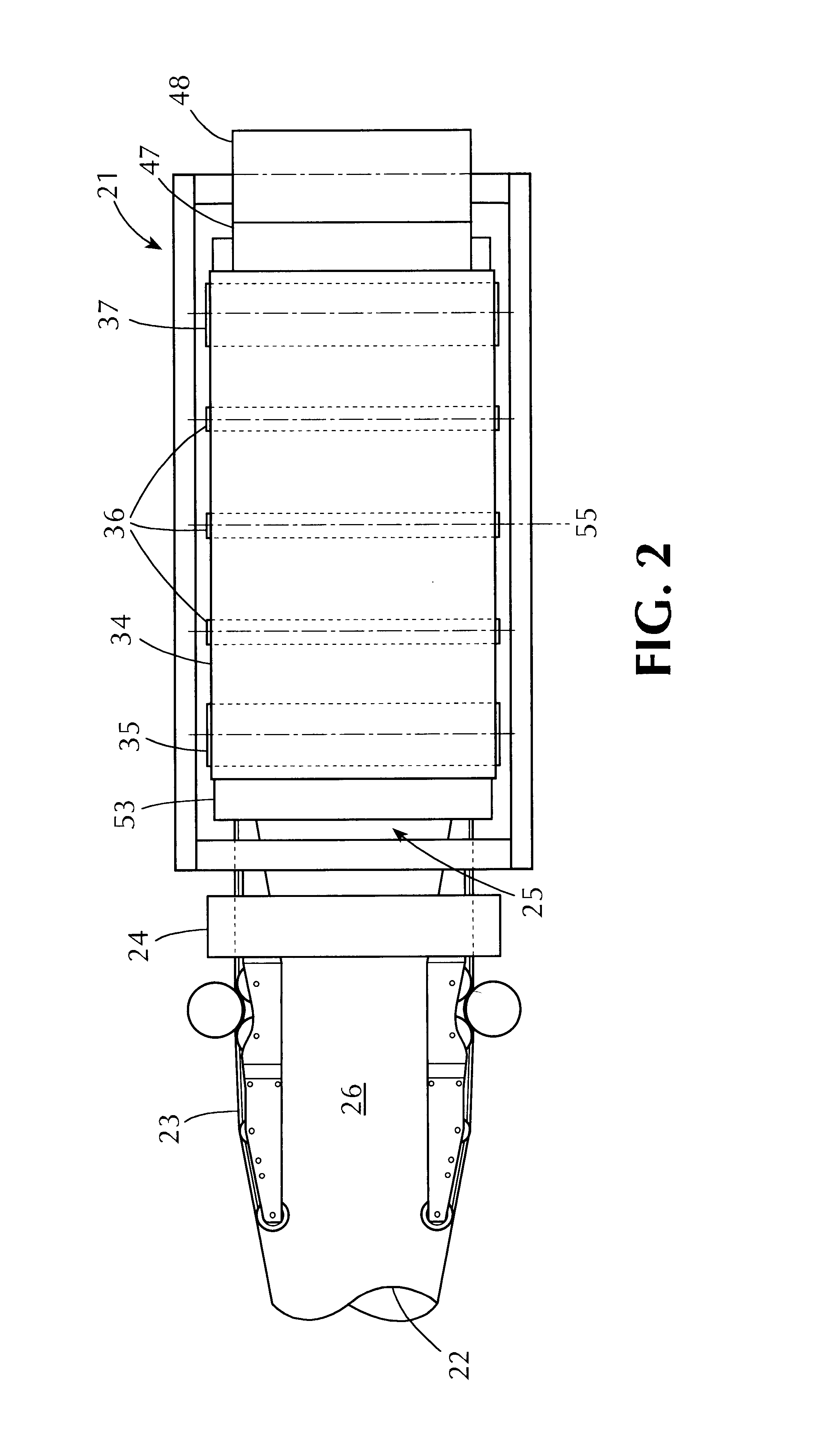

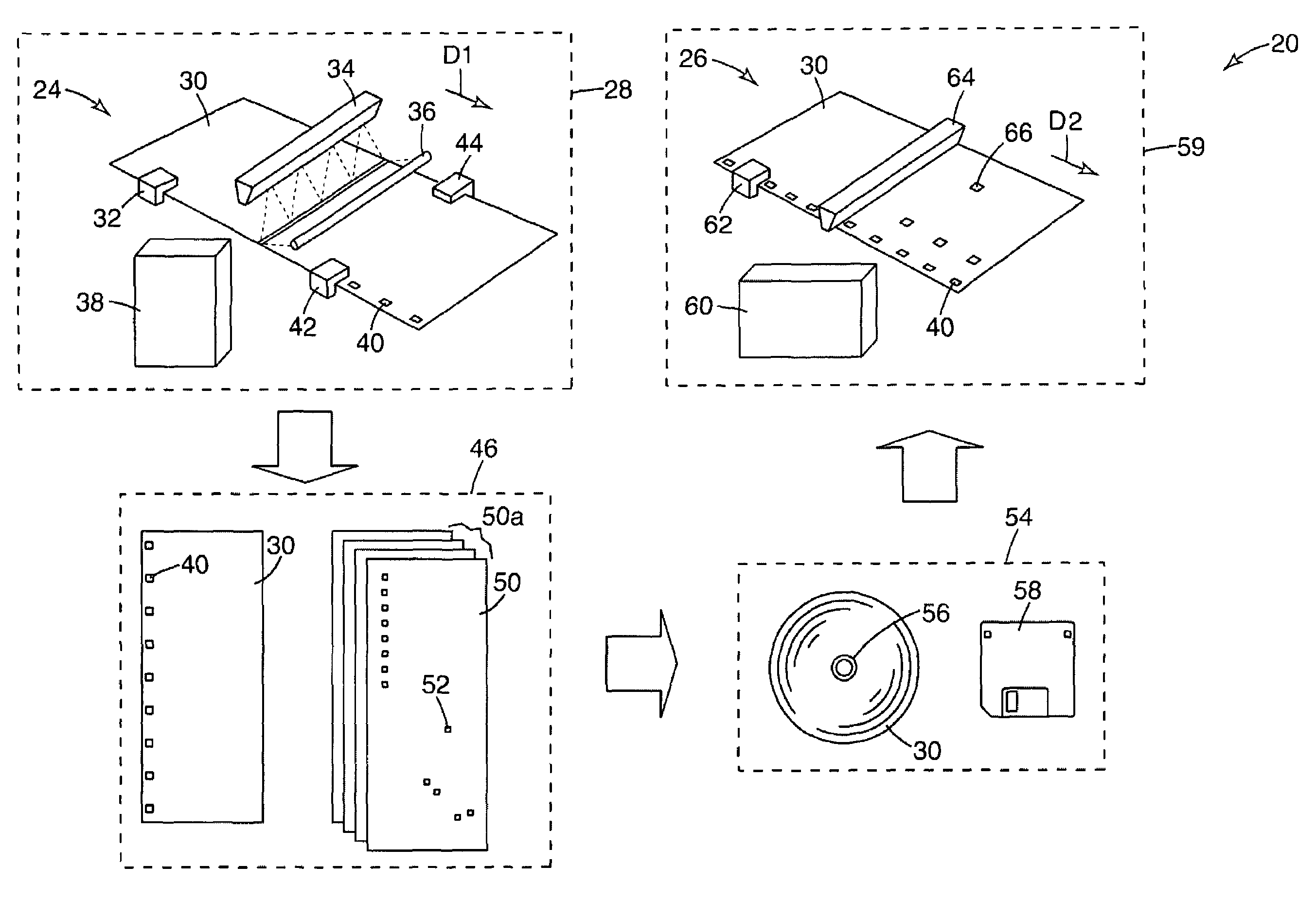

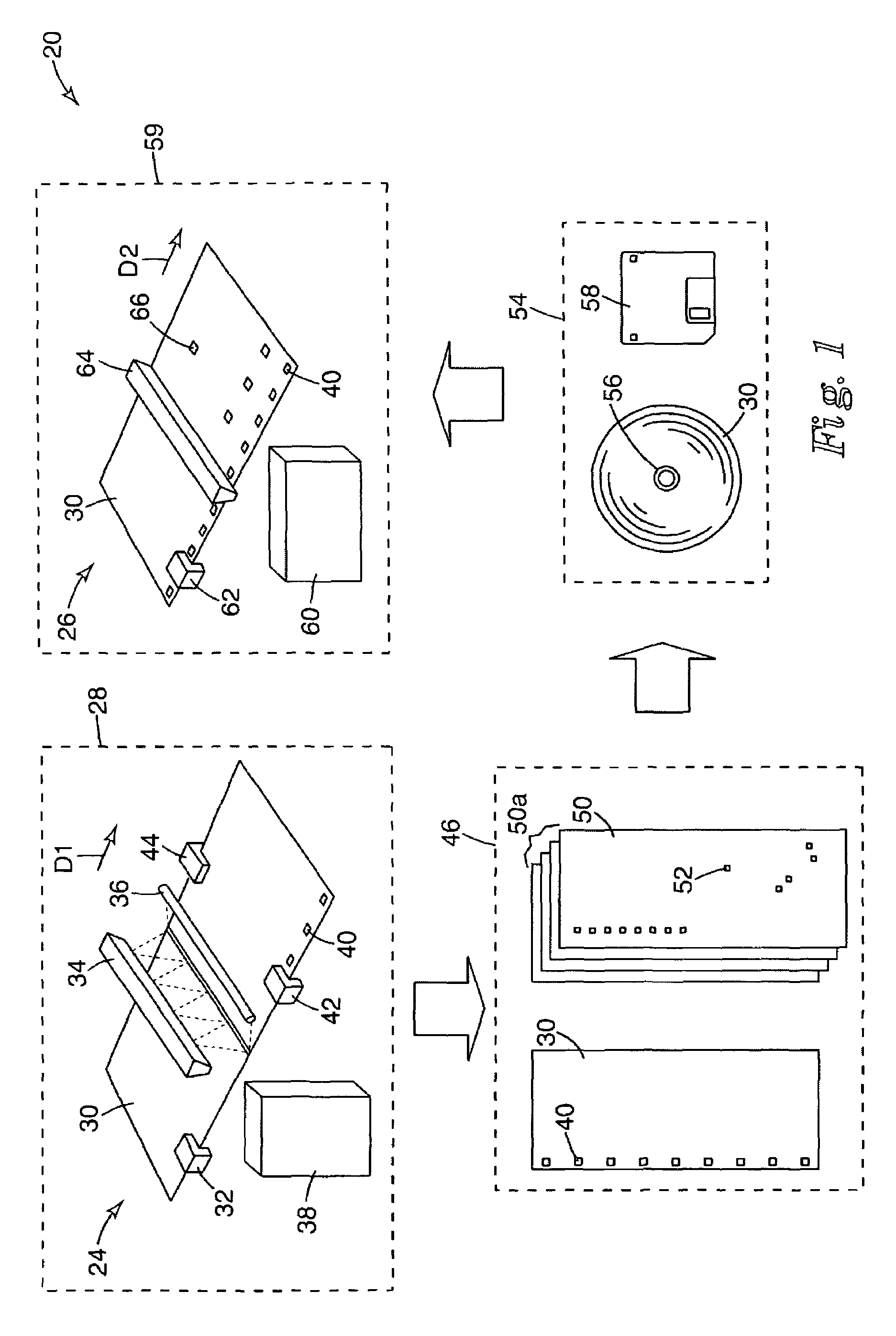

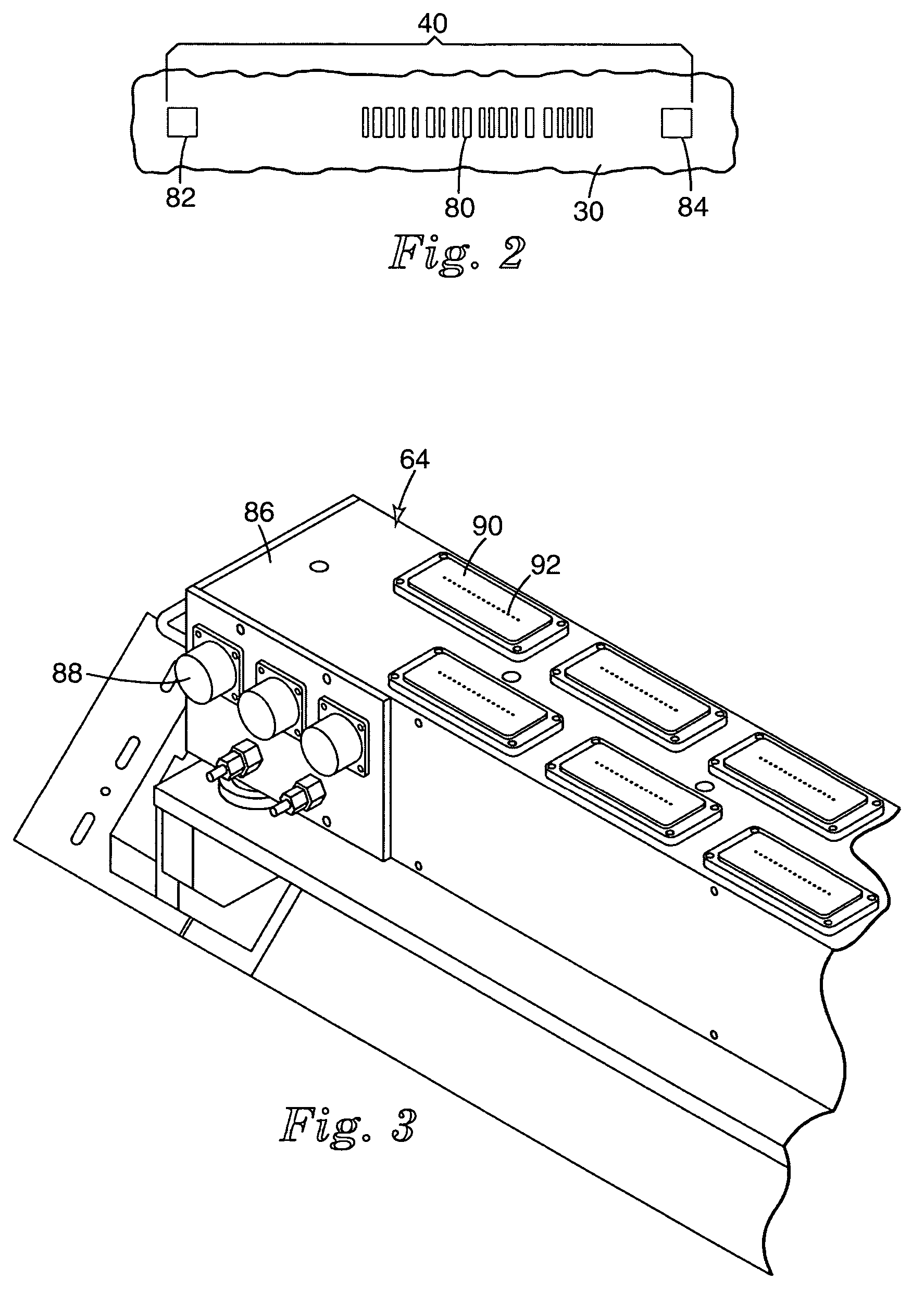

Apparatus and method for the automated marking of defects on webs of material

ActiveUS20050232475A1Conveniently performedReduce material wasteMarking textilesInspecting textilesEngineering

A system for the characterization of webs that permits the identification of anomalous regions on the web to be performed at a first time and place, and permits the localization and marking of actual defects to be performed at a second time and place.

Owner:3M INNOVATIVE PROPERTIES CO

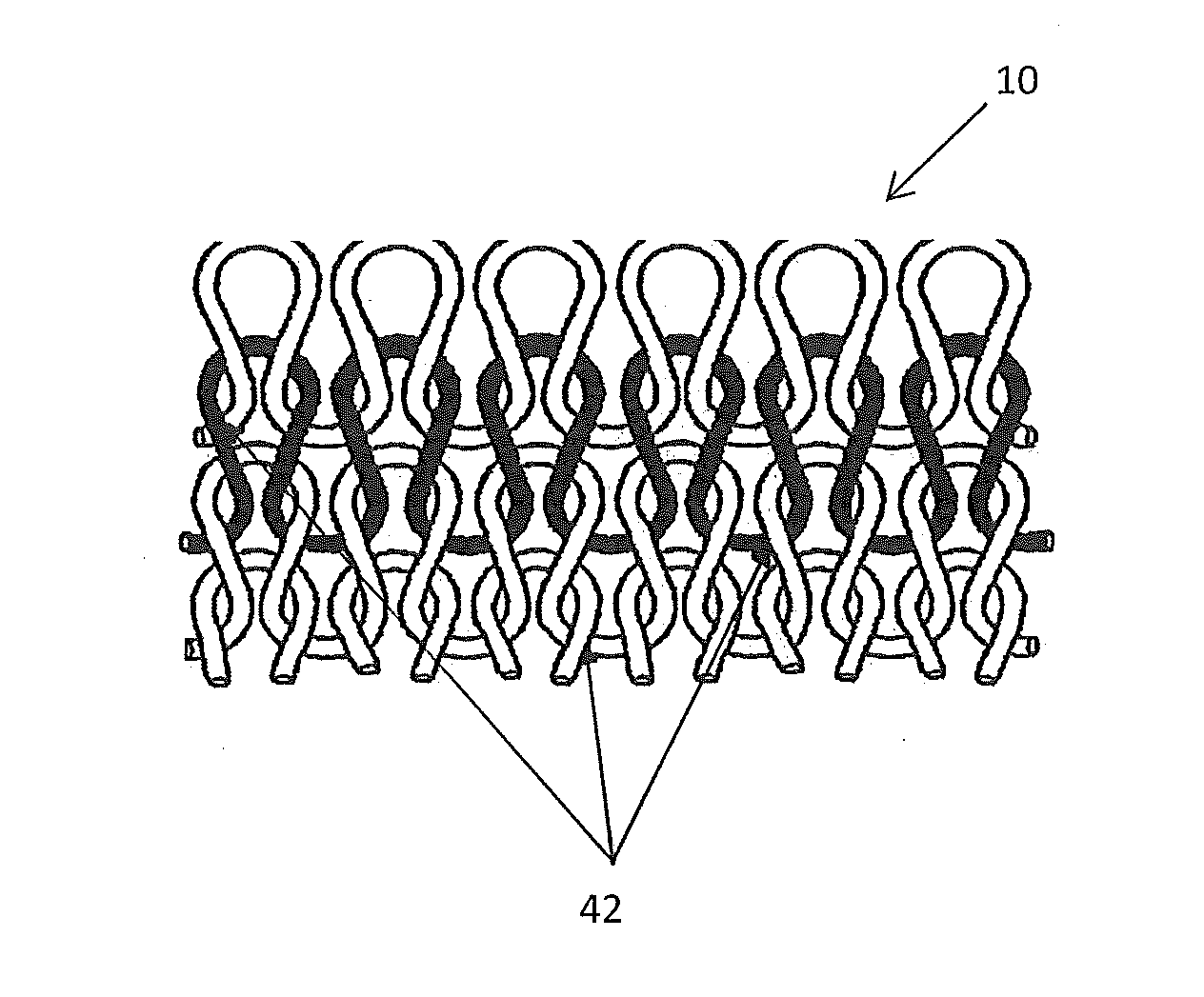

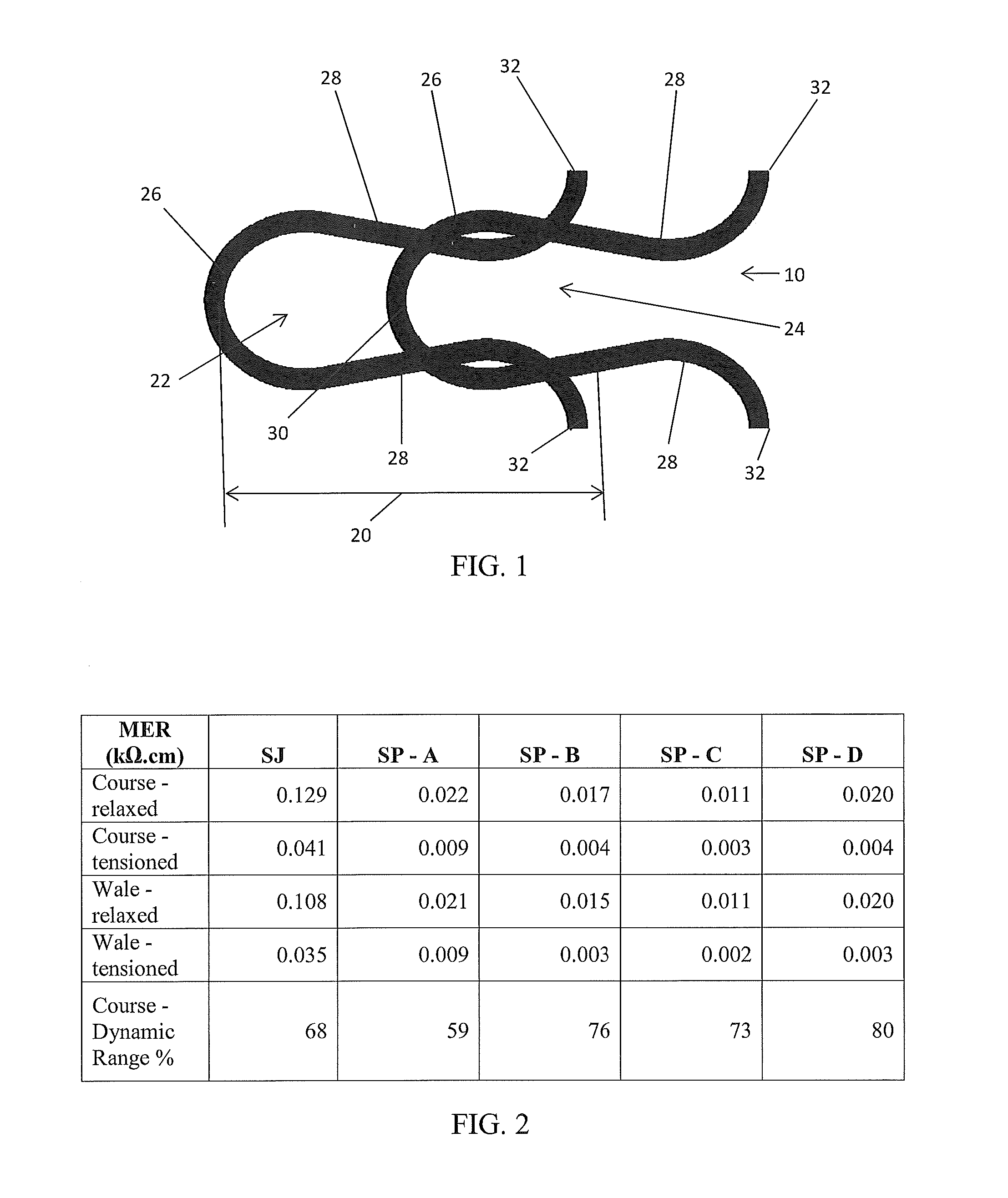

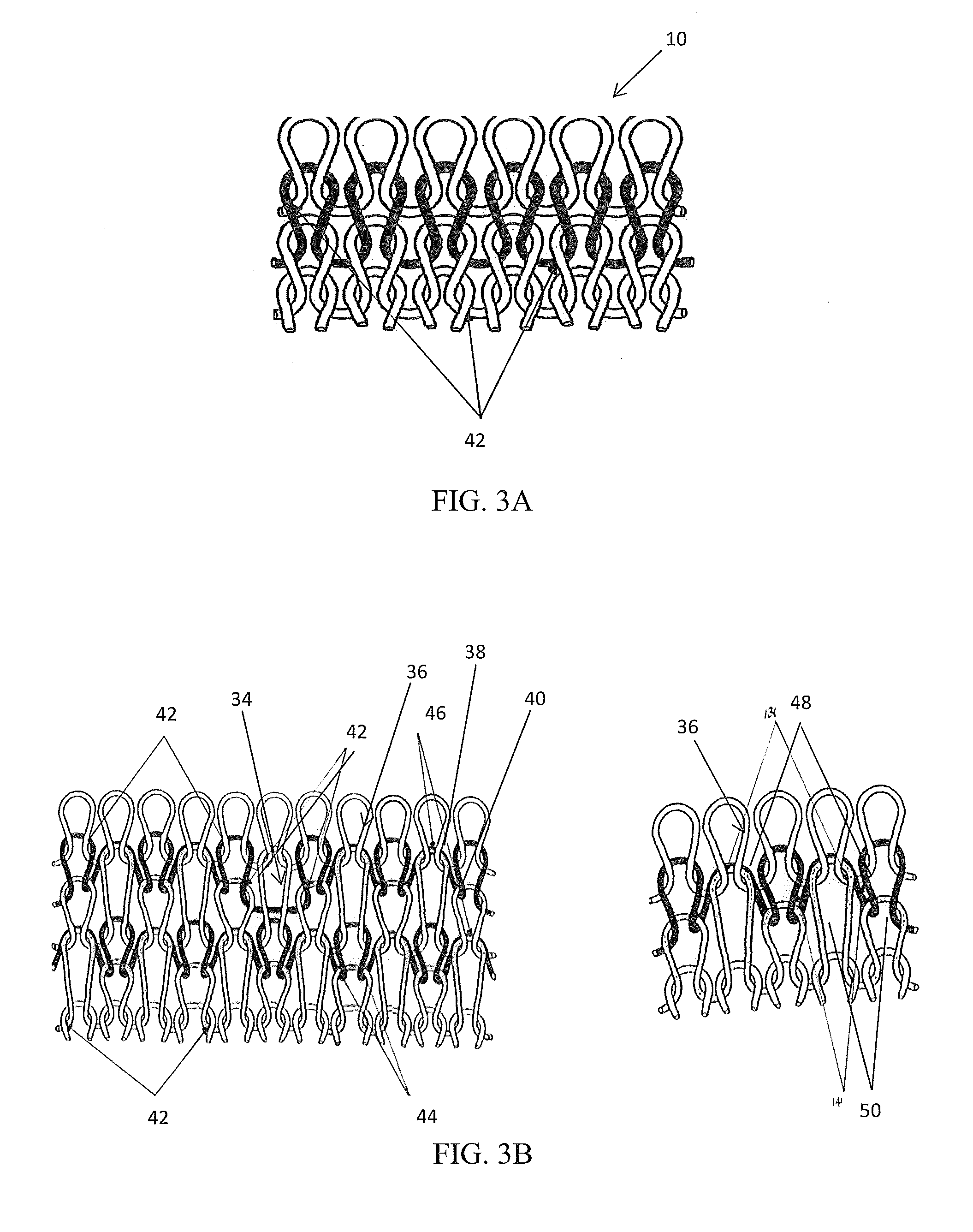

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

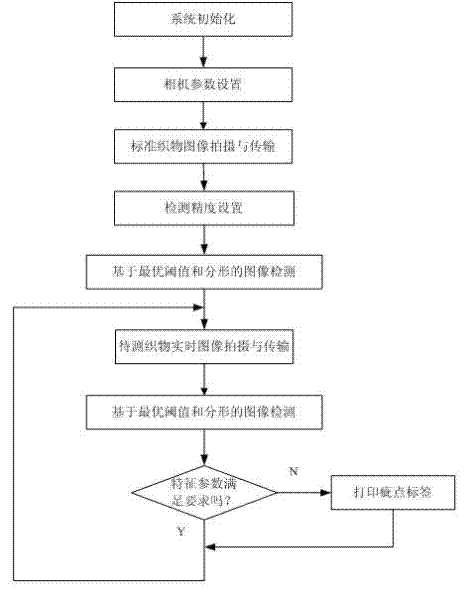

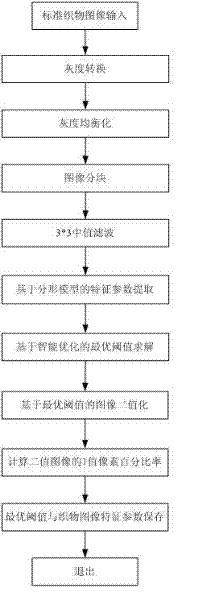

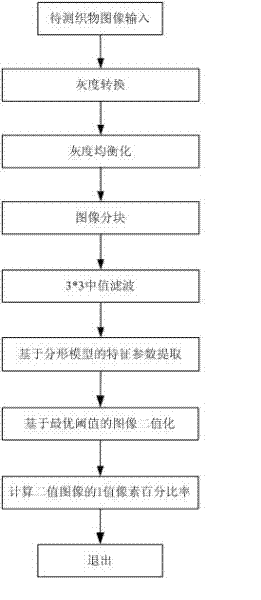

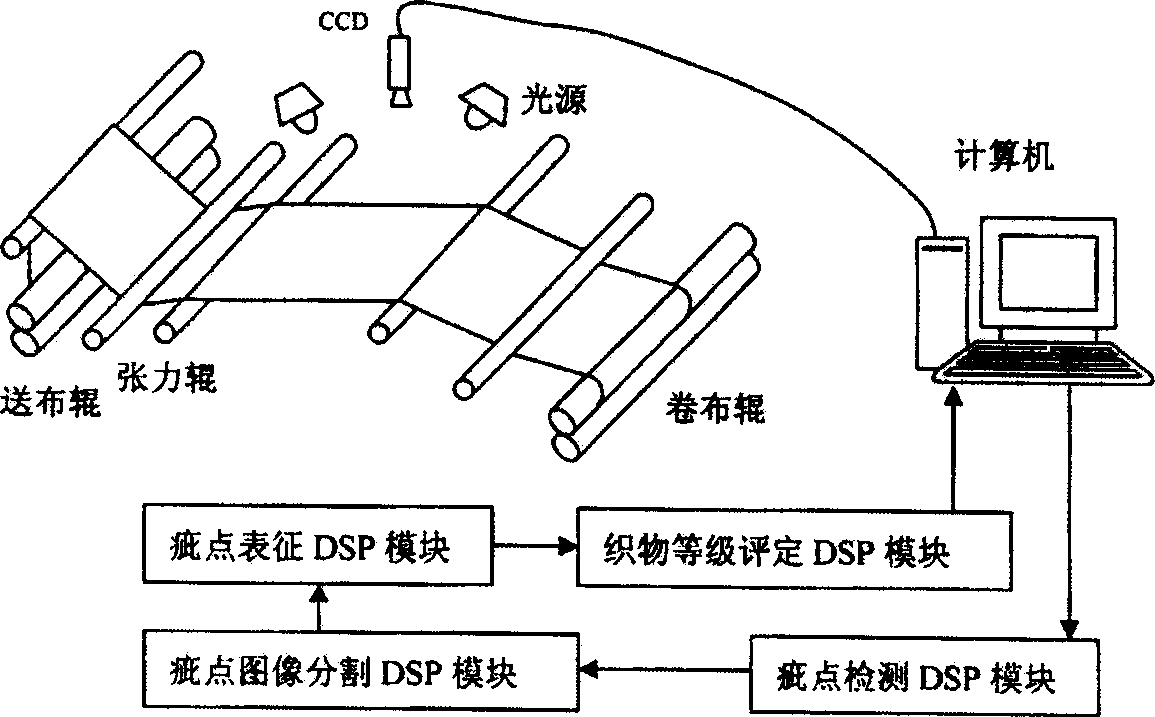

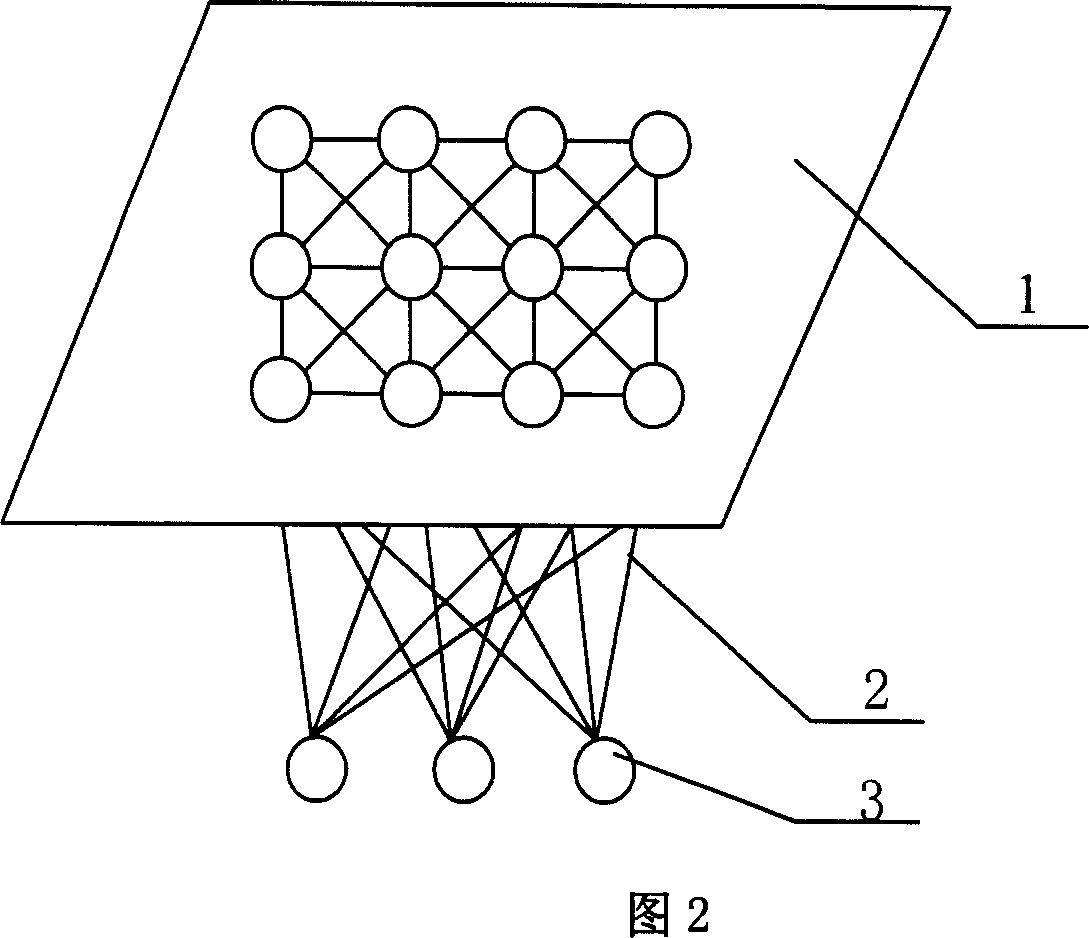

Online automatic detection method of fabric defects based on machine vision and device thereof

InactiveCN102221559AOvercome labor intensityOvercome visualInspecting textilesMaterial analysis by optical meansMachine visionFeature parameter

The invention relates to an online automatic detection method of fabric defects based on machine vision and a device thereof, wherein the clear and integral standard fabric images without the defects of the fabric are shot on a batching and burling machine as a standard image template by utilizing an industrial camera in order to solve the problems of great labor intensity and poor detection quality of the traditional manual detection method; the corresponding characteristic parameters are extracted and stored into a computer; the range of the fabric defect detection characteristic parameters is set according to the requirements of users; the fabric images which are shot in real time are transmitted to the computer to be compared with the standard image template by utilizing the industrial camera and compared with the standard characteristic parameters; if the fabric characteristic parameters are not in conformity with the set requirements, the alarm is started by detection software; the defects are analyzed; and the printing of defects labels is executed. The invention has the advantages of high detection accuracy and high speed; and the labor intensity is greatly reduced.

