Patents

Literature

69 results about "Hydroxyanthraquinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydroxyanthraquinone (formula: C₁₄H₉O₂(OH)) is any of several organic compounds that can be viewed as derivatives of an anthraquinone through replacement of one hydrogen atom (H) by a hydroxyl group (-OH).

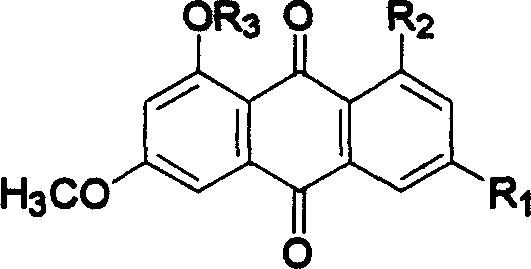

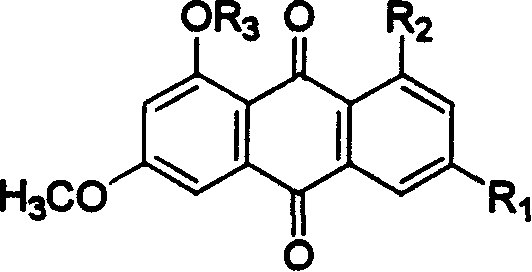

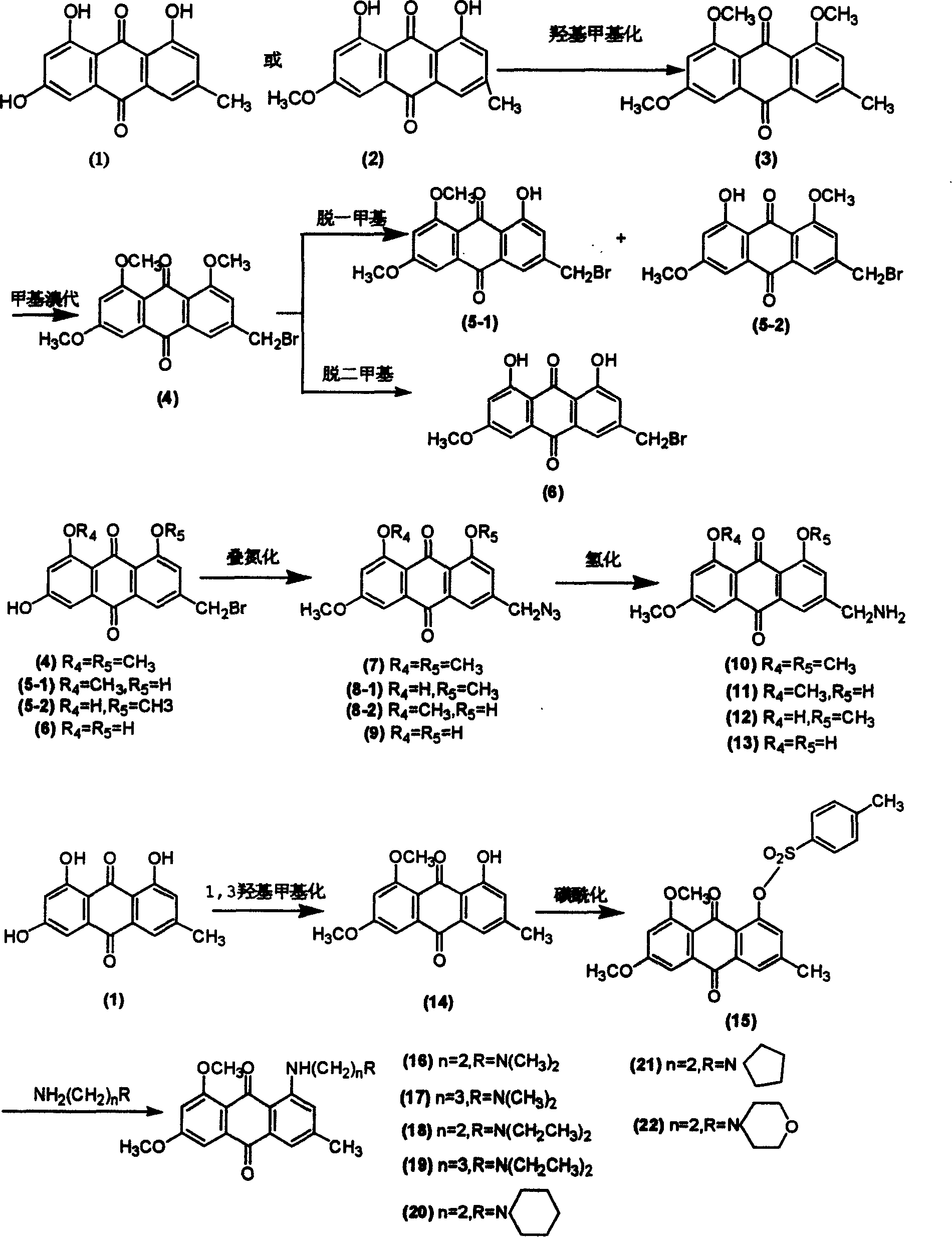

Hydroxyanthraquinone derivatives and their application in preparation of anticancer medicines

InactiveCN1546451AGood inhibitory effectLow toxicityOrganic active ingredientsOrganic chemistryHydroxyanthraquinoneAnthraquinone Derivatives

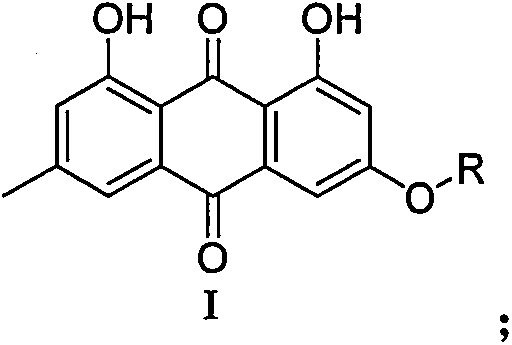

The invention relates to hydroxy anthraquinone derivatives and their use in preparing anti-cancer medicament, test has shown that the hydroxy anthraquinone derivatives have appreciable inhibitory action for various tumor cell strains, thus can be used in preparing cancer treatment medicament. The chemical structural formula of the hydroxy anthraquinone derivatives is shown by I, wherein R1, R2,R3 are defined in the description.

Owner:SUN YAT SEN UNIV

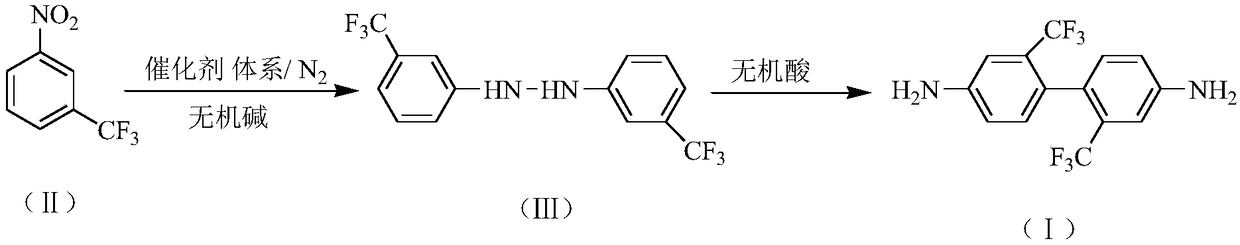

Preparation method of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl

InactiveCN109232273AReduce generationHigh purityHydrazine preparationPreparation by rearrangement reactionsHydroxyanthraquinoneDodecylsulfonic acid

The invention relates to a preparation method of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl. The preparation method comprises the following steps: synthesizing 3,3'-bis(trifluoromethyl)hydrazo-benzene in an inorganic alkaline aqueous solution by adopting nitrobenzotrifluoride as a raw material, adopting a phase transfer catalyst, a co-catalyst and Pd / C as a catalytic system and adopting aromatic hydrocarbon as a solvent, and performing the re-arrangement reaction on the 3,3'-bis(trifluoromethyl)hydrazo-benzene in an inorganic acid aqueous solution, thus obtaining 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl, wherein the phase transfer catalyst is one or a mixture of more of sodium dodecyl benzene sulfonate, sodium dodecyl sulfate and cetyl trimethyl ammonium bromide, and the co-catalyst is one or a mixture of more of 2,3-dichloro-1,4-naphthoquinone, 2-hydroxyanthraquinone and 2,6-dioxyanthraquinone. The preparation method has the advantages of mild reaction condition, simple process, high product quality and yield, low production cost, environmental friendliness, suitability for continuous production and the like.

Owner:烟台海川化学制品有限公司

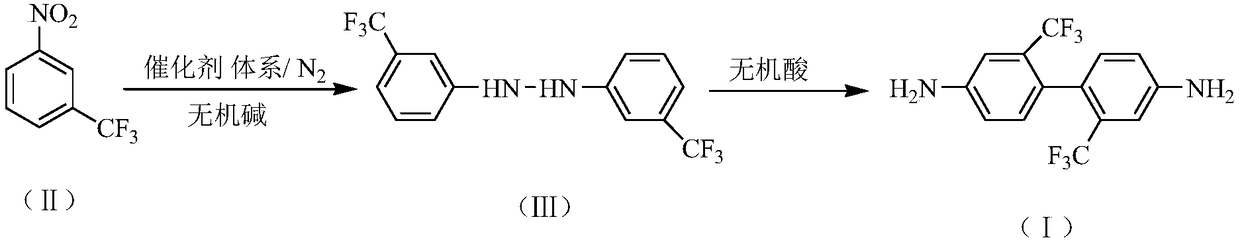

Method for preparing 1,4-dihydroxy anthraquinone

InactiveCN104926636AImprove catalytic performanceReduce dosageOrganic compound preparationQuinone preparationHydroxyanthraquinonePtru catalyst

The invention discloses a method for preparing 1,4-dihydroxy anthraquinone by taking a boric acid dehydration compound as a catalyst. The method comprises the following steps: (1) heating boric acid at 100-250 DEG C to prepare the boric acid dehydration compound; (2) adding fuming sulphuric acid, phthalic anhydride, the boric acid dehydration compound and parachlorophenol into a condensation kettle in sequence, and carrying out condensation reaction at 100-250 DEG C; (3) adding a proper amount of water and the materials in the condensation kettle into a hydrolysis kettle, carrying out hydrolysis reaction at 50-115 DEG C, discharging a reactant, filtering the reactant by pressing, washing and drying the reactant to prepare 1,4-dihydroxy anthraquinone. According to the method, the boric acid dehydration compound is used as the catalyst, so that the addition amount of the raw materials including fuming sulphuric acid and phthalic anhydride is reduced; the resource consumption can be reduced; the cost is reduced; the waste emission is reduced; the method is relatively environmentally-friendly and economical.

Owner:JIANGSU YABANG DYE

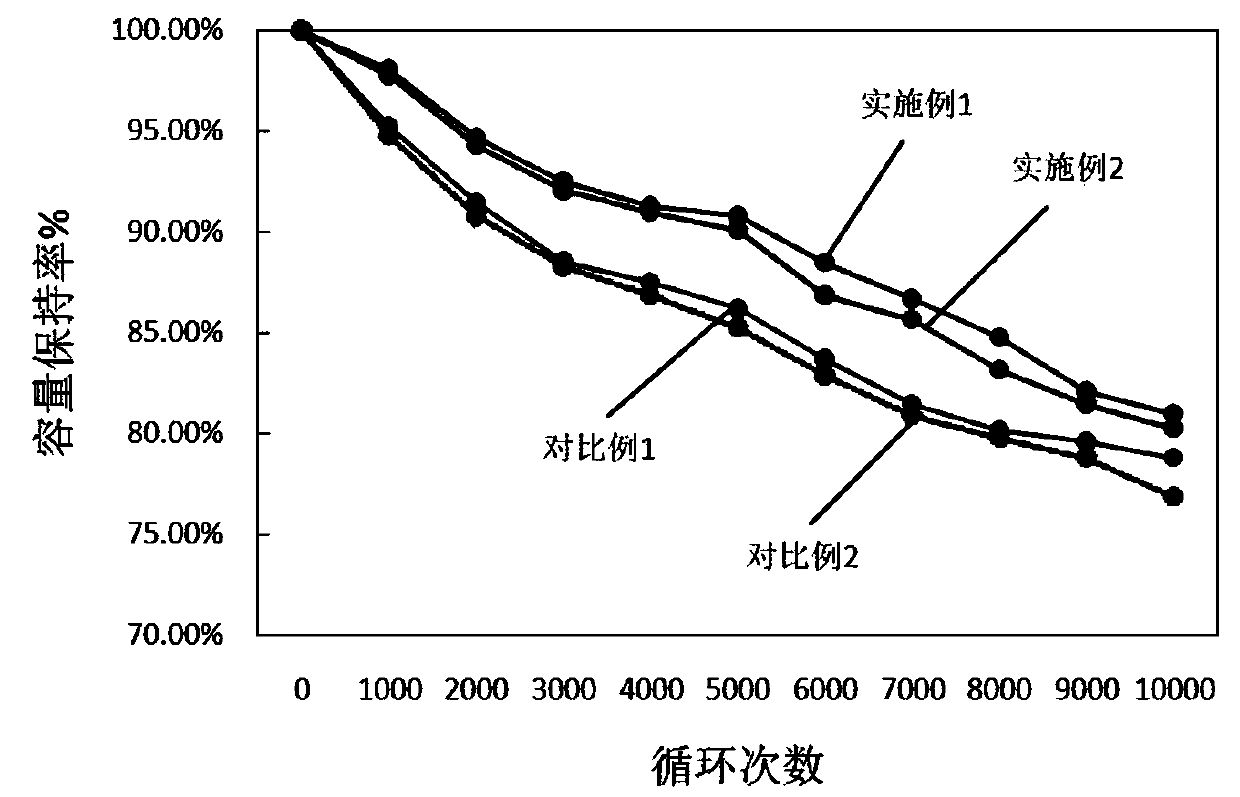

Low-cost flow battery anode electrolyte and preparation method thereof

InactiveCN104835962ALow costEliminate Energy Storage BarriersElectrode manufacturing processesSupporting electrolyteUninterruptible power supply

The invention belongs to the field of flow batteries and discloses low-cost anode electrolyte and a preparation method thereof. The low-cost flow battery anode electrolyte is based on a sulfuric acid solution of small organic molecule 1,2-dihydroxy anthraquinone-3-sodium sulfonate (ARS). The preparation method of the low-cost flow battery anode electrolyte comprises the following steps: adding electrolyte raw material 1,2-dihydroxy anthraquinone-3-sodium sulfonate or derivatives thereof or a mixture of the 1,2-dihydroxy anthraquinone-3-sodium sulfonate and derivatives thereof in water, dissolving and evenly mixing the added materials, using ion exchange resin to remove positive ions, then adding supporting electrolyte sulfuric acid, and diluting the obtained solution to a preset volume to obtain the low-cost flow battery anode electrolyte. The flow battery is simple in structure, low in cost, high in energy density and watt density. Compared with a vanadium flow battery, the flow battery using the anode electrolyte provided by the invention is 50% lower in cost. The flow battery can be used as a large-scale electric energy storage device in a wind energy and solar power system, and can be used for regulating peak load, supplying power for remote areas and providing uninterruptible power supply.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

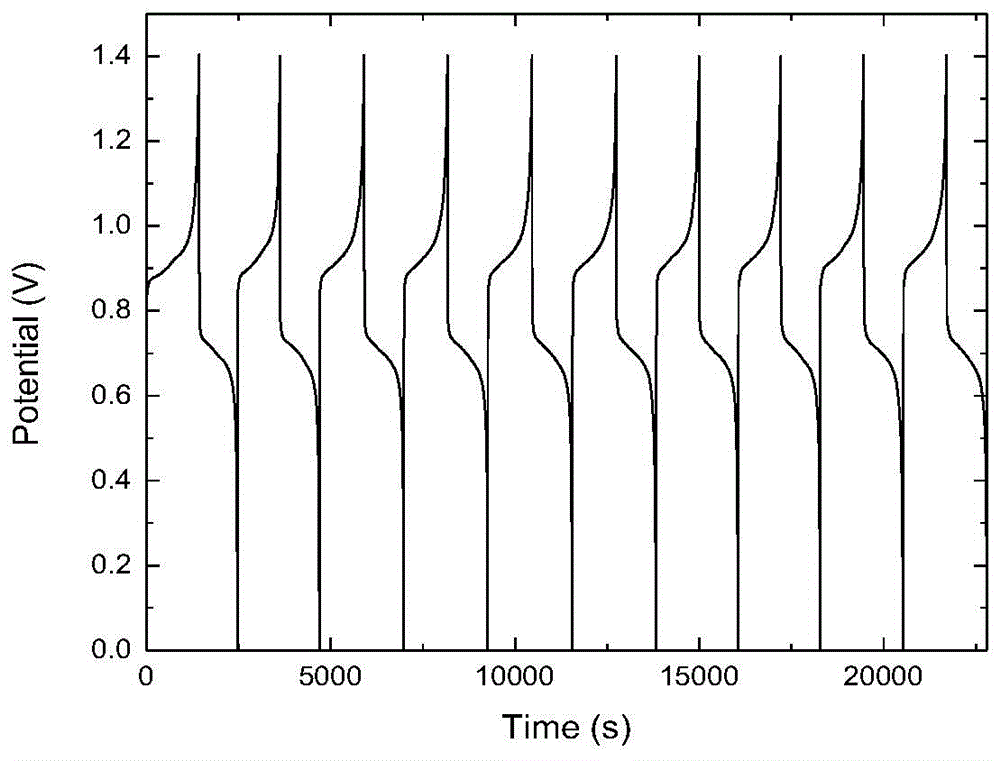

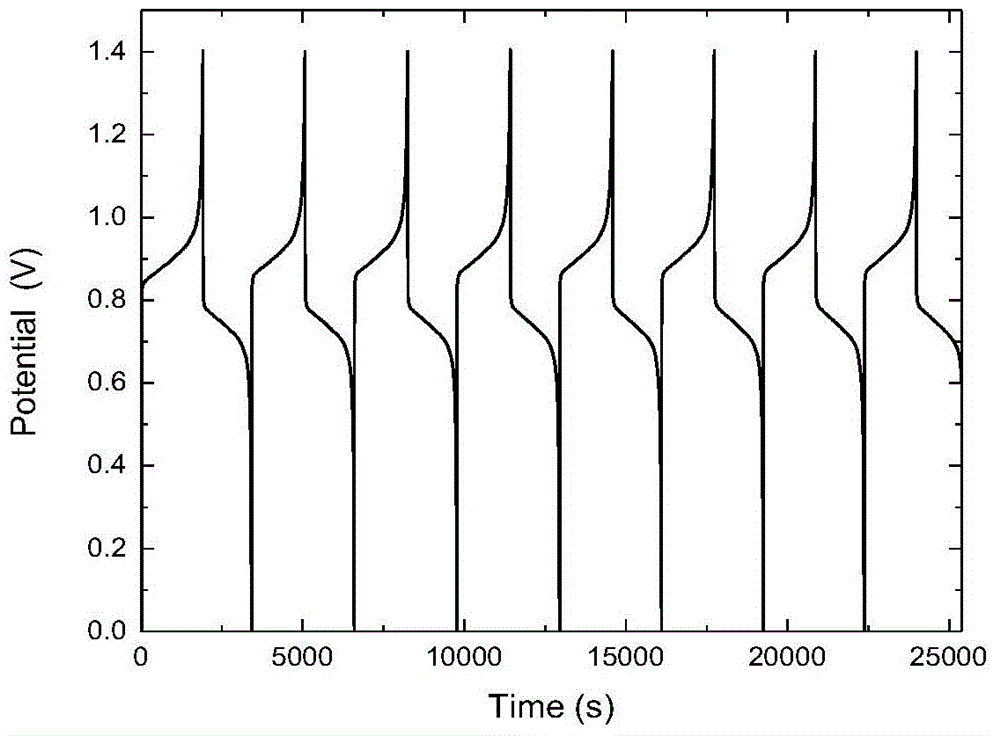

Method for synthesizing N-[4-[(4-hydroxyanthraquinone-1-yl) amino] benzyl] acetamide

ActiveCN102050757AIncrease contentReduce contentOrganic compound preparationCarboxylic acid amides preparationPolyesterHydroxyanthraquinone

The invention relates to a method for synthesizing N-[4-[(4-hydroxy anthraquinone-1-yl) amino] benzyl] acetamide. The method comprises the steps of: with hydrochloric acid as a catalyst, carrying out condensation reaction on 1,4-dihydroxy anthraquinone, a 1,4-dihydroxy anthraquinone leuco body and p-phenylenediamine for 10-16h at 95-105 DEG C in a butanol-water solution medium; after the condensation reaction is completed, sequentially carrying out water adding and distilling, filtering, heating treatment with dilute alkali liquor, water washing till reaching a neutral state and drying to obtain a condensation material; and carrying out acylation reaction on the condensation material and acetic anhydride for 2h at 110-112 DEG C in a acetic acid medium, cooling to normal temperature, filtering, washing and drying to obtain a product of N-[4-[(4-hydroxy anthraquinone-1-yl) amino] benzyl] acetamide. The N-[4-[(4-hydroxy anthraquinone-1-yl) amino] benzyl] acetamide product synthesized with the method has high purity, controllable content, fewer 1,4-dihydroxy anthraquinone residues, and low byproduct content and product ash content, and is suitable for polyester spinning and dying.

