Patents

Literature

56results about "Manufacturing rigid-tube cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

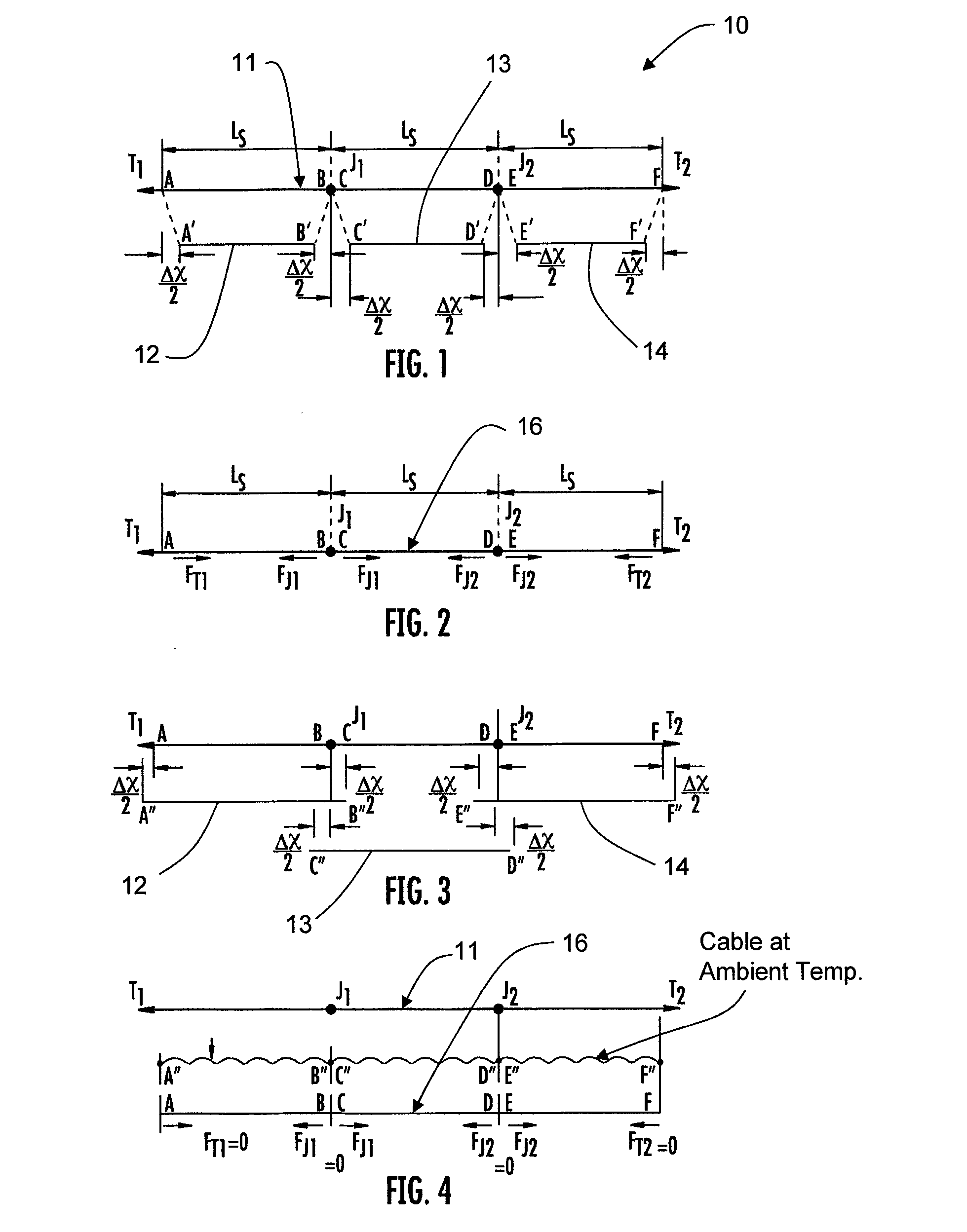

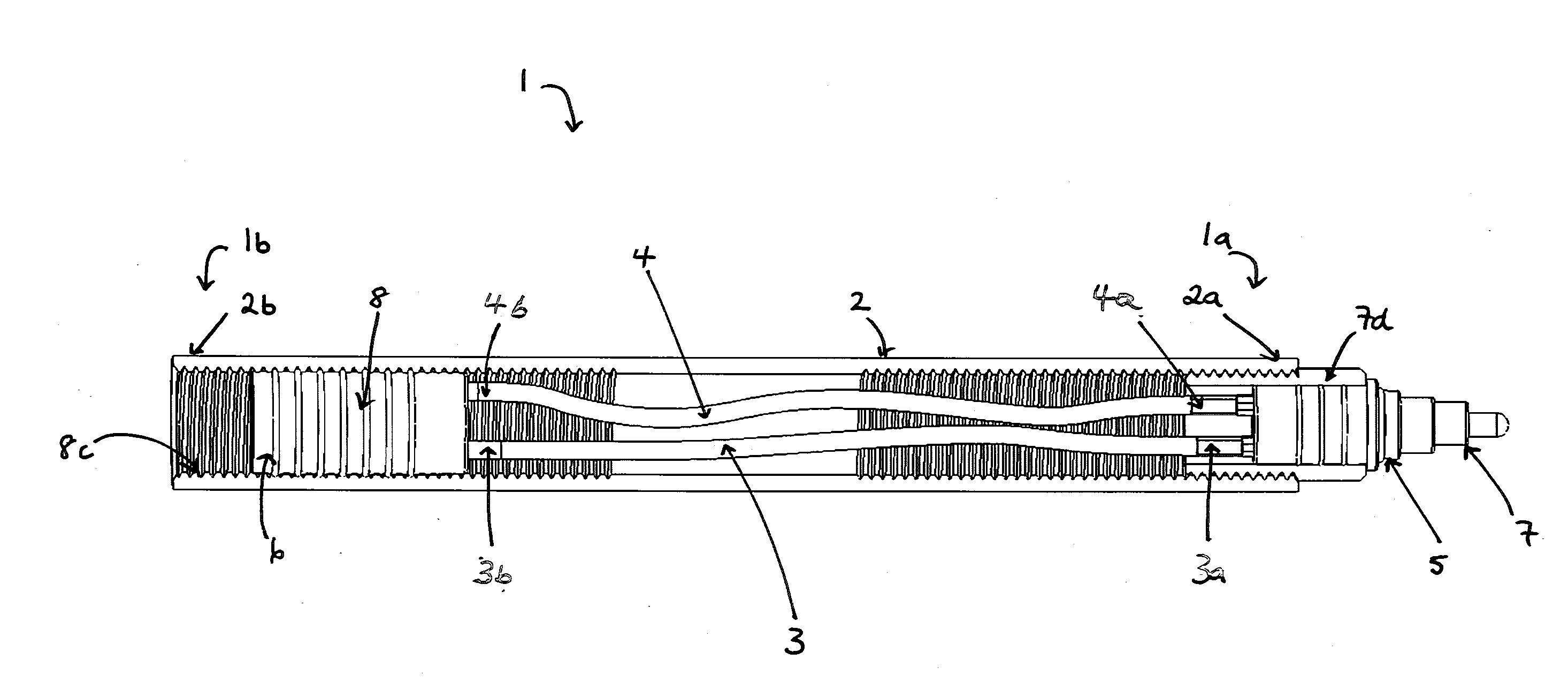

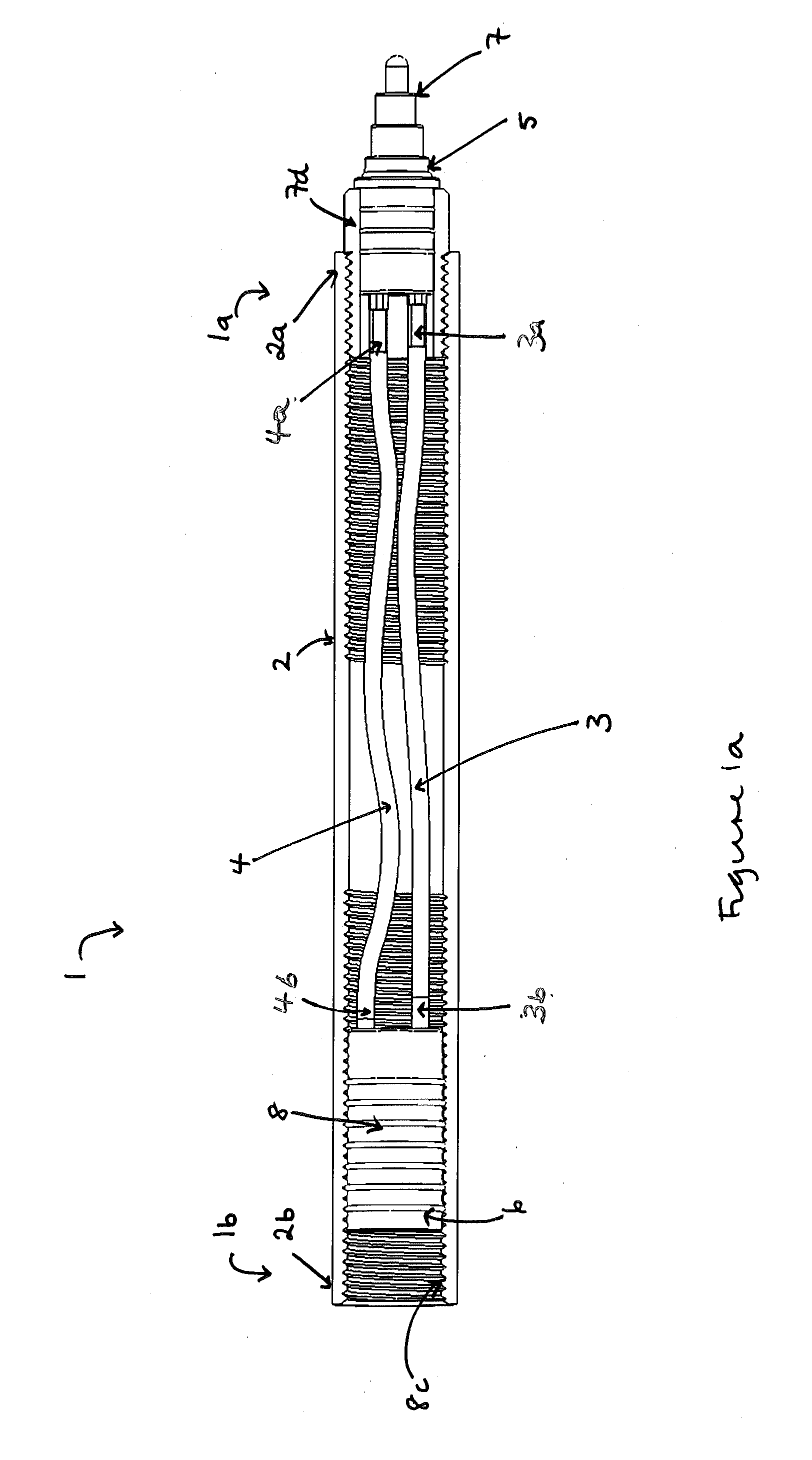

Thermal contraction compensation for superconducting and cryo-resistive cables

InactiveUS20100285968A1Eliminate and reduce magnitude of thermomechanicalSuperconductors/hyperconductorsApparatus for feeding conductors/cablesEngineeringThermal contraction

A method of compensating for thermal contraction of superconducting and cryo-resistive cables. The method includes the steps of determining a compensation length for a cable such that when the cable is subjected to an operating temperature, the cable is in or near a stress-free state, and installing the cable into a pipe such that portions of the cable extend outwardly past ends of the pipe. The method further includes the steps of marking each end of the cable such that the determined compensation length is visibly shown, forcing the cable into the pipe at an ambient installation temperature such that a cable pattern is formed therein, and maintaining the cable in the pipe to prevent the cable from being pushed out of the pipe.

Owner:ELECTRIC POWER RES INST INC

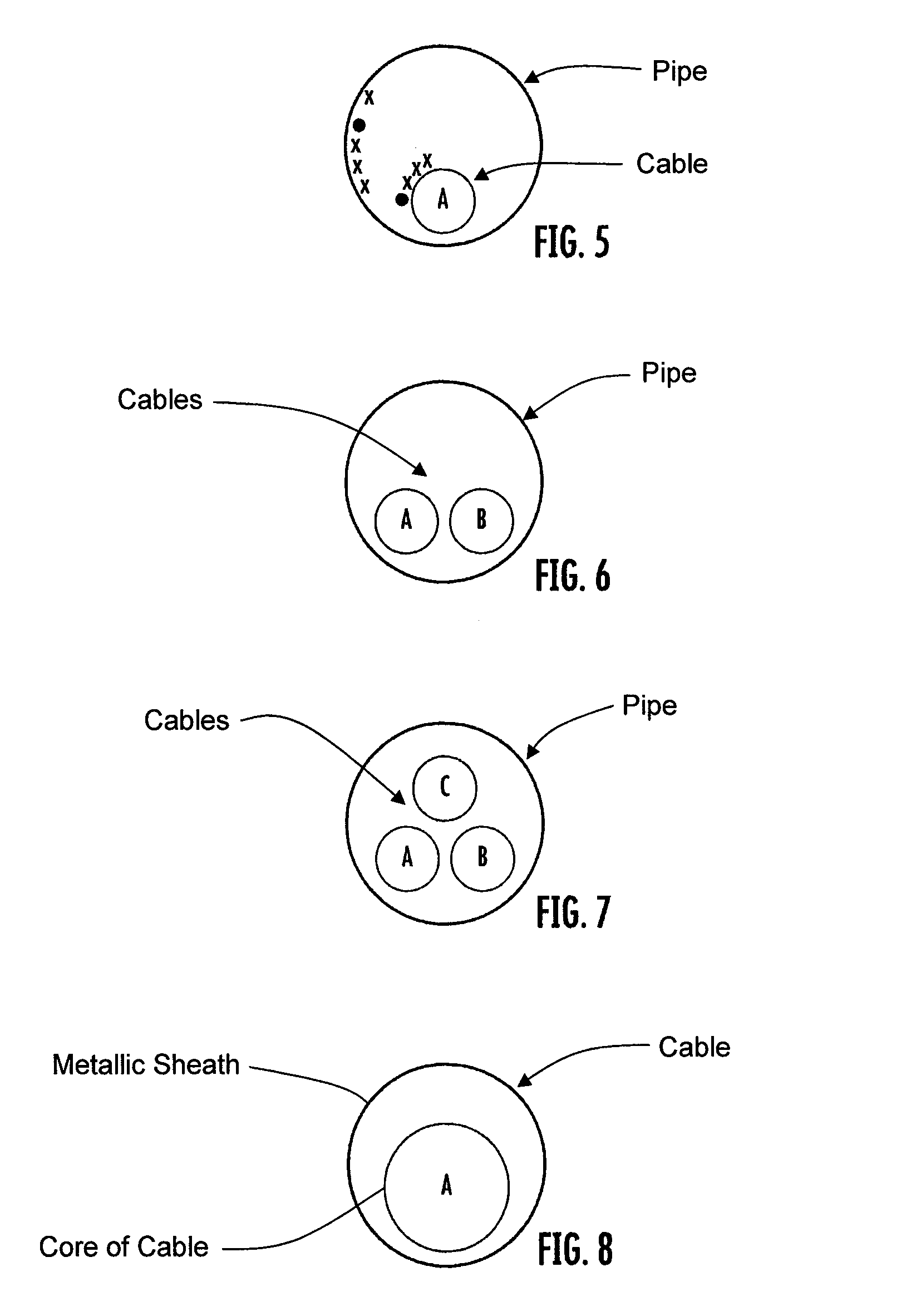

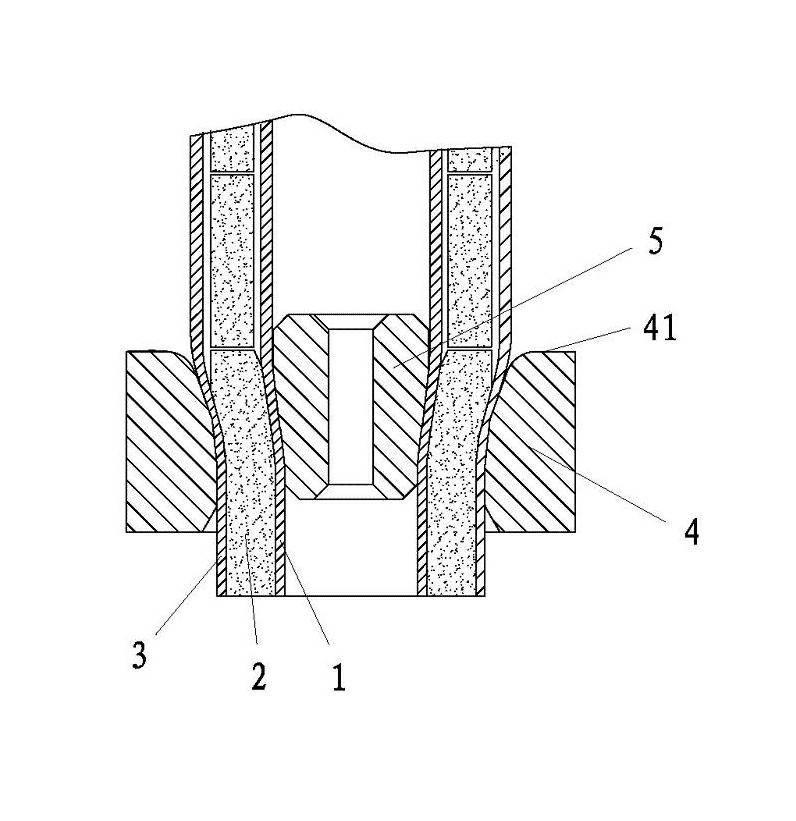

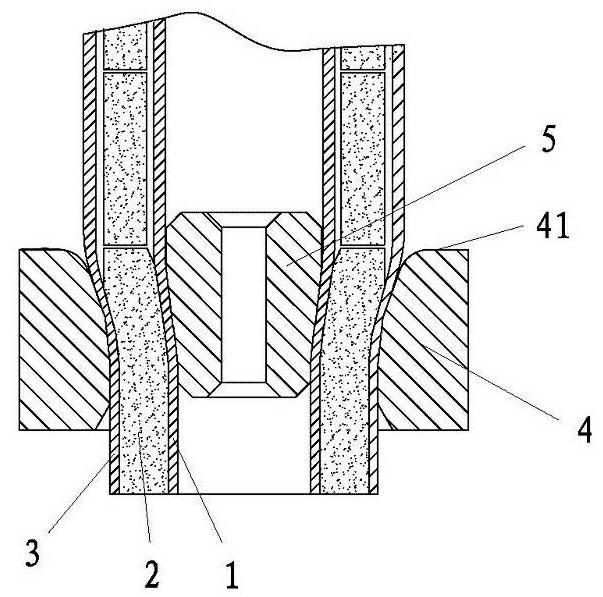

Composite insulating tube type bus and method for preparing the same

ActiveCN101339824AImprove insulation performanceImprove securityRigid-tube cablesManufacturing rigid-tube cablesState of artElectrical conductor

The invention discloses a compound insulating tube busbar and a preparation method thereof in the technical field of high voltage insulated conduction. The compound insulating tube busbar comprises a conductor tube, a compound insulating layer, a semiconductor electric strip layer, a shielding layer and a sleeve, wherein, the conductor tube is positioned on the innermost layer; a plurality of the compound insulating layers and the semiconductor electric strip layers are crosswise arranged at the external part of the semiconductor tube; a copper foil layer is arranged at the external part of the semiconductor electric strip layer and the sleeve is arranged at the external part of the copper foil layer. The preparation method of the invention adopts different properties of a solid buddle-free insulating film strip and insulating liquid to enwind and solidify the shaped insulating tube busbar on the surface of the tubular conductor, which causes the production procedure to be simple and the maintenance to be simple and convenient; compared with the prior art, the compound insulating tube busbar has better insulating property and longer service life, and can be applied to bitter environments.

