Patents

Literature

129results about How to "Overcoming productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

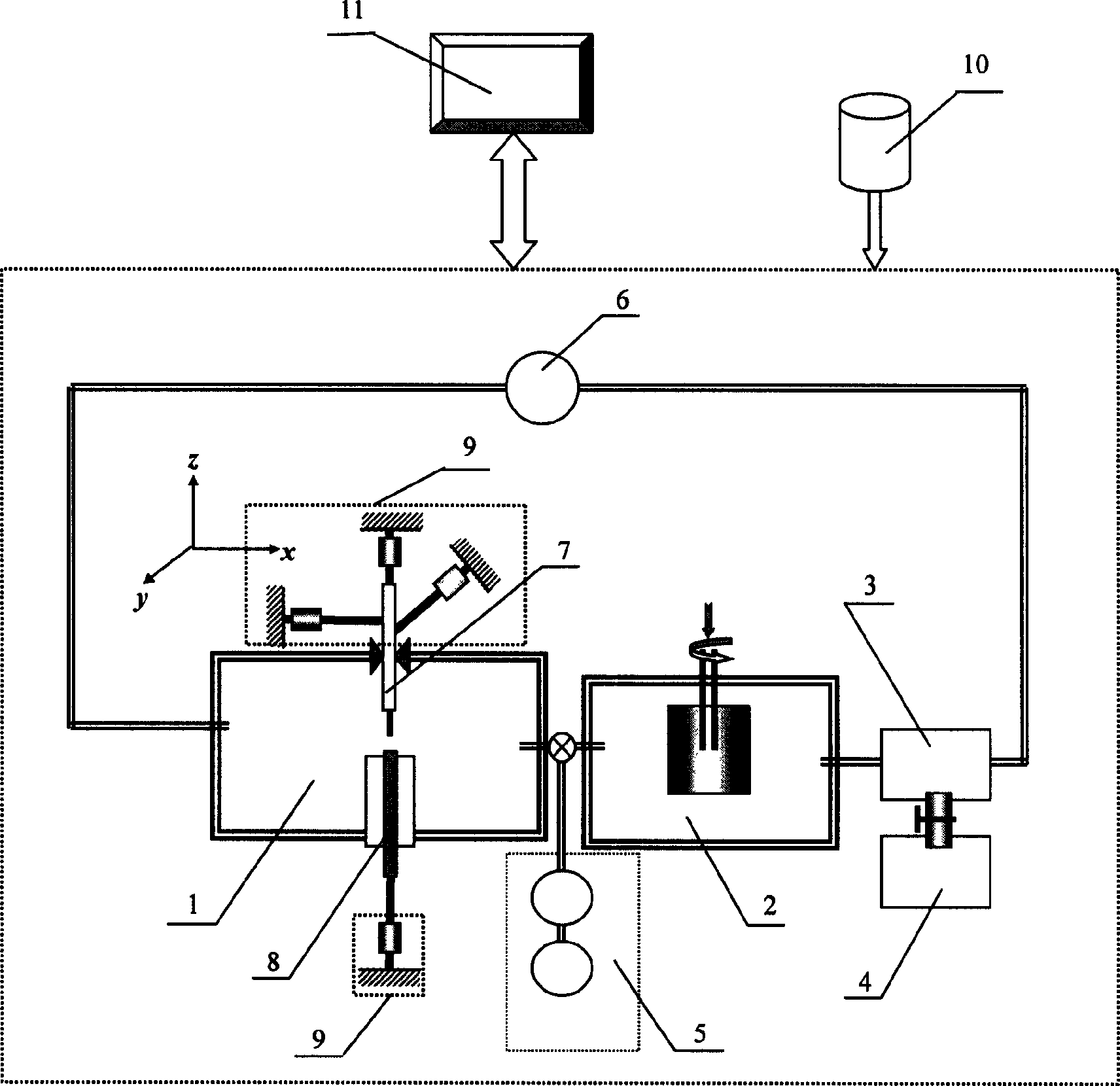

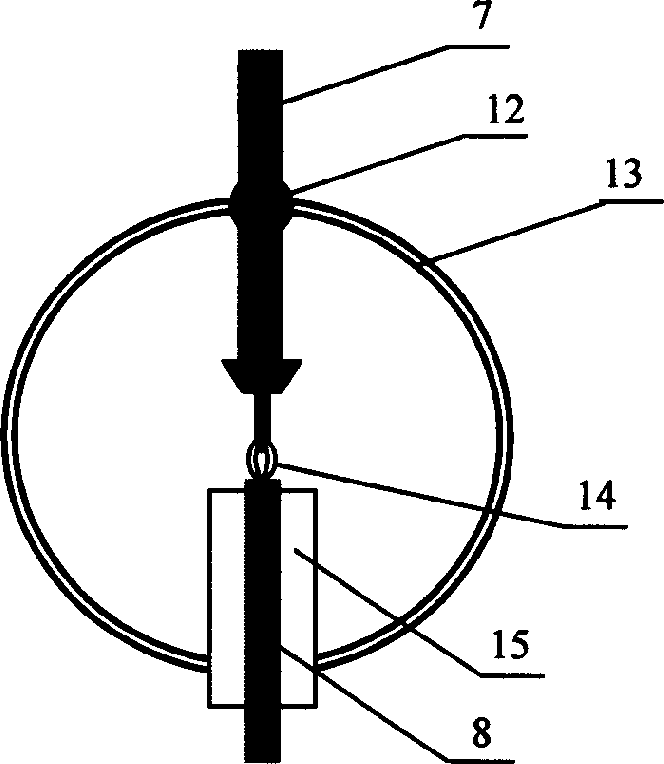

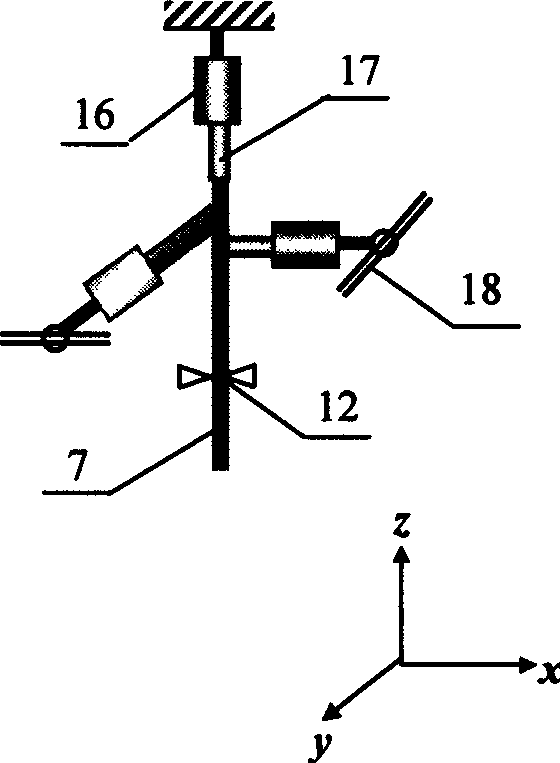

Equipment and method for producing metal nanometer power by automatic control DC electric arc

A method for preparing metallic nanoparticles features that 3D movement of DC arc cathode and the 1D movement of anode are automatically controlled for continuous and stable prodution and the products are classified according their granularities in vacuum condition. Its apparatus is composed of generating chamber, classifying chamber, gathering chamber and processing chamber.

Owner:DALIAN UNIV OF TECH

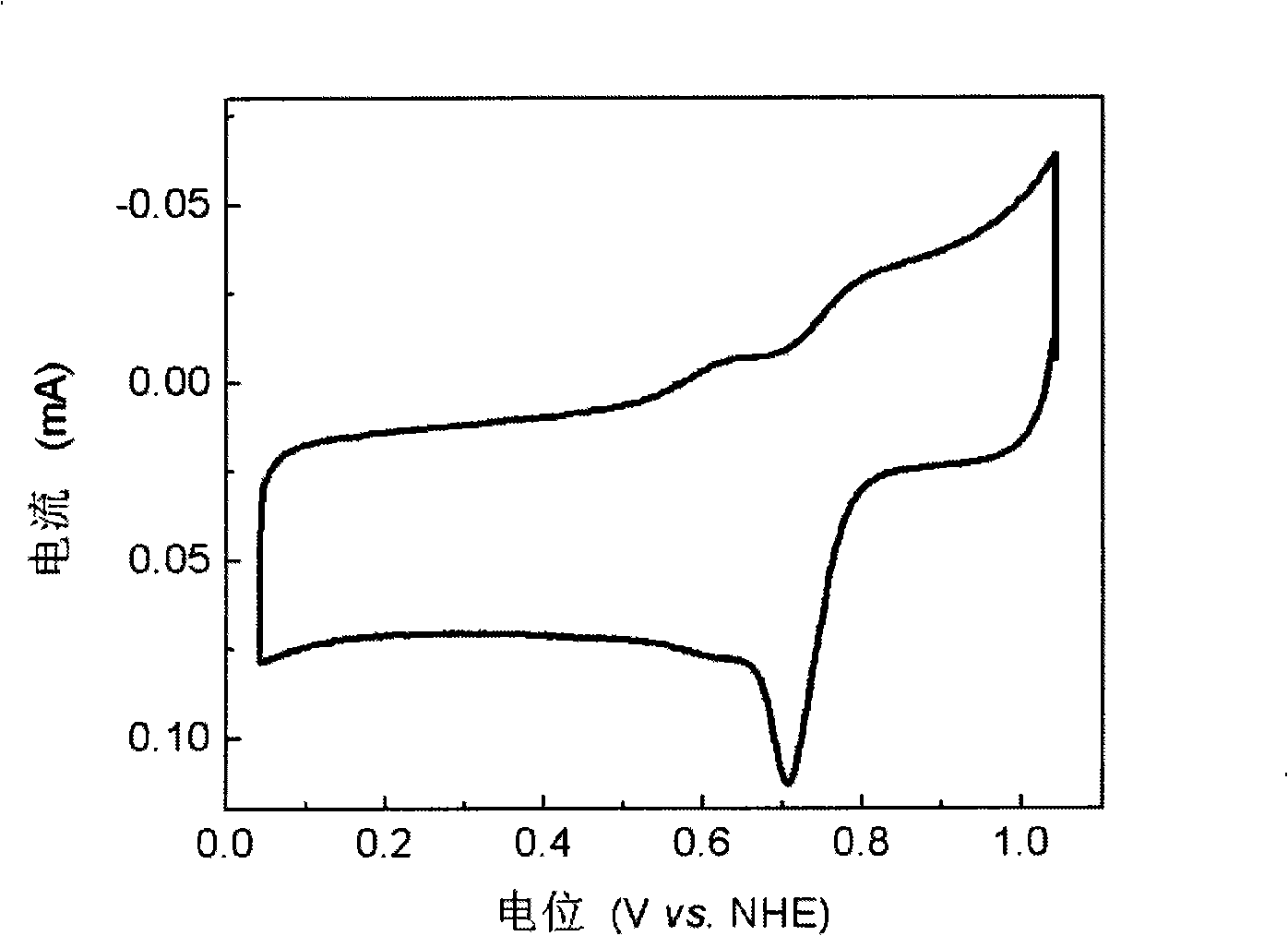

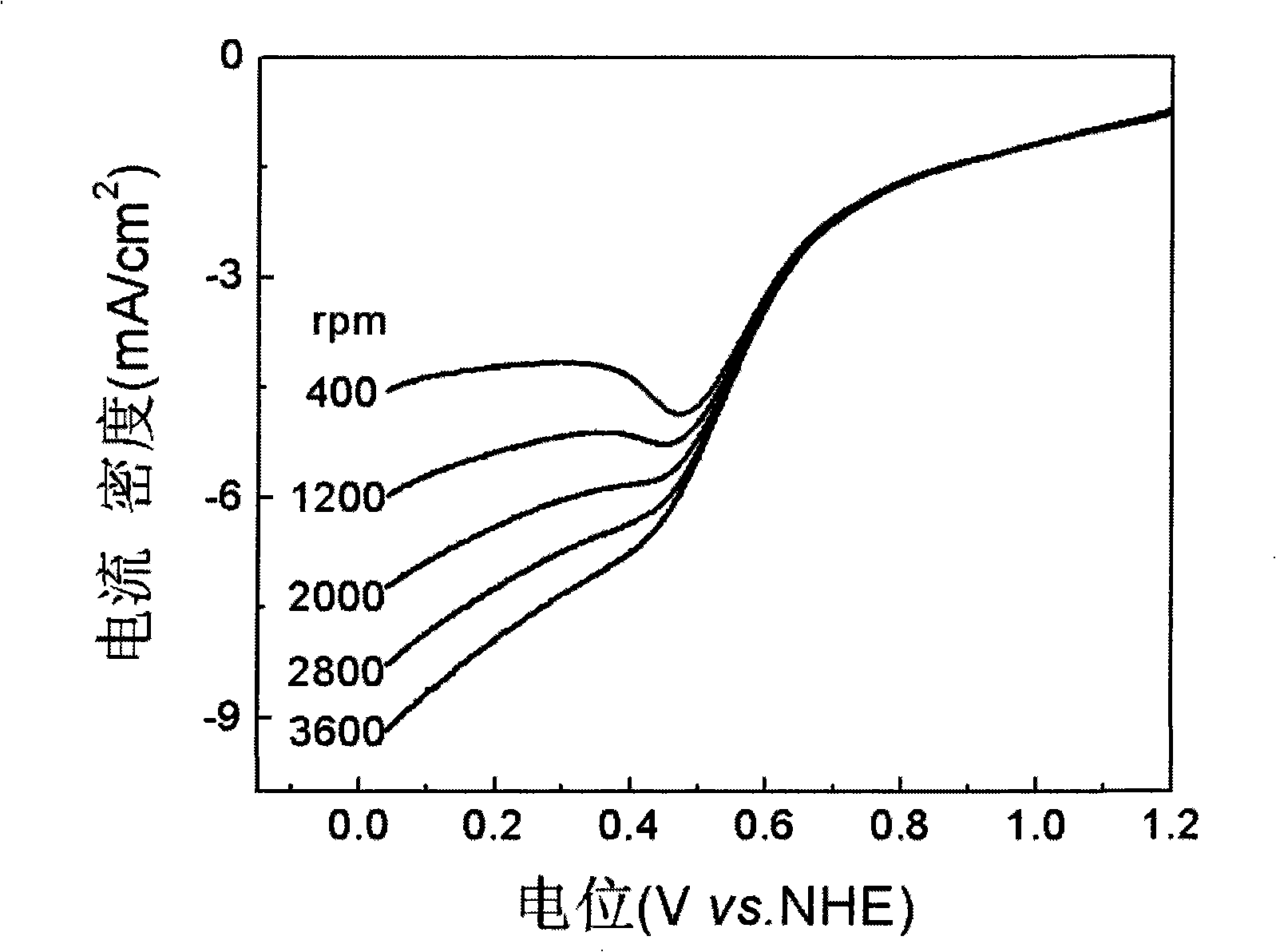

Oxygen reduction catalyst for fuel cell and preparation method thereof

InactiveCN101306385AOvercome costsOvercoming craftOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesPorphyrinPhthalocyanine

The invention discloses a fuel battery used oxygen reduction catalyst and the preparation method thereof, and relates to a loaded catalyst which is composed of a transition metal chelate and a carbon black carrier, wherein, the transition metal chelate is prepared through the reaction of transition metal salt and diethylene triamine. MN3 structure is included in the molecule of the transition metal chelate (M is transition metal and N is nitrogen atom), and an active site is provided for catalyzing the oxygen reduction reaction. The catalyst takes the diethylene triamine with low cost as the raw material; overcomes the problems of the traditional oxygen reduction catalyst of the macrocyclic compound, such as metalloporphyrin and metal phthalocyanine, that the cost of the raw materials is high, and the traditional oxygen reduction catalyst is not suitable for the large scale production industrial production; and has the advantages of simple preparation technology, mild condition, secure process, low cost, and so on. The catalytic performance of the catalyst is equivalent to the oxygen reduction of the metalloporphyrin, the catalytic has good anti carbinol oxygenic property, and can be applied to the oxygen reduction reaction of the cathode of the battery.

Owner:SHANGHAI JIAO TONG UNIV

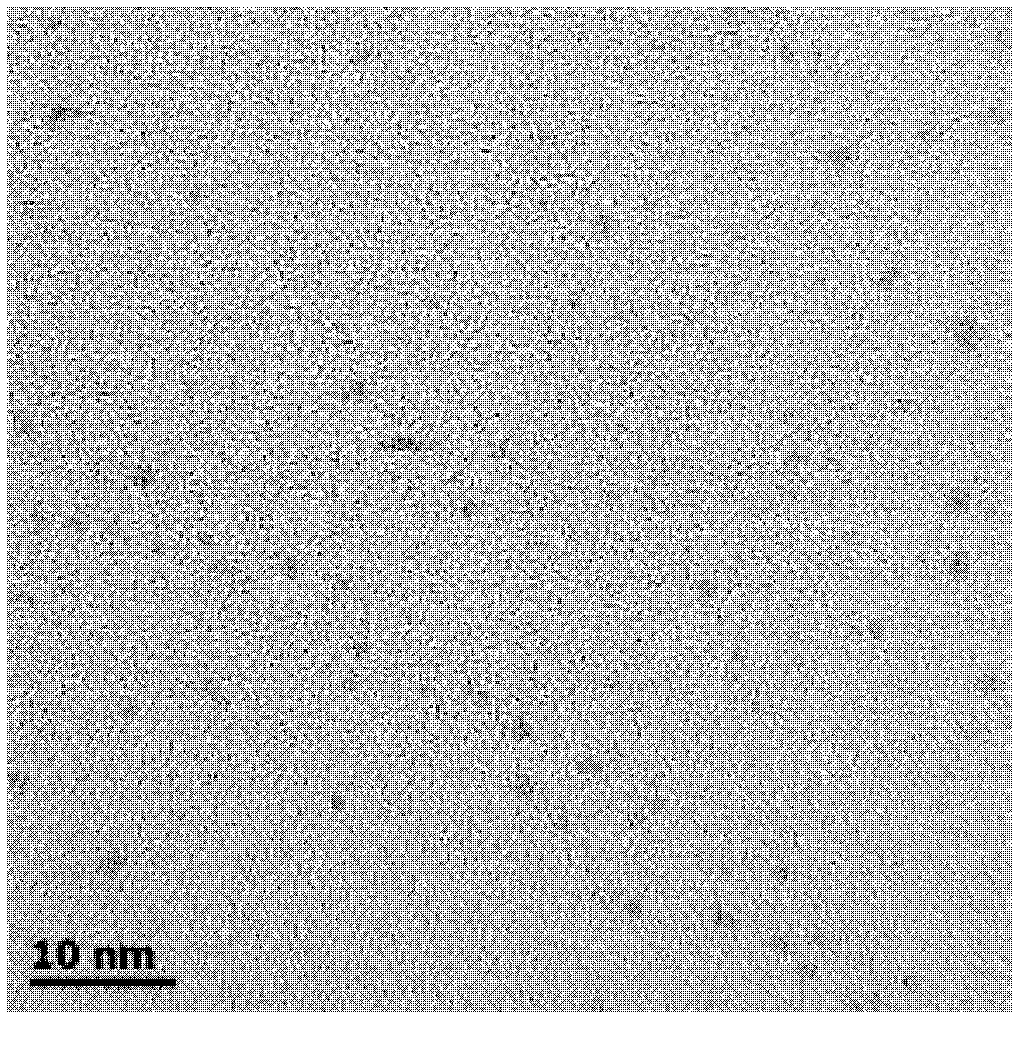

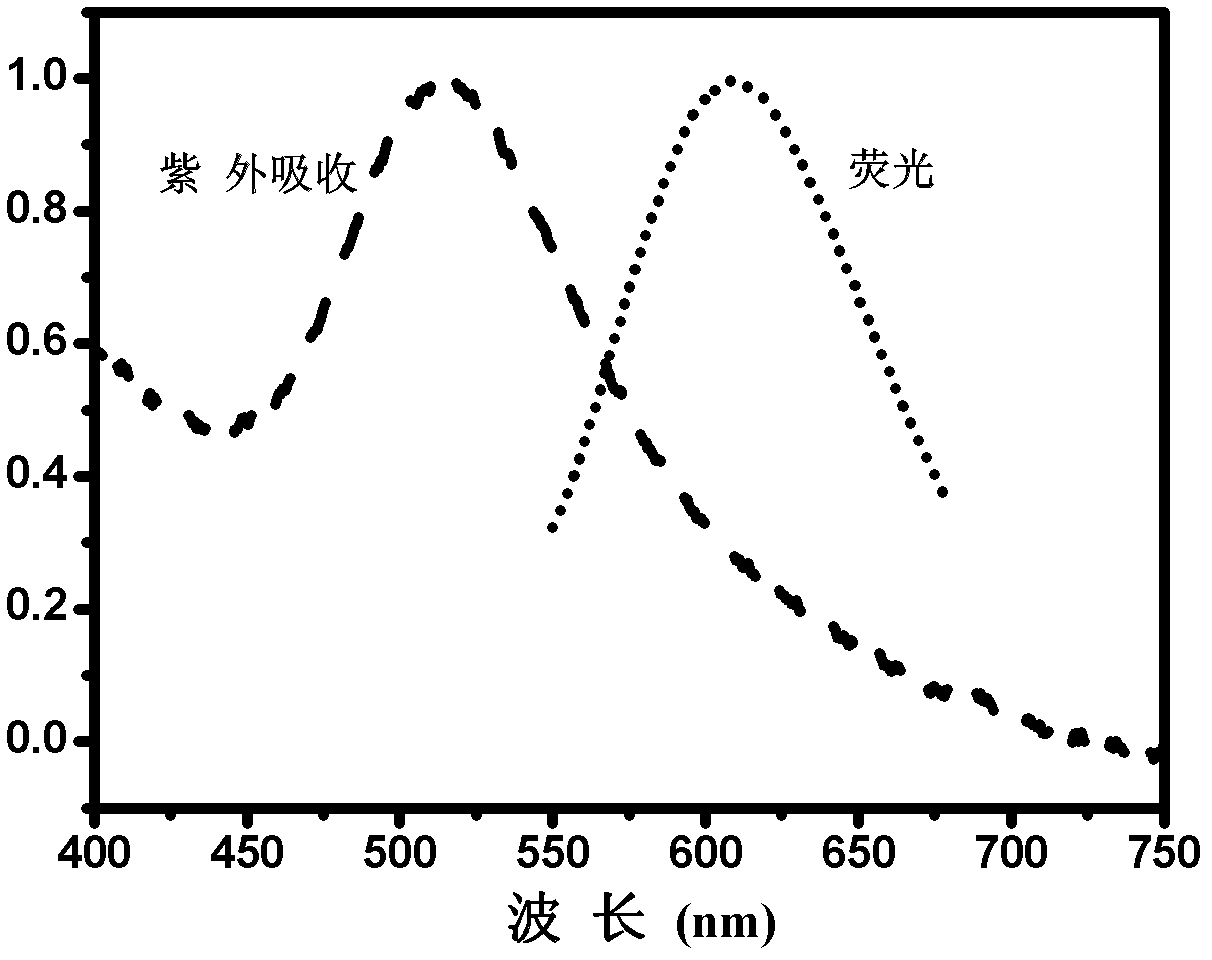

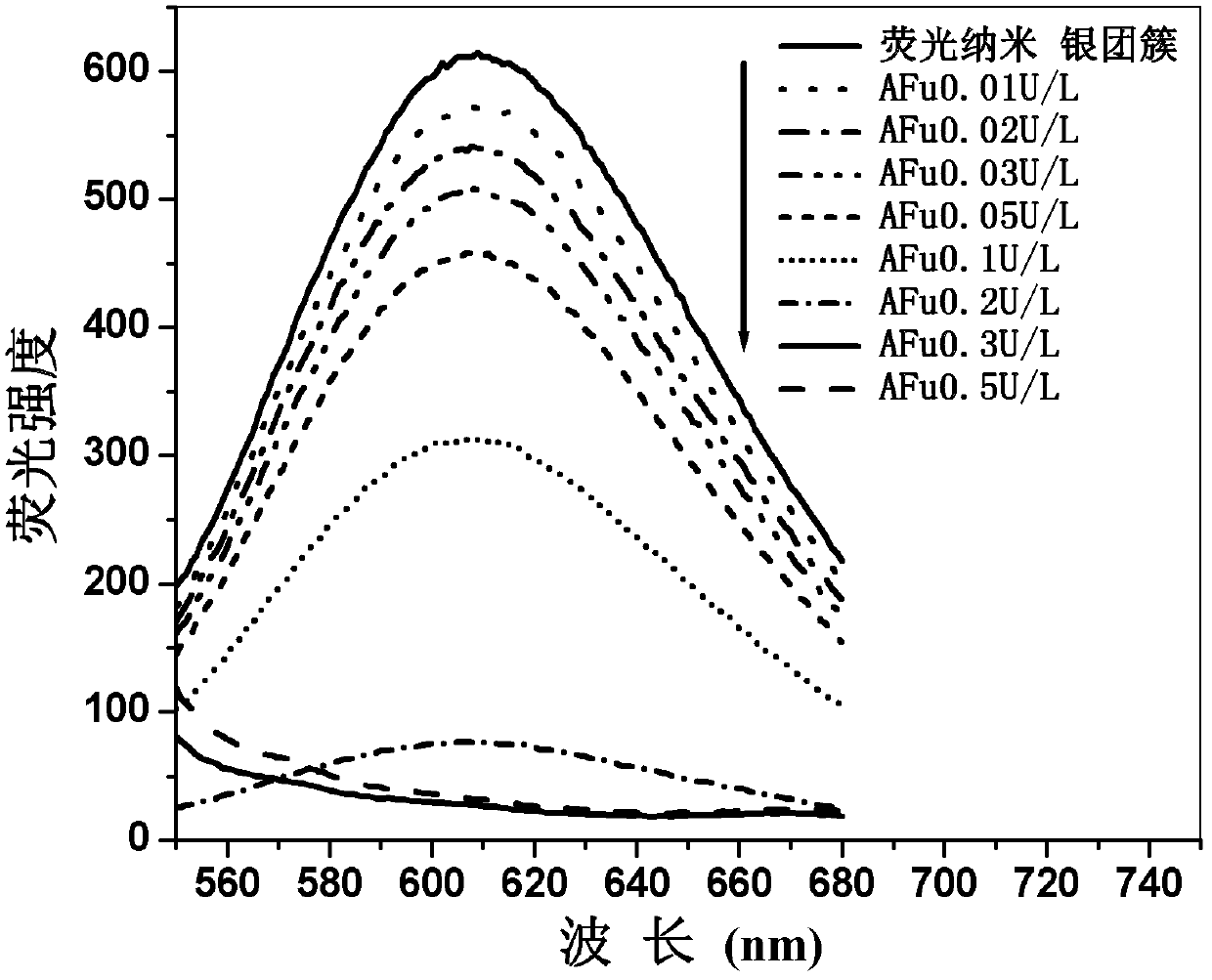

Fluorescent silver nanocluster as well as preparation method and application thereof