Owner:HOHAI UNIV CHANGZHOU

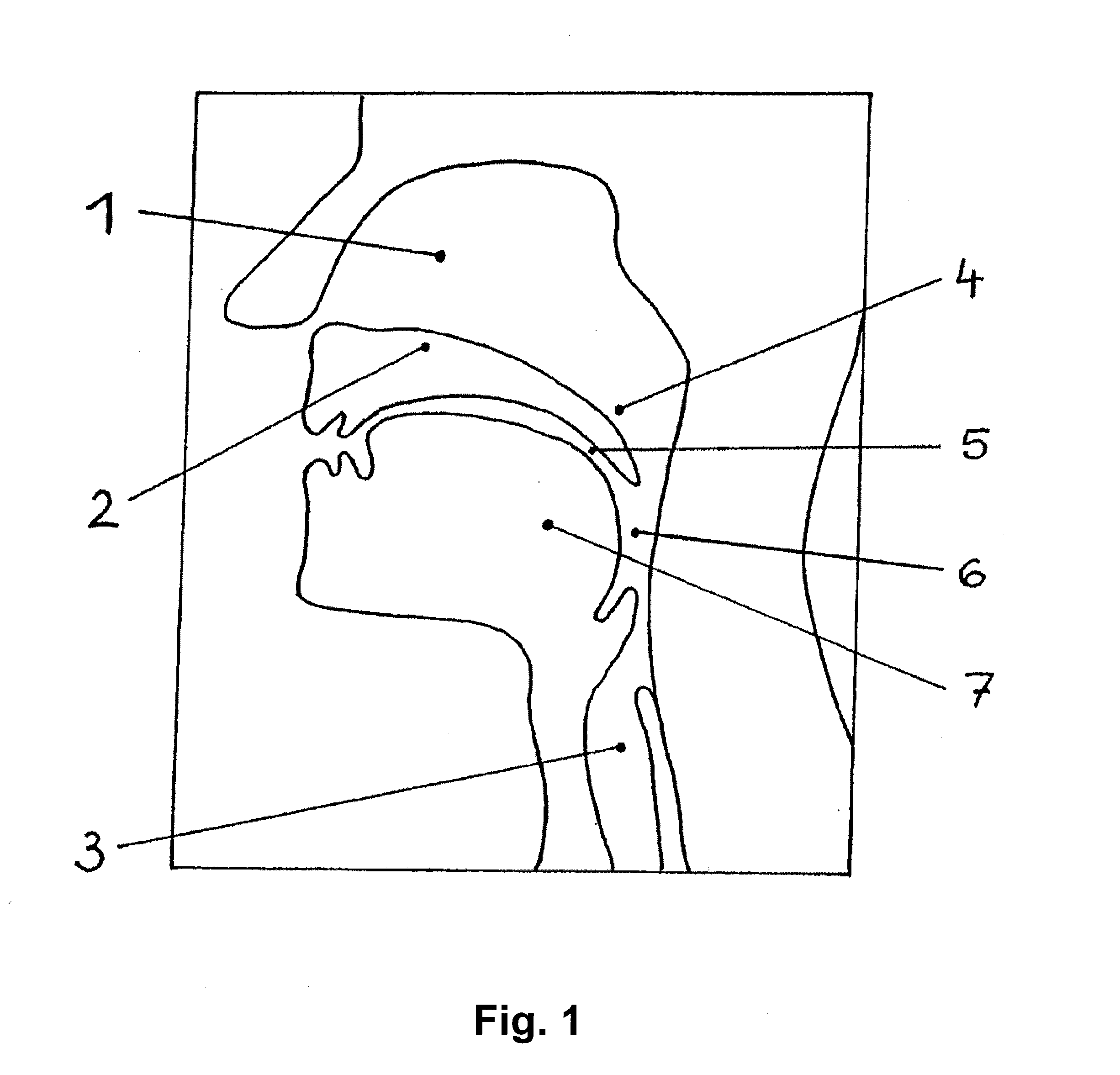

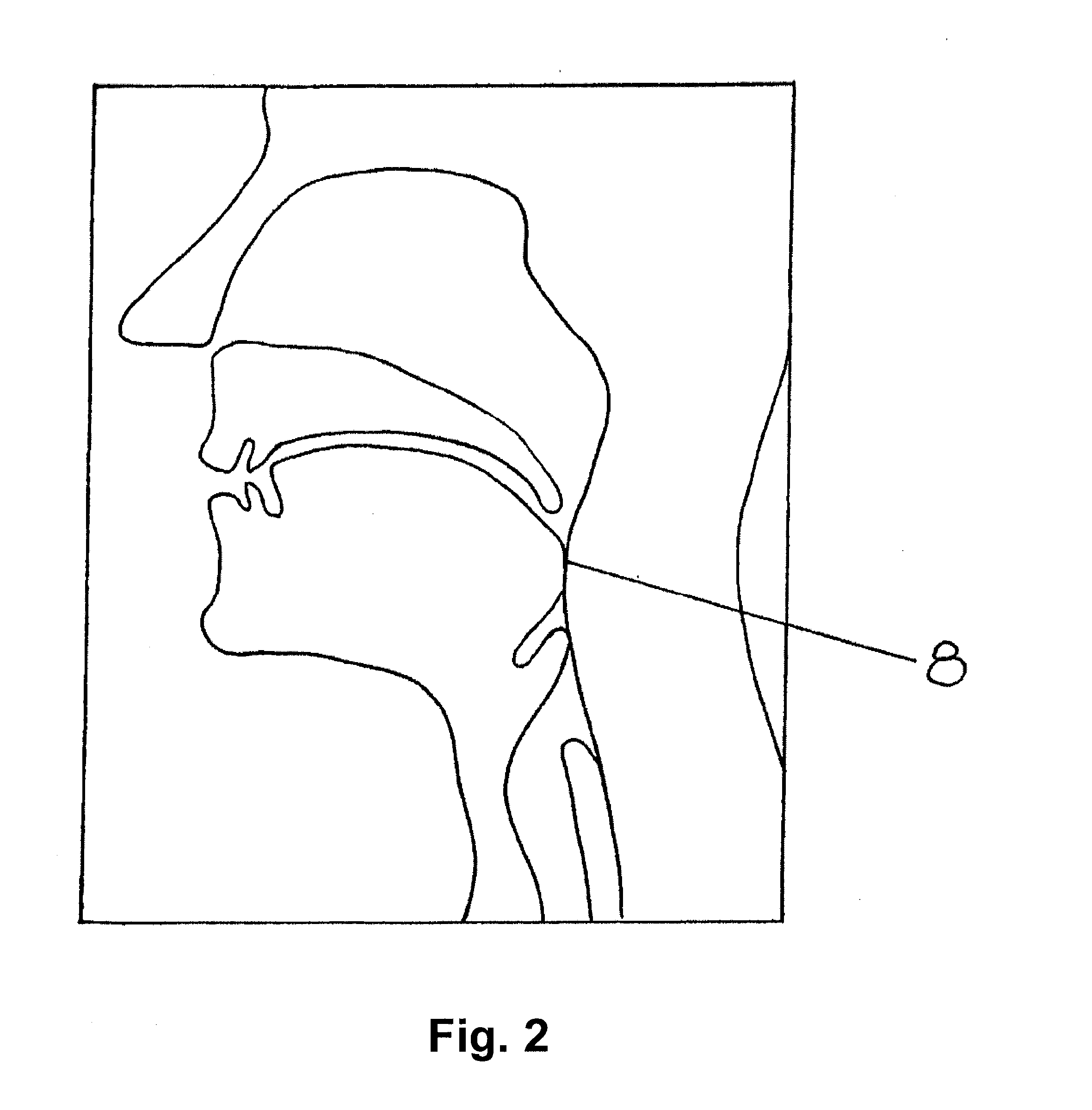

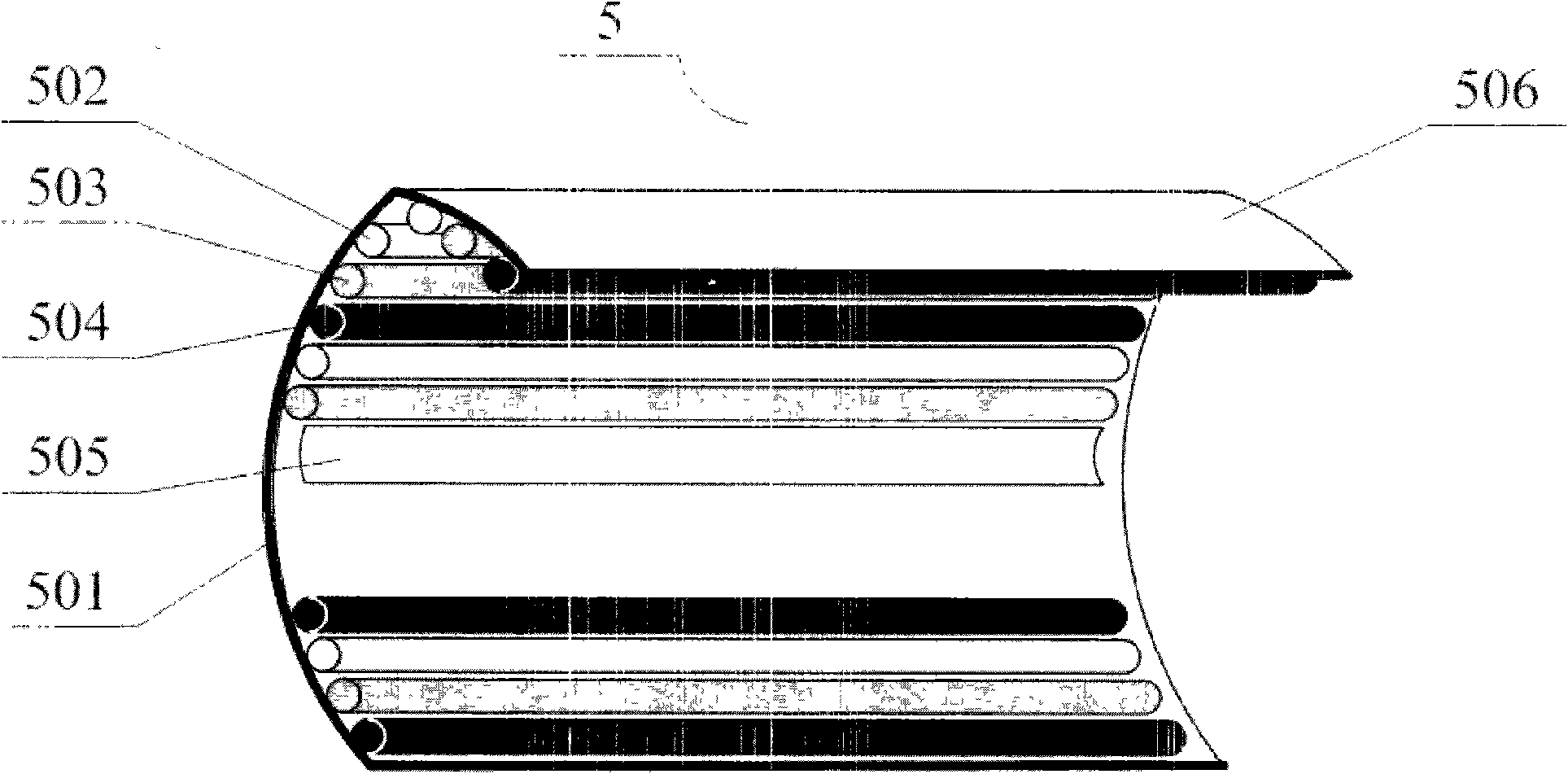

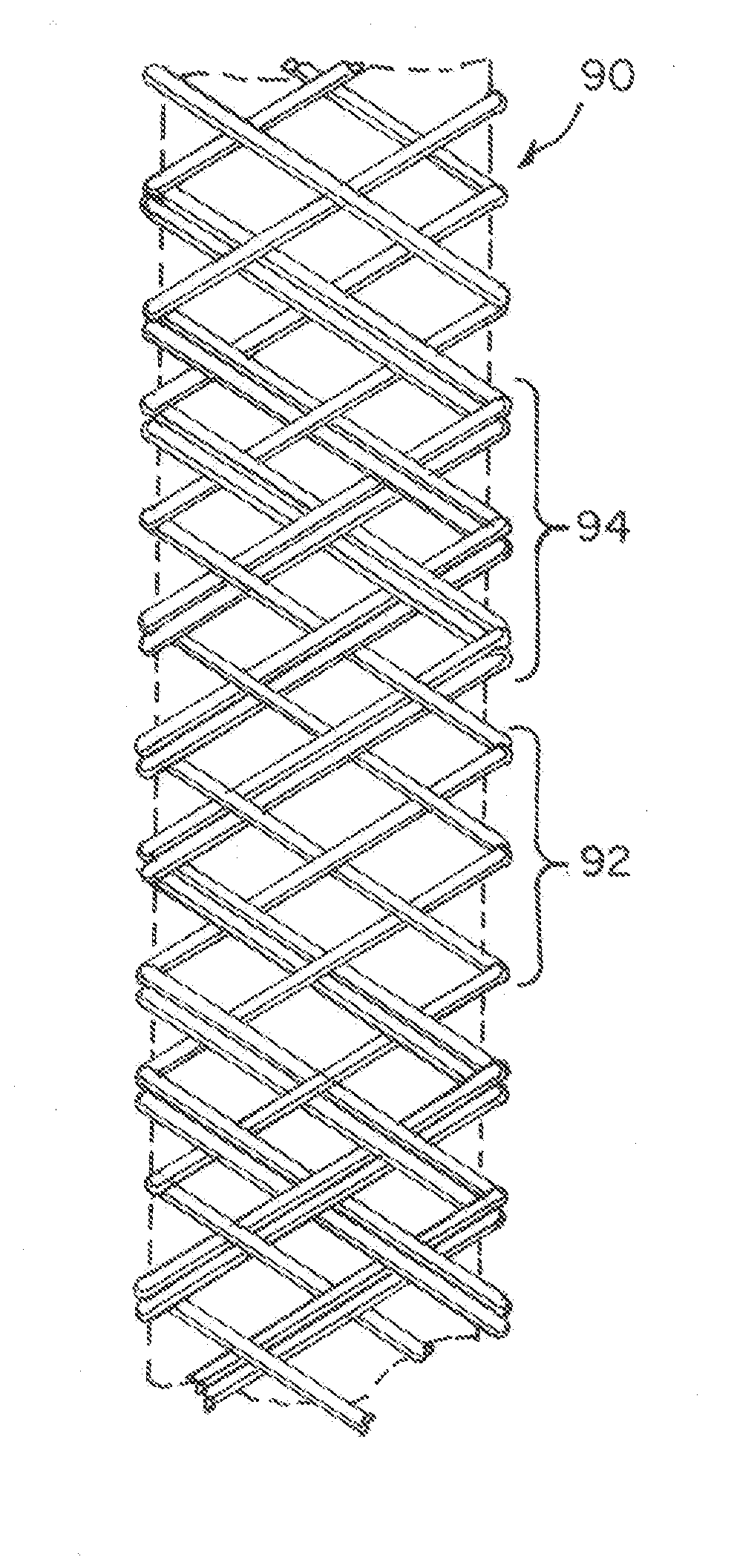

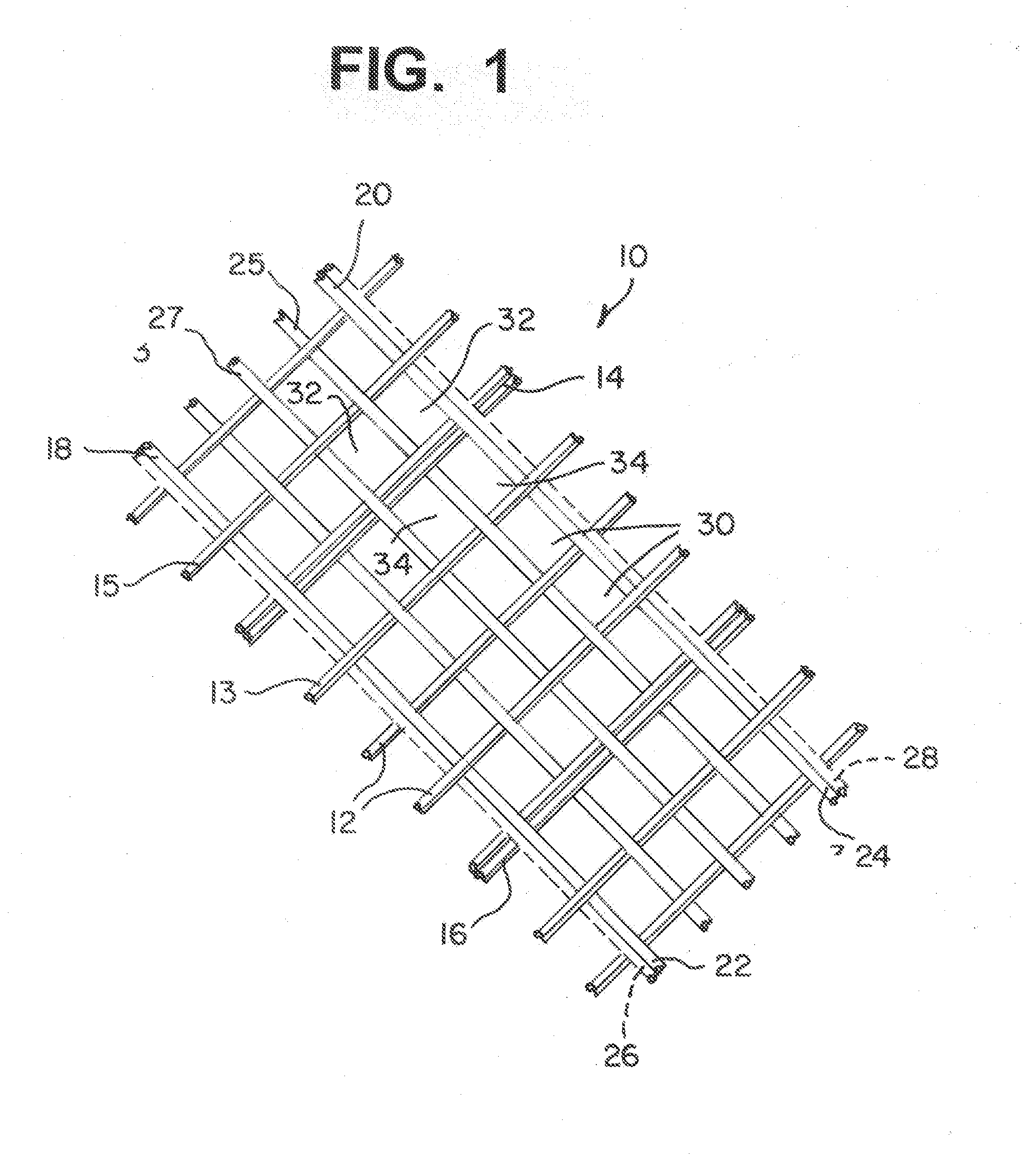

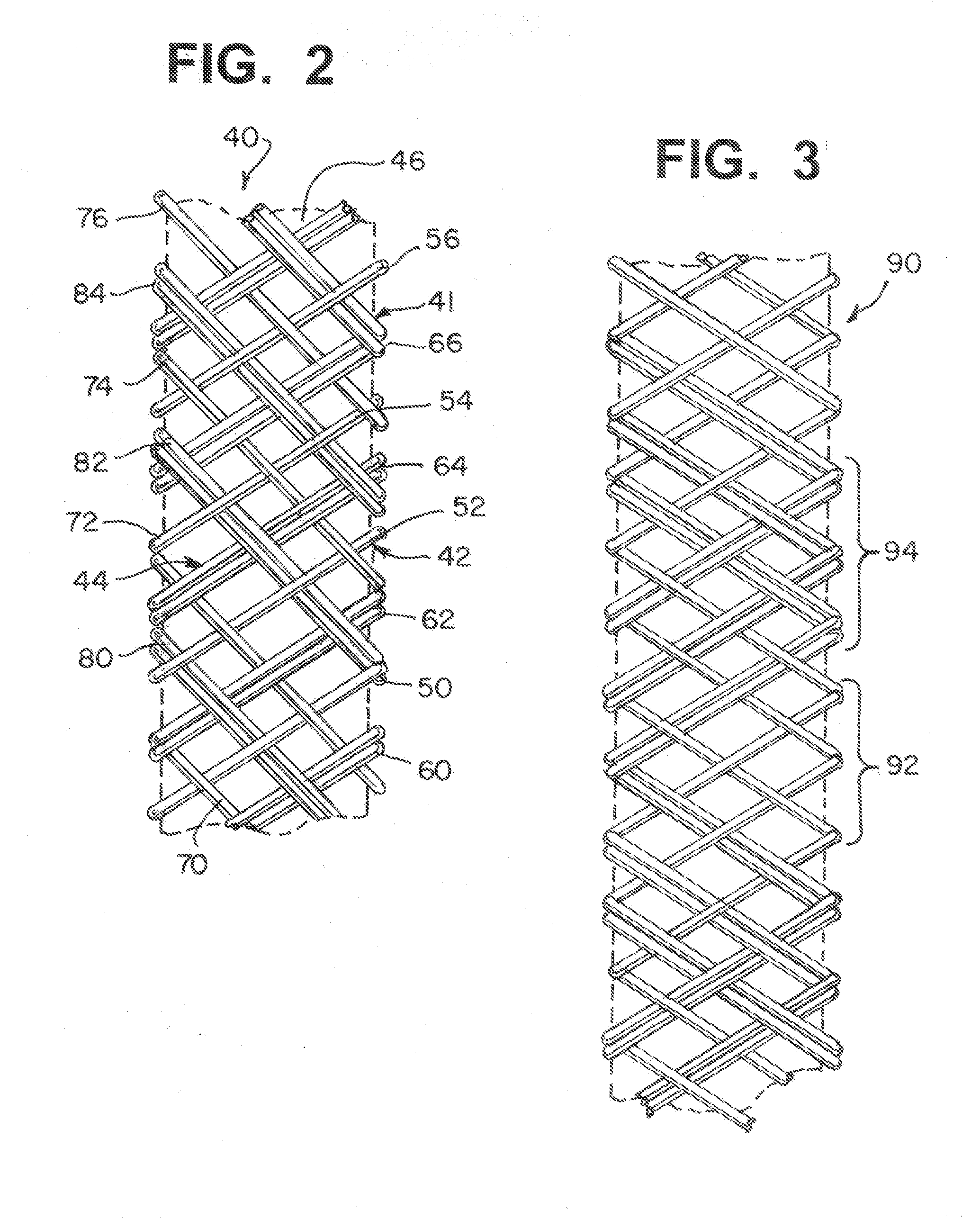

Device for splinting a cavity, organ duct and/or vessel

ActiveUS20130090720A1Easy to disassembleEasy to insertMechanical cleaningPressure cleaningSurgeryAnimal body

The invention relates to a device for splinting and / or maintaining a cavity, an organ duct and or a vessel in a human or animal body, said device including at least one compressible and self-expanding stent that is composed of at least three phases.

Owner:DURING KLAUS

Automatic system for assessing grade of cloth inspection objectively

InactiveCN1760437AReduce computational workloadHigh speedInspecting textilesOptically investigating flaws/contaminationComputer moduleImage conversion

The present invention relates to an automatic cloth inspection grade objective evaluation system. It mainly includes CCD camera, fabric holding device, light source, computer and image-collecting card. Said objective evaluation method includes the following steps: utilizing image-collecting card to convert the fabric image into digital image, using fabric defect detection DSP to detect fabric defect, using defect image separation DSP module to separate fabric image with defect, using defect characterization DSP module to make automatic characterization of defect, inputting the characterized result into fabric grade evaluation DSP module to make automatic evaluation of fabric grade.

Owner:DONGHUA UNIV

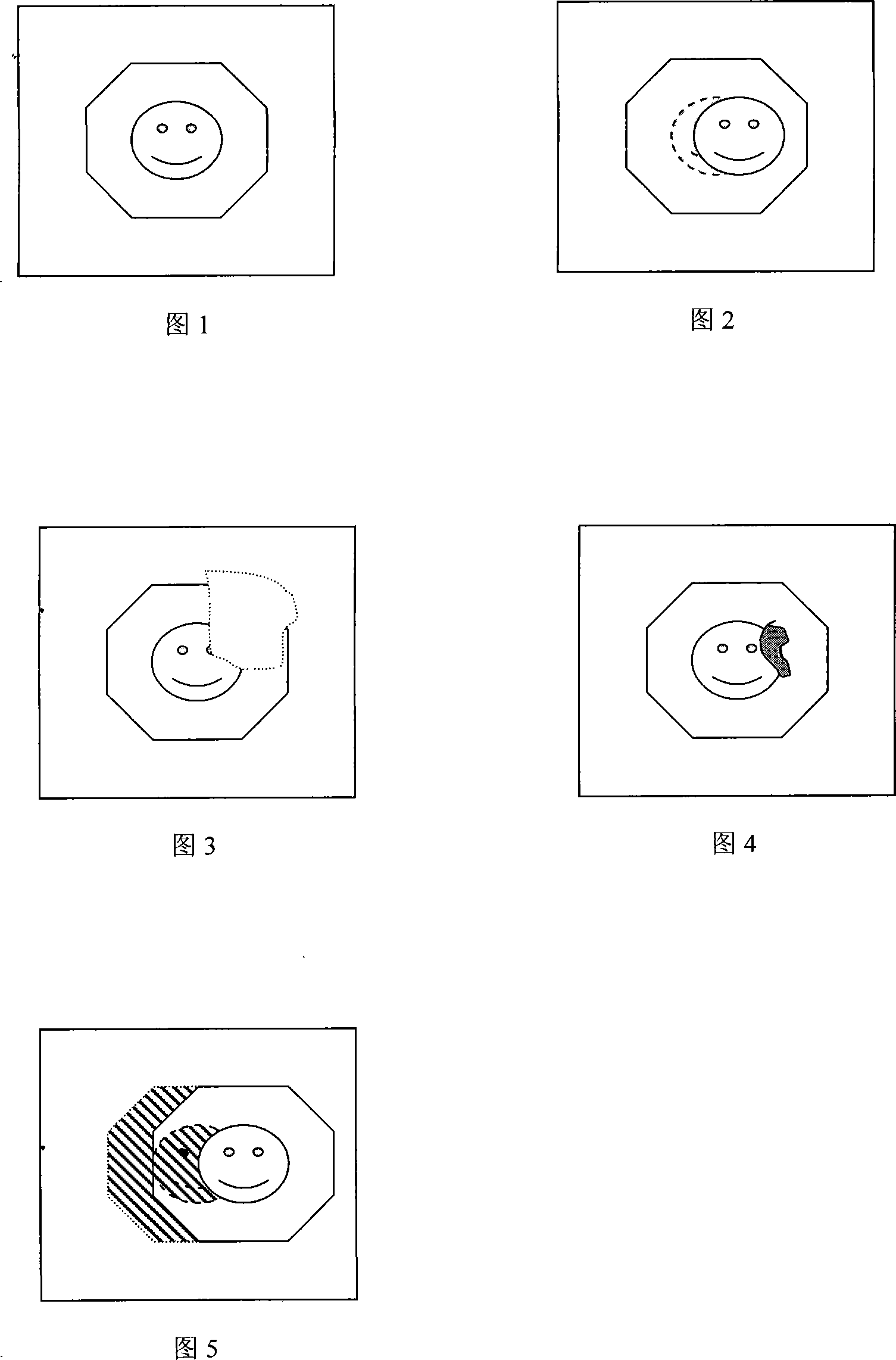

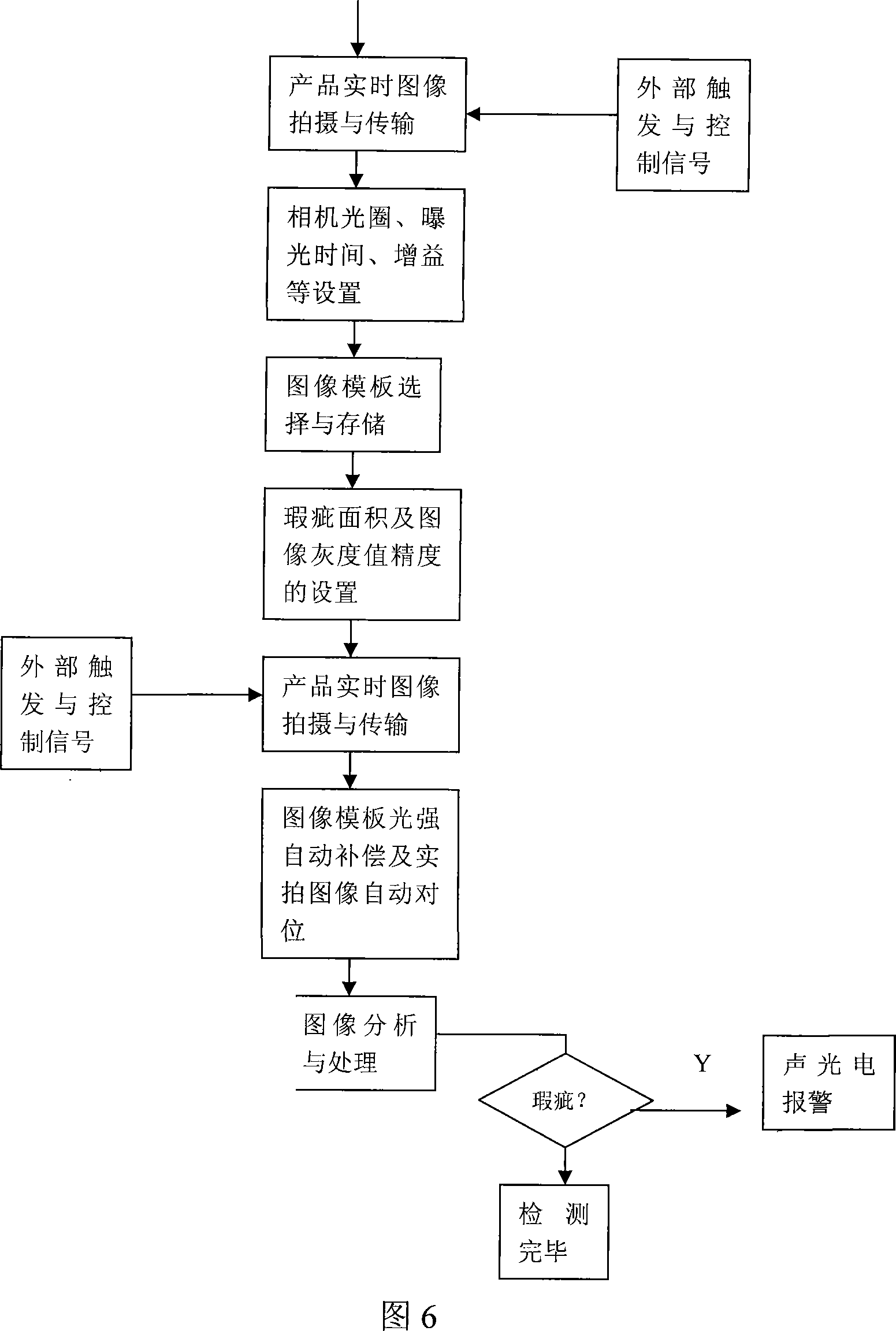

On-line detecting method of machine vision system for printed calico flaw

InactiveCN101158650AReduce testing labor intensityGuaranteed accuracyInspecting textilesMaterial analysis by optical meansVisual perceptionComputer science

The invention relates to an online detecting method of a machine vision system for detecting blemishes of a printed cloth. The invention aims at solving the problem that the labor intensity of manual online detecting blemishes of the printed cloth is high, and the detecting quality is bad. Clear and thorough, and spotless graphs are shot on the running printed cloth through industrial camera. The clear and thorough, and spotless graphs are stored in the calculating machine as a standard graph molding board. The blemish area and graphic gray value are taken as the detecting parameter of the blemish. The precision scope of the detecting parameter is arranged according to the requirement of the consumer. The graphs of the running printed cloth are shot in real-time, and are conveyed to the calculating machine. The real-timely shot graphs are compared with the standard graph molding board and are dealt with. If a blemish appears, the operating personnel are indicated to deal with the blemish of the printed cloth through an alarm. The alarm is started through the calculating machine. The invention can carry out light intensity self-compensating of the standard graph molding board, and dynamically correcting the shift of the pixel of the real-timely shot printed cloth graphs. The invention has the advantages of high precision and fast speed of detecting blemishes of the printed cloth, and greatly reduced labor intensity of manual detecting.