Owner:宁波龙欣精细化工有限公司

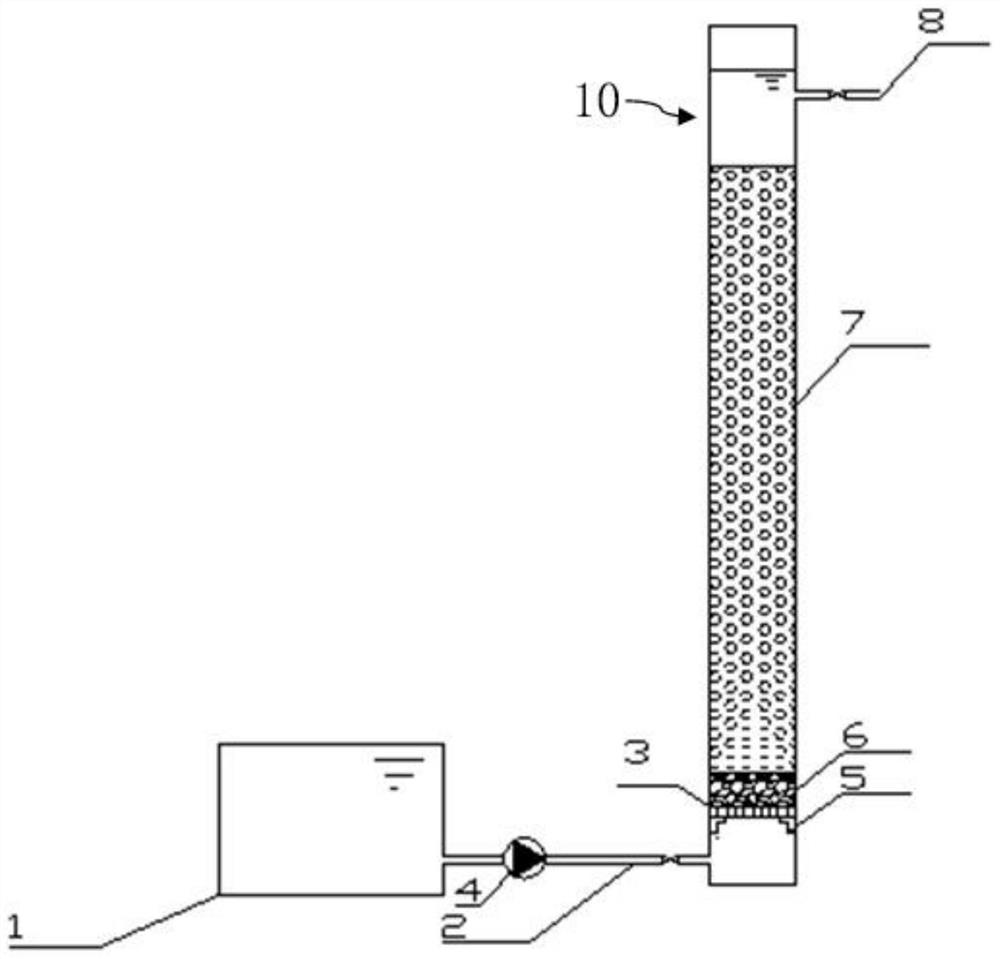

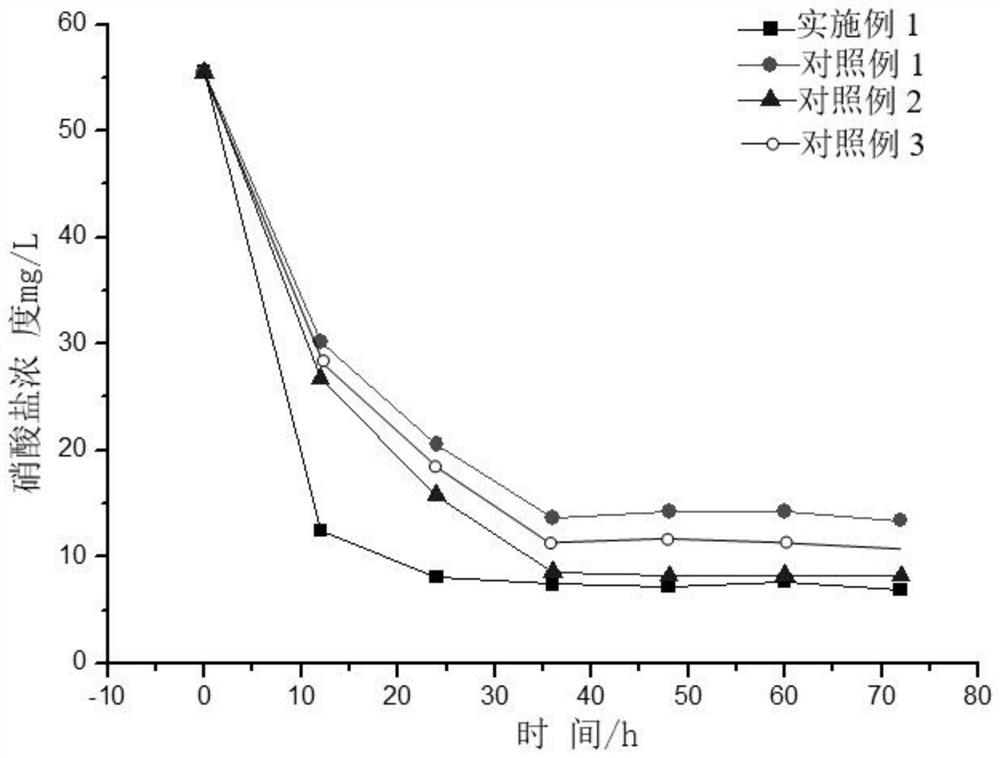

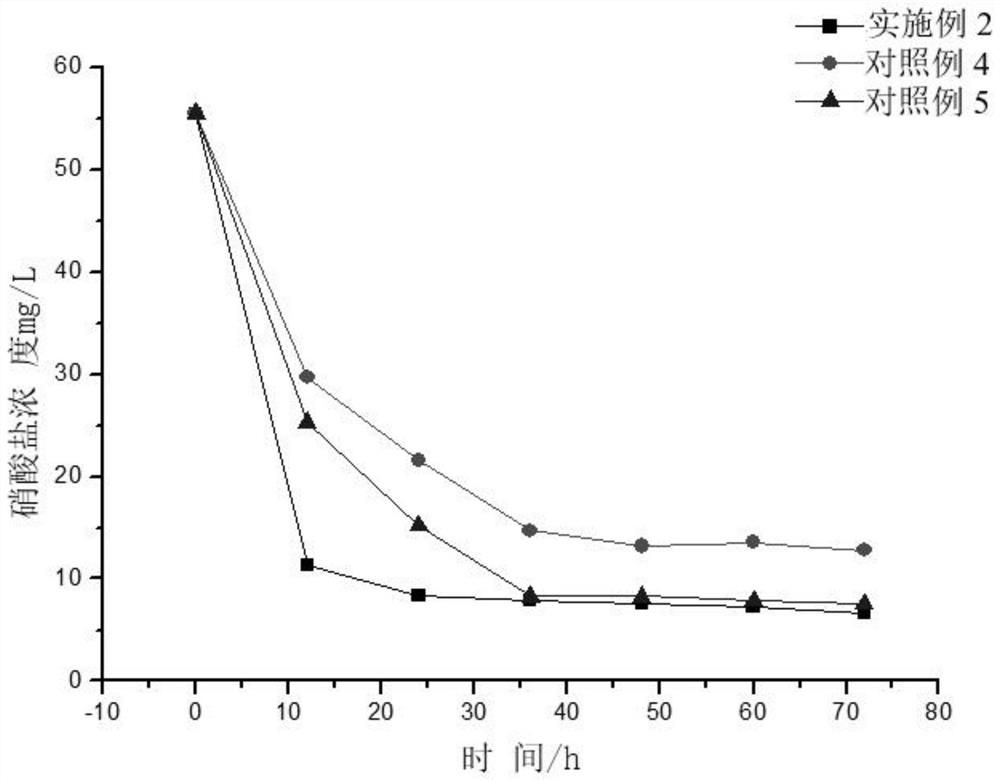

Biological filler embedded with anthraquinone and thiobacillus denitrificans, and sulfur autotrophic denitrification method

PendingCN111943351AHigh activityIncrease mass transfer rateImmobilised enzymesWater contaminantsHydroxyanthraquinonePolyvinyl alcohol

The invention relates to a biological filler embedded with embedding anthraquinone and thiobacillus denitrificans. The biological filler comprises an embedding agent and an embedding material, whereinthe embedding material contains scallop shell powder, 1,5-dihydroxy anthraquinone and thiobacillus denitrificans, and the embedding agent comprises a polyvinyl alcohol sodium alginate blend membraneand a cross-linked composite membrane. According to the present invention, a quinone compound 1,5-dihydroxy anthraquinone is fixedly embedded to achieve the adjustment of the sulfur autotrophic denitrification rate, and the quinone compound, thiobacillus denitrificans and scallop shell powder with characteristics of good biocompatibility and low price are fixedly embedded together, such that the activity of microbial thalli can be improved so as to prevent the loss of the microbial thalli, the mass transfer rate can also be increased, and the denitrification reaction rate and conversion rate can be increased; and the invention also improves the embedding agent, and solves the technical problems existing in pure use of polyvinyl alcohol or sodium alginate for embedding in the prior art.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

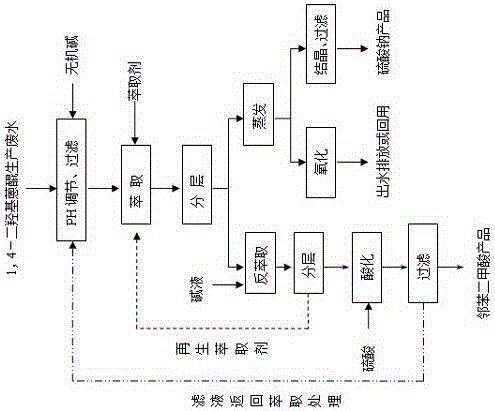

Comprehensive treatment method for 1,4-dihydroxy anthraquinone production wastewater

ActiveCN105271592AReasonable workmanshipAchieve governanceWater contaminantsMultistage water/sewage treatmentAnthraquinonesHydroxyanthraquinone

The invention provides a comprehensive treatment method for 1,4-dihydroxy anthraquinone production wastewater. The method comprises the steps of extraction, back extraction, acidification, evaporation and the like. After the pH value of the 1,4-dihydroxy anthraquinone production wastewater is regulated with alkali and filtration treatment is performed, acidic substances in the wastewater are complexly extracted, back extraction is performed with alkali liquor on a load extraction agent, the extraction agent is recycled after being regenerated, strip liquor is acidized and filtered to recycle phthalic acid, and filtrated stock returns to an extraction system; raffinate is transferred into an with alkali liquor system and processed through evaporation separating to obtain a sodium sulfate by-product, and evaporation condensate water is processed through oxidation treatment to be drained or recycled after reaching the standard. According to the method, not only is the 1,4-dihydroxy anthraquinone production wastewater treated, but also resource utilization and comprehensive treatment of the wastewater are achieved.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

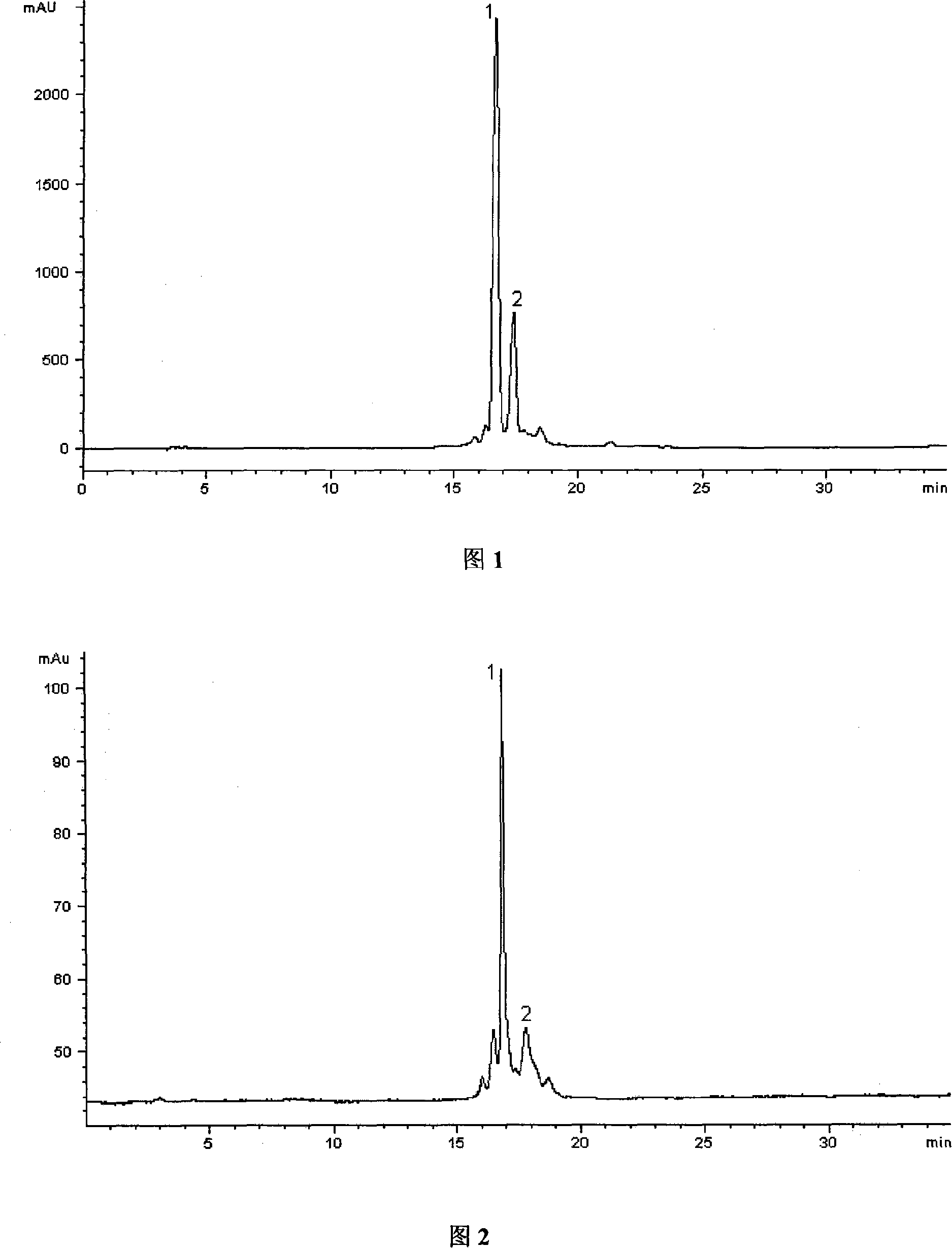

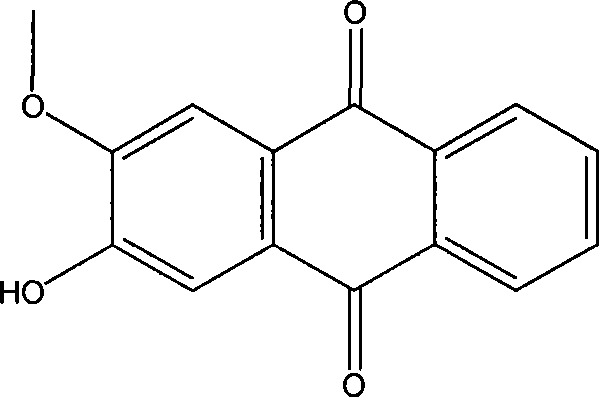

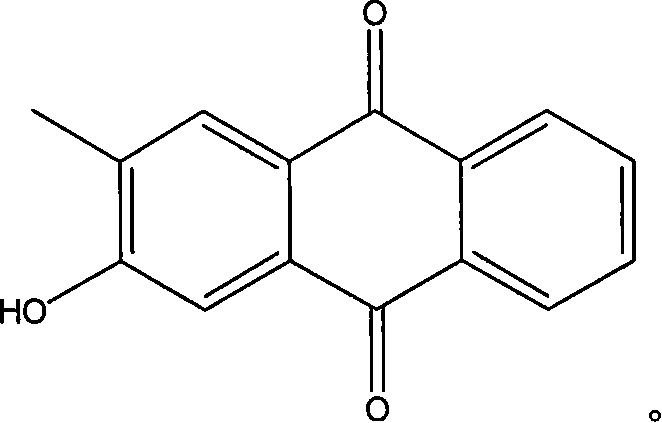

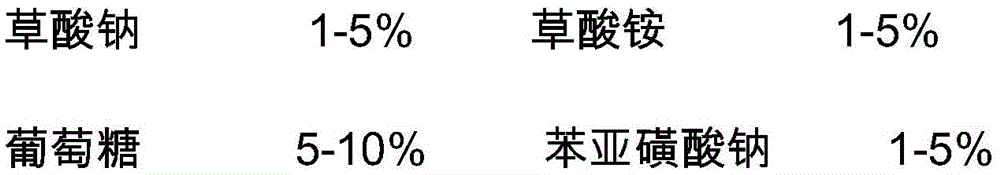

Effective component of hedyotis diffusa and method of preparing the same and application

InactiveCN101129521AEfficient removalIncrease contentQuinone separation/purificationAntineoplastic agentsChromatographic separationHydroxyanthraquinone

The invention provides the effective constituents of oldenlandia, which mainly contain two compounds of 2-methoxyl-3-hydroxyanthraquinone (A) and 2-methyl-3-hydroxyanthraquinone (B), wherein the content of A is 55-75%, the content of B is 15-25%. The constituents are obtained through steps of heating, extracting, concentrating, separating with silica gel column, eluting, concentrating and drying the eluent, continuously conducting liquid phase chromatographic separation, collecting the solution, concentrating and drying the solution. The effective constituents can be used for treating and preventing tumors.