Owner:SHANGHAI XIBANG ELECTRIC

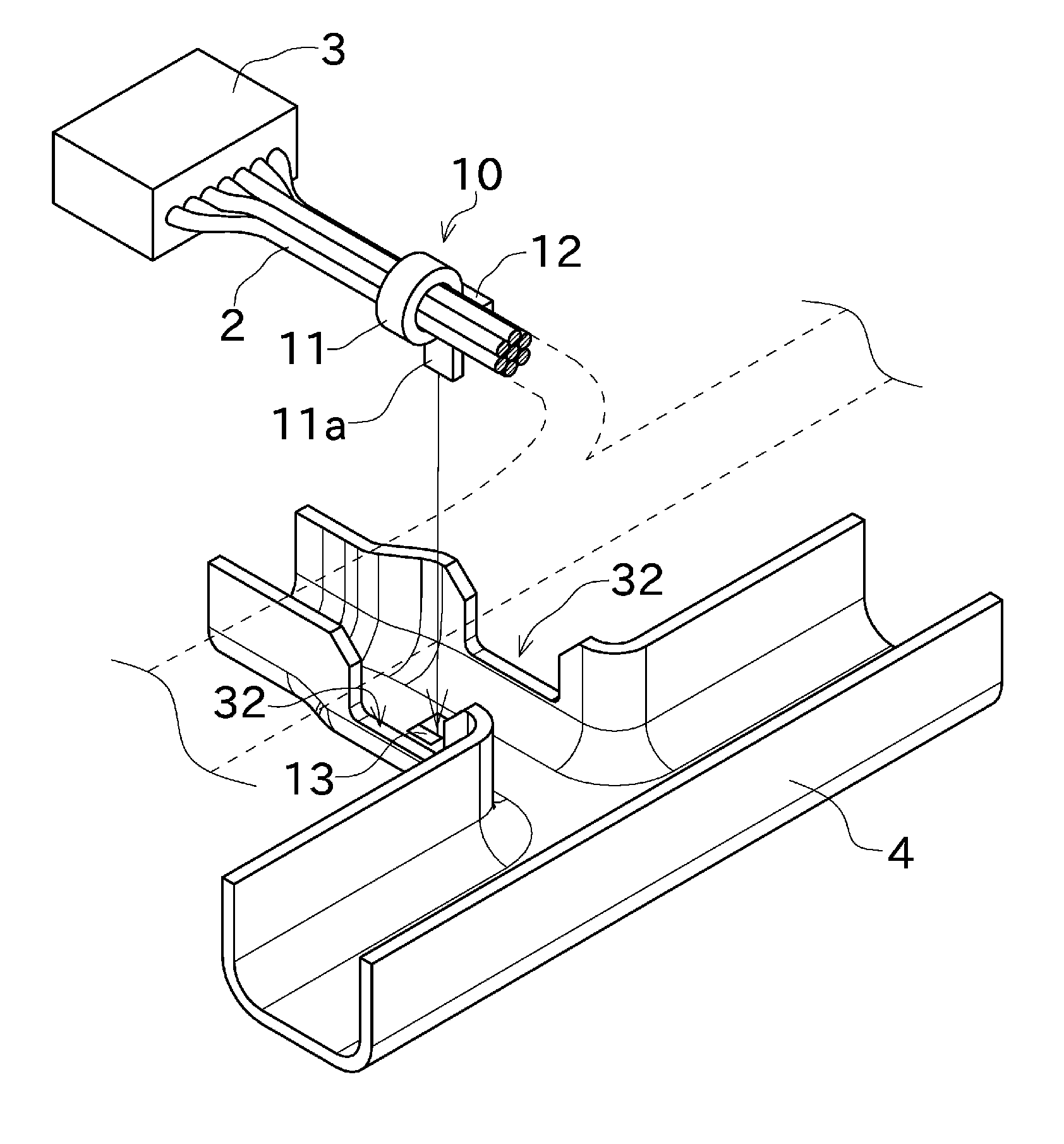

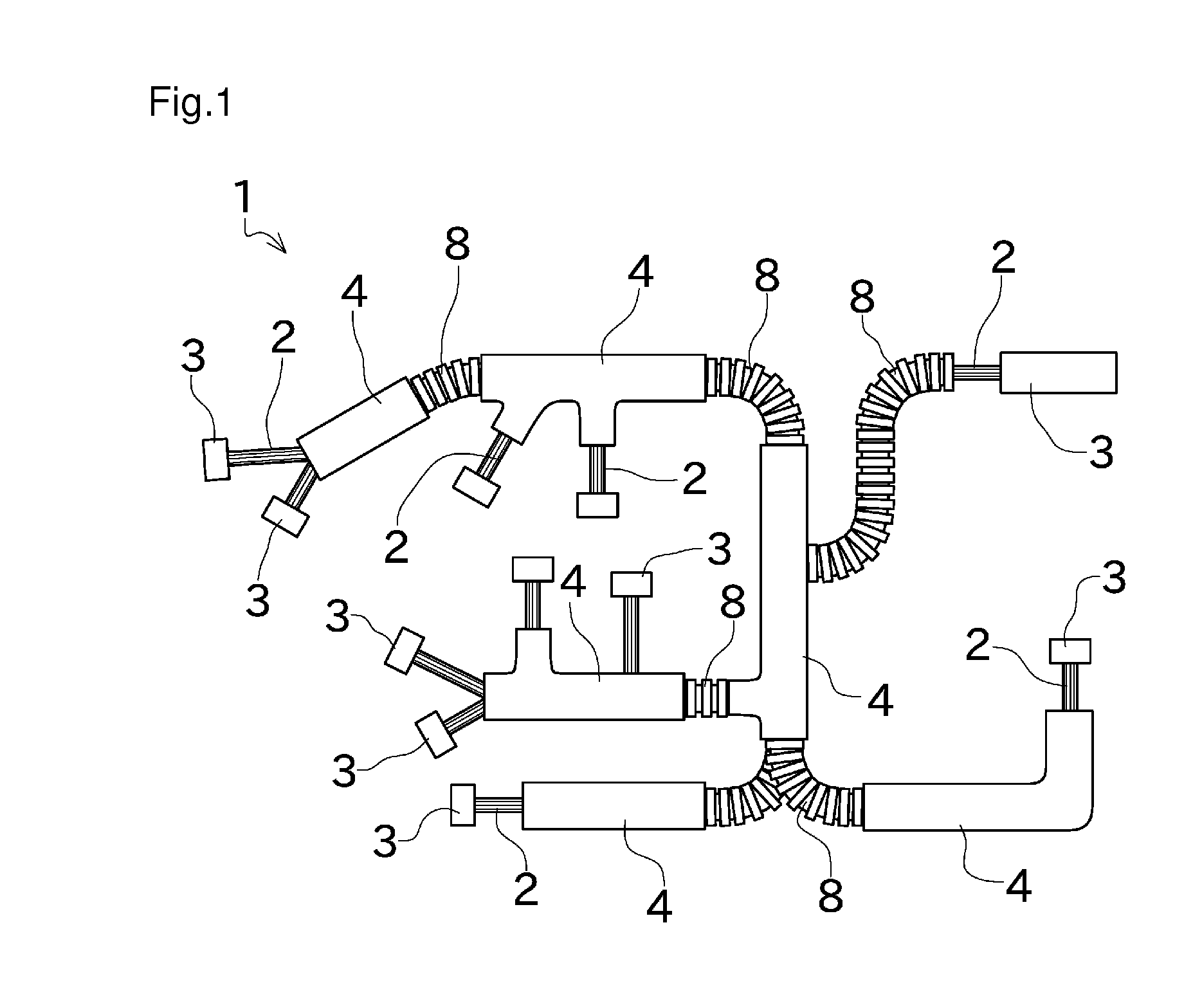

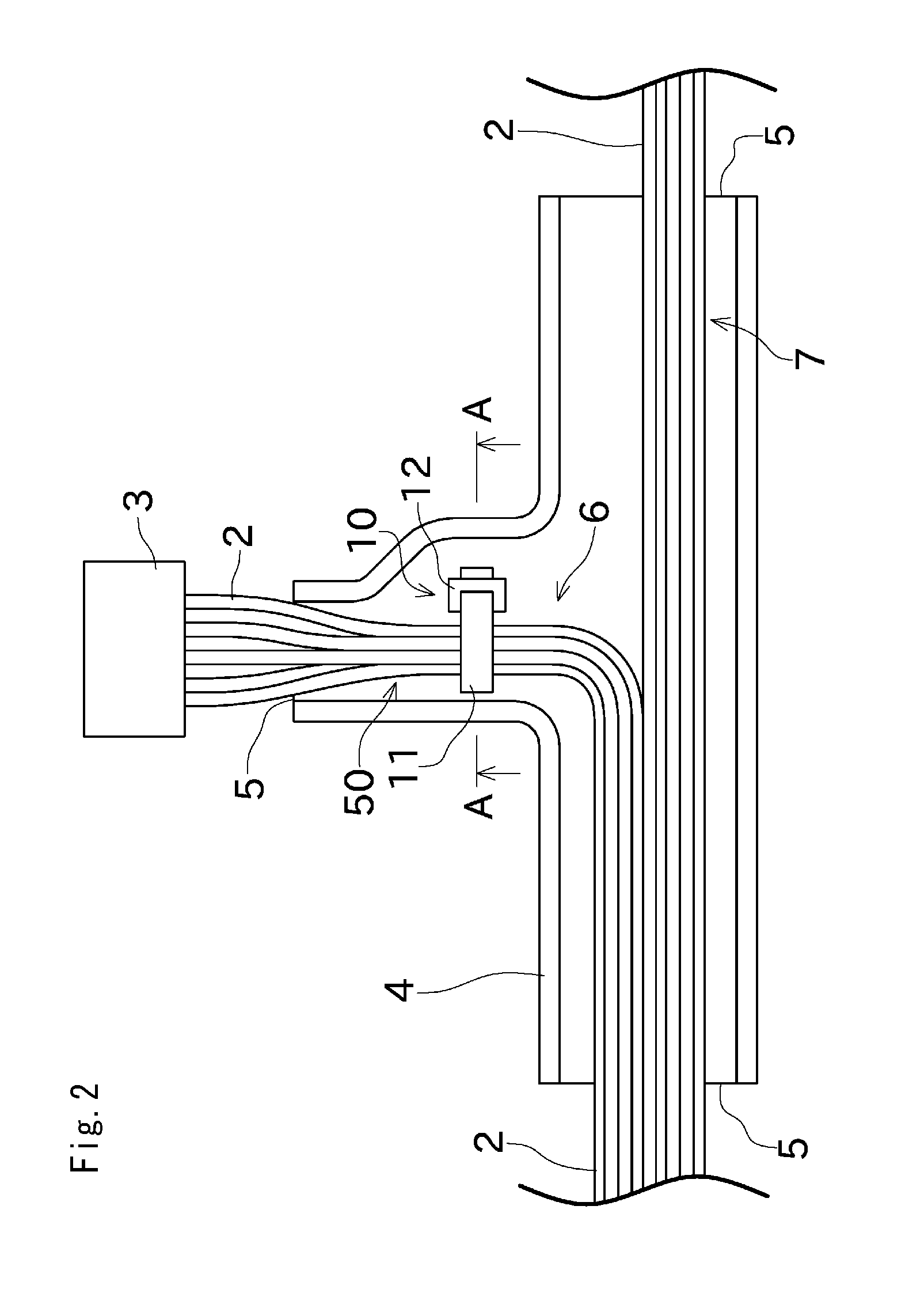

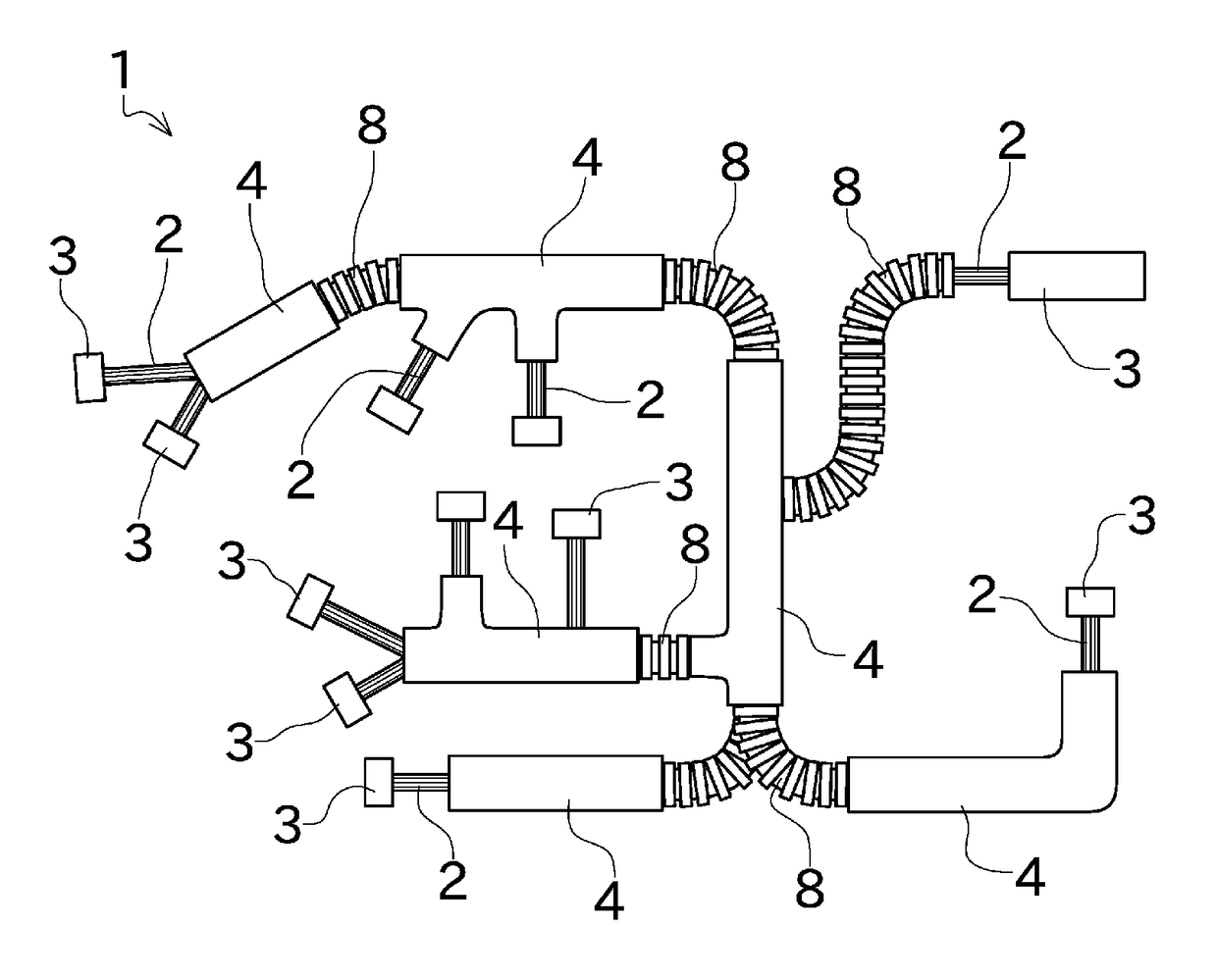

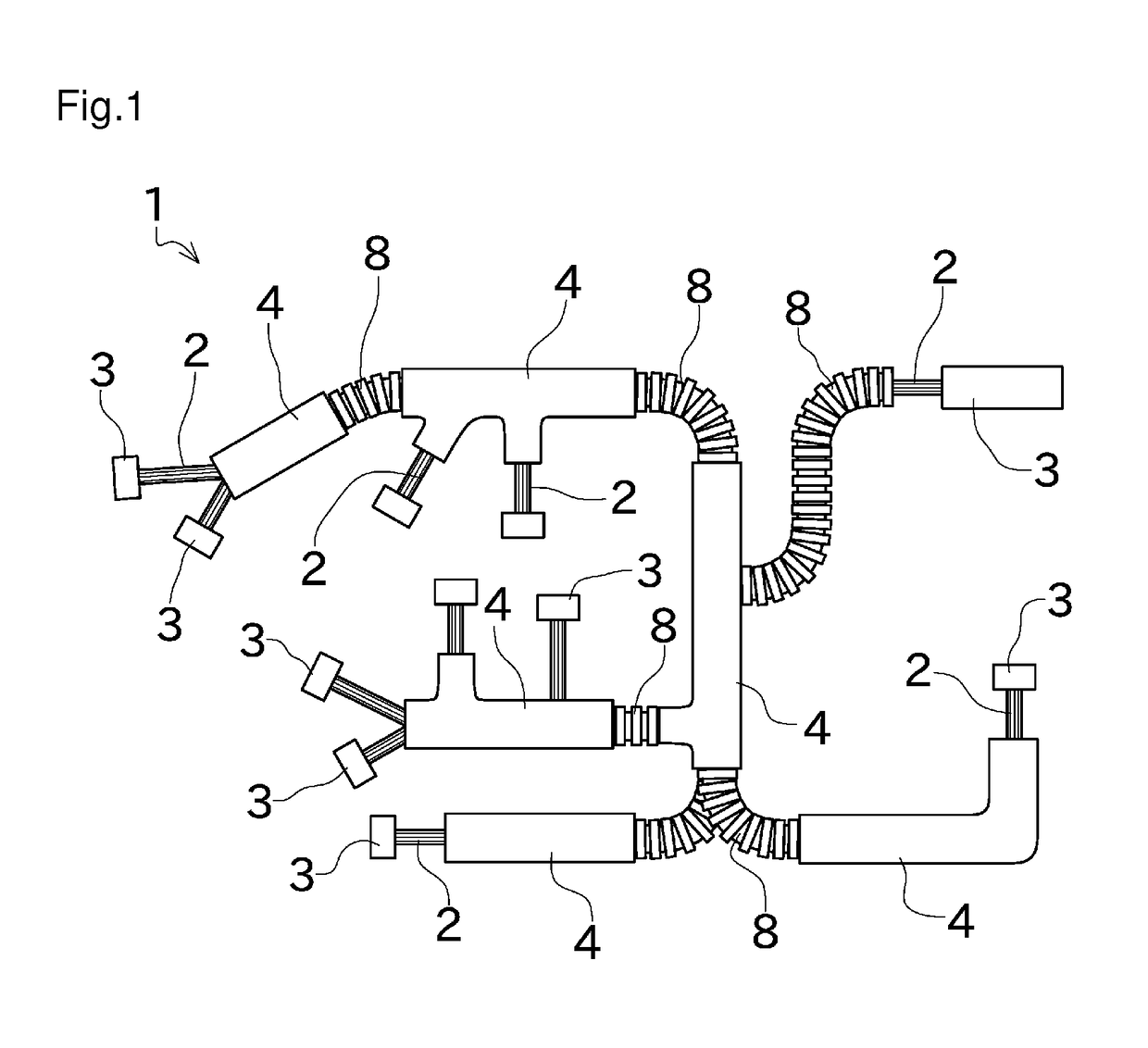

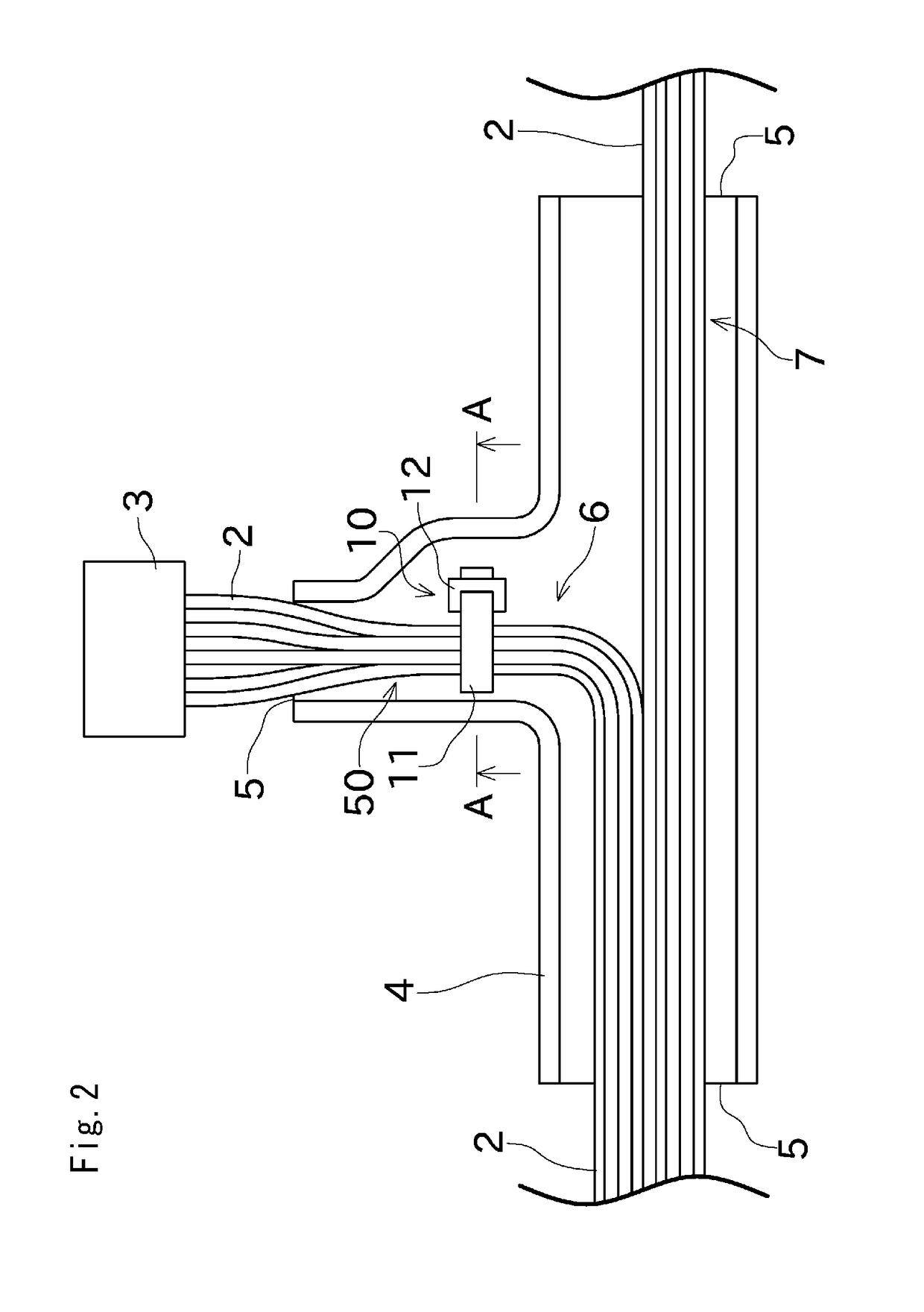

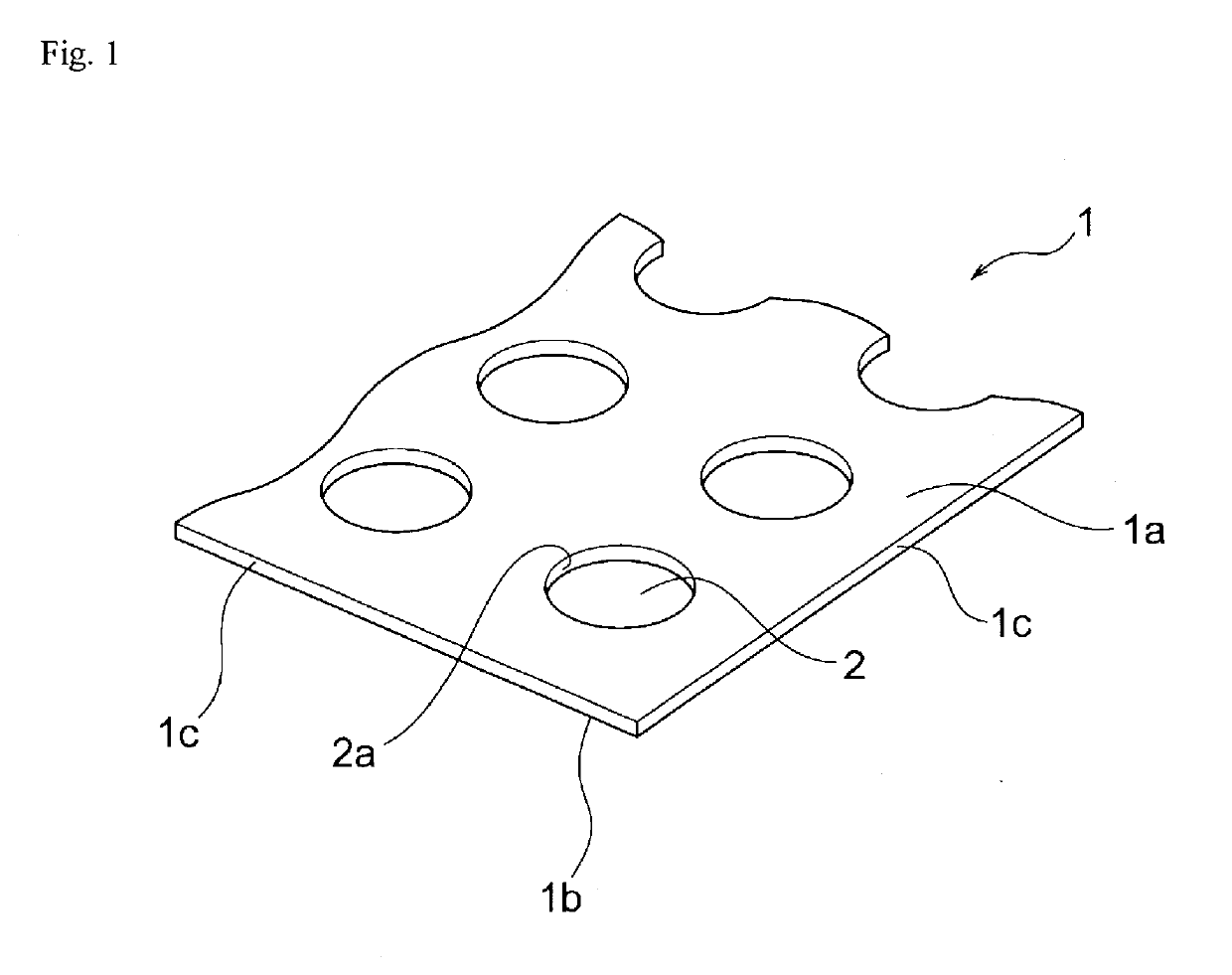

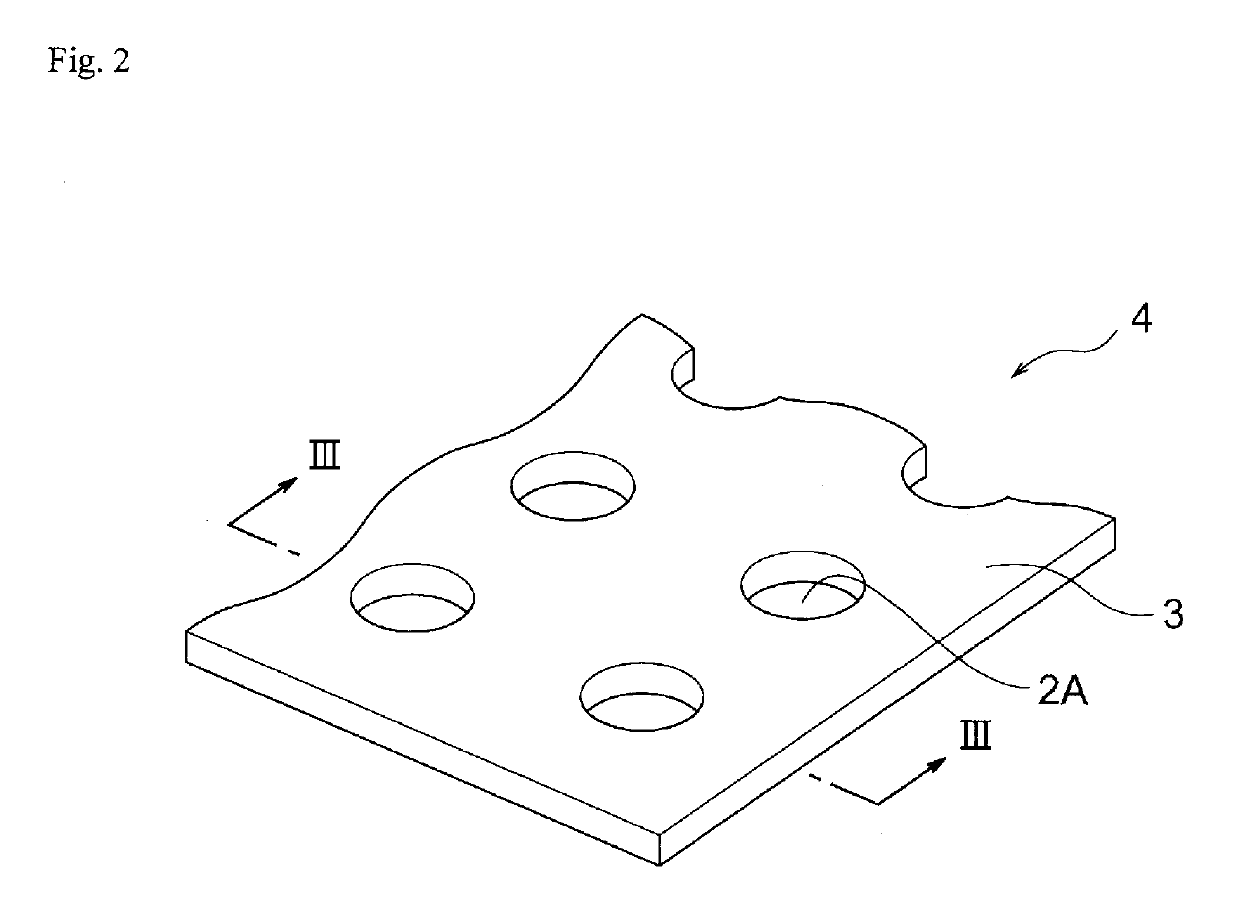

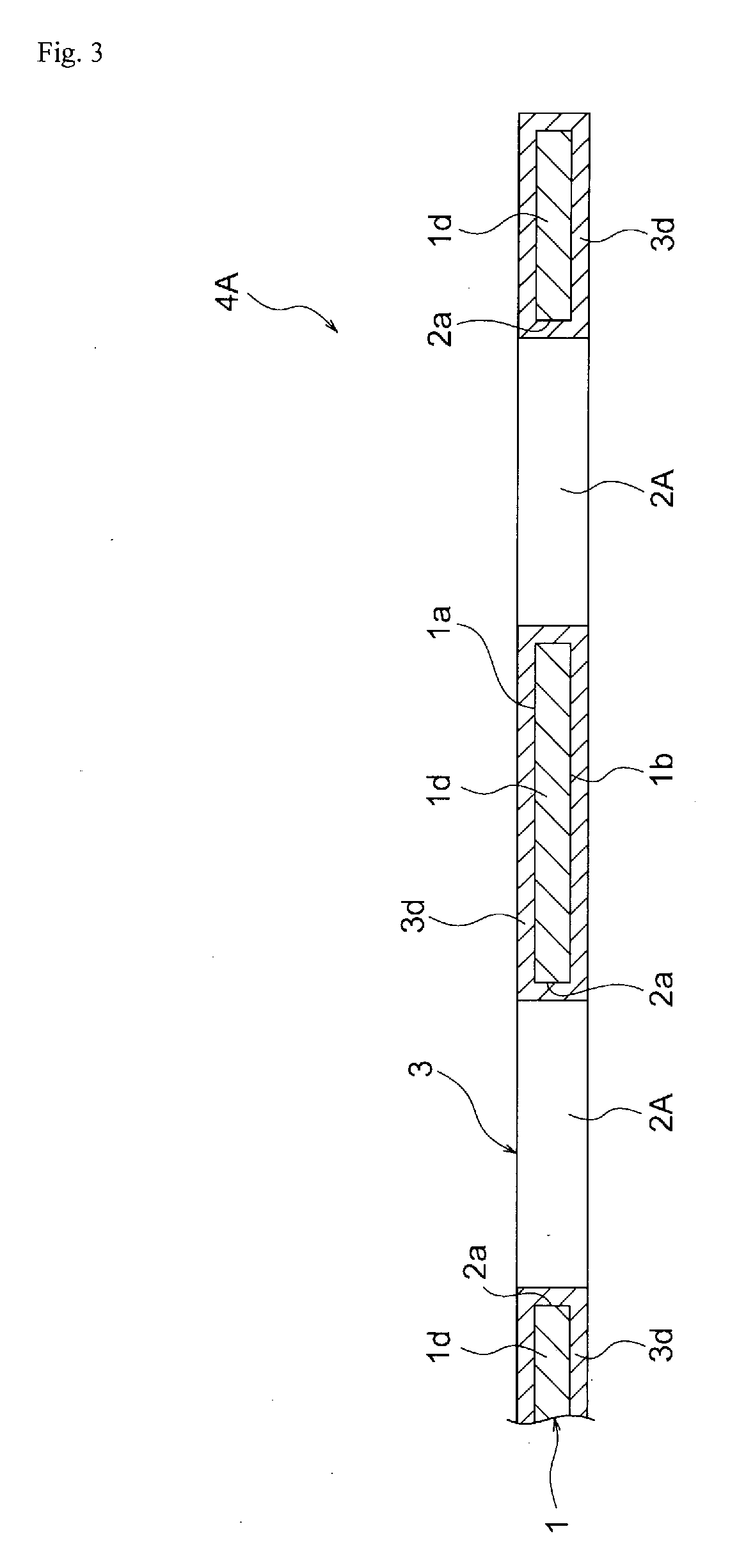

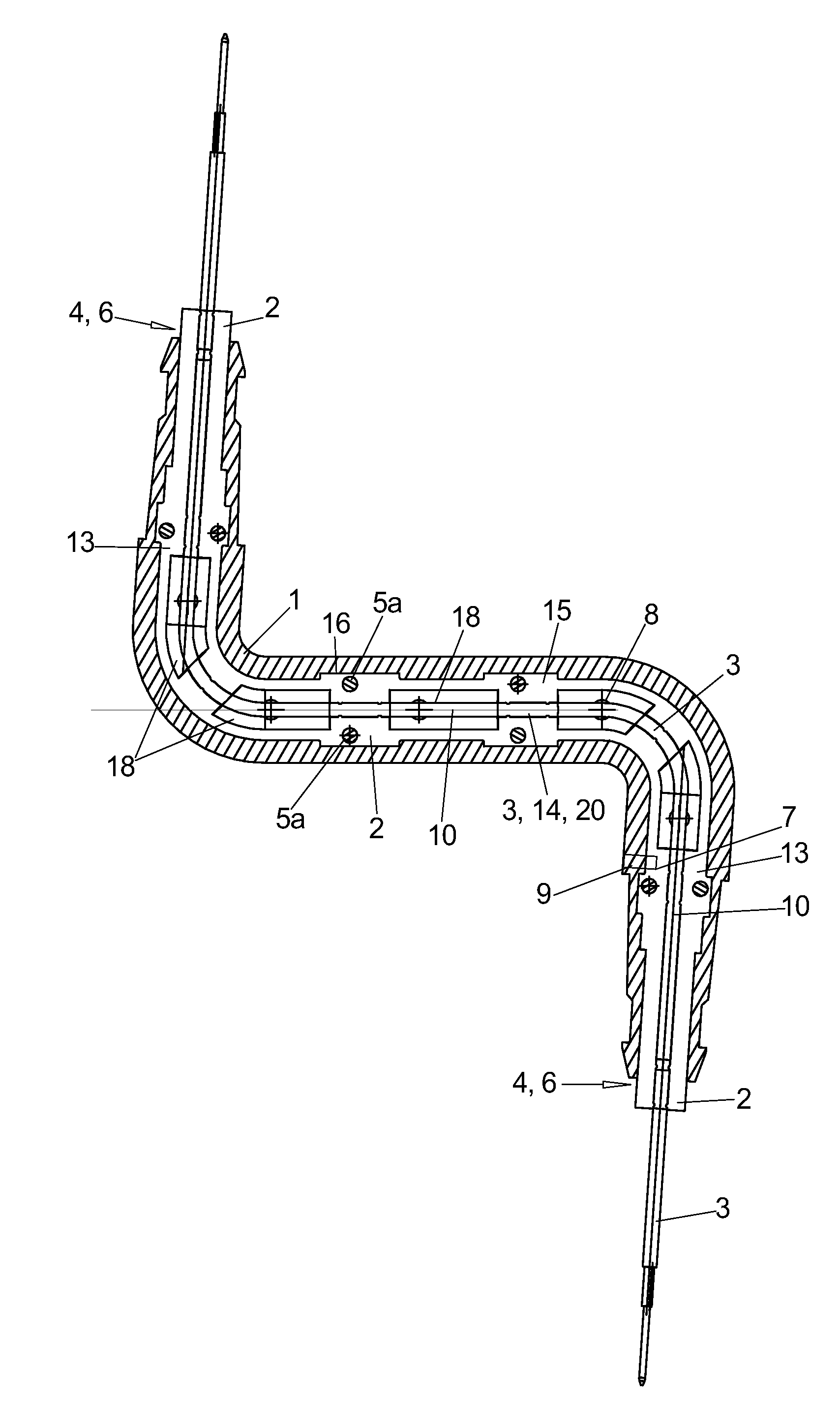

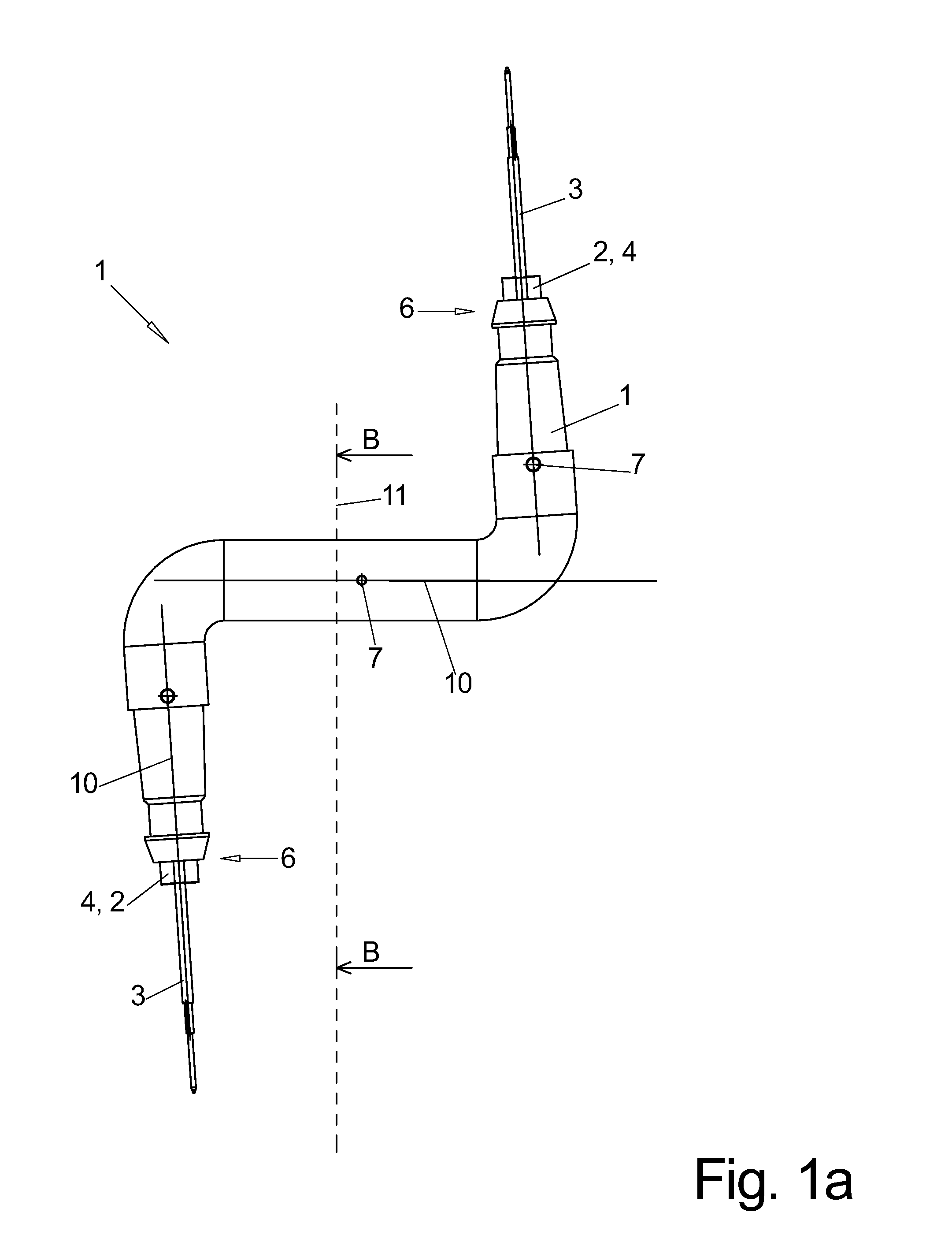

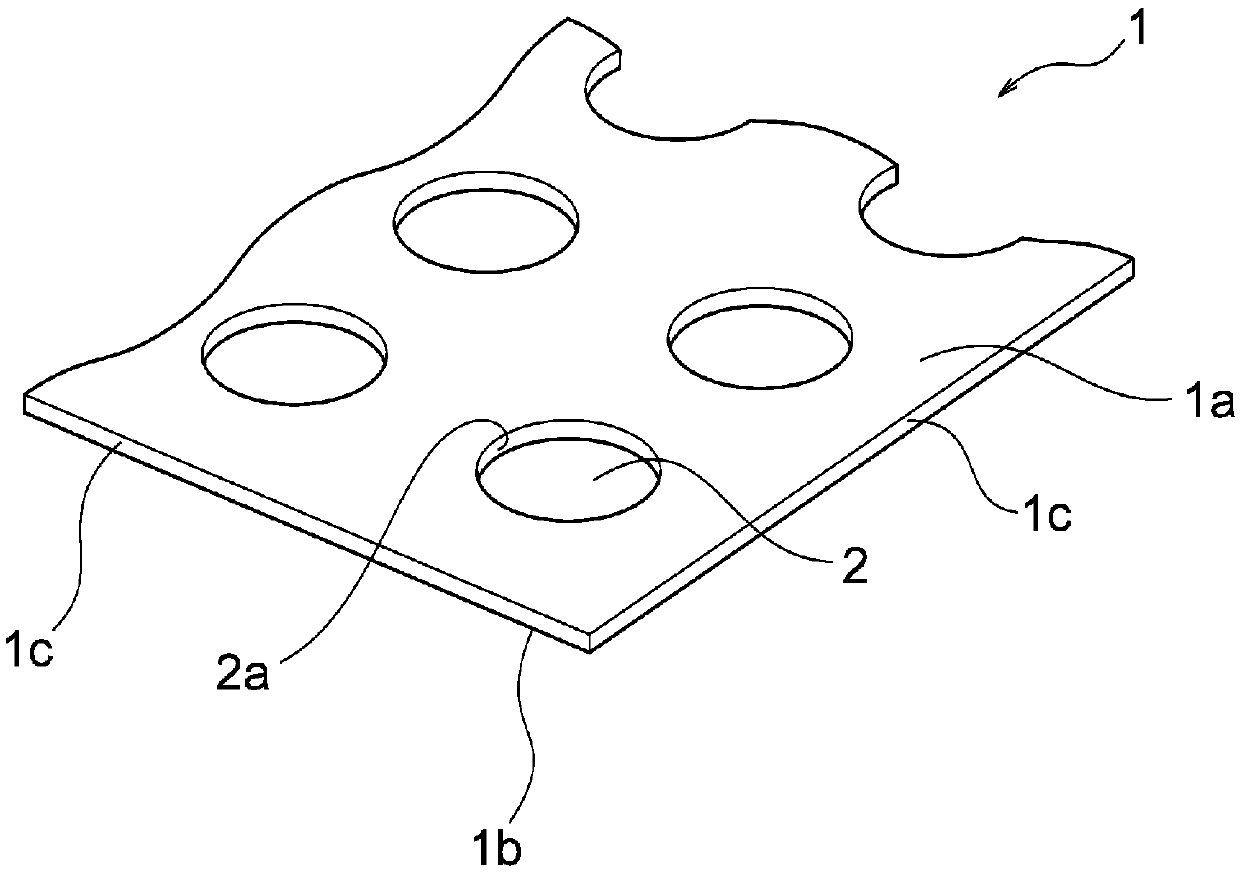

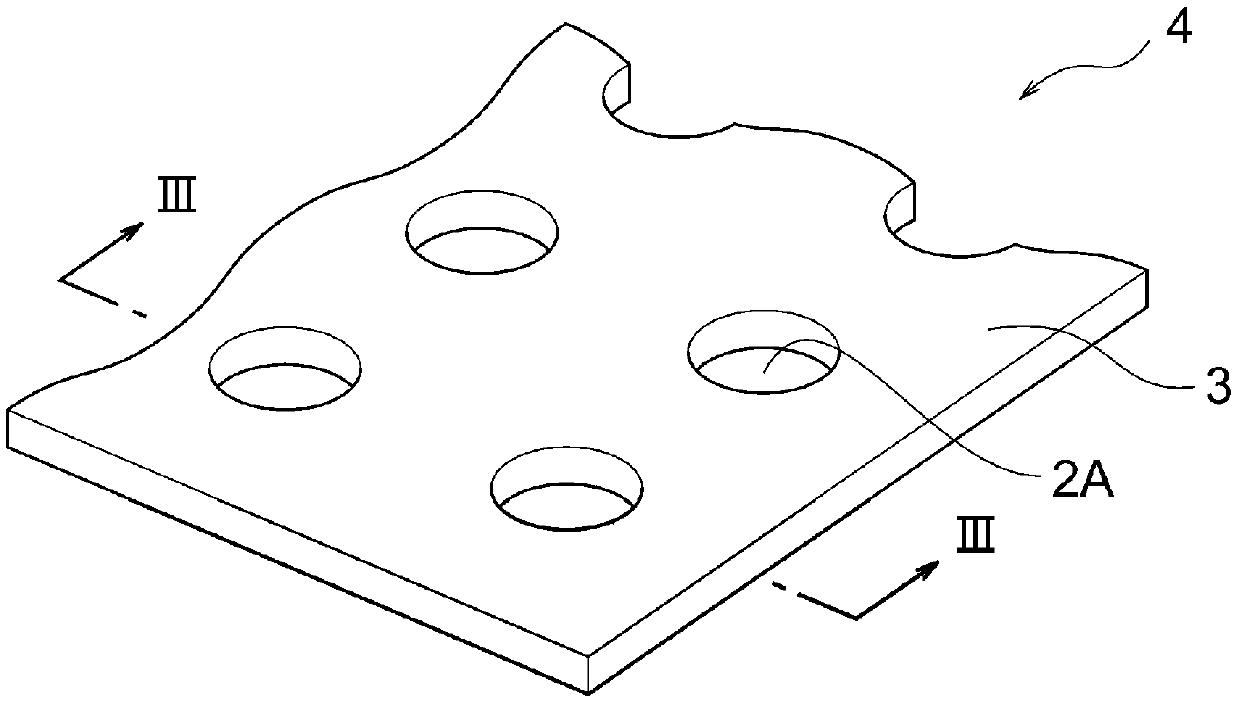

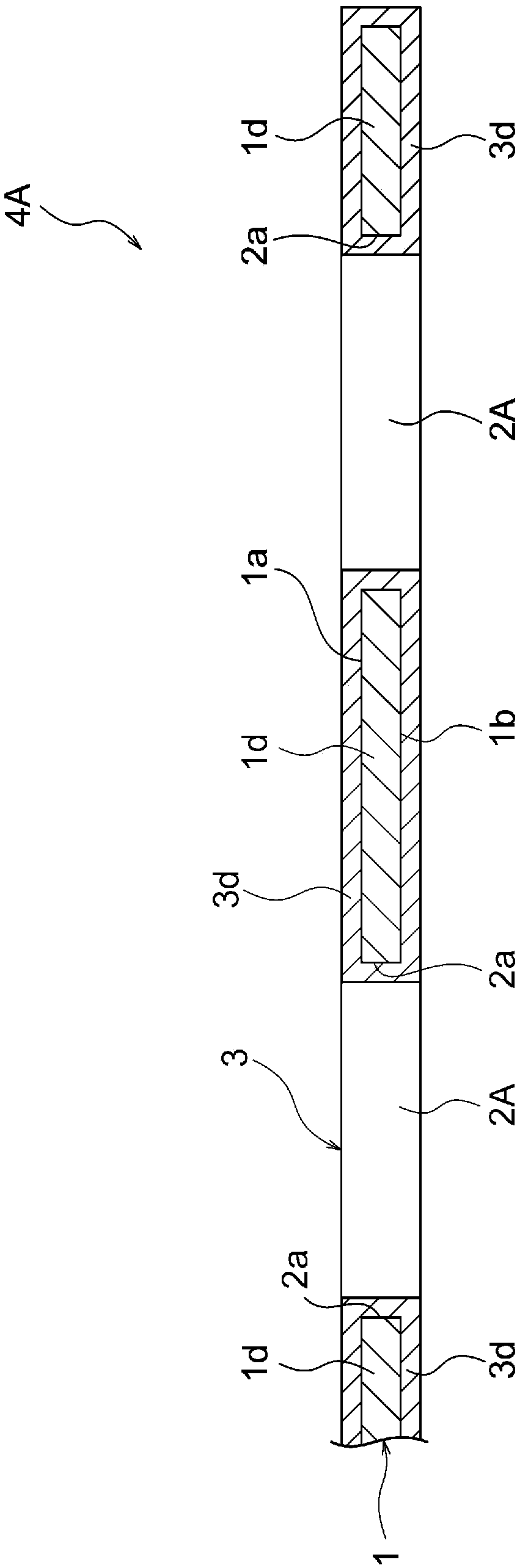

Wire harness and method for manufacturing wire harness

ActiveUS20150294768A1Efficient arrangementSuitable for installationLine/current collector detailsRigid-tube cablesDistal portionElectric wire

The invention of the present application provides a wire harness with an improved accuracy of the dimension, that can be manufactured with an easy operation. A protector (4) defines at least either one of a bending shape and a branching shape of a plurality of electric wires (2). A cable tie (10) is attached to the electric wires (2), and includes a distal portion (11a) to be attached to the protector (4). The protector (4) includes an engaging portion (13) engageable with the distal portion (11a). Positions of the electric wires (2) and the protector (4) relative to each other are settled by engagement of the distal portion (11 a) of the cable tie (10) attached to the electric wires (2) with the engaging portion (13).

Owner:FURUKAWA ELECTRIC CO LTD +1

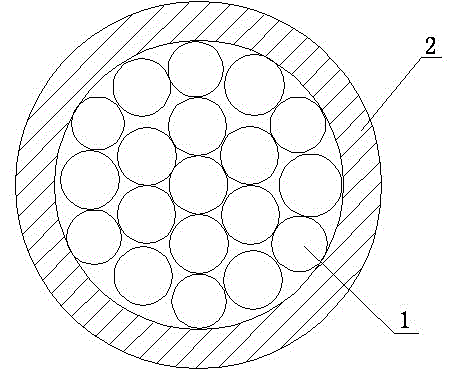

Railway through ground wire and preparation process thereof

ActiveCN103337294AQuality assuranceGuaranteed lifeInsulated cablesManufacturing rigid-tube cablesAnti stressRare earth

The invention relates to a railway through ground wire. The railway through ground wire comprises copper stranded wires (1); the exterior of the copper stranded wires (1) is coated with an outer sheath layer (2) which is made of a rare earth copper alloy material. The outer sheath of the through ground wire is made of rare earth copper alloy, and therefore, defects of zinc-containing brass can be eliminated, and the outer sheath has strong waterproof, anti-corrosion and anti-stress performances, so the quality and the service life of the railway through ground wire can be ensured; the outer sheath has strong tensile strength and high elongation at break and low resistance, and is not easily influenced by stress, and therefore, usage requirements of the railway through ground wire can be better satisfied; the contents of mercury, lead, cadmium and chromium in the outer sheath are lower, and therefore, after being used for a long term, the outer sheath of the railway through ground wire will not pollute environment; and the copper stranded wires are sheathed in the outer sheath which is a seamless pipe, and therefore, problems of cracks appearing on existing outer sheaths and affected conductivity of the copper stranded wires caused by welding-caused high temperature can be solved.

Owner:江阴和宏精工科技有限公司

High-temperature resistant and radiation-resistant inorganic insulating hollow cable as well as manufacturing method and mold thereof

ActiveCN102110495AGood electrical performanceImprove electrical performanceRigid-tube cablesManufacturing rigid-tube cablesAviationElectrical conductor