ActiveCN103289684AAchieve qualitativeEasy to detectNanoopticsFluorescence/phosphorescenceFluorescenceImaging biomarker

The invention belongs to the technical fields of preparation and application of metal optical function nano materials and in particular relates to a fluorescent silver nanocluster as well as a simple preparation method and application thereof. The fluorescent silver nanocluster is synthesized by reacting soluble silver salt with a stabilizer, wherein the fluorescent silver nanocluster has the mean particle size of more than 1.5nm and less than 2nm; the fluorescence emitted by the fluorescent silver nanocluster has the wavelength of 610nm under excitation of light with the wavelength of 510nm; the emitted fluorescence has high illumination stability. The method is readily available in raw materials, simple in process, convenient to operate, low in biotoxicity and easy to popularize and apply. The synthesized fluorescent silver nanocluster can be applied to the fields of optical imaging, biological markers, biological or chemical sensors and the like, and especially can be used for qualitative and quantitative detection on the activity of alpha-L-fucosidase.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Ice grape culture overwintering technology

InactiveCN103026940AGuaranteed SustainabilityStable outputCultivating equipmentsHorticulture methodsClimate changeOverwintering

The invention relates to a grape planting method, in particular to ice grape culture overwintering technology. Methods of the ice grape culture overwintering technology include: covering between lines and soil covering cold-proof method after harvest; and multiple vane replacing and soil covering cold-proof method. By adopting management technology to guarantee that a fruiting main vane, a preparing main vane and a cultivating main vane are maintained on a frame surface all the time, namely multiple vane circulation replacement. Thus, stable ice grape output can be guaranteed no matter how winter climate changes, the problem between ice grape production and tree overwintering is solved, persistence of the ice grape production is guaranteed, ice grapes with high quality can be produced, and production capacity of large-scale ice grape planting can be achieved.

