Patents

Literature

279 results about "Bisphenol AF" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

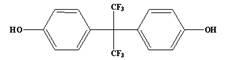

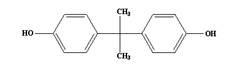

Bisphenol AF (BPAF) is a fluorinated organic compound related to bisphenol A in which the two methyl groups are replaced with trifluoromethyl groups. Whereas BPA binds with human estrogen-related receptor gamma (ERR-γ), BPAF all but ignores ERR-γ. Instead, BPAF activates ERR-α and binds to and disables ERR-β.

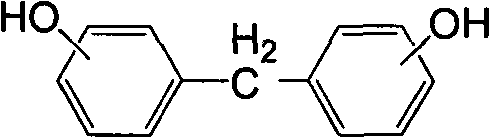

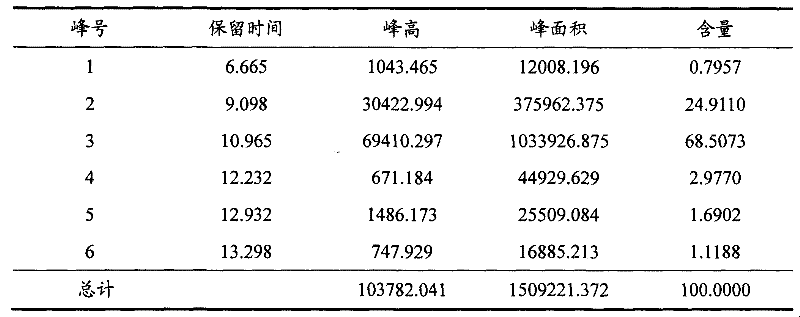

Preparation method for bisphenol F

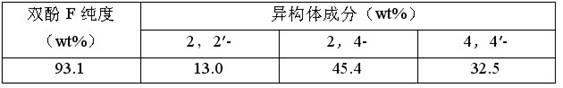

ActiveCN102491879AEasy to separate and recycleThe synthesis process is simpleOrganic chemistryOrganic compound preparationAluminium chlorideSynthesis methods

The invention discloses a synthesis method for bisphenol F, in which aluminium chloride, titanium tetrachloride and modified cation exchange resin are adopted as catalysts, and phenyl hydroxide and formaldehyde are adopted as raw materials. The invention has the technical effects as follows: the aluminium chloride, the titanium tetrachloride and the modified cation exchange resin are adopted for catalysis to synthesize the bisphenol F, and the resin catalyst is easy to separate and recover and can be used repeatedly; 2, a recrystallization and reduced pressure distillation combined separation technology is adopted for coproduction of high-purity bisphenol F and common bisphenol F products, the maximum yield of the bisphenol F reaches 90 percent, the content of 4, 4'-bisphenol F in a dimethyl benzene recrystallization product reaches 93.5 percent, reduced pressure distillation after-products are mainly other two isomers, and the separation of the 4, 4'-bisphenol F is realized effectively; 3, the requirement for the concentration of the formaldehyde raw material is not strict while the traditional one stage process require that the concentration of formaldehyde is above 40 percent; and 4, the synthesis technology is simple, the operation is convenient, and the realization of industrial production is easy.

Owner:湖南嘉盛德材料科技股份有限公司

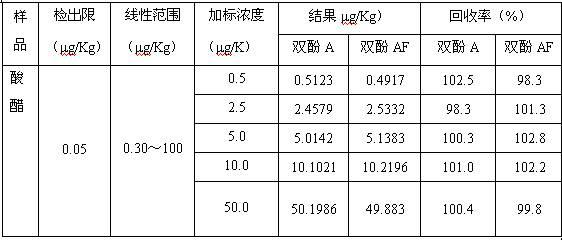

Method for rapidly detecting bisphenol A and bisphenol AF in food

The invention relates to a method for detecting bisphenol A and bisphenol AF in food, belonging to technical field of analytical chemistry determination method. With ionic liquid (1-butyl-3-methylimidazole hexafluorophosphate) as an extractant and TritonX-100 or acetone as an dispersant, ultrasonic oscillation is carried out to form emulsion; after centrifugal separation, extraction drops at the lower layer are directly subjected to HPLC (high performance liquid chromatography) quantitative analysis. The method disclosed by the invention has the advantages of simpleness in detection steps, easiness in operation, low detection limit and high enrichment multiple, greatly reduced detection cost. The method disclosed by the invention is a rapid, efficient and environmentally friendly pre-treatment technology and has a wider application prospect in the field of food analysis.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

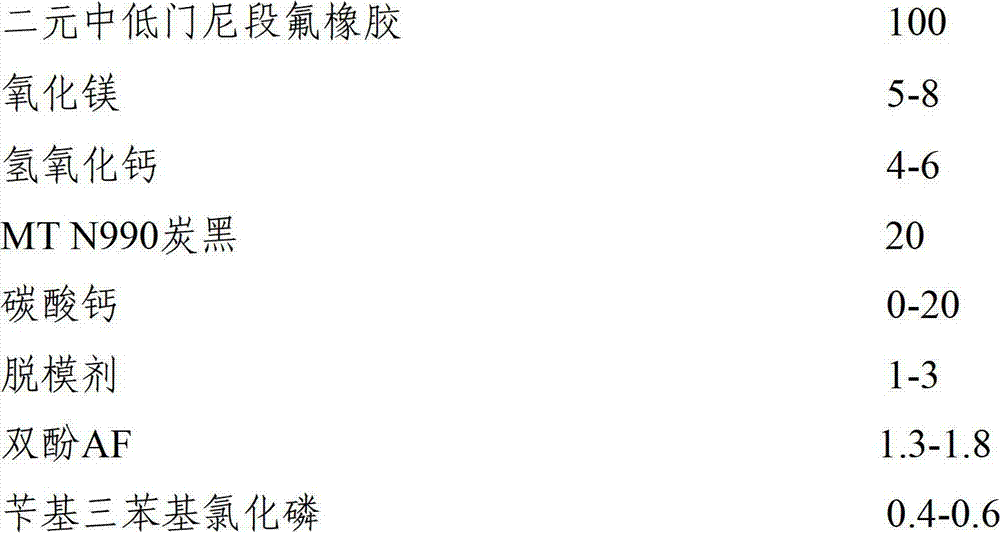

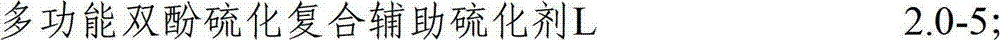

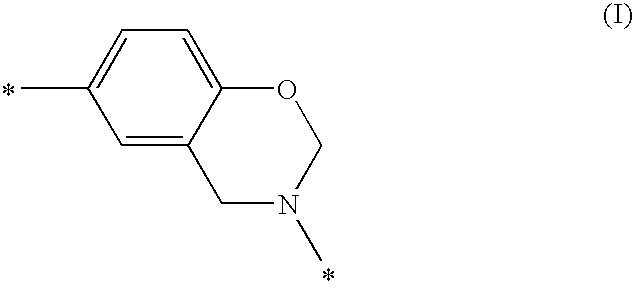

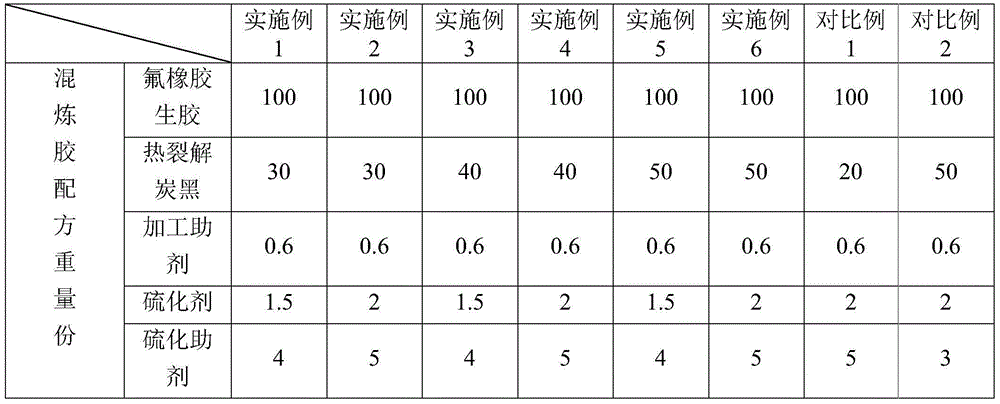

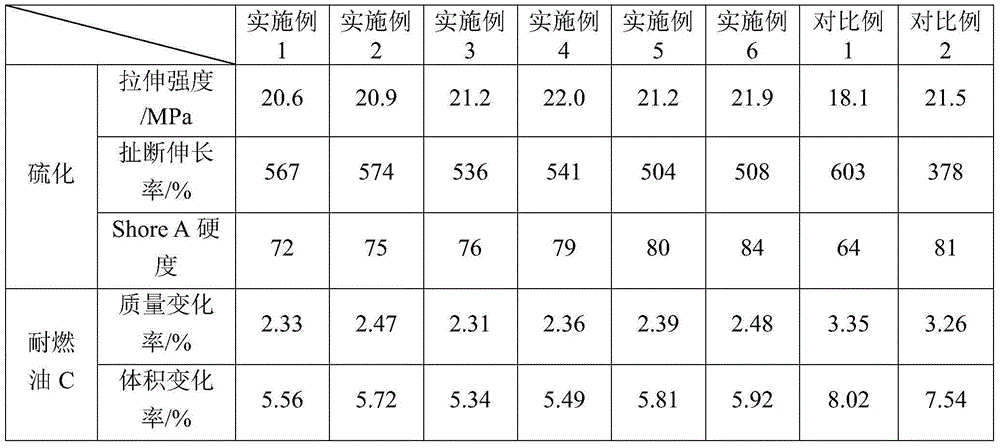

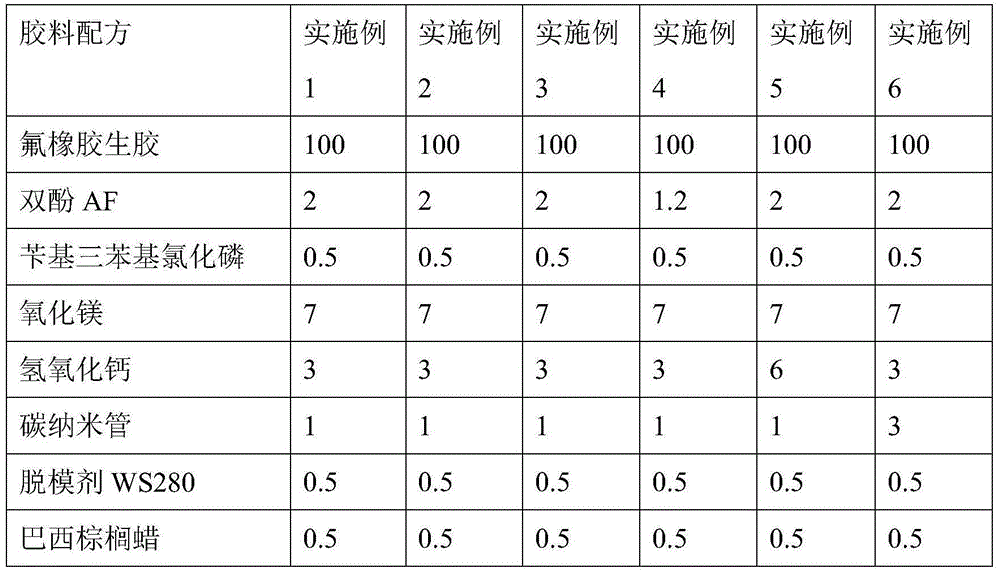

Fluororubber rubber compound and preparation method thereof

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Rubber compositions for oil seal of rubber framework and method for manufacturing same