The invention relates to a high-temperature resistant and radiation-resistant inorganic insulating hollow cable as well as a manufacturing method and mold thereof, belonging to the technical field of power transmission cables and high-temperature winding lines. The high-temperature resistant and radiation-resistant inorganic insulatinghollow cable comprises a conductor, an insulating layer and a sheath layer, wherein the insulating layer is coated outside the conductor, and the sheath layer is coated outside the insulating layer. The conductor is a hollow metal tube; and the insulating layer is prepared from one or mixture of more of magnesium oxide, aluminum oxide or silicon dioxide with the purity above 99% and the grain size below 180 mum. The high-temperature resistant and radiation resistant inorganic insulating hollow cable provided by the invention has good electrical performance; the conductor is filled with a refrigerant so that the conductor can work for a long time at the temperature over 1000 DEG C; and the cable is suitable for the fields of nuclear stations, nuclear fusion devices, space flight and aviation and the like.

Owner:久盛电气股份有限公司

Wire harness and method for manufacturing wire harness

ActiveUS9672959B2Efficient arrangementSuitable for installationRigid-tube cablesManufacturing wire harnessesDistal portionEngineering

The invention of the present application provides a wire harness with an improved accuracy of the dimension, that can be manufactured with an easy operation. A protector (4) defines at least either one of a bending shape and a branching shape of a plurality of electric wires (2). A cable tie (10) is attached to the electric wires (2), and includes a distal portion (11a) to be attached to the protector (4). The protector (4) includes an engaging portion (13) engageable with the distal portion (11a). Positions of the electric wires (2) and the protector (4) relative to each other are settled by engagement of the distal portion (11a) of the cable tie (10) attached to the electric wires (2) with the engaging portion (13).

Owner:FURUKAWA ELECTRIC CO LTD +1

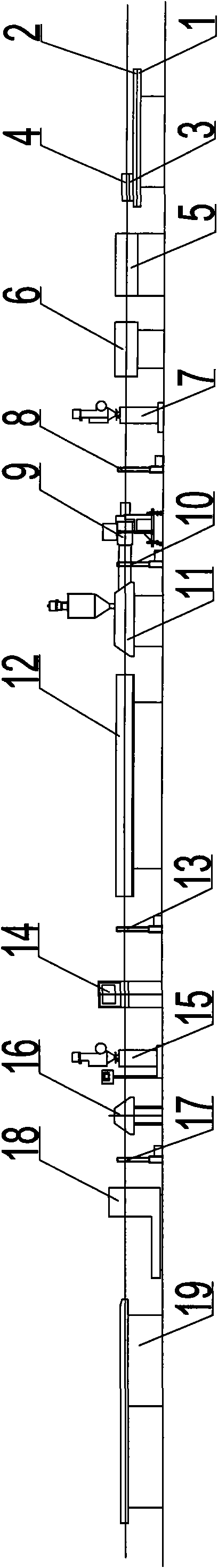

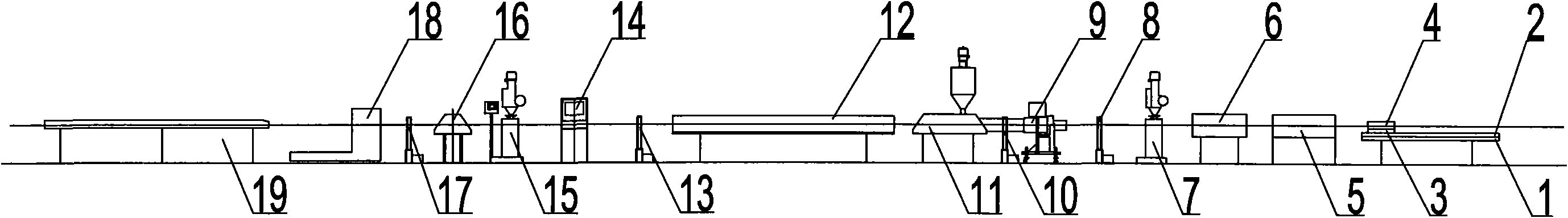

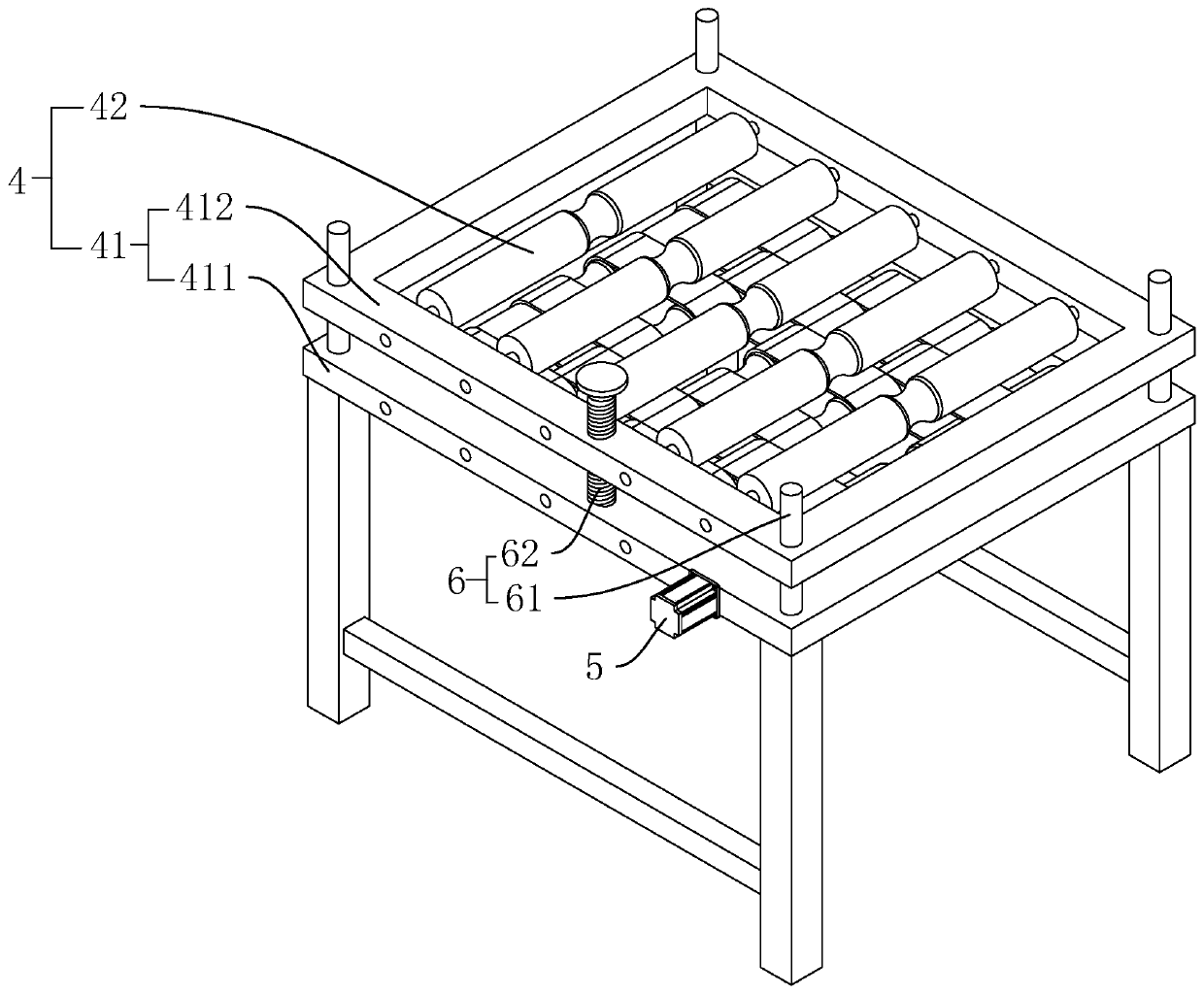

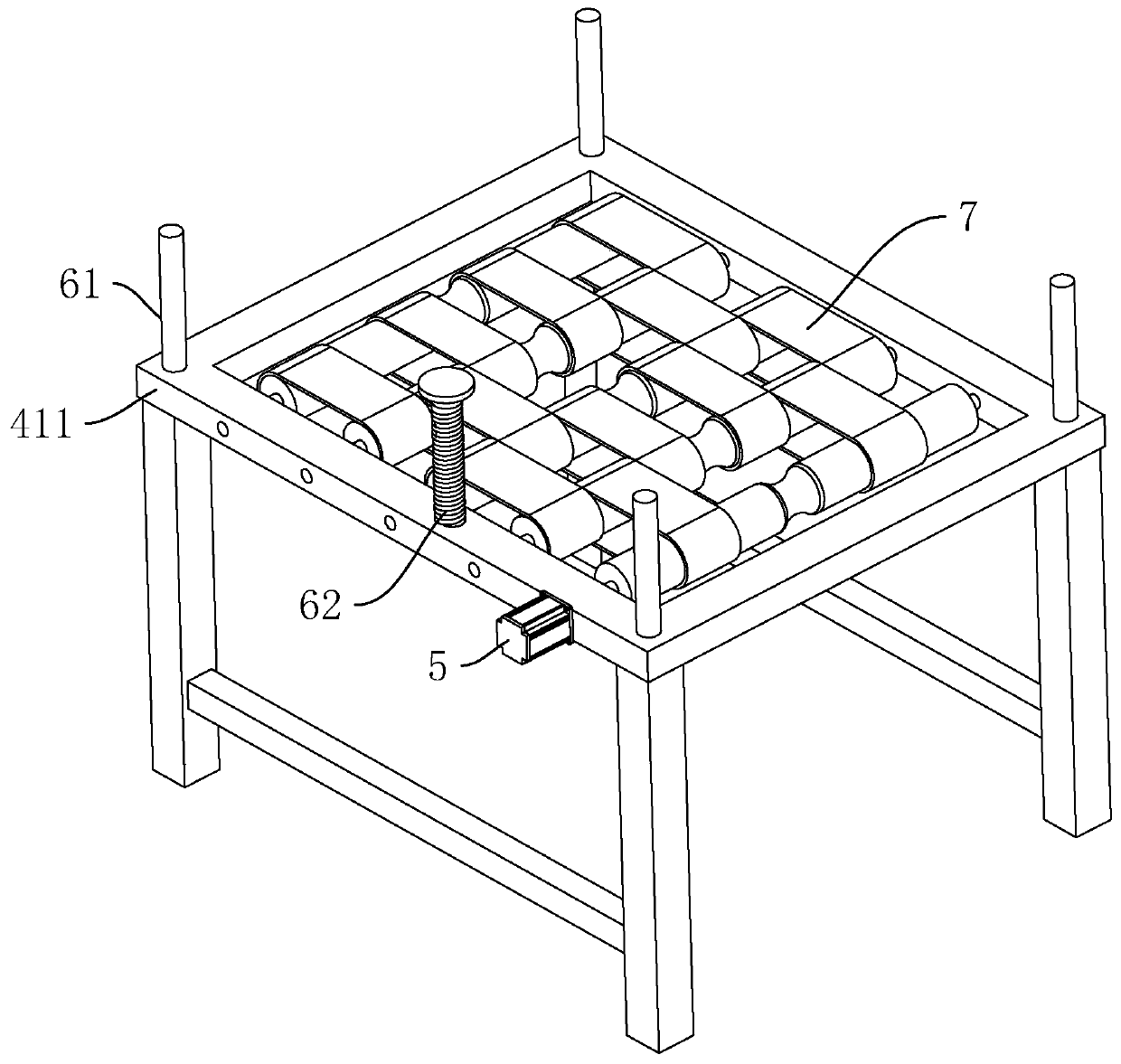

Production process and production device of plastic-coated thick-wall metal pipes

InactiveCN101916627AHigh degree of automationSimple structureManufacturing rigid-tube cablesThick wallMetal

The invention relates to production process and production device of plastic-coated thick-wall metal pipes. The production device comprises a pipe rack (1), a dynamic bracket (2), a built-in device (3) for connecting pipes, a pipe connecting device (4), a traction conveying roller (5), a heating device (6), a first extruder (7), a first air cooler (8), a second extruder (9), a second air cooler (10), a soaking water tank (11), a spraying water tank (12), a third air cooler (13), a high-frequency heating device (14), a third extruder (15), a cooling water tank (16) and a fourth air cooler (17). The production process is completed through operating the devices in sequence, has high automation degree, and can improve the technological level and production efficiency. And the devices utilized in the production process of plastic-coated thick-wall metal pipes are characterized by simple structure, good control property and stable and reliable operation.