Owner:WUXI DONGWANG TECH

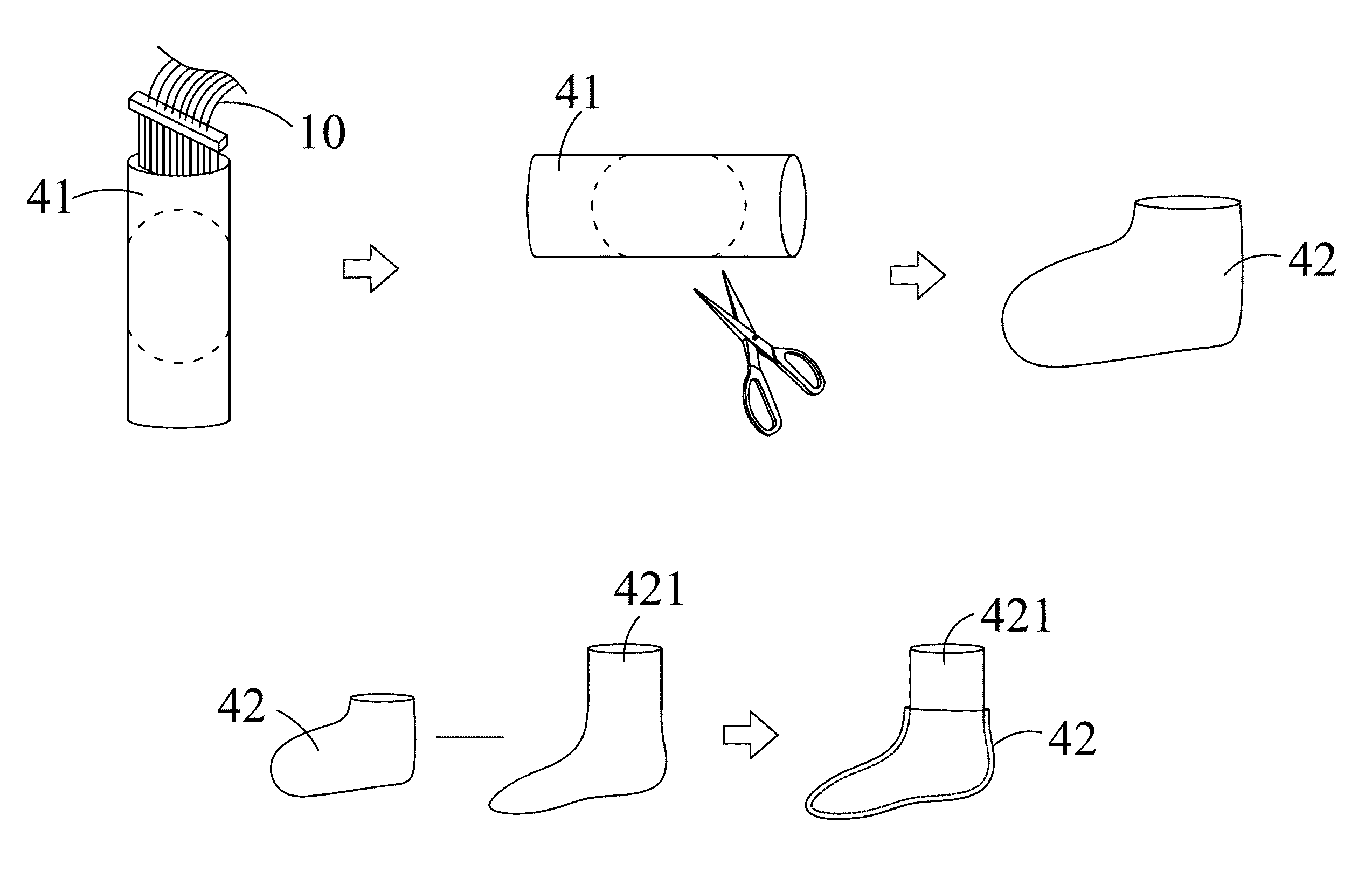

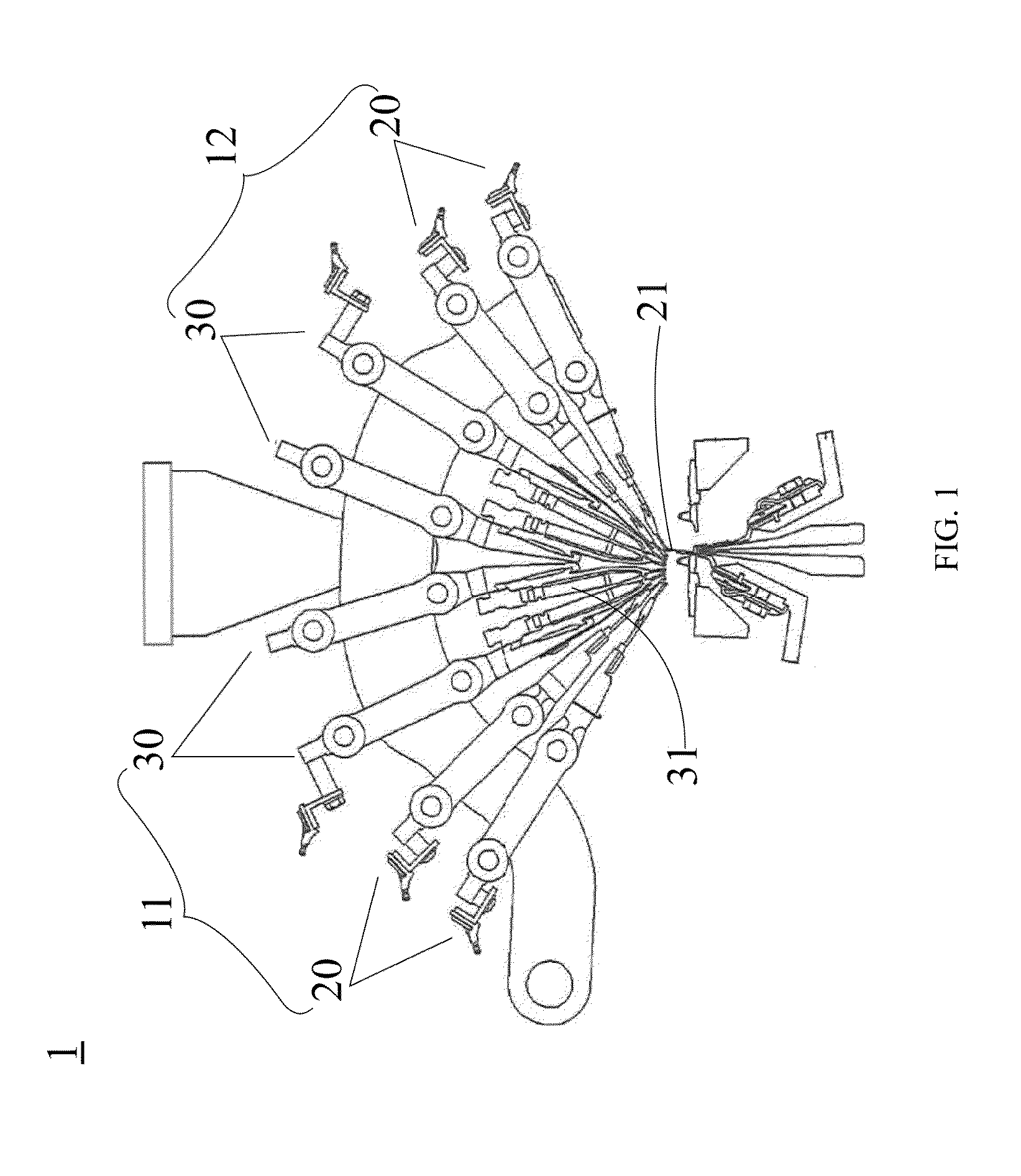

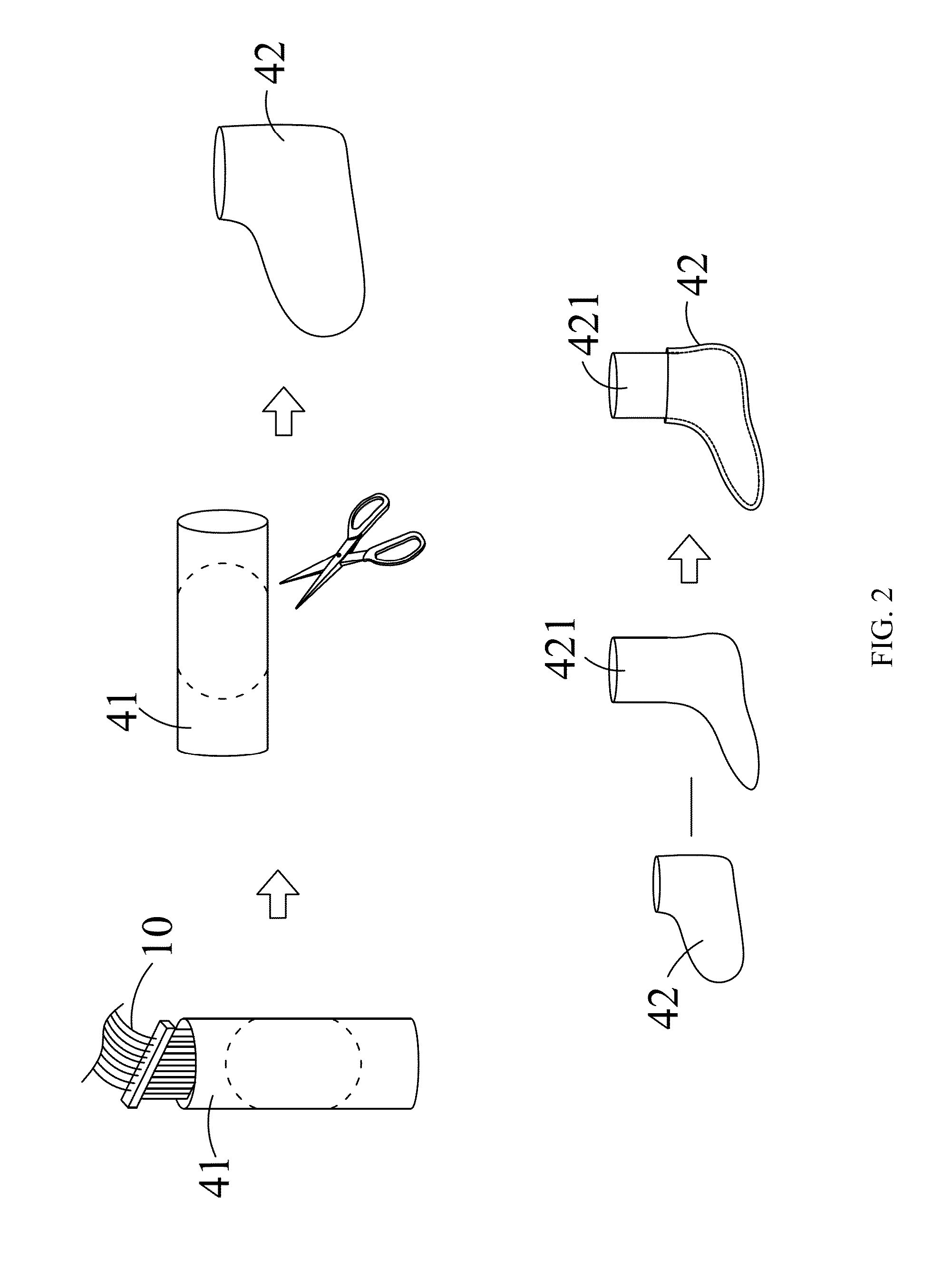

Weaving Method of Three-Dimensional Vamp

ActiveUS20140082905A1Increase labor costEliminate needMechanical cleaningPressure cleaningEngineeringHot melt

A weaving method of a three-dimensional vamp includes the steps of: weaving yarn by a warp-knitting machine to form a top vamp by a first part needle bar of the warp-knitting machine which is interactively woven with a bottom vamp formed by a second part needle bar of the warp-knitting machine so as to form a tube-shaped fabric; cutting the tube-shaped fabric to form a sock-shaped fabric; disposing the sock-shaped fabric on a shoe last; and heating the sock-shaped fabric to tighten the sock-shaped fabric in order to seal the shoe last and consequently obtain the three-dimensional vamp. The heat shrinkable and irreversible properties of a high shrinkage yarn or hot melt yarn are used to seal the sock-shaped fabric with the shoe last, thereby achieving the substantial physical properties. The turner cost and the fabric flotsam can be reduced by the process of manufacturing the integrally formed vamp.

Owner:LONG JOHN TSUNG RIGHT IND

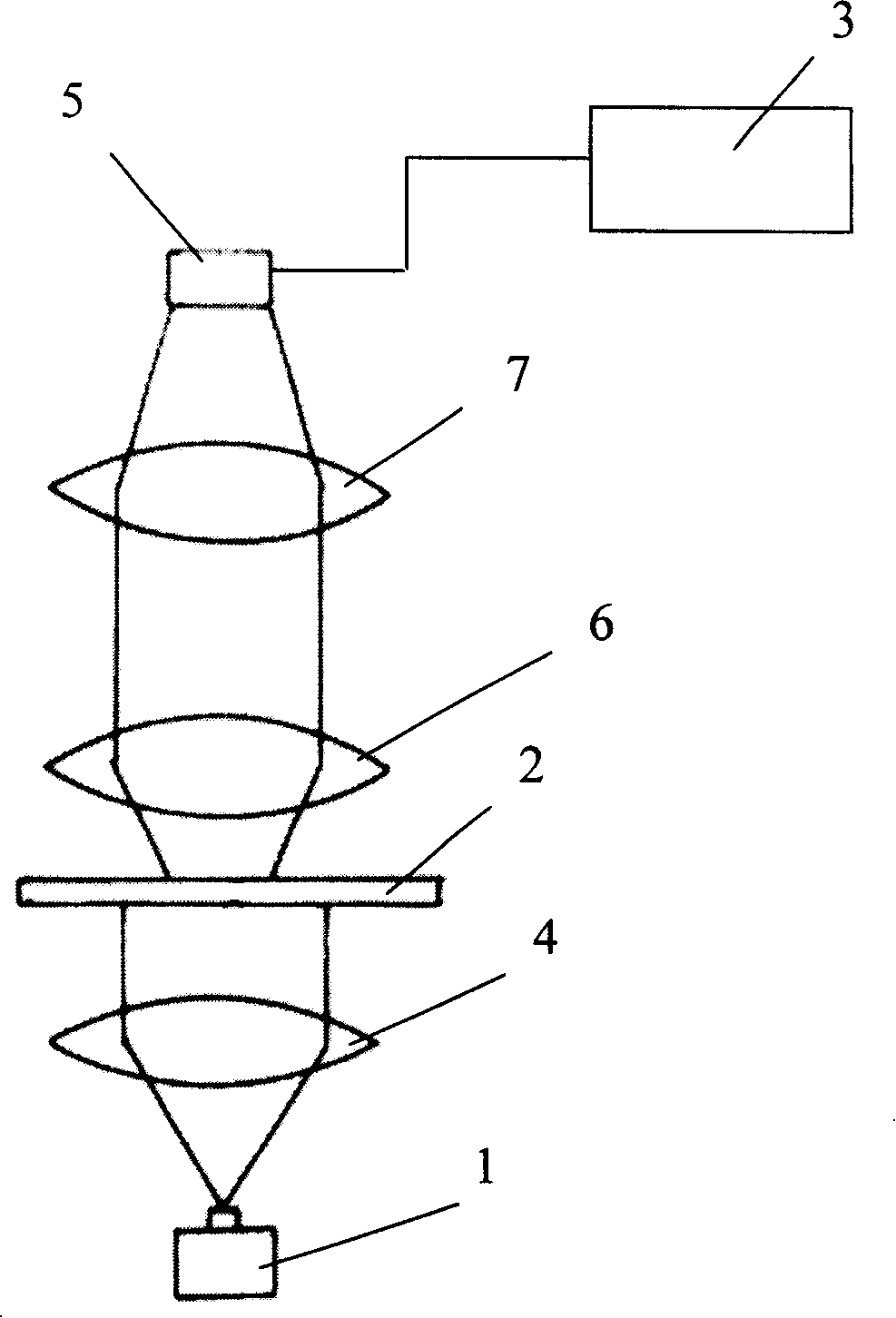

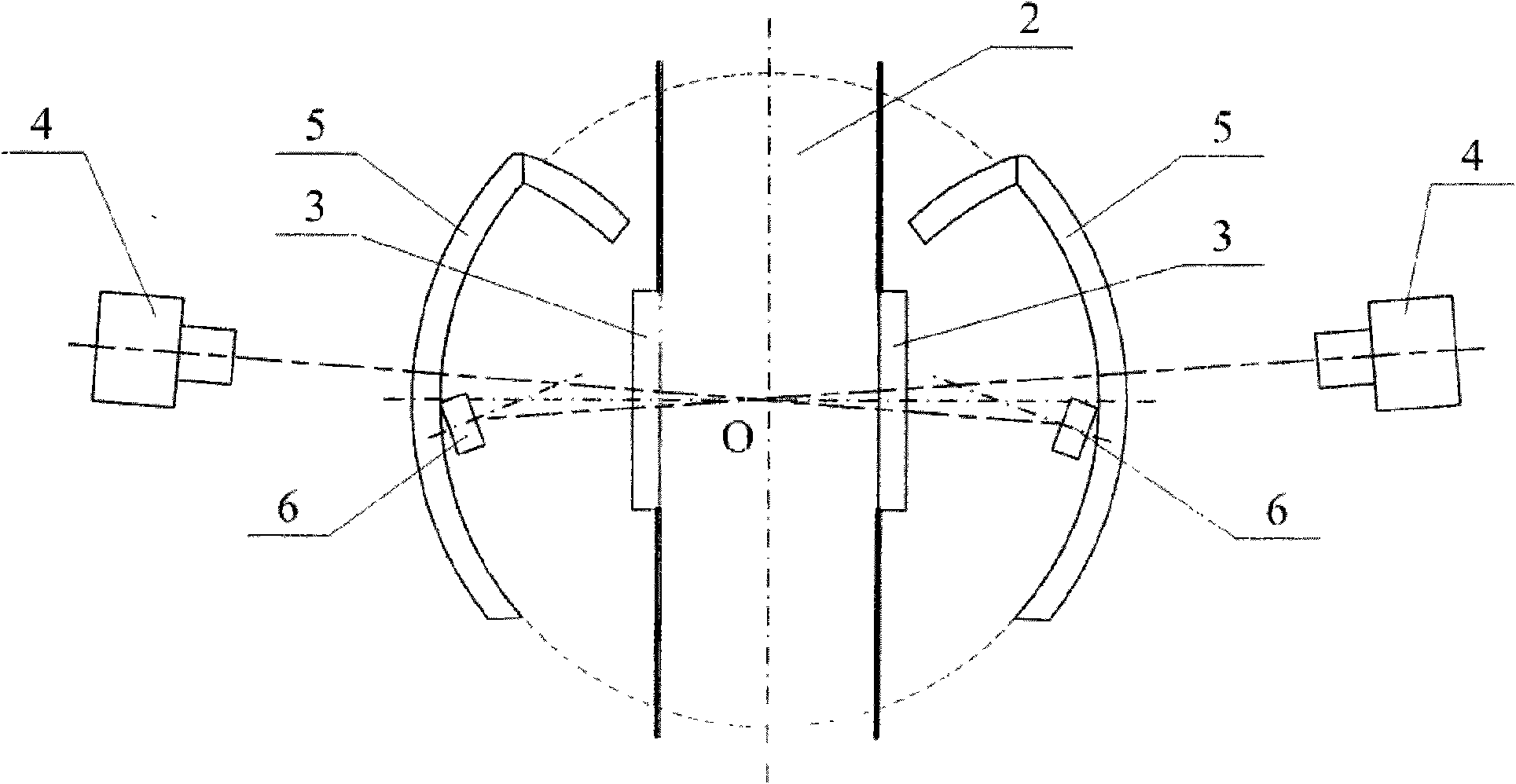

Method and device for detecting textile structure and dying defect using infrared laser

InactiveCN101187640AConvenient and accurate analysis and identificationInspecting textilesMaterial analysis by optical meansDisplay deviceOptoelectronics

The invention discloses a method for detecting textile structures and dyeing defects through infrared laser, which comprises projecting the infrared laser on a textile sample, collecting infrared laser transmitting images of the textile sample, displaying the infrared laser transmitting images of the textile sample on a displaying component. A device for detecting textile structures and dyeing defects through infrared laser is composed of a semiconductor laser and a infrared photography device, wherein the semiconductor laser and the infrared photography device are arranged fixedly on two ends of an optical path, a textile sample holdfast is arranged in the optical path which is between the semiconductor laser and the infrared photography device, a piece of condensing lens is arranged on the optical path which is between the semiconductor laser and the textile sample holdfast, a piece of object lens is arranged on the optical path which is between the textile sample holdfast and the infrared photography device, the infrared photography device is connected with a display. The infrared laser transmitting images of textile materials with grey scale and contrasting chrominance are displayed on the displaying component. The infrared laser transmitting images are provided for technological analysis and identifications.

Owner:上海市纤维检验所

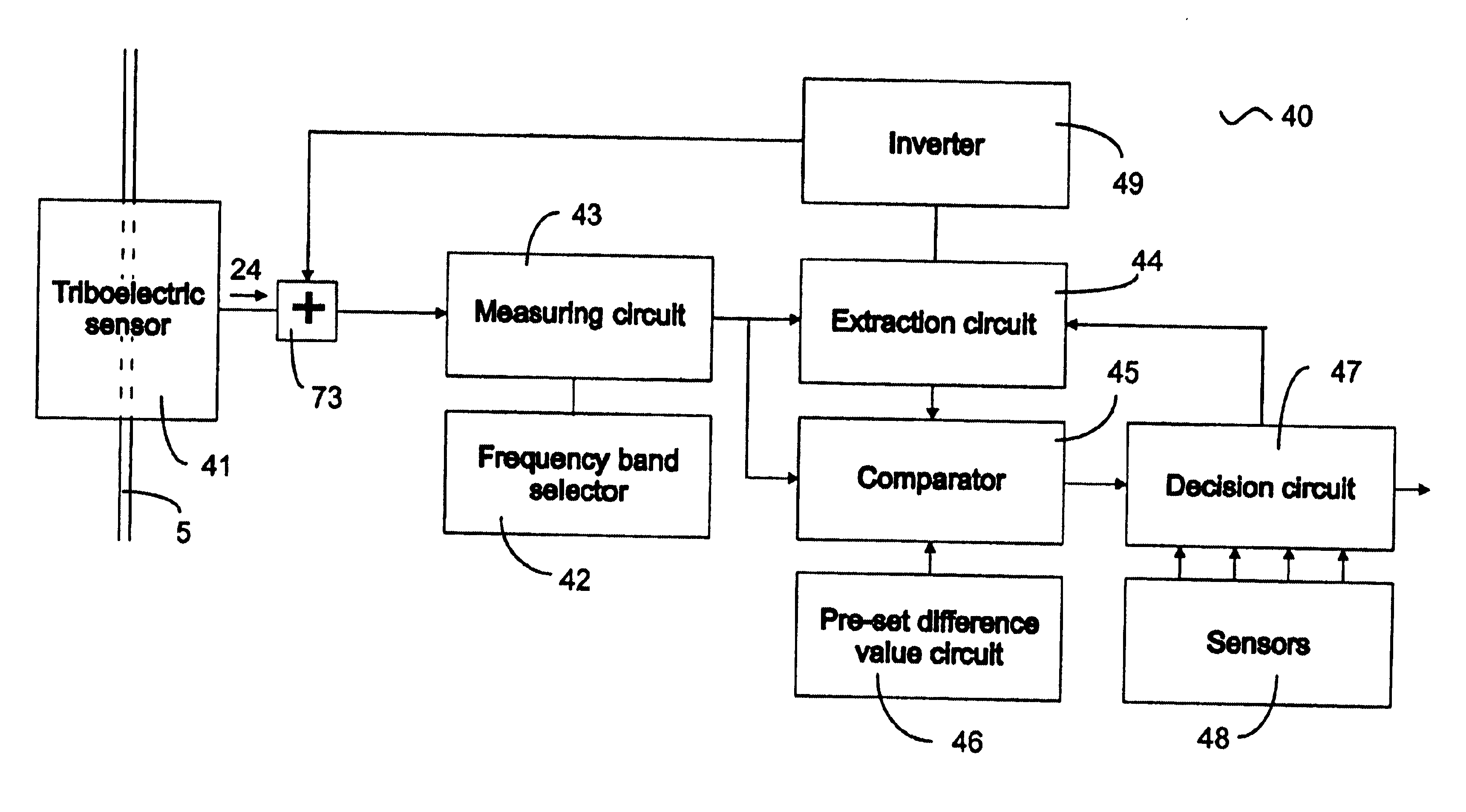

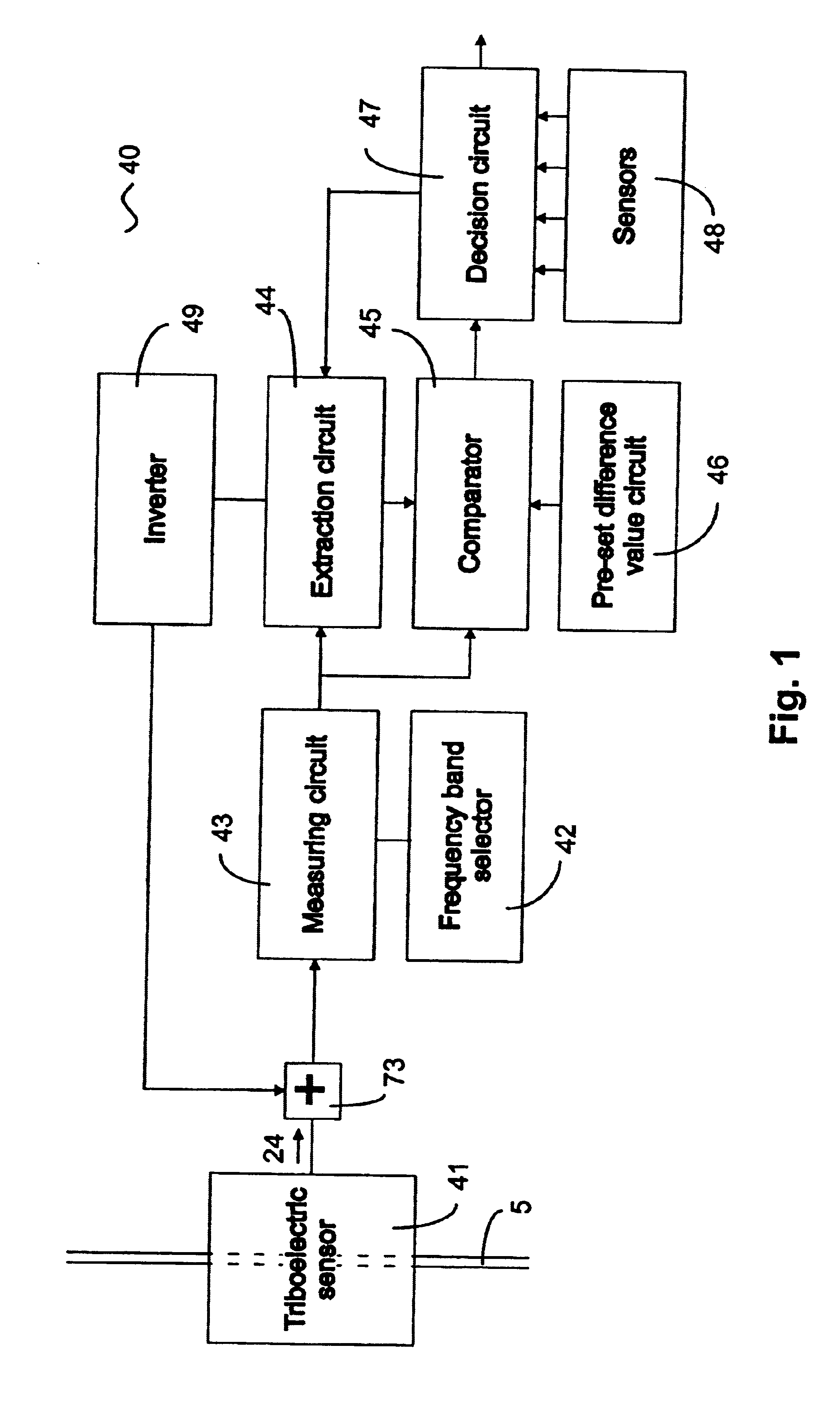

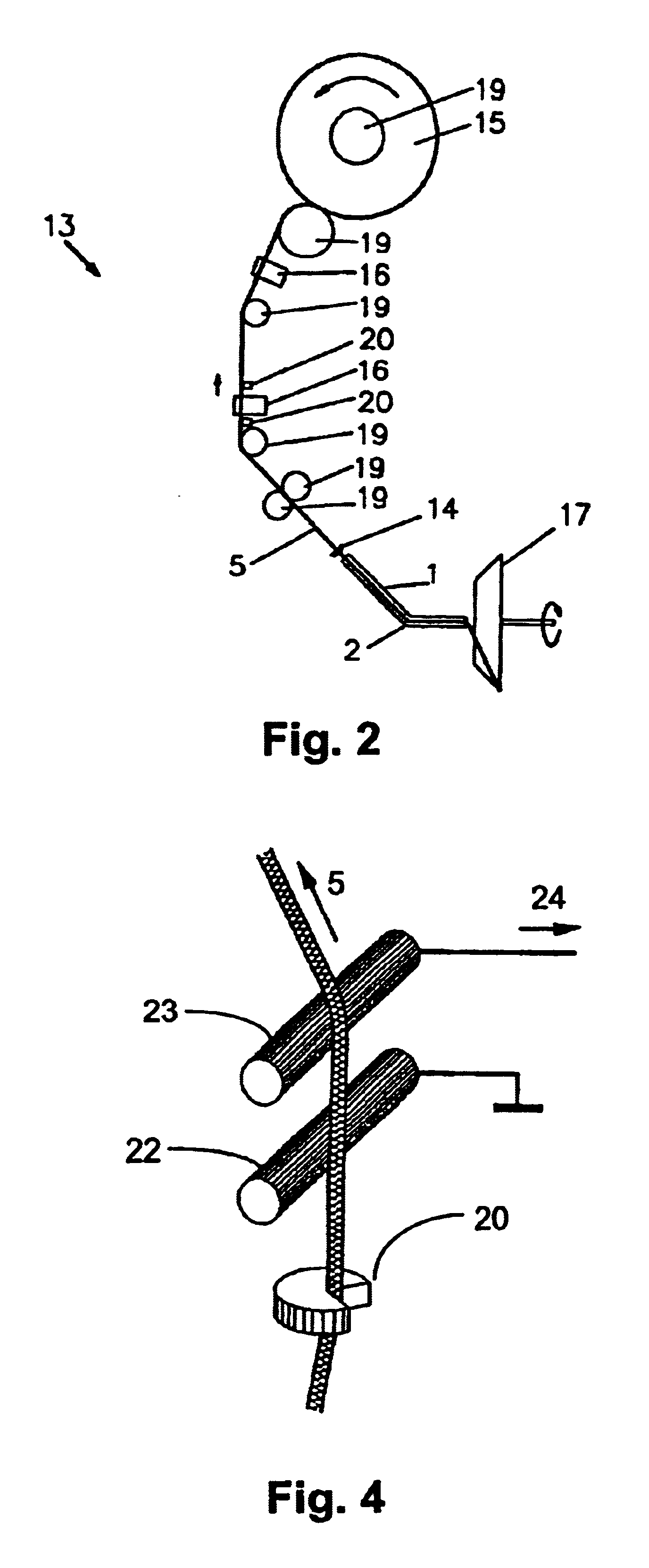

Method and apparatus for the detection of foreign materials in moving textile materials

InactiveUS6650959B1Inspecting textilesMaterial analysis by electric/magnetic meansWinding machineForeign matter

A method and an apparatus for detecting foreign fibers in a moving textile material, in particular in moving threads, yarns or slivers, include providing a probe for picking up triboelectric signals from the moving textile material and comparing the output of the probe with a reference value to provide a signal representative of detection of a foreign fiber in the textile material. The apparatus may be used in a card, a drawing bench, a ring spinning machine, an air-jet spinning machine, an open-end spinning machine, a chemical spinning machine, a bobbin winding machine a doubling machine, a combing machine, a bobbin frame, a texturing machine or a loom.