Owner:青岛茂林橡胶制品有限公司

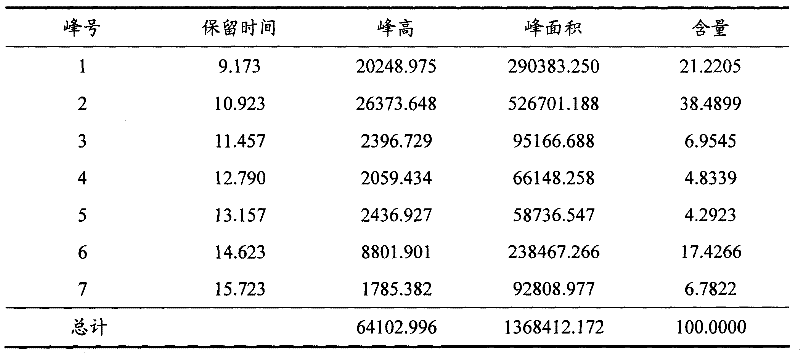

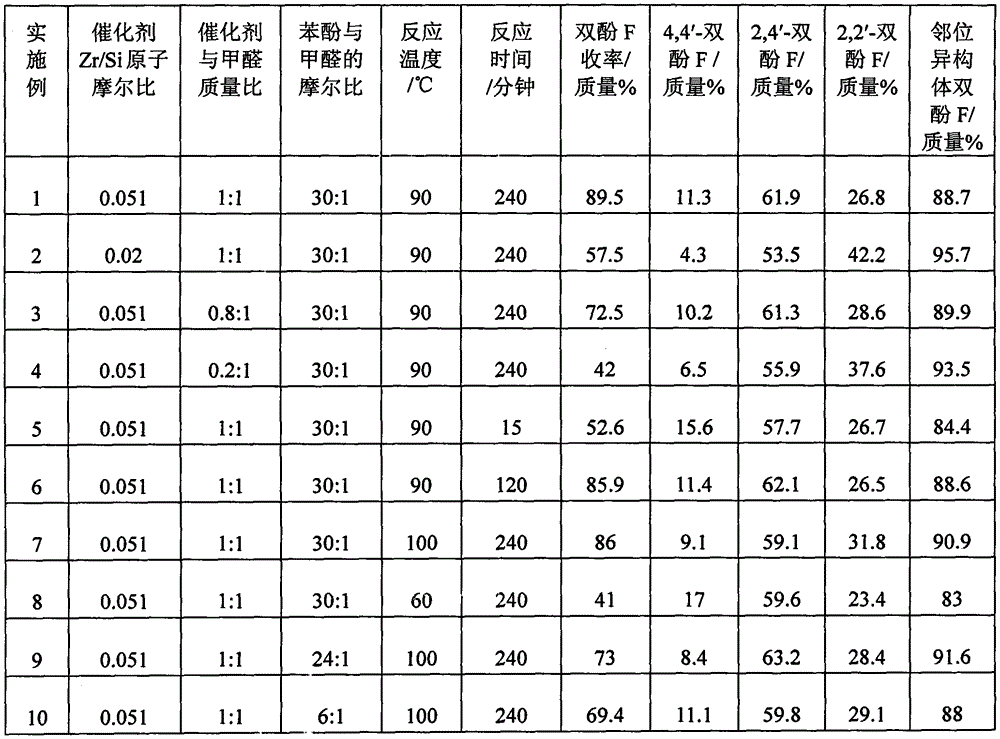

Preparation method of bisphenol F with high ortho-position isomer content

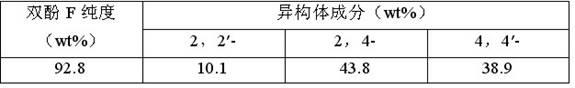

ActiveCN102070409ARaw materials are easy to getEasy to operateOrganic chemistryOrganic compound preparationOrtho positionSynthesis methods

The invention discloses a preparation method of bisphenol F with high ortho-position isomer content. The preparation method comprises the following steps: synthesizing the bisphenol F by adopting a two-step method, separating an organic phase and a phosphoric acid phase, neutralizing the organic phase and removing salt, and recovering phenol under the reduced pressure to obtain the bisphenol F product, wherein in the first step of the two-step synthesis method, the phenol reacts with formaldehyde under the weakly acidic condition; and in the second step, a large amount of catalyst phosphoric acid and formaldehyde are added into the reaction liquid obtained in the first step, and the formaldehyde completely reacts. The invention overcomes the defects that the content of the ortho-position isomer in the bisphenol F prepared by the existing bisphenol F preparation method is low, the curing speed of the synthesized bisphenol F epoxy resin is slow, the resin is easy to crystallize and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

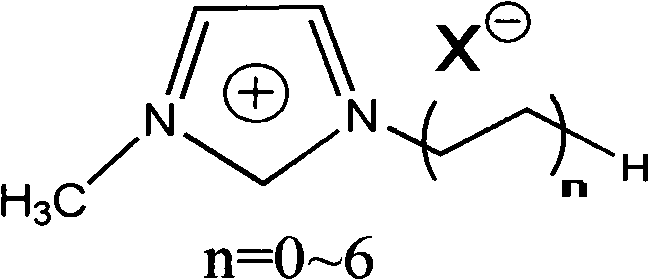

Method for preparing bisphenol F by using 1-alkyl-3-methylimidazole acidic ionic liquid

InactiveCN102584541AExtended service lifeNot corrosiveOrganic chemistryOrganic compound preparationOrganic solventSolvent

The invention relates to a method for preparing bisphenol F by using a 1-alkyl-3-methylimidazole acidic ionic liquid. According to the invention, phenol and formaldehyde are used as raw materials, and the 1-alkyl-3-methylimidazole acidic ionic liquid is used as a solvent and a catalyst, and bisphenol F can be prepared by condensation reaction. As for the method, other organic solvents easy to volatilize are not used, the defects that the reaction time is long, recovery is difficult, the service life is short, the corrosivity is strong and the like when the bisphenol F is subjected to catalytic synthesis by common bronsted acid can be solved, and the method provided by the invention is a novel bisphenol F preparing method which is efficient and environment-friendly.

Owner:XIANGTAN UNIV

High hardness fluorubber material with low-temperature pliability

InactiveCN1919921AImprove the shortcomings of poor low temperature performanceImprove performancePliabilityCompression set

The invention discloses a fluorubber sizing with low temperature pliability and high hardness, which concludes 80-100% fluoride olefin terpolymer, 1-8% activated magnesium oxide, 1-10% superfine calvital, 0.1-3.0% phenmethyl triphenyl phosphoric chloride / Dbu, 0.5-5% fluorine wax / parting medium, 10-50% strengthening agent, 1-5% promoting agent, 1.5-5.0% bisphenol AF, 5-20% plasticizer, 0.1-1.0% peroxide and 0.15-1.5% cross bonding accessory ingredient.

Owner:SHANGHAI XINGLUO SPECIAL SEALS

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

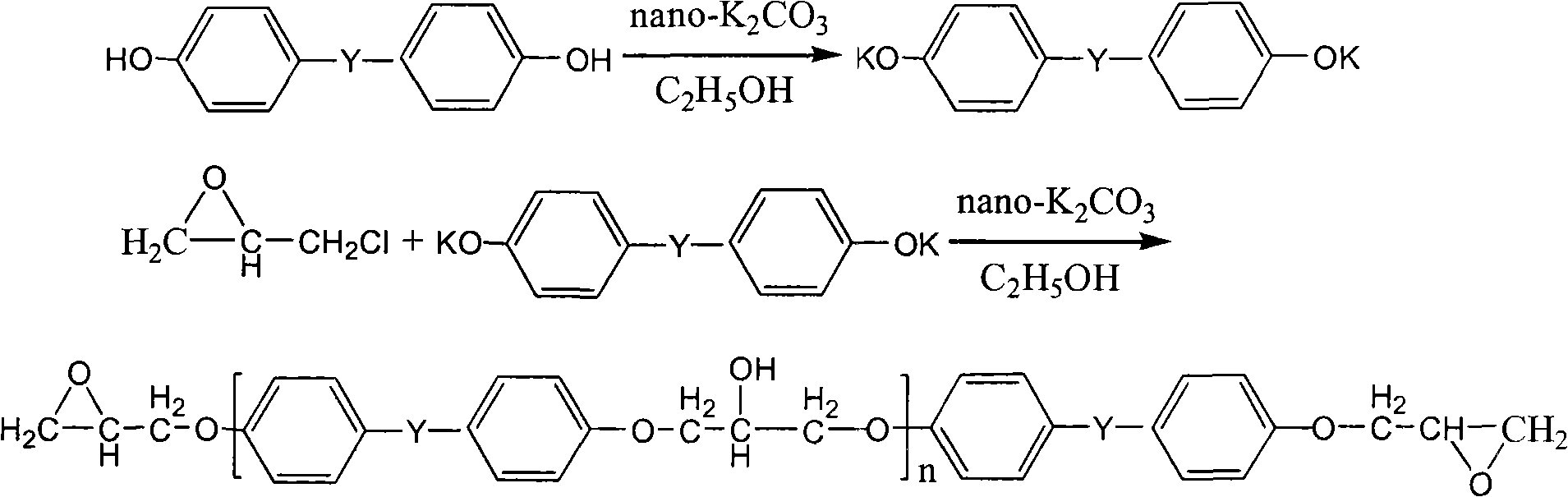

Synthesis method of low-molecular weight epoxy resin

InactiveCN102040568ALong reaction stepsExtend life cycleOrganic chemistrySynthesis methodsReaction temperature

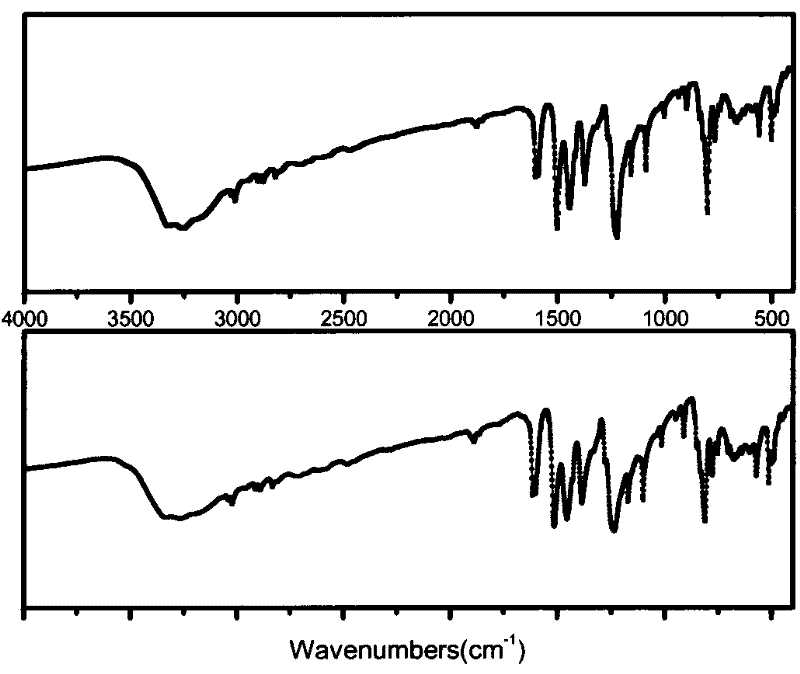

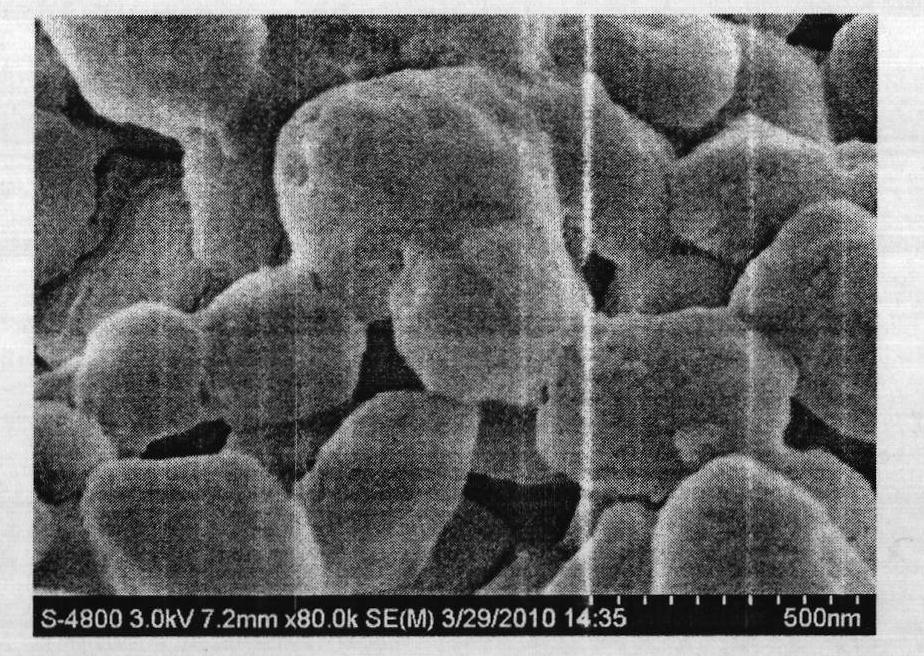

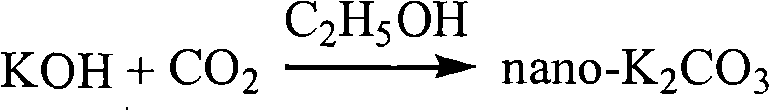

The invention provides a preparation method of low-molecular weight epoxy resin. The method comprises the following steps: adding bisphenol A, epoxy chloropropane, potassium carbonate having grain size of 100-300 nanometer and solvent into a reactor for reaction; and distilling or rectifying the reaction liquid, and recycling the solvent to obtain the low-molecular weight colorless liquid bisphenol A type epoxy resin. The same effect is obtained by replacing bisphenol A with bisphenol S, bisphenol F or bisphenol fluorene to synthesize corresponding bisphenol S, bisphenol F or bisphenol fluorene type low-molecular weight epoxyresin. The method for synthesizing the low-molecular weight epoxy resin has the advantages of low reaction temperature, short reaction time, simple operation, high epoxy value of product, no production of industrial wastewater and good industrial prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Synthesis method of bisphenol F in salt bath system

InactiveCN103319314AHigh yieldIncrease contentOrganic chemistryOrganic compound preparationOrganic solventSynthesis methods

The invention relates to a synthesis method of bisphenol F in a salt bath system. The bisphenol F, which is relatively high in yield, high in content of 4,4-dihydroxy diphenyl methane and good in selectivity, is prepared from a reaction of phenol and formaldehyde under a salt bath system and a catalyst through regulating and controlling technological parameters. And the preparation method is simple, and the synthesis process is free from an organic solvent, thus being light in environmental pollution.