Owner:李志雄

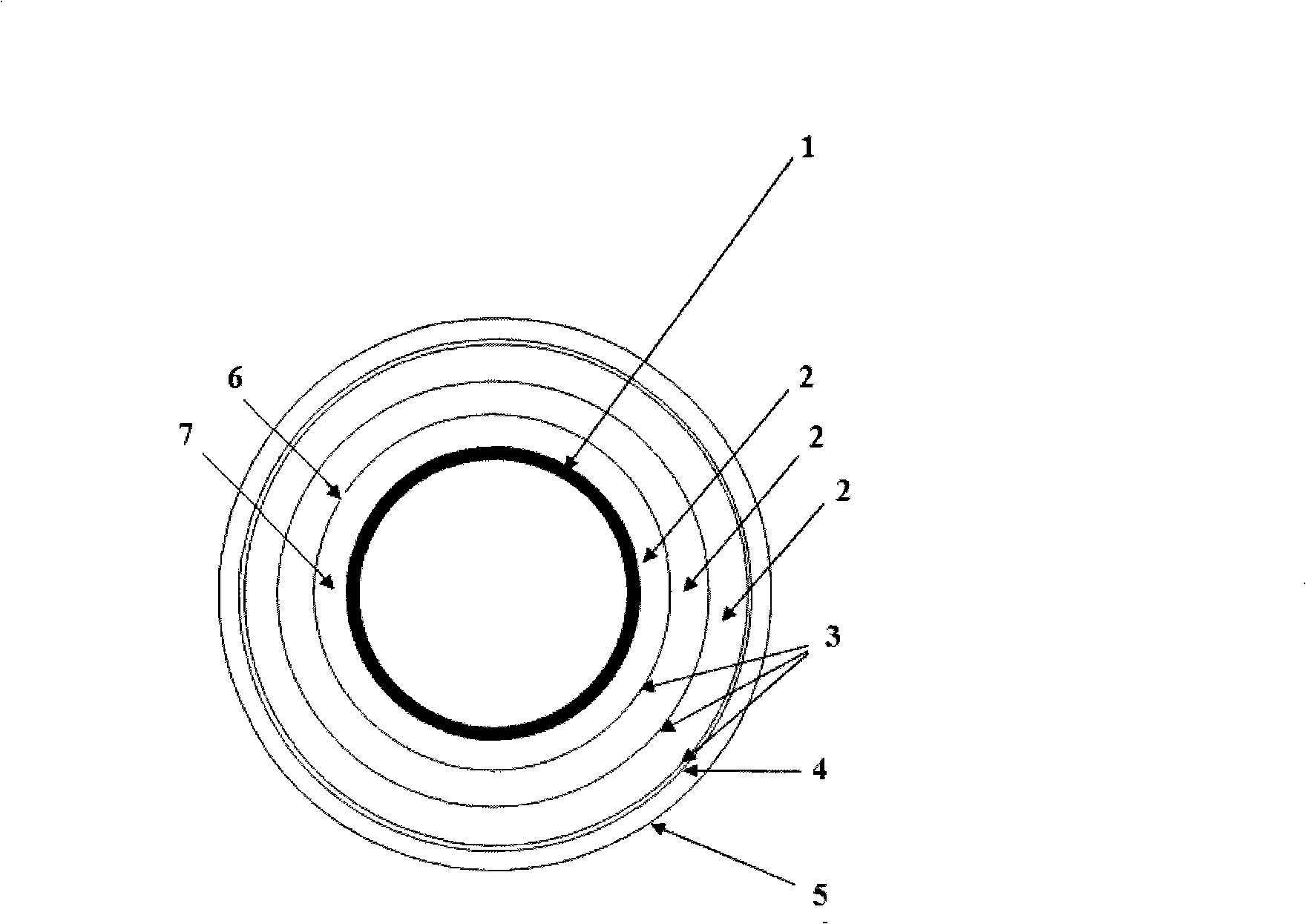

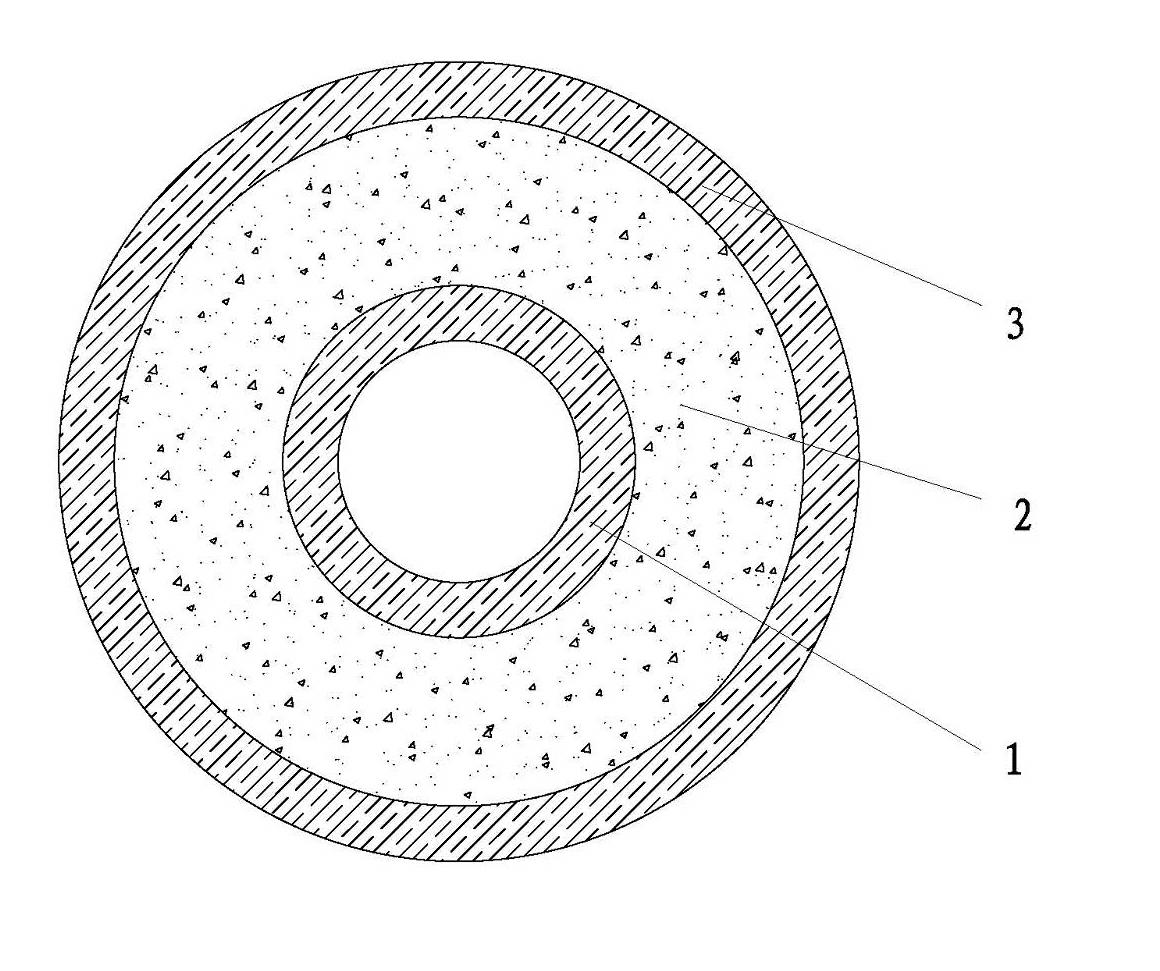

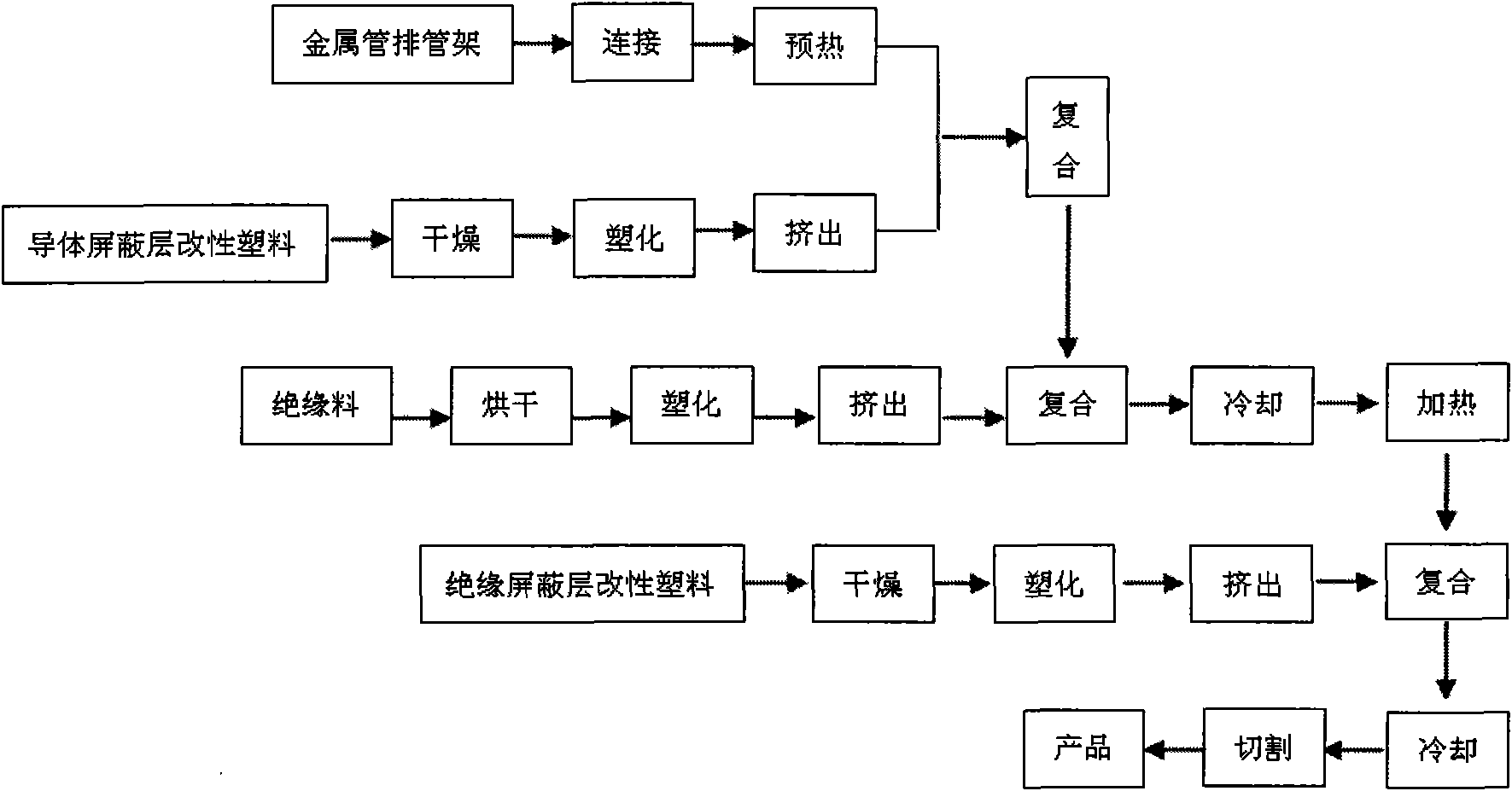

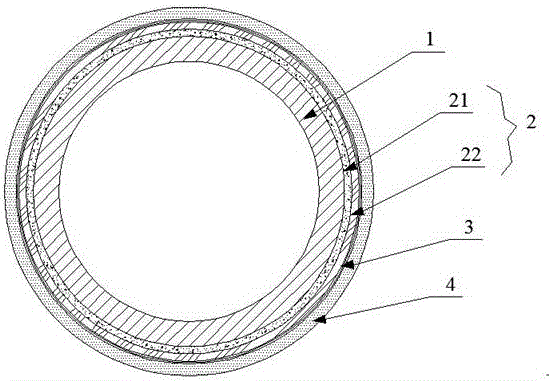

Insulated tubular busbar having composite insulation layer and in voltage class of 1kV and below and preparation method thereof

InactiveCN105931700AAvoid enteringLong aging lifeSingle tube conductorsPower cables with screens/conductive layersPolyolefinElectrical conductor

The invention discloses an insulated tubular busbar having a cold-hot shrinkage composite insulation layer and in a voltage class of 1kV and below and a preparation method thereof. The cross section structure of a tubular busbar is a four-layer structure, which is formed by a metal tube conductor layer, a cold-hot shrinkage composite insulation layer (the inner layer is an ethylene propylene diene monomer cold shrinkage layer, and the outer layer is a polyolefin hot shrinkage layer), a metal grounding shielding layer and an outer protection cover layer from the inside out in sequence. The provided insulated tubular busbar product suitable for the voltage class of 1kV and below is characterized in that a shrinkage tube co-extruded by the cold-hot shrinkage composite insulation layer can be fit to a metal conductor pipe very well without leaving a gap inbetween after heating shrinkage, and the phenomenon of heat expansion and cold contraction does not appear due to the influence of hot and cold environment. The preparation method is simple and feasible; works and labor intensity are reduced; product quality is not influenced by human factors; production efficiency and finished product ratio are improved greatly; cost is reduced; and comprehensive competitiveness of an enterprise is improved.

Owner:深圳市智豪特材科技有限公司

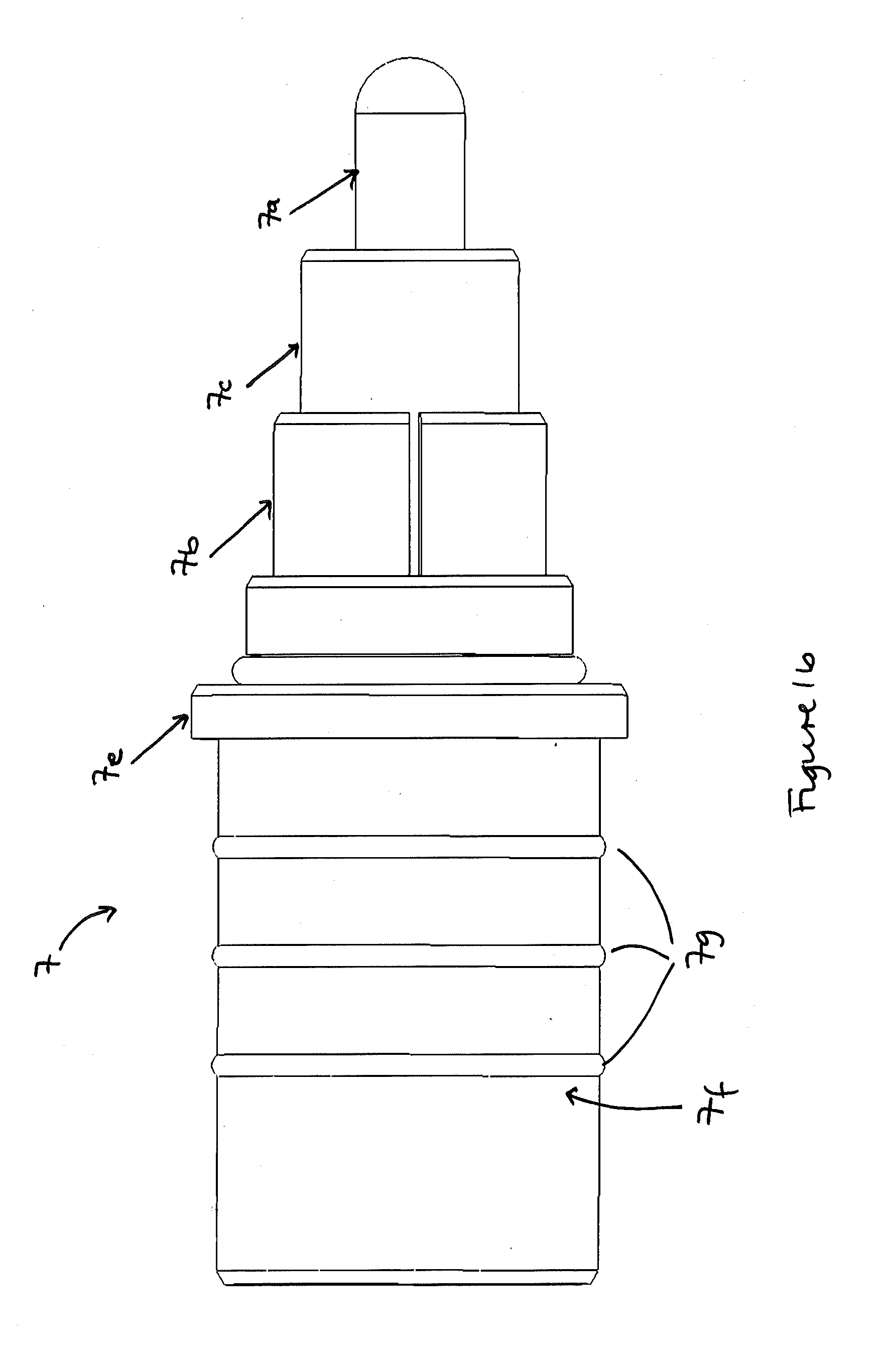

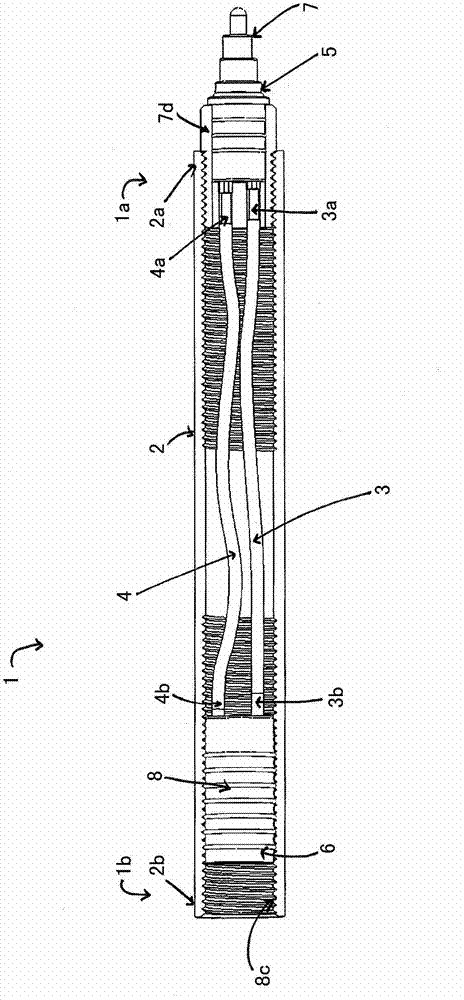

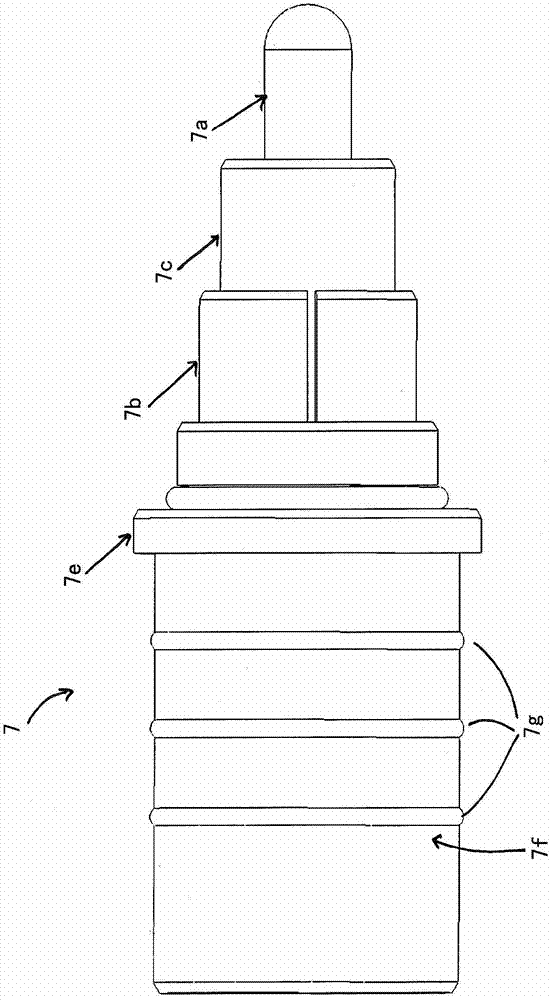

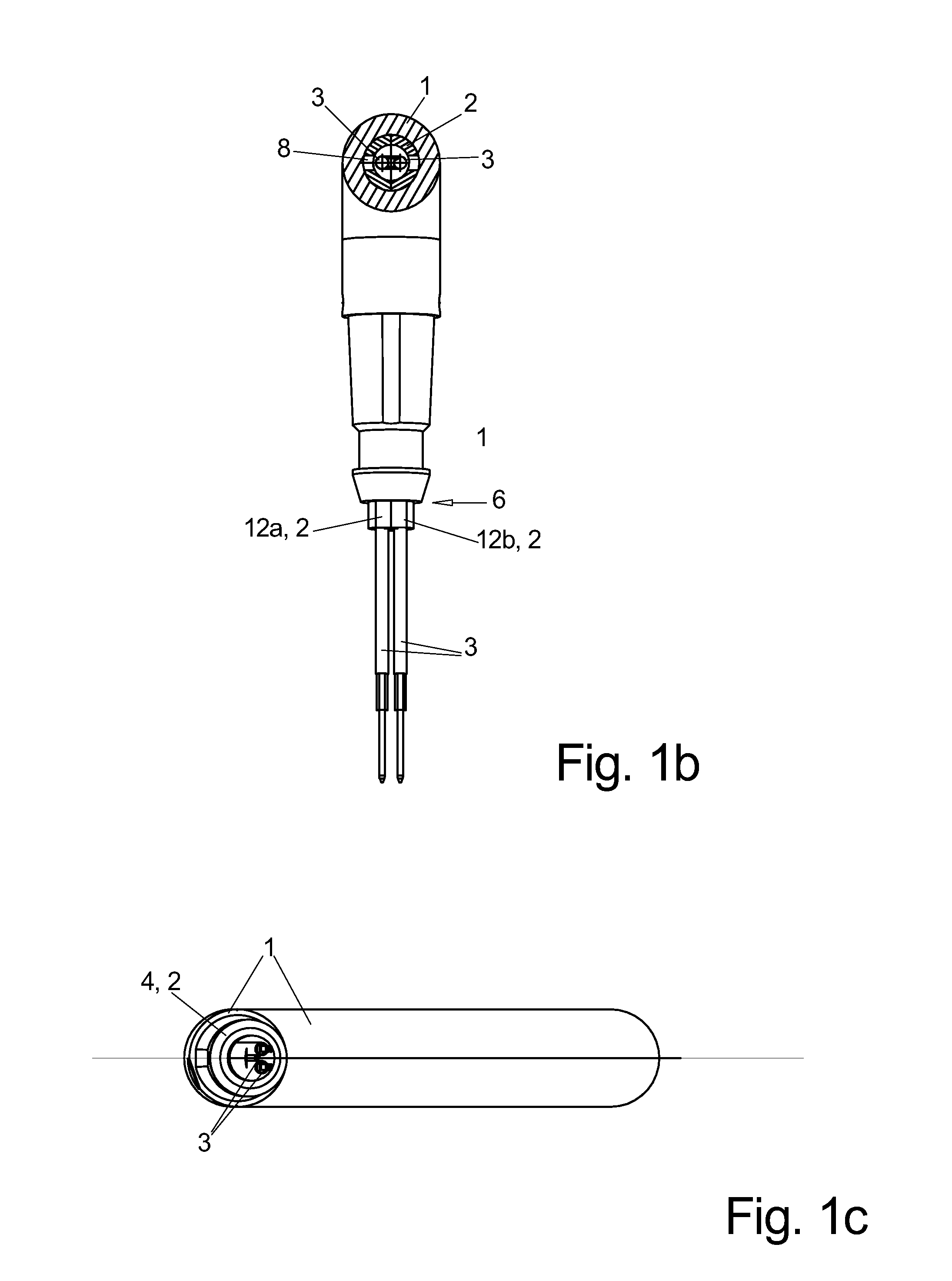

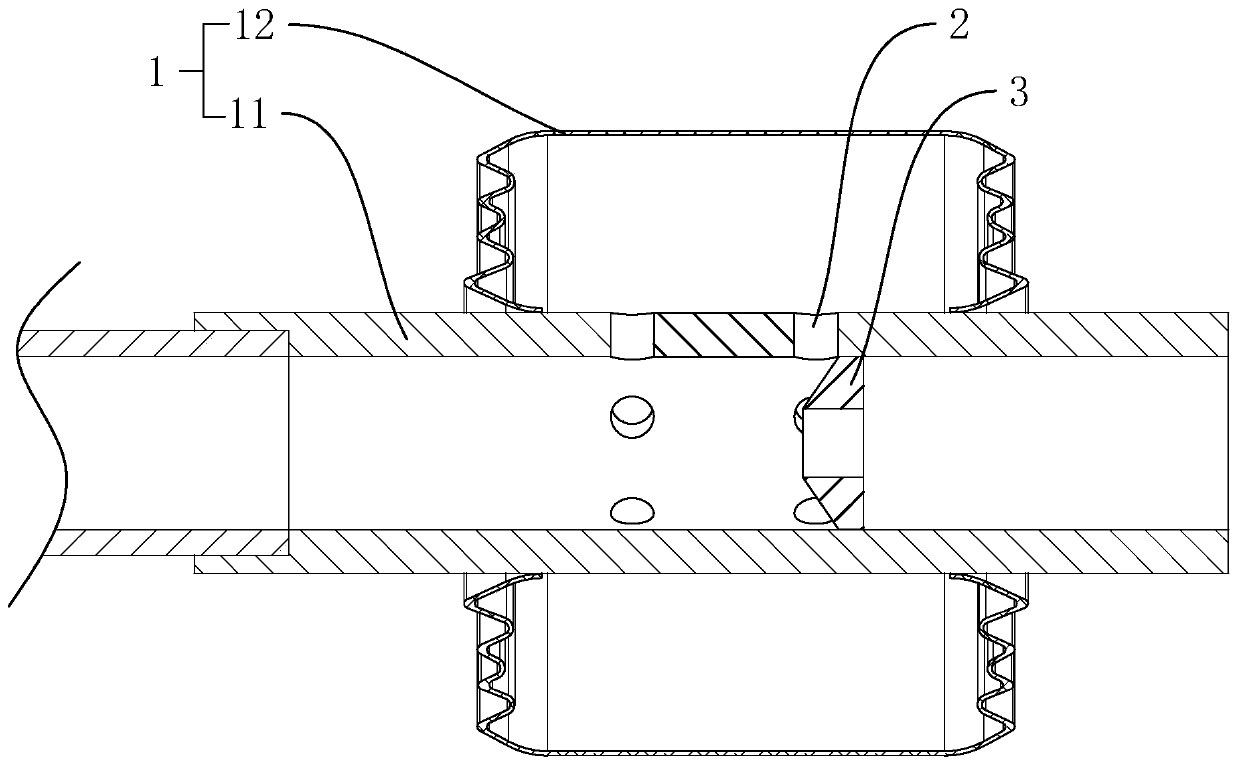

Low voltage rigid cable

A first aspect of the invention relates to a low voltage rigid cable comprising a substantially rigid housing, a live conductor arranged within the housing, a neutral conductor arranged within the housing, a first coupling means to couple the rigid cable with a first member, a second coupling means configured to couple the rigid cable with a second member and protection means to protect against electric shock. The protection means may comprise an earth conductor and insulating means configured to form an insulating barrier between the conductive parts of the rigid cable. In an embodiment of the invention, the housing may be configured to form an earth conductor. Further aspects of the invention relate to a rigid cable structure.

