Halogen-free flame-retardant polyimide resin composition and prepreg and laminate made with same

A technology of polyimide resin and resin composition, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problem of low heat resistance of bisphenol A epoxy resin, bismaleyl Improve the heat resistance of the imine resin composition and other problems, and achieve the effects of excellent dielectric properties, good toughness, strong peeling and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

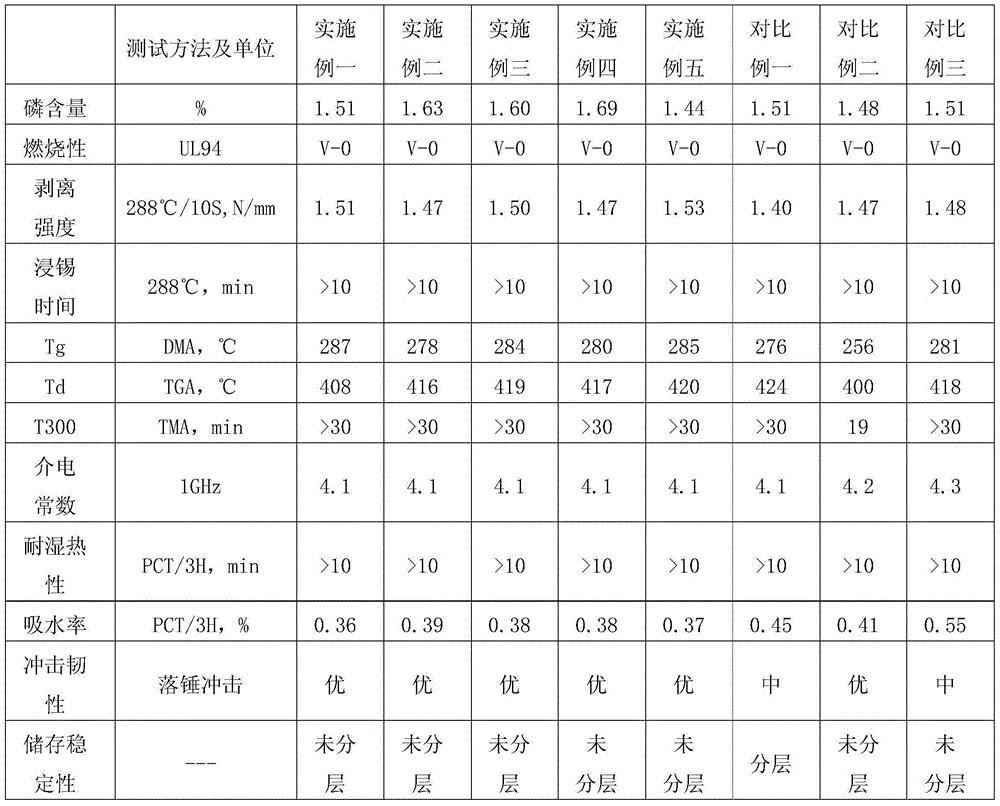

Examples

Embodiment 1

[0042] Take 100g of 4,4'-diphenylmethane bismaleimide, 70g of diallyl bisphenol A diglycidyl ether (epoxy equivalent 256g / eq), and 20g of phosphorus-containing compound (A) into a 500mL reaction bottle In the process, use an oil bath to slowly heat to 120-160° C. and keep stirring for 30 minutes to obtain a halogen-free flame-retardant polyimide resin composition. After the reaction is completed, cool to room temperature.

Embodiment 2

[0044] Take 30g of 4,4'-diphenyl ether bismaleimide, 90g of 4,4'-diphenylmethane bismaleimide, 40g of diallyl bisphenol A, diallyl bisphenol A di Put 20g of glycidyl ether (epoxy equivalent 220g / eq), 23g of phosphorus-containing compound (A) into a 500mL reaction bottle, heat slowly to 120-160°C in an oil bath and keep stirring for 50min to obtain a halogen-free flame retardant The polyimide resin composition is cooled to room temperature after the completion of the reaction.

Embodiment 3

[0046] Get 4,4'-diphenyl ether bismaleimide 125g, allyl phenoxy resin 20g, diallyl bisphenol A diglycidyl ether 50g (epoxy equivalent 215g / eq), phosphorus compound ( B) 30g was put into a 500mL reaction bottle, slowly heated to 120-160°C using an oil bath and kept stirring for 60min to obtain a halogen-free flame-retardant polyimide resin composition, which was cooled to room temperature after the reaction was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com