Owner:SHAANXI NORMAL UNIV

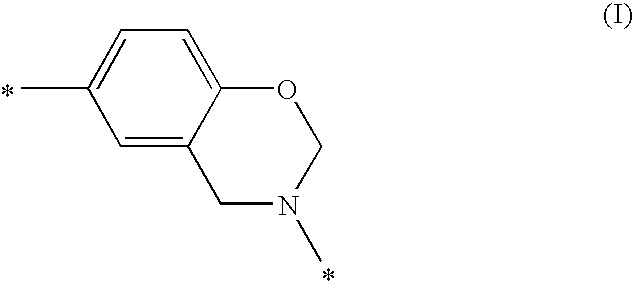

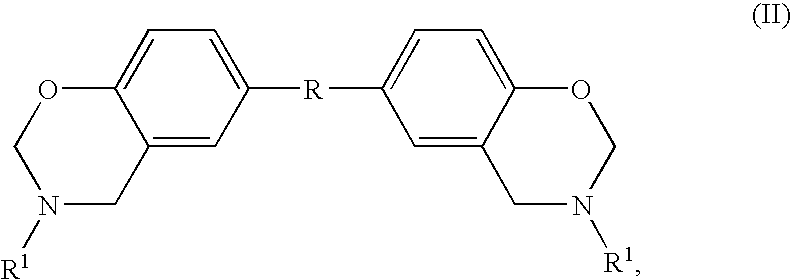

Composition Comprising Benzoxazine and Epoxy Resin

ActiveUS20080302471A1Reduce flammabilityFavorable curing conditionGroup 4/14 element organic compoundsSynthetic resin layered productsPolymer networkBisphenol AF

The instant invention relates to compositions comprising a benzoxazine resin and an advancement resin based on bisphenol A diglycidyl ether and bisphenol S and, optionally, ferrocene and aluminium trihydrate. Such compositions are, when cured to form polymeric networks, difficultly inflammable and resistant to high temperatures. Such compositions may especially be used in the production of printed wiring boards.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC +1

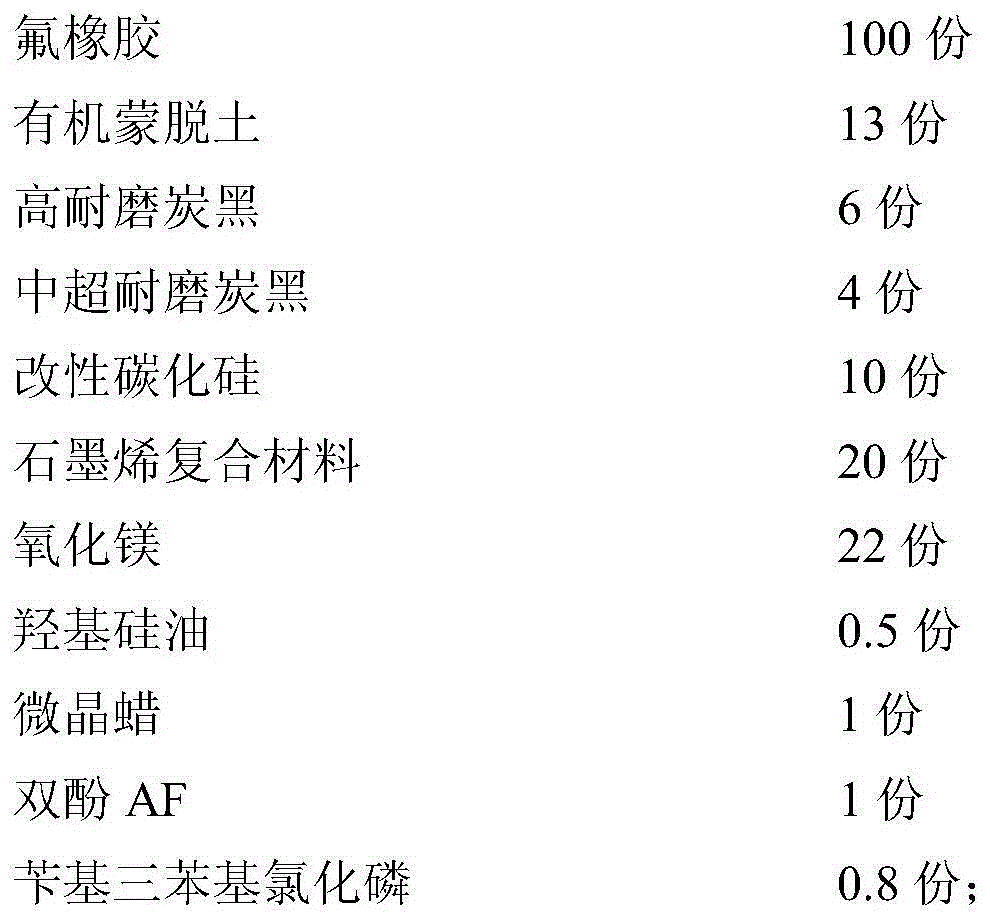

Modified fluororubber compounded stock and preparation method thereof

The invention discloses a modified fluororubber compounded stock. The modified fluororubber compounded stock comprises the following components in parts by weight: 100 parts of raw rubber of fluororubber, 10-30 parts of thermal cracking carbon black, 10-30 parts of furnace black with high wear resistance, 2-8 parts of wear-resistant additives, 0.2-0.6 part of processing additives, 2-4 parts of active magnesium oxide, 5-9 parts of calcium hydroxide, 1.5-3.0 parts of bisphenol A and 0.4-0.8 part of benzyl triphenylphosphonium chloride. The invention further discloses a preparation method of the compounded stock, the hardness of the obtained high-strength, high-elasticity and oil-resistant fluororubber compounded stock after vulcanization can be controlled within 70-85, and the modified fluororubber compounded stock has the advantages of good processability, low cost, simple method and easiness in industrialization.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Modified fluororubber gross rubber and method of producing the same

InactiveCN101153120AImprove low temperature resistanceImprove performancePolymer scienceBisphenol AF

The present invention discloses a modified fluorin rubber compound and the preparation method. The modified fluorin rubber compound comprises the following components: 100 portion of virgin rubber of fluorin rubber, 10 portion to 12 portion of ZnO, 3 portion to 5 portion of MgO, 2 portion to 3 portion of CaF2, 4 portion to 8 portion of Ca(OH)2, 1 portion to 2 portion of iron oxide red, 2 portion to 3 portion of bisphenol AF and 0.5 portion to 1.5 portion of thiofide BPP. The preparation method comprises the following steps: 1) the virgin rubber of fluorin rubber is plasticized for 10 minutes to 15 minutes; 2) the ZnO, Ca(OH)2, CaF2, MgO and iron oxide red are added in order, thin-pass and are then mixed well; 3) the bisphenol AF and BPP are added, thin-pass and are then mixed well; 4) the product is prepared. The modified fluorin rubber compound of the present invention has good processing fluidity and good low-temperature resistance. The temperature range for normal use can be between 80 DEG C below zero and 250 DEG C.

Owner:扬中市橡胶塑料厂有限公司

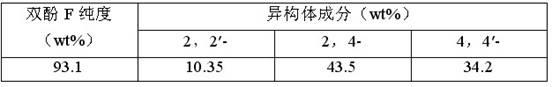

Preparation method of bisphenol F

InactiveCN102516035AIncrease production capacityLow operating costOrganic chemistryOrganic compound preparationOxygenBisphenol AF

The invention relates to a preparation method of bisphenol F, which is characterized in that under the condition of existence of an acid catalyst, phenol and formaldehyde are reacted to obtain the product. The acid catalyst is a mixture of inorganic acid and organic acid, and the mol ratio of the inorganic acid to organic acid is 10-2:1; the inorganic acid is oxygen-containing acid of phosphor, the organic acid is C1-C4 straight chain or branched chain monoacid or diacid. The invention has the advantages that under the condition that P / F is less than or equal to 10, the bisphenol F with high ortho-isomer (especially 2,4'-isomer ) content can be obtained, the production capability of the device can be increased, and the operation cost and the energy consumption are reduced.