Owner:ZHEJIANG UNIV

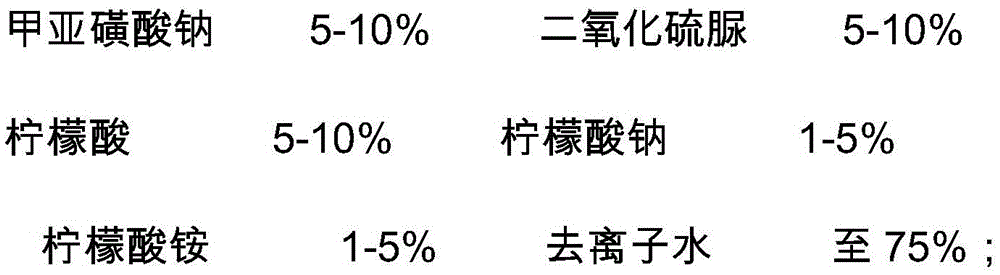

Laser heat thermal induction reduction reaction type discharge printing agent as well as preparation method and application thereof

The invention discloses a laser heat thermal induction reduction reaction type discharge printing agent as well as a preparation method and application thereof. The laser heat thermal induction reduction reaction type discharge printing agent is composed of an active component and a catalytic component, wherein the active component comprises sodium oxalate, ammonium oxalate, glucose, sodium benzene sulfinate, sodium methanesulphinate, thiourea dioxide, citric acid, sodium citrate, ammonium citrate and de-ionized water; the catalytic component comprises hydroxyanthraquinone, zinc sulfate, a discharging-resisting fluorescent whitening agent, glycerin, polyethylene glycol and de-ionized water. According to the laser heat thermal induction reduction reaction type discharge printing agent, respective technical advantages of traditional chemical-method discharge printing and modern laser etching printing and graphic image digital control are combined together to create a new discharge printing technology which is different from the traditional chemical-method discharge printing, is also different from the present new laser etching printing, and has the characteristics of good white discharge effect, less damages on fabric fibers, less drop of fabric strength, short technical flow, convenience in operation, flexibility, energy conservation, environmental friendliness and the like.

Owner:CHENGDU TEXTILE COLLEGE

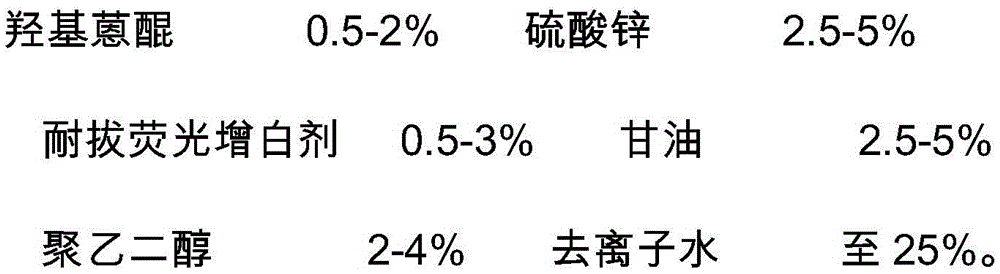

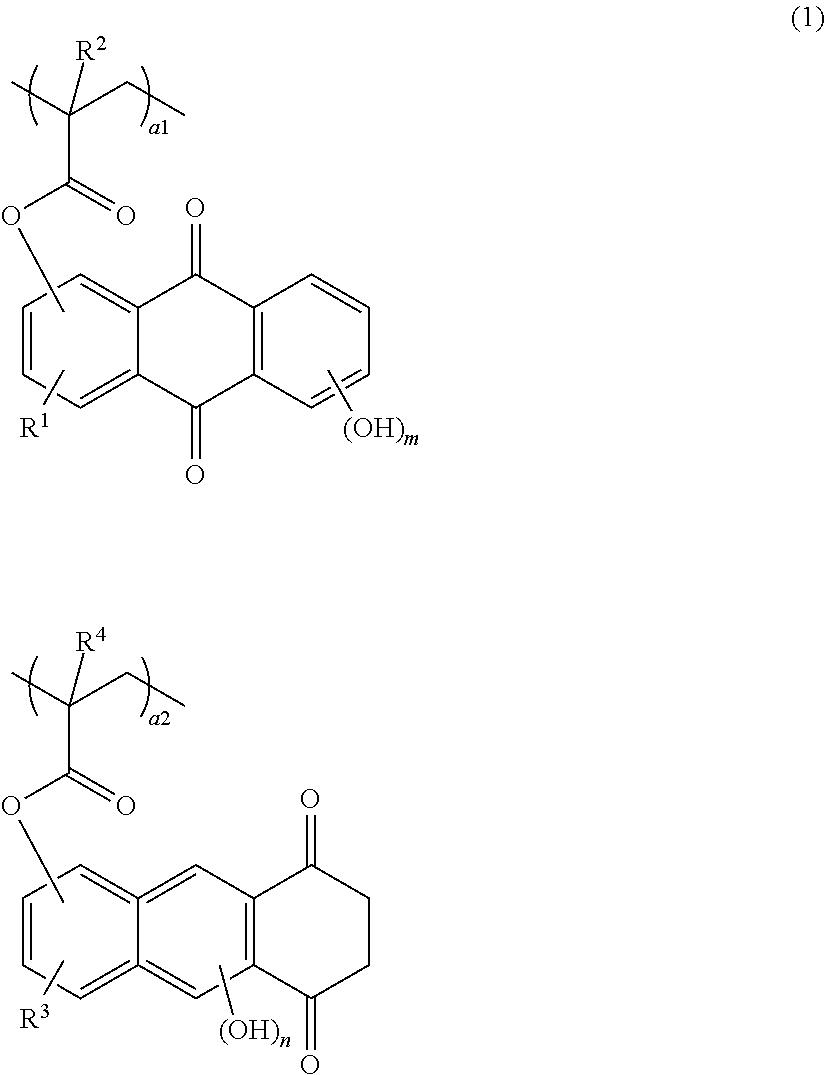

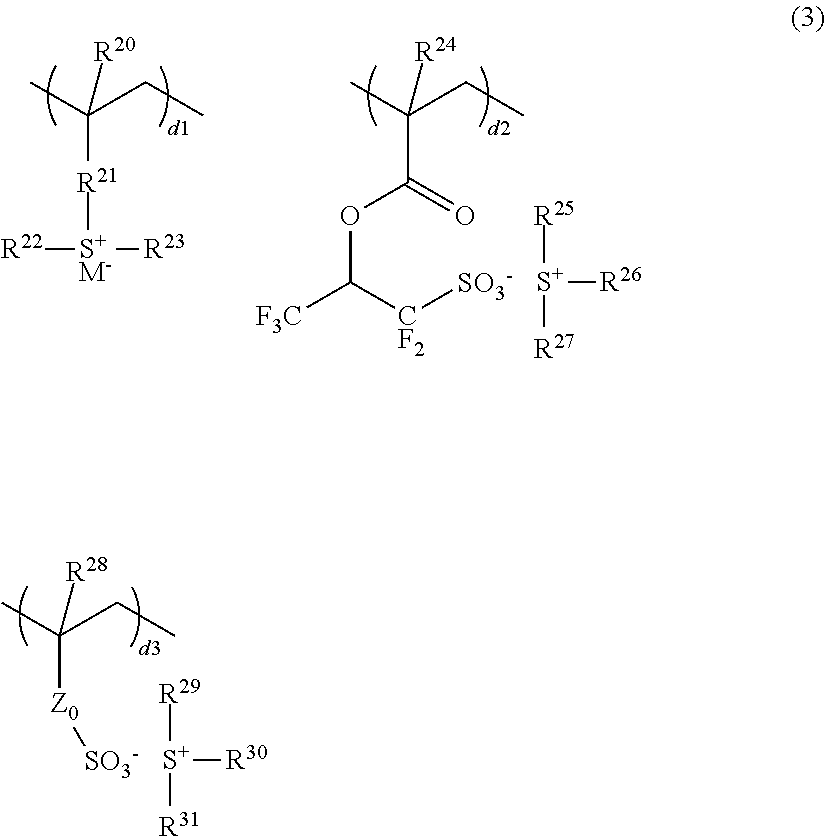

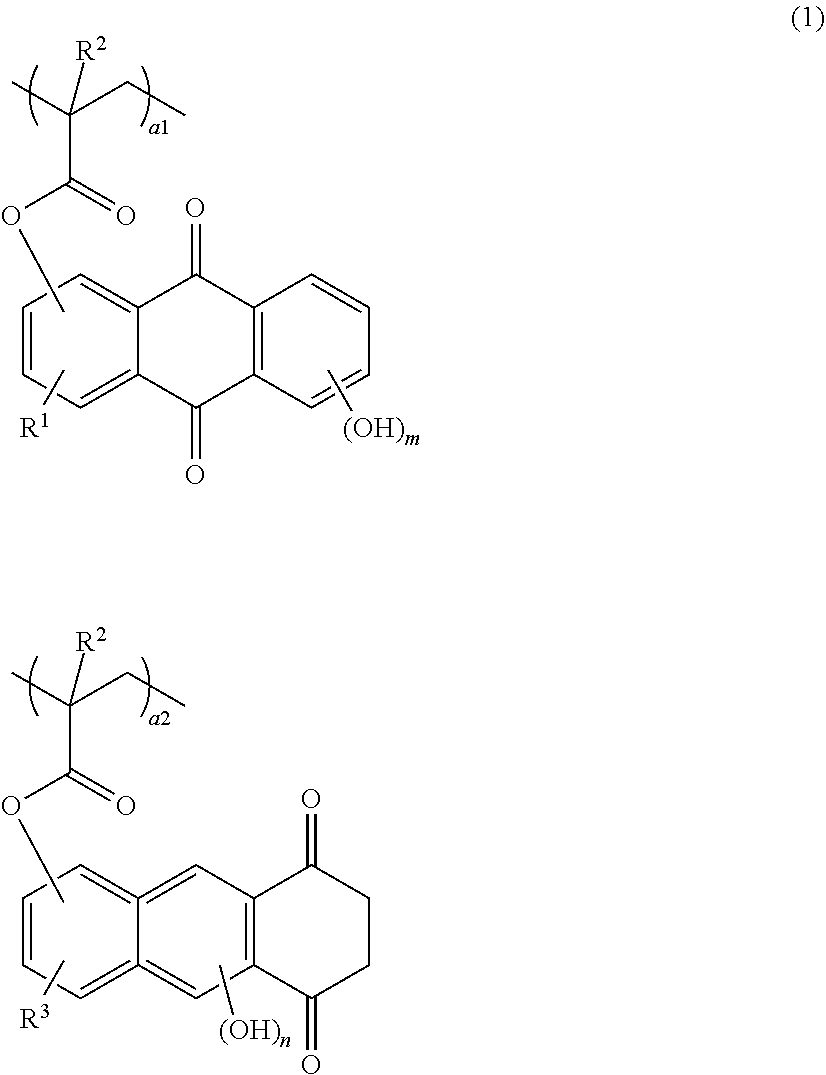

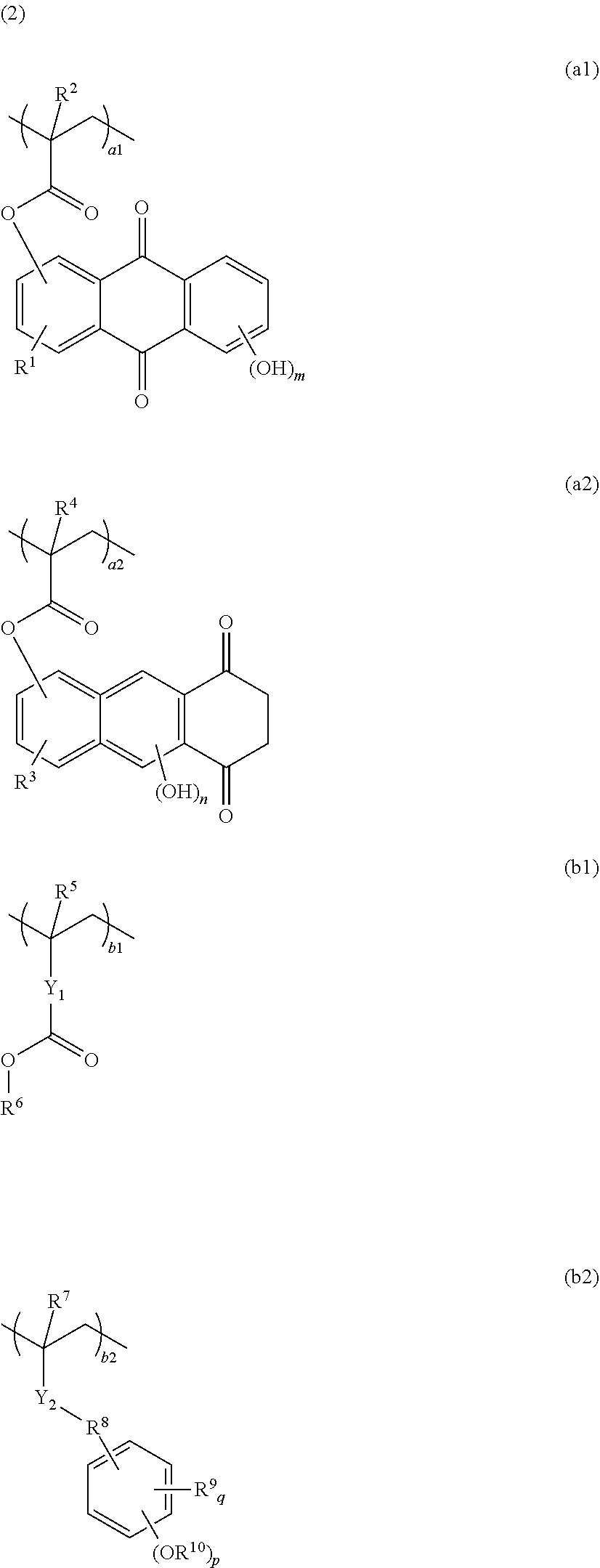

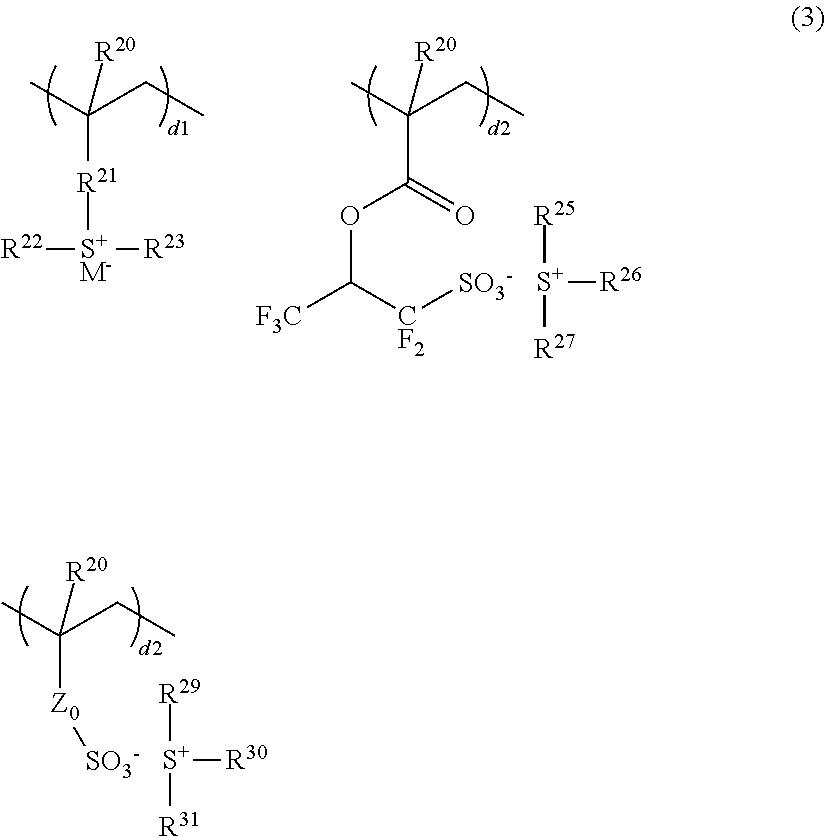

Positive resist composition and patterning process

ActiveUS9244350B2Satisfactory effect of suppressing acid diffusionHigh resolutionPhotomechanical exposure apparatusPhotosensitive material processingHydroxyanthraquinoneHydroxy group

A positive resist composition is provided comprising a polymer comprising recurring units having a carboxyl or phenolic hydroxyl group substituted with an acid labile group and recurring units of hydroxyanthraquinone or hydroxy-2,3-dihydro-1,4-anthracenedione methacrylate, and having a Mw of 1,000-500,000. The resist composition has a satisfactory effect of suppressing acid diffusion and a high resolution, and forms a pattern of good profile and minimal edge roughness after exposure.

Owner:SHIN ETSU CHEM IND CO LTD

Positive resist composition and patterning process

ActiveUS20150017586A1Satisfactory effect of suppressing acid diffusionHigh resolutionElectric discharge tubesPhotosensitive materialsHydroxyanthraquinoneHydroxy group

A positive resist composition is provided comprising a polymer comprising recurring units having a carboxyl or phenolic hydroxyl group substituted with an acid labile group and recurring units of hydroxyanthraquinone or hydroxy-2,3-dihydro-1,4-anthracenedione methacrylate, and having a Mw of 1,000-500,000. The resist composition has a satisfactory effect of suppressing acid diffusion and a high resolution, and forms a pattern of good profile and minimal edge roughness after exposure.

Owner:SHIN ETSU CHEM IND CO LTD

Key material of modified straw flocculant and technical method for same

InactiveCN106242006ASynchronization of the production processInhibit productionWater/sewage treatment by flocculation/precipitationHydroxyanthraquinoneSuccinic acid

The invention discloses a key material of a modified straw flocculant and a technical method for same. The key material includes, by weight part ratio: ozonized ultrapure water, straw powder, phenyl succinic acid, nonyl phenol sulfosuccinic monoester disodium salt, N-(2-methphenyl)trichloroacetamide, 1-amino-2-bromo-4-[(4-methphenyl)amino]-9,10-anthracenedione, 1-amino-4-bromoanthraquinone, 3,5-dimethoxybromobenzene, berkelium nano particles, 1-amino-2-bromo-4-hydroxyanthraquinone, 2-[(4-chloro-2-nitrophenyl)azo]-N-(2,3-dihydro-2-oxy-1H-benzoimidazole-5-yl)-3-oxo-butanamide, and 2-[[4-cyclohexylamino-9,10-dihydro-9,10-dioxy-1-anthryl]amino]-5-ethoxybenzenesulfonic sodium salt. The key material herein achieves synchronization of an organic flocculant during production and avoids complex steps of producing and purifying a bio-flocculant and compounding the bio-flocculant with the organic flocculant to complete the production of the compound flocculant, thereby reducing synthesize process and reducing cost.

