Patents

Literature

416 results about "Bisphenol S" patented technology

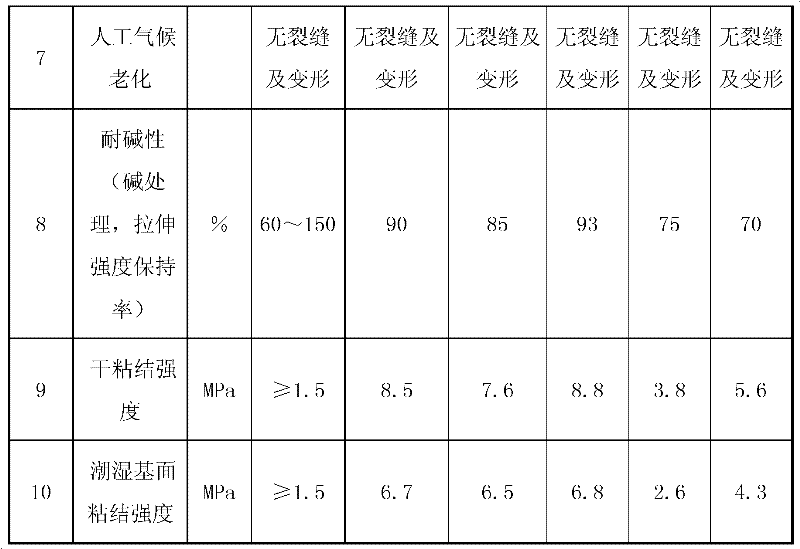

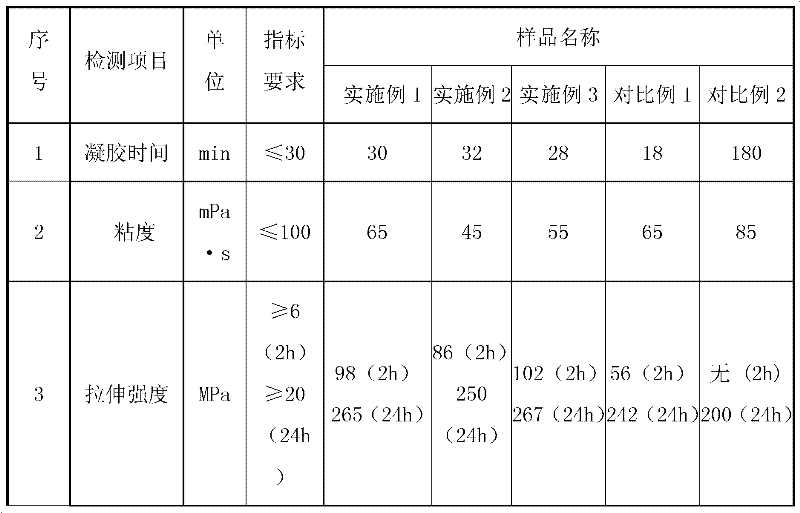

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

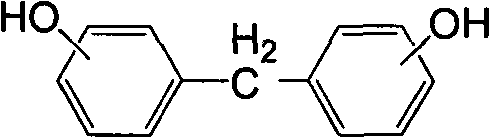

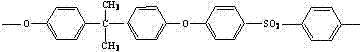

Bisphenol S (BPS) is an organic compound with the formula (HOC₆H₄)₂SO₂. It has two phenol functional groups on either side of a sulfonyl group. It is commonly used in curing fast-drying epoxy resin adhesives. It is a bisphenol, and a close analog of bisphenol A (BPA) in which the dimethylmethylene group (C(CH₃)₂) is replaced with a sulfone group (SO₂).

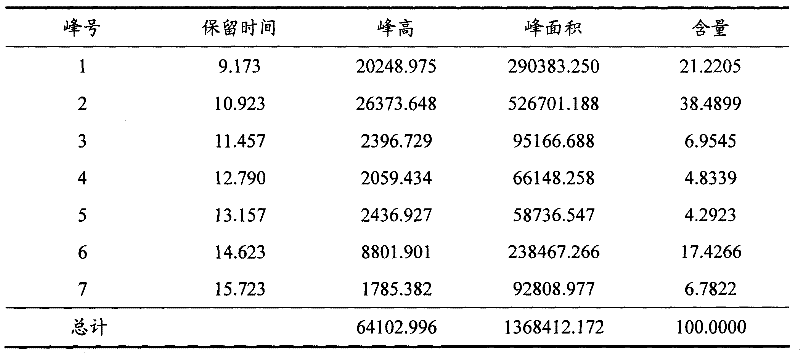

Preparation method for bisphenol F

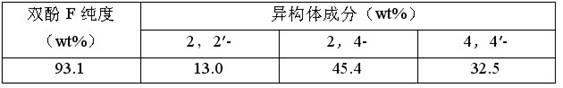

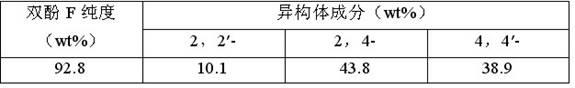

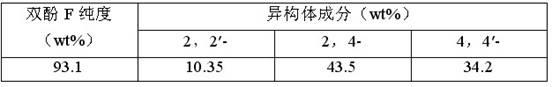

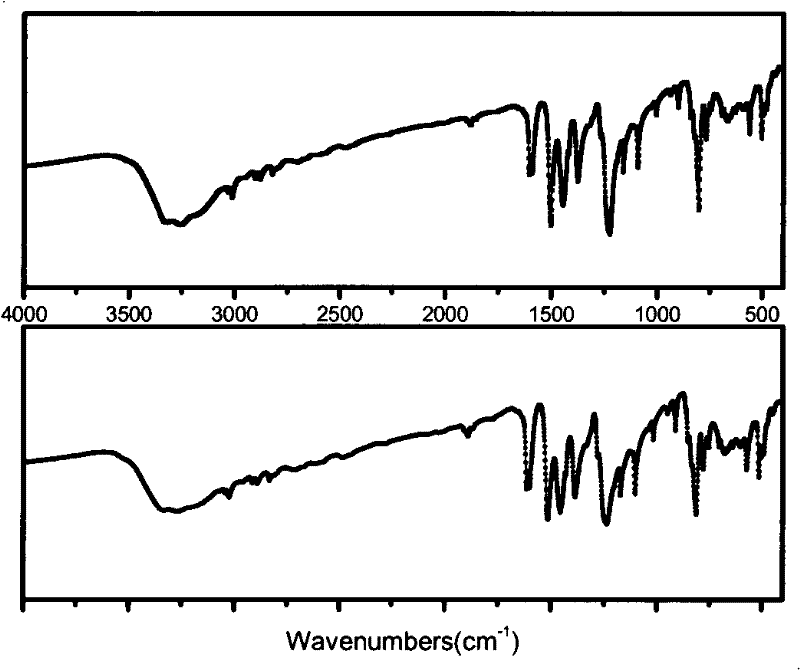

ActiveCN102491879AEasy to separate and recycleThe synthesis process is simpleOrganic chemistryOrganic compound preparationAluminium chlorideSynthesis methods

The invention discloses a synthesis method for bisphenol F, in which aluminium chloride, titanium tetrachloride and modified cation exchange resin are adopted as catalysts, and phenyl hydroxide and formaldehyde are adopted as raw materials. The invention has the technical effects as follows: the aluminium chloride, the titanium tetrachloride and the modified cation exchange resin are adopted for catalysis to synthesize the bisphenol F, and the resin catalyst is easy to separate and recover and can be used repeatedly; 2, a recrystallization and reduced pressure distillation combined separation technology is adopted for coproduction of high-purity bisphenol F and common bisphenol F products, the maximum yield of the bisphenol F reaches 90 percent, the content of 4, 4'-bisphenol F in a dimethyl benzene recrystallization product reaches 93.5 percent, reduced pressure distillation after-products are mainly other two isomers, and the separation of the 4, 4'-bisphenol F is realized effectively; 3, the requirement for the concentration of the formaldehyde raw material is not strict while the traditional one stage process require that the concentration of formaldehyde is above 40 percent; and 4, the synthesis technology is simple, the operation is convenient, and the realization of industrial production is easy.

Owner:湖南嘉盛德材料科技股份有限公司

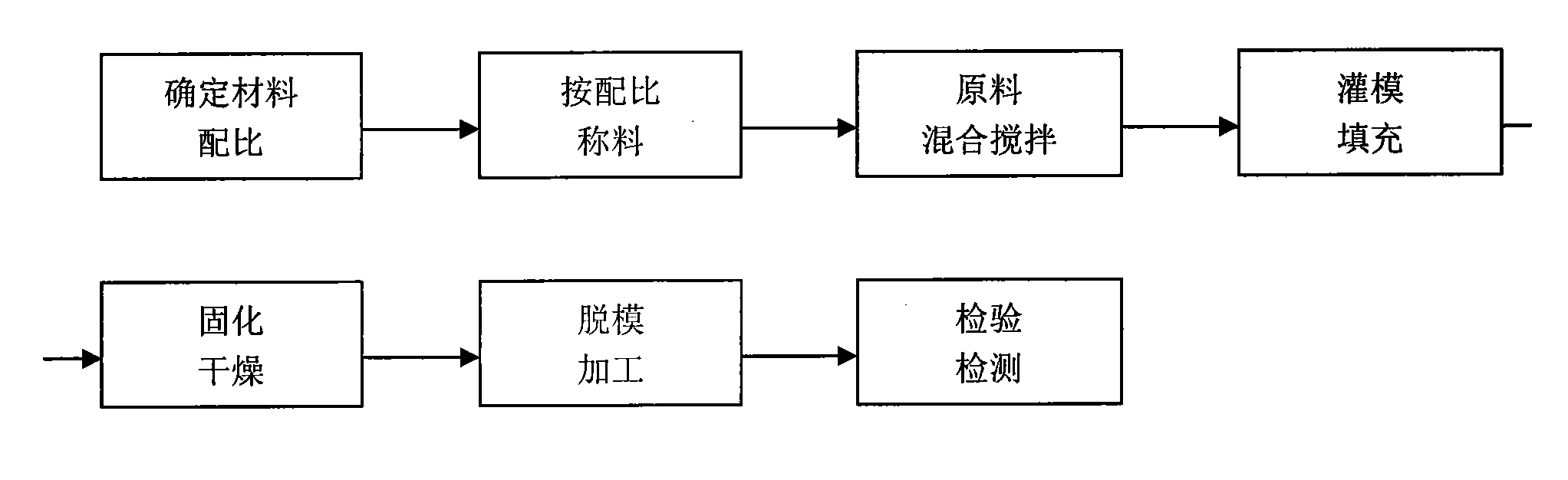

Machinable solid buoyancy material and preparation method thereof

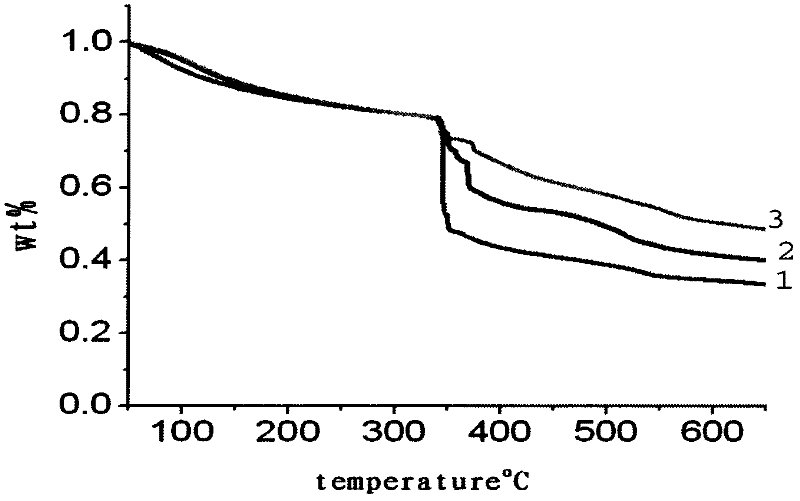

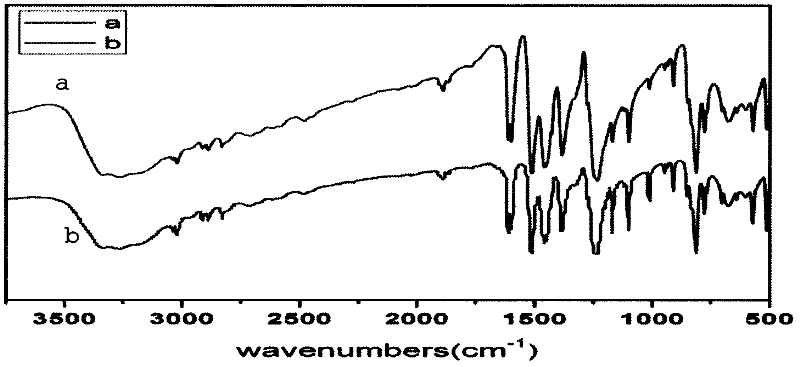

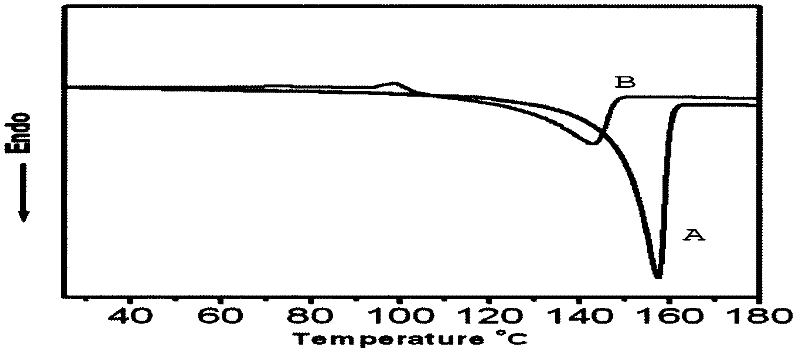

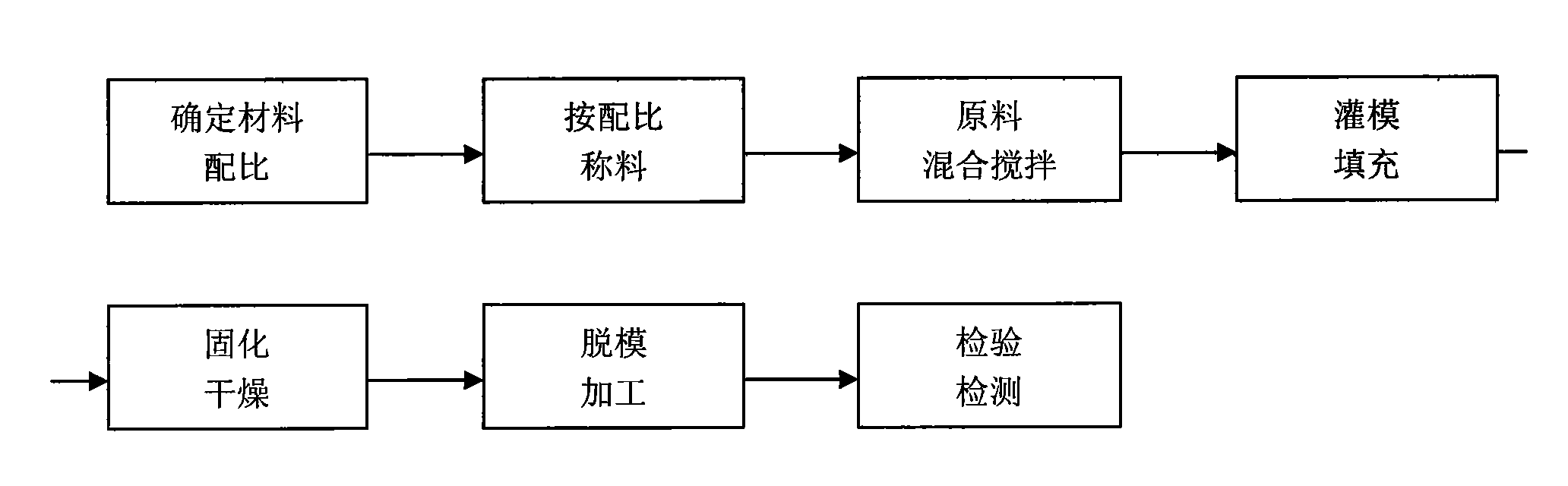

The invention relates to a machinable solid buoyancy material and a preparation method thereof. The machinable solid buoyancy material belongs to a functional nonmetallic material and comprises the following components in part by mass: 100 parts of epoxy resin, 15 to 55 parts of amine epoxy curing agent and 30 to 130 parts of glass beads, wherein the epoxy resin is bisphenol S type epoxy resin or glycidol epoxy resin; and the amine epoxy curing agent is polyamide 650, polyamide 651, tertiary nitrogen type organic amine or quaternary nitrogen type organic amine, bismaleimide, low molecular weight polyacrylamide, imidazoles or organic acid anhydride compounds. The preparation method comprises the following steps of: heating the epoxy resin and the amine epoxy curing agent, weighing the epoxy resin and the amine epoxy curing agent, blending and stirring the epoxy resin and the amine epoxy curing agent, adding the glass beads, stirring again, kneading the materials, after taking the material out, coating a mould release agent on the inner wall of a die and sticking mould release paper; filling the material into the die; covering by using a cover; curing the die in a drying oven; and separating the material from the die on a demoulding machine. The machinable solid buoyancy material can meet the requirements on underwater projects, permanent buoys and the like.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Powder coating containing modified sepiolite powder and preparing method thereof