Owner:胶州市精细化工有限公司 +1

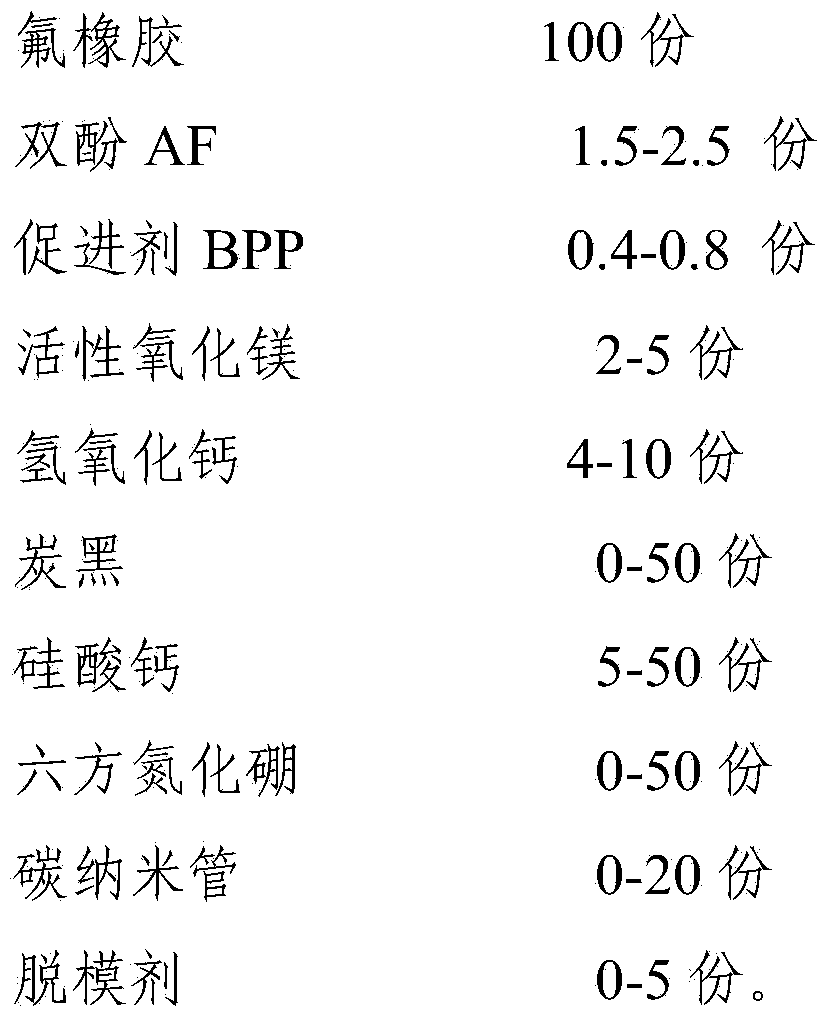

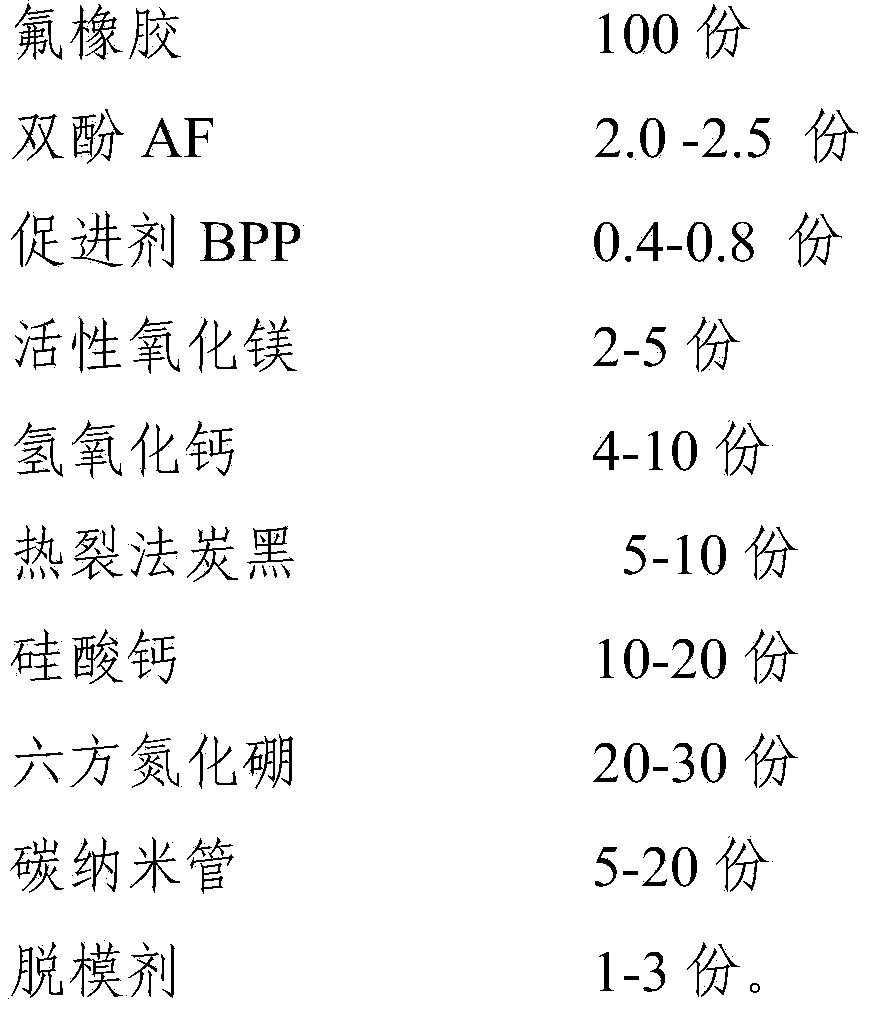

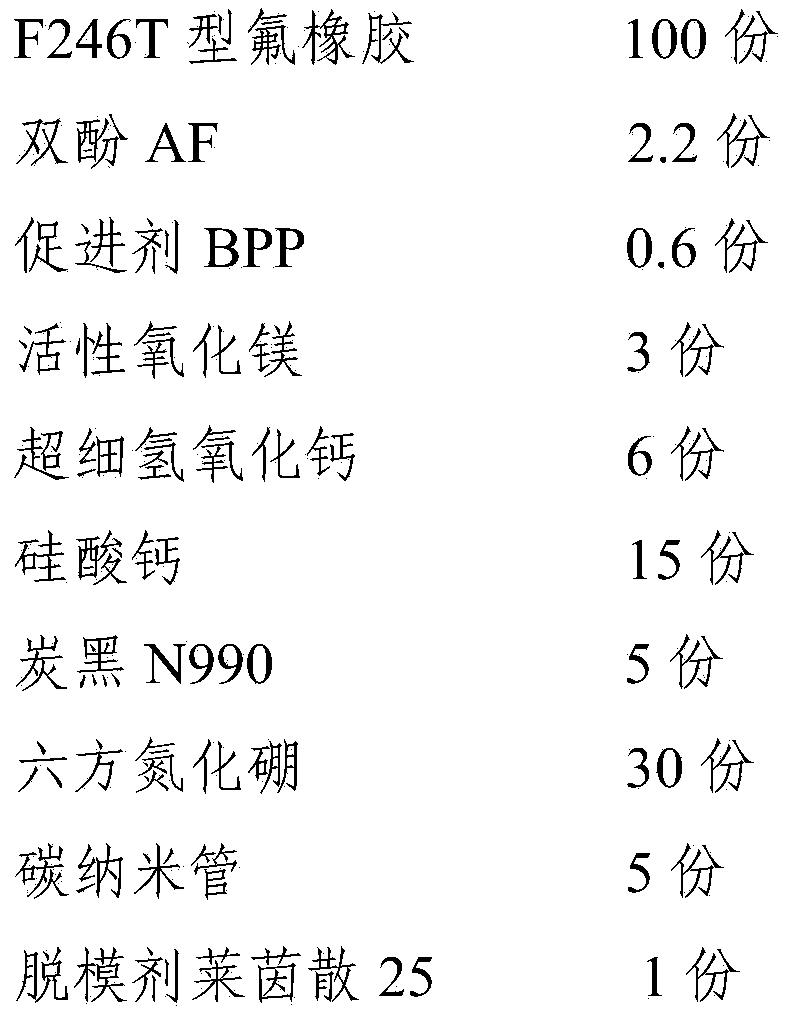

Mixture for automobile high-speed rotation oil seals

InactiveCN104327429APhysical and mechanical properties unchangedOptimize the formula systemCalcium silicatePolymer science

The invention belongs to the field of organic compound processing, and provides a mixture for automobile high-speed rotation oil seals, which is prepared from the following components in parts by weight: 100 parts of fluororubber, 1.5-2.5 parts of bisphenol AF, 0.4-0.8 part of accelerator BPP, 2-5 parts of active magnesium oxide, 4-10 parts of calcium hydroxide, 0-50 parts of carbon black, 5-50 parts of calcium silicate, 0-50 parts of hexagonal boron nitride, 0-20 parts of carbon nanotube and 1-3 parts of mold release agent. By adopting the fluororubber F246 (the Mooney viscosity is 100-150) as the base unvulcanized rubber and optimizing the formula system, the physical and mechanical properties of the vulcanized fluororubber of the original formula are basically unchanged. The two different types of heat-conducting fillers are compounded to enhance the heat conductivity coefficient of the compounded rubber under the synergic actions, and the heat-conducting property of the vulcanized rubber product for manufacturing is obviously enhanced.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Compositions based on elastomeric polymers of vinylidene fluoride, hexafluoropropene and optionally tetrafluoroethylene, suitable for providing microcellular foamed articles

The present invention relates to compositions based on elastomeric polymers of vinylidene fluoride, hexafluoropropene and optionally tetrafluoroethylene suitable for providing microcellular foamed vulcanized articles by extrusion or compression molding. In the case of the production of extruded articles based on vinylidene fluoride and hexafluoropropene copolymers, the compositions comprise: the copolymer, bisphenol AF, a quaternary phosphonium or aminophosphonium salt, azodicarbonamide, MgO, Ca(OH)2, zinc stearate and a plasticizer, each of the components being contained in an exactly defined proportion.

Owner:AUSIMONT SPA

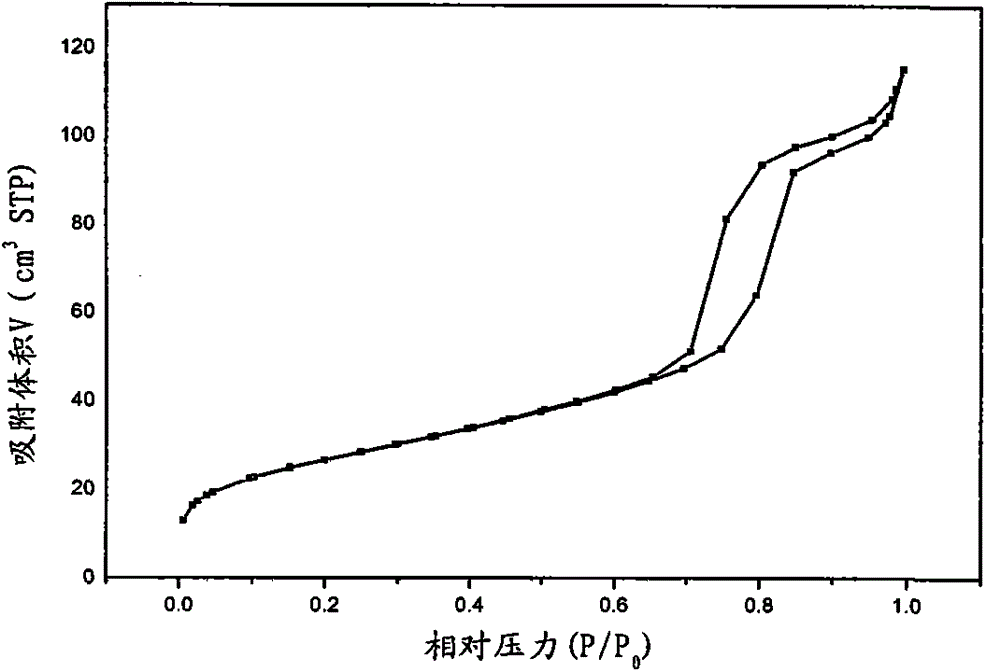

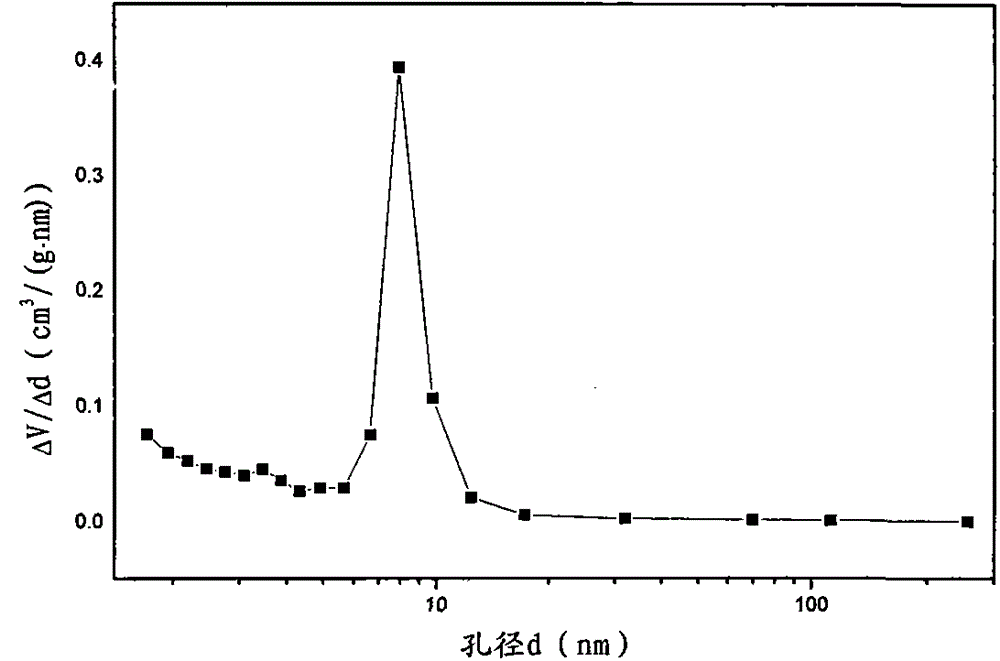

Preparation method of bisphenol F with high ortho-isomeride content

InactiveCN104130109AHigh ortho contentEasy to makeOrganic chemistryOrganic compound preparationMolecular sieveWastewater

The invention discloses a preparation method of bisphenol F with high ortho-isomeride content. The preparation method comprises the following step: through an acidic mesoporous molecular sieve Zr-SBA-15 catalyst, catalyzing phenol and formaldehyde aqueous liquor with the mass percentage of 35-40%, to synthesize the bisphenol F, wherein the adopted acidic mesoporous molecular sieve Zr-SBA-15 catalyst is synthesized in one step, and the activity of the catalyst can be regulated by regulating the mole ratio of Zr / Si atoms of the catalyst. The preparation method is simple in technology, high in catalysis efficiency, the bisphenol F with high ortho-isomeride content can be obtained, the catalyst is easily separated and recovered and repeatedly used, and no equipment corrosion and waste water treatment problems exist, so that the preparation method is an environment-friendly high-efficiency preparation method of the bisphenol F with high ortho content.

