Patents

Literature

52 results about "Phenyl hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for bisphenol F

ActiveCN102491879AEasy to separate and recycleThe synthesis process is simpleOrganic chemistryOrganic compound preparationAluminium chlorideSynthesis methods

The invention discloses a synthesis method for bisphenol F, in which aluminium chloride, titanium tetrachloride and modified cation exchange resin are adopted as catalysts, and phenyl hydroxide and formaldehyde are adopted as raw materials. The invention has the technical effects as follows: the aluminium chloride, the titanium tetrachloride and the modified cation exchange resin are adopted for catalysis to synthesize the bisphenol F, and the resin catalyst is easy to separate and recover and can be used repeatedly; 2, a recrystallization and reduced pressure distillation combined separation technology is adopted for coproduction of high-purity bisphenol F and common bisphenol F products, the maximum yield of the bisphenol F reaches 90 percent, the content of 4, 4'-bisphenol F in a dimethyl benzene recrystallization product reaches 93.5 percent, reduced pressure distillation after-products are mainly other two isomers, and the separation of the 4, 4'-bisphenol F is realized effectively; 3, the requirement for the concentration of the formaldehyde raw material is not strict while the traditional one stage process require that the concentration of formaldehyde is above 40 percent; and 4, the synthesis technology is simple, the operation is convenient, and the realization of industrial production is easy.

Owner:湖南嘉盛德材料科技股份有限公司

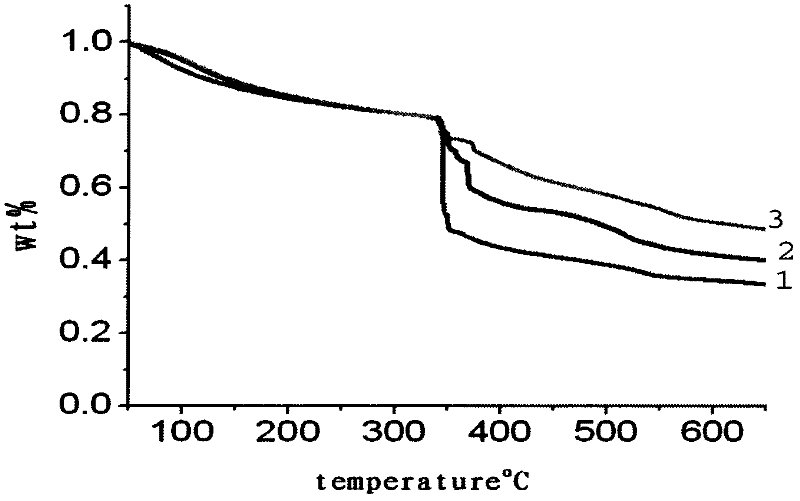

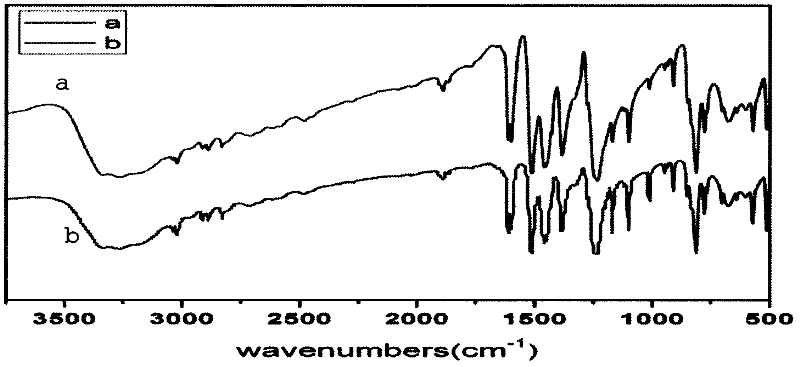

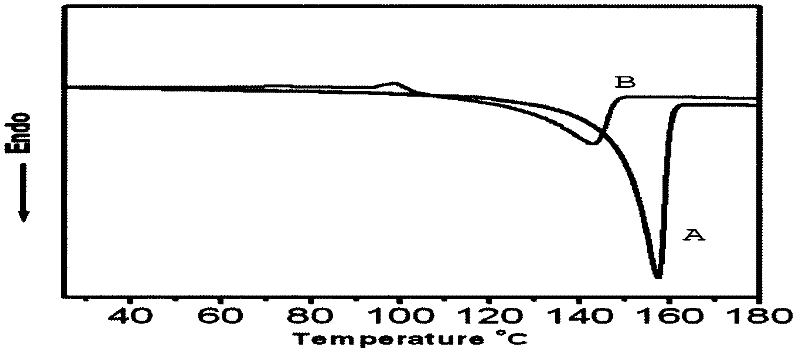

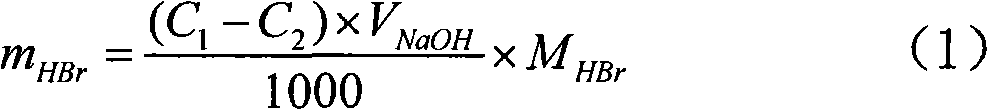

Pyrolyzation and debromination method of waste printed circuit board

InactiveCN101829666AInhibition formationImprove effective utilizationOrganic chemistryOrganic compound preparationLiquid productEpoxy

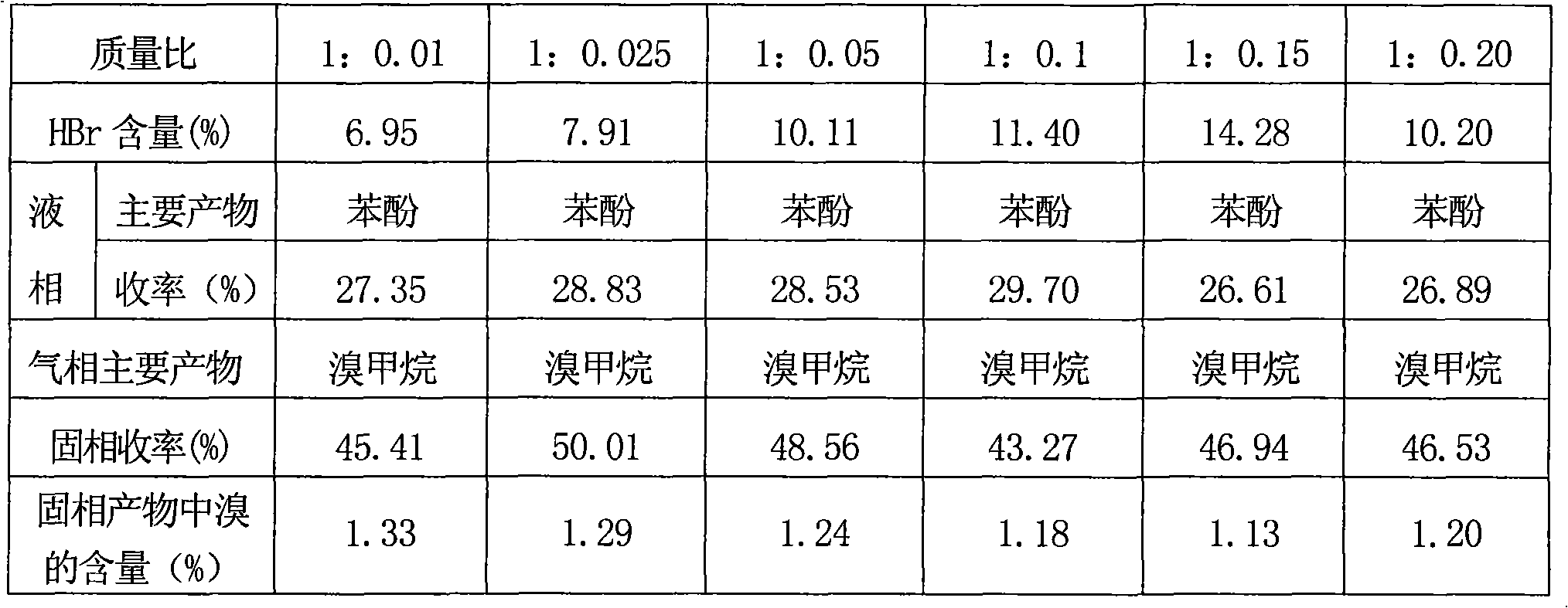

The invention relates to a pyrolyzation and debromination method of a waste printed circuit board. A nonmetal substance containing the main components of epoxy resin and glass fiber is separated from the waste print circuit board, a nitrogen-contained compound which is cheap and easy to obtain is used as a catalyst, pyrolyzation and debromination are carried out in three temperature stages through controlling a pyrolyzation temperature raising procedure, so that bromine in a nonmetal separator of the waste printed circuit board is volatilized and removed in a low molecular bromide gas product way (HBr, CH3Br), the formation of dioxin as an objectionable constituent is effectively avoided, and meanwhile, a liquid product taking phenol derivatives (phenyl hydroxide, australol) as the main components is obtained, and finally, the effective utilization ratio of the nonmetal material in the waste printed circuit board is improved. The invention has the advantages of simple method, easy obtaining of raw materials, no environment pollution, and the like, and can be widely applied to the recycling of the waste printed circuit board.

Owner:SHAANXI NORMAL UNIV

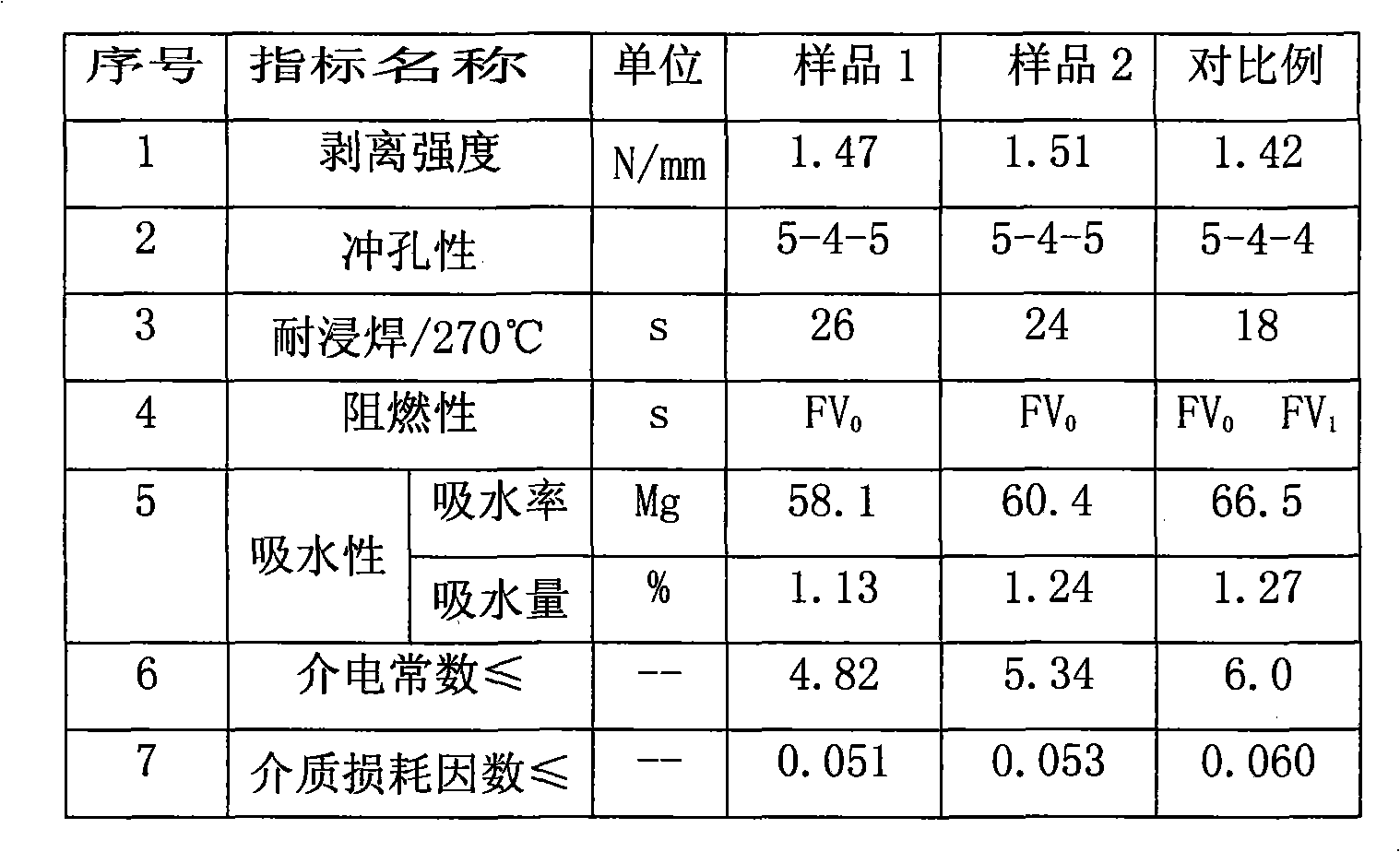

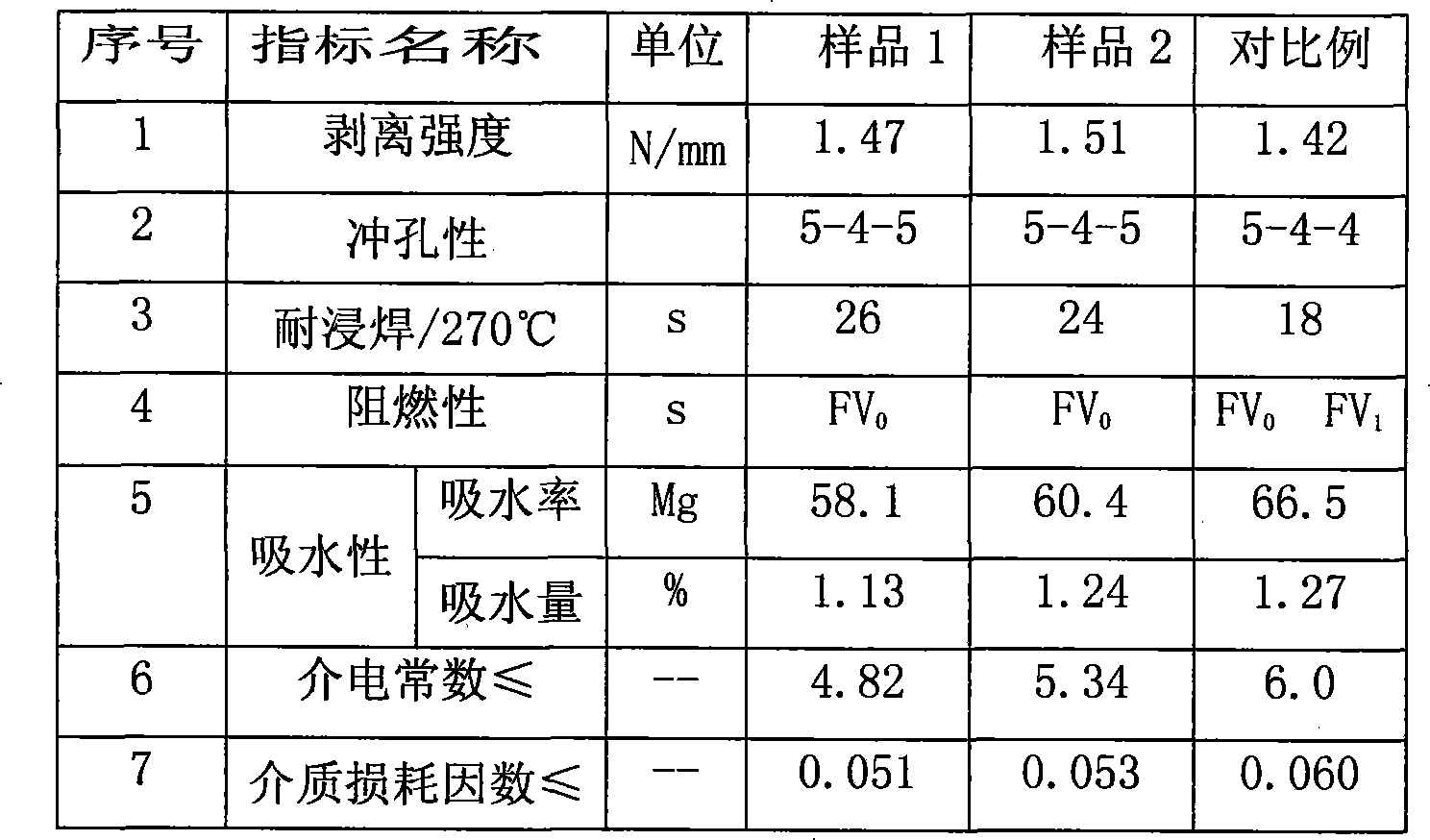

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Hot melt type phenolic resin modified by using enzymatic hydrolysis lignin or derivatives thereof, and preparation thereof