ActiveCN103059696AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified sepiolite powder and a preparing method thereof. The powder coating containing the modified sepiolite powder is composed of raw materials comprising modified epoxy resin, bisphenol S epoxy resin, linear low density polyethylene resin, modified sepiolite powder, polyethylene wax, film forming resin, polydimethylsiloxane, benzoin, silver powder, acrylic resin, superfine talcum powder, hexamine, 2,6-di-tert-butyl-4- dimethylamino methyl) phenol, n-butyl methacrylate and polyacrylamide. The powder coating is a green and environment-friendly coating, nontoxic and heat-resistant, contains no solvent, and discharges no volatile organic compound (VOC), and furthermore the modified sepiolite added in the powder coating enhances compatibility of the modified epoxy resin, the bisphenol S epoxy resin and the linear low density polyethylene resin, improves surface leveling of the powder coating, has high gloss retention, and enhances decorating performance of the powder coating, and therefore, an obtained finished product is high in pass percent, and industrialization mass production can be achieved.

Owner:CHUZHOU HONGYUAN SPRAYING

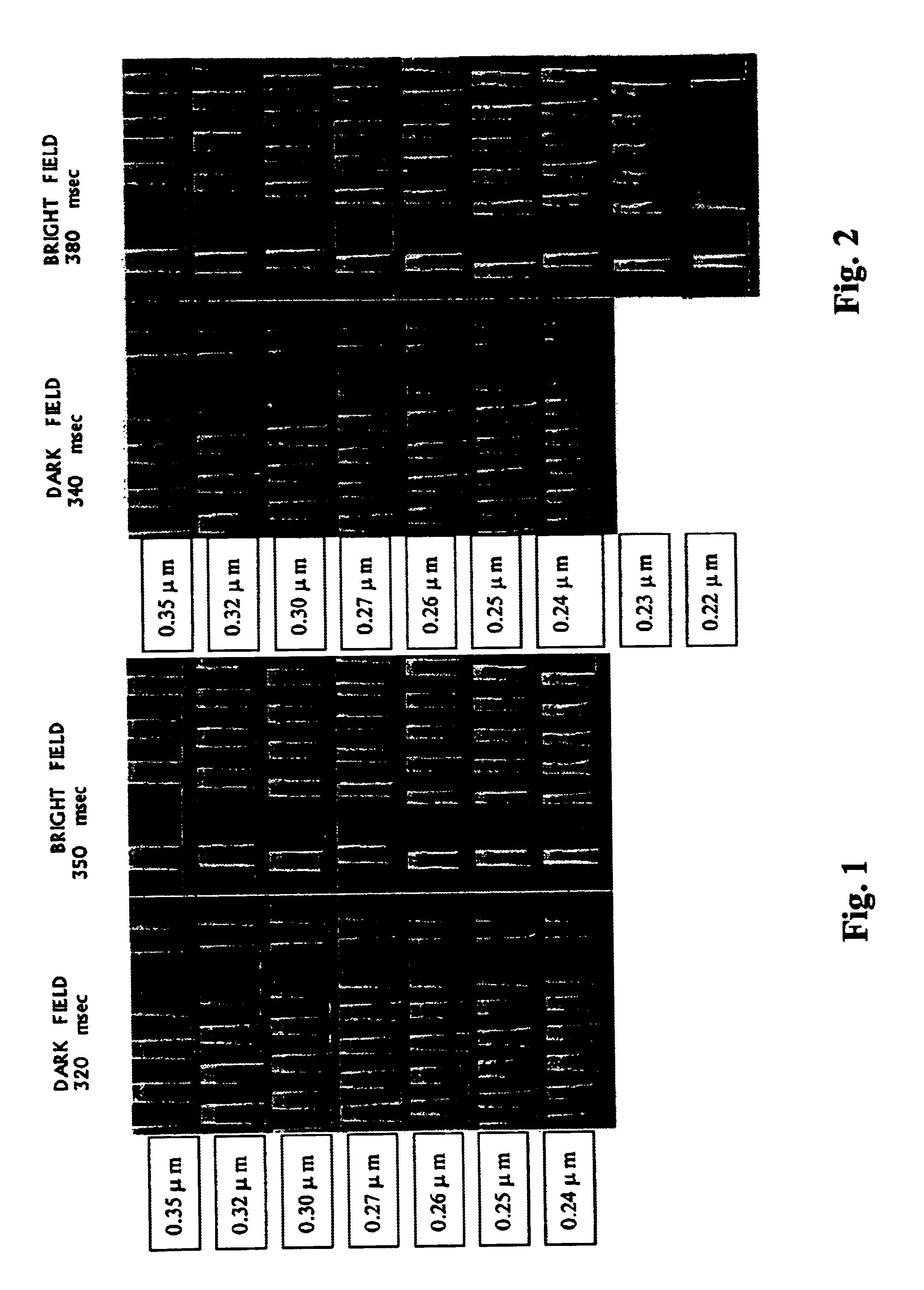

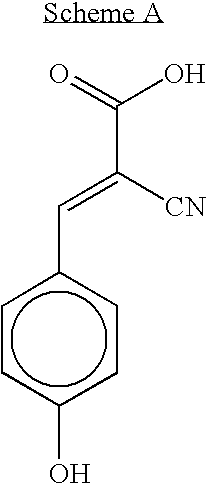

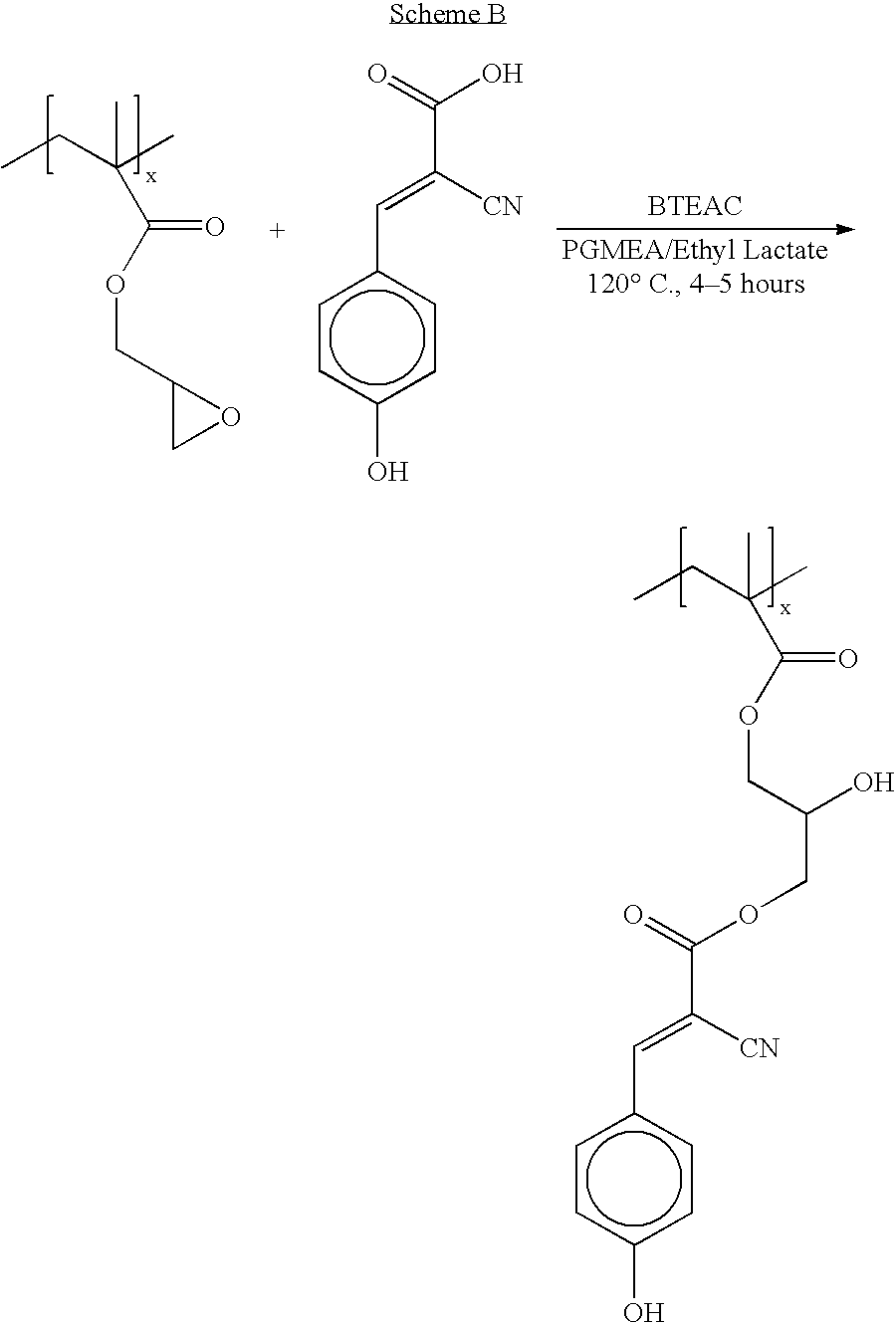

Anti-reflective coating composition with improved spin bowl compatibility

InactiveUS6962769B2Extended shelf lifeRadiation applicationsLayered productsAnti-reflective coatingAdditive ingredient

Anti-reflective compositions and methods of using those compositions to form circuits are provided. The compositions comprise a polymer dissolved or dispersed in a solvent system. In one embodiment, the compositions comprise less than about 0.3% by weight of a strong acid. In another embodiment, the weight ratio of strong acid to weak acid in the composition is from about 0:100 to about 25:75. Examples of preferred weak acid compounds include phenolic compounds (e.g., Bisphenol S, Bisphenol A, α-cyano-4-hydroxycinnamic acid), carboxylic acids (e.g., acetic acid), phosphoric acid, and cyano compounds. The polymer and other ingredients are preferably physically mixed in a solvent system. The resulting compositions are spin bowl compatible (i.e., they do not crosslink prior to the bake stages of the microlithographic processes or during storage at room temperature).

Owner:BREWER SCI

Preparation method of bisphenol F with high ortho-position isomer content

ActiveCN102070409ARaw materials are easy to getEasy to operateOrganic chemistryOrganic compound preparationOrtho positionSynthesis methods

The invention discloses a preparation method of bisphenol F with high ortho-position isomer content. The preparation method comprises the following steps: synthesizing the bisphenol F by adopting a two-step method, separating an organic phase and a phosphoric acid phase, neutralizing the organic phase and removing salt, and recovering phenol under the reduced pressure to obtain the bisphenol F product, wherein in the first step of the two-step synthesis method, the phenol reacts with formaldehyde under the weakly acidic condition; and in the second step, a large amount of catalyst phosphoric acid and formaldehyde are added into the reaction liquid obtained in the first step, and the formaldehyde completely reacts. The invention overcomes the defects that the content of the ortho-position isomer in the bisphenol F prepared by the existing bisphenol F preparation method is low, the curing speed of the synthesized bisphenol F epoxy resin is slow, the resin is easy to crystallize and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

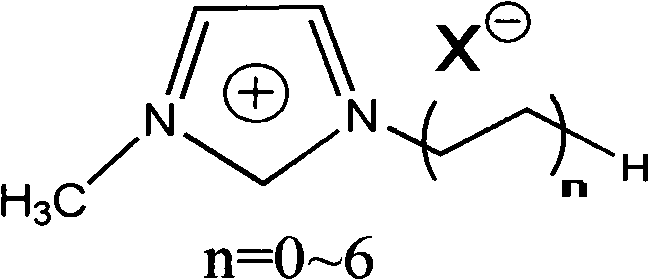

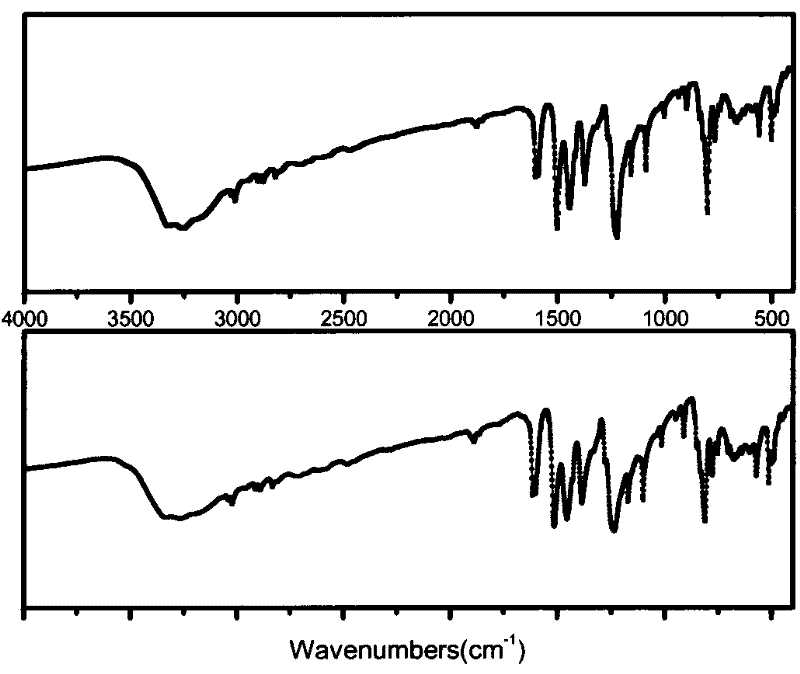

Method for preparing bisphenol F by using 1-alkyl-3-methylimidazole acidic ionic liquid

InactiveCN102584541AExtended service lifeNot corrosiveOrganic chemistryOrganic compound preparationOrganic solventSolvent

The invention relates to a method for preparing bisphenol F by using a 1-alkyl-3-methylimidazole acidic ionic liquid. According to the invention, phenol and formaldehyde are used as raw materials, and the 1-alkyl-3-methylimidazole acidic ionic liquid is used as a solvent and a catalyst, and bisphenol F can be prepared by condensation reaction. As for the method, other organic solvents easy to volatilize are not used, the defects that the reaction time is long, recovery is difficult, the service life is short, the corrosivity is strong and the like when the bisphenol F is subjected to catalytic synthesis by common bronsted acid can be solved, and the method provided by the invention is a novel bisphenol F preparing method which is efficient and environment-friendly.