Owner:XIANGTAN UNIV

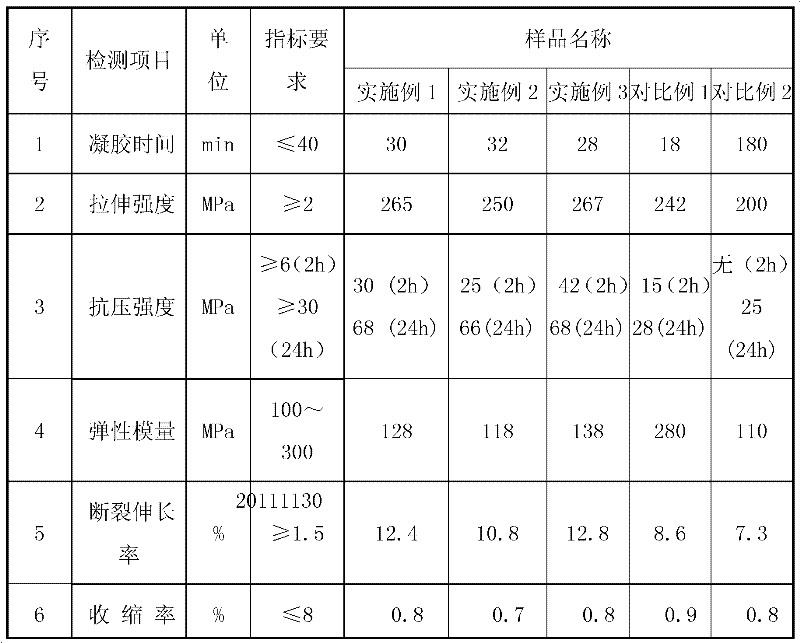

Method for preparing composite curing agent modified bisphenol F thermosetting adhesive repairing agent special for ballastless track gap and crack damage

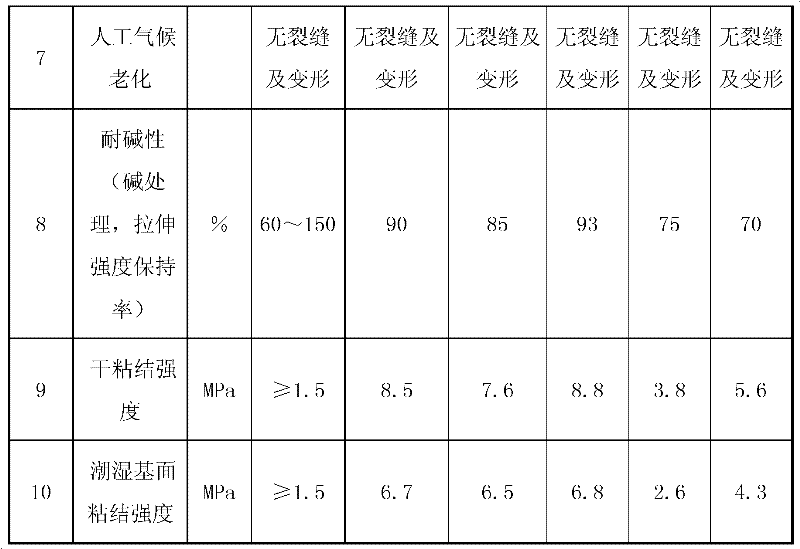

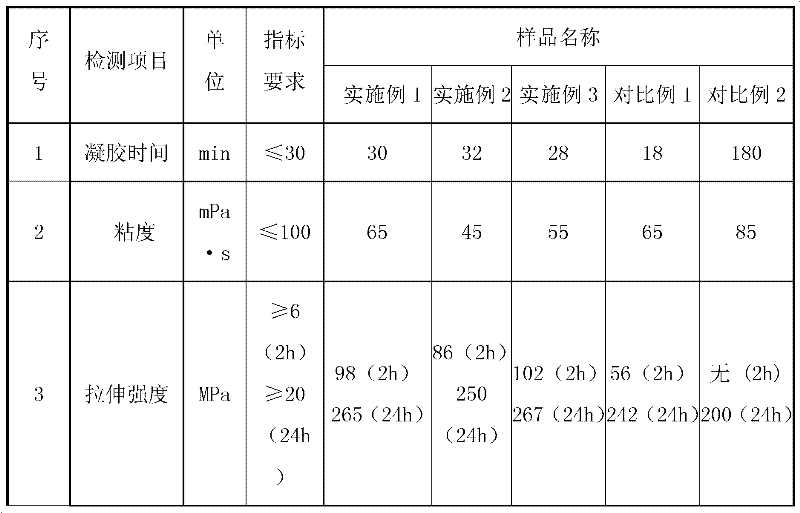

ActiveCN102516912ALow curing temperatureFast curingRailway track constructionEpoxy resin adhesivesBisphenol AFViscosity

The invention discloses a method for preparing a composite curing agent modified bisphenol F thermosetting adhesive repairing agent special for ballastless track gap and crack damage. The method comprises three steps of: preparing a bisphenol F epoxy resin main agent, compositing a polythiol-aminal type composite modified curing agent and curing the bisphenol F epoxy resin by the polythiol-aminaltype composite modified curing agent. The repairing agent prepared by the method has the characteristics of low viscosity, low curing temperature, rapid curing, stable volume stability and wide application prospect.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

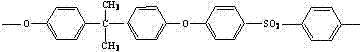

Synthesis method of polysulfone resin

The invention relates to a synthesis method of polysulfone resin. The method mainly comprises the following step: with bisphenol A and 4,4-dichlorodiphenylsulfone, of which the molar ratio is 1:1, as raw materials, N-methylpyrrolidone as a solvent used in the reaction process, chlorobenzene as a dehydrating agent and NaOH as a salt-forming agent, blocking by a chloromethane gas, wherein the overall reaction process is carried out under protection of nitrogen. The solid content of the system is controlled at 25-40%; chlorobenzene is 10-20% of weight of the solvent; the molar weight of NaOH is 1.01-1.10 times of that of the bisphenol A. The synthesis method is reasonable in formula, and simple to operate. The chloromethane gas is adopted to block, so as to prepare polysulfone resin with good liquidity by controlling the reaction time. By adopting the synthesis method, the reaction time can be shortened, a part of raw materials are saved, the production cycle can be shortened on production, and the cost is also reduced.

