Preparation method of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl

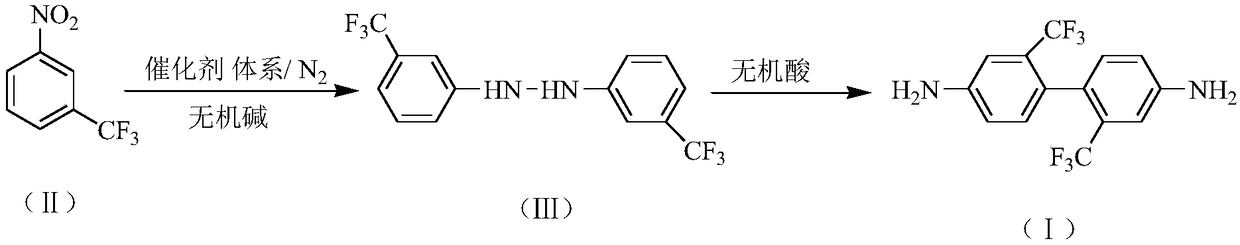

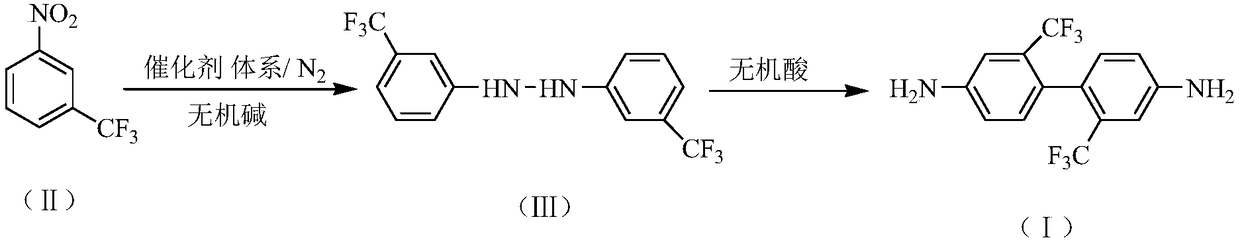

A technology of diaminobiphenyl and trifluoromethyl is applied in the field of preparation of 2,2'-bis-4,4'-diaminobiphenyl, and can solve the problems of low product quality, complicated process, unfavorable environmental protection and the like, Achieve the effect of less discharge of three wastes, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Under nitrogen protection, with 300g m-nitrobenzotrifluoride as raw material, add 3g Pd / C, 3g sodium dodecylbenzenesulfonate, 1.5g 2,3-dichloro-1,4-naphthoquinone, 150g 25 % sodium hydroxide aqueous solution, 900g toluene, pressure 3-5 atm, temperature 55-65°C, keep warm for 5-8 hours, cool down to 20-30°C, take out the material, and obtain 1150g 3,3'-bis (Trifluoromethyl)diphenylhydrazine in toluene, the purity is 95.1%.

[0031] Under the protection of nitrogen, add 960g of 80% sulfuric acid to the reaction flask equipped with a stirrer and dropping funnel, and slowly add one step of 3,3'-bis(trifluoromethyl) Diphenylhydrazine toluene solution, add dropwise for 2-3 hours, keep warm for 1 hour, add 350g of water, heat up to 70-75°C, separate the liquids, neutralize the water phase with lye to pH=7, a off-white solid precipitates, add 500g of toluene to extract , washed with water, and recrystallized to obtain 130.6g of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl as...

Embodiment 2

[0033]Under nitrogen protection, with 300g m-nitrobenzotrifluoride as raw material, add 1.5g Pd / C, 1.5g sodium dodecylbenzenesulfonate, 0.75g 2,3-dichloro-1,4-naphthoquinone, 120g 25% sodium hydroxide aqueous solution, 800g toluene, pressure 3-5atm, temperature 55-65°C, keep warm for 5-8 hours, cool down to 20-30°C, take out the material, and obtain 1050g 3,3' after liquid separation - Bis(trifluoromethyl)diphenylhydrazine in toluene with a purity of 94.5%.

[0034] Under the protection of nitrogen, add 800 g of 80% sulfuric acid to the reaction flask equipped with a stirrer and dropping funnel, and slowly add one step of 3,3'-bis(trifluoromethyl) di Phenylhydrazine toluene solution, after 2-3 hours of dropwise addition, keep warm for 1 hour, add 350g of water, heat up to 70-75°C, separate the liquids, neutralize the water phase with lye to pH=7, a off-white solid precipitates, add 500g of toluene to extract, Washing with water and recrystallization gave 125.7 g of 2,2'-bis(t...

Embodiment 3

[0036] Under nitrogen protection, with 300g m-nitrobenzotrifluoride as raw material, add 4.5g Pd / C, 5.0g sodium dodecylbenzenesulfonate, 2.5g 2,3-dichloro-1,4-naphthoquinone, 160g of 25% sodium hydroxide aqueous solution, 900g of toluene, pressure of 3-5 atm, temperature of 55-65°C, heat preservation reaction for 5-8 hours, cooling to 20-30°C, taking out the materials, and obtaining 1150g of 3,3' after liquid separation - Bis(trifluoromethyl)diphenylhydrazine in toluene with a purity of 96.1%.

[0037] Under the protection of nitrogen, add 85% 760g sulfuric acid to the reaction flask equipped with a stirrer and dropping funnel, and slowly add 3,3'-bis(trifluoromethyl) di Phenylhydrazine toluene solution, after 2-3 hours of dropwise addition, keep warm for 2 hours, add 350g of water, heat up to 70-75°C, separate the liquids, neutralize the water phase with lye to pH=7, a off-white solid precipitates, add 600g of toluene to extract, Washed with water and recrystallized to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com