Owner:XIANGTAN UNIV

Method for preparing low content of organic chlorine epoxy resin

The invention relates to a method for preparing epoxy resin with low content of organic chlorine. The method is characterized in that: when in preparation, the used raw materials comprise: bisphenol A and the derivative thereof or linear phenol-formaldehyde resin or bisphenol S, quaternary ammonium salt, epichlorohydrin, sodium hydroxide and water; the preparation steps are as follows: the bisphenol A and the derivative thereof or the linear phenol-formaldehyde resin or the bisphenol S and the epichlorohydrin are dissolved and etherified; the temperature is controlled, the removed epichlorohydrin is returned to a three-neck flask, the water is remained in a liquid divider, the dripping time is 2 to 4h, the temperature and the pressure are kept for 0.5 to 1h after the completion of the dripping; a filter paper is used for filtering the salt which is generated by the reaction, and the epichlorohydrin is removed, thus obtaining the light yellow liquid or the solid epoxy resin. The preparation method which is provided by the invention can allow the synthetic epoxy resin to achieve the low content of the organic chlorine without being refined, thus greatly improving the yield of the epoxy resin, reducing the cost and having important practical significance on the development and the application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

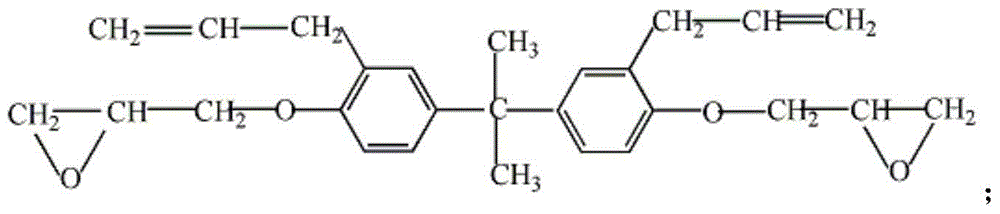

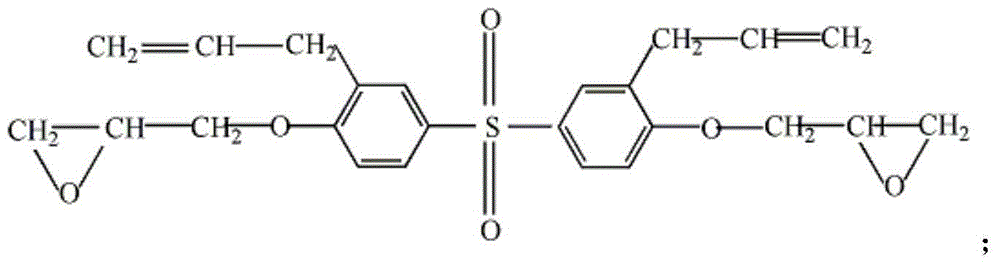

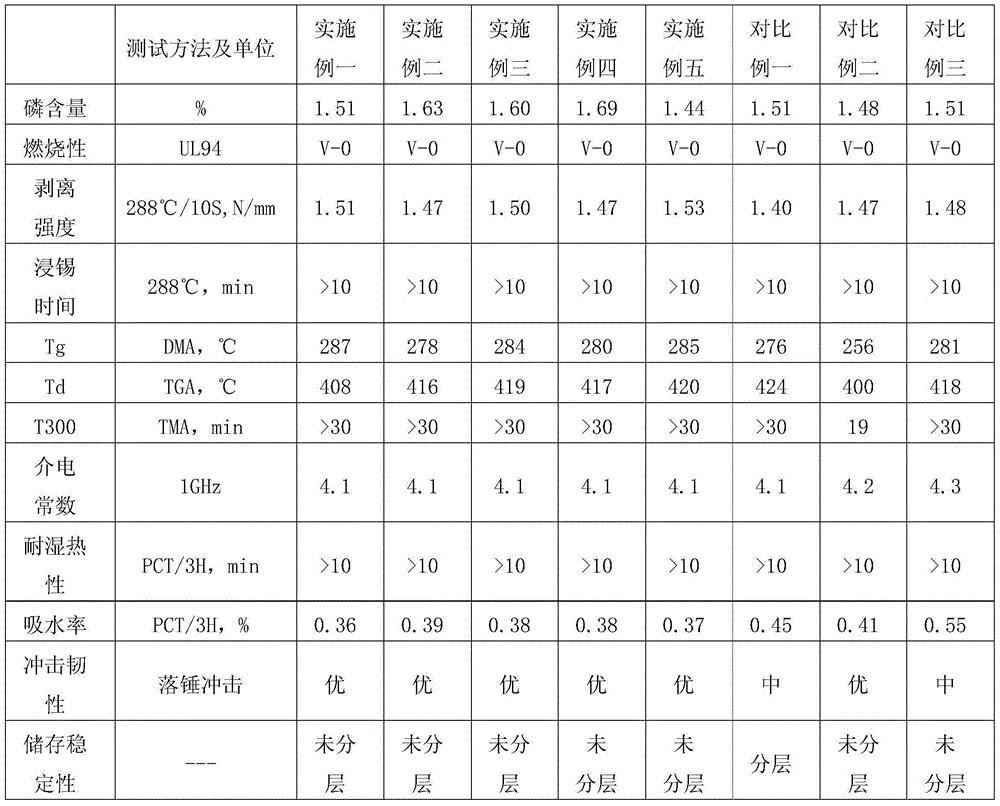

Thermosetting resin composition, and prepreg and laminated board made from thermosetting resin composition

ActiveCN104861652AImprove toughnessHigh peel strengthSynthetic resin layered productsLaminationBottleFire retardant

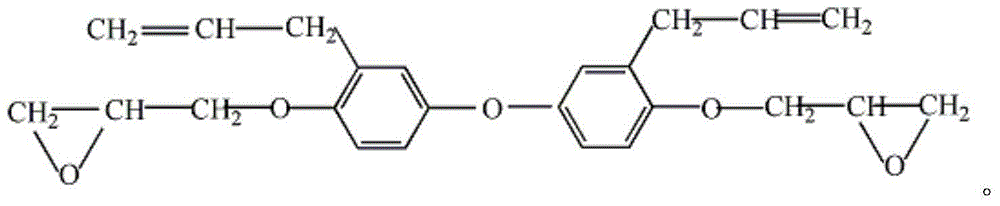

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following solids by weight: (a) a modified bismaleimide prepolymer, (b) a curing accelerator, (c) a fire retardant, and (d) inorganic fillers. A preparation method of the modified bismaleimide prepolymer comprises the following step: heating bismaleimide and a composite allyl compound in a reaction bottle, wherein the composite allyl compound is composed of a first-class allyl compound and a second-class allyl compound, the first-class allyl compound is selected from one or more of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin and diallyl diphenyl ether, and the second-class allyl compound is selected from one or more of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether and diallyl diphenyl ether diglycidyl ether. A laminated board integrates high heat resistance, high toughness, low water absorption, excellent dielectric property and good fire resistance.

Owner:SHENGYI TECH SUZHOU

Preparation method of light-resistant water-based polyurethane coating

InactiveCN103436155AGood compatibilityGood light fastnessPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of a light-resistant water-based polyurethane coating. The preparation method comprises the following steps of: mixing bisphenol S and diisocyanate in the presence of a dibutyltin dilaurate catalyst, and stirring to react at 60-85 DEG C for 1.5-3.5 hours to obtain a polyurethane prepolymer A; adding a hydrophilic chain extender with carboxyl content accounting for 1.2%-4.6% of the weight of A into A, then adding a solvent which accounts for 15%-35% of the weight of A, and stirring to react under the condition of 80-95 DEG C for 1.0-4.0 hours; adding triethylamine according to the condition that the mole ratio of COOH / NH2 is 0.6:(1-1.6):1 for neutralization, stirring to react for 30-70 minutes, and adding water for emulsification to form the light-resistant water-based polyurethane coating. The prepared light-resistant water-based polyurethane is environmentally-friendly and low in cost and can meet the requirement of the market on the property of light-resistant polyurethane.

Owner:HESHAN YIXIN CHEM CO LTD

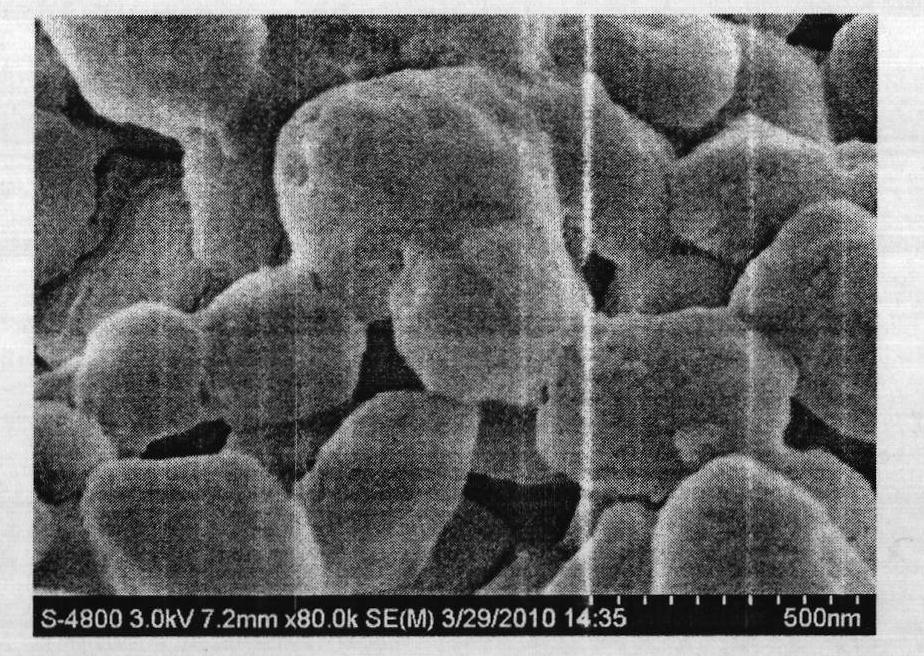

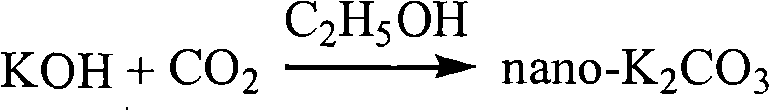

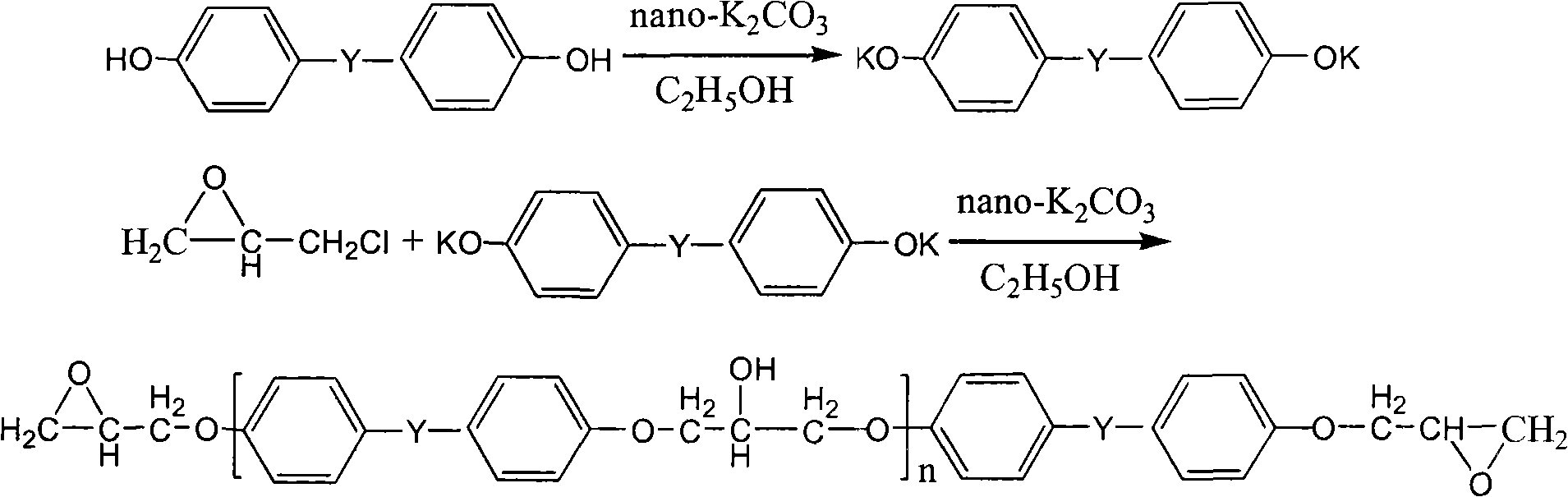

Synthesis method of low-molecular weight epoxy resin

InactiveCN102040568ALong reaction stepsExtend life cycleOrganic chemistrySynthesis methodsReaction temperature

The invention provides a preparation method of low-molecular weight epoxy resin. The method comprises the following steps: adding bisphenol A, epoxy chloropropane, potassium carbonate having grain size of 100-300 nanometer and solvent into a reactor for reaction; and distilling or rectifying the reaction liquid, and recycling the solvent to obtain the low-molecular weight colorless liquid bisphenol A type epoxy resin. The same effect is obtained by replacing bisphenol A with bisphenol S, bisphenol F or bisphenol fluorene to synthesize corresponding bisphenol S, bisphenol F or bisphenol fluorene type low-molecular weight epoxyresin. The method for synthesizing the low-molecular weight epoxy resin has the advantages of low reaction temperature, short reaction time, simple operation, high epoxy value of product, no production of industrial wastewater and good industrial prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Synthesis method of bisphenol F in salt bath system

InactiveCN103319314AHigh yieldIncrease contentOrganic chemistryOrganic compound preparationOrganic solventSynthesis methods

The invention relates to a synthesis method of bisphenol F in a salt bath system. The bisphenol F, which is relatively high in yield, high in content of 4,4-dihydroxy diphenyl methane and good in selectivity, is prepared from a reaction of phenol and formaldehyde under a salt bath system and a catalyst through regulating and controlling technological parameters. And the preparation method is simple, and the synthesis process is free from an organic solvent, thus being light in environmental pollution.