Owner:XUZHOU UNIV OF TECH

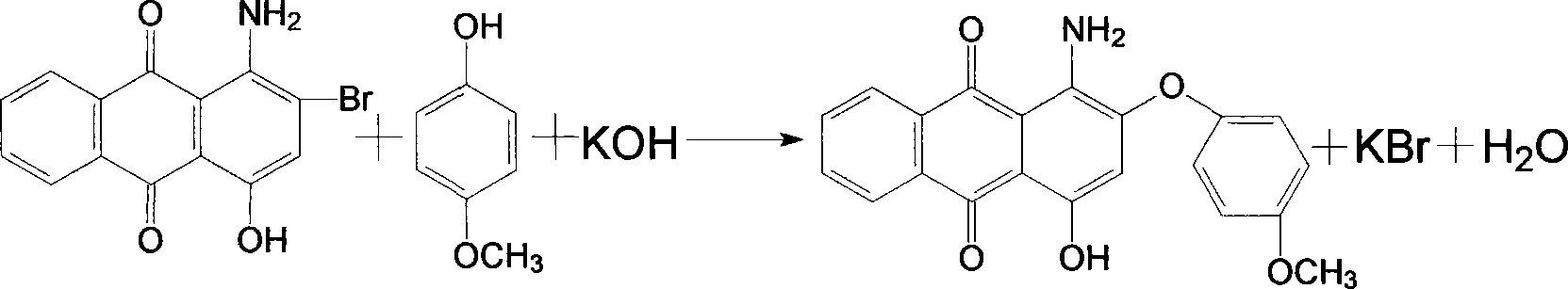

Preparation method for disperse red 60

ActiveCN104448886AHigh yieldApproximate colorAmino-hydroxy-anthraquinone dyesAnthraquinonesHydroxyanthraquinone

The invention relates to a preparation method for disperse red 60. The preparation method comprises the step of conducting reaction on dried 1-amino-2-bromine-4-hydroxy-anthraquinone with phenol under the existence of an acid-binding agent, wherein the moisture content of the dried 1-amino-2-bromine-4-hydroxy-anthraquinone is controlled under 0.2 wt%; the condensation reaction is implemented through the following steps: (1) adding potassium carbonate and phenyl hydroxide in a reaction vessel; mounting a dehydration device; conducting dehydration and temperature increasing to 130-155 DEG C under normal pressure or negative pressure; when no water is dehydrated in the dehydration device, adding the dried 1-amino-2-bromine-4-hydroxy-anthraquinone in a system passing the step (1); maintaining the temperature at 150-158 DEG C for reaction. The yield is up to 93%; the chromatograph content of the obtained disperse red 60 product is above 99.5%; compared the cloth dyed by the disperse red 60 with standard cloth, the clothes are similar in color and luster, and good in quality.

Owner:苏州市罗森助剂有限公司

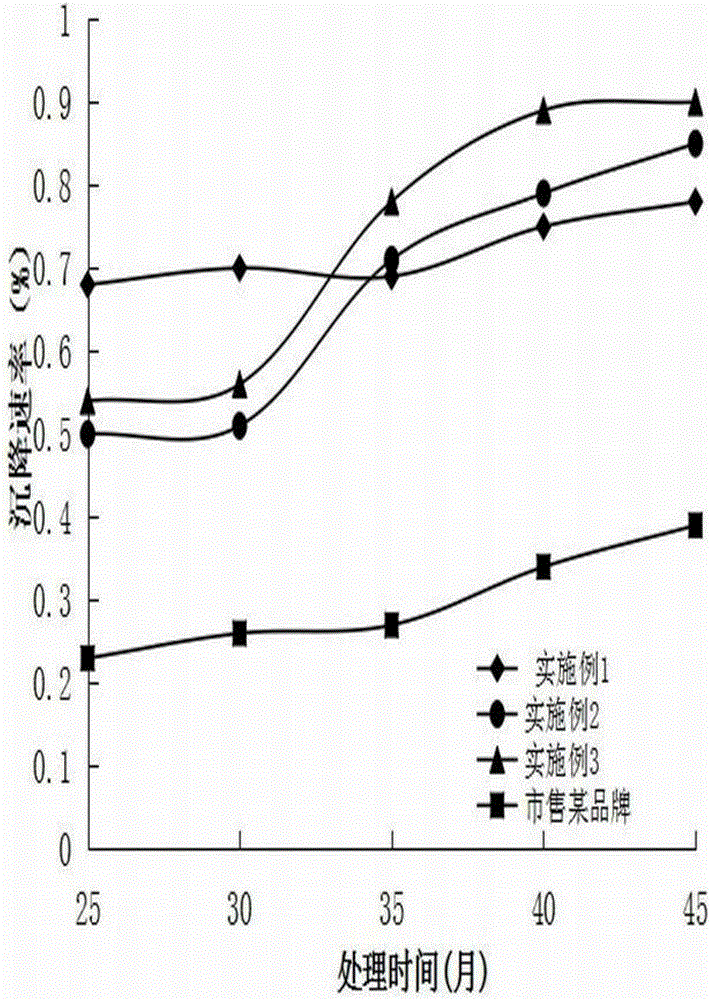

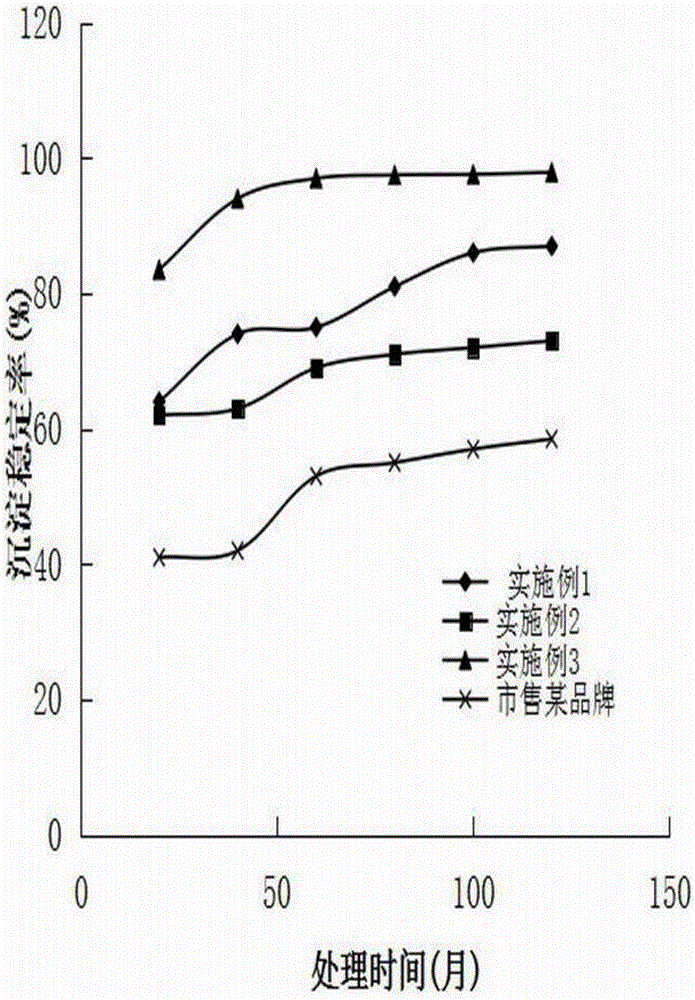

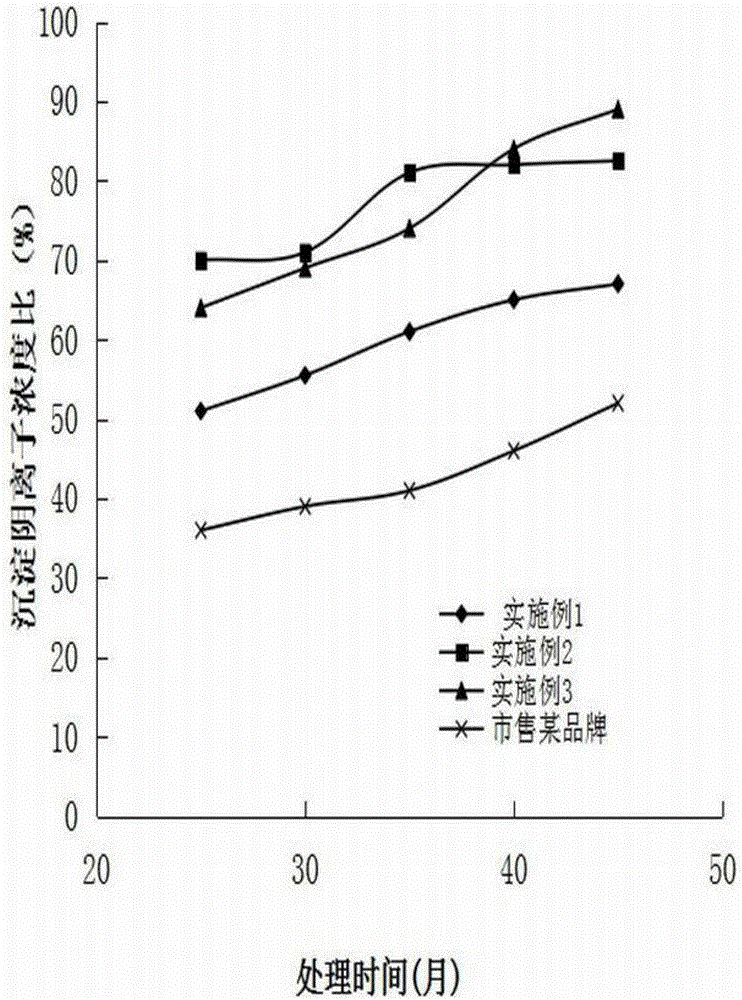

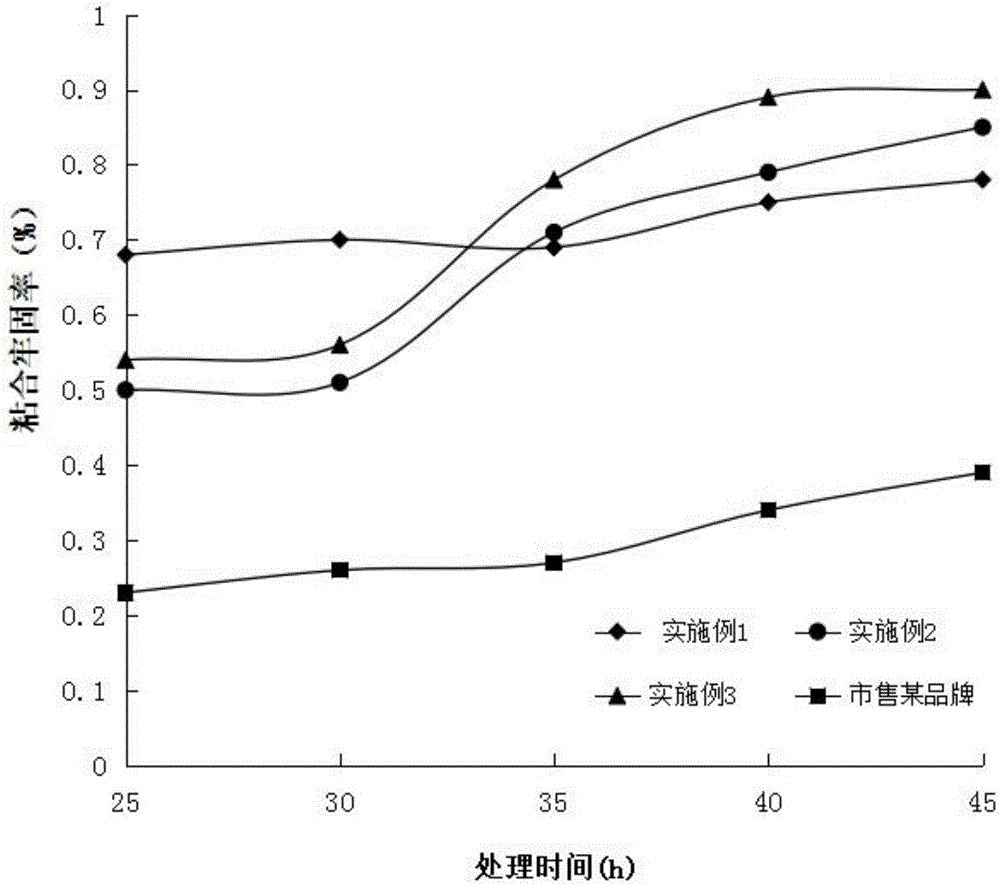

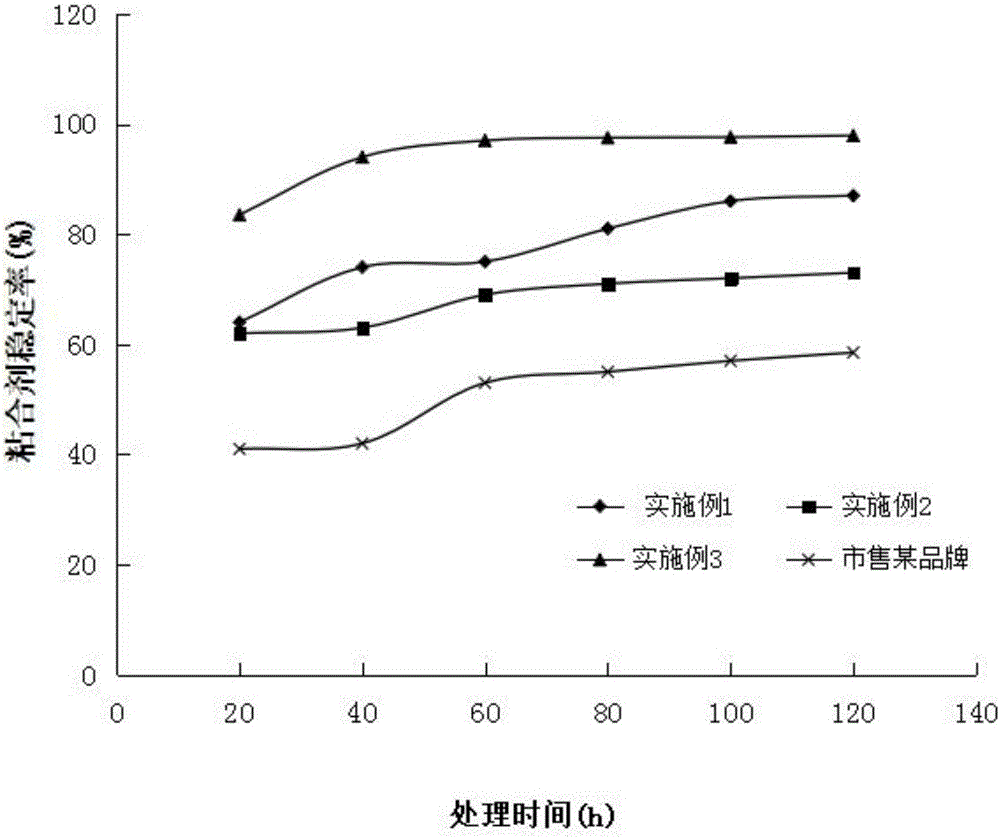

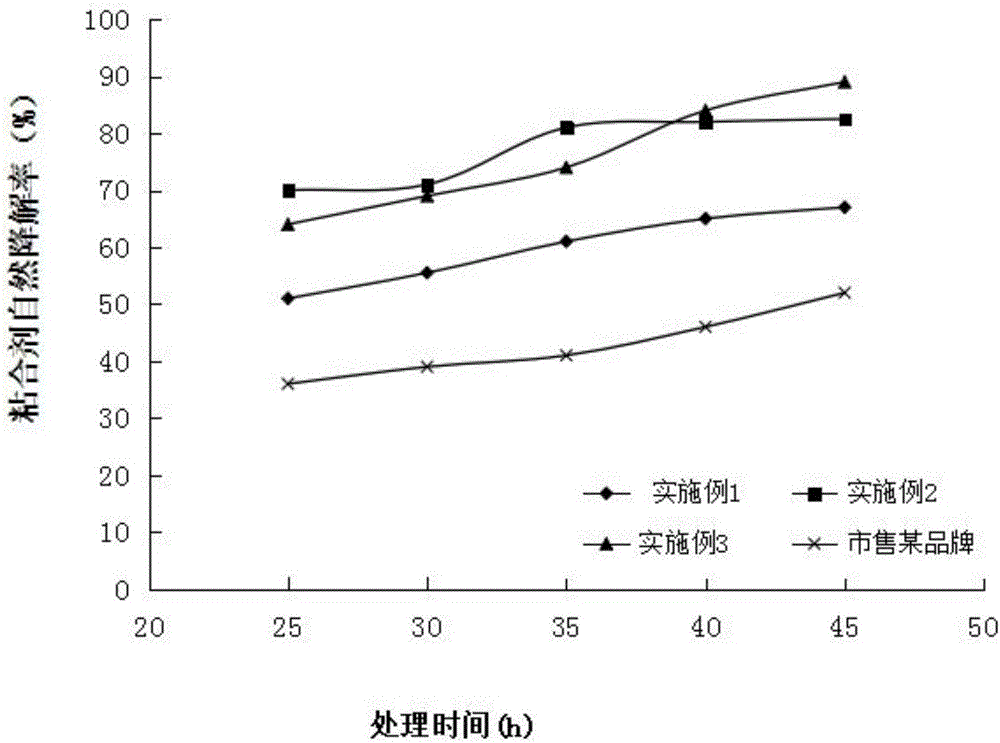

Preparation method and application of desulfurized fly ash energy-saving environmental-friendly building material adhesive

The invention discloses a preparation method and application of a desulfurized fly ash energy-saving environmental-friendly building material adhesive. The desulfurized fly ash energy-saving environmental-friendly building material adhesive consists of the following components in parts by weight: cation water, fatty alcohol polyethylene oxide ether sodium sulfate salt, succinic anhydride, N-cyclohexyl para toluene sulfonamide, N,N-dimethyl-p-nitrosoaniline, 1-amino-5-hydroxyl-4-[(1-methyl propyl] amino]-8-nitro-9,10-anthraquinone, 1-phenylamino-4-hydroxyanthraquinone, p-Methylthiobenzyl alcohol, gold nanoparticles, 4,4'-diamido-triphenylmethane, succinic anhydride, 4,4'-(3,3'-dichlorobiphenyl-4,4'-dinitrogen)di(4,5-dihydro-5-oxo-1-phenylpyrazole-3-formic acid) diethyl ester, benzotriazole-1-tri(trimethylamino)-trifluorophosphate, N-(2-benzimidazolyl) methyl carbamate and alpha-bromonaphthalene. The preparation method has the advantages that the adhesive is prevented from saponification, the surface tension of mixtures is reduced, and the mixtures can be relatively solidly adhered to one another; the adhesive has the advantages of stable chemical properties, wide application and high surface cleanliness ratios of molded structures.