Owner:辽宁太阳谷庄园葡萄酒业股份有限公司

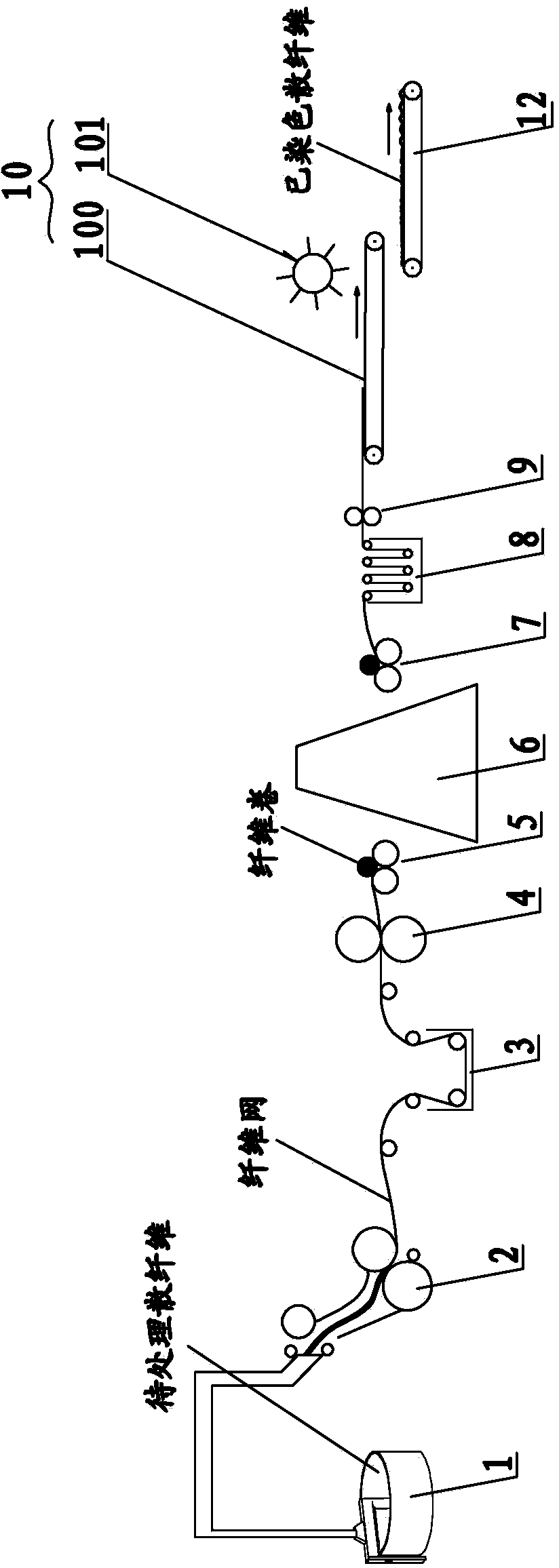

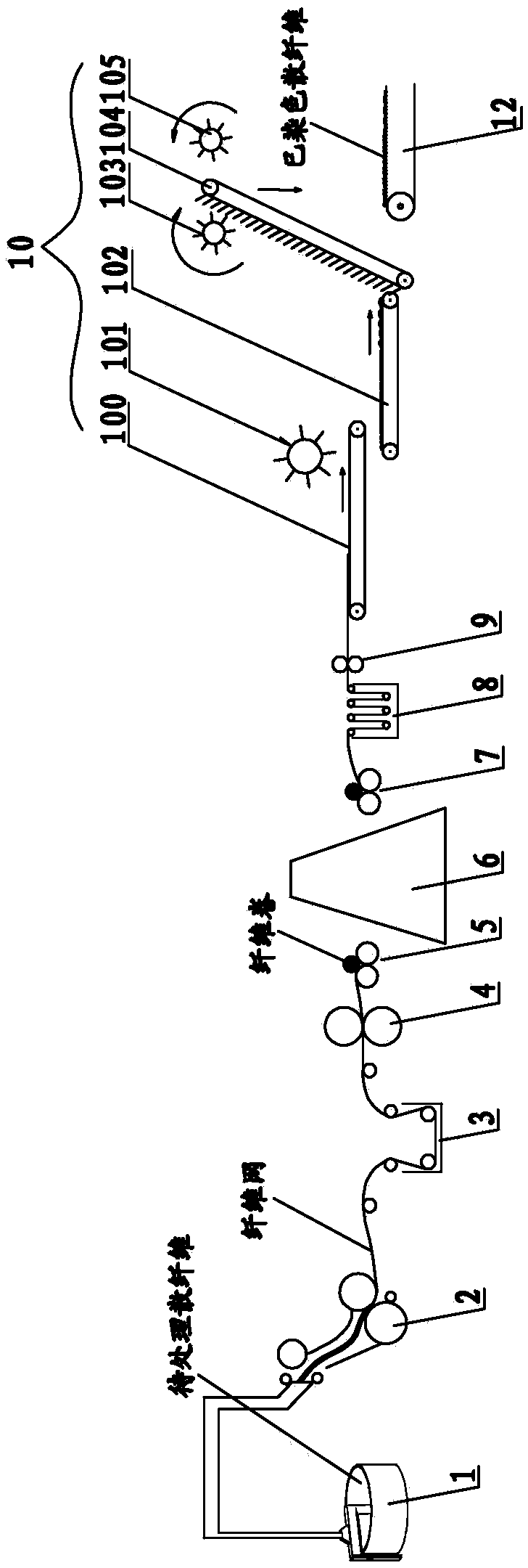

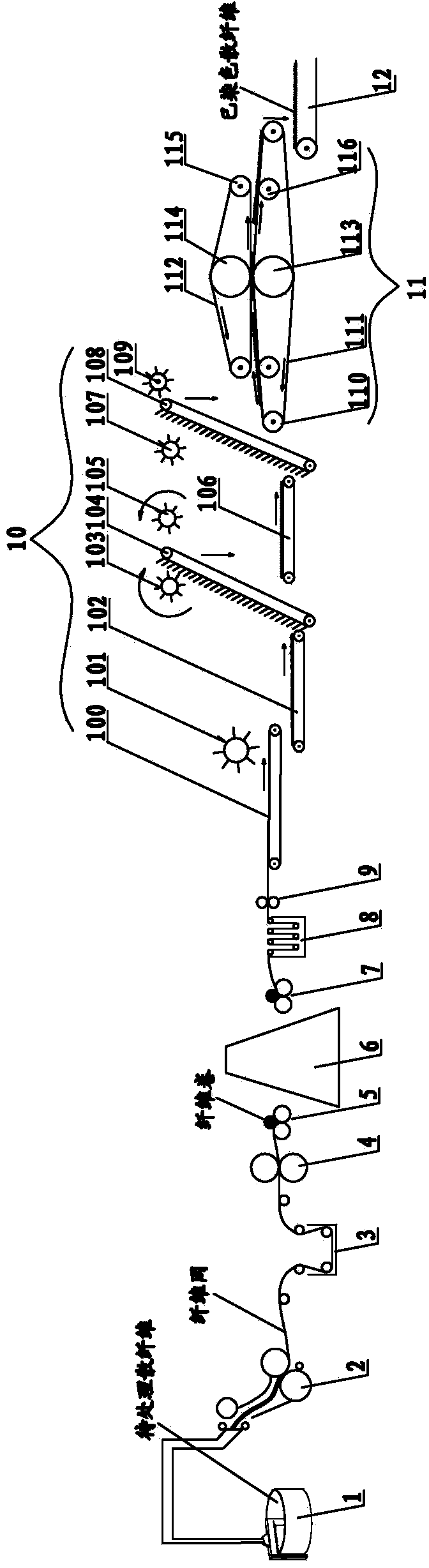

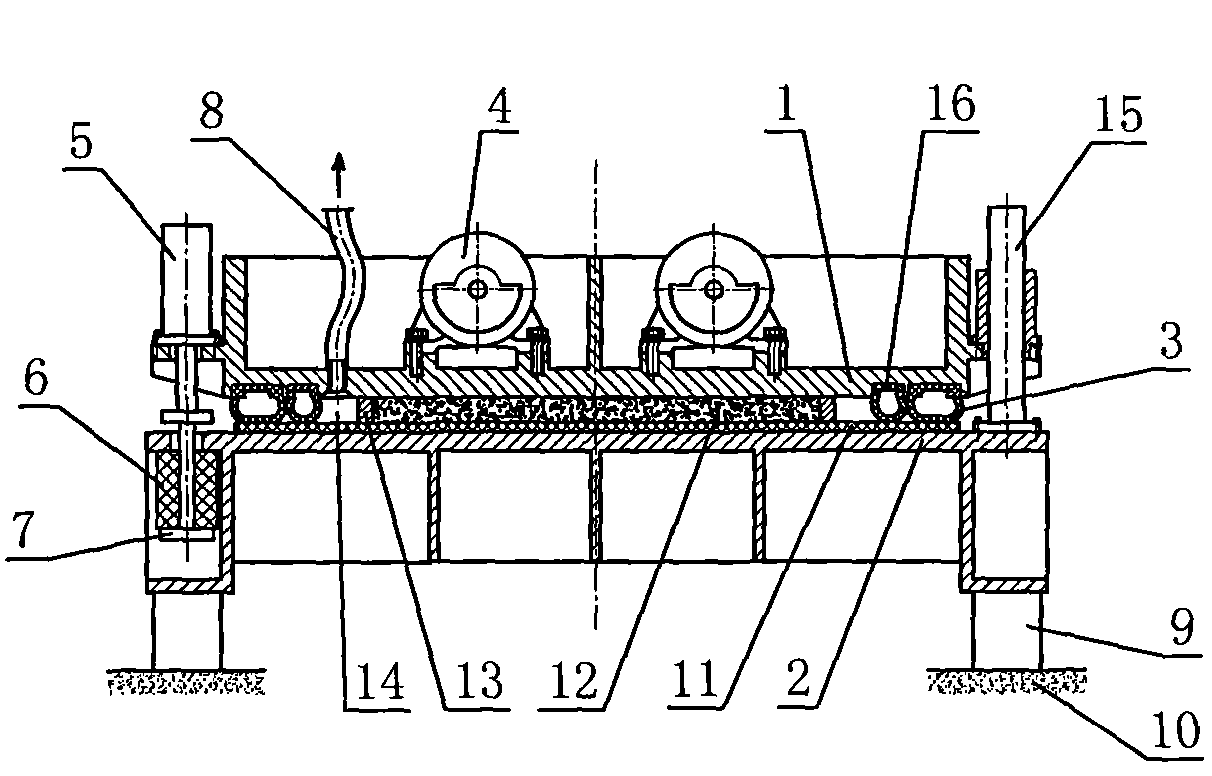

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

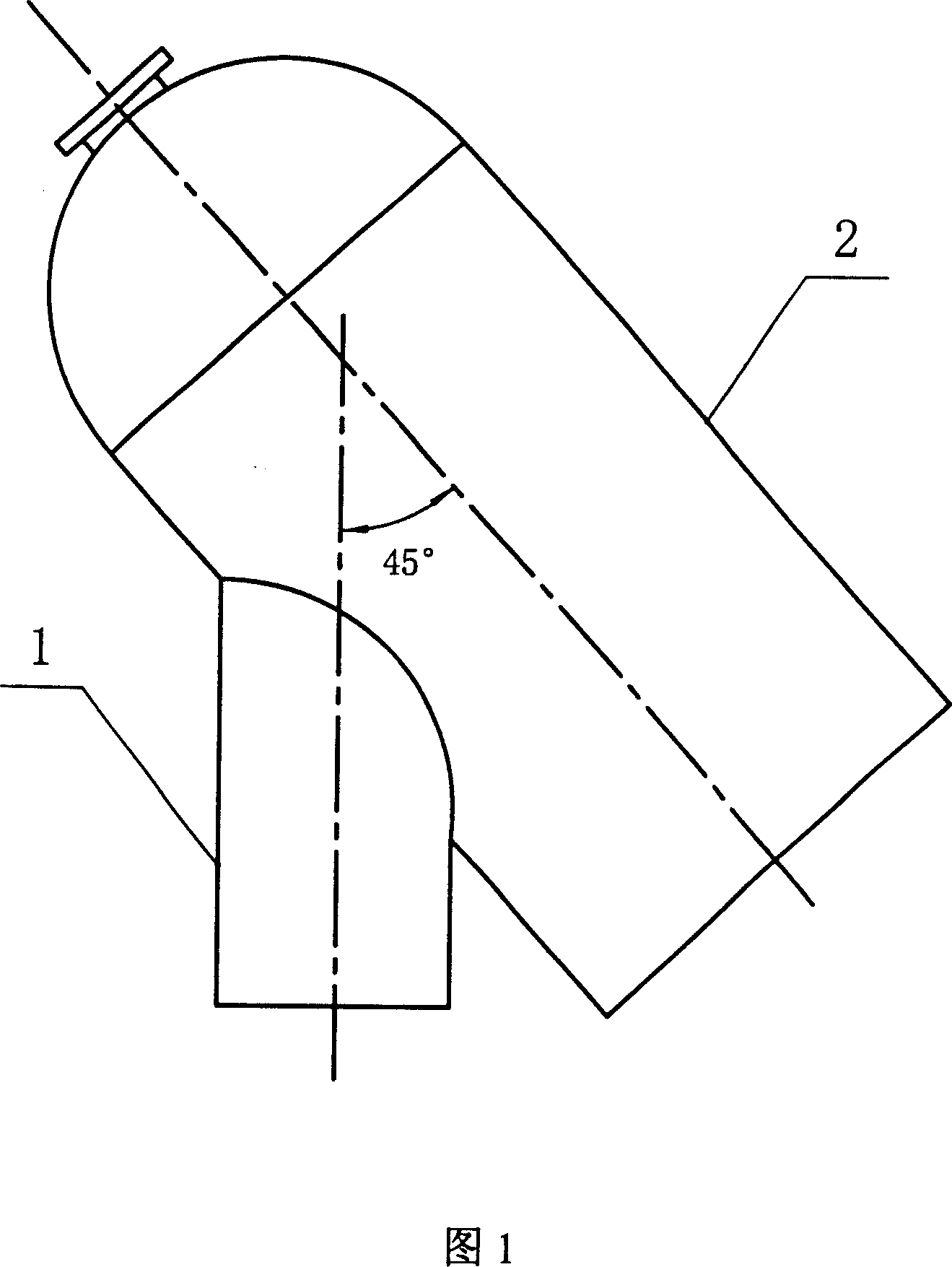

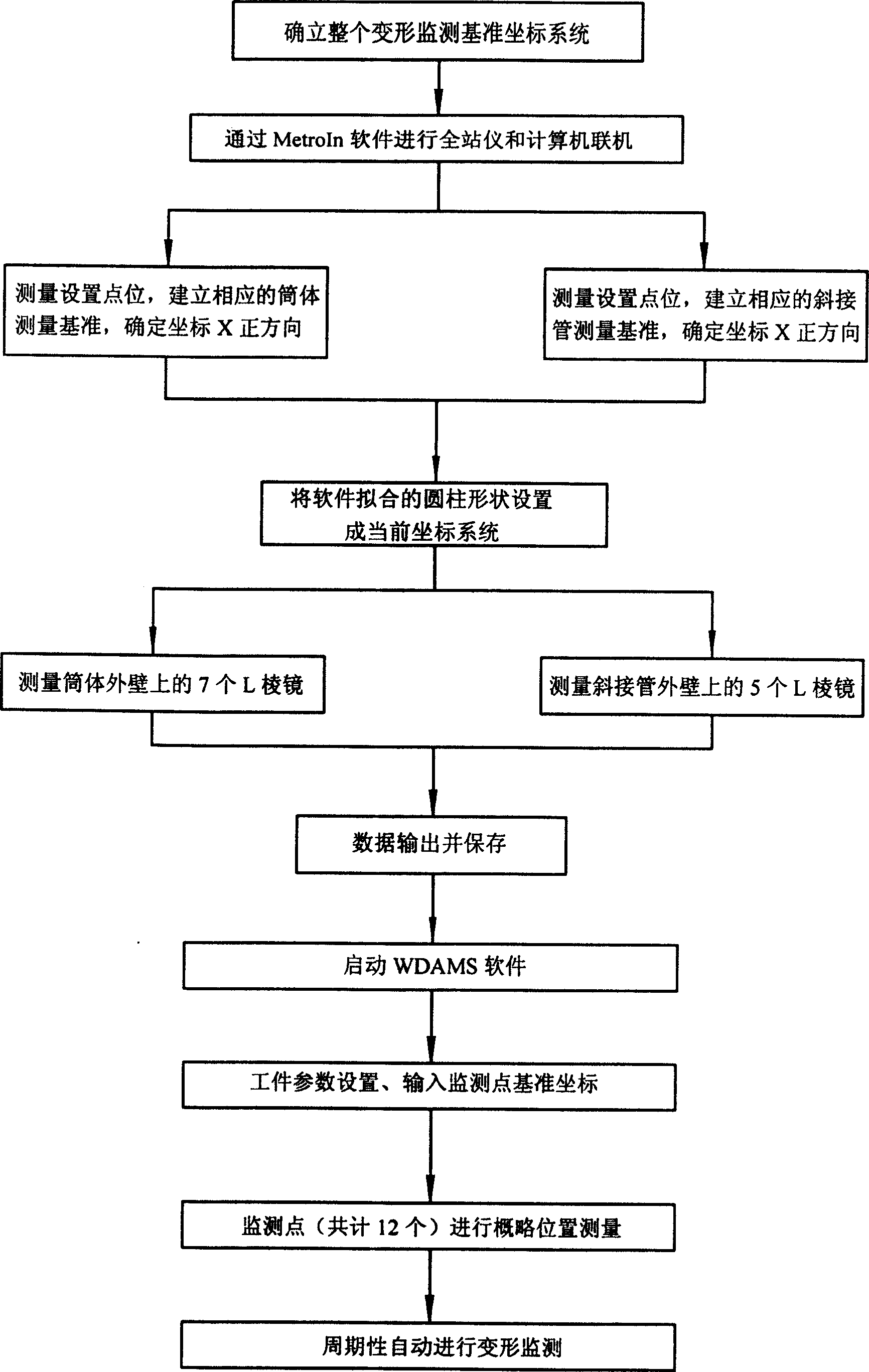

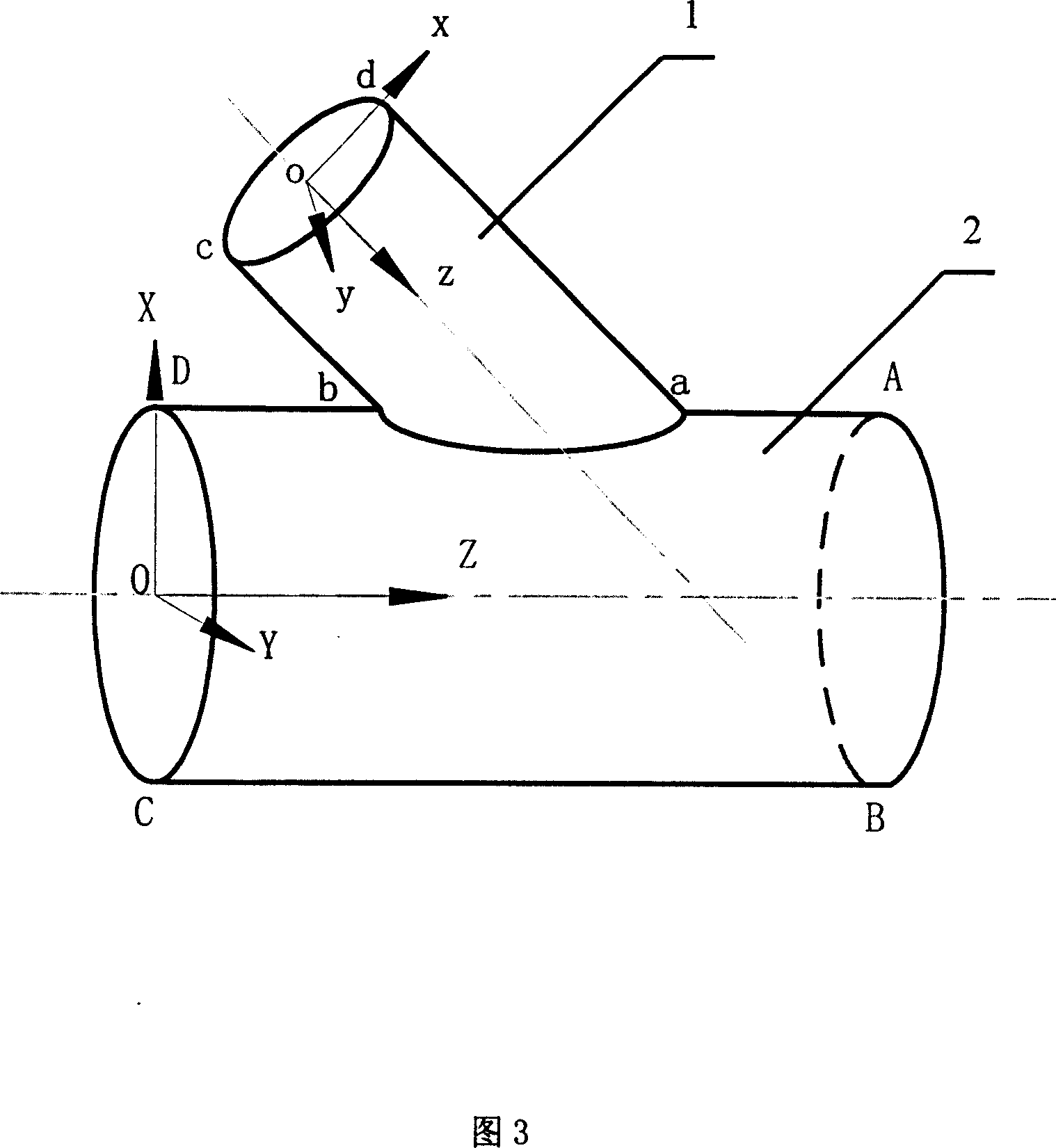

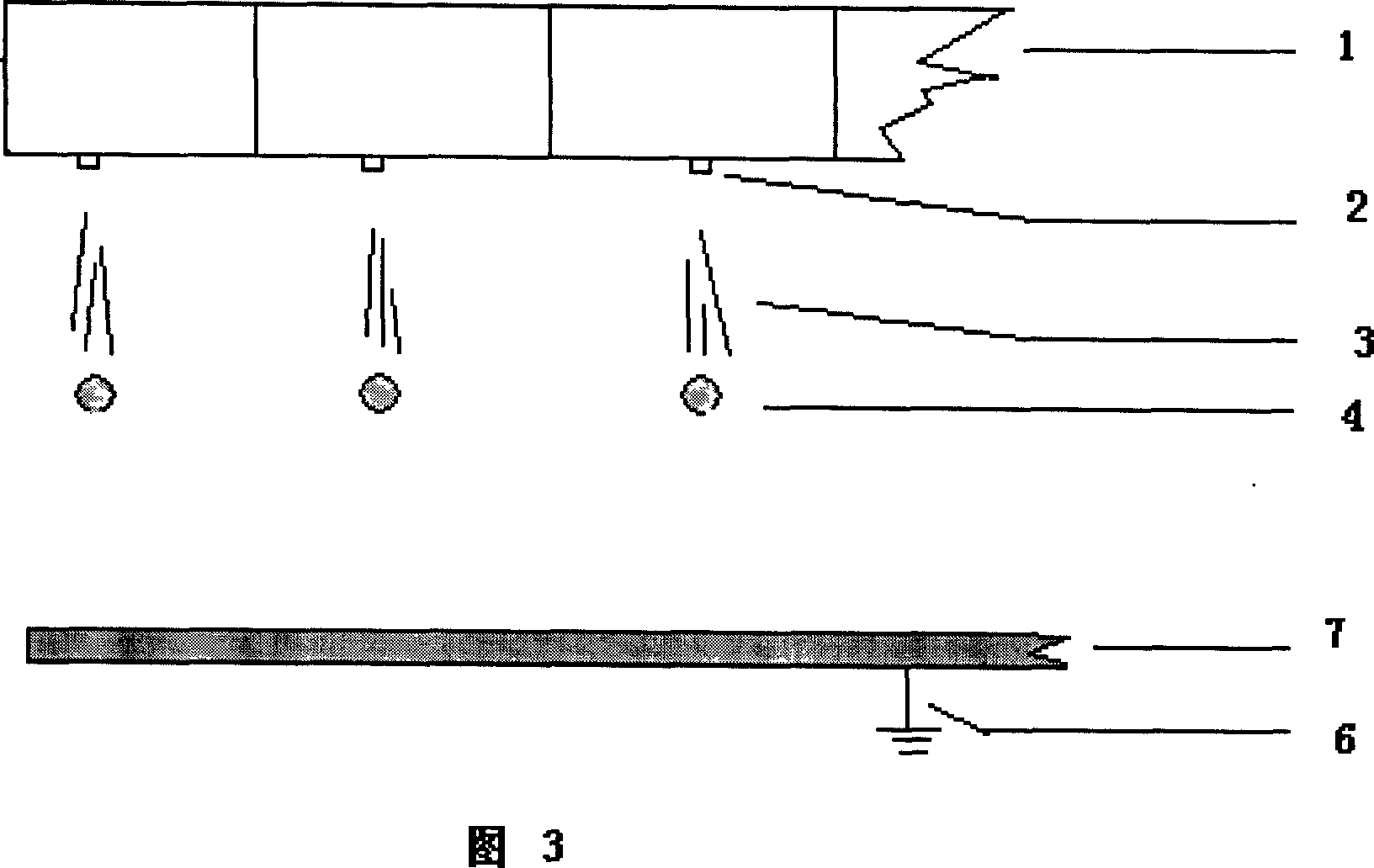

Large component assembling and welding deformation auto-real-time monitoring method

InactiveCN1948901AReal-time monitoring of displacementReal-time monitoring of deformationUsing optical meansDeformation monitoringWelding deformation

The invention relates to large scale component assembling and welding deformations automatic real time monitoring method. Its feature is that it uses coordinate system as measuring basis expressed by axes and generatrix in whole measuring system. The method includes the following steps: establishing the coordinate system for the whole deformation measuring basis; setting measuring point at the outer wall of the component 1 and 2; measuring the coordinate for all the measuring points; processing component 1 and 2 installing measuring and welding deformation monitoring. The invention has the advantages of realizing the monitoring without setting fixed measuring installation onsite and special tool set up, fast measuring speed, high working efficiency means three minutes per period.

Owner:SHANGHAI BOILER WORKS

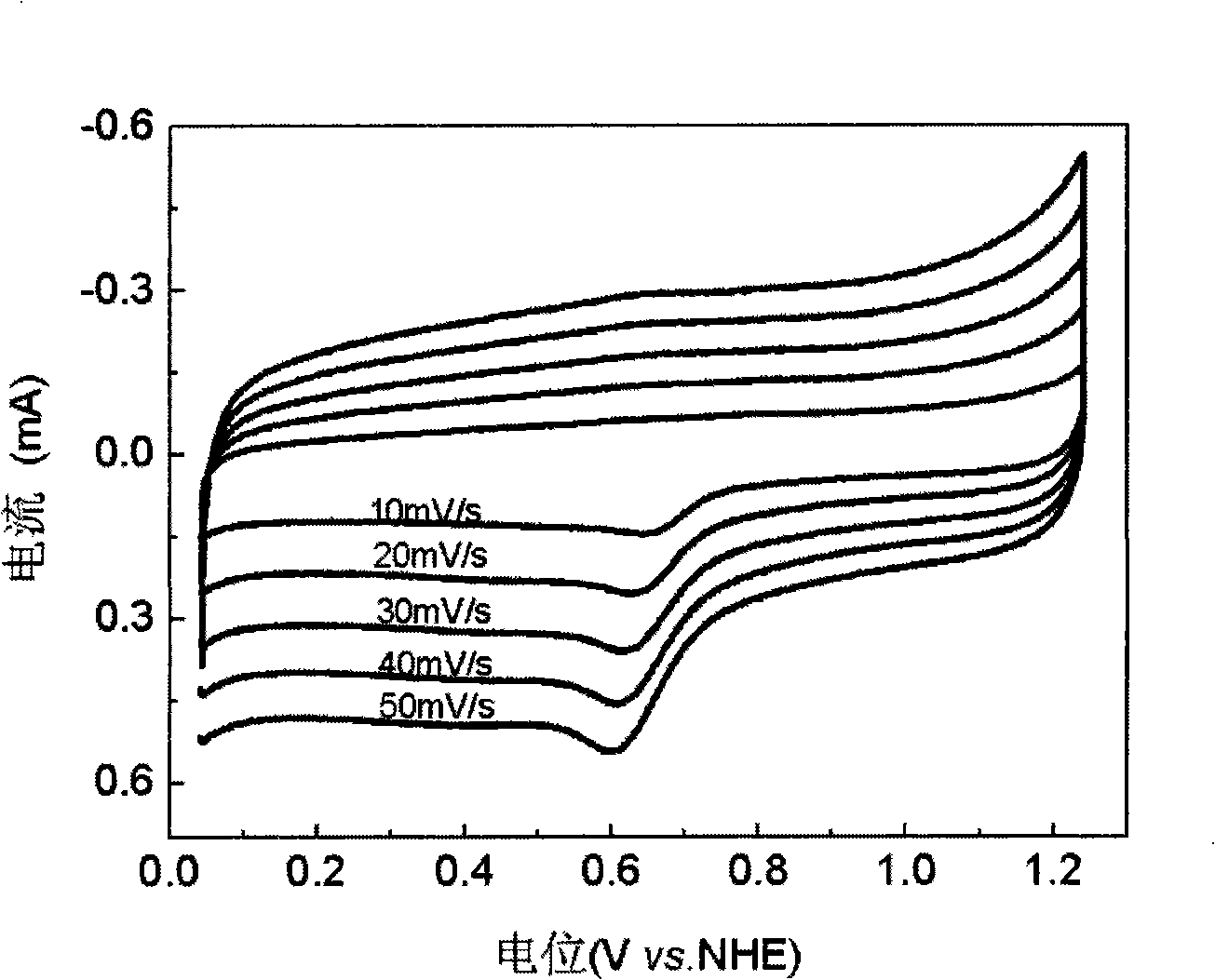

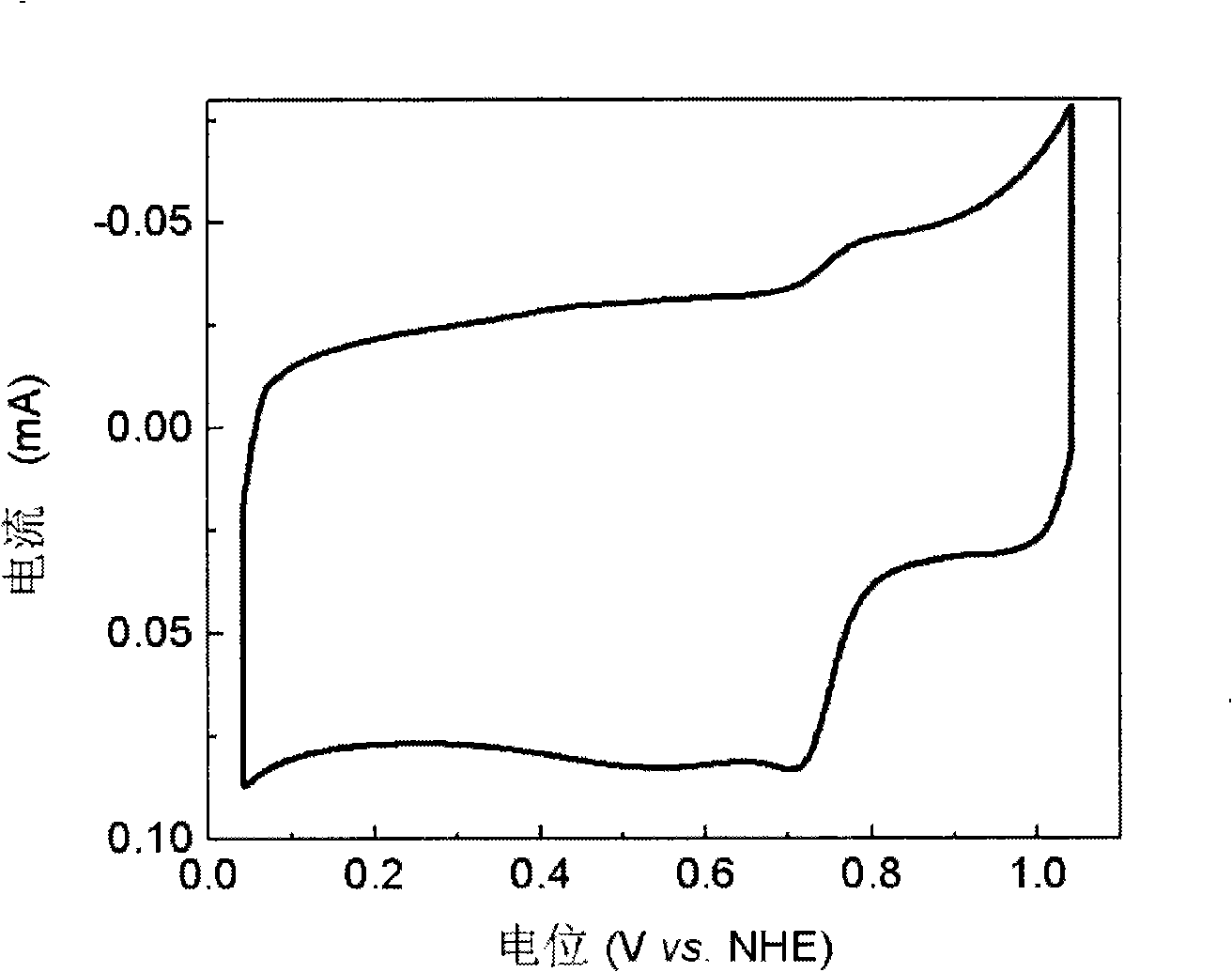

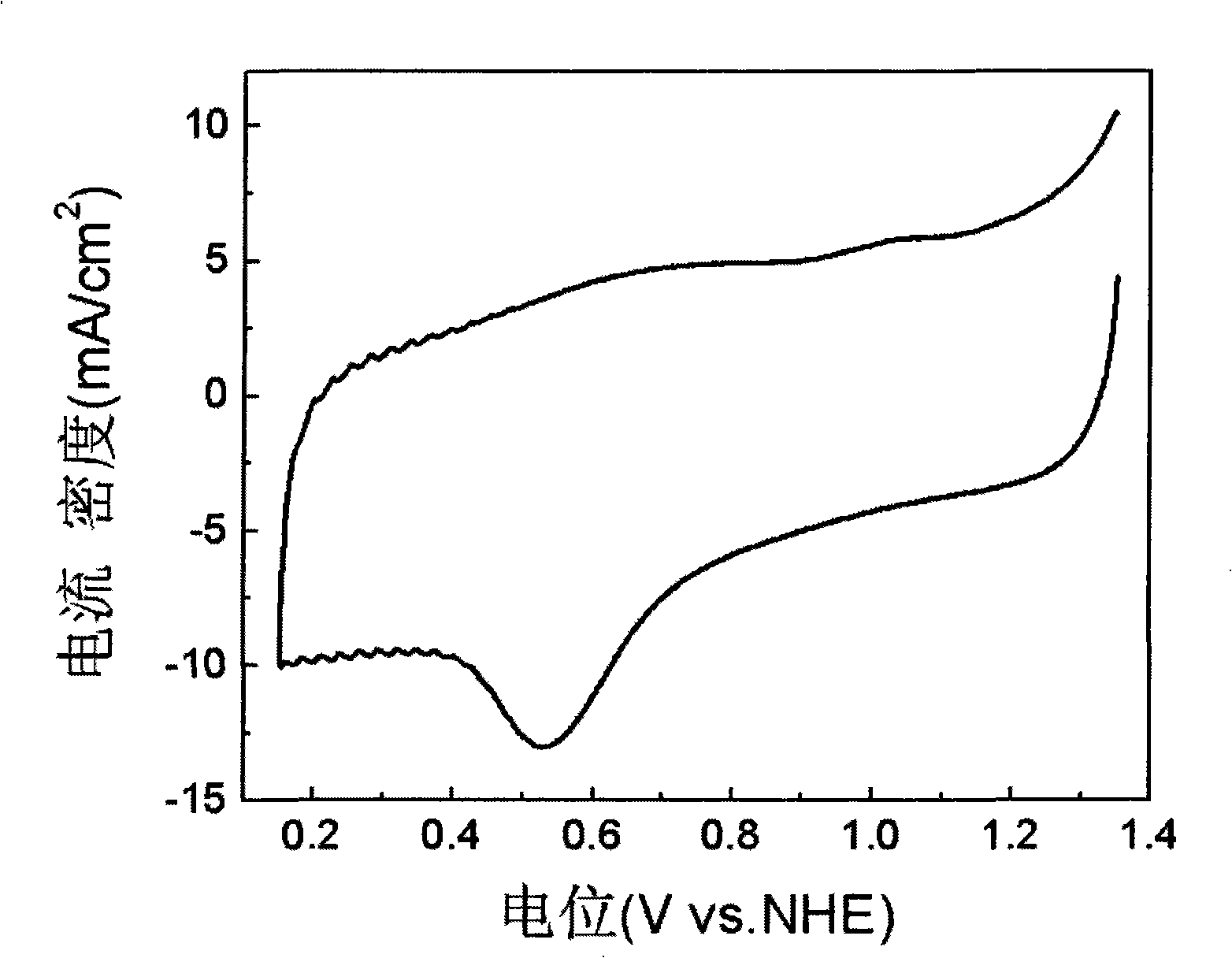

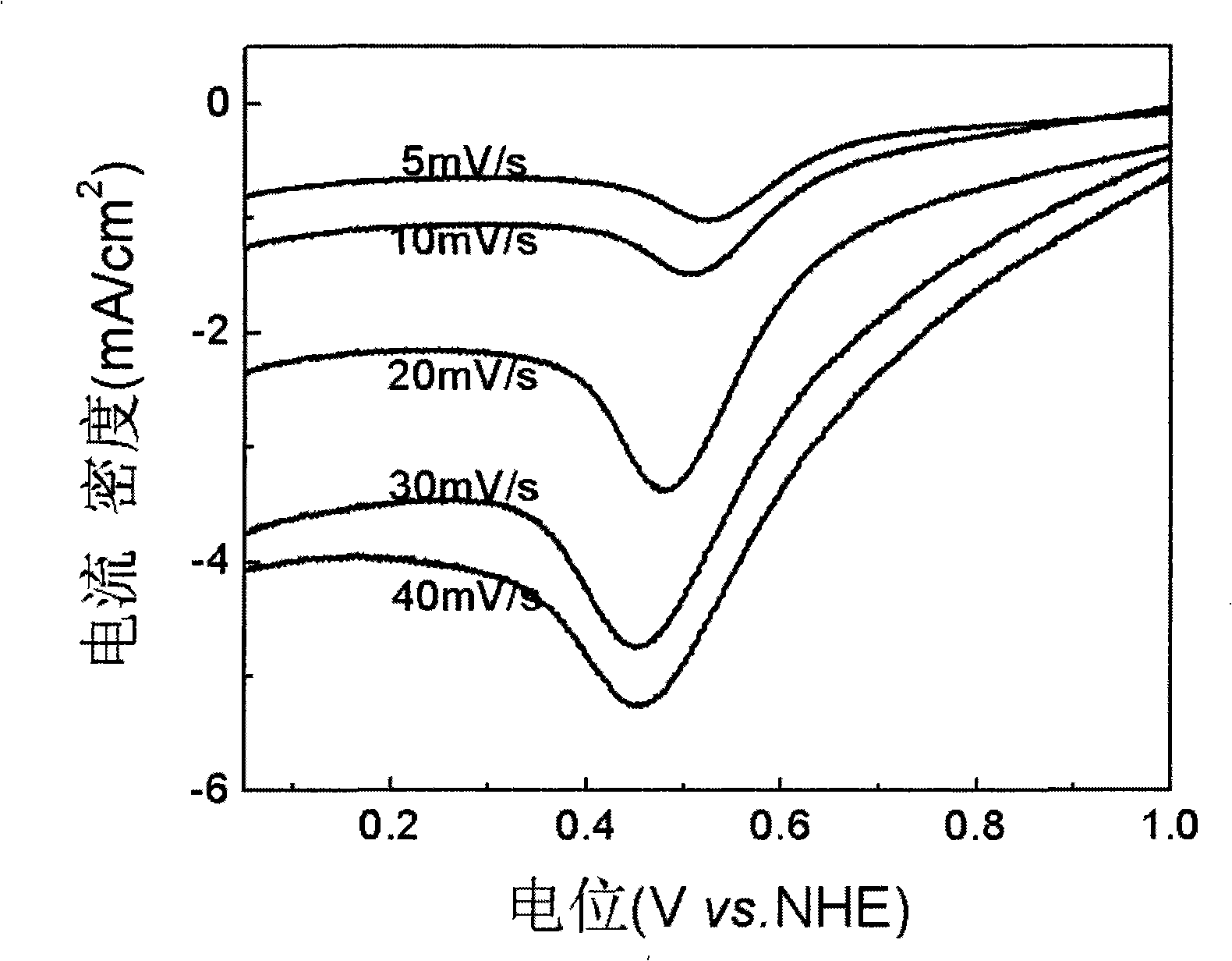

Oxygen reduction electrocatalyst and preparation thereof

InactiveCN101259437AReduce manufacturing costOvercome costsCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsAlcohol fuelPorphyrin

The invention discloses an oxygen reduction electrocatalyst and a preparation method thereof, which is a load type catalyst and consists of a transition metal triethylene tetramine chelate complex and a carbon black carrier; wherein, the transition metal triethylene tetramine chelate complex is obtained by the reaction of transition metal-salt and triethylene tetramine. The oxygen reduction electrocatalyst of the invention uses the triethylene tetramine having simple structure and low cost, which overcomes the defects of traditionally used macrocyclic compound porphyrin and Phthalocyanine and derivatives thereof and has simple preparation technique, low cost, friendly environment and a better catalytic activity; a oxygen reduction peak potential is 0.6745 (vs. NHE) and a oxygen reduction peak current is 1.493mA / m<2>; stability is relatively high, and oxygen reduction catalytic performance is not obviously reduced after recycling for 24 hours. The oxygen reduction electrocatalyst of the invention can be applied to the fields of proton exchange membrane fuel batteries, direct alcohol fuel cells, and cathode materials of metal-air battery, etc.