Owner:SHAANXI NORMAL UNIV

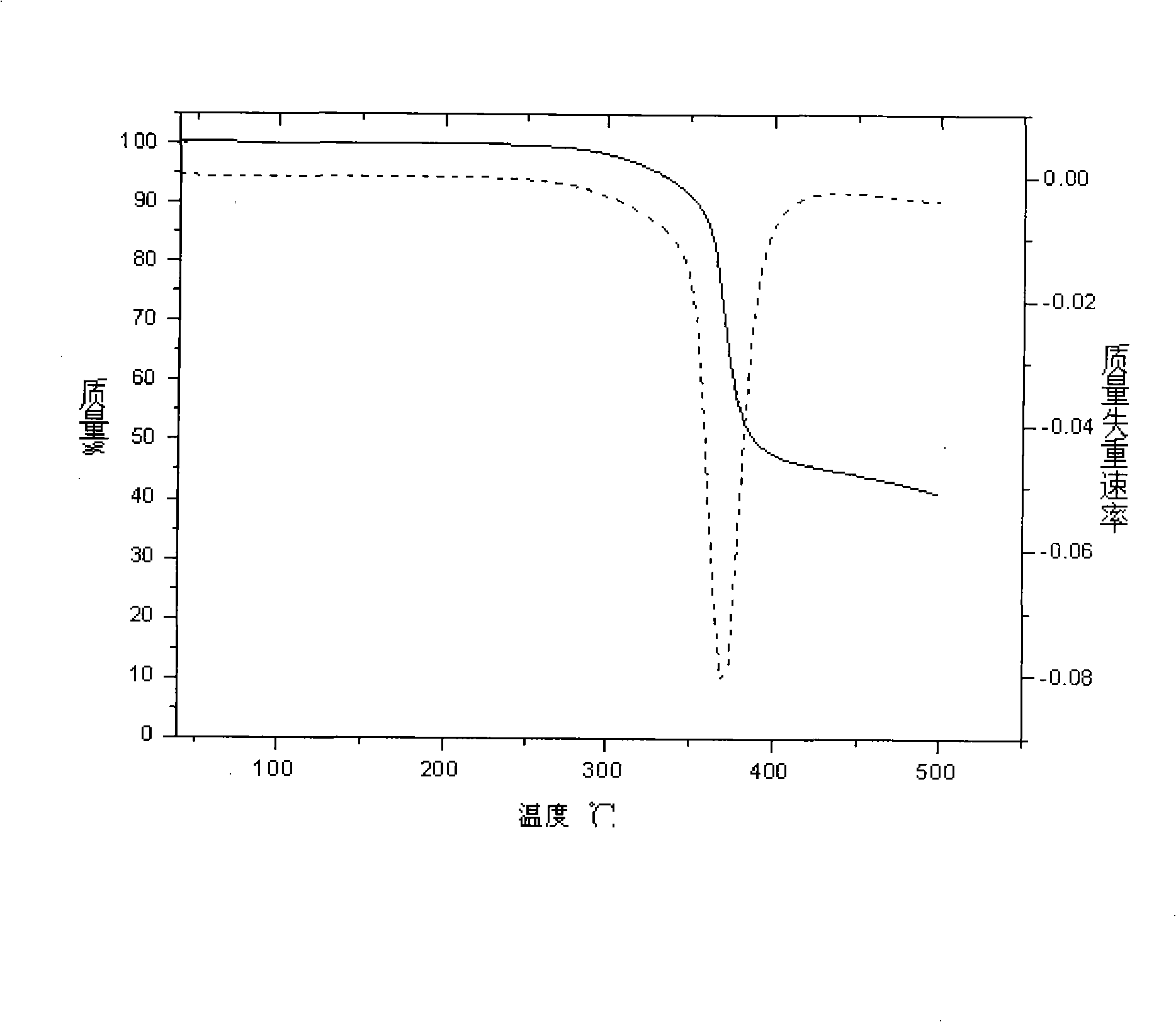

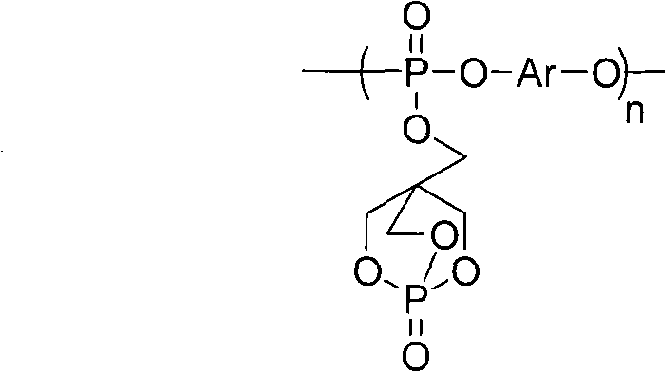

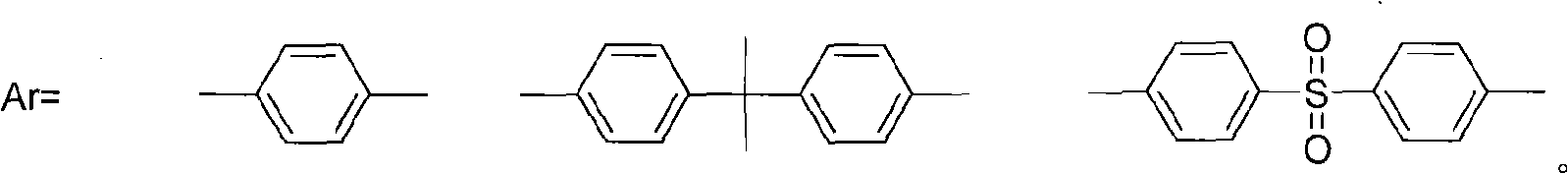

Preparation of polyphosphate flame retardant having dicyclic phosphoric acid ester structure

InactiveCN101328269AImprove thermal stabilityHigh decomposition temperatureGroup 5/15 element organic compoundsPolyesterPhosphoric Acid Esters

The invention discloses a method for preparing olyphosphate ester flame retardant with a bicyclic phosphate ester structure, which belongs to the polymerization type organophosphorous flame retardant structure and preparation method technical field. The invention is characterized in that: polyphosphate ester provided with a repeating unit structure shown at right is prepared, wherein, Ar is equal to bisphenol A, bisphenol S or hydroquinone. The method has the advantages that: the flame retardant has the characteristics of good heat stability, high decomposition temperature, narrow decomposition intervals, good char-forming property and so on. The method can be used for the flame-retarding modification of materials with higher processing temperature such as polyester, polyamide, polycarbonate, a blend of the polyester, the polyamide and the polycarbonate and so on. The preparation method is simple and easy to control.

Owner:DALIAN UNIV OF TECH

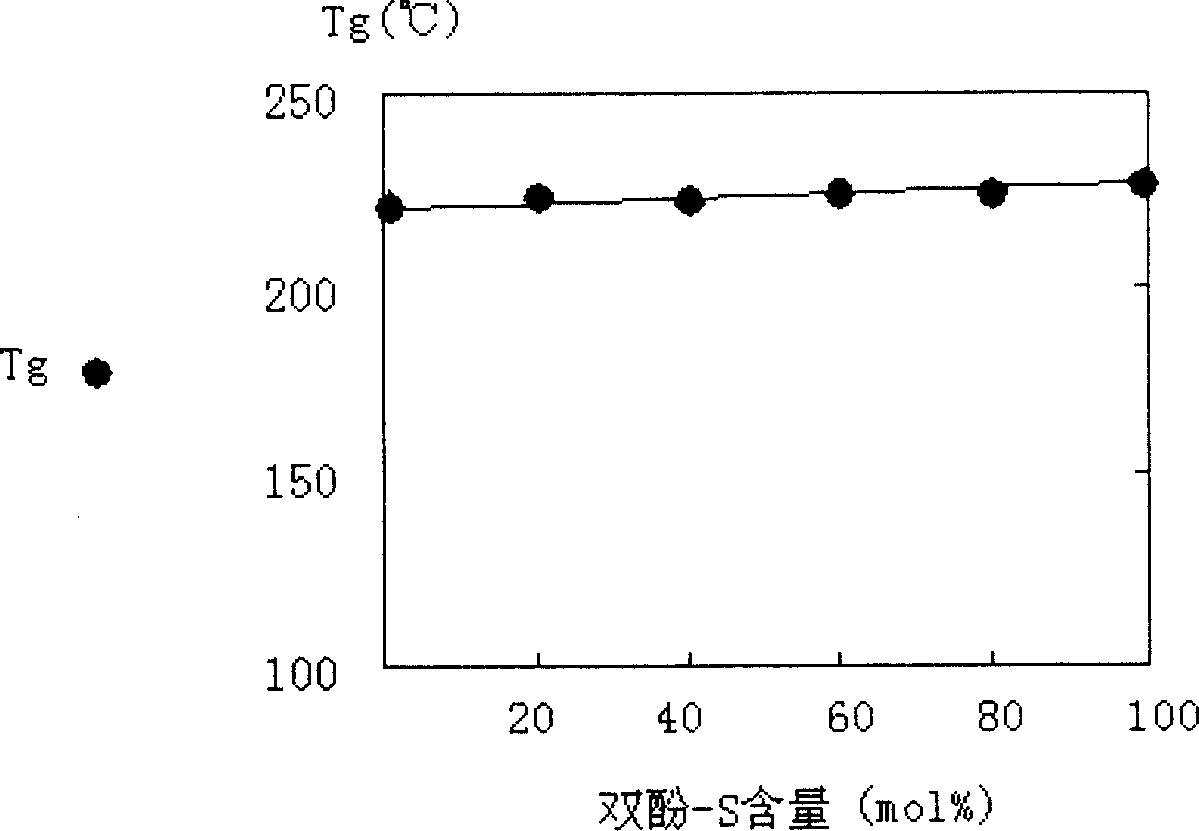

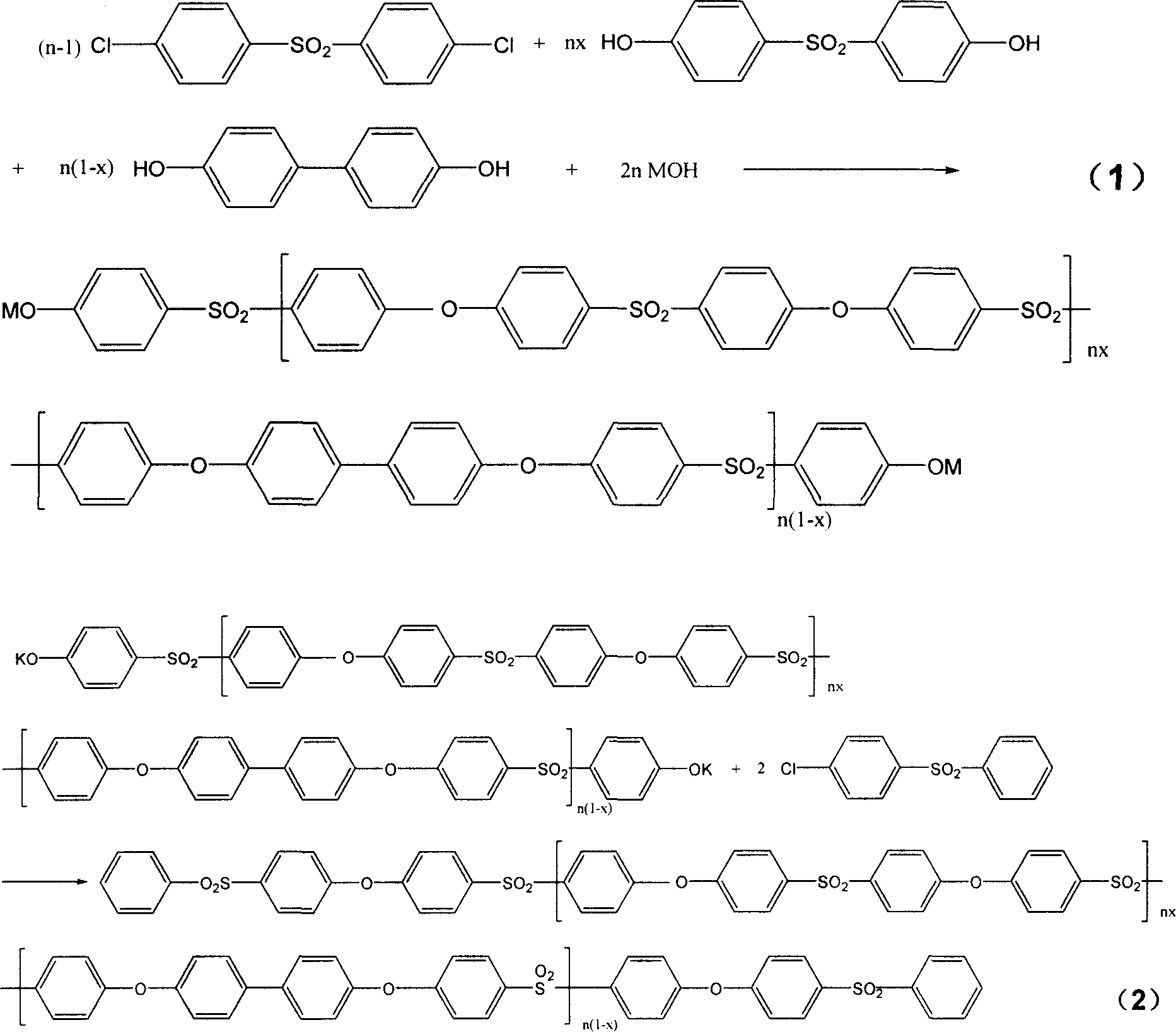

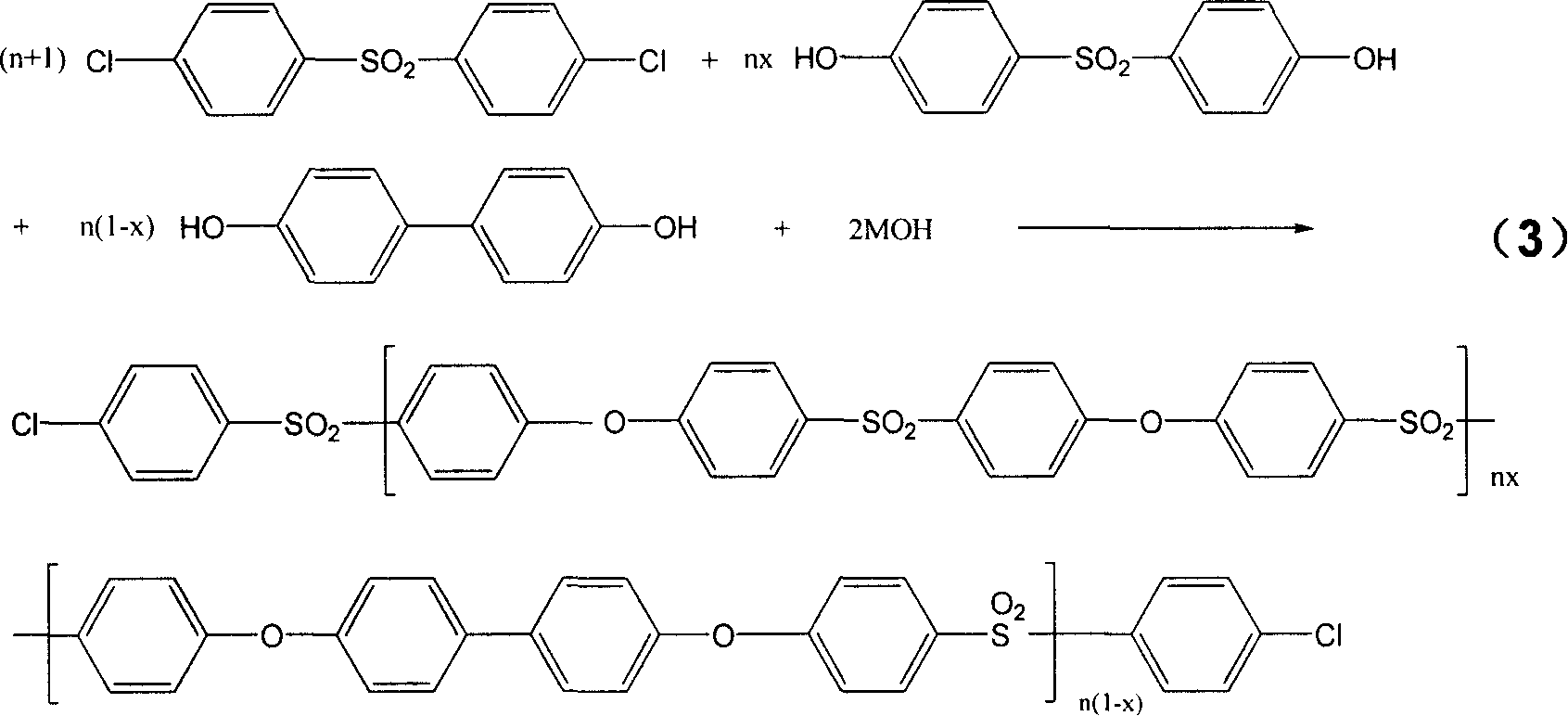

Process for preparing copolymer containing biphenyl polyether ether-sulfone and poly(ether sulfone)

The invention relates to a method for preparation of phenyl end group biphenyl polyetherethersulfone -chloride end group biphenyl polyetherethersulfone -polyethersulfone terpolymer. In the ternary copolymerized reaction system, add organic solvent, dichlorine, bisphenol-S and phenyl bisphenol with 25-40% solids content in the solvent, then add dimethylbenzene, stir and heat-up to 75-80 DEG C then add caustic potash or caustic soda which is of 2 times mole numbers of the bisphenol-S and phenyl bisphenol with a concentration of 25-30%, constantly react for 3-4 hours with the temperature of the reaction system keeps up to 220-250 DEG C, then add dead-end agent of sulfone monochloride with 2 times mole numbers of the dichlorine, then go on reacting for 0.5-1.5 hours, stop reaction to cool and disintegrate the polymer mucilage, then add some water to repeatedly boil until the dissolvent and the by-product are fully removed, dry the refined polymer powder in the bake oven and obtain the said phenyl end group biphenyl polyetherethersulfone - chloride end group biphenyl polyetherethersulfone-polyethersulfone terpolymer.