Owner:BELGIAN MONITORING SYST BMS

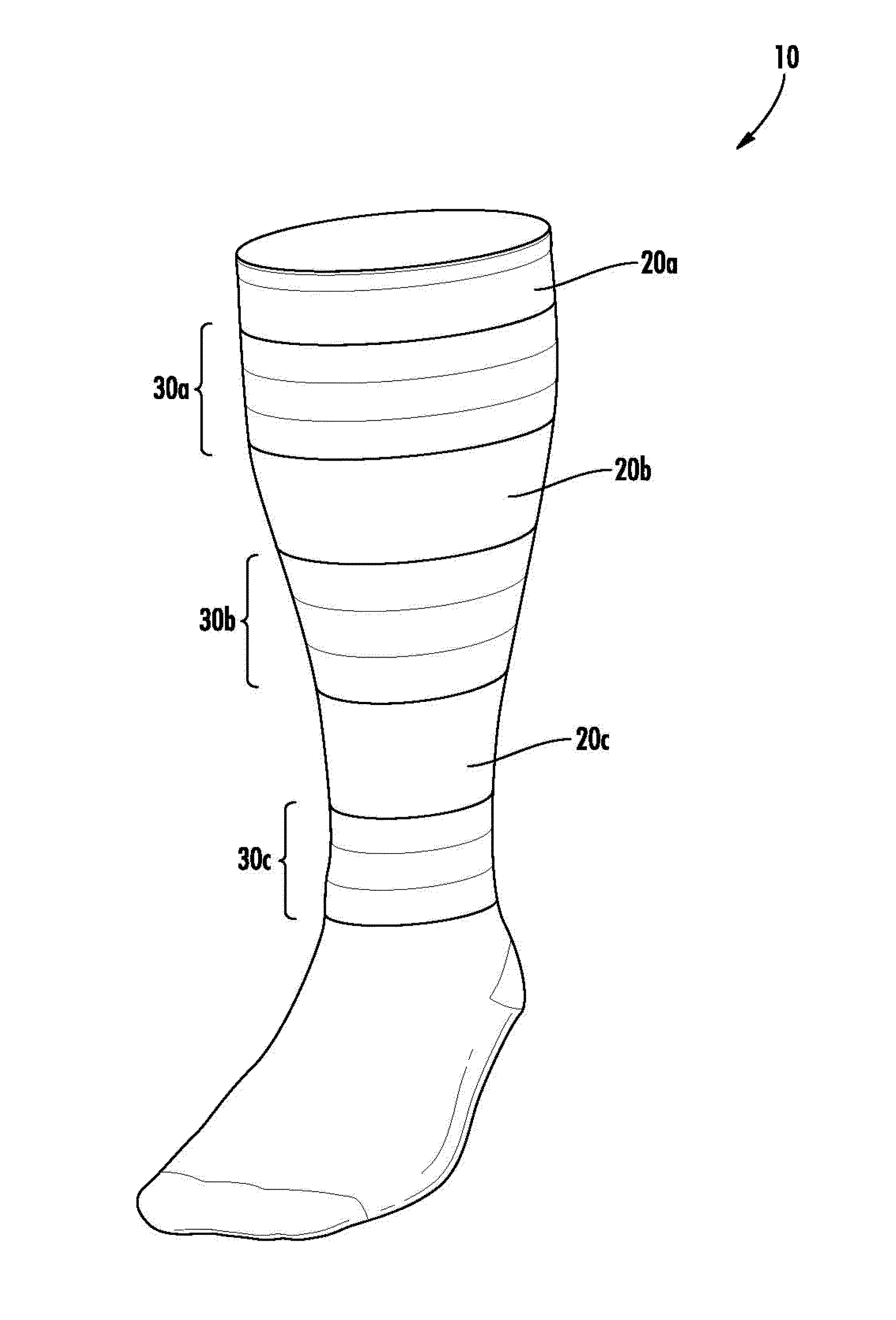

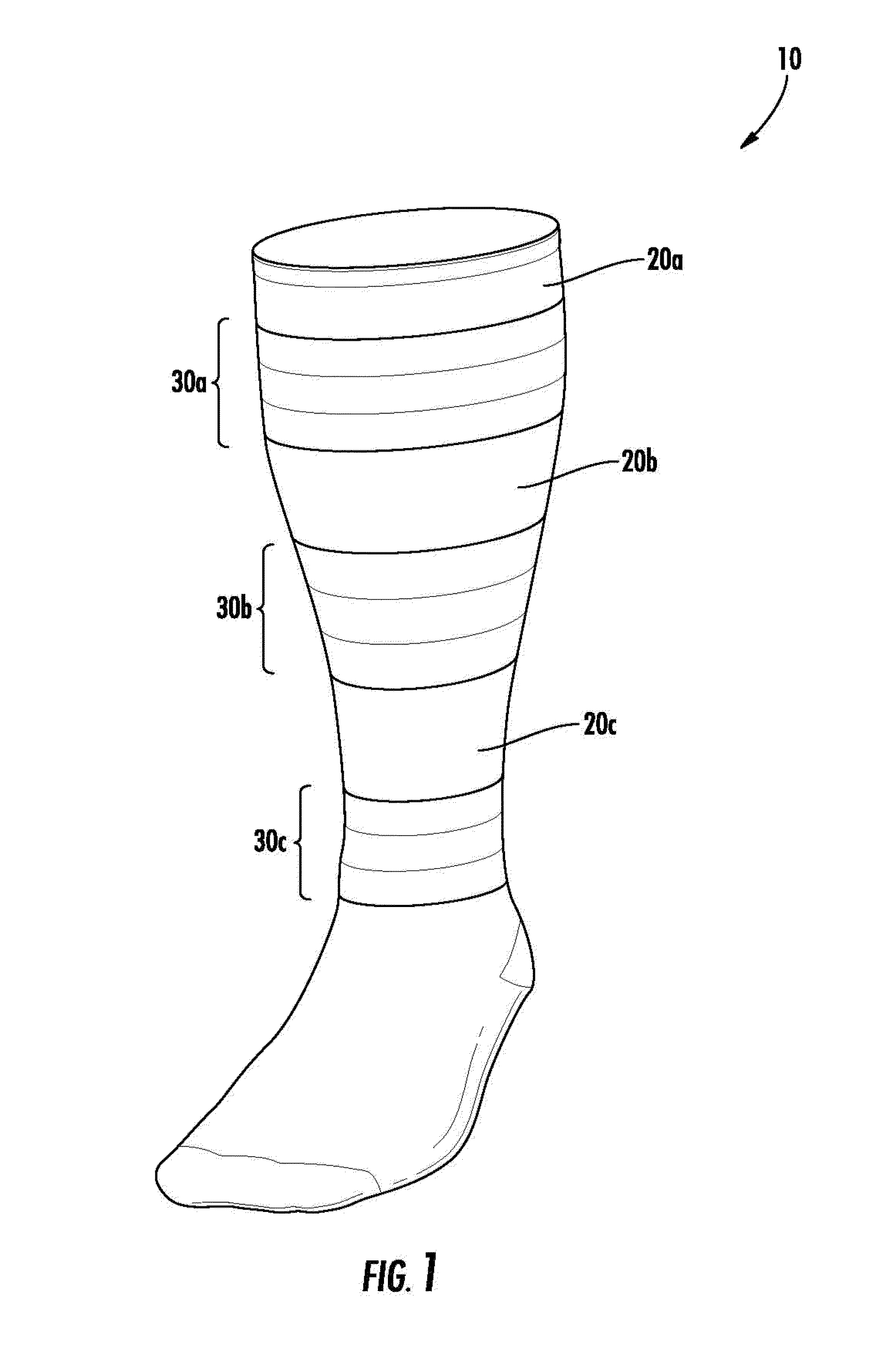

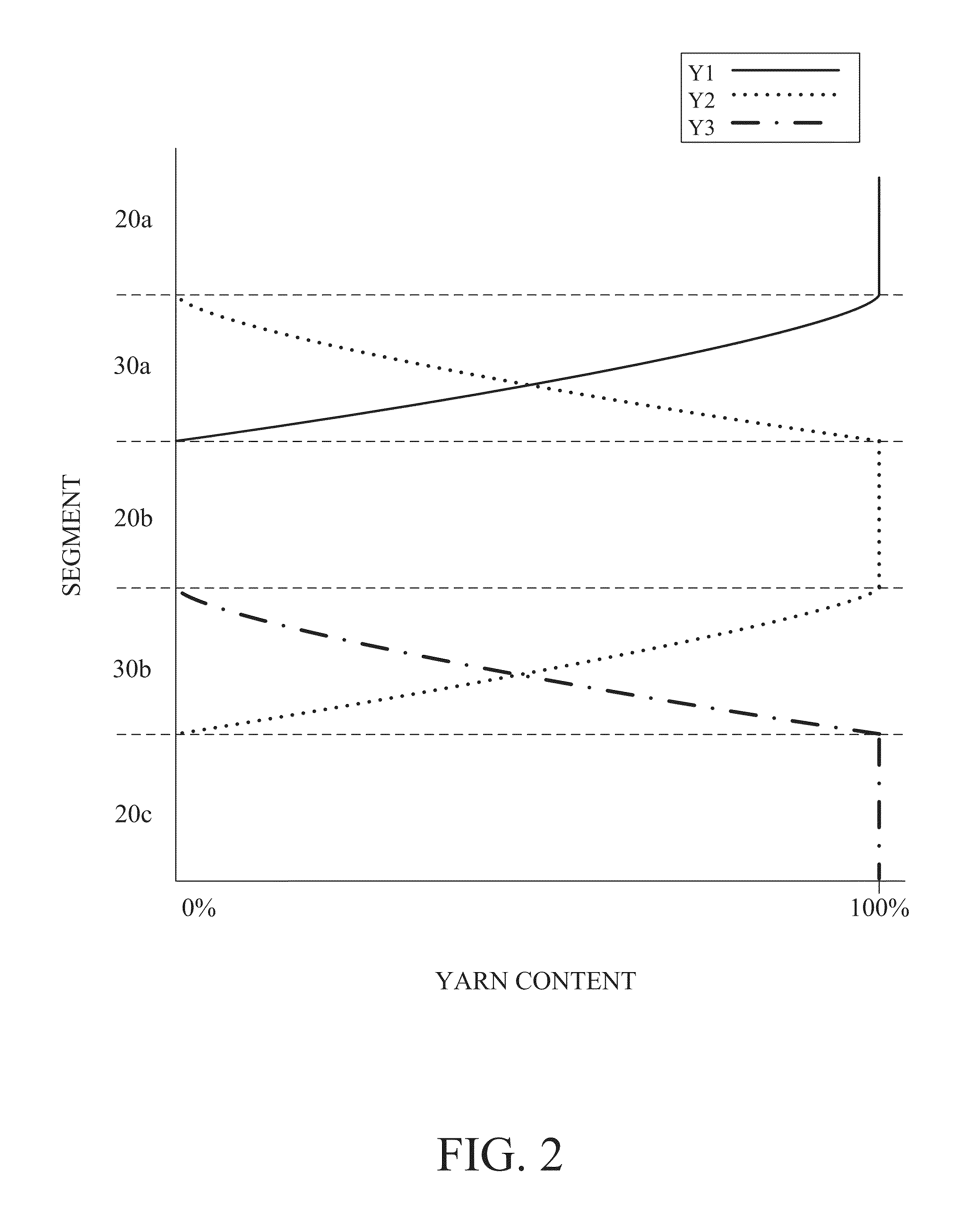

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

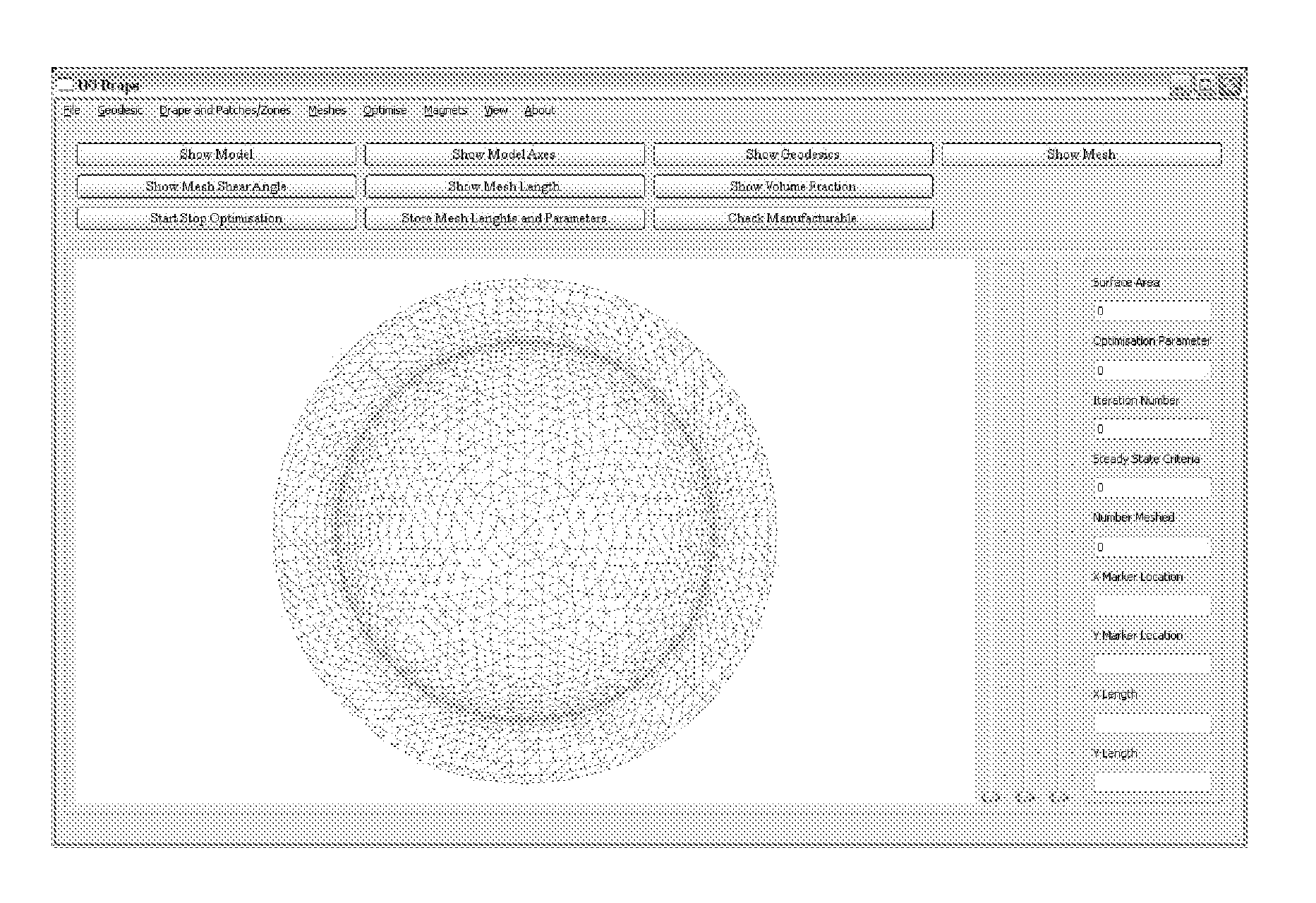

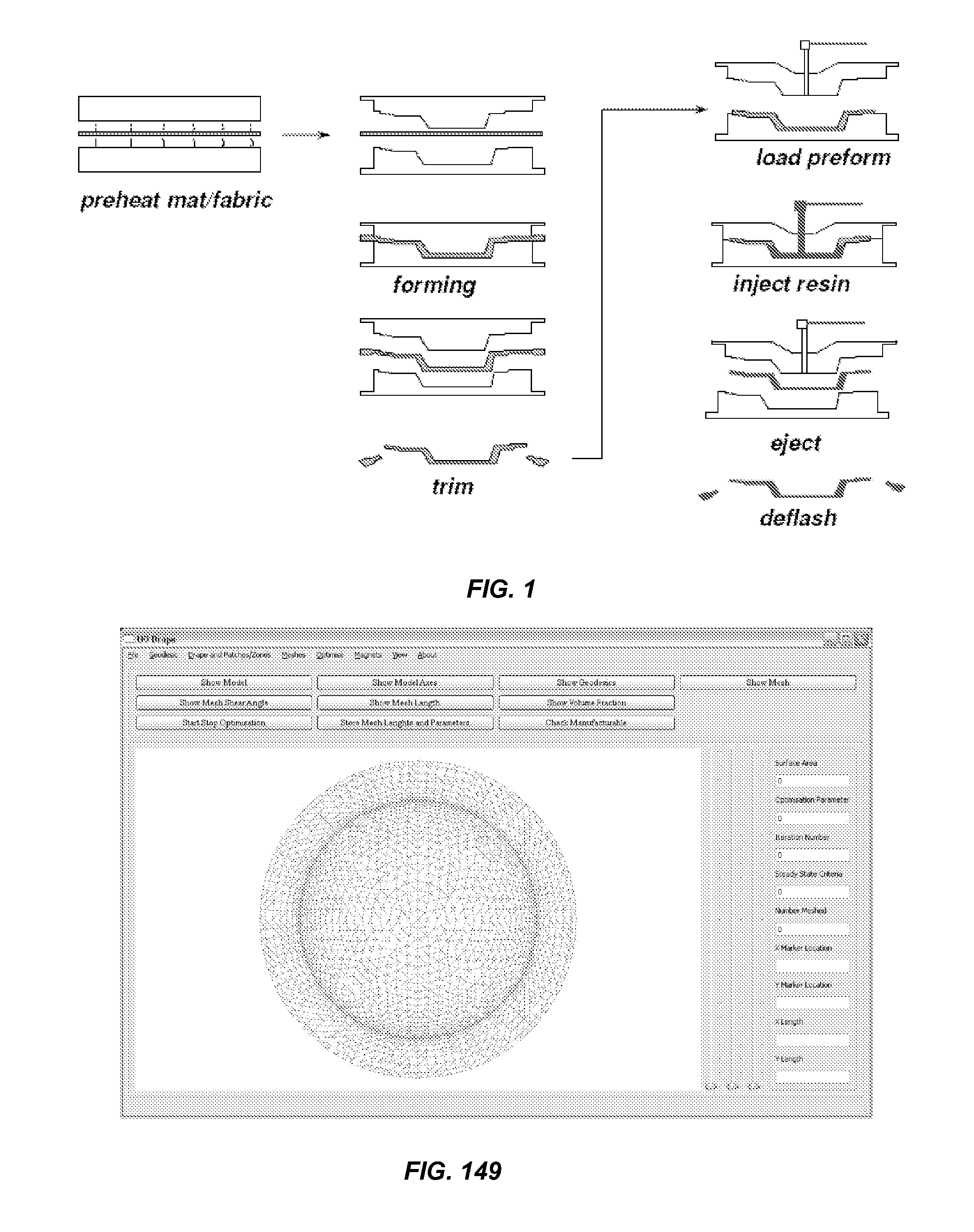

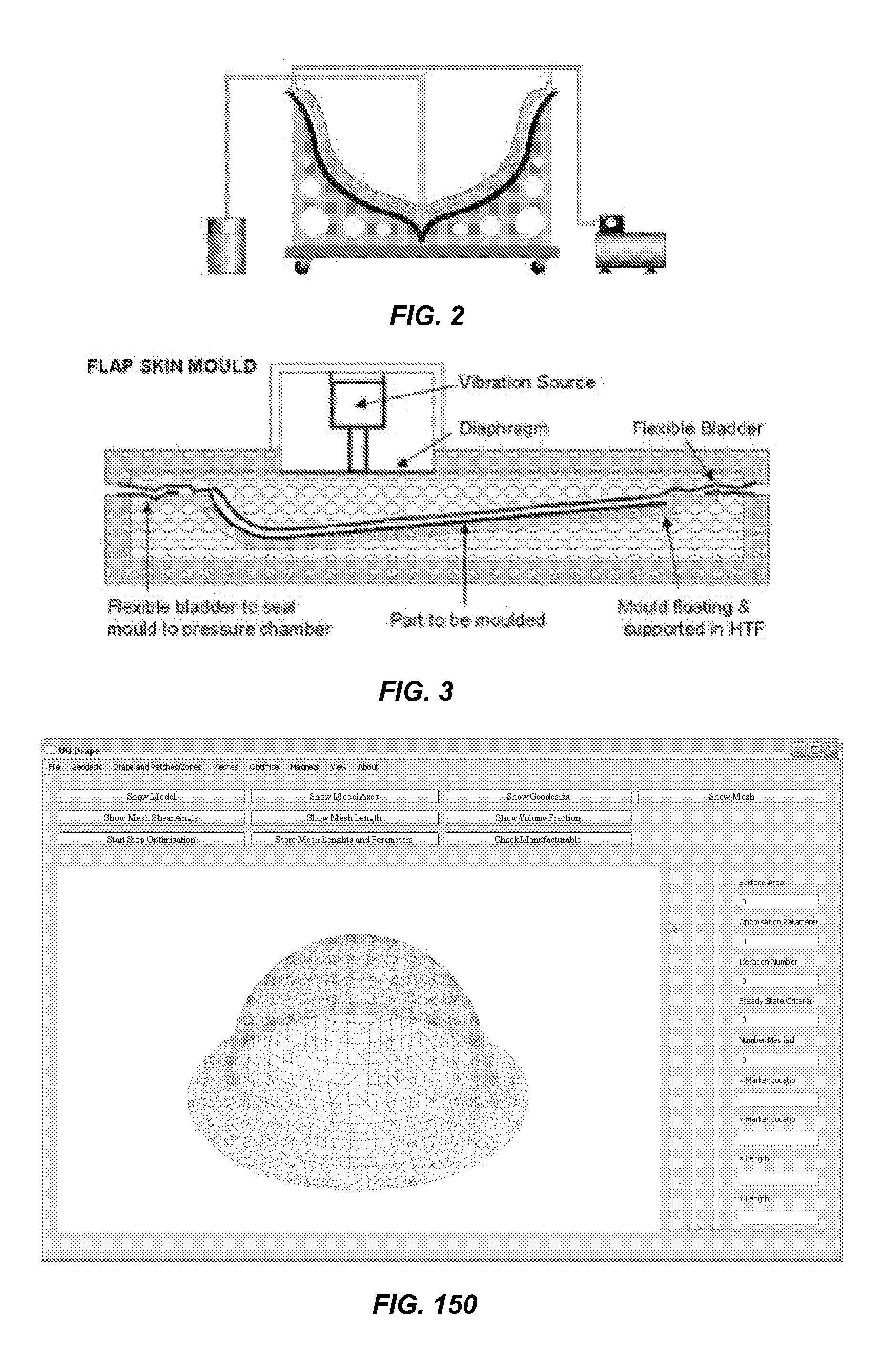

Novel composite parts, methods and apparatus for manufacturing the same

Owner:UNIVERSITY OF OTTAWA

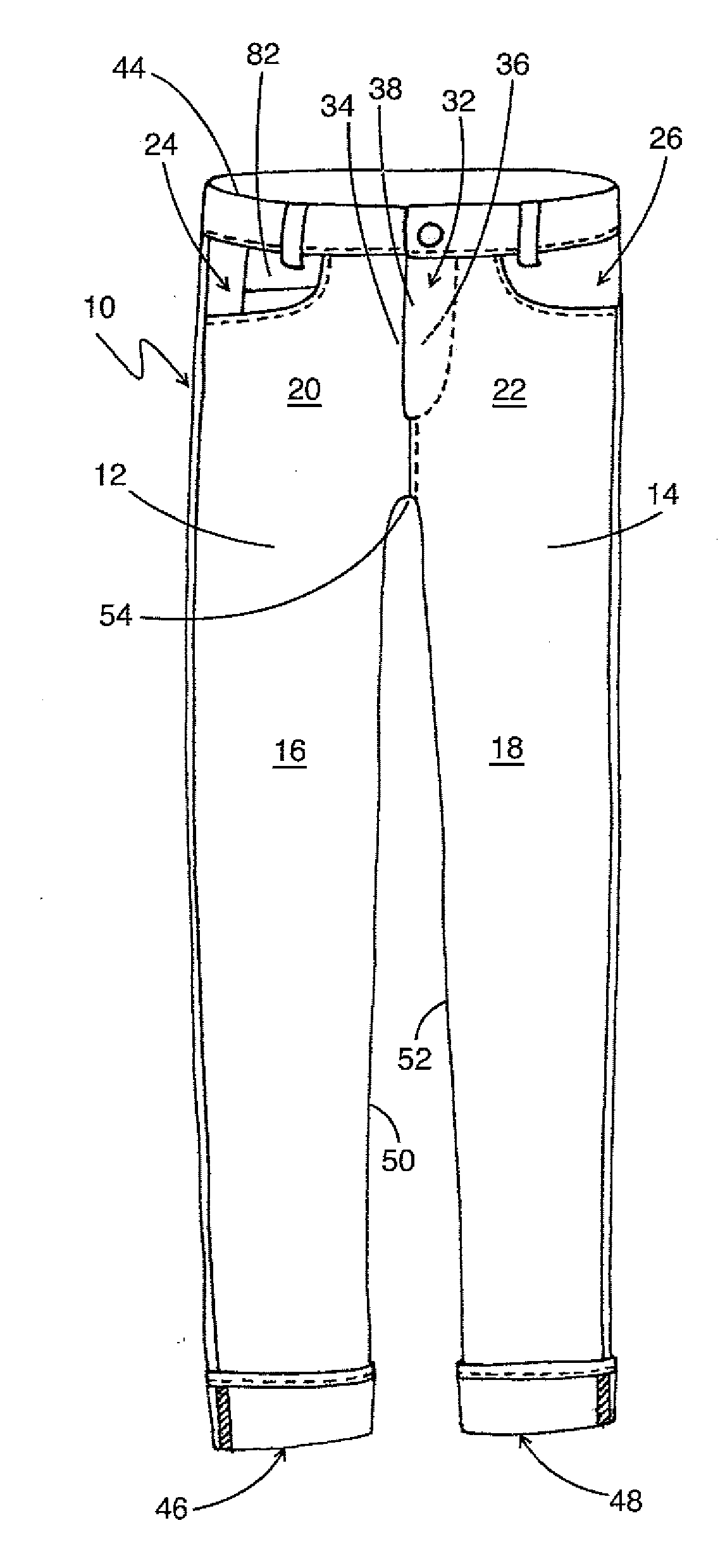

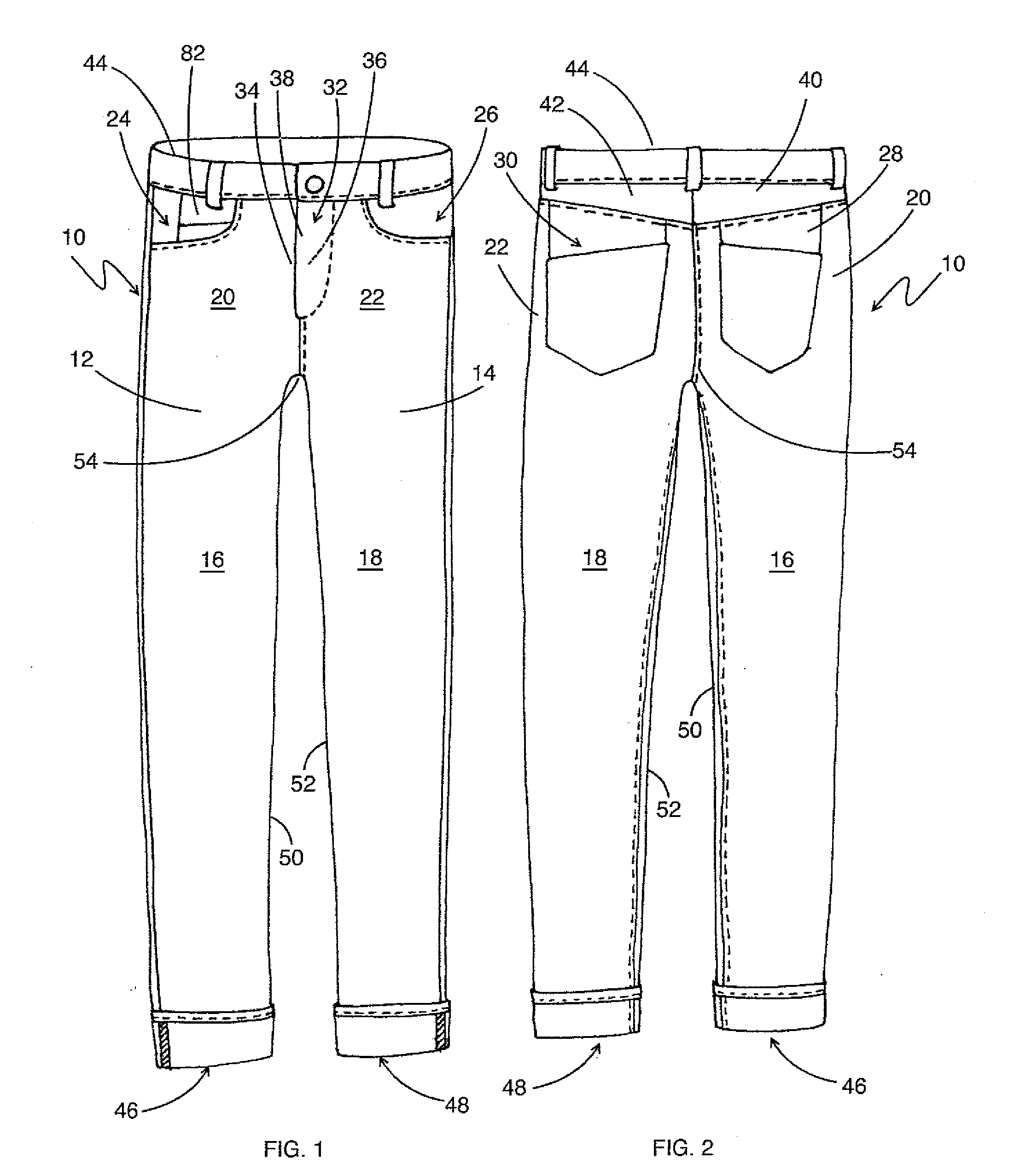

Methods for producing and merchandising a custom fit pant and custom fit pants

Methods for producing a pant, pants and methods for merchandising a pant. A pant is produced at a production facility by weaving right and left portions thereof using a multi-layer weaving process so as to produce an outer woven fly-cover layer and an inner woven left fly extension layer, or to form at least one pocket in at least one such portion, or both, and attaching the left portion of the pant to the right portion of the pant by stitching at least a portion of the crotch seam. The pant is then finished at a point of sale by stitching any remaining portion of the crotch seam and the inseams based on body dimensions and preferences of a purchaser to provide a custom fit. A pant produced at least in part by these steps is also presented.