Owner:TP24

Method for producing hollow structure, plated composite and hollow structure

ActiveUS20190218667A1Smooth dischargeEasy dischargeSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingHeat sink

A method for producing a hollow structure useful as a base material for a heat sink or the like which increases a heat dissipation property of devices mounted in various kinds of electronic apparatuses, without sacrificing downsizing, thinning, weight reduction, and multifunctionality, and provides a hollow structure. The method including: producing a plated composite by coating a surface of a core made of aluminum to form a copper plating layer; cutting off part of the plated composite to expose cut surfaces of the core; and turning a part corresponding to the core into a hollow part by immersing the plated composite in a sodium solution which dissolves aluminum but does not dissolve copper and selectively dissolving and removing only the aluminum, thereby producing a hollow structure whose skeletal part is composed of all copper plating layers.

Owner:ASAHI DENKA KENKYUSHO

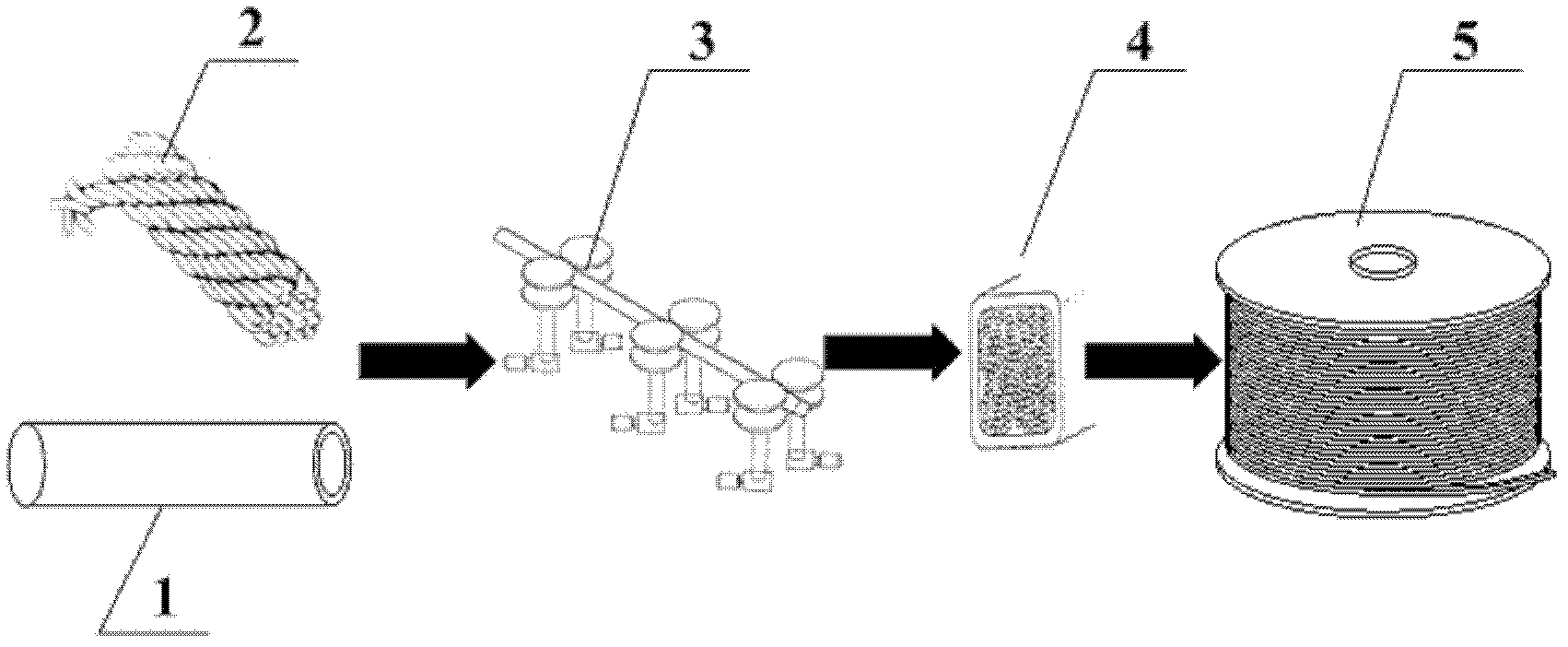

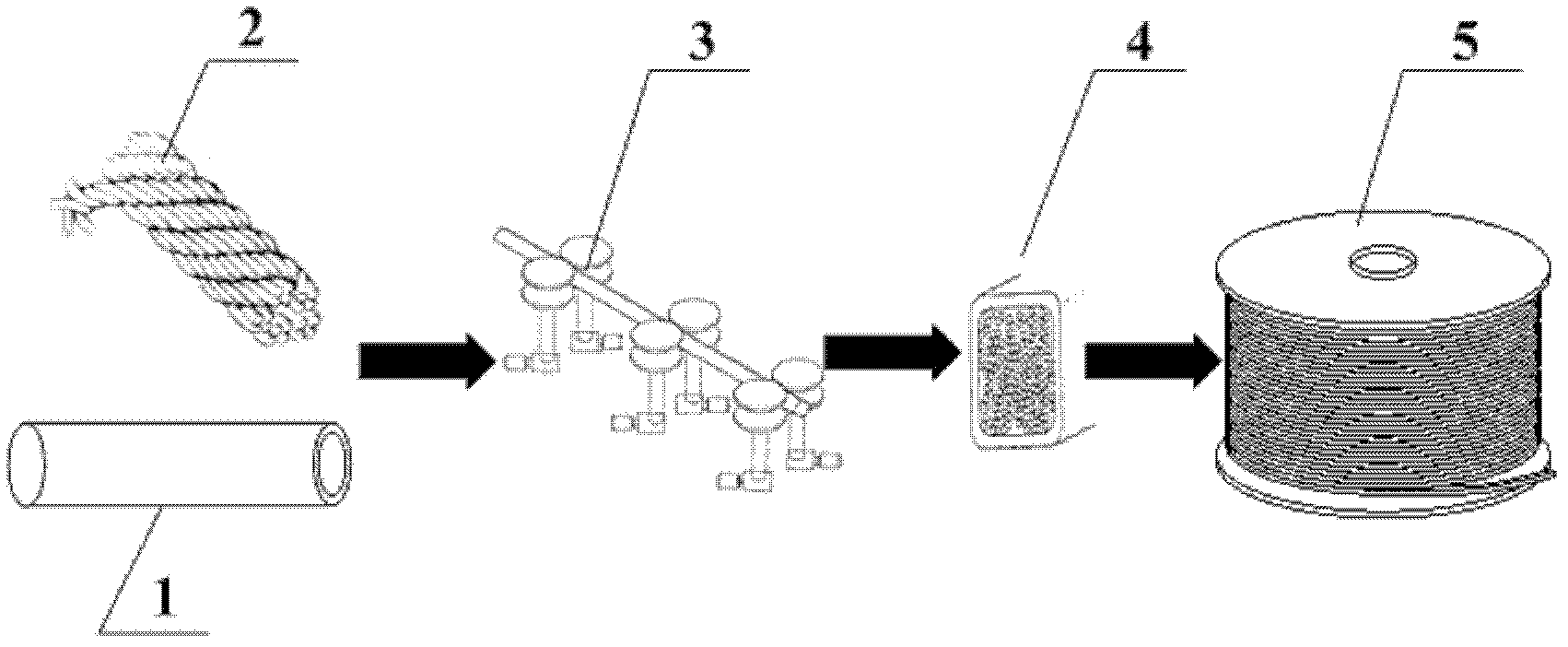

Seamless through ground line preparation technology

ActiveCN107785122ASmall footprintFlexible placementApparatus for heat treatmentManufacturing rigid-tube cablesGrounding lineFracture Problem

The invention reveals a seamless through ground line preparation technology comprising the following steps: sheath straightening, penetrating cable core, rolling, annealing and post-processing. The seamless through ground line preparation technology uses the rolling step to reduce the sheath outer diameter, thus reducing the equipment occupation area, preventing fracture problems caused by the drawing process, realizing higher speed when compared with a horn technology, and improving the processing efficiency.

Owner:ZHONGTIAN ALLOY TECH

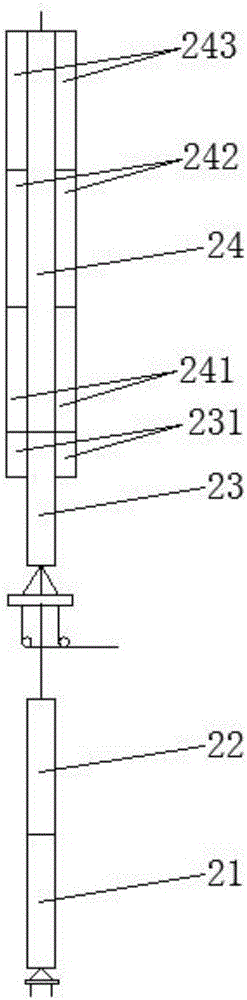

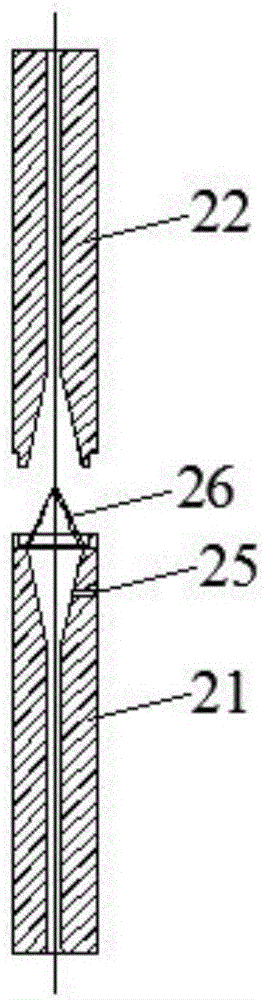

Producing method of niobium three stannum cable-in-conduit conductors of large superconducting magnets

InactiveCN102568705AReduce porosityReduce displacementManufacturing rigid-tube cablesElectrical conductorSuperconducting Coils

The invention discloses a producing method of niobium three stannum cable-in-conduit conductors of large superconducting magnets, which includes steps of conducting cleaning, pressing leakage detecting and flaw detection on a stainless steel tube serving as the conductor armor; welding the stainless steel tube into a homogeneous tube, and detecting probable flaws of welding beads; enabling superconducting cables of multistage stranded cables to penetrate into the stainless armor; conducting hole shrinkage and molding on the conductor by using multistage rollers, controlling the voidage inside the conductor within about 30%, and producing the conductor into a rectangle conductor; and pre-bending the molded rectangle conductor, conducting pressing leakage detecting and flaw detection of the whole to produce the niobium three stannum cable-in-conduit conductors. By means of the producing method, the niobium three stannum cable-in-conduit conductors can decrease and even eliminate the degradation of conductor superconducting performance caused by the electric magnetic circulation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Insulation tube bus generation method

InactiveCN107731417AUniform density distributionIncrease short circuit currentApparatus for heat treatmentManufacturing rigid-tube cablesCopper wireEngineering

The invention relates to the technical field of transmission equipment, in particular to an insulation tube bus generation method. The method comprises the steps of insulating material pouring, solidifying and shielded copper wire winding. The invention provides the bus production method capable of cutting off static electricity and shielding electromagnetism, thereby solving the problems of extrapower loss and economic loss.

Owner:江苏众众热能科技有限公司

A preparation process for seamlessly penetrating ground wire

ActiveCN107785122BSmall footprintFlexible placementApparatus for heat treatmentManufacturing rigid-tube cablesGrounding lineFracture Problem

The invention reveals a seamless through ground line preparation technology comprising the following steps: sheath straightening, penetrating cable core, rolling, annealing and post-processing. The seamless through ground line preparation technology uses the rolling step to reduce the sheath outer diameter, thus reducing the equipment occupation area, preventing fracture problems caused by the drawing process, realizing higher speed when compared with a horn technology, and improving the processing efficiency.

Owner:ZHONGTIAN ALLOY TECH

Low voltage rigid cable

A first aspect of the invention relates to a low voltage rigid cable comprising a substantially rigid housing, a live conductor arranged within the housing, a neutral conductor arranged within the housing, a first coupling means to couple the rigid cable with a first member, a second coupling means configured to couple the rigid cable with a second member and protection means to protect against electric shock. The protection means may comprise an earth conductor and insulating means configured to form an insulating barrier between the conductive parts of the rigid cable. In an embodiment of the invention, the housing may be configured to form an earth conductor. Further aspects of the invention relate to a rigid cable structure.

Owner:TP24

Nanowire layer adhesion on a substrate

Owner:SEOUL NAT UNIV R&DB FOUND

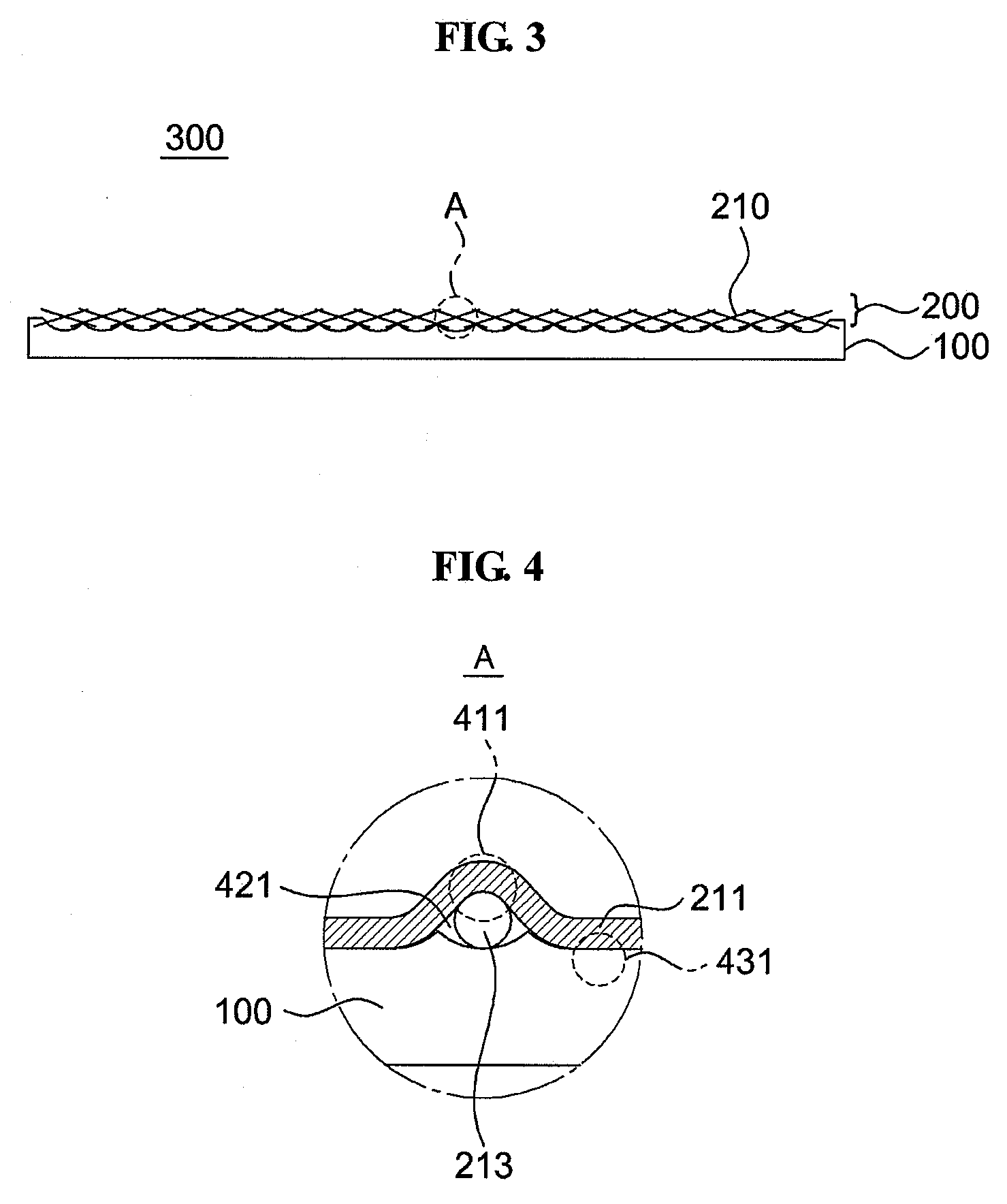

Method for the application of a tubular hull to an electric cable

PendingUS20220029398A1Efficient methodManufacturing rigid-tube cablesApparatus for joining/termination cablesStructural engineeringElectric cables