Owner:PANJIN ZHONGRUN SUPER ENG PLASTICS

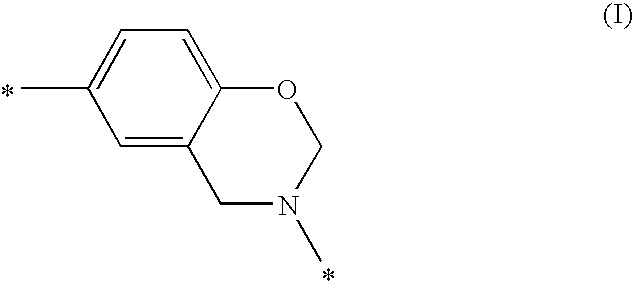

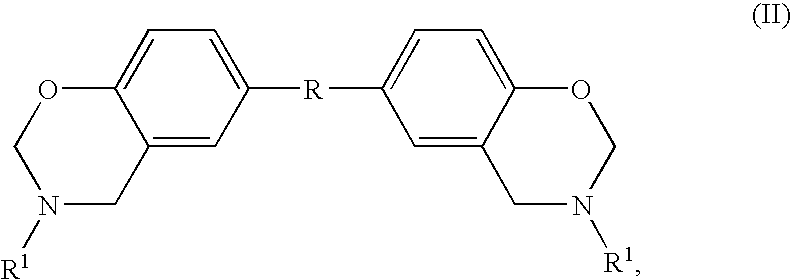

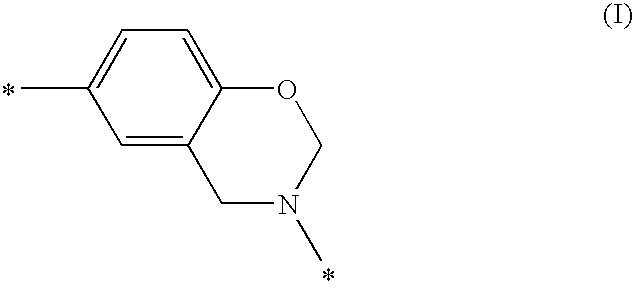

Composition Comprising Benzoxazine and Epoxy Resin

ActiveUS20080302471A1Reduce flammabilityFavorable curing conditionGroup 4/14 element organic compoundsSynthetic resin layered productsPolymer networkBisphenol AF

The instant invention relates to compositions comprising a benzoxazine resin and an advancement resin based on bisphenol A diglycidyl ether and bisphenol S and, optionally, ferrocene and aluminium trihydrate. Such compositions are, when cured to form polymeric networks, difficultly inflammable and resistant to high temperatures. Such compositions may especially be used in the production of printed wiring boards.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC +1

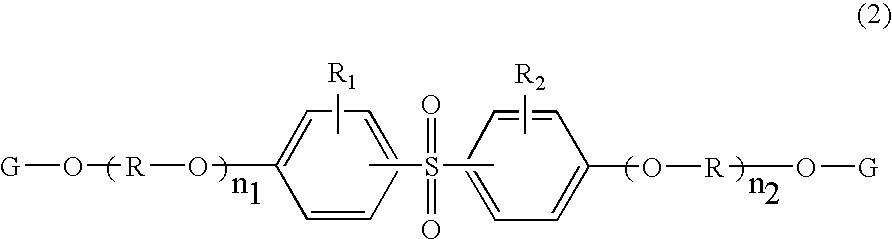

Liquid crystal sealing agent and liquid crystalline display cell using the same

InactiveUS7521100B2Liquid crystal compositionsLamination ancillary operationsLiquid crystallineEpoxy

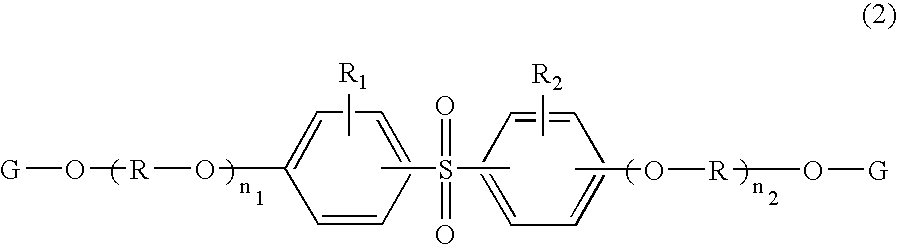

The present invention relates to a sealant for liquid crystals having extremely low contamination nature to a liquid crystal, excellent coatability and bondability to a substrate, long service life and pot life and high adhesive strength. A sealant for liquid crystals of the present invention is characterized by comprising (a) an epoxy resin represented by general formula (1):(wherein a represents an integer of 2 to 4; n represents 0 to 3 (average value); R represents a divalent hydrocarbon group of 2 to 6 carbon atoms; A represents a polyvalent aromatic group; and G represents a glycidyl group, provided that when n is 0, (a) an epoxy resin represented by general formula (1) is a bisphenol S-type.), (b) a thermo-curing agent, (c) and a filler having average particle diameter of not larger than 3 μm.

Owner:NIPPON KAYAKU CO LTD

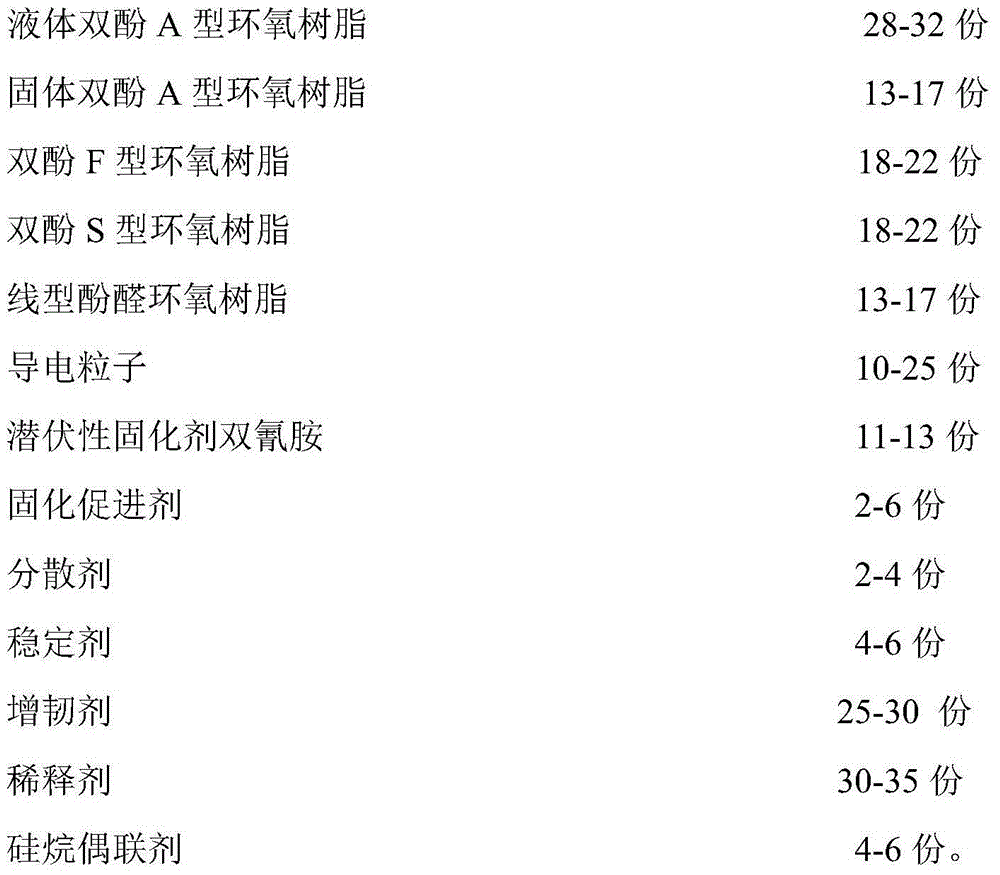

Formula and preparation method of epoxy resin based anisotropic conductive adhesive film

ActiveCN104673111ALow heat resistanceImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryBisphenol S

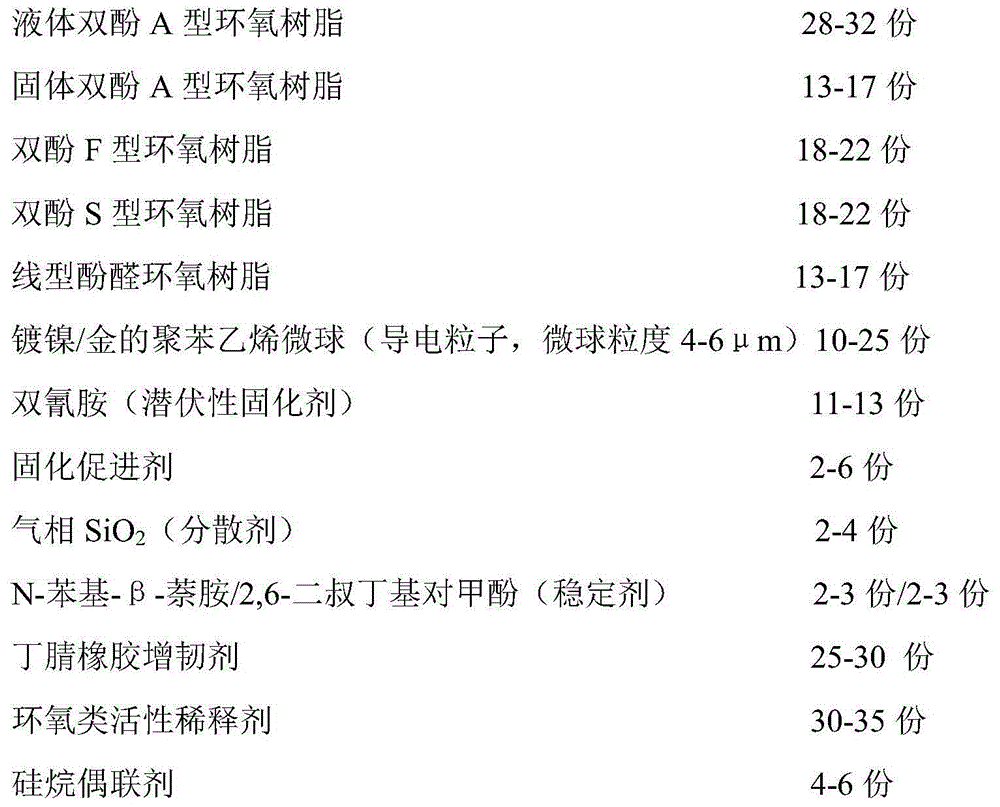

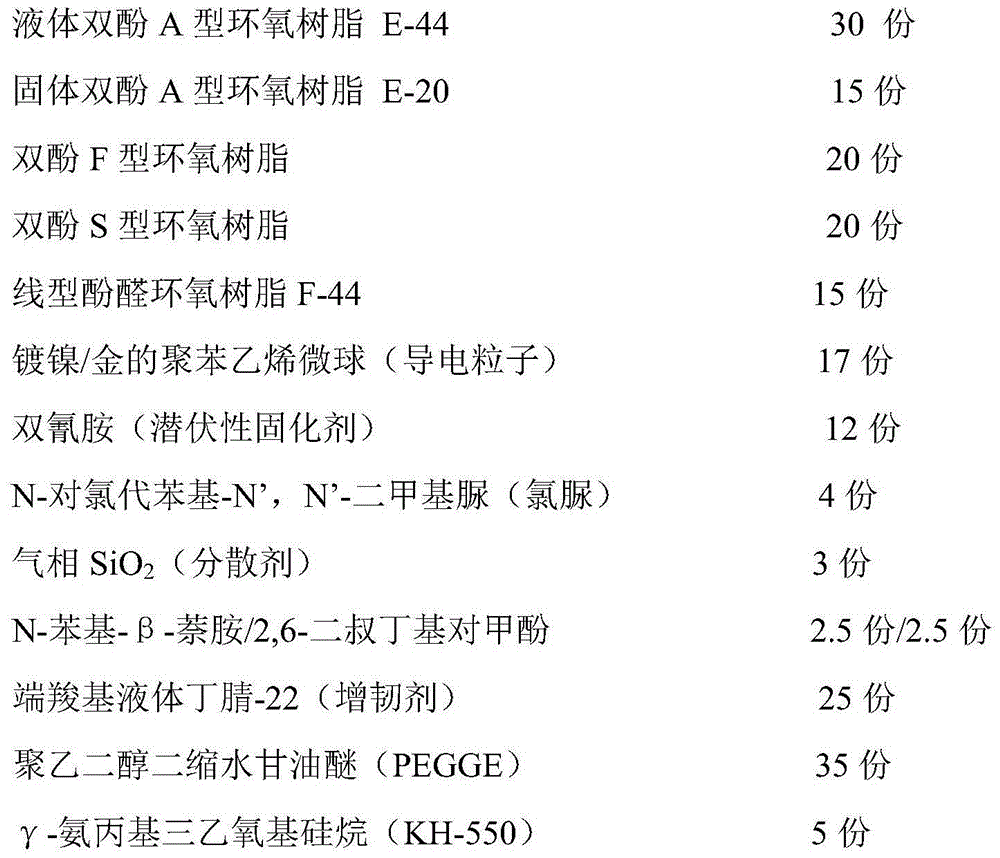

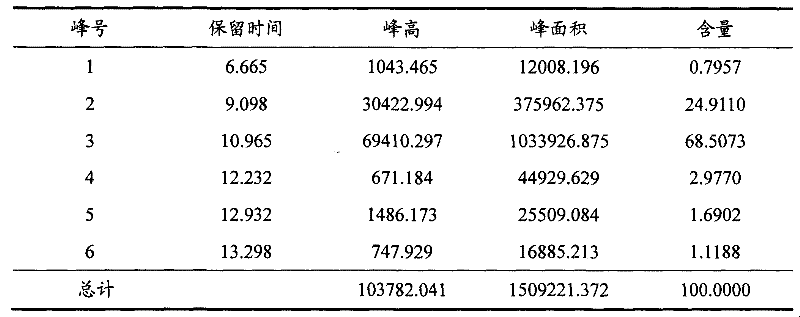

The invention discloses a formula and preparation method of an epoxy resin based anisotropic conductive adhesive film. The formula comprises the following components in parts by weight: 28-32 parts of liquid bisphenol-A epoxy resin, 13-17 parts of solid bisphenol-A type epoxy resin, 18-22 parts of bisphenol-F epoxy resin, 18-22 parts of bisphenol-S epoxy resin, 13-17 parts of linear phenolic epoxy resin, 10-25 parts of conductive particles, 11-13 parts of a latent curing agent dicyandiamide, 2-6 parts of a curing accelerator, 2-4 parts of a dispersant, 4-6 parts of a stabilizer, 25-30 parts of a toughening agent, 30-35 parts of a thinner, and 4-6 parts of a silane coupling agent. The preparation method is implemented by using the formula. Experiments show that an ACAF formula obtained finally has good storage stability and thermal stability, and can be rapidly cured at low temperature, and the mechanical and electrical properties and the like of the ACAF formula also can satisfy the use requirements.