The invention provides enzymatic lignin or a derivative for the enzymatic lignin, namely modified hot-melt phenol-formaldehyde resin and a preparation method thereof, wherein the enzymatic lignin or the derivative for the enzymatic lignin, phenols, aldehydes and catalysts are taken as raw materials. The preparation method comprises the following steps: the enzymatic lignin or the derivative for the enzymatic lignin is mixed with the phenols according to the proportion; the mixture is heated and dissolved, added with the aldehydes and the catalysts, and subjected to heating and refluxing for a period of time; and residual water in the system is distilled, and the enzymatic lignin or the derivative for the enzymatic lignin, namely the modified hot-melt phenol-formaldehyde resin is obtained. The preparation method fully utilizes reproducible biological resources, overcomes the defects caused by extracting lignosulphonate from paper-making 'black liquor' in the prior art, can replace partial raw materials of the petrochemical industry, reduce the cost of preparing the phenol-formaldehyde resin by adopting phenyl hydroxide, select proper types of enzymatic lignin additives according to the modification requirements of different types of hot-melt phenol-formaldehyde resin, and improve the performance of the enzymatic lignin or the derivative for the enzymatic lignin, namely the modified hot-melt phenol-formaldehyde resin, has simple technology, is easy to implement, reduces the production cost, and improves the competitive power of products.

Owner:FUZHOU UNIV

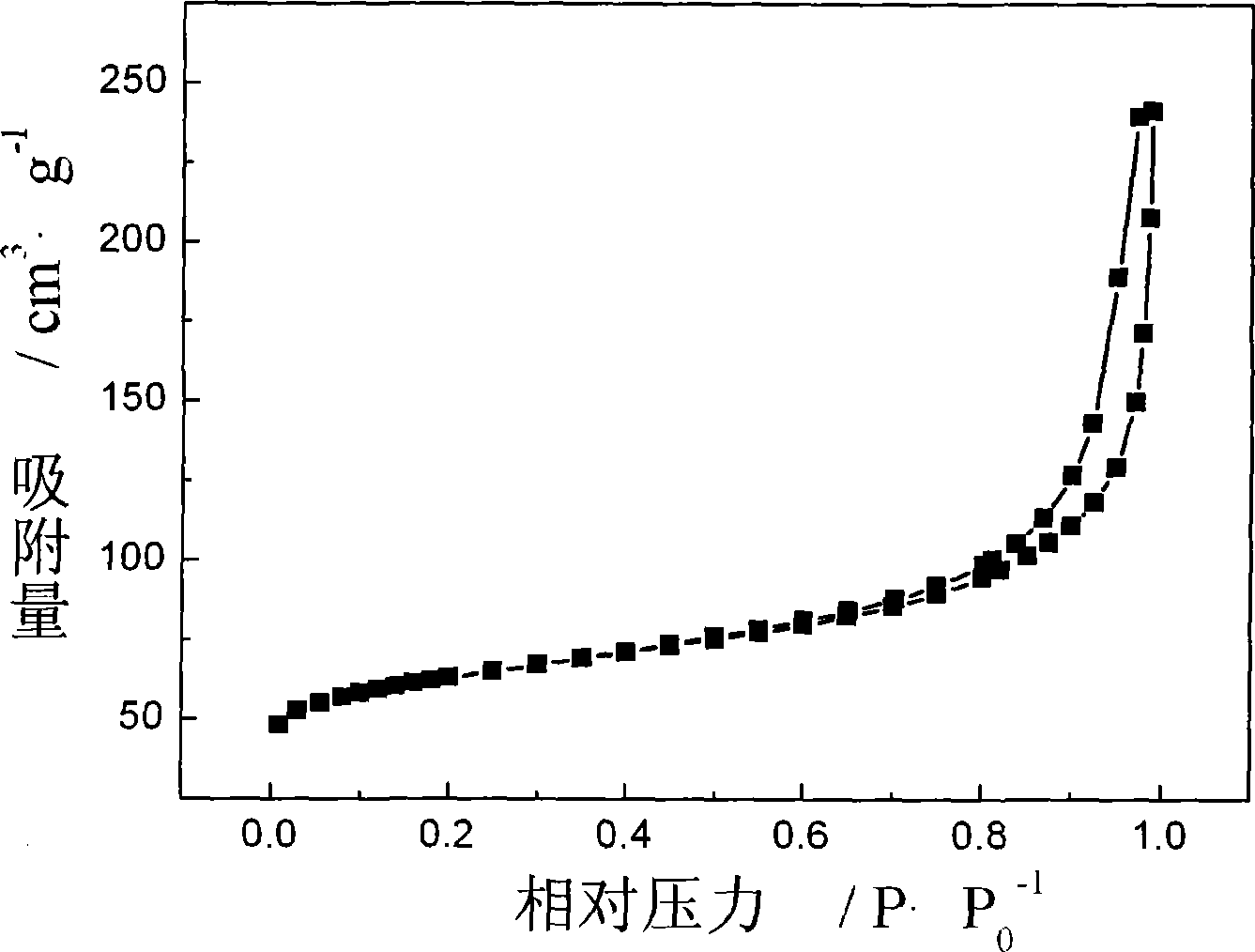

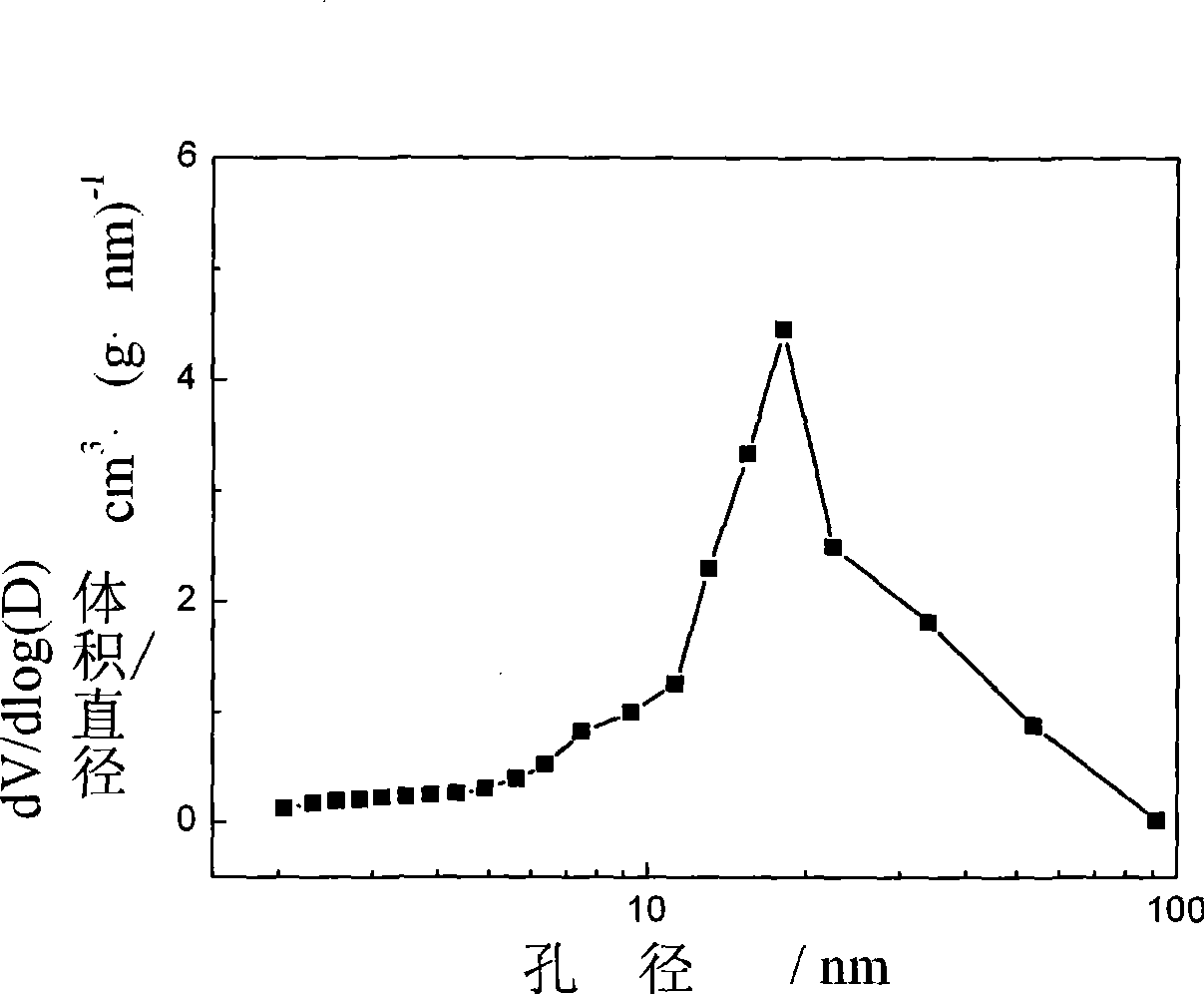

Method for preparing carbon aerogel desulfurizing agent

InactiveCN101376097APrevent collapseAvoid volumeOther chemical processesGas purification with selectively adsorptive solidsPotassiumPhenyl hydroxide

The invention provides a preparation method for a carbon aerogel desulfurization agent. The invention utilizes phenyl hydroxide, methanal and melamine as polymer precursors and utilizes nano-scale silica sol as an inorganic template. The precursors are mixed at a certain proportion and carry on sol-gel reaction; and pure carbon aerogel is produced after the processes of drying, high-temperature carbonizing and template removing. The invention has the advantages of mild preparation condition and conventional production device, and is suitable for large scale industrial production. The desulfurization agent produced by the method of the invention has large breakthrough sulfur capacity and saturated sulfur capacity, thereby being adopted in H2S removing process in oil and gas, synthesis gas, and the tail gas in sewage treatment plants.