Owner:XUZHOU UNIV OF TECH

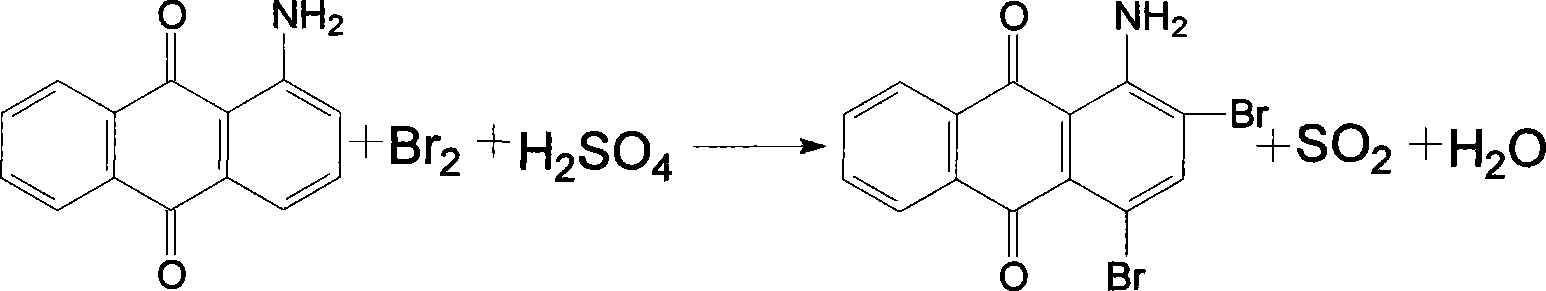

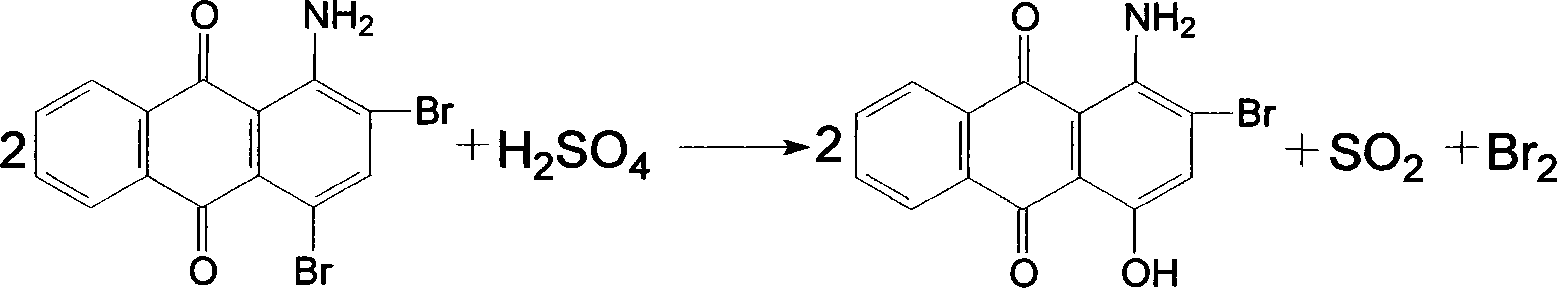

Dispersion red 146 condensation process improvement

InactiveCN101113244AReduce cokingQuality improvementAmino-hydroxy-anthraquinone dyesHydroxyanthraquinoneSolvent

The invention relates to an improved condensation process of disperse red 146. 1-amino-anthraquinone is taken as raw material, 1-amino-2-bromo-4-hydroxyanthraquinone is obtained by bromination and hydrolysis in sulfuric acid solution; the 1-amino-2-bromo-4-hydroxyanthraquinone is condensed with phydroxy phenol in mixed solvent medium, with the existing of acid binding agent and catalyst, and the temperature reduces to 75-80 DEG C after reaching the end point and methanol is dripped with controlling the temperature, and the segregation is done, the temperature is reduced under 50 DEG C after the segregation; the disperse red 146 is produced after standing, filtering and then the filter cake is cleaned by methanol and hot water. The invention is characterized in that: the 1-amino-2-bromo-4-hydroxyanthraquinone used in the condensation is wet cake added with the mixed solvent medium as well as the catalyst. By applying 1-amino-2-bromo-4-hydroxyanthraquinone wet cake directly, drying process is saved and operation is simplified, thereby reducing equipment investment and improving operation environment and reducing labor intensity; besides, the method also improves reaction yield and product quality and the economic benefit is very obvious.

Owner:JIANGSU YABANG DYE

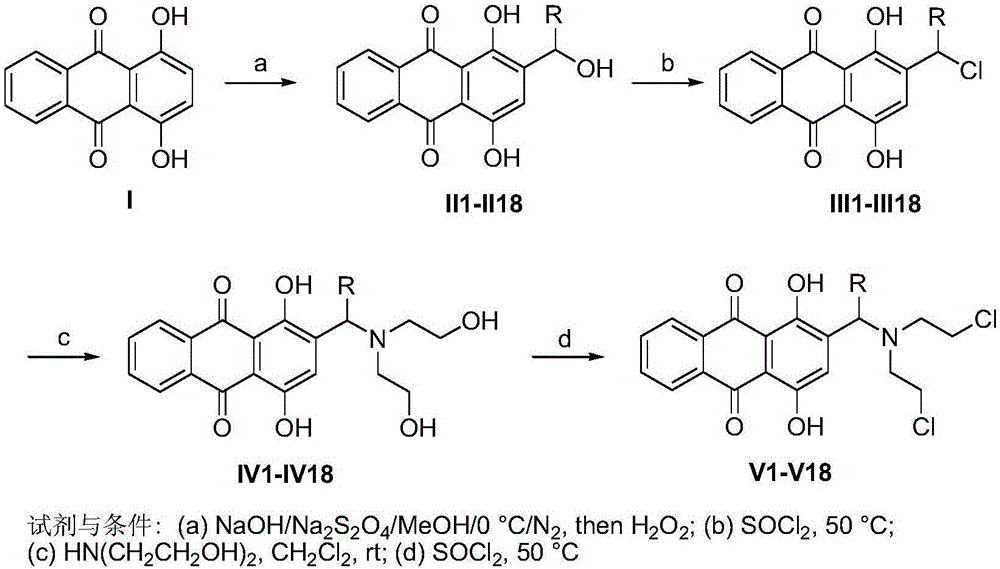

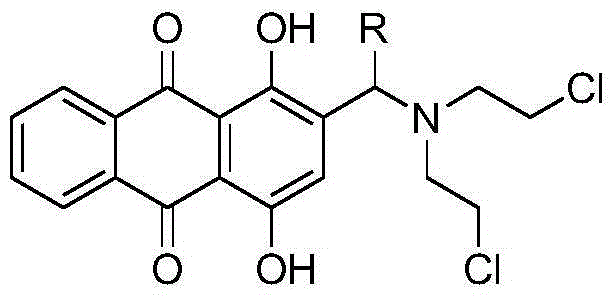

Hydroxyanthraquinone chlormethine derivative having antitumor activity, and preparation method thereof

InactiveCN105037181AThe synthetic route is simpleEasy post-processingOrganic chemistryOrganic compound preparationHydroxyanthraquinoneMethyl group

The invention relates to a hydroxyanthraquinone chlormethine derivative having antitumor activity, and a preparation method thereof, and belongs to an antitumor drug derivative and a preparation method thereof, wherein the hydroxyanthraquinone chlormethine derivative is a 2-(1-substituted-bis(2-chloroethylamino)methyl)-1,4-dihydroxy-9,10-anthraquinone derivative. The preparation method comprises that 1,4-dihydroxyanthraquinone is adopted as a raw material, hydroxyalkyl is introduced into the site 2 of the 1,4-dihydroxyanthraquinone through hydroxyalkylation to obtain 2-(1-substituted-1-hydroxymethyl)-1,4-dihydroxy-9,10-anthraquinone, the 2-(1-substituted-1-hydroxymethyl)-1,4-dihydroxy-9,10-anthraquinone reacts with thionyl chloride to chlorinate the hydroxyalkyl so as to obtain 2-(1-substituted-1-chloromethyl)-1,4-dihydroxy-9,10-anthraquinone, the 2-(1-substituted-1-chloromethyl)-1,4-dihydroxy-9,10-anthraquinone reacts with diethanolamine at a room temperature, and finally the produced 2-(1-substituted-bis(2-hydroxyethylamino)methyl)-1,4-dihydroxy-9,10-anthraquinone reacts with thionyl chloride to obtain the 2-(1-substituted-bis(2-chloroethylamino)methyl)-1,4-dihydroxy-9,10-anthraquinone derivative. The compounds of the present invention have good antitumor activity.

Owner:XUZHOU NORMAL UNIVERSITY

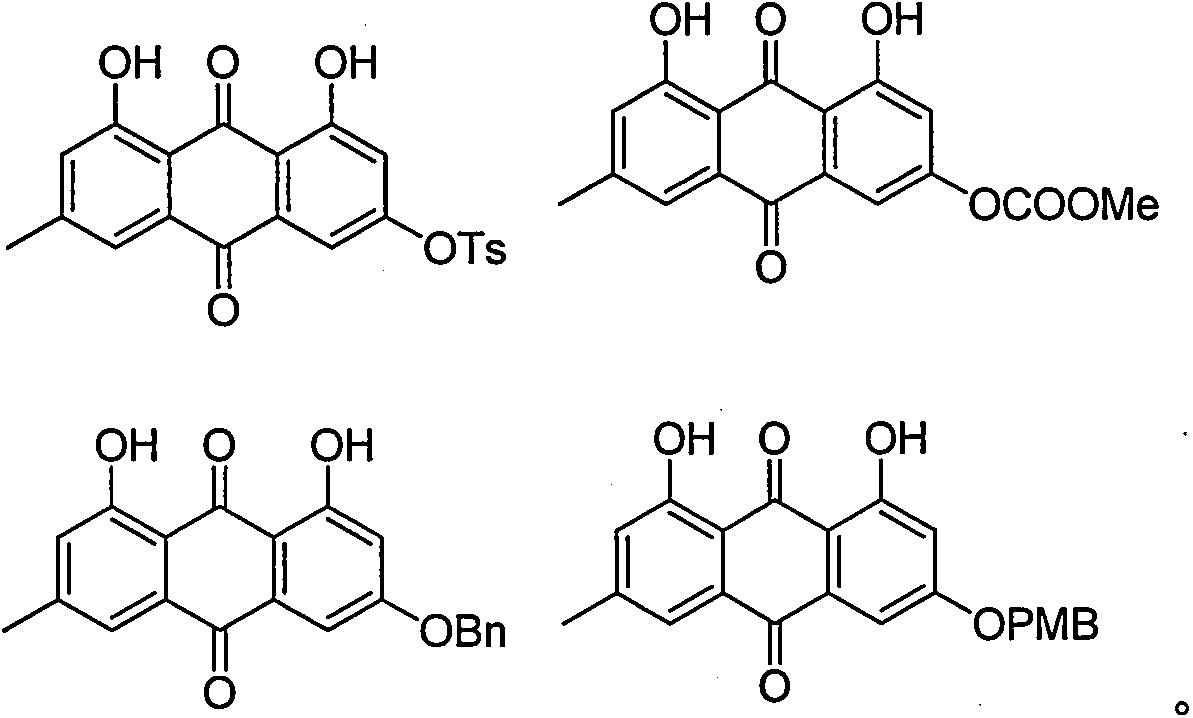

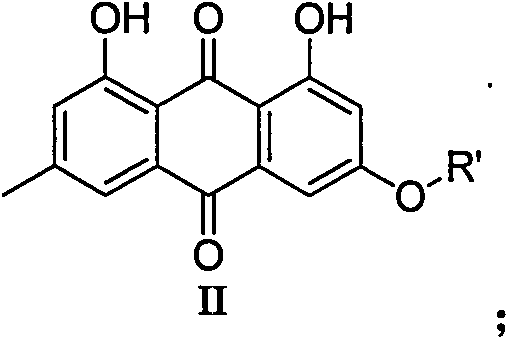

1,8-dihydroxyl-9,10-anthraquinone derivative and preparation method and application thereof

ActiveCN109748828AGood anti-HCV activityOrganic active ingredientsOrganic compound preparationAnthranilAnthraquinone Derivatives

The invention discloses a 1,8-dihydroxyl-9,10-anthraquinone derivative and a preparation method and application thereof and provides application of a 1,8-dihydroxyl-9,10-anthraquinone derivative shownin a formula I or a pharmaceutically acceptable salt of the 1,8-dihydroxyl-9,10-anthraquinone derivative to preparation of medicines for treatment and / or prevention of hepatitis C. The formula I is as shown in the specification, wherein R refers to C1-C6 alkoxy carbonyl, R<1> substituted or non-substituted benzenesulfonyl, or R<2> substituted or non-substituted benzyl, and R<1> and R<2> are C1-C4alkyl or C1-C4 alkoxy independently. The 1,8-dihydroxyl-9,10-anthraquinone derivative is high in anti-HCV activity.

Owner:SHANGHAI INST OF PHARMA IND +1

Functional material for fixing phorate degrading bacteria based on polycarbonate modification

InactiveCN107435043AHigh mechanical strengthEnhanced mass transferOn/in organic carrierHydroxyanthraquinoneAlcohol

The invention discloses a functional material for fixing phorate degrading bacteria based on polycarbonate modification. Polycarbonate is cleaned and is then prepared into a substance B through being modified by a mixed solution prepared from 2,5-furandicarboxylic acid, ethyl alcohol, 3-chloro-4-methylpyridazine, 2-hydroxyanthraquinone, 3-flavonol and N-2-naphthyl-3-hydroxyl-2-naphthanilide; the substance B is modified by a mixed solution prepared from acetone phenylhydrazone, ethyl alcohol, quinoline-8-carboxaldehyde, 4-benzopyrone-2-carboxylic acid and 4-chloro-3-nitropyridine; and an obtained substance is the functional material for fixing the phorate degrading bacteria based on polycarbonate modification.

Owner:光合强化(北京)生物科技有限公司

Production method of 2,2'-dimethyl[1,1'-biphenyl]-4,4'-diamine

ActiveCN110590596AHigh selectivityHydrazine preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneHydroxyanthraquinone

Owner:CHANGZHOU SUNLIGHT PHARMA

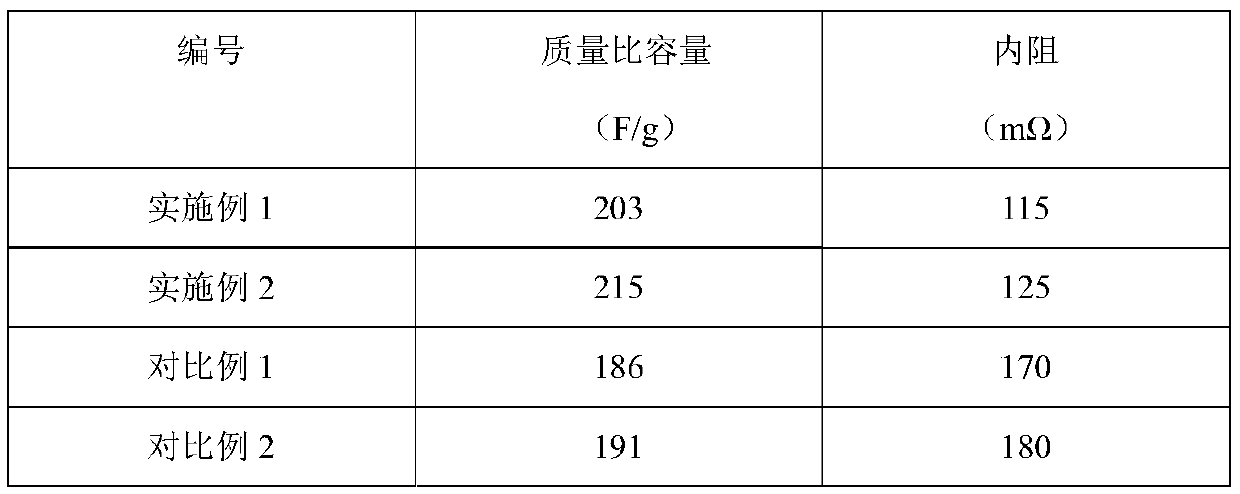

Electrode composite material for lithium ion capacitor, manufacturing method thereof and electrode manufacturing

ActiveCN111009424AUniform adhesionEvenly dispersedHybrid capacitor electrodesHybrid/EDL manufactureHydroxyanthraquinoneLithium metal

The invention provides a manufacturing method of an electrode composite material for a lithium ion capacitor and manufacturing of an electrode. The preparation method of the electrode composite material for the lithium ion capacitor comprises the following steps of dissolving 40-96% of lithium-containing metal oxide, 2-30% of a carbon active material and 2-30% of hydroxyanthraquinone quaternary ammonium salt into an alcohol substance, uniformly dispersing to obtain a precursor; and sintering the precursor at a high temperature to obtain the electrode composite material for the lithium ion capacitor. The hydroxyanthraquinone quaternary ammonium salt is introduced to serve as an intermediate medium, two different types of active materials can be better combined together, performance of the two materials is brought into play to the maximum extent, and meanwhile the hydroxyanthraquinone quaternary ammonium salt can play a role in improving a capacity. According to the composite material formed through the method, a requirement for an electrode manufacturing process is greatly lowered, the requirement for an electrode manufacturing environment is reduced, a process is simpler and more convenient, operation is easy, and the electrode can be manufactured in various modes.

Owner:锦州凯美能源有限公司

Preparation method of 4,4'-diamino-2,2'-dimethyl-1,1'-biphenyl

ActiveCN110590596BHigh selectivityHydrazine preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydroxyanthraquinonePtru catalyst

The invention discloses a preparation method of 4,4'-diamino-2,2'-dimethyl-1,1'-biphenyl, which uses m-nitrotoluene as a starting material, and first reduces to obtain 3 ,3'-dimethyldiphenylhydrazine, and then rearranged to obtain 4,4'-diamino-2,2'-dimethyl-1,1'-biphenyl; the reduction is based on Pd / C as the main catalyst, Anthraquinone compound + sodium dioctyl succinic acid sulfonate as a cocatalyst; the anthraquinone compound is one of 1,4-dihydroxyanthraquinone, 2-hydroxyanthraquinone, 2,6-dihydroxyanthraquinone or two kinds. After a large number of experiments, the present invention finds that the combination of sodium dioctyl succinic acid sulfonate and anthraquinone compound as a cocatalyst can greatly improve the reaction selectivity of m-nitrotoluene reduction to prepare 3,3'-dimethyldiphenylhydrazine, and finally The ability to obtain a reaction yield of more than 70% creates conditions for its extensive application in the preparation of special materials.

Owner:CHANGZHOU SUNLIGHT PHARMA

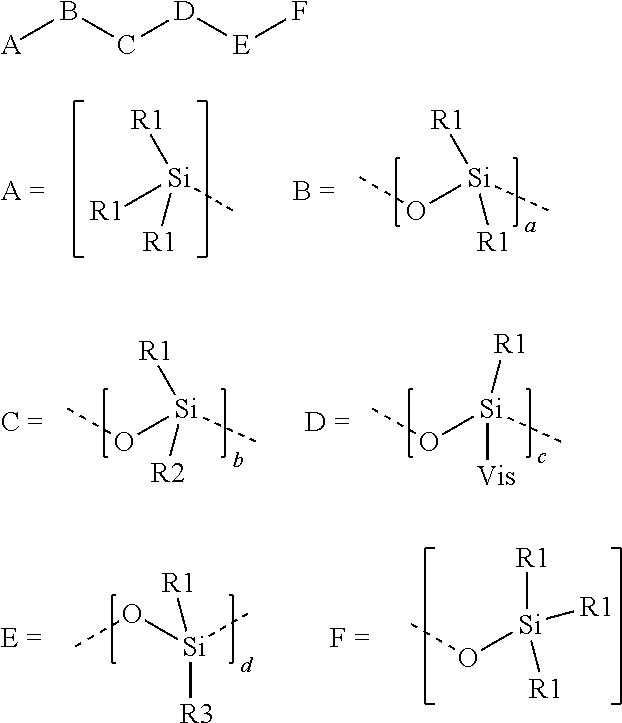

Silicone compound and photoprotective personal care compositions comprising the same

ActiveUS8846010B2Reduce volatilityImprove impactCosmetic preparationsSilicon organic compoundsPersonal careSunscreen agents

The present invention relates to silicone compounds which have photoprotective properties and personal care compositions comprising the same. The present inventors, in developing a sunscreen that gives protection against both UV radiation and visible radiation, found that when a certain moiety generally occurring in nature i.e. hydroxyanthraquinone having uv-visible absorption activity are attached to crosslinked silicone polymers they provide not only the desired photoprotection but also excellent spreadability on skin.