Owner:CANDRIAN NATALIE A

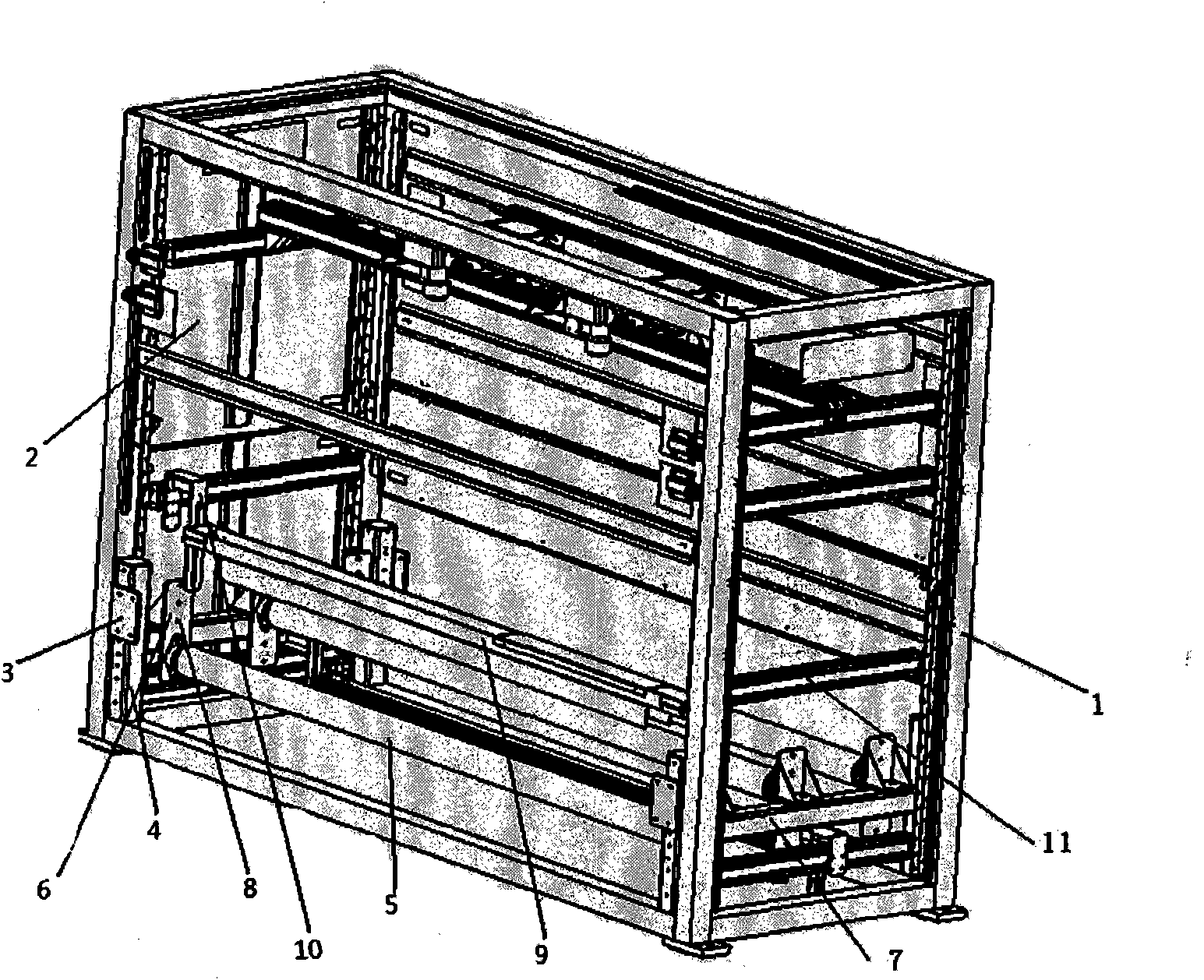

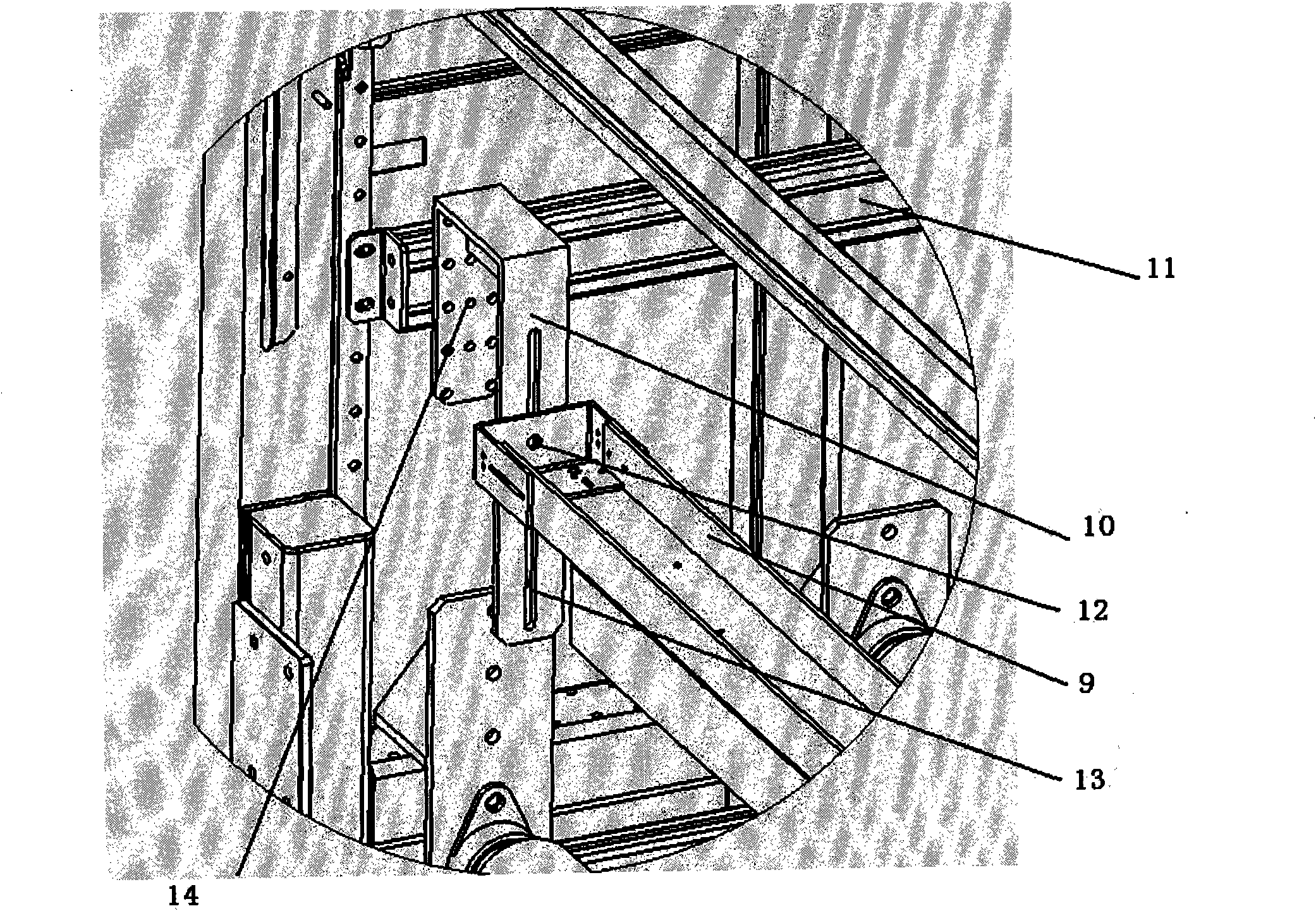

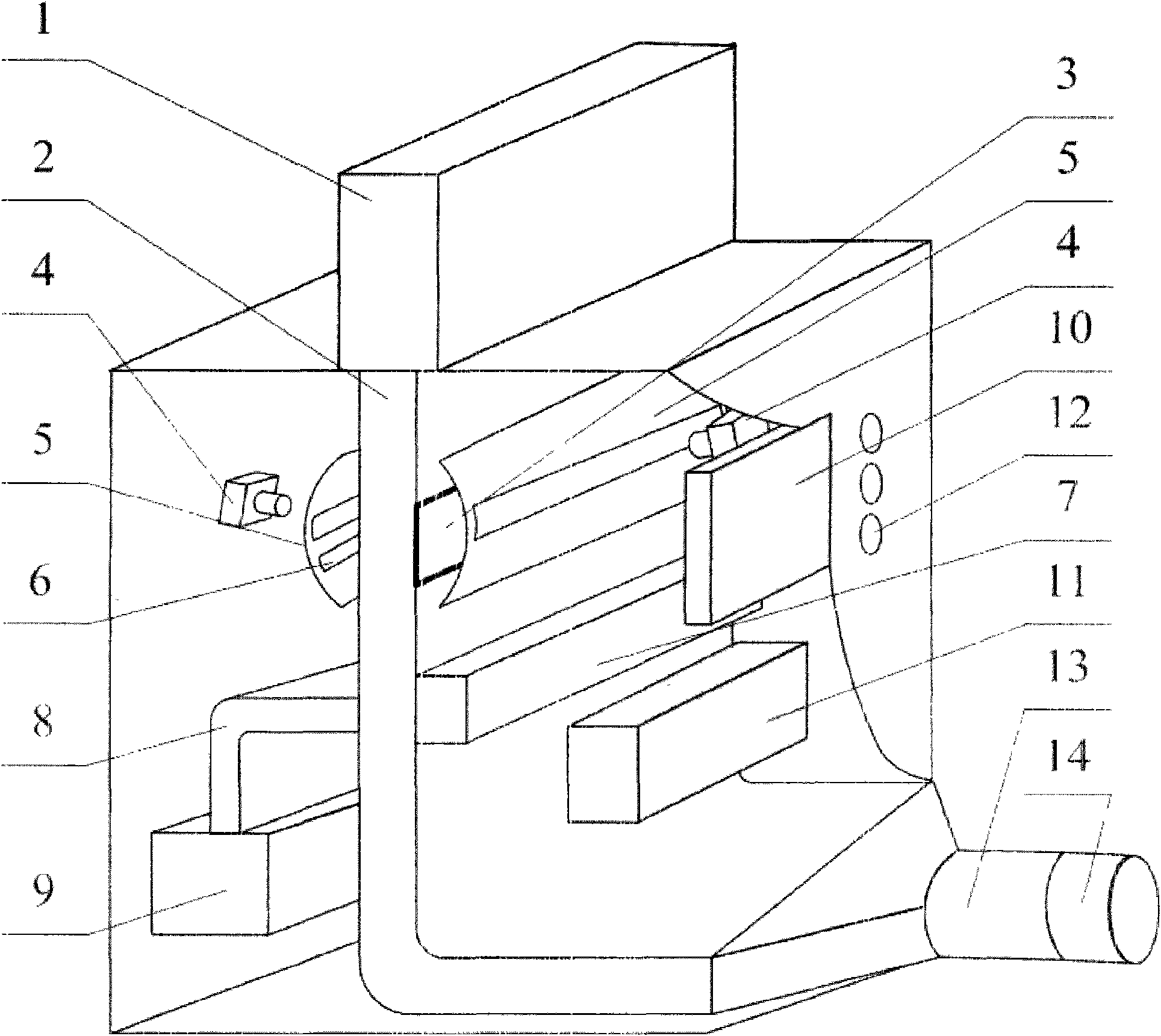

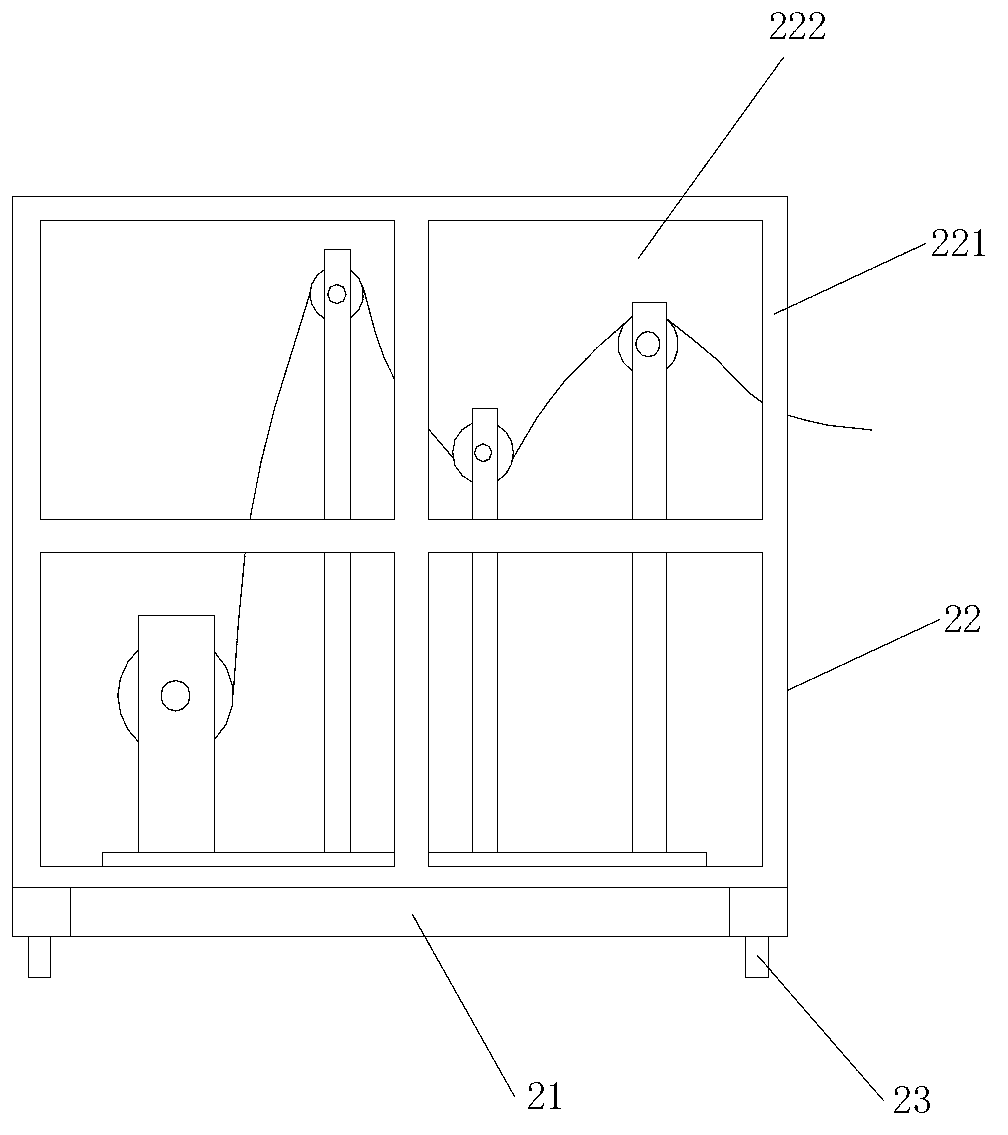

Automatic cloth inspecting machine

InactiveCN101851849ASimple structureEasy to operateInspecting textilesOptically investigating flaws/contaminationLighting systemOptical sensing

The invention aims to provide an automatic cloth inspecting machine, which is an optical sensing device-based automatic cloth inspecting machine. The automatic cloth inspecting machine of the invention has a simple structure, is convenient to operate and greatly improves working efficiency and cloth inspecting quality. The automatic cloth inspecting machine of the invention comprises a frame, baffle plates, a cloth guiding system, an illuminating system and an image pickup system, wherein the baffle plates are arranged around the frame; and the cloth guiding system, the illuminating system and the image pickup system are arranged in the frame respectively.

Owner:BEIJING JINGWEI TEXTILE MACHINERY NEW TECH

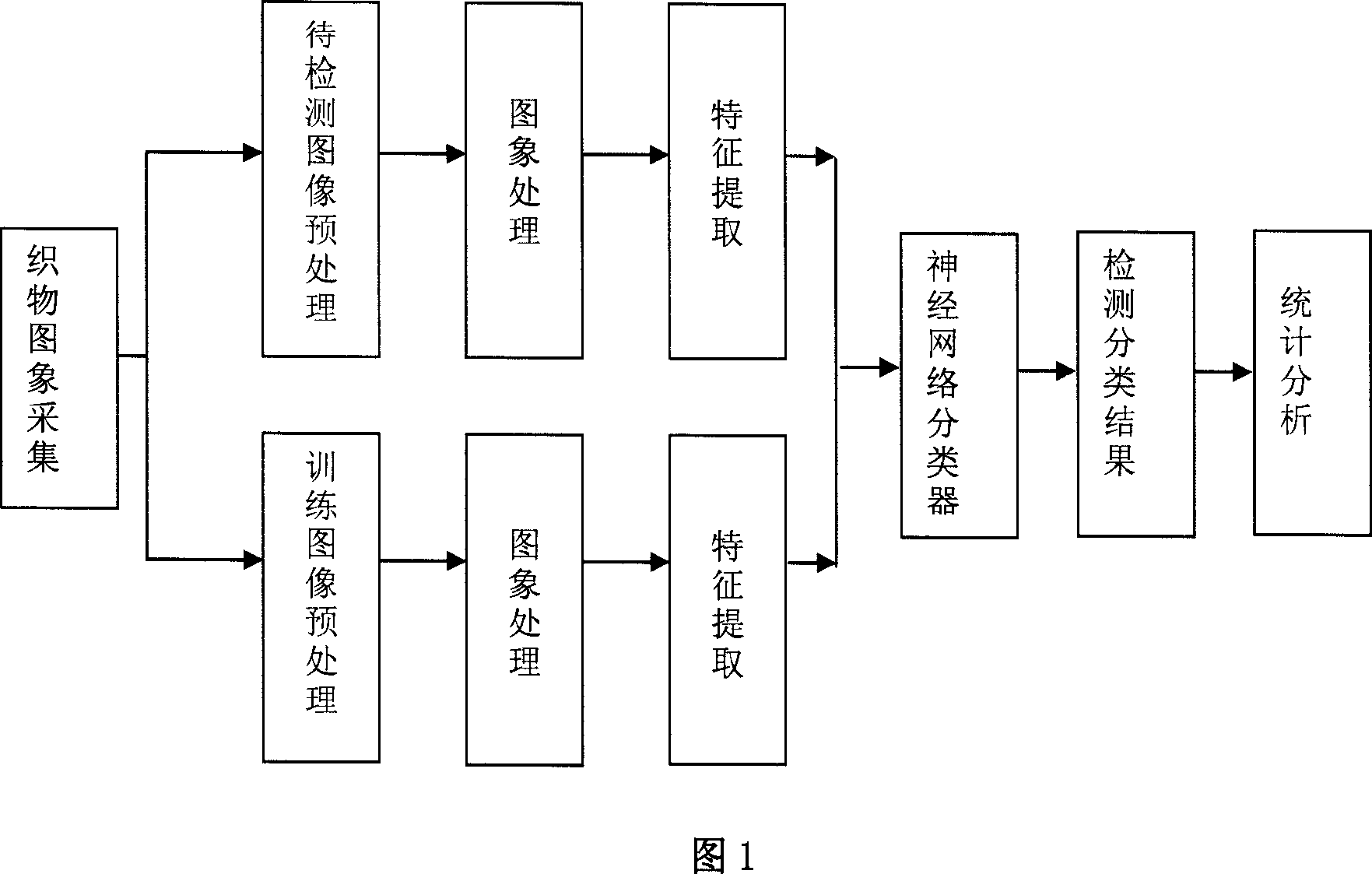

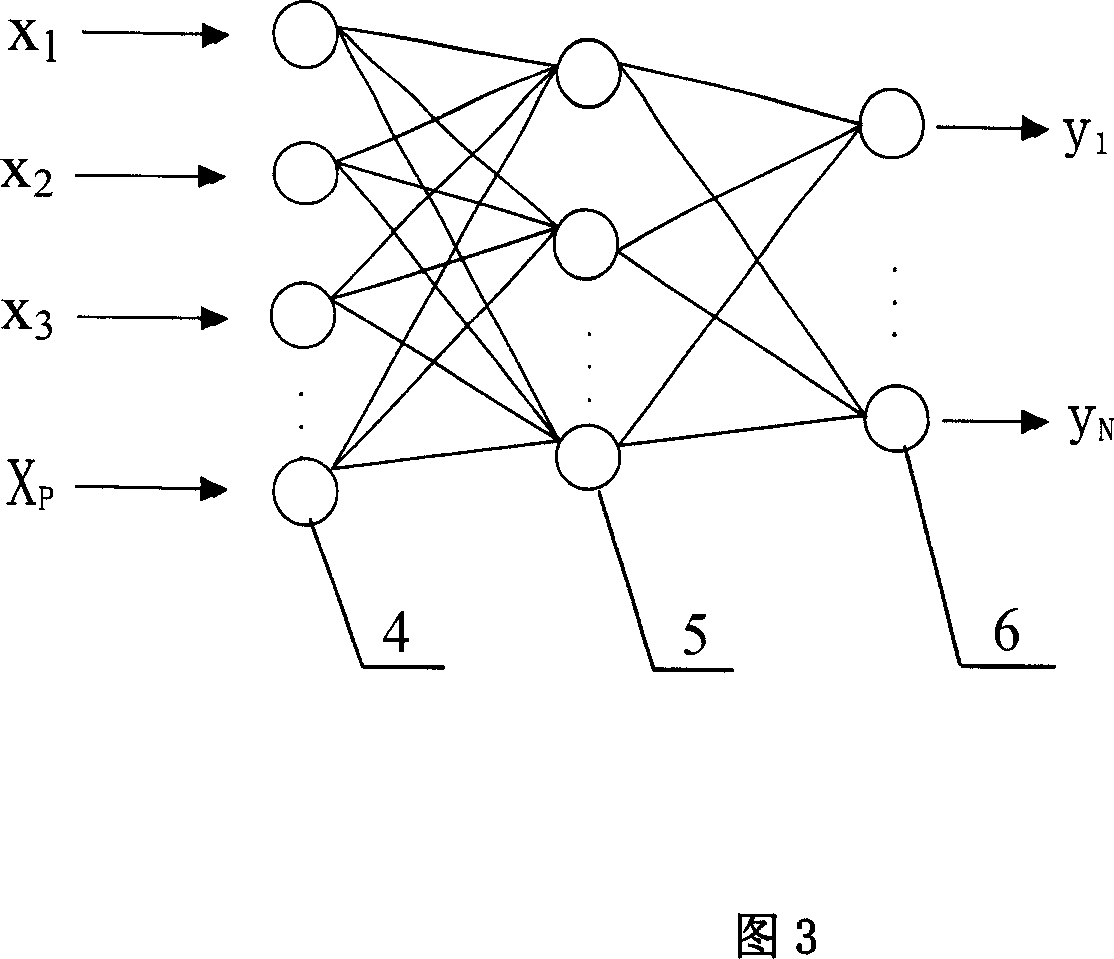

Method of identifying woven fabric defect

InactiveCN1948603AImprove accuracyComprehensive input parametersInspecting textilesMaterial analysis by optical meansNeural network systemFeature parameter

The invention discloses a method to identify flaw on surface of woven. Input the image signal which gained from image acquisition system to computer and proceed filtering and enhancement. Extract energy, entropy, contrast, deficit moment and correlation from vertical and horizon high frequency detail of image signal on woven flaw as five texture distinction parameter of woven. Use optimal edge detection algorithm on image signal of woven flow. Abstract apsidal ratio from image signals as a form characteristic parameter of woven. Input these six parameters to neural network system to proceed identifying and assorting on flows. The invention put texture and morphological character as evidence of differentiating flows of woven. Using neural network system to proceed identifying and assorting, the accuracy of flows can be increased obviously. Because of simple operation, fast detection and high efficient, the method has good prospect for applying.

Owner:SUZHOU UNIV

Method and device for online detection of foreign fiber in cotton

InactiveCN101629336AStrong discriminationLow costFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberFrequency conversion

The invention provides a method and a device for online detection of foreign fiber in cotton. The device comprises a cotton opener, channels, windows, a CCD (Charge Coupled Device) camera, an illumination light source, a background plate, a nozzle array, a foreign fiber channel, a foreign fiber collecting unit, a computer, an electrical equipment cabinet, operating buttons, a frequency conversionfan and a cotton conveyance pipe. The method comprises the following steps: opening lint cotton; feeding the lint cotton into the detection area of the CCD camera through the channels; performing theillumination and CCD camera sampling in three steps, and further collecting the detection results of the three steps for identifying the foreign fiber; calculating the time for nozzles in the corresponding positions to the foreign fiber to open and close by combining the action delay time of each nozzle; controlling the corresponding nozzles to operate, so as to remove the foreign fiber; and meanwhile, outputting clean cotton with the foreign fiber being removed from the clean cotton output channel, wherein, by combining the performance parameters of the CCD camera, the cotton flow rate in the corresponding area of each nozzle can be calculated from the data obtained through infrared LED illumination and sampling, and the average cotton flow rate can be further calculated; and then, the cotton flow rate in the channels can be stabilized within a per-determined range by controlling the frequency conversion fan.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

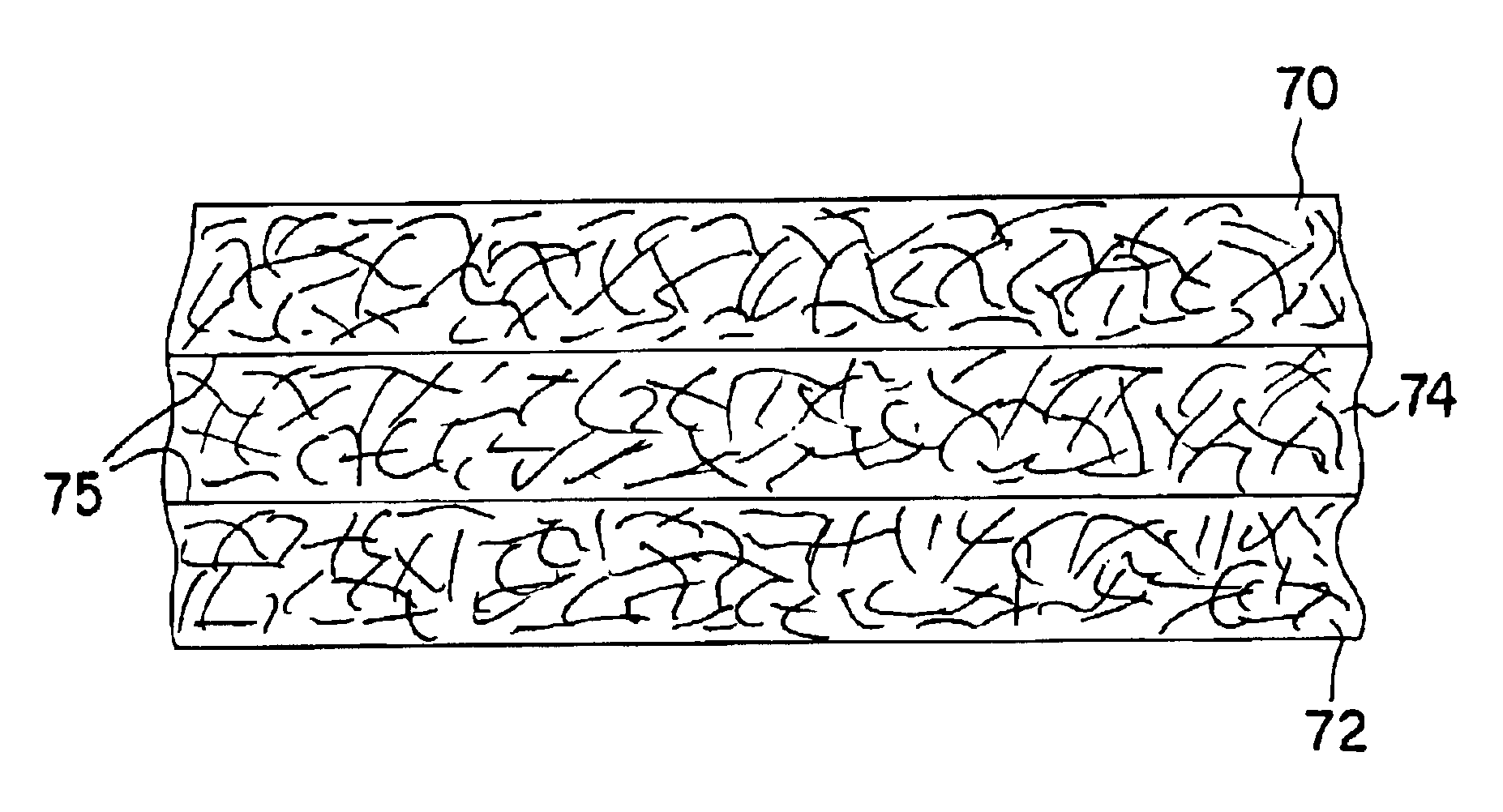

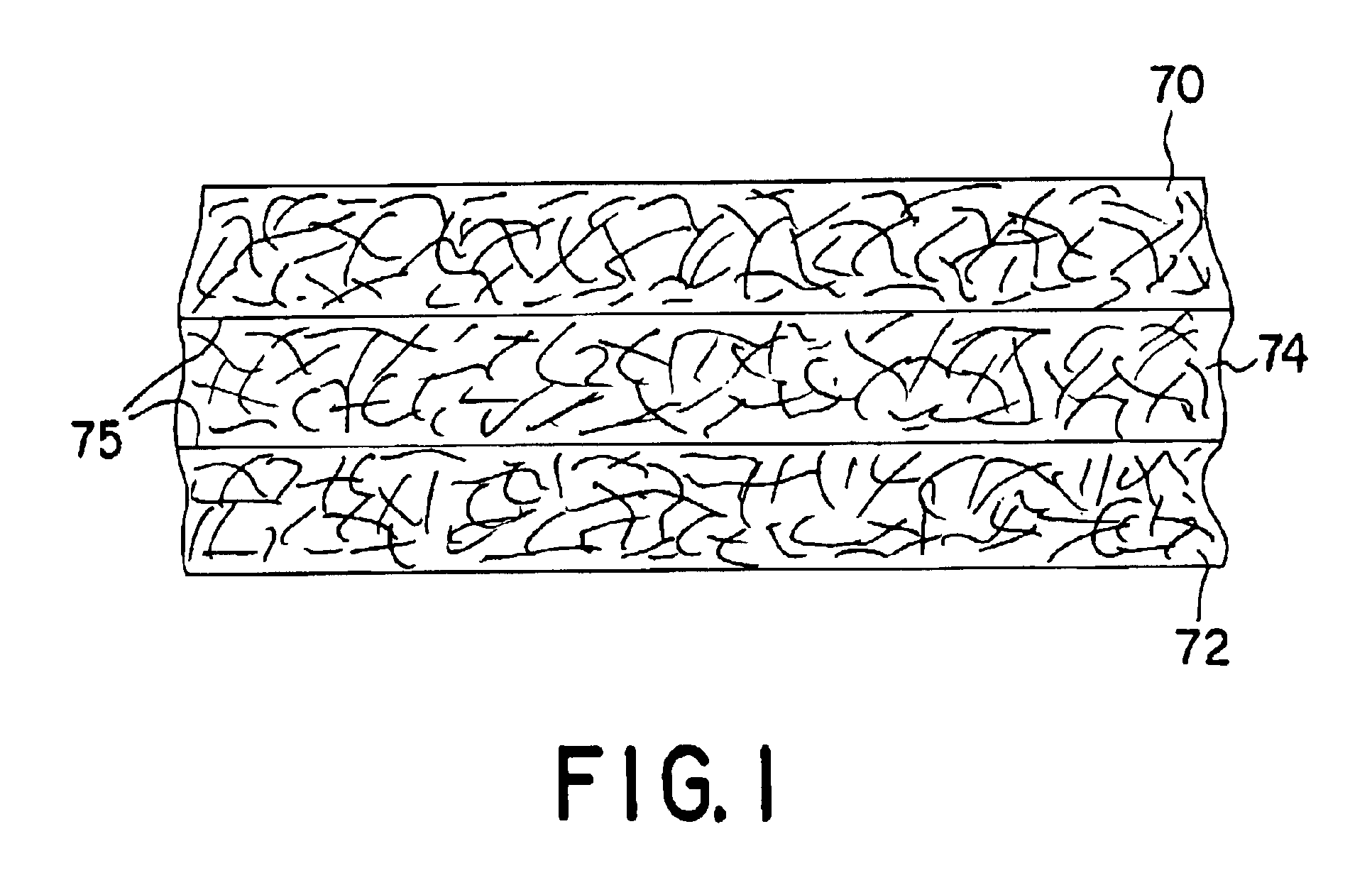

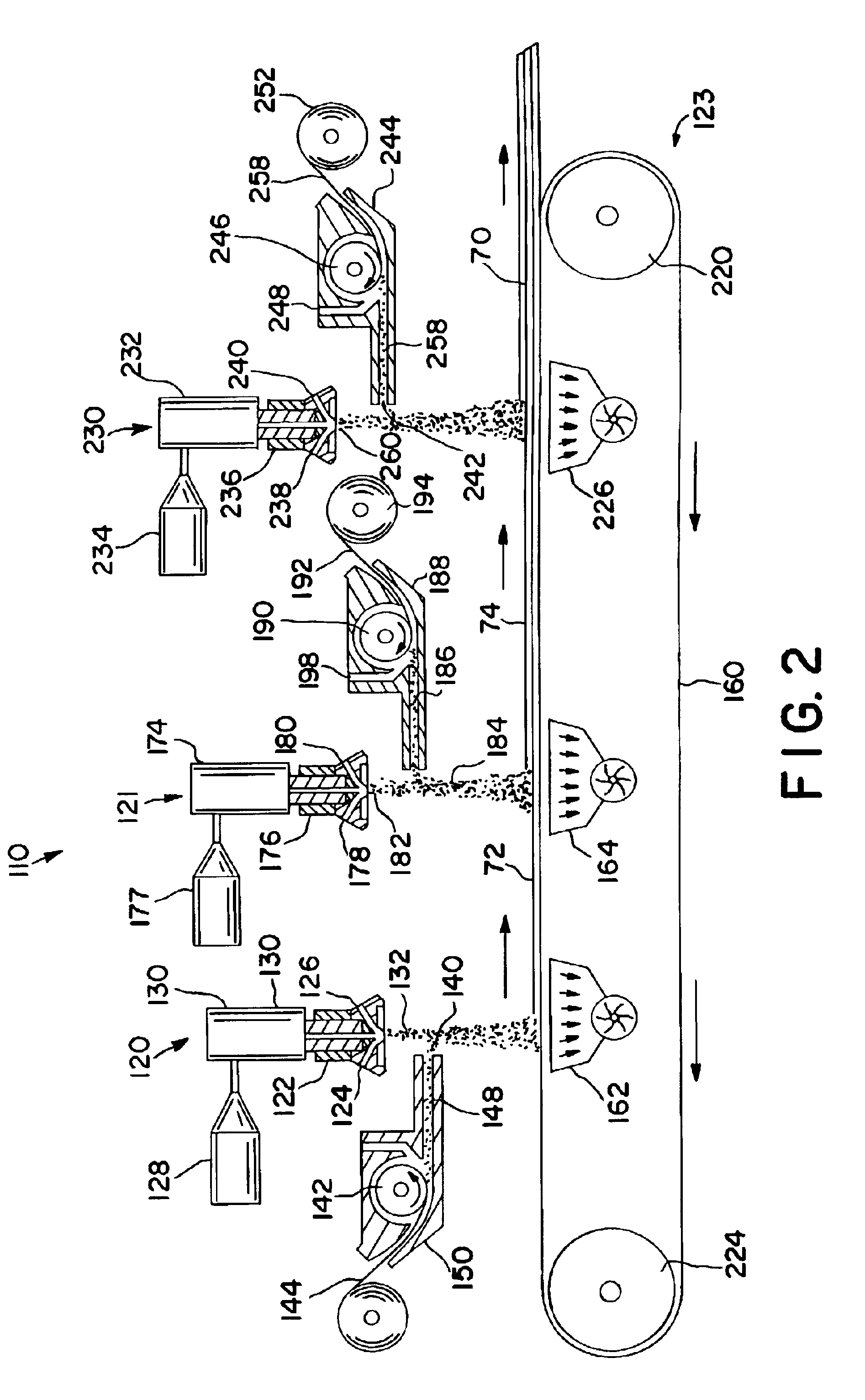

Method of forming composite absorbent members

InactiveUS6932929B2High weight percentageSmall diameterCrochetingInspecting textilesFiberEngineering

A method for forming a composite absorbent member is provided that includes:a) extruding a first fibrous component through a first meltblowing die and intermingling pulp fibers with the first fibrous component to form a first admixture;b) extruding a second fibrous component through a second meltblowing die and intermingling pulp fibers with the second fibrous component to form a second admixture; andc) codepositing the first and second admixtures on a collecting surface so as to form a composite structure having at least a first layer and a second layer. The second layer has a higher weight percentage of pulp fibers than the first layer, and the average diameter of the pores within the second layer is smaller than the average diameter of the pores within the first layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

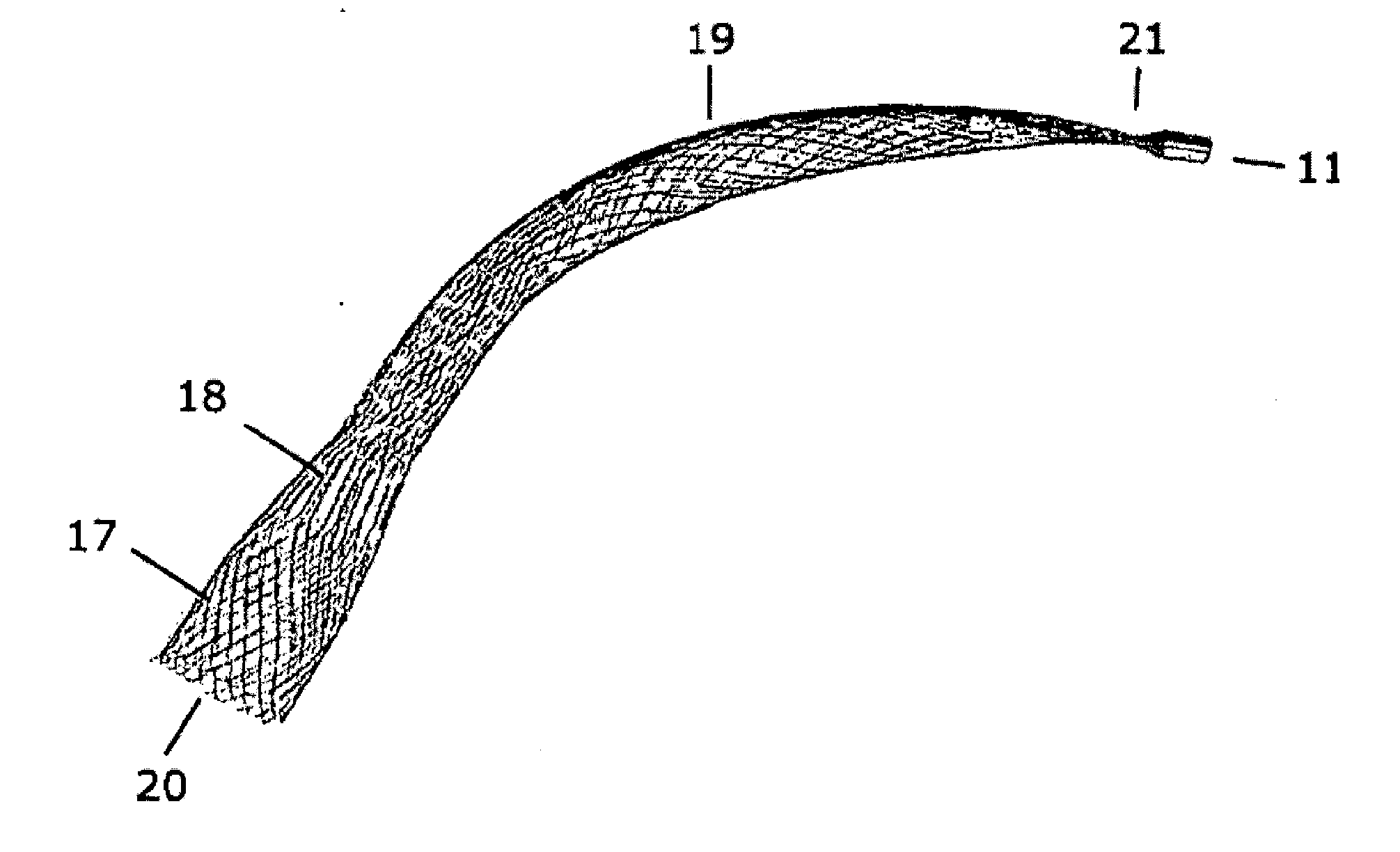

Multi-strand implant with enhanced radiopacity

ActiveUS20160058524A1Improve radiopacityMinimize changesMechanical cleaningPressure cleaningSingle strandBiomedical engineering

An implant for medical use, and methods of making same, having a body formed of a plurality of single strands of a first material. The body further includes at least one multi-strand of radiopaque material incorporated among the single strands, the multi-strand having at least two side-by-side filaments of radiopaque material that lie substantially contiguous to each other over substantially the entire length of the multi-strand.