Owner:EAST CHINA UNIV OF SCI & TECH

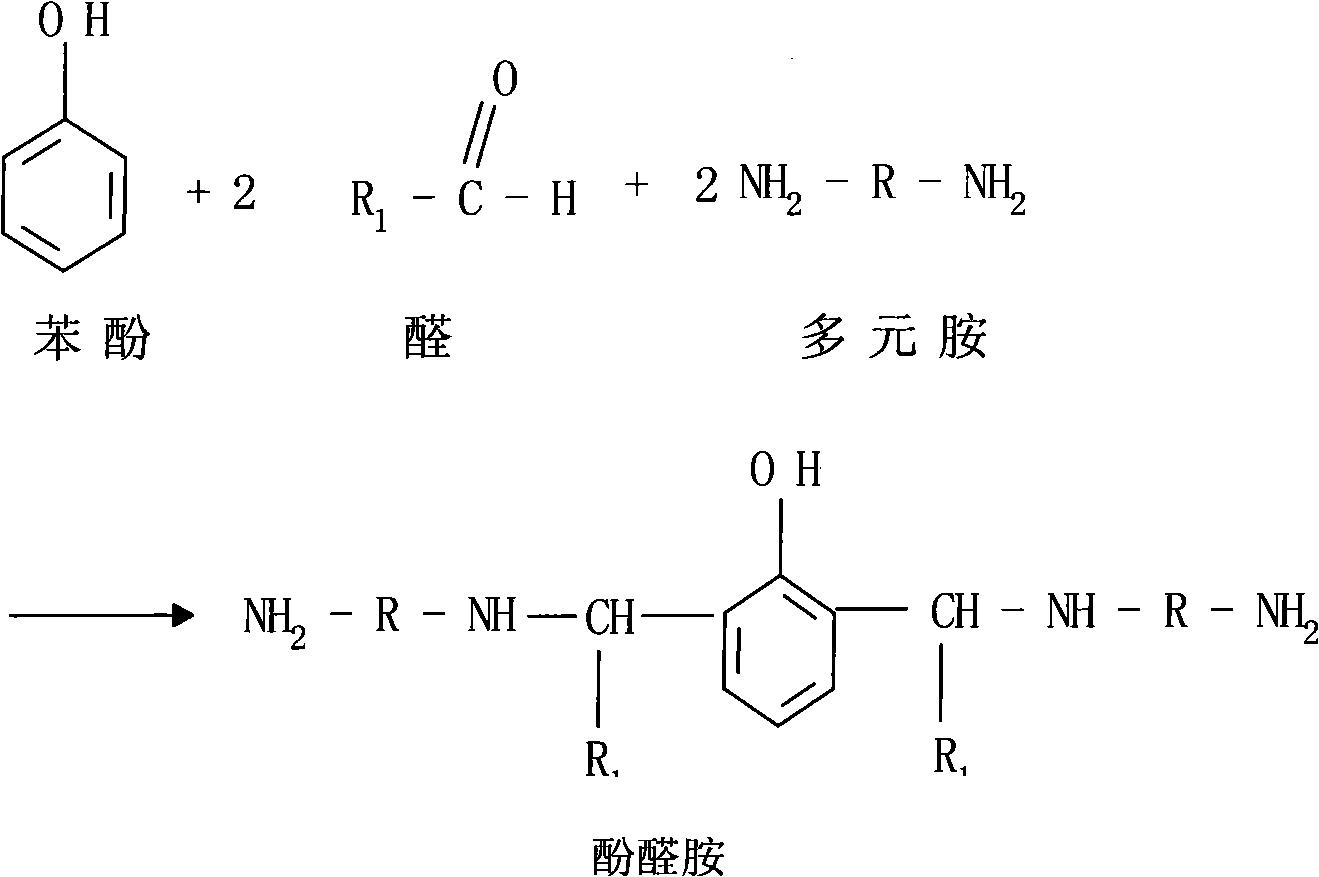

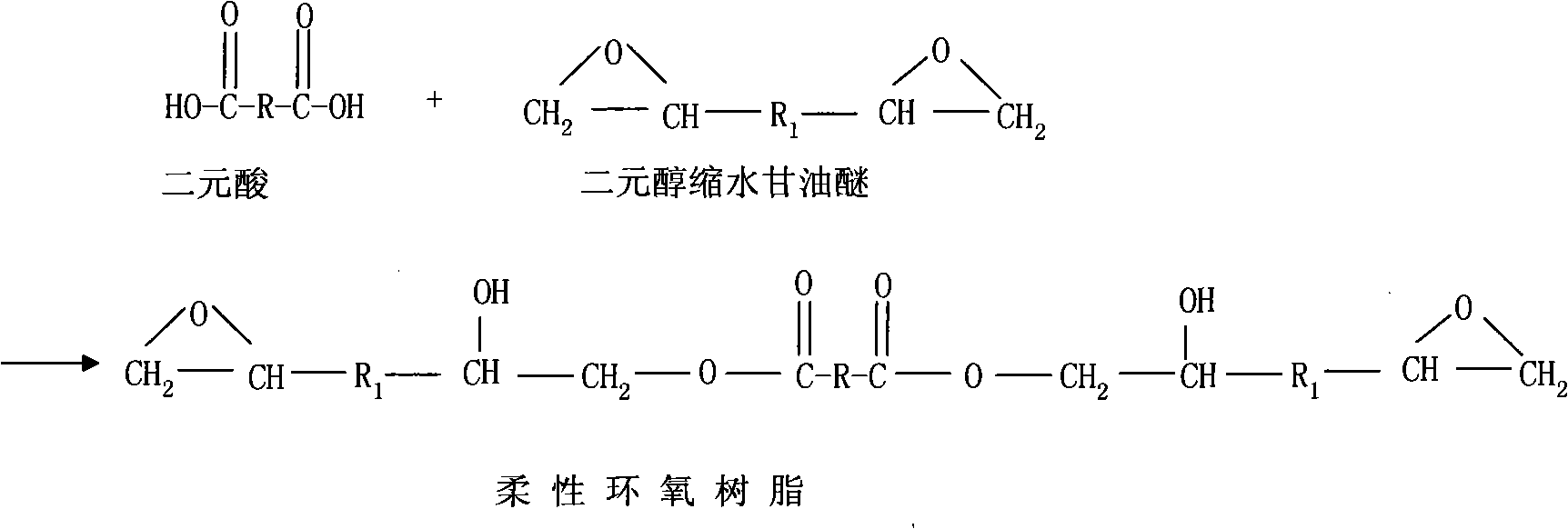

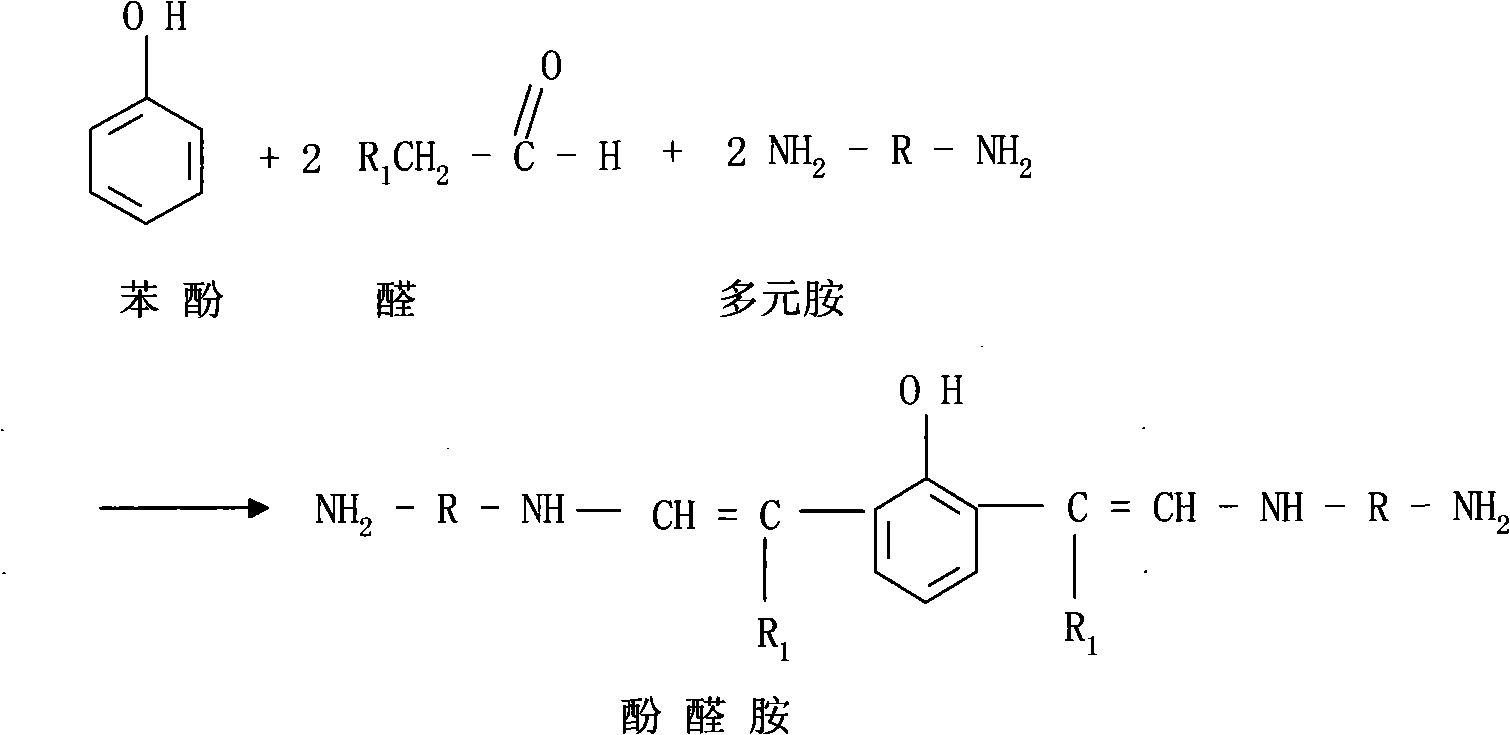

Brush-making structural adhesive and preparation method thereof

InactiveCN101892025AAvoid harmReduce harmNon-macromolecular adhesive additivesOrganic compound preparationBristleAdhesive

The invention discloses a brush-making structural adhesive and a preparation method thereof. The brush-making structure adhesive is prepared by compounding raw materials such as a component A and a component B in a mass ratio of 100:20 to 30, wherein the component A comprises the following components in part by mass: 100 parts of epoxy resin 128, 10 to 30 parts of flexible epoxy resin, 5 to 20 parts of environmentally-friendly biological plasticizer and 80 to 100 parts of inorganic packing; and the component B comprises the following components in part by mass: 80 parts of phenolic aldehyde amine and 20 parts of dimer acid polyamide, and the phenolic aldehyde amine is a reaction product of phenyl hydroxide, polyamine and organic aldehyde. The brush-making structural adhesive prepared by the method is mainly used for brush manufacturing industries taking bristles as main bodies of brushes, has the characteristics of low cost, low toxicity, environmental protection, convenient operation, high adhesive force and the like, and has a wide industrial application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

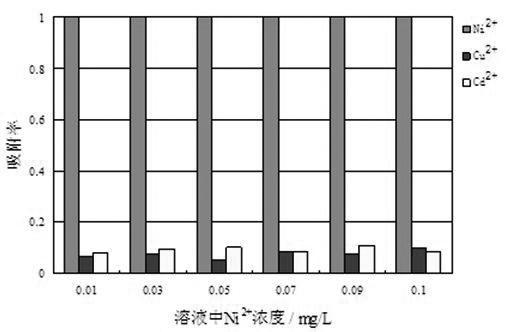

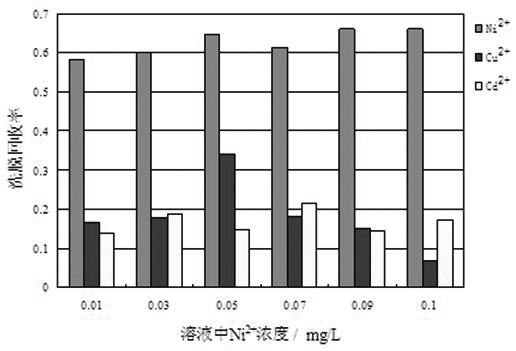

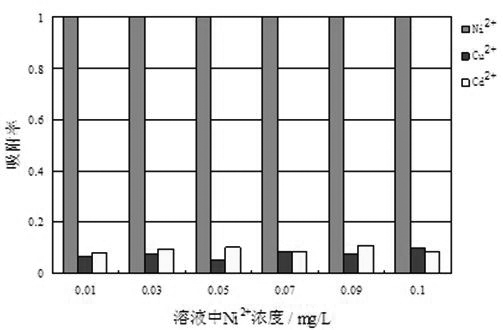

Method for preparing highly-selective nickel ion absorption resin

InactiveCN101979421AHighly selective adsorptionHigh elution recoveryOther chemical processesWater/sewage treatment by ion-exchangeCu2 ionsSulfate

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

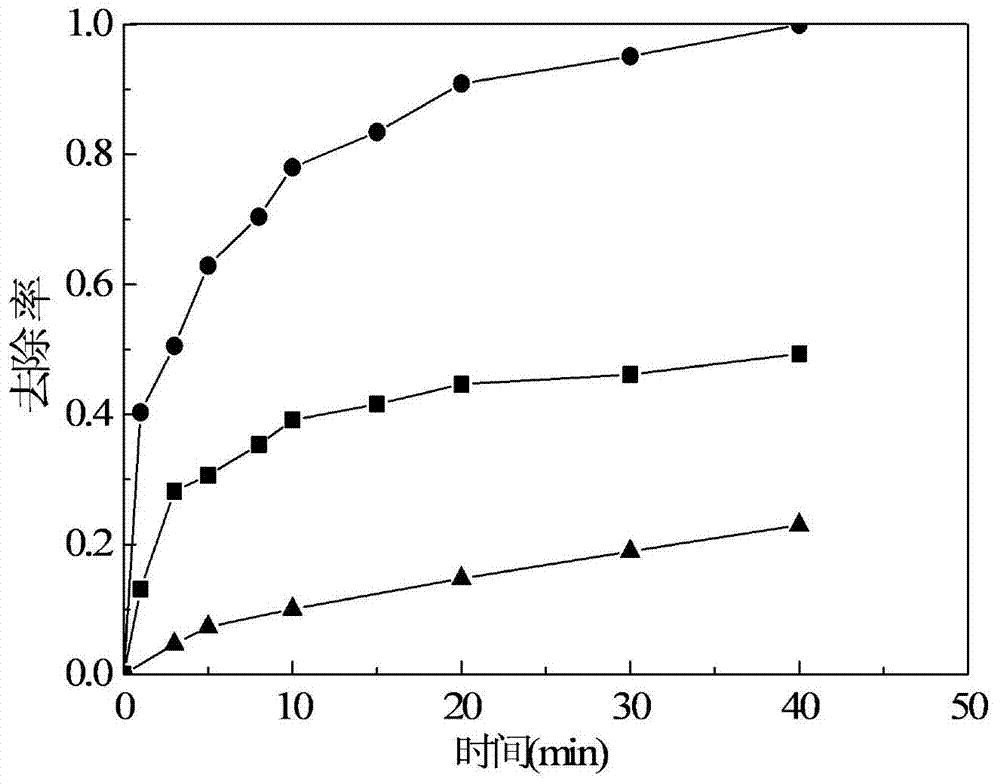

Water treatment method utilizing heterogeneous catalytic oxidation of permanganate

ActiveCN103508548AAvoid the problem of high total manganese concentrationWater/sewage treatment by oxidationCatalytic oxidationPERMANGANATE ION

The invention relates to a water treatment method, particularly to a water treatment method utilizing heterogeneous catalytic oxidation of permanganate, and aims to solve the problem in the scheme provided by the prior art, when water is treated, nondegradable organic materials such as phenyl hydroxide react slowly, and the removal ratio is low. The water treatment method is characterized in that during water treatment, permanganate and a carbon catalyst are added in water to be treated to carry out heterogeneous catalytic oxidation of permanganate, and the permanganate and the carbon catalyst are removed through coagulation, sedimentation and filtering, so as to obtain output water and complete the water treatment process. The water treatment method has the advantages that nondegradable organic materials such as phenyl hydroxide react quickly, and the removal ratio is high, particularly, the removal ratio can reach 100% after the reaction lasts for 40 min. the method provided by the invention is used for treating water containing organic pollutants.

Owner:HARBIN INST OF TECH

Macroreticular resin capable of lowering content of phenyl hydroxide in cigarette smoke and preparation method thereof

InactiveCN103408686ALarge specific surface areaFully contactedOther chemical processesMass ratioHazardous substance

