Textile color stability and color aberration grading method

A color fastness, textile technology, applied in the field of textile color fastness and color difference rating, can solve the problems of side effects, single, unable to choose the sample area at will, and simultaneous multi-point testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

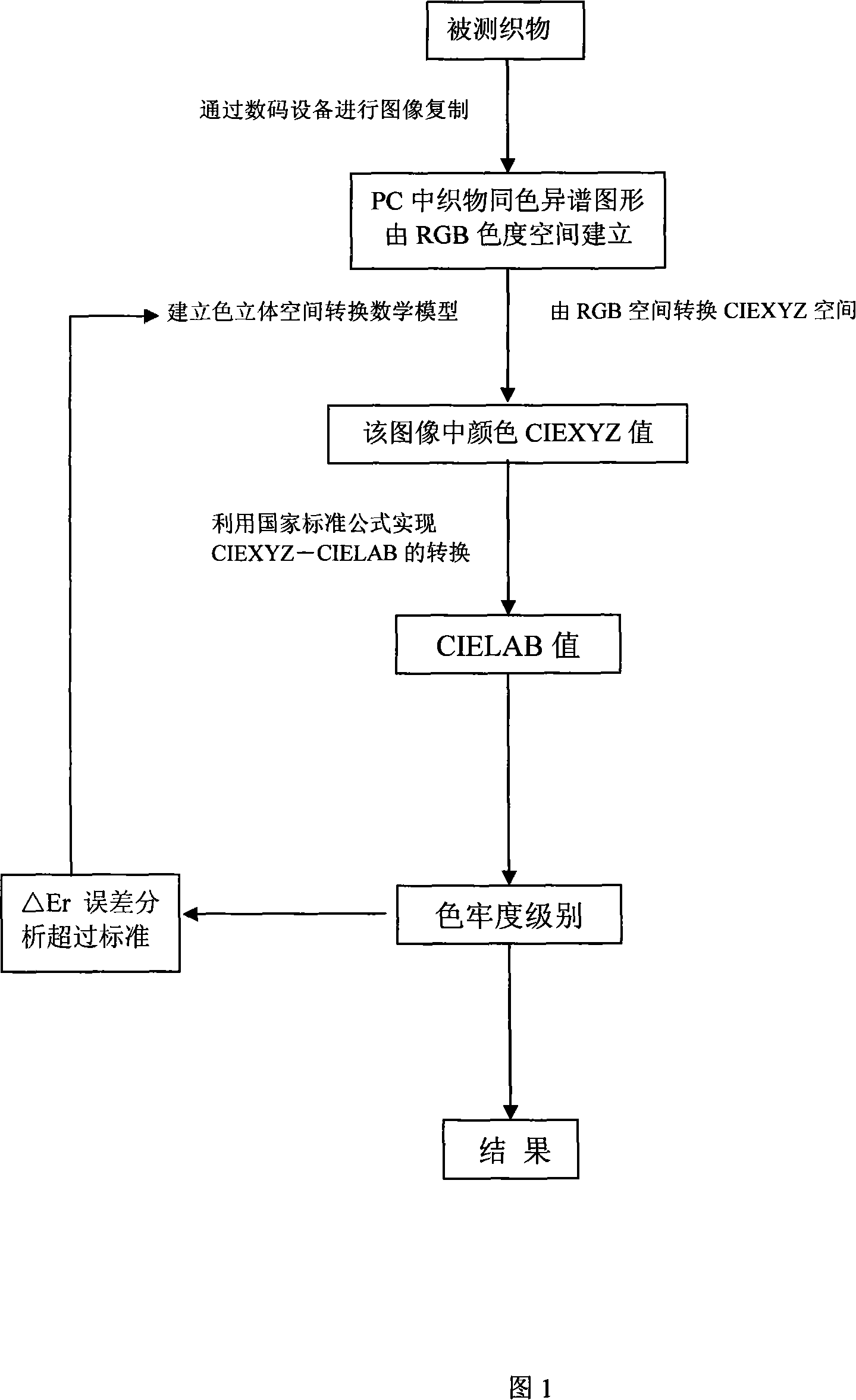

[0031] The method of the present invention is described in further detail below:

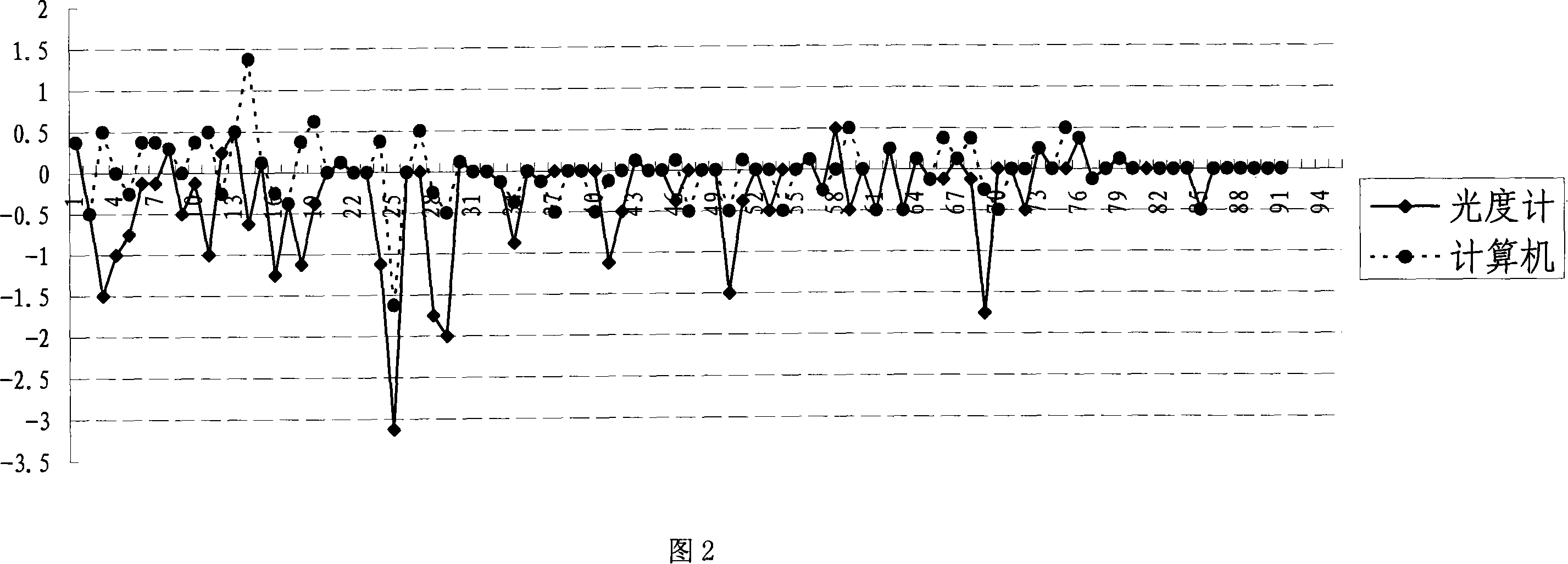

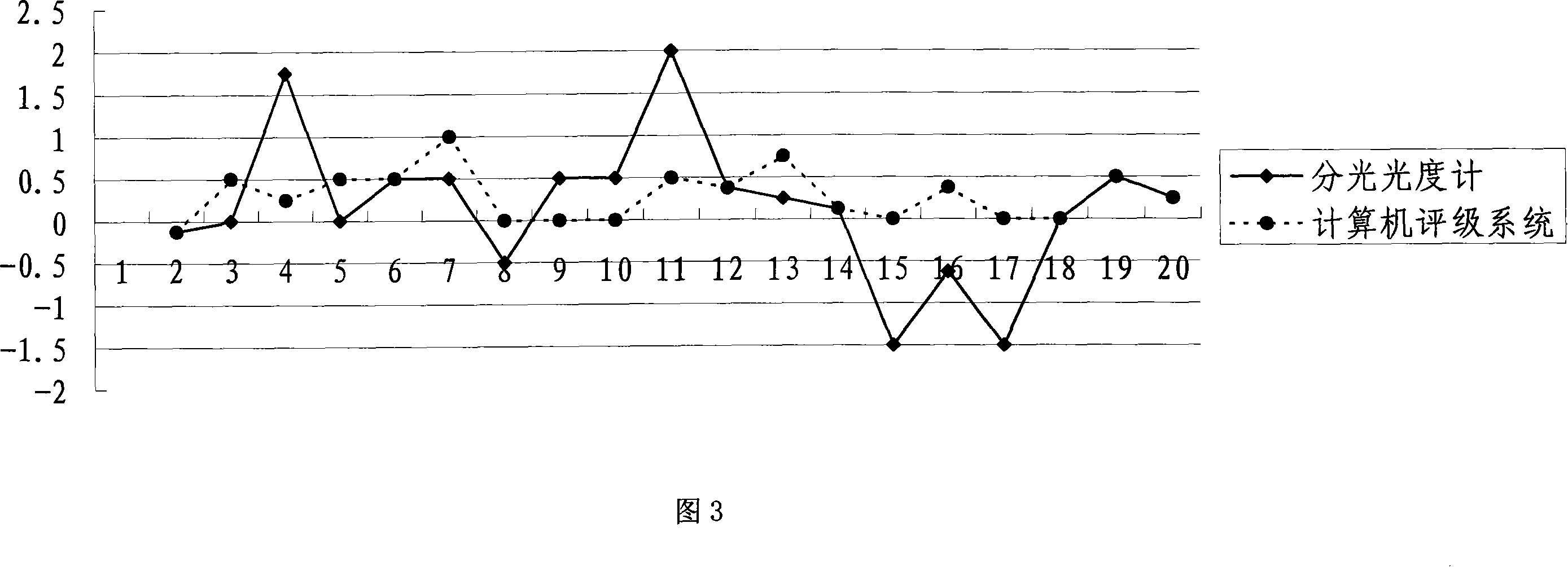

[0032] (1) Research on the stability of digital imaging measurement and selection of equipment The ultimate goal of describing, reconstructing and measuring the color of objects in nature must be consistent with the observation of human eyes. Therefore, the higher the accuracy and stability of the map-taking equipment, the better, but in practical applications, the equipment can be used as long as its error is within the allowable range. Through the actual scanning experiment and error analysis, the present invention selects EPSON PERFECTION 1260 drawing equipment as the fabric image acquisition equipment.

[0033] (2) Determination of external conditions for forming metameric images

[0034] In traditional optical measurement, the requirements for external conditions such as light source are determined (that is, D65 light source 10° or 2° field of view), and the image acquired by the digital i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com