Owner:GUANGDONG DANBOND TECH

Preparation method of bisphenol F

InactiveCN102516035AIncrease production capacityLow operating costOrganic chemistryOrganic compound preparationOxygenBisphenol AF

The invention relates to a preparation method of bisphenol F, which is characterized in that under the condition of existence of an acid catalyst, phenol and formaldehyde are reacted to obtain the product. The acid catalyst is a mixture of inorganic acid and organic acid, and the mol ratio of the inorganic acid to organic acid is 10-2:1; the inorganic acid is oxygen-containing acid of phosphor, the organic acid is C1-C4 straight chain or branched chain monoacid or diacid. The invention has the advantages that under the condition that P / F is less than or equal to 10, the bisphenol F with high ortho-isomer (especially 2,4'-isomer ) content can be obtained, the production capability of the device can be increased, and the operation cost and the energy consumption are reduced.

Owner:胶州市精细化工有限公司 +1

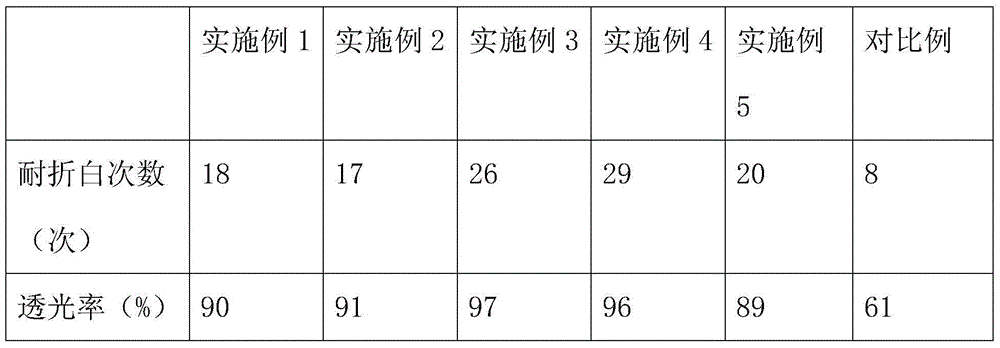

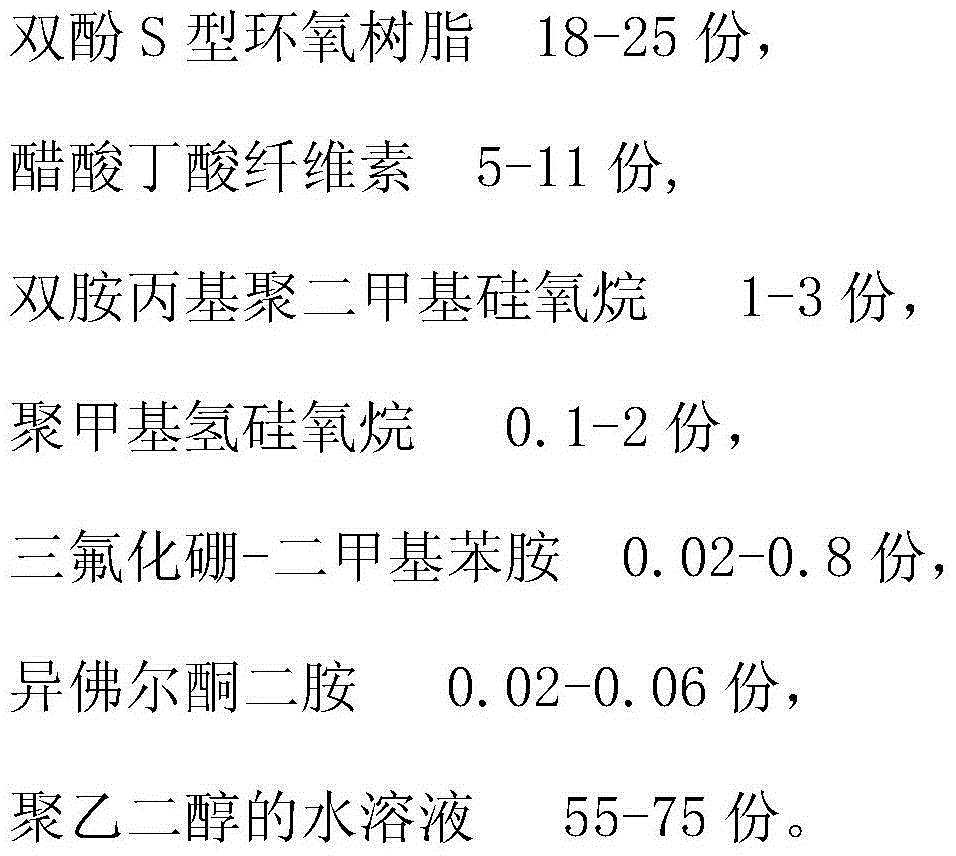

Fold-resistant white plastic film and preparation method thereof

InactiveCN104877310AGood light transmissionImprove high temperature resistanceEpoxyDimethylaniline N-oxide

The invention relates to a fold-resistant white plastic film and a preparation method thereof. The fold-resistant white plastic film is prepared from the following components in parts by weight: 18 to 25 parts of bisphenol S-type epoxy resin, 5 to 11 parts of cellulose acetate butyrate, 1 to 3 parts of diaminopropyl polydimethylsiloxane, 0.1 to 2 parts of polymethyl hydrogen siloxane, 0.02 to 0.8 parts of boron trifluoride-dimethylaniline, 0.02 to 0.06 parts of isophorone diamine and 55 to 75 parts of aqueous solution of polyethylene glycol. The invention also provides the preparation method of the fold-resistant white plastic film.

Owner:苏州靖羽新材料有限公司

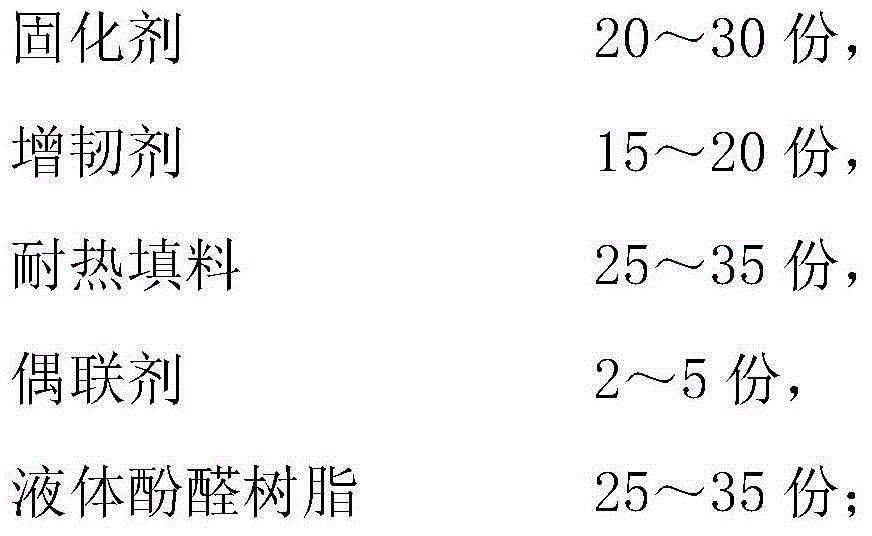

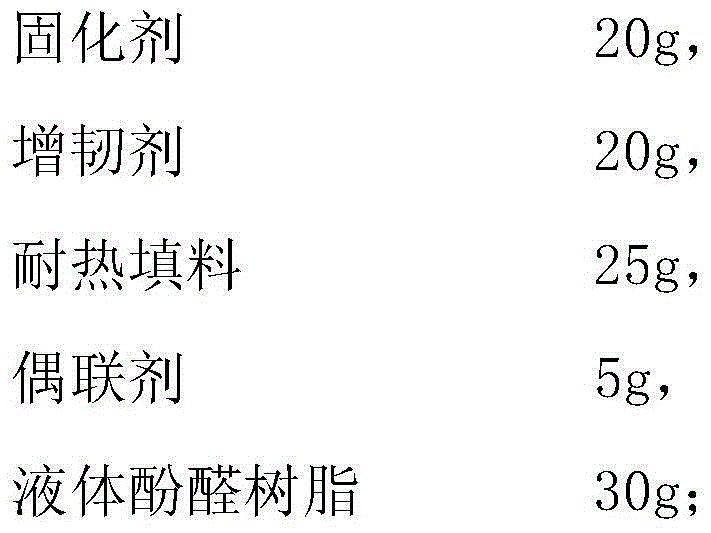

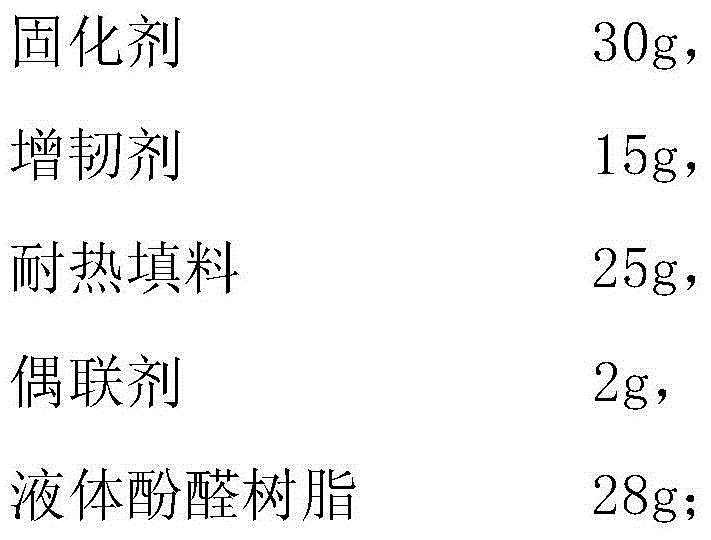

Novel high temperature-resistant epoxy resin structure adhesive and preparation method thereof

InactiveCN104804693AImprove heat resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveReactive diluent

The invention provides a novel high temperature-resistant epoxy resin structure adhesive, which consists of components A and components B; the components A include the following components in parts by weight: 60 to 75 parts of bisphenol S epoxy resin, 5 to 12 parts of reactive diluent and 20 to 30 parts of novolac epoxy resin; the components B include the following components in parts by weight: 20 to 30 parts of curing agent, 15 to 20 parts of flexibilizer, 25 to 35 parts of heat-resistant filler, 2 to 5 parts of coupling agent and 25 to 35 parts of liquid phenolic resin; the weight ratio of the components A to the components B is 1:1. The invention also discloses a preparation method of the novel high temperature-resistant epoxy resin structure adhesive. The novel high temperature-resistant epoxy resin structure adhesive provided by the invention has good high temperature resistance.