Owner:SHANGHAI JIAO TONG UNIV

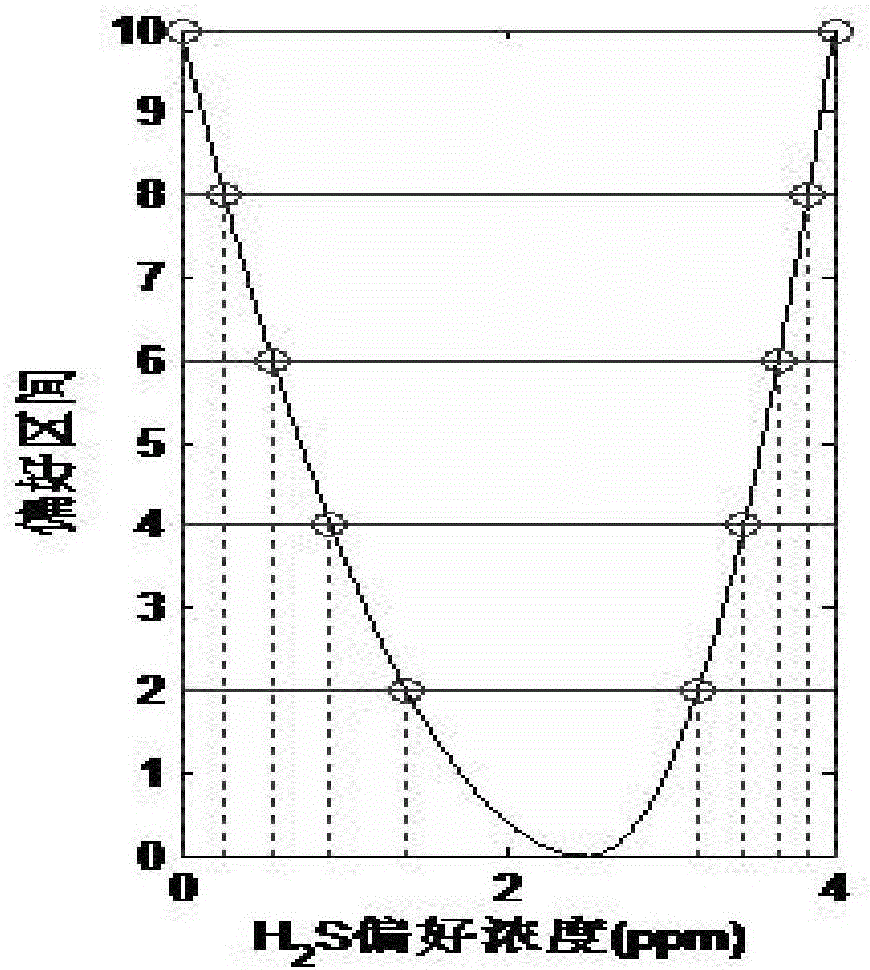

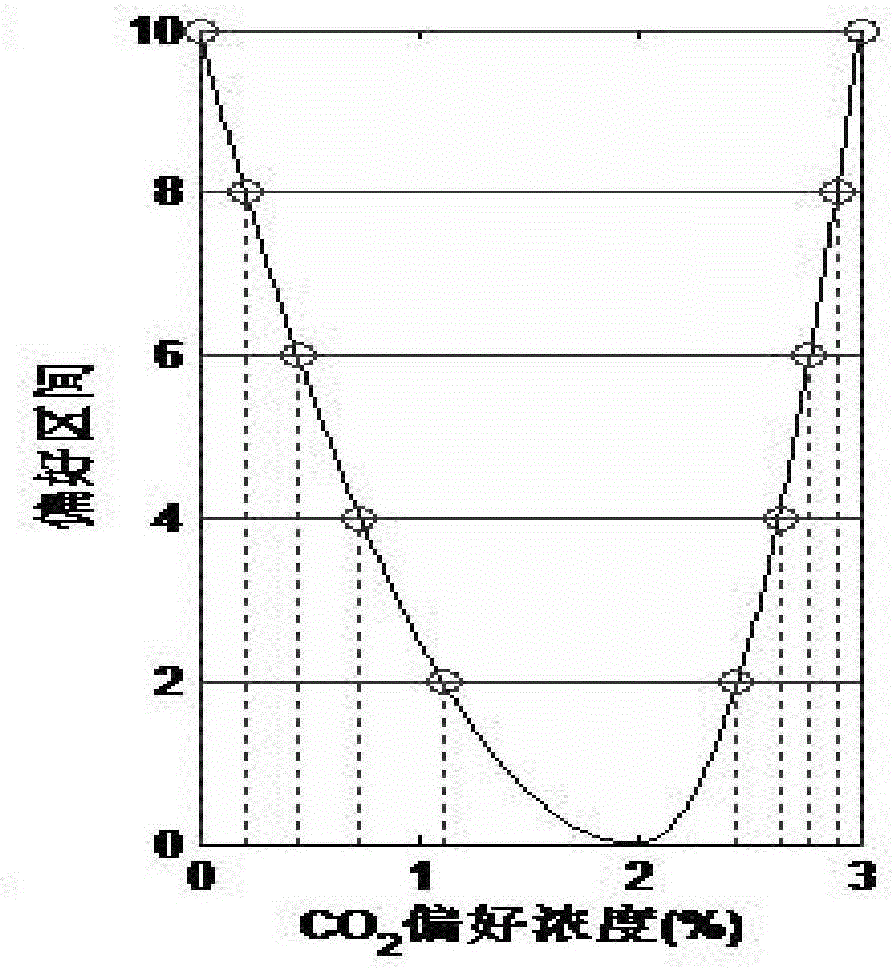

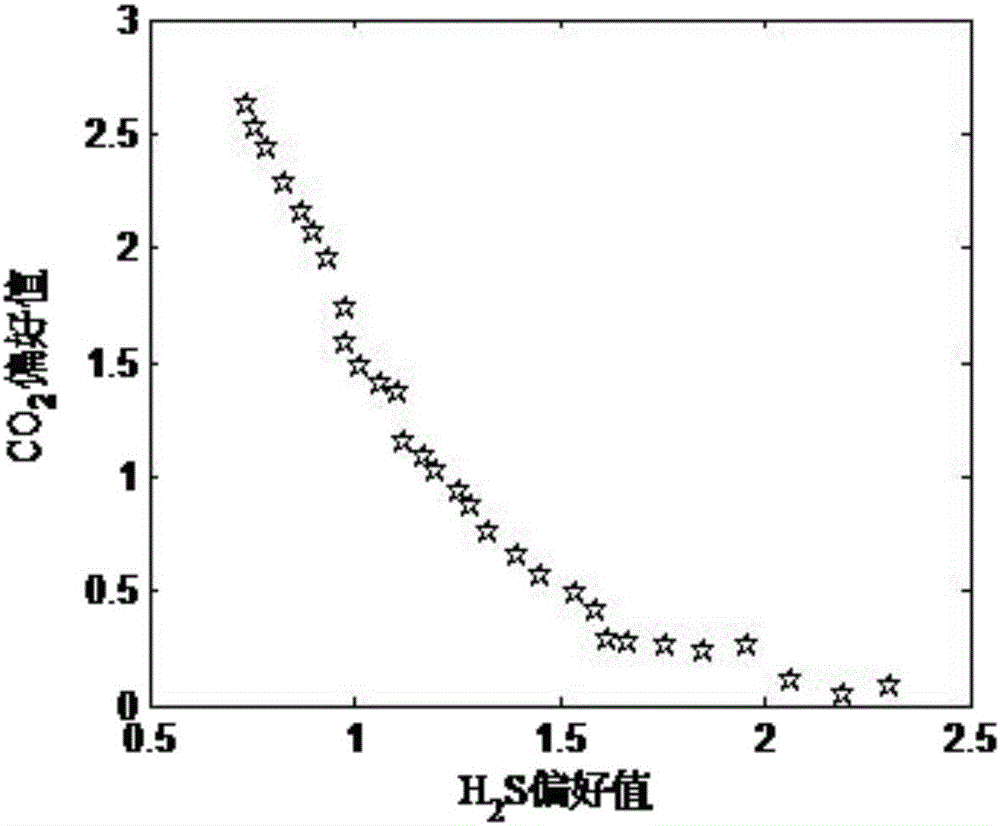

Modeling and optimizing method of high-sulfur natural gas purification process oriented to energy saving and consumption reduction

ActiveCN106777866AImprove the economic benefits of processingEffective trackingGaseous fuelsChemical processes analysis/designProcess orientedState variable

The invention provides a modeling and optimizing method of a high-sulfur natural gas purification process oriented to energy saving and consumption reduction. The method comprises the steps that process parameters influencing the desulfurization efficiency and performance indexes of a desulfurization unit are selected and then are acquired to form sample sets; normalization is conducted on the sample sets to form normalized sample sets, and a training sample and a testing sample set are selected from the normalized sample sets; a neural network model is established based on the training sample, and initial state variables of the neural network model are determined; the optimal state variable of the neural network model is estimated by utilizing an ST-UPFNN algorithm; according to the optimal state variable, the neural network model is updated; preference functions of H2S concentration and CO2 concentration are established respectively; process parameters of H2S concentration and CO2 concentration are optimized by utilizing an MOGA algorithm, and the optimized process parameters are introduced into the updated neural network model, the system performance of the optimized process parameters is calculated, and average values of the system performance of actual samples are compared. The production efficiency of high-sulfur natural gas purification can be improved by utilizing the method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

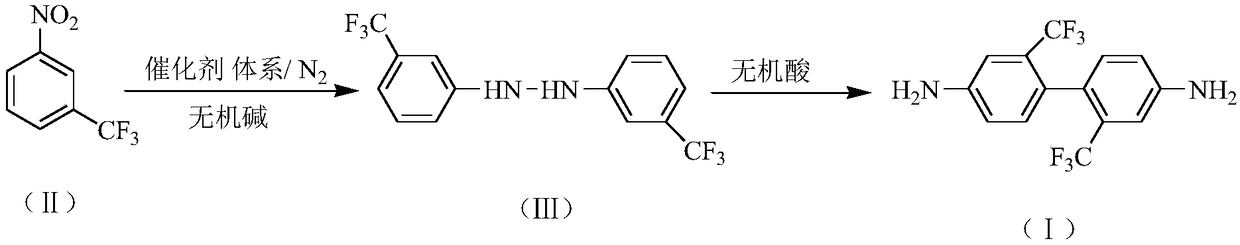

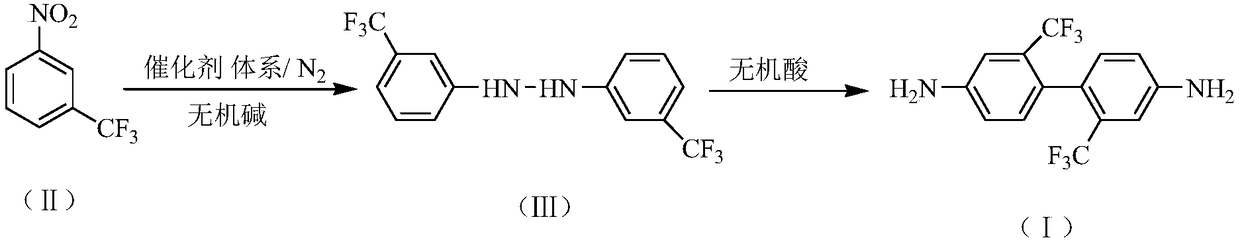

Preparation method of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl

InactiveCN109232273AReduce generationHigh purityHydrazine preparationPreparation by rearrangement reactionsHydroxyanthraquinoneDodecylsulfonic acid

The invention relates to a preparation method of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl. The preparation method comprises the following steps: synthesizing 3,3'-bis(trifluoromethyl)hydrazo-benzene in an inorganic alkaline aqueous solution by adopting nitrobenzotrifluoride as a raw material, adopting a phase transfer catalyst, a co-catalyst and Pd / C as a catalytic system and adopting aromatic hydrocarbon as a solvent, and performing the re-arrangement reaction on the 3,3'-bis(trifluoromethyl)hydrazo-benzene in an inorganic acid aqueous solution, thus obtaining 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl, wherein the phase transfer catalyst is one or a mixture of more of sodium dodecyl benzene sulfonate, sodium dodecyl sulfate and cetyl trimethyl ammonium bromide, and the co-catalyst is one or a mixture of more of 2,3-dichloro-1,4-naphthoquinone, 2-hydroxyanthraquinone and 2,6-dioxyanthraquinone. The preparation method has the advantages of mild reaction condition, simple process, high product quality and yield, low production cost, environmental friendliness, suitability for continuous production and the like.

Owner:烟台海川化学制品有限公司

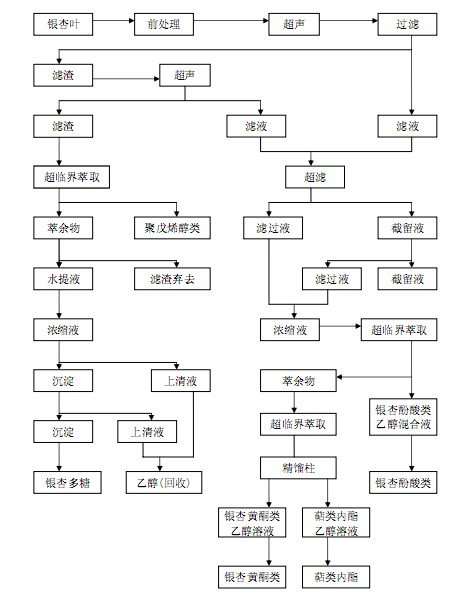

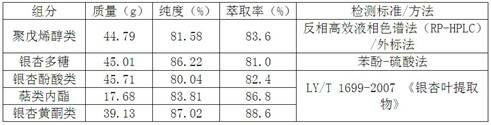

Separation technology for multiple components in ginkgo leaf

ActiveCN102603482AHigh puritySolve the problem of toxic phenolic acid exceeding the standardHydroxy compound separation/purificationBulk chemical productionHas active ingredientDistillation

The invention discloses a separation technique for multiple components in ginkgo leaves. Ginkgo leaves are used as a raw material. By combination of ultrasonic extraction and supercritical CO2 extraction-distillation, separation of multiple effective components is realized. The separation technique provided by the invention comprises the following steps: firstly, extracting the ginkgo leaves by ultrasonication in ethanol solutions with different concentrations for two times, and carrying out the following processes on filter liquor and filter residue obtained by filtration: (1) carrying out supercritical CO2 extraction and separation on the filter residue to obtain polyprenol compounds, and separating raffinate by water extraction and alcohol precipitation to obtain ginkgo polysaccharides; and (2) carrying out ultrafiltration and concentration on the filter liquor, and firstly separating to obtain ginkgolic acids by the supercritical CO2 extraction at a proper temperature and a properpressure; and changing extraction conditions, starting a rectifying column, heating by the temperature variation in the axial direction in four segments, and continuously extracting and separating toobtain ginkgo terpene lactones and flavonoid compounds. The separation technique provided by the invention has the advantages that active ingredients are difficult to decompose or destroy, harmful chemical reagent residues do not exist, the extraction efficiency is high, the separation effect is good and the like, solves the problem that the content of poisonous phenolic acid in ginkgo leaf extract exceeds the standard, and is an environment-friendly, economic and industrialization-suitable technique.

Owner:福建华尔康生物科技有限公司

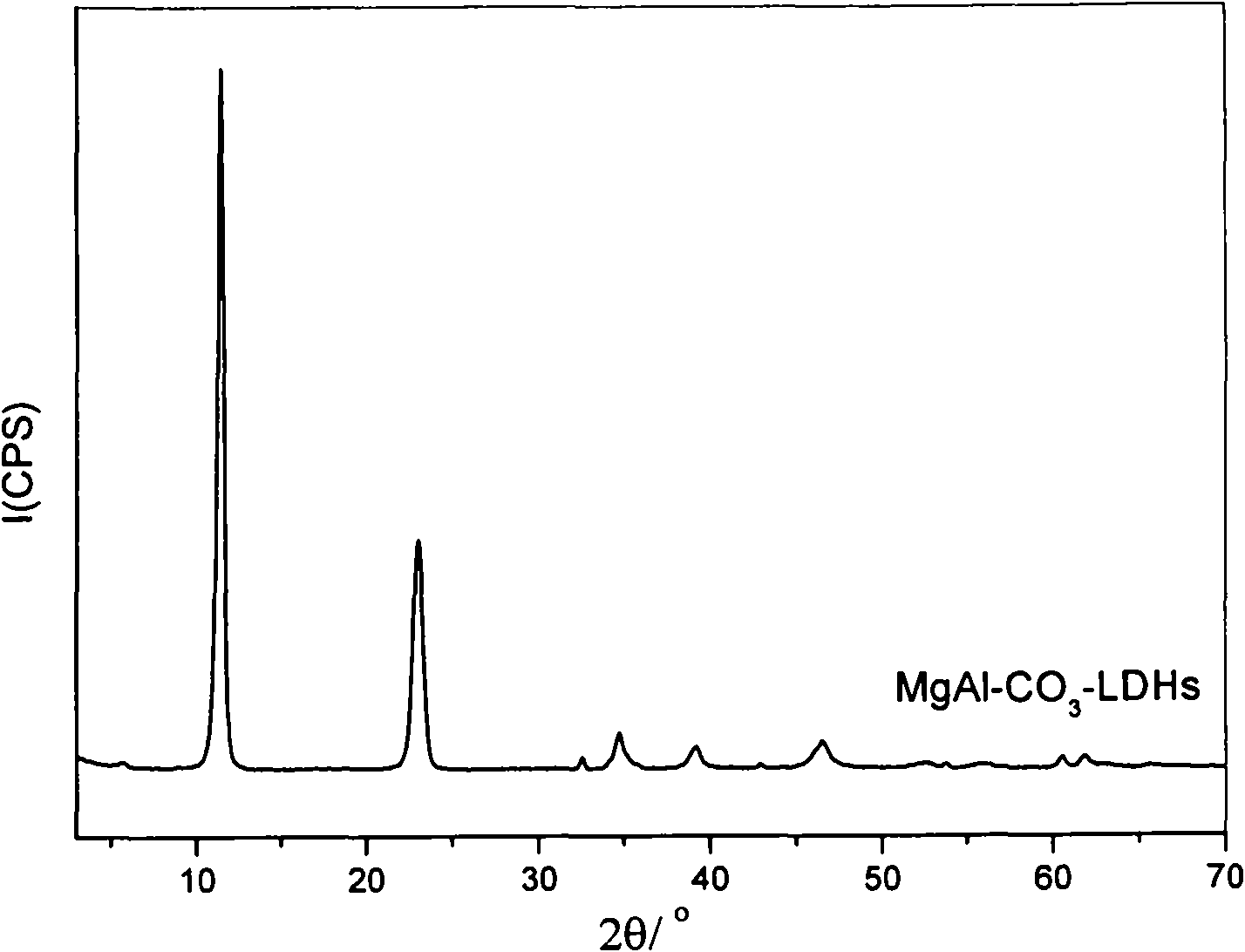

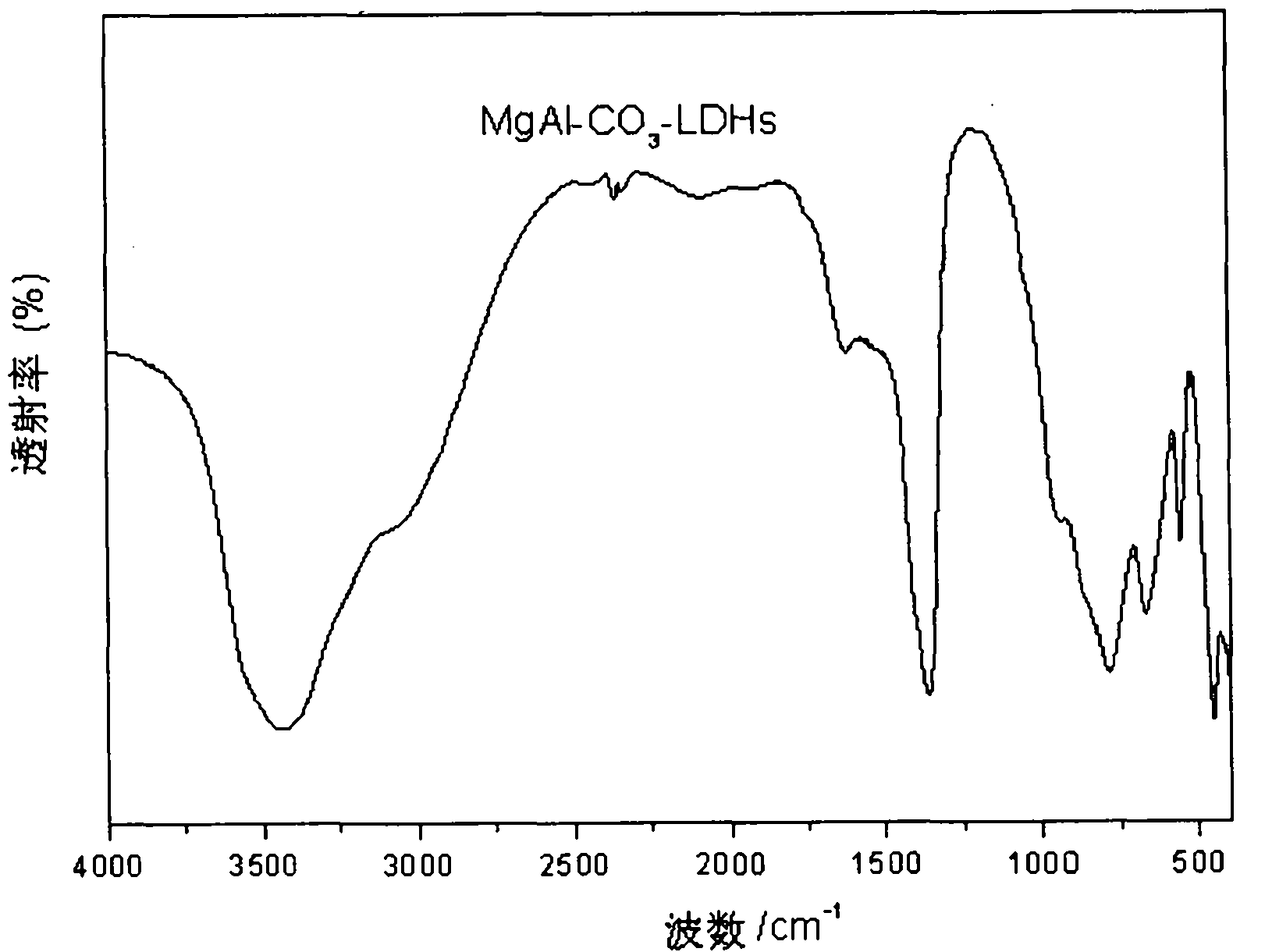

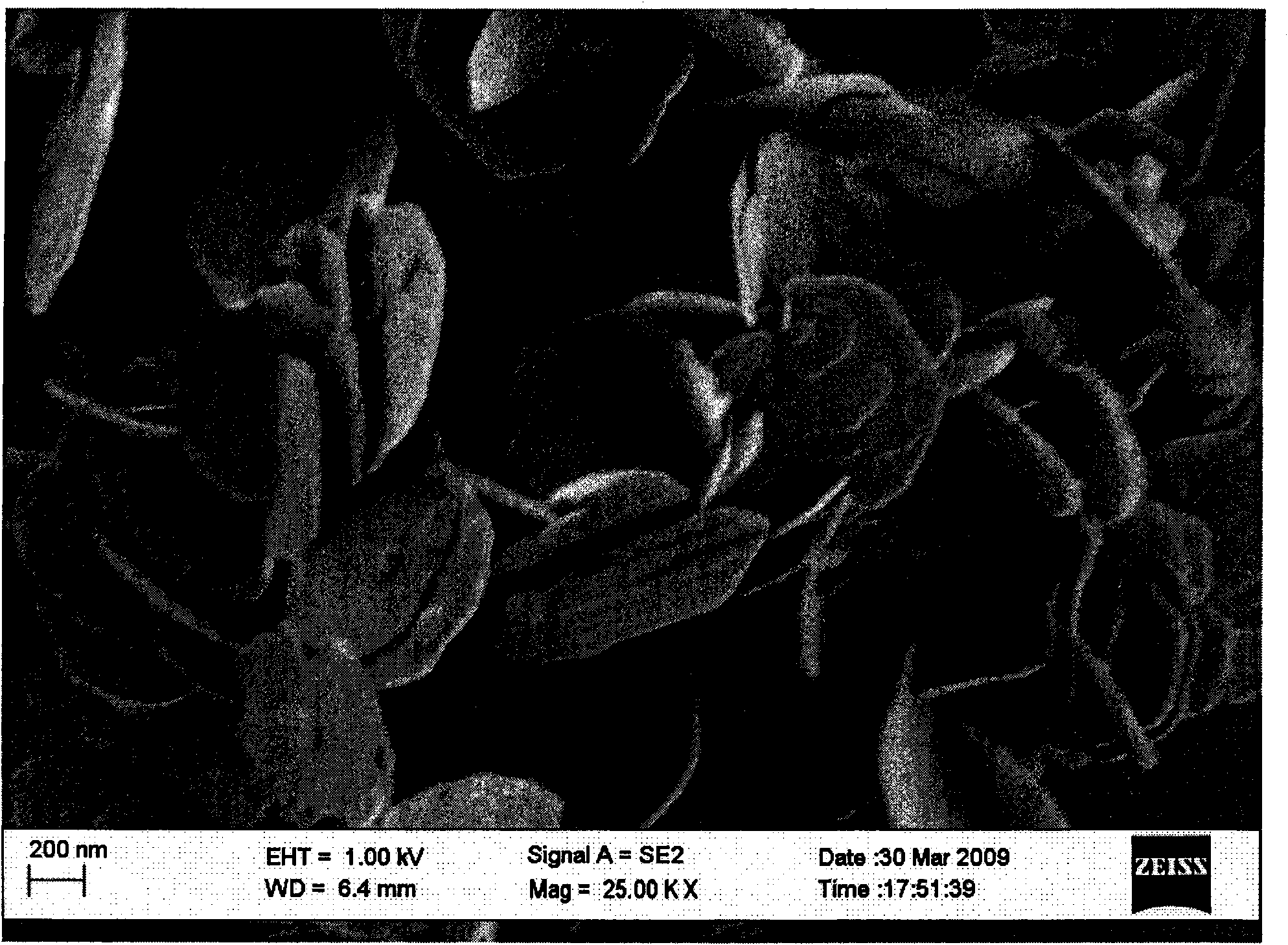

Method for preparing laminated composite metal hydroxide

InactiveCN101905869AOvercome costsOvercoming productivityOxide/hydroxide preparationAcid waterHydrogen

