Automatic system for assessing grade of cloth inspection objectively

An automatic, graded technology, applied in the inspection of textile materials, textile and papermaking, optical testing of flaws/defects, etc., can solve the problem of no automatic evaluation system for fabric grades, and achieve the effect of small calculation workload and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

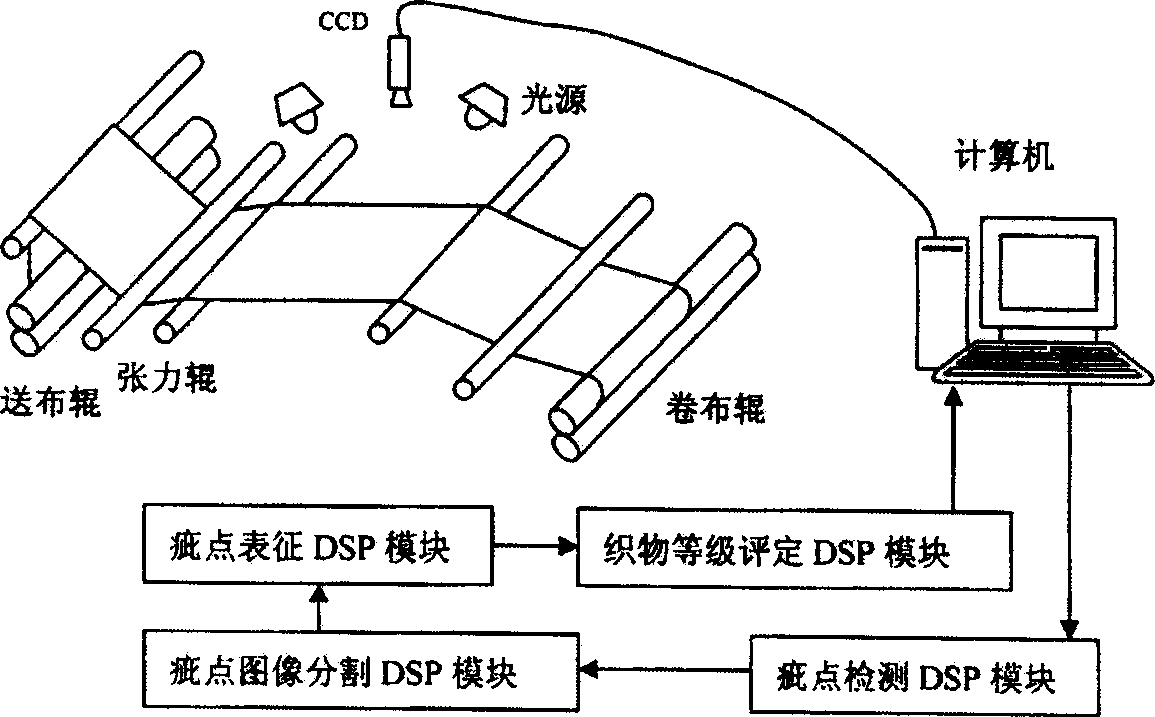

[0024] see figure 1 , which is a schematic structural diagram of the system of the present invention. The system of the present invention uses CCD to collect fabric images, uses wavelet transform to detect defects, and divides the defective fabric images, and the computer automatically characterizes the segmented defects, and then combines the defect detection based on computer vision according to the reference manual defect scoring method and rating rules The scoring method and rating rules formulated based on the characteristics of image segmentation can automatically score the characterized defects and automatically grade the fabric.

[0025] 1. Hardware composition

[0026] Depend on figure 1 It can be seen that the hardware components of this system mainly include: CCD camera, fabric holding device, light source, computer, image acquisition card and so on. The fabric holding device is refitted from a small hand-made trial weaving machine, which is equipped with a mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com