Owner:叶芳

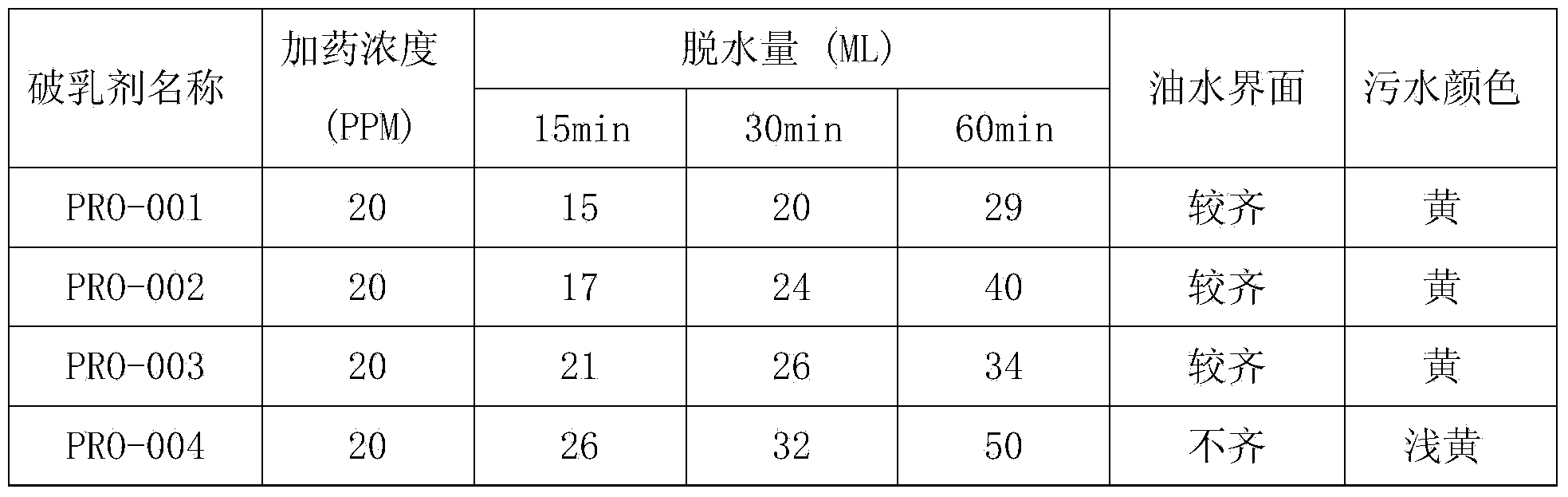

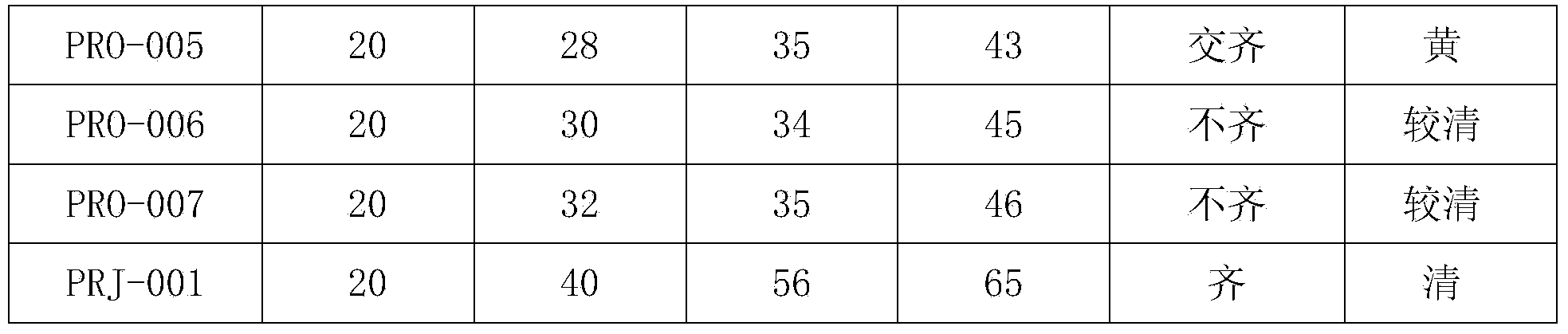

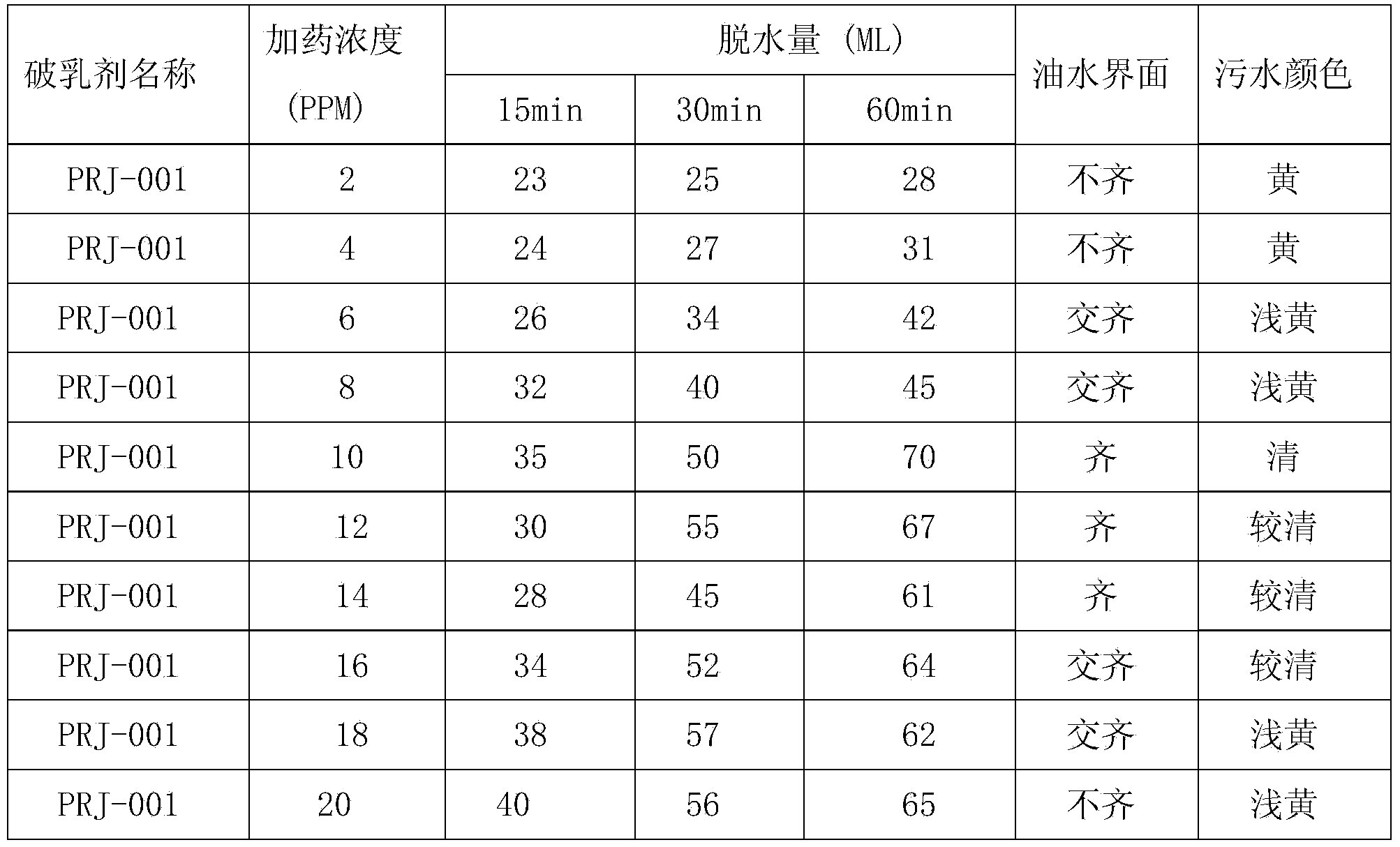

High-water-cut heavy oil demulsifier used for oil fields and preparation method thereof

ActiveCN103642518AImprove dehydration effectPromote demulsificationDewatering/demulsification with chemical meansFreeze-dryingFiltration

The invention relates to a high-water-cut heavy oil demulsifier used for oil fields and a preparation method thereof, belonging to the technical field of crude oil dehydration. The preparation method of the high-water-cut heavy oil demulsifier used for oil fields comprises the following steps: 1. synthesizing an initiator: dropwise adding a formaldehyde solution to polyethylene polyamine and bisphenol S at 30-60 DEG C, heating the materials to 100-150 DEG C to react for 1-5 hours, and freeze-drying a product; 2. synthesizing polyether: carrying out catalytic polymerization on the initiator as well as ethylene oxide and propylene oxide with KOH, neutralizing a product with acetic acid, and carrying out suction filtration and desalination; 3. synthesizing epoxy polyether: after diluting polyether with a xylene solution, reacting polyether with epoxy chloropropane to obtain epoxy polyether A; dropwise adding 2-methyl crotonate to triethylene diamine, and then reacting with epoxy chloropropane to obtain epoxy polyether B; 4. synthesizing a demulsifier: dissolving epoxy polyether A and epoxy polyether B in xylene to obtain the high-water-cut heavy oil demulsifier. The preparation method is simple in process, is convenient to operate and is accessible in raw materials and low in cost. The obtained demulsifier has the advantages of small dosage, high dehydration speed, good demulsification effect and the like.

Owner:滨州乾坤化工机械有限公司

Composite insulating material, casting busway and preparation method of composite insulating material

The invention discloses a composite insulating material, a casting busway and a preparation method of the composite insulating material. The composite insulating material is prepared from the following raw materials in parts by weight: 100 parts of epoxy resin, 35-80 parts of curing agent, 12-15 parts of flame retardant, 6-10 parts of promoter, 10-18 parts of flexibilizer, 0.3-0.7 part of defoaming agent, 30-38 parts of aluminium hydroxide and 20-28 parts of silica powder, wherein the epoxy resin is one or more than one of bisphenol A epoxy resin, bisphenol F epoxy resin, bisphenol S epoxy resin, epoxidation polybutadiene and phenol aldehyde epoxy resin; the curing agent is one or more than one of imidazole curing agent, amine curing agent and anhydride curing agent. The casting busway comprising the composite insulating material has the advantages that insulation resistance can be more than 500Mohm, and a withstand voltage can be more than 5KV; waterproofness is good, the casting busway can be used in water and is resistant to acid, alkali and corrosion and is flame retardant; protection grade is IP68, and short-time tolerant current intensity is better than that of the existing aluminium alloy shell or other metal shell busways.

Owner:广州市半径电力铜材有限公司

Halogen-free flame-retardant polyimide resin composition and prepreg and laminate made with same

ActiveCN104877134AImprove solubilityGood storage stabilityMetal layered productsHigh resistanceDiphenyl ether

The invention discloses a halogen-free flame-retardant polyimide resin composition, comprising, by weight, bismaleimide a, composite allyl compound b, and phosphorous compound c. A preparing method of the halogen-free flame-retardant polyimide resin composition includes: heating the bismaleimide, the composite allyl compound and the phosphorous compound in a reaction flask for reaction, with the composite allyl compound being composed of first allyl compound and second allyl compound. The first allyl compound is made from one or any of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin, and diallyl diphenyl ether. The second allyl compound is made from one or any of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether, diallyl diphenyl ether diglycidyl ether. A laminate made from the halogen-free flame-retardant polyimide resin composition has the advantages of high resistance, high toughness, low water absorption rate, and excellent dielectric property and flame retardance.

Owner:SHENGYI TECH SUZHOU

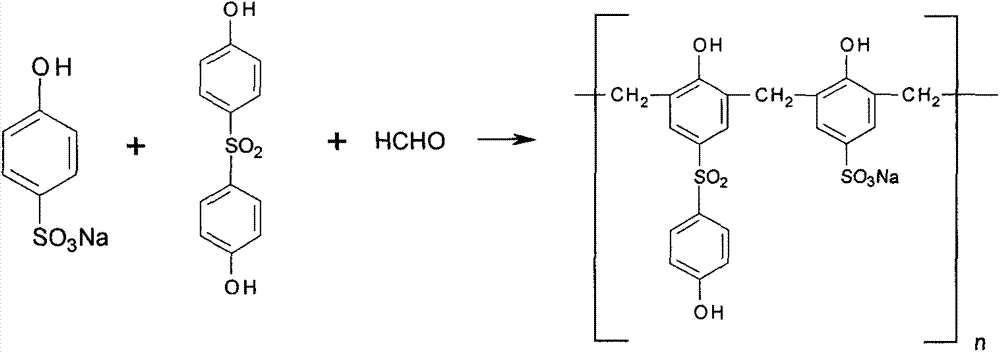

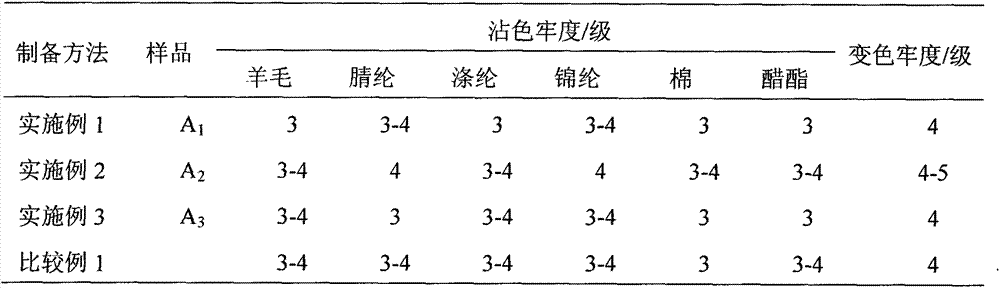

Acidic dye-fixing agent and preparation method thereof

InactiveCN104513349AGood color fixing effectSimple preparation processDyeing processSODIUM PHENOLSULFONATEBisphenol S

The invention relates to an acidic dye-fixing agent and a preparation method thereof. The dye-fixing agent is a condensation product prepared through the condensation polymerization reactions among bisphenol S, sodium phenolsulfonate, and formaldehyde in the presence of a catalyst. The obtained acidic dye-fixing agent has the advantages of good dye-fixing effect, simple preparation technology, easily-available raw materials, and low cost.

Owner:WUYI UNIV

Resin composition, and cured product (1) thereof

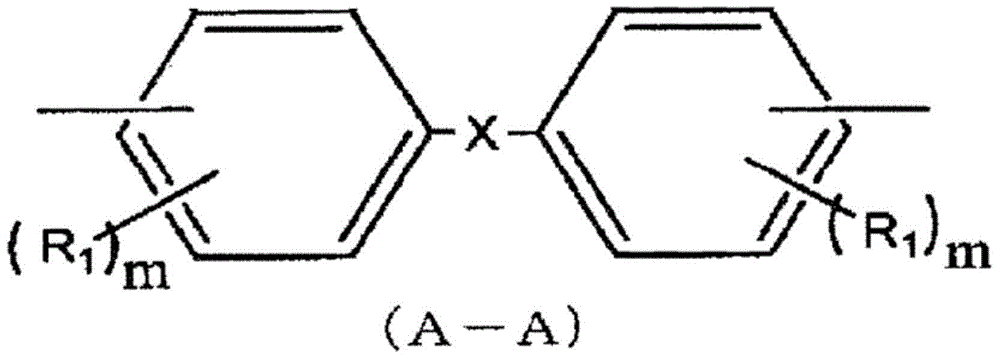

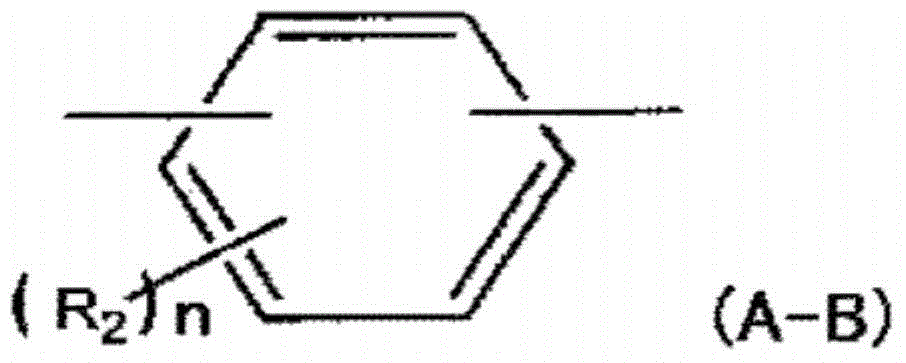

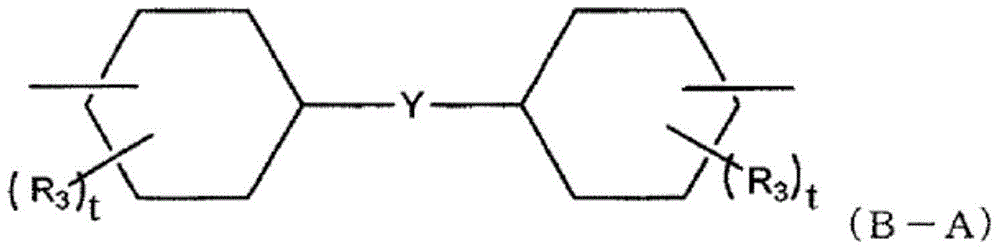

ActiveCN104813741ALow viscosityGood light fastnessElectroluminescent light sourcesSolid-state devicesRefractive indexAlicyclic Hydrocarbons

The present invention relates to a resin composition which has a low viscosity (at 25˚C) of not more than 1300mPa·s and a relatively high liquid refractive index of at least 1.50, which is used to seal a surface of an organic electroluminescent (EL) element, and with which a cured product exhibiting excellent visible light transmission, excellent light resistance, a high Tg, and a low water vapour transmission rate can be obtained. The resin composition has a viscosity measured at 25˚C of not more than 1300mPa·s, and includes an aromatic compound (A) and a cyclic compound (B). Aromatic compound (A) has an oxetanyl group or an epoxy group, and has at least one skeleton selected from the group consisting of: a skeleton of biphenyl, bisphenol A, bisphenol F, bisphenol S, or the like represented by formula (A-A) […]; a phenylene skeleton which may be substituted with a C1-4 alkyl group, and which is represented by formula (A-B) […]; an anthracene skeleton; and a phenanthrene skeleton. Cyclic compound (B) has an oxetanyl group or an epoxy group, and satisfies the following conditions (conditions for cyclic compound (B): that the ring in cyclic compound (B) be an aromatic ring, an aliphatic ring, or a heterocycle; in cases when the ring is (a) an aromatic ring, that the cyclic compound have an oxetanyl group or an epoxy group, and an aromatic ring having a structure different to that of the compound used as aromatic compound (A); and, in cases when the ring is (b) an aliphatic ring, that the cyclic compound be either an alicyclic epoxy resin, or, a cyclic compound having an oxetanyl group or an epoxy group, and a cycloalkylene skeleton or an alicyclic hydrocarbon skeleton having a cross-linking structure).

