Preparation method of bisphenol F with high ortho-isomeride content

An isomer, high ortho-position technology, applied in the preparation of organic compounds, chemical instruments and methods, chemical recovery and other directions, can solve the problems of complex preparation process and low content of bisphenol F ortho-isomer, and achieve high efficiency. The preparation method and the production process are simple, and the effect of easy separation, recovery and repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

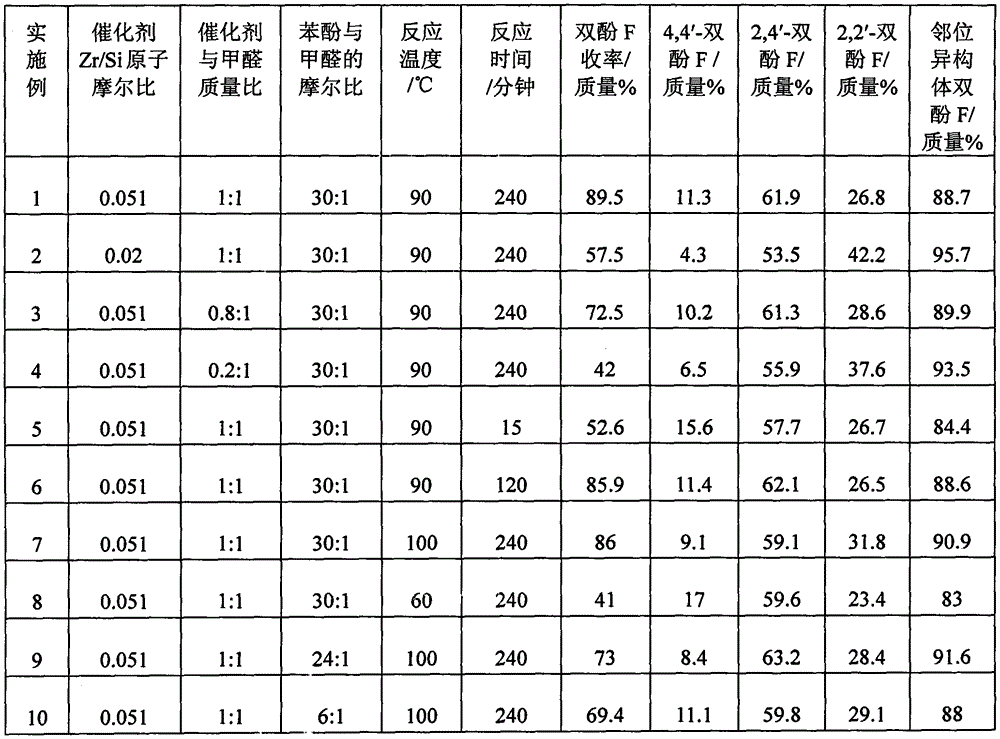

Examples

Embodiment 1

[0013] (1) Preparation of acidic mesoporous molecular sieve Zr-SBA-15 catalyst

[0014] 4 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, 2.527 grams of NaCl, 9 grams of tetraethyl orthosilicate, 160 grams of deionized water, 0.7082 grams of ZrOCl 8H 2 O was added to the reaction kettle, mixed evenly, stirred and reacted for 24 hours under the condition of 40°C water bath, then put into the crystallization kettle, placed in a 100°C oven for crystallization for 24 hours, cooled to room temperature, filtered, and the obtained solid was first heated at 60°C Dry it in an oven for 6 hours, then put it into a muffle furnace for roasting, raise the temperature from room temperature to 550°C at a rate of 10°C / min and keep it for 8 hours, and then get the acidic mesoporous molecular sieve Zr-SBA-15 catalyst after cooling down.

[0015] (2) Catalytic synthesis of bisphenol F

[0016] Add 9.42 grams of phenol and 0.1 gram of acidic mesoporous molec...

Embodiment 2

[0018] Operation steps are with embodiment 1, and its difference is that added ZrOCl 8H 2 O is 0.2784 grams, and the molar ratio of the Zr of catalyst and Si atom is 0.02, and the yield of bisphenol F is 57.5%, and the quality of 4,4'-, 2,4'- and 2,2'-bisphenol F The percentages are 4.3%, 53.5% and 42.2%, respectively.

Embodiment 3

[0020] The operation steps are the same as in Example 1, the difference is that the amount of catalyst used is 0.08 g, and the yield of bisphenol F is 72.5%, and the mass percentages of 4,4'-, 2,4'- and 2,2'-bisphenol F 10.2%, 61.3% and 28.6% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com