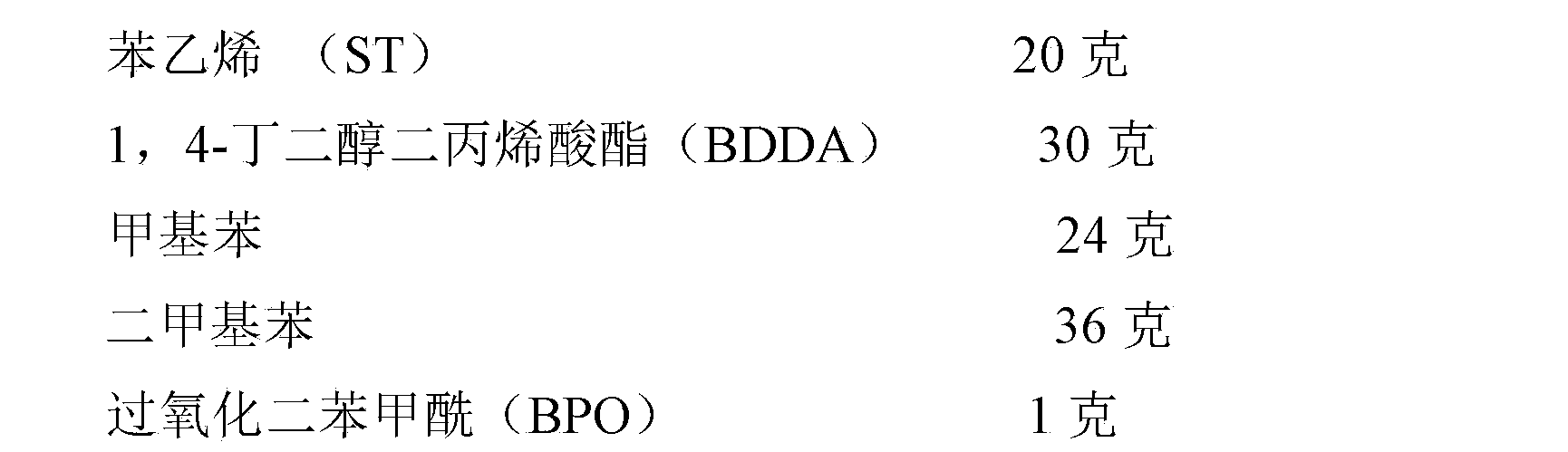

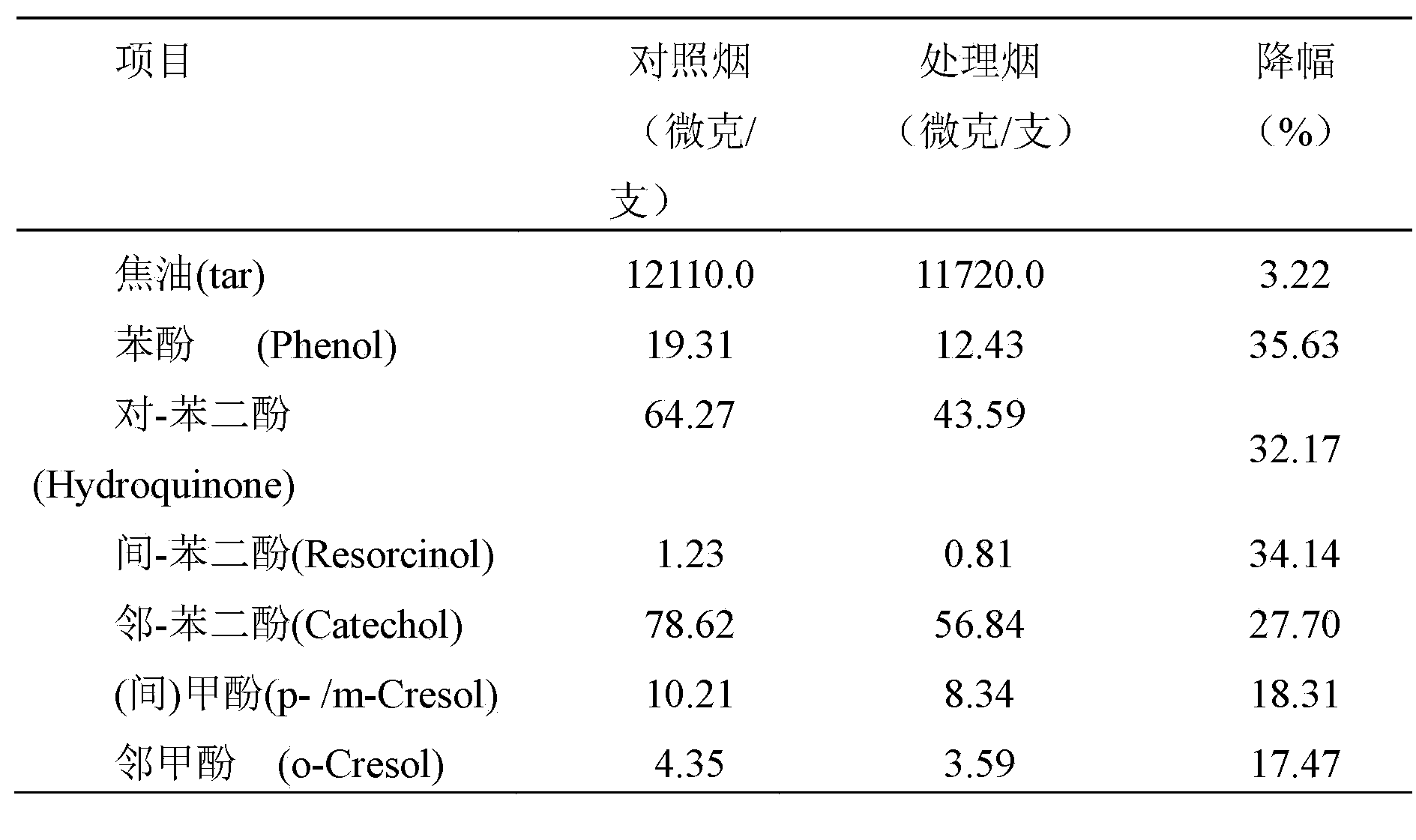

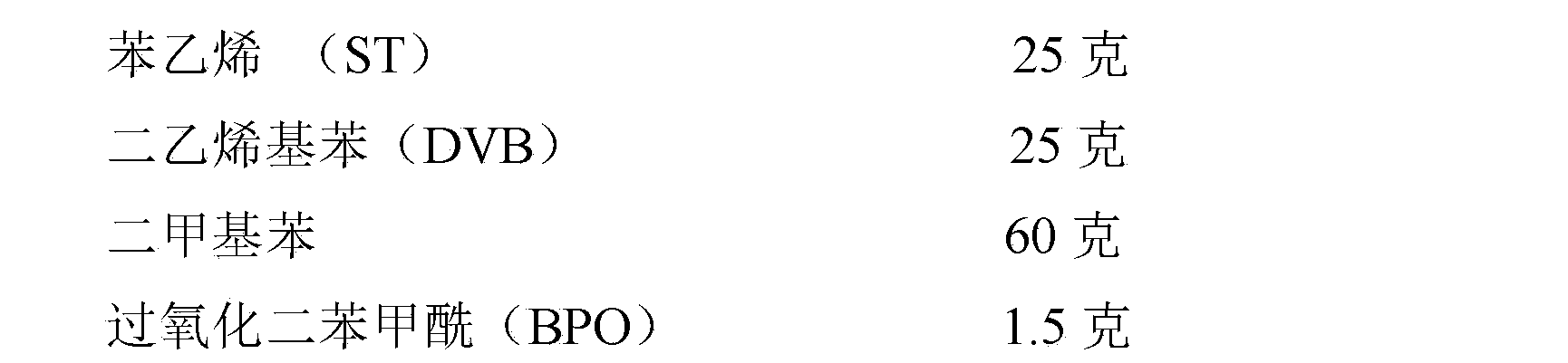

The invention discloses a macroreticular resin capable of lowering the content of phenyl hydroxide in cigarette smoke and a preparation method thereof. The macroreticular resin comprises the following components in parts by mass: oil phase: 20-30 parts of phenethylene, 10-30 parts of cross-linking agent, 40-60 parts of pore-foaming agent and 1-2 part (s) of initiator; water phase: 300-400 parts of deionized water, 2-3 parts of dispersant and 25-40 parts of NaCl; the mass ratio of the oil phase to the water phase is 1: (3-4). The macroreticular resin provided by the invention can effectively and selectively reduce the release amount of phenyl hydroxide in mainstream smoke of cigarettes by more than 30%, and the addition amount of the macroreticular resin in a mouthpiece can be optionally adjusted as required; the macroreticular resin can selectively absorb poisonous substances such as phenyl hydroxide in smoke while keeping the smoke aroma unchanged and the release amount of tar oil approximately unchanged or slightly reduced without causing adverse impact on the smoking quality of cigarettes, thereby achieving the purpose of selectively reducing the release amount of phenyl hydroxide in cigarette smoke.

Owner:HUBEI CHINA TOBACCO IND +1

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352BLow costImprove heat resistanceCircuit susbtrate materialsEnvironmental resistanceTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Steel surface treatment paint

InactiveCN104073041APrevent infiltrationHigh densityAnti-corrosive paintsGlycidyl methacrylateMaterials science

The invention discloses a steel surface treatment paint which comprises the following raw material ingredients in parts: 3-5 parts of phenyl hydroxide, 20-22 parts of epoxy resin, 18-20 parts of polyester resin, 12-15 parts of rosin resin, 10-12 parts of terpene resin, 8-10 parts of alkyd resin, 10-12 parts of amino resin, 15-18 parts of acrylic resin, 5-6 parts of a lacquer thinner, 8-10 parts of organosilicon oil, 5-8 parts of glycerine, 3-5 parts of ethyl acetate, 5-6 parts of activated zinc oxide, 5-6 parts of fast-dissolving sodium silicate, 3-6 parts of dimethyl malonate, 3-5 parts of glycidyl methacrylate, 5-8 parts of ferric hydroxide, 2-3 parts of polyvinyl alcohol, 20-25 parts of vinyl acetate-acrylic emulsion and 20-30 parts of acrylic emulsion. The steel surface treatment paint mainly plays a wetting and permeating effect on loose rust to separate and wrap the rust to prevent further development of rusting; meanwhile, after forming a film, the paint interacts with the rust by virtue of slow hydrolysis to form an acid complex to achieve the purpose of rust removal; the paint has stable properties, and increases the density of the paint film to prevent permeation of water and oxygen in air.

Owner:周彩球

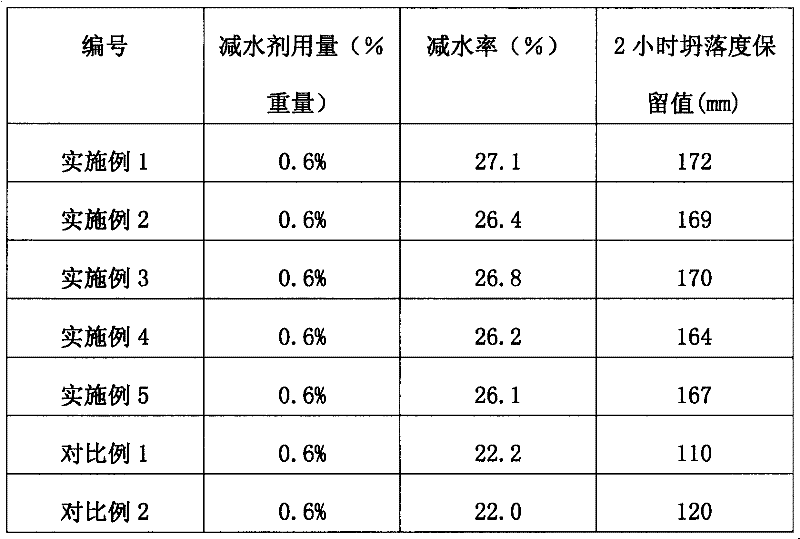

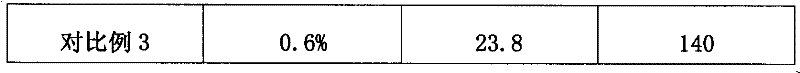

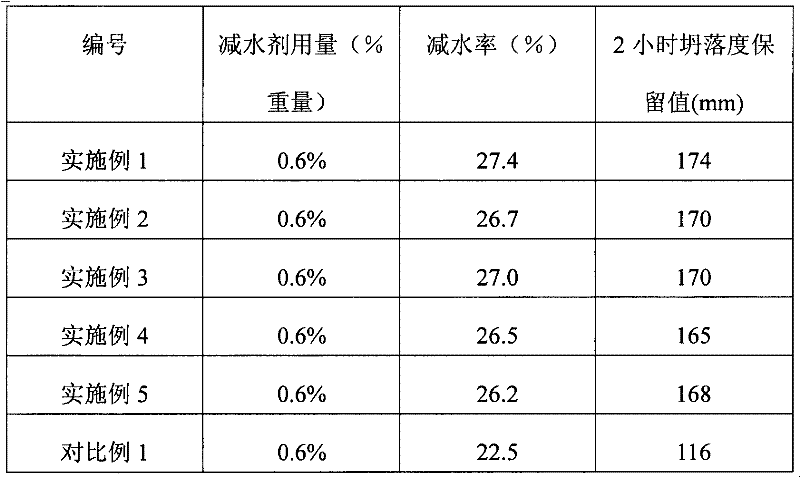

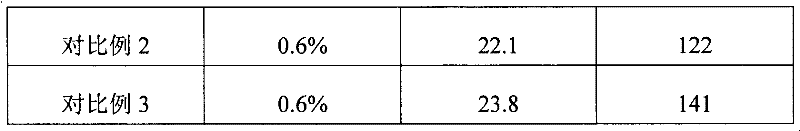

Cement-based grouting material containing modified naphthalene-series water reducing agent and preparation method thereof

InactiveCN102211910AHigh strengthImprove bleeding rateSolid waste managementPulverized fuel ashCarboxylic acid

The invention provides a cement-based grouting material containing a modified naphthalene-series water reducing agent and a preparation method thereof. The cement-based grouting material comprises the following components in parts by weight: 350-500 parts of cement clinker, 80-130 parts of pulverized fuel ash, 20-30 parts of expanding agent, 80-120 parts of gypsum, 1-2 parts of pH value regulating agent, 8-15 parts of polyester type carboxylic acid water reducing agent and 300-500 parts of quartz sand, wherein the water reducing agent consists of a material A and a material B; the material A is prepared from naphthalene, concentrated sulfuric acid, formaldehyde, water and sodium hydrate; the material B is prepared from phenyl hydroxide, sodium hydroxide, formaldehyde, sulfamic acid and para-aminobenzene sulfonic acid; and the weight ratio of the material A to the material B is (20:1)-(5:1). The grouting material has high strength and low bleeding rate; and the strength character of the grouting material is hardly influenced by sub-zero weather.

Owner:马清浩

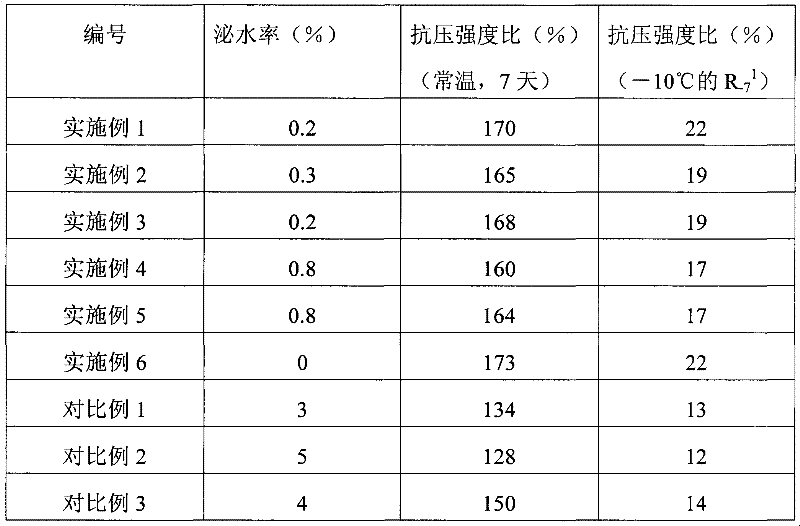

Electrochemical oxidation device

ActiveCN103408112AEfficient removalImprove biodegradabilityWater/sewage treatment using germicide/oligodynamic-processElectrolysisPhenyl hydroxide

The invention discloses an electrochemical oxidation device which comprises a housing, a water inlet, a liquid distributor, an anode bed, a cathode bed, a micro-electrolysis packing layer, a water outlet, a power supply, a stuffing discharging port, a filler pressure plate and an overflow dam. The device uses coking wastewater containing phenyl hydroxide contaminant as a processing object, allows the degradation-resistant organic materials to change into carbon dioxide, water, inorganic ions and other innocuous substances through oxidative degradation by utilizing an electrochemical oxidation system formed by the cathode bed and the anode bed, wherein the anode material of the oxidation system can improve the hydroxyl free radical generating rate to accelerate organic materials oxidative degradation efficiency. Compared with a traditional electrochemical method, the energy consumption required for processing the waste water is reduced, spiral strip-shaped carbon steel chips are adopted as micro-electrolysis stuffing, and the processing effect is ensured while the cost is saved. The device is easy to manage, simple to operate and stable in running.

Owner:KUNMING UNIV OF SCI & TECH

Anti-ultraviolet polyphenyl thioether filament and preparation method thereof

ActiveCN102677218AGuaranteed mechanical strengthReduce the amount of darkeningFilament forming substance formingArtificial filament heat treatmentUltraviolet lightsPhenyl hydroxide

The invention relates to an anti-ultraviolet polyphenyl thioether filament and a preparation method thereof. The polyphenyl thioether filament comprises, by mass fraction, 90 to 99.9 percent of polyphenyl thioether resin and 0.01 to 10 percent of photostabilizer. The preparation method comprises the following steps: (1) mixing titanate coupling agent with ethanol water, then adding nano TiO2 particles, and drying after constant temperature reflux; (2) the TiO2 particles treated by the titanate coupling agent, 2, 2'-methene di-(6-(2H-benzotriazole-2-yl)-4-(1, 1, 3, 3-tetramethyl butyl) phenyl hydroxide and polyphenyl thioether, and then kneading, uniformly mixing and drying to obtain dry powder; and (3) extruding and pelletizing the dry powder, drying to obtain dry anti-ultraviolet polyphenyl thioether chips, performing melt spinning, drawing and performing heat shaping to obtain the anti-ultraviolet polyphenyl thioether filament. The stability of the modified filament under ultraviolet light is remarkably improved, and the preparation method is simple to operate and low in cost.

