Method for preparing composite curing agent modified bisphenol F thermosetting adhesive repairing agent special for ballastless track gap and crack damage

A technology of composite curing agent and ballastless track, which is applied in the direction of adhesive, track, track maintenance, etc., can solve the problems of unable to meet the rapid repair of damaged parts, small shrinkage, bond strength, slow curing reaction speed, etc., and achieve thin layer curing Strong ability, good anti-aging performance, and short gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

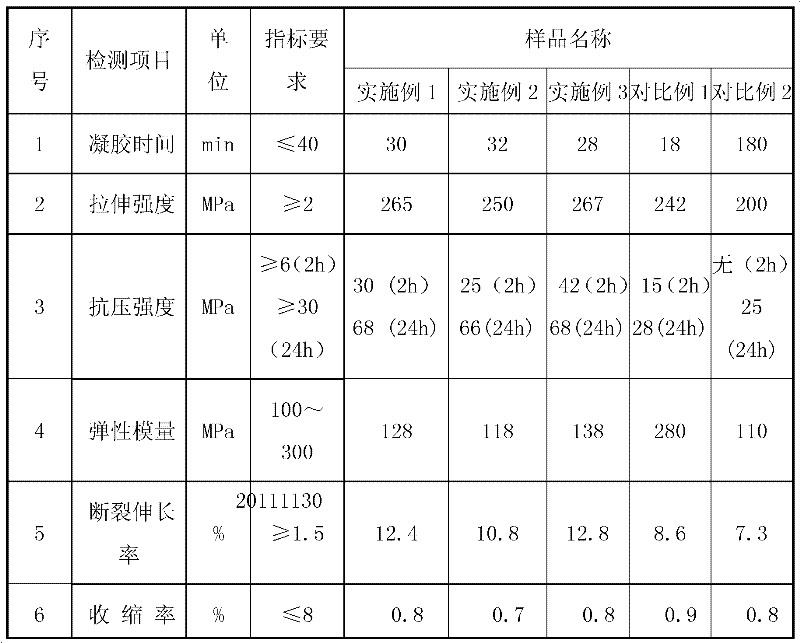

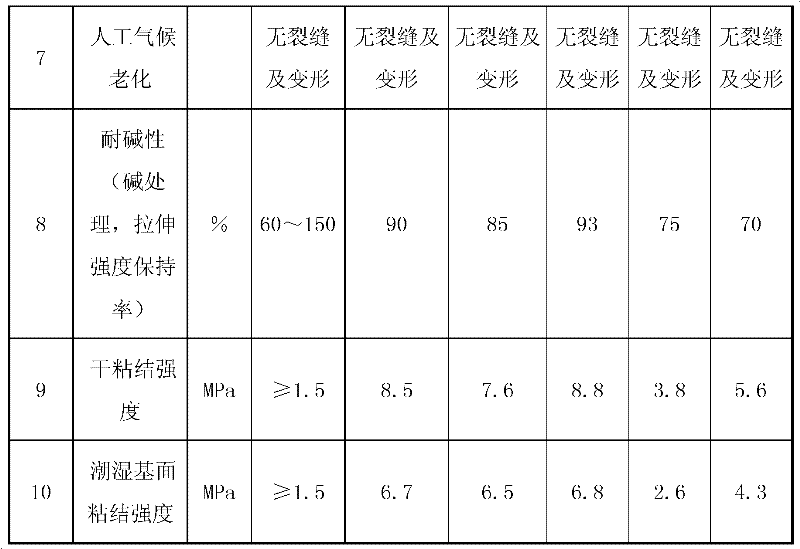

Examples

Embodiment 1

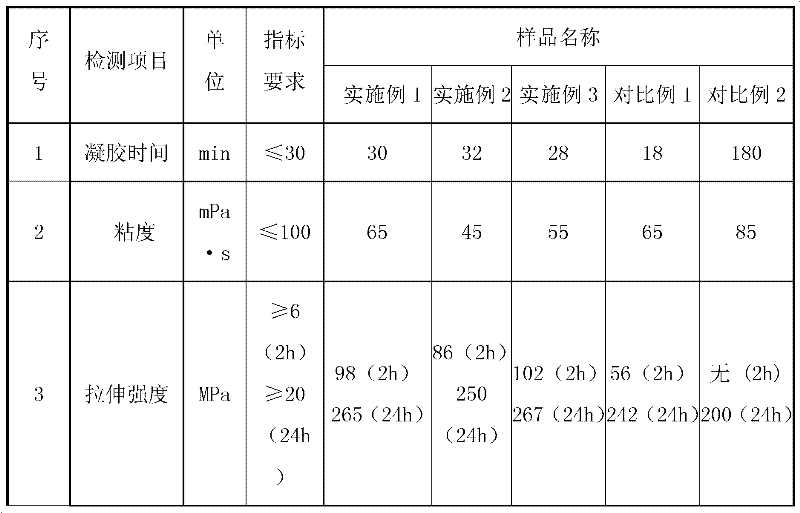

[0019] Embodiment 1: The preparation method of the special composite curing agent modified bisphenol F thermosetting adhesive repair agent for ballastless track away from the crack damage, including:

[0020] (1) Preparation of bisphenol F epoxy resin main agent: 100Kg bisphenol F diglycidyl ether, 50Kg reactive diluent 1,6-hexanediol diglycidyl ether were added to the reaction kettle, stirred and dissolved at 40°C, The main agent of bisphenol F epoxy resin with a viscosity of 75mPa·S was prepared

[0021] (2) Synthesis of polythiol-amine composite curing agent: 20Kg 2-2'-dimercaptoethyl sulfide, 25Kg trimethylolpropane triacrylate and 0.25Kg triethylamine are placed in a nitrogen-protected reactor In the middle, stir and react at 60°C for 7 hours, then add 215Kg 105 amine epoxy curing agent, stir evenly and keep it warm for 1.5 hours to obtain a composite curing agent with a viscosity of 10mPa·S;

[0022] (3) Bisphenol F epoxy resin cured by polythiol-amine composite modifie...

Embodiment 2

[0023] Embodiment 2: The preparation method of the special composite curing agent modified bisphenol F thermosetting adhesive repair agent for ballastless track away from the crack damage, including:

[0024] (1) Preparation of main ingredient of bisphenol F epoxy resin: Add 100Kg of bisphenol F diglycidyl ether and 75Kg of active diluent 1,6-hexanediol diglycidyl ether into the reaction kettle, stir and dissolve at 40°C , to prepare a viscosity of 65mPa·S bisphenol F epoxy resin main agent;

[0025] (2) Synthesis of polythiol-amine composite curing agent: 20Kg 2-2'-dimercaptoethyl sulfide, 25Kg trimethylolpropane triacrylate and 0.25Kg triethylamine are placed in a nitrogen-protected reactor In the middle, stir and react at 60°C for 7 hours, then add 200Kg of amine curing agent, stir evenly and keep it warm for 1.5 hours to obtain a composite curing agent with a viscosity of 10mPa·S;

[0026] (3) Bisphenol F epoxy resin cured by polythiol-amine composite modified curing agen...

Embodiment 3

[0027] Embodiment 3: The preparation method of the special composite curing agent modified bisphenol F thermosetting adhesive repairing agent for ballastless track away from the crack damage, including:

[0028] (1) Preparation of bisphenol F epoxy resin main agent: 100Kg bisphenol F diglycidyl ether, 50Kg reactive diluent 1,4-butanediol diglycidyl ether were added to the reaction kettle, stirred and dissolved at 40°C, The prepared viscosity is 75mPa·S bisphenol F epoxy resin main agent;

[0029] (2) Synthesis of polythiol-amine composite curing agent: 2-2'-dimercaptoethyl sulfide, 25Kg of trimethylolpropane triacrylate and 0.5Kg triethylamine are placed under nitrogen protection In a reaction kettle, stir and react at 60°C for 8 hours, then add 200Kg of amine curing agent, stir evenly and keep it warm for 1 hour to obtain a composite curing agent with a viscosity of 10mPa·S;

[0030] (3) Bisphenol F epoxy resin cured by polythiol-amine composite modified curing agent: Take 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com