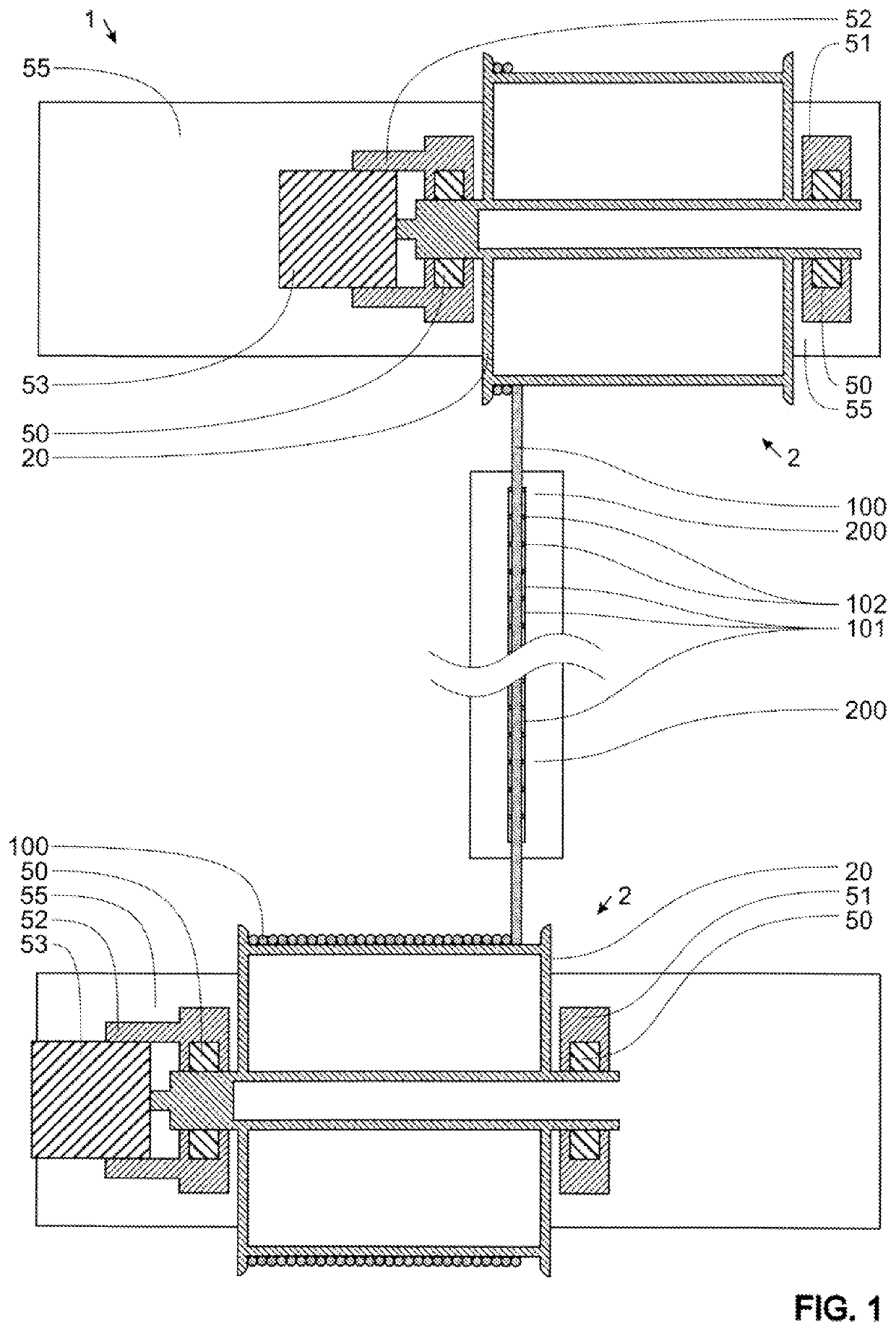

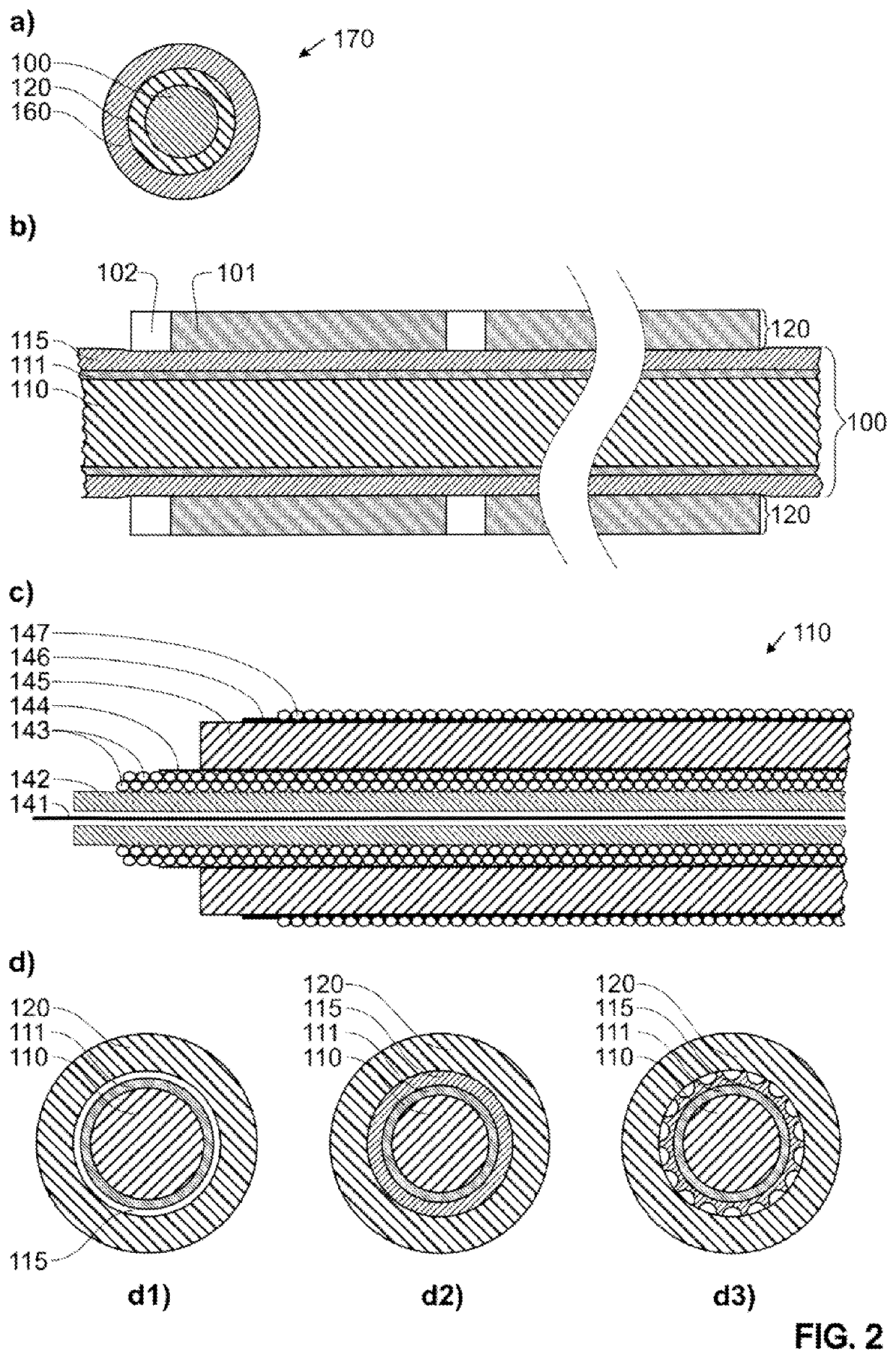

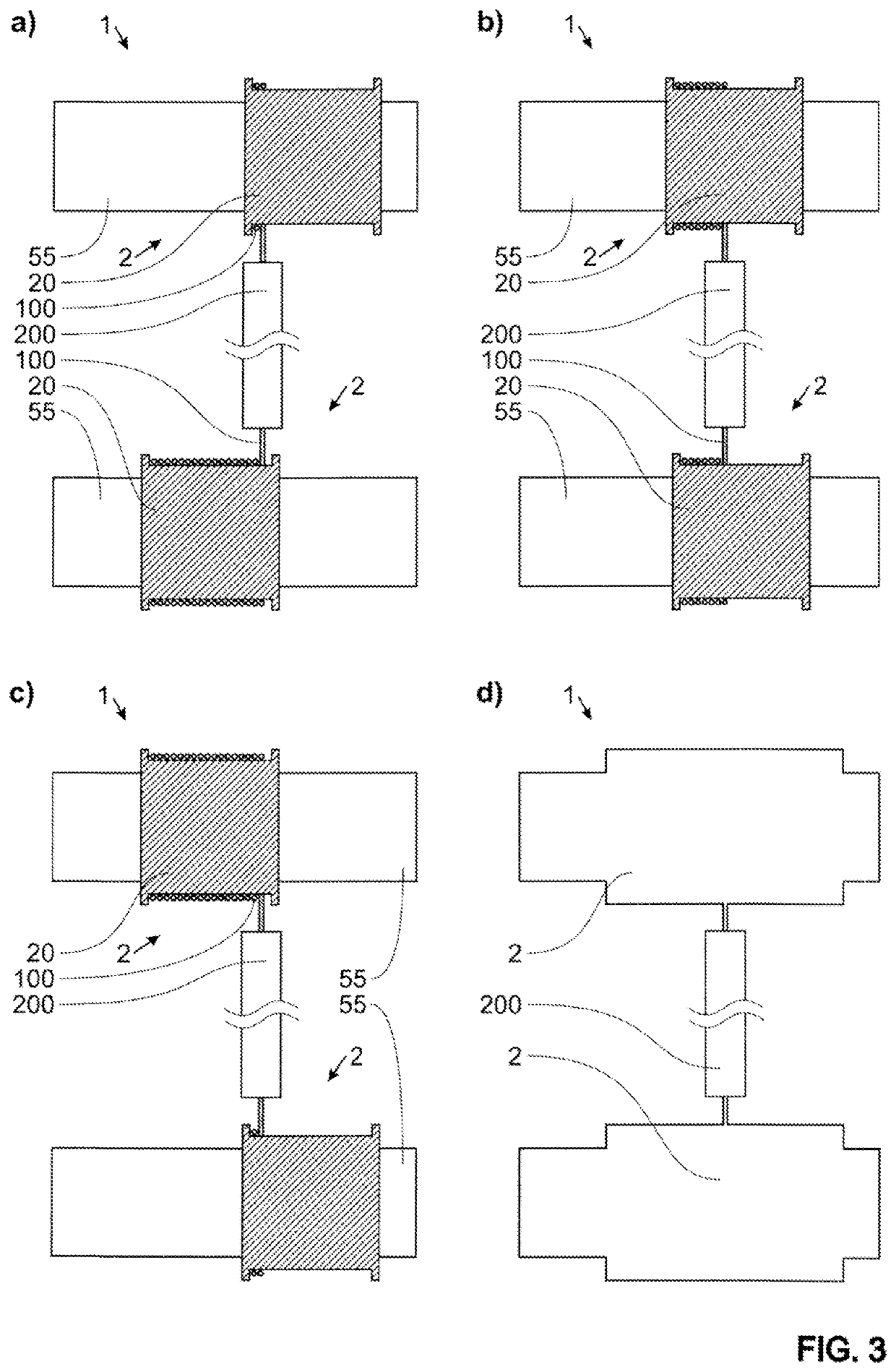

A method for the application of a tubular hull (120) to an electric cable (100) is provided. The tubular hull (120) comprises a plurality of ring-shaped elements (102) and / or of tube-shaped elements (101). The method comprises at least the following steps: a.) pre-arranging a part of the tubular hull (120) by means of a tubular hull application unit (200); b.) inserting the electric cable (100) into the tubular hull application unit (200) and into the pre-arranged part of the tubular hull (120); c.) removing the electric cable (100) from the tubular hull application unit (200); and x.) repeating steps a.), b.) and c.) at least two times and in consecutive order. Furthermore, a tubular hull application unit adapted for carrying out such a method and a tether produced according to this method and comprising an electric cable and a tubular hull are provided.

Owner:SWISS INVENTIX GMBH

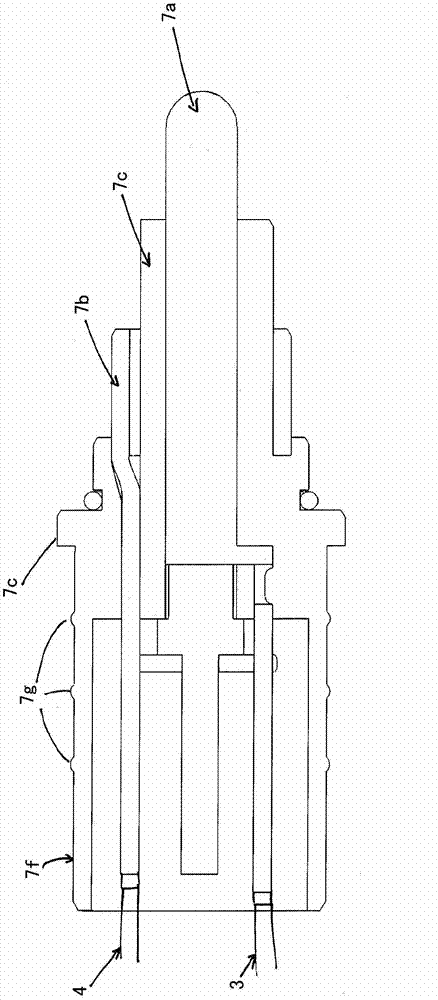

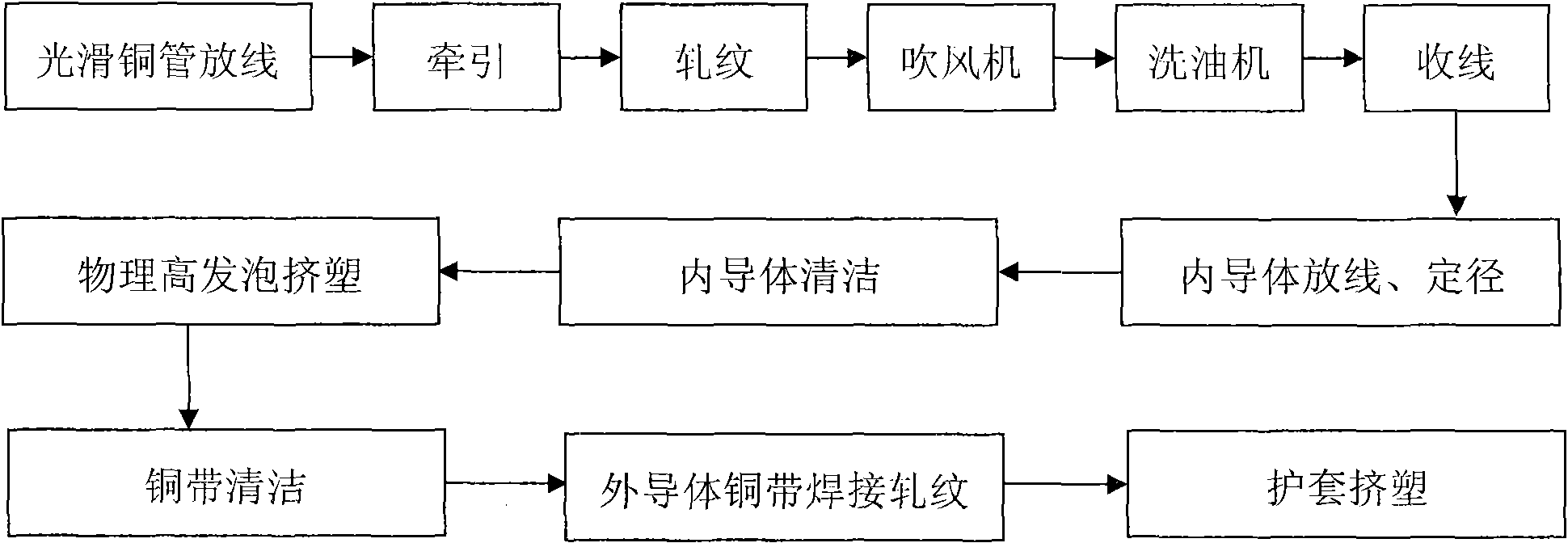

Metal wrinkled external conductor forming device of radio-frequency telecommunication cable

InactiveCN101030464AVSWR is smallLittle impact on performanceManufacturing rigid-tube cablesElectrical conductorTelecommunications cable

The invention is concerned with the forming equipment for radio frequency communication cable metal rumple outer conductor, consists of the rolling-grain main traction machine, the drawing-line assistant traction machine, the rolling-gain mainframe, and the controlling system, the characteristic is: the controlling system connects with the rolling-grain main traction machine, the drawing-line assistant traction machine, the putting-line assistant traction machine and the rolling-gain mainframe. The advantages of the invention are: (1) reducing the voltage standing wave ratio of the product, the voltage standing wave ratio of the cable is below 1.08 when the frequency range is 5-3000MHz. (2) reduces the affects of the capability that creates by the drawbacks of the rolling-grain equipment or the mould.

Owner:江西省光电线缆工程技术研究中心

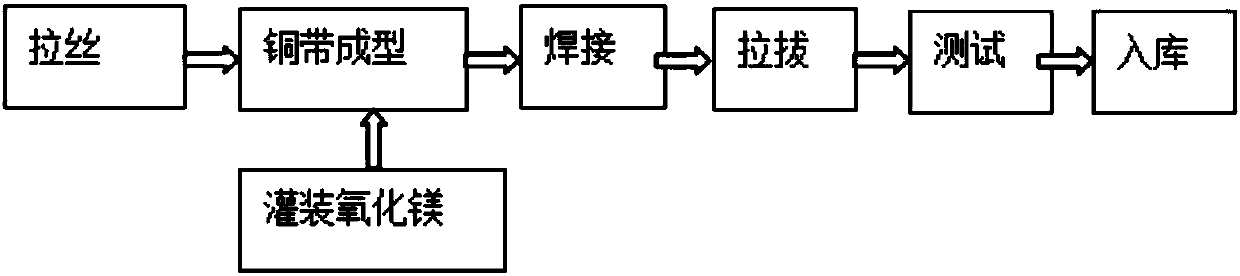

Production method of BTTZ fireproof cable

InactiveCN108053942AReduce manufacturing costSave labor costsManufacturing rigid-tube cablesInsulating conductors/cablesWork in processMaterials science

The invention discloses a production method of a BTTZ fireproof cable. The method comprises the following steps of shaping a flat copper strip through shaping dies and gradually bending the copper strip into a copper tube; before two sides of the copper tube are close to each other to be closed, firstly fixing a conductive wire core in the middle of the copper tube before filling magnesium oxide,and then automatically filling the magnesium oxide through equipment; closing the copper tube and then welding the copper tube; directly conveying the welded copper tube to a front guide wheel throughguide wheels, wherein the copper tube needs to pass through 10 groups of guide wheels in all, the 10 groups of guide wheels are arranged at 360 degrees and the diameters of each group of guide wheelsare 0.2mm greater than those of the previous group of guide wheels; preliminarily compacting the magnesium oxide to prepare a semi-finished product; and extruding and drawing the semi-finished product through annular equipment to obtain the BTTZ fireproof cable. According to the production method, primary shaping of the cable of which the minimum length is 3,000m according to the size of a take-up reel is achieved, the production cost is reduced, the construction difficulty of a worker is reduced, the characteristics of the fireproof cable are kept and the production efficiency is improved.

Owner:ZHEJIANG ZETASTONE SPECIAL CABLE CO LTD

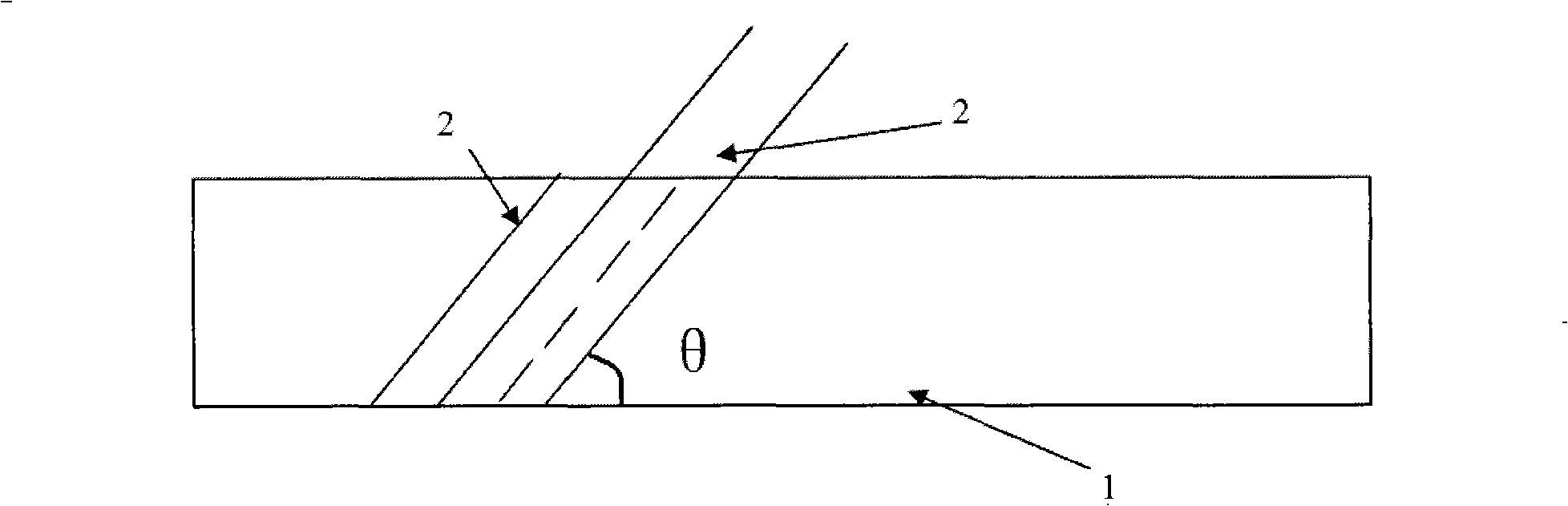

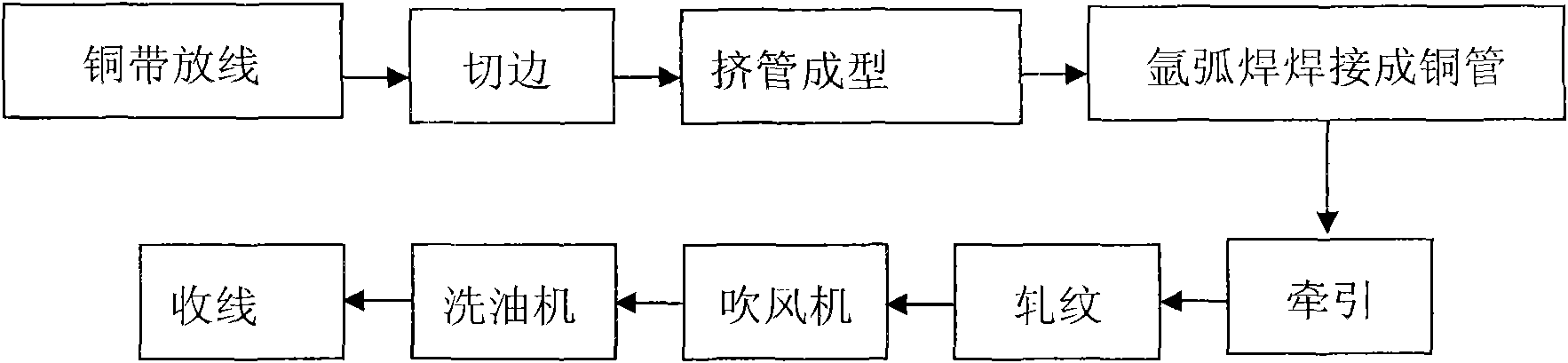

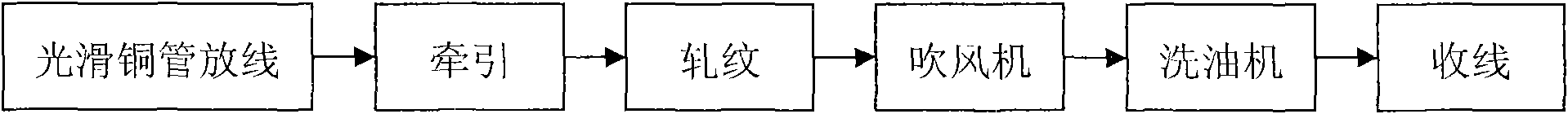

Manufacturing process of ultra-soft feed line inner conductor

ActiveCN101819834AIncrease production speedImprove product qualityConductive materialManufacturing rigid-tube cablesCoaxial cableEngineering

The invention relates to the field of communication, in particular to a manufacturing process of a novel ultra-soft feed line inner conductor. In the manufacturing process of the ultra-soft feed line inner conductor, the ultra-soft feed line inner conductor is formed by carrying out deep spiral pattern rolling by directly adopting a smooth copper pipe as a raw material; the oxygen content in a cast blank of the smooth copper pipe is controlled to be below 10ppm, and the phosphorus content is controlled to be below 30ppm; the wall thickness of the smooth copper pipe is 0.19-0.27 mm, and the tensile strength is 240-270MPa; and the elongation ratio A is not less than 45 percent. The manufacturing process of a coaxial cable inner conductor improves the production speed and the product quality of a traditional ultra-soft feed line inner conductor, the smooth copper pipe is used for directly rolling patterns to replace a series of original production working procedures of pattern rolling and the like after the welding of a copper tape reeling pipe, and the manufacturing process has the greatest advantage that the working procedures of edge cutting and welding of a copper tape are saved, thereby improving the production efficiency of the inner conductor and greatly reducing the loss of a copper material.