Owner:WEIHAI JIERUI MEDICAL PRODUCTS CO LTD

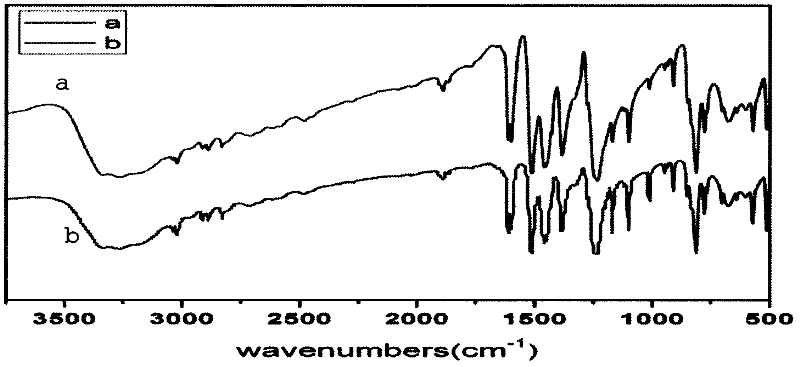

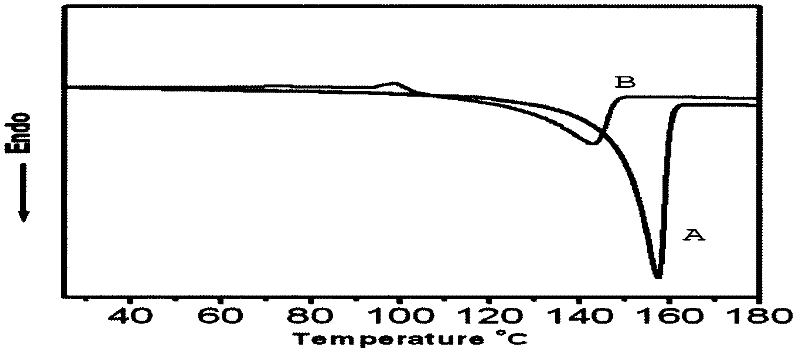

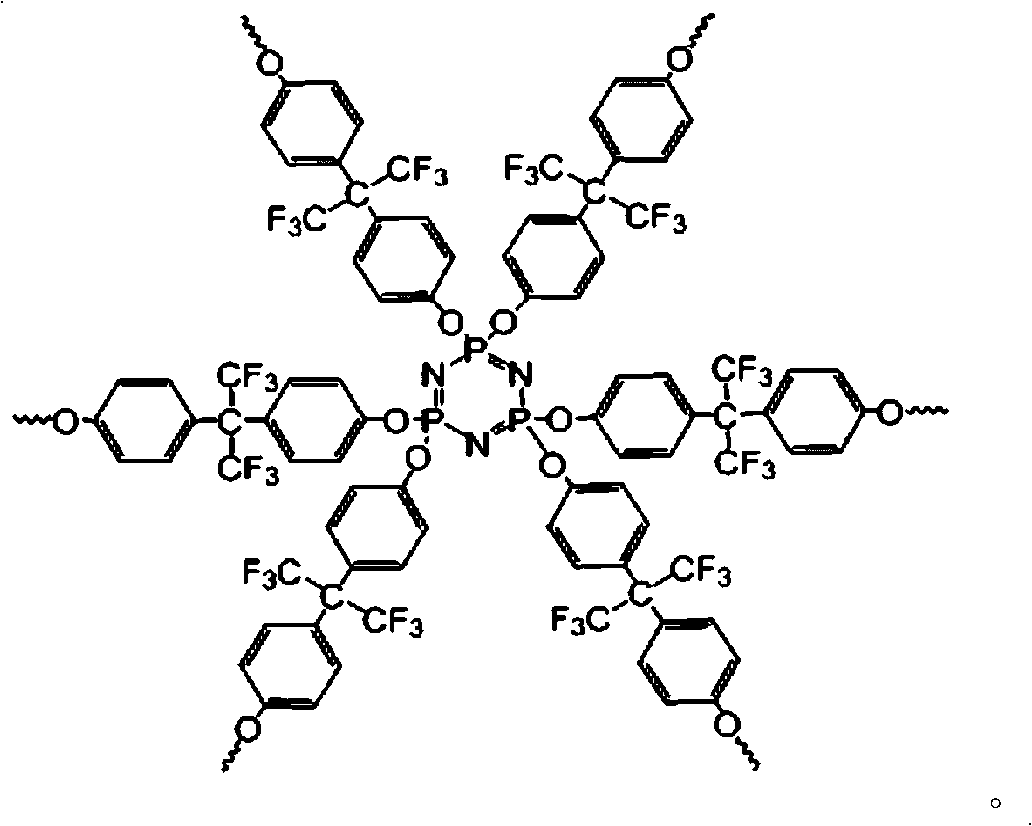

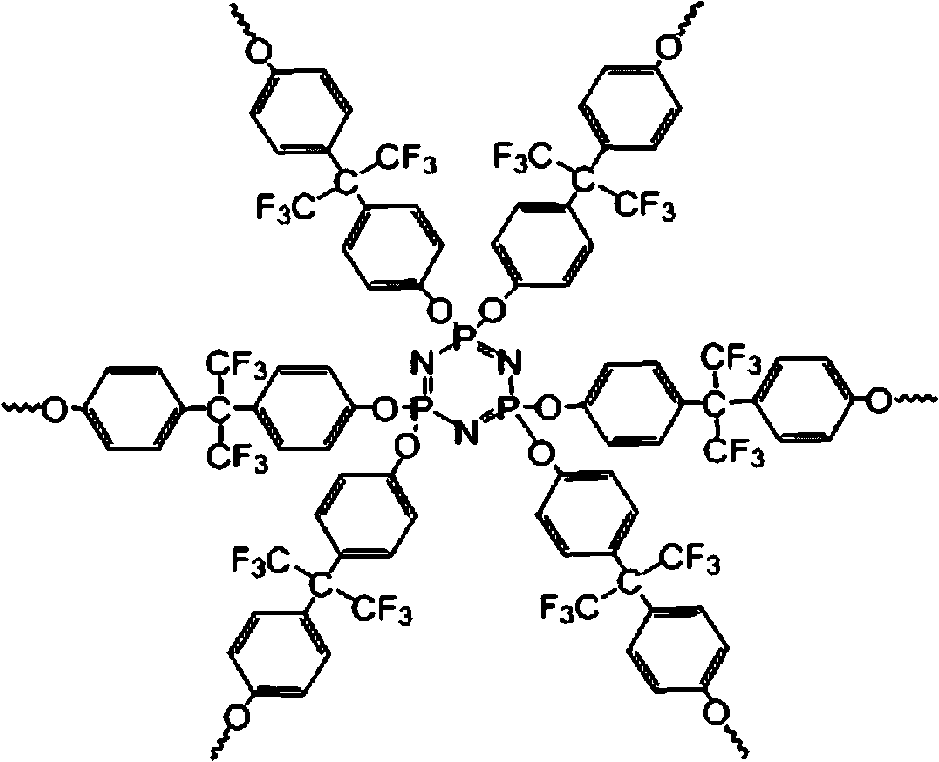

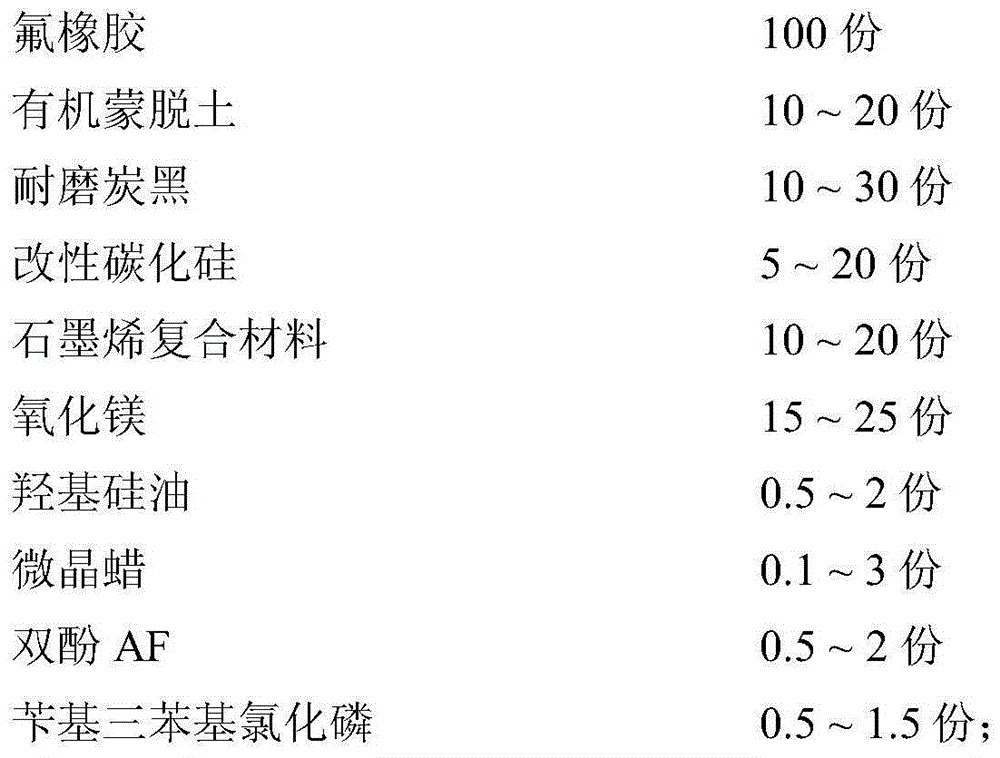

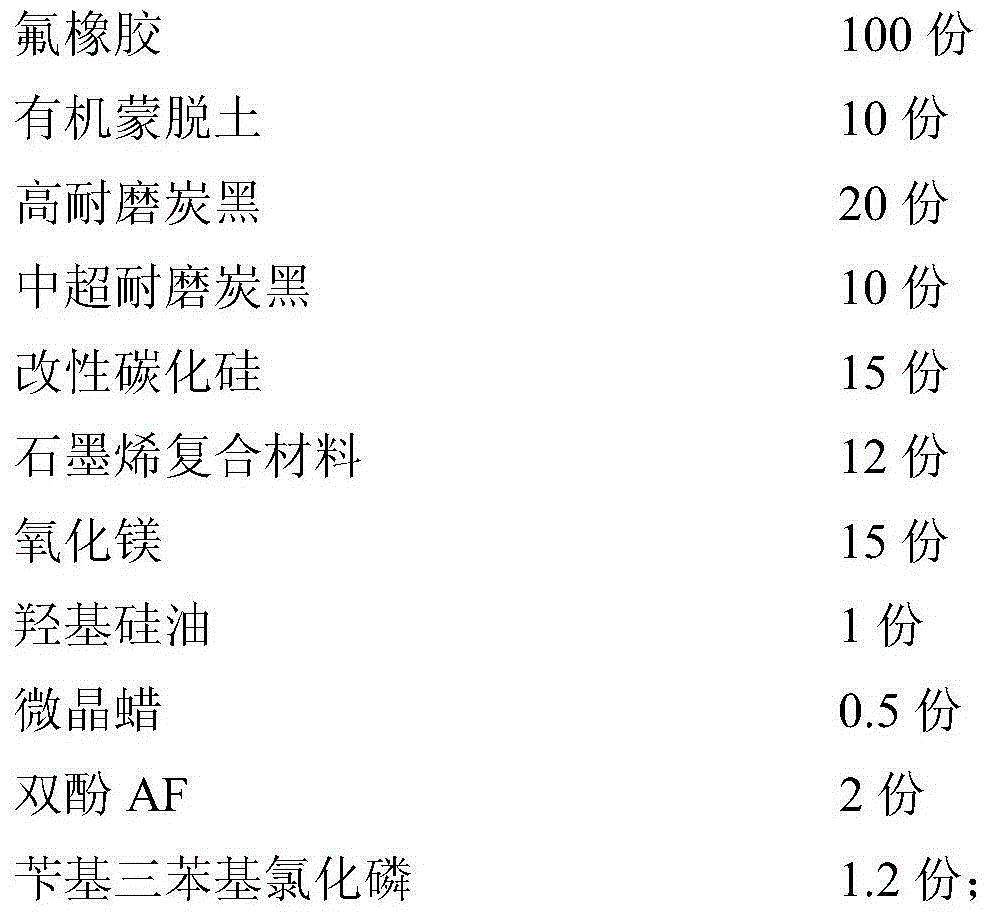

Polyphosphazene microsphere as well as preparation method, and application and implementation method thereof

InactiveCN101875728ALow costImprove thermal stabilityCoatingsMicroballoon preparationPolyphosphazeneOrganic solvent

The invention relates to a polyphosphazene microsphere as well as a preparation method and an application thereof in the technical field of materials. The polyphosphazene microsphere has the structural formula as disclosed in the specification. The preparation method of the polyphosphazene microsphere comprises the following steps of: (1) in the presence of an acid binding agent and an organic solvent, carrying out polycondensation reaction on hexachlorocyclotriphosphazene and bisphenol AF to obtain a solution; (2) and filtering the solution, washing a filtering medium, and drying to obtain the polyphosphazene microsphere. The invention also relates to application of the polyphosphazene microsphere in the preparation of a super-hydrophobic surface. The polyphosphazene microsphere has the advantages of low cost, excellent thermostability, flame retardance, chemical durability and radiation resistance. The preparation method has the advantages of short time, mild reaction conditions and simple process. The super-hydrophobic surface prepared from the polyphosphazene microsphere has excellent super-hydrophobicity.

Owner:SHANGHAI JIAO TONG UNIV

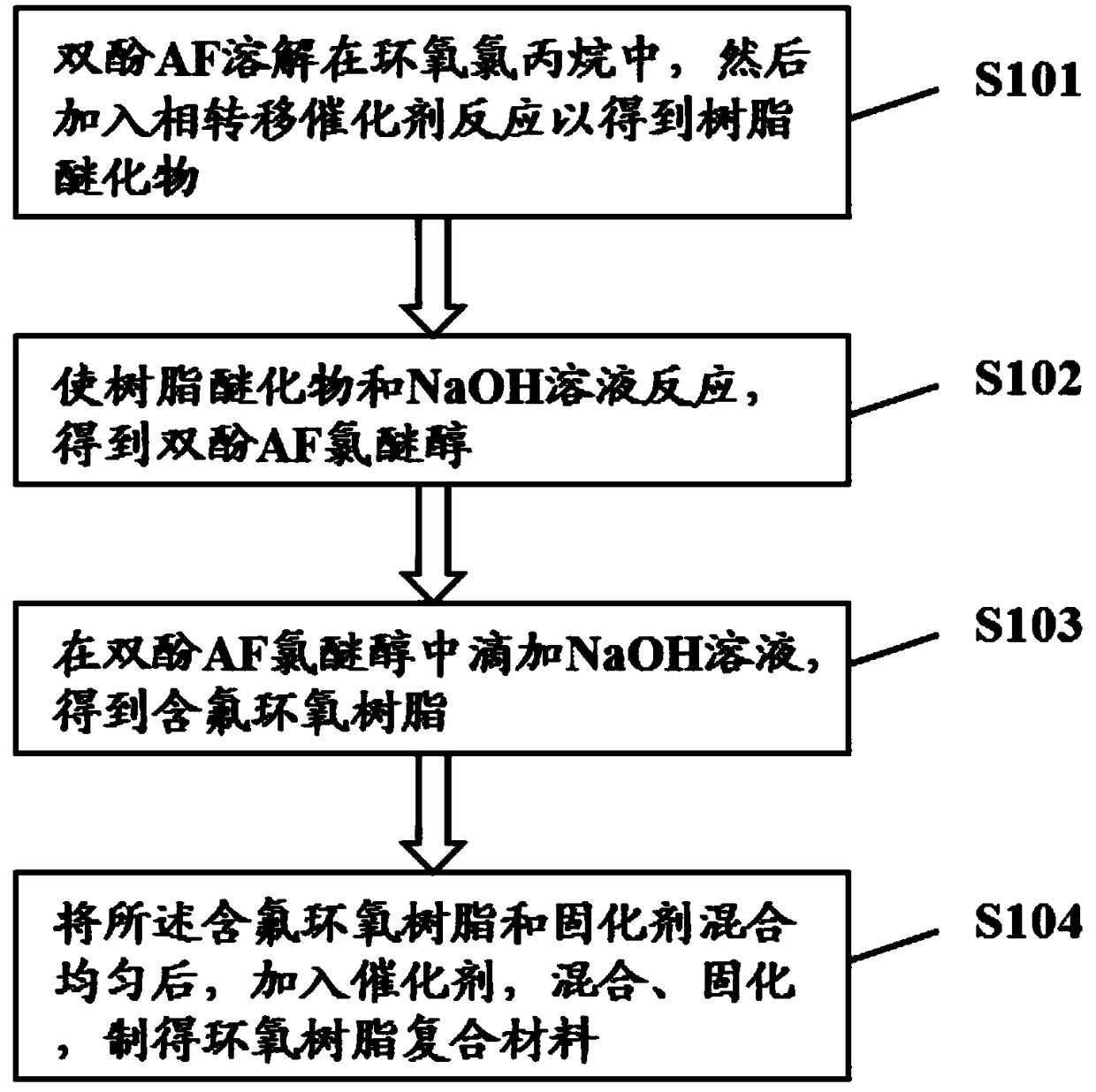

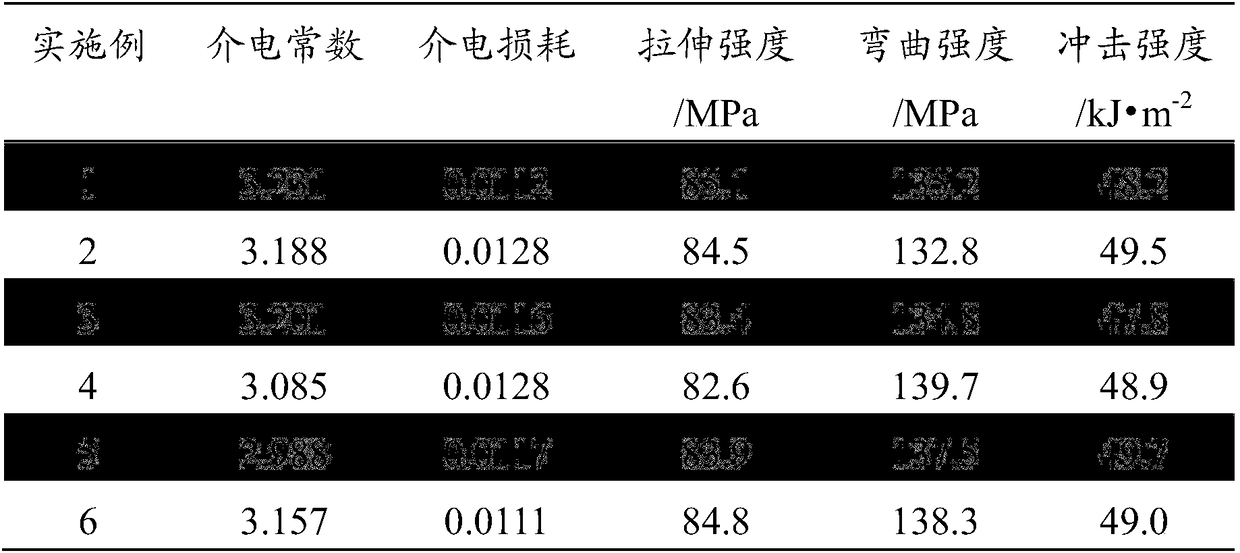

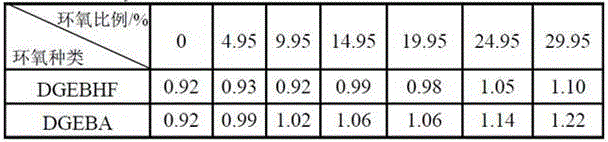

Epoxy resin composite material as well as preparation method and application thereof