The invention discloses a method for preparing a laminated composite metal hydroxide, comprising the following steps of: mixing M(OH)2 and N(OH)3 according to the molar ratio of 2-4:1; and subjecting the mixture and an acid water solution to a reaction for 0.1-10 days at 100-300DEG C under the stirring condition, wherein the consumption of the acid water solution is 1-1,000 parts by weight, on the basis of the total weight of M(OH)2 and N(OH)3 as 1 part by weight, the molar ratio of acid in the acid water solution to N in the N(OH)3 is (n-1):1 to (n+1):1 and n expresses the number of nitrogen in each molecule of acid. When the laminated composite metal hydroxide is prepared from the method, various components in raw materials participate in the reaction to generate a target product or water molecule, no side product is generated in the process, water resources are saved and the environment is protected. In addition, in the method, by using brucite and pseudo-boehmite with low price as raw materials, the invention overcomes the defects that the clean preparation method in the prior art requires raw materials with high cost and is difficult to be applied to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

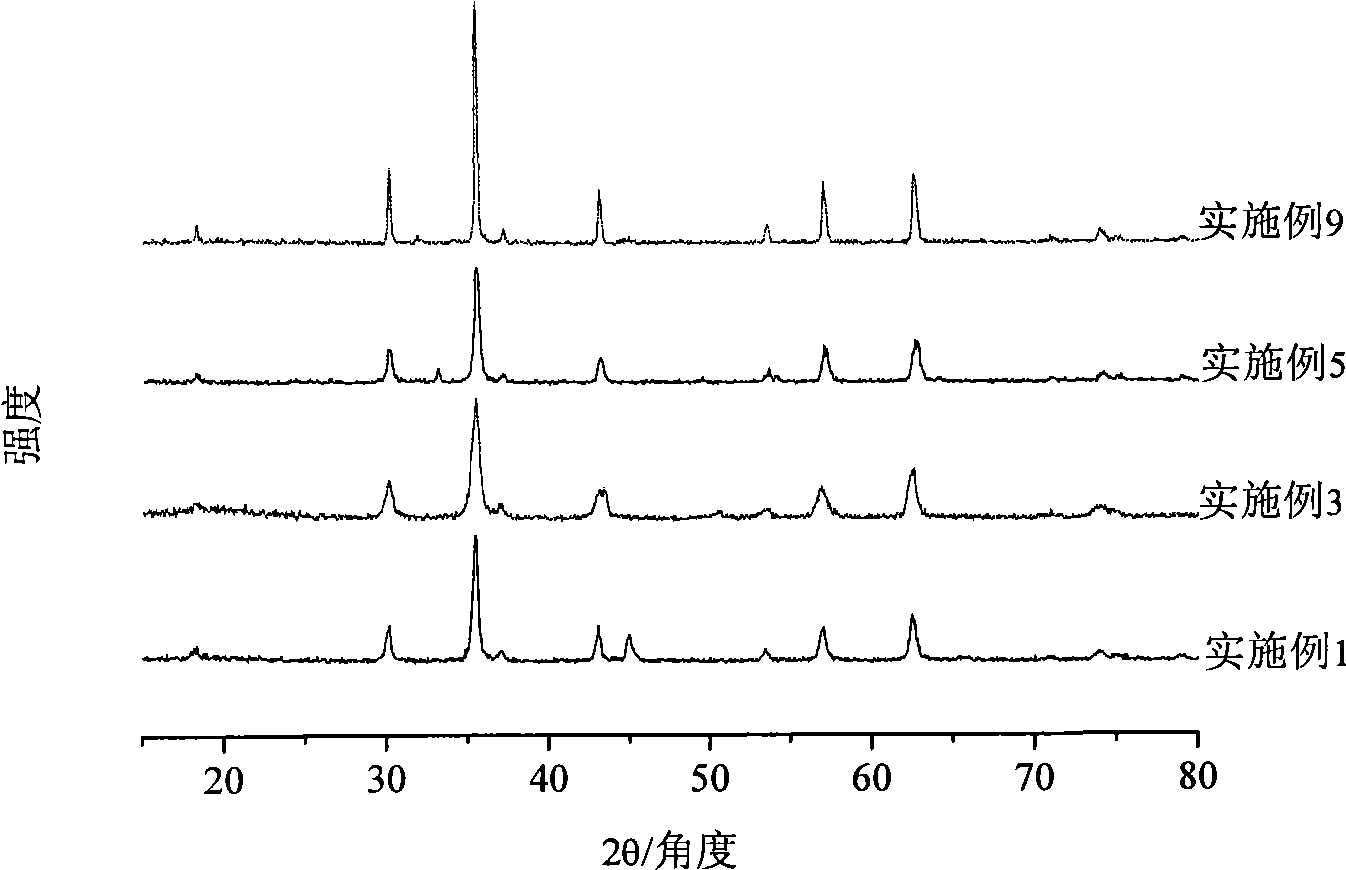

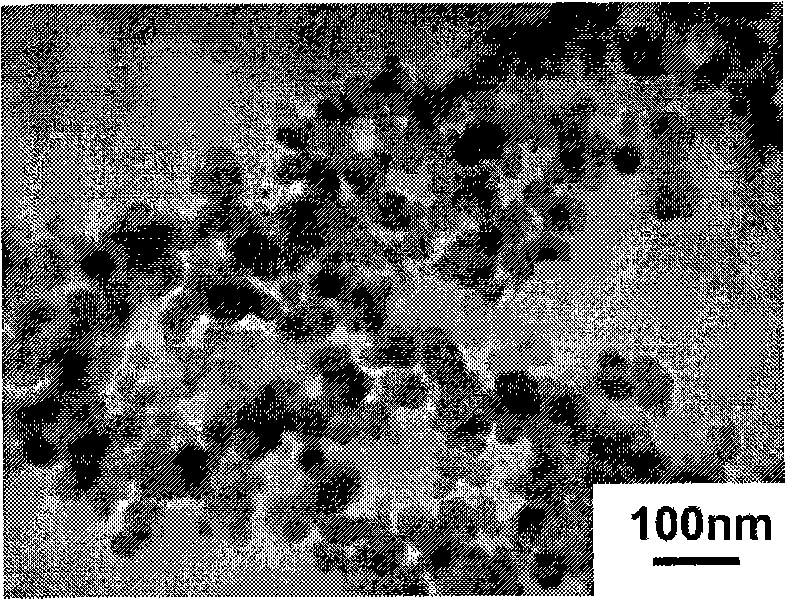

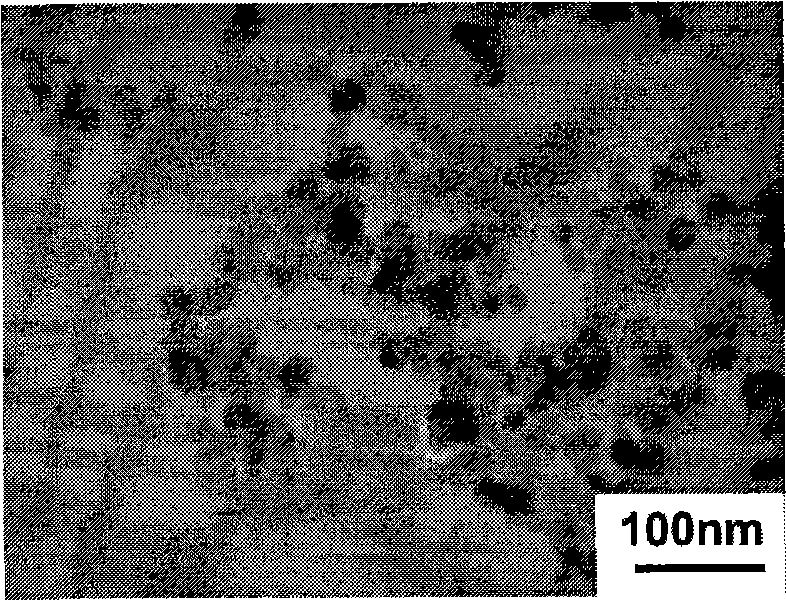

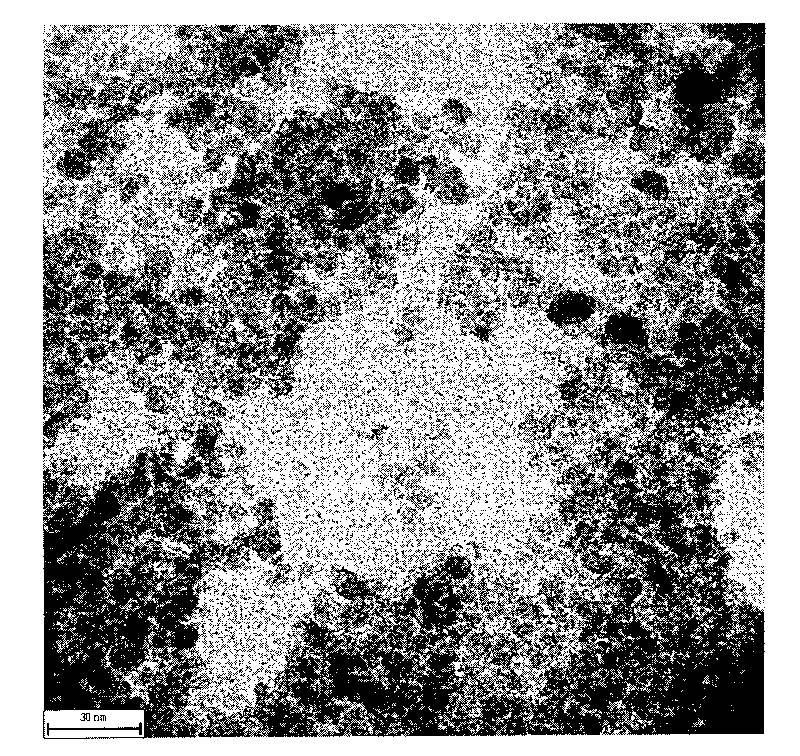

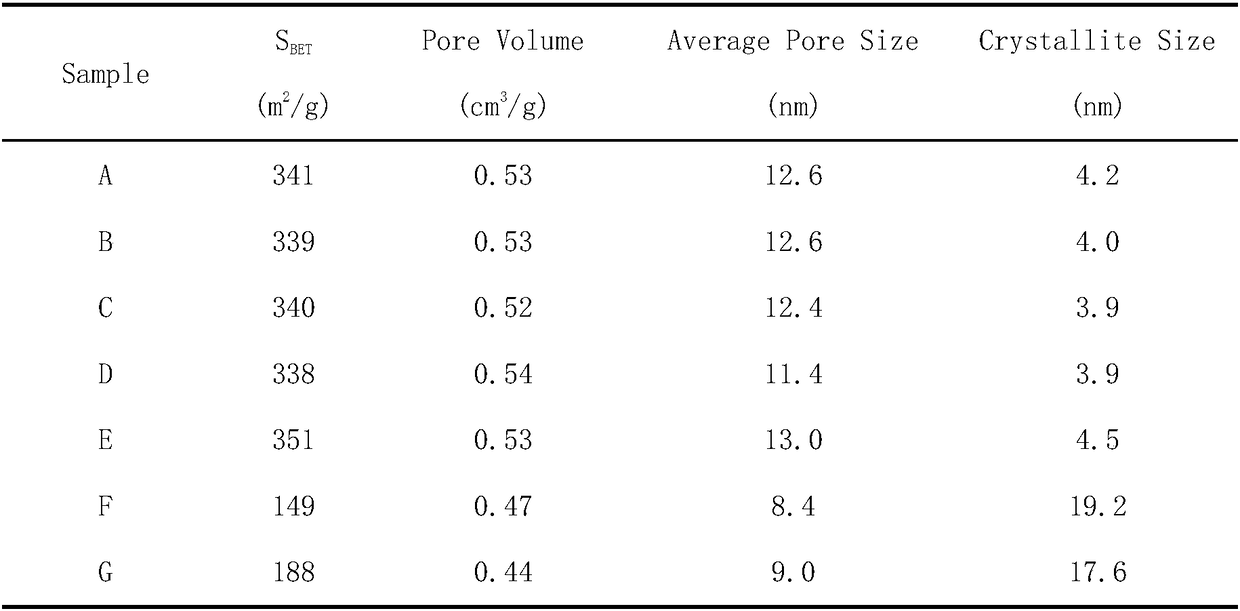

Magnetic spinel structure ferrite nano particle and preparation thereof

InactiveCN101486492AOvercoming productivityOvercoming the use of large amounts of organic solventsIron compoundsCobalt compoundsOctahedronSpinel

The invention discloses magnetic spinel-structure ferrite nano-particles and a preparation method thereof, which pertains to the field of magnetic nano-materials and aims at solving the problem that in the prior art, the defects of high production cost, low yield, environmental pollution, complicated operations, inadaptability to the commercial production and the like exist. The molecular formula of the magnetic spinel-structure ferrite nano-particles is CoxCuyZnzFe3-x-y-zO4, wherein, x ranges from 0 to 1, y ranges from 0 to 1 and z ranges from 0 to 1; and the magnetic spinel-structure ferrite nano-particles have the diameter of 20nm to 400nm and take the shapes of a ball, a regular tetrahedron, a regular hexahedron, a regular octahedron or a stick. The preparation method comprises the steps that: a soluble salt solution plated with transition metal ions is mixed with an alkali metal-hydroxide solution according to the volume ratio of 16:1-8 so as to carry out hydrothermal treatment, with the hydrothermal temperature of 120 DEG C to 180 DEG C and the hydrothermal time of 2 hours to 6 hours. The preparation method has the advantages of low cost, simple processes, strong applicability, adaptability to the industrialized production, and the like.

Owner:BEIJING UNIV OF CHEM TECH

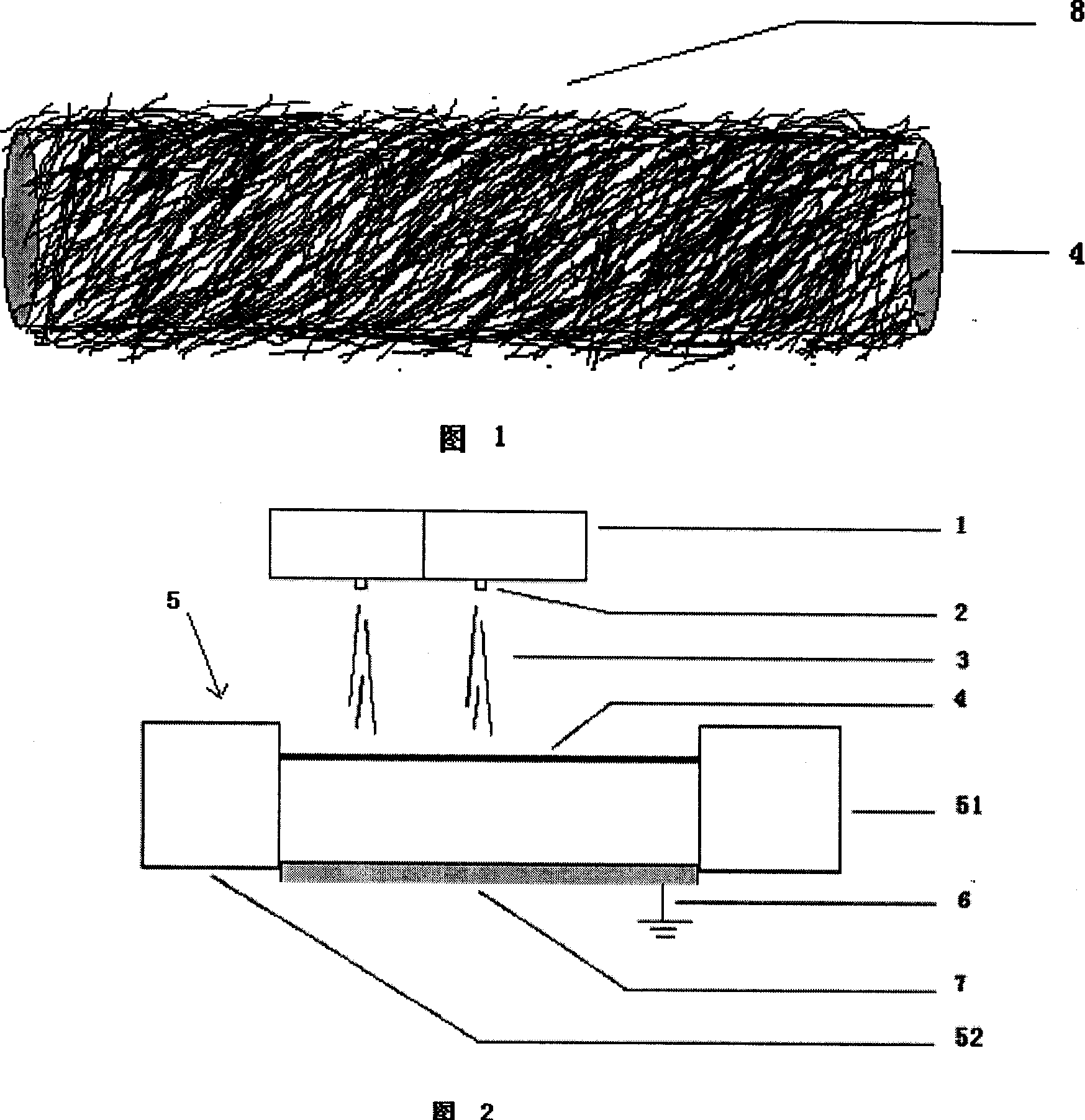

Nano fiber coated linear composite material and its preparing method

The invention relates to nanometer fiber covering linear recombination material that is made up of linear basal material and nanometer fiber covering layer. It conquers the disadvantages of nanometer fiber itself, and has the feature and function of nanometer fiber and keeps all the capability advantages of linear recombination material itself. It could be used in all fields that use linear material.

Owner:上海兰度科技有限公司

Method for preparing single-crystal copper bonding wire

InactiveCN101524721AHigh strengthHigh elongationPolycrystalline material growthSolid-state devicesMegasonic cleaningSingle crystal

The invention relates to a method for preparing a single-crystal copper bonding wire, which uses copper as a raw material. The method comprises the following steps: melting high purity copper of which the purity is higher than 99.995 percent by using a high-vacuum furnace, raising the temperature to between 1,100 and 1,180 DEG C, refining the copper for 60 to 120 minutes, and adopting high purity argon for protection in the whole melting process; broaching single-crystal copper rods of phi 4 to phi 8 mm in a directional solidification mode, and then coldworking the single-crystal copper rods to between phi 0.95 and phi 1.102 mm with the broaching working rate of 15 to 25 percent for each gate; broaching the single-crystal copper rods to between 0.020 and 0.05 mm with 47 to 70 gates and the working rate of 7.59 to 17.82 percent for each gate; and carrying out sonicleaning on the surface of the single-crystal copper bonding wire when the wiredrawing temperature is between 35 and 45 DEG C, carrying out heat treatment on the cleaned single-crystal copper bonding wire, and using H2+Ar2 for protection with the temperature of between 410 and 425 DEG C, the time of between 0.7 and 2.0s and the annealing rewinding tension of between 0.6 and 2.8g.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method of silver/titanium dioxide compound

ActiveCN101693196AOvercome the cumbersome preparation processOvercome costsMetal/metal-oxides/metal-hydroxide catalystsAlcoholOrganic matter

The invention discloses a preparation method of a silver / titanium dioxide compound, comprising the following steps: firstly, fully mixing nanometer silver, polyvinylpyrrolidone k30 and absolute alcohol and conducting high dispersing treatment, thus obtaining relative stable nanometer silver / alcohol suspending liquid; secondly, slowly dropping tetrabutyl titanate into the nanometer silver / alcohol suspending liquid under the condition of stirring, then slowly dropping mixed solution with PH value of 1-3 and prepared from absolute alcohol, deionized water and nitric acid, and then continuing stirring for 1-2 hours after the dropping is finished, thus obtaining silver / titanium dioxide sol; and thirdly, removing organic matter and water from the silver / titanium dioxide sol, thus obtaining the silver / titanium dioxide compound. The preparation method solves the problems such as rigmarole processes, relative high cost, difficulty in large-scale production and the like, and has the advantages of low cost, simple operation and applicability to industrialized production.