Owner:ZHUHAI HANSEN TECH CO LTD

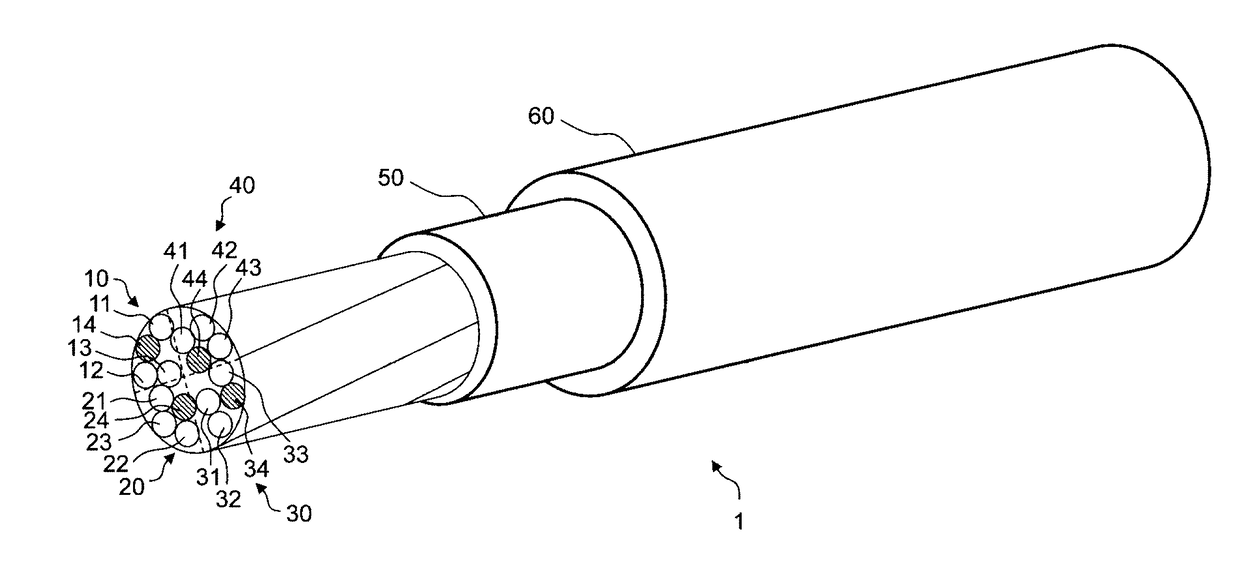

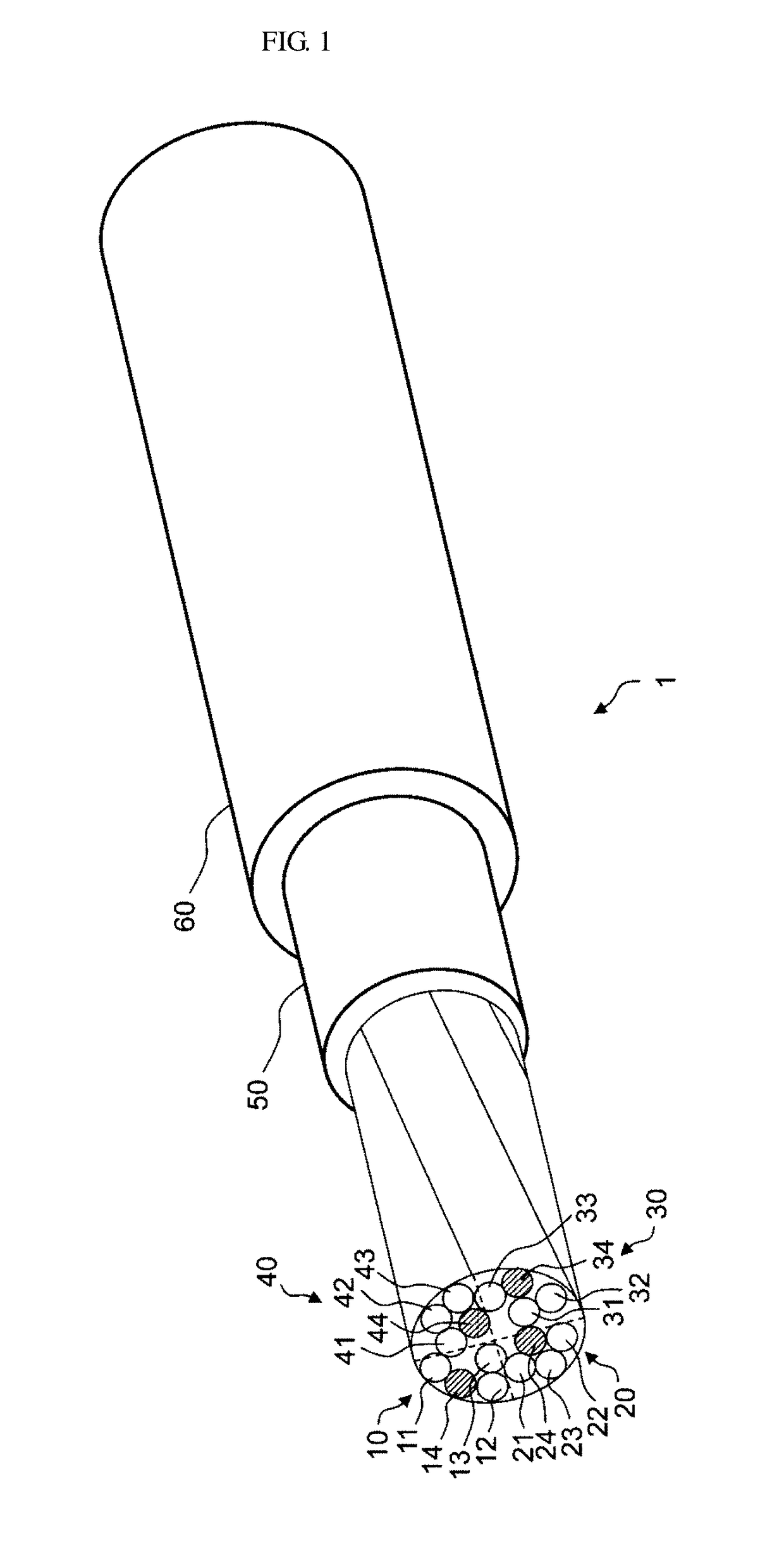

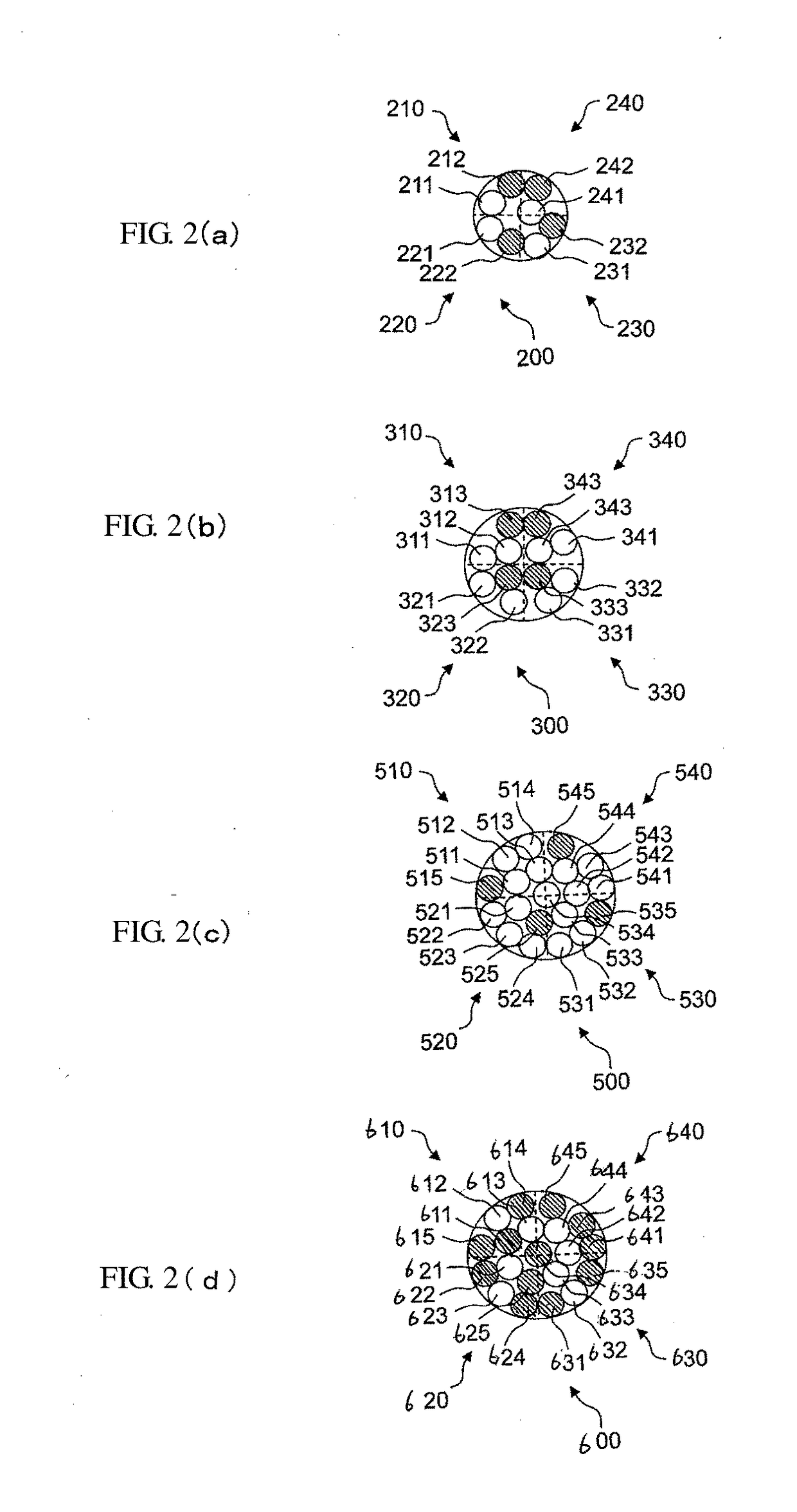

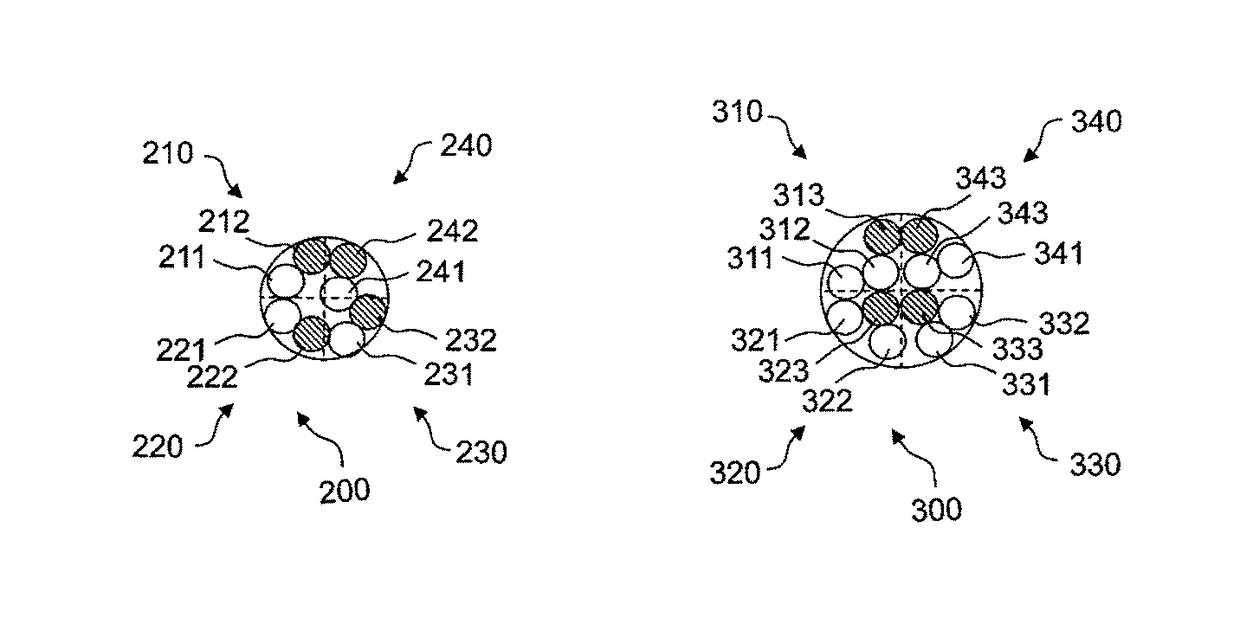

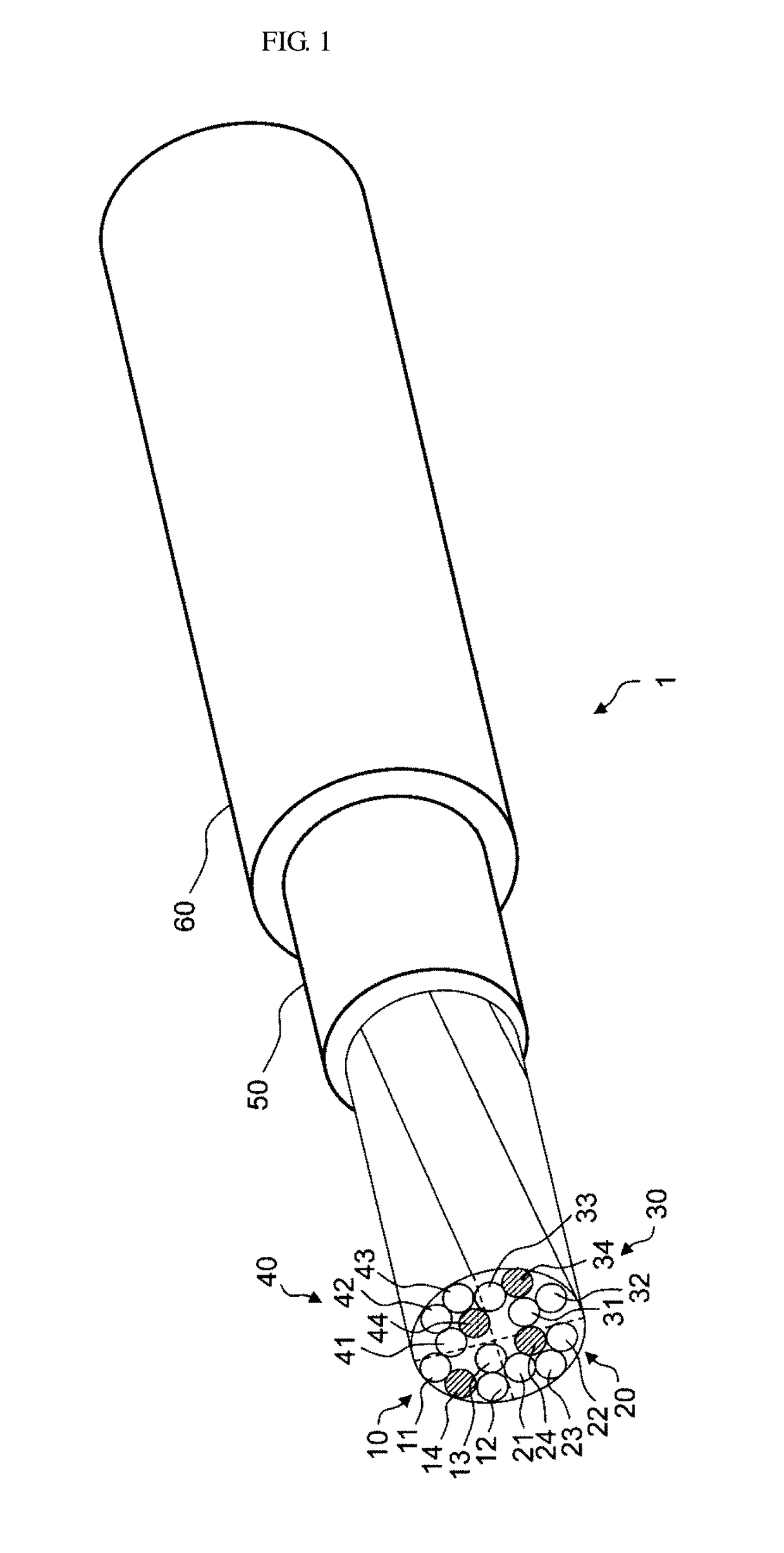

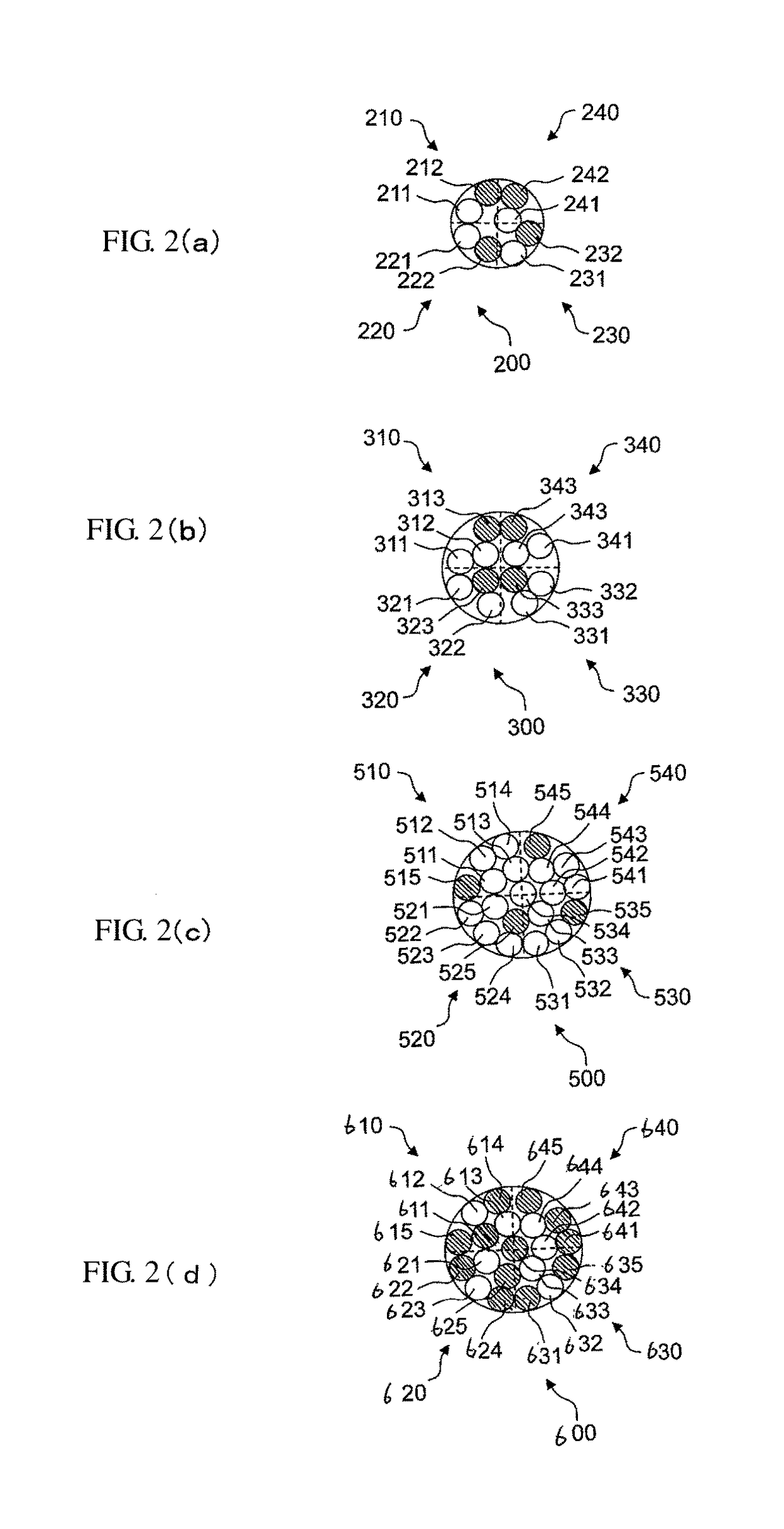

Multi-Core Cable and Production Method Therefor

ActiveUS20170330652A1Reduce the possibilityInsulated cablesReduction of cables/conductors sizeMulticore cableElectrical conductor

Provided herein is a multi-core cable through which positions of a plurality of insulated conductors and a plurality of non-insulated conductors in a cross section in a longitudinal direction are changed and a likelihood of transmission performance being reduced is low. A multi-core cable includes n conductor bundles.

Owner:JUNKOSHA

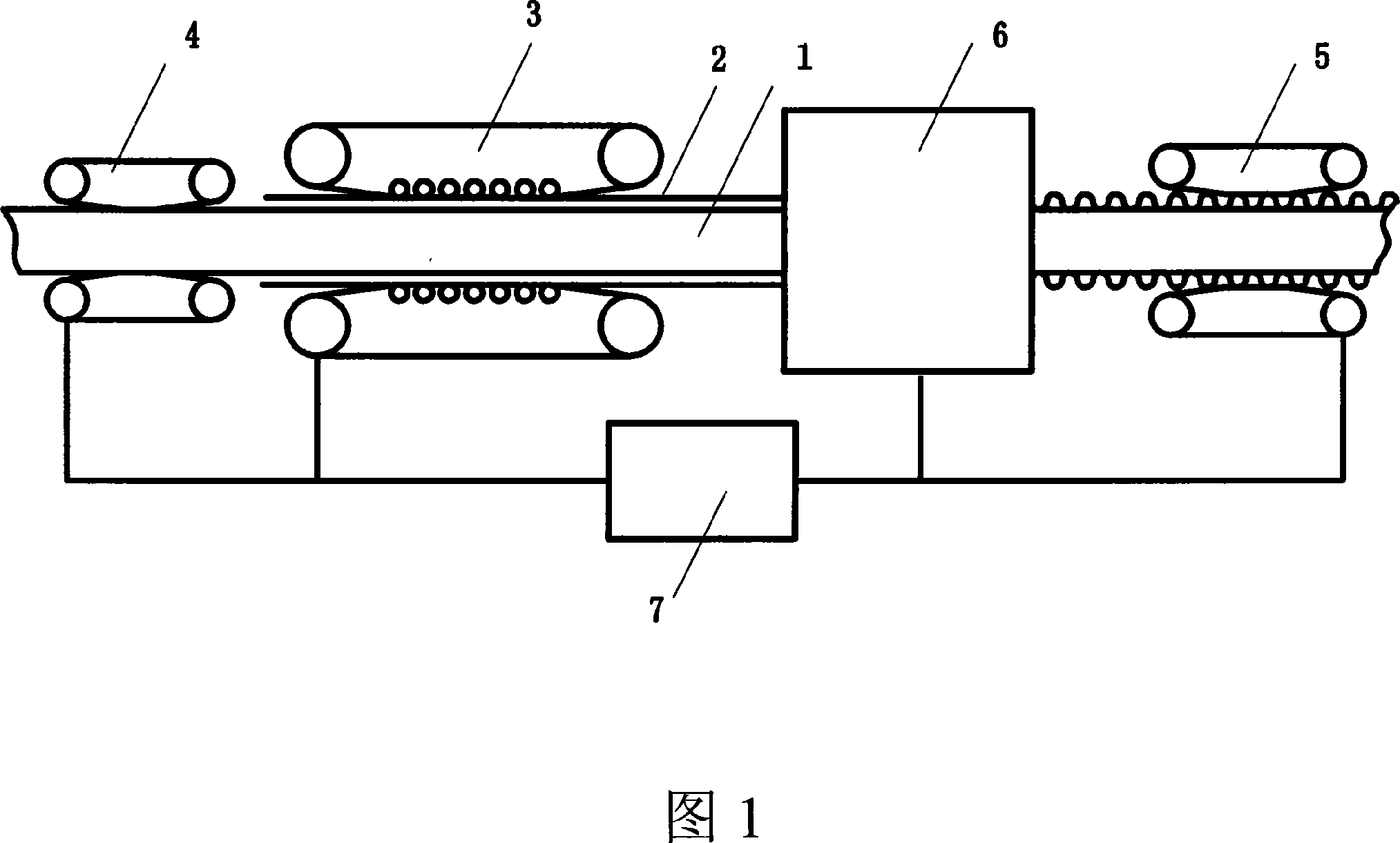

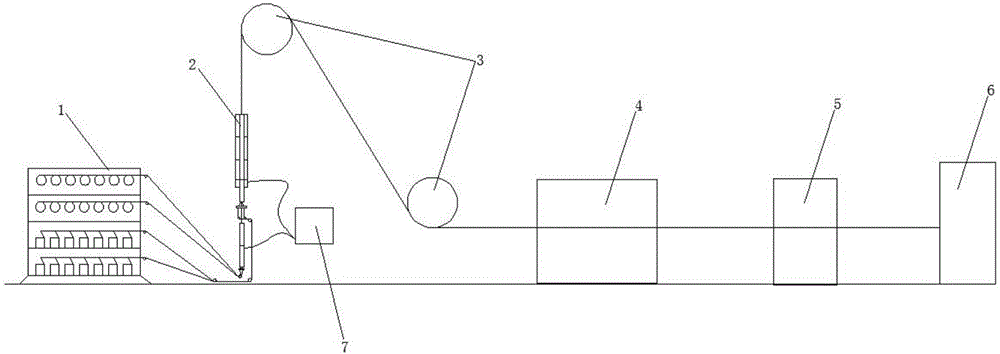

Smart energy carbon fiber complex core production line

ActiveCN106340356AContinuous productionRapid productionApparatus for feeding conductors/cablesManufacturing rigid-tube cablesGlass fiberProduction line

The invention discloses a smart energy carbon fiber complex core production line. The smart energy carbon fiber complex core production line comprises a yarn rack, a preformation solidification apparatus, a steeling wheel set, a traction system, an online nondestructive detection system, a wire collection system and a glue injection system used for glue injection of the preformation solidification apparatus which are successively arranged according to production operation, wherein carbon fibers and glass fibers are arranged on the yarn rack, and the preformation solidification apparatus is of a vertical structure. According to the invention, continuous and rapid production of carbon fiber complex cores can be realized, the preformation solidification apparatus of the vertical structure enables a mold itself to be used as a rubber compound storage tool, the storage space is tight, and waste of rubber compounds and generation of old rubber can be effectively reduced.

Owner:FAR EAST CABLE +2

Injection molded element and production method

InactiveUS20140120347A1Simple and repeatable mannerOptimizationRigid-tube cablesCable fittingsElectrical conductorPlastic materials

Owner:DITTER PLASTIC

Alloy ground wire production process

ActiveCN111029038AReduce the situation of ground pipe burstReduced pipe burstsApparatus for heat treatmentManufacturing rigid-tube cablesAlloyHigh pressure gas

The invention discloses an alloy ground wire production process, which relates to the field of ground wire production, and is characterized by comprising the following steps of: S1, raw material preparation: preparing a copper stranded wire and a copper pipe, S2, conducting copper pipe pretreatment, specifically, feeding air into one end of the copper pipe through an air blowing device and blowingthe air out from the other end, S3, raw material core penetrating: penetrating a copper stranded wire into the copper pipe for later use, S4, rolling and reducing: rolling the copper pipe with the copper stranded wire through a rolling mill, and reducing the diameter of the copper pipe by using a roller of the rolling mill, so that the copper stranded wire is hooped by the copper pipe to form anouter sheath, S5, conducting annealing treatment, putting the rolled and reduced alloy ground wire into an annealing cavity to be annealed, and S6, conducting passivating treatment, passivating the annealed alloy ground wire, and then conducting cleaning and blow-drying after passivation. The residual water in the copper pipe can be cleaned through the blown high-pressure gas, so that the situation that the alloy ground wire is exploded due to water vaporization during annealing after rolling is reduced, and the overall production is more stable.

Owner:上海安捷防火智能电缆有限公司

Production method of copper and aluminium interface alloy composite conductor energy-efficient tubular bus duct

InactiveCN106128639AStrong binding strengthEnsure quality stabilityMetal/alloy conductorsManufacturing rigid-tube cablesElectrical conductorResin-Based Composite

The invention belongs to the technical field of preparation of power transmission wires, in particular to a method for producing an energy-saving tubular bus duct with a copper-aluminum interface alloy composite conductor, comprising the following steps: 1) pretreatment 2) sleeve head 3) interface bonding 4) calendering and compounding 5 ) drawing forming 6) surface treatment 7) pouring 8) assembly. The invention adopts the method of pouring the surface of the bus bar with composite resin. The composite resin has excellent insulation, strong weather resistance and corrosion resistance, can effectively prevent interphase short circuit caused by damage, and improve the compressive strength of the bus bar so that it can reach 45KV. Improved security. Composite resin has an expansion coefficient similar to that of the busbar, which further improves its durability and prevents damage due to thermal expansion.