The invention provides a preparation method of an epoxy resin composite material. The preparation method of the epoxy resin composite material comprises the following steps: completely dissolving bisphenol AF into epoxy chloropropane, adding a catalyst and reacting to obtain resin etherate; performing reaction on the resin etherate and a NaOH solution to obtain bisphenol AF chlorine ether glycol;adding the NaOH solution into the bisphenol AF chlorine ether glycol dropwise to obtain fluorine-containing epoxy resin; and mixing the fluorine-containing epoxy resin and a curing agent uniformly, adding a catalyst, mixing and curing to prepare the epoxy resin composite material. The invention also provides the epoxy resin composite material prepared by the above method as well as the applicationof the epoxy resin composite material serving as an electronic material and a wave-transmitting material. C-F is formed in introducing F into the resin structure to replace C-H, and the polarity of the resin structure is reduced, so that the epoxy resin composite material with low dielectric constant, low dielectric loss and high heat stability is prepared and can be widely applied to the fieldsof printed circuit boards, coating, microelectronics and the like.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

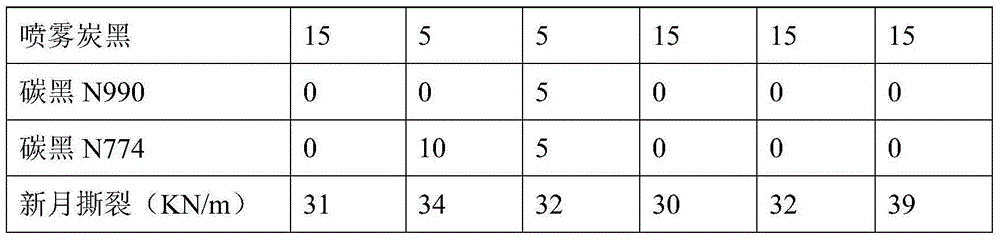

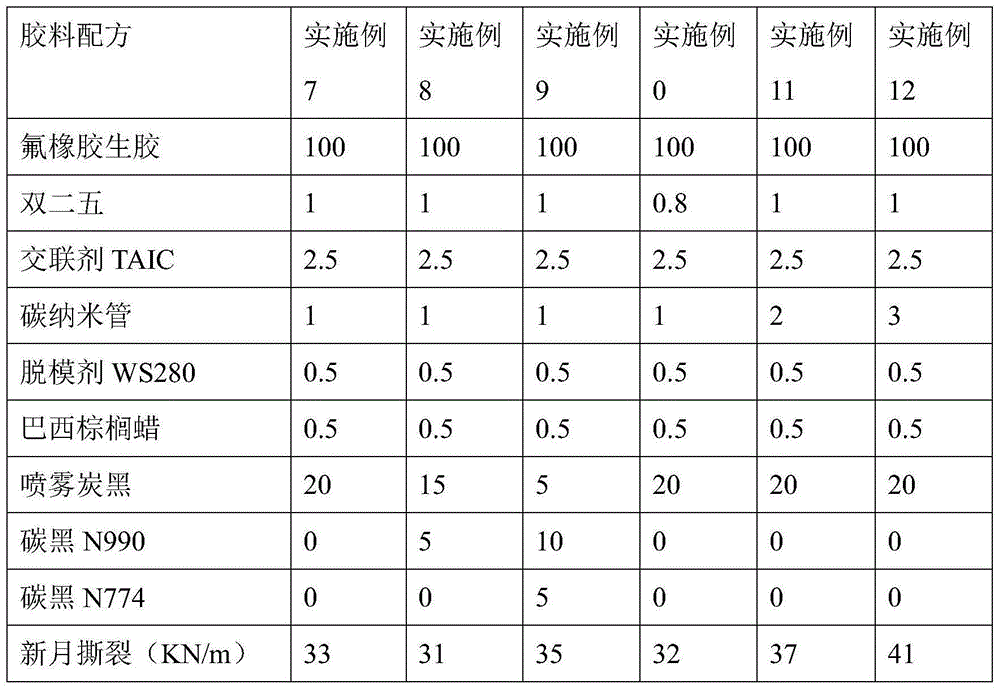

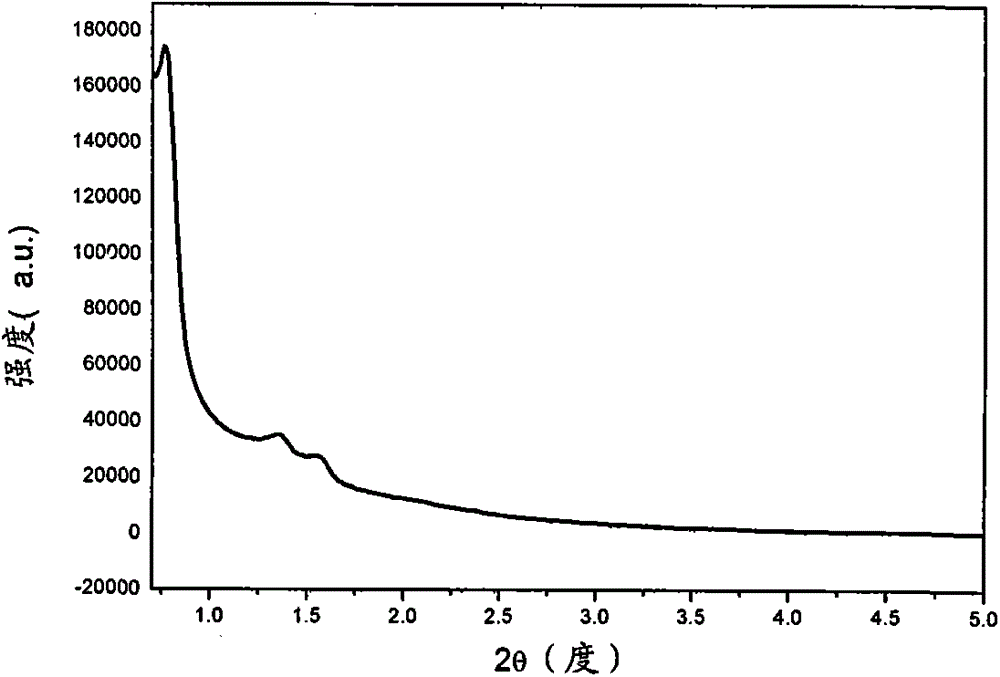

Tear-resistant fluoro-rubber mixed compound and preparation method thereof

The invention provides a tear-resistant fluoro-rubber mixed compound and a preparation method thereof, which belong to the filed of mixed compound application. The tear-resistant fluoro-rubber mixed compound is formed by mixing a binary fluoro-rubber, a ternary fluoro-rubber, active magnesium oxide, calcium hydroxide, a vulcanization system (bisphenol vulcanization system: bisphenol AF, benzyl triphenyl phosphorus chloride or peroxide vulcanization system: DBPH, TAIC), a carbon nanotube, a releasing agent, a reinforcing agent, and the like. The mixed compound prepared according to the invention is good in tear resistance, and can be widely used in rubber products.

Owner:NANJING ORIENTLEADER TECH CO LTD

Method for preparing bisphenol F

InactiveCN103936562ASimple preparation processShorten the production cycleOrganic chemistryOrganic compound preparationPhosphomolybdic acidHeteropoly acid

The invention discloses a method for preparing bisphenol F. The method is characterized in that phenol and formaldehyde serving as raw materials and a solid acid catalyst serving as a catalyst are used to prepare the target product bisphenol F, wherein the solid acid catalyst is prepared from heteropoly acid modified clay, and the mass dosing ratio of the catalyst to formaldehyde is (0.01-0.6):1; and the heteropoly acid is one or more of phosphotungstic acid, phosphomolybdic acid, silicotungstic acid, silicomolybdic acid and the like, wherein the clay is one or more of bentonite, kaoline, montmorillonoid, metakaolin, diatomaceous earth and the like. The method has the prominent advantages that the yield of the product bisphenol F is up to 93 percent, the selection to bisphenol F is 96 percent, the catalyst is friendly to environment, the preparation process is simple, the production cycle is short, the catalyst activity and catalytic selection are high, separation and reclamation are easy, recycling is available, and industrialization is facilitated.

Owner:HUNAN UNIV

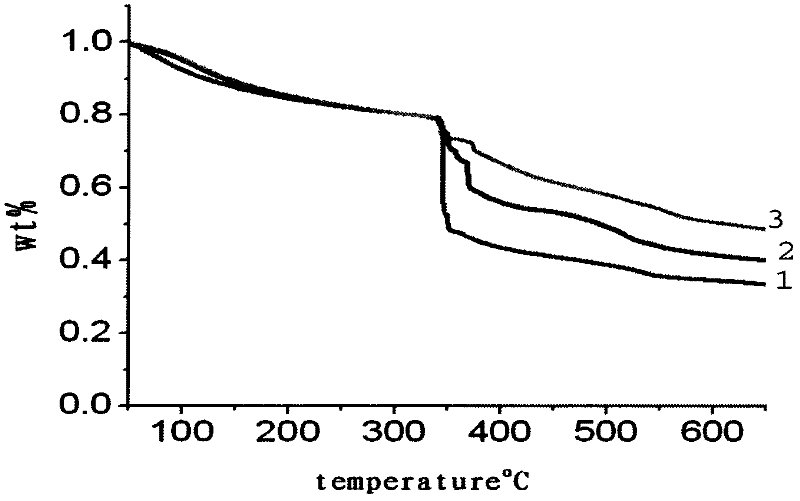

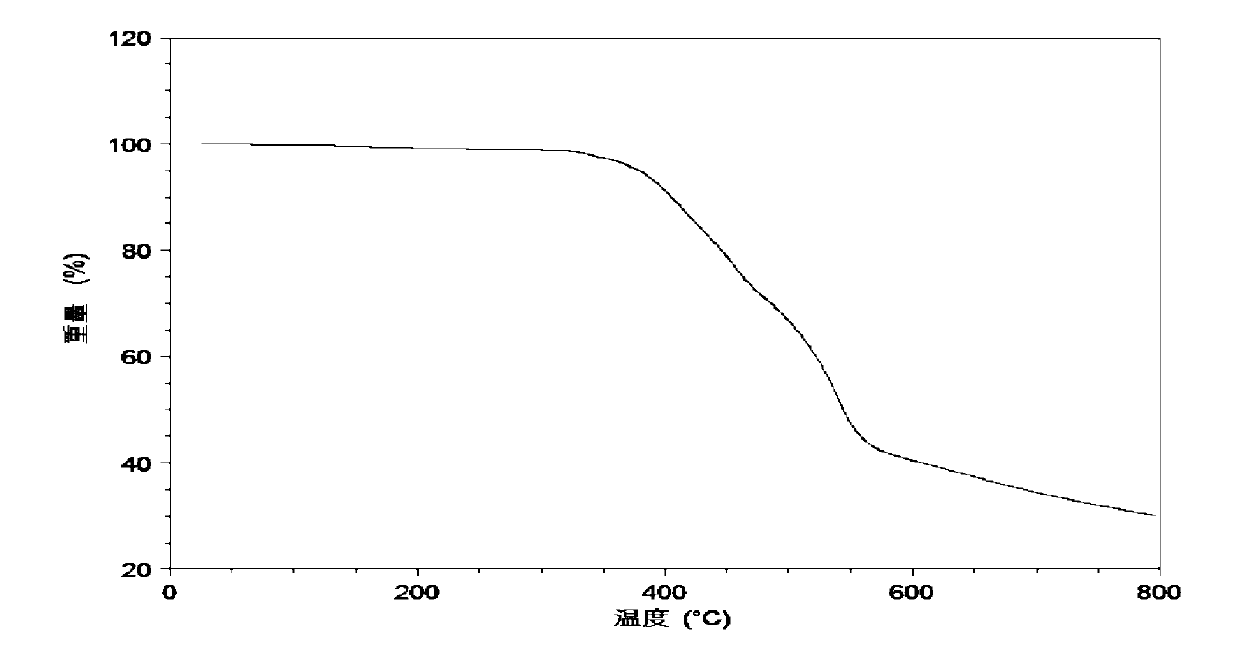

Hydrophobic metal-organic framework/poly(cyclotriphosphazene-co-bisphenol AF) flame retardant and preparation method thereof