Owner:DONGHUA UNIV

Wood modifier and preparation method thereof

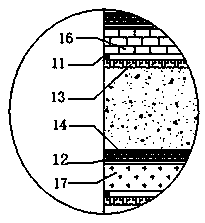

InactiveCN104118022AGood dimensional stabilityImprove mechanical propertiesWood impregnation detailsPhosphatePhosphoric acid

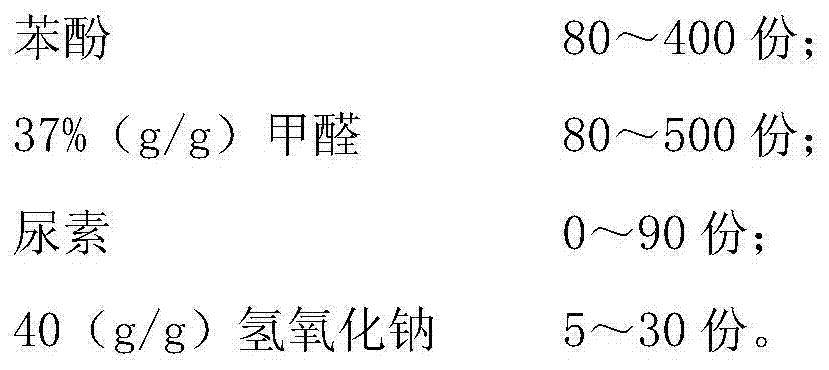

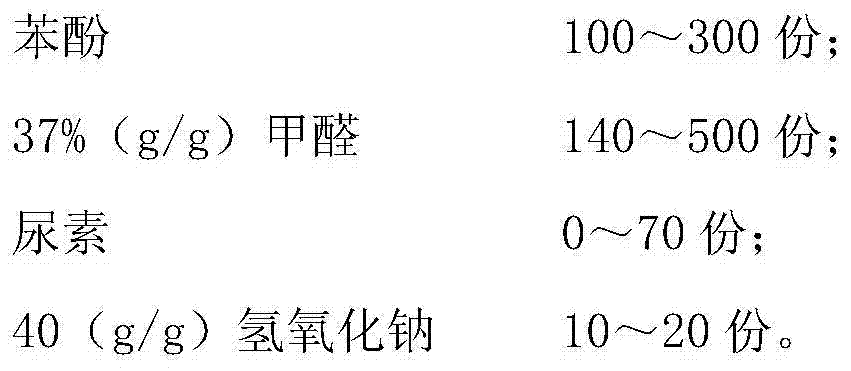

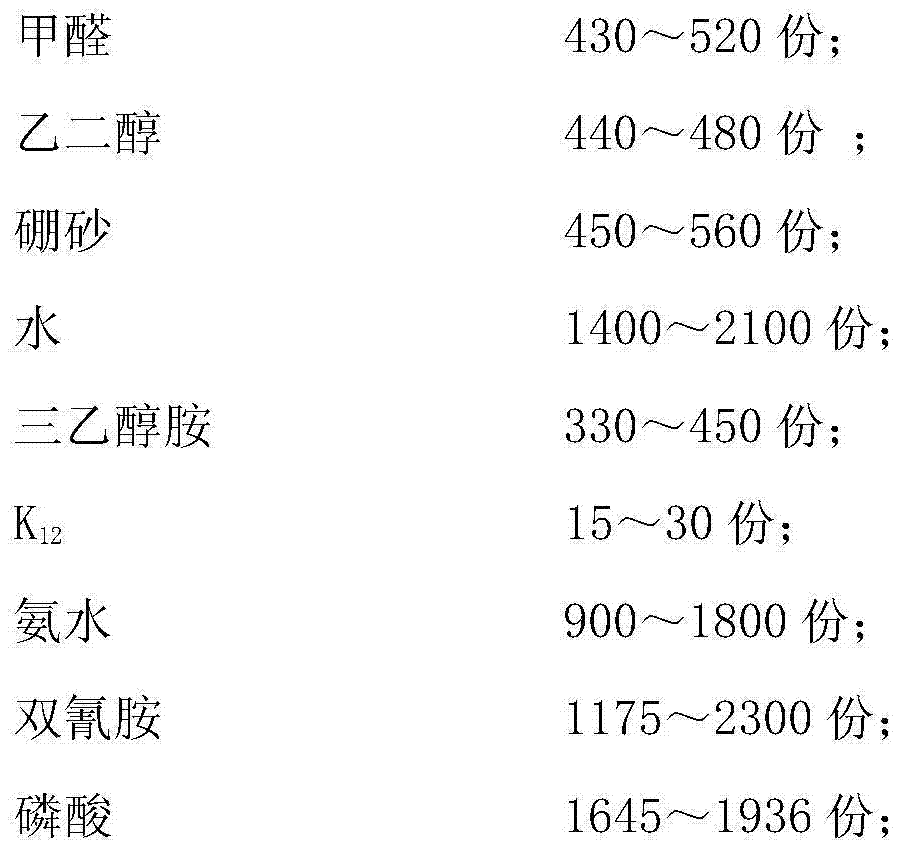

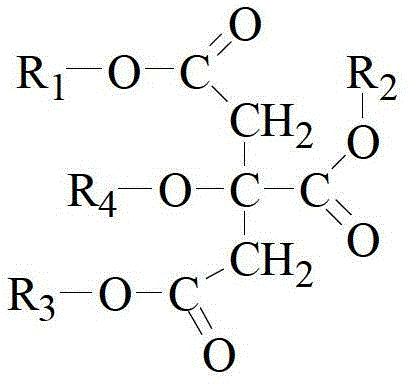

The invention discloses a wood modifier which comprises the following components in parts by weight: 60 to 200 parts of low molecular weight phenolic resin, 10 to 120 parts of a fire retarding agent, and 50 to 800 parts of water; the low molecular weight phenolic resin comprises the following components by weight: 80 to 400 parts of phenyl hydroxide, 80 to 500 parts of formaldehyde with the content of 37 percent (g / g), 0 to 90 parts of urea, and 5 to 30 parts of sodium hydroxide with the content of 40 percent (g / g); the fire retarding agent comprises the following components by weight: 430 to 520 parts of formaldehyde, 440 to 480 parts of ethylene-glycol, 450 to 560 parts of borax, 1400 to 2100 parts of water, 330 to 450 parts of triethavolamine, 15 to 30 parts of K12, 900 to 1800 parts of ammonia water, 1175 to 2300 parts of dicyandiamide, 1645 to 1936 parts of phosphate and 1200 to 1545 parts of boric acid.

Owner:NANJING AIBUNA SEALING TECH CO LTD

Preparation method of boric acid modified high-ortho phenolic fiber

ActiveCN103409841AImprove stabilityLow viscosityMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentOrtho positionPhenyl hydroxide

A preparation method of a boric acid modified high-ortho phenolic fiber comprises the following steps: (1) matching phenyl hydroxide and formaldehyde to obtain a solution A, and reacting under the action of sodium carbonate or zinc acetate to obtain a salicylidene phenol solution; (2) adding boric acid in the salicylidene phenol solution to obtain a boric acid modified high-ortho phenolic mother liquor; (3) matching phenyl hydroxide and formaldehyde to obtain a solution B, performing an additive reaction under the action of zinc acetate, mixing the reactant with the high-ortho phenolic mother liquor obtained in the step (2), and adding strong sulfuric to obtain a boric acid modified high-ortho phenolic solution; (4) performing high-temperature water cleaning so as to obtain boric acid modified high-ortho thermoplastic phenolic resin suitable for spinning after temperature reduction; (5) performing melt spinning on the obtained boric acid modified high-ortho thermoplastic phenolic resin to obtain the boric acid modified high-ortho phenolic fiber. Compared with the prior art, the reaction is simple and feasible, the curing rate and the fiber heat resistance are high, the mechanical property is excellent, and the spinning stock solution is prepared by mixing with the mother liquor, so that the spinning performance is improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Composite phenol removal agent capable of removing high-concentration phenyl hydroxide waste water and application method thereof

InactiveCN102674522AHigh speedNo secondary pollutionWater contaminantsWater/sewage treatmentHigh concentrationMolecular sieve

The invention discloses a composite phenol dispose agent capable of removing high-concentration phenyl hydroxide waste water and an application method thereof. The compound phenol dispose agent consists of 46wt%-98wt% of oxidizers and 2wt%-8wt% of catalysts. The application method comprises the following steps of: fixedly loading the compound phenol dispose agent prepared at the ratio on a molecular sieve; activating at the temperature of 700-800 DEG C for 4-8 hours and sieving to obtain a particulate matter with the particle size of 80-100 meshes; adding the prepared particulate matter into the high-concentration phenyl hydroxide waste water, wherein the addition amount of the paritculate matter is 20-40ppm; regulating the pH value of the waste water to 3.0-6.0 by use of acid; and aerating for 1.0-2.0 hours, wherein the phenyl hydroxide emission amount of effluent is lower than the first national emission standard. The composite phenol removal agent disclosed by the invention has the advantages of rapid phenyl hydroxide degradation speed, no secondary pollution, available raw materials, less addition amount, low cost and simple phenyl hydroxide removal method; and when the composite phenol removal agent is used for removing the high-concentration phenyl hydroxide waste water, 400mg / L-4000mg / L high-concentration phenyl hydroxide waste water can be degraded to achieve the effect that the concentration is not greater than 0.2mg / L through one step, and the removal rate is up to above 99.9%.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

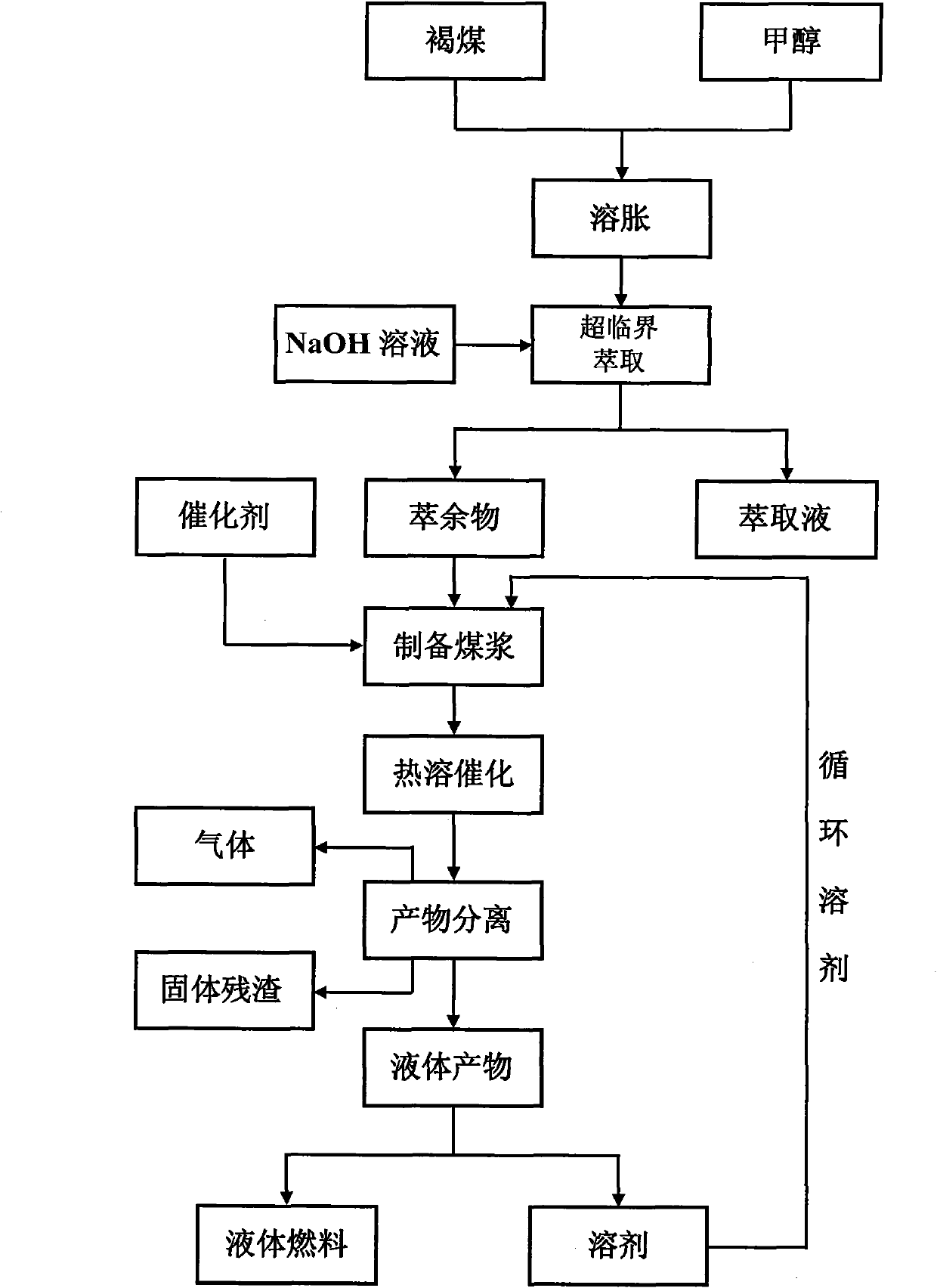

Processing method of lignite

ActiveCN101787301AImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationLiquid fuelPhenyl hydroxide