Owner:四川瀚舟铜铝复合材料有限公司

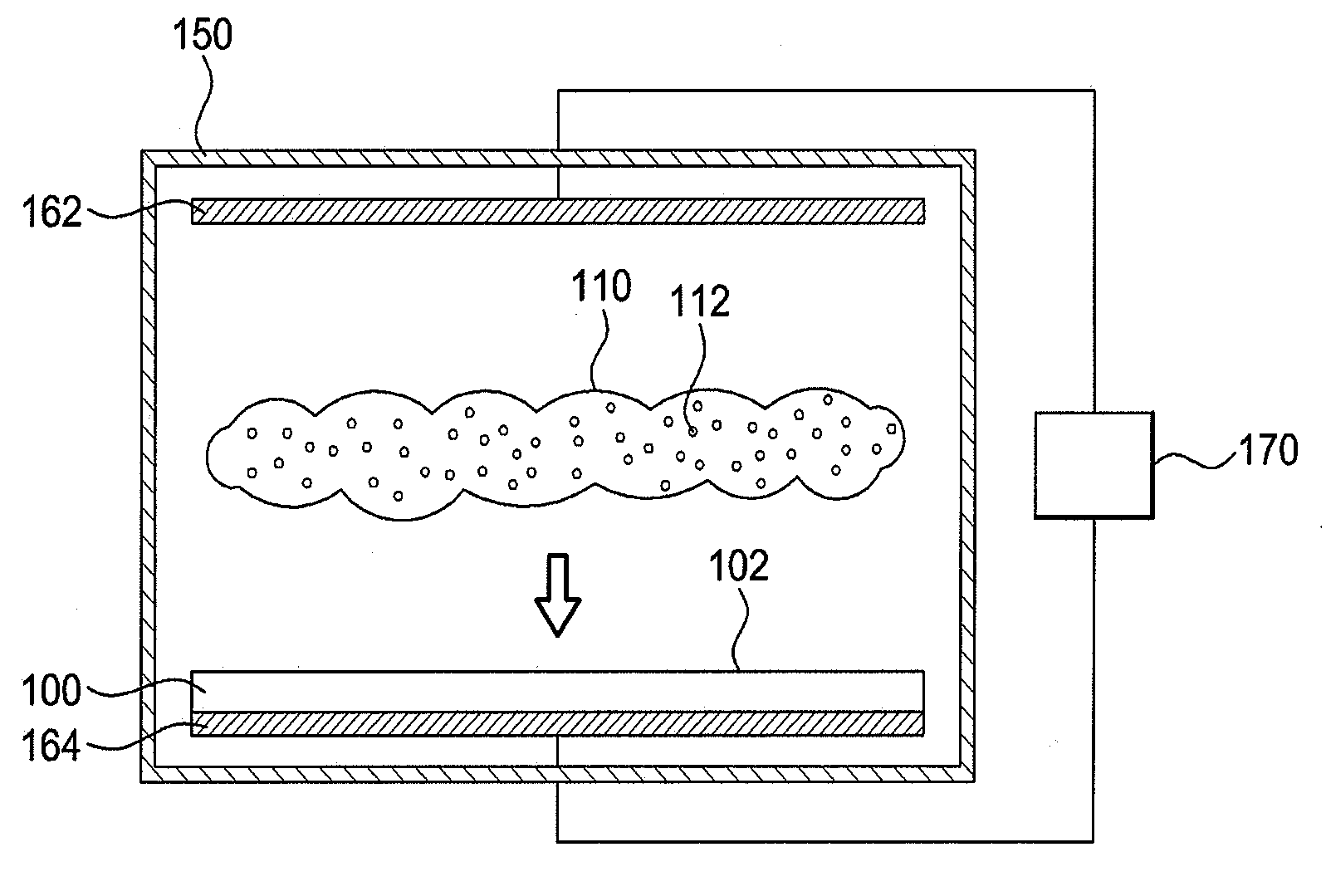

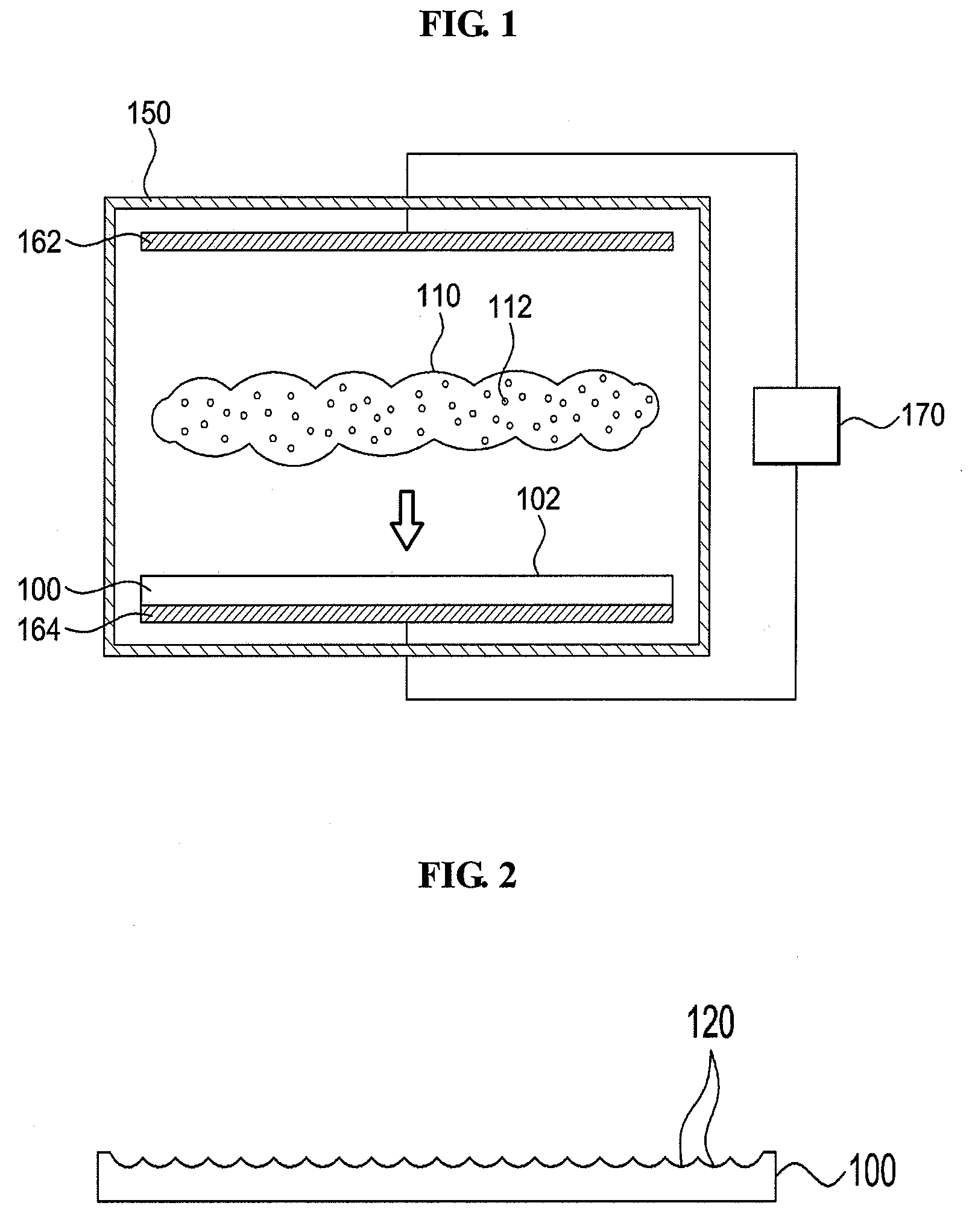

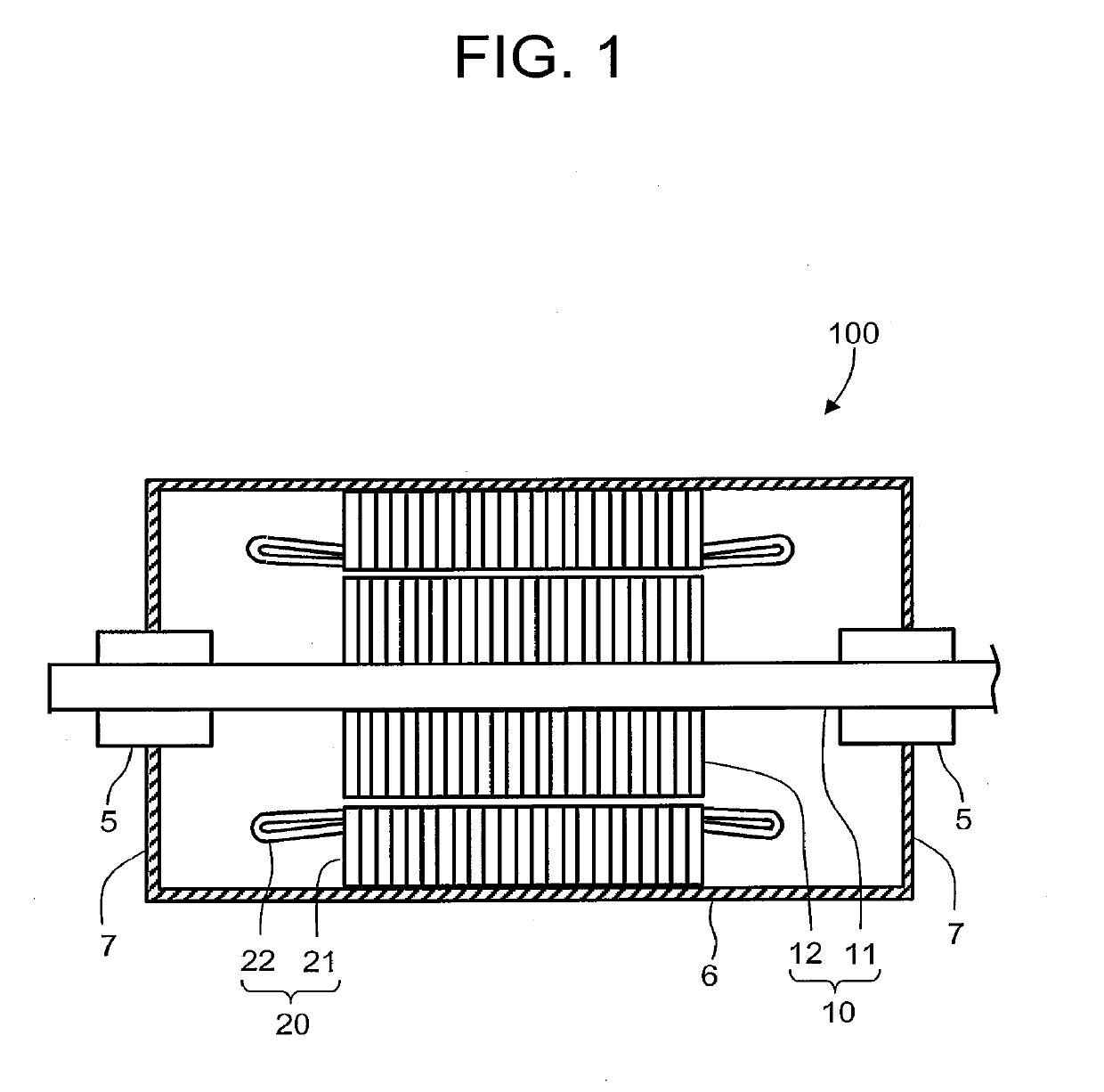

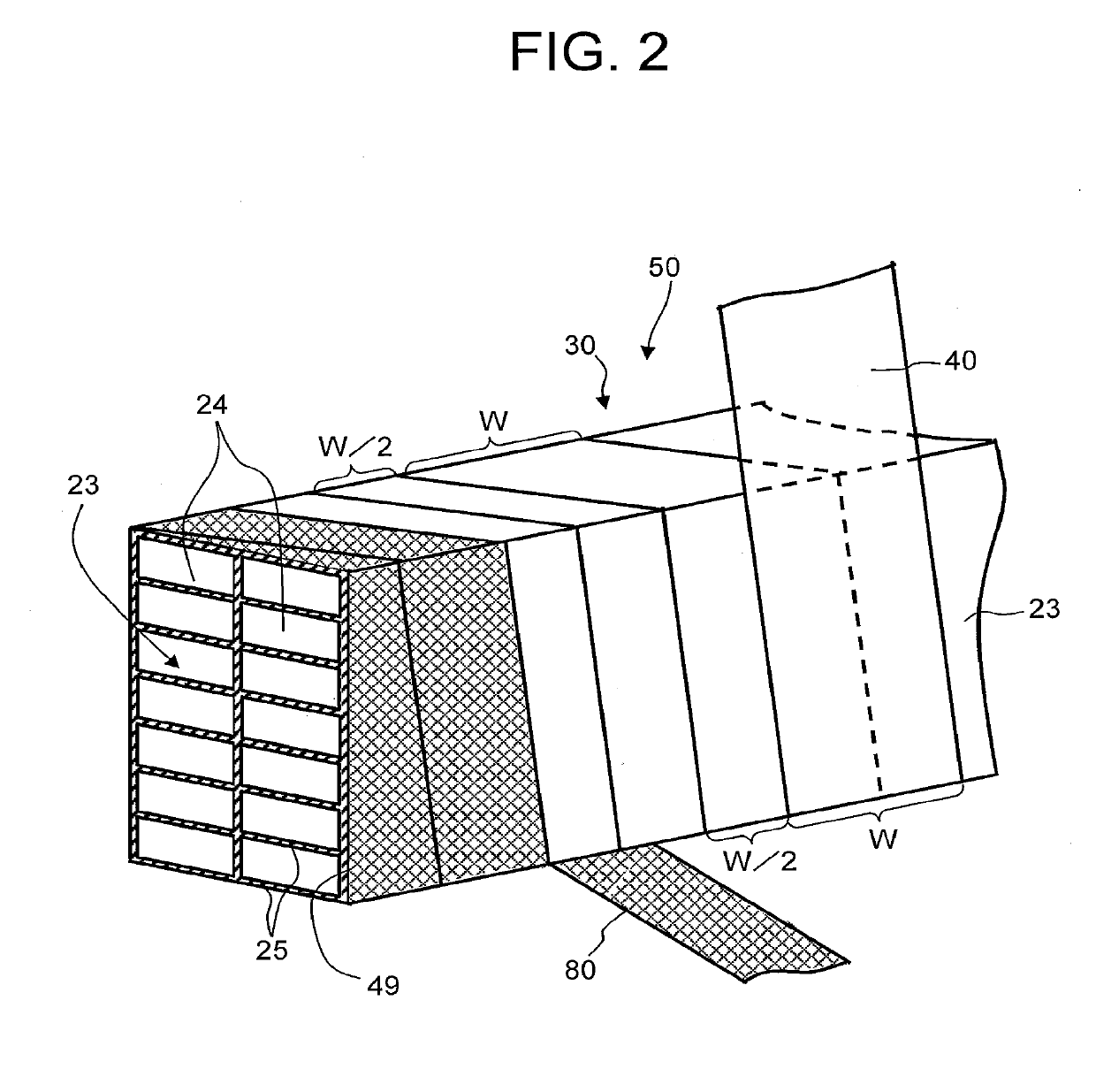

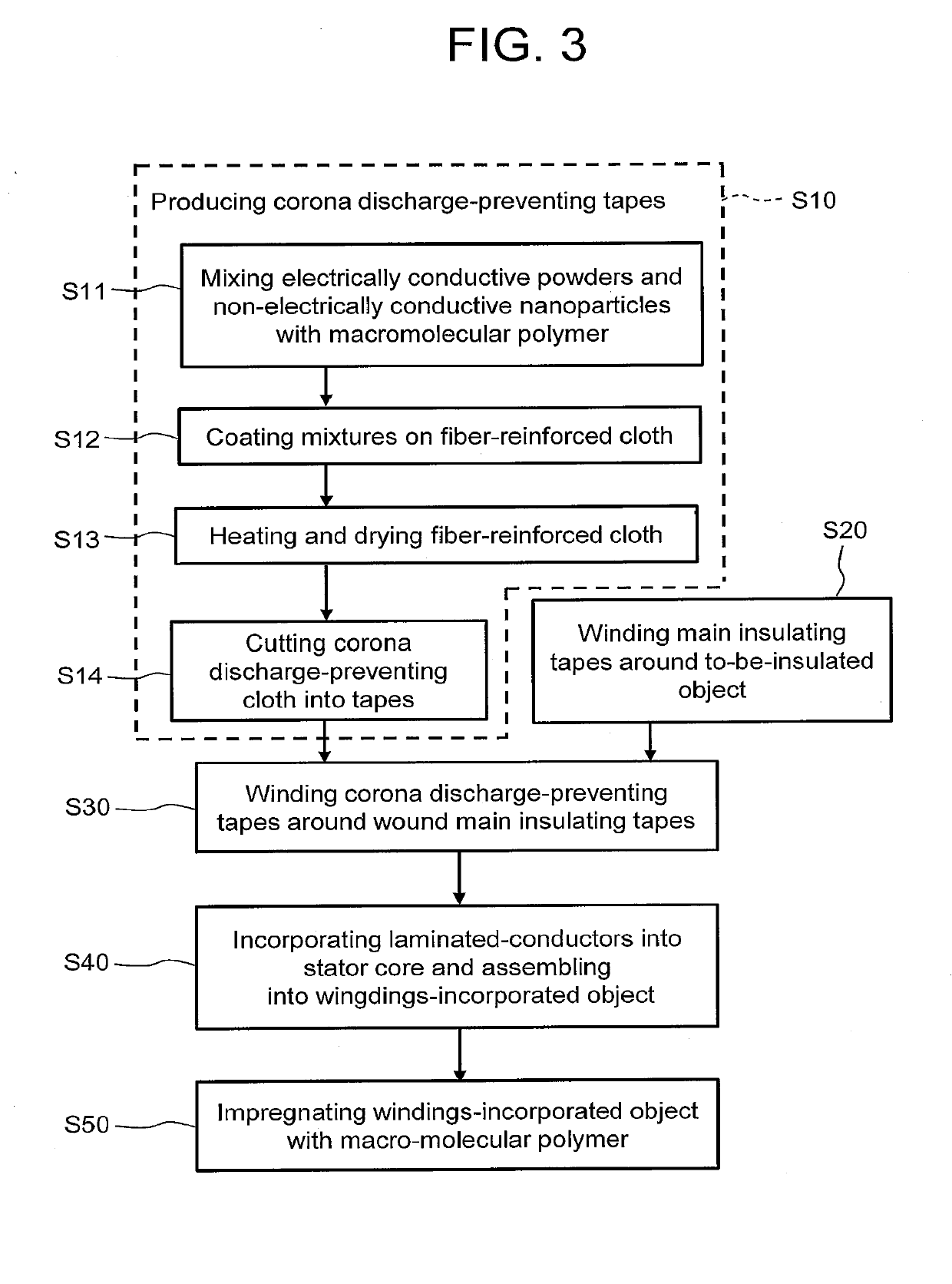

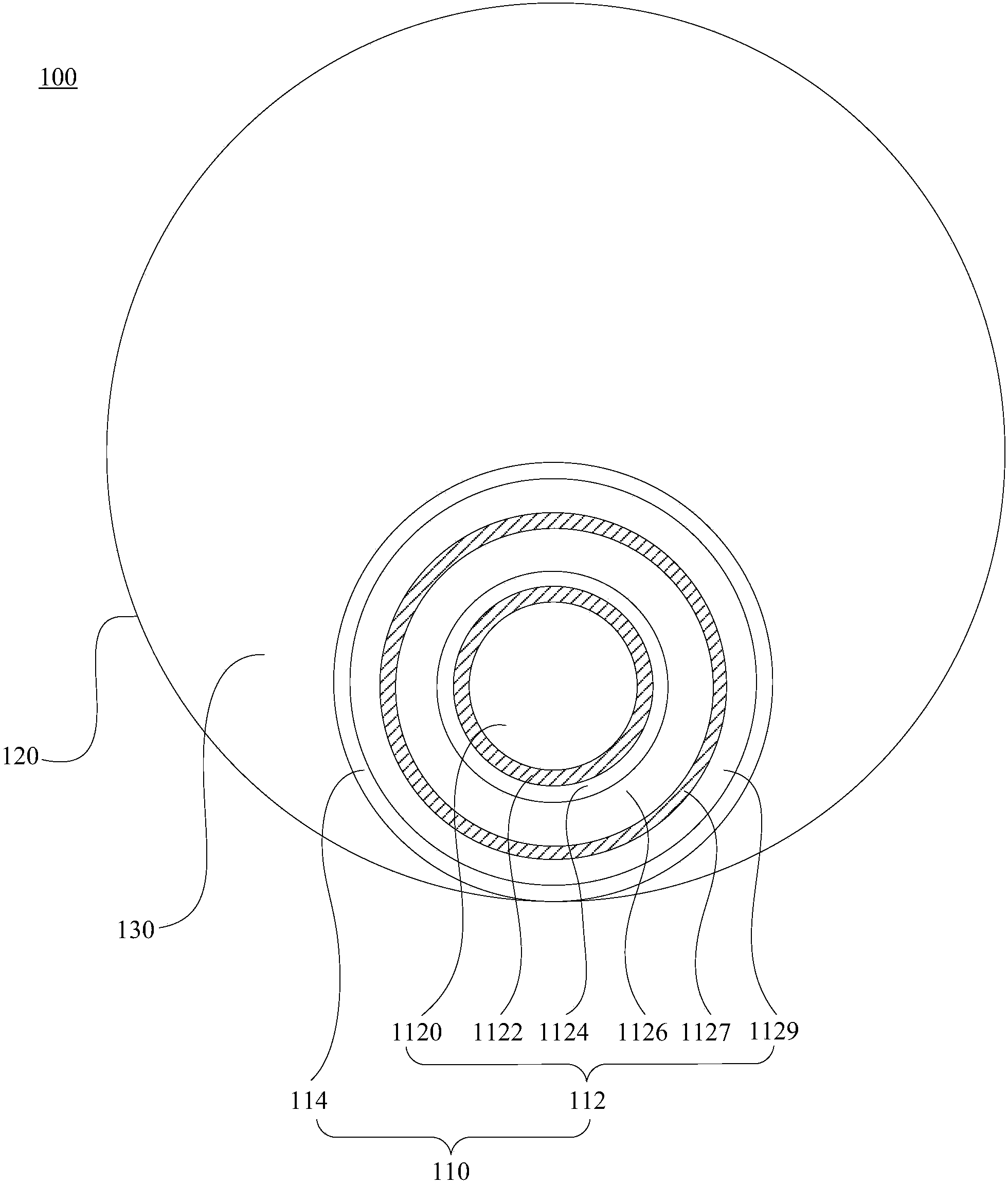

Method for producing corona discharge-preventing structure, corona discharge-preventing structure, and rotating electrical machine

InactiveUS20190149006A1Enhance anti-corona discharge propertyWindings insulation materialWindings insulation shape/form/constructionElectricityNanoparticle

A method for producing a corona discharge-preventing structure for covering the outer surface of a to-be-insulated object is presented. The method comprises: a tape producing step of producing a corona discharge-preventing tape including a macromolecular polymer added with electrically conductive powders and non-electrically conductive nanoparticles; a main insulating step of winding a main insulating tape around the to-be-insulated object; and a winding step of winding the corona discharge-preventing tape around the outer surface of the to-be-insulated object around which the main insulating tape has been wound.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

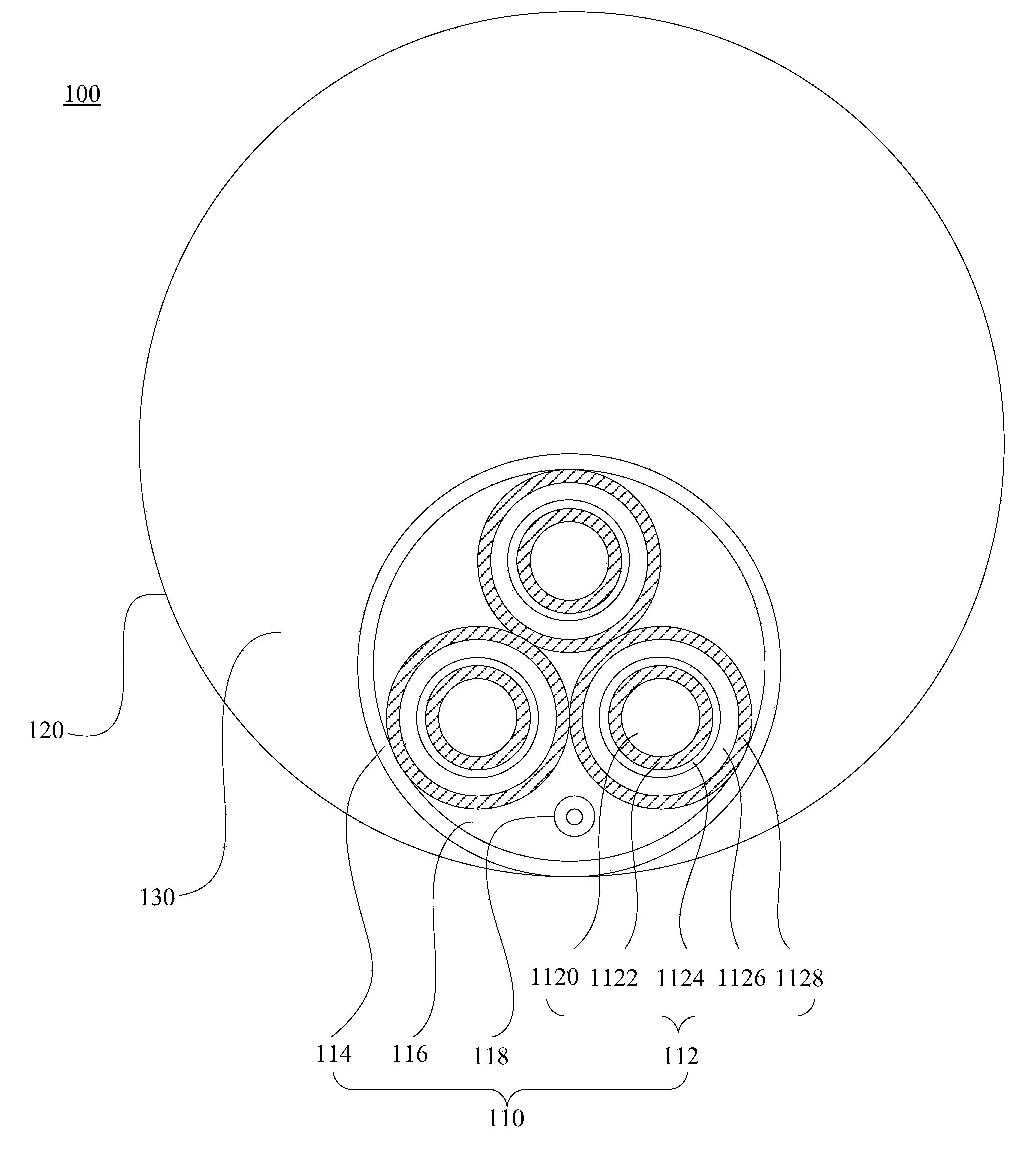

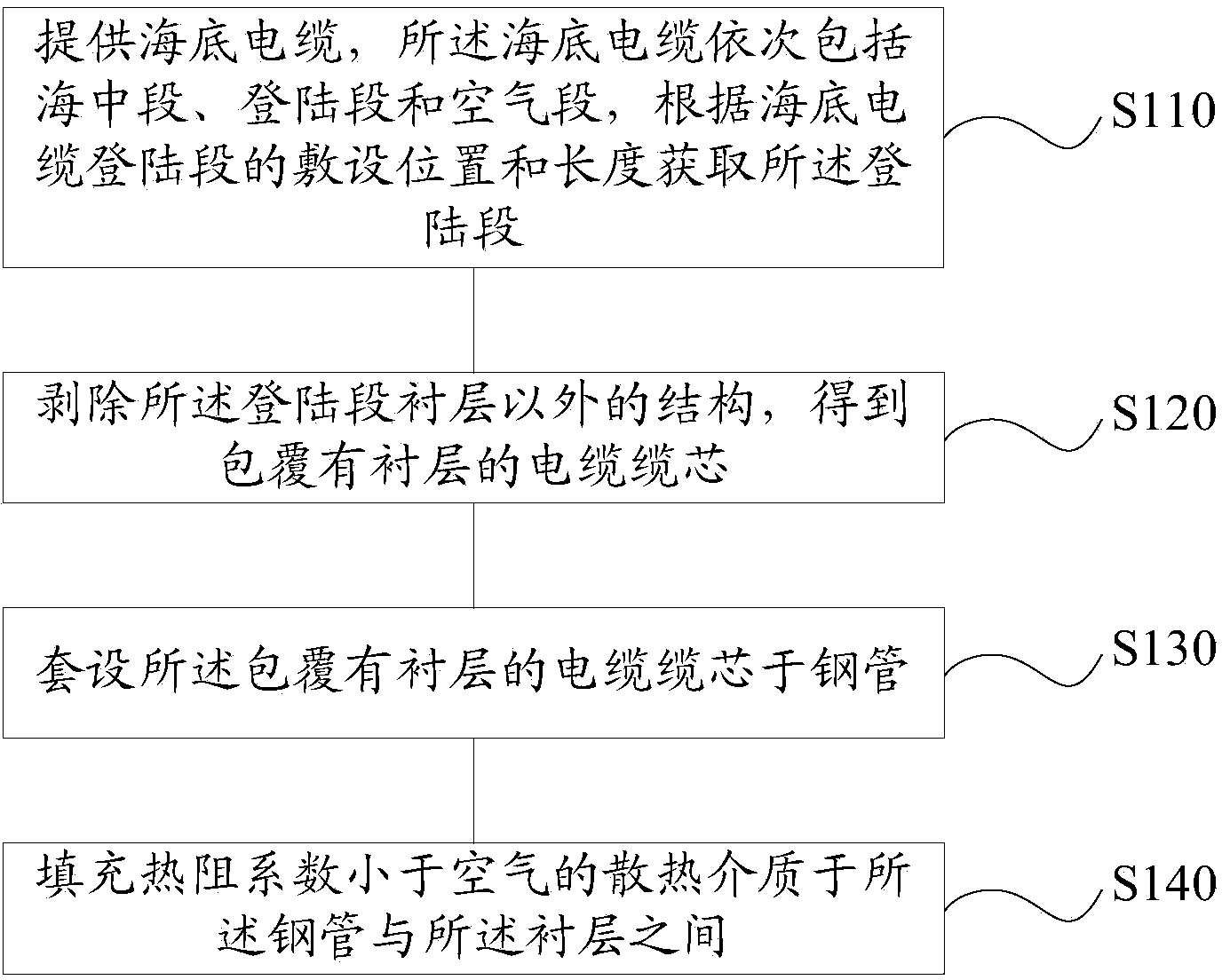

Submarine cable and construction method thereof

ActiveCN103531280AIncrease ampacityImprove distributionSubmarine cablesManufacturing rigid-tube cablesCarrying capacityElectrical conductor

A submarine cable sequentially comprises a submarine section, an ashore section and an air section, wherein the ashore section comprises a cable body, and the cable body comprises a cable core and a lining layer which is wrapped on the outer surface of the cable core; the cable body is sleeved in a steel pipe, the steel pipe is of a hollow structure, and a heat radiating medium of which the heat resistance coefficient is smaller than that of air is arranged between the inner wall of the steel pipe and the lining layer of the cable body. As the heat resistance coefficient of the heat radiating medium is smaller than that of air, the heat of the ashore section can be conveniently radiated, and the current carrying capacity of the ashore section is improved. Meanwhile, the unvaried cross section of a conductor of the ashore section and the arrangement of the steel pipe ensure that the ashore section can adapt to mechanical stress during laying or reworking. Therefore, the current carrying capacity of the ashore section of the submarine cable is improved, and the submarine cable has strong operability. The invention further provides a submarine cable construction method.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Multi-core cable and production method therefor

ActiveUS10096402B2Reduce the possibilityPlastic/resin/waxes insulatorsInsulated cablesMulticore cableElectrical conductor

Provided herein is a multi-core cable through which positions of a plurality of insulated conductors and a plurality of non-insulated conductors in a cross section in a longitudinal direction are changed and a likelihood of transmission performance being reduced is low. A multi-core cable includes n conductor bundles.

Owner:JUNKOSHA

Preparation technology of high strength copper aluminum interface alloy composite busbar

InactiveCN106128640AImprove thickness uniformityHigh bonding strengthManufacturing rigid-tube cablesBusbarAlloy composite

The invention discloses a preparation technology of a high strength copper aluminum interface alloy composite busbar, which belongs to the technical field of metal processing. The preparation technology comprises the steps of copper pipe and aluminum rod cleaning, small deformation amount drawing, copper-clad aluminum tube blank high-temperature induction heating through a continuous passing type induction heating furnace and multi-pass continuous rolling. The problems of large copper layer thickness and poor copper layer thickness uniformity in the prior art are solved.

Owner:四川瀚舟铜铝复合材料有限公司

Method for producing hollow structure, plated composite and hollow structure

ActiveCN109642335AEasy dischargePrevent collapseSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingHeat sink

The present invention provides: a method for producing a hollow structure that is useful as a base material for heat sinks, etc. that increase heat dissipation of devices installed in various kinds ofelectronic equipment without sacrificing size reduction, thickness reduction, weight reduction and multifunctionality thereof; and a hollow structure. A hollow structure 5 comprising a skeleton 5B that is made of a sum of copper plating layers 3a, 3b and 3c is produced by: covering the surface of an aluminum core 1 to form a copper plating layer 3 and produce a plated composite; cutting portionsof the plated composite to reveal cut surfaces of the core 1; and then immersing said plated composite in an aqueous sodium solution that dissolves aluminum but does not dissolve copper to selectivelydissolve and remove only the aluminum and make certain sites of the core 1 into hollow parts 5A.

Owner:ASAHI DENKA KENKYUSHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com