Online automatic detection method of fabric defects based on machine vision and device thereof

A machine vision and automatic detection technology, applied in the direction of measuring devices, textile material inspection, instruments, etc., to improve production efficiency and pass rate, improve detection speed, and overcome the effects of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and given embodiments.

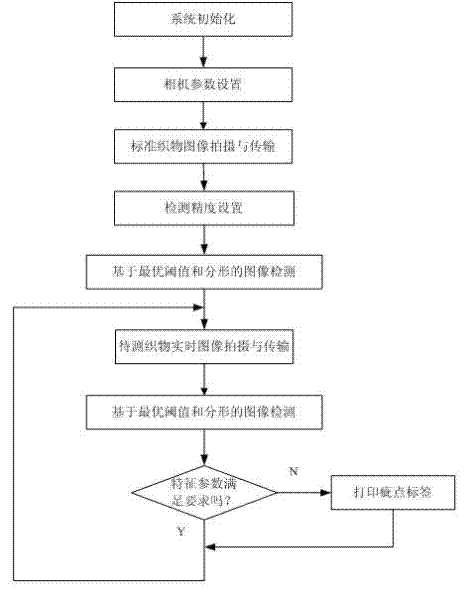

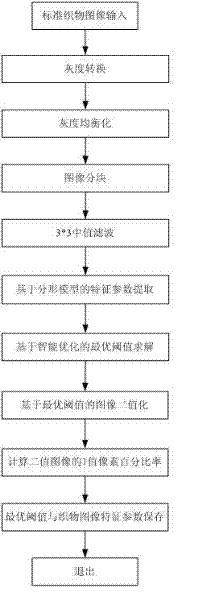

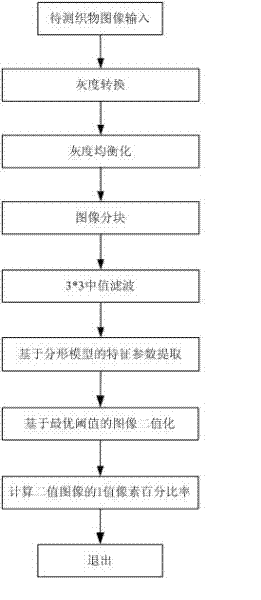

[0059] Such as figure 1 , 2 , Shown in 3, a kind of online automatic detection method of fabric defect based on machine vision, its steps include:

[0060] a. Use the industrial camera to take pictures of the fabric on the cloth rolling and inspecting machine at regular intervals, and send the pictures of the fabric to the computer;

[0061] b. According to the accuracy requirements of the fabric image, set the parameters of the camera for capturing clear images;

[0062] c. Select a clear and complete fabric image as a standard image template, perform image algorithm processing and extract corresponding feature parameters to store in the computer, store a standard image template for each type of fabric, and the feature parameters include the fabric image. Fractal dimension , gray mean ,variance and the 1-valued pixel percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com