Owner:CONOPCO INC D B A UNILEVER

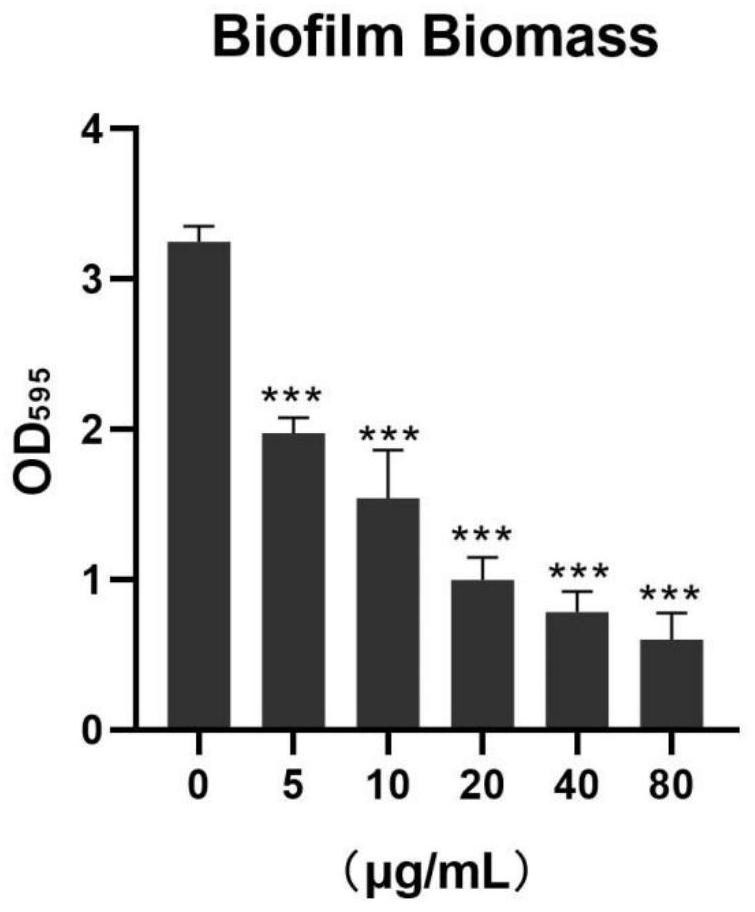

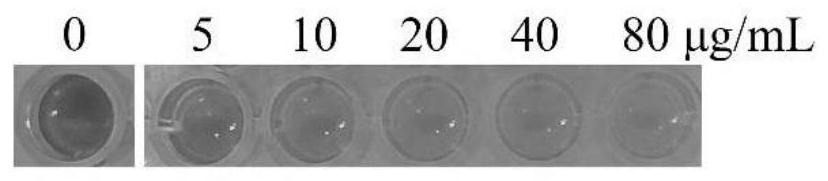

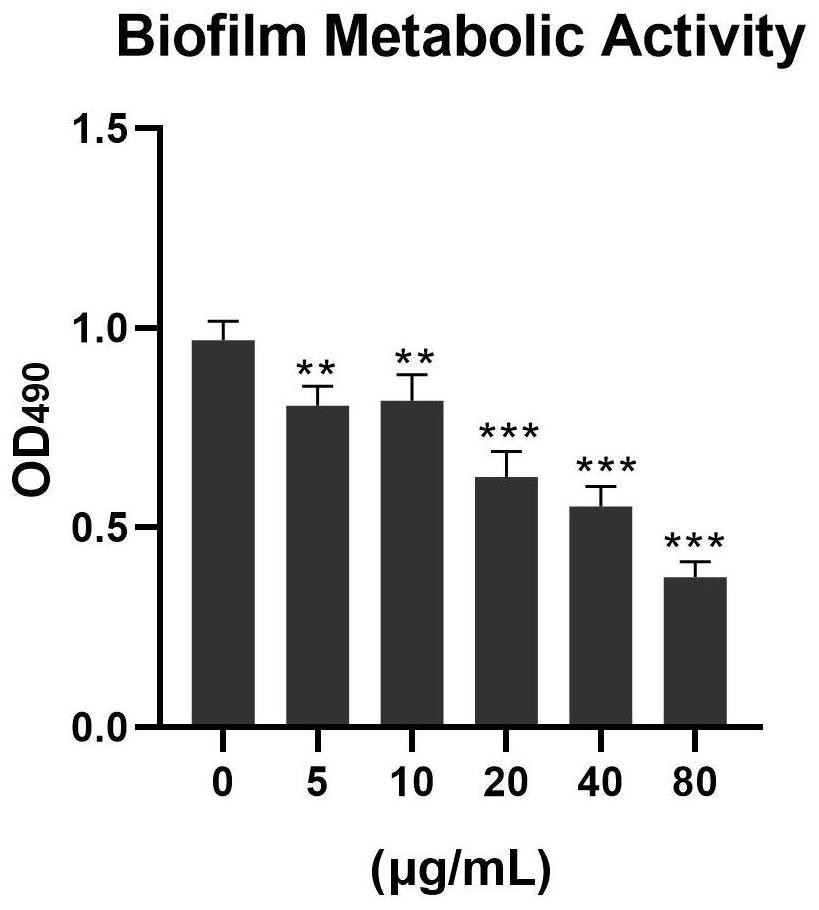

Application of 2-substituted anthraquinone derivative to preparation of medicine for treatment of candida albicans infection

The invention belongs to the technical field of medicines, and relates to an application of a 2-substituted anthraquinone derivative in treatment of candida albicans infection. Candida albicans can cause infection of the tissues and organs of a host or any part of the skin surface and can be adhered to the surfaces of various medical devices, and many diseases caused by the candida albicans are related to biofilm formation. Experiments prove that 2-ethylanthraquinone, 2-methylanthraquinone, 2-tert-butylanthraquinone and 2-hydroxyanthraquinone have an inhibiting effect on biofilm formation of the candida albicans and can reduce the metabolic activity of biofilm cells, and the 2-ethylanthraquinone also has an effect of inhibiting mycelia formation of the candida albicans. It is proved that the 2-substituted anthraquinone derivative has a good application prospect in preparation of a medicine for treatment of the candida albicans infection.

Owner:CHINA PHARM UNIV

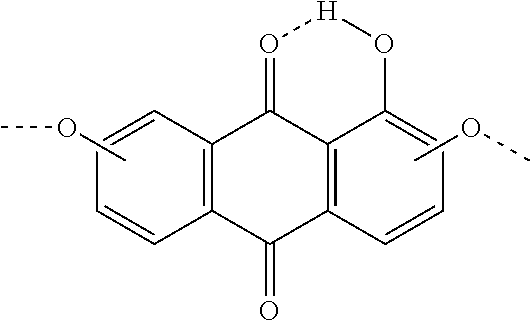

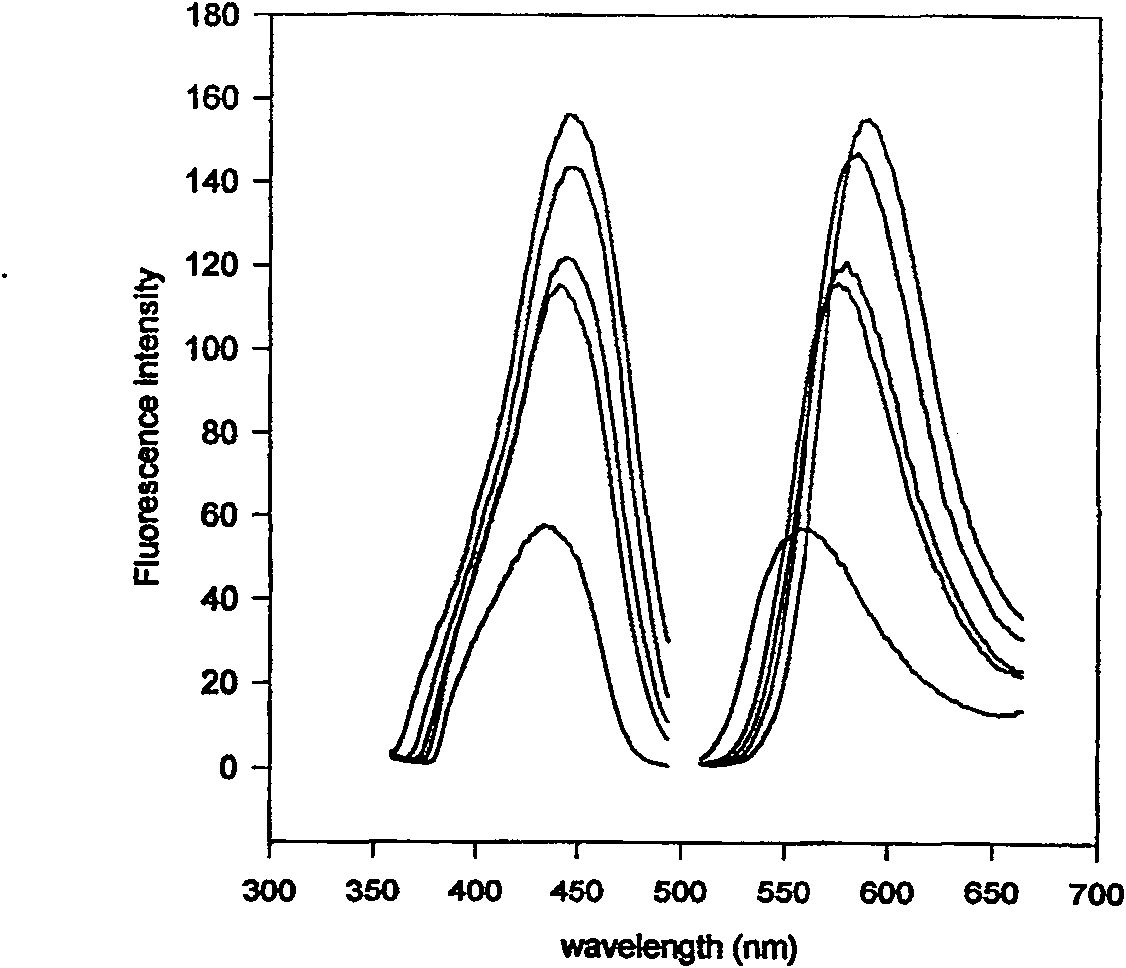

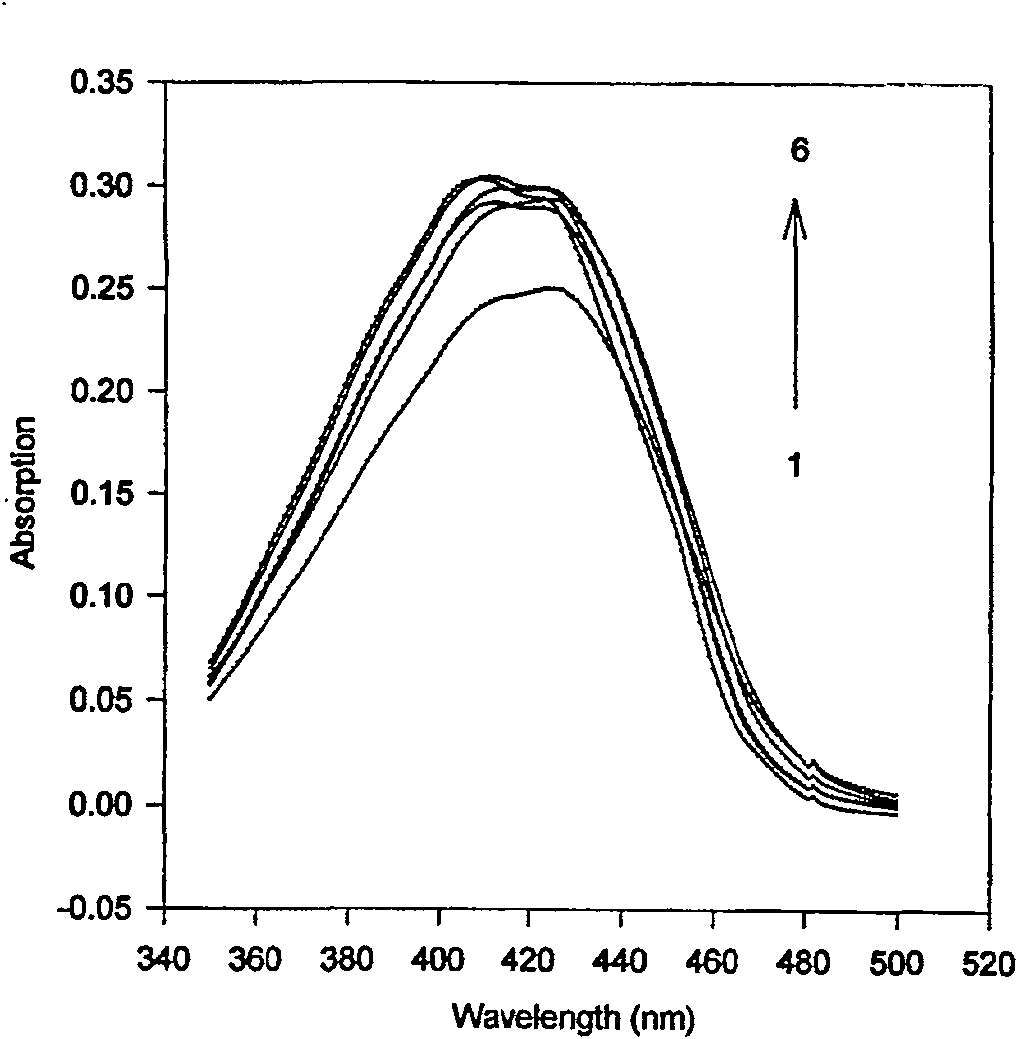

1-propylene oxygen basis-4-hydroxyanthraquinone-9, 10-diketone and method of preparing the same and application thereof

InactiveCN100575931CStable fluorescence intensity valueLess washback timeOrganic compound preparationChemiluminescene/bioluminescenceQuantum yieldHydroxyanthraquinone

The invention relates to an anthraquinone compound, in particular to the 1- propylene oxygen group-4- hydroxyanthraquinone-9, 10- diketone and the preparation and the application. The molecular structure is shown as follows: the compound has stronger fluorescence quantum yield and good light stability. When the organic solvent contains little water, the fluorescence carrier molecule easily forms hydrogen bond compound with water so as to make the fluorescence intensity rise rapidly. The characteristics of the above fluorescence response produced by the anthraquinone derivatives in the organic solvent with water can be used to make fluorescent sensors and can realize the in-situ testing and real-time testing on the small quantities of water in organic solvent.