Owner:DEPUY SYNTHES PROD INC

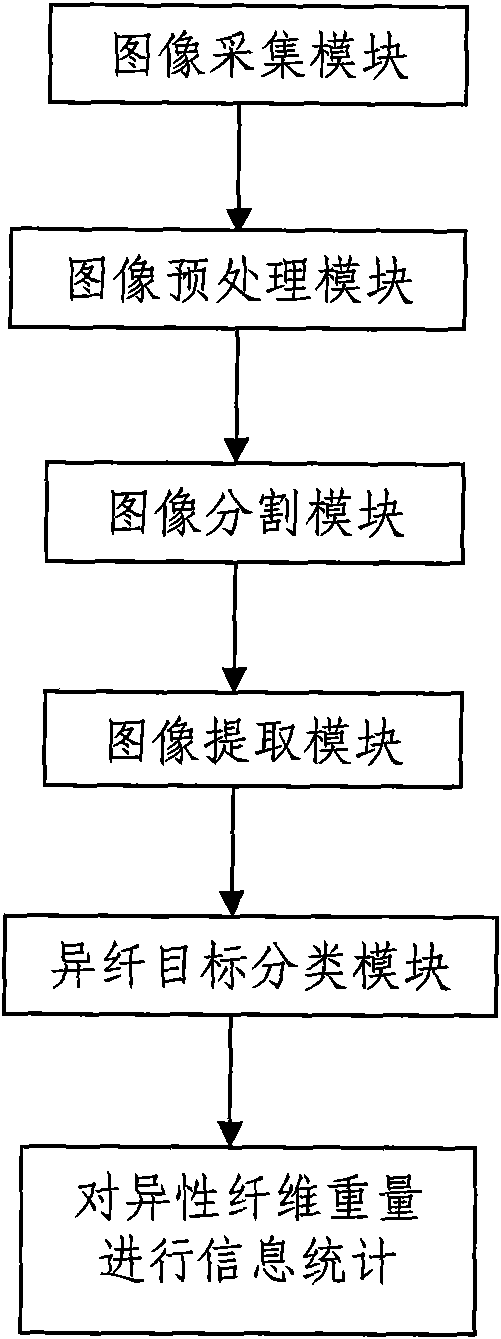

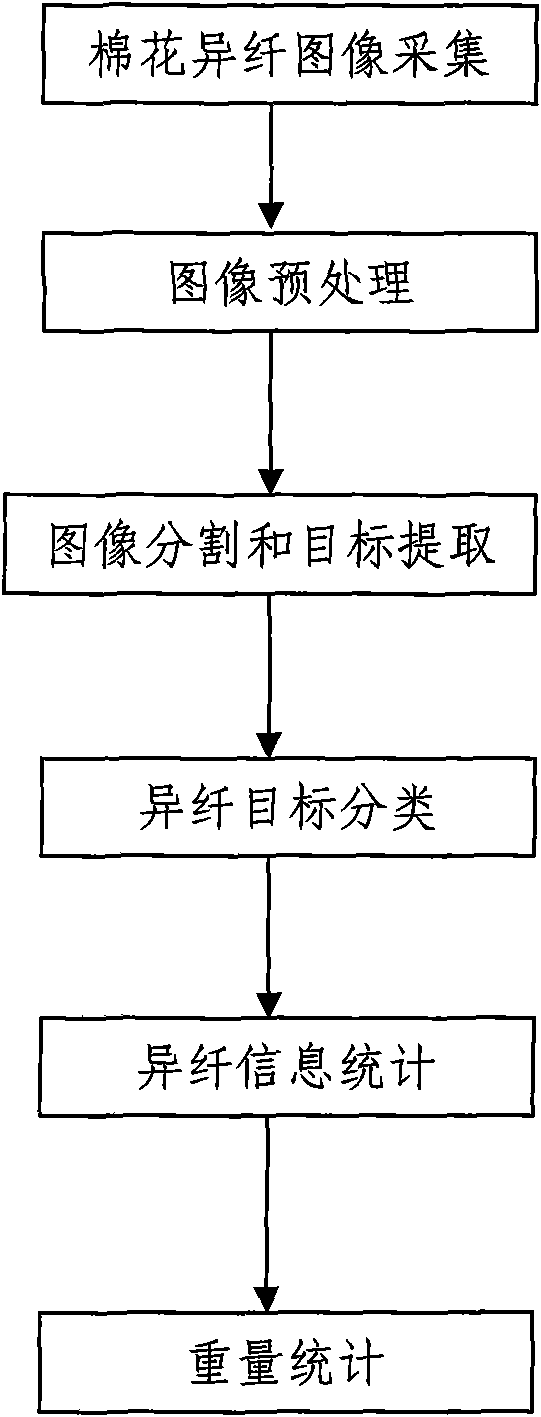

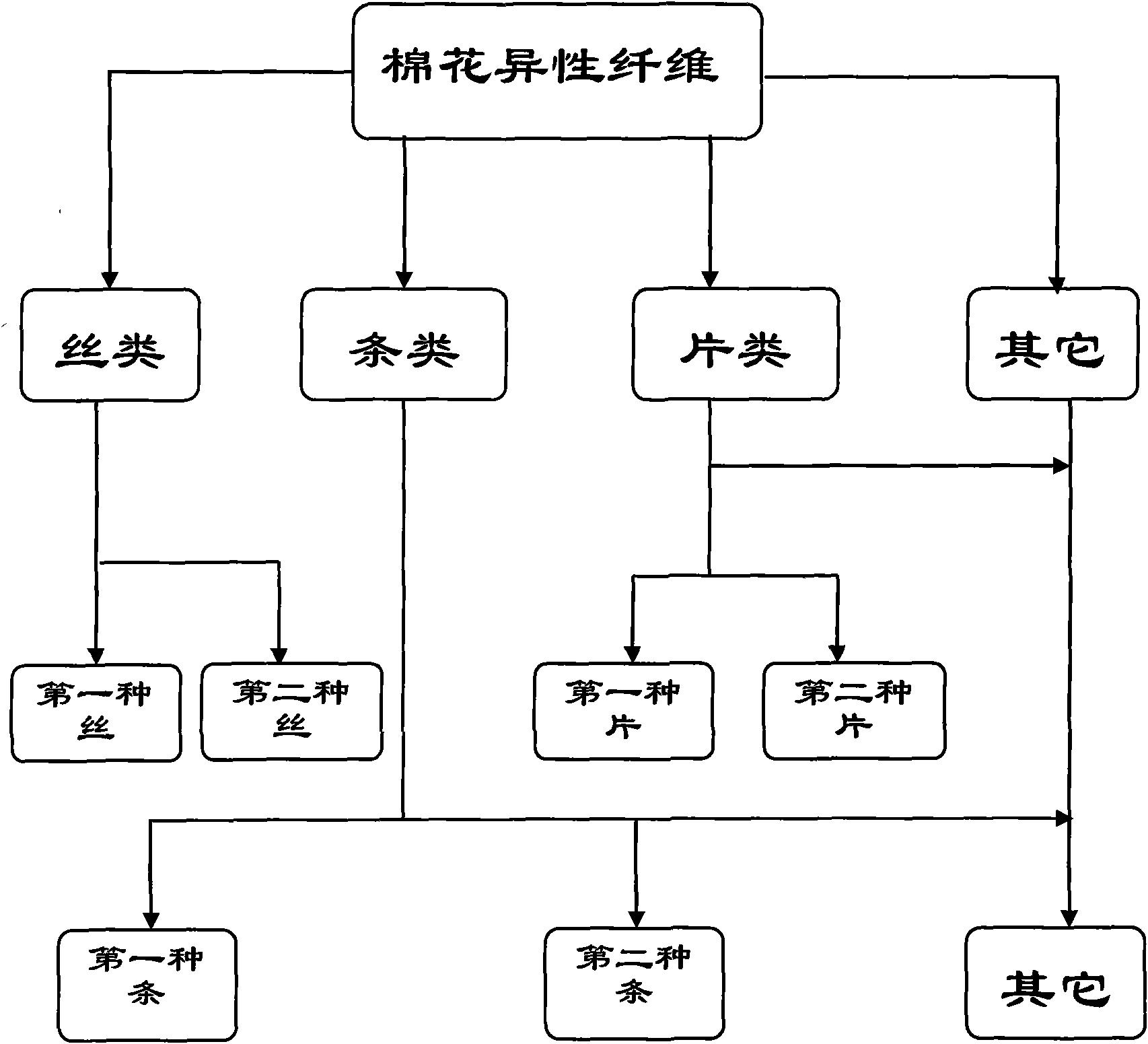

Measuring method and system for weight of cotton foreign fiber based on machine vision technique

InactiveCN101555661AHigh speedImprove accuracyInspecting textilesFibre cleaning/openingImage basedFiber

The invention relates to a measuring method and system for the weight of cotton foreign fiber based on machine vision technique. The measuring system for the weight of cotton foreign fiber comprises a cotton foreign fiber image acquisition module, an image processing module used for preprocessing acquired images, a module used for carrying out target division and extraction for the preprocessed images, a module used for classifying the extracted targets and a module used for carrying out statistical operation for the classified result. The system can accurately obtain the unit area weight of cotton foreign fiber based on image processing technique and can be used for intelligent identification and weight measurement of the cotton foreign fiber combining with on-site image processing technique. The invention also provides a measuring method for the weight of cotton foreign fiber based on the machine vision technique. By utilizing the method and the system, the accuracy, the periodicity, the timeliness of the diction of the foreign fiber as well as the detection efficiency are all improved, and the harm of the foreign fiber is efficiently reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

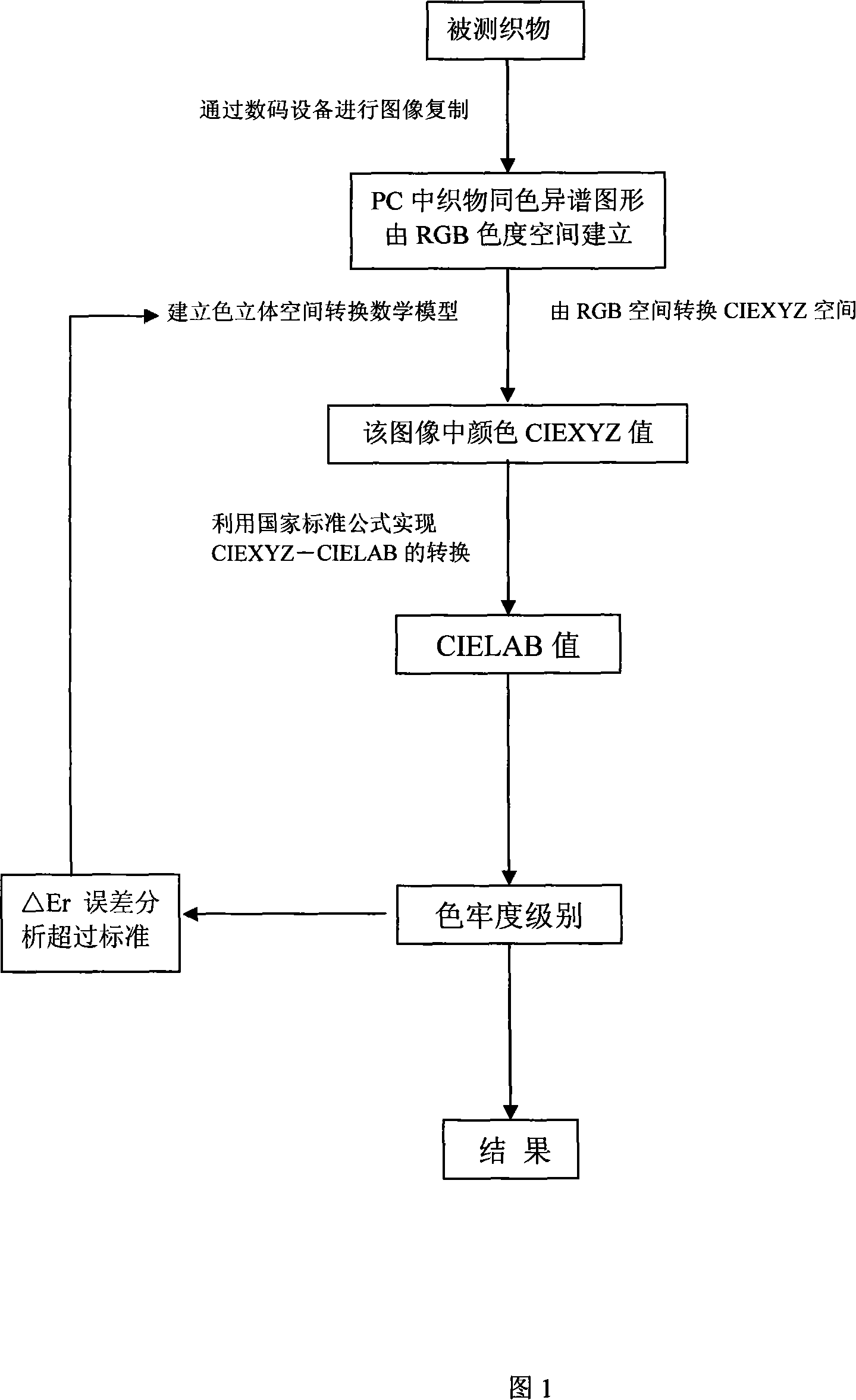

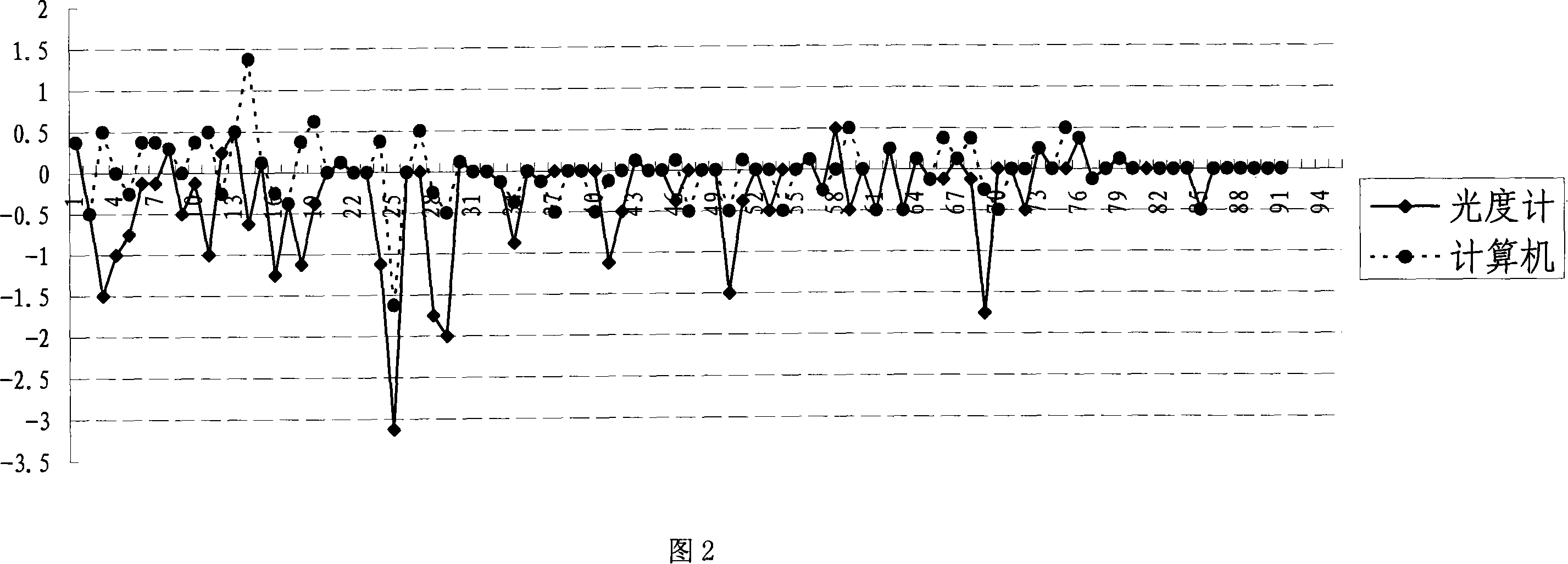

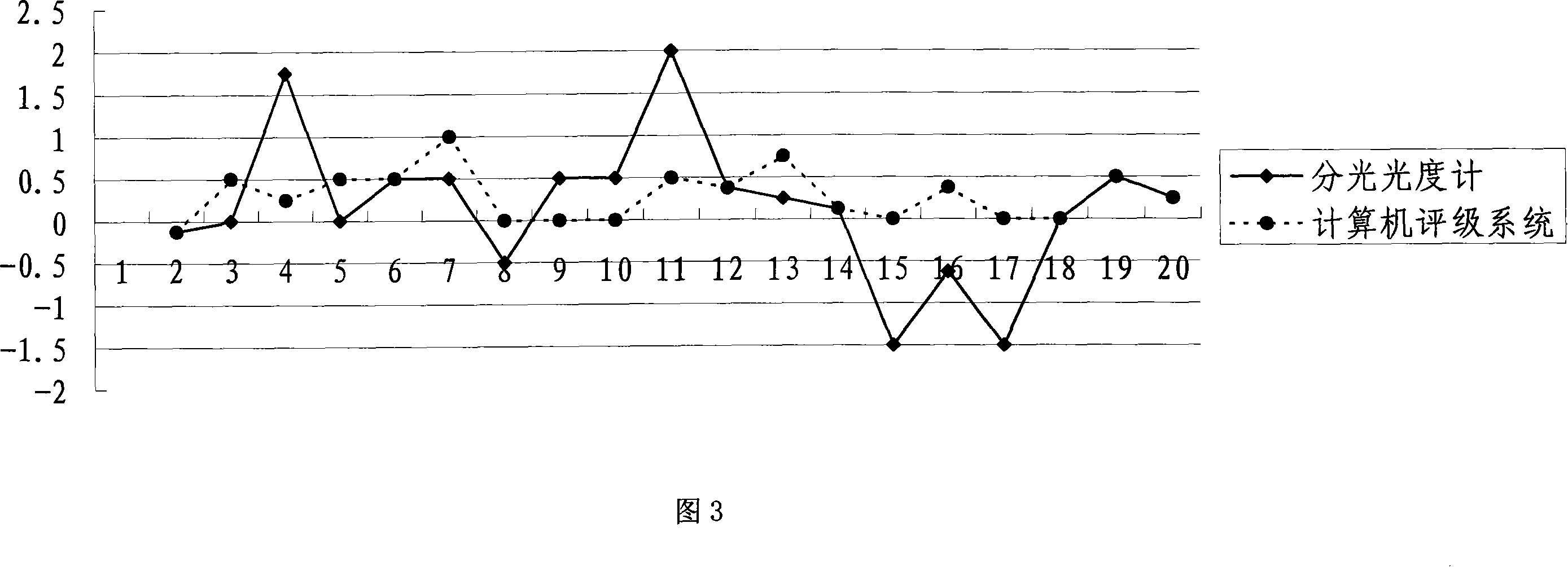

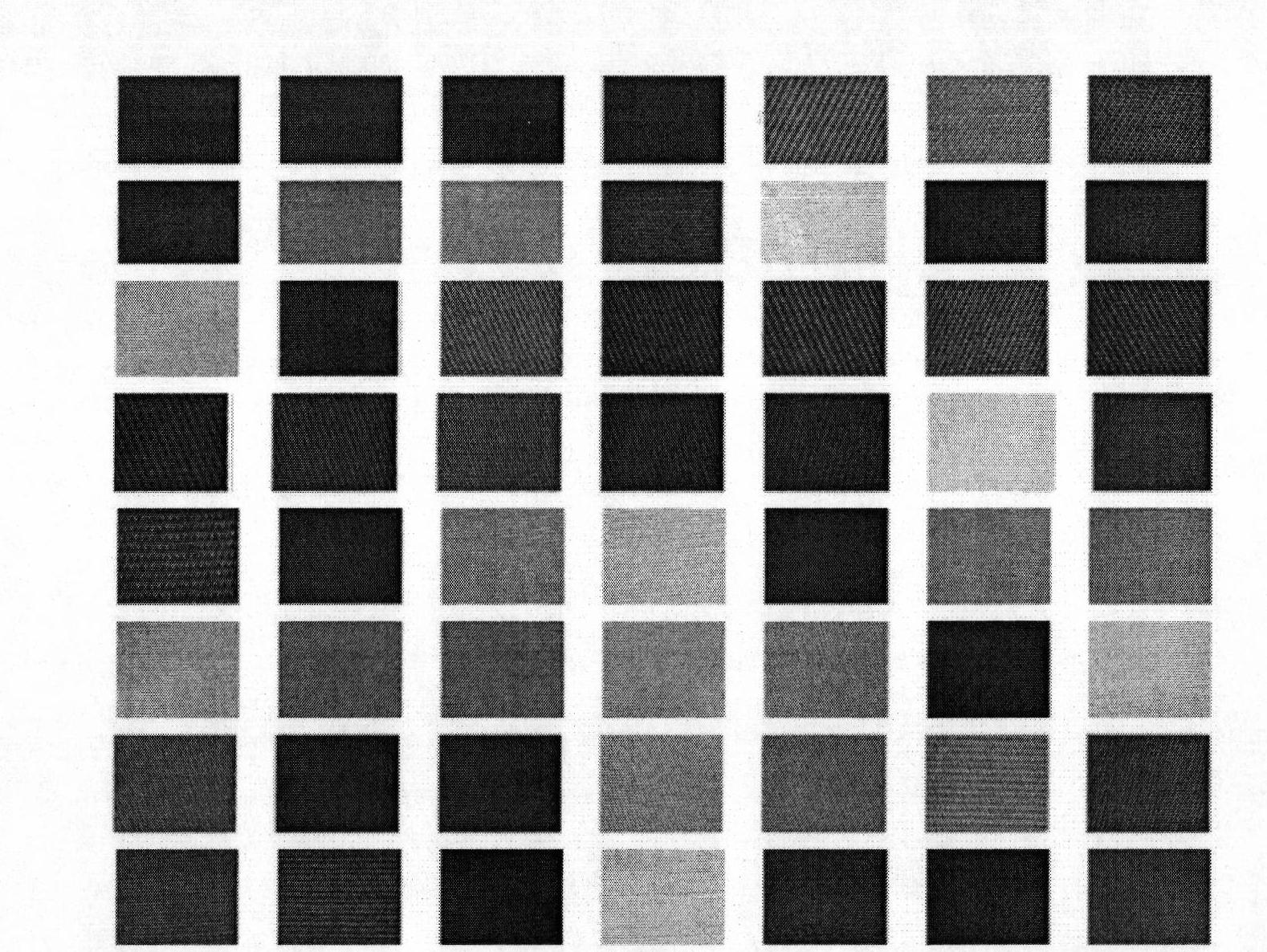

Textile color stability and color aberration grading method

InactiveCN101100807AWith automatic ratingReduce labor intensityInspecting textilesRGB color spaceColor difference

The invention discloses fabric color fastness color difference grading method. It includes the following steps: copying fabric color character and transmitting to the computer to obtain homochromatic different spectra image in RGB color space coordinates; analyzing and measuring. It has the advantages of practical, reliable, easy operation, fast analyzing, automatic grading etc.

Owner:QINGDAO ENTRY EXIT INSPECTION & QUARANTINE BUREAU P R CHINA +2

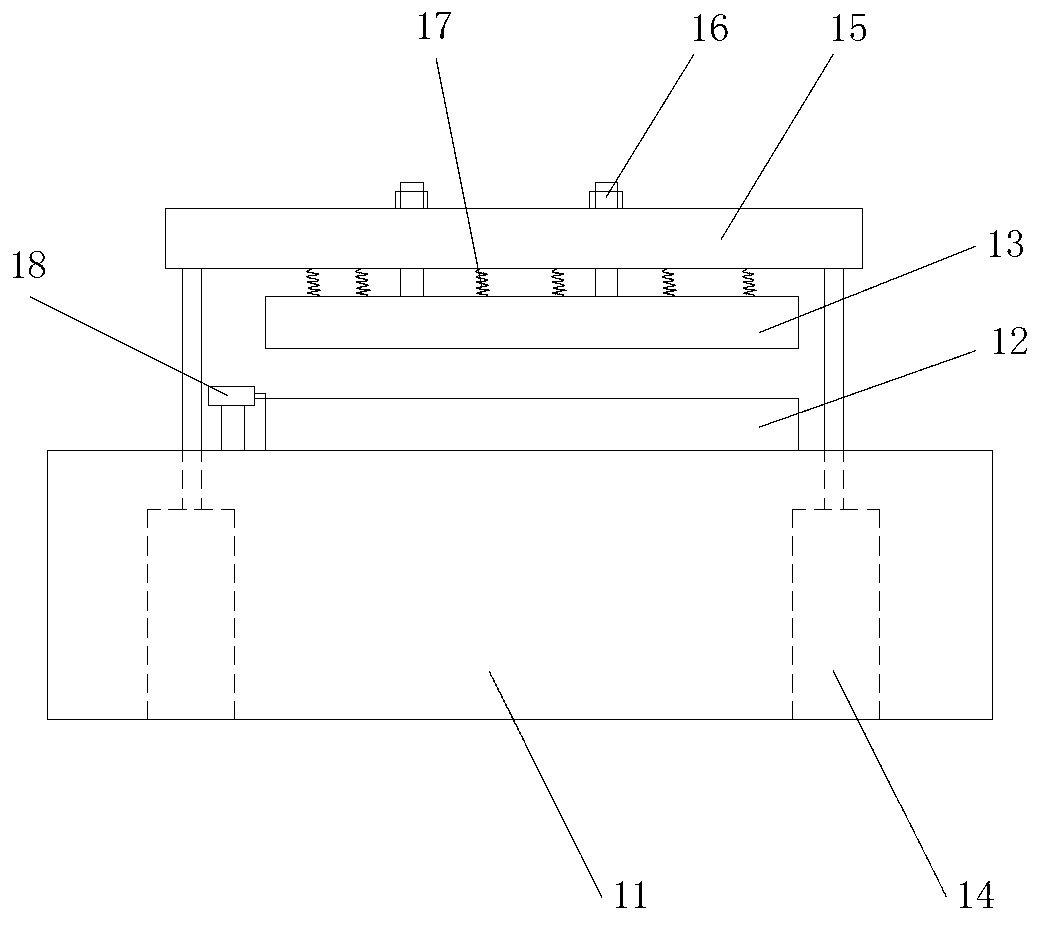

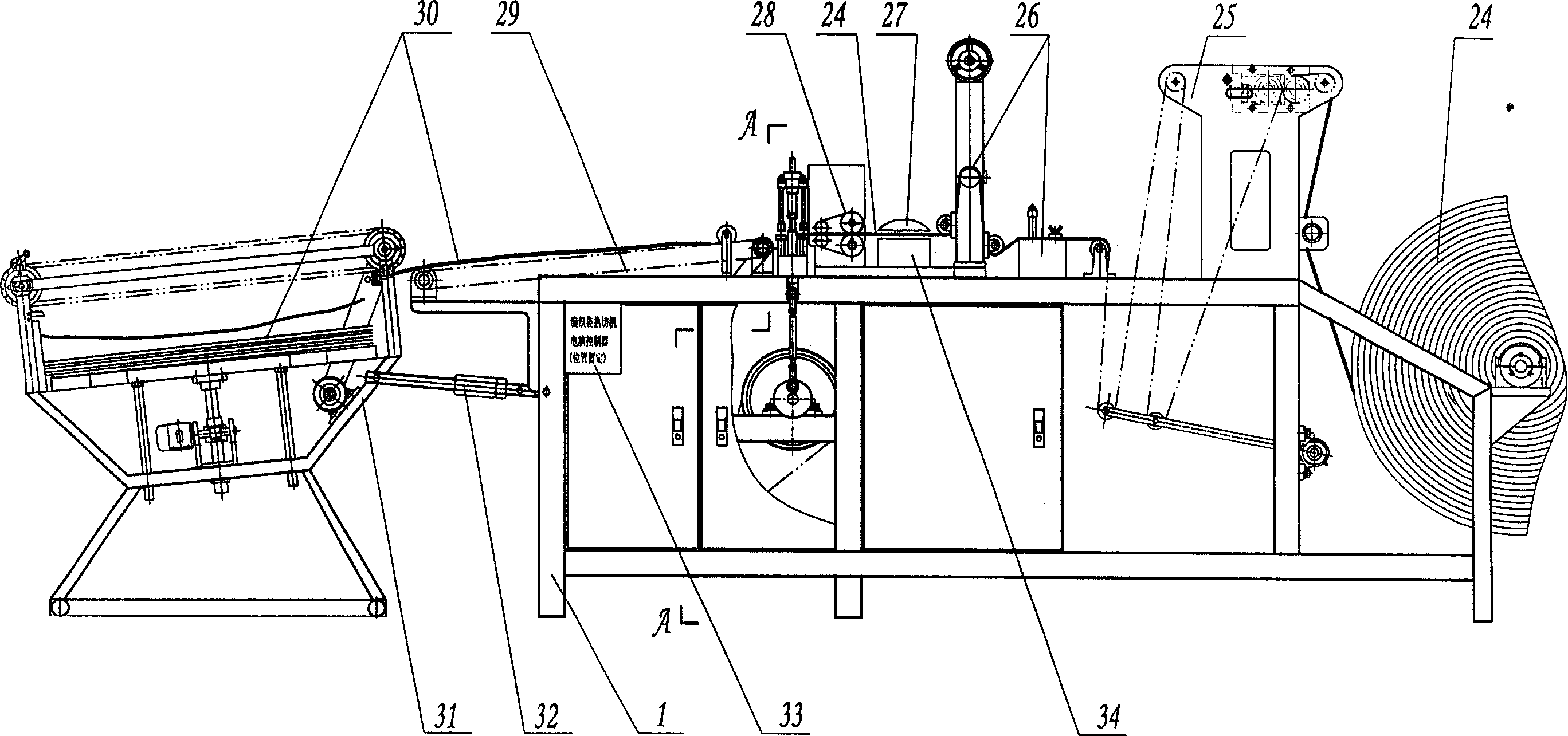

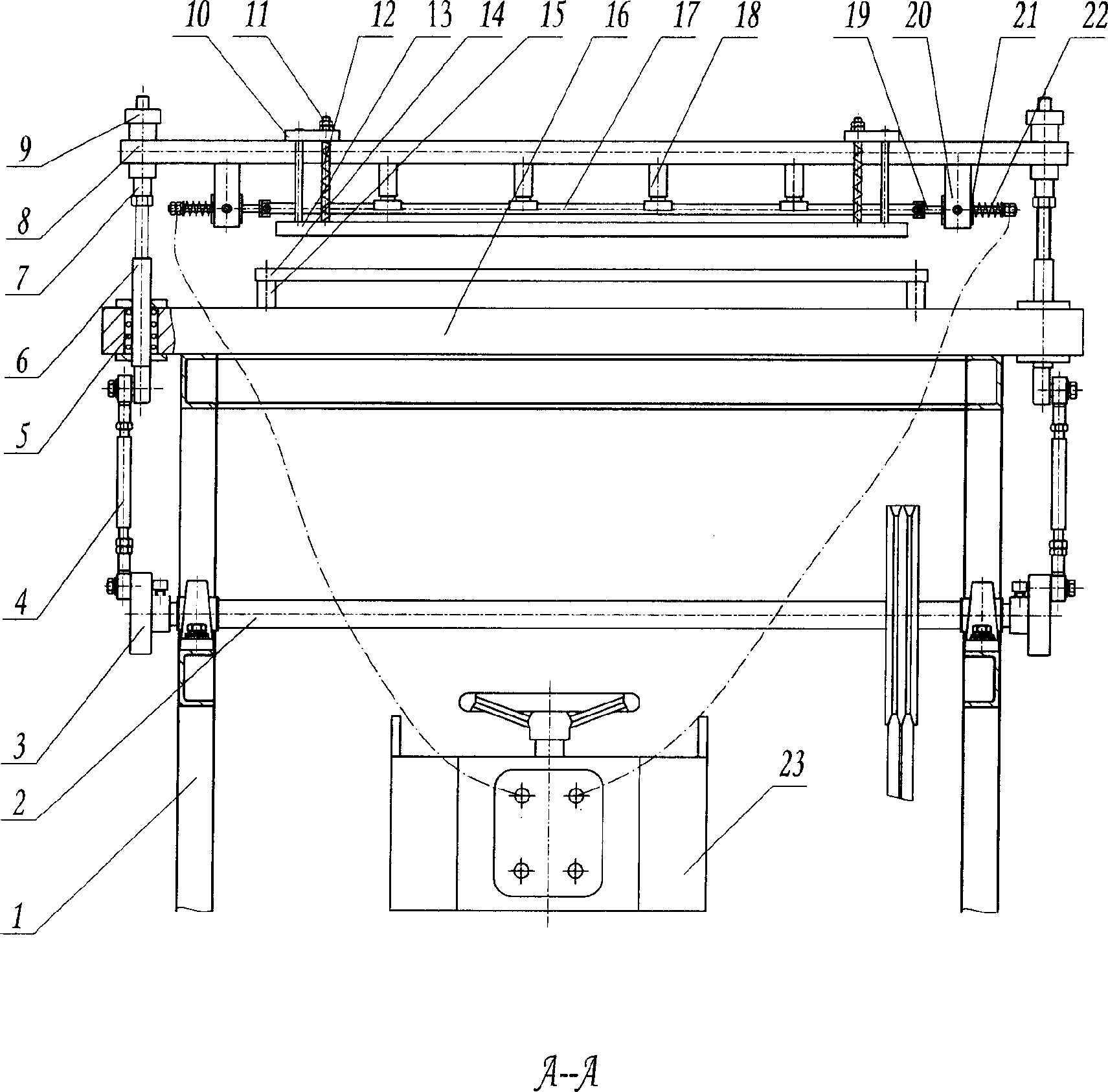

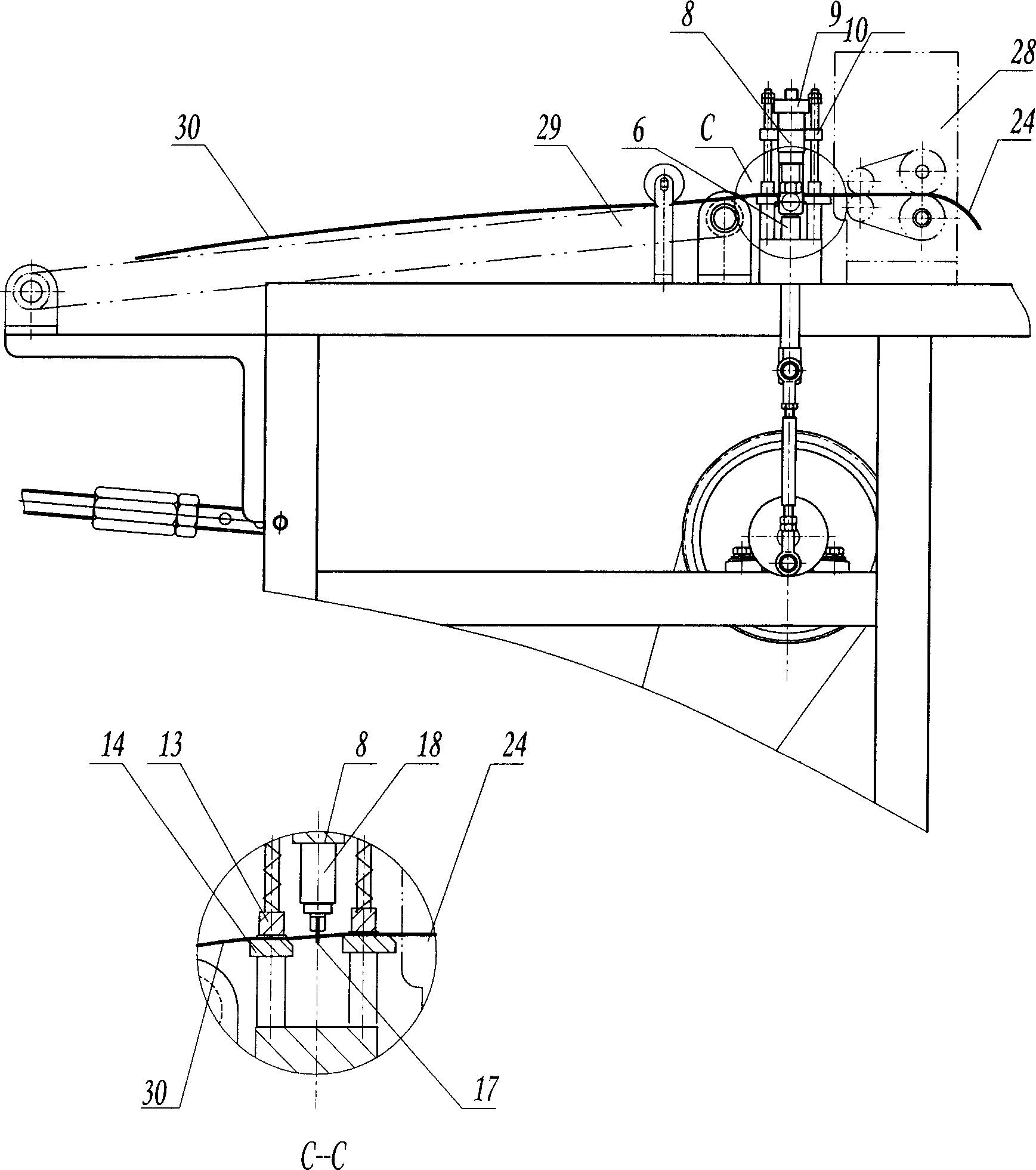

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Woven bag hot-cutting machine

InactiveCN1699678AOvercome three major problemsImprove production efficiencyInspecting textilesSevering textilesEngineeringMechanical engineering

The present invention relates to a kind of hot cutting machine for woven bags, consisting of a feeding and adjusting mechanism, inspection device, an output apparatus, a cutting-separation mechanism, a bag conveying and collecting mechanism. The invention has replaced the way of cutting bags by hand and overcome three difficult problems: using silicon electron inspection device to check pictures by silicon light so as to inspect the warp and weft of the bag surface materials in the course of weaving; using pressing bag cutting-separation mechanism to press a bag by a pressure bar and fix it and then cut it with hot knife, which is made of nickel chromium material, heated by adjusting voltage and cut by controlling the temperature and speed so as to achieve non-lose edge on the woven bags after cutting and separating; using chain belt ring caterpillar bag mouth binding mechanism to raise production efficiency by 4 times and save one man operation.

