Canate-bimaleimide resin adhesive and preparation method

A technology of bismaleimide resin and maleimide resin, applied in the direction of adhesives, etc., can solve the problems of low dielectric performance, insufficient bonding performance, poor heat resistance, etc., and achieve low dielectric constant, Ease of handling and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

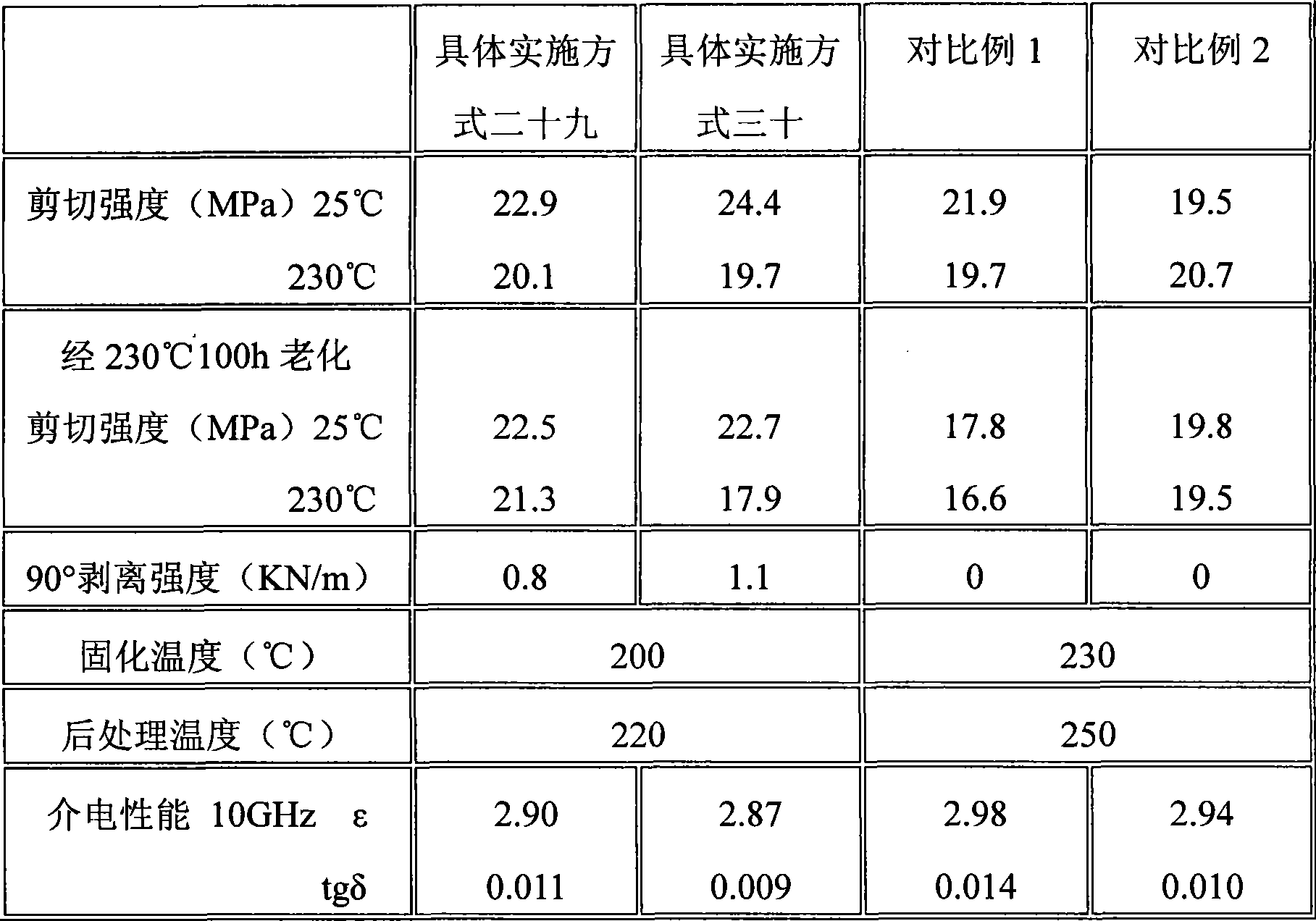

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: In this embodiment, the cyanate-bismaleimide resin adhesive consists of 100 parts by weight of cyanate resin, 40-80 parts of bismaleimide resin, 20-60 parts It is made of internal toughening phenolic resin, 10-40 parts of epoxy resin and 0.5-3 parts of catalyst.

specific Embodiment approach 2

[0024] Specific embodiment two: In this embodiment, the cyanate-bismaleimide resin adhesive is composed of 100 parts by weight of cyanate resin, 50-70 parts of bismaleimide resin, 30-50 parts It is made of internal toughening phenolic resin, 20-30 parts of epoxy resin and 1-2 parts of catalyst.

specific Embodiment approach 3

[0025] Specific embodiment three: in this embodiment, the cyanate ester-bismaleimide resin adhesive is made of 100 parts of cyanate ester resin, 60 parts of bismaleimide resin, 40 parts of internal toughened phenolic resin resin, 25 parts epoxy resin, and 1.5 parts catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com