InactiveCN110467820AImprove thermal stabilityExcellent superhydrophobic propertiesPolycarbonateBisphenol AF

The invention relates to a hydrophobic metal-organic framework / poly(cyclotriphosphazene-co-bisphenol AF) flame retardant and a preparation method thereof, and belongs to the technical field of flame retardant materials. The preparation method comprises: preparing a metal-organic framework ZIF-B from cobalt nitrate hexahydrate, zinc nitrate hexahydrate, nickel nitrate hexahydrate and 2-methylimidazole; and introducing the ZIF-B into the reaction of hexachlorocyclotriphosphazene, bisphenol AF and an acid binding agent, and participating into heterogeneous nucleation to prepare a flame retardant.According to the present invention, the flame retardant has an initial decomposition temperature of 382+ / -3 DEG C, a maximum thermal decomposition rate of more than 450 DEG C, and a residue amount ofmore than 35% at a temperature of 800 DEG C, has good thermal stability, is rich in a large number of fluorine atoms on the surface, has a water contact angle of more than 140 DEG C, has good superhydrophobic performance, and further has good effects of water resistance, flame retardancy, and smoke suppression in the application in flame retardant polypropylene, polycarbonate and epoxy resins.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-toughness low-temperature-resistant modified rubber sealing member and preparation method thereof

The invention discloses a high-toughness low-temperature-resistant modified rubber sealing member, prepared from the following raw materials in parts by weight: 35-45 parts of chlorosulfonated polyethylene rubber, 15-25 parts of a modified copolymer, 2-6 parts of butadiene-acrylonitrile rubber, 4-8 parts of fluororubber, 2-5 parts of vinylidene fluoride hexafluoropropylene rubber, 3-6 parts of polyvinyl chloride, 2-5 parts of carbon black N550, 3-6 parts of dibutyl phthalate, 2-5 parts of dibutyl sebacate, 3-4 parts of an anti-aging agent RD, 4-8 parts of modified glass fibers, 4-8 parts of magnesium oxide, 8-9 parts of zinc oxide, 3-6 parts of a silane coupling agent KH-570, 3-6 parts of bisphenol AF, 2-5 parts of stearic acid, and 4-6 parts of a vulcanization accelerator DCP. The invention also provides a preparation method of the high-toughness low-temperature-resistant modified rubber sealing member. The rubber sealing member prepared by the method provided by the invention has excellent toughness and low temperature resistance.

Owner:安徽亚兰密封件股份有限公司

Method for realizing catalytic synthesis of bisphenol F by virtue of flaky Al-SBA-15 mesoporous molecular sieve

ActiveCN104086373AReduced Diffusion ResistanceHigh catalytic activityOrganic chemistryMolecular sieve catalystsPolyethylene oxideSolvent

The invention discloses a method for realizing catalytic synthesis of bisphenol F by virtue of a flaky Al-SBA-15 mesoporous molecular sieve catalyst. The method comprises the following steps: on the basis of taking polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (Pluronic 123) as a template, tetraethoxysilane (TEOS) as a silicon source and aluminum isopropoxide as an aluminum source, adding zirconium oxychloride under very low hydrochloric acid concentration, and adopting a hydrothermal process for preparing the flaky Al-SBA-15 mesoporous molecular sieve catalyst; on the basis of taking phenol and formaldehyde as raw materials and a flaky Al-SBA-15 mesoporous molecular sieve as a catalyst, performing condensation reaction to prepare bisphenol F, wherein the yield of bisphenol F is 98.8%. According to the method, the catalyst is high in activity, other solvents are not used in catalyst preparation and bisphenol synthesis processes, environmental friendliness is achieved, and the catalyst is low in preparation cost, easy to separate and recover and reusable.

Owner:XIANGTAN UNIV

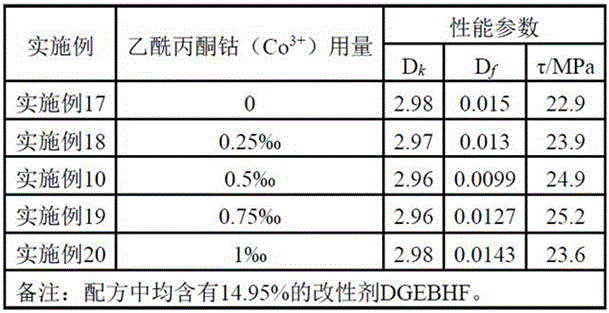

Cyanate ester adhesive with low dielectrics and high toughness, and preparation method thereof

The invention discloses a cyanate ester adhesive with low dielectrics and high toughness, and a preparation method thereof, and belongs to the field of high polymer materials. Bisphenol AF type epoxy resin (DGEBHF) and organic metal salt catalyst are used for jointly modifying cyanate ester so as to solve the problem of poor dielectrics, poor toughness and insufficient adhesion of the cyanate ester. The cyanate ester adhesive is used for the bonding of electronic products. The preparation method comprises the following steps: (1) at a ratio of 70-95%, weighing cyanate ester resin, smelting at the temperature of 100-120DEG C, cooling to 75-90DEG C, and adding 4.9-29.957% of DGEBHF to be stirred to be transparent to obtain premixing adhesive; (2) adding 0.025-0.1% of organic metal salt catalyst into the premixing adhesive obtained in (1) to be evenly mixed at the temperature of 75-90DEG C to obtain the cyanate ester adhesive with low dielectrics and high toughness. The cyanate ester adhesive has the advantages of excellent dielectricity, toughness, adhesion and solidification, simple preparation technology, low equipment requirement and environment protection.

Owner:SOUTHWEAT UNIV OF SCI & TECH

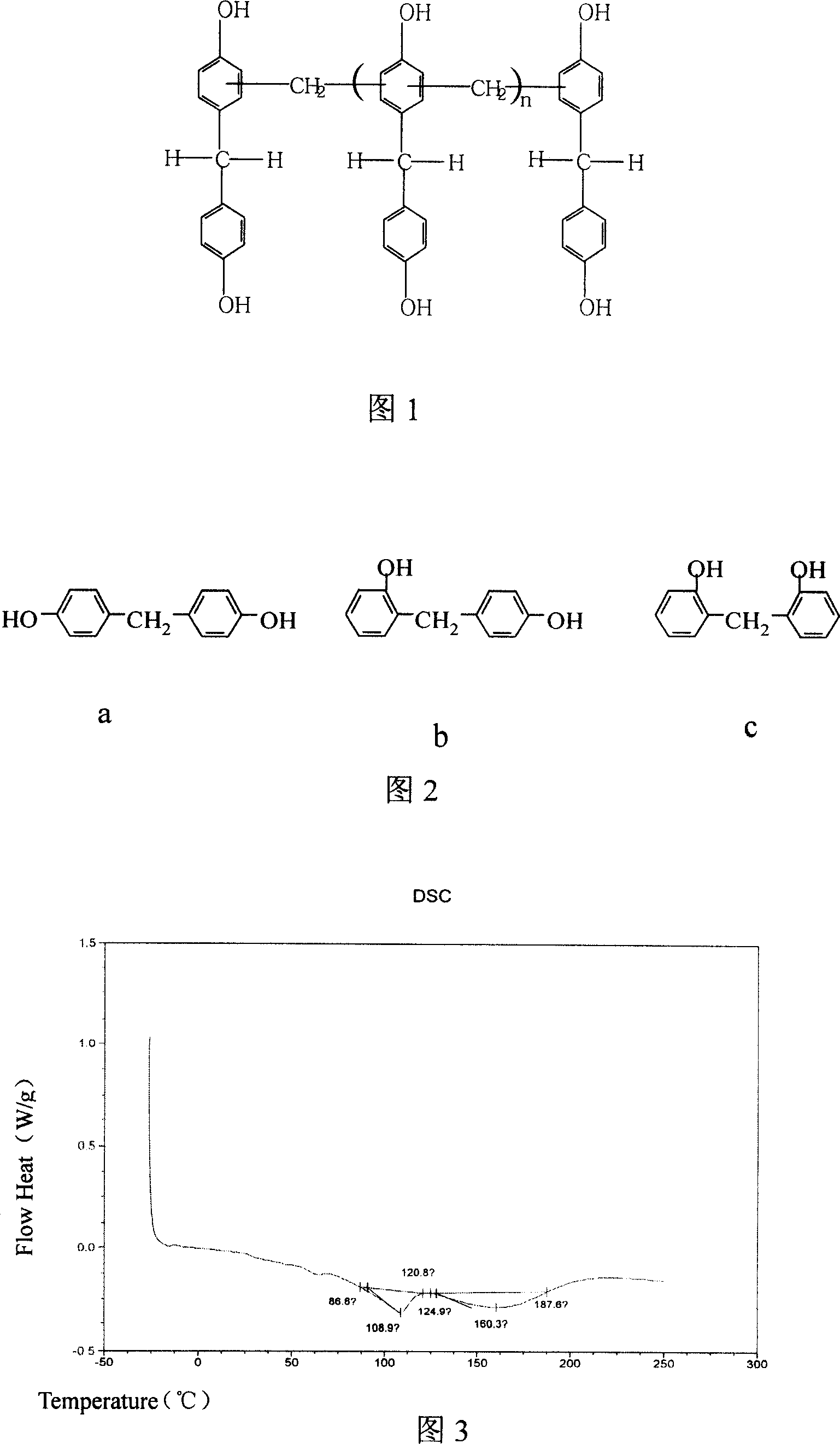

Linetype bisphenol F phenolic resin and preparation method thereof

The invention relates to a method for preparing a linear bisphenol F formaldehyde-phenol resin, which is characterized by the following: synthesizing the bisphenol F firstly; synthesizing bisphenol F formaldehyde-phenol resin secondly. The method comprises the following steps: mixing fenol, 138.4 phosphoric acid and water according to the proportion; dropping the extractant of formaldehyde and methyl isobutyl ketone with uniform speed; washing the product with distilled water; getting white solid state bisphenol F by vacuum dehydration; adding formaldehyde, oxalic acid, alcaine and water in bisphenol F and heating until boiling; stopping the reaction after keeping the temperature; aspirating the upper layer acid liquor; washing with distilled water; proceeding with vacuum dehydration; getting the linear bisphenol F formaldehyde-phenol resin. The invention avoids the roofing copper system property step-down problem of high free phenol in linear bisphenol F formaldehyde-phenol resin, which avoids the bad shockproof property problem of the roofing copper system in linear bisphenol F formaldehyde-phenol resin.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for catalyzed synthesis of bisphenol F by using modified hydroxyapatite

InactiveCN103772154AHigh selectivityLess corrosiveOrganic chemistryOrganic compound preparationAluminium chlorideBisphenol AF

The invention discloses a method for the catalyzed synthesis of bisphenol F by using modified hydroxyapatite. The method is implemented by taking phenol and formaldehyde as raw materials and taking modified hydroxyapatite as a catalyst through a step of carrying out a condensation reaction on the raw materials and the catalyst so as to obtain bisphenol F. The adopted catalyst is prepared by carrying out load modification by taking hydroxyapatite subjected to preliminary pretreatment as a carrier and taking any one or more of aluminium chloride, zinc chloride, copper chloride, titanium tetrachloride or ferric chloride as modifiers. The adopted catalyst is cheap and easy to obtain, the catalyst is good in dispersibility, high in catalytic efficiency, easy to separate and reusable in the reaction, and overcomes the defects of too high by-products, strong corrosivity, and the like in the process of synthesizing bisphenol F by using other catalysts; and in the process of reaction, other organic solvents are not required to be added, therefore, the method conforms to the principle of green economy.

Owner:XIANGTAN UNIV

Grinding roller sealing ring materials and preparation method thereof

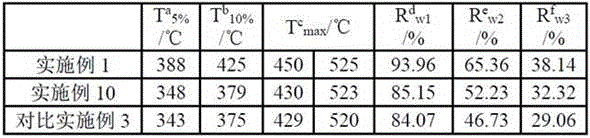

ActiveCN104530611ASolve difficult peelingSolve densityOther chemical processesMicrocrystalline waxBisphenol AF

The invention relates to grinding roller sealing ring materials. The grinding roller sealing ring materials are characterized by comprising, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. The graphene composites are graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction. The graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the grinding roller sealing ring materials, the function of the graphene is fully played, and the wear resistance and heat resistance of the grinding roller sealing ring materials are effectively improved.

Owner:宁波佳乐特橡塑机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com