Owner:黄友总

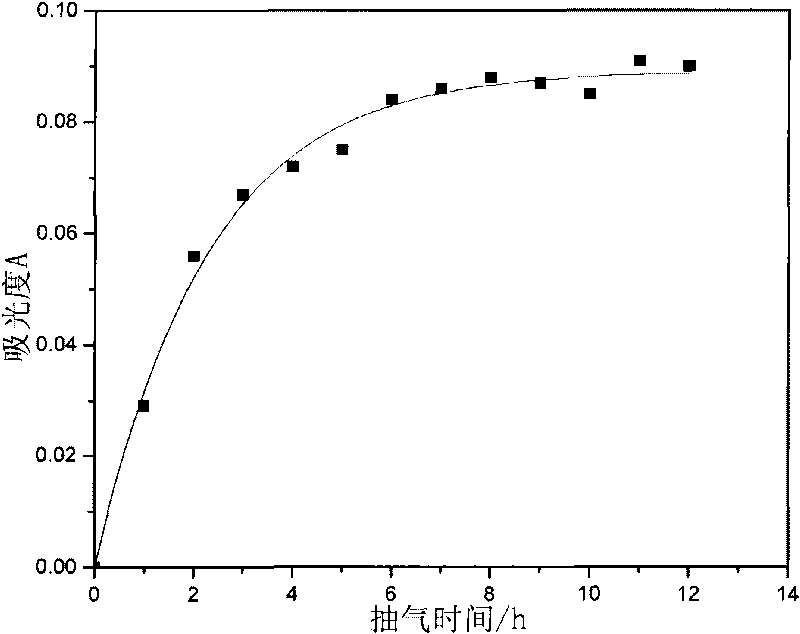

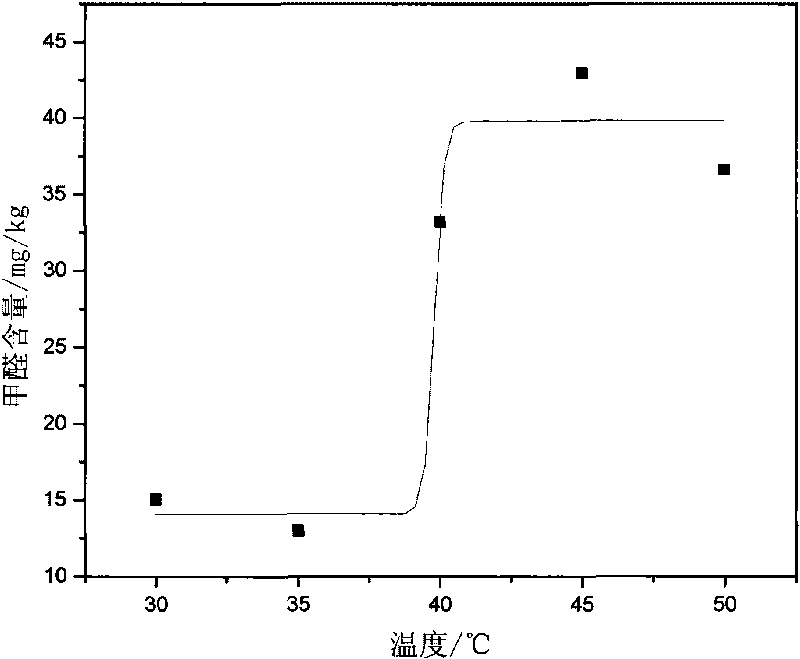

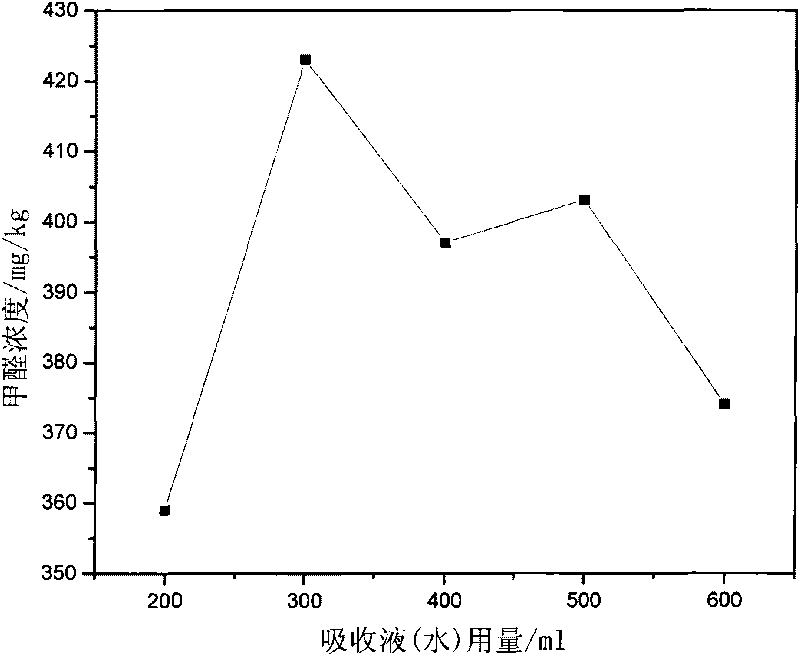

Non-destructive testing method for formaldehyde content of textiles

InactiveCN101736569AEasy to moveEvenly distributedMaterial analysis by observing effect on chemical indicatorInspecting textilesNon destructiveQuantitative determination

The invention discloses a non-destructive testing method for formaldehyde content of textiles, which is characterized by comprising the following steps: (1) placing a to-be-tested whole textile in a sealed container, feeding air into the sealed container, sending gas containing a to-be-tested volatile-matter sample in the sealed container to an absorption container holding formaldehyde-absorbing solution and allowing the absorbing solution to absorb the gas from the sealed container; (2) continuing to feed air into the sealed container and send the gas in the sealed container into the absorbing solution for at least 30 minutes and then stopping the process that the water absorbs the gas; and (3) taking the absorbing solution obtained in a step (2) to perform formaldehyde qualitative identification or quantitative determination. The method can test the formaldehyde in the whole textile without damaging the textile, and can test the content of low-concentration formaldehyde in the textile.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

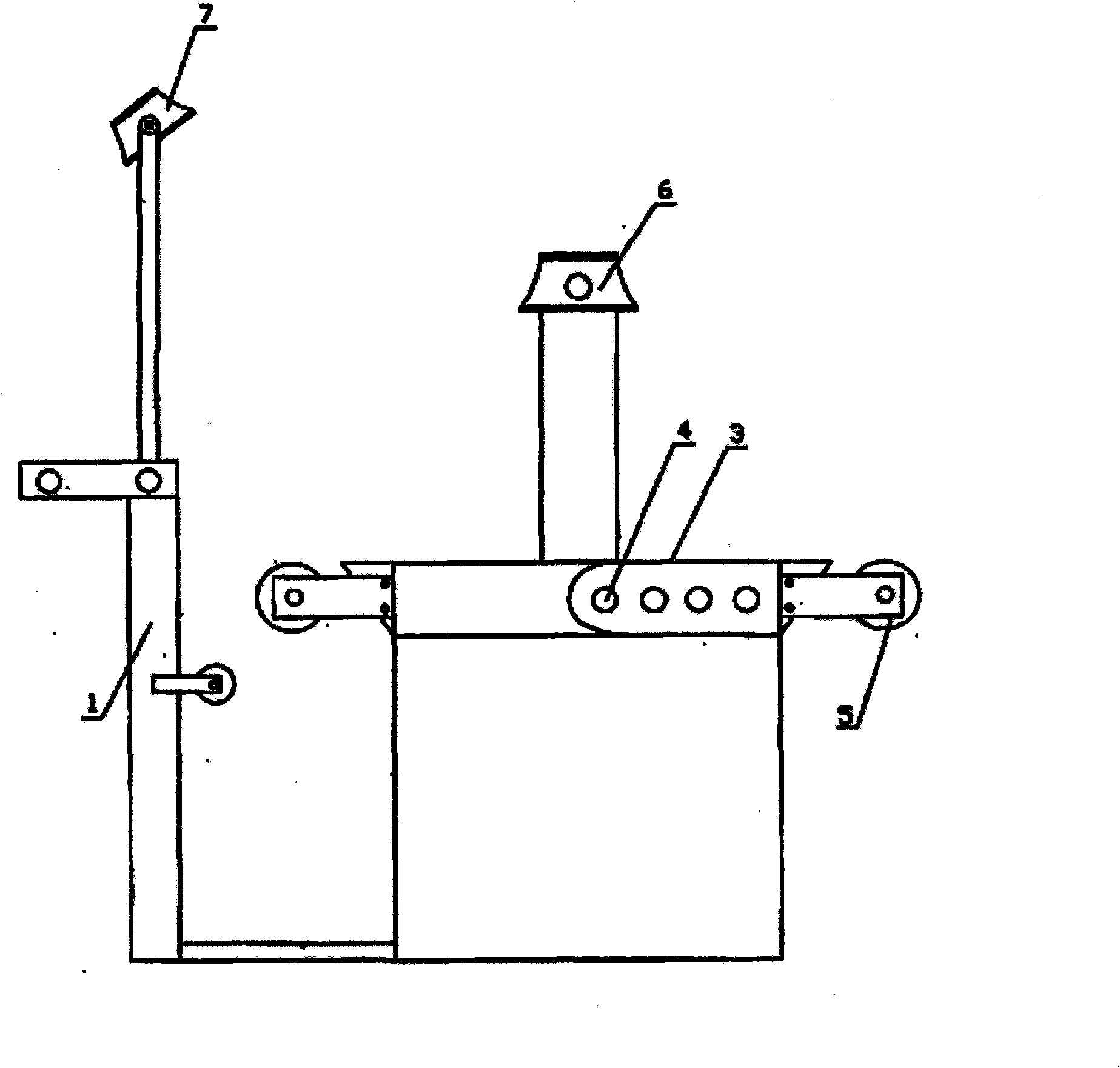

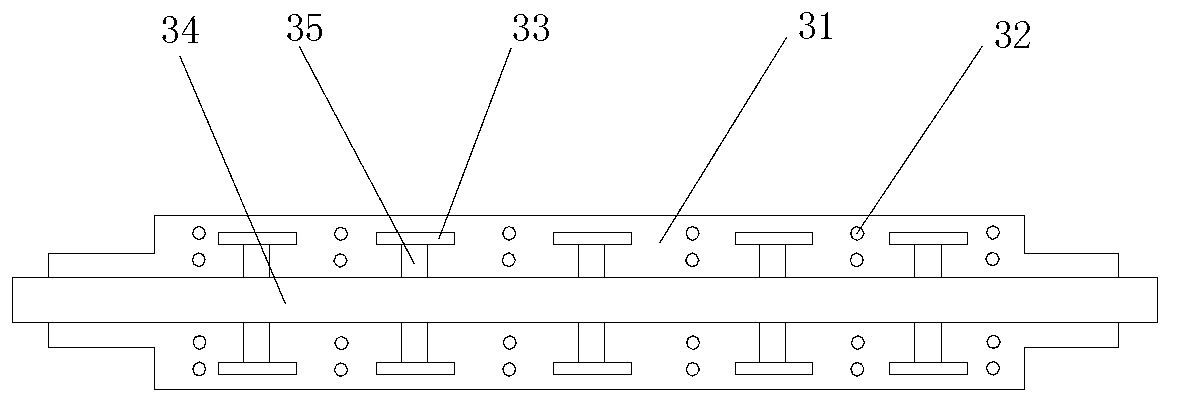

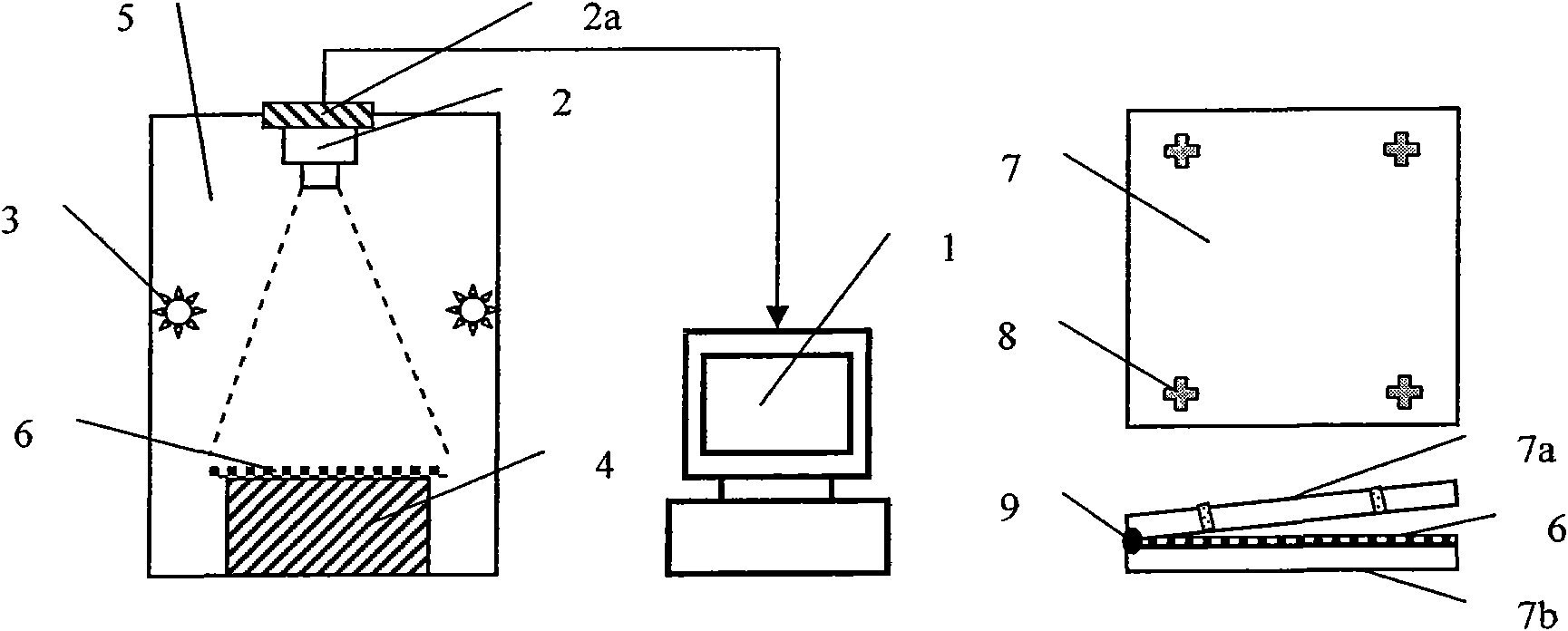

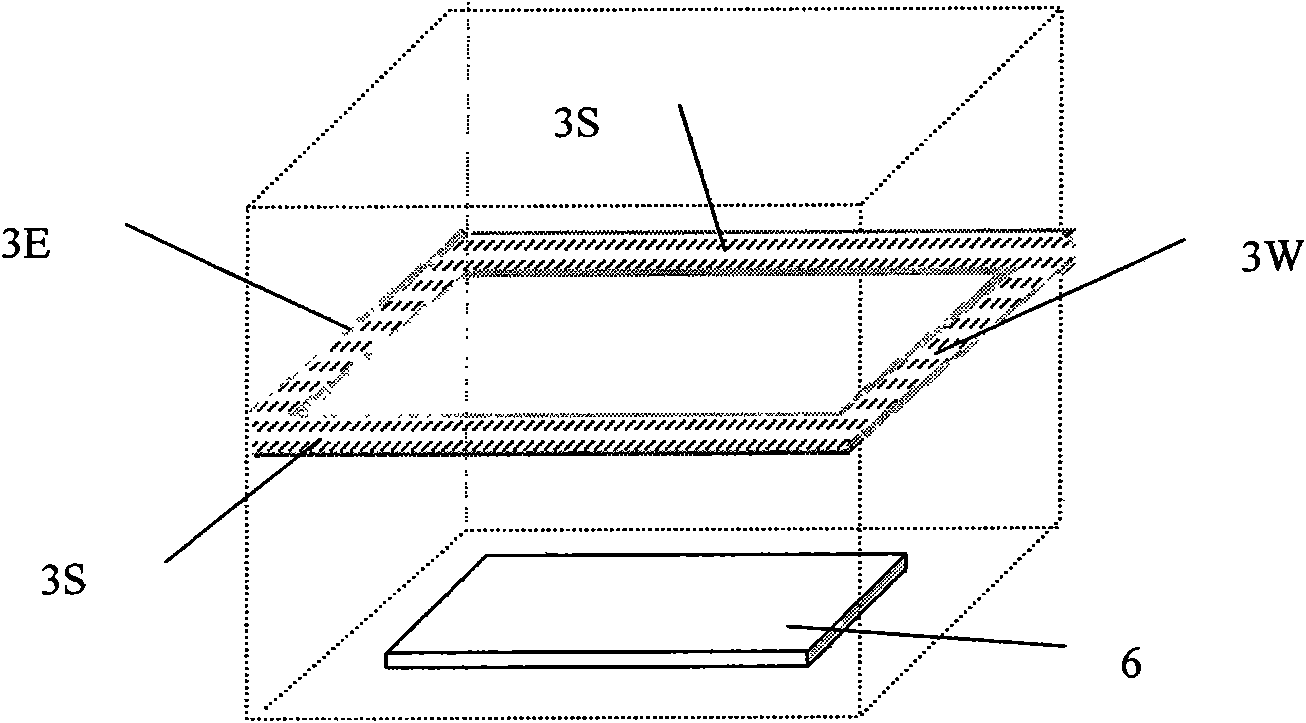

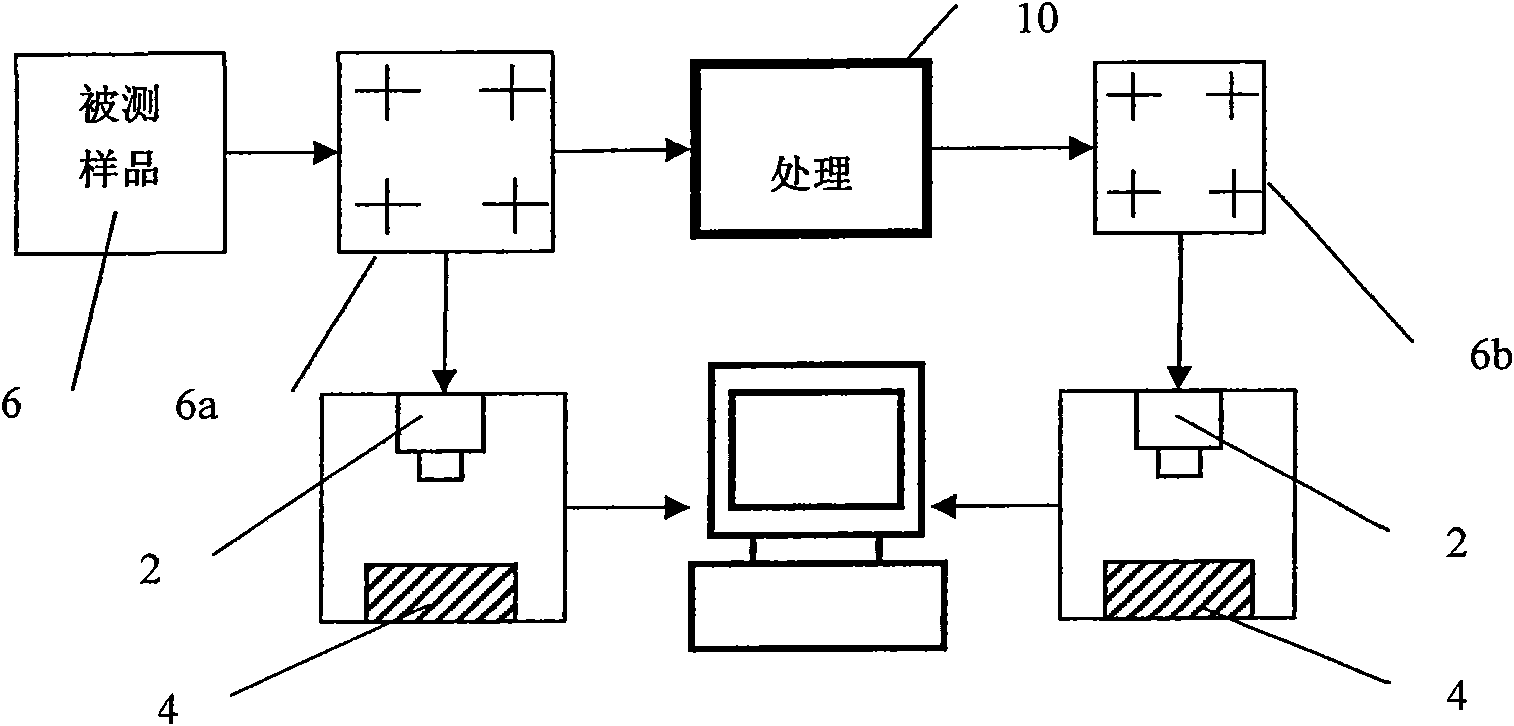

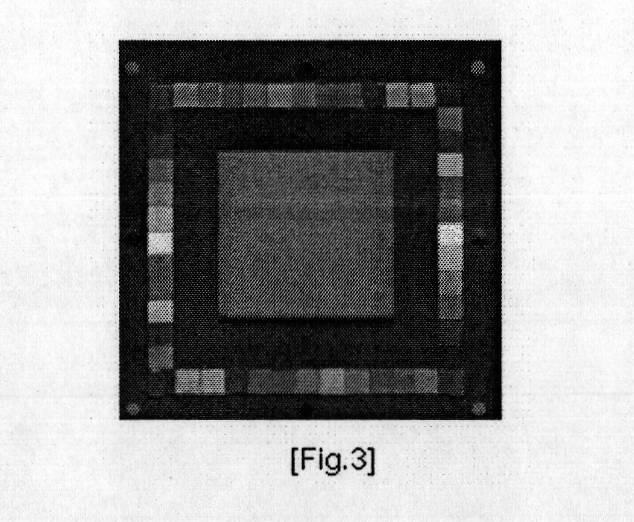

Digital test system and method for dimension variety and distortion of textile

InactiveCN101644565APromote research and developmentPromote application developmentInspecting textilesUsing optical meansImaging processingSample image

A digital test system for the dimension variety and distortion of textile includes a marking template (7) for marking a measured sample (6), an illumination box (5) forming a close space, an imaging apparatus (2) for the measured sample image shooting, a fixture for installing the imaging apparatus (2) in the illumination box (5), an illuminator (3) for illuminating the surface of the measured sample, a sample table (4) for arranging and fixing the measured sample (6) in the illumination box (5), a software package for image processing and calculating the dimension variety and distortion, anda computer (1). A digital test method, a arithmetic and a programme for the dimension variety and distortion of textile.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Device and method for testing fabric color

The invention relates to a device and method for testing the fabric color by using a scanner. The normal fabric is subjected to the scanner characteristic by using the fabric standard based on the standard color card. According to the invention, in the presence of multiple light sources and a complex observer, a CIE device independent color coordinate can be obtained according to the RGB value of the scanned measured area (ROI) without expensive equipment such as a colorimeter, a spectrophotometer and a multiple-light-source camera. The fabric color analyzing system is suitable for different materials such as wool, silk or other natural or synthetic fabrics, after a user defines an allowable 2.color difference, the color classification and automatic color matching is conducted on the different materials according to the information in a database. The characterization method can be used in a number of commercial flatbed scanners, the device for testing the fabric color, taken as a quality testing tool in the surface color industrial application field, is used for testing the quality of fabric, picture, paper, leather, plastic, printed matters and the like.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

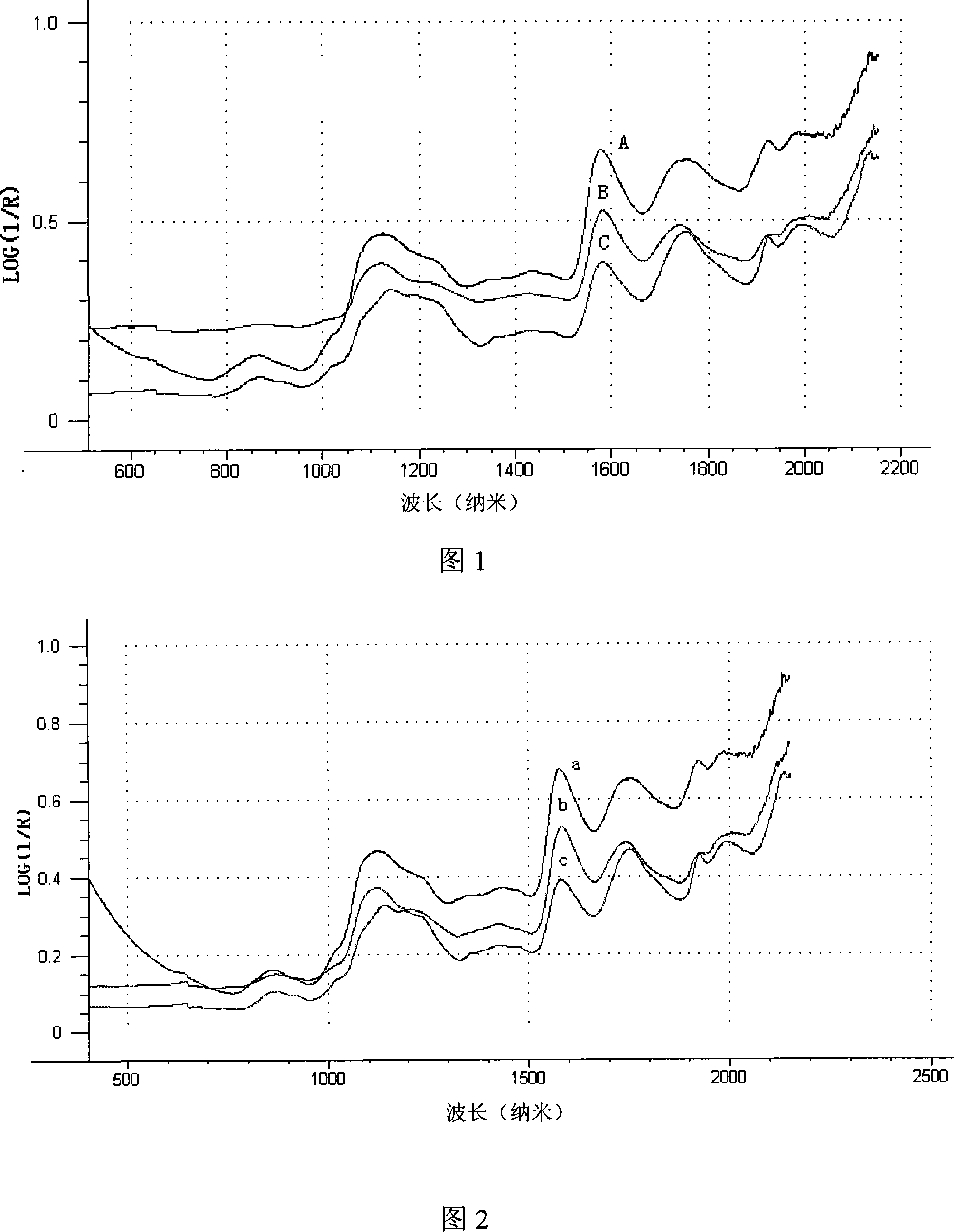

Textile fibre identification method

InactiveCN101140223AThe identification result is accurateInspecting textilesColor/spectral properties measurementsFiberInfrared

A fiber authentication method collects near infrared spectrum data of fibers to be authenticated, utilizes chemical metrological method to analyze relativity between the near infrared spectrum data of the fibers to be authenticated and near infrared spectrum of standard fiber samples and authenticates whether the fibers to be authenticated belong to a same sort with the standard fiber sample according to relevant coefficients. The fiber authentication method of the present invention only collects near infrared spectrum data of fibers to be authenticated and utilizes chemical metrological method to analyze relativity of near infrared spectrum data of fibers to be authenticated and standard sample fibers to authenticate whether the fiber to be authenticated belongs to a same sort with the standard fiber sample, thus completing authentication in several minutes and bringing accurate authentication results.

Owner:国际竹藤网络中心

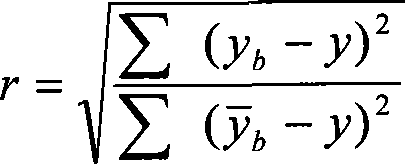

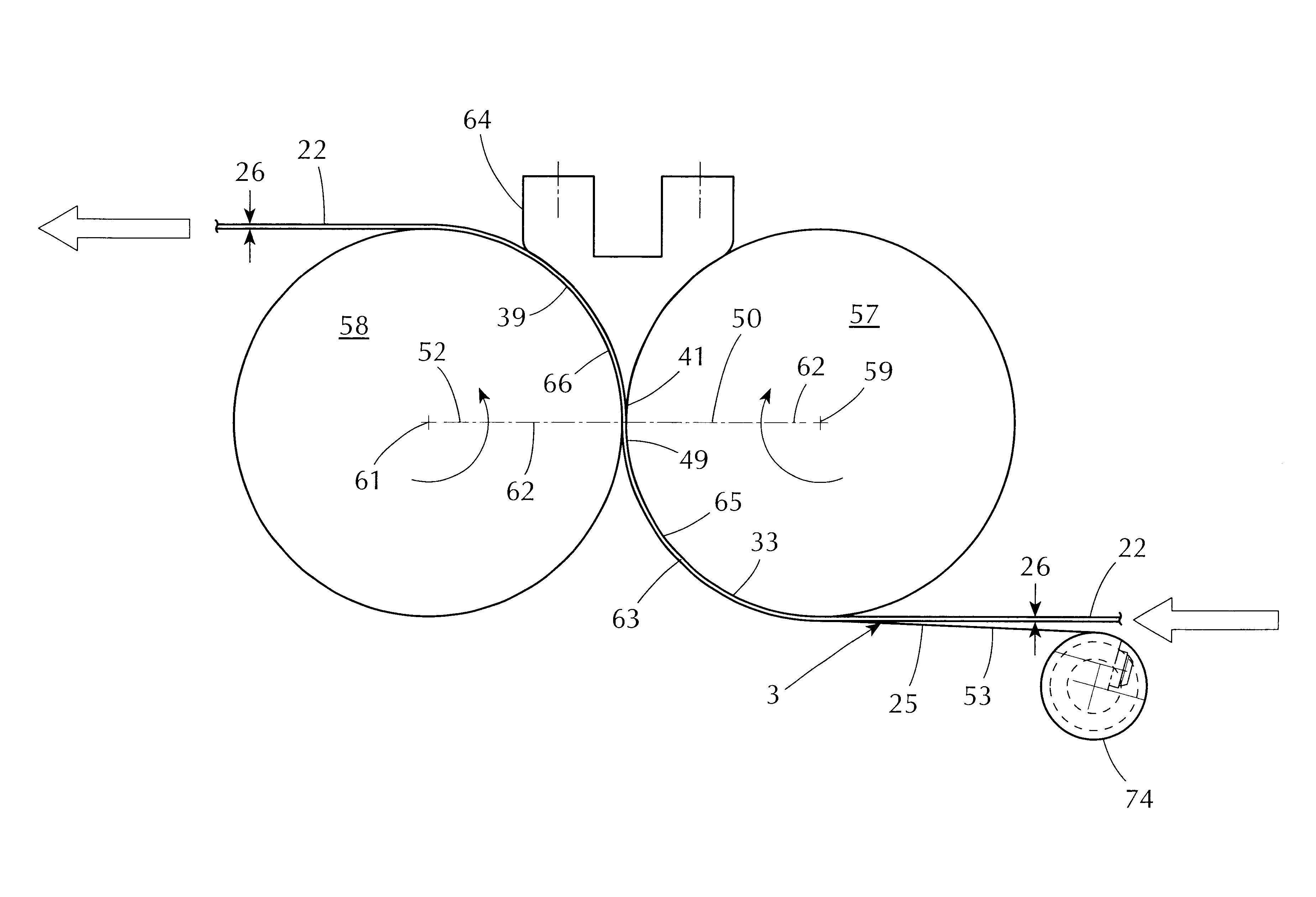

Dual-slip compressive shrink-proofing apparatus for fabric and related method

InactiveUS6681461B1Superior-quality controlled permanent compactionReduced Power RequirementsShrinkingMechanical cleaningFiberYarn

A method and related apparatus for shrink-proofing a fabric, typically a knitted textile composed of interlocked loops of yarn made of natural and / or man-made fibers. The loops interlock along stitch rows that may become skewed. According to the invention the fabric is confined from expanding as it is delivered to and discharged from an in-line compression zone free of obstructions such as crimps, bends or kinks. The fabric is confined, preferably resiliently, coming to, passing through and leaving the compression zone so as to accommodate variation of thickness and irregularities of the fabric being compacted in the compression zone. The interlocked loops are organized whereby they are allowed to move toward each other orthogonally along their related stitch row so as to reduce volume of the fabric. Non-woven textiles, papers, papers with additives and the like are shrink-proofed in the same manner.