Owner:NIPPON KAYAKU CO LTD

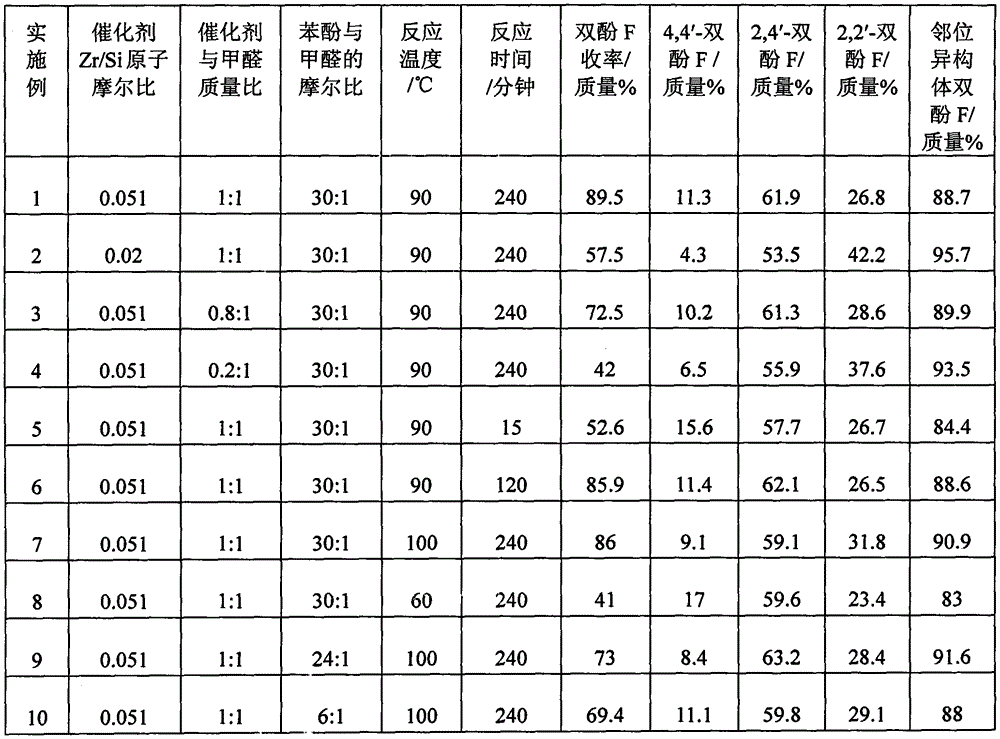

Preparation method of bisphenol F with high ortho-isomeride content

InactiveCN104130109AHigh ortho contentEasy to makeOrganic chemistryOrganic compound preparationMolecular sieveWastewater

The invention discloses a preparation method of bisphenol F with high ortho-isomeride content. The preparation method comprises the following step: through an acidic mesoporous molecular sieve Zr-SBA-15 catalyst, catalyzing phenol and formaldehyde aqueous liquor with the mass percentage of 35-40%, to synthesize the bisphenol F, wherein the adopted acidic mesoporous molecular sieve Zr-SBA-15 catalyst is synthesized in one step, and the activity of the catalyst can be regulated by regulating the mole ratio of Zr / Si atoms of the catalyst. The preparation method is simple in technology, high in catalysis efficiency, the bisphenol F with high ortho-isomeride content can be obtained, the catalyst is easily separated and recovered and repeatedly used, and no equipment corrosion and waste water treatment problems exist, so that the preparation method is an environment-friendly high-efficiency preparation method of the bisphenol F with high ortho content.

Owner:XIANGTAN UNIV

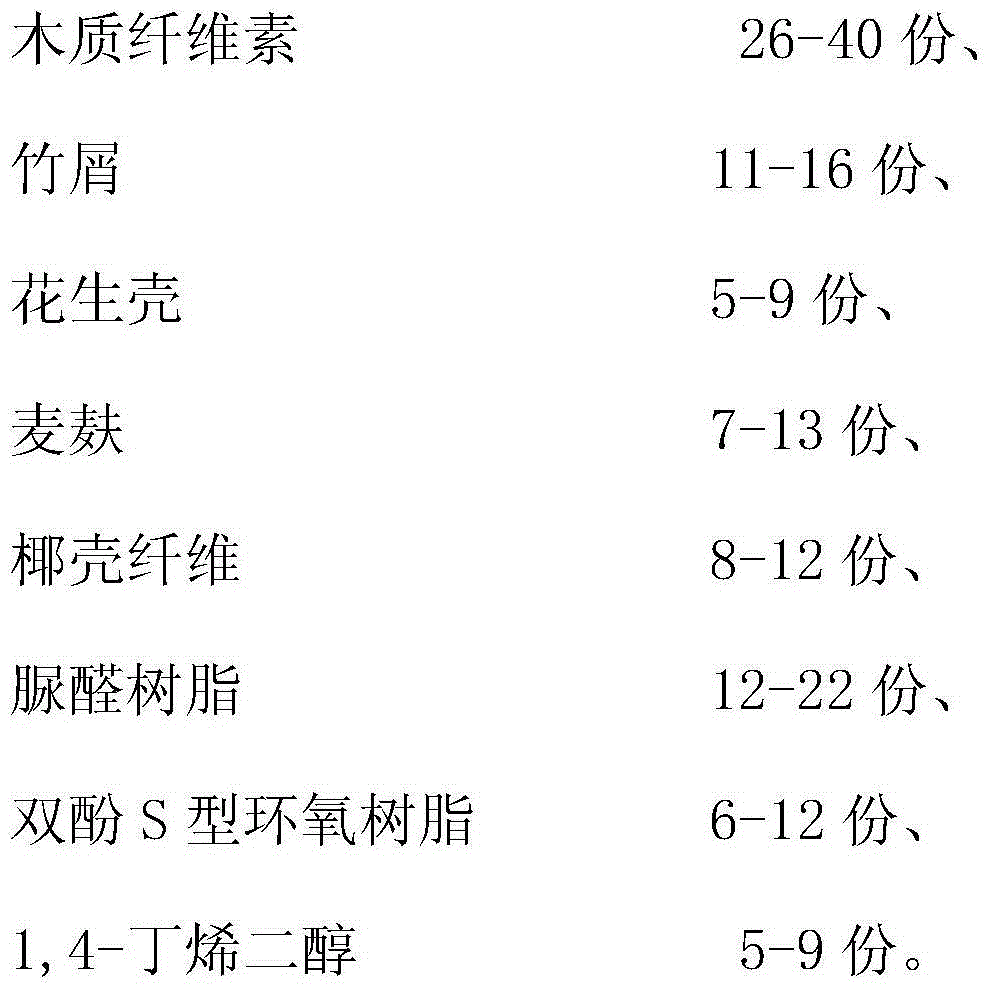

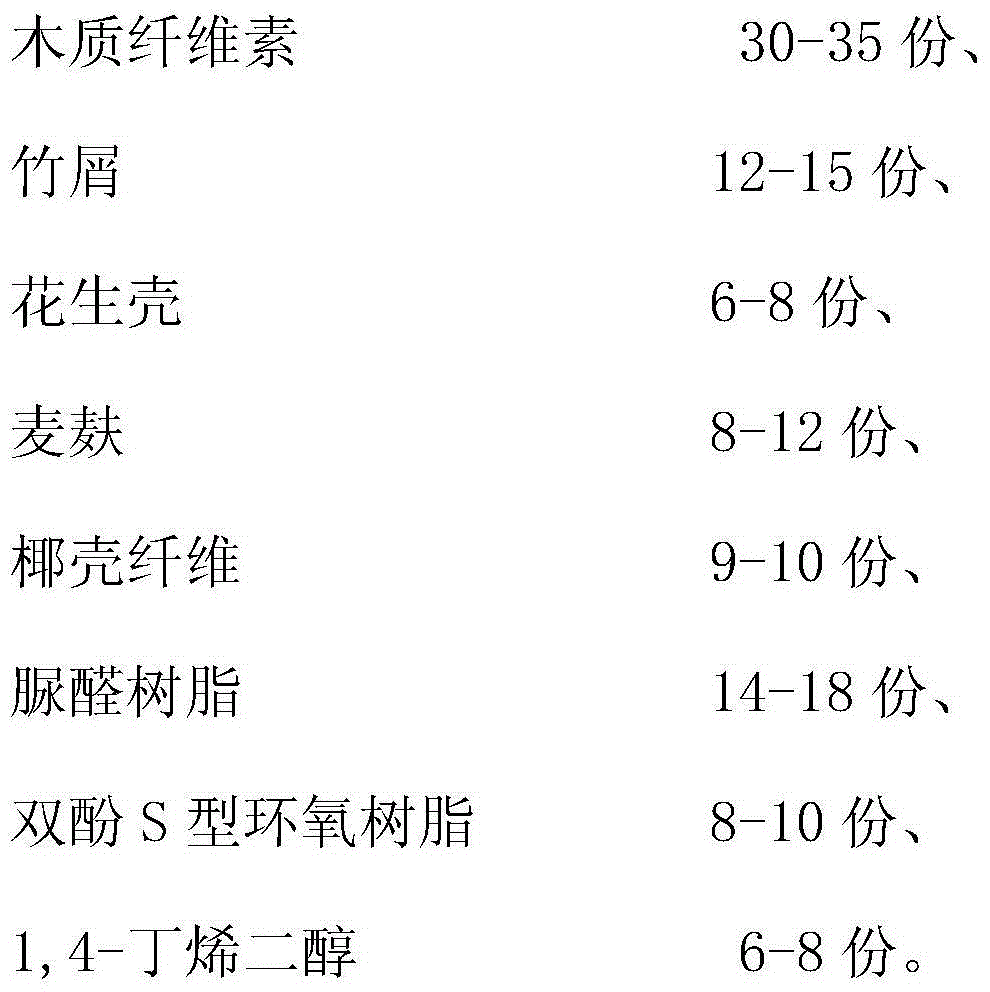

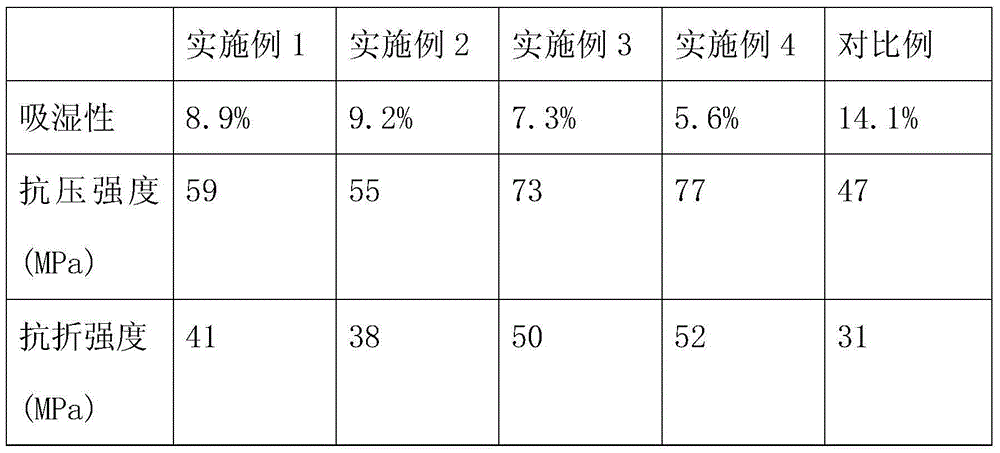

Novel composite fiberboard material and novel manufacturing method and application thereof

The invention belongs to the field of wooden floors and discloses a composite fiberboard material and the manufacturing method and application thereof. The composite fiberboard material comprises lignocellulose, bamboo scraps, peanut shells, wheat bran, coconut fiber, urea resin, bisphenol-S epoxy resin and 2-Butene-1,4-diol. The method for manufacturing the fiberboard material comprises the steps of (1) smashing raw materials, (2) drying the smashed raw materials obtained from the step (1), (3) mixing lignocellulose, bamboo scraps, peanut shells, wheat bran and coconut fiber mechanically evenly, (4) adding urea resin, bisphenol-S epoxy resin and 2-Butene-1,4-diol to the powder obtained from the step (3) and stirring the new mixture evenly, and (5) pressing the base fiberboard material obtained from the step (4) in a die to be formed.

Owner:深圳文业装饰设计工程有限公司

Toughening method of poly(3-hydrox butyrate) and poly(3-hydroxy butyrate-3-hydroxy pentanoate)

The present invention relates to a toughening method of poly(3-hydroxy butyrate) and poly(3-dydroxy butyrate-3-hydroxy pentanoate). The raw material includes the first component of poly(3-hydroxy butyrate) or poly(3-dydroxy butyrate-3-hydroxy pentanoate) with 3-hydroxy pentanoate monomer molar content less than 20%; the second copmonent of p-tert-butylphenol, bisphenol A, bisphenol S or 2,4,6-tri(2'-hydroxy-4'-butoxyphenyl)-1,3,5- triazine; and the optional component including plasticizer and stuffing. The weight ratio between the first component and the second component is 70-90 to 10-30 andthe optional component is 0-30 wt% of the first component. By means of solution blending or melting blending, modified material with excellent toughness may be obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

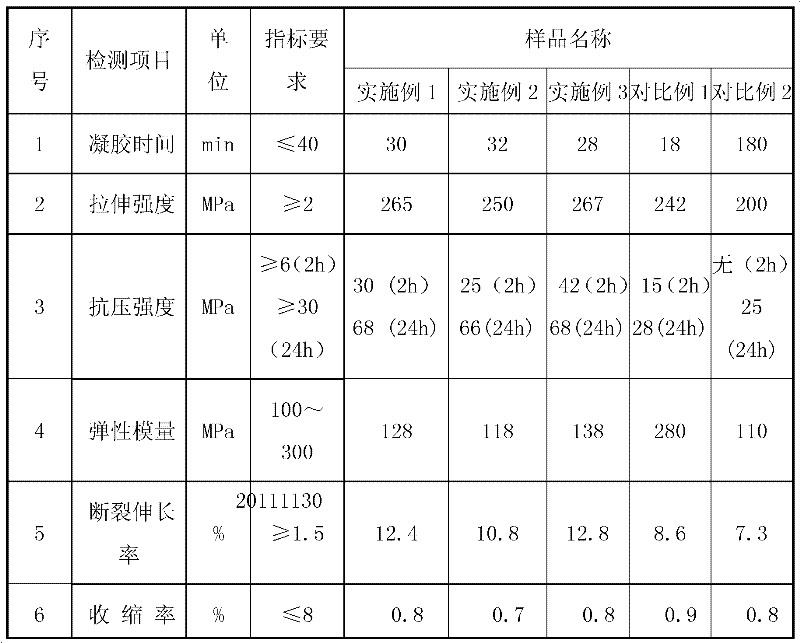

Method for preparing composite curing agent modified bisphenol F thermosetting adhesive repairing agent special for ballastless track gap and crack damage

ActiveCN102516912ALow curing temperatureFast curingRailway track constructionEpoxy resin adhesivesBisphenol AFViscosity

The invention discloses a method for preparing a composite curing agent modified bisphenol F thermosetting adhesive repairing agent special for ballastless track gap and crack damage. The method comprises three steps of: preparing a bisphenol F epoxy resin main agent, compositing a polythiol-aminal type composite modified curing agent and curing the bisphenol F epoxy resin by the polythiol-aminaltype composite modified curing agent. The repairing agent prepared by the method has the characteristics of low viscosity, low curing temperature, rapid curing, stable volume stability and wide application prospect.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Synthesis method of polysulfone resin

The invention relates to a synthesis method of polysulfone resin. The method mainly comprises the following step: with bisphenol A and 4,4-dichlorodiphenylsulfone, of which the molar ratio is 1:1, as raw materials, N-methylpyrrolidone as a solvent used in the reaction process, chlorobenzene as a dehydrating agent and NaOH as a salt-forming agent, blocking by a chloromethane gas, wherein the overall reaction process is carried out under protection of nitrogen. The solid content of the system is controlled at 25-40%; chlorobenzene is 10-20% of weight of the solvent; the molar weight of NaOH is 1.01-1.10 times of that of the bisphenol A. The synthesis method is reasonable in formula, and simple to operate. The chloromethane gas is adopted to block, so as to prepare polysulfone resin with good liquidity by controlling the reaction time. By adopting the synthesis method, the reaction time can be shortened, a part of raw materials are saved, the production cycle can be shortened on production, and the cost is also reduced.

Owner:WEIHAI JIERUI MEDICAL PRODUCTS CO LTD

Liquid crystal sealing agent and liquid crystalline display cell using the same

InactiveUS20060208219A1Liquid crystal compositionsLamination ancillary operationsLiquid crystallineAryl

The present invention relates to a sealant for liquid crystals having extremely low contamination nature to a liquid crystal, excellent coatability and bondability to a substrate, long service life and pot life and high adhesive strength. A sealant for liquid crystals of the present invention is characterized by comprising (a) an epoxy resin represented by general formula (1): (wherein a represents an integer of 2 to 4; n represents 0 to 3 (average value); R represents a divalent hydrocarbon group of 2 to 6 carbon atoms; A represents a polyvalent aromatic group; and G represents a glycidyl group, provided that when n is 0, (a) an epoxy resin represented by general formula (1) is a bisphenol S-type.), (b) a thermo-curing agent, (c) and a filler having average particle diameter of not larger than 3 μm.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com