Owner:ZHONGBEI UNIV

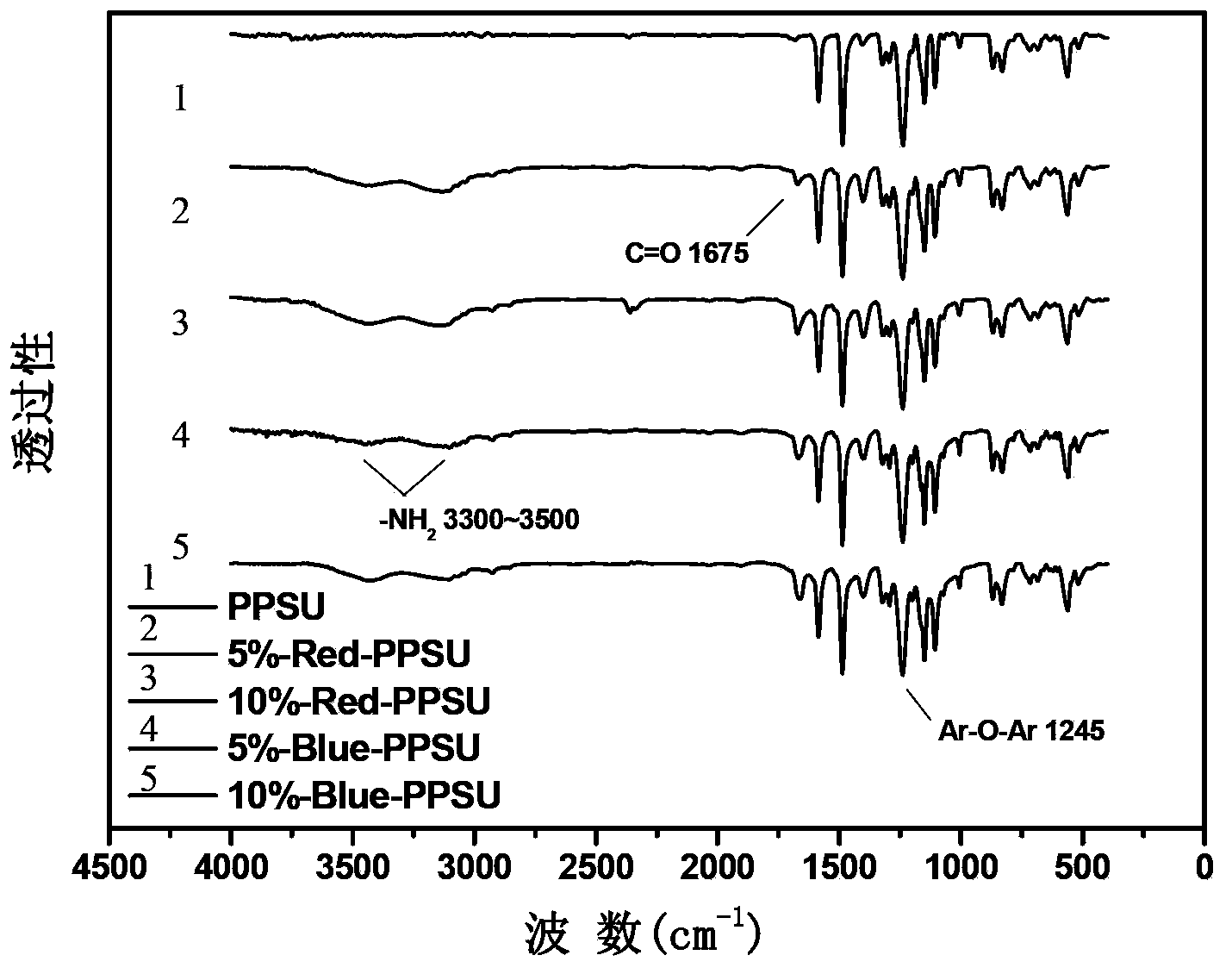

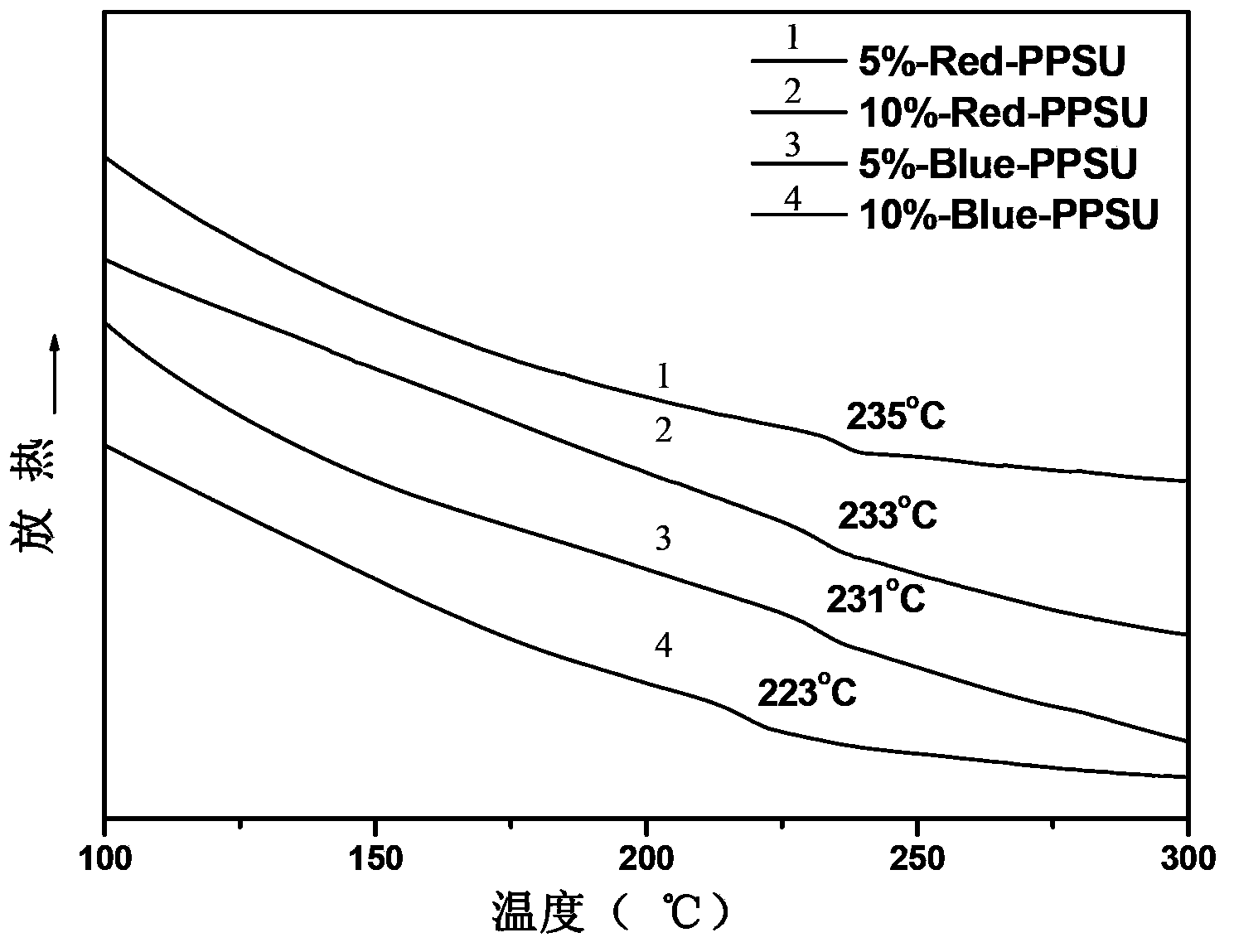

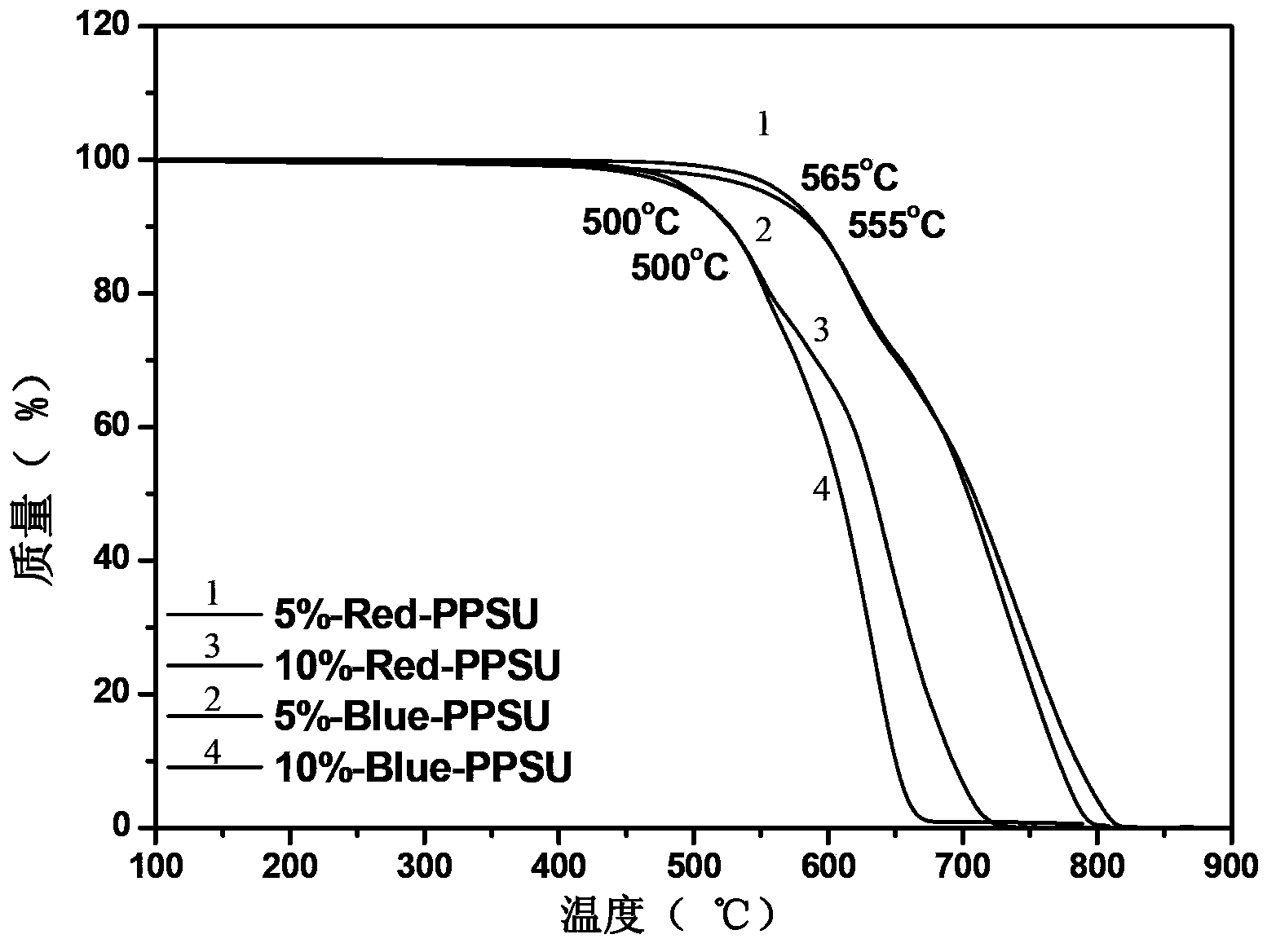

Red and blue anthraquinone-contained polyphenylene sulfone copolymers and preparation methods and applications thereof

The invention discloses red and blue anthraquinone-contained polyphenylene sulfone copolymers and preparation methods and applications thereof, belongs to the technical field of preparation of polyether sulfone copolymers, and in particular relates to red and blue anthraquinone-contained polyphenylene sulfone copolymers and preparation methods thereof, and the applications of red and blue anthraquinone-contained polyphenylene sulfone copolymers in the dying of pure polyphenylene sulfone. According to the preparation methods, 4,4'-difluoro diphenyl sulfone, 4,4'-biphenyl diphenol and 1-aminoanthraquinone or 1,5-diamido-4,8-dihydroxy anthraquinone are employed as raw materials, a nucleophilic polycondensation method is employed to introduce anthraquinone chromophoric molecules with high thermal stability into a polyphenylene sulfone system in a covalent bond manner, thus the novel red and blue anthraquinone-contained polyphenylene sulfone copolymers with anthraquinone content of 1%-30% and thermal decomposition temperature of more than 500 DEG C can be prepared. The series of polymers have high molecular weight, good solubility and heat stability, and meanwhile have intrinsic red and blue colors and good transparency.

Owner:JILIN UNIV

Disperse red 60 condensation process

InactiveCN111154287AIncrease chance of contactHigh activityAmino-hydroxy-anthraquinone dyesAnthraquinonesCondensation process

The invention relates to the technical field of dyes, in particular to a disperse red 60 condensation process. The process comprises the following steps: in a condensation kettle, firstly adding phenol and a 1-amino-2-bromo-4-hydroxyanthraquinone dry product, then adding sodium carbonate and a catalyst, heating to 140-160 DEG C, carrying out reactions at a constant temperature; after the reactionis finished, cooling to 90-100 DEG C, adding water within the temperature range, dropwise adding liquid caustic soda, cooling to 50-55 DEG C after dropwise adding is finished, filtering, cleaning, anddrying to obtain 1-amino-2-phenoxy-4-hydroxyanthraquinone, namely disperse red 60. According to the process, a condensed acid-binding agent (potassium carbonate) is directly substituted by sodium carbonate with a lower price, and a certain amount of a proper phase transfer catalyst is added, so that the contact probability and activity of condensation reactions are improved, the aims of improvingthe product quality and yield and reducing the production cost are fulfilled, and the cost of the disperse red 60 can be reduced by 1500 yuan / ton.

Owner:JIANGSU YABANG DYE

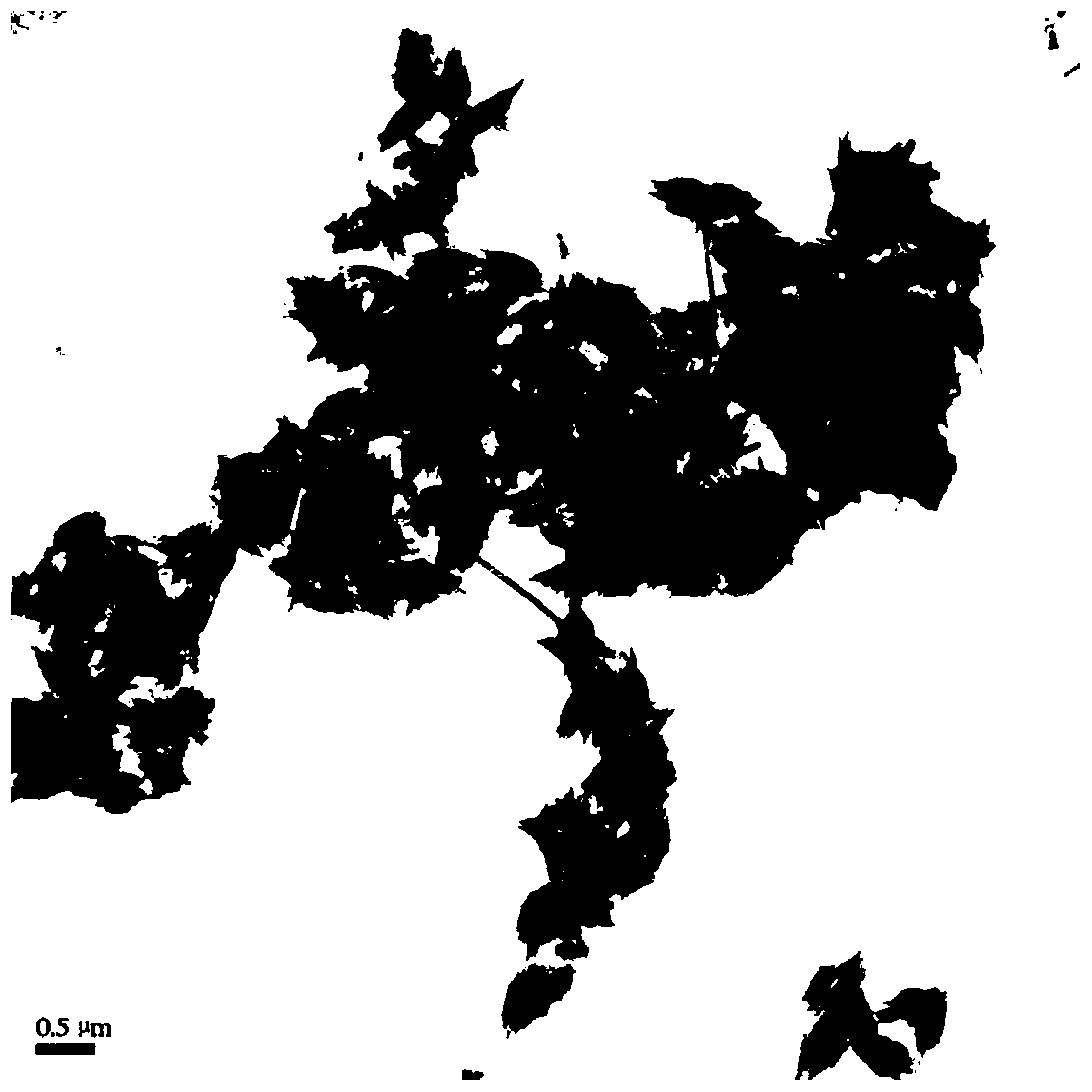

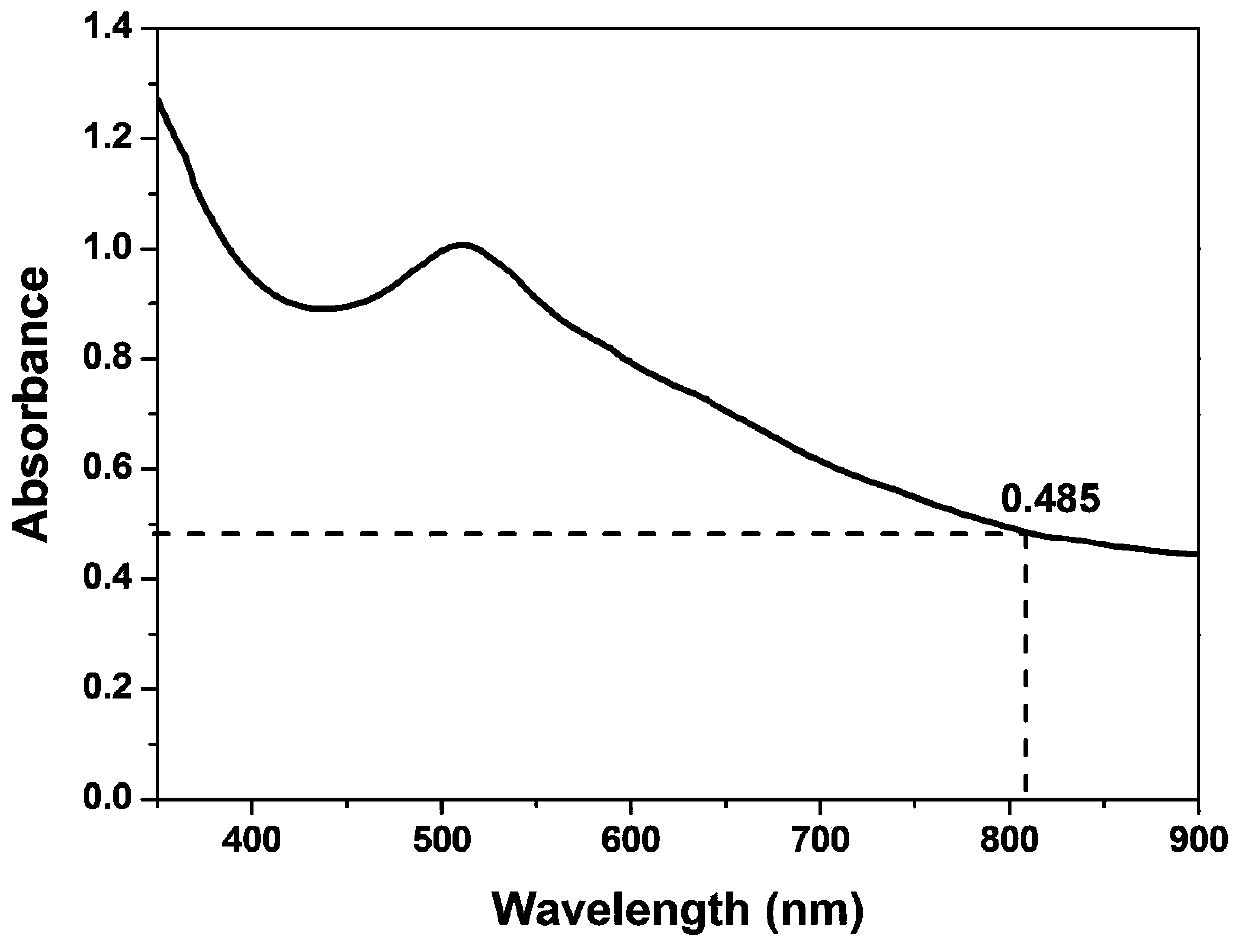

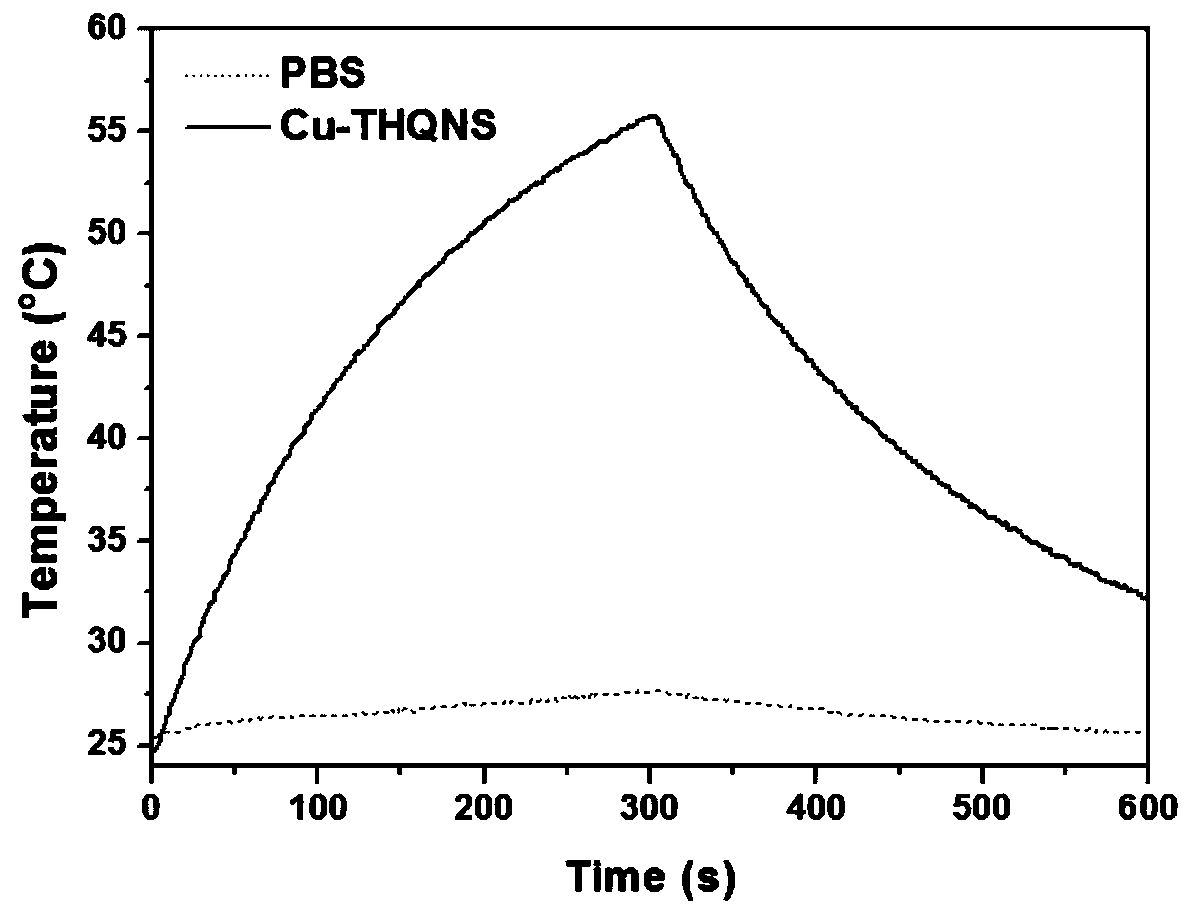

A PEG-modified two-dimensional nanosheet light-to-heat conversion material and its application

ActiveCN107625962BHigh absorption coefficientImprove light and heat stabilityEnergy modified materialsPharmaceutical non-active ingredientsHydroxyanthraquinoneLight absorption coefficient

The invention relates to a PEG-modified two-dimensional nanosheet photothermal conversion material. The material is formed through coordination self-assembling of tetrahydroxyanthraquinone and bivalent copper ions and modification with PEG, and the diameter of the above nanosheet is 500-800 nm, wherein a molar ratio of the tetrahydroxyanthraquinone to the bivalent copper ions is (1.5-2):1. The two-dimensional nanosheet has a high light absorption coefficient in the near-infrared region, high photothermal conversion ability under the irradiation of near-infrared laser, expands existing photothermal conversion materials, and can be used in the photothermal therapy of tumors.