Owner:CATALLO FRANK

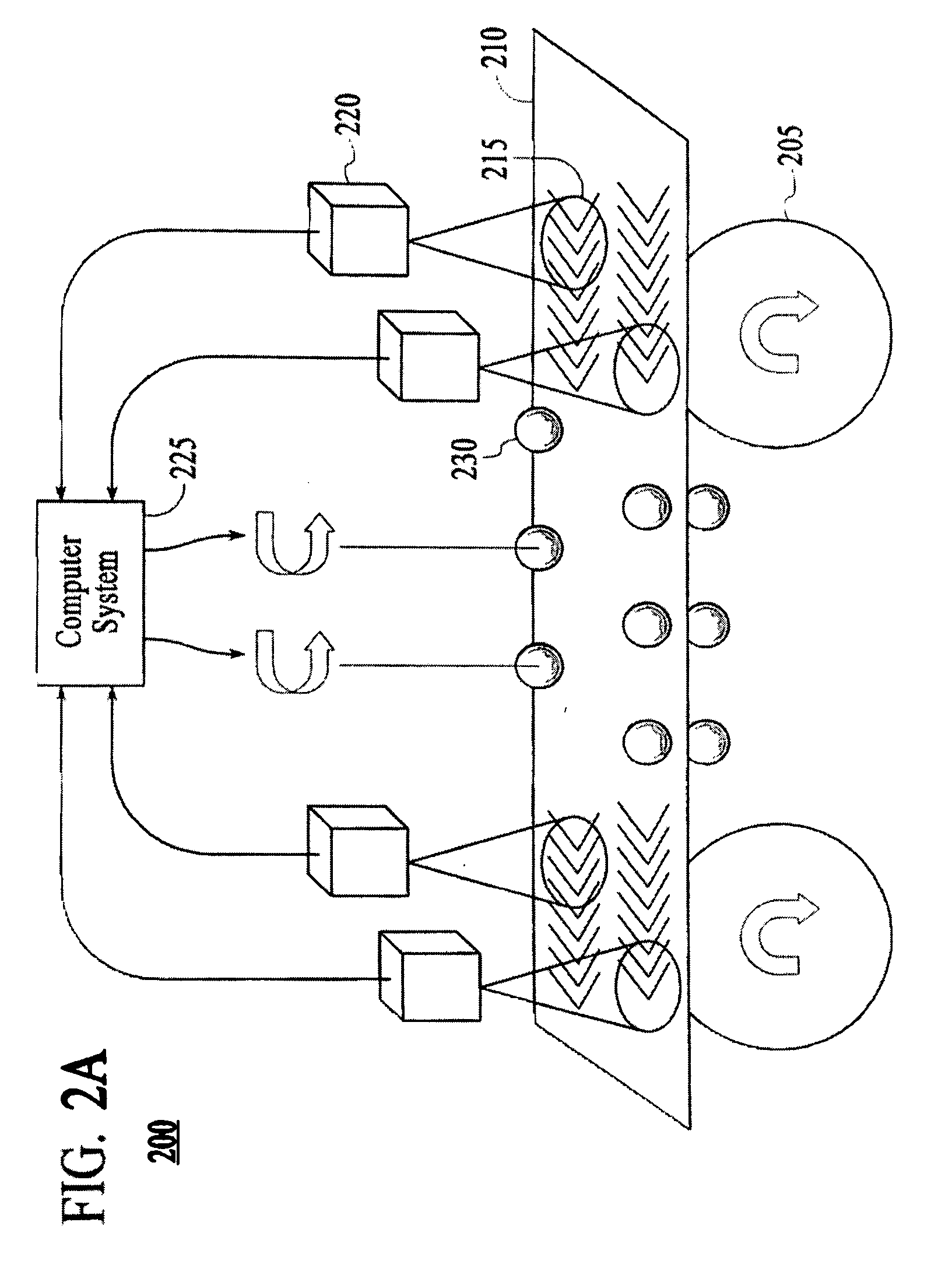

Apparatus and method for the automated marking of defects on webs of material

ActiveUS7623699B2Reduce material wasteConveniently performedMarking textilesInspecting textilesEngineering

A system for the characterization of webs that permits the identification of anomalous regions on the web to be performed at a first time and place, and permits the localization and marking of actual defects to be performed at a second time and place.

Owner:3M INNOVATIVE PROPERTIES CO

Dyeing and printing products on-line quality monitoring method based on computer pattern recognition principle

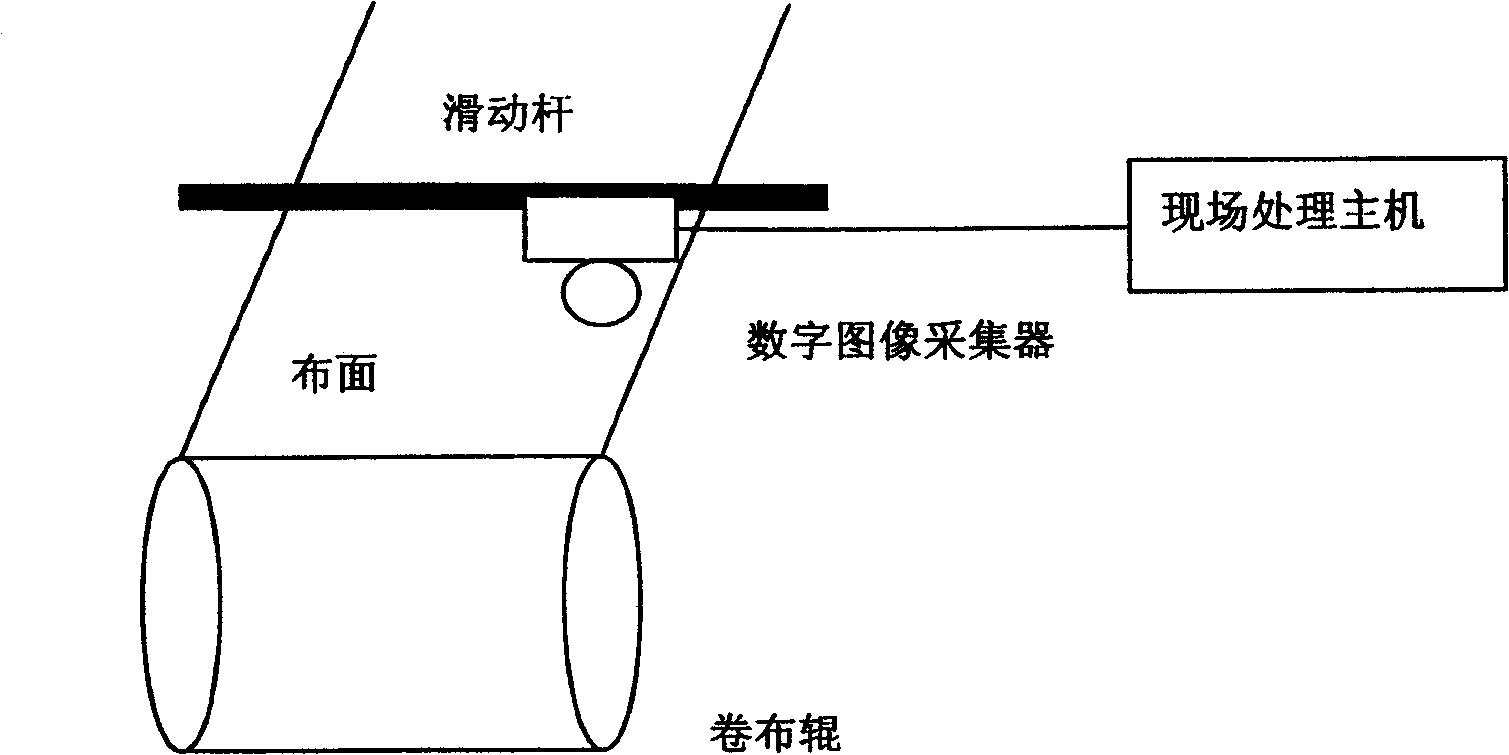

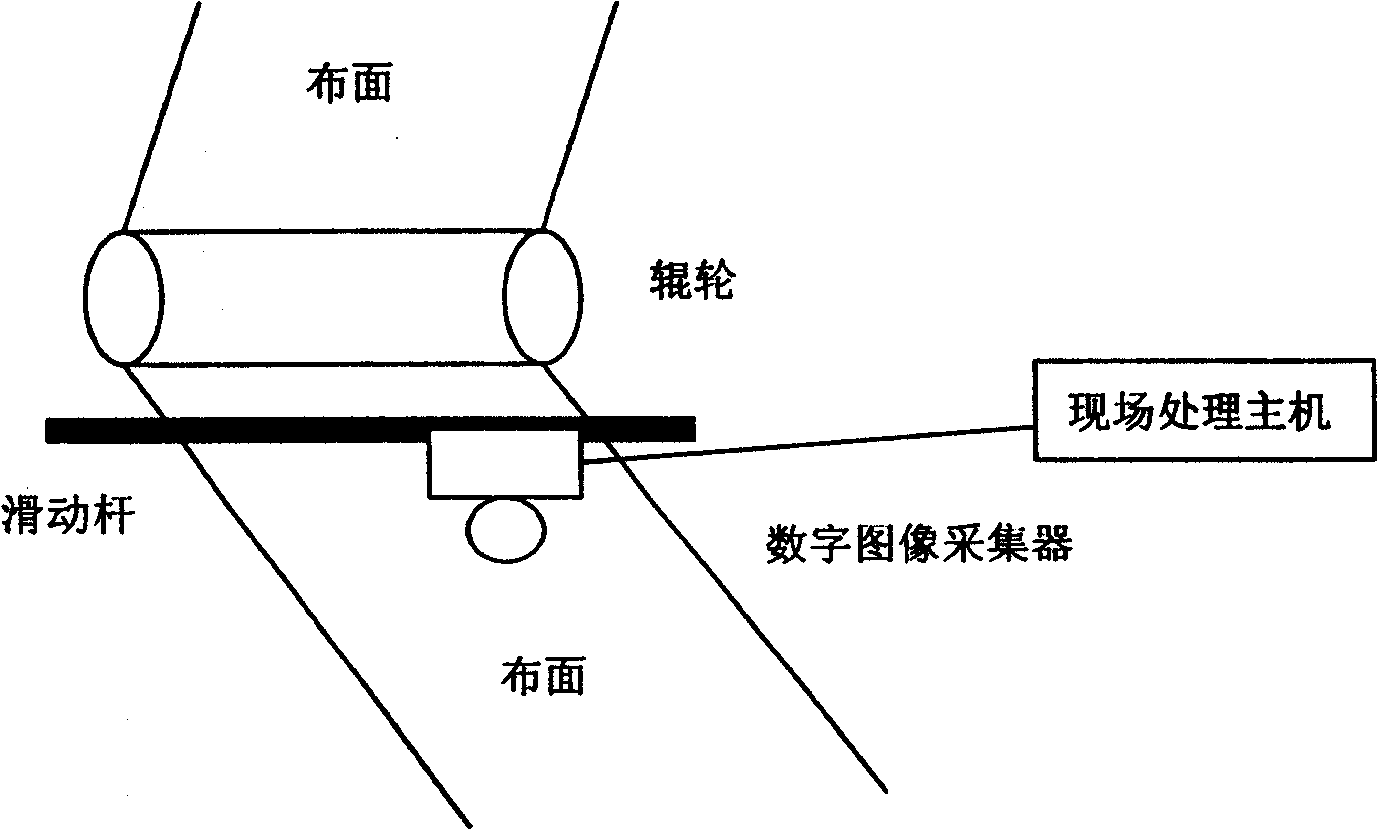

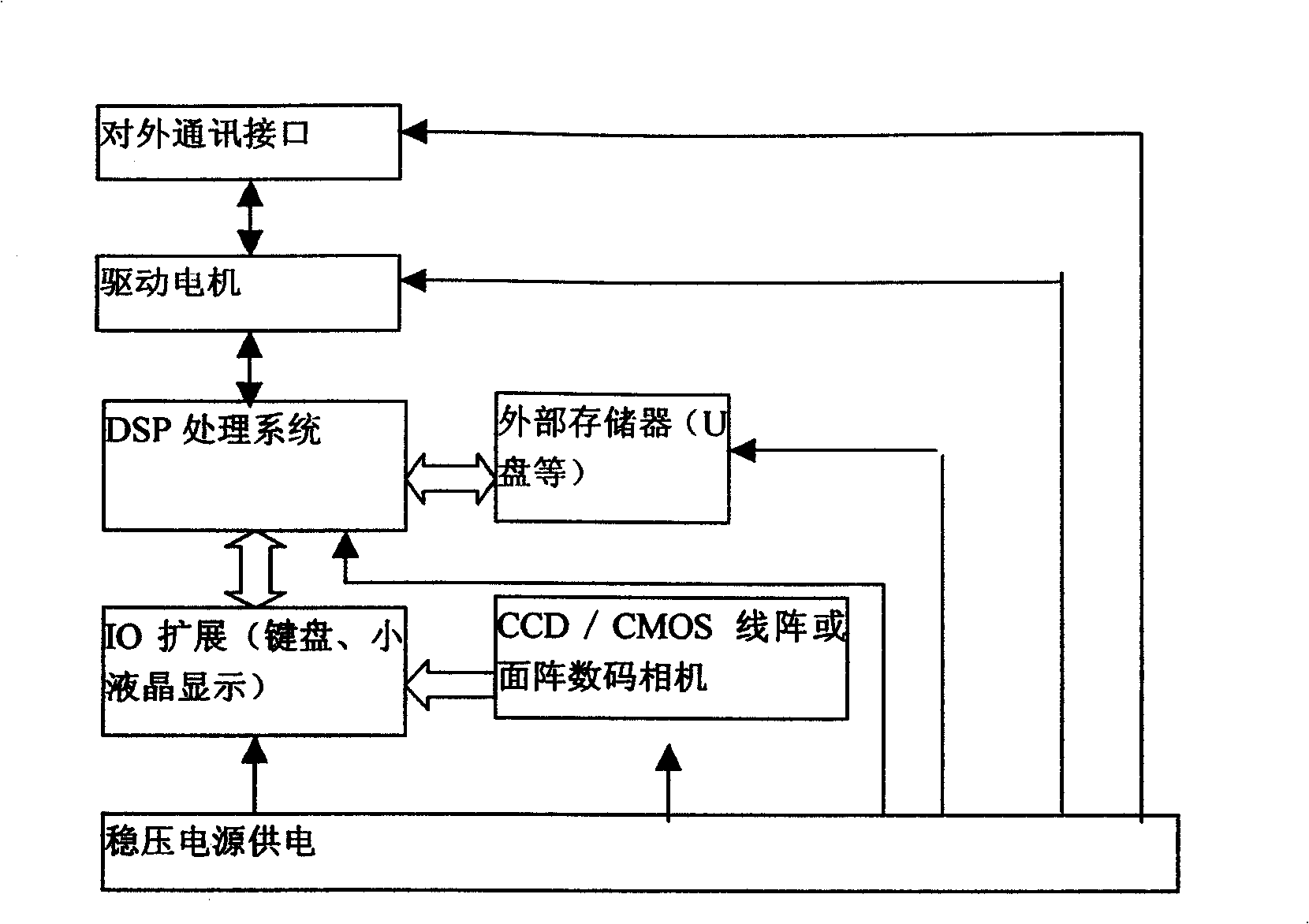

InactiveCN101334367AReduce generationReduce usageInspecting textilesTextile testingSites treatmentReciprocating motion

The invention relates to an online quality monitoring method of dyed products that is based on the computer graphic identification principle, adopts a digital image collector which is arranged and fixed on a slide rod above a rolling wheel or a cloth roller that are related to each technique in the dyeing, a camera shot side of the camera faces to a cloth surface, uninterrupted photographing of the moving cloth surface is implemented according to the set shooting frequency in unit time and repeated motion speed on the slide rod, and collected digital linear array or area array images are transmitted to an in-site processing host in real time; the in-site processing host is internally arranged with a standard cloth sample library and a defect library and implements fabric defect judgment, once a defect is determined, an alarming signal is emitted and leads the machine to halt, defect type on the fabric piece goods is reported, and concrete defect position is computed and indicated. The online quality monitoring method of the invention can implement the uninterrupted quality inspection of the products during the device running process, judge the product defects and indicate the defect type and the defect position.

Owner:何峰

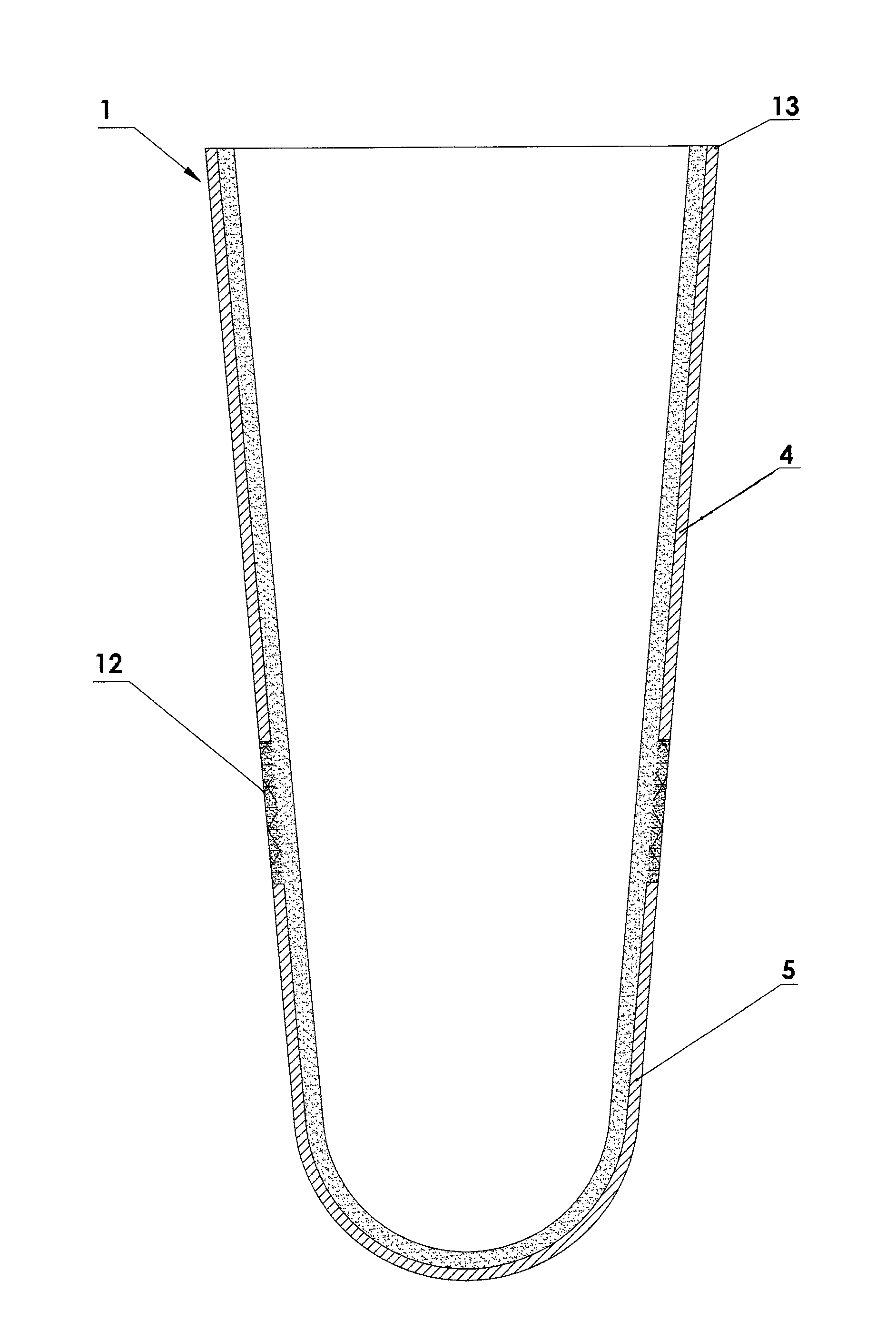

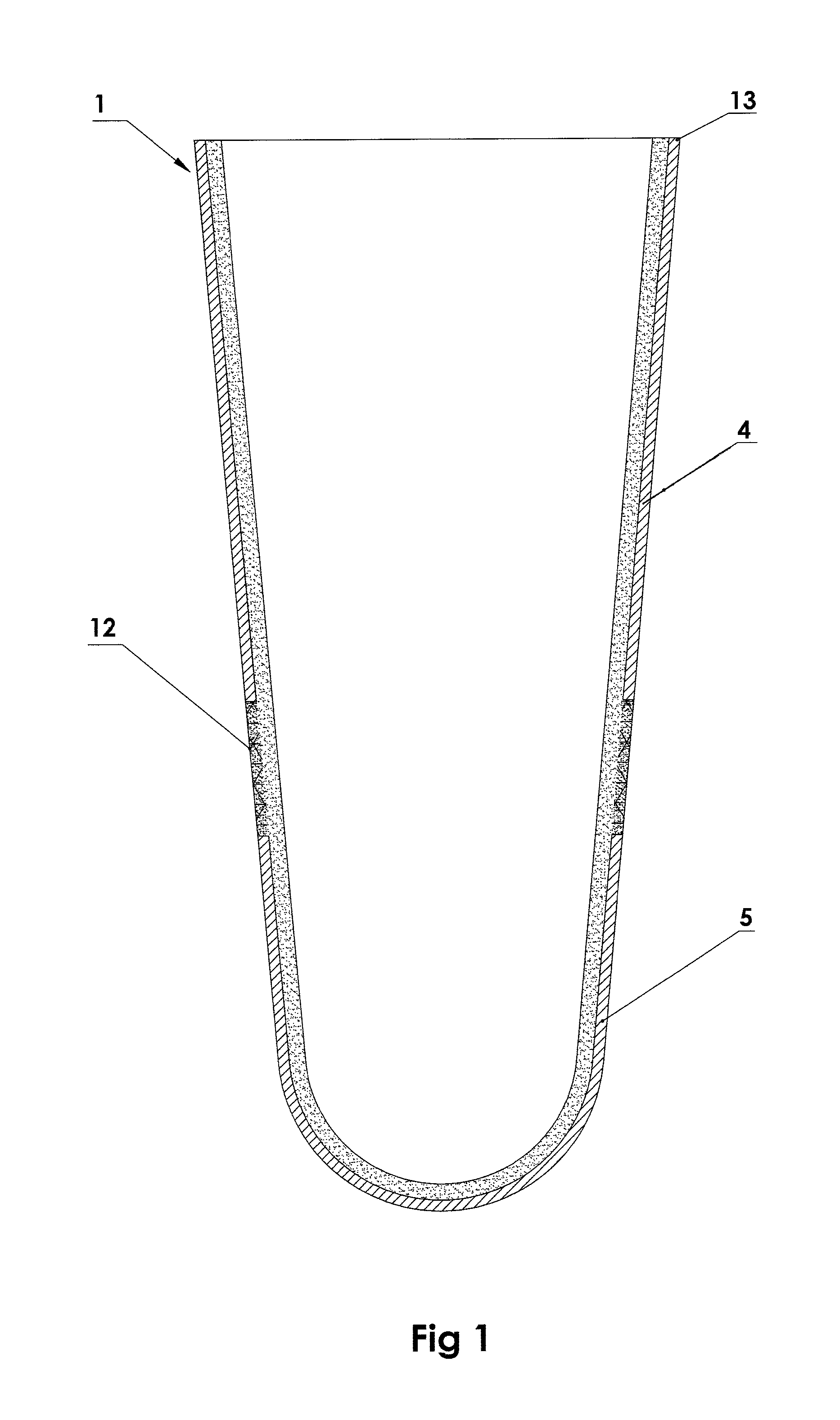

Method and apparatus of an integrated gel sealing liner

ActiveUS20140249650A1Sacrificing levelLess discomfortMechanical cleaningPressure cleaningYarnEngineering

A gel liner made by starting initially with a one-piece knitted tubular sock-shaped fabric having a closed distal end section of gel impermeable knitted fabric and an open proximal end section of gel impermeable knitted fabric and being a gel permeable loosely knitted fabric. Molding the liner to have a gel cushion layer on its interior surface with the gel passing through and partially embedding the yarns of the proximal fabric section with the outermost portions of the yarns free of gel to form at least one annular seal whereby the proximal end section forming a seal not inhibited in deformation and / or elongation by the fabric when the liner is worn thereby reducing or eliminating any twisting or discomfort of the liner during ambulation caused by the annular seal.

Owner:ALPS SOUTH EURO

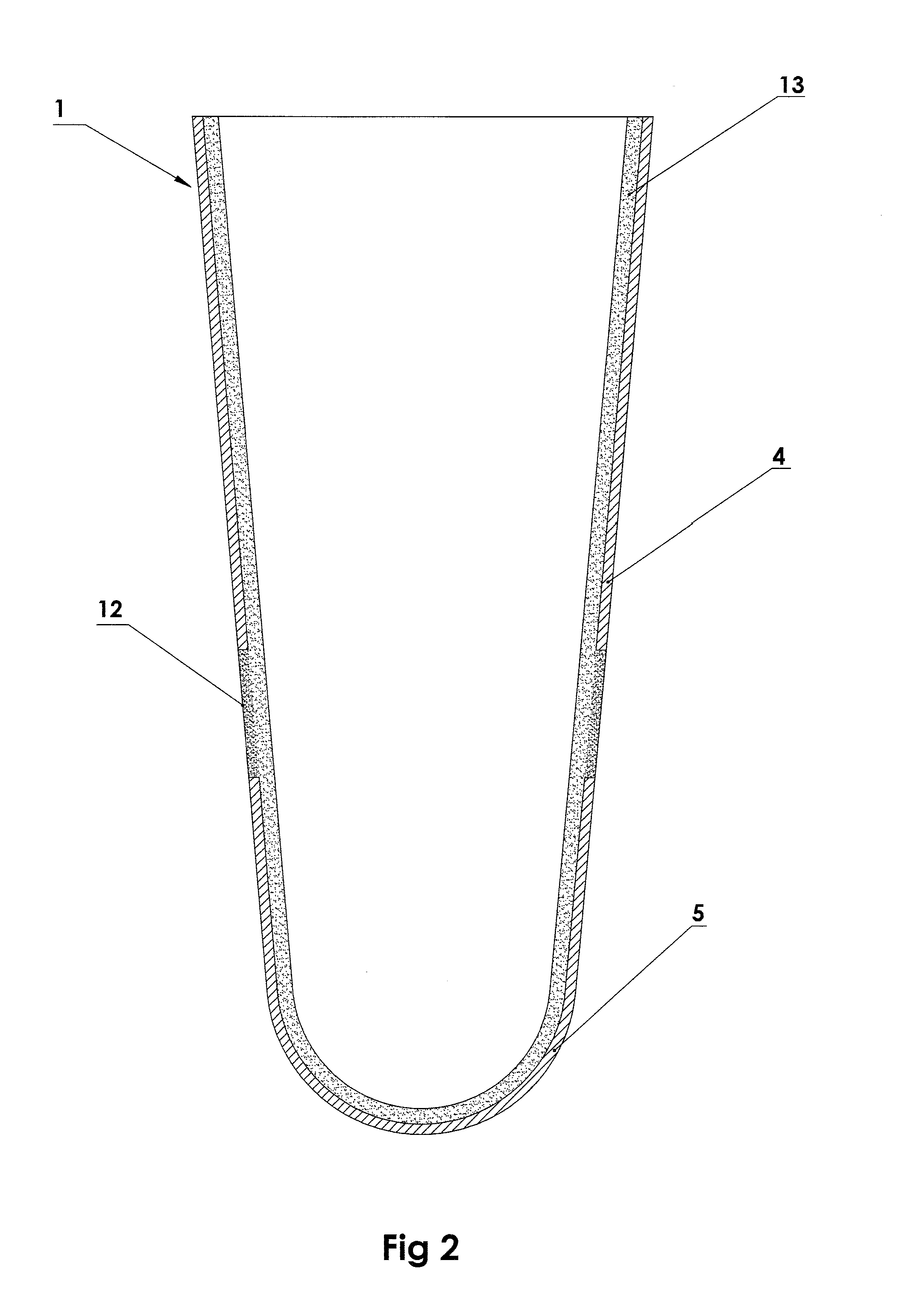

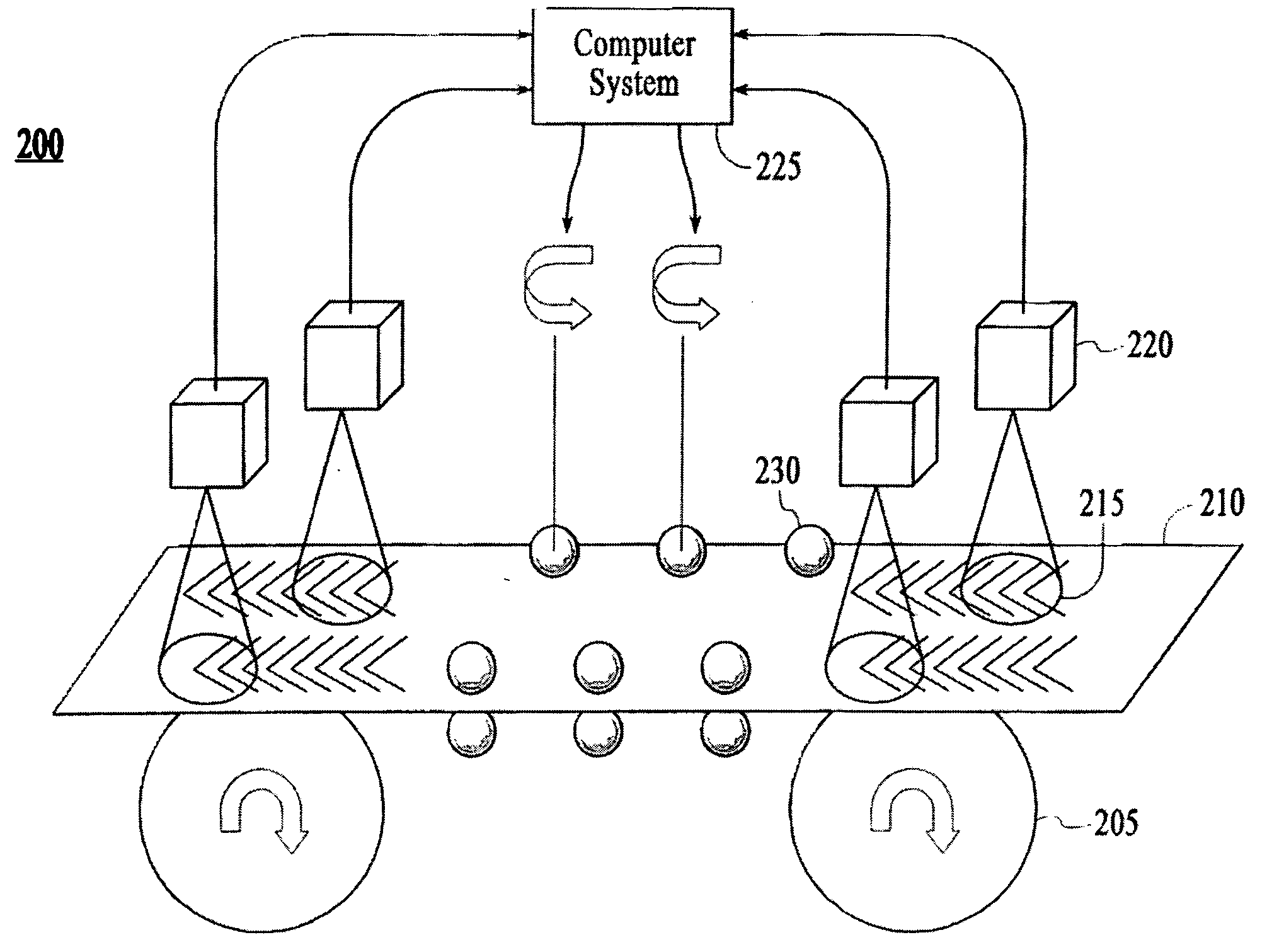

Method and system for correcting web deformation during a roll-to-roll process

InactiveUS20050087578A1Reduce Overlap CapacitanceHigh resolutionAutomatic control devicesPrecision positioning equipmentCapacitanceElectronic structure

The present invention includes a method and system for correcting web deformation during a roll-to-roll process. The present invention includes controllable mechanical components that are capable of dynamically adjusting the planarity of the web during the roll-to-roll process. By adjusting the web during the roll-to-roll process, the accuracy of the layer-to layer alignment of successive patterning steps is greatly increased thereby enabling the production of electronic structures with lower overlap capacitance and higher resolution. A first aspect of the present invention is a method for correcting web deformation during a roll-to-roll process. The method includes initiating a roll-to-roll process involving a flexible web substrate, detecting deformation in the flexible web substrate during the roll-to-roll process and dynamically aligning the flexible web substrate based on the detected deformation.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com