Owner:安庆市观成科技有限公司

Preparation method and application for iron oxyhydroxide

ActiveCN108101116AIncrease reaction rateGrowth inhibitionIron oxides/hydroxidesHydrocarbon oil crackingSlurryIron oxyhydroxide

The invention belongs to the technical field of preparation of metal oxyhydroxides, and specifically relates to a preparation method and an application for iron oxyhydroxide. The preparation method comprises the following steps: under the condition of supergravity, mixing a Fe2+ metal salt solution with an alkaline solution, and allowing oxygen to reversely contact with a reaction solution at thesame time so as to obtain a mixed reaction slurry; subjecting the mixed reaction slurry to gas-liquid separation, and subjecting an obtained liquid to aging under the conditions of stirring and bubbling oxidation so as to prepare a suspension containing the iron oxyhydroxide; and subjecting the suspension to liquid-solid separation, and subjecting an obtained solid phase to washing and drying so as to obtain the iron oxyhydroxide. According to the invention, the precipitation process and the bubbling aging process of a supergravity reaction are performed in different reactors, so the processesof crystal nucleus generation and crystal nucleus growth are separated; through adjustment of parameters of temperature, time and stirring degree in bubbling aging, the environment of crystal nucleusgrowth is controlled; and preferably, nanoscale or submicron iron oxyhydroxide can be prepared, and has the characteristics of small average particle size, large specific surface area and uniform particle size distribution.

Owner:FUZHOU UNIV +1

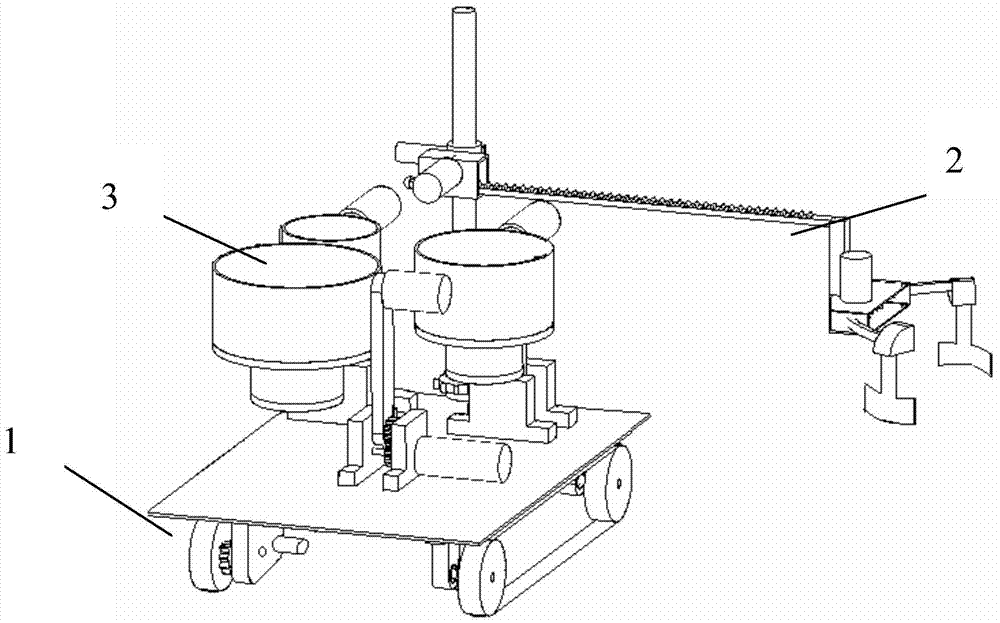

Mechanical picking device for greenhouse cultivated tomatoes

The invention discloses a mechanical picking device for greenhouse cultivated tomatoes. The device comprises a driving mechanism, a picking mechanism and three collecting and pouring mechanisms, wherein a driving part of the driving mechanism is driven by a front driving motor and a rear driving motor respectively; the picking mechanism is fixed on a bottom plate of the driving mechanism; the three collecting and pouring mechanisms are of a complete structure, and are triangularly distributed on the bottom plate. According to the device, the driving part is driven by the front driving motor and the rear driving motor, so that the device can move forwards and backwards and turn flexibly; the greenhouse cultivated tomatoes are automatically picked, so that the problems of high operation labor intensity, low production rate and the like are solved, the labor investment and the production cost are reduced, and large-scale plantation and production can be organized favorably.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Single crystal copper bonding lead and preparation method thereof

InactiveCN102637657AHigh strengthHigh elongationSemiconductor/solid-state device detailsSolid-state devicesCopper wireDying processes

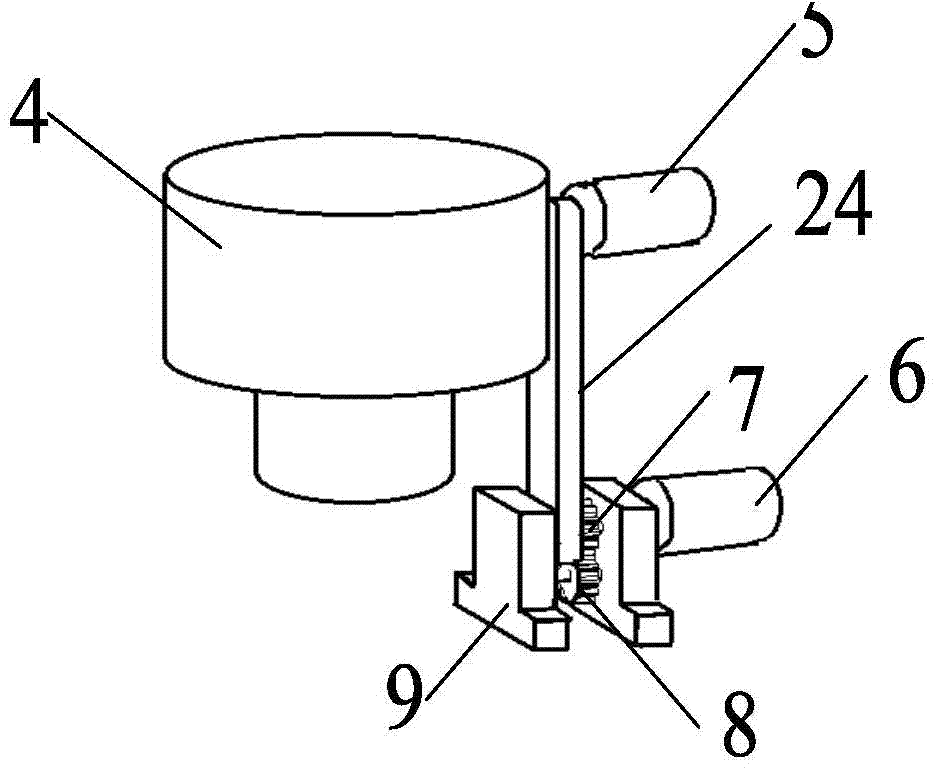

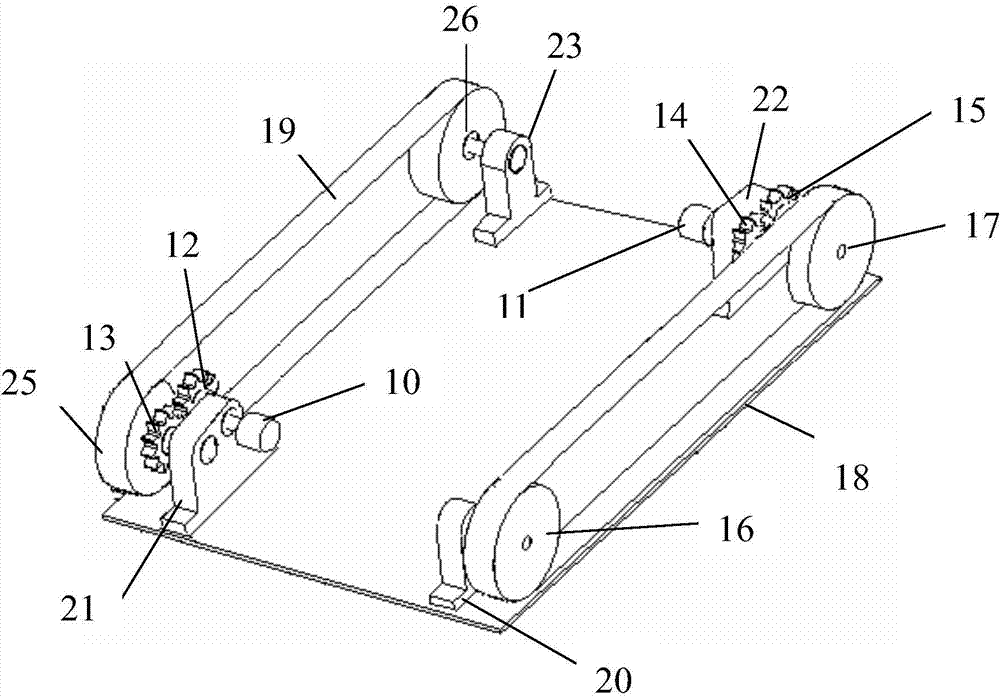

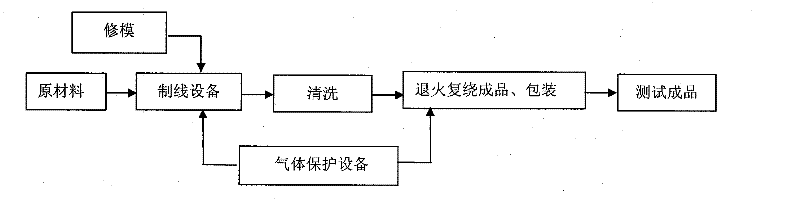

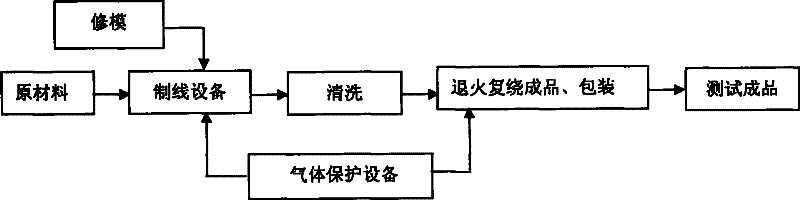

The invention discloses a single crystal copper bonding lead and a preparation method thereof, relating to the field of production of microelectronic materials. The production technology integrates a metal material preparation process, a heat treatment process and a diamond die process, ensures the production consistency and reliability and realizes the large-scale production. The adopted production process comprises the steps of providing die repair and gas protection equipment, smelting, wiredrawing, cleaning, and compounding, packaging and testing a finished product. The single crystal copper bonding lead has the beneficial effects that as a signal crystal copper material has a compact solidification structure, lateral crystal boundaries are eliminated, the casting defects of shrinkage cavities, pores and the like are avoided, the plastic working performance, the mechanical performance, the electric performance and the like of the signal crystal copper material are obviously higher than those of the conventional oxygen-free copper, the defects of more end breakage, low quality and low productivity in the wiredrawing process of the conventional copper wire are overcome, and an electronic packaging bonding wire with the wire diameter reaching 0.015m, high strength, high elongation and stable performance can be prepared.

Owner:宋东升

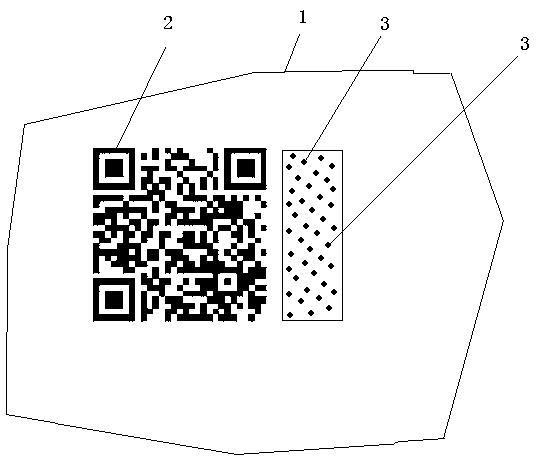

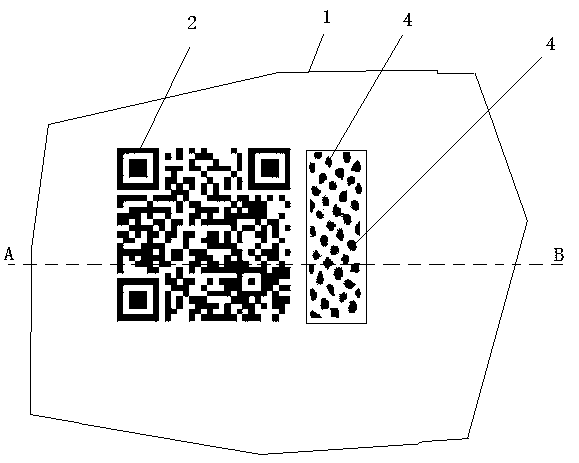

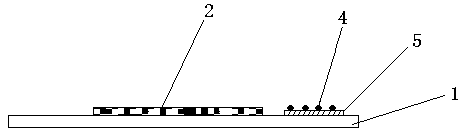

An over-limit ink dot anti-counterfeiting method and a printed matter

InactiveCN109711511AOvercoming low printing speedOvercoming productivityStampsCommerceDot matrixEngineering

The invention provides an over-limit ink dot anti-counterfeiting method and a printed matter. The method comprises the steps that codes are printed, ink dot matrixes are printed on a printing surfacewith the infiltration characteristic, the ink dot matrixes are randomly opened to be changed into ink block lattices in a random shape, the ink block lattices are amplified and shot to obtain shape characteristic information of ink blocks, and the characteristic information of the ink blocks serves as an anti-counterfeiting characteristic information file; when a consumer checks the authenticity,an ink block dot matrix is shot by using a mobile phone, and the characteristic information of the ink block is matched with the anti-counterfeiting characteristic information file so as to identify the authenticity. Compared with the prior art, a short-staple printing unit is omitted, and the defects that an existing short-staple printing unit is low in printing speed, prone to plate blocking andprone to shutdown of a production line are overcome.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

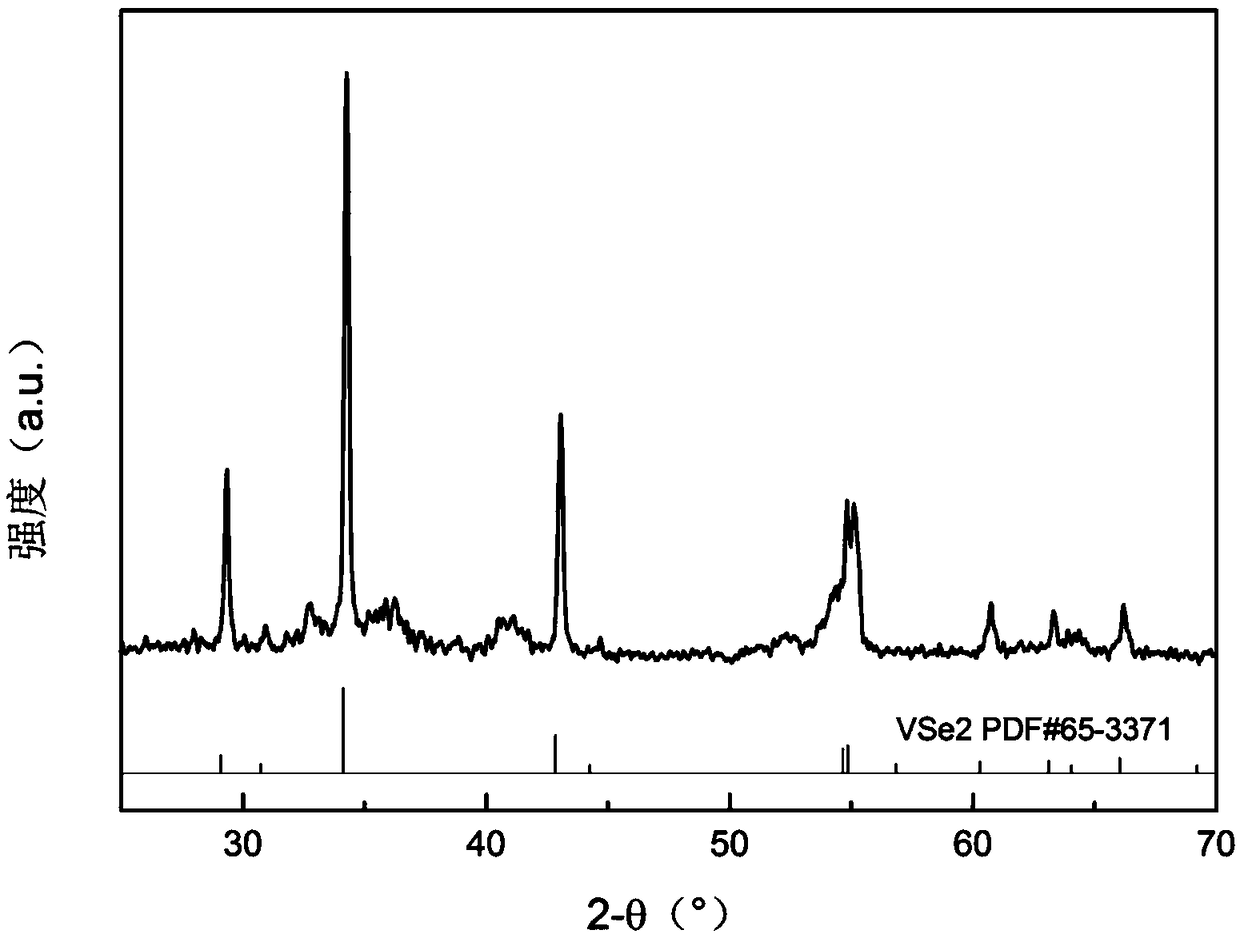

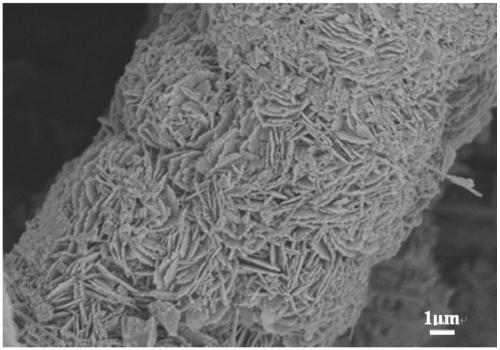

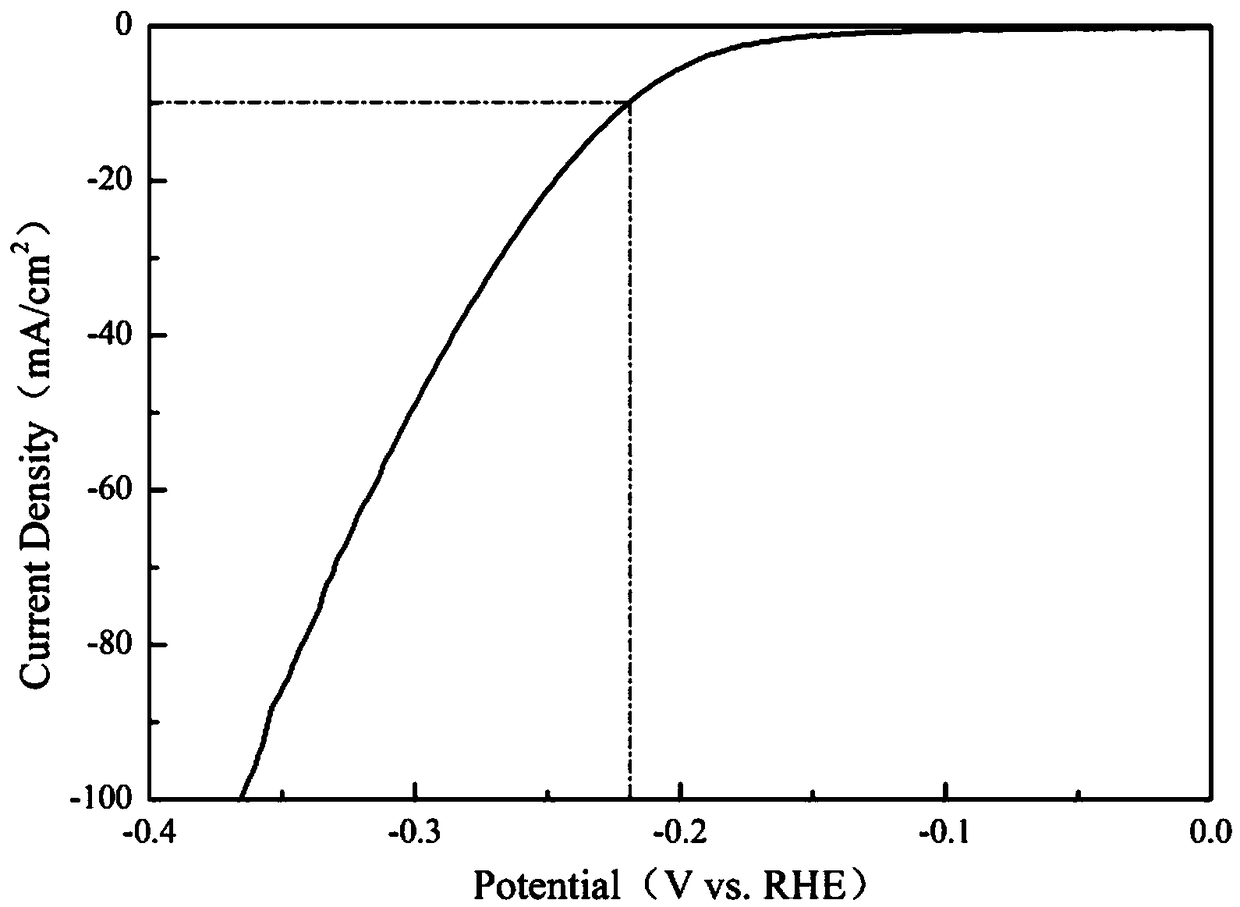

Method for synthesizing self-assembled VSe2 nanosheets

ActiveCN109279584ASimple processShort preparation cyclePhysical/chemical process catalystsHydrogen productionSynthesis methodsHigh pressure

The invention discloses a method for synthesizing self-assembled VSe2 nanosheets. The method comprises the steps: (1) performing pretreatment of carbon cloth; (2) weighing selenourea and a vanadium source, dissolving the weighed selenourea and vanadium source in 30 mL of a solution, performing magnetic and uniform stirring, and then putting the treated carbon cloth (CC) so as to obtain a mixed liquid; and (3) transferring the mixed liquid obtained in the step (2) to a 50 mL high-temperature high-pressure reactor with a para-polybenzene lining, then adding an ammonium fluoride morphology regulating agent to the reactor, sealing the reactor, and placing the sealed reactor in an oven for a hydrothermal reaction; and performing natural cooling to room temperature, taking the carbon cloth out,and performing rinsing and vacuum drying so as to obtain a self-assembled VSe2 / CC nanosheet array self-supporting electrode. Through adoption of the hydrothermal method, the advantages of a simple process, a short preparation cycle and easily controllable reaction conditions are achieved, and the reaction process and the morphology and size can be controlled through adjustment of the temperature,so that multiple special morphology structures are obtained, and different morphological features have great influences on the properties of the material.