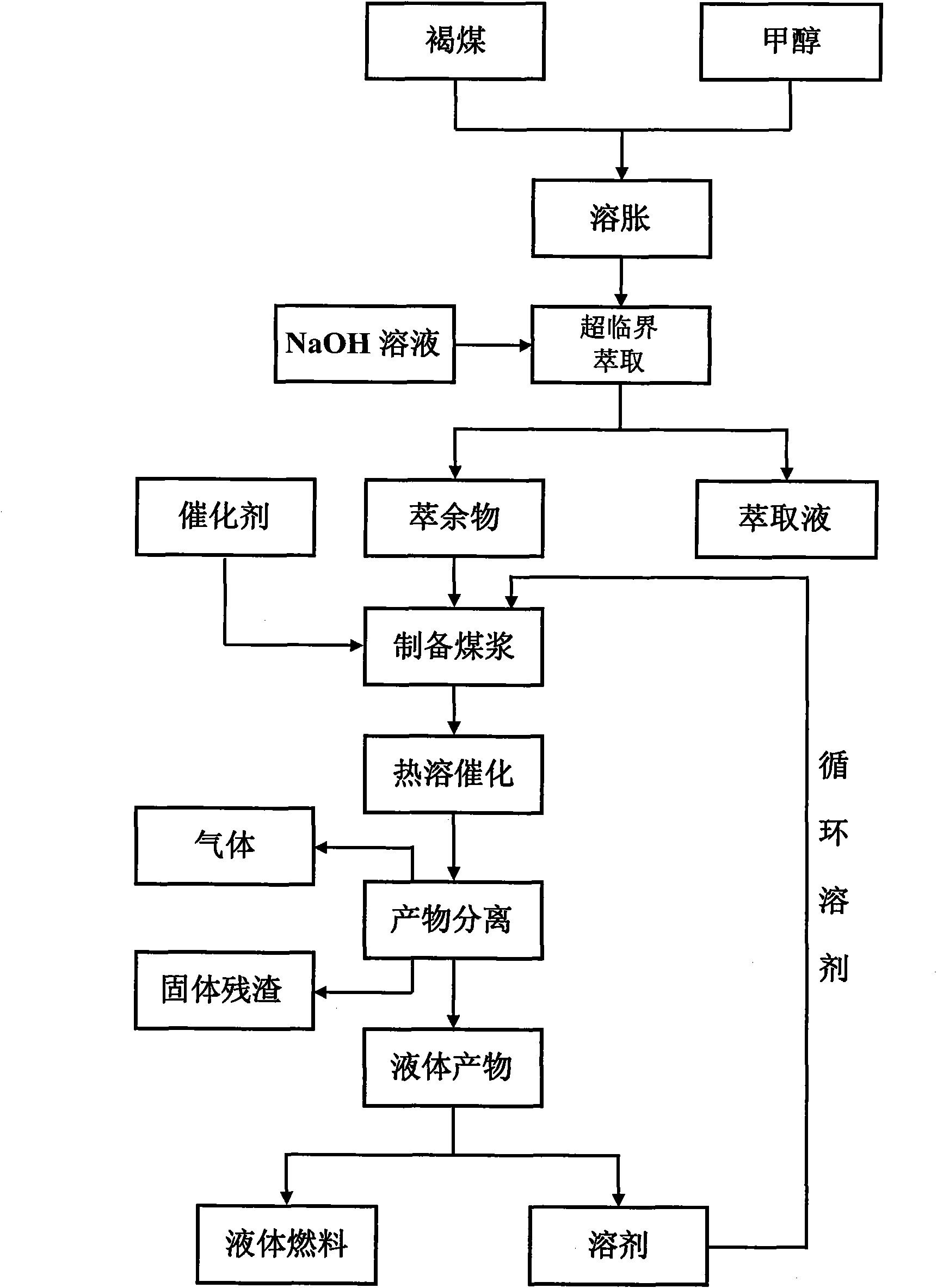

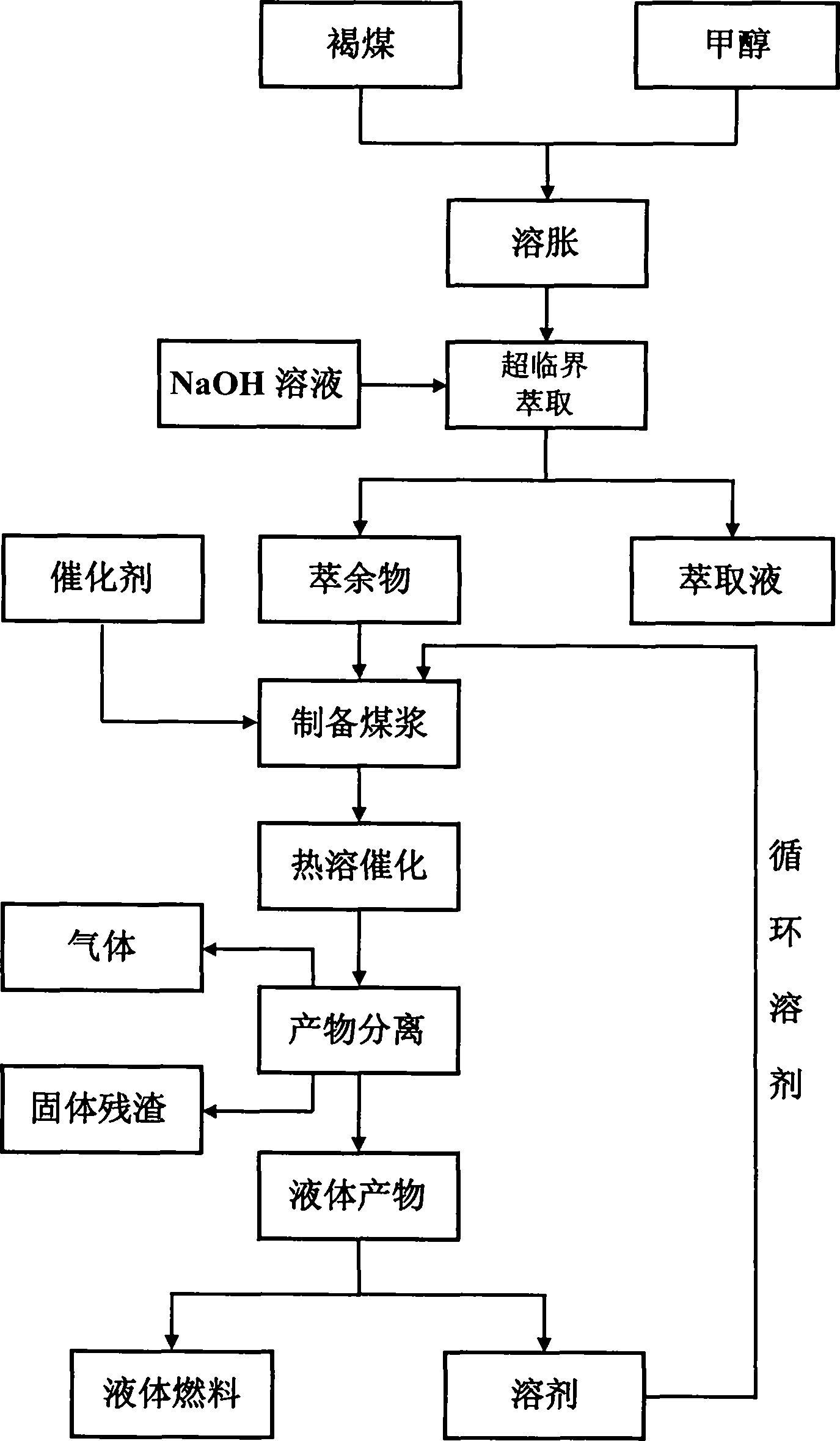

The invention discloses a processing method of lignite, comprising the following steps: A, taking methyl alcohol as extractant to carry out supercritical extraction processing to the lignite to obtain extraction liquid and raffinate; B, carrying out hot melt catalysis liquefaction processing to the raffinate to obtain liquid fuel. The invention has the beneficial effect: 1, the invention has moderate reaction condition, simple operation technology, high liquid oil yield, high domestication degree, low input and low cost and is safe and stable, and higher conversion rate of lignite; 2, the invention can obtain humic acid, organic acid methyl ester and phenol substances (phenyl hydroxide, cresol, dimethyl phenol and the like) and increase the additional value of products; 3, the supercritical methyl alcohol adopted by the invention removes R-OH and R-COOH class micromolecule substances in the lignite, which can reduce hydrogen consumption amount in the process of hot melt catalysis liquefaction so as to reduce hydrogen consumption; meanwhile, CO2 discharge amount in the process of hot melt catalysis liquefaction can be greatly reduced so as to achieve the purpose of greenhouse gas emission reduction; and 4, the invention performs swelling pretreatment to the lignite, changes lignite micropore structure, amplifies response ratio superficial area and improves the conversion rate of the lignite.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

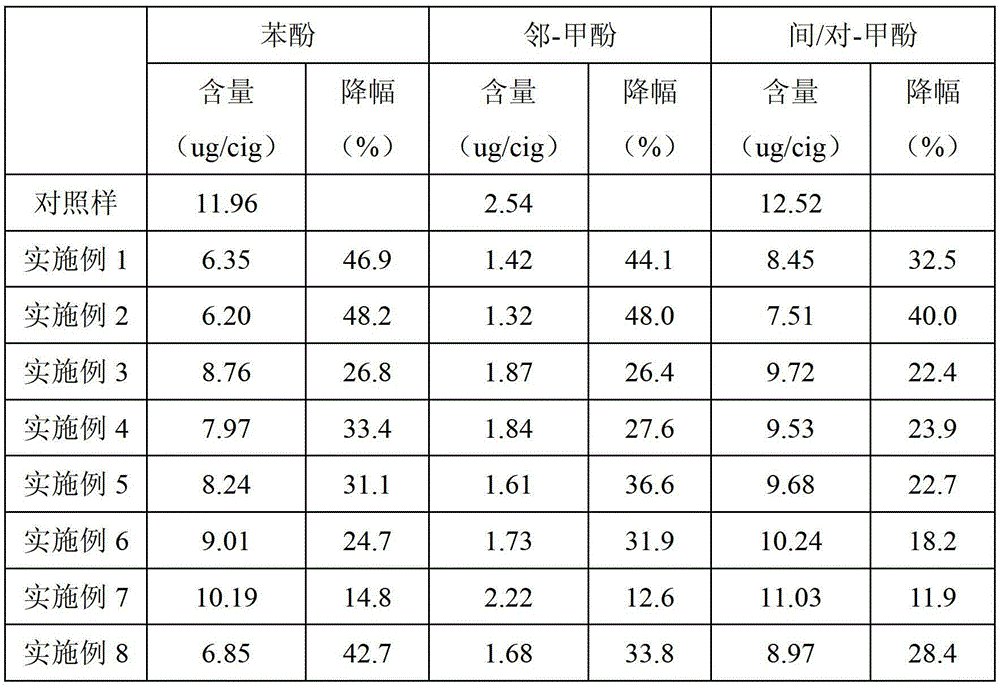

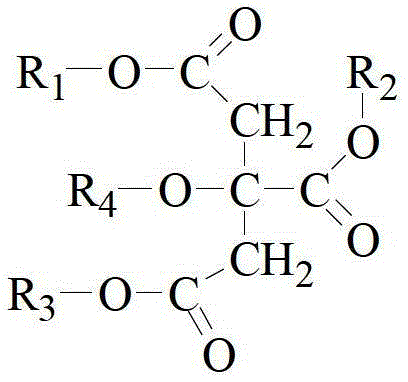

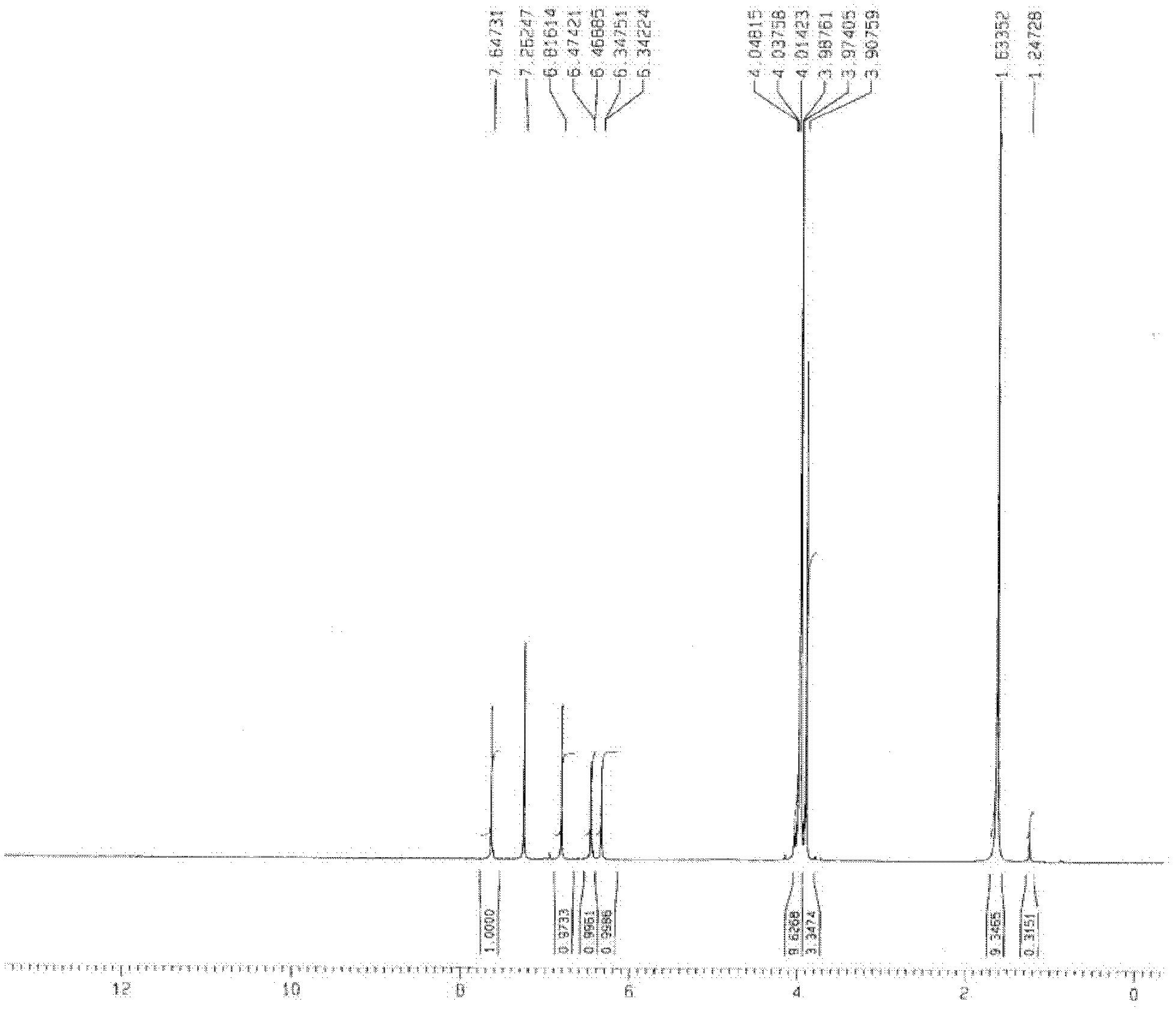

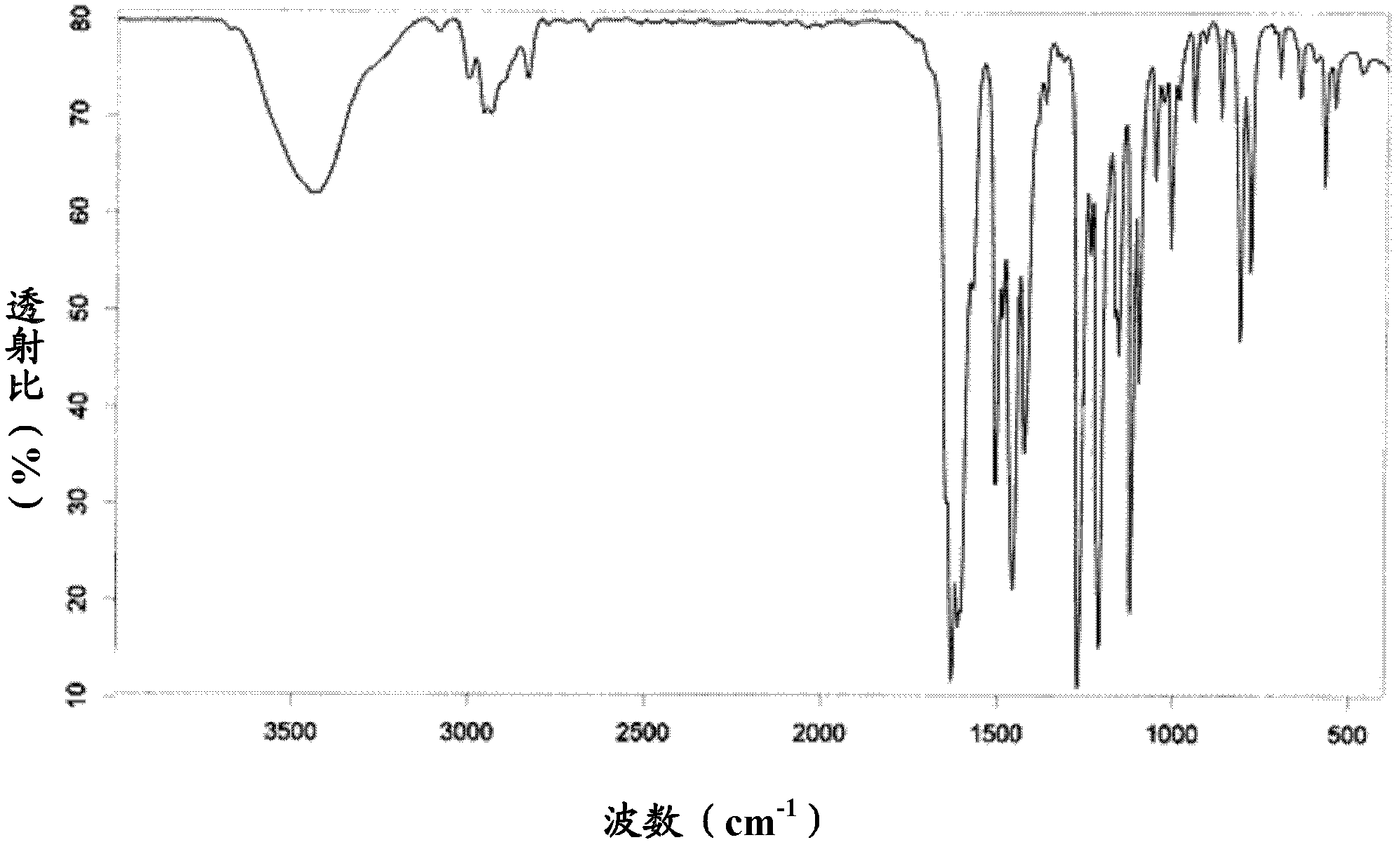

Groove filter stick cellulose paper additive capable of selectively reducing phenolic compounds in cigarette mainstream smoke and application