Owner:MENGCHAO HEPATOBILIARY HOSPITAL OF FUJIAN MEDICAL UNIV

Process for preparing disperse red 60

InactiveCN101343419BReduce dosageAvoid emissionsAmino-hydroxy-anthraquinone dyesHydroxyanthraquinoneDistillation

The invention relates to a producing method of disperse red 60. The producing method mainly comprises the steps that firstly, 1-anthraquinone is adopted as raw material to make 1-amino-2-bromine-4-hydroxyanthraquinone dry product; secondly, the 1-amino-2-bromine-4-hydroxyanthraquinone dry product reacts with phenol to perform condensation reaction under the existence of acid binding agent to generate 1-amino-2-phenoxy -4-hydroxyanthraquinone, in the second step, the condensation reaction is performed in inert solvent with a high boiling point, the mass ratio of the inert solvent with a high boiling point, the phenol and the 1-amino-2-bromine-4-hydroxyanthraquinone dry product is 2.5 to 3.5 : 1.7 to 1.05 : 1, the inert solvent with a high boiling point is organic solvent which is insolublein water and has a higher boiling point than that of the phenol, when the condensation reaction reaches the end, the phenol is removed through pressure reduction and distillation, 1-amino-2-phenoxy -4-hydroxyanthraquinone is separated through cooling, and the disperse red 60 is obtained through filtering. The producing method is simple, no wastewater is discharged, and the producing method can meet the requirement for clean production.

Owner:苏州市罗森助剂有限公司

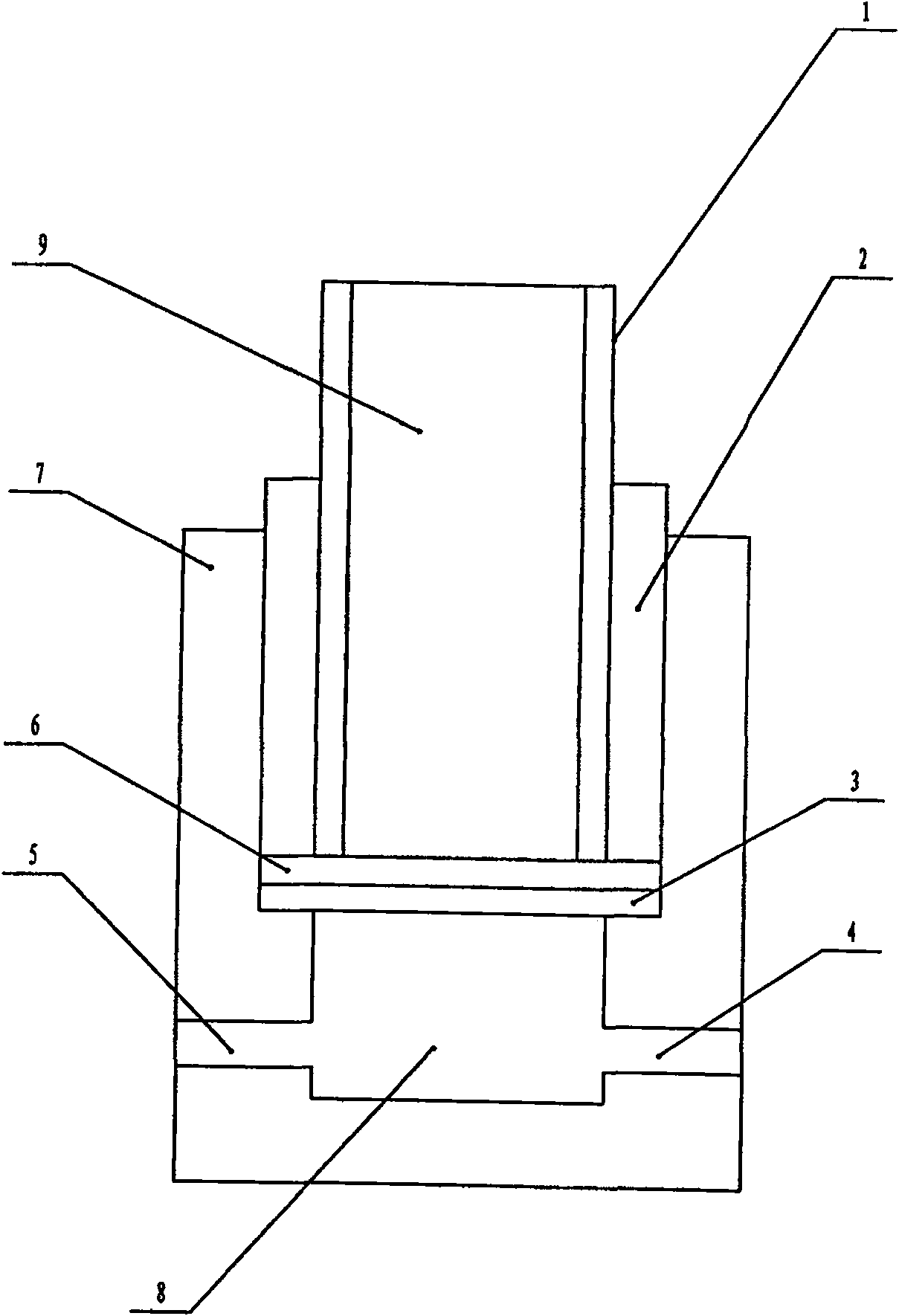

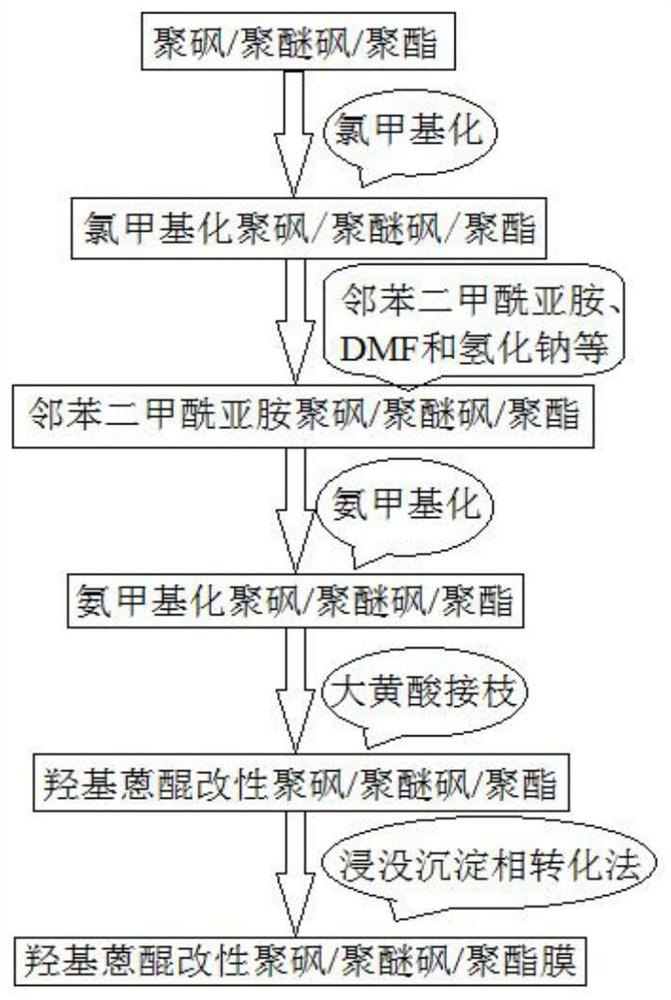

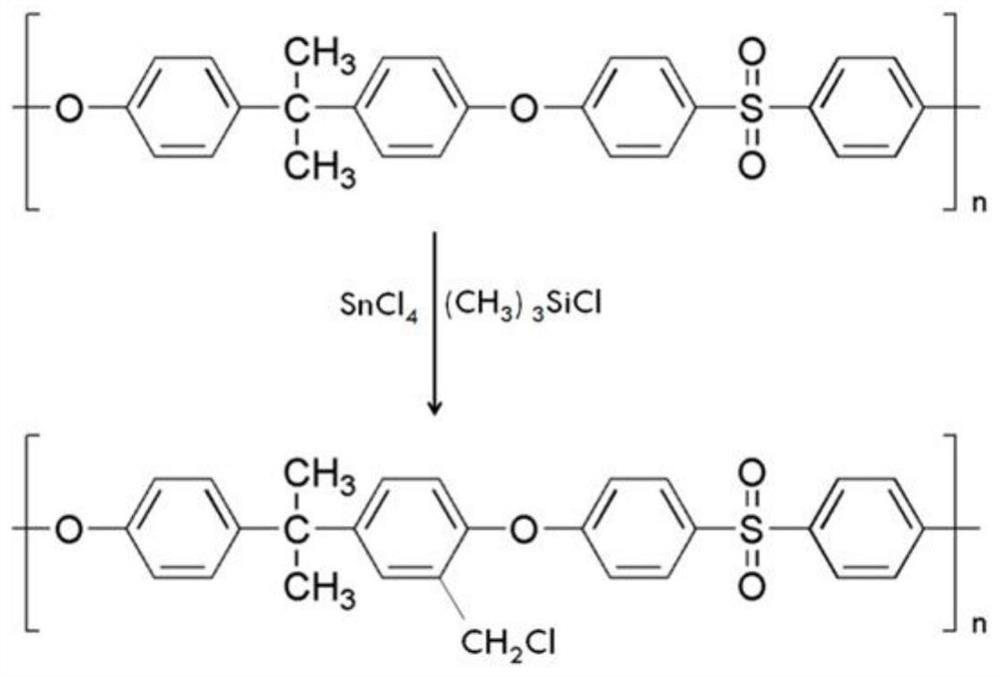

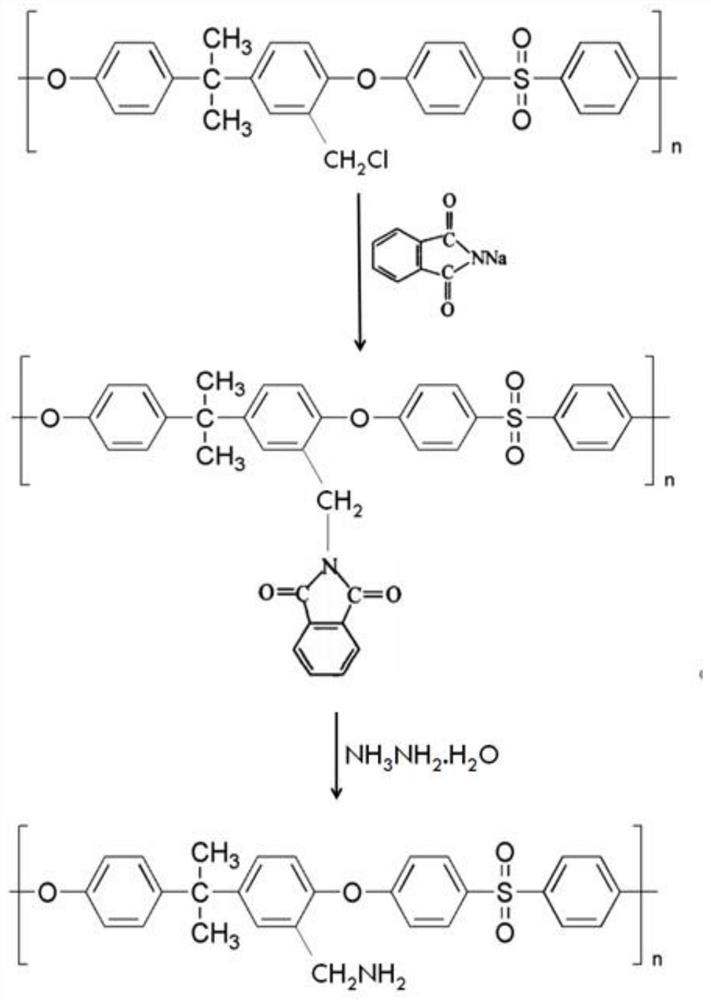

A kind of preparation method of hydroxyanthraquinone extracorporeal circulation modified membrane

The invention provides a preparation method of a hydroxyanthraquinone extracorporeal circulation modified membrane. The present invention first chloromethylates polysulfone / polyethersulfone / polyester to prepare chloromethylated polysulfone / polyethersulfone / polyester, then chloromethylates polysulfone / polyethersulfone / polyester with Phthalimide, DMF and sodium hydride are mixed to prepare phthalimide polysulfone / polyethersulfone / polyester, and then phthalimide polysulfone / polyethersulfone / polyester Aminomethylation of ester to obtain aminomethylated polysulfone / polyethersulfone / polyester, and then graft 1,8-dihydroxy-3-carboxyanthraquinone to aminomethylated polysulfone / polyethersulfone / polyester On the ester, obtain hydroxyanthraquinone modified polysulfone / polyethersulfone / polyester, and finally prepare hydroxyanthraquinone modified polysulfone / polyethersulfone / polyester into hydroxyanthraquinone modified polysulfone by immersion precipitation phase inversion method / polyethersulfone / polyester membrane. The method has simple steps, can be used for industrial batch production, and solves the existing technical problem of high hemolysis rate of biological materials.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV +1

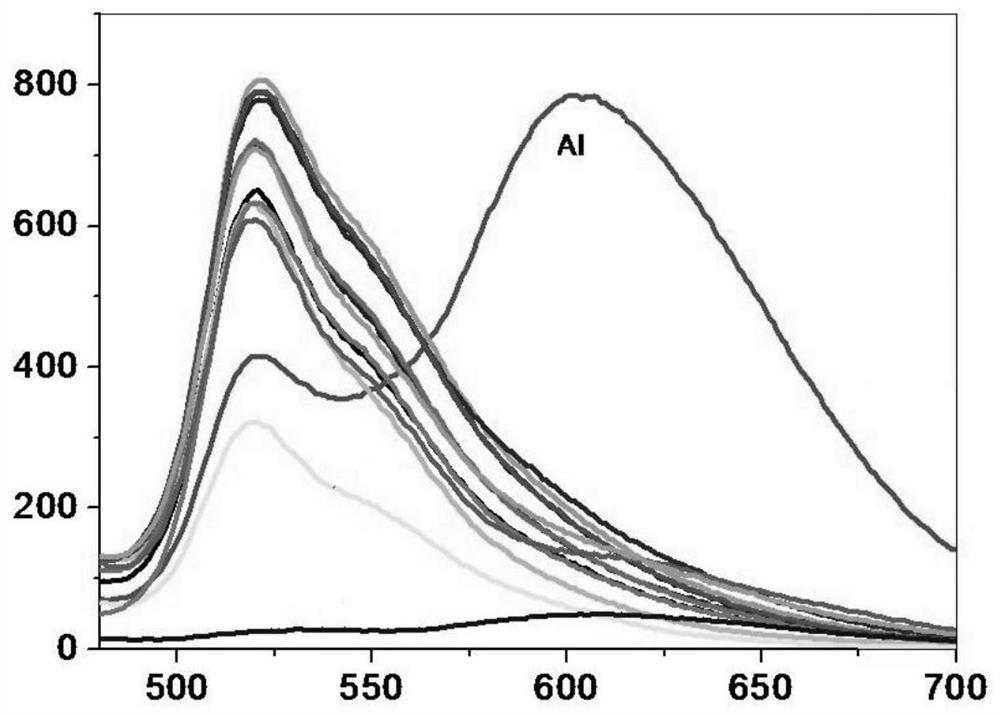

Preparation and application of aluminum indicator

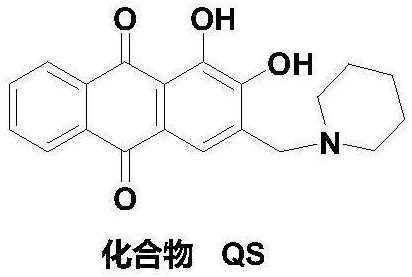

PendingCN113087685AEasy to synthesizeMild conditionsOrganic chemistryMaterial analysis by observing effect on chemical indicatorAnthraquinonesPolyoxymethylene

The invention discloses preparation and application of an aluminum indicator, which are characterized in that 1,2-dihydroxy anthraquinone and polyformaldehyde are added into an ethanol solution, alkali is added, the mixture is subjected to a heating reaction, and separation and purification are performed to obtain a compound QS, namely the aluminum indicator. A probe prepared by the invention is simple to synthesize, stable in property and mild in determination condition, and can be stably stored for a long time; selectivity is high, and color changes exist; the indicator is suitable for construction site rapid detection. The indicator is simple in method, convenient, rapid, high in sensitivity, resistant to interference and easy to popularize.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing N-[4-[(4-hydroxyanthraquinone-1-yl) amino] benzyl] acetamide Method for synthesizing N-[4-[(4-hydroxyanthraquinone-1-yl) amino] benzyl] acetamide](https://images-eureka.patsnap.com/patent_img/6ed0e043-8bde-4019-80ff-0988495ad228/BSA00000370286200021.PNG)

![Method for synthesizing N-[4-[(4-hydroxyanthraquinone-1-yl) amino] benzyl] acetamide Method for synthesizing N-[4-[(4-hydroxyanthraquinone-1-yl) amino] benzyl] acetamide](https://images-eureka.patsnap.com/patent_img/6ed0e043-8bde-4019-80ff-0988495ad228/BSA00000370286200022.PNG)