Owner:SHAANXI UNIV OF SCI & TECH

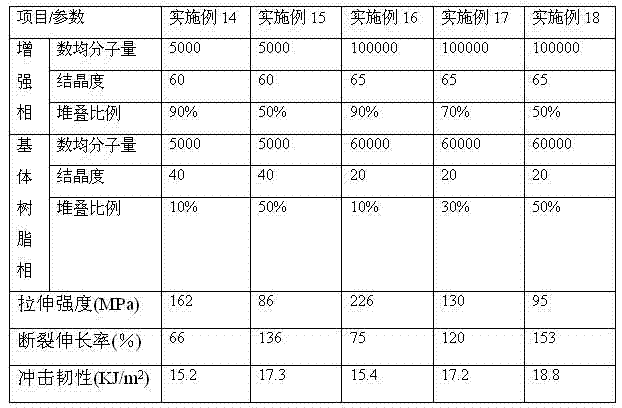

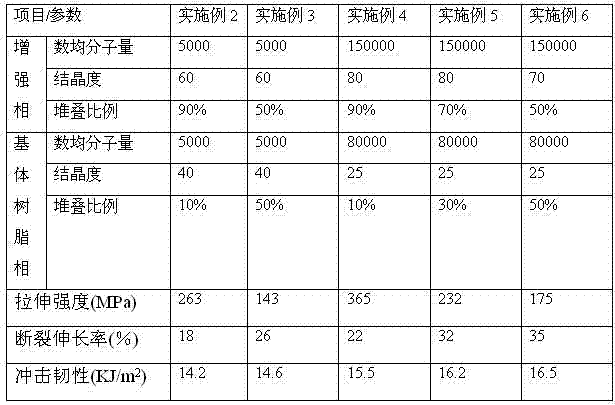

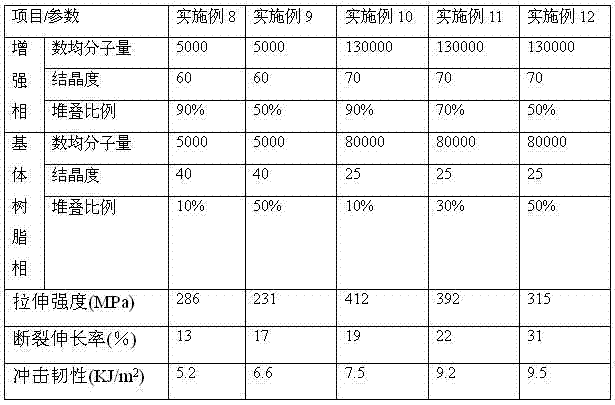

Self-reinforced bionic material and manufacture method thereof

The invention discloses a self-reinforced bionic material, comprising a reinforced phase prepared from a biodegradable polymer A with high molecular weight and high crystallinity, and a matrix resin phase prepared from a biodegradable polymer B with molecular weight and crystallinity lower than those of the biodegradable polymer A; the reinforced phase and the matrix resin phase are stacked by a guide die; and the stacking percentage of the reinforced phase is 30-90%, and the stacking percentage of the matrix resin phase is 5-60%. The invention also provides a manufacturing method of the self-reinforced bionic material. The invention employs ultrasonic transient heating and interface mechanism with controllable strength to solve a problem for keeping melting fiber morphology when the difference of melting temperature between matrix and the reinforced phase is small; and fiber distribution gradient is constructed to prepare a biodegradable self-reinforced biomimetic material with bamboo imitation structure, high strength and high toughness.

Owner:GUANGZHOU MEDICAL UNIV

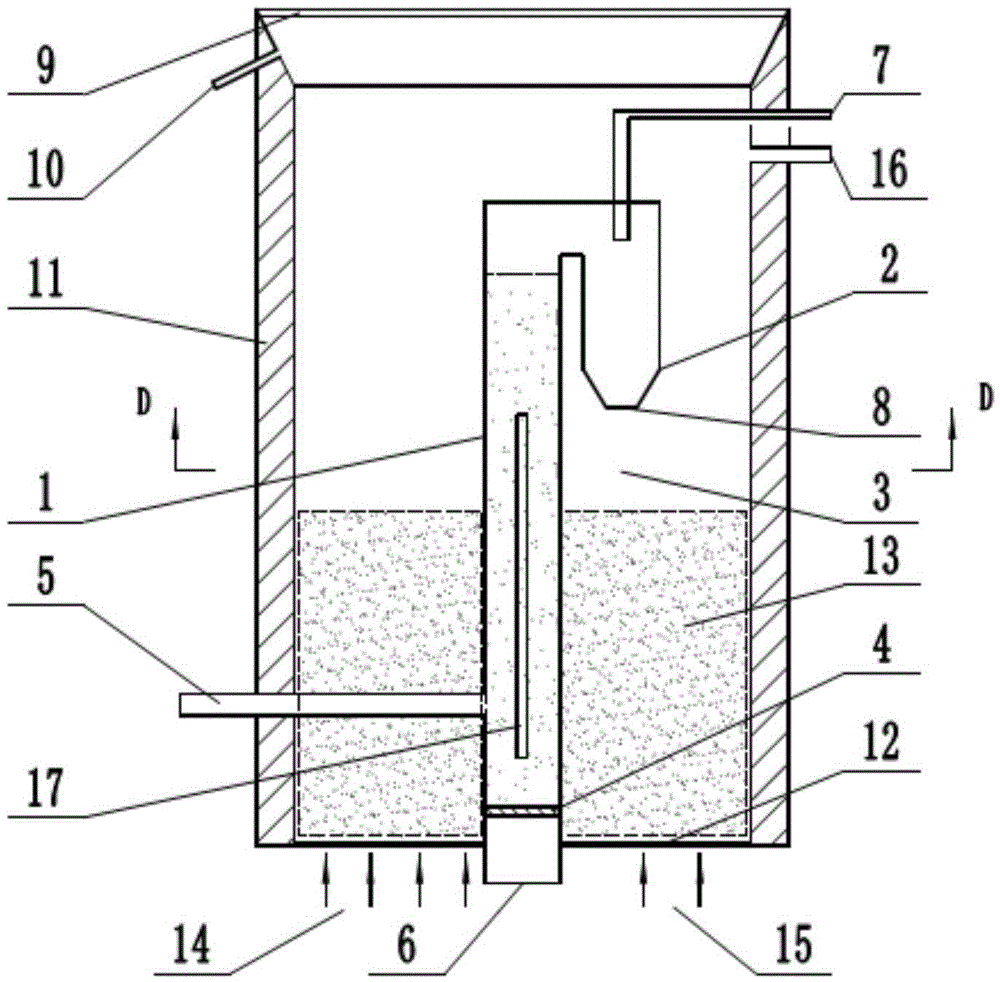

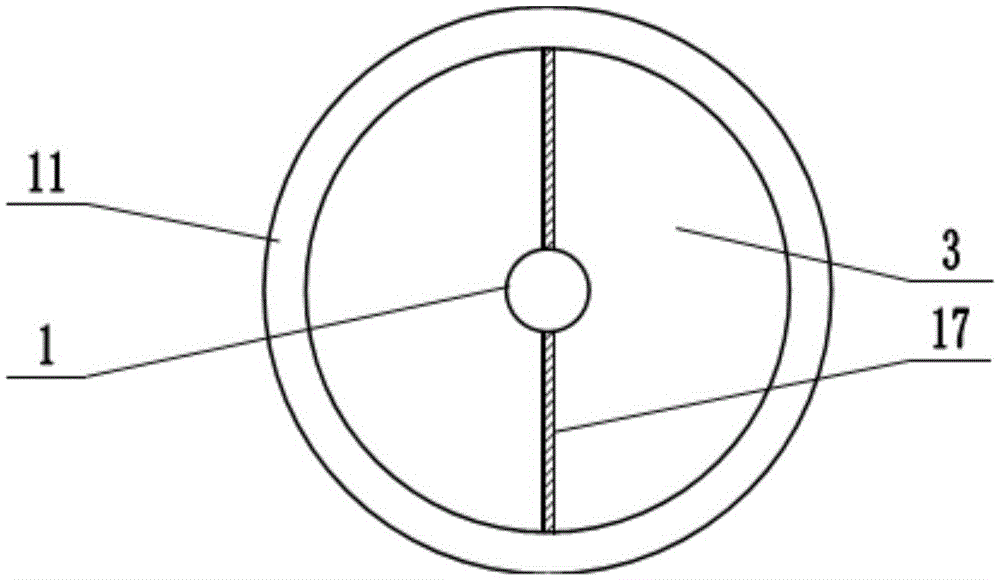

Solar energy-driven coal pyrolysis coupling coalite gasification reactor and method

InactiveCN105623744AAchieve matchingSimple structureEnergy inputGasification processes detailsInsulation layerFluidized bed

The invention discloses a solar energy-driven coal pyrolysis coupling coalite gasification reactor and a method. The reactor mainly comprises a lifting pipe, a cyclone separator and an annulus inner circulation fluidized bed, wherein an outlet of the lifting pipe is connected to the cyclone separator, and the lifting pipe and the cyclone separator are arranged inside the annulus inner circulation fluidized bed; the lifting pipe is located at the center of the annulus inner circulation fluidized bed, a pipe wall of the lifting pipe is parallel to the wall surface of the annulus inner circulation fluidized bed, and an inlet of the lifting pipe extends out of the bottom of the annulus inner circulation fluidized bed for a distance; an air distributor is arranged at the bottom of the lifting pipe, and a coal feeding pipe is connected to the side wall of the lifting pipe; the top of the annulus inner circulation fluidized bed is provided with a light inlet window, the outer wall of the annulus inner circulation fluidized bed is coated with a heat insulation layer, and the bottom of the annulus inner circulation fluidized bed is provided with an annular air distributor.

Owner:NORTHWEST UNIV(CN) +1

Production process for high-moisture-absorption polyester down-proof fabric used for home textiles

ActiveCN107099908AGood flexibilityImprove compactnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterFiber

The invention relates to a production process for a high-moisture-absorption polyester down-proof fabric used for home textiles. The production process includes the following steps that weaving is conducted, wherein polyester DTY silk serves as warp yarn, sea-island fibers serve as weft yarn, and weaving is conducted on a water-jet loom; the sea-island fibers refer to PET, the island refers to COPET, the on-loom warp density is 137-200 per inch, the weft density is 100-200 per inch, and a gray fabric is formed by weaving; one side of the fabric is brushed; refining and splitting are conducted, the brushed fabric is fed into an overflow dyeing machine, splitting is conducted in the overflow dyeing machine, and the softness and compactness of the fabric are improved; water washing and plastification are conducted, fluffing and setting are conducted, the fabric obtained after water washing and plastification is subjected to pad-roll processing with a polyester bulking agent before passing through a setting machine, and a finished fabric product is formed after being subjected to setting through the setting machine. The process does not require the high-count and high-density weaving process required by a traditional down-proof fabric, so that the gray fabric weaving production difficulty is low, at the same time, the disadvantages that the coated down-proof fabric production process requires coating operation and thus causes long production process, hard hand feeling and easy-to-fall-off coatings are overcome, and therefore the production process is more suitable for the down-proof fabric used for the home textiles.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

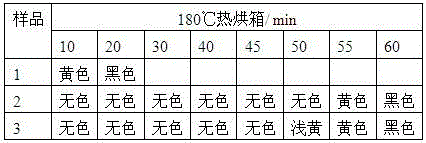

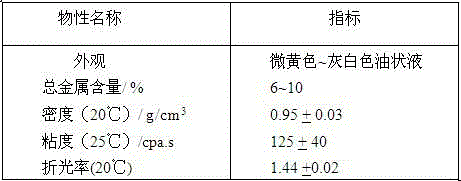

Method for preparing modified liquid metal soap thermal stabilizer through potassium ion characteristic doping

ActiveCN102746595AOvercome the technical defects of complex traditional production processesImprove long-term thermal stabilityCarboxylic acid salt preparationCompound organicDistillation

The invention relates to a method for preparing a modified liquid metal soap thermal stabilizer through potassium ion characteristic doping, belonging to the technical fields of fine chemical engineering and high molecular material application. The invention researches and develops a potassium-ion-doped PVC (polyvinyl chloride) liquid metal soap thermal stabilizer. The synthesis method of the thermal stabilizer comprises the following steps: adding composite organic acid into a three-neck flask, stirring, and heating to 90-100 DEG C; adding solid potassium hydroxide in batches; after the reaction is complete, performing reduced-pressure distillation to dewater; cooling to 80 DEG C, then adding a liquid metal soap and a solvent, and continuously stirring to react; and finally, performing reduced-pressure filtration to obtain a yellowish transparent oily liquid. By utilizing the fact that metal potassium salt has fine long-term thermal stability, produces an obviously strong inhibition effect on zinc burning and has obvious cooperativity with other metal salt, the potassium-ion-doped PVC liquid metal soap thermal stabilizer is directly prepared through a solid-liquid one-step reaction method. The thermal stabilizer has the advantages of low cost, no toxicity, environment friendliness, simple process, fine performance, light appearance color and the like, and is easy to popularize and apply.

Owner:JIANGNAN UNIV

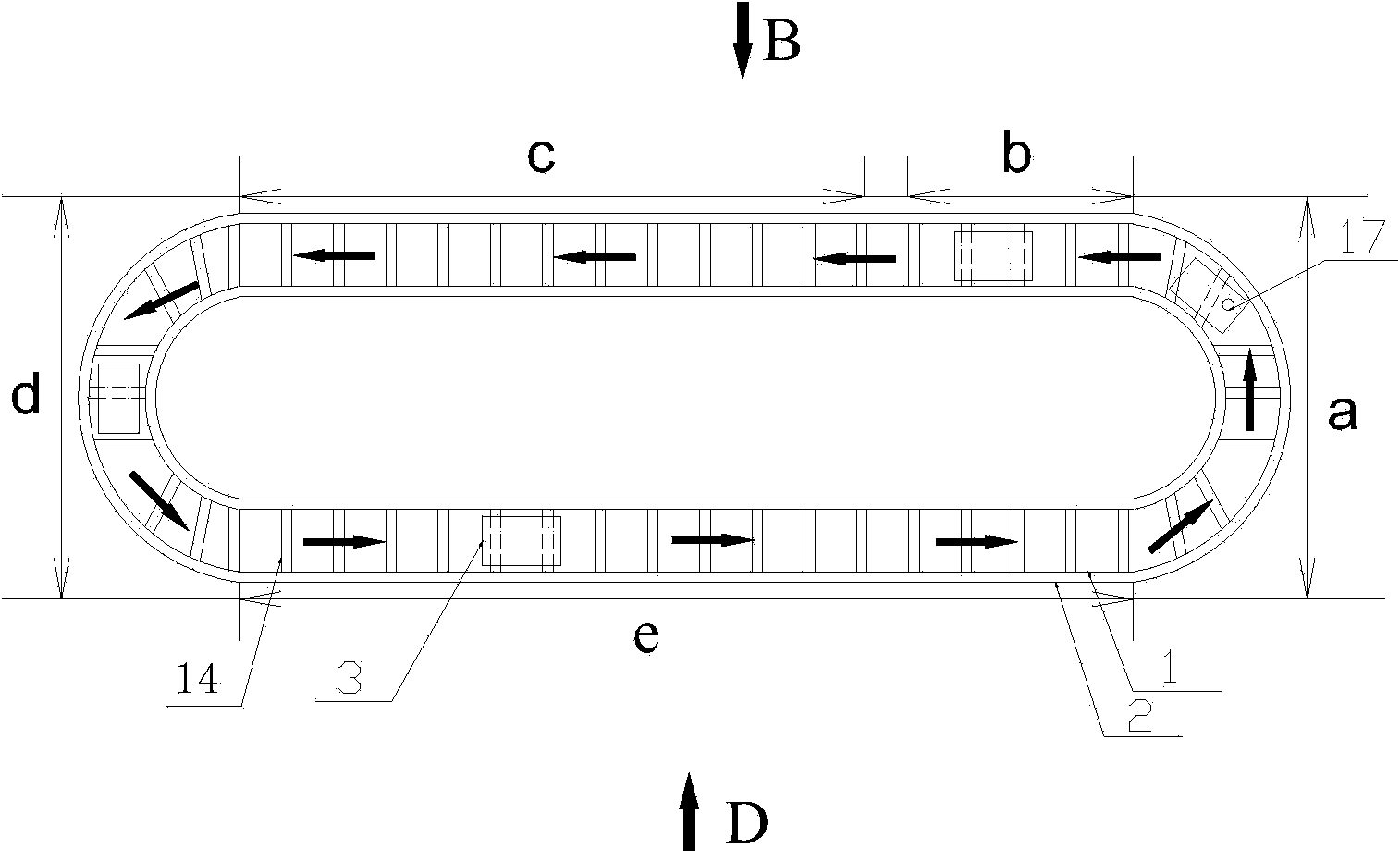

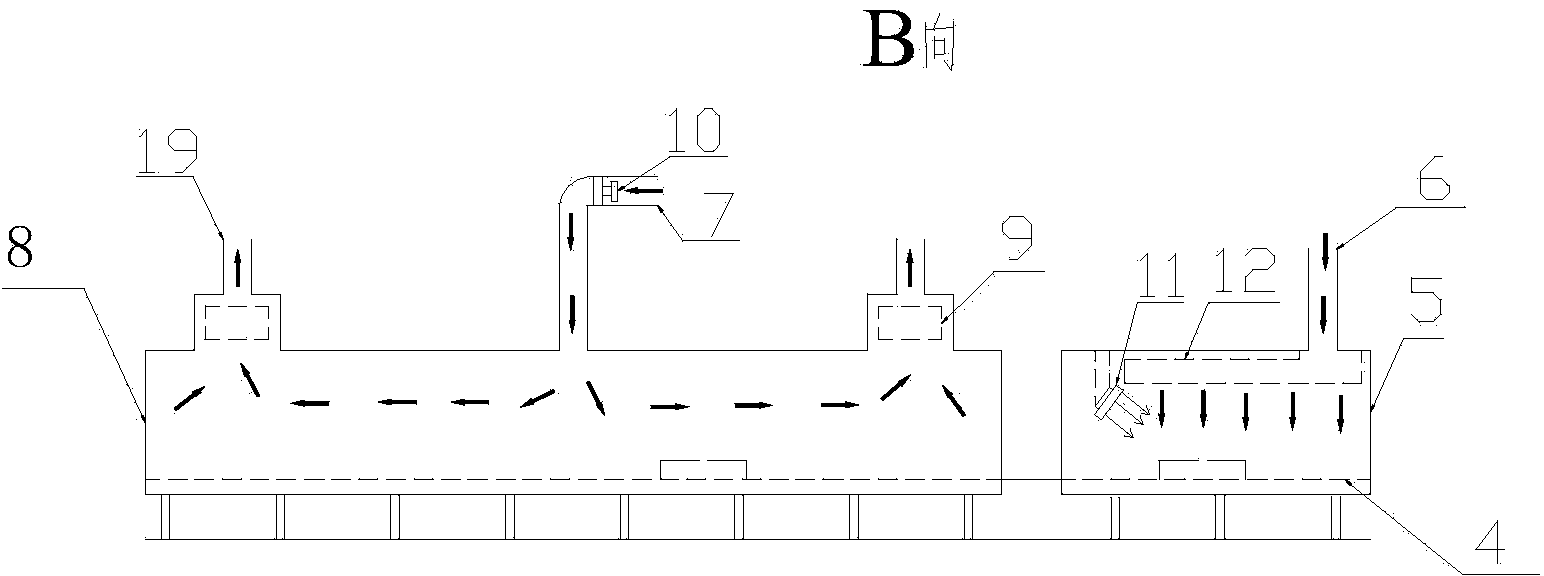

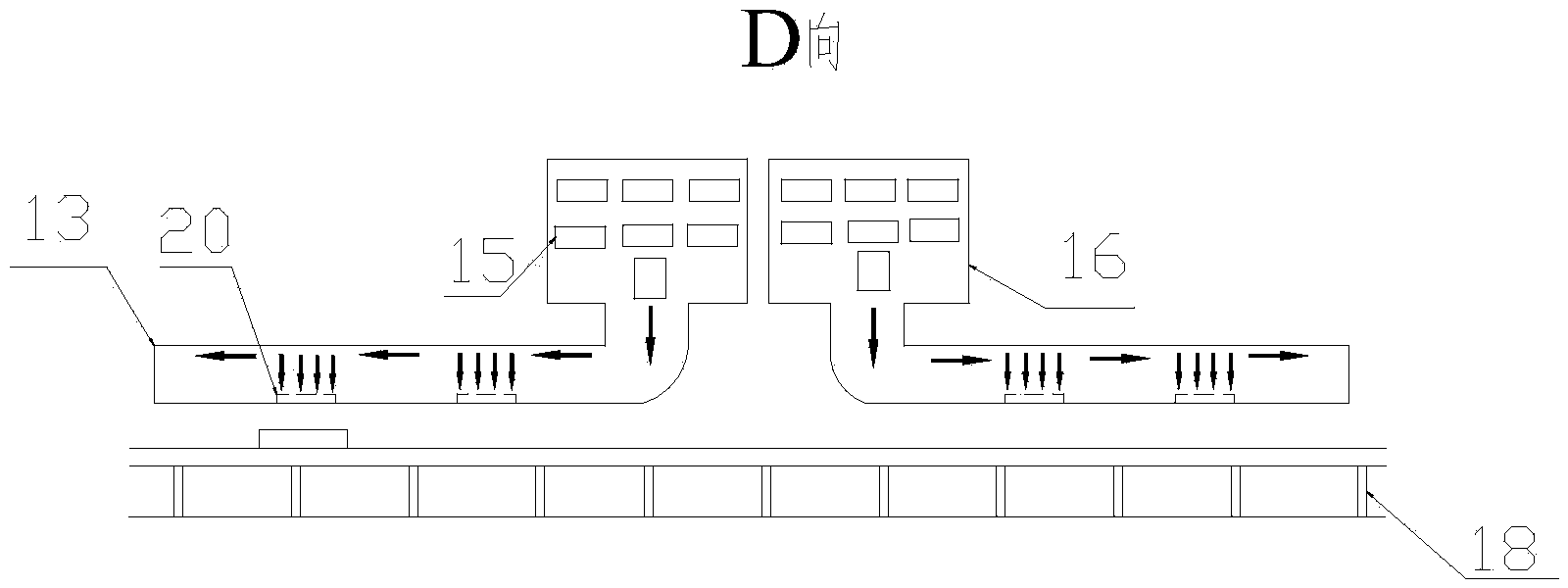

Latex pillow production line

ActiveCN104015291AOvercome poor connectionOvercoming productivityCoatingsProduction lineWork in process

The invention discloses a latex pillow production line. The invention provides a latex pillow production line which is convenient to operate, saves the labor time and improves the work efficiency. The latex pillow production line comprises a bracket and a conveying device, wherein the conveying device comprises a motor and an annular conveyor belt, the annular conveyor belt is arranged on the bracket, and an injection molding section, a drying section, a finished product section, a demoulding section and a die assembly section are sequentially arranged on the annular conveyor belt. According to the invention, through carrying out series connection and circulation on each device and process, defects that production part are connected defectively, and the transfer of semi-finished products needs too much manpower in the process of production are overcome, the efficiency of production is improved, and the cost of production is reduced. The latex pillow production line disclosed by the invention is simple and easy to operate, can realize automatic production, saves manpower and material resources, and greatly reduces the production cost.

Owner:江苏金世缘乳胶制品股份有限公司

Method for preparing (methyl)acrylic acid-3,4-epoxycyclohexyl methyl ester by microchannel reactor

ActiveCN108299343ARaw materials are cheap and easy to getEasy to operateOrganic chemistryCyclohexeneMethyl group

The invention discloses a method for preparing (methyl) acrylic acid-3,4-epoxycyclohexyl methyl ester by a microchannel reactor. The method is characterized in that firstly, 3-cyclohexene-1-methanol and (methyl)acryloyl chloride are used as raw materials; esterification reaction is performed in the microchannel reactor to prepare an intermediate of (methyl)acrylic acid-3-cyclohexenyl methyl ester;then, peroxyacetic acid is used as an oxidizing agent; chlorohydrocarbon is used as a reaction medium; selective epoxidation reaction is performed in the microchannel reactor to prepare a target product. The esterification reaction temperature is low; the side reactions are few; the efficiency is high; the aftertreatment is simple; an in-situ method is used; peroxyacetic acid is prepared; meanwhile, olefin epoxidation reaction is performed; the technological process is easy to operate; the reaction yield is high; the product purity is high; the operation of the product separation process is simple; the method is suitable for continuous production; when a curing resin composition prepared by the product is used, a good cured matter with high sealing performance and chemical resistant performance on a base material can be obtained, and can be suitable for being used in the field of electronic materials.

Owner:JIANGSU TETRA NEW MATERIAL TECH

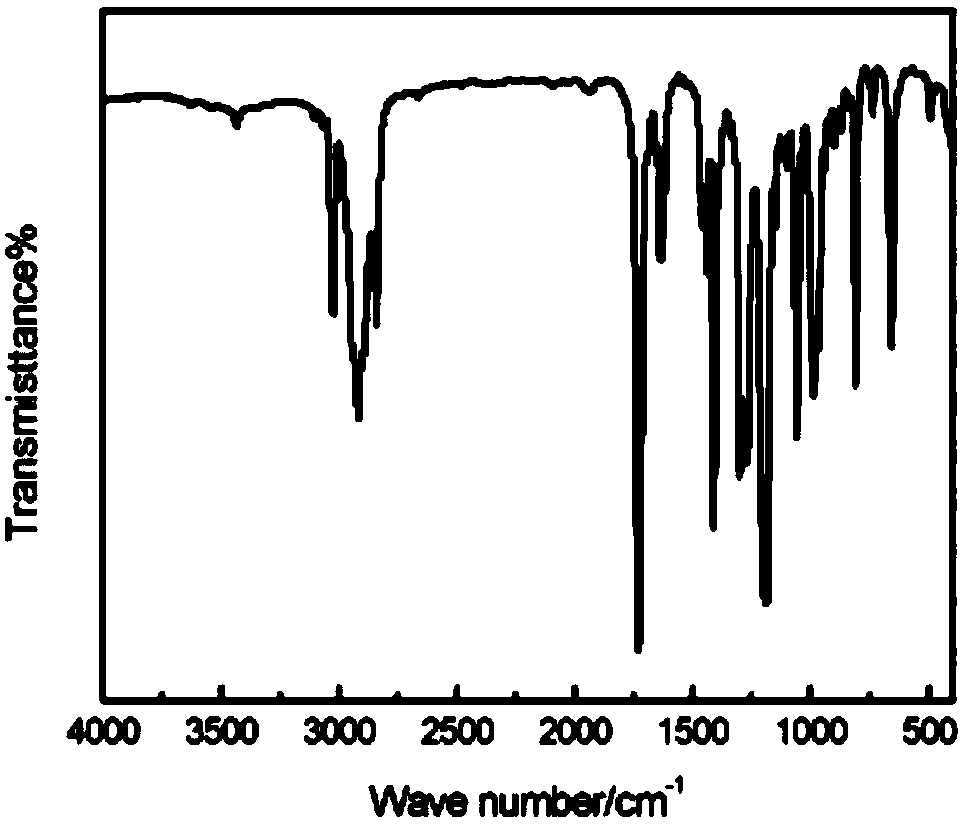

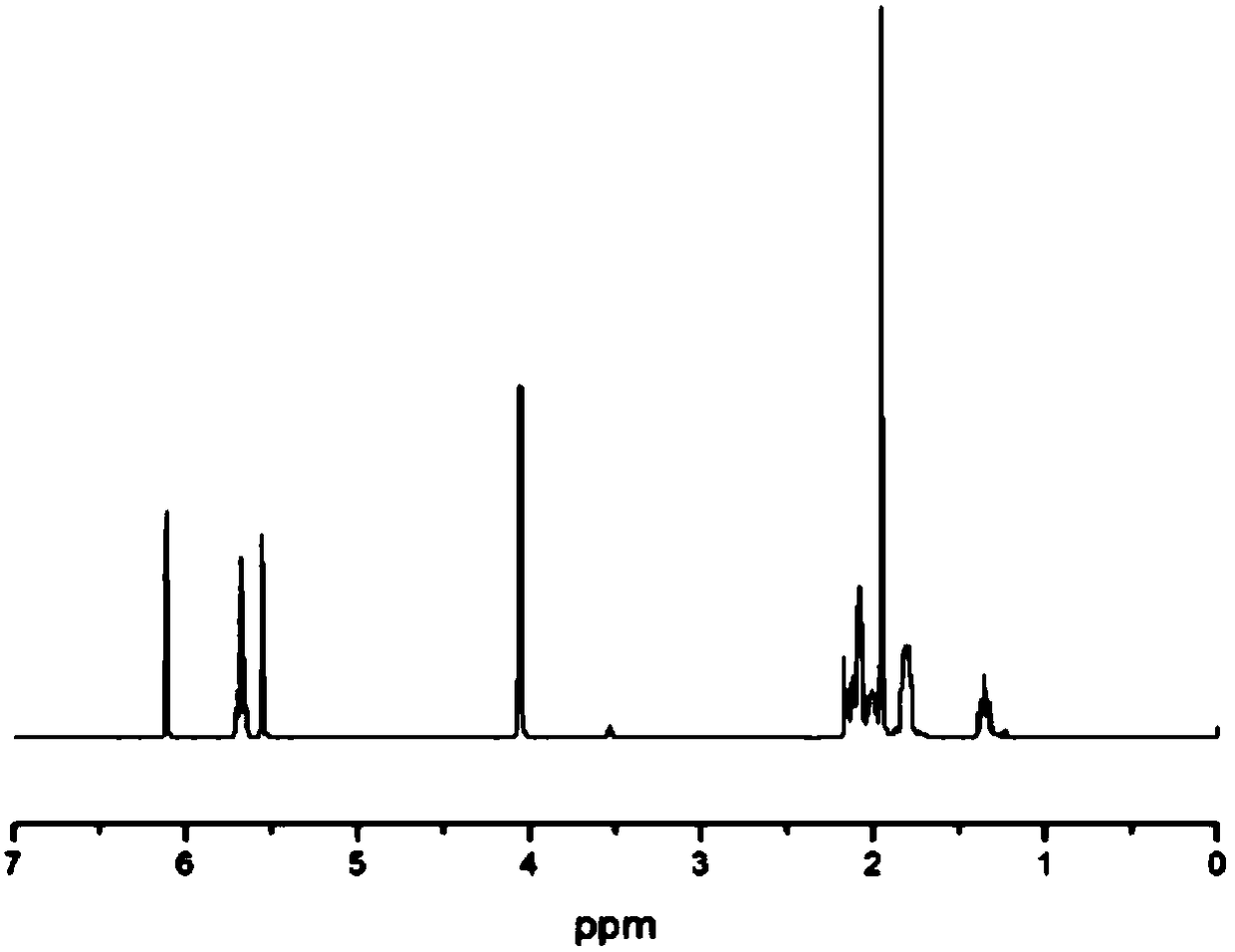

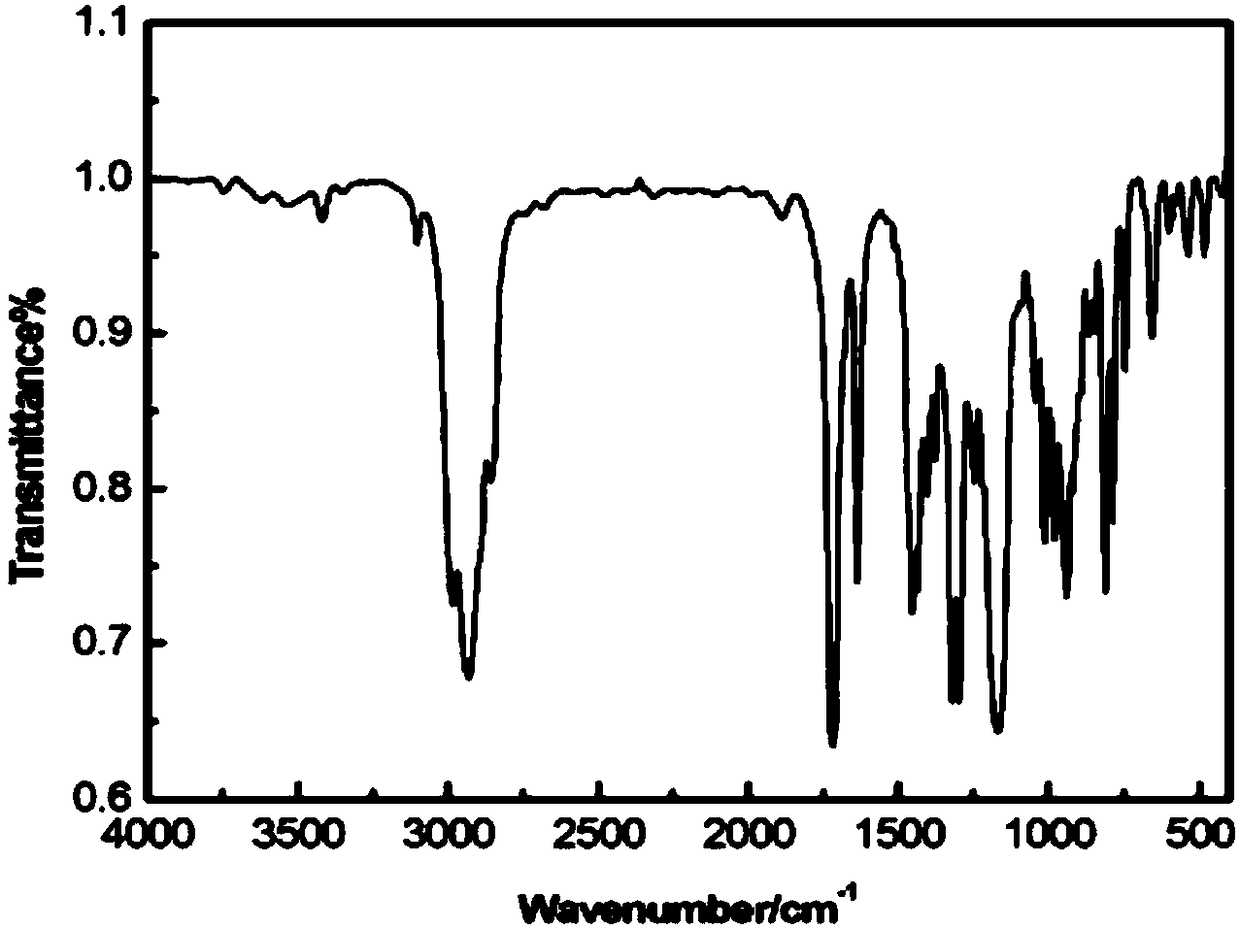

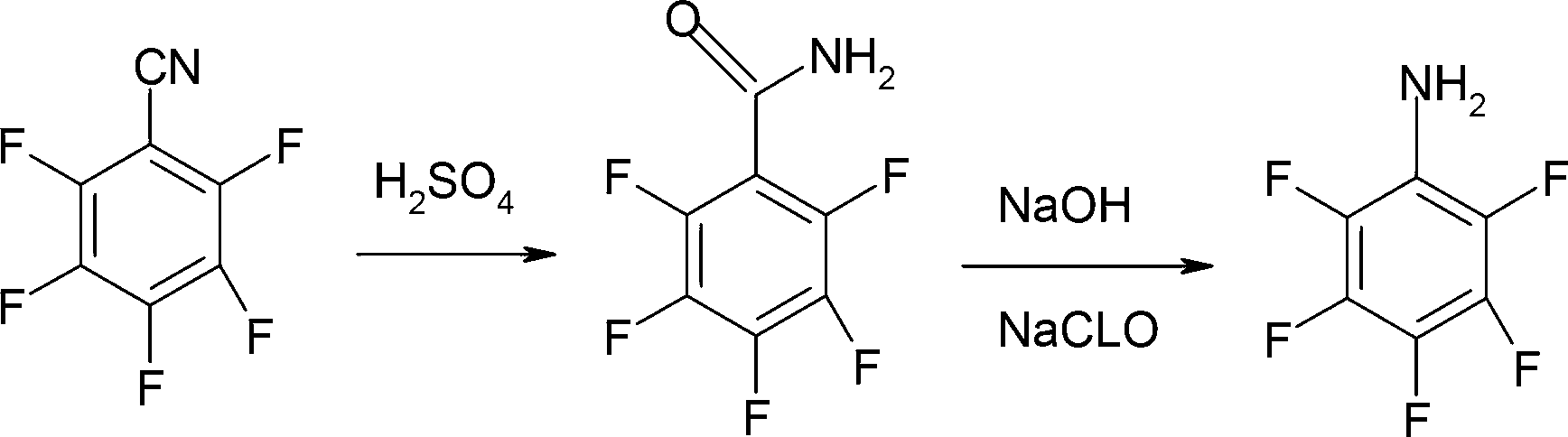

Preparation method of pentafluoroaniline

ActiveCN103012162AOvercoming not easy to getOvercome high pricesPreparation by rearrangement reactionsPentafluoroanilineSteam distillation

The invention provides a preparation method of pentafluoroaniline. The preparation method is characterized by comprising the following steps of: (1) adding pentafluorobenzonitrile into sulfuric acid with the concentration of 70-98% for hydrolysis, controlling the hydrolysis temperature to be 70-120 DEG C and the reaction time to be 3-5 hours, and then adding the product into water to separate out, and filtering to obtain pentafluorobenzamide; and (2) mixing the pentafluorobenzamide prepared by step (1) with alkali solution and halogen or hypohalite, preserving the heat for 4-6 hours at -10 to 20 DEG C and then heating up to 70-110 DEG C to carry out Hoffman degradation, controlling the reaction time to be 0.5-3 hours, and then performing steam distillation to obtain the pentafluoroaniline. The method provided by the invention has the advantages that the raw materials are easily available, the process is simple, the operation is convenient, the product purity is high (99% or higher), the yield is high (as high as over 80%), the cost is low, and the method is safe and efficient with energy conservation, consumption reduction and little discharge of three wastes, so the method provided by the invention is suitable for industrial production on a large scale.

Owner:FUXIN RUIGUANG FLUORINE CHEM

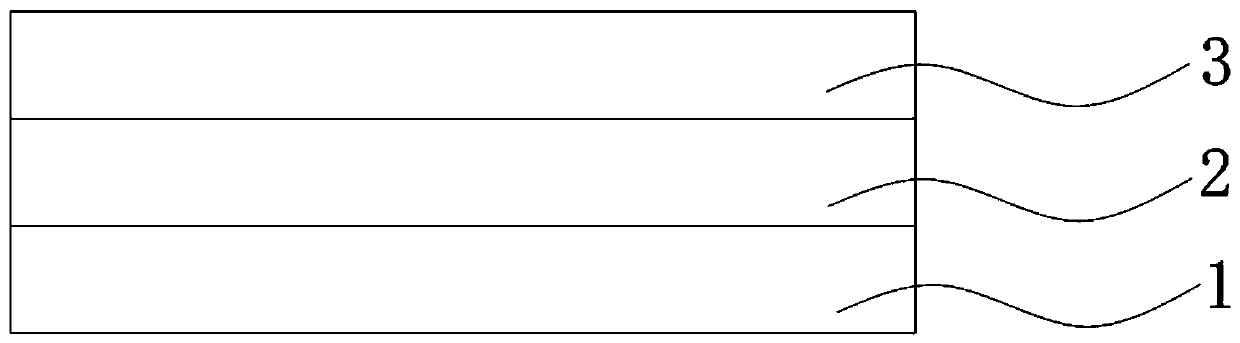

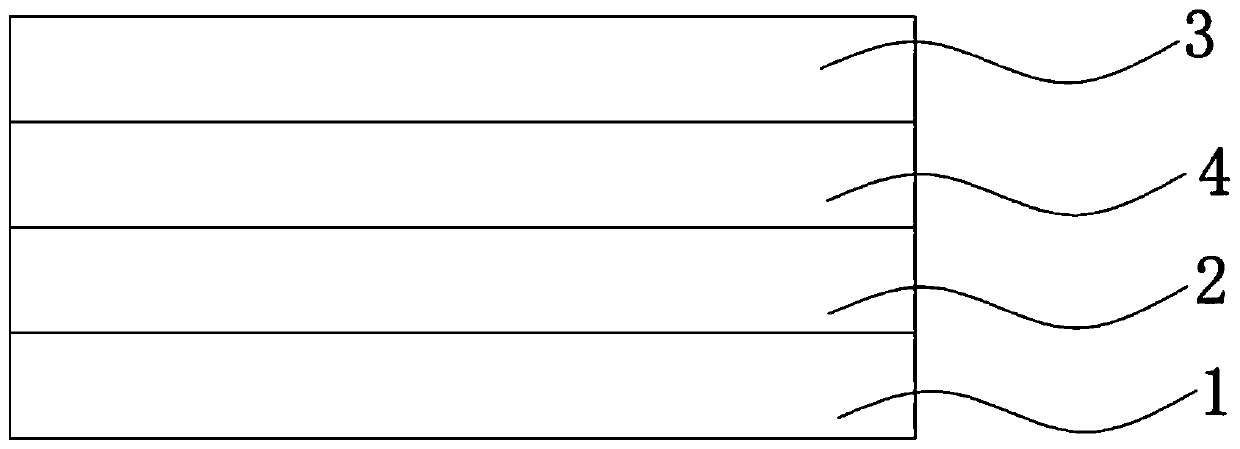

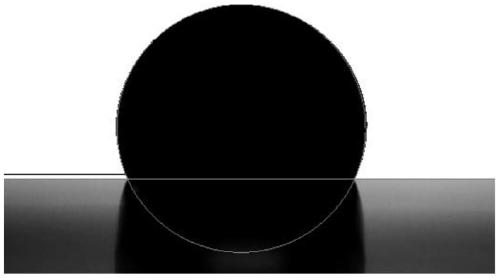

Thin film with low friction coefficient and high water contact angle and preparation method thereof

InactiveCN111286061AReduce coefficient of frictionLower water contact anglePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceUV curing

The invention provides a thin film with a low friction coefficient and a high water contact angle and a preparation method thereof. The thin film comprises a transparent base film, a bottom coating layer and an AF layer which are sequentially attached from bottom to top. The preparation method comprises the following steps: step S001, taking materials: selecting a transparent base film made of a proper material; step S002, preparing a bottom coating solution: diluting an unsaturated functional group-containing polymer and a photoinitiator with a solvent to form a base coating solution; step S003, attaching a bottom coating layer: coating the transparent base film with the base coating solution, and carrying out heating curing, UV curing or dual curing through a drying oven to form the basecoating layer; S004, attaching an AF layer: coating the semi-finished product formed in the step S003 with an AF solution, and forming the AF layer through cross-linking curing after being heated bythe drying oven. According to the thin film with the low friction coefficient and the high water contact angle and the preparation method thereof, the defects that an existing thin film is smooth, poor in anti-fingerprint effect, complex in preparation process and not suitable for mass production are overcome.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

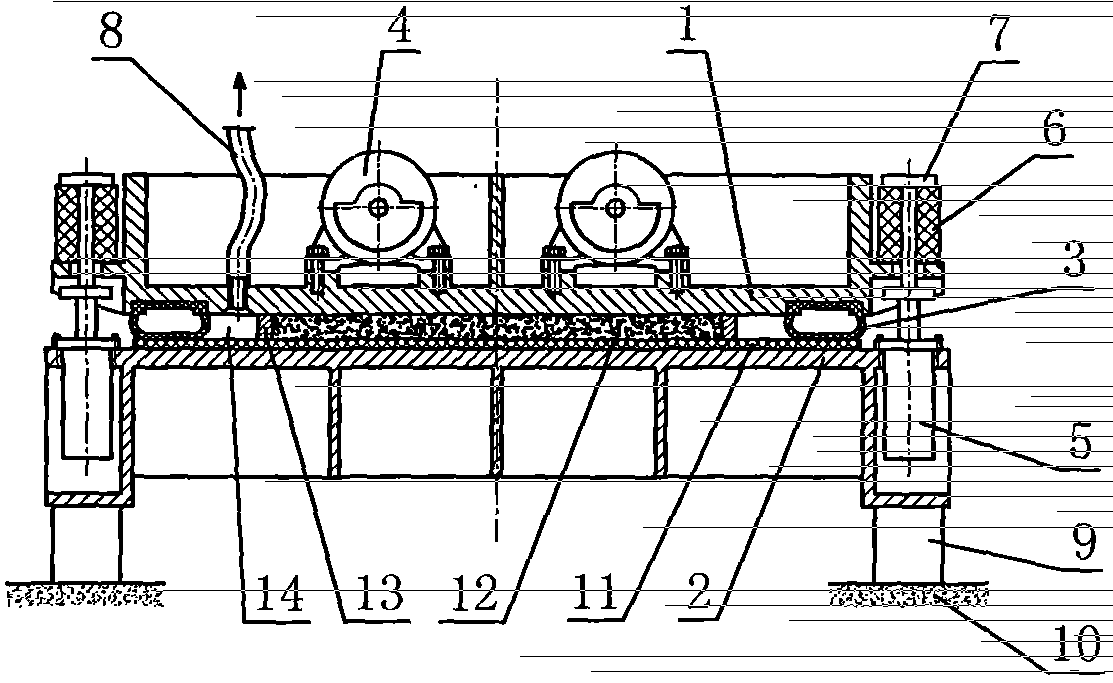

Pressing plate vacuum chamber

InactiveCN103465350AImprove product qualitySmall volumeShaping press ramVacuum chamberEnergy consumption

The invention relates to the technical field of sheet material molding. A pressing plate vacuum chamber comprises a pressing head and a base, wherein the pressing head is located above the base; the pressing head can be ascended and descended relative to the base; a sealing ring is arranged below the pressing head; when the pressing head is descended, a closed cavity is formed among the inner side of the sealing ring, the pressing head and the base; a blank and a mould are covered and closed in the closed cavity; the pressing head is provided with a vacuumizing pipe for communicating the outside with the closed cavity. According to the technical scheme, the sealing ring arranged between the pressing head and the base has various functions of sealing, bearing pressure, buffering, absorbing vibration, absorbing sounds, isolating sounds and the like; the capacity of the closed cavity is reduced so as to be good for shortening vacuumizing time, reducing energy consumption, improving the productivity and improving the product quality of a pressing plate; a main body steel structure is only composed of two members including the pressing head and the base, so that the structure is simplified, the manufacturing and maintenance costs are reduced and the vibration noises are reduced. The pressing plate vacuum chamber provided by the invention can be widely applied to pressing plate equipment pressed and molded in vacuum by an artificial sheet material.

Owner:唐玮

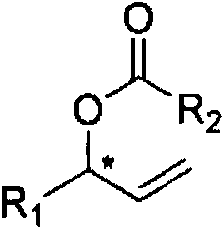

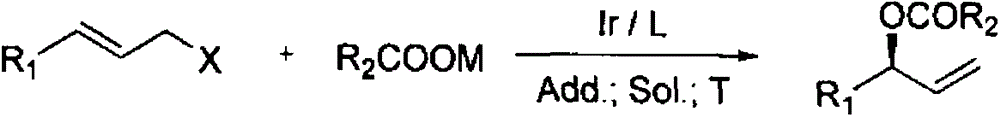

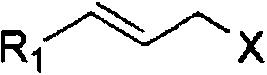

Chiral allyl ester compound and preparation method thereof

InactiveCN104402718AOvercoming productivityOvercoming selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIridiumOrganic synthesis

The invention relates to a chiral allyl ester compound and a preparation method thereof. The structural formula of the chiral allyl ester compound is represented in the description. The preparation method comprises the following steps: adding raw materials (carboxylate and allyl halide) into an organic solvent, then adding an iridium catalyst, which is prepared by reacting an iridium complex with a ligand, adding additives, controlling the reaction temperature in a range of 0 to 120 DEG C, carrying out reactions for 1 to 36 hours, and separating the reaction products so as to obtain the chiral allyl ester compound. In the prior art, when active allyl halide is taken as the substrate, the reaction yield is low and the enantioselectivity is bad, and the provided preparation method overcomes the problems mentioned above. Moreover the preparation method has the characteristics of high reaction yield, good region-selectivity, and high enantioselectivity, and thus is widely used in the organic synthesis methodology and natural product synthesis.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com