ActiveCN103141941AEasy to implementGood reduction effectNon-fibrous pulp additionTobacco smoke filtersCelluloseCresol

The invention discloses a groove filter stick cellulose paper additive capable of selectively reducing phenolic compounds in cigarette mainstream smoke, a groove filter stick cellulose paper compound additive capable of selectively reducing phenolic compounds in cigarette mainstream smoke and application. The additive takes one or more citric acid ester compounds as effective constituents; the compound additive comprises the following constituents by volume: 38-80% of effective constituents and 20-62% of auxiliaries. The application is as follows: one or more citric acid ester compounds are taken as effective constituents to be applied to preparation of the groove filter stick cellulose paper additive capable of selectively reducing phenolic compounds in cigarette mainstream smoke. Groove filter sticks made of cellulose paper containing the additive can effectively and selectively reduce the contents of phenolic compounds in cigarette mainstream smoke, wherein the content of phenyl hydroxide can be reduced by up to 48.2%, the content of o-cresol can be reduced by up to 48.0%, and the content of m / p-cresol can be reduced by up to 40.0%.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Economic, practical, and environment friendly method for preparing norathyriol

The invention relates to the field of medicinal chemistry, and discloses a two-step method for preparing norathyriol. The method comprises steps that: 2-bromine-4,5-dimethoxybenzoic acid is added to 1,2-dichloroethane; thionyl chloride is added to the mixture, and the mixture is heated and refluxed for 1 hour; zinc chloride and 3,5-dimethyoxy phenyl hydroxide are added to the mixture, the mixtureis stirred, and are heated for 2 to 4 hours under a temperature of 40 to 80 DEG C; the 1,2-dichloroethane solvent is removed through reduced-pressure distillation; 10% to 30% of a sodium hydroxide solution by mass is added to the mixture, and the mixture is heated and refluxed for 2 to 3 hours, such that 1,3,6,7-xanthone tetramethoxide is produced; 1,3,6,7- xanthone tetramethoxide is added to an ethylene glycol solvent, and hydrochloric acid is added to the mixture; the mixture is heated and refluxed for 3 to 5 hours, such that norathyriol is obtained. Compared to prior arts, the preparation method provided by the invention has advantages of short synthetic route, less step, simple operation, and high yield. The raw materials adopted in the method are cheap and easy to obtain. The processes are safe, and bring low toxicity. The method is environment friendly, and is suitable for industrialized productions. The method provides high economical and practical values.

Owner:KPC PHARM INC

Preparation method for disperse red 60

ActiveCN104448886AHigh yieldApproximate colorAmino-hydroxy-anthraquinone dyesAnthraquinonesHydroxyanthraquinone

The invention relates to a preparation method for disperse red 60. The preparation method comprises the step of conducting reaction on dried 1-amino-2-bromine-4-hydroxy-anthraquinone with phenol under the existence of an acid-binding agent, wherein the moisture content of the dried 1-amino-2-bromine-4-hydroxy-anthraquinone is controlled under 0.2 wt%; the condensation reaction is implemented through the following steps: (1) adding potassium carbonate and phenyl hydroxide in a reaction vessel; mounting a dehydration device; conducting dehydration and temperature increasing to 130-155 DEG C under normal pressure or negative pressure; when no water is dehydrated in the dehydration device, adding the dried 1-amino-2-bromine-4-hydroxy-anthraquinone in a system passing the step (1); maintaining the temperature at 150-158 DEG C for reaction. The yield is up to 93%; the chromatograph content of the obtained disperse red 60 product is above 99.5%; compared the cloth dyed by the disperse red 60 with standard cloth, the clothes are similar in color and luster, and good in quality.

Owner:苏州市罗森助剂有限公司

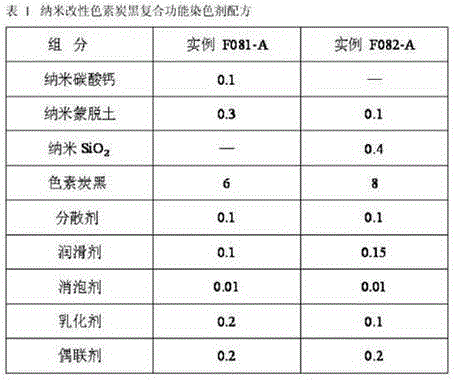

Phenolic resin black function master batch and preparation method thereof

The invention provides a phenolic resin black function master batch and a preparation method thereof. The phenolic resin black function master batch is prepared from the following raw materials by weight: 200 parts of phenyl hydroxide, 148 to 152 parts of formaldehyde, 2 to 10 parts of a catalyst, and 4 parts of a composite functional black coloring agent. The preparation method comprises the following steps: first, adding molten phenyl hydroxide into a three-mouth beaker equipped with a stirrer, a condenser and a thermometer, adding formaldehyde according to the weight ratio, and carrying out stirring and heating to ensure that the temperature of the reaction system is 100 to 104 DEG C; adding the catalyst according to the weight ratio for a 1 to 2 hours' reaction when the liquid flows back; adding the composite functional black coloring agent according to the weight ratio when the liquid becomes turbid, carrying out a backflow reaction for 1.5 to 2 hours, dehydrating under decompression, carrying out a polycondensation synthesis reaction when the viscosity of resin reaches up to a certain value, discharging fast after the polycondensation synthesis reaction is finished, and carrying out cooling and smashing for treatment. The master batch is good in dyeing property and flowability, can be added with an optional quantity, and can be used for improving toughness effect and rising heat distortion temperature, so that the comprehensive performance is improved remarkably.

Owner:延安金瓯科技发展有限公司

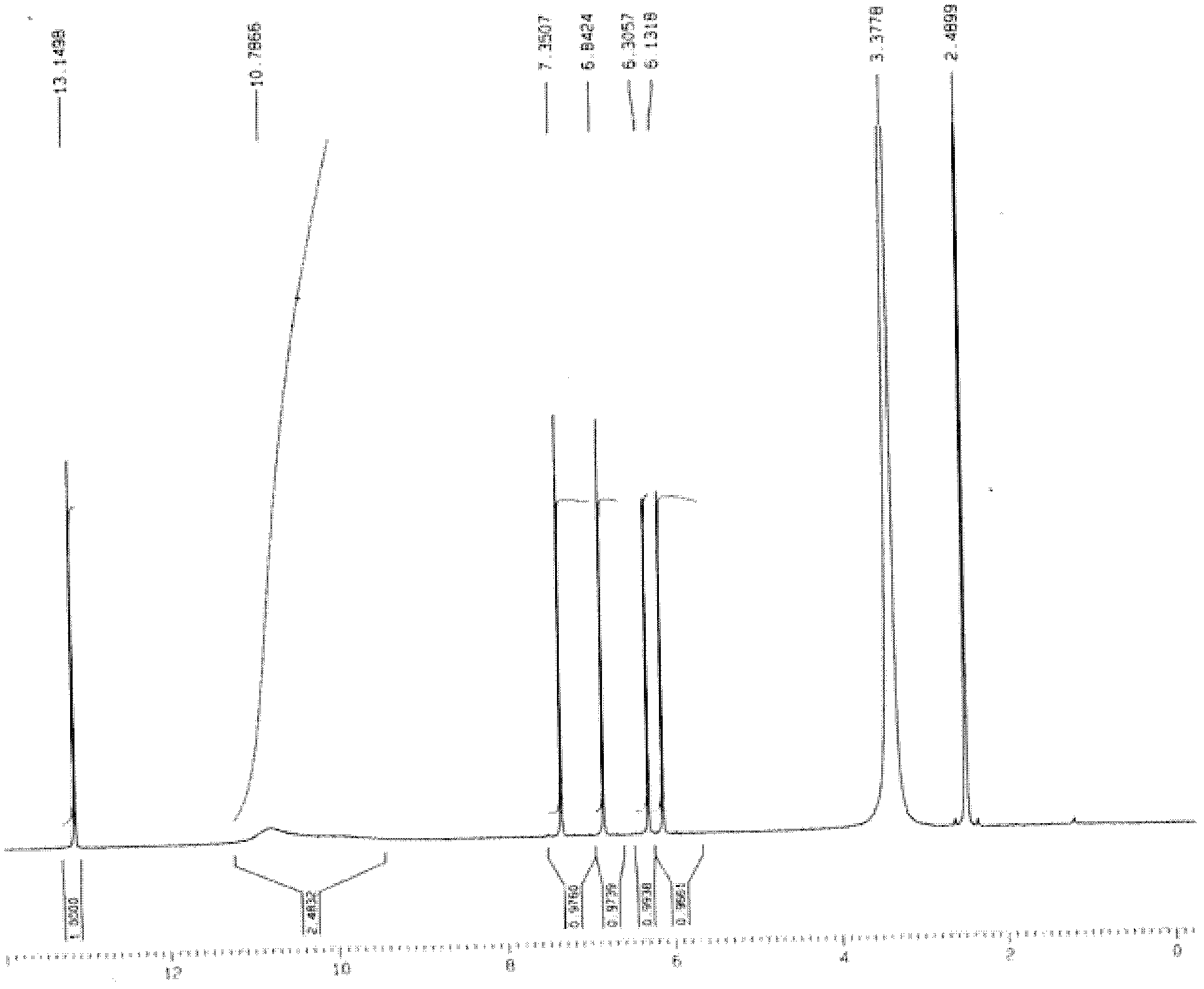

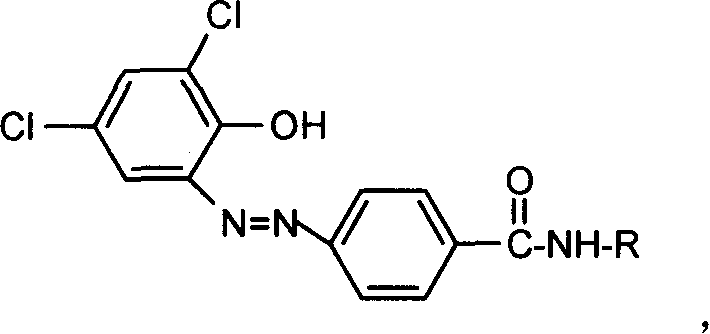

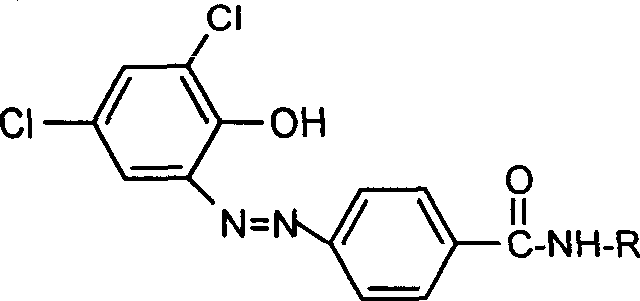

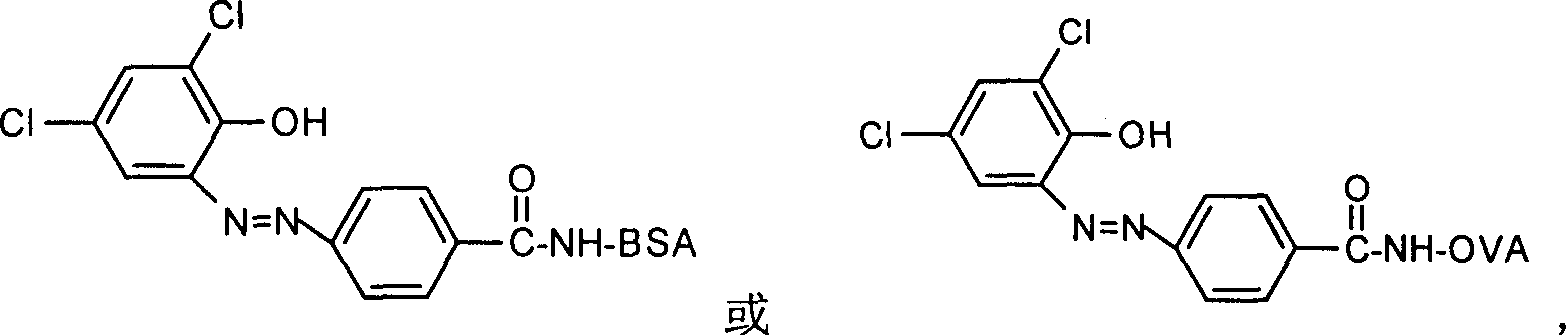

2, 4-dichlorophen artificial antigen, and its preparing method and use

InactiveCN1317302CThe pre-processing process is simpleEasy to handleOvalbuminSerum albuminFluorescenceBovine serum albumin

The invention relates to a preparation method and use for 2, 4-di-chlorophenol artificial antigen. It is synthesized by hapten 2, 4-dichlor-6-(4-hydroxyl phenyl azo) phenyl hydroxide through activating fat or admixing acid anhydride. The antigen can be used to make 2, 4-di-chlorophenol antibody, set 2, 4-di-chlorophenol indirect competing fluorescence immunity method, or testing its residuum in the aquatic environment. The advantages of the invention are that the antibody has great practicability and good stability; the preparation method is easy and feasible; the cost is low; and it is easy to produce in industrial scale.

Owner:DONGHUA UNIV

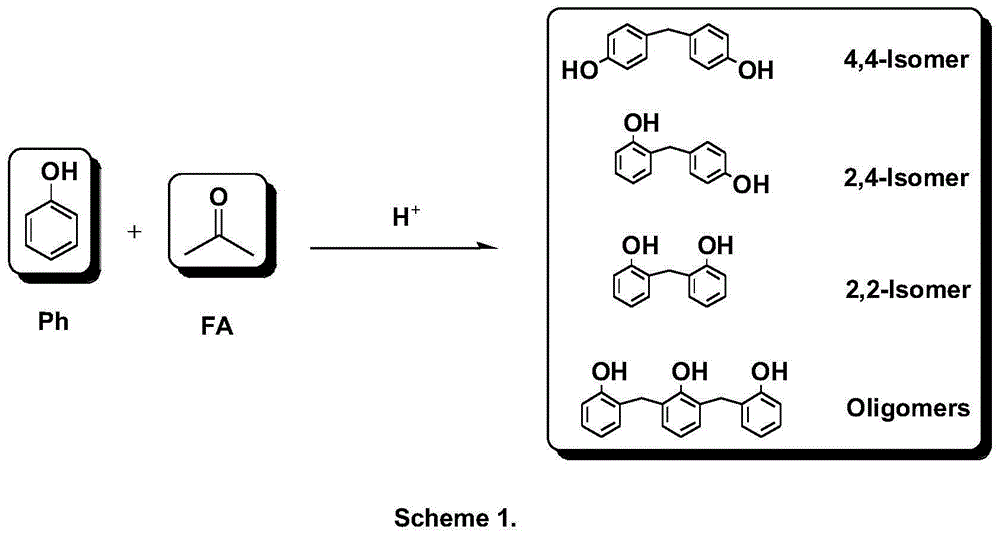

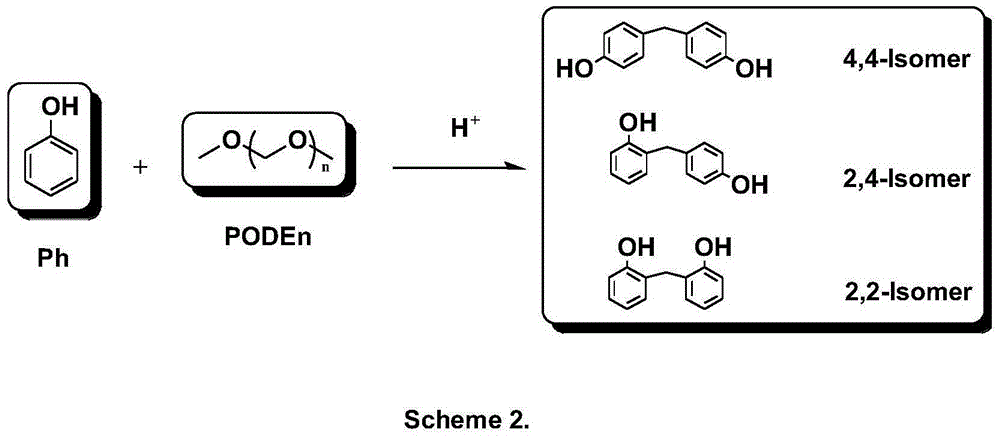

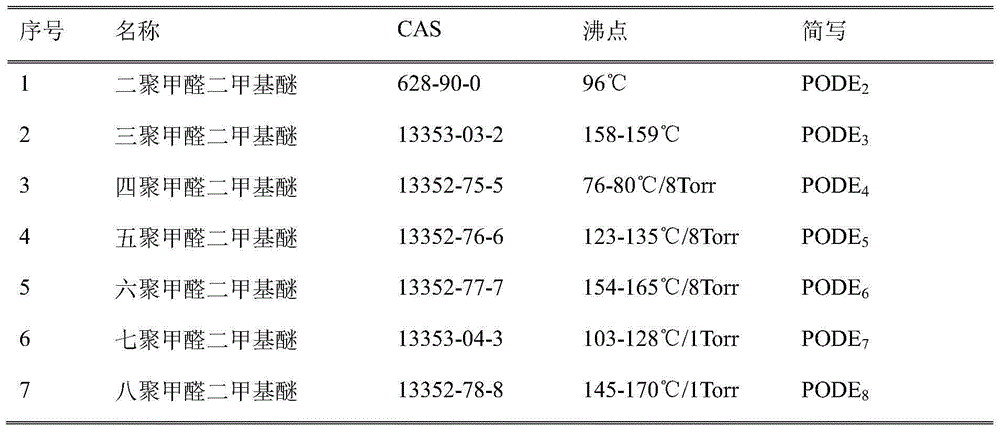

Method for preparing bisphenol F by adopting polyoxymethylene dimethyl ethers as raw material

ActiveCN105152866AImprove solubilityMild responseOrganic chemistryOrganic compound preparationSolubilityPhenyl hydroxide

Owner:SHEYANG RES INST OF NANJING UNIV

Automobile windshield wipe cleaner and preparation method thereof

InactiveCN103666826ADecontamination fastEasy to rinseSurface-active detergent compositionsDetergent compounding agentsPhenyl hydroxideDioxyethylene Ether

The invention provides an automobile windshield wipe cleaner and a preparation method thereof. The wipe cleaner comprises the following ingredients in parts by mass: 3-8 parts of alkyl naphthalene sulfonate, 6-15 parts of alpha-pinene, 1-3.5 parts of dioctyl phthalate, 3-8 parts of bergmeal, 2.5-9 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of polyether modified silicone, 10-18 parts of isopropyl alcohol, 0.1-0.3 part of phenyl hydroxide, 0.8-2 parts of lipase and 60-75 parts of water. The automobile windshield wipe cleaner contains enzyme and other stain removal ingredients, and is quick in stain removal, good in stain removal effect, and easy for rinsing, and the surface of the windshield wiped by the wipe cleaner is free from stain.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

High temperature resistant liquid anhydride curing agent and preparation method thereof

The invention discloses a high-temperature-resistant liquid anhydride curing agent, comprising the following components in parts by weight: 45-55 parts of maleic anhydride, 5-15 parts of phenyl hydroxide, 33-35 parts of diethylene glycol, 4-6 parts of triethanolamine and 1-1.2 parts of concentrated sulphuric acid. The raw materials are mixed according to requirements and react to generate the curing agent disclosed by the invention, then the curing agent disclosed by the invention can cure epoxy resin at the high temperature of 150 DEG C after being subjected to glue mixing with epoxy resin, the cured epoxy resin has high toughness and excellent mechanical strength, working temperature can resist 200 DEG C, insulation resistance is more than 1012 Omega, and the curing agent is applicable to filling and sealing constructions on a dry type transformer, a mutual inductor, a relay, a temperature sensor and various integrated circuits.

Owner:舒城金泽信环保材料有限公司

Cement-based grouting material containing modified naphthalene-series water reducing agent and preparation method thereof

InactiveCN102211911AHigh strengthImprove bleeding rateSolid waste managementPolyesterCarboxylic acid

The invention provides a cement-based grouting material containing a modified naphthalene-series water reducing agent and a preparation method thereof. The cement-based grouting material comprises the following components in parts by weight: 350-500 parts of cement clinker, 80-130 parts of pulverized fuel ash, 20-30 parts of expanding agent, 80-120 parts of gypsum, 1-2 parts of pH value regulating agent, 8-15 parts of polyester type carboxylic acid water reducing agent and 300-500 parts of quartz sand, wherein the water reducing agent consists of a material A and a material B; the material A is prepared from naphthalene, anthracene, concentrated sulfuric acid, formaldehyde, water and sodium hydroxide; the material B is prepared from phenyl hydroxide, sodium hydroxide, formaldehyde, sulfamic acid and para-aminobenzene sulfonic acid; and the weight ratio of the material A to the material B is (20:1)-(5:1). The grouting material has high strength and low bleeding rate; and the strength character of the grouting material is hardly influenced by sub-zero weather.

Owner:马清浩

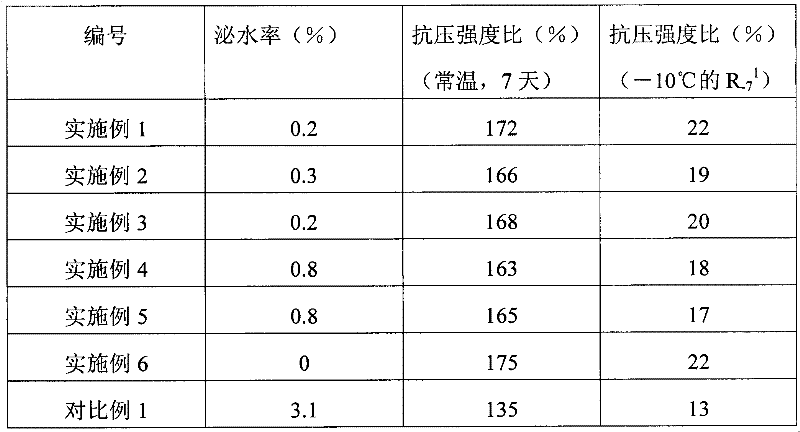

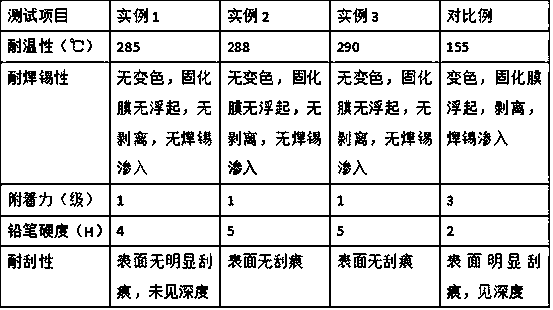

Preparation method of composite resin-based solder resist ink

The invention discloses a preparation method of a composite resin-based solder resist ink and belongs to the technical field of printing ink preparation. Firstly, phenyl hydroxide, a formaldehyde solution and hydrogen peroxide are mixed and stirred for reaction to obtain self-made phenolic resin, blending the self-made phenolic resin with gingelly oil, anhydrous ethanol and hexamethylenetetramine,and then adding a bisphenol A type epoxy resin in the reaction process of acrylic resin synthesis, wherein the bisphenol A type epoxy resin has strong cohesion, two blend resin molecules, namely a modified phenolic resin and a modified acrylic emulsion, contain hydroxys and double bonds, so that a system obtains extremely high functionality and reactivity and has a light-heat dual-curing function. Therefore, the crosslinking density of a solder resist ink coating is effectively improved; and since a large amount of hydroxys are contained on an aerosil surface, and can be in chemical reactionwith hydroxys in blend resin molecules to form a cross-linked network structure, scratch resistance of solder resist ink is further improved, and the preparation method provided by the invention has awide application scope.

Owner:邹峰

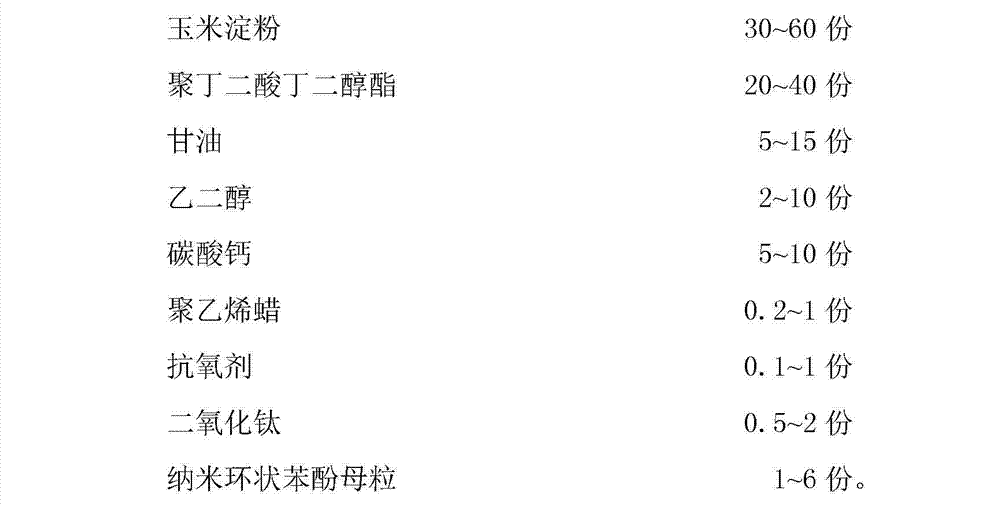

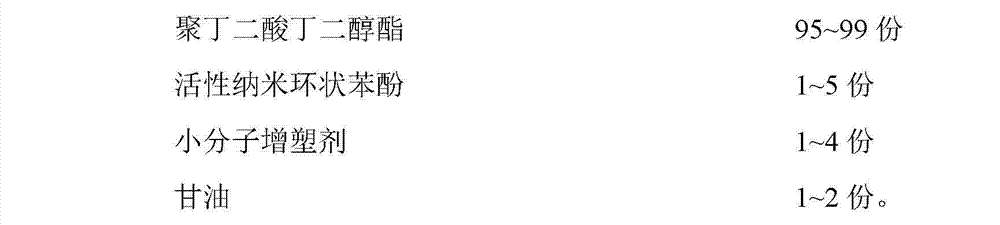

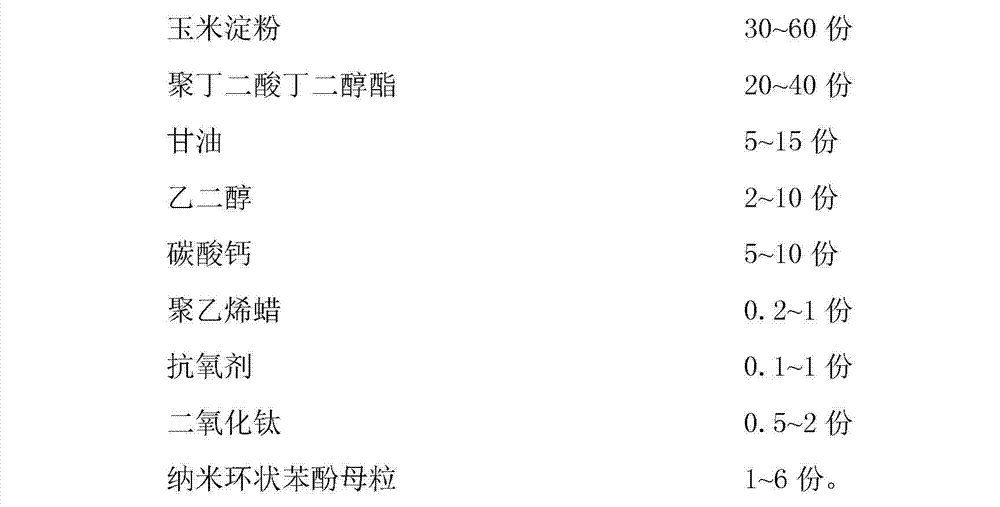

Nano cyclic phenyl hydroxide modified starch/PBS biology base degradation dedicated material and preparation method thereof

InactiveCN102924885AImprove physical performanceImprove mechanical propertiesGlycerolPhenyl hydroxide

The invention discloses a nano cyclic phenyl hydroxide modified starch / PBS biology base degradation dedicated material and a preparation method thereof. The material mainly comprises the following components: corn starch, poly butylenes succinate, glycerin, ethylene glycol, calcium carbonate, polyethylene wax, antioxygen, titanium dioxide, and a nano cyclic phenyl hydroxide master batch, wherein nano cyclic phenyl hydroxide master batch comprises the following components as poly butylenes succinate, active nano cyclic phenyl hydroxide, micro molecule plasticizer and glycerin. The preparation method is realized through the following steps: firstly feeding the corn starch, the glycerin, the ethylene glycol, calcium carbonate, the polyethylene wax, the antioxygen and titanium dioxide into an agitator for agitation at 70-90 DEG C, then feeding the poly butylenes succinate and the nano cyclic phenyl hydroxide for agitation at 105-120 DEG C, and finally mixing fully and feeding into a double-screw extruder for melt blending and extruding at 160-180 DEG C, thereby obtaining the biology base degradation dedicated material. The product made of the biology base degradation dedicated material prepared through the method has greatly improved mechanical and physical performances.

Owner:宁夏卓业生物科技工程有限公司

Processing method of lignite

ActiveCN101787301BImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationLiquid fuelPhenyl hydroxide

The invention discloses a processing method of lignite, comprising the following steps: A, taking methyl alcohol as extractant to carry out supercritical extraction processing to the lignite to obtain extraction liquid and raffinate; B, carrying out hot melt catalysis liquefaction processing to the raffinate to obtain liquid fuel. The invention has the beneficial effect: 1, the invention has moderate reaction condition, simple operation technology, high liquid oil yield, high domestication degree, low input and low cost and is safe and stable, and higher conversion rate of lignite; 2, the invention can obtain humic acid, organic acid methyl ester and phenol substances (phenyl hydroxide, cresol, dimethyl phenol and the like) and increase the additional value of products; 3, the supercritical methyl alcohol adopted by the invention removes R-OH and R-COOH class micromolecule substances in the lignite, which can reduce hydrogen consumption amount in the process of hot melt catalysis liquefaction so as to reduce hydrogen consumption; meanwhile, CO2 discharge amount in the process of hot melt catalysis liquefaction can be greatly reduced so as to achieve the purpose of greenhouse gas emission reduction; and 4, the invention performs swelling pretreatment to the lignite, changes lignite micropore structure, amplifies response ratio superficial area and improves the